Patents

Literature

121results about "Building material packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

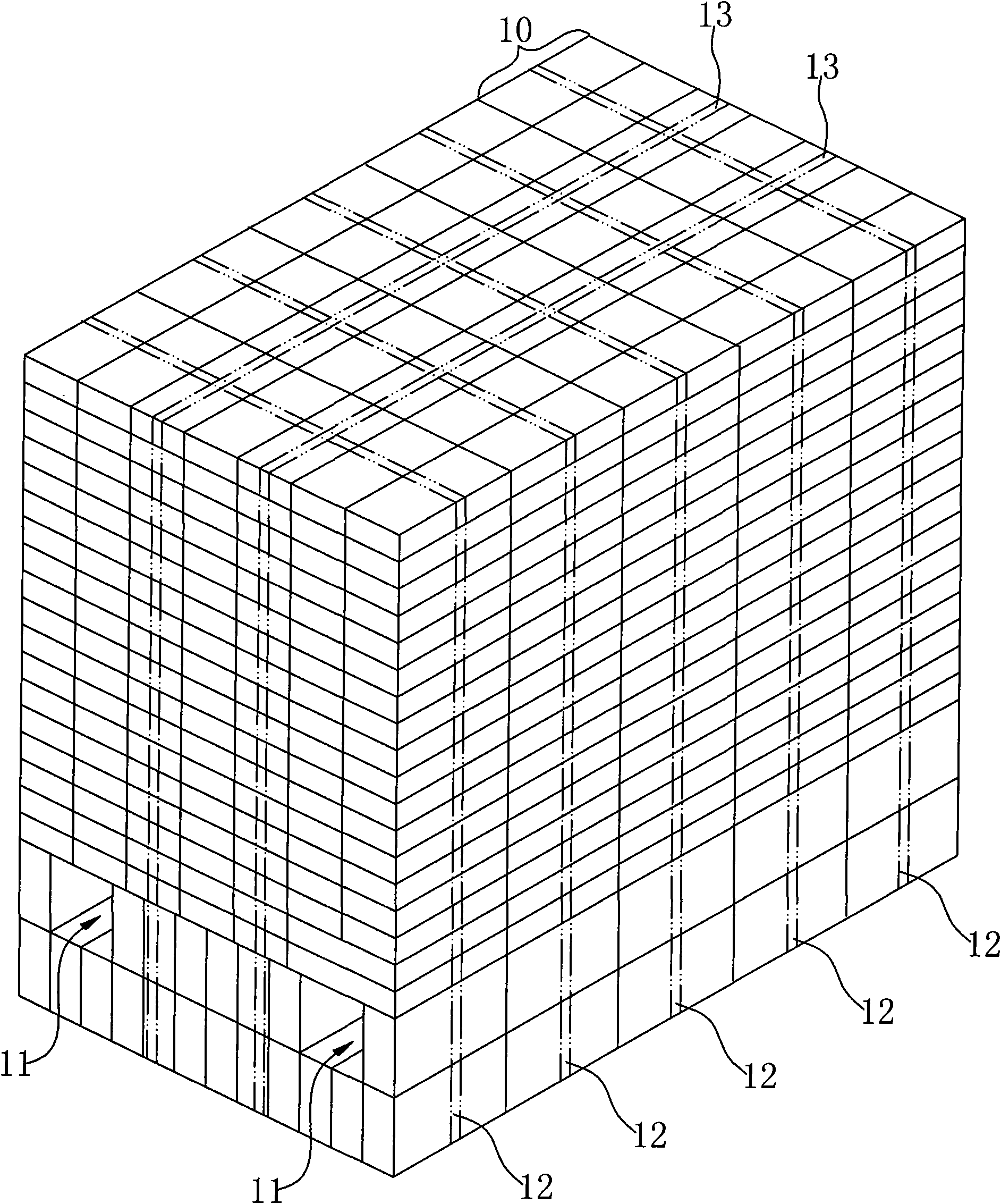

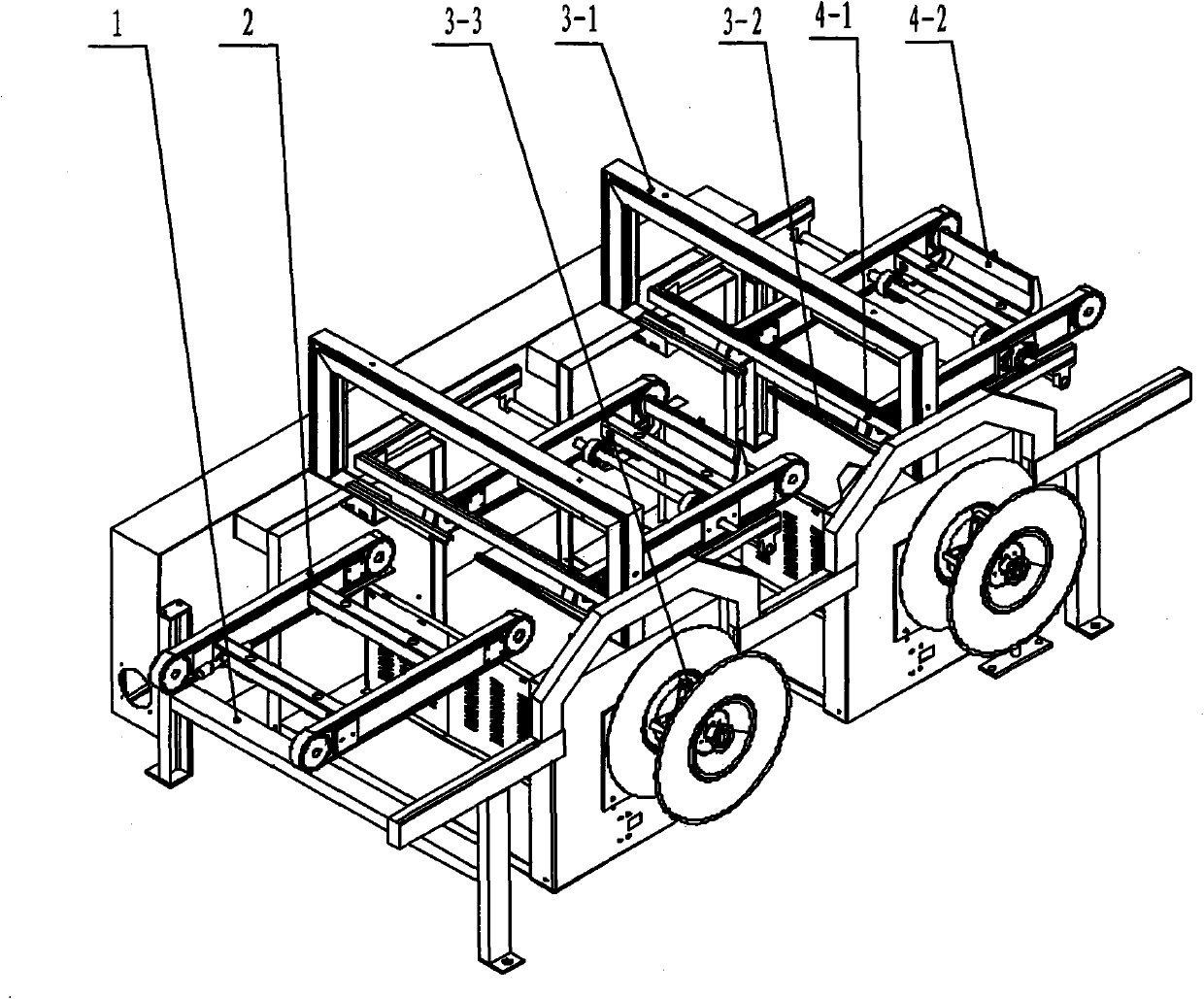

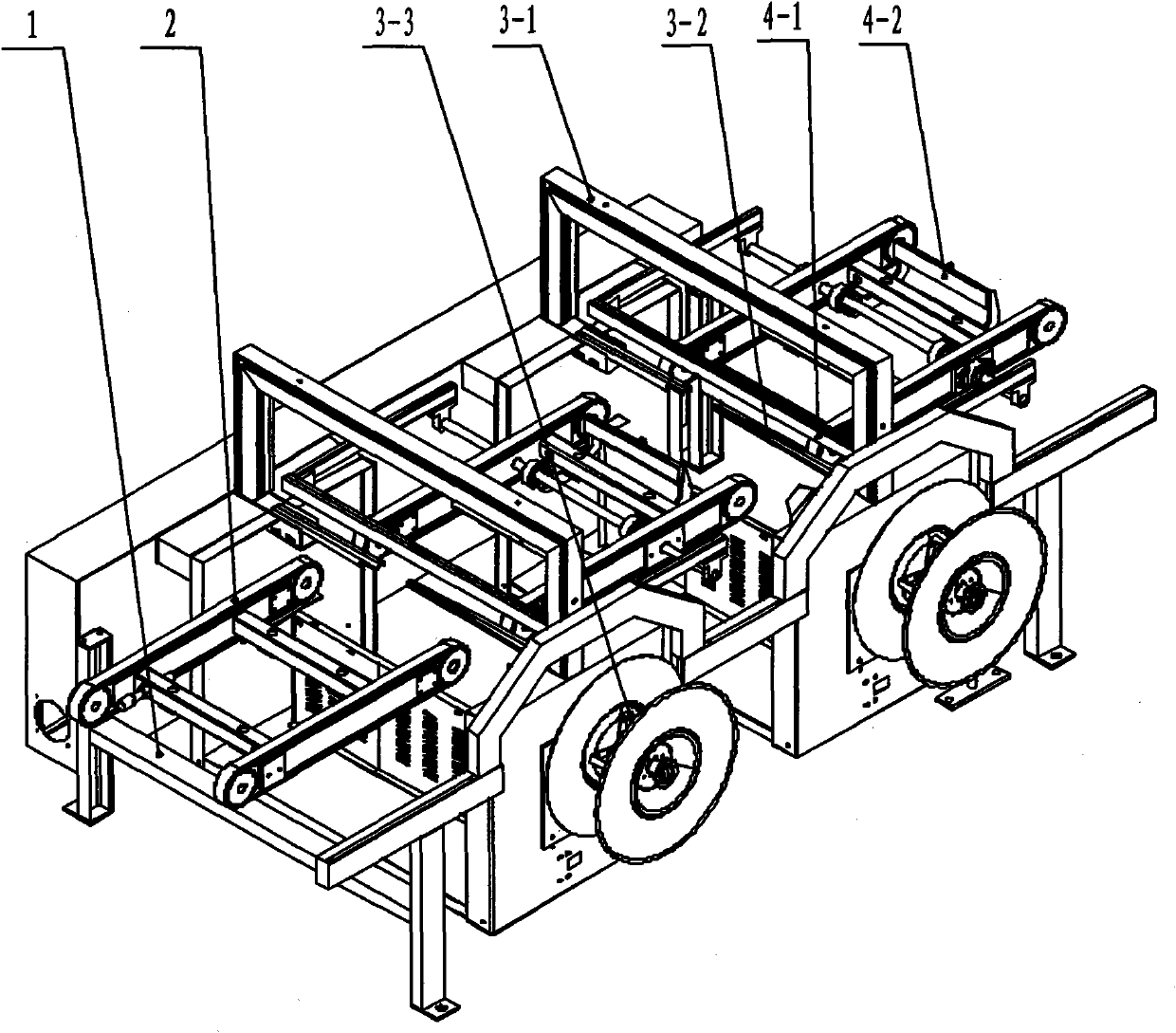

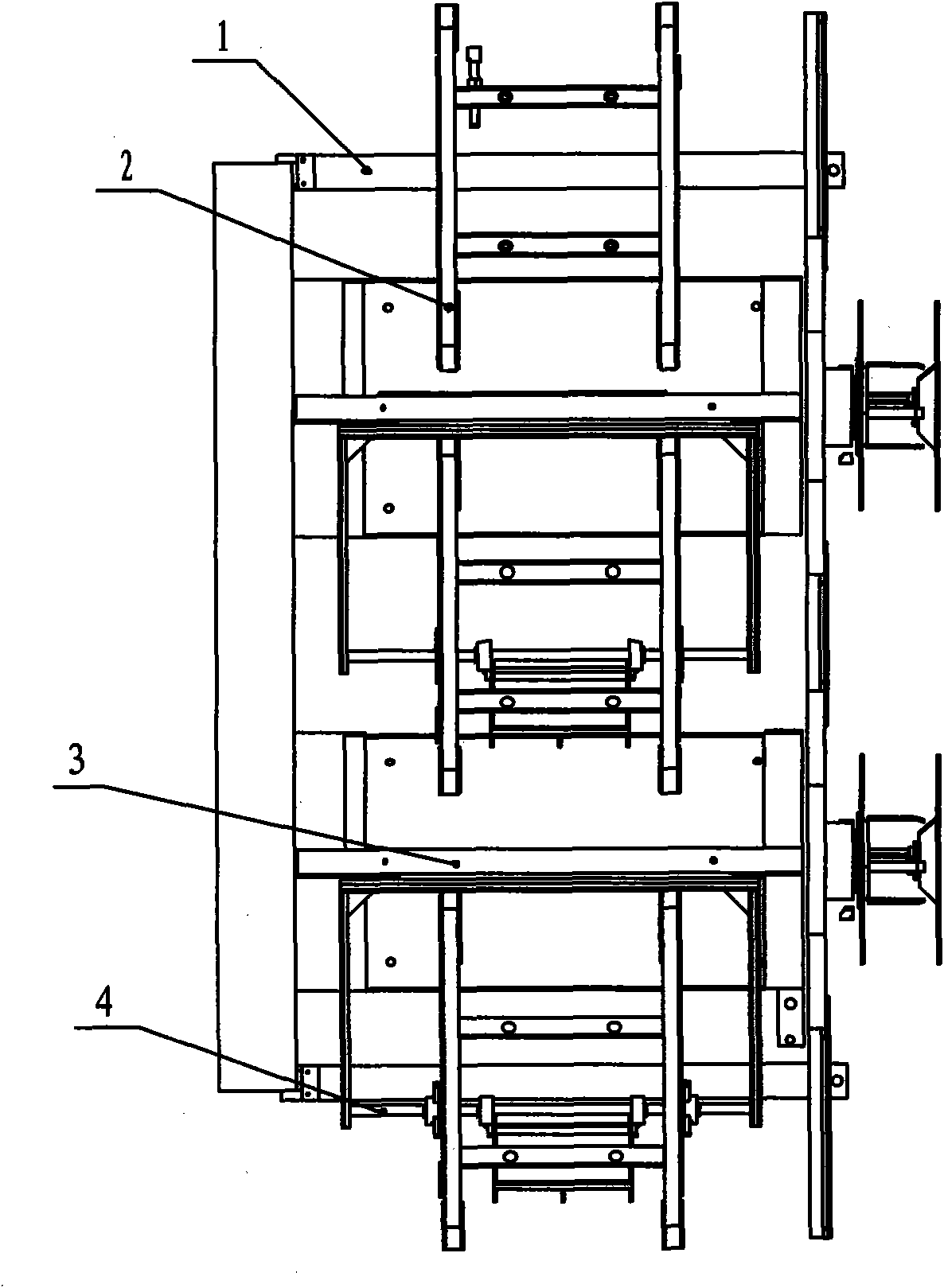

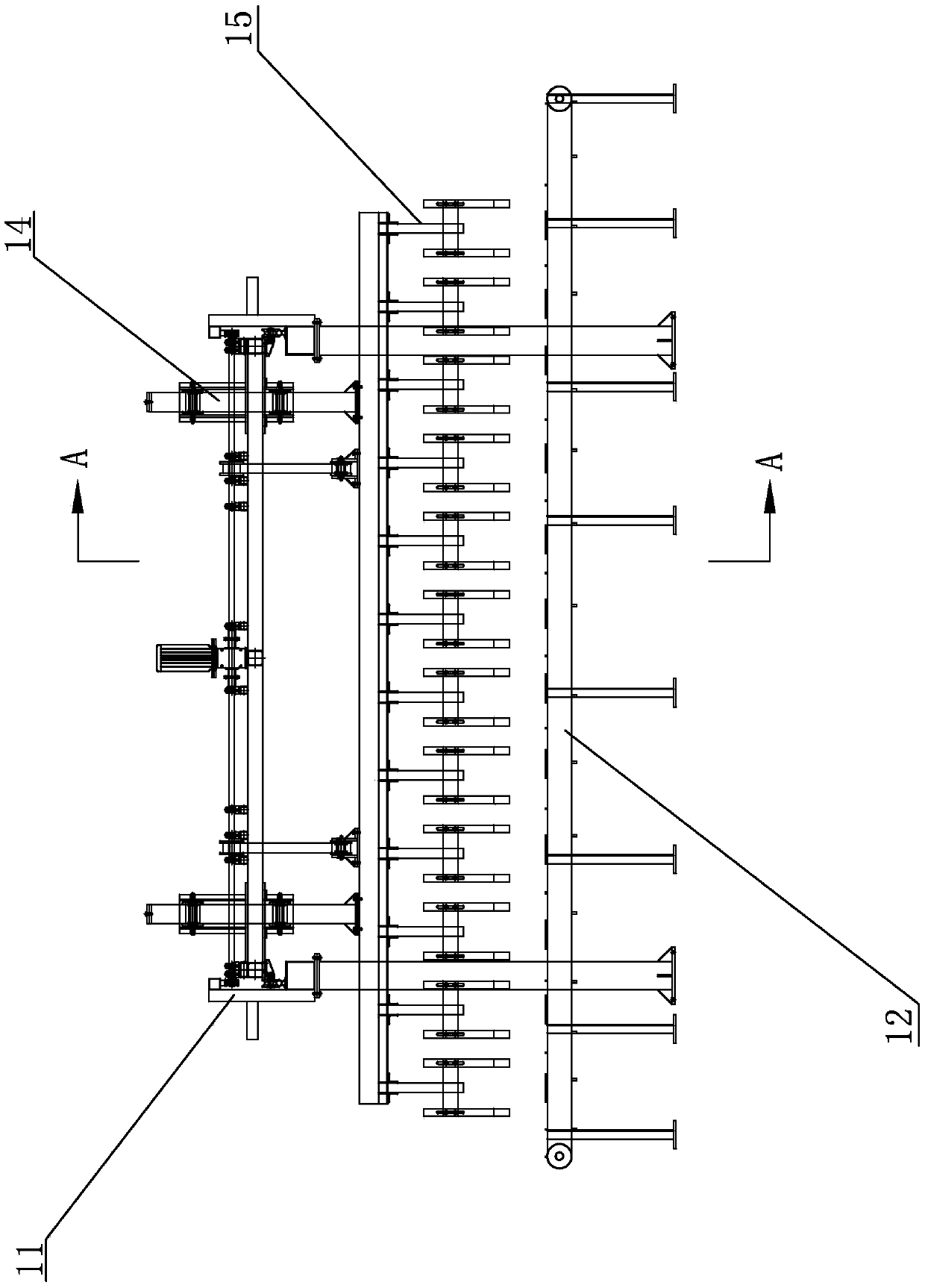

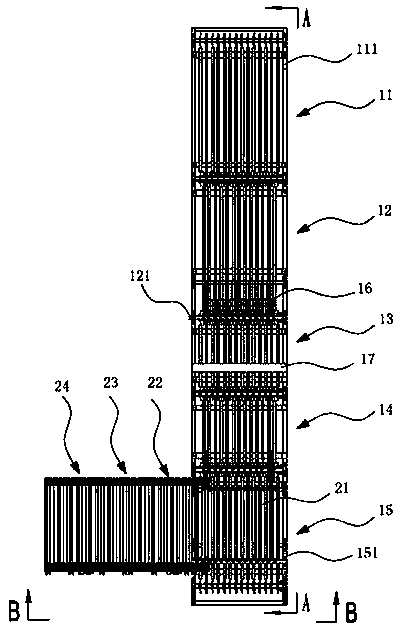

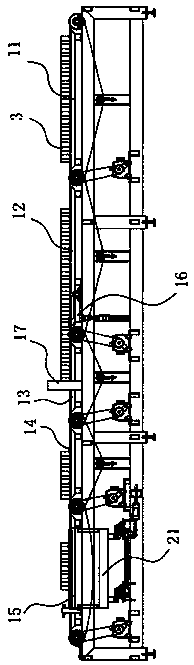

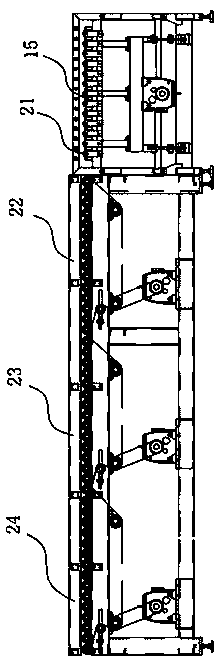

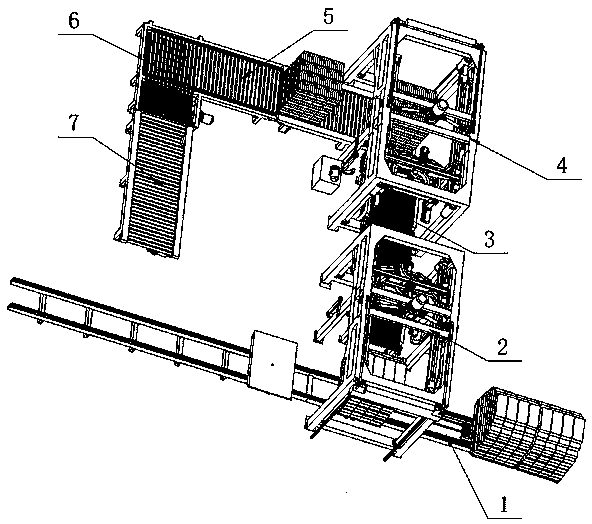

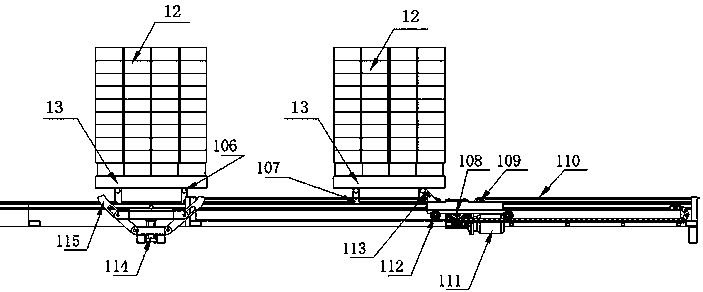

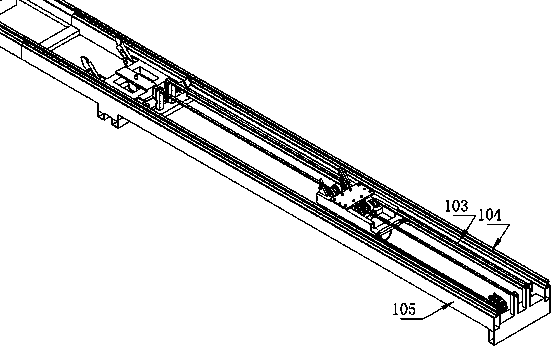

Brick pile packaging method and brick pile packaging production line

InactiveCN102556399ACompact and stable structureSimple structureBuilding material packagingAuxillary shaping apparatusProduction lineBrick

The invention belongs to the technical field of packaging machinery, and particularly relates to a brick pile packaging method and a brick pile packaging production line. A brick pile on a steam-curing car is mechanically divided into a plurality of packaging piles, the packaging piles are placed on pallets, two corner beads are covered on two diagonal lines of each packaging pile respectively, and bricks in each of a plurality of brick rows along with the corresponding pallet and the diagonal lines are bundled by a bundling strap, so that the bricks form a firm whole by bundling each packaging pile. The packaging production line comprises a pile dividing device, a brick holding device, two vertical bundling machines, four bead clamping and cutting devices, two pallet bins and two packaging conveying devices, wherein the pile dividing device is used for dividing the pile, the brick holding device is used for holding the bricks to place each two packaging piles onto the pallets of the packaging conveying devices respectively by means of pile division, the bead clamping and cutting devices are used for covering and cutting the corner beads, and the vertical bundling machines are used for vertically bundling the packaging piles. The bundled brick piles are compact and firm in structure, the whole packaging production line realizes mechanized production, production efficiency is greatly improved, and labor intensity of workers is relieved.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

Device and method for automatically stacking and packaging bricks

InactiveCN101870369AFast molding speedReduce wasteBuilding material packagingBrickMechanical equipment

The invention relates to a device and a method for automatically stacking and packaging bricks, in particular to bricks for building and a series of automatic machinery. The device comprises an accepting device, an aligning device, a line conveying stacking device group, a hanging clip hook device group, a conveying belt, and the like. The device can automatically stack pre-determined number of bricks with required volume through the one-by-one conveying operation of the conveying belt and the corresponding one-by-one capturing shifting operation of the hanging clip hook devices of the hanging clip hook device group; and with cooperation of a packaging machine, the device can perform automatic packaging operation; and two long rectangular grooves are reserved on the second layer of bricks and are used for inserting two inserted links of a fork lift truck. The device stacks and packages the bricks according to the required number and volume layer by layer by using automatic mechanical equipment and has the advantages of reducing labor waste, increasing the forming speed of brick stacking and packaging and increasing the use value in industry.

