Patents

Literature

92results about How to "Be at ease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

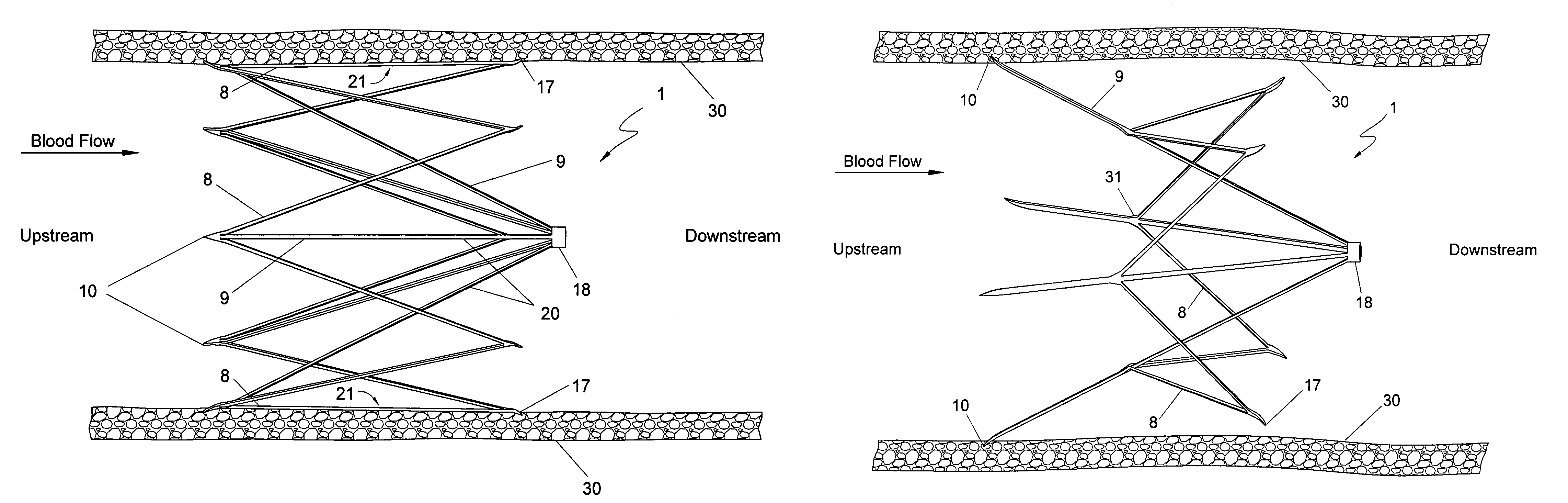

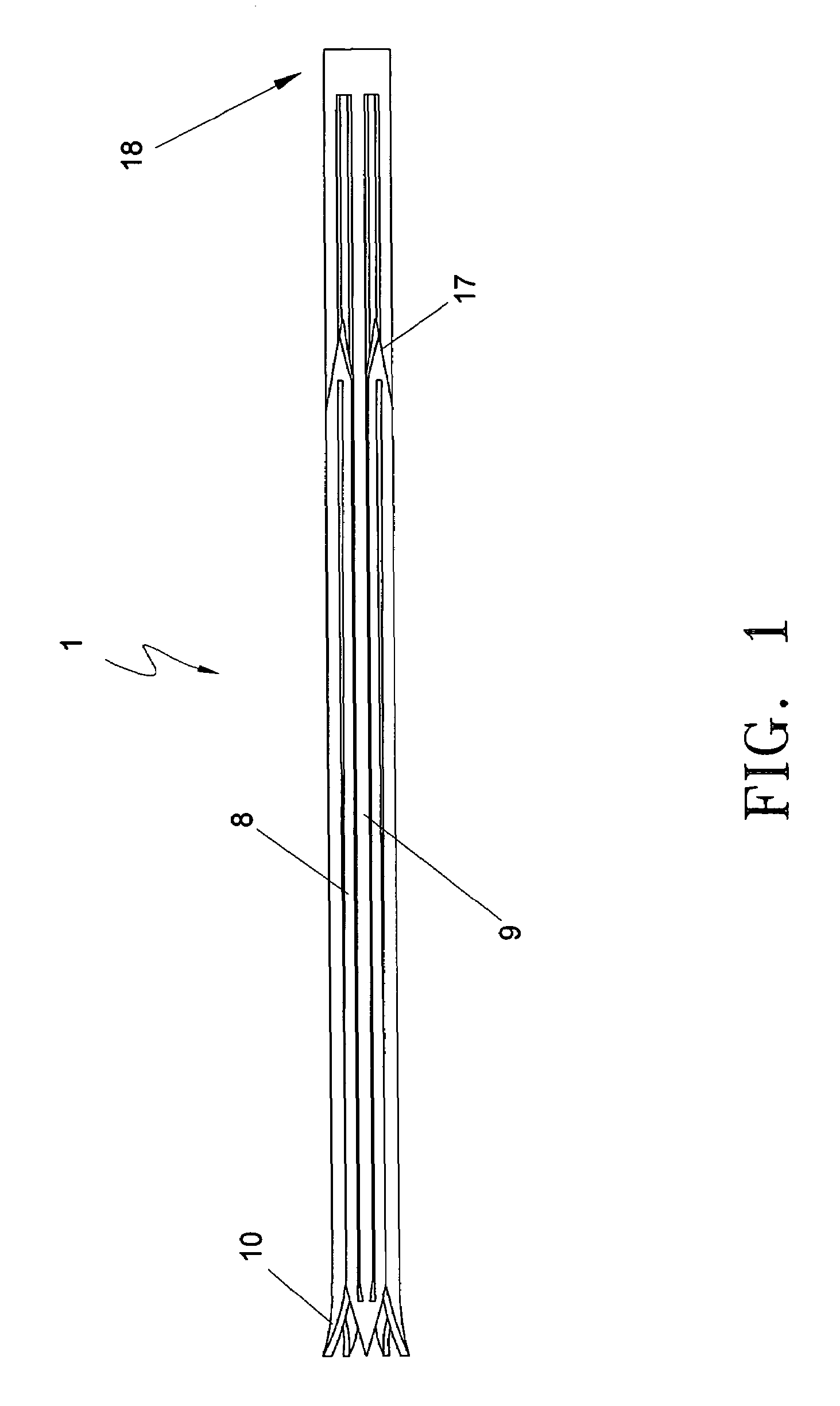

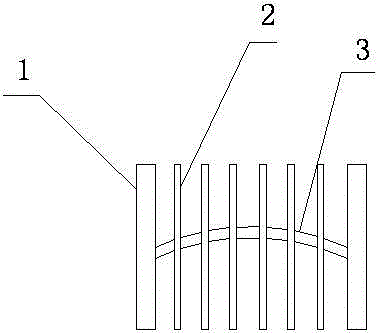

Blood clot filter

InactiveUS20050288703A1Be at easeImproves Structural IntegritySurgeryDilatorsEngineeringStructural integrity

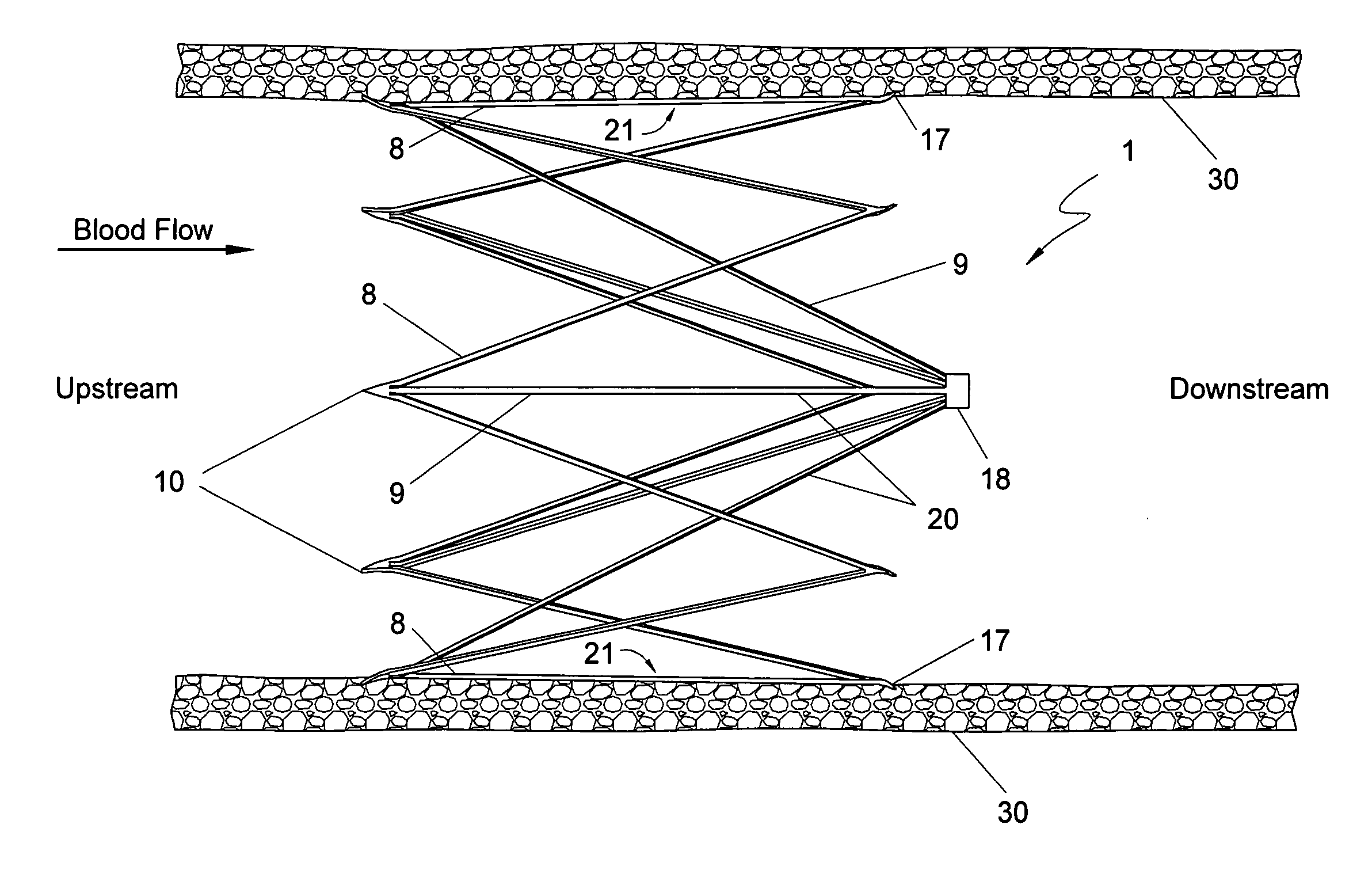

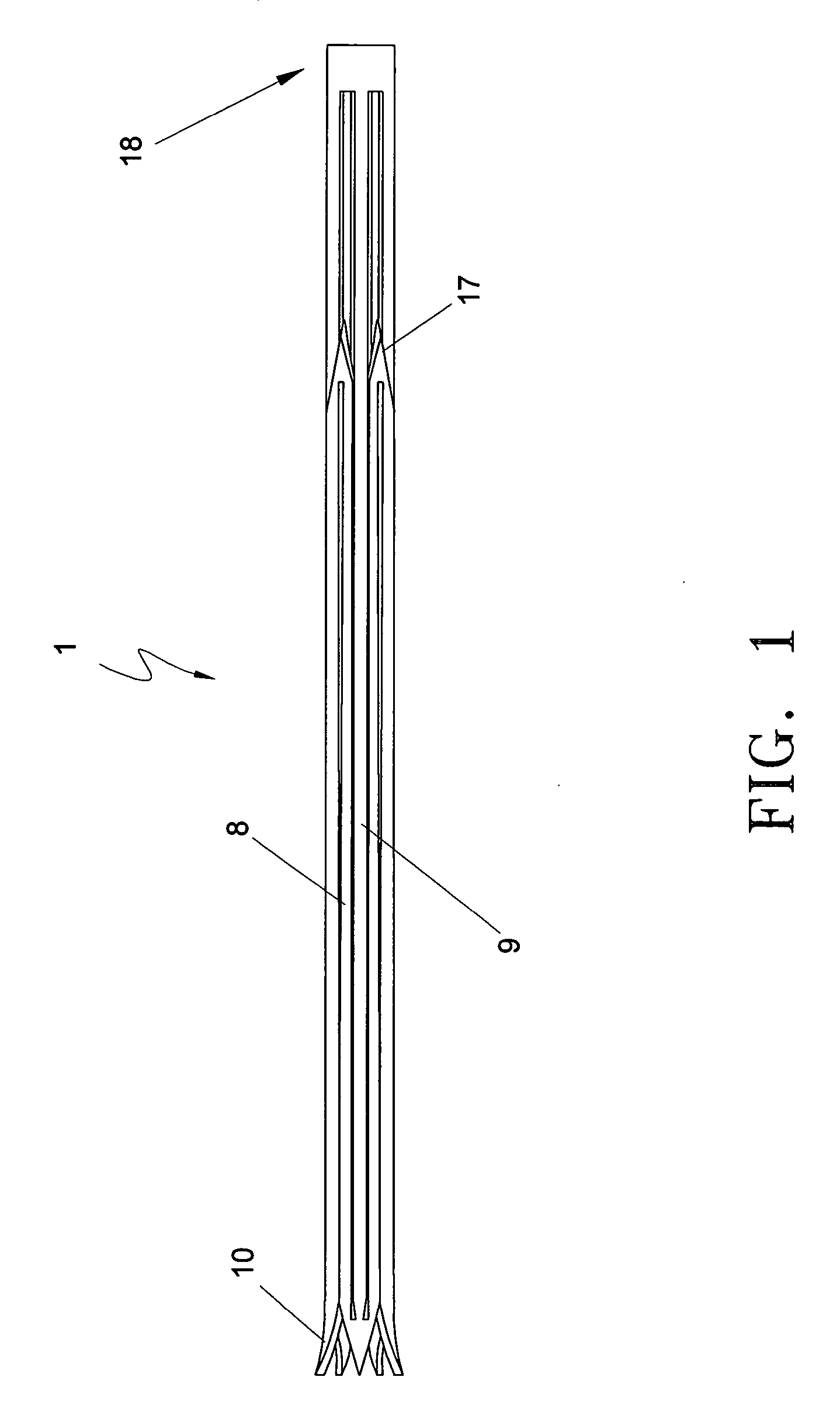

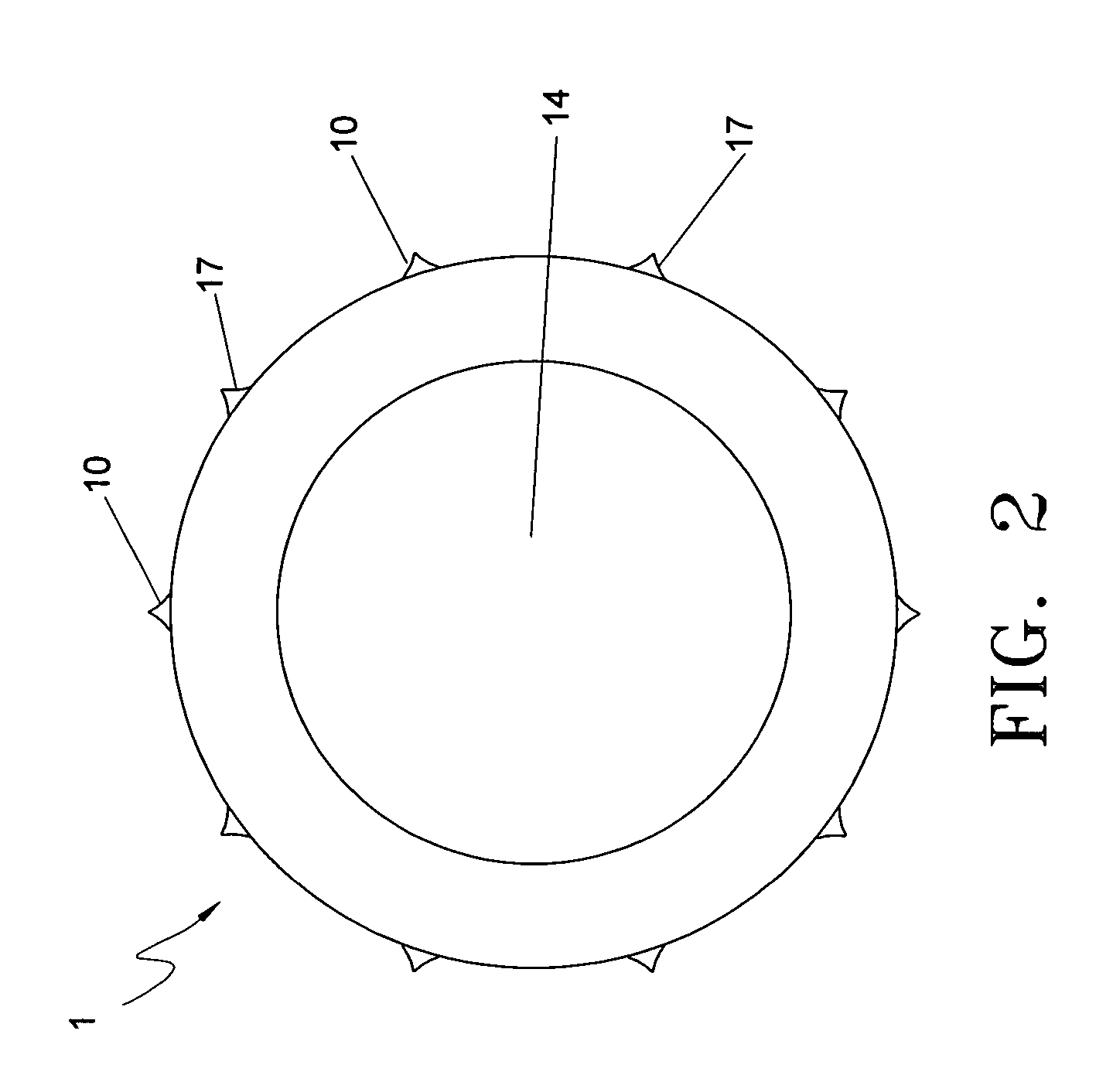

A compact blood clot filter having an alignment section that overlaps with a filter section in an axial direction is formed from a single tube without any welding points to provide high structural integrity, low profile and low manufacturing cost. The filter section has filter struts that extend radially and longitudinally from a hub. The alignment section has alignment struts in which the downstream end of each alignment strut forms a junction with the downstream end of an adjacent alignment strut while the upstream end of each alignment strut forms a junction with the upstream end of an adjacent alignment strut and with one of the filter struts to ensure symmetrical deployment of the filter struts and provide stable centering of the filter section.

