Patents

Literature

330results about How to "Avoid clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

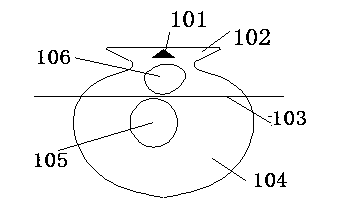

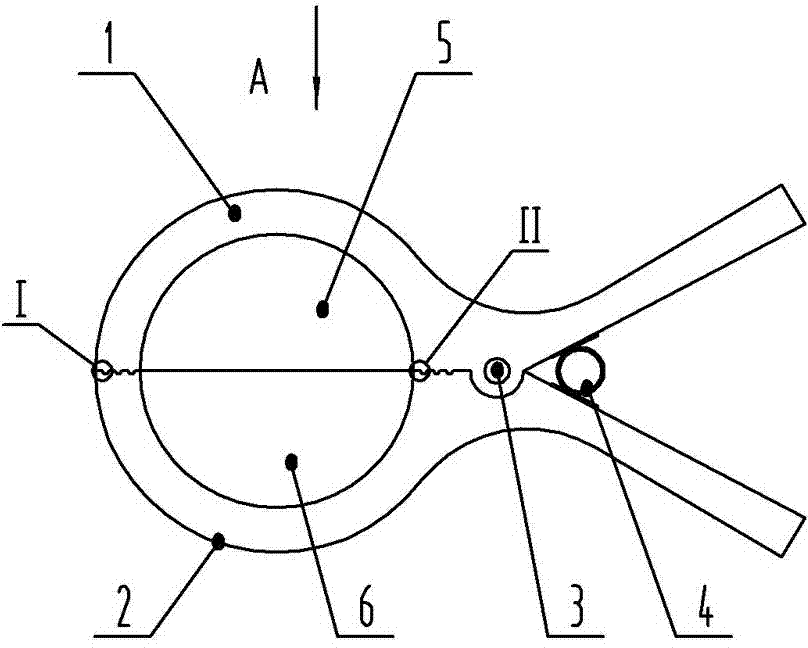

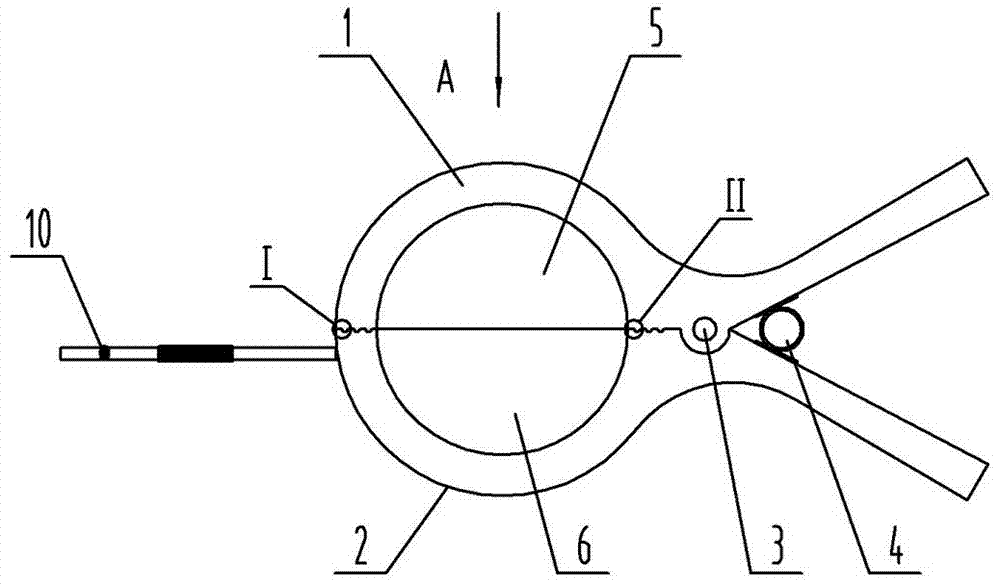

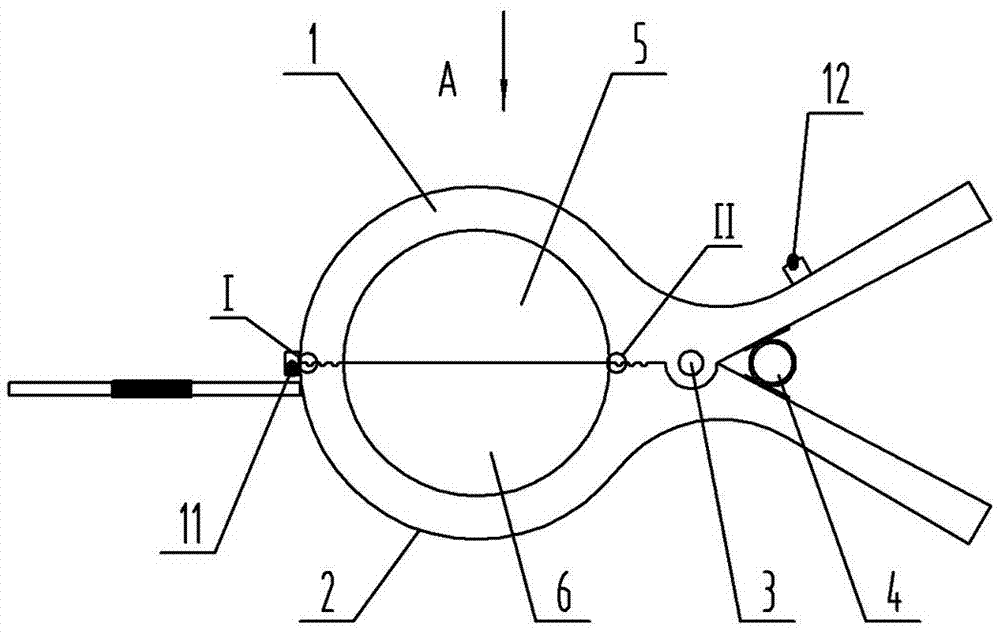

Device for taking scallop by opening scallop shell

InactiveCN103300123AAvoid clampingImprove personal protectionBivalves processingElectric machineryEngineering

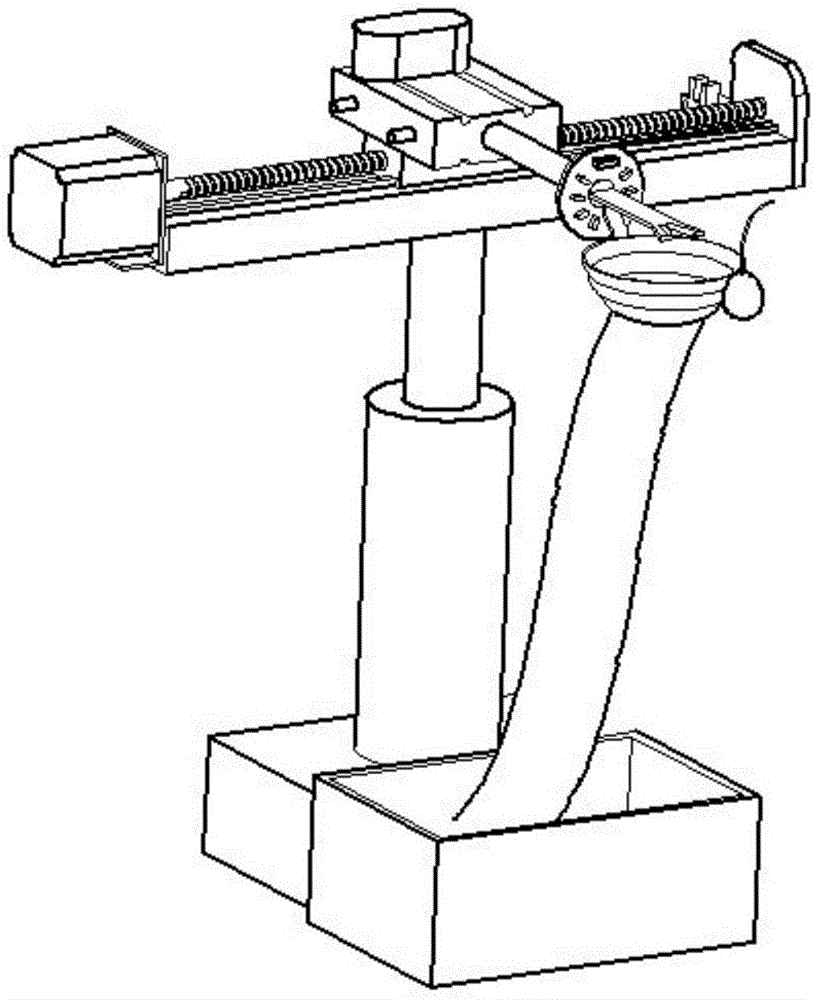

The invention discloses a device for taking a scallop by opening a scallop shell. The device comprises a rack, wherein the rack is provided with a runner; a wheel surface of the runner is provided with scallop clamping mechanism at an interval; the rack is provided with a motor; the motor is connected with a cutting blade; the cutting blade is located above the wheel surface of the runner; the rack is provided with a blade sleeve and the blade sleeve is opposite to the wheel surface of the runner; a scraping and cutting blade is mounted on a tool apron and stretches into the blade sleeve; the tool apron is connected with an air cylinder mounted on the rack; a first water spraying pipe is aligned to a wheel surface of the lower side of the runner. The device disclosed by the invention ensures that the scallop shell is safely opened to take out the scallop, is high in automation degree and is convenient to use.

Owner:HEBEI AGRICULTURAL UNIV.

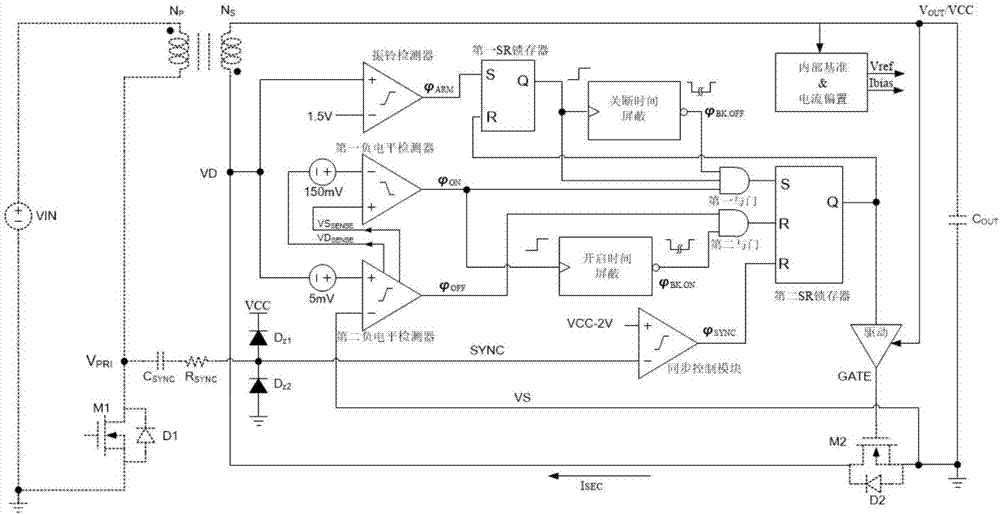

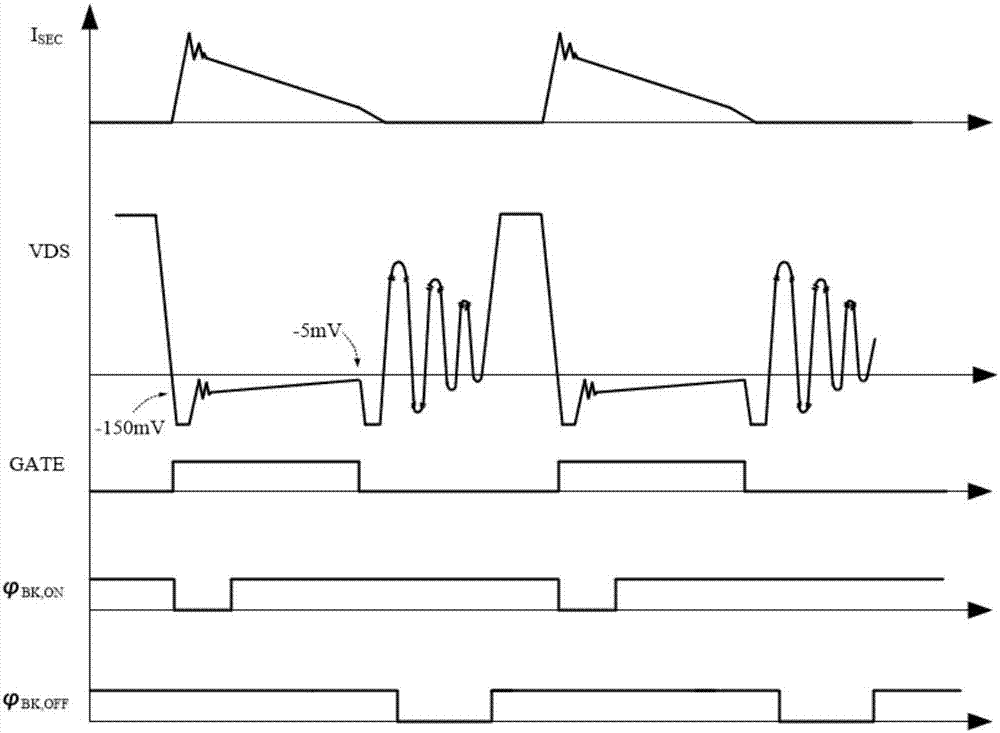

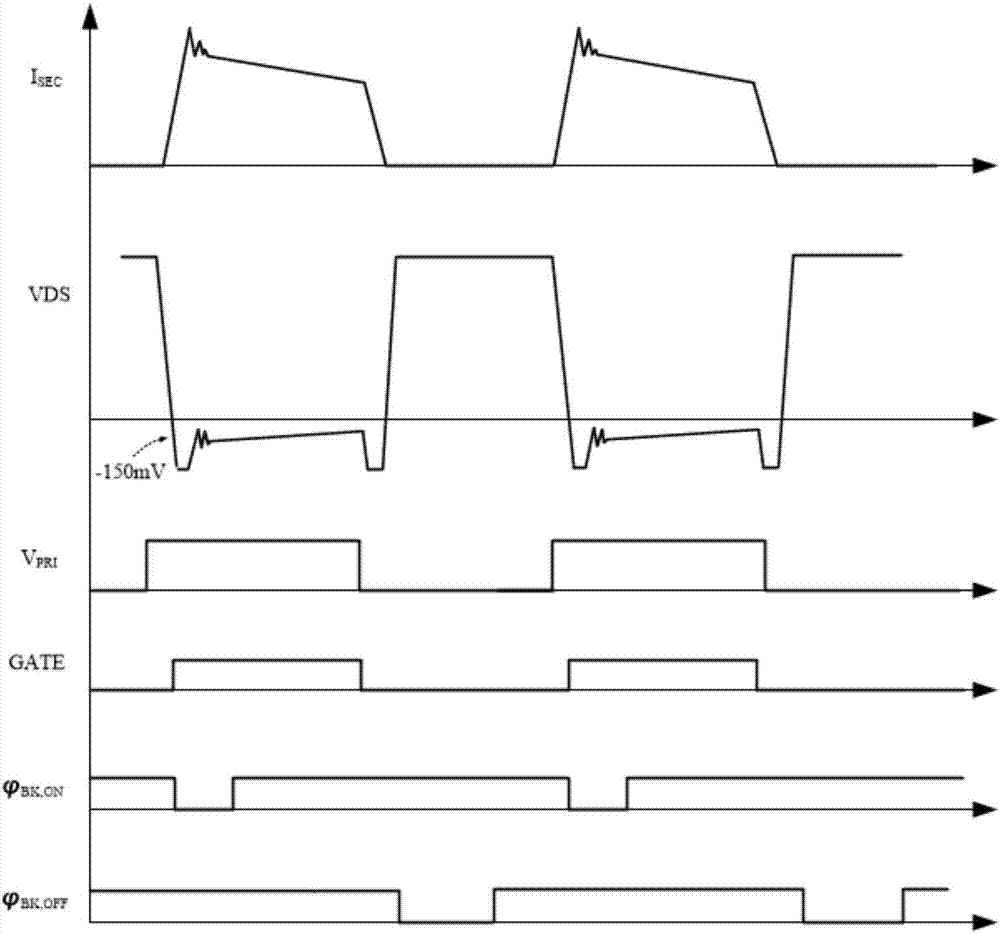

Dual-mode synchronous rectification control circuit for DCM and CCM

ActiveCN107346943AAchieve high efficiencyAvoid accidental openingEfficient power electronics conversionAc-dc conversionDual modeDead time control

The invention provides a dual-mode synchronous rectification control circuit for a DCM and a CCM, belonging to the technical field of power management. The structure of the circuit is simple, the rectification conduction loss can be effectively reduced, and high efficiency of synchronous rectification is realized. Minimum dead time control is realized by a second negative level detector. A turn-off time shielding module prevents the wrong turn-on of a synchronous rectifier tube M2, and a turn-on time shielding module prevents the wrong turn-off of the synchronous rectifier tube M2. Drain electrodes of LDMOS and DEMOS high voltage devices are used by a first sampling end to bear high voltage, the clamping of a drain end VD of the synchronous rectifier tube M2 by a Zener is avoided, and the current leakage to the ground by the drain end VD of the synchronous rectifier tube M2 is prevented. The high efficiency of synchronous rectification is realized by the above measures together. In addition, a synchronous control module is introduced, and the synchronous rectification in a current continuous mode CCM is realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

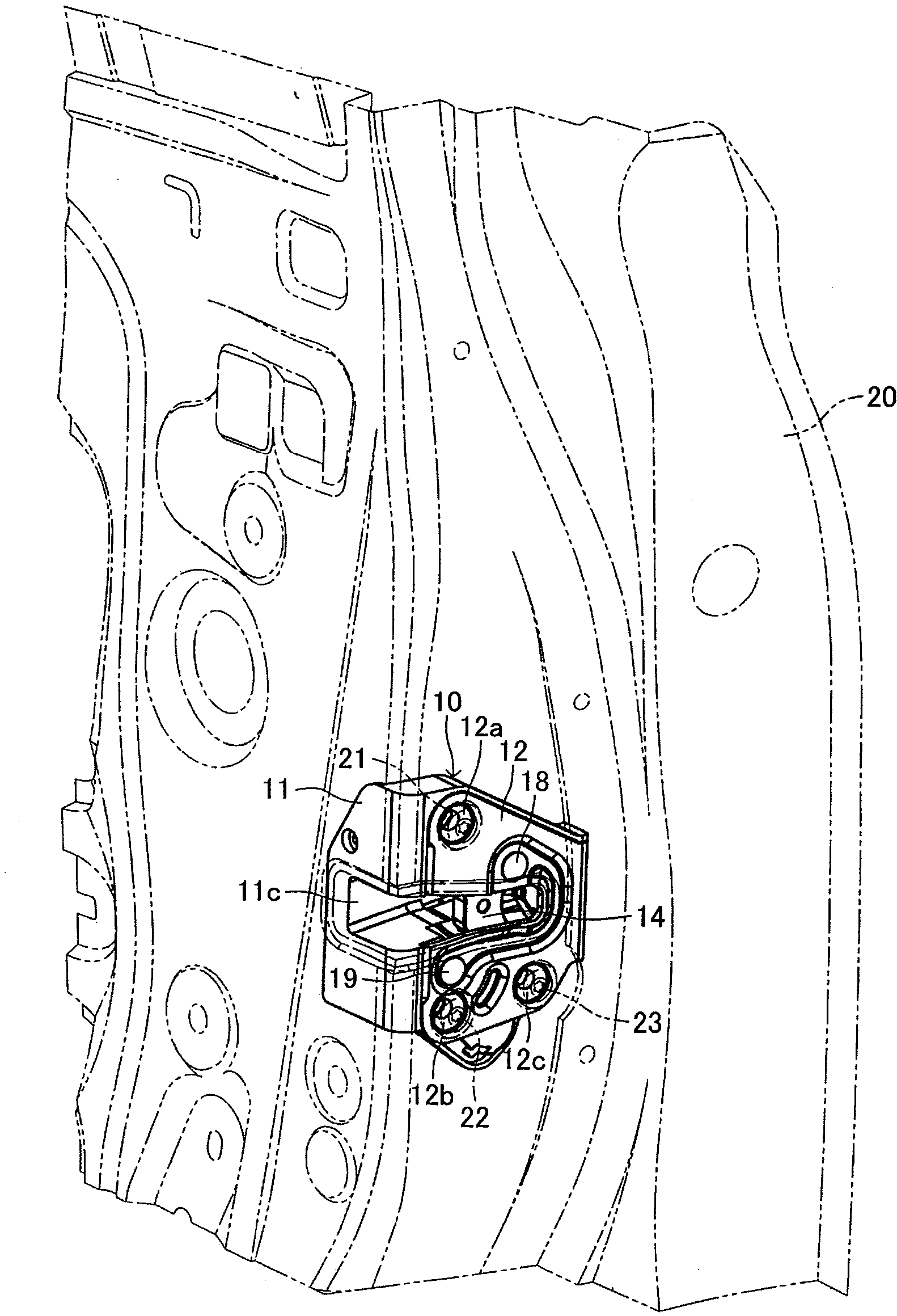

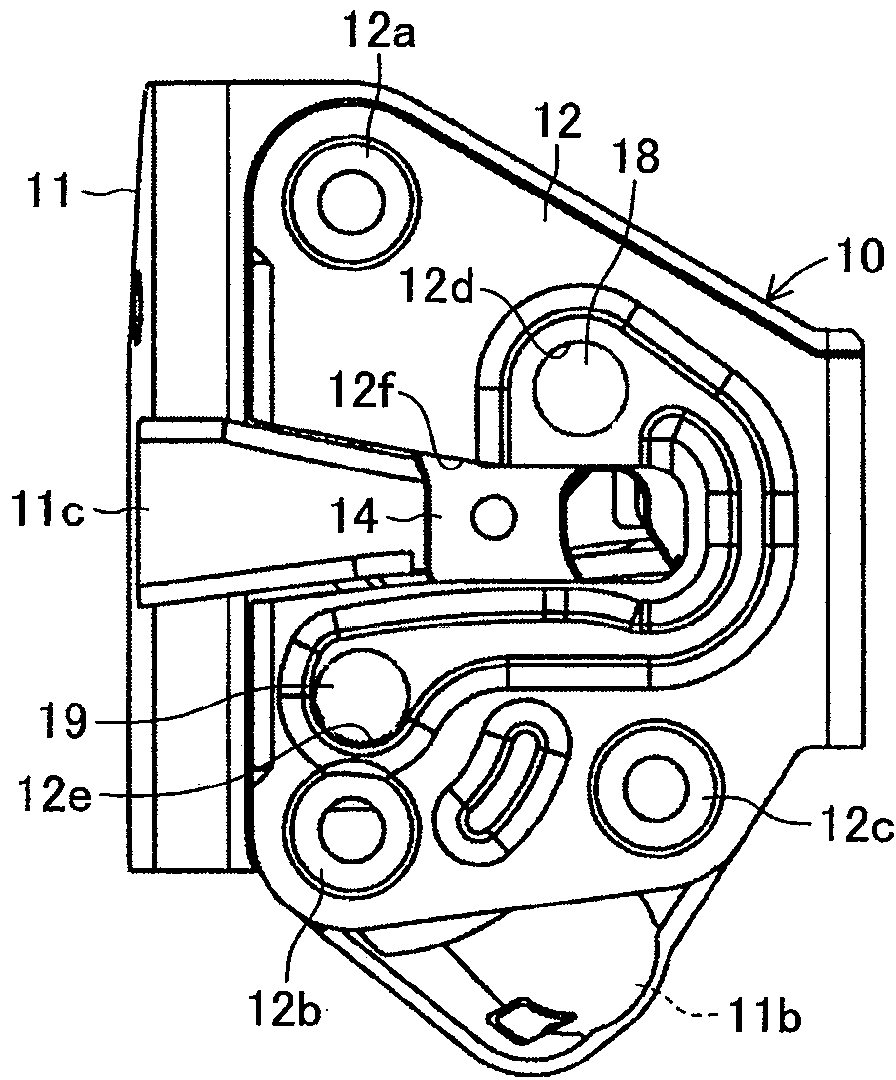

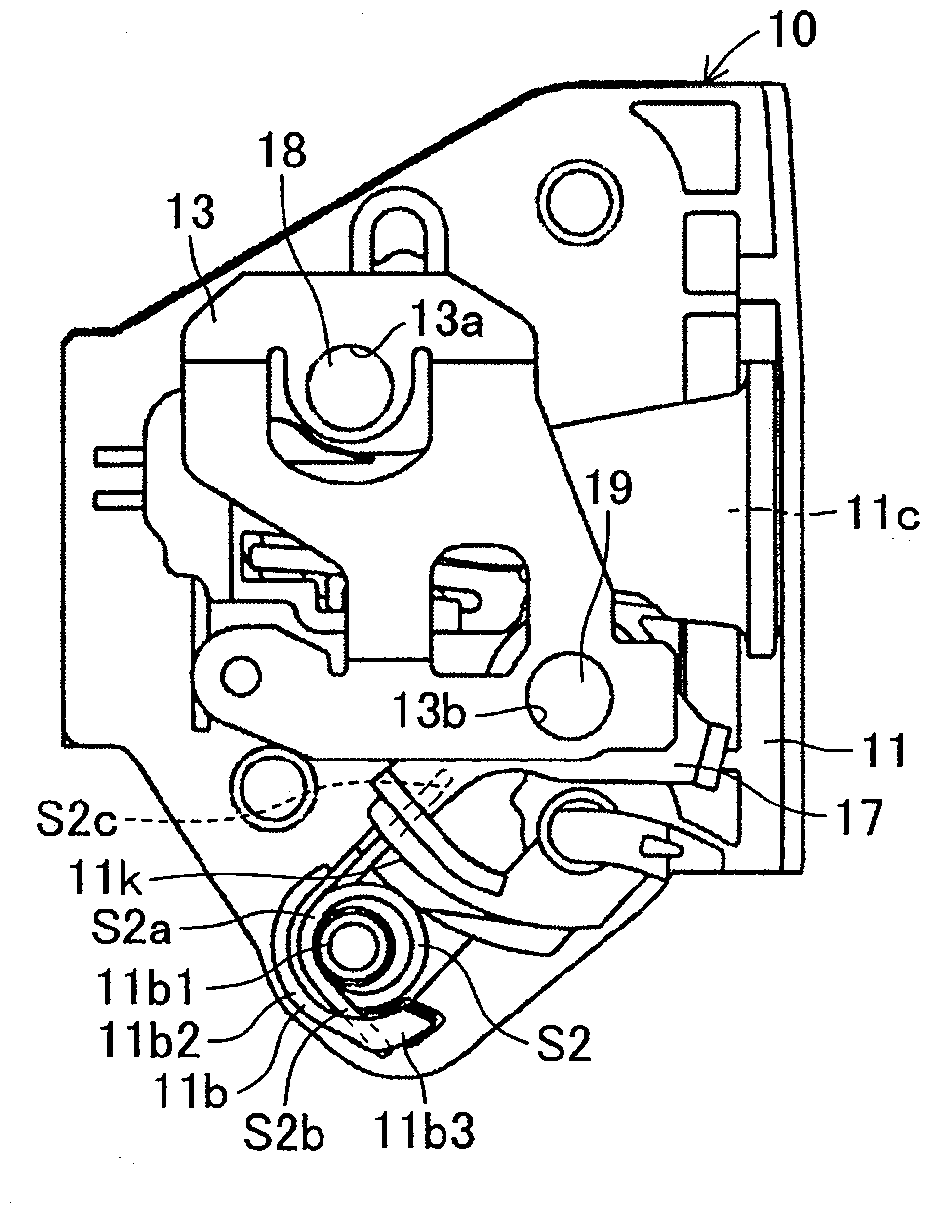

Automotive door latch device

ActiveCN102762807AImprove discharge efficiencyInhibition of undesired accumulationFastening meansDoorsEngineeringCar door

An automotive door latch device is provided with a latch which rotates by being pushed into motion by a striker; a latch return spring which applies force to the latch in the direction of the return position; a pawl which engages with the latch and prevents the same from rotating in the door opening direction (in the direction of the return position); and a pawl return spring which applies force to the pawl in the direction of the return position. A housing section, which belongs to the body and houses the latch and the pawl, opens downward at a location which is at one side of the body and is below the pawl. A pawl return spring is mounted on a spring mounting section formed at a location which is at the other side of the body and is away and downward from the rotation support section of the pawl. The pawl side end of the pawl return spring engages with the pawl via a through hole provided in the body. Due to the above, it is possible to enhance the discharging of powder dust or the like intruding inside the housing section, which belongs to the body and houses the latch and the pawl, outside the body.

