Strong impulse current auxiliary copious cooling different speed asynchronous rolling device and method for preparing ultra-fine grain metal strip

A technology of strong pulse current and metal strip, which is used in the driving device of metal rolling mill, metal rolling, metal rolling, etc., can solve the problems of inability to use plate and strip products, easy cracks on the edge of the rolling piece, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

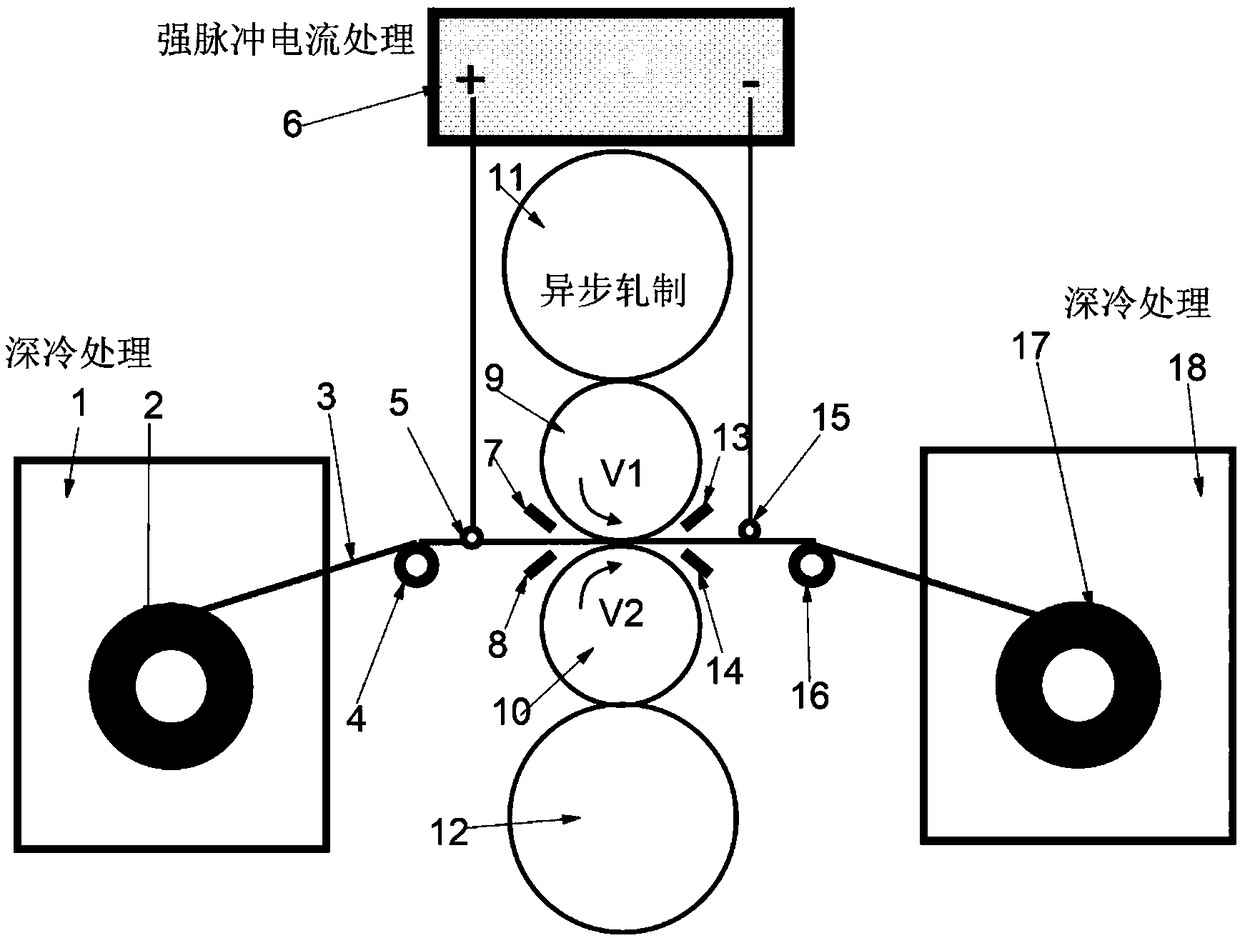

[0044] Preparation of ultra-fine grain aluminum alloy AA5083 strip by intensive pulse current cryogenic all-speed asynchronous rolling, refer to figure 1 ,Proceed as follows:

[0045] Step 1: The metal strip 3 is an aluminum alloy AA5083 strip with a width of 300mm and a thickness of 1.2mm before rolling.

[0046] Step 2: Put the metal strip 3 on the crimping device 2 of the left cryogenic box, open the gap between two work rolls, and place one end of the metal strip 3 on the crimping device 17 of the right cryogenic box.

[0047] Step 3: Turn on the cryogenic box 1 on the left, use nitrogen gas for cooling, and control the cooling time according to the amount of strip material, so that the metal strip 3 is evenly cooled to -170°C.

[0048] Step 4: Turn on the cryogenic box 18 on the right, and the temperature is -170°C.

[0049] Step 5: Turn on all the nitrogen nozzles and set the temperature of the nitrogen to -160°C.

[0050] Step 6: Turn on the strong pulse current powe...

Embodiment 2

[0055] Preparation of ultra-fine grain T3 copper strip by intensive pulse current cryogenic all-speed asynchronous rolling, refer to figure 1 ,Proceed as follows:

[0056] Step 1: The metal strip 3 is a T3 copper strip with a width of 200 mm and a thickness of 1.0 mm before rolling.

[0057] Second step: put the metal strip 3 on the crimping device 2 of the left cryogenic box, open the two work roll gaps, and place one end of the metal strip 3 on the crimping device 17 of the right cryogenic box.

[0058] Step 3: Turn on the cryogenic box 1 on the left, use nitrogen gas for cooling, and control the cooling time according to the amount of strip material, so that the metal strip 3 is evenly cooled to -180°C.

[0059] Step 4: Turn on the cryogenic box 18 on the right, and the temperature is -180°C.

[0060] Step 5: Turn on all the nitrogen nozzles and set the temperature of the nitrogen to -160°C.

[0061] Step 6: Turn on the strong pulse current power supply 6 with a current ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com