Patents

Literature

111results about How to "Moderate content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of extinction polyvinyl chloride resin

The invention provides a preparation method of extinction polyvinyl chloride resin. The preparation method comprises the following steps: acquiring vinyl chloride monomer, deionized water, an initiator, a buffering agent, a dispersant and a matting agent which serve as reaction raw materials; performing pre-emulsification treatment on the matting agent by use of part of the dispersant; adding the vinyl chloride monomer, the deionized water, the initiator, the buffering agent and the rest dispersant into a polymerization kettle, performing polyreaction, and adding the matting agent subjected to pre-emulsification treatment during the reaction process so as to prepare the extinction polyvinyl chloride resin, wherein the matting agent is a monomer or polymer containing two or more reaction active functional groups, the dosage of the deionized water accounts for 105-200% of the weight of the vinyl chloride monomer, the dosage of the initiator accounts of 0.04-0.18% of the weight of the vinyl chloride monomer, the total dosage of the dispersant accounts for 0.04-0.15% of the weight of the vinyl chloride monomer, the dosage of the buffering agent accounts for 0.06-0.18% of the weight of the vinyl chloride monomer, and the dosage of the matting agent accounts for 0.01-8.0% of the weight of the vinyl chloride monomer. The prepared extinction polyvinyl chloride resin is fewer in crystal spot and good in extinction effect.

Owner:HANGZHOU ELECTROCHEM GROUP

Rapid salting method of low-salt salted pork

ActiveCN103750389AModerate contentLittle damage to human healthClimate change adaptationFood mechanical treatmentFleshChemistry

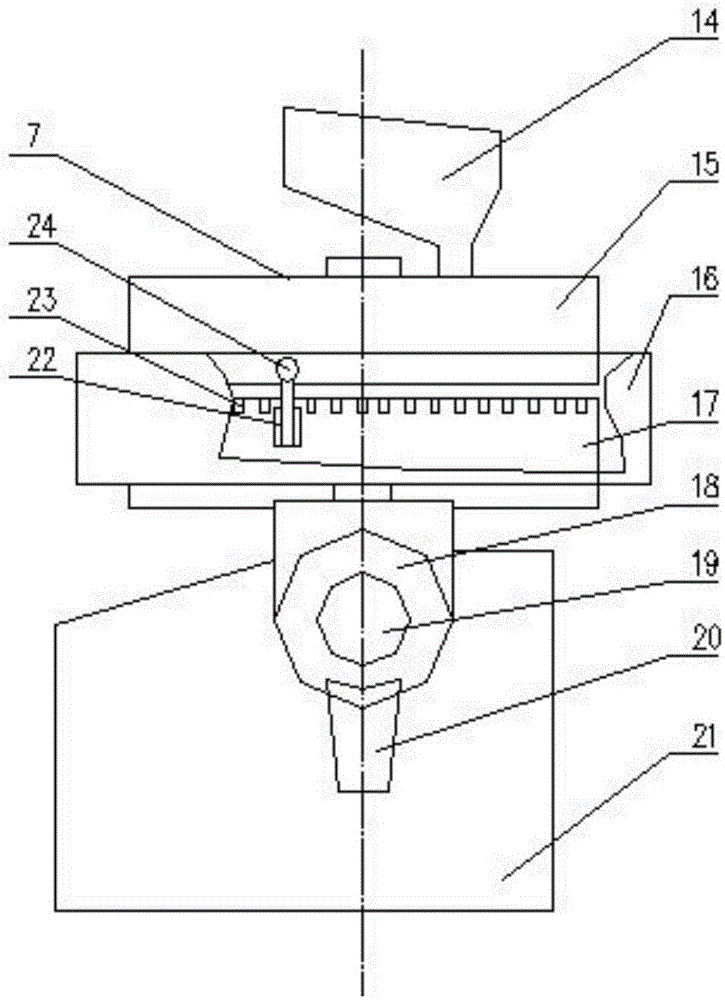

The invention relates to a rapid salting method of low-salt salted pork. The method comprises the following steps of 1. cutting selected streaky pork with equivalent fat-muscle into strips; 2. measuring table salt and pork according to the salt-to-pork ratio being 3 to 4 percent, dissolving 2 percent of table salt into little water, and uniformly injecting the salty water into the pork by utilizing a salty water syringe; 3. respectively measuring 2 to 2.5 percent of white spirit, 0.2 to 0.6 percent of paprika powder and 0.2 to 0.4 percent of fennel powder, mixing the white spirit, the paprika powder and the fennel powder with the residual table salt, and kneading the pork with the mixture; 4. arranging the pork into a rolling kneading machine, and vacuum intermittently rolling kneading the pork at the low temperature at the condition of controlling the temperature at 0 to 4 DEG C, the vacuum degree to be 0.08MPa and the rotating speed to be 10r / min,; 5. hanging the pork under the condition that the temperature is 8 to 12 DEG C and the relative humidity is 60 to 70 percent, and standing and drying the pork for 2days; 6. Carrying out fire curing; 7. naturally carrying out air drying and cooling for 24h, and carrying out vacuum packaging on the pork to obtain a finished product. The low-salt salted pork is bright in color, delicious in taste, tender in tissue and obvious in scent and can be reserved for one year under the vacuum packaging cold storage condition without going bad.

Owner:西林县招商中心

Method for making ice cream manually

The invention provides a method for making ice cream manually. The method is characterized in that the method comprises the following making steps: first, raw materials used for making ice cream are put into a container, stirred fully and uniformly, and ice cream liquid mixture is obtained; second, an appropriate amount of liquid inert gases is added into the ice cream liquid mixture in batches, the ice cream liquid mixture is whipped manually or through devices; third, the ice cream liquid mixture is whipped manually or through devices in refrigeration and crystallization processes, and the formed ice crystals can be smaller under the action of external force; fourth, when the ice cream liquid mixture is refrigerated into solid completely, the ice cream is obtained. In the method, liquid inert gases are used as refrigeration medium, that fresh fruits and vegetables or alcohol-containing drink are used as raw materials for making manual ice cream can be possible. The air content of the ice cream is moderate, the taste and the color are changeable, the ice crystals are small, and the mouthfeel is soft.