Owner:AISIN SEIKI KK

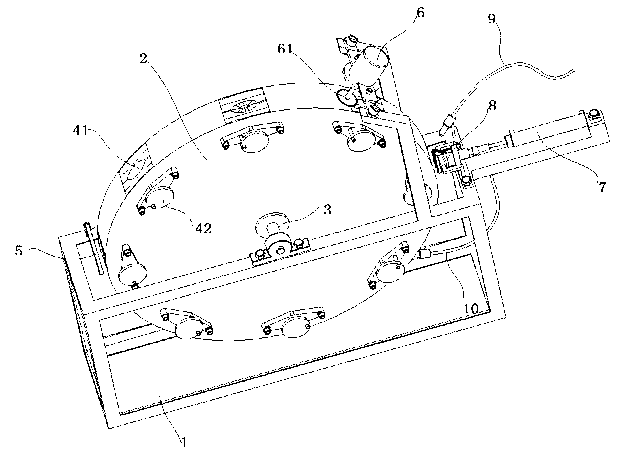

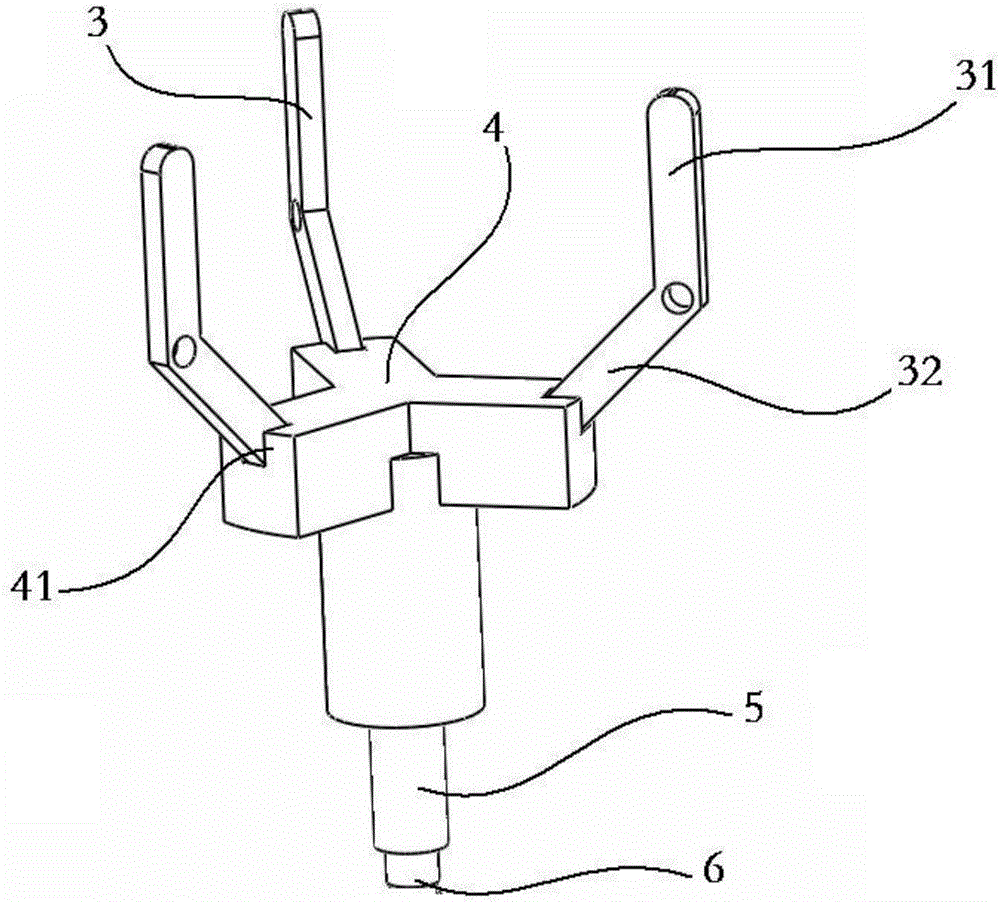

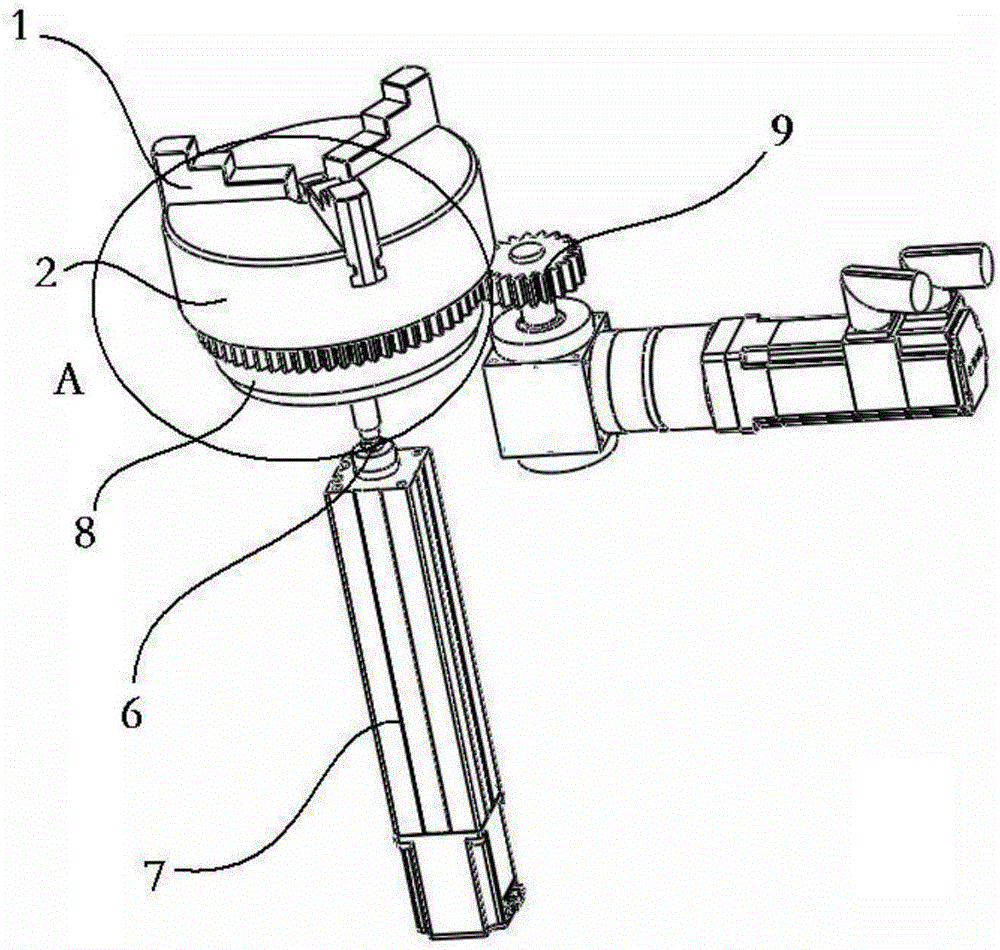

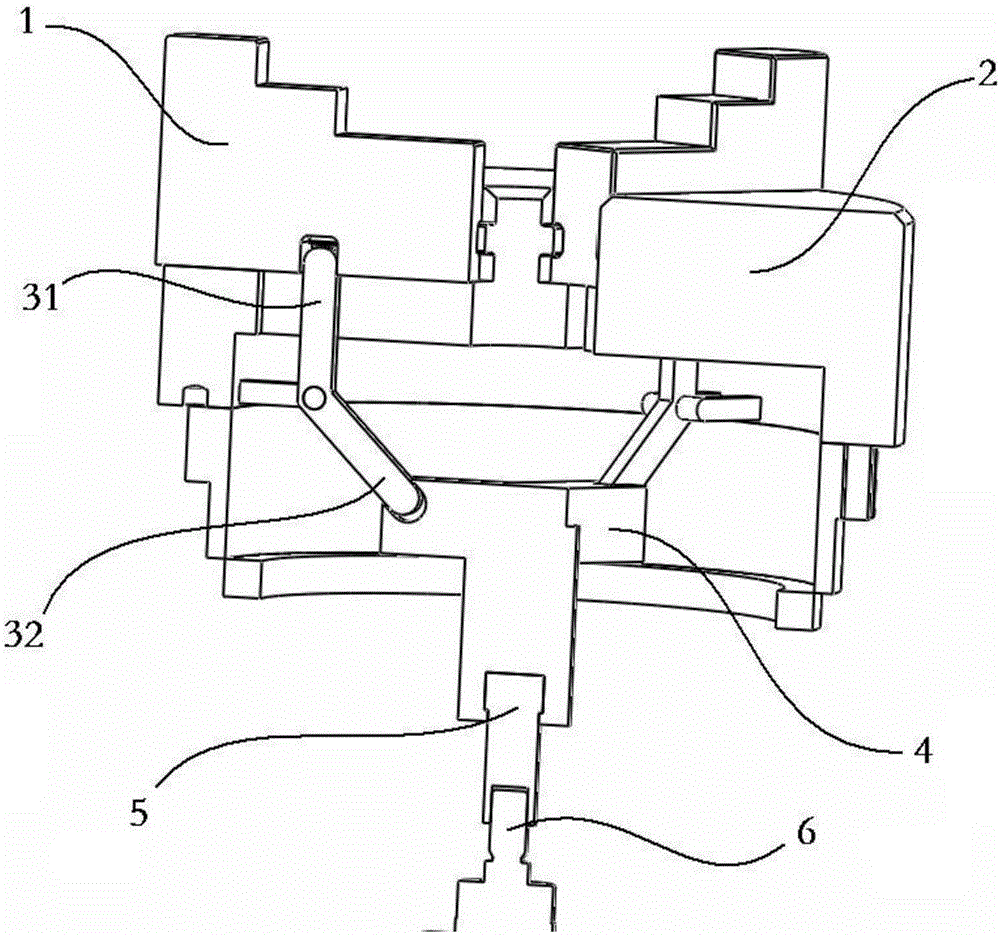

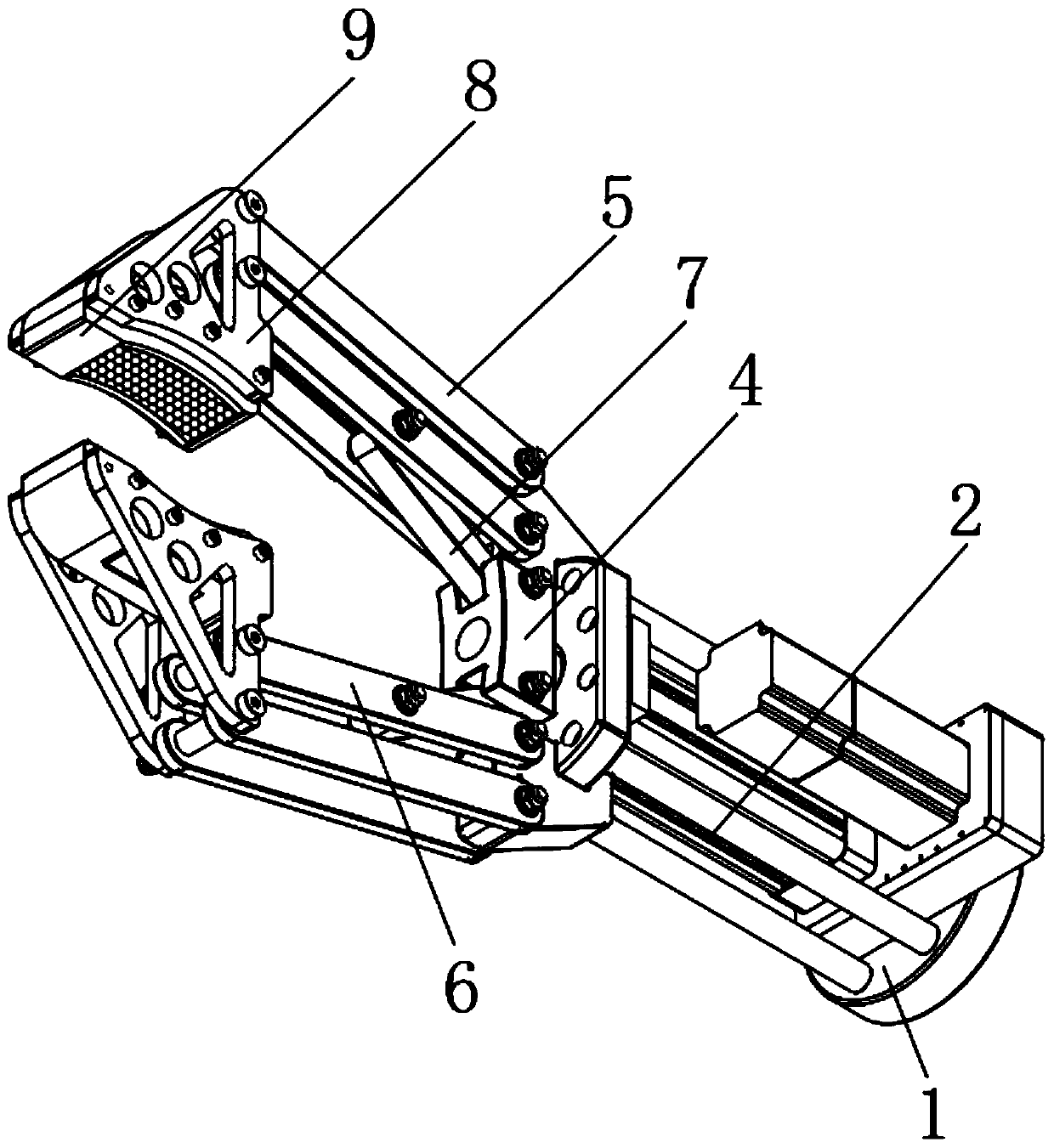

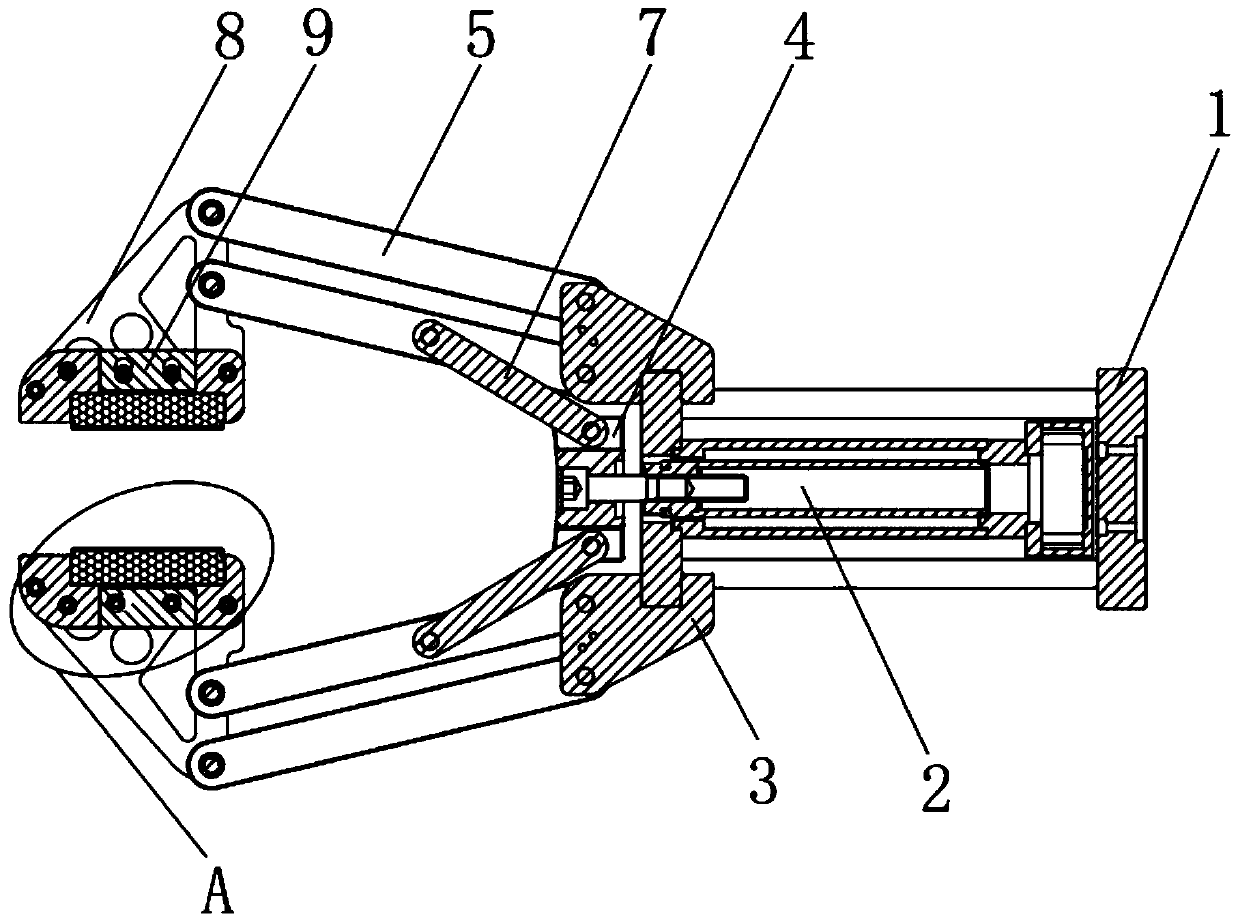

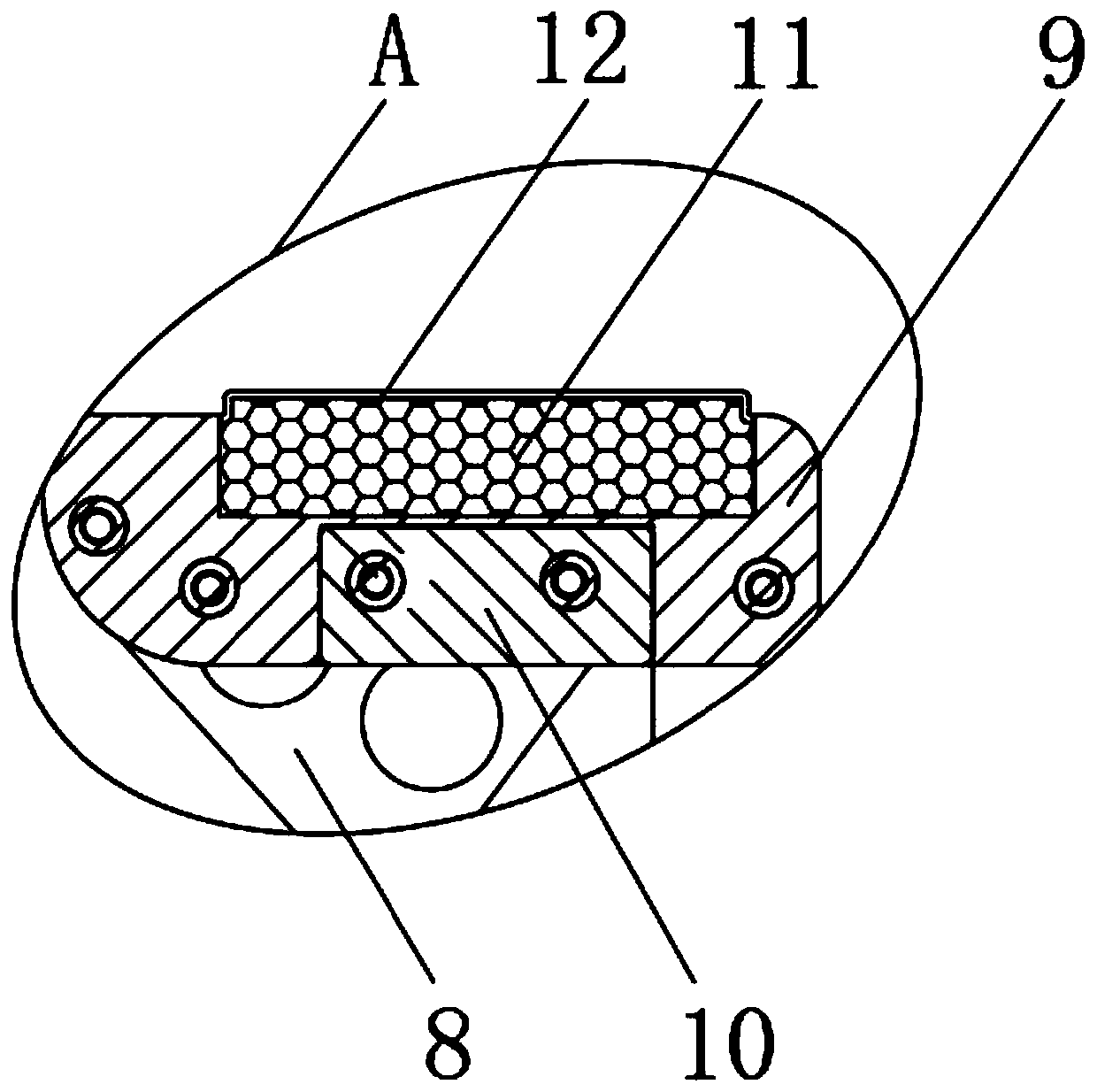

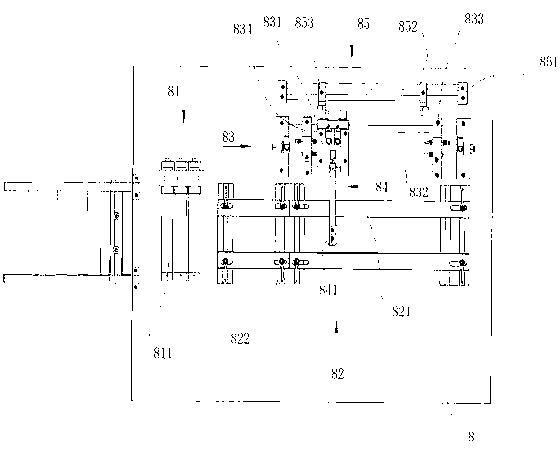

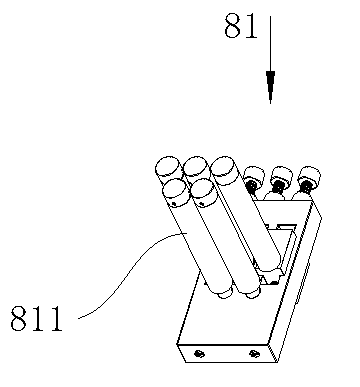

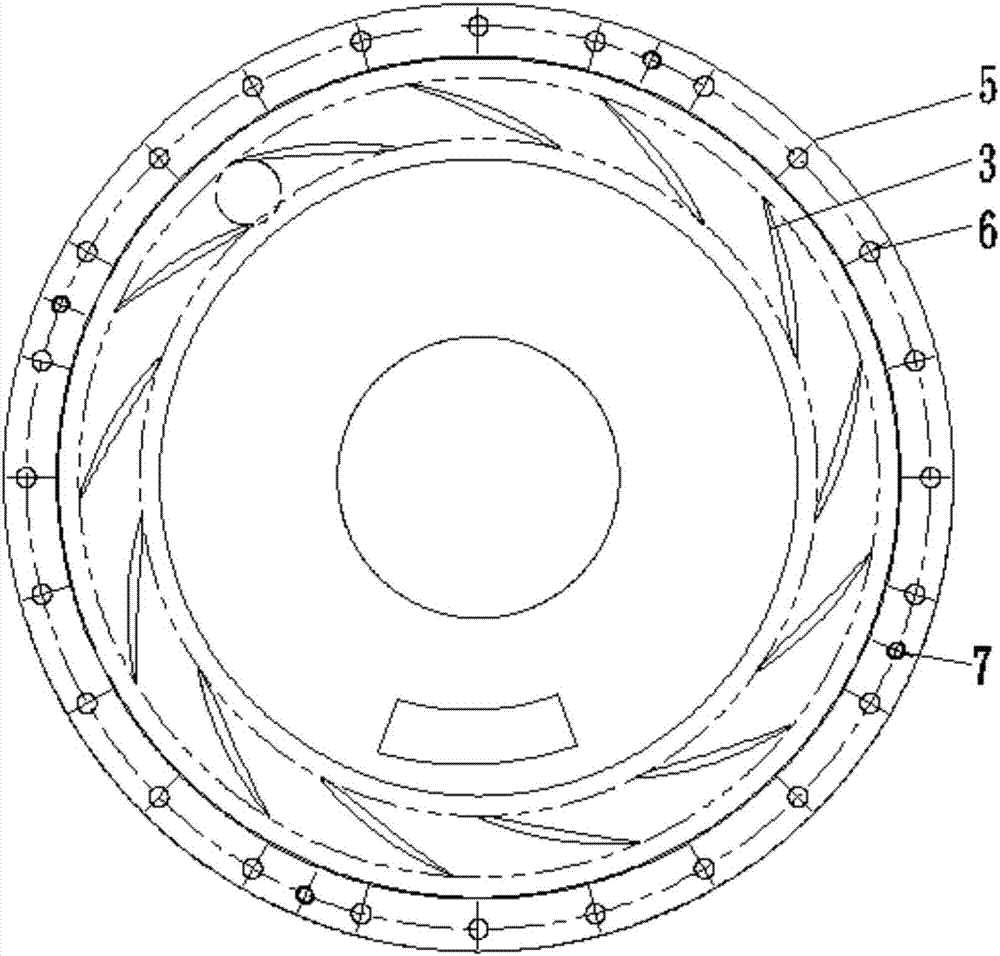

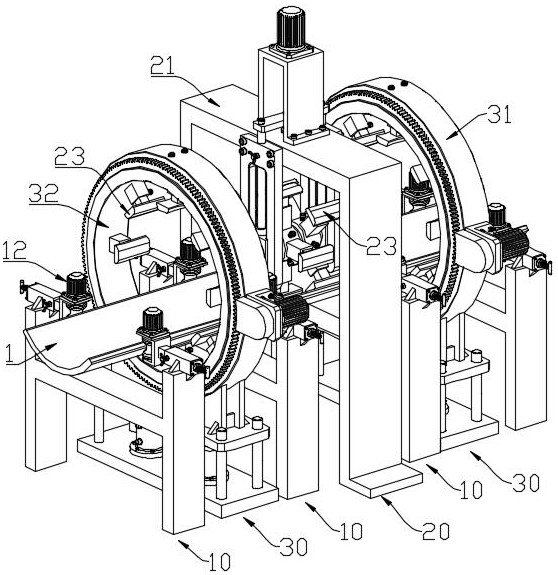

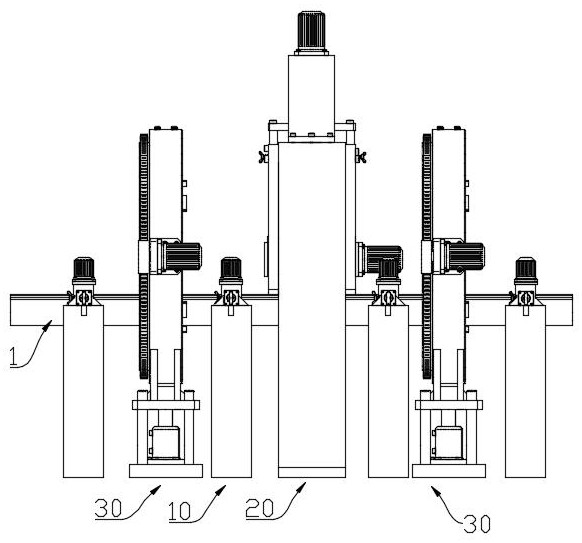

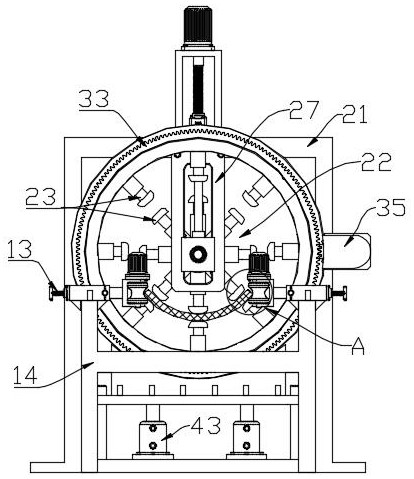

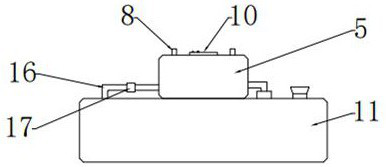

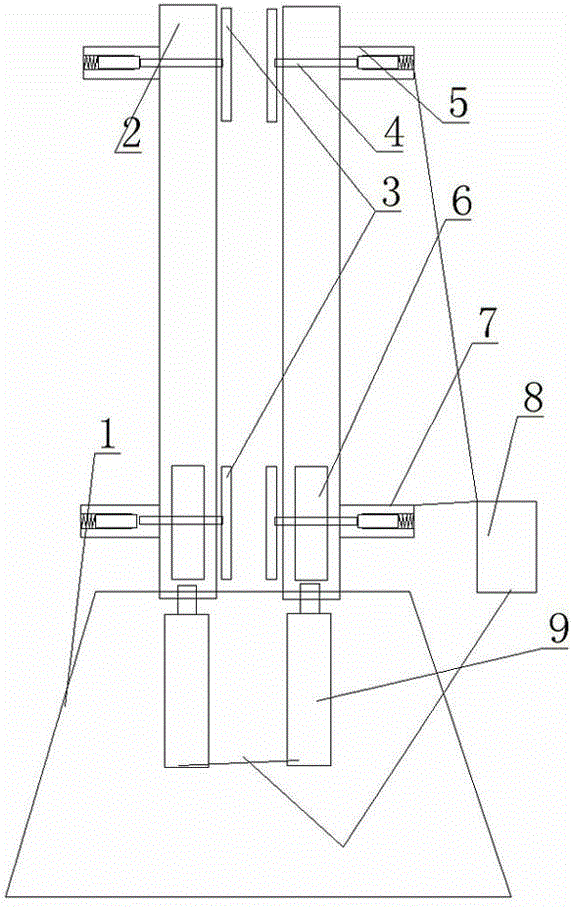

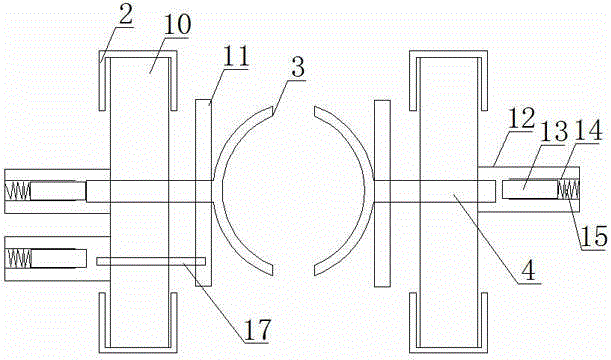

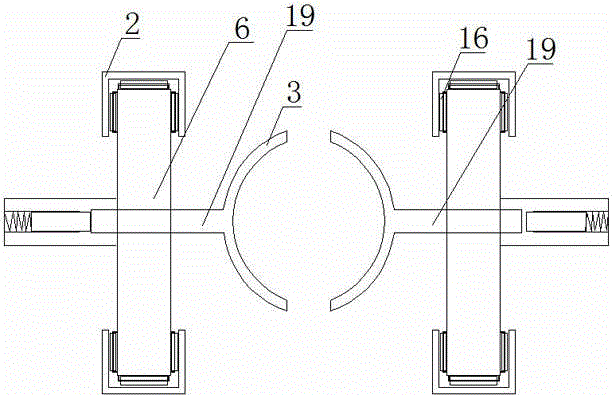

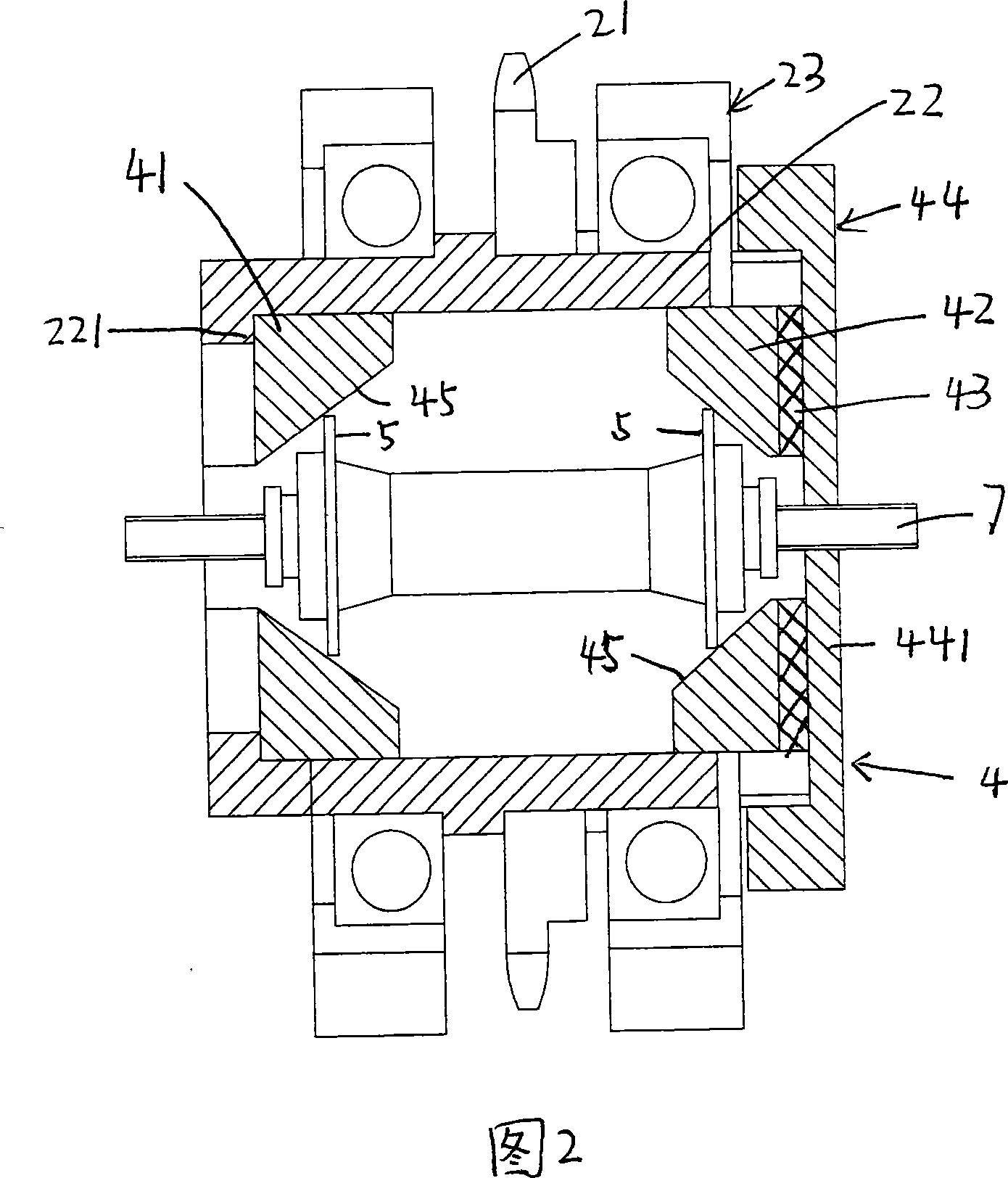

Driving mechanism driving moving pieces to move back and forth on installation base in radial direction and chuck

ActiveCN106112038ARealize radial push and pullThe mechanical transmission process is simple and reliableChucksMechanical transmissionEngineering

The invention discloses a driving mechanism driving moving pieces to move back and forth on an installation base in the radial direction and a chuck. The driving mechanism comprises stirring pieces and a driving assembly. The stirring piece can rotate relative to the installation base and rotate in the plane determined by the radial direction of the moving pieces corresponding to the stirring pieces and the axial direction of the installation base, and the stirring pieces are connected with the corresponding moving pieces. The driving assembly is provided with stirring piece connecting parts, wherein distribution of the stirring piece connecting parts is consistent with that of the stirring pieces. The stirring pieces are hinged to the corresponding stirring piece connecting parts. When the driving assembly moves back and forth in the axial direction of the installation base, the stirring pieces are driven to rotate to drive the moving pieces to move back and forth in the radial direction of the installation base. According to the driving mechanism driving the moving pieces to move back and forth on the installation base in the radial direction and the chuck, a mechanical transmission assembly is simple in structure, stable and reliable, and non-interference rotation of the chuck can be achieved.

Owner:BEIJING XUANYU INTELLIGENT TECH CO LTD

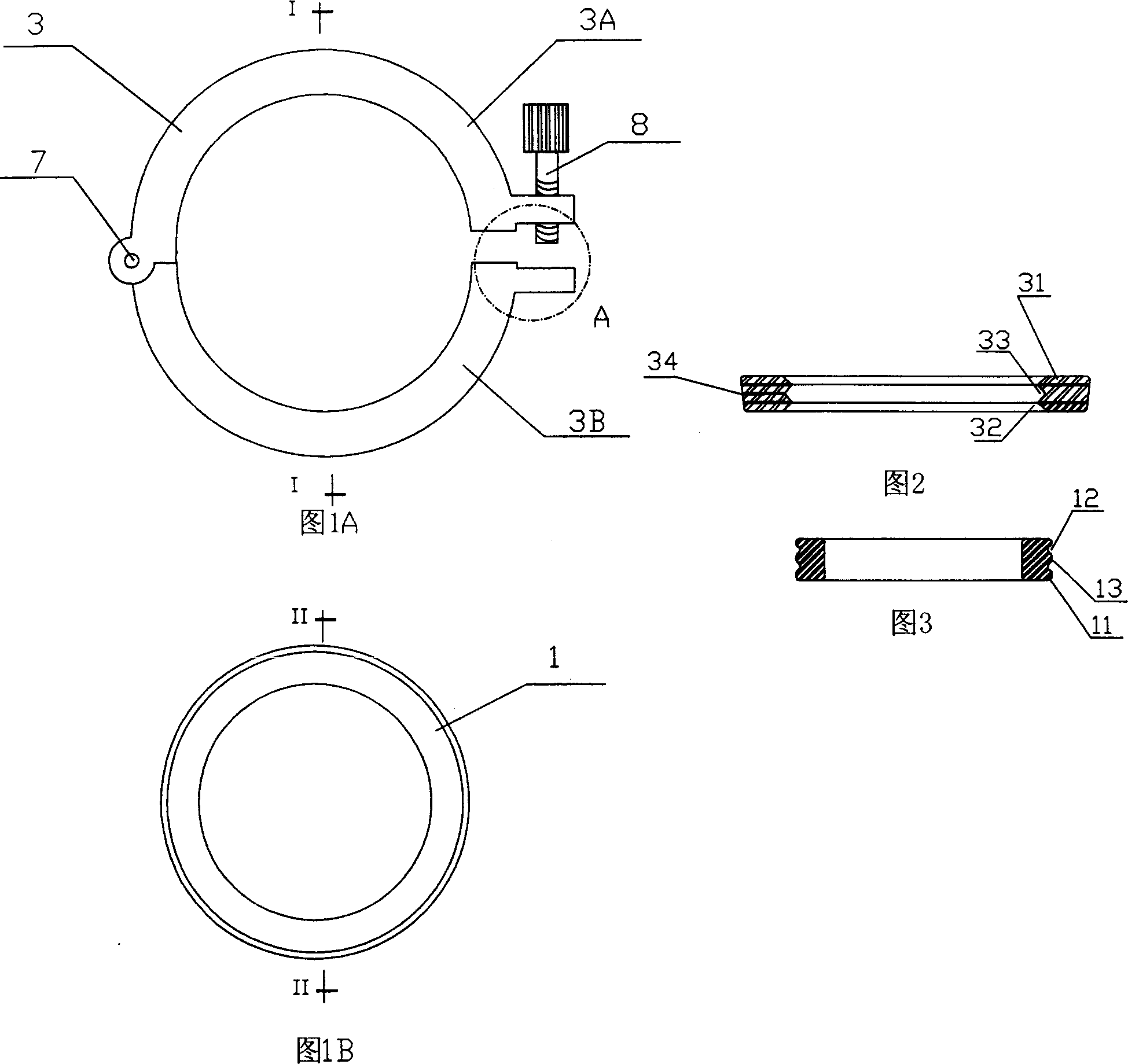

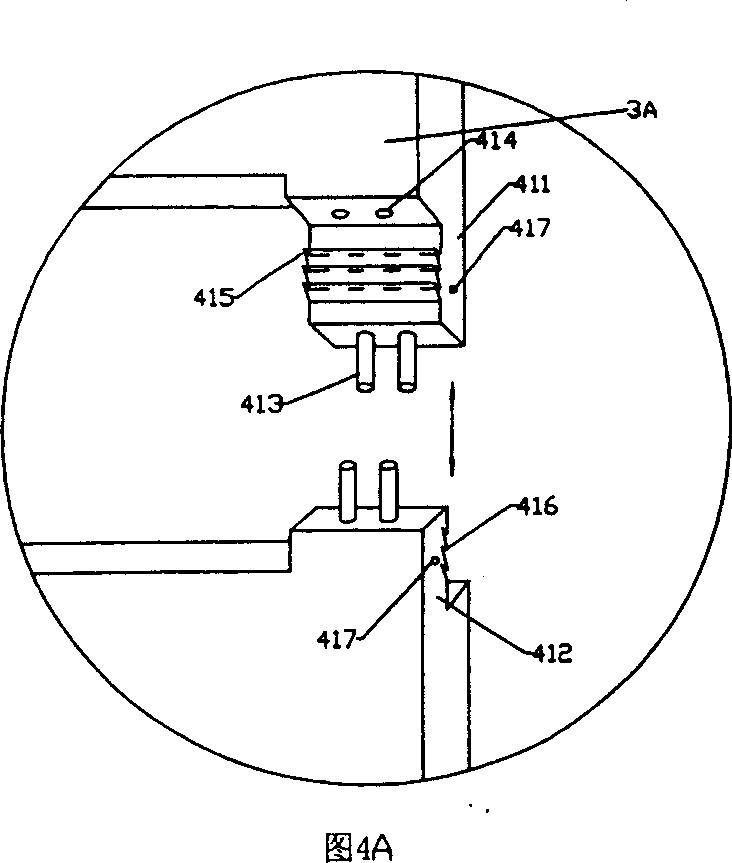

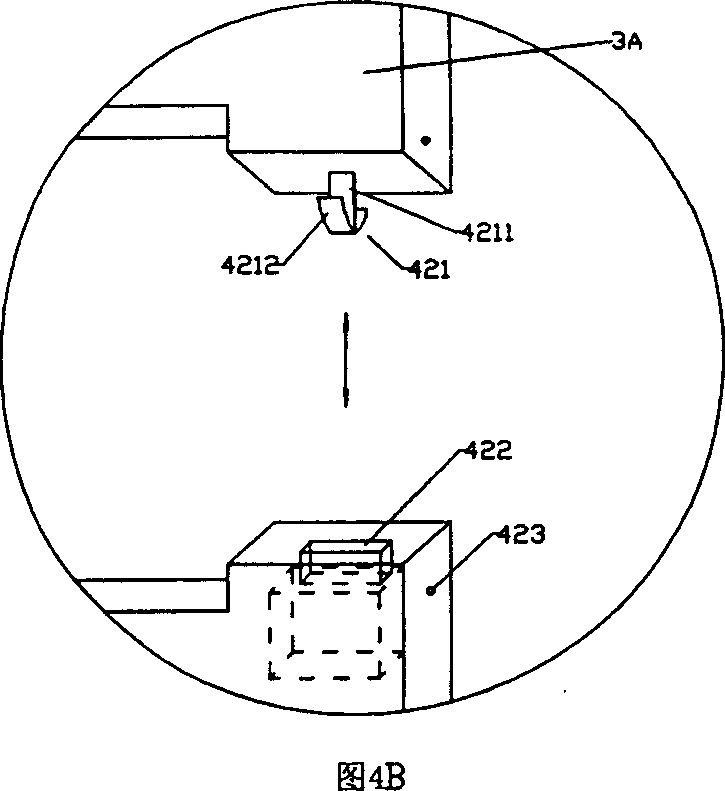

Foreskin loop cutter

The invention discloses a prepuce ring-cutter, which consists of tightening device and balan loop, wherein two or more first flutes are set on the external edge of balan loop, which forms first projection, two or more second projections are formed in the tightening device, which mate the first flute, the second flute is formed in the second projection, which mates the first projection to contain drug liquid in the cavity, the drug injecting channel is opened on the tightening device, which connects cavity.

Owner:WUHU SHANGRING TECH CO LTD

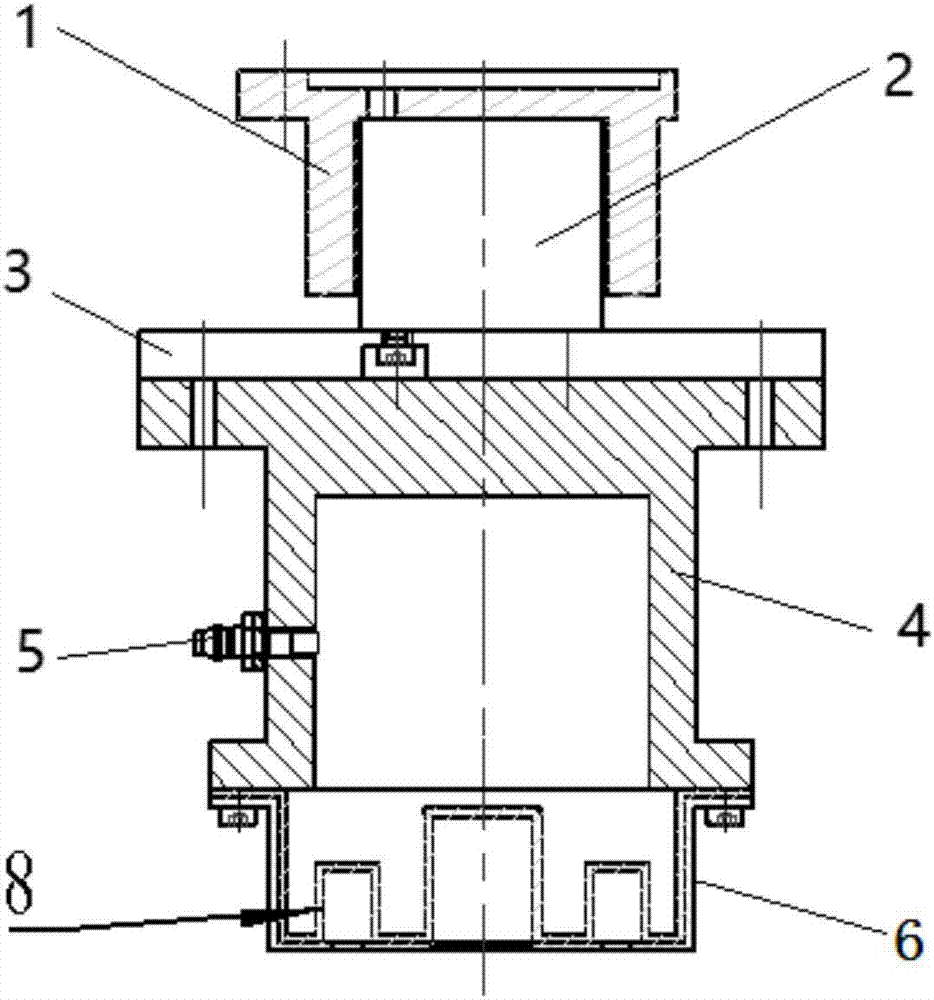

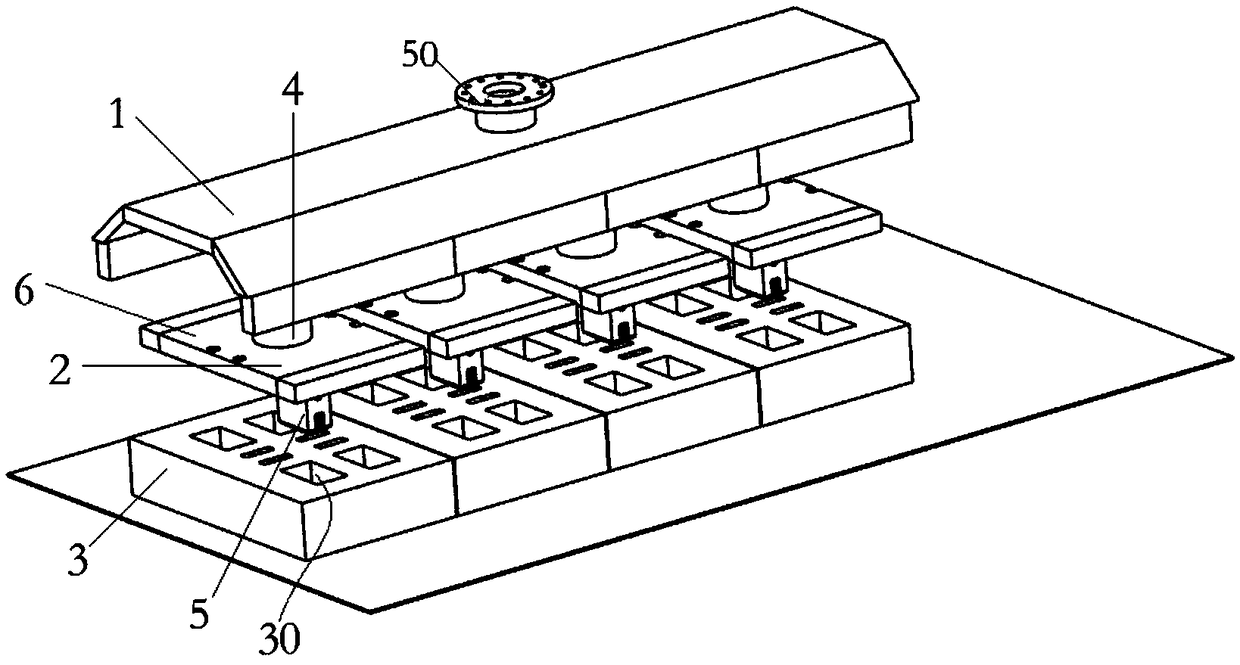

Air bag clamping device used for lossless clamping of low-rigidity framework type part

ActiveCN107414448APrecise and non-destructive clampingAvoid clampingProgramme-controlled manipulatorGripping headsButt jointEngineering

