Patents

Literature

133 results about "Strong pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The opposite of a weak pulse is a bounding pulse. Very forceful and strong, a bounding pulse is sometimes, but not always, visible in thin-skinned areas of the body. Bounding pulses are not always rapid, and they can be completely normal. If you’ve just run five miles, you probably have a strong, bounding pulse.

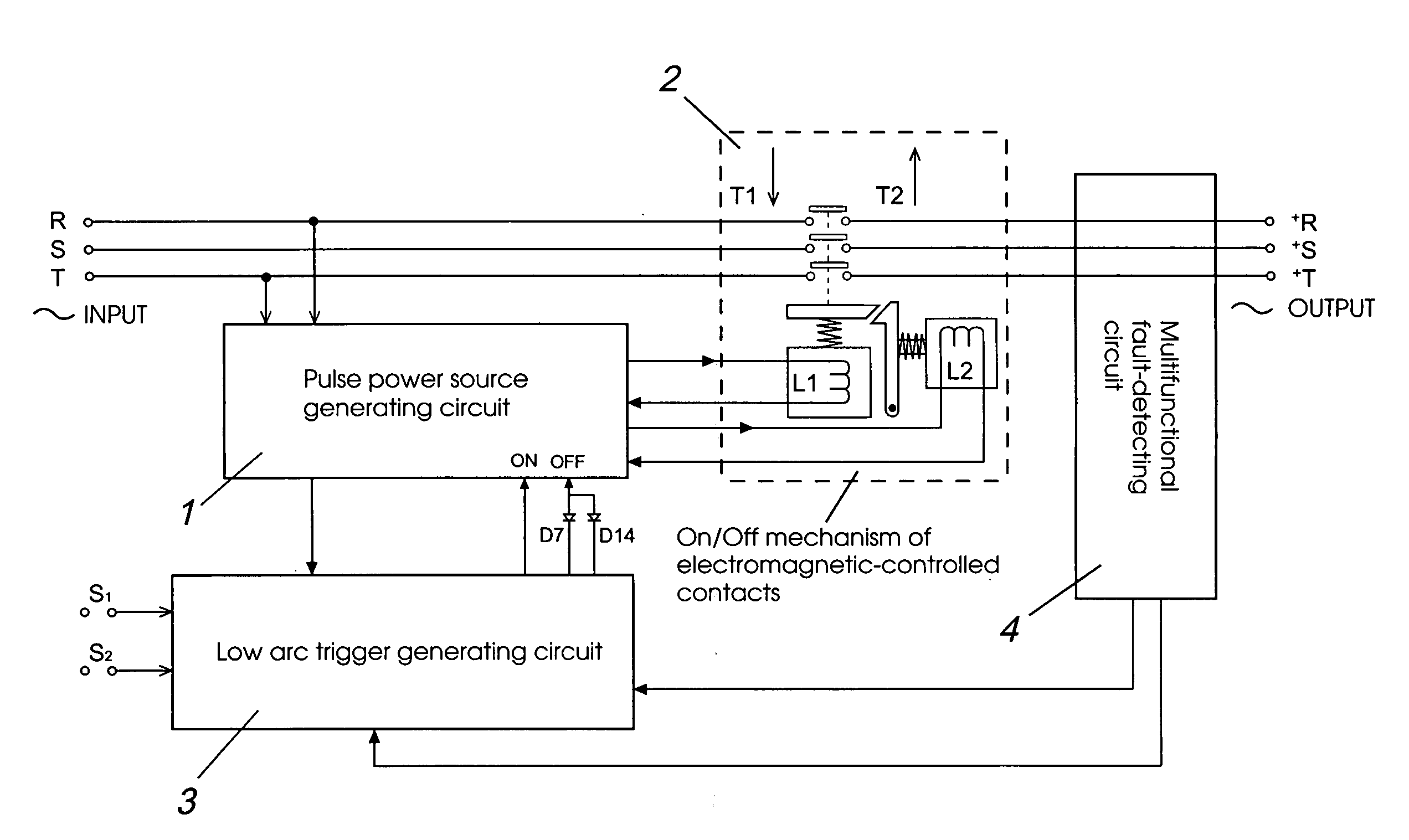

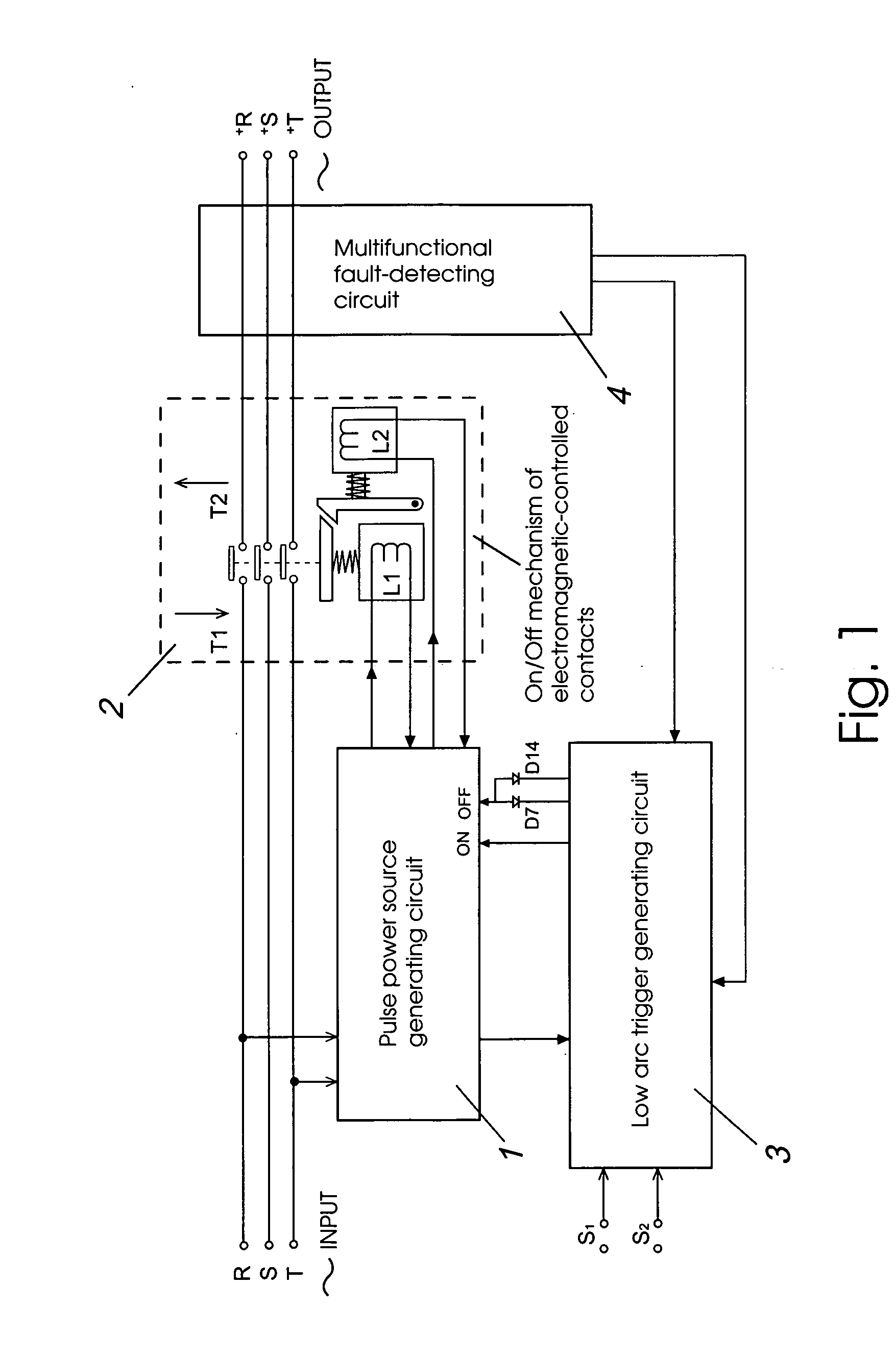

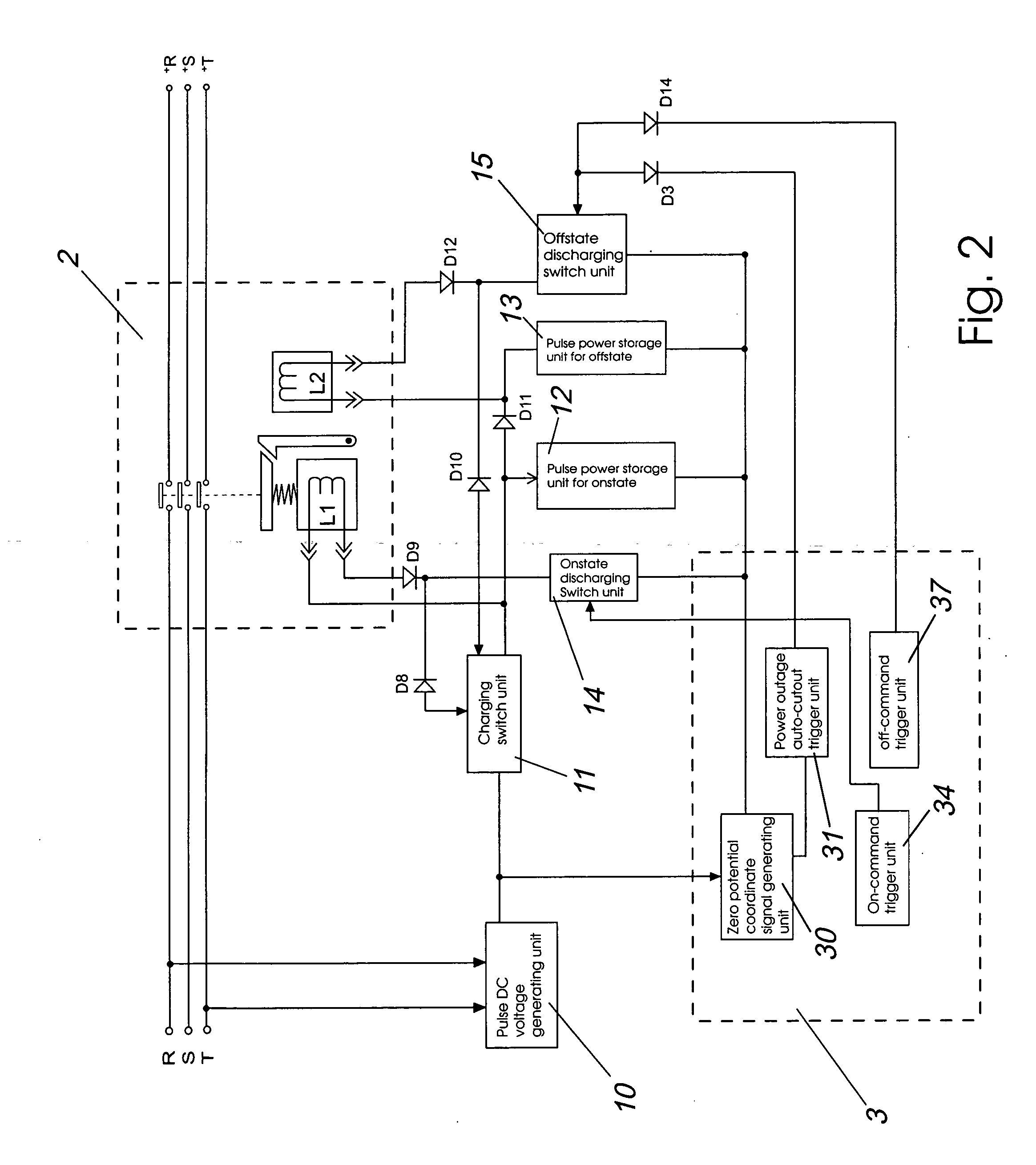

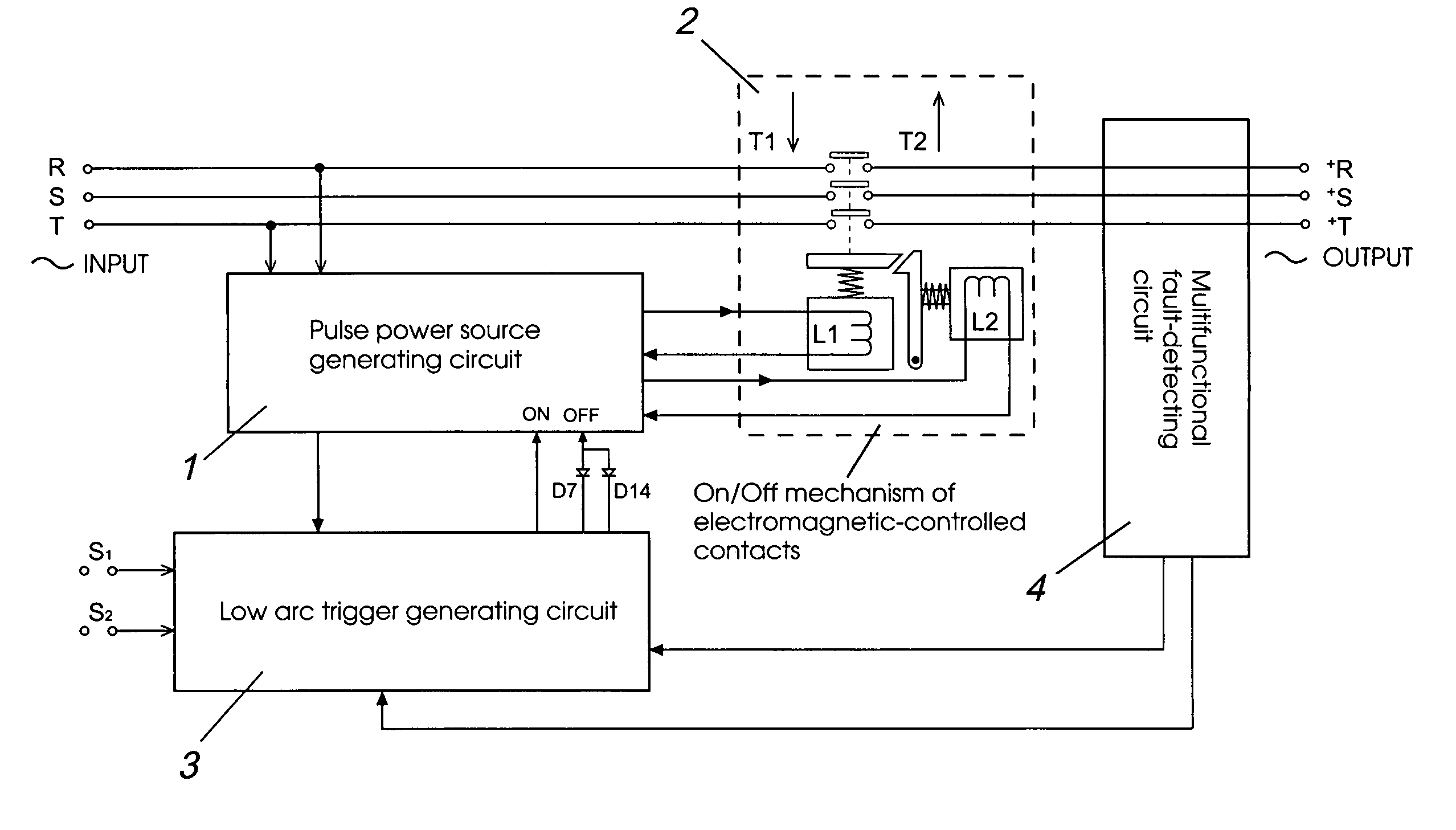

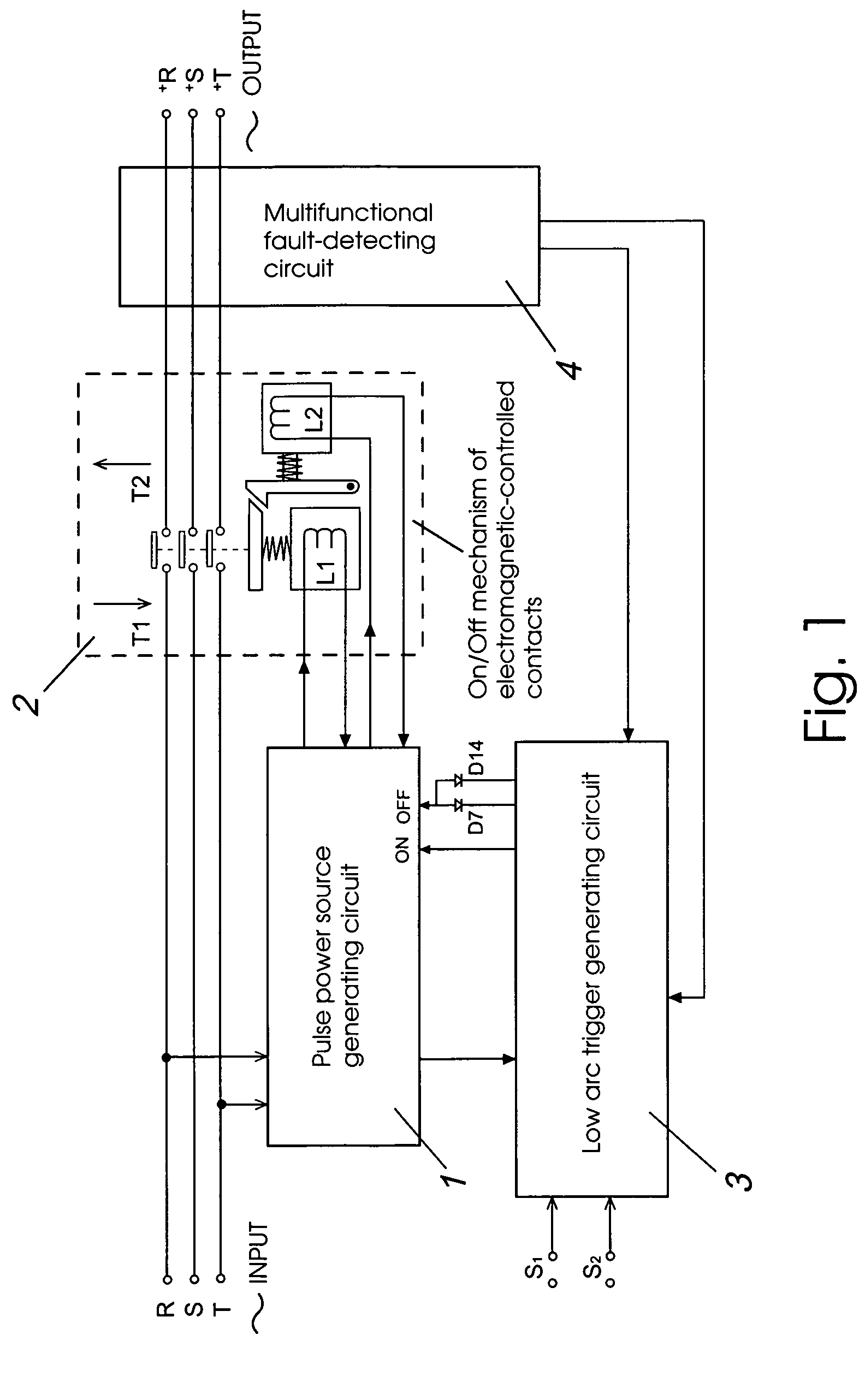

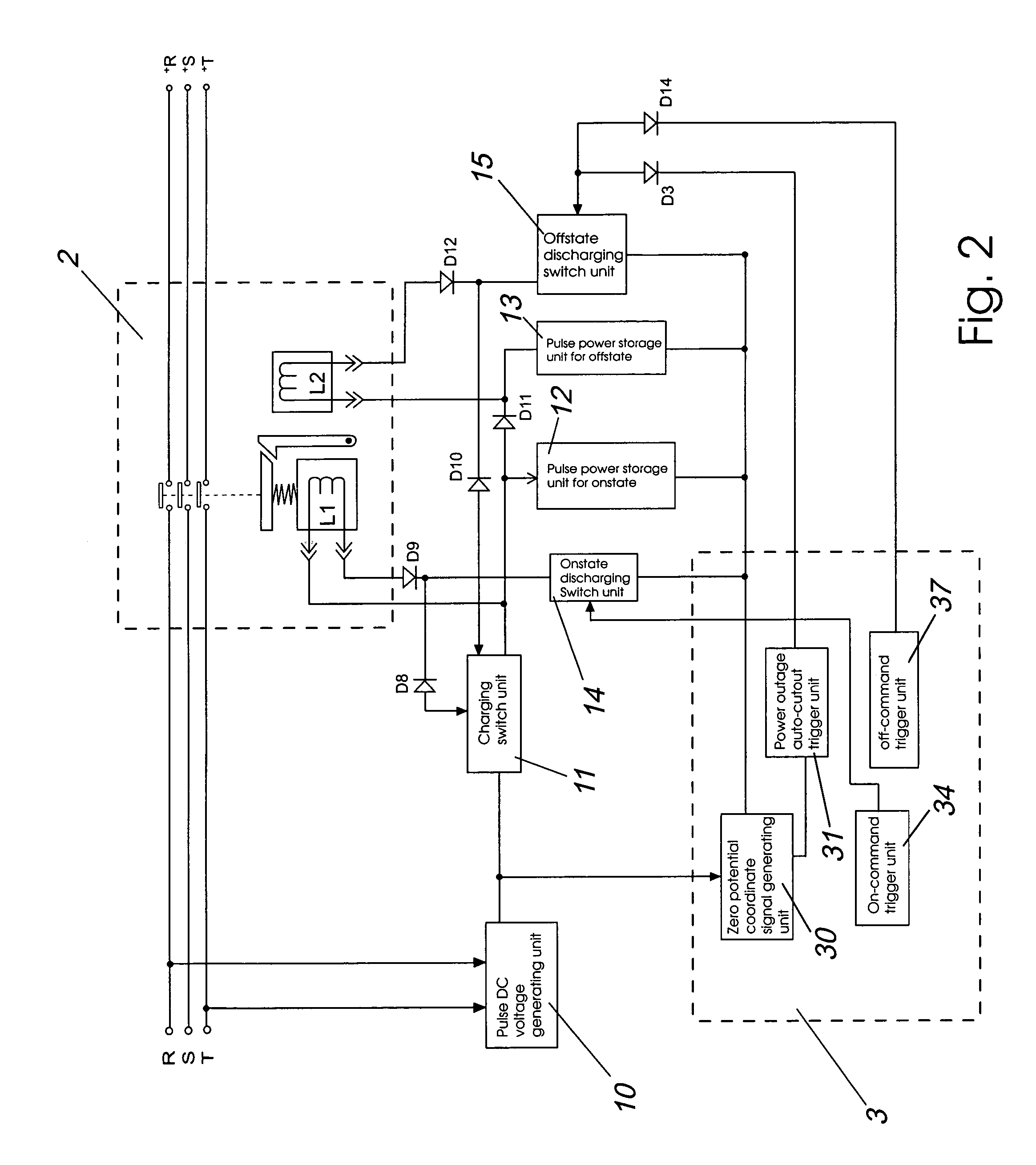

Low arc AC contactor

InactiveUS20060061920A1Small sizeHigh safety factorEmergency protective arrangement detailsElectric switchesLow voltageCoupling

A low arc AC contactor comprises an on / off mechanism electromagnetic-controlled contact, a pulse power source generating circuit, a low arc trigger generating circuit, and a multifunctional fault-detecting circuit. The contactor converts an instantaneous strong current into strong pulse magnetic field energy to actuate contacts of mechanical portion of the contactor, so that the power source load is on or off. Each of the actuating process will be controlled by the electric circuit to perform at the lowest potential of AC voltage for reducing arc's destructive power. Moreover, the contactor uses photoelectric coupling circuits, in which it can be controlled by external low voltage signal commands, as well as providing protection from overload, phase loss, short circuit, and leakage current.

