Patents

Literature

130results about How to "Achieve harmless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

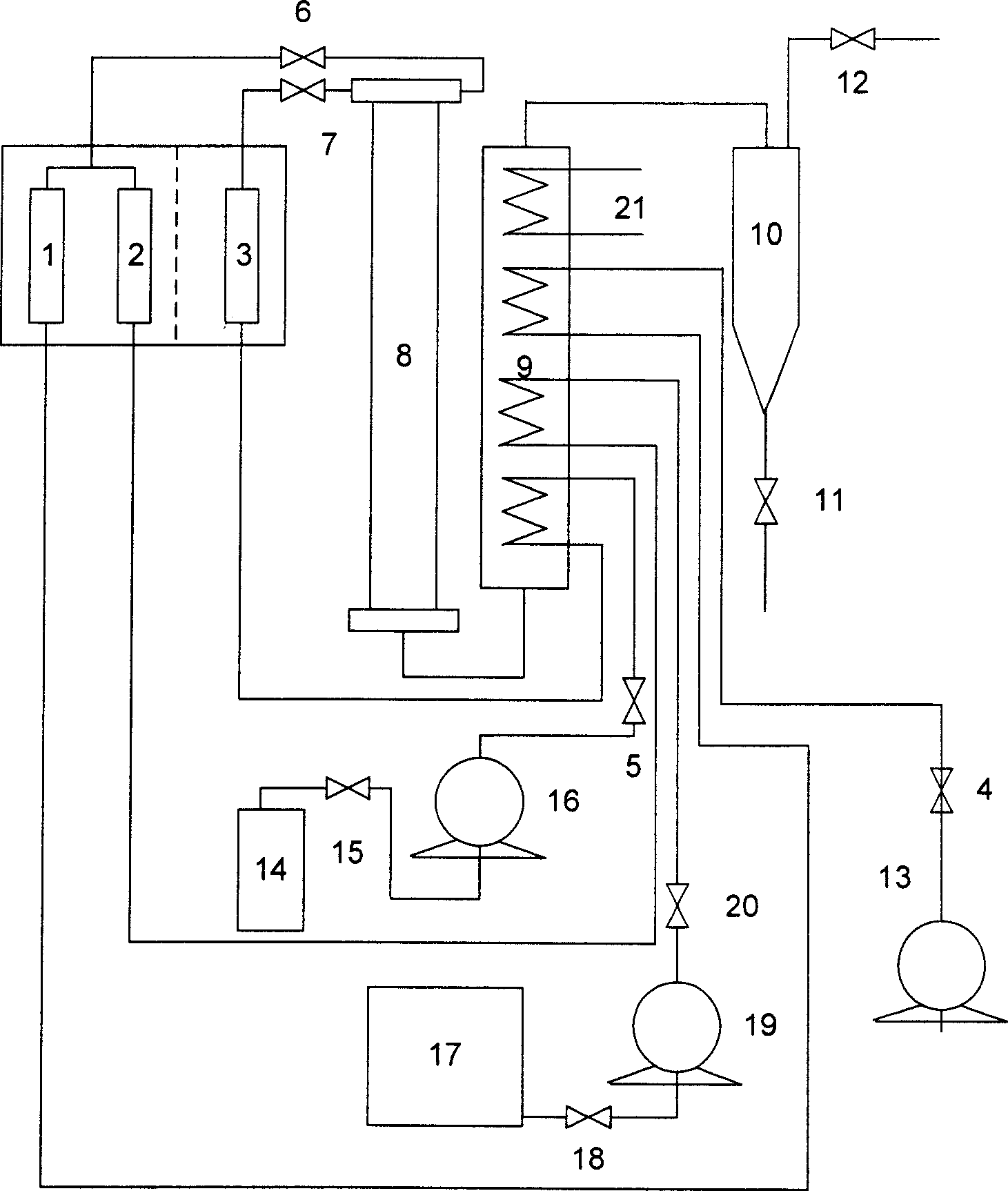

Super critical water treatment system of waste organic liquid pollution less discharge and resources utilization

InactiveCN1868915AWarm up fastAvoid cloggingWater/sewage treatment by heatingWater/sewage treatment by oxidationWater treatment systemResource utilization

A supercritical water treating system for reclaiming the rejected organic sewage and recovering its energy without draining of pollutants features that it has three preheaters (gas preheater, liquid preheater and material preheater) for respectively preheating the gas oxidant, liquid oxidant (or reaction medium) and material to suppress the generation of tar and coke and simplifying the design of reactor, and the oxidizing reaction and gasifying reaction are simultaneously preformed in this system.

Owner:XI AN JIAOTONG UNIV

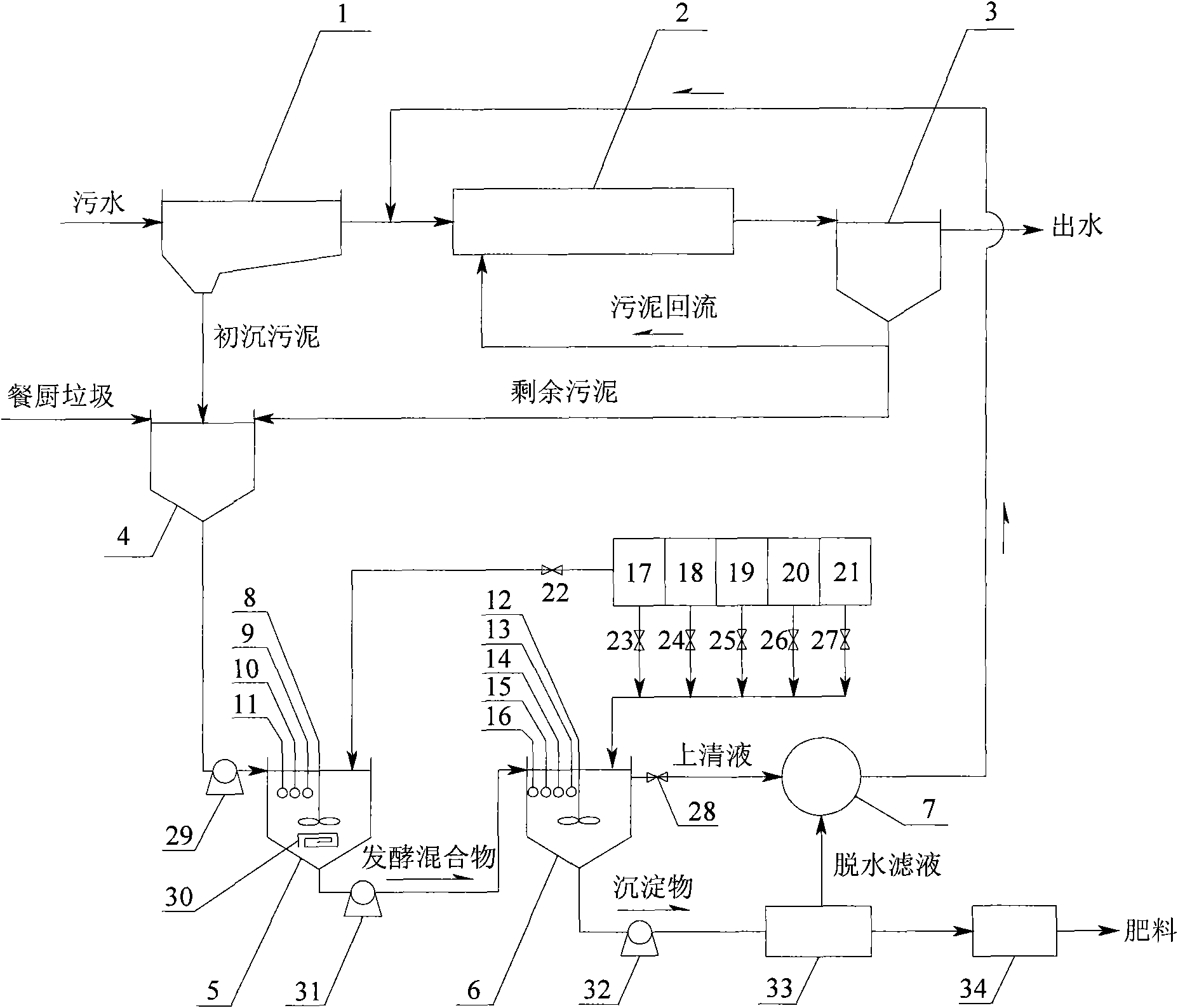

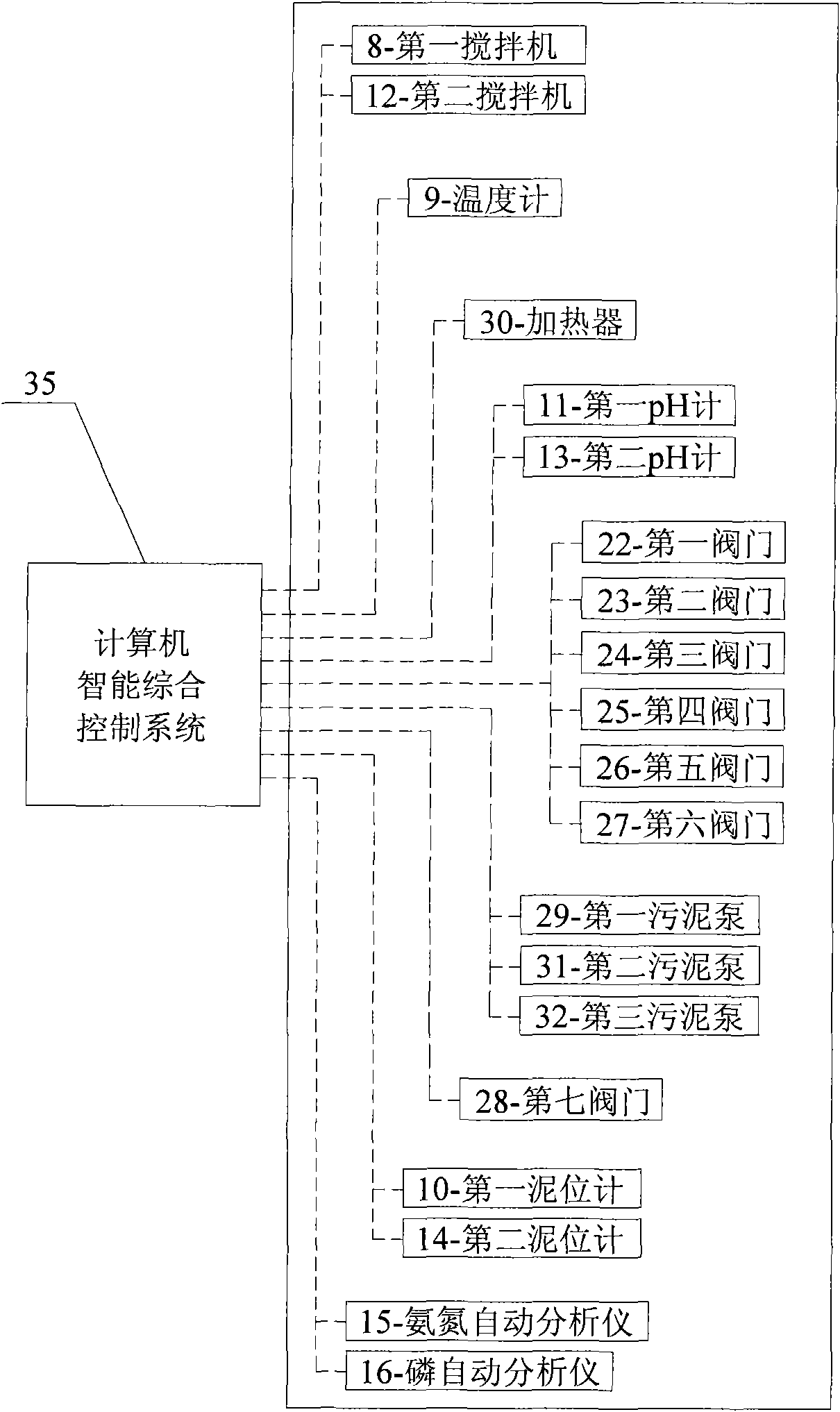

Home position strengthening fermentation regenerated carbon source sewage disposal system for sewage plant

ActiveCN101538101ASolve the problem of insufficient carbon sourcesSolve the poor effect of nitrogen and phosphorus removalSludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeFermentation

The invention belongs to the technical field of environment protection, particularly relates to a home position strengthening fermentation regenerated carbon source sewage disposal system for sewage plant. The system comprises structures including a primary adjusting tank, an alkaline fermentation tank, an adjusting tank a carbon source storage and the like tank, and devices including a pipeline, a meter and a dehydration, anhydration control system and the like. Primary sludge, excess sludge and urban utensil garbage from sewage plant are taken as the raw materials for strengthening fermentation to regenerate carbon source in the alkaline fermentation tank under certain temperature and certain pH after being adjusted by the primary adjusting tank, and then chemical agent is added into the adjusting tank, thus not only obtaining high-quality carbon source simply but also obtaining a byproduct which can be used as a fertilizer, and realizing stabilization, reduction, decontamination and utilization of waste sewage. The technique has the advantages of low investment, low running cost, steady quality of regenerated carbon source, high-value byproduct and the like.

Owner:TONGJI UNIV

Biological treatment method for waste mud in petroleum and natural gas exploration drilling work

ActiveCN101830614AEasy to handleThe role and effect are obviousBiological sludge treatmentWell drillingWater source

The invention discloses a biological treatment method for waste mud in petroleum and natural gas exploration drilling work, which is characterized by comprising the following steps of: a, forming a microbial treatment layer, namely inoculating special microbial strains to the waste mud in a weight ratio of 3-5: 100, mixing the strains and the waste mud uniformly, stirring the mixture and natural soil with water content of 10 to 10 percent and grain diameter of less than 0.5 centimeter uniformly according to the density condition of the waste mud in a following mode to form the microbial treatment layer, adding the natural soil in an amount which is 2.5 to 3 times that of the waste mud into the waste mud with density of 1 to 1.5kg / L, adding the natural soil in an amount which is 2 to 2.5 times that of the waste mud into the waste mud with density of 1.5 to 2.5kg / L, and controlling the water content of the microbial treatment layer to be between 25 and 30 percent; b, treating the soil; and c, treating plants. The method can solve the technical problem that effusion enters underground water to pollute a water source because the natural soil with high water content and large grain diameter is easily scoured by hard rain under the condition that pollutants in a pretreatment mixture are not yet effectively degraded in the prior art.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