The invention discloses an air bag clamping device used for lossless clamping of a low-rigidity framework type part and belongs to the technical field of microoperation and micro electro mechanical systems. The air bag clamping device comprises an air cavity seat, a holding frame, an air bag and an air way assembly. The air bag is of a structure with one end opened and one end closed, wherein the closed end of the air bag is provided with a cylindrical cavity concave inwards and a circular-ring-shaped cavity coaxial with the cylindrical cavity, the circular-ring-shaped cavity is used for being matched with a ring-shaped face of a framework type part, and the cylindrical cavity is used for being in shaft fit with the assembling position. The shape of the holding frame and the shape of the air bag are consistent, and one or more openings are machined in each of the two opposite circumferential faces of a circular-ring-shaped cavity of the holding frame. The opening end of the air cavity seat is in butt joint with the opening end of the air bag. The holding frame is arranged on the outer surface of the air bag in a sleeving manner and is fixed to the end face of the opening end of the air cavity seat. The air way assembly communicates with a cavity of the air cavity seat through an air pipe connector and is used for inflating and deflating of the air bag. By means of the air bag clamping device, the low-rigidity framework type to-be-assembled part can be extruded in double directions accurately in a lossless manner.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

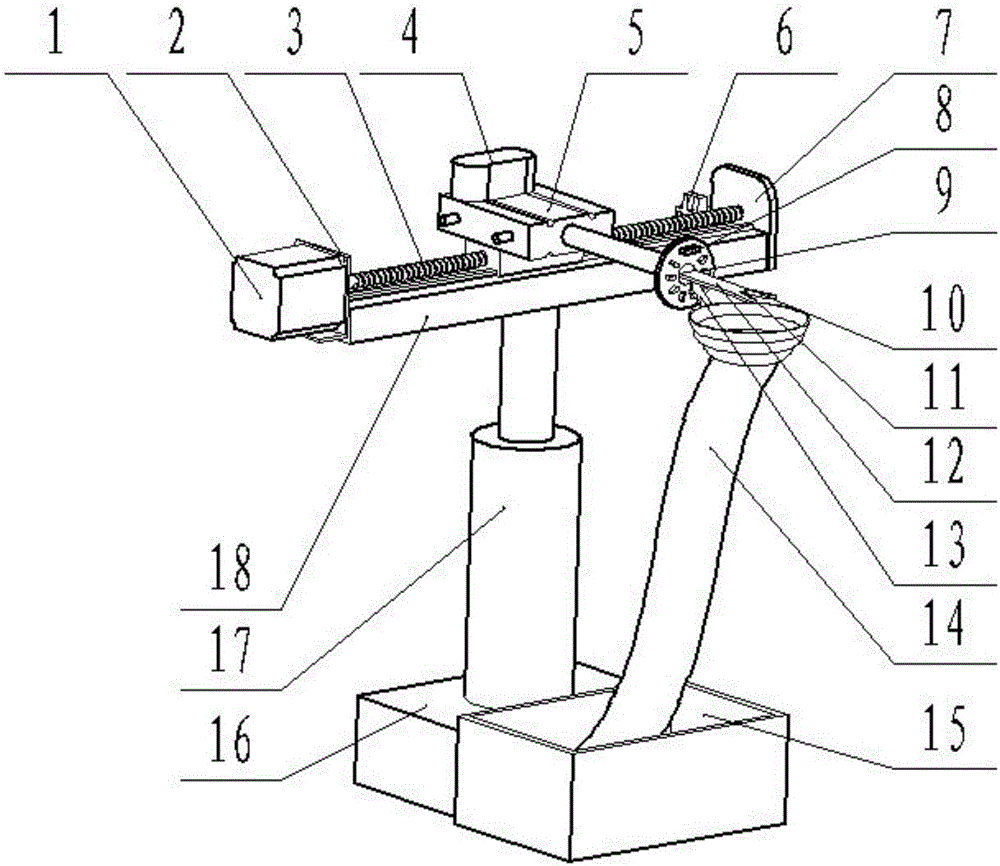

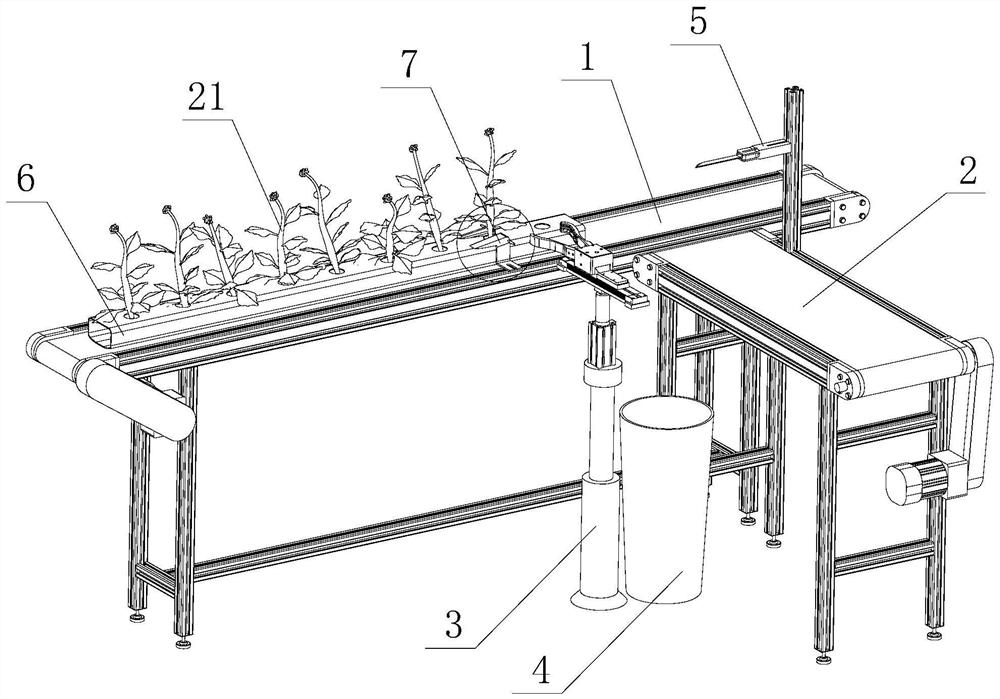

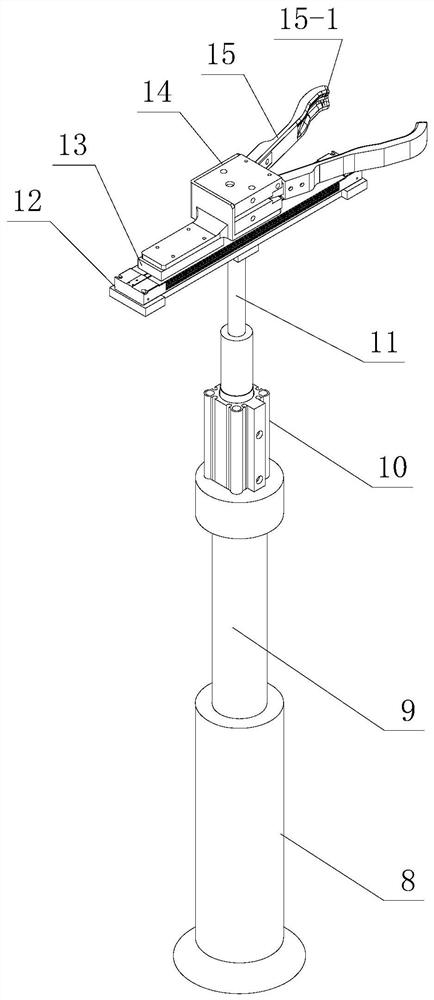

Electric heating cutting type strawberry picking terminal executor and corresponding picking mechanism and method

InactiveCN107517656ARealize the whole process of automatic harvestingPrevent dehydrationPicking devicesMultiple sensorAgricultural engineering

The invention provides an electric heating cutting type strawberry picking terminal executor and a corresponding picking mechanism and a method, and relates to the field of an agricultural picking robot; the electric heating cutting type strawberry picking terminal executor is composed of a terminal executor, a corrugated pipe, a containing box, a moving platform and a lifting mechanism, wherein the terminal executor further comprises a stepping motor, an L-shaped installing plate, a ball screw, an electric heating wire power supplier, an air cylinder, a limiting switch, a side vertical plate, a Kinect sensor, a light supplementing unit, a right electric heating wire cutter blade, a left electric heating wire cutter blade, a terminal telescopic plate, a connector, a slide rail and an installing disk. The cutting place of a strawberry fruit stem is coagulated for being heated, and water loss can be effectively prevented; through acquiring and sensing the working environment and strawberry information in real time through fusing information of multiple sensors, the full automatic strawberry harvesting work is realized during the processes of aligning fruits, closing to the fruit stem and electric heating cutting on the basis of not damaging the strawberry; besides, the terminal executor also solves the technical difficulties that the manual strawberry picking wastes time and labor, and the strawberry picking is easy to get injury and water is easy to loss.