Owner:ANGIODYNAMICS INC

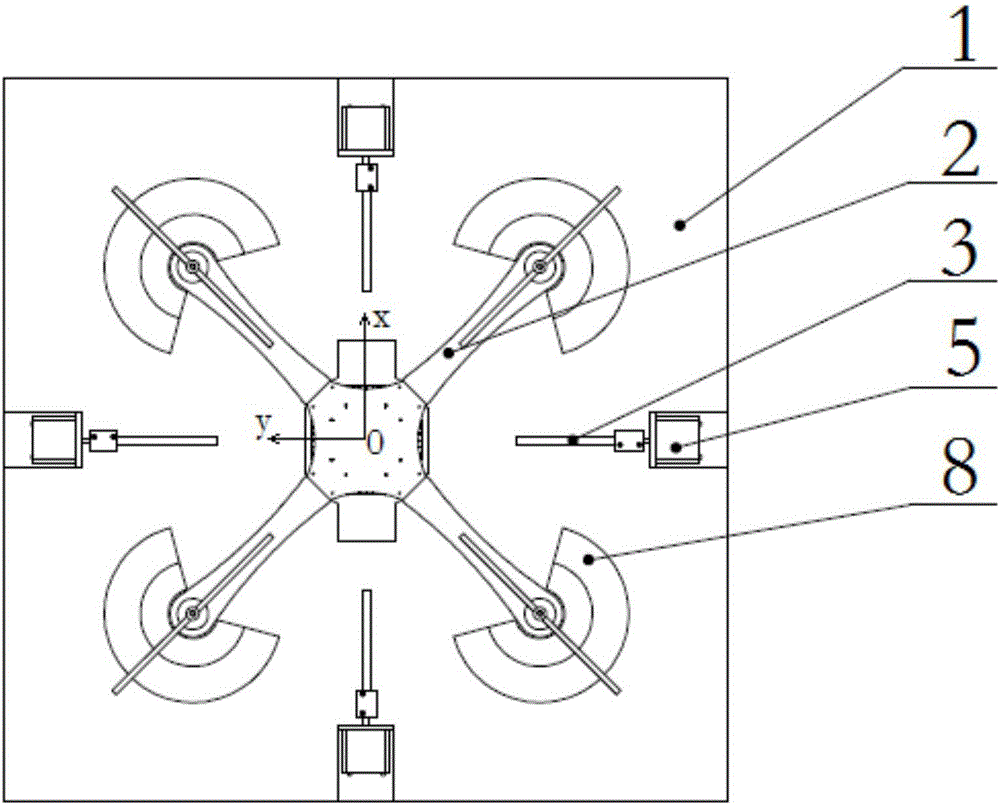

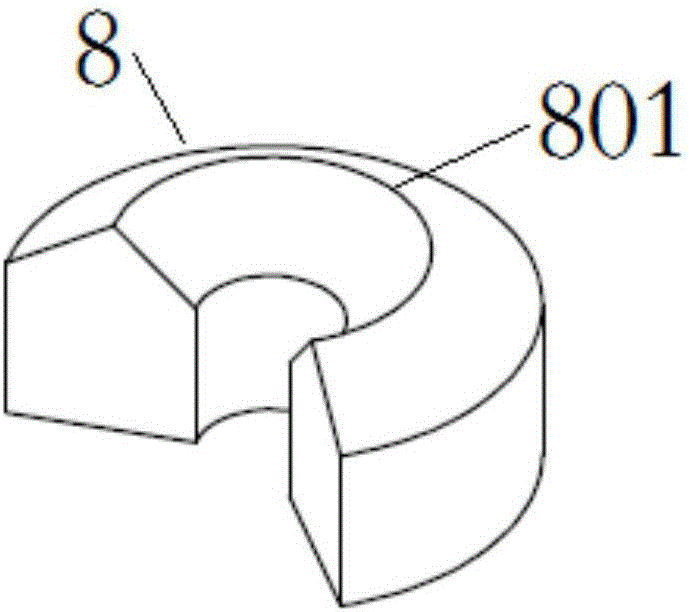

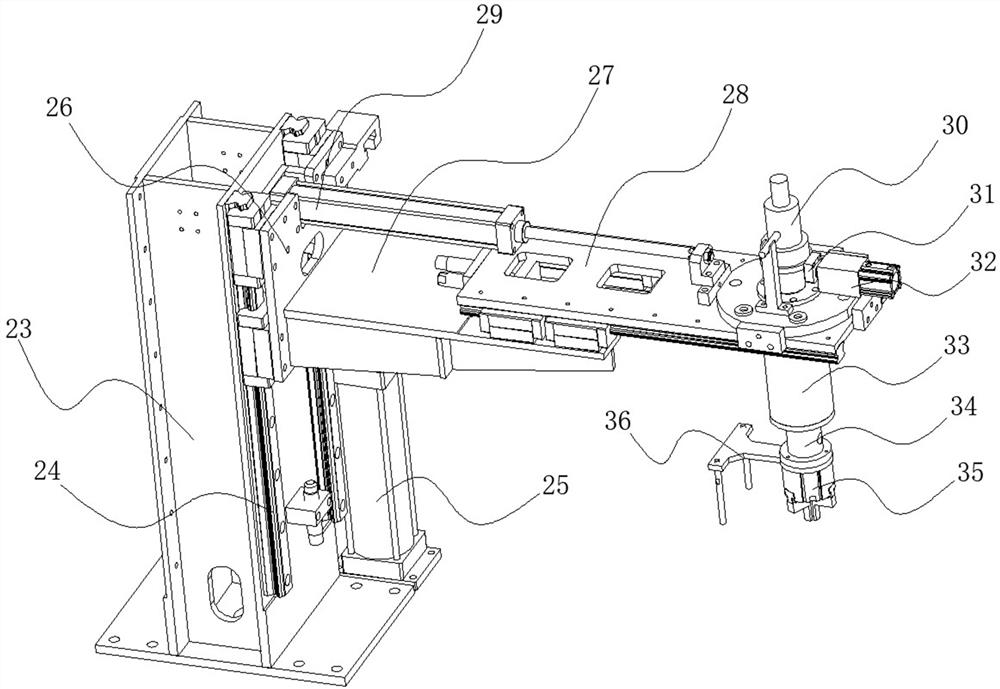

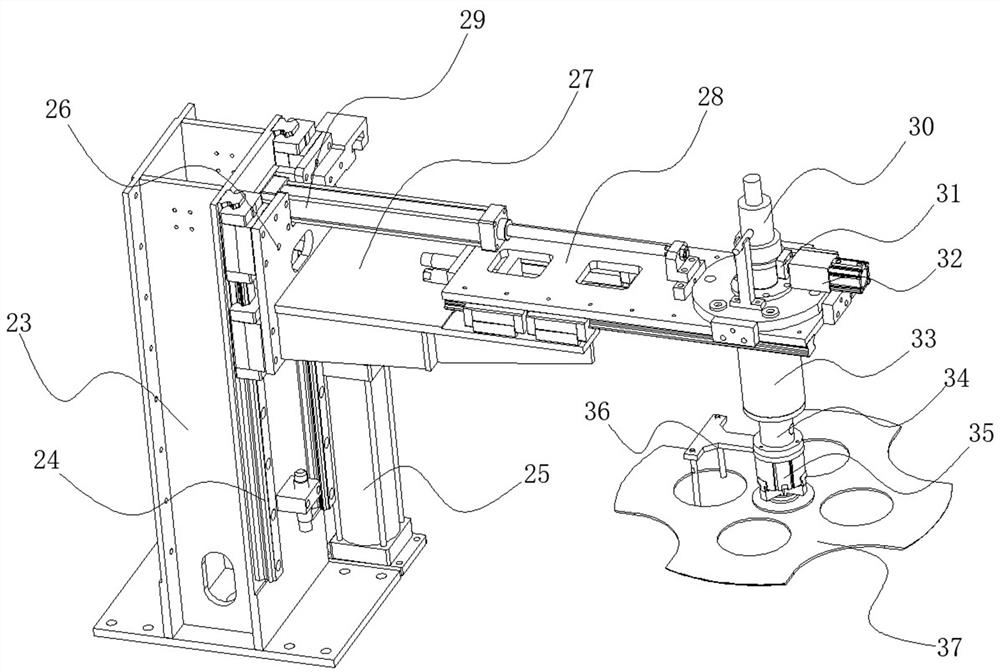

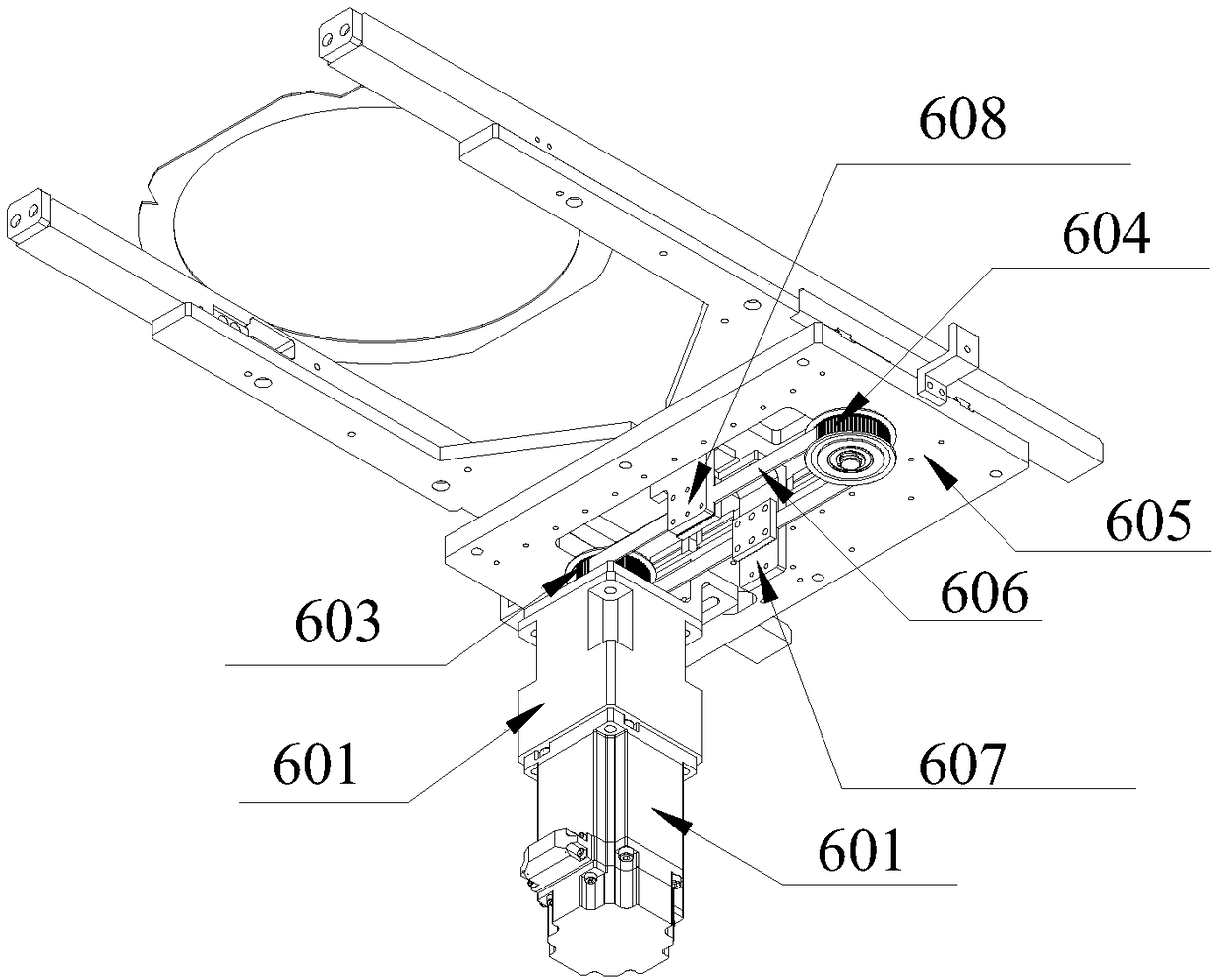

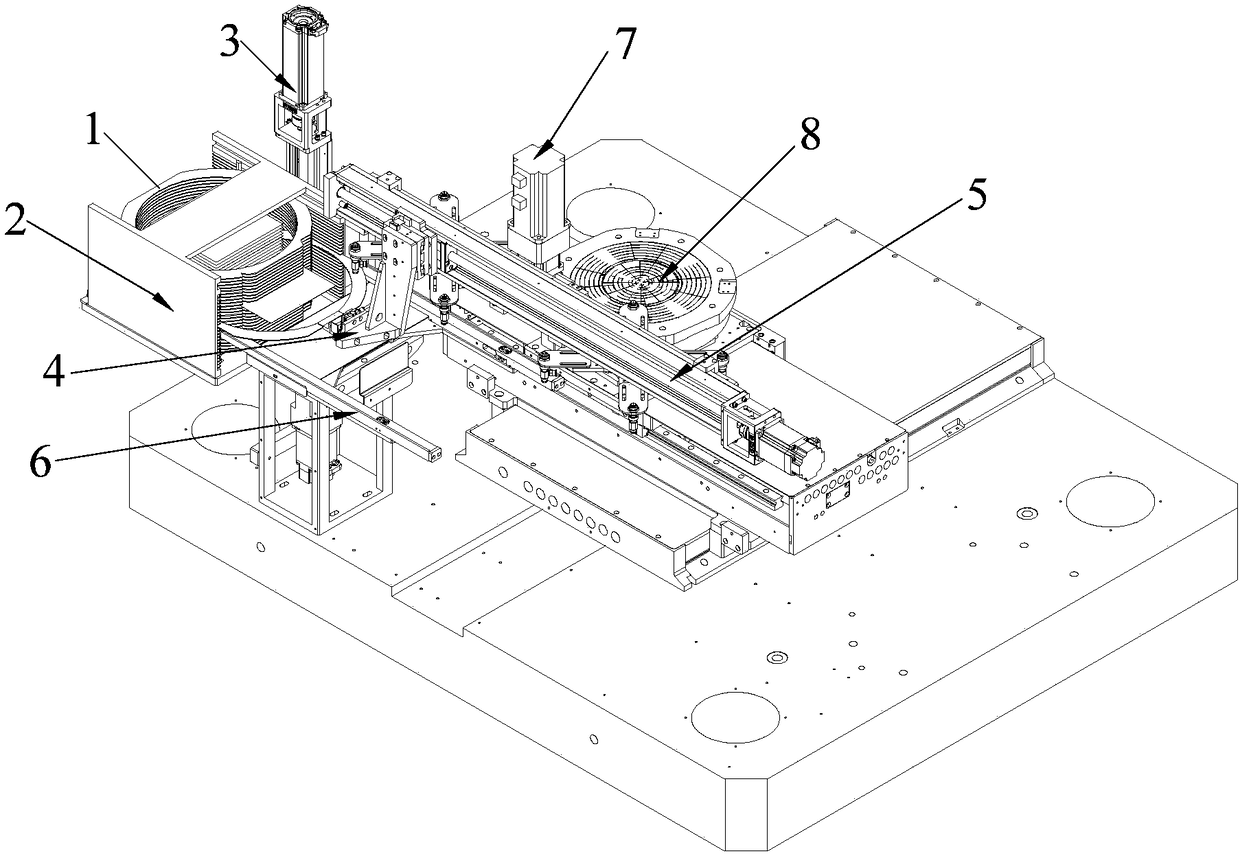

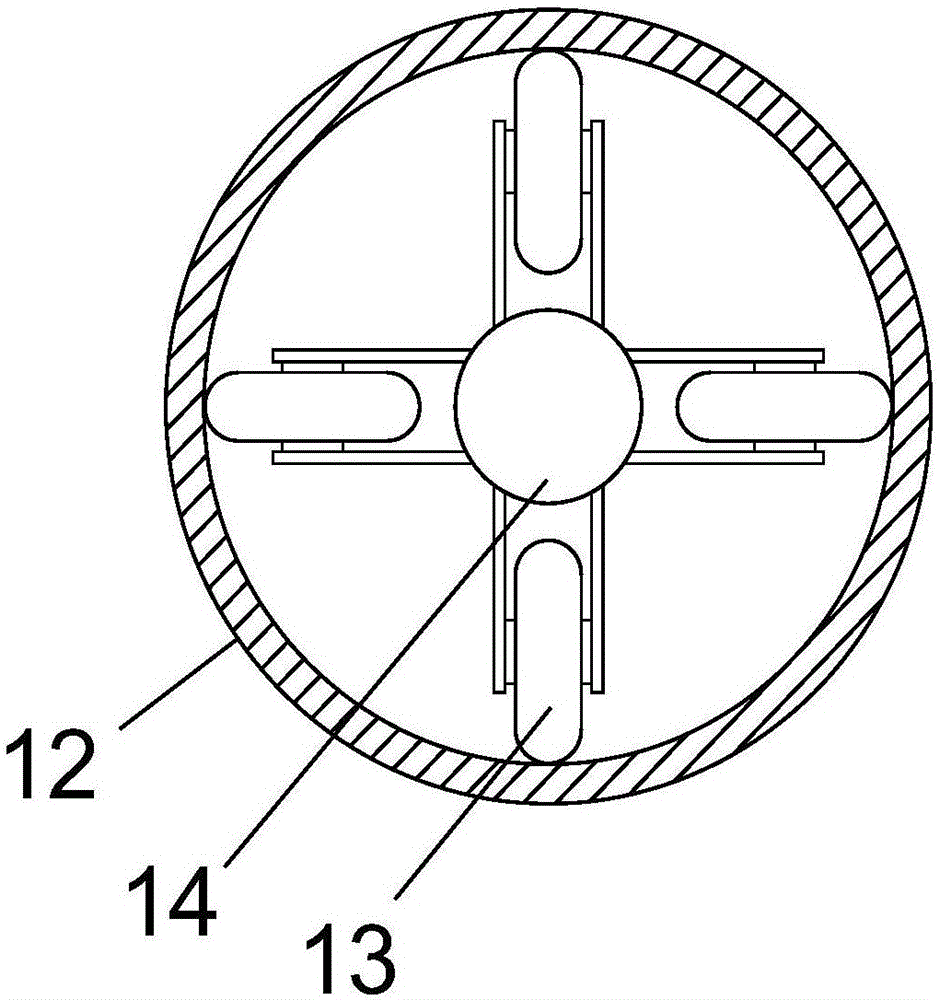

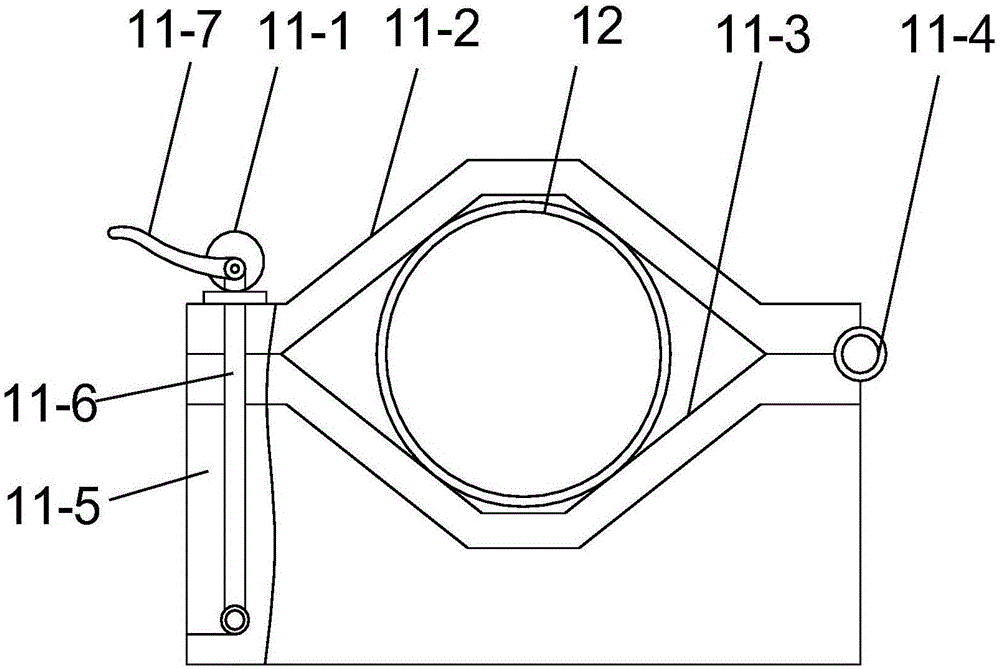

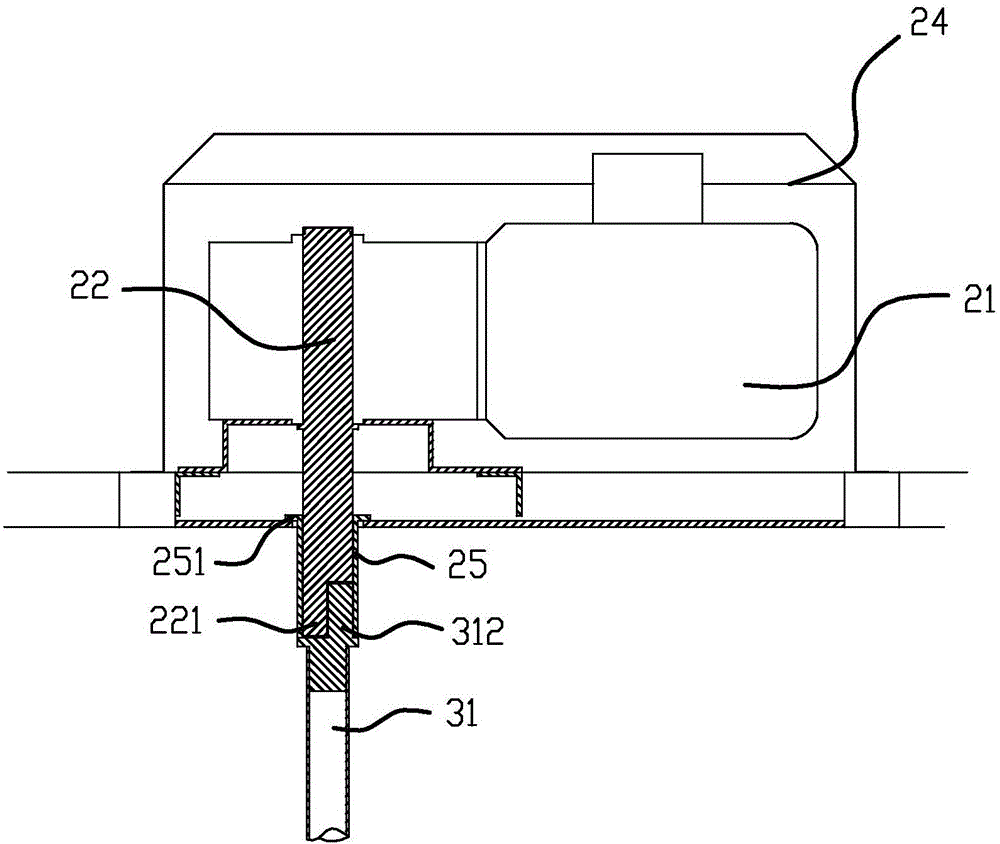

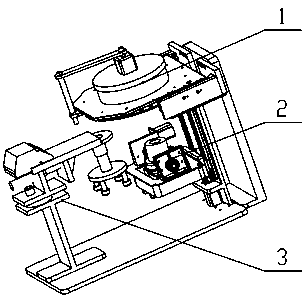

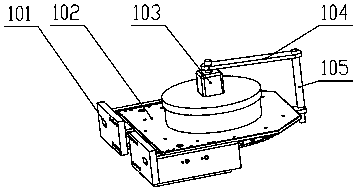

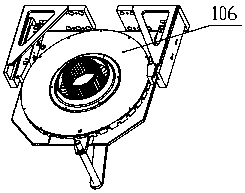

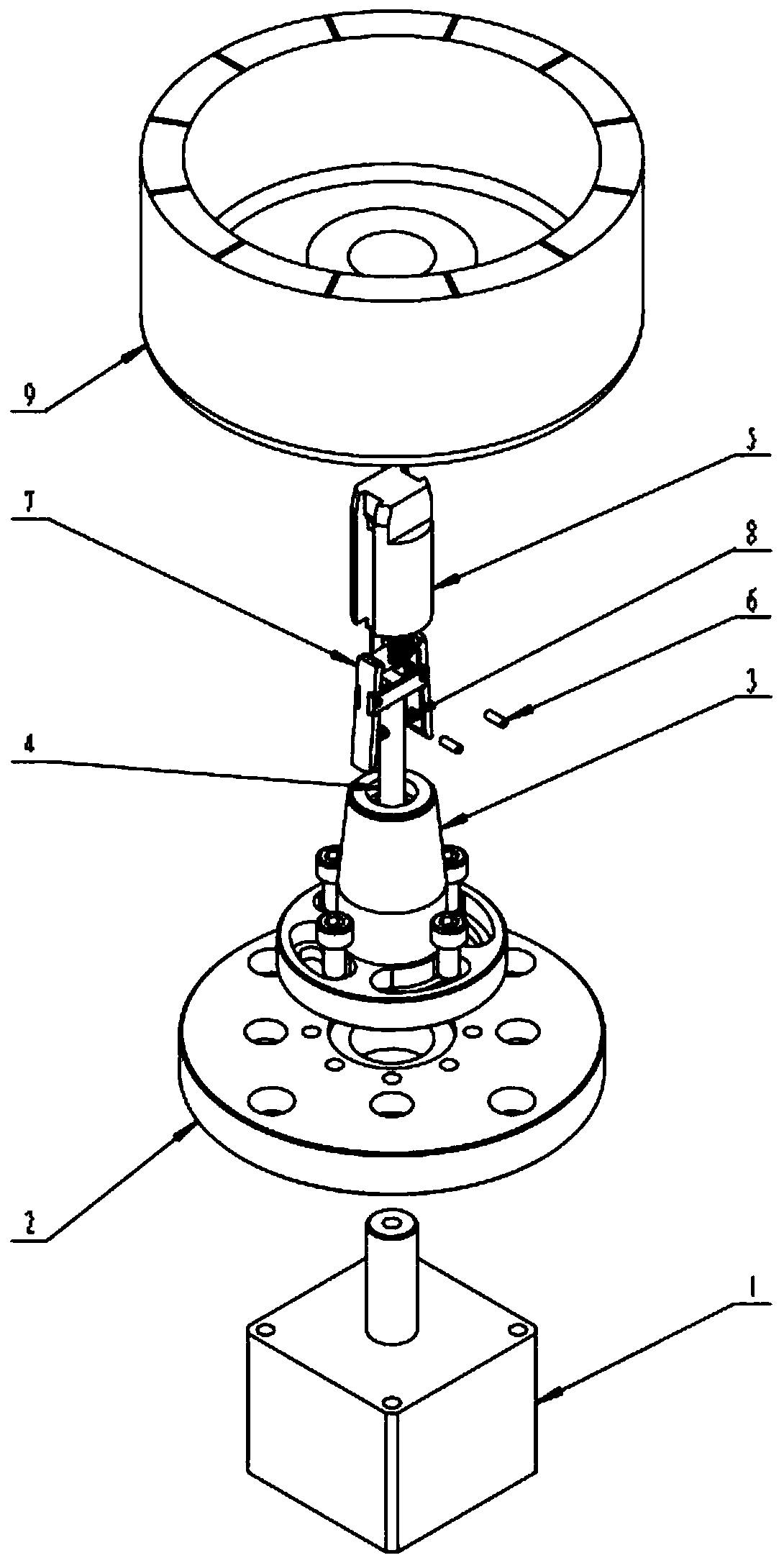

Quick charging system for unmanned aerial vehicle and charging method thereof

InactiveCN104979882AImprove efficiency and accuracyGuaranteed stabilityBatteries circuit arrangementsCoupling device detailsAerospace engineeringPre-charge

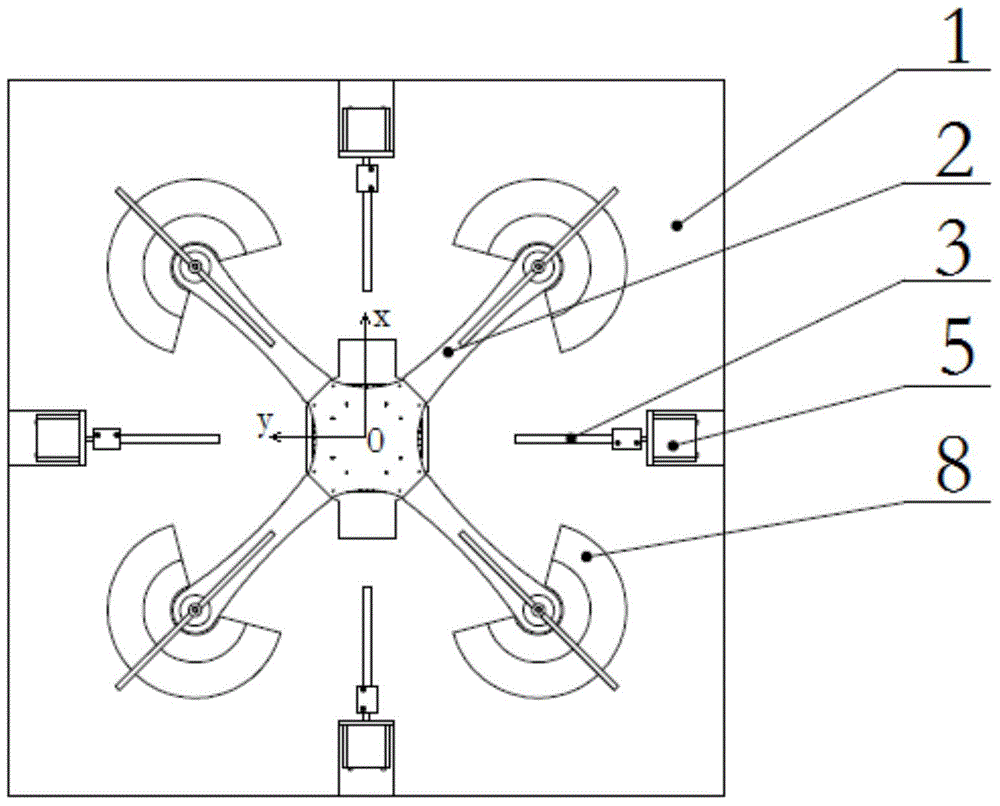

The invention discloses a quick charging system for an unmanned aerial vehicle and a charging method thereof, wherein the quick charging system and the charging method belong to the field of unmanned aerial vehicle charging. The quick charging system for the unmanned aerial vehicle comprises a supporting module, a positioning module and a charging module. The supporting module is used for assisting the unmanned aerial vehicle body in landing and supporting the unmanned aerial vehicle body. The positioning module is used for performing return positioning on the unmanned aerial vehicle body so that the unmanned aerial vehicle body lands on the supporting module. The charging module is used for controlling a charging process. The charging method according to the quick charging system comprises an unmanned aerial vehicle body returning step, an image acquiring and positioning step, a quick landing step, a charging step, etc. The charging process comprises three periods, namely pre-charging, multi-step constant-current charging and pulse charging. According to the quick charging system, the supporting module is combined with other modules for forming a complete charging system, so that the unmanned aerial vehicle body can accurately and quickly land on the supporting module, thereby greatly improving charging efficiency and realizing high autonomy and convenient use.

Owner:安徽啄木鸟智能科技有限公司

Blood clot filter

InactiveUS7722635B2Be at easeImproves Structural IntegritySurgeryDilatorsEngineeringStructural integrity

A compact blood clot filter having an alignment section that overlaps with a filter section in an axial direction is formed from a single tube without any welding points to provide high structural integrity, low profile and low manufacturing cost. The filter section has filter struts that extend radially and longitudinally from a hub. The alignment section has alignment struts in which the downstream end of each alignment strut forms a junction with the downstream end of an adjacent alignment strut while the upstream end of each alignment strut forms a junction with the upstream end of an adjacent alignment strut and with one of the filter struts to ensure symmetrical deployment of the filter struts and provide stable centering of the filter section.