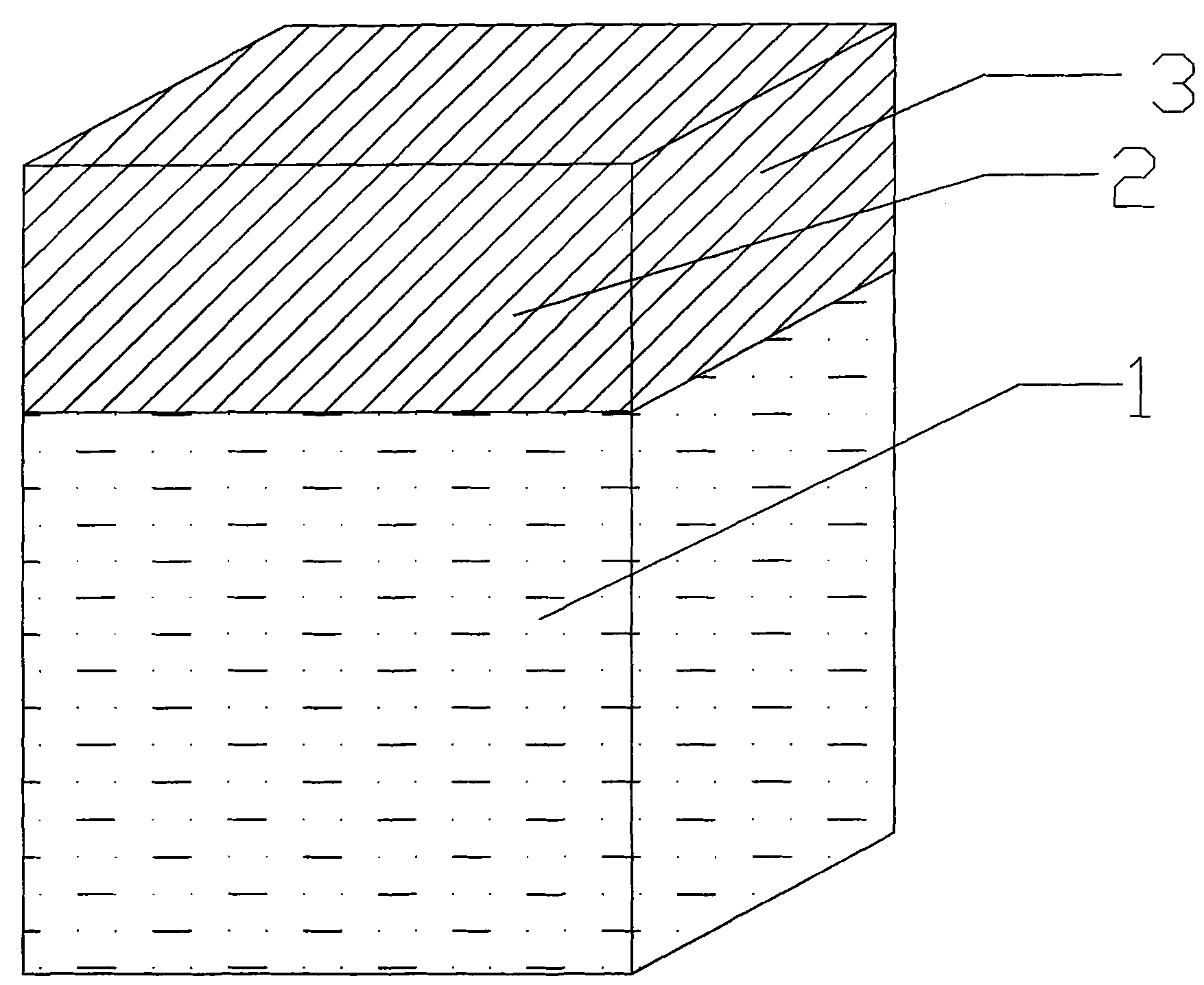

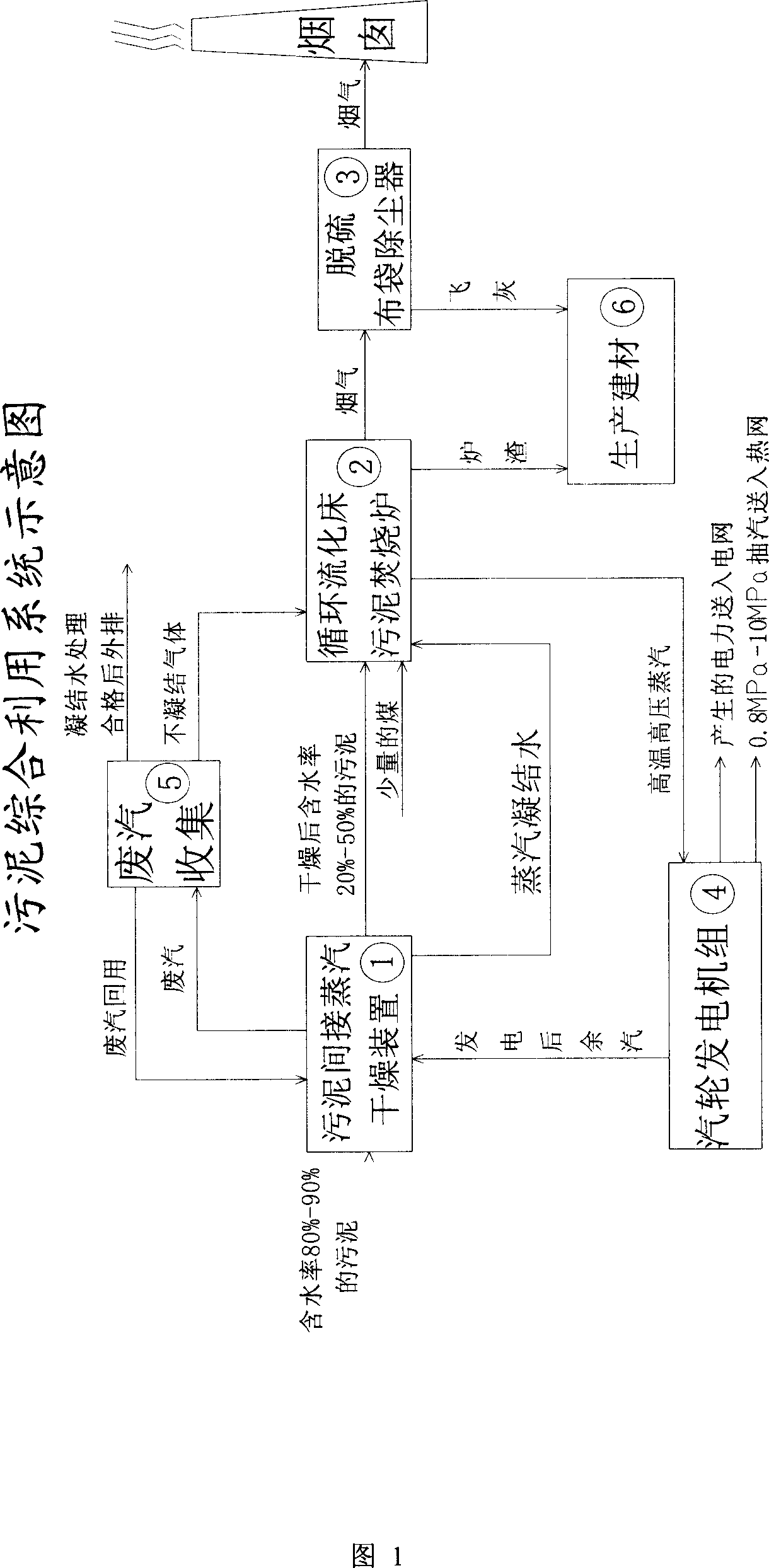

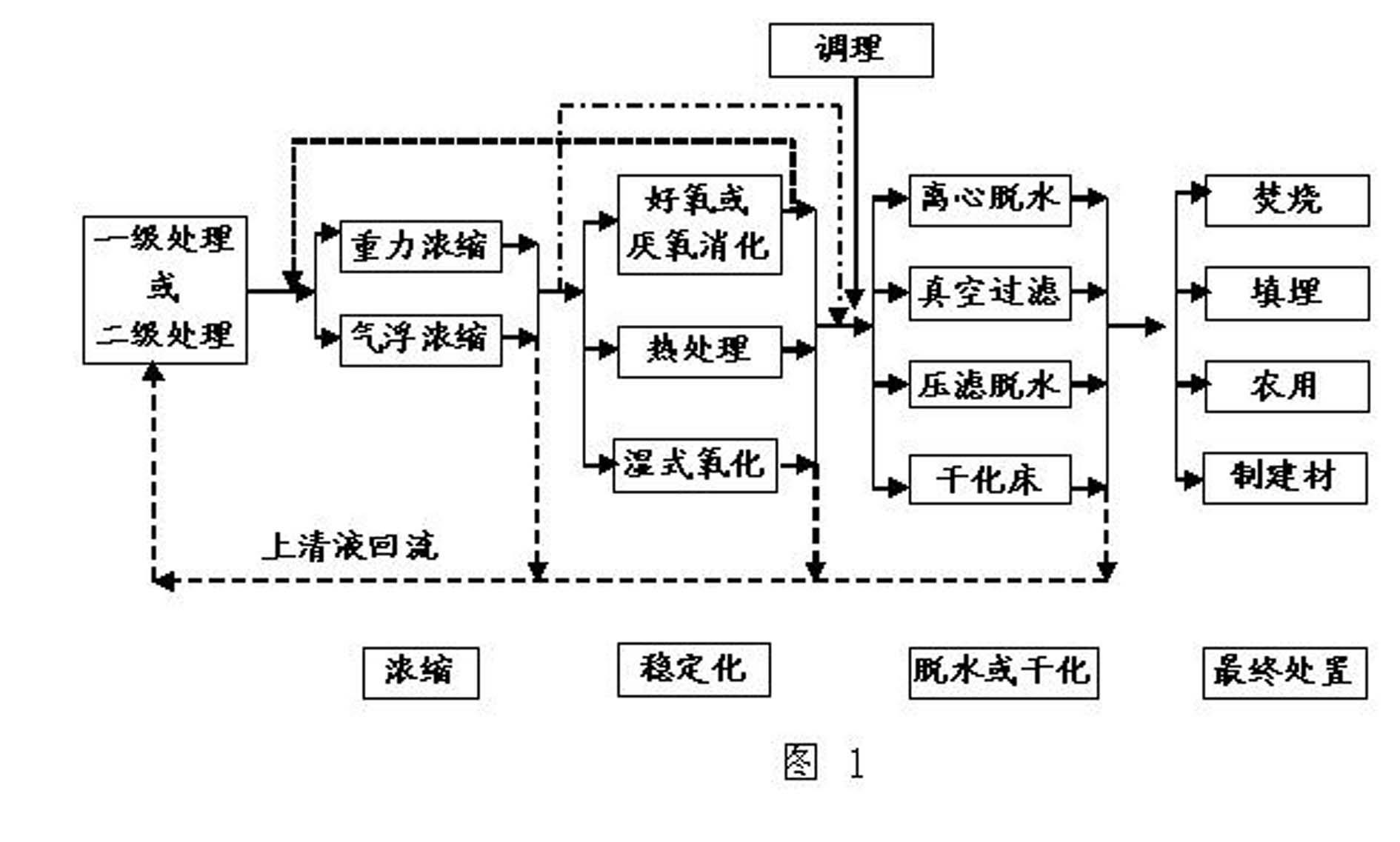

City sludge comprehensive utilization

InactiveCN1978348AAchieve harmlessTo achieve the purpose of resource utilizationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeTurbine

This invention discloses a method for using city sludge in combination composed of 1, a sludge drying unit, 2, a burning and processing unit, 3, a smoke process unit, 4, a turbine-generator set generation unit, 5, a waste gas collection and process unit, 6, a producing unit for construction materials, which mainly utilizes the steam exhaust generated by the steam turbine set and waste steam generated when drying sludge.

Owner:陈梅铭 +2

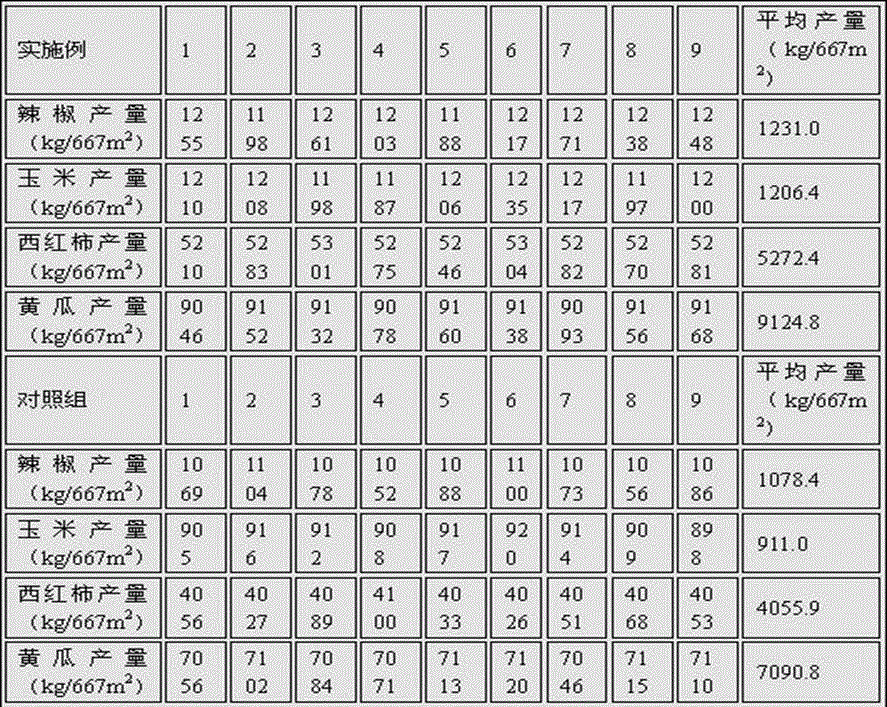

Dairy manure biological organic fertilizer and preparation method thereof

InactiveCN106748533AIncrease temperatureGood deodorizing effectBio-organic fraction processingExcrement fertilisersChemistryCrop

The invention discloses a dairy manure biological organic fertilizer which is prepared from dairy manure, straws, a compound culture and a compound fermentation enzyme. The invention also discloses a preparation method of the organic fertilizer. The preparation method comprises the following steps: crushing and uniformly mixing dehydrated dairy manure and straws and performing pile fermentation; uniformly spraying the compound culture and the compound fermentation enzyme for fermentation; introducing oxygen at a fixed time; detecting the temperature of the pile fermenting fermented material; turning the pile fermenting fermented material; and then aging the fermented material to obtain the organic fertilizer. By adopting various microorganisms to ferment the dairy manure to produce the biological organic fertilizer, pathogenic bacteria can be killed and quickly deodorized by means of a fermenting action of the microorganisms; then, the biological organic fertilizer disclosed by the invention is rich in nutritional components needed for growth and development of crops, and can also serve as a soil conditioning agent, so that phenomena of soil agglomeration and salinization are effectively improved. The dairy manure biological organic fertilizer disclosed by the invention is fast and full to decompose, the fermentation time is shortened, the production cost is favorably lowered, and industrial production is facilitated.

Owner:LIUZHOU SANYUAN TIANAI DAIRY

Organic fertilizer fermentation method

InactiveCN104261918AReduce the impact of unfavorable factorsAchieve harmlessBio-organic fraction processingClimate change adaptationMicroorganismContinuous fermentation

The invention discloses an organic fertilizer fermentation method which adopts pool type aerobic continuous fermentation. The method specifically comprises the following steps: A, uniformly mixing solid organic wastes, a microbial fermentation bacterial agent and auxiliary materials in proportion to obtain a fermentation raw material, wherein the solid organic wastes, the microbial fermentation bacterial agent and the auxiliary materials are in a ratio of (70-75) to (29.99-24.99) to 0.01, so that the carbon nitrogen ratio in the fermentation raw material is (25-30) to 1; B, carrying out primary aerobic fermentation not less than 7 days on the fermentation raw material at the temperature not lower than 55 DEG C to obtain a primary fermentation product; C, carrying out secondary fermentation on the primary fermentation product at normal temperature to obtain a secondary fermentation product within 10-15 days; and D, drying the secondary fermentation product to obtain an organic fertilizer. By using fresh chicken manure as a main fermentation raw material, the organic fertilizer fermentation method disclosed by the invention achieves the purposes of harmless treatment, recycling treatment and reducing treatment.

Owner:QINGHAI LVJIE SPECIAL BREED AQUATICS

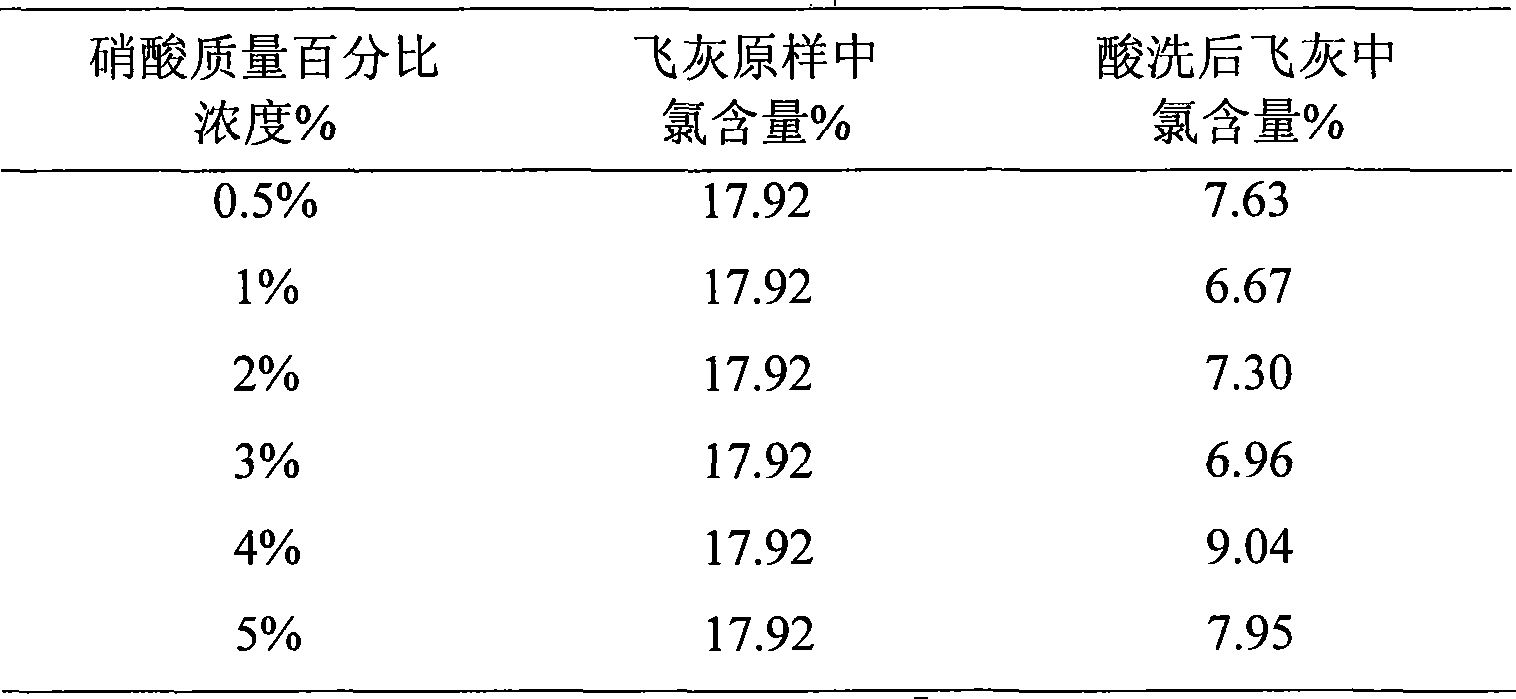

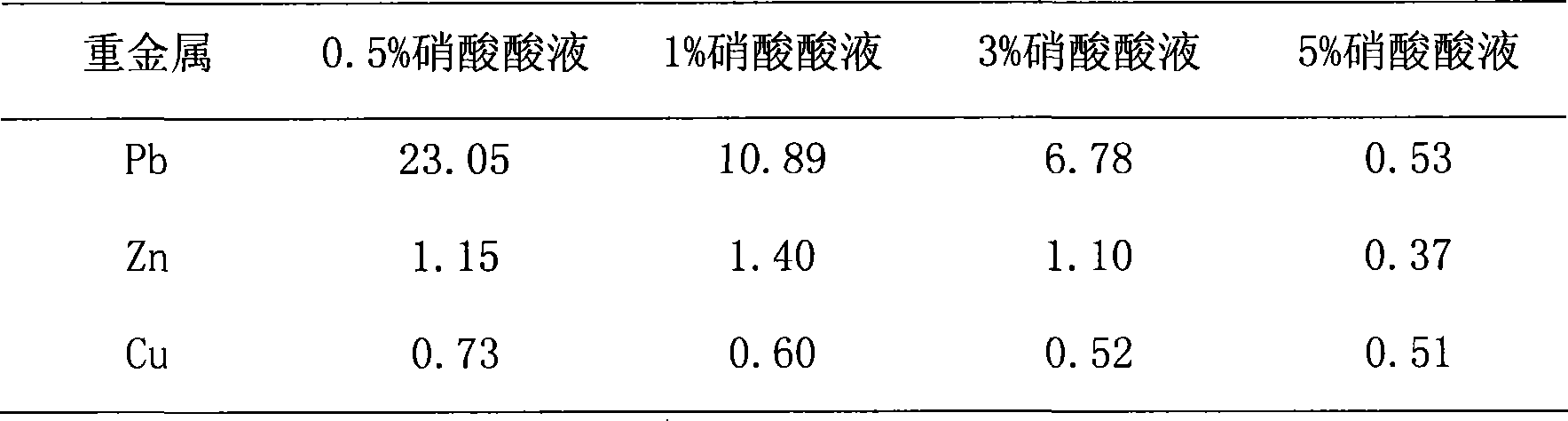

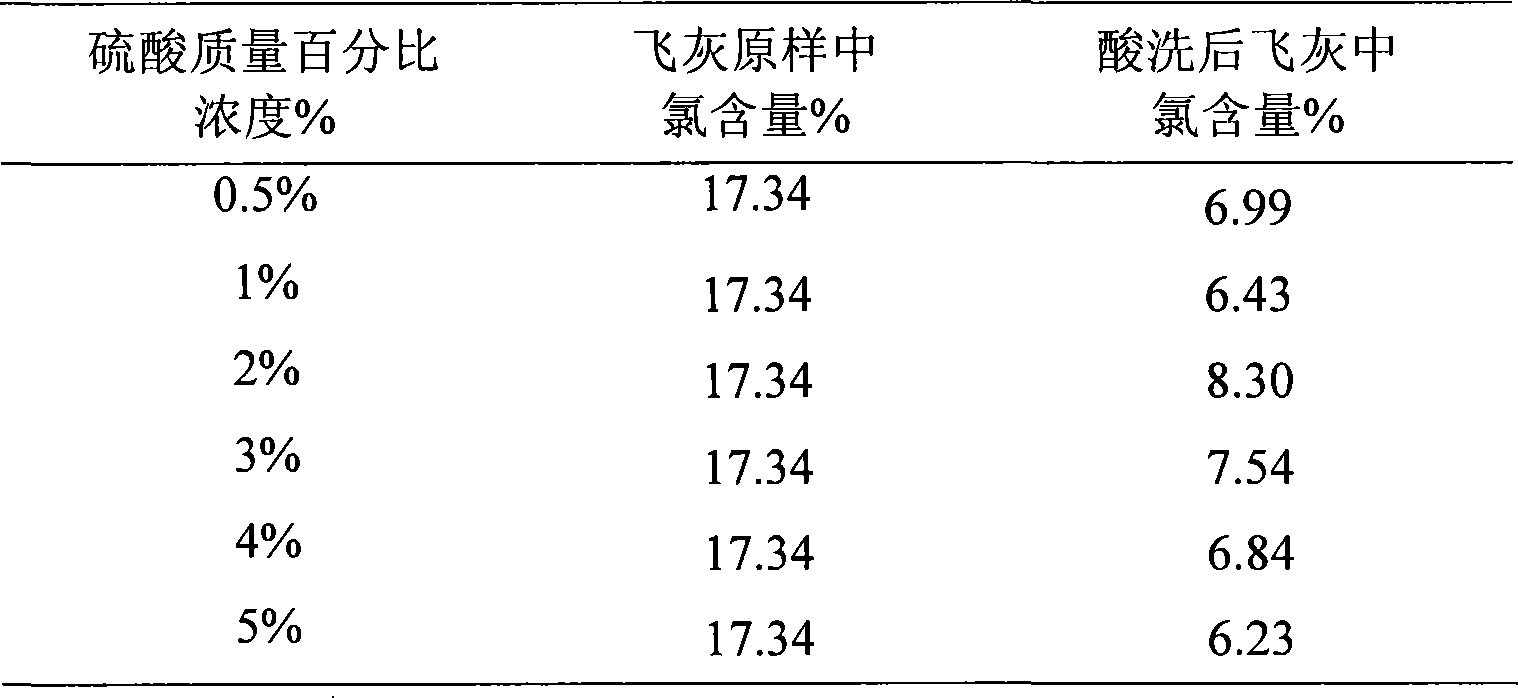

Sulfuric acid refining preprocessing method of life refuse burning flying ash

InactiveCN101239298AReduce leaching toxicityHarmless landfill resource utilizationGaseous chemical processesChemistryHeavy metals

The present invention provides an acid cleaning pretreatment method of household garbage fly ash, belonging to the environmental engineering technical field. The method is separating supernatant fluid to fly ash by mixing the household garbage fly ash with sulphuric acid, hydrochloric acid, citric acid, phosphoric acid etc under the normal temperature, blending and static settlement. The invention also can remove a mass of contamination such as soluble chloride salt and part heavy metalin the household garbage fly ash; the fly ash after acid cleaning achieves harmless aim, futher filled or resource utilization.