Owner:谷新运

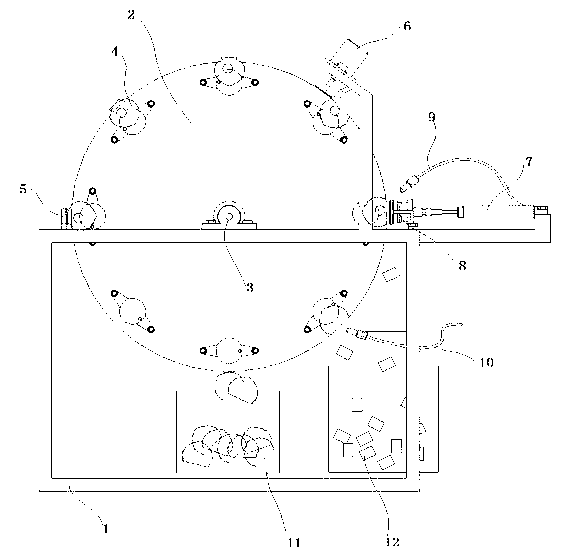

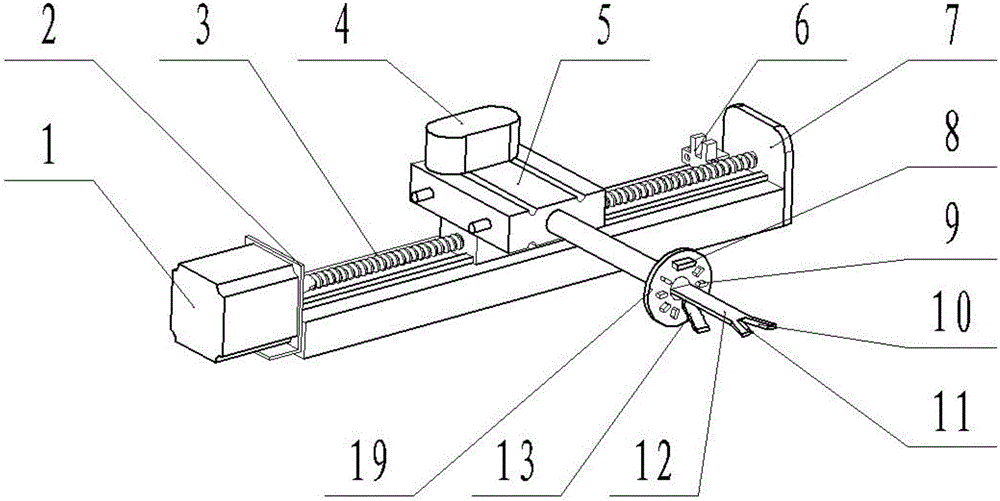

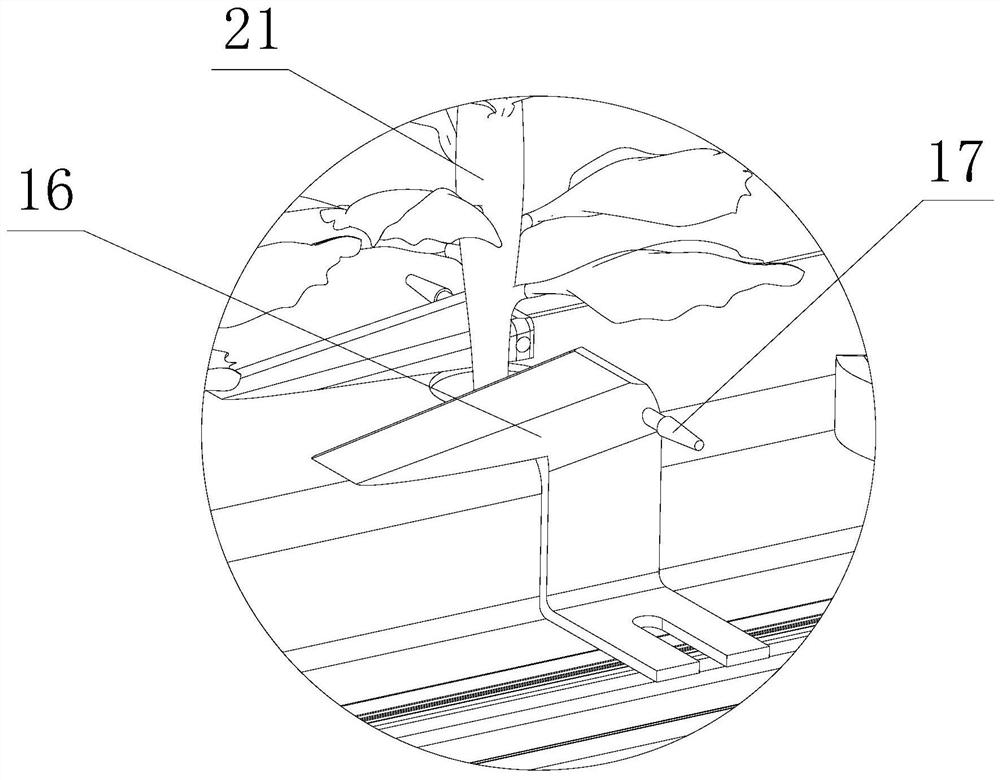

Automatic absorption-type picking equipment for strawberries

ActiveCN107615989ARealize the whole process of automatic harvestingAvoid clampingPicking devicesMultiple sensorWorking environment

The invention provides automatic absorption-type picking equipment for strawberries, and relates to the field of agricultural picking robots. The equipment is composed of a rubber cup, a lower cuttingblade, an upper cutting blade, a fruit stem gap, an absorption pipeline, a vision unit, light-supplementing units, an installation disc, a detection door mechanism, an exhaust fan, a containing box,a lifting mechanism, a rotating mechanism and a mobile platform. The detection door mechanism comprises a detection door, a microsensor, a small connecting rod and an electromagnetic valve. Based on anegative pressure absorption principle, by fusing multiple sensor messages, the working environment and strawberry messages are obtained and sensed in real time, the working procedures of fruit aligning, fruit closing, absorption cutting and fruit falling detection are completed on the premise that the strawberries are not damaged, the strawberries are automatically harvested in the whole process, and the technical problems that the strawberries are prone to being damaged during picking, and the efficiency is low when each strawberry is picked are solved.

Owner:阜阳市胜源农业科技有限公司

Clamping jaw mechanism controlled by servo electric cylinder

The invention discloses a clamping jaw mechanism controlled by a servo electric cylinder. The clamping claw mechanism comprises a clamping jaw fixing base and a motor base, wherein an electric cylinder is fixedly arranged between the clamping jaw fixing base and the motor base; a movable bracket is arranged at a top end of the electric cylinder; first connecting rods and second connecting rods aresymmetrically arranged on both sides of the motor base; front clamping pieces are arranged between other ends of the first connecting rod and the second connecting rod on the same side; rubber blocksare arranged on opposite outer surfaces of the two clamping pieces; air bags are embedded into top ends of the rubber blocks; and pressure sensors are arranged inside the front clamping pieces. According to the clamping jaw mechanism controlled by the servo electric cylinder disclosed by the invention, pressure sensors are arranged at back ends of the rubber blocks, and can be used for detectingthe pressure on the surface of an object to be clamped by the rubber blocks, so that the situation of over large or over small clamping force is avoided. Moreover, the air bags are arranged at the front ends of the rubber blocks, and nickel-titanium meshes are arranged inside the rubber blocks, so that the clamping jaw mechanism can fit closely with the surfaces of the objects of different shapesto be clamped, and the adaptability of the device is improved.

Owner:张梅

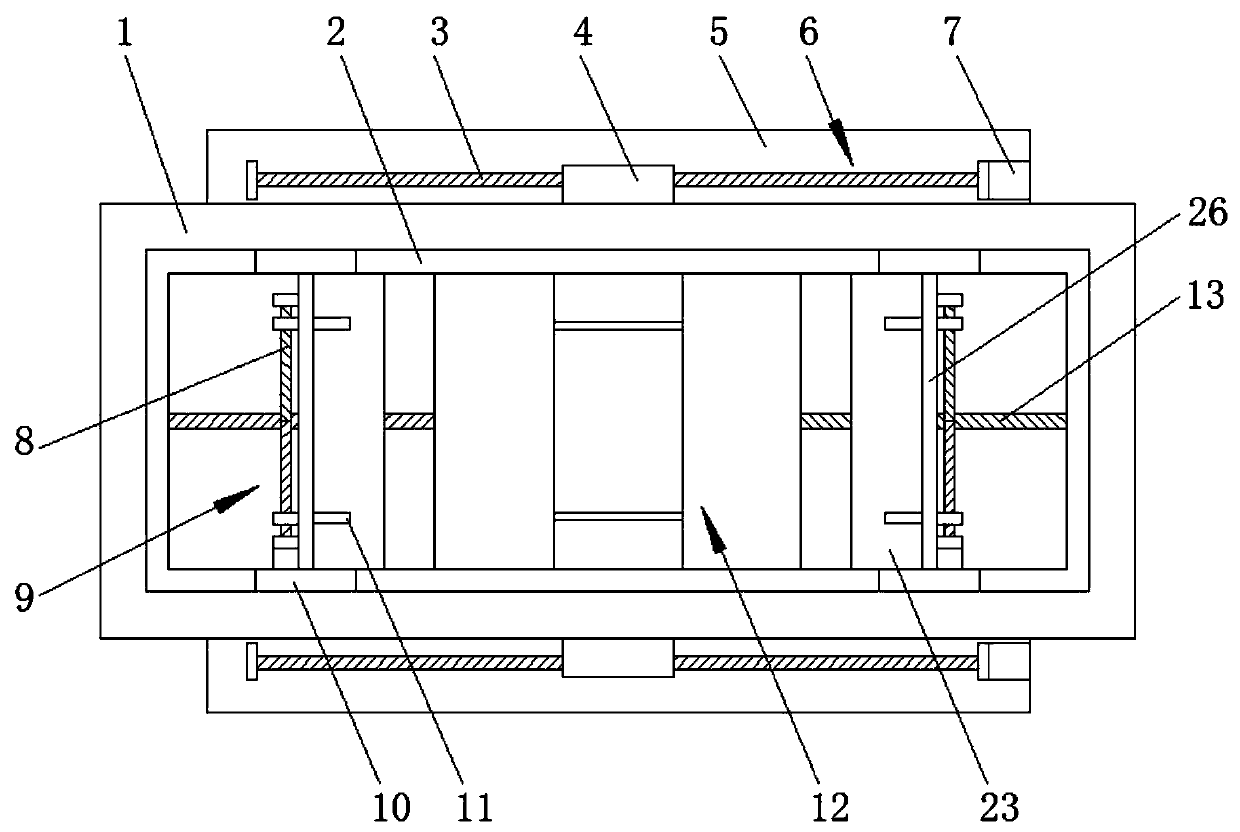

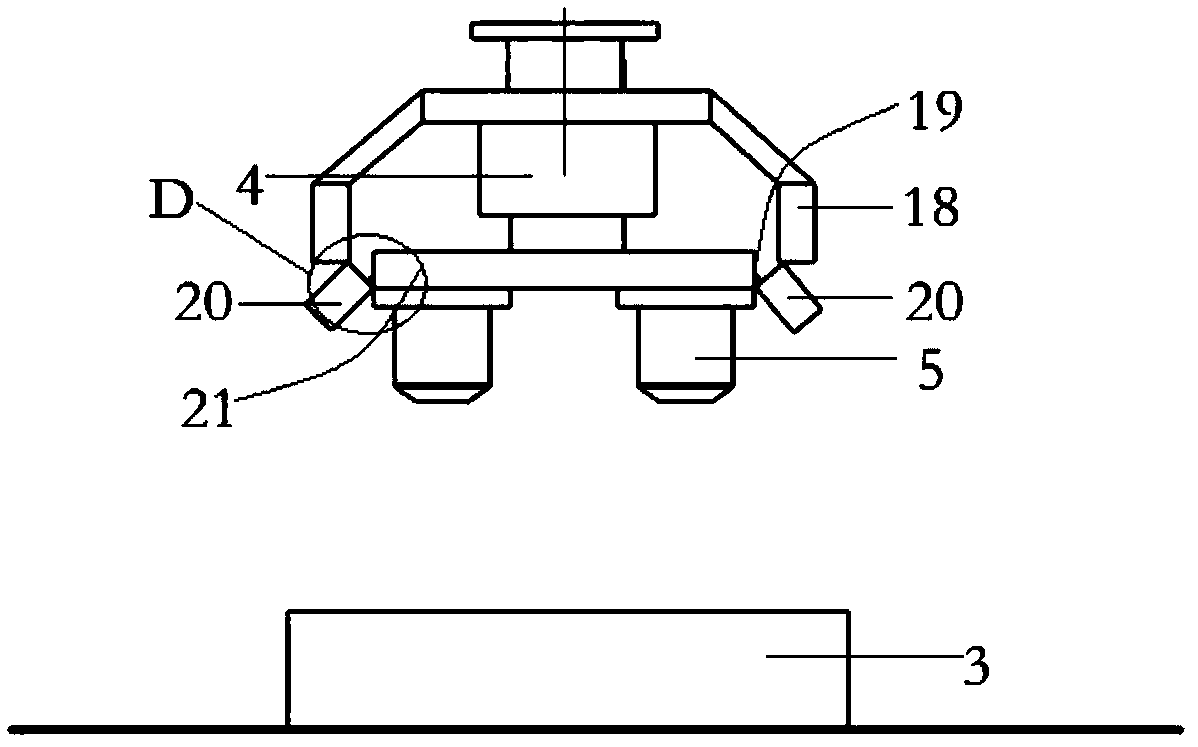

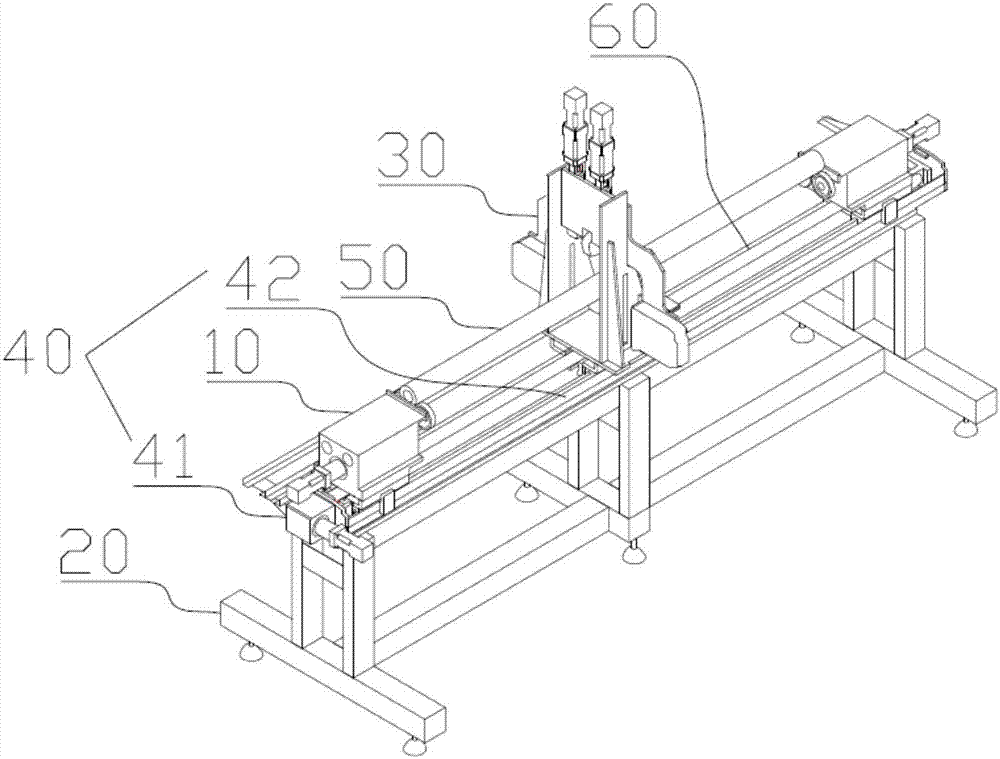

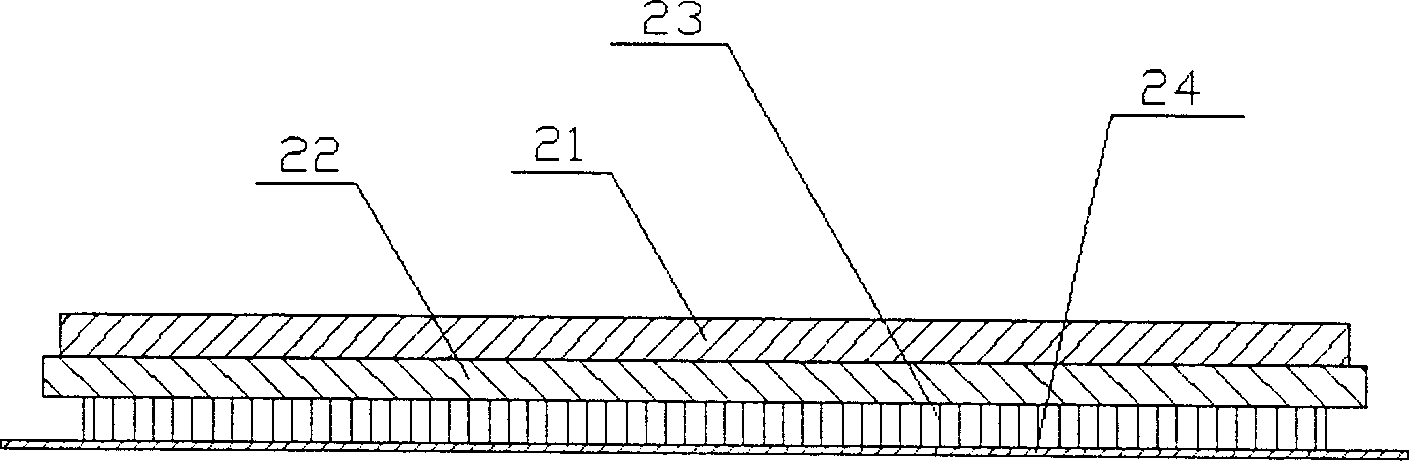

Concave pit notching and cutting composite mould for integrated chip lead frame

ActiveCN102909268AAvoid clampingHeight adjustableShaping toolsMetal-working feeding devicesPunchingStructural engineering

The invention discloses a concave pit notching and cutting composite mould for integrated chip lead frame, overcomes the defect of singular notching of the conventional notching mould, and provides the composite mould which is precise in notching, system positioning and cutting. The concave pit notching and cutting composite mould comprises an upper mould seat, a lower mould seat and a controller; the upper and lower moulds are slidingly connected through four guide mechanisms; movable sliders are arranged on guide columns; a concave mould is arranged on the lower mould seat; a square concave pit is formed in the middle of the concave mould; positioning pins are symmetrically arranged on front and back sides of the square concave pit; a square through hole is formed in the corresponding part of the movable sliders and the square concave pit; a positioning pin hole is formed in the corresponding part of the movable sliders and the square concave pit; a convex mould is arranged in the middle of the upper mould seat; the head of the convex mould slidably penetrates through the square through hole; a height adjusting device is arranged at the upper end of the convex mould; a fixed length transmission device of the integrated chip lead frame is arranged on the left side of the lower mould seat; and a cutting device of the integrated chip lead frame is arranged on the right side of the lower mould seat. By the concave pit notching and cutting composite mould, the concave part can be notched precisely; the system positioning is precise, and fixed length cutting is accurate; and guide rail error of a punching machine can be prevented.

Owner:浙江捷华电子有限公司

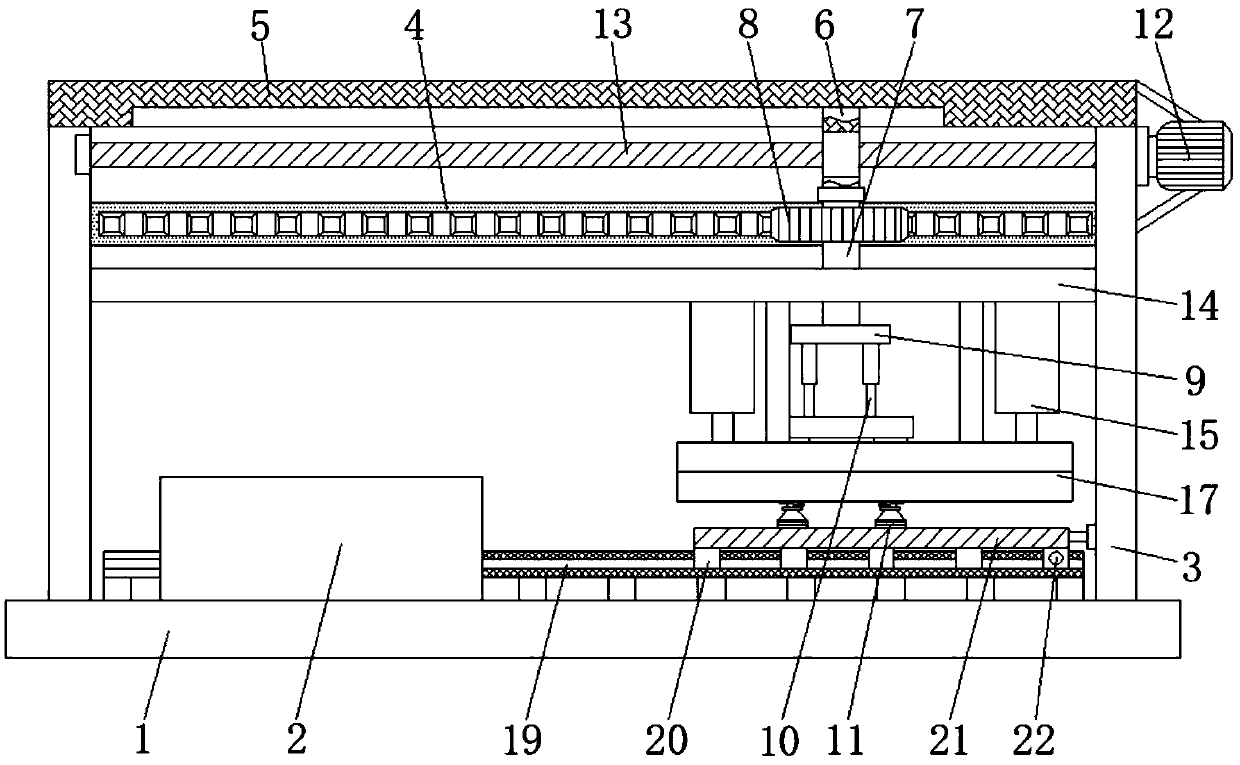

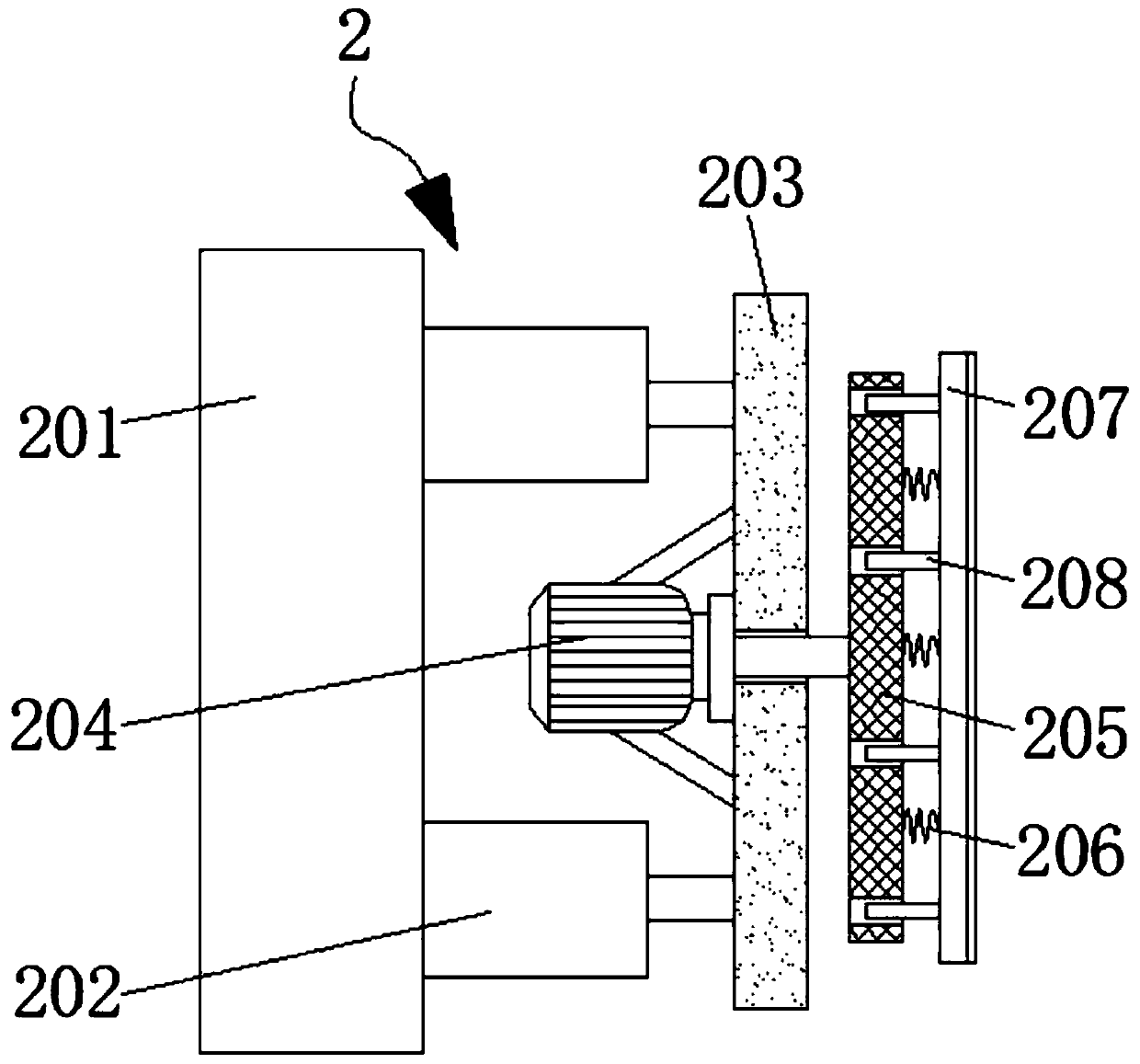

Cutting and polishing integrated equipment for poplar wood processing

ActiveCN109591121AImprove work efficiencySave time at workEdge grinding machinesGrinding drivesArchitectural engineeringSlide plate

The invention relates to the technical field of plate processing, and discloses cutting and polishing integrated equipment for poplar wood processing. The cutting and polishing integrated equipment comprises a base, wherein two grinding mechanisms are fixedly installed on the top of the base, the top of the base is fixedly provided with two vertical plates, a fixing plate is fixedly installed between adjacent side faces of the two vertical plates, a straight rack is arranged on the front surface of the fixing plate, a top plate is fixedly installed between the top ends of the two vertical plates, a sliding groove is arranged at the bottom of the top plate, a sliding plate is clamped in the sliding groove, and a rotating rod is rotatably connected with the bottom of the sliding plate through a first fixing bearing. The cutting and polishing integrated equipment solves the problems that existing wood board cutting equipment is low in wood board cutting efficiency and poor in corner smoothness, has no polishing function, increased equipment can improve input cost and the work efficiency is low, and achieves the effects of integrated processing, improving work efficiency, saving inputcost and high processing quality.

