Machining and positioning device and machining method for lining holes at two ends of connecting rod

A positioning device and bushing hole technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems affecting the torque wrench, the inconsistency of the center verticality of the big head hole, and the difficulty of clamping, etc., to improve the processing positioning. Accuracy, avoid accumulative error, the effect of stable accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0038] Aiming at the processing accuracy, consistency and stability requirements of the large and small end holes of the connecting rod, the present invention designs a new positioning device and process method based on improving positioning accuracy, reducing cumulative errors, reducing clamping deformation, and reducing human factors. .

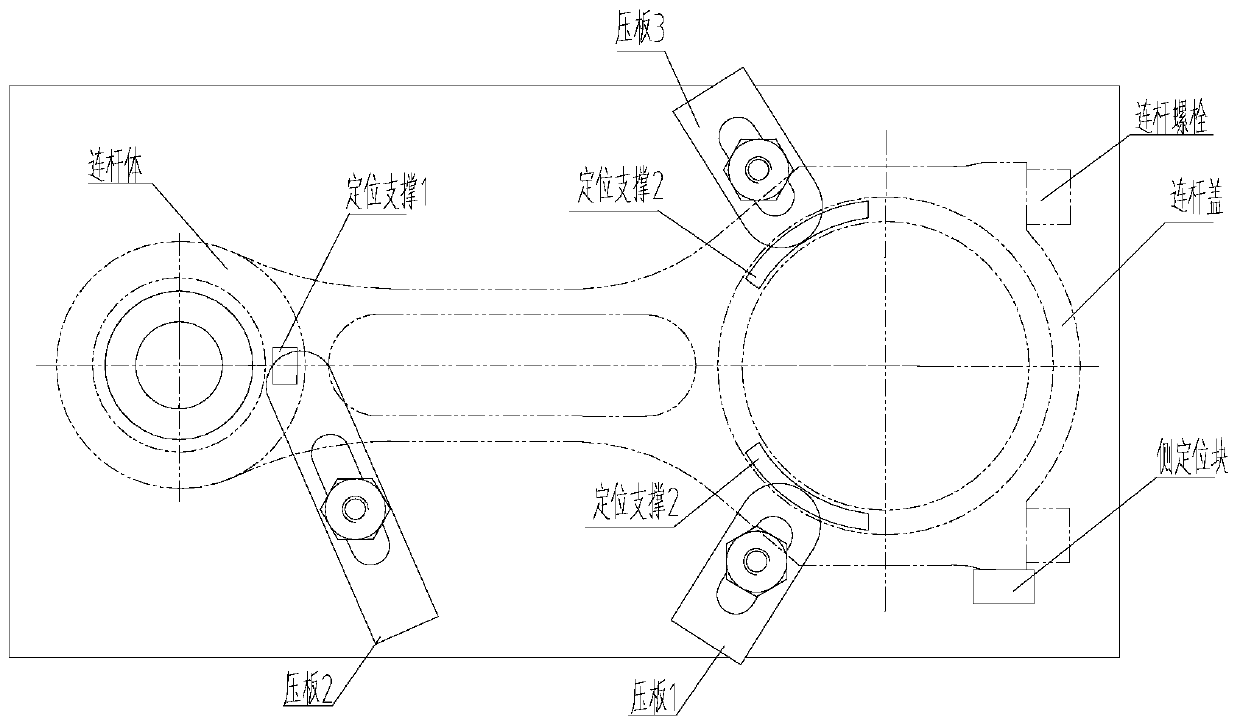

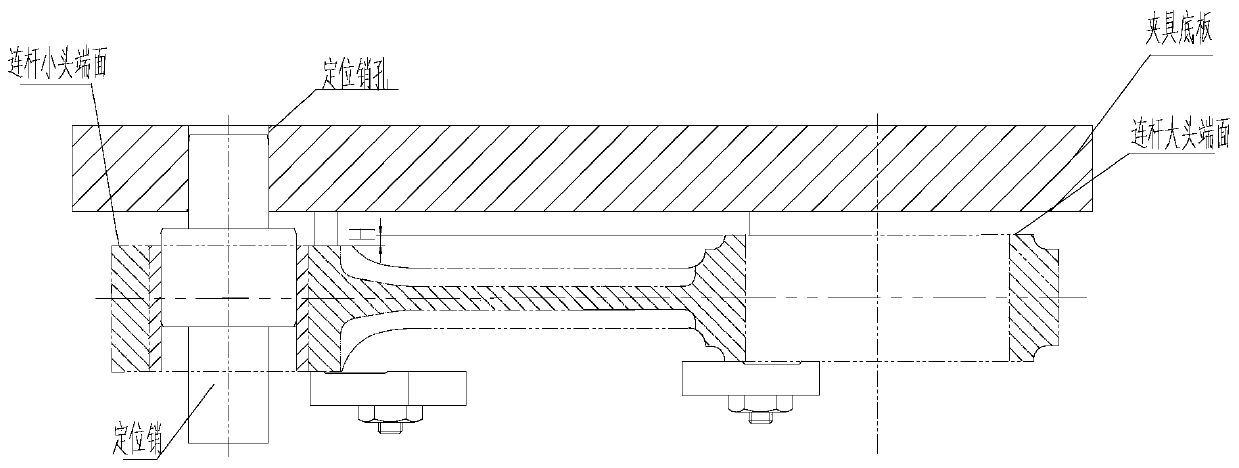

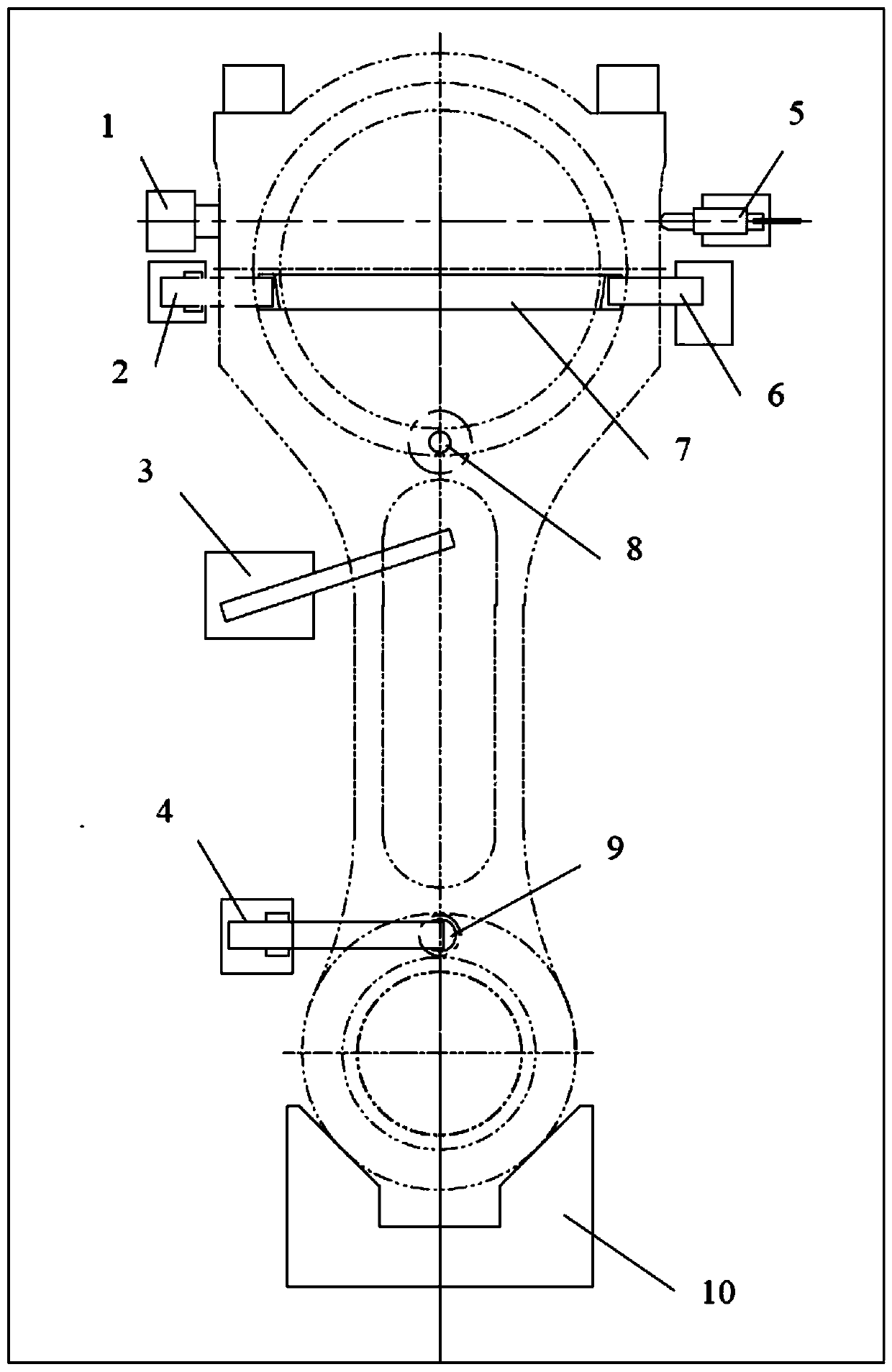

[0039] refer to image 3 with Figure 4 As shown, the positioning device of the present invention includes: a pressing mechanism, a bottom plate, and a V-shaped support 10 fixed on the bottom plate, a floating support 9, a first bottom support 7, a second bottom support 8 and a side positioning block 1, and the V-shaped support 10 support and position the small end of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com