Owner:王惠璇

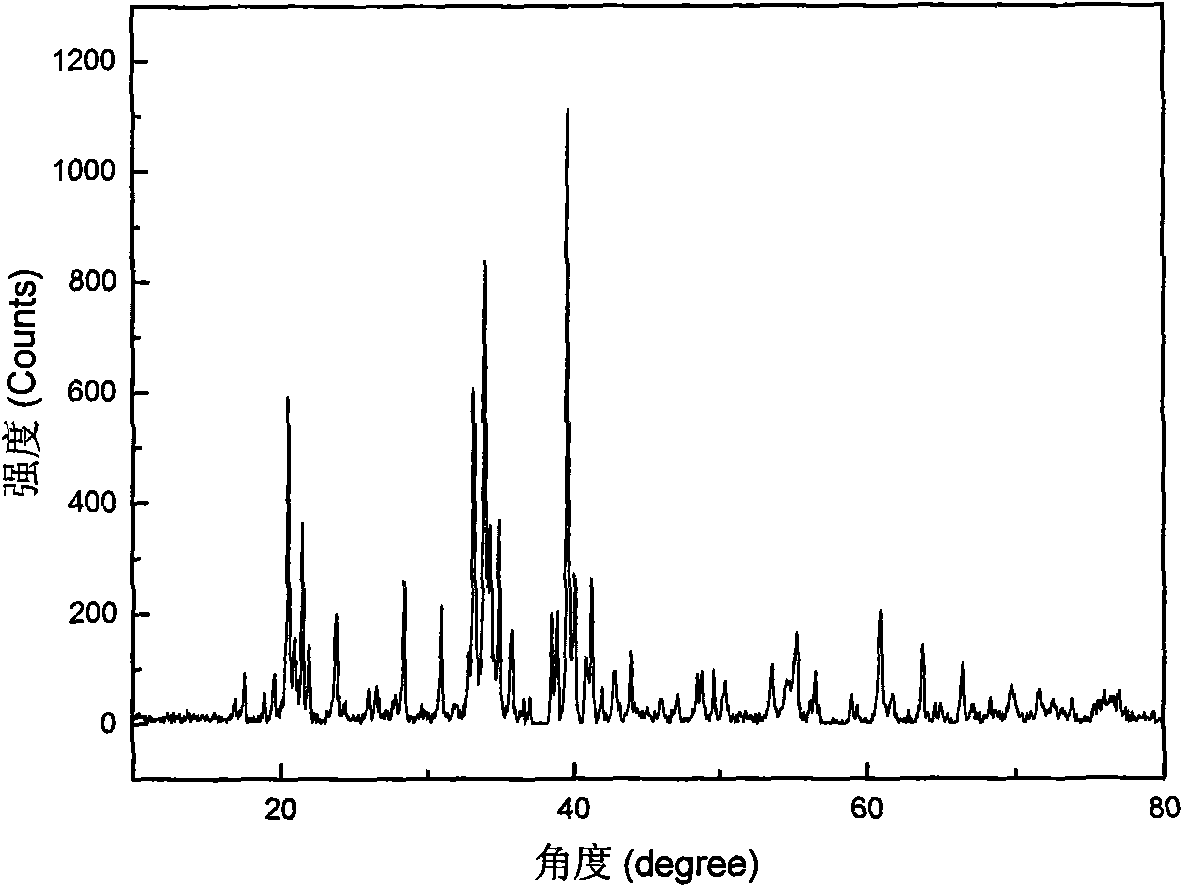

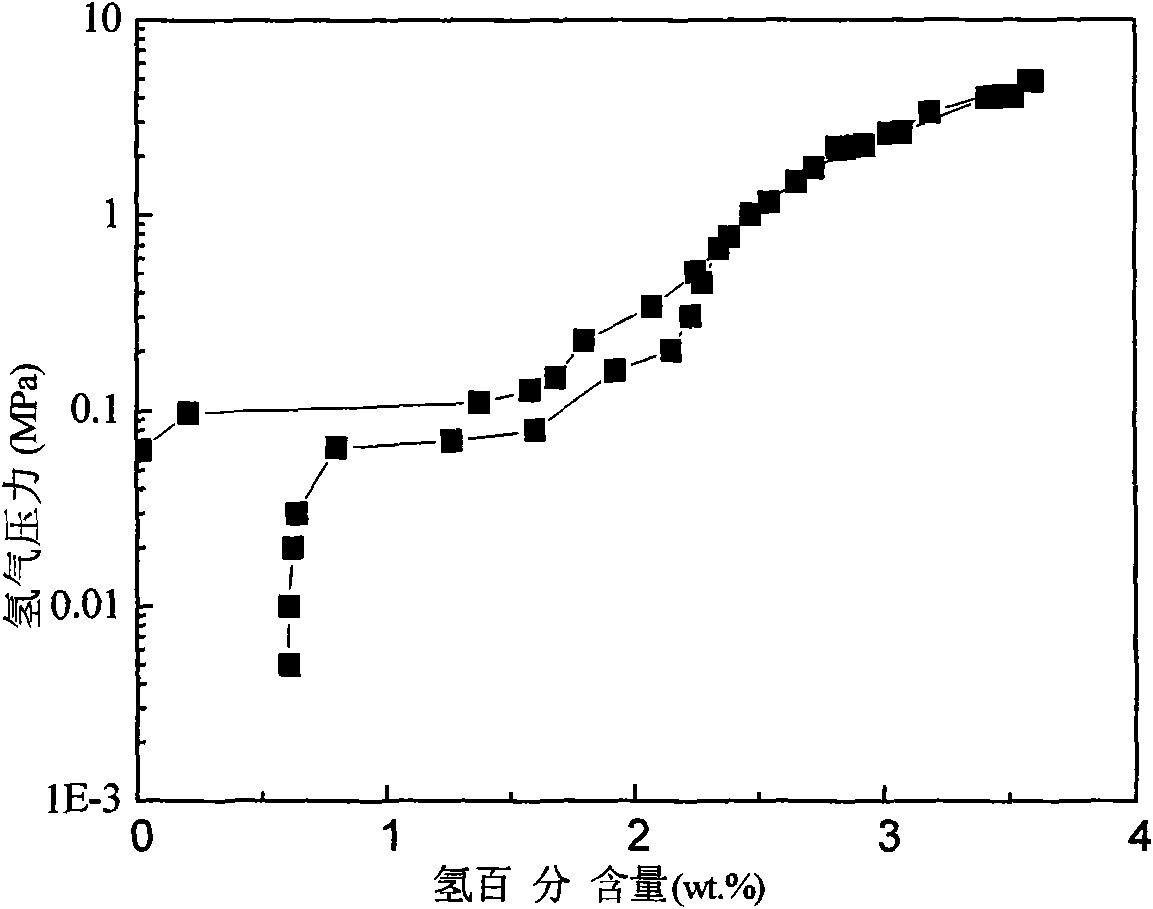

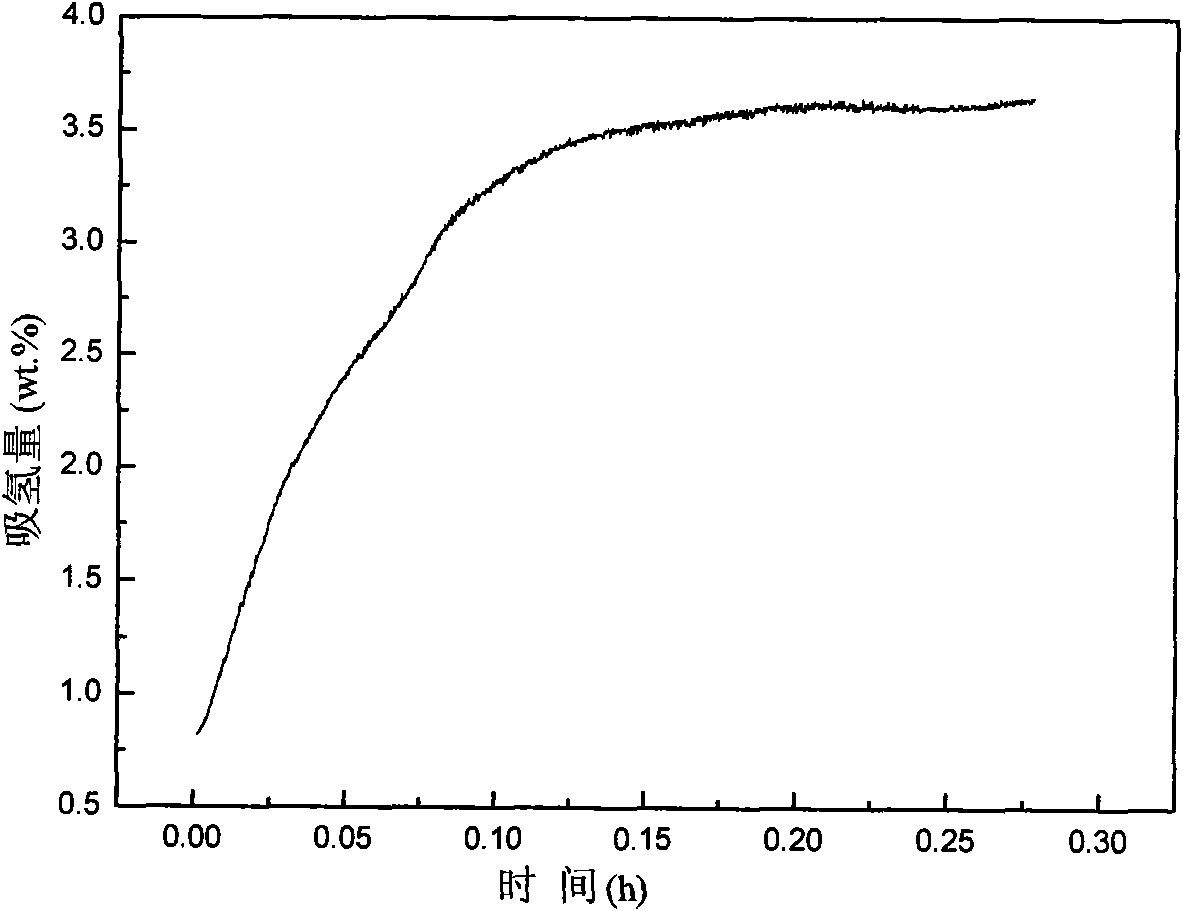

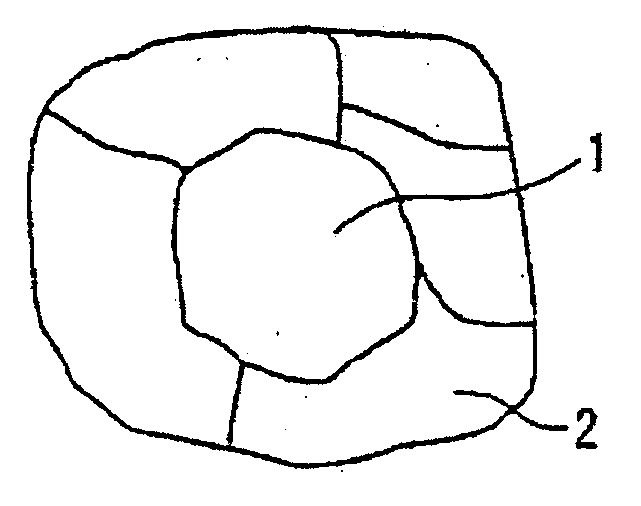

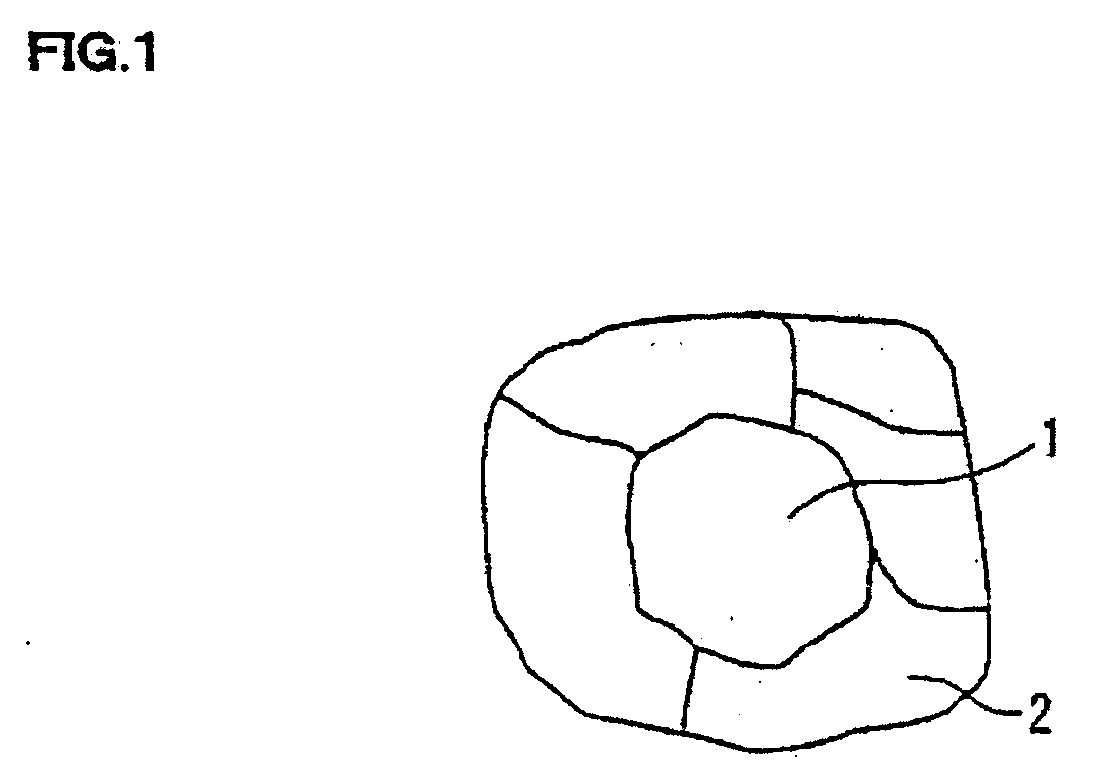

Rare earth-magnesium-transition metal base hydrogen storage metal and preparation method thereof

The invention relates to a rare earth-magnesium-transition metal base hydrogen storage metal with high hydrogen storage capacity and moderate hydrogen storage temperature and preparation method thereof. The metal is characterized in that the chemical formula thereof is REMgxMy, wherein x is more than 1 and less than 2, y is more than 1 and less than 3; RE is one or more than one of rare earth metals of La, Ce, Pr, Nd, cerium rich mish metal Mm and lanthanum rich mish metal M1; M is one or more than one of transition metals of Cu, Ni, Mn, Fe and Zn. The rare earth-magnesium-transition metal base hydrogen storage metal provided by the invention is also characterized in that the metal at least contains a multiphase structure of CeMg3 type LaMg3 phase and LaMg2Cu2 phase. The invention also provides a preparation method of the rare earth-magnesium-transition metal base hydrogen storage metal. The preparation method mainly includes that induction melting is adopted, Mg base master alloy is utilized to substitute magnesium and used as raw material, secondary charging is used for preparing the metal, and the metal is annealed. The hydrogen storage metal of the invention has the advantages that the hydrogen storage capacity at 200 DEG C is more than 3wt% and the metal can be used as solid-state hydrogen storage material.

Owner:YANSHAN UNIV

High compressibility iron powder, and iron powder for dust core and dust core using the same

InactiveUS20120048063A1Easy to compressModerate contentLiquid surface applicatorsSynthetic resin layered productsProduction rateHigh density

High compressibility iron powder that is suitably used for parts with excellent magnetic characteristics or high density sintered parts and that has good productivity is provided from pure iron powder which includes, as impurities in percent by mass, C: 0.005% or less, Si: more than 0.01% and 0.03% or less, Mn: 0.03% or more and 0.07% or less, P: 0.01% or less, S: 0.01% or less, O: 0.10% or less, and N: 0.001% or less, and whose particle includes four or less crystal grains on average and has a micro Vickers hardness (Hv) of 80 or less on average. The circularity of the iron powder is preferably 0.7 or more.

Owner:JFE STEEL CORP

Fodder for relieving constipation of pregnant sow and production method thereof

InactiveCN106071212AKeep healthyReduce constipationFood processingLactobacillusAdditive ingredientCalcium

Owner:济南天惠饲料有限公司

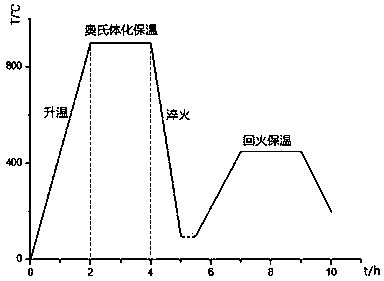

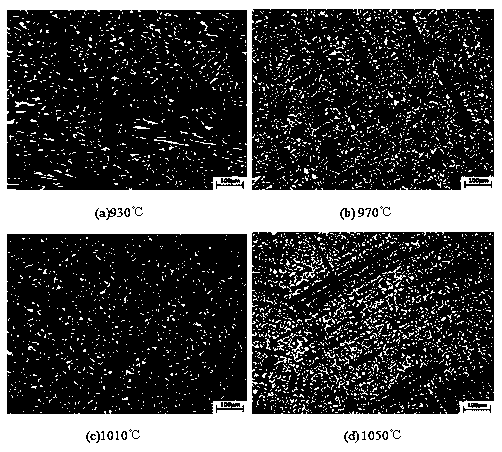

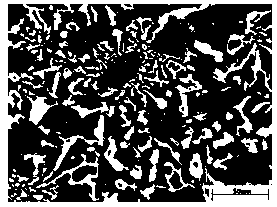

High-chromium cast iron heat treatment process

The invention relates to a high-chromium cast iron heat treatment process. The process includes steps: heating high-chromium cast iron in a heating furnace for 1.5-2, and after the heating temperaturereaches 1010-1050DEG C, keeping the temperature for 1.5-2h to realize austenization; discharging the high-chromium cast iron, and quenching; reheating the quenched high-chromium cast iron in the furnace for 1.5-2h, and after the heating temperature reaches 450-460DEG C, keeping the temperature for 1.5-2h; discharging the high-chromium cast iron, and performing air cooling to the room temperature.By reasonable optimization of the quenching temperature and the temper temperature, the quenched high-chromium cast iron structure is appropriate in content of martensite, retained austenite and carbides, and Rockwell hardness, impact toughness and comprehensive mechanical properties are greatly improved as compared with those of a cast sample.

Owner:ANHUI FENGXING WEAR RESISTANT MATERIALS CO LTD +1

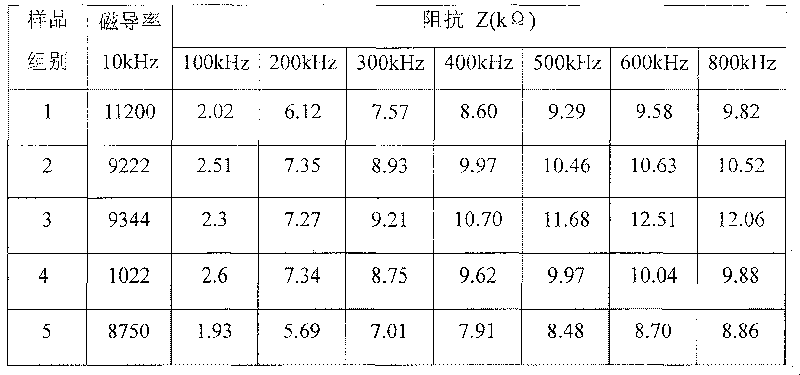

Mn-Zn ferrite magnetic material with high magnetoconductivity and high impedance and method for making the same

ActiveCN101231902AImprove permeabilityHigh impedance characteristicInorganic material magnetismFerrimagnetismMaterials science

The invention relates to a Mn and Zn ferrimagnetism material and a preparation method thereof. The Mn and Zn ferrimagnetism material is made of principal ingredients and subsidiary ingredients. The weight percentages of the principal ingredients which are oxides are calculated as follows: Fe2O3 accounts for 61 percent to 75 percent by weight; ZnO accounts for 12 percent to 30 percent by weight; the rest principal ingredient is Mn3O4. The subsidiary ingredients are one or a plurality of kinds of CaCO3 accounting for 0 to 300ppm by weight; SiO2 accounting for 50ppm to 250ppm by weight; Bi2O3 accounting for 0 to 500ppm by weight. The Mn and Zn ferrimagnetism material has both high magnetic permeability and high impedance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

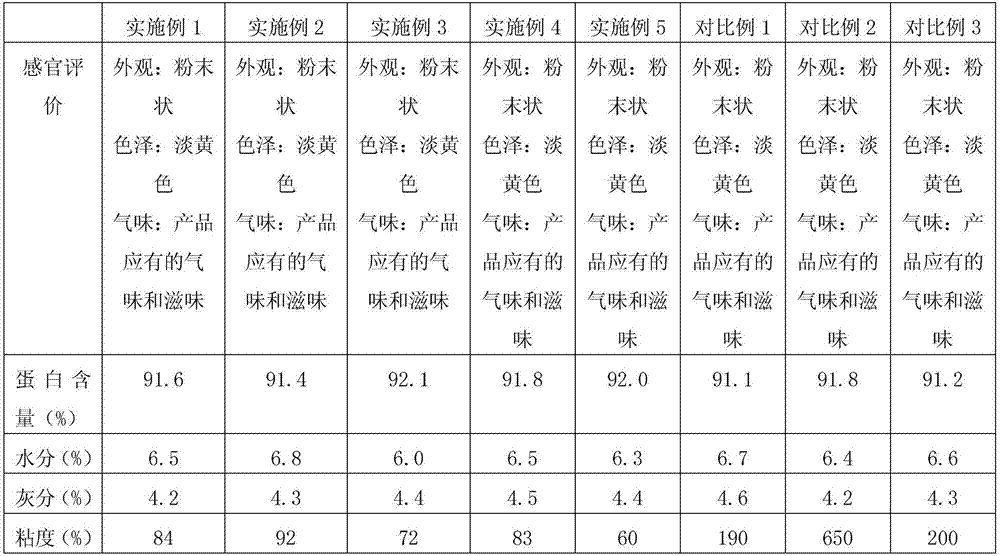

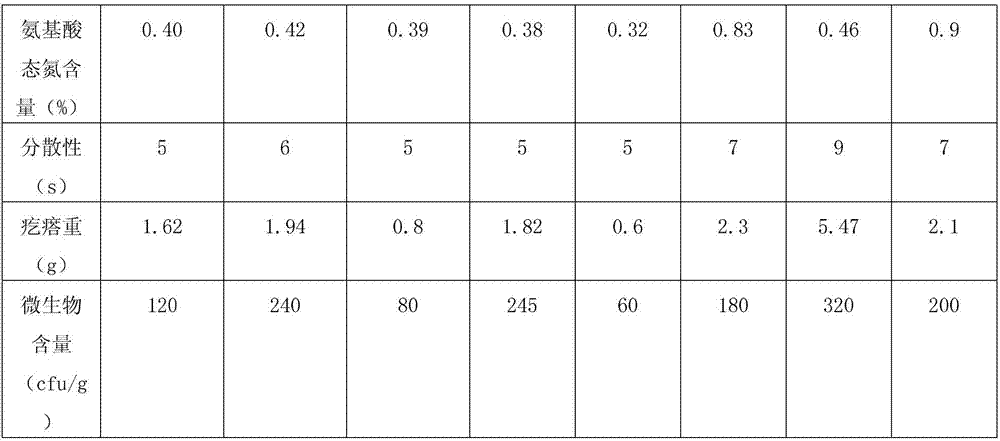

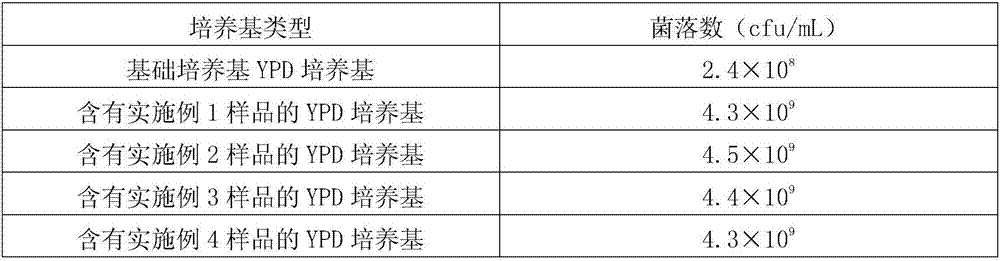

Method for preparing microorganism-dedicated soybean protein isolate

ActiveCN107312813AAppropriate degree of enzymatic hydrolysisAppropriate molecular weightPlant peptidesFermentationAlkaline proteaseNeutral protease

