Patents

Literature

1300 results about "Ferrite (magnet)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ferrite is a ceramic material made by mixing and firing large proportions of iron(III) oxide (Fe₂O₃, rust) blended with small proportions of one or more additional metallic elements, such as barium, manganese, nickel, and zinc. They are both electrically non-conductive, meaning that they are insulators, and ferrimagnetic, meaning they can easily be magnetized or attracted to a magnet. Ferrites can be divided into two families based on their resistance to being demagnetized (magnetic coercivity).

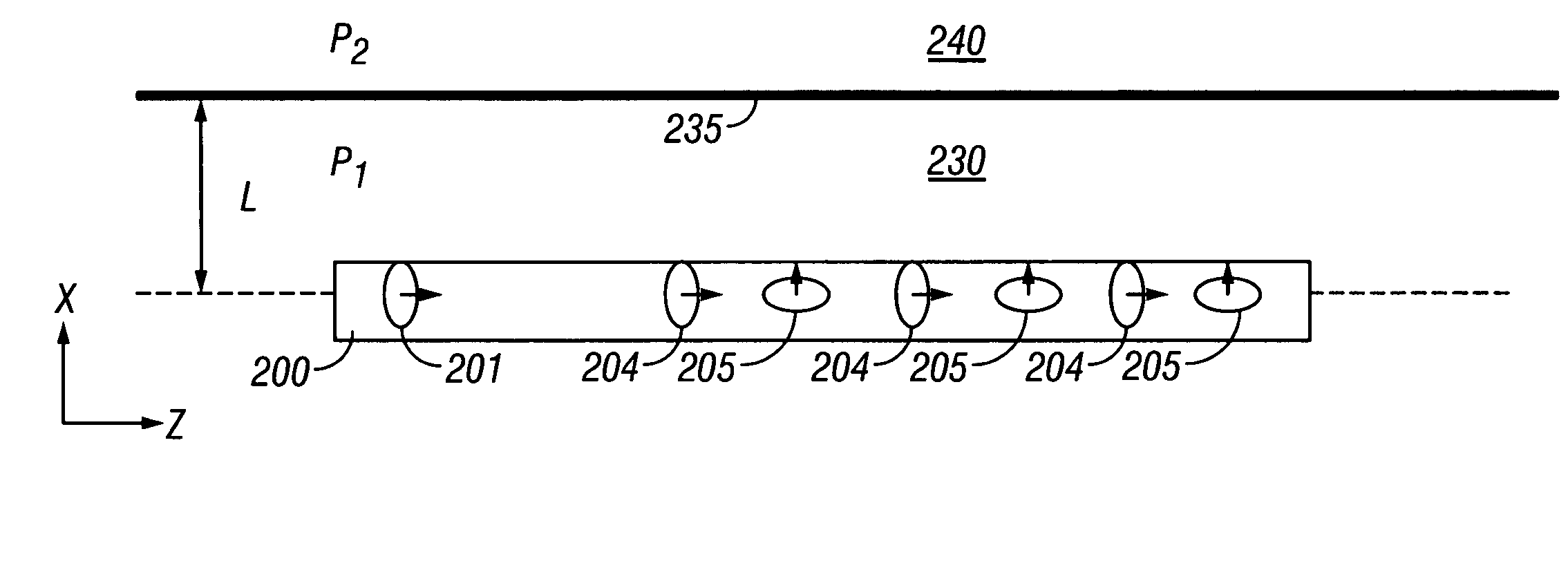

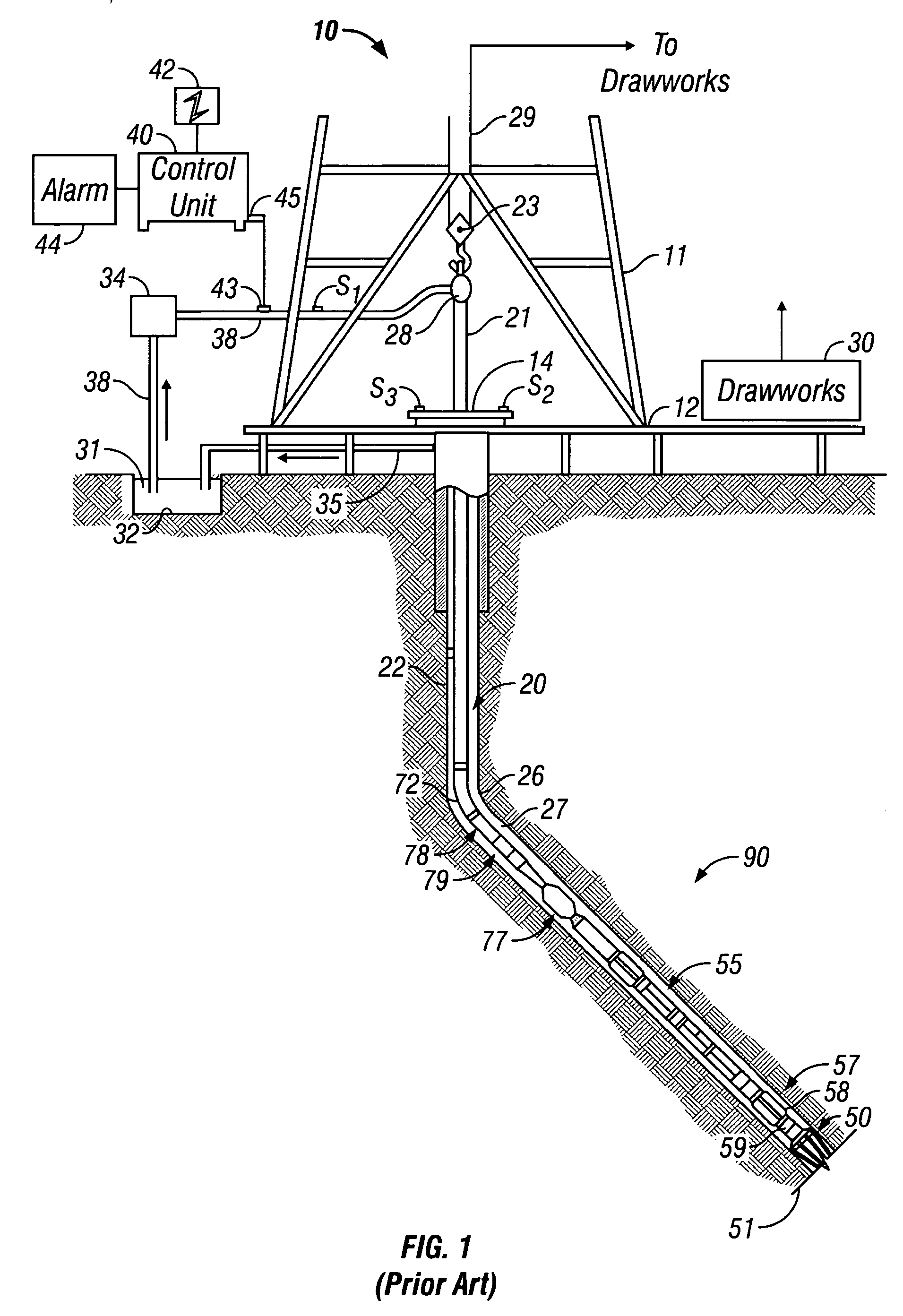

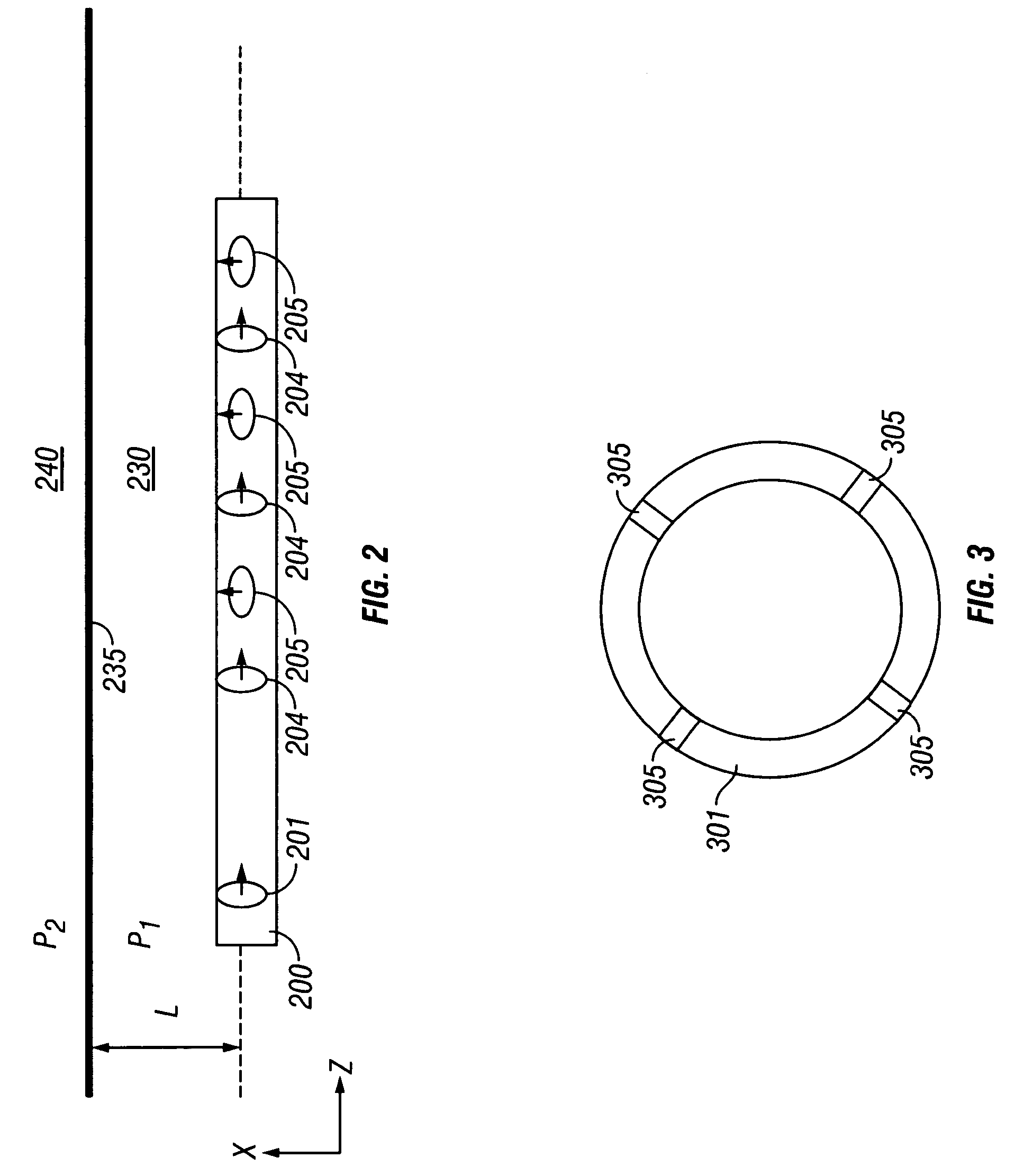

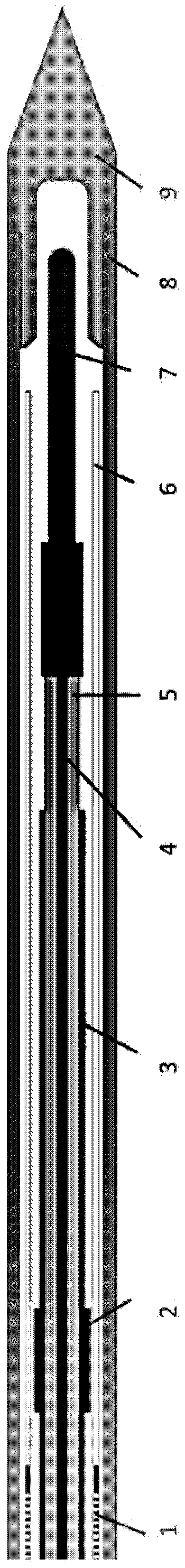

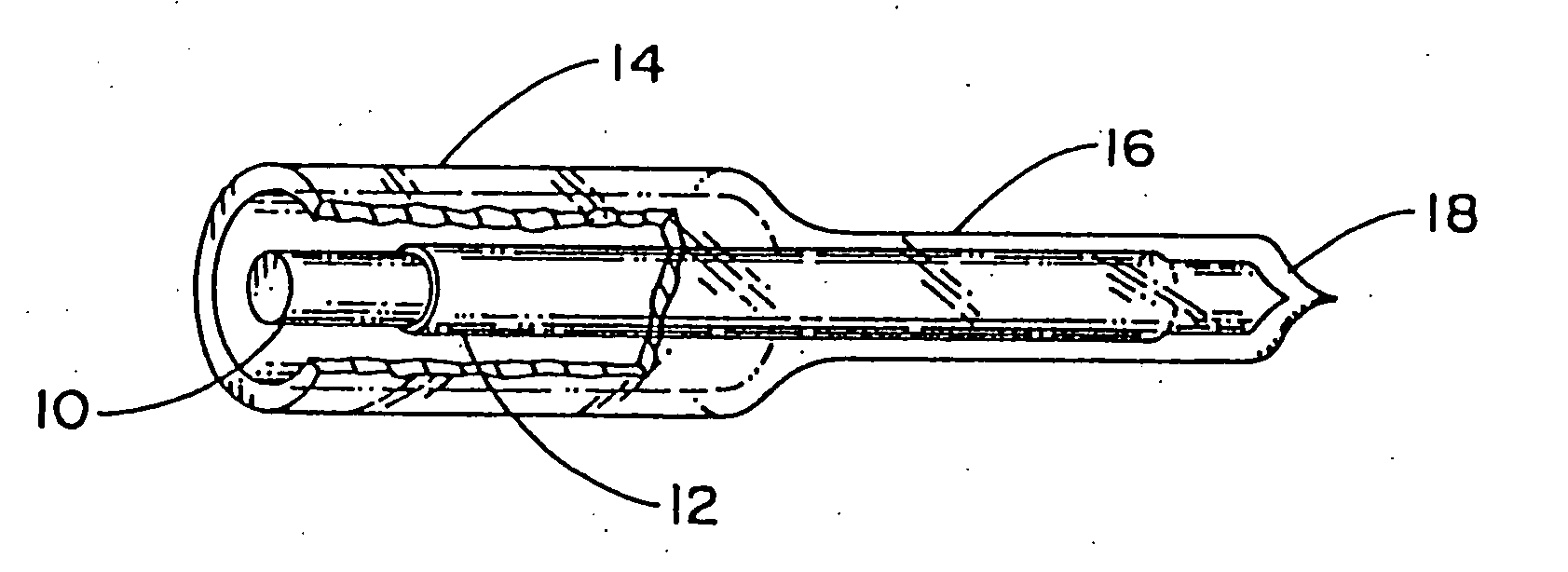

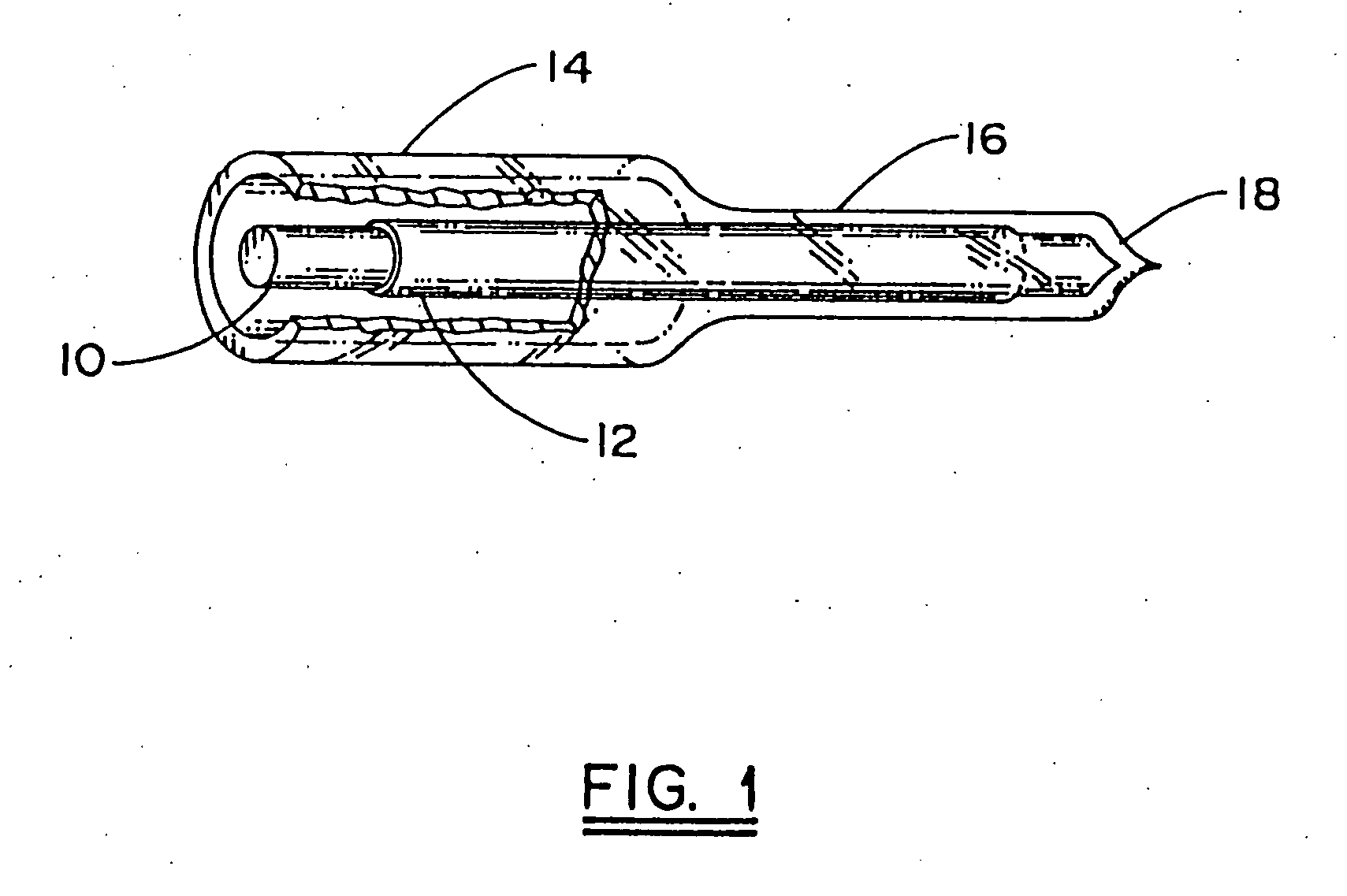

Method of eliminating conductive drill parasitic influence on the measurements of transient electromagnetic components in MWD tools

ActiveUS7150316B2Electric/magnetic detection for well-loggingFluid removalEngineeringConductive materials

A transmitter on a bottomhole assembly (BHA) is used for generating a transient electromagnetic signal in an earth formation. A receiver on the BHA receives signals that are indicative of formation resistivity and distances to bed boundaries. The transmitter and receiver may have axes that are parallel to or inclined to the axis of the BHA. The transmitter and the receiver are on a tubular on a damping portion of the BHA that includes cuts for attenuating eddy currents. The damping portion may include non conducting material such as a ferrite on the outer surface.