Owner:陈有福

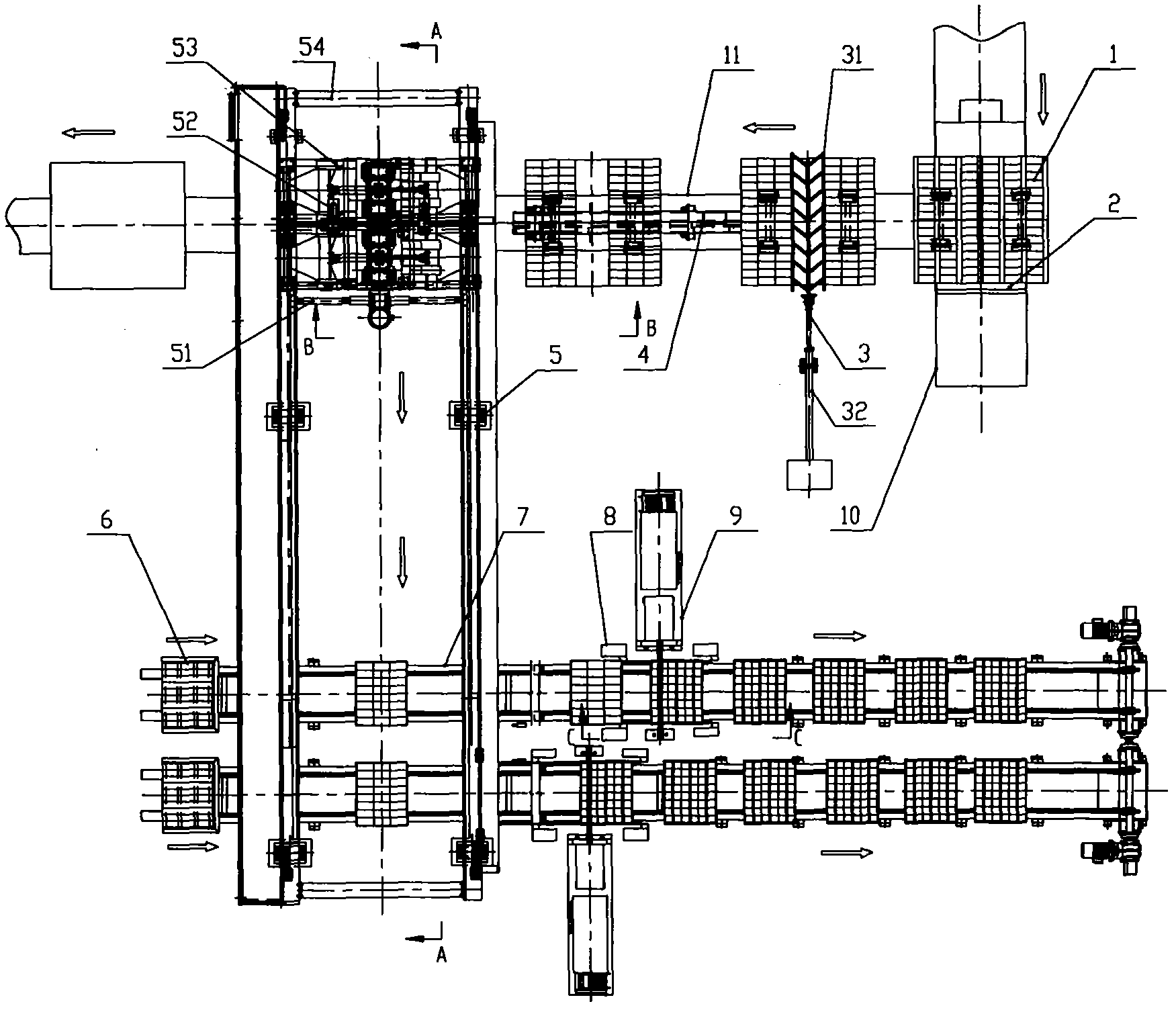

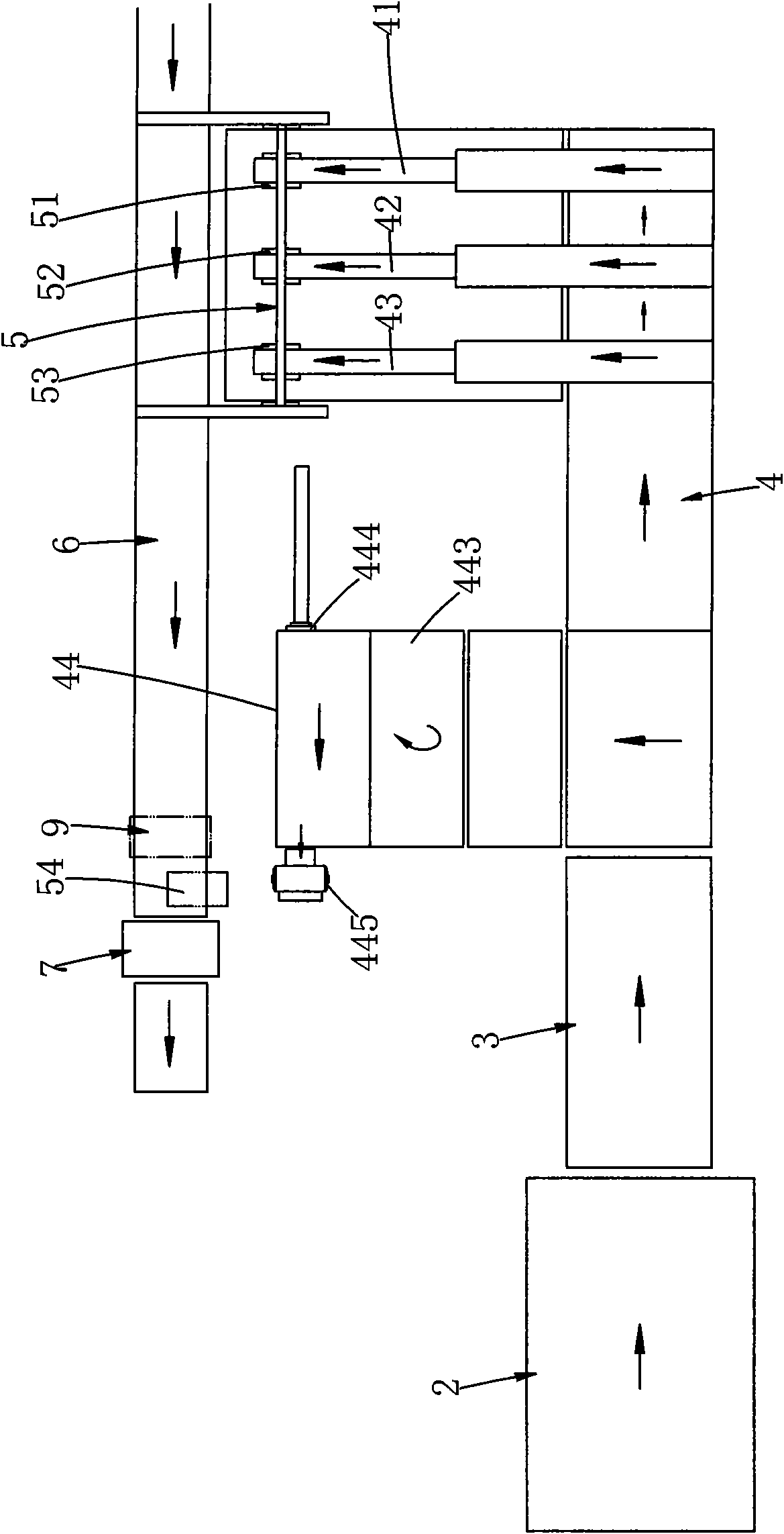

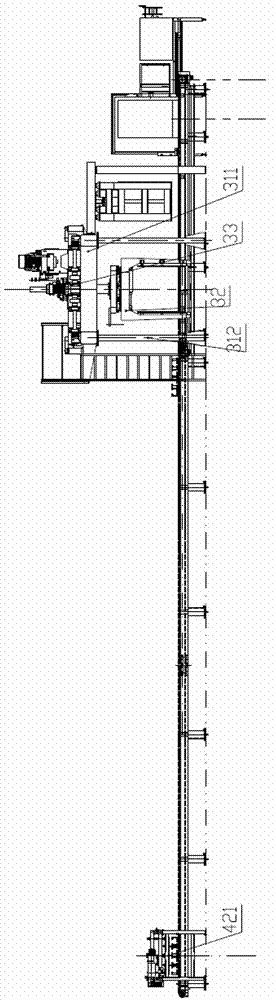

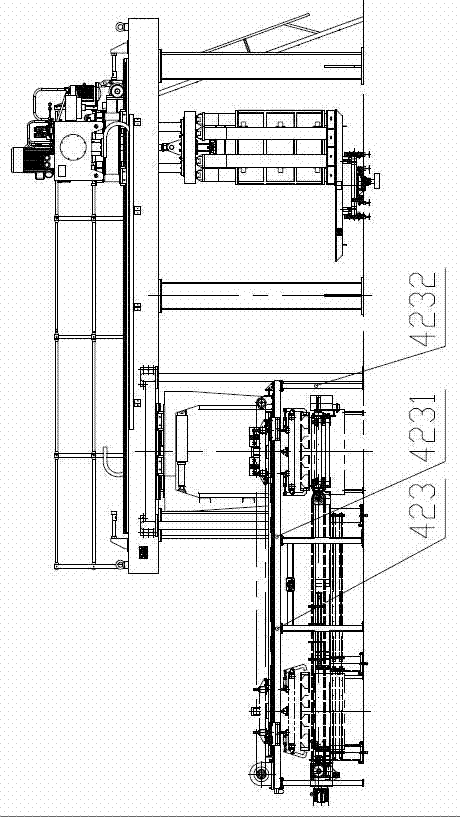

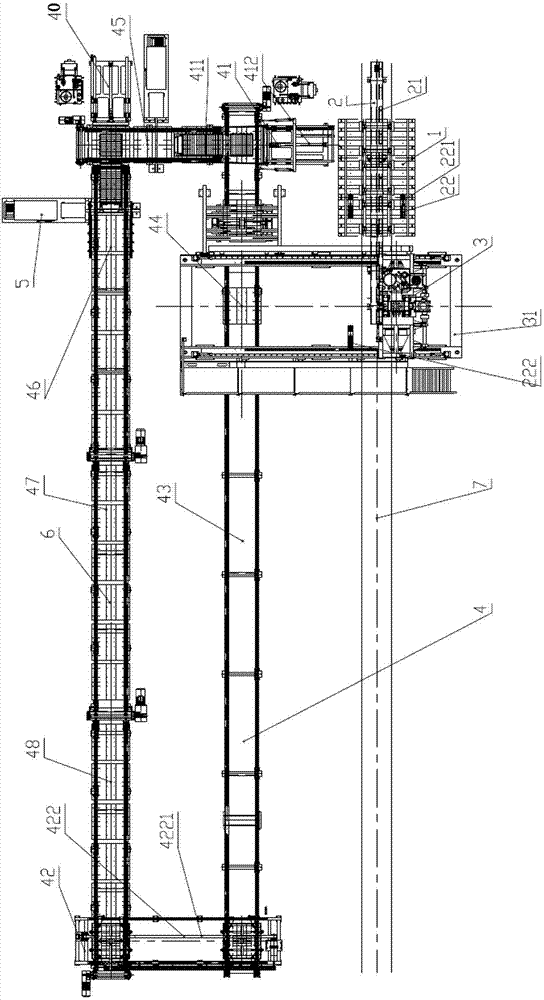

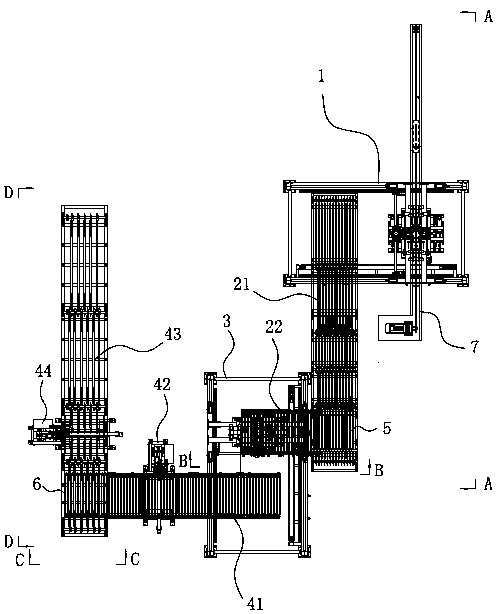

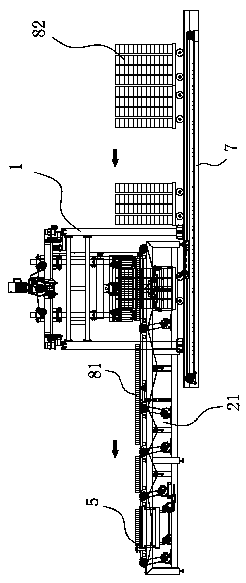

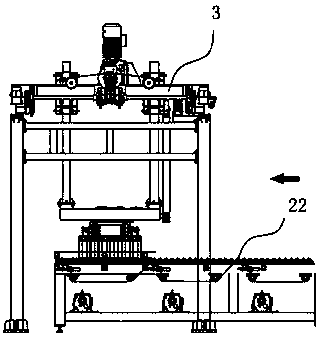

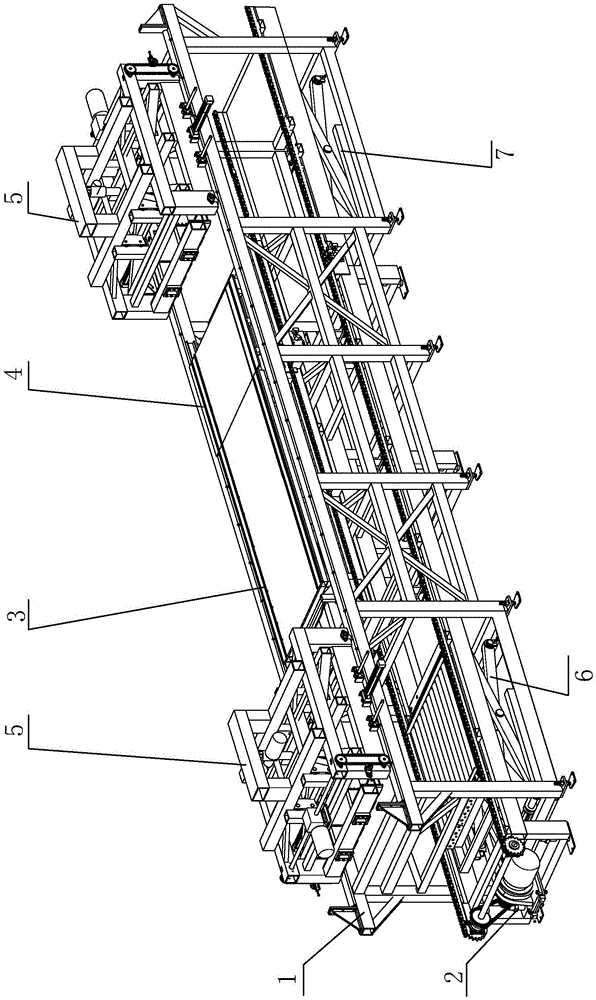

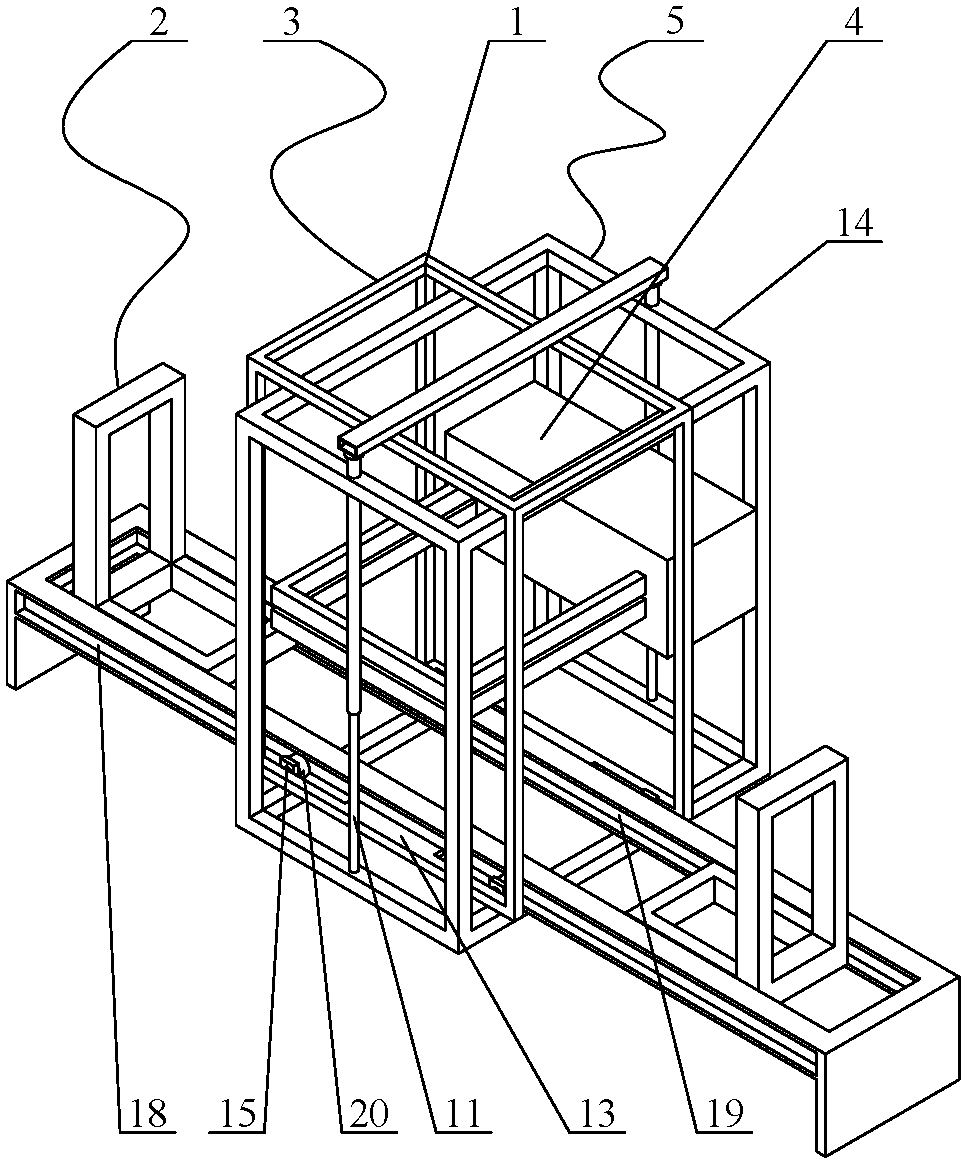

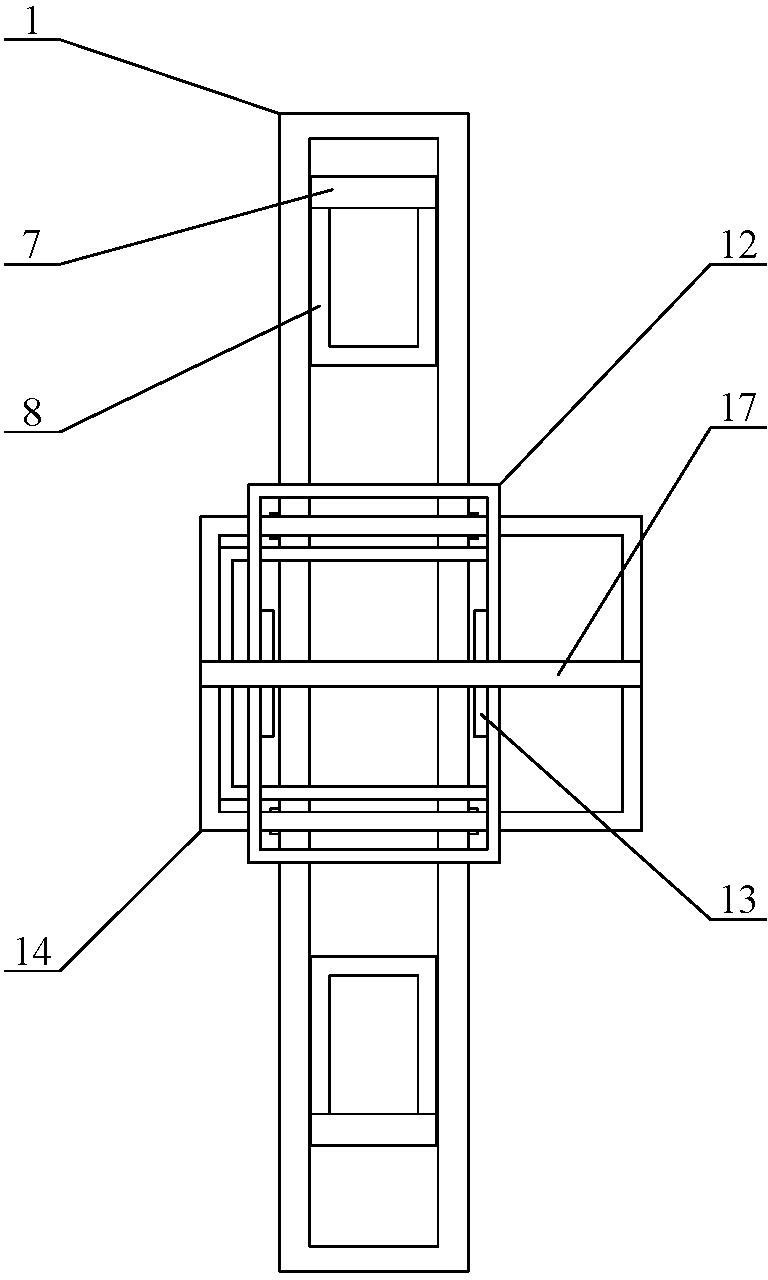

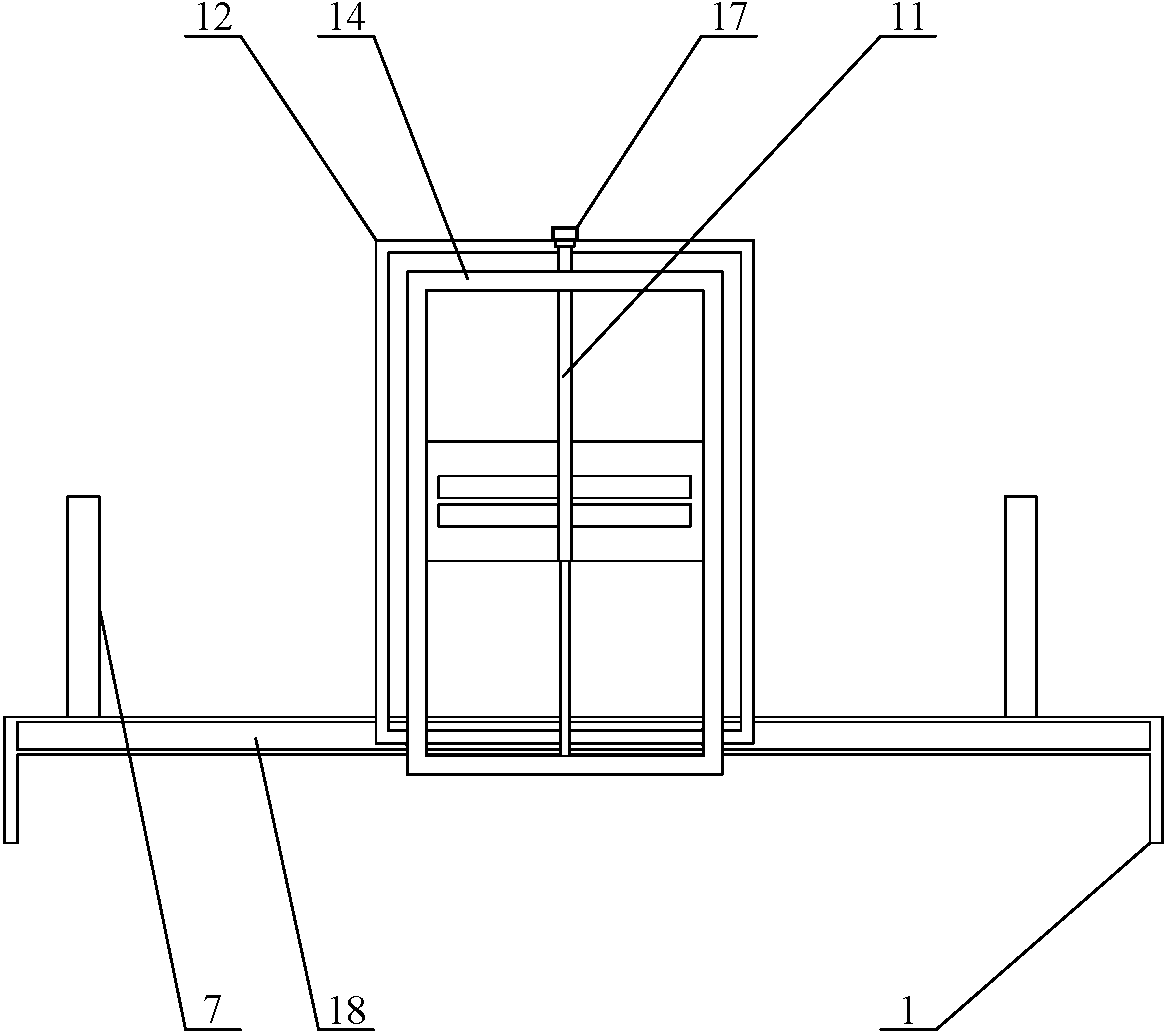

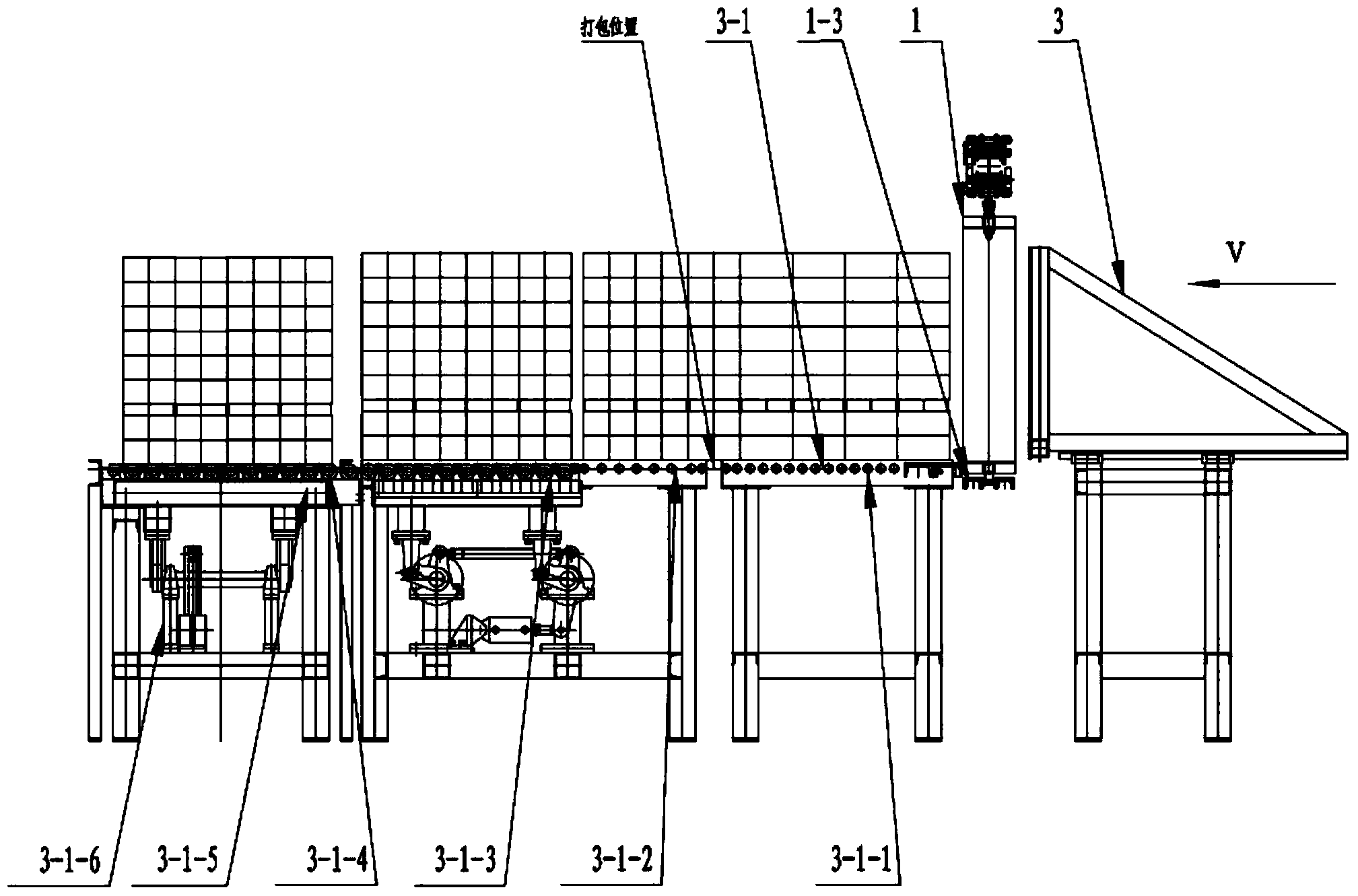

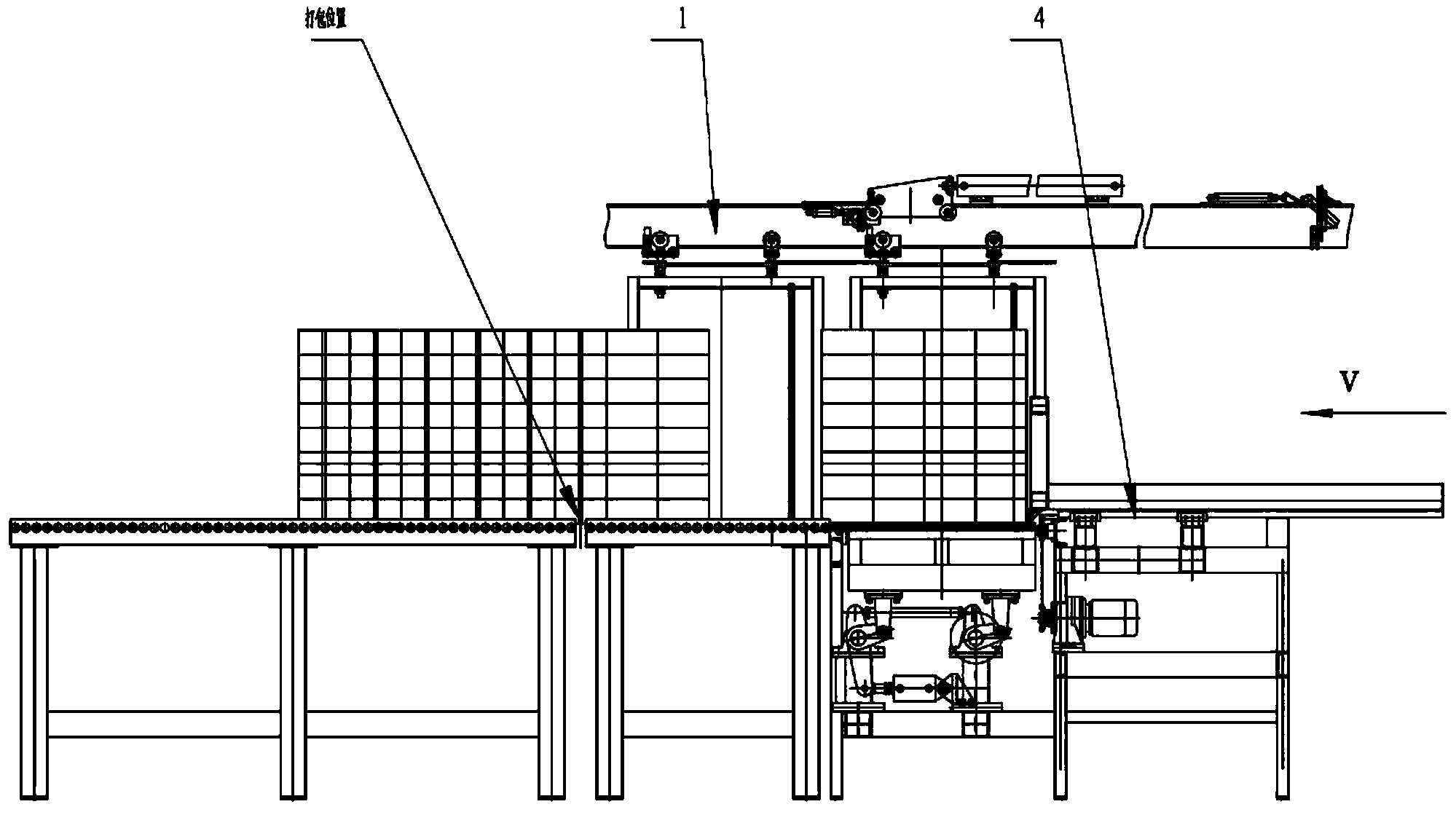

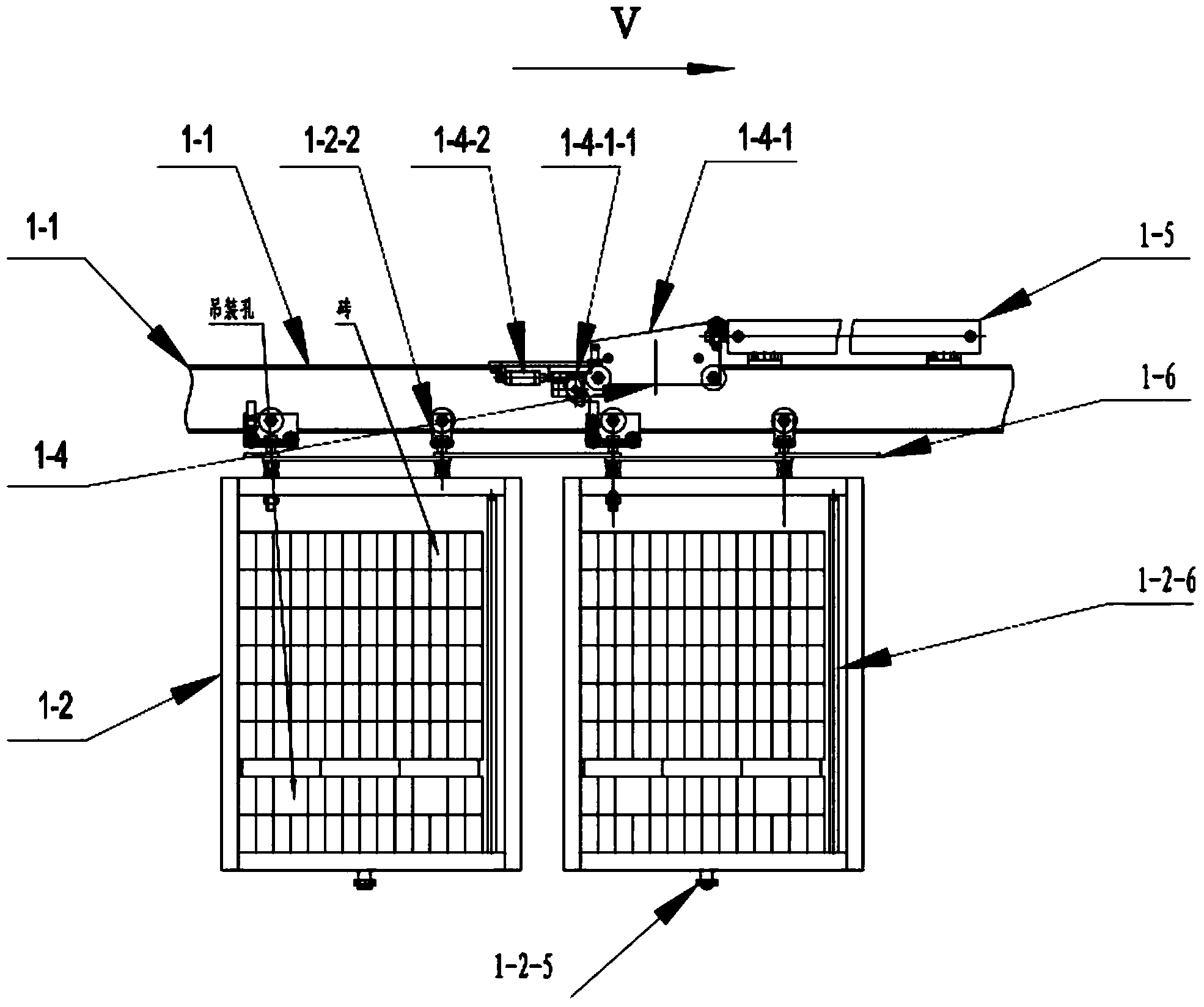

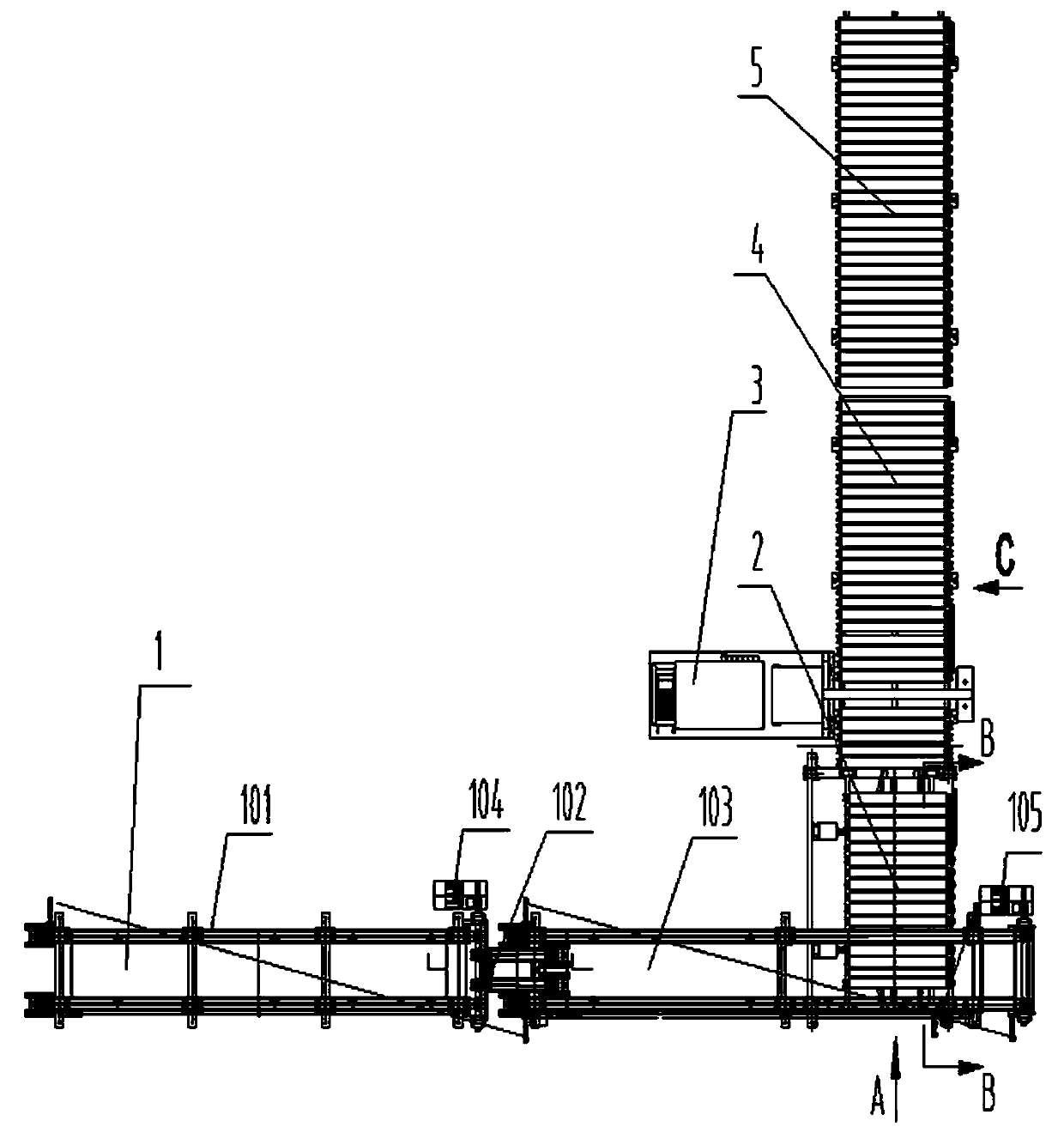

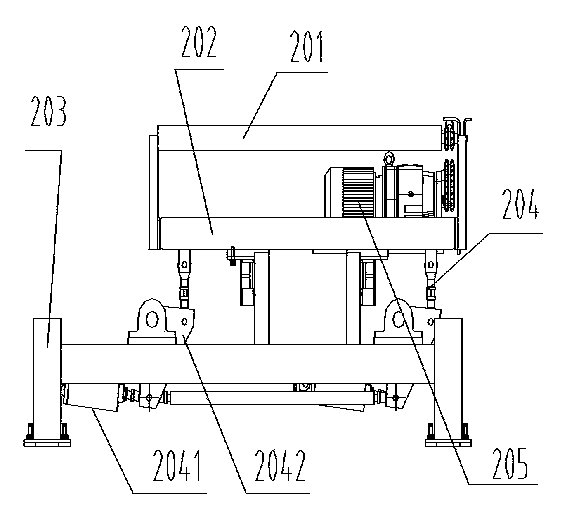

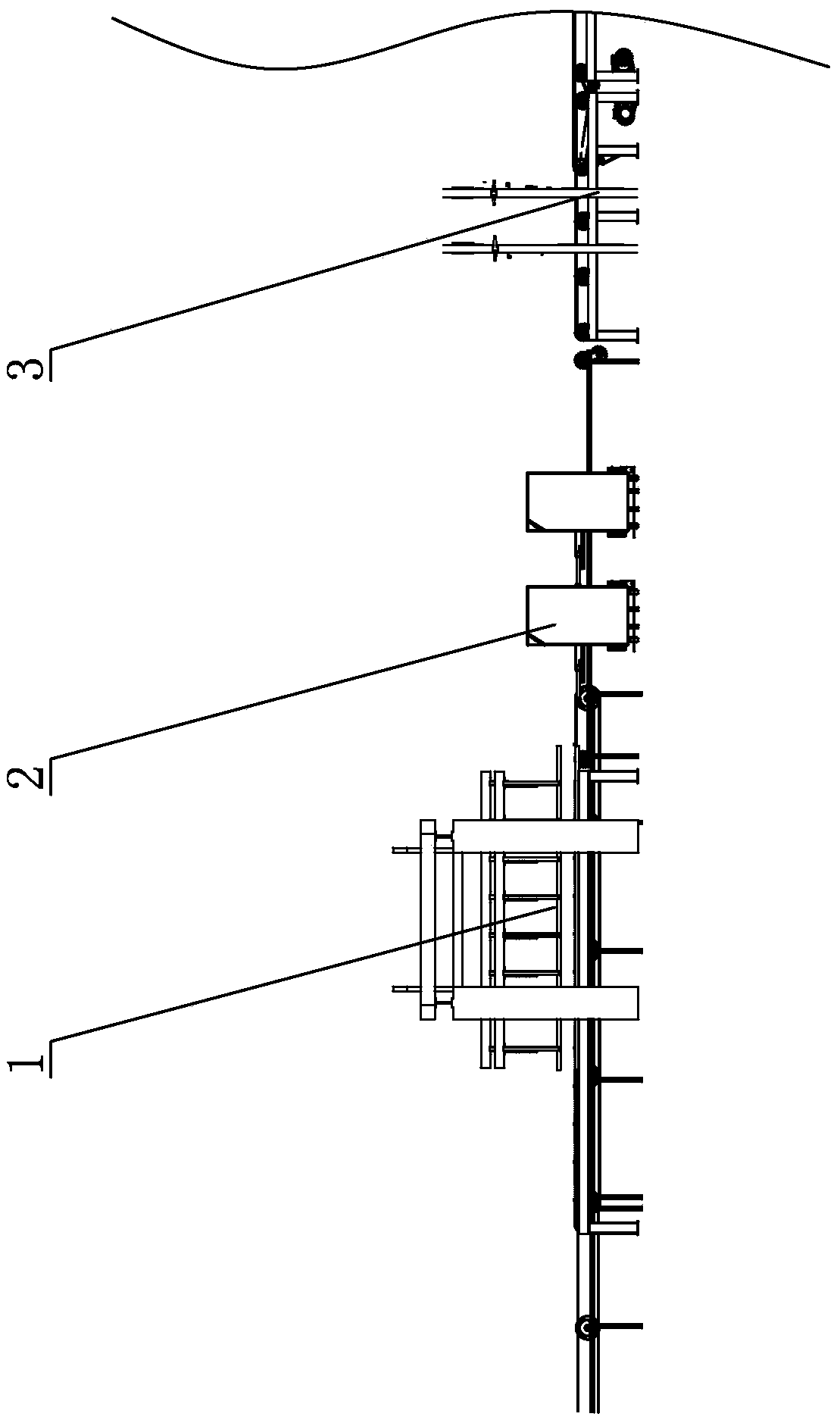

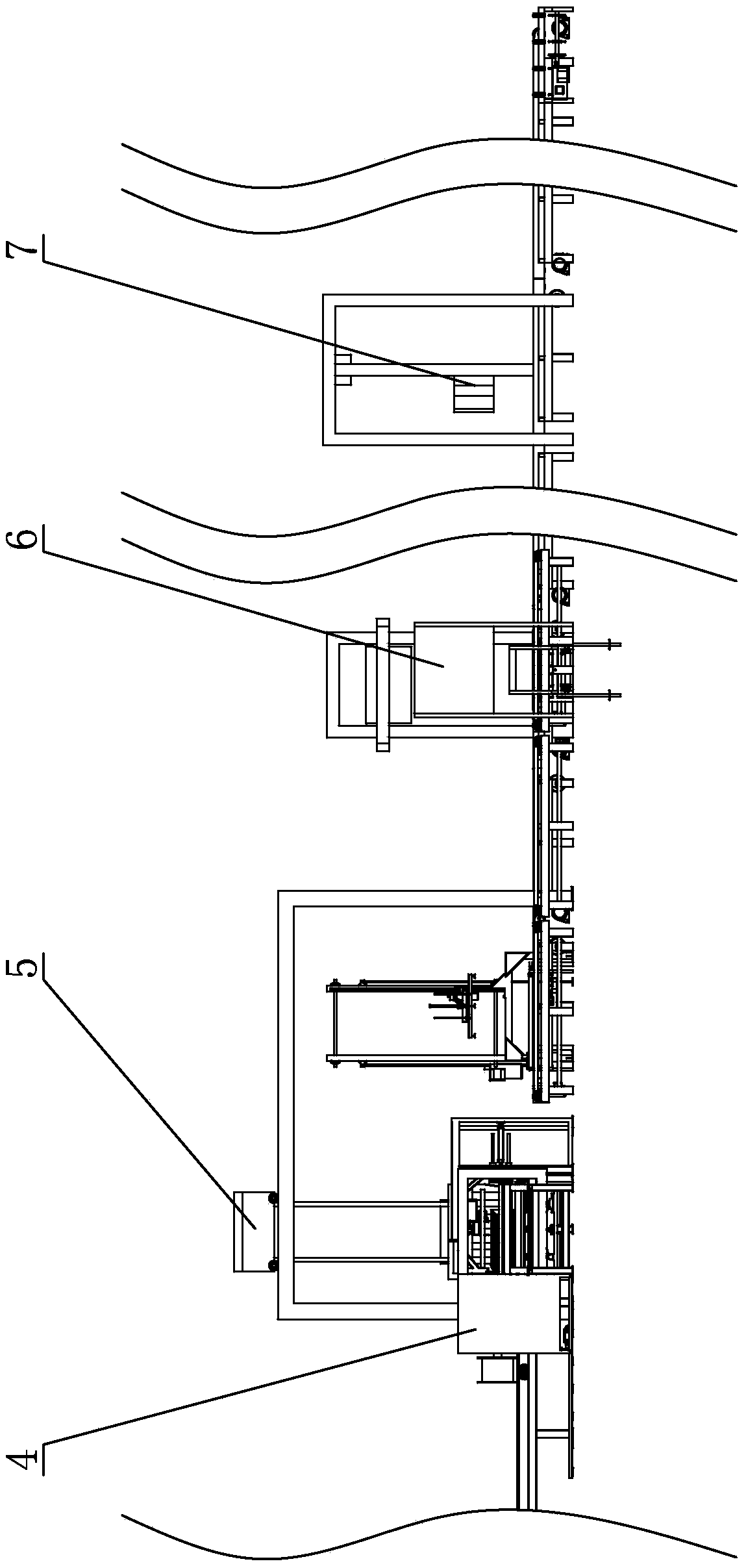

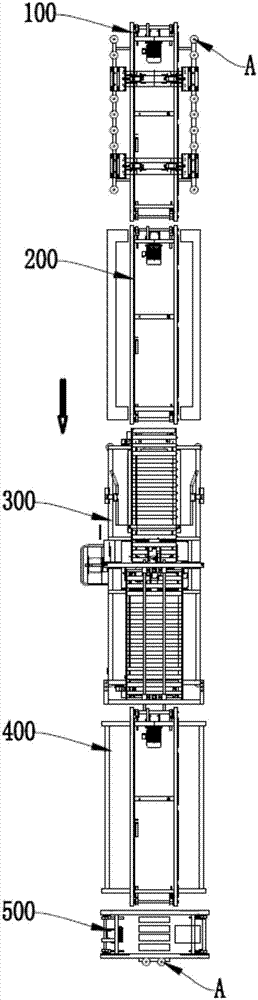

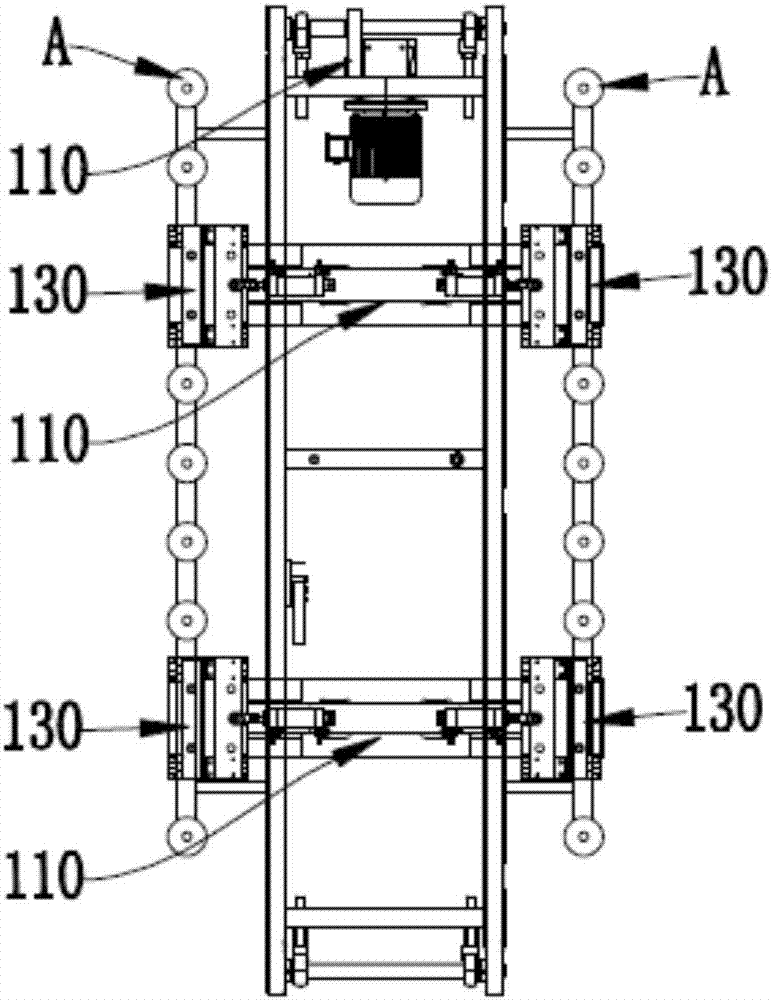

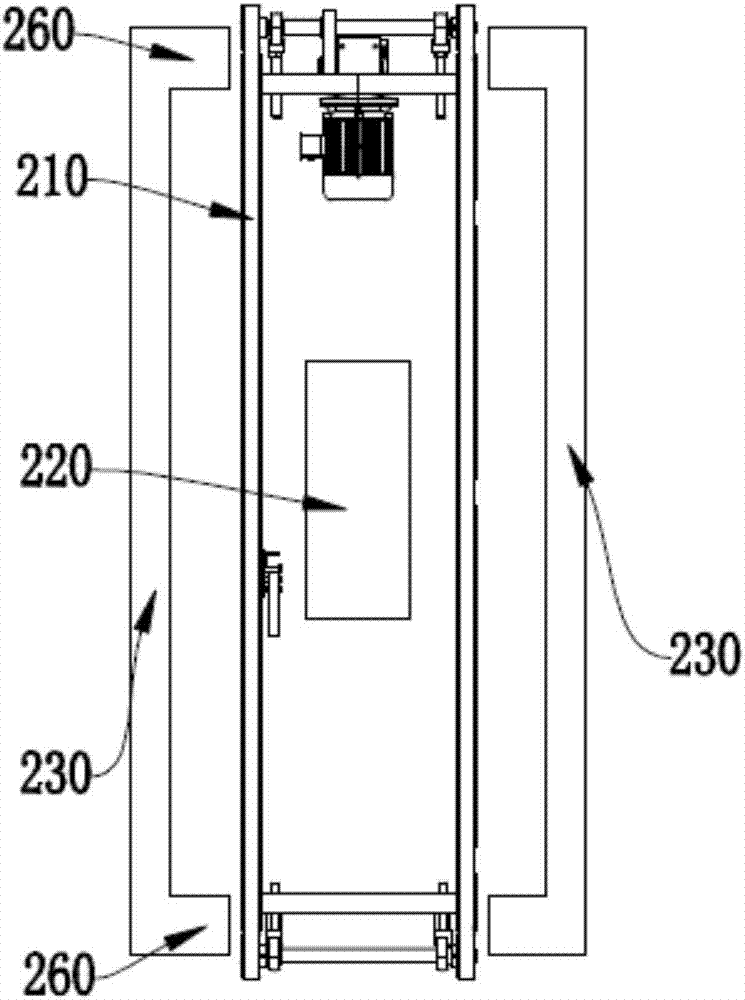

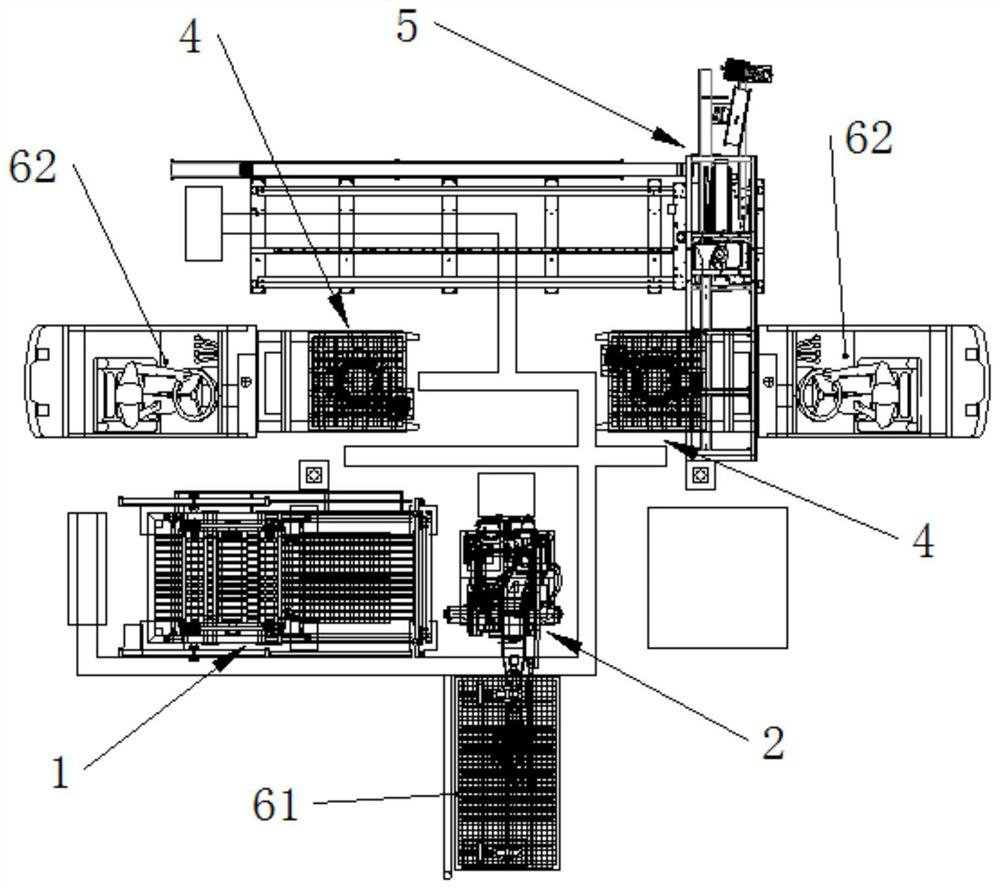

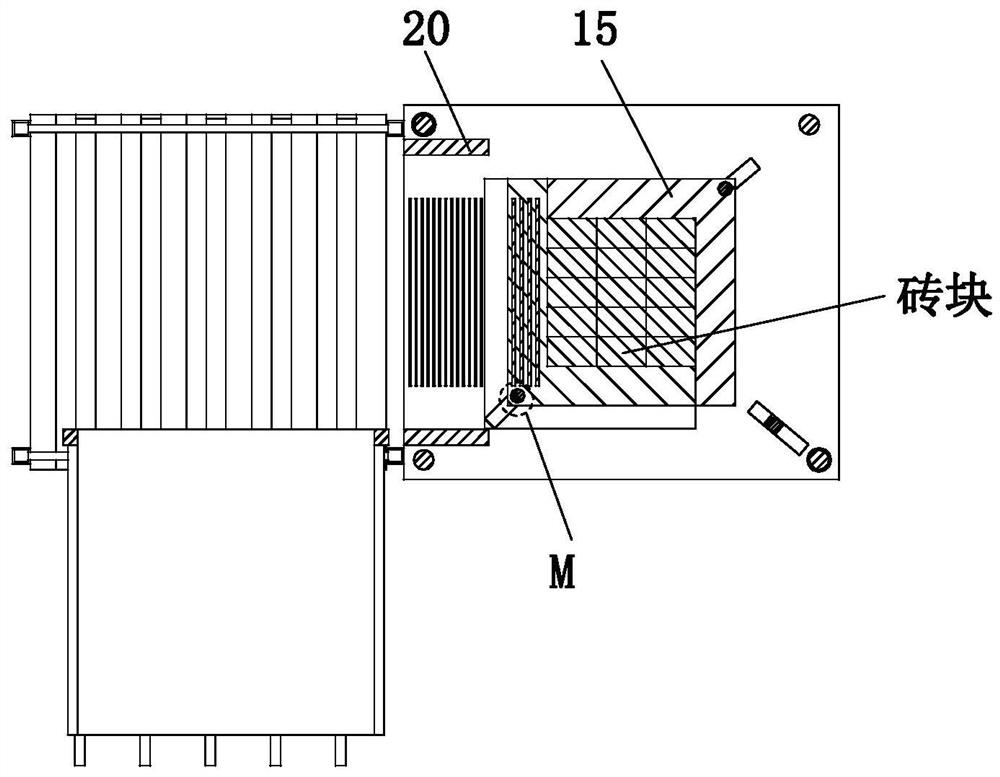