The invention discloses a method for preparing microorganism-dedicated soybean protein isolate. The method comprises the following steps: soaking low-temperature degreased soybean meal in an alkali solution with a pH value of 9.5 to 10.0 at a temperature of 50 to 55 DEG C, adjusting the pH value to 6.8 to 7.4, the sugar content to 8.0 to 9.0, stirring for 40 to 60min, and performing solid-liquid separation to obtain a crude protein extracting solution; adding an acid solution into the crude protein extracting solution at room temperature, stirring for 10 to 50min, and centrifuging to obtain acid-precipitated protein; dissolving the acid-precipitated protein in water at room temperature, adjusting the pH value to 6.00 to 6.30 and the sugar content to 18.0 to 19.5 to obtain an acid-precipitated protein solution; adding neutral protease and alkaline protease, reacting at 50 to 60 DEG C for 0.5 to 3h to obtain enzymatic hydrolysate; performing sterilization, flash treatment and spray drying to obtain the microorganism-dedicated soybean protein isolate. The soybean protein isolate prepared according to the invention has good dispersibility, low viscosity and suitable amino acid nitrogen, and has the advantages of simple process, easy operation, strong protein practicability, wide application in fermentation industry and better popularization value.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

Detection agent for determining content of nickel in water

InactiveCN103278457ALow priceEasy to carryColor/spectral properties measurementsEthylenediaminePolyethylene glycol

The invention relates to a detection agent for determining the content of nickel in water. According to the detection agent, firstly, sodium citrate, potassium hydroxide and ethylenediamine tetraacetic acid disodium are weighed according to the mass ratio of 12: 6: 1, are mixed uniformly and are then ground so as to obtain powder I; then, ammonium citrate, potassium iodide, iodine and dimethyl glyoxime are weighed according to the mass ratio of 16: 2: 1: 1, are mixed uniformly and are then ground so as to obtain powder II; and finally, the powder I, the powder II and polyethylene glycol are weighed according to the mass ratio of 5: 1: 1 and are mixed uniformly, thereby obtaining the detection agent for determining the content of nickel in water. During use, 0.7g of the detection agent is poured into 10ml of a water sample to be determined, shaking is carried out for 1 min so as to dissolve the detection agent, and a colorimeter or spectrophotometer is utilized for measuring. According to the detection agent disclosed by the invention, the carrying is convenient, the storage is easy, any reagent is not required for being added during use, and the determination results are accurate, so that the detection agent is applicable to the on-site detection on the content of nickel in surface water, seawater and industrial wastewater.

Owner:TONGJI UNIV

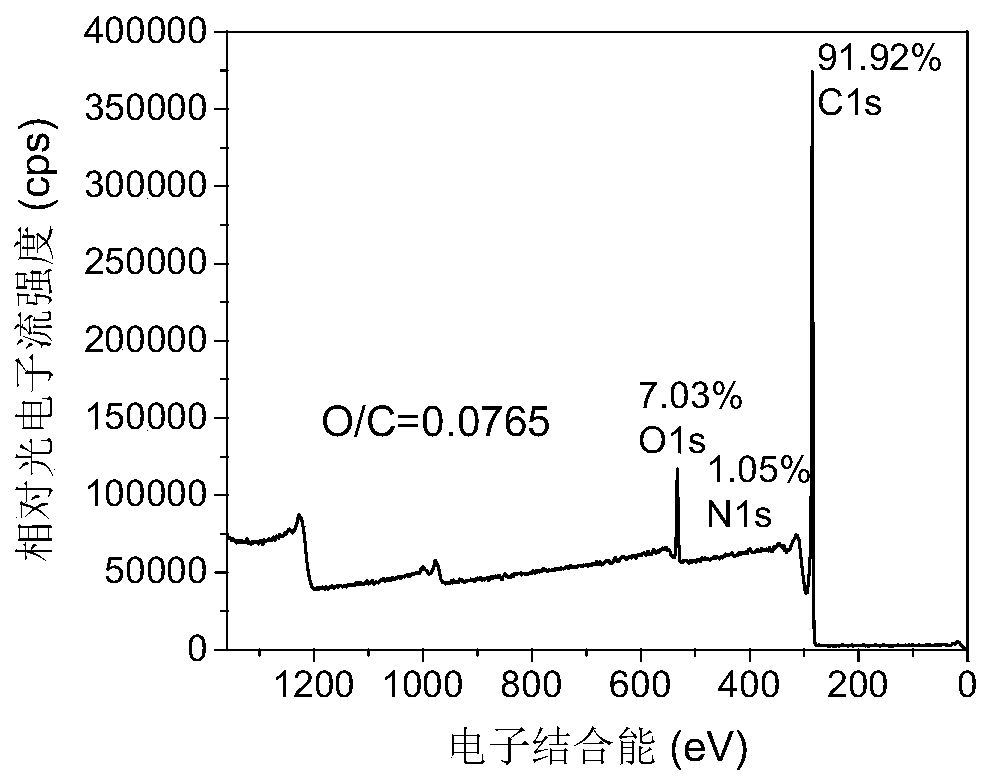

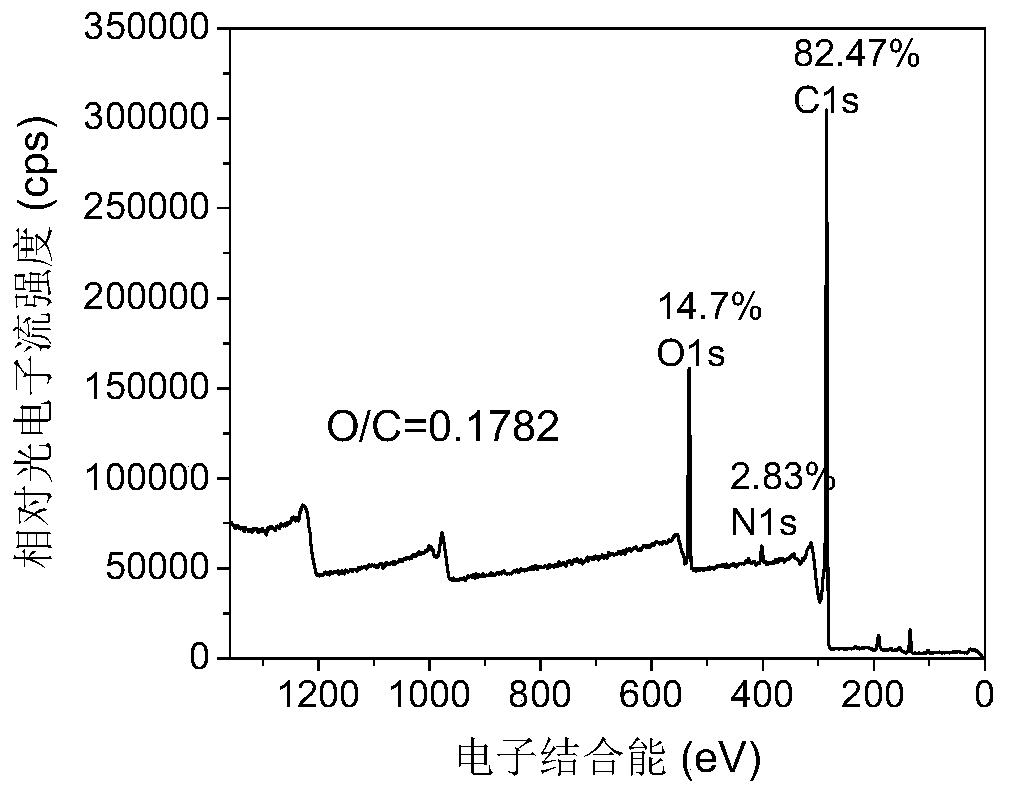

CF/PEEK composite material with chemical bond strong interface and preparation method thereof

The invention relates to a CF / PEEK composite material with a chemical bond strong interface and a preparation method thereof. The method comprises the following steps: (1) carrying out high-temperature decomposition on an original sizing agent on the surface of CF; (2) simultaneously carrying out microwave radiation and ultraviolet irradiation on CF in a saturated water vapor environment, and marking a product as ACF; (3) immersing ACF into the aminated PEEK / dimethylformamide / carbon nanotube suspension, performing heating to enable aminated PEEK to react with ACF, taking out, and drying, so asto obtain sized modified carbon fiber MCF; and (4) laminating and hot-pressing the MCF and the PEEK material, the CF / PEEK composite material with the chemical bond strong interface is obtained. The bending strength of the finally prepared CF / PEEK composite material with the chemical bond strength interface is 900-1100 MPa, the bending modulus of the finally prepared CF / PEEK composite material is57-65 GPa, the interface shear strength of the finally prepared CF / PEEK composite material is 100-120 MPa, and the residual compression strength of the finally prepared CF / PEEK composite material after impact is 210-250 MPa. The method disclosed by the invention has the characteristics of high efficiency, environmental friendliness and capability of realizing large-scale production, and the prepared CF / PEEK composite material can replace metal to be applied to the fields of aerospace, medical treatment, machinery, automobiles, rail transit and the like.

Owner:DONGHUA UNIV

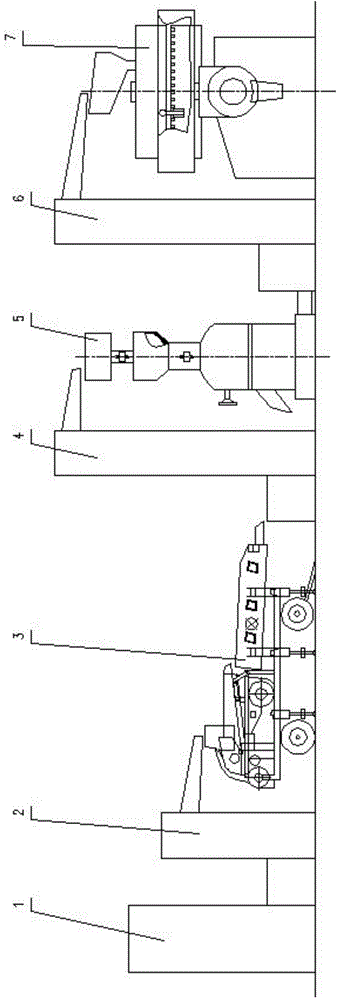

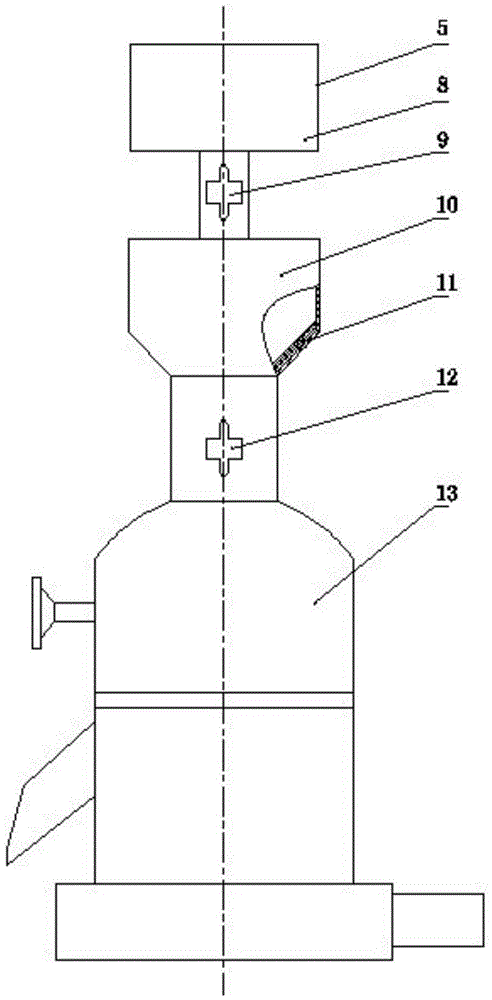

Flour production system

ActiveCN104689878AUniform qualityAchieve high integrationCocoaGrain treatmentsQuality levelMillstone

The invention relates to a flour production system. The flour production system comprises a grain storing silo, a first section material lifting machine, a wheat sorting screening machine, a second section material lifting machine, a wheat peeling device, a third section material lifting machine and a millstone flour mill, which are arranged in sequence. A discharging end of the grain storing silo is connected with an input end of the first section material lifting machine, an output end of the first section material lifting machine is connected with an input end of the wheat sorting screening machine, an output end of the wheat sorting screening machine is connected with an input end of the second section material lifting machine, an output end of the second section material lifting machine is connected with an input end of the wheat peeling device, an output end of the wheat peeling device is connected with an input end of the third section material lifting machine, and an output end of the third section material lifting machine is connected with an input end of the millstone flour mill. The flour production system is simple in structure and scientific and reasonable in design. According to the flour production system, the flour production process and the processing process are integrated together, the high integration of flour production is achieved, the time and the labor are saved, plenty of manpower and material power are saved, the working efficiency is improved, and the product quality level is improved.

