Patents

Literature

563results about How to "High curie temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

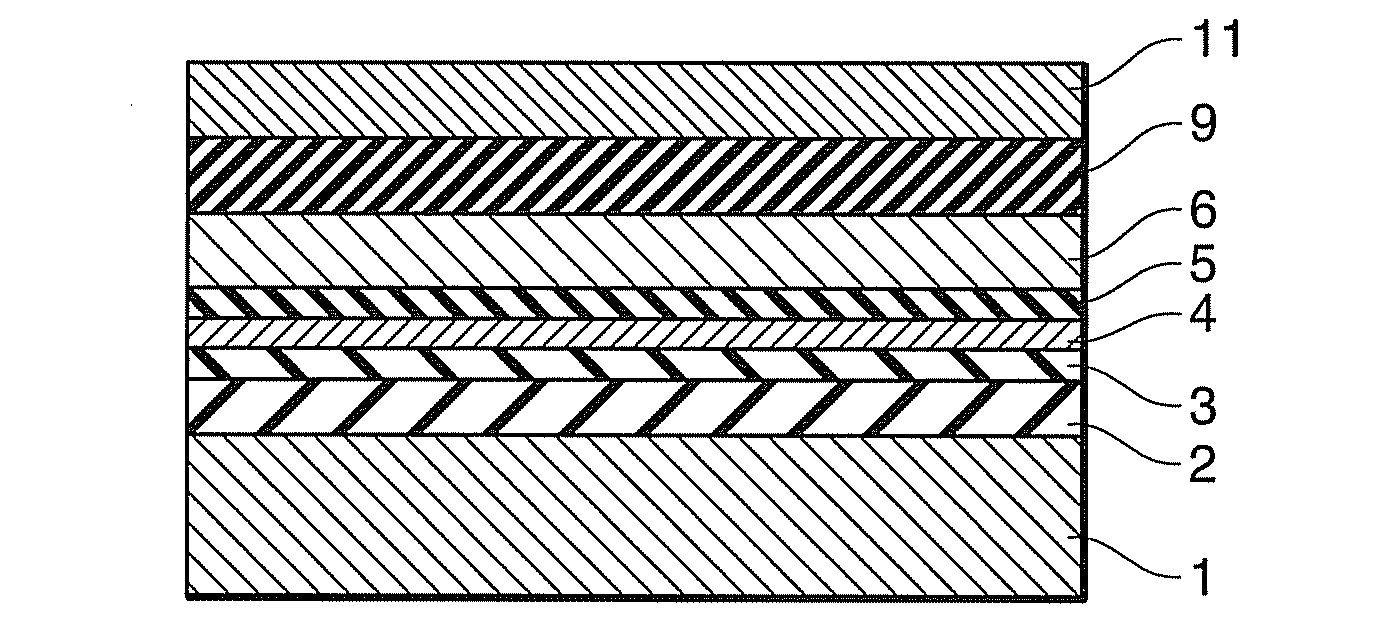

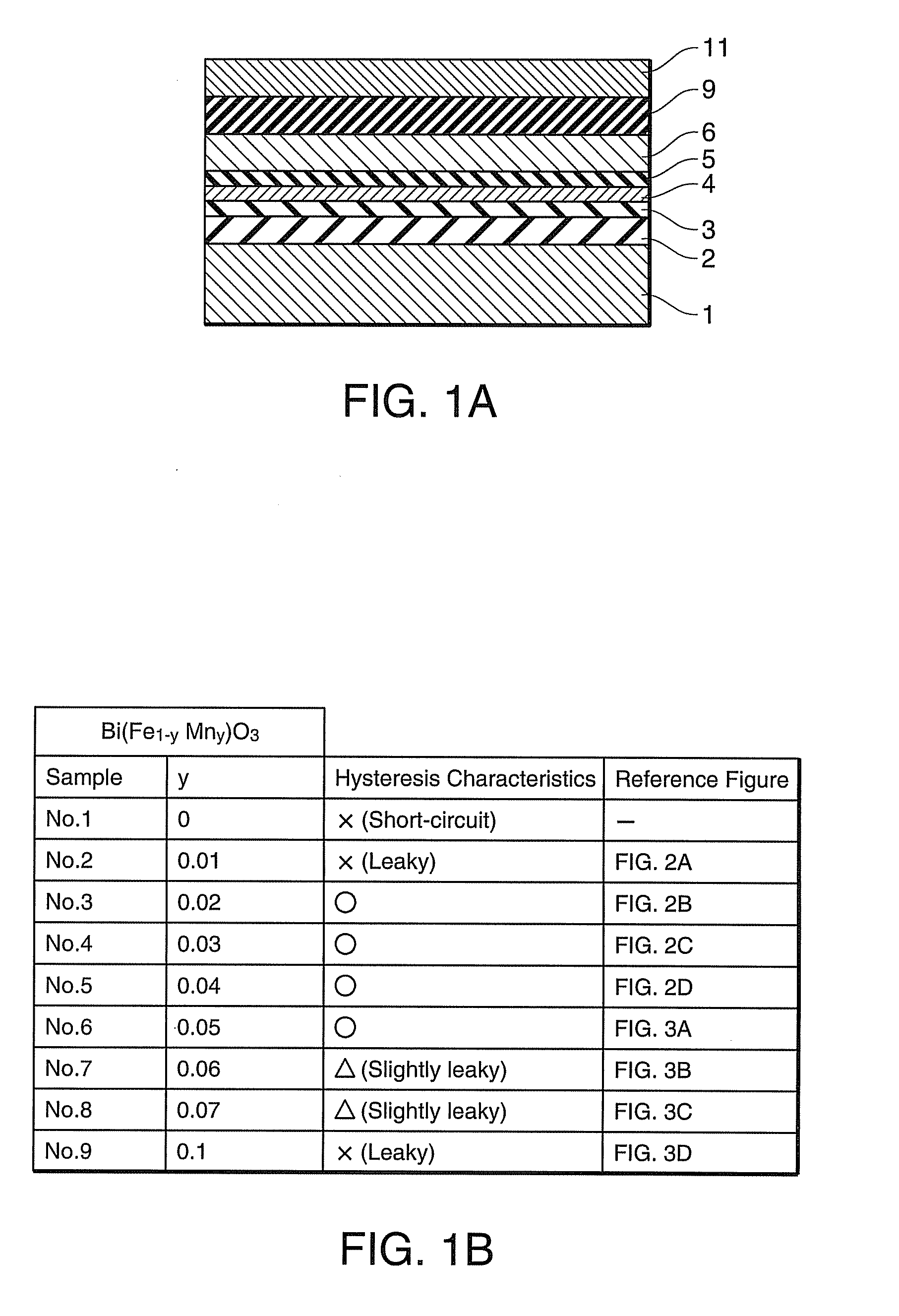

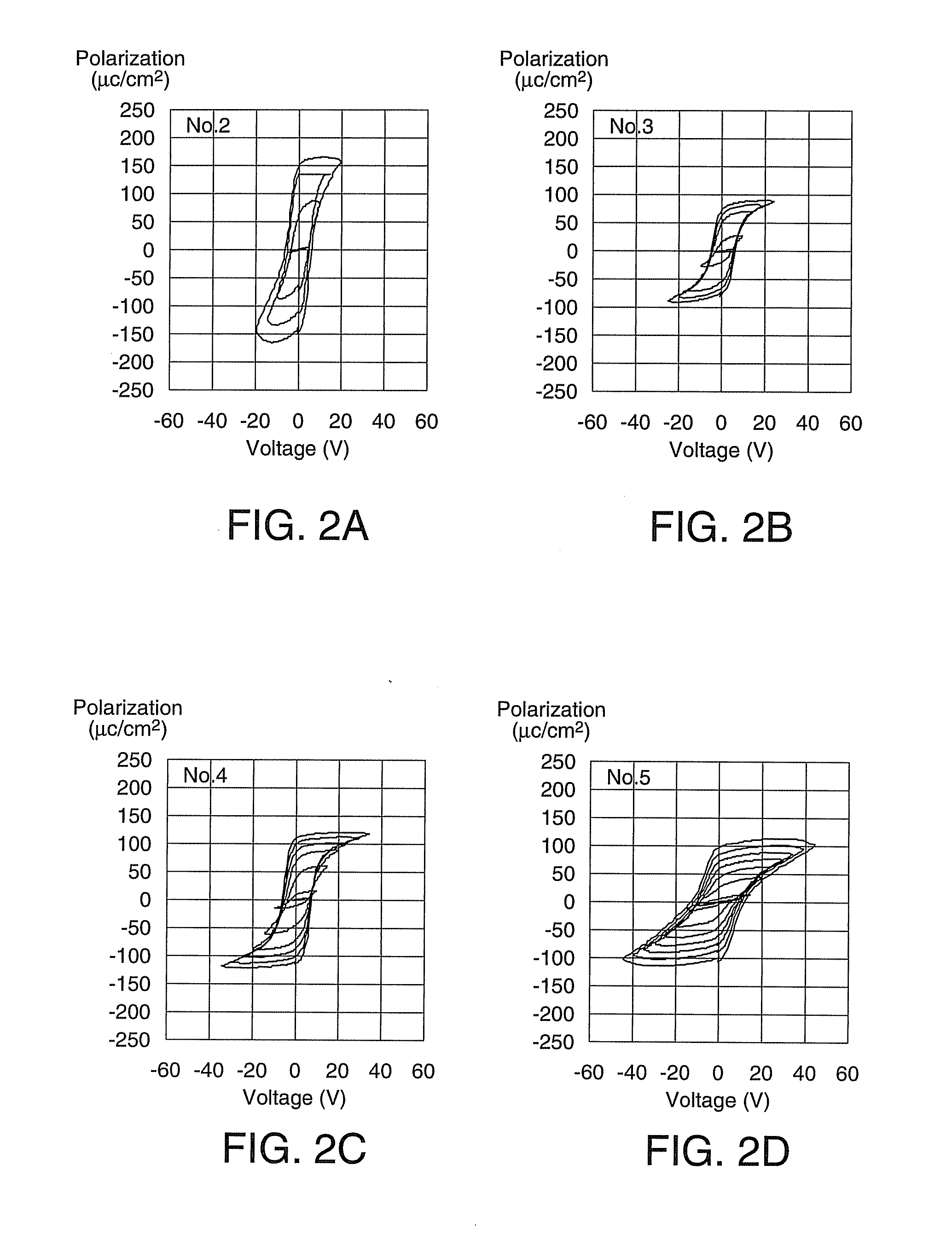

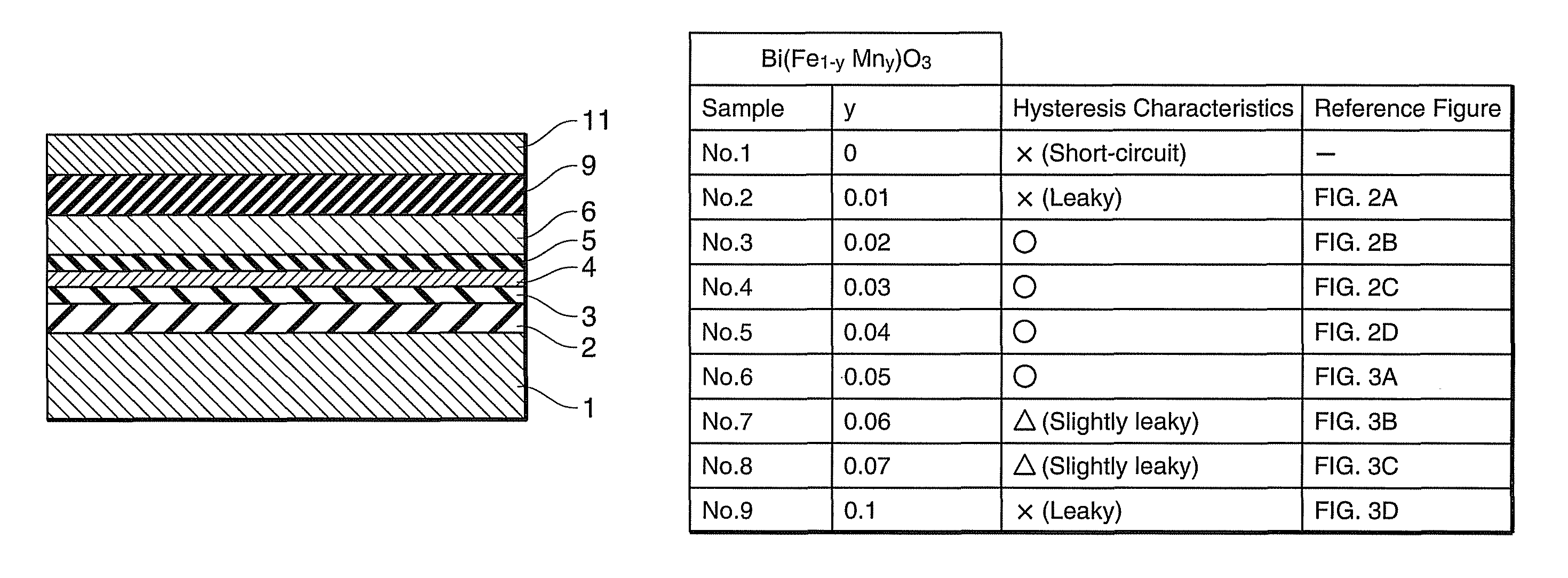

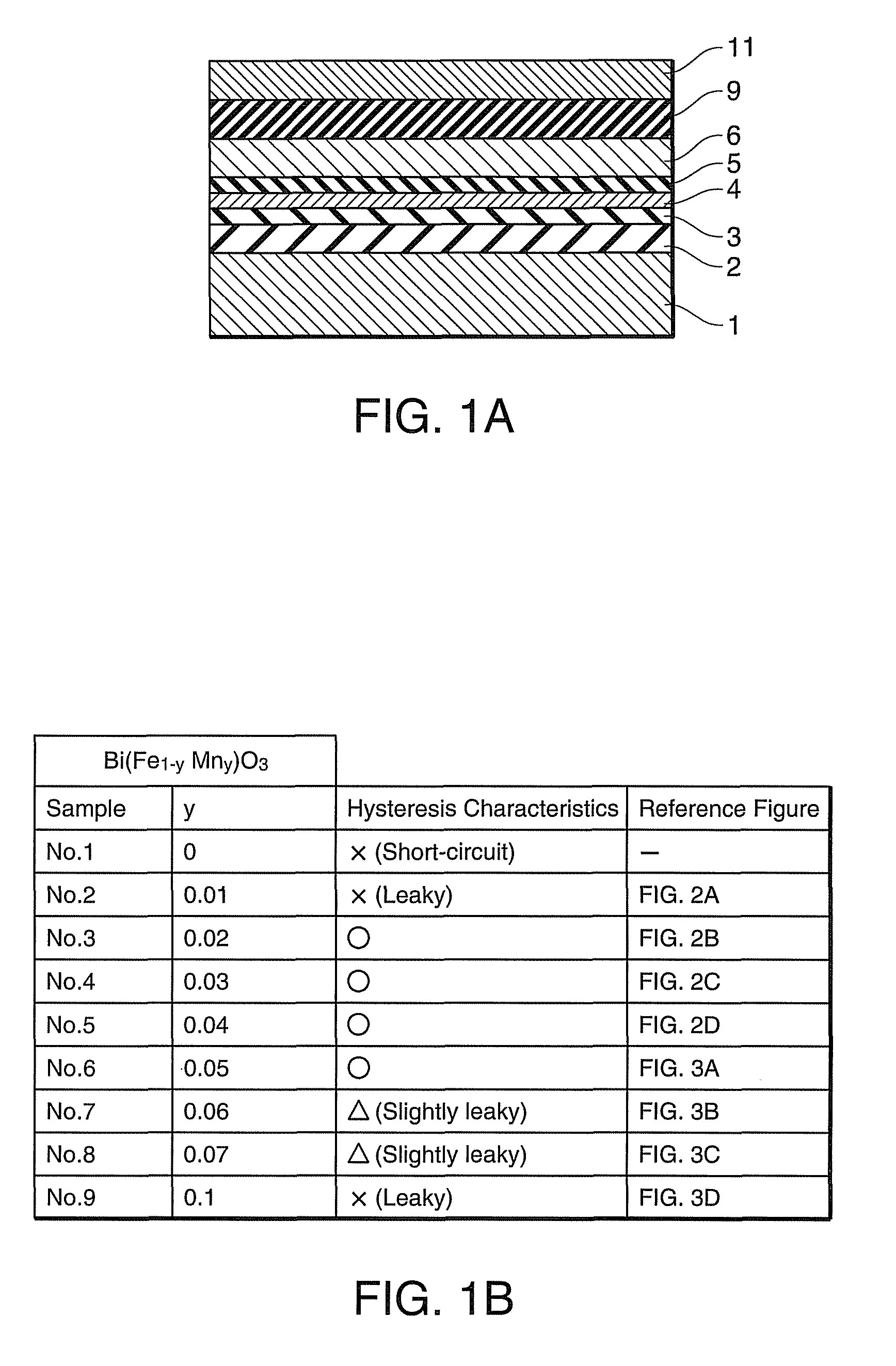

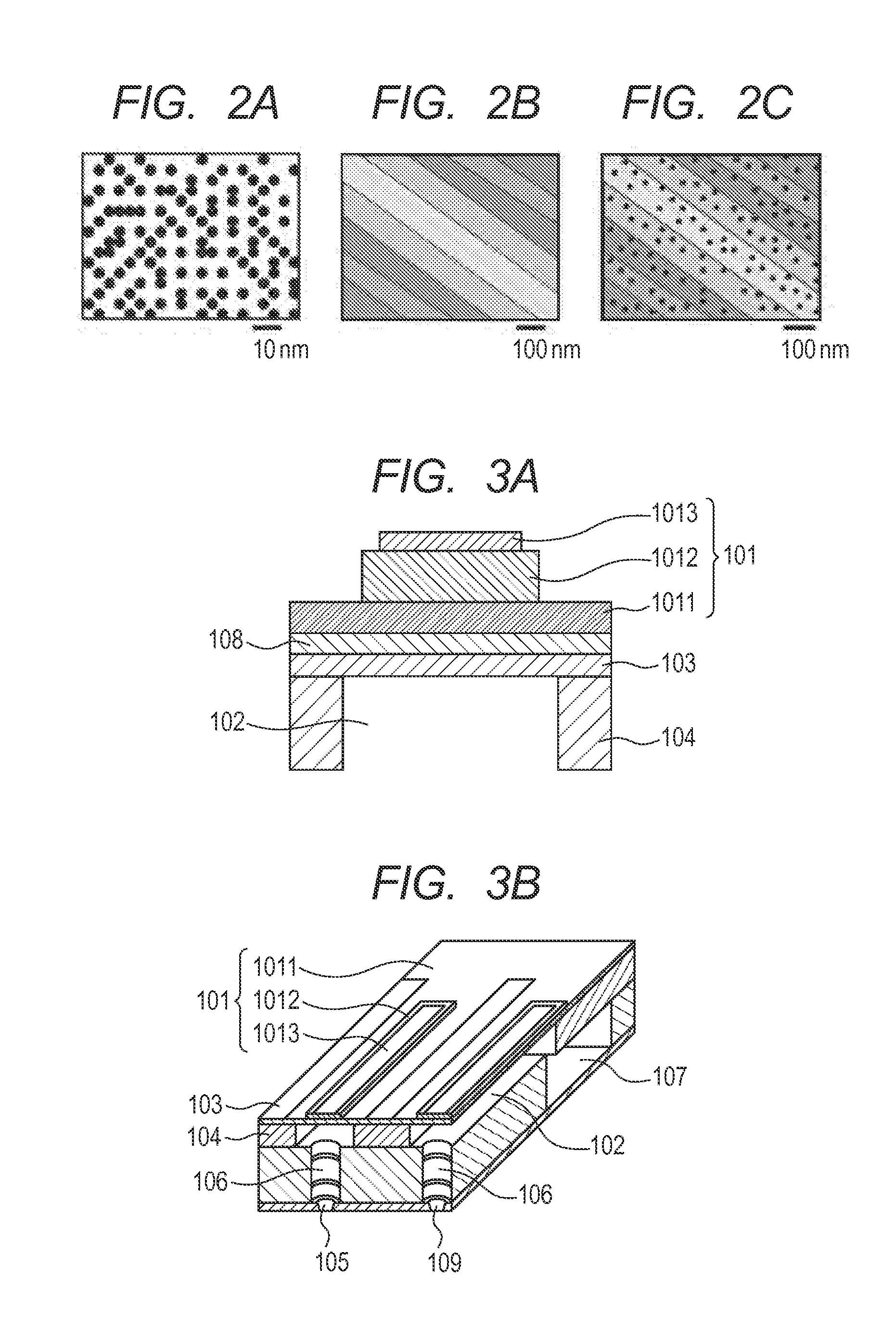

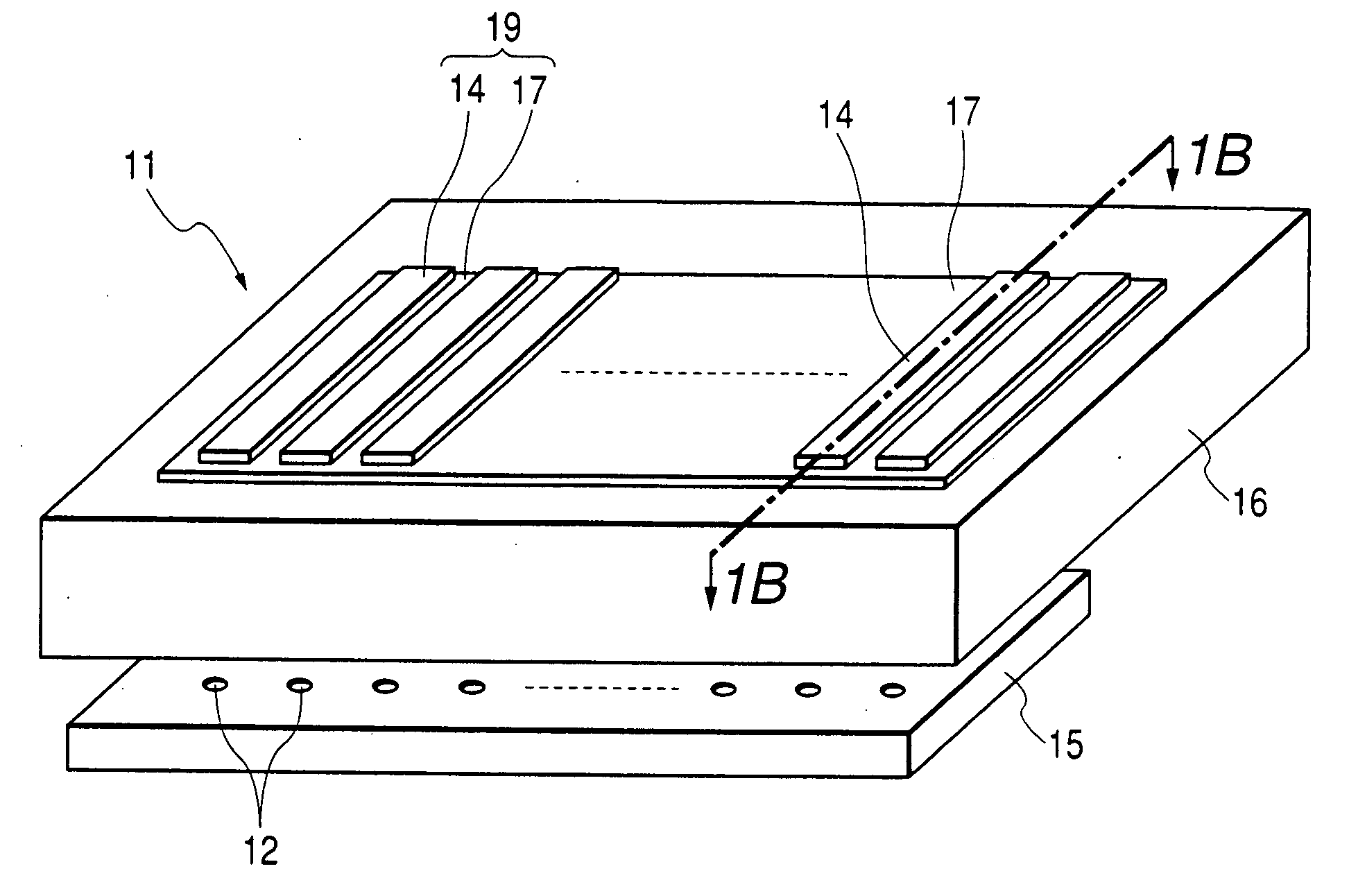

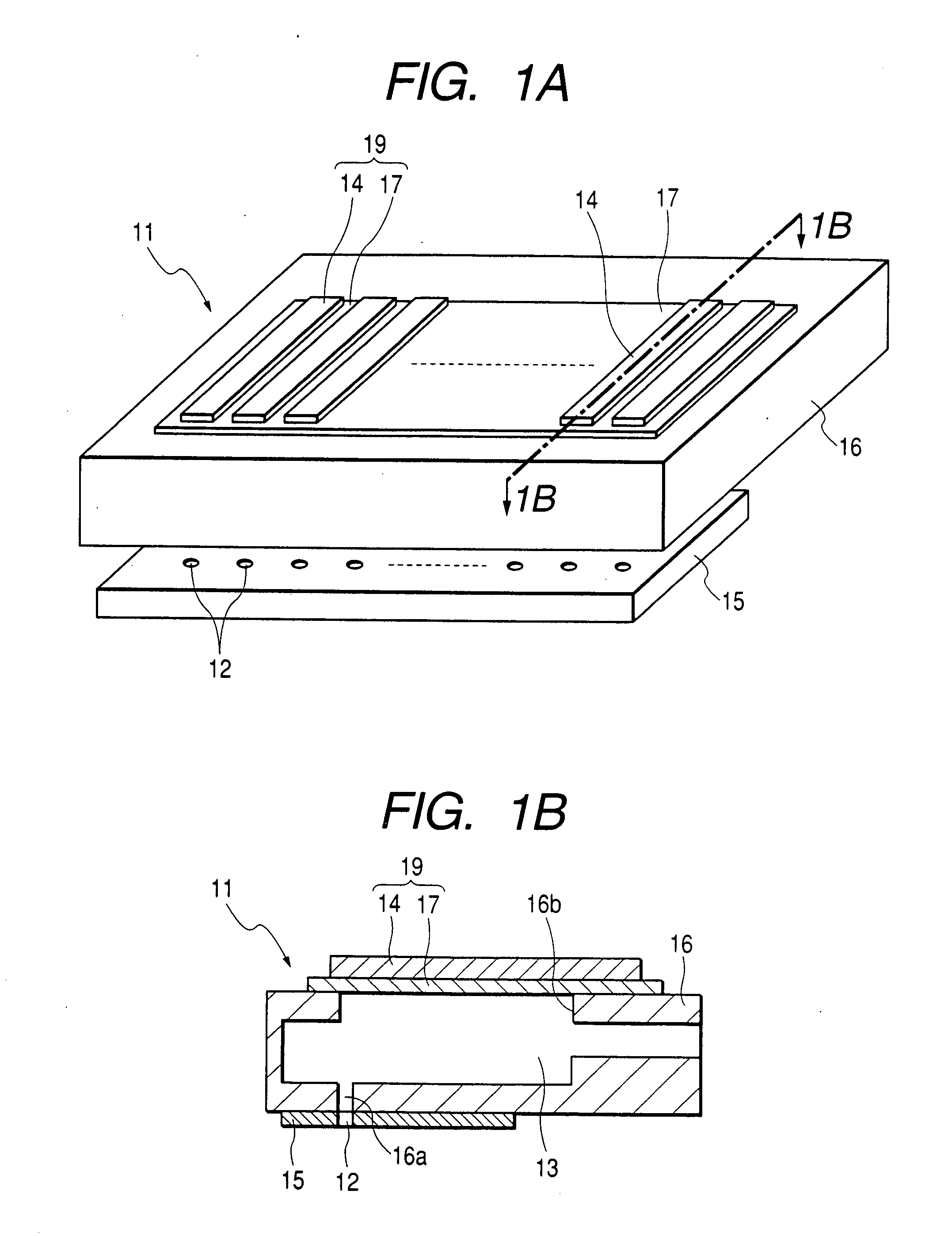

Piezoelectric material and piezoelectric element

ActiveUS20090243438A1Large piezoelectric constantHigh Curie temperaturePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesComposite materialSpontaneous polarization

A piezoelectric element includes a first electrode, a piezoelectric film disposed on the first electrode, and a second electrode disposed on the piezoelectric film. The piezoelectric film is composed of piezoelectric material that is lead free and formed by mixing 100(1−x)% of material A having a spontaneous polarization of 0.5 C / m2 or greater at 25° C. and 100 x % of material B having piezoelectric characteristics and a dielectric constant of 1000 or greater at 25° C., wherein (1−x)Tc(A)+xTc(B)≧300° C., where Tc(A) is the Curie temperature of the material A and Tc(B) is the Curie temperature of the material B.