Owner:BAKER HUGHES HLDG LLC

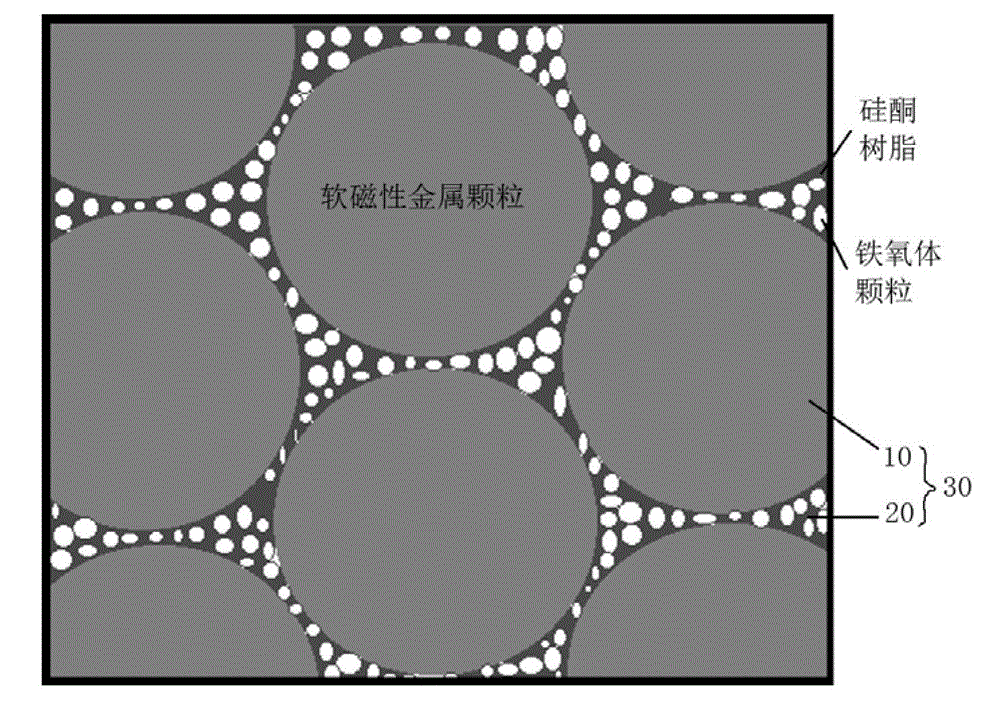

Composite silicone rein-ferrite-coating soft magnetic powder core and preparation method thereof

InactiveCN103151134AImprove adhesionHigh resistivityInorganic material magnetismInsulation layerVolumetric Mass Density

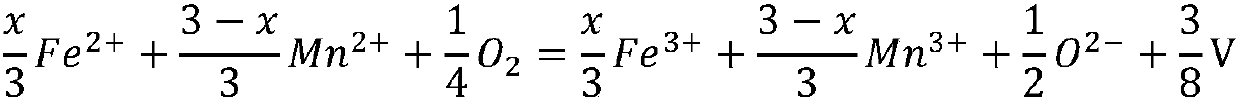

The invention discloses a composite silicone rein-ferrite-coating soft magnetic powder core and a preparation method thereof, and belongs to the metallurgical industry of magnetic functional material and powder. The soft magnetic powder core is formed by pressing and forming composite magnetic particles, wherein each composite magnetic particle comprises a soft magnetic metal particle and a composite insulation film, and each composite insulation film is coated on the surface of each soft magnetic metal particle. The preparation method of the soft magnetic powder core comprises the following steps of surface modification and coupling treatment of the soft magnetic metal particles, forming of the composite insulation coating around each soft magnetic metal particle, pressing and forming, and high-temperature heat treatment at 300 DEG C to 650 DEG C. Compared with the prior art, the soft magnetic powder core and the preparation method have the advantages that the adopted organic resin can resist the high temperature of 600 DEG C; since the soft magnetic ferrite power is added into the composite coating agent, the damage of the insulation layer to the magnetic performance of a substrate is reduced; and the magnetic conductivity is high, the density is high, the rapture strength is high, the loss is low, and the industrial production is easy.

Owner:UNIV OF SCI & TECH BEIJING

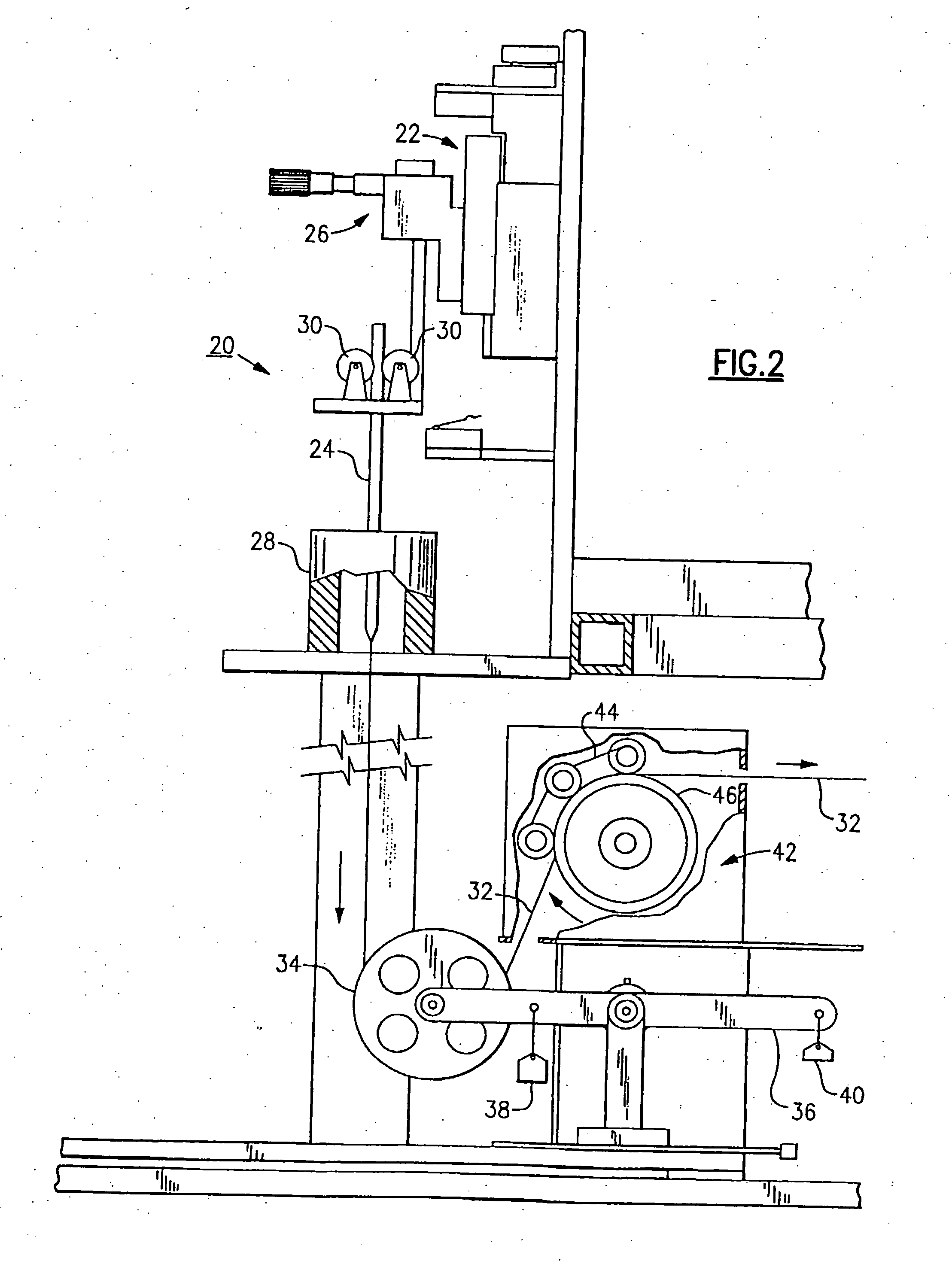

Induction cured power coatings for temperature sensitive substrates

According to the present invention, powder coating compositions comprise one or more than one thermoplastic or thermosetting polymer or resin and one or more than one finely divided magnetic material, such as a ferromagnetic material. Preferred magnetic materials include Ni1−xZnxFe2O4 compounds, wherein 0.4≦X≦0.75, piezoelectric compounds, ferrimagnetic δFeOOH, Fe—Ni—B, Cu2MnIn, transparent polymer-Cobalt oxide nanocomposites and soft ferrites. In addition, the present invention provides methods of making powder coatings on a substrate comprising applying to a substrate a resinous powder coating composition comprising one or more than one magnetic material to form a powder coating layer, followed by induction heating to melt the applied powder coating to form a coating film and, optionally, to cure the powder coating. The powder coatings remain at a pre-selected temperature equal to or less than the Curie temperature (TC) of the one or more than one finely divided magnetic material during induction heating of the powder coating without directly heating the substrate. Powder coatings on metal parts may also be induction heat cured.

Owner:ROHM & HAAS CO

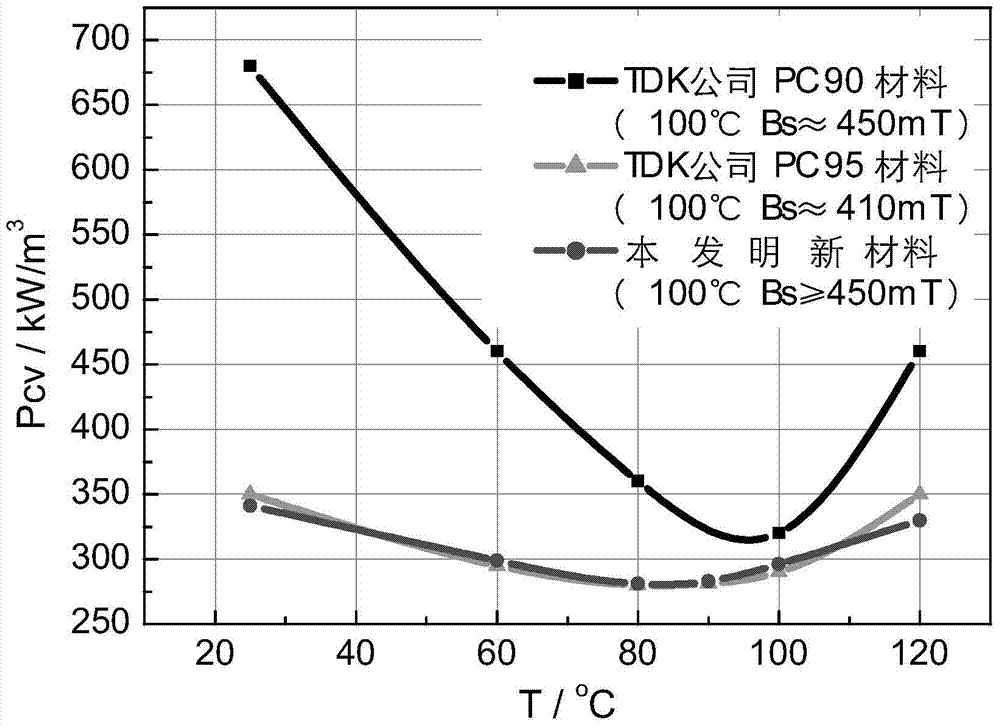

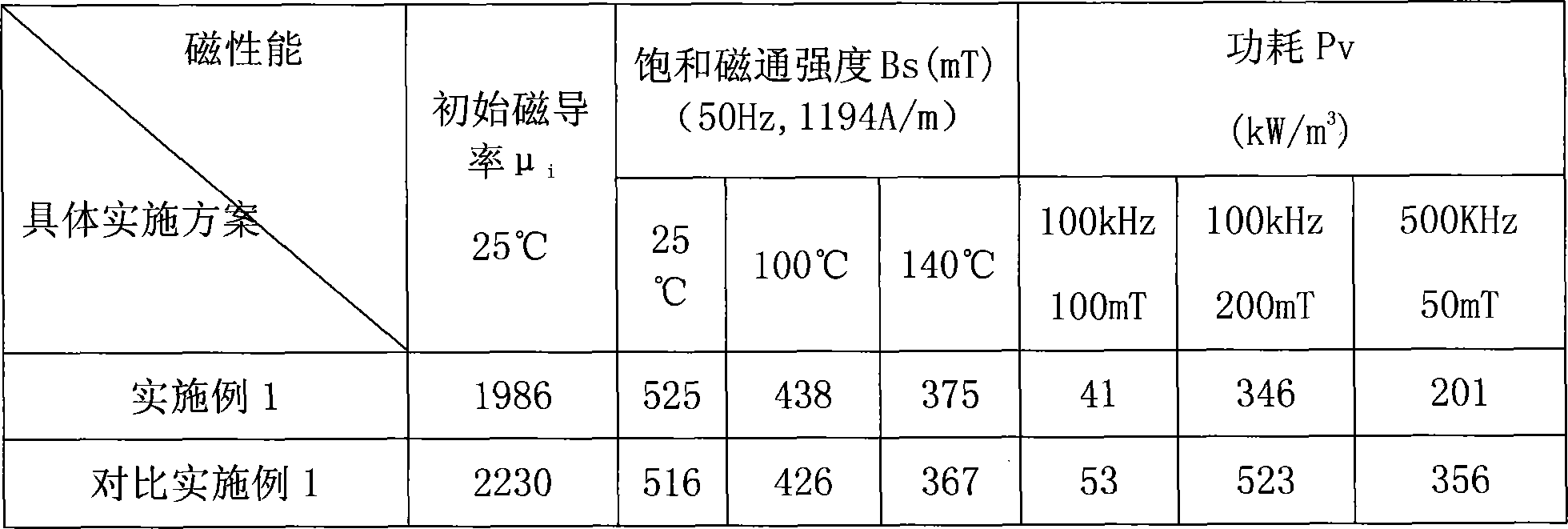

Atmosphere control method for sintering process of high-frequency wide-temperature low-loss MnZn ferrite

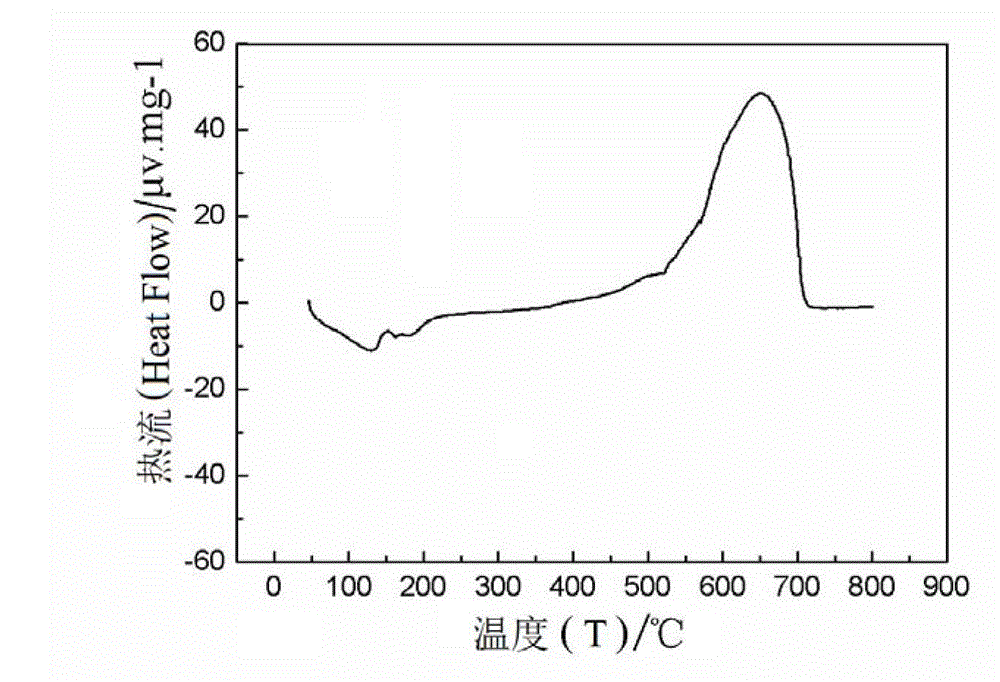

ActiveCN107555984AHigh densityIncreased power lossInorganic material magnetismInductances/transformers/magnets manufactureHeat conservationFerrite (magnet)

The invention provides a sintering atmosphere control method in preparation of high-frequency wide-temperature low-loss MnZn ferrite. The method comprises the following steps: carrying out primary heating and heat preservation, carrying out secondary heating and heat preservation, cooling, carrying out heat preservation, and finally cooling. According to the method, corresponding oxygen partial pressure is adjusted at different temperatures and in different temperature changing processes, zinc loss in a sintering process can be reduced, and element valence change and impure phase precipitationat high temperature are inhibited, so that the soft magnetic property of the material is improved; and by adding reasonable heat preservation time, sintering internal stress can be effectively reduced, and the material is prevented from cracking in the sintering process. The method provided by the invention is applicable to preparation of multiple MnZn ferrites, and the wide-temperature low-lossMnZn power ferrite used at the frequency of 0.1-5MHz can be obtained; reasonable technological parameters can improve yield in preparation process, and a product with uniform and stable performance can be beneficially obtained; and the method is simple and practicable and has practical value.

