Patents

Literature

264results about How to "High initial permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano crystal soft magnetic alloy superthin belt and mfg method thereof

This invention relates to a new type nanometer crystal Fe-Zr-Nb-Si-Al-Cu series soft magnetic alloy super thin band and its process technology in which, the mother alloy is smelted by vacuum IF induction oven, an amorphous band is processed by a single quick cooling device to be processed by magnetic field heating at last to get the needed product with good soft magnet performance and iron core made by the super thin band improves its magnetic performance greatly.

Owner:TONGJI UNIV

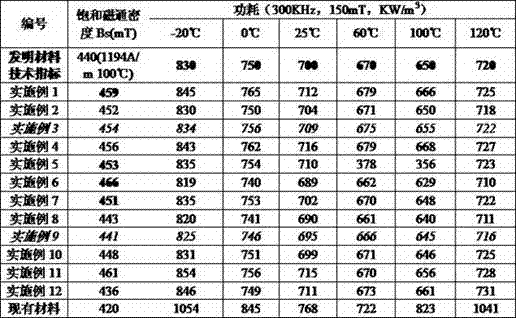

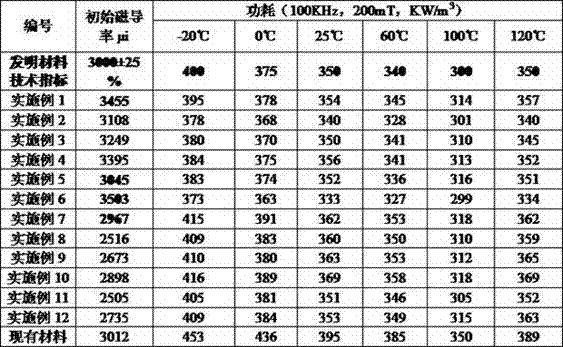

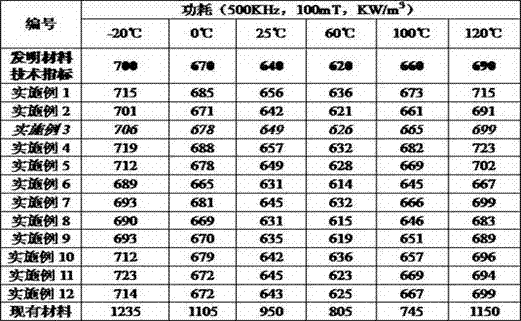

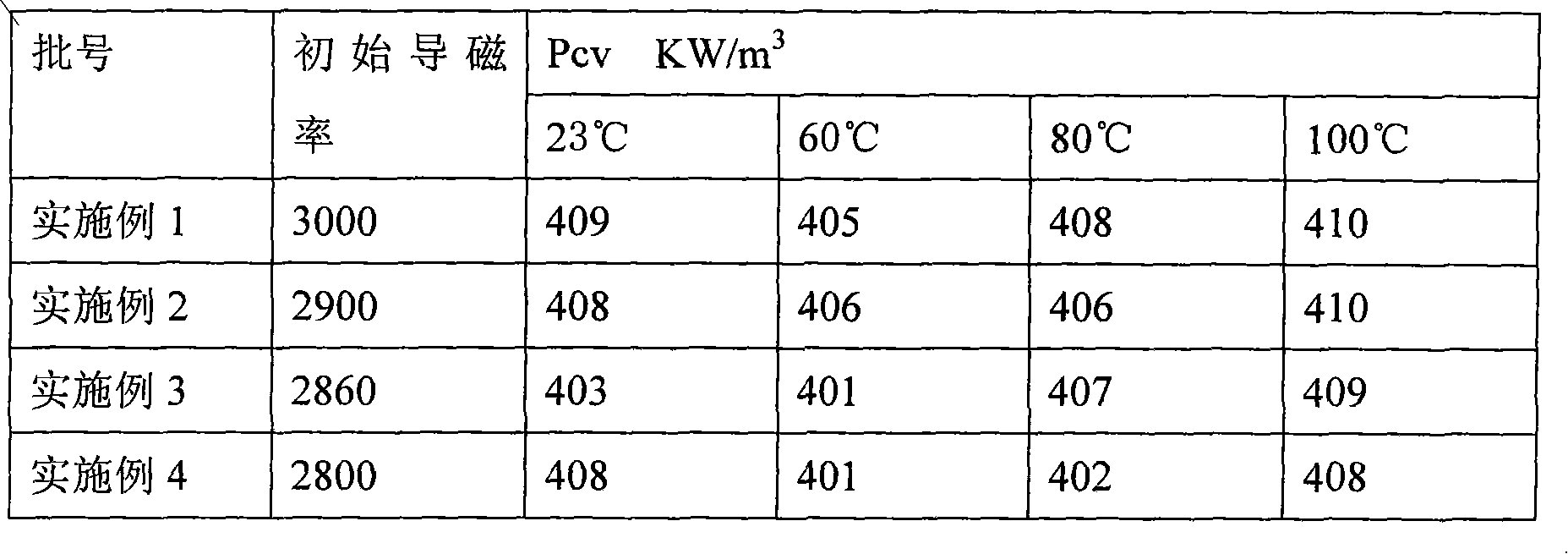

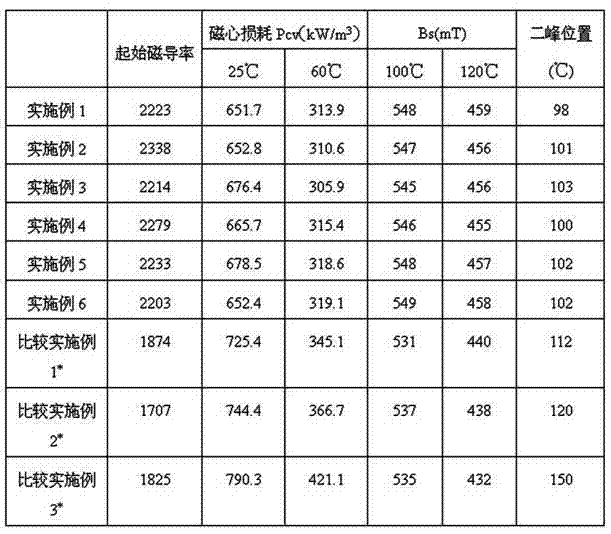

Broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material and preparation method thereof

ActiveCN107473727AImprove workabilityLow high frequency lossInorganic material magnetismSpray GranulationManganese

The invention discloses a broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material. The material comprises main ingredients, an auxiliary ingredient A and an auxiliary ingredient B, wherein the main ingredients comprise the following components in percentage by weight: Fe2O3, MnO and ZnO; based on the weight of the main ingredients, the auxiliary ingredient A comprises at least three of CaCO3, Nb2O5, NiO, SnO2 and Co3O4; and the auxiliary ingredient B comprises at least three of SiO2, Y2O3, K2CO3, Al2O3, CuO, MoO and Bi2O3. The preparation method of the material sequentially comprises the following steps: primary batching, primary sanding, pre-sintering, secondary batching, secondary sanding, performing component analysis, performing spray granulation, molding and sintering. The material disclosed by the invention has low loss in a temperature range from 20 DEG C below zero to 120 DEG C under the conditions of 100-500KHz and 100-200mT, and has high magnetic conductivity and high high-temperature saturation flux density. Compared with the conventional material, the material disclosed by the invention is energy-saving and can enable a switching power module to be miniature and efficient.

Owner:郴州市久隆旺高科电子有限公司

Anti-interference magnesium-zinc ferrite and producing method

InactiveCN1587192AHigh resistivityHigh initial permeabilityInorganic material magnetismAdhesiveHigh resistivity

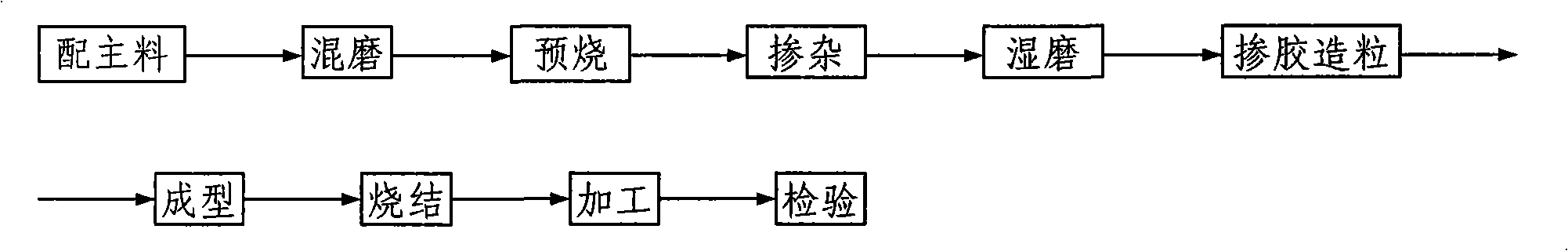

The anti-interference magnesium-zinc ferrite is produced with MgO, ZnO and Fe2O3 in certain proportion as main material, and through mixing, calcining at 1000-1200 deg.c for 30-90 min, adding supplementary material, crushing, mixing, adding adhesive, spray pelletizing to obtain grains of 180 micron average size, pressing to form magnetic core, sintering at 1250-1350 deg.c for 2-5 hr and cooling. The present invention has simple production process, and the produced magnesium-zinc ferrite has high initial magnetic permeability, high resistivity, excellent magnetic curve characteristic, low cost, wide application range and good use effect.

Owner:秦会斌 +1

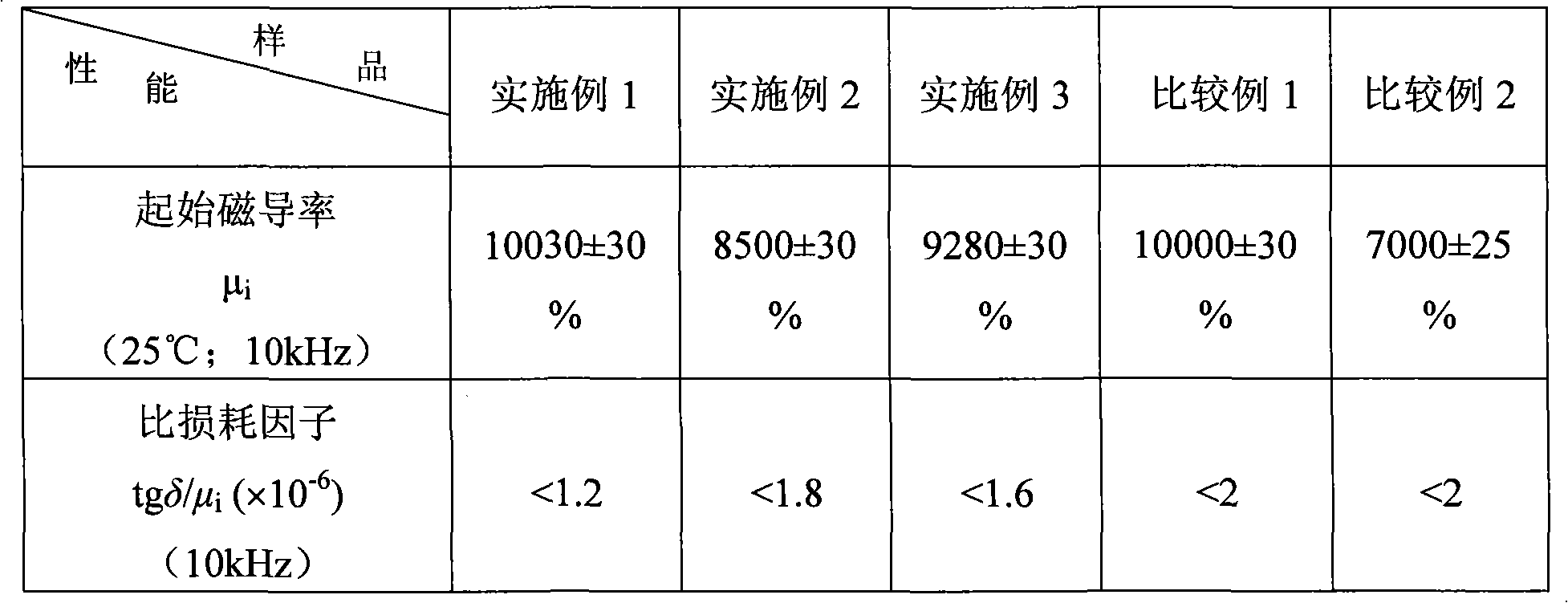

Wide-temperature low-distortion mangan zinc ferrite and preparation method thereof

ActiveCN101728048AReduce production energy consumptionBurn-in lowInorganic material magnetismLow distortionTransformer

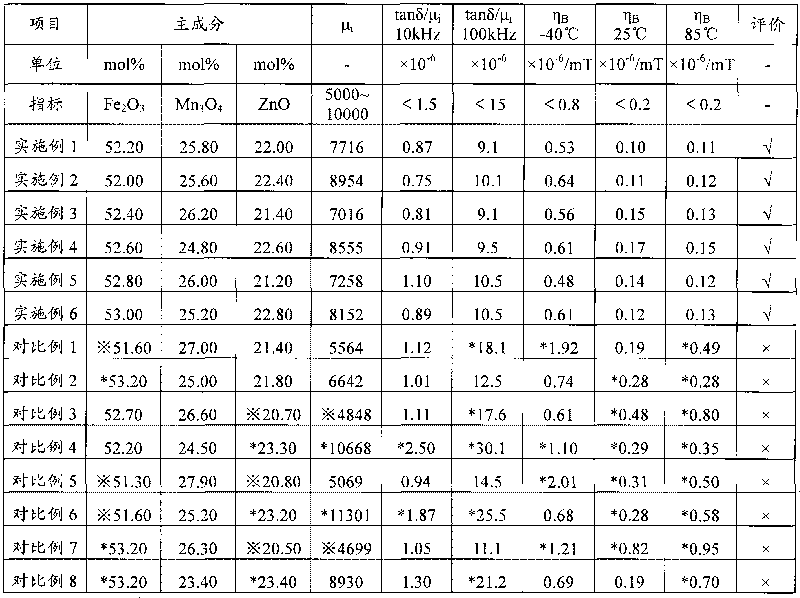

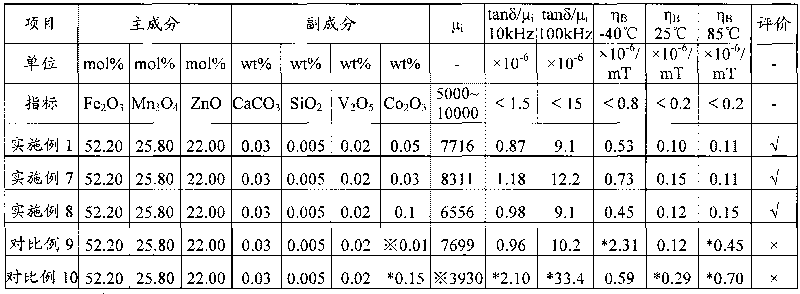

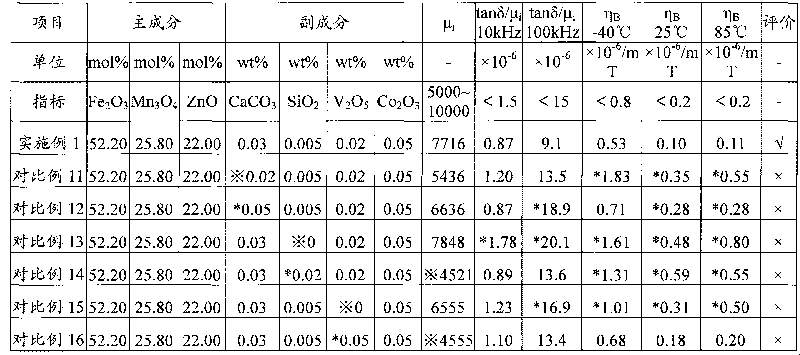

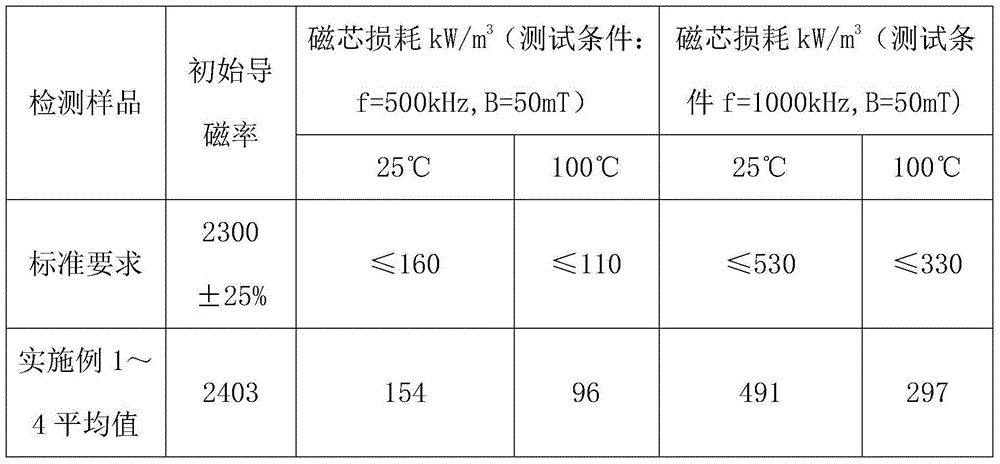

The invention relates to a wide-temperature low-distortion mangan zinc ferrite applicable to a broadband network transformer and a preparation method thereof. The mangan zinc ferrite mainly comprises the following components: 52.0 to 53.0 mol percent of iron oxide computed by Fe2O3, 21.0 to 23.0 mol percent of zinc oxide computed by ZnO, and the balance of trimanganese tetroxide, and also comprises the following auxiliary components in percentage by weight (wt %) computed by respective standard substance CaCO3, SiO2, V2O5 and Co2O3: 0.03 to 0.04 of CaCO3, 0.005 to 0.01 of SiO2, 0.01 to 0.03 of V2O5 and 0.03 to 0.1 of Co2O3. The mangan zinc ferrite is prepared by an oxide method and sintered under the condition of bell-type furnace densification. A product has higher initial magnetic permeability mu i, low relative loss factor tan delta / mu i, and wide-temperature low-magnetic hysteresis coefficient eta B (-40 to 85 DEG C), is capable of reducing waveform distortion, reducing transmission errors and prolonging transmission distance in the process of transmitting signals, and meets the requirement of the application in outdoor severe environment.

