Patents

Literature

624results about How to "Realize fully automatic operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

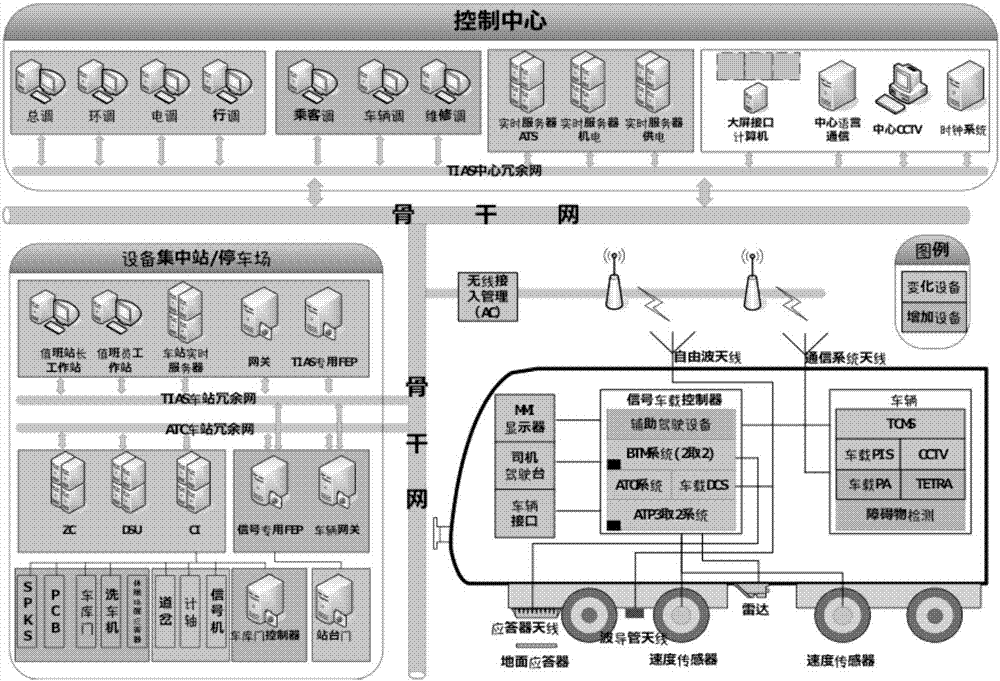

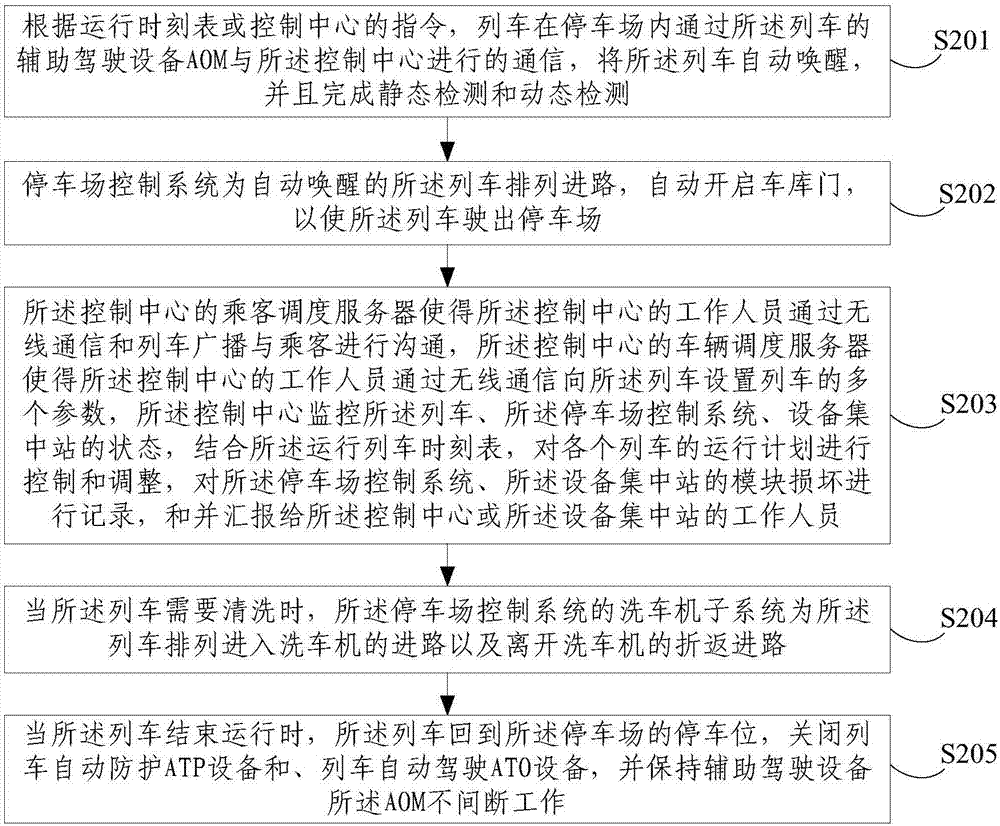

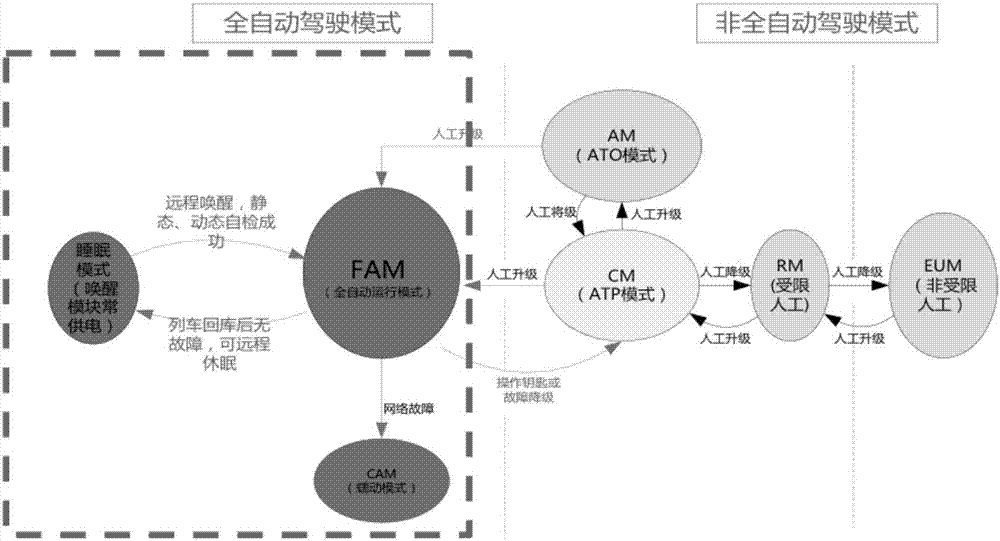

Train full-automatic running method and system

ActiveCN107226099ARealize fully automatic operationImprove reliabilityAutomatic systemsLocomotivesAutomatic train protectionProgram planning

The invention provides a train full-automatic running method and system. The train full-automatic running method comprises the following steps that according to a running schedule or a command of a control center, trains are automatically awakened, and static detection and dynamic detection are completed; a parking lot control system performs route arrangement on the trains which are automatically awakened; the control center monitors the condition of the trains, the condition of the parking lot control system and the condition of an equipment centralization station, and controls and adjusts the running plan of each train combining the running schedule; when the trains need cleaning, a train washing machine sub system of the parking lot control system arranges a route for the trains to enter the train washing machine and a reentrant route for the trains to leave from the train washing machine; and when the trains stop running, automatic train protection ATP equipment and automatic train operation ATO equipment are closed, and AOM is kept working continuously. Compared with a conventional CBTC system, the train full-automatic running method disclosed by the invention realizes full-automatic running, the reliability, the safety, the availability and the maintainability of the train full-automatic running system are further improved, the operating emergency handling level is improved, the automation level is improved, and the labor strength is reduced.

Owner:TRAFFIC CONTROL TECH CO LTD

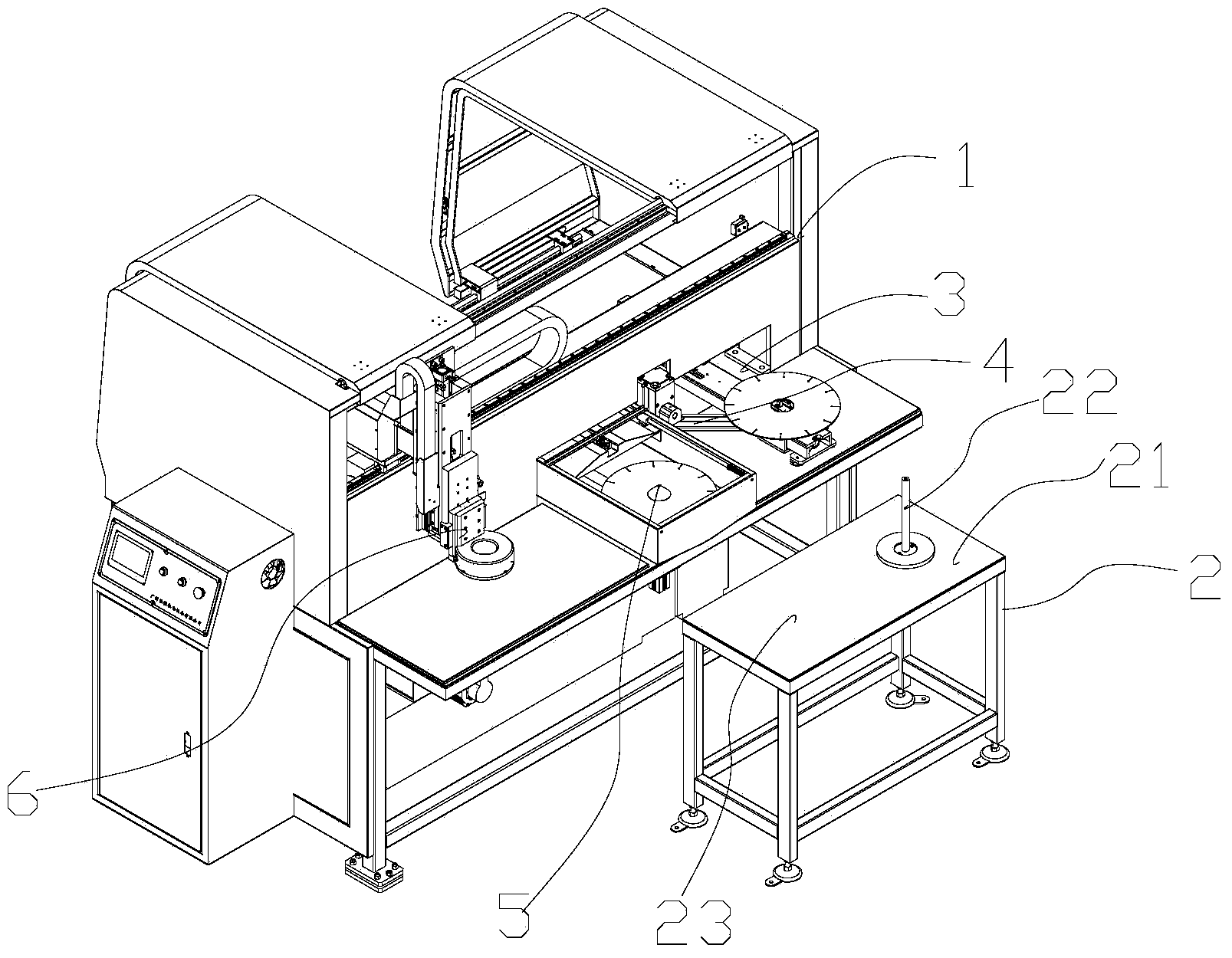

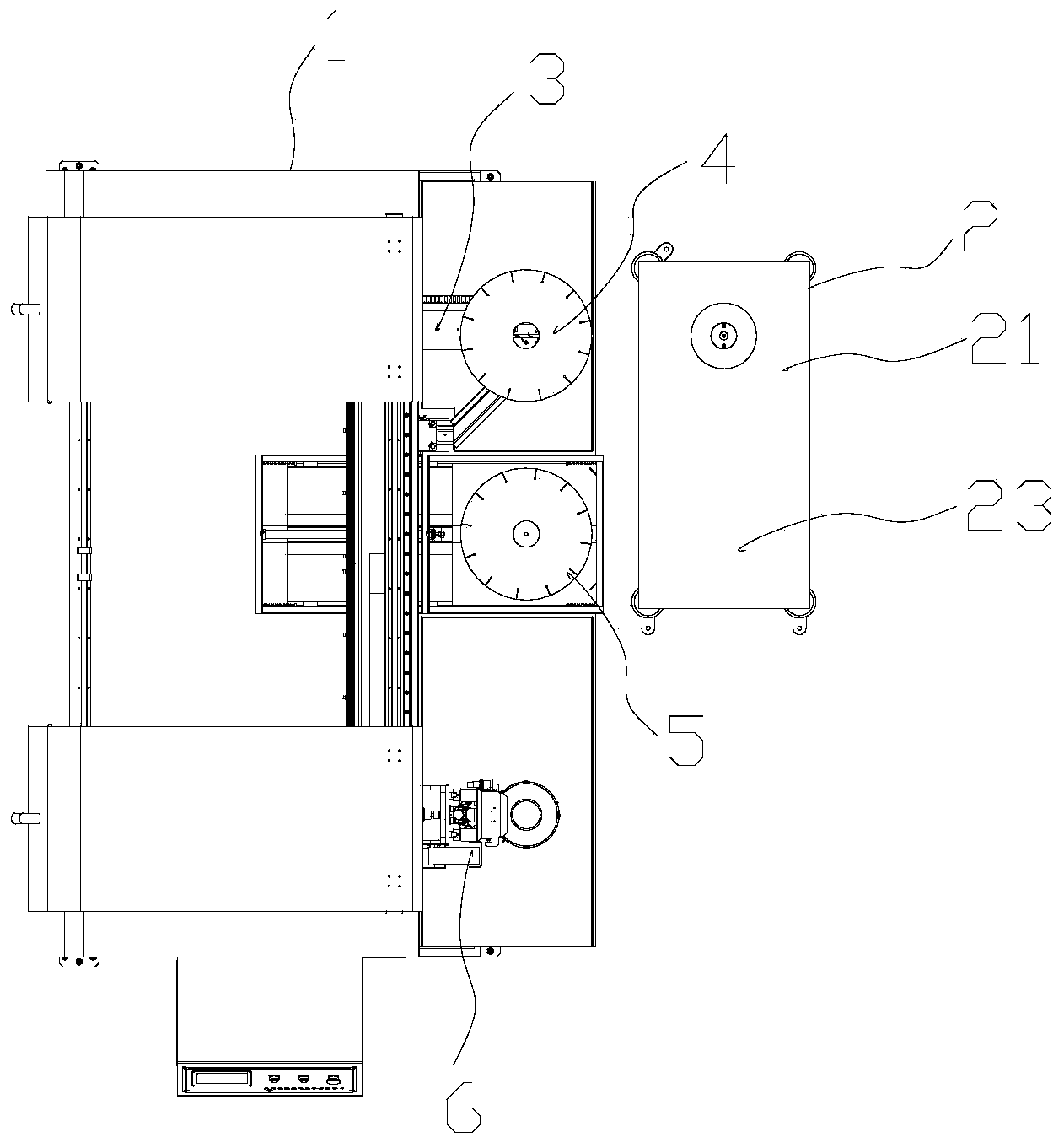

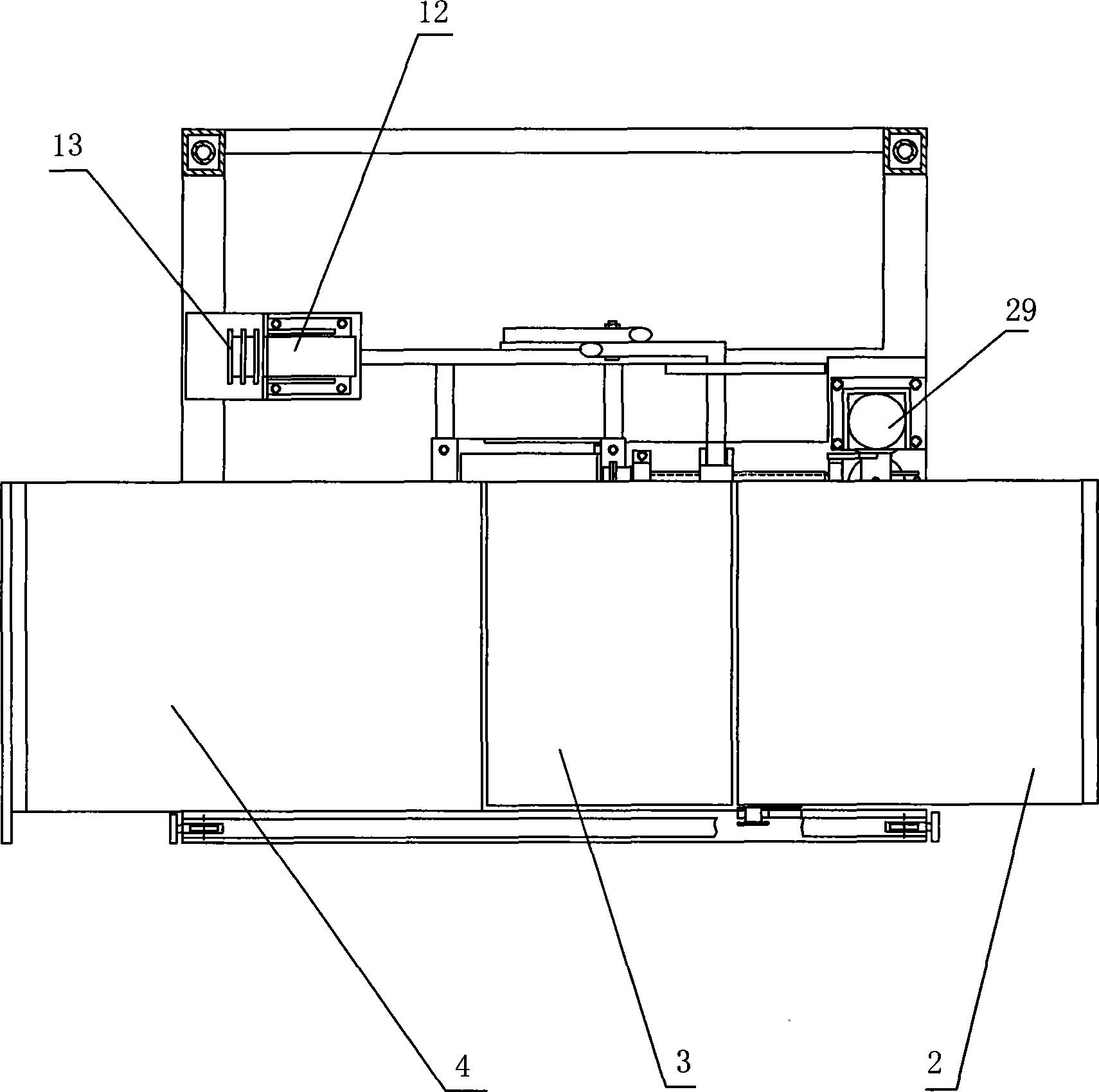

Full-automatic horizontal surface grinding machine mechanical arm

ActiveCN103831680AReduce labor costsImprove pass rateProgramme-controlled manipulatorGripping headsWork periodNumerical control

The invention discloses a full-automatic horizontal surface grinding machine mechanical arm which comprises a machine table and a product containing table. An automatic detection device, a turning device, a cleaning device and a grabbing mechanical arm body are arranged on the machine table. The product containing table and the machine table are arranged side by side. The automatic detection device, the turning device, the cleaning device and the grabbing mechanical arm body are all installed on the machine table, and an automatic grinding machine device is connected with the machine table. By means of the automatic detection device, the turning device, the cleaning device, the grabbing mechanical arm body and the automatic grinding machine device, saw blades are fed, discharged, detected, cleaned and ground in a full-automatic mode, full-automatic operation of the whole process is achieved, and labor cost of an enterprise is greatly reduced; by means of accurate numerical control operation, cost is reduced, the yield is improved, and the production loss rate is reduced; production efficiency is improved, and working time is shortened; by means of full-automatic production, guarantees can be provided for workers on the aspects of mechanical contusion, tiny dust and exhaust gas inhalation and metal dirty water corrosion to human bodies.

Owner:GUANGZHOU HENGWEI ELECTROMECHANICAL EQUIP CO LTD

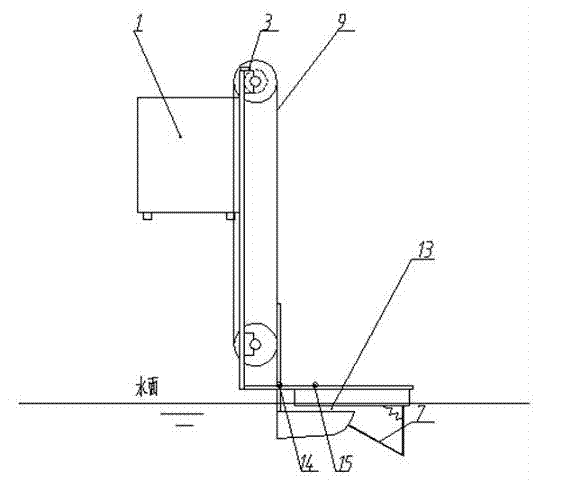

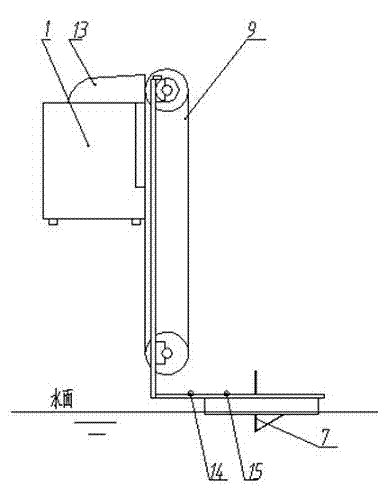

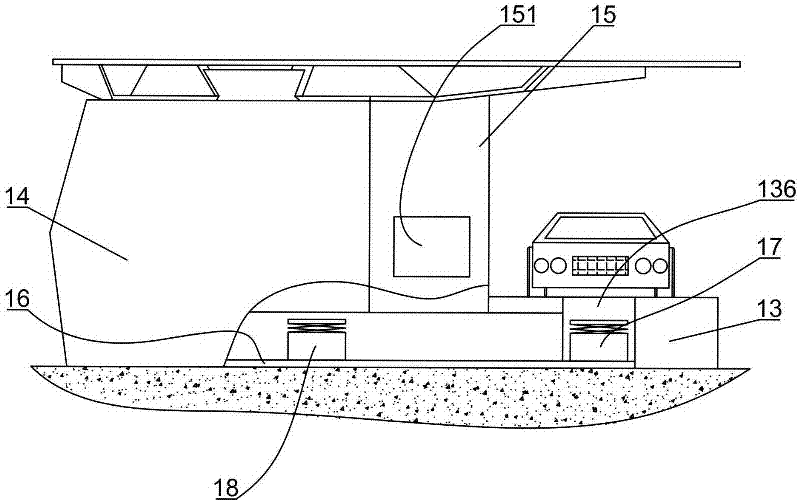

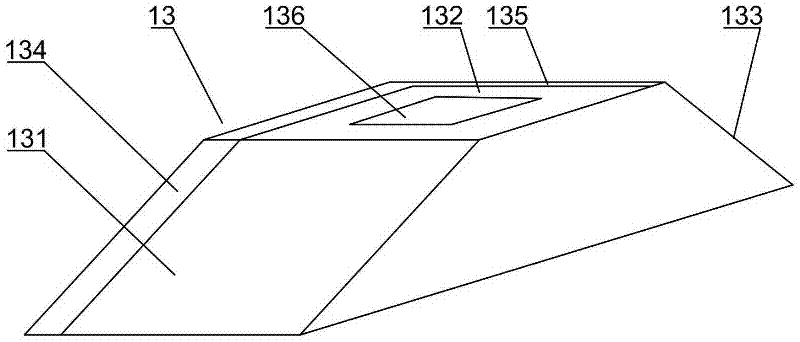

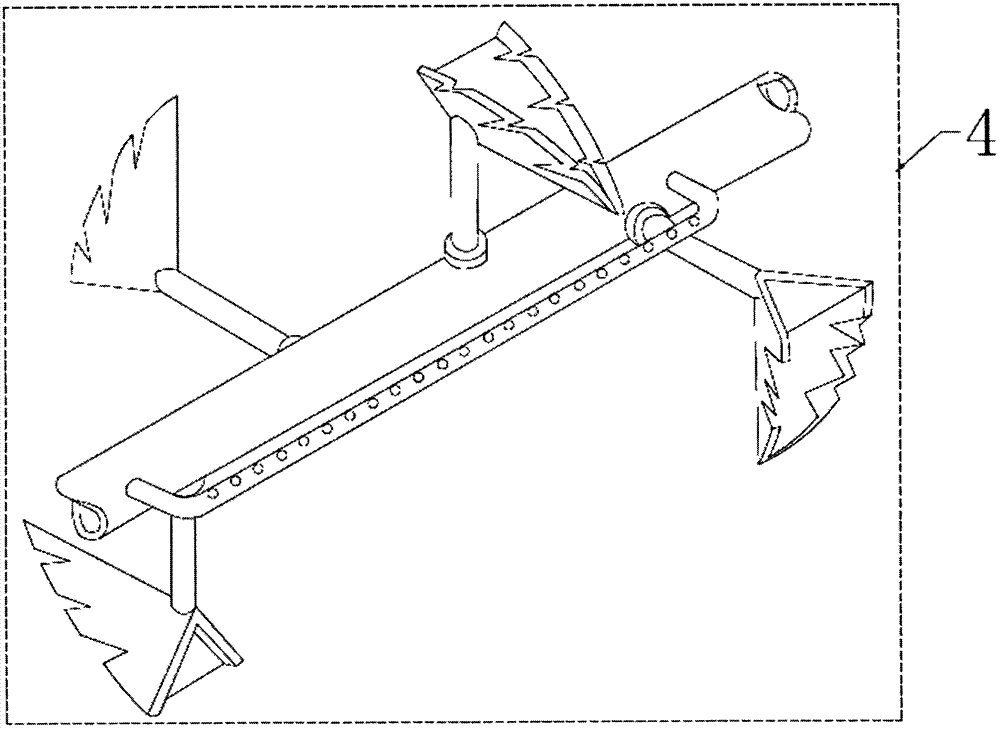

Automatic clearing ship for rubbish on water

InactiveCN102963505ASimple structureReduce operating costsWater cleaningWaterborne vesselsElectric machineryCollection system

The invention discloses an automatic clearing ship for rubbish on water and belongs to the technical field of cleaning the rubbish on the water. The ship comprises a ship body, a rubbish collection system and a rubbish transport system, wherein the rubbish collection system comprises a rubbish storage bin, a chain shaft, guide arms, an arresting barrier, chains and a collection basket; the rubbish transport system comprises a guide rail transmission stand and a lifting stand; the guide rail transmission stand consists of transverse guide rails and longitudinal guide rails by crossing; and the lifting stand comprises a hook, a sleeve, diagonal rods, a base, a vertical rod, a cross rod, a motor and a screw rod. The ship body is simple in structure, so that the structure of the complete ship is simplified on the basis of function addition, the operation cost and manufacturing cost are lowered greatly, the energy consumption is reduced correspondingly, the popularization and use of the clearing ship are facilitated, and the automatic clearing of the rubbish on the water can be achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Battery exchanging method and arrangement of battery exchanging station

InactiveCN102442277ACompact structureSmall footprintElectric propulsion mountingElectric/fluid circuitElectrical batterySmall footprint

The invention discloses a battery exchanging method and arrangement of a battery exchanging station. The battery exchanging station comprises a battery exchanging platform, a battery storing and charging device and a control device, wherein batteries are replaced from an upper part and a lower part, and are synchronously stored and charged through a wheel carrier; a plurality of battery racks arearranged on the wheel carrier at equal intervals along the circumferential direction; the top of each battery rack is provided with an electromagnetic control hook for fixing a battery; and a track as well as a first conveying trolley and a second conveying trolley which can move on the track and ascend and descend automatically are arranged between the battery exchanging platform and the batterystoring and exchanging device. The battery exchanging station has a compact overall structure and small occupied area; and full-automatic operation of the battery exchanging station can be realized.

Owner:ZHEJIANG HAOQING AUTOMOBILE MFG CO LTD +1

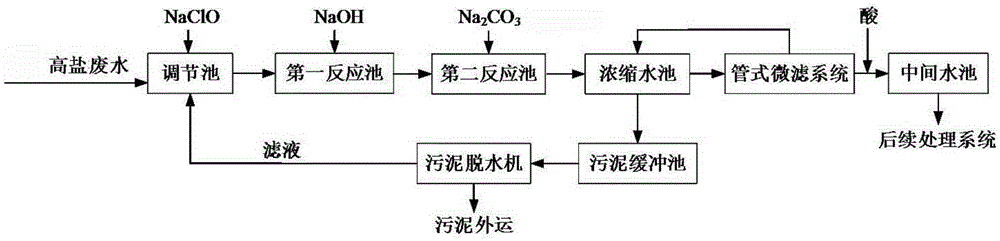

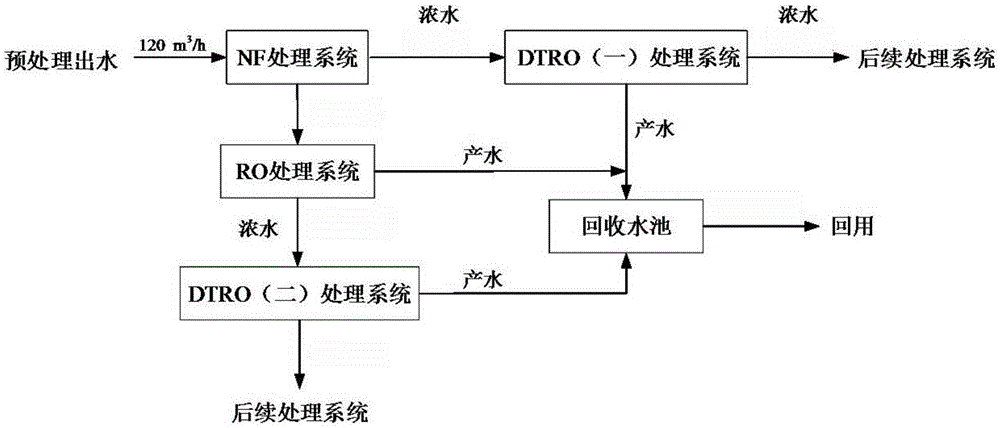

High-salt waste water zero emission and salt separation processing method and device

ActiveCN105254106AShort processReduce doseWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemistryPre treatment

The invention discloses a high-salt waste water zero emission and salt separation processing method and device. The method includes the following steps of 1, waste water preprocessing, 2, waste water decrement and concentration and 3, crystallization. By means of the high-salt waste water zero emission and salt separation processing method and device, waste water can be processed efficiently, liquid and salt ingredients in the waste water are effectively separated, a product obtained after waste water can be recycled or sold as other industrial products, so that zero emission of waste water is achieved. The method is simple and easy to implement, high in processing efficiency and small in energy consumption; by the adoption of the method, pollution to the environment is avoided, an active function is played on improvement of regional water environment quality, the utilization rate of waste water is raised, production cost is saved, and environmental and social benefits are quite remarkable. The device is high in operation efficiency, convenient to assemble, low in cost and small in energy consumption.