Owner:ZHEJIANG UNIV +1

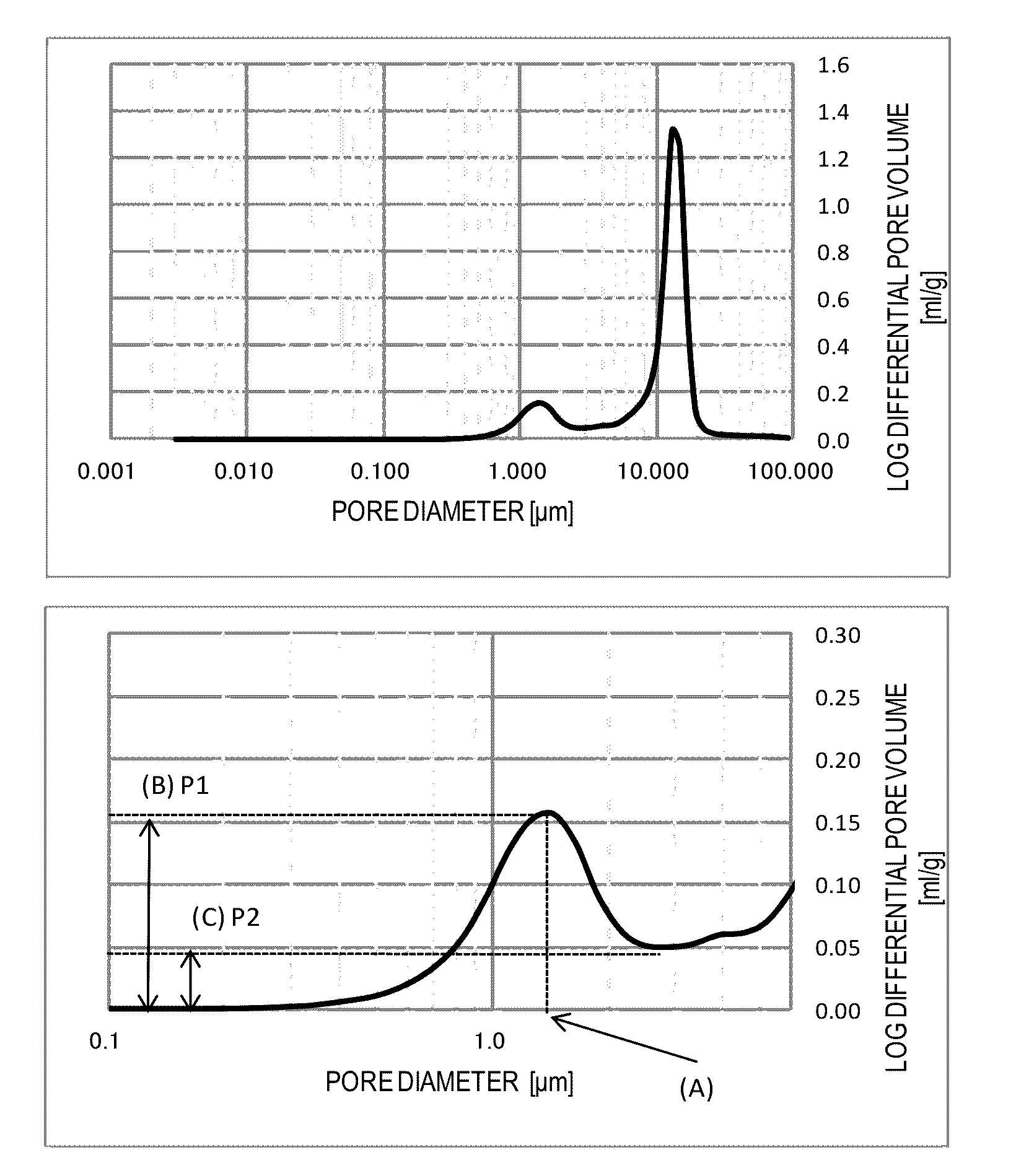

Magnetic carrier and two-component developer

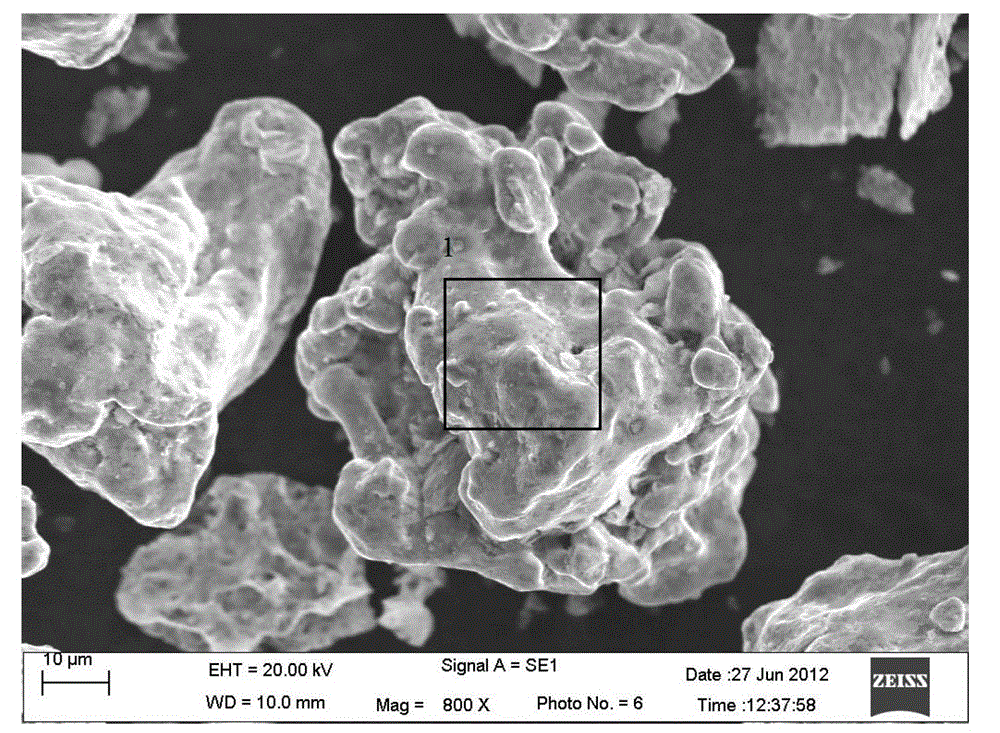

ActiveUS9058924B2Improve charging effectAvoid it happening againInorganic material magnetismDevelopersPore diameterMetal

A magnetic carrier having a resin-containing ferrite particles each containing a porous ferrite core and a resin in pores of the porous ferrite core, wherein the porous ferrite core has a particular pore diameter corresponding to the maximum logarithmic differential pore volume in a pore diameter range from at least 0.10 μm to not more than 3.00 μm, the resistivity of the porous ferrite core is in a particular range, and the porous ferrite core contains an oxide of Mg in a particular amount and contains a particular amount of a oxide of at least one metal selected from the group consisting of Mn, Sr, and Ca.

Owner:CANON KK

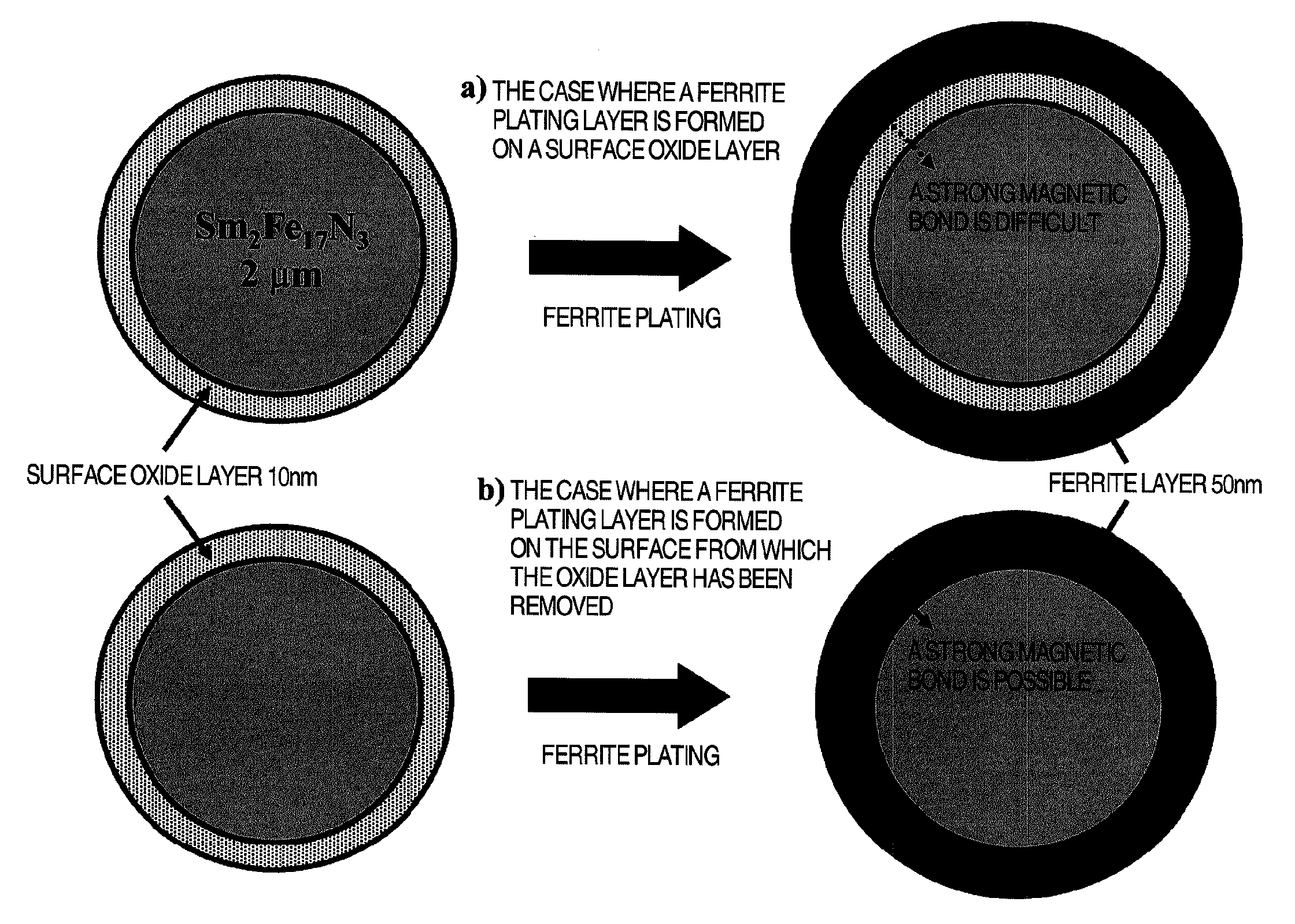

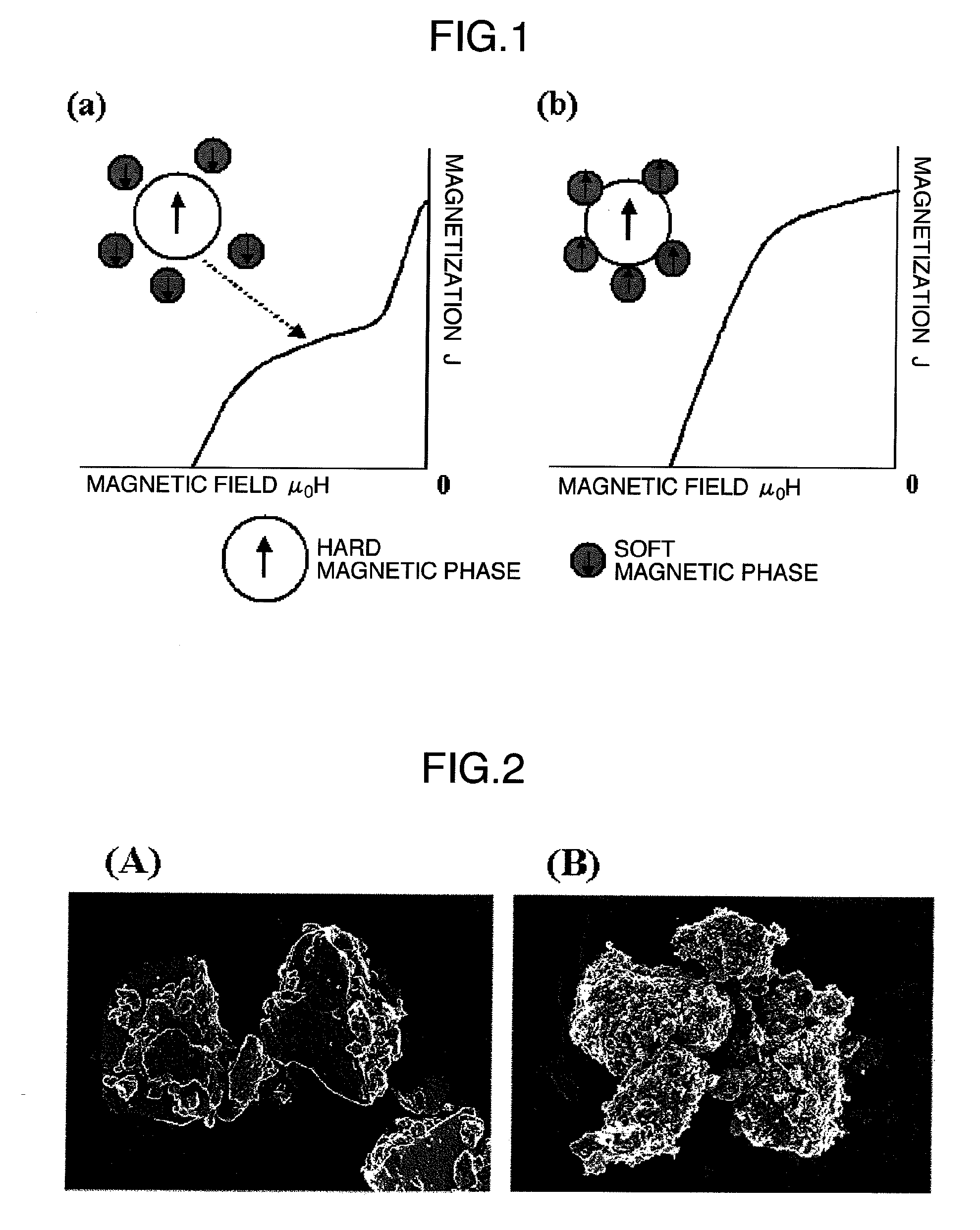

Composite magnetic material for magnet and method for manufacturing such material

InactiveUS20100261038A1Improve featuresHigh resistivityTransportation and packagingMetal-working apparatusRare earthNitrogen

Provided is a composite magnetic material having high magnetic characteristics and high electrical resistivity to be used for a magnet, especially a composite magnetic material to be suitably used for a rotary motor magnet or the like which functions in a high frequency region. The composite magnetic material for the magnet is provided by covering the surface of a rare earth-iron-nitrogen based magnetic material with a ferrite based magnetic material.

Owner:TOKYO INST OF TECH +1

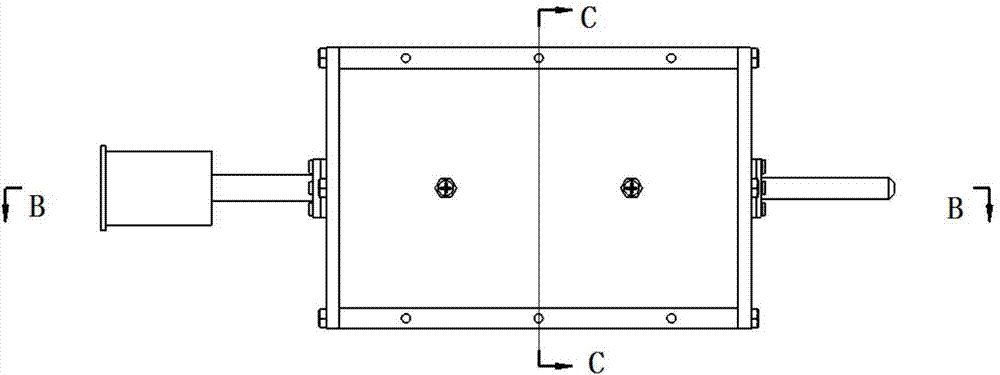

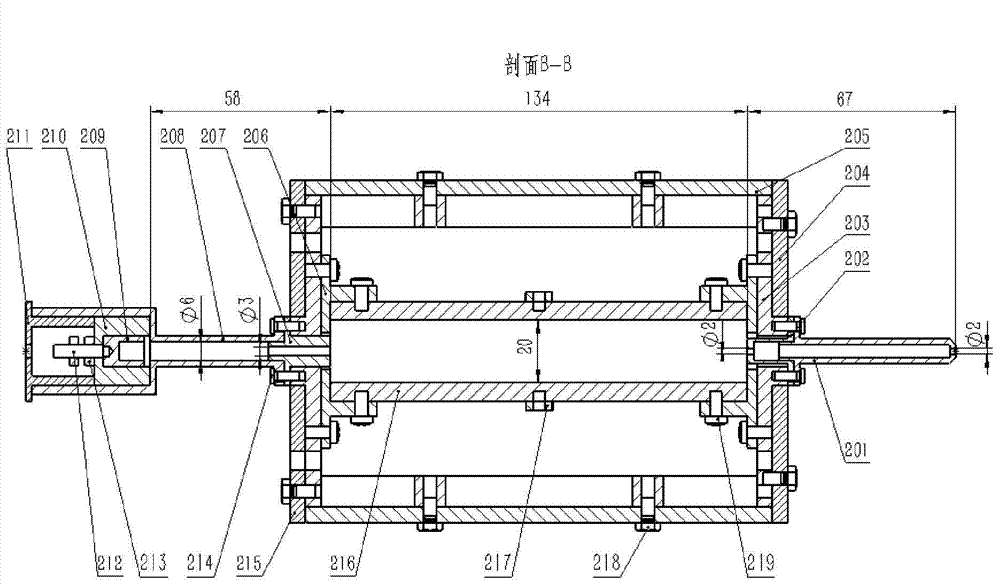

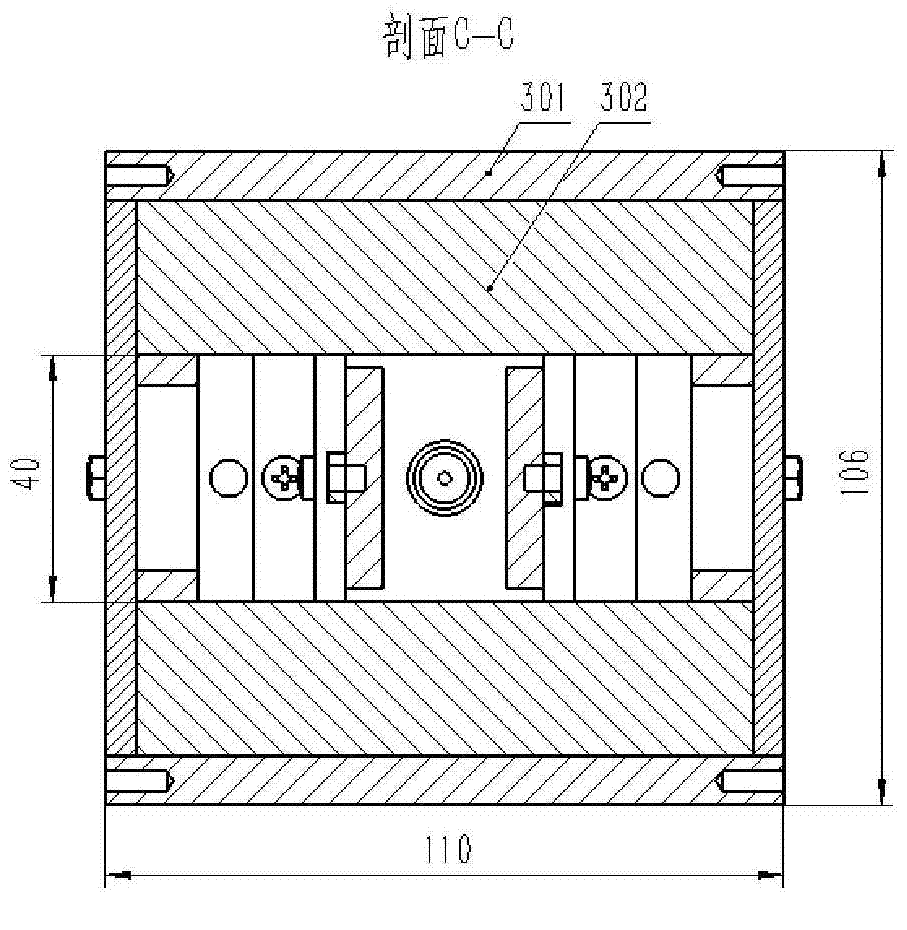

Near-field plume mass-spectroscopic diagnostic E*B probe based on Faraday cup

InactiveCN104730066AGuaranteed OrthogonalityGuaranteed collimationAnalysis by thermal excitationMass spectrometryDrift tube