Owner:FAT KWONG TSE

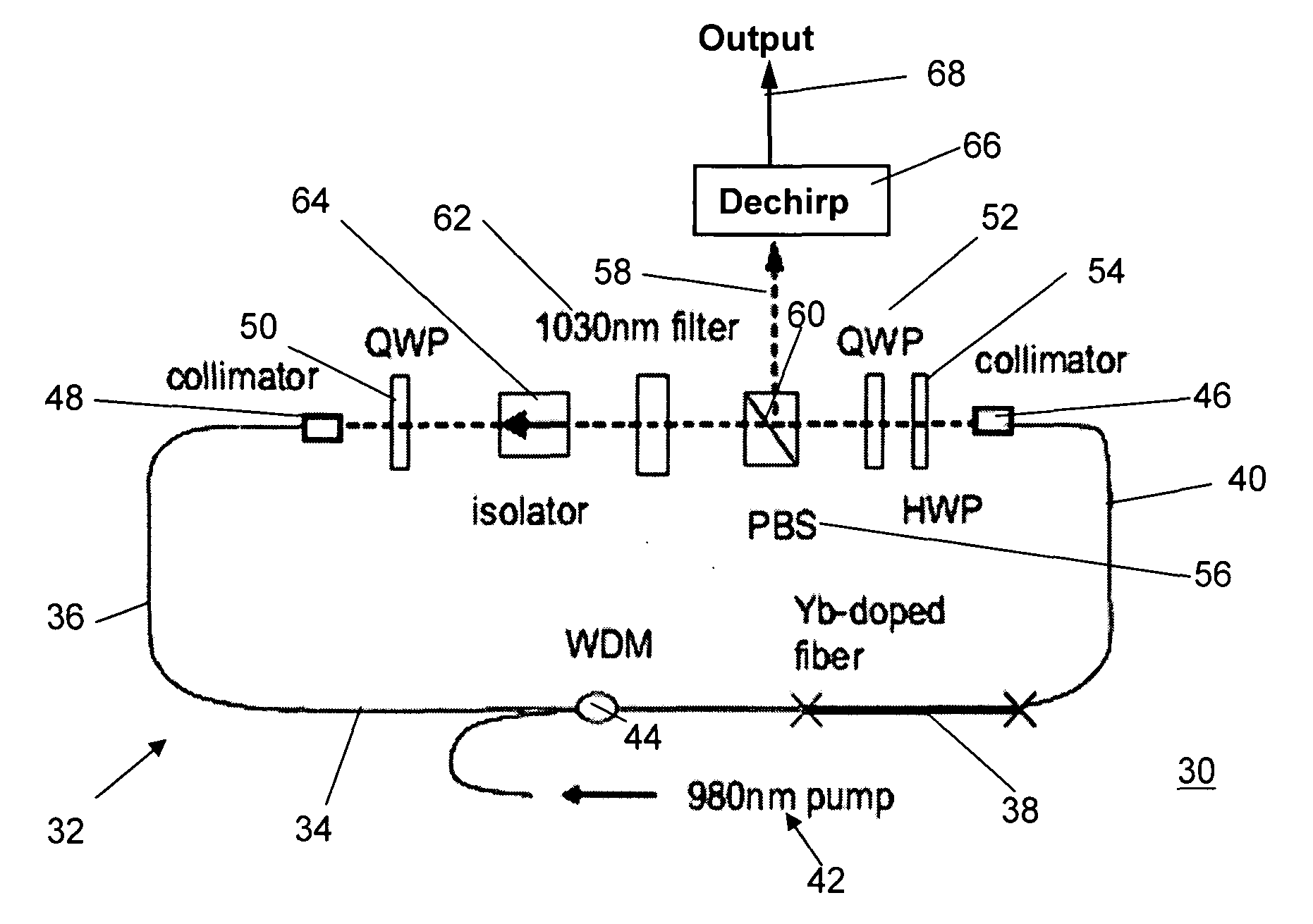

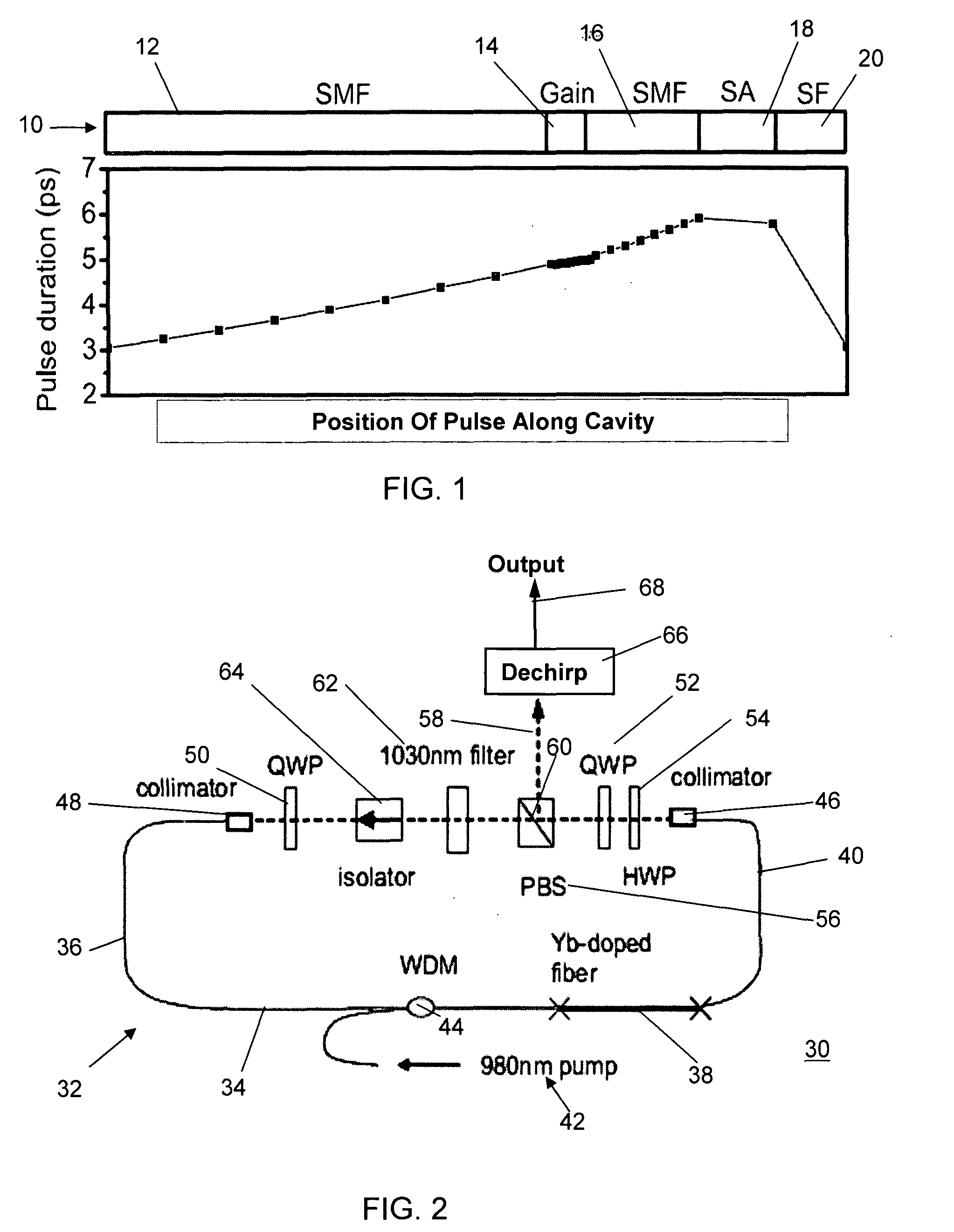

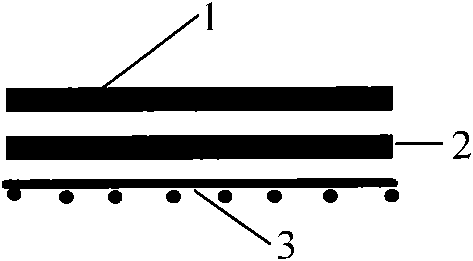

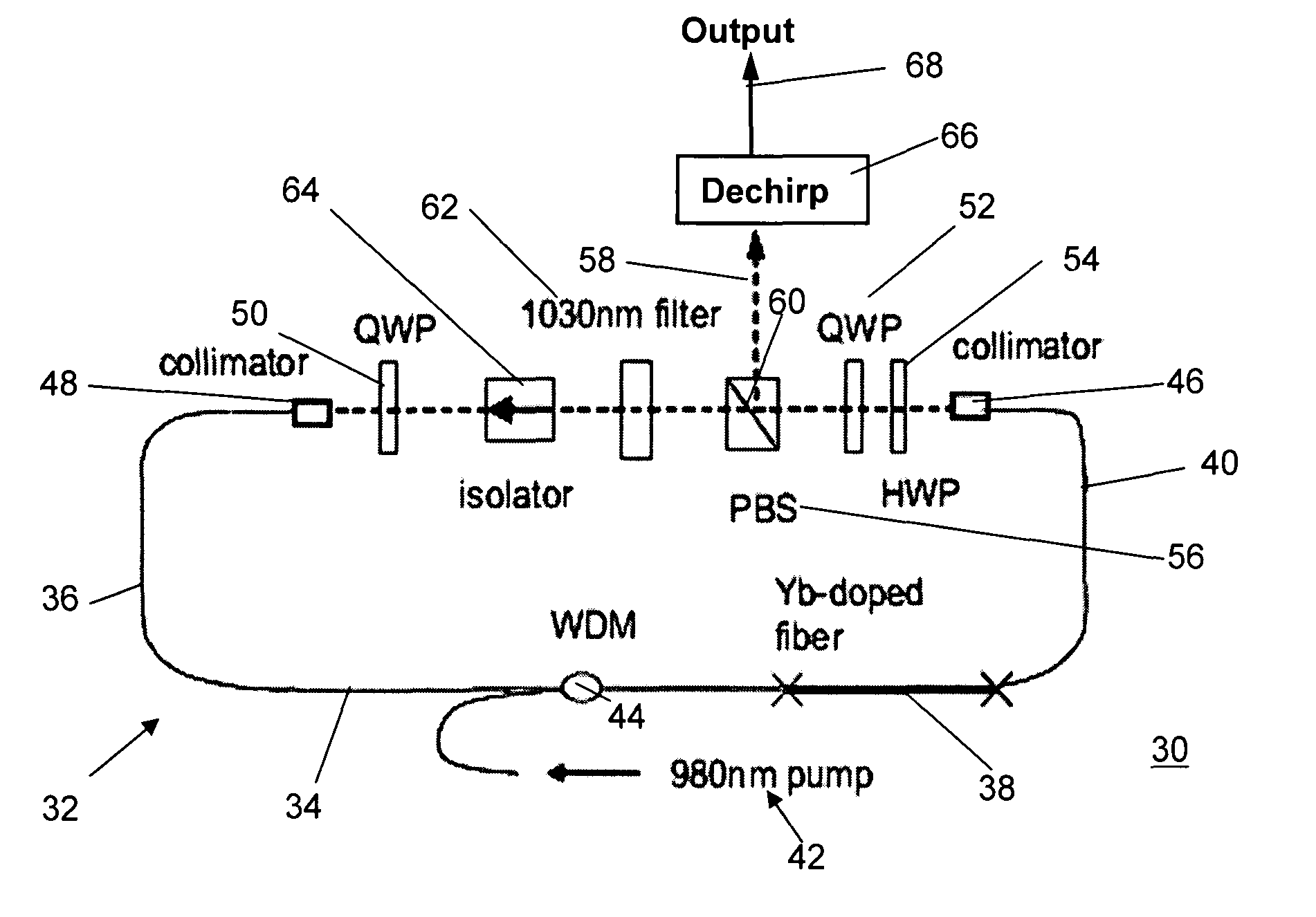

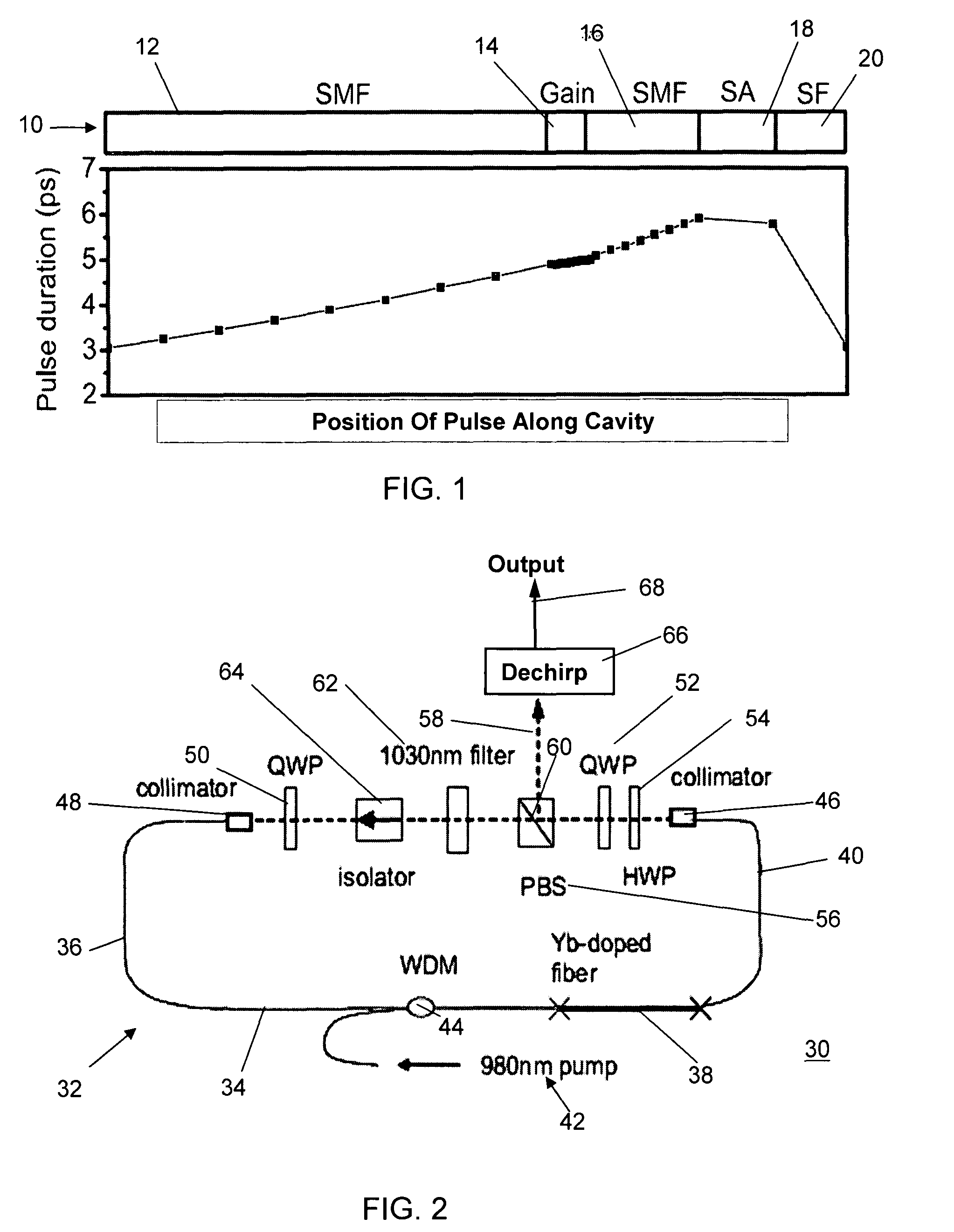

All-Normal-Dispersion Femtosecond Fiber Laser

ActiveUS20100220751A1Easy to adjustLaser using scattering effectsActive medium shape and constructionMode locked fiber laserOptoelectronics

A modelocked fiber laser is designed to have strong pulse-shaping based on spectral filtering of a highly-chirped pulse in the laser cavity. The laser generates femtosecond pulses without a dispersive delay line or anomalous dispersion in the cavity.

Owner:CORNELL CENT FOR TECH ENTERPRISE & COMMLIZATION CCTEC

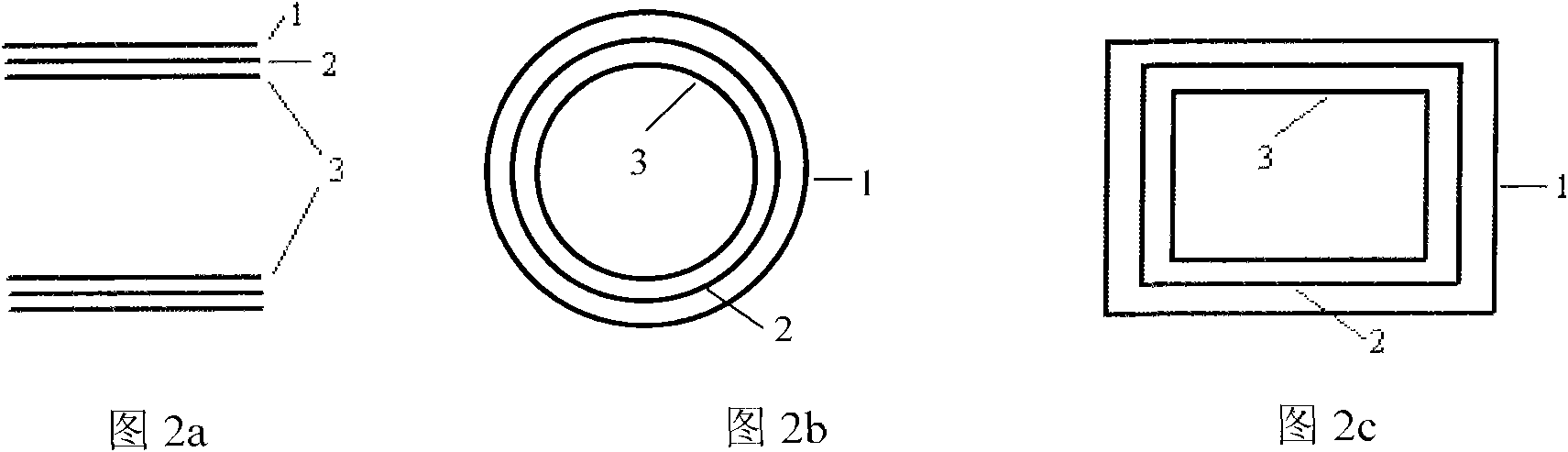

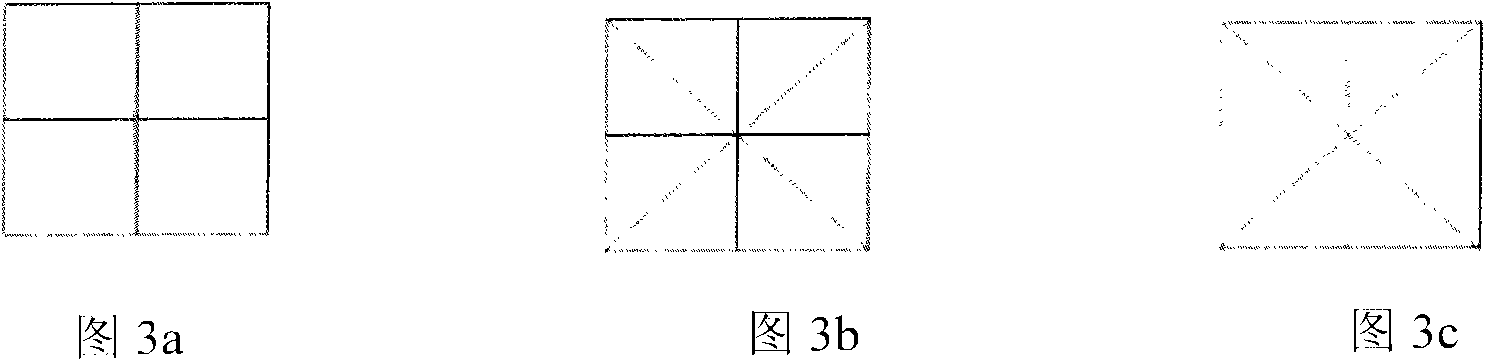

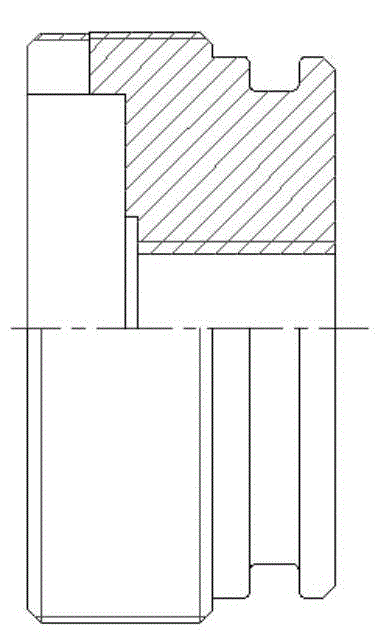

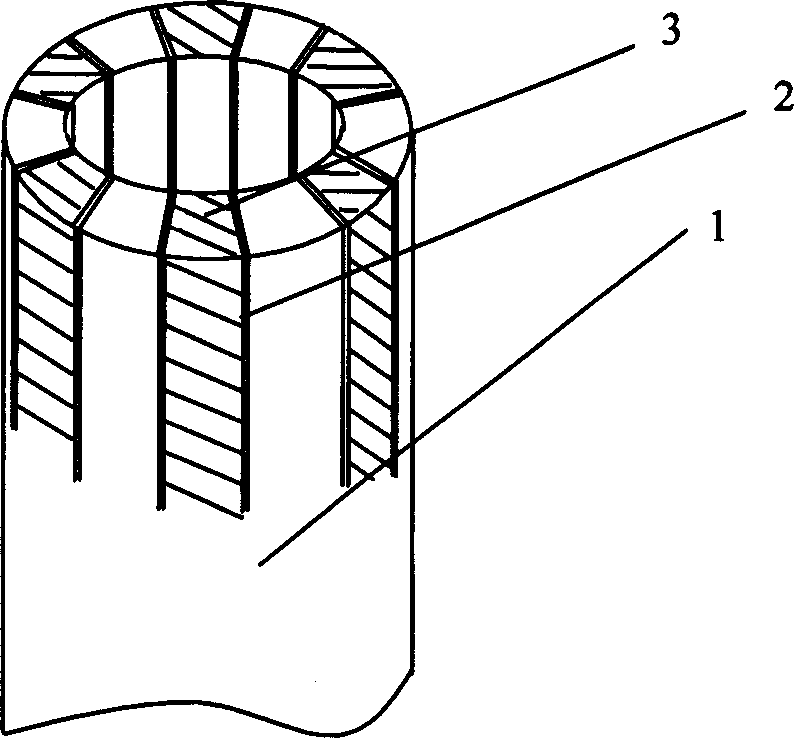

Dielectric barrier corona discharge reactor

InactiveCN102026468AReduce air gap discharge field strengthArcing suppressionPlasma techniqueCorona dischargeStrong pulse

The invention discloses a dielectric barrier corona discharge reactor which comprises an outer electrode, an inner electrode and a dielectric barrier layer positioned between the outer electrode and the inner electrode, wherein the outer electrode is connected with a power supply, and the inner electrode is grounded. The dielectric barrier corona discharge reactor can generate and transmit more charges under same external voltage and discharge spatial clearance due to corona ionization effect and simultaneously output higher discharge power. The dielectric barrier corona discharge reactor can obtain stronger pulse voltage and current during discharge and enable energy during the discharge to be more centralized.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