Owner:LIXIN DONGHUA FLOUR

Fancy carp feed

The invention discloses fancy carp feed, which is prepared from blood worm meal, chicken meal, duck meal, loach meal, chicken intestine meal, fish gut meal, corn protein powder, strawberry protein powder, bone meal, liquoric root powder, eucommia bark powder, lucid ganoderma powder, pinellia tuber powder, Chinese angelica powder, Chicken's gizzard-membrane powder, bulked powder and sweet potato powder. All kinds of powder are combined in a proportion, the mixture is fed into a mixer to be mixed for 200 minutes, the mixture is taken out and fed into a grinder to be ground into 40 mesh powder, the powder is taken out and fed into a dryer, the dryness of the dried material is controlled to be 85 to 90 percent, the powder is taken out, cooled and fed into the mixer again to be mixed for 160 minutes, the powder is taken out and fed into a bulking machine to be bulked, the temperature of the bulking machine is controlled to be 70 to 80 DEG C, the bulking time is 1 to 2 hours, the dryness of the bulked material is controlled to be 85 to 90 percent, and the bulked material is taken out, cooled and packaged by specific weight.

Owner:丁全畦

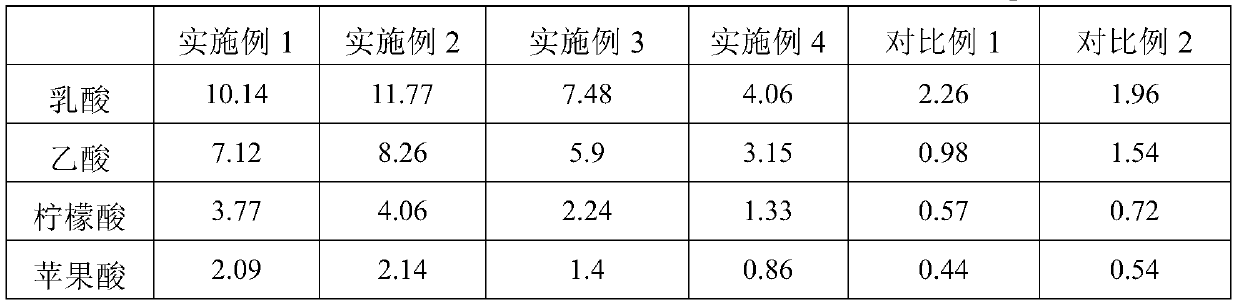

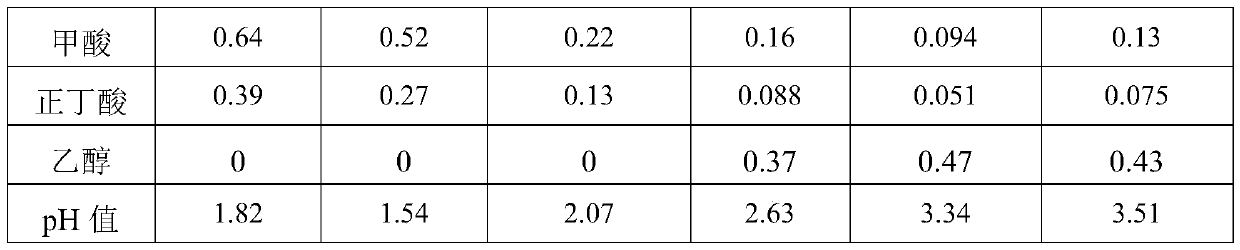

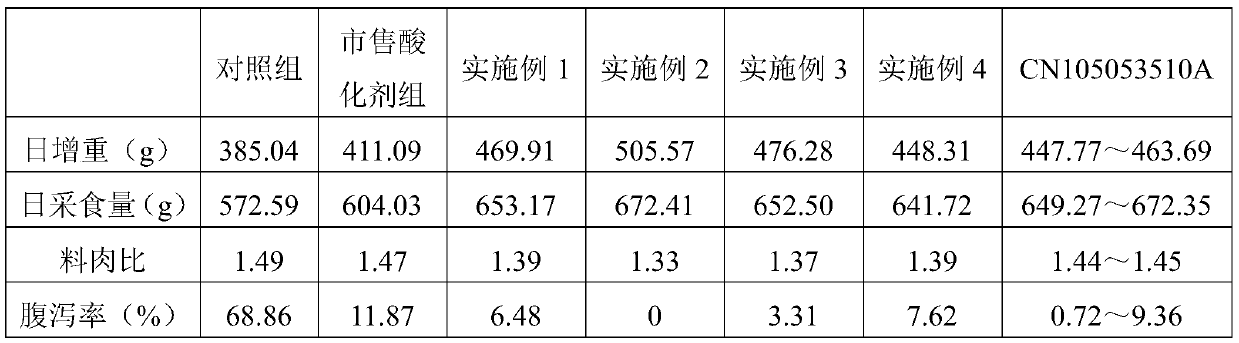

Acidifying agent as well as compound bacterium one-step fermentation preparation method and application thereof

InactiveCN109805175AAvoid mechanical stirringReduce energy consumptionFood processingAnimal feeding stuffBiotechnologyEthylic acid

The invention provides an acidifying agent as well as a compound bacterium one-step fermentation preparation method and application thereof. According to the compound bacterium one-step fermentation preparation method, fruit and vegetable wastes are used as fermentation raw materials and are subjected to one-step-method surface layer air-blowing fermentation through compound bacteria of saccharomycetes, lactic acid bacterium and acetobacter aceti to prepare the acidifying agent. According to the method provided by the invention, nutrient components in the fermentation raw material can be efficiently utilized, types and content of organic acids in a fermentation solution are effectively improved, the fermentation time is shortened, the pH (Potential of Hydrogen) value is reduced, a fermentation technology is simple and the cost is low. The acidifying agent prepared by the method has the advantages that the types of the organic acid are more and the content is moderate, the pH value is lower and the content of alcohol is relatively low; the acidifying agent can be directly used as a feed additive or is subjected to dreg removal and concentration to be used as the feed additive, and is mixed with feed to feed animals; the acidifying agent has good palatability and a high digestion rate; the feed intake and the daily weight gain of the animals are easy to improve and the diarrhea rate is reduced; the acidifying agent has a good application prospect.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

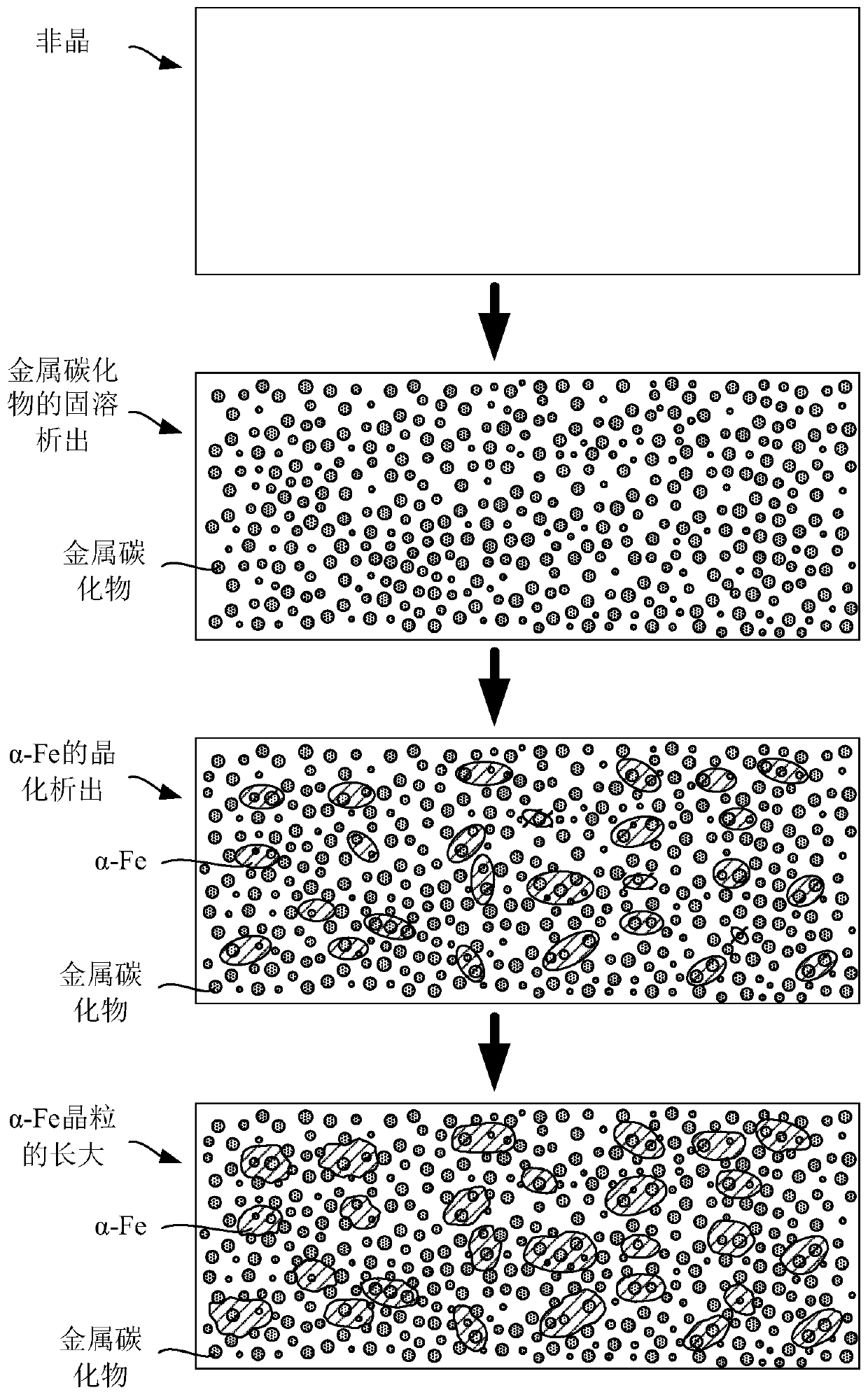

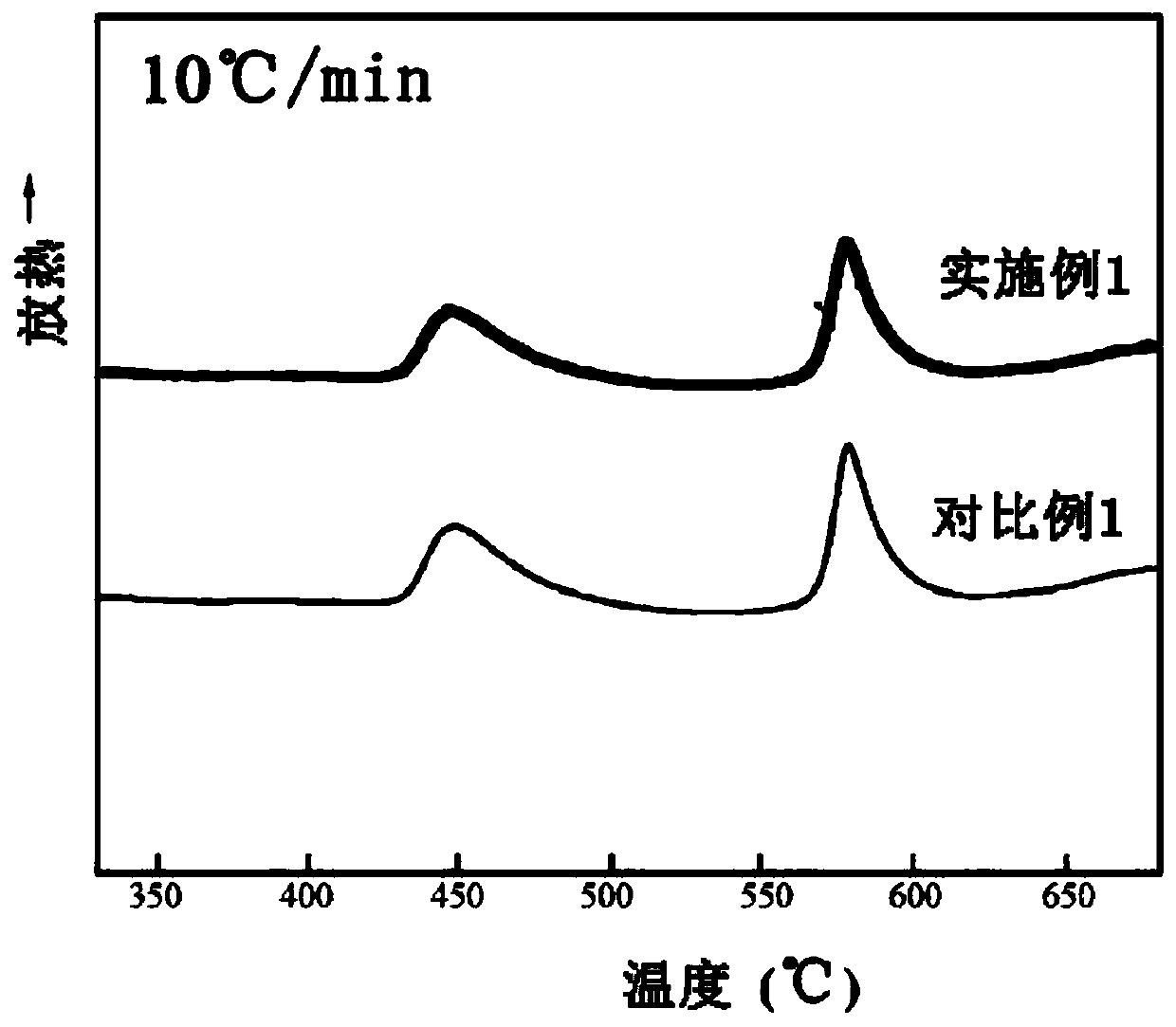

Amorphous-nanocrystalline soft magnetic material, preparation method and application thereof, amorphous strip, amorphous-nanocrystalline strip and amorphous-nanocrystalline magnetic sheet