Owner:SEIKO EPSON CORP

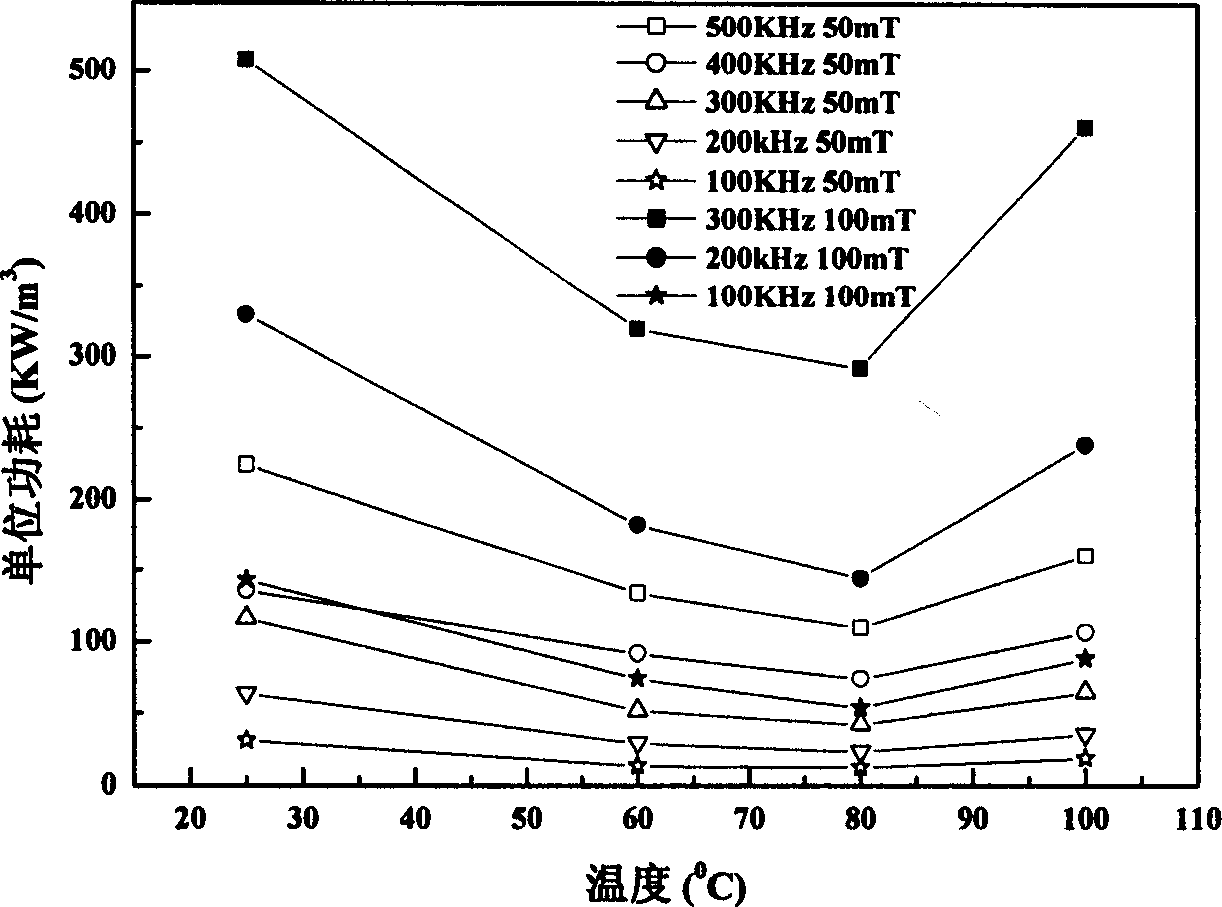

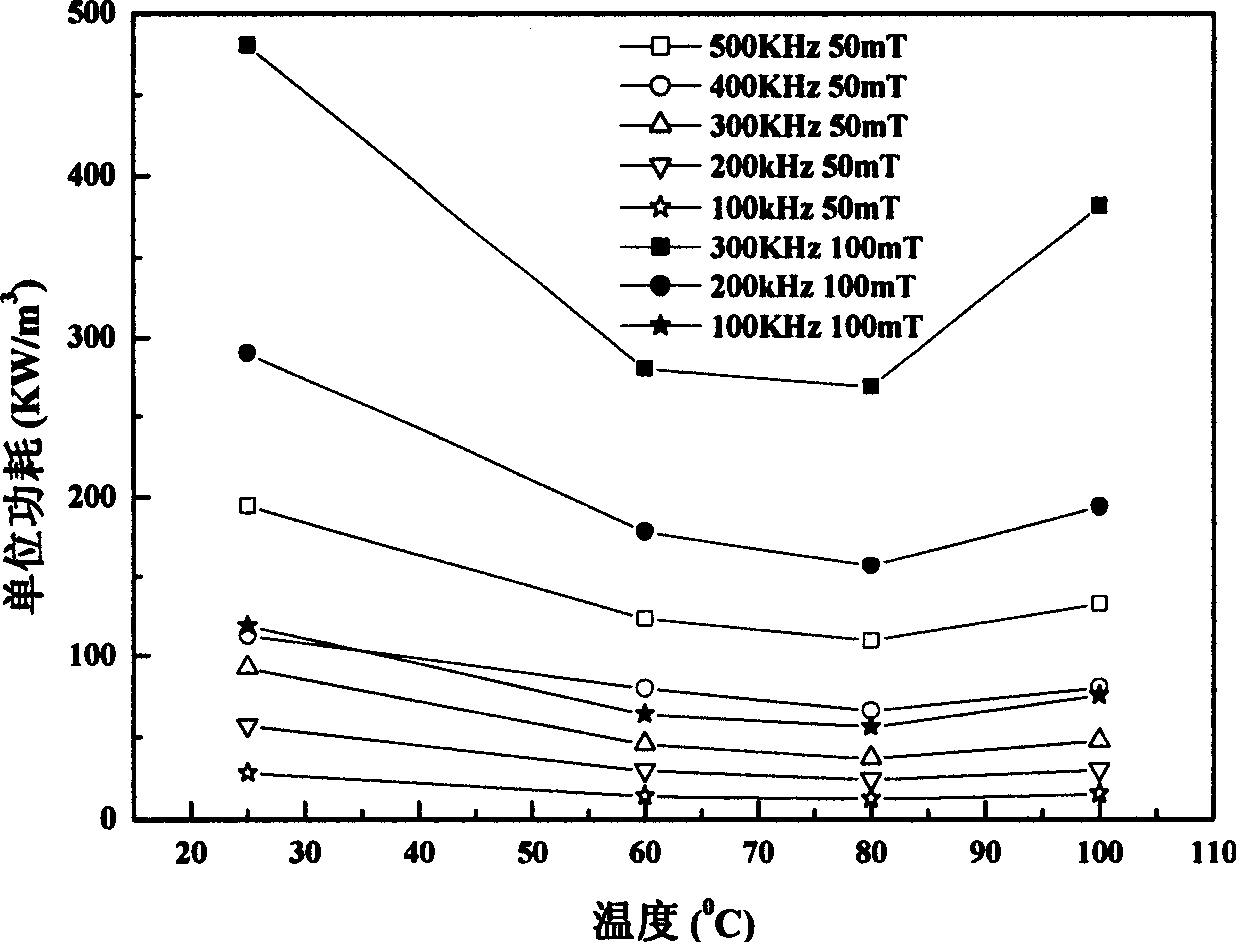

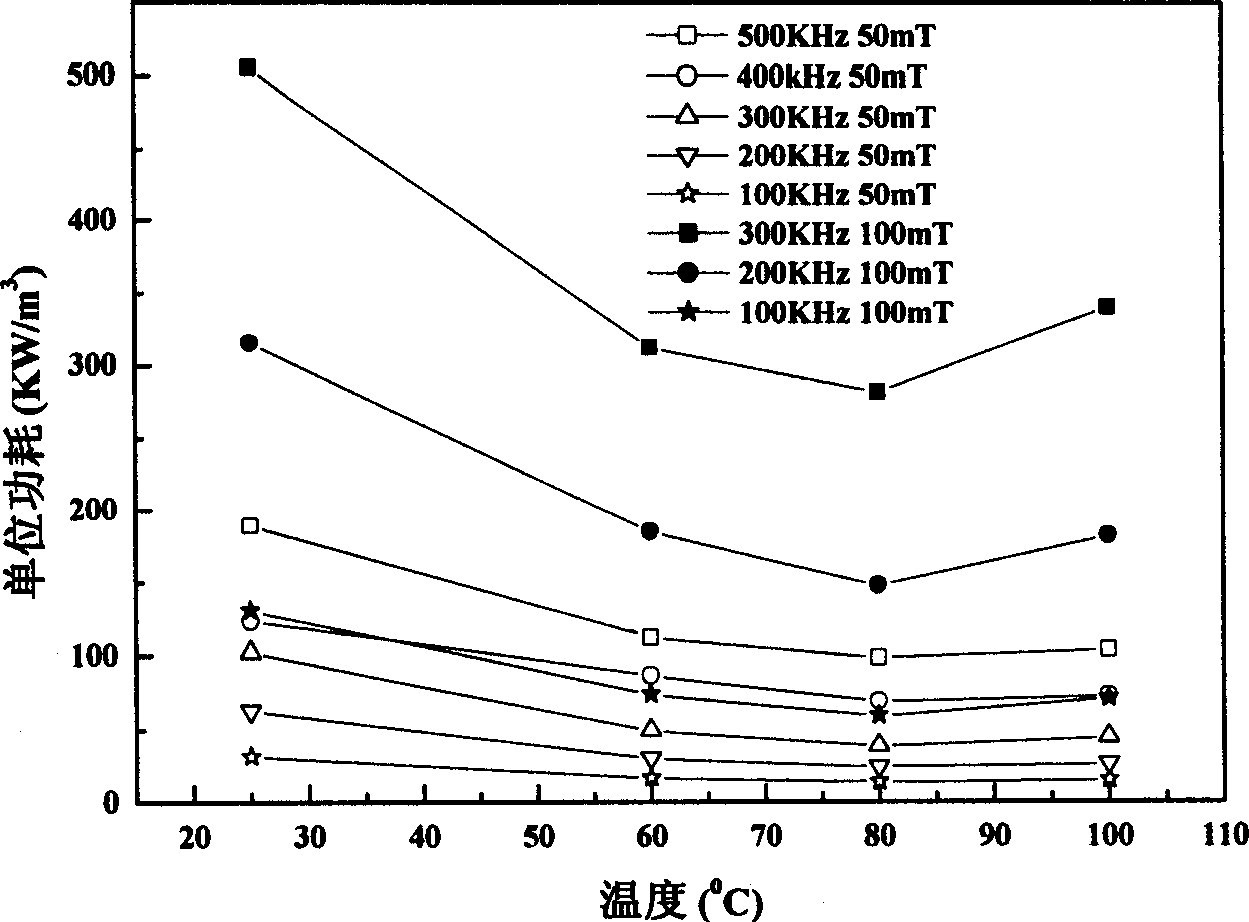

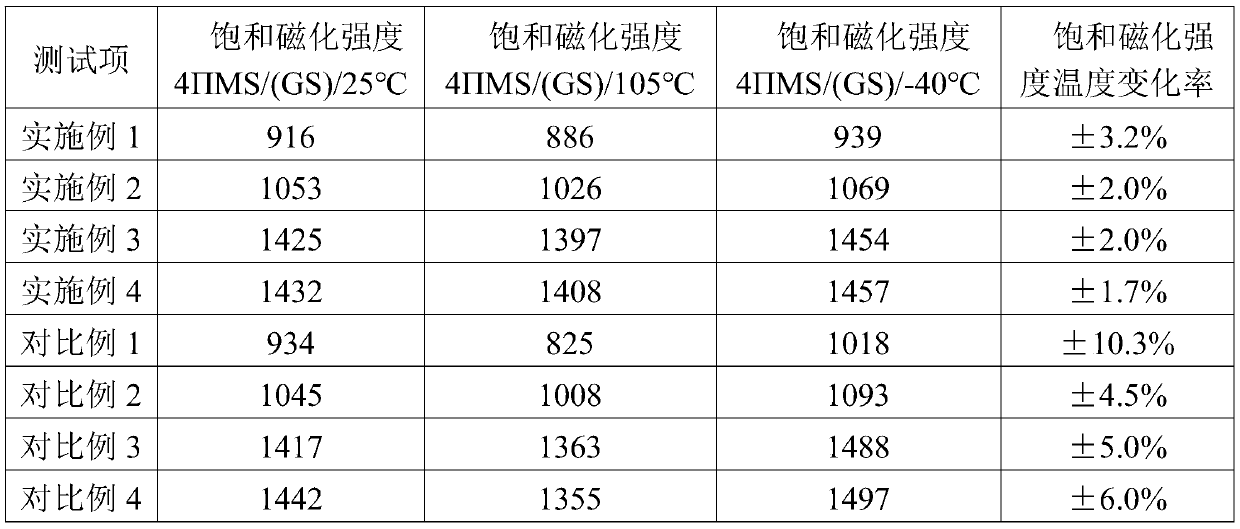

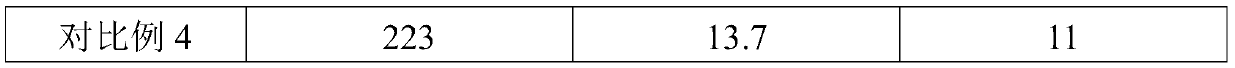

High performant low consumption manganese zine ferrite material and preparation process thereof

The invention relates to a high capacity low power consumption manganese-zinc ferrite material manufacturing method. The constituents includes 69.1-72.5wt% Fe2 O3, 22-24wt% Mn3O4, and ZnO. In the process of grinding and sintering, two or more from TiO2, Gd2 O3, SnO2, Co2O3, Ta2O5, Nb2O5, CaCO 3 could be added into the raw material. After grinding, pressure molding, sintering following certain temperature curve, the manganese-zinc ferrite material would be gained. The invention is simple and cost low. It has the feature of wide bandwidth and wide temperature.

Owner:SHANGHAI JIAO TONG UNIV

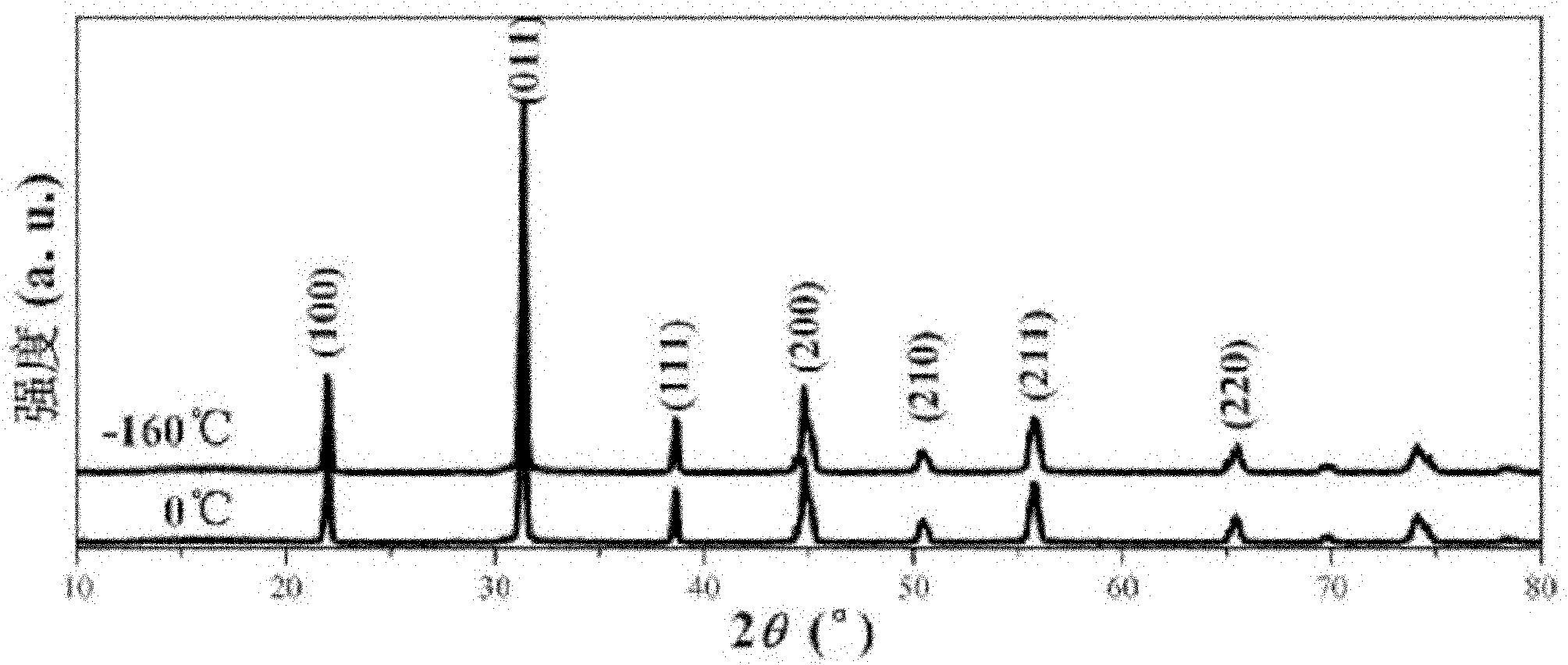

Ternary system relaxation ferroelectric single crystal material and preparation method thereof

InactiveCN101985775ASmall sizeQuality improvementPolycrystalline material growthFrom frozen solutionsBridgman methodSingle crystal

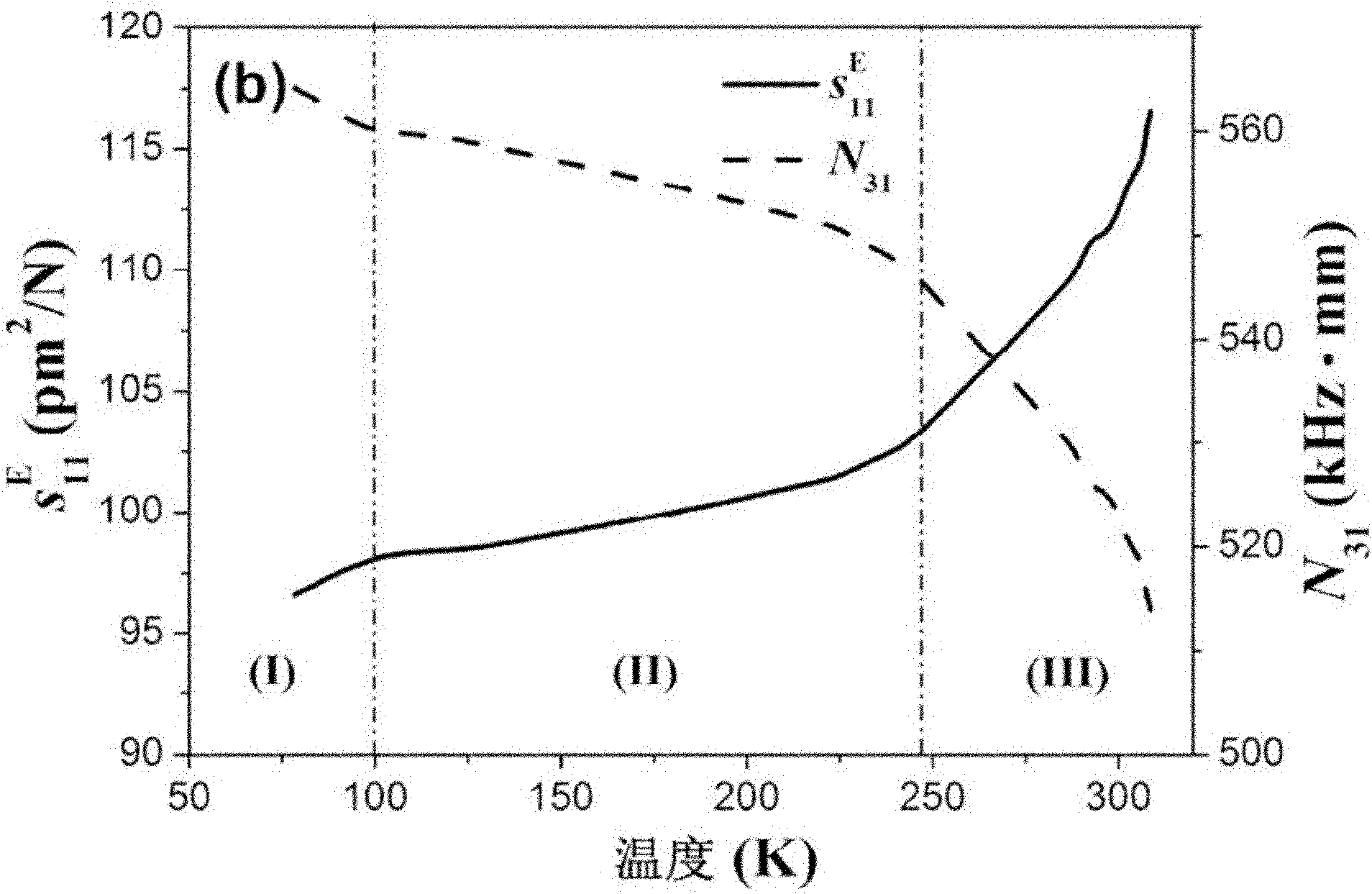

The invention discloses a ternary system relaxation ferroelectric single crystal material. The material comprises the following chemical components: xPb(In1 / 2Nb1 / 2)O3-yPb(Mg1 / 3Nb2 / 3)O3-(1-x-y)PbTiO3, wherein the x is equal to 0.1-0.45, and the y is equal to 0.1-0.5. A preparation method of the single crystal material PIMNT is an improved Bridgman method and comprises the following steps of: processing raw materials, melting by raising the temperature, and performing crucible degrowth and crystal cooling growth. The prepared single crystal material overcomes the defects of over low Curie point of PMNT single crystals, difficult crystallization and difficult batch growth of the PINT single crystals in the prior art, has high piezoelectric performance and pyroelectric performance, higher temperature stability and wide application prospect and adds a new product in the field.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

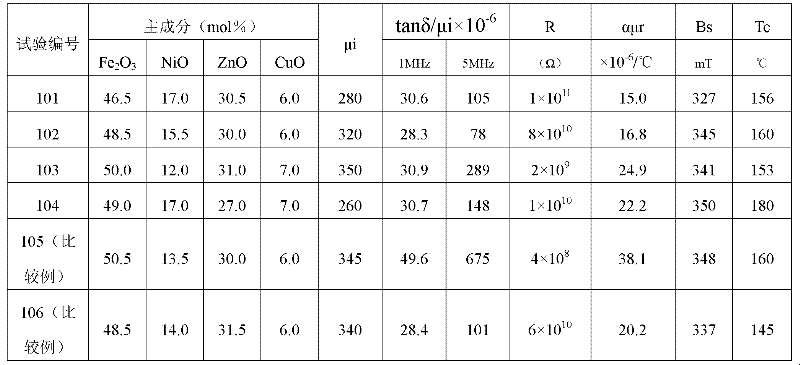

Soft-magnetic nickel-copper-zinc ferrite material and preparation method thereof

The invention belongs to the field of soft magnets, and particularly provides a soft-magnetic nickel-copper-zinc ferrite material which comprises major components and minor components, wherein the major components comprise the following components in percentage by mol: 46.5-50.0 mol% of Fe2O3, 12.0-17.0 mol% of NiO, 27.0-31.0 mol% of ZnO and 4.0-8.0 mol% of CuO; and the minor components comprise manganese oxide and bismuth oxide, wherein on the basis of the total weight of the major components, the total weight percent of the minor components and standard substances thereof MnO and Bi2O3 is 0.1-1.0 wt%. Under the wide frequency of 50 KHz-10 MHz and especially high frequency of 1 MHz-10 MHz, the material provided by the invention has the characteristics of high magnetic conductivity (mu i is approximately equal to 300, and f is equal to 1 MHz), high resistivity, low specific loss, low specific temperature coefficient and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

