Patents

Literature

256results about How to "Accurate clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

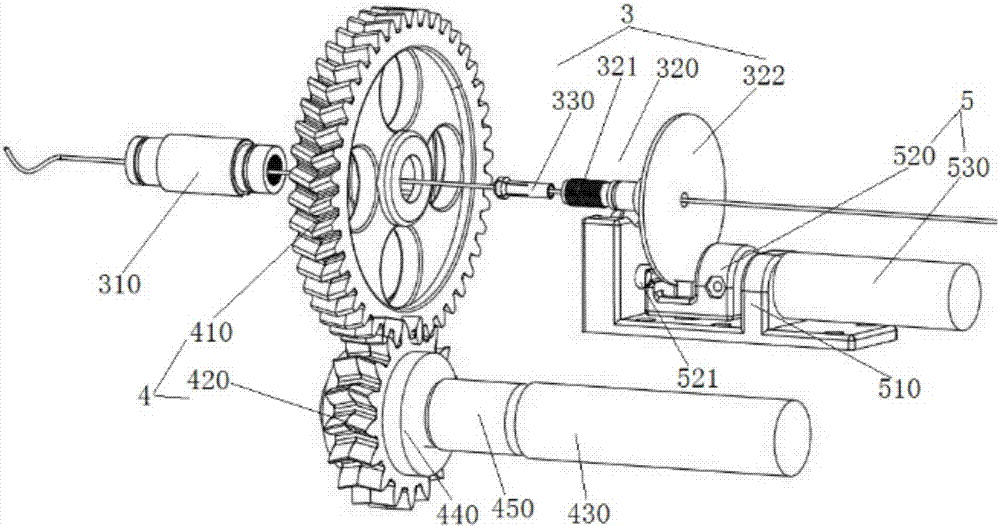

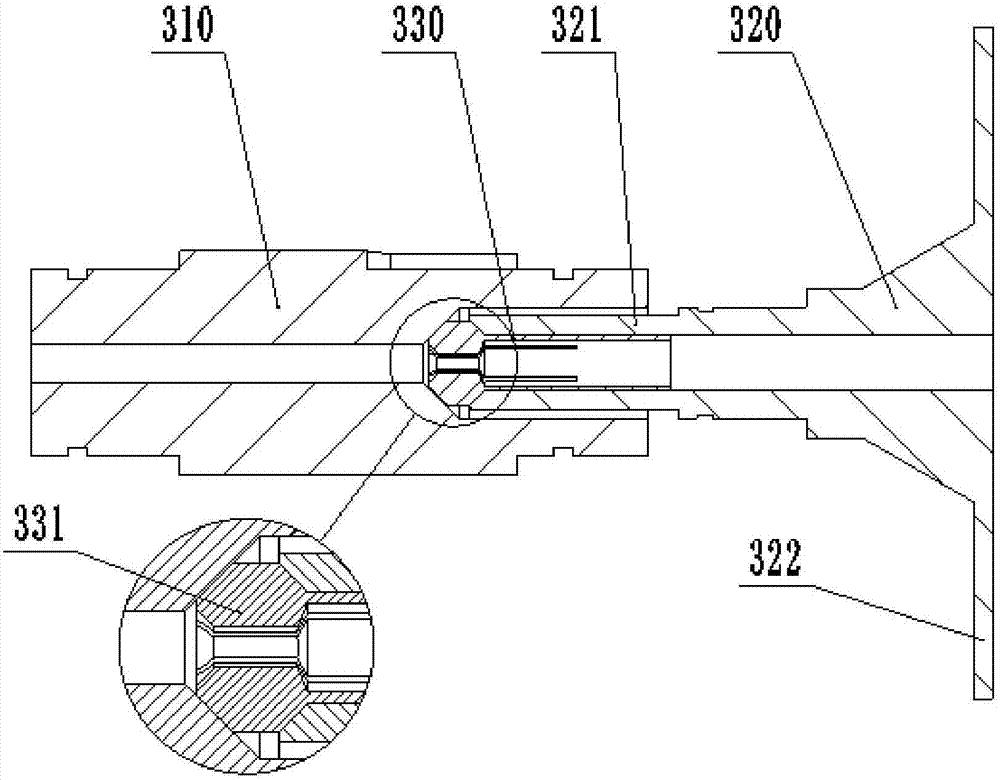

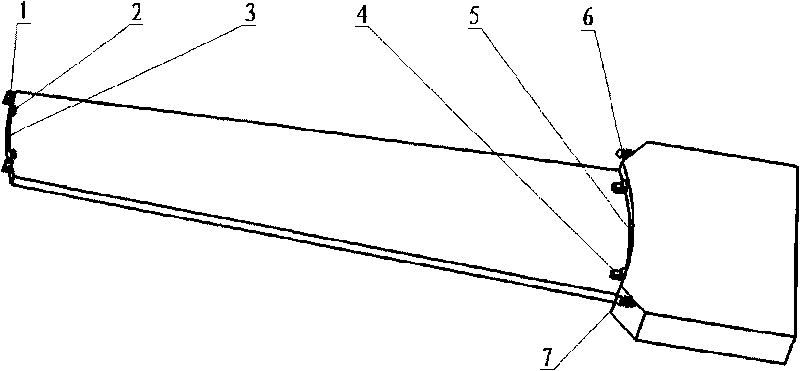

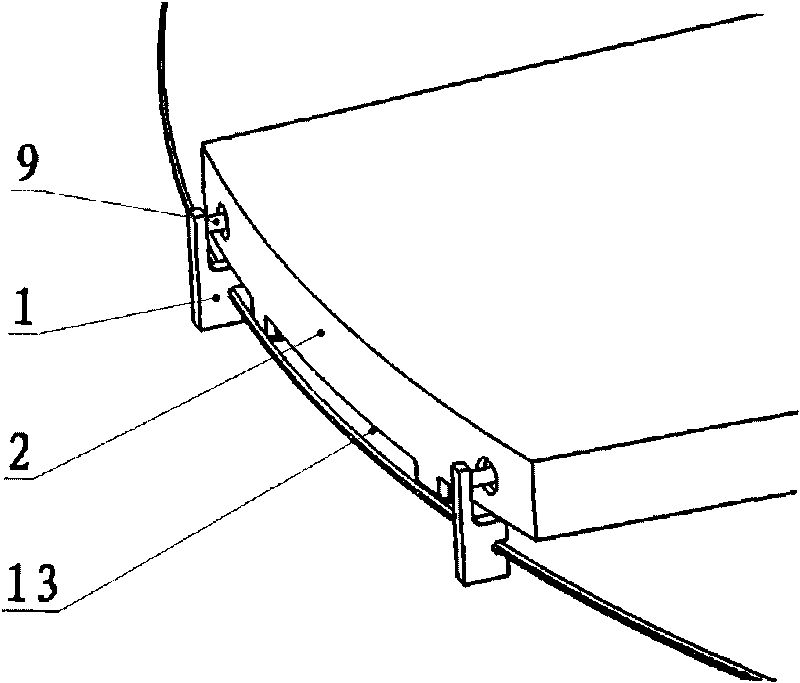

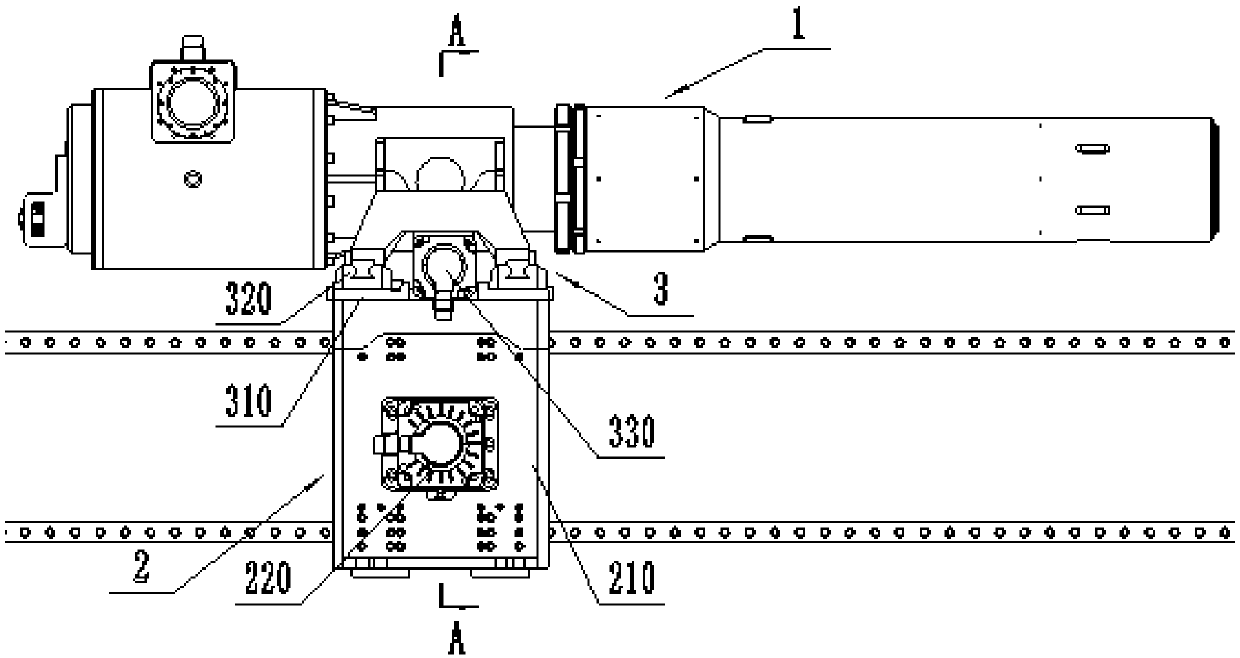

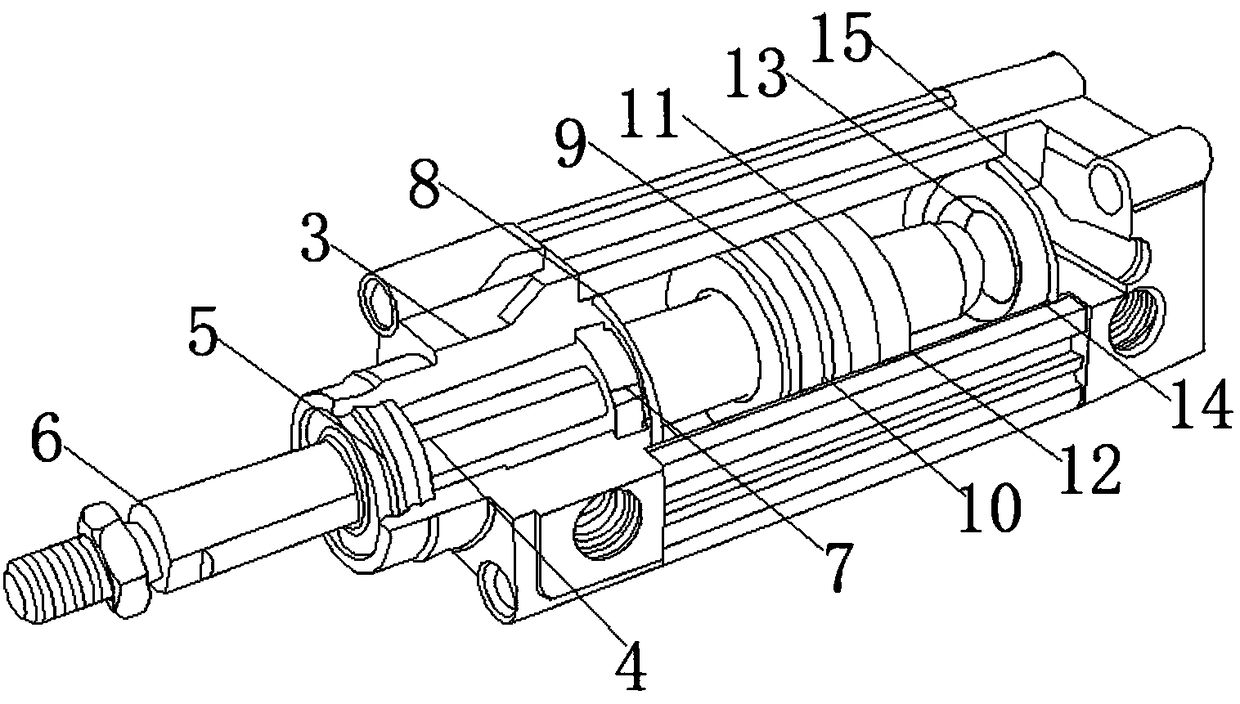

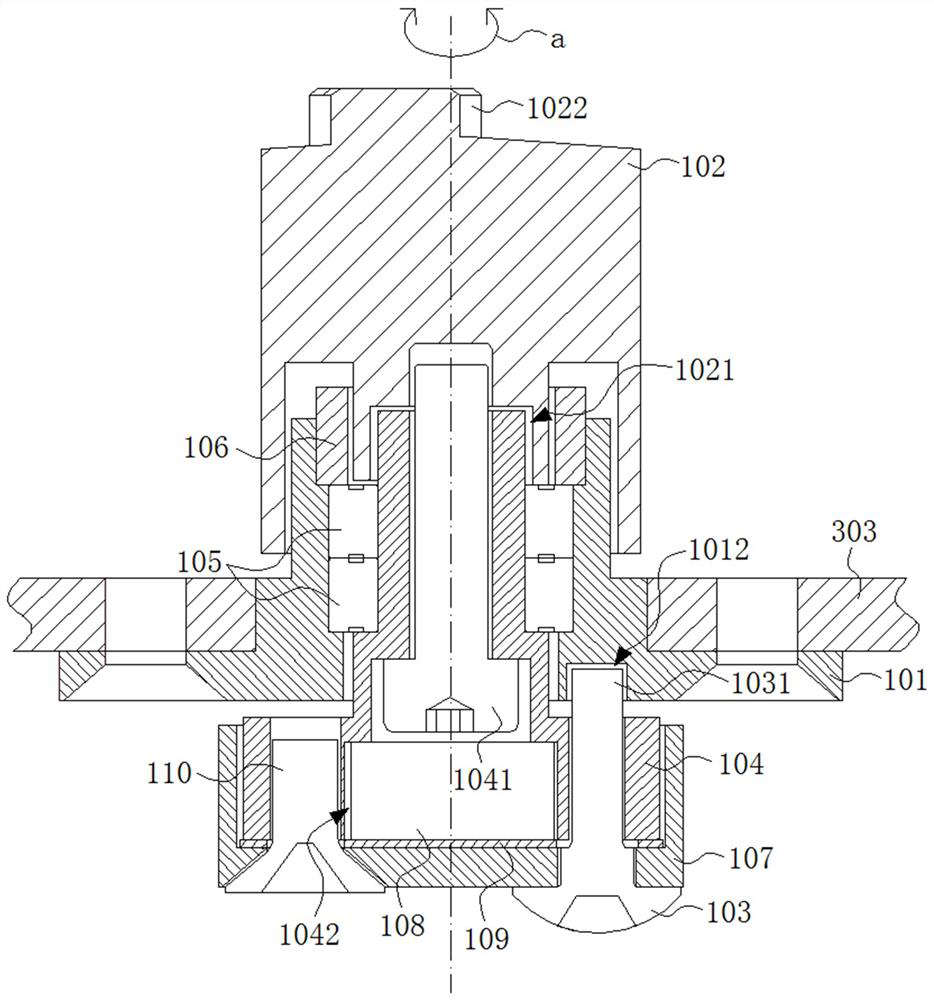

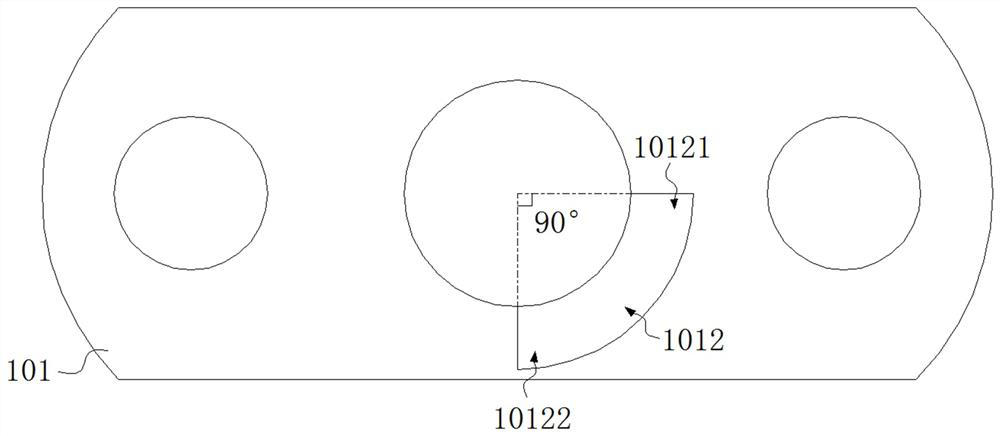

Catheter and guide wire control device for interventional operation and control method of catheter and guide wire control device

PendingCN107349514AEffective clampingAccurate clampingGuide wiresMedical devicesEngineeringGuide wires

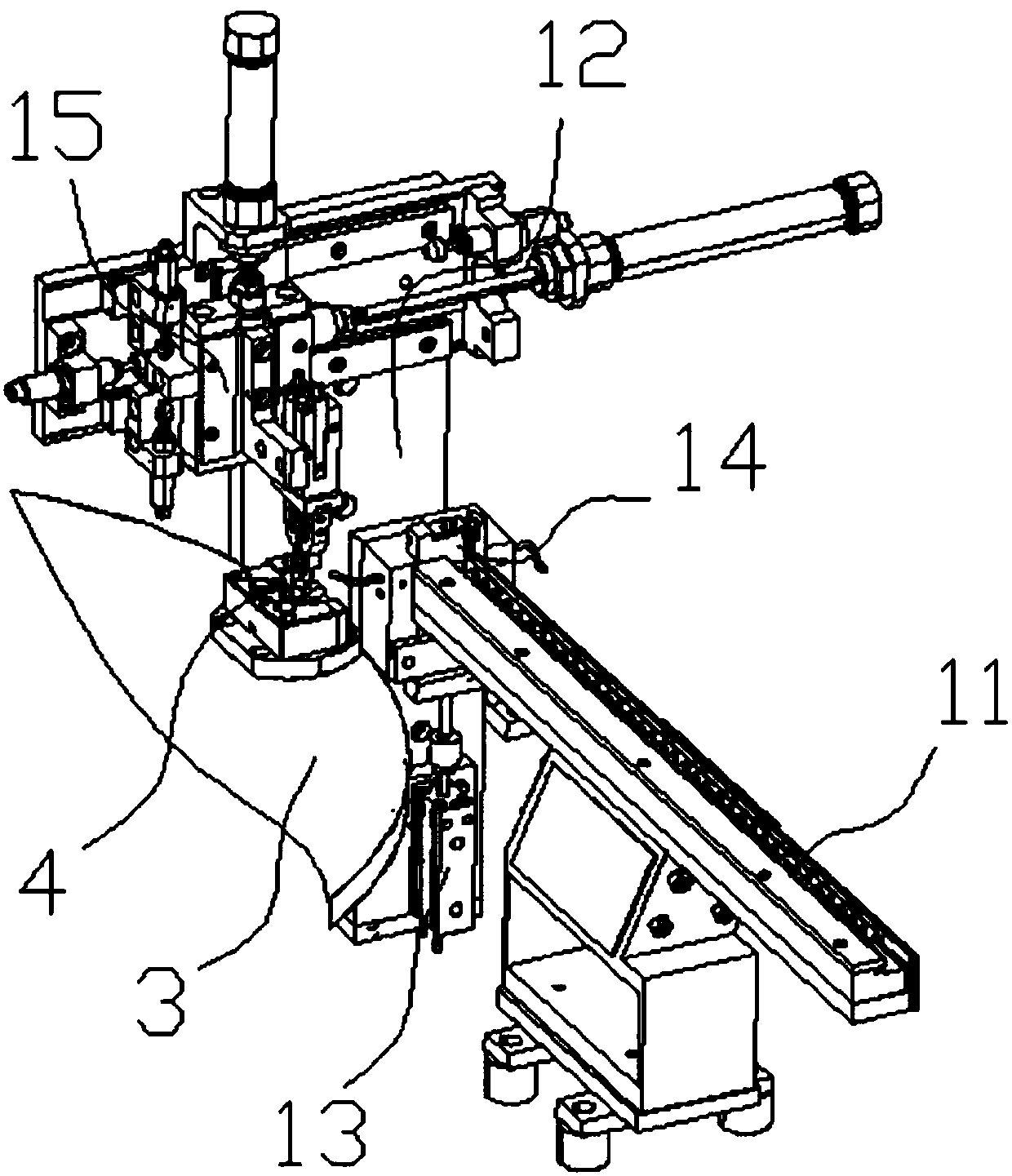

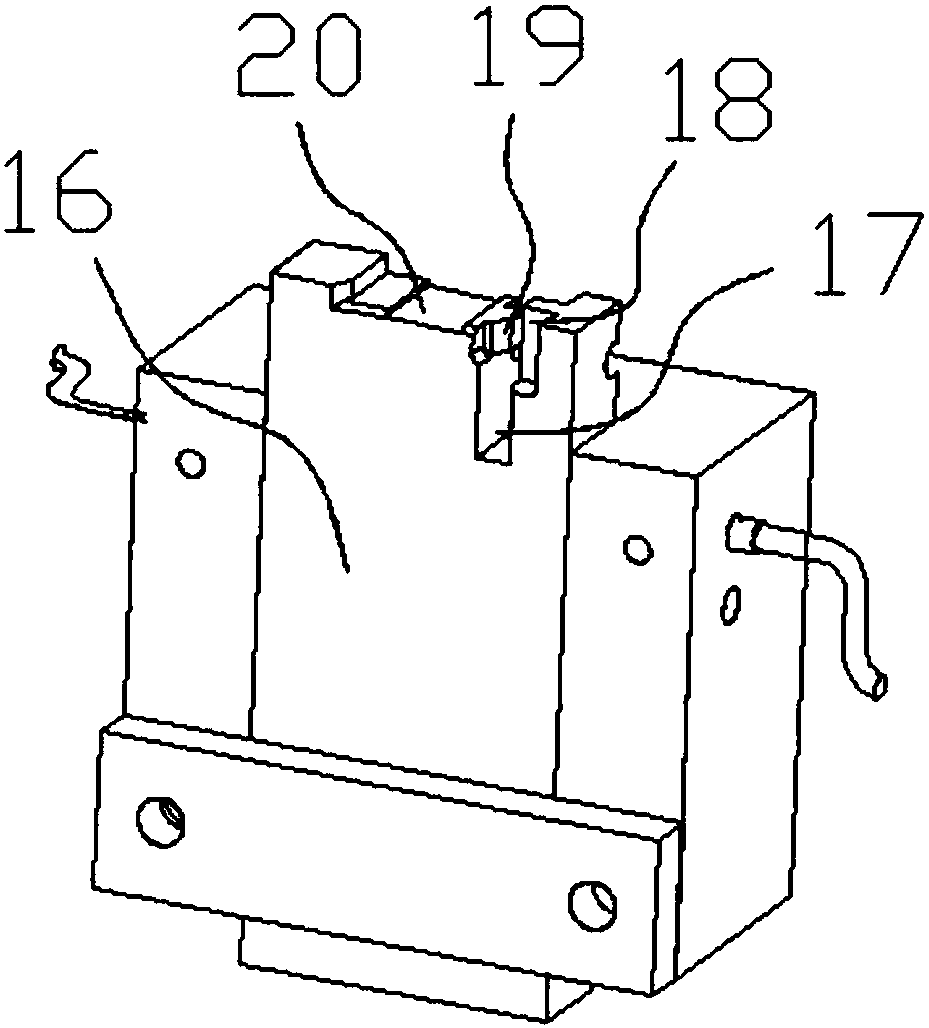

The invention discloses a catheter and guide wire control device for an interventional operation and a control method of the catheter and guide wire control device, belonging to the technical field of minimally invasive vascular interventional operations. The device comprises a clamping mechanism, a sleeve driving assembly and a brake braking assembly, wherein the clamping mechanism comprises a sleeve, a braking part and a clamping part, after the clamping part with a clamping end is mounted in the braking part, the braking part is in threaded connection with the sleeve, a notch is formed in one end, with the clamping end, of the clamping part, and the clamping end is in conical fit with the sleeve; the sleeve driving assembly is used for driving the sleeve to rotate; the brake braking assembly is used for clamping or loosening the braking part. With the method, a catheter or a guide wire can be clamped, pushed and twisted, and force measurement also can be realized; the efficient, accurate and nondestructive clamping and loosening for the guide wire and the catheter can be realized, and the catheter and the guide wire can be cooperatively operated.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

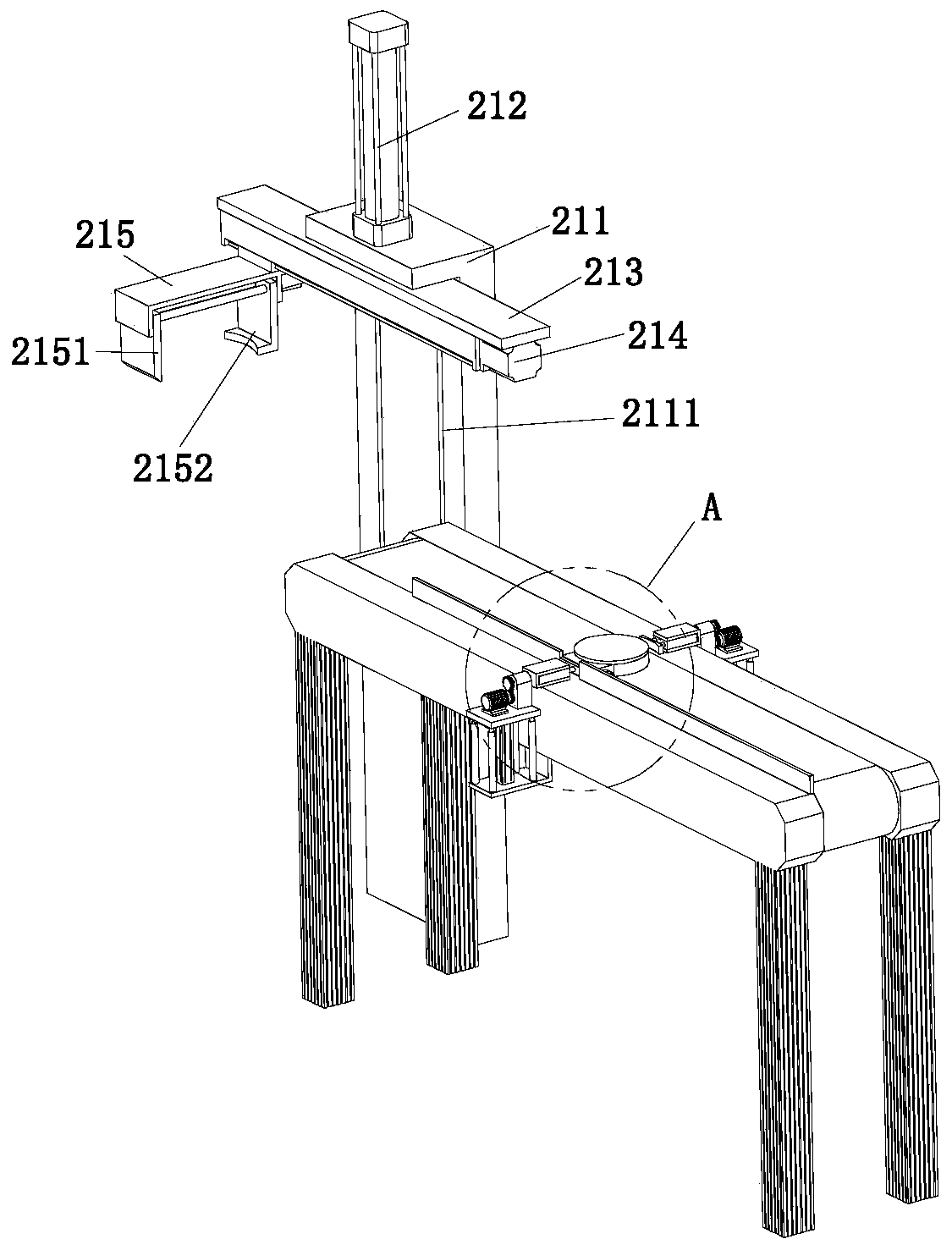

Novel garbage disposal manipulator system and intelligent control method thereof

InactiveCN106607925AAccurate clampingEfficient and accurate sortingProgramme-controlled manipulatorGripping headsEngineeringBottle

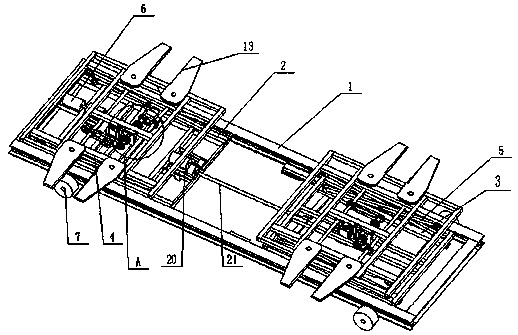

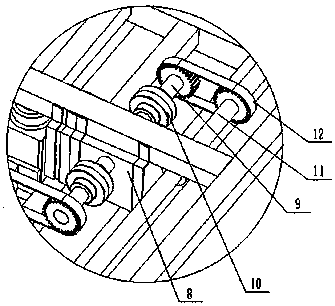

The invention discloses a novel garbage disposal manipulator system and an intelligent control method thereof. The overall structure mainly comprises a support, two manipulators, a conveying belt, eight classifying boxes and eight classifying plates. The two four-freedom-degree manipulators of the same structure are arranged; and three clamping claws arranged in a staggered manner is adopted for a tail end executor of each manipulator. The manipulator system is simple in structure, fast in response and convenient to control, and improves the clamping effectiveness. By adopting the above intelligent control system, the manipulators can accurately reach target bottles and cans, and achieves automatic classification. The sorting and classification problem of bottles and cans in travel rubbish is solved, and technical supporting is provided for healthy development of the travel industry.