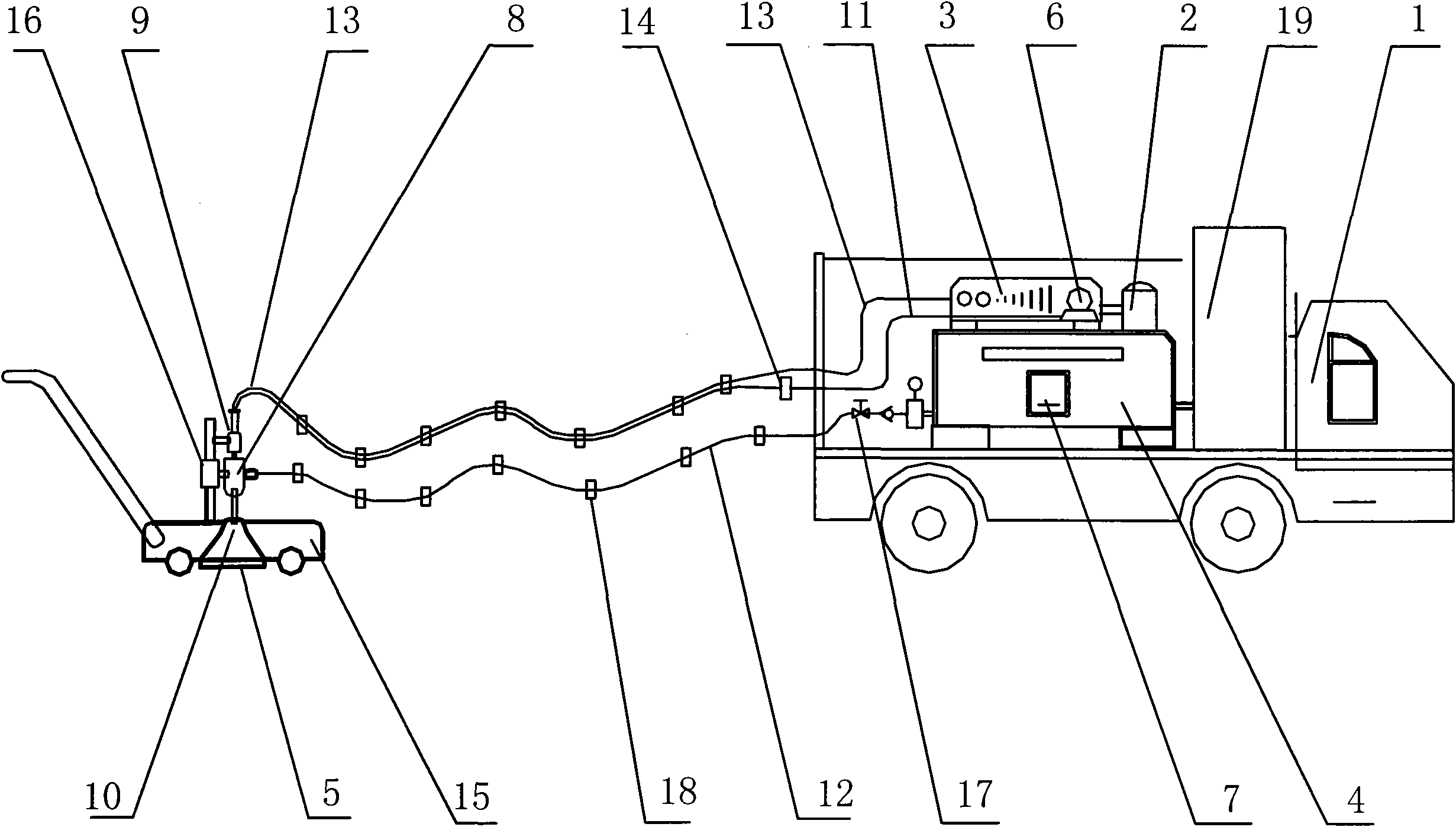

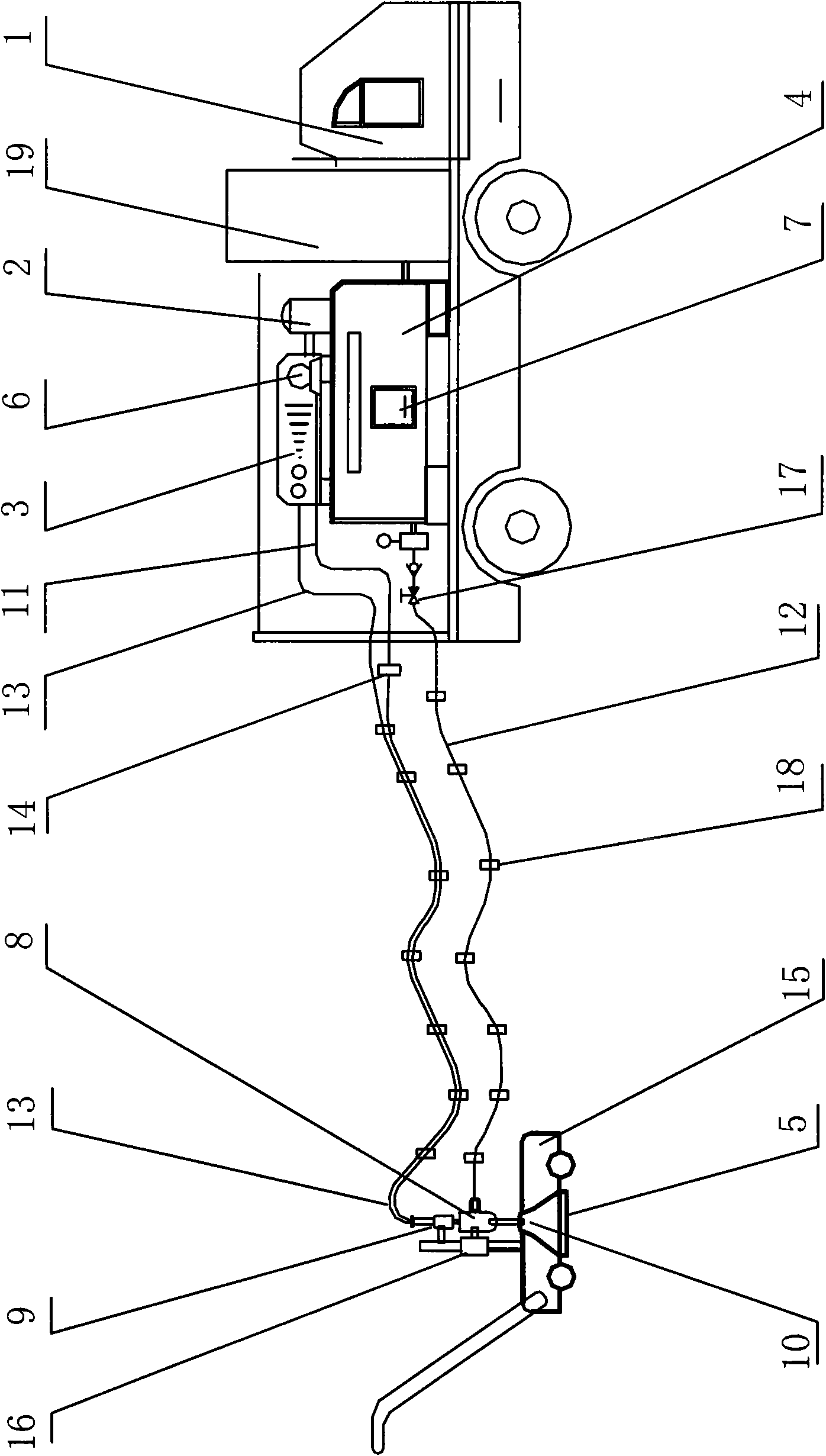

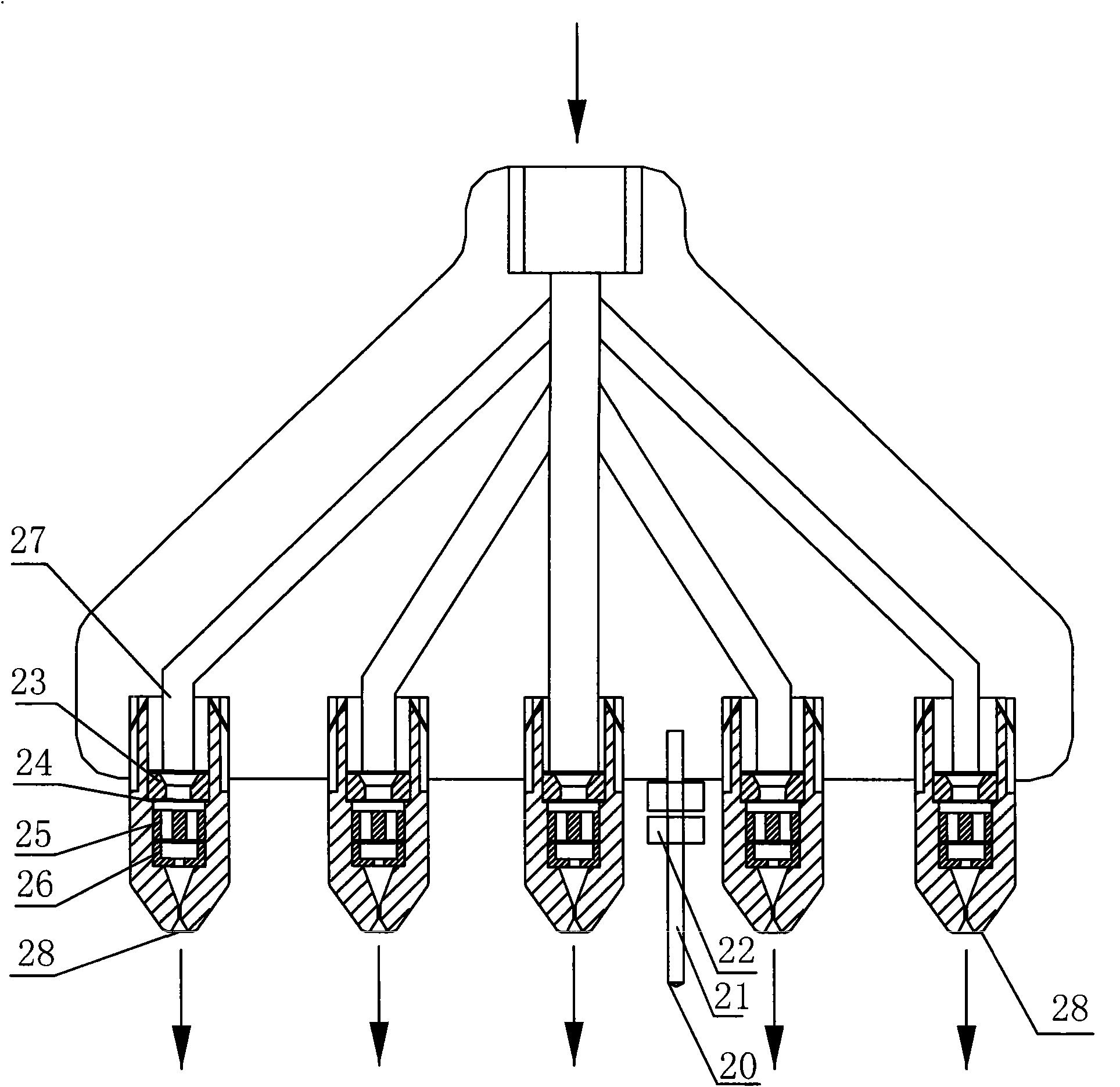

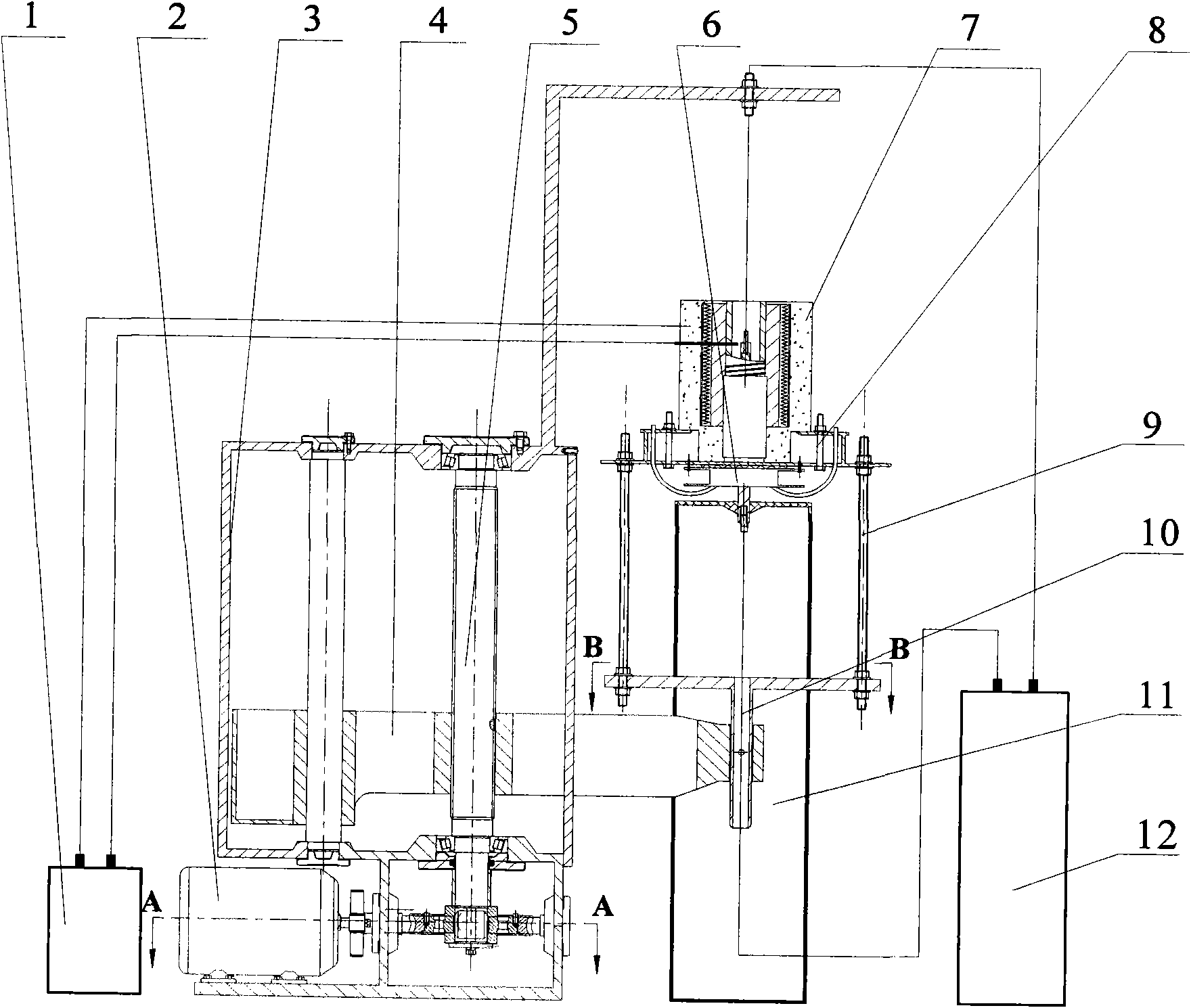

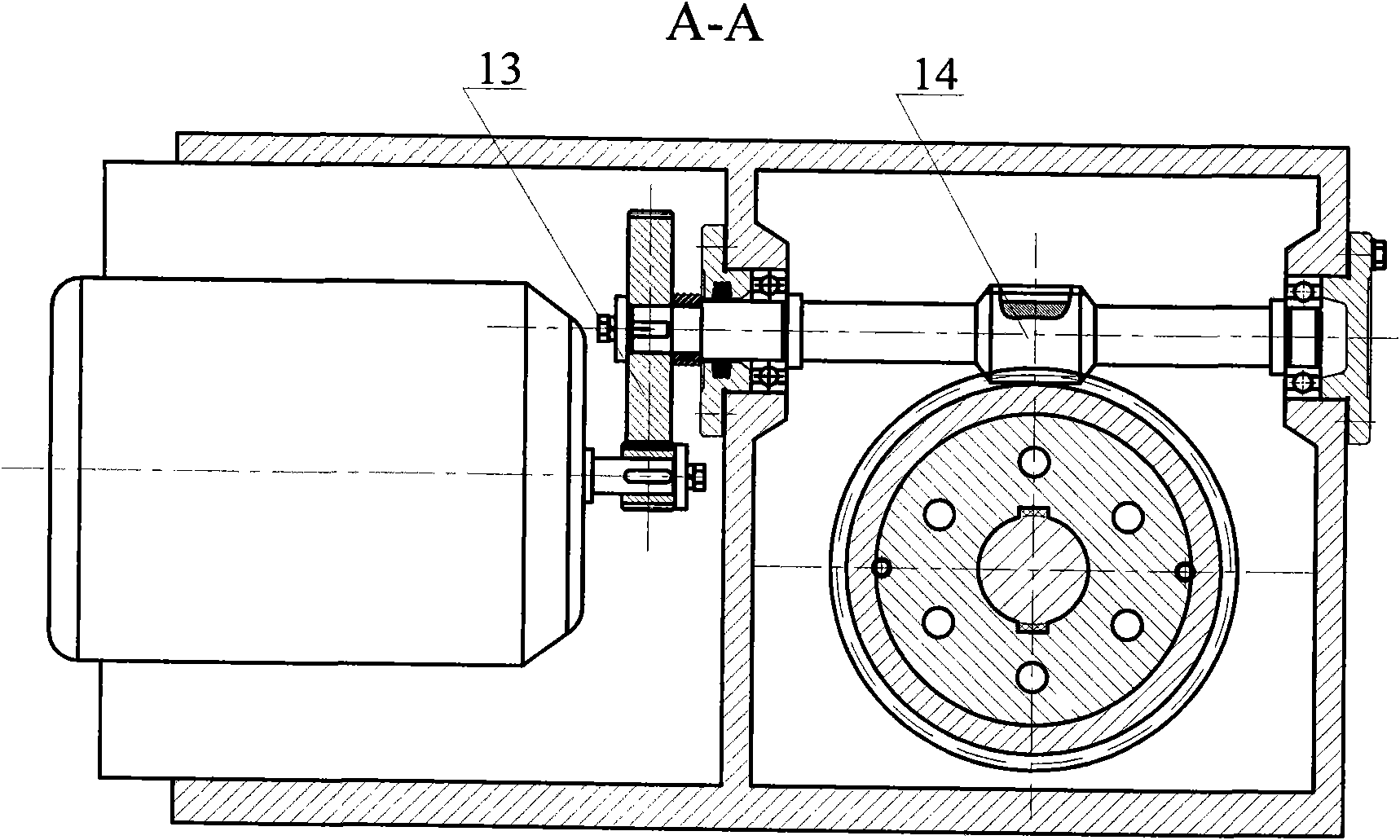

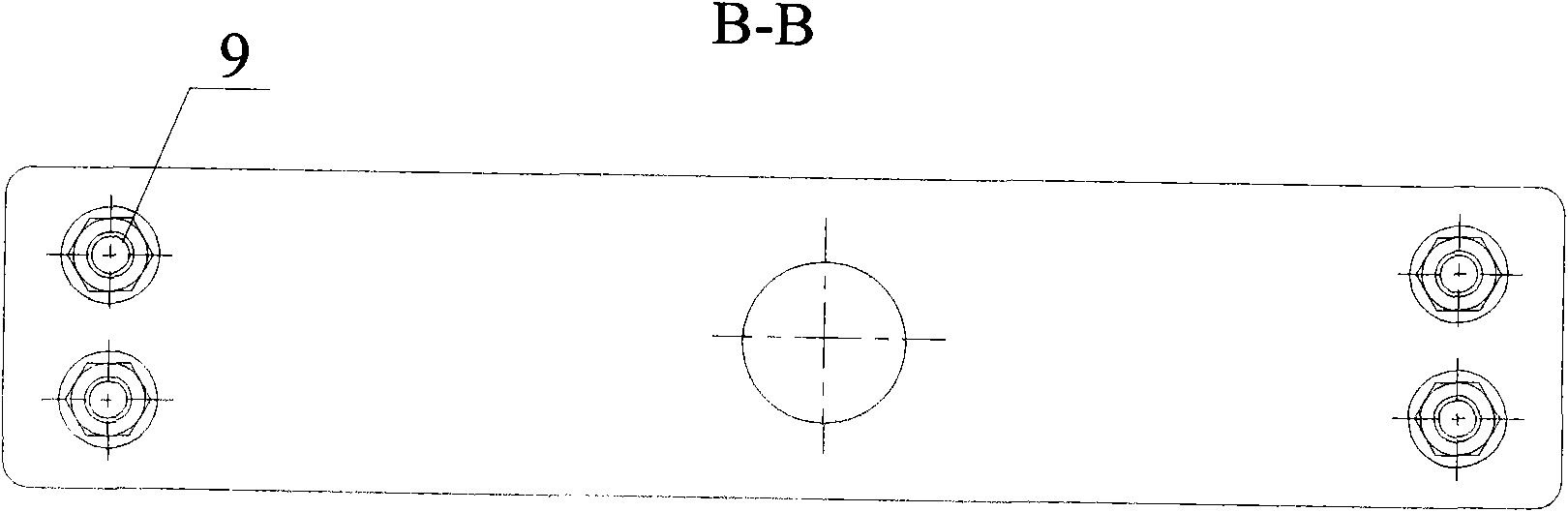

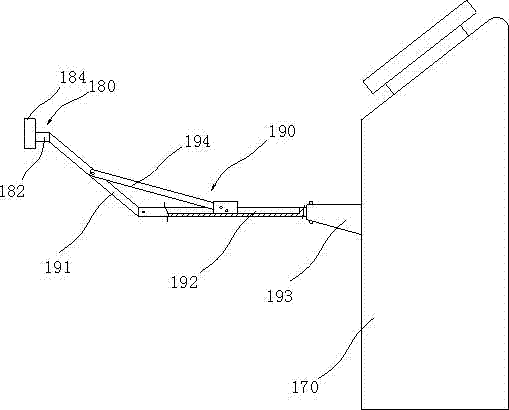

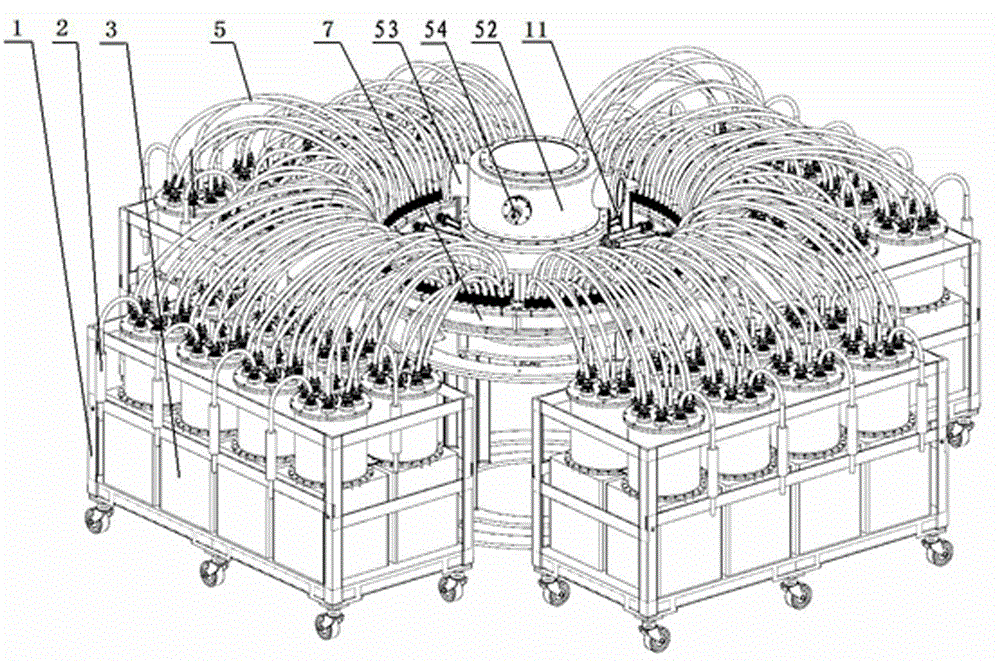

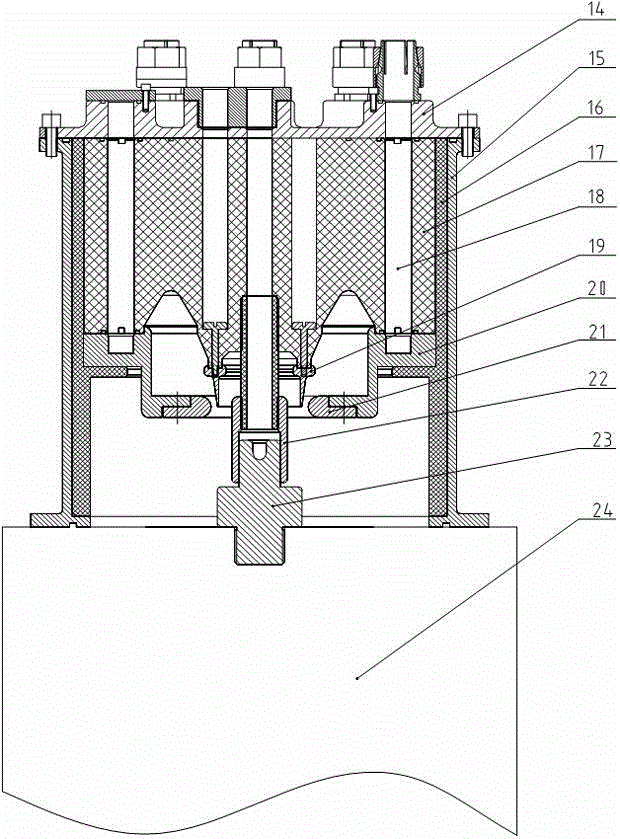

Vehicle-mounted eddy strong pulse resonant jet cleaning device

InactiveCN101811121AImprove crushing effectImprove energy efficiencySpray nozzlesCleaning using liquidsHigh pressure waterHigh pressure

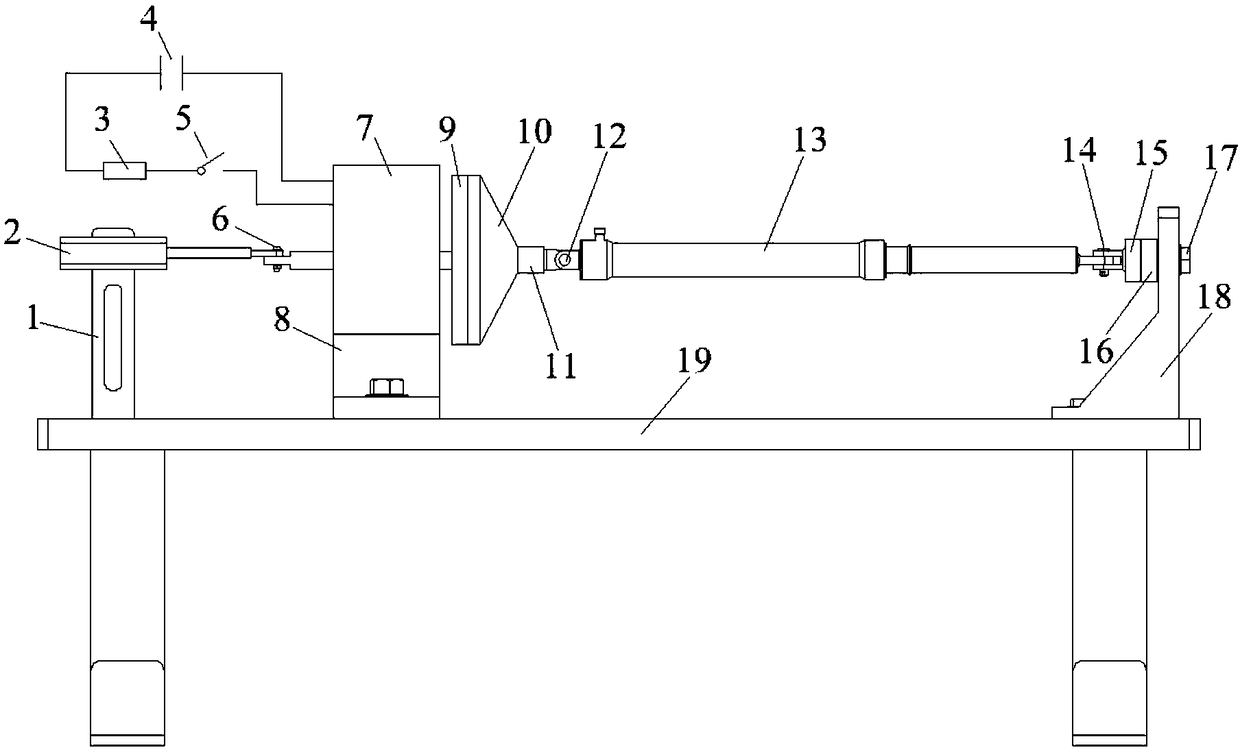

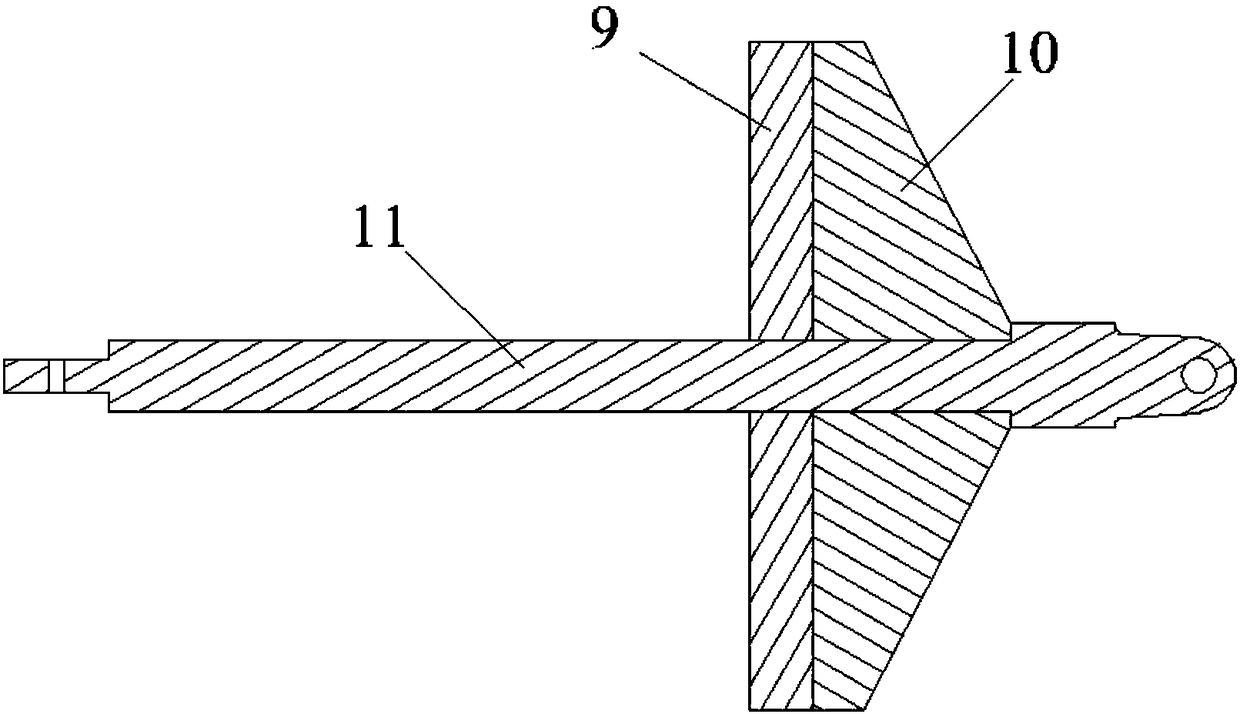

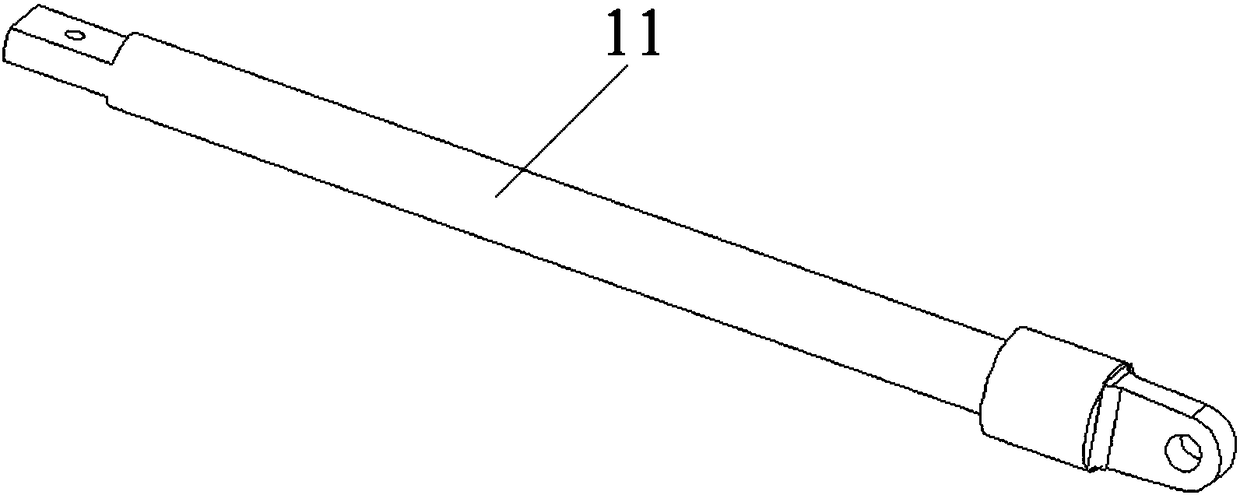

The invention discloses a vehicle-mounted eddy strong pulse resonant jet cleaning device comprising a carrying vehicle 1, a power supply 2, an electrical control device 7, an ultrasonic generating device 3, an air cooling device 6, a high-pressure water jet generating device 4 and a spray head device, wherein the spray head device comprises an ultrasonic transduction vibrator 9, an amplitude transformer 10, a strong pulse vibrating chamber 8 and an eddy resonant jet spray head 5; the ultrasonic transduction vibrator 9 is connected with the ultrasonic generating device 3 by an ultrasonic transmission cable 13 and is connected with the air cooling device 6 by a cooling compressed air tube 11; and the strong pulse vibrating chamber 8 is connected with the high-pressure water jet generating device 4 by a high-pressure water inlet pipeline 12. In the invention, the energy of high-pressure water jet and eddy resonance and the energy of strong high-frequency mechanical vibration pulses generated by the ultrasonic generator are sufficiently utilized to form a stable eddy strong pulse resonant jet in the vibration chamber, which obviously improves the energy efficiency of the jet and reinforces the washing action and the crushing action generated on the surface of a material by the pulse jet; and the complete set of device does not need to be configured with additional power supply and cooling air source by customers. The cleaning device has a style of the own, convenient operation and better cleaning effect and is especially suitable for field work and maneuvering work.