Owner:安徽省大欣木业股份有限公司

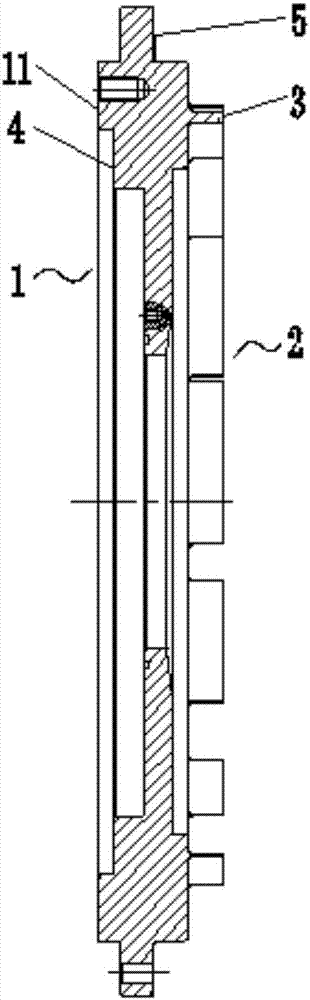

Manufacturing method of steam compressor pressure expander

InactiveCN107234404AImprove processing efficiencyGuaranteed height dimensionSurface flatnessPetroleum engineering

The invention discloses a manufacturing method of a vapor compressor diffuser, which comprises the following steps: a. rough heat treatment; b. rough turning of the diffuser big end, outer circle, inner hole and first stepped surface; c. rough turning The small end, outer circle, inner hole and the second step surface of the diffuser; d, the large end, outer circle, inner hole and the first step surface of the semi-finishing diffuser; Milling blades, after finishing milling, send three-coordinate inspection; f, after passing the inspection, finish turning the end surface and inner hole of the small end of the diffuser; g, finishing turning the end surface and inner hole of the large end of the diffuser; h, marking and drilling Use the center line for alignment, drill and tap; i, file and repair the bottom of the blade flow path; j, conduct a penetration test on the blade. The invention has the advantages of high profile of blade profile, high requirements on flatness and verticality of end faces, and good process performance.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

Pipeline cultivation leafy vegetable harvesting device and method

ActiveCN112166808AGuaranteed economic valueAvoid hand collisionHarvestersLeafy vegetablesAgricultural engineering

The invention discloses a pipeline cultivation leafy vegetable harvesting device and method. The device is provided with a pipeline conveyor and a flowering Chinese cabbage conveyor which are connected; at least one group of grabbing manipulator and at least one group of root cutting mechanism are arranged at the joint of a conveying platform of the pipeline conveyor and a conveying platform of the flowering Chinese cabbage conveyor; vegetable root collectors are arranged at one sides of the grabbing manipulators; a cultivation tank is conveyed by the pipeline conveyor; two guide positioning mechanisms for righting and positioning leafy vegetables are symmetrically arranged at the two sides of the pipeline conveyor; and the guide positioning mechanisms are arranged in front of the grabbingmanipulators in the conveying direction of the cultivation tank. The method includes the steps of continuously conveying the cultivation tank with the leafy vegetables by the pipeline conveyor; righting and positioning the leafy vegetables by the guide positioning mechanisms firstly; then clamping the leafy vegetables by the grabbing manipulators; cutting and separating by the root cutting mechanisms; conveying out the separated flowering Chinese cabbage by the flowering Chinese cabbage conveyor; and collecting rhizomes and roots falling into the vegetable root collectors. According to the pipeline cultivation leafy vegetable harvesting device and method, efficient and damage-free harvesting of the pipeline cultivation leafy vegetables can be well achieved.

Owner:SOUTH CHINA AGRI UNIV

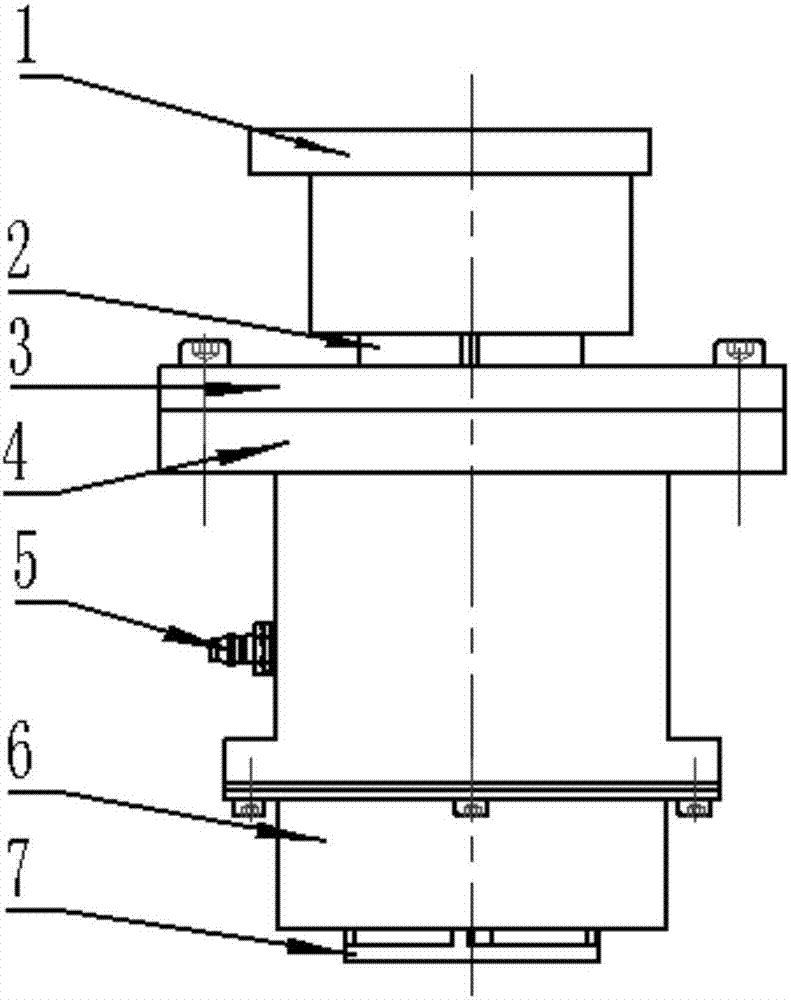

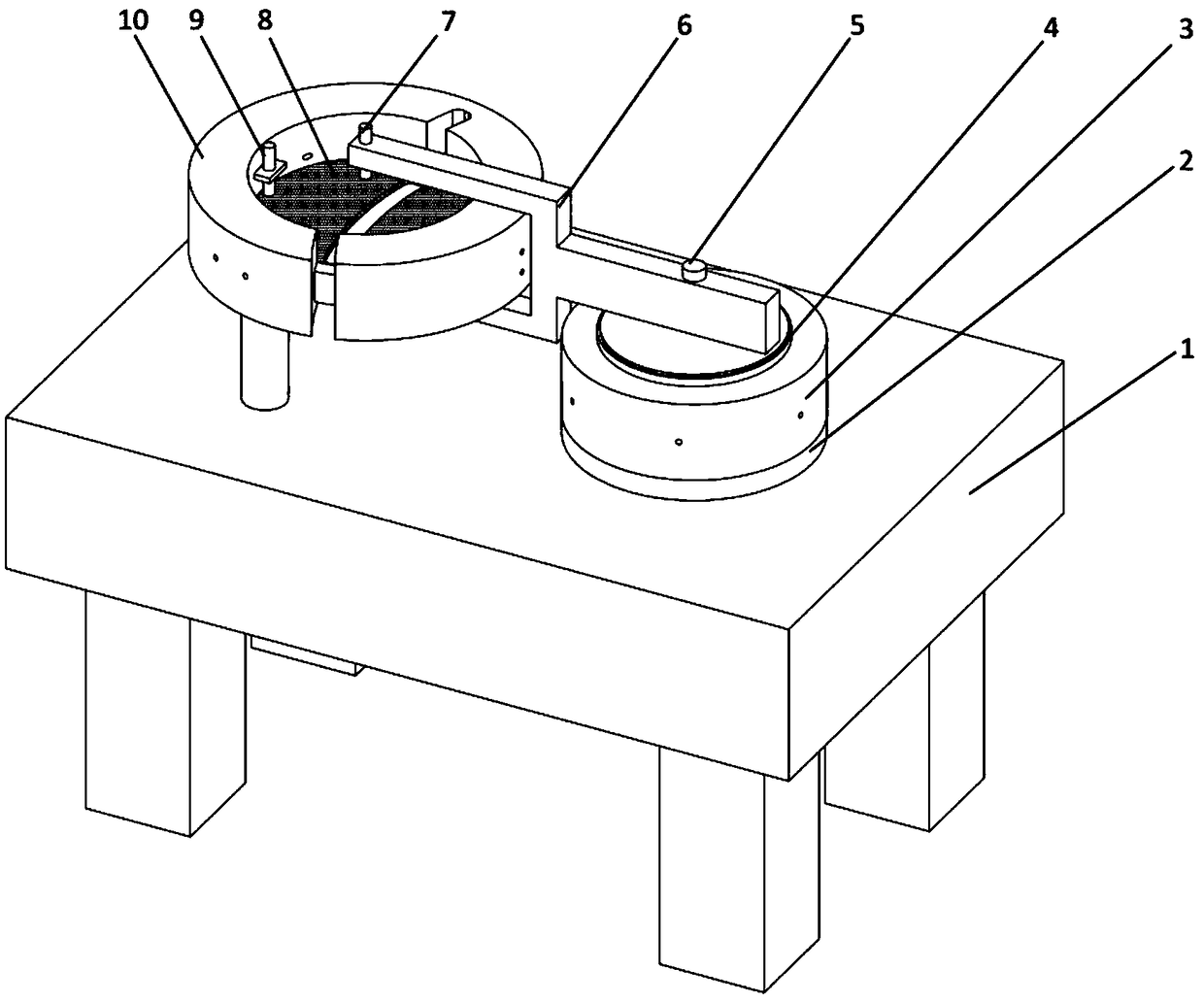

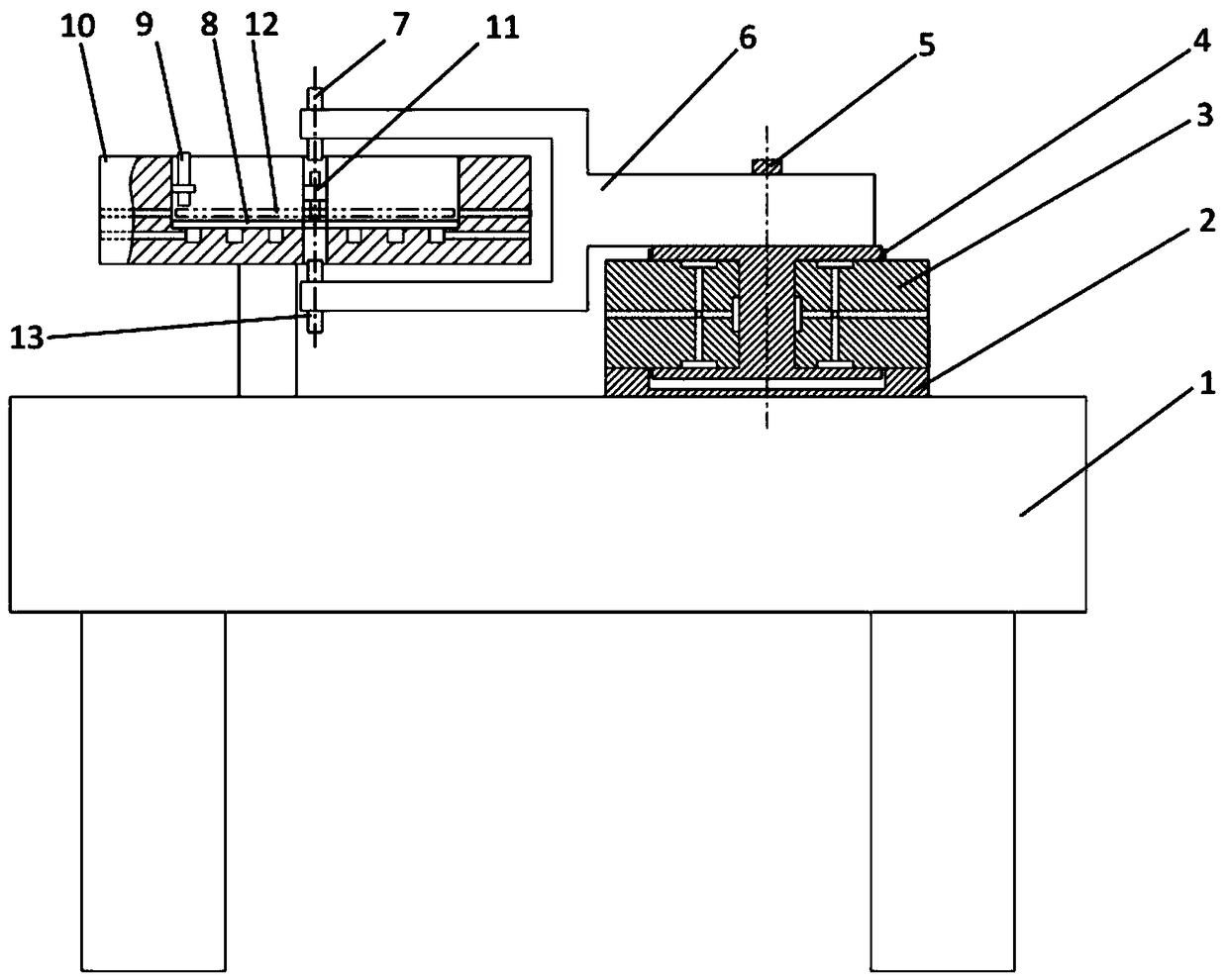

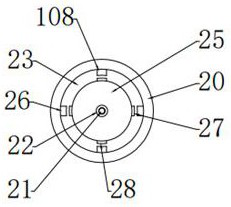

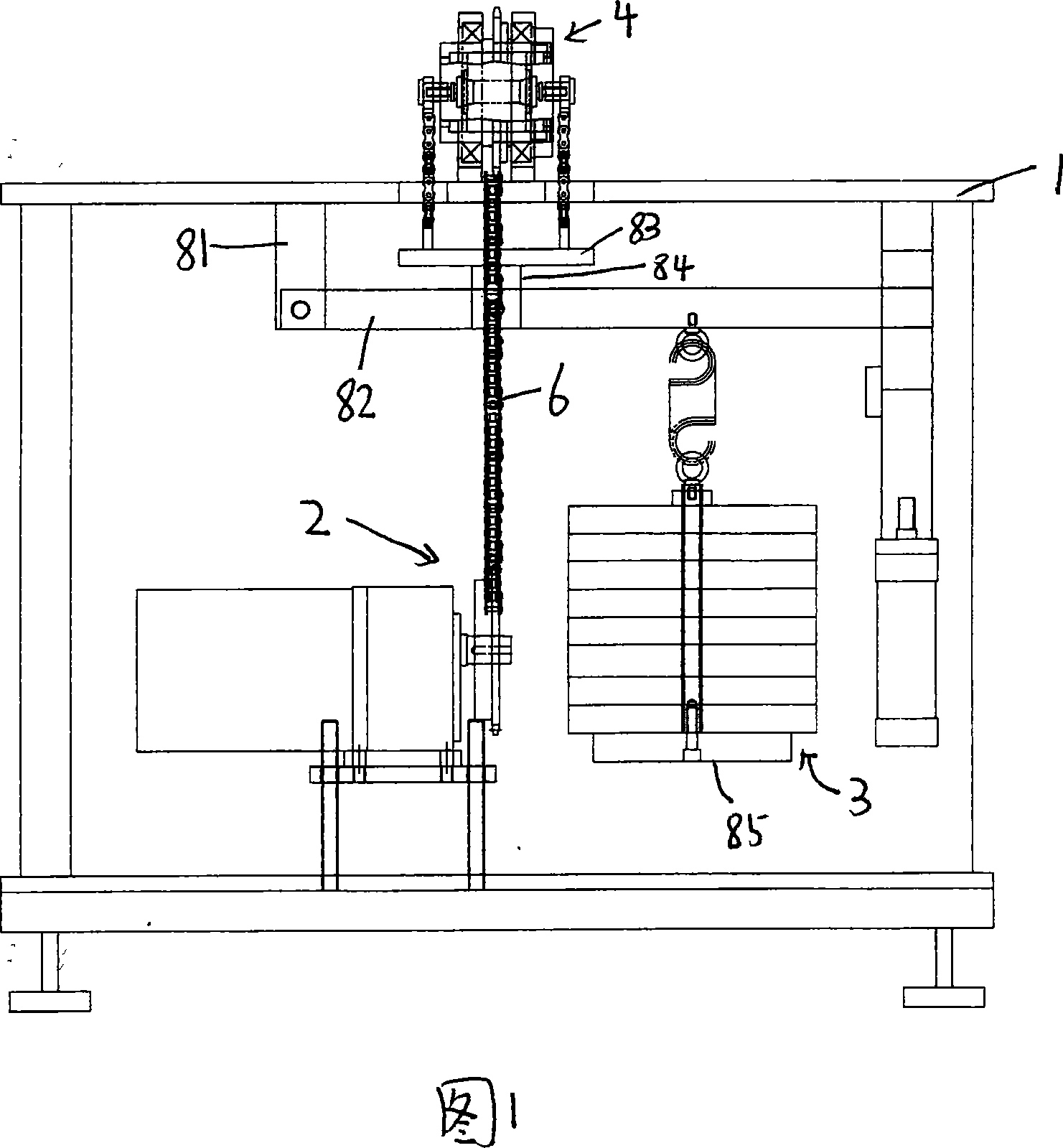

Device and method for measuring parallelisms and flatness of circular low-stiffness workpiece

ActiveCN109238210AAvoid clampingMitigate the impact of measurement resultsMeasurement devicesEngineeringNon magnetic

The invention discloses a device and a method for measuring the parallelisms and the flatness of a circular low-stiffness workpiece. The device comprises a vibration isolation platform, a gas static pressure bearing unit, a swing arm unit, a gas channel seat unit, and a data processing unit. The gas static pressure bearing unit and the gas channel seat unit are fixed on the vibration isolation platform in parallel. The swing arm unit is connected with the gas static pressure bearing unit through a positioning hole. The device and the method adopt multiple channels for ventilation, so that theworkpiece is in suspension state during measurement, thereby avoiding the use of a special or universal fixture for clamping the workpiece. The non-contact measurement is performed by a distance sensor to reduce the influence on measurement results caused by the deformations of the low-stiffness workpiece. The motion mode of using a gas static pressure spindle to drive a swing arm for measurementis adopted, so that the motion process is stable, and the positioning precision of a repeated rotation can be controlled within 0.1 degree. Since the device and the method use a gas suspension mode for positioning, the flatness and the parallelisms of the circular low-stiffness non-magnetic material workpiece can be measured.

Owner:DALIAN UNIV OF TECH

Cutting device for electrical equipment production and cutting method

InactiveCN110153489AReasonable structural designConvenient whereaboutsShearing machinesShearing machine accessoriesEngineeringElectrical equipment

The invention discloses a cutting device for electrical equipment production. The cutting device comprises a movable framework, a longitudinal clamping assembly, a transverse clamping assembly, a workpiece moving assembly, a pre-bearing table, a movable cutting assembly and a top beam, wherein the longitudinal clamping assembly and the transverse clamping assembly are arranged at the interior of the movable framework, the transverse clamping assembly comprises two transverse clamping plates which are synchronously and reversely moved in sliding grooves, a longitudinal clamping assembly is arranged on each of the two transverse clamping plates, ech longitudinal clamping assembly comprises two longitudinal clamping plates which are synchronously and reversely moved, the pre-bearing table isfixed on the bottom end surface of the movable framework between the two transverse clamping plates through a side plate, the pre-bearing table comprises a pre-bearing plate and a limiting strip, andlifting plates used for lifting a to-be-cut workpiece on the pre-bearing plate are fixed at the bottom ends of the opposite side surfaces of the two transverse clamping plates. The cutting device forthe electrical equipment production has the advantages of being reasonable in structural design, practical, reliable and the like, and can be widely popularized and used.