Owner:华电水务工程有限公司 +1

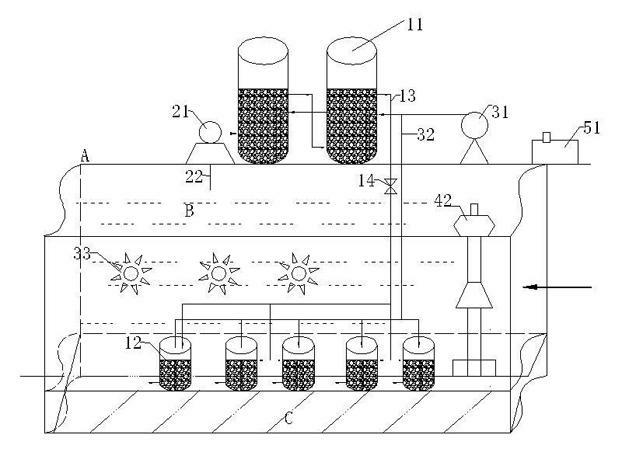

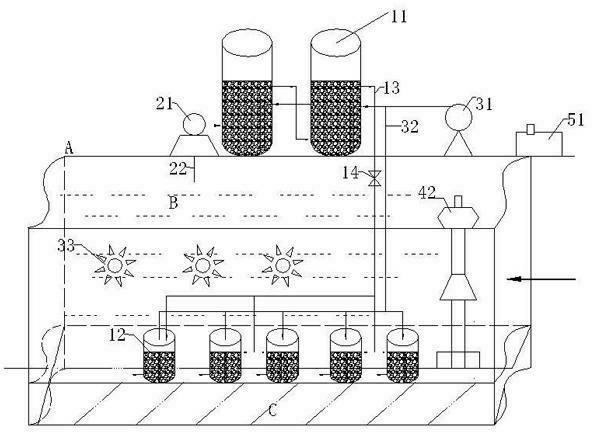

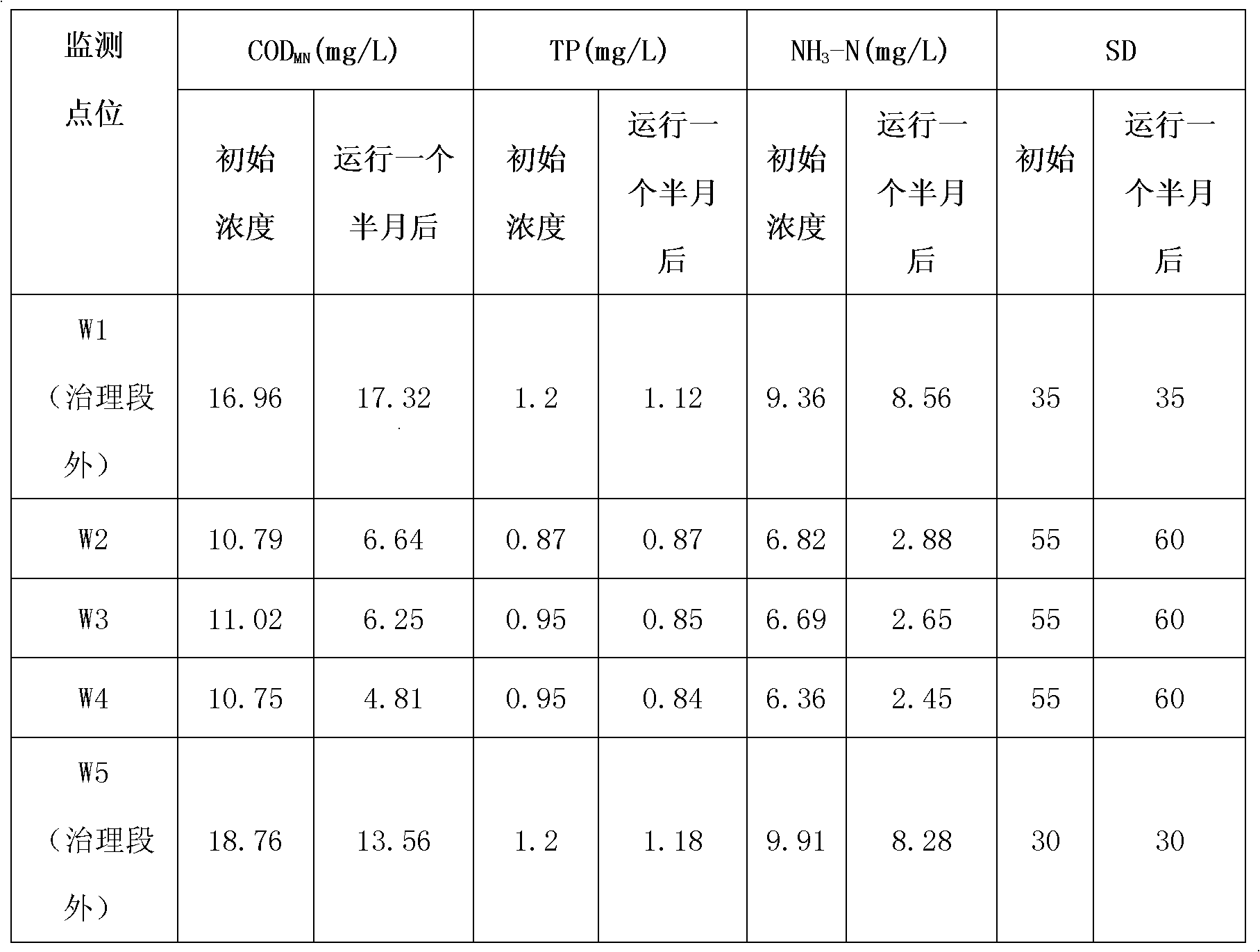

Method and device for utilizing microorganism in-situ circulation cultivation to treat water body pollution

InactiveCN102531201AIncrease environmental capacityImprove self-cleaning abilityBiological water/sewage treatmentMicroorganismDecomposition

The invention discloses a method for utilizing microorganism in-situ circulation cultivation to treat water body pollution, (1) riverway sewage is utilized to be in-situ cultured, circulated, acclimatized and separated microorganisms out in a culture tank and an biological generator for being put into a water body, and the water body pollution is removed through microorganism absorption, decomposition and transfer; (2) an aerating device is adopted to aerate and provide a good environment for the culture tank, the biological generator and the riverway water body; and (3) a mixer is adopted to stir water sediment, so the pollutant of the sediment enters the water to be utilized by the microorganisms, and the ecological dredging is realized. The invention further discloses a device which is adopted by the method. The method takes nutrients in the reverway sewage as a strain medium, the microorganism environment is improved through aeration and stirring, the added foreign bacterium is more applicable to the water body, is mass propagated and has strong decomposition capacity, so the excellent speed is improved, the source is stable, the purposes of high efficiency, continuity, thoroughness and low cost are realized, meanwhile, the device has strong movability, is convenient to install and dismantle, and has a wide application scope.

Owner:浙江天韵生态环境工程有限公司

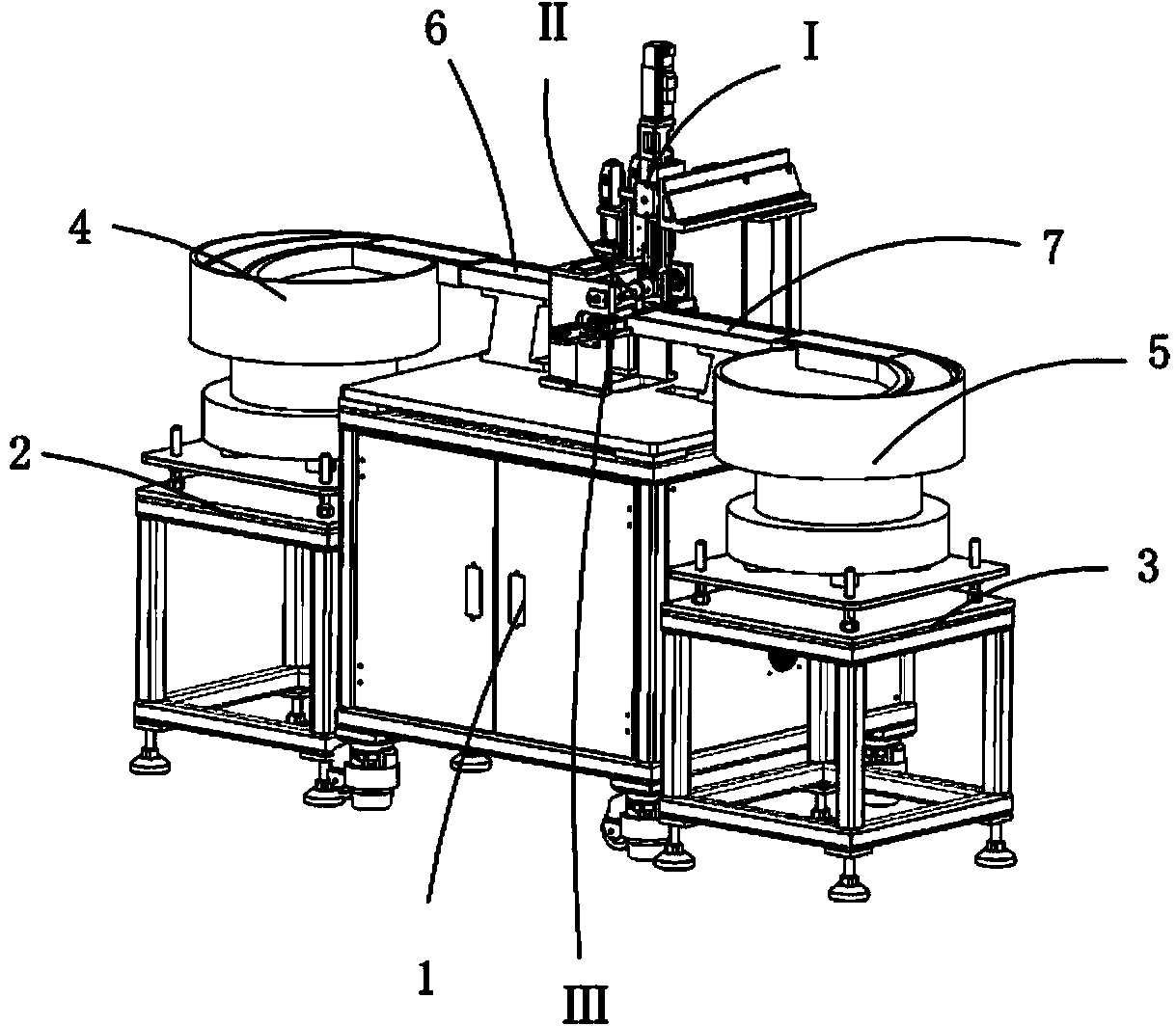

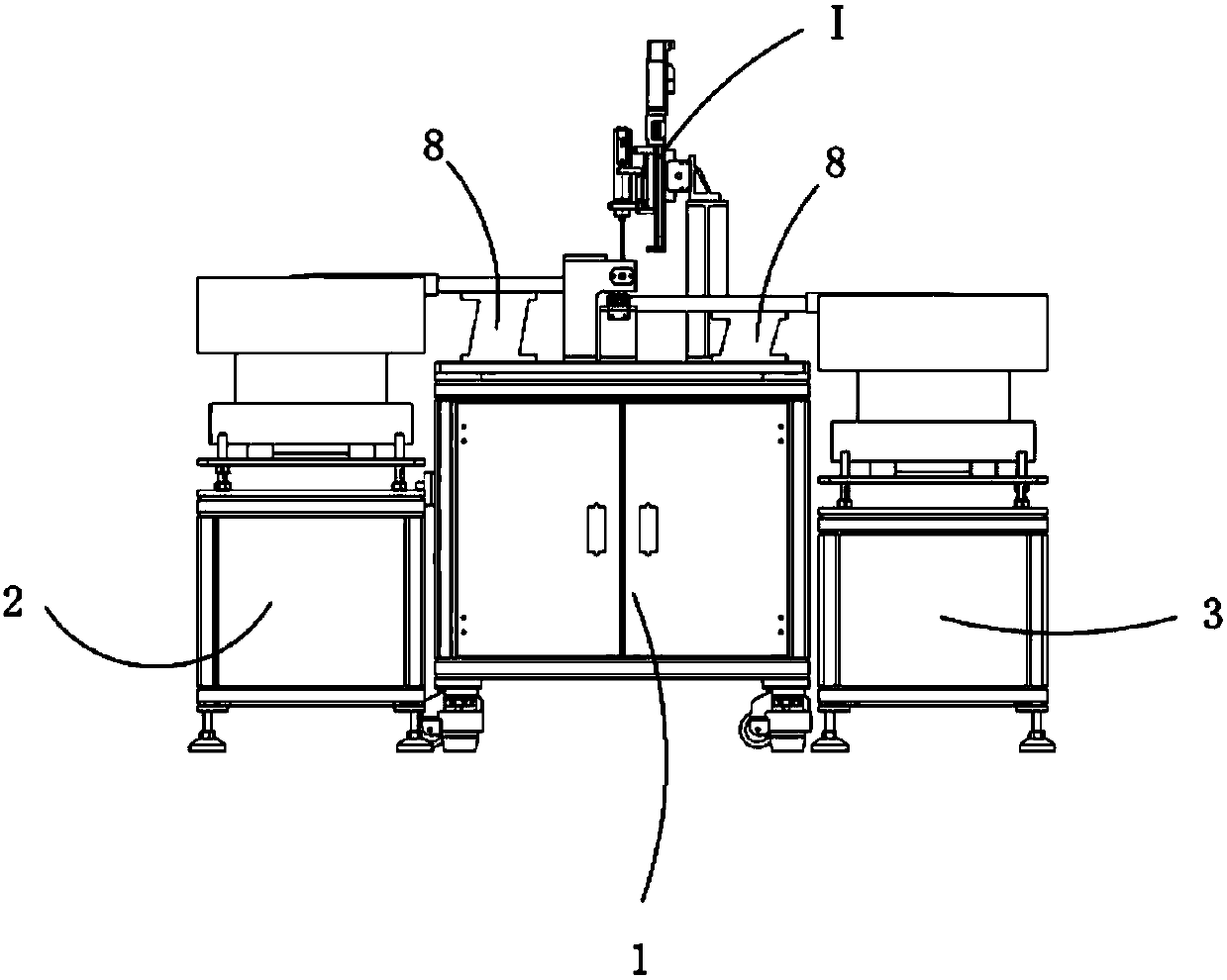

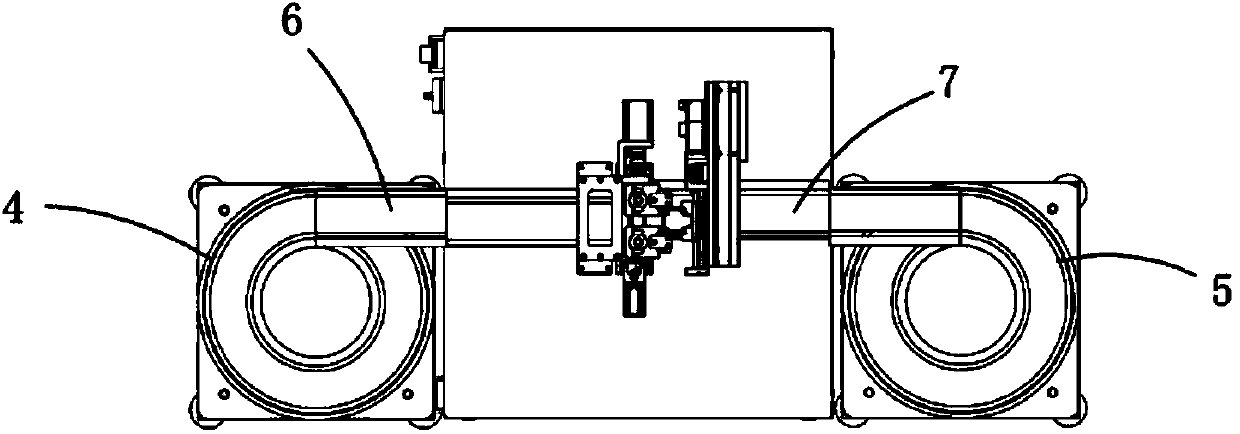

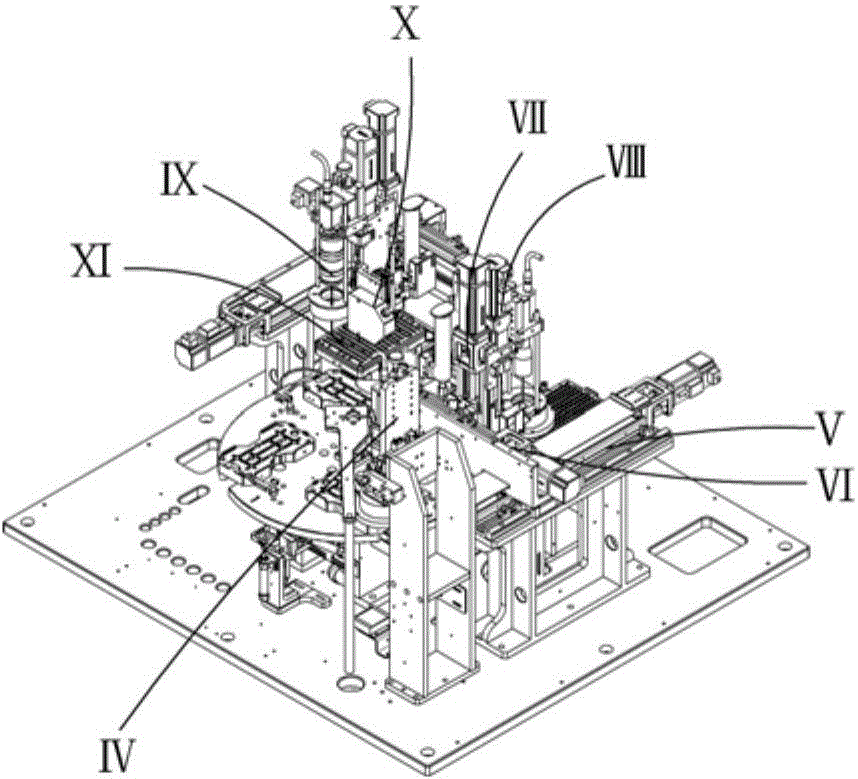

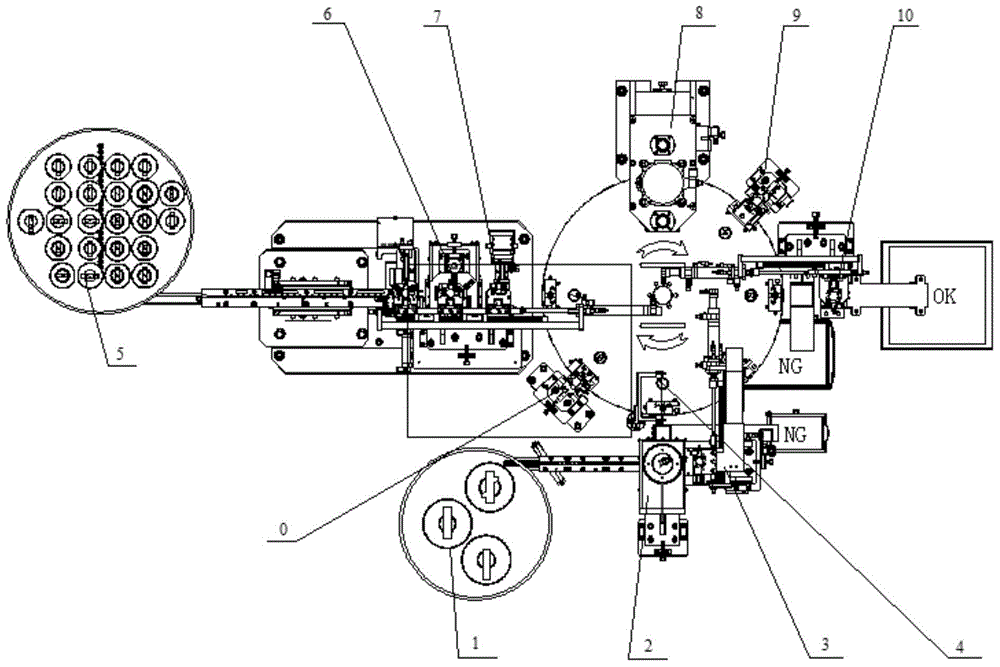

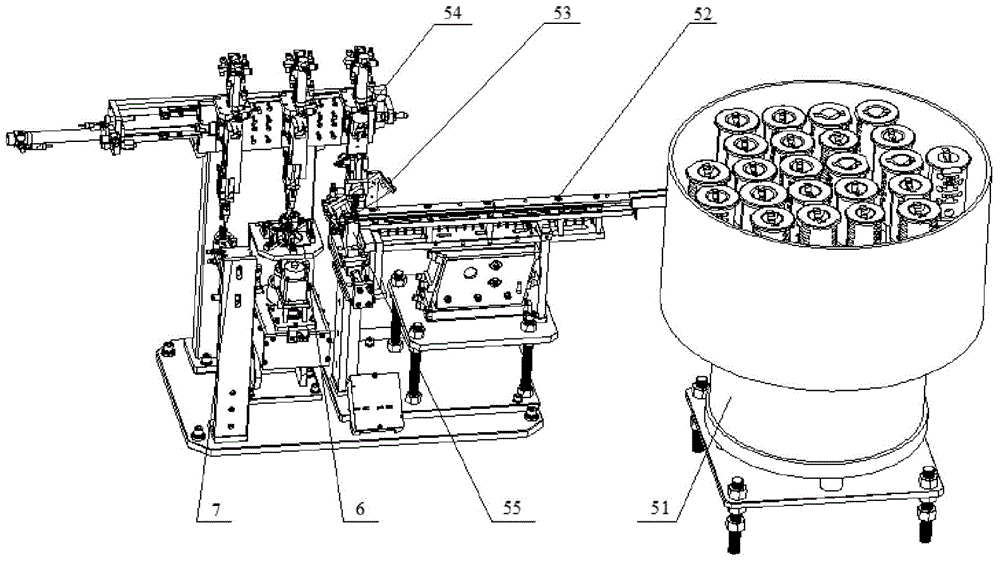

Automatic nut and screw assembling mechanism

ActiveCN103692202AReduce labor intensityImprove work efficiencyMetal working apparatusMechanical engineeringEngineering

The invention relates to an automatic nut and screw assembling mechanism. A locking and attaching mechanism, a rotary feed mechanism and a feed and discharge mechanism are disposed on the case of the assembling mechanism. The left vibrating plate of the mechanism allows two groups of screws to enter the rotary feed mechanism. The right vibrating plate of the mechanism allows two groups of nuts to enter and the feed and discharge mechanism. The stepping motor of the rotary feed mechanism drives a feed shaft to rotate 90 degrees anticlockwise so as to allow the two horizontal feed holes to be vertical and be concentric with the through holes in a mandrel, and the screws can be guided to the through holes. The nuts entering through the two feed inlets in the connecting plate of the feed and discharge mechanism are pushed below a guide sleeve to be concentric with the same by a feed air cylinder. The X-axis component and Z-axis component of the locking and attaching mechanism moves screwdriver heads above the two vertical feed holes so as to perform locking and attaching of two screws simultaneously. After the locking and attaching, the discharge air cylinder of the feed and discharge mechanism pushes a discharge plate to perform discharging, and the locked and attached screws and nuts are fed into a discharge frame.