Owner:SHANGHAI UNIV

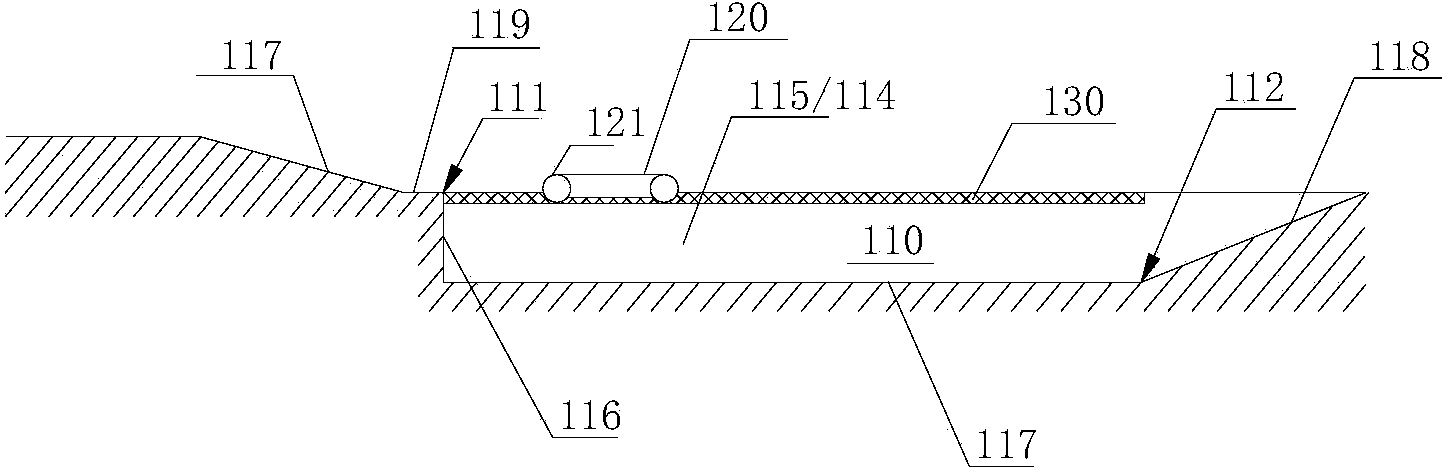

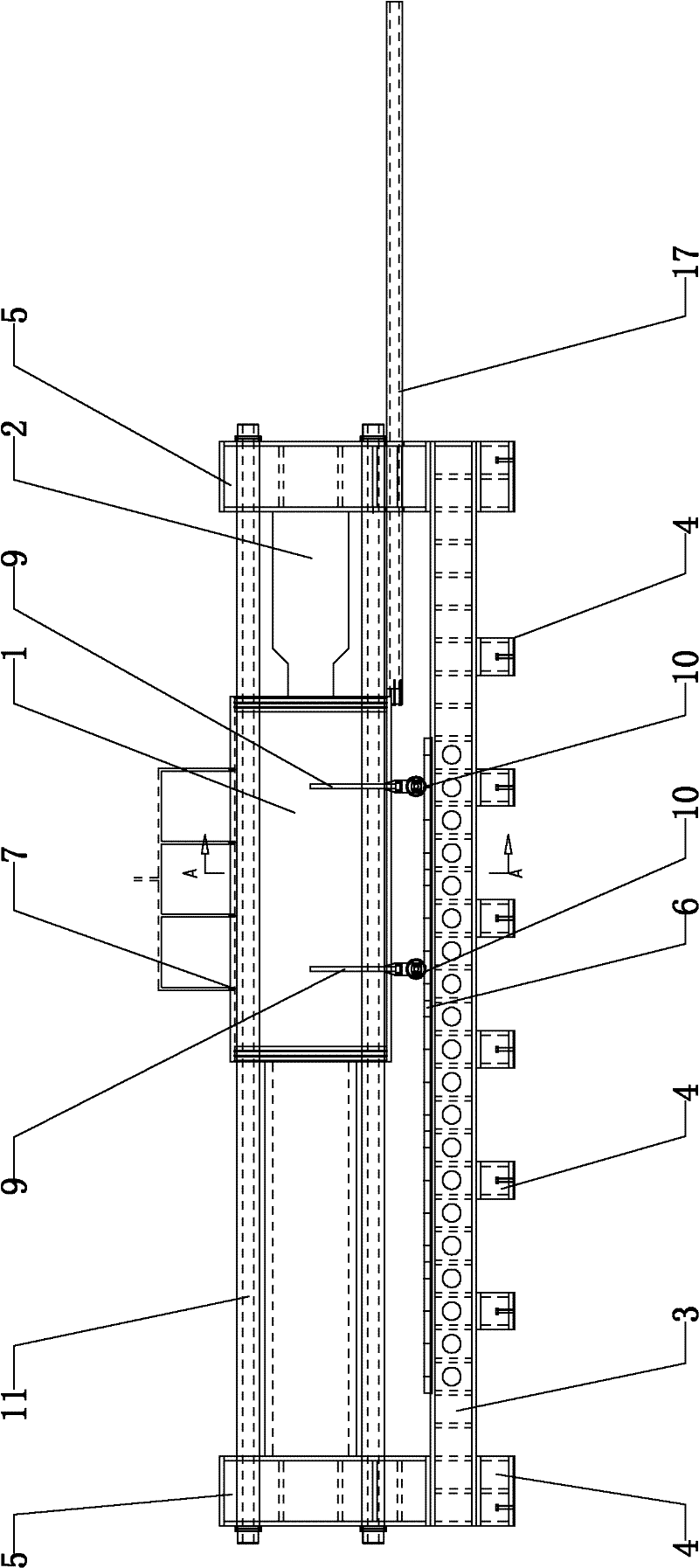

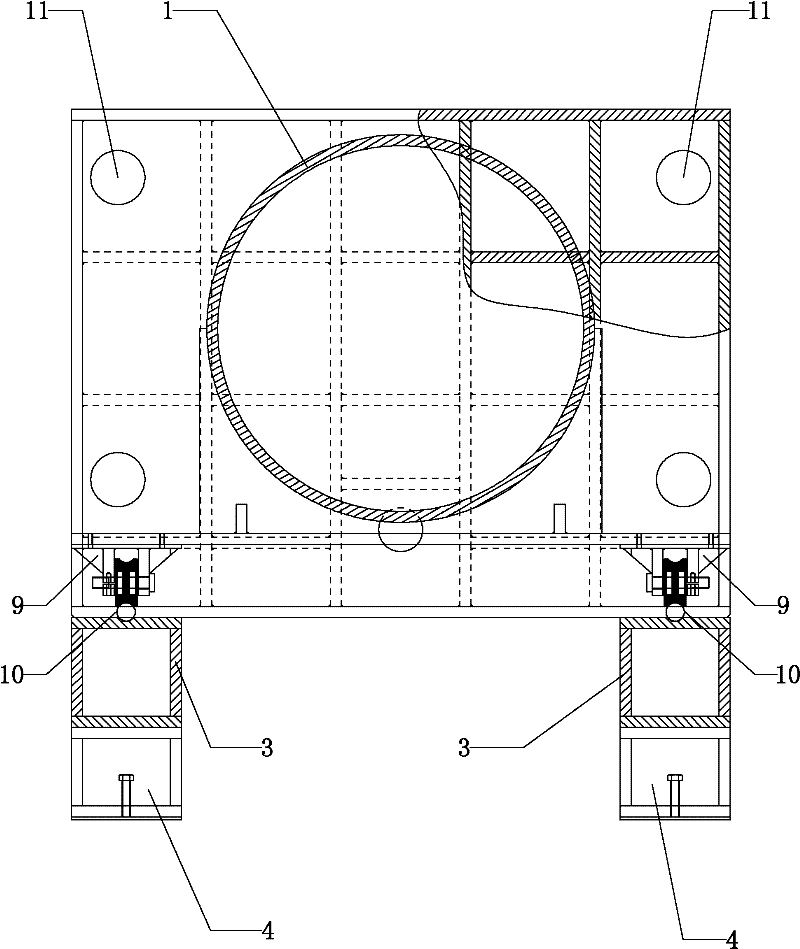

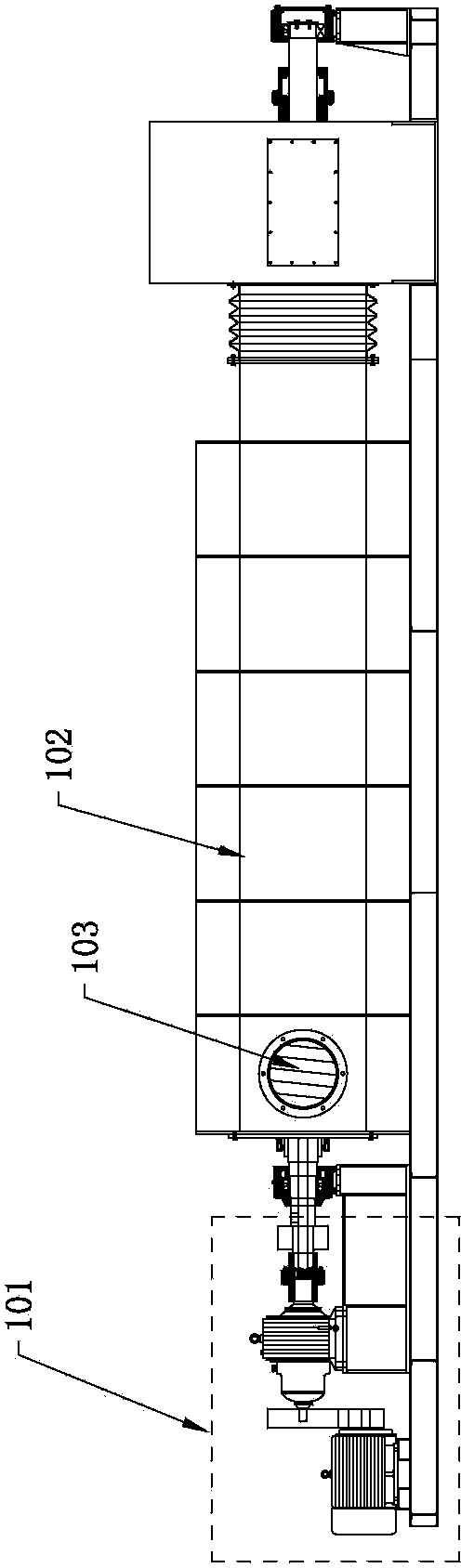

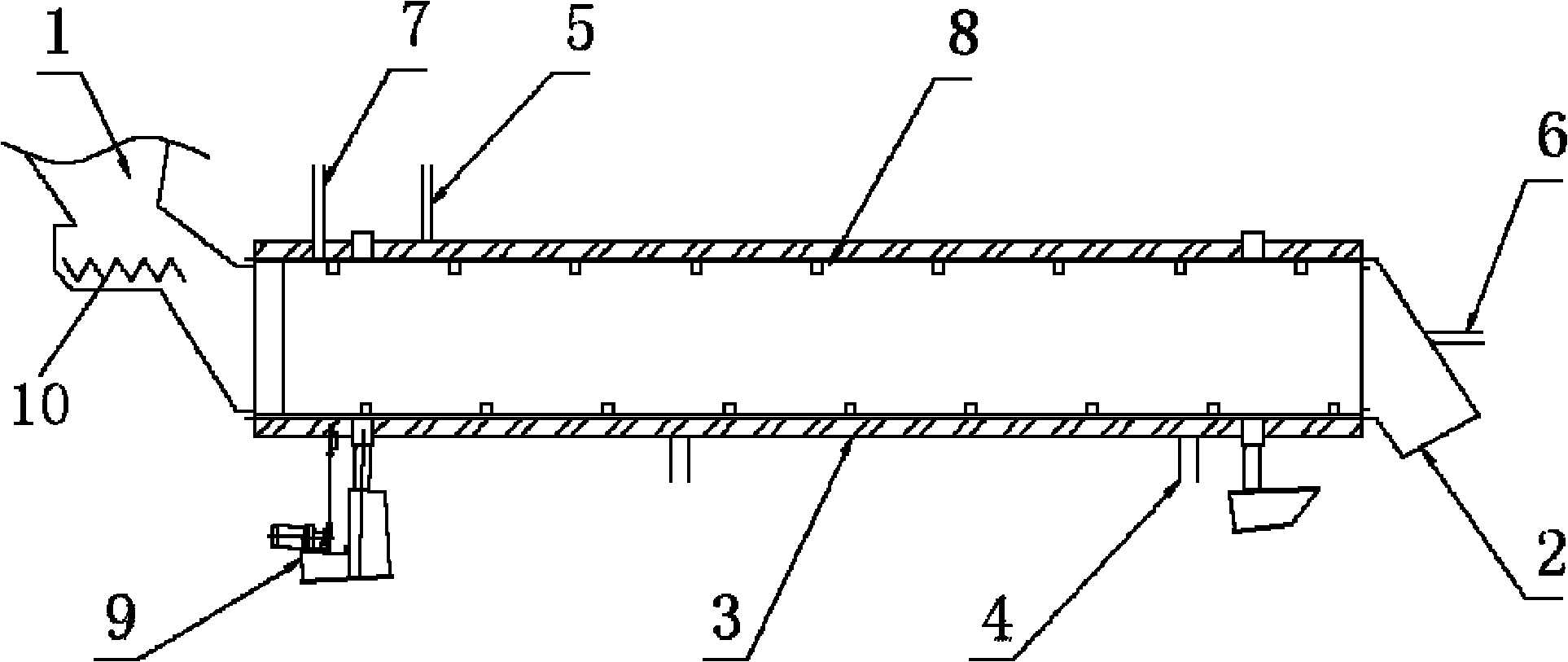

High-dryness filter and method

InactiveCN102247720AIncrease solid contentIncrease productionFiltration separationHydraulic cylinderPulp and paper industry

The invention relates to a high-dryness filter and a method. The high-dryness filter comprises a cylinder body, a hydraulic cylinder and two crossbeam binders, wherein a plurality of foot box binders are welded on the bottoms of the two crossbeam binders respectively; lateral box binders are arranged at the positions, which are close to both ends, on the tops of the two crossbeam binders; the bottoms of the lateral box binders are welded on the two crossbeam binders respectively; guide rails are arranged at the positions, which are close to middle parts, on the two crossbeam binders; the cylinder body is arranged above the guide rails; the front and rear sides of the cylinder body are provided with a plurality of cylinder body support binders respectively; the bottoms of the cylinder body support binders are arranged on the guide rails through wheels; a fixed piston on the left side of the cylinder body is connected with the lateral box binder on the left side through welding; and a movable piston on the right side of the cylinder body is connected with a hydraulic rod of the hydraulic cylinder. The high-dryness filter has the advantages that: the solid content of mud cakes is improved, the automation degree is extremely high, and the energy consumption is extremely low; and the moisture content of the mud cakes is low, the mud cakes are convenient to transport and treat, and the aim of drying, and the aims of emission reduction and innocent treatment are also fulfilled.

Owner:扬州永泰环保科技有限公司 +2

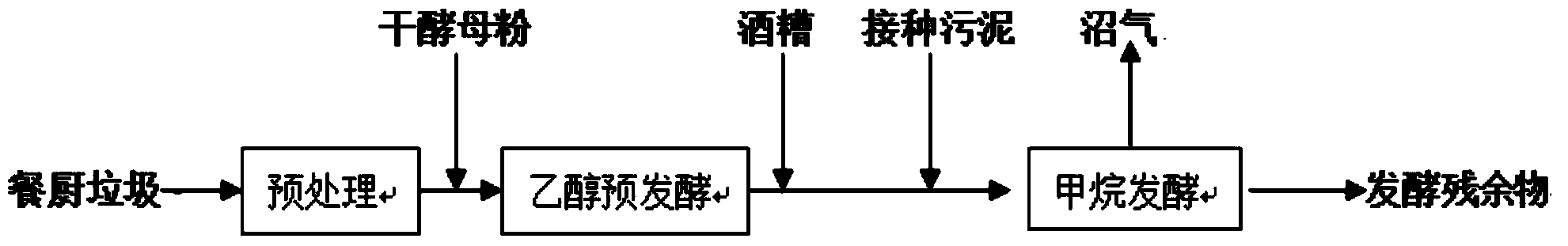

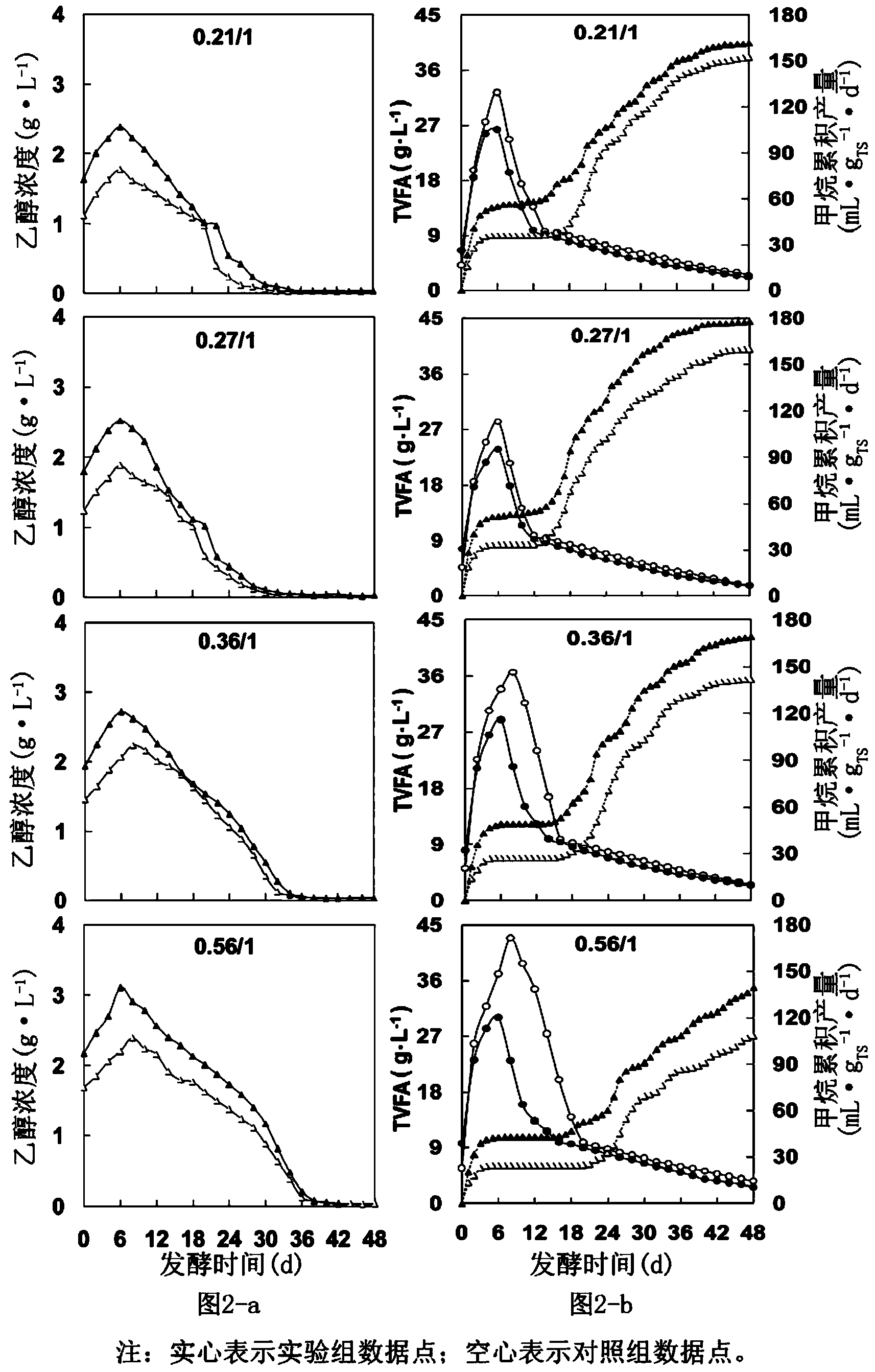

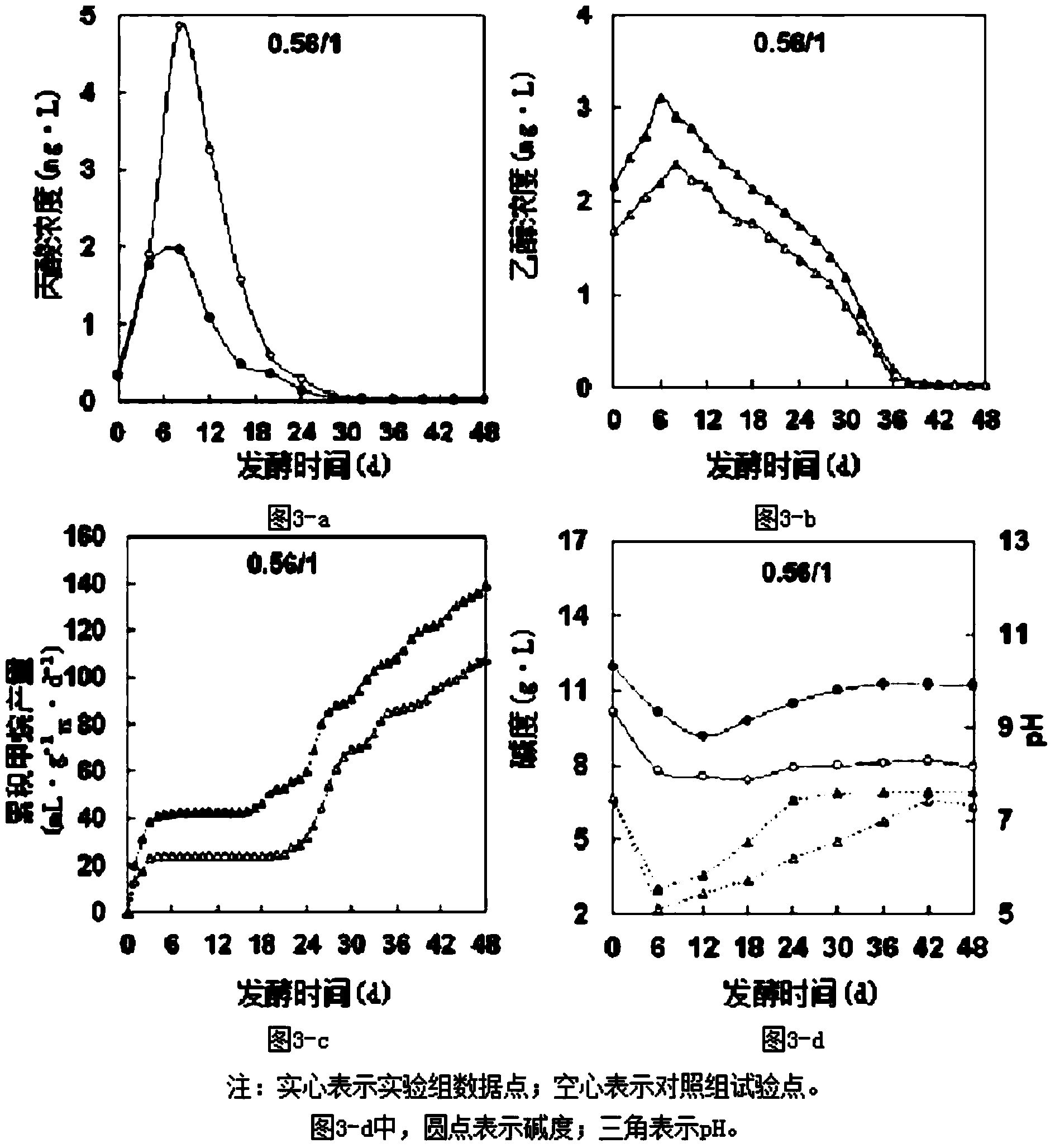

Method for producing marsh gas by two-phase dry-type mixed anaerobic fermentation

The invention provides a method for producing marsh gas by two-phase dry-type mixed anaerobic fermentation, belonging to the technical field of renewable energy sources. The method mainly comprises the following steps: ethanol prefermentation: inoculating a certain amount of dried yeast into kitchen waste to carry out ethanol prefermentation; and methane fermentation: mixing the kitchen waste subjected to ethanol prefermentation and vinasse in a ratio of 1:1 (on the basis of VS) as a substrate for subsequent anaerobic fermentation, and inoculating long-term acclimatized sludge in a ratio of 1:1 (sludge:substrate (on the basis of VS)). The method searches the possibility of optimizing methane anaerobic fermentation by ethanol prefermentation, and optimizes the experimental conditions for ethanol prefermentation. The method can effectively relieve the problem of volatile acid inhibition in the anaerobic digestion process, and obviously enhances the methane yield, thereby enhancing the energy recovery rate. The method is simple to operate, and thus, has high practical value.