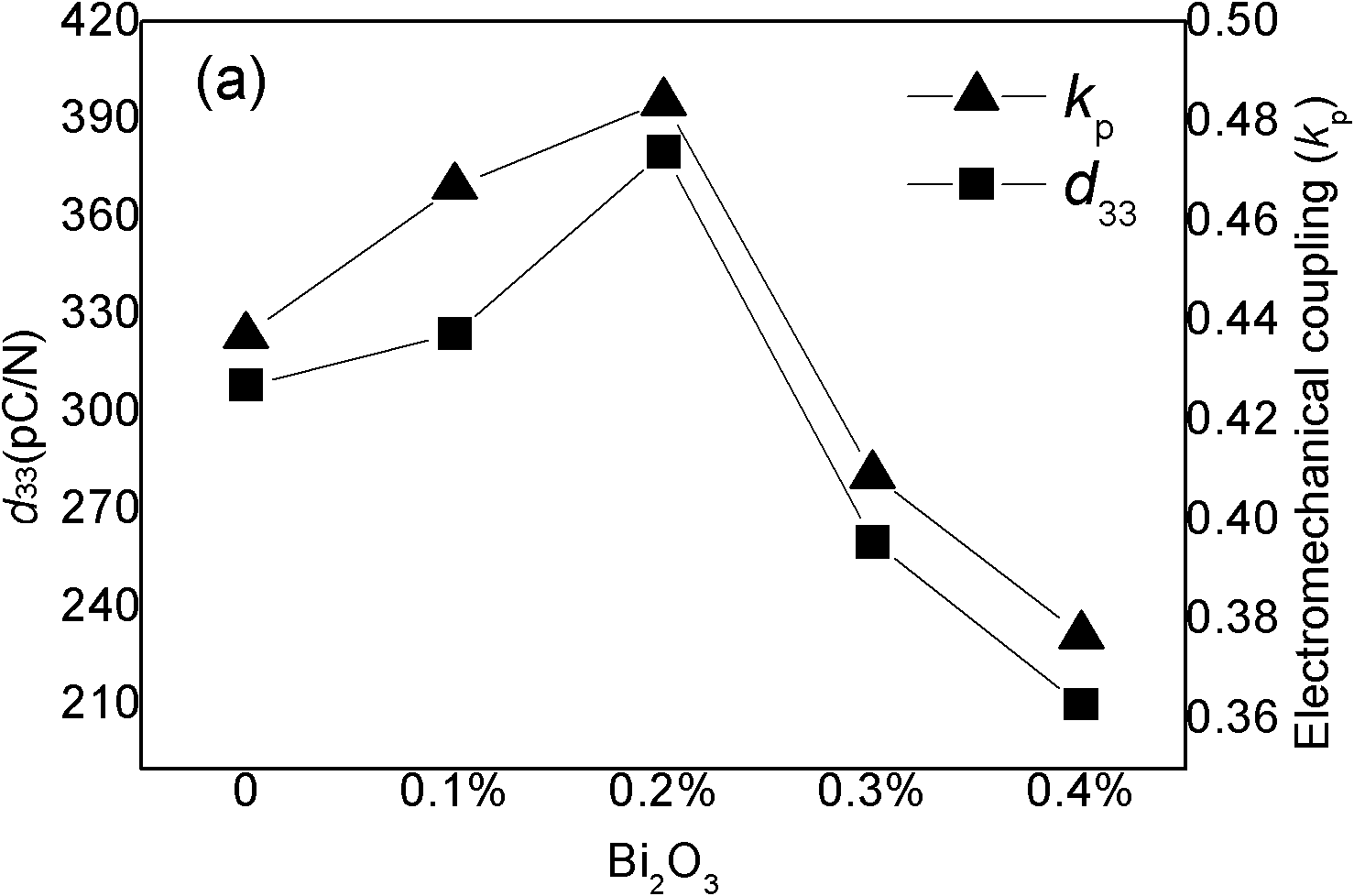

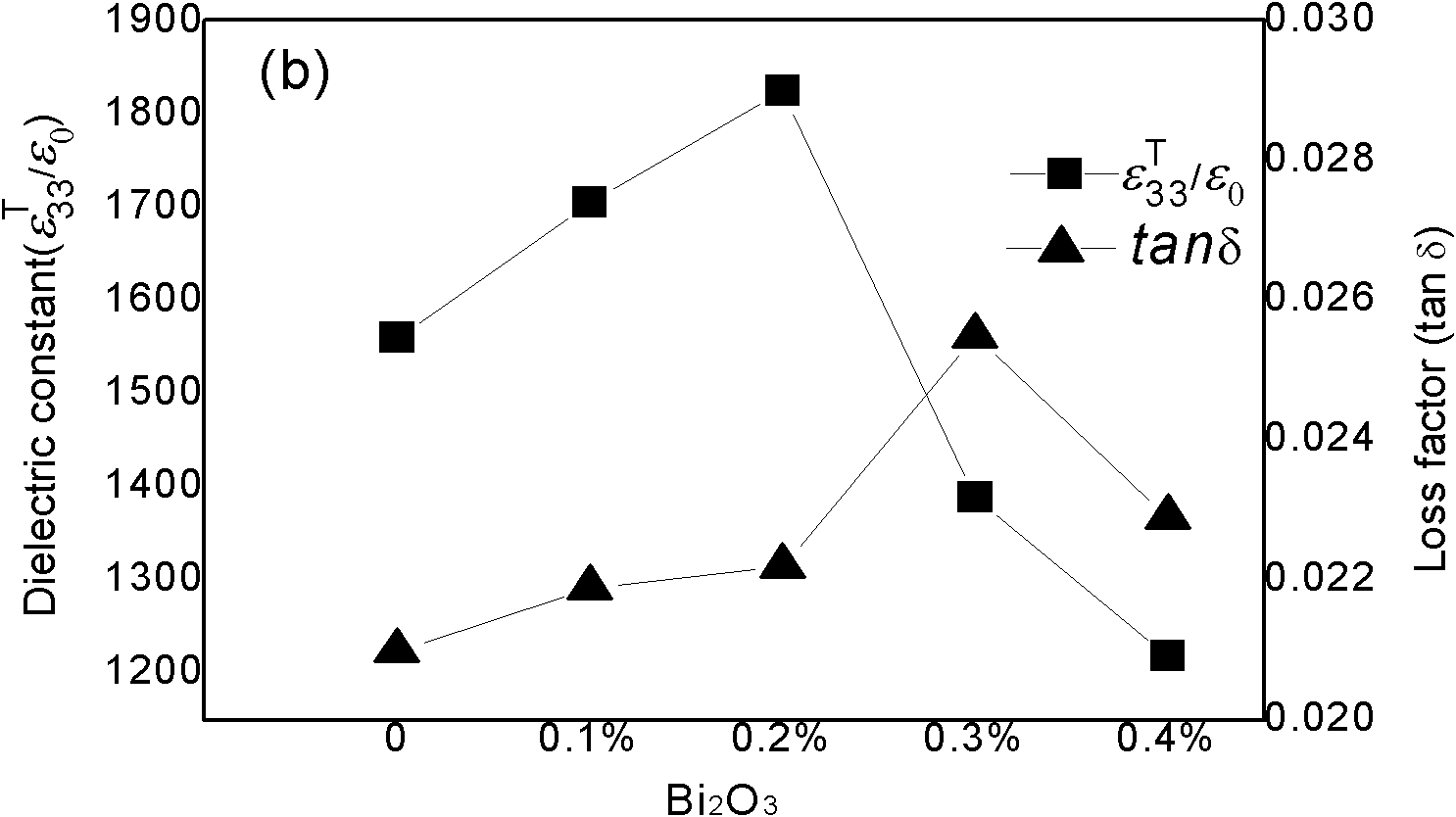

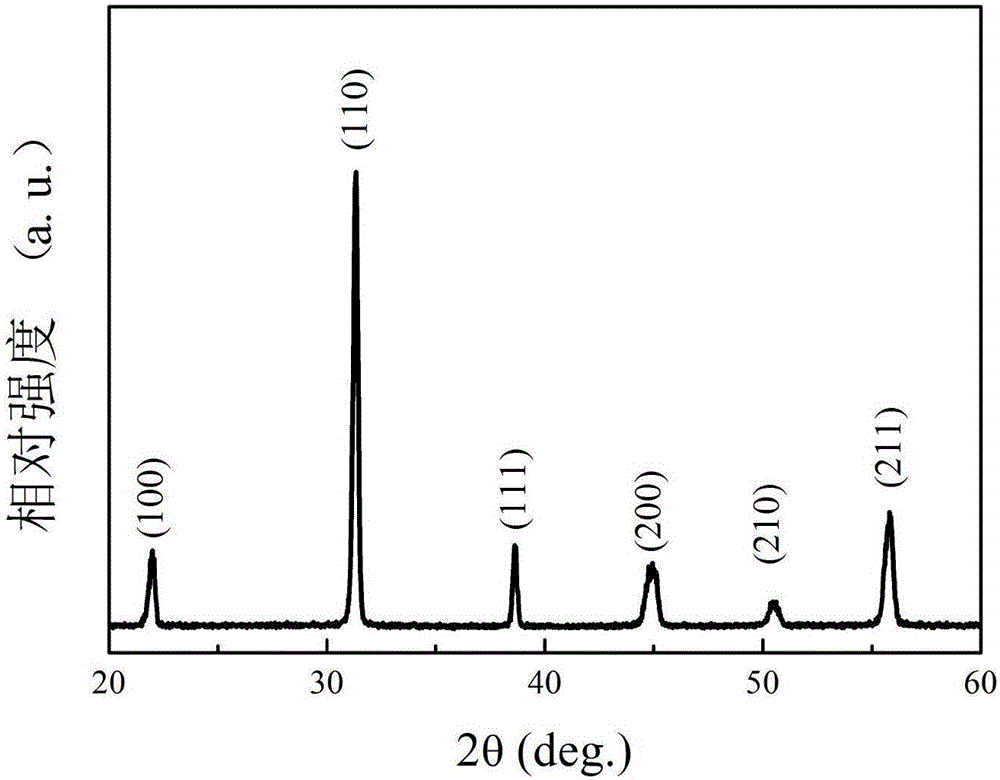

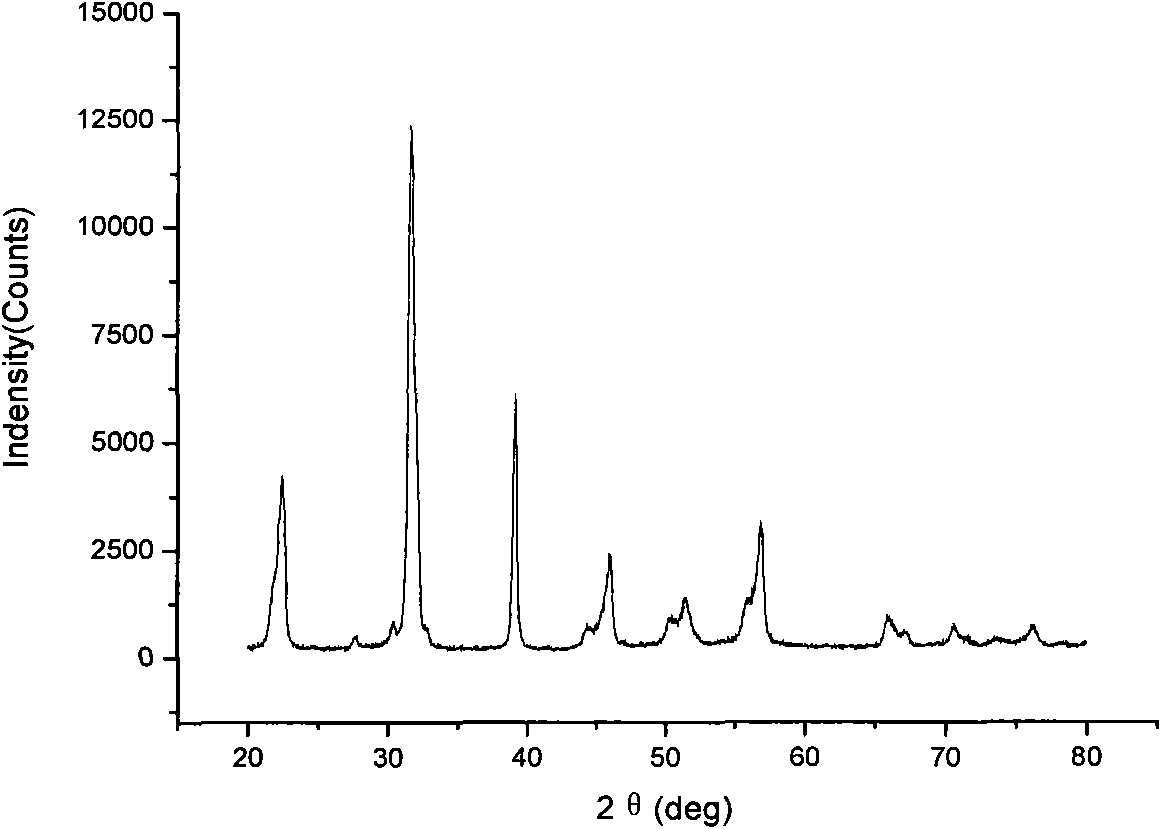

Bismuth scandate-lead titanate high-temperature piezoelectric ceramic material and preparation method thereof

InactiveCN102180665AStoichiometric ratio is accurateLower sintering temperatureCeramic sinteringCurie temperature

The invention discloses a bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material comprises a matrix with the chemical formula of xBiScO3-(1-x)PbTiO3 and bismuth trioxide (Bi2O3) in an amount which is less than 0.4 percent of the total weight of the matrix. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material is prepared by adding excess Bi2O3 into raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3, wherein x is 0.35 to 0.38; and the using amount of the excess Bi2O3 is 0.1 to 0.4 percent of the total weight of the raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material solves the problems that ceramic sintering temperature is increased and piezoelectric and dielectric properties are reduced due to deviation of a stoichiometric ratio caused by bismuth volatilization in the sintering process of BSPT ceramic, and has high Curie temperature, excellent piezoelectric property and an actual application value in high-temperature electronic equipment. The invention also discloses a preparation method for the bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. In the preparation method, the piezoelectric ceramic material is prepared by synthesizing and sintering at lower temperature, so production cost is reduced, process steps are simplified, and the material has actual application value.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

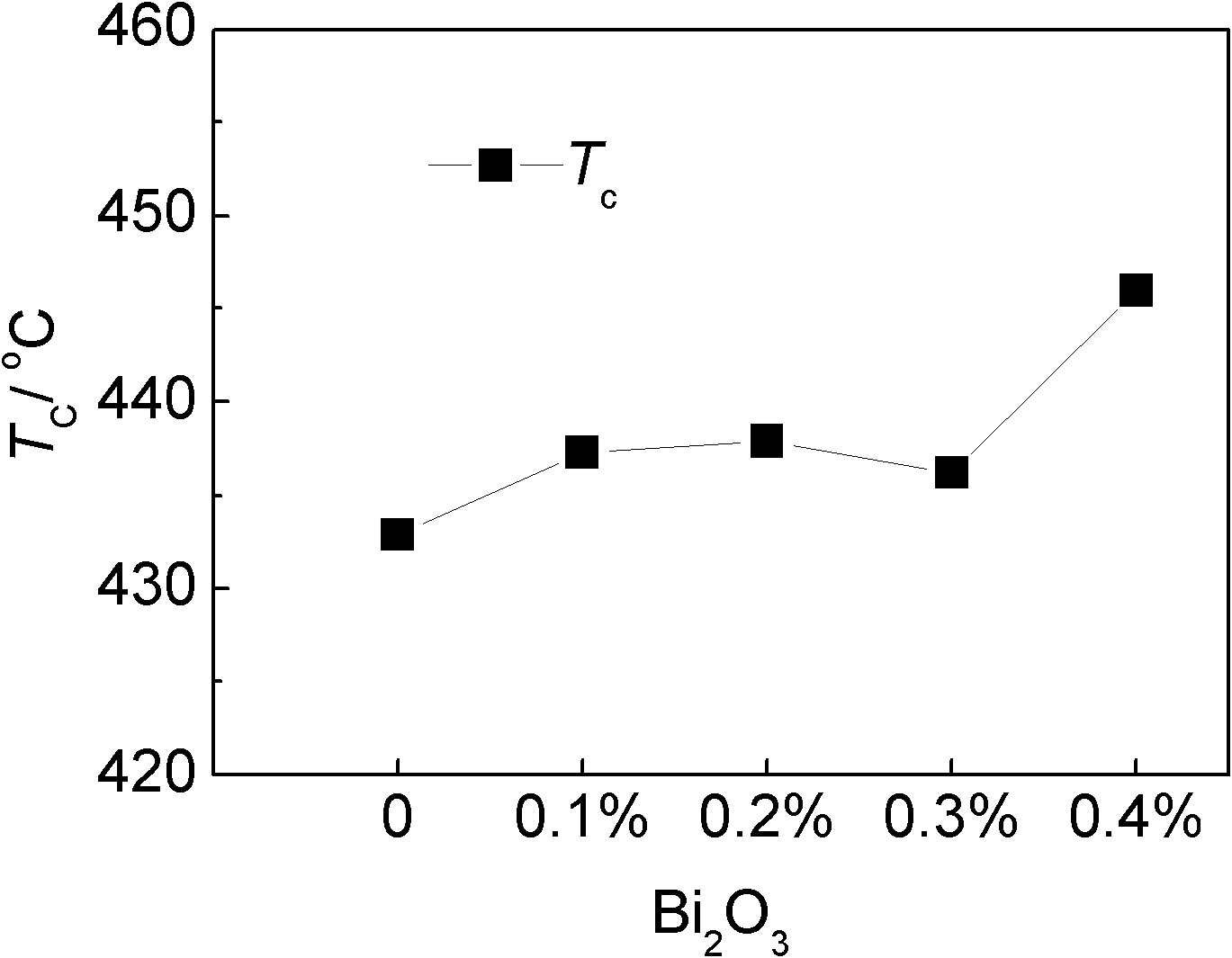

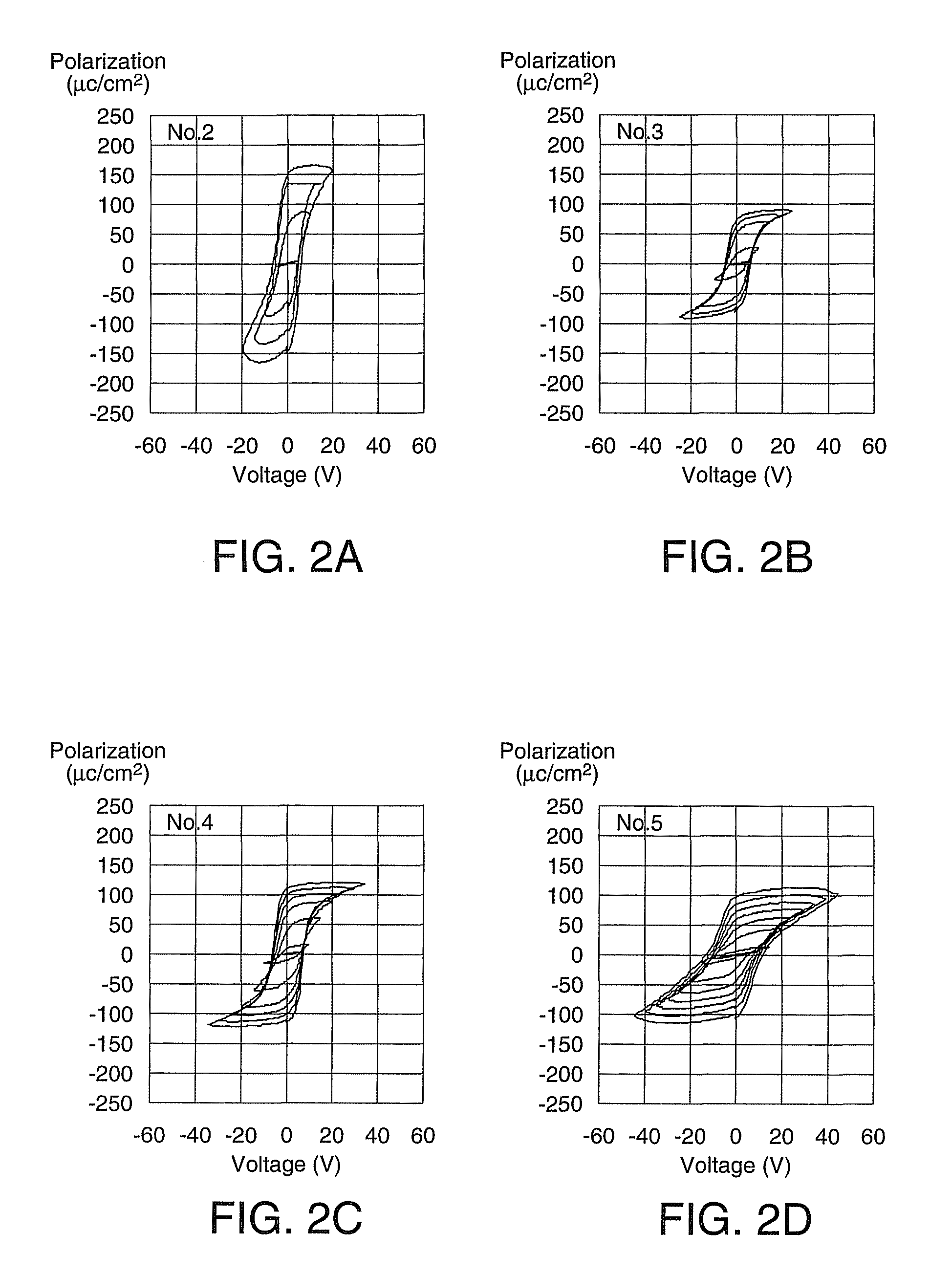

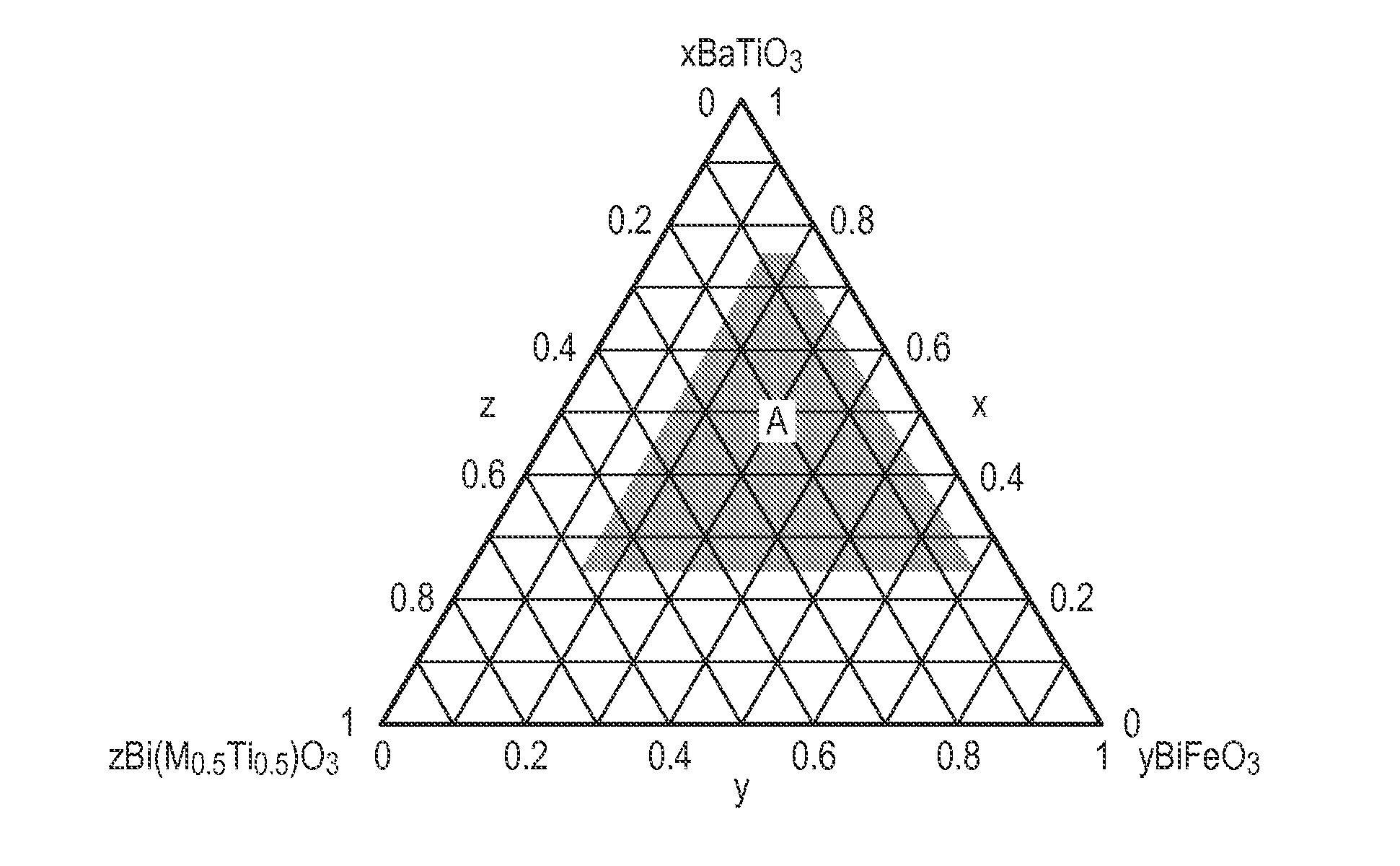

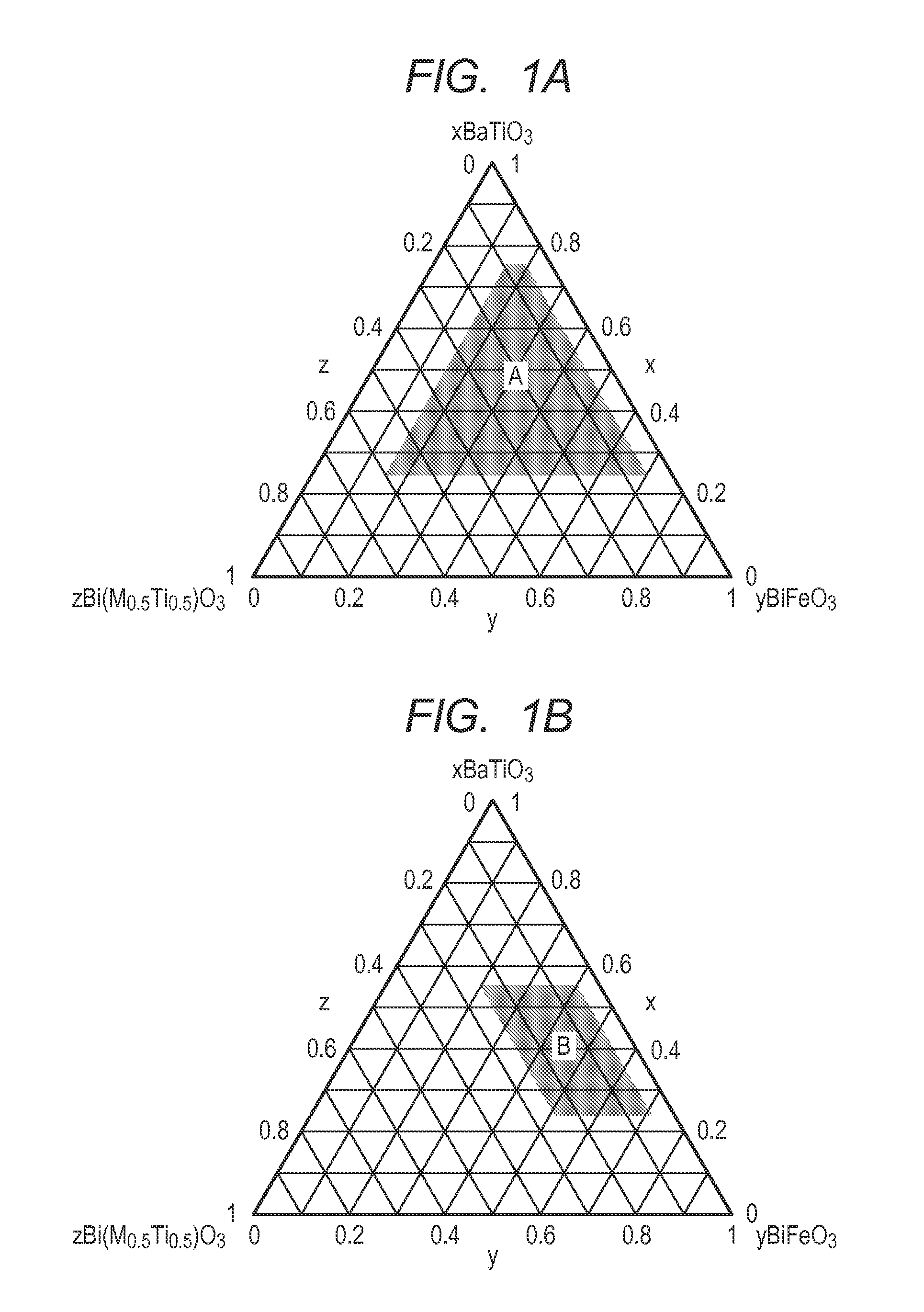

Piezoelectric ceramics, manufacturing method for piezoelectric ceramics, piezoelectric element, liquid discharge head, liquid discharge apparatus, ultrasonic motor, optical apparatus, vibration generator, dust removing device, imaging apparatus, and electronic apparatus

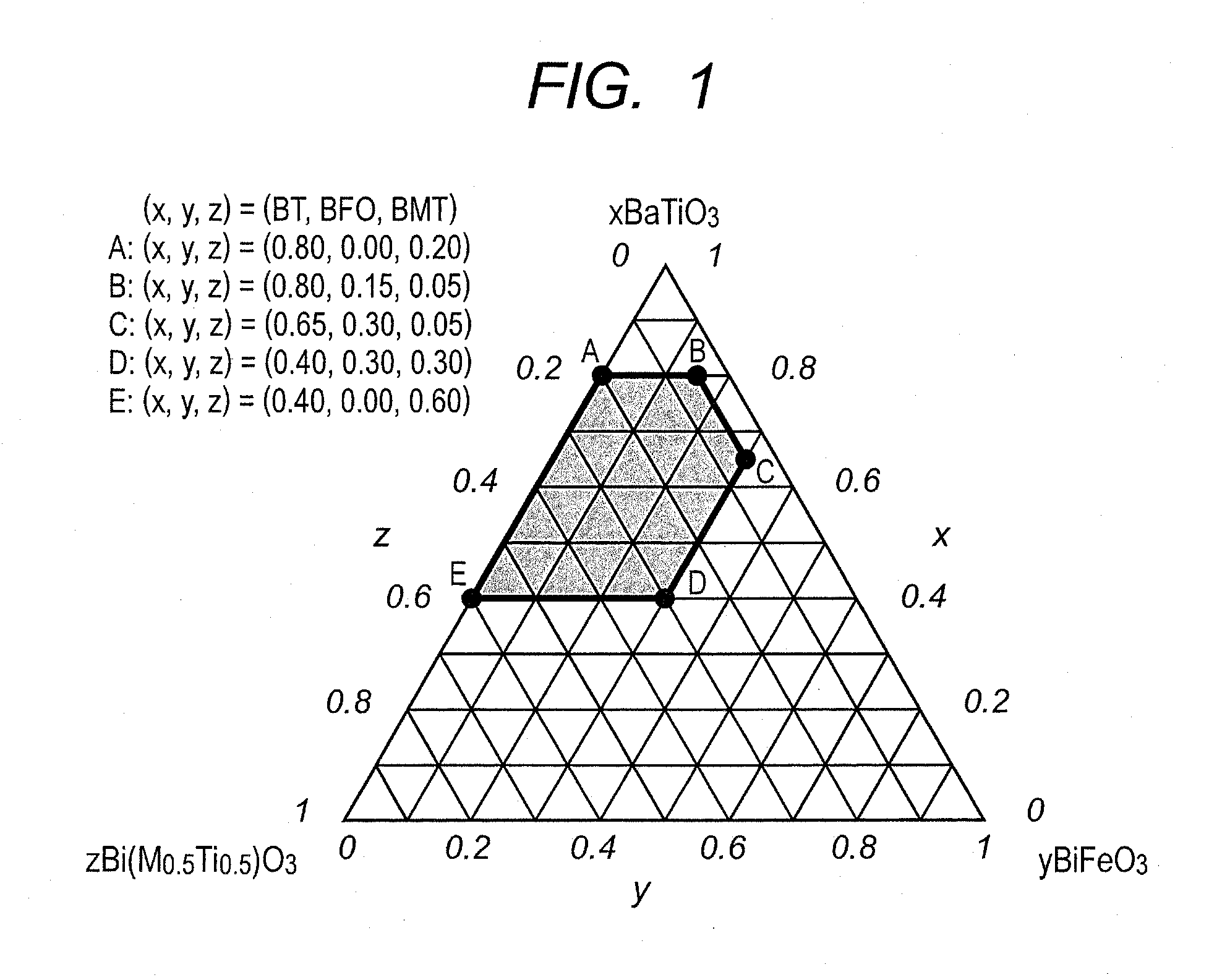

ActiveUS20130056671A1High curie temperatureAlkaline earth titanatesPiezoelectric/electrostrictive device manufacture/assemblyCeramicOxide

Provided is a piezoelectric ceramics that can achieve both high piezoelectric performance and a high Curie temperature. Also provided are a piezoelectric element, a liquid discharge head, an ultrasonic motor, and a dust removing device, which use the piezoelectric ceramics. The piezoelectric ceramics include a perovskite-type metal oxide expressed by a general formula (1): xBaTiO3-yBiFeO3-zBi(M0.5Ti0.5)O3, where M represents at least one type of element selected from the group consisting of Mg and Ni, x satisfies 0.40≦x≦0.80, y satisfies O≦y≦0.30, z satisfies 0.05≦z≦0.60, and x+y+z=1 is satisfied, and are oriented in a (111) plane in a pseudocubic expression.