Owner:BOZHON PRECISION IND TECH CO LTD

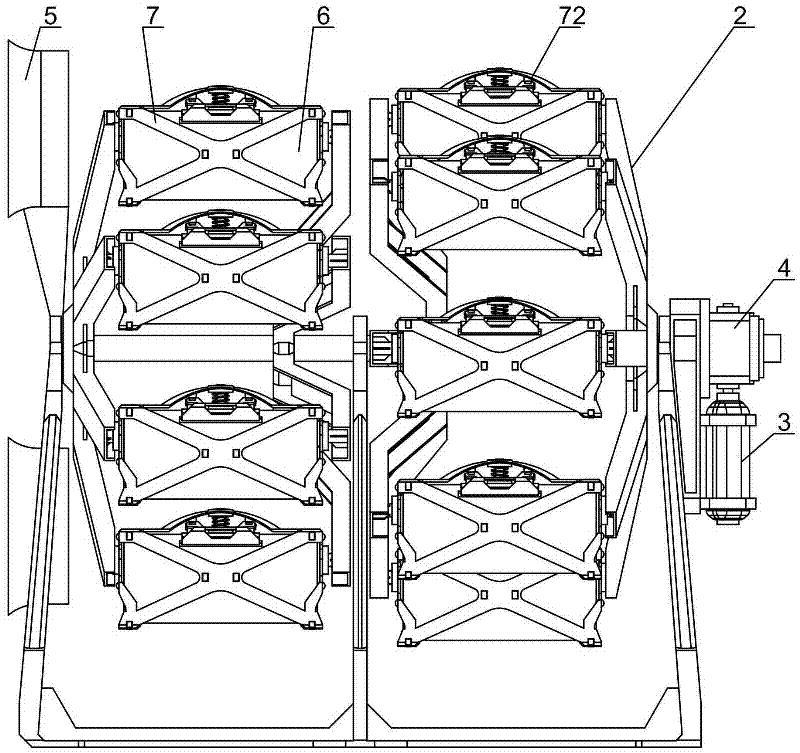

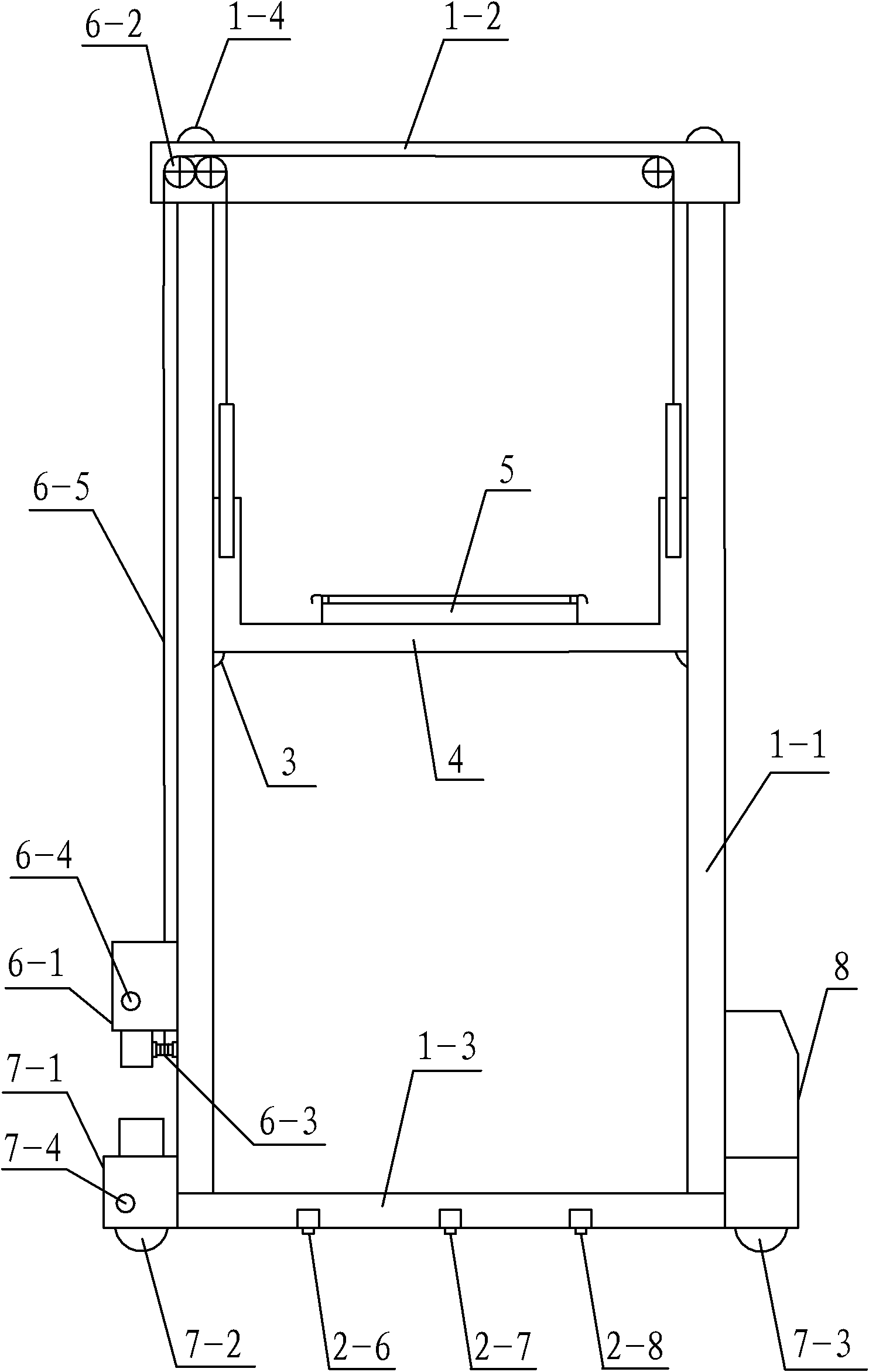

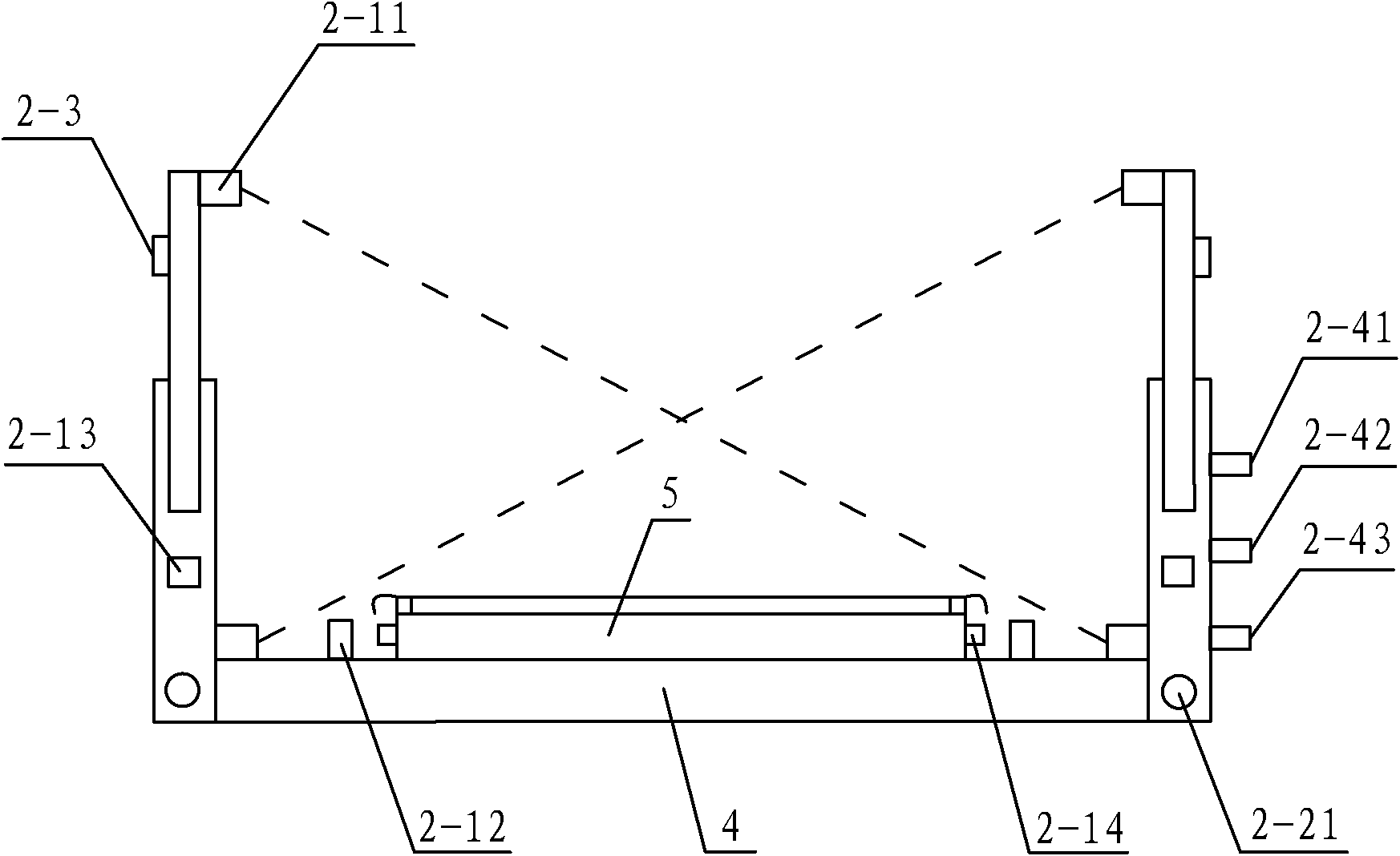

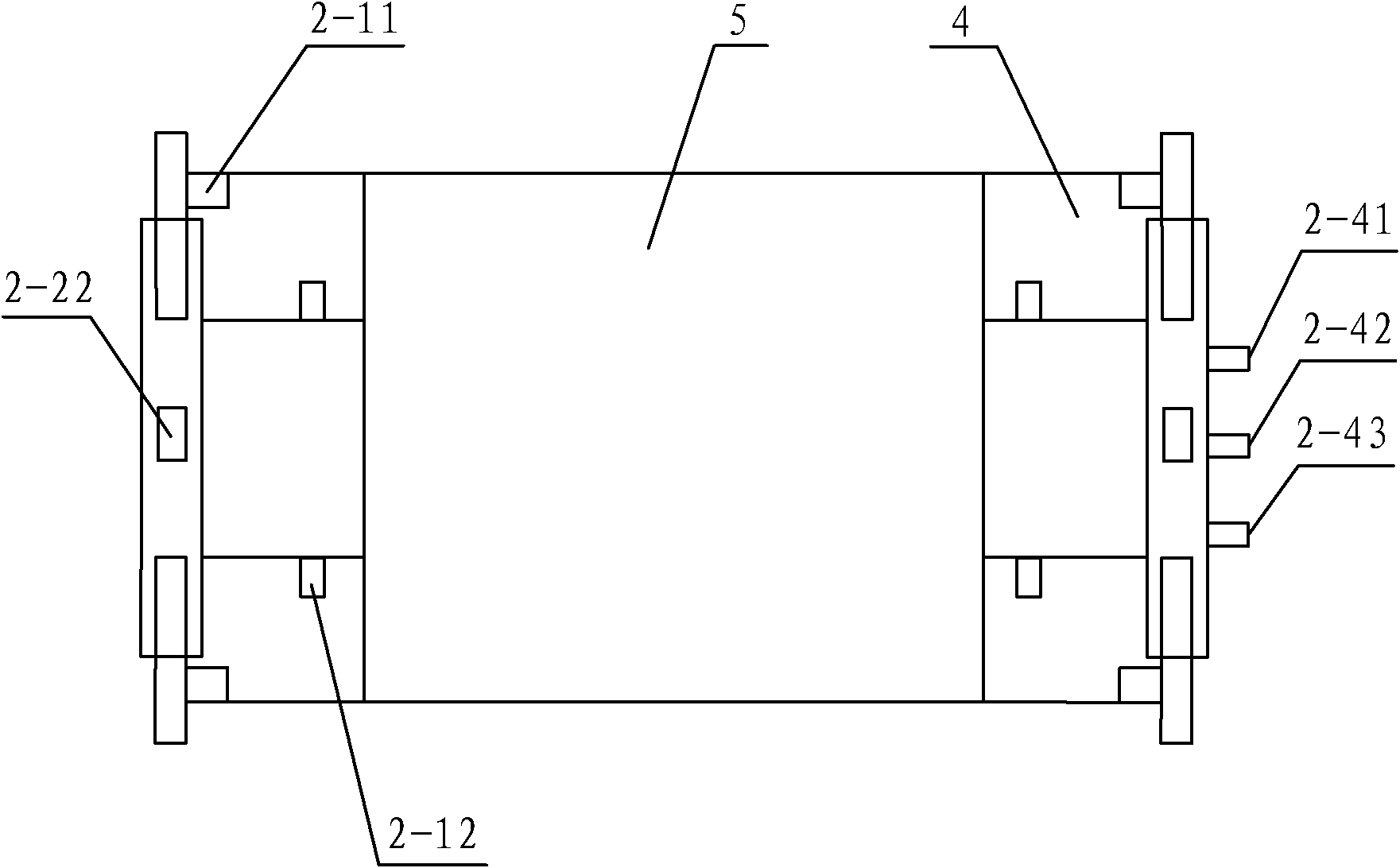

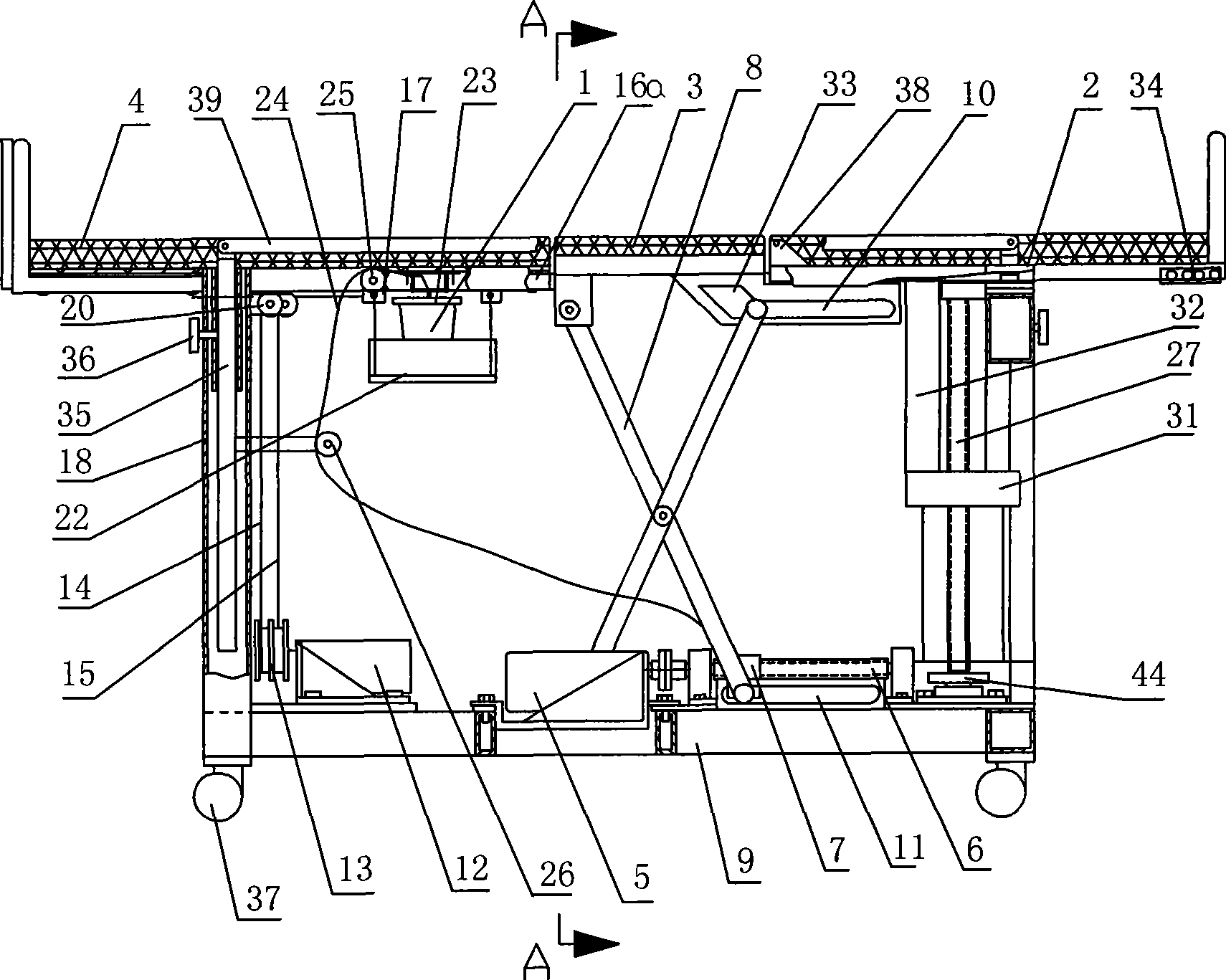

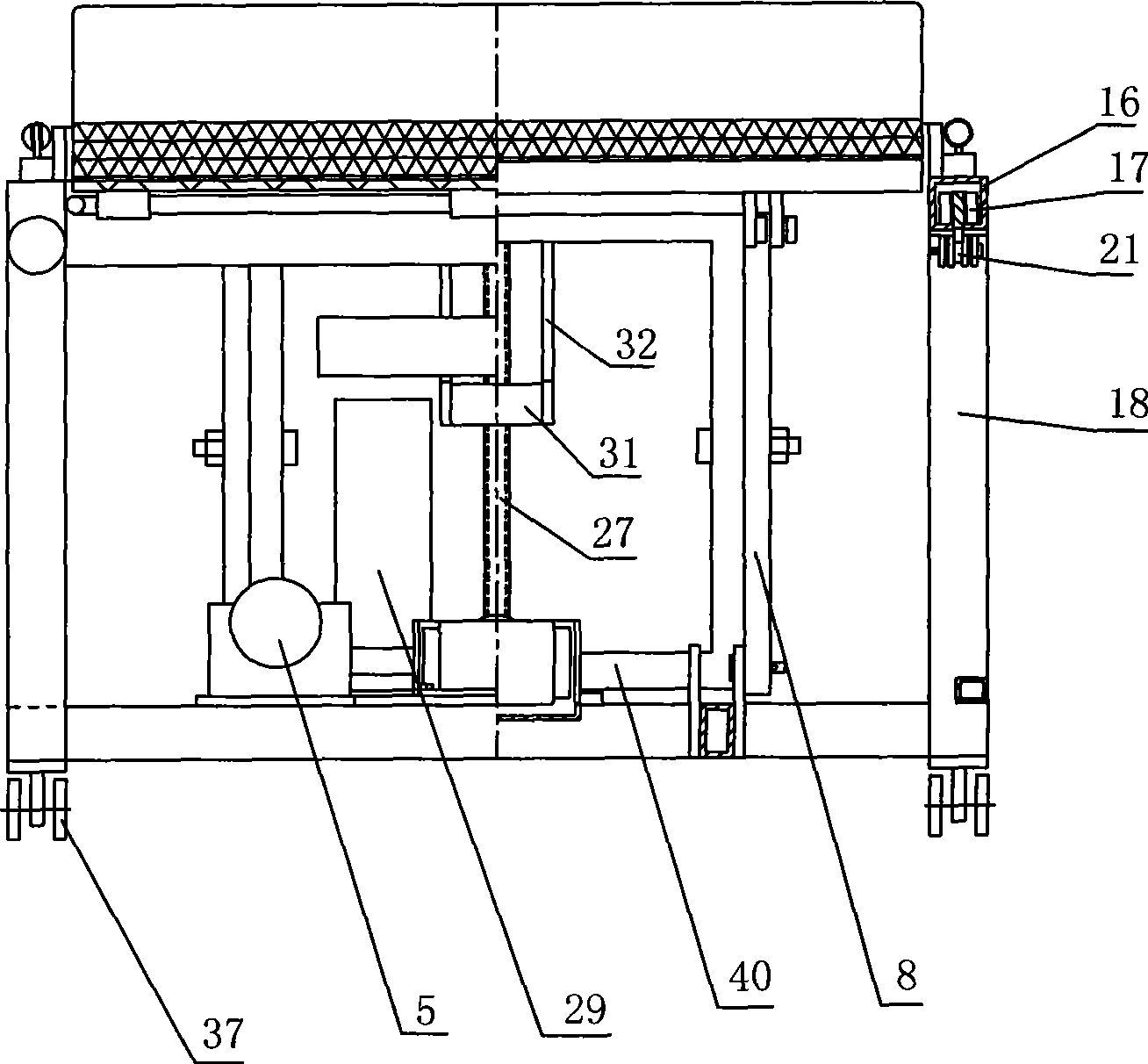

Heavy duty stacker for containers

InactiveCN102040177AReasonable structural designEasy to operateSafety devices for lifting equipmentsDrive wheelOperability

The invention discloses a heavy duty stacker for containers. The heavy duty stacker comprises a stacker frame, a safety protection device, a loading platform, a container hooking and taking device, a lifting device, an operation driving device and an electrical control device, wherein the stacker frame comprises four upright posts, an upper cross beam and a lower cross beam; the safety protection device comprises a cargo state detection device, a broken rope protection device, a power outage protection device, a travel speed-limiting device, a detection and positioning device and a progression speed reduction, walking emergency stop and retreat speed reduction switch; the container hooking and taking device comprises a lower fork, a middle fork, an upper fork and a hooking and taking driving mechanism composed of a normally closed electromagnetic braking motor, a chain wheel and a chain; the lifting device comprises a speed reduction motor, a pulley group, a steel wire rope reel, an encoder and a steel wire rope; and the operation driving device comprises a motor, a driving wheel, a driven wheel and an encoder. The heavy duty stacker is reasonable in structural design, strong in operability, good in safety performance and good in stable performance, and can meet the loading demand of large containers at ports and docks, and be convenient for popularization.

Owner:威仁(西安)仓储设备有限公司

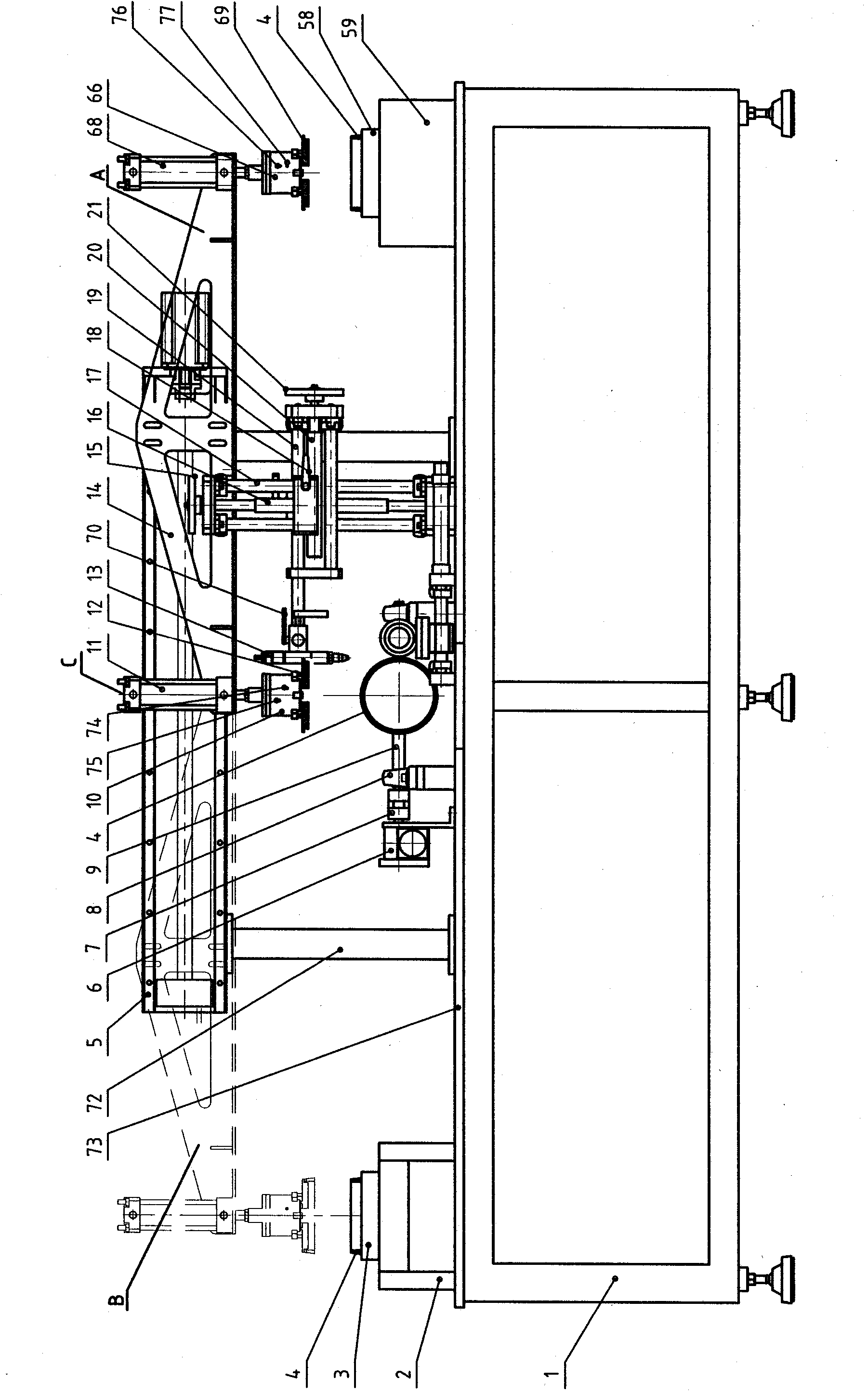

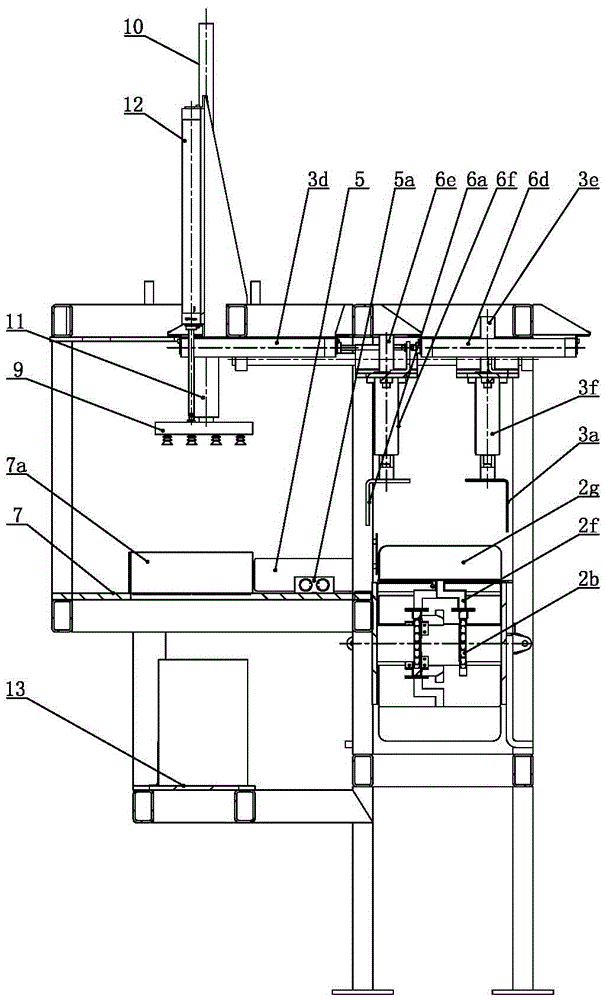

Fully-automatic gluing equipment suitable for various parts

ActiveCN102553774AApply glue evenlyMitigate threats to your healthLiquid surface applicatorsCoatingsEngineeringFully automatic

The invention provides fully-automatic gluing equipment suitable for various parts and relates to the fully-automatic gluing equipment. The fully-automatic gluing equipment solves the problem that the conventional cylindrical, ring-shaped, conical, circular truncated cone-shaped and circular truncated cone ring-shaped parts cannot be fully automatically glued on the same equipment. The fully-automatic gluing equipment comprises a machine frame, and a feeding workbench, a transmission platform, a part transverse transmission device, a tensioning collet A, a tensioning collet C, a rotary collet device, a swinging device, a glue head adjusting device and a glue scraping device which are fixed on the machine frame, wherein the feeding workbench comprises a feeding positioning die; the feeding positioning die is fixed on a feeding workbench panel; and the feeding positioning die is used for accurately positioning the parts and placing the parts in to the positioning die. The fully-automatic gluing equipment has high generality, can glue on the outer surfaces of the cylindrical, ring-shaped, conical, circular truncated cone-shaped and circular truncated cone ring-shaped parts and can glue on the inner surfaces of the cylindrical, ring-shaped, conical, circular truncated cone-shaped and circular truncated cone ring-shaped parts.

Owner:DALIAN HUAGONG INNOVATION TECH

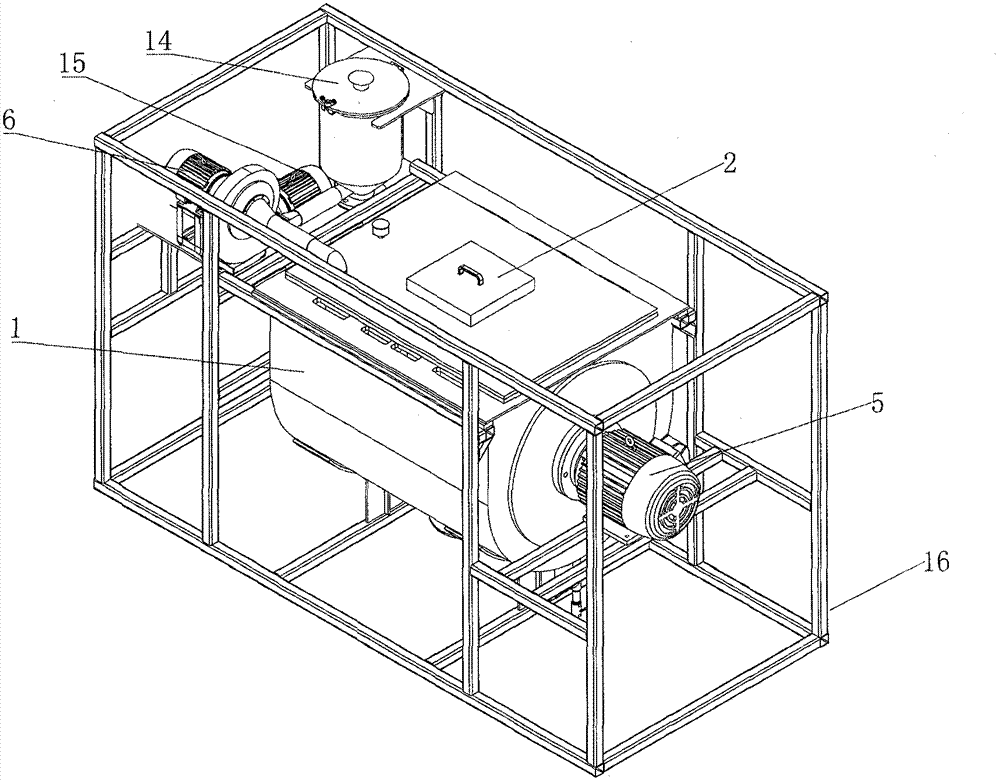

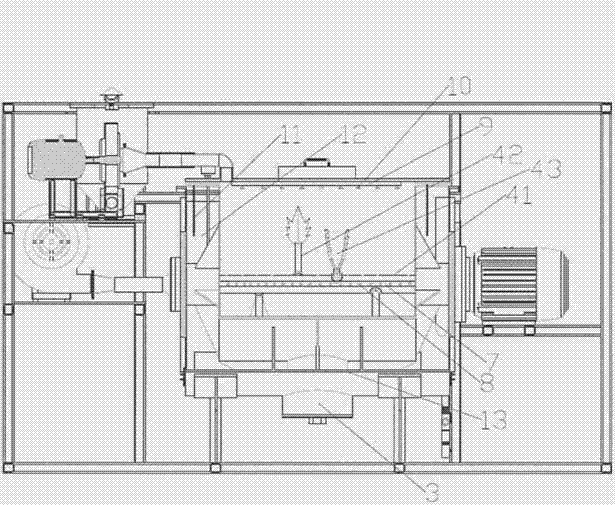

Novel kitchen garbage fermentation device and usage method

InactiveCN102786363AAvoid circulationLow costClimate change adaptationChemical industryMotor driveEngineering

The invention provides a novel kitchen garbage fermentation device and a usage method, which belongs to the environmental protection device field. The device provided by the invention comprises a U-shaped fermenter, a feed inlet, a discharge port, a fragmentation stirrer, a variable frequency motor, a blower, a ventilation duct, an air vent, a microbe inlet pipe, a charging nozzle, an electric heating pipe, a water interlayer, a protection layer, a deodorizing tower, a support and the like. The fragmentation stirrer is composed of a stirring horizontal shaft, a blade support and a triangle cone blade with arc bottom. Several electric heaters are arranged in the interlayer of a double layer U-shaped fermenter. The variable frequency motor drives the fragmentation stirrer to perform fragmentation stirring on the kitchen garbage. The electric heating pipe heats the water interlayer so that the temperature of the fermenter can be kept between 40-60 DEG C, air is introduced in the ventilation duct through the blower, and a microbe liquid bacteria agent is inoculated in the fermenter through a nozzle on the microbe inlet pipe. The product is discharged out of the fermenter through the discharge port, thereby the minimization of the kitchen garbage can be realized, and the product can be used as a soil organic fertilizer conditioning agent.

Owner:TIANJIN ECOLOGY CITY ENVIRONMENTAL PROTECTION +1

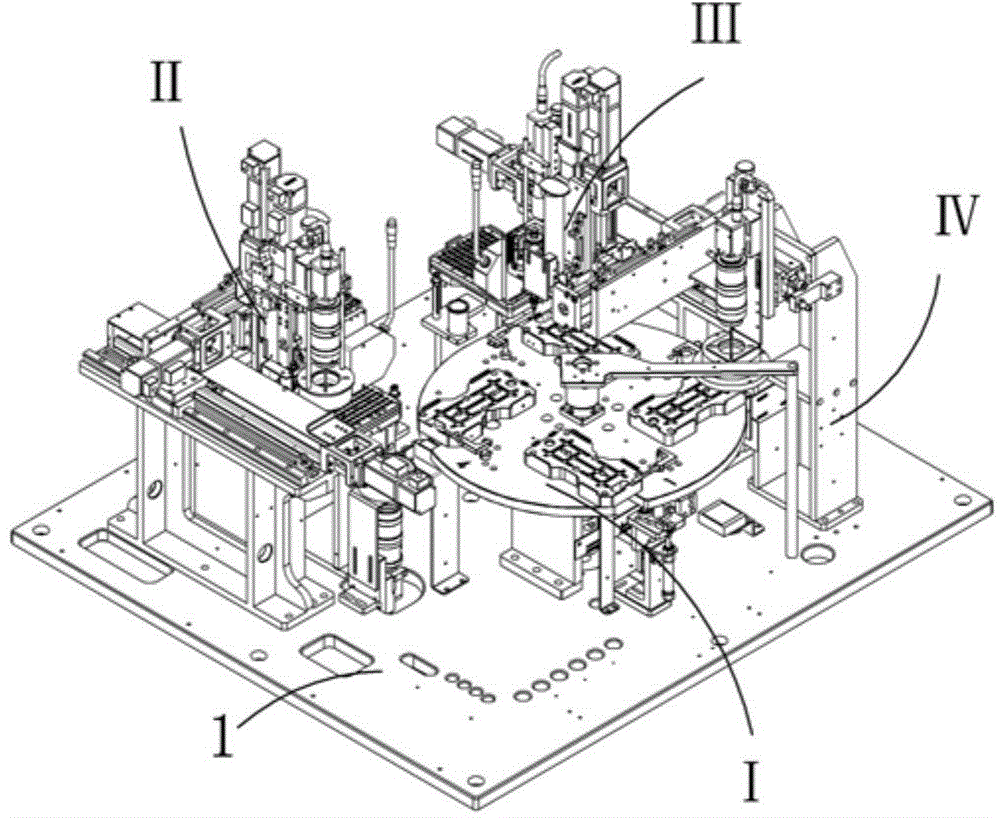

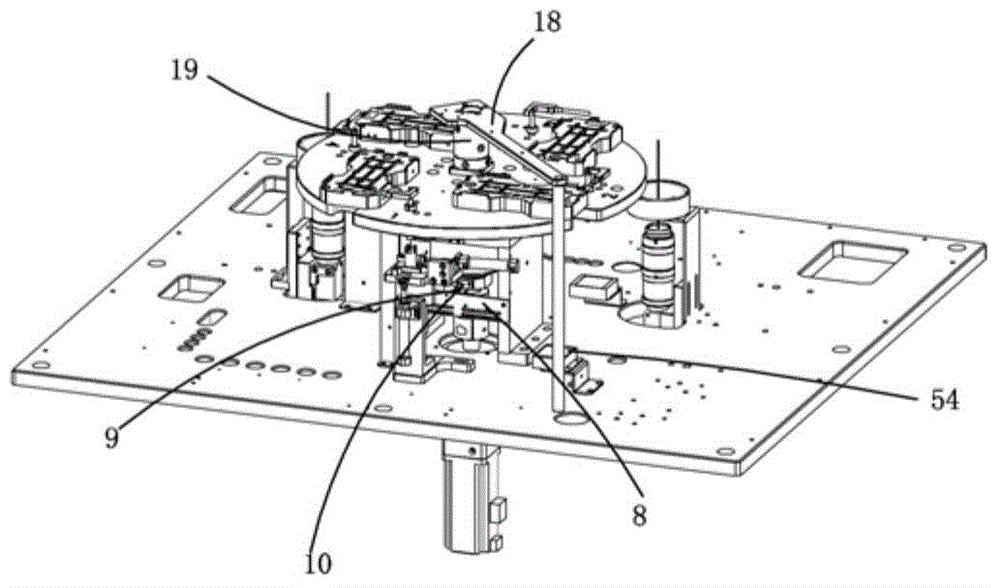

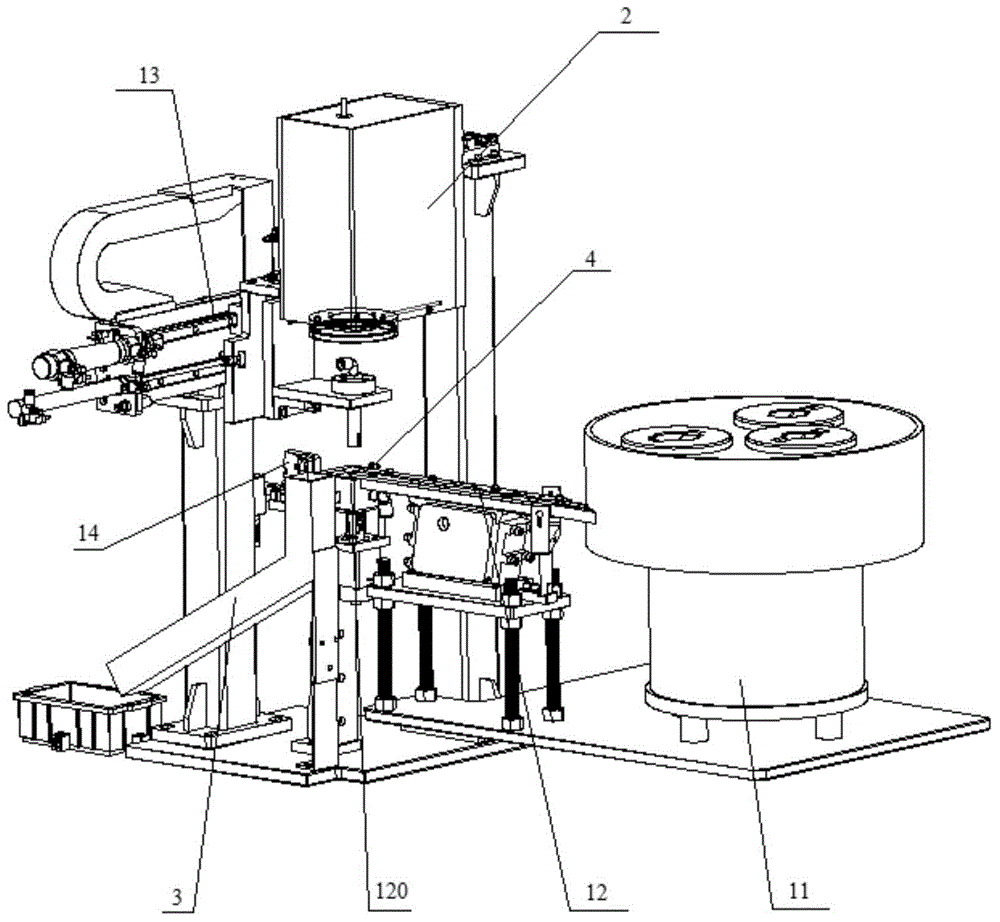

Full-automatic part assembly machine

ActiveCN104551660APrevent camera alignment and other workQuick and accurate assemblyAssembly machinesEngineeringWorkstation