Owner:UNIV OF SCI & TECH BEIJING

Garbage thermal cracking treatment technology

ActiveCN103464448AAchieve decompositionTo achieve the purpose of sterilizationSolid waste disposalThermodynamicsCombustible gas

The invention discloses a garbage thermal cracking treatment technology which comprises the following steps: (1) coarse crushing; (2) magnetic separation; (3) sieving; (4) fine crushing; (5) drying; (6) thermal pretreatment; (7) high temperature cracking. The garbage thermal cracking treatment technology disclosed by the invention is reasonable in design of working procedures and simple in structure, and can be used for effectively treating city household garbage and solving the problem of environmental pollution caused by the city household garbage; products, such as coke coal, tar and combustible gas, obtained from city household garbage treatment, can be collected and recycled; the garbage thermal cracking treatment technology creates new economic benefits, fully meets the requirements on reutilization, harmless treatment and reduction of garbage, and realizes zero release of garbage treatment and maximum benefit of reutilization of garbage treatment products.

Owner:GAOZHOU ZHONGLIANG MACHINERY MFG

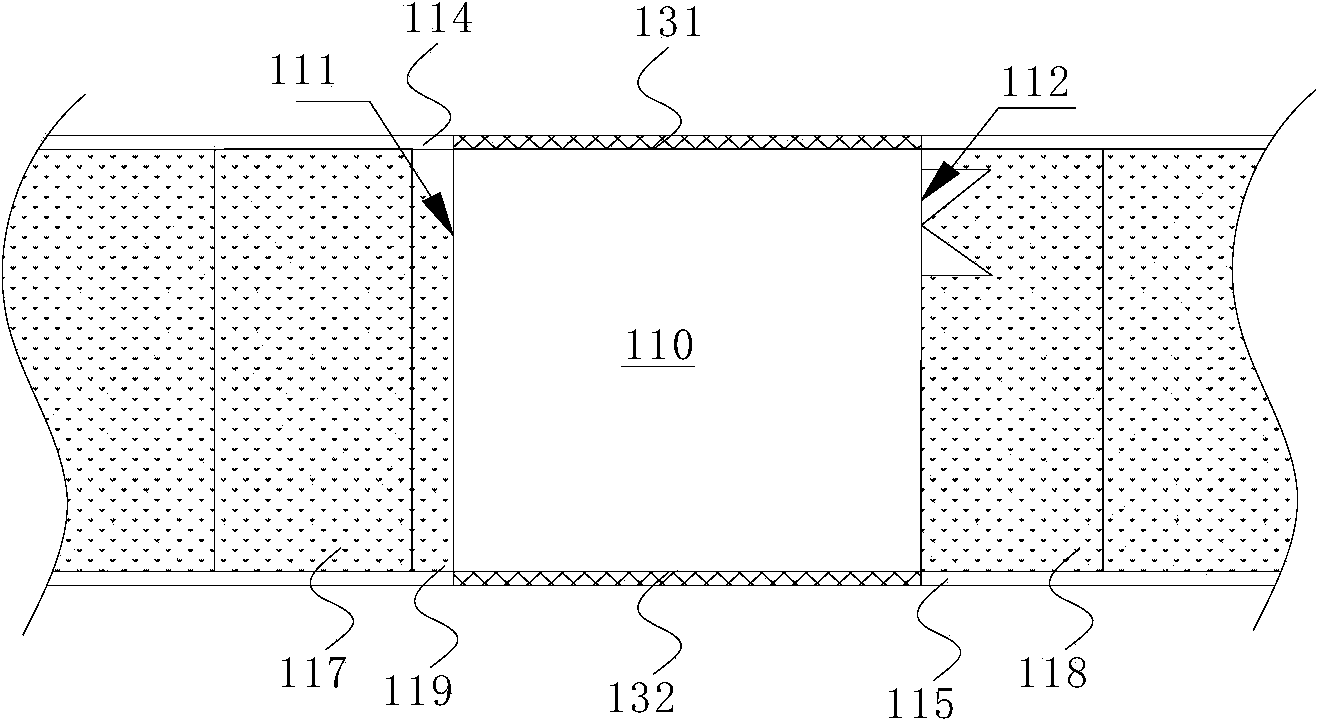

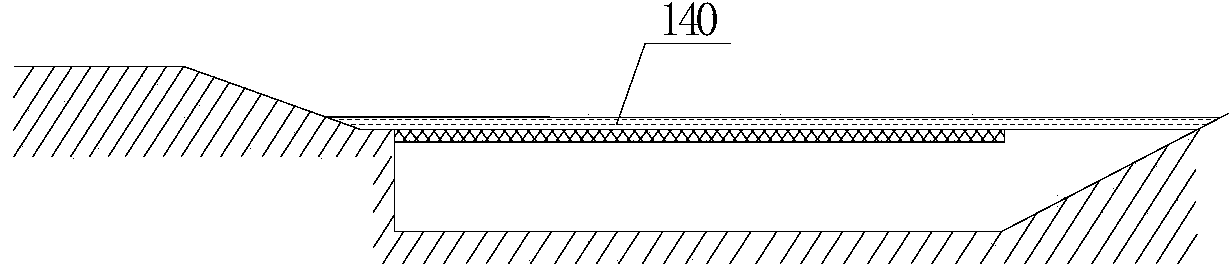

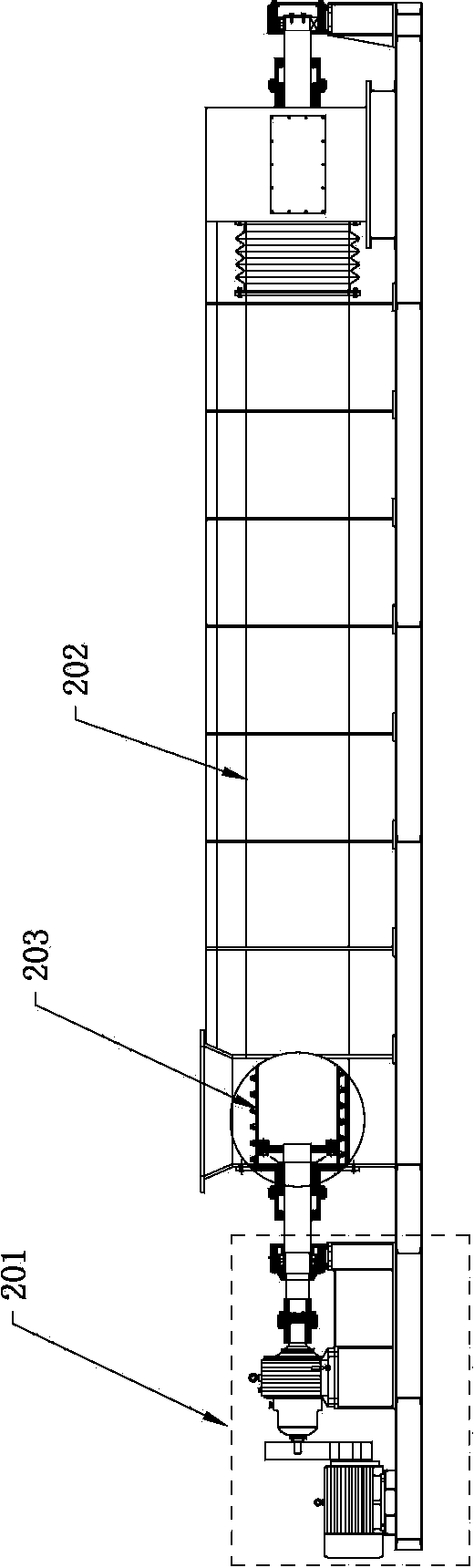

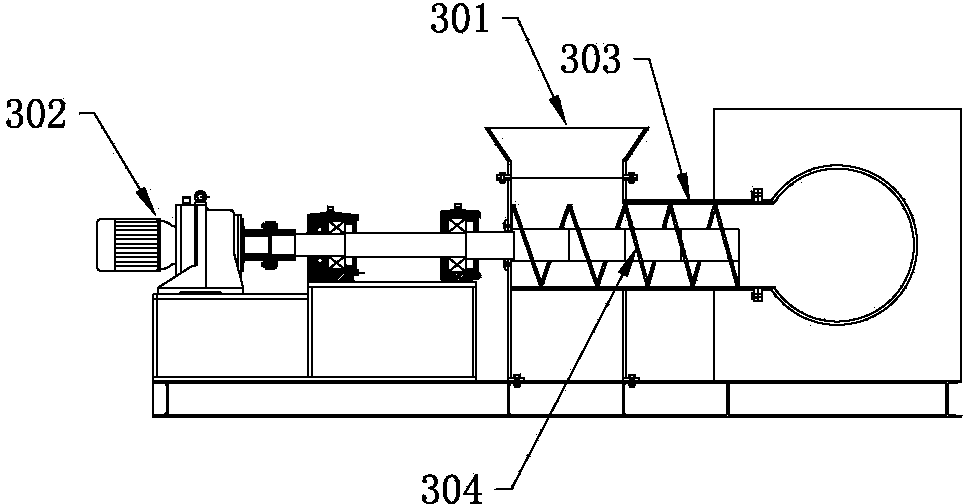

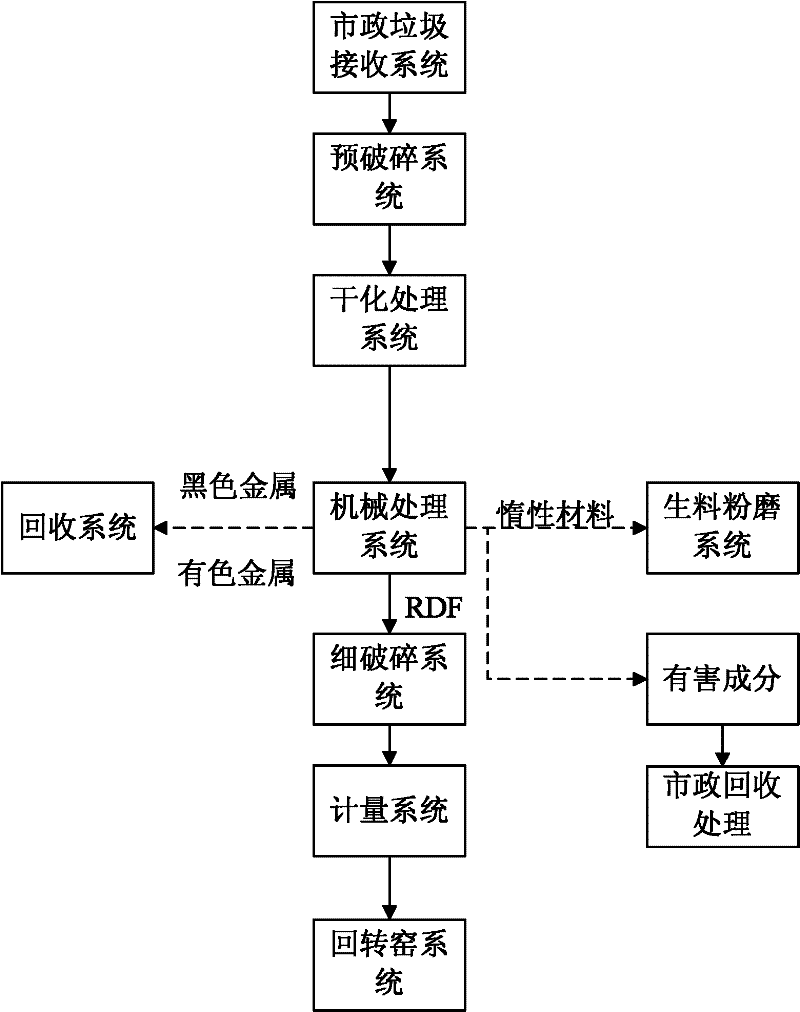

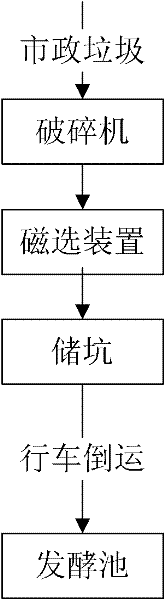

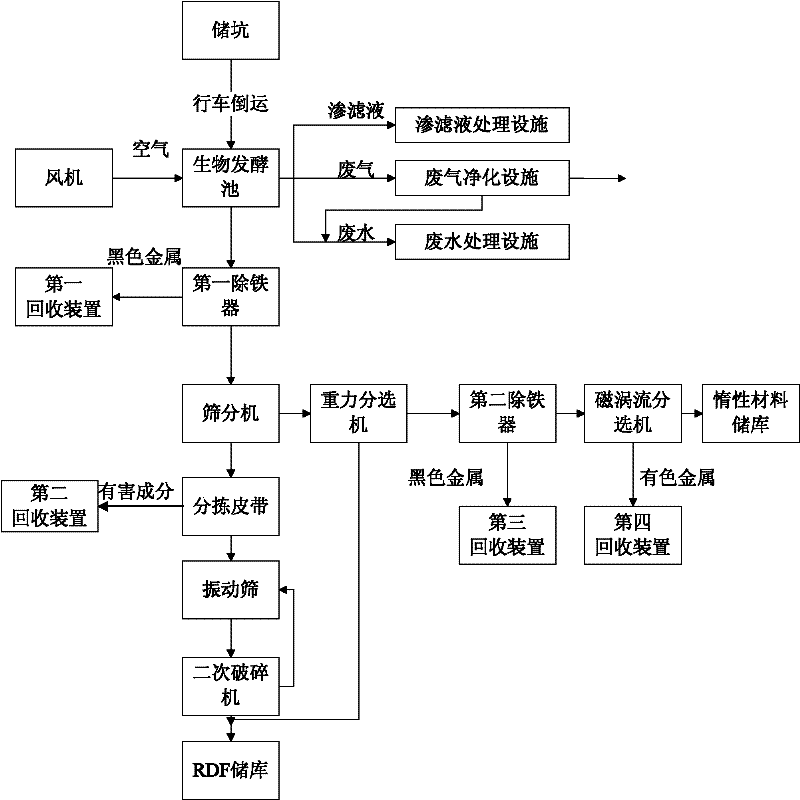

Linkage process of municipal waste pre-treatment and cement kiln resource comprehensive utilization and system thereof

ActiveCN102357516AHigh fuel substitution rateConserve traditional fossil fuelsSolid waste disposalPre treatmentCement kiln

The invention relates to a linkage process of municipal waste pre-treatment and cement kiln resource comprehensive utilization and a system thereof. The linkage process of municipal waste pre-treatment and cement kiln resource comprehensive utilization is characterized by comprising the steps as follows: 1 municipal waste enters a waste receiving system after measurement and radioactivity detection; 2 the municipal waste is crushed in advance; 3 crushed waste is dried and stabilized through a drying treatment system; 4 dried waste is treated in mechanical mode through a mechanical treatment system; and 5 separated flammable materials are refined by a refining system, measured by a measuring system and sent to a kiln head burner, a kiln tail decomposing furnace or a pre-burning chamber of a cement kiln system for burning, and traditional fuel used in the process of cement production is replaced. Separated inert components participate in dosing of cement raw materials and enter the cement kiln system from a raw meal mill. The process achieves safe, harmless, recycling and energy-saving treatment and utilization of the municipal waste.

Owner:华新环境工程有限公司

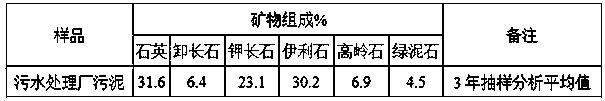

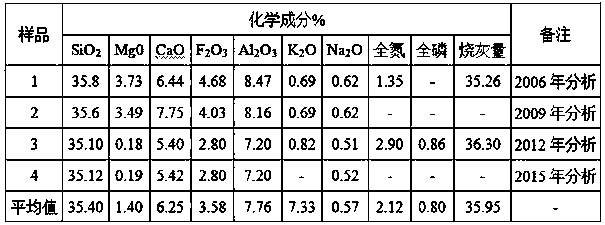

Method for pressing steaming-free and baking-free wall body block from dehydrated sludge in sewage treatment plant

The invention discloses a method for pressing a steaming-free and baking-free wall body block from dehydrated sludge in a sewage treatment plant. The method specifically comprises the following steps:dehydrating sludge of the sewage treatment plant, modifying the dehydrated sludge by virtue of seashell dust, ferrous sulfate and calcium hydroxide, so as to obtain modified sludge; mixing the modified sludge, the seashell dust, calcium sulfate, silica fume, slag charge, an F14 liquid activating agent and water, so as to obtain a mixture; digesting the mixture, so as to obtain a digested material; mixing the digested material, a solidifying agent and a YW-type surfactant, so as to obtain a blank preparing material; preparing a product workblank from the blank preparing material by virtue of apunching system; and carrying out pre-maintenance on the product workblank, and carrying out thermal air circulating reaction maintenance on the product workblank, so as to obtain the wall body block. The method has the beneficial effects that the problems in the effective treatment and resource utilization of the dehydrated sludge and industrial waste residue or engineering muck in the sewage treatment plant are solved, the cost is low, an obtained baking-free brick has excellent compressive strength, has no radioactivity, can be used for producing multiple specifications of wall body blocksand can be manufactured into building components for various uses.

Owner:宁波纯恒固废科技有限公司

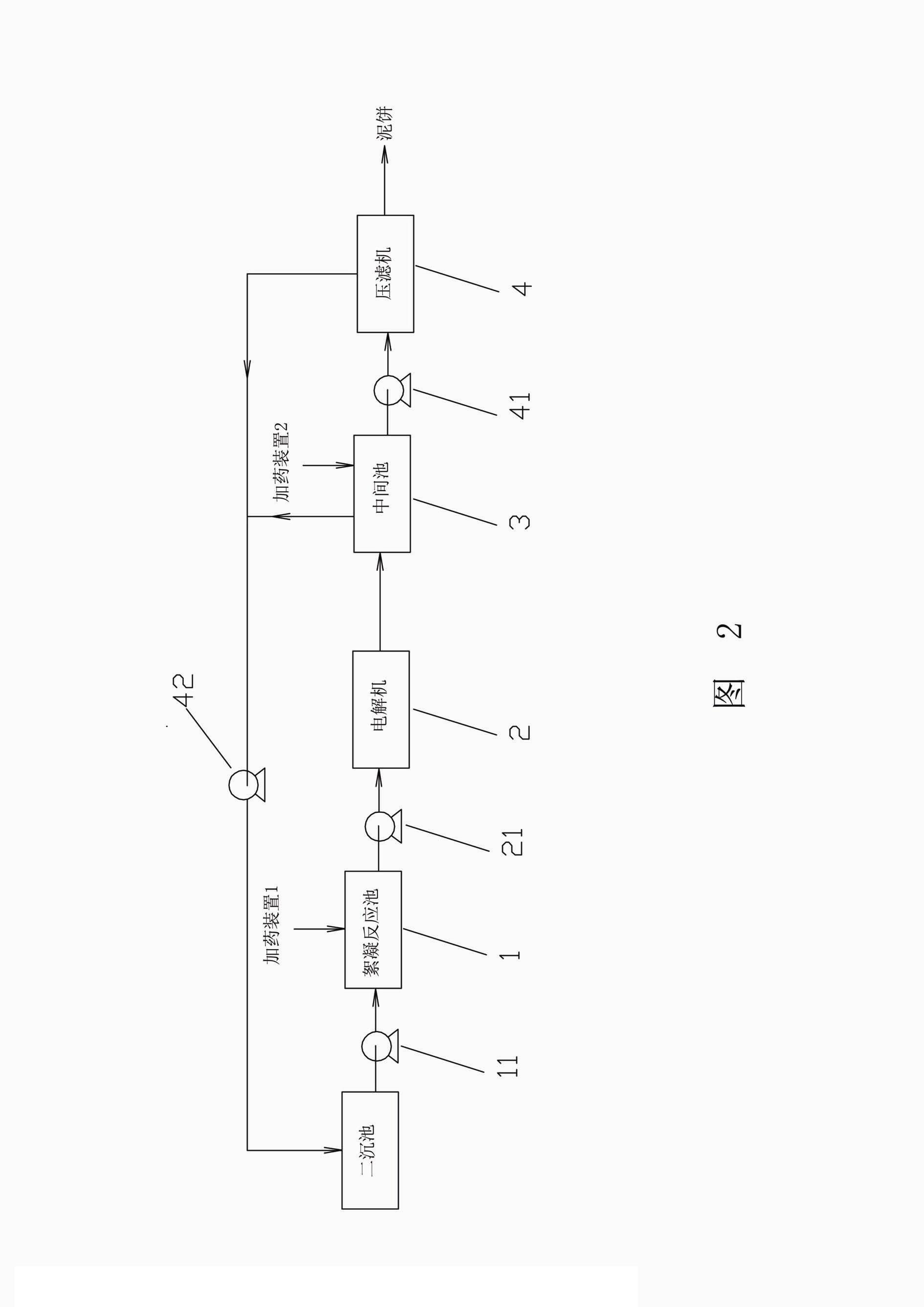

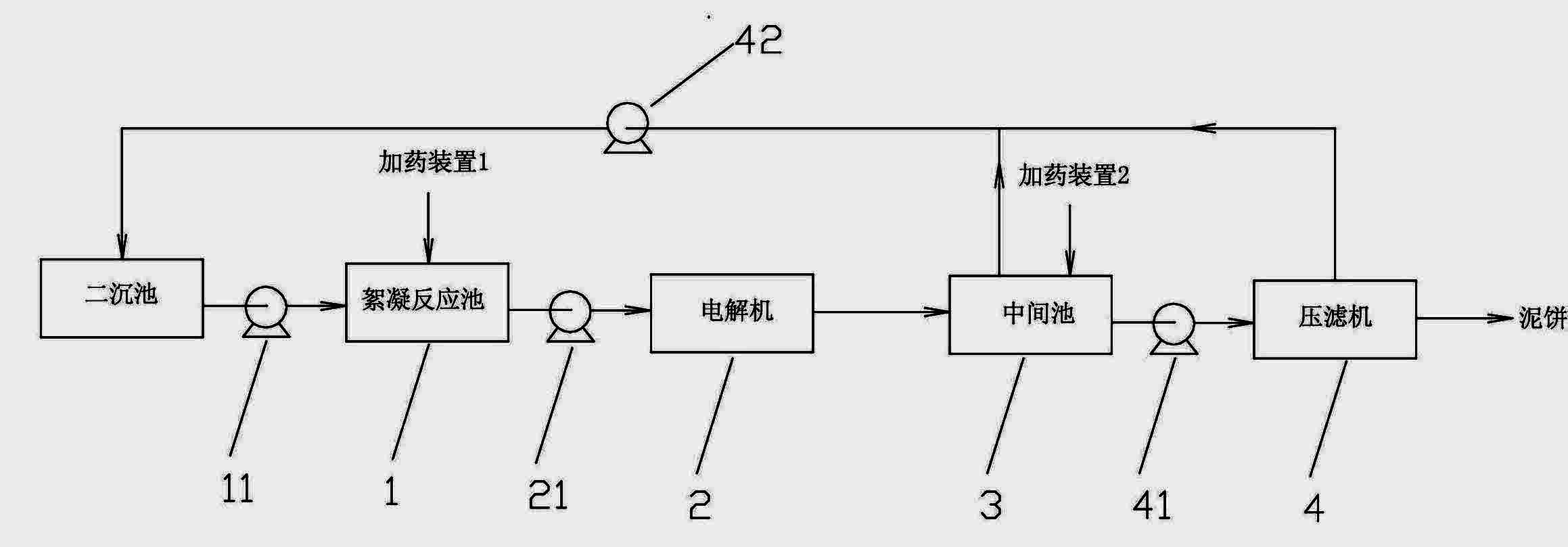

Sludge treatment device based on electrolysis and pressure filtration technologies and method thereof

