A low power consumption Mn-Zn ferrite magnetic material for ultra-high temperature condition and its making method

A technology of magnetic materials and ferrites, applied in the field of magnetic materials, can solve the problems of large increase in power loss, and achieve the effects of low production cost, saturation magnetic induction intensity, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

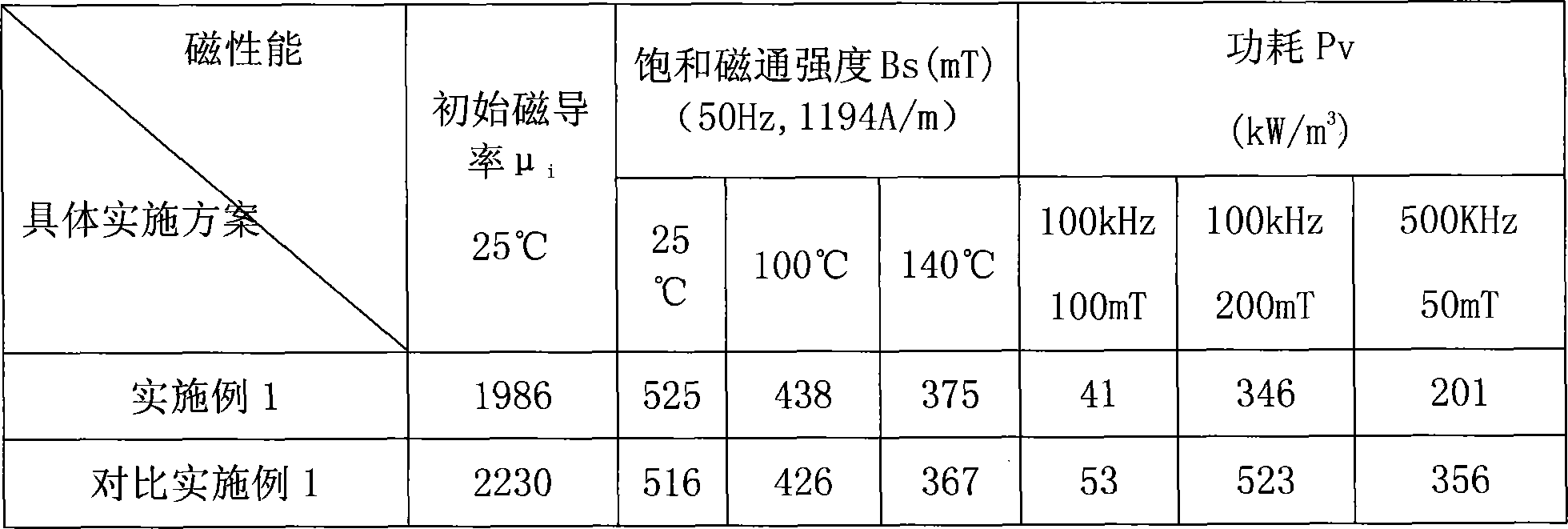

Examples

Embodiment 1

[0034] 1. Ingredients: according to the weight percentage of the main formula and auxiliary formula in terms of oxides, the main formula is Fe 2 o 3 is 53.18mol%; ZnO is 6.17ol%; MnO is 40.65mol%; the auxiliary formula is CaO: 600ppm, Nb 2 o 5 : 250ppm, ZrO 2 : 150ppm, Co 2 o 3 : 1800ppm.

[0035] 2. Ball milling: dry strong mixing with a V-shaped mixer, and the mixing time is 0.7 hours;

[0036] 3. Vibration grinding: Vibration grinding machine is used for vibration grinding, and the vibration grinding time is 0.6 hours;

[0037] 4. Pre-burning: The powder is directly pre-fired in an air kiln at a temperature of 950°C for 2.5 hours.

[0038] 5. Sand milling: use a circulating sand mill for sand milling, and the sand milling time is 2 hours; wherein material: ball: water = 1: 1: 0.6; the average particle size of the powder after sand milling is 1.0-1.2 μm.

[0039] 6. Granulation molding: use a granulator for granulation, and then use a fully automatic dry press for mo...