Owner:TDG HLDG CO LTD

Soft magnetic ferrite material and preparation process thereof

The invention discloses a soft magnetic ferrite material. Raw materials for preparing the soft magnetic ferrite material comprise composite materials and auxiliary materials. The composite materials comprise iron oxide, manganese oxide and zinc oxide. The auxiliary materials comprise 0-6000 ppm of nickel oxide, 100-800 ppm of calcium carbonate, 0-500 ppm of lithium carbonate, 20-120 ppm of silicon dioxide, 0-230 ppm of magnesium oxide, 0-180 ppm of niobium oxide, 700-2000 ppm of cobalt oxide, 0-350 ppm of bismuth oxide, 100-600 ppm of vanadium oxide, 0-2500 ppm of titanium dioxide, 0-500 ppm of copper oxide, and 100-500 ppm of zirconium oxide. The invention also discloses a preparation process of the soft magnetic ferrite material. The soft magnetic ferrite material has high initial magnetic permeability and low magnetic core loss.

Owner:ZHONGDE ELECTRONICS

High-frequency high-power Ni-Zn base magnetic ferrite material and manufacturing method thereof

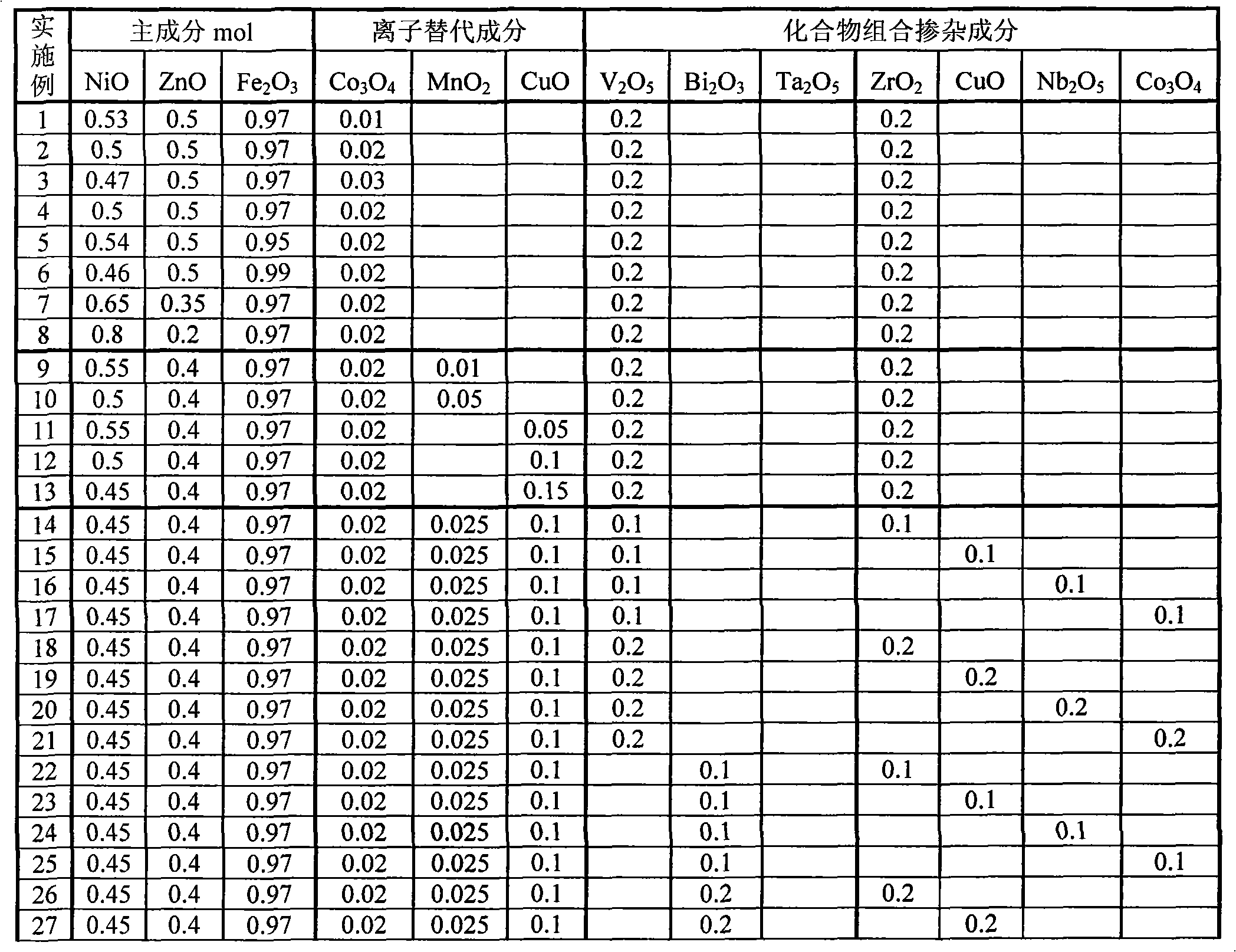

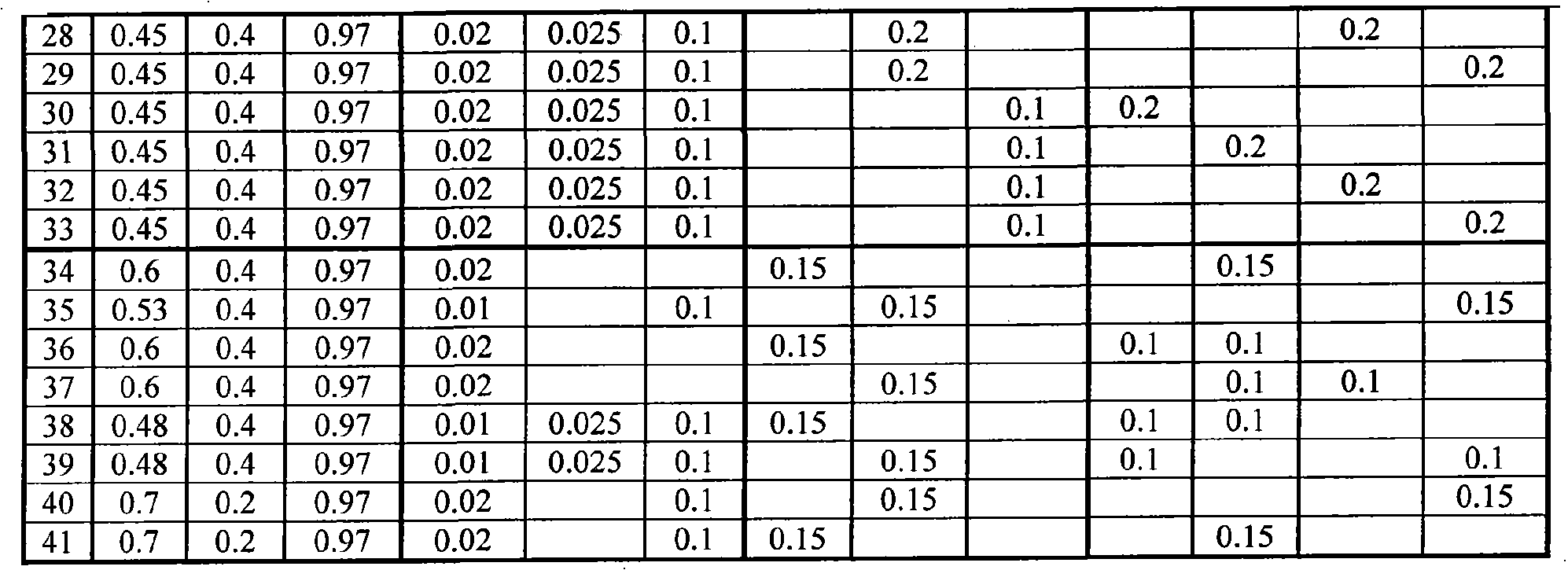

The invention discloses a high-frequency high-power Ni-Zn base magnetic ferrite material and a manufacturing method thereof. The Ni-Zn base magnetic ferrite material comprises a main ingredient, an ionic substitute ingredient and a compound composite and doped ingredient, wherein the main ingredient comprises Fe2O3, ZnO and the balance of NiO; the ionic substitute ingredient comprises one or more kinds of Co3O4, MnCO3 and CuO containing Co3O4; and the compound composite and doped ingredient comprises 2-3 kinds of V2O5, Bi2O3, Ta2O5, ZrO2, CuO, Nb2O5 and Co3O4. The manufacturing method comprises the following steps: (a) preparing a Ni-Zn base ferrite main ingredient mixture; (b) preparing a main ingredient pre-sintered material; (c) preparing micro-fine ferrite powder; (d) preparing a raw blank of a magnetic core; and (e) sintering the magnetic core. The invention obtains the Ni-Zn base magnetic ferrite material with high electromagnetic performance, high strength, high frequency and low loss by optimizing the composite design of a formulation and adopting the manufacturing method of the high-frequency high-power Ni-Zn base magnetic ferrite material. The Ni-Zn base magnetic ferrite material is used for high-power equipment of 1-30MHz and used as the magnetic core for a transformer, an inductor, a filter, a tuner, and the like.

Owner:CHONGQING MATERIALS RES INST

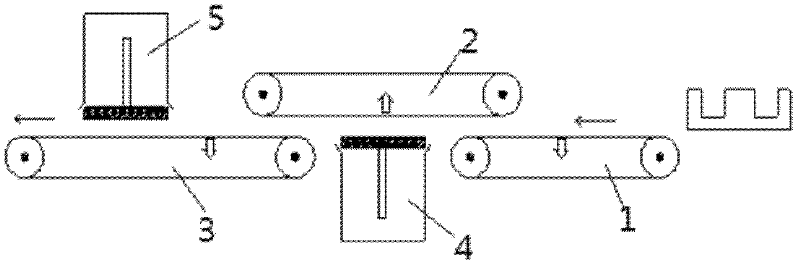

Method for producing soft magnetic ferrite core

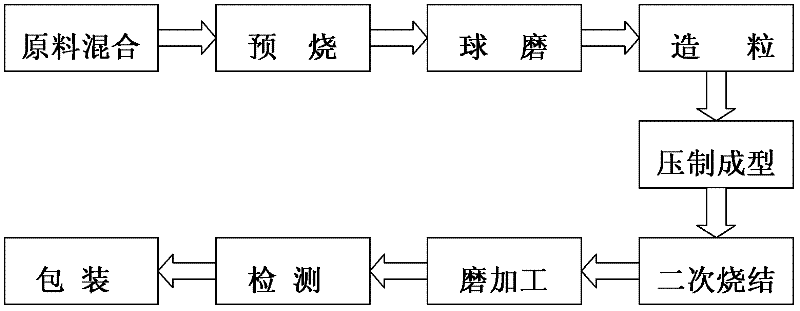

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

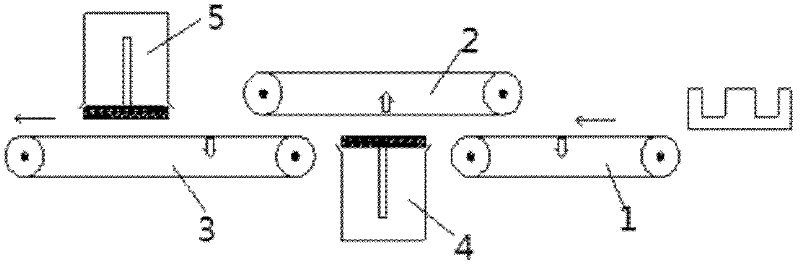

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

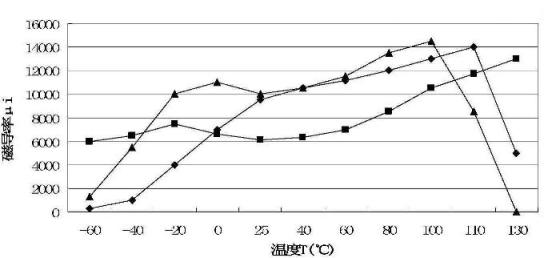

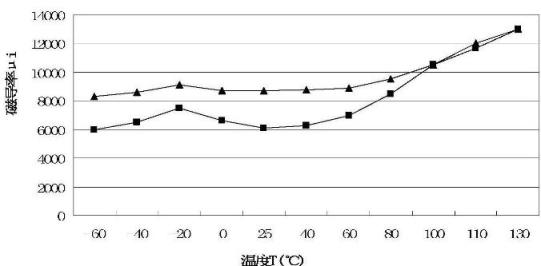

Mn-Zn ferrite material with wide temperature and high initial magnetoconductivity and preparation method thereof

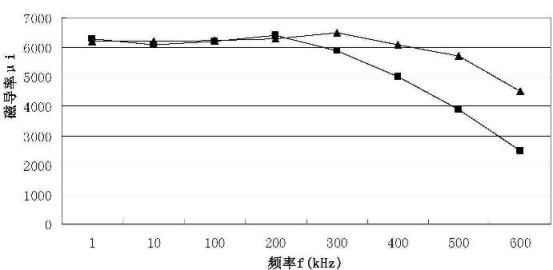

The invention belongs to the field of soft magnetic ferrite, particularly relates to a Mn-Zn ferrite material and provides a Mn-Zn ferrite material with a high initial magnetoconductivity in a wide temperature scope. The Mn-Zn ferrite material is prepared by main components and auxiliary components. The main components are as follows: 51-56 mol% of ferric oxide, 16-26 mol% of zinc oxide and the balance manganese oxide; the auxiliary components comprise one or a combination of more of 50-500ppm of calcium oxide, 50-1000ppm of bismuth oxide, 50-800ppm of molybdenum oxide, 50-800ppm of vanadium oxide or 50-800ppm of indium oxide based on the total weight amount of the main components. In a preferred proposal, one or a combination of more of zirconium oxide, titanium oxide, cobalt oxide or niobium oxide is further added in the auxiliary components. The Mn-Zn ferrite material of the invention is prepared according to a production process of a conventional drying method, and has the characteristic that the initial magnetoconductivity mui is above 5000 within a temperature zone of minus 60 DEG C-130 DEG C, thereby meeting the requirement of electronic devices on a magnetic core with high magnetoconductivity at a lower temperature.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