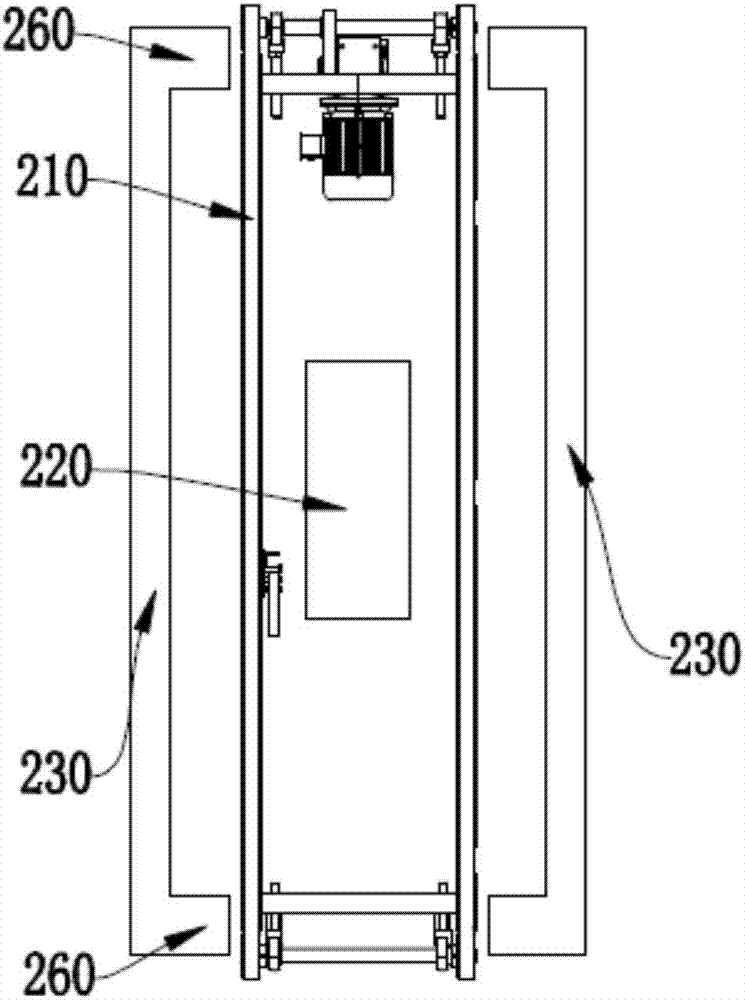

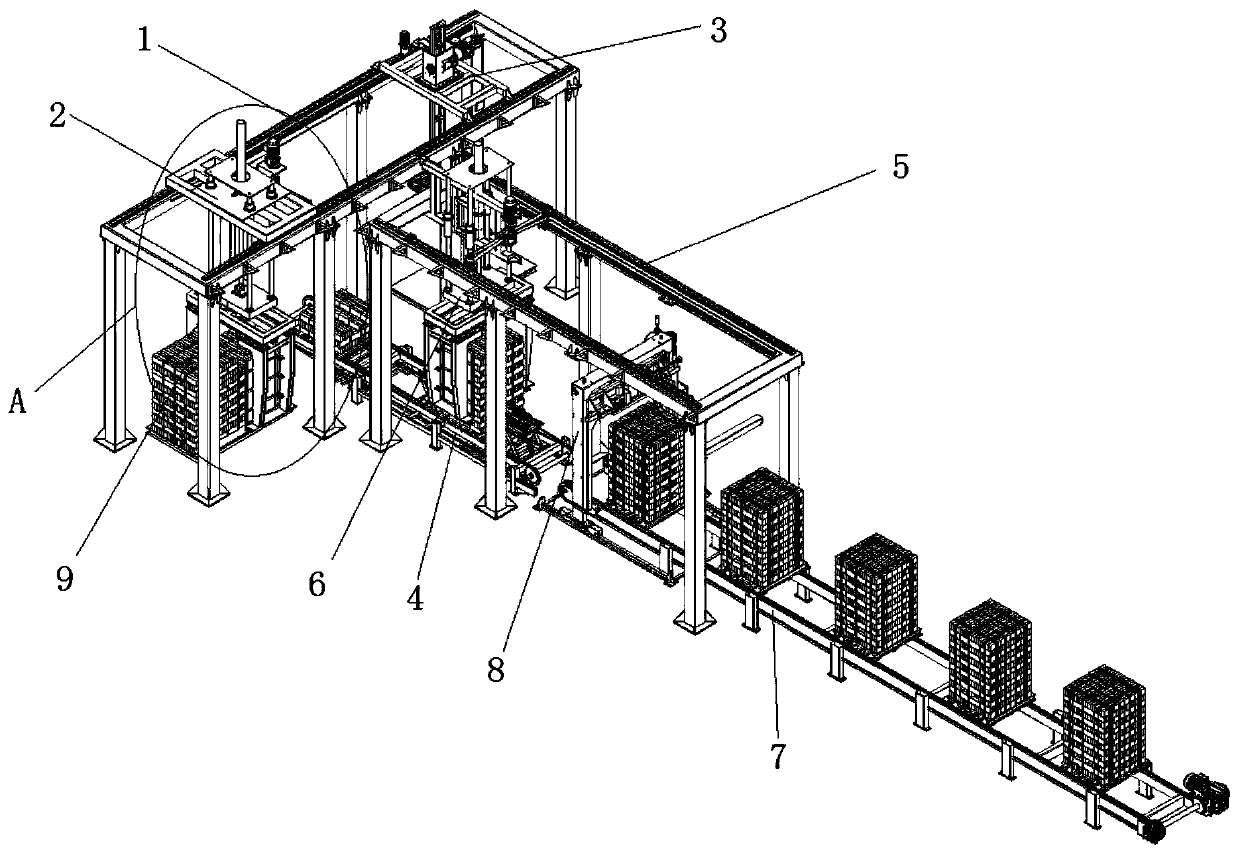

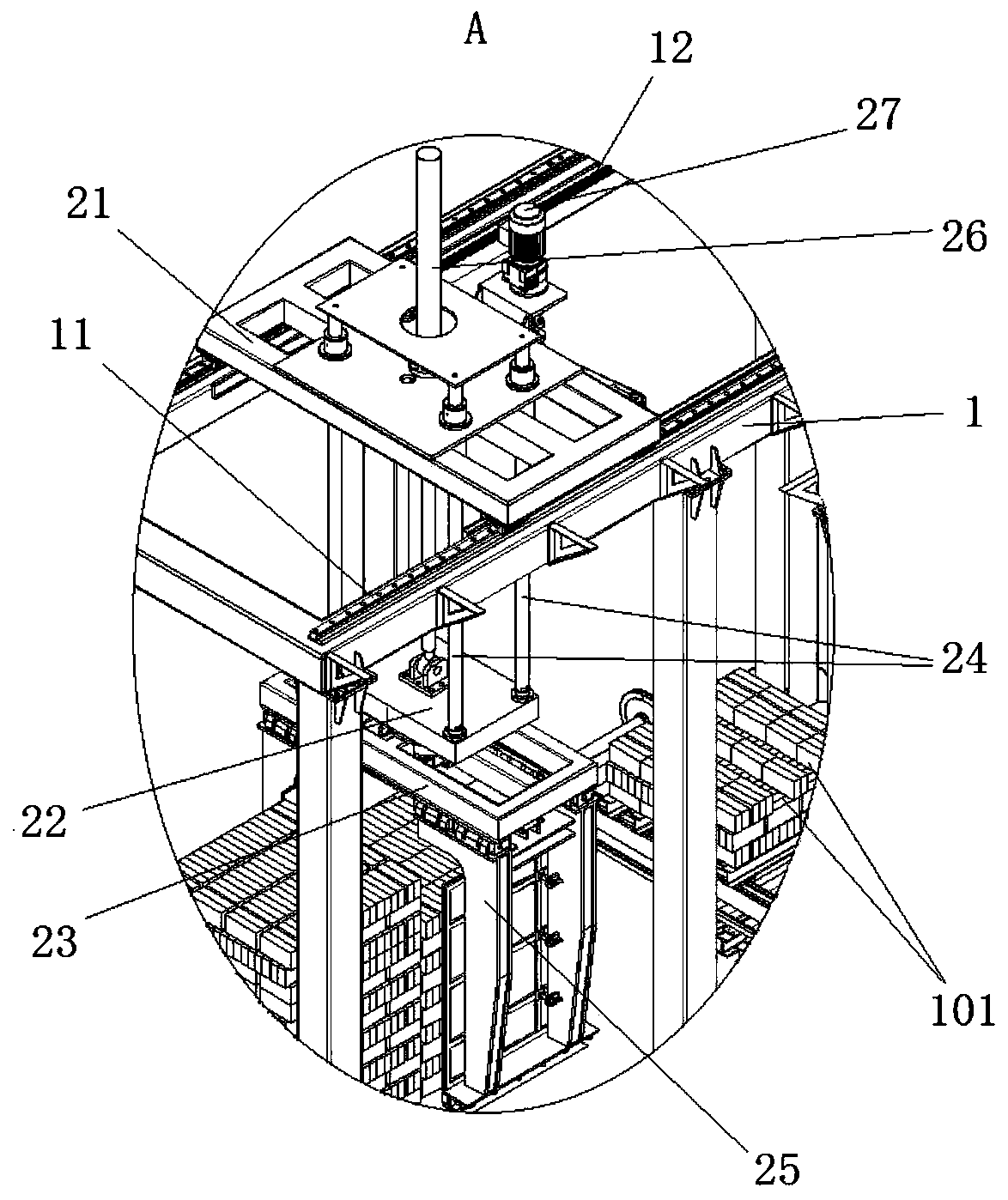

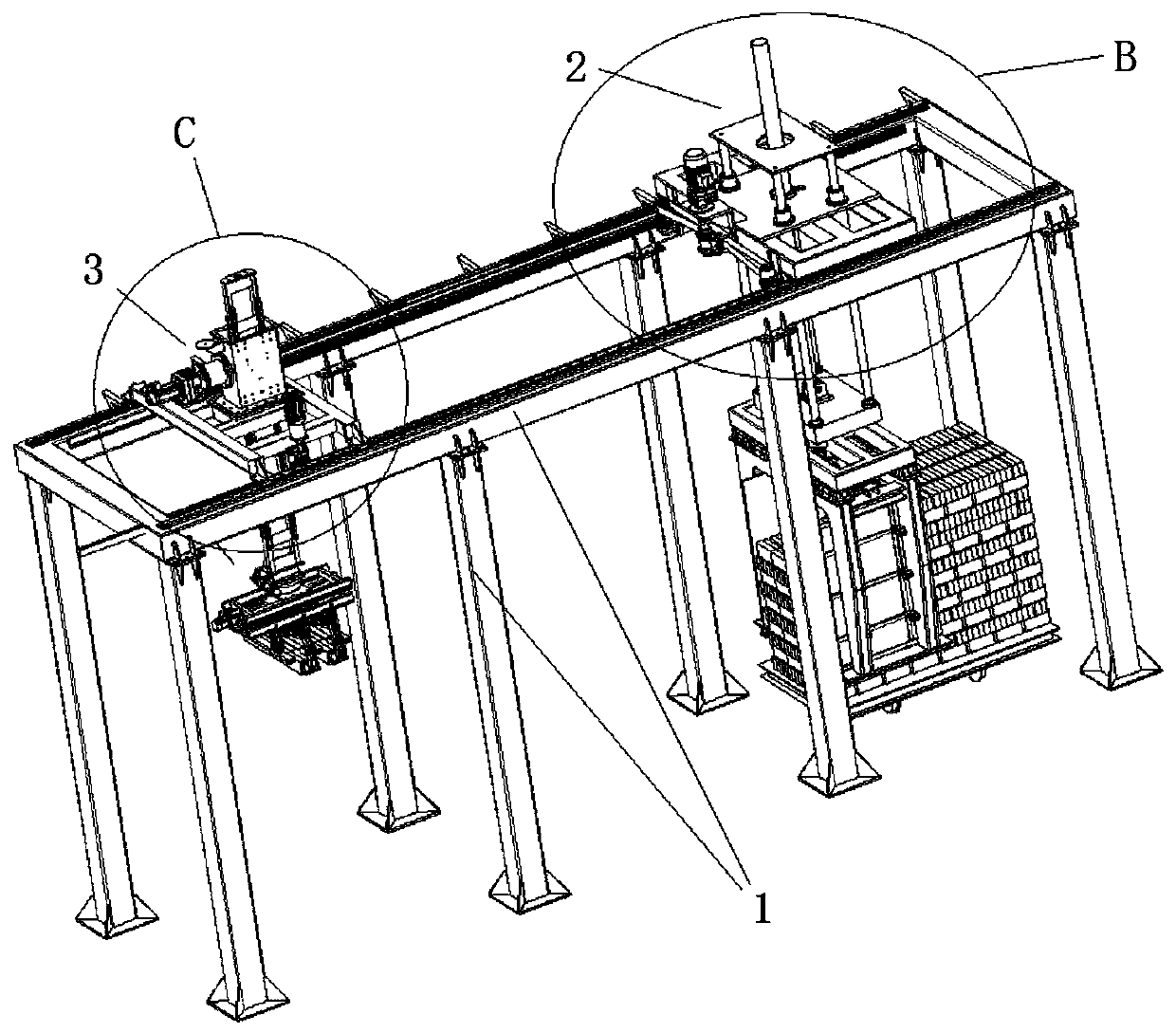

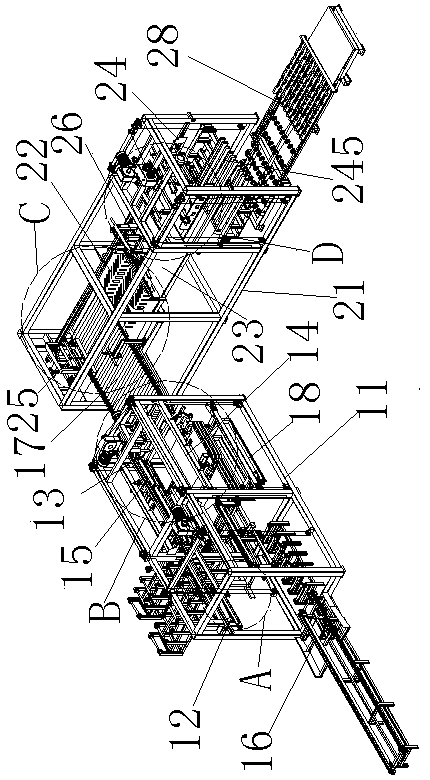

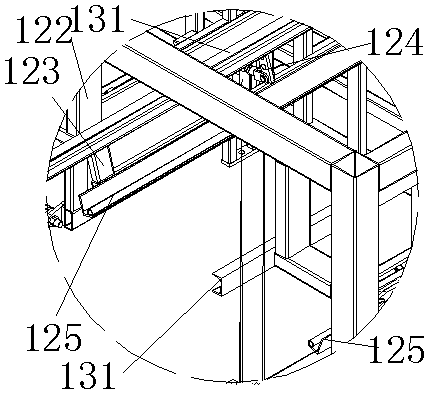

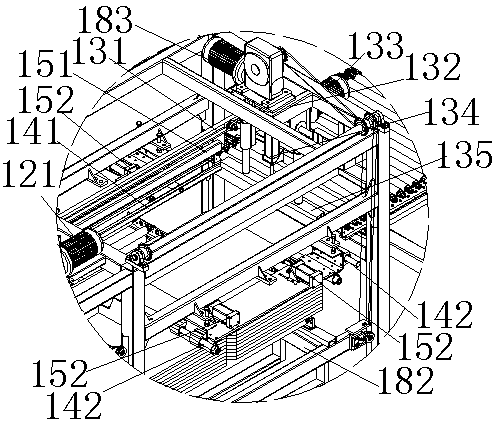

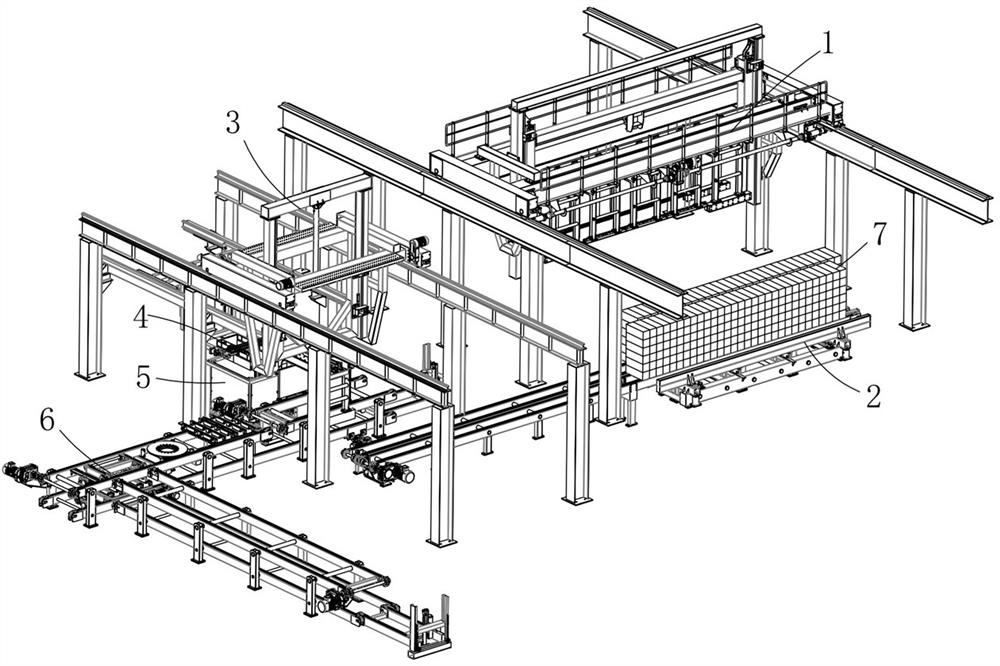

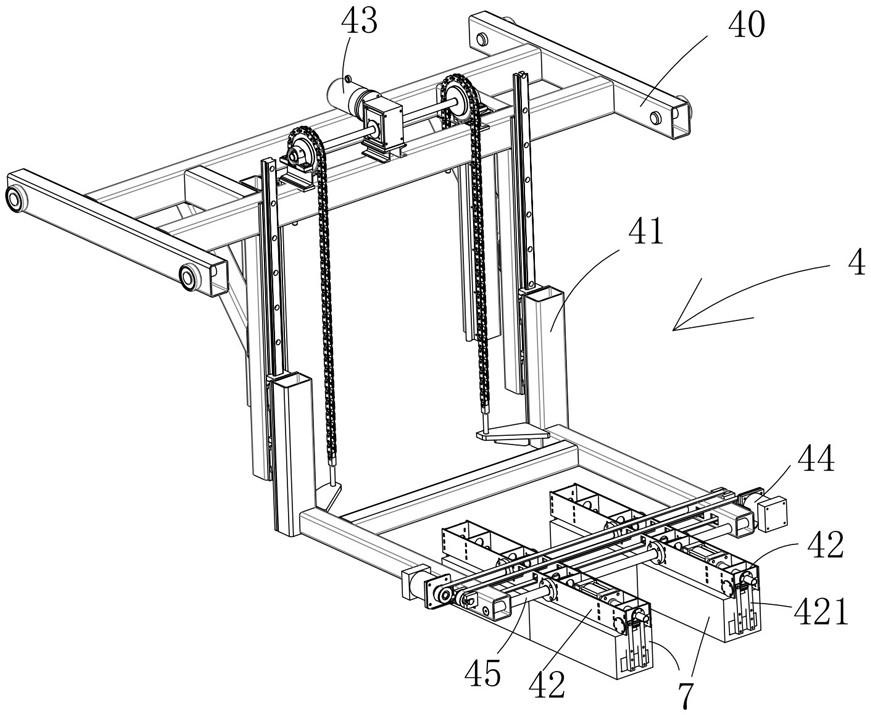

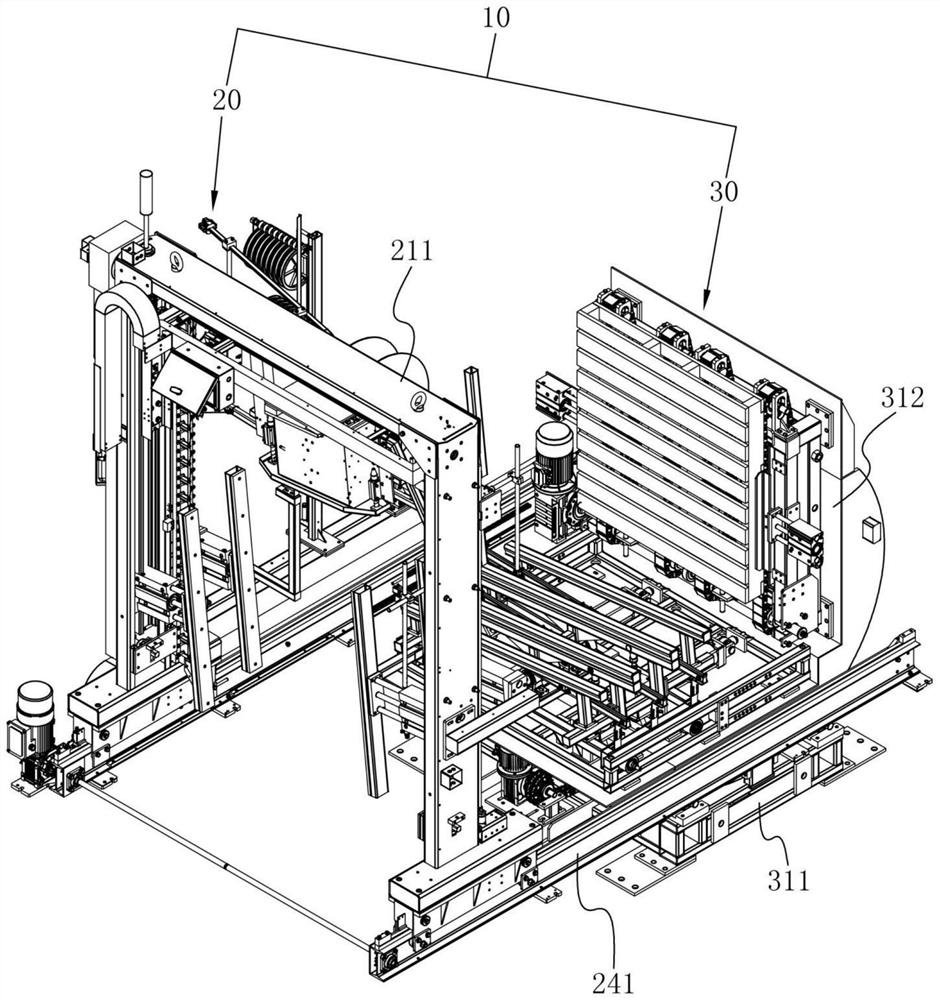

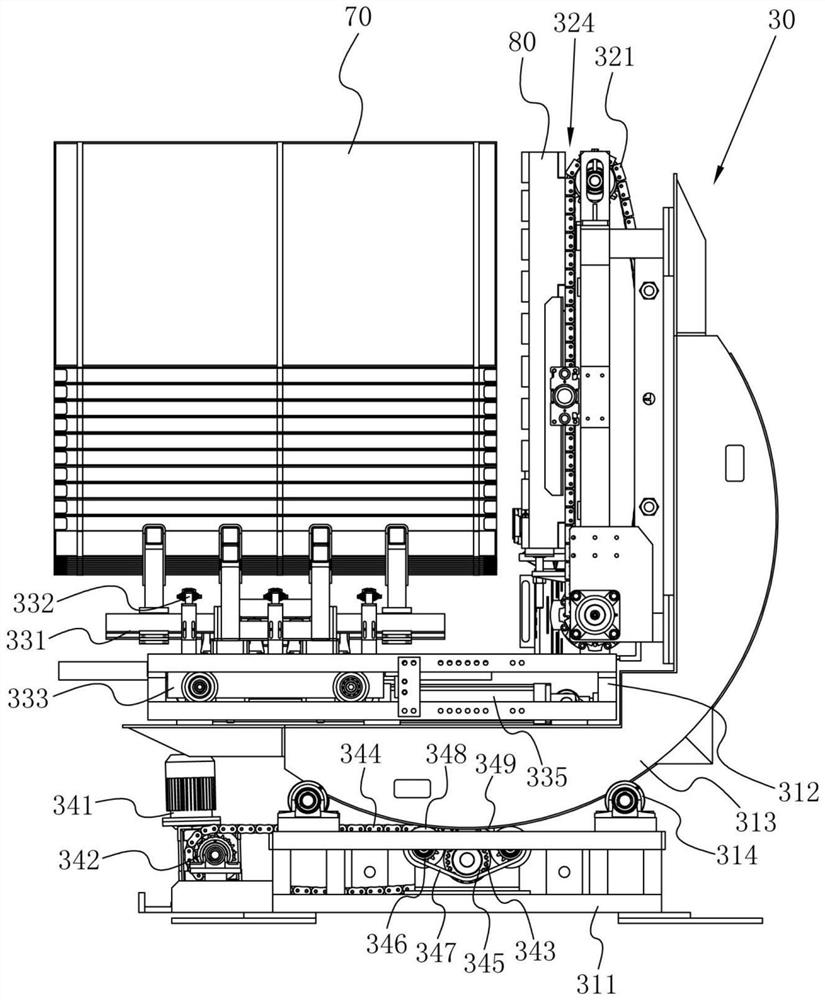

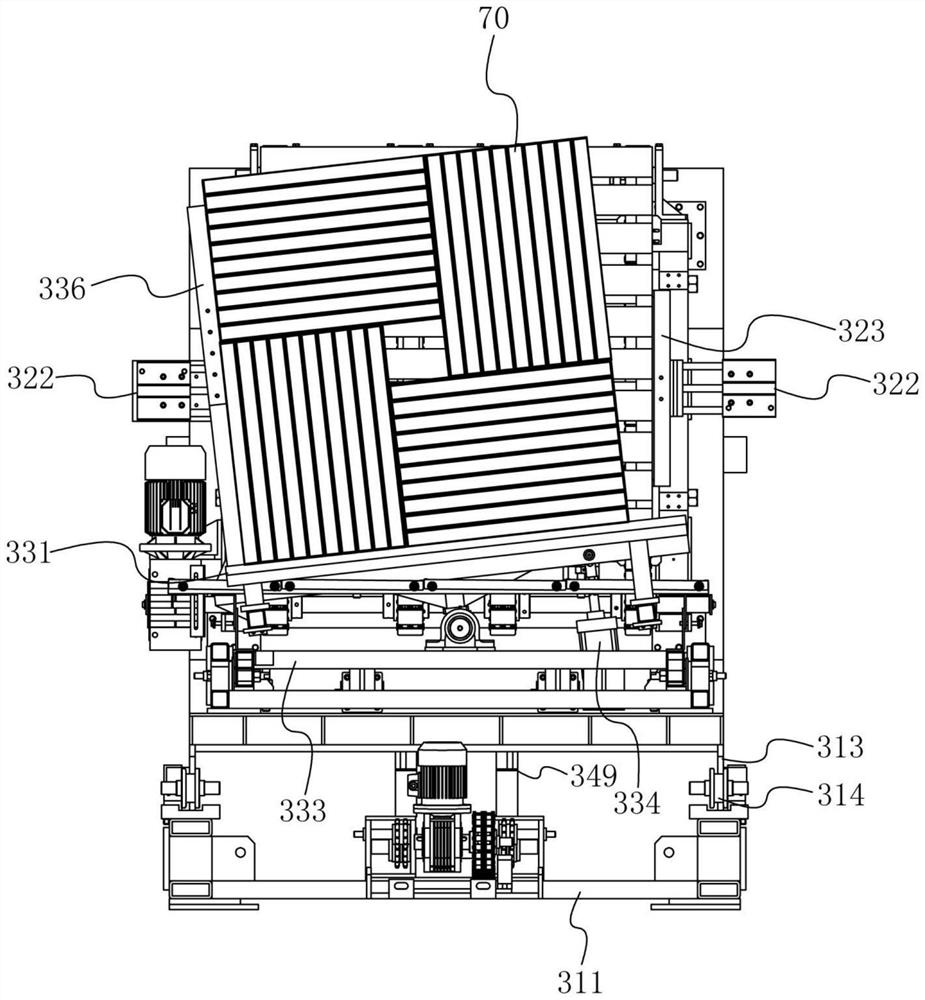

Full-automatic packaging system of autoclaved aerated concrete blocks

ActiveCN106218948AEasy to palletizeStable flowBuilding material packagingEngineeringMechanical engineering

The invention discloses a full-automatic packaging system of autoclaved aerated concrete blocks, and belongs to the field of packaging devices of the concrete blocks. The system is characterized in that one end of a block conveying mechanism (5) is connected with an autoclave, the other end of the block conveying mechanism (5) is a stack outlet output end, a stack unloading mechanism (1) reciprocates and transversely moves between the stack outlet output end and the input end of a blank turning mechanism (2) through a transverse moving sliding mechanism, and vertically ascends and descends on the input end of the blank turning mechanism (2), the output end of the blank turning mechanism (2) is connected with a double-way packaging mechanism (4), and a mechanical arm stacking mechanism (3) is arranged between the output end of the blank turning mechanism (2) and the double-way packaging mechanism (4). In the whole conveying process, trays do not need to be used, a large number of trays are removed, in stacking work, several stacking clamps at the designated positions can be selectively selected for carrying out the clamping action, cavities or through holes are formed in a whole block stack, carrying through a forklift can be directly carried out, the trays do not need, the trays are thoroughly removed, and a large amount of production cost is saved.

