Press working method and press working apparatus

A processing method and technology of processing equipment, applied in the direction of manufacturing tools, presses, etc., to achieve the effect of simple operation

Inactive Publication Date: 2007-10-17

HONDA MOTOR CO LTD

View PDF4 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, the operator must have sufficient experie

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

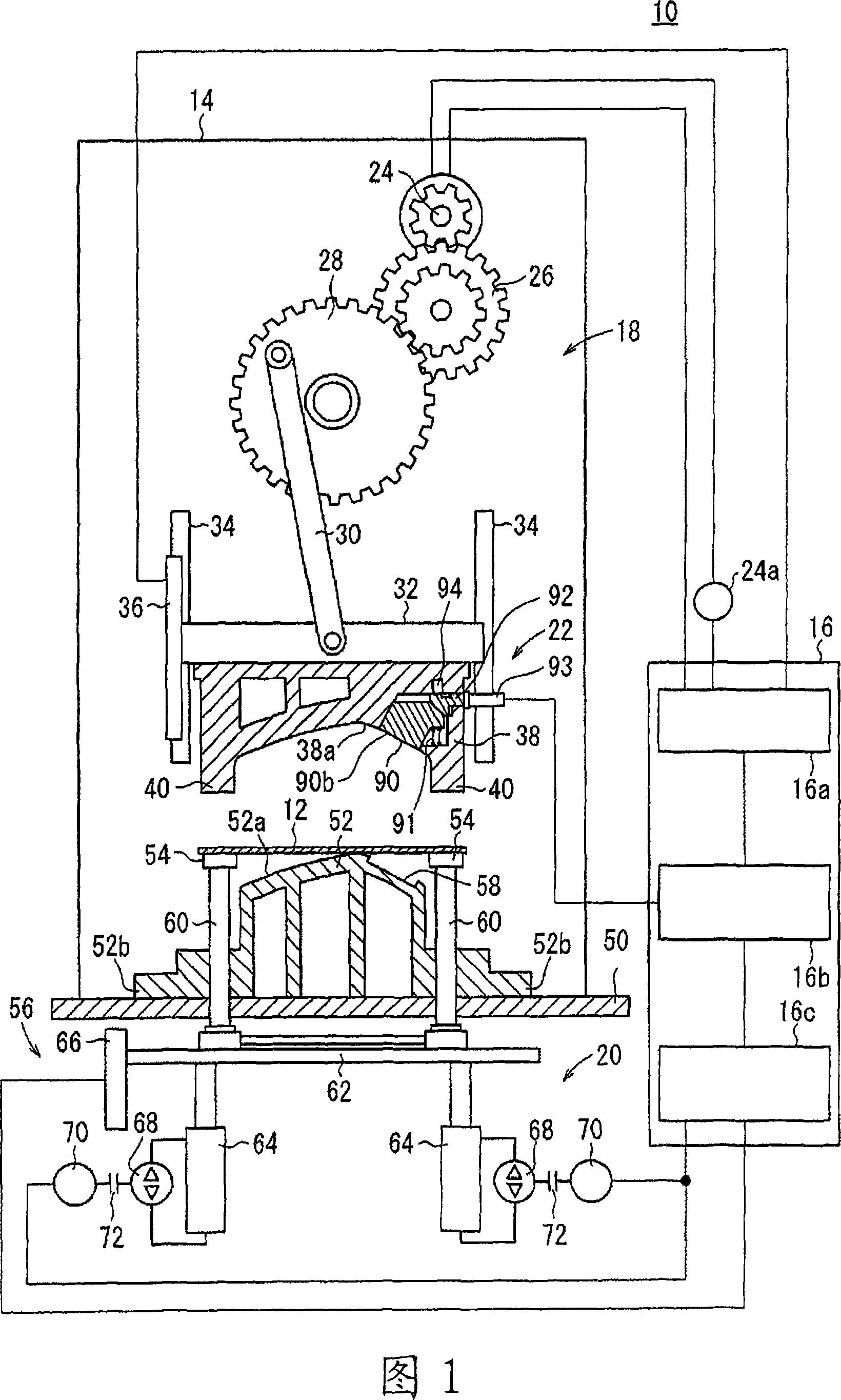

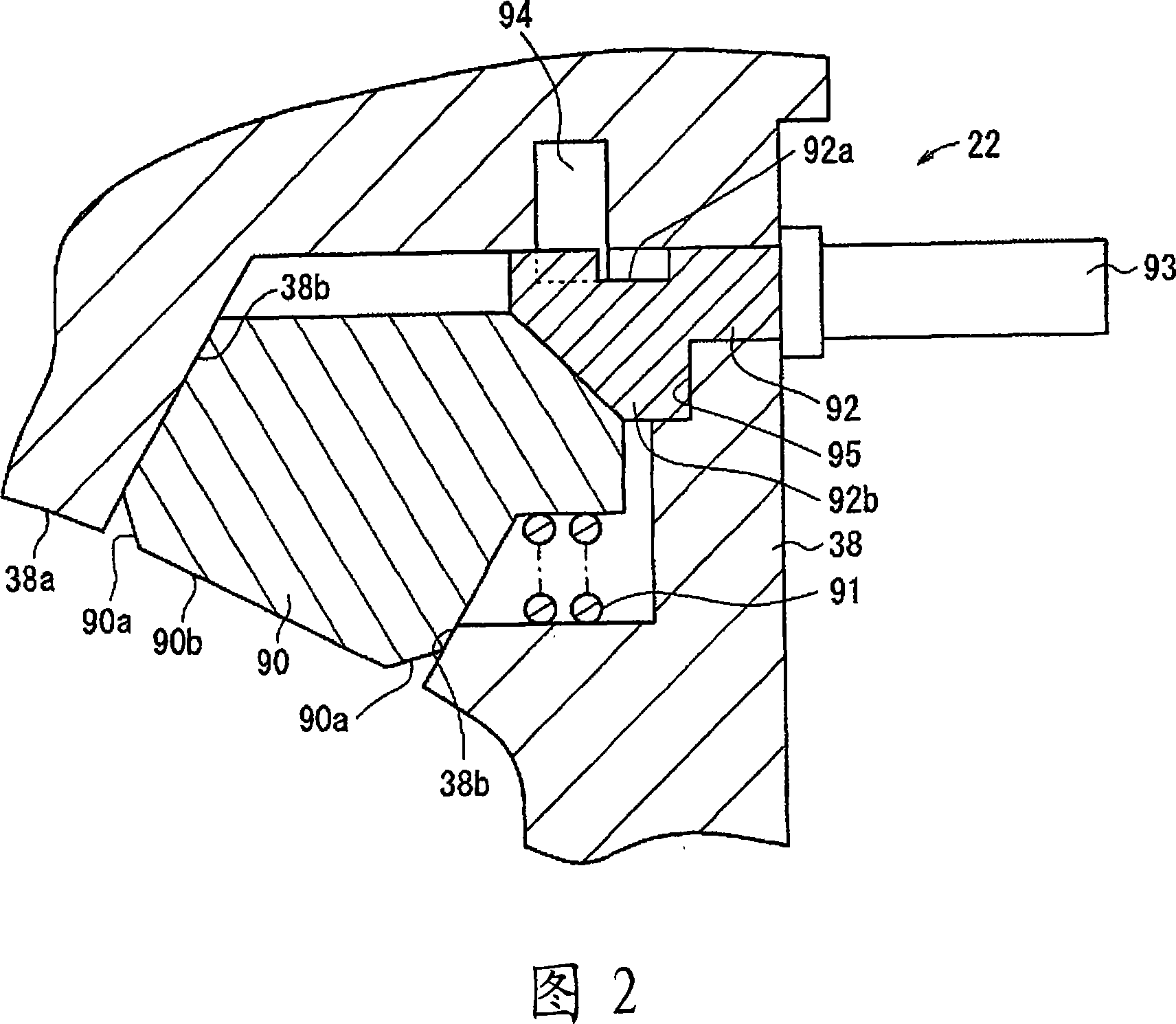

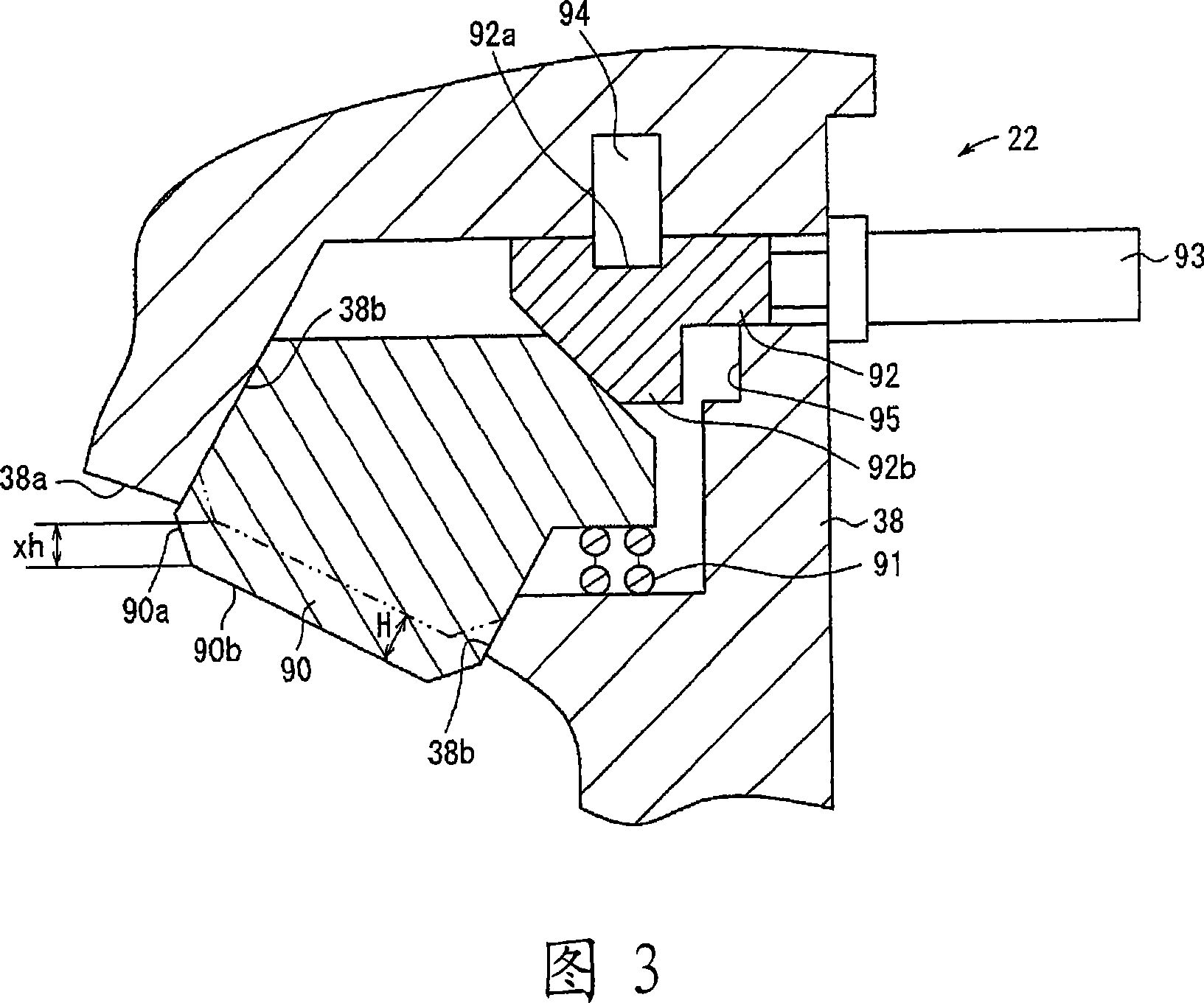

The present invention provides a press working apparatus and its manufacturing device. In the press working apparatus 10, while a servo motor 24 is acting, an upper die 38 is made to come close to a lower die 52 and press working of the first time is conducted on a steel plate 