Owner:任保林

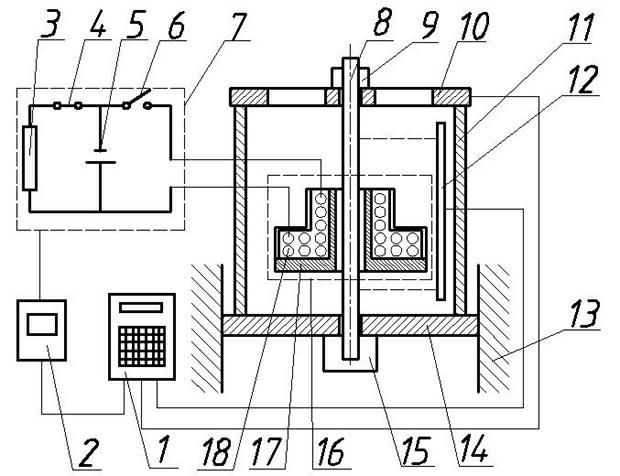

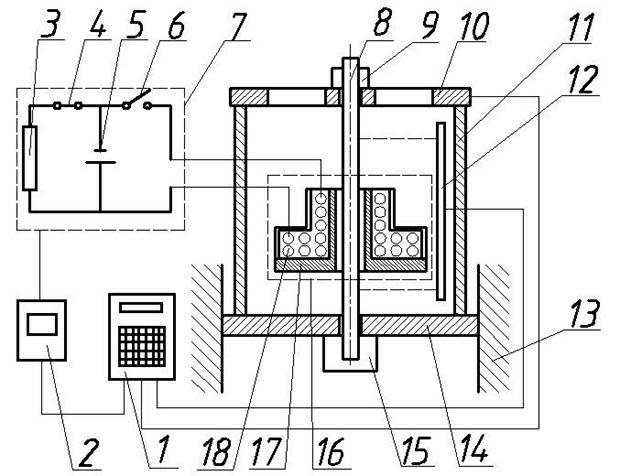

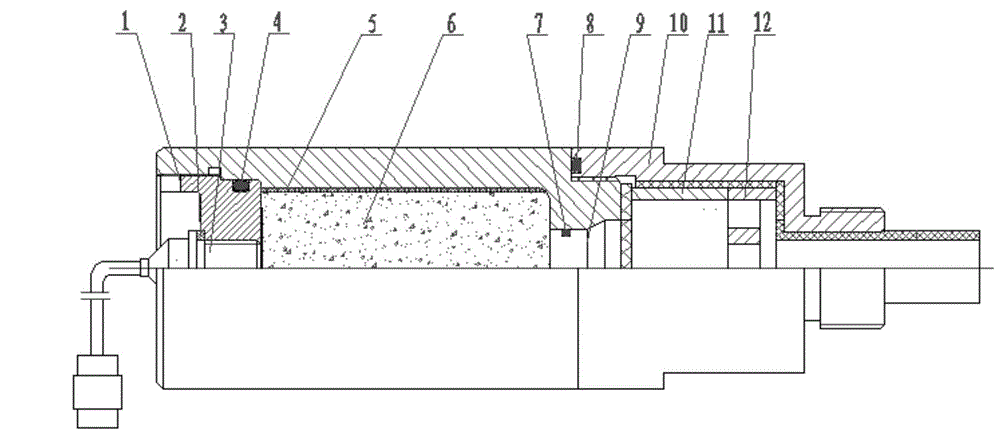

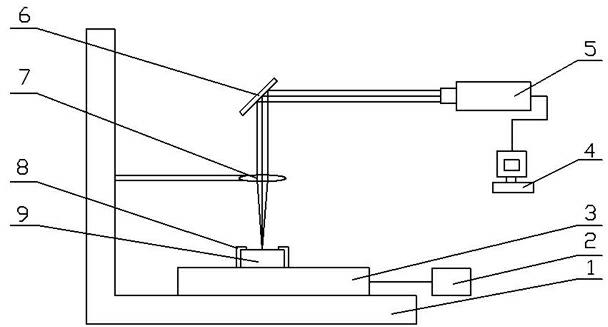

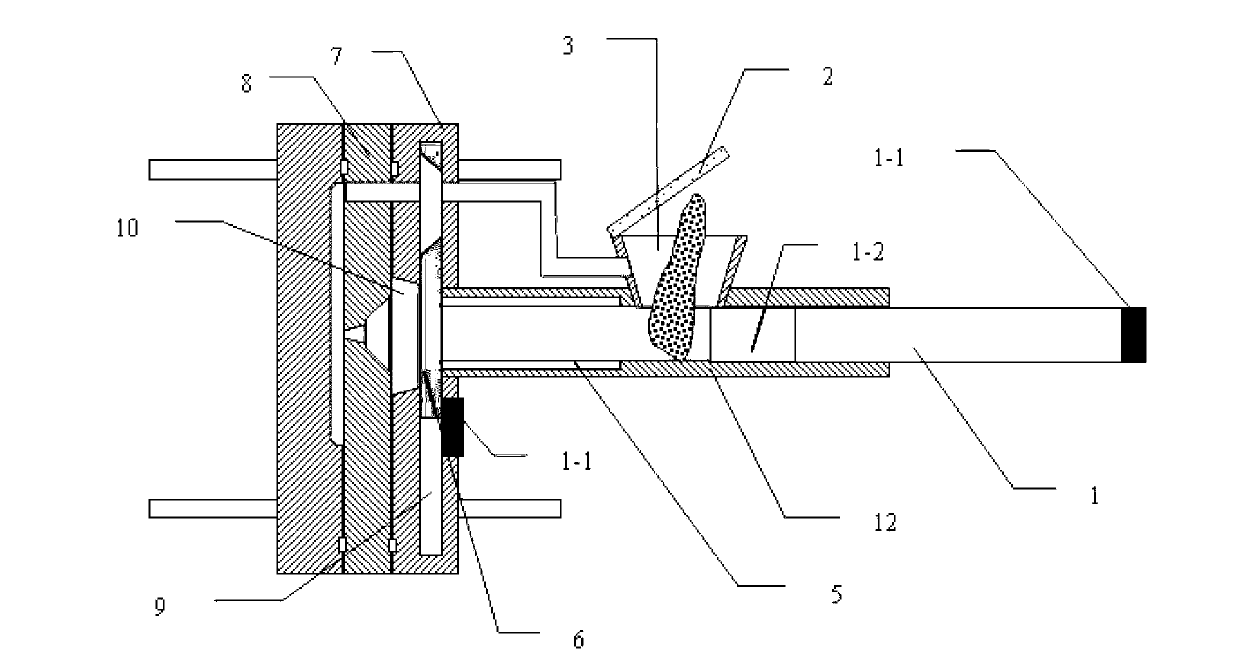

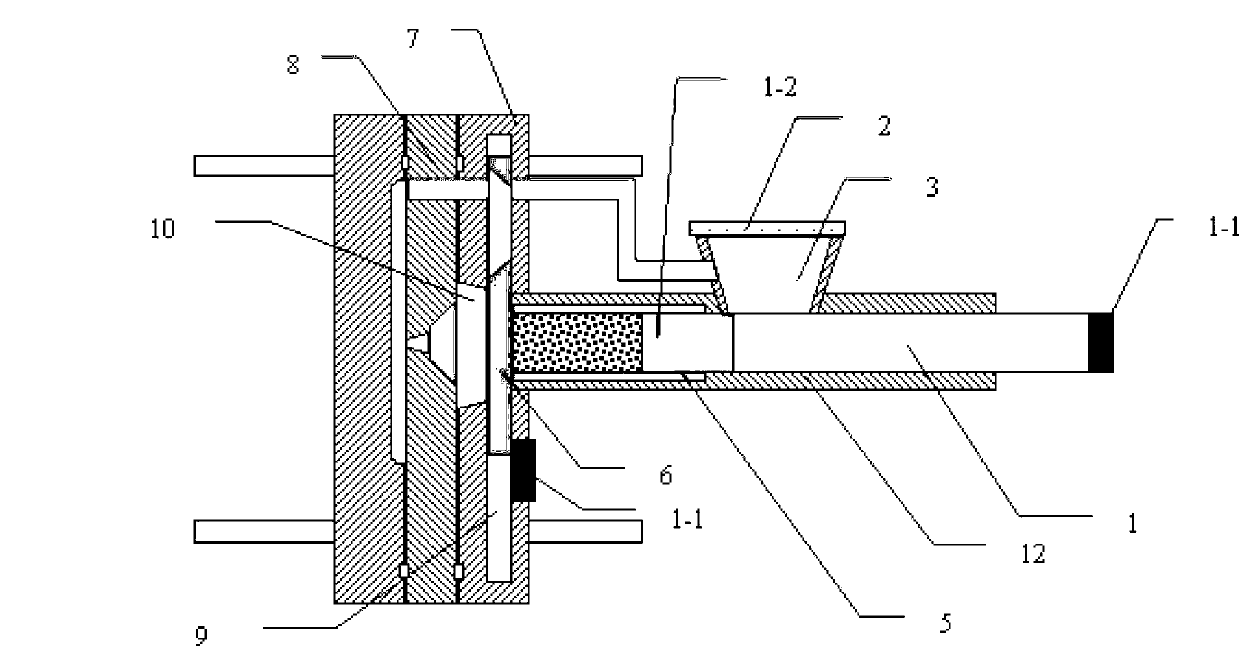

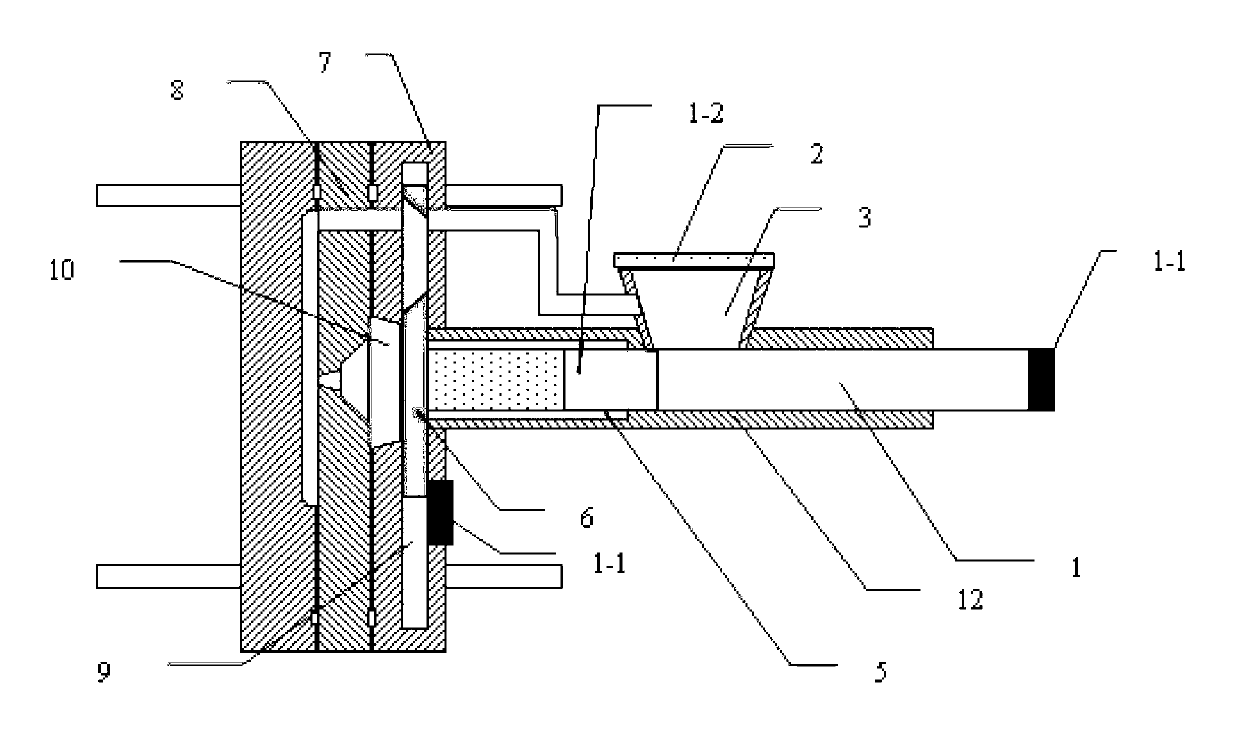

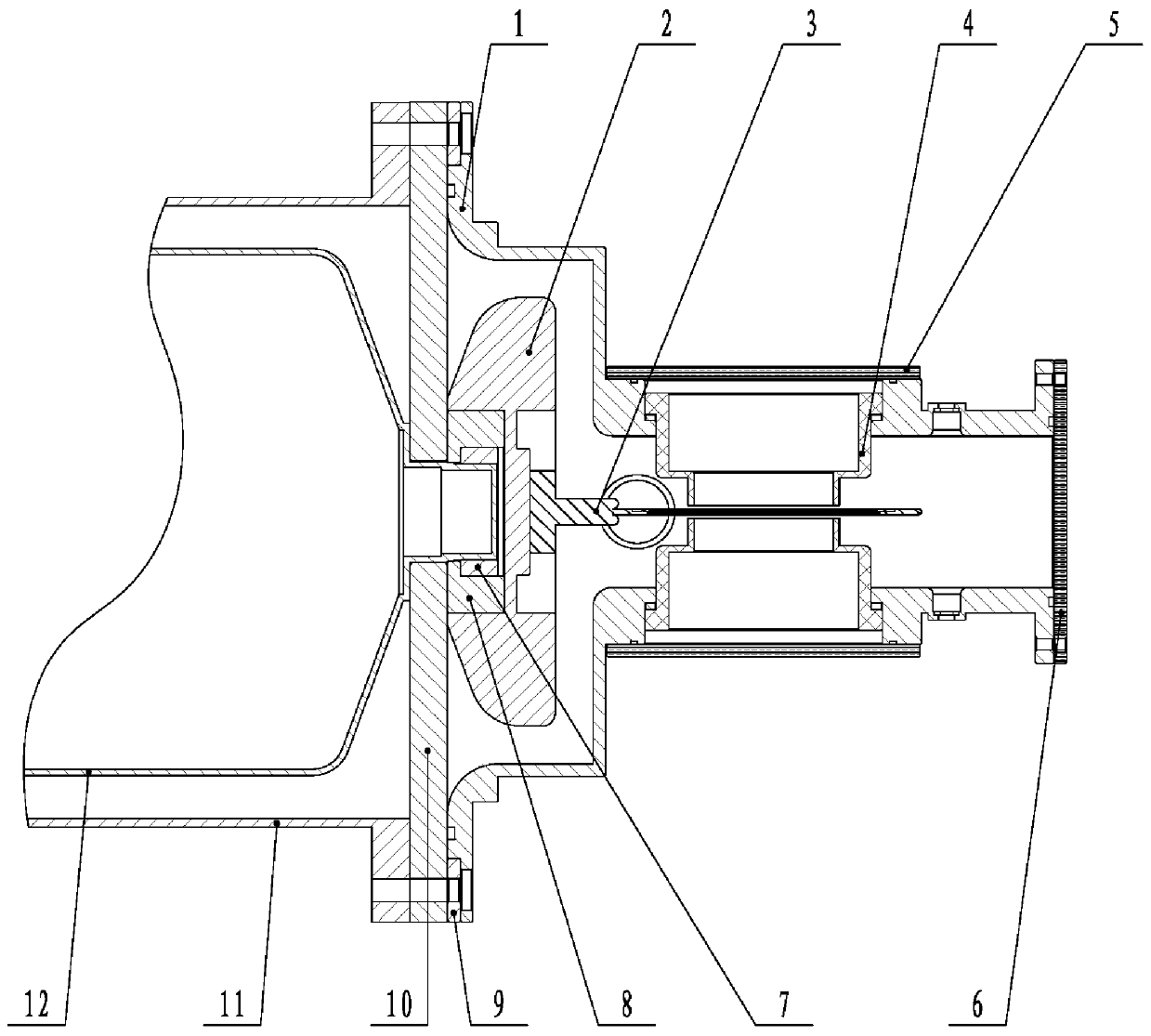

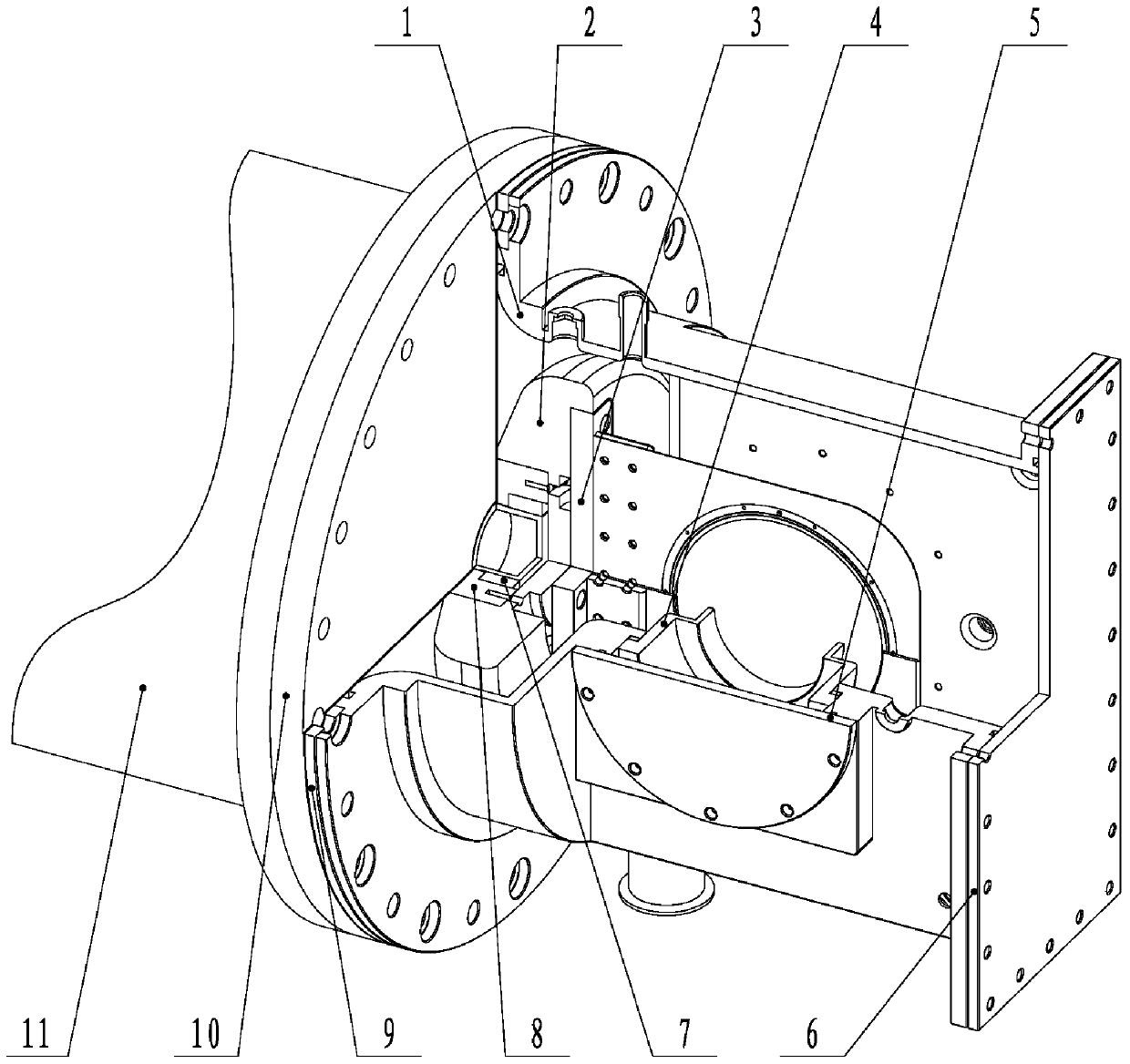

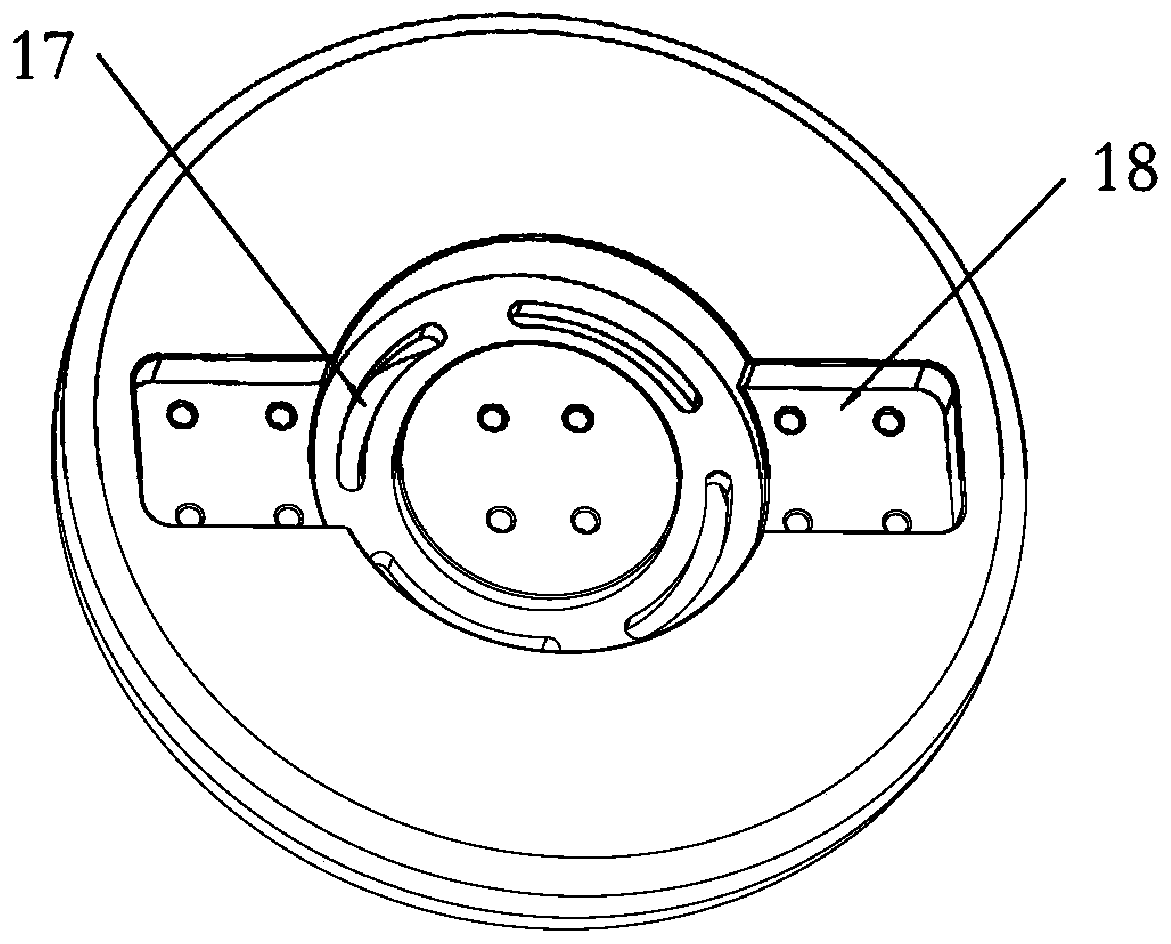

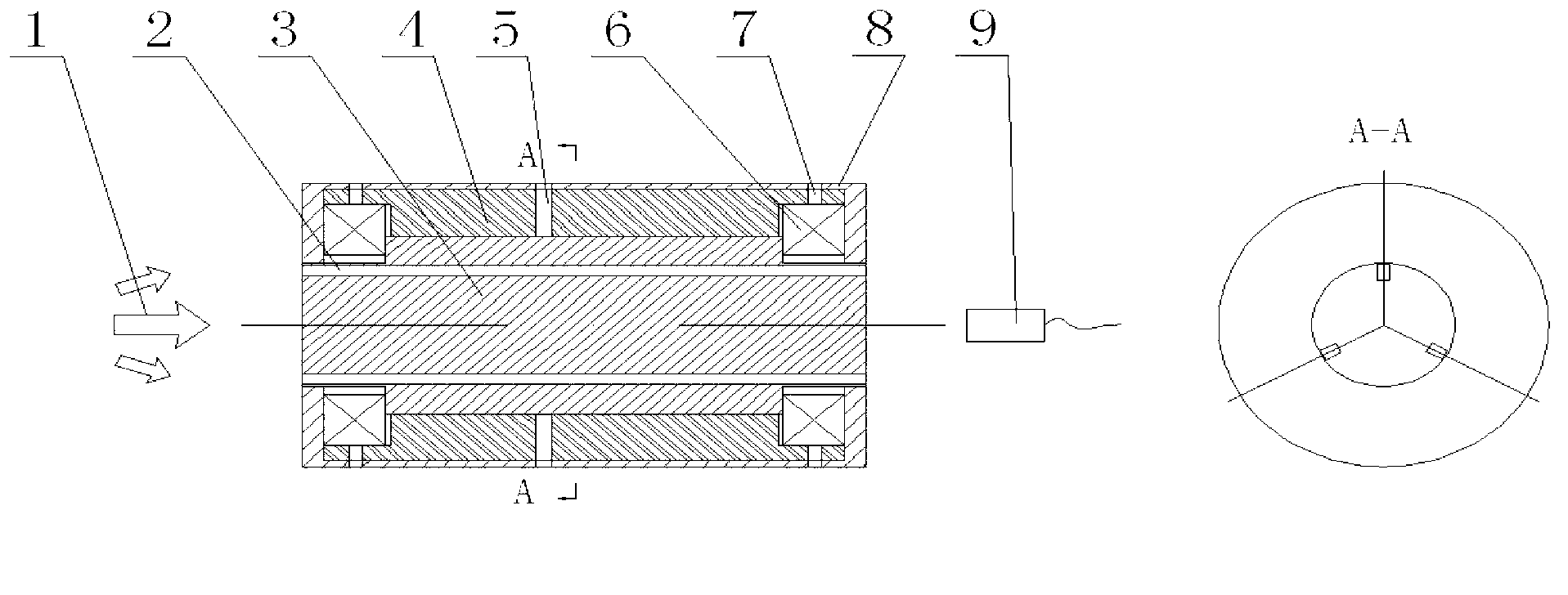

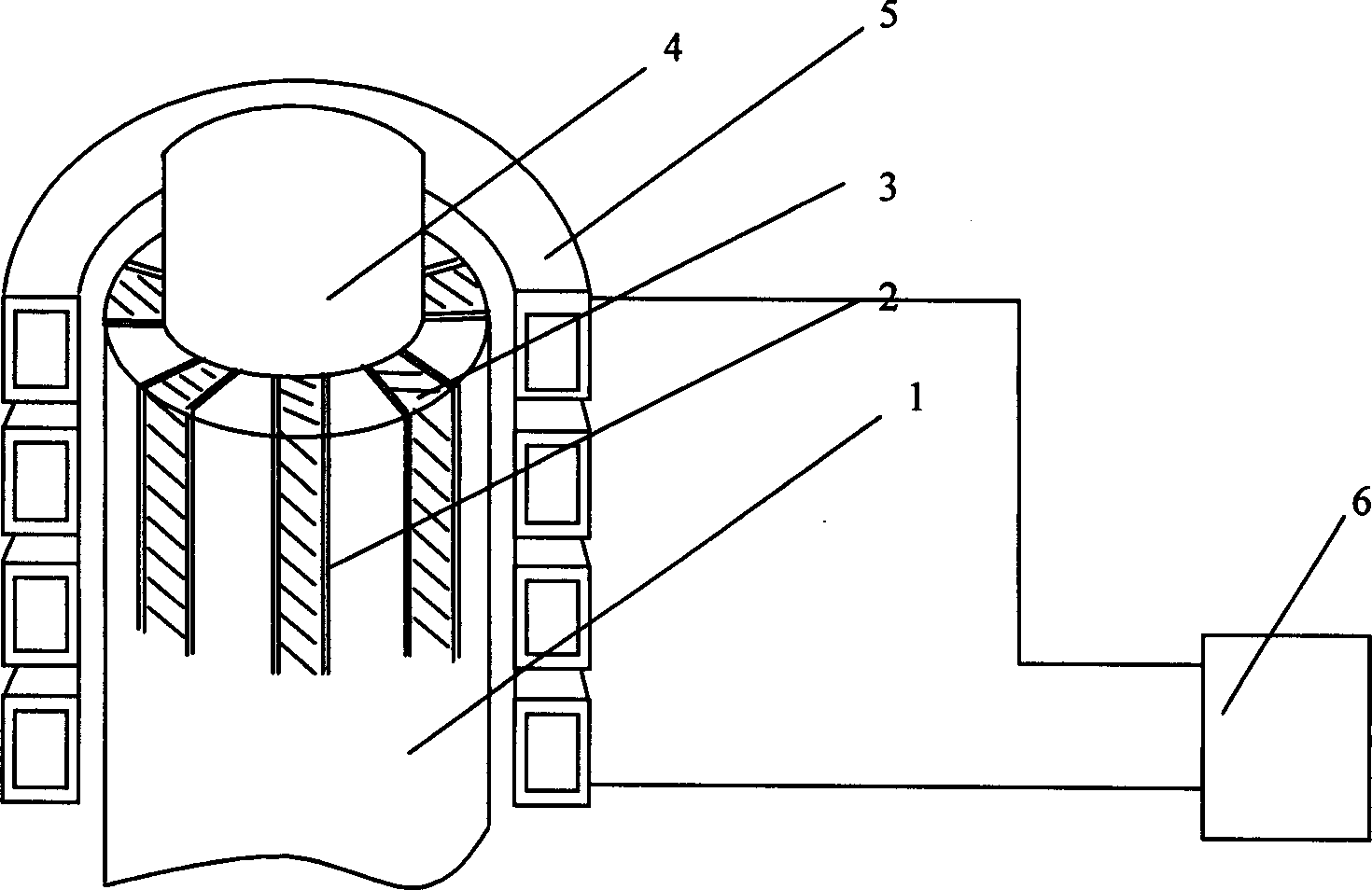

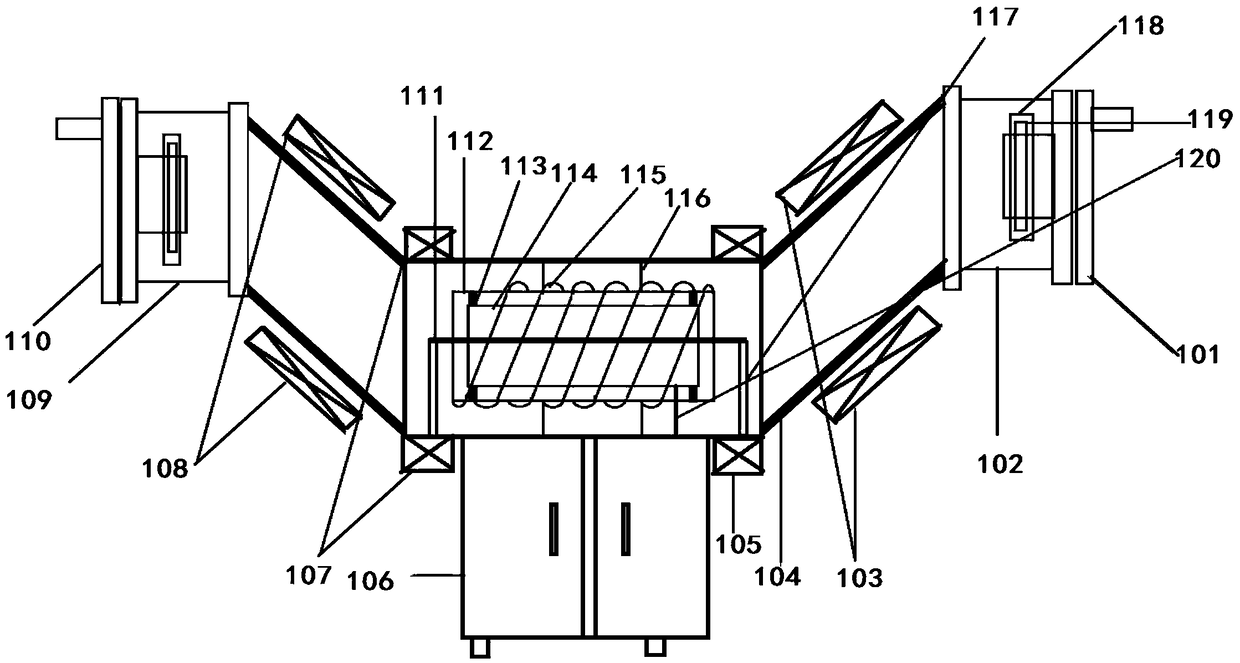

Electromagnetic impact dynamic tensile test method and device

ActiveCN102109436AAchieving Dynamic StretchEasy to controlMaterial strength using tensile/compressive forcesStrong pulseElectromagnetic pulse

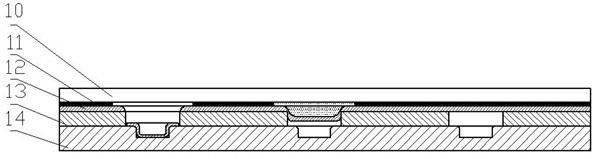

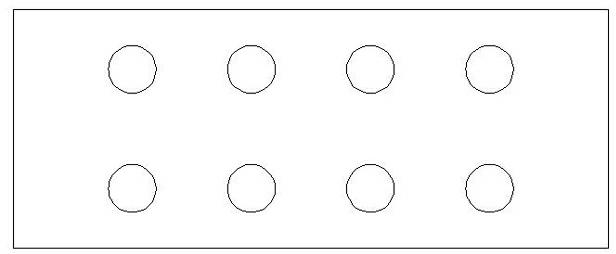

The invention relates to an electromagnetic impact dynamic tensile test method and a device, and belongs to the technical field of dynamic tensile mechanical property test of materials. The device adopts an electromagnetic pulse to load; a tensile test piece (8) passes through a central hole of an electromagnetic pulse device (16); the electromagnetic pulse device (16) is used for arousing a strong-pulse magnetic field; the action of electromagnetic force is generated between a target (14) and an electromagnetic pulse coil (18), so that the tensile test piece (8) mounted between the target (14) and a bracket (10) obtains direct instantaneous tensile force to finish the dynamic tensile test of the tensile test piece (8). The method and the device are used for measuring the dynamic stress and strain relationship of the materials in a high strain state; and the device has simple structure and simple test process, can be used for carrying out direct dynamic tensile test as well as the dynamic tensile test of the materials under the conditions of different high strain rates and ultrahigh strain rates, and has low cost and good application prospect.

Owner:JIANGSU UNIV

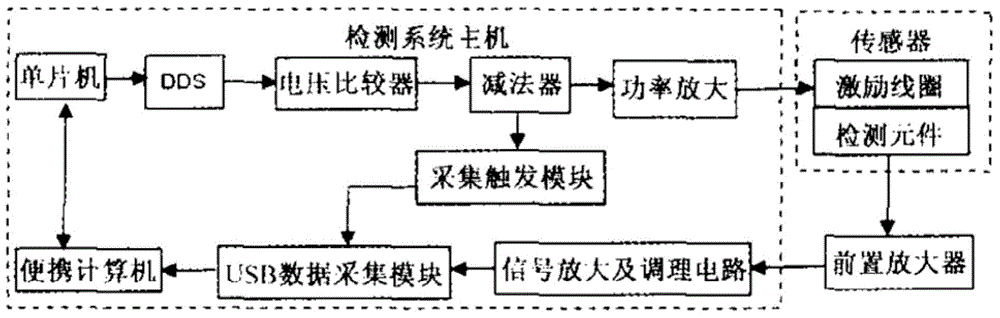

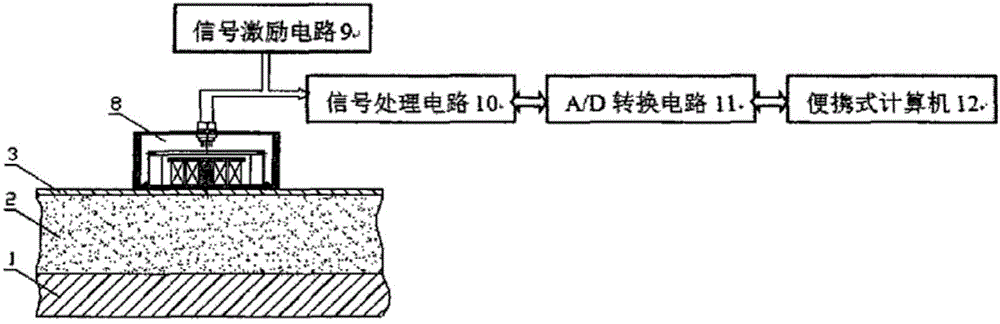

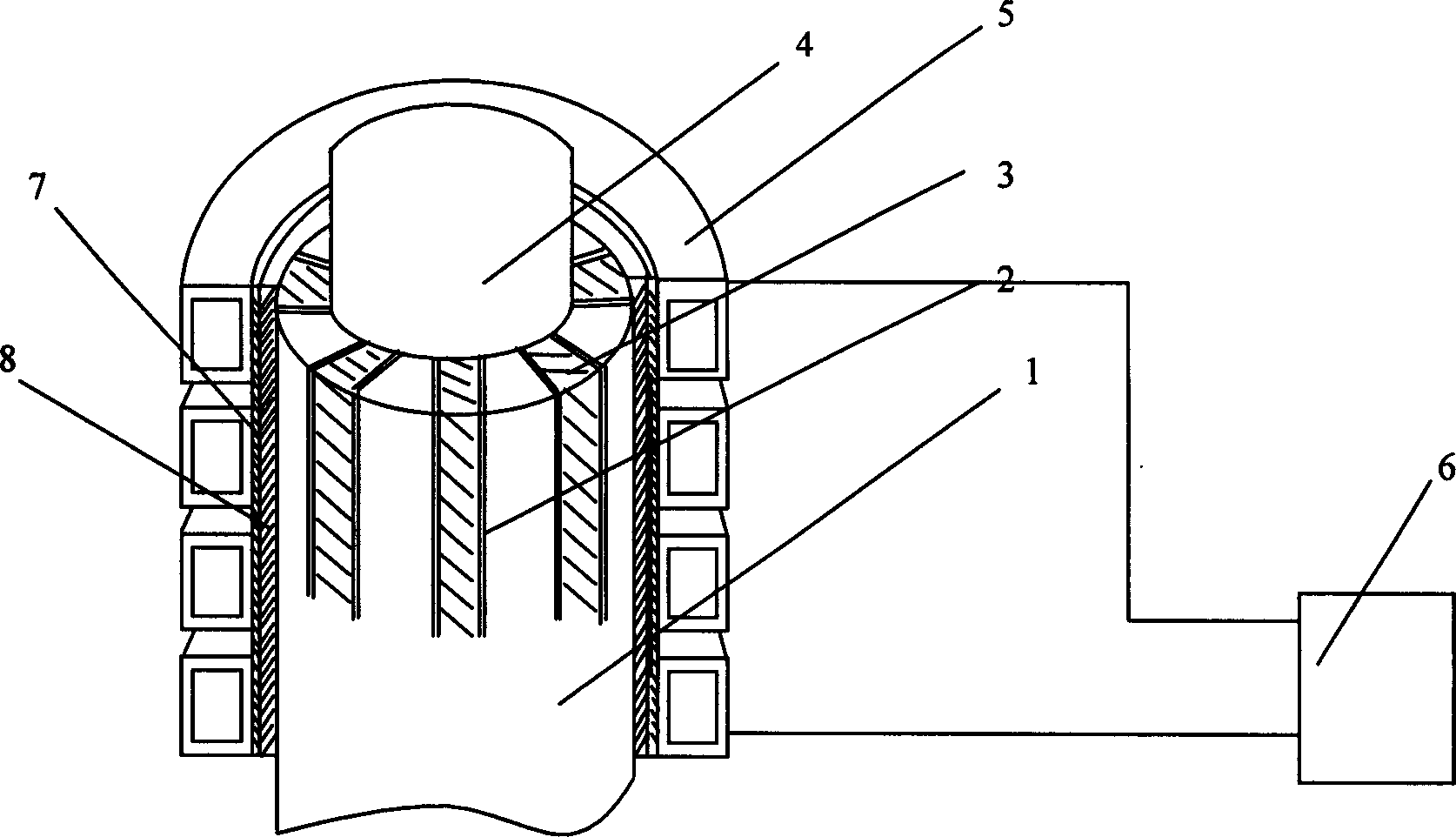

Pulse eddy electromagnetism nondestructive detection method based on probe with iron core coil

ActiveCN104155361ASmall magnetic resistanceEasy to detectElectrical/magnetic thickness measurementsMaterial magnetic variablesDiffusionHigh lift

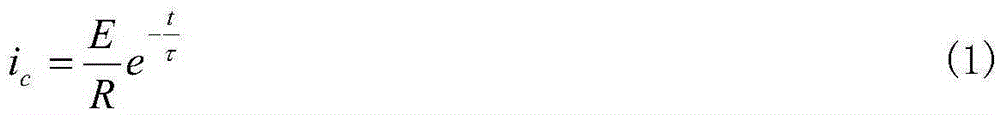

The invention discloses a pulse eddy electromagnetism nondestructive detection method based on a probe with an iron core coil. The probe consists of an iron core bundle, an excitation coil and a detection coil, wherein the iron core bundle is arranged in the center of the excitation coil; the detection coil is arranged outside the excitation coil. When the probe with the iron core coil is adopted to perform pulse eddy detection on a part, a strong pulse magnetic field of a dense space can be generated, an excitation magnetic field is increased, the signal to noise ratio of a signal is increased, and pulse eddy detection on a component with a relatively large wall thickness can be achieved under a relatively high lift-off condition. When a pulse eddy electromagnetism nondestructive detection system