Owner:于平

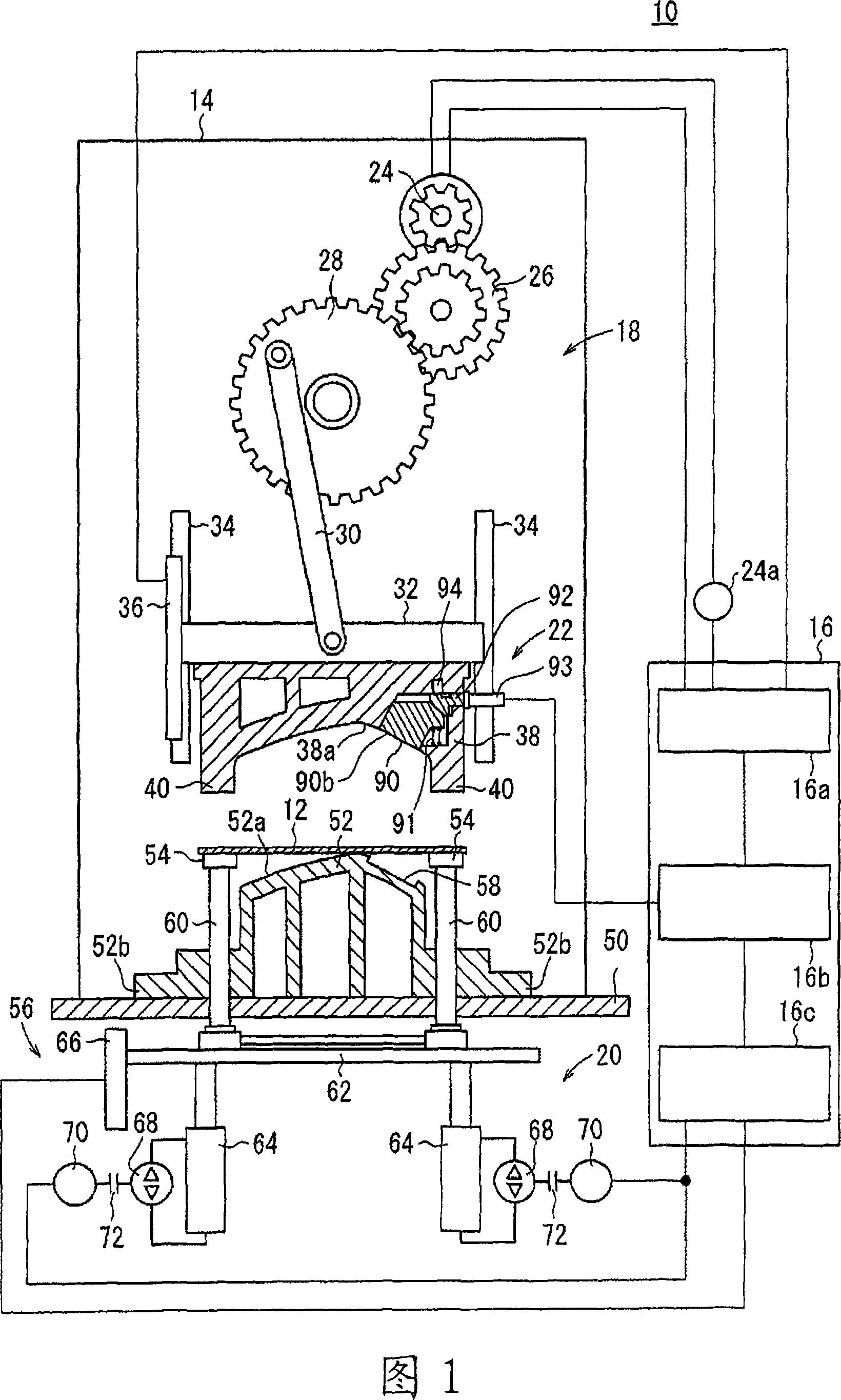

Press working method and press working apparatus

Owner:HONDA MOTOR CO LTD

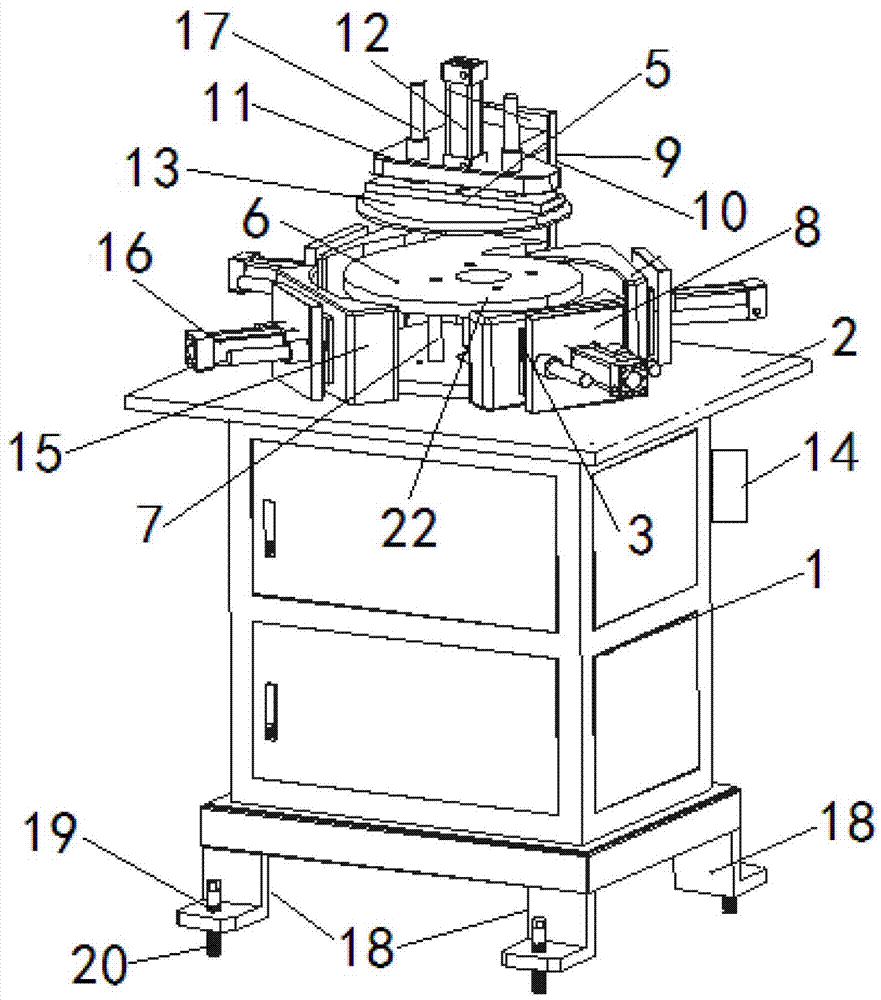

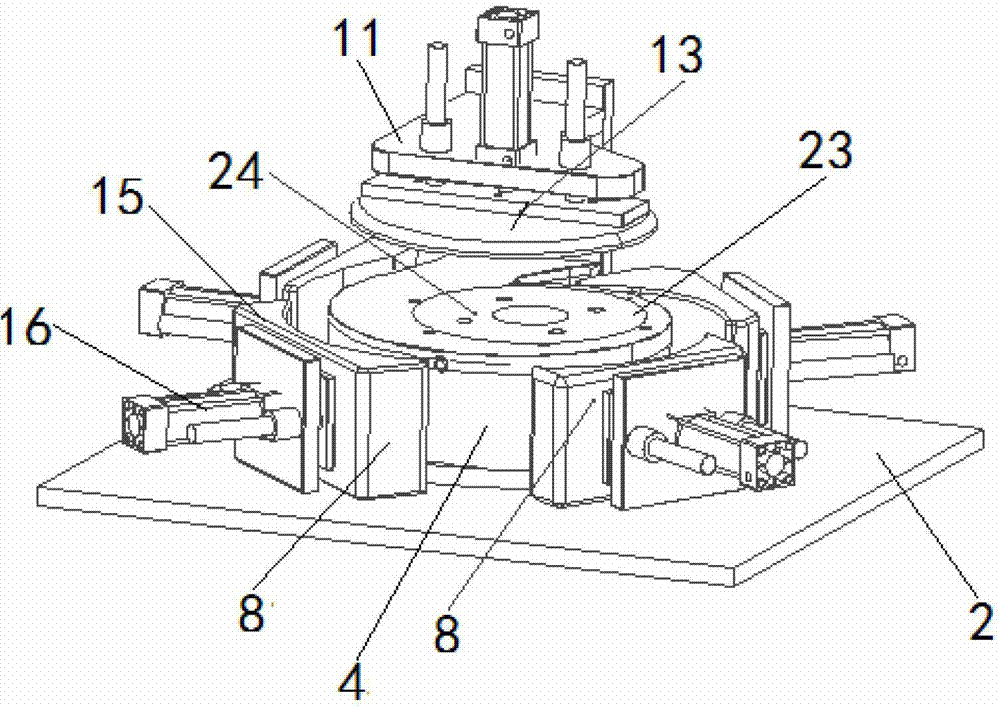

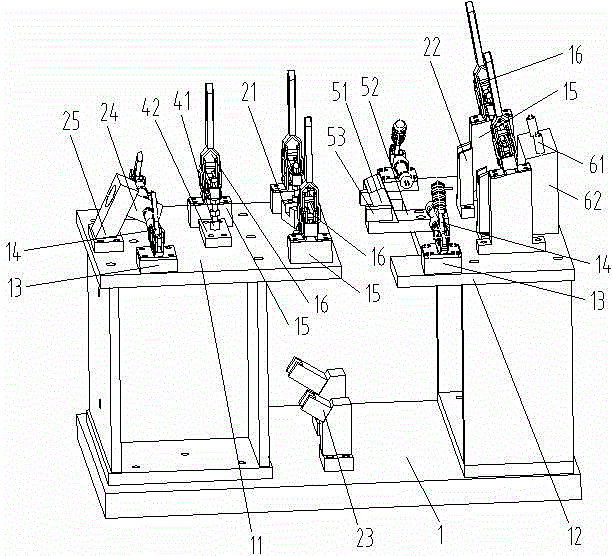

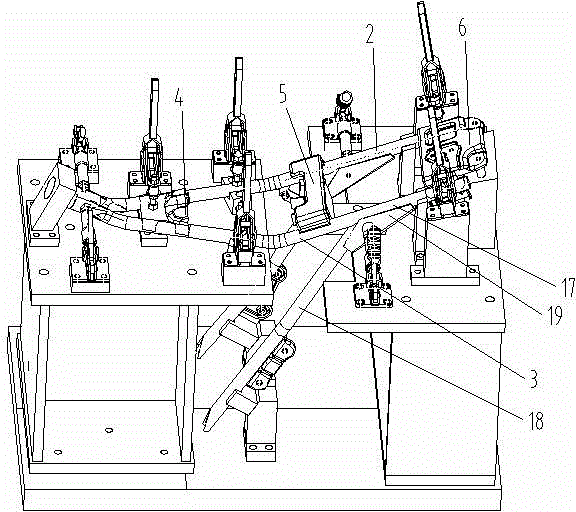

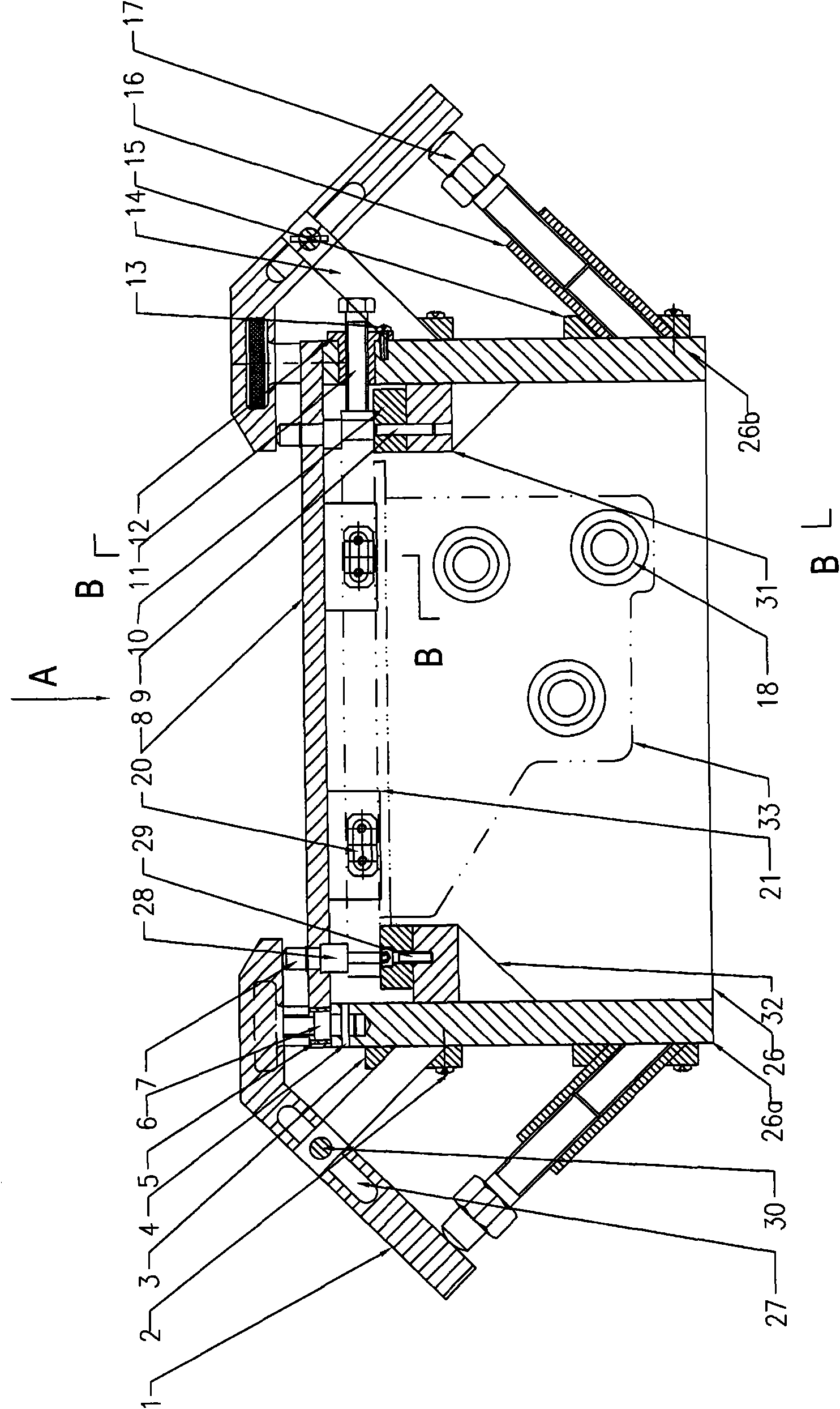

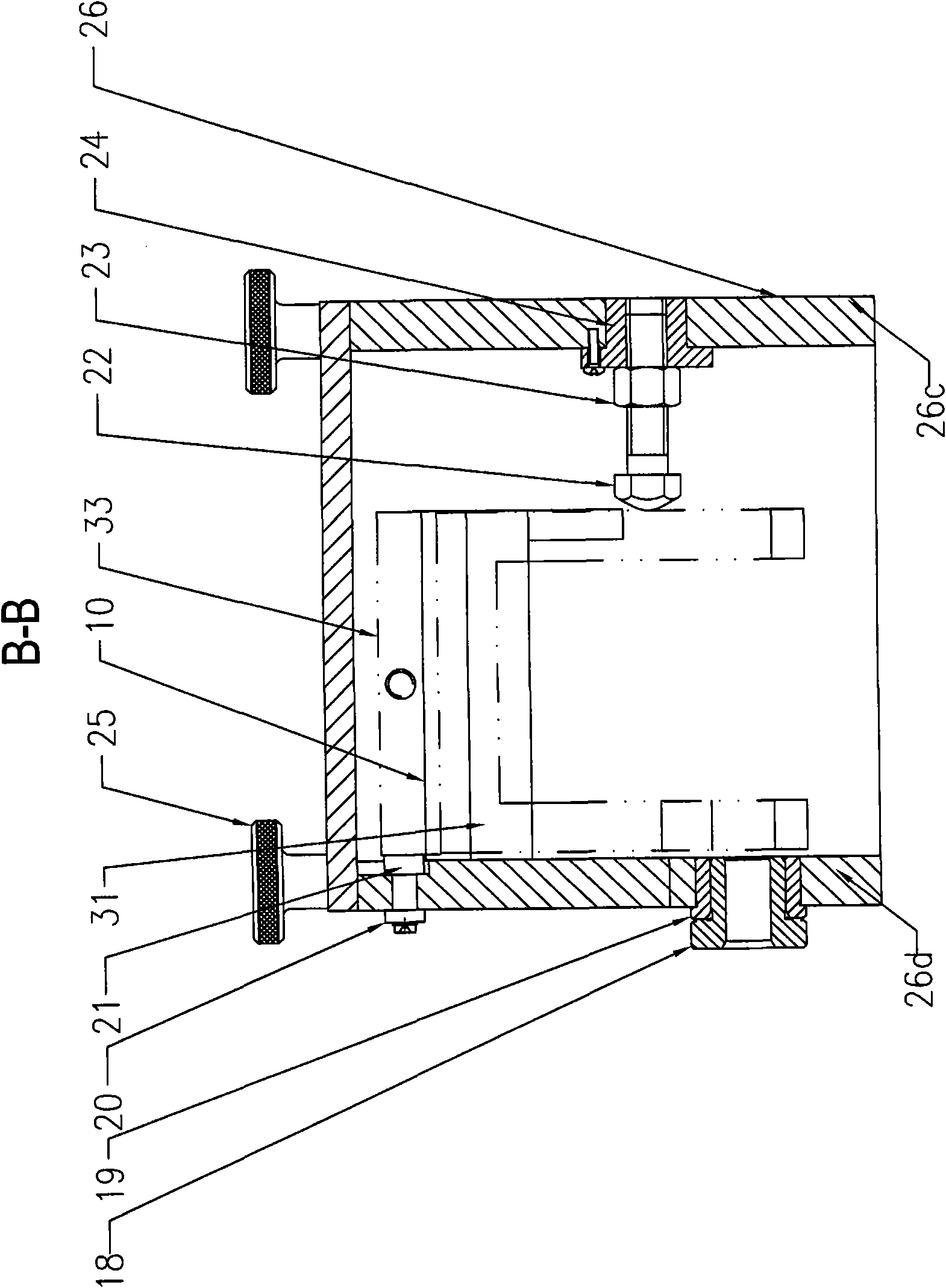

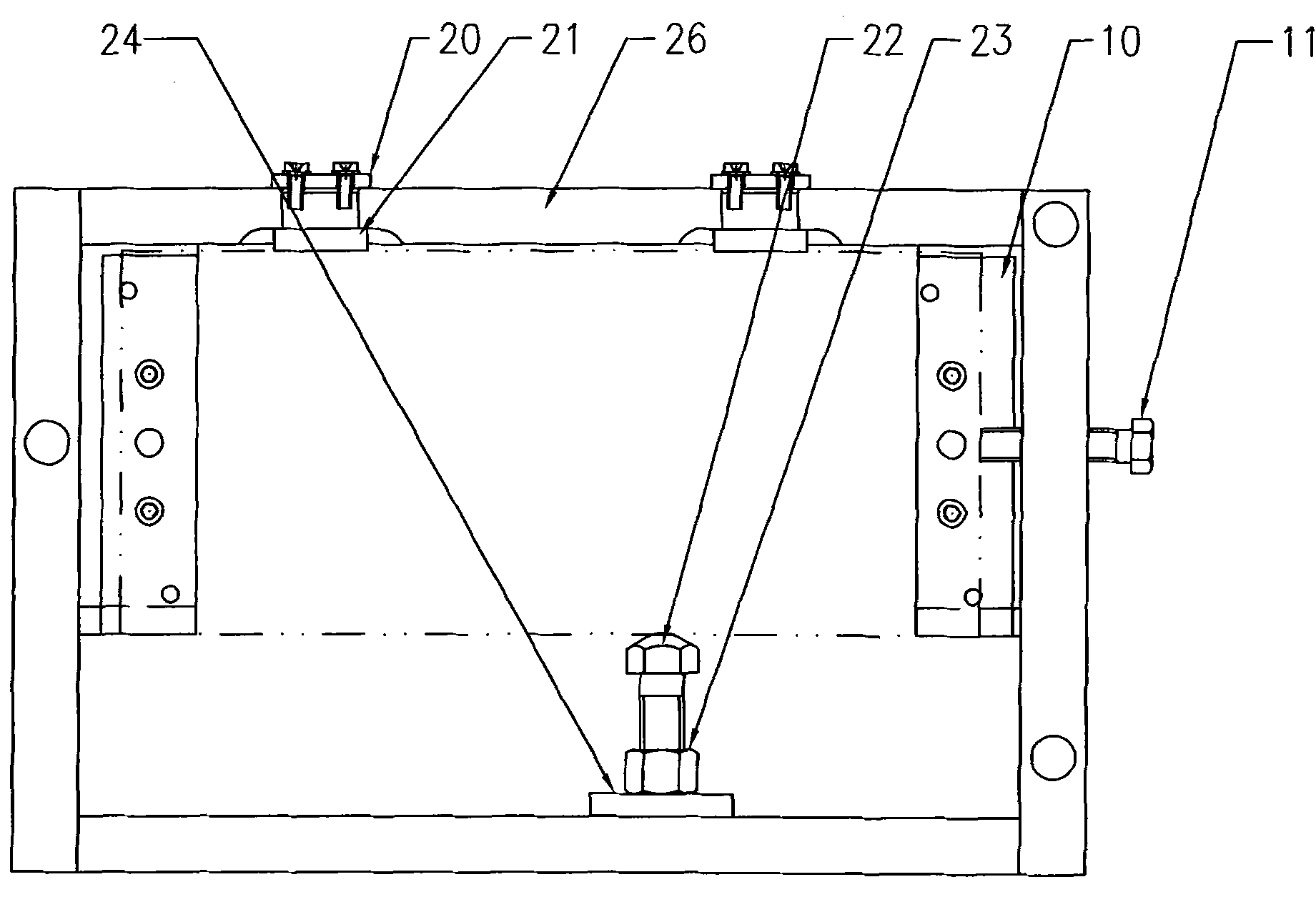

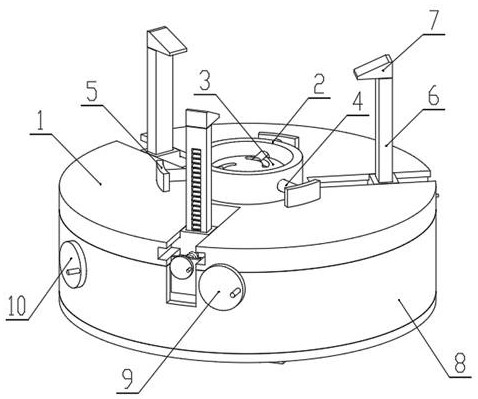

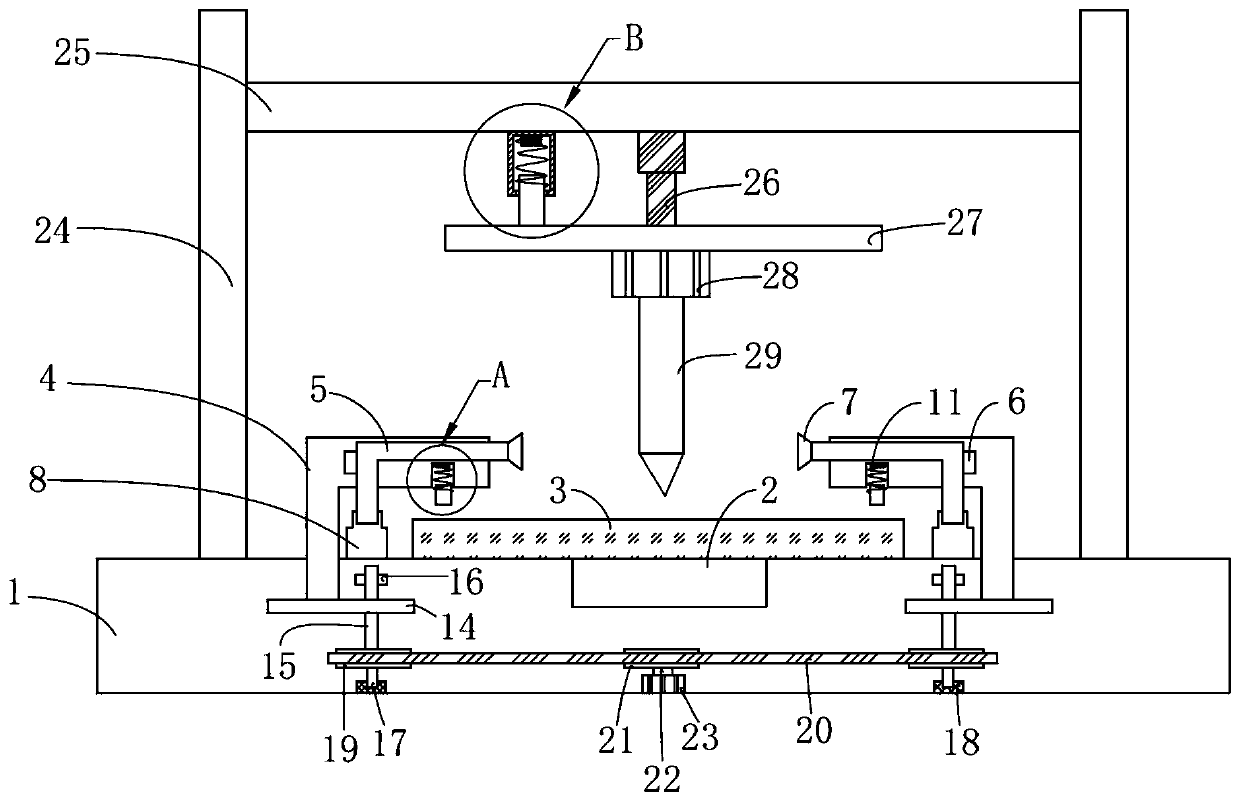

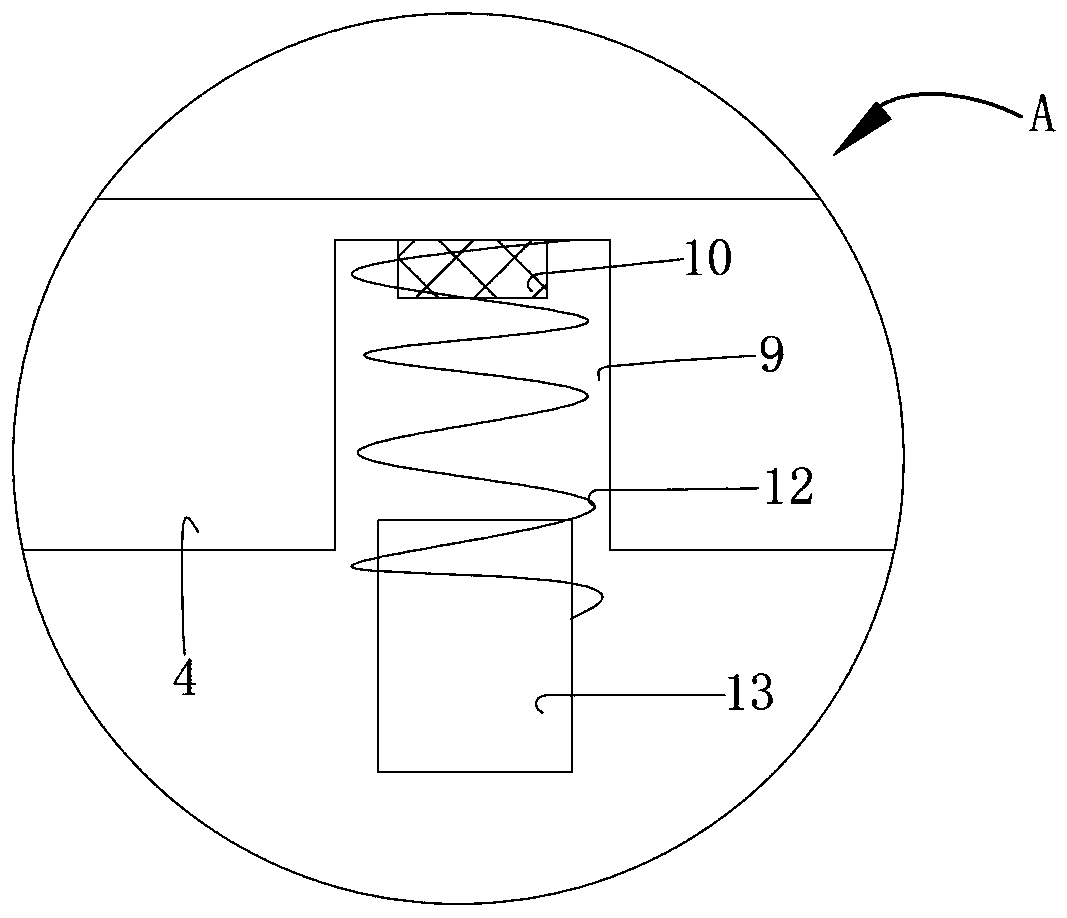

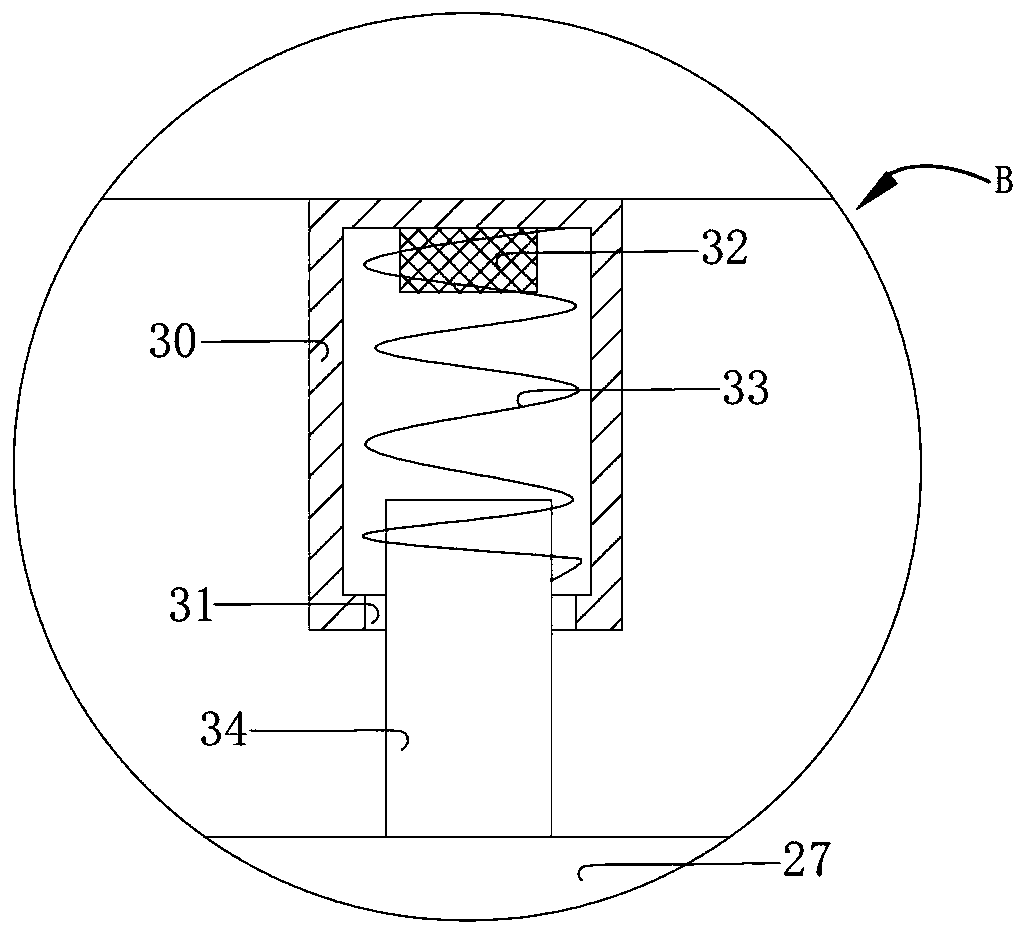

Locating fixture for volute welding

ActiveCN103028878AAchieve clampingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention provides a locating fixture for volute welding, which is applied to the technical field of volute welding. The locating fixture for volute welding comprises a fixture base (1), wherein a fixture bottom plate (2) is arranged on the fixture base (1), an internal locating part (3) is arranged on the fixture bottom plate (2), a volute(4) is set to be of a structure capable of being buckled on the internal locating part (3), and a pressing part (5) capable of tightly pressing the volute (4) on the internal locating part (3) is arranged on the fixture bottom plate. The locating fixture for volute welding has a simple structure, is convenient for clamping, and can accurately realize clamping and locating of the volute, thereby being capable of remarkably improving the welding quality of a volute top plate and a volute bottom plate.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