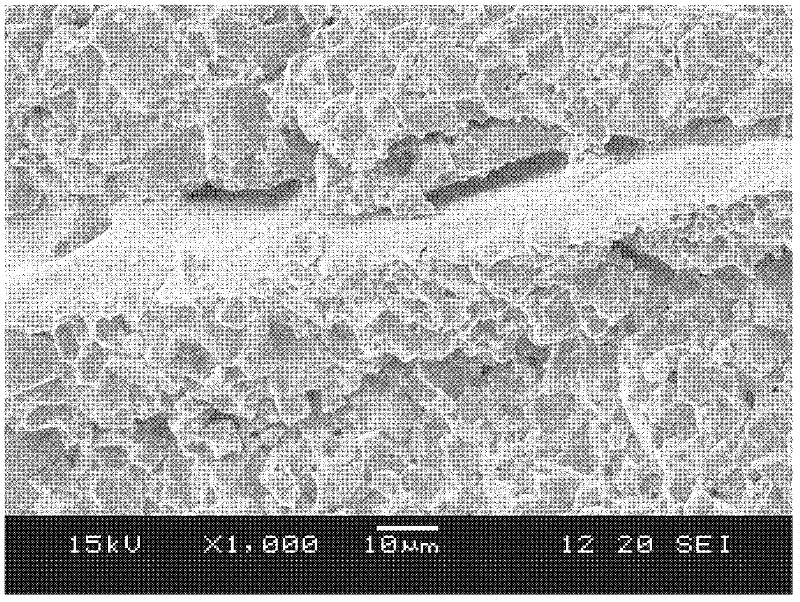

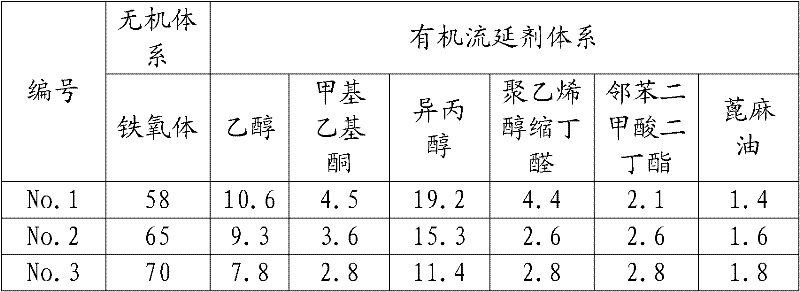

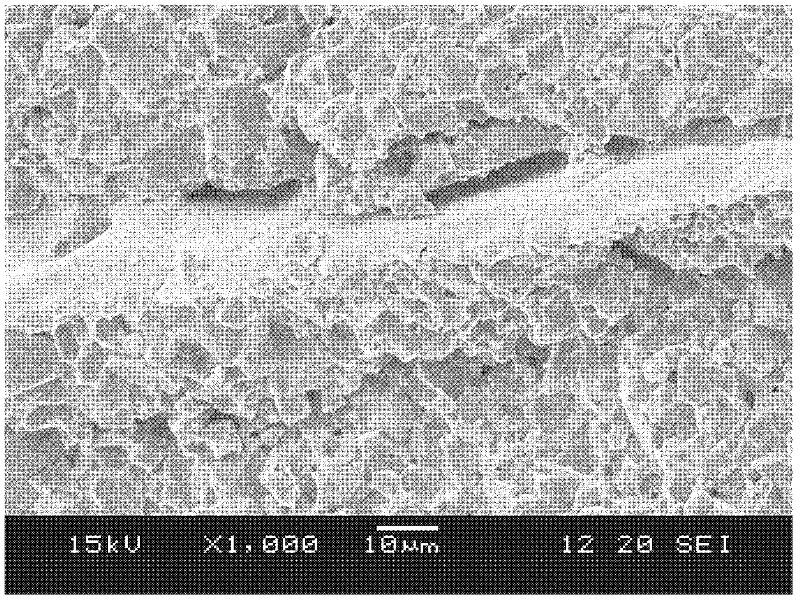

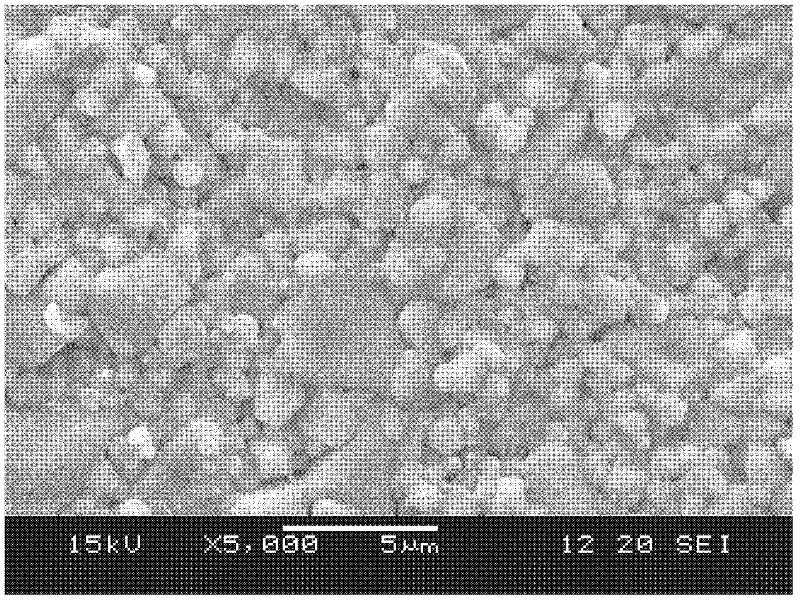

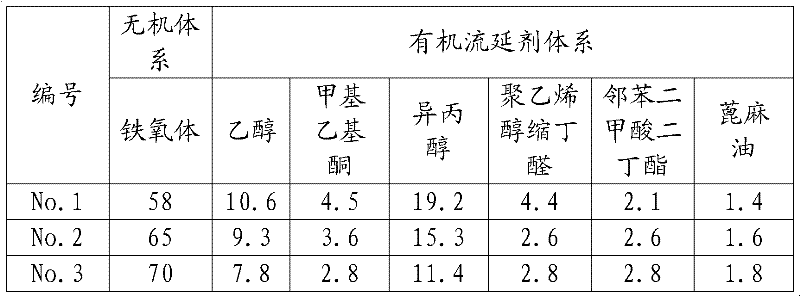

Broadband and high-magnetic-permeability ferrite teflon tape and production method thereof

The invention relates to a broadband and high-magnetic-permeability ferrite teflon tape and a production method thereof. The teflon tape comprises pre-burned ferrite powder and an organic tape casting system, wherein the pre-burned ferrite powder comprises ferric oxide, nickel oxide, copper oxide, zinc oxide, bismuth oxide and an additive, and the organic tape casting system comprises a solvent, a dispersant, a binder and a plasticizer. The LTCF (Low Temperature Cofired Ferrite) teflon tape prepared in the invention has a flat surface, is sintered at 900 DEG C for compactness, and a sintered body has an excellent performances: the initial permeability is not smaller than 450H / m at 100kHz, and the resistivity is not smaller than 109 ohm.cm. A chip inductor element manfauctured by using theteflon tape has high inductance and high quality factors, meanwhile, a low-temperature glass protective coating is coated in a silver paste circuit printing process of the inductor element, so that adevice failure caused by Ag diffusion when the device is used is prevented. Therefore, the broadband and high-magnetic-permeability ferrite teflon tape and the production method thereof have huge application prospect.

Owner:JIANGSU HUAXING ELECTRONICS CO LTD

A high temperature resistant solder nickel zinc soft ferrite material

The invention discloses a nickel and zinc soft magnetic ferrite material and a preparation method thereof. A high-temperature-resistant soldering tin, nickel and zinc soft magnetic ferrite material comprises the following components in parts: 45-50mol percent of Fe2O3, 26-32 mol percent of ZnO, 17-21 mol percent of NiO and 4-8 mol percent of CuO, and also comprises the following components in parts: 0.2-0.5 wt percent of auxiliary material A and 0.1-0.2 wt percent of auxiliary material B, wherein the auxiliary material A is one or two of Bi2O3, SiO2 and Ta2O5, and the auxiliary material B is one or more of TiO2, ViO5 and Nb2O5. The high-temperature-resistant soldering tin, nickel and zinc soft magnetic ferrite material has the characteristics of high frequency, high magnetic conductivity,high Bs and TC (Temperature Curie).

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +2

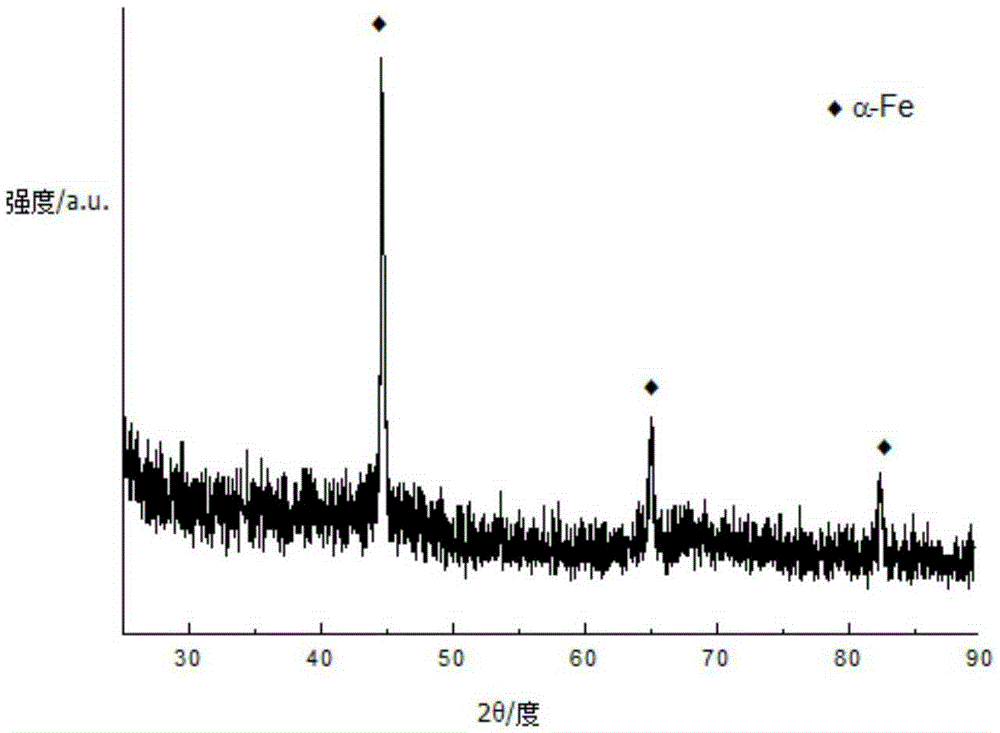

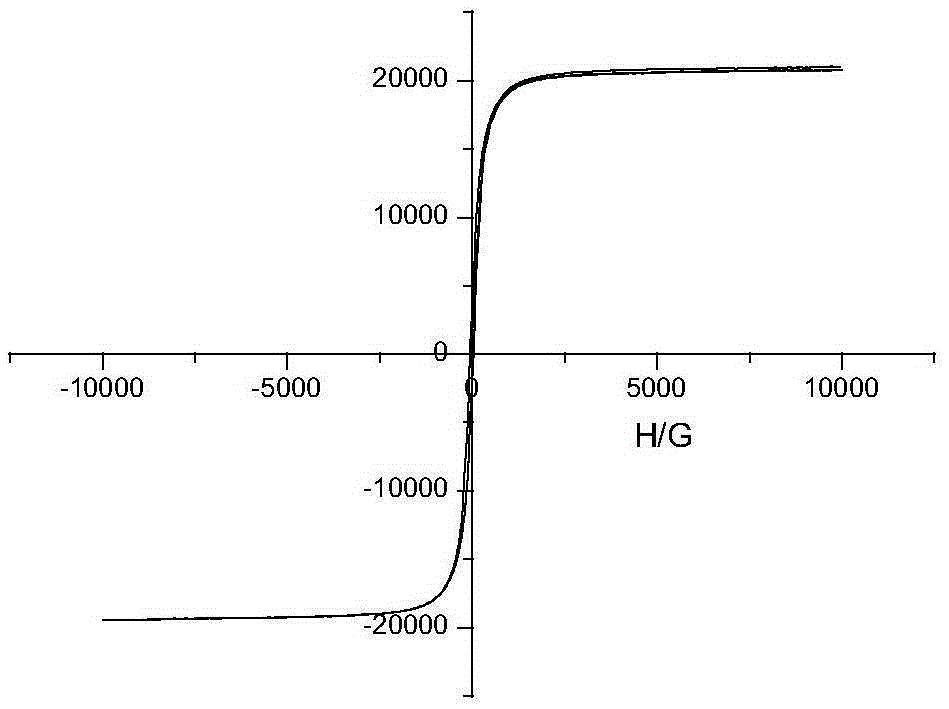

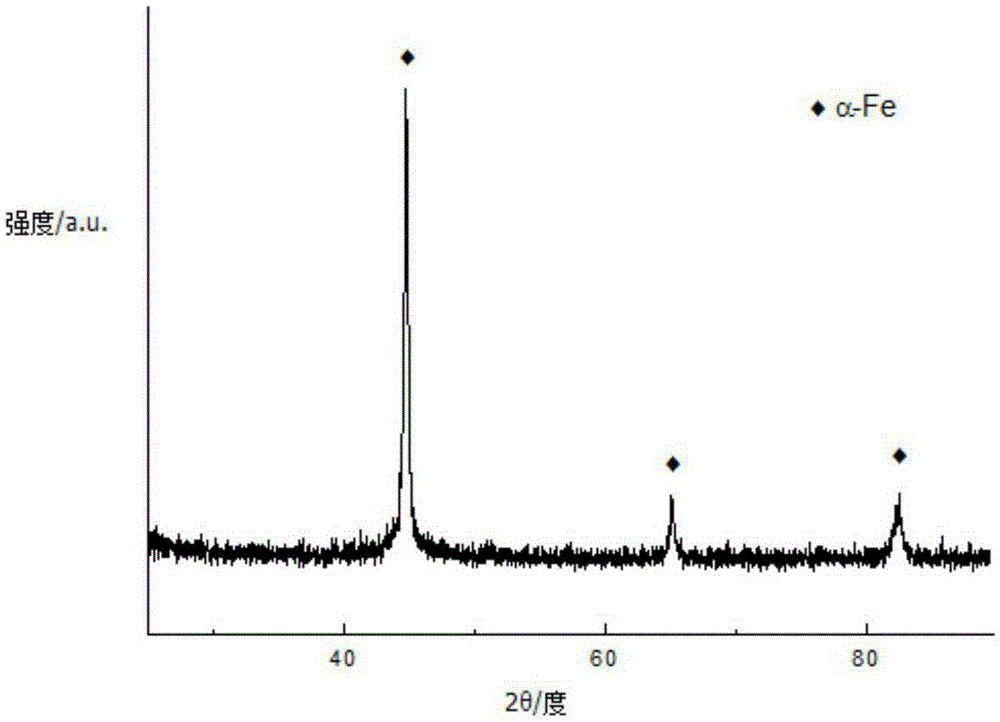

Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon and preparation method thereof

InactiveCN105261435AHigh saturation magnetic inductionGood soft magneticInductances/transformers/magnets manufactureMagnetic materialsTransformerThermal stability

The invention provides a Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon. Components of the Fe-based amorphous and nanocrystalline soft magnetic ribbon are as shown in FeSiB<c>P<d>Cu<e>Me<f>, wherein a, b, c, d, e and f respectively represent the content of Fe, Si, B, P, Cu and Me in the alloy ribbon on the basis of mass fractions of atoms; a is less than or equal to 90 and greater than or equal to 80; b is less than or equal to 5 and greater than or equal to 0.5; c is less than or equal to 12 and greater than or equal to 5; d is less than or equal to 9 and greater than or equal to 1; e is less than or equal to 2 and greater than or equal to 0.3; f is less than or equal to 3 and greater than or equal to 0.3; and a+b+c+d+e+f=100. According to the Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon, by addition of microelements, the Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon with high saturation flux density can be obtained without a heat treatment; and the alloy ribbon can be prepared in high vacuum or argon protection, has excellent soft magnetic property and high heat stability and is suitable for a transformer, an engine, a motor, a generator, a magnetic sensor and the like.

Owner:WANGWEI NEW MATERIALS (PIZHOU) CO LTD

Soft magnetic ferrite material containing magnesium, nickel and zinc element as well as manufacturing method thereof

InactiveCN101354941AHigh initial permeabilityMagnetically stableInorganic material magnetismCopper oxideInductor

The invention discloses a soft magnetic ferrite material containing magnesium element, nickel element and zinc element, which comprises the following compositions in mol portion: 60 to 66 mol percent of ferric oxide Fe2O3, 7 to 10 mol percent of nickel oxide NiO, 7 to 10 mol percent of magnesia MgO, 10 to 15 mol percent of zinc oxide ZnO and 3 to 6 mol percent of copper oxide CuO. The manufacturing method comprises the following steps of the processing of raw material, batching, primary ball milling, drying, pulverization or sifting, preburning, secondary batching, secondary ball milling, secondary drying and secondary pulverization or sifting, in a preburning condition, the soft magnetic ferrite material is presynthesized in an air furnace at a temperature of between 800 and 900 DEG C. The prepared soft magnetic ferrite material has the initial magnetic conductivity of about 100, stable magnetic performance and low production cost when the soft magnetic ferrite material is used to produce a laminated sheet type inductor.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +3

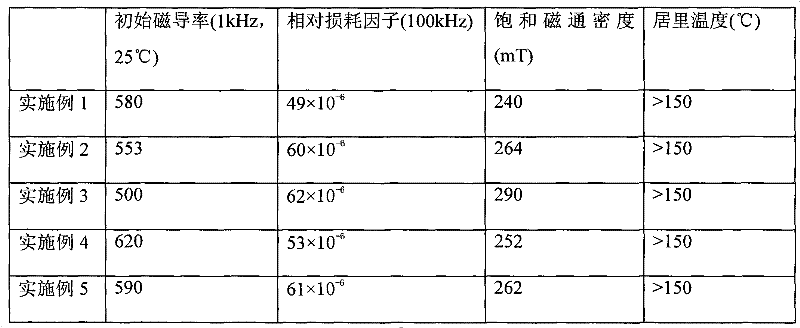

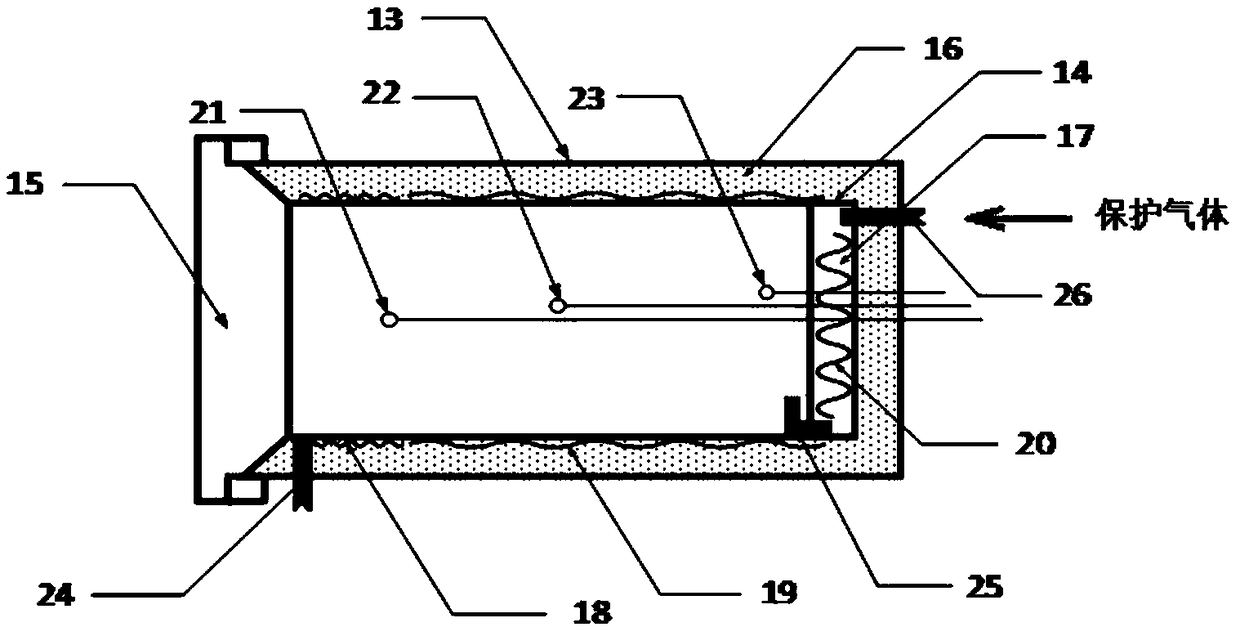

MnZn ferrite material of high initial permeability and low loss and preparation method thereof

ActiveCN101807463AHigh initial permeabilityLow loss characteristicInorganic material magnetismInitial permeabilityMaterials science

The invention discloses an MnZn ferrite magnetic material with high initial permeability and low loss and a preparation method thereof, the MnZn ferrite is prepared by principal components and auxiliary components, and the principal components and the mass percentage by oxide are as follows: 60-73wt% of Fe2O3, 13-33wt% of ZnO and balance Mn3O4; the auxiliary components are five oxides: 0.01-0.04wt% of SnO2, 0.01-0.04wt% of TiO2, 0.03-0.05wt% of Er2O3, 0.05-0.08wt% of Bi2O3 and 0.03-0.08wt% of PbO; and the soft magnetic ferrite material has not only high initial permeability but also low loss, and has excellent comprehensive soft magnetic properties.

