Road surface structure of rolled press polymer modified cement concrete and its constructure method

A cement concrete and pavement structure technology, which is applied to coagulating pavements, roads, roads and other directions paved on site, can solve the problem of poor water stability, temperature stability, chemical aging resistance of pavement, high requirements for asphalt construction, and low pavement strength. problems, to achieve the effect of superior deformation performance, excellent mechanical properties, and strong pavement deformation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0081] The general and detailed implementation of the present invention are as follows:

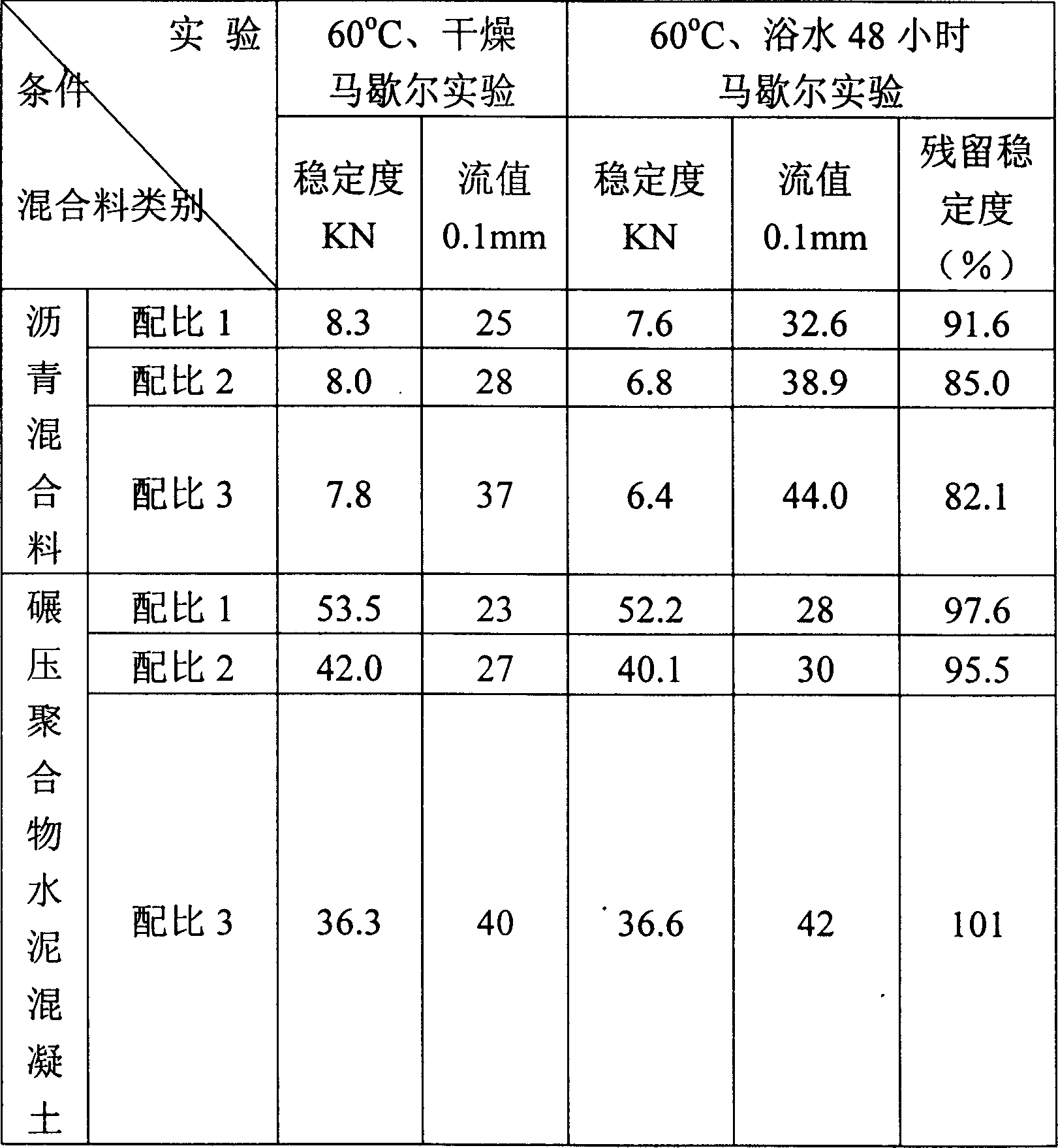

[0082] (1) Preparation and performance of RCC polymer modified cement concrete

[0083] When the existing polymer-modified cement concrete is prepared, it is required to have a certain fluidity, so as to ensure the compactness of vibration during construction (see "Background Technology Supporting Information 1"). Because what the present invention adopts is a rolling process, the prepared polymer modified cement concrete is different from the existing polymer modified cement concrete, so the present invention puts the word "rolling" in front of the polymer modified cement concrete, To show the difference between the present invention and the existing polymer modified cement concrete.

[0084] The roller-compacted polymer-modified cement concrete in the present invention is formed by uniformly mixing the slurry formed of the mixed polymer and cement—cement material—with crushed stones, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com