The invention relates to a full-automatic part assembly machine. A rotary plate mechanism is mounted at the center of the bottom plate, a first part assembly workstation and a second part assembly workstation are identical in structure and mounted on the left rear portion and the right rear portion of the bottom plate respectively, and a detecting workstation is mounted on the front portion of the right side of the bottom plate. An operator places a workpiece on a carrier, a rotary motor rotates the carrier on a rotary plate to the first part assembly workstation, and a small part a is assembled onto the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the second part assembly workstation, and a small part b is assembled on the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the detecting workstation, a CCD on the detecting workstation takes pictures and detects whether the assembled workpiece is qualified or not; after detection, the rotary motor rotates the rotary plate to the initial position. The full-automatic part assembly machine is simple to operate, the small parts can be quickly and accurately assembled to the workpiece, labor is saved, production efficiency is improved, and production cost of enterprises is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

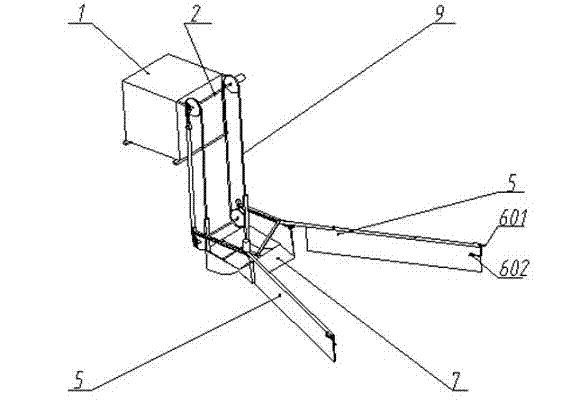

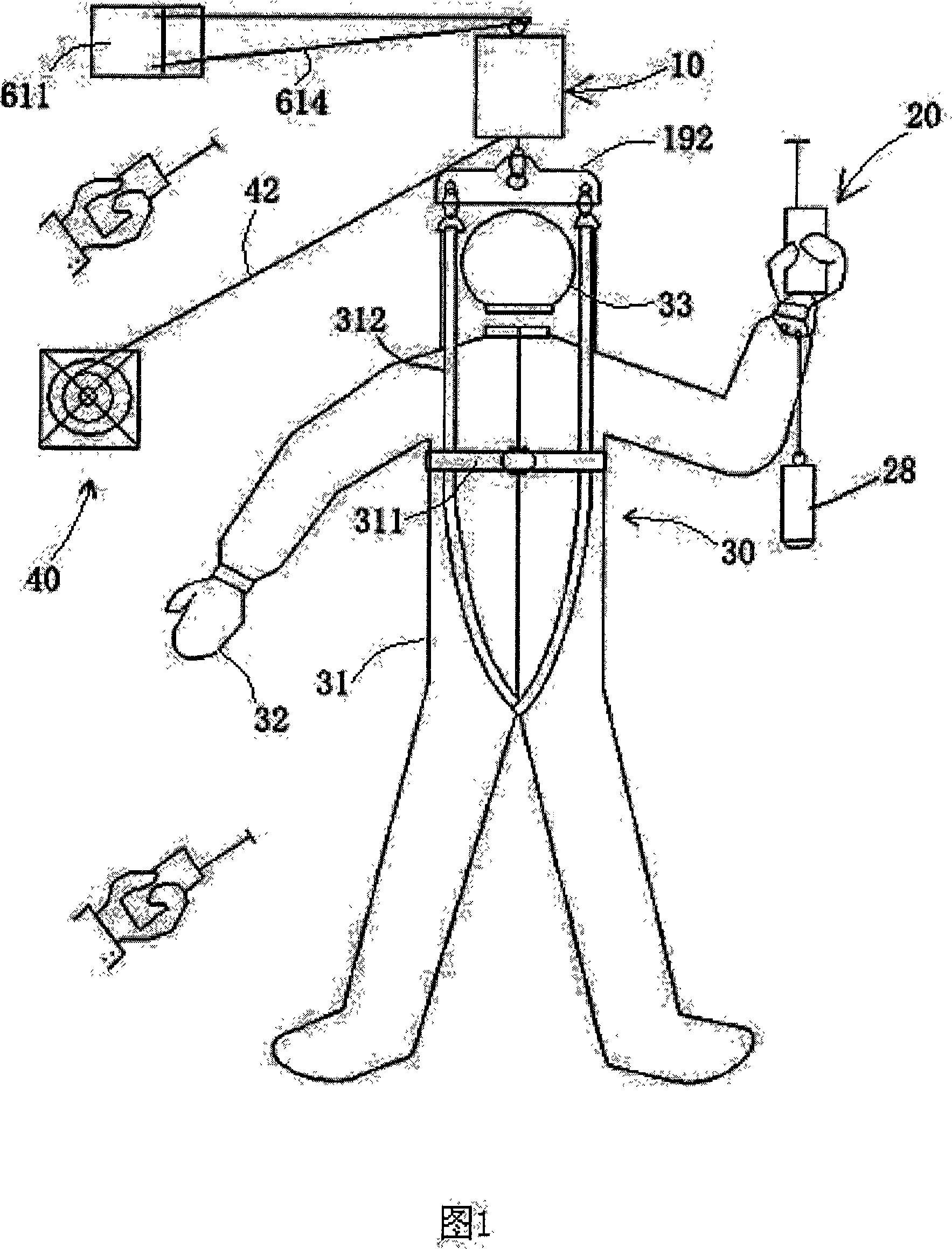

Fire disaster self-saving high-speed escaping machine that can be operated and controlled by micro-computer in wireless mode

InactiveCN101095971AEliminate critical defectsQuick and efficient escapeProgramme controlTelemetry/telecontrol selection arrangementsFire - disastersHand held

The invention relates to a fire self-rescuing high-speed life device controlled by micro computer, which can be controlled without wire. The device comprises host computer component, at least a hand-hold wireless remote controller, falling load device and sling component, wherein the host computer component is set at the special life port of building or in the refuge safe room and is connected with the building. The hand-hold wireless remote controller is taken by escaping man or escaping man, escort and ground meeting man all take hand-hold wireless remote controller. The falling load device is connected with the host computer component. The sling component is connected with the falling load device and the host computer component respectively. The device also comprises an air locator, which control the air location of falling load device and the distance between the falling load device and the building outer wall. The air locator is connected with the falling load device and is communicated with the hand-hole wireless remote controller without wire. The device can be controlled by escaping man or escaping man and ground rescuing man. It can control falling speed and space location. It is provided with fire proof and collision prevention performance and safe and reliable use.

Owner:唐海山

Rope threading device of handbag

ActiveCN108115986AIncrease productivityImprove processing qualityBag making operationsPaper-makingEngineeringChannel use

The invention discloses a rope threading device of a handbag. According to the technical scheme, the device includes two bases and a clamp drive part; the surfaces, opposite to each other, of the twobases are provided with abutting and sealing surfaces, rope threading grooves are formed in the abutting and sealing surfaces, and when the two bases are attached to each other, the two rope threadinggrooves are buckled to form a rope threading channel used for making a rope slide in; the rope threading channel includes a rope inlet and a rope drawing hole located at the two ends of the rope threading channel respectively, the rope drawing hole of the rope threading channel is provided with a negative pressure part used for drawing a rope body from the rope inlet into the rope threading channel through suction, one base is provided with a rope accumulation part used for storing the rope body from the rope inlet into the rope threading channel, the rope inlet of the rope threading channelis provided with a blocking part used for blocking the rope threading channel from the rope inlet, and the other base is provided with a push part used for pushing the rope body stored in the rope threading channel from the rope drawing hole. The device is high in processing efficiency, the processing quality is stable, and the production cost of a factory is esily reduced.