Owner:苏州天铭磁业有限公司

Magnesium-zinc soft magnetic ferrite and preparation method thereof

InactiveCN102344283AImprove quality factor Q valueLower sintering temperatureCopper oxideNickel zinc

The invention provides a magnesium-zinc soft magnetic ferrite. The magnesium-zinc soft magnetic ferrite comprises main ingredients and accessory ingredients, wherein the main ingredients comprise the following components in percentage by weight: 68.92 to 70.59 percent of ferric oxide, 16.03 to 18.52 percent of zinc oxide, 8.07 to 9.83 percent of magnesium oxide and 3.62 to 3.86 percent of copper oxide; and the accessory ingredients comprise the following components in percentage by weight: 0.1 to 0.3 percent of bismuth trioxide and 0.1 to 0.3 percent of vanadium pentoxide. The invention also relates to a method for preparing the magnesium-zinc soft magnetic ferrite. The performance of the material is close to that of a nickel-zinc soft magnetic ferrite, the loss of the magnesium-zinc soft magnetic ferrite is low when the magnesium-zinc soft magnetic ferrite is used at high frequency, and the cost is relatively lower.

Owner:BYD CO LTD

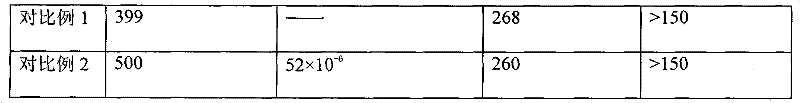

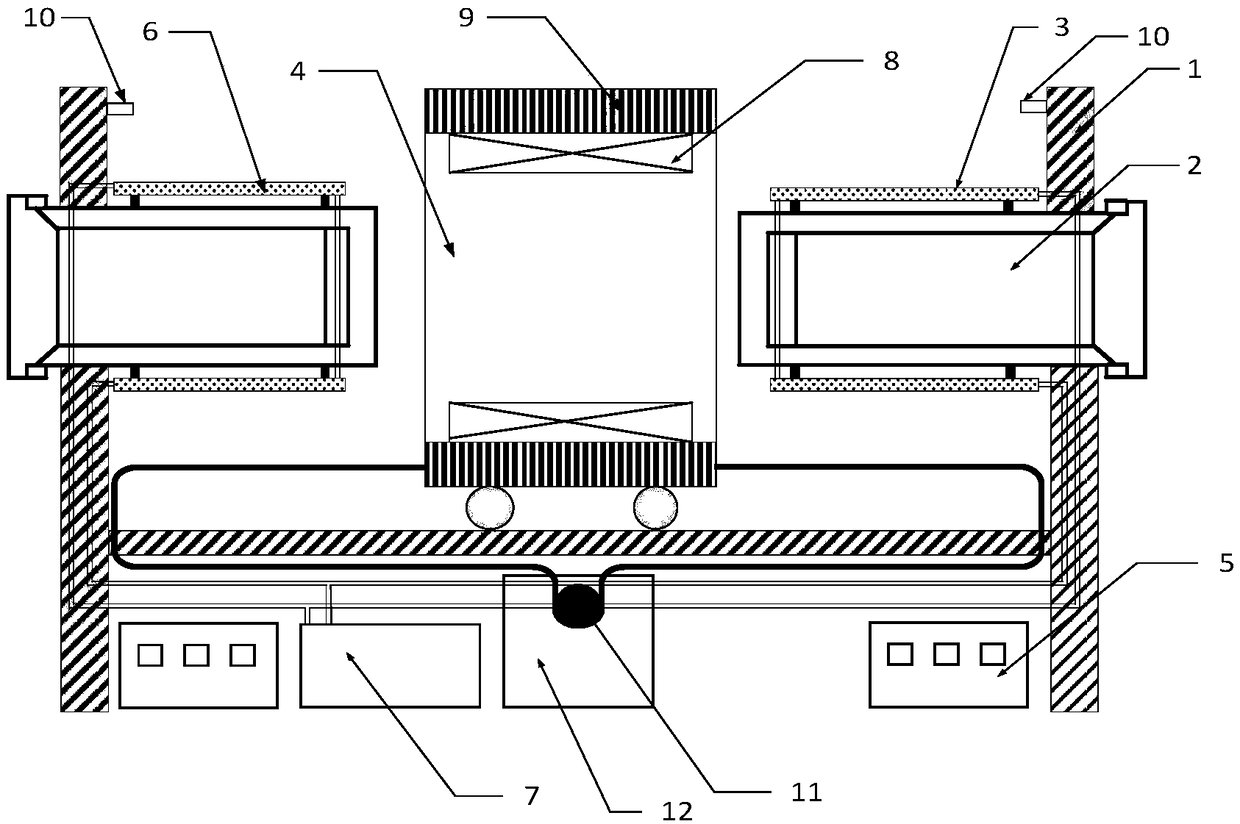

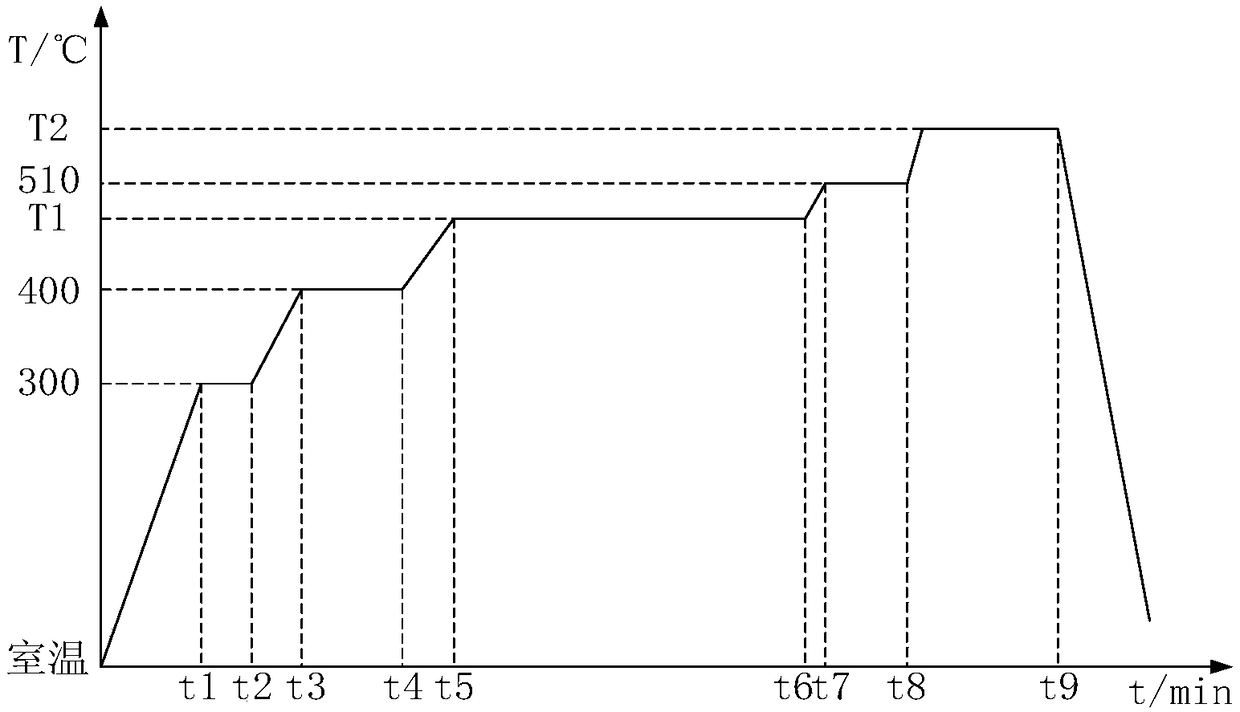

Amorphous nanocrystalline magnetic core heat treatment method

ActiveCN108998633AHigh initial permeabilityLow coercivityFurnace typesMagnetic materialsShielding gasRoom temperature

The invention discloses an amorphous nanocrystalline magnetic core heat treatment method. The amorphous nanocrystalline magnetic core heat treatment method comprises the steps that (1) a to-be-treatedmagnetic core is placed into a transverse magnetic field heat treatment furnace, and protective gas is led in; (2) heat treatment and magnetic treatment are carried out, wherein in the first stage, the temperature rises to about 300 DEG C from the room temperature, the wasted time is about 60 min, heat preservation is carried out for about 30 min, then the temperature rises to about 400 DEG C, the wasted time is about 30 min, and heat preservation is carried out for about 60 min; in the second stage, the temperature rises to T1 from about 400 DEG C, the wasted time is about 30 min, heat preservation is carried out at T1 for about 210 min, and meanwhile, a transverse magnetic field is applied in the second stage; in the third stage, the magnetic field is removed, meanwhile, the temperaturerises to about 510 DEG C from T1, the wasted time is about 20 min, heat preservation is carried out for about 40 min, then the temperature rises to T2 to be subjected to heat preservation, and the wasted time is about 90 min; and in the fourth stage, heating is stopped, cooling is carried out to the room temperature, wherein the T1 is 460 DEG C-480 DEG C, and the T2 is 560 DEG C-570 DEG C.

Owner:YANGZHONG INTELLIGENT ELECTRICAL INST NORTH CHINA ELECTRIC POWER UNIV

Method for manufacturing chip inductance element from low-temperature cofired ferrite raw material belt

ActiveCN102412059AImprove performanceHigh initial permeabilityInductances/transformers/magnets manufactureFixed signal inductancesSilver pasteScreen printing

The invention relates to a method for manufacturing a chip inductance element from a low-temperature cofired ferrite raw material belt. The method comprises the following steps of: 1, preparing the low-temperature cofired ferrite raw material belt; and 2, preparing the chip inductance element: positioning and drilling on the ferrite raw material belt according to the structure of a chip inductor; filling a through hole with a silver paste by adopting a screen printing method; printing a silver paste conductor pattern on the raw material belt, and printing a layer of low-temperature glass protective coating on the surface of the silver paste pattern; placing the printed raw material belt into a closely-laminated die in turn according to pre-designed layer number and order, and isopressing to form a complete multilayer base plate blank; dividing the multilayer base plate blank into small specific blocks, placing the small specific blocks into a furnace, raising the temperature to 450 DEG C, keeping the temperature for 3 hours, discharging rubber, raising the temperature from 450 DEG C to 900 DEG C, maintaining the temperature for 3 hours, and sintering; controlling the temperature for 10 hours during cooling until the temperature is 250 DEG C, and then naturally cooling along with the furnace; and manufacturing an electrode by brushing silver and capping the end of the sintered electronic element to obtain the chip inductance element.

Owner:JIANGSU HUAXING ELECTRONICS CO LTD

Nano-crystal soft magnetic iron core, heat treatment method and application thereof

InactiveCN1905091AHigh initial permeabilityEnsuring Comprehensive Magnetic PerformanceTransformers/inductances magnetic coresInductances/transformers/magnets manufactureInitial permeabilityTransformer

The invention relates to nanometer crystal soft magnet core. It includes the cyclic magnet core with 0.027-0.03mm thickness. Its magnet core alloy constituent atom percentages are as follows: Fe 67-80, Ni or Co or Ni and Co 0.1-0.6, Nb 2-4, Cu 0.5-1.5, Si 10-17, and B 6-10. It replaces Ni or Co by Fe to process better initial permeability and 0.5-0.85 magnetic performance ratio. The heat treatment can make the magnet core reach optimal efficiency which can be used in electromagnetic residual current protective circuit breaker and current voltage transformer.

Owner:黄付贵

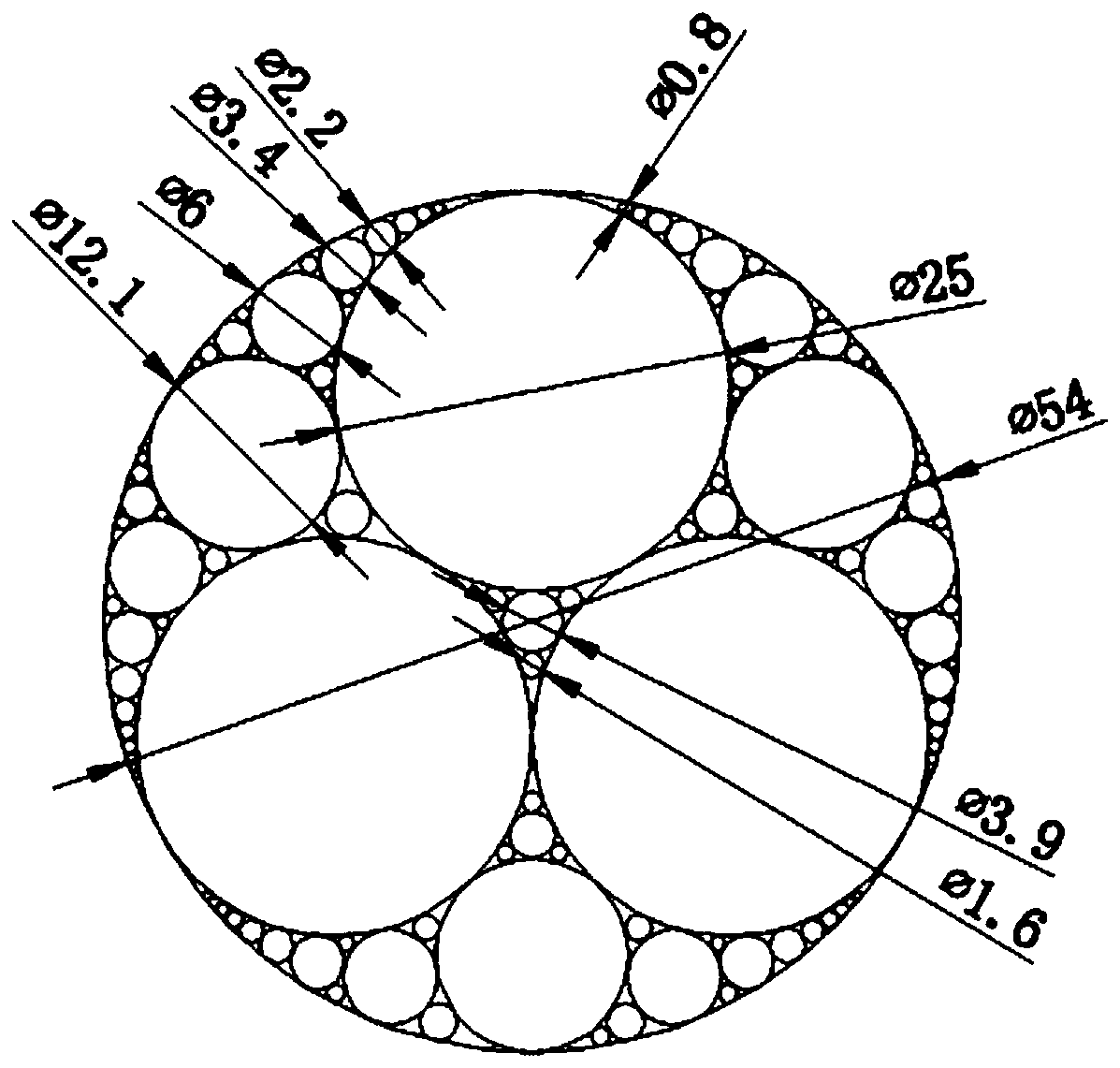

Mixed soft magnetic material and integrally molded inductor prepared thereby

InactiveCN110310794ADensity maximizationHigh initial permeabilityTransportation and packagingMetal-working apparatusHigh densityInitial permeability

The invention discloses a mixed soft magnetic material and an integrally molded inductor prepared thereby. According to the technical scheme, two or more kinds of large, medium and small soft magneticpowder are used; the density of the soft magnetic powder filled per unit volume is maximized through grain size distribution of the mixed soft magnetic powder required for preparation; the soft magnetic powder used for mixing are in various large, medium and small particle size distributions in the shape of a sphere, a spheroid, a polygon or a plate; and the integrally molded power inductor madeof the soft magnetic material prepared with the high-density mixed powder has the advantages of higher initial permeability, better saturation characteristics, lower product loss and higher efficiency.