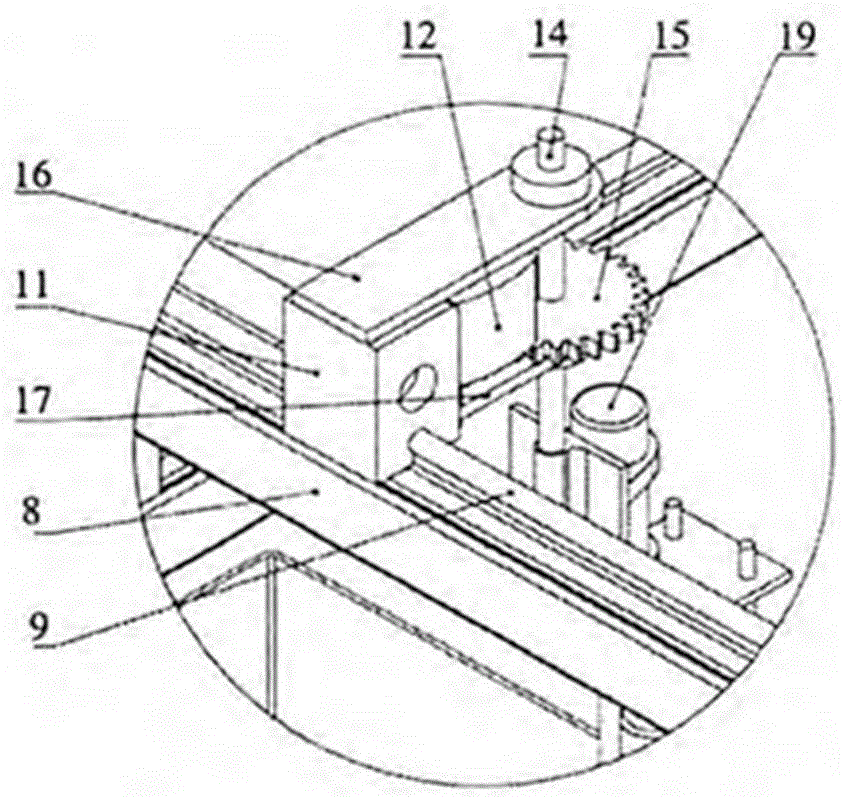

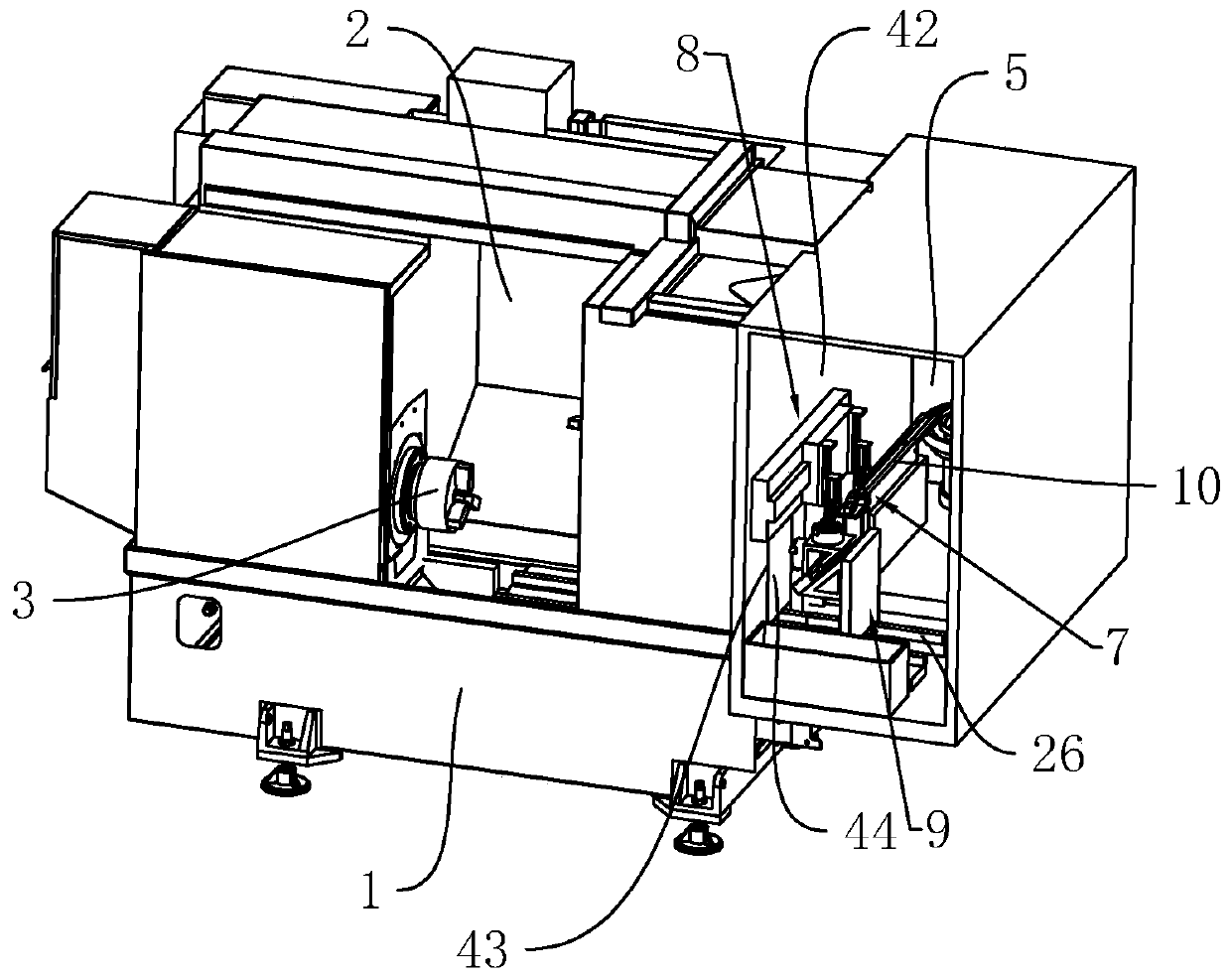

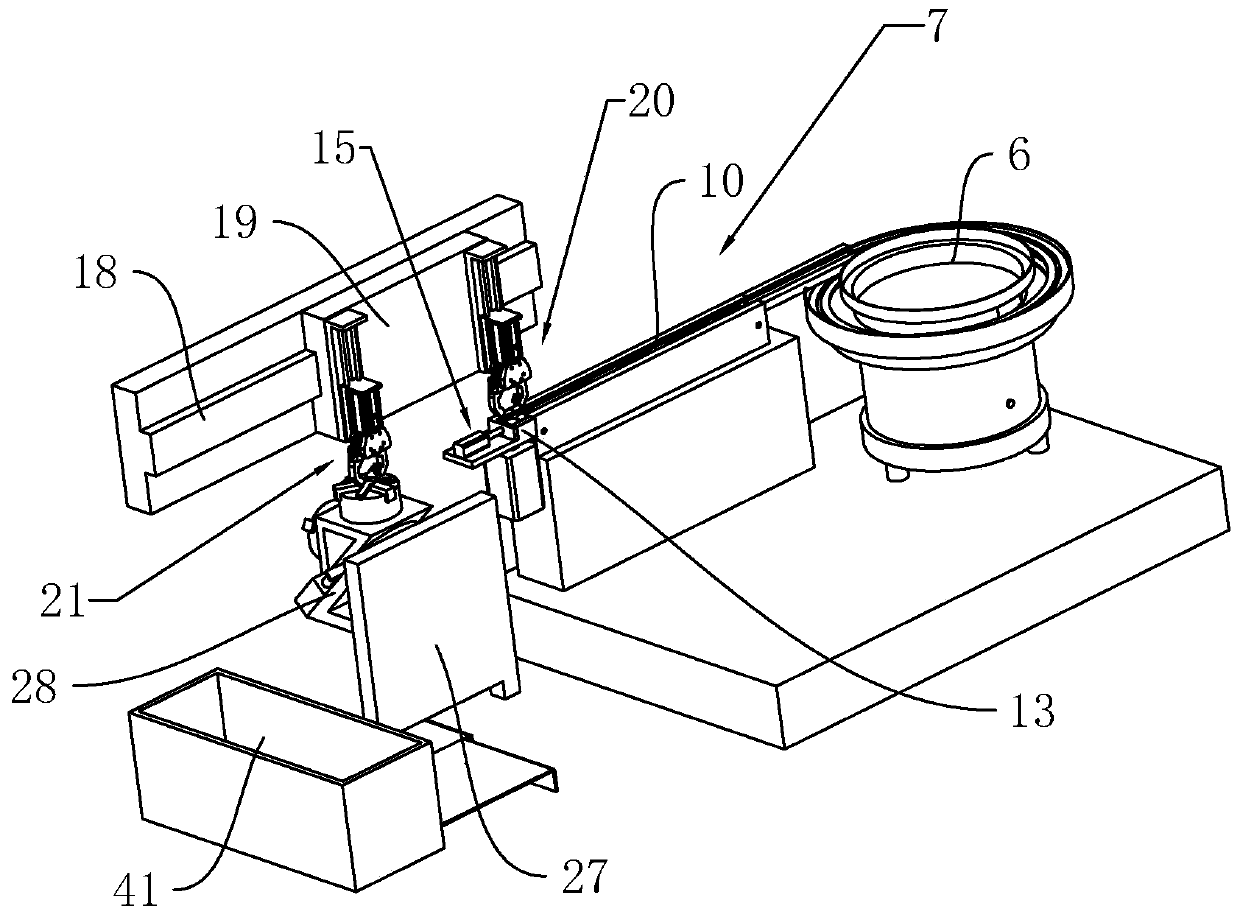

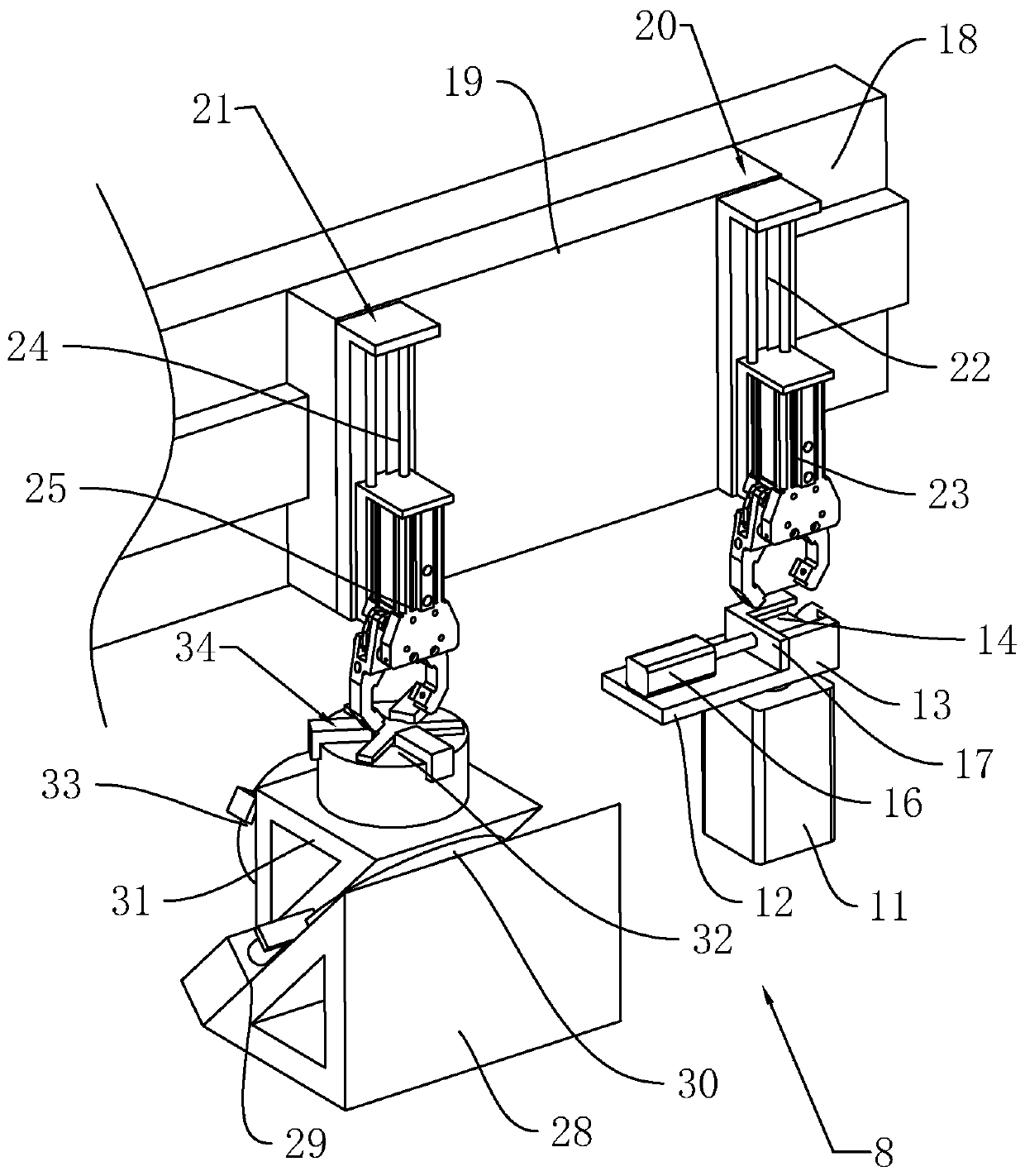

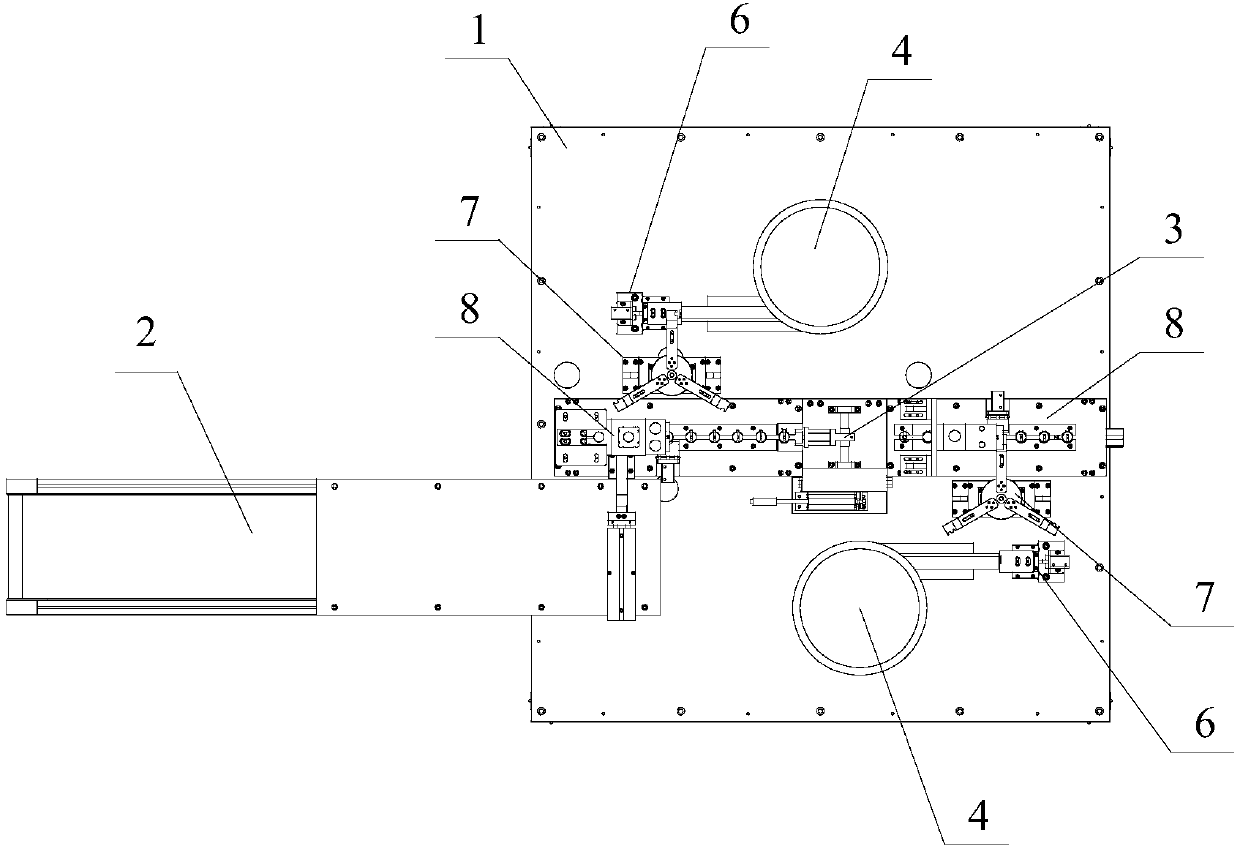

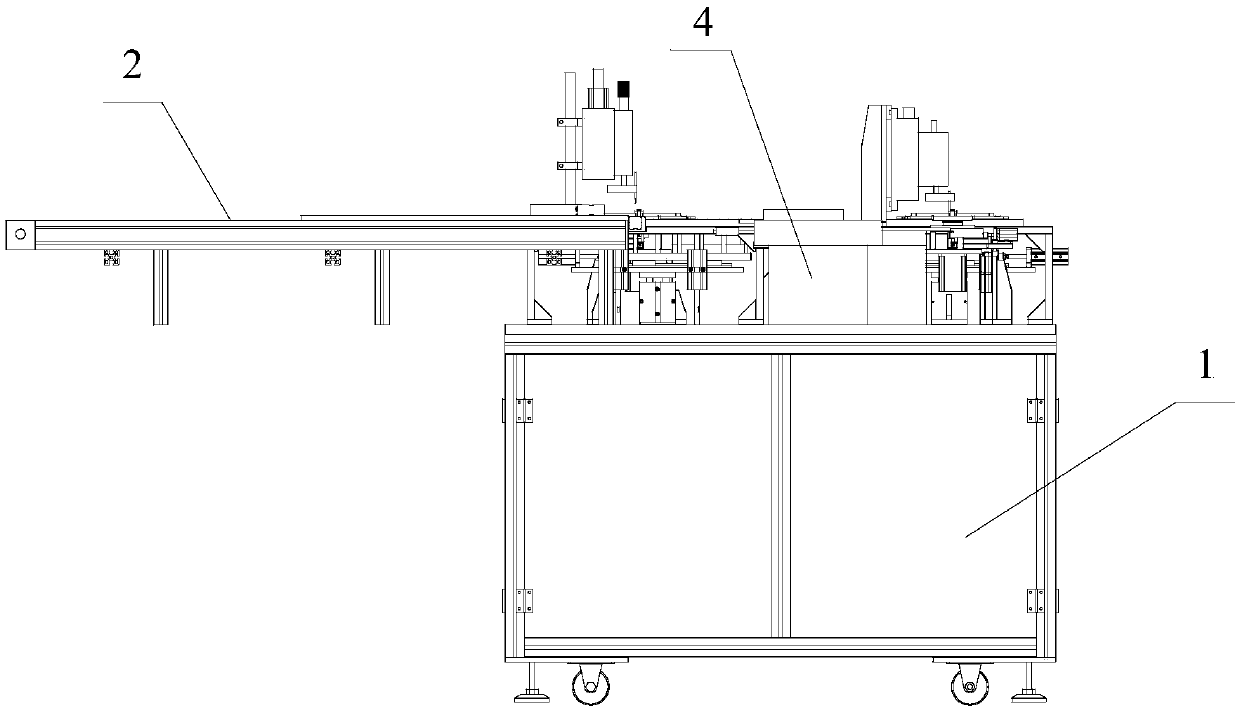

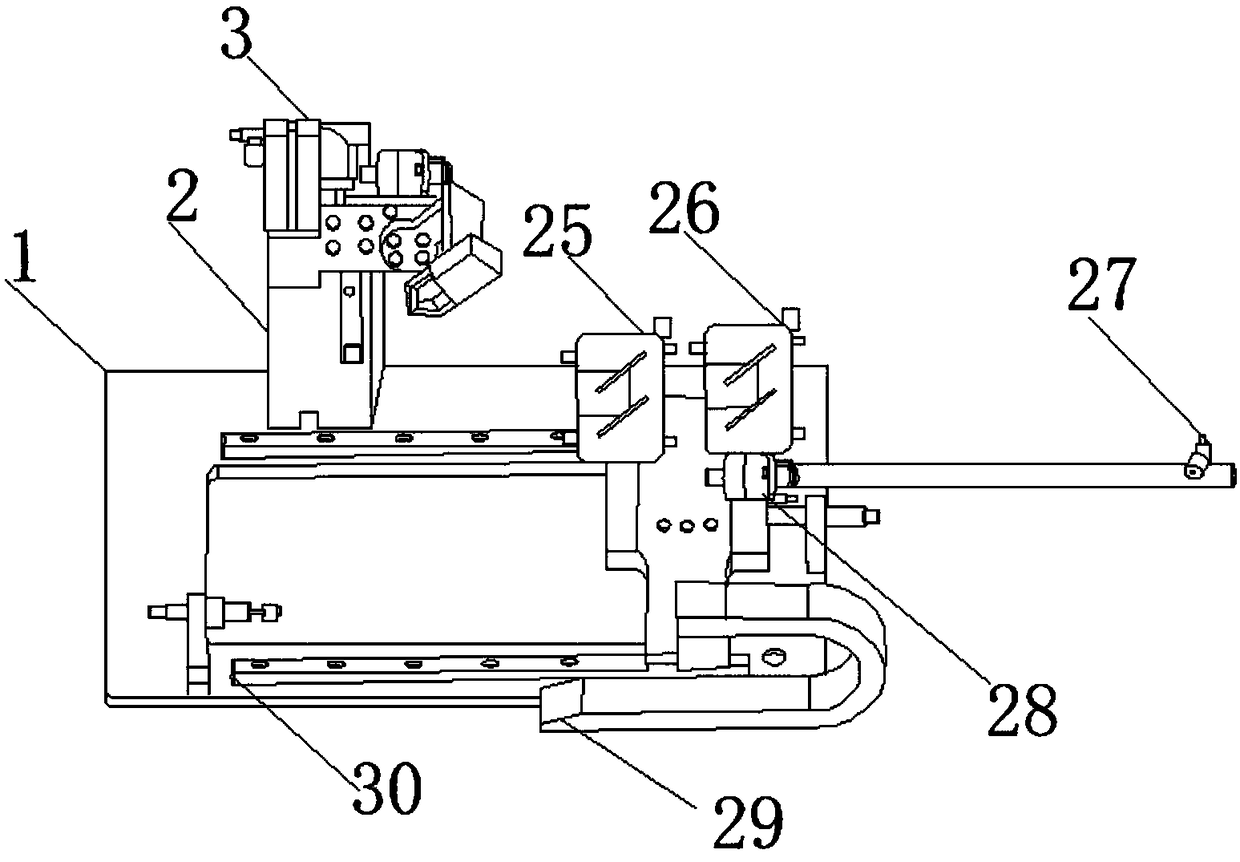

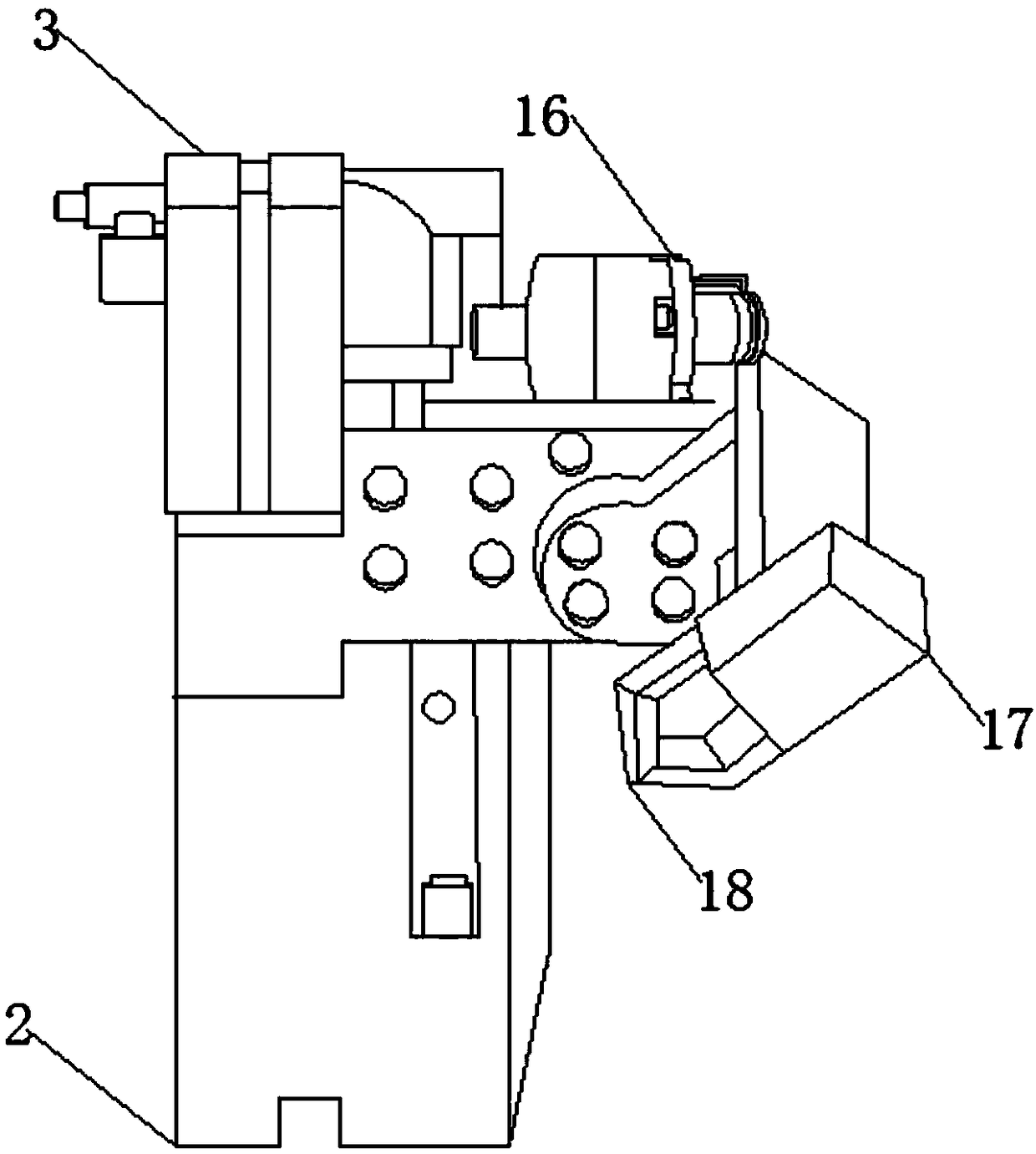

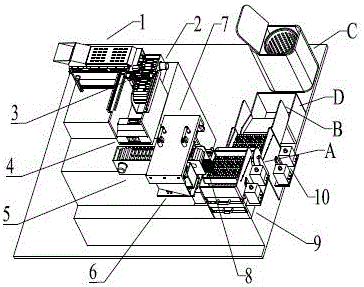

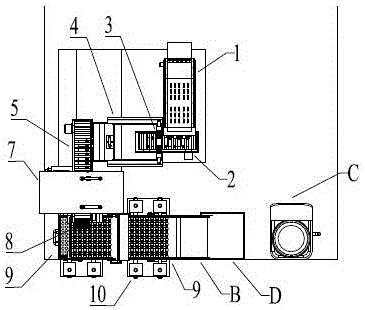

Feeding and discharging machine tool in full-automatic machine

PendingCN111015340ASave time at workImprove processing efficiencyPositioning apparatusMetal working apparatusEngineeringProcess engineering

The invention relates to a feeding and discharging machine tool in a full-automatic machine. The machine tool comprises a tool body and a processing bin arranged on the tool body. A spindle and a cutting assembly for processing a workpiece are arranged in the processing bin. The machine tool is characterized in that the tool body is provided with a conveying bin communicating with the processing bin, a vibration disc is arranged in the conveying bin, the discharging end of the vibration disc is provided with a feeding mechanism, a transfer assembly for clamping and conveying the workpiece is slidingly arranged on the upper end of the tool body, a conveying mechanism is slidingly arranged on the tool body, and the side, located on the feeding mechanism, of the conveying mechanism can slideto the spindle. The feeding and discharging machine tool in the full-automatic machine has the advantages that continuous feeding and discharging can be achieved, and accordingly the processing efficiency is improved.

Owner:津上精密机床(浙江)有限公司

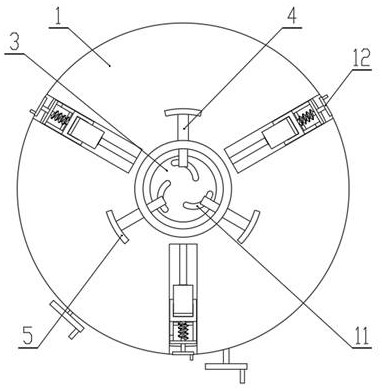

Edge contact clamping type wafer end actuator

InactiveCN101728302AQuick gripAccurate clampingPolishing machinesSemiconductor/solid-state device manufacturingUnresolved IssueThinning

The invention provides an edge contact clamping type wafer end actuator belonging to the technical field of chemical mechanical polishing equipment. The edge contact clamping type wafer end actuator comprises a wafer seat, the wafer seat is at least internally provided with two telescopic type edge contact clamping finger hooks which are connected with a telescopic device; and the wafer seat is at least provided with a third edge contact clamping contact. The invention well solves the problems which exist for a long time and are unsolved all the way in the prior art, clamps wafers in an edge contact way, fast, accurately and safely clamps the wafers without pollution, has simple structure, safe and convenient use and reduced cost, automatically determines the circle centers of the wafers and can be widely used for the processing, i.e. chemical mechanical polishing (CMP), grinding, thinning, and the like of the wafers.