Owner:温州临界科技有限公司

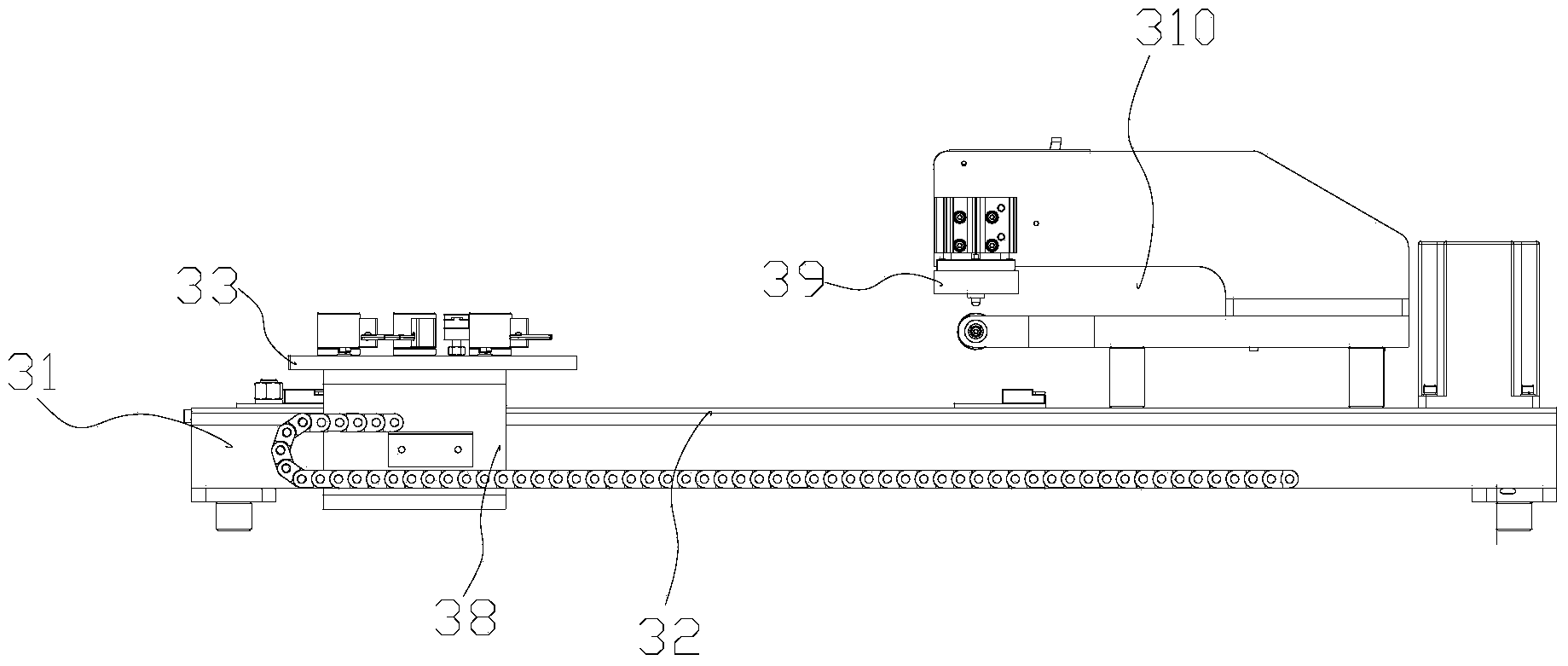

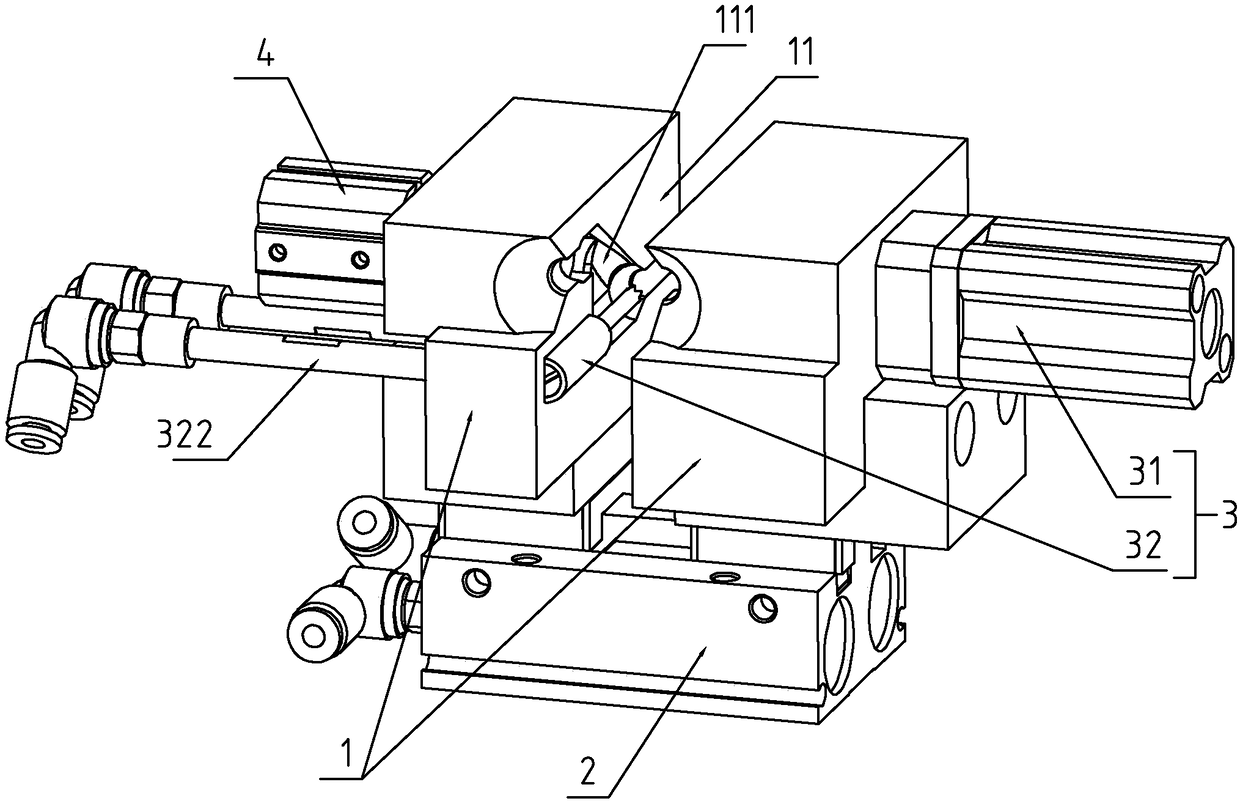

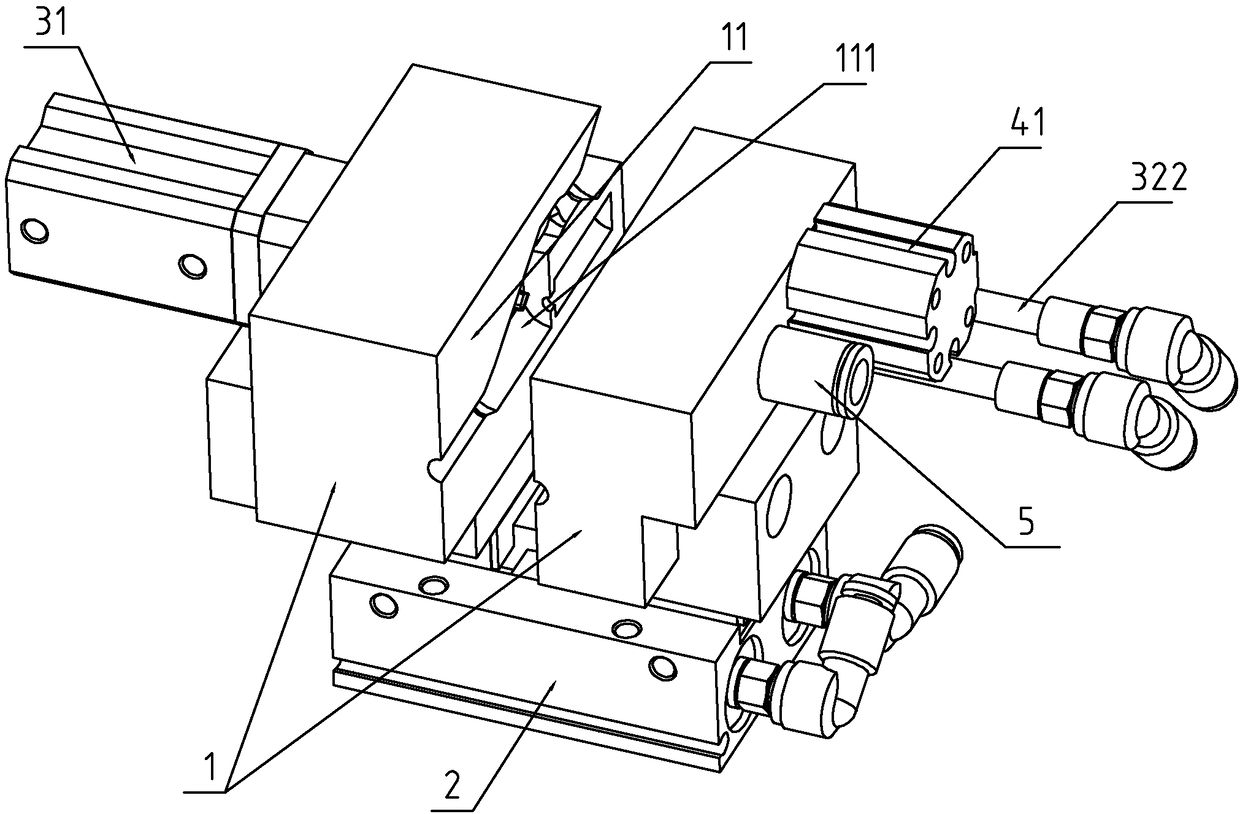

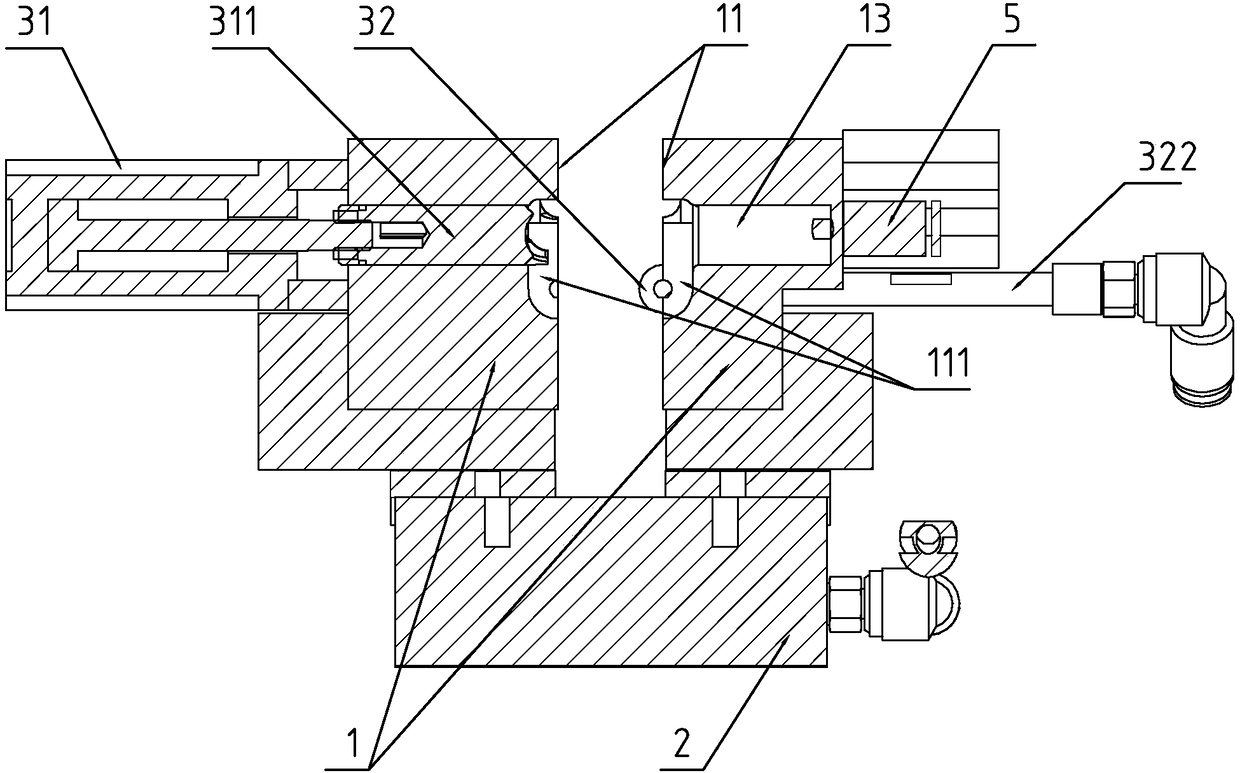

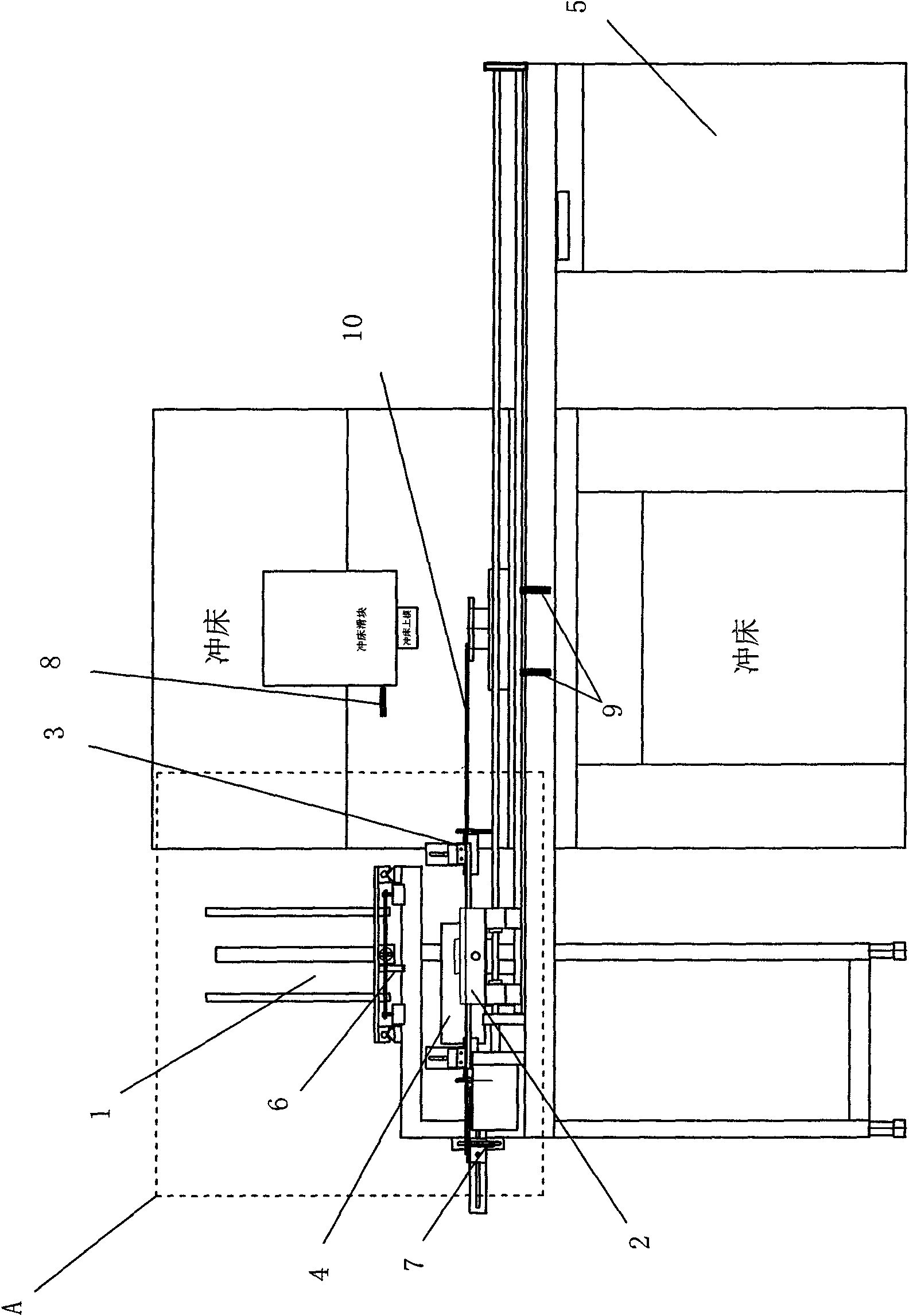

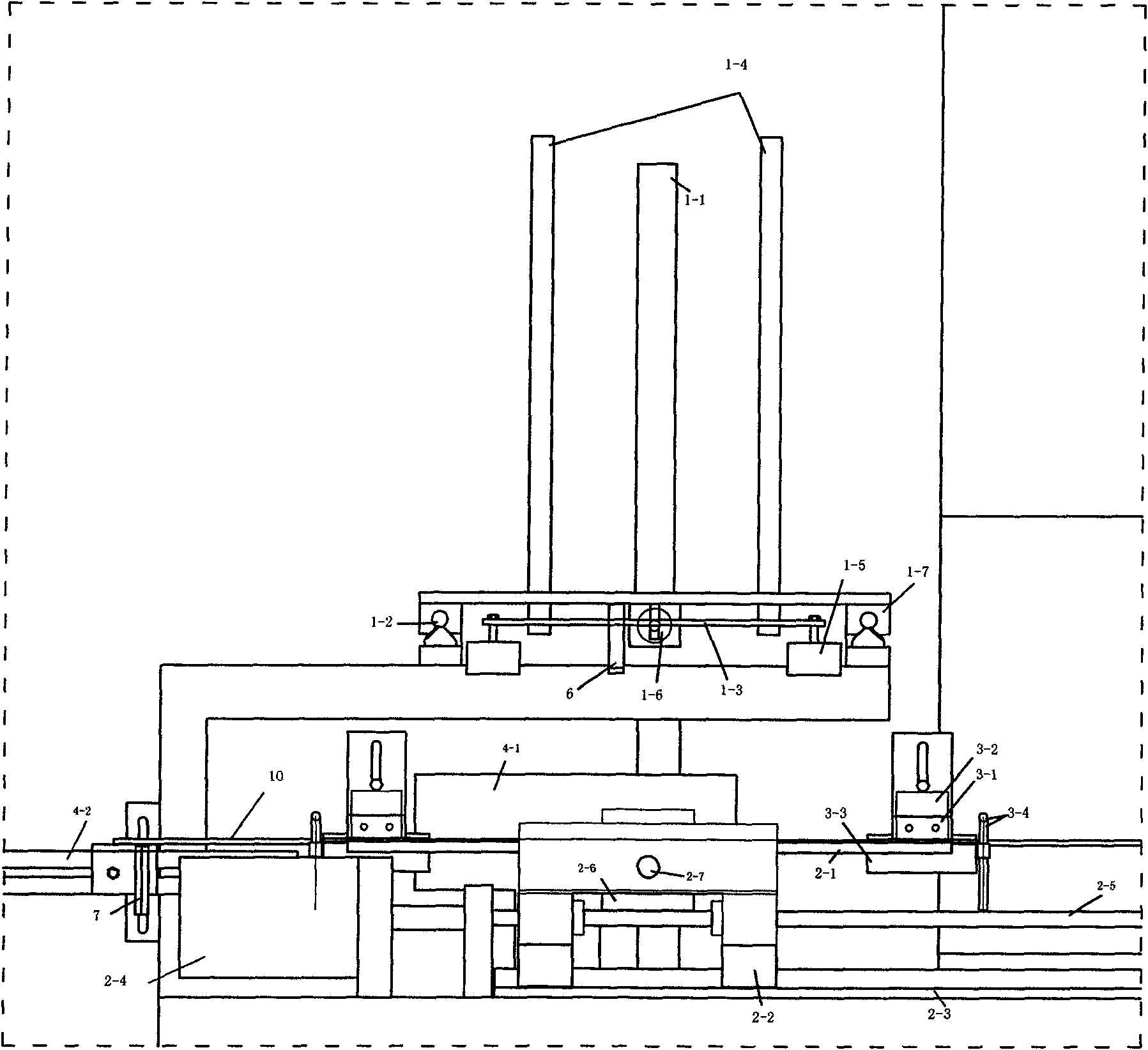

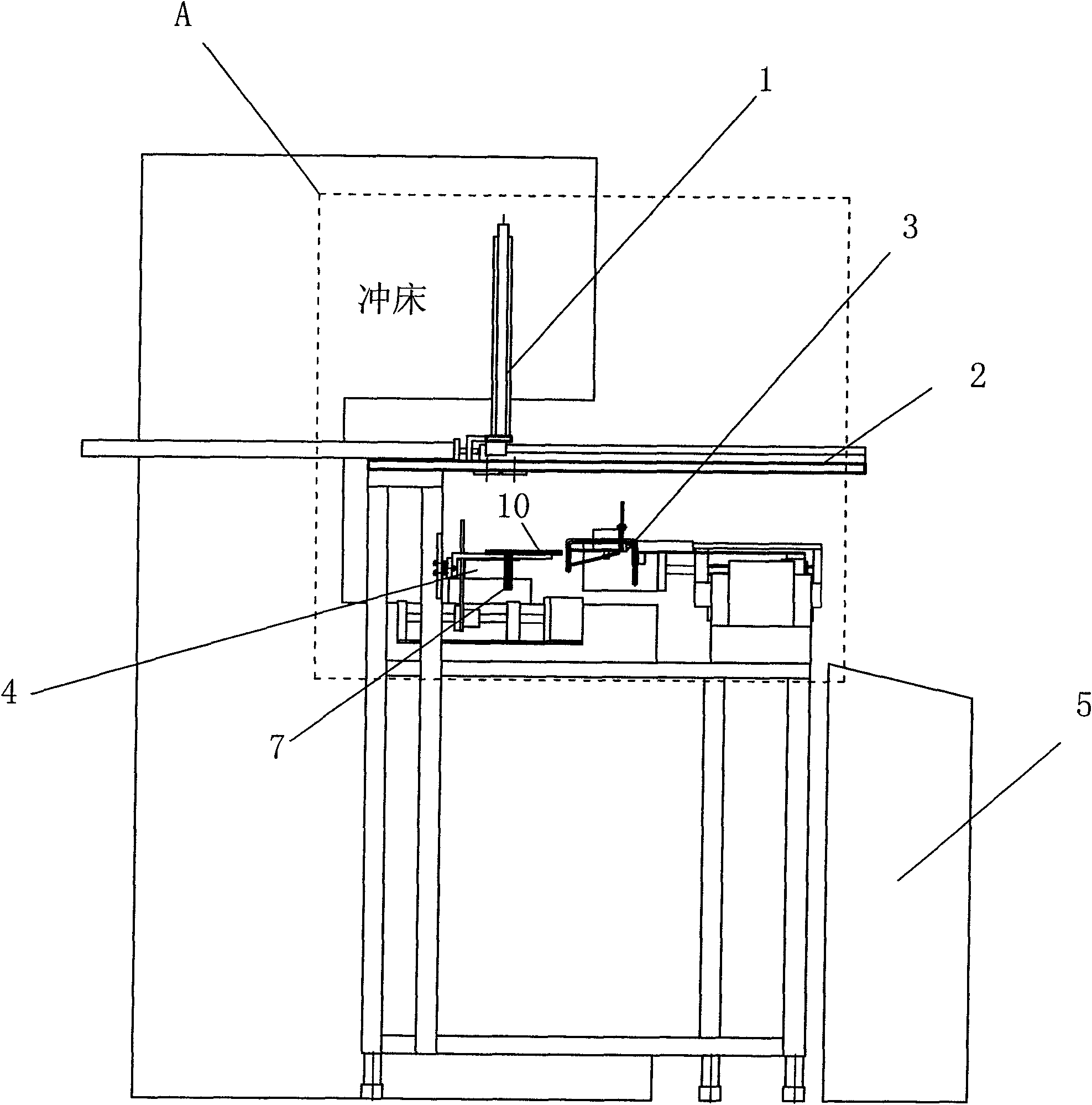

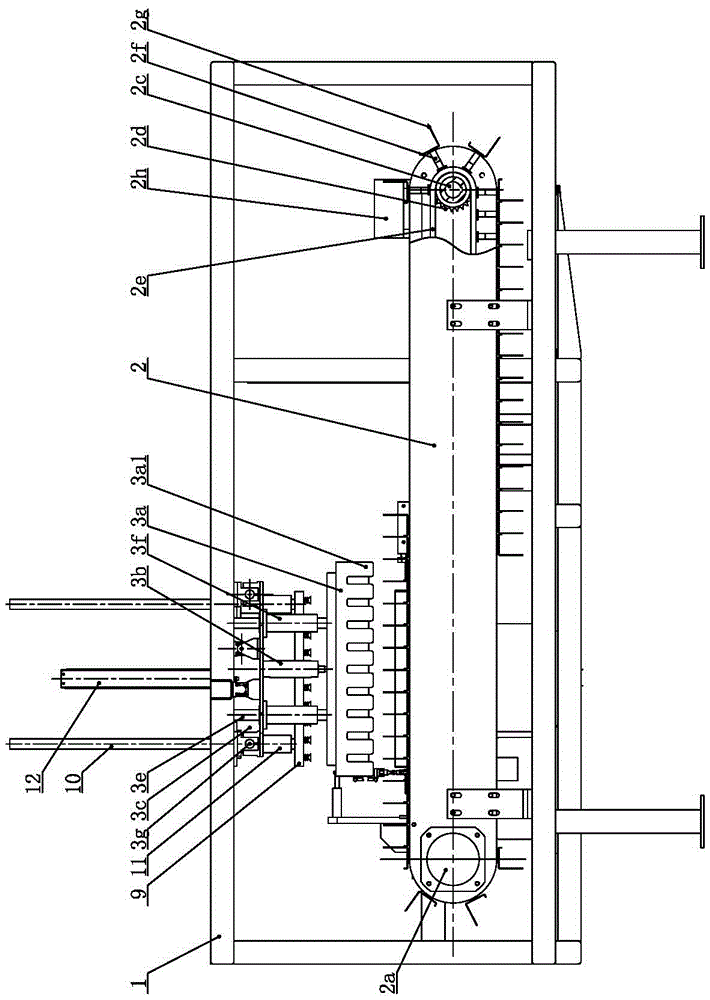

Automatic material loading, feeding and unloading equipment for bar stock blanking and method thereof

InactiveCN102180366AIncrease profitEasy to switchArticle feedersArticle separationPunch pressMulti machine

The invention discloses automatic material loading, feeding and unloading equipment for bar stock blanking and a method thereof. The equipment comprises a material loading mechanism, a feeding mechanism and an electric cabinet, wherein the feeding mechanism is provided with a mechanical arm, and the mechanical arm is connected with a manipulator. The equipment has the following beneficial effects: 1, the equipment can replace workers in the whole process to realize full-automatic operation of material loading, feeding and unloading, thus the purpose that one worker operates multiple machines can be realized; 2, varieties are convenient to switch; 3, in the feeding process, the manipulator has a function of automatically avoiding a punch die so as to realize multi-row reciprocating operation, especially automatic punching operation of narrow bar stock relatively to the die width; 4, although the structure is installed in front of the punch die, the structure barely affects workers to assemble, disassemble and adjust a die in front of a punch; 5, the shutdown rate of the punch is improved; 6, the equipment has the advantages of simple mechanical structure and low cost and is convenient to maintain; and 7, after material is automatically fed, the bar stock can be subjected to multiple-particle blanking because feeding position is accurate.

Owner:吴丽威

Lock cylinder cover cap riveting device and riveting method thereof

ActiveCN104438945ARealize fully automatic operationIncrease productivityMetal-working apparatusPulp and paper industry

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

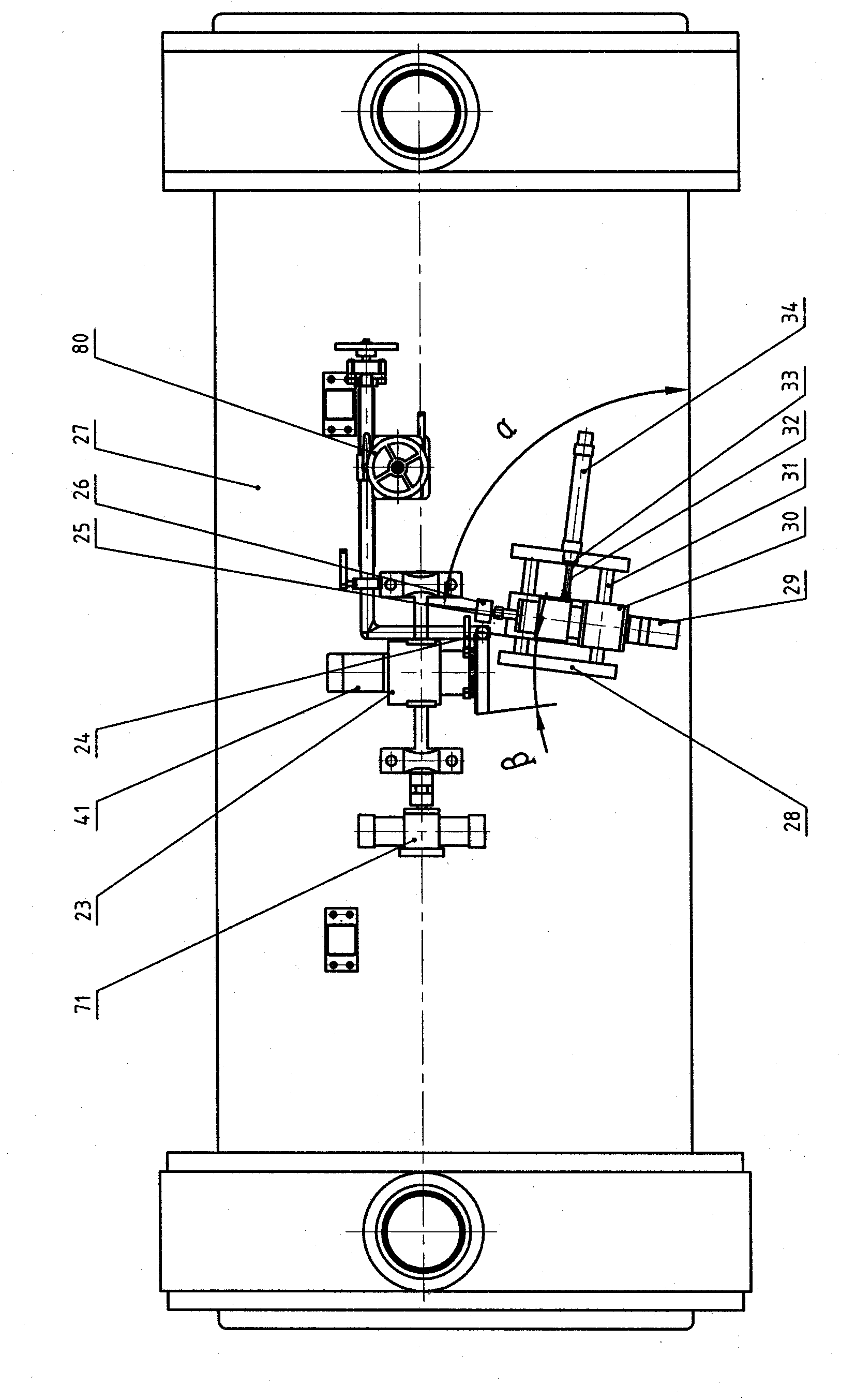

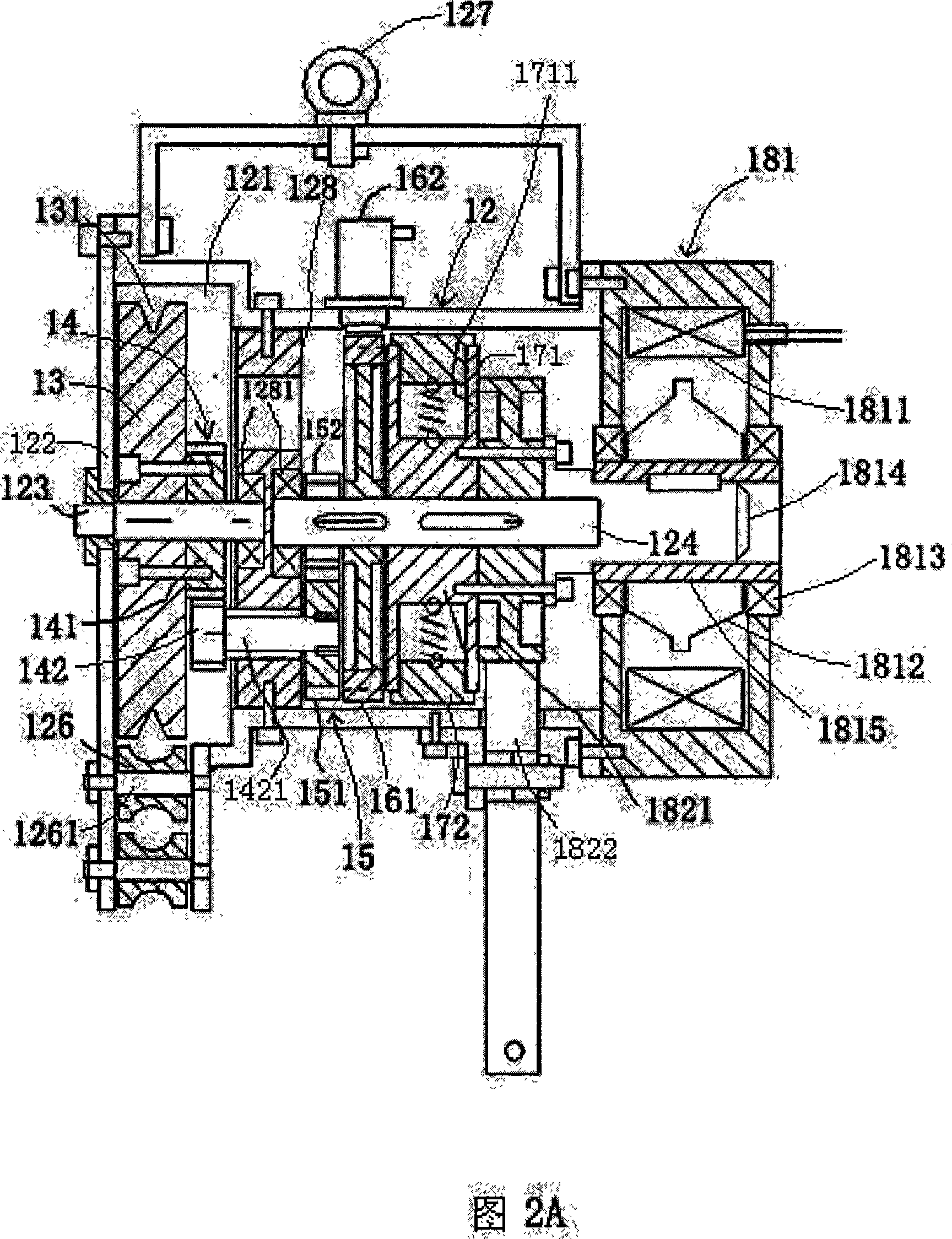

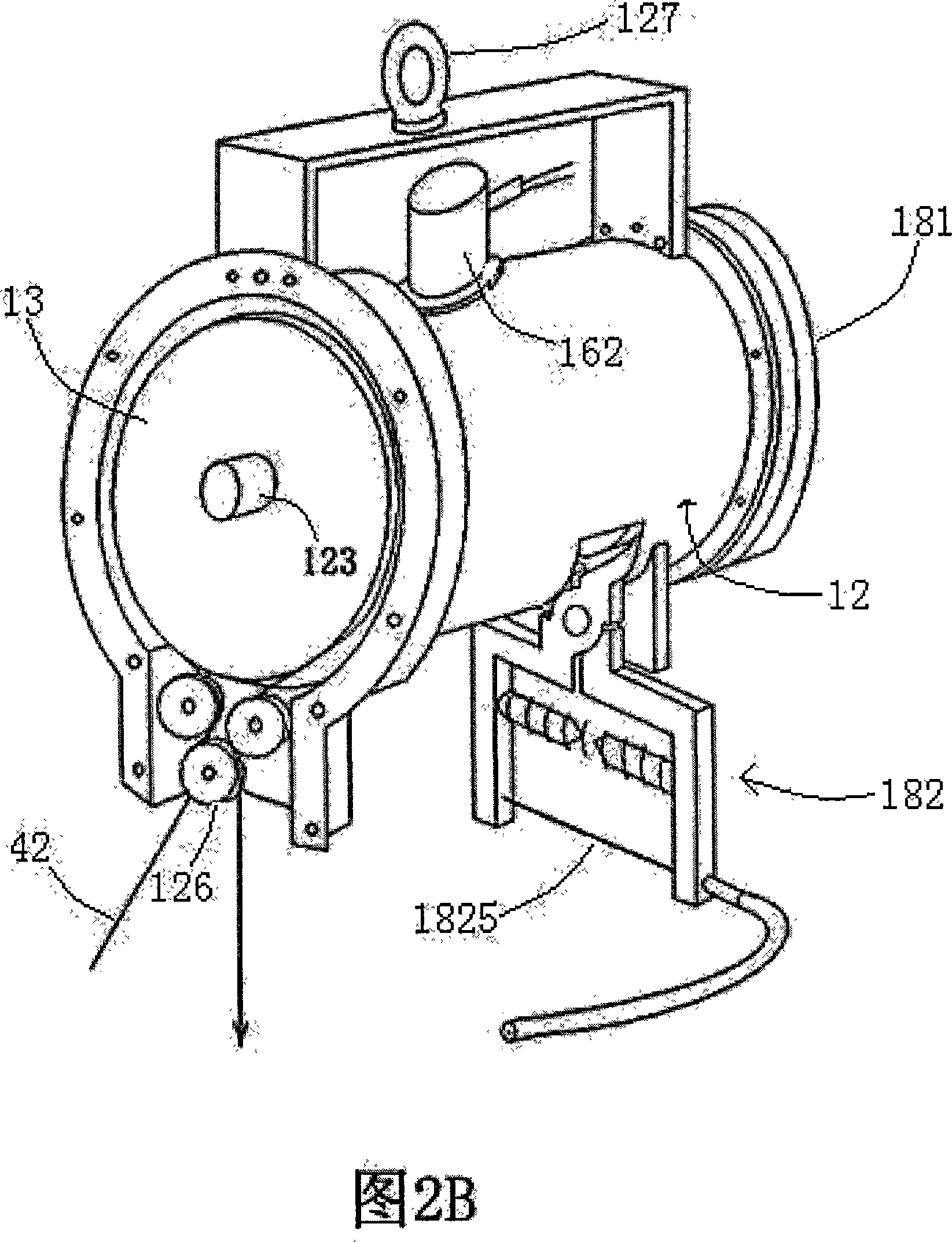

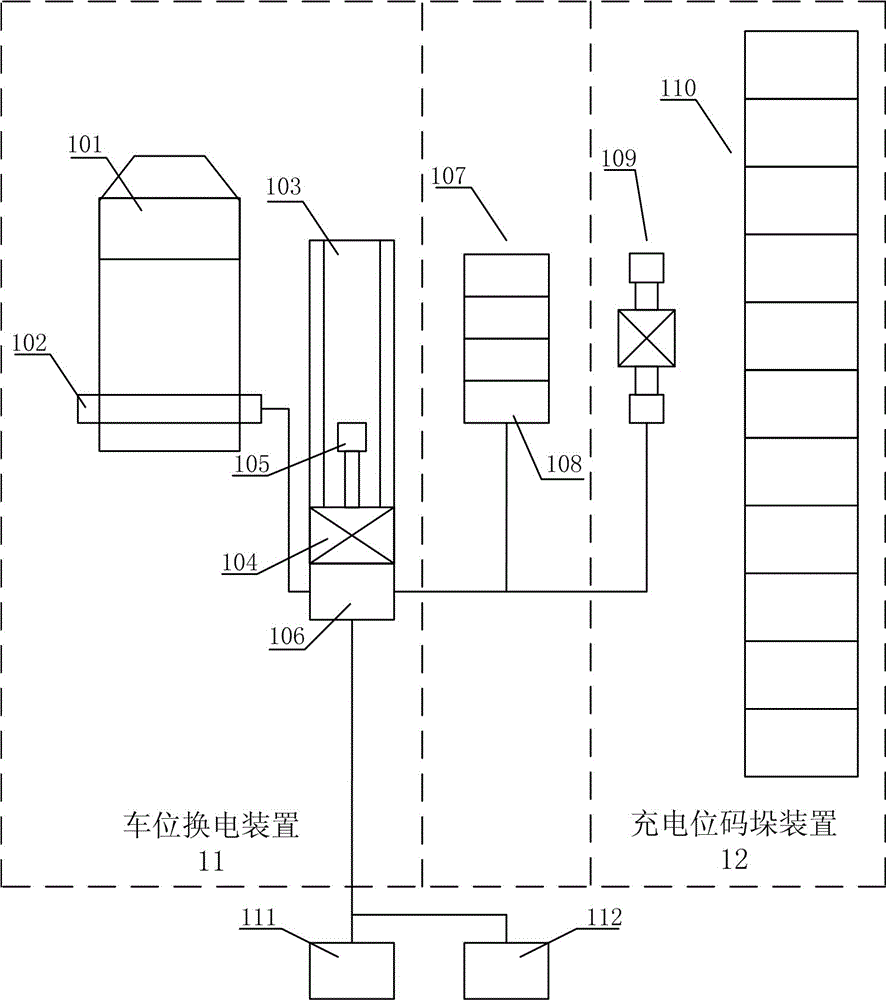

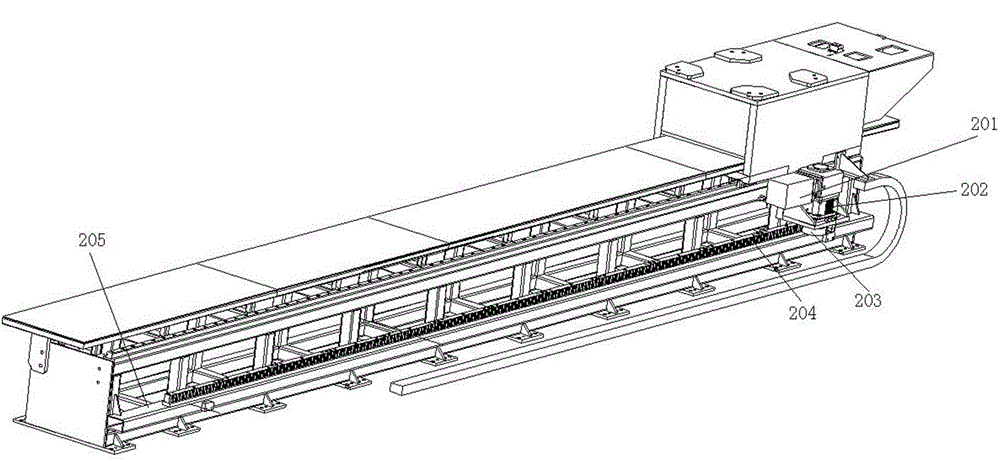

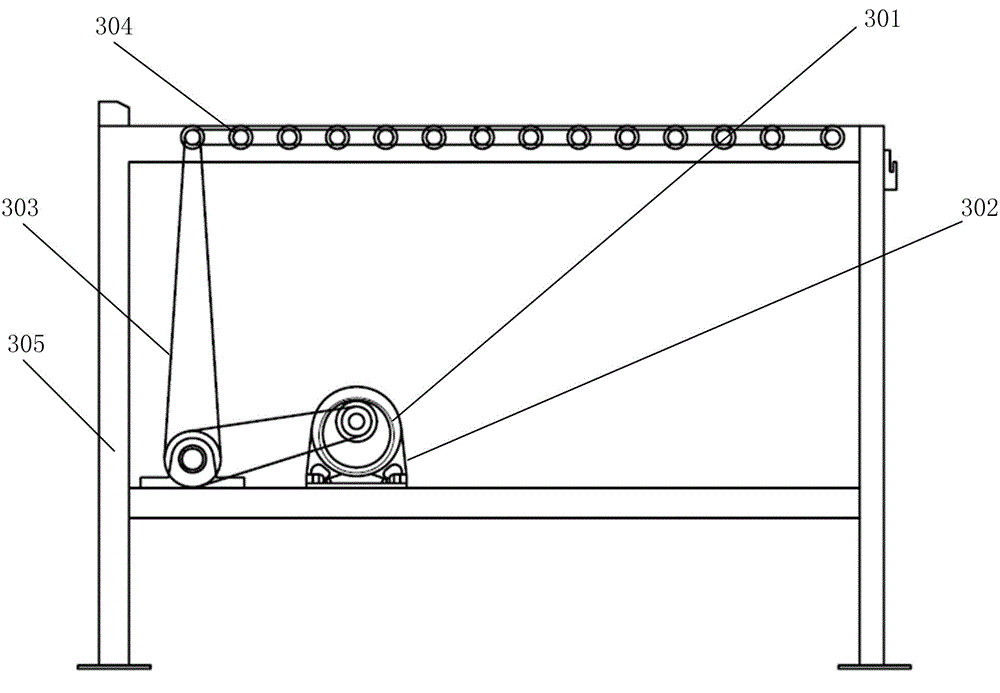

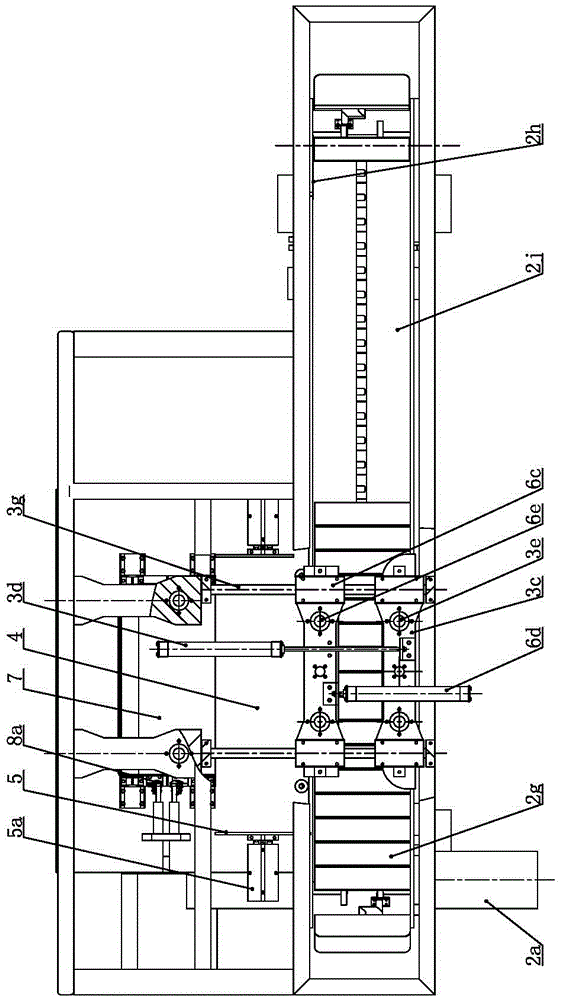

System for automatically replacing batteries by using robot and method thereof

InactiveCN102941842AImprove replacement efficiencyRealize fully automatic operationElectric propulsion mountingElectric/fluid circuitElectrical batteryAutomotive engineering

The invention provides a system for automatically replacing batteries by using a robot. The system comprises a vehicle position battery transfer device, a transport mechanism, a charging position stacking device and a system control unit. The vehicle position battery transfer device is used for transporting the batteries between an electric vehicle and the transport mechanism, the transport mechanism is used for placing charged batteries and to-be-charged batteries, the charging position stacking device is used for transporting the batteries between a charging bin rack and the transport mechanism, and the system control unit is used for controlling the operations of the vehicle position battery transfer device, the transport mechanism and the charging position stacking device. A method for automatically replacing batteries by using a robot is also disclosed. The method comprises the following steps: transporting the batteries between the transport mechanism and the charging bin rack through the stacking device, and transporting the batteries between the electric vehicle and the transport mechanism through the vehicle position battery transfer device. The battery automatic replacement system and method thereof can ensure full automatic operation of replacing the batteries of the electric vehicle and increase the efficiency of battery replacement.

Owner:YASKAWA SHOUGANG ROBOT CO LTD

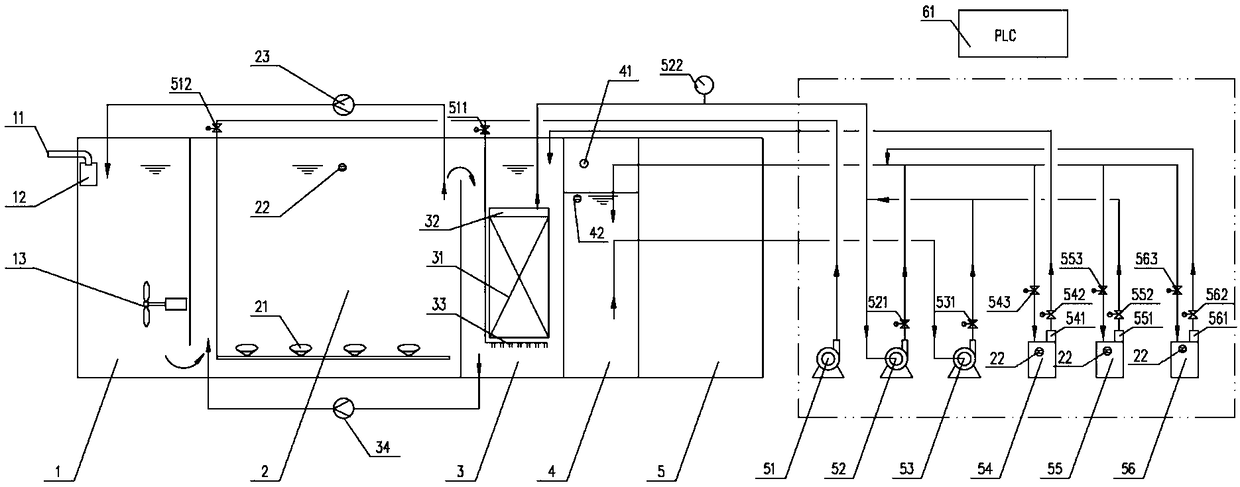

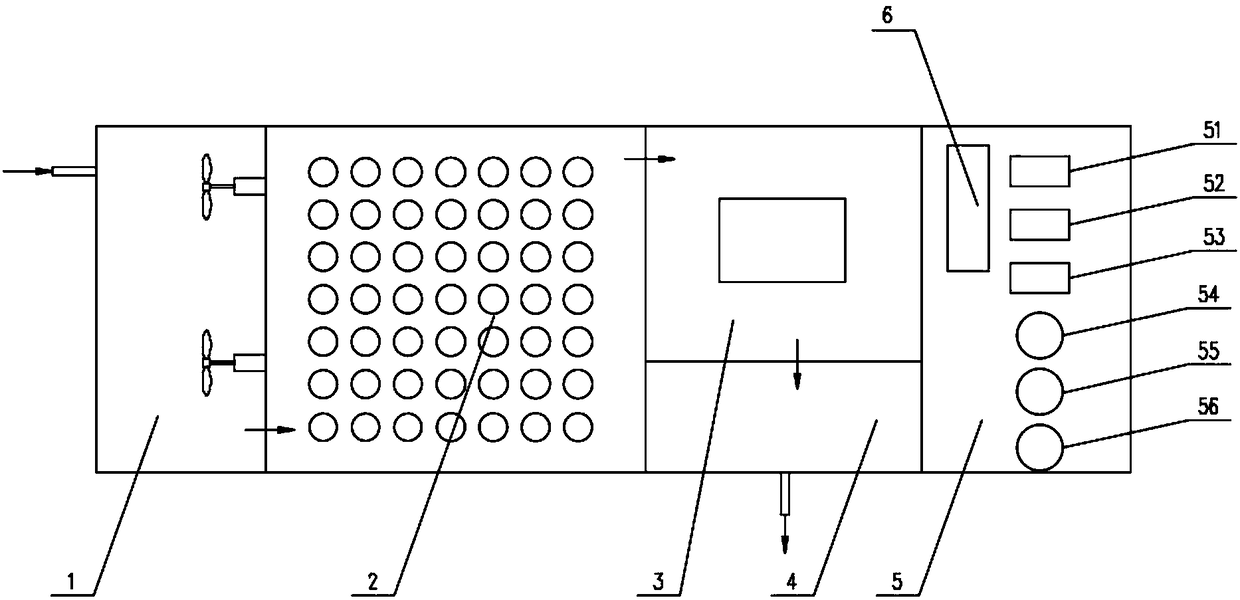

Smart integrated MBR sewage purifying device

InactiveCN108892331AControllable production cycleCompact structureSpecific water treatment objectivesWater contaminantsNitrationSewage

The embodiment of invention provides a smart integrated MBR sewage purifying device. The device comprises an oxygen deficit pool, an aerobic pool, a membrane pool, a clear water pool and an equipmentroom. The oxygen deficit pool is communicated with the bottom of the aerobic pool, the aerobic pool is communicated with the top of the membrane pool, the clear water pool and the membrane pool are not communicated in the same pool, and the equipment room is next to the clear water pool and comprises a phosphorous removal system, a back flush system, a sterilizing system and an electric control cabinet; the oxygen deficit pool primarily filters sewage, a denitrification reaction occurs, the sewage has the denitrification reaction through the aerobic pool to generate nitration liquid, the membrane pool performs deep-layer filtering through an MBR membrane device and is connected with the phosphorous removal system to remote phosphorous in the sewage, and the clear water pool is connected with the sterilizing system to sterilize produced water by the membrane pool, so that clear water is obtained. By the adoption of the modularized design, the production period is controllable, quality is good, the structure is compact, the size is small, transportation and installation are simple, full-automatic operation can be realized, remote monitoring can be realized, and the demand for treating the sewage in villages and small towns can be met.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

Multifunctional bed

The invention discloses a multifunctional bed. The multifunctional bed comprises a bed surface and a bed frame. The bed surface consists of a bed head section, a bed tail section and a middle section arranged between the bed head section and the bed tail section; the bed head section and the bed tail section are arranged on the bed frame; the bed also comprises a middle section drive device; the middle section drive device drives the middle section to lift in vertical direction; the bed also comprises a convenient device arranged on the lower part of the bed surface and a convenient device drive device; the convenient device drive device drives the convenient device to vertically and horizontally move in the lower part of the bed surface; the bed surface of the multifunctional bed consists of three sections; the middle section is driven to lift up and down by the drive device; the lower part of the bed surface is provided with the convenient device; after the middle section declines, the convenient device is horizontally moved to the upper part of the middle section through the convenient device drive device, is convenient for the elderly, handicapped with inconvenient walking and bedridden patients to relieve the bowels at any moment and relieves living and economic burden for families.