Owner:ANGIODYNAMICS INC

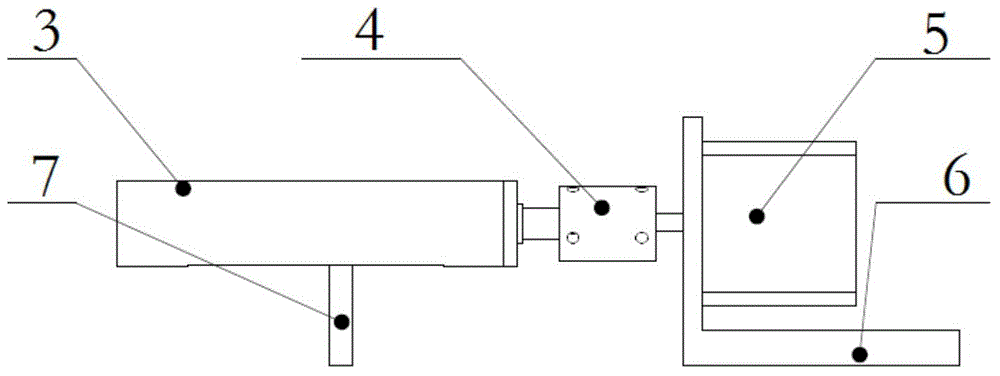

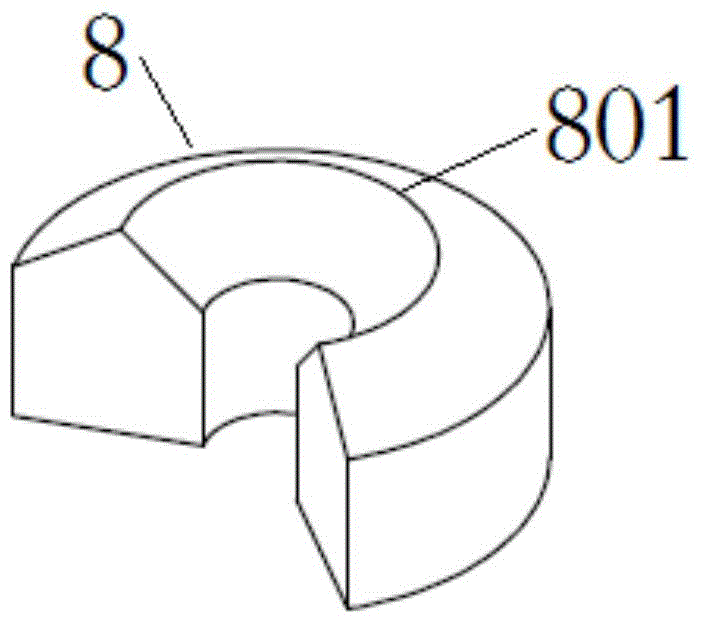

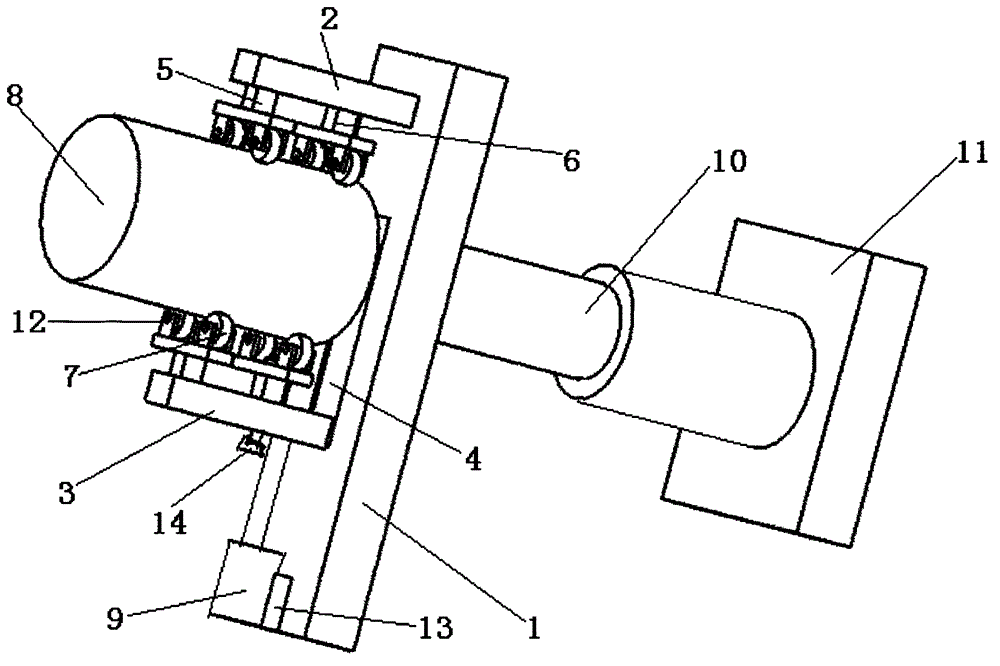

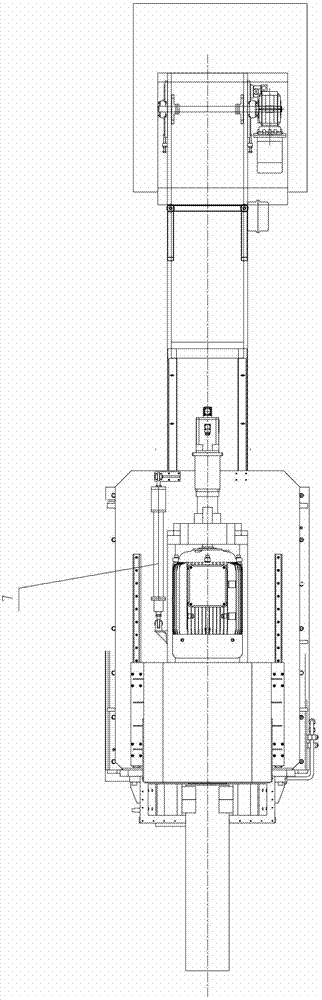

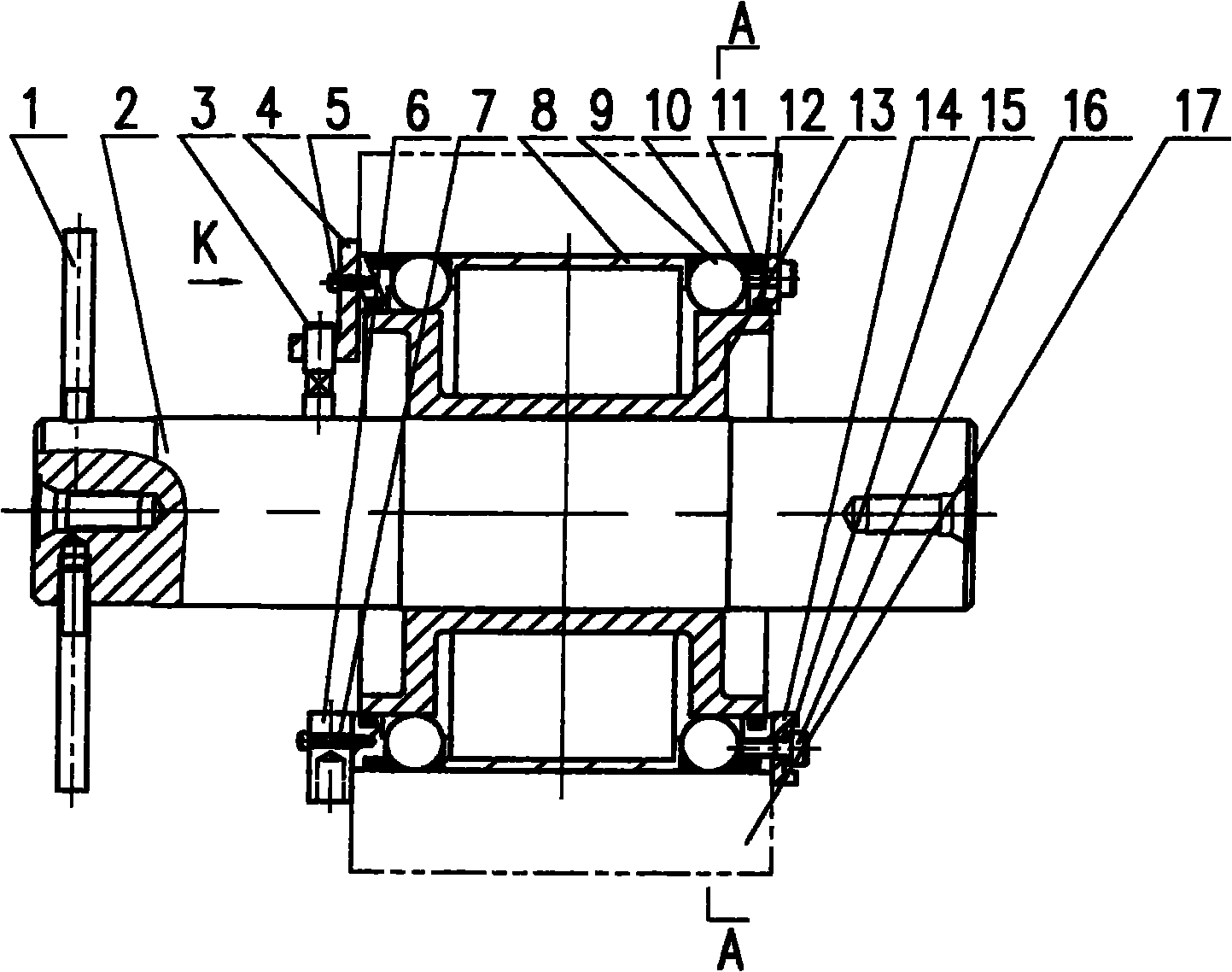

Machining tool for cylindrical workpieces

ActiveCN104985465AQuick clampingSmooth rotationWork clamping meansWelding/cutting auxillary devicesEngineeringMachine tool

The invention provides a machining tool for cylindrical workpieces. The machining tool comprises a bottom plate, a fixed support, a movable support, a first sliding groove, a fixed roller carrier, a sliding roller carrier, rollers, a first air cylinder, a second air cylinder and a locking bolt. By the adoption of the rollers, rapid workpiece clamping and accurate centering can be achieved, and workpieces can rotate conveniently in grinding or turning or welding or the like. By the adoption of the action of the air cylinders, automatic workpiece clamping can be achieved. By the arrangement of the first sliding groove and a second sliding groove, the distance between the fixed support and the movable support and the distance between the sliding roller carrier and the fixed roller carrier can be adjusted according to needs so that workpieces of different diameters can be clamped or different portions of workpieces can be clamped, and accordingly the universality and reliability of the tool are improved. The machining tool for the cylindrical workpieces is high in automation degree and clamping efficiency, greatly shortens the workpiece machining period, improves productivity and lowers the production cost.

Owner:ANHUI SCI & TECH UNIV

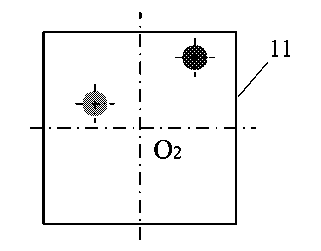

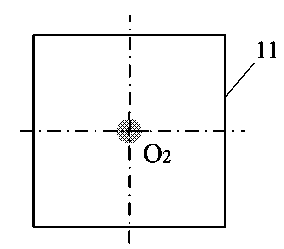

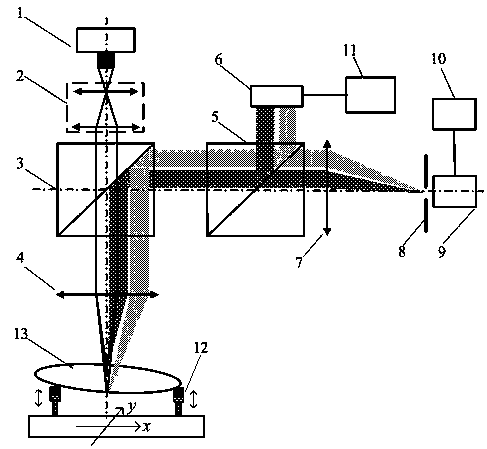

Spectrum confocal type measurement method and device for thickness of center of lens

InactiveCN104061867AHigh coincidenceReduce wasteUsing optical meansMeasurement deviceComputational physics

The invention relates to a spectrum confocal type measurement method and device for the thickness of the center of a lens. An existing method and device have large errors and consume much time when carrying out measurement. The measurement method includes the steps that an area-array cameras and a television image are utilized for assisting in centering, the thickness of the center of the optical lens is measured through the spectrum confocal means, accuracy of the measured thickness is ensured, and accuracy of test results is largely improved. The measurement device is additionally provided with a monitor optical way for the process of measuring the thickness of the lens through the spectrum confocal means, the ratio of overlapping of a centering optical way and a measurement optical way is high, unnecessary hardware waste is reduced, and cost of the measurement device is effectively controlled.