InactiveCN102603132AImprove biodegradabilityImprove working environmentSludge treatmentFlocculationElectrolysis

The invention relates to a sludge treatment device based on electrolysis and pressure filtration technologies. The sludge treatment device is characterized in that the sludge treatment device is provided with a first-stage sludge pump, a flocculation reaction tank, a second-stage sludge pump, an electrolysis machine, an intermediate tank, a third-stage sludge pump, a sewage pump and a pressure filter, wherein an inlet of the flocculation reaction tank is linked with sludge outlets of the first-stage sludge pump and a secondary sedimentation tank of a sewage treatment plant through pipelines, an outlet of the flocculation reaction tank is linked with the inlet of electrolysis machine via the second-stage sludge pump, the outlet of the electrolysis machine is connected with the inlet of the intermediate tank, one line of the outlet of the intermediate tank is connected with the inlet of the pressure filter via the third-stage sludge pump, the other line of the outlet of the intermediate tank is connected with a water inlet of the secondary sedimentation tank via the sludge pump, and outlet water of the pressure filter is linked with the water inlet of the secondary sedimentation tank through the pipeline. A corresponding sludge treatment method comprises the steps of flocculation, sedimentation, electrolysis, settling separation and pressure filtration. The sludge treatment device and the corresponding sludge treatment method, disclosed by the invention, adopt electrolysis as pretreatment and further have the following prominent effects: (1) inhibiting and killing microorganisms and viruses in sludge; (2) deodorizing; (3) decomposing a large number of organic matters in the sludge; (4) decoloring; and (5) reducing the dosage of chemical agents in the follow-up sludge reduction process and reducing the sludge quantity by 30-45%.

Owner:BOYING XIAMEN SCI & TECH

Silkworm excrement innocent treatment method

InactiveCN102771451AIncrease temperatureAccelerate biodegradationAnimal husbandryDiseaseMicroorganism

The invention discloses a silkworm excrement innocent treatment method. The method comprises the following steps of: building a silkworm excrement chamber by a silkworm raiser by taking a family as a unit, uniformly spraying the silkworm excrement by using diluent formed by microorganism bacterium agents per liter with 70 to 100 kg of water after matured silkworm mount cocooning frame and before silkworm excrement cleaning, so that each liter of microorganism bacterium agents can spray 360 to 450 kg of silkworm excrement; conveying the silkworm excrement spayed by the diluent to a silkworm excrement chamber provided with a rainproof top cover and a port for performing retting fermentation; thoroughly decomposing the silkworm excrement after the retting fermentation within 10 to 20 days, recycling the silkworm excrement under the required conditions, otherwise spraying the diluent on the newly generated silkworm excrement and adding the silkworm excrement into the silkworm excrement chamber, and performing retting fermentation on the silkworm excrement stack which is being fermented or has been fermented. Due to the rate and operating steps of the microorganism bacterium agents and the silkworm excrement amount are controlled, the silkworm excrement is subjected to aerobic retting treatment, the silkworm disease pathogens are killed or inactivated by high temperature generated by utilizing the microorganism bacterium agent fermentation, and the aim of performing innocent treatment on the silkworm excrement is fulfilled.

Owner:柳州市农业科学研究所

Method for preparing sulphoaluminate cement by using fluorine-containing sludge

The invention provides a method for preparing sulphoaluminate cement by using fluorine-containing sludge, and belongs to the technical field of environmental engineering. The method comprises the following steps that 1, solidifying and desiccating fluorine-containing sludge; and 2, producing sulphoaluminate cement, wherein (1) preparation of raw materials: preparing the sulphoaluminate cement by using the following raw materials in percentage by weight: over 45 percent of CaO, 25 to 35 percent of Al2O3, less than 15 percent of SiO2, over 10 percent of gypsum and 1 to 3 percent of fluorine-containing sludge; (2) burning of chamotte: calcining the raw materials in a rotary kiln at the temperature of between 1,300 and 1,400 DEG C; and (3) preparation of cement: mixing 75 to 80 percent of the chamotte and 20 to 25 percent of the fluorine-containing sludge and grinding the chamotte and the fluorine-containing sludge until a specified specific surface area is reached. According to the method, the aims of innocent, stabilized and recycling use of sludge are achieved by adding the fluorine-containing sludge into the sulphoaluminate cement and burning the mixture of fluorine-containing sludge and the sulphoaluminate cement, so not only energy is saved, but also environment is protected and mankind is benefited.

Owner:苏州伟宇天诚环保科技有限公司

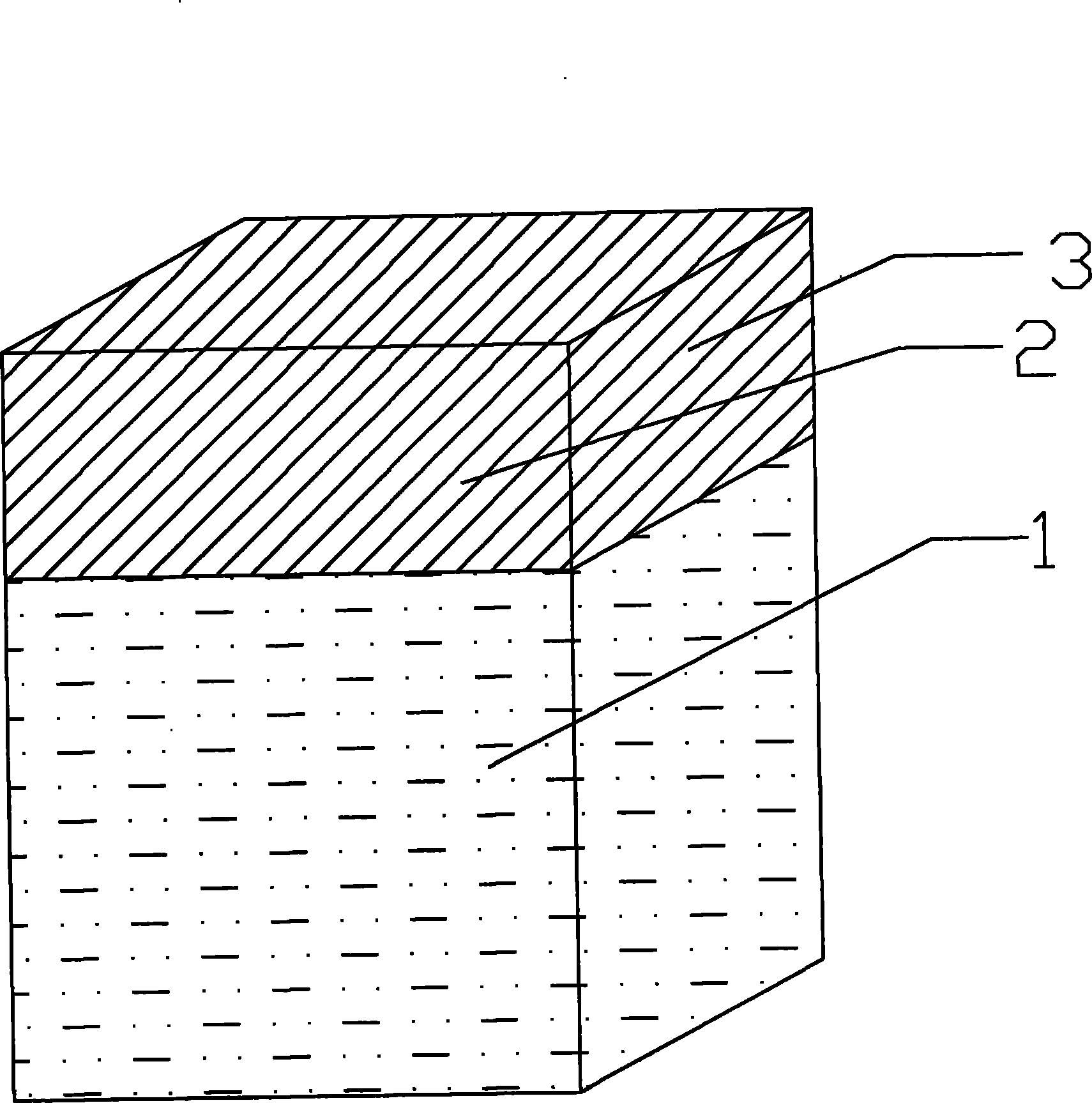

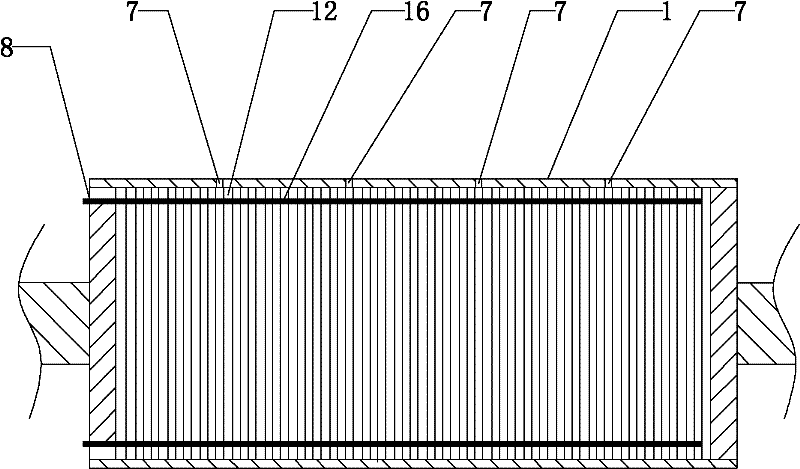

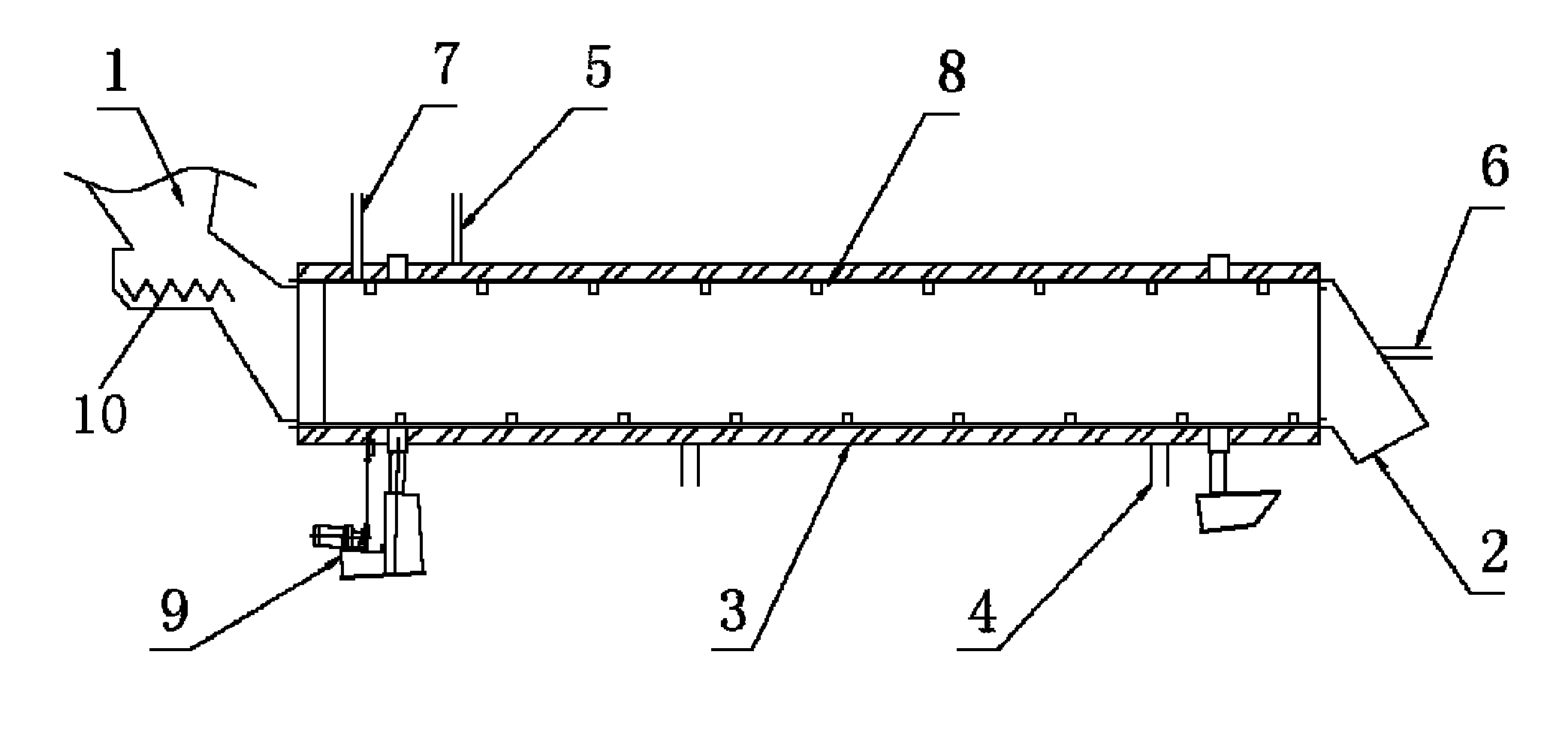

Continuous high-temperature sterilization dehydration equipment

InactiveCN102179396AAchieve reductionImprove processing efficiencySolid waste disposalDrying gas arrangementsEngineeringDehydration

The invention discloses continuous high-temperature sterilization dehydration equipment, which comprises a rotary drum, wherein the outer drum wall of the rotary drum is provided with an interlayer (3); the interlayer (3) is provided with a hot air inlet (4) and a hot air outlet (5) formed at two ends of the rotary drum; a discharge hole (2) is provided with a steam inlet (6); and the rotary drum is provided with a steam outlet (7) close to a feeding hole (1) of the rotary drum. The equipment can adopts two heating modes; one heating mode is that the equipment heats garbage through hot air in the interlayer (3) of the drum wall, high temperature steam entering the tail of the drum directly enters the drum to keep the temperature required by sterilizing the drum, and the whole equipment can work continuously; and the other heating mode is that the steam is only used for heating.