Owner:THE 45TH RES INST OF CETC

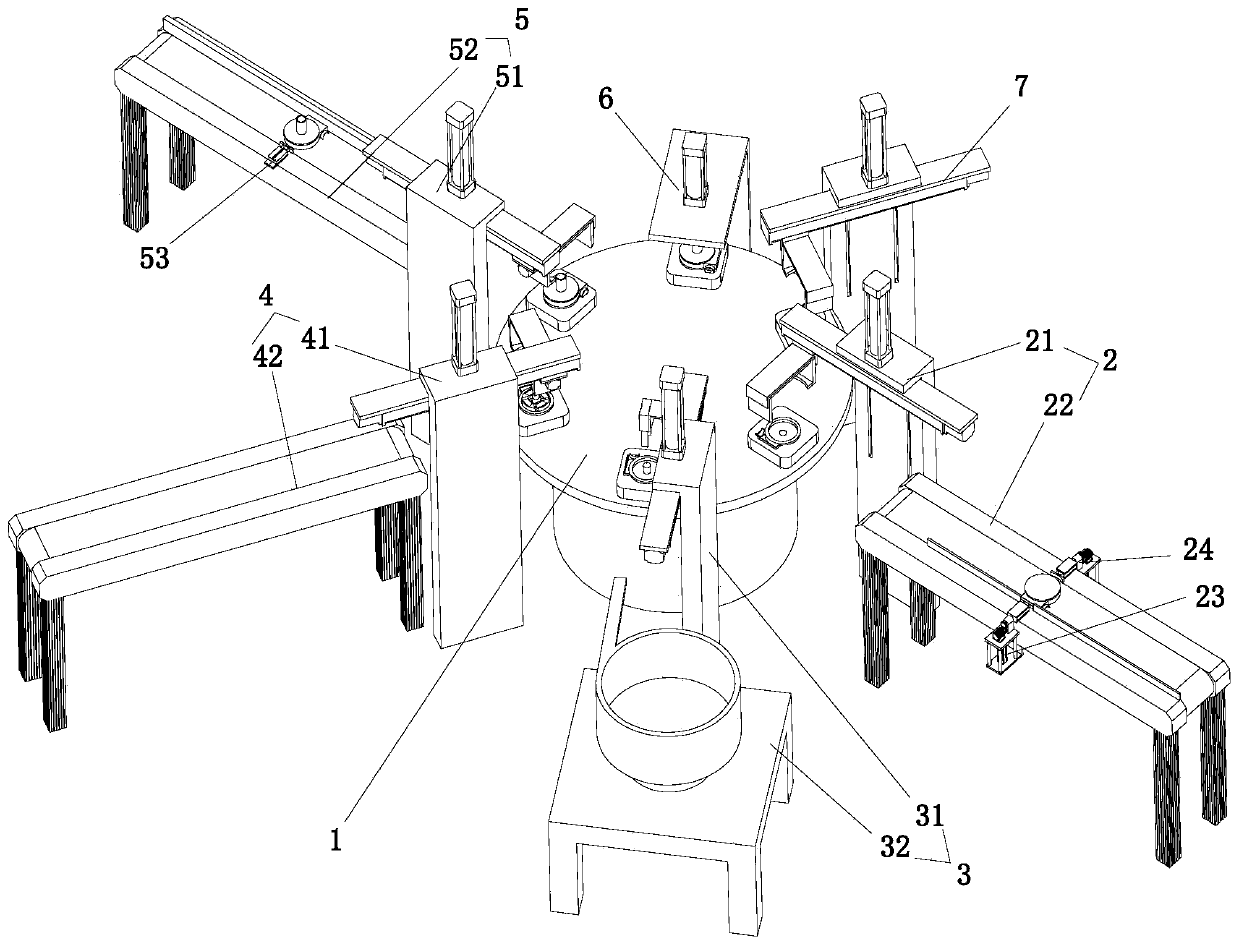

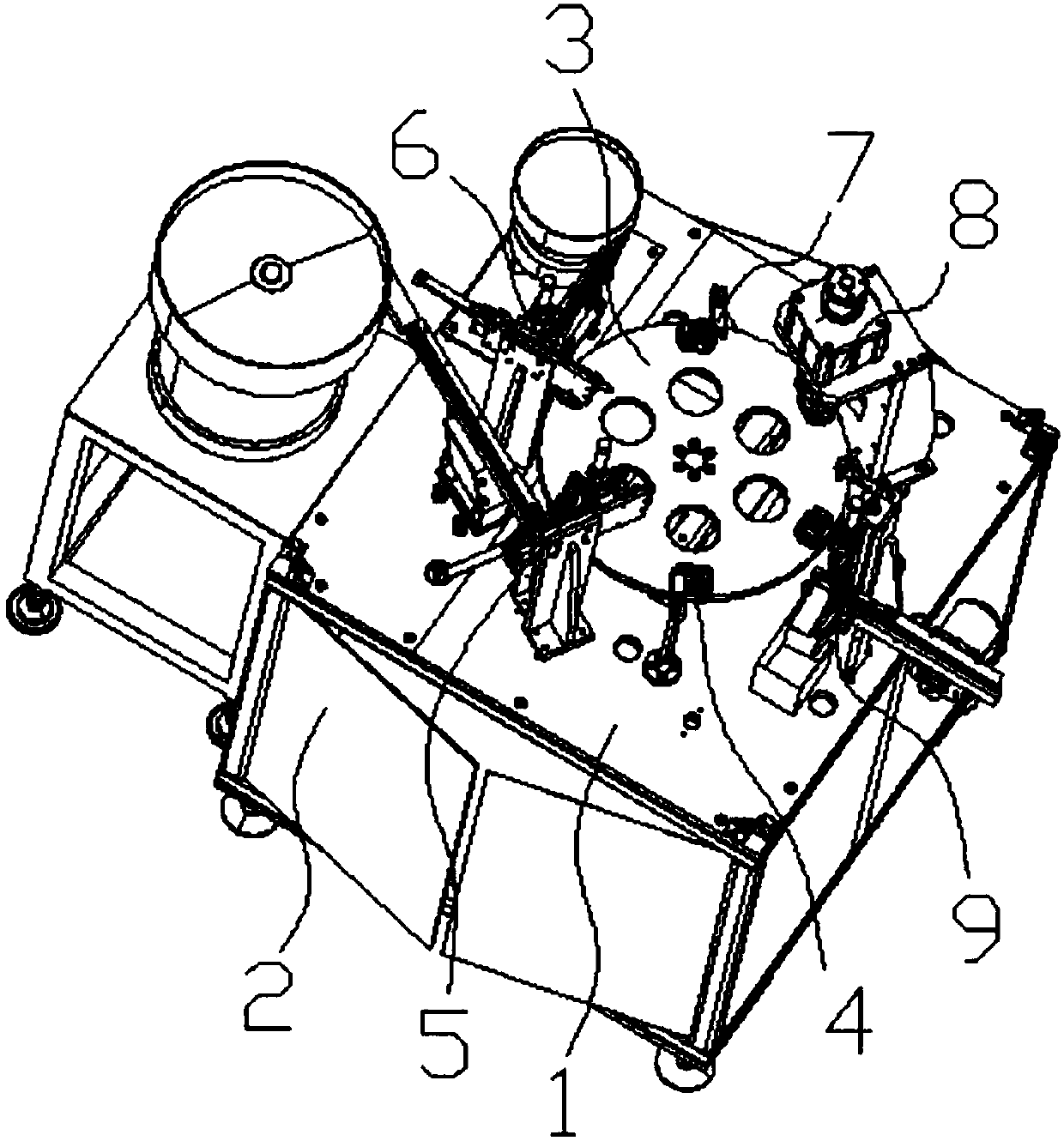

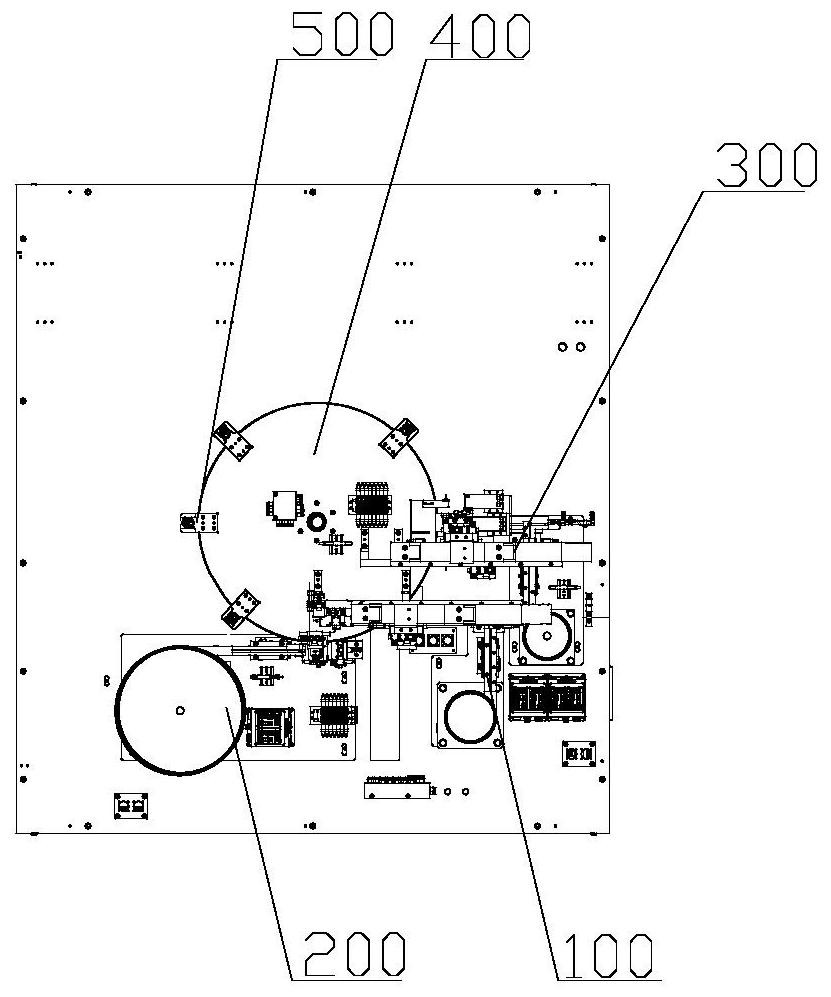

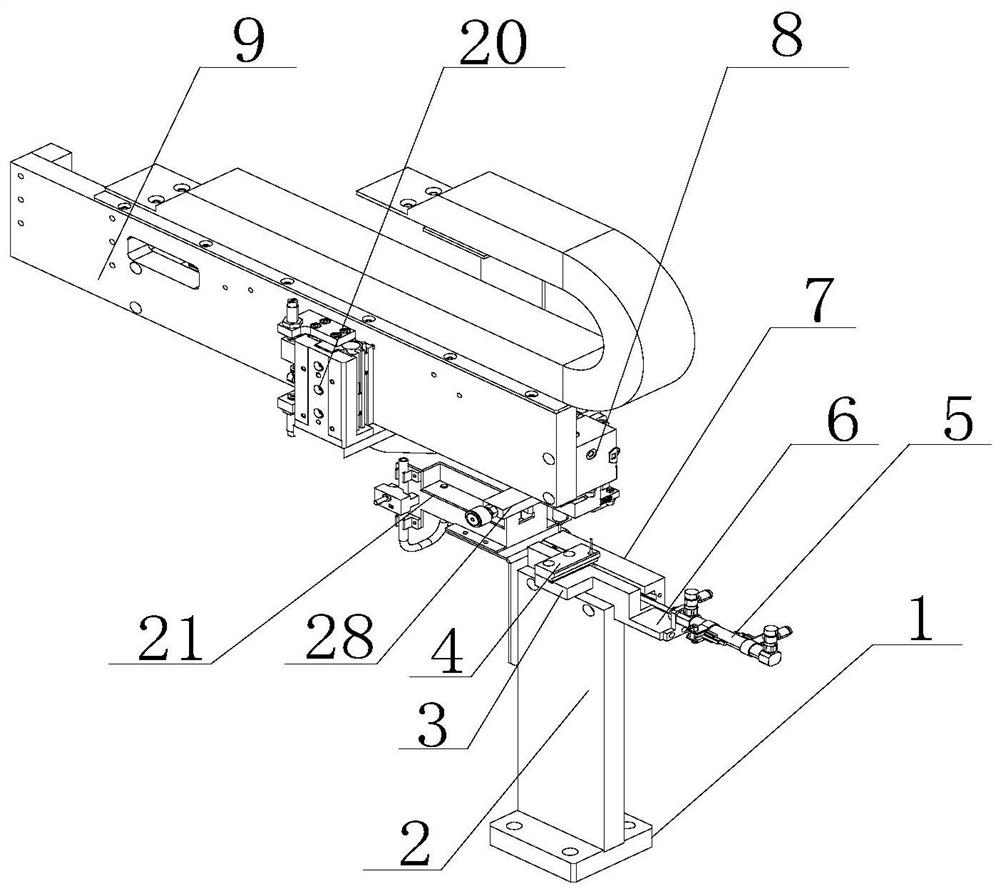

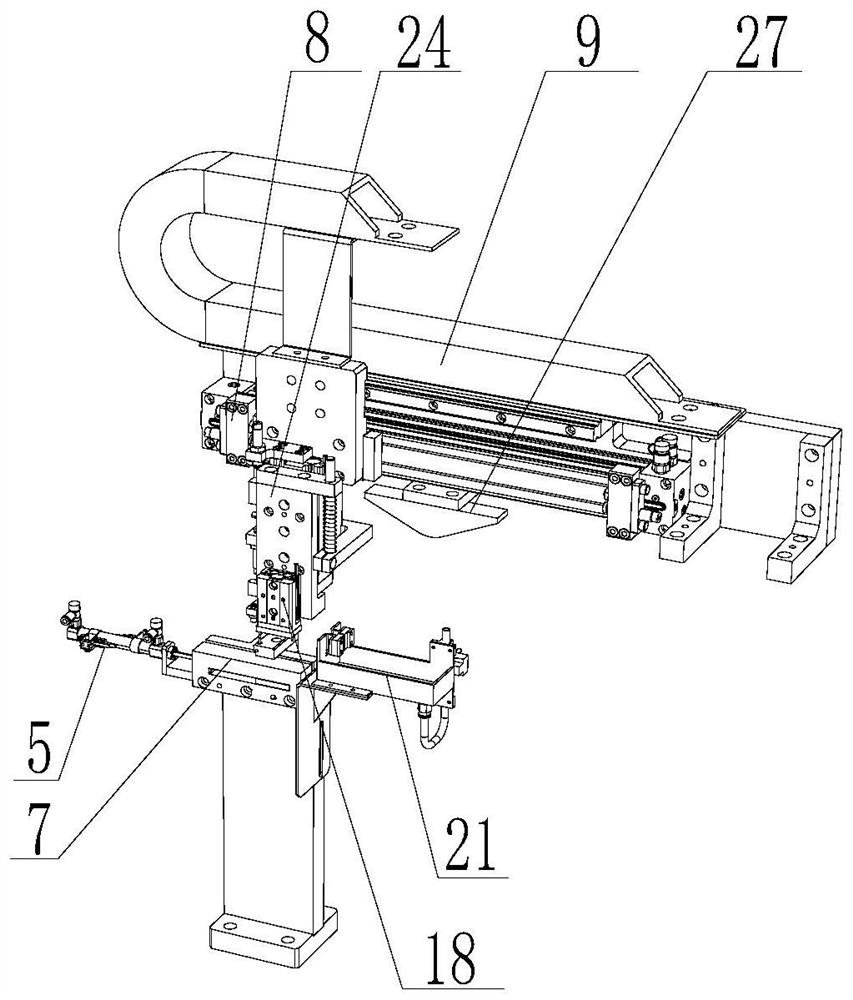

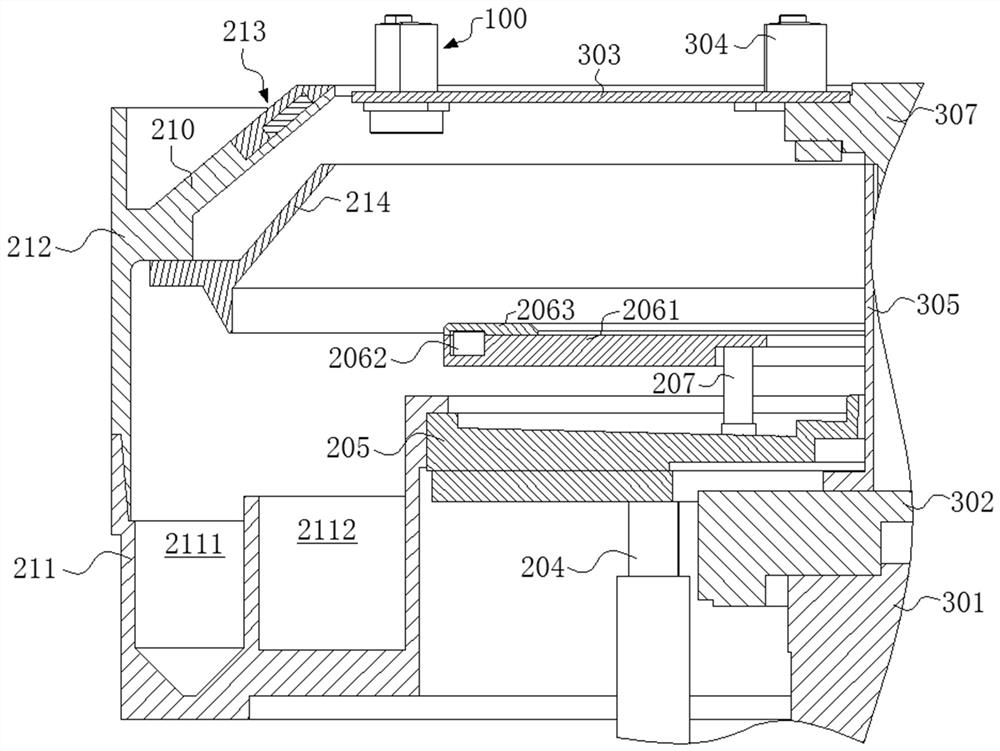

Automatic production line of magnetic suspension artificial heart blood pump

InactiveCN111331358AIncrease productivityRealize automated assemblyBlood pumpsMedical devicesElectric machineryImpeller

The invention provides an automatic production line of a magnetic suspension artificial heart blood pump. The automatic production line comprises a rotating mechanism, wherein a lower housing feedingmechanism, a central shaft housing feeding mechanism, an impeller feeding mechanism, an upper housing feeding mechanism, a pressing mechanism and a discharging mechanism are sequentially arranged around the rotating mechanism; the lower housing feeding mechanism comprises a first carrying manipulator and a lower housing conveying belt, and a first overturning assembly and a second overturning assembly are arranged on the lower housing conveying belt; the central shaft housing feeding mechanism comprises a second carrying manipulator and a feeding assembly; the impeller feeding mechanism comprises a third carrying manipulator and an impeller conveying belt, and automatic blood pump rotor assembling equipment is arranged beside the impeller conveying belt; the upper housing feeding mechanismcomprises a fourth carrying manipulator and an upper housing conveying belt, and a positioning assembly is arranged on the upper housing conveying belt; and the blood pump rotor assembling equipmentcomprises a conveying belt, a bearing magnetic stack press-fitting mechanism, a motor magnet mounting mechanism and a base welding mechanism. According to the automatic production line, the magnetic suspension artificial heart blood pump can be automatically produced, and the production efficiency is improved.

Owner:韶关市武江区冠启自动化设备设计有限公司

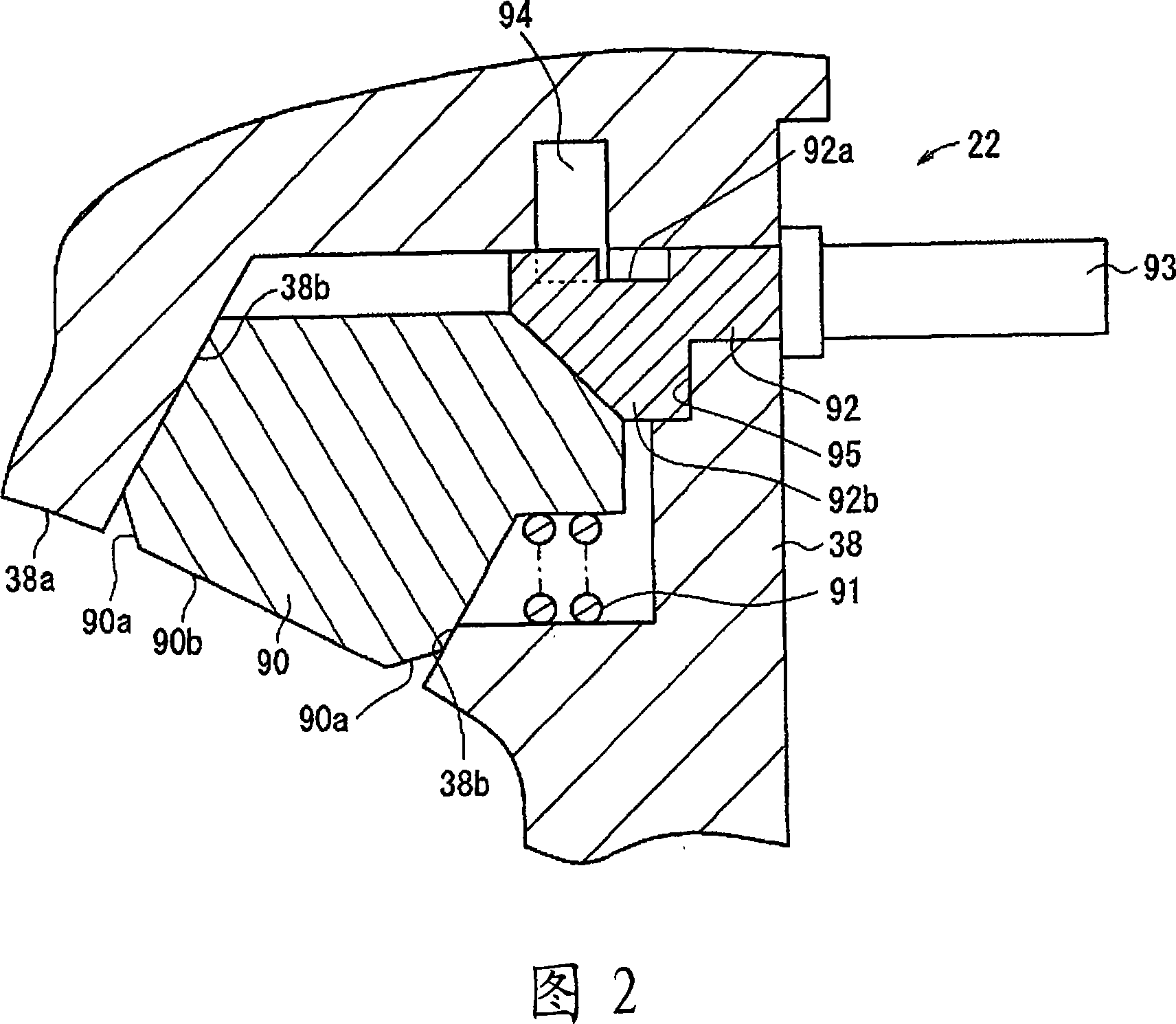

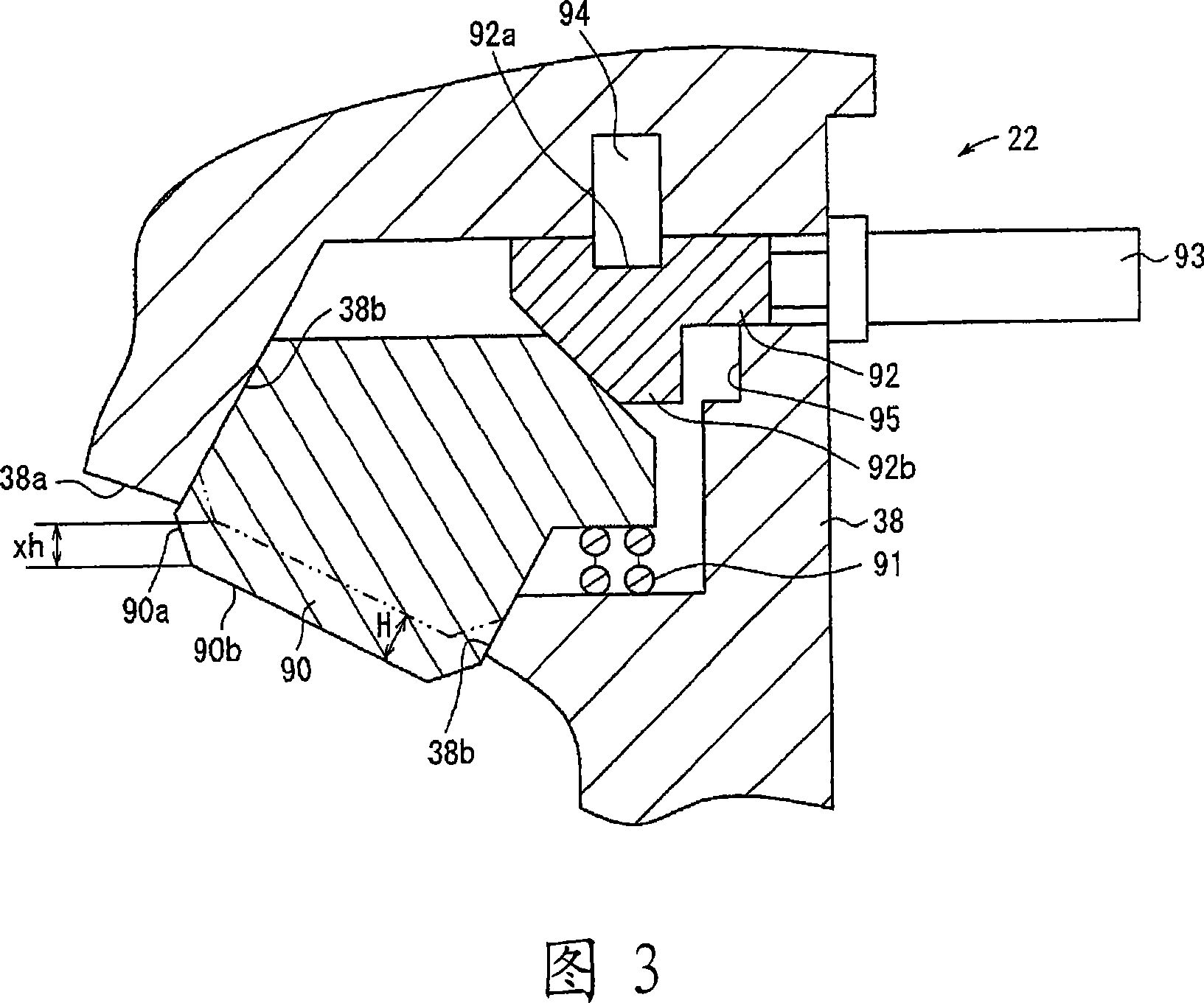

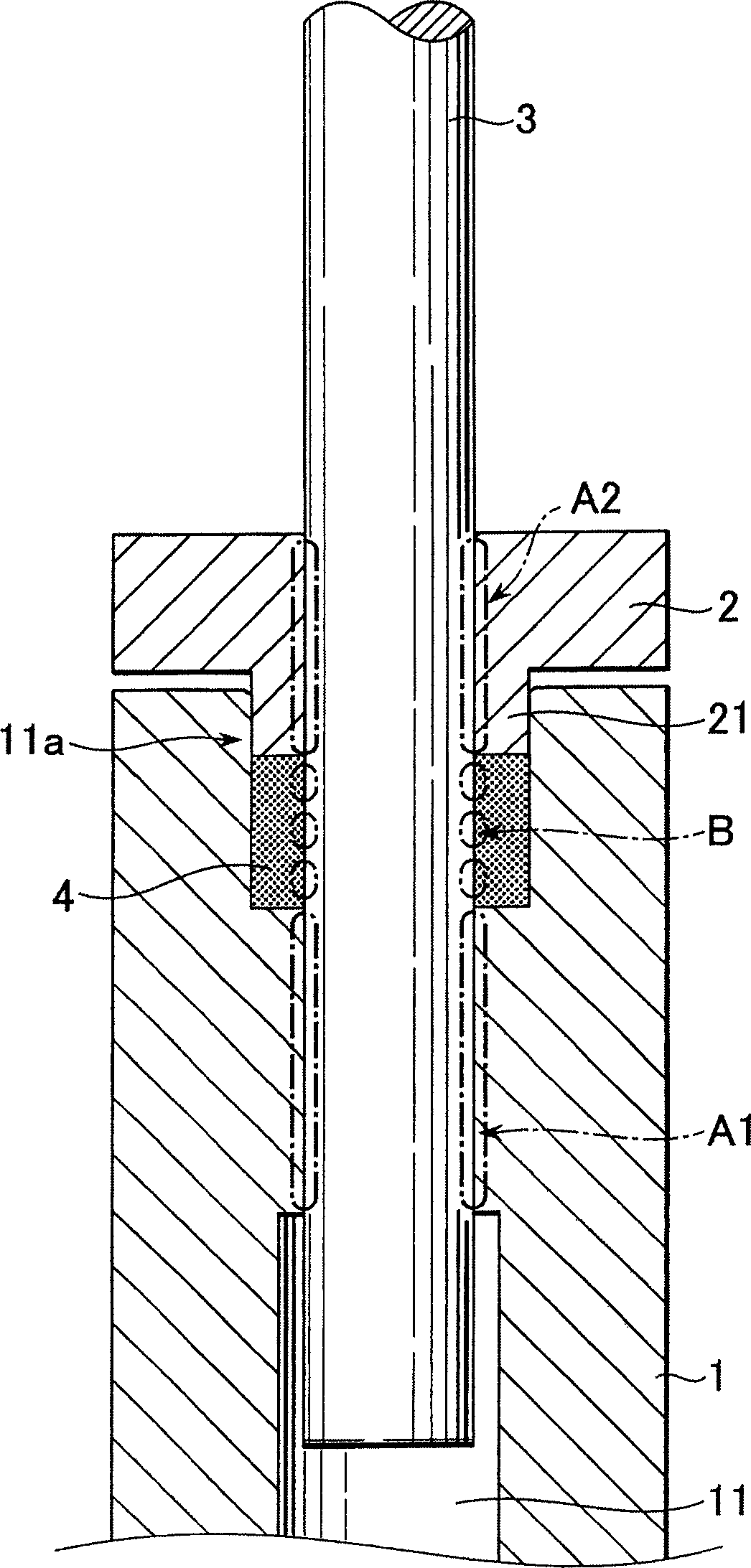

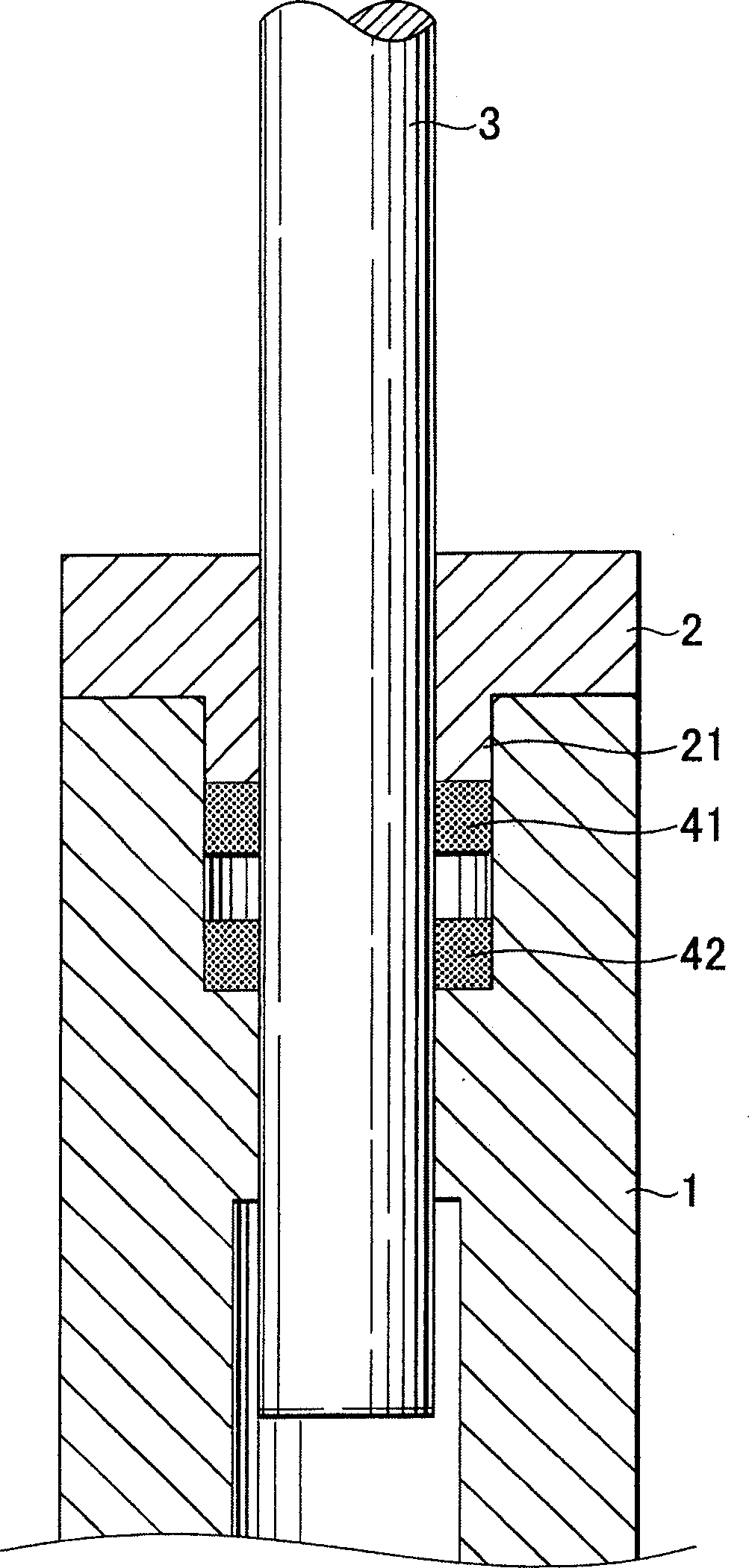

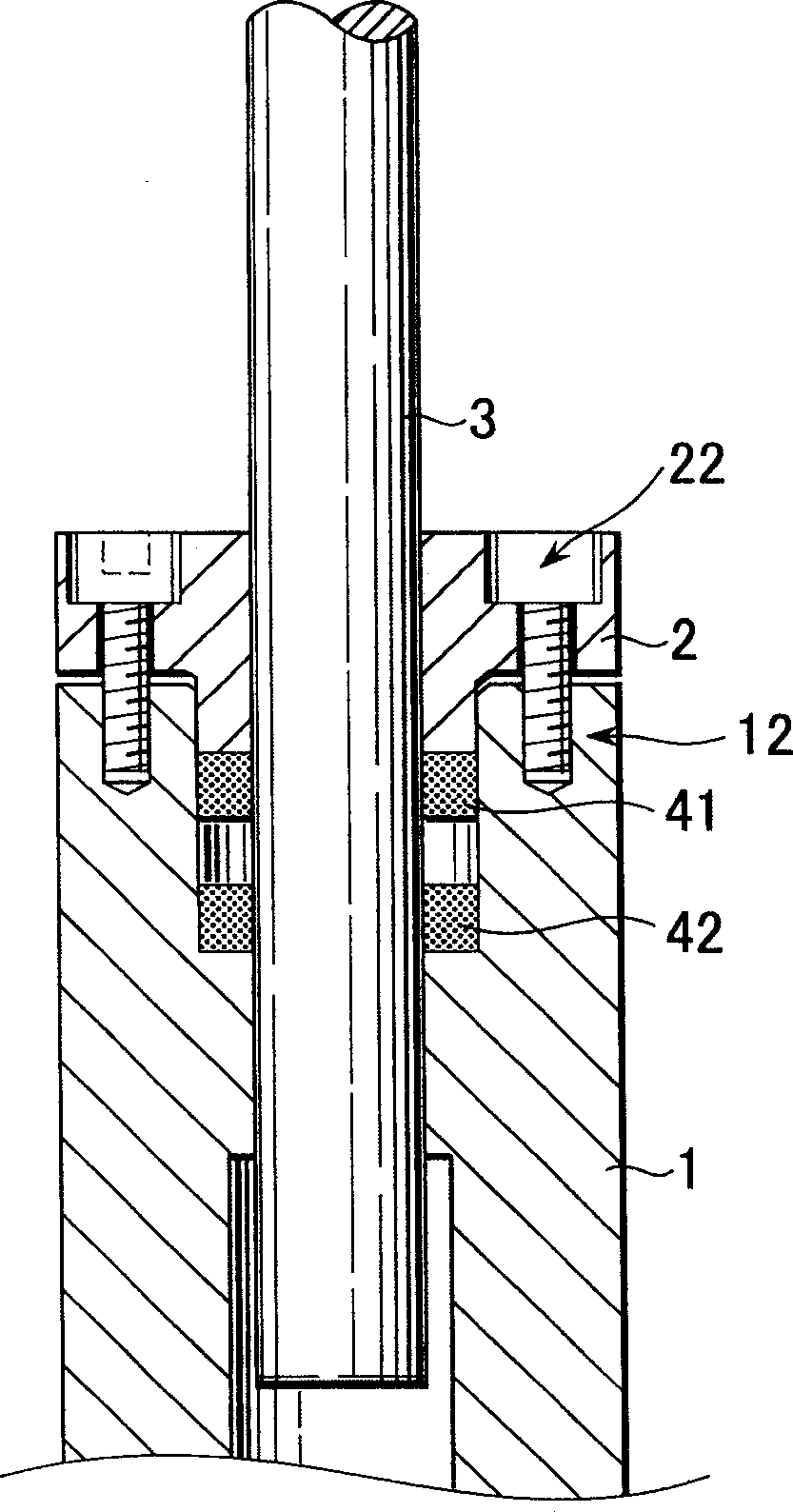

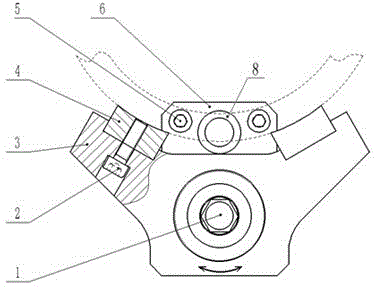

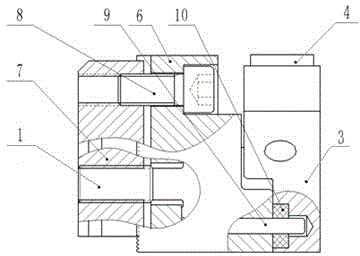

Tool holding structure

InactiveCN1880009AAccurate clampingMade preciselyChucksPositioning apparatusAxial compressionEngineering