Owner:TRIO TECH SUZHOU

Mn-Zn wide-temperature soft magnetic ferrite material and preparation method thereof

The invention belongs to the technical field of soft magnetic material and discloses a Mn-Zn wide-temperature soft magnetic ferrite material and a preparation method thereof. The Mn-Zn wide-temperature soft magnetic ferrite material comprises the main materials by weight percentage: 69 to 74 percent of Fe2O3, 20 to 25 percent of Mn3O4 and 6 to 10 percent of ZnO; the sum of Fe2O3, Mn3O4 and ZnO is100 percent. The soft magnetic ferrite material has low manufacturing cost, simpleness, easy operation, lower power consumption, less heating quantity, higher primary magnetic permeability and excellent performance.

Owner:上海华源磁业股份有限公司

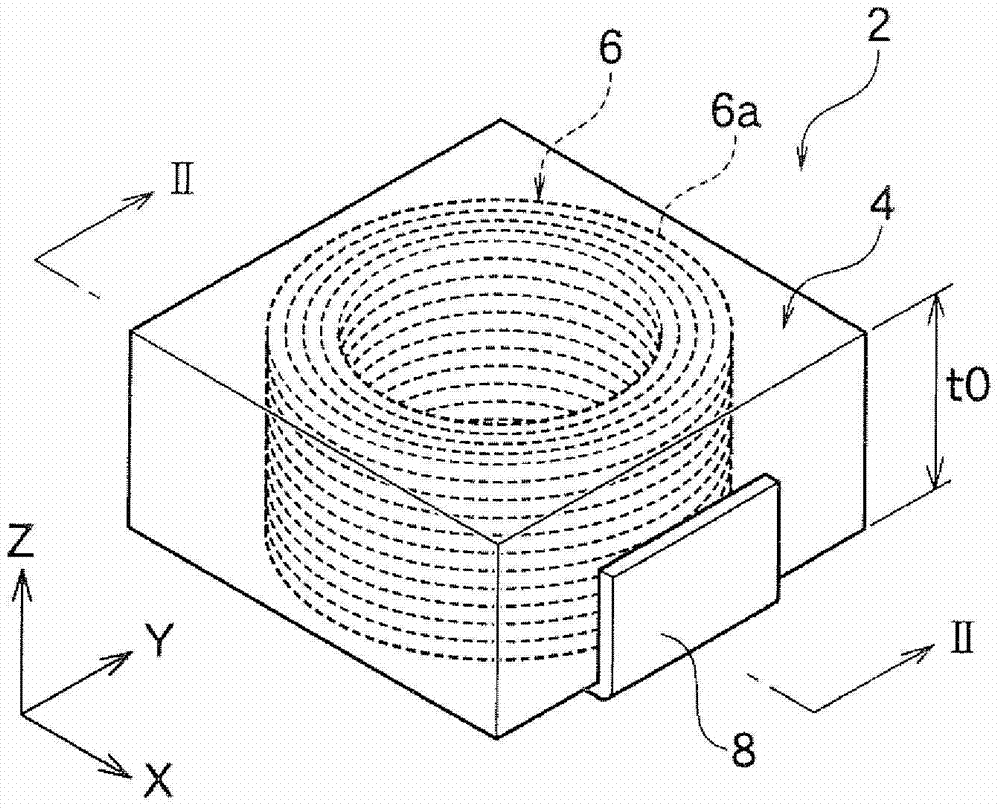

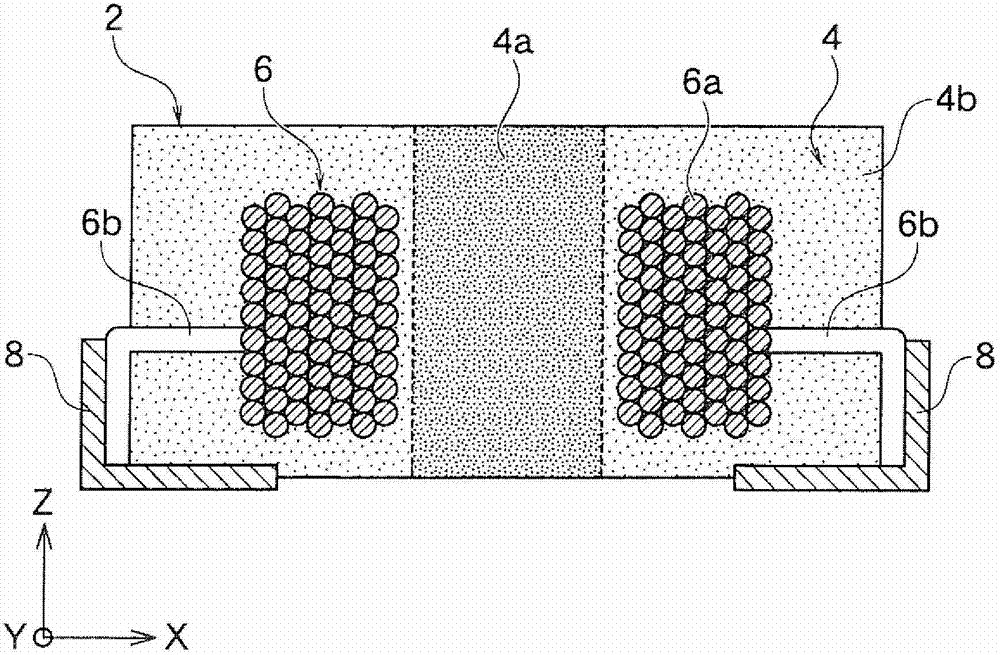

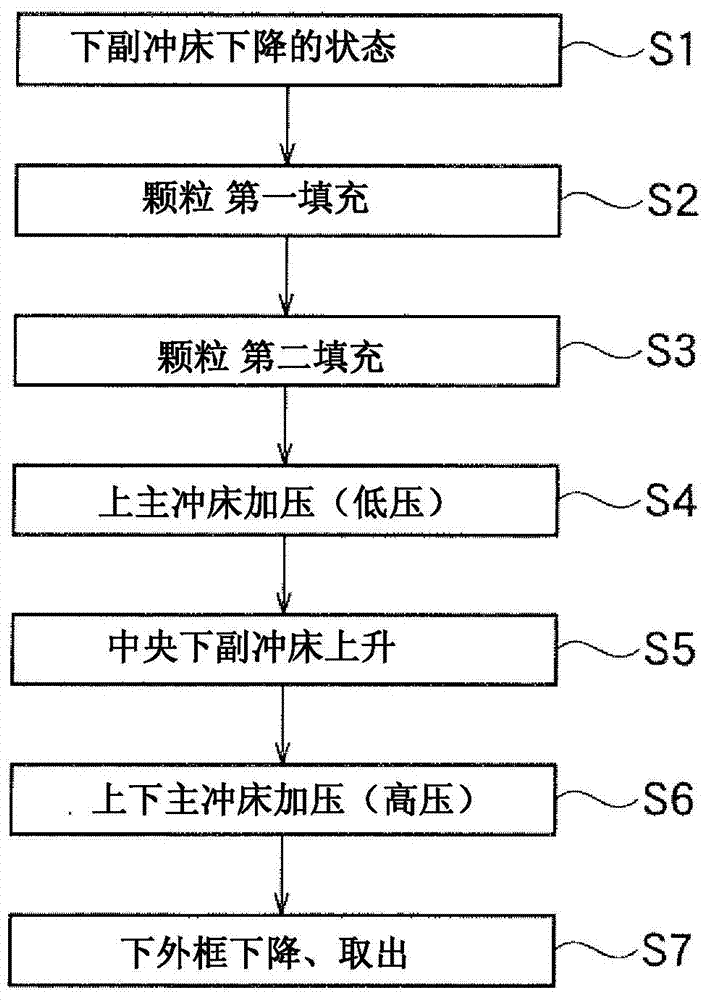

Inductor and manufacturing method thereof

ActiveCN103714961AReduce generationLow costTransformers/inductances magnetic coresInductances/transformers/magnets manufactureInductorMagnetic powder

The invention provides an inductor which generates fewer cracks, has high initial magnetic permeability and is unlikely to cause short circuit failure, and a method for easily manufacturing the inductor with low cost. The magnetic powder density of the inner peripheral portion (4a) and the outer peripheral portion (4b) of a wiring portion (6) in a core portion (4) is different, and the magnetic powder density of the core portion (4) in the inner peripheral portion (4a) of the wiring portion (6) is higher than that of the core portion (4) in the outer peripheral portion (4b) of the wiring portion (6).

Owner:TDK CORPARATION

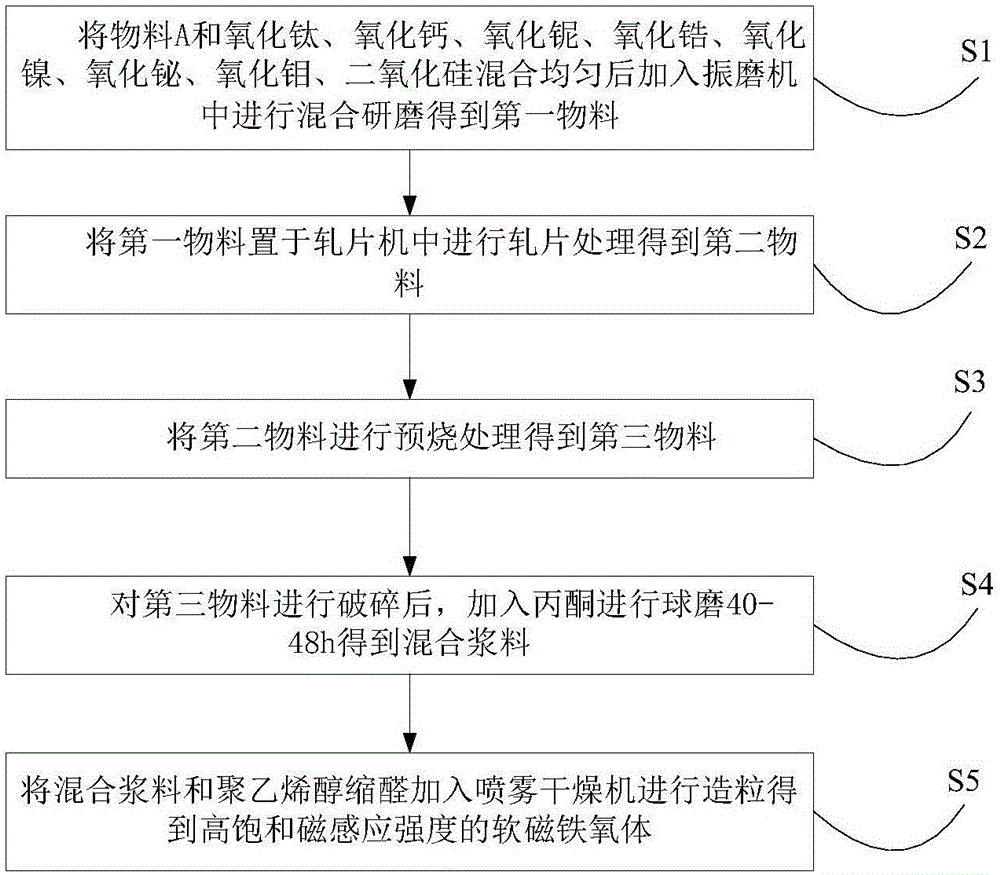

Soft-magnetic ferrite with low loss and high saturation flux density and preparation method therefor

The invention discloses a soft-magnetic ferrite with low loss and a high saturation flux density. The raw materials comprise materials A and materials B. The materials A comprise, by mole, 56-60 parts of iron oxide, 40-45 parts of manganese oxide, 7-10 parts of zinc oxide and 2-4 parts of copper oxide. With the total weight of the materials A as a base, the materials B comprise 2500-3000ppm, 300-700ppm of calcium oxide, 100-300ppm of niobium oxide, 400-800ppm of zirconium oxide, 1500-2000ppm of nickel oxide, 300-800ppm of bismuth oxide, 300-500ppm of molybdenum oxide, 200-500ppm of silicon oxide and 2000-2500ppm of bonding agents. The invention also discloses a preparation method for the soft-magnetic ferrite with low loss and a high saturation flux density.

