Method and device for forming and assembling micro-scale parts

A technology of micro-scale and parts, which is applied in the field of micro-scale parts forming and assembly, can solve the problems of micro-scale mold processing difficulties, the difficulty of accurately controlling the thickness of the release agent, and the lack of substantive standards, so as to achieve rapid mass production. Production, solve the problem of rapid processing and forming, and realize the effect of integration of forming and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

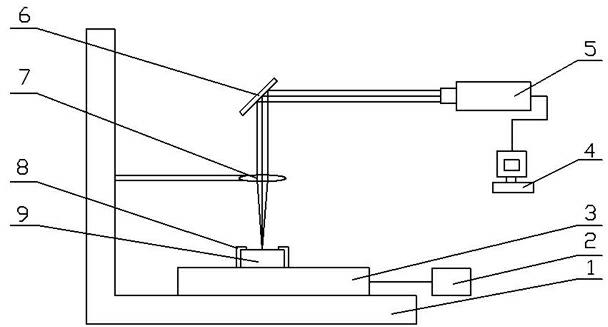

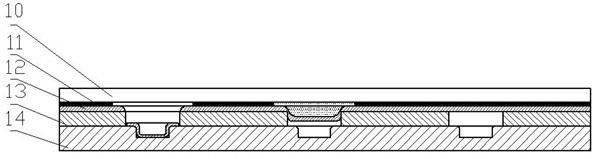

[0020] The new high-efficiency micro-scale parts forming and assembling device proposed by the present invention is as follows: figure 1 , figure 2 As shown, the whole device consists of 14 parts. The intense pulsed laser beam emitted by the Nd:YAG flat-top laser 5 passes through the mirror 6 and the lens 7 , passes through the confinement layer 10 after being focused, and reaches the absorption layer 11 on the impact target 12 . The constraining layer 10, the absorbing layer 11, the target material 12, the shearing mold 13 and the parts to be assembled 14 are all fixed on the three-dimensional mobile working platform 3 by the clamping device 8, and are accurately moved and positioned by the computer through the three-dimensional mobile platform controller 2 .

[0021] The implementation process is as follows:

[0022] First, according to the characteristics of the micro-scale parts to be processed, and on the premise of meeting the functional requirements, design the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com