Owner:CANON KK +1

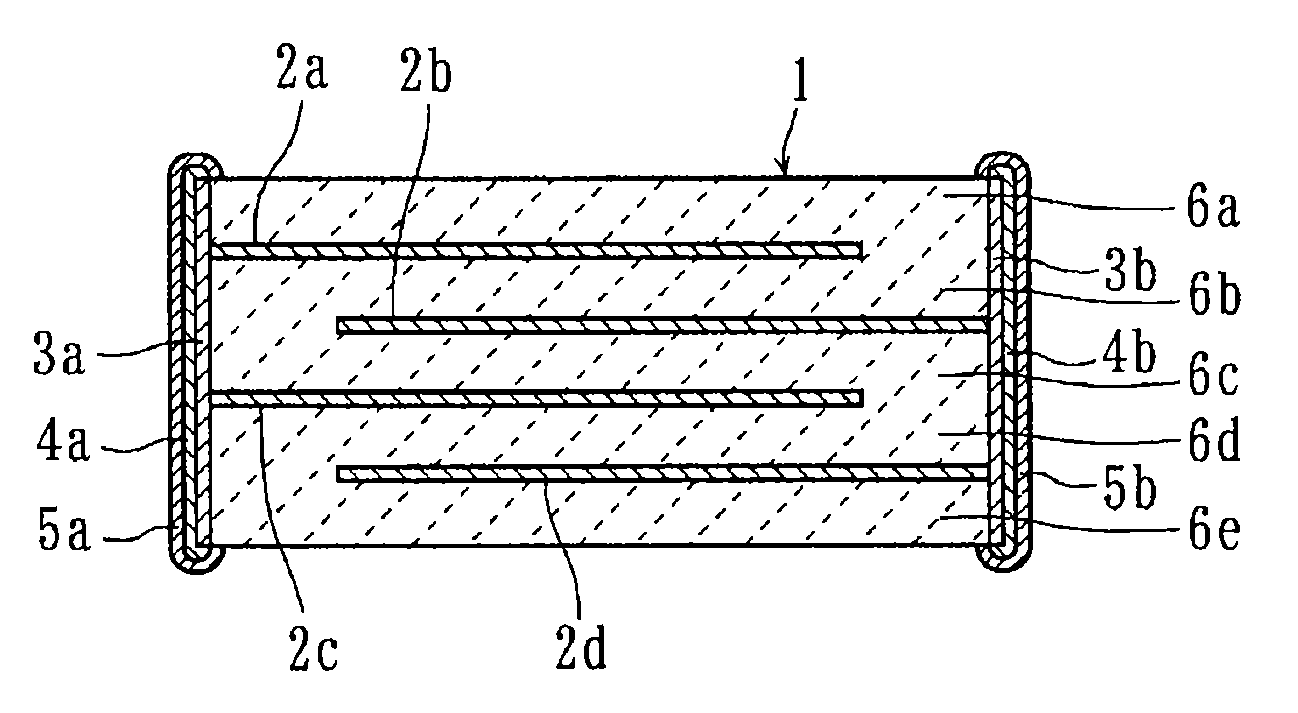

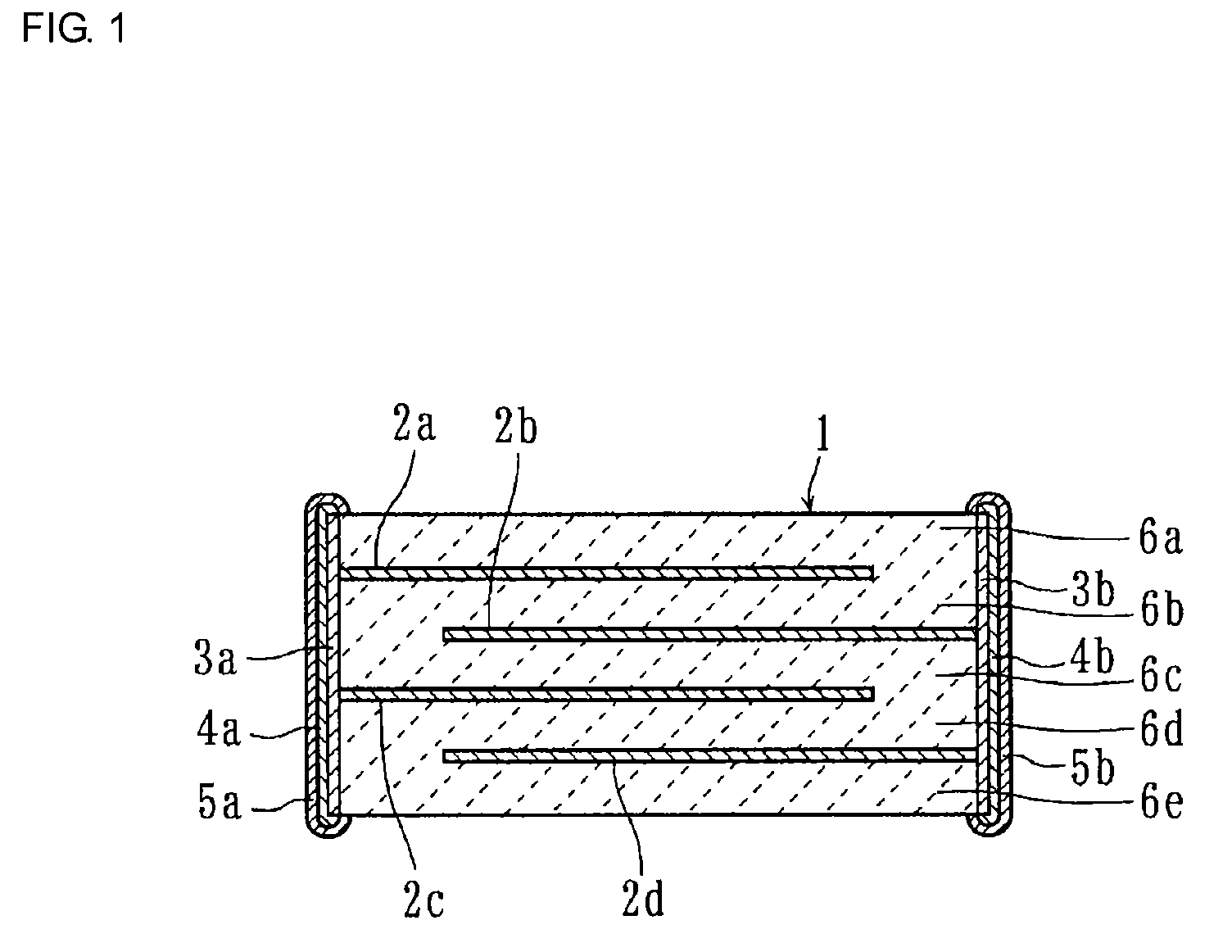

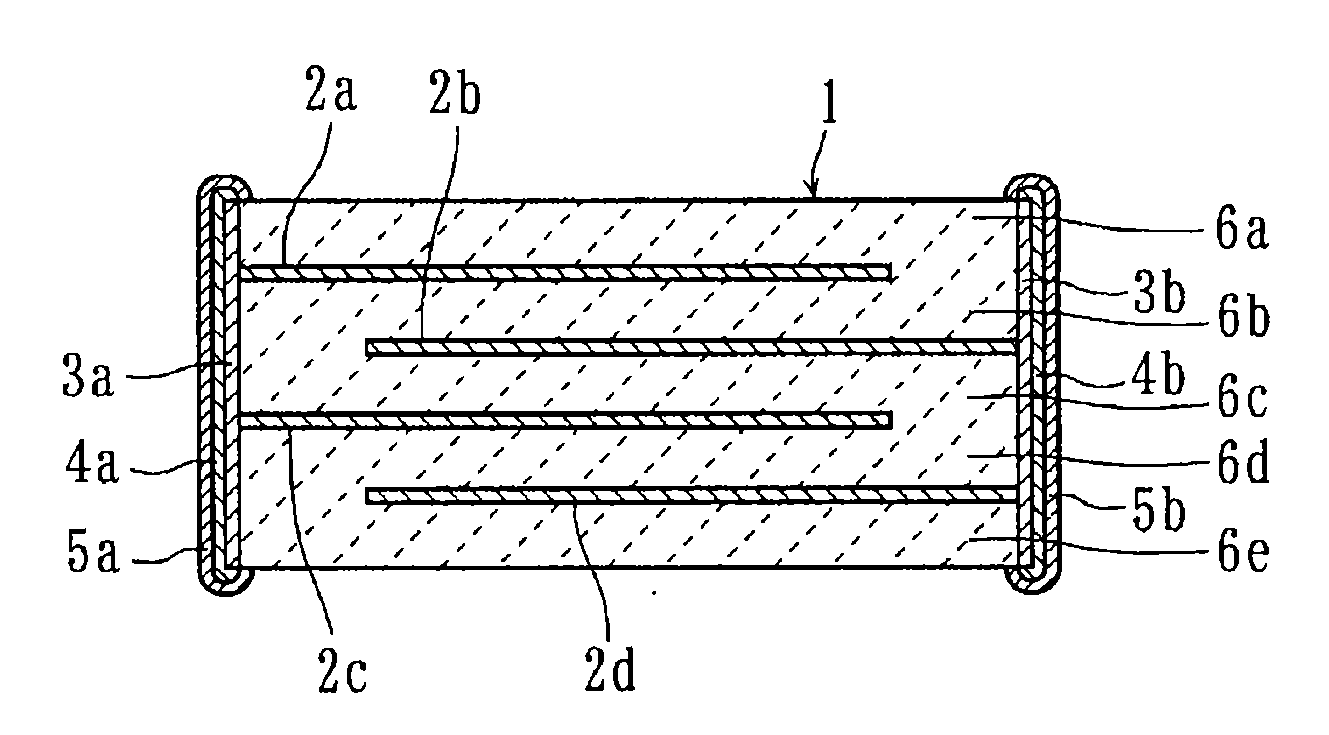

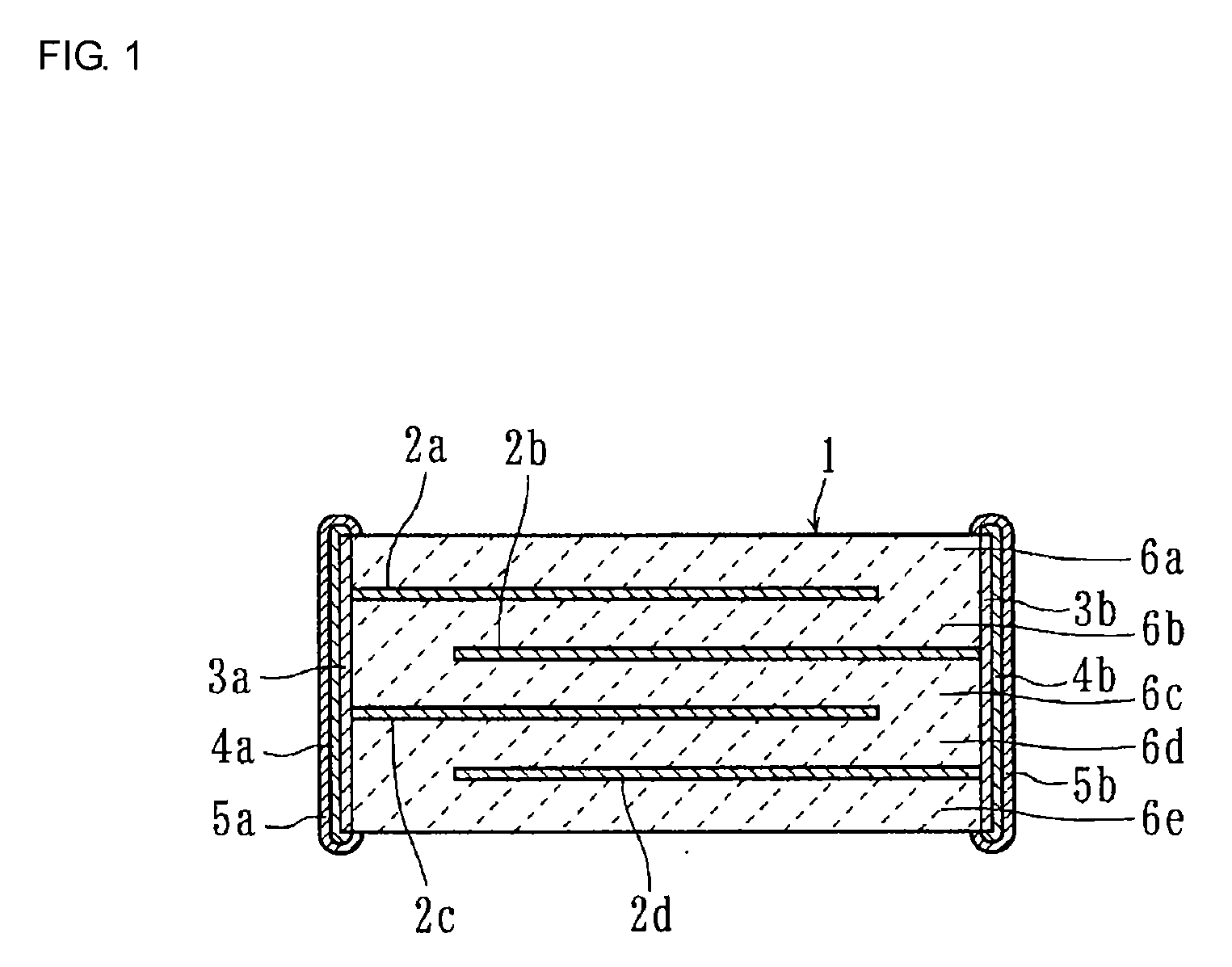

Dielectric ceramic, ceramic electronic element, and multilayer ceramic capacitor

ActiveUS7595975B2Easy to adjustEasy to useFixed capacitor dielectricZirconium compoundsDielectricCeramic capacitor

A dielectric ceramic including a perovskite compound represented by the general formula {(Ba1-x-yCaxSny)m(Ti1-zZrz)O3} as a primary component in which the x, y, z, and m satisfy 0.02≦x≦0.20, 0.02≦y≦0.20, 0≦z≦0.05, and 0.99≦m≦1.1 and is processed by a thermal treatment at a low oxygen partial pressure of 1.0×10−10 to 1.0×10−12 MPa. Accordingly, there are provided a dielectric ceramic which can be stably used in a high-temperature atmosphere without degrading dielectric properties, properties of which can be easily adjusted, and which generates no electrode breakage even when ceramic layers and conductive films are co-fired, and a ceramic electronic element, such as a multilayer ceramic capacitor, which uses the above dielectric ceramic.

Owner:MURATA MFG CO LTD

Antimony potassium-sodium niobate leadless piezoelectric ceramics and preparation method thereof

Antimony potassium-sodium niobate leadless piezoelectric ceramics provided by the invention is a compound with its chemical formula expressed as (1-x)K1-yNayNb1-zSbzO3-x(Bi0.5-uMu)R0.5ZrO3 or (1-x)K1-yNayNb1-zSbzO3-x(Bi0.5-uMu)R0.5ZrO3-aQ, wherein x is less than or equal to 0.08 and greater than or equal to 0; y is less than or equal to 0.68 and greater than or equal to 0.4; z is less than or equal to 0.04 and greater than or equal to 0; u is less than or equal to 0.05 and greater than or equal to 0.04; M element is one of lanthanide Sm, Nd and La; R element is at least one of Na, K, Li and Ag; Q is a metallic oxide; a is molar percentage of the metallic oxide Q in the compound (1-x)K1-yNayNb1-zSbzO3-x(Bi0.5-uMu)R0.5ZrO3; and the metallic oxide Q is one of Zn oxide, Cu oxide and Mn oxide. The antimony potassium-sodium niobate leadless piezoelectric ceramics can further raise and enhance piezoelectric property of potassium-sodium niobate (KNN) leadless piezoelectric ceramics.

Owner:SICHUAN UNIV

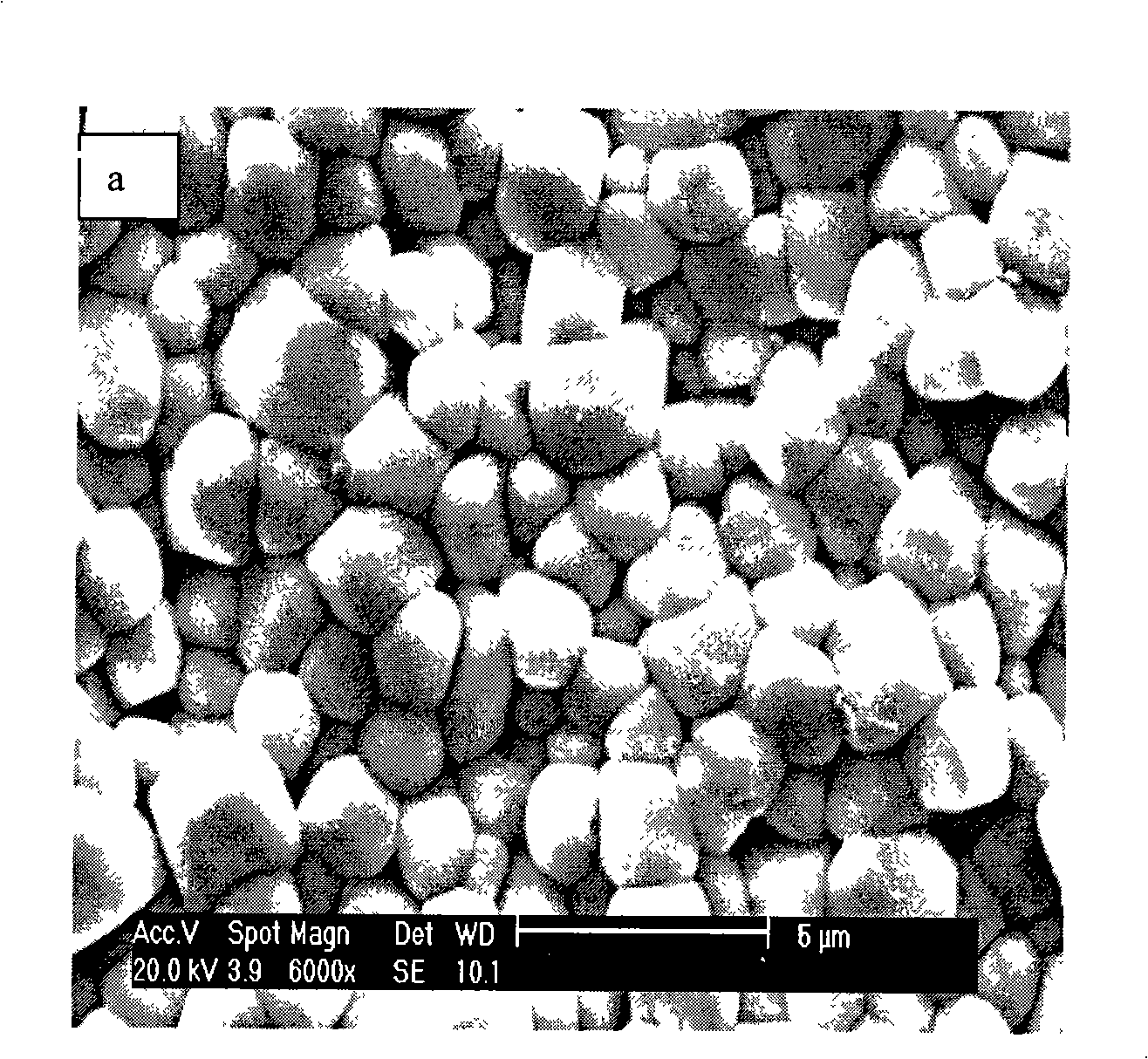

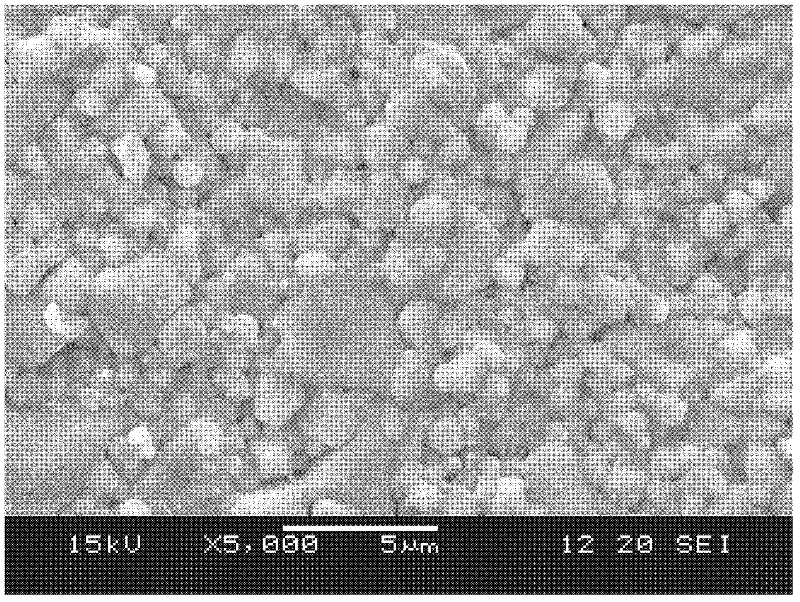

Strontium and barium doping lead niobium-stibium zirconate-titanate series piezoelectric ceramic and preparation method thereof

InactiveCN101265090ALow priceAbundant raw materialsPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateElectronic communication

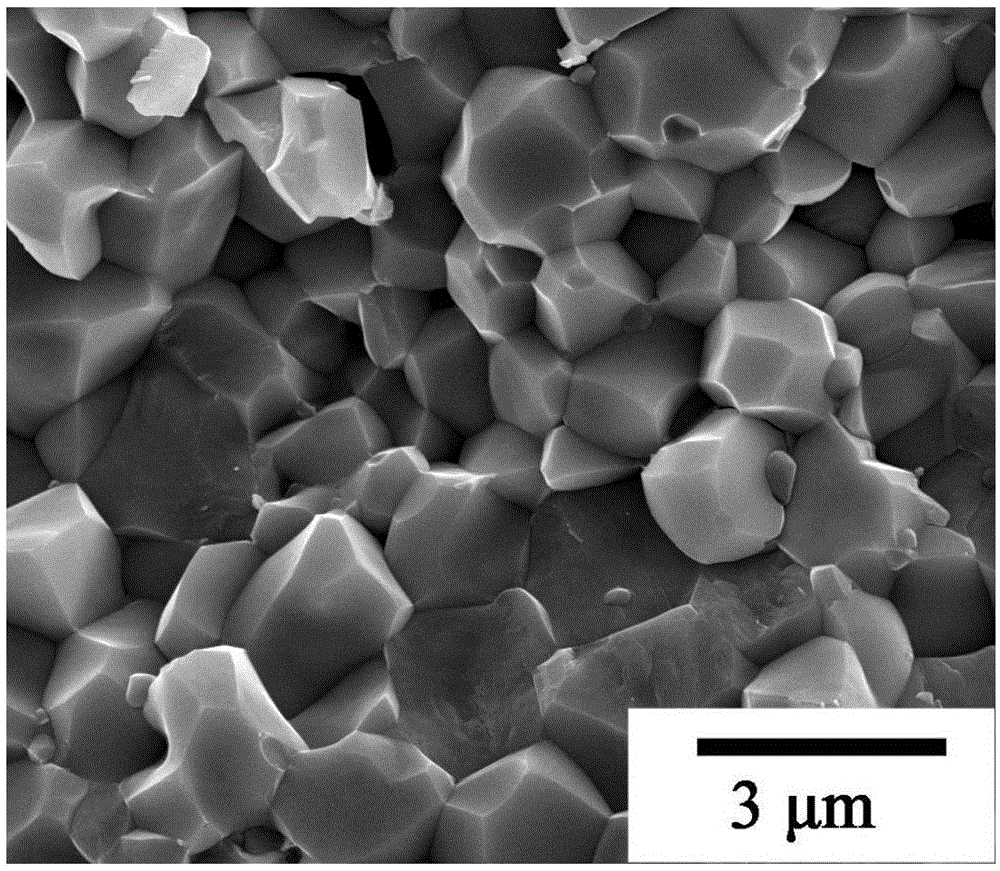

The invention discloses a Sr and Ba-doped lead niobium-stibium zirconate-titanate (PNSZT)-based piezoelectric ceramic. The piezoelectric ceramic has the chemical formula as follows: Pb0.96Sr0.03Ba0.03(Sb1 / 2Nb1 / 2)0.02(ZrxTi0.98-x) O3, wherein x is in the range of 0.51-0.525. The raw materials of the piezoelectric ceramic include Pb3O4, Nb2O5, Sb2O3, ZrO2, TiO2, SrCO3 and BaCO3. The invention also discloses a production method of the piezoelectric ceramic. The method comprises the following steps: (1) material compounding, (2) granulation, (3) molding, (4) adhesive removal, (5) sintering and (6) grinding, cleaning and polarization. The piezoelectric ceramic provided in the invention has the advantages of low price, easily-accessible raw materials, good dielectric and piezoelectric performances, good uniformity in crystal morphology, high Curie temperature, low optimal sintering temperature, and wide sintering range; and is widely used in the fields of machinery, electronics and communication.

Owner:TIANJIN UNIV

Dielectric ceramic, ceramic electronic element, and multilayer ceramic capacitor

ActiveUS20090128989A1Improve sintering performanceEasy to useFixed capacitor dielectricZirconium compoundsDielectricCeramic capacitor

A dielectric ceramic including a perovskite compound represented by the general formula {(Ba1-x-yCaxSny)m(Ti1-zZrz)O3} as a primary component in which the x, y, z, and m satisfy 0.02≦x≦0.20, 0.02≦y≦0.20, 0≦z≦0.05, and 0.99≦m≦1.1 and is processed by a thermal treatment at a low oxygen partial pressure of 1.0×10−10 to 1.0×10−12 MPa. Accordingly, there are provided a dielectric ceramic which can be stably used in a high-temperature atmosphere without degrading dielectric properties, properties of which can be easily adjusted, and which generates no electrode breakage even when ceramic layers and conductive films are co-fired, and a ceramic electronic element, such as a multilayer ceramic capacitor, which uses the above dielectric ceramic.

Owner:MURATA MFG CO LTD

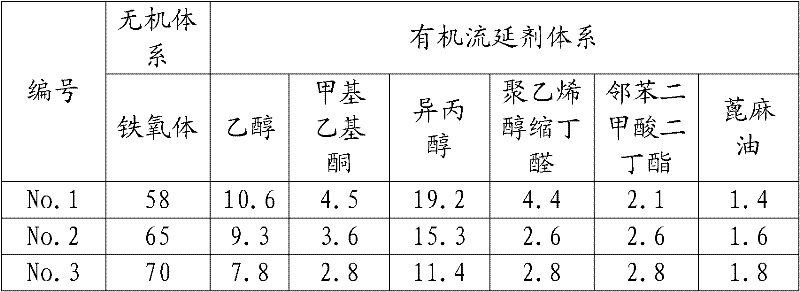

Broadband and high-magnetic-permeability ferrite teflon tape and production method thereof

The invention relates to a broadband and high-magnetic-permeability ferrite teflon tape and a production method thereof. The teflon tape comprises pre-burned ferrite powder and an organic tape casting system, wherein the pre-burned ferrite powder comprises ferric oxide, nickel oxide, copper oxide, zinc oxide, bismuth oxide and an additive, and the organic tape casting system comprises a solvent, a dispersant, a binder and a plasticizer. The LTCF (Low Temperature Cofired Ferrite) teflon tape prepared in the invention has a flat surface, is sintered at 900 DEG C for compactness, and a sintered body has an excellent performances: the initial permeability is not smaller than 450H / m at 100kHz, and the resistivity is not smaller than 109 ohm.cm. A chip inductor element manfauctured by using theteflon tape has high inductance and high quality factors, meanwhile, a low-temperature glass protective coating is coated in a silver paste circuit printing process of the inductor element, so that adevice failure caused by Ag diffusion when the device is used is prevented. Therefore, the broadband and high-magnetic-permeability ferrite teflon tape and the production method thereof have huge application prospect.

Owner:JIANGSU HUAXING ELECTRONICS CO LTD

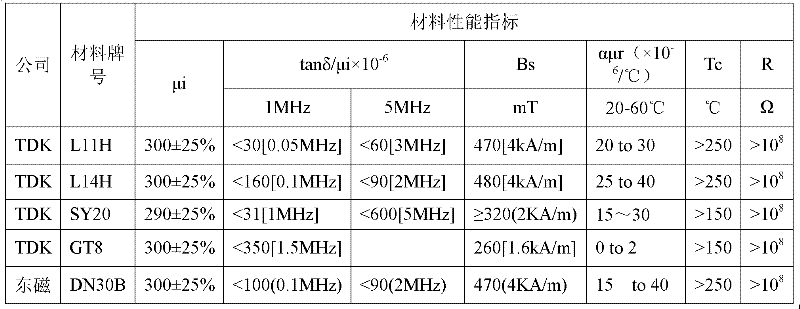

High-frequency nickel-copper-zinc ferrite and preparation thereof

The invention relates to a high frequency nickel-copper-zinc ferrite and a method for preparing the same, which belong to the technical field of nickel series soft magnetism ferrite. The main components of the ferrite are ferric oxide, nickel oxide, zinc oxide, and copper oxide, the accessory components comprise cobalt oxide, bismuth oxide, and silicon oxide, and the ferrite is prepared by an oxide method. The invention adopts an iron deficiency formulation, a low calcination temperature, and a low sintering temperature so that the prepared high frequency nickel-copper-zinc ferrite has good performances of low initial permeability, low relative dissipation factor between 50MHz and 200MHz, and high Curie temperature, and can better satisfy the use requirement of communication electronic parts and components; besides, the preparation process is stable, and the production process has low energy consumption.