Owner:淄博捷达机械有限公司

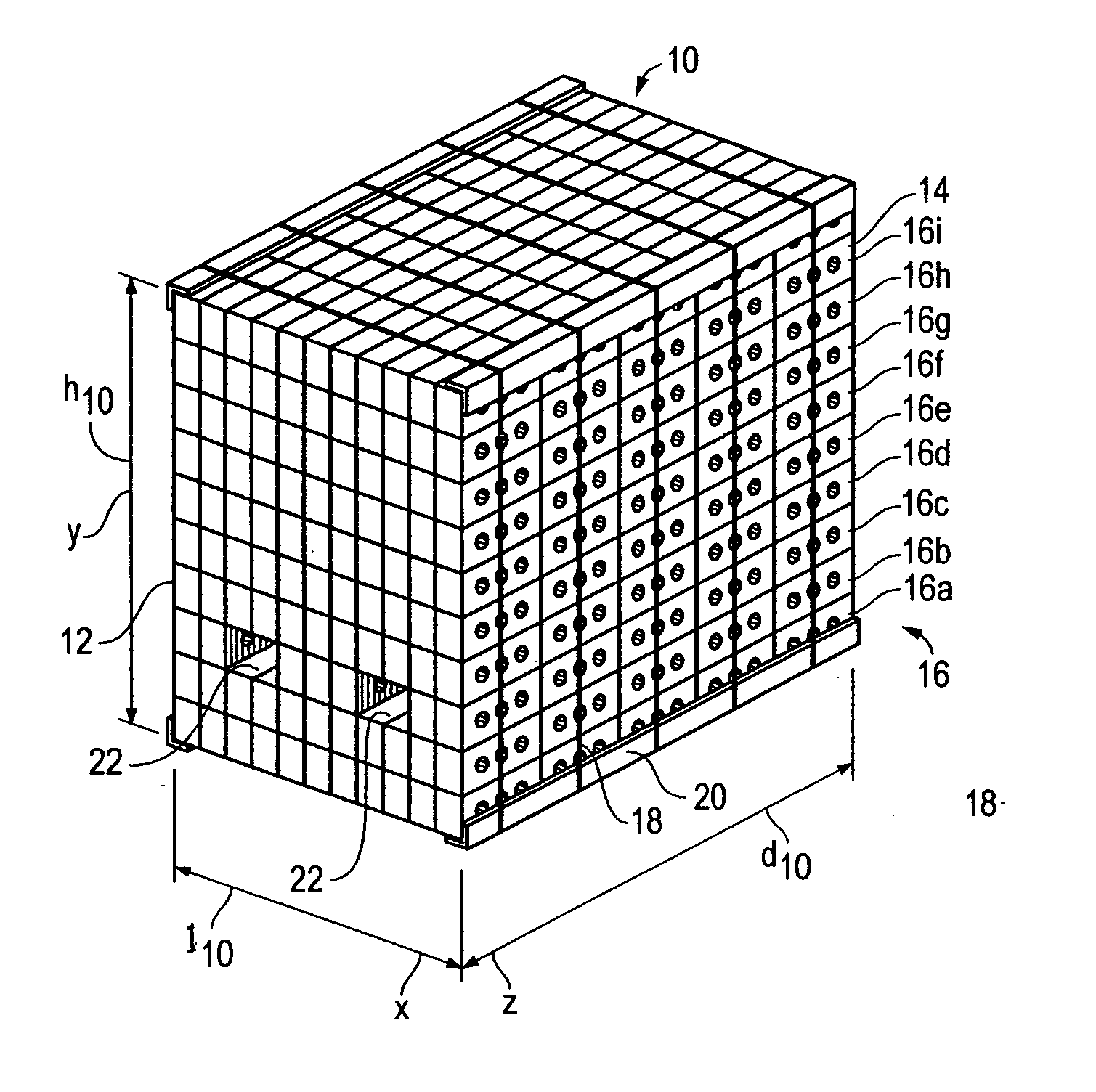

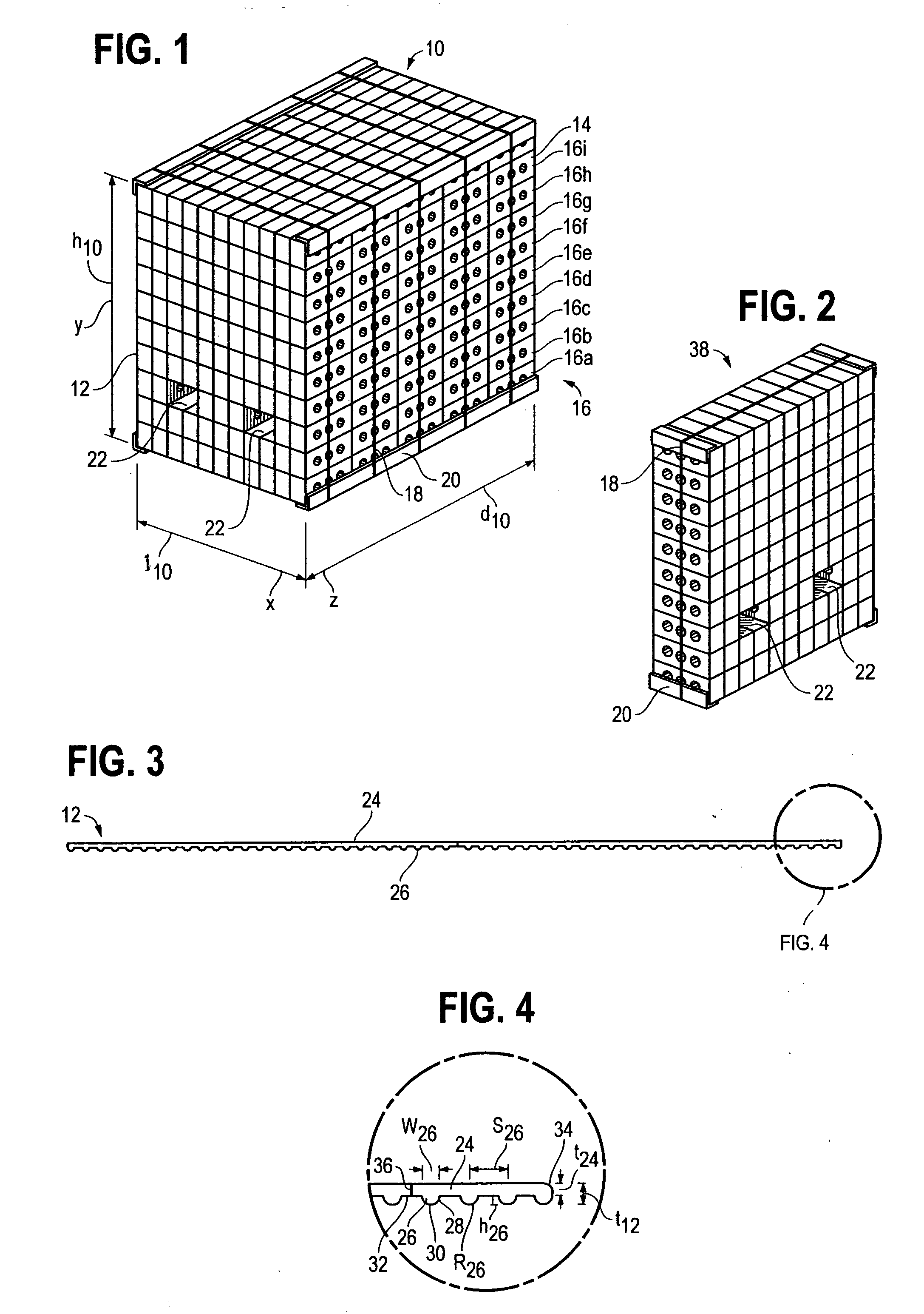

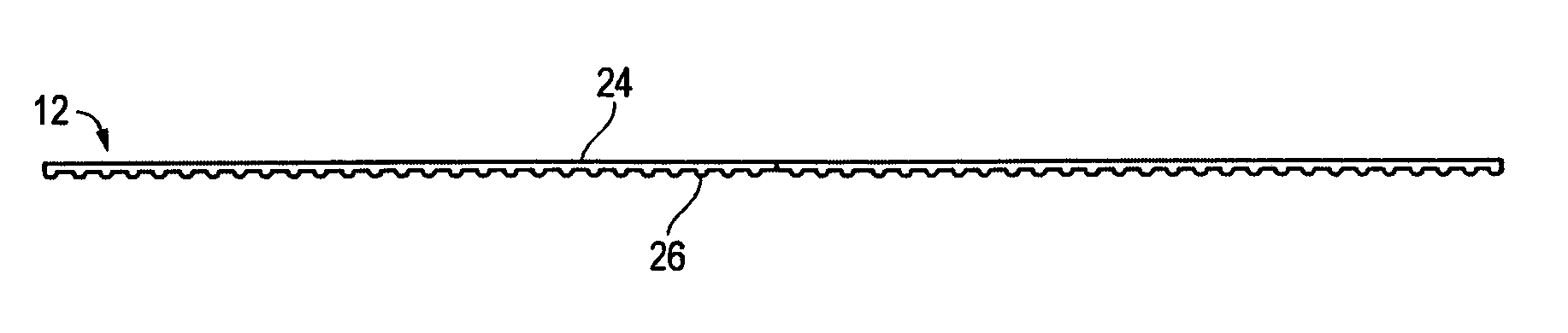

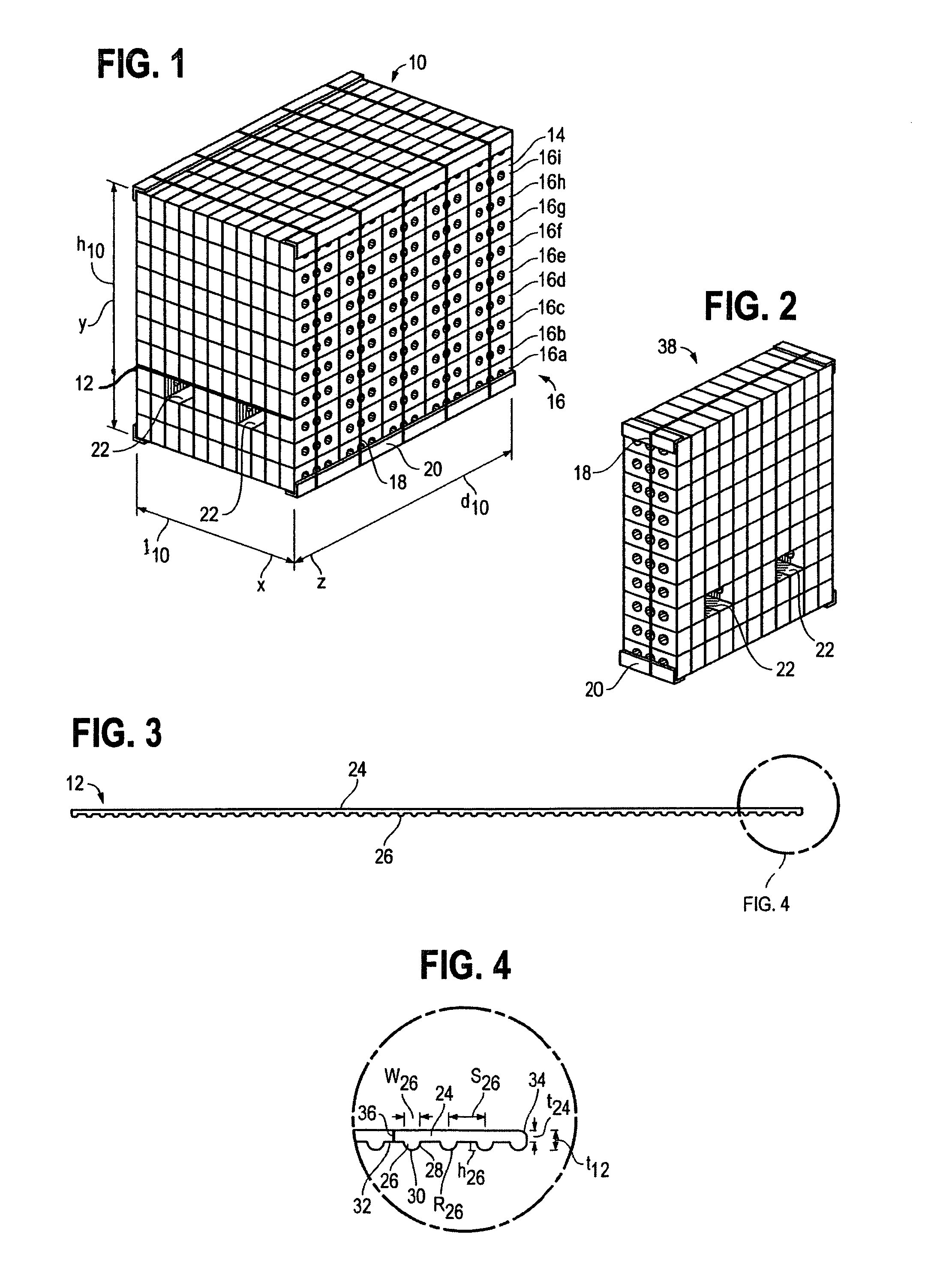

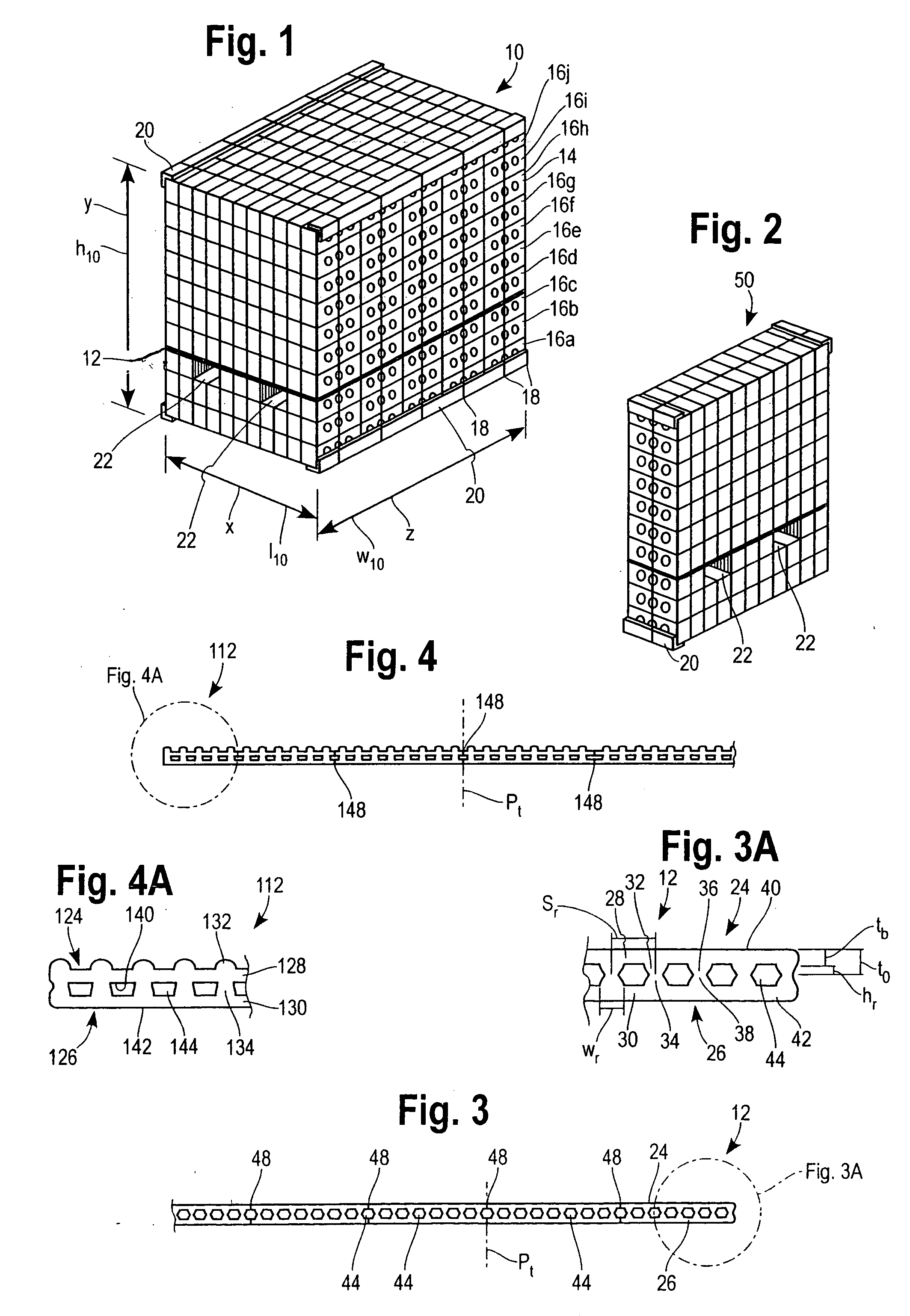

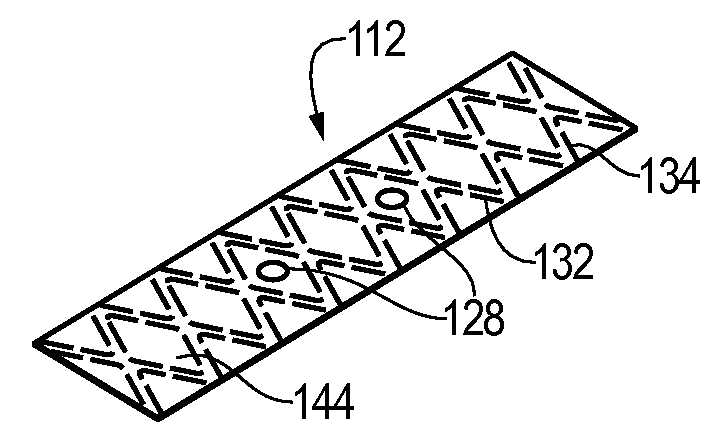

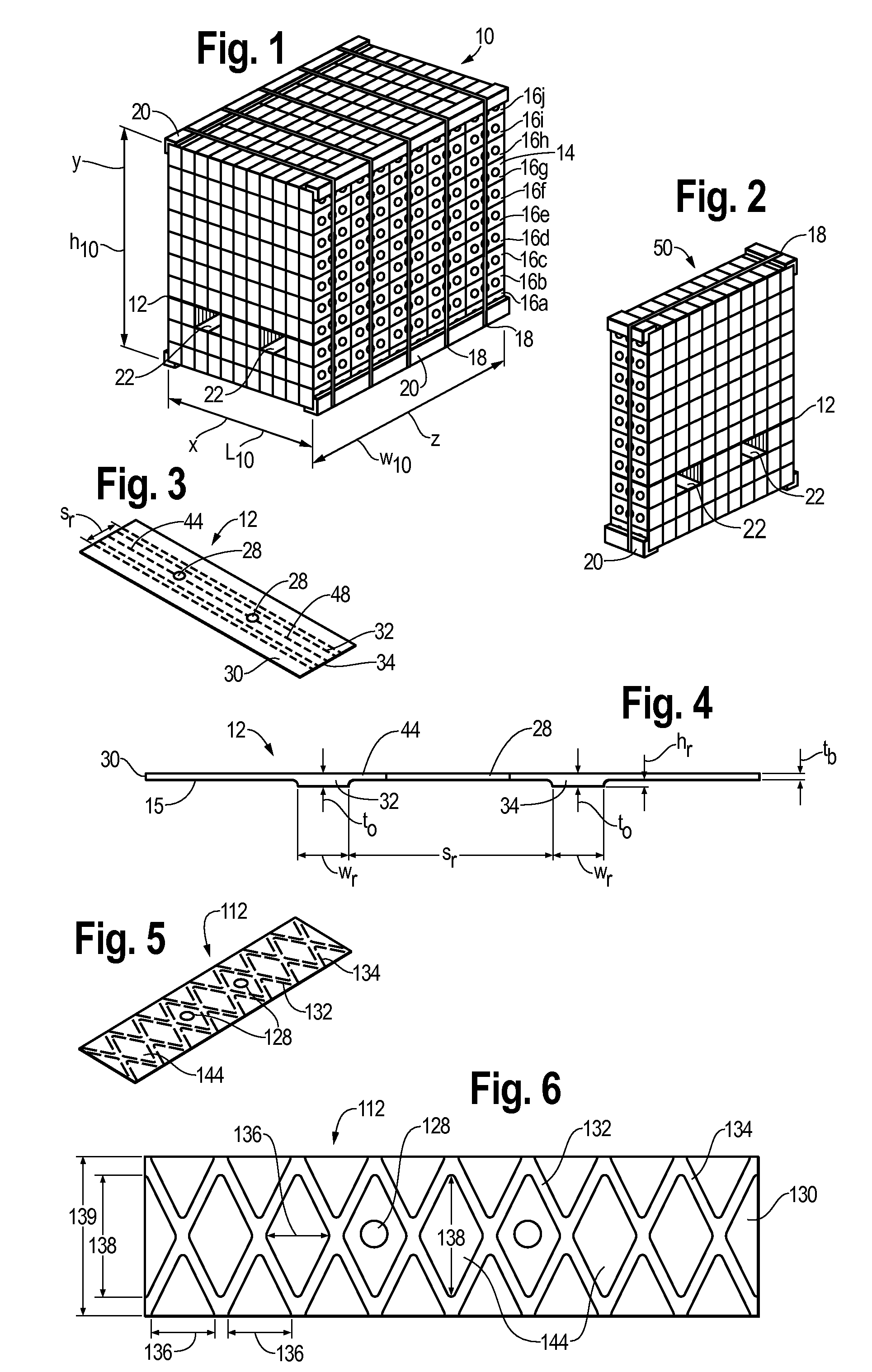

Polymeric void-board

An extruded polymeric void-board is configured for placement between adjacent horizontal layers of bricks to maintain an opening in a lower layer of the bricks. The void-board is formed as a relatively thin planar element having first and second surfaces. A plurality of parallel ribs extend from and generally transverse to the first side. The ribs have a predetermined height to width ratio and have a height that is less than a thickness of the planar element. The ribs being formed parallel to one another. A method for forming a bundle of bricks with the void-board is also disclosed.

Owner:ILLINOIS TOOL WORKS INC

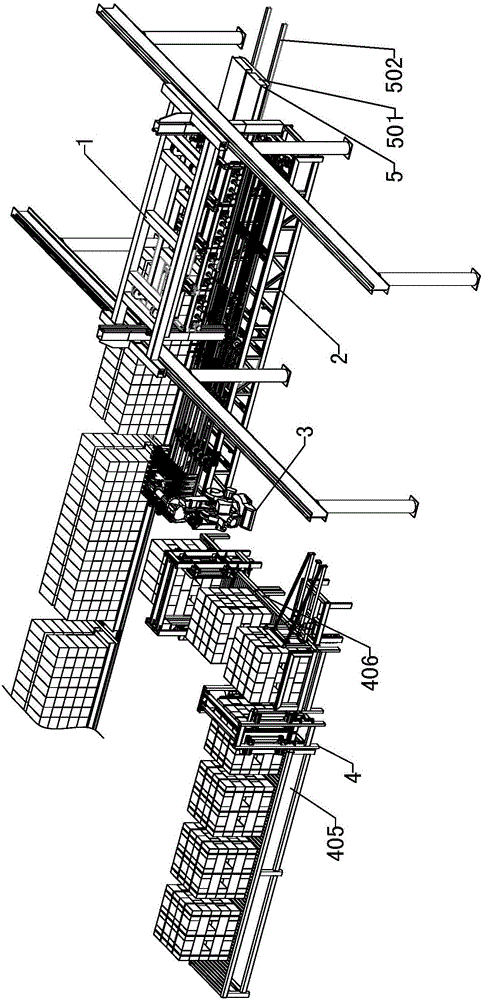

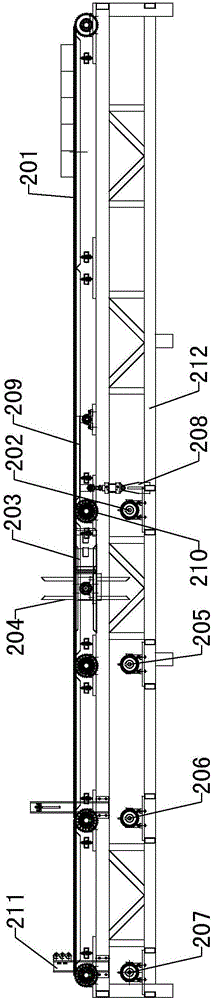

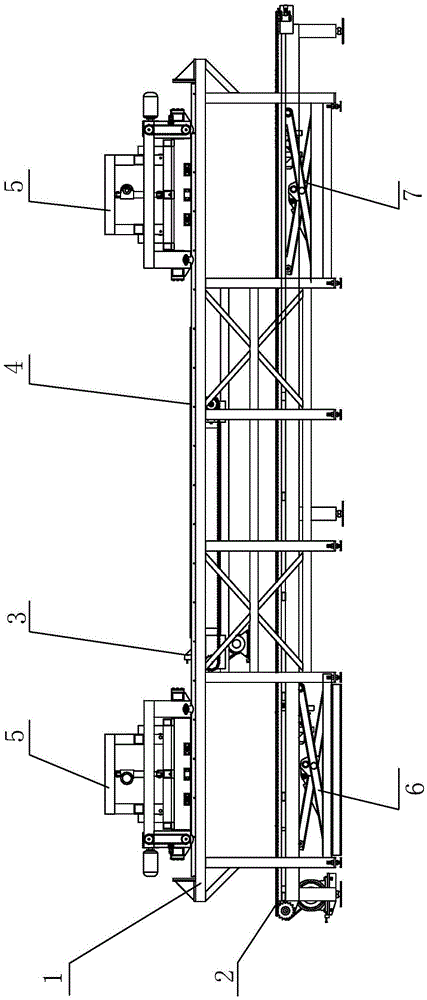

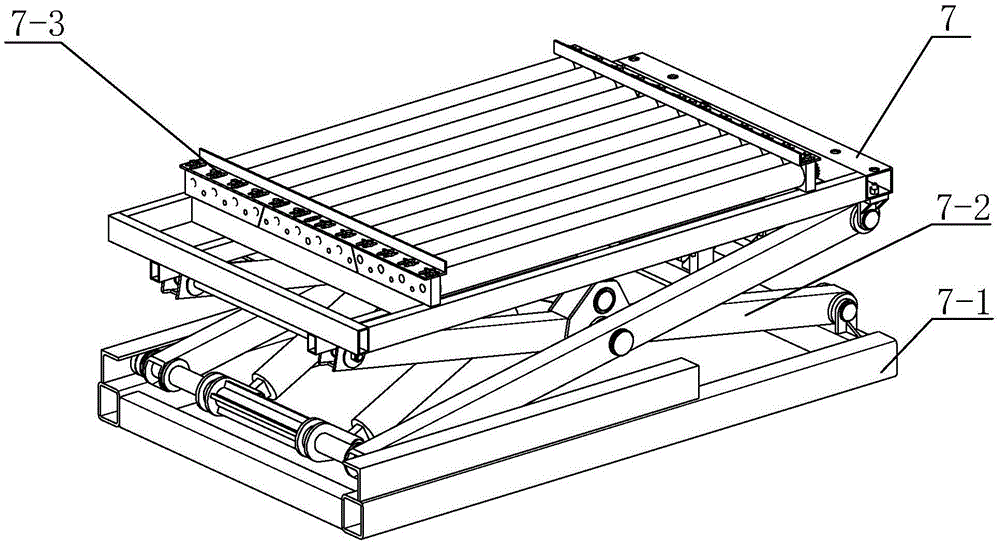

Tray-free packing method and tray-free packing device of brick stack

The invention discloses a tray-free packing method and a tray-free packing device of a brick stack. The tray-free packing device comprises a feeding machine, a clamping and transporting device, a cyclic conveying line, binding machines and a plurality of transfer trays; the feeding machine is arranged on a return track to complete the movement and positioning of a steaming-curing truck, and the return track runs through the clamping and transporting device; the cyclic conveying line is a closed rectangular annular cyclic conveying chain and comprises an empty-tray conveying chain-type conveyor belt, a secondary folding and clamping chain-type conveyor belt, an elevation and pushing mechanism, a primary binding chain-type conveyor belt, a secondary elevation and pushing mechanism, a secondary binding chain-type conveyor belt, a stack unloading chain-type conveyor belt, an empty-tray feeding chain-type conveyor belt and the a tray transportferring device; two binding machines respectively stretches across the primary binding chain-type conveyor belt and the secondary binding chain-type conveyor belt so as to bind the brick stack in the two mutually-vertical directions; and a transportferring tray is horizontally arranged on each station of the cyclic conveying line. Due to the adoption of the device, the production efficiency is greatly improved, and the labor intensity of workers is greatly alleviated.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

Polymeric void-board

InactiveUS6989184B2Consistent qualityConsistent consistencyStampsWrappersBrickMechanical engineering

An extruded polymeric void-board is configured for placement between adjacent horizontal layers of bricks to maintain an opening in a lower layer of the bricks. The void-board is formed as a relatively thin planar element having first and second surfaces. A plurality of parallel ribs extend from and generally transverse to the first side. The ribs have a predetermined height to width ratio and have a height that is less than a thickness of the planar element. The ribs being formed parallel to one another. A method for forming a bundle of bricks with the void-board is also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Full-automatic brick stack packing line and packing method

PendingCN109625488ACause wear and tearQuality improvementBuilding material packagingPackaging machinesNon destructiveBrick

The invention discloses a full-automatic brick stack packing line and packing method, and relates to the field of steam-cured brick packing. The full-automatic brick stack packing line comprises a brick discharging machine, a grouping conveying table, a brick stacking machine and a packing conveying table; the grouping conveying table comprises a chain type grouping table and a roller type grouping table, wherein the chain type grouping table and the roller type grouping table are arranged in the conveying direction and are perpendicularly arranged in the horizontal plane; and the packaging conveying table comprises a roller type conveying table and a chain type conveying table, wherein the roller type conveying table and the chain type conveying table are arranged in the conveying direction and are perpendicularly arranged in the horizontal plane, the roller type conveying table is provided with a first packing machine and the chain type conveying table is provided with a second packing machine. According to the full-automatic brick stack packing line, the technical problems that in the prior art, the arrangement mode of the packing line is single, and limitation of the installation site is large are solved; according to the brick stack packing method, the technical problems that in the prior art, the arrangement mode of the packing line is single, requirements on the installation site is high and the stability of the packing efficiency is poor; and the full-automatic brick stack packing line has the functions of brick stack regrouping and non-destructive turning and packing, so that the requirement on the performance of the packing machines is reduced.