Owner:XIAN TECH UNIV

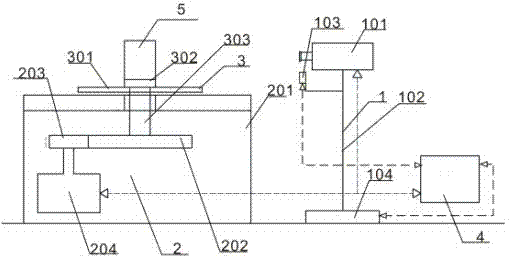

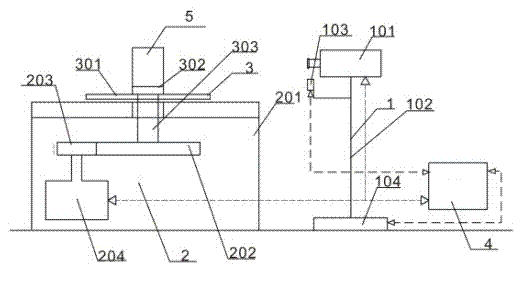

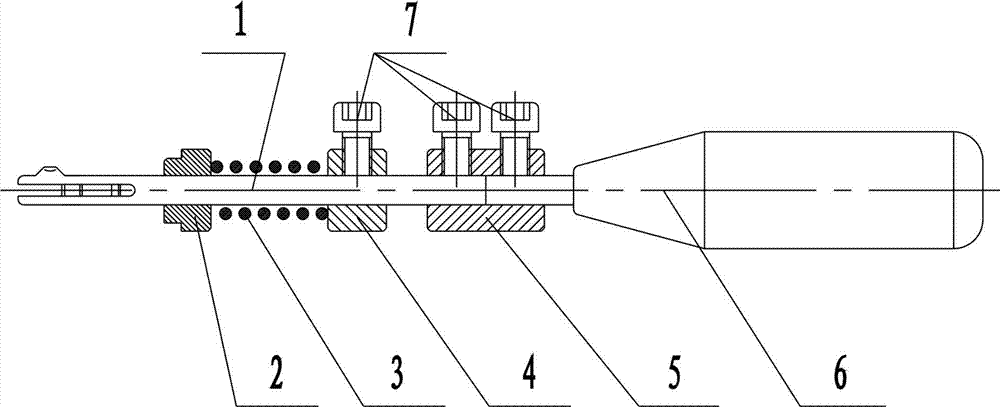

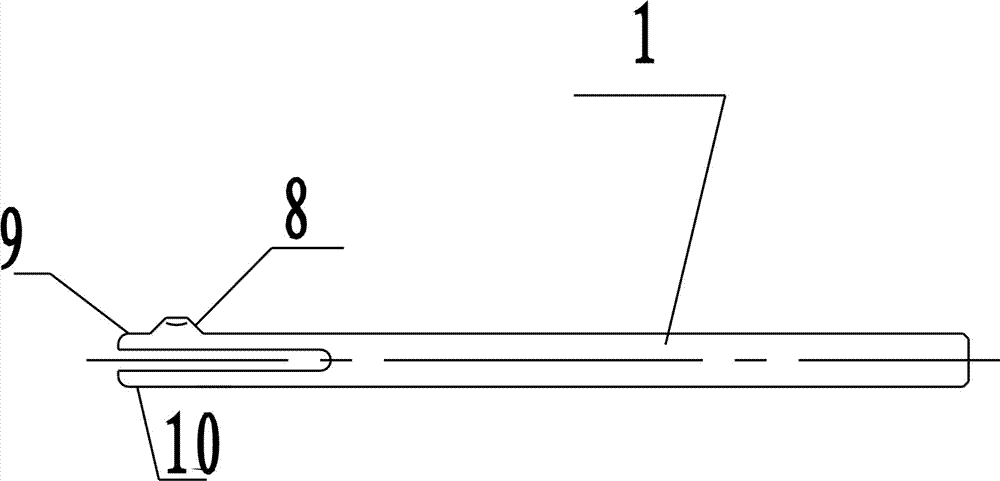

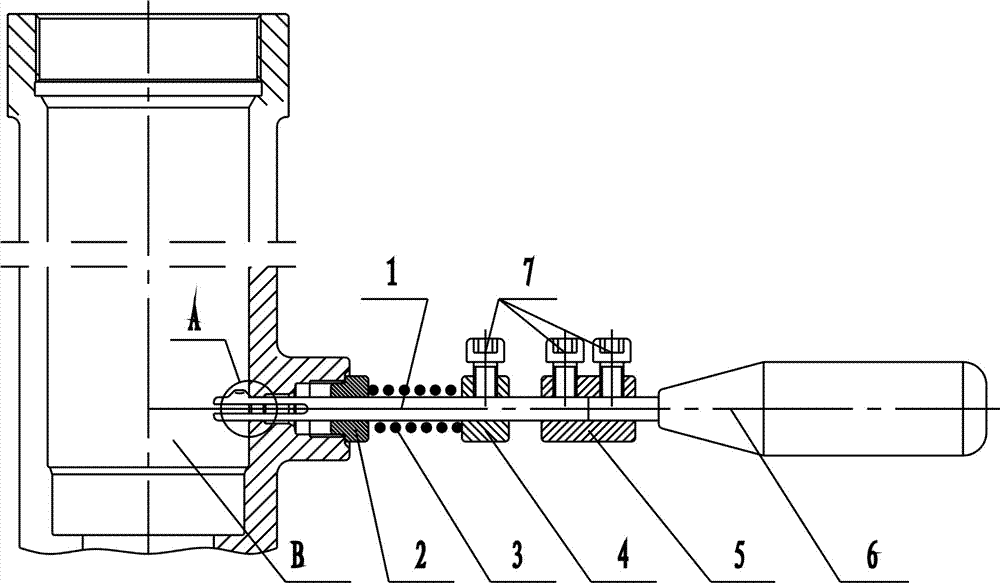

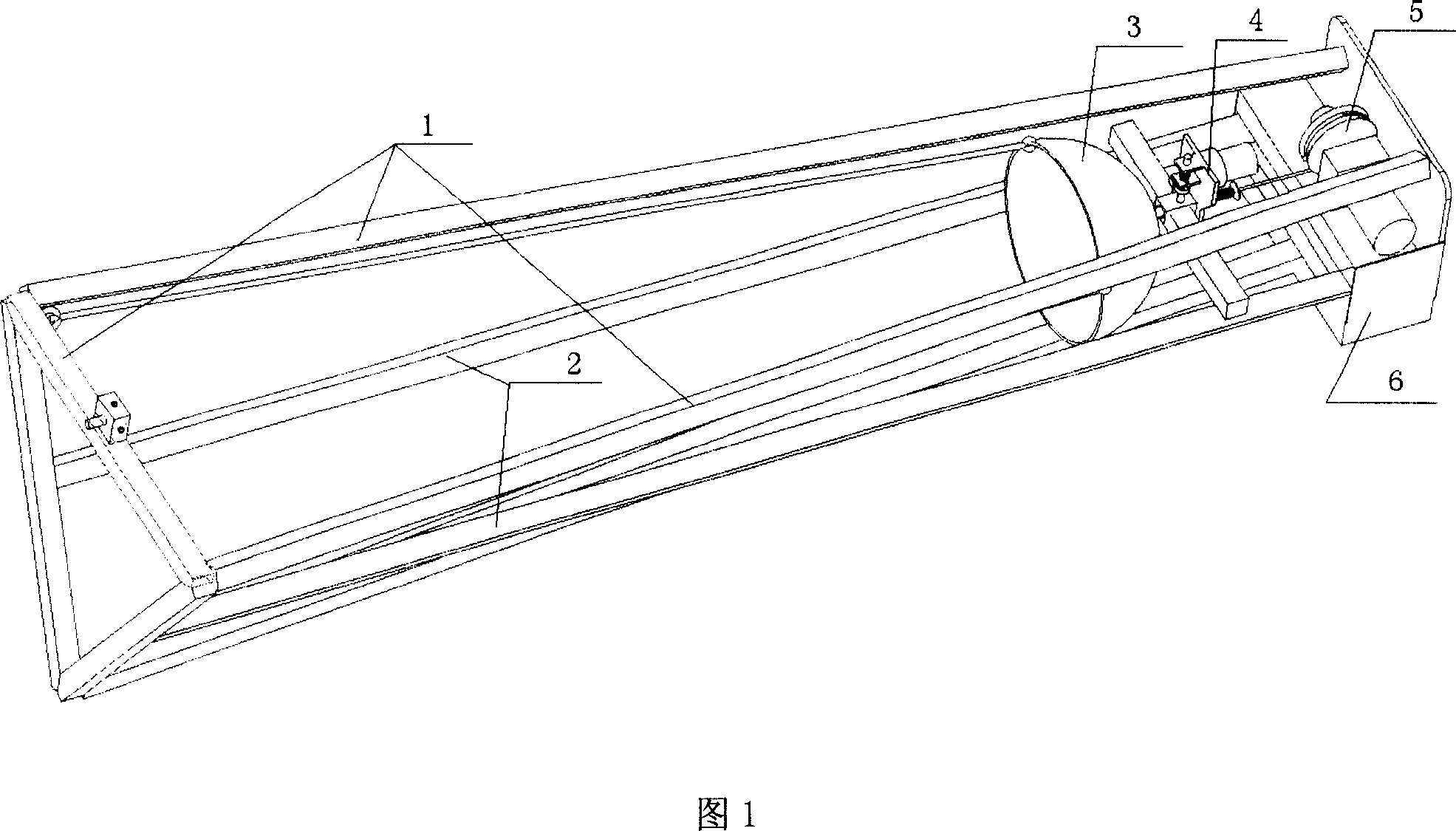

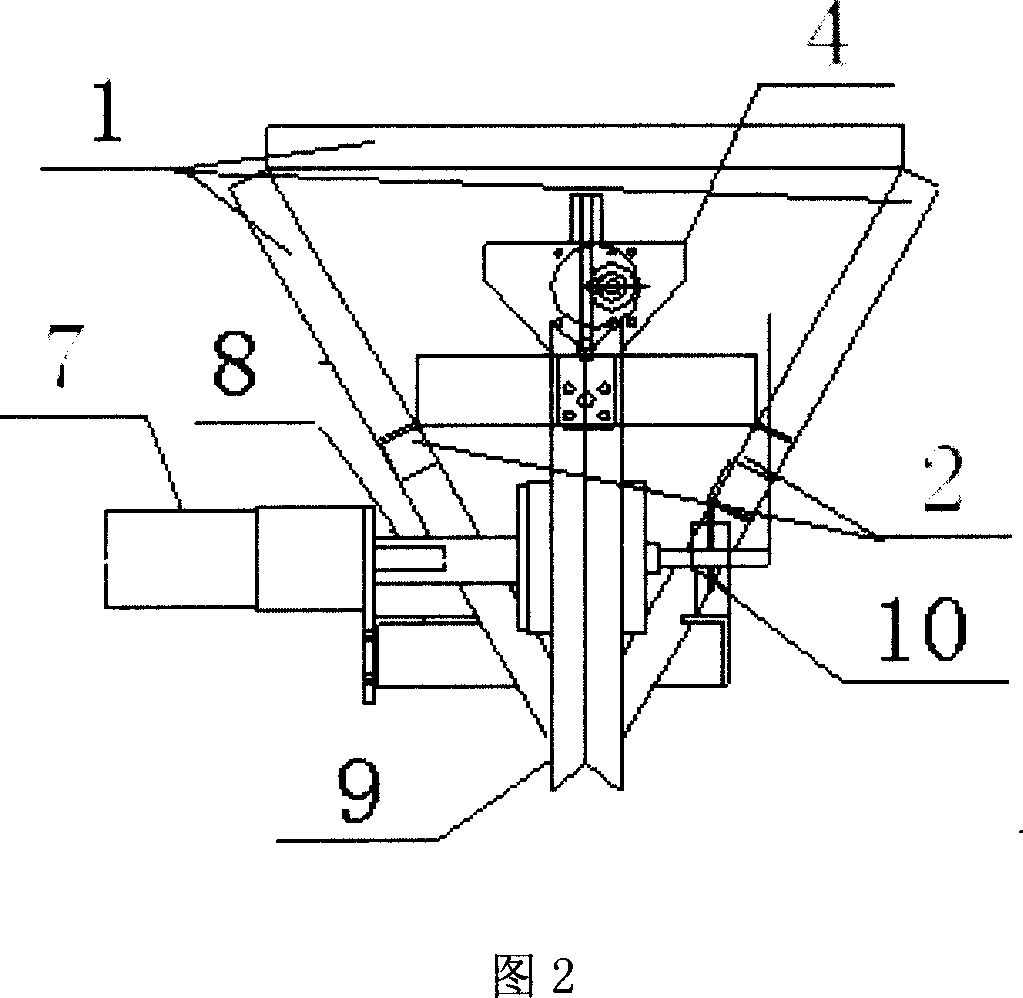

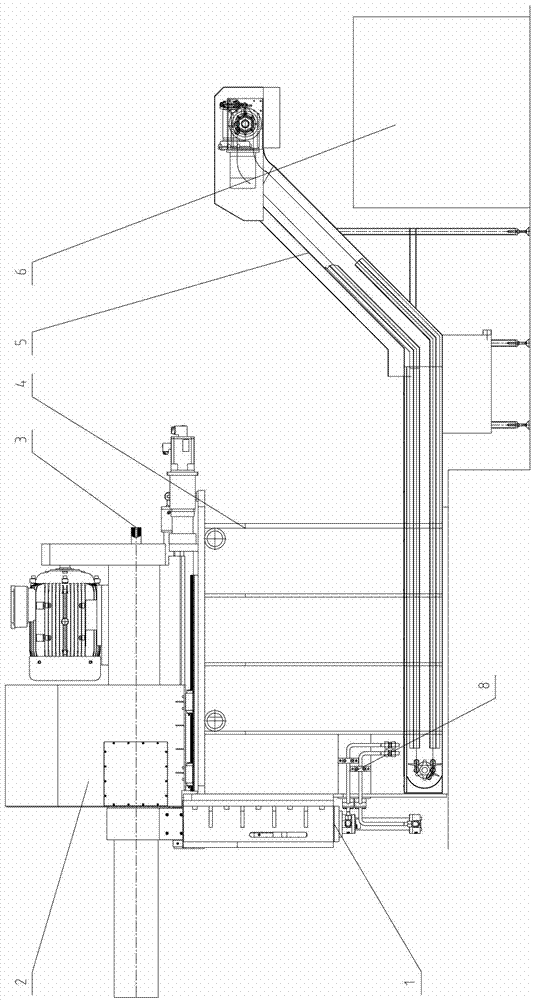

Linear array camera based automatic panoramic acquisition system for outer surface of cylindrical surface

InactiveCN102589465ABe at easePrecisely adjustable number of rotationsMaterial analysis by optical meansUsing optical meansEngineeringInternal combustion engine

The invention discloses a linear array camera based automatic panoramic acquisition system for the outer surface of a cylindrical surface, which mainly comprises a cylinder centering and clamping device, a rotating device, a shooting device and a central controller. A programmed program is burnt into a central controller consisting of a singlechip and the like, and N cycles are performed, so that pictures on the periphery of the outer surface of the cylindrical surface can be acquired; and the acquired pictures are combined in an organic form, so that an accurate panoramic developed pattern of the outer surface of the cylindrical surface is obtained. According to the system, the problem of panoramic development of the outer surface of the cylindrical surface is solved; the system can be applied to scientific experimental study such as acquisition of the developed outer surface of a cylinder sleeve of an internal combustion engine, research on cavitation distribution of the surface and fingerprint investigation and evidence collection for the police; and moreover, the system has wide application prospects in the fields of education, entertainment and military.

Owner:HENAN UNIV OF SCI & TECH

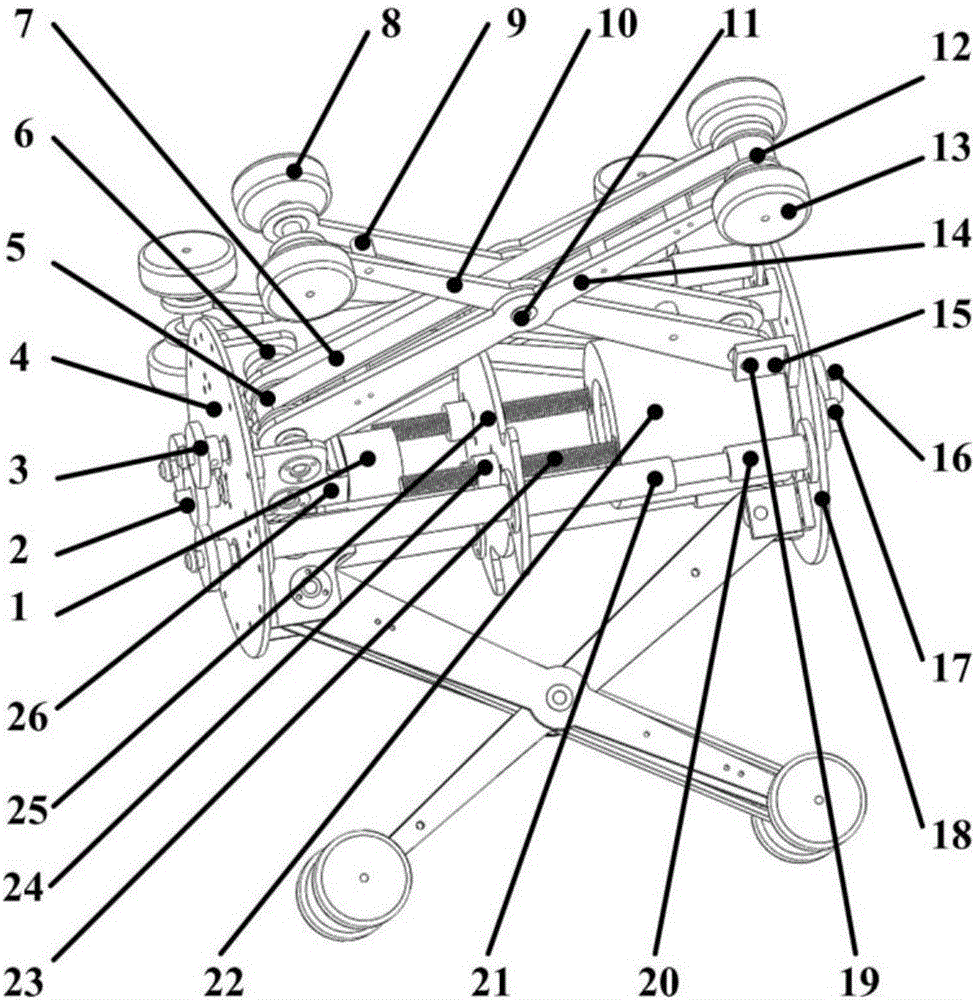

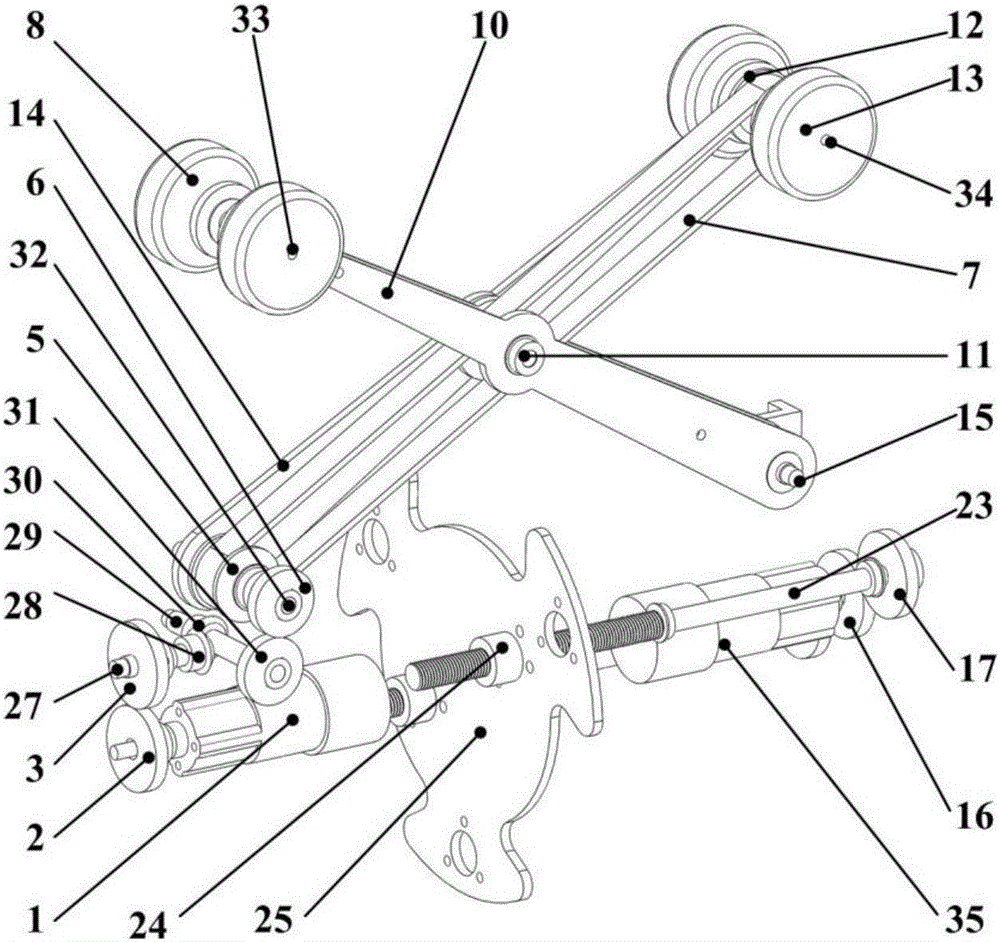

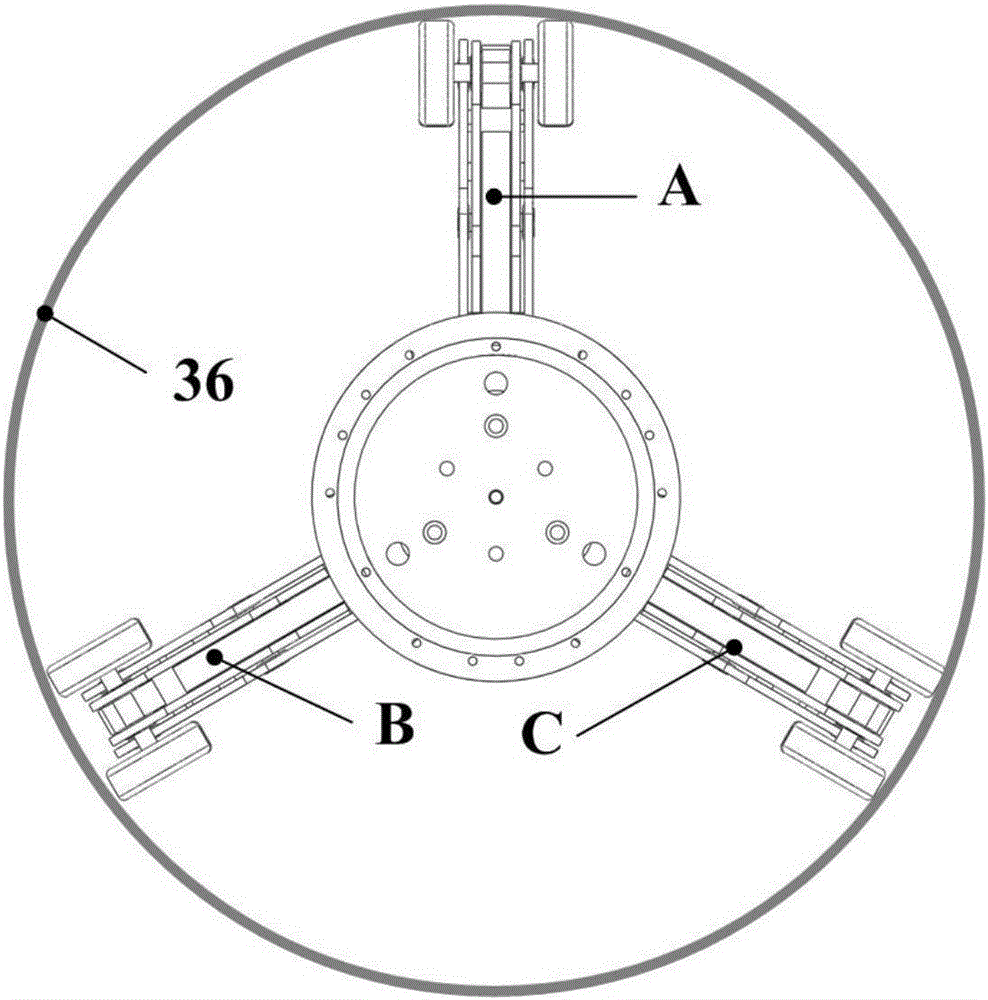

Portable type large-variable-diameter all-wheel-drive type pipeline robot

The invention provides a portable type large-variable-diameter all-wheel-drive type pipeline robot which comprises a front end plate, a rear end plate, a front rocker arm, a rear rocker arm, a scissor-type reducing mechanism and a positioning all-wheel-drive mechanism, wherein the positioning all-wheel-drive mechanism is arranged on the front end plate; the scissor-type reducing mechanism is arranged on the rear end plate; one end of the front rocker arm is hinged with the front end plate; the rear rocker arm is hinged with the rear end plate; the front rocker arm is hinged with the rear rocker arm to form a shears-fork structure; the scissor-type reducing mechanism is connected with the positioning all-wheel-drive mechanism; and the scissor-type reducing mechanism can slide relative to the positioning all-wheel-drive mechanism to drive the front rocker arm and the rear rocker arm to form shears-fork motion. According to the portable type large-variable-diameter all-wheel-drive type pipeline robot provided by the invention, when the reducing motor rotates, a nut pulls the front end plate to get close to a guide post or get away from the guide post, and scissor-type rocker arms which are synchronously fixedly arranged on the front end plate and the rear end plate open and close, so that a supporting radius of the robot is changed.