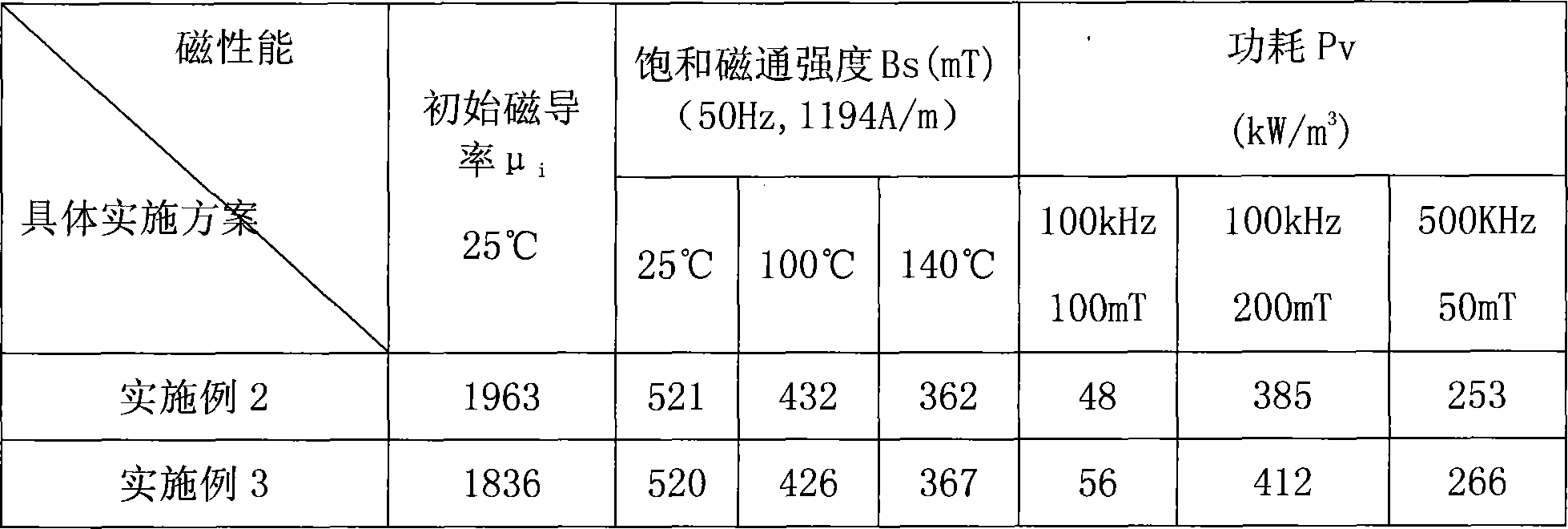

Embodiment 2

[0055] 1. Fe 2 o 3 is 53.18mol%; ZnO is 6.17mol%; MnO is 40.65mol%; the auxiliary formula is CaO: 600ppm, Nb 2 o 5 : 250ppm, ZrO 2 : 150ppm, Co 2 o 3 : 1000pm.

[0056] 2. Ball milling: dry strong mixing with a V-shaped mixer, and the mixing time is 0.7 hours;

[0057] 3. Vibration grinding: Vibration grinding machine is used for vibration grinding, and the vibration grinding time is 0.6 hours;

[0058] 4. Pre-burning: The powder is directly pre-fired in an air kiln at a temperature of 950°C for 2.5 hours.

[0059] 5. Sand milling: use a circulating sand mill for sand milling, and the sand milling time is 2 hours; wherein material: ball: water = 1: 1: 0.6; the average particle size of the powder after sand milling is 1.0-1.2 μm.

[0060] 6. Granulation molding: use a granulator for granulation, and then use a fully automatic dry press for molding, wherein the inlet temperature is controlled at 270°C during granulation, the outlet temperature is 130°C, and the density o...

Embodiment 3

[0064] 1. Ingredients: according to the weight percentage of the main formula and auxiliary formula in terms of oxides, the main formula is Fe 2 o 3 is 53.18mol%; ZnO is 6.17mol%; MnO is 40.65mol%; the auxiliary formula is CaO: 600ppm, Nb 2 o 5 : 250ppm, ZrO 2 : 150ppm, Co 2 o 3 : 5000ppm. .

[0065] 2. Ball milling: dry strong mixing with a V-shaped mixer, and the mixing time is 0.7 hours;

[0066] 3. Vibration grinding: Vibration grinding machine is used for vibration grinding, and the vibration grinding time is 0.6 hours;

[0067] 4. Pre-burning: The powder is directly pre-fired in an air kiln at a temperature of 950°C for 2.5 hours.

[0068] 5. Sand milling: use a circulating sand mill for sand milling, and the sand milling time is 2 hours; wherein material: ball: water = 1: 1: 0.6; the average particle size of the powder after sand milling is 1.0-1.2 μm.

[0069] 6. Granulation molding: use a granulator for granulation, and then use a fully automatic dry press fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com