The invention provides a simplified holding structure for a tool for a machine tool that makes accurate tool holding possible. The tool shank is inserted through a through hole of a sleeve and into a tool shank insertion hole. The sleeve insertion part is inserted into a large-diameter part and fixed coaxially to the spindle with bolts or the like, so as to axially compress at least one annular elastic member provided on the large-diameter part. A first shank-supporting portion is provide inside the tool shank insertion hole and a second shank-supporting portion is provided on the sleeve through hole. A front end part of the insertion part is semicircular or trapezoidal in axial cross-section. The tool shank insertion hole, the sleeve through hole and the annular elastic member have cross-sections in directions perpendicular to the axis of the tool shank shaped that match the tool shank.

Owner:FANUC LTD

Miniature lithium battery butt welding assembly

InactiveCN107717195APrecise and efficient butt welding assemblyReduce time consumptionAssembling battery machinesFinal product manufactureEngineeringAnode

The invention discloses a miniature lithium battery butt welding assembly. The miniature lithium battery butt welding assembly comprises a case and a conveying mechanism used for conveying battery pieces; the case is provided with an anode butt welding mechanism for conducting butt welding assembling on anode pieces, a cathode butt welding mechanism for conducting butt welding assembling on cathode pieces, and a turnover mechanism for turning over the battery pieces subjected to butt welding assembling; the turnover mechanism is arranged between the anode butt welding mechanism and the cathodebutt welding mechanism; and the conveying mechanism is connected with the anode butt welding mechanism or the cathode butt welding mechanism. According to the miniature lithium battery butt welding assembly, the automation degree is high, the safety and precision are improved, the machine service life is long, the production cost is reduced, and meanwhile, high-efficiency high-quality lithium battery butt welding work is achieved.

Owner:胡梁嘉

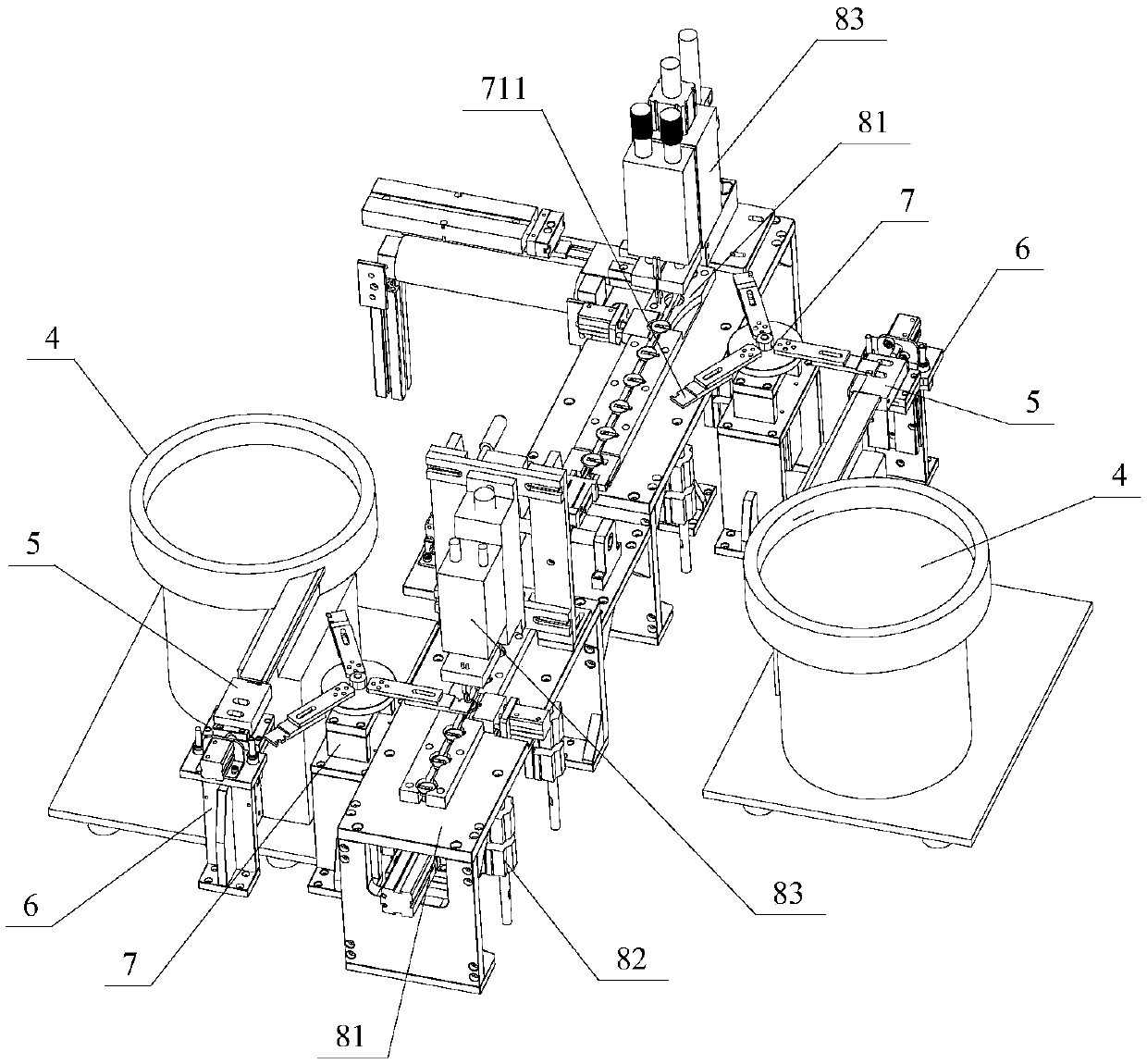

Continuous automatic assembly machine of lug plate elastic piece

ActiveCN107553107AGuaranteed accuracyAvoid elastic deformationMetal working apparatusDistribution controlButt joint

The invention relates to a continuous automatic assembly machine of a lug plate elastic piece. The continuous automatic assembly machine comprises a rack, a power distribution control box, a rotary disc and carriers. A lug plate feeding mechanism, an elastic piece feeding mechanism, a press-fitting mechanism and a discharging mechanism are arranged on the rack. Each carrier comprises a carried material mounting seat embedded into the rotary disc. A carried material seat lifting block penetrating the rotary disc is arranged in each carried material mounting seat. A vertical carried material seat composite spring is arranged between each carried material seat lifting block and the lower portion of the corresponding carried material mounting seat. A carried material seat cooperating with a product is arranged above each carried material seat lifting block. A press-fitting device comprises a press-down device cooperating with the products on the carriers and a carried material seat jackingdevice which is located below the press-down device and cooperates with the carried material seat lifting blocks. According to the continuous automatic assembly machine, the carried material seat lifting blocks and the press-down device can be in butt joint precisely, meanwhile, pressing assembly of a lock piece and a lug plate can be achieved, it can be ensured that the press-down portion is a flat plate between two elastic piece mounting columns, the press-fitting precision is ensured, elastic deformation of the elastic pieces is avoided, and meanwhile continuous automatic machining is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV

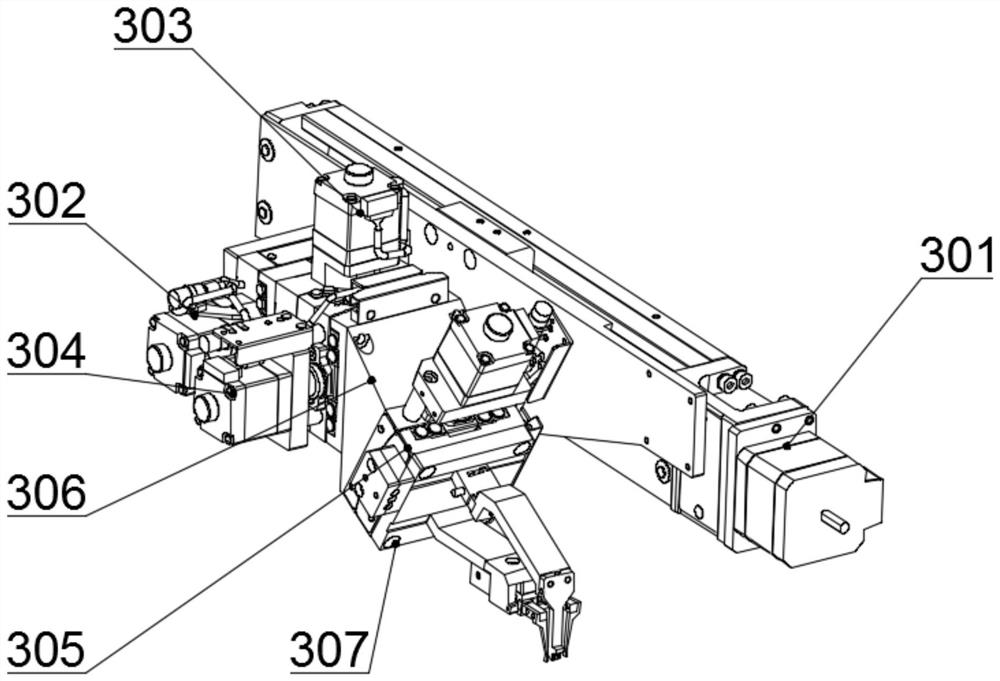

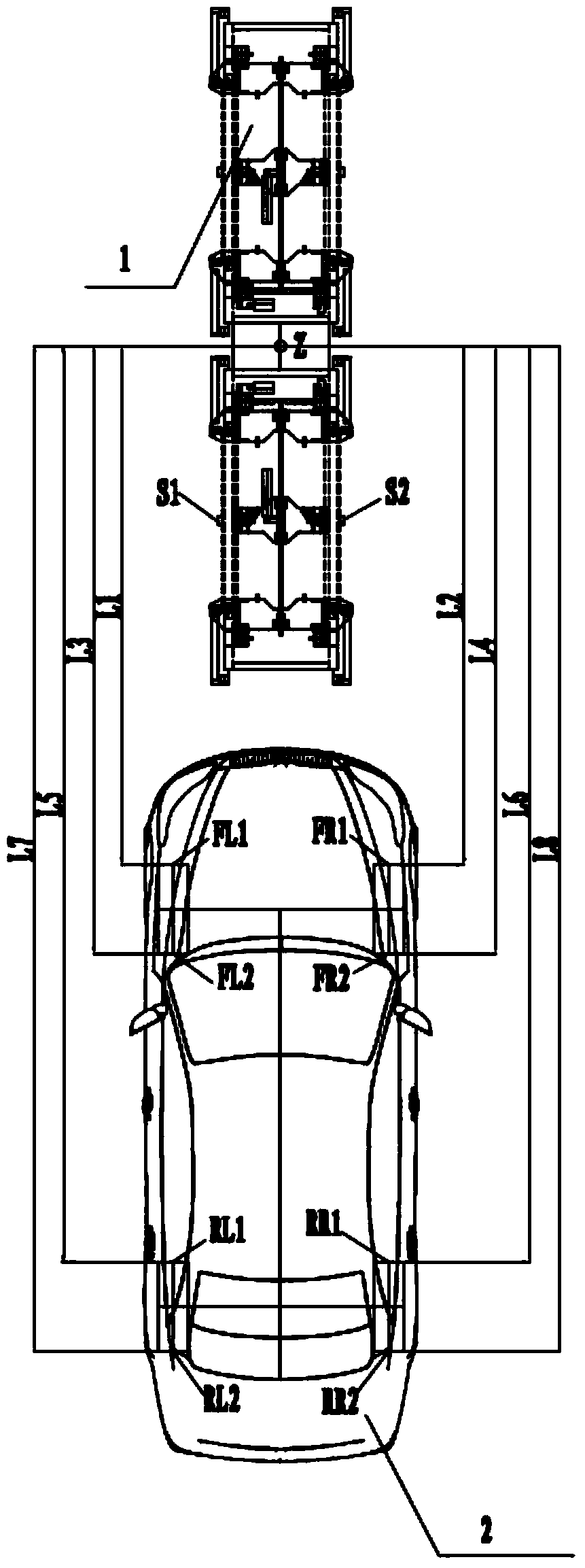

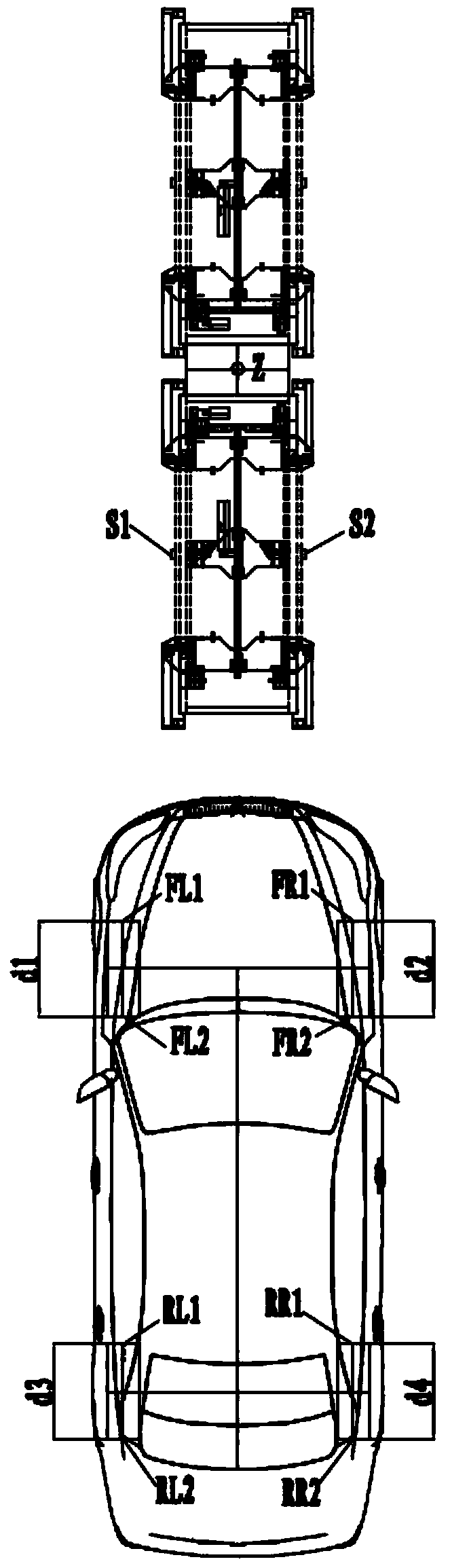

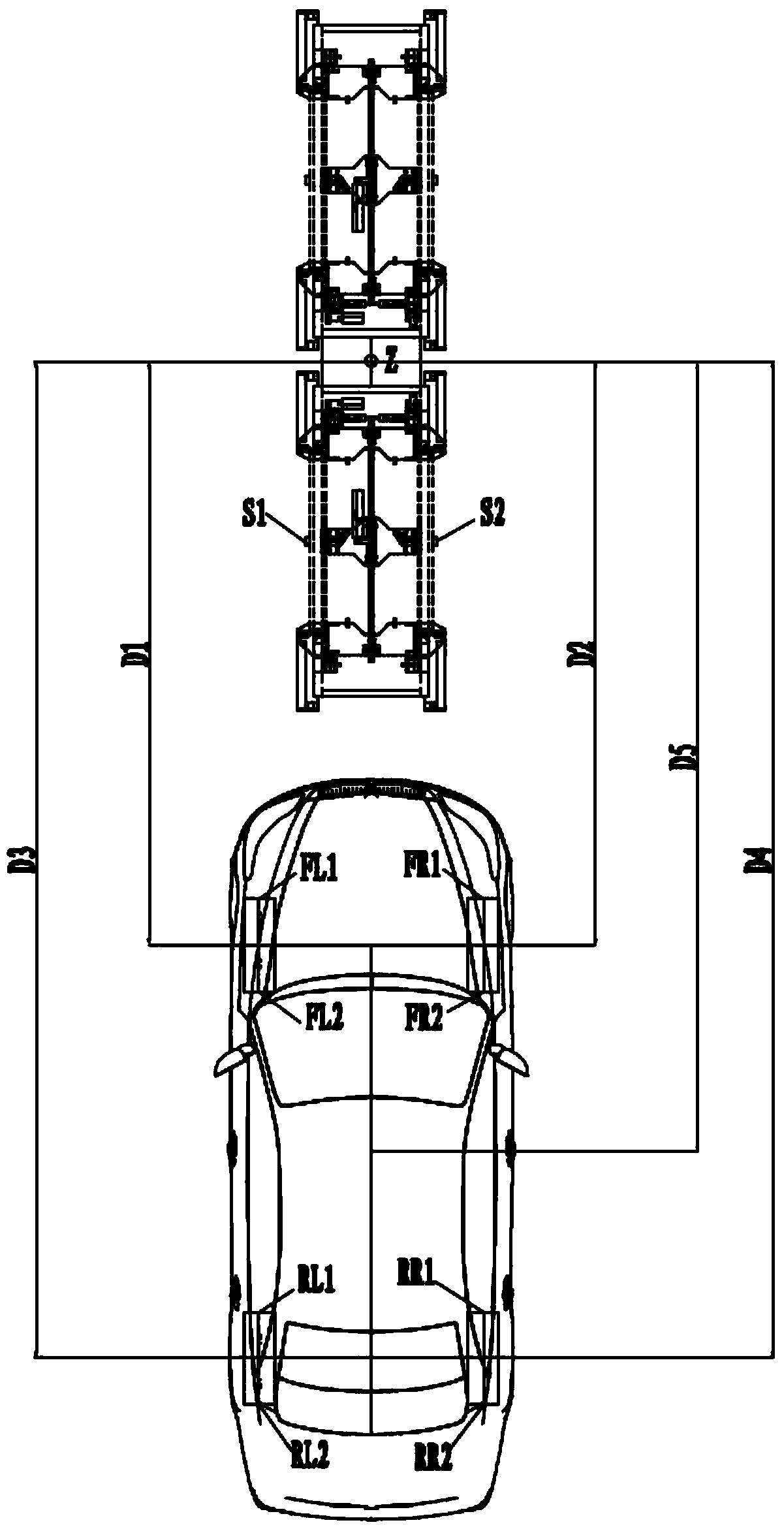

Vehicle parking method based on AGV

The invention discloses a vehicle parking method based on an AGV. A waiting and stopping position for waiting of the AGV is arranged at an entrance of a parking lot, wherein the AGV is positioned in the waiting and stopping position; the AGV is provided with a front frame and a rear frame; at least one frame can move front and back to change the distance between the front frame and the rear frameso as to adapt to the distance between front wheels and rear wheels of a vehicle; the AGV is provided with four sets of clamping arms corresponding to the four wheels; each set of clamping arms is provided with two clamping arms; the two sets of clamping arms corresponding to the two front wheels are positioned on the left side and the right side of the front frame; the two sets of clamping arms corresponding to the two rear wheels are positioned on the left side and the right side of the rear frame; and in the waiting and stopping state, all the clamping arms are folded in the AGV and are inthe longitudinal state, the front frame and the rear frame are adjusted in place according to the distance between the front wheels and the rear wheels of the vehicle, the two clamping arms in each set rotate by 90 degrees relatively and extend out to be in the transverse state, and in the transverse state, the distance between the two clamping arms in each set is smaller than the diameter of thewheels. The parking process is simple, the vehicle clamping stability is high, and the stability of the AGV can be effectively improved.

Owner:因特帕克科技集团有限公司

Full-automatic steel-bead butt welder

PendingCN107378359AQuick cutAccurate clampingWelding/cutting auxillary devicesOther manufacturing equipments/toolsMetallurgyWire cutting

The invention discloses a full-automatic steel-bead butt welder which comprises a frame. The frame is at least provided with a wire clamping mechanism, a welding mechanism and a wire cutting mechanism, the welding mechanism is arranged at least on one side of the wire clamping mechanism and is at least composed of an electrode wire clamping assembly and an electrode bead clamping assembly, and the electrode bead clamping assembly is horizontally arranged on one side of the electrode wire clamping assembly; the wire cutting mechanism is located on one side of the wire clamping mechanism. By the arrangement of the wire cutting mechanism, steel wires can be cut rapidly; meanwhile, by the arrangement of the wire clamping mechanism and the welding mechanism, the steel wires and steel beads can be accurately clamped and subjected to butt-welding rapidly and accurately, a manual cutting and welding process is replaced, production efficiency and quality are improved, material cost and labor cost are lowered, operations are facilitated, and the full-automatic steel-bead butt welder is suitable for scale production.

Owner:江门市新会区国正机电设备有限公司

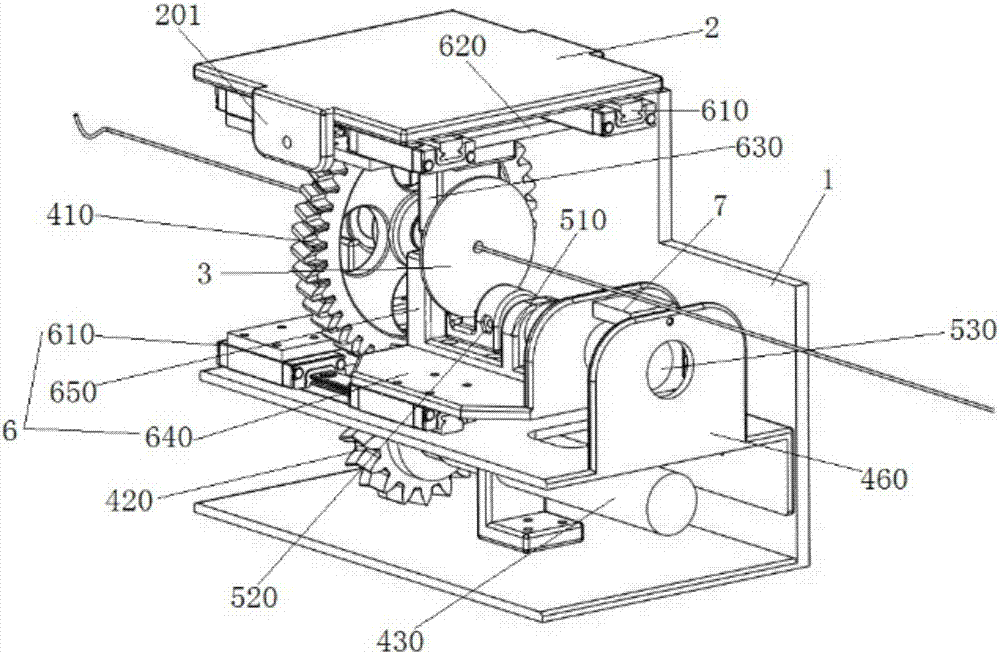

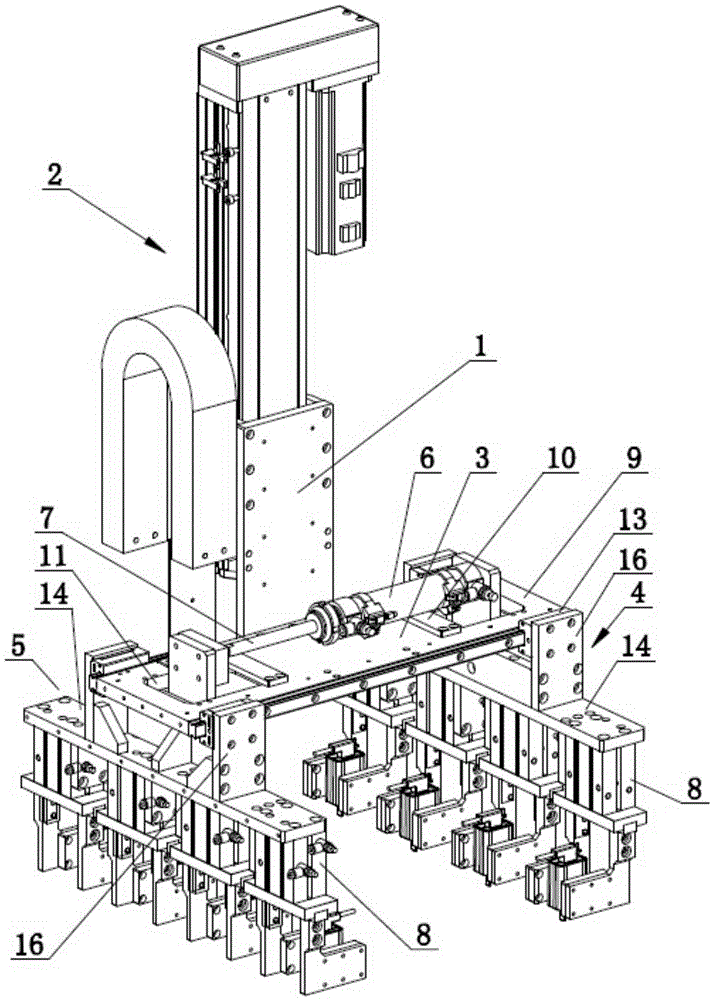

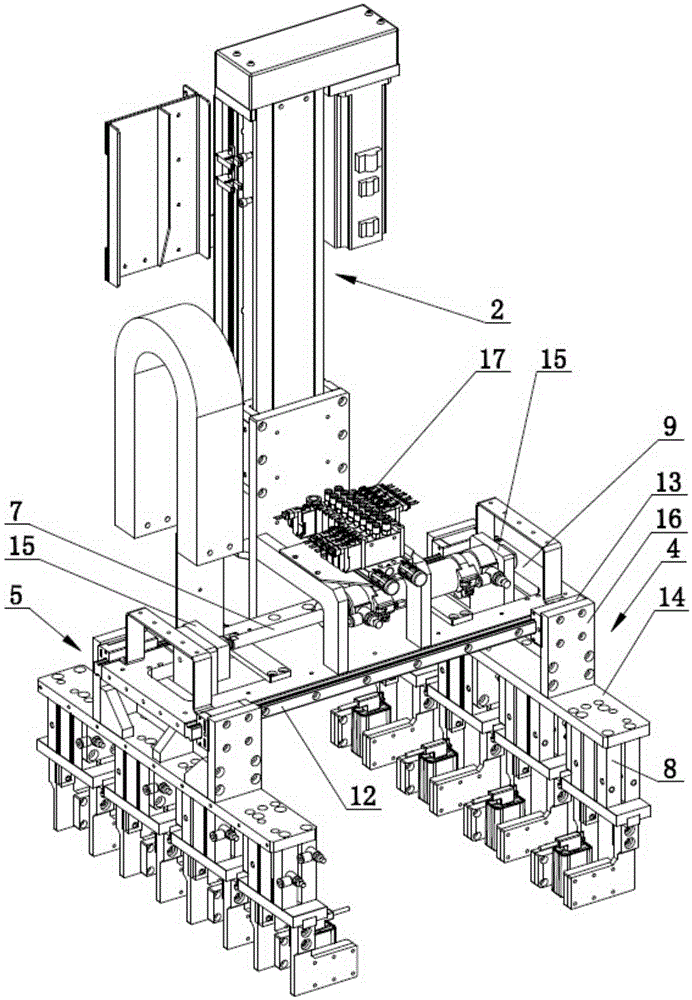

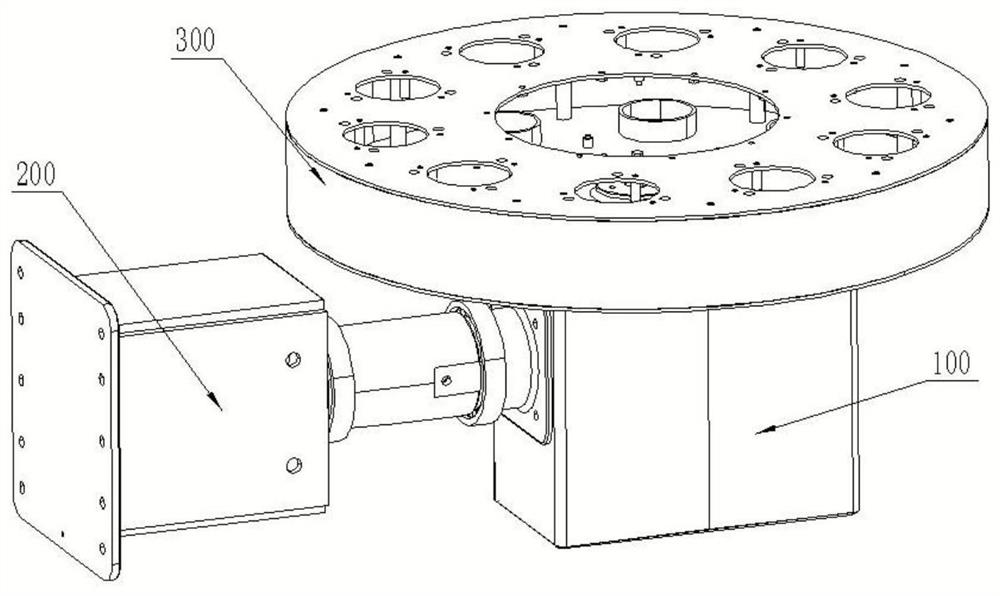

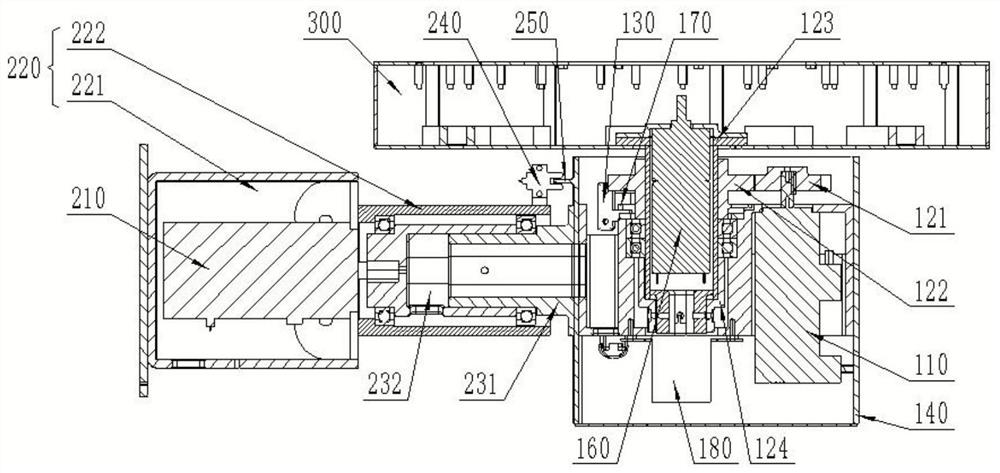

Internet of Things intelligent gas meter speed reducer output end installation system and method