Owner:ZHONGDE ELECTRONICS

Power supply wave shape correcting filter

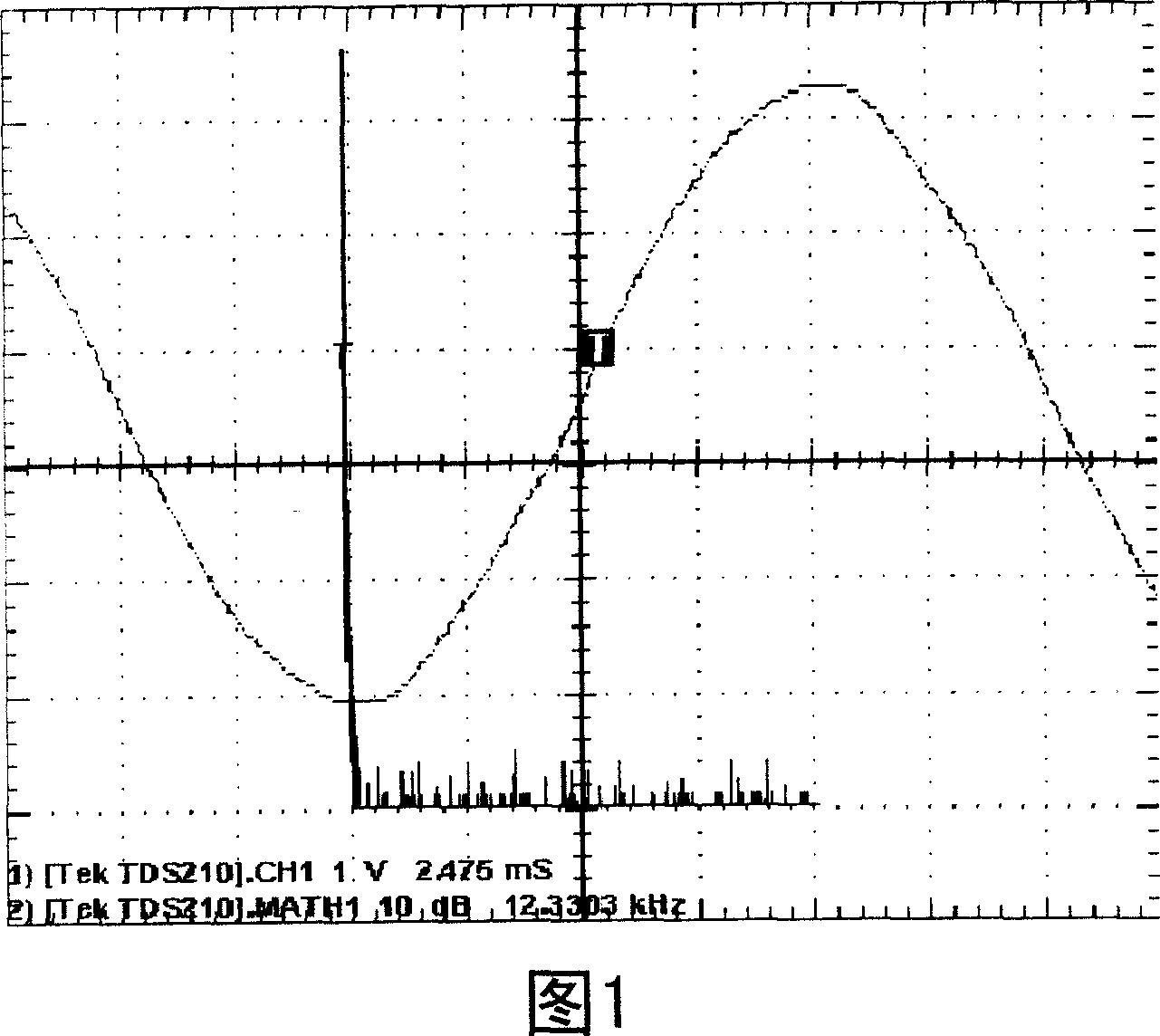

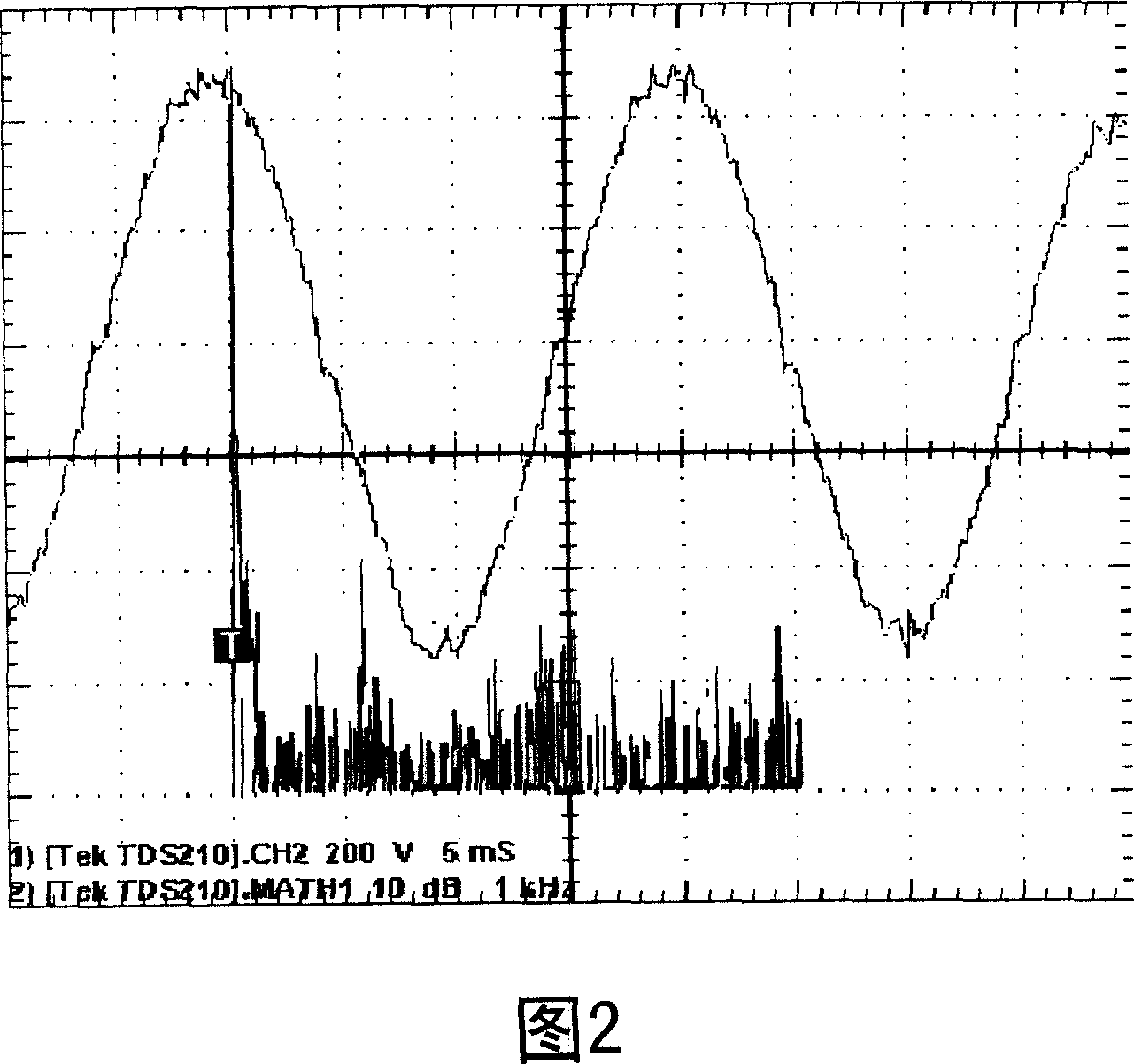

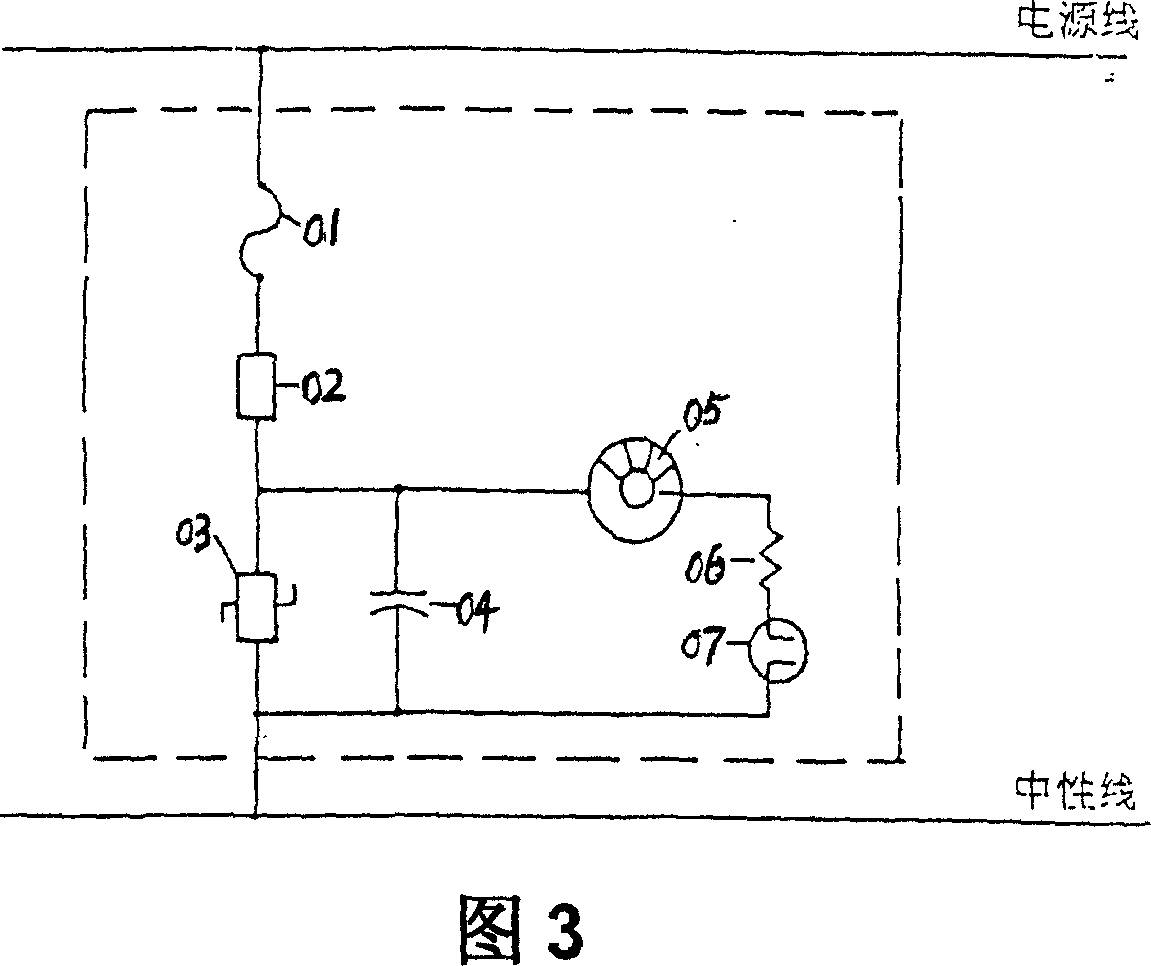

InactiveCN1933273AQuality improvementGuaranteed uptimeHarmonic reduction arrangementAc network to reduce harmonics/ripplesNonlinear resistorWave shape

This invention discloses a filter for correcting supply waveforms including a parallel non-linear resistor and a first capacitor, a first inductor and a second inductor with coils of the same turns winded on a same magnetic core reversely, a second capacitor and a third and fourth capacitors in series, in which, the two input ends of the two inductors are connected to both ends of the first capacitor, the second capacitor is bridged between the outputs of the first two inductors, the serial ends of the third and the fourth capacitors are bridged between the outputs of the first two inductors to be parallel to the second capacitor, the connecting point of the third and fourth capacitors is connected to the earth, the filter also includes a first resistor connected between the output of the first inductor and the input of the second inductor and said core is a nano-grain alloy ring one.

Owner:上海浩顺科技有限公司 +1

Method for preparing rare-earth-doped manganese-zinc ferrite material

InactiveCN109553408AChanging grain boundary compositionChange ionic valencePolyvinyl alcoholRare earth

The invention relates to the technical field of magnetic materials, and discloses a method for preparing a rare-earth-doped manganese-zinc ferrite material, comprising the steps of adding manganese oxide, zinc oxide and iron oxide as main components to a ball mill and conducting ball milling to obtain a mixture A; pre-firing the mixture A, and then conducting cooling to room temperature to obtaina pre-fired material; adding the pre-sintered material, vanadium oxide, niobium oxide, bismuth trioxide, molybdenum oxide, phosphorus pentoxide, copper oxide and a composite rare earth additive into aball mill, and conducting secondary ball milling and drying to obtain a mixture B, wherein the composite rare earth additive is composed of cerium oxide, yttrium oxide and lanthanum oxide; adding a polyvinyl alcohol solution to the mixture B, conducting mixing and granulation, and then conducting sieving by a sieve of 40-80 mesh, so as to obtain pellets; adding the pellets into a molding machinefor pressing, so as to obtain a blank; and sintering the blank and conducting cooling. The rare-earth-doped manganese-zinc ferrite material prepared by the method of the invention has high initial magnetic conductivity and saturation magnetic flux density.

Owner:ZHONGDE ELECTRONICS

Composite material with capacitance and inductance performance and its preparing method

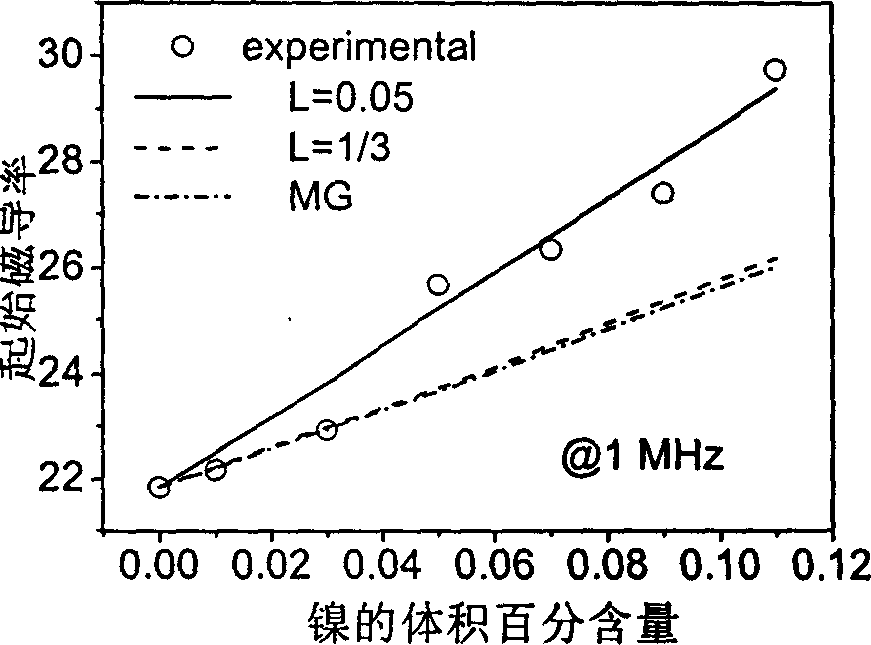

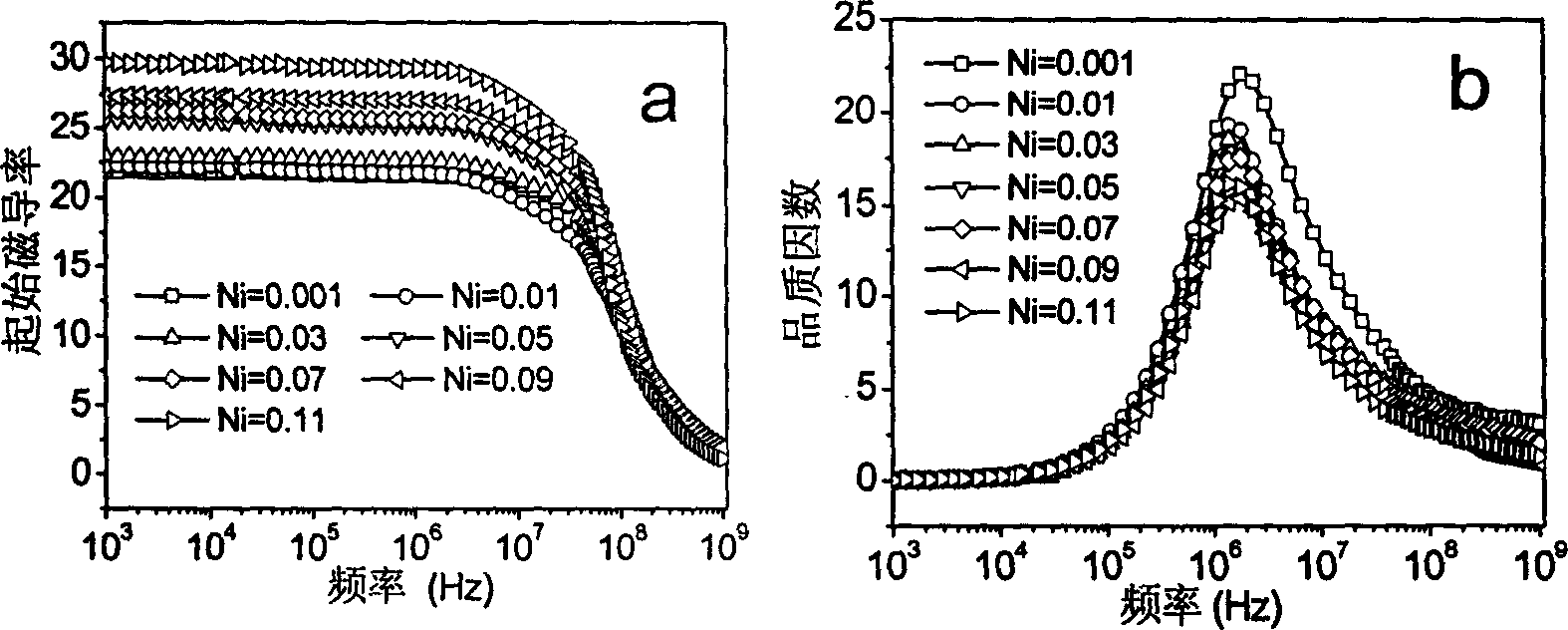

The present invention relates to a kind of composite material with capacitance and inductance performance, and belongs to the field of electronic composite material technology. The composite material is ternary composite material Ni0.3Zn0.7Fe1.95O4-Ni-PVDF and ternary composite material Ba3Co2Fe23O41-Ni-PVDF. It is prepared through mixing ferrite, metal nickel grain and polyvinylidene fluoride, and molding the mixture at temperature of 180-220 deg C and pressure of 10-15 MPa for 20 min. The Ni0.3Zn0.7Fe1.95O4-Ni-PVDF system has initial magnetic permeability of about 30 in the pressure below 10 MHz and dielectric constant at 1 KHz below up to about 200; and the Ba3Co2Fe23O41-Ni-PVDF system has initial magnetic permeability of about 4.0 in the pressure below 500 MHz and dielectric constant at 10 MHz below up to about 130. The composite material possesses unique double seepage structure, and has low preparation temperature, simple preparation process and excellent industrial application foreground.

Owner:TSINGHUA UNIV

High-temperature high-Bs low-loss MnZn ferrite material and preparation method thereof

InactiveCN102219488AHigh initial permeabilitySolve the problem of loss deteriorationManganese oxideIron oxide

The invention provides a high-temperature high-Bs low-loss MnZn ferrite material which comprises main components and auxiliary components, wherein the main components comprise 53mol%-56mol% of ferrite, 34mol%-42mol% of manganese oxide and 4mol%-10mol% of zinc oxide, wherein the content of manganese oxide is accounted by Mn; the auxiliary components are selected from at least four out of CaCO3, SiO2, Nb2O5, V2O5, CoO, NiO, Ni2O3 and Li2CO3, and based on the total weight of the main components, the weight percentage of the auxiliary components is as follows: 0.02-0.08wt% of CaCO3, 0.002-0.01wt% of SiO2, 0.02-0.06 wt% of Nb2O5, 0.01-0.05wt% of V2O5, 0.03-0.20wt% of CoO, 0.03-0.20wt% of NiO, 0.03-0.14wt% of Ni2O3, and 0.01-0.10wt% of Li2CO3. The invention also provides a preparation method of the high-temperature high-Bs low-loss MnZn ferrite material.