based on the probe with the iron core coil is adopted for detection, the influence of the pulse eddy field inside the iron core to the detection signal can be measured according to a probe time constant tau s. When tau s is greatly smaller than a part diffusion time constant tau e, the influence of the pulse eddy field inside the iron core to the detection signal can be ignored, the function of the probe with the iron core coil can be approximated to be linear amplification of the detection signal, and thus the signal processing difficulty is reduced.

Owner:BEIHANG UNIV

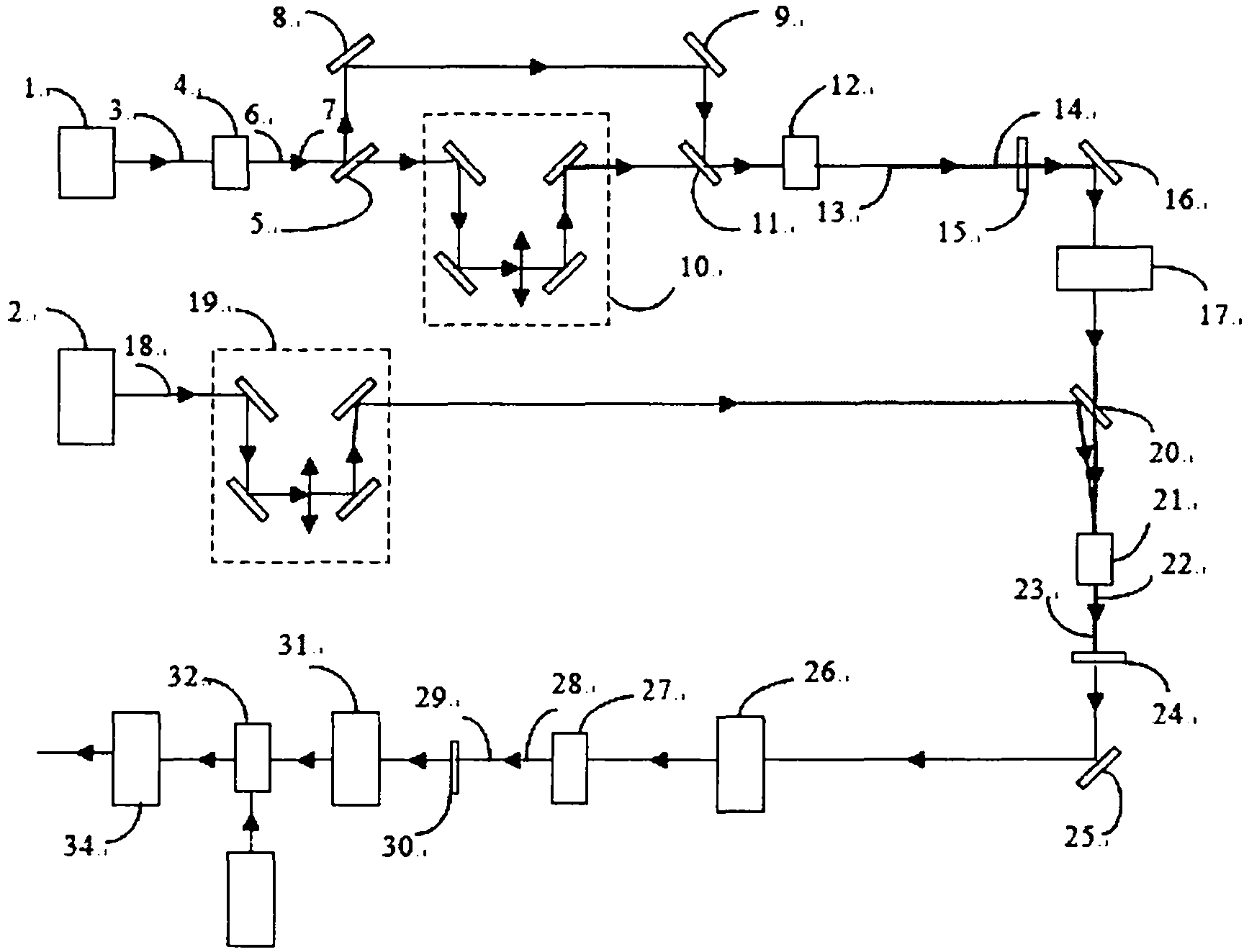

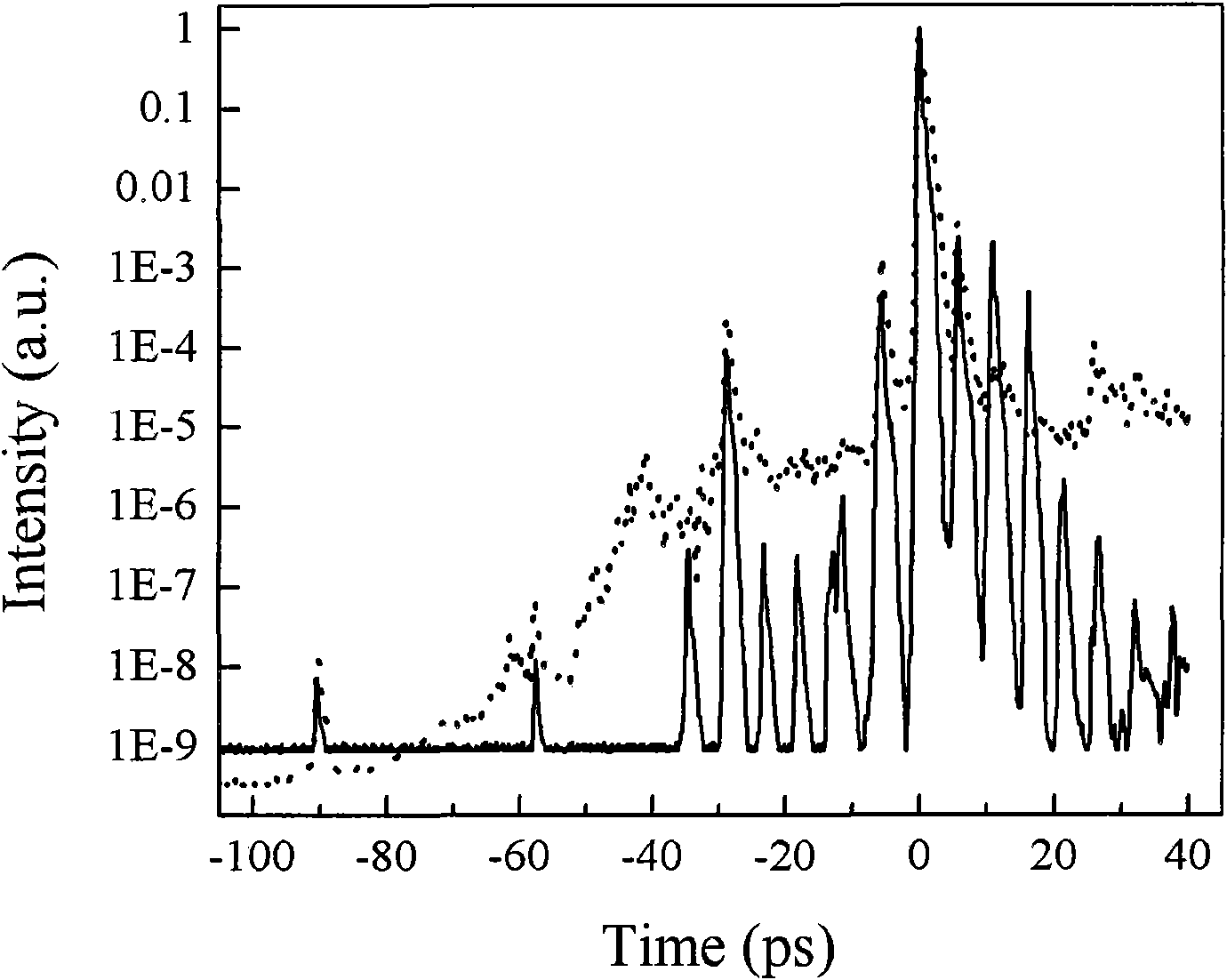

Device for generating high signal-to-noise ratio pulse based on frequency-doubling type cascading chirped pulse amplification

InactiveCN101867141AImprove purification efficiencyImprove purification effectLaser arrangementsNon-linear opticsLaser technologySignal-to-noise ratio (imaging)

The invention belongs to the technical field of laser, in particular to a device for generating high signal-to-noise ratio optical pulse. The device mainly consists of a multi-level chirped pulse amplification part and a pulse frequency-doubling purification part, wherein each level of chirped pulse amplification system respectively operates in different wavelengths (namely fundamental wave and harmonic wave); and non-linear purification of the pulse and conversion matching of the wavelengths can be realized through the frequency-doubling process between the fundamental wave and the harmonic wave, so as to obtain the high signal-to-noise ratio pulse. The device has the advantages of strong pulse purification ability, high overall efficiency and favorable expansibility performance towards a heavy calibre high energy state, and can be used for constructing laser systems of the petawatt magnitude.

Owner:FUDAN UNIV

Pulse trigger

The invention provides a pulse trigger. A medicine box is a hollow chamber; a thermal insulating layer covers the internal wall of the chamber; the chamber is full of ignition powder; two ends of the medicine box are respectively connected with an end cap and a connecting chamber assembly; the middle of the end cap is fixedly connected with an ignition tube; the connecting chamber is a through hollow chamber; the thermal insulating layer covers the internal wall of the chamber; a separation plate is arranged and positioned inside the connecting chamber through a supporting ring; the separation plate is provided with a plurality of through holes; a communicating part of the medicine box and the connecting chamber positions a sealing piston assembly through a stepped hole; the sealing piston assembly comprises a sealing piston and a thermal insulating layer; the sealing piston seals the communicating position of the medicine box and the connecting chamber and can be separated under combustion pressure of ignition powder; the medicine box and the connecting chamber are guaranteed to be communicated; the thermal insulating layer covers the sealing piston. The pulse trigger can increase the working pressure strong pulse by 0 to 20% in 0 to 5millisecond short time at any time during working of and engine and saves target range test costs.