Owner:SHANGHAI SUJIE ROBOT TECH

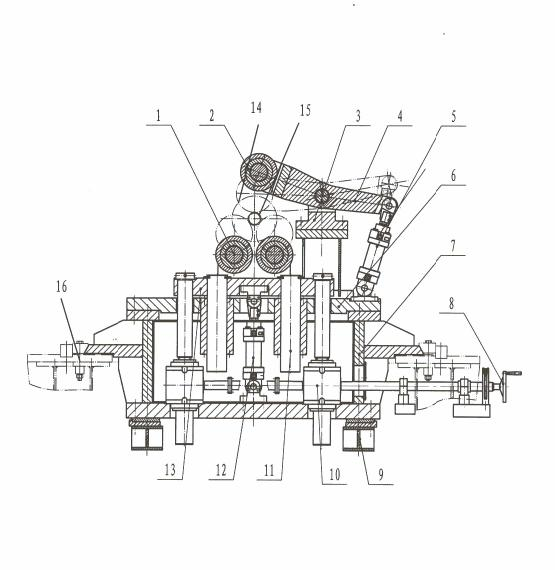

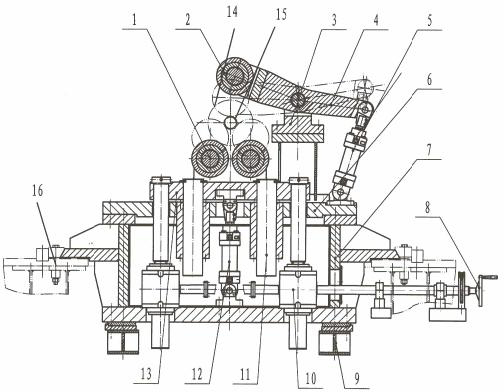

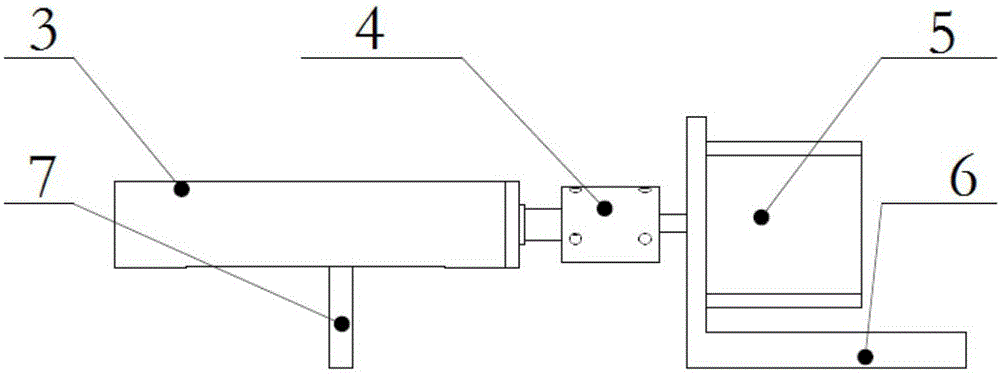

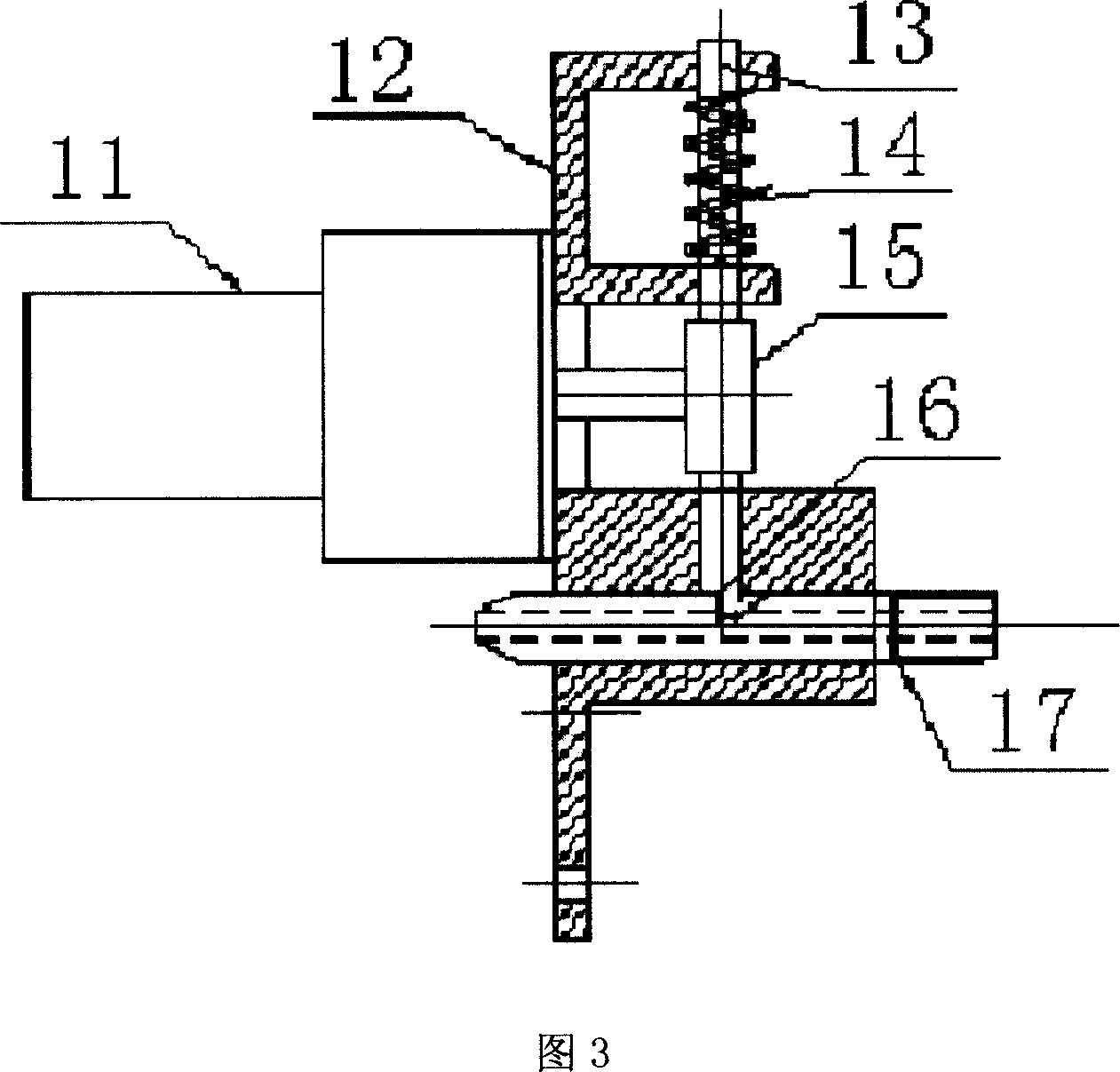

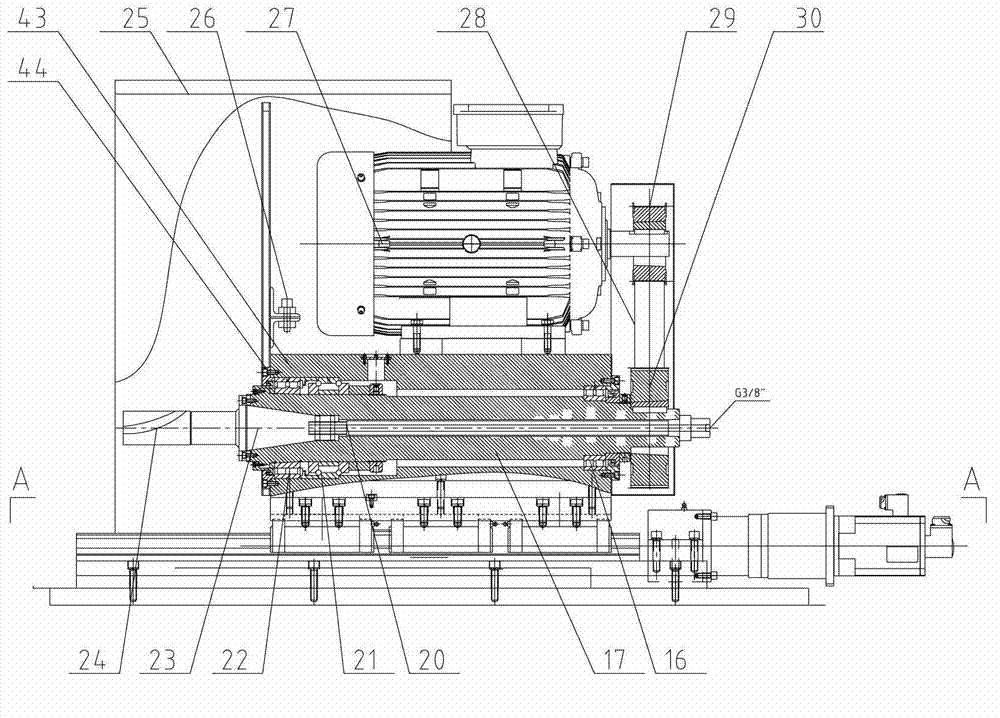

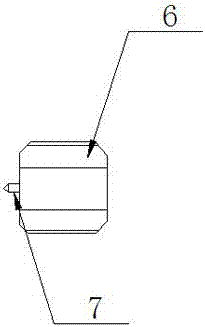

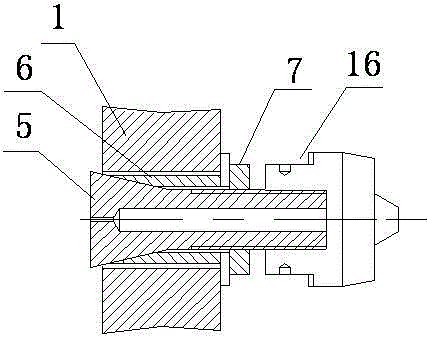

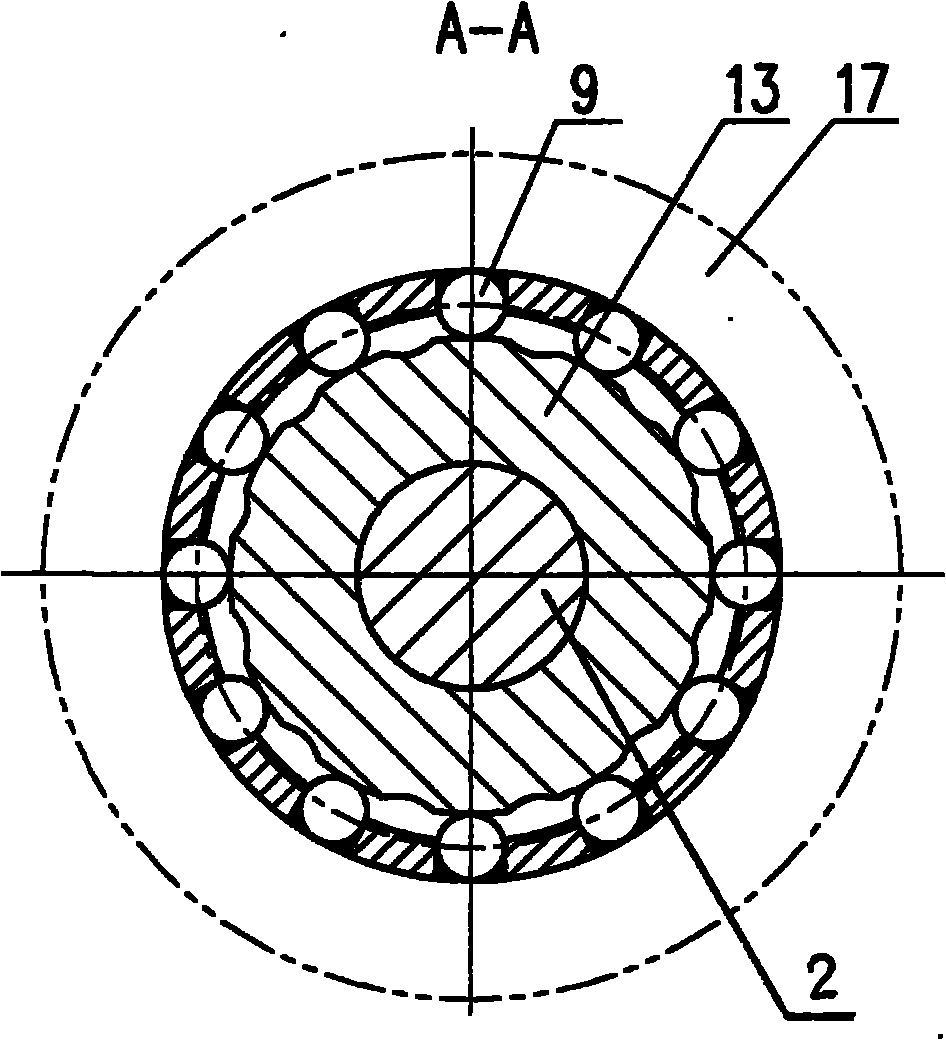

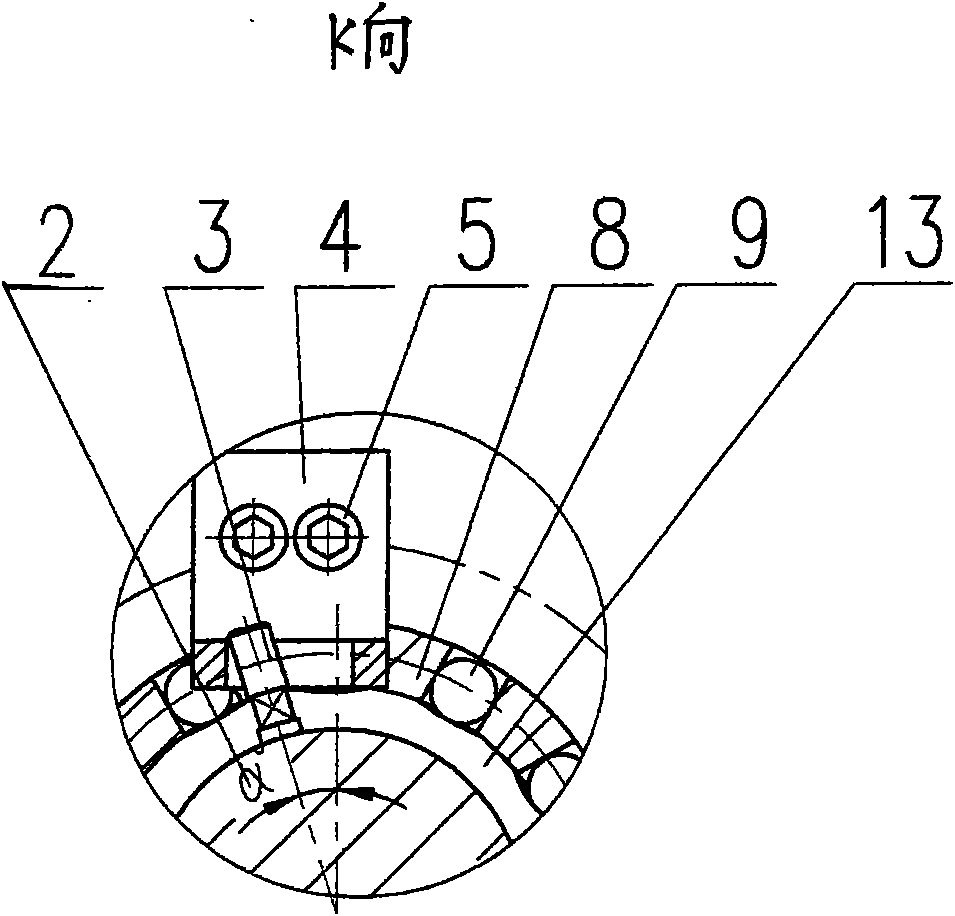

Tappet centering device for perforating machine

InactiveCN102327897ABe at easeMeet the requirements of support orientationMandrelsMetal rolling arrangementsHydraulic cylinderEngineering

The invention discloses a tappet centering device for a perforating machine, which solves the problems of inaccurate positioning and high possibility of bending of an ejector rod existing in the conventional perforating machine centering device. The device comprises a centering device base frame (7) fixedly arranged on a backstage second-segment base (16) and two lifting screw rod devices (10), wherein upwards output shafts of the two lifting screw rod devices (10) pass through the top surface of the centering device base frame (7) and then are fixedly connected with a supporting roller support (13); two supporting rollers (1) are parallelly arranged on the supporting roller support (13) along the direction of the ejector rod of the perforating machine; an oscillating rod support (3) and a hydraulic cylinder (5) are arranged on a mounting platform (6) respectively; the oscillating rod support (3) is hinged with the middle part of an oscillating rod (4) together through a hinge; the output shaft of the hydraulic cylinder (5) is connected with the tail part of the oscillating rod (4); and a compaction roller (2) is arranged on the head part of the oscillating rod (4). By the device, a tappet can be centered accurately, the requirement of supporting orientation of the ejector rod is met, and the ejector rod is prevented from bending.

Owner:TAIYUAN TONGZE HEAVY IND

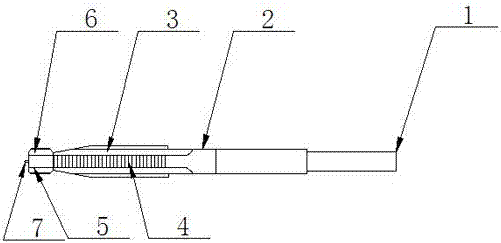

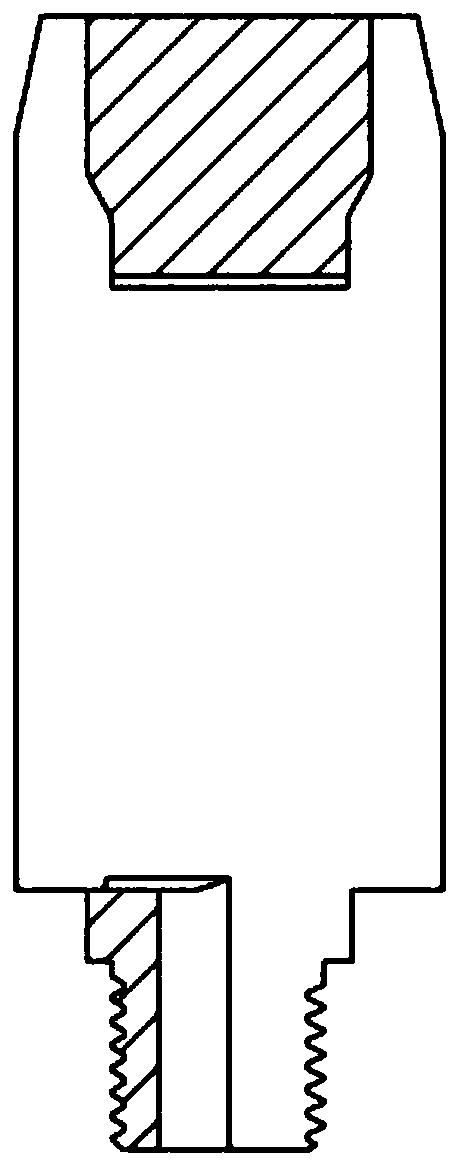

Tool for deburring orifice of small hole communicated with inner wall of deep hole

The invention discloses a tool for deburring an orifice of a small hole communicated with an inner wall of a deep hole. The tool comprises a burred knife and a handle, the edge part of the burred knife is shaped like an elastic fork with two fork branches, and the outer side of one fork branch is provided with an edge; a rod of the burred knife is provided with a guide sleeve, a compression spring and a stopping block, wherein the guide sleeve is arranged near the edge part, the inner hole of the guide sleeve is matched with the periphery of the rod of the burred rod, and the compression spring is arranged between the guide sleeve and the stopping block; and the stopping block can move along the axial direction of the rod of the knife and is provided with a stopping screw. The tool has the advantages of low cost and simple structure.