Owner:江门安磁电子有限公司

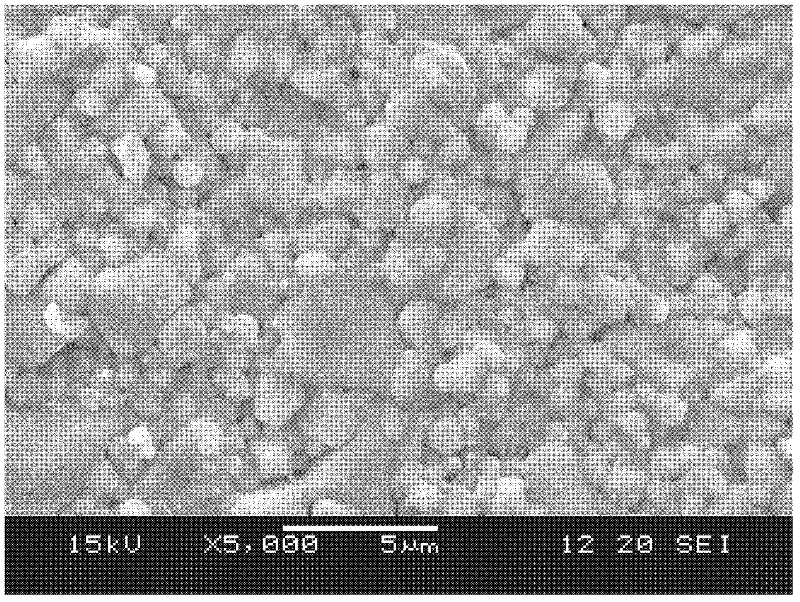

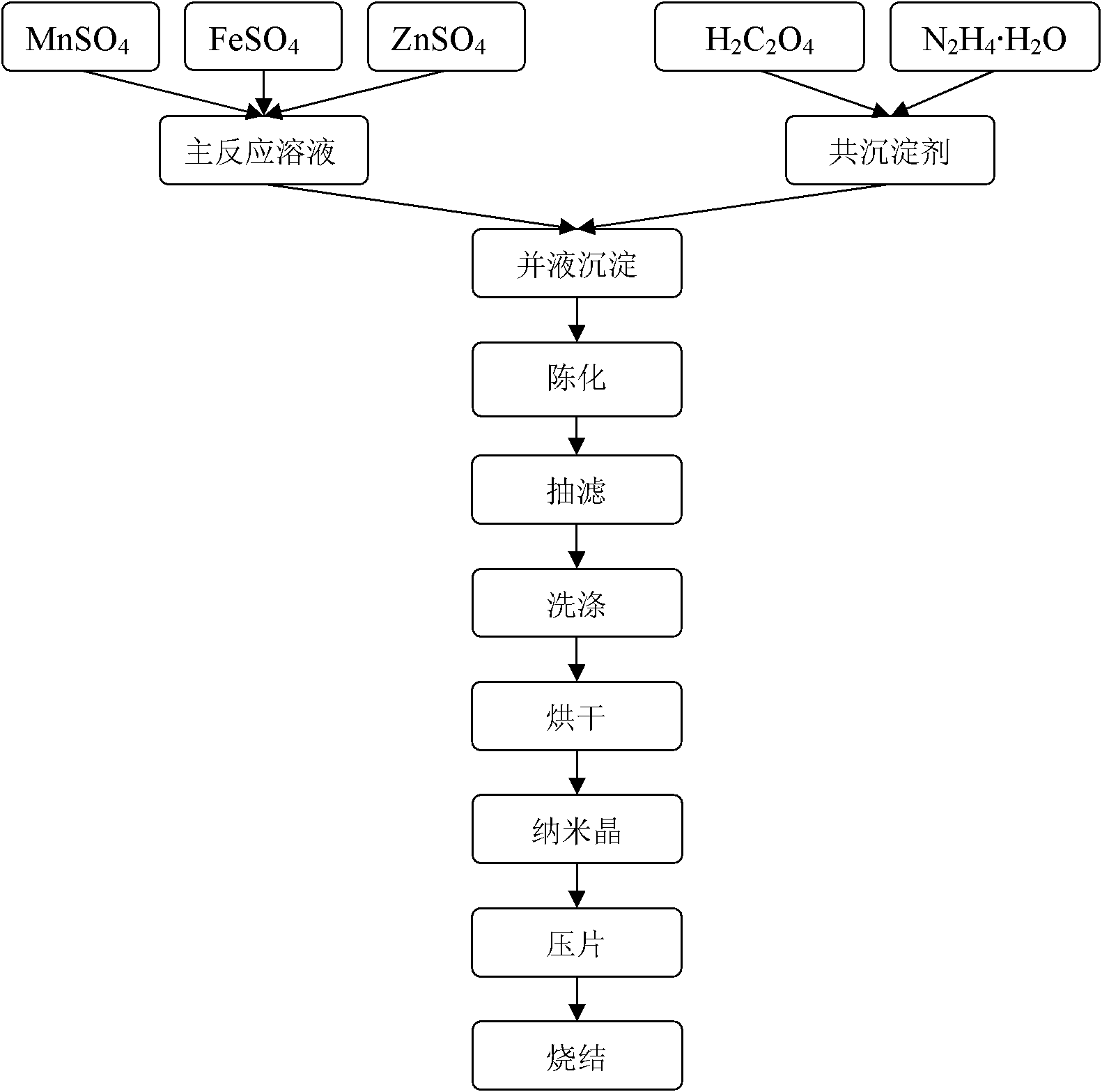

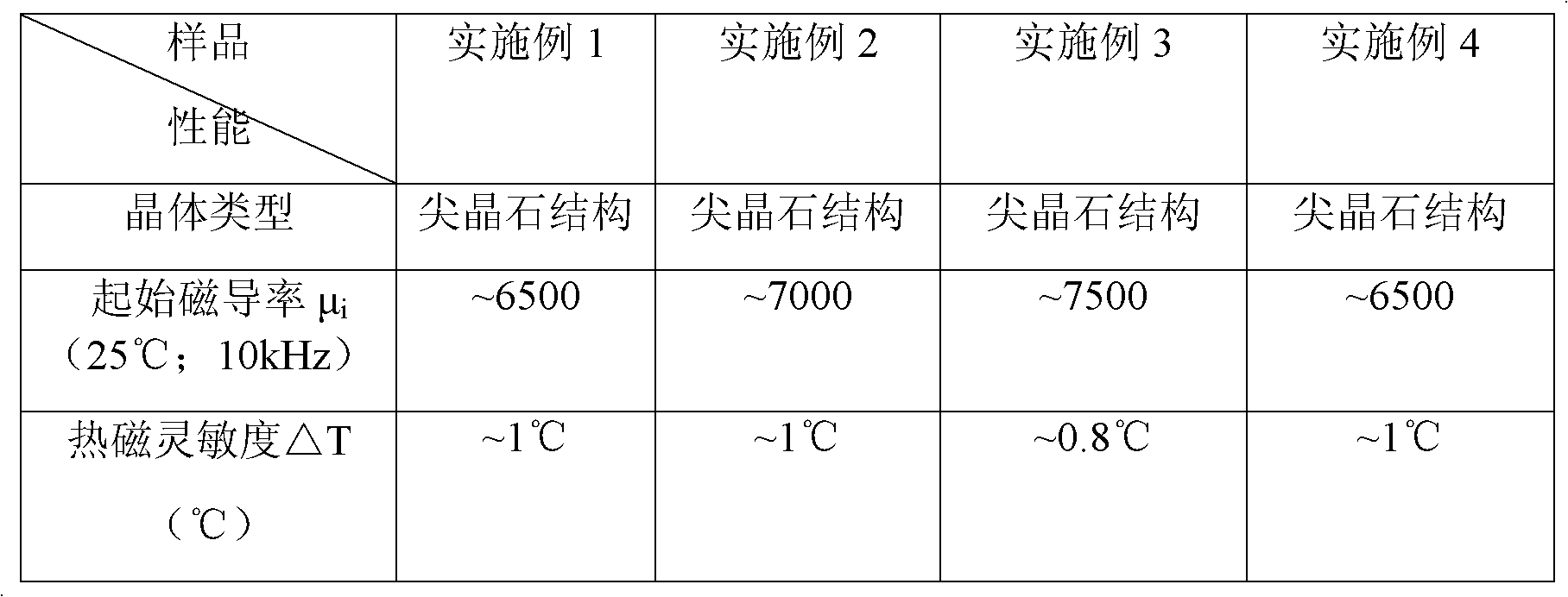

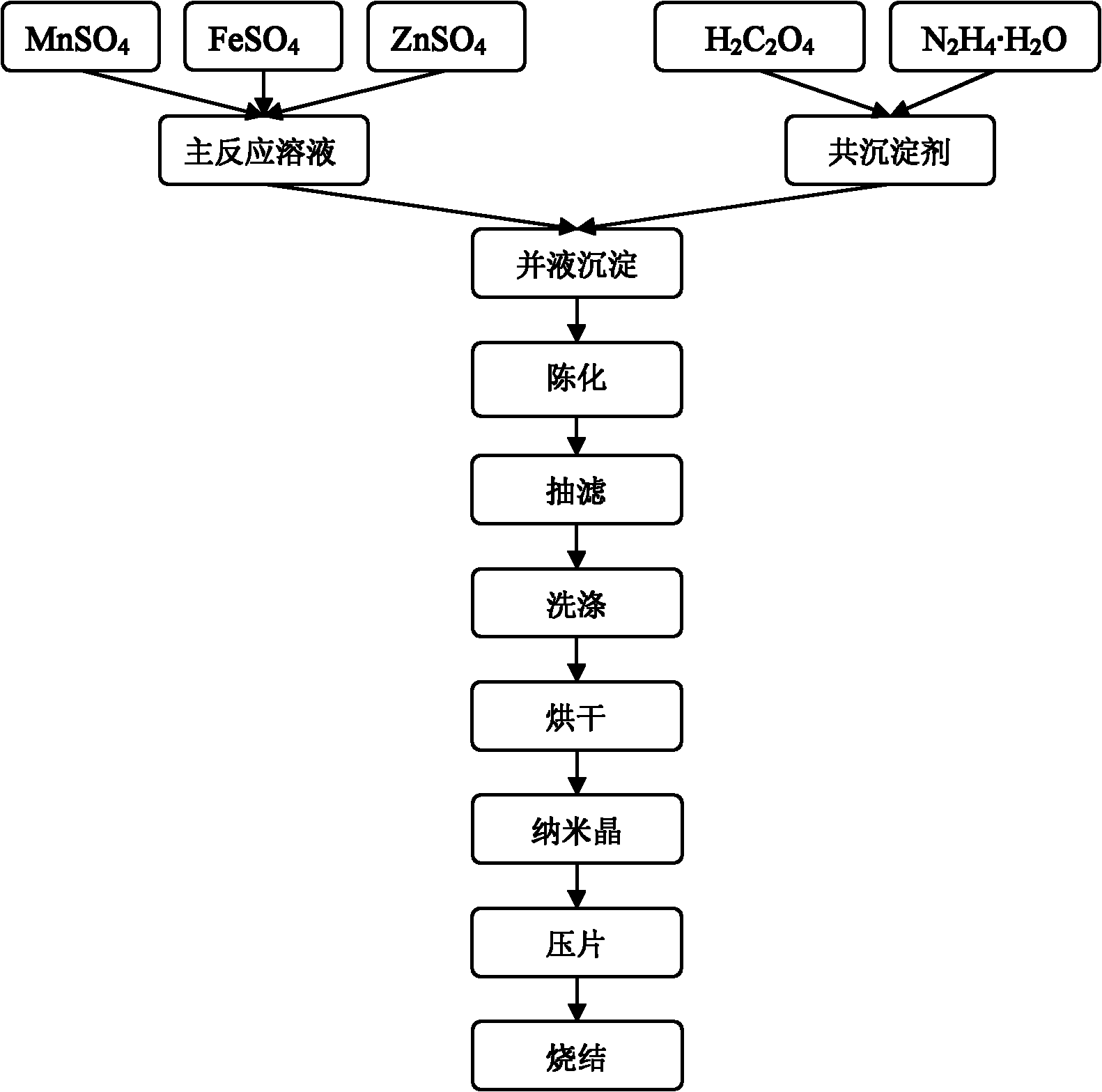

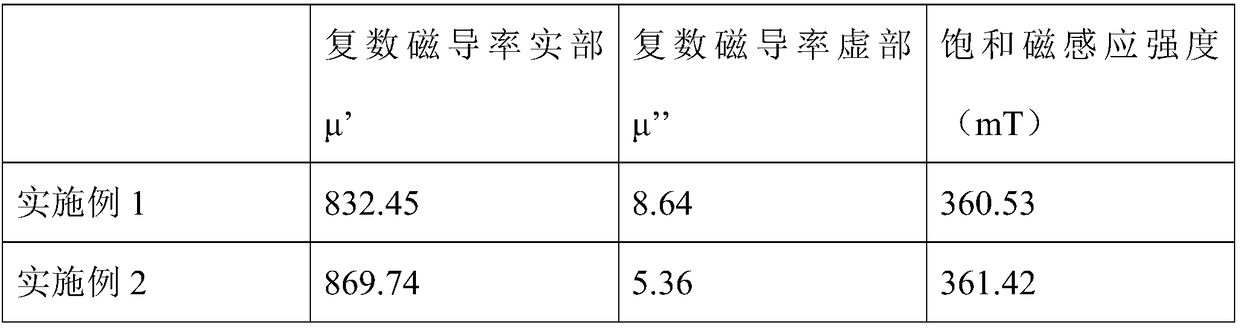

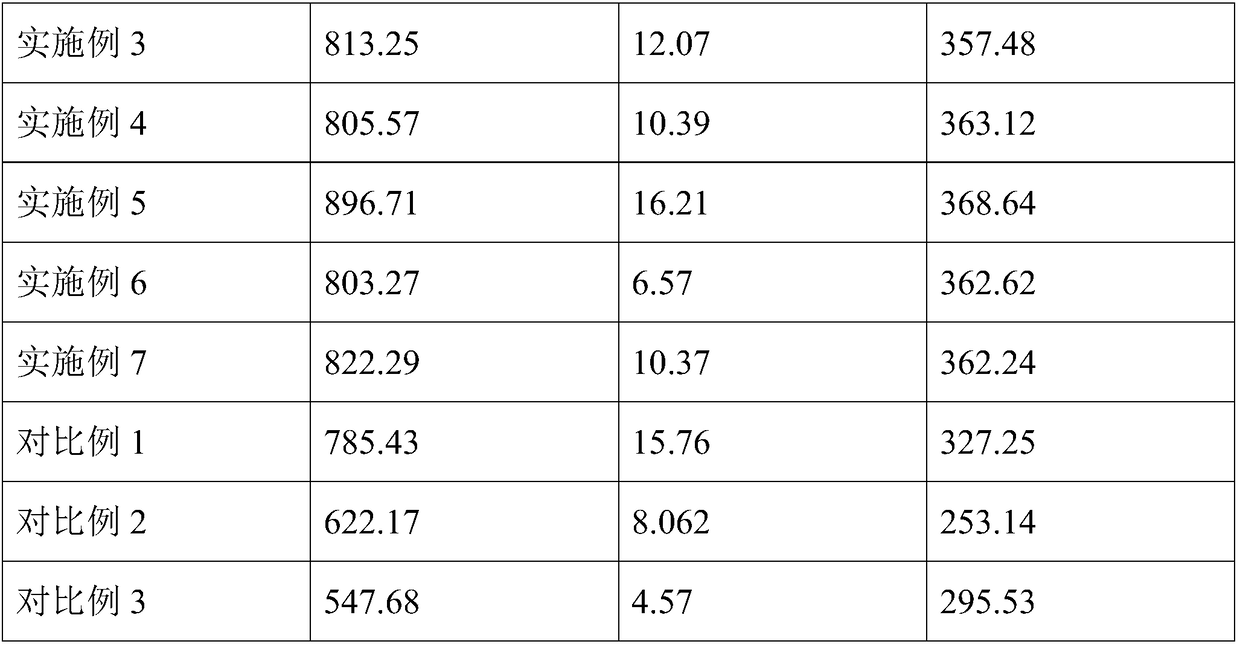

Nano-crystal Mn-Zn ferrite magnetic material with high initial permeability and high thermal-magnetic sensitivity and preparation method of nano-crystal Mn-Zn ferrite magnetic material

The invention relates to a nano-crystal Mn-Zn ferrite magnetic material with high initial permeability and high thermal-magnetic sensitivity and a preparation method of the nano-crystal Mn-Zn ferrite magnetic material. When the Mn-Zn ferrite material is prepared, a raw material is composed of a main reactant and a precipitator, wherein the main reactant comprises the following components in percentage by weight: 68-72% of FeSO4, 8-15% of ZbSO4 and the balance of MnSO4; and the precipitator is hydrazine oxalate (H2C2O4N2H4.H2O). By using the preparation method, the initial permeability of the prepared Mn-Zn ferrite is up to 7500 at 25 DEG C, and the thermal-magnetic sensitivity of the prepared Mn-Zn ferrite is about 1 DEG C. the Mn-Zn ferrite prepared by the method can be widely applied to temperature detection and control systems such as household appliances, industrial machinery and the like.