Owner:QINGDAO HUANGHAI UNIV

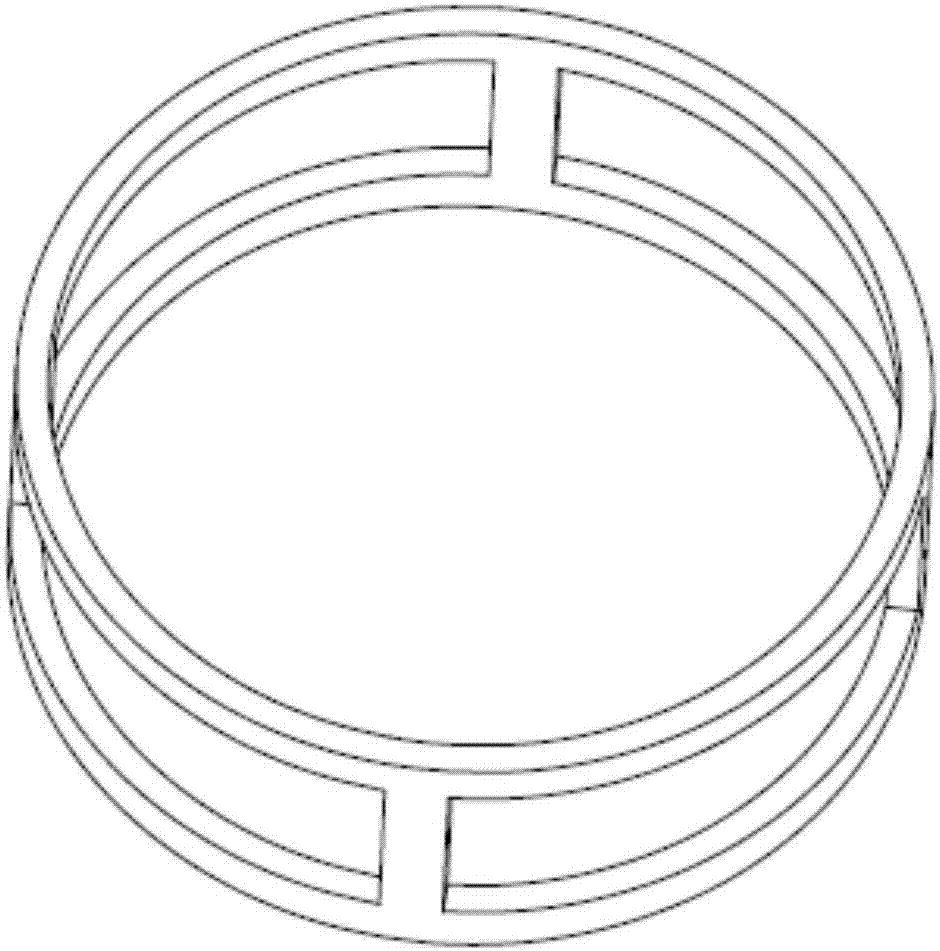

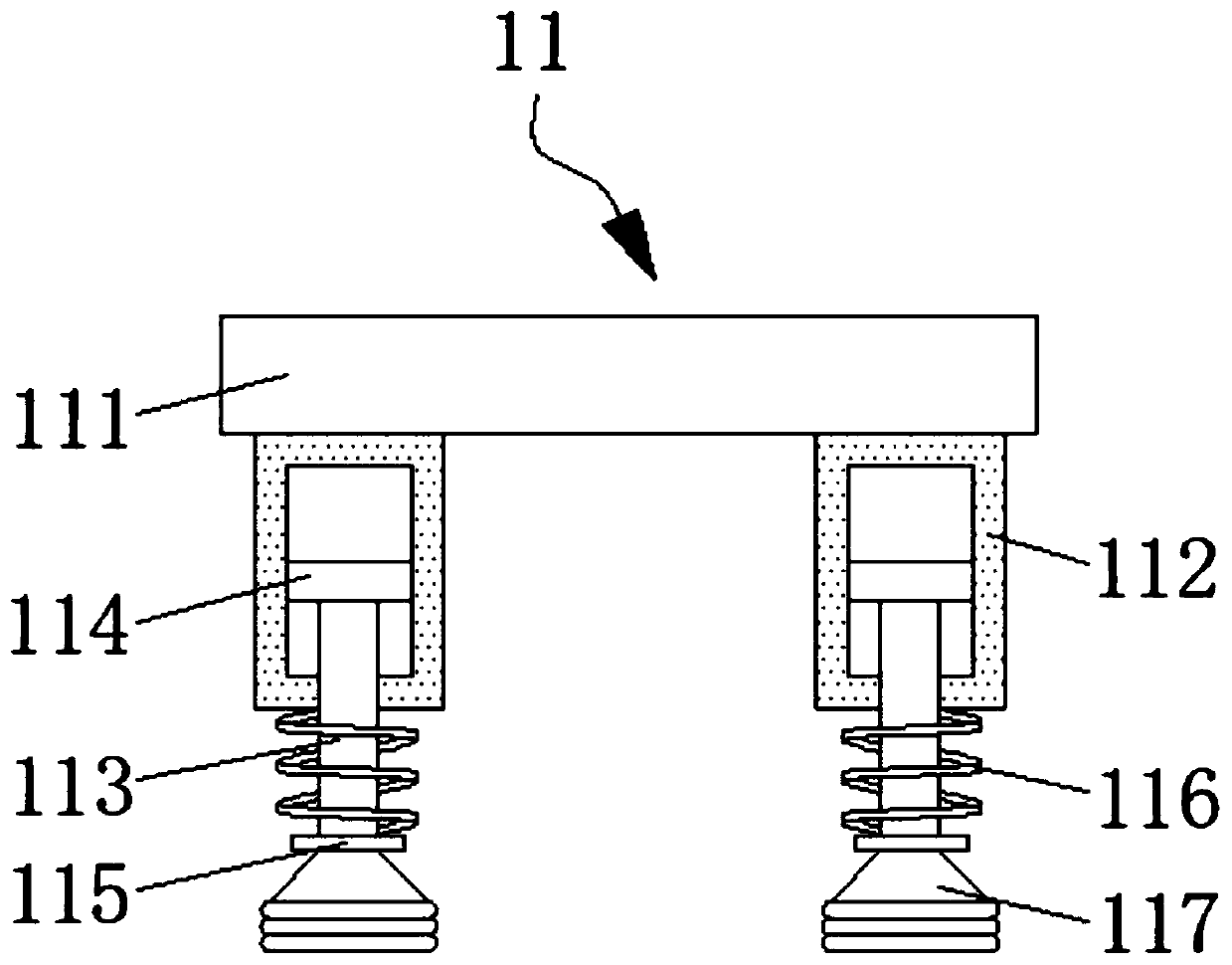

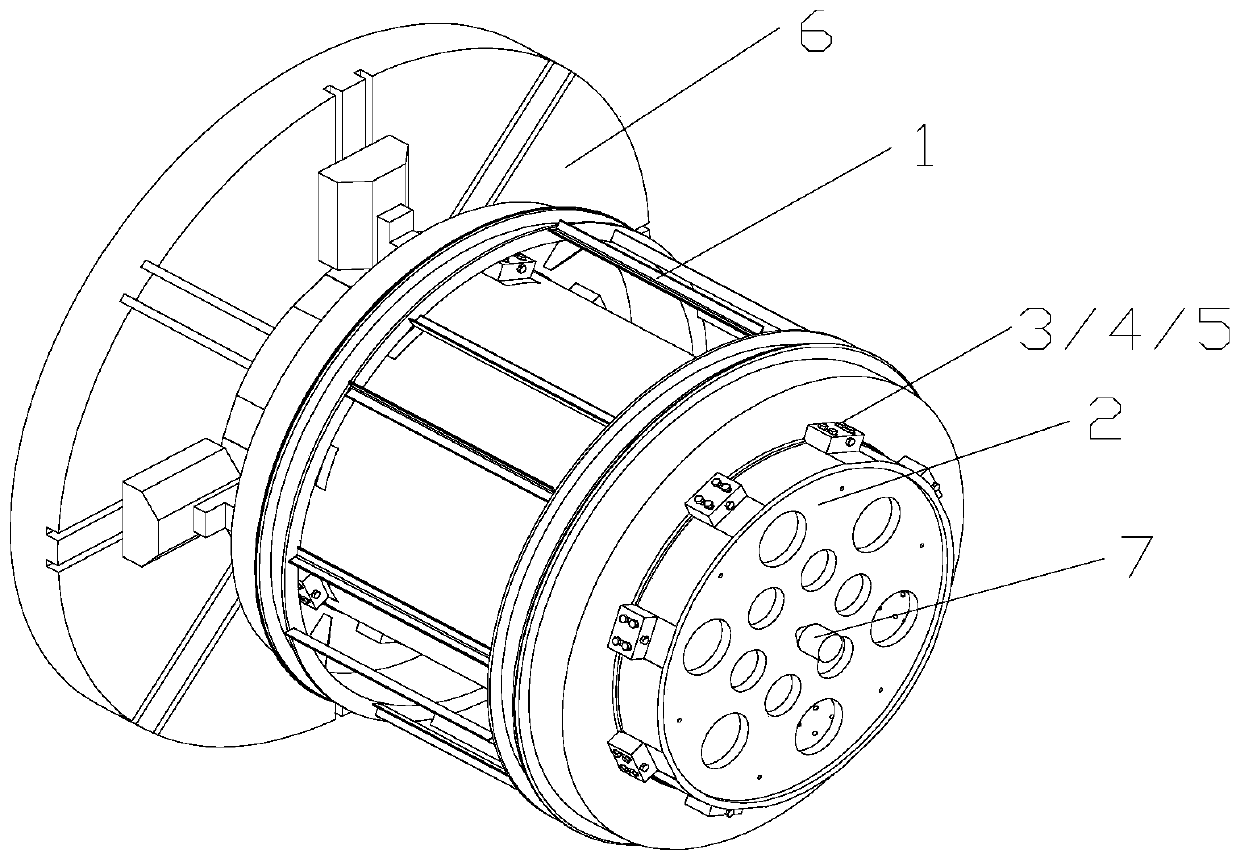

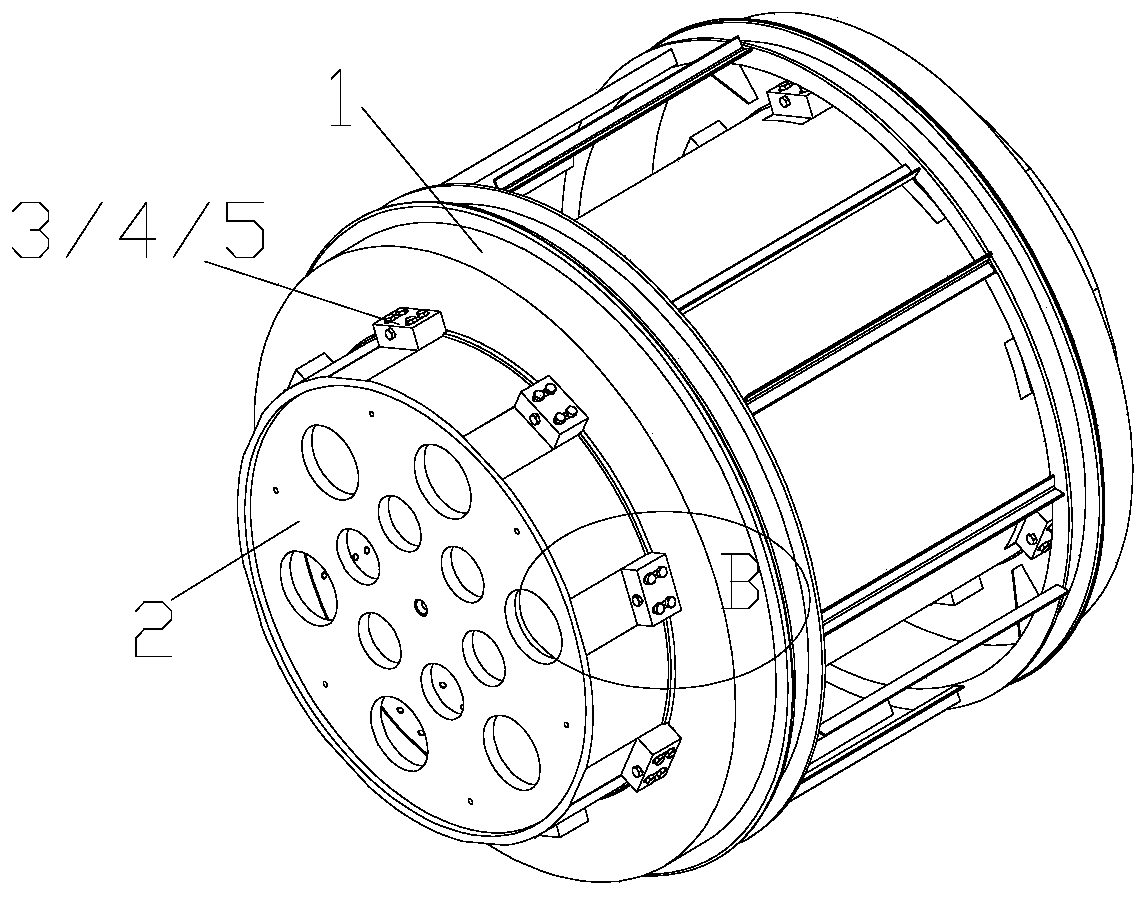

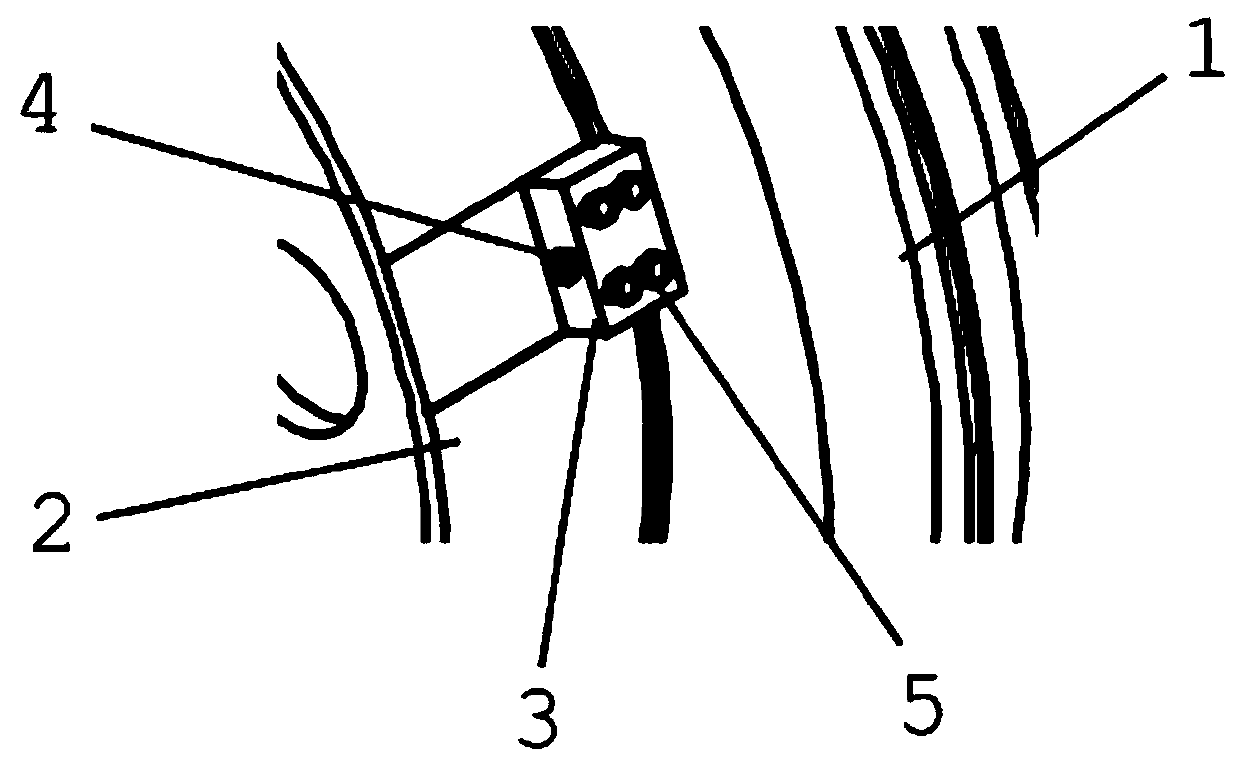

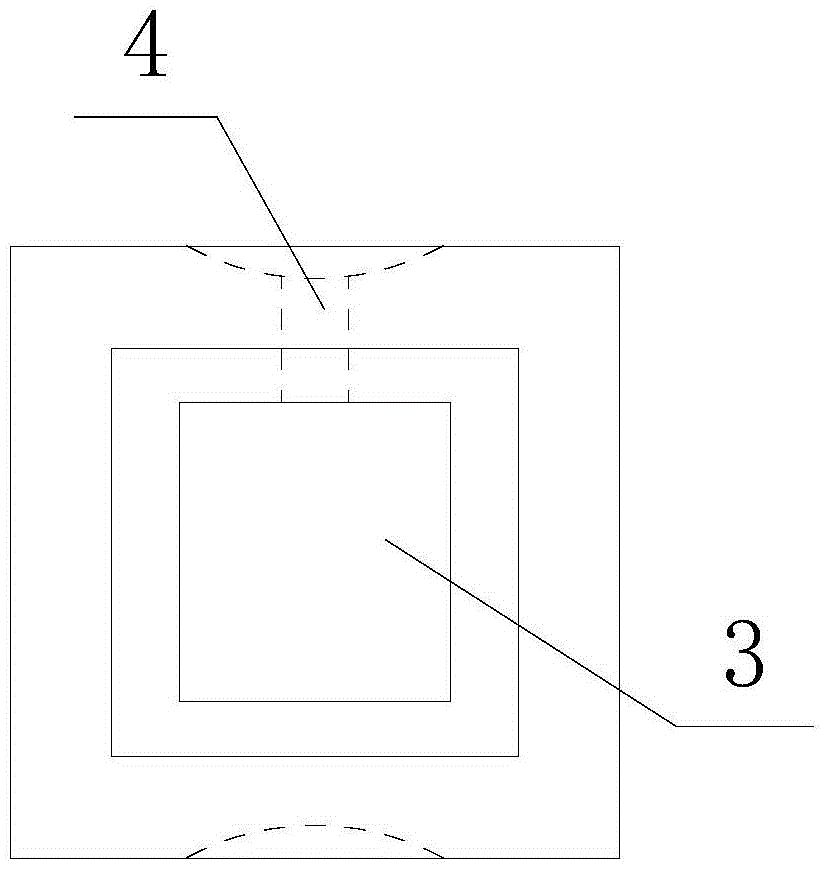

Processing clamping device for thin-walled framework and clamping method

PendingCN110480378AAvoid clampingReduce processing stepsPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention relates to a processing clamping device for a thin-walled framework. The device comprises a main coil clamping tube mounted inside a main coil framework, wherein a plurality of positioning block components distributed along the peripheral direction are arranged on the outer peripheral surface of the main coil clamping tube; the positioning block components comprise outer side positioning blocks and inner side positioning blocks which are symmetrically arranged; the outer side positioning blocks and the inner side positioning blocks are separately connected with the main coil framework through main coil clamping bolts; and the outer side positioning blocks and the inner side positioning blocks are separately fixedly connected with the main coil clamping tube through positioning block mounting bolts. The device has the advantages that the device can not only avoid clamping damage to high precision outer periphery caused by direct clamping of the outer peripheral surface ofthe thin-walled framework, but also realize the fact that processing of two ends of the thin-walled framework is accomplished at one step after the thin-walled framework is clamped, avoids concentricity error at the two ends caused by turning processing of a workpiece, and thoroughly solves twist deformation to the workpiece by the rolling torque of a machine tool.

Owner:CSSC NANJING LUZHOU MACHINE

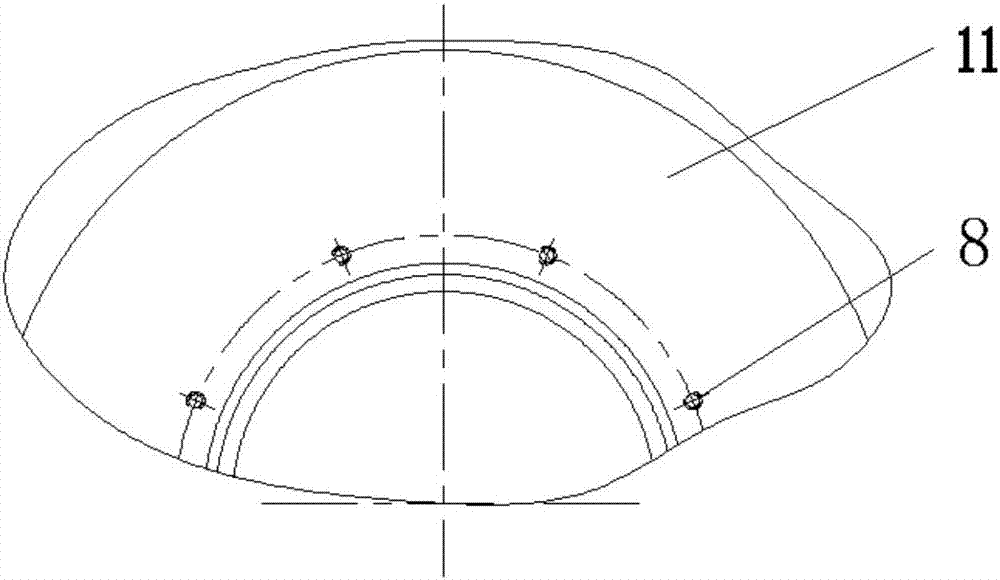

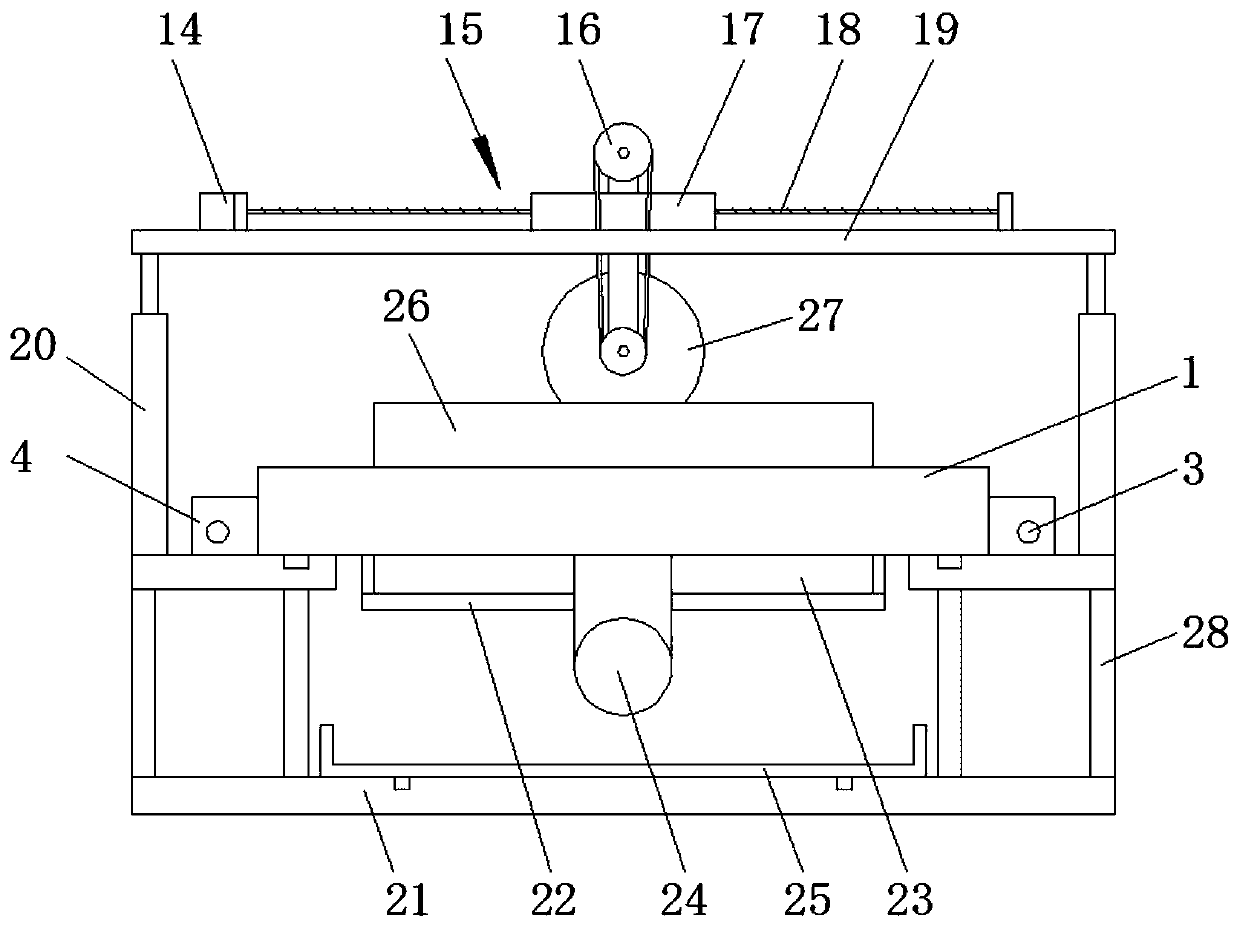

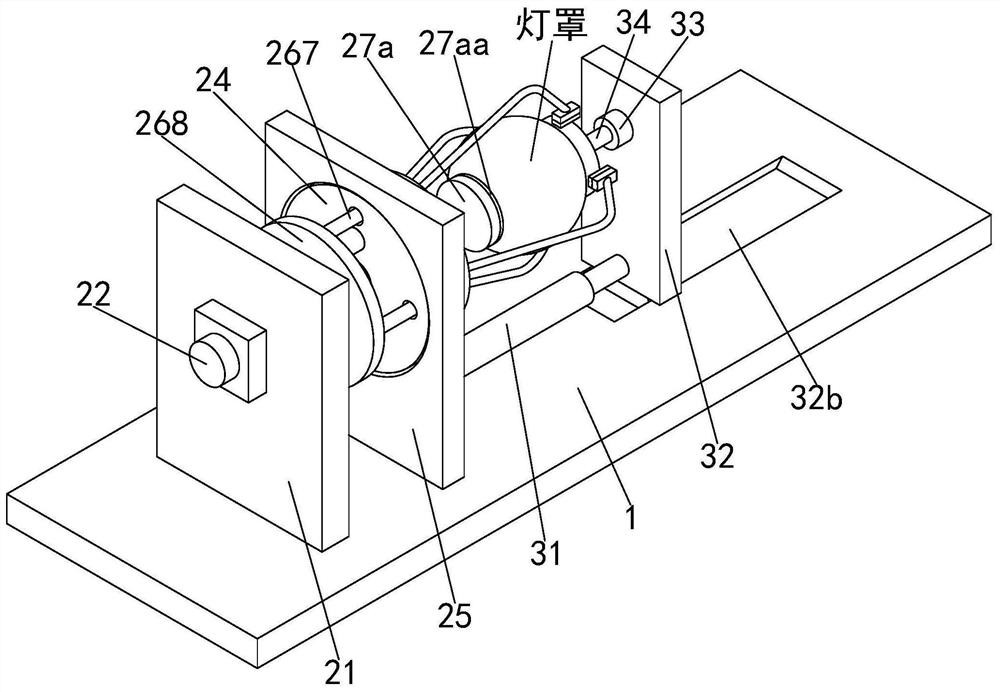

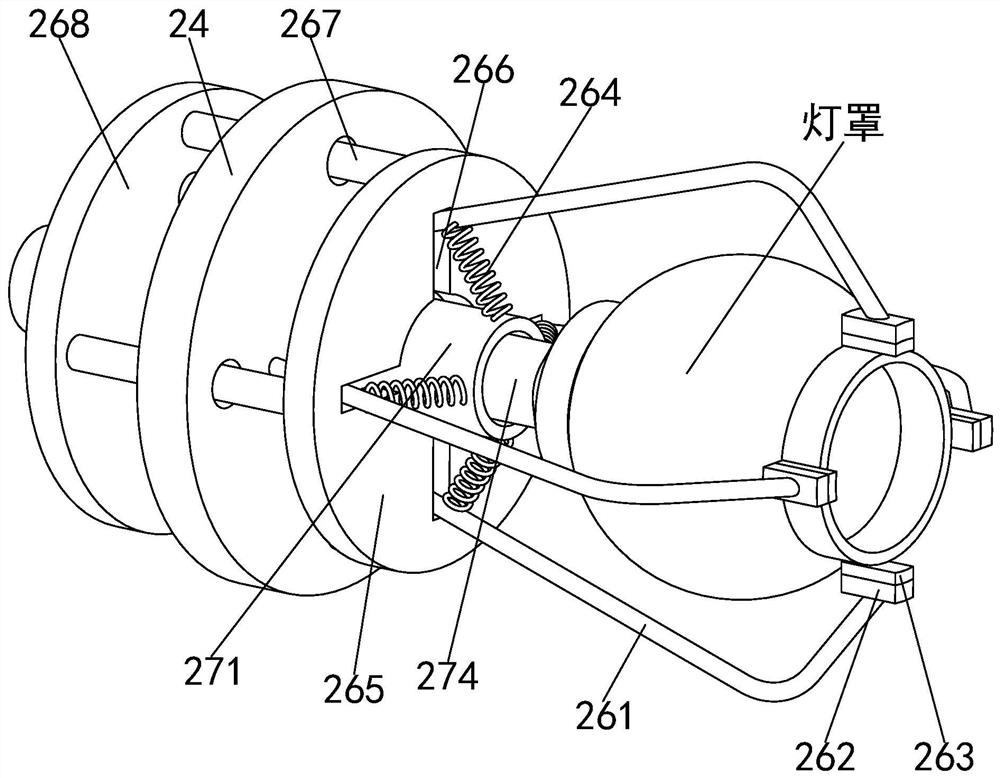

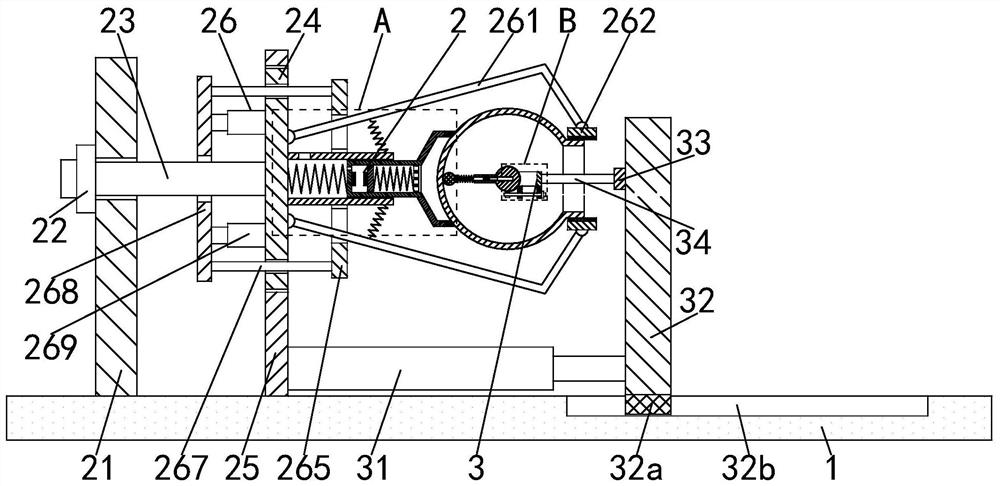

Fine machining equipment for manufacturing lampshade of solar street lamp and machining method

InactiveCN113714873APolished evenlyNot practicalGrinding carriagesRevolution surface grinding machinesPolishingSolar street light

The invention provides fine machining equipment for manufacturing a lampshade of a solar street lamp and a machining method. The fine machining equipment comprises a workbench, a clamping device and a grinding device, and the clamping device and the grinding device are sequentially arranged on the upper end face of the workbench from left to right. The fine machining equipment can solve the following problems existing in the manufacturing and finish machining process of the lampshade of the solar street lamp, specifically, a, in the machining and polishing process of the inner wall of a traditional lampshade of the solar street lamp, due to the fact that the overall structure of the lampshade is light, an existing clamping device is prone to causing clamping deformation of the lampshade and scratching of the outer surface during clamping, and therefore, the lampshade needs to be subjected to secondary maintenance processing; b, when the inner wall of the existing lampshade of the solar street lamp is polished, a polishing head generally needs to be moved into the lampshade, so that the polishing head is difficult to observe manually during polishing, and all-dimensional uniform polishing of the inner wall of the lampshade cannot be guaranteed; and c, most existing polishing equipment cannot polish lampshades of different sizes, and the practicability of the equipment is not high.

Owner:江苏二五七特显科技集团有限公司

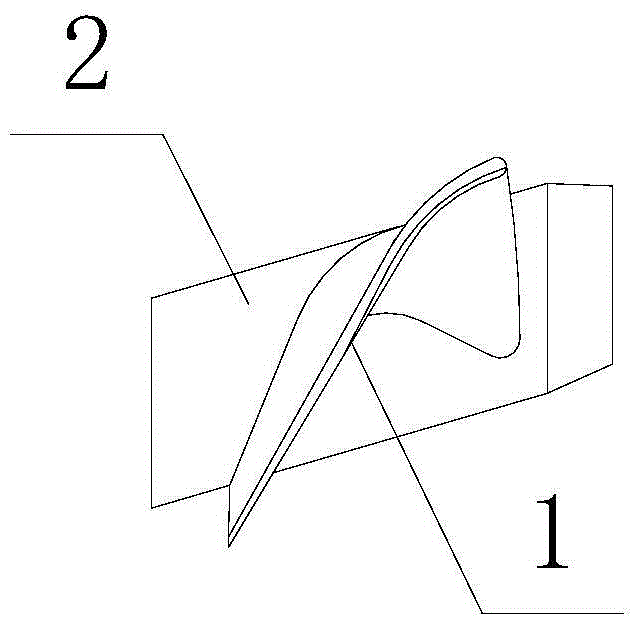

A Method for Using Alloy Casting to Satisfy the Positioning of Complicated Shaped Workpieces

ActiveCN105382202BAvoid clampingStrong application spaceFoundry mouldsFoundry coresTurbine bladeAlloy

The invention discloses a method for meeting the positioning requirement of a complex-shaped workpiece through alloy casting and belongs to the field of machining. The method relates to a turbine blade. The turbine blade is composed of a blade body and a tenon. The method comprises the following steps that a square box and a pouring body are prepared; an upper front template and an upper rear template of the pouring body are taken down; the square box is installed, and the turbine blade is arranged; alloy casting is conducted; the square box is taken out; extra alloy is removed; whether the tenon of the turbine blade is located in the center of the square box or not is detected through a height gauge; if the tenon of the turbine blade is located in the center of the square box, the tenon of the turbine blade is ground through the square box; if the tenon of the turbine blade is not located in the center of the square box, casting is conducted for height adjustment; and after the tenon of the turbine blade is ground, the alloy is melted, the turbine blade is taken out, and the square box and the pouring body are used repeatedly for machining the next turbine blade. By means of the method, the clamping and positioning requirements can be met, installation is convenient, and clamping machining is facilitated.

