Full-automatic brick stack packing line and packing method

A fully automatic, brick stacking technology, used in packaging, packaging machines, building materials packaging, etc., can solve the problems of single packaging line layout, poor packaging efficiency and stability, and large installation site requirements, and achieves diversified station combination. The effect of improving quality and efficiency, reducing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, further elaborate the present invention.

[0032] The orientations involved in this manual are all based on the orientation of the automatic brick stacking and packaging line when it is working normally, and do not limit its orientation during storage and transportation. It only represents a relative positional relationship, not an absolute positional relationship.

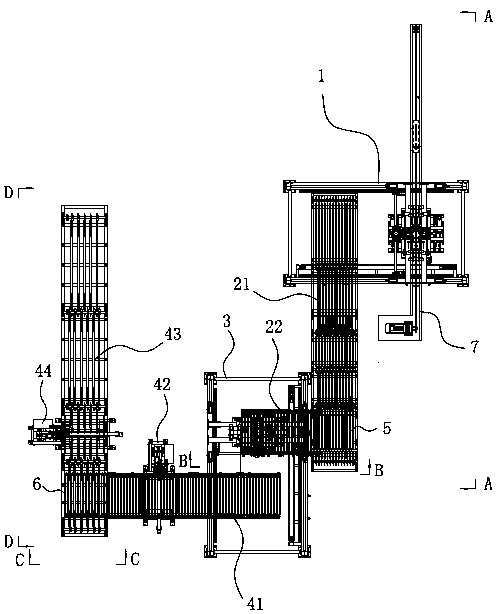

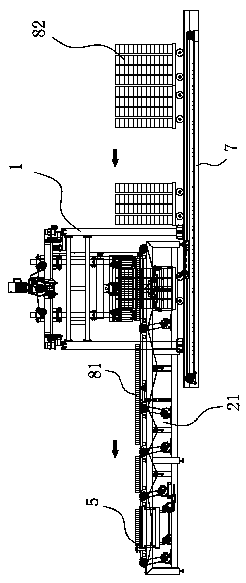

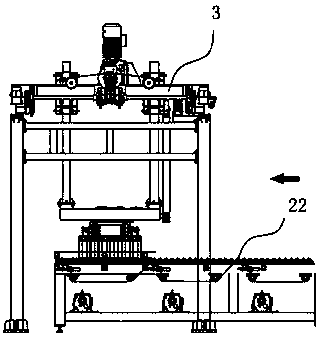

[0033] Such as figure 1 As shown, a fully automatic brick stack packaging line includes a brick unloading machine 1, a marshalling conveyor, a brick coder 3, and a packing conveyor. The brick unloader 1 disassembles the original brick stack 83 on the marshalling conveyor, The conveyor table regroups the single-layer bricks 81, and the brick coder 3 codes the reorganized single-layer bricks 81 into new brick piles 83, and then enters the packing conveyor table for packing.

[0034] Such as figure 1 and figure 2 Commonly shown, the marshalling conveyor table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com