Owner:苏州天铭磁业有限公司

MnZn ferrite magnetic isolation shim as well as preparation method and application thereof

ActiveCN108793991AHigh resistivityHigh saturation magnetizationLayered productsInorganic material magnetismNiobiumGadolinium

The invention provides a MnZn ferrite magnetic isolation shim as well as a preparation method and application thereof. The MnZn ferrite magnetic isolation shim is mainly prepared from main componentsand auxiliary components, wherein the main components are prepared from MnO, Fe2O3 and ZnO; the auxiliary components are prepared from calcium element, zirconium element, niobium element, silicon element, vanadium element, cobalt element and gadolinium element. The preparation method comprises the following steps: (1) dosing and breaking; (2) presintering; (3) secondary breaking and slurrying; (4)tape casting moulding; (5) sintering. According to the MnZn ferrite magnetic isolation shim provided by the invention, by reasonably matching the main components and the auxiliary components, the prepared magnetic isolation shim has high saturation induction density and high magnetic conductivity; the preparation method provided by the invention is simple and efficient and suitable for factory mass production and improves the tape-casting preparation efficiency of raw shims.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

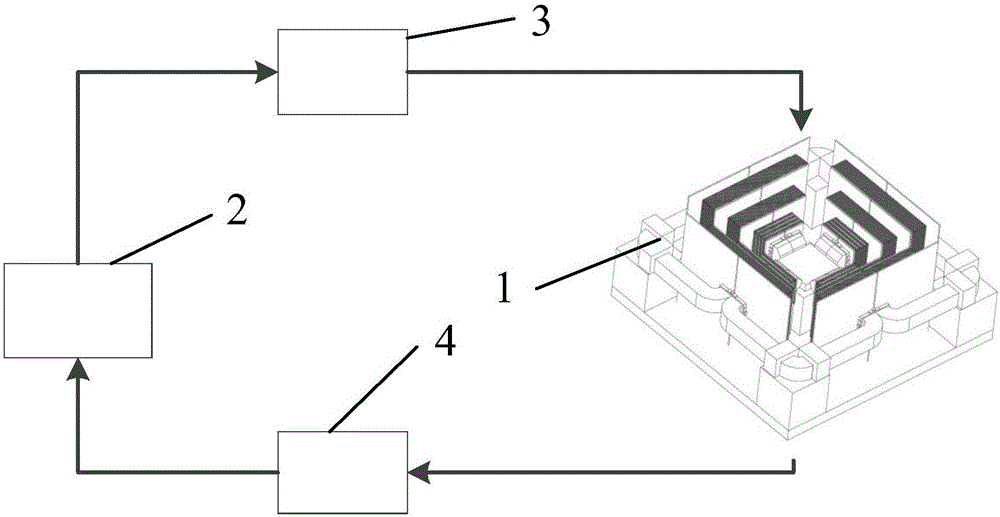

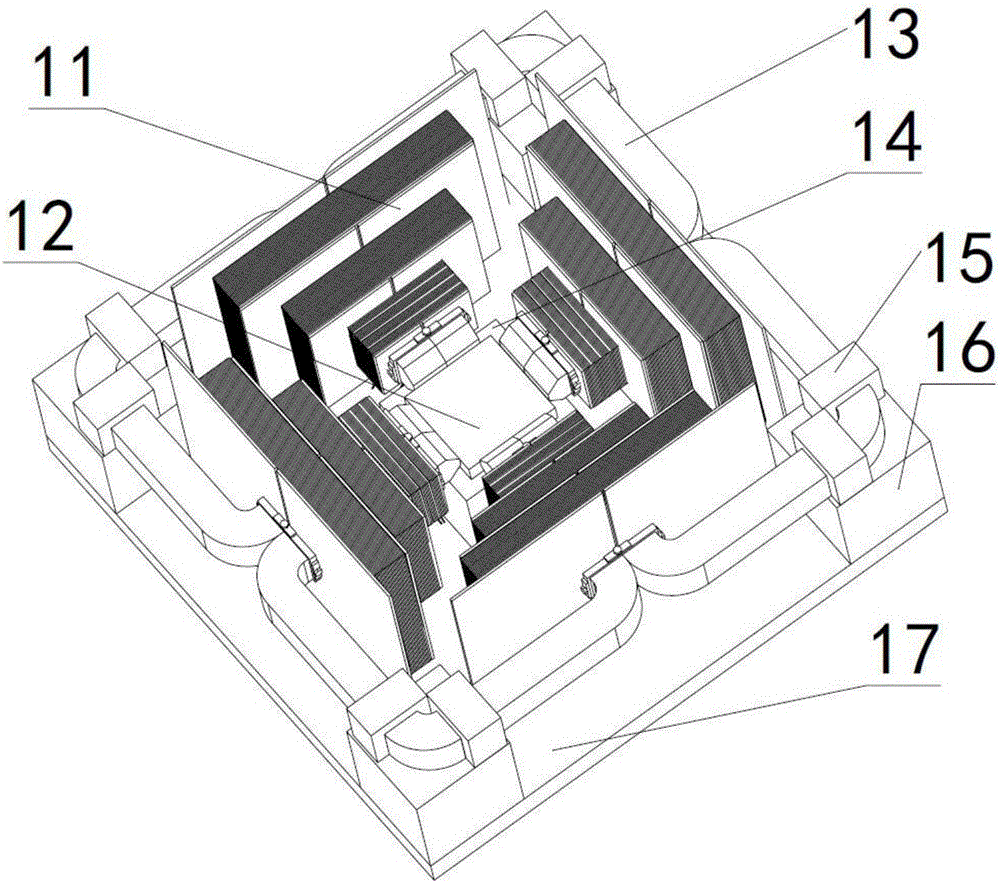

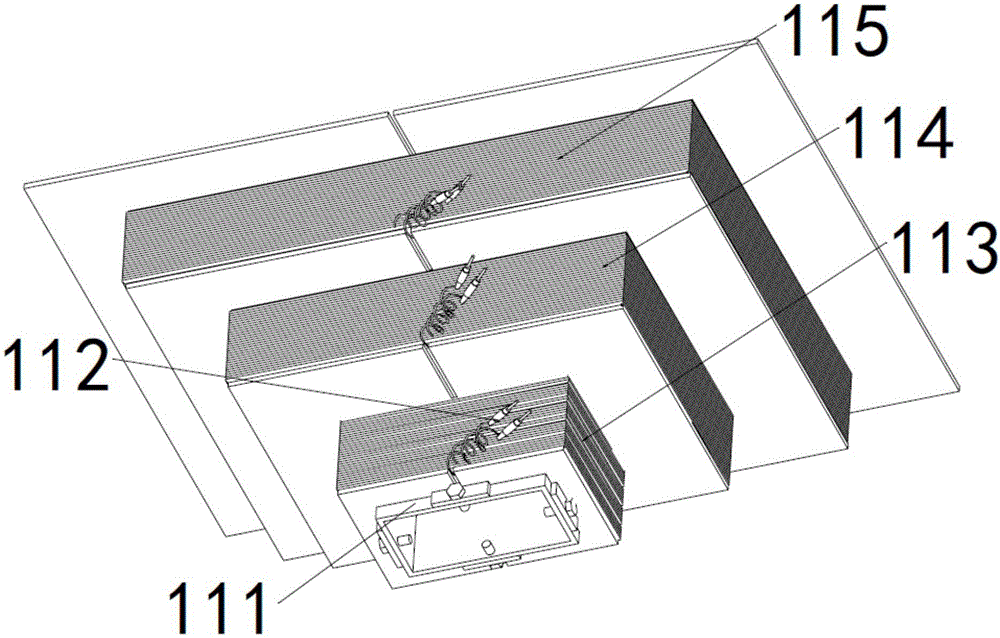

Wideband rotating magnetic characteristic measuring system and method based on flexible excitation coil

ActiveCN106842083AHigh Saturation Magnetic DensityHigh initial permeabilityMagnetic property measurementsDigital signal processingConductor Coil

The invention discloses a wideband rotating magnetic characteristic measuring system and method based on a flexible excitation coil. The measuring system comprises a detection device, a digital signal processing unit, a power amplifier, and a differential amplification circuit. The digital signal processing unit is connected with the power amplifier and the differential amplification circuit. The detection device is connected with the power amplifier and the differential amplification circuit. The detection device comprises a three-stage frustum-shaped excitation winding, a sample holder, a horizontal structure magnetic ring, a center pillar, a buckle, a corner pillar and a base. The excitation winding of the measuring system is designed as a multi-stage frustum-shaped structure to realize a wideband magnetic characteristic test. The measuring method comprises first giving an excitation signal with a low frequency, gradually increasing the frequency of the excitation signal until the sample is saturated; replacing the excitation winding connection mode after the sample is completely measured in the excitation winding connection method, and repeating the measurement process until the highest detection band.

Owner:HEBEI UNIV OF TECH

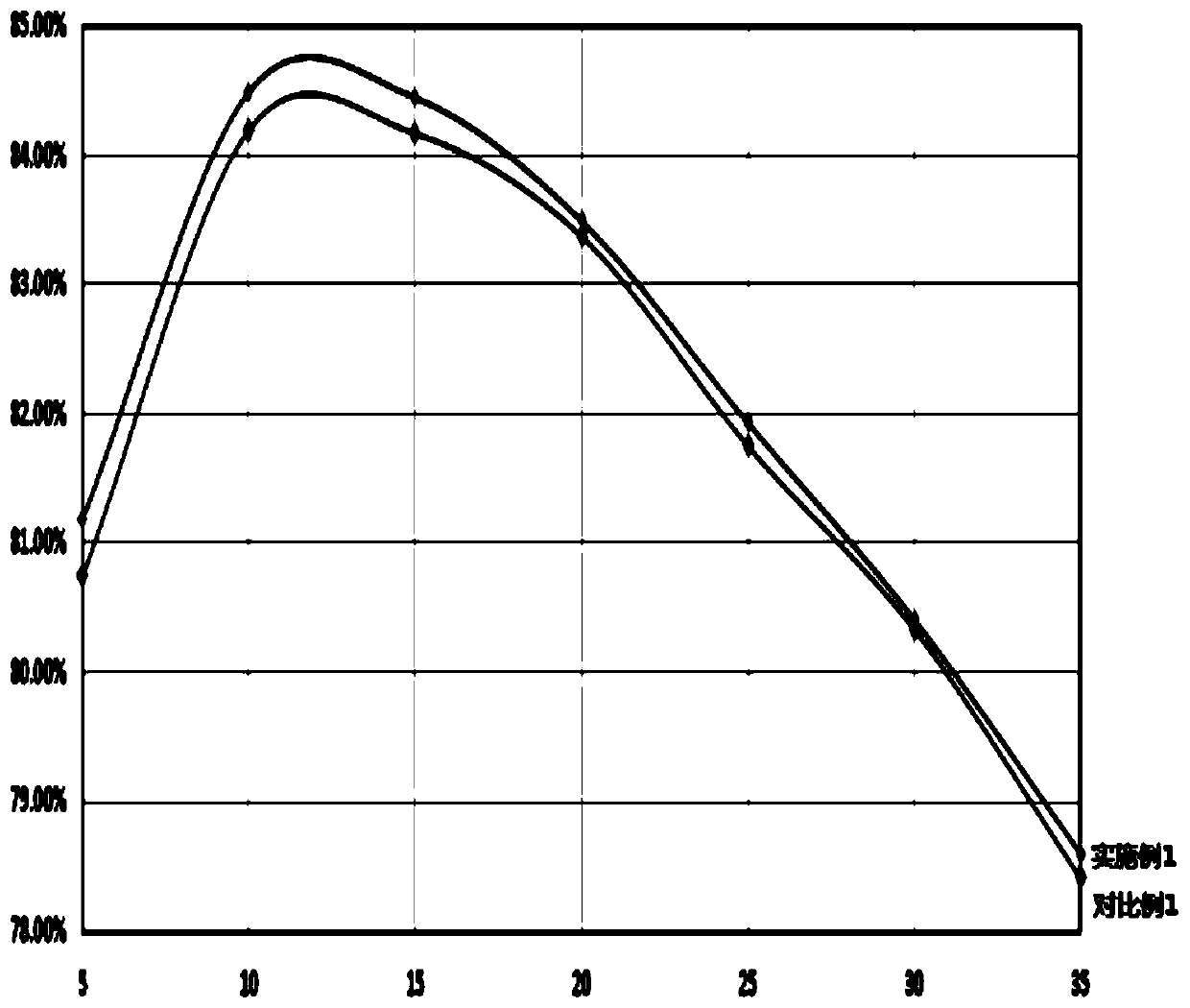

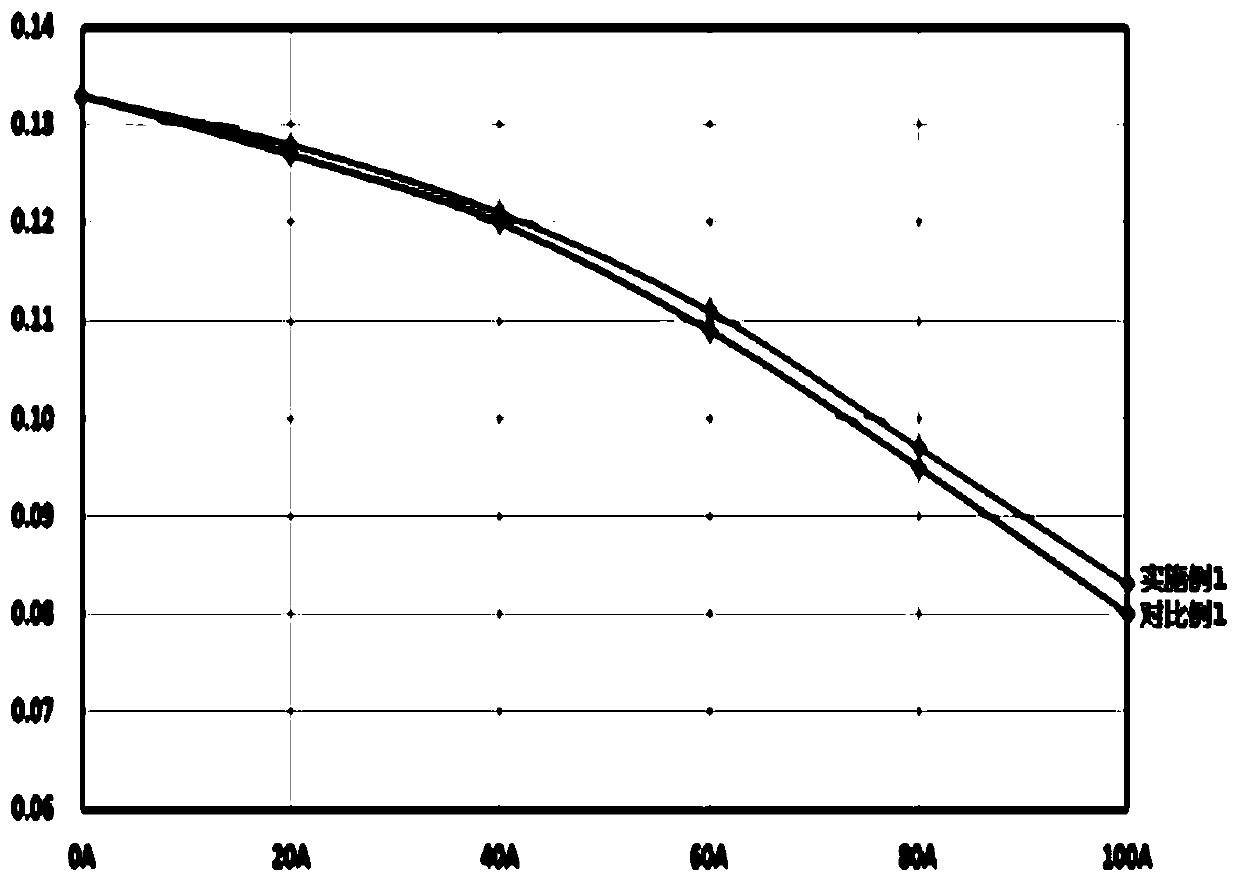

Iron-silicon-ferrite composite magnetic core and preparation method therefor

ActiveCN106504846AReduce transient lossSolve the problem of transient current distortionInductances/transformers/magnets manufactureMagnetic materialsSilicon alloyMaterials science

The invention provides an iron-silicon-ferrite composite magnetic core. The iron-silicon-ferrite composite magnetic core is prepared from the following raw materials based on mass percentage through pressing and thermal treatment in sequence: 80-99% of iron-silicon alloy powder, 0.5-8% of insulating coating agent and the balance of ferrite magnetic core, wherein the iron-silicon alloy powder, the surface of which is coated with the insulating coating agent, coats the surface of the ferrite magnetic core. By adoption of the iron-silicon-ferrite composite magnetic core provided by the invention, the high-current unsaturated capability of the iron-silicon alloy and the high magnetic conductivity of the ferrite magnetic core can be made into full play, so that the problem of transient state current distortion of a low-impedance high switching current is solved; the result of the embodiment proves that the initial magnetic conductivity of the composite magnetic core provided by the invention is improved; when the magnetic field strength is 0.2(Oe), the magnetic conductivity of the iron-silicon-ferrite composite magnetic core can reach 10,000, which is far higher than the initial magnetic conductivity of an iron-silicon magnetic core 57 under the same condition and is 169 times of the magnetic conductivity of the iron-silicon magnetic core in the prior art.

Owner:JIANGXI AITE MAGNETS +1

Method for lot production of MnZn power ferrite containing high frequency and low loss

ActiveCN101206940AReduce power lossHigh initial permeabilityInorganic material magnetismSurface roughnessOil production

The invention belongs to the magnetic material field, in particular relates to a method for the mass production of a MnZn power ferrite with high-frequency and low loss. The invention mainly solves the technical problems existing in the prior art that the utilization range is limited, and the energy consumption is large, etc., and provides the method for the mass production of the MnZn power ferrite with high-frequency and low loss. The invention comprises the following main steps: raw materials are weighed, and then vibrated and milled to obtain powder lot; the powder lot is directly pre-burned by adopting a double push plate air kiln to obtain preburning material; the preburning material is sanded by adopting a sand mill; the preburning material is molded by adopting a fully automatic dry press machine; a molded blank is sintered by adopting an asintering furnace; the granule manufacture is performed to the blank by adopting a spray drying granulating machine; the surface of the blank is processed to the roughness degree that Ra is equals to 0.2 to 1.4 microns by adopting a double axle grinding machine.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com