Owner:中国航天科工集团第六研究院二一〇所

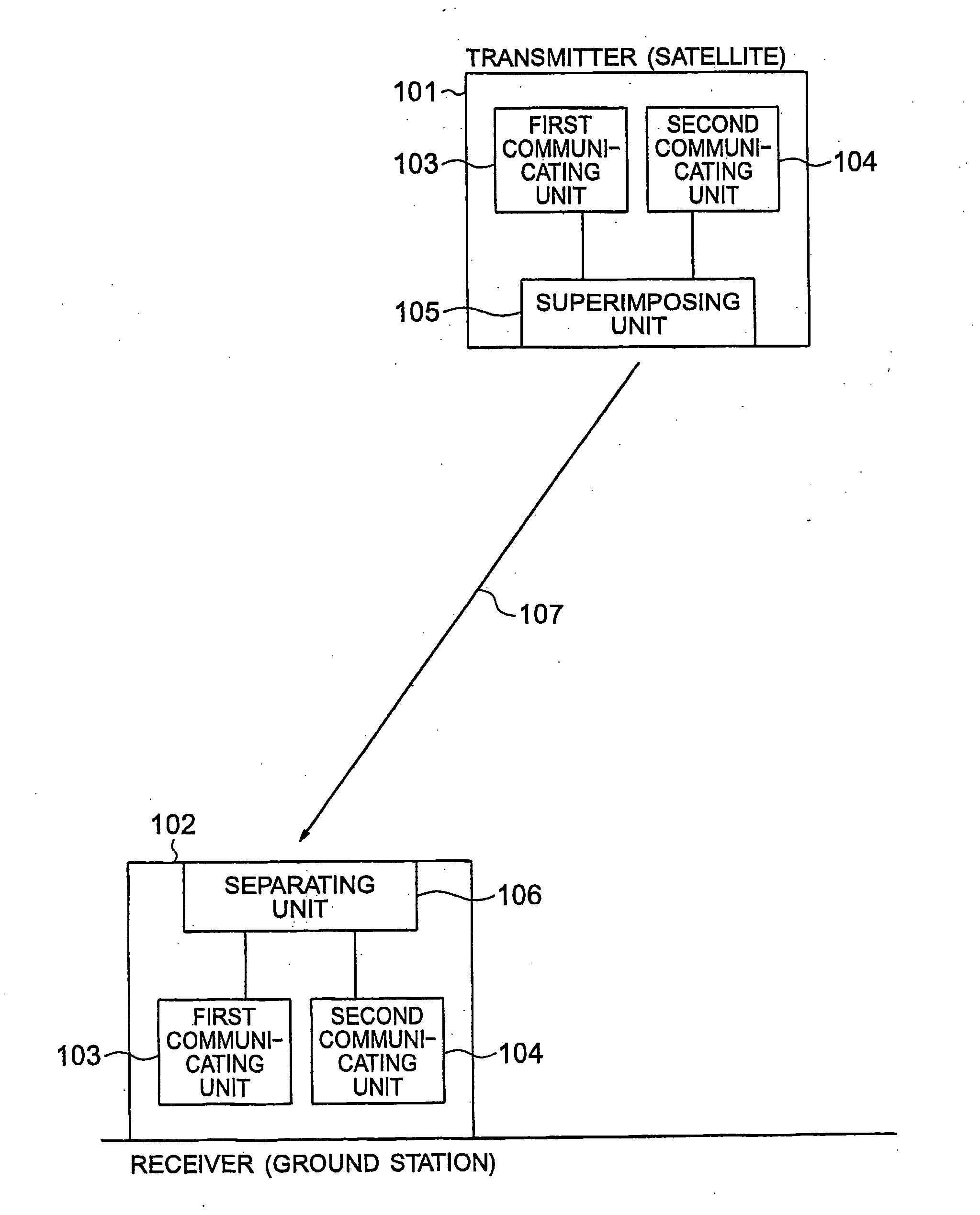

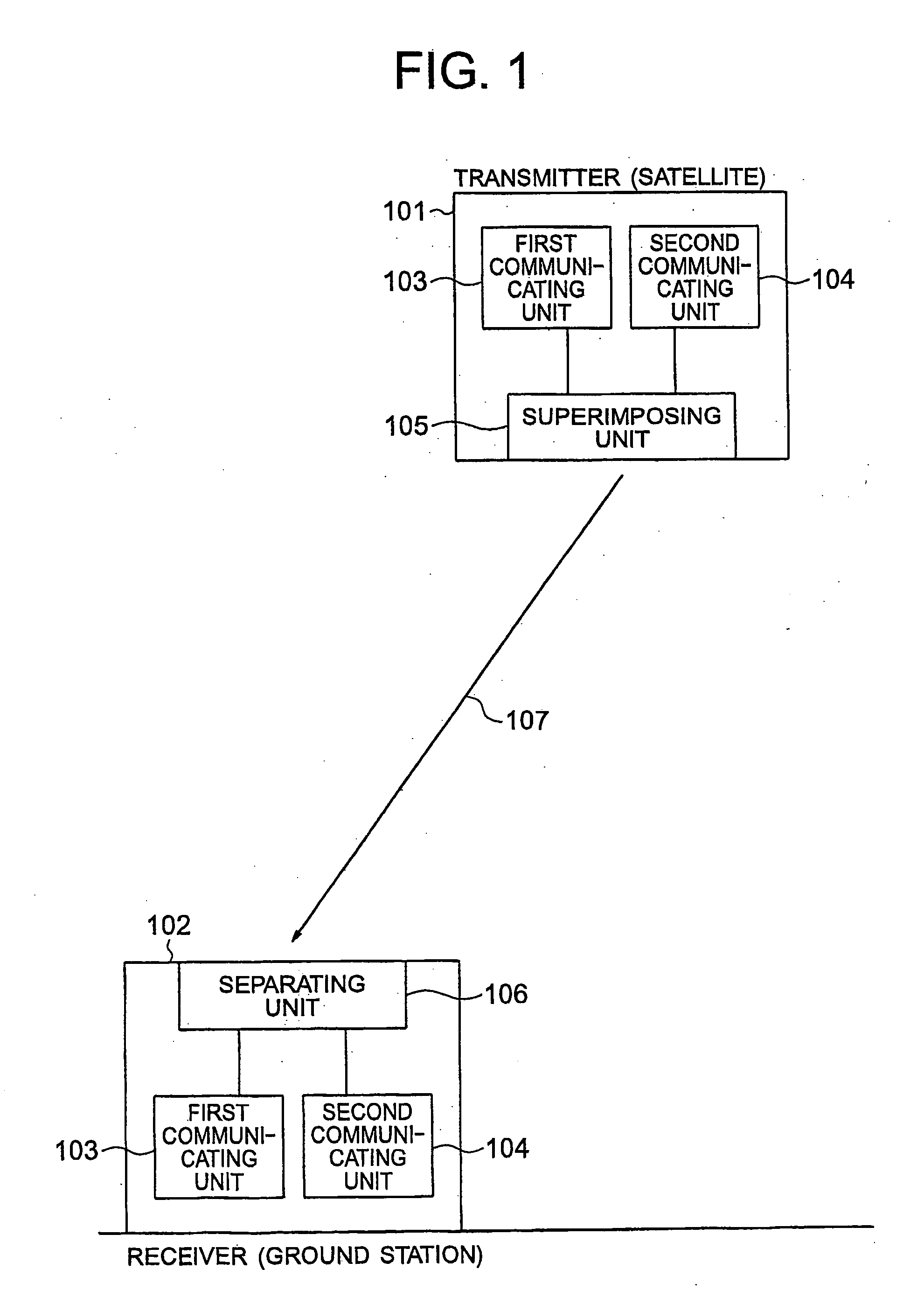

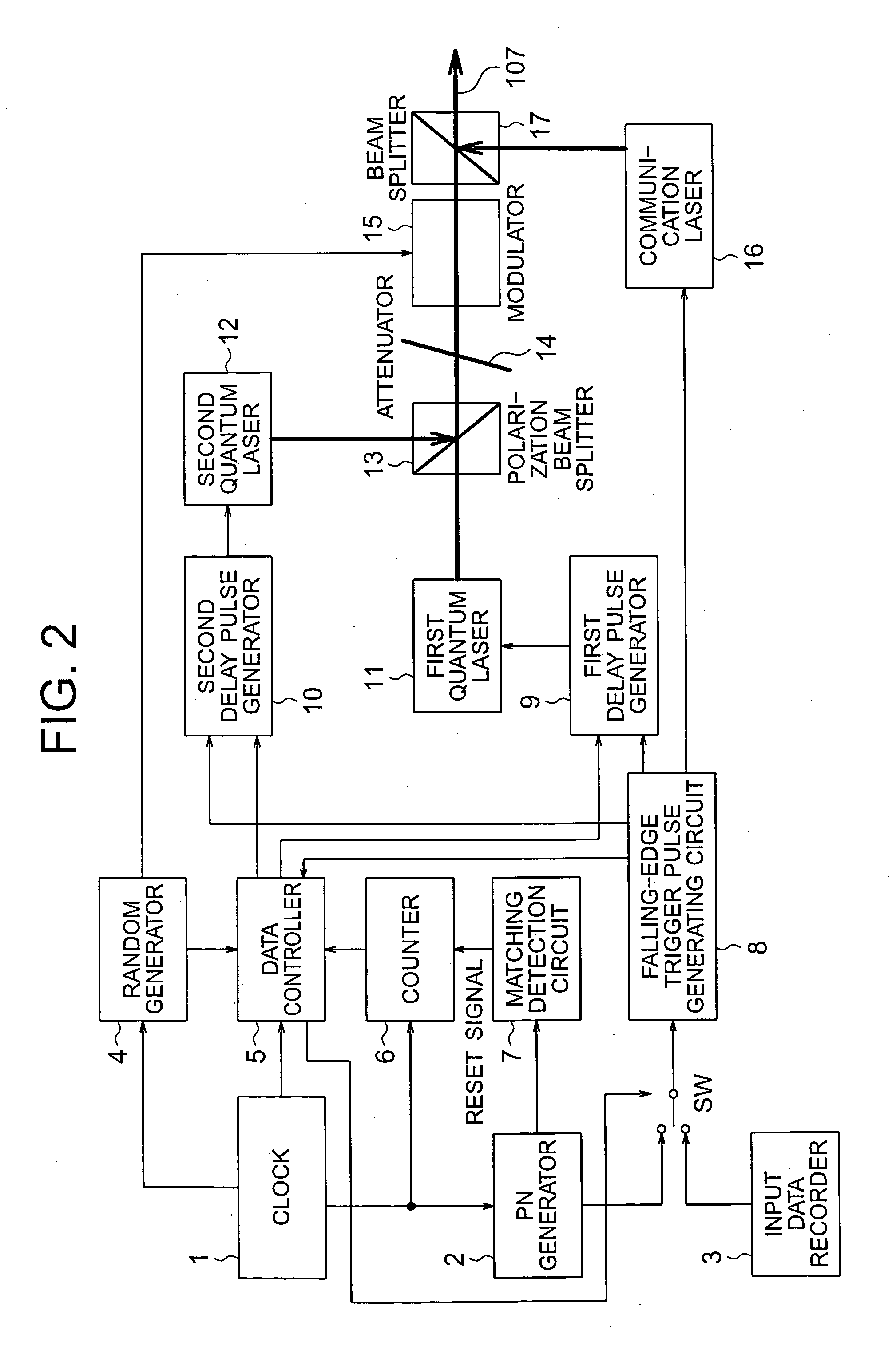

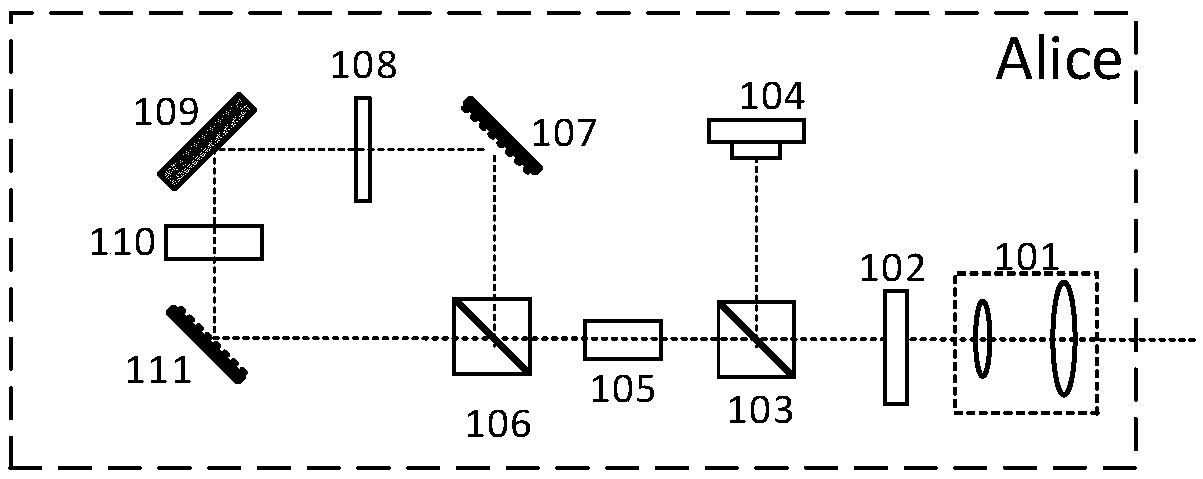

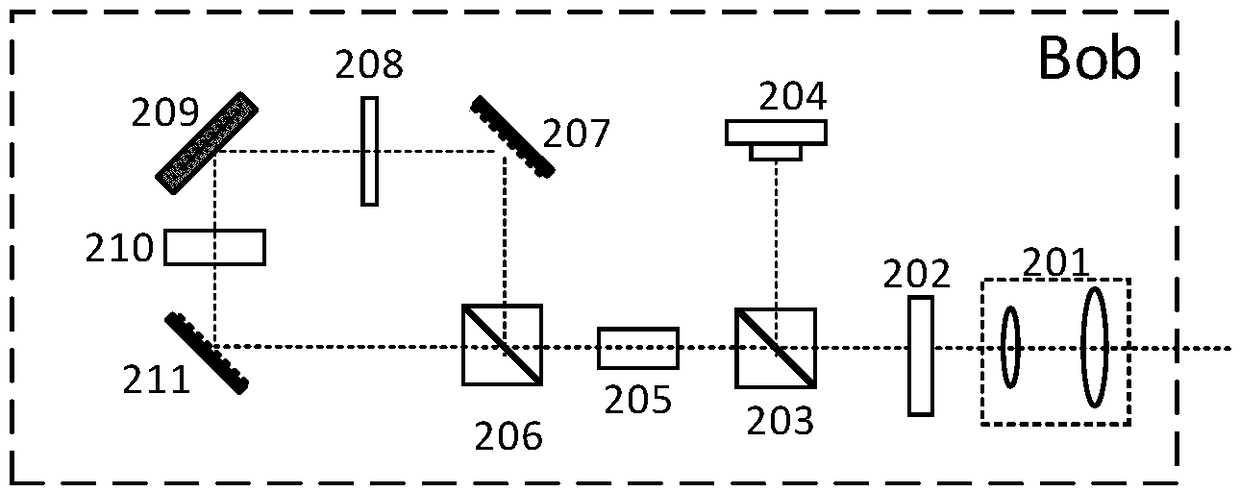

Apparatus and method for quantum cryptography communication

ActiveUS20100208893A1Reduce necessityEasy to adjustSynchronising transmission/receiving encryption devicesSecret communicationStrong pulseQuantum

A quantum cryptography communication apparatus performs quantum cryptography communication between a transmitter and a receiver. The quantum cryptography communication apparatus includes first communicating unit transmitting and receiving a communication signal including relatively strong pulse light between the transmitter and the receiver, and second communicating unit transmitting and receiving a relatively weak quantum cryptography signal between the transmitter and the receiver in a period in which the communication signal is off and the attitude axis for the receiver can be adjusted to that for the transmitter by the second communicating unit.

Owner:NAT INST OF INFORMATION & COMM TECH

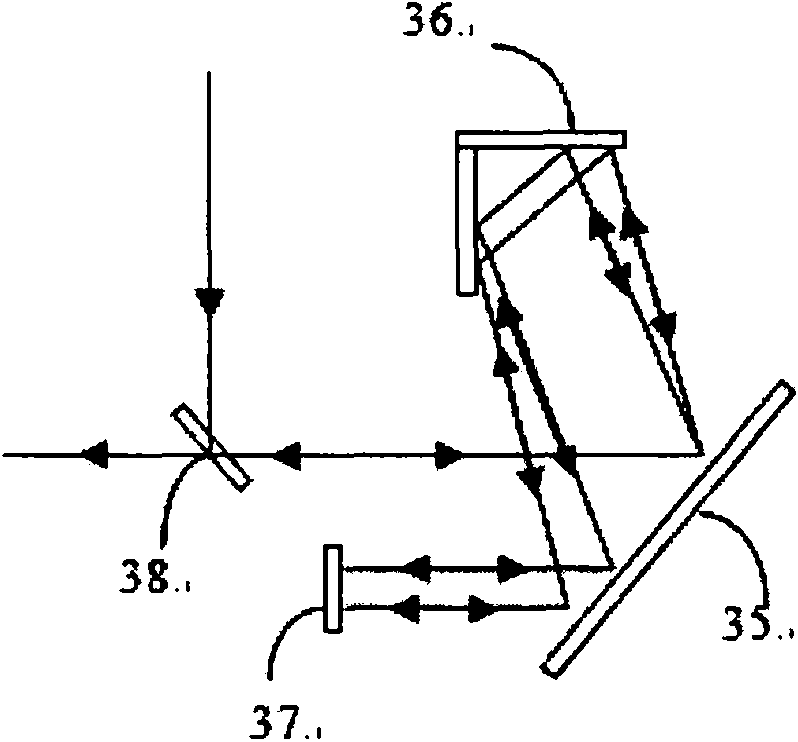

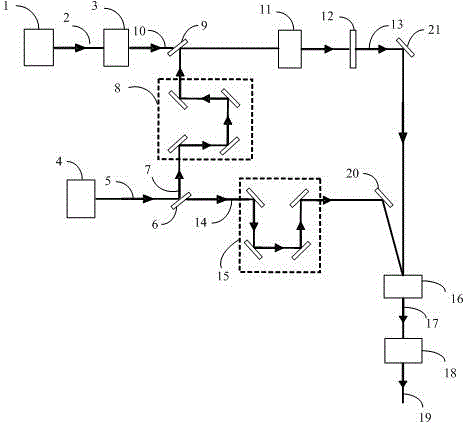

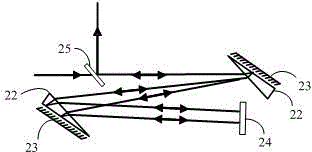

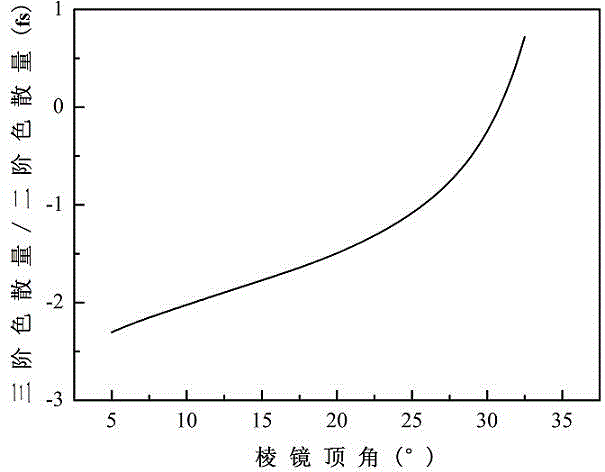

Mid-infrared chirped pulse amplifying device

ActiveCN104391416AReduce usageEliminate third order dispersionNon-linear opticsPicosecond laserBeam splitter

The invention discloses a mid-infrared chirped pulse amplifying device. The mid-infrared chirped pulse amplifying device comprises a femtosecond laser, a synchronous narrowband picosecond laser, a beam splitter, a near-infrared pulse stretcher, a non-linear frequency converter, an optical parametric chirped pulse amplier and a mid-infrared pulse compressor. Due to the fact that grism pairs and grating pairs are matched with each other to serve as the pulse stretcher and the pulse compressor, usage of a mid-infrared pulse stretcher is avoided, residual third-order dispersion in compression pulses in the process that the grating pairs serve as the pulse stretcher and the pulse compressor is eliminated, and the mid-infrared chirped pulse amplifying device is particularly suitable for generation of mid-infrared ultra-short ultra-strong pulse lasers with the frequency lower than hundreds of femtoseconds.

Owner:SHENZHEN UNIV

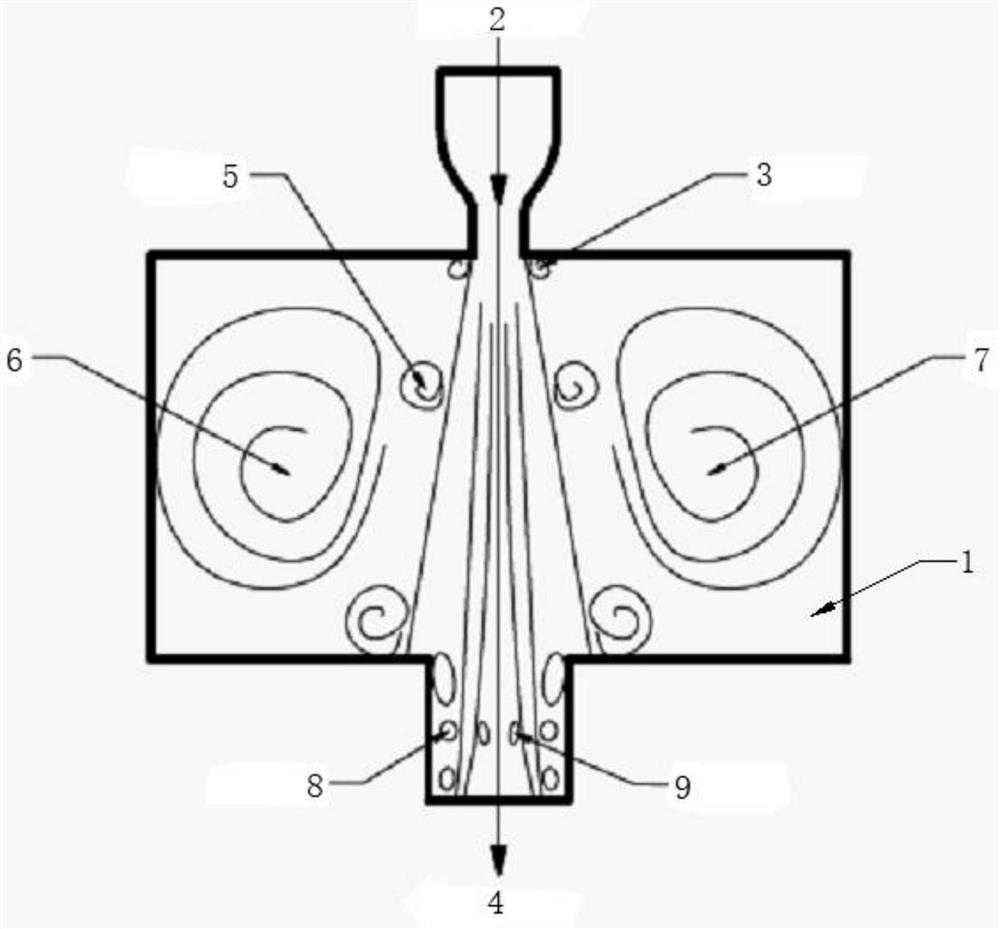

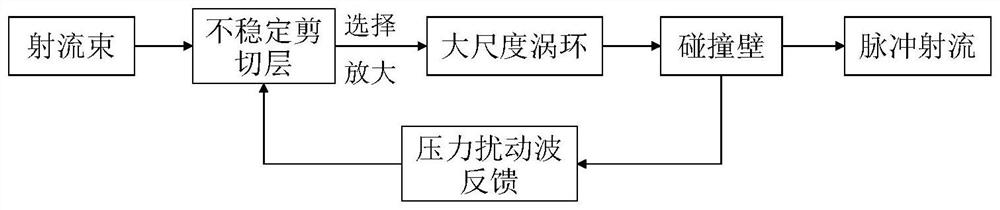

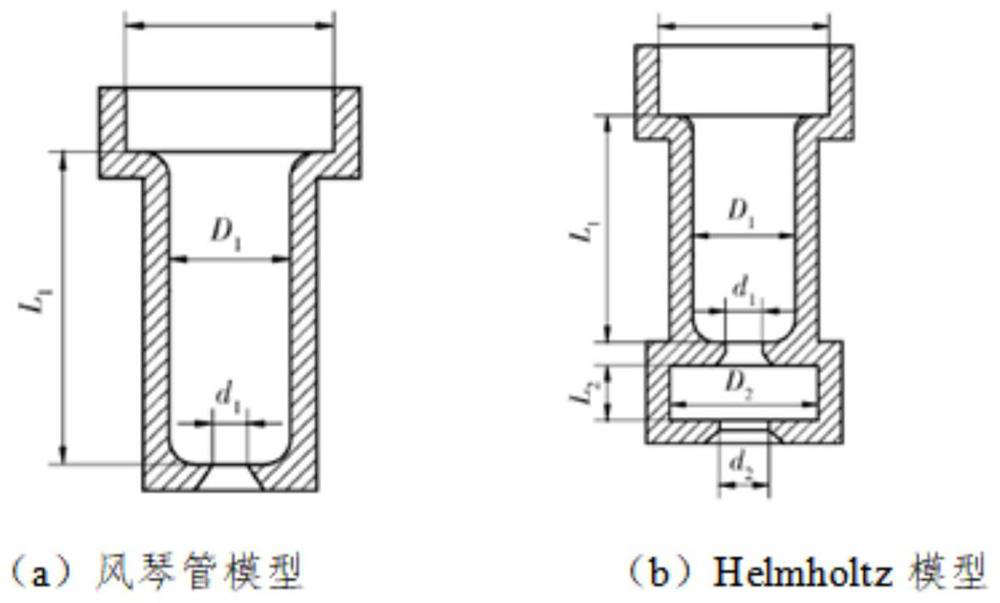

Pulse oscillation device constructed and designed based on mathematical model

The invention discloses a pulse oscillation device constructed and designed based on a mathematical model, and relates to the technical field of pulse oscillators. The pulse oscillation device comprises a shell, a jet flow inlet, a first discrete vortex, a jet flow outlet, a second discrete vortex, a first air steam bag, a second air steam bag, first air bubbles and second air bubbles, and the jetflow inlet is fixedly formed in the top of the shell. According to the pulse oscillation device constructed and designed based on the mathematical model, the jet flow impact performance is high, thepulse signal mutability is high, the amplitude change is stable, the improvement on jet flow impact performance is facilitated, the characteristic of the stable pulse effect is achieved, an internal system is stable, large-scale vortexes existing in an oscillation cavity and the pulse pressure oscillation effect can cause vortex cavitation and oscillation cavitation formation in a self-oscillationcavity, and therefore the cavitation effect of the jet flow outlet is enhanced, the cavitation effect of the jet flow is effectively promoted, meanwhile, transmission and superposition of water pressure signals are facilitated, and the cracking problem is not prone to occurring.