Owner:江苏神力起重设备有限公司

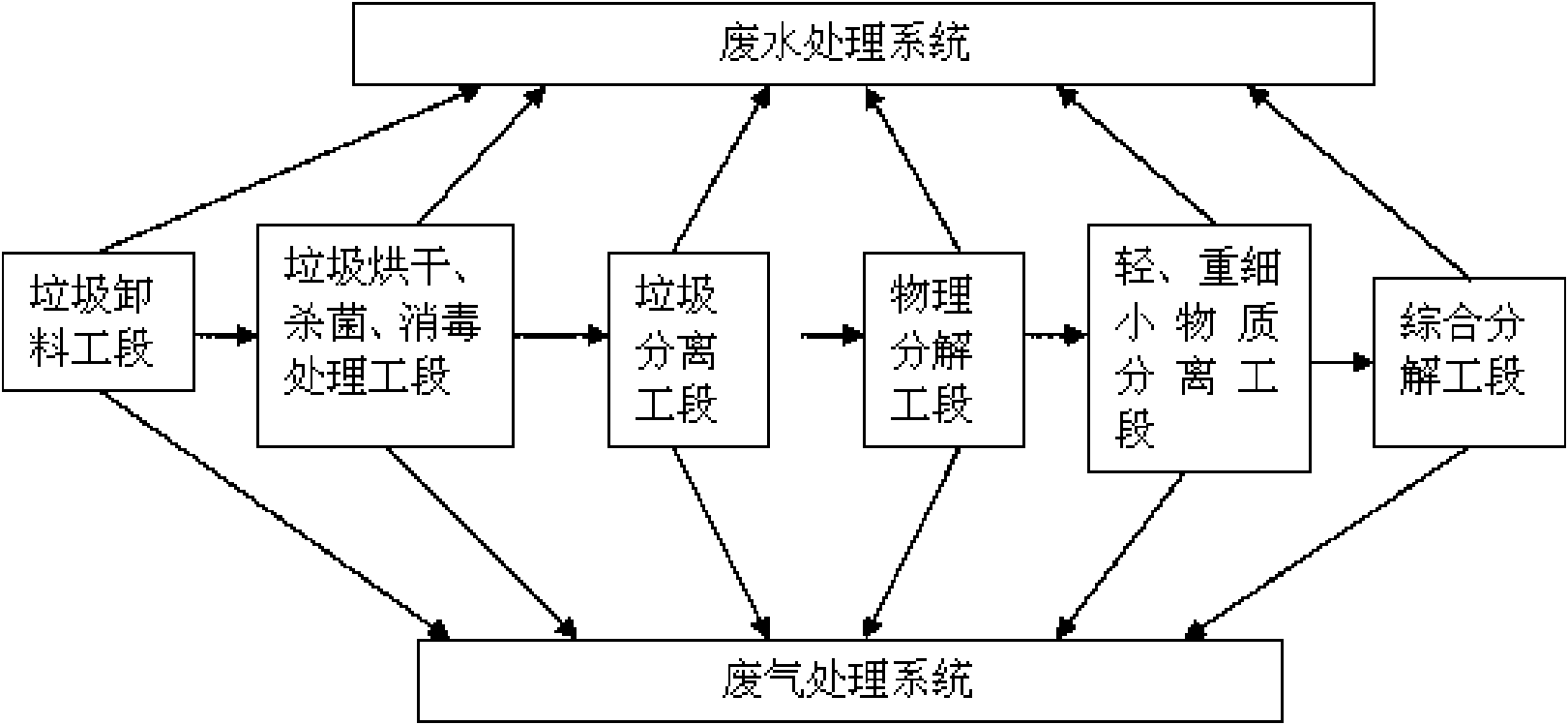

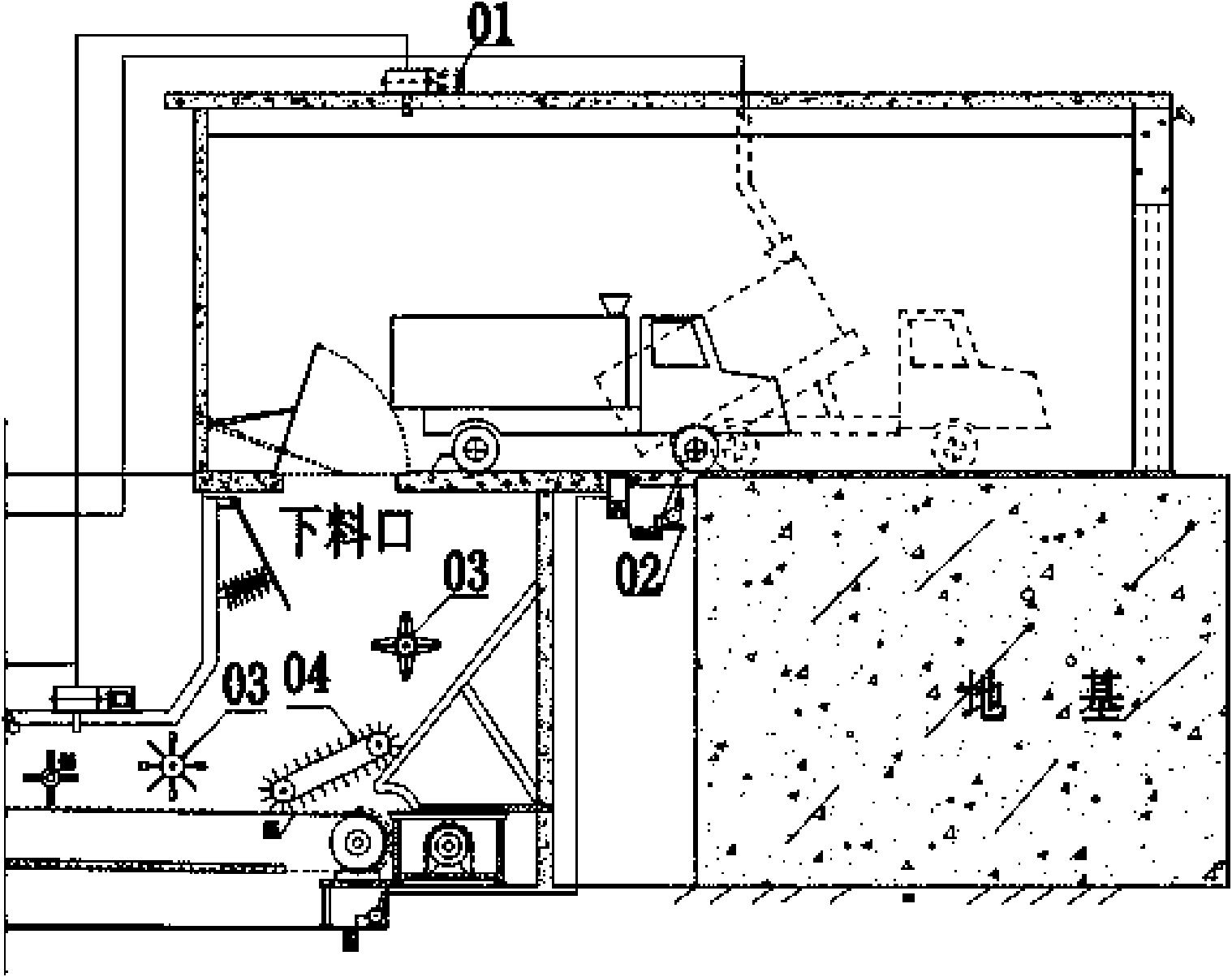

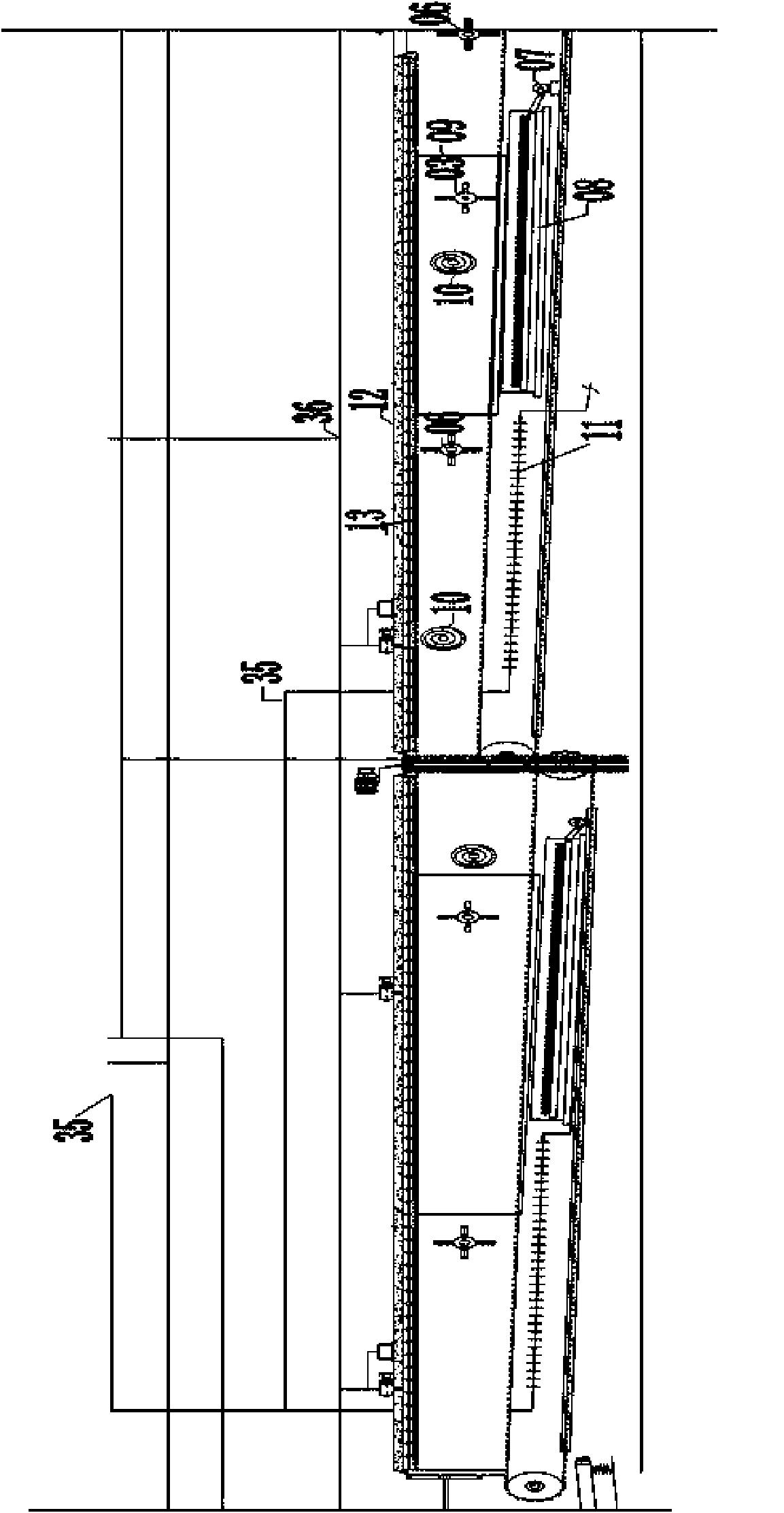

Complete decomposition processing process for urban domestic garbage substance

InactiveCN101628295AAchieve harmlessAchieve full resourcingSolid waste disposalWater/sewage treatment by magnetic/electric fieldsWater treatment systemLitter

The invention discloses a complete decomposition processing process for an urban domestic garbage substance, which comprises a garbage unloading bin working section, a garbage drying, sterilizing and disinfecting processing working section, a garbage separation working section, a physical decomposition processing working section, a light-weight, heavy-weight and thin substance decomposition working section, a comprehensive decomposition working section, a wastewater processing system and a waste gas processing system. The processing method and the process completely convert garbage into a reusable substance source in a state of completely seal and no odor and dust under the condition of no direct contact between a staff and the garbage on the premise of adopting a physical principle and not destructing substance properties. The garbage has no original property destruction and is completely converted into a non-poisonous and harmless substance in the processing process. The invention thoroughly replaces methods in an embedding way, a burning way, a composting way, and the like of the urban domestic garbage for a long time and really achieves the effects of processing the urban domestic garbage in ways of decontamination, complete recycling and thorough reduction.

Owner:吕小鸥

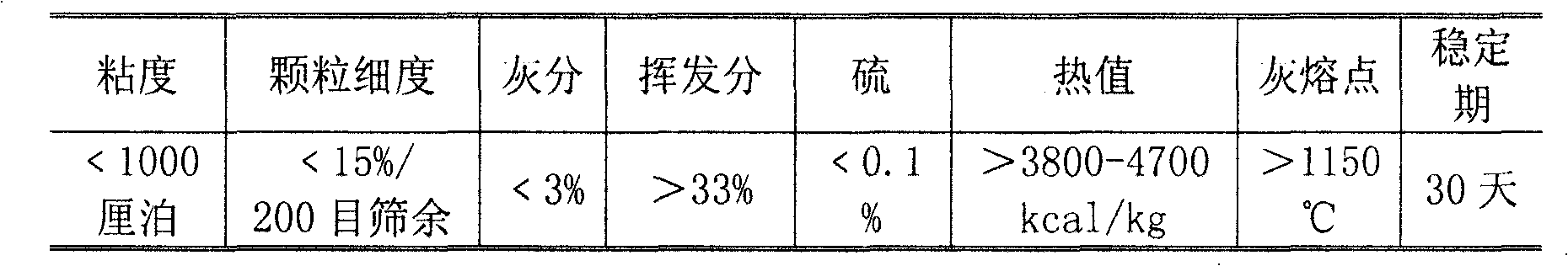

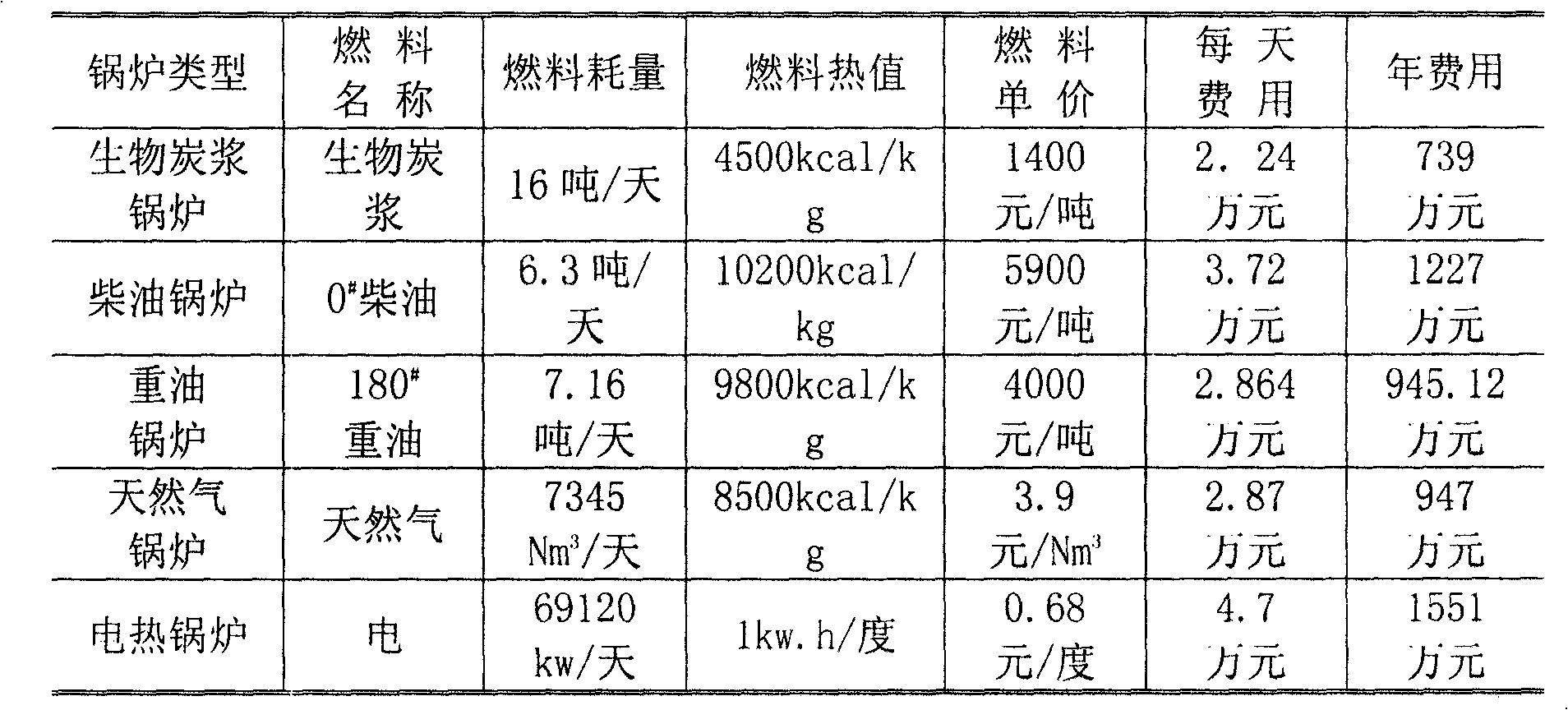

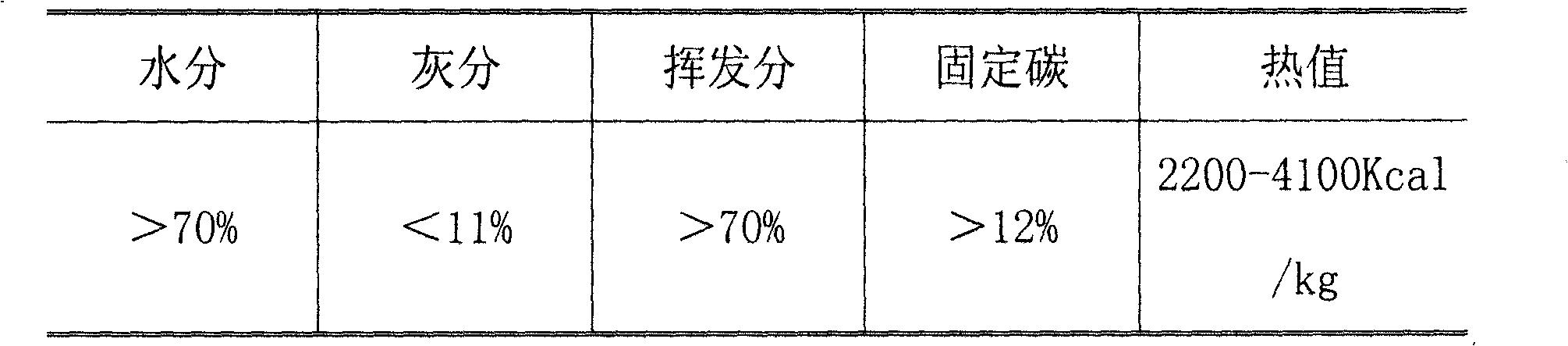

Biochar pulp prepared from garbage leachate serving as raw material and preparation process thereof

ActiveCN101787312AEmission reductionLow in sulfur and nitrogenLiquid carbonaceous fuelsPower stationEnvironmental engineering

The invention discloses a biochar pulp prepared from garbage leachate serving as a raw material and a preparation process thereof, and aims to provide the biochar pulp prepared from the garbage leachate serving as the raw material and the preparation process thereof, which have the advantages of the combination of energy saving and emission reduction and environmental management and low cost. Thepreparation process comprises the following steps of: mixing biochar, the garbage leachate, methanol, high-temperature sand and additives serving as raw materials; and crushing, homogenizing and filtering the mixed raw materials to prepare the biochar pulp. The biochar pulp is used for replacing fuel oil so as to effectively save energy and reduce fuel cost, plays a good part in managing urban environment, and fulfills the aims of promoting economic and environmental health and sustainable development. The biochar can be widely applied in the fields of substitute oil firing such as industrialboilers, power station boilers, industrial furnaces and the fields of urban environment management and the like.

Owner:珠海中水环保科技有限公司

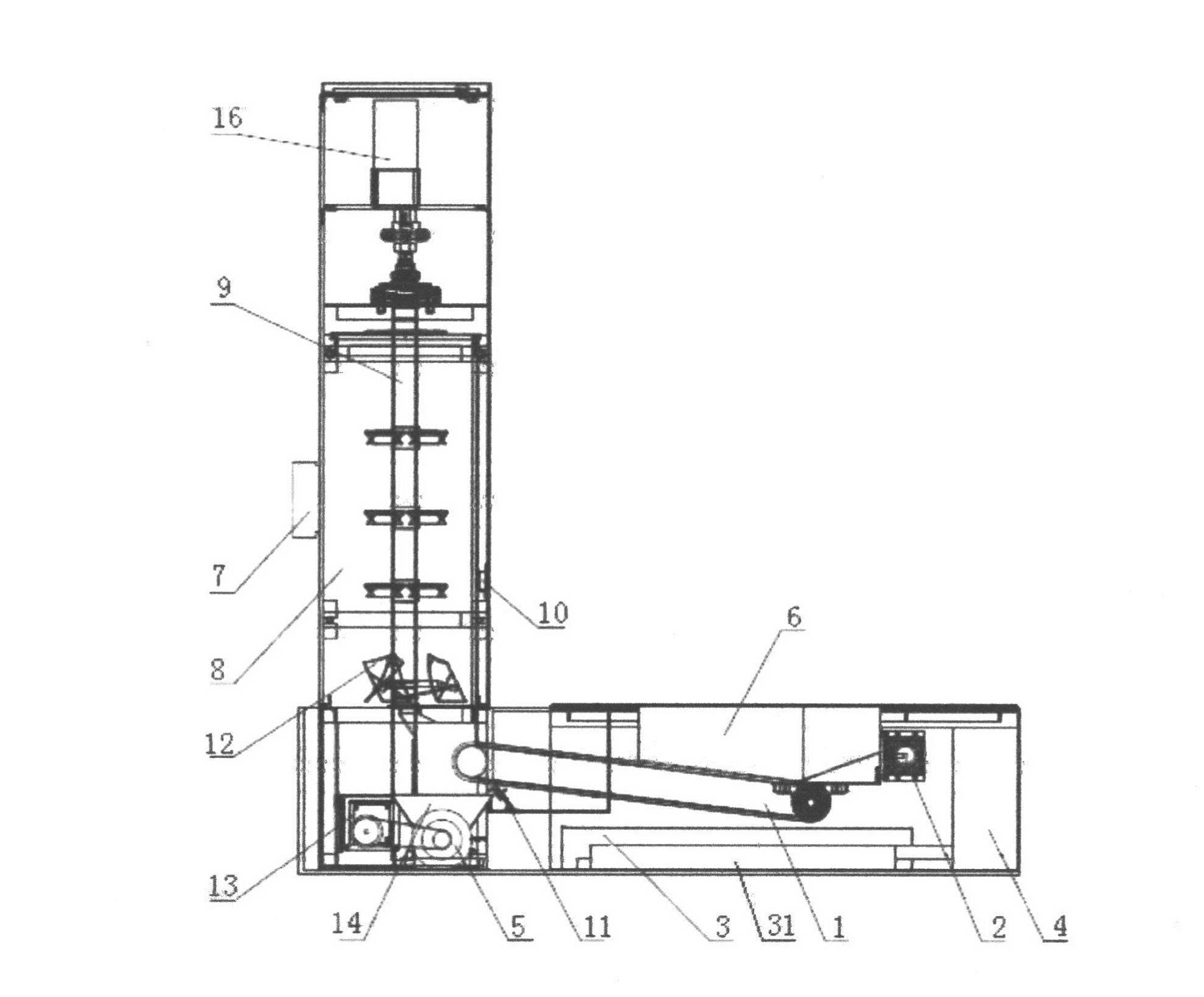

Source separated recycling water-free ecological restroom

ActiveCN102641092AAchieve reductionAchieve harmlessBathroom accessoriesMultistage water/sewage treatmentTherapeutic effectConveyor belt

The invention discloses a source separated recycling water-free ecological restroom comprising a source separation system and a dry bioreactor, wherein the source separation system comprises a closestool, a conveyor belt located below the closestool and inclining forward, a urine collecting tank located below the conveyor belt, and a urine nitrogen fixation and phosphorus extraction device communicated with the urine collecting tank; the dry bioreactor comprises three vertical reaction chambers; a stirring device is arranged in the first reaction chamber and vertical screws are arranged in both of the second reaction chamber and the third reaction chamber; the lower parts of the second reaction chamber and the third reaction chamber are communicated with each other through a transverse auger conveyor which is located below the rear end of the conveyor belt; and the auger conveyor is provided with an opening corresponding to the rear end of the conveyor belt. The source separated recycling water-free ecological restroom has the advantages of being completely free of water, capable of recycling materials, simple to maintain, low in operating cost, free of secondary pollution and limit on the number of people using the restroom, odorless, good in sanitation condition, excellent in treatment effect, low in occupied space and on the like.