Owner:SICHUAN CRRC YUCHAI ENGINE CO LTD

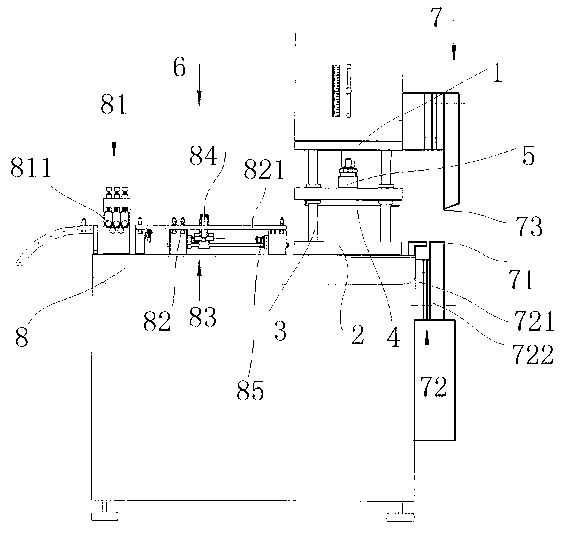

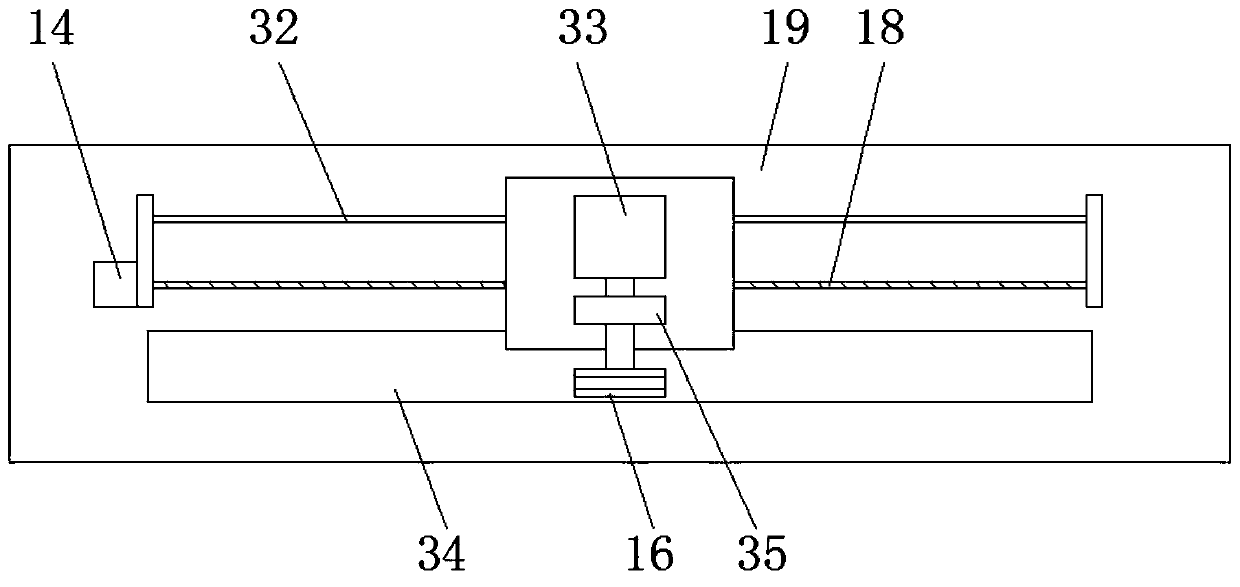

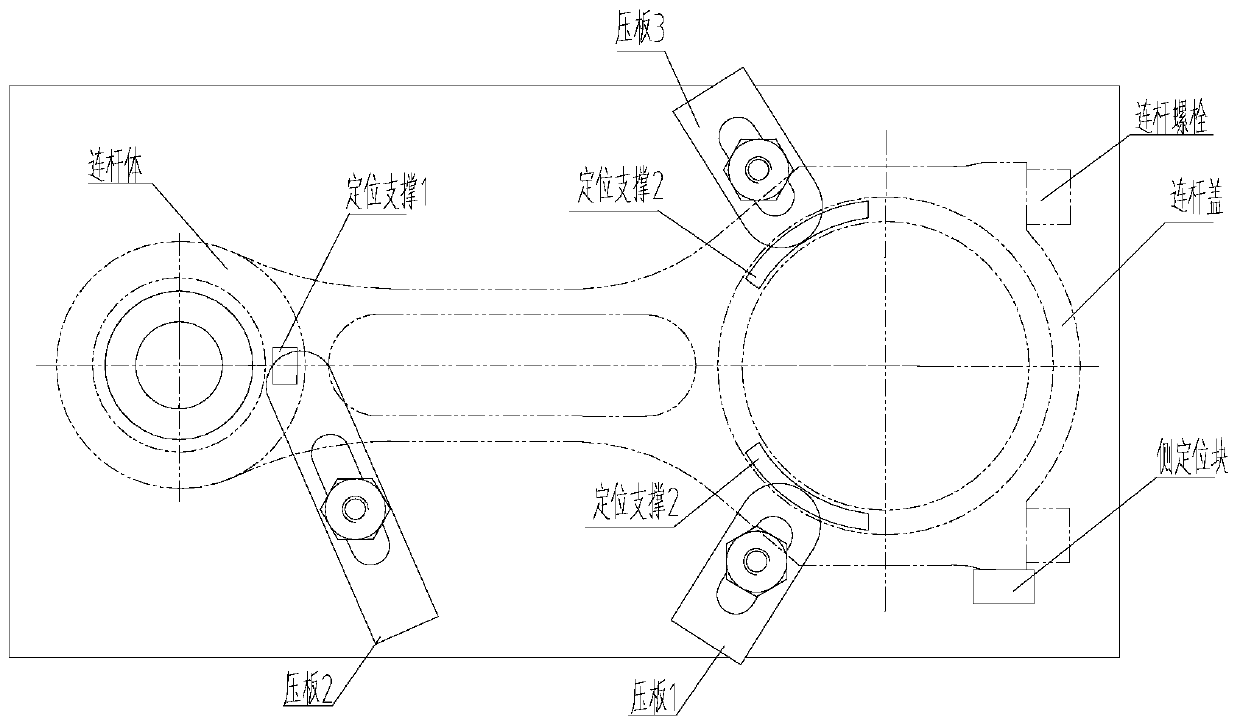

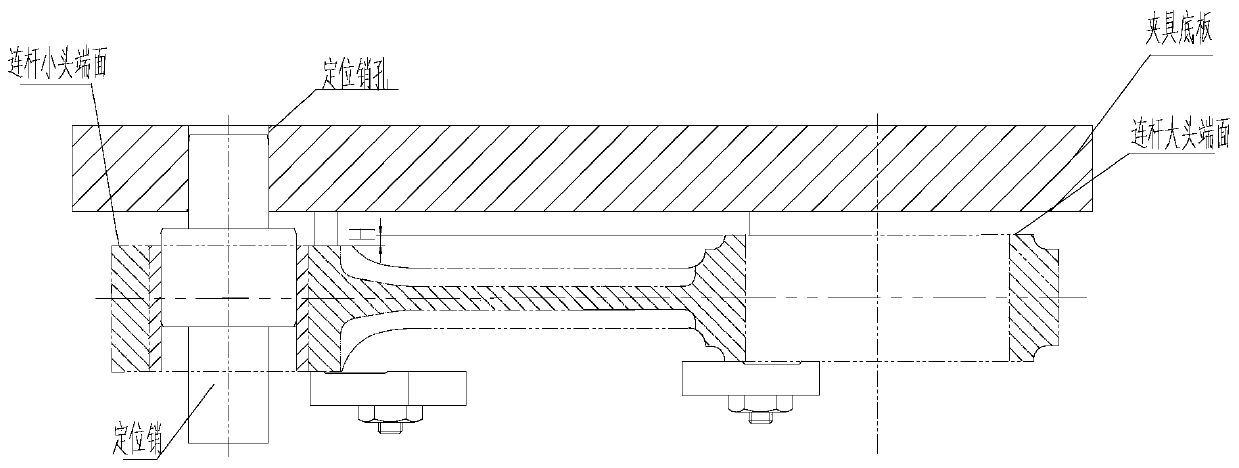

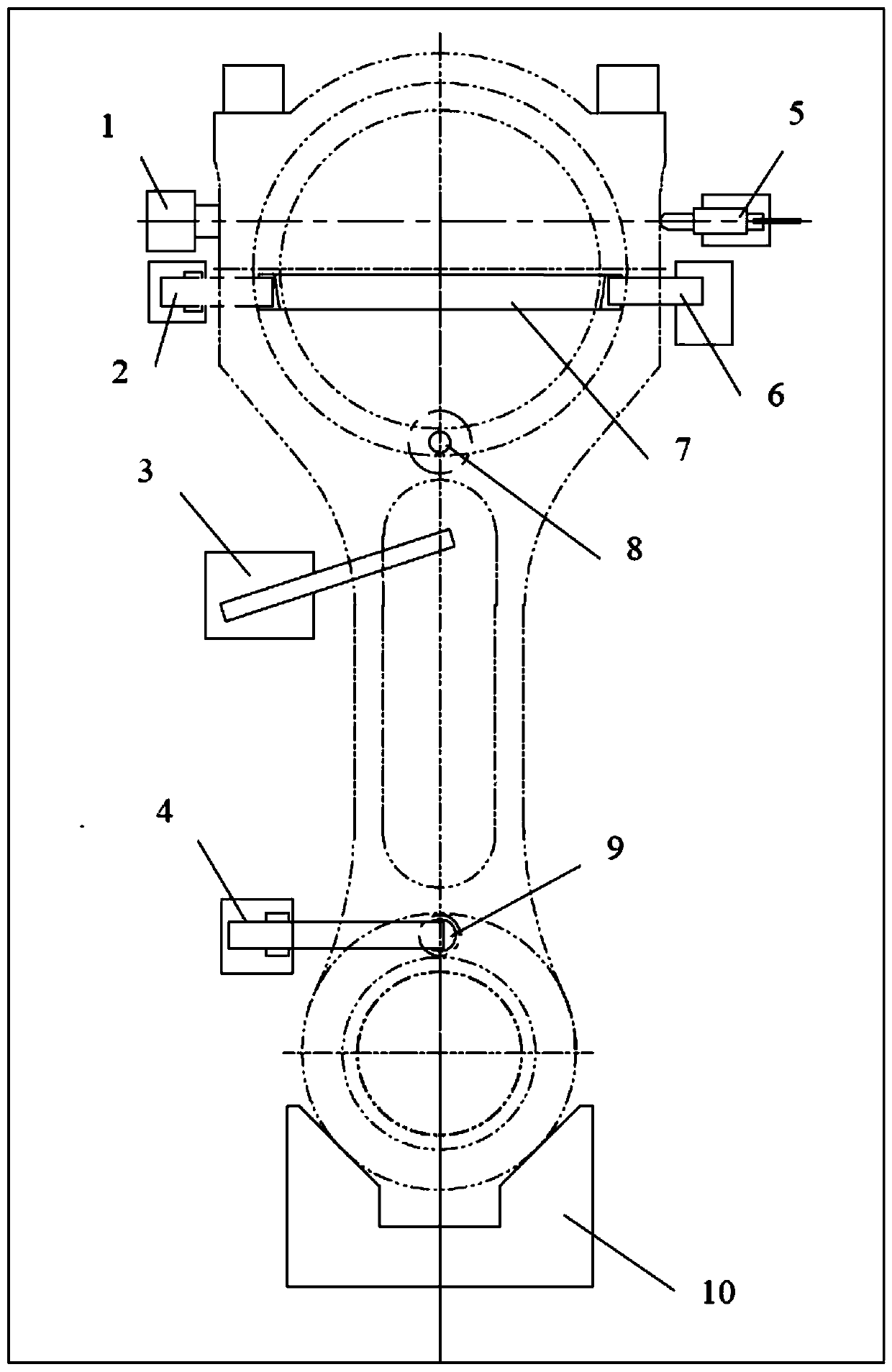

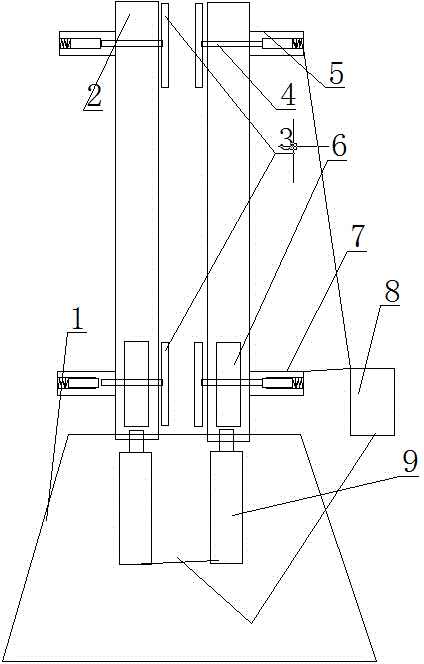

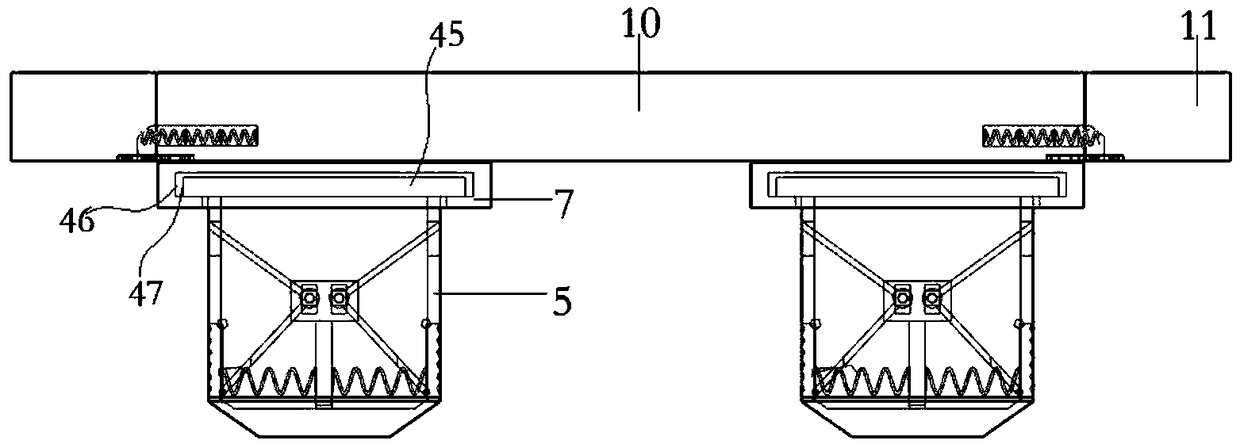

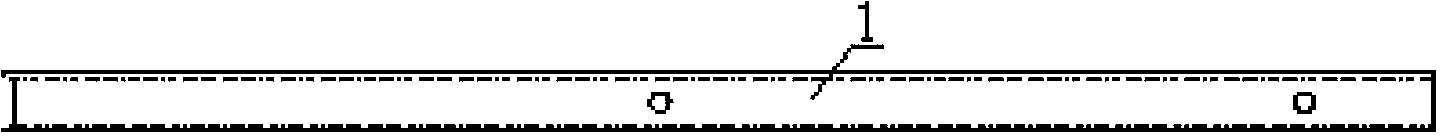

Machining and positioning device and machining method for lining holes at two ends of connecting rod

ActiveCN110170868AImprove machining positioning accuracyGuaranteed sizePositioning apparatusMetal-working holdersMachining deformationPulp and paper industry

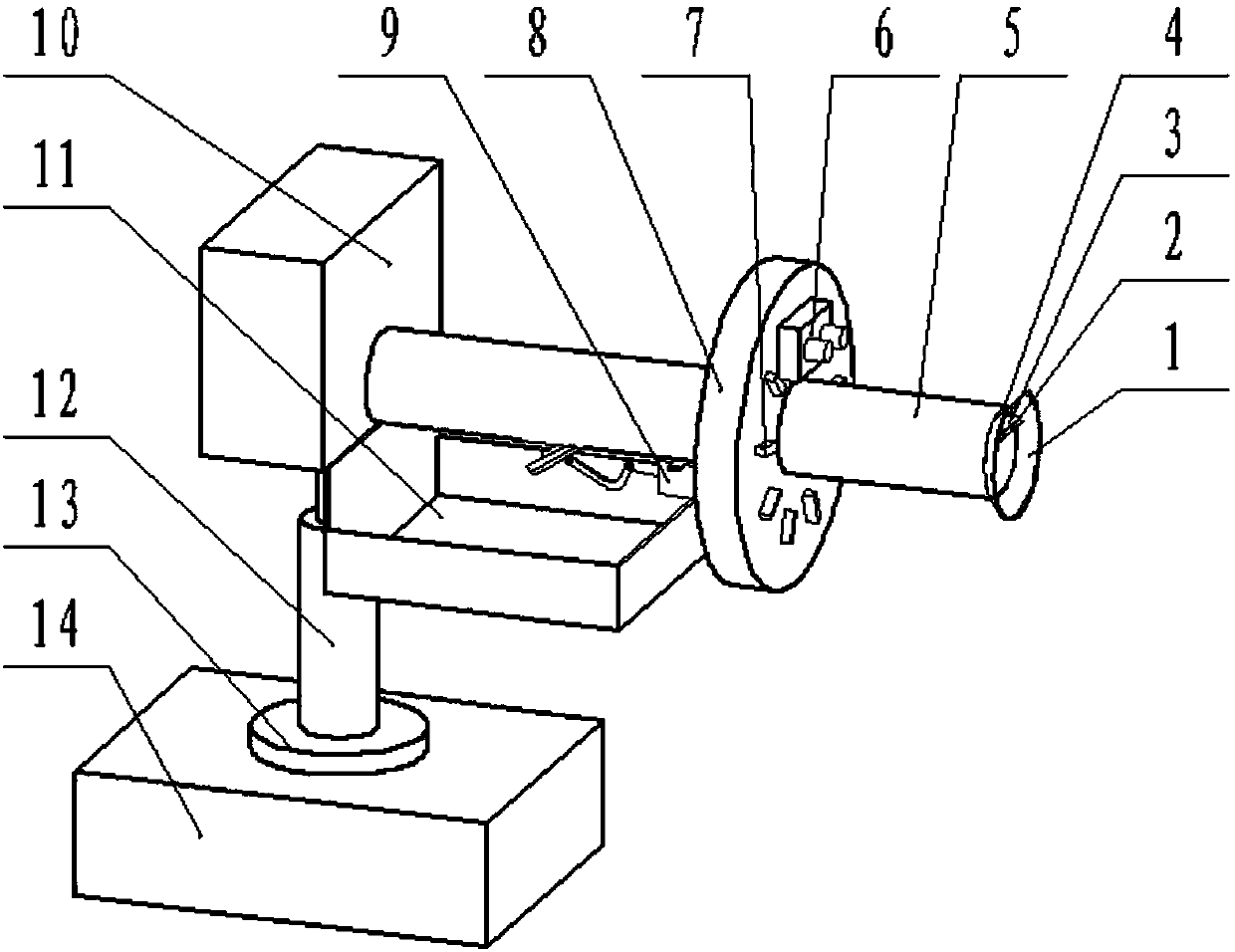

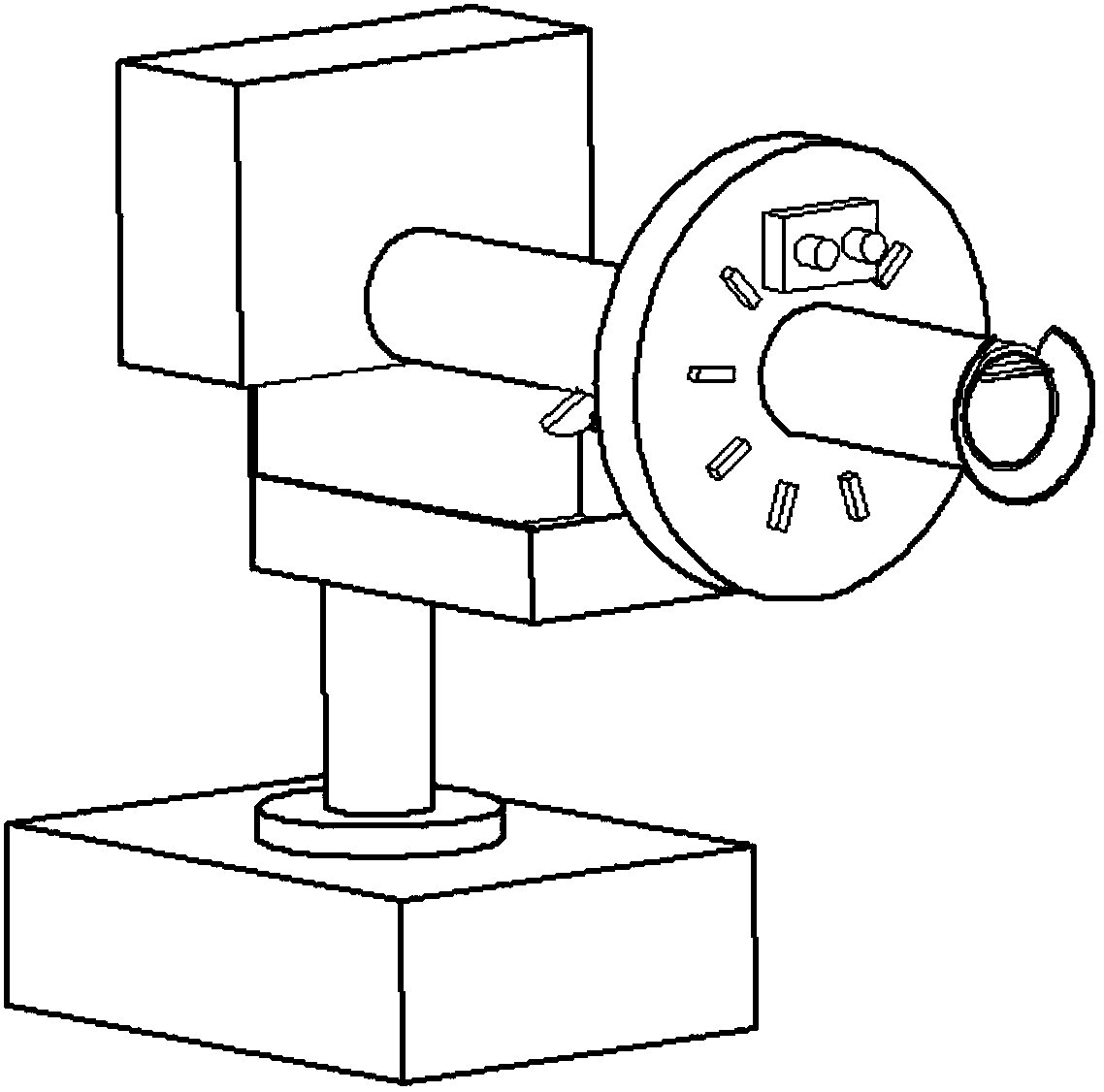

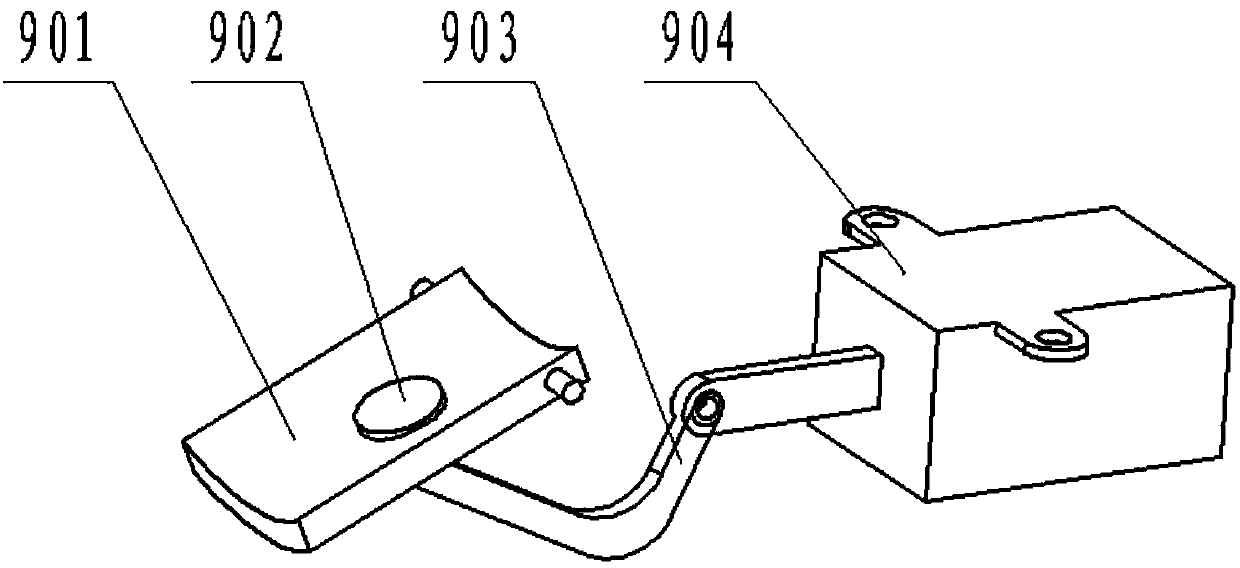

The invention discloses a machining and positioning device for lining holes at two ends of connecting rod. The positioning device comprises a pressing mechanism, a bottom plate, a V-shaped support(10)fixed on the bottom plate, a floating support(9), a first bottom support(7), a second bottom support(8), and a side positioning block(1), the V-shaped support(10) is used for supporting and positioning the small head end of the connecting rod to be machined, the floating support(9) is arranged at the small head end of the to-be-machined connecting rod, the first bottom support(7) and the second bottom support(8) are arranged at the large head end of the to-be-machined connecting rod, the side positioning block(1) is arranged on one side of the large head end of the connecting rod to be machined, and the pressing mechanism presses and positions the large head end and the small head end of the connecting rod to be machined. The machining and positioning precision of the connecting rod sizehead hole can be improved, the accumulative error and the clamping and machining deformation are effectively avoided, the connecting rod large-head hole is ensured, the size and shape position precision of the small-head bushing hole are high, the precision is stable, the consistency is better controlled, and a good effect is achieved.

Owner:STATE RUN NO 616 FACTORY

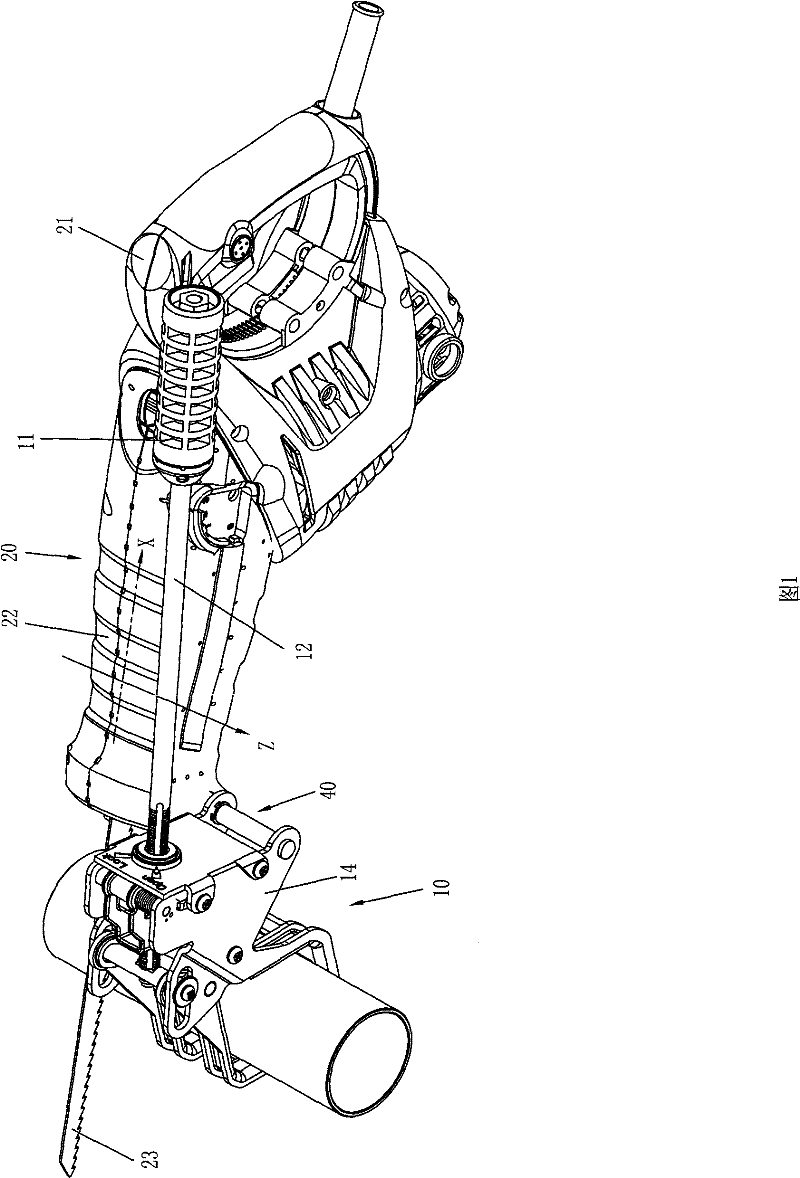

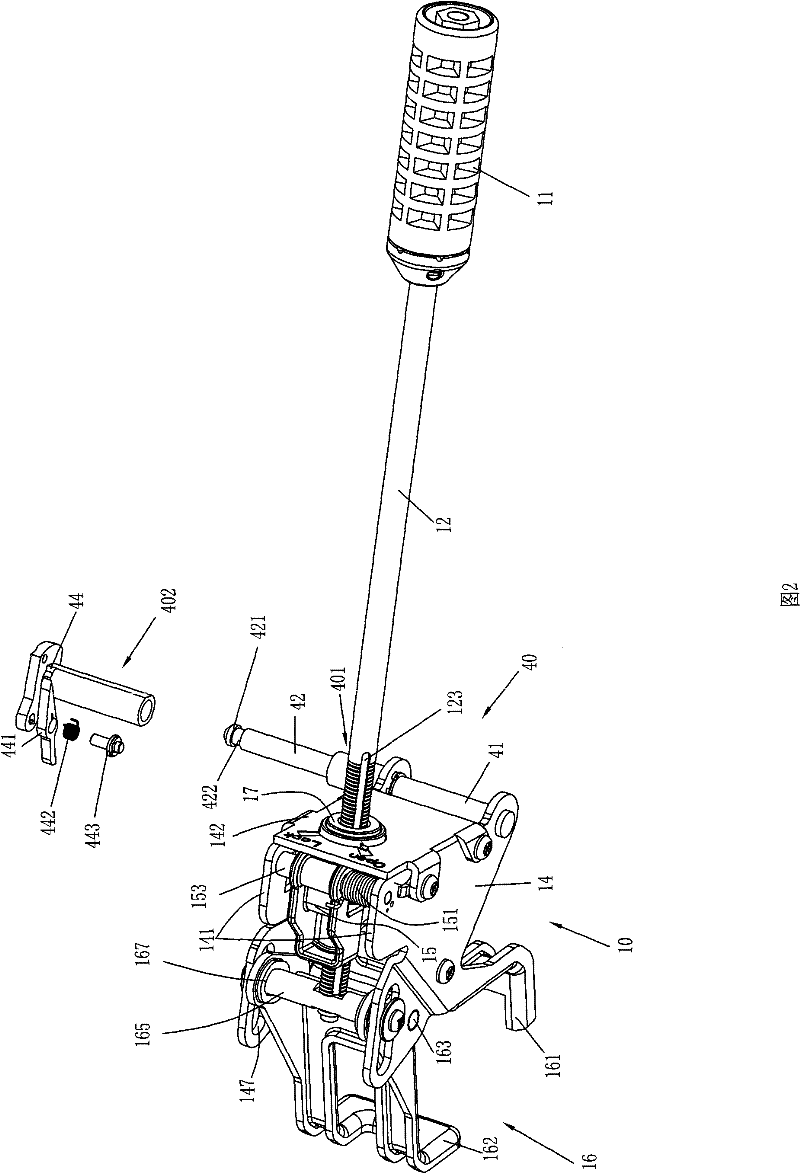

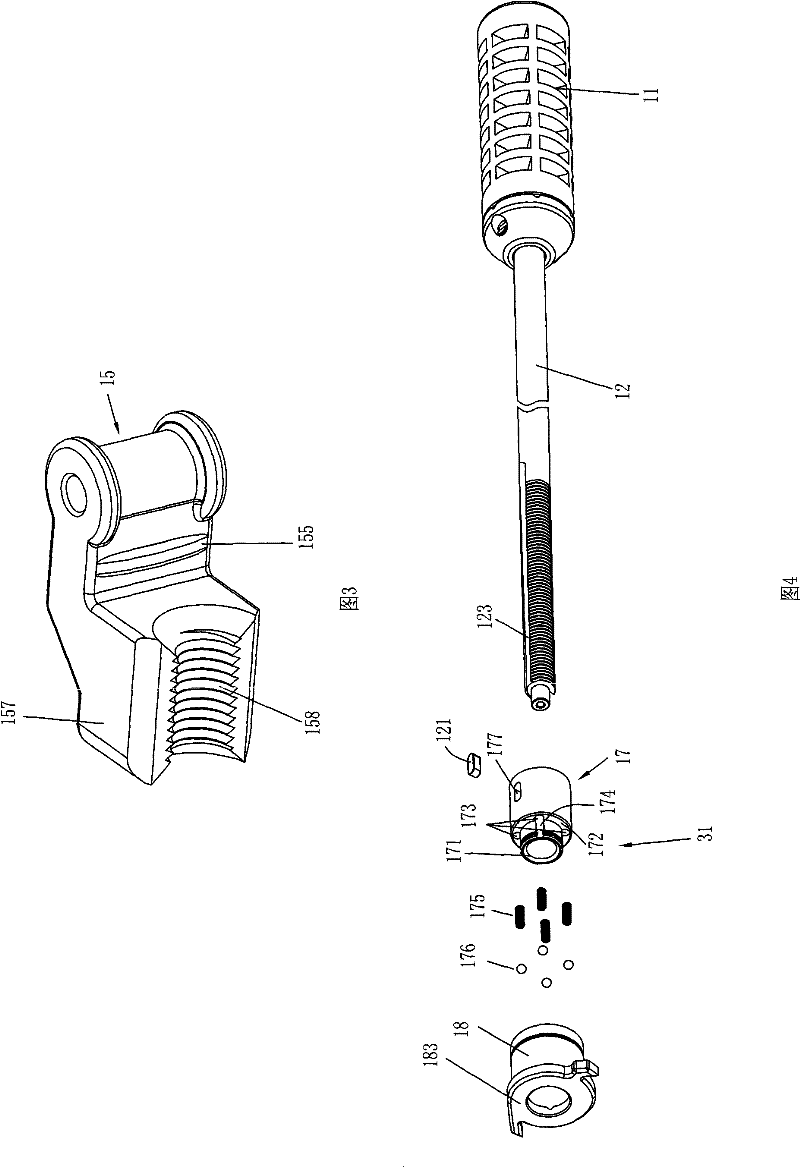

Reciprocating saw

InactiveCN101758294BControl clamp tightnessAvoid clampingMetal sawing devicesAutomatic clutchesEngineeringClutch

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Medical intervention catheter or guide wire fixing clip

The invention relates to a medical intervention catheter or guide wire fixing clip. The clip comprises an upper clip body, a lower clip body, a rotating shaft and a torsional spring, wherein the upper clip body and the lower clip body respectively comprise a clamping part at the front end and a handle part at the rear end; the middles of the upper and lower clips are hinged through the rotating shaft; the torsional spring is arranged on the rotating shaft in a sleeving manner; one end of the torsional spring is connected with the handle part at the rear end of the upper clip body, and the other end of the torsional spring is connected with the handle part at the rear end of the lower clip body; a clamping cavity is formed between the clamping parts of the upper and lower clip bodies; front and back parts of the clamping cavity are joint parts of the two clamping parts; an upper half sponge body and a lower half sponge body, which correspond to the upper clip body and the lower clip body, are embedded in the clamping cavity; the two half sponge bodies are compressed together under a normal state; the surfaces, corresponding to sponge body mounting positions, of the clamping parts of the upper and lower clip bodies are provided with a plurality of wetting through holes. The fixing clip is simple in structure and high in clinical practicability, does not damage a catheter or a guide wire, fixes the catheter or the guide wire firmly, can wet the guide wire, provides great convenience for clinical interventional operation, and is suitable for implementation.