Owner:UNIV OF SCI & TECH BEIJING

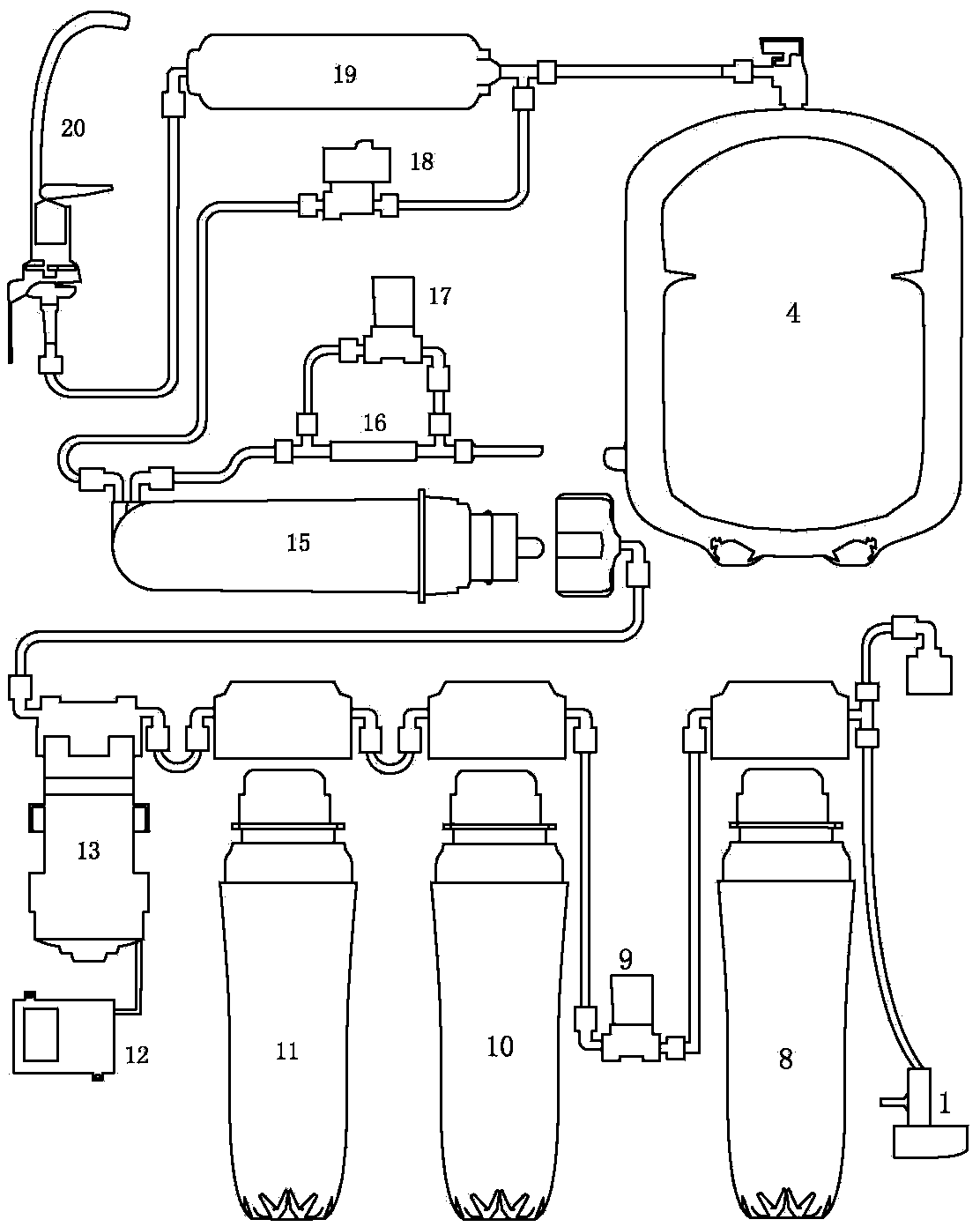

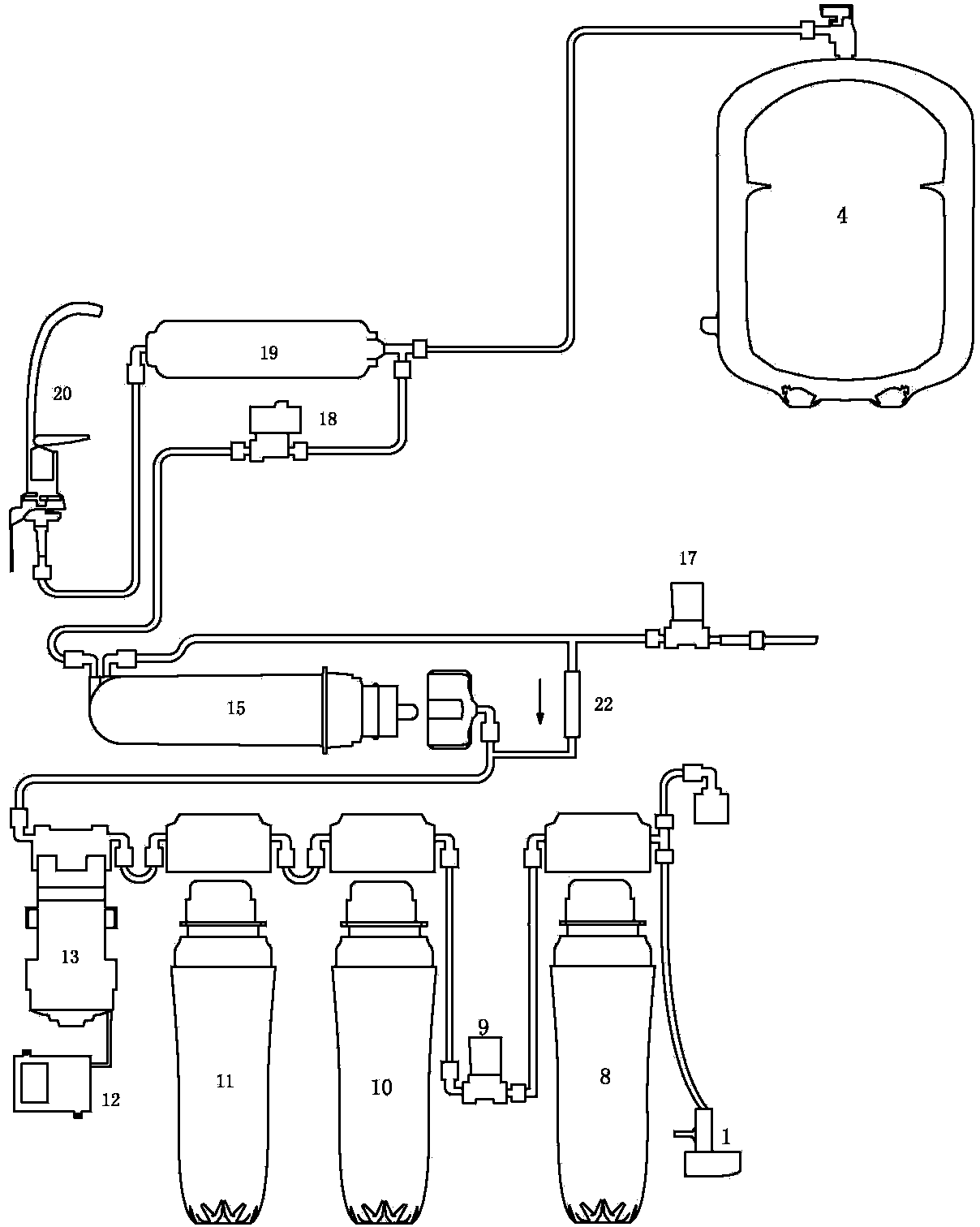

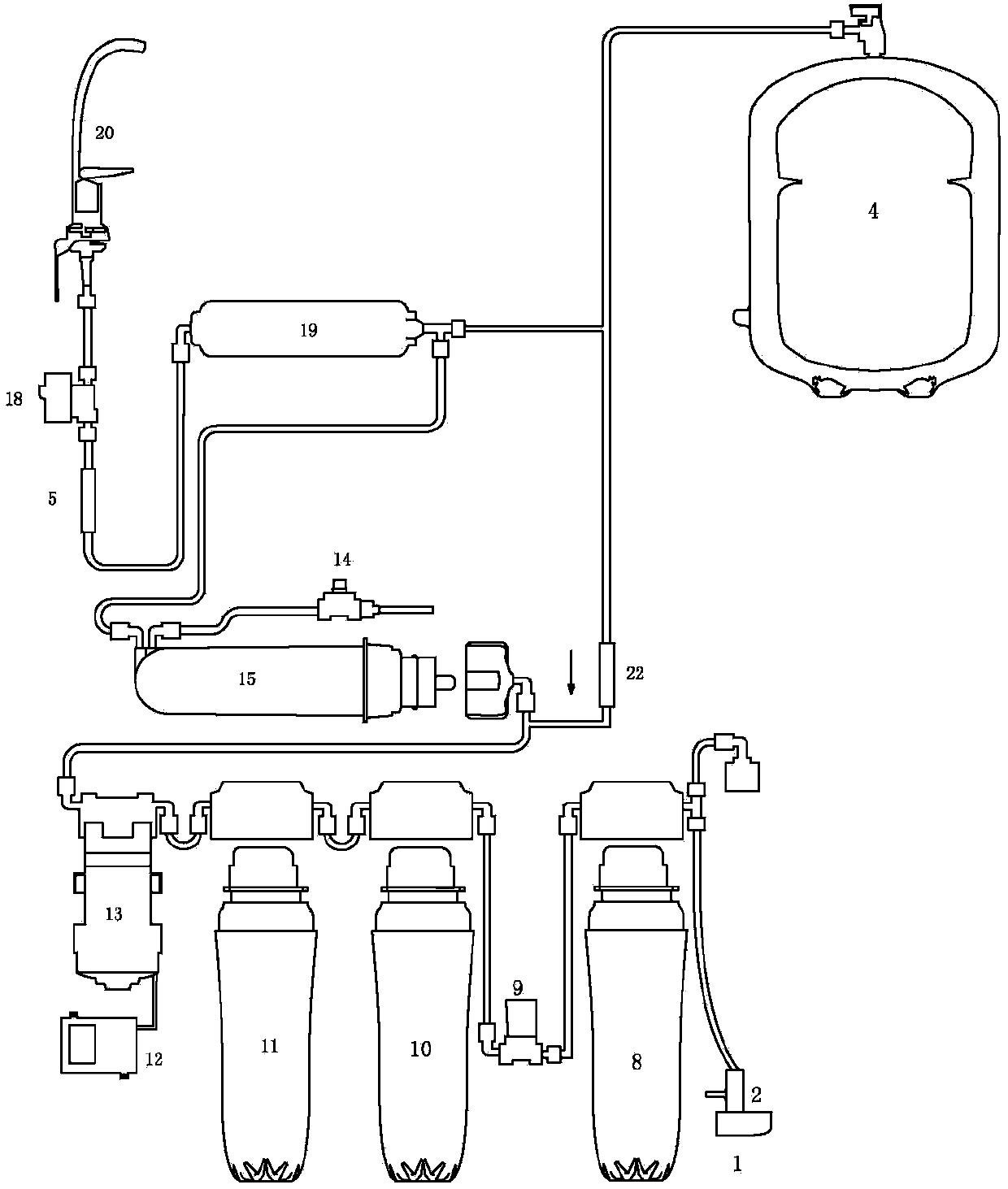

Strong-pulse micro-wastewater emission and purification system

ActiveCN103803736AHigh quality outputImprove raw water utilizationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentActivated carbon filtrationReverse osmosis

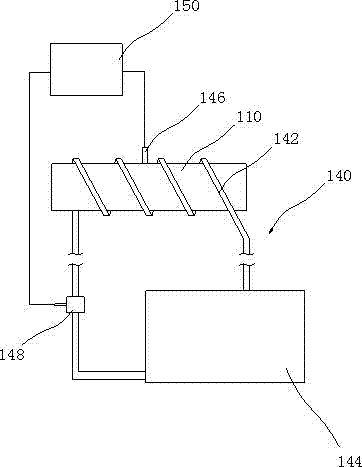

The invention discloses a strong-pulse micro-wastewater emission and purification system which comprises a water inlet tee joint (1), a front filter group, a booster pump (13), a reverse osmosis membrane filter (15), and a rear active carbon filter (19) which are sequentially connected through a pipeline, wherein an outlet of the rear active carbon filter is connected with a water outlet (20) through a high-pressure switch (18), an outlet of the reverse osmosis membrane filter is connected with a water storage pressure barrel (4) through a pipeline, a wastewater discharge pipeline is arranged at an outlet of the reverse osmosis membrane filter, a pulse electromagnetic valve (14) is arranged on the pipeline, and after the water storage pressure barrel reflows trace pure water to the front end of the reverse osmosis membrane filter (15) through a pipeline and a one-way valve (22) and after the trace pure water is produced, a reverse osmosis membrane is soaked. According to the strong-pulse micro-wastewater emission and purification system, through two measures of rapid instant pulse pollution discharging and washing of the reverse osmosis membrane and pure water reflowing and washing and soaking and protecting of the reverse osmosis membrane, the raw water utilization rate is greatly increased to above 75 percent.

Owner:深圳市君脉膜科技有限公司

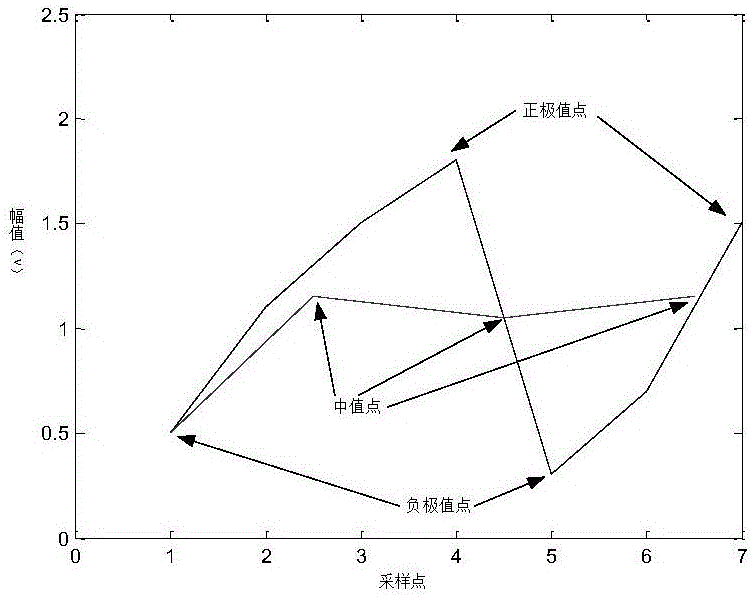

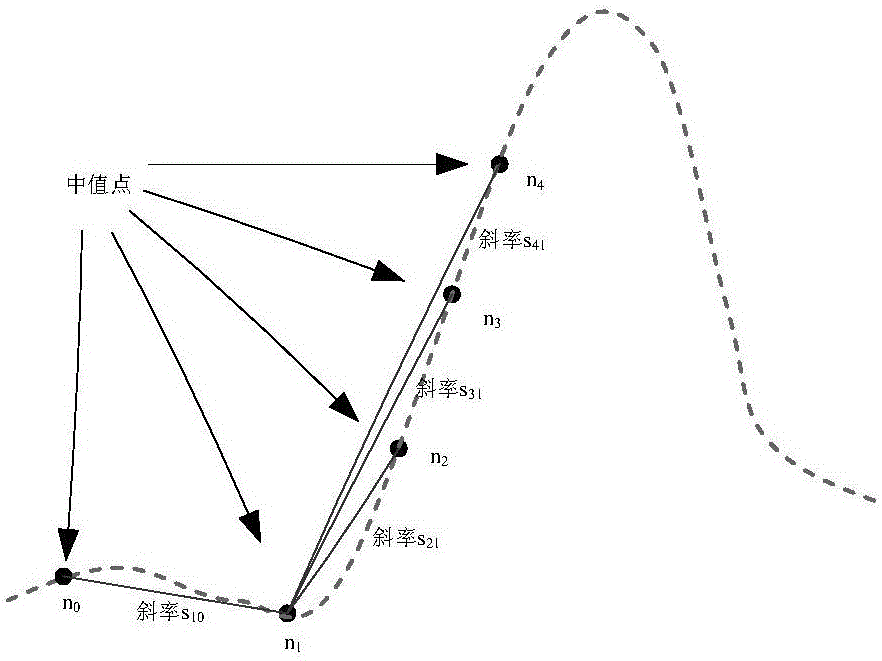

Recognition method of strong pulse signal based on slope and amplitude difference value threshold

InactiveCN106645434AMeet the requirements of long-term underwater autonomous workGuaranteed recognition success rateProcessing detected response signalStrong pulsePhysics

The invention discloses a recognition method of a strong pulse signal based on a slope and amplitude difference value threshold. The recognition method comprises the following steps: obtaining an acoustic signal through an acoustic sensor and converting the acoustic signal into an electrical signal to be sent to a preprocessing circuit so as to be amplified, filtered, detected, sampled and smoothed, finally obtaining a smooth curve; obtaining the slope between various points and adjacent points which form the curve by aiming at the smooth curve, and calculating slope difference values of the adjacent points, selecting the point of which the difference value of the slope with that of adjacent sampling points on two sides is greater than a preset threshold as a mutation point; taking the slope between the mutation point and the former adjacent sampling point of the mutation point as an initial value, calculating the slope difference value between the slope of the mutation point on the smooth curve and the follow-up point of the mutation point and the initial value, and an amplitude difference value between the mutation point and the follow-up point, if the amplitude difference value and the slope difference value of the follow-up points and the mutation points of set number are both greater than a set threshold value, judging the signal to be the strong pulse signal. The recognition method of the strong pulse signal based on the slope and amplitude difference value threshold disclosed by the invention can recognize the strong pulse signal.

Owner:CSIC NO 710 RES & DEV INST

Strong pulse current orientated solidification grain ultra-fining method and device

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method and device for forming and assembling micro-scale parts

ActiveCN102274887AAchieve fixationRealize the assemblyLaser beam welding apparatusEngineeringStrong pulse

Owner:SANMENXIA ZHONGYUAN PRECISION

Multi-functional laser cosmetic instrument

PendingCN107343986APrevent and treat agingPromote blood circulationLight therapyLight treatmentOptoelectronics

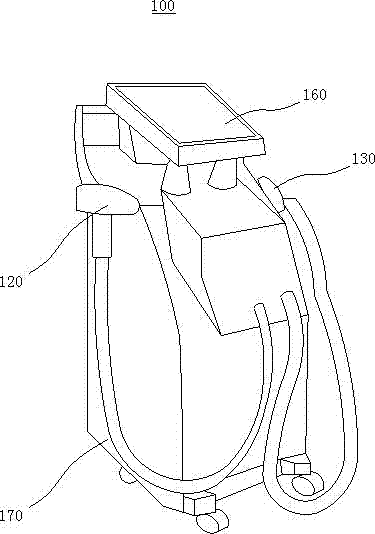

The invention provides a multi-functional laser cosmetic instrument which belongs to the field of cosmetic equipment. The multi-functional laser cosmetic instrument mainly comprises a laser generator, a laser treatment head, a radio frequency generator, a radio frequency treatment head, a strong pulse light generator, a strong pulse light treatment head, a cooling device, a controller, an operation panel and a casing body. The laser generator, the strong pulse light generator and the radio frequency generator are arranged in the casing body. The operation panel is connected with the casing body. The laser treatment head, the radio frequency treatment head and the strong pulse light treatment head of the multi-functional laser cosmetic instrument are mainly used for freckle removing, wrinkle removing, mole removing, hair removing, wart removing and the like. The cooling device is arranged in the casing body, and is mainly used to cool the laser generator.

Owner:CHINA JILIANG UNIV

Pulse discharge auxiliary die-casting device and method

The invention discloses pulse discharge auxiliary die-casting device and method, relates to discharge plasma die-casting device and method, belongs to the field of die-casting technologies and aims to solve the problems that the existing die-casting technology is high in energy consumption, preparation material is low in density, complex parts cannot be manufactured due to uneven pulse discharge temperature and pressure in the pulse discharge sintering technology. The pulse discharge auxiliary die-casting device comprises a feed rod, a hopper cover, a hopper, a graphite die, a graphite electrode, an auxiliary die, a die and a guide tube. The graphite die, the graphite electrode, a copper electrode and a graphite press head are added on the basis of conventional die-casting for pulse discharge, raw material applies machining residual metal scrap or waste metal fragments, material is placed in the hopper and pushed into the graphite die to be subjected to vacuum pumping, strong pulse is applied to two ends of the material to melt the material, and molten metal is extruded into a die cavity for forming. The pulse discharge auxiliary die-casting device and method are mainly applied to the die-casting technical fields, and waste raw material is effectively utilized to achieve environment friendliness.

Owner:HARBIN UNIV OF SCI & TECH

All-normal-dispersion femtosecond fiber laser

ActiveUS8416817B2Easy to adjustLaser using scattering effectsMode locked fiber laserSpectral filtering

Owner:CORNELL CENT FOR TECH ENTERPRISE & COMMLIZATION CCTEC

Bremsstrahlung reflection triode

ActiveCN110047721ATake advantage ofLower average energyX-ray tube electrodesCathode ray concentrating/focusing/directingHard X-raysStrong pulse

The invention relates to a bremsstrahlung reflection triode for generating strong pulse hard X rays. The problems that the gap potentials of two cathodes and anodes of an existing bremsstrahlung reflection triode are inconsistent, and a radiation field cannot be fully utilized are solved. The triode comprises a reflection triode cavity, an anode base, an anode, cathodes, transverse cover plates, aforward cover plate, an insulation plate fixing nut, an insulation plate transition piece and an insulation plate. The part, connected with the insulation plate, of the reflection triode cavity is acylinder, the part, away from the insulation plate, of the reflection triode cavity is transited into a closed cavity, and two parallel flat plates are arranged on the opposite surfaces of the closedcavity; the two cathodes are respectively arranged on the two flat plates of the closed cavity; the anode is positioned between the two cathodes; the anode is arranged on the anode base, the anode base is installed on a water line inner cylinder through the insulation plate transition piece, and the insulation plate transition piece is fixed through the insulation plate fixing nut. The transversecover plates are arranged on the two flat plates of the closed cavity respectively, and the forward cover plate is arranged at the axial tail end of the closed cavity.

Owner:NORTHWEST INST OF NUCLEAR TECH

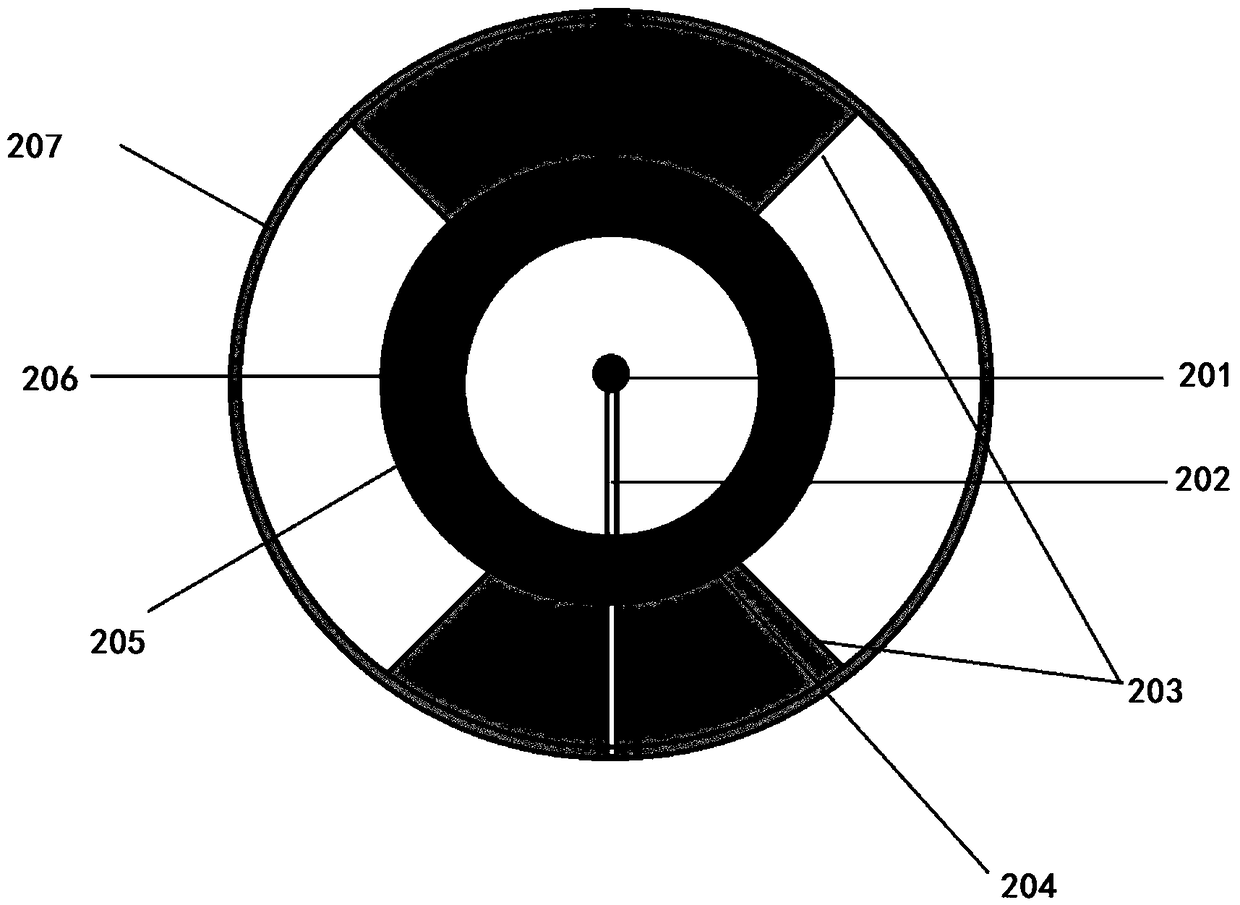

System and method for rotatably obtaining strong pulse gamma radiation field by thickness collimator

InactiveCN103077760AEasy to control high-speed rotationGood shielding functionHandling using diaphragms/collimetersX/gamma/cosmic radiation measurmentGamma rayStrong pulse

The invention relates to a system and a method for rotatably obtaining a strong pulse gamma radiation field by a thickness collimator. A rotor and a fixed housing are combined to form a combined shutter which has a good shielding function and is convenient to rotate at a high speed so as to cut pulse of a stable gamma ray. The fixed housing is a section of cylindrical body which is internally sleeved with a rotary collimator provided with a through hole or a trough. An extremely small gap is reserved between two substances for controlled rotation of the rotor at the high speed. The rotating manner can be realized by a way of a roller, floating or magnetic levitation and the like, so that the narrow pulse of the gamma ray is further formed. The fixed housing is arranged, so that the weight of the rotary collimator is reduced, shielding to scattered rays around the rotor is increased, the quality parameter of the collimator after pulse incision is improved, and the weight of the rotary collimator is effectively reduced, so that a higher rotating speed is conveniently formed and the narrow pulse is obtained.

Owner:NORTHWEST INST OF NUCLEAR TECH

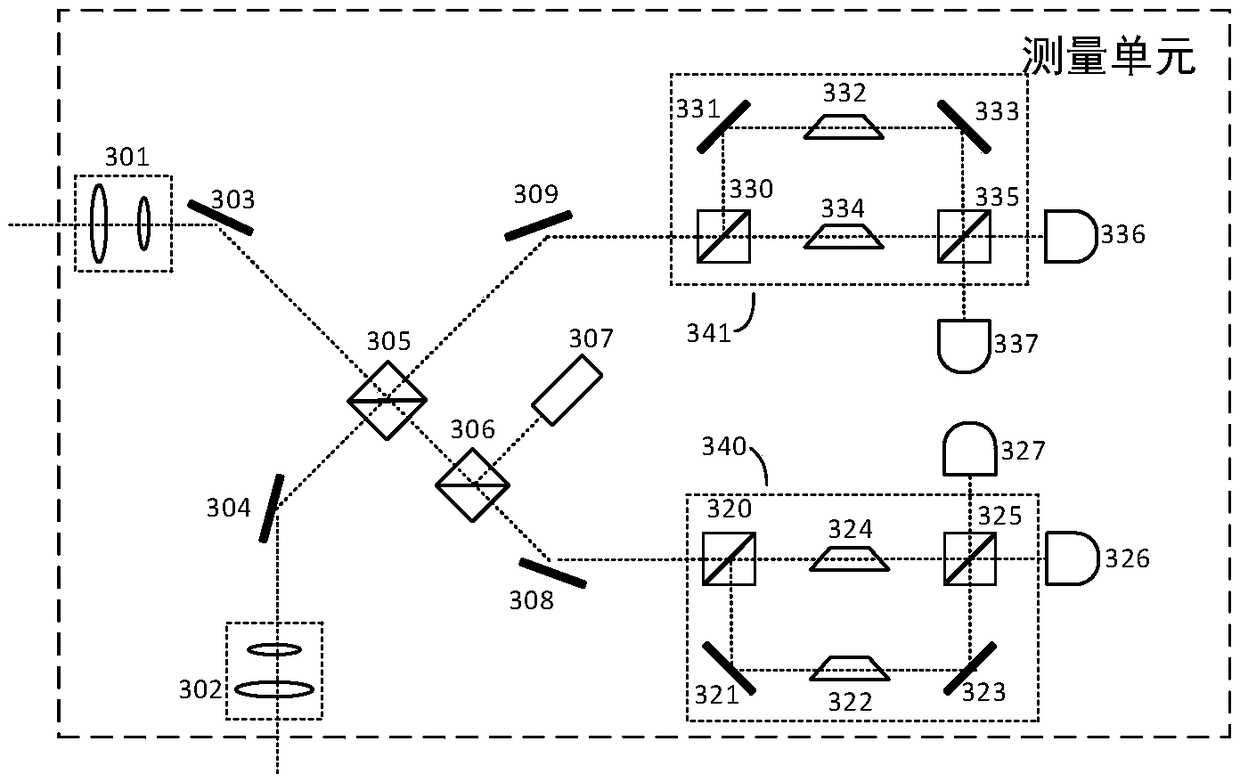

OAM measurement device-independent quantum key distribution system and method based on real-time tracking compensation

PendingCN109495261AImprove anti-interference abilityAvoid attackKey distribution for secure communicationSynchronisation information channelsMeasurement deviceEngineering

The invention discloses an OAM measurement device-independent quantum key distribution system and method based on real-time tracking compensation. The system comprises a user end Alice, a user end Boband a measurement unit; the user end Alice and the user end Bob utilize strong pulse laser from a measurement unit to realize real-time monitoring and phase distortion compensation of a channel environment; and the measuring unit adopts an M-Z interferometer composed of a Dove prism to realize separation of odd / even orbital angular momentum order photons, and can carry out Bell state measurementon the photons with orbital angular momentum. The measurement device-independent quantum key distribution based on the orbital angular momentum is realized; a user uses an orbital angular momentum state to carry out coding; and the distribution system and method has the characteristics of high stability, high code forming rate and high expansibility.

Owner:GUANGDONG INCUBATOR TECH DEV CO LTD

Low arc AC contactor

InactiveUS7262942B2Reduce power consumptionSmall sizeEmergency protective arrangement detailsElectric switchesLow voltageCoupling

A low arc AC contactor comprises an on / off mechanism electromagnetic-controlled contact, a pulse power source generating circuit, a low arc trigger generating circuit, and a multifunctional fault-detecting circuit. The contactor converts an instantaneous strong current into strong pulse magnetic field energy to actuate contacts of mechanical portion of the contactor, so that the power source load is on or off. Each of the actuating process will be controlled by the electric circuit to perform at the lowest potential of AC voltage for reducing arc's destructive power. Moreover, the contactor uses photoelectric coupling circuits, in which it can be controlled by external low voltage signal commands, as well as providing protection from overload, phase loss, short circuit, and leakage current.