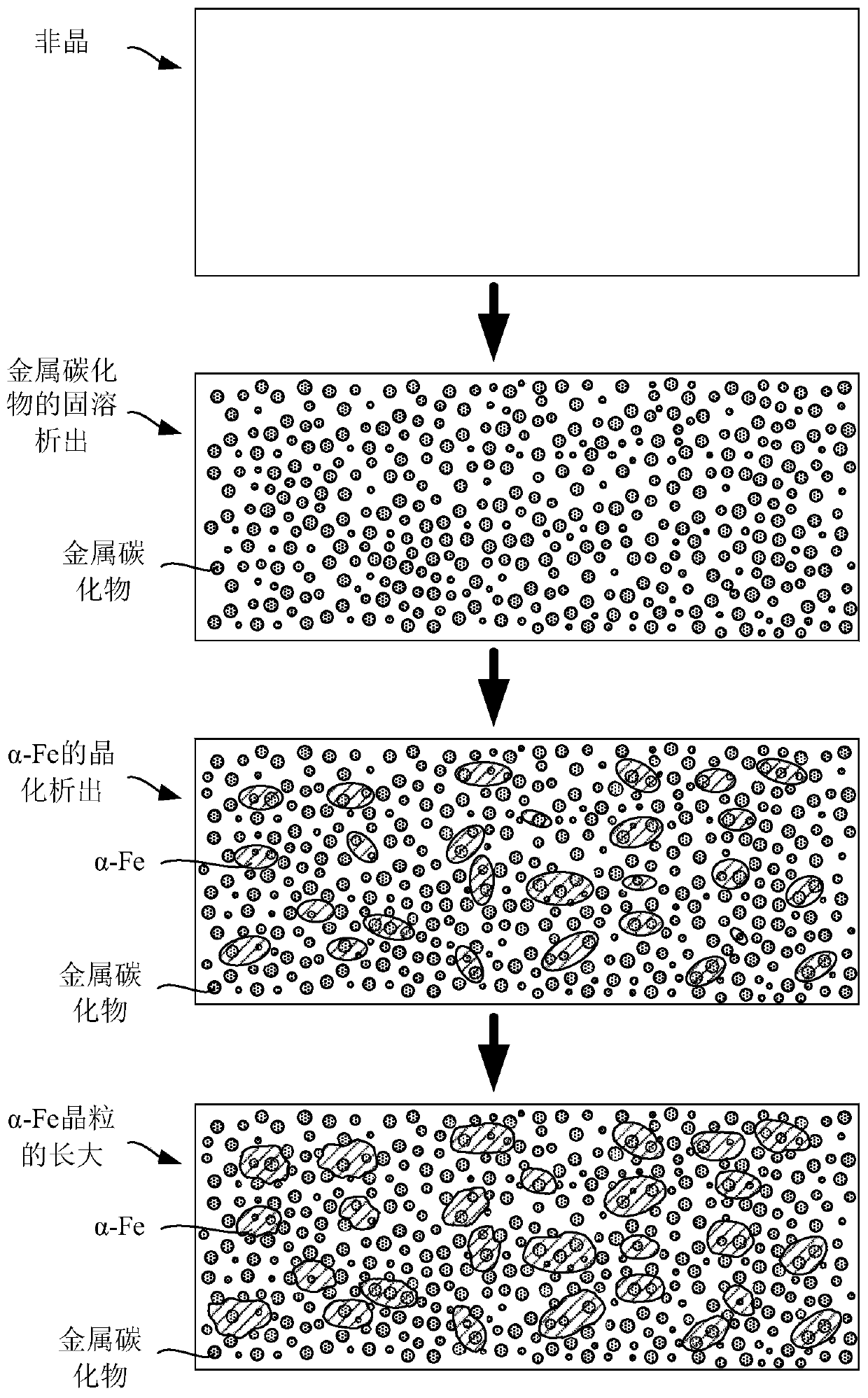

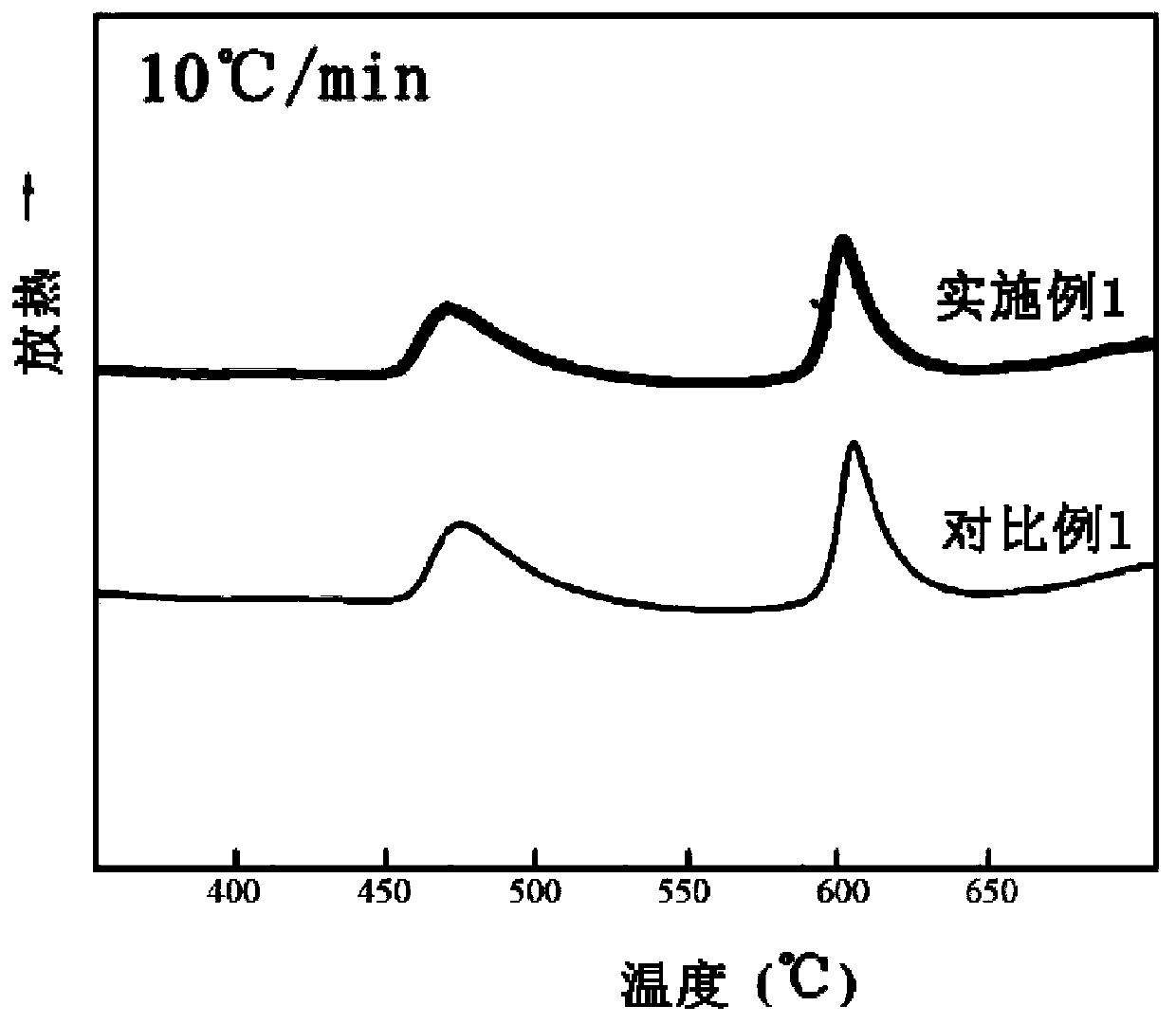

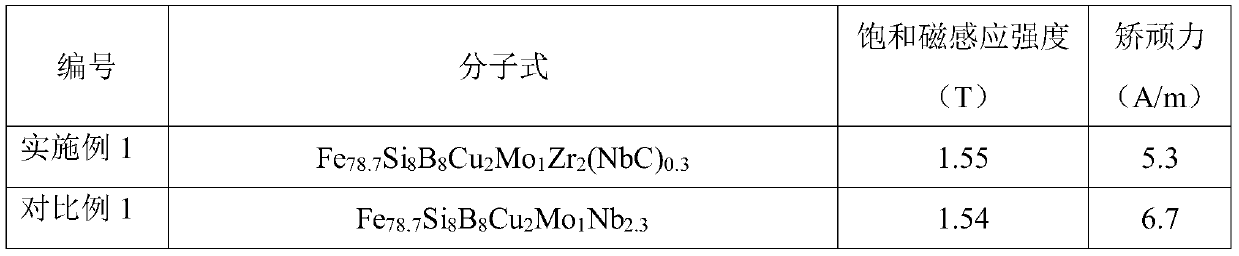

ActiveCN110284082AImproved Amorphous Formation AbilityBalance strengthInductances/transformers/magnets manufactureMagnetic materialsCarbideNanocrystalline silicon

The invention provides an amorphous-nanocrystalline soft magnetic material, a preparation method and application thereof, an amorphous strip, an amorphous-nanocrystalline strip and an amorphous-nanocrystalline magnetic sheet. The soft magnetic material comprises an amorphous matrix phase, a nanocrystalline phase distributed in the amorphous matrix phase, and fine crystalline particle distributed in the amorphous matrix phase and the nanocrystalline phase, wherein the amorphous matrix phase comprises Fe, Si and B, the fine crystalline particle comprise metal carbide, and the soft magnetic material comprises Fe, Si, B, X and Cu, wherein X is Nb and / or V. the preparation method comprises the following steps of, 1), preparing the raw materials in the formula amount, and then preparing an amorphous alloy; and 2) carrying out two-stage crystallization on the amorphous alloy under a protective condition, and cooling the amorphous alloy to obtain the soft magnetic material. The soft magnetic material solves the technical problems that the saturation magnetic induction intensity is relatively low and the cost is relatively high in a Fe-Si-B-Nb-Cu alloy system in the prior art.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

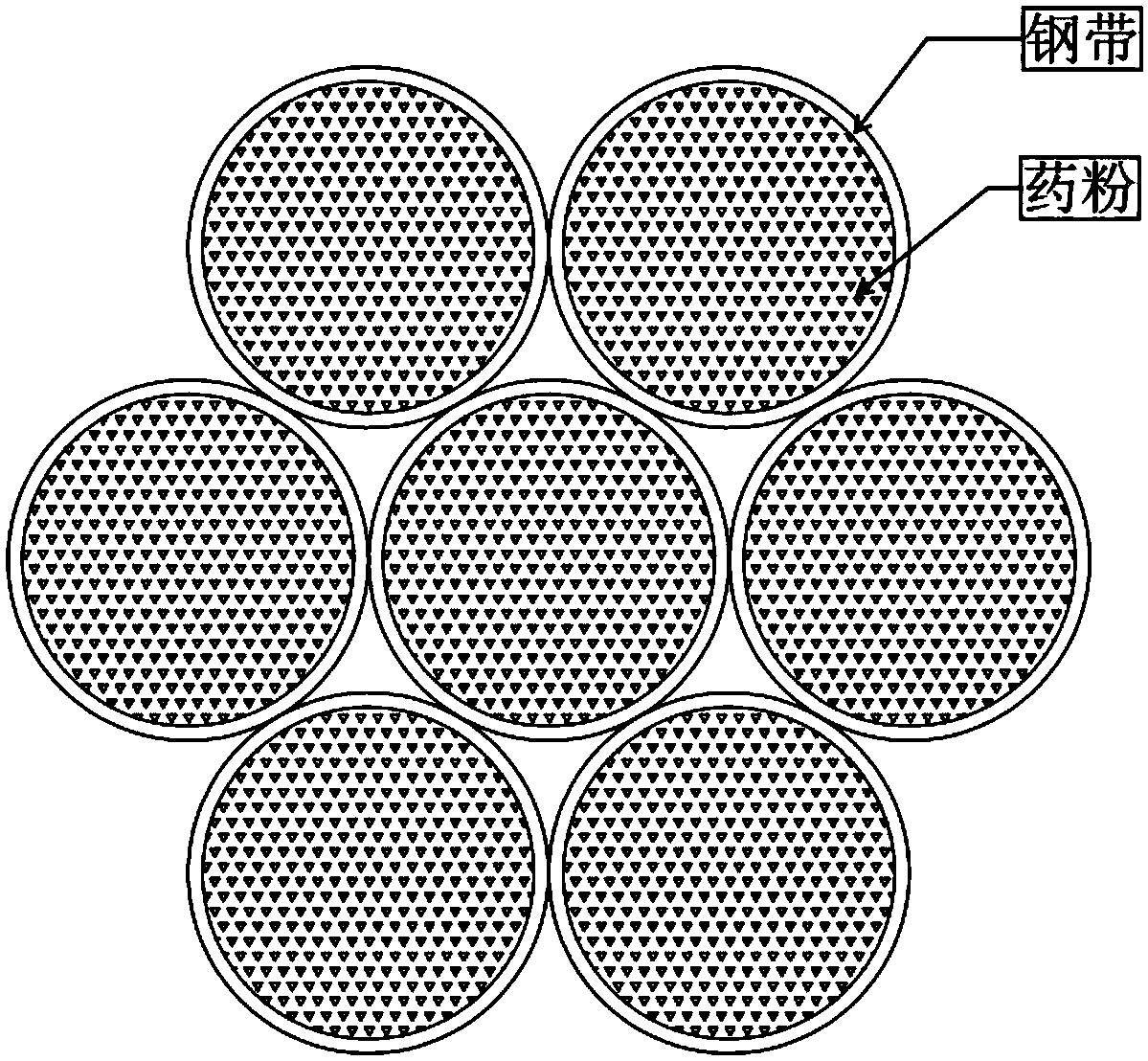

Twisted-type submerged-arc flux-cored wire with high efficiency and crack resistance and preparation method thereof

InactiveCN109623200AGood composition uniformityUnusually smallWelding/cutting media/materialsSoldering mediaTungstenVoltage

The invention discloses a twisted-type submerged-arc flux-cored wire with high efficiency and crack resistance and a preparation method thereof. The twisted-type submerged-arc flux-cored wire is formed by spirally twisting at least seven steel strips coated with flux-cored powder, wherein the flux-cored powder comprises the following components of, in percentage by mass, 0.08%-0.18% of carbon, 1.0%-2.0% of manganese, 0.3%-1.2% of silicon, less than or equal to 0.03% of phosphorus, less than or equal to 0.03% of sulfur, 5.0%-6.2% of chromium, 0.7%-1.5% of tungsten, 0.8%-1.6% of molybdenum, 0.1%-0.7% of vanadium, 0.02%-0.05% of niobium and the balance iron and inevitable impurity elements. The twisted-type submerged-arc flux-cored wire is formed by spirally twisting a plurality of thin flux-core monofilaments, can be made into thicker welding wires with good coiling performance and is convenient to transport, storage and welding, the current and the voltage required by welding is relatively small, a larger welding speed is achieved under the condition of the same welding standard, the hardness of the prepared surfacing layer is medium, the crack sensitivity is low, and the crack resistance is excellent.

Owner:江苏联捷焊业科技有限公司

A preparation method of mullet feed

InactiveCN102258131ARich in proteinModerate proportionClimate change adaptationAnimal feeding stuffDiseaseAdditive ingredient

A preparation method of mullet feed, which is composed of: pig liver powder, sorghum protein powder, bitter melon powder, corn gluten powder, pine needle powder, bloodworm powder, green shrimp powder, apple powder, milk powder, asparagus powder, loofah powder Composition, the stated percentages are percentages by weight; the ingredients are cheap, the feeding effect is good, the fish has good palatability, easy absorption, fast growth speed, strong disease resistance, and the raised fish are generally fat and delicious, effectively overcoming Due to insufficient content of various nutrients in the existing feed ingredients, it is easy to cause the defects of slow growth and development of mullet, small size, light weight, low activity, poor palatability, and susceptibility to various infectious diseases.