Owner:HANGZHOU SHIBAO AUTO STEERING GEAR

Clamping device and clamping method

InactiveCN102416568AAchieve clampingAchieve peace of mindLarge fixed membersPositioning apparatusMotor synergiesMechanical engineering

Owner:GROB WERKE & K G

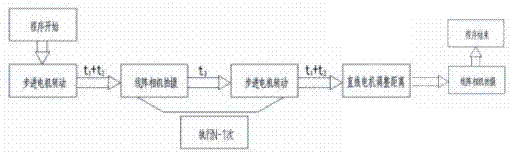

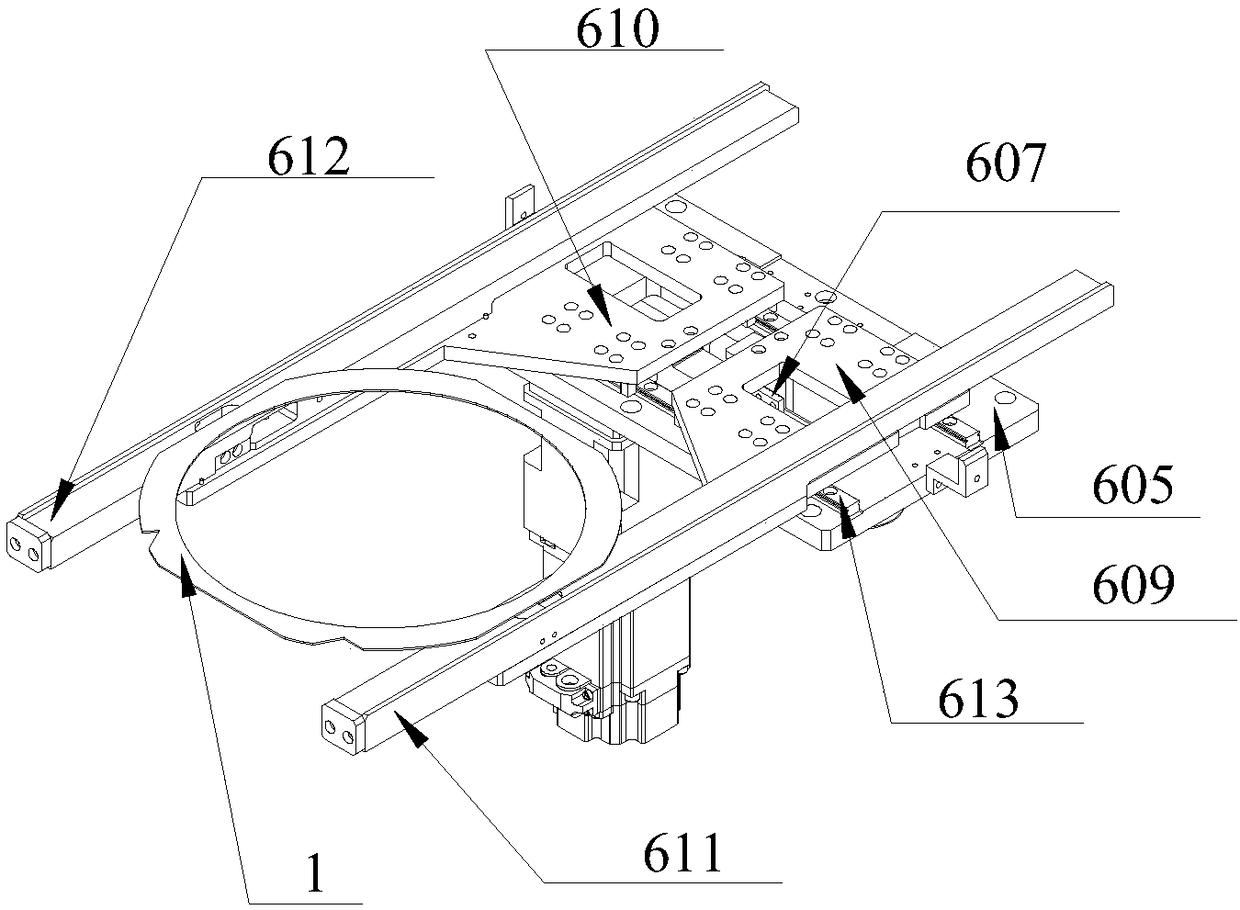

Charging method of quick unmanned aerial vehicle (UAV) charging system

InactiveCN106712160AImprove accuracyImprove efficiencyBatteries circuit arrangementsCoupling device detailsThree stageConstant current

The invention discloses a charging method of a quick unmanned aerial vehicle (UAV) charging system, belonging to the field of charging of UAVs. The charging method utilizes the quick charging system for charging the UAV; the charging system comprises a support module, a locating module and a charging module, wherein the support module is used for assisting a UAV body to land and supporting the UAV body; the locating module is used for returned voyage location of the UAV body so as to enable the UAV body to land onto the support module. The charging method comprises the processes of enabling the UAV body to make a return voyage, carrying out image acquisition and positioning, enabling the UAV body to rapidly land, charging, and the like, wherein the charging process comprises three stages, i.e., precharging, constant-current charging in stages and pulse current charging. The complete charging system is formed by combining the support module and other modules, so that the UAV body can accurately and rapidly land onto the support module, and the charging efficiency is greatly improved; the charging system is high in autonomy and convenient to use.

Owner:ANHUI WOODPECKER INTELLIGENT TECH CO LTD

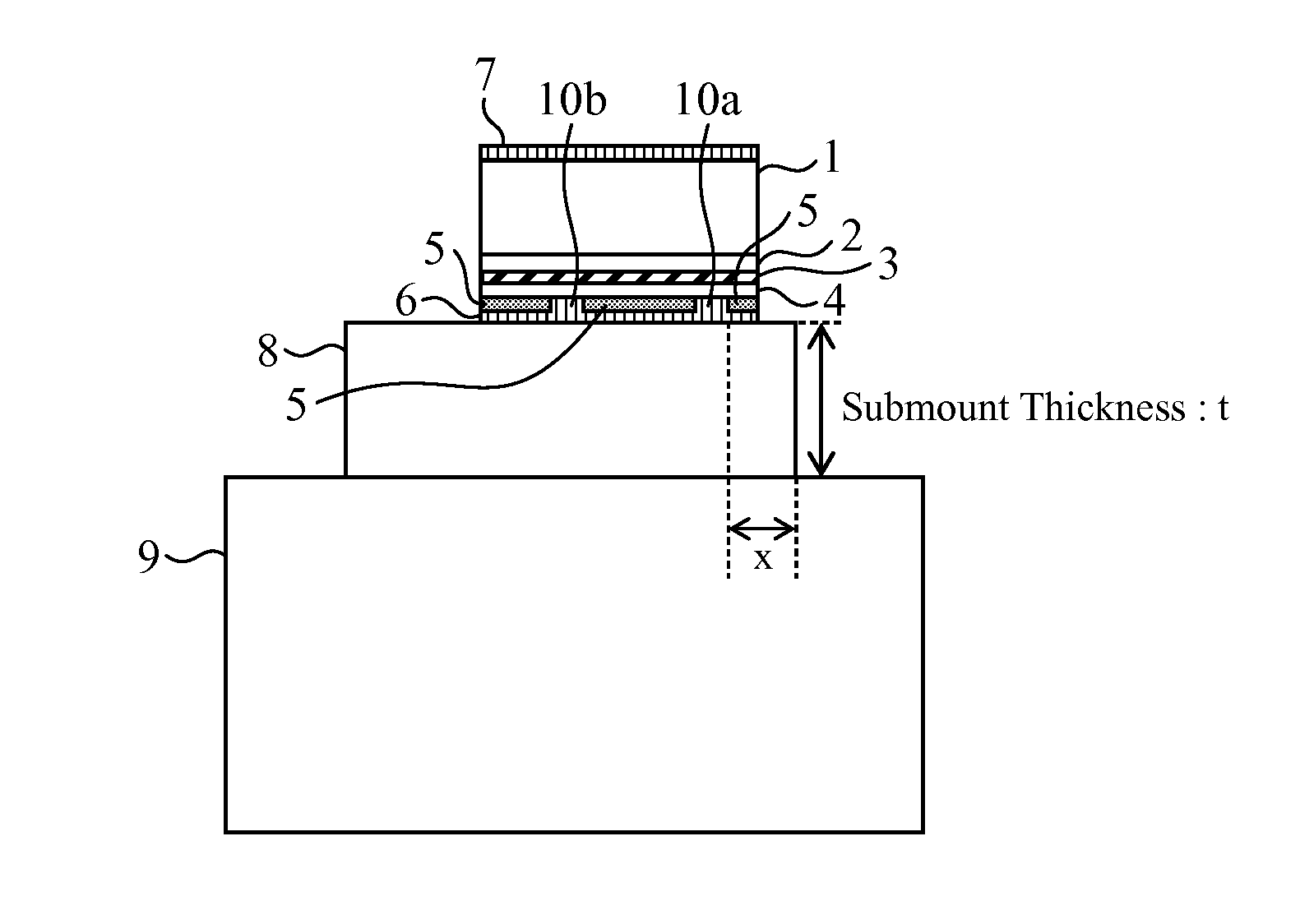

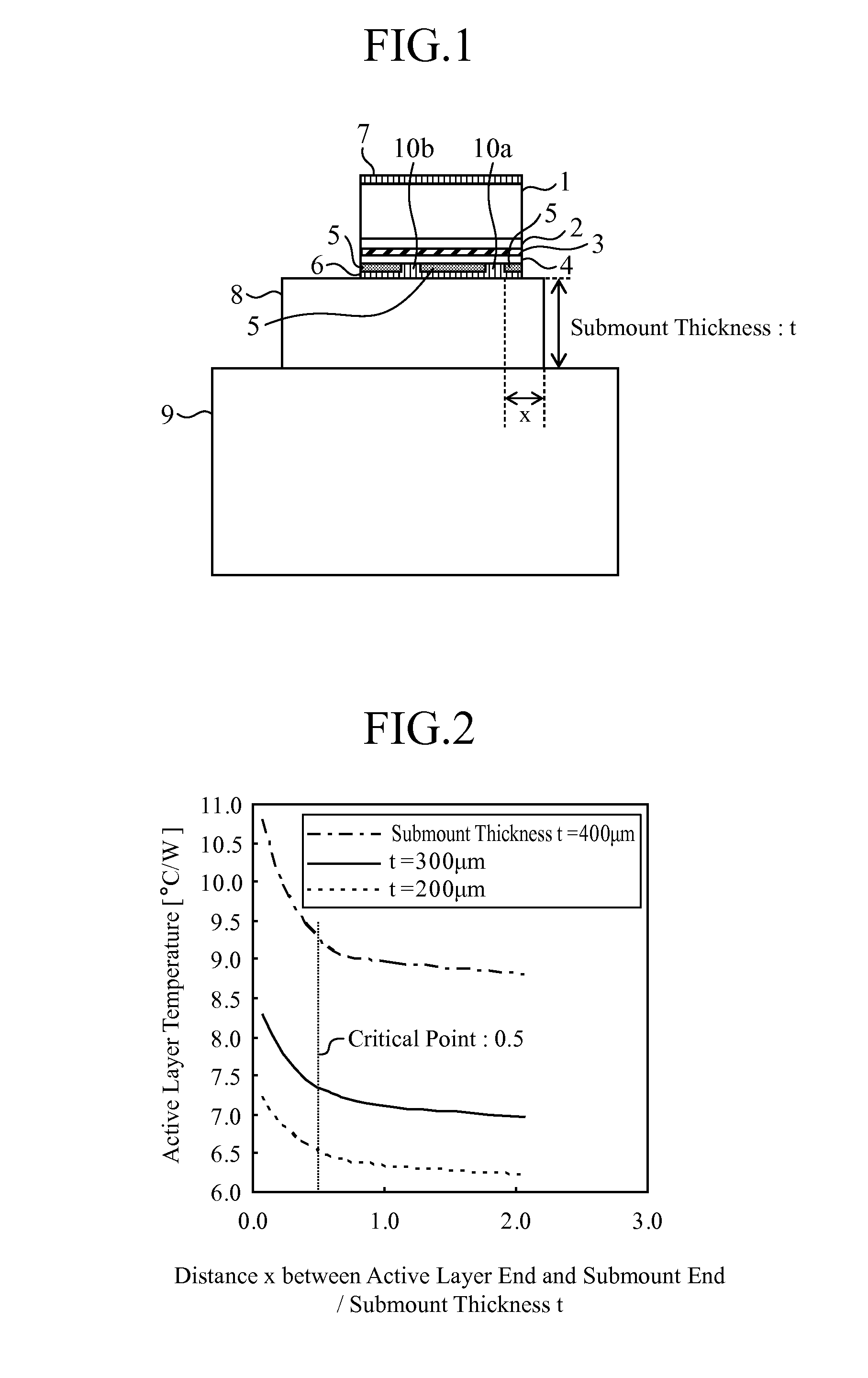

Semiconductor laser device

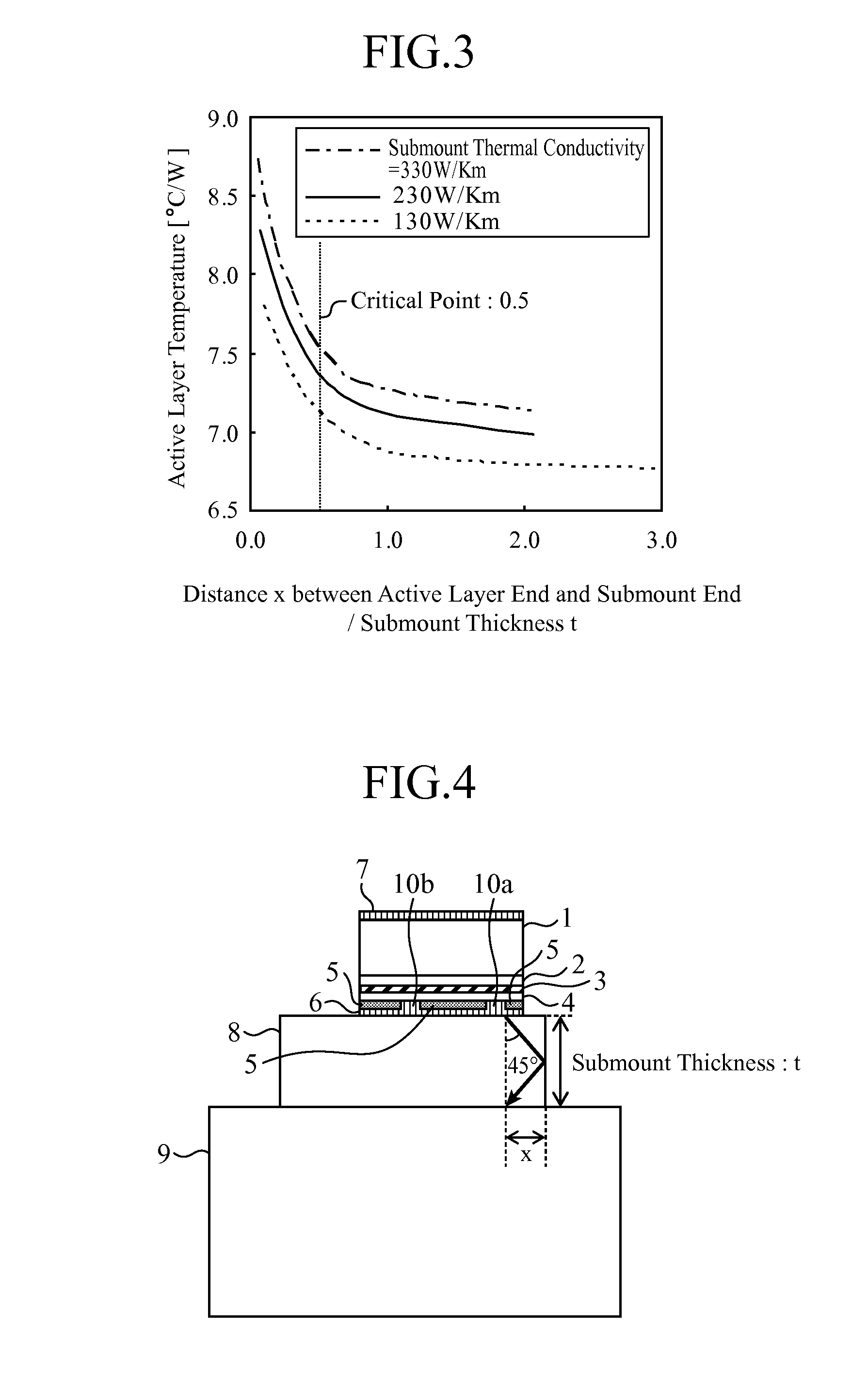

ActiveUS20160099543A1Suppress speckle noiseLow costLaser active region structureLaser cooling arrangementsSemiconductorLaser

In at least one opening of a plurality of openings 10a and 10b, the following inequality is satisfied:x≦½·t·(kx / ky)where x represents a minimum distance in a horizontal direction between an end of the one opening and an end of a submount 8, and t represents a thickness of the submount, andin at least one of the other openings different from the one opening, the following inequality is satisfied:x>½·t·(kx / ky)

Owner:MITSUBISHI ELECTRIC CORP

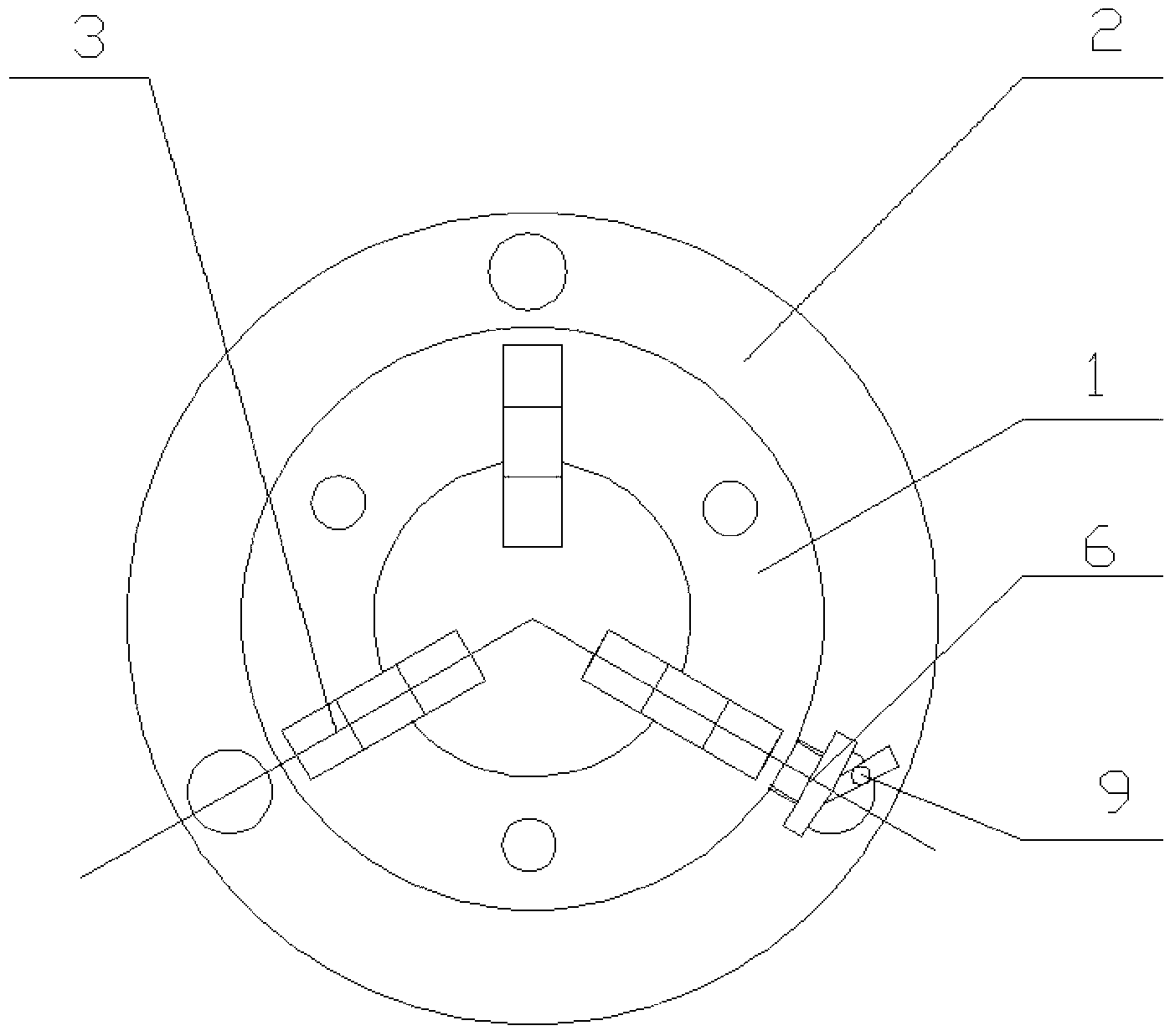

Synchronous centering and clamping mechanism

InactiveCN103495885AThe overall structure is simpleSmall footprintPositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a synchronous centering and clamping mechanism which comprises a base. Two sliding blocks are arranged on the base through sliding rails, a nut is fixedly arranged in each sliding block, the two nuts are both matched with the same lead screw, the rotating directions of the threads of the two nuts are opposite, one end of the lead screw is connected with the output shaft of a motor, a chuck is connected to each sliding block, and clamping blocks for clamping workpieces are arranged on the opposite inner sides of the two chucks. The synchronous centering and clamping mechanism is simple in overall structure, small in occupied space, accurate in centering and alignment, convenient to mount and maintain and capable of improving machining quality.