Owner:潍坊路友建设机械有限公司

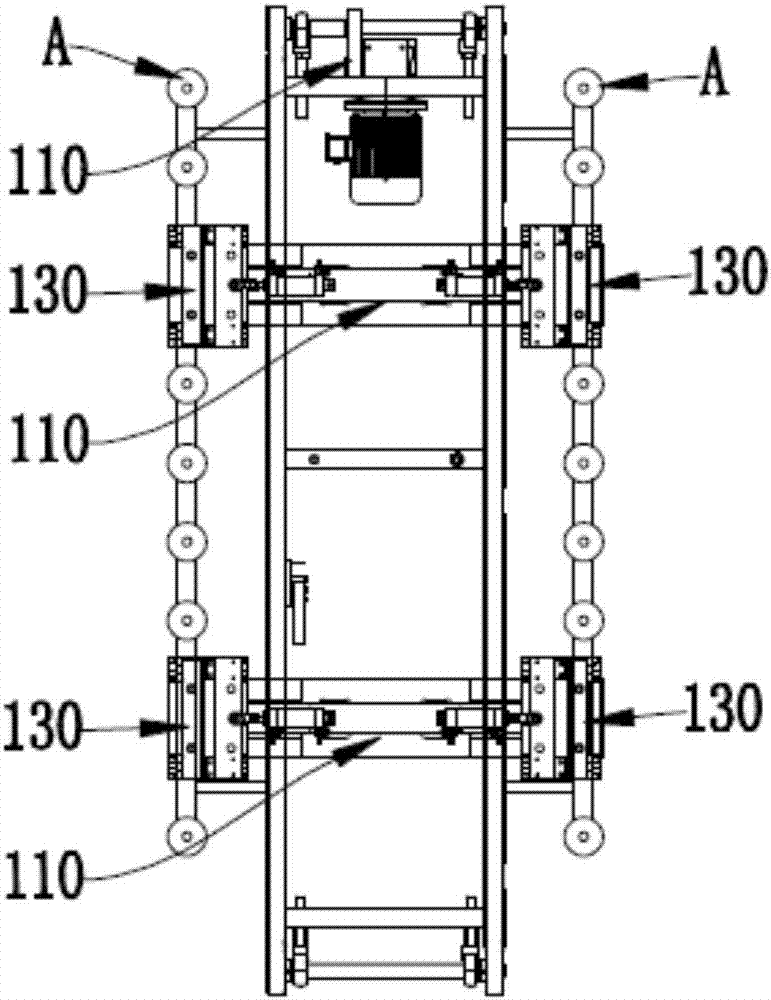

Brick stacker system

ActiveCN105480726AReduce labor intensityStableBuilding material packagingStacking articlesBrickEngineering

The invention discloses a brick stacker system. The brick stacker system comprises a rack, a conveyor, a brick pushing mechanism, two clamp trolleys, a lifting roller bed unit and a lifting rotating platform, wherein the conveyor is arranged at the lower part of the rack; the lifting roller bed unit is arranged right below the conveyor; the first clamp trolley is arranged at the upper part of the rack and located above the lifting roller bed unit; the brick pushing mechanism and the second clamp trolley are both arranged at the upper part of the rack and sequentially located in front of the first clamp trolley in the conveying direction; the lifting rotating platform is arranged below the second clamp trolley. Bricks on pallets are stacked through the conveyor, the brick pushing mechanism, the clamp trolleys, the lifting roller bed unit and the lifting rotating platform, an upper layer of bricks and a lower layer of bricks are stacked to form the cross-shaped brick stack structure through the lifting rotating platform, brick stacks are more stable and cannot collapse, and following loading and unloading are facilitated.

Owner:GUANGXI YIPIN INVESTMENT

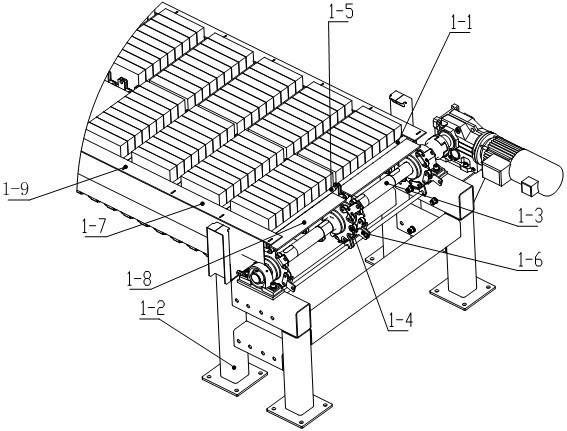

Ceramic tile flexible container bundling table

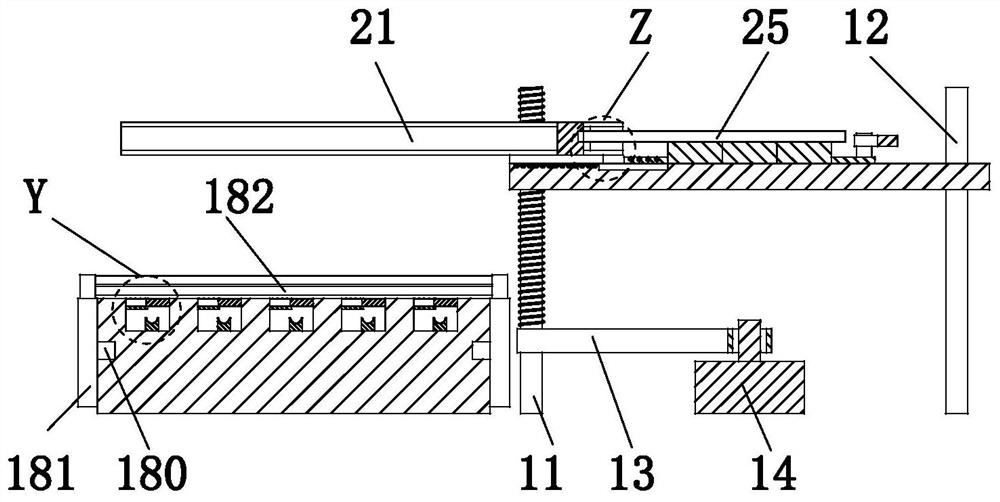

ActiveCN102700753AIncrease the number of palletizing layersWon't fallBuilding material packagingBundling machine detailsMotor driveEngineering

The invention discloses a ceramic tile flexible container bundling table, which comprises a rack, clamping devices, a translating device, a packer, a lifting device and a motor driving device, wherein the rack is provided with an outer guide rail and an inner guide rail and is provided with a pair of clamping devices; the clamping devices can be used for clamping ceramic tiles to move horizontally along with the inner guide rail; the translating device is arranged on the rack and can move horizontally along the outer guide rail; the lifting device is arranged in the translating device and is used for lifting the ceramic tiles clamped by the clamping devices; and the packer is arranged in the translating device and is used for bundling ceramic tile flexible containers lifted by the liftingdevice. The ceramic tile flexible container bundling table has the beneficial effects that a plurality of ceramic tile flexible containers are firmly bundled so as to be directly hoisted to a warehouse by a crane, the labor is saved and the efficiency is increased. Meanwhile, the bundle ceramic tile flexible container does not topple over during placement, the bearing capacity is increased, the layer of a ceramic tile stack can be greatly increased, the warehouse space is effectively utilized, and the storage cost of a ceramic tile production factory is greatly reduced.

Owner:南通市力达集装箱配件有限公司

Ceramic tile redundant binding method and binding machine

InactiveCN101948015AAchieve continuous operationShorten the timeBuilding material packagingShock-sensitive articlesProduction lineBrick

The invention discloses a ceramic tile redundant binding method. A device with independent binding function is additionally arranged on the conventional ceramic tile packaging and binding production line, so when one device fails binding ceramic tiles, the other device automatically starts for continuous work to realize continuous operation. The invention also discloses a binding machine, which comprises a frame, and a feeding device, binding devices, positioning and tile blocking devices and an electrical control system which are arranged on the frame, and is characterized in that: each binding device comprises two or more than two ring frames, machine cores and strip coils; and the positioning and tile blocking devices corresponding to the binding devices respectively consist of a front tile blocking mechanism and a rear tile blocking mechanism. The method and the device can realize simultaneous normal binding and simple breakdown maintenance, greatly reduce outage time, and have the advantages of convenience, quickness and high work efficiency.