Owner:TDG HLDG CO LTD

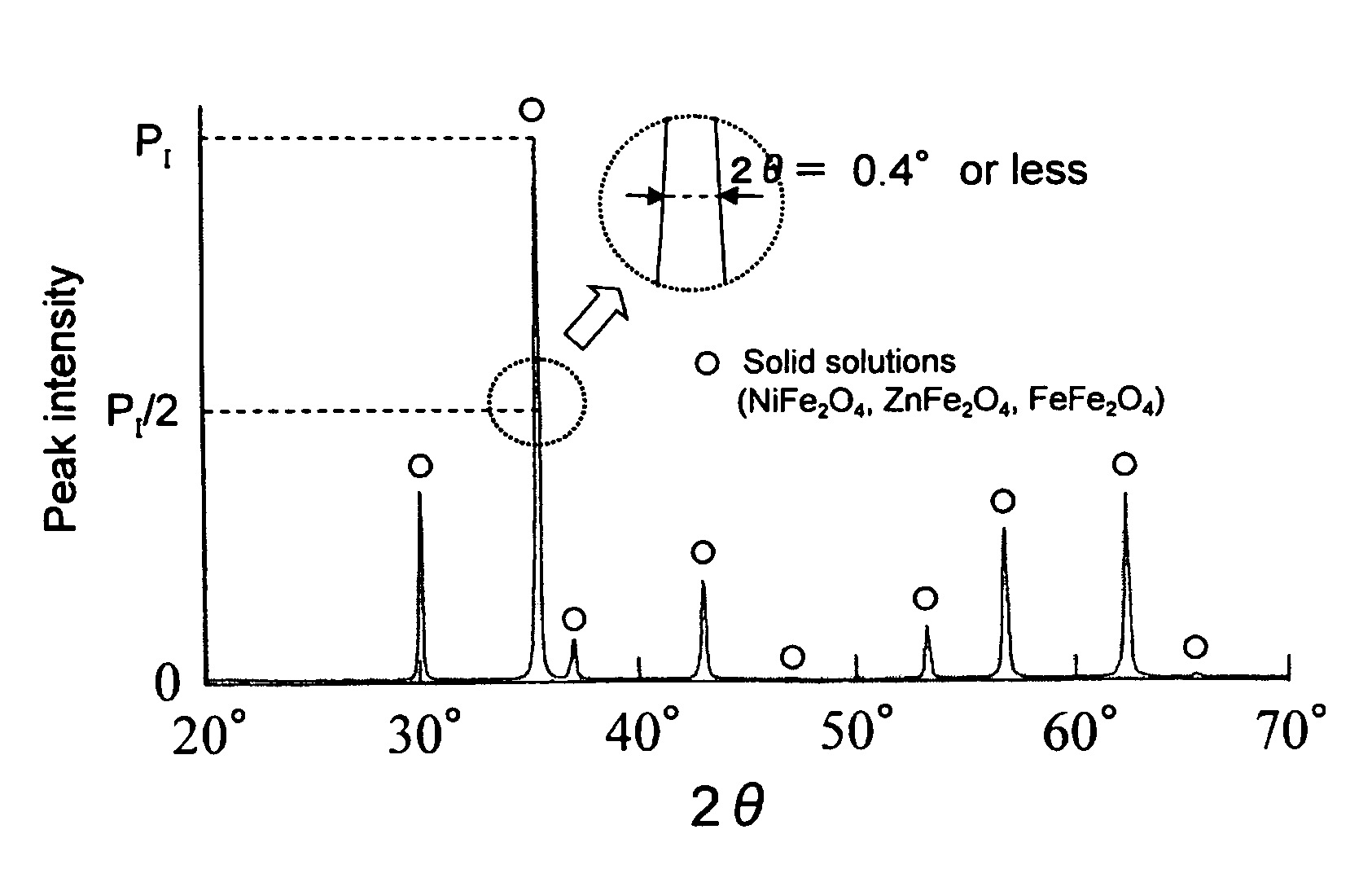

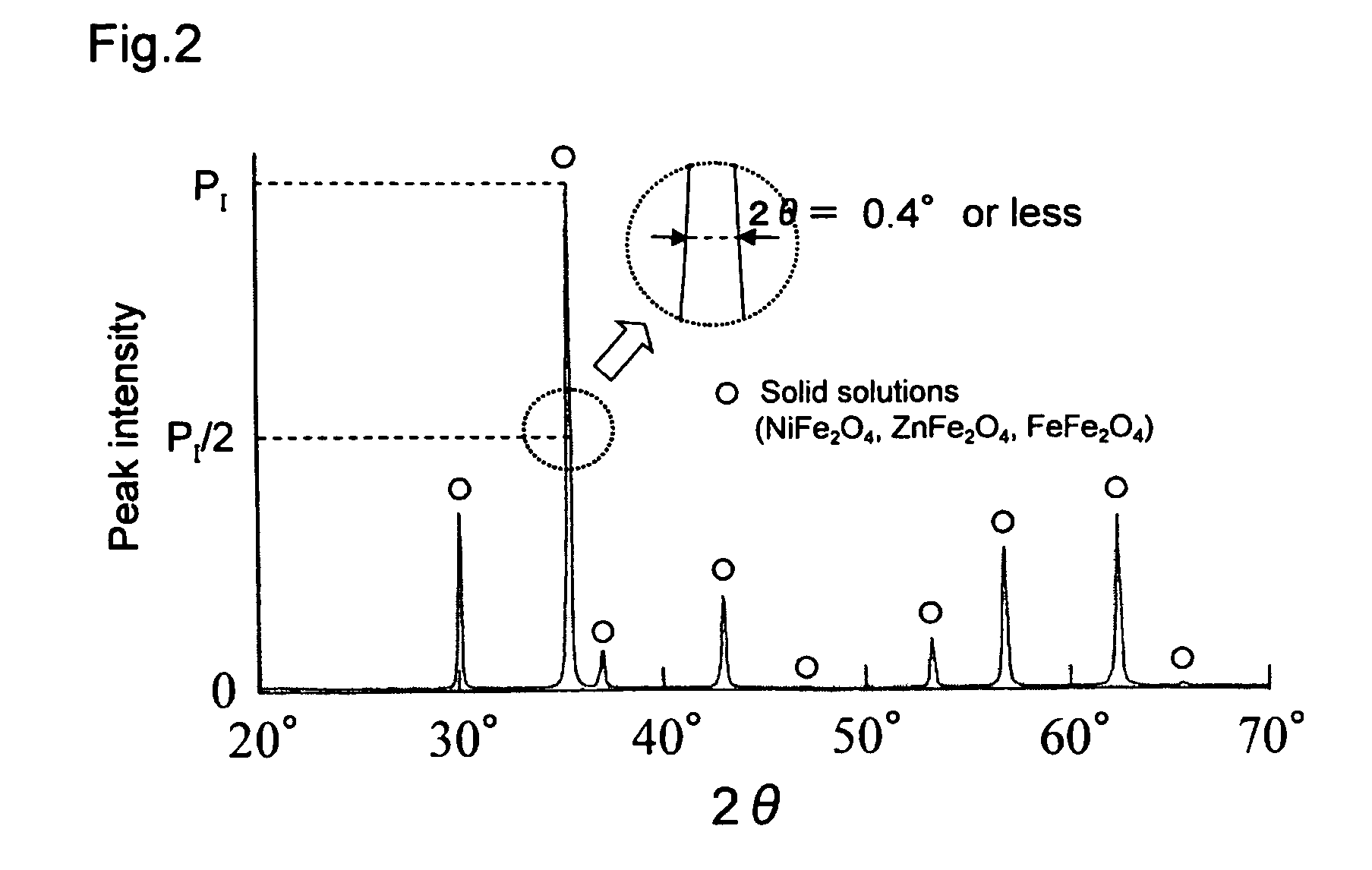

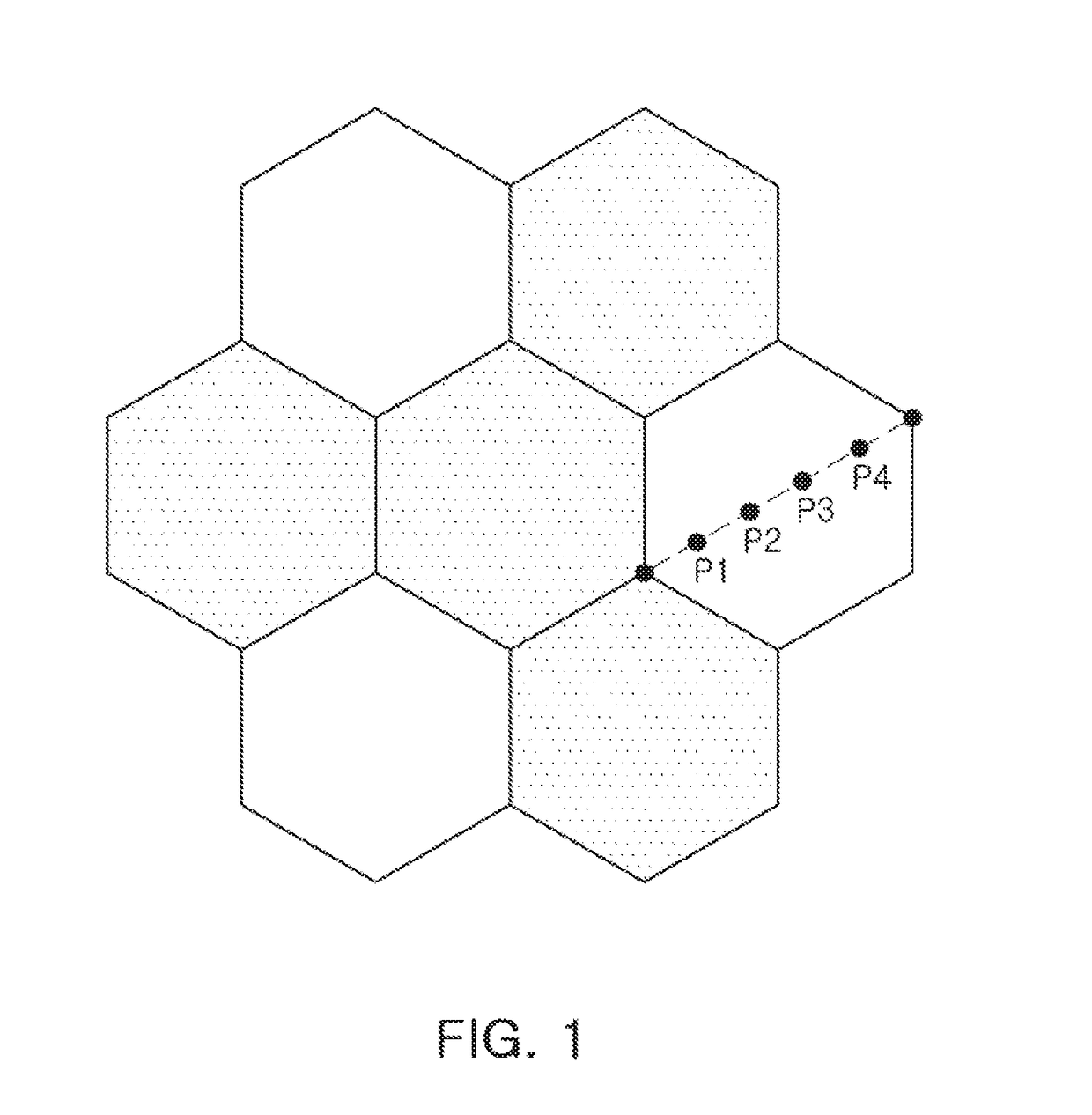

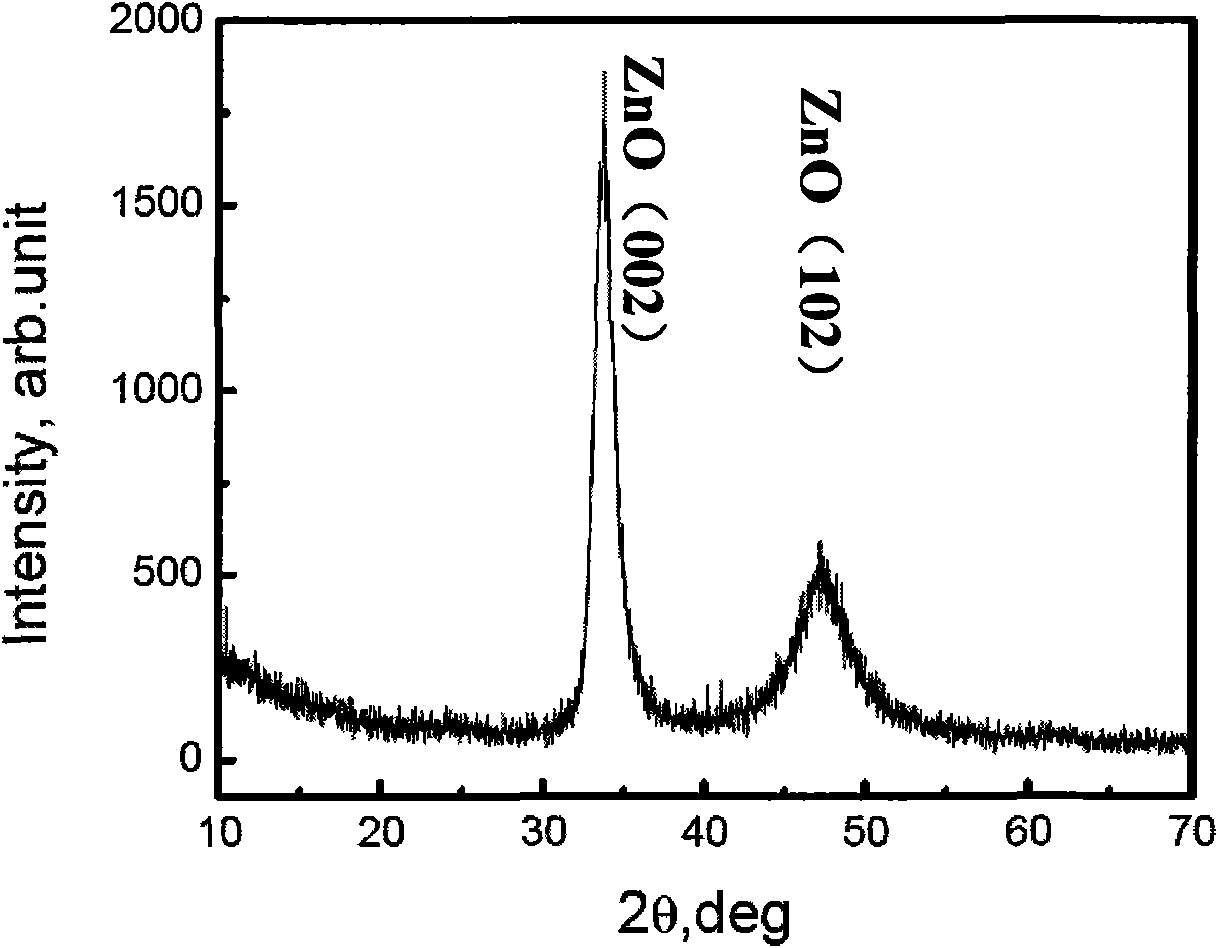

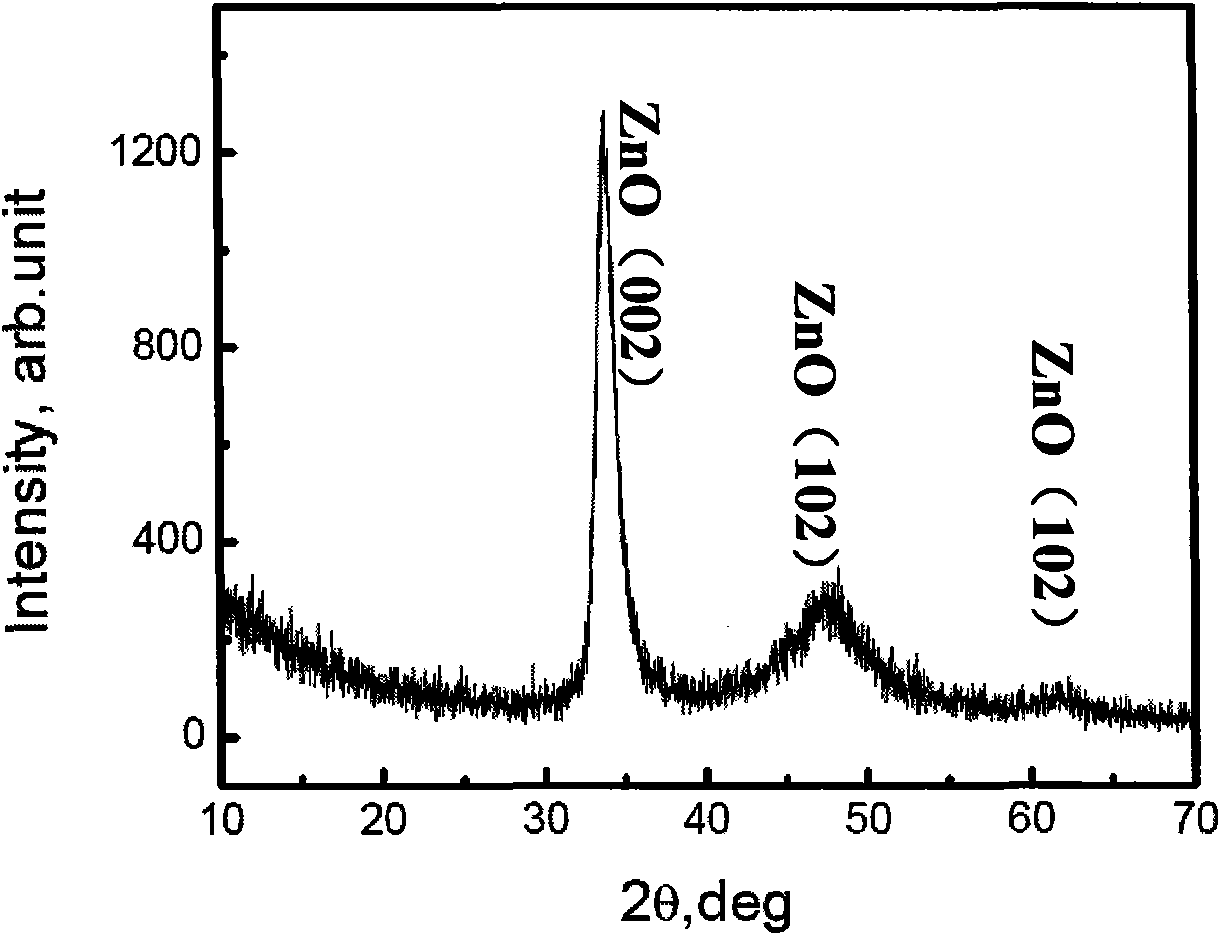

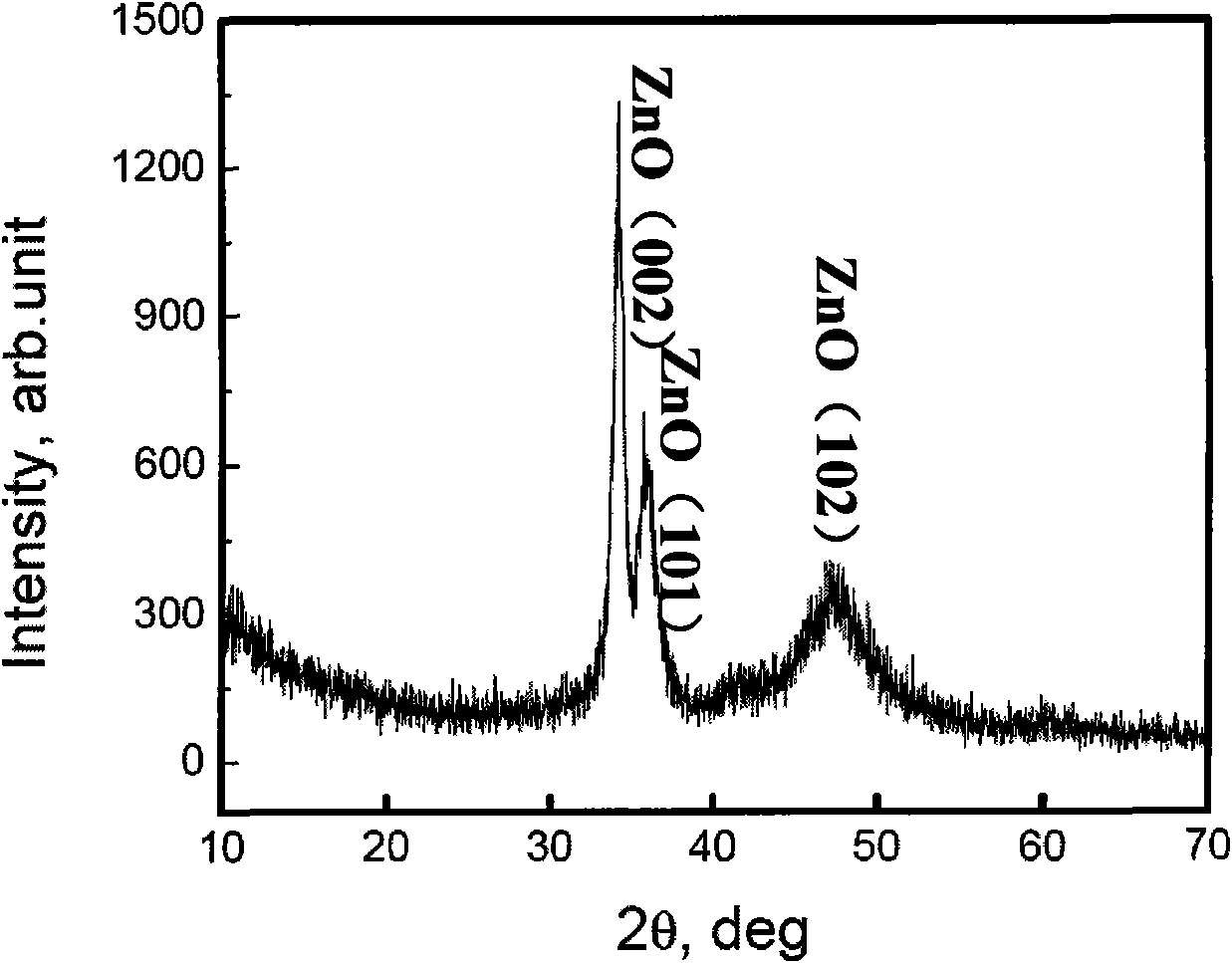

Ferrite core for RFID application, method of manufacturing the same, and ferrite coil using the same

ActiveUS7195717B2Low core lossHigh curie temperatureFoundry mouldsInorganic material magnetismFull width at half maximumX-ray

Owner:KYOCERA CORP

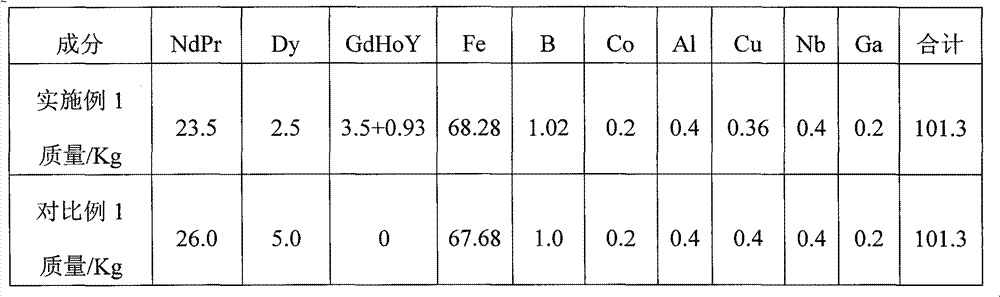

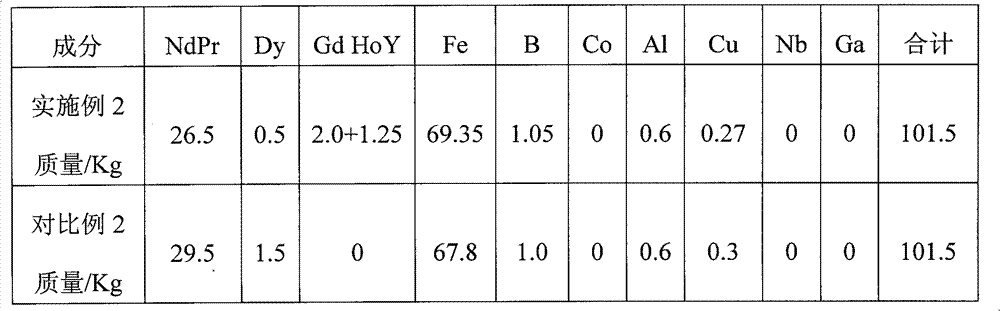

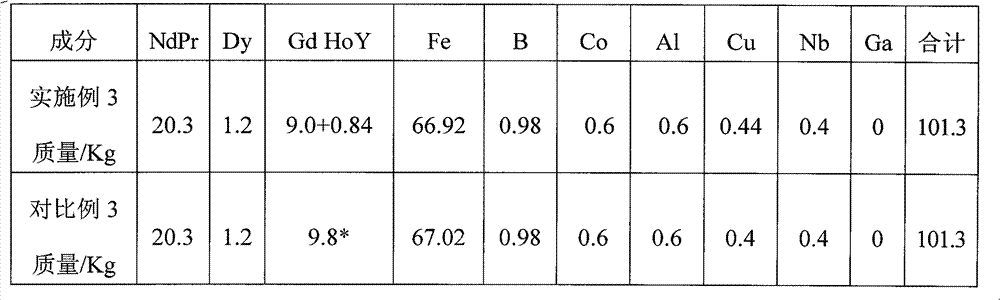

Method for preparing composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium

ActiveCN102956336AImprove remanenceIncrease the maximum energy productInorganic material magnetismRare-earth elementCurie temperature

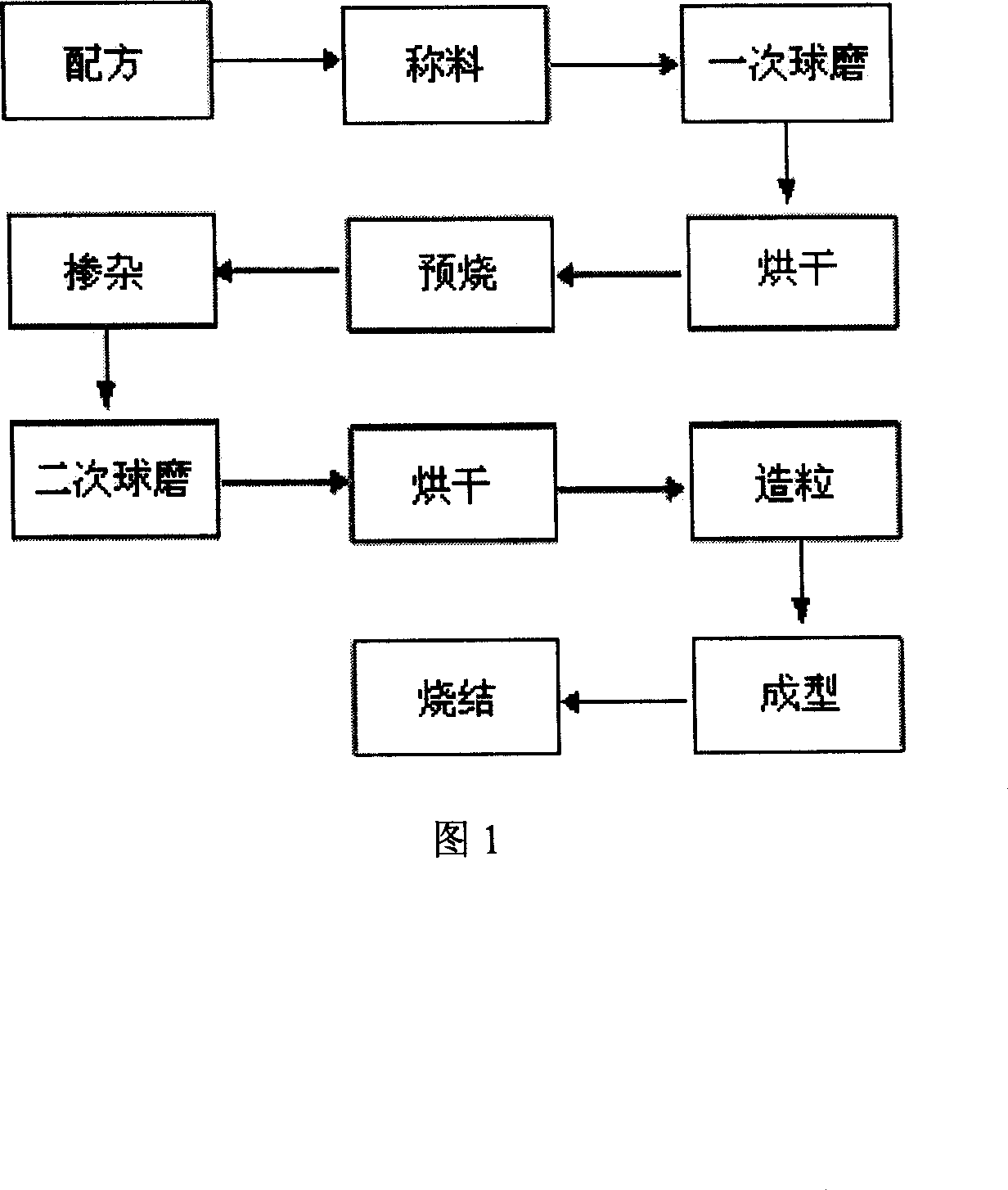

The invention provides a method for preparing a composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium. The method includes the steps of primary batching, fusion casting, milling, secondary batching, powder mixing, forming, sintering and heat treatment, wherein in the primary batching step, iron alloy added with three rare earth elements of the gadolinium, the holmium and the yttrium is composited, and in the secondary batching step, oxide added with the three rare earth elements of ultrafine gadolinium, holmium and yttrium and cuprous oxide powder are composited. By the method, the relative surplus and cheap gadolinium, holmium and yttrium can be used for partially substituting for rare earth elements of neodymium, praseodymium or dysprosium, and accordingly neodymium, praseodymium or dysprosium consumption can be decreased by 10-30wt.%. Besides, Curie temperature and coercivity force of the prepared neodymium-iron-boron permanent magnet material are increased, corrosion resistance is enhanced, operating temperature and toughness are increased, and processability is improved.

Owner:GANZHOU JIATON ADVANCED MATERIALS

Piezoelectric material and piezoelectric element

ActiveUS8102100B2Free and easy to prepareLarge constantPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesCurie temperatureComposite material

A piezoelectric element includes a first electrode, a piezoelectric film disposed on the first electrode, and a second electrode disposed on the piezoelectric film. The piezoelectric film is composed of piezoelectric material that is lead free and formed by mixing 100(1−x)% of material A having a spontaneous polarization of 0.5 C / m2 or greater at 25° C. and 100 x % of material B having piezoelectric characteristics and a dielectric constant of 1000 or greater at 25° C., wherein (1−x)Tc(A)+xTc(B)≧300° C., where Tc(A) is the Curie temperature of the material A and Tc(B) is the Curie temperature of the material B.