Owner:FAT KWONG TSE

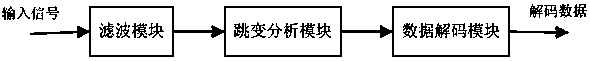

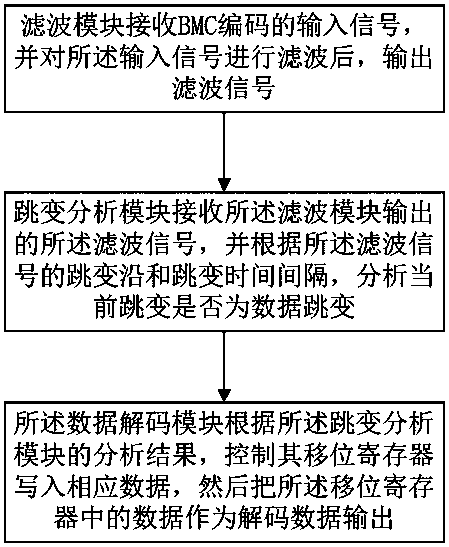

Decoding system and decoding method of BMC code

InactiveCN108551433AEliminate distractionsSimple structureIndividual digits conversionTransmitter/receiver shaping networksDecoding methodsStrong pulse

The invention relates to a decoding system and decoding method of a BMC code. The decoding method of the BMC code includes the following steps: firstly, filtering an input signal by using a filteringmodule, eliminating burr interference, and then performing jump edge detection and analysis on the filtered signal to avoid the effect of strong pulse width distortion on the signal, and finally, carrying out decoding according to a jump edge detection result. High decoding accuracy and decoding efficiency can be achieved. In addition, the decoding system using the decoding method is simple in structure and low in cost.

Owner:AMICRO SEMICON CORP

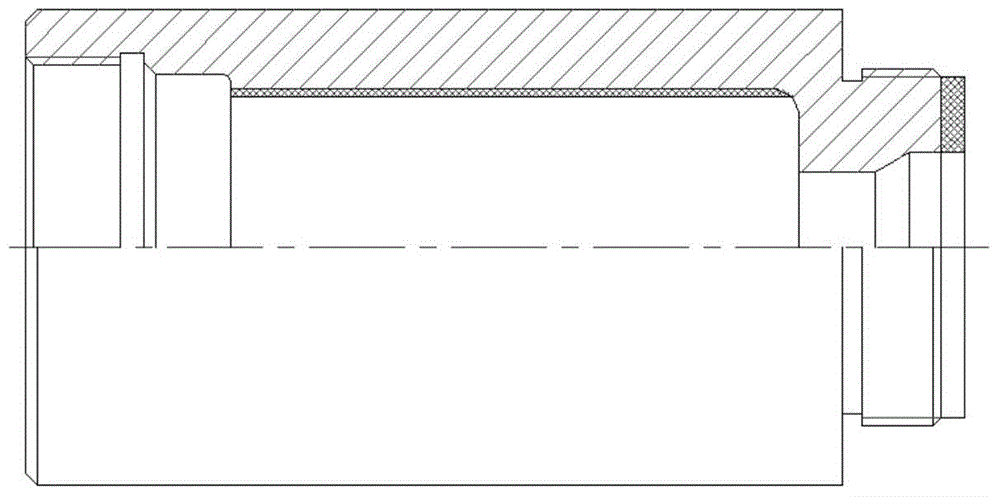

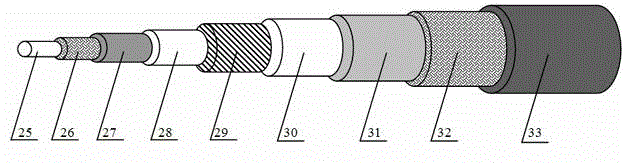

Cable transmission and multi-module current collection strong pulse current device

ActiveCN104158088AIncrease vacuumReduce inductanceSpark gaps with auxillary triggeringSpark gap circuitsCable transmissionX-ray

The invention discloses a cable transmission and multi-module current collection strong pulse current device. The device is composed of dozens of low-inductance capacitor / discharge switch / capacitor modules in parallel, hundreds of low-resistance high-voltage coaxial cables are connected to a cable transition turning-connection component in parallel in a transmission mode, and the transmission cables become dozens of ceramic high-voltage cable connecting parts through the cable transition turning-connection component in a transition mode, and therefore energy of the device enters a vacuum experiment target chamber in a transmission mode. Due to different loads, strong pulse currents can be generated, wherein the amplitude value of the currents is 2 MA-3 MA, and the rise time of the currents is 600 ns-800 ns; a strong X-ray radiation source can be generated by metal wire electrical explosion, or nanometer particle materials of metal wire electrical explosion can be prepared, or dynamics behavior research can be performed on plane solenoid drive oblique wave loading materials.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

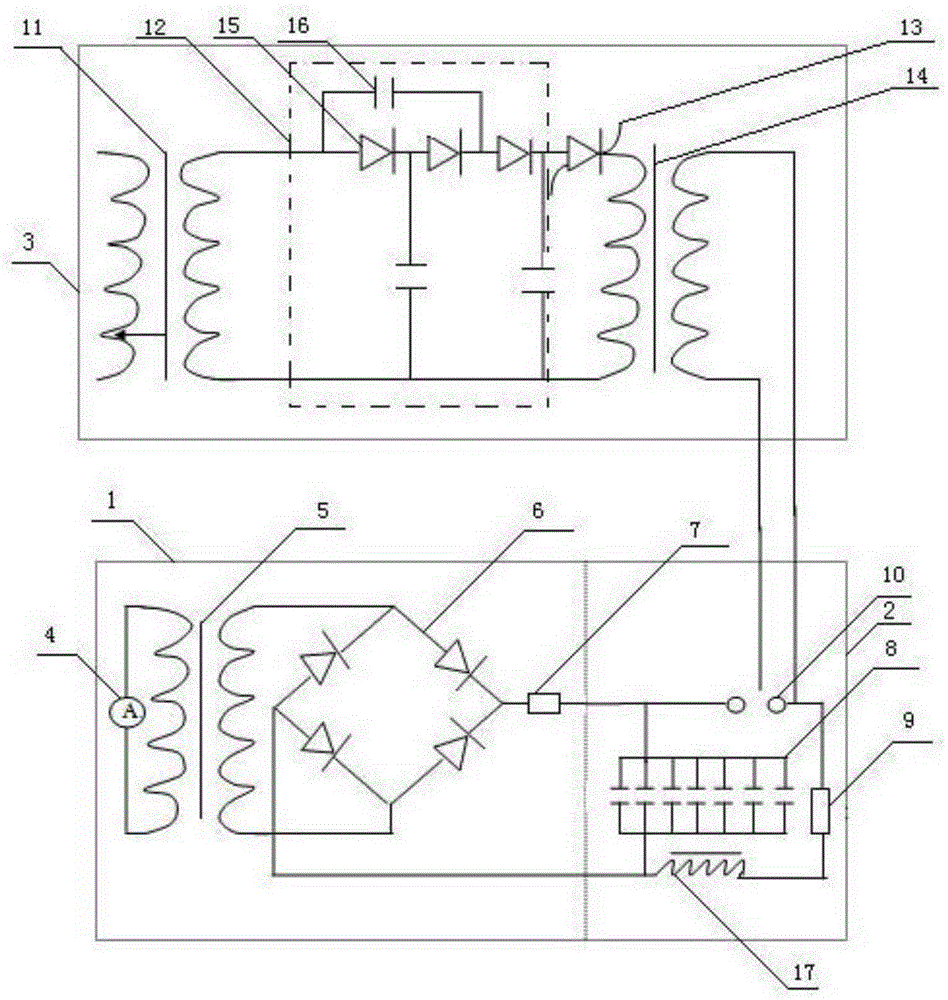

High-intensity pulse current crack arrest discharge apparatus

InactiveCN105429203AAvoid the disadvantages caused by capacitor switching controlSolve the problem of energy consumptionElectric powerLoad supplying circuitsStress concentrationHigh pressure

The invention discloses a high-intensity pulse current crack arrest discharge apparatus. The apparatus comprises a charge loop unit, a trigger loop unit and a discharge loop unit. The trigger loop unit is introduced; a relatively high-intensity pulse current is generated by utilizing a principle that a high-voltage pulse capacitor bank generates an instant strong pulse current during energy storage and discharge; and at the moment that the pulse current passes through a metal plate with a crack, joule heat can be generated at a crack tip under a bypass current concentration effect, and the local temperature of the crack tip is increased and even exceeds a melting point of a material, so that the crack tip is molten to form a molten hole, the curvature radius of the crack tip is increased, the stress concentration is eliminated, and crack emerging and spreading of the crack tip can be inhibited. The apparatus is low in charge power, high in instant output electric energy and mature in technical principle, has intelligence and selectiveness for crack repair, and is simple to operate and small in influence on surrounding environment.

Owner:SHENYANG JIANZHU UNIVERSITY

Impact testing device for parachute landing unmanned aerial vehicle damper and method thereof

The invention relates to an impact testing device for a parachute landing unmanned aerial vehicle damper and a method thereof. The impact testing device comprises a displacement sensor, an electric discharging loop, an electric discharging coil, an induction coil, a conical driving head, a guiding shaft and a pressure sensor. The electric discharging loop performs instantaneous electric discharging on the electric discharging coil. Strong pulse current is generated in the discharging coil and furthermore an alternated high-strength magnetic field is formed at the periphery of the discharging coil. The induction coil closely abuts against the electric discharging coil. Because electromagnetic induction generates strong eddy current, the directions of the magnetic fields generated by the electric discharging coil and the induction coil are opposite, thereby generating an electromagnetic repulsion force, namely an electromagnetic impact force. The electromagnetic impact force performs impact loading on a to-be-tested damper through the conical driving head and the guiding shaft. Impact force data are acquired through a pressure sensor. Compression amount of the damper is acquired through the displacement sensor. The impact testing device and the method have advantages of accurate controllable impact force, high stability, simple operation and small land occupation. The impact testing device and the method thereof overcome defects of large land occupation, tedious operation and limited impact energy in a landing vibration testing platform for damper impact testing.

Owner:XIAN AISHENG TECH GRP +1

Method for sealing lancing type crystallizer copper pipe using electromagnetic pressure

InactiveCN1803336AImprove connection strengthStrong electromagnetic forceDielectricElectromagnetic pulse

The invention discloses a sealing method of kerf-typed crystallizer brass pipe, which comprises the following steps: filling the sealing dielectrics in the kerf part of kerf-typed crystallizer brass pipe; setting electromagnetic working coil on the periphery of crystallizer brass pipe and next to the brass pipe; connecting the electromagnetic working coil with the high-power electromagnetic pulse current generation power; setting inside core mould in the brass pipe; outputting strong pulse current from high-power electromagnetic pulse current generation power; generating alternating magnetic field when the pulse current passes the electromagnetic working coil; deforming the brass pipe of diameter-reducing plasticity through electromagnetic pressure; forming sealing combination of brass pipe and sealing dielectrics.

Owner:BAOSHAN IRON & STEEL CO LTD

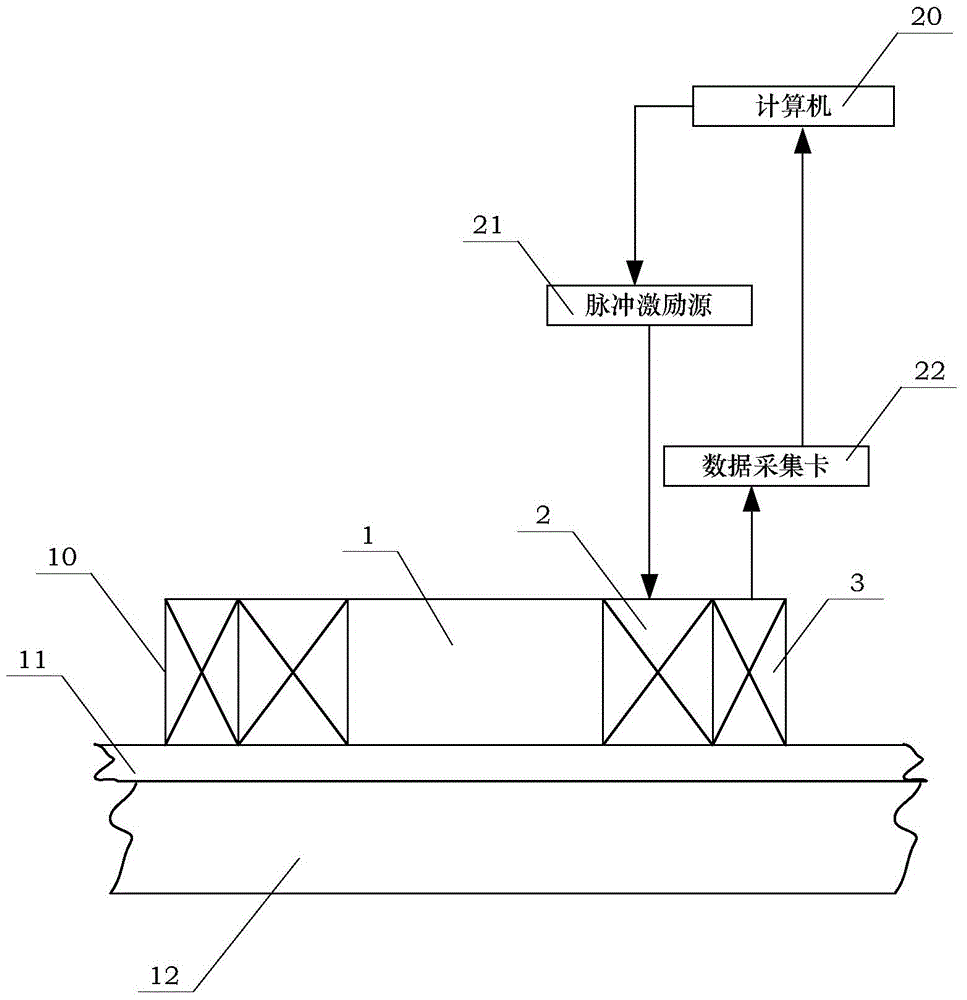

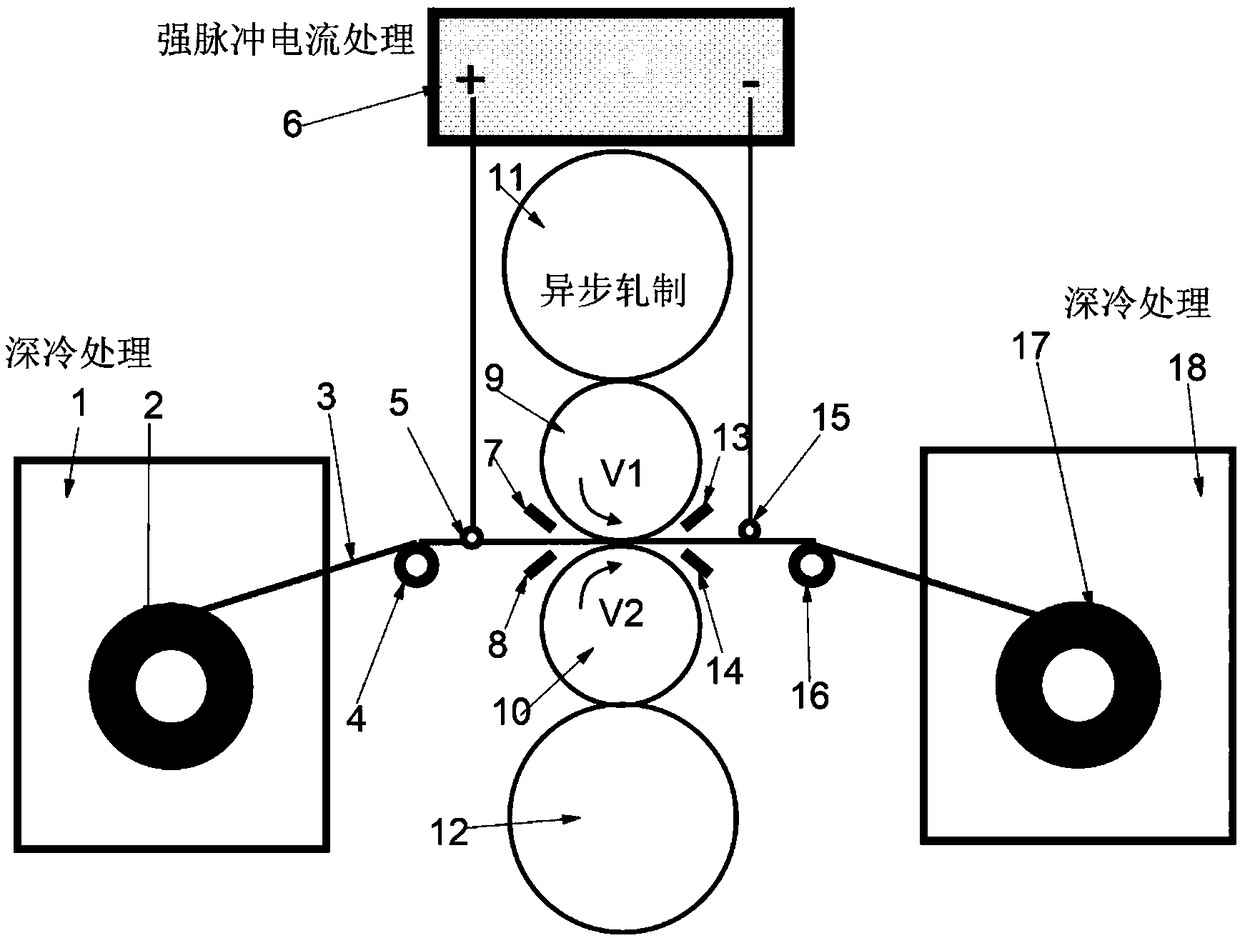

Strong impulse current auxiliary copious cooling different speed asynchronous rolling device and method for preparing ultra-fine grain metal strip

InactiveCN109174968AImprove deformation abilityImprove mechanical propertiesTemperature control deviceRolling mill drivesPower flowEngineering

A strong impulse current auxiliary copious cooling different speed asynchronous rolling device for preparing an ultra-fine grain metal strip comprises a left side copious cooling box and a right sidecopious cooling box; a left side metal crimping device is arranged in the left side copious cooling box; a right side metal crimping device is arranged in the right side copious cooling box; the two ends of a to-be-rolled metal strip are arranged on the left side metal crimping device and the right side metal crimping device correspondingly; an upper work roller and a lower work roller used for rolling the metal strip are arranged above and the below the middle position of the metal strip correspondingly; a left side conductive roller and a right side conductive roller connected with a strongpulse current power source are correspondingly arranged on the two sides of the upper work roller and the lower work roller; the left side conductive roller and the right side conductive roller act onthe metal strip, and apply a strong pulse current on the metal strip; and the upper work roller and the lower work roller are different in rotating speed. The invention further provides a corresponding strong impulse current auxiliary copious cooling different speed asynchronous rolling method, the method is suitable for preparing a large-size ultra-fine grain high-performance strip, it can be avoided that cracks occur on the edge portion of a rolled piece, and important using prospects are achieved.

Owner:CENT SOUTH UNIV

Technology and equipment for coating film in deep hole

ActiveCN109295414AConvenient industrial application of internal platingImprove thickness uniformityVacuum evaporation coatingSputtering coatingMetallurgySurface cleaning

Owner:广东省广新离子束科技有限公司

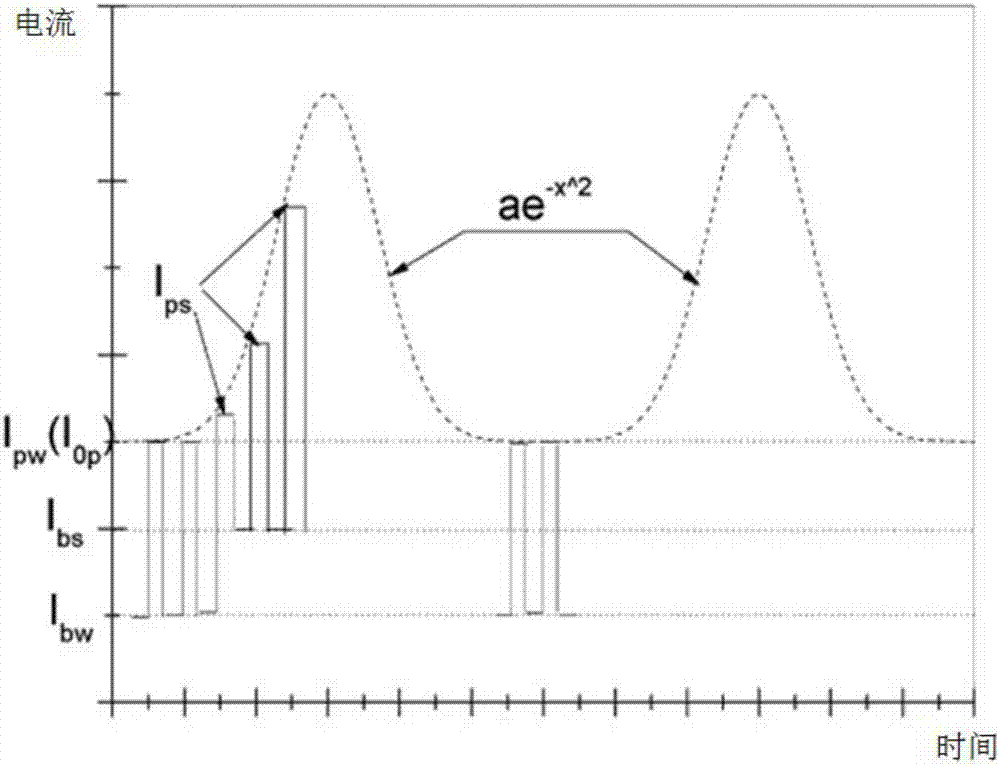

Pulse welding method

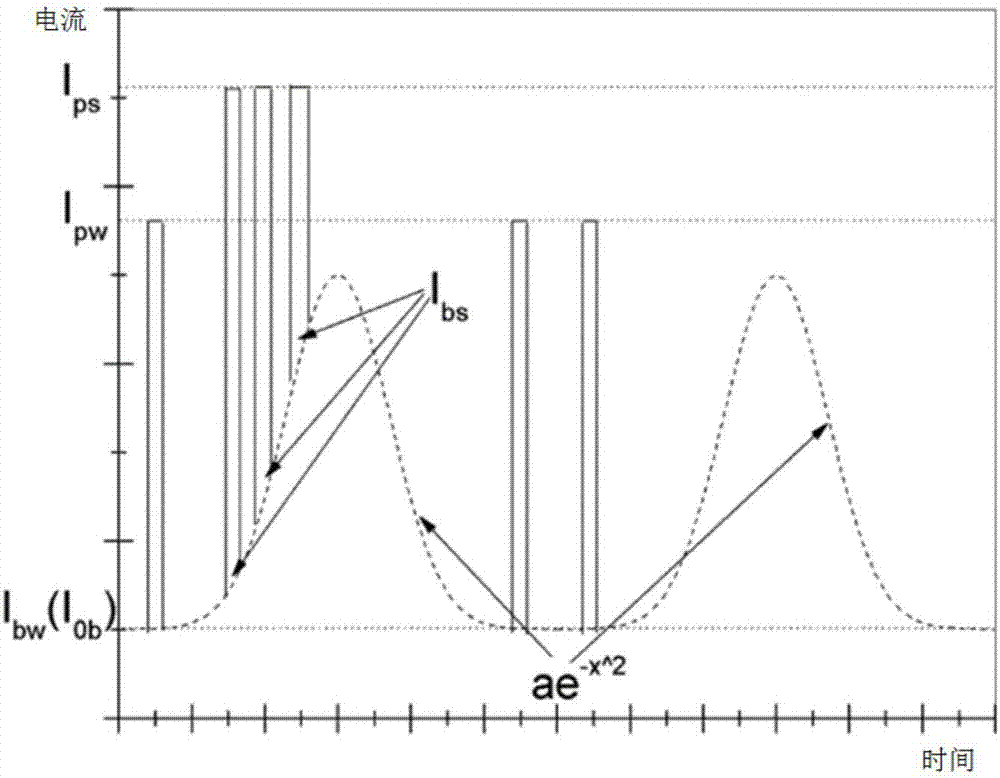

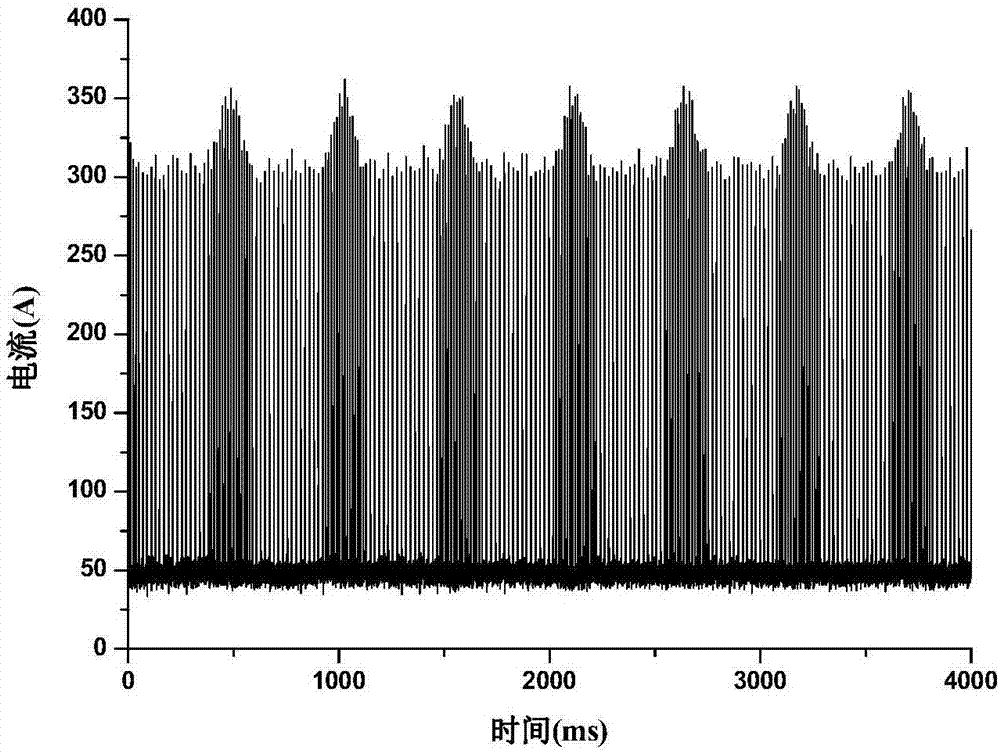

The invention discloses a pulse welding method, wherein the welding current waveform is cycled an repeated in periodicity. A unit period waveform is composed of a Gaussian wave strong pulse set and a rectangular wave weak pulse set, wherein a Gaussian function modulation mode of the Gaussian wave strong pulse set is divided into a Gaussian wave pulse peak value modulation and Gaussian wave pulse basic value modulation. In the unit period waveform, the time of basic value currents of the Gaussian wave strong pulse is equal, and the time of all peak value currents of the Gaussian wave pulse is equal. During the Gaussian wave pulse peak value modulation, magnitude and duration time of the basic value currents of the Gaussian wave pulse in the unit period waveform are equal, the magnitude of the peak currents is modulated according to a Gaussian function, and the time of the peak value currents is equal. During the Gaussian wave pulse basic value modulation, magnitude and duration time of the peak value currents of the Gaussian wave pulse in the unit period waveform are equal, the magnitude of the basic currents is modulated according to a Gaussian function, and the time of the basic value currents is equal. The welding method is capable of concentrating energy, good in controllability, and particularly suitable for welding sheet aluminum alloy.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com