Owner:王继华

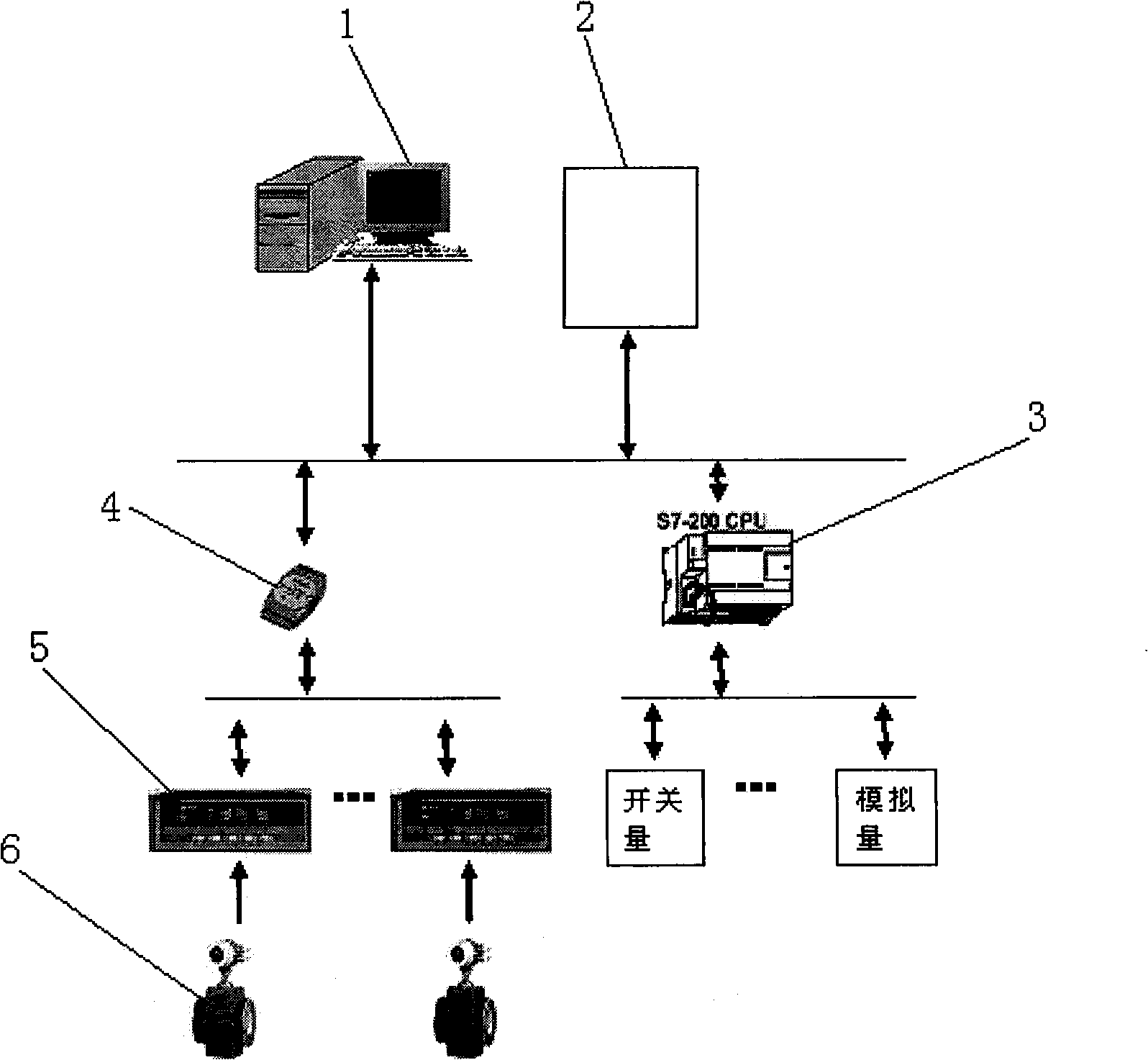

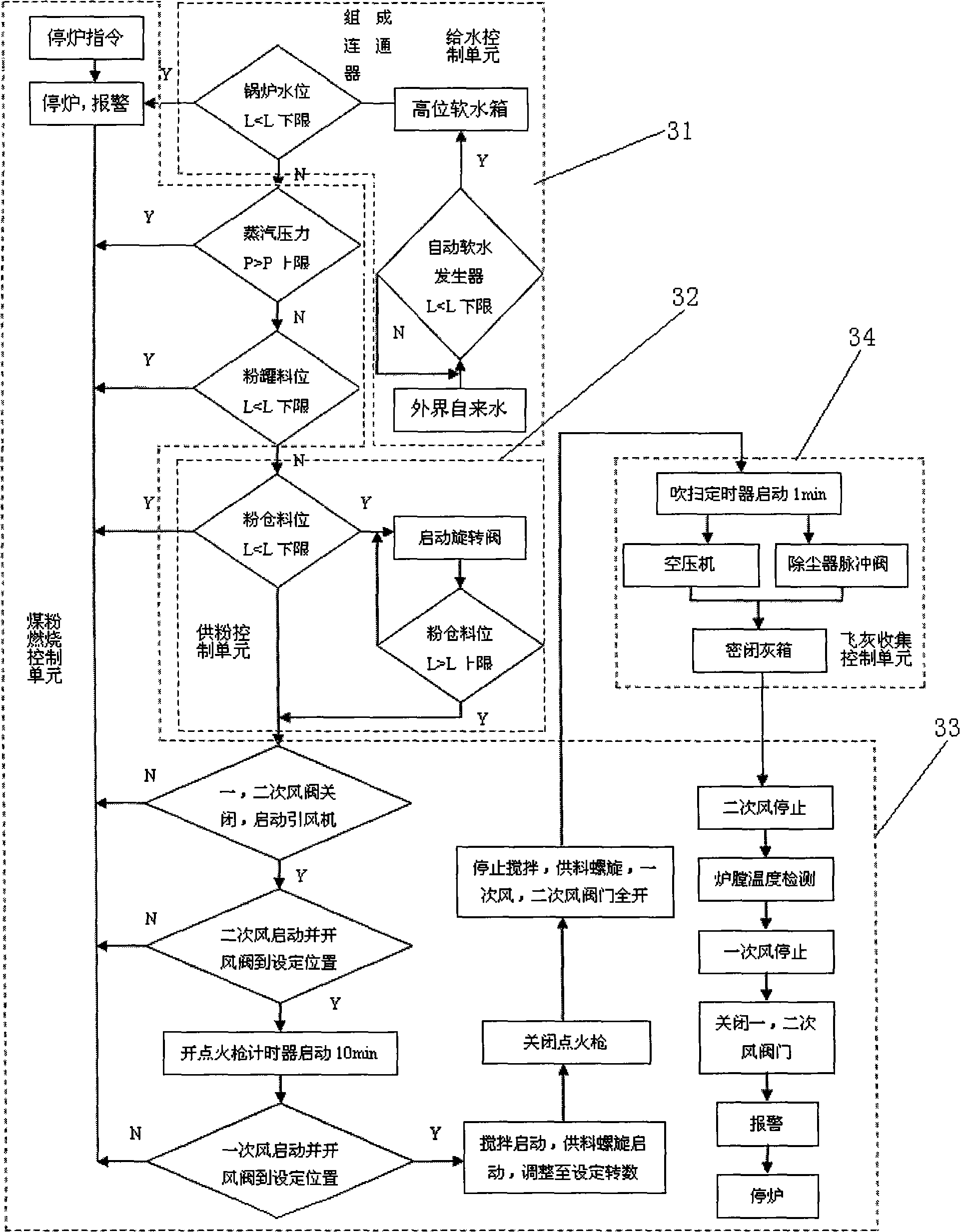

Automatic control system for industrial coal powder boiler

ActiveCN101576247AGuaranteed uptimeWith self-diagnosis functionBoiler controlWater feed controlAuto regulationAutomatic train control

The invention relates to an automatic control system for an industrial coal powder boiler, which is characterized by comprising an industrial computer, a control cabinet, a core controller, an RS signal converter, an intelligent display instrument and a plurality of sensors; the output terminals of the sensors are connected with the input terminal of the intelligent display instrument, the output terminal of the intelligent display instrument is connected with the input terminal of the RS signal converter, and the output terminal of the RS signal converter is connected with the industrial computer and the control cabinet; the core controller is directly connected with the industrial computer and the control cabinet; and the core controller comprises a water supply controlling unit, a powder supply controlling unit, a pulverized-coal combustion controlling unit and a fly ash collection controlling unit. The invention not only can finish the acquisition of the related technical parameters of the boiler, ensure the normal running of the boiler, and achieve the optimum burning effect, but also can realize the automatic regulation and control of water supply, powder supply, starting and stopping and dust removal and ensure the normal running of the boiler under the condition without being monitored by a person.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Tube-bead embroidery automatic feeding device

InactiveCN101603254ARealize fully automatic operationImprove sewing qualityAutomatic machinesAuxillary devicesReciprocating motionEngineering

The invention relates to an embroidering machine, and aims to provide a special sewing machine for tubes or beads, which can realize the automatic sewing of tubes or beads, and has the advantages of good sewing quality, high working efficiency and low processing cost. The technical proposal of the invention is characterized in that: the tube-bead embroidery automatic feeding device comprises a feeding device and a pushing device which is matched with the feeding device and is capable of making the straight reciprocating motion, wherein the feeding device is provided with a vibration type feeder, and a bead guide tube of the feeder is an output pipeline of tubes or beads; the pushing device faces the outlet end of the bead guide tube and is provided with a bead guide seat provided with a horizontal track, a bead pushing plate capable of making the reciprocating motion along the track, a swinging mechanism driving the bead pushing plate to move and an air suction device sucking air in a cavity in the bead guide seat through an air suction tube; and the front end of the bead guide seat is provided with a bead guide hole vertically downward, and a space is reserved between the bottom end face of the bead guide hole and the surface of the working table, so that the tubes or beads can be conveniently outputted.

Owner:ZHUJI MAYA ELECTRIC APPLIANCE MACHINERY

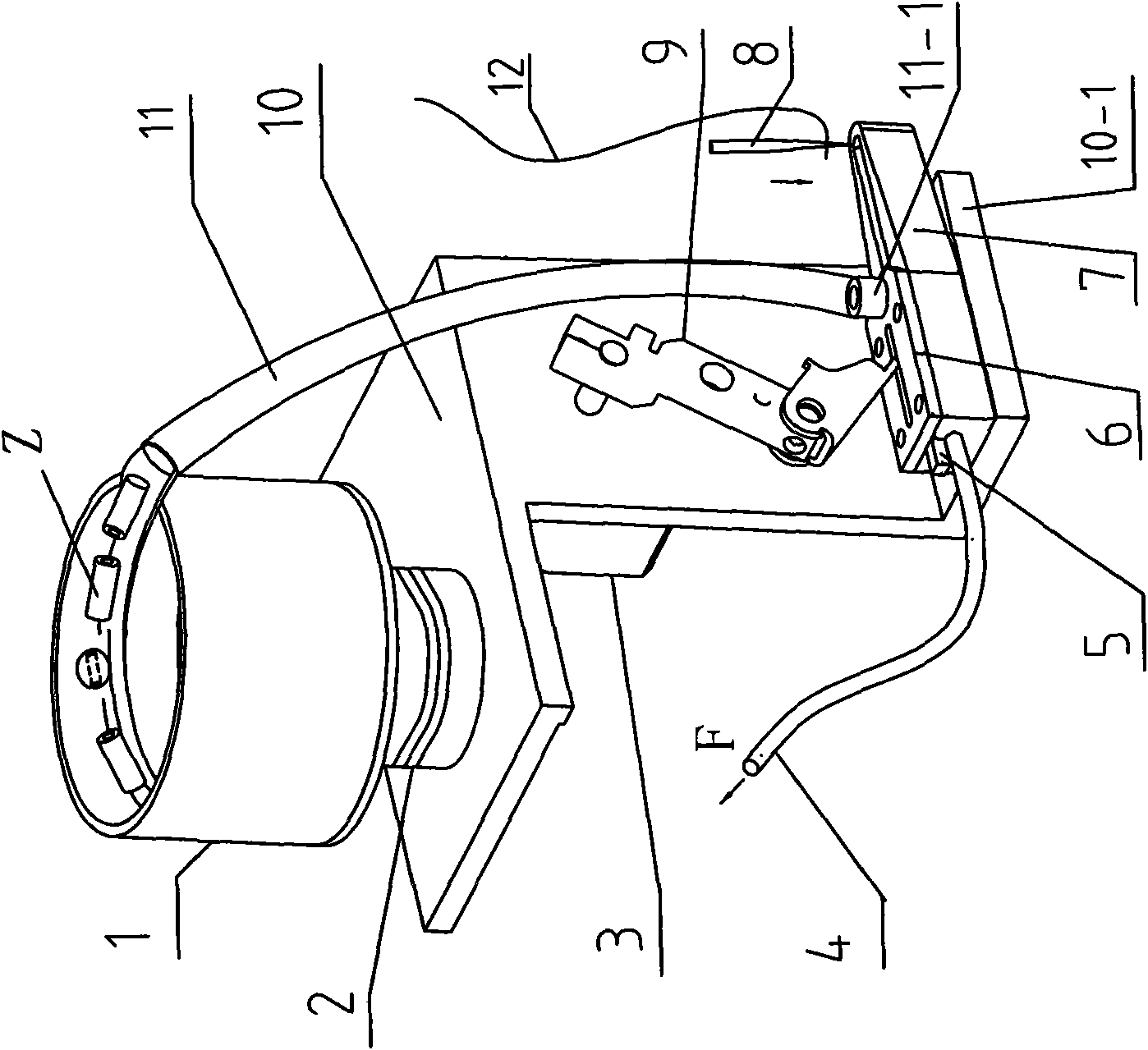

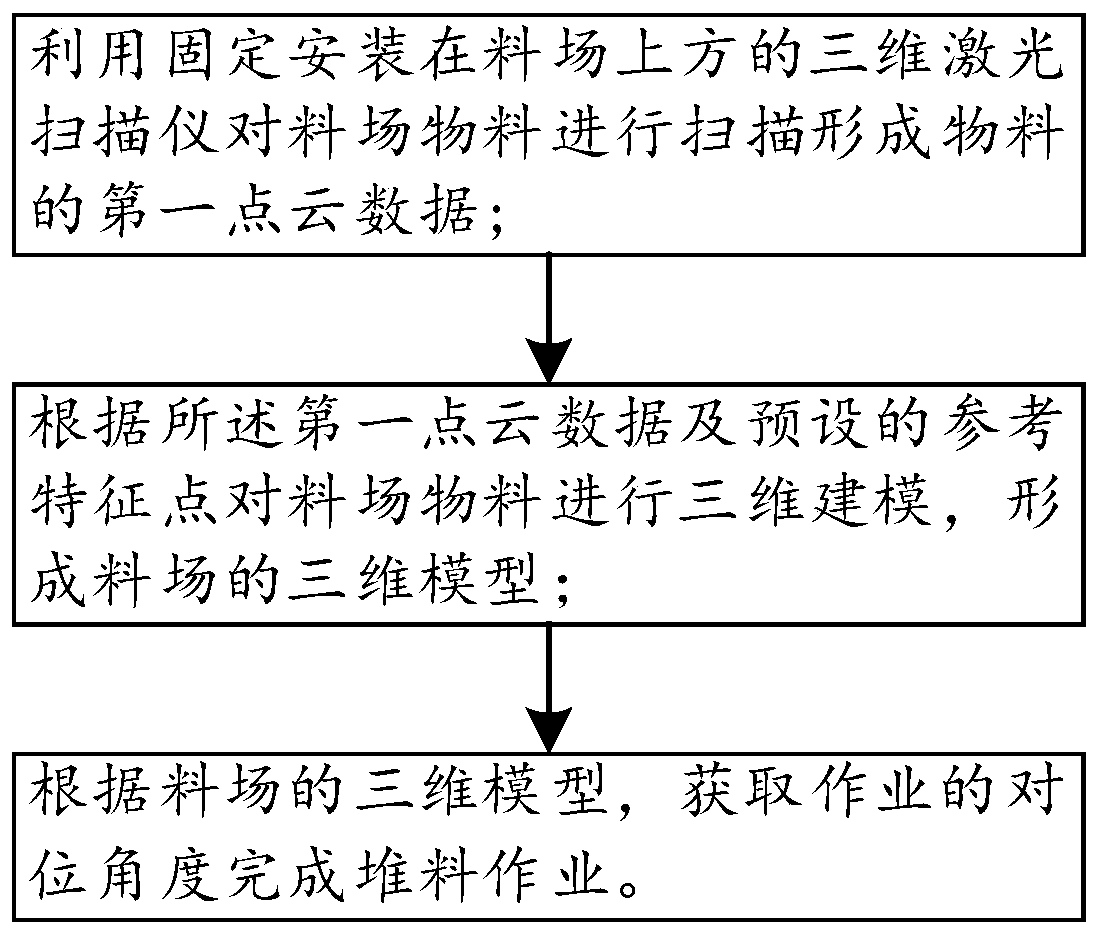

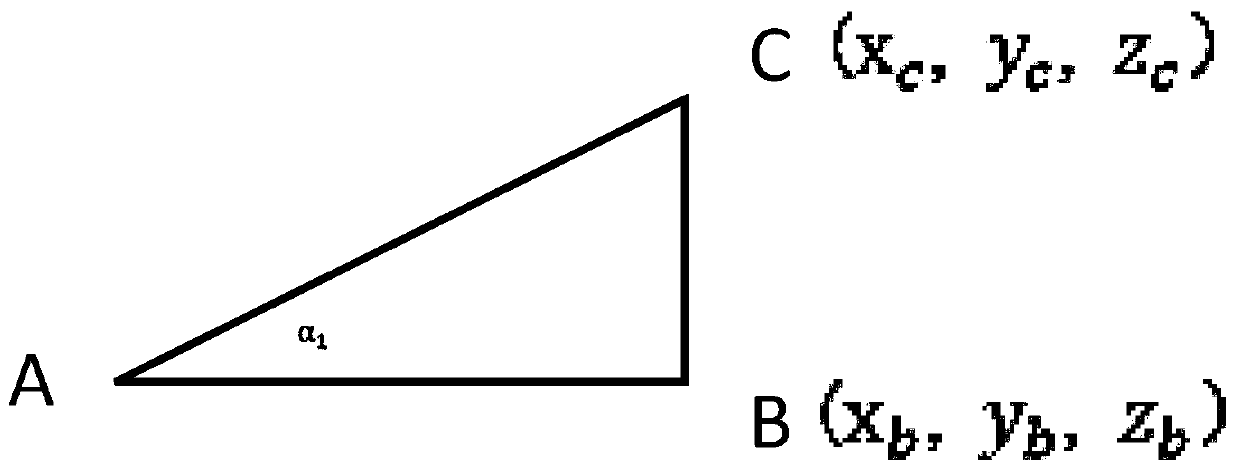

Automatic material stacking, material taking and material stacking and taking method and system for material yard

ActiveCN110194375AReduce empty runsRealize fully automatic operationUsing optical meansLoading/unloadingPoint cloudStack machine

The invention relates to an automatic material stacking and material taking method for a material yard. The method comprises the steps of scanning materials in the material yard by using a three-dimensional laser scanner fixedly installed above the material yard to form point cloud data of the materials, and carrying out three-dimensional modeling according to the point cloud data of the materialsand preset reference characteristic points and finishing material stacking and material taking operations, wherein forming of a three-dimensional model of the material yard comprises a cleaning step,a splicing step, a removing step, a filling step and a modeling step. The invention further discloses an automatic material stacking, material taking and material stacking and taking system. The three-dimensional laser scanner fixed above the material yard is used for scanning the point cloud data of the materials in the material yard, no material stacking and material taking machine participatesin the scanning process, the three-dimensional laser scanner can independently run in real time, working time is saved, and material stacking and material taking operations can be more accurately carried out by acquiring the alignment angle of a material stacking machine or acquiring a starting point and an ending point of a material taking machine.

Owner:BEIJING ZHONGSHENG BOFANG ENVIRONMENTAL PROTECTION ENG TECH

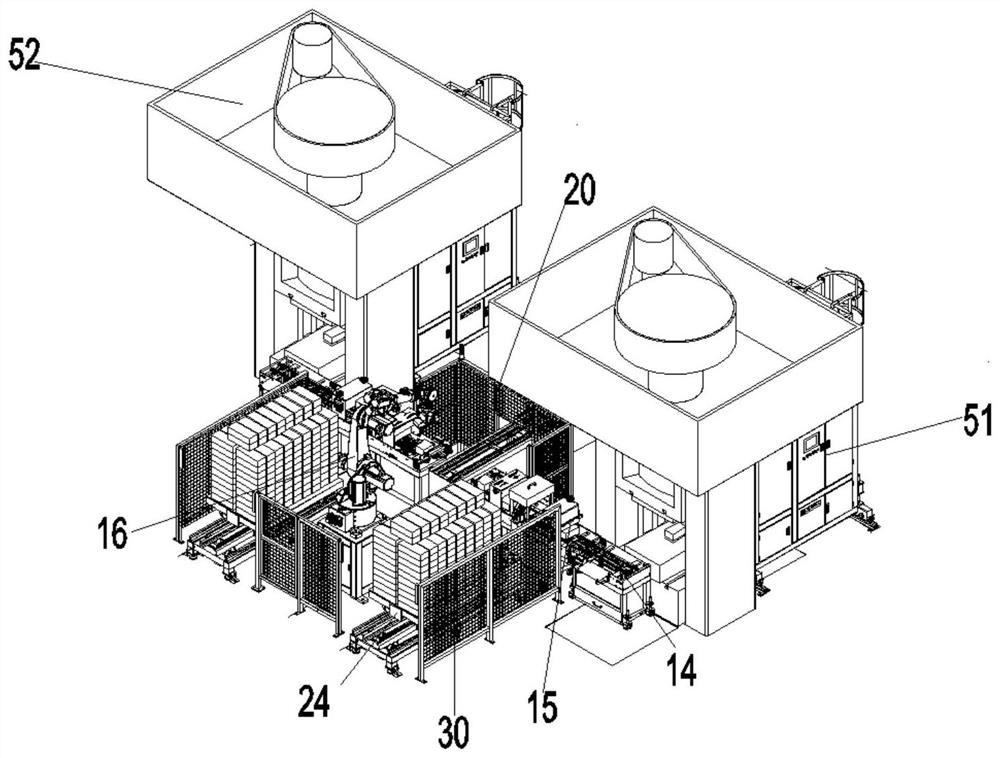

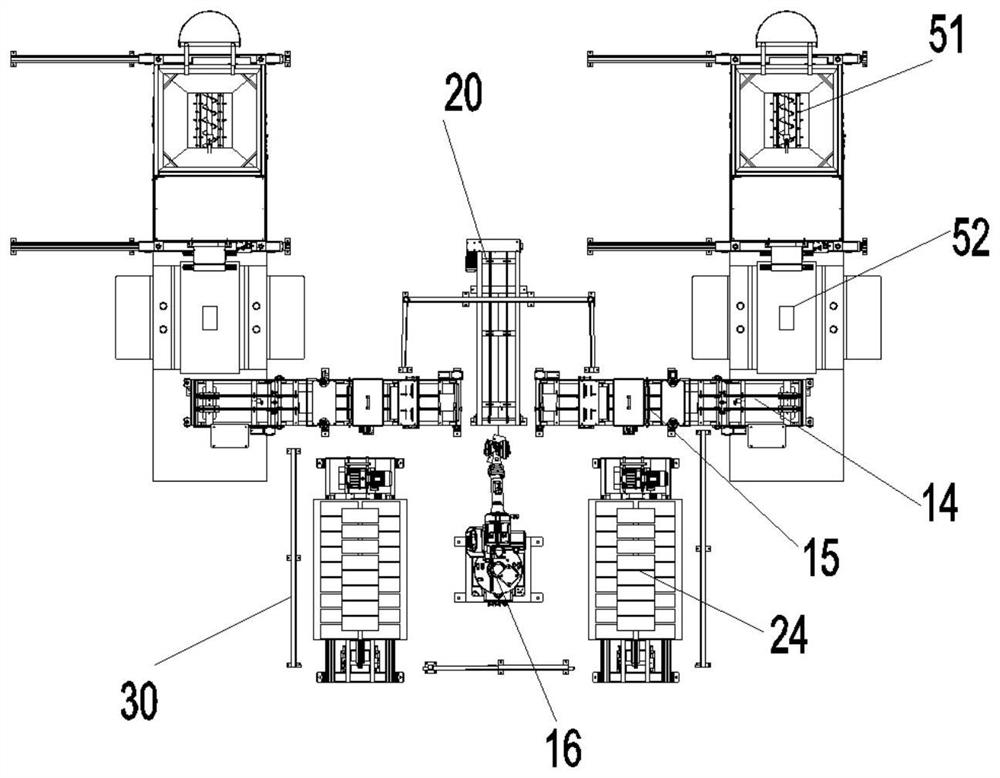

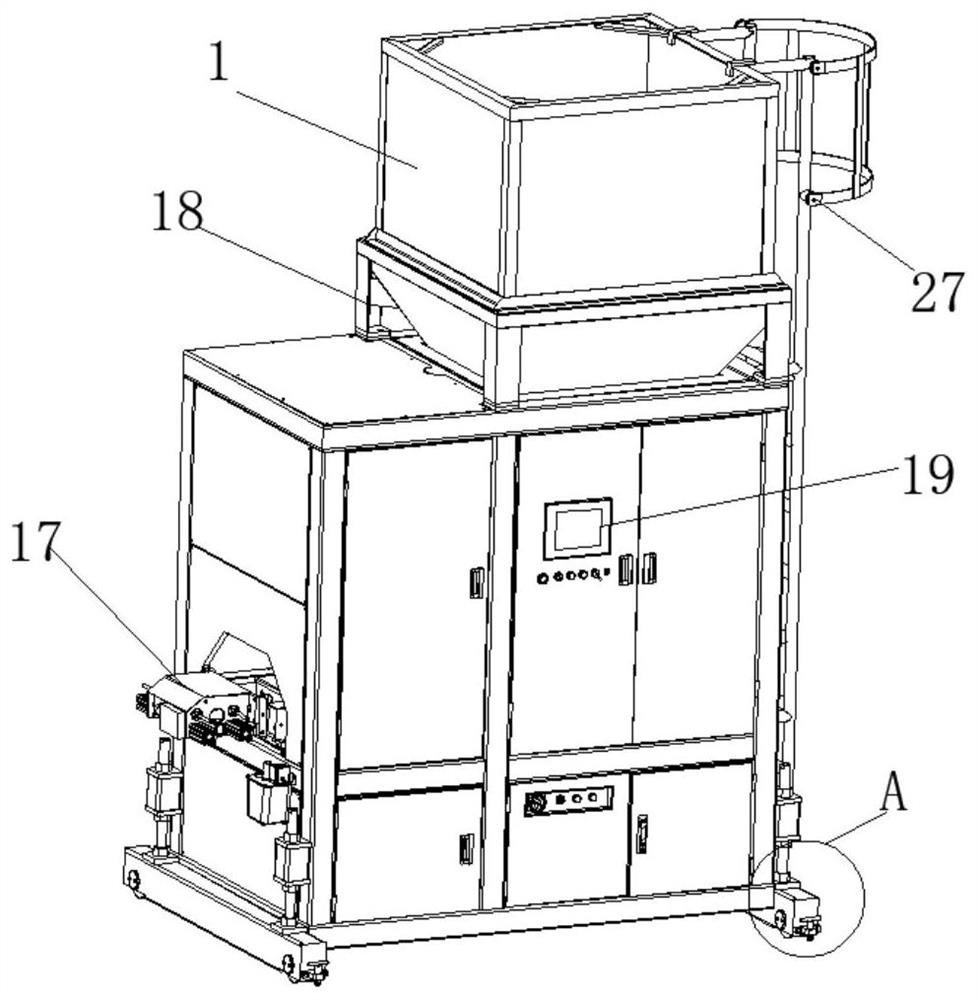

Automatic marshalling and binning device and binning method of small packaging boxes

ActiveCN105667878ARealize fully automatic operationImprove packaging efficiencyPackaging automatic controlIndividual articlesEngineeringUltimate tensile strength

The invention relates to an automatic marshalling and binning device and a binning method of small packaging boxes. A marshalling conveyor for marshalling the small packaging boxes is arranged on the right side of an equipment frame; a sorting platform is arranged on the left side of a discharging station of the marshalling conveyor; a binning platform is arranged on the left side of the sorting platform; a discharging mechanism for horizontally moving the small packaging boxes to the sorting platform is arranged above the discharging station of the marshalling conveyor; box clamping mechanisms for clamping the small packaging boxes are arranged on the front side and the rear side of the sorting platform; and a box moving mechanism for horizontally moving the small packaging boxes to the binning platform is arranged above the sorting platform. The small packaging boxes are firstly fed and marshaled and then are moved to the discharging station; and the small packaging boxes are discharged to the sorting platform by the discharging mechanism and then are clamped by clamping plates, the small packaging boxes are pushed to a binning supporting plate by the box moving mechanism, and the small packaging boxes are sucked by a suction cup assembly and downwards contained in a large packaging box. The device and method are low in human cost and labor intensity and high in automation degree.

