Garbage thermal cracking treatment technology

A pyrolysis treatment and preheat treatment technology, applied in the removal of solid waste, etc., can solve the problems of incomplete decomposition, easy environmental pollution, large land occupation, etc., achieve reasonable design of steps and procedures, solve environmental pollution, and achieve zero emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

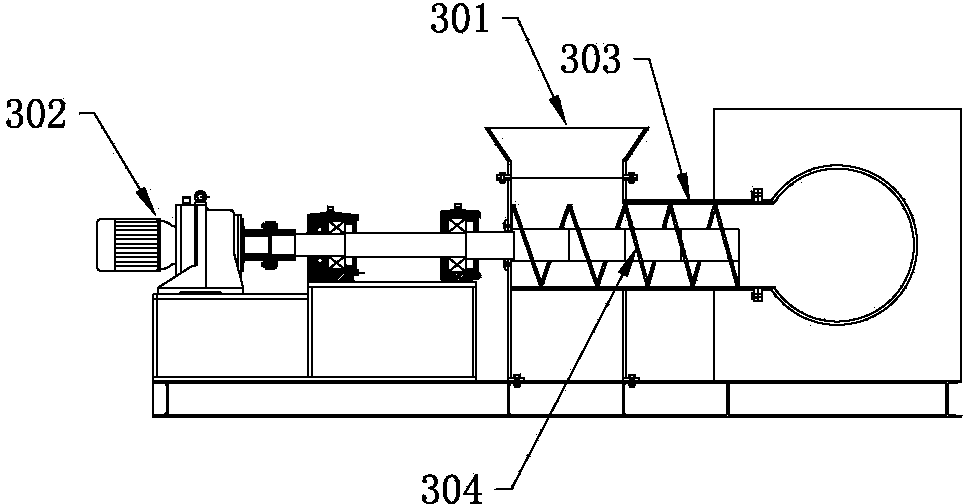

[0050] A kind of rubbish crushing and cracking treatment process of the present embodiment comprises the following steps,

[0051] (1) Coarse crushing, the garbage is sent to the first crusher for crushing, and inorganic substances such as stones, bricks and sediment are sorted out;

[0052] (2) Magnetic separation, using iron remover or magnetic separator to remove magnetic metal;

[0053] (3) Screening, using a screening device to screen the garbage treated by magnetic separation to remove sand, soil and stones with a large proportion;

[0054] (4) Fine crushing, sending the sieved garbage into the second shredder for further crushing;

[0055] (5) Drying, the finely crushed garbage is sent to the dryer for processing to obtain organic garbage; the garbage collected from urban life has a large proportion of moisture, and it needs to be dried before entering the next process to avoid moisture affecting the preheating of the garbage and cracking;

