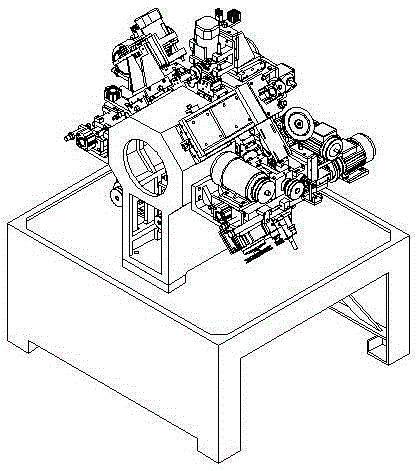

Eight-station automatic processing machine for terminal parts

An automatic processing, eight-station technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of human harm, large power loss, waste of copper scraps, etc., to protect the environment, reduce noise, and improve processing positioning. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

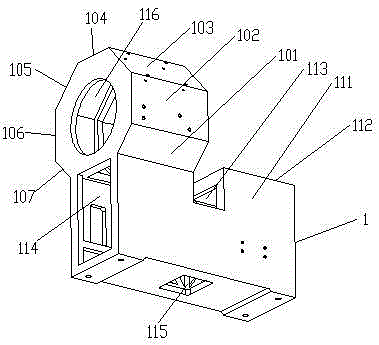

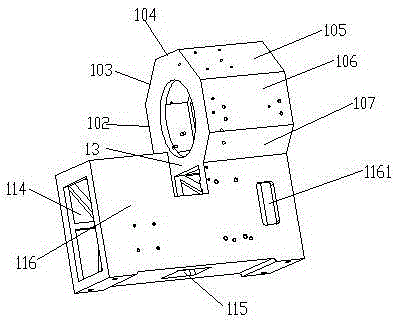

[0024] Attached below figure 1 to attach Figure 17 Embodiments of the invention are illustrated:

[0025] An eight-station automatic processing machine for terminal parts is provided, and a base 1 is provided. The front end of the base 1 has a base head, and the base head is provided with first to seventh loading platforms 101, 102, 103, 104, 105, 106, 107, the first to seventh loading platforms 101, 102, 103, 104, 105, 106, 107 are distributed sequentially along the eighth equal circle of the center hole 116 of the frame head (such as figure 2 and Figure 14 As shown), the rear end of the machine base 1 is also provided with an eight-station indexer platform 112, and the middle part of the machine base 1 is provided with a groove 113 for placing the eight-station clamp fixture 2, and the eight-station clamp The shaft hole 22 of the fixture 2 is connected and fixed with the central shaft of the eight-station indexer 3, the axis of the shaft hole 22 of the eight-station c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com