Owner:GUANGDONG DEKE ROBOT TECH & EQUIP

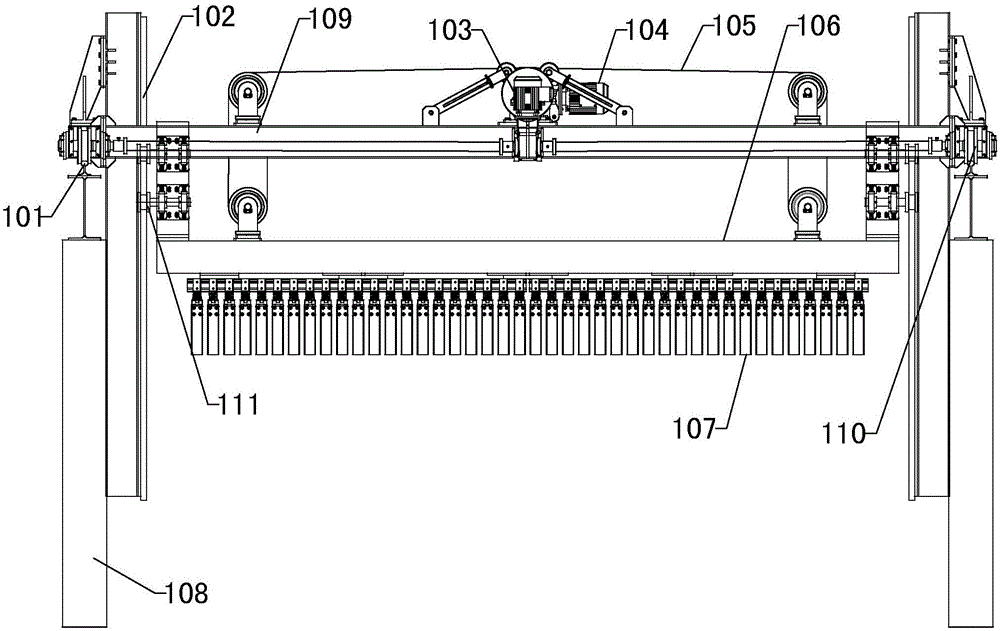

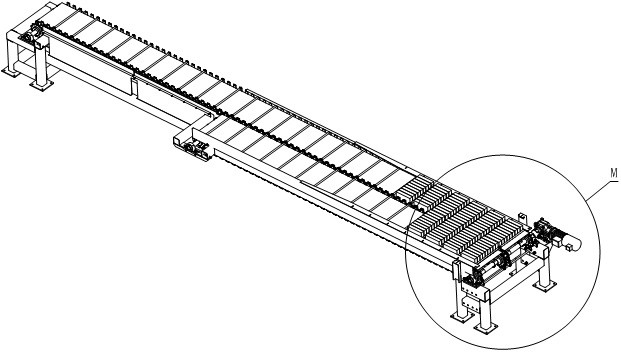

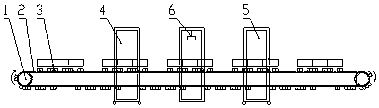

Brick automatically packing production line

InactiveCN104290954AEliminate back and forthIncrease profitBuilding material packagingShock-sensitive articlesProduction lineBrick

Disclosed is a brick automatically packing production line. The brick automatically packing production line comprises a circulatory feeding system, a brick pushing mechanism, a piled brick longitudinally packing system, a pile pushing mechanism, a piled brick transversely packing system and an automatic detection controlling system. The circulatory feeding system crosses over a plurality of brick carts and is arranged at the feeding end of the piled brick longitudinally packing system to feed brick materials to the longitudinally packing system; the brick pushing mechanism is used for pushing piled bricks on the circulatory feeding system onto the piled brick longitudinally packing system, is close to the feeding end of the piled brick longitudinally packing system and is arranged on the ring-shaped inner side of the circulatory feeding system; the piled brick longitudinally packing system is composed of a rolling carrier roller brick conveying mechanism and a packing head assembly, wherein the rolling carrier roller brick conveying mechanism is used for conveying the piled bricks through carrier rollers, and the packing head assembly comprises a guide unit, a lateral brick pressing unit and a packing head; the piled brick longitudinally packing system is used for longitudinally packing single-layer piled bricks to achieve grouping of the piled bricks; the pile pushing mechanism is used for pushing the longitudinally-packed piled bricks towards the piled brick transversely packing system and arranged on the side surface of the tail end of the piled brick longitudinally packing system; the piled brick transversely packing system is similar to the piled brick longitudinally packing system and is used for transversely packing the grouped piled bricks and arranged on the side surface of the tail end of the piled brick longitudinally packing system; the automatic detection controlling system is used for coordinating actions of all the parts.

Owner:XIANGTAN HUAKAI MACHINE MFG

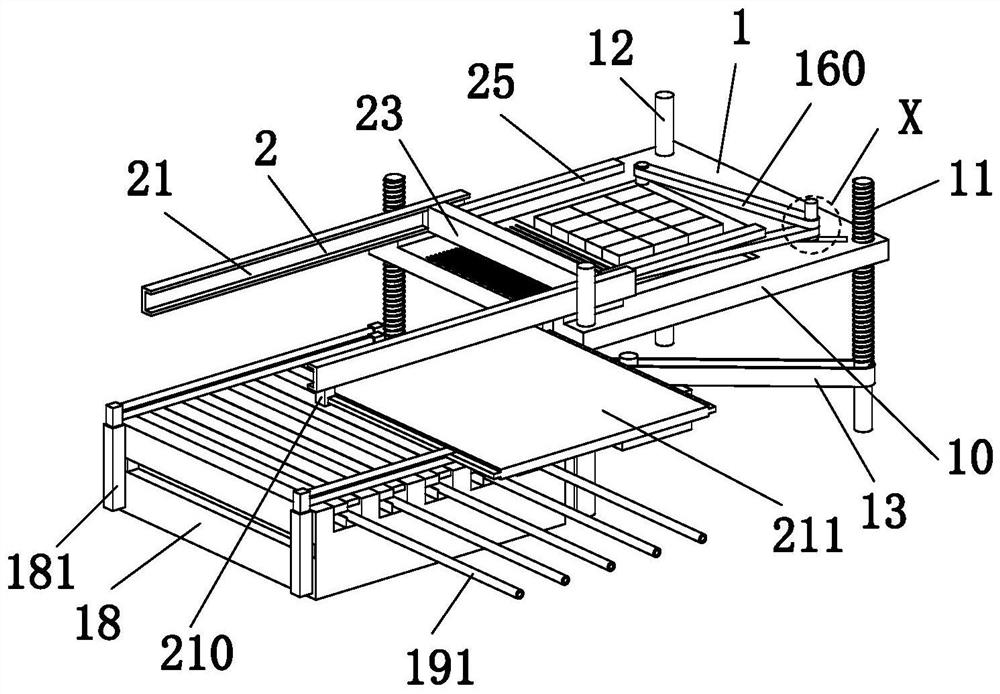

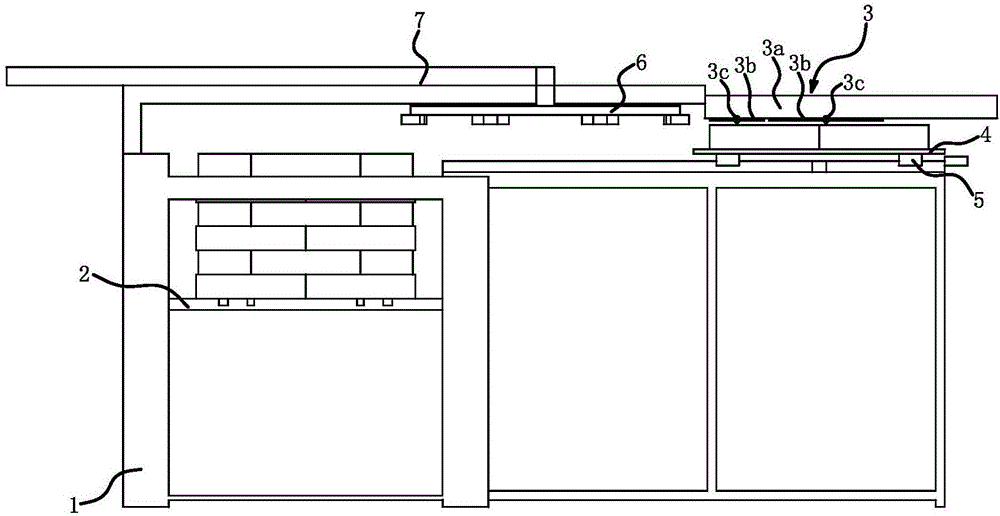

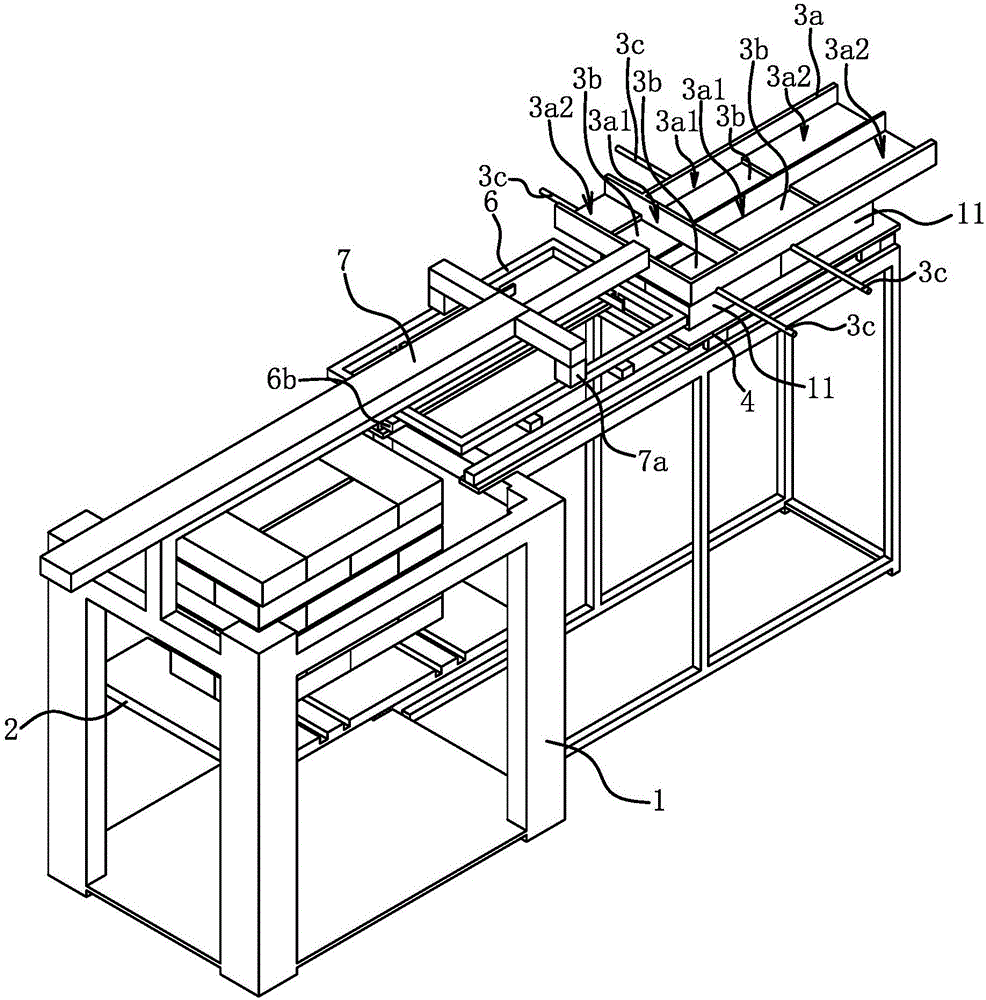

Packaging unit and packaging method of aerated concrete block

ActiveCN103538745ASimple structureEasy to operateBuilding material packagingEngineeringConveyor belt

The invention relates to a packaging unit and a packaging method of an aerated concrete block. The packaging unit comprises a transmission device, a lifting roller platform used for dividing stacks and steering, a packaging roller platform jointed with the lifting roller platform and a bundling machine arranged on a corresponding position of the packaging roller platform. Two parallel conveyor belts are arranged on the transmission device at intervals. The lifting roller platform is installed at the tail end of the transmission device and comprises a row of lifting carrier rollers which are parallel to the conveyor belts and can ascend and descend at the same time, wherein part of the lifting carrier rollers are located between the two conveyor belts and used for lifting up part of aerated concrete block stacks erected between the two conveyor belts, so that the part of the aerated concrete block stacks is separated from the rest of the aerated concrete block stacks. The part of the aerated concrete block stacks is conveyed to the packaging roller platform through the lifting roller platform. According to the packaging unit and the packaging method of the aerated concrete block, the packaging unit is used for packaging aerated concrete blocks without any pallet and the whole packaging unit is simple in structure and easy to operate and achieves fully-automatic mechanical production. The production efficiency is greatly improved and labor intensity of workers is reduced.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

Automatic packaging and producing line of tiles and implementation method thereof

ActiveCN105501510ASafety in transitRealize unmannedBuilding material packagingProduction lineConductor Coil

The invention provides an automatic packaging and production line of tiles. The automatic packaging and production line of the tiles successively comprises an automatic tile stacking mechanism, a primary bundling and conveying mechanism, a discharging and conveying mechanism, a secondary bundling and conveying mechanism, a mechanical arm stacking mechanism, a third bundling and conveying mechanism and a winding and film-coating mechanism. The automatic packaging and production line is used for bundling the tiles for three times and coating films; the conventional mode of boxing and selling by only packaging for one time is replaced, so that the package is more reliable; the tiles are safer in the transporting process; the unmanned operation of the tile packaging line can be achieved; the labor resource is saved; the enterprise competitiveness is improved. The invention also provides an implementation method of the automatic packaging and production line of the tiles. The automatic packaging and production line can be used for packaging and producing the tiles.

Owner:FOSHAN CLEV ROBOT

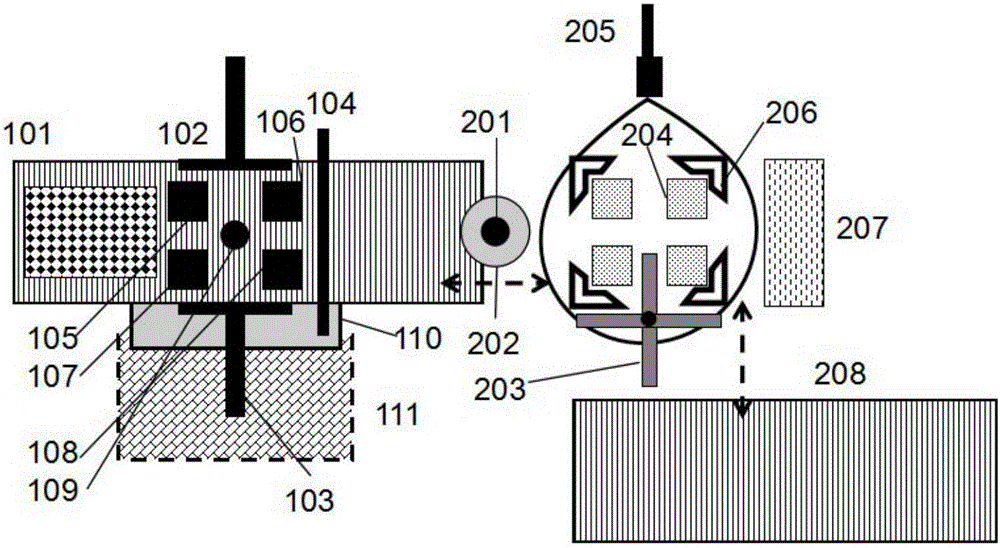

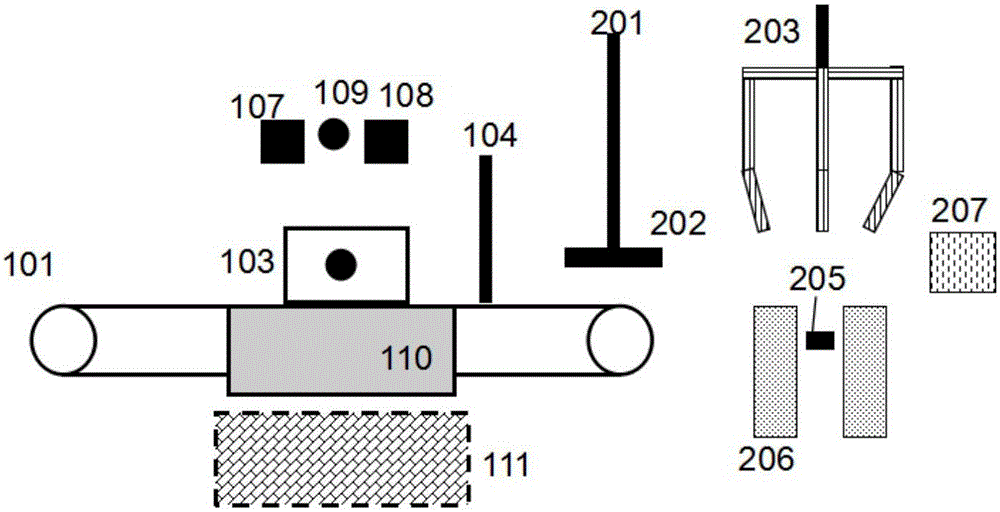

Ceramic tile packaging method capable of automatically detecting flatness of ceramic tiles

ActiveCN106743524AAutomate the packaging processConveyorsBuilding material packagingMetallurgyMaterial resources

The invention discloses a ceramic tile packaging method capable of automatically detecting the flatness of ceramic tiles and belongs to the field of automatic package. Ceramic tile packaging equipment capable of automatically detecting the flatness of the ceramic tiles is adopted to package the ceramic tiles while automatically detecting the flatness of the ceramic tiles, and the ceramic tile packaging equipment comprises a ceramic tile flatness detection system (1), a ceramic tile packaging system (2) and a central control host. Distance detectors are adopted to detect the flatness of the ceramic tiles, and a sucker and a manipulator are adopted to pack the ceramic tiles, so that stacking package of the ceramic tiles can be performed while the flatness of the ceramic tiles is automatically detected, and accordingly, lots of manpower and material resources are saved.

Owner:SUZHOU YUNSHOU SOFTWARE TECH CO LTD

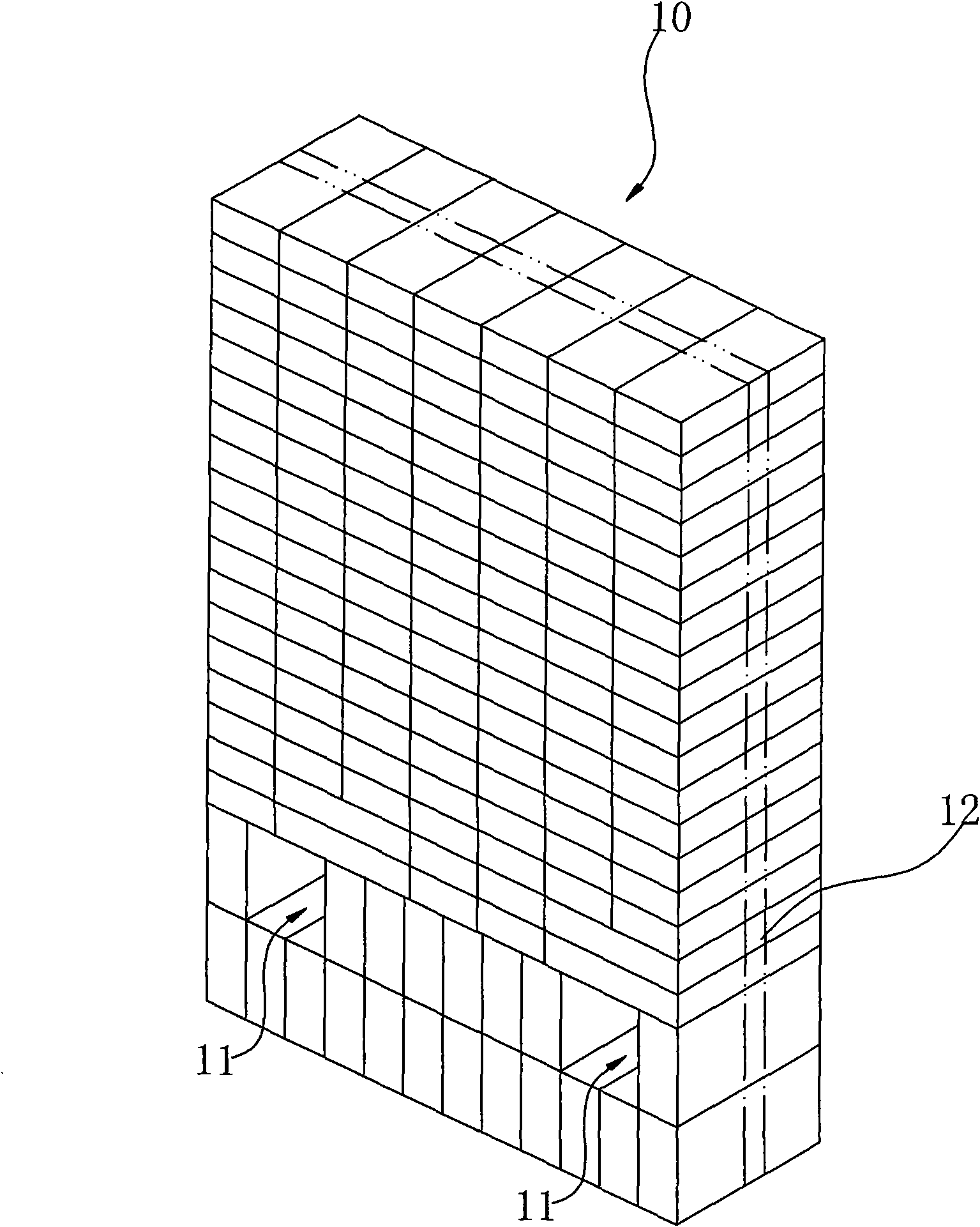

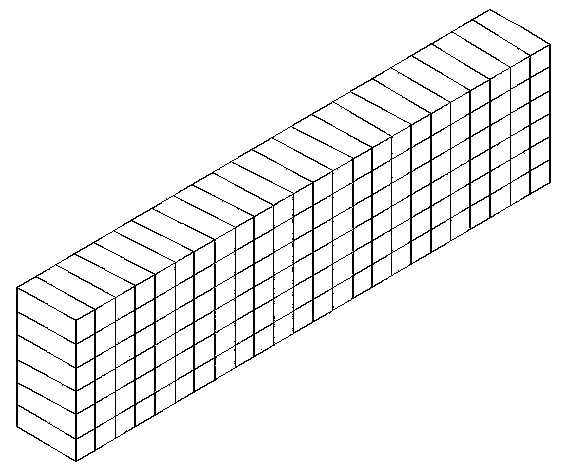

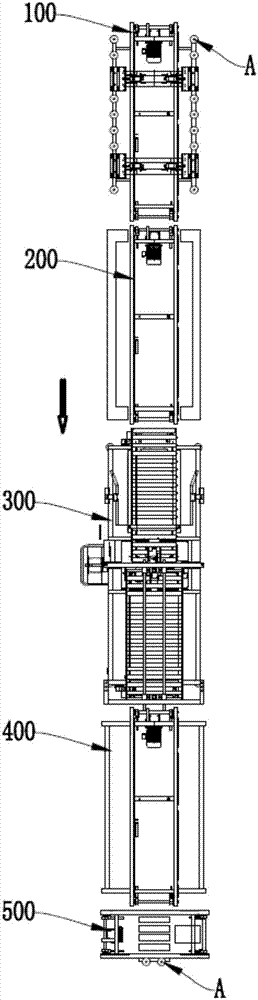

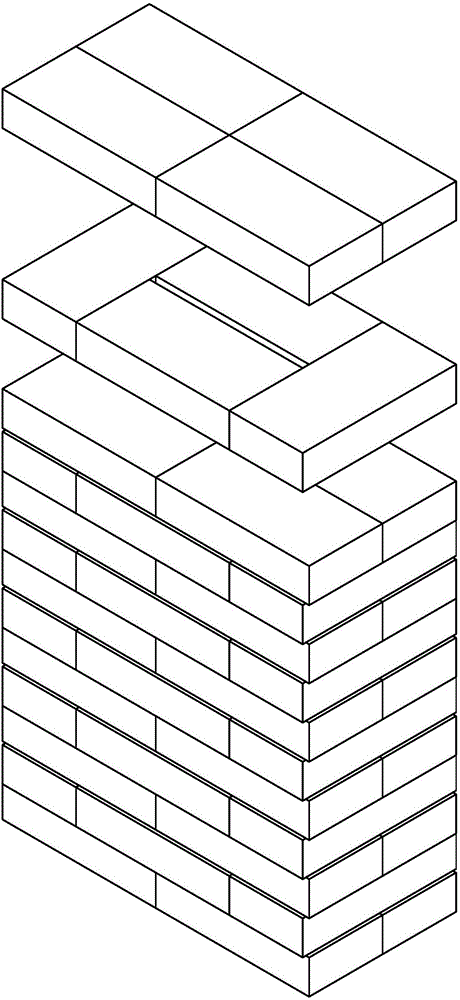

Brick stacking and packaging system and brick row placing and conveying method

InactiveCN112224513AMeets requirements for accurate insertion into forklift holesImprove operational convenienceBuilding material packagingWeb rotation wrappingBrickStructural engineering

The invention provides a brick stacking and packaging system and a brick row placing and conveying method. According to the brick row placing and conveying method, a brick stack formed by stacking comprises a brick layers, each brick layer comprises b brick rows, each brick row comprises m or n bricks, and m is larger than n. The brick row placing and conveying method comprises the steps of: for the brick rows conveyed by a conveying line, placing n bricks in each row of b brick rows in the brick layer used for forming forklift holes; placing m bricks in each row of b brick rows in the rest ofbrick layers; and after a brick layers are stacked to form the brick stack, forming forklift holes in the corresponding brick layers where n bricks are placed in each row. The requirement for large forklift holes is met by placing different numbers of bricks in the brick conveying process, and therefore a forklift can conveniently and accurately insert the holes.

Owner:QINGDAO FANRONG DA TECH CO LTD

Packaging method and packaging assembly line for ceramic sheets

ActiveCN107054737AJust the right stiffnessIncrease stiffnessBuilding material packagingWrapper folding/bending apparatusPaperboardCeramic materials

The invention provides a packaging method and packaging assembly line for ceramic sheets. The packaging method for ceramic sheets comprises the steps of (1) stacking of ceramic sheets, specifically, three or more ceramic sheets are stacked, and thus multiple ceramic sheets are stacked; (2) packaging of the ceramic sheets, specifically, packaging paperboards are placed at the bottoms of the two sides of the ceramic sheets, and the packaging paperboards are folded so as to package the two sides of the stacked ceramic sheets; (3) binding of the packaging paperboards, specifically, the packaged ceramic sheets are conveyed to a packing device, and the packaging paperboards packaging the two sides of the ceramic sheets are bound through the packing device; (4) turning of the packed ceramic packages, specifically, the packed ceramic packages are turned, so that the bottom surfaces of the ceramic packages are in contact, and the upper surfaces of the ceramic packages are in contact; and (5) stacking of the packed ceramic packages, specifically, the packed ceramic packages are rectangular, and the packed ceramic packages are erected through a stack supporting device and then conveyed to a supporting frame after being conveyed to the stack supporting device. By adoption of the method and device, packaging can be completed without manual work.