PendingCN113492314ARealize automated assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusReduction driveControl engineering

The invention discloses an Internet of Things intelligent gas meter speed reducer output end installation system which comprises an index plate, the index plate can rotate clockwise around the axis of the index plate, and a plurality of clamps used for containing a speed reducer shell are further arranged on the index plate. The system further comprises a movable sealing ring assembling mechanism, a movable sealing ring plug assembling mechanism and a swing frame assembly assembling mechanism. The movable sealing ring assembling mechanism is used for assembling a movable sealing ring into the speed reducer shell. The movable sealing ring plug assembling mechanism is used for assembling a movable sealing ring plug into the speed reducer shell provided with the movable sealing ring. The swing frame assembly assembling mechanism is used for assembling a swing frame assembly into the speed reducer shell provided with the movable sealing ring plug, and the movable sealing ring assembling mechanism, the movable sealing ring plug assembling mechanism and the swing frame assembly assembling mechanism are sequentially distributed on the circumferential face of the index plate in the rotating direction of the index plate. According to the Internet of Things intelligent gas meter speed reducer output end installation system, automatic assembly of the output end of a speed reducer can be achieved, and the assembly efficiency and the assembly quality of the speed reducer are improved.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

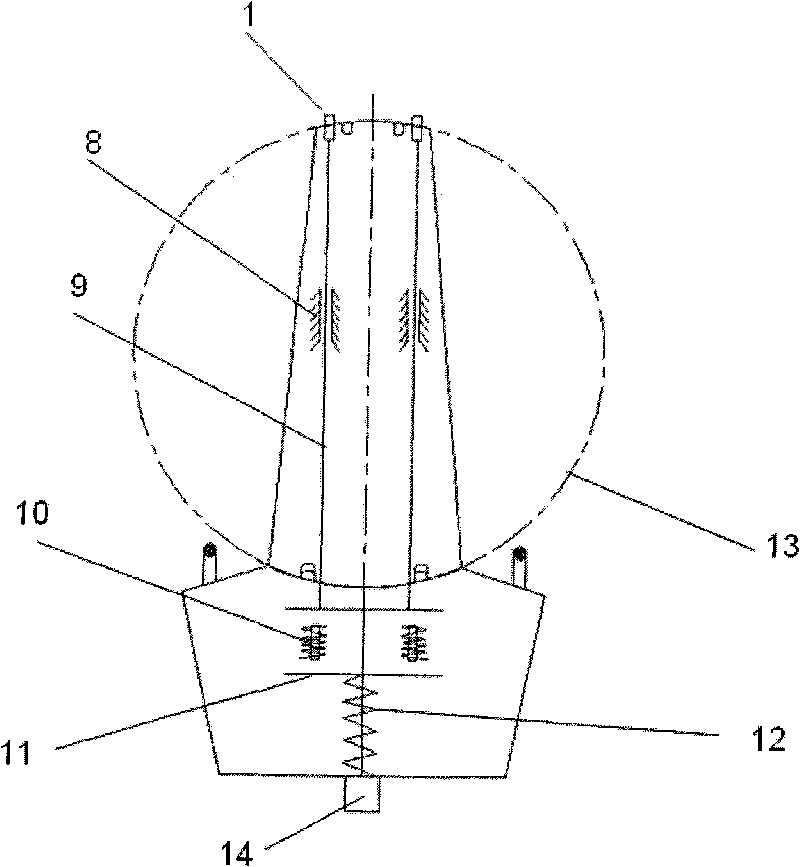

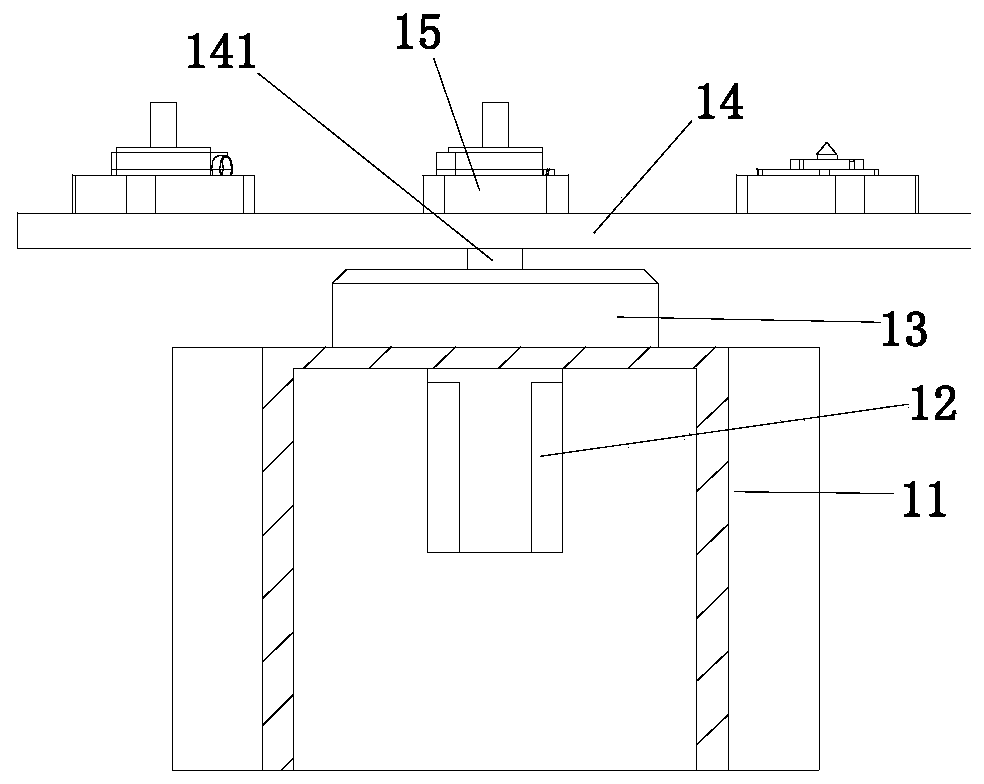

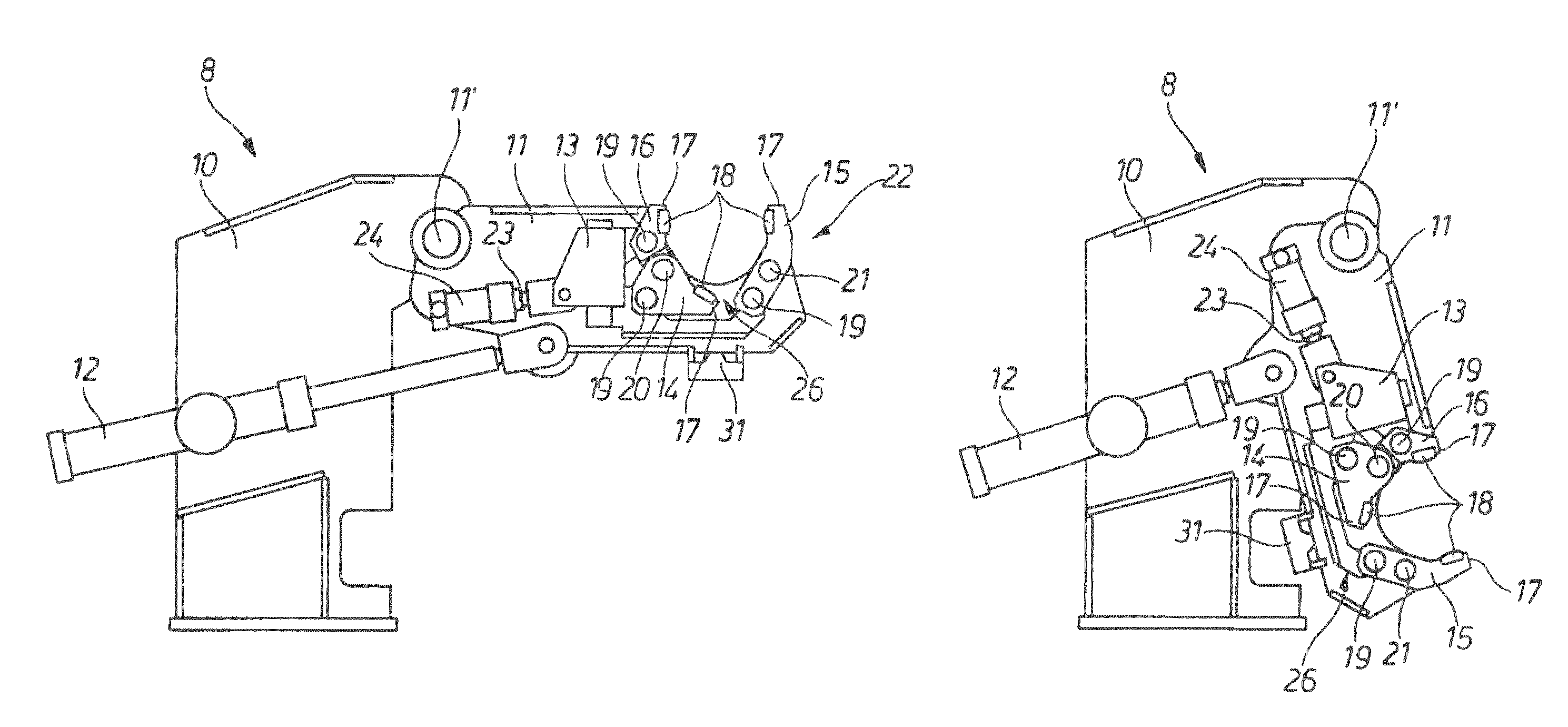

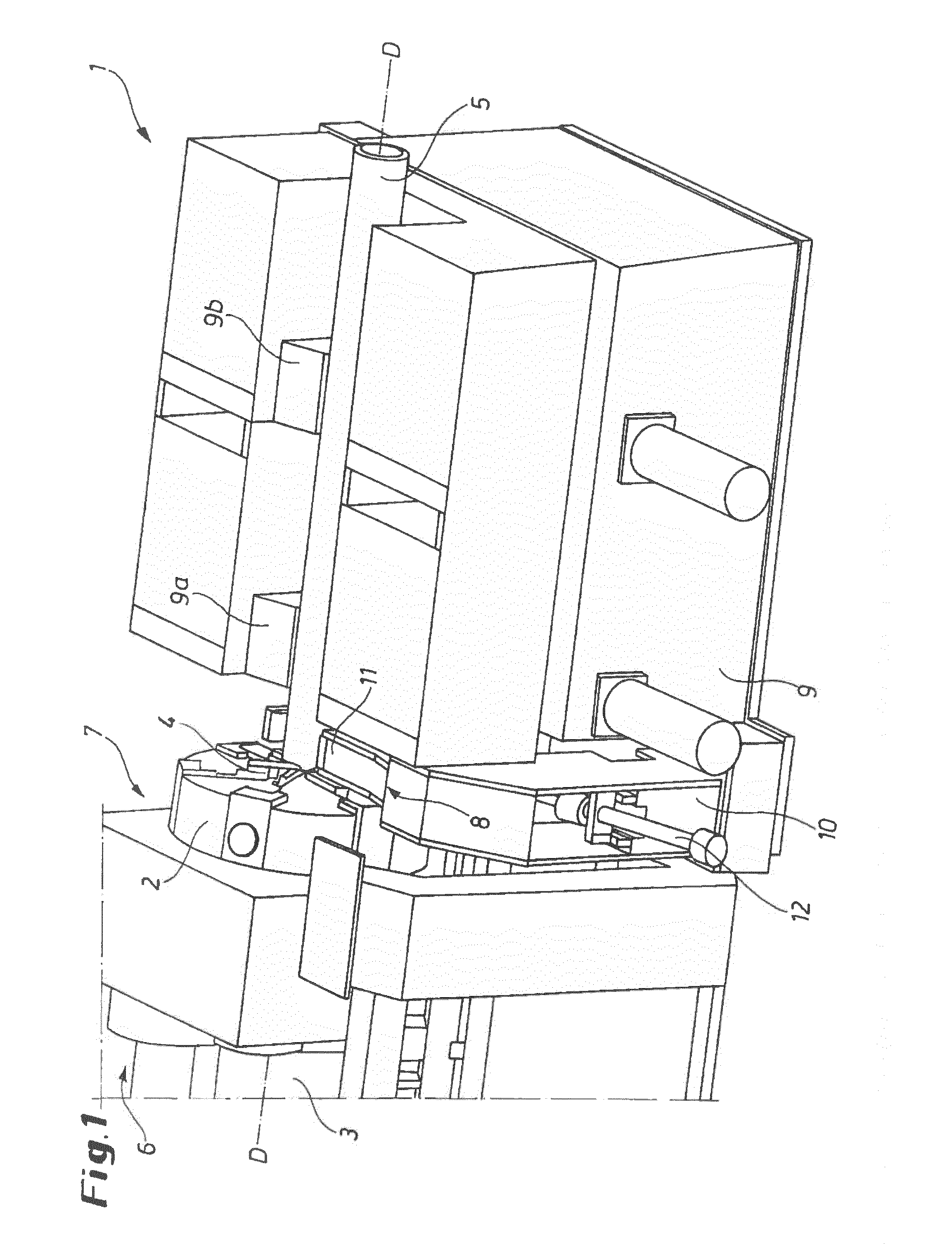

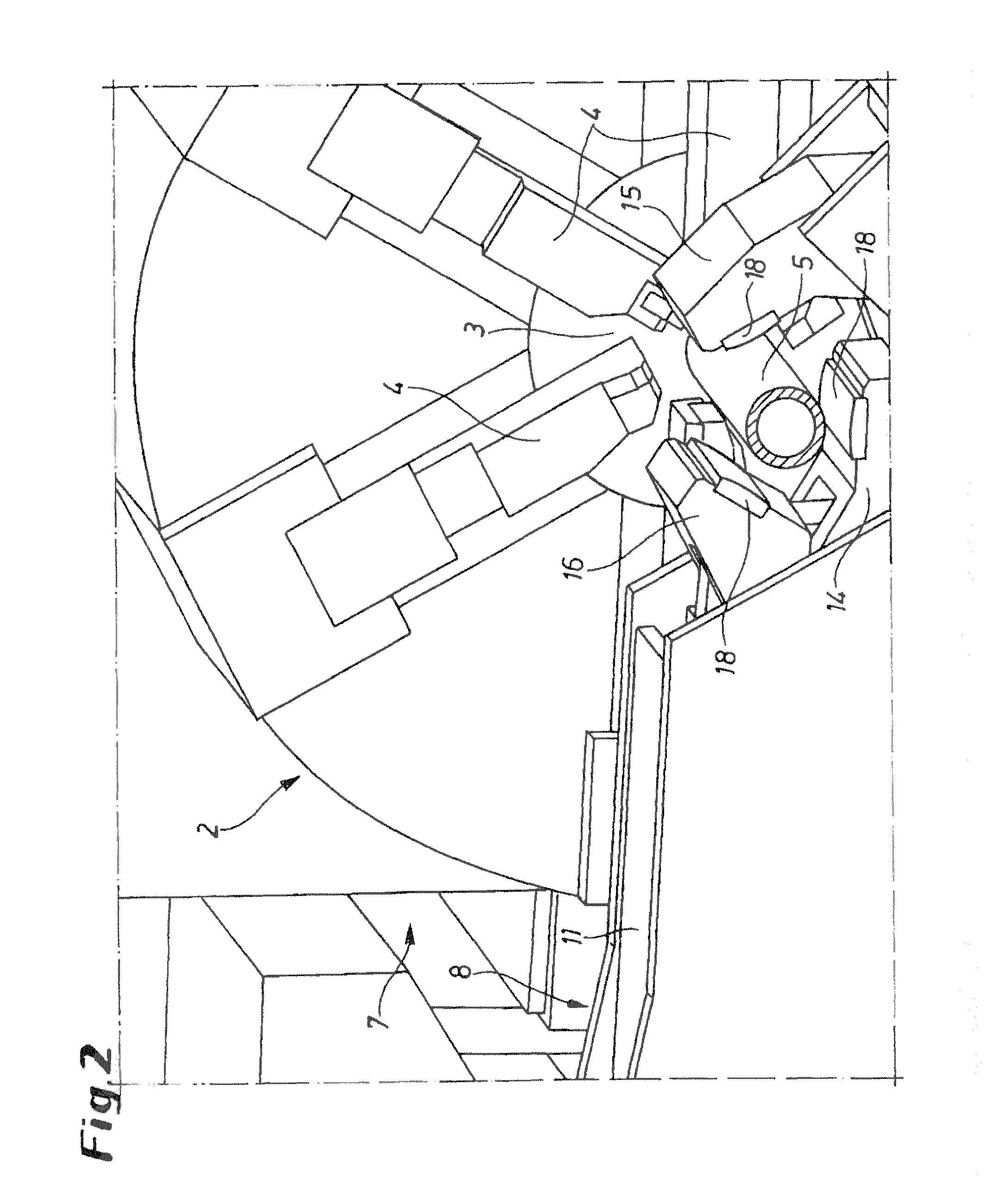

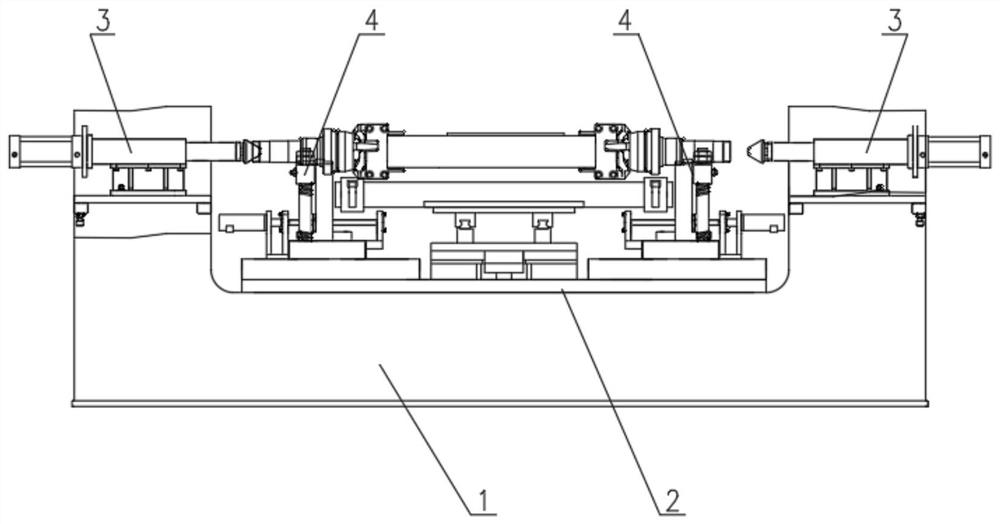

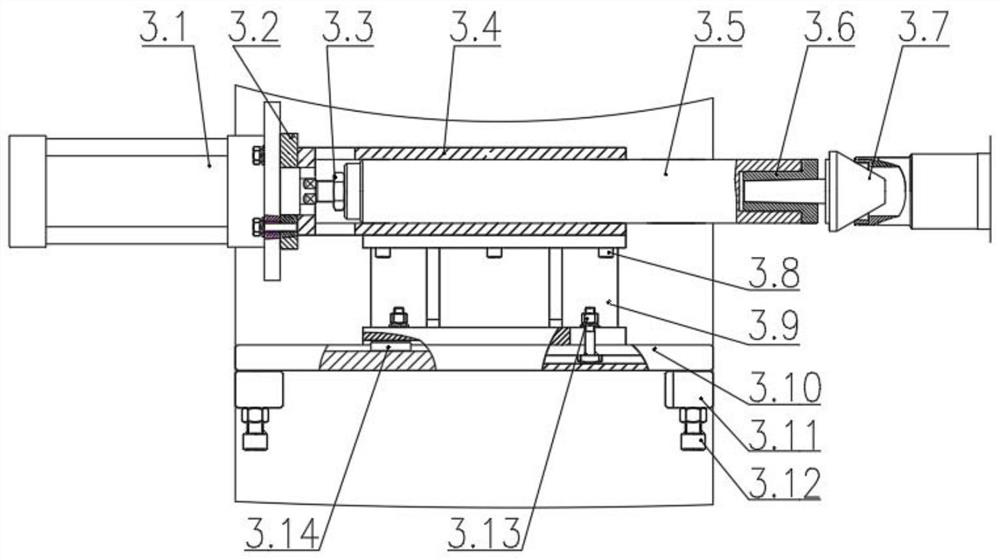

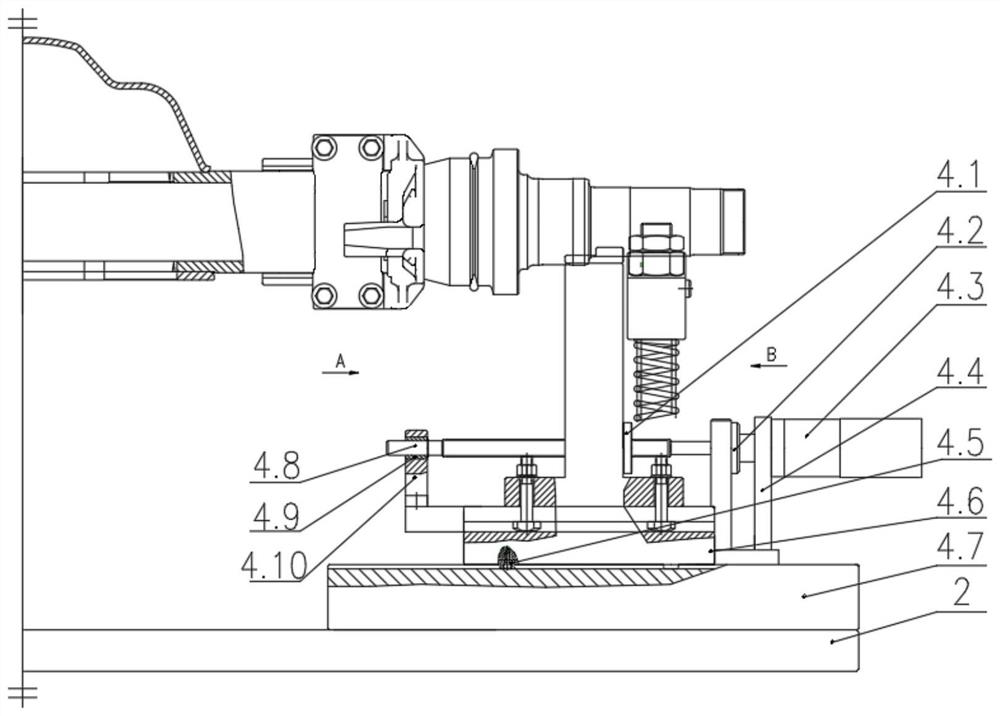

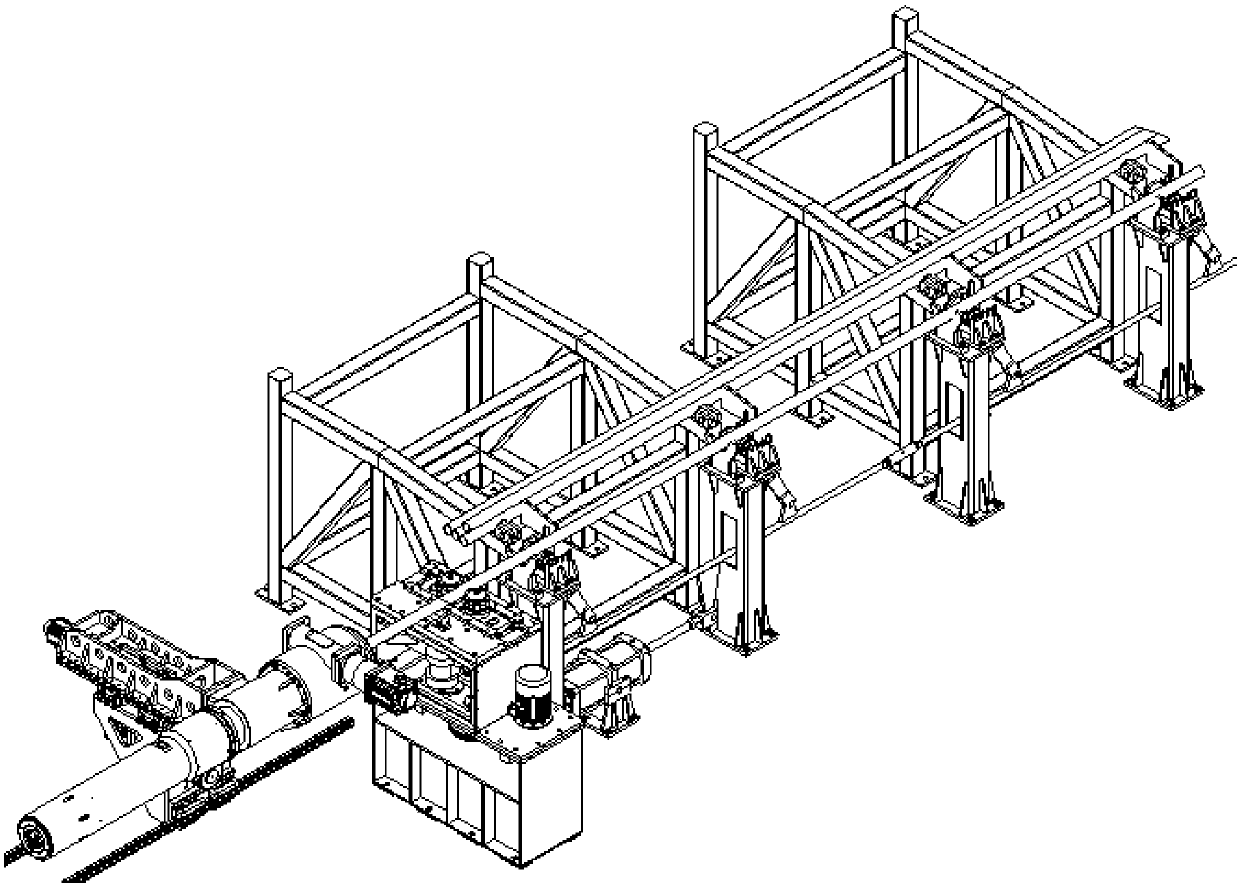

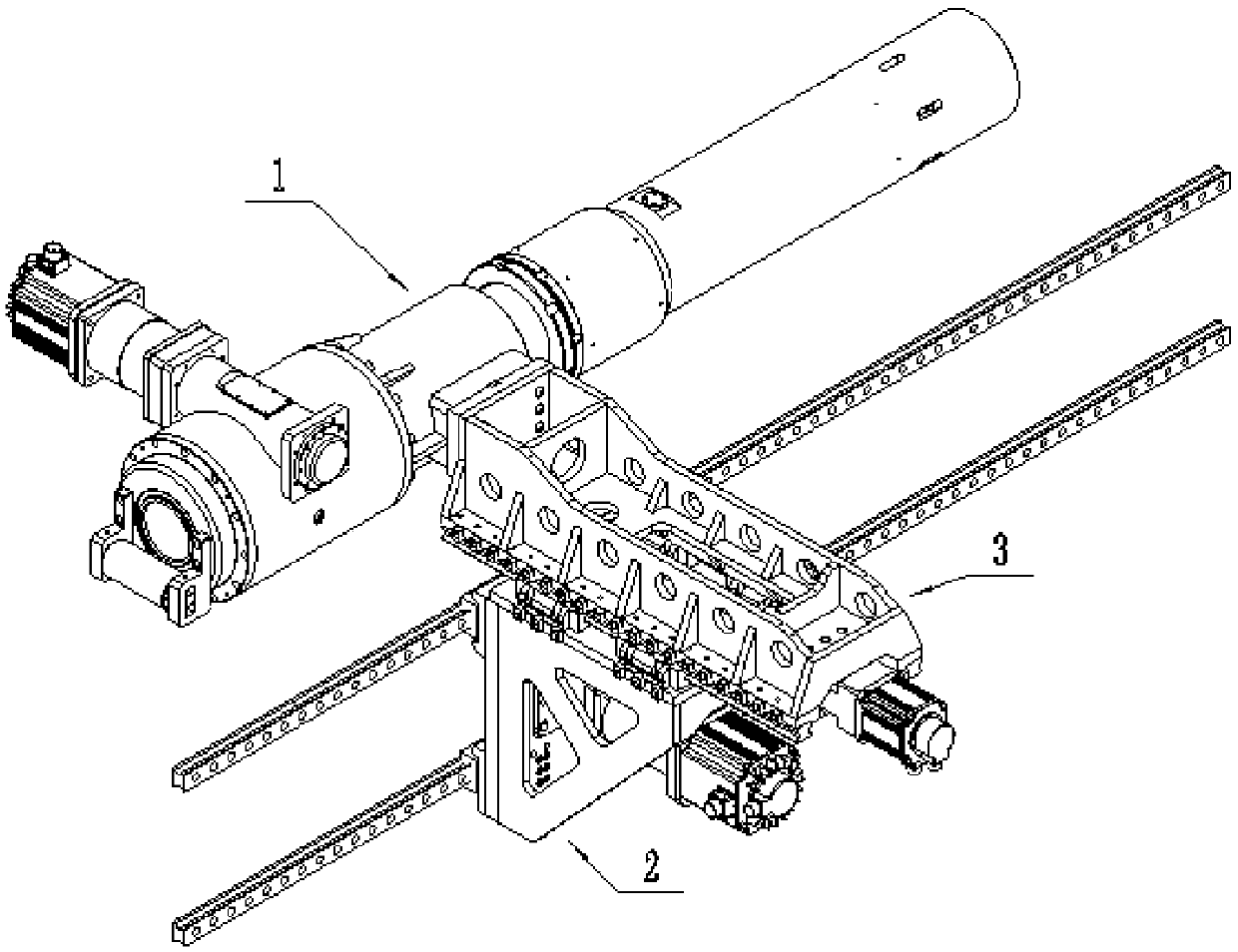

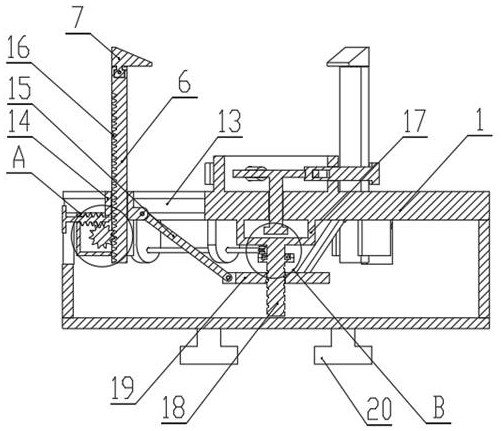

Machine for machining pipe ends, having a centering device for centering a tubular workpiece in relation to an axis of rotation

InactiveUS9533355B2Accurate clampingPrecise positioningLathesAuxillary equipmentMechanical engineering

The invention relates to a machine (1) for machining pipe ends. At least one centering device (8; 35) is associated to said machine, which centering device centers a tubular workpiece (5, 5′) in relation to an axis of rotation (D) of the machine for machining pipe ends extending in the center of the machine, the tubular workpiece either being stationary in the case of a rotating tool head (4) or rotating in the case in which the tubular workpiece is fastened in the machine chuck (9). Precise centering of the tubular workpiece (5, 5′) is quickly and simply achieved in that the centering device (8; 35) has a clamping housing (13; 130) that is open toward the axis of rotation (D), which clamping housing is designed comprising at least three means (14, 15, 16; 140, 150, 160) for contacting the tubular workpiece at the outer circumference and for clamping the tubular workpiece (5, 5′) in a centered manner, which means are circumferentially distributed and adjust mechanically independently of each other to the particular diameter of the workpiece (5, 5′) to be machined.