Owner:YANGZHOU SINO-EU IND ROBOT CO LTD

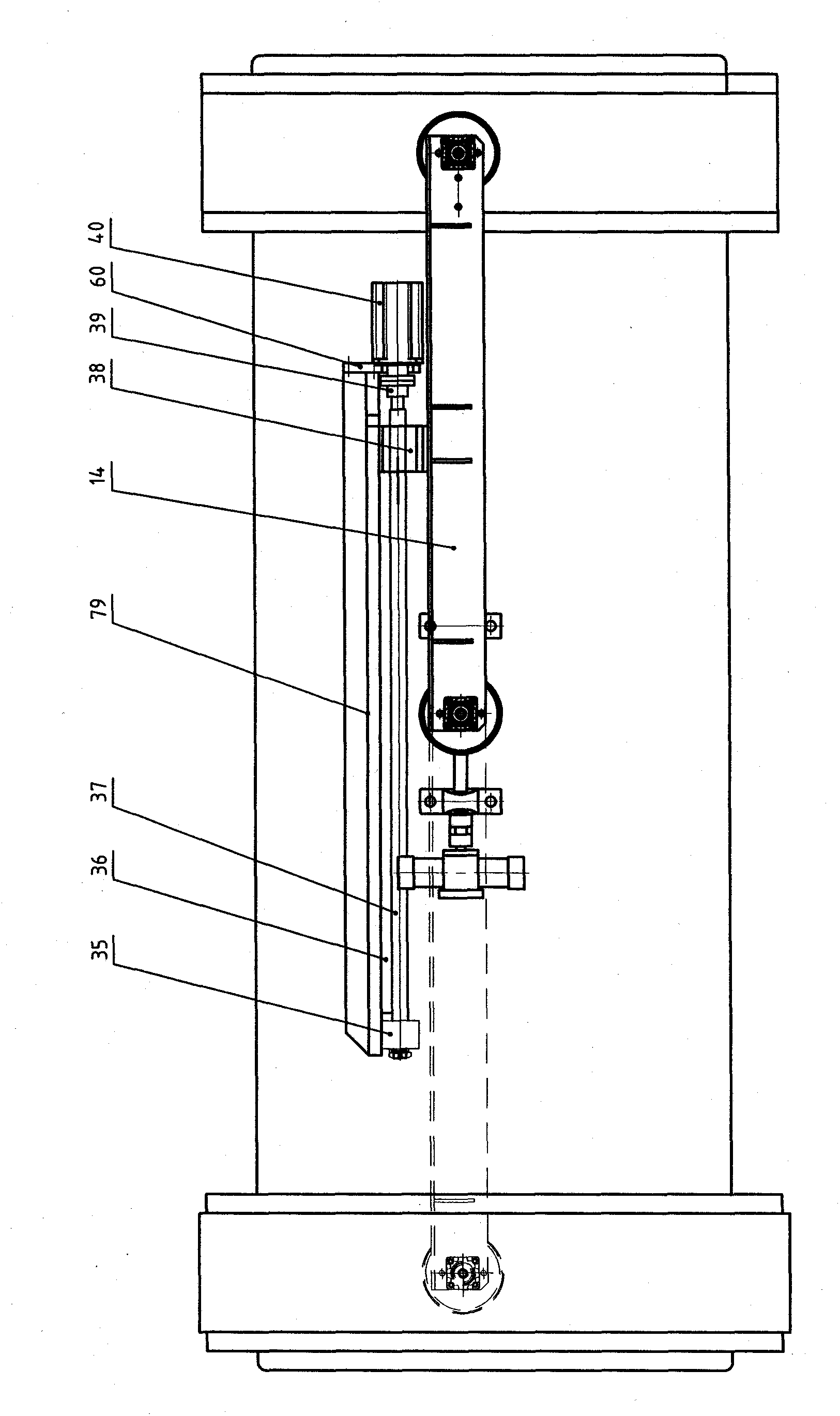

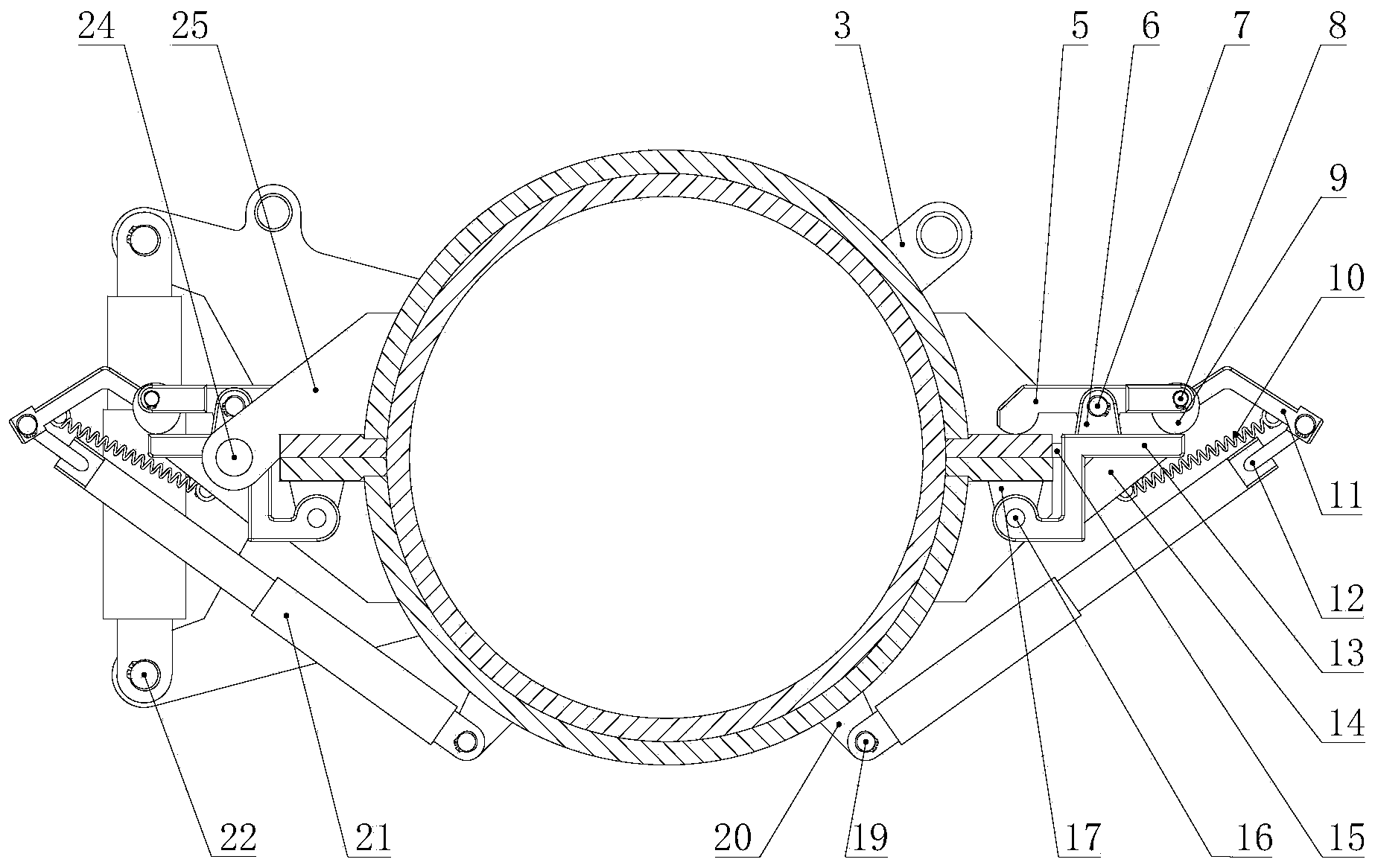

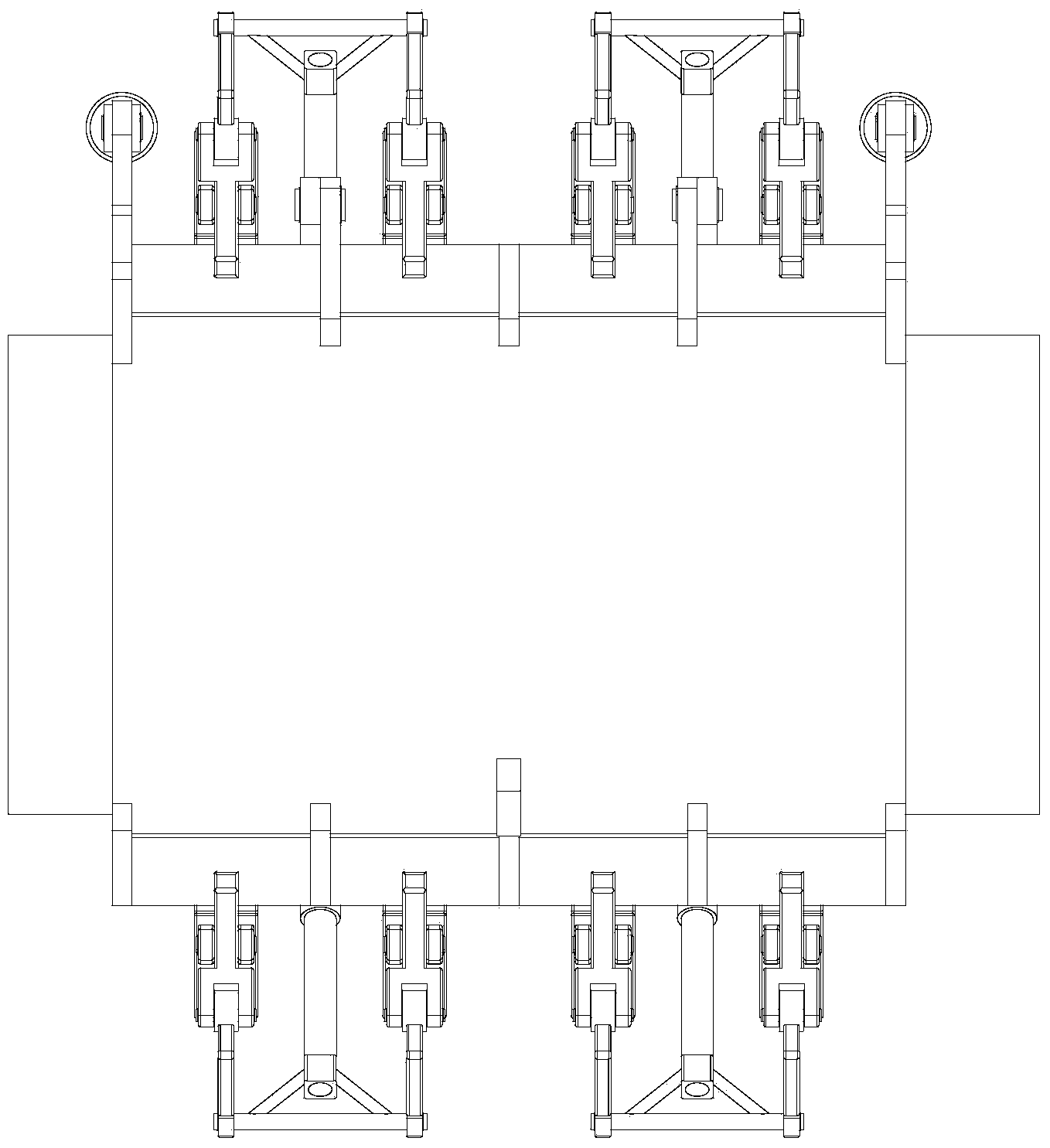

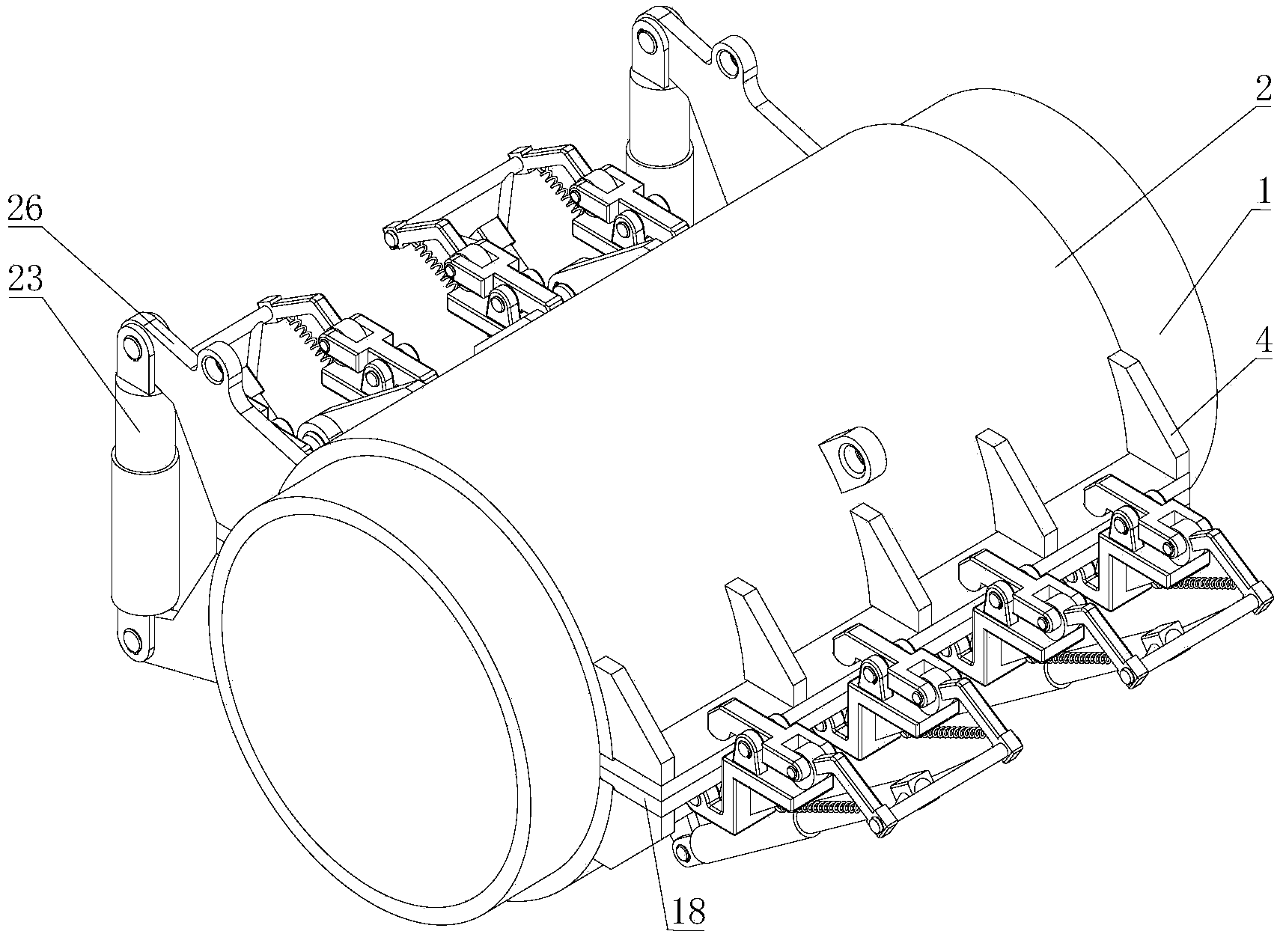

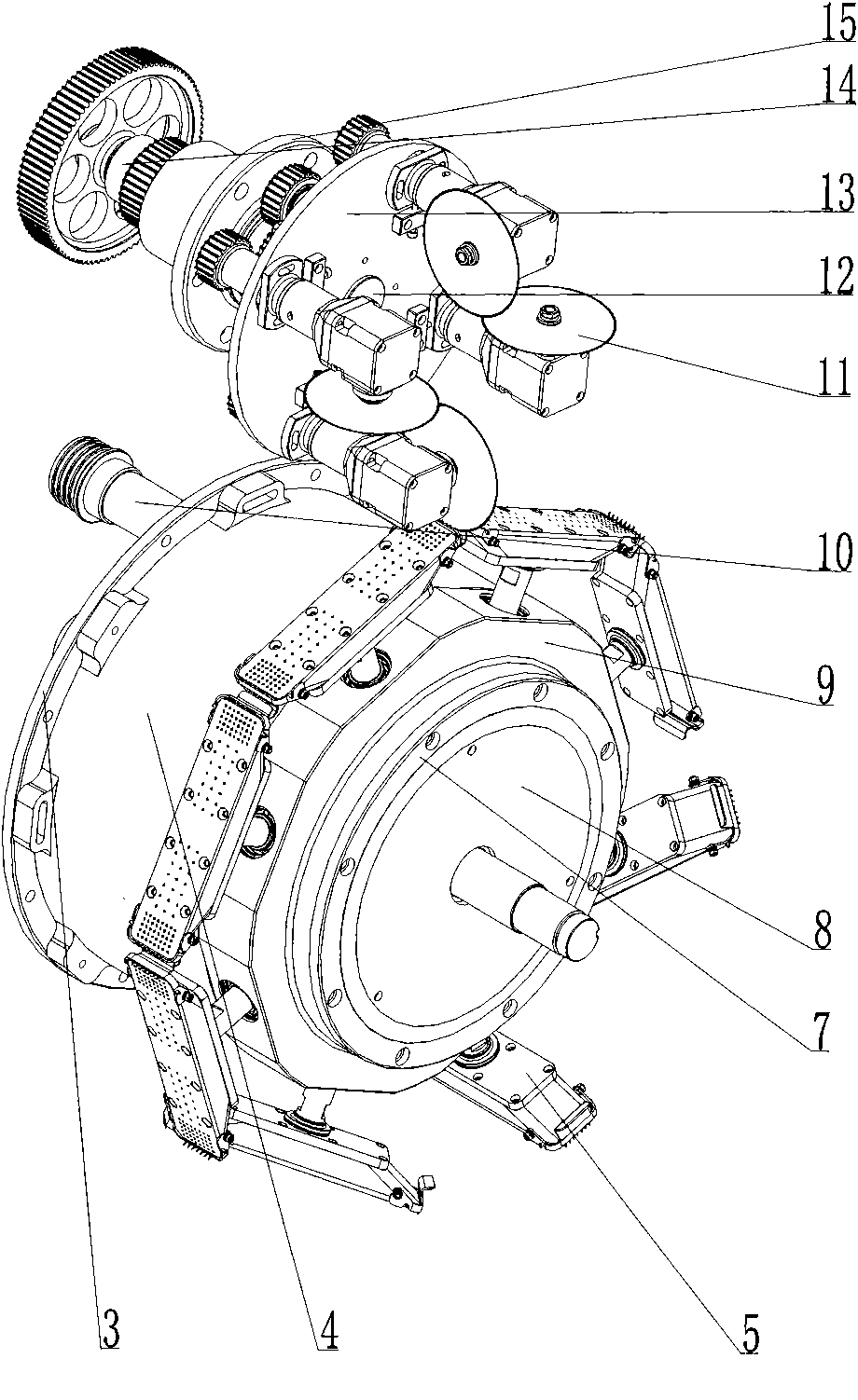

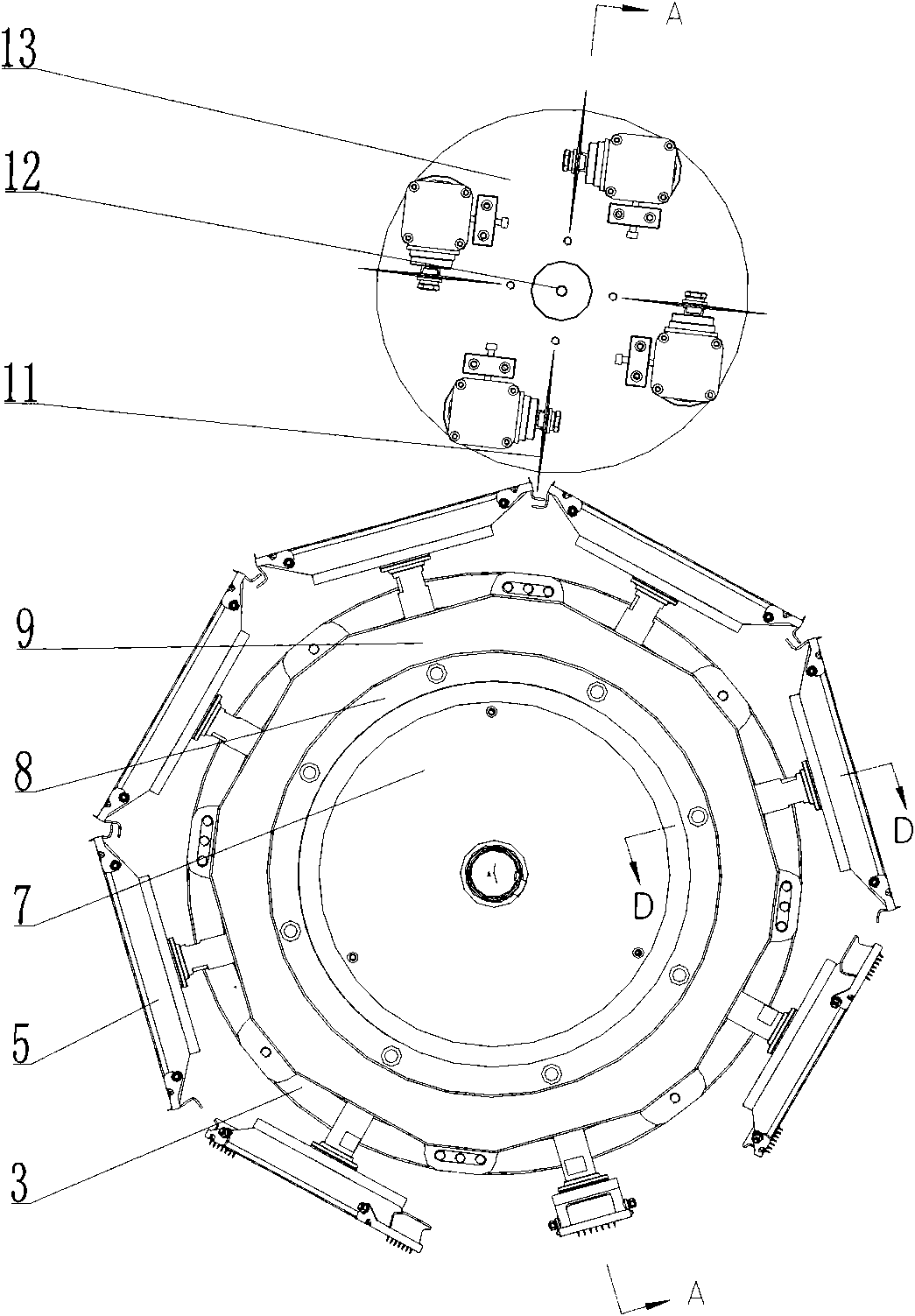

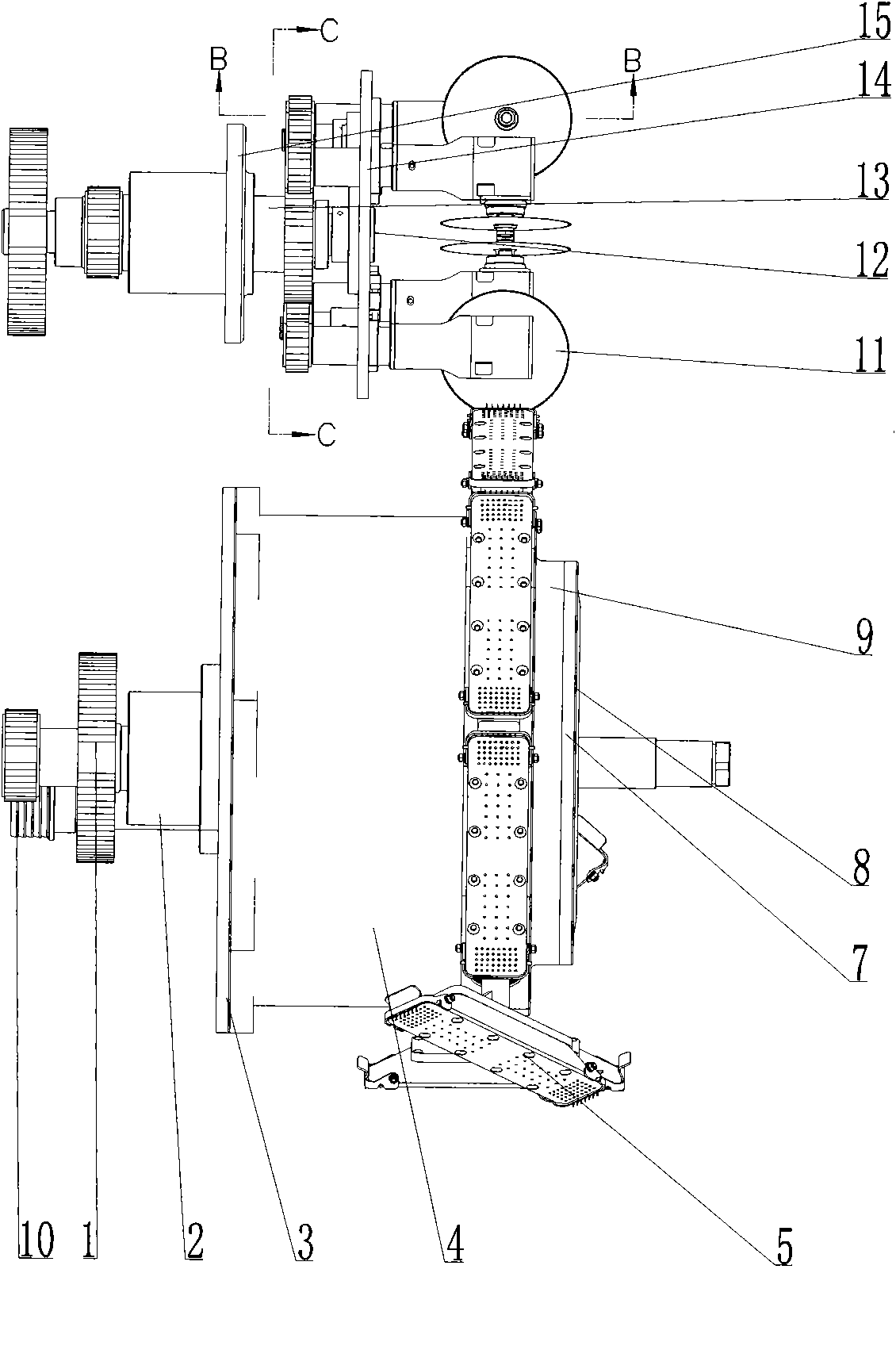

Full-automatic clamping hoop used for seabed jacket repairing

InactiveCN103615596ARealize fully automatic operationPipe supportsPipe elementsHydraulic cylinderLocking mechanism

The invention provides a full-automatic clamping hoop used for seabed jacket repairing. The full-automatic clamping hoop comprises a jacket, an upper saddle plate and a lower saddle plate, the upper saddle plate and the lower saddle plate are connected through a revolving shaft, a hydraulic opening-closing mechanism is arranged on one sides of the upper saddle plate and the lower saddle plate, hydraulic locking mechanisms are arranged on two sides of the upper saddle plate and the lower saddle plate, the hydraulic opening-closing mechanism comprises two connected closed hydraulic cylinder reinforcing ribs and closed hydraulic cylinders which are fixedly on the upper saddle plate and the lower saddle plate respectively, and the hydraulic locking mechanism comprises a compression hydraulic cylinder, a connecting rod, a pushing rod, a spring, a locking cam, a compression lever and a side plate. The clamping hoop is integrally moved to the jacket to be repaired through a suspension cable, the hydraulic cylinders control the saddle plates to open, the position of the suspension cable is adjusted to enable the saddle plates to wrap the jacket, and the hydraulic cylinders return to control the saddle plates to close; a locking hydraulic cylinder extends out, a buckle plate is pushed to rotate, and the cam is pushed to enable the lever to compress the side plate; self-locking of the whole clamping hoop is completed by the cam, and repairing work of the jacket is completed.