The invention discloses a near-field plume mass-spectroscopic diagnostic E*B probe based on the Faraday cup and belongs to the technical field of plasma mass-spectroscopic diagnosis. The probe mainly applied to measuring near-field plumes of an ion thruster and of a Hall thruster comprises a central frame, ferrite permanent magnets, a flat electrode plate, an electrode plate holder, a collimator tube, a drift tube, a Faraday cup, six carbon steel shells and an anti-sputtering heat-insulating layer. According to the connectional relation, the central frame is used as a core part, the ferrite permanent magnets are distributed on upper and lower surfaces of the central frame, the electrode plate is fixed in the central frame, and an orthogonal electromagnetic field area is formed. The six carbon steel shells are used for packaging, and the front ends of the shells are coated with an anti-sputtering heat-insulating layer. The collimator tube of stainless steel and the drift tube are fitly fixed to the centers of two ends of the central frame through shaft holes. Ions different in valence are screened by adjusting voltage among the electrode plates, univalent and bivalent ion currents are acquired with the Faraday cup of aluminum, and the ratio of near-field plum bivalent ions is acquired by analytical computing.

Owner:BEIHANG UNIV

Induction cured powder coatings for temperature sensitive substrates

According to the present invention, powder coating compositions comprise one or more than one thermoplastic or thermosetting polymer or resin and one or more than one finely divided magnetic material, such as a ferromagnetic material. Preferred magnetic materials include Ni1−xZnxFe2O4 compounds, wherein 0.4≦X≦0.75, piezoelectric compounds, ferrimagnetic δFeOOH, Fe—Ni—B, Cu2MnIn, transparent polymer-Cobalt oxide nanocomposites and soft ferrites. In addition, the present invention provides methods of making powder coatings on a substrate comprising applying to a substrate a resinous powder coating composition comprising one or more than one magnetic material to form a powder coating layer, followed by induction heating to melt the applied powder coating to form a coating film and, optionally, to cure the powder coating. The powder coatings remain at a pre-selected temperature equal to or less than the Curie temperature (TC) of the one or more than one finely divided magnetic material during induction heating of the powder coating without directly heating the substrate. Powder coatings on metal parts may also be induction heat cured.

Owner:ROHM & HAAS CO

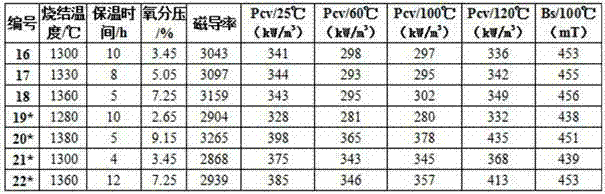

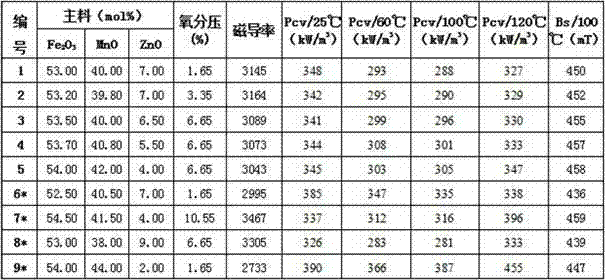

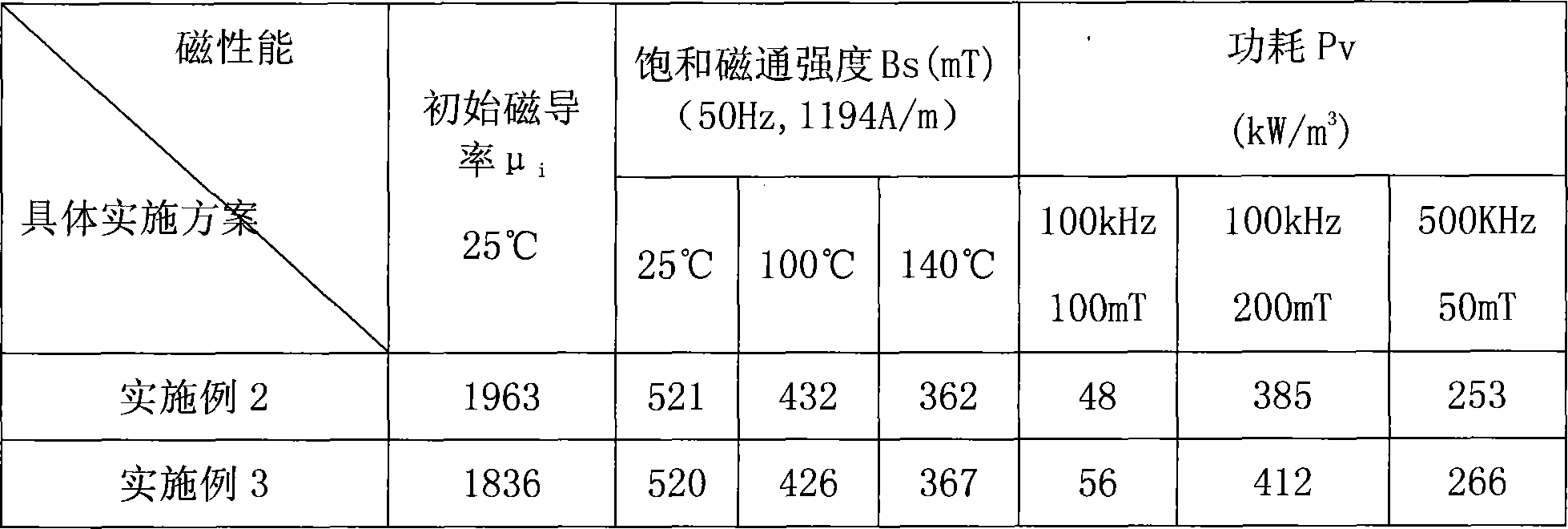

Ni-free MnZn ferrite magnetic core with double characteristics and manufacture method

ActiveCN103496963AOvercome the inability to take into account multiple featuresImprove performanceFerrite (magnet)Condensed matter physics

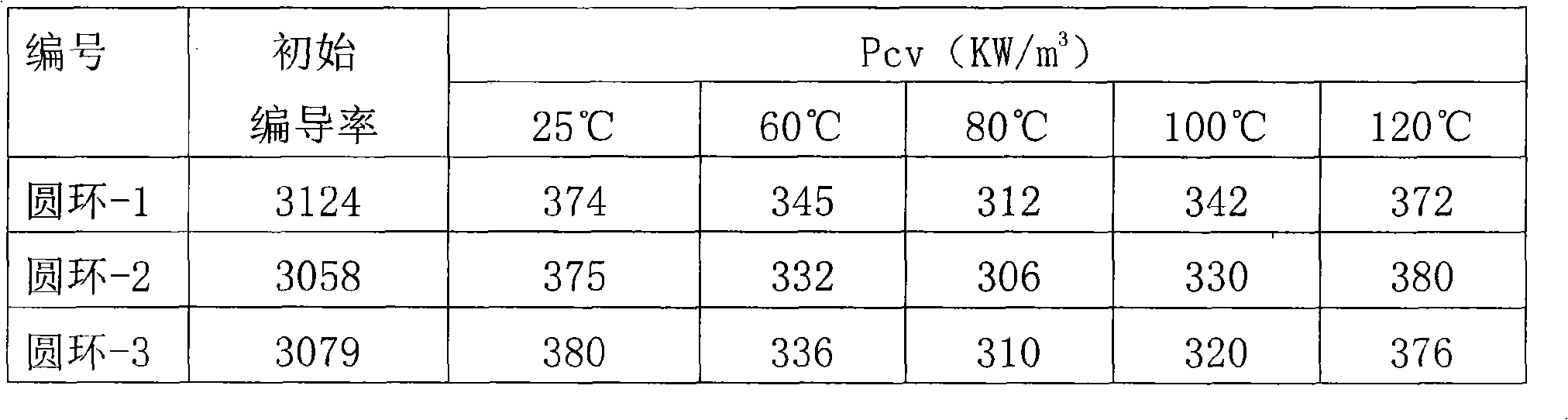

The invention provides a Ni-free MnZn ferrite magnetic core with double characteristics and a manufacture method thereof, wherein the double characteristics mean high temperature and high Bs, and wide temperature and low loss. The ferrite magnetic core comprises main components and auxiliary components. The main components comprise: 53 mol%-54 mol% of Fe2O3, 39 mol%-42 mol% of MnO and 4 mol%-7 mol% of ZnO; and the auxiliary components comprise: Co2O3 or CoO or Co3O4 as a first auxiliary component, SiO2 and CaCO3 as a second auxiliary, and a third auxiliary component which is one or more selected from MoO3, TiO2, SnO2, Nb2O5, V2O5, Sm2O3 and ZrO2. The provided MnZn ferrite magnetic core with double characteristics has unit volume loss Pcv (100kHz, 200mT) less than 350 kW / m<3> at the temperature of 25 DEG C to 120 DEG C, lowest loss of 300 kW / m<3> at the temperature of about 90 DEG C, and saturation magnetic flux density up to 450 mT at the temperature of 100 DEG C.