Owner:SMS MEER

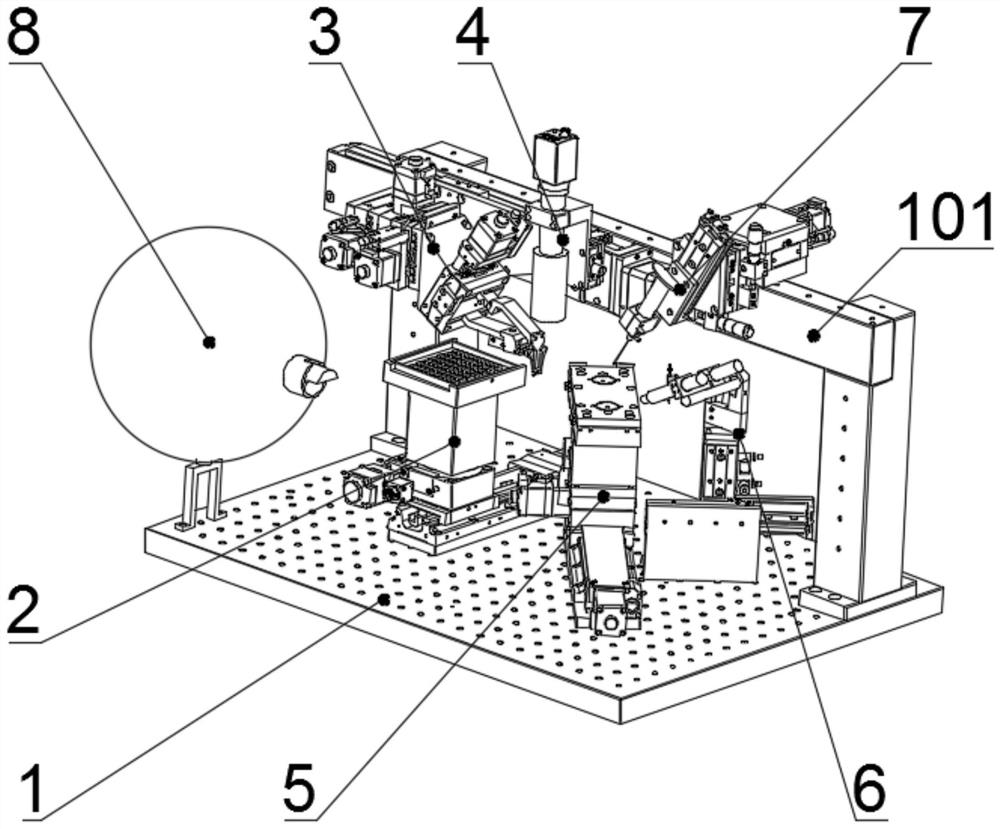

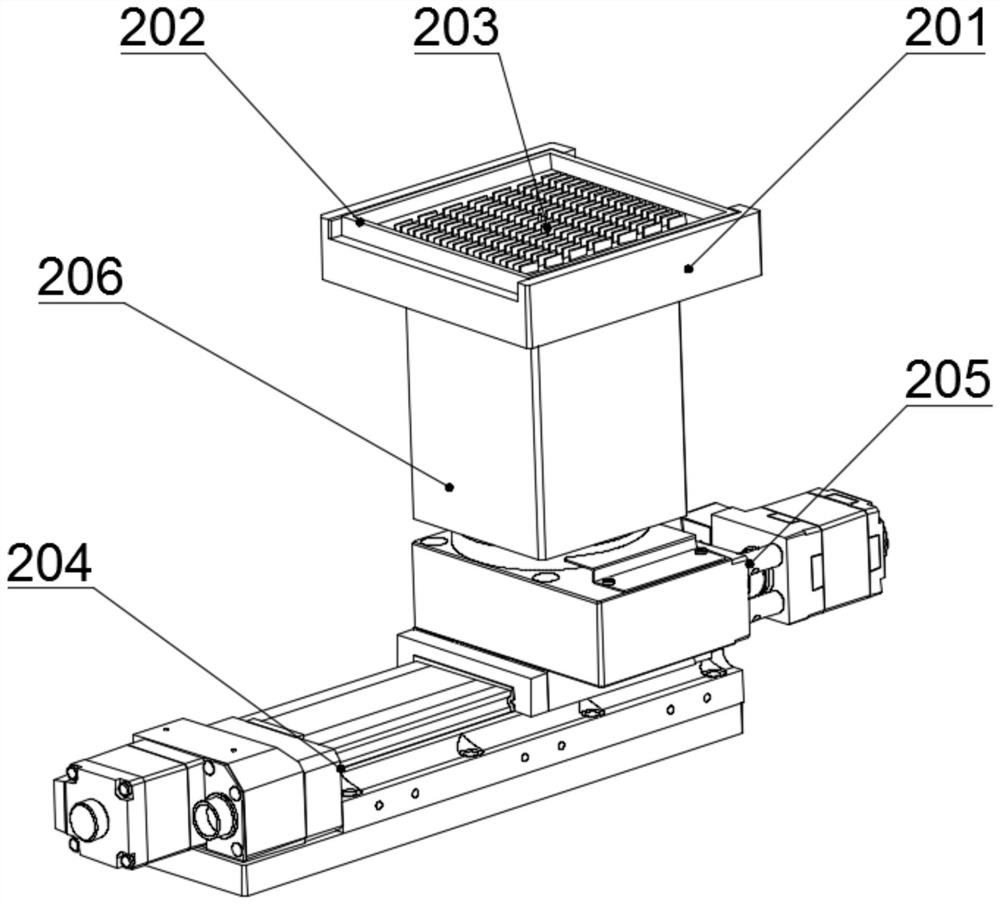

Semiconductor laser array reflector coupling device based on power detection

InactiveCN112387542AAchieve installationAccurate clampingMaterial gluingPretreated surfacesVisual monitoringLaser array

The invention provides a semiconductor laser array reflector coupling device based on power detection, comprising a device bottom plate, a tray unit, a clamp unit, a visual monitoring unit, a materialunit, a probe unit, a dispensing unit and an integrating sphere. The probe unit can power on a laser chip to emit light; the clamp unit clamps a reflector from the tray unit and transports the reflector to the coupling position of the material unit; the reflector is fixed to the coupling position through dispensing and curing of the dispensing unit; a clamp movement mechanism of the clamp unit can drive a clamp mechanism to move freely to implement precise displacement; the clamp mechanism can implement precise clamping through the double effects of clamping and adsorption; and finally, the integrating sphere can determine whether coupling is completed or not according to reflector reflected light received by a light receiving probe. The device is reasonable in structural design, high inautomation degree, capable of implementing automatic coupling and installation of the reflector, high in clamping precision and capable of effectively improving the coupling efficiency.

Owner:CENT SOUTH UNIV

Device and method for measuring wheel base under vehicle stationary state

The invention discloses a device and method for measuring the wheel base under the vehicle stationary state. The device comprises a vehicle getting device, a controller, a servo driver, a servo motor and an encoder. Detection switches are installed on the two sides of the vehicle getting device respectively and connected with the controller. The detection switches transmit detection signals to the controller, and the detection signals are processed through the controller. The controller is connected with the servo driver and the encoder, the servo driver is connected with the encoder and the servo motor, the controller controls running of the servo motor through the servo driver, the servo driver transmits the signals to the controller through the encoder, and the signals are processed through the controller. The servo motor drives the vehicle getting device to run. The device and method have the advantages that as long as a vehicle is parked in the specialized area and is parked uprightly, the measuring result cannot be affected even when steering wheels are not returned in place, and great convenience is brought to a driver to park the vehicle. Four wheels are detected, accepting or rejecting is carried out after the comparison of calculation results, and the accuracy is high.

Owner:SHENYANG YUANDA SCI & TECH PARK

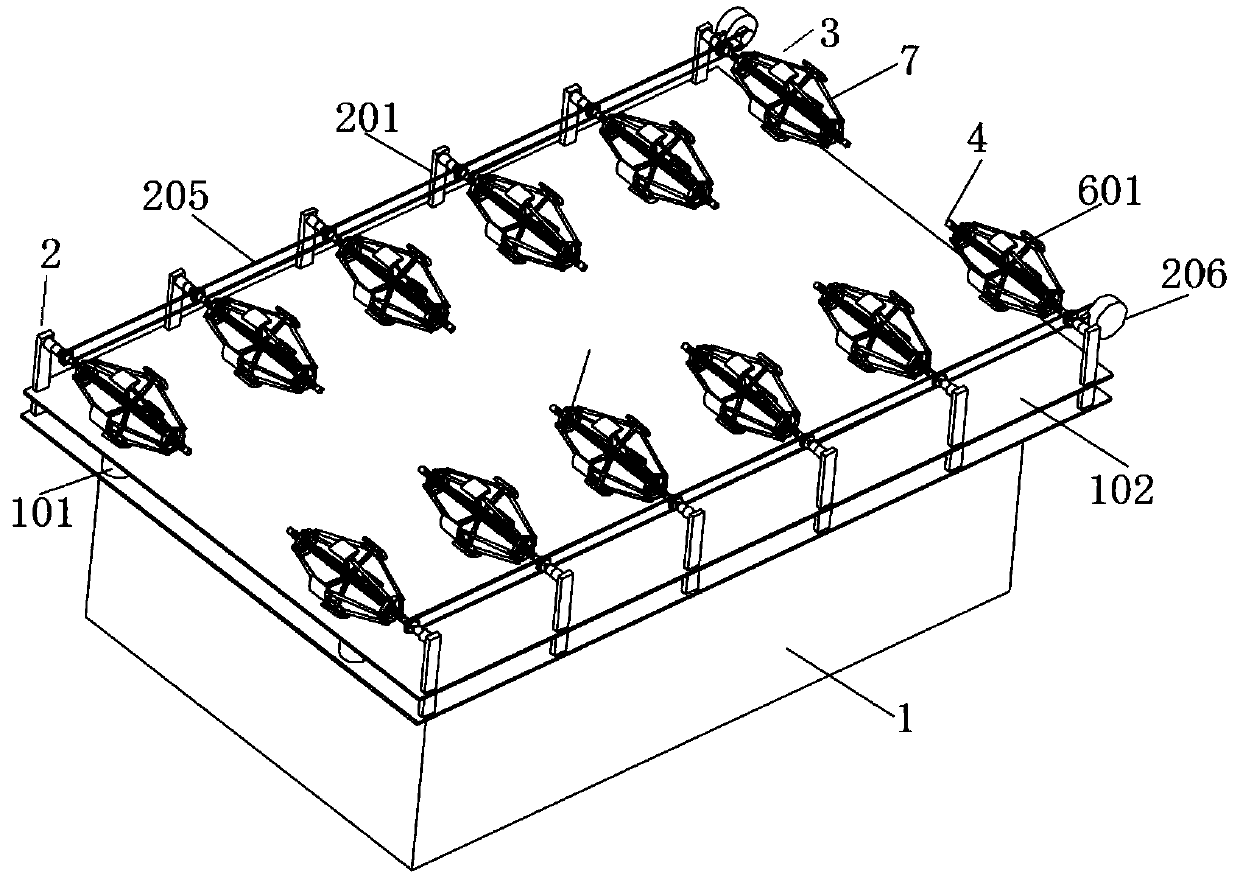

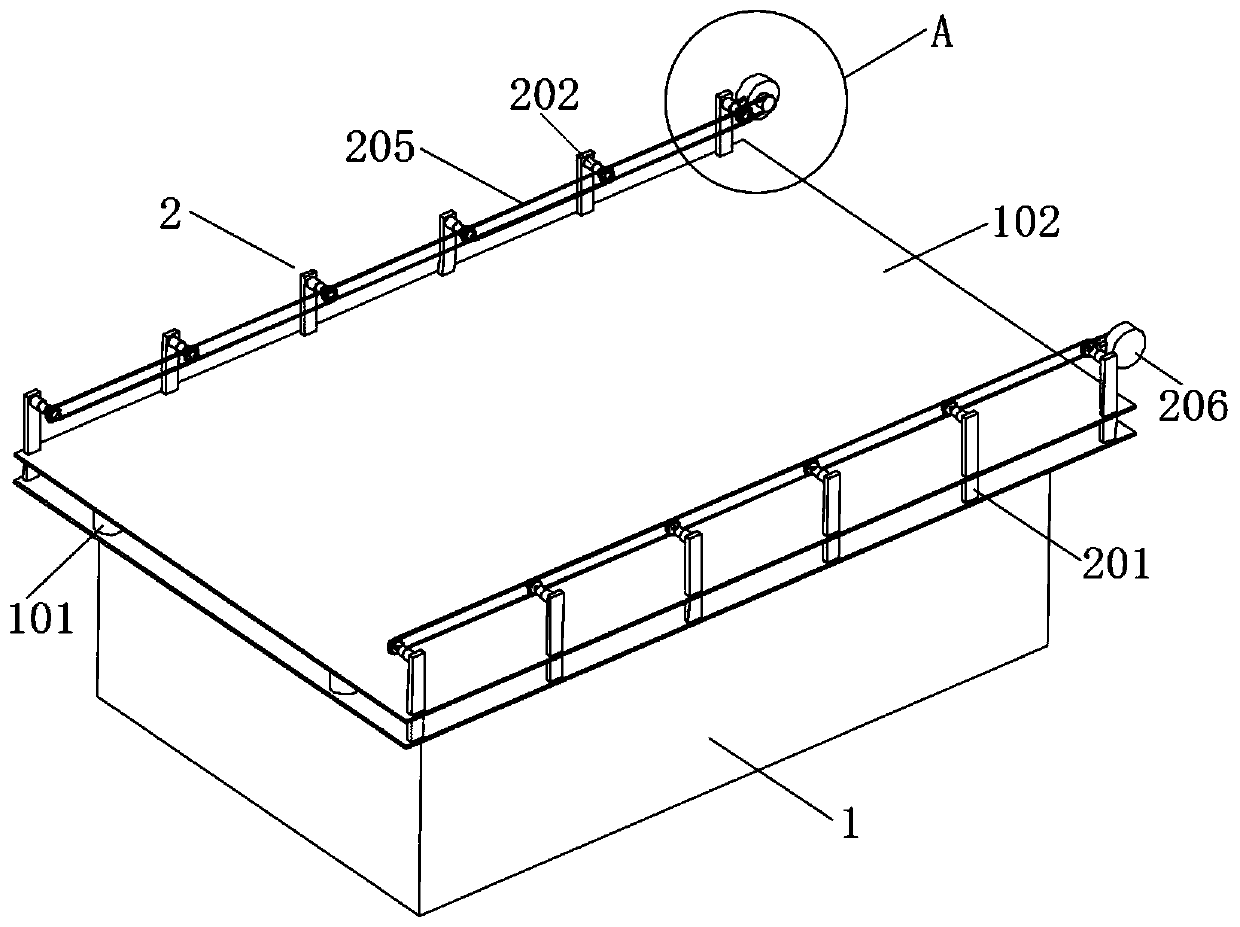

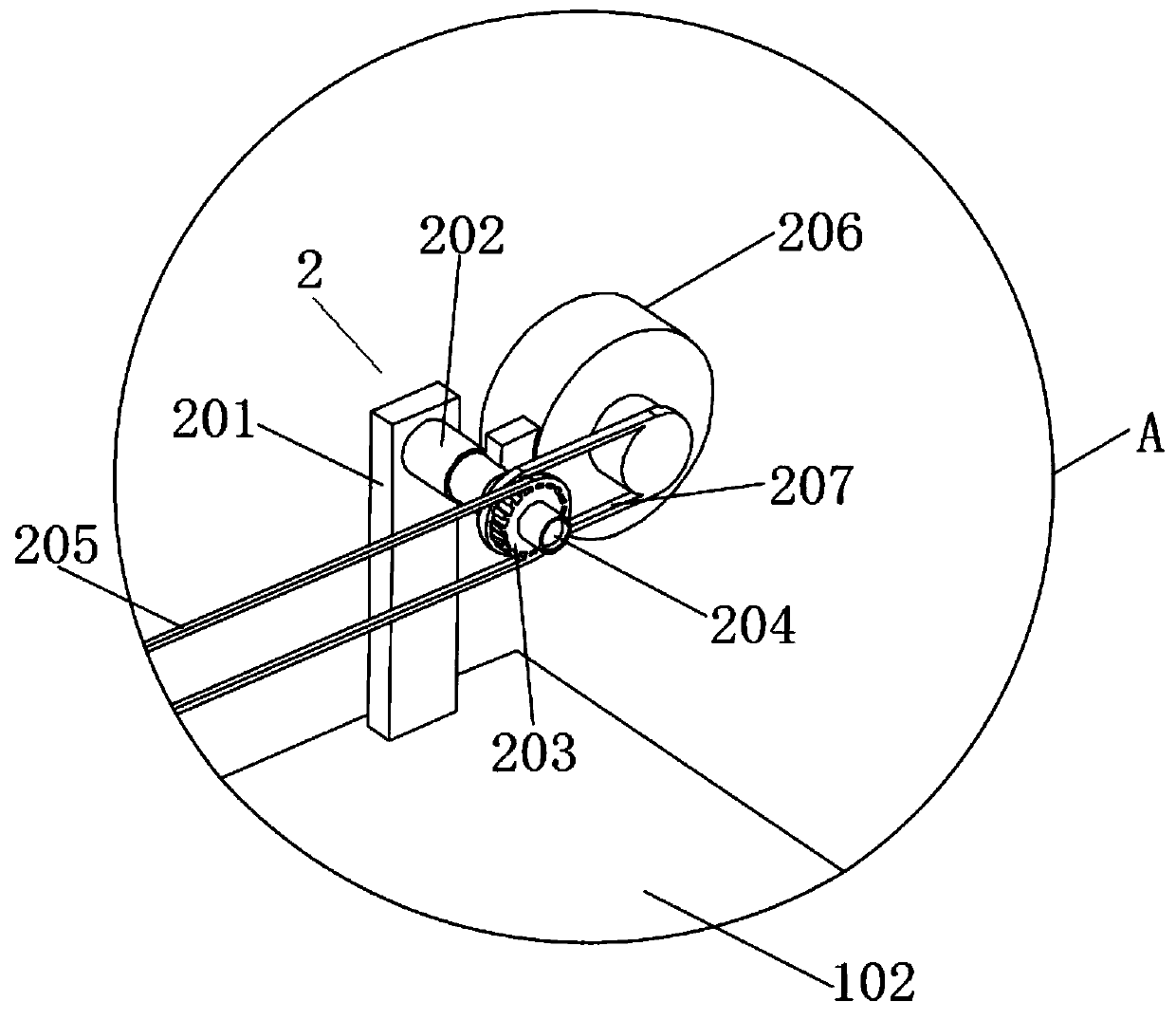

Multi-pipe diameter clamping device c

ActiveCN111013878AAccurate clampingEasy to operateSpraying apparatusPipe fittingStructural engineering

The invention discloses a multi-pipe diameter clamping device based on automation, and relates to the technical field of machinery. The multi-pipe diameter clamping device comprises a working platform, wherein a plurality of pairs of movable assemblies are arranged on the upper surface of the working platform, a clamping assembly is arranged in each movable assembly, each clamping assembly comprises a sliding rod, a plurality of supporting pipes are movably connected to the circumferential side face of the sliding rod, supporting blocks are movably connected to the inner walls of the supporting pipes, connecting rods are movably connected to the two sides of each supporting block, connecting rods on each side of the supporting blocks are movably connected to a fixing ring, a plurality of electric lifting rods are fixedly connected to the upper surface of the working platform, and the telescopic ends of the electric lifting rods are fixed to the lower surface of the supporting platform.According to the device, through the action of the working platform, the movable assemblies, the clamping assemblies, the sliding rods, the supporting pipes, the supporting blocks and the connectingrods, pipes with different diameters and different lengths can be conveniently clamped, the pipes can be conveniently processed in batches, the operation is convenient, and the machining efficiency ishigh.

Owner:浙江五梅开酒业有限公司

Motorcycle frame rear body assembly welding jig

InactiveCN104690472AMeets targeting requirementsSimple structureWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameLeft half

The invention discloses a motorcycle frame rear body assembly welding jig. The motorcycle frame rear body assembly welding jig is characterized in that a lower bottom plate is provided with a left half body assembly positioning mechanism, a right half body assembly positioning mechanism, a fuel tank rear mounting bracket component positioning mechanism, a left and right connecting plate positioning mechanism, and a seat lock mounting bracket component positioning mechanism; the left half body assembly positioning mechanism and the right half body assembly positioning mechanism are symmetrically arranged; an upper front bottom plate and an upper rear bottom plate are respectively arranged on the two sides of the lower bottom plate through support structures; a certain space is reserved between the upper front bottom plate and the upper rear bottom plate, so that a left half body assembly support pipe and a right half body assembly support pipe can pass in a downwardly inclined manner. The motorcycle frame rear body assembly welding jig provided by the invention has the advantages that clamp positioning of all parts of a motorcycle frame rear body assembly is integrated, so that the jig structure is simplified, fewer clamp positioning points and rapid clamping are achieved, accordingly, the product loading / unloading time for the jig is shortened, and the welding efficiency is improved; meanwhile, the positioning of all the parts is more accurate and precise, and the assembly positioning requirements are better met, so that the forming quality of the welded frame rear body assembly is higher.

Owner:力帆科技(集团)股份有限公司

Straightening auxiliary device

PendingCN112474895AQuick changeEasy to replaceMetal-working feeding devicesPositioning devicesReciprocating motionBall screw

The invention discloses a straightening auxiliary device which comprises ejector pin mechanisms which are fixed to the two sides of a machine body stand column respectively and used for clamping a workpiece, and a V-shaped supporting and floating mechanism which is matched with the ejector pin mechanisms and used for supporting the workpiece. The V-shaped supporting and floating mechanism comprises a V-shaped supporting base, a floating supporting base arranged on the back of the V-shaped supporting base and used for supporting the workpiece together with the V-shaped supporting base, a servomotor in drive connection with the V-shaped supporting base, and a ball screw assembly. The servo motor drives the V-shaped supporting base and the floating supporting base to do horizontal reciprocating motion in the axial direction of the workpiece through the ball screw assembly. According to the straightening auxiliary device provided by the invention, a servo speed reducer and the ball screware adopted for transmission, so that left-right movement of the V-shaped supporting and floating mechanism is achieved; a left ejector pin and a right ejector pin are pneumatically driven, so that workpiece clamping and positioning functions of the ejector pin mechanisms are achieved; and lifting adjustment can be conducted on the ejector pin mechanisms according to needs, so that the straightening speed and precision of a pressing machine and the convenience of product replacement are improved.