Owner:GUANGDONG SINID TECH

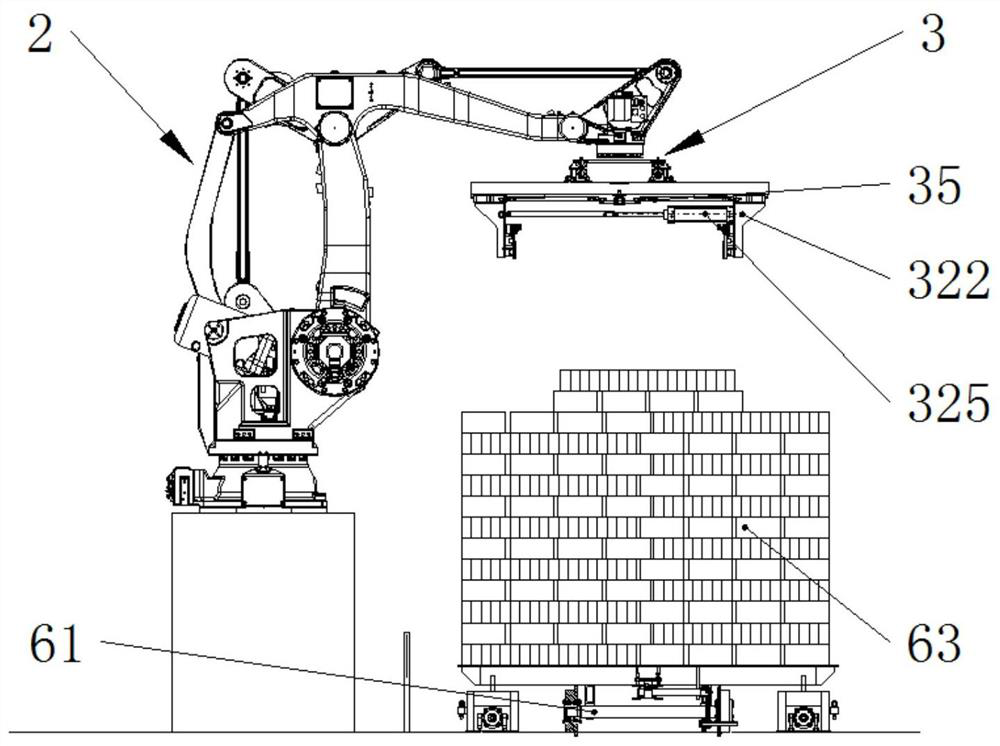

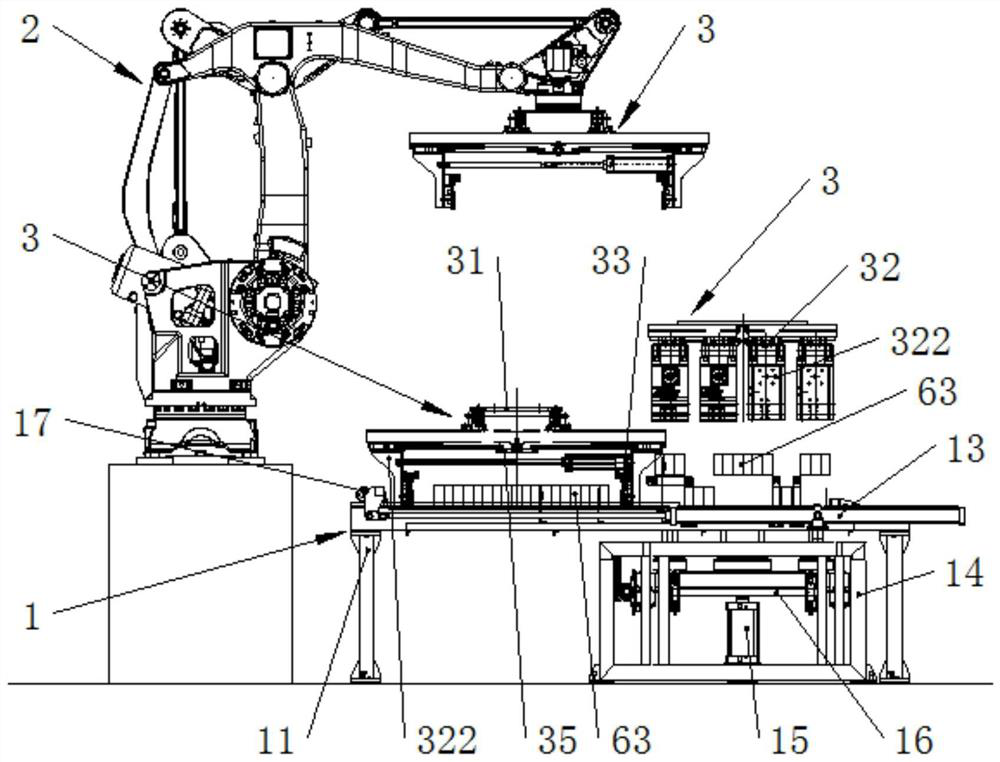

Automatic brick packaging system and packaging method thereof

PendingCN112124686AFlexible and compact layoutGuaranteed uptimeBuilding material packagingBundling machine detailsBrickRobot hand

The invention relates to an automatic brick packaging system and a packaging method thereof. The automatic brick packaging system comprises a brick separating machine, an industrial robot, a stackingmechanical arm rotatably fixed to a mechanical arm of the industrial robot, a rotary disc device, an automatic packaging machine, a blank vehicle and a forklift. Bricks are placed on the blank vehicle, the brick separating machine is used for separating joints of the bricks, forklift hole sites are reserved, the stacking mechanical arm can clamp the bricks and close up gaps between the bricks, thestacking mechanical arm can move the bricks on the blank vehicle to the brick separating machine or the rotary disc device, or move the bricks with the reserved forklift hole sites on the brick separating machine to the rotary disc device, the rotary disc device can rotate by 90 degrees, and brick stacks formed after the bricks are stacked can be packaged from two faces conveniently. The automatic packaging machine is used for packaging the brick stacks on the rotary disc device, and the forklift is used for transferring the packaged brick stacks.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

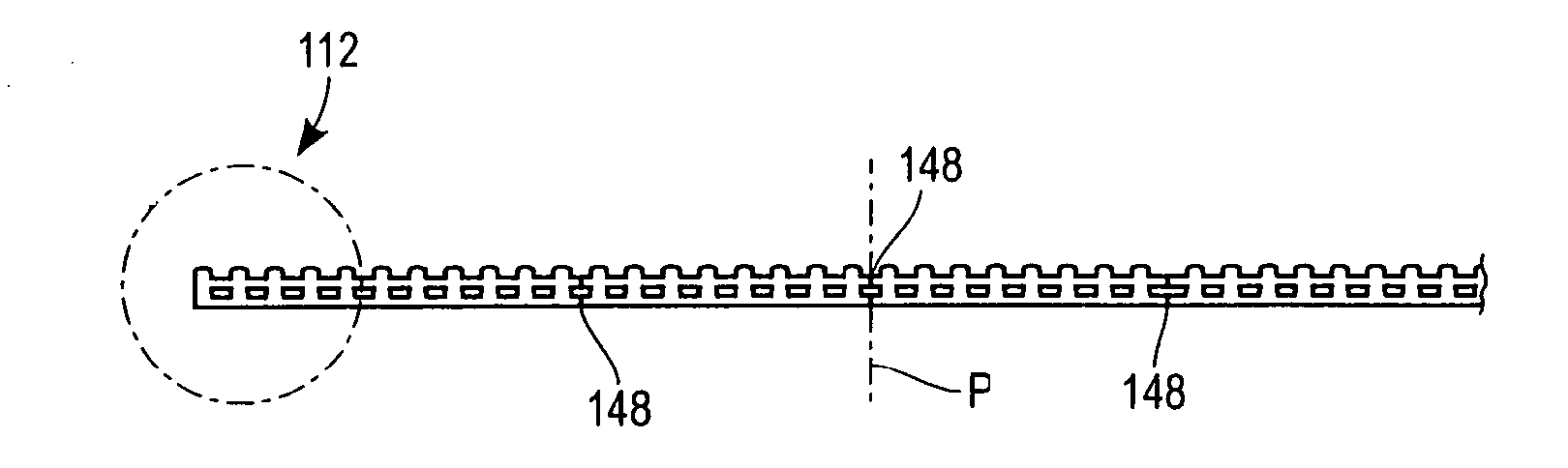

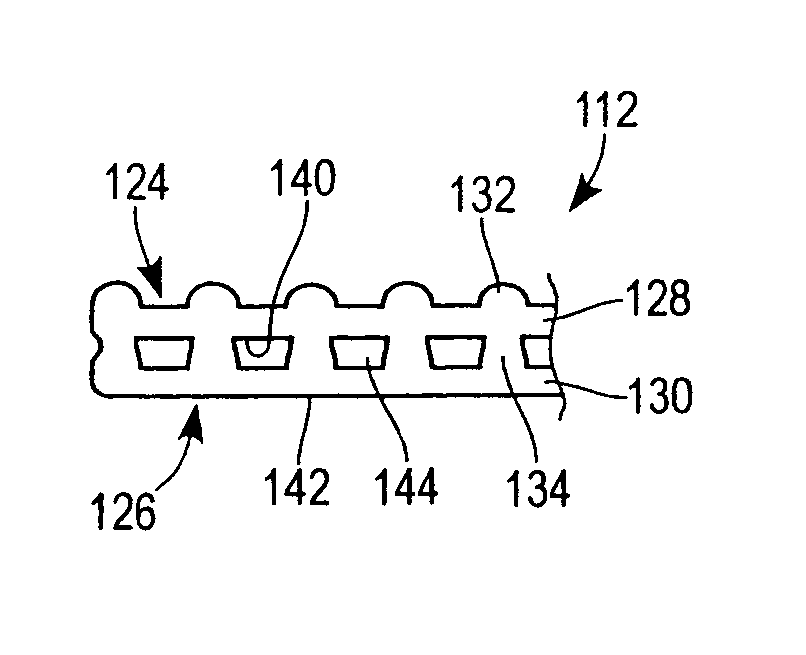

Corrugated polymeric void board

A polymeric void-board is placed between adjacent horizontal layers of bricks to maintain an opening in a lower of the layers. The void-board is fabricated from a first relatively thin planar element having first and second surfaces having a plurality of parallel ribs extending from and generally transverse to the first surface and a second relatively thin planar element having first and second surfaces having a plurality of parallel ribs extending from and generally transverse to the first surface. The first and second elements are joined to one another with the ribs of the first element engaging and joined to the second element.

Owner:SIGNODE IND GRP

Corrugated polymeric void board

A polymeric void-board is placed between adjacent horizontal layers of bricks to maintain an opening in a lower of the layers. The void-board is fabricated from a first relatively thin planar element having first and second surfaces having a plurality of parallel ribs extending from and generally transverse to the first surface and a second relatively thin planar element having first and second surfaces having a plurality of parallel ribs extending from and generally transverse to the first surface. The first and second elements are joined to one another with the ribs of the first element engaging and joined to the second element.

Owner:SIGNODE IND GRP

Finished brick grouping device and method

PendingCN109625487AReduce dependenceMarshallingBuilding material packagingPackaging machinesWork rollBrick

The invention discloses a finished brick grouping device and method and relates to the field of autoclaved brick packaging. The finished brick grouping device comprises a chain type grouping line anda roll type grouping line. The chain type grouping line sequentially comprises a temporary storage chain table, a working chain table, a sub matrix chain table and a matrix storage chain table in theconveying direction. A lifting platform is arranged below an end point of the working chain table and can move upwards to pass through a chain belt gap of the working chain table. The sub matrix chaintable is provided with a brick barrier mechanism. The roll type grouping line sequentially comprises a lifting roll table, a temporary roll table, a working roll table and a brick picking roll tablein the conveying direction. The lifting roll table is located below the matrix storage chain table and can move upwards to pass through a chain belt gap of the matrix storage chain table. The workingroll table is provided with a first photoelectric detection switch. By means of the finished brick grouping device, the problem that the line numbers of pressed bricks produced through a hydraulic brick machine are not consistent, so that automatic packaging is difficult to conduct subsequently is solved; original brick stacks can be regrouped according to the packaging requirement; and dependenceon the hydraulic brick machine and the specification of a packaging line is lowered.

Owner:潍坊路友建设机械有限公司

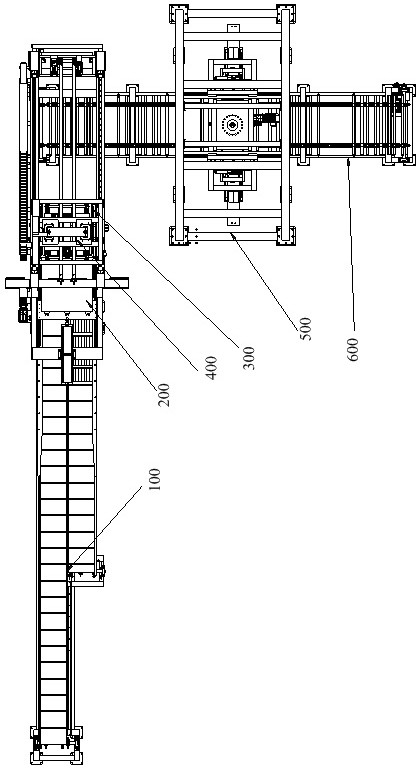

Tray-free packaging equipment for autoclaved aerated concrete blocks

ActiveCN111907779AGuarantee the degree of stabilityPlay limitBuilding material packagingTransfer mechanismAutoclaved aerated concrete

The invention relates to tray-free packaging equipment for autoclaved aerated concrete blocks. The tray-free packaging equipment comprises a stacking mechanism and a transferring mechanism, the lowerend of the stacking mechanism is installed on the existing working ground, and the transferring mechanism is arranged at the upper end of the stacking mechanism. The tray-free packing equipment for the autoclaved aerated concrete blocks adopts the design concept that a single layer is matched with a stacking structure step by step for tray-free packing of the autoclaved aerated concrete blocks, the stacking mechanism and the transferring mechanism are matched to realize single-layer arrangement and overall transportation of the bricks and stacking operation taking the single layer as a cardinal number, so that the overall working efficiency is improved; and the stacking mechanism can achieve the limiting and shape fixing effects on the single-layer bricks, meanwhile an external fixing structure is arranged, so that the overall stability degree in the brick stacking process can be guaranteed.

Owner:安徽阜阳富龙建筑材料有限责任公司

Ceramic sheet packaging assembly line

ActiveCN106864889AAvoid breakingNot easy to transportConveyorsBuilding material packagingAssembly lineEngineering

Disclosed is a ceramic sheet packaging assembly line. The ceramic sheet packaging assembly line comprises a jacking sheet laminating device, a packaging device, a bundling device, a bag overturning device and a stacking device which are connected in sequence. The jacking sheet laminating device comprises a first twin-belt conveyor. The first twin-belt conveyor is provided with a sheet laminating jacking device and at least two sets of clamping mechanisms. The sheet laminating jacking device is installed between conveying belts of the first twin-belt conveyor. The sheet laminating jacking device comprises a jacking cylinder and a jacking platform arranged at the working end of the jacking cylinder. The two sides of the jacking platform are both provided with the corresponding clamping mechanisms. The jacking platform is located inside belt circles of the conveying belts, and the clamping mechanisms are located on the outer sides of the conveying belts. According to the ceramic sheet packaging assembly line, the five devices are adopted to achieve five functions in packaging altogether, a plurality of ceramic sheets are bundled together, the bundled ceramic sheets have certain internal force and cannot be pressed to be broken or cracked easily, and transportation is facilitated.

Owner:GUANGDONG SINID TECH

Full-automatic packing method and device capable of achieving brick stacking and reserving forklift holes

PendingCN110203443ANot easy to stackEasy to transportBuilding material packagingBundling machine detailsPacking methodMechanical engineering

The invention relates to a full-automatic packing method and device capable of achieving brick stacking and reserving forklift holes. A first grabbing clamp is used for grabbing at least two layers ofgreen bricks from a stacked brick stack, and the green bricks are placed on a first conveying device; a second grabbing clamp is used for taking two rows or two columns of green bricks along the intervals from the green bricks at the uppermost layer on the first conveying device; a plurality of layers of green bricks remaining are grabbed by the first grabbing clamp and placed above the green bricks of the first conveying device; a third grabbing clamp is used for closing gaps of the brick stack; the third grabbing clamp is used for grabbing the spliced brick stack onto a second conveying device, a bundling device is used for carrying out first bundling, and after the first bundling is finished, the first bundled brick stack is grabbed by the third grabbing clamp to rotate by 90 degrees,and bundling is carried out for the second time by the bundling device; and a forklift is used, two forklift arms of the forklift are inserted into the reserved forklift holes, and transportation is carried out. According to the device, the automatic packing and brick stacking can be automatically achieved, the forklift holes can be reserved, and meanwhile, the brick stack is stable in transportation and not prone to collapsing.

Owner:河南省机械院机械装备股份有限公司

Stacking assembly line

PendingCN111017523AHigh degree of automationIncrease productivityBuilding material packagingStacking articlesCartAssembly line

The invention discloses a stacking assembly line, and belongs to the technical field of brick making equipment. The stacking assembly line comprises a first conveying line, a clamping and conveying mechanism, an itemized conveying mechanism, a rotatable clamping and conveying mechanism, a longitudinal packing and conveying line, a corner conveying mechanism and a horizontal packing and conveying line, wherein the first conveying line comprises a main body frame, a pile pushing mechanism, a clamping and positioning device and a cart outlet guide rail; the main body frame is a fifth rectangularframework; and an upper guide rail and a lower guide rail are fixedly mounted on a left beam and a right beam of the fifth rectangular framework. According to the stacking assembly line disclosed by the invention, the stacking production line combines machines with a procedure, manual operations are replaced with the machines, so that after piled bricks with a cart are put on an assembly line andare operated by the assembly line, the piled bricks which can be directly transported by a forklift and do not have supporting plates can be produced, the automation degree is high, the production efficiency is high, the stacking assembly line only needs 2-3 people to operate, and labor cost is low.

Owner:广东昂锐机械制造有限公司

Production line capable of separating building blocks and supporting plates and stacking building blocks

PendingCN111422412AAvoid damageAchieve shapingBuilding material packagingProduction lineArchitectural engineering

The invention discloses a production line capable of separating building blocks and supporting plates and stacking building blocks. The production line comprises a building block and supporting plateseparation system, a building block stacking system and a control device. The building block and supporting plate separation system comprises a building block and supporting plate separation system rack, a gabbing plate mechanism mounted on the building block and supporting plate separation system rack and capable of ascending and descending, a third pushing device capable of moving front and backand ascending and descending, a movable supporting plate mechanism, a shaping mechanism, a plate stack conveying device, a building block conveying roller set and a building block and plate conveyingdevice. The production line can achieve automatic separating and stacking of separating building blocks and supporting plates and has the advantages of being small in damage to building blocks, efficient in stacking and the like.

Owner:山东川利机械有限公司

Pallet-free building block stacking and packaging assembly line

PendingCN113443195ACutting costsImprove production efficiencyBuilding material packagingBundling machine detailsAssembly linePallet

The invention innovatively provides a pallet-free building block stacking and packaging assembly line. The pallet-free building block stacking and packaging assembly line comprises a building block transferring lifting appliance, a dual-mode conveying device, a building block rotating lifting appliance and a pallet circulating conveying device. The building block rotating lifting appliance is used for transferring double rows of building blocks on the dual-mode conveying device to pallets of the pallet circulating conveying device. The assembly line is characterized in that a building block arranging and stacking device is arranged on one side of the tray circulating conveying device, and the building block arranging and stacking device comprises a building block clamping and conveying mechanism and a building block stacking mechanism. According to the pallet-free building block stacking and packaging assembly line, pallet-free bundling and packaging can be achieved, so that unnecessary expenditure is greatly saved, and production benefits are improved.

Owner:浙江瑞港机械有限公司

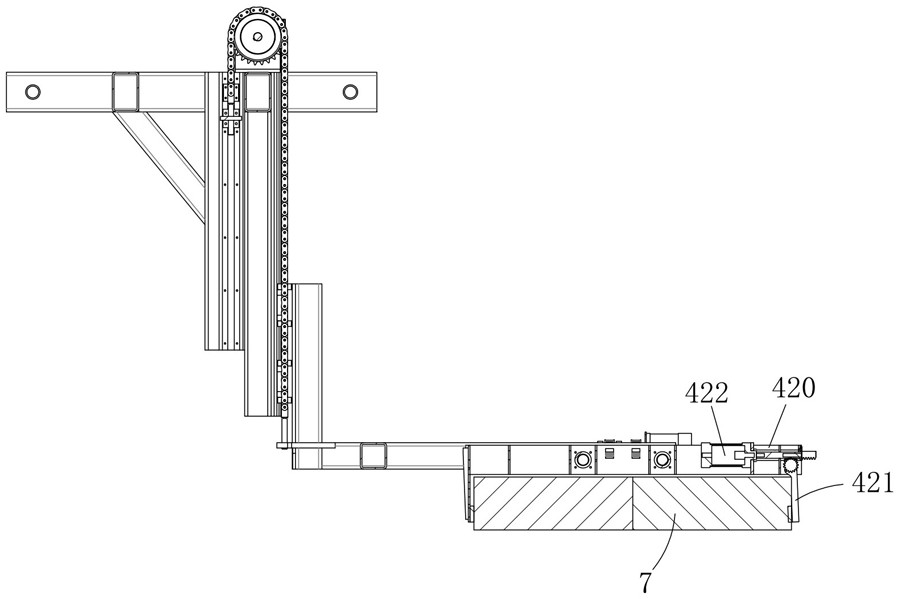

Movable type inclined jacking and bundling equipment, system and method

PendingCN113800032ACompact structureSimple compositionBuilding material packagingBinding material applicationLogistics managementMovable type

The invention discloses movable type inclined jacking and bundling equipment which comprises a bundling device and a turnover device. The invention further discloses a movable type inclined jacking and bundling system which comprises an automatic pallet warehouse, bag stacking equipment, logistics conveying equipment and the movable type inclined jacking and bundling equipment. The invention further discloses a movable type inclined jacking and bundling method. The movable type inclined jacking and bundling method comprises the following steps that a pallet is arranged; an overturning frame rotates; to-be-bundled objects are obliquely placed; bundling is carried out; the bundled objects are turned over; and the bundled objects are conveyed. The movable type inclined jacking and bundling equipment, system and method have the beneficial effects that the movable type inclined jacking and bundling equipment has the advantage of being compact in structure, a single-line or multi-line bundling logistics conveying intelligent system of a whole factory can be formed on a logistics conveying line, a multi-line bundling logistics conveying intelligent system can be conveniently formed, the function of bundling operation of horizontal stacking and vertical stacking of various specifications can be achieved, the automatic conveying efficiency can be improved, and the operation efficiency is high.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Tray-free operation mechanism for brick stack packaging

The invention discloses a tray-free operation mechanism for brick stack packaging. The tray-free operation mechanism comprises a rack, a circulation chain, stack loading components, a stack rotating front packaging component, a stack rotating rear packaging component and a stack rotating component and is characterized in that the circulation chain performs stepping circulation motions on the rack,the stack loading components are equationally installed on the circulation chain at a certain distance, formed by horizontal flexible connection combination of a plurality of branch section bars andcapable of performing corresponding combination according to different brick types and stack types, and spaces between the adjacent section bars facilitate passing of a packaging strap; the stack rotating front packaging component, the stack rotating rear packaging component and the stack rotating component are installed on the rack at appropriate separation distances to perform own correspondingmotions independently; the stack loading components are hinged to the circulation chain together to perform stepping type motions, complex actions of tray loading, tray unloading, tray moving and trayreturning are omitted, time is effectively saved, the production quantity is increased, meanwhile, the fabrication maintenance cost is lowered, and the equipment failure rate is reduced; in addition,the stack loading components can be reassembled according to the different brick types, and requirements for the different brick types and stack types are simply and quickly met; and meanwhile, the stack rotating front packaging component, the stack rotating rear packaging component and the stack rotating component can be installed with the rack together being taken as independent parts, and whole machine components are concise and compact in structure and easy to maintain and install.

Owner:SHANDONG JUXIANG MACHINERY

Brick stacking device, method for controlling arrangement manner of stacked bricks and brick stacking machine

ActiveCN106697964AReduce the amount of damageReduce shipping costsBuilding material packagingBinding material applicationBrickEngineering

The invention provides a brick stacking device, a method for controlling an arrangement manner of stacked bricks and a brick stacking machine and belongs to the technical field of operation. The brick stacking device solves the problem that due to the fact that existing bricks are stacked manually, labor intensity is high. The brick stacking device comprises a temporary brick storing platform and a brick bearing part. Three temporary brick storing holes are formed in the temporary brick storing platform. The two temporary brick storing holes are parallel and are formed adjacently, and the other temporary brick storing hole is perpendicular to the other two temporary brick storing holes and formed adjacent to the other two temporary brick storing holes. Bottom plates are arranged on the bottoms of the temporary brick storing holes correspondingly. The temporary brick storing platform is provided with a brick placing execution part which enables the bottom plates to be moved horizontally and slide. The brick bearing part is located right below the temporary brick storing holes. The brick storing device is suitable for the odd layer arrangement manner of the stacked bricks and the even layer arrangement manner of the stacked bricks, and therefore has the beneficial effect of high universality. The brick stacking machine remarkably improves the stacking efficiency and remarkably reduces labor.

Owner:TAIZHOU VOCATIONAL & TECHN COLLEGE

Enhanced void board

An enhanced polymeric void board for placement between adjacent horizontal layers of masonry materials to maintain an opening in a lower of the layers, the enhanced void board comprising a relatively thin planar element having a plurality of ribs extending along the length of the planar element and a plurality of holes through the planar element.

Owner:ILLINOIS TOOL WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com