Owner:江门安磁电子有限公司

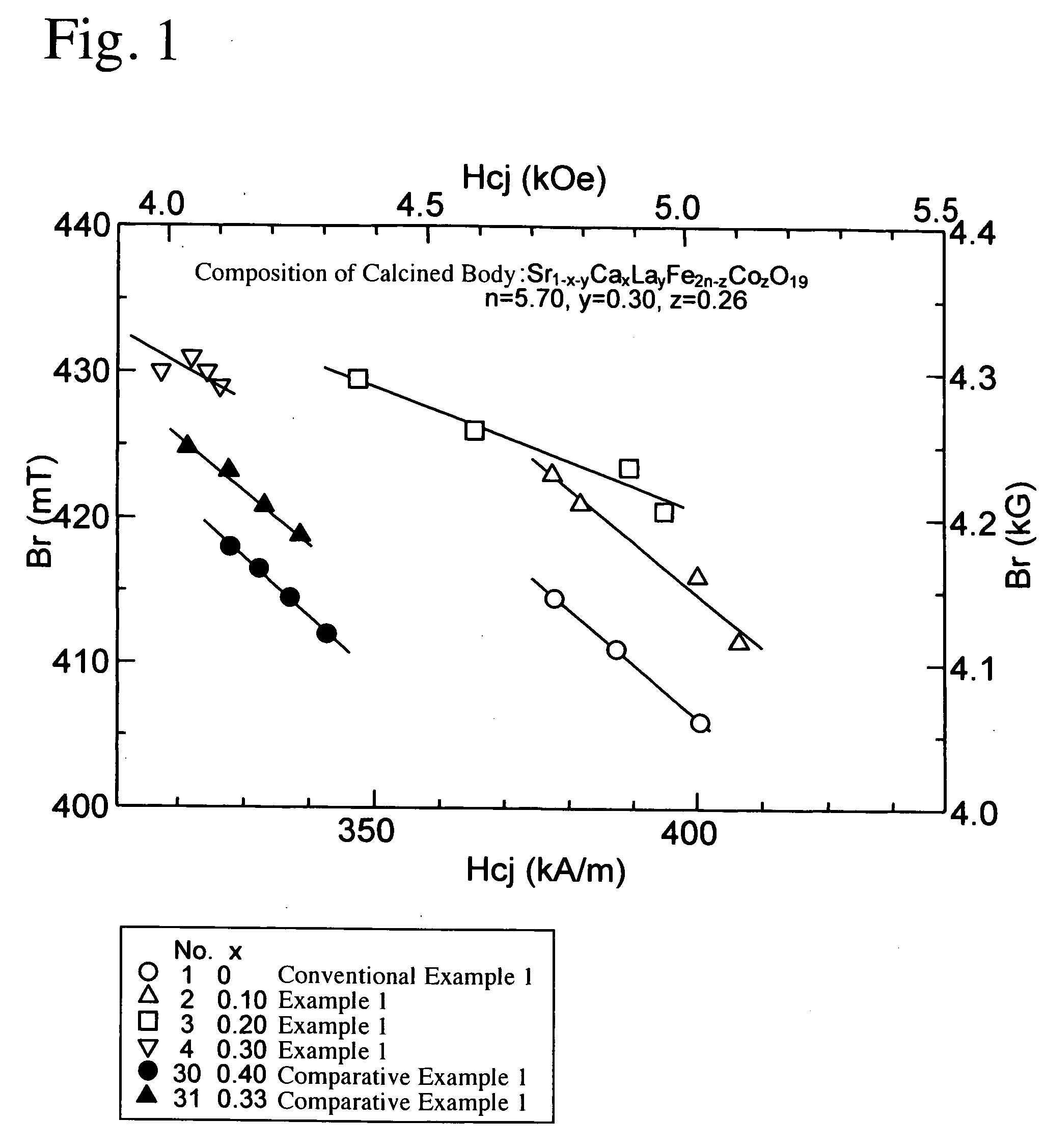

Ferrite sintered magnet

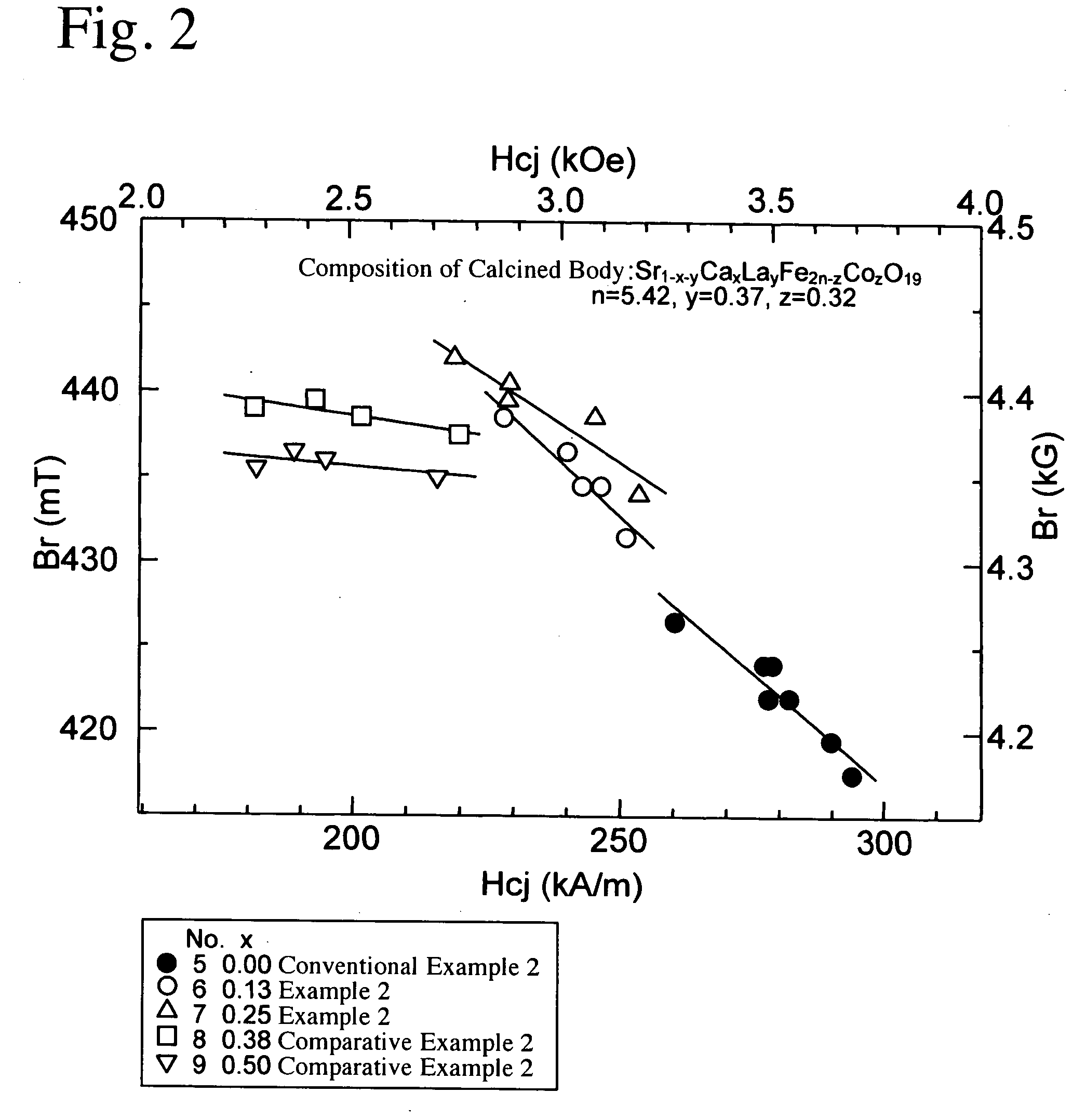

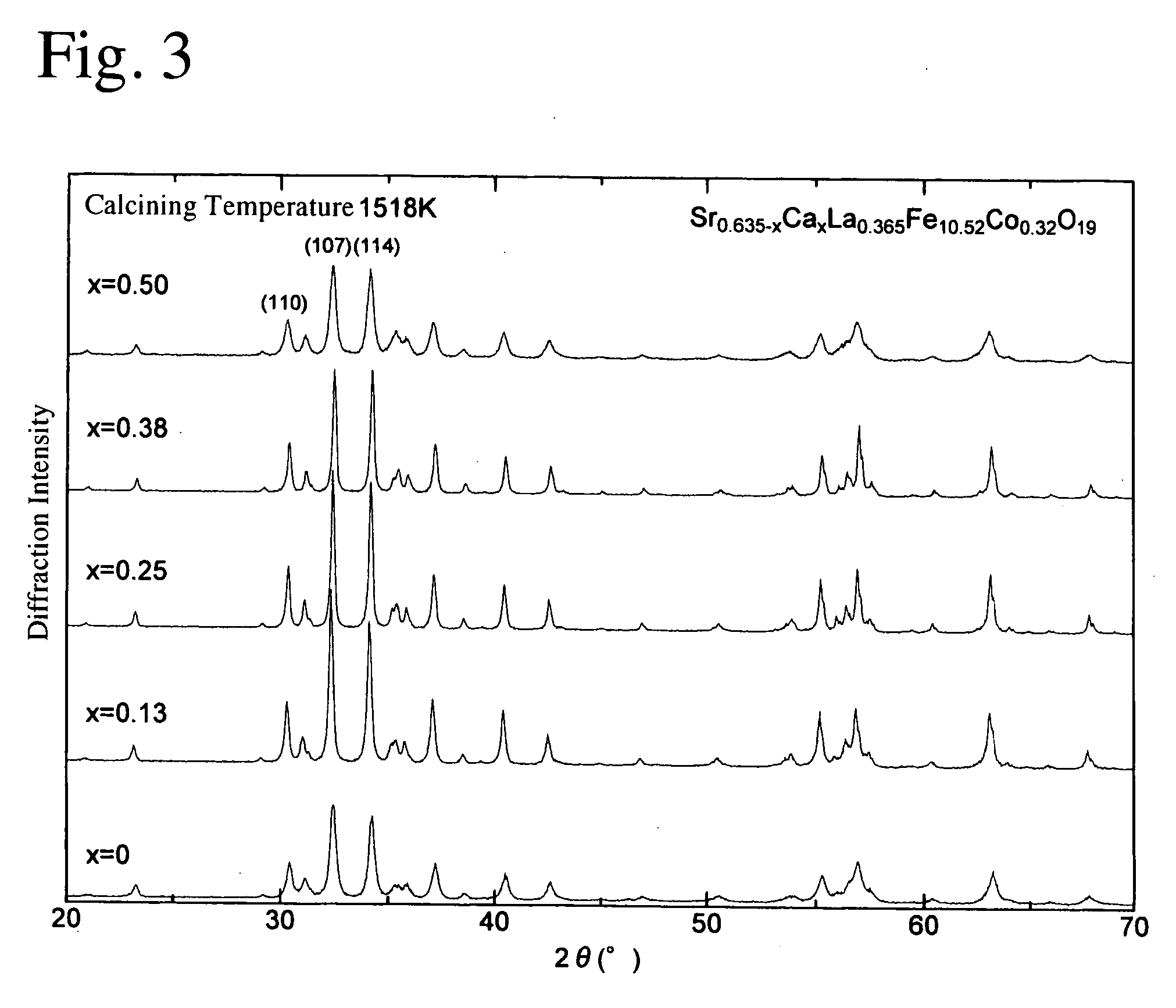

ActiveUS20060284136A1High residual magnetic flux density BrImprove intrinsic coercive forceInorganic material magnetismFerroso-ferric oxidesSintered magnetsFerrite (magnet)

A sintered ferrite magnet having a basic composition represented by the general formula: A1−x−y+aCax+bRy+cFe2n−zCoz+dO19 (atomic ratio), wherein a, b, c and d represent the amounts of an A element, Ca, an R element and Co added in the pulverization step of an oxide magnet material, which are numerals meeting the conditions of 0.03≦x≦0.4, 0.1≦y≦0.6, 0≦z≦0.4, 4≦n≦10, x+y≦1, 0.03≦x+b≦0.4, 0.1≦y+c≦0.6, 0.1≦z+d≦0.4, 0.50≦[(1−x−y+a) / (1−y+a+b)]≦0.97, 1.1≦(y+c) / (z+d)≦1.8, 1.0≦(y+c) / x≦20, and 0.1≦x / (z+d)≦1.2.

Owner:HITACHI METALS LTD

Super low-loss and small-line width microwave ferrite material and preparation method for microwave ferrite material

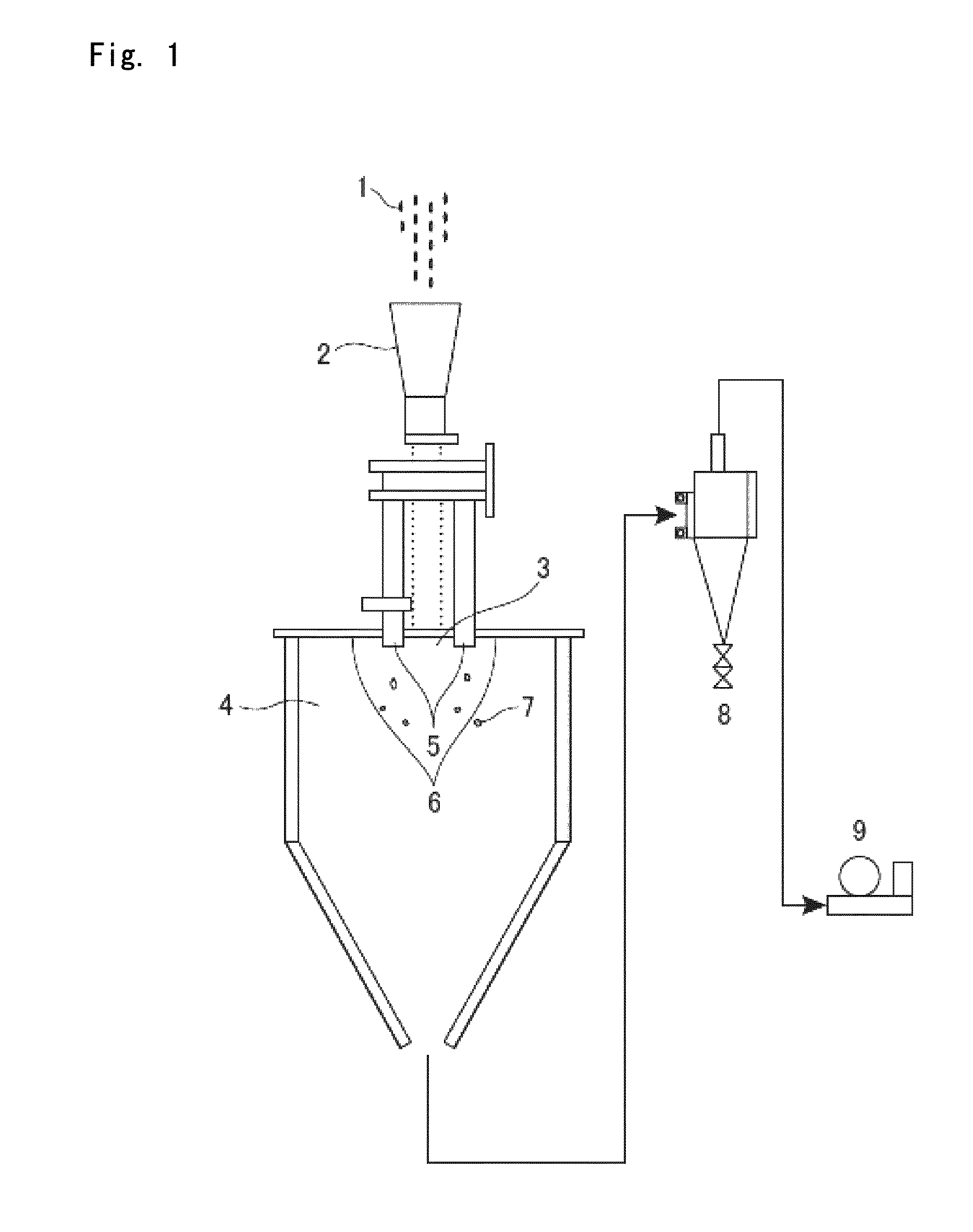

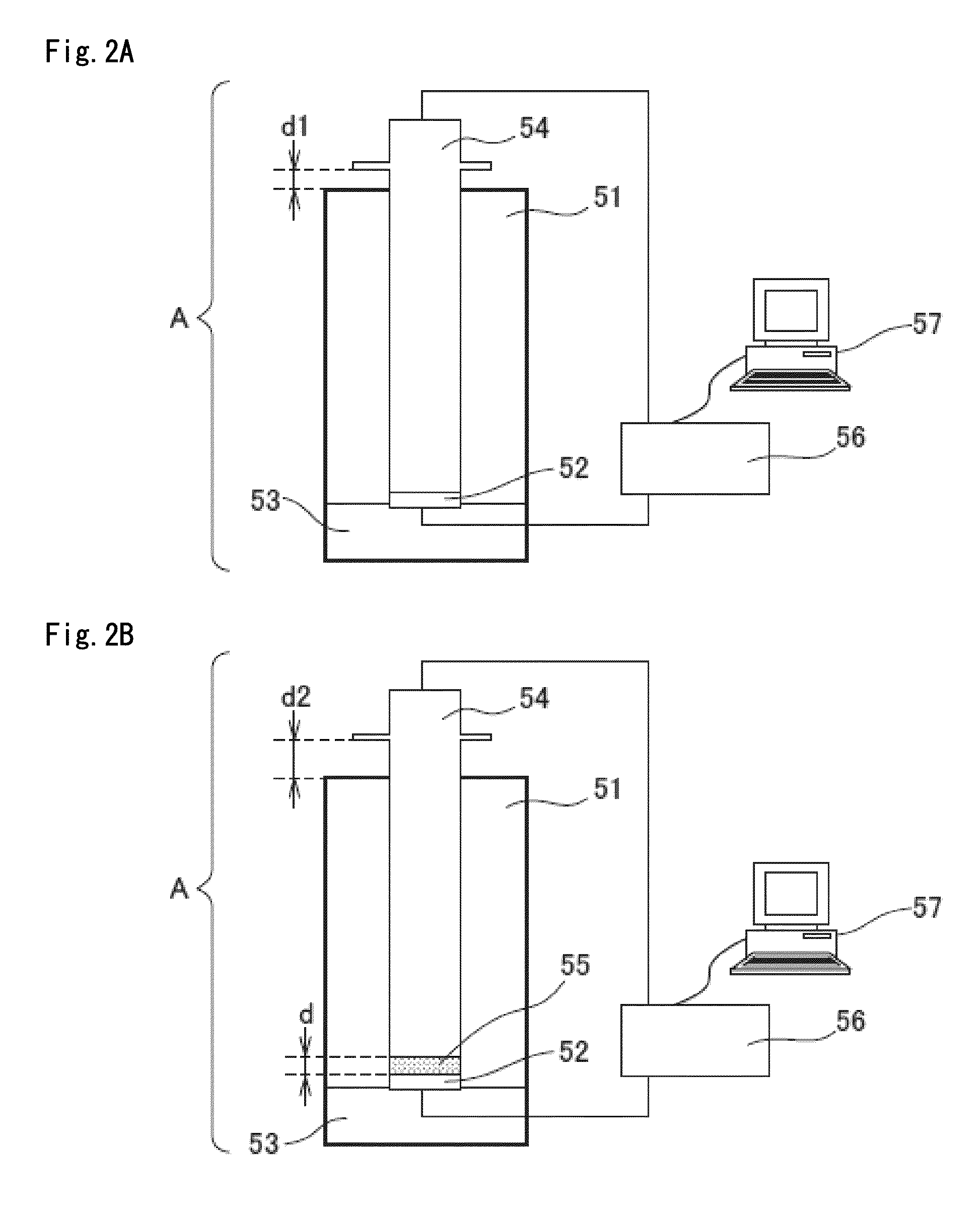

The invention relates to a super low-loss and small-line width microwave ferrite material and a preparation method for the microwave ferrite material and belongs to the field of microwave communication and magnetic materials. The main phase of the material is of a johnstonotite structure, and the chemical formula of the material is Y3-2x-yCa2x+yFe5-x-y-zVxZryAlzO12, wherein x is not less than 0.02 but is not more than 0.25, y is not less than 0.05 but is not more than 0.25, and z is not less than 0.01 but is not more than 0.25. The preparation method comprises the following steps of: calculating according to chemometry and weighing a raw material, vibratory milling, presintering, vibratory grinding and coarse crushing, sanding fine crushing, spray granulation, compression moulding and sintering. Proved by testing, the ferromagnetic resonance line width deltaH of the obtained material is not more than 1.27KA / m, the dielectric loss tgdeltae is not more than 0.5*10-4, and the insertion loss of an assembled microwave device is not more than 0.21dB, and thereby, the stability and the reliability of the obtained material are greatly enhanced, and the application range is broadened. The manufactured microwave ferrite device has the advantages of wide working band and low insertion loss.