Owner:SEIKO EPSON CORP

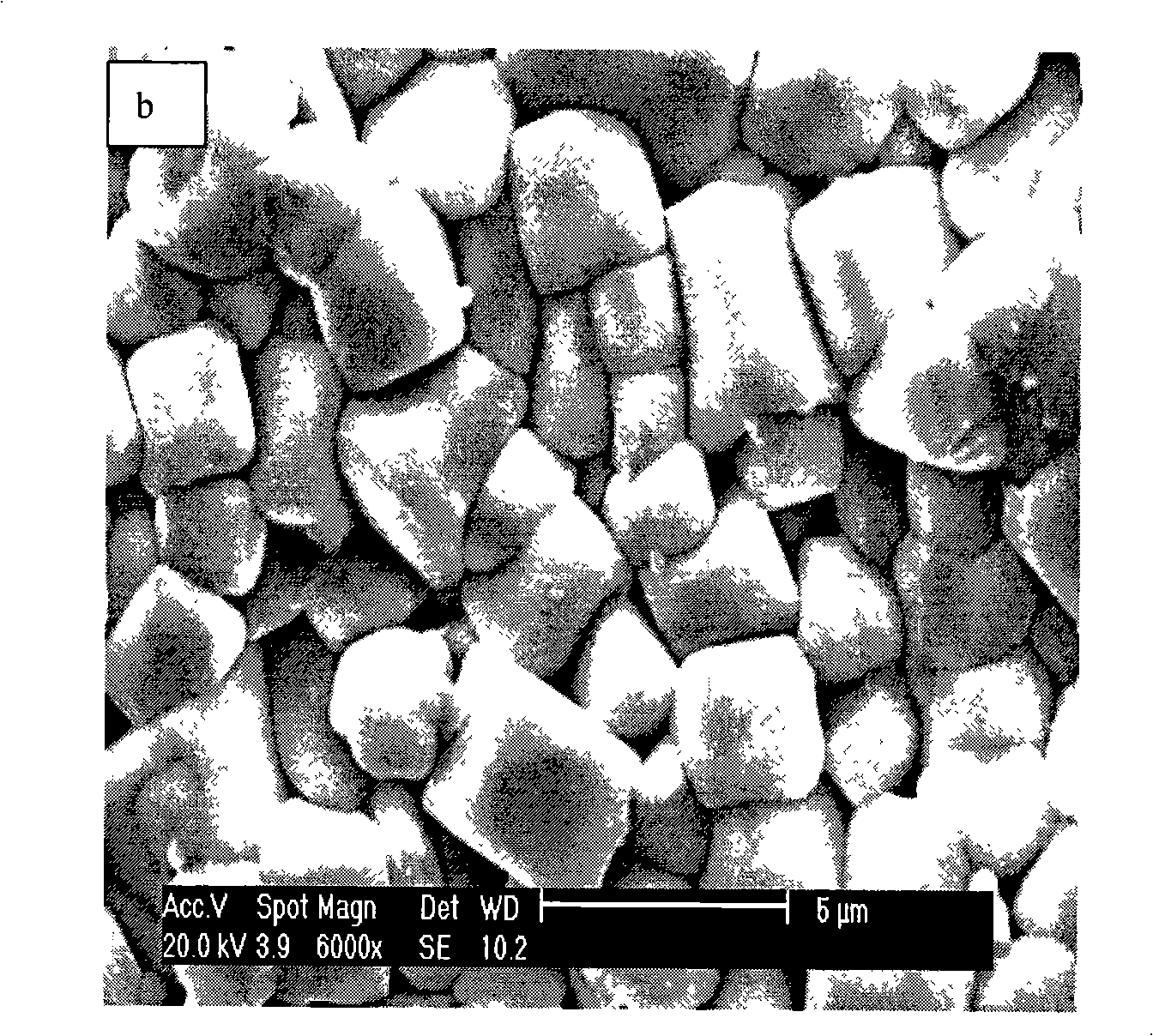

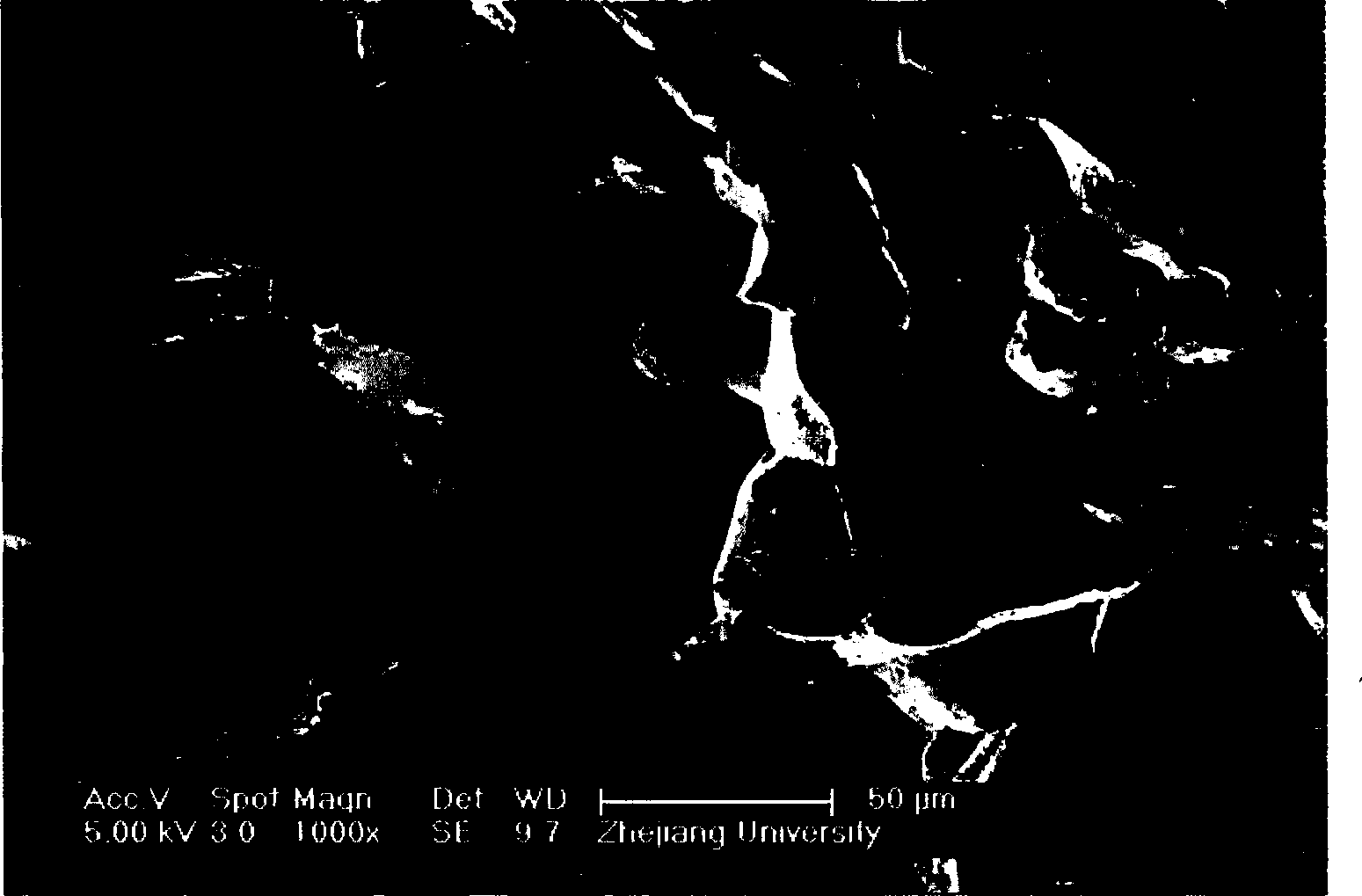

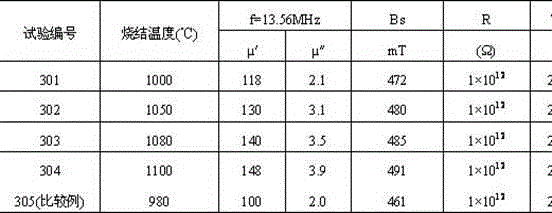

Super high magnetic conductivity, high courier temperature Mn-Zn ferrite and its preparation method

ActiveCN101106003AImprove display structureHigh permeabilityInorganic material magnetismInductances/transformers/magnets manufactureManganese oxideBrown iron oxide

The invention provides a Mn-Zn ferrite with high magnetic conductivity and high magnetic inversion temperature; major components of the ferrite include manganese oxide, zinc oxide, and iron oxide, and auxiliary components include bismuth oxide, molybdenum oxide, and niobium oxide; wherein, the constituents of the major components are: manganese oxide calculated by 23-27 Moore (percent) of Mno, zinc oxide calculated by 20-26 Moore (percent) of ZnO; the rest is iron oxide; constituents of the auxiliary components are: bismuth oxide calculated by 0-0.08 weight (percent) (excluding zero) of Bi2O, molybdenum oxide calculated by 0-0.12 weight (percent) (excluding zero) of MoO3, and niobium oxide calculated by 0.01-0.1 weight (percent) (excluding zero) of Nb2O5; the crystal particle of Mn-Zn ferrite is 50-180micron; under the condition of 25 DEG C, 10KHz, and 0.25mT, the initial magnetic conductivity of the Mn-Zn ferrite is 15000-18000; under the condition of 100KHz and 0.25mT, the initial magnetic conductivity is 13000-15000, and the magnetic inversion temperature is above or equal to 130 DEG C; in addition, the method provides the production method for the Mn-Zn ferrite.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Piezoelectric material, piezoelectric element, liquid discharge head, ultrasonic motor, and dust removing device

ActiveUS20130270965A1High curie temperatureDriving durabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksCurie temperatureUltrasonic motor

Provided is a piezoelectric material that achieves both high piezoelectric performance and high Curie temperature. In addition, provided are a piezoelectric element, a liquid discharge head, an ultrasonic motor, and a dust removing device, which use the piezoelectric material. The piezoelectric material includes a perovskite-type metal oxide that is expressed by the following general formula (1): xBaTiO3-yBiFeO3-zBi(M0.5Ti0.5)O3 (1), where M represents at least one type of element selected from the group consisting of Mg and Ni, x satisfies 0.25≦x≦0.75, y satisfies 0.15≦y≦0.70, z satisfies 0.05≦z≦0.60, and x+y+z=1 is satisfied.

Owner:CANON KK +1

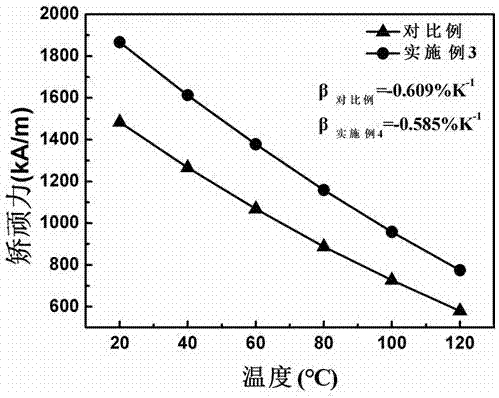

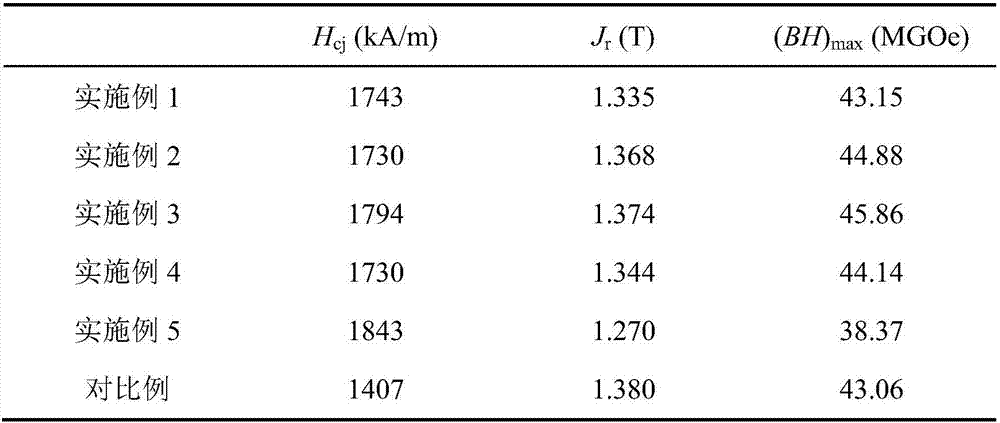

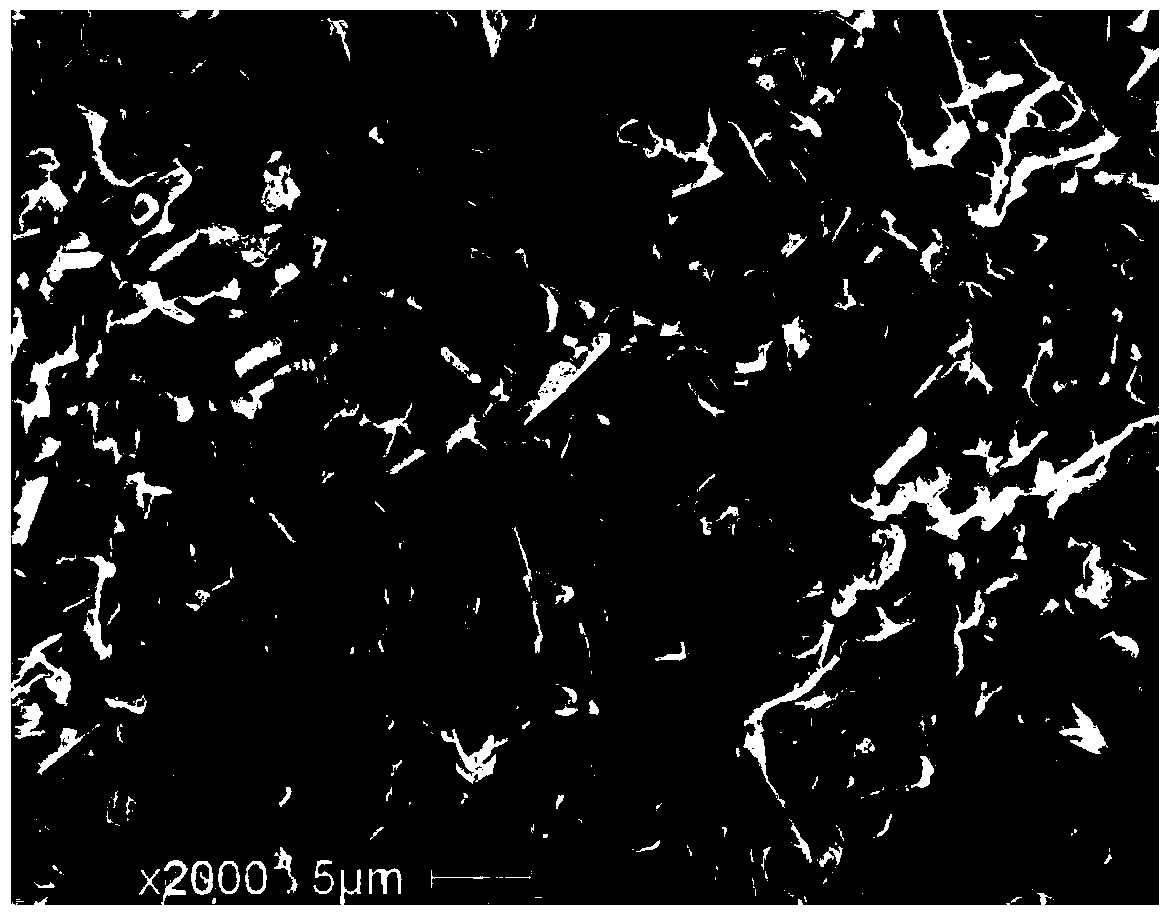

Crystal boundary diffusion method for improving coercive force and thermal stability of neodymium-iron-boron magnet

InactiveCN107093516ADiffusion rate is fastInhibit growthInductances/transformers/magnets manufactureRare earthHeat treated

The invention discloses a crystal boundary diffusion method for improving the coercive force and the thermal stability of a neodymium-iron-boron magnet, and belongs to the field of rare earth permanent magnet materials. According to the method, a quaternary alloy Dy-Ni-Al-Cu with a low melting point is used as a diffusion source and melted and prepared into a rapid-hardening strip, after coarse breaking, the strip casting is laid around the neodymium-iron-boron magnet, and by the adoption of a heat treatment method, the rapid-hardening strip diffuses and enters the magnet along the crystal boundary. After the processing, the coercive force of the magnet is significantly improved, and the magnetic energy product is improved to a certain extent; meanwhile, since the temperature of the diffusion treatment is low, energy consumption can be reduced, the cost can be lowered, and Nd2Fe14B crystal grains can be prevented from growing up; compared with a coating and magnetron sputtering method, the crystal boundary diffusion method omits a powder preparing and coating process in a coating technology and a thin film preparing process in a magnetron sputtering technology. After the technology processing of the crystal boundary diffusion method, the neodymium-iron-boron magnet with the high coercive force and the high thermal stability is finally obtained.

Owner:SOUTH CHINA UNIV OF TECH

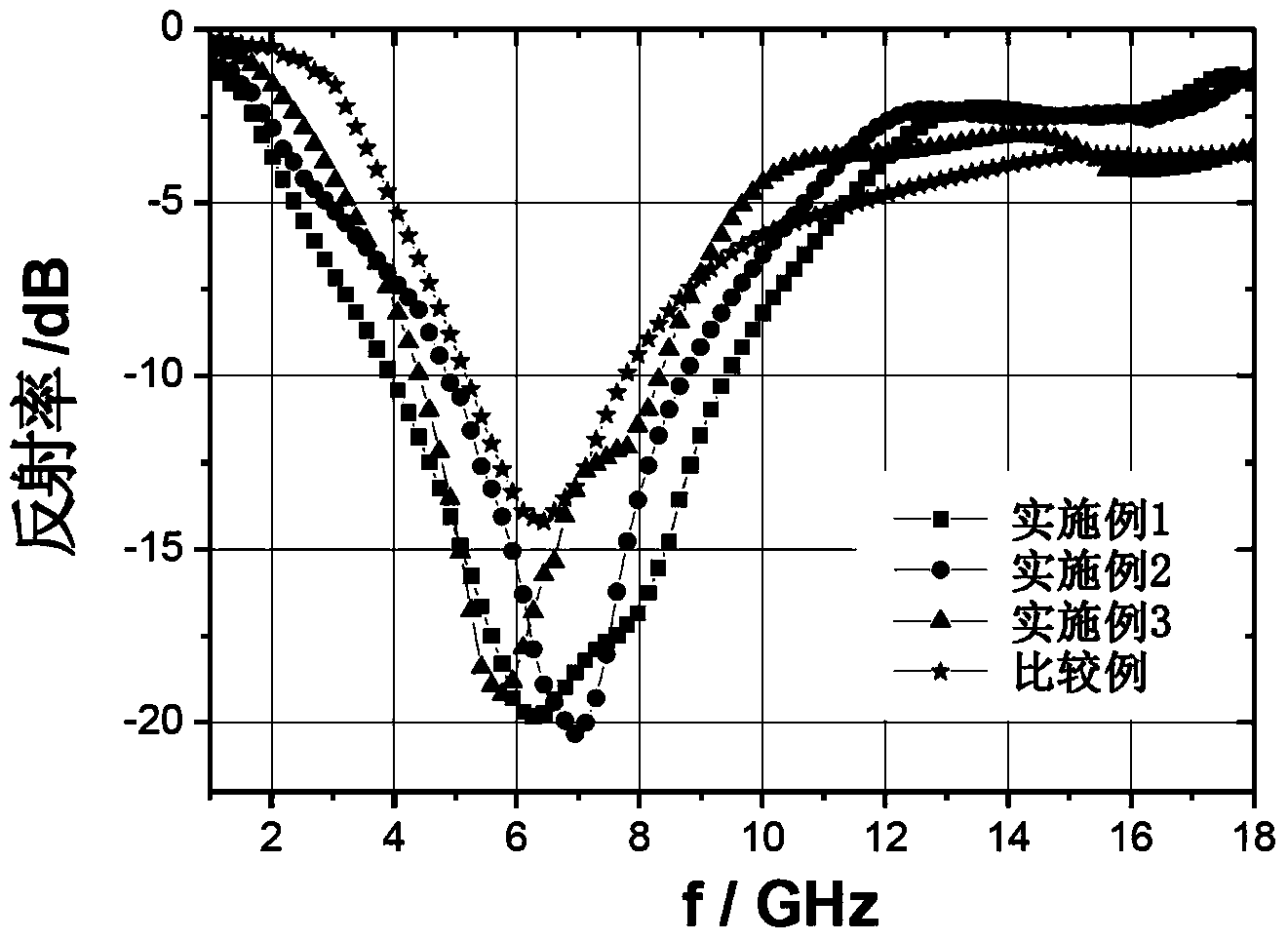

Ferrite wave-absorbing material and preparation method thereof

InactiveCN103482969AHigh strengthHigh curie temperatureOther chemical processesCeramic sinteringRare-earth element

The invention relates to a ferrite wave-absorbing material and a preparation method of the ferrite wave-absorbing material. A ferrite is mingled with a rare earth element of samarium and is of a Co2 Z-type planar hexagonal structure. The chemical formula of the ferrite is 3(Ba0.5Sr0.5)O 2CoO yFe2O3 xSm2O3, wherein x and y are mole numbers, 0.15<=x<=0.5, and 10<=y<=12. According to the preparation method of the ferrite wave-absorbing material, on the basis of the traditional ferrite ceramic sintering technology, the Sm element is mingled in to adjust and control the microstructure of the material. Thus, the purpose of improving the electromagnetic property of the material is achieved, the raw materials are easy to obtain, complex equipment is not needed, the technology is easy to operate and master, the cost is low, and the preparation method of the ferrite wave-absorbing material is suitable for large-scale production. The Co2 Z-type ferrite wave-absorbing powder mingled with the rare earth element of samarium can be used for preparing a wave-absorbing coating and has high practical value and extensive application prospects in the electromagnetic shielding and cloaking field.

Owner:CENT IRON & STEEL RES INST

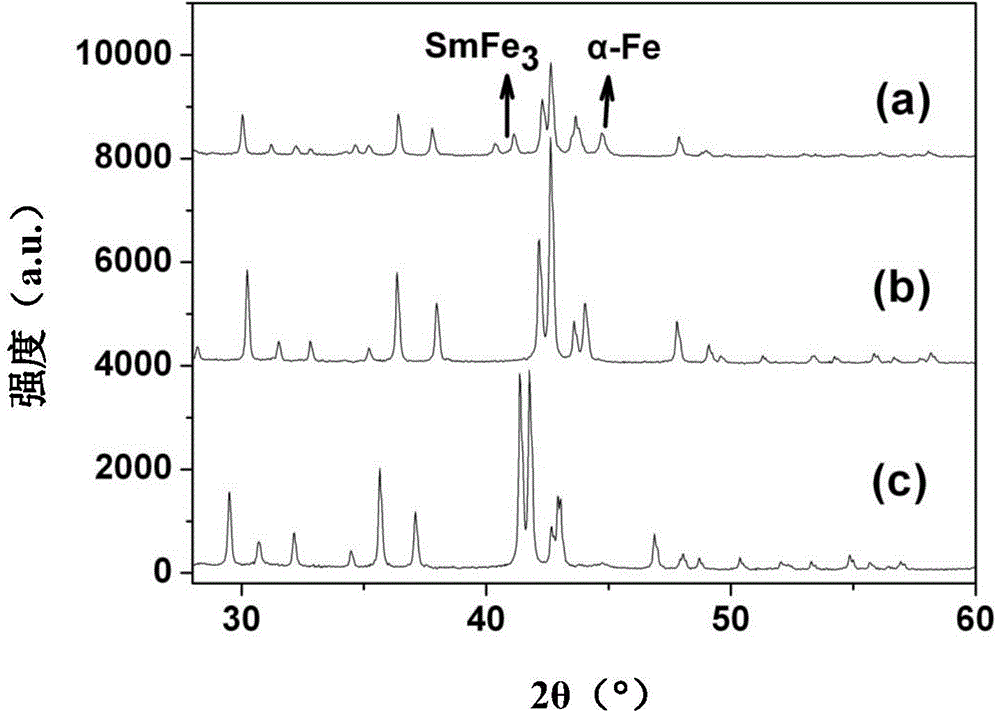

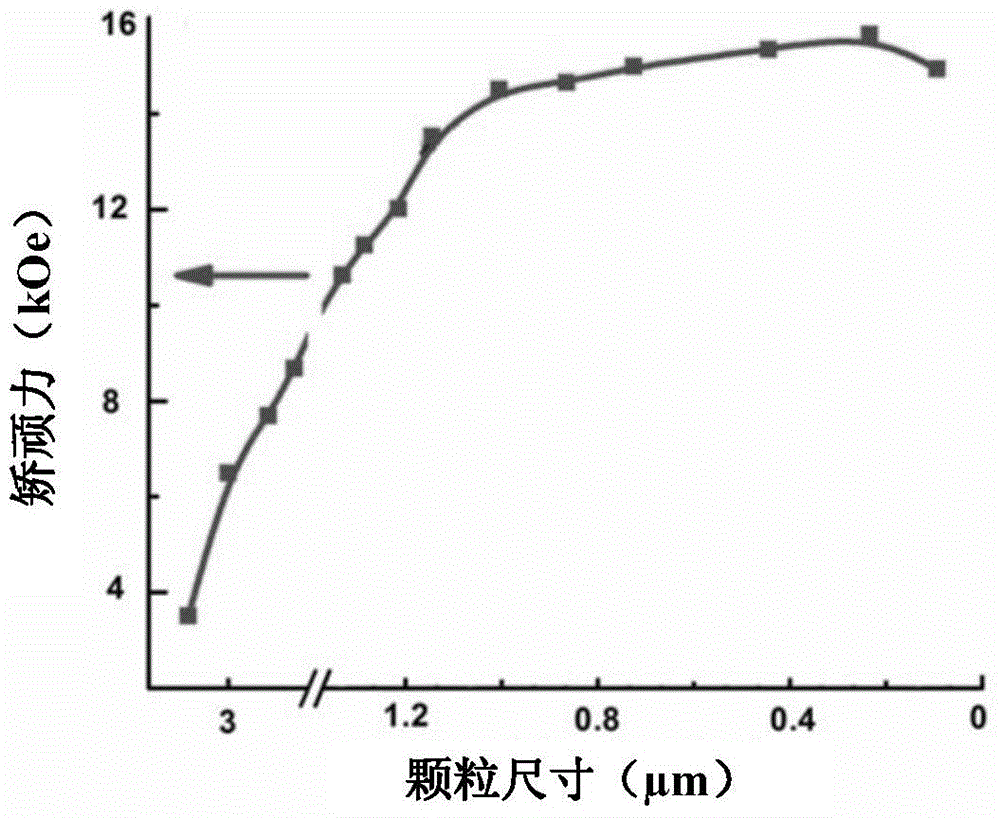

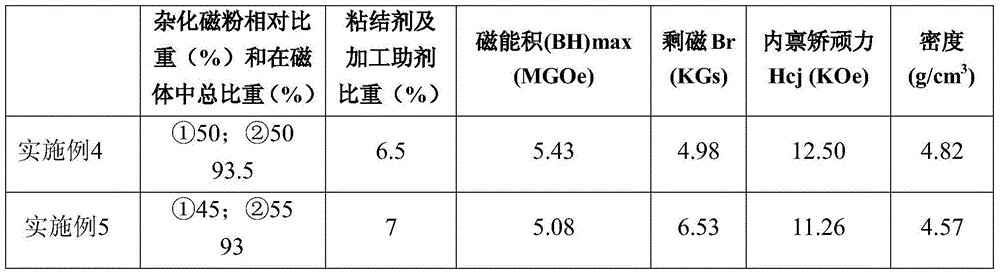

A submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom

ActiveCN106312077AHigh energy productImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsAdditive ingredientSingle crystal

The invention provides a submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom. Samarium-iron alloy is prepared by using a quick setting sheet technology; the samarium-iron alloy is made to perform gas-solid phase reaction in nitrogen or mixed gas of nitrogen and hydrogen to form samarium-iron-nitrogen alloy; then airflow milling and / or ball milling is performed to obtain anisotropic samarium iron nitrogen single-crystal particle magnet powder with a particle size of 0.01-3 [mu]m. Further, the samarium iron nitrogen single-crystal particle magnet powder, as a first ingredient, is mixed with a second ingredient consisting of permanent magnetic ferrite, rapid quenching isotropic neodymium iron boron, anisotropic neodymium iron boron, samarium cobalt and / or neodymium iron nitrogen to form hybrid magnetic powder; processing agents are added; a hybrid bonded magnet is prepared by using a rolling, mould pressing, extrusion or injection method. The prepared samarium iron nitrogen magnet powder are high in magnetic energy product, residual magnetism and intrinsic coercive force, is low in cost and small in particle size; the corresponding hybrid bonded magnet exploits the advantages of different magnetic powder ingredients, is high in shaping degree and mechanical strength and is good in temperature performance.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

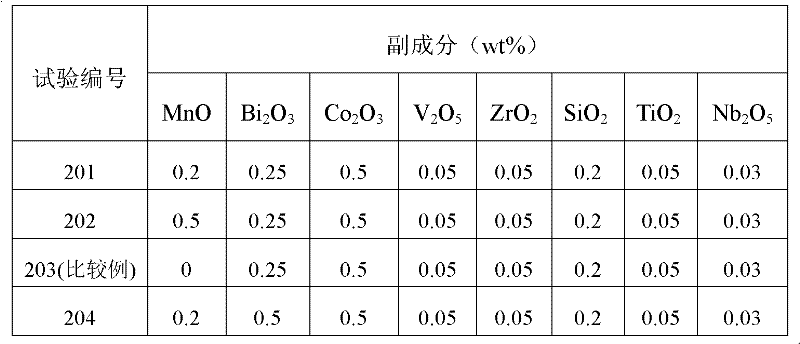

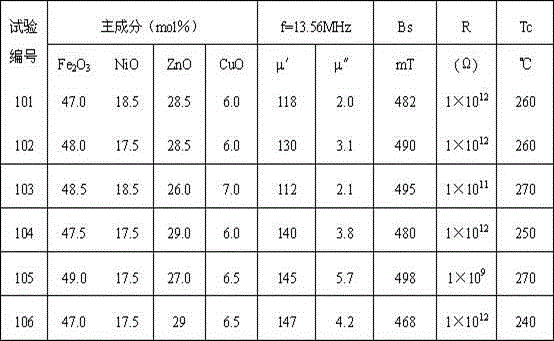

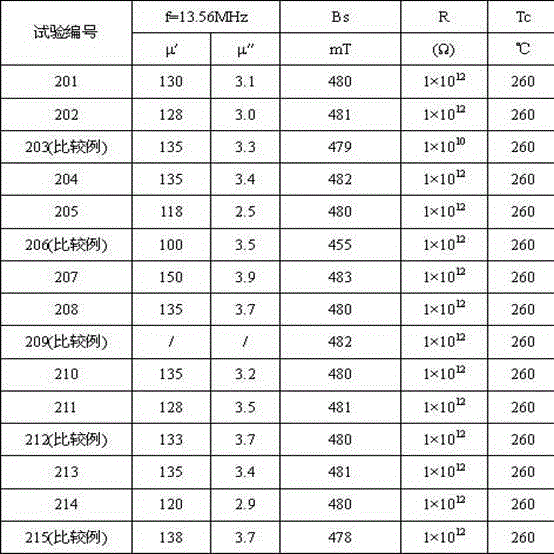

Soft-magnetic nickel-copper-zinc ferrite material and preparation method thereof

The invention belongs to the field of soft-magnetic ferrite materials. The objective of the invention is to provide a soft-magnetic nickel-copper-zinc ferrite material and a preparation method thereof. The material provided by the invention comprises major components and minor components. The major components comprise the following raw materials in mole percentage: 47.0-49.0mol% of Fe2O3, 17.5-18.5mol% of NiO, 26.0-29mol% of ZnO and 6.0-7.0mol% of CuO. The minor components comprise, based on the total weight of the major components, 0.1-0.40% of MnO, 0.1-0.5% of Bi2O3 and 0.3-0.5% of Co2O3. Under a high frequency of 13.56 MHz, the material provided by the invention has the characteristics of high magnetic conductivity ([mu]' is approximately equal to 130), low complex magnetic permeability [mu]''(namely low loss), high resistivity, high Curie temperature, high saturation magnetic induction density Bs, and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