Owner:大连机床(数控)股份有限公司

Three elastic band rail gun barrel type launching mechanism

The three elastic band rail gun barrel type launching mechanism includes one frame, one ejecting orbit, one string winding and unwinding mechanism, one trigger mechanism and one ball loading mechanism, as well as one coupling connecting the motor of the string winding and unwinding mechanism to the string winding wheel, one pedestal for the string winding wheel to be fixed on, ball throwing rod in the trigger mechanism connected to the ball loading mechanism, ball throwing rod connecting steel wire connected to the string winding and unwinding mechanism, three elastic bands connected between the ball throwing rod and the frame, and the motor in the trigger mechanism connected to cam and fixed on the support. The present invention may be used in robot sports, ball training, recreation facility, life saving apparatus, etc to complete object throwing task.

Owner:HARBIN ENG UNIV

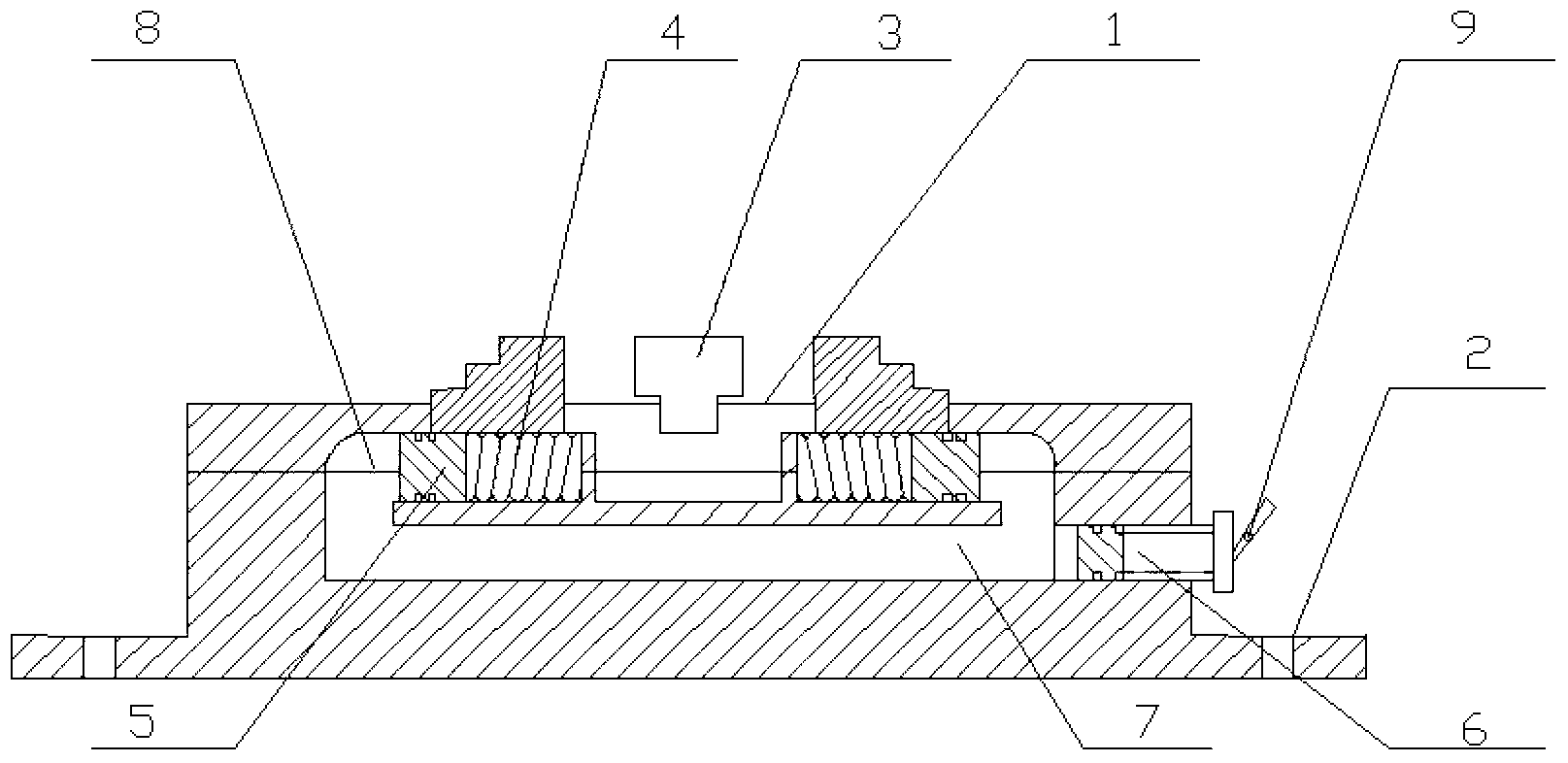

Hydraulic chuck

The invention discloses a hydraulic chuck. A chuck body is located in the middle of a flange, a circular main hydraulic cavity is formed by the chuck body and a flange body and is communicated with three auxiliary hydraulic cavities below the chuck body, springs are located in the auxiliary hydraulic cavities, one end of each spring butts against the inner end wall of each auxiliary hydraulic cavity, the other end of each spring is fixedly connected with each piston, the pistons are matched with the auxiliary hydraulic cavities through piston sealing rings, a hydraulic oil injection hole on the outer side of the flange body is communicated with the main hydraulic cavity, a pressing nut is matched with the hydraulic oil injection hole, the front end of the pressing nut is used for fixing a plunger with a sealing ring, and claws are evenly distributed on and fixedly connected with the upper surface of the chuck body with the chuck body as the center. Through clamping force transmitted by hydraulic oil in the main hydraulic cavity and the auxiliary hydraulic cavities, the three claws and the pistons are stressed to move along guide rails simultaneously, and centering accuracy is guaranteed. After processing is finished and hydraulic force is removed, the springs achieve loosening of the claws and keep the positions of the claws at ordinary time. A wrench is installed at the end of the pressing nut and is foldable. The flange is installed on an operation platform of a machine tool.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

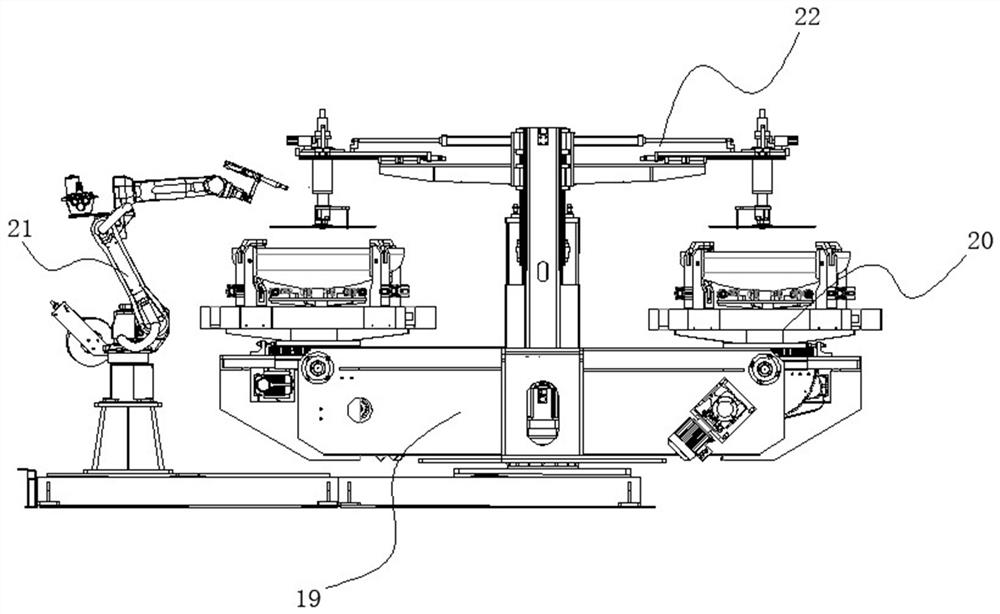

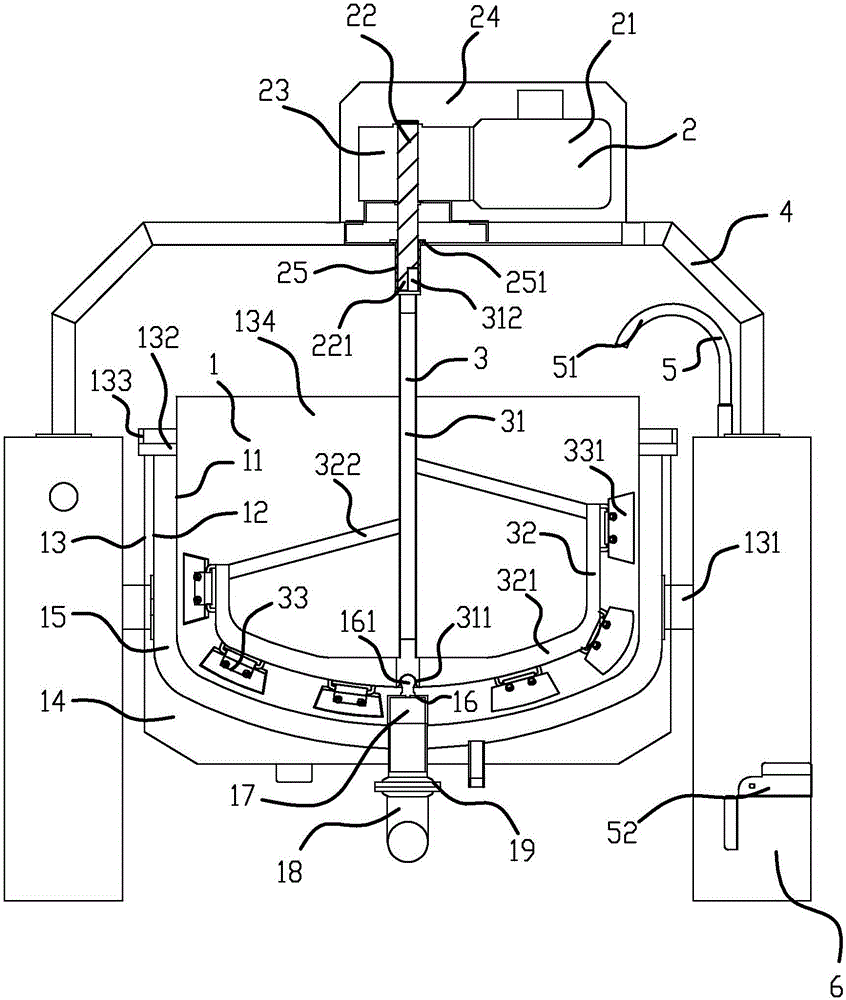

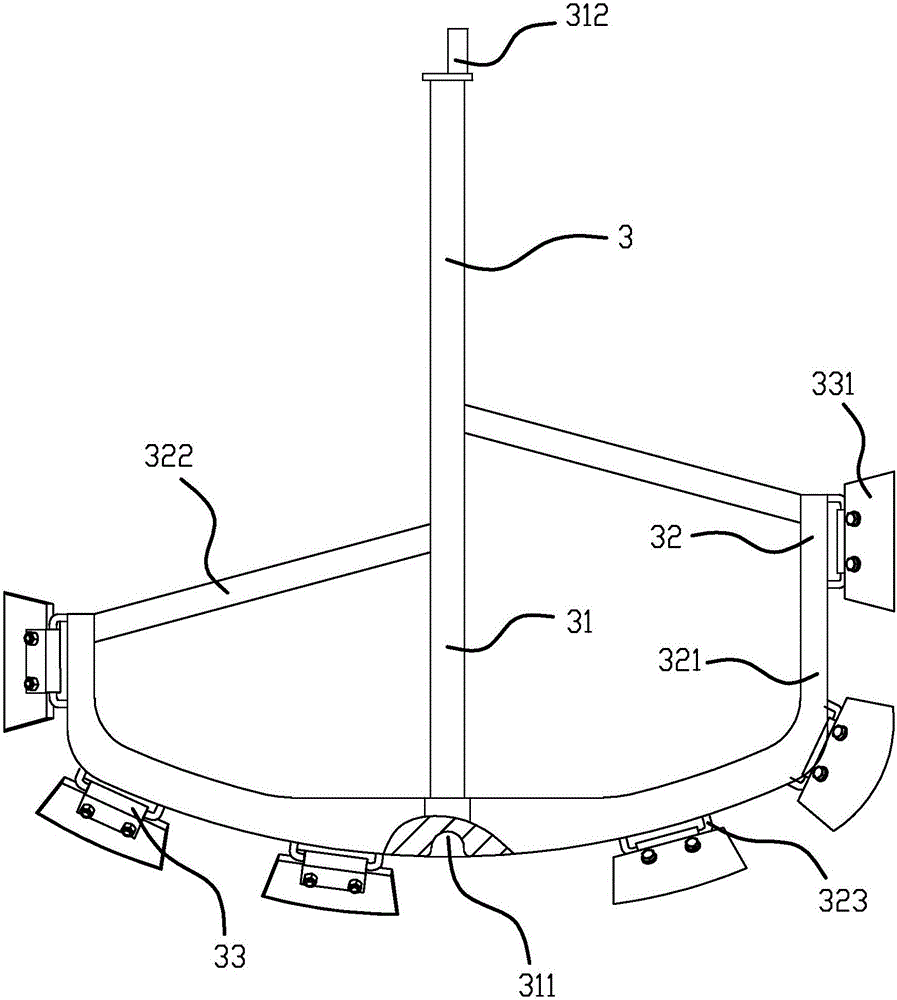

End socket welding device

PendingCN113478159ALow costIncrease productivityProgramme-controlled manipulatorGripping headsEngineeringCircular disc

The invention relates to the technical field of end socket welding, and particularly discloses an end socket welding device. The end socket welding device comprises a rotary table, at least two end socket positioning clamps are symmetrically arranged on the rotary table around the rotary center, two welding robots are arranged on one side of the rotary table, disc positioning clamps corresponding to the end socket positioning clamps in number are arranged on the rotary table, each end socket positioning clamp corresponds to one disc positioning clamp, a supporting frame is arranged at the top of the rotary table, the disc positioning clamps are fixedly installed on the supporting frame, the disc positioning clamps are used for positioning discs on end sockets, and a jacking air cylinder is arranged at the bottom of the supporting column and used for jacking the supporting column. The end socket welding device has the advantages that the rotary table is provided with multiple stations, each station is provided with one end socket positioning clamp and one disc positioning clamp, welding can be conducted during feeding and discharging through the multiple stations, therefore, the welding efficiency is improved, manual welding is replaced, and the manufacturing cost is reduced.

Owner:成都磐拓谷科技有限公司

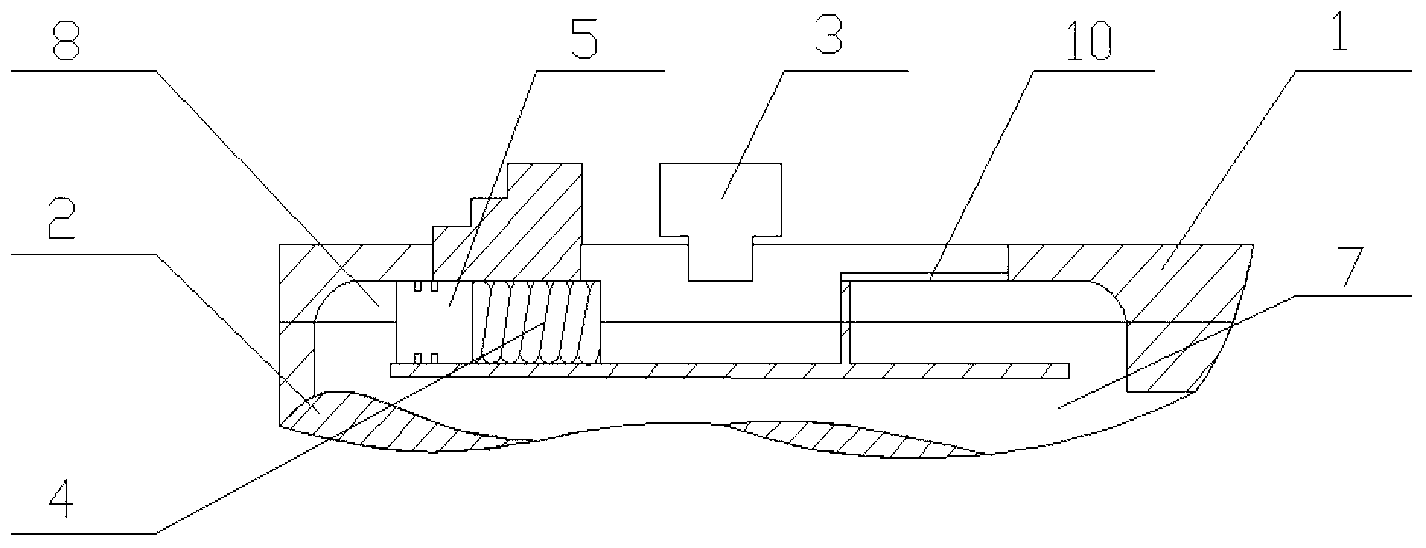