Owner:HARBIN ENG UNIV

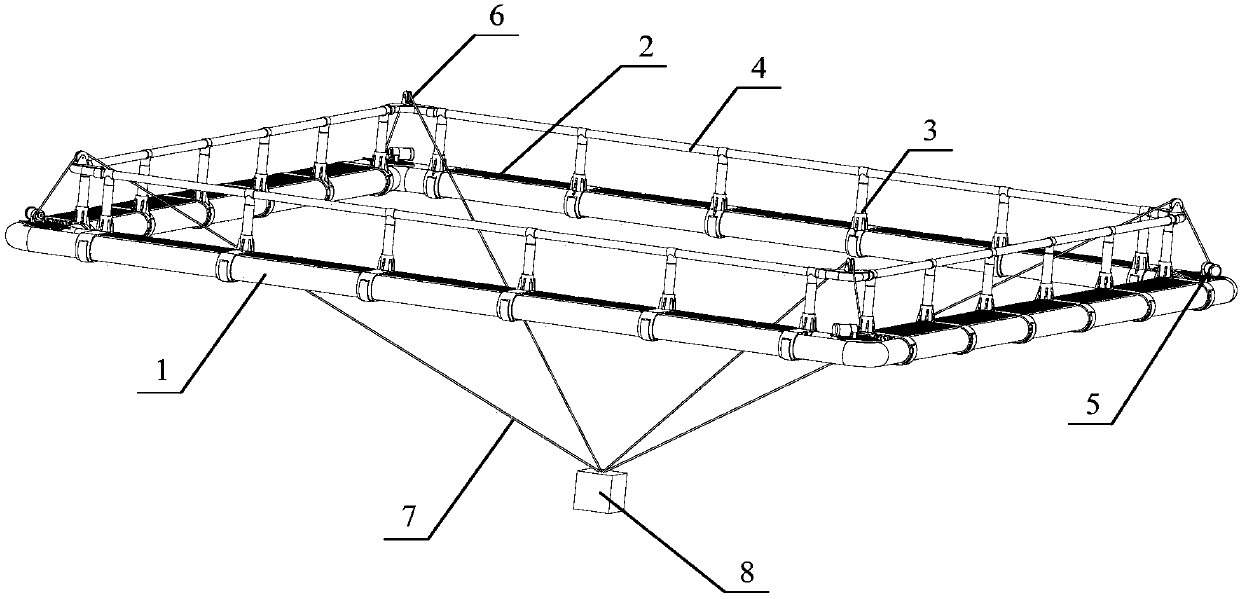

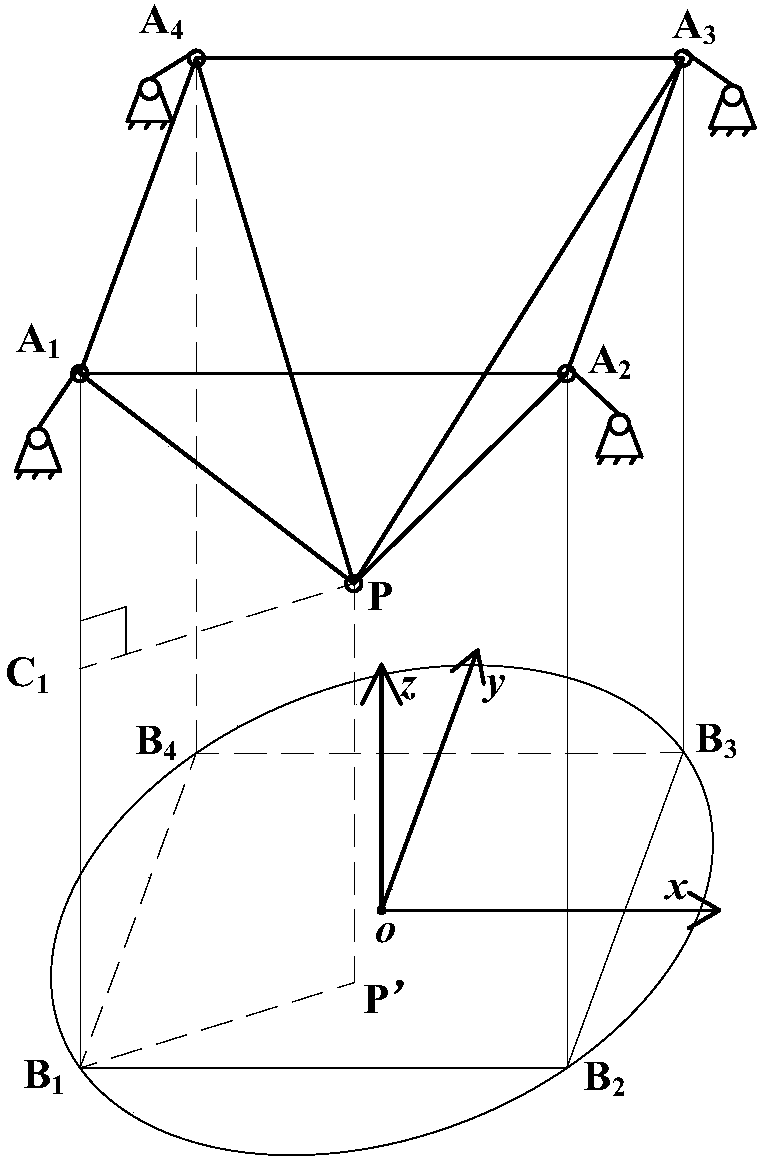

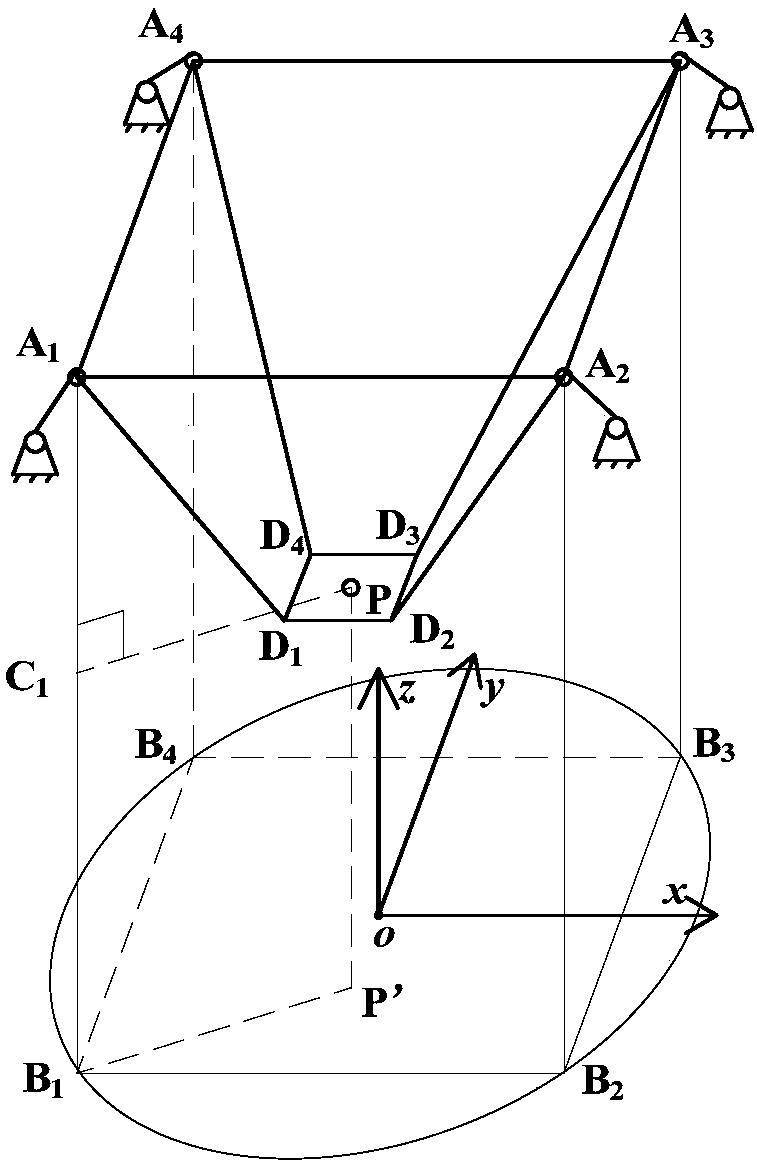

Cable parallel driving based offshore cage cleaning robot and cleaning method

PendingCN107309866AAvoid influenceReduce motion lagProgramme-controlled manipulatorHollow article cleaningUnderwaterMotion controller

The invention relates to a cable parallel driving based offshore cage cleaning robot and a cleaning method. The robot comprises a tail end cleaning mechanism, a motion controller and at least two flexible rope parallel branch chains uniformly distributed on a cage body, wherein the tail end cleaning mechanism is located in the cage, and the flexible rope parallel branch chains are connected between the cage body and the tail end cleaning mechanism; each flexible rope parallel branch chain comprises a winding motor fixed on the cage body as well as a driving cable, and the driving cable is connected to the tail end cleaning mechanism by the winding motor; the motion controller controls coordinating motion of the at least two flexible rope parallel branch chains, so that the tail end cleaning mechanism performs underwater three-dimensional motion in the cage. Underwater three-dimensional motion of the tail end cleaning mechanism is realized by means of a parallel driving manner, multiple driving cables of the tail end cleaning mechanism are mutually restrained, so that underwater stability is improved, positioning precision is improved easily, and the requirement of the offshore cage for automatic cleaning can be met.

Owner:SOUTH CHINA AGRI UNIV

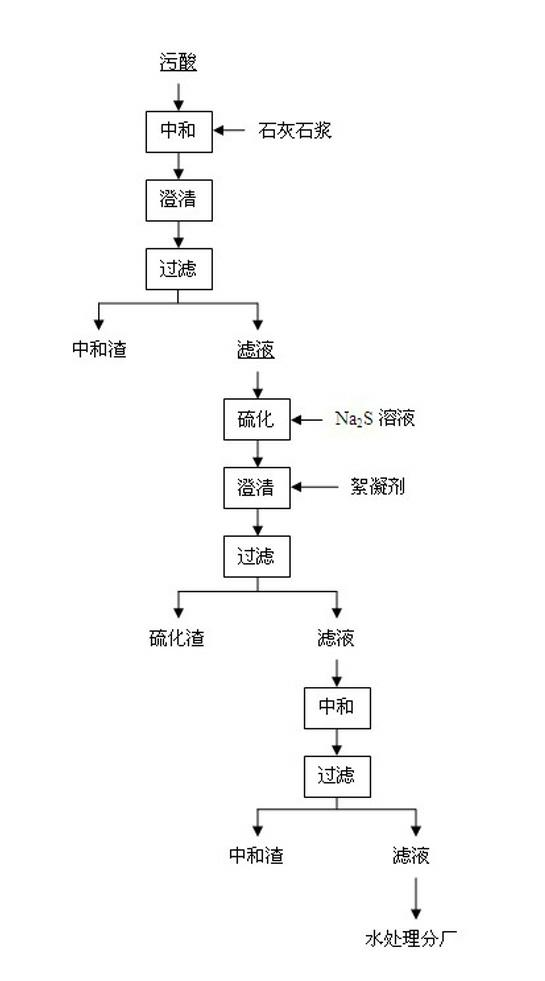

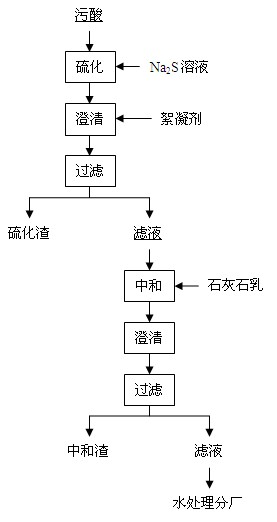

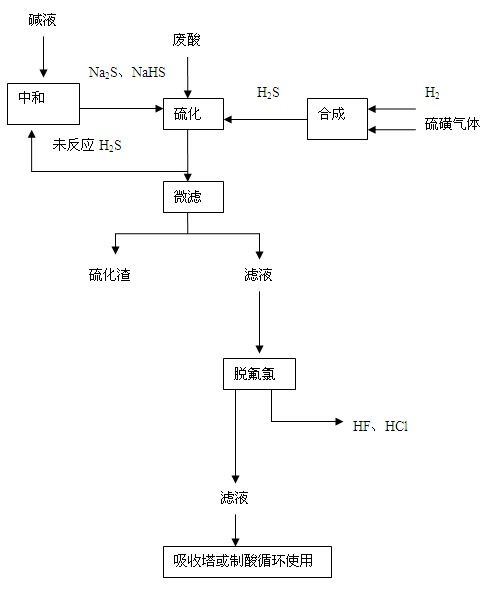

Method for treating acidic heavy metal wastewater and recycling treated wastewater

ActiveCN102502993ANo secondary pollutionHigh gas efficiencyMultistage water/sewage treatmentHydrogenWastewater

The invention relates to a method for treating acidic heavy metal wastewater and recycling the treated wastewater, comprising the following main steps of: forming hydrogen sulphide gas from sulphur gas and hydrogen in a mixing tower; charging the hydrogen sulphide gas in a multi-stage absorption tower to absorb; reacting all heavy metals in acidic solution to generate a sulphide precipitate; absorbing the trace hydrogen sulphide by alkaline solution to ensure no hydrogen sulphide gas contained in discharged gas; filtering the sulphide by a polytetrafluoroethylene membrane, and then perform pressure-filtering to convert the sulphide into a solid phase; and removing fluorine and chlorine from fluorine-containing and chlorine-containing wastewater via a fluorine and chlorine removal tower, and then returning the acidic solution to a purification tower or acid-making water. The process is more environment-friendly, without secondary pollution due to no generation of gypsum, high in treatment efficiency, and low in cost.

Owner:株洲三特环保节能股份有限公司

Elastic material cutting transverse state converter on production line of disposable sanitary articles

The invention relates to an elastic material cutting transverse state converter on a production line of disposable sanitary articles, which comprises a suction disc mechanism and a cutting mechanism, wherein the suction disc mechanism comprises a transverse state conversation main shaft, a positioning disc, an air suction ring, a rotating disc support seat and a rotating disc, eight suction discs are uniformly distributed in the radial direction of the rotating disc through bearings and hollow suction disc shafts, the cutting mechanism comprises a rotating cutting main shaft, a rotating cutting middle bearing seat, a rotating cutting fixed bearing seat and a cutter assembly fixing plate, four groups of cutter assemblies are uniformly distributed on the outer side surface of the cutter assembly fixing plate, and a belt transmission mechanism is arranged on the inner side surface of the cutter assembly fixing plate. The device of the invention has the advantages of compact structure and reasonable design, and realizes full-automatic operation.

Owner:ANQING HENG CHANG MACHINERY

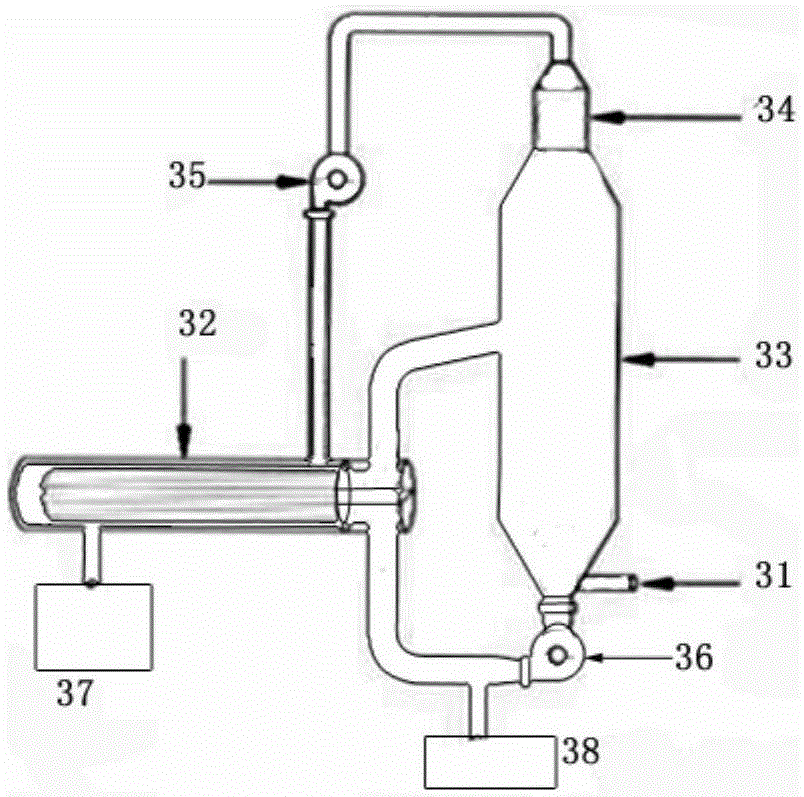

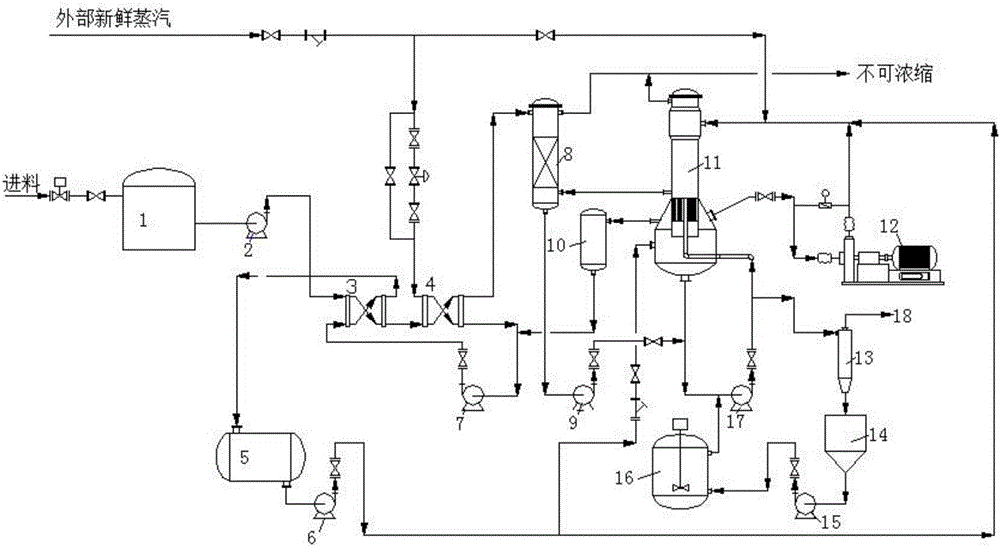

Mechanical steam recompression falling film evaporation process method and system

ActiveCN104986910AImprove thermal efficiencySave energyMultistage water/sewage treatmentSteam pressureSteam condensation

The invention provides a mechanical steam recompression falling film evaporation process method comprising the following specific steps: (1) high-salt wastewater pretreatment is carried out, wherein a material is delivered into a preheater through a feeding pump; condensate water of falling film evaporator secondary steam condensation is adopted as a heat source of the preheater, and the material is preheated; the preheated material is delivered into a liquid mixing device, and is mixed with liquid from an evaporation chamber of the falling film evaporator; and the mixture is delivered into the falling film evaporator; (2) a falling film evaporation system is established, wherein after the material enters the falling film evaporator, with indirect heating of evaporator shell-side steam, the material absorbs heat and the temperature is increased; the material enters the evaporation chamber; with the negative pressure in the evaporation chamber, the material is instantly evaporated, and most of water is converted into secondary steam and is discharged from a secondary steam outlet; and (3) a steam compression recycling system is established, wherein secondary steam from the evaporation chamber enters a steam compressor; with the compression of the steam compressor, steam pressure and temperature are both increased; and the steam is returned to the shell-side of the falling film evaporator again and is reused.

Owner:JIANGSU DUBLE ENG

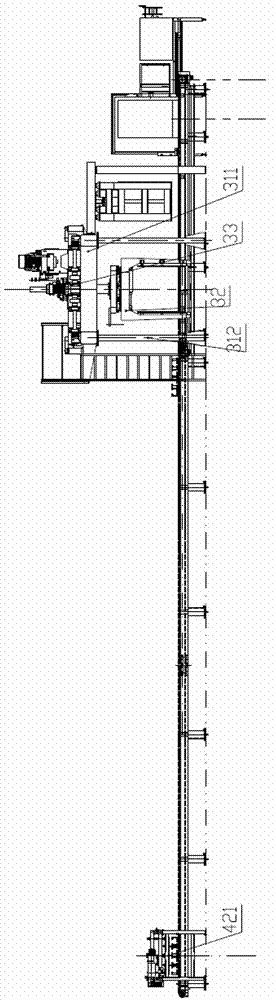

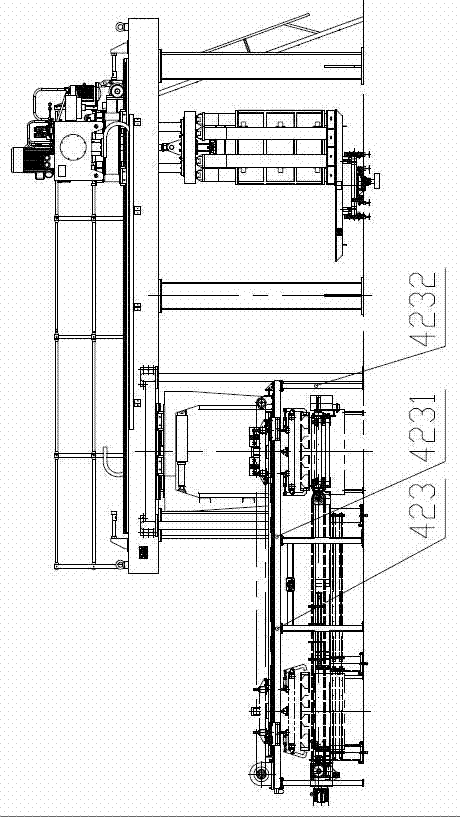

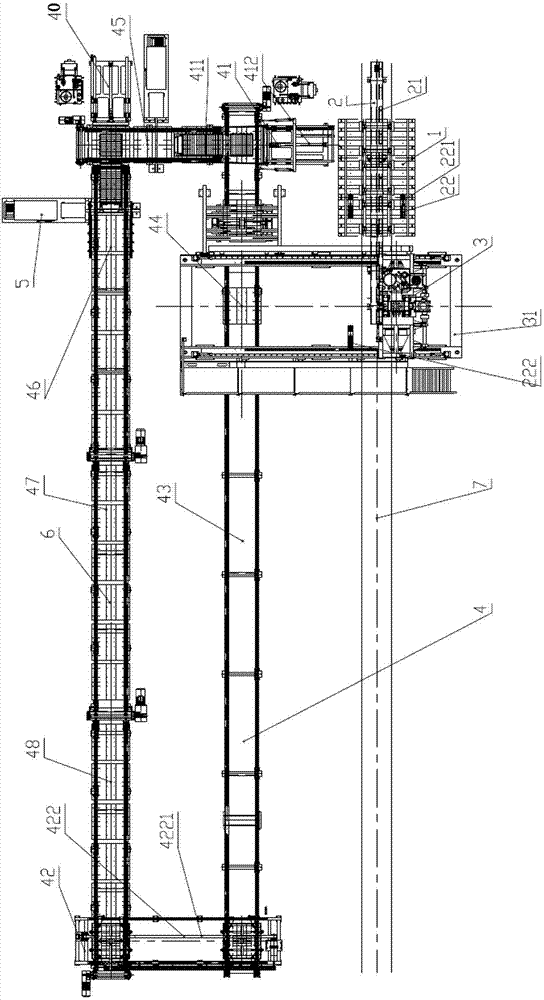

Tray-free packing method and tray-free packing device of brick stack

The invention discloses a tray-free packing method and a tray-free packing device of a brick stack. The tray-free packing device comprises a feeding machine, a clamping and transporting device, a cyclic conveying line, binding machines and a plurality of transfer trays; the feeding machine is arranged on a return track to complete the movement and positioning of a steaming-curing truck, and the return track runs through the clamping and transporting device; the cyclic conveying line is a closed rectangular annular cyclic conveying chain and comprises an empty-tray conveying chain-type conveyor belt, a secondary folding and clamping chain-type conveyor belt, an elevation and pushing mechanism, a primary binding chain-type conveyor belt, a secondary elevation and pushing mechanism, a secondary binding chain-type conveyor belt, a stack unloading chain-type conveyor belt, an empty-tray feeding chain-type conveyor belt and the a tray transportferring device; two binding machines respectively stretches across the primary binding chain-type conveyor belt and the secondary binding chain-type conveyor belt so as to bind the brick stack in the two mutually-vertical directions; and a transportferring tray is horizontally arranged on each station of the cyclic conveying line. Due to the adoption of the device, the production efficiency is greatly improved, and the labor intensity of workers is greatly alleviated.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

Full-automatic production system for refractory bricks

ActiveCN111702949AOvercoming automationOvercome efficiencyDischarging apparatusMixing operation control apparatusFire brickProcess engineering

The invention discloses a full-automatic production system for refractory bricks. The system is sequentially provided with automatic weighing and distributing devices, pressing machines, brick receiving and conveying tables, detecting machines, a defective product conveying table, a brick taking and stacking device and kiln car positioning areas according to refractory brick forming procedures. According to the system, raw materials are automatically detected and screened after being pressed and formed through the automatic weighing and distributing devices and the pressing machines, the bad bricks are automatically removed, the qualified bricks are stacked and loaded into a kiln car through the brick taking and stacking device, and finally, the kiln car full of the qualified bricks is fedinto a kiln through an intelligent control system for firing, and the finished bricks are obtained; and the full-automatic operation is achieved, the defects that refractory brick manufacturing in the prior art is low in automation degree, low in manufacturing efficiency and the like are overcome, and therefore, the labor cost is reduced, the working efficiency is improved, and meanwhile, the safety risk is greatly reduced, the life safety of people is guaranteed, the influence of dust on the health of people in the brick pressing process is reduced, the labor intensity is reduced, and the problem of difficulty in recruiting workers is solved.

Owner:CHANGXING RONGLI MACHINERY

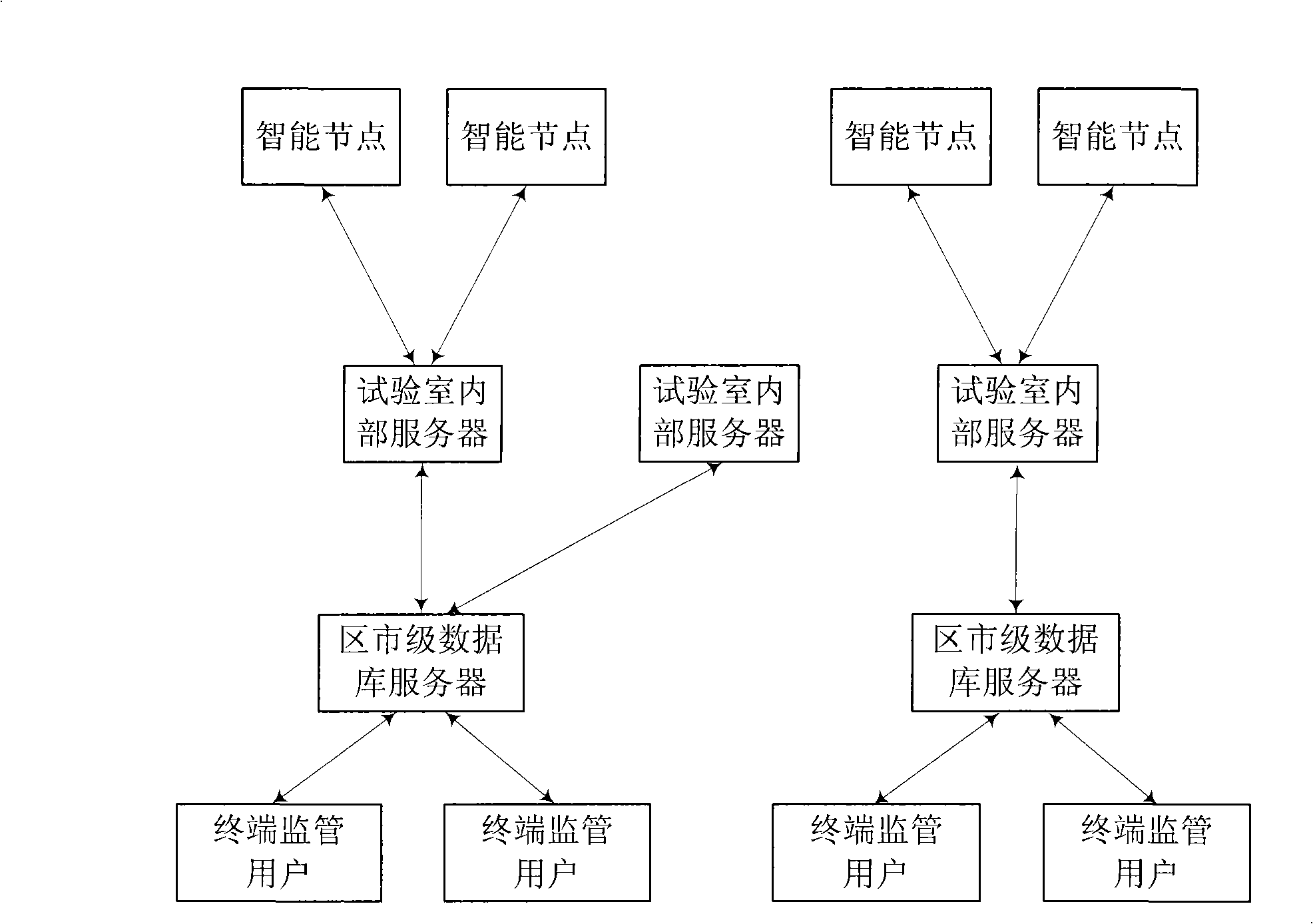

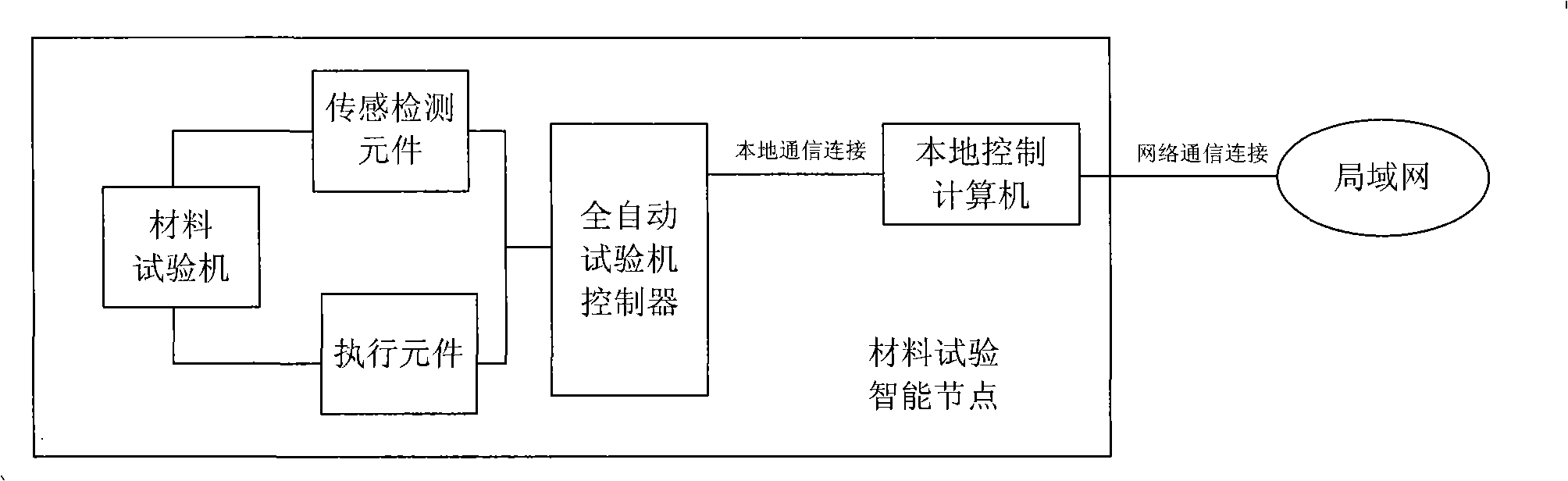

Material detecting and remote monitoring system for implementing supervision

InactiveCN101271122ARealize automatic and precise controlRealize real-time automatic collectionStrength propertiesAutomatic controlControl layer

A material detection and remote monitoring system for realizing the supervision comprises a material testing machine, a sensing detection element, an actuating element and a full-automatic testing machine controller, the material detection and remote monitoring system comprises a control layer, a detection layer and a supervision layer; the control layer comprises the material testing machine, a computer for local control, the sensing detection element, the actuating element and the full-automatic testing machine controller; the full-automatic testing machine controller comprises a signal collecting / processing module, a drive actuating module, a local data communication module and a remote communication module, the detection layer comprises a data server, the data server comprises a detection terminal database, a storage module and a laboratory-based C / S detection management software module; the supervision layer comprises a remote supervision computer and a supervision server, the remote supervision computer comprises a network browser; and the supervision server comprises a monitoring terminal database, a B / S supervision module and a supervision pre-alarm module. The material detection and remote monitoring system can automatically control the material test, have accuracy and reliability and realize the effective supervision.

Owner:杭州中盛科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com