Owner:逯党辉

Polishing device for arc-shaped slot array antenna mounting plate

ActiveCN112454147AImprove polishing efficiencySave disassembly timePolishing machinesGrinding feedersPhysicsDrive motor

The invention relates to a polishing device for an arc-shaped slot array antenna mounting plate. The polishing device is characterized in that each conveying mechanism comprises a pair of parallel conveying wheels used for conveying the antenna mounting plate, the distance between the conveying wheels is adjustable, the conveying wheels are connected with driving motors, and multiple sets of conveying mechanisms are arranged; at least one set of inner cambered surface polishing mechanisms are arranged, each inner cambered surface polishing mechanism comprises a portal frame and a rotating part, a plurality of polishing brushes are uniformly arranged on each rotating part along the circumference, and the distance between the head of each polishing brush and a rotating shaft of the corresponding rotating part is adjustable; and at least one set of outer cambered surface polishing mechanisms are located between the conveying mechanisms, at least one set of conveying mechanisms are arranged between the inner cambered surface polishing mechanisms and the outer cambered surface polishing mechanisms, each outer cambered surface polishing mechanism comprises an outer ring base and an innerring coaxially and rotationally arranged in the outer ring base, a lifting mechanism is arranged at the bottom of each outer ring base, a plurality of polishing brushes are evenly arranged on the inner wall of each inner ring in the circumferential direction, and the positions of the polishing brushes in the normal direction of the corresponding inner ring are adjustable. According to the polishing device, mounting plates of different thicknesses and different structures can be polished, and the polishing efficiency is high.

Owner:CHENGDU NANJIAO TECH

Device and method for maintaining and cleaning isolating switches

InactiveCN104409996AReduce resistancePrevent slipping outCleaning using toolsSwitchgearPush pullSelf locking

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

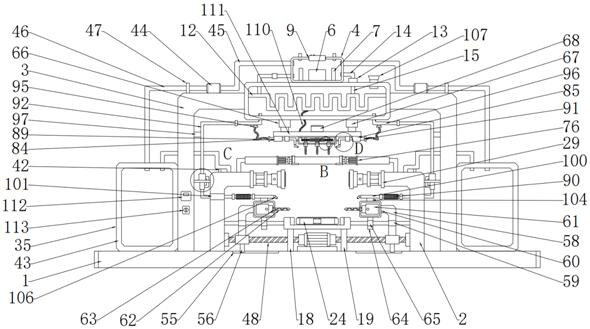

Dynamic clamping and drilling equipment for pump body and end cover of magnetic cooling type vibration-free water pump

ActiveCN113547150AEnables rotary machiningEfficient rotary machiningPositioning apparatusMaintainance and safety accessoriesEngineeringMachining

The invention discloses dynamic clamping and drilling equipment for a pump body and an end cover of a magnetic cooling type vibration-free water pump. The dynamic clamping and drilling equipment comprises a bottom plate, an embedded supporting plate, an externally embedded supporting plate, a quick response type refrigerating mechanism, an unpowered angle rotating mechanism, a self-adaptive clamping mechanism, a multi-pipe acting type deformation resetting mechanism, a bidirectional stepping type drilling mechanism, a multi-hole synchronous type machining mechanism, a self-locking type fixing machining mechanism and a spray type quick cooling mechanism. The invention belongs to the technical field of water pump machining equipment, and particularly provides the dynamic clamping and drilling equipment capable of efficiently drilling the pump body and the end cover, synchronously cooling a drill bit and removing scrap iron, clamping and fixing the surfaces of different machined objects, and stably rotating the machined objects.

Owner:徐州精一泵业有限公司

Online detection device for sulfur hexafluoride gas of high-altitude circuit breaker and detection method

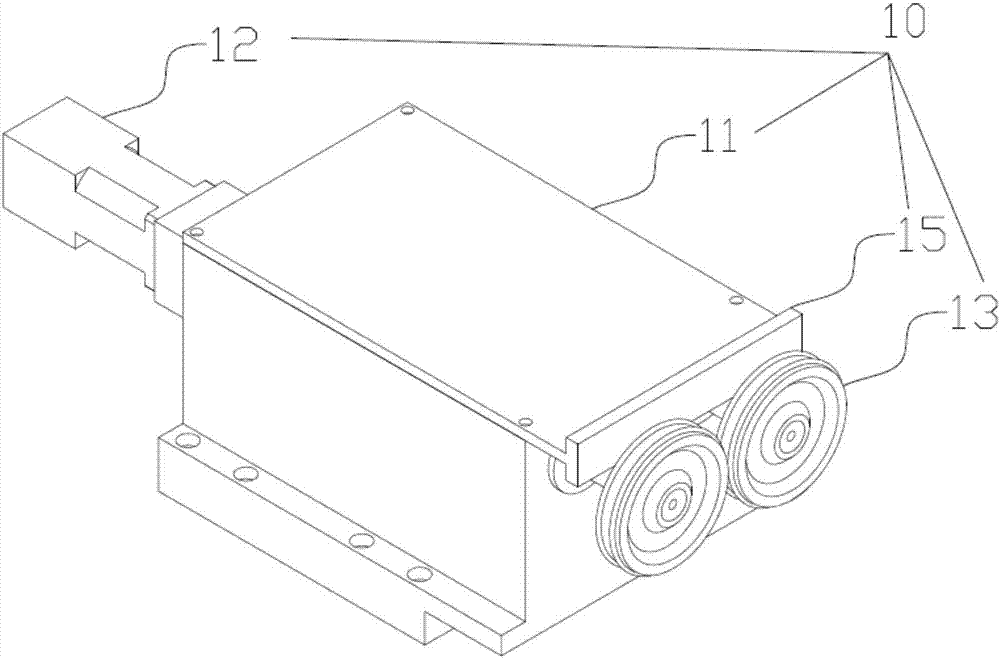

InactiveCN104165973AReduce resistancePrevent slipping outMaterial analysisSulfur hexafluoridePower equipment

The invention discloses an online detection device for sulfur hexafluoride gas of a charged high-altitude circuit breaker and a detection method. The online detection device comprises a frame body with universal self-locking roller wheels at the bottom part and a plurality of operating rods, wherein the frame body is provided with two symmetrical sliding-way mechanisms; each sliding-way mechanism comprises two sliding rails symmetrically arranged on the frame body; a sliding block is arranged between the sliding rails; a limiting block is arranged between the upper parts of the two sliding rails and is provided with an angle and tightness adjusting mechanisms of the operating rods; the sliding block is provided with a tightness adjusting mechanism of the operating rods; the frame body is internally provided with an electric pushing-pulling rod connected with the sliding block; and one end of each operating rod is provided with a detecting mechanism. The online detection device and the detection method disclosed by the invention have advantages that the pointing angles of the operating rods are conveniently adjusted, and convenience is brought for online horizontal-vertical detection of high-altitude power equipment with 360-degree rotation by maintainers.

Owner:STATE GRID HENAN FANGCHENG POWER SUPPLY CO

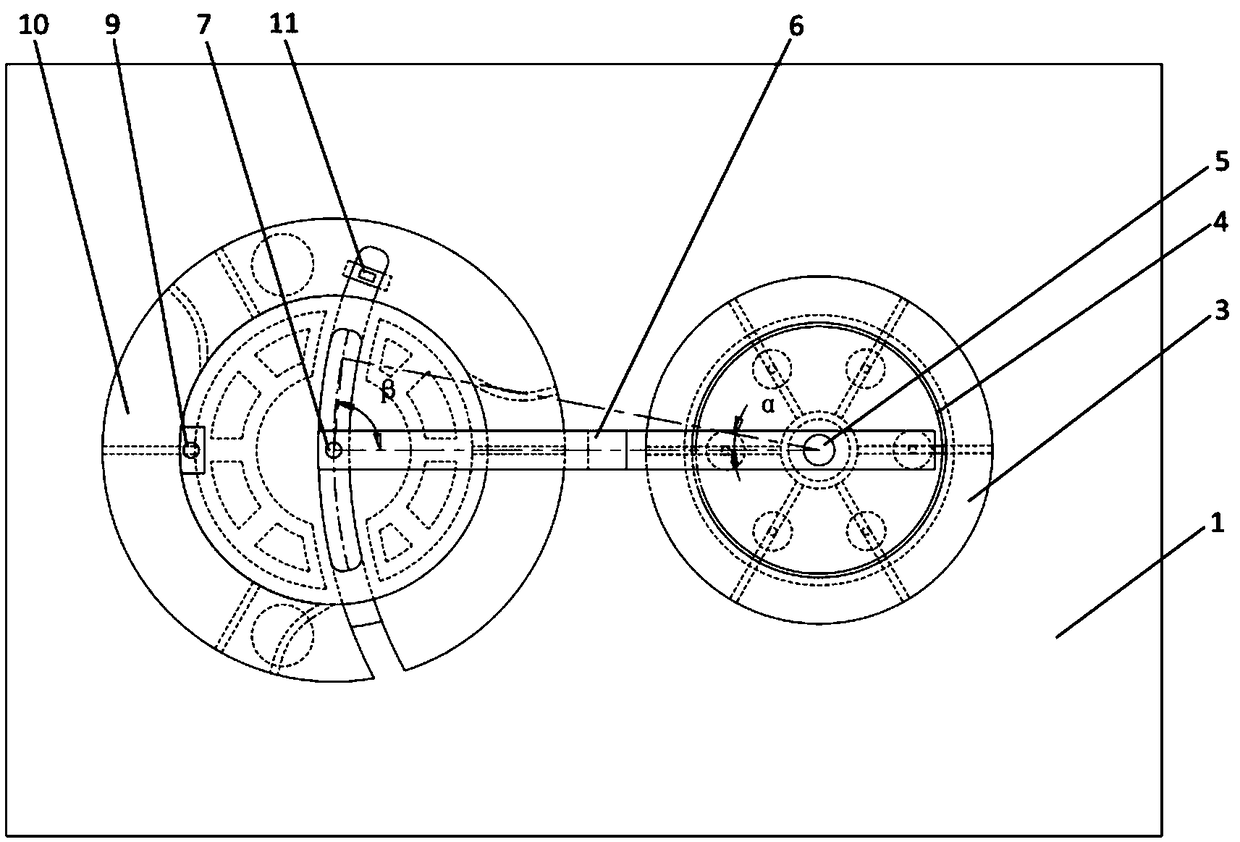

Front and rear axle abrasive experimental device for bicycle

InactiveCN101074902AAvoid clampingReasonable structural optimizationMachine gearing/transmission testingEngineeringSprocket

A wear-proof tester of front and back shafts on bicycle is prepared as setting external surface of two ends on erection cartridge in internal circle of two support bearings, fixing base of said bearing on support platform, fixing chain wheel on erection cartridge, setting the first and second fixing jacket and regulation washer actively in erection cartridge, arranging locking unit at another end of erection cartridge to press regulation washer and setting load unit on support platform under base of bearing.

Owner:中华人民共和国昆山出入境检验检疫局

Stacking, loading and carrying device for hollow bricks and method thereof

ActiveCN109051883AAvoid destructionAvoid clutterStacking articlesDe-stacking articlesBrickEngineering

The invention discloses a stacking, loading and carrying device for hollow bricks. The stacking, loading and carrying device comprises a supporting frame, clamping devices and lifting devices, whereinthe supporting frame is arranged at the driven end of a mechanical arm; the lifting devices are linearly arranged below the supporting frame at intervals; the clamping devices are separately arrangedon the lifting devices; each clamping device comprises an ejecting plate and a plurality of clamping mechanisms; the ejecting plates are parallel to the placement surface of the hollow bricks; the clamping mechanisms separately correspondingly extend into hollow holes of the hollow bricks; and the clamping mechanisms are tightly abutted against the inner walls of the hollow holes. The hollow holes of the hollow bricks are clamped by the clamping mechanisms, so that the damage to the appearances of the hollow bricks can be avoided; the hollow holes of the hollow bricks are clamped, so that gaps cannot be reserved between bricks, and the phenomena of scattering, missed clamping and unstable clamping are effectively prevented; and the hollow holes are clamped, so that the hollow bricks can still be neatly placed when being carried from the stacking part to a truck, and the brick scattering is avoided.

Owner:广东长海建设工程有限公司

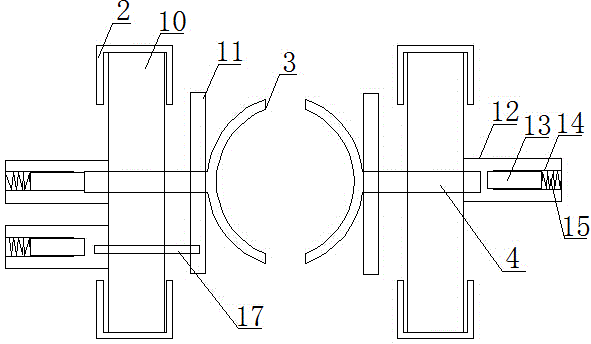

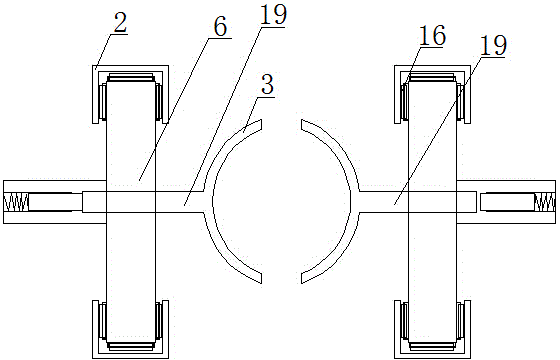

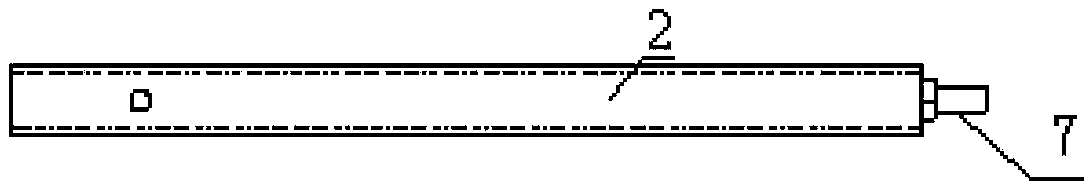

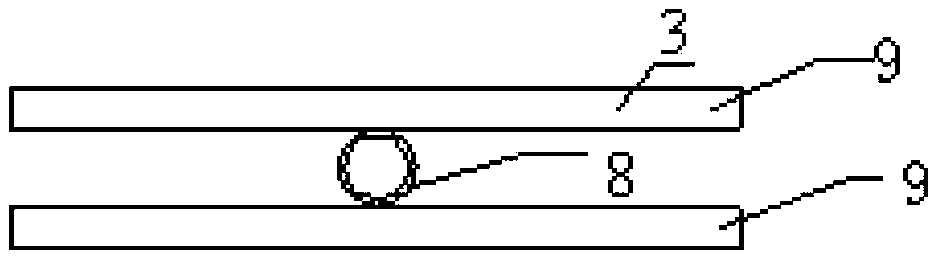

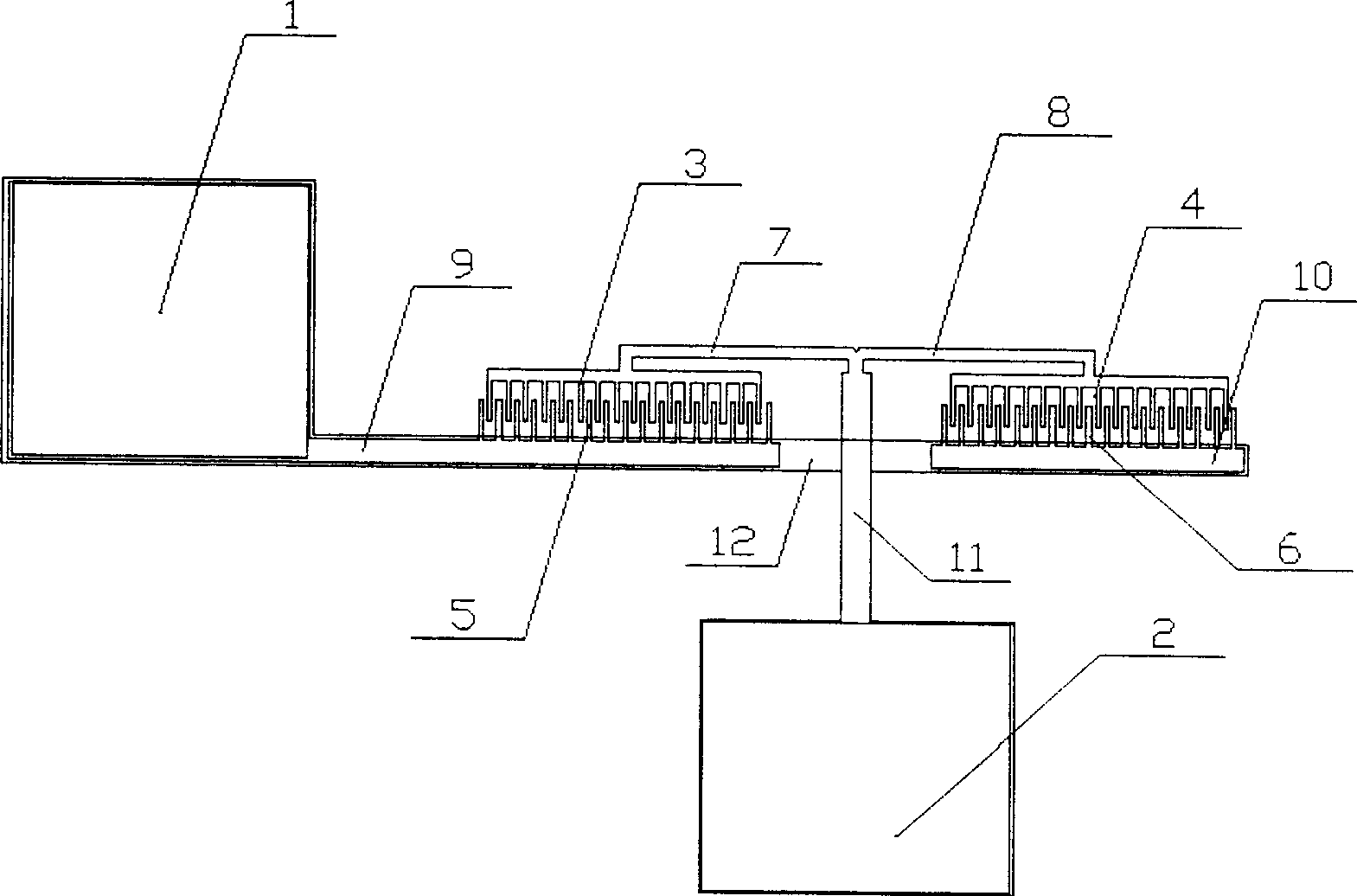

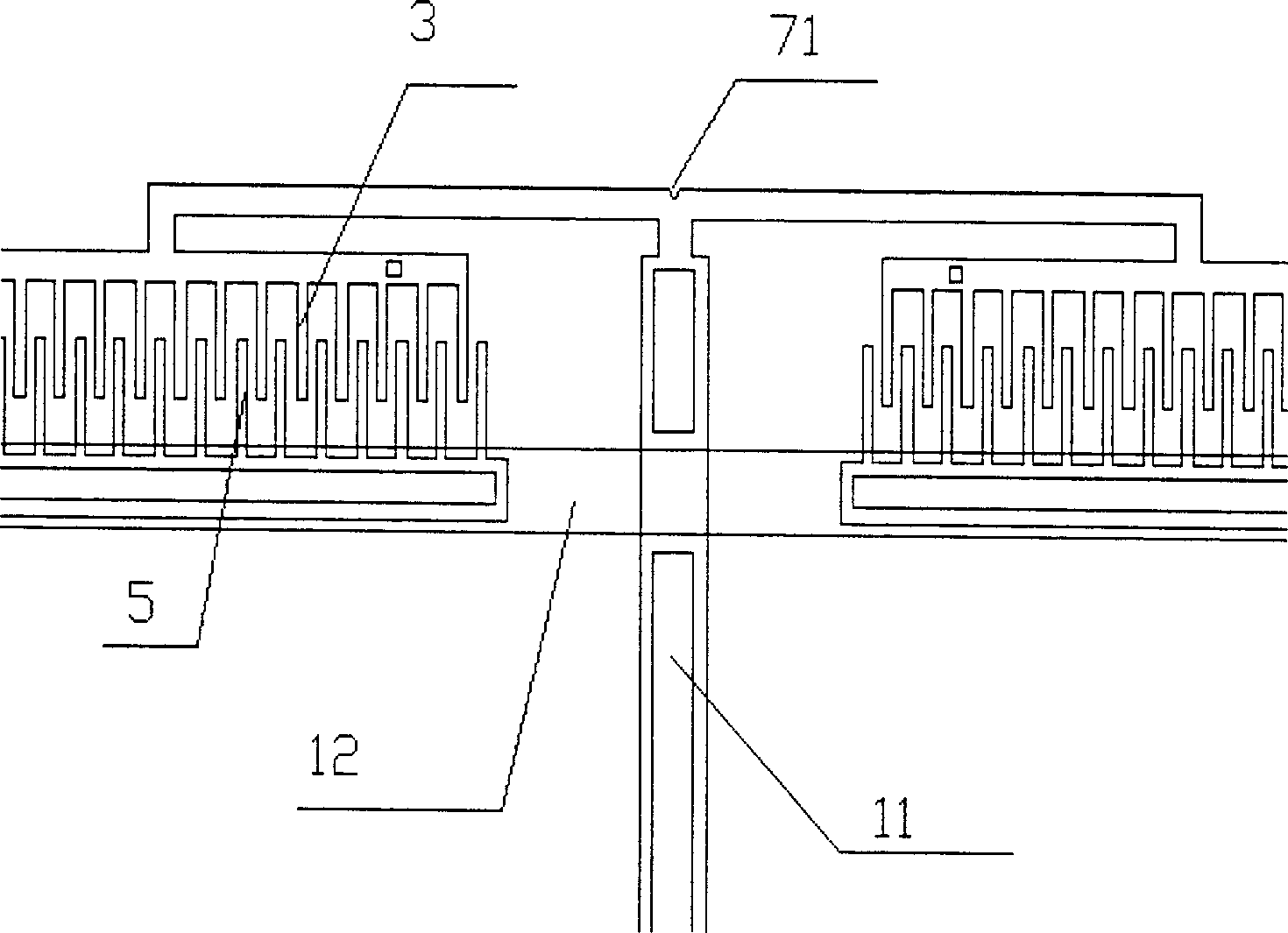

Tubing fixing assembly, and tubing detection apparatus and method

PendingCN106895785AAvoid clampingQuick installationUsing optical meansNuclear energy generationElectric machineryRotational axis

The invention discloses a tubing fixing assembly, and a tubing detection apparatus and method. The tubing fixing assembly includes two relatively arranged tubing support mechanisms, wherein each tubing support mechanism includes a support pedestal, two rotating shafts, a rotation motor and supporting wheels; the rotating shafts penetrate the support pedestal, and are connected through a chain or a conveyor belt; the rotation motor is arranged at one side of the support pedestal, and is used for driving any one rotating shaft to rotate; the supporting wheels are fixed on the rotating shafts and at the end portion of the other side of the support pedestal; and the supporting wheels of the two tubing support mechanisms are arranged oppositely. The tubing fixing assembly has the advantages of being simple and quick in mounting, having low requirement for machining accuracy, and avoiding damaging quartz glass tubes.

Owner:久智光电子材料科技有限公司

Device and method for improving roadway base plate anchor rod anchor cable pore-forming efficiency and anchoring performance

InactiveCN103410542AImprove pore forming efficiencyImprove the anchoring effectAnchoring boltsSlurryDrilling machines

The invention discloses a device and a method for improving pore-forming efficiency and anchoring performance of a roadway base plate anchor rod anchor cable. The device comprises a special drill rod, a connecting rod and a rod taking device. The special drill rod is successively utilized to perform twice drilling operations and reserved in a hole after the operations of the special drill rod are finished, then a common drill rod is inserted into the inner cavity of the special drill rod to continue to perform drilling till the designed depth is reached, the common drill rod is taken out, an anchoring agent is placed into the hole, an anchor rod or the anchor cable is installed, and finally the special drill rod is taken out through the rod taking device. When the device and the method are adopted to perform drilling and installation of the anchor rod or the anchor cable, the special drill rod is always reserved in the hole so that hole collapse can be effectively prevented. The smooth mud return of an anchor rod anchor cable drilling machine is ensured in the drilling process, water in mud is prevented from entering a loose fractured rock mass at the shallow portion of a base plate, accordingly rock soil is prevented from depositing at the drilling bottom, and borer clamping is avoided. The device for improving the pore-forming efficiency and the anchoring performance of the roadway base plate anchor rod anchor cable is simple in structure and convenient to use, the drilling rate reaches to 100%, the anchoring effects of the anchor rod and the anchor cable are good, the borer clamping is effectively prevented in the drilling process, and the construction efficiency is improved remarkably.

Owner:CHINA UNIV OF MINING & TECH

Electrostatic force driven apparatus for testing resonant two-side flexural-tensile fatigue of microstructure

InactiveCN1800815AAvoid clamping and centeringIncreased stress levelsMaterial strength using repeated/pulsating forcesMicrostructureTensile fatigue

The invention discloses a microstructure resonance dual-side bending fatigue experiment device driven on electrostatic force, which comprises: an electrode connected to ac and fixed lifetime with two side arms by the bottom electrode layer, another electrode grounding, a structure layer crossed opposite to said fixed comb and connected to a suspension comb with side arms, a horizontal side arm between two fixed combs connected to the ac electrode, a T-shaped side arm between two suspension combs and with horizontal side arm connected to suspension combs and vertical side arm connected to the grounding electrode by suspension beam as the fatigue test piece. This invention improves greatly the strain level of test piece.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com