12. A slider 32 is raised to a movable punch preparation position. A movable punch 90 is protruded from a die face 38a of the upper die 38 by width H and locked by a mechanical lock 94. The upper die 38 is made to come close to the lower die 52 again and the steel plate 12 is pushed with the upper die 38 and at the same time an additional worked portion 12a is pushed and deformed with the movable punch 90 so as to conduct press working of the second time. After the movable punch 90 has been retracted, the slider 32 is raised.

Description

technical field [0001] The present invention relates to a press working method and press working equipment for pressing a formed product by servo press working. Background technique [0002] In conventional mechanical pressing, pressing is performed while a crankshaft rotation motor drives up and down a slider connected to the crankshaft. In this mechanical pressing, since the die is continuously moved up and down, it is difficult to change the speed of the die according to the processing conditions. In addition, it is also difficult to temporarily stop the mold. [0003] Due to the above circumstances, a servo press that can flexibly control the movement of a mold using a servo motor has recently been used. For this subject, refer to Japanese Patent Laid-Open No. 2001-150200 and Japanese Patent No. 3537287. In this type of servo pressing, the die can be stopped at a predetermined position in the middle of one stroke of the die's up and down motion. [0004] In this rega...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B30B13/00B30B15/00

Inventor 永井裕一廻秀夫武田谦三江河隆幸

Owner HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com