Dairy manure biological organic fertilizer and preparation method thereof

A bio-organic fertilizer and cow dung technology, applied in the agricultural field, can solve the problems of being easily affected by weather, large area and long processing time, and achieve the effects of improving comprehensive resistance, high temperature, and rapid and sufficient decomposing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

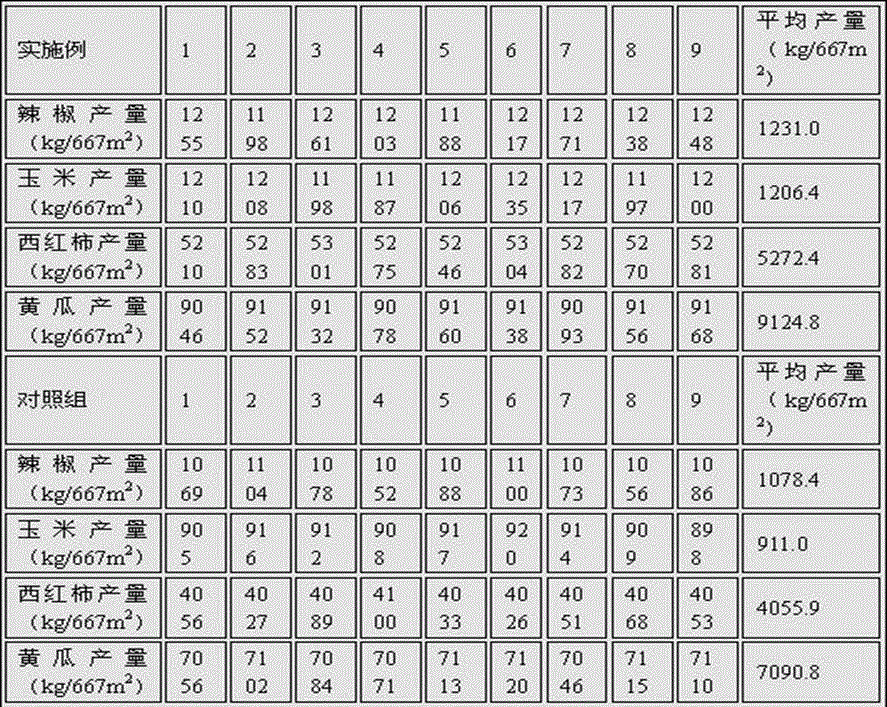

Examples

Embodiment 1

[0027] Weigh 1000kg of cow dung and 200kg of straw, pre-built a drying shed with four walls left empty, spread the cow dung evenly in the drying shed for natural drying until the water content of the cow dung is 20%, then crush the cow dung; Crushing, mixing the crushed cow dung and straw evenly, the pre-fermented material is processed in a pile, and the water content is controlled to 50% by spraying to add water; then 1kg of compound is sprayed evenly on the piled fermented material Strains and 0.5kg of compound fermentation enzymes are covered with waterproof materials on the fermentation materials to avoid rain; oxygen is regularly introduced into the fermentation materials during the fermentation period to control the temperature of the fermentation materials. When the temperature reaches 50℃, The pile of fermented materials is turned over; after 5 days of fermentation, the materials are kept in the state of piles without oxygen and controlled temperature. After aging for 2 ...

Embodiment 2

[0031] Weigh 1100 kg of cow dung and 240 kg of straw, pre-built a drying shed with four walls left empty, spread the cow dung evenly in the drying shed for natural drying until the moisture content of the cow dung is 18%, then crush the cow dung; Crush, mix the crushed cow dung and straw evenly, and process the pre-fermented material into a pile, and control its moisture content to 54% by spraying to add water; then spray 1.5kg evenly on the piled fermented material Compound strains and 0.8kg of compound fermentation enzymes are covered with waterproof material on the fermentation materials to avoid rain; during the fermentation period, oxygen is regularly introduced into the fermentation materials to control the temperature of the fermentation materials. When the temperature reaches 56°C, Turn over the pile of fermented materials; after 6 days of fermentation, keep the materials in the state of piles, no more oxygen and control the temperature, and aging for 3 days.

[0032] The...

Embodiment 3

[0035] Weigh 1200kg of cow dung and 280kg of straw, pre-built a drying shed with four walls left empty, spread the cow dung evenly in the drying shed for natural drying until the moisture content of the cow dung is 15%, then crush the cow dung; Crushing, mixing the crushed cow dung and straw evenly, the pre-fermented material is processed in a pile, and the water content is controlled to 57% by spraying to add water; then 1.7kg is sprayed evenly on the piled fermented material Compound strains and 1kg of compound fermentation enzymes are covered with waterproof material on the fermentation materials to avoid rain; during the fermentation period, oxygen is regularly introduced into the fermentation materials to control the temperature of the fermentation materials. When the temperature reaches 60℃, The pile of fermented materials is turned over; after 7 days of fermentation, the materials are kept in the state of piles, no oxygen is supplied and the temperature is controlled, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com