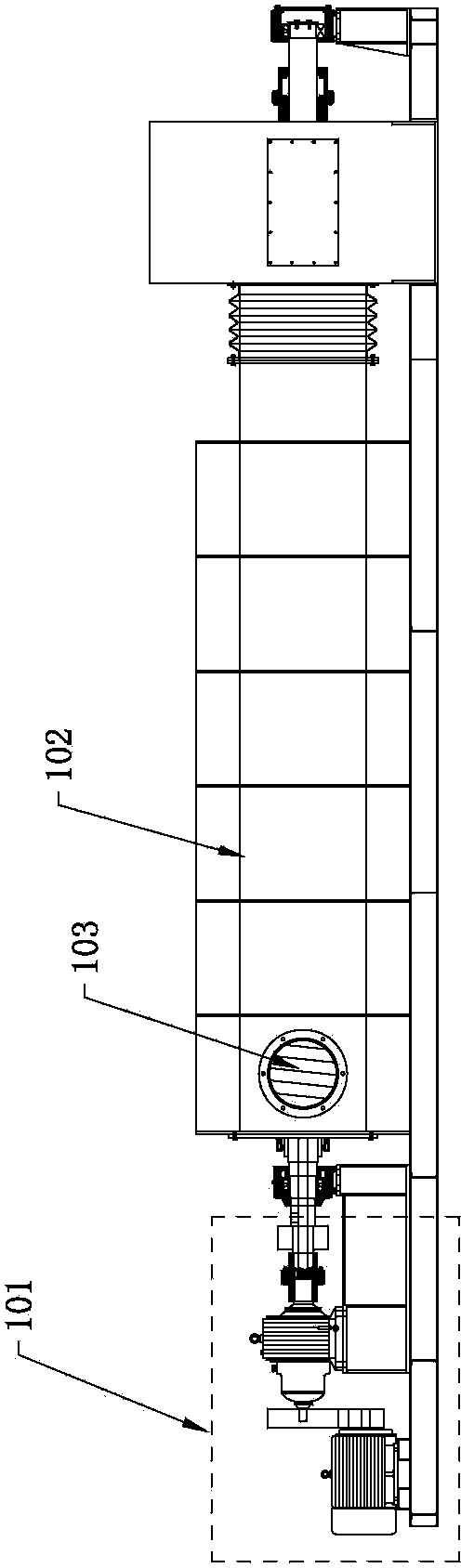

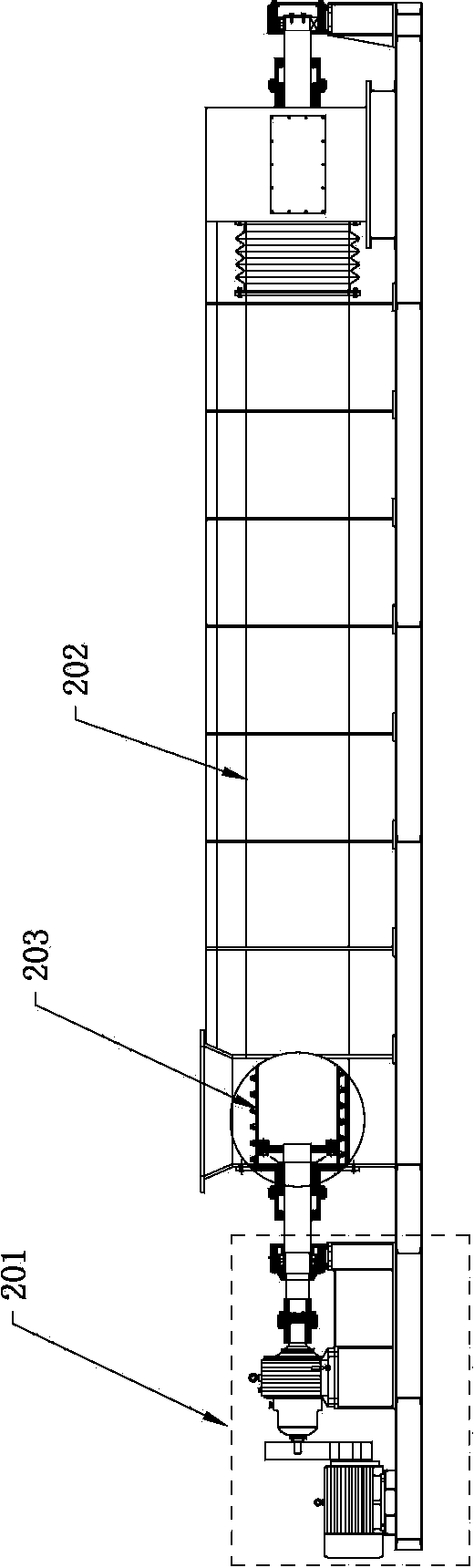

[0056] (6) Preheating tre...

Embodiment 2

[0062] The difference between the waste pyrolysis treatment process of this embodiment and that of Example 1 is that the first heating layer of the preheating treatment device includes 5 heating zones whose temperature gradually rises gradually, and the 5 heating zones work independently of each other. And the heating temperature is 250°C, 300°C, 350°C, 400°C and 450°C in sequence. The preheating zone corresponds to the five heating zones of the first heating layer to form five preheating spaces with gradient temperature rise. Harmful and toxic substances such as halogen-containing substances in organic waste materials are gradually decomposed by gradient heating in the preheating space, and the decomposition rate is high. Good sterilization effect.

[0063] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here.

Embodiment 3

[0065]The difference between a kind of garbage pyrolysis treatment process of this embodiment and embodiment 1 is that the second heating layer of the pyrolysis device includes 5 heating zones whose temperature gradually rises gradually, and the 5 heating zones work independently of each other and The heating temperature is 900°C, 950°C, 1000°C, 1050°C and 1100°C in sequence. The pyrolysis zone corresponds to the 5 heat-generating zones of the second heat-generating layer to form 5 pyrolysis spaces with gradient temperature rise. The organic matter in the organic waste material is gradually pyrolyzed, and the depth of organic matter pyrolysis gradually deepens as the temperature rises. The pyrolysis reaction is thorough and efficient. Generate coke coal, tar, and CH with high carbon and high combustion calorific value 4 、H 2 , CO, CO 2 , NO, NO 2 、C 2 h 4 、C 2 h 6 , NH 3 、H 2 S, HCl, SO 2 CH 4 、H 2 , CO, CO 2 、C 2 h 4 , and C 2 h 6 and other flammable gases. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com