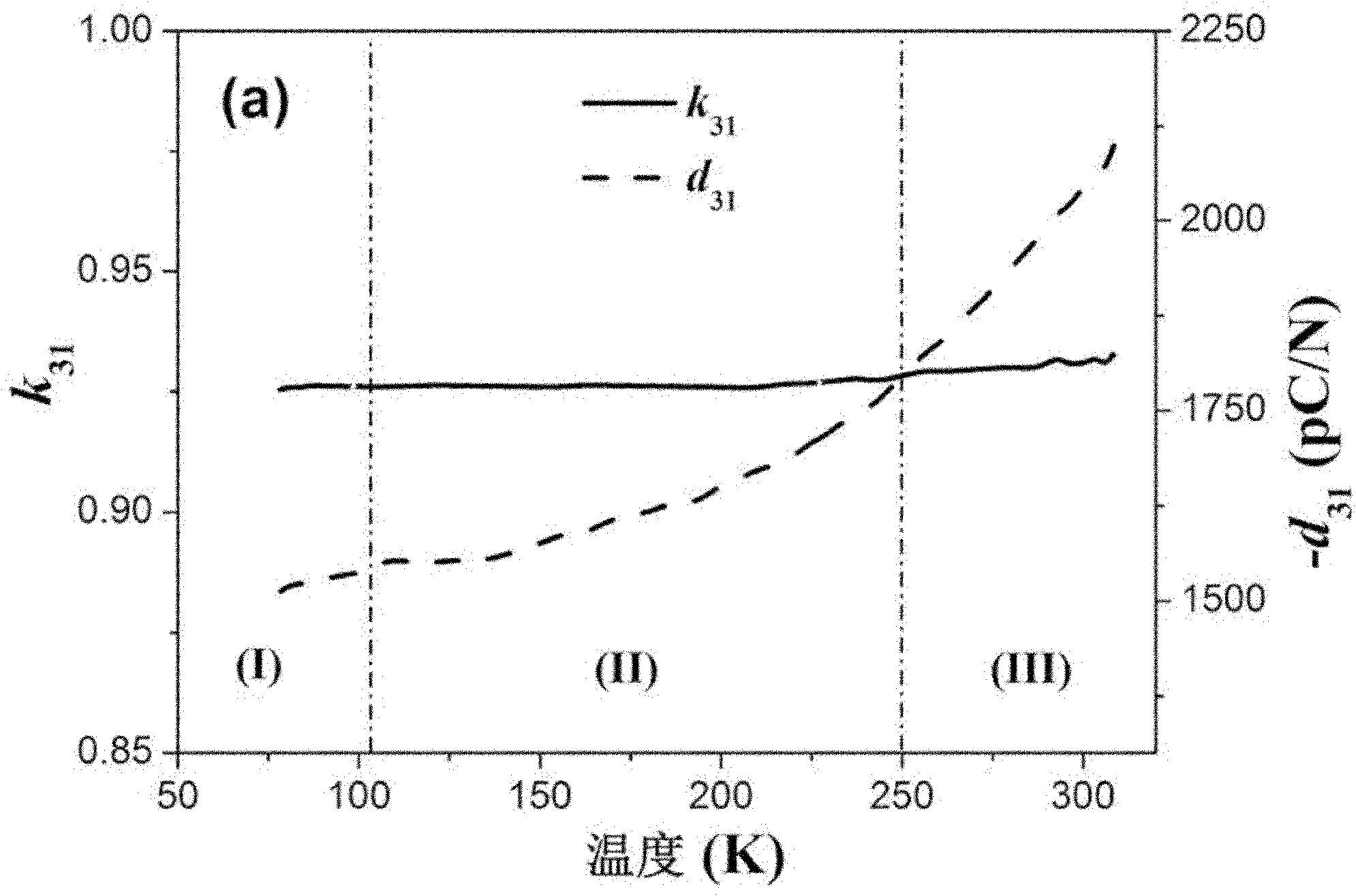

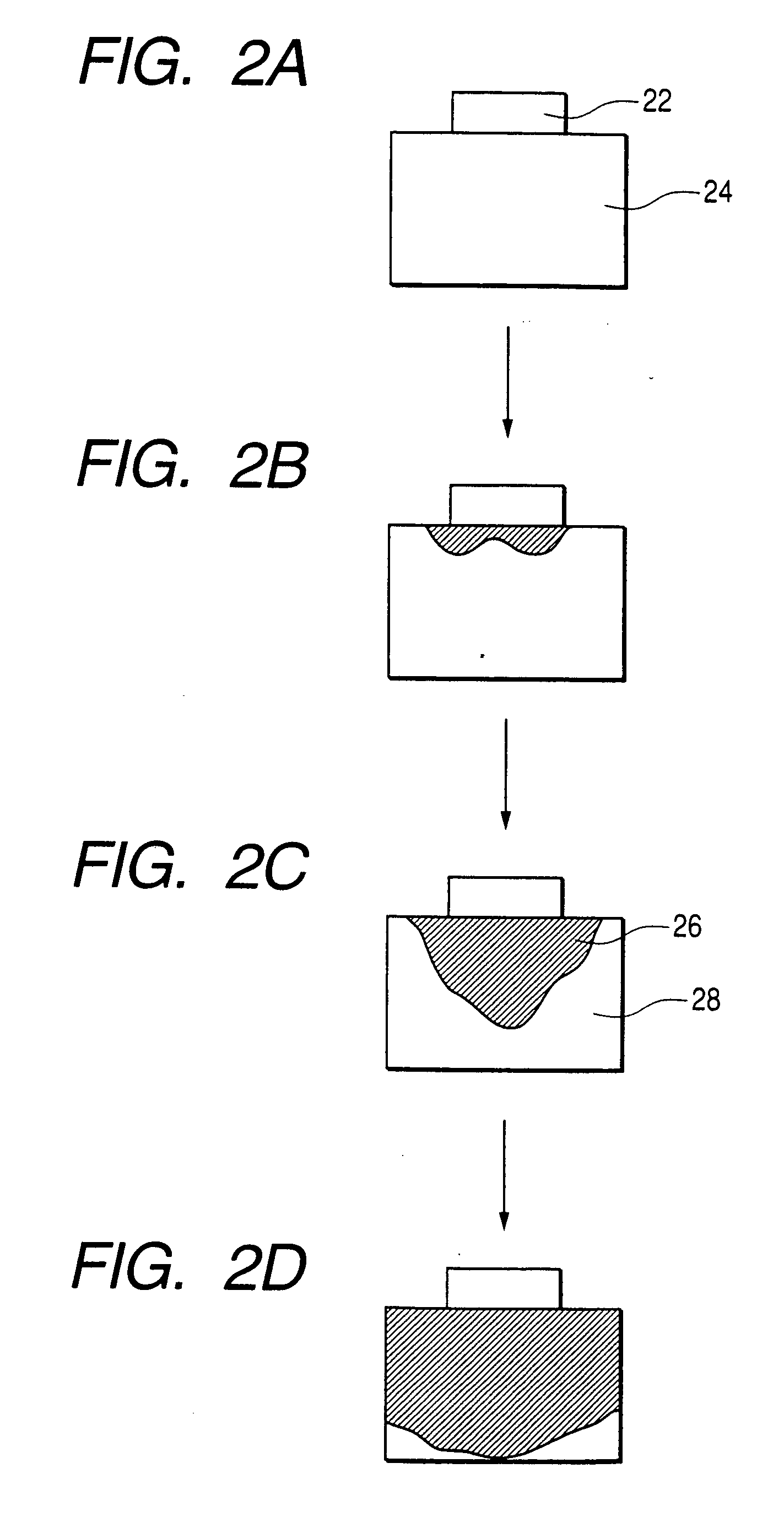

BaTiO3-PbTiO3 series single crystal and method of manufacturing the same, piezoelectric type actuator and liquid discharge head using such piezoelectric type actuator

InactiveUS20040231581A1Low amountNarrow rangePolycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyElectricityProduction rate

BaTiO3-PbTiO3 series single crystal is single-crystallized by heating BaTiO3-PbTiO3 compact powder member or sintered member having a smaller Pb-containing mol number than Ba-containing mol number, while keeping the powder or substance in non-molten condition. In this way, this single crystal can be manufactured at a crystal growing speed faster still and stabilized more, significantly contributing to improving the dielectric loss and electromechanical coupling coefficient for the provision of excellent BaTiO3-PbTiO3 series single crystal in various properties, as well as for the provision of piezoelectric material having a small ratio of lead content, which is particularly excellent in piezoelectric property and productivity.

Owner:CANON KK

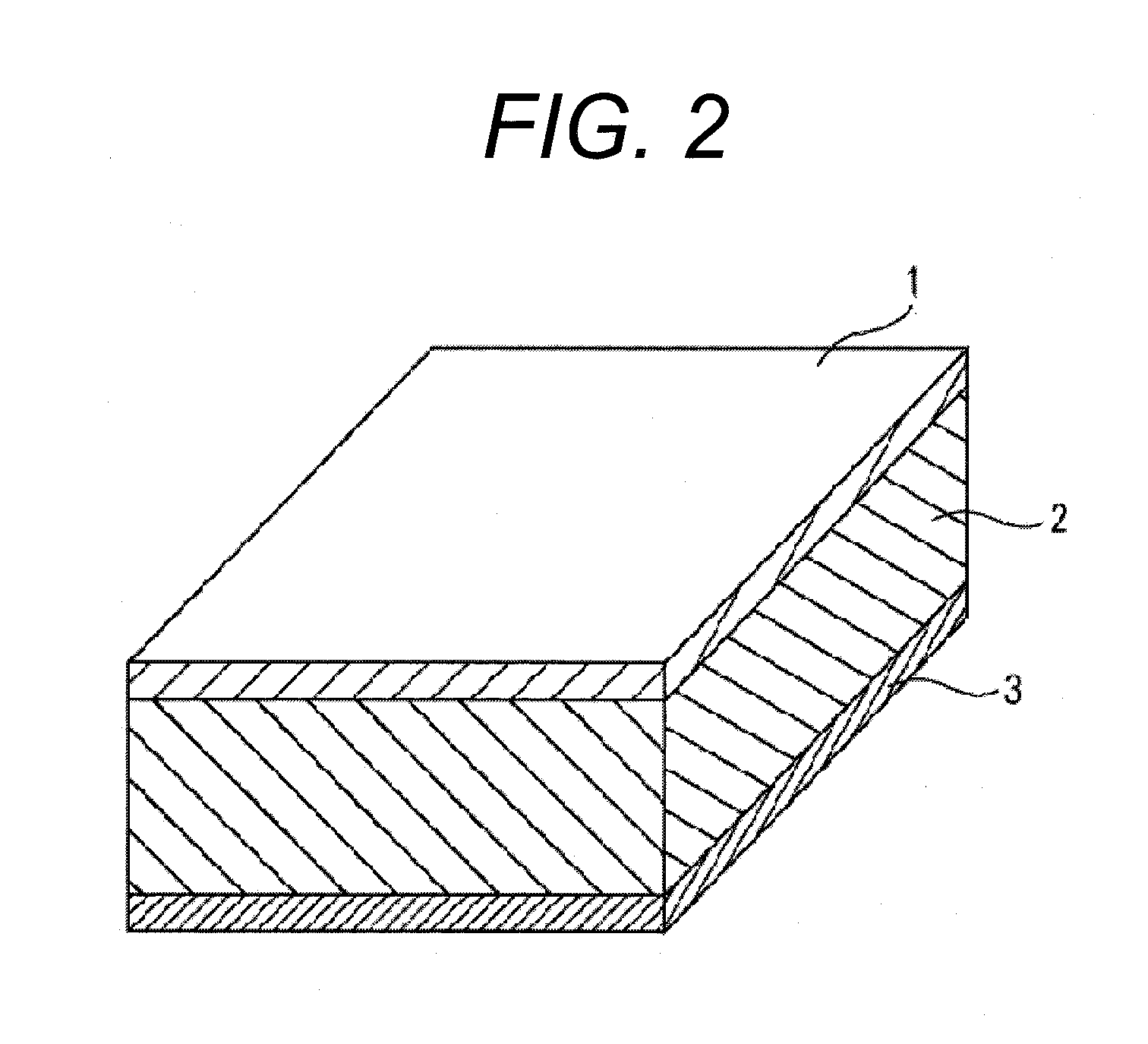

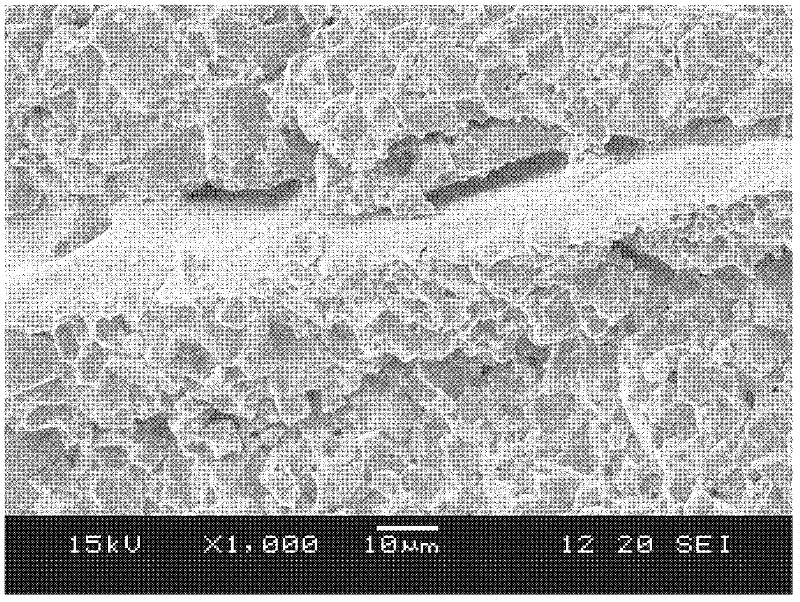

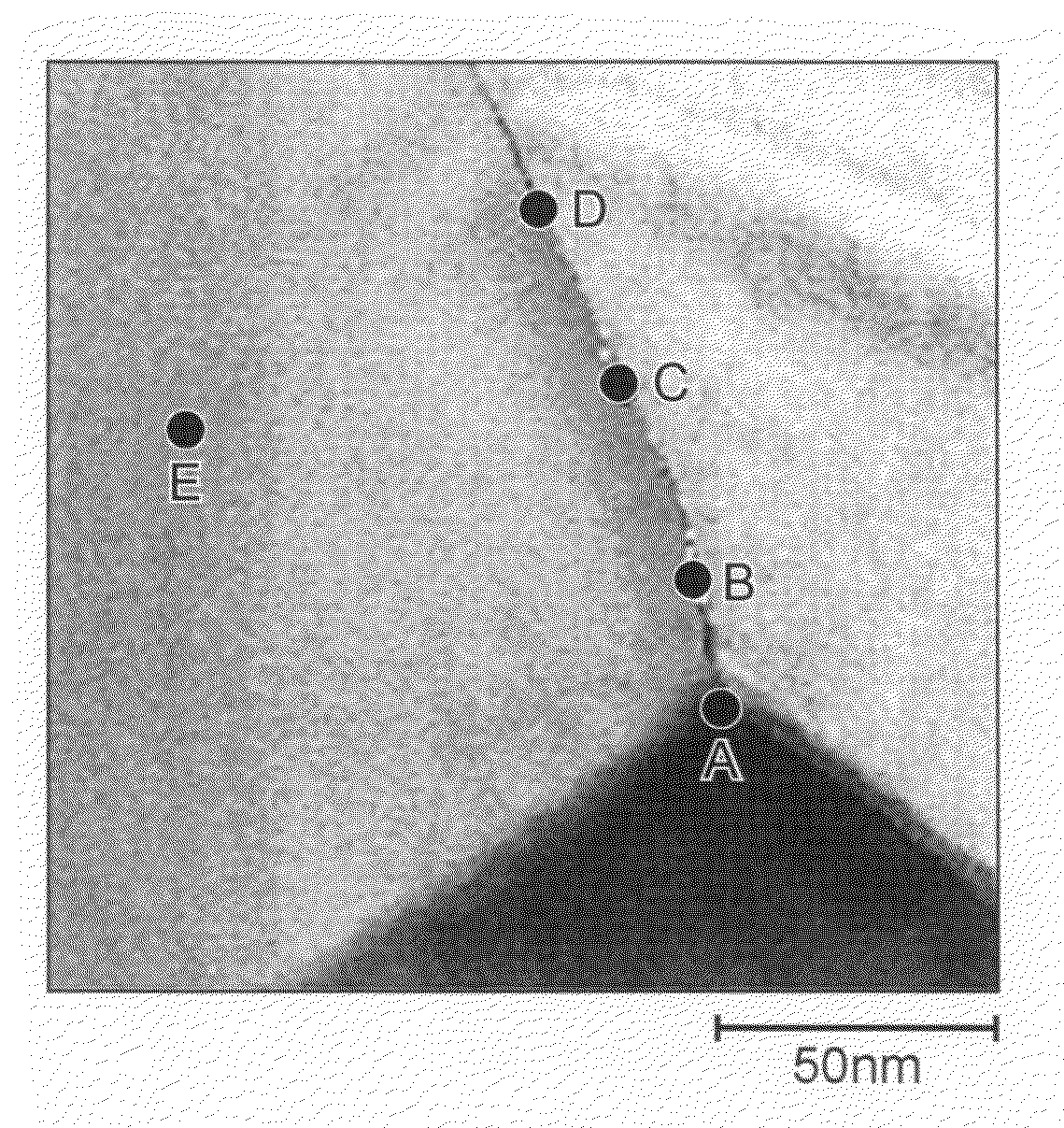

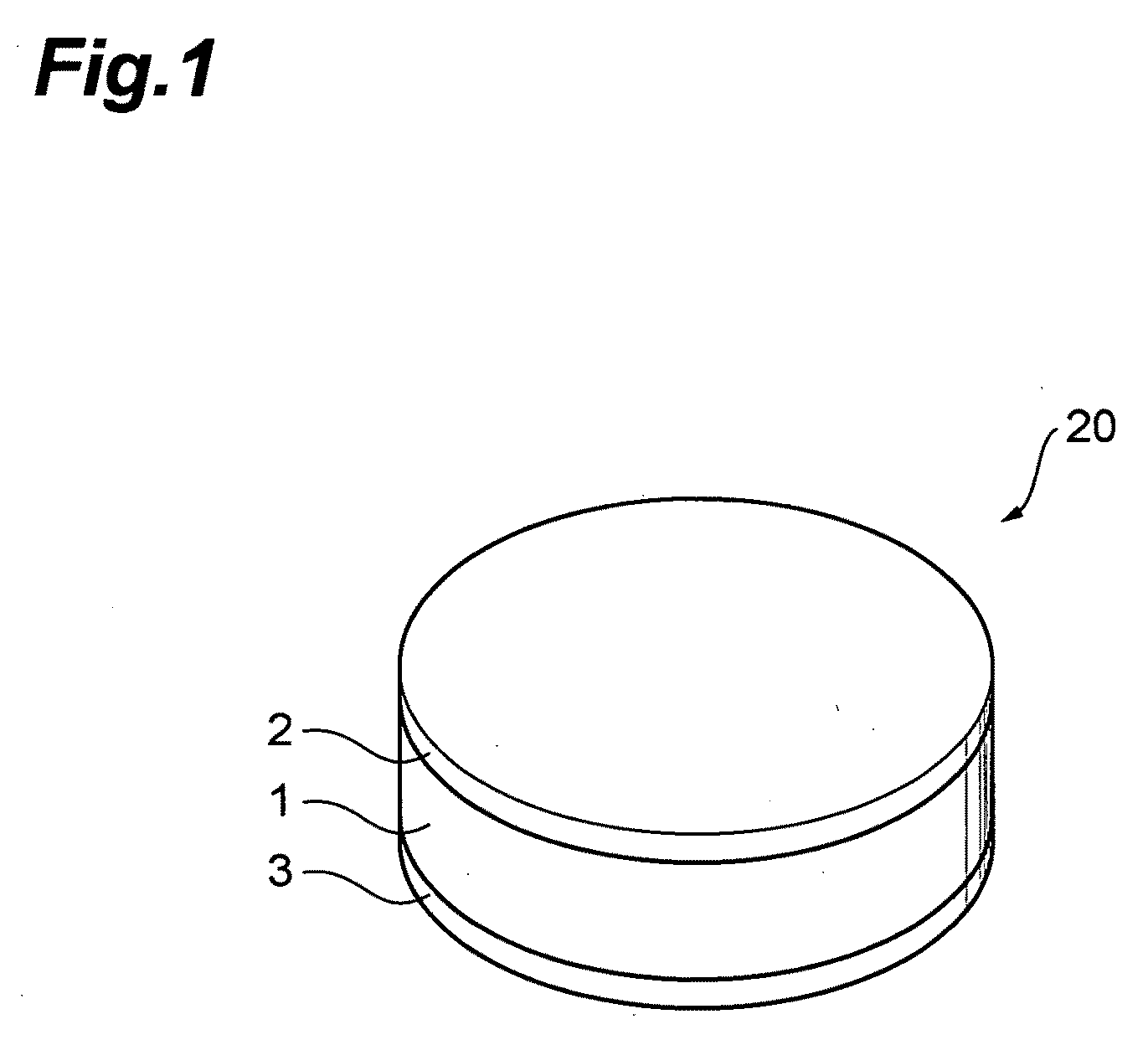

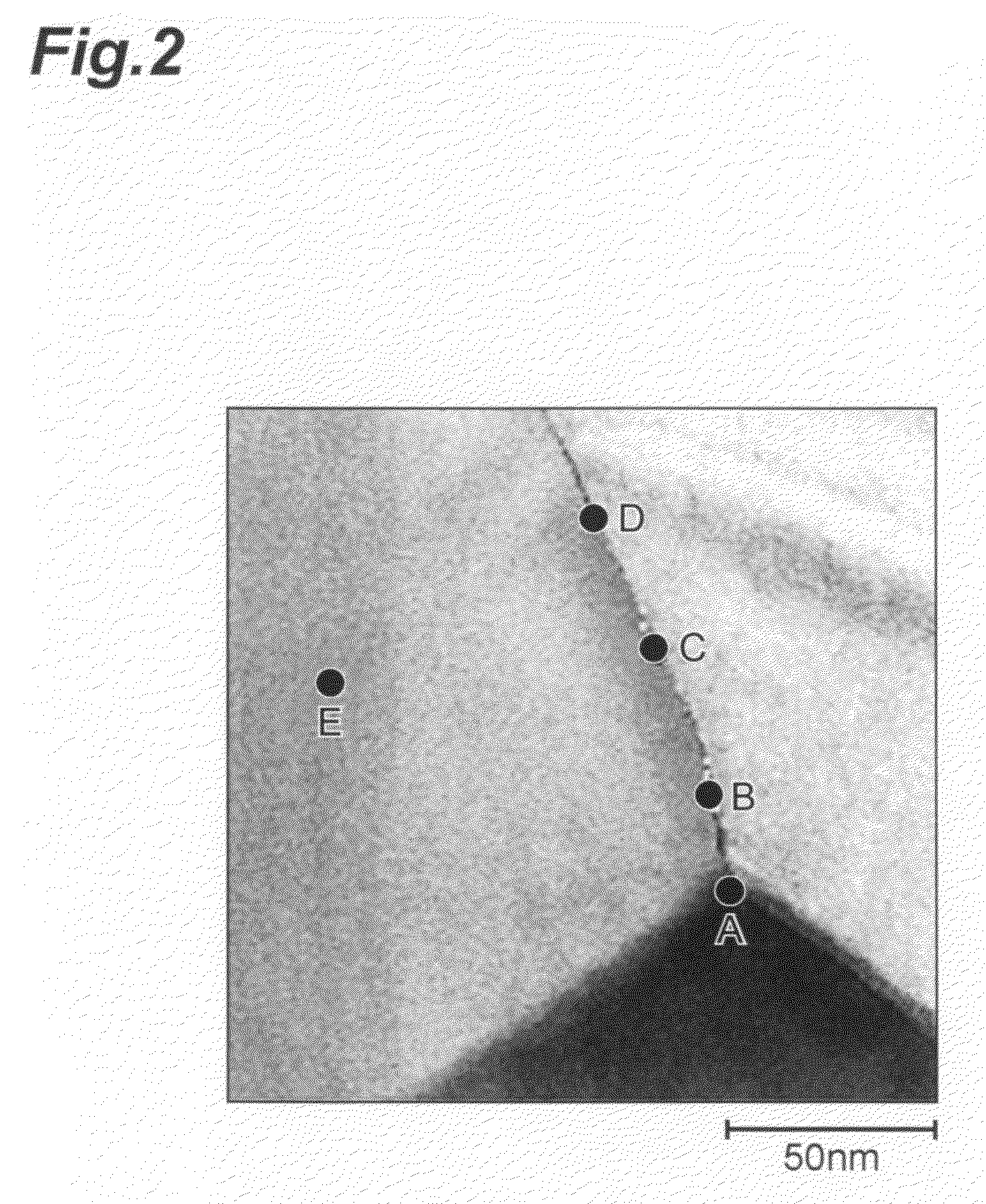

Piezoelectric ceramic and piezoelectric element employing it

InactiveUS20090243439A1Reduce contentExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesGrain boundaryAlkali metal

A piezoelectric ceramic 1 in a piezoelectric element 20 contains, as a major component, a composition containing one or more complex oxides with metal elements other than lead as constituent elements. At least one of the complex oxides includes an alkali metal and Nb as constituent elements. Also, either or both of the elements Mn and Cu are segregated at the grain boundaries of the composition.

Owner:TDK CORPARATION

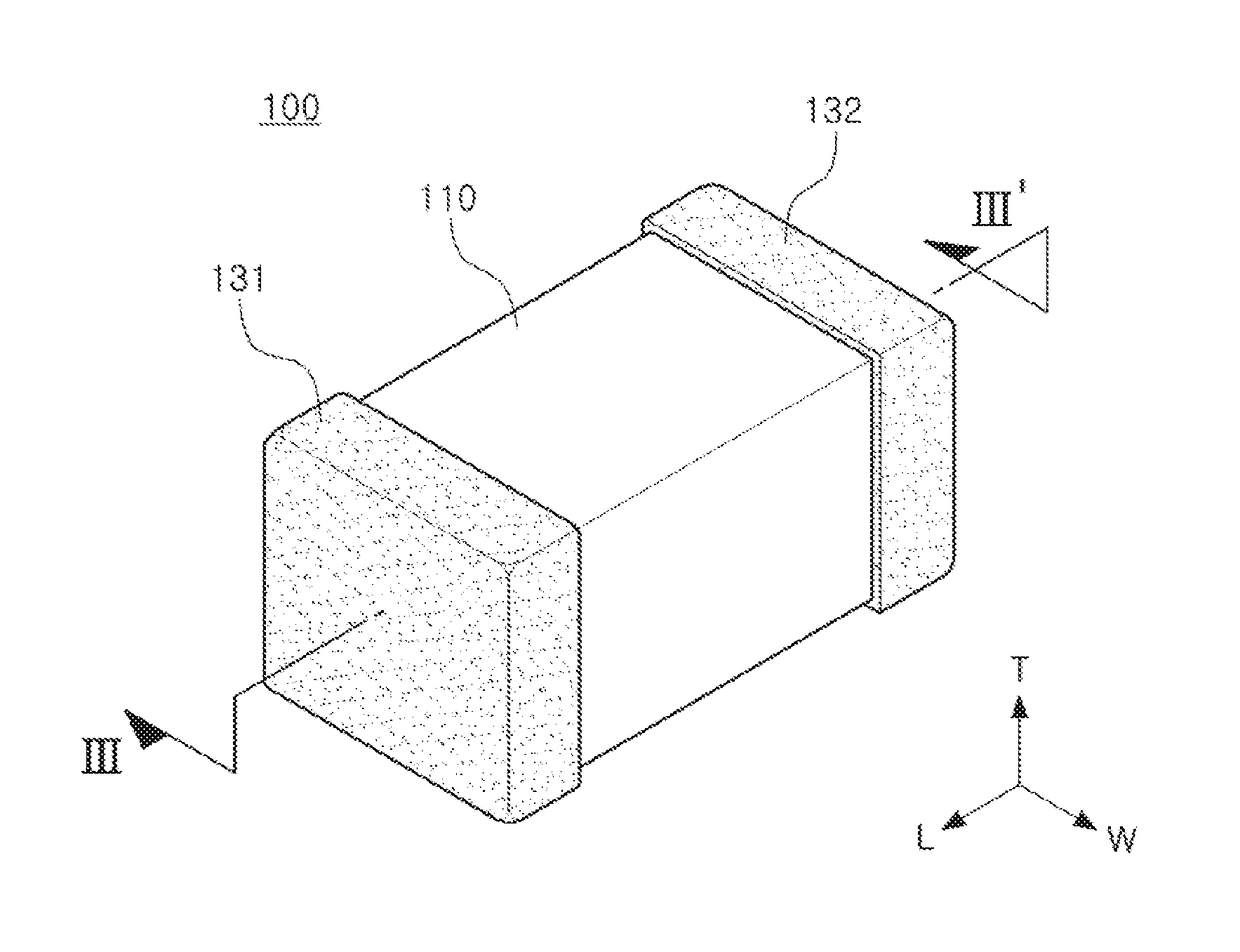

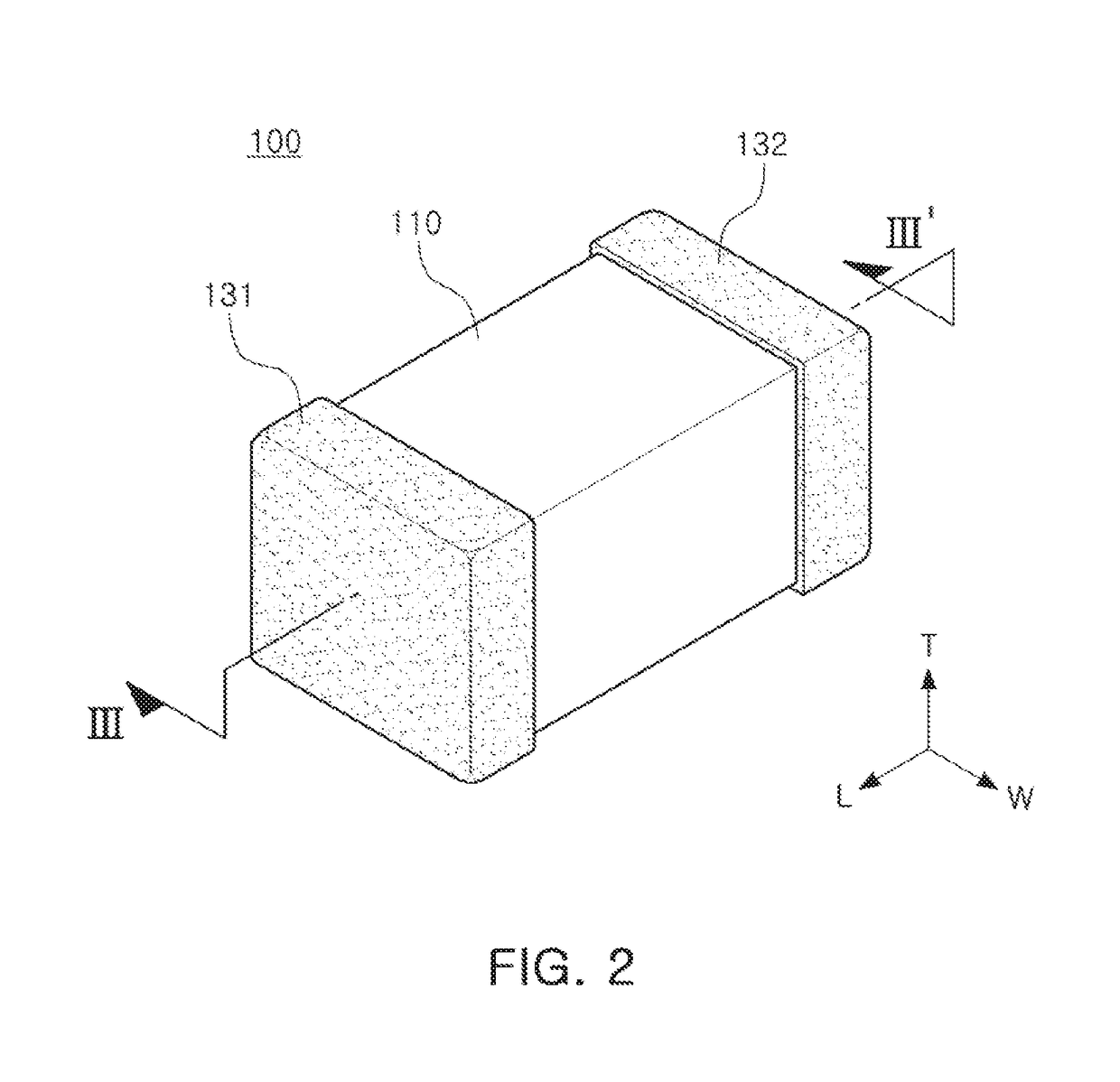

Dielectric ceramic composition, multilayer ceramic capacitor containing the same, and method for manufacturing multilayer ceramic capacitor

ActiveUS20170190626A1High curie temperatureHigh dielectric constantFixed capacitor dielectricStacked capacitorsMetallurgyCeramic capacitor

A dielectric ceramic composition contains a first main ingredient of BaTiO3 and a second main ingredient of BaTi2O5, and a base material powder containing the first and second main ingredients is represented by (1-x)BaTiO3-xBaTi2O5 and x satisfies 0.1≦x≦0.8. The dielectric ceramic composition may include additional accessory ingredients, and may be used to form ceramic sheets having internal electrodes of a multilayer ceramic capacitor disposed thereon.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

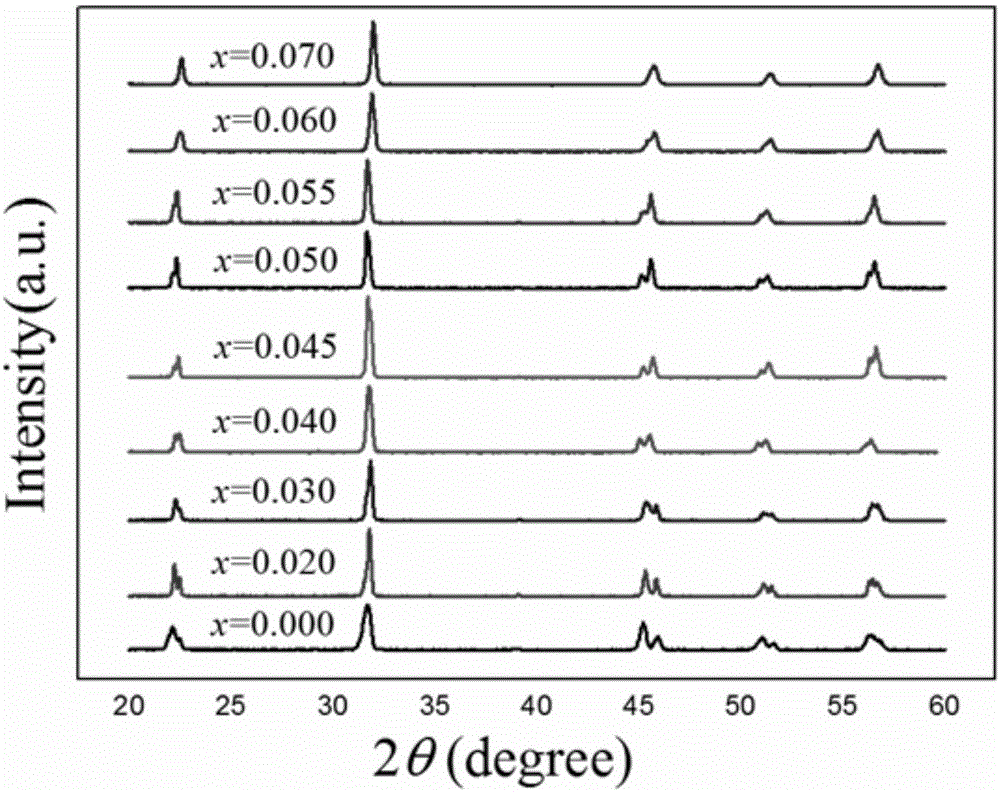

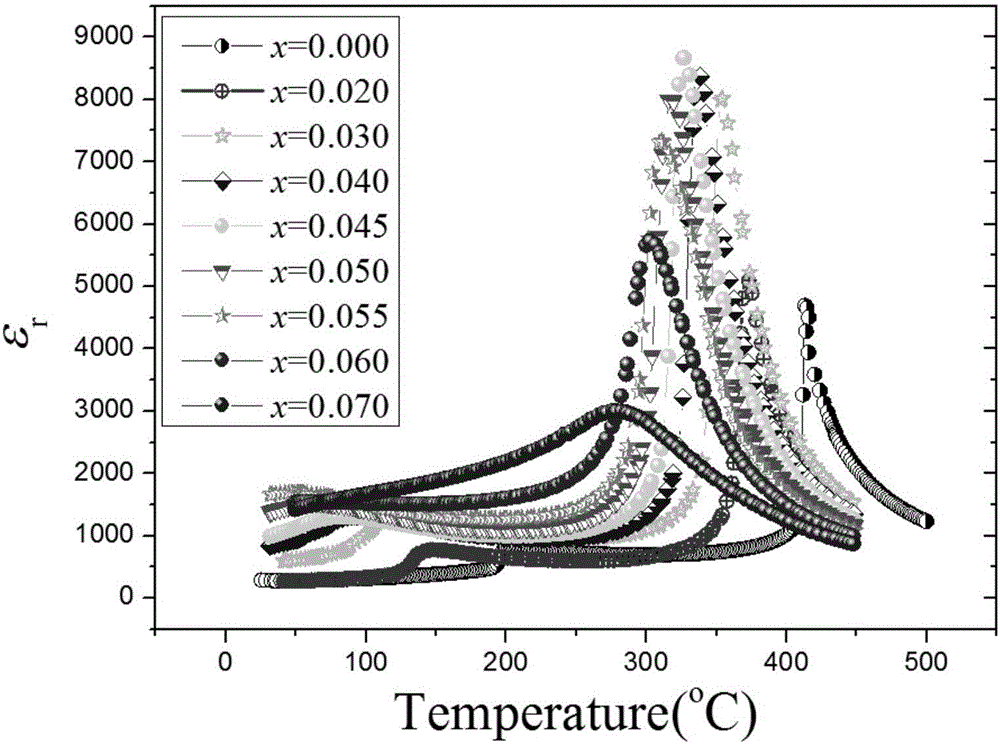

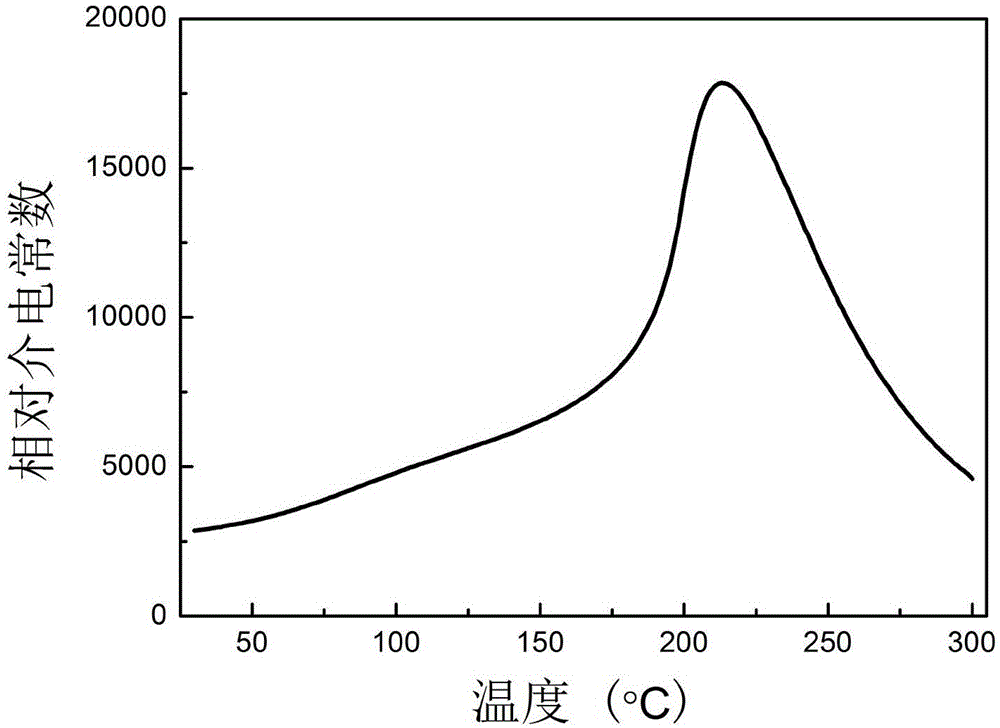

Low-temperature sintered ternary system relaxor ferroelectric ceramic material, preparation method and application of low-temperature sintered ternary system relaxor ferroelectric ceramic material

ActiveCN105084898AHigh curie temperatureImproved high-field piezoelectric performanceCeramic sinteringMetallurgy

The invention relates to a low-temperature sintered ternary system relaxor ferroelectric ceramic material, a preparation method and application of the low-temperature sintered ternary system relaxor ferroelectric ceramic material. The problems that existing PIN-PMN-PT ceramic sintering temperature is high, environmental pollution is caused by severe lead volatilization, the material performance is reduced, and the production cost is high are solved. The chemical general formula of the ceramic material is xPb(In1 / 2Nb1 / 2)O3-(1-x-y)Pb(Mg1 / 3Nb2 / 3)O3-yPbTiO3-awt.%CuO. The method includes the steps of firstly, conducting a solid-phase reaction to synthesize a precursor of MgNb2O6; secondly, conducting a solid-phase reaction to synthesize a precursor of InNbO4; thirdly, conducting a solid-phase reaction to synthesize matrix powder of PIN-PMN-PT; fourthly, preparing low-temperature sintered ternary system relaxor ferroelectric ceramic through the combination of the solid-phase synthesis technology and the curtain coating lamination process. The low-temperature sintered ternary system relaxor ferroelectric ceramic material, the preparation method and the application are used for preparing high-power piezoelectric buzzers and multi-layer piezoelectric devices.

Owner:HARBIN INST OF TECH

High-stability garnet microwave ferrite magnetic sheet and preparation method thereof

PendingCN111187064AHigh dielectric constantReduce the anisotropy coefficient KInorganic material magnetismInductances/transformers/magnets manufacturePorosityMicrowave

The invention belongs to the technical field of magnetic materials, and discloses a high-stability garnet microwave ferrite magnetic sheet and a preparation method thereof. The material composition ofthe high-stability garnet microwave ferrite magnetic sheet is Y<3-f-2d-a>Gd<f>Ca<2d+a>Bi<e>Fe<5-a-b-c-d-sigma>SnInMn<c>V<d>O<12>, wherein a is more than 0 and no more than 0.7; b is more than 0and no more than 0.7; c is more than 0 and no more than 0.6; d is more than 0 and no more than 1.5; e is more than 0 and no more than 0.6; f is more than 0 and no more than 0.8; and sigma is more than 0 and no more than 0.4. According to the high-stability garnet microwave ferrite magnetic sheet, Bi<3+> ions are added into the material, so the dielectric constant of the material is improved, anda Curie temperature is increased; and in addition, SnO<2>, In<2>O<3>, SnO<2> and In<2>O<3> are added into the material, so the anisotropy coefficient K of the material can be reduced, and the ferromagnetic resonance linewidth Delta(H) of the material is reduced. In terms of the process, high-pressure sintering is adopted to replace normal-pressure sintering, so sintering density is improved, the porosity of the material is reduced, and the ferromagnetic resonance linewidth Delta(H) of the material is reduced. Thus, the problem that the temperature coefficient of the material is poor is solved,and the material is guaranteed to have low ferromagnetic resonance linewidth Delta(H), high dielectric constant and high Curie temperature.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

NiZn soft magnetic ferrite material with high magnetic conductivity and high Curie temperature and its preparing method

InactiveCN1929048AHigh curie temperatureRaise the burn-in temperatureInorganic material magnetismCurie temperatureMagnetocrystalline anisotropy

This invention relates to regular high magnetic rate NiZn iron oxidation formula and provides one NIZn iron oxidation materials and its process method, which adopts metal oxidation as materials by use of oxidation wet method, which comprises Fe2O3,NiO,ZnO,CuO and WO3 with each content as: Fe2O3 for 50.5-51mol %; NiO for 13.5-14mol%; ZnO for 31.5-32mol%; CuO for 3.5-4.5mol%; WO3 for 0.1-0.3mol%.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing Cr doped ZnO-based diluted magnetic semiconductor film material

InactiveCN101615467ASimple preparation processIncrease deposition rateVacuum evaporation coatingSputtering coatingDevice materialCurie temperature

The invention relates to a method for preparing a Cr doped ZnO-based diluted magnetic semiconductor film material, belonging to the preparation field of novel semiconductor spintronics device materials. The method adopts double targets cosputtering of chromium and zinc oxide, wherein the background vacuum degree of the system is 10<-5>Pa-10<-3>Pa; high-purity argon is used as working gas in the sputtering process; the flow rate of the high-purity argon is 5-15 cm<3> / min; the working gas pressure is 10<-2>-10<-1>Pa in the sputtering process; and the distance between a target material and a basal body is 35-70 mm. Ultrasonic cleaning is carried out on the basal body, oxide and other impurities of the surface of the basal body are removed, and the ZnO-based diluted magnetic semiconductor film materials with different doping concentrations are obtained through changing different target powers. The method has simple preparation process and high deposition rate and can obtain the diluted magnetic semiconductor film material with room-temperature ferromagnetism, high Curie temperature and controllable performance, thereby having important research value and wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

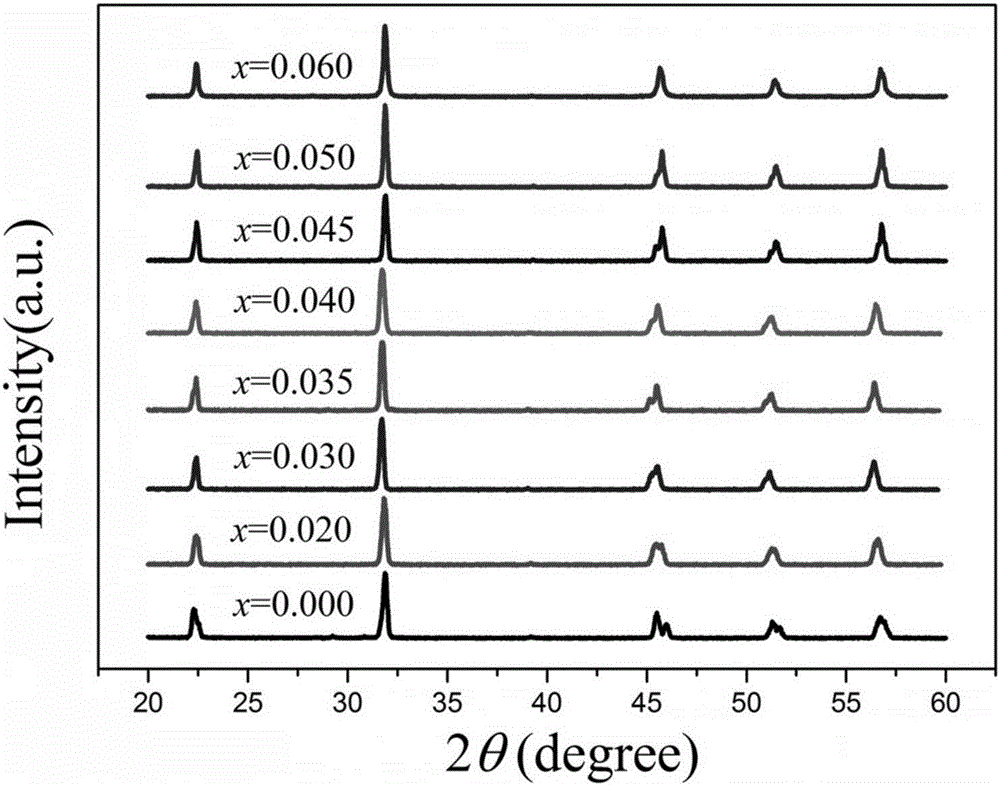

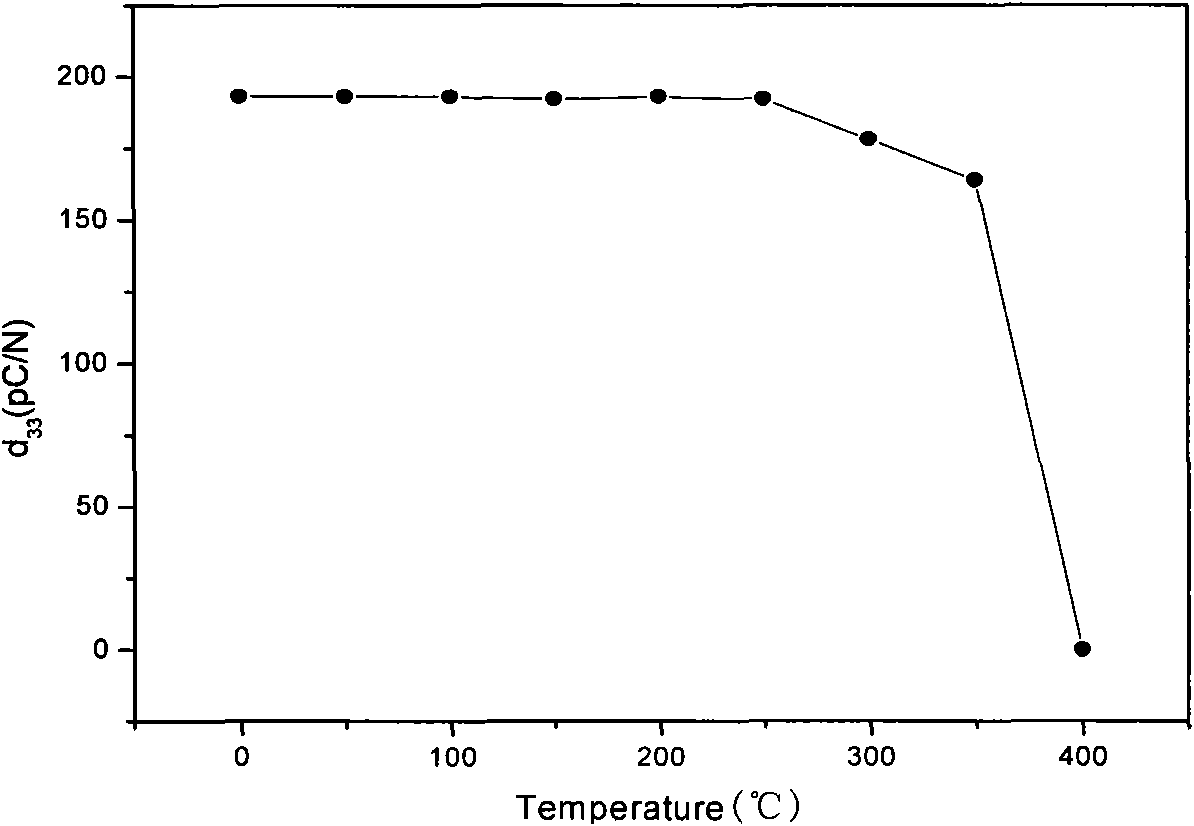

Magnesium titanate bismuth-lead titanate piezoelectric ceramics suitable for high-temperature field

The invention discloses a magnesium titanate bismuth-lead titanate piezoelectric ceramics suitable for a high-temperature field, belonging to perovskite structure piezoelectric ceramics. The invention can be represented by the general formula: (1-x)Bi(Mg1 / 2Ti1 / 2)O3-xPbTiO3+alphaMnO2(mol%), wherein x=0.32-0.42, x represents the molar percent of PbTiO3, alpha=0-2 mol%, and the alpha is the molar percent for MnO2 to account for the raw material total amount; MnO2 is a doped metallic oxide and can lower the loss factor of the piezoelectric ceramics. The piezoelectric ceramics is prepared by the traditional piezoelectric ceramics preparation technology, lead tolerance is lower than 42 mol%; d33 can be kept at 170 pC / N at the temperature of 350 DEG C; and after MnO2 is doped, Curie temperature Tc can be 520 DEG C, d33 is 120 pC / N, and the loss factor tan delta is lowered to 0.018. The invention has huge high-temperature application potential and practical application value.

Owner:TIANJIN UNIV

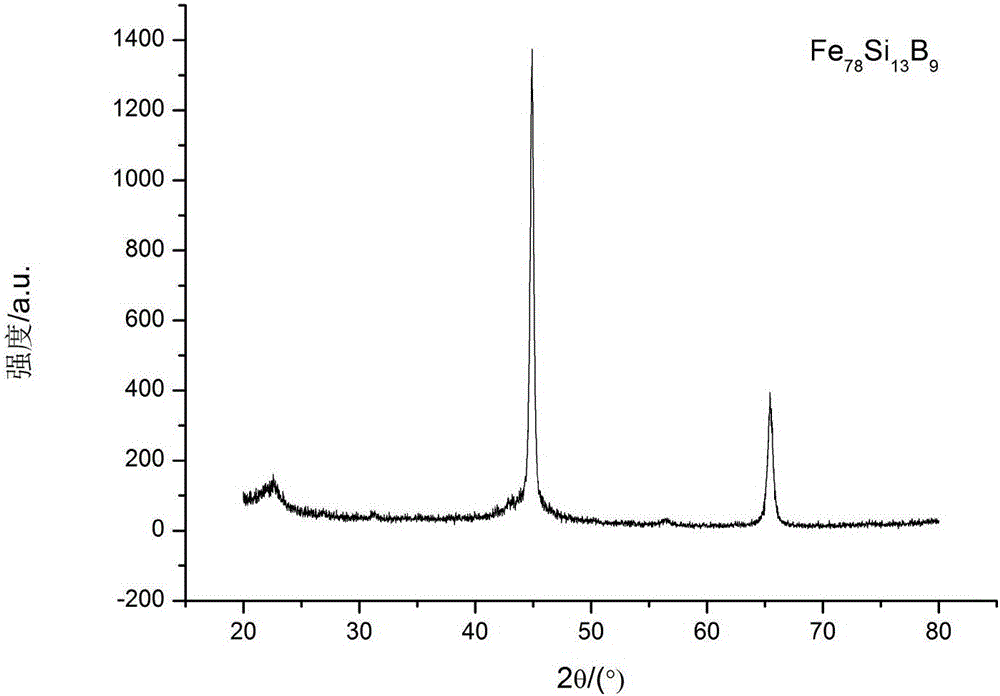

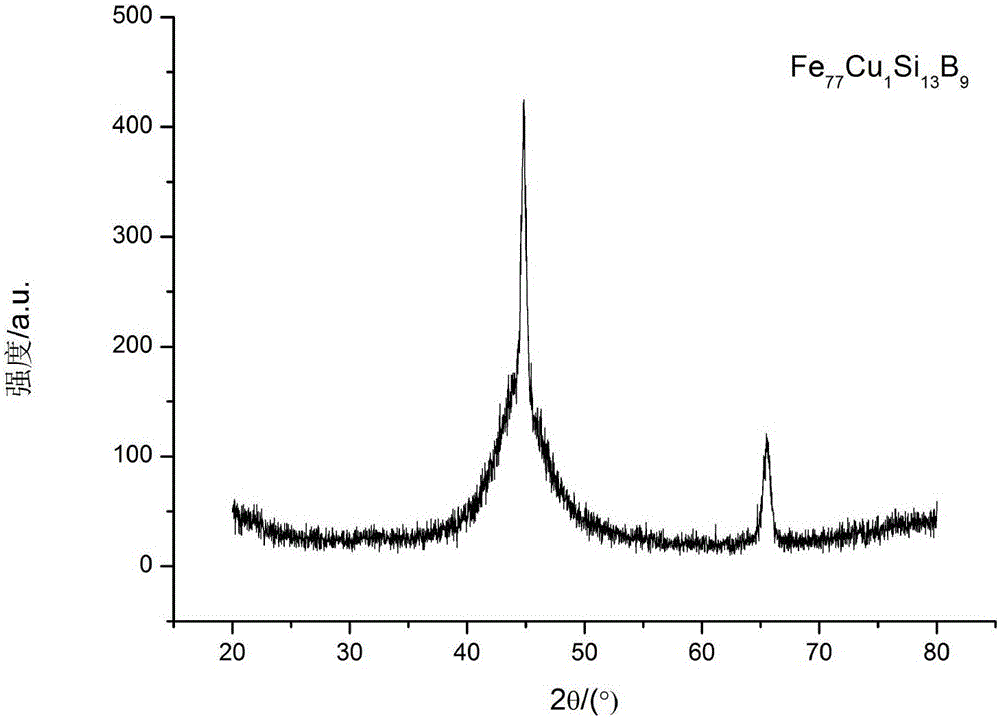

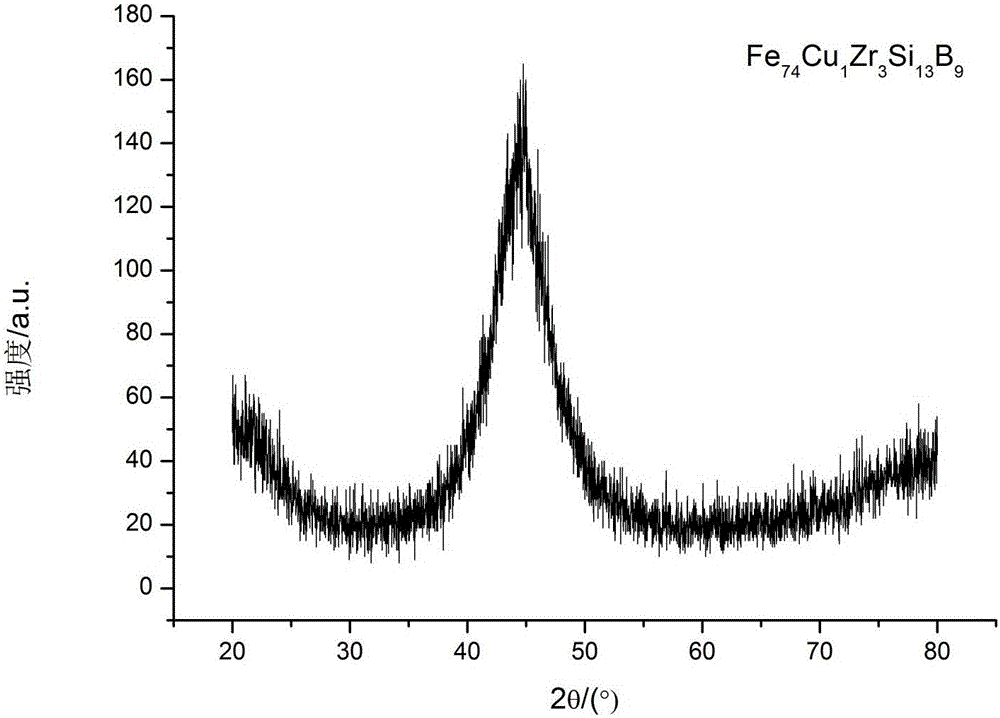

Fe-based amorphous/nanocrystalline soft magnetic alloy thin belt and preparation method thereof

The invention relates to a Fe-based amorphous / nanocrystalline soft magnetic alloy thin belt. A chemical expression formed by elements of the alloy thin belt is FeaSibBaCudMee, wherein the atomic percent of the elements is shown as follows: a is equal to 80-85, b is equal to 2-13, c is equal to 5-13, d is equal to 0.5-2, e is equal to 0.5-5, a+b+c+d+e is equal to 100; Me is Zr, Nb or Mo. The alloy thin belt has a thickness of 15-40 [mu]m and a width of 1-5 mm. Through adding the Me element in the method, the nucleation rate of super-cooled liquid is effectively improved, and the precipitation of a BCC nanocrystalline iron phase is promoted, Fe-based nano alloy is prepared, and the magnetostriction coefficients of a material are reduced, so that the initial magnetic conductivity is improved, and the saturated magnetic induction intensity is obviously improved.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com