Owner:TDG HLDG CO LTD

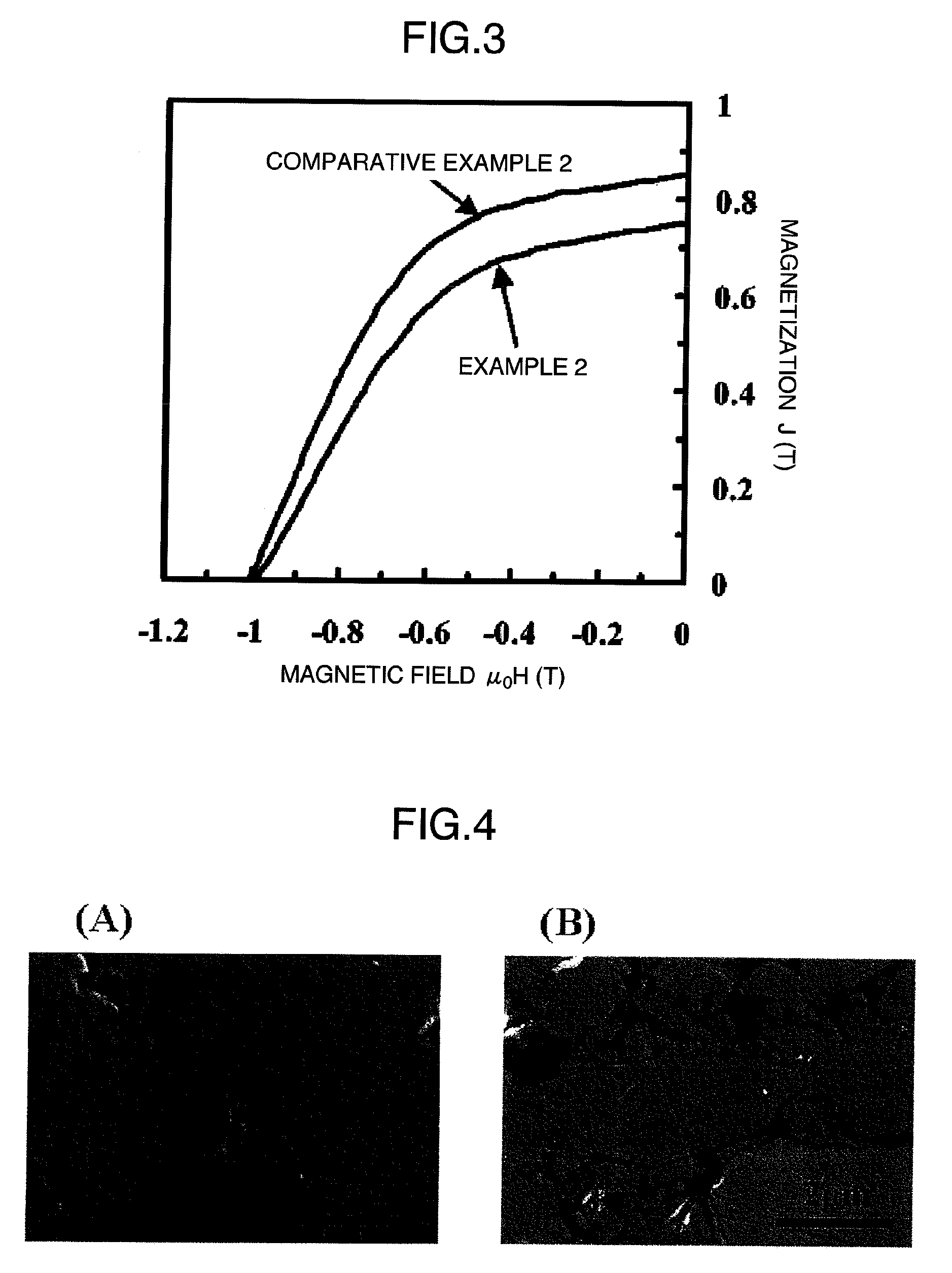

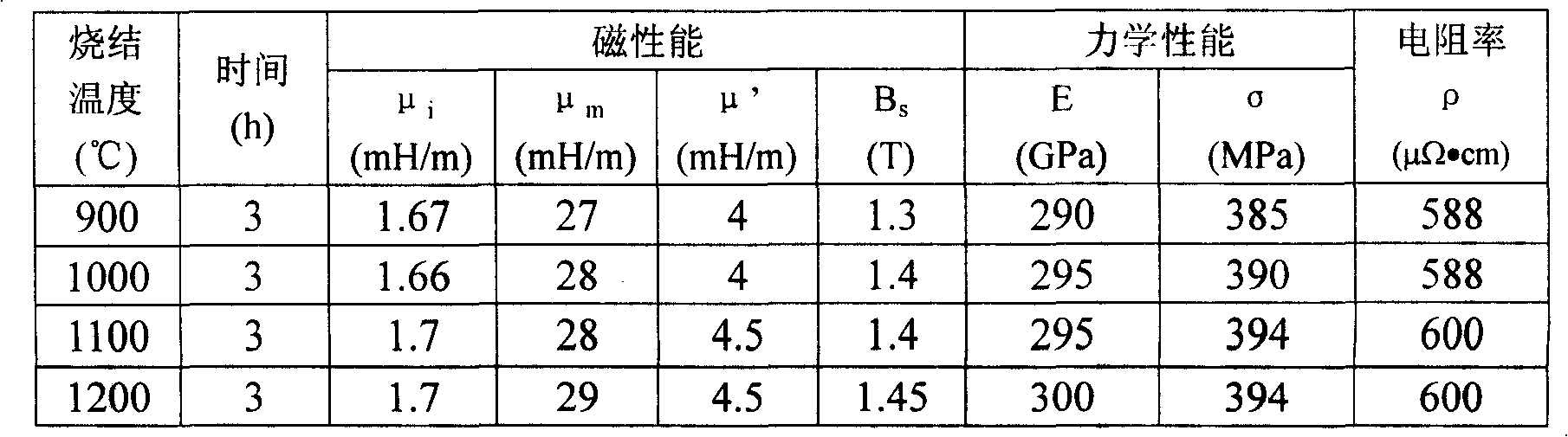

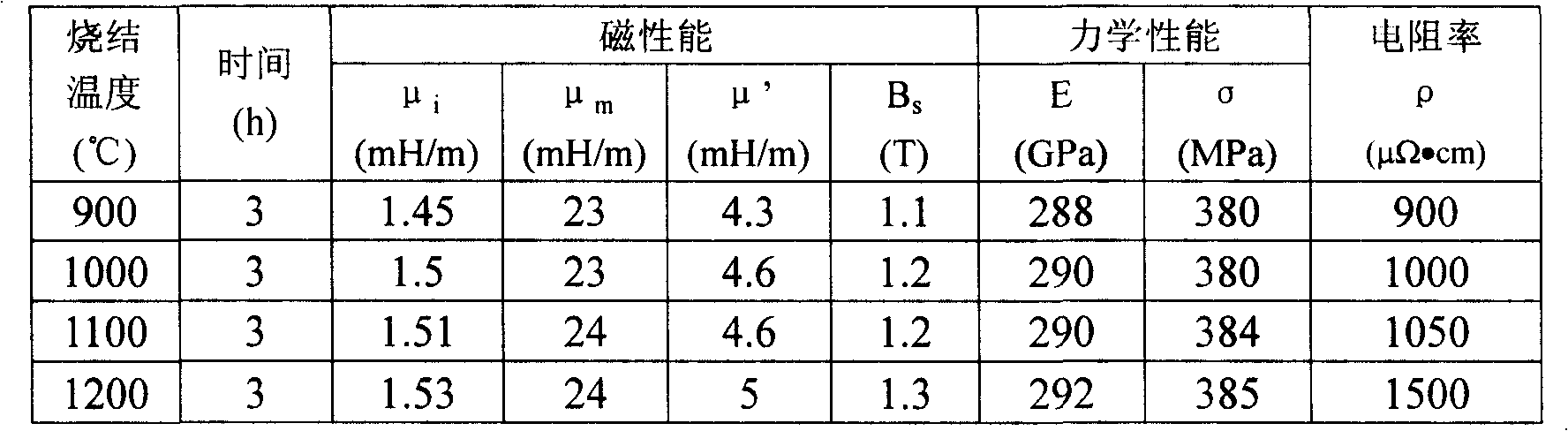

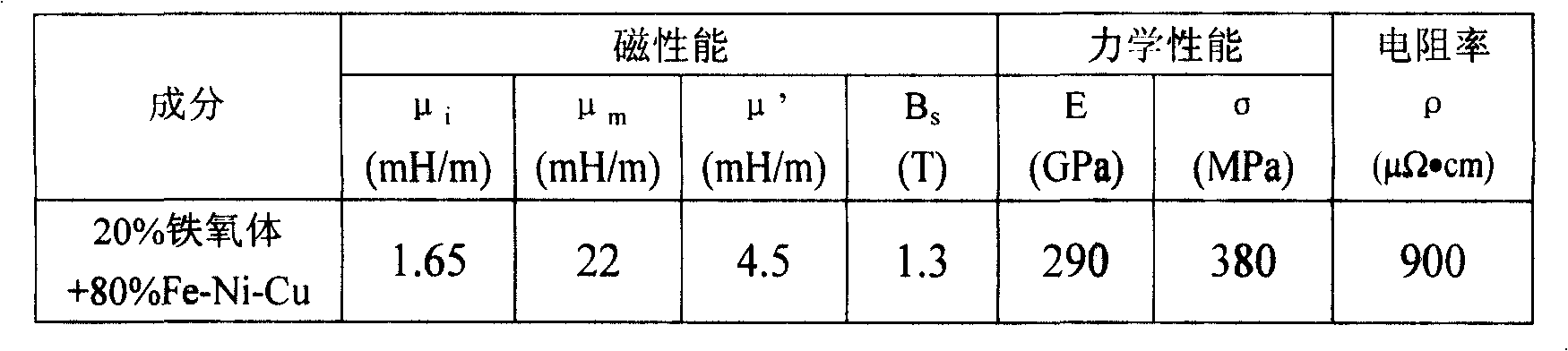

High-efficiency soft magnetic material and method for producing the same

InactiveCN101246773AGuaranteed mechanical propertiesExcellent soft magnetic propertiesInorganic material magnetismInductances/transformers/magnets manufactureMetalMagnet

The invention relates to a highly efficient soft magnetic material and the preparing method thereof. The soft magnetic material is composed of metal soft magnetic material and soft magnetic ferrite, the metal soft magnetic material is composed of at least one selected from Fe-Ni-Me system (Me is one or more than two selected form Cu, Cr, Nb, V, W, Si, Pd, Zn, Al, Ti and Mn), Fe-Co system, Fe-Co-V system, Fe-Al system and Fe-Al-Me system (Me is one or more than two selected form Co, Cr and Mo), the soft magnetic ferrite is composed of at least one selected form Mn-Zn system, Ni-Zn system, Li-Zn system, Cu-Zn system and Mg-Zn system soft magnetic ferrites. The preparing method of the soft magnetic material comprises the steps of: cold pressing, and sintering, hot pressing or spark plasma sintering. The soft magnetic material does not have the drawbacks of low resistivity of the metal soft magnetic and low magnetic strength of the ferrite, as well as keeps the superior properties of the metal soft magnetic and low magnetic strength of the ferrite.

Owner:GRIREM ADVANCED MATERIALS CO LTD

MnZn soft magnetic ferrite material with high frequency, low temperature coefficient and low loss and preparation method thereof

The invention discloses a MnZn soft magnetic ferrite material with high frequency, low temperature coefficient and low loss and a preparation method thereof. The material employs 68 wt%-72 wt% of Fe2O3, 5 wt%-9 wt% of ZnO, and the balance MnO as main components, and is prepared by steps of first ball milling, first sintering, second material preparing, second ball milling, granulation, compaction molding, second sintering and the like. The innovativeness of the invention is that by appropriate component proportions, ion composite doping and substituting and material preparation technology, a domain-wall-free structure is formed, domain wall resonance is inhibited, and the obtained MnZn power magnetic ferrite can work at a frequency highest to 5 MHz, and the material has relatively high temperature stability and relatively low power loss.

Owner:ZHEJIANG UNIV

Silica-magnetic composite micropartical and its preparation method

InactiveCN101090018ALarge specific surface areaGood dispersionInorganic material magnetismMesoporous silicaSuperparamagnetism

This invention relates to mesoporous SiO2-magnetic compound particles and their preparation method, in which, the kernel of the particle is a super-paramagnetic nm ferrite particle covered by SiO2, the shell is mesoporous SiO2, the particle includes multiple kernels and the specific area is 180-210m2 / g. The preparation method includes: preparing ferrite particles with a coprecipitation method, then scatters the cleaned ferrite particles directly in a solution containing SiO2 soluble inorganic salt to cover them with inorganic silicon source then takes cetyl trimethyl ammonium bromide as the template agent and metasilicic acid ethyl as the silicon source to carry out cover of mesoporous SiO2.

Owner:JILIN UNIV

Method for preparing permanent magnet oxysome material

The invention belongs to the permanent-magnet material field and provides a method for preparing permanent magnet oxysome material, which mainly comprises a novel technique adopted in wet ball-milling stage, that is, being receiving wet ball-milling to reach a certain granularity, a pre-sintering material firstly receives low-temperature resintering, and then receives wet remilling for a short time, so as to prepare needed slurry for facilitating sintering after forming. Through adopting the method provided by the invention, the sample coercitive force is effectively upgraded to obtain excellent comprehensive magnetic property on the basis that magnetic remanence is not reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

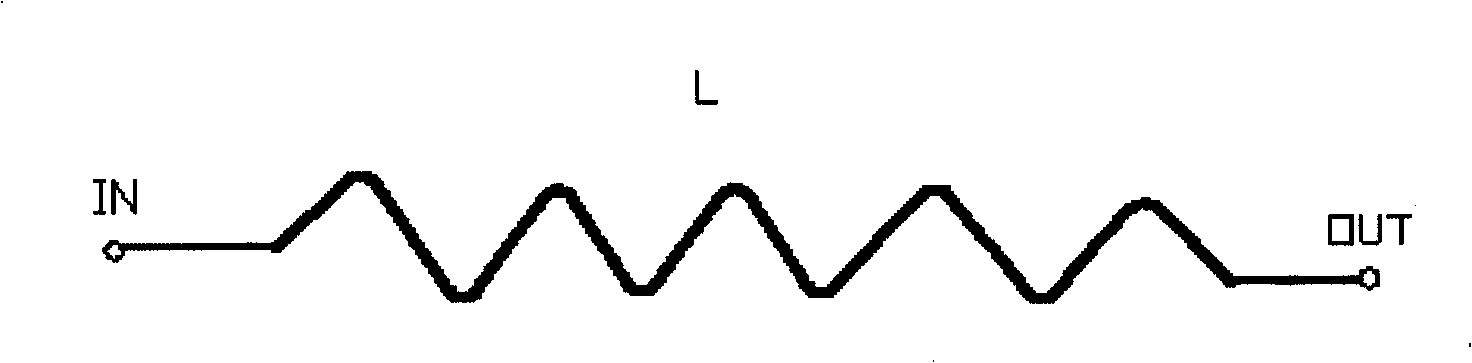

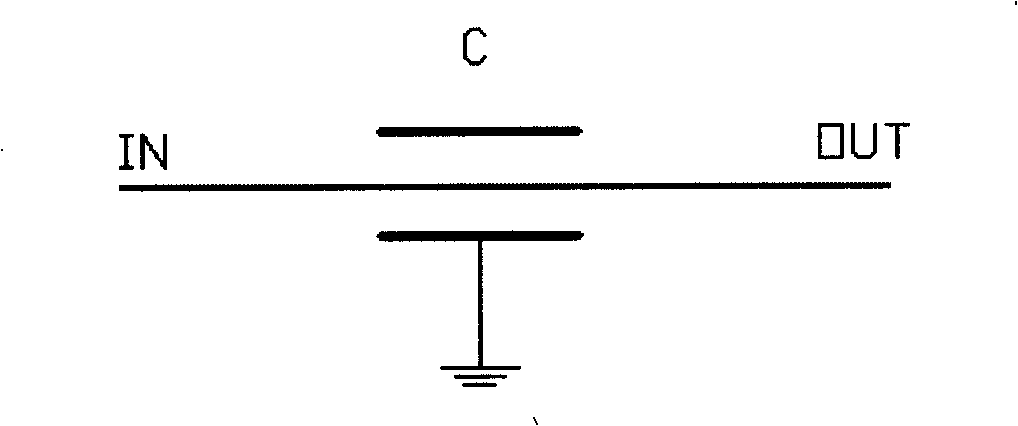

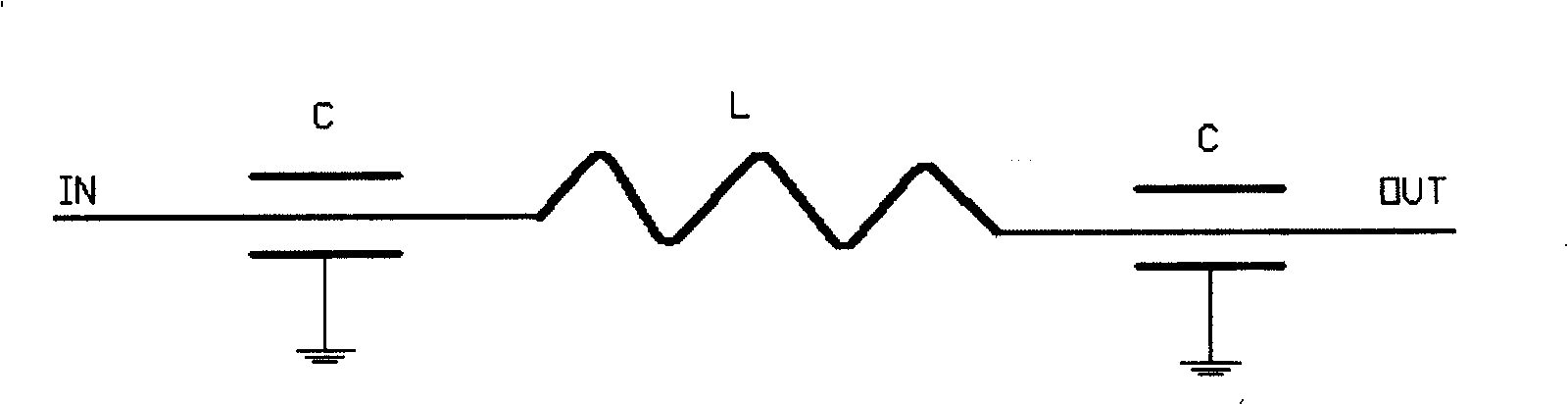

Lamination sheet type wave filter and method for producing the same

InactiveCN101404485ARaise the sensory valueLarge inductance inductorMultiple-port networksCapacitanceElectrical conductor

The invention belongs to the technical field of electronic components and relates to a multi-layer chip filter and a preparation method thereof. The filter leads in ceramics and ferrite in the same chip and simultaneously realizes large inductance and large capacitance; wherein, the inductance consists of a hollow inductance (a 'magnetic core' is a ceramic material) and a magnetic core induction (the magnetic chip is ferrite material). The hollow inductance is characterized by small inductance value, large quality factor, high self-resonance frequency, and the like, thus being capable of better broadening the working frequency section of the filter; the magnetic core inductance has the characteristics of large inductance value, low self-resonance frequency, and the like, thus better reducing the in-band insertion loss of a filter with a low cut-off frequency and improving the effect of the transmission signal of the filter. The preparation method of the multi-layer chip filter includes the steps such as material preparing, casting, punching, pore filling, conductor printing, chip overlapping, isostatic pressing, gumming, sintering, etc. The filter has the advantages of small size, large rectangle degree, large out-band rejection as well as broad working frequency. The preparation method has high controllability and can be compatible with the technique of the existing chip components.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

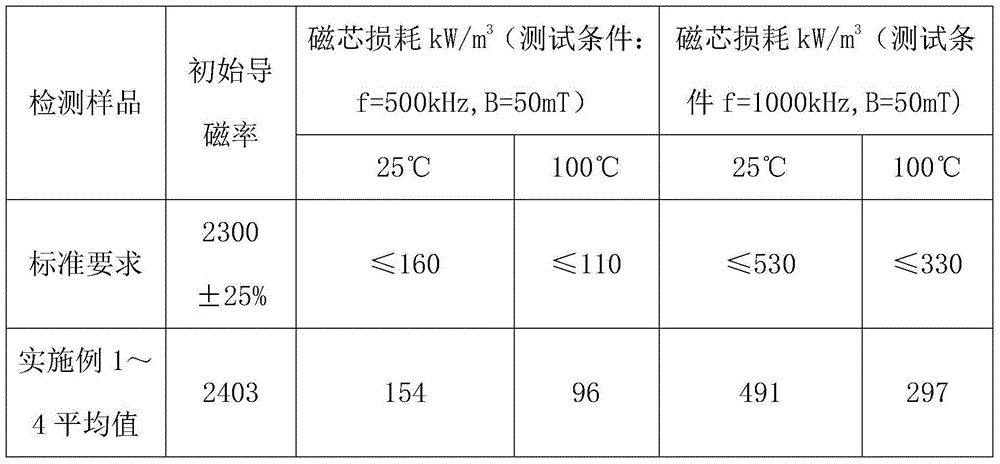

Soft magnetic ferrite material and preparation process thereof

The invention discloses a soft magnetic ferrite material. Raw materials for preparing the soft magnetic ferrite material comprise composite materials and auxiliary materials. The composite materials comprise iron oxide, manganese oxide and zinc oxide. The auxiliary materials comprise 0-6000 ppm of nickel oxide, 100-800 ppm of calcium carbonate, 0-500 ppm of lithium carbonate, 20-120 ppm of silicon dioxide, 0-230 ppm of magnesium oxide, 0-180 ppm of niobium oxide, 700-2000 ppm of cobalt oxide, 0-350 ppm of bismuth oxide, 100-600 ppm of vanadium oxide, 0-2500 ppm of titanium dioxide, 0-500 ppm of copper oxide, and 100-500 ppm of zirconium oxide. The invention also discloses a preparation process of the soft magnetic ferrite material. The soft magnetic ferrite material has high initial magnetic permeability and low magnetic core loss.

