High-stability garnet microwave ferrite magnetic sheet and preparation method thereof

A ferrite magnetic, high stability technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc. It can reduce the porosity, reduce the ferromagnetic resonance linewidth, and increase the Curie temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

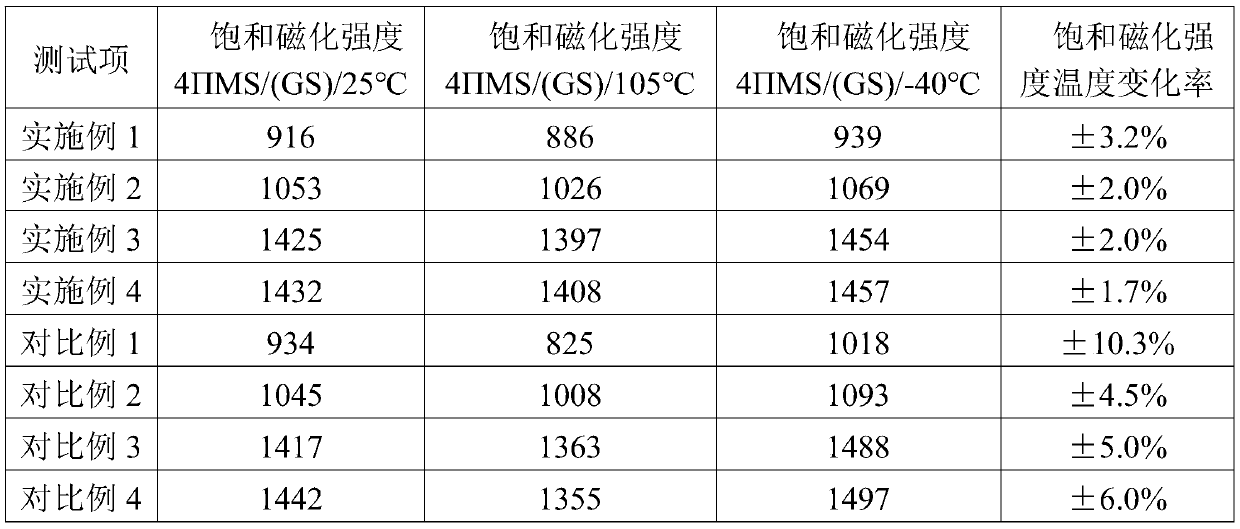

Examples

Embodiment 1

[0034] 1. According to chemical formula Y (3-f--2d-a) Gd f Ca (2d+a) Bi e Fe (5-a-b-c-d-σ) sn a In b mn c V d o 12 , where: a=0.08, b=0.03, c=0.05, d=0.5, e=0.05, f=0.25, σ=0.15, calculate and weigh the required raw materials, the purity of which is not less than 99.4% Fe 2 o 3 , Y 2 o 3 , CaCO 3 , SnO 2 , MnCO 3 , Bi 2 o 3 , Gd 2 o 3 , In 2 o 3 , V 2 o 5 , with a total weight of 3Kg.

[0035] 2. One ball mill

[0036] Mix the raw materials weighed in 1 into a stainless steel ball mill tank, add steel balls and deionized water according to the ratio of material: ball: water = 1:4.5:0.9 and perform a wet ball mill for 18 hours.

[0037] 3. Drying

[0038] Pass the ball-milled material through a 100-mesh sieve, and dry it at 150°C for 15 hours to obtain a dry material.

[0039] 4. Pre-sintering

[0040]Pass the dried powder through a 30-mesh sieve, put it in a bowl and put it in a high-temperature electric furnace for pre-burning at a temperature of 1...

Embodiment 2

[0060] 1. According to chemical formula Y (3-f--2d-a) Gd f Ca (2d+a) Bi e Fe (5-a-b-c-d-σ) sn a In b mn c V d o 12 , where: a=0.08, b=0.03, c=0.05, d=0.5, e=0.06, f=0.15, σ=0.15 Calculate and weigh the required raw materials, the raw materials taken are not less than 99.4% in purity Fe 2 o 3 , Y 2 o 3 , CaCO 3 , SnO 2 , MnCO 3 , Bi 2 o 3 , Gd 2 o 3 , In 2 o 3 , V 2 o 5 , with a total weight of 3Kg.

[0061] 2. One ball mill

[0062] Mix the raw materials weighed in 1 into a stainless steel ball mill tank, add steel balls and deionized water according to the ratio of material: ball: water = 1:4.5:0.9 and perform a wet ball mill for 18 hours.

[0063] 3. Drying

[0064] Pass the ball-milled material through a 100-mesh sieve, and dry it at 150°C for 15 hours to obtain a dry material.

[0065] 4. Pre-sintering

[0066] Pass the dried powder through a 30-mesh sieve, put it in a bowl and put it in a high-temperature electric furnace for pre-burning at a t...

Embodiment 3

[0086] 1. According to chemical formula Y (3-f--2d-a) Gd f Ca (2d+a) Bi e Fe (5-a-b-c-d-σ) sn a In b mn c V d o 12 , where: a=0.12, b=0.04, c=0.05, d=0.05, e=0.06, f=0.25, σ=0.15 Calculate and weigh the required raw materials, the raw materials taken are not less than 99.4% in purity Fe 2 o 3 , Y 2 o 3 , CaCO 3 , SnO 2 , MnCO 3 , Bi 2 o 3 , Gd 2 o 3 , In 2 o 3 , V 2 o 5 , with a total weight of 3Kg.

[0087] 2. One ball mill

[0088] Mix the raw materials weighed in 1 into a stainless steel ball mill tank, add steel balls and deionized water according to the ratio of material: ball: water = 1:4.5:0.9, and perform a wet ball mill for 18 hours.

[0089] 3. Drying

[0090] Pass the ball-milled material through a 100-mesh sieve, and dry it at 150°C for 15 hours to obtain a dry material.

[0091] 4. Pre-sintering

[0092] Pass the dried powder through a 30-mesh sieve, put it in a bowl and put it into a high-temperature electric furnace for pre-burning at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com