Owner:丁大奎

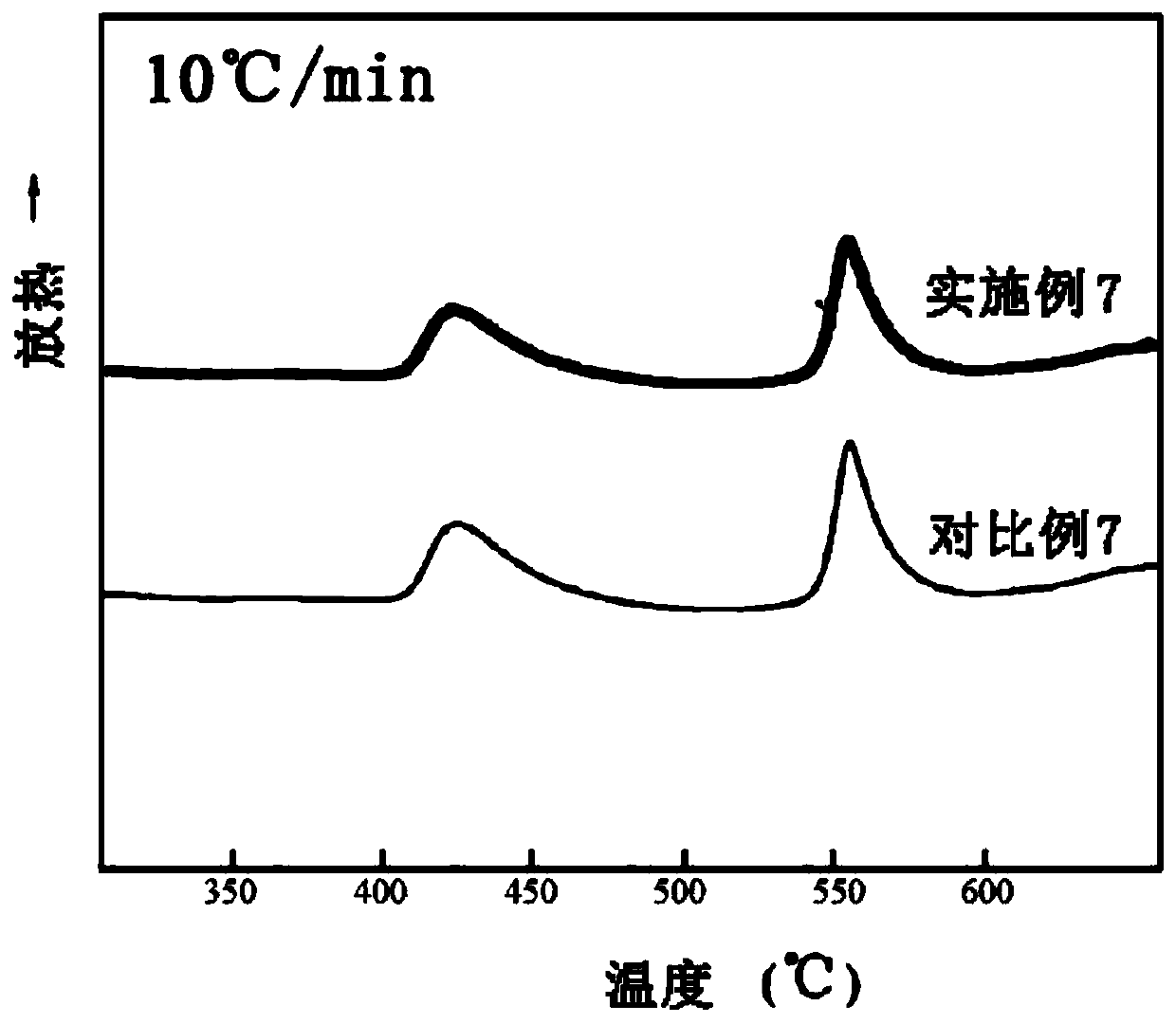

Amorphous-nanocrystalline soft magnetic material and preparation method and application thereof, amorphous strip, amorphous-nanocrystalline strip and amorphous-nanocrystalline magnetic sheet

ActiveCN110257735AImproved Amorphous Formation AbilityBalance strengthTransformers/inductances detailsFurnace typesNanocrystalline siliconCarbide

The invention provides an amorphous-nanocrystalline soft magnetic material and a preparation method and application thereof, an amorphous strip, an amorphous-nanocrystalline strip and an amorphous-nanocrystalline magnetic sheet. The soft magnetic material comprises an amorphous substrate phase, nanocrystalline phases which are distributed in the amorphous substrate phase, and fine-grain particles which are distributed in the amorphous substrate phase and the nanocrystalline phases, wherein the amorphous substrate phase comprises Fe, Si and B; the fine-grain particles include metal carbide; and the soft magnetic material comprises Fe, Si, B, P and Cu. The preparation method comprises the following steps: 1) preparing the raw materials based on the dosage in a formula to obtain an amorphous alloy; and 2) performing two-stage crystallizing on the amorphous alloy under the protective condition; and cooling to obtain the soft magnetic material; and the crystallizing temperature in the second stage is beyond the crystallizing temperature in the first stage. According to the amorphous-nanocrystalline soft magnetic material and the preparation method thereof, the problems of high coercivity of a Fe-Si-B-P-Cu alloy system in the prior art and high technology difficulty can be solved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

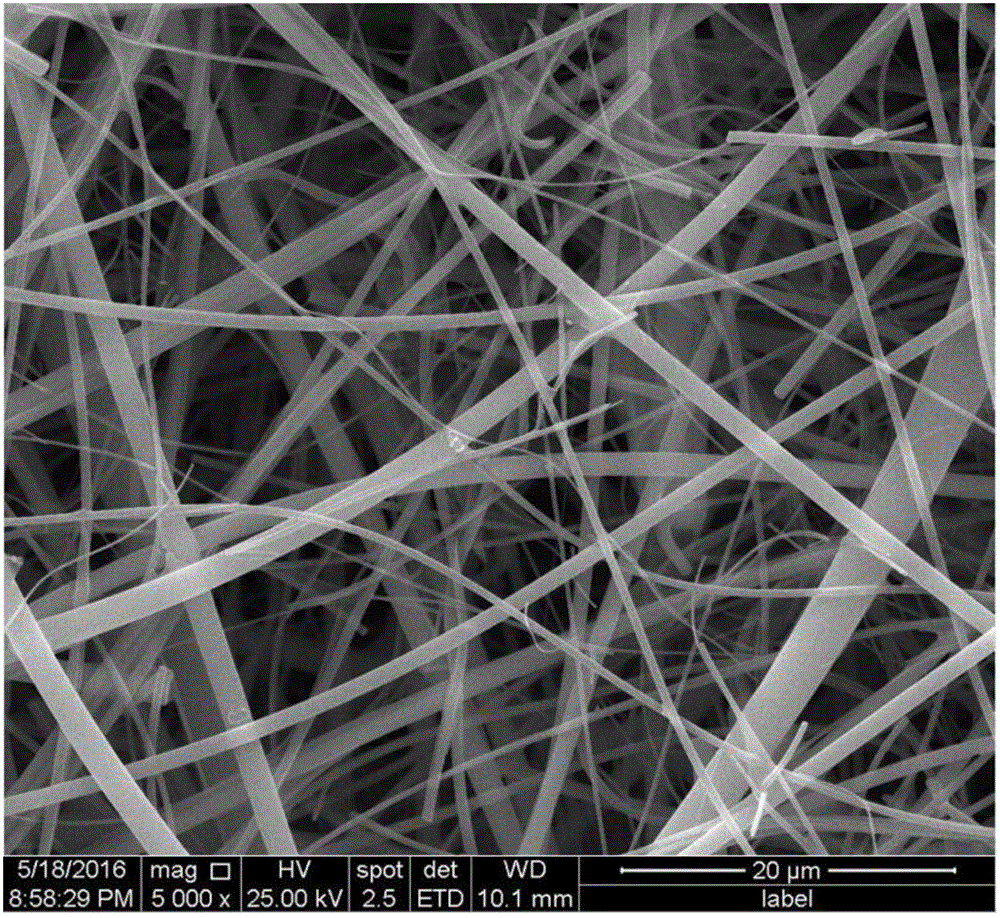

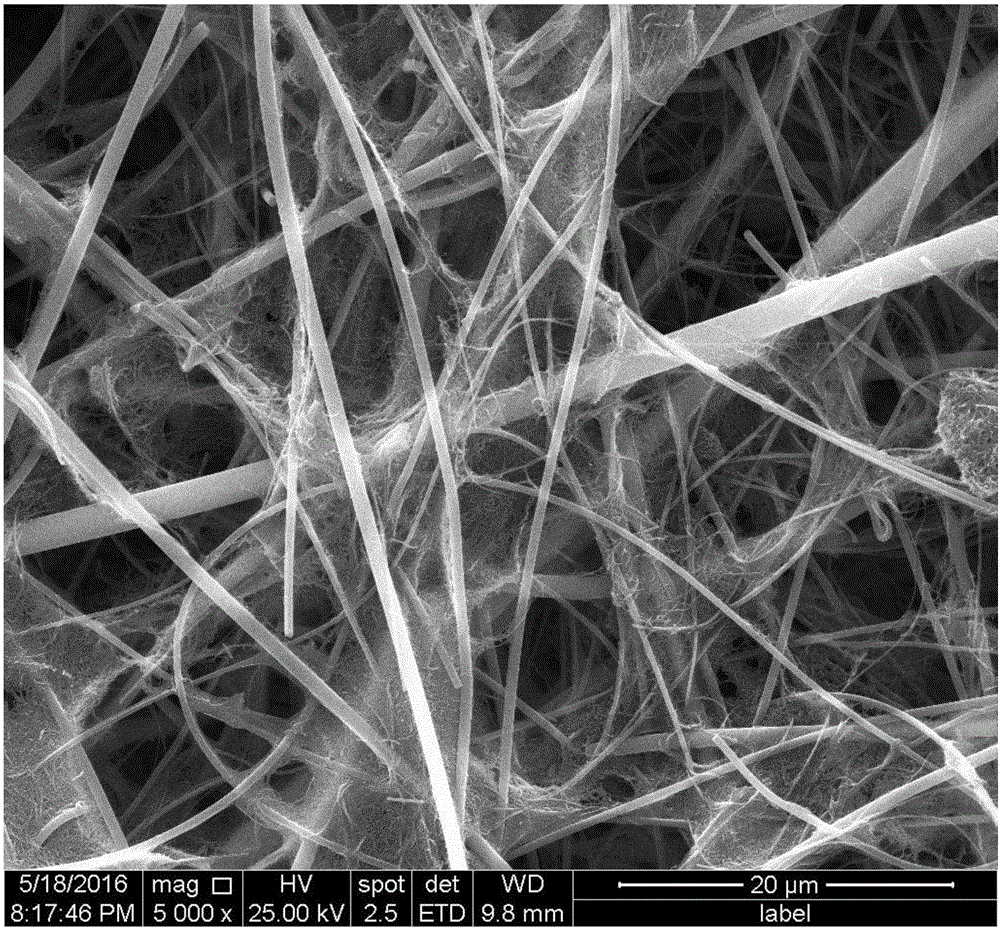

Glass-fiber air filter paper containing carbon nanometer materials and preparing method thereof

ActiveCN105862516AFully contactedSolve the problem of falling powderPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperGlass fiberAir filter

The invention relates to glass-fiber air filter paper containing carbon nanometer materials and a preparing method thereof. The preparing method includes the following steps that 1, the carbon nanometer materials are added into an anion-dispersing-agent water solution, the mixture is subjected to ultrasonic dispersion, and carbon-nanometer-material dispersion liquid is prepared; 2, glass fiber materials are added into water, acid is added, the pH value is adjusted to 2.5 to 3.5, then the mixture is dispersed, then a stabilizer water solution is added, and glass-fiber-material dispersion liquid is prepared; 3, the carbon-nanometer-material dispersion liquid and the glass-fiber-material dispersion liquid are mixed to be even and fed to a forming device to be sucked, then forming wet paper is obtained, sizing and drying are carried out, and the glass-fiber air filter paper is obtained. The glass-fiber air filter paper containing the carbon nanometer materials prepared with the method is of a functional double-layer structure, and is applied to the field of air filter paper, air resistance is small, filter efficiency is high, powder falling is avoided, and the excellent antimicrobial performance is achieved.

