High-frequency high-power Ni-Zn base magnetic ferrite material and manufacturing method thereof

A soft ferrite, high-power technology, applied in the high-frequency high-power nickel-zinc-based soft ferrite material and its manufacturing field, can solve the problems of high temperature magnetic core, bursting products, and failure to work normally, and achieve high saturation Magnetic induction intensity, high Curie temperature characteristics, and the effect of improving electromagnetic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

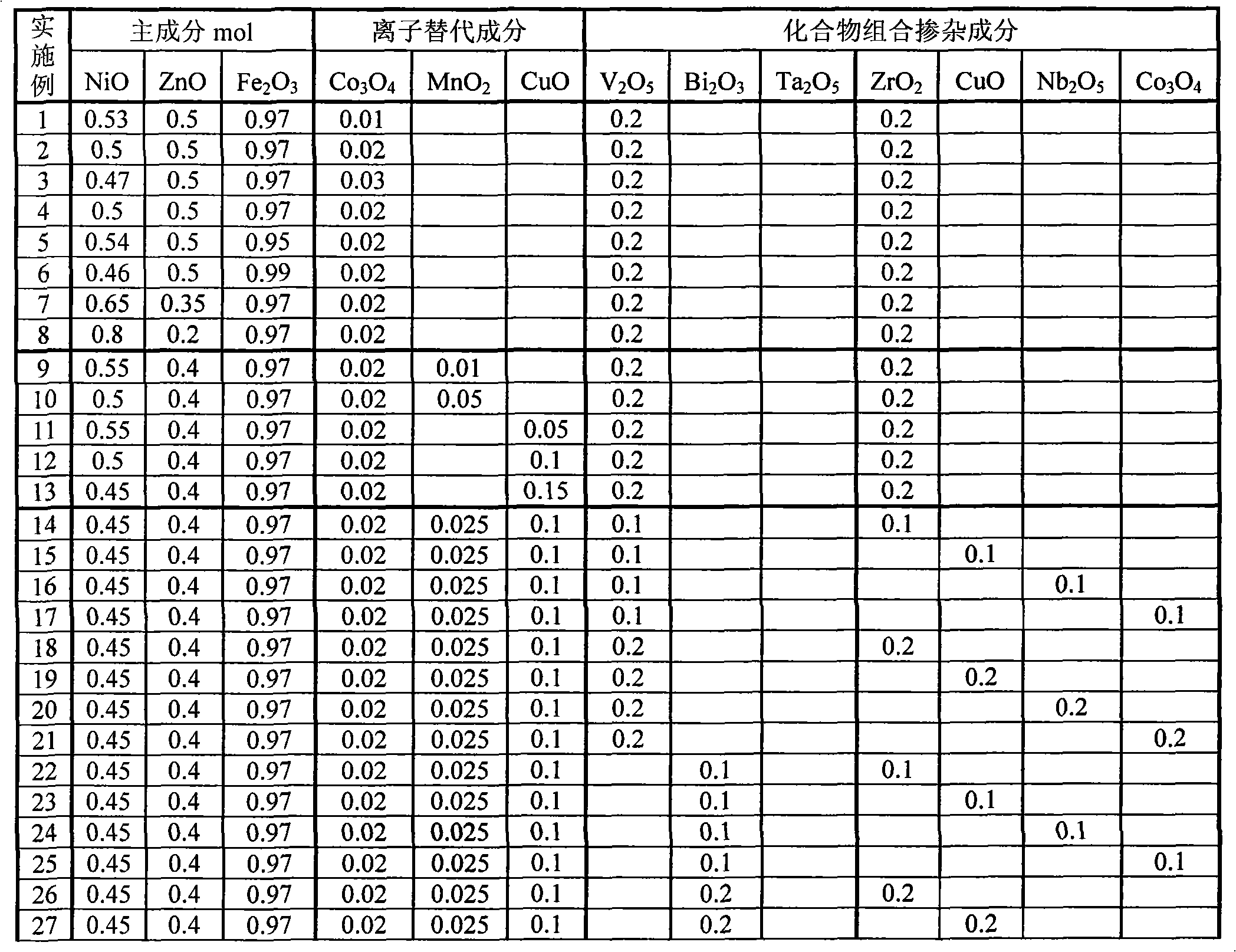

[0031] Specific examples of high-frequency high-power nickel-zinc-based soft ferrite material composition of specific examples of the composition ratio shown in Table 1:

[0032] Table 1 Composition

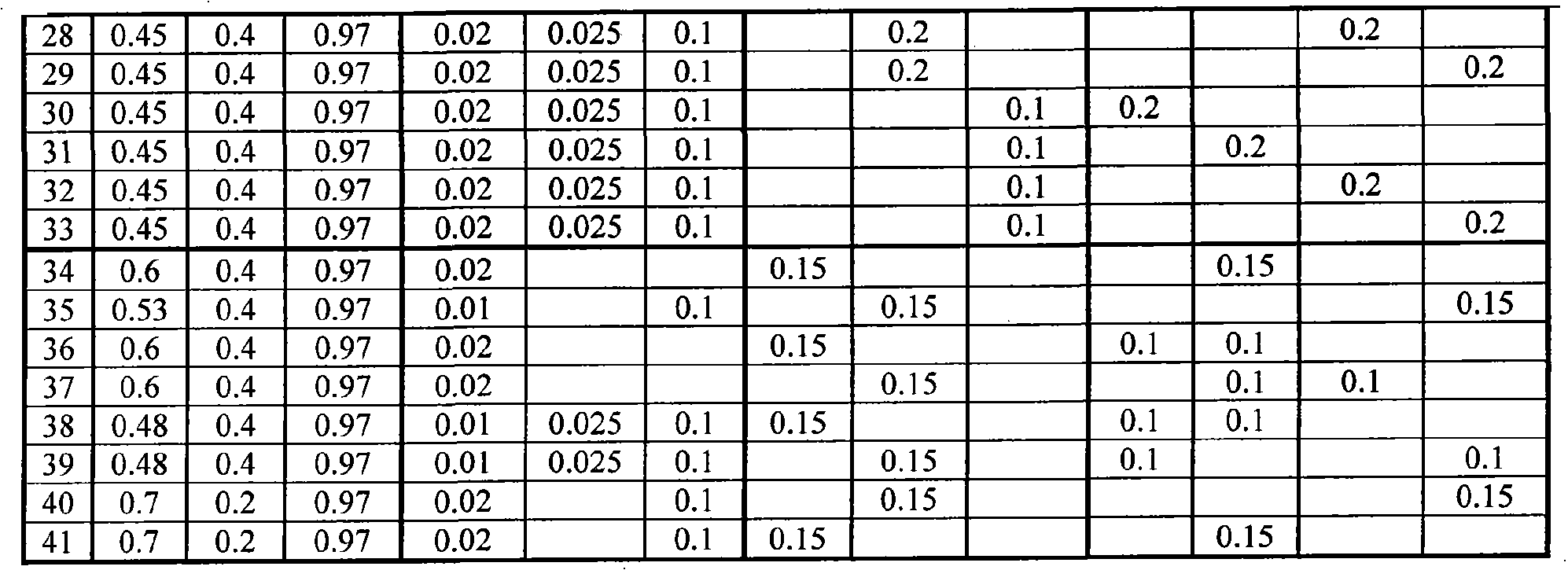

[0033]

[0034]

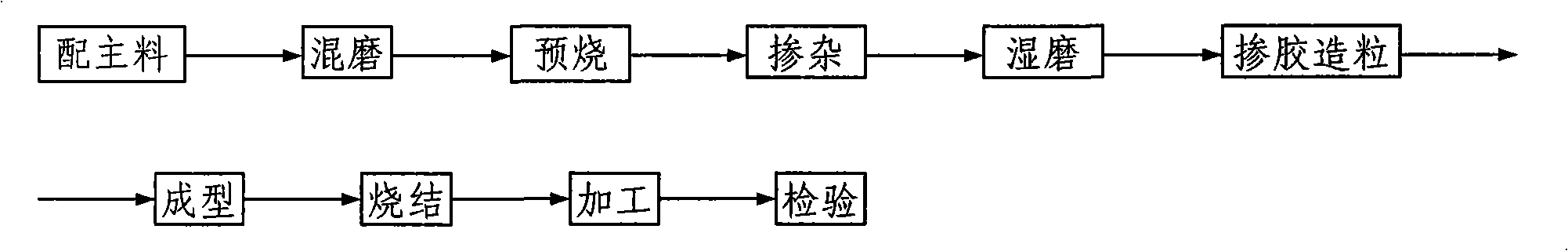

[0035] A method for preparing a high-frequency and high-power nickel-zinc-based soft ferrite material, comprising the following steps:

[0036] a), wet mixing and grinding to prepare NiZn-based ferrite main material mixture

[0037] Proportionally weigh the main material, deionized water with 1.1 times the weight of the main material, and steel balls with 2 times the weight of the main material, and place them in the steel tank of the ball mill for wet mixed grinding. The linear speed of the mixed grinding is not less than 300m / min. The mixing and grinding time is not less than 2 hours to obtain a well-uniform mixture, which is dried and pulverized through a 40-mesh sieve for later use;

[0038] b), low temperature sintering and rapid cooling to prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Actual density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com