Owner:CHANGSHA HYSO ENVIRONMENTAL BIOTECH

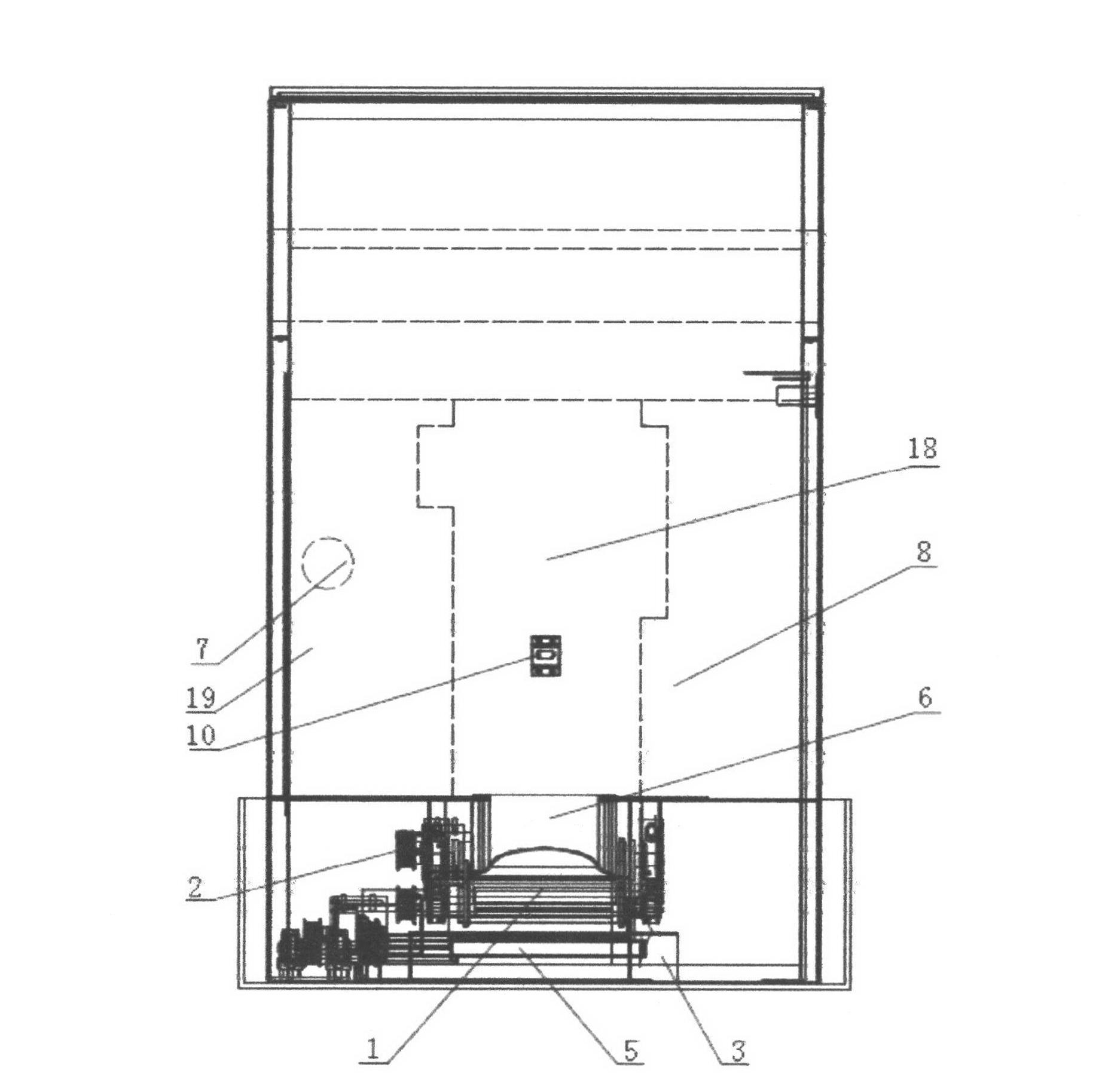

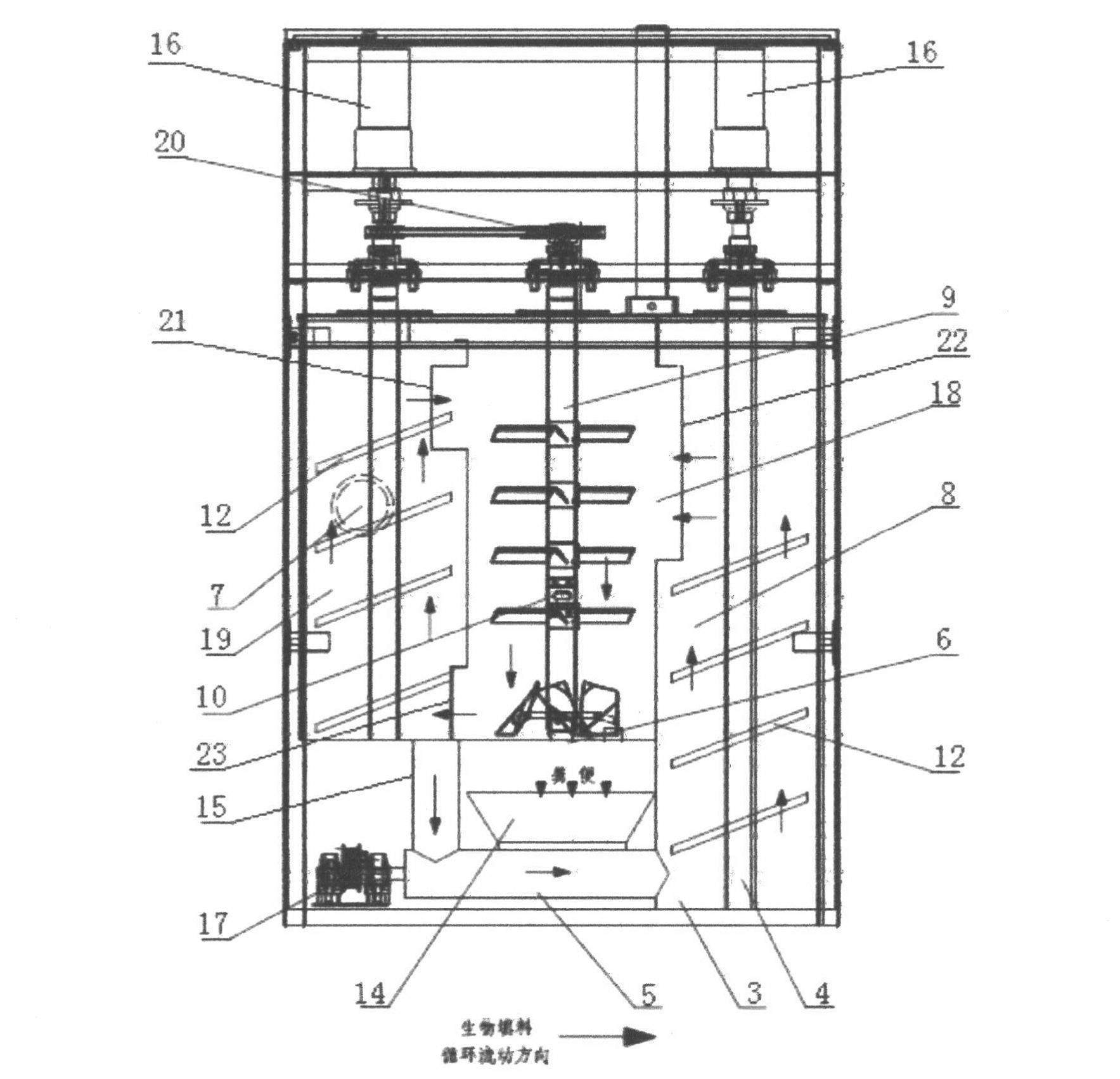

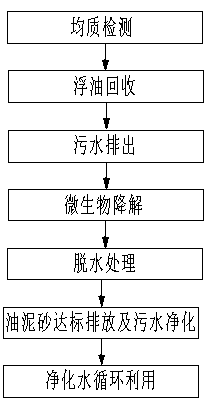

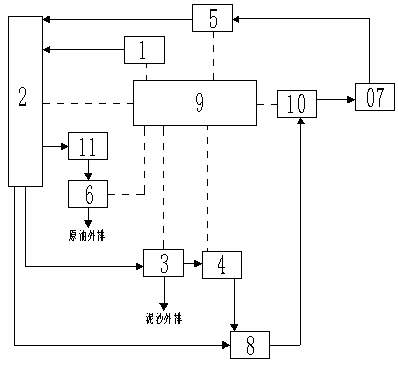

Microbiological treatment technology for oil-containing silt in oil field and processing system thereof

PendingCN108821528AEnable recyclingShort cycleWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningWater cyclingOil field

The invention belongs to the technical field of oil field environmental protection, and relates to a microbiological treatment technology for oil-containing silt in oil field and a processing system thereof. The method comprises seven steps of homogeneity detection, floating oil recovery, sewage discharge, microbe degradation, dehydration treatment, standard discharge of oil-containing silt, sewage purifying, and purified water reutilization, and the microbiological treatment system comprises a feeding apparatus, a microbiological treatment apparatus, a dehydrated apparatus, a sewage treatmentapparatus, a filtering apparatus, a water storage apparatus, a circulating pump, a crude oil retrieving apparatus, a control apparatus, and a circulating pump. The system has the advantages of simpleprocessing flow and short processing period, greatly recovers crude oil in the oil-containing silt, realizes harmlessness processing of the oil-containing silt, and has low cost, sewage in the system can be recycled, and a purpose of resourcing and harmlessness of the system can be achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

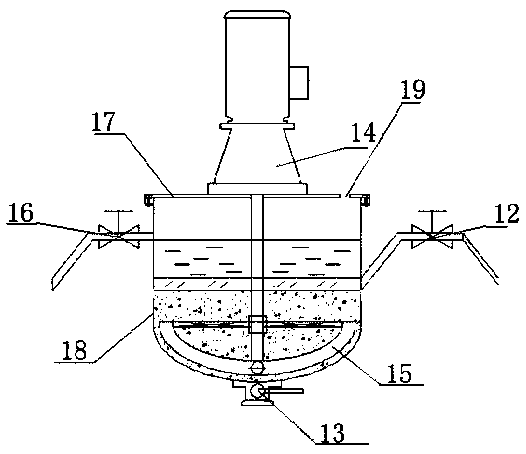

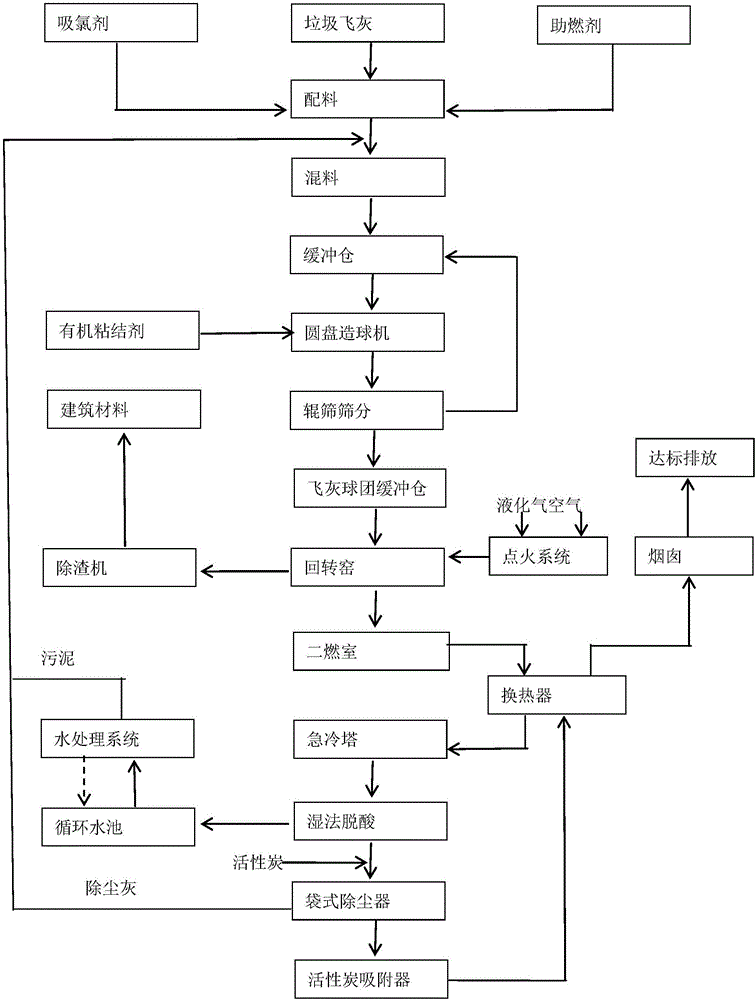

Method for achieving harmless disposal of garbage fly ash by means of rotary kiln technology

InactiveCN106524183ANo secondary pollutionAchieve harmlessEmission preventionCombustion technology mitigationFlue gasFly ash

The invention provides a method for achieving harmless disposal of garbage fly ash by means of a rotary kiln technology. According to the method, the rotary kiln technology is utilized, the processes of burdening, uniform mixing, pelleting, screening, feeding, igniting, calcining, residue collecting, flue gas purifying and the like are used for achieving harmless disposal of the garbage fly ash, harmless disposal is achieved, and meanwhile residues can be used as building materials, so that the purposes of harmlessness, stabilization, reduction and reclamation of the garbage fly ash are achieved.

Owner:重庆兴满和企业管理咨询有限公司

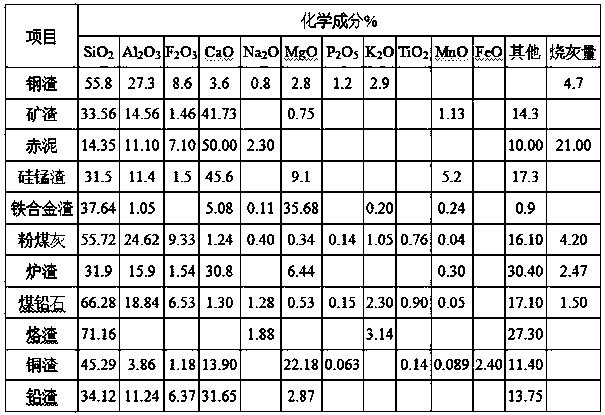

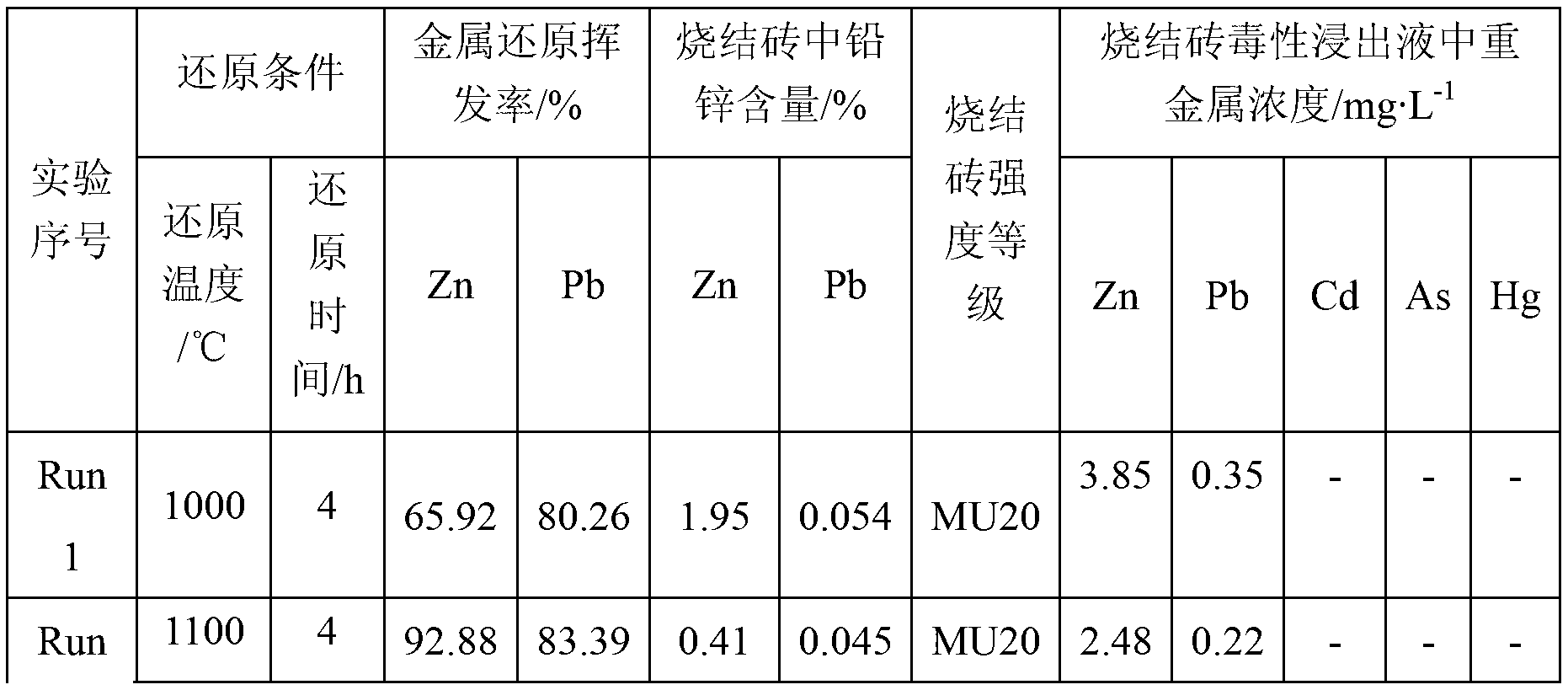

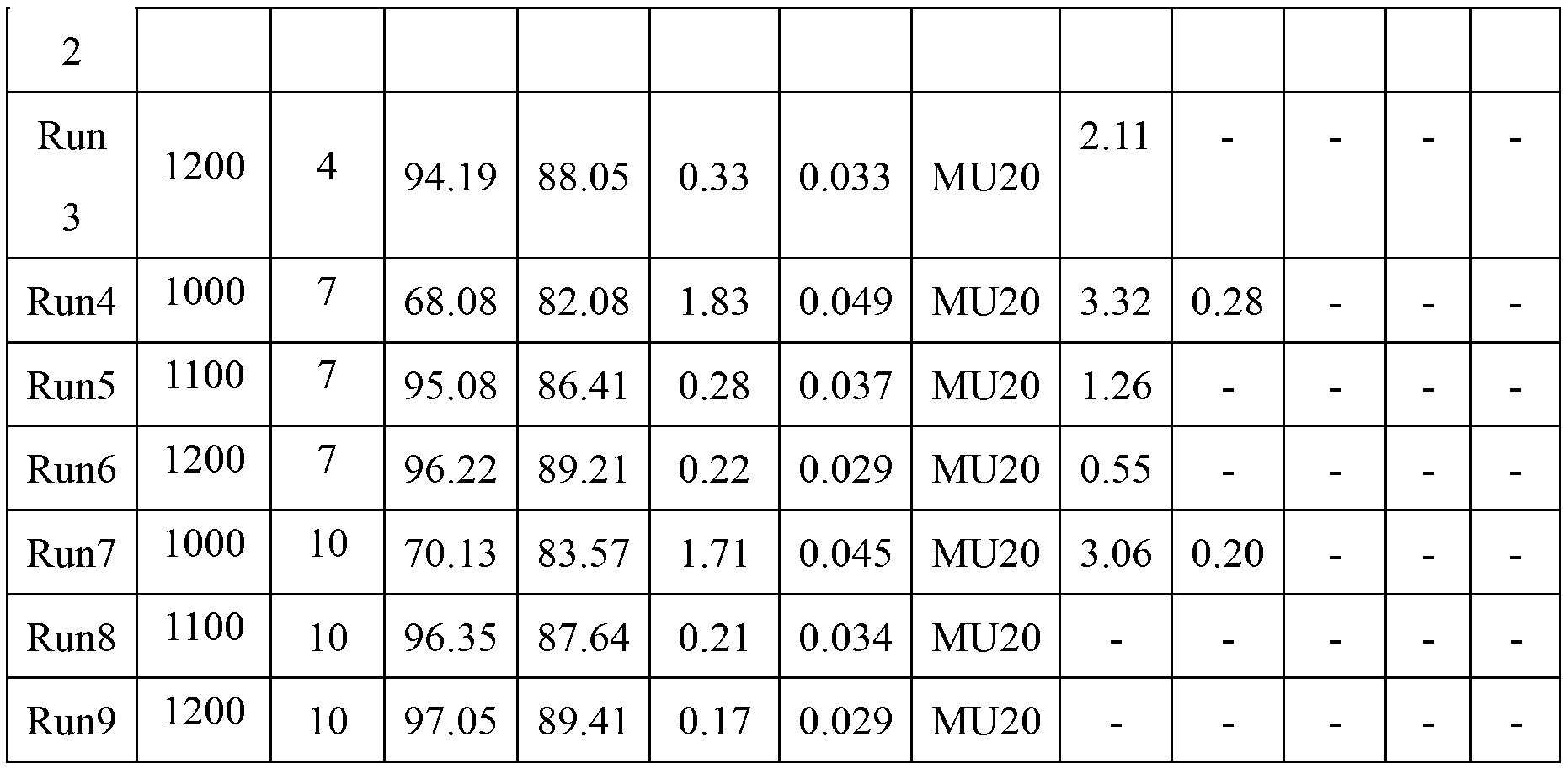

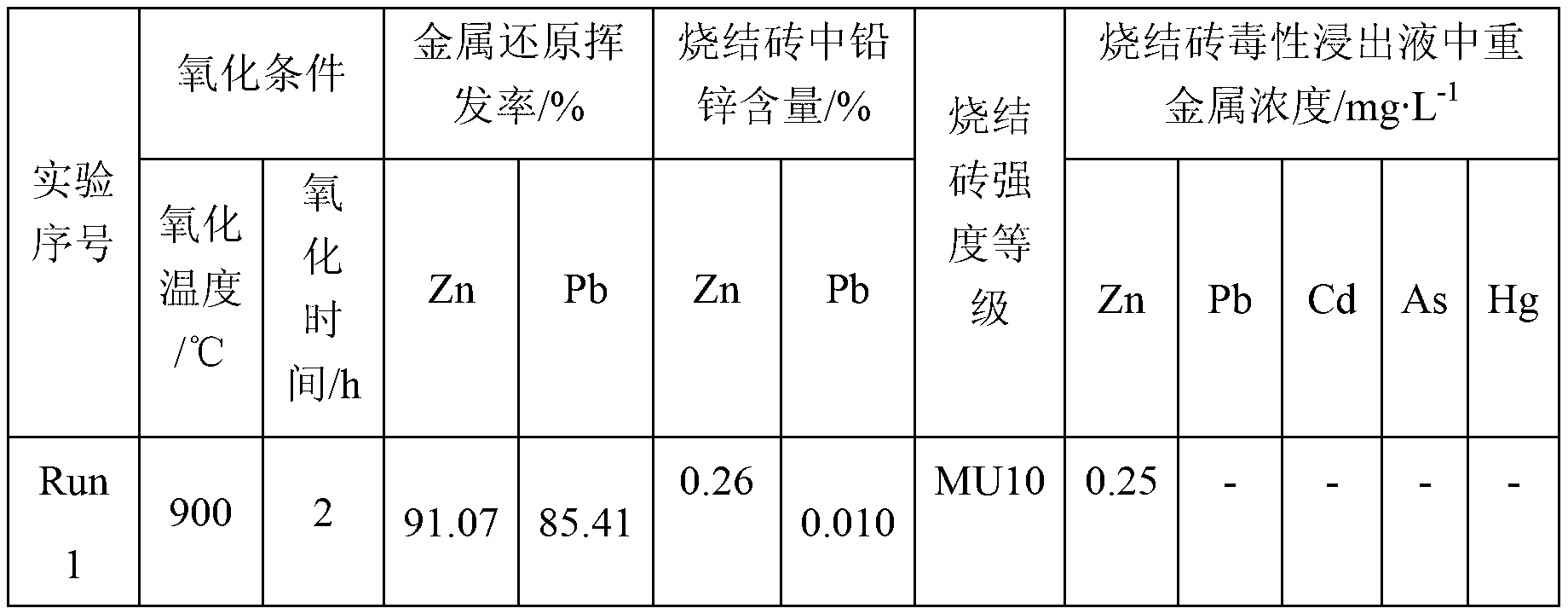

Recycling method for zinc-containing waste residue and urban domestic sludge

The invention relates to a recycling method for zinc-containing waste residue and urban domestic sludge. The recycling method comprises the following steps of: a, crushing and sieving the indigenous zinc-smelting waste residues; b, uniformly mixing 40%-80% (in percentage by weight) of the indigenous zinc-smelting waste residues with 20%-60% of urban domestic sludges, and ageing the mixture under the normal temperature; c, pressing and forming the aged mixture, an drying the pressed and formed mixture to obtain a dry body; d, reducing and volatilizing the dry body in a high-temperature sealed furnace, and collecting the volatile component to obtain the zinc-enriched smoke dust, wherein the reducing temperature is 1000 DEG C to 1200 DEG C and the reducing time is 6 hours to 10 hours; and f, ventilating air to the high-temperature sealed furnace for oxidizing and roasting, wherein the oxidizing and roasting temperature is 900 DEG C to 1100 DEG C and the oxidizing time is 2 hours to 8 hour, and cooling with the furnace to obtaine a sintered brick.