Owner:KUNMING NATAI TECH CO LTD

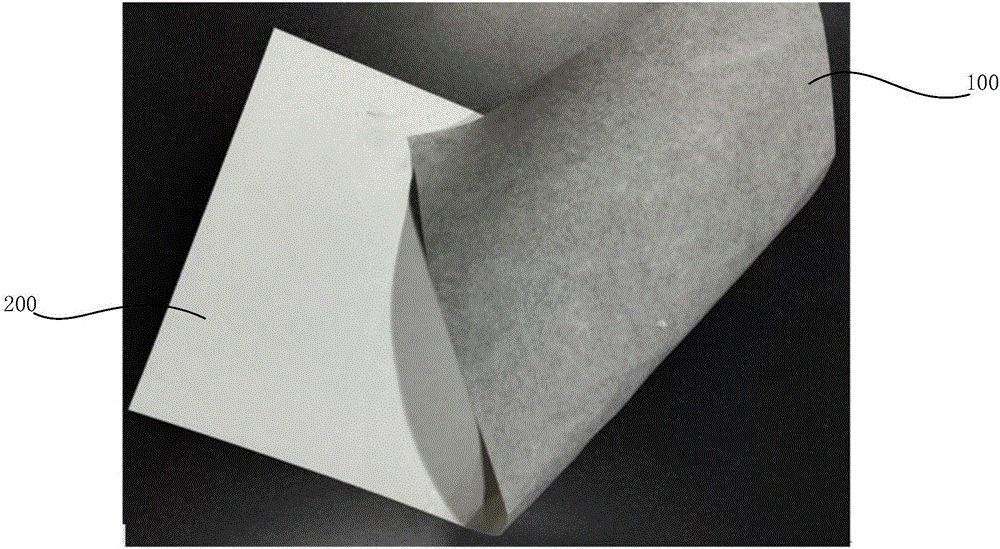

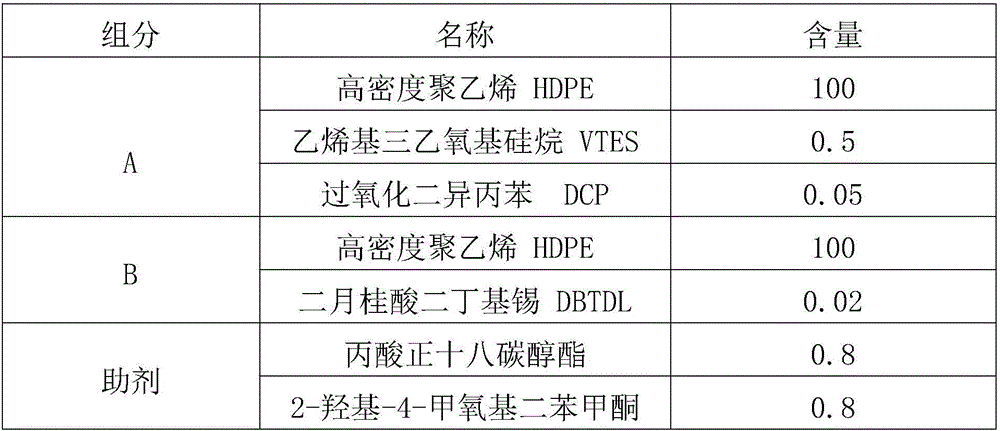

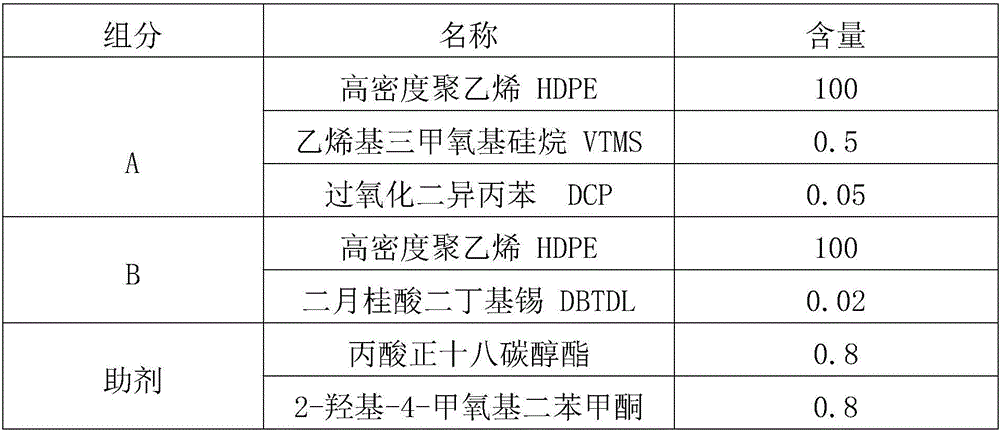

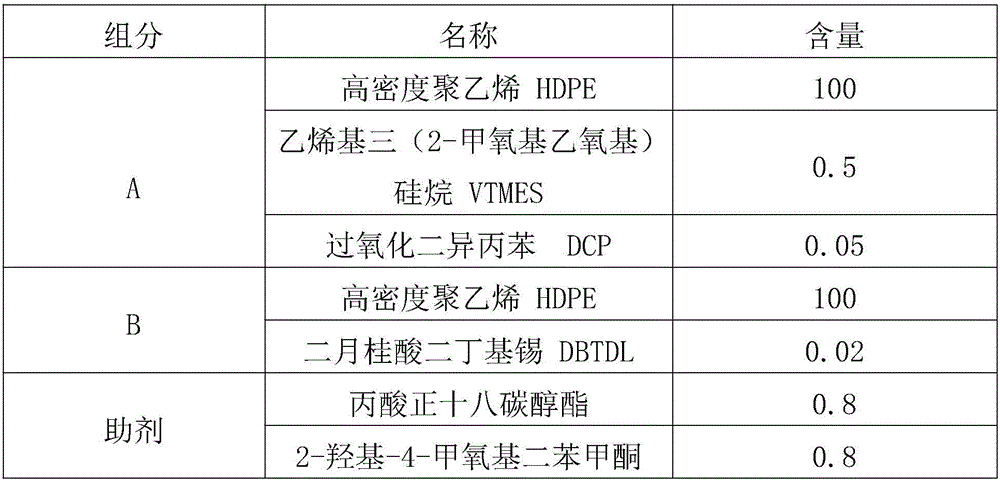

High-strength polyethylene tube for communication and preparation method thereof

The invention discloses a high-strength polyethylene tube for communication, wherein a component A comprises 100 parts of high-density polyethylene, 0.5-3.0 parts of silane and 0.05-0.15 part of dicumyl peroxide; a component B comprises 100 parts of high-density polyethylene and 0.02-1 part of dibutyltin dilaurate; and an additive component C comprises 0.5-1.5 parts of antioxidant and 0.6-0.8 part of benzophenone ultraviolet absorbent. The formula of the polyethylene tube for communication is improved by a mode of silane cross-linked with polyethylene, the strength of the tube is improved, and the tube has the advantages of rigid texture, better toughness and better environmental resistance.

Owner:WUJIANG JIATONG OPTICAL FIBER CO LTD

Cellulose powder for cold-light spraying fireworks and preparation method thereof

InactiveCN109320387AImprove drug stabilityActs as an oxidizing agentExplosive working-up apparatusNitrocelluloseNitrogen

The invention discloses cellulose powder for cold-light spraying fireworks. The cellulose powder is prepared from the following components in parts by weight: 85 to 90 parts of nitrocellulose, 2 to 3parts of diphenylamine, 3 to 8 parts of calcium nitrate and 3 to 4 parts of graphite, wherein the nitrogen content of the nitrocellulose is less than or equal to 12.5 percent and the water content is23 to 27 percent. Smokeless propellant powder disclosed by the invention has better explosive stability, moisture resistance and environment friendliness and is suitable for various cold-light fireworks to use.

Owner:彭隆章

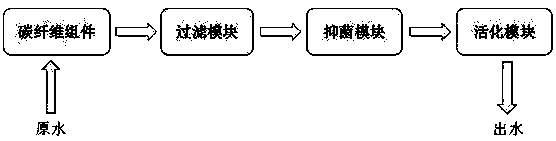

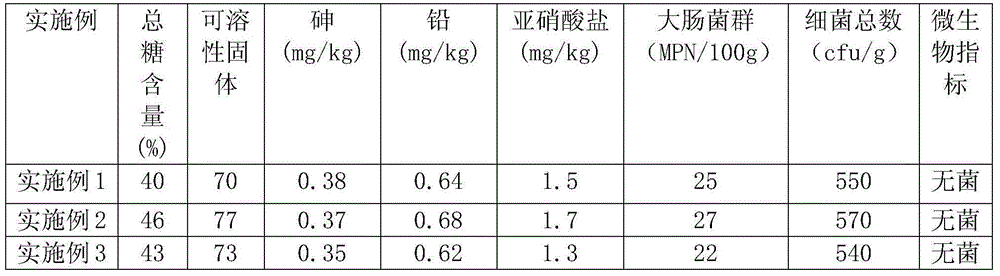

Drinking water treatment technology adopting carbon fibers

InactiveCN109748445AReduce processing costsLess investmentWater contaminantsMultistage water/sewage treatmentFiberCarbon fibers

The invention relates to the technical field of drinking water purification and particularly relates to a drinking water treatment technology adopting carbon fibers. According to the drinking water treatment technology, the problems of turbid water quality, abnormal water odor and off-odor can be effectively solved, and inorganic substances such as iron, manganese and the like in water are effectively purified; in addition, organic compounds and bacteria such as cyanogen, chlorine, fluorine, phenol and the like in a water body can be removed and the existing drinking water safety problems canbe effectively solved. The drinking water treatment technology comprises the following steps: firstly, adsorption treatment: effectively adsorbing and removing macromolecular substances in water by utilizing relatively large empty area and specific surface area of the carbon fibers; secondly, filtration treatment: carrying out further treatment on pollutants in the water body through the adsorption of ores in a filtration module; thirdly, bacteriostatic treatment: killing microorganisms in the water body and inhibiting regeneration of the microorganisms; fourthly, activation treatment: carrying out activation treatment on the water quality through the action of a gradient magnetic field.

Owner:北京太和洁源科技发展有限公司

Preparation method of feed for goldfishes

The invention relates to a preparation method of feed for goldfishes. The feed is prepared by the following raw materials in percentage by weight: 8-10 egg powder, 2-6 pork liver powder, 3-9 swine blood meal, 10-17 nymph meal, 10-12 spinach powder, 15-25 soybean cake powder, 12-15 fresh shrimp meal, 6-8 milk powder, 1-3 balloonflower root, 1-3 Sichuan fritillary bulb, 1-3 chickens gizzard-membrane, 1-3 auckandia root, 1-3 honeysuckle flower, 1-3 kuhseng and 2-6 expanded powder; and the powders are all combined together in proportion and put in an agitator to be stirred for 180 min, the mixture is put in a crusher to be crushed into 0 mesh of powder after being taken out, then the powder is put in a drier after being taken out, the dryness of the dried powder is controlled between 90 percent and 95 percent, the dried powder is taken out, cooled and then put in the agitator to be stirred for 180 min, the mixed powder is put in a bulking machine after being taken out for bulking at the temperature of 80-85 DEG C for 2-3h, the dryness of the bulked mixed powder is controlled between 90 percent and 95 percent and the bulked mixed powder can be packaged according to specific gravity after being taken out to cool.

Owner:朱希胜

Watermelon jam and making method thereof

The invention relates to the field of food jam processing, in particular to watermelon jam and a making method thereof. The watermelon jam comprises, by weight, 250-350 parts of watermelon peel, 100-200 parts of watermelon pulp, 60-100 parts of soybean, 20-50 parts of sesame, 20-50 parts of cannabis sativa, 10-25 parts of pepper, 25-50 parts of vegetable oil, 2-8 parts of salt, 5-15 parts of fresh smashed ginger, 5-15 parts of smashed garlic, 5-15 parts of brown sugar, 0.5-4 parts of citric acid and 100-200 parts of water. The making method of the watermelon jam comprises the following steps that 1, raw materials are obtained in a weighed mode according to weight; 2, the soybean, the sesame and the cannabis sativa are pre-treated; 3, the watermelon raw materials are pre-treated; 4, slurry is decocted; 5, the watermelon jam is made through mixing; 6, canning, sterilizing and packaging are conducted. The watermelon jam is simple in technology, rich in nutrient and free of preservative, pigment, essence and additive, and the utilization rate of watermelons is increased.

Owner:邹健

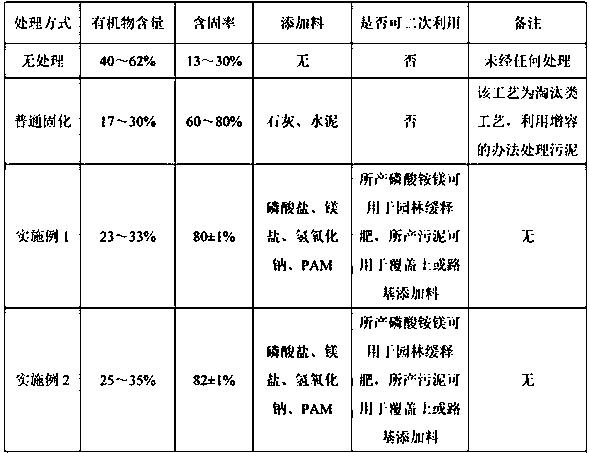

Sludge treatment method

ActiveCN110902981ARealize resourcesAchieve stabilizationWater treatment parameter controlSludge treatment by de-watering/drying/thickeningAmmoniacal nitrogenMagnesium salt

The invention discloses a sludge treatment method, which comprises the following steps: (1) preheating and diluting raw material sludge, and carrying out hydrothermal treatment; (2) carrying out heatexchange on the mud-water mixture subjected to hydrothermal treatment; (3) carrying out solid-liquid separation on the sludge-water mixture subjected to heat exchange to obtain sewage and thickened sludge, and carrying out low-temperature drying on the thickened sludge to obtain dried sludge and condensate; (4) carrying out anaerobic digestion on the sewage, filtering, and carrying out first quality conditioning; (5) evaporating and concentrating the sewage to obtain a sewage concentrated solution and ammonia nitrogen water obtained by condensation; and (6) performing second quality conditioning on the obtained ammonia nitrogen water by adopting phosphate and a magnesium salt, and performing solid-liquid separation to obtain a magnesium ammonium phosphate solid and filtrate. The method islow in comprehensive energy consumption, low in cost, easy in process implementation, short in treatment time, good in harmless effect, high in resource recovery rate, high in stability and high in energy utilization rate.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

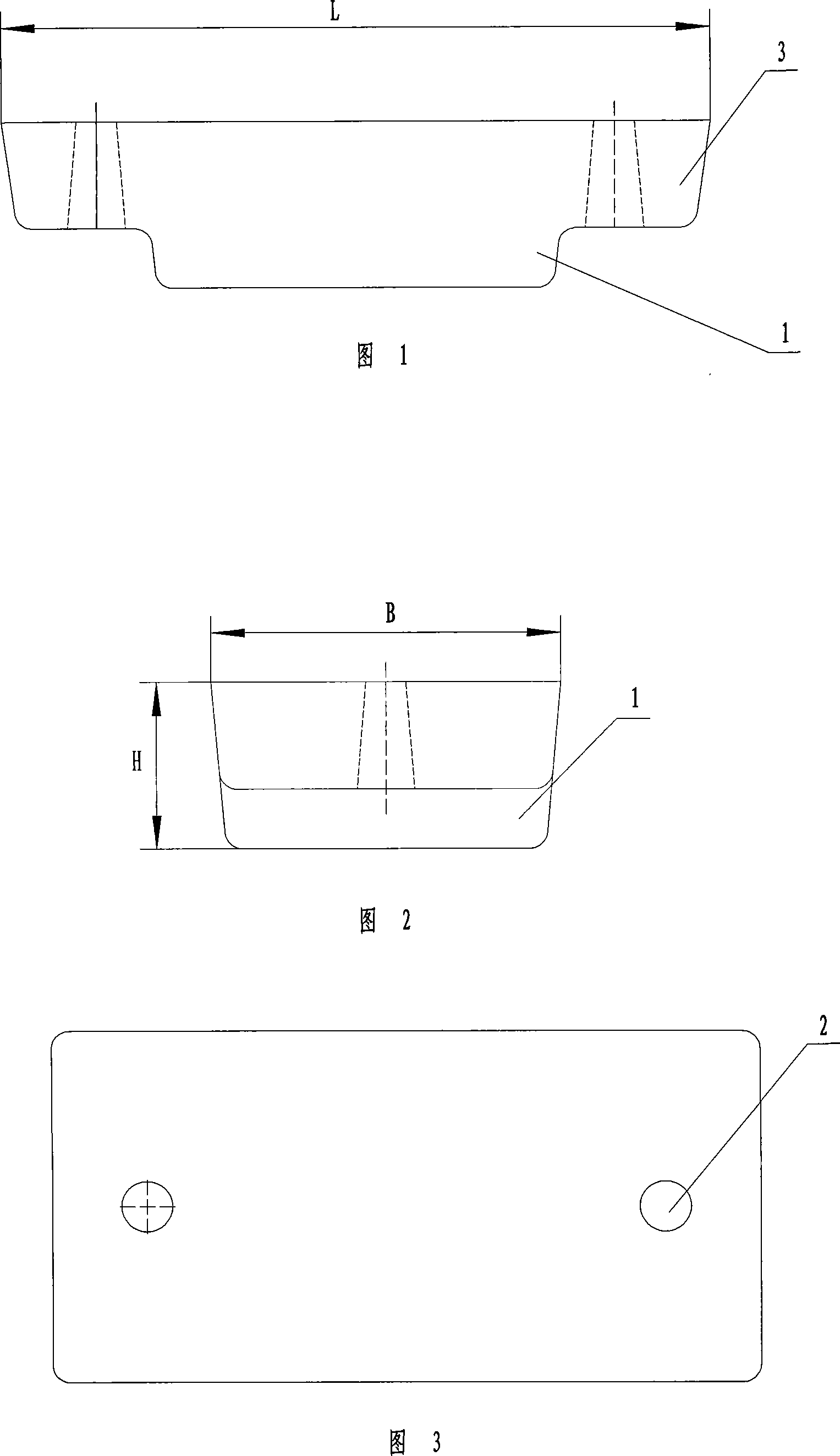

Hot dipping zinc aluminum nickel bismuth rare earth alloy used for steel component hot dipping zinc and ingot case and method thereof