Owner:HEFEI METALFORMING MACHINE TOOL

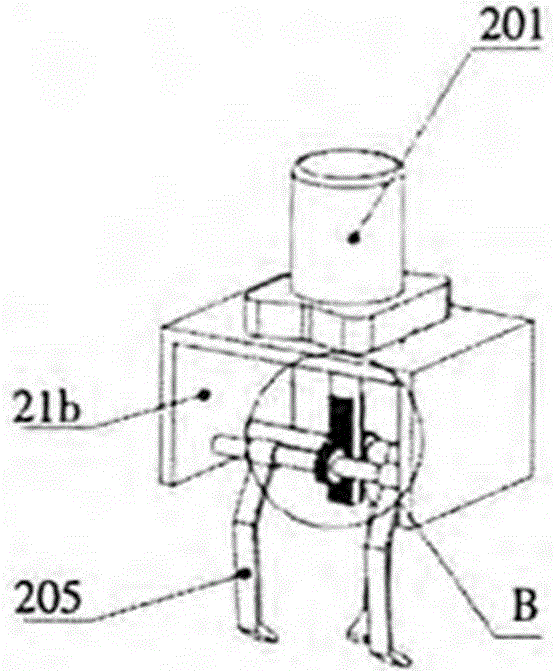

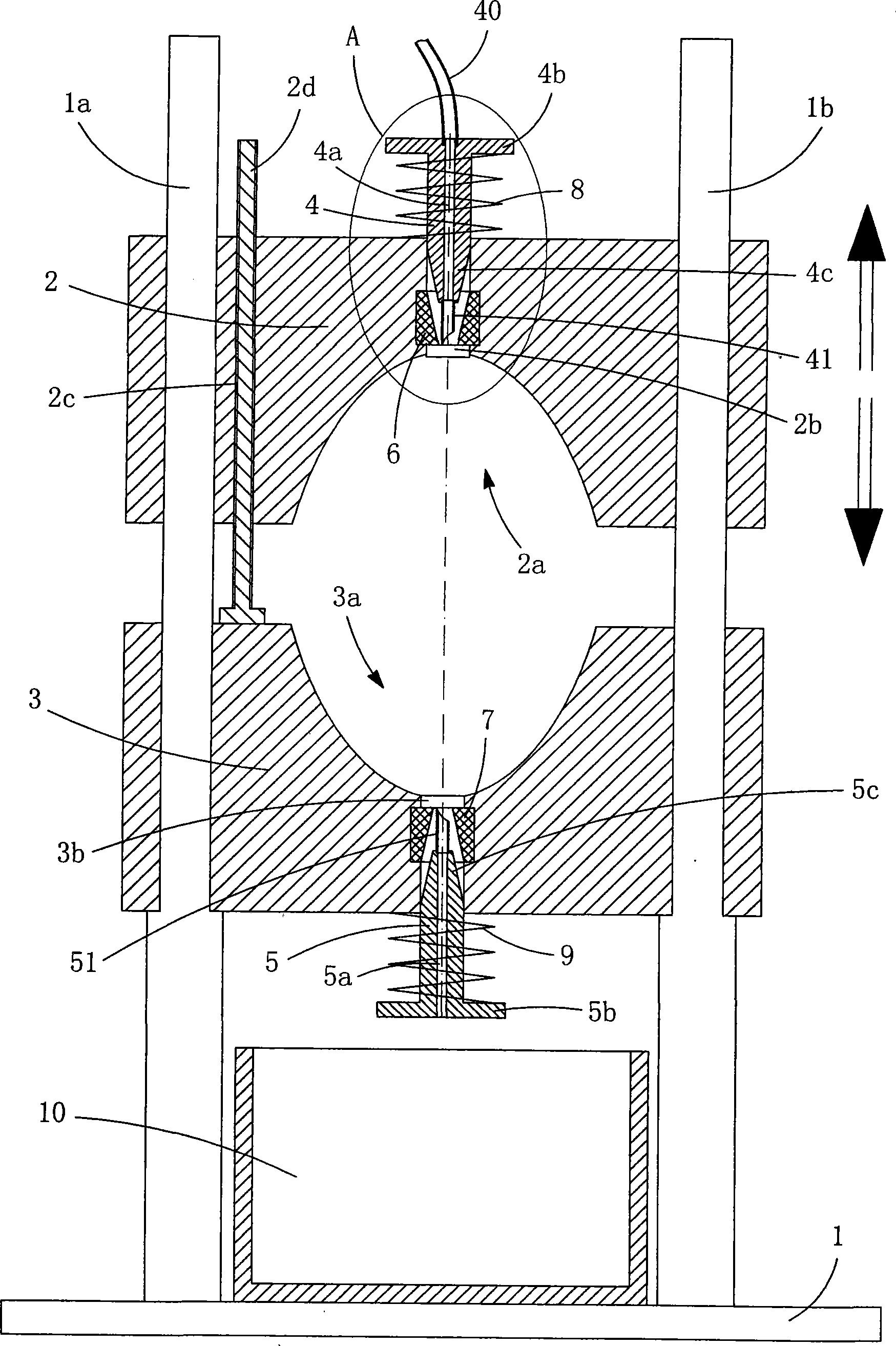

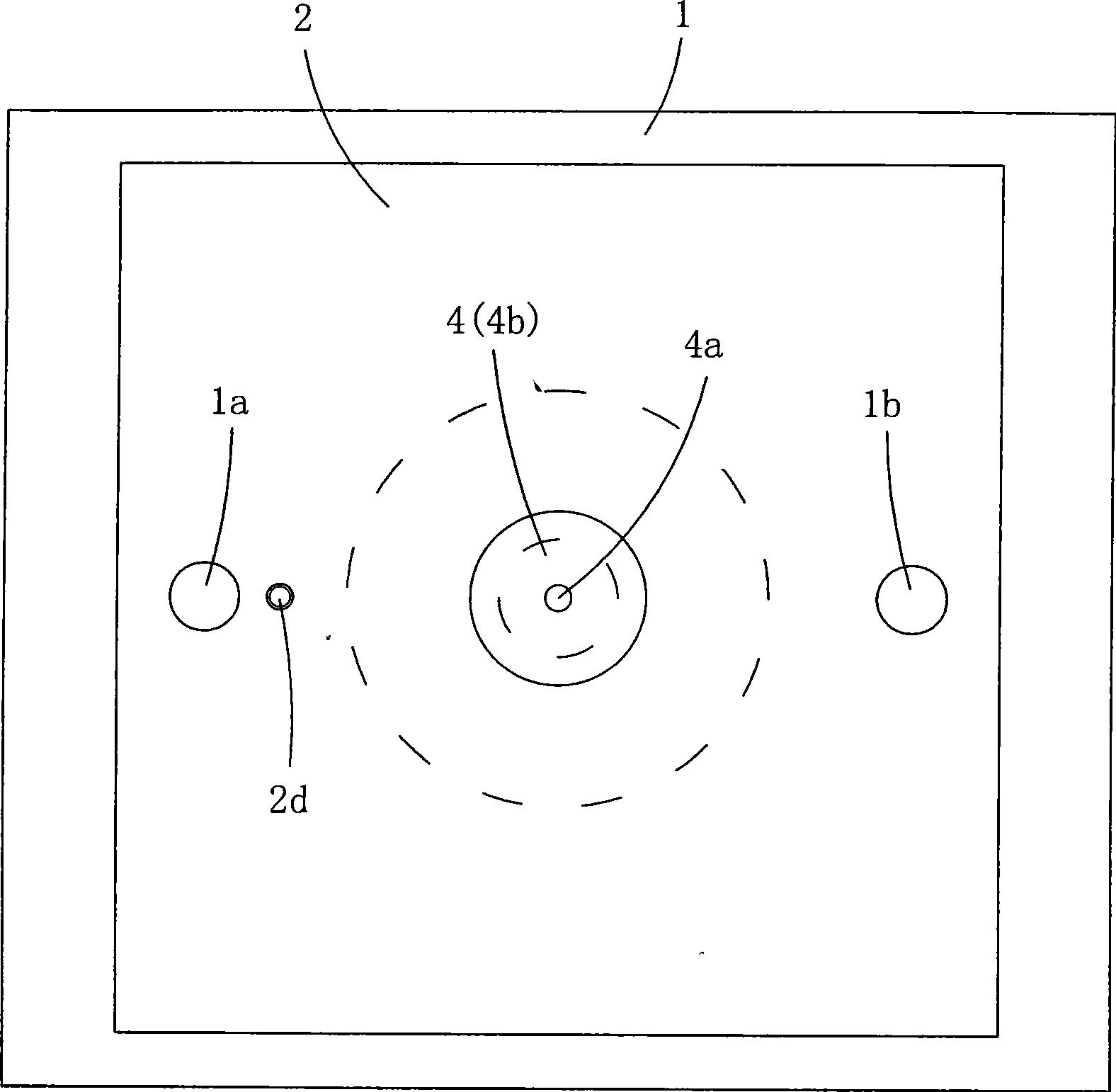

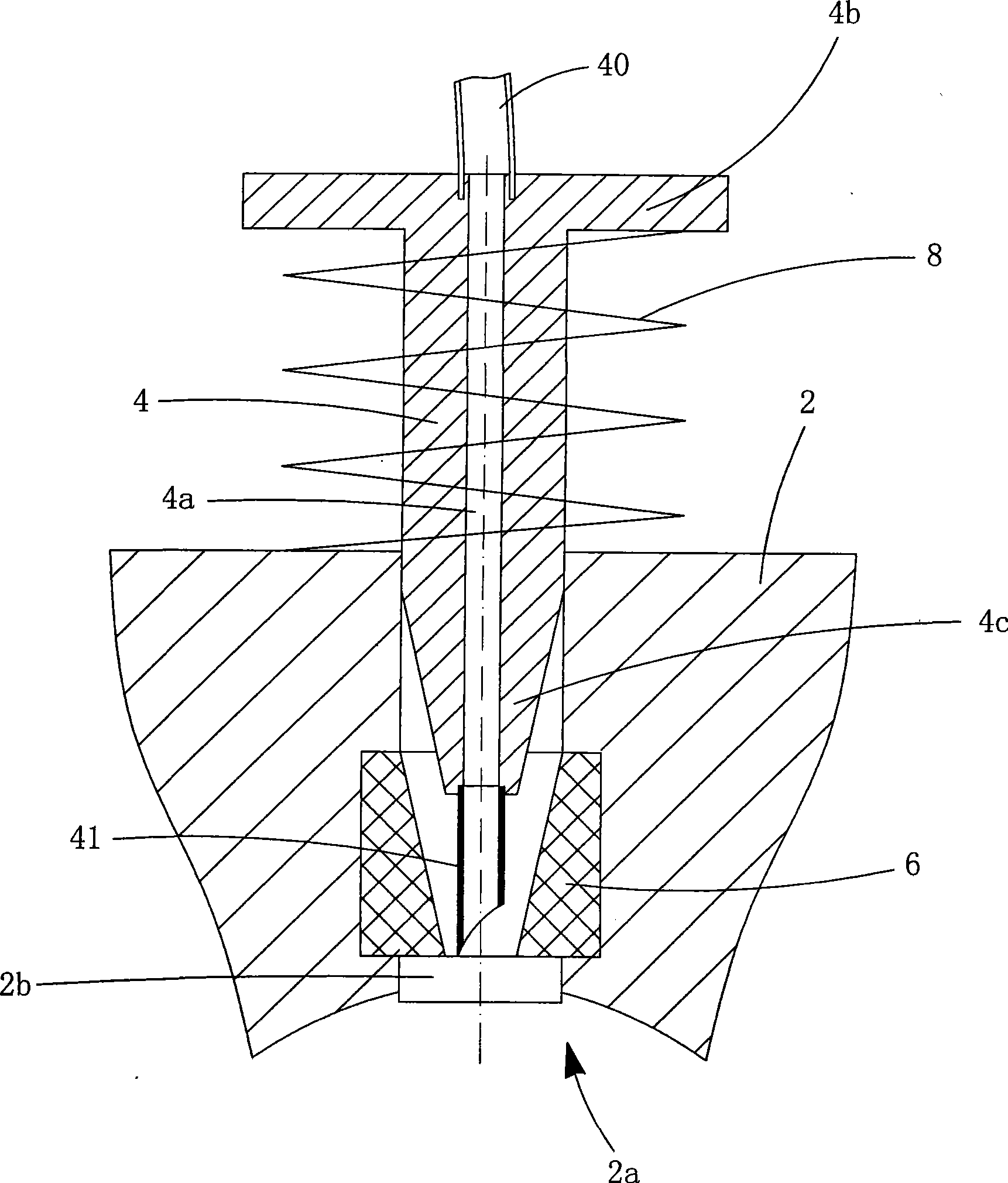

Device for producing complete empty eggshell

InactiveCN101519017AAccurate clampingAccurate piercingSpecial ornamental structuresKitchen equipmentEggshellEngineering

The invention relates to a device for producing a complete empty eggshell. The device is characterized by comprising a horizontal base plate, an upper seat body and a lower seat body, wherein an upright post which is upwards and vertically extended is fixed on the horizontal base plate, and the upper seat body and the lower seat body are correspondingly arranged on the upright post; the lower seat body is fixed at the middle lower part of the upright post, the upper seat body is correspondingly and moveably sheathed on the upright post above the lower seat body, and the upper seat body can slide up and down along the upright post; the middle parts of the opposite faces of the upper seat body and the lower sat body are correspondingly provided with egg cutting concave cavities in a concave way, and the bottoms of the two concave cavities are correspondingly provided with central through holes lengthwise and vertically arranged. The device also comprises hand push rods which are in slide fit in the central through holes of the upper seat body and the lower seat body, and needle heads are correspondingly inserted in the middle parts of the inner end heads of the hand push rods; and positioning and reset mechanisms are arranged between the corresponding hand push rods and the seat bodies. A vertical raw egg can be accurately clamped by the upper seat body and the lower seat body of which the opposite faces are correspondingly provided with the egg cutting concave cavities, and the upper and lower needle heads which are matched with each other are used for accurately piercing the eggshell, thereby preventing the raw egg manually held and nipped from being broken during the process of piercing, and guaranteeing the process of piercing is accurate, safe and reliable.

Owner:洪雄赐

Floating clamping jaw for lathe machining

The invention discloses a floating clamping jaw for lathe machining. The floating clamping jaw comprises a floating clamping jaw body, a floating clamping jaw base and a floating jaw T-shaped block which are sequentially connected through a floating jaw screw, the floating clamping jaw base and the floating jaw T-shaped block are fixed through a clamping screw, the floating clamping jaw is limited to the floating jaw screw in a rotating mode, the working face of the floating clamping jaw is fixedly provided with a plurality of floating jaw cushion blocks, the floating clamping jaw base is connected with the floating clamping jaw body through a positioning pin, and an elastic deformation body is further arranged between the positioning pin and the floating clamping jaw body in a sleeved mode. By means of the method, parts to be machined through a lathe can be positioned and clamped precisely and reliably, problems of inclined clamping, deformation of part clamping, clamping jaw wear and the like are avoided and clamping accuracy is improved.

Owner:CHANGSHU CHANGZHOU BEARING

Drill clamp for connecting rod rest of needle core bed

InactiveCN101954607AStable processingPrecise processingPositioning apparatusDrill jigsBiomedical engineeringMachining

The invention belongs to the field of textile machinery machining tools, in particular to a drill clamp for a connecting rod rest of a needle core bed. The drill clamp comprises a rectangular body of which at least one end is provided with an opening; the periphery of the body comprises a main surface, a back surface and two side surfaces; a supporting plate is arranged in the body; a bush plate is arranged at the opening; the two side surfaces of the body are provided with longitudinal clamping devices, wherein the wall of at least one side surface is provided with an axial positioning mechanism; the main surface of the body is provided with a positioning device which is vertical to both the longitudinal direction and the axial direction in space; the back surface is provided with a plurality of through drill holes and a support structure; the bush plate is provided with a clamp body; the clamp body is extended into the body from the outside of the bush plate; and the clamping devices act on the clamp body and form coordination. The drill clamp for the connecting rod rest of the needle core bed has the advantages of forming precise, firm and stable positioning and clamping for the connecting rod rest of the needle core bed, so that hole drilling, hole expanding and reaming can be performed on a drilling machine rapidly and stably; and therefore, production efficiency and machining precision are improved.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

Product plugging and unplugging device

ActiveCN105406327AAccurate clampingPracticalCoupling device engaging/disengagingTesting/measuring connectorsEngineeringManipulator

The invention relates to the technical field of automatic equipment, in particular to a product plugging and unplugging device. The product plugging and unplugging device comprises a lifting module, a lifting plate, a telescopic device, a first moving part and a second moving part, wherein the first moving part and the second moving part are movably arranged on the lifting plate and can close up each other and can be far away from each other; the telescopic device comprises a body and a telescopic part; the telescopic part extends and retracts relatively to the body; the lifting plate is provided with a limiting component which is used for limiting the movement range of the first moving part or the second moving part; and a plurality of mechanical grippers are arranged at the bottom parts of the first moving part and the second moving part. When the product plugging and unplugging device is close to a charger, the first moving part and the second moving part can achieve transverse movement in the horizontal direction under the action of the telescopic device, so that the condition that the mechanical grippers can relatively accurately clamp the charger is ensured; the mechanical grippers can bypass or avert other components of equipment in spatial movement in a practical application; and the practicability is relatively high.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

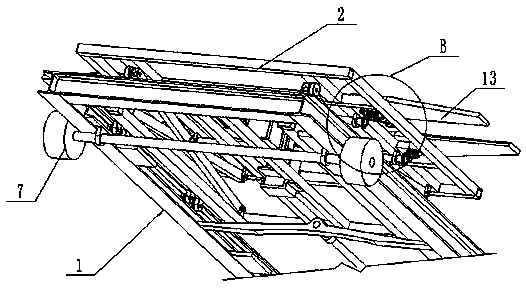

Automatic tube-inversing and loading device of tube bending machine and using method of automatic tube-inversing and loading device

PendingCN107716766ARealize fully automatic operationRealize integrated automatic operationMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The invention discloses an automatic tube-inversing and loading device of a tube bending machine and a using method of the automatic tube-inversing and loading device, and belongs to the technical field of tube bending machines. The device comprises a material tube rack used for placing a to-be-bent tube, a material supporting part, a tube inversing drive part and a tube inversing mechanism, wherein the material supporting part is arranged at one side of the material tube rack, and a material supporting wheel is arranged on the material supporting part; the tube inversing mechanism comprises aconnecting rod supporting base and a driven connecting rod, and a connecting rod shaft is arranged on the connecting rod supporting base; one end of the driven connecting rod is connected with the connecting rod shaft, and the other end of the driven connecting rod is connected with a tube inversing plate; the upper end surface of the tube inversing plate is an inclined surface; and the tube inversing drive part is used for driving the connecting rod shaft. The automatic tube-inversing and loading device is matched with a charging pushing device and a feeding device, and can realize integrated fully-automatic operation of loading, charging and feeding of the tube bending machine. According to the using method of the automatic tube-inversing and loading device disclosed by the invention, tubes on the material tube rack are automatically inversed and placed onto the material supporting wheel, so that preparation is made for charging, and therefore, efficient loading operation of the tube bending machine is realized.

Owner:ANHUI DEXI DHI TECH

Combined clamp for machining automobile transmission gear

ActiveCN112958854AEasy to switch clamping in both directionsFast and accurate two-way switching clampingGear-cutting machinesGear teethGear wheelAutomotive transmission

The invention discloses a combined clamp for machining an automobile transmission gear. The combined clamp comprises a clamping platform, a circular ring body is fixedly connected to the middle of the upper end face of the clamping platform, a driving rotating disc is connected to the portion, inside the circular ring body, of the clamping platform through a shaft, a driving groove is formed in the driving rotating disc, a jacking column is connected into the driving groove through a shaft, one end of the jacking column is fixedly connected with a positioning block, the lower end face of the clamping platform is connected with a centering screw rod, one end of the centering screw rod is connected with a centering rocking handle, the other end of the centering screw rod is fixedly connected with a connecting block, and the lower end of a connecting shaft of the driving rotating disc is connected with a driving plate. According to the combined clamp for machining the automobile transmission gear, self-centering clamping can be conveniently carried out on the gear, so that a gear workpiece can be rapidly and accurately clamped, bidirectional switching clamping can be conveniently carried out on the gear, so that clamping machining can be carried out on an inner ring or an outer ring of the gear, the clamping stability of the gear can be conveniently improved, and therefore, the machining precision of the gear is improved.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Gear positioning device and processing device thereof

InactiveCN110064773ANo offsetImprove accuracyPositioning apparatusMaintainance and safety accessoriesGear wheelSlag

The invention discloses a gear positioning device and a processing device thereof. A bottom plate is included, the bottom plate is provided with a hole groove, L-shaped positioning plates are symmetrically arranged at the positions, on the two sides of the hole groove, of the bottom plate, L-shaped suction pipes are arranged in the L-shaped positioning plates, and the ends, far away from a horn opening, of the L-shaped suction pipes are inserted into a slag gathering bottle; grooves are formed in the sides, close to the bottom plate, of the L-shaped positioning plates, and a first switch assembly and a second switch assembly are arranged in the grooves in the two sides; a positioning rotary motor and a micro suction fan are electrically connected to the first switch assembly; and a drilling motor is fixedly arranged on the side, far away from a telescopic cylinder, of a flat plate, and a drill rod is fixedly arranged at the output end of the drilling motor. By means of the gear positioning device, gears with different thicknesses can be accurately clamped, and debris and slag can be absorbed in time during processing. The invention also discloses the processing device including anabove-mentioned box structure, the automation degree of the device is high, and the processing efficiency is effectively improved.

Owner:BENGBU COLLEGE

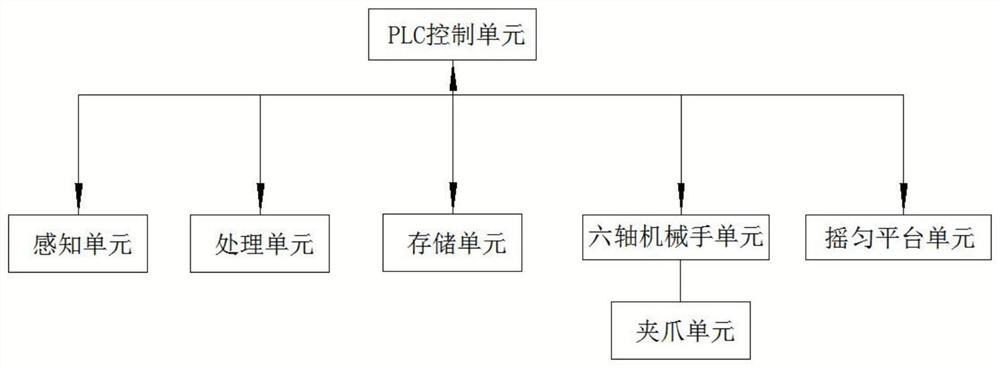

Automatic liquid preparation system and method based on industrial robot

ActiveCN113001564ARelieve stressImprove dosing efficiencyProgramme-controlled manipulatorGripping headsMedical equipmentPenicillin

The invention belongs to the technical field of medical equipment, particularly relates to an automatic liquid preparation system and method based on an industrial robot, and aims at solving the problems that an existing liquid preparation system is low in automation degree and poor in precision. The system comprises a sensing unit, a storage unit, a processing unit, a PLC control unit, a six-axis mechanical arm unit, a shaking platform unit and a clamping jaw unit arranged at the end of the six-axis mechanical arm unit. The six-axis mechanical arm unit drives the clamping jaw unit to extract liquid in a liquid bag; the sensing unit is used for detecting the types of penicillin bottles and transmitting information to the processing unit; the processing unit is matched with a preset instruction in the storage unit based on the acquired information; and the PLC control unit issues an instruction of whether to start the six-axis mechanical arm unit to extract liquid or prepare liquid and issues an instruction of whether to start the shaking platform unit based on the matching information acquired by the processing unit. According to the automatic liquid preparation system and method based on the industrial robot, automatic and accurate liquid preparation of the penicillin bottles can be realized, manual participation is effectively reduced, and the working efficiency is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

Automatic film tearing mechanism of manipulator

PendingCN108437605ALow costAvoid air bubblesLamination ancillary operationsLaminationPistonWear resistant

The invention discloses an automatic film tearing mechanism of a manipulator. The automatic film tearing mechanism of the manipulator comprises a base, wherein a mechanical column is fixedly mounted on the outer surface of one side of the upper end of the base; a film throwing lifting cylinder is fixedly mounted on the outer surface of the upper end of the mechanical column; a bearing is fixedly mounted in the center of the inside of the film throwing lifting cylinder; a plug rod sealing piece is fixedly mounted at the front end of the bearing; a plug rod is movably mounted in the center of the inner surface of the plug rod sealing piece; a buffer sealing ring is fixedly mounted on the outer surface of one side of the bearing; an end cap sealing ring is fixedly mounted on the outer surfaceof one side of the buffer sealing ring; a piston sealing piece is fixedly mounted on one side of the end cap sealing ring; a piston is fixedly mounted on one side of the piston sealing piece; a magnet is fixedly mounted on the outer surface of one side of the piston; and a wear-resistant ring is fixedly mounted on the outer surface of one side of the magnet. The film tearing mechanism is simple and practical, and is rapid and convenient, carrying films which are torn off are automatically collected in a waste box, a clamping end carries a film corner to finish film tearing, easily torn stickers are not required, and thus, costs are saved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

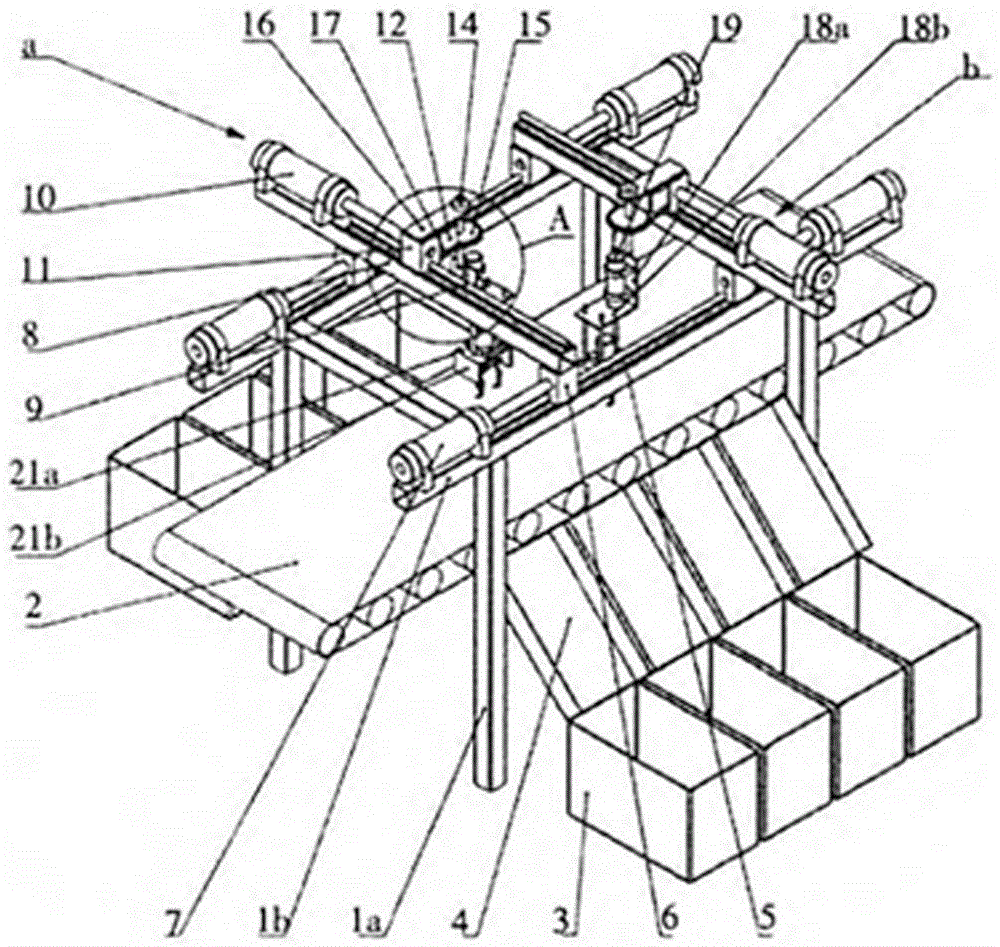

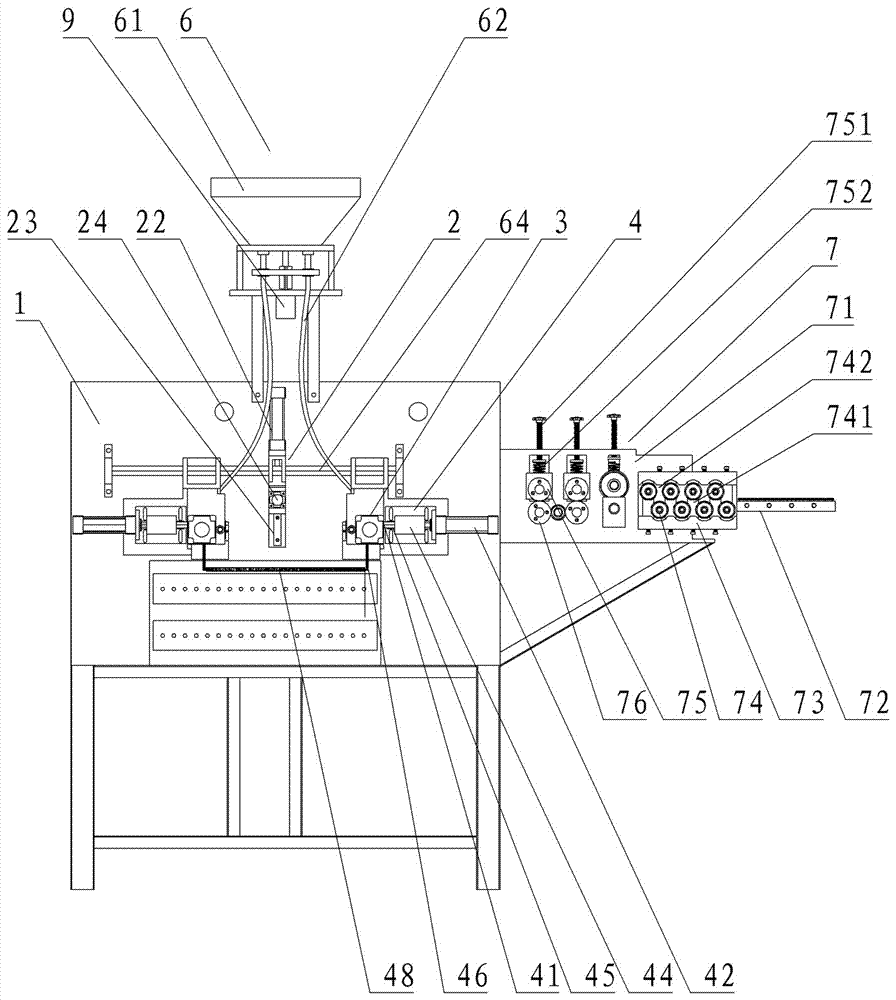

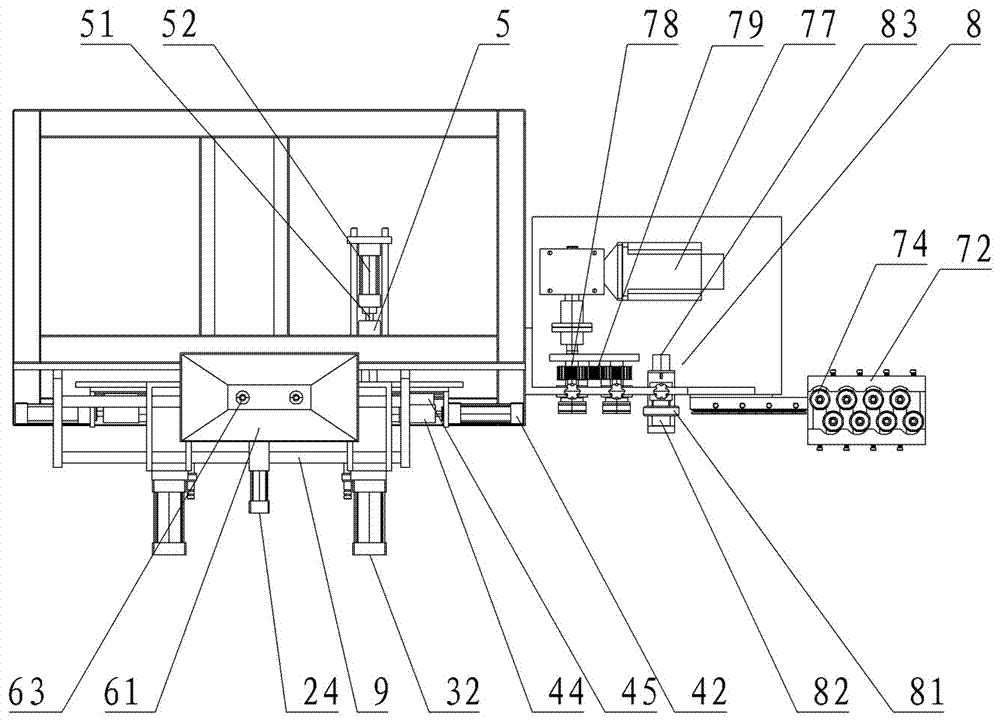

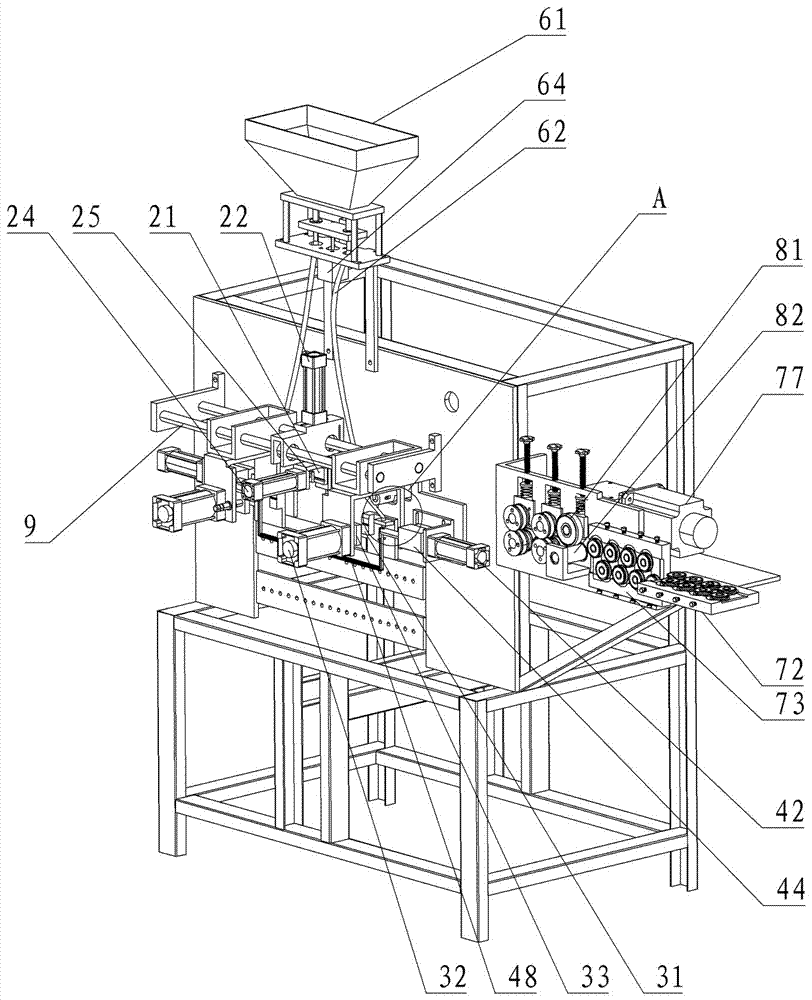

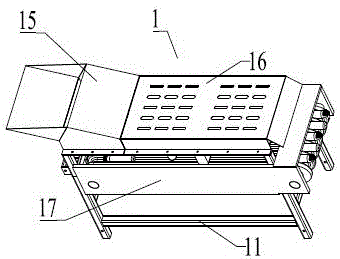

Full-automatic damage-free corn stigma harvesting machine

ActiveCN106576615AFully automated processingIncrease productionHarvestersThreshersEngineeringAutomatic processing

The invention discloses a full-automatic damage-free corn stigma harvesting machine. The full-automatic damage-free corn stigma harvesting machine comprises a corn arranging device (1), a corn conveying device (2), a clamping and delivery device (3), a clamping and delivery device rack (4), a kernel removing and conveying device (5), a cob kernel tipping bucket (6), a corn cob kernel removing device (7), a connecting net (8), a separating device (9), a corn stigma collecting device (10), a turnover device (A) and a corn peel separating device (B). The full-automatic damage-free corn stigma harvesting machine achieves full-automatic processing of corns, saves labor, can complete classified collection through cooperation of all the components, and can also complete automatic collection of corn stigmas, thereby greatly improving the yield of the corn stigmas and ensuring the quality of the corn stigmas. The corn stigma collecting device can well collect the corn stigmas, the collection requirements of the corn stigmas are met, the yield of the corn stigmas is improved, integrity of the corn stigmas can be ensured, and various requirements for the corn stigmas can be met.

Owner:YANGXIN JINFENG ECOLOGICAL FIBER CO LTD

Magnetic clamping block and semiconductor substrate cleaning device

ActiveCN114653660AAvoid damageThe axial rotation angle is too large or too smallSemiconductor/solid-state device manufacturingDirt cleaningWaferStructural engineering

The invention provides a magnetic clamping block and a semiconductor base material cleaning device. The magnetic clamping block and the semiconductor base material cleaning device comprise a mounting base, a pivoting cylinder formed on one side of the mounting base, and a limiting assembly formed on the other side of the mounting base and coaxially arranged with the pivoting cylinder. The limiting assembly comprises a mounting part, a first magnetic block embedded in the mounting part, a mounting cover formed on the outer side of the mounting part and used for limiting axial sliding of the first magnetic block, and a limiting rod longitudinally and continuously penetrating through the mounting cover and the mounting part, and the tail end of the limiting rod extends into an arc-shaped pivoting groove formed in the mounting base. And the axial rotation angle of the pivoting cylinder relative to the mounting seat is provided through the arc-shaped pivoting groove. According to the invention, the axial rotation angle of the magnetic clamping block is accurately controlled, so that the magnetic clamping block can accurately clamp the edge of the wafer.

Owner:ZHICHENG SEMICON EQUIP TECH (KUNSHAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com