Owner:CENT SOUTH UNIV +1

Sludge processing method

InactiveCN103449688AAchieve stabilizationAchieve harmlessSludge treatment by de-watering/drying/thickeningBiofuelsSludgeConveyor belt

The invention relates to a sludge processing method, the sludge processing method comprises the following steps: A, crushing combustible waste into granular; B, using a mixer to mix sludge having the water content of 70%-80% and the granular combustible waste together to reduce the water content of a mixed mixture to 40%-60%; C, conveying the mixed mixture into an extruder by a conveyor belt, again performing extrusion dehydration treatment of the mixture by the extruder to reduce the water content of the mixed mixture to 10%-15%; and D, performing finished-product shape molding treatment of the mixture in step C by a shaping machine; and the molded mixture is convenient to store and transport. According to the sludge processing method, a combustible matter is prepared by simple mixing, extruding, shaping and drying of the sludge and the combustible waste of wood dust and wood residue or balloonflower root and rice husk, and the like, various harmful substances in the sludge are killed, and secondary pollution of the sludge on the environment and occupation of land can be reduced.

Owner:SUZHOU KEYU ELECTRONICS TECH SERVICE

Harmless oil mud treatment process

InactiveCN105254144AAchieve harmlessLow costSludge processingBiological sludge treatmentMicroorganismPseudomonas putida

The present invention belongs to the field of environmental protection, and discloses a harmless oil mud treatment process, which comprises four steps such as oil mud fluidization, biological treatment, sludge dewatering and biological induction, and comprises that Candida lipolytica Y-57 and Pseudomonas putida P-101 are poured into a biological reaction tank, an aeration biological reaction is performed to achieve the oil content in the oil mud (calculated as the absolute dry mud) of less than 3% and the oil content in the water of less than 130 mg / L, the floating oil on the upper portion of the water surface is recycled through an oil collection device, the fine mud sand on the bottom portion achieves the standard emission, and the oil mud enters the sludge dewatering step. According to the present invention, the microbial treatment method, the biological induction method and the mechanical method are combined, such that the oil content in the sludge can achieve the 0.5% standard, the sludge environment can be recovered, and the resource and harmlessness purpose can be achieved.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Microbiological oil sludge treatment process

ActiveCN103449695AReach resourcesAchieve harmlessSludge processingBiological sludge treatmentLaboratory cultureBiology

The invention belongs to the environment-friendly field and discloses a microbiological oil sludge treatment process. The microbiological oil sludge treatment process comprises four steps of oil sludge fluidization, biological treatment, sludge dehydration and biological induction, wherein the biological treatment step is to add candida lipolytica Y-57 with a preservation number of CGMCC (China General Microbiological Culture Collection Center) No.5790 and pseudomonas putida P-101 with the preservation number of CGMCC No.5801 into a biological reaction tank, wherein after aeration biological reaction, in terms of absolute dry mud, the oil content of the oil sludge is less than 2%, and the water contains less than 150mg / L of oil; floating oil on the upper part of water surface is recycled by an oil receiving device, fine sediment on the bottom is exhausted after reaching the standards, and the oil sludge enters the sludge dehydration step. According to the microbiological oil sludge treatment process disclosed by the invention, a microbiological treatment method, a biological induction method and a mechanical method are combined for application, so that the oil content of the sludge reaches 0.3%-standard to recover a sludge environment, thereby achieving a purpose of recycling and hazard-free treatment.

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

Treatment method for landfill leachate membrane treatment evaporated and concentrated liquor

InactiveCN108911324AFast curingStrong penetration resistanceWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSulfateTherapeutic effect

The invention discloses a treatment method for landfill leachate membrane treatment evaporated and concentrated liquor. The treatment method is characterized in that sulfate aluminum cement is adopted, and has high curing speed and strong permeability resistance in comparison with conventional silicate cement. Silicate cement, a heavy metal ion chelating agent and an additive are taken as curing agent main components, and can be effectively combined with pollutants such as organic substances and heavy metal in landfill leachate membrane treatment evaporated and concentrated liquor, so that thepollutants are cured in a curing body, and therefore, the harmless and stable purpose is achieved. The treatment method is simple in process, is high in practicability, is good in treatment effect, is taken as a deep treatment technology, makes up the defects of an existing landfill leachate membrane treatment evaporated and concentrated liquor treatment technology, and effectively solves the treatment problem of the landfill leachate membrane treatment evaporated and concentrated liquor.

Owner:武汉天源环保股份有限公司

Process of synthesizing high purity iolite material with industrial sludge from aluminium section plant

InactiveCN1609034ATo achieve resourceAchieve benefitsSolid waste managementSolid waste disposalSludgeSolid reaction

The present invention is process of synthesizing high purity iolite material with industrial sludge from aluminum section plant. The materials include industrial sludge from aluminum plant 48-50 wt%, talcum powder 24-25 wt%, clay 25-27 wt% and TiO2 0-3 wt%; and the synthesized product has iolite content over 95 % and mullite content of 0.5-5 wt%. The present invention uses the sludge from aluminum plant with large surface area and high activity favorable to solid phase reaction and sintering as main material, and has high economic utility and social utility.

Owner:FUZHOU UNIV

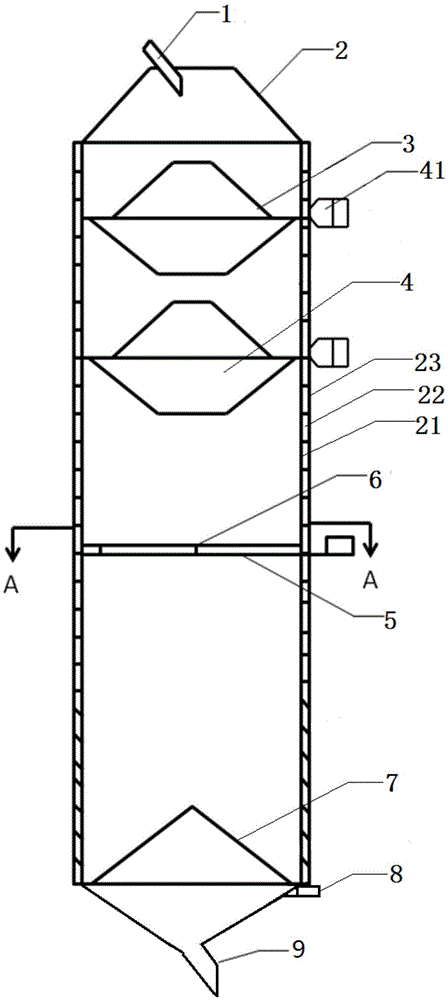

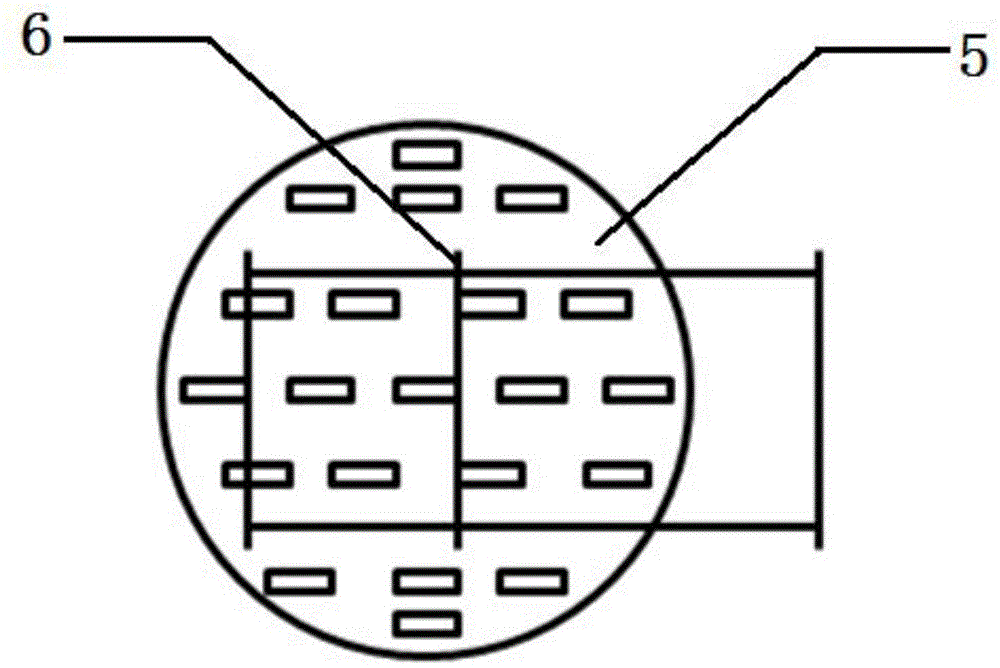

Vertical type drying and incineration equipment for municipal sludge

ActiveCN105541076AAchieving self-sustaining incinerationSimplify the incineration processSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSlagSludge

The invention discloses vertical type drying and incineration equipment for municipal sludge. The vertical type drying and incineration equipment comprises a furnace body, a feeding pipe arranged at the top of the furnace body, and a slag discharging pipe arranged at the bottom of the furnace body, wherein a preheating region, a drying region, an incineration region, a cooling region and a crushing region are arranged in the furnace body in sequence from top to bottom; the preheating region is positioned below the feeding pipe and consists of a plurality of groups of bulk grate cones and preheated grate basins which are combined in different angles and stacked up and down; the drying region comprises a drying fire grate and a scraper blade arranged on the drying fire grate; the incineration region is positioned below the drying fire grate and allows sludge for self maintaining incineration; the cooling region is a furnace slag cooling region communicated with the incineration region; the crushing region comprises a crushing tower grate communicated with the furnace slag cooling region; the bottom of the crushing tower grate is communicated with the slag discharging pipe. The vertical type drying and incineration equipment has the advantages that drying and incineration of the municipal sludge are integrated; no other fuel is added other than fire, so that self maintaining incineration of the municipal sludge is realized; therefore, an incineration treatment technology for the municipal sludge is simplified, and reducing, stable, harmful and resourceful treatment is realized.

Owner:YANCHENG INST OF TECH

Sound absorption ceramic panel using kitchen waste as raw material and preparation method thereof

The invention discloses a sound-absorbing ceramic plate using kitchen waste as raw material and preparation method thereof. Through a drying process, organic matter of kitchen solid waste ecological material are used as raw material, charring in a high temperature nitrogen protective stove to form porosint. Smashing charring matter then adding with pore forming agent such as eleaostearic acid, oxene resin and PVC resin powder, the mixture is mixed fully through uniform stirring and supersonic wave oscillation. After oscillation, the mixture material is filled in a molding cavity under pressure, then putting into an oven to cure; a sound-absorbing ceramic plate is got after natural cooling. The preparation technology of the invention is simple, has low cost, raw material is kitchen waste, can get harmless rubbish with decrement, resource treatment when getting sound-absorbing ceramic plates. The sound-absorbing ceramic plate can be applied to construction business and decoration field.

Owner:ZHEJIANG SCI-TECH UNIV

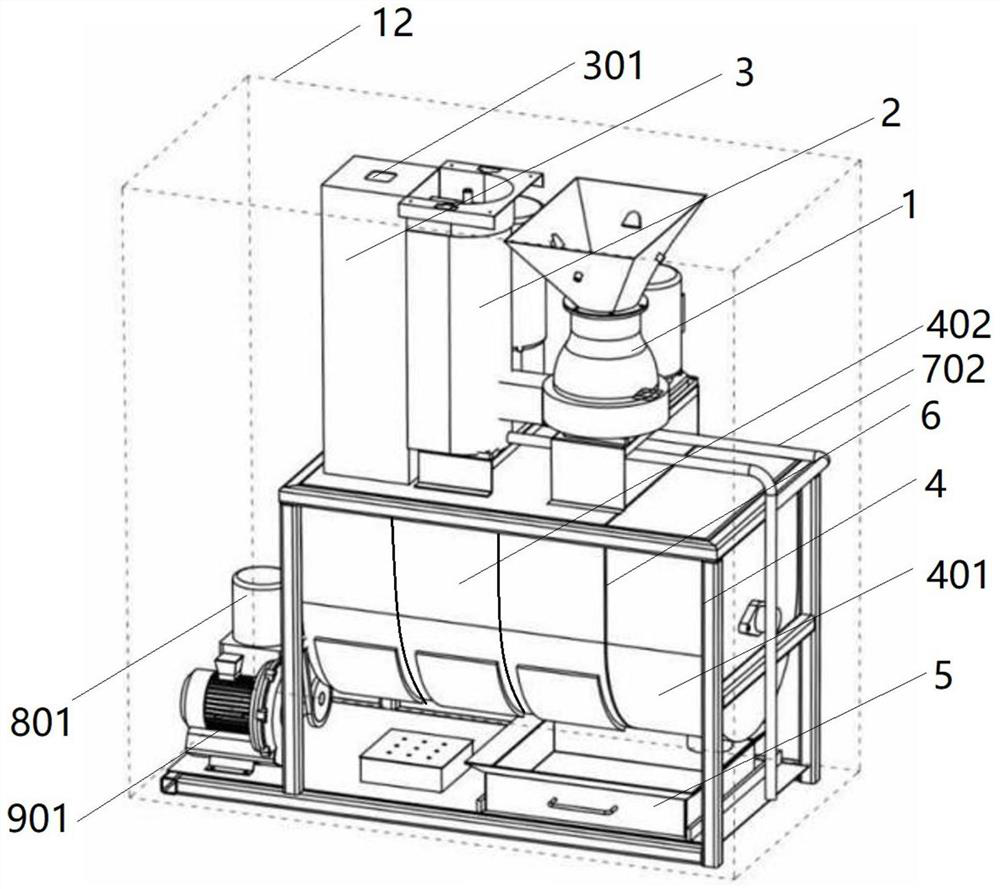

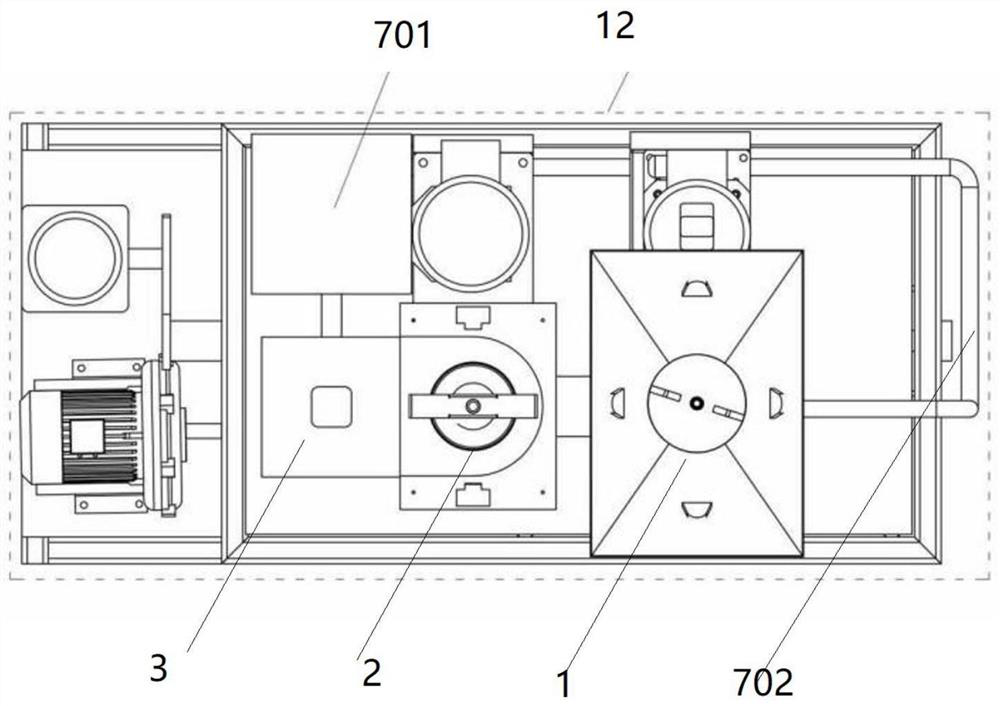

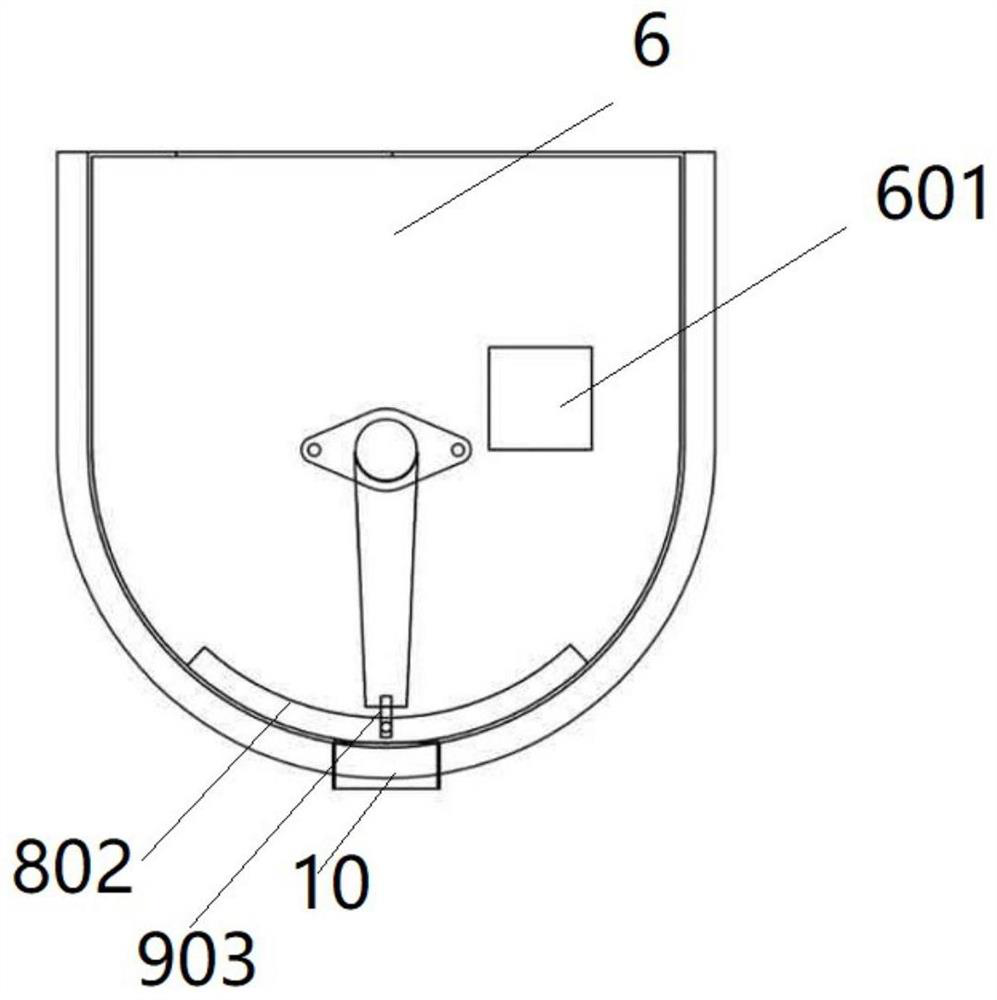

Integrated household kitchen waste composting equipment

PendingCN111662100AEasy to operateNo manual operationClimate change adaptationOrganic fertilisersEnvironmental engineeringRefuse Disposals

The invention discloses integrated household kitchen waste composting equipment which comprises a feeding and crushing device; a squeezing device; a feeding channel on which a strain inoculation portis formed; and a biochemical system, wherein kitchen waste enters the biochemical system sequentially through the feeding and smashing device, the squeezing device and the feeding channel, and a microbial inoculum enters the biochemical system through the feeding channel; the biochemical system comprises a biochemical bin and a post-decomposition bin; the biochemical bin is axially divided into aplurality of bin bodies, every two adjacent bin bodies are separated through a partition plate, holes are formed in the partition plates, the last bin body is a discharging bin, the other bin bodies are fermentation bins, a feeding port is formed in the first fermentation bin and communicated with the feeding channel, and a discharging port is formed in the discharging bin and communicated with the rear decomposing bin. The biochemical bin is provided with an aeration device, a stirring device and a heating device. According to the equipment, the kitchen waste is treated by adopting bin separation type fermentation so that the operation process is simplified, the labor and time costs are reduced, the fertilizer is rapidly formed, and secondary pollution is avoided while the recycling efficiency is improved.

Owner:ZHONGNONGXINKE SUZHOU ORGANIC RECYCLING RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com