Sludge treatment method

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of energy waste, large capacity of anaerobic digestion tank, poor wall breaking effect, etc. Achieve the effects of improving process stability, excellent dehydration performance, and reducing solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

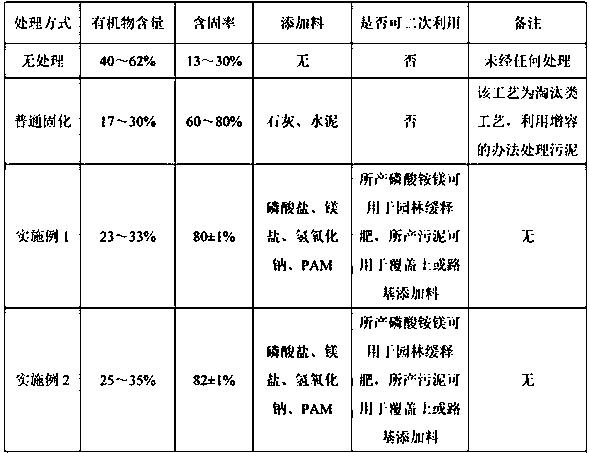

Examples

Embodiment 1

[0051] A sludge treatment method of the present invention, comprising the steps of:

[0052] (1) The sludge from the municipal government first enters the receiving silo for storage. At this stage, the solid content of the sludge is about 20%; the sludge in the receiving silo is pumped into the preheating equipment, and the preheating equipment absorbs water The decompression steam generated in the hot stage is simultaneously added with high-temperature dilution water for preheating heat treatment.

[0053] (2) The preheated mud-water mixture enters the hydrothermal system, where the sludge is treated at high temperature and high pressure. The operating temperature of the hydrothermal system is 170°C, the pressure is 0.8Mpa, the solid content of the sludge is 15.2%, and the time is 30 minutes.

[0054] (3) The mud-water mixture after hydrothermal reaction enters the heat energy recovery system, for example, a heat exchanger is used to reduce the temperature of the mud-water m...

Embodiment 2

[0067] A sludge treatment method of the present invention, comprising the steps of:

[0068] (1) The sludge from the municipal government first enters the receiving material for storage. At this stage, the solid content of the sludge is about 18%; the sludge in the receiving silo is pumped into the preheating equipment, and in the preheating equipment, it passes through the stage of absorbing water and heat. The generated decompression steam and simultaneous addition of high-temperature dilution water are used for preheating heat treatment.

[0069] (2) The preheated mud-water mixture enters the hydrothermal system, where the sludge is treated at medium temperature and medium pressure. The operating temperature of the hydrothermal system is 152°C, the pressure is 0.55Mpa, and the solid content of the sludge is 15.2%. for 30 minutes.

[0070] (3) After the hydrothermal reaction, the mud-water mixture enters the heat energy recovery system to reduce the temperature to 50°C.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com