ActiveCN101109053AAvoid uneven compositionImprove corrosion resistanceHot-dipping/immersion processesRare earthZinc alloys

The invention relates to a zinc alloy used by steel structural component in zinc hot dip plating and the ingot shape and the method thereof. The alloy component and the weight per cent are of 0.008 per cent (wt) to 0.012 per cent (wt) Al, 0.04 per cent (wt) to 0.06 per cent (wt) Ni, 0.02 per cent (wt) to 0.08 per cent (wt) Bi, 0.006 per cent (wt) to 0.01 per cent (wt) RE, and zinc and impurity as the rest composition. The ingot shape is of T-shaped cuboid with two symmetrical ear curls; wherein, the bottom of the cuboid is a plane; the ear curls are provided with hoisting holes; the cuboid is of four included side planes, taking in a big top and small bottom shape. The zinc hot dip plating method is to melt the alloy directly into zinc bath; the application is simple; the zinc bath alloy elements Al, Bi, Ni and RE with stable and uniform content can alleviate or eliminate the Sandelin Effect generated by an active steel galvanization, perfect the wetting behavior and flow property of the iron matrix and the zinc bath, improve corrosion resistance performance and mechanical performance of the coating, reduce the thickness of the coating and lower the cost. With the appropriate shape as well as ingot weight, the zinc alloy ingot shape has the advantages of able to meet zinc adding requirement of the large capacity galvanization equipment, convenient hoisting and fork transport, small specific surface area, suitable for storage and multiple layers stacking tier, saving storing room, and stability as well as safety.

Owner:ZHUZHOU SMELTER GRP

Bramble gallogen chewable tablet and processing method thereof

InactiveCN103190612AUnique formulaNutritional balanceFood shapingFood preparationNutrientSodium erythorbate

The invention discloses a bramble gallogen chewing tablet and a processing method thereof. The bramble gallogen chewing tablet comprises 70-75% of bramble fiber powder; 2-5% of glucose powder; 0.1-0.3% of barley malt powder; 0.1-0.5% of pumpkin powder; 0.5-2% of soybean lecithin; 5-10% of xylitol; 1-4% of r bramble gallogen; 2.1-3.1% of high fructose corn syrup; 0.1-0.3% of citric acid; 0.1-0.3% of sodium hydroxymethyl starch; 0.1-0.3% of sodium D-isoascorbate; and 1-3% magnesium stearate. The processing method has the beneficial effects that the formula is special, and the process is simple and feasible; and the produced bramble gallogen chewing tablet has the characteristics of being fragrant, refreshing, balanced in nutrients, long in shelf life, convenient to carry, convenient to eat and the like. The bramble gallogen chewing tablet is especially suitable for tumor patients, children, the elderly, and those suffering from cardiovascular diseases, doing heavy physical labor, having acid constitution and obesity.

Owner:耿家君 +1

Health preservation lotus seed cake and preparation method thereof

InactiveCN104856041AEliminate cumbersome proceduresSimple processFood preparationSugarCrataegus pinnatifida

The invention discloses a health preservation lotus seed cake and a preparation method thereof. The health preservation lotus seed cake is prepared from the following raw materials in parts by weight: 50-75 parts of lotus seeds, 20-40 parts of poria, 10-20 parts of Chinese yam, 75-100 parts of glutinous rice, 50-80 parts of old rice, 1-3 parts of white granulated sugar, 10-20 parts of Chinese dates, 10-20 parts of fruits of Chinese wolfberry, 10-20 parts of haw and 10-20 parts of walnut kernel. According to the health preservation lotus seed cake, the content of traditional Chinese medicine materials is moderate, the impact to the taste of the product is low, and the taste of original food is furthest maintained; the health preservation lotus seed cake has the advantages that the mouth feel while eating is good, the pungent odor of the medical materials is light, and the like.

Owner:刘发元

Mn-Zn ferrite magnetic material with high magnetoconductivity and high impedance and method for making the same

ActiveCN101231902BImprove permeabilityHigh impedance characteristicInorganic material magnetismFerrimagnetismMaterials science

The invention relates to a Mn and Zn ferrimagnetism material and a preparation method thereof. The Mn and Zn ferrimagnetism material is made of principal ingredients and subsidiary ingredients. The weight percentages of the principal ingredients which are oxides are calculated as follows: Fe2O3 accounts for 61 percent to 75 percent by weight; ZnO accounts for 12 percent to 30 percent by weight; the rest principal ingredient is Mn3O4. The subsidiary ingredients are one or a plurality of kinds of CaCO3 accounting for 0 to 300ppm by weight; SiO2 accounting for 50ppm to 250ppm by weight; Bi2O3 accounting for 0 to 500ppm by weight. The Mn and Zn ferrimagnetism material has both high magnetic permeability and high impedance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

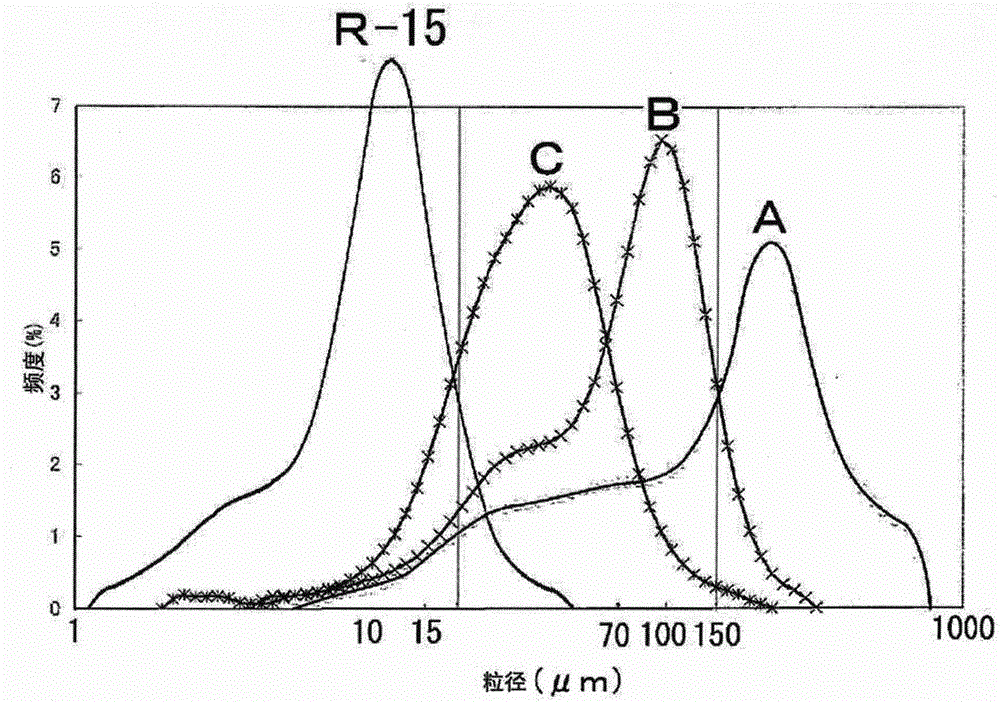

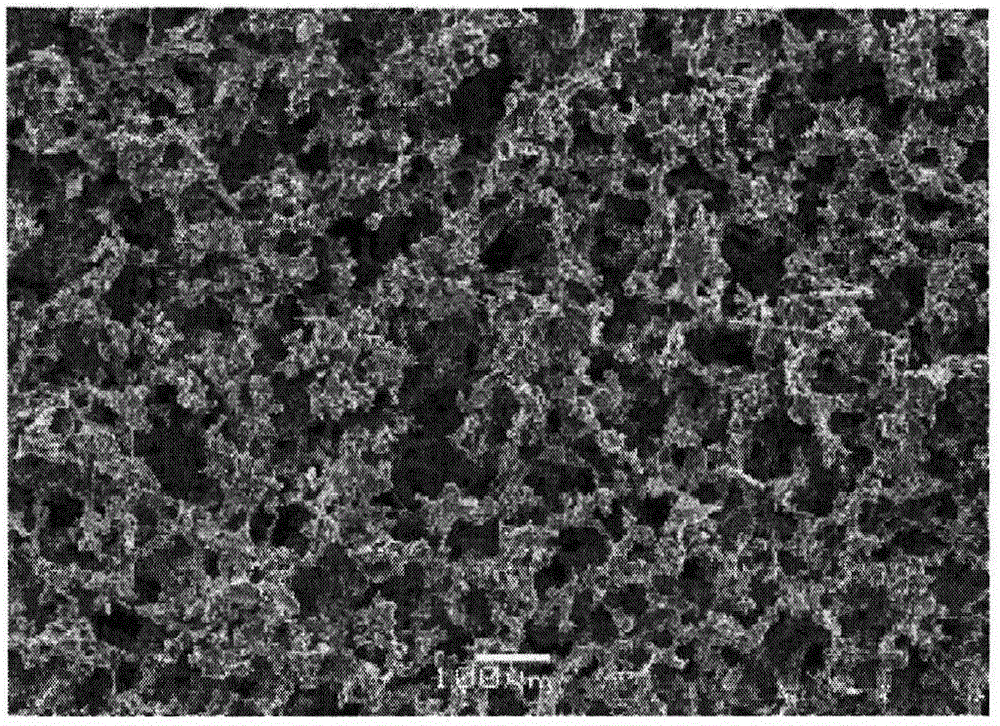

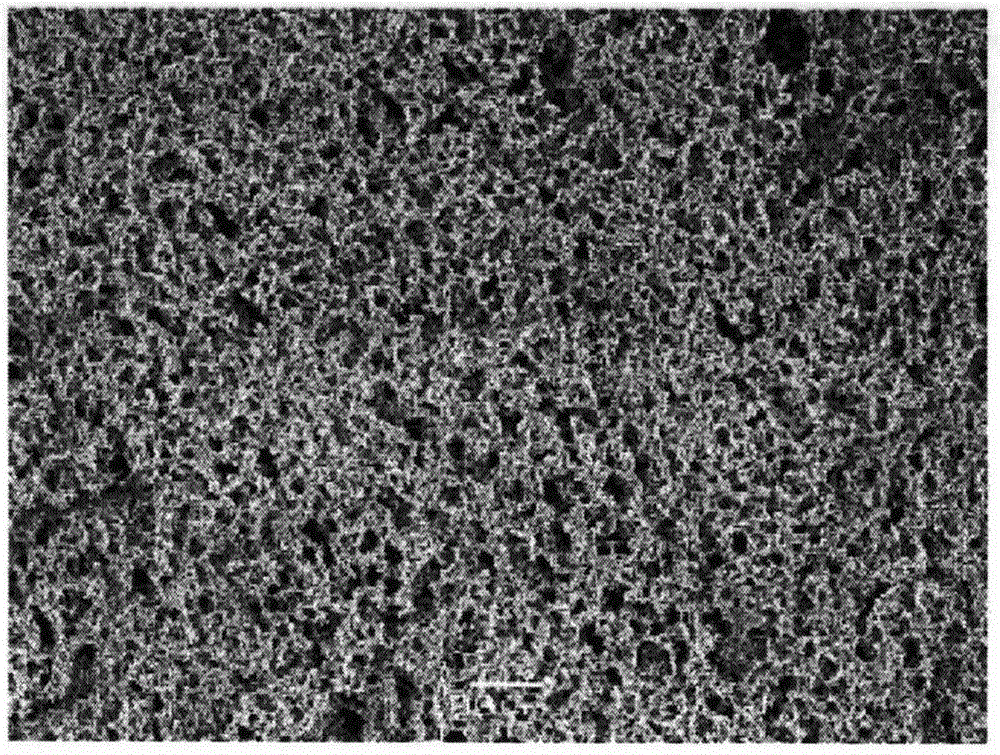

Cosmetic sponge, process for producing elastic polyurethane object, and applicator for cosmetic preparation

ActiveCN105025751ALow viscosityModerate thixotropyPackaging toiletriesPackaging cosmeticsPolyurethane elastomerInorganic salts

Provided is a cosmetic sponge which is constituted of an elastic polyurethane object of a three-dimensional membranous structure, wherein the elastic polyurethane object has an ethanol permeation time in the range of 10-400 seconds, excluding 400 seconds, has cells so that in an area of 1.0 mm × 1.0 mm within the section thereof, there are 150 or more cells having a maximum diameter of 15-150 μm and 10 or less cells having a maximum diameter exceeding 10 μm and that the number of cells having a maximum diameter of 15-75 μm is 80% or more of the number of cells having a maximum diameter of 15-150 μm, and has an apparent density of 120-200 kg / m3. Even when the cosmetic sponge is used for applying a cosmetic preparation that is low in thixotropic property and viscosity, the cosmetic preparation is less apt to infiltrate deeply into the inner part of the sponge and is moderately absorbed thereinto, and the cosmetic preparation can be spread over a larger area. Also provided are: a process for producing the elastic polyurethane object by an aqueous coagulation method using particles of an inorganic salt that have a specific particle size distribution; and an applicator for cosmetic preparations which employs the cosmetic sponge.

Owner:FUSHIMI PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com