Owner:ZHONGDE ELECTRONICS

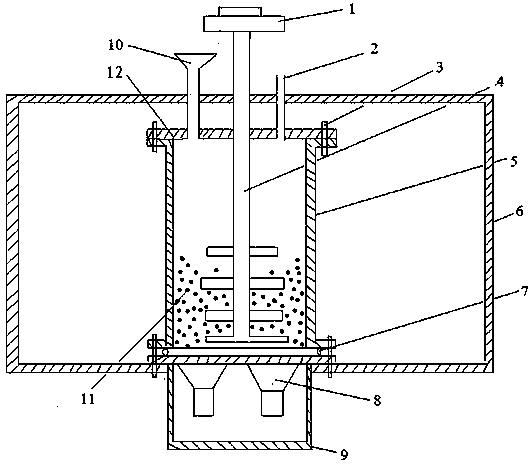

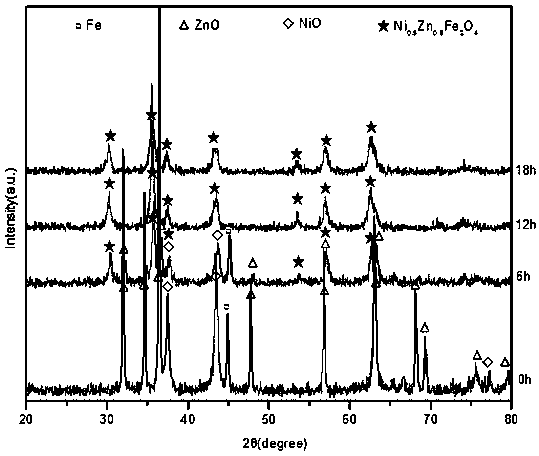

Microwave and ultrasound combined assisted ball-milling device and process for preparing high-performance nanopowder

The invention discloses a microwave and ultrasound combined assisted ball-milling device and process for preparing high-performance nanopowder. According to the device, a ball mill is placed in a microwave generator, and a bottomless ball-milling tank in the ball mill is connected with the top of an ultrasonic generator, so that the microwave and ultrasound combined assisted ball-milling device is formed. The process is characterized in that a medium solution and raw material powder in the ball-milling tank are subjected to cavatition of ultrasonic waves, the radiation effect of microwaves and the action of mechanical force of ball milling simultaneously, so that the speeds of reduction, oxidization, synthesis, decomposition and other reactions are greatly increased, and chemical reactions which cannot be realized by means of independent microwave-assisted ball milling or independent ultrasound-assisted ball milling in the prior art can happen. The device can be used for preparing multiple kinds of nanometer functional powder such as metallic oxide, ferrite, composite ferrite, wave-absorbing materials, luminescent materials and magnetic materials.

Owner:HUNAN UNIV

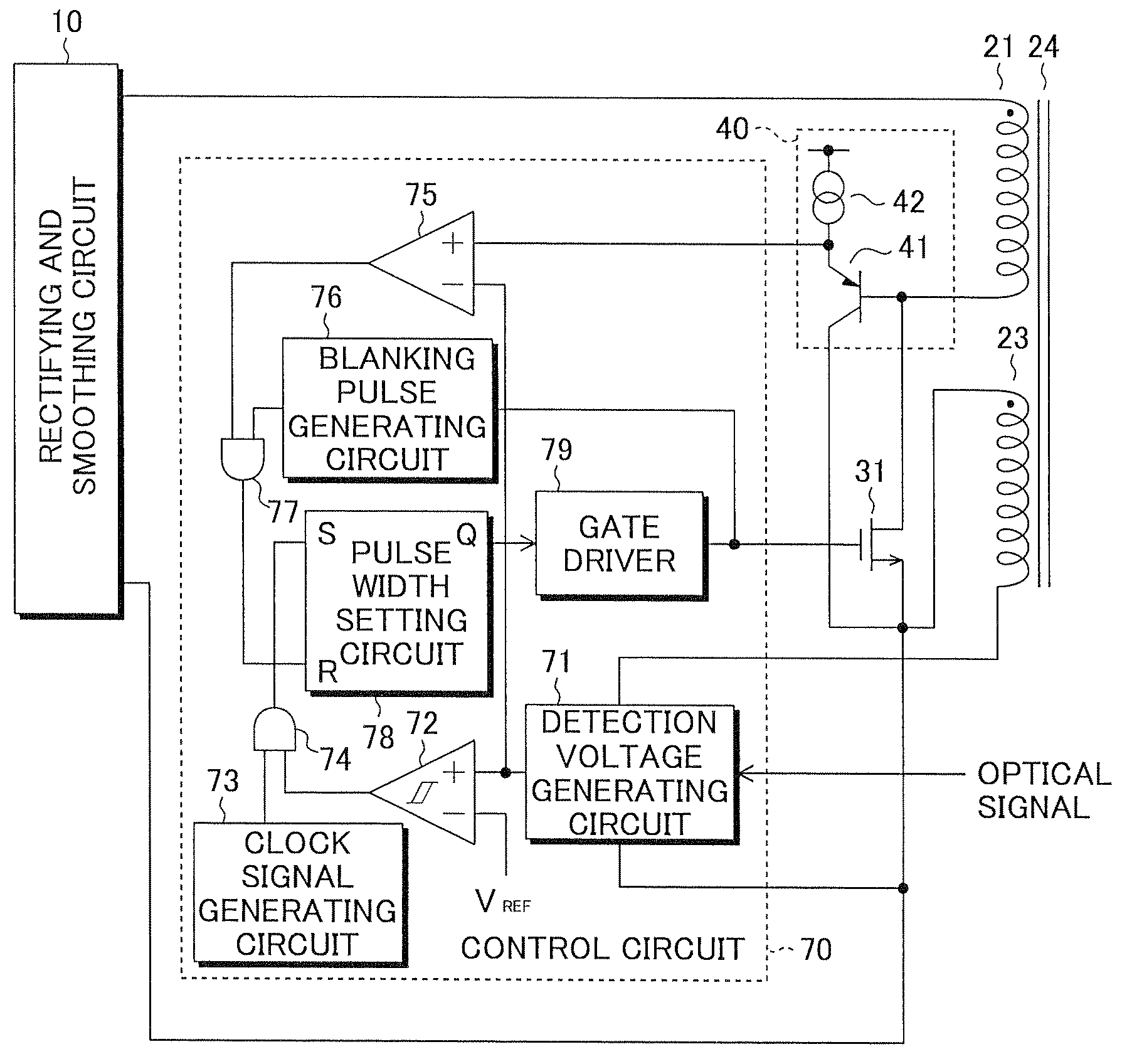

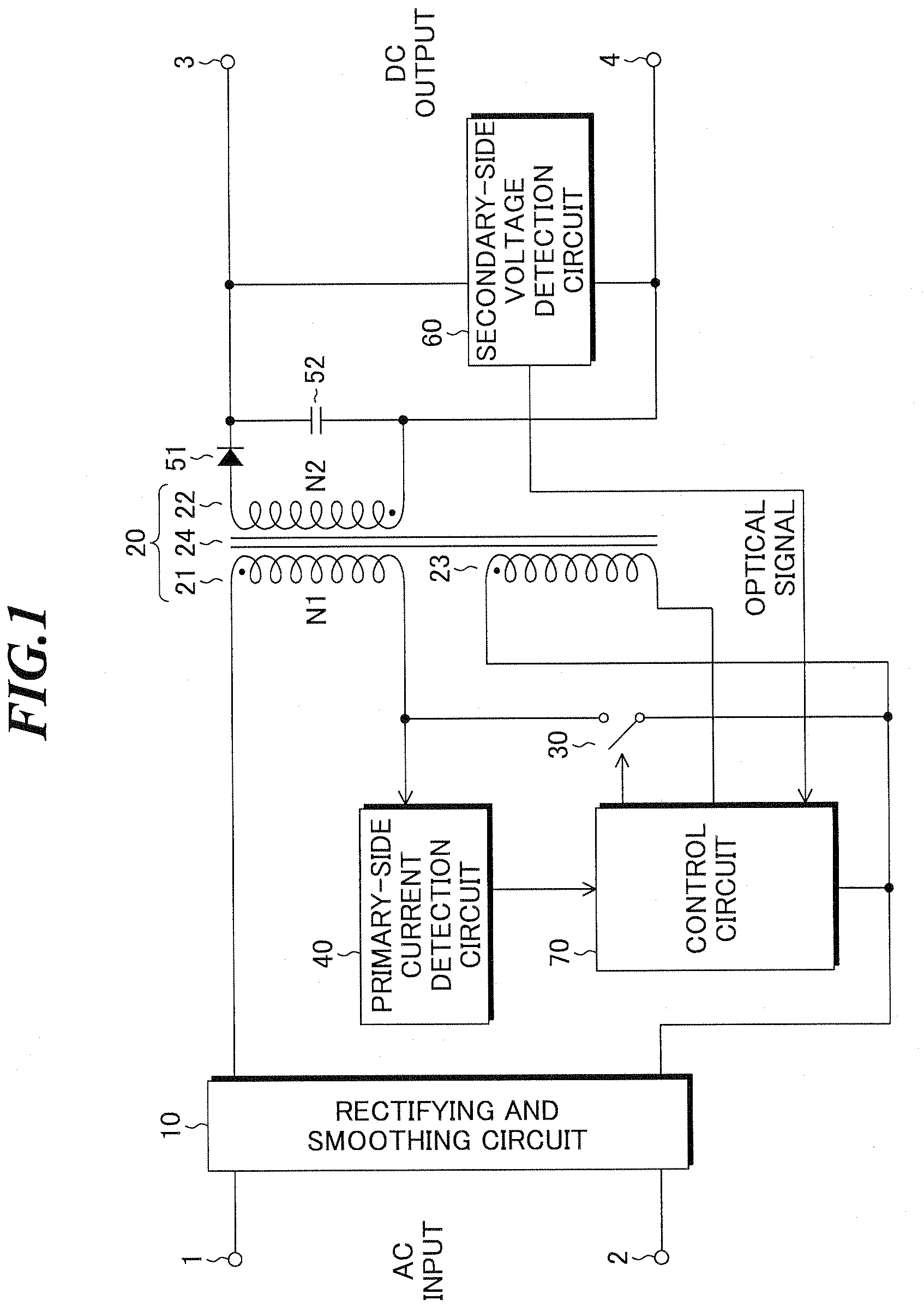

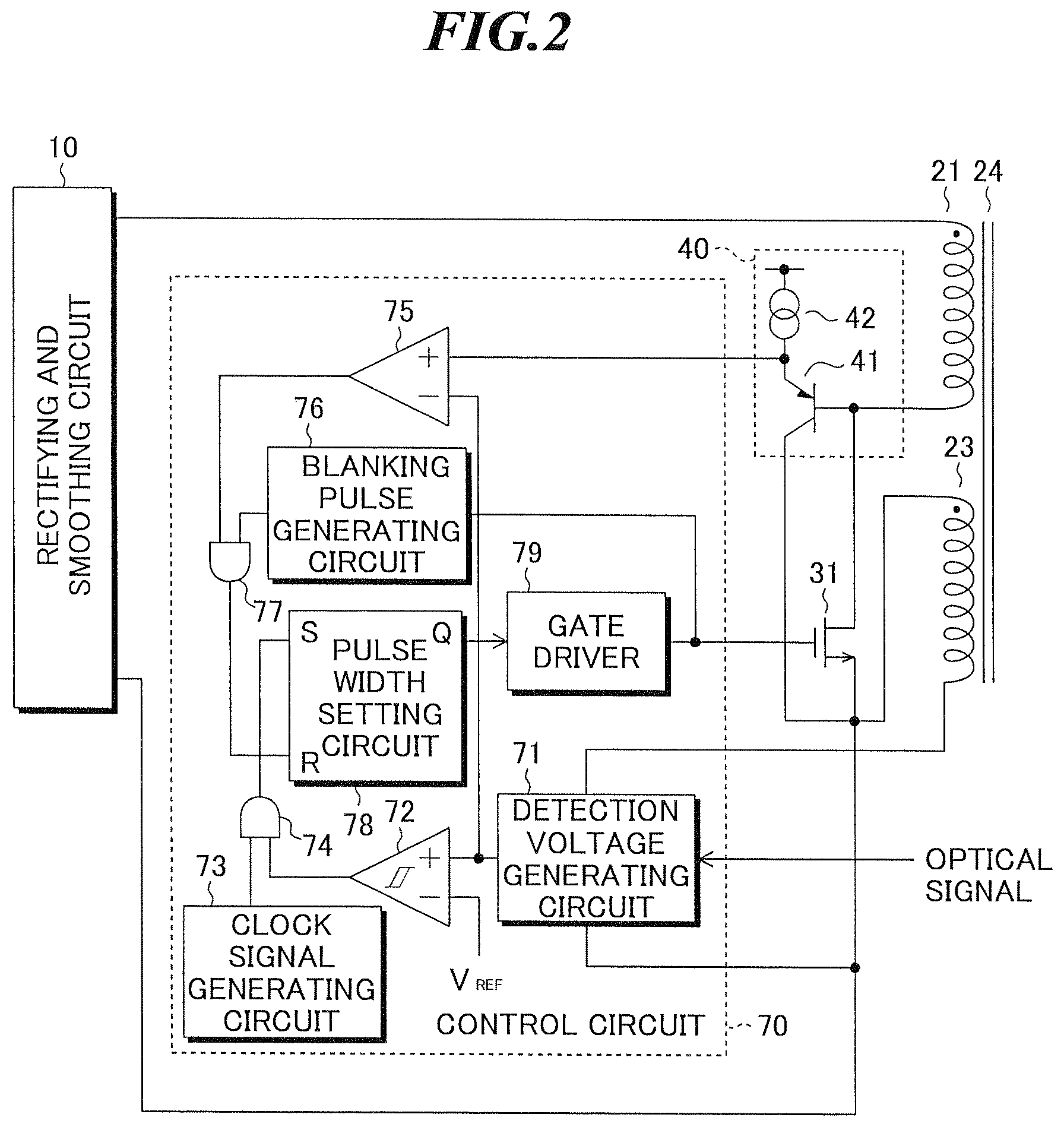

Switching power supply circuit

InactiveUS7894223B2Improve power performanceImprove featuresConversion with intermediate conversion to dcDc-dc conversionFerrite (magnet)Control theory

A switching power supply circuit uses a magnetic material that is harder to be magnetically saturated than ferrite as a core of a transformer or a choke coil and suitably protects a switching element. The circuit includes a transformer having a core made of a magnetic material of amorphous metal, a primary-side winding and a secondary-side winding. The circuit further includes a switching element for flowing current through the primary-side winding of the transformer according to a pulsive drive signal, and a primary-side current detection circuit for detecting the current flowing through the primary-side winding. The circuit further includes plural circuit elements for rectifying and smoothing a voltage generated in the secondary-side winding of the transformer to generate an output voltage, and a control circuit for generating the drive signal based on at least a detection result of the primary-side current detection circuit, and limiting a period for flowing the current in the primary-side winding.

Owner:OKI POWER TECH

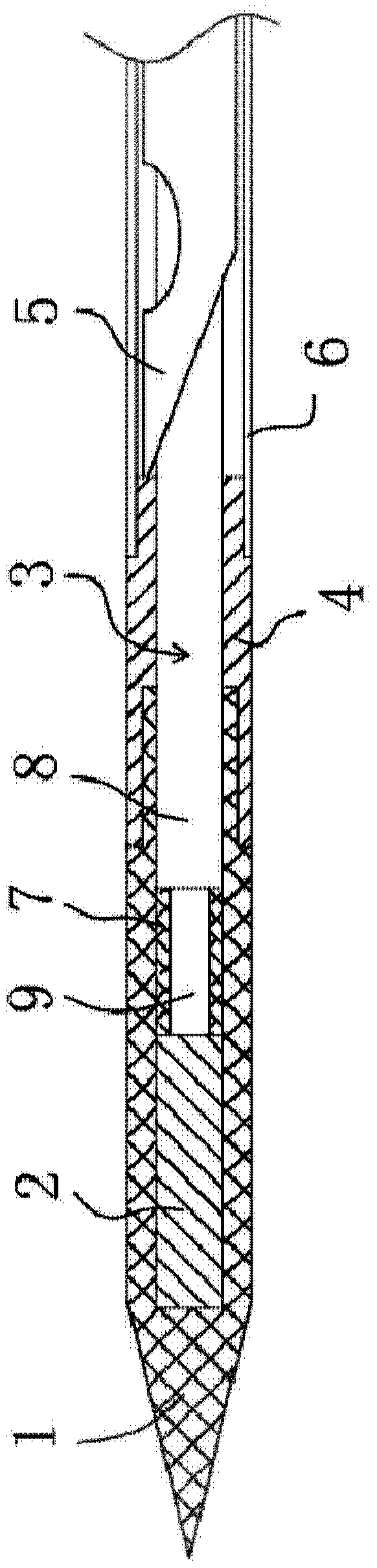

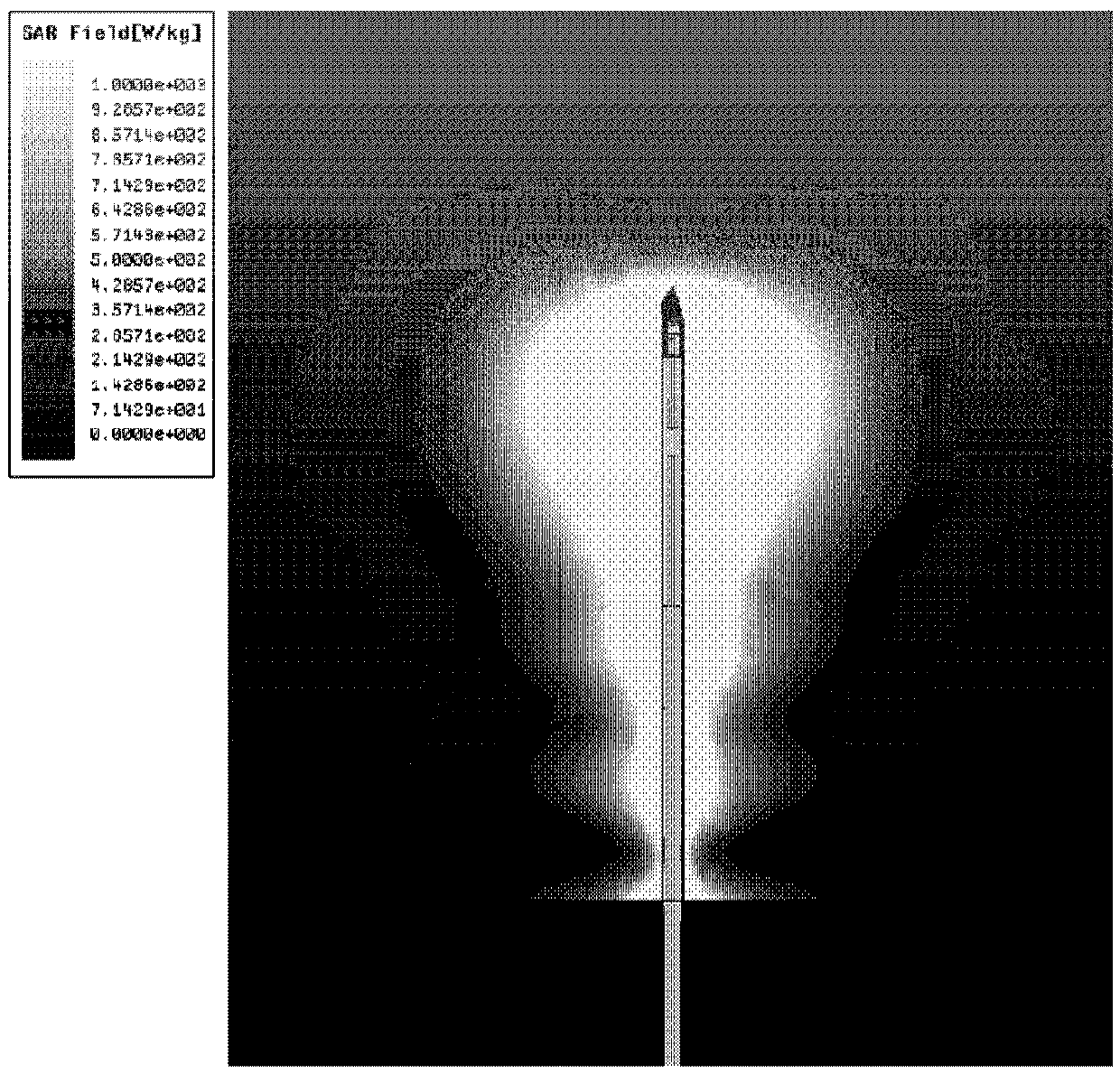

Antenna component used for microwave ablation and microwave ablation needle adopting same

ActiveCN105596079AAvoid transmissionTemperature controlSurgical needlesSurgical instruments using microwavesMicrowaveSoft magnet

The invention relates to an antenna component used for microwave ablation. The antenna component used for the microwave ablation comprises a cooling water channel, a coaxial line and a radiator, wherein a circle of soft magnetic ferrite film is plated on the outermost layer of the coaxial line. The invention also relates to a microwave ablation needle adopting the antenna component used for the microwave ablation. The antenna component used for the microwave ablation has the advantages that the soft magnetic ferrite film can effectively inhibit microwave transmitted backward along the outer wall of the coaxial line, a radiation zone does not need to be filled with a stable medium, circulating water is allowed to enter the radiation zone, temperature at the head of the ablation needle can be effectively controlled, and the ablation needle is prevented from being burned out due to overhigh temperature and a medical accident is avoided.

Owner:SINOSURGICAL HEALTHCARE TECH ZHEJIANG CO LTD

Permanent magnetic ferrite production method and magnetic body thereof

The invention relates to the field of permanent magnetic ferrites, particularly a production method of a permanent magnetic ferrite, which comprises the following steps: after secondarily proportioning permanent magnetic ferrite primary presintering powder and permanent magnetic ferrite reclaimed material, adding secondary additives, preparing a pulp, forming and sintering to obtain the permanent magnetic ferrite material. The invention solves the technical problems of low utilization value of permanent magnetic ferrite reclaimed material and incapability of producing high-performance permanent magnetic ferrite from the permanent magnetic ferrite reclaimed material, implements cyclic utilization of the permanent magnetic ferrite reclaimed material, changes wastes into valuable substances, enhances the utilization ratio of the raw materials, lowers the production cost of the material, and increases the cost performance of the material. The permanent magnetic ferrite magnetic body has the following properties: the residual flux density Br is greater than or equal to 4400Gs, the coercive force Hcb is greater than or equal to 3250Oe, the intrinsic coercive force Hcj is greater than or equal to 3500Oe, and the maximum magnetic energy product (BH)max is greater than or equal to 4.3MGOe.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

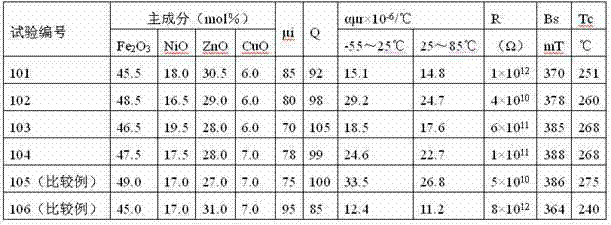

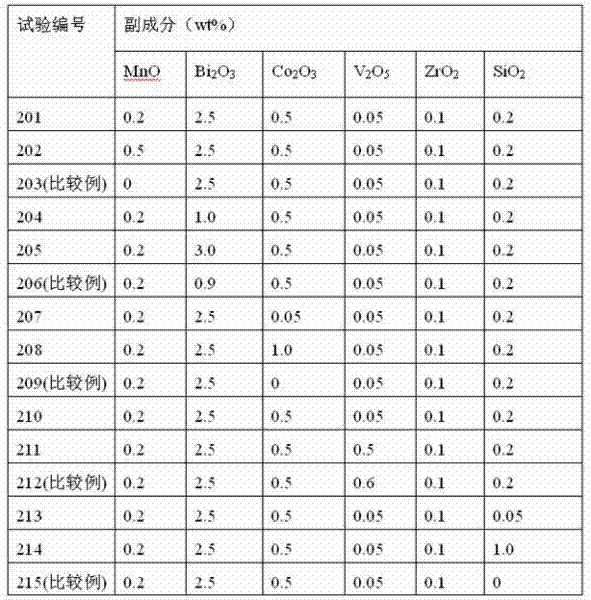

NiCuZn soft magnetic ferrite material used for low temperature co-sintering and preparation method thereof

The invention belongs to the field of soft magnetic ferrite materials, and in particular, relates to a NiCuZn soft magnetic ferrite material used for low temperature co-sintering. The material comprises major constituents and accessory constituents, wherein: the major constituents consist of ferric oxide, nickel oxide, zinc oxide and copper oxide, the molar percentage content of each major constituent being Fe2O3 45.5-48.5 mol%, NiO 16.5-19.5 mol%, ZnO 28.0-30.5 mol% and CuO 6.0-8.0 mol%; the accessory constituents comprise manganic oxide and bismuth oxide, compared with the gross weight of the major constituents, the weight percentage gross of the accessory constituents being 1.1-3.5 wt% calculated by taking MnO and Bi2O3 as standard. The invention also provides a preparation method for the ferrite material. When used for preparing MLCI devices under high frequency usage, the material of the invention has advantages in that: the material has a relatively low sintering temperature and metallic silver is not easy to diffuse during co-sintering; and the material ensures that the MLCI devices can obtain excellent magnetic properties and have a relatively good consistency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Composite ferrite composition and electronic device

ActiveUS20140333405A1Improve sintering performanceImprove permeabilityInorganic material magnetismCoilsFerrite (magnet)Non magnetic

A composite ferrite composition comprises a magnetic material and a non-magnetic material. A mixing ratio of said magnetic material and said non-magnetic material is 20 wt %:80 wt % to 80 wt %:20 wt %. Ni—Cu—Zn based ferrite is used as the magnetic material. Oxides of Zn, Cu, and Si are at least included in a main component of said non-magnetic material. Borosilicate glass is included in a subcomponent of said non-magnetic material.

Owner:TDK CORPARATION

MnZn ferrite material and method for preparing magnet core

InactiveCN101409124AReduce power lossOvercome the bottleneck of power consumption temperature characteristicsInorganic material magnetismMaterials scienceMagnet

The invention relates to a MnZn ferrite material and a method thereof for manufacturing a magnetic core out of the material. According to mol rate, the ingredients of principal crystalline phase include 48.5-53.8 percent of Fe2O3, 35.6-40.8 percent of MnO and the rest of ZnO. By weight, the principal crystalline phase needs to be further added with 100-600ppm of a first accessory constituent, 50-3000ppm of a second accessory constituent and 100-6000ppm of a third accessory constituent. The first accessory constituent means one or the two of SiO2 and Ta2O5, the second accessory constituent means one or more of CaCO3, Bi2O3, Nb2O5 and WO3 and the third accessory constituent means one or more of TiO2, V2O5 and Co3O4. Within the wide temperature range from 25 to 100 DEG C, the MnZn ferrite material has surely low power loss of 100kHz and 200mT and the power loss of Pcv of not more than 380KW / m<3>. The magnetic core prepared by adopting the materials of the invention greatly reduces the power loss of 'secondary power supply' in the state of standby, idle load or light load, thus achieving the aim of saving energy.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

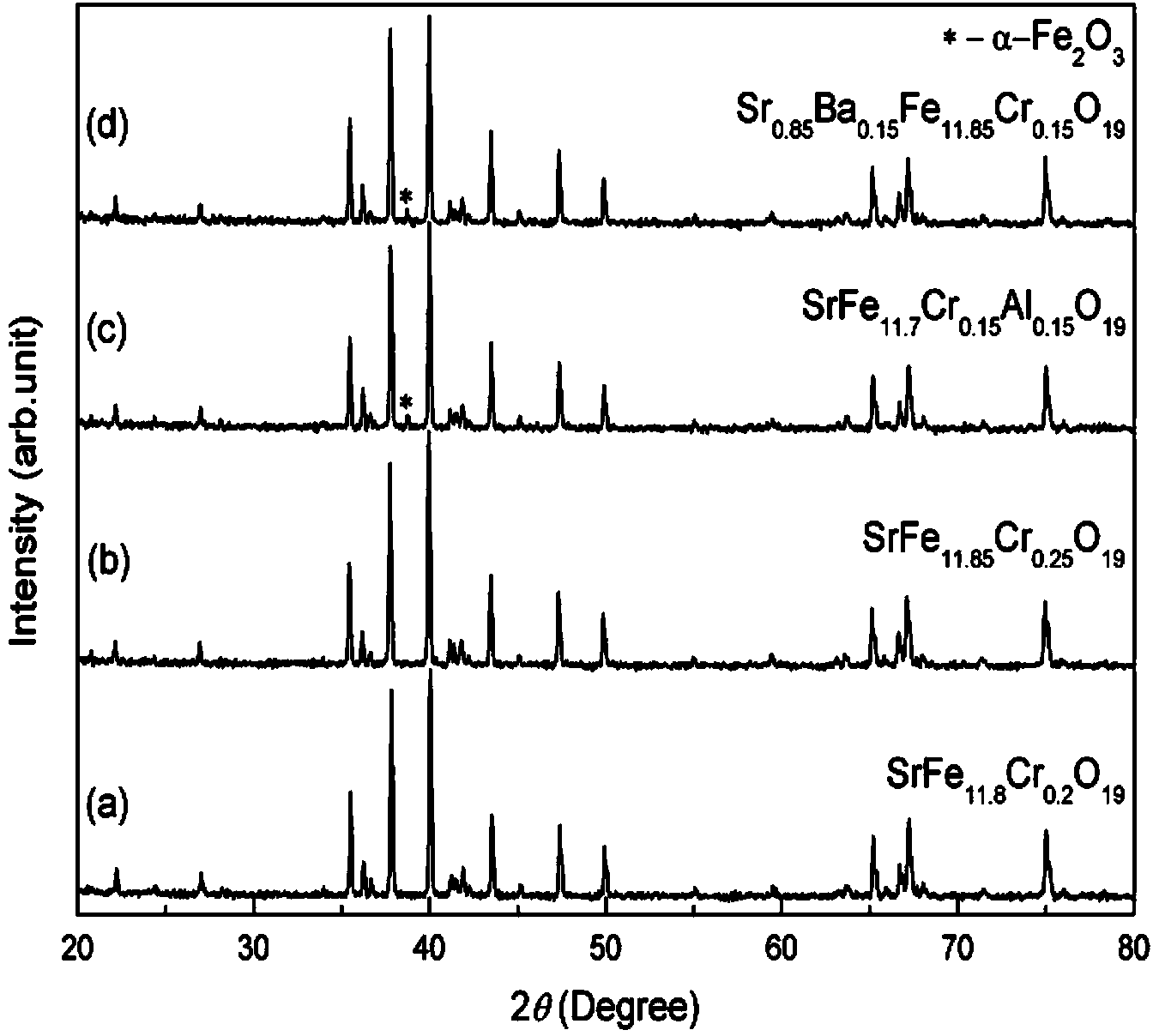

High-performance permanent magnet ferrite material and preparing method thereof

The invention relates to a high-performance permanent magnet ferrite material and a preparing method thereof and belongs to the technical field of magnetic function material preparation. The invention adopts the technical scheme as follows: carrying out preparation according to a main phase molecular formula Sr1-xBaxO.nFe(12-y) / nRy / nO3, wherein x is not smaller than 0 and not bigger than 0.998, n is not smaller than 5.75 and not bigger than 6.15, y is bigger than 0 and not bigger than 0.6, R refers to Cr or Cr and Al, and the content of Cr and Al is smaller than or equal to 0.6 when R refers to Cr and Al; secondarily adding one or more than two of industrial-purity CeO2, Ga2O3 and MoO3. The rest magnetism Br value of the high-performance permanent magnet ferrite prepared by the method is larger than or equal to 390mT, the intrinsic coercivity Hcj value is larger than or equal to 346.1kA / m, and the magnetic energy product (BH)max value is larger than or equal to 28.7kJ / m<3>. The method has the advantages that the high-performance permanent magnet ferrite material with a high performance-to-cost ratio is prepared through the relatively cheap chromium or chromium and aluminum substituted combination additive without adding expensive rare earth and rare metal oxide.

Owner:合肥领远新材料科技有限公司

Soft magnetic ferrite material containing magnesium, nickel and zinc element as well as manufacturing method thereof

InactiveCN101354941AHigh initial permeabilityMagnetically stableInorganic material magnetismCopper oxideInductor

The invention discloses a soft magnetic ferrite material containing magnesium element, nickel element and zinc element, which comprises the following compositions in mol portion: 60 to 66 mol percent of ferric oxide Fe2O3, 7 to 10 mol percent of nickel oxide NiO, 7 to 10 mol percent of magnesia MgO, 10 to 15 mol percent of zinc oxide ZnO and 3 to 6 mol percent of copper oxide CuO. The manufacturing method comprises the following steps of the processing of raw material, batching, primary ball milling, drying, pulverization or sifting, preburning, secondary batching, secondary ball milling, secondary drying and secondary pulverization or sifting, in a preburning condition, the soft magnetic ferrite material is presynthesized in an air furnace at a temperature of between 800 and 900 DEG C. The prepared soft magnetic ferrite material has the initial magnetic conductivity of about 100, stable magnetic performance and low production cost when the soft magnetic ferrite material is used to produce a laminated sheet type inductor.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +3

Method of fabricating a cylindrical optical fiber containing a light interactive film

InactiveUS20050252248A1Ensure continuityThe material is lowGlass making apparatusOptical fibre with multilayer core/claddingMetal alloyThermal coefficient

A method of forming a preform which has a glass core surrounded by an outer glass cladding with a coating of a light interactive material disposed between the core and cladding. The method includes providing a glass core having a viscosity which lies within a given preselected temperature range, followed by forming a substantially homogeneous coating of a light interactive material over the surface of the core, with the coating material having a viscosity which is equal to or less than the viscosity of the glass core. A glass cladding is formed over the coated layer, with the cladding glass having a viscosity which overlaps the viscosity of the core glass and a thermal coefficient of expansion compatible with that of the core. The light interactive material is an inorganic material which includes a metal, metal alloy, ferrite, magnetic material and a semiconductor.

Owner:SYRACUSE UNIVERSITY

Porous ferrite core material for electrophotographic developer, resin-filled ferrite carrier and electrophotographic developer using the ferrite carrier

InactiveUS20110129772A1Increased durabilityIncreased operating lifeDevelopersUltimate tensile strengthFerrite core

A porous ferrite core material for an electrophotographic developer, the porous ferrite core material including Mg in a content of 0.3 to 3% by weight, Ti in a content of 0.4 to 3% by weight and Fe in a content of 60 to 70% by weight, and the porous ferrite core material having a pore volume of 0.04 to 0.16 ml / g, a peak pore size of 0.4 to 1.6 μm, a saturation magnetization of 40 to 80 Am2 / kg, a remanent magnetization of less than 7 Am2 / kg and a coercive force of less than 43 A / m; a resin-filled ferrite carrier for an electrophotographic developer obtained by filling a resin in the voids of the porous ferrite core material; and an electrophotographic developer using the ferrite carrier.

Owner:POWDERTECH

A low power consumption Mn-Zn ferrite magnetic material for ultra-high temperature condition and its making method

ActiveCN101169996AModerate contentReduce power consumptionInorganic material magnetismVolumetric Mass DensityHigh-temperature corrosion

The invention relates to a Mn-Zn ferrite magnetic material and a preparation method thereof. The main component and content of the Mn-Zn ferrite magnetic material are calculated as oxides: 52-56 mol% of Fe2O3; 2-10 mol of ZnO %; MnO is 38-42mol%; auxiliary components are: CaO: 400-800ppm, Nb2O5: 100-400ppm, ZrO2: 100-800ppm, Co2O3: 1000-5000ppm or a combination, it is a kind of high saturated Mn-Zn ferrite magnetic material with magnetic induction, low power consumption and excellent electromagnetic characteristics under ultra-high temperature conditions.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Method for directly preparing ferro-magnetic microcrystal glass by thermal state steel slag

The invention discloses a method for directly preparing ferro-magnetic microcrystal glass by thermal state steel slag, comprising the steps of founding base glass by steel slag and preparing ferro-magnetic microcrystal glass by thermal treatment. The method comprises the following steps of: firstly, milling and evenly mixing auxiliary material components, heating the mixture for 2-4h at the temperature of 1400-1450DEG C, melting into liquid, pouring thermal state steel slag into an auxiliary material melt and evenly mixing, casting in a mold to be formed, annealing, and cooling to room temperature, so that a base glass blank can be formed; and carrying out the nucleating and crystallizing thermal treatment on the glass blank, preserving heat preservation after the crystallization temperature is higher than 950DEG C and then cooling down, so that the magnetic microcrystal glass where the diopside and the ferrite are taken as a main crystalline phase can be obtained. Due to a preparation method of the ferro-magnetic microcrystal glass provided by the invention, a mass of sensible heat in the thermal state steel slag can be sufficiently used, the environment pollution can be avoided, and the iron in the slag can be effectively used. The prepared microcrystal glass is good in magnetic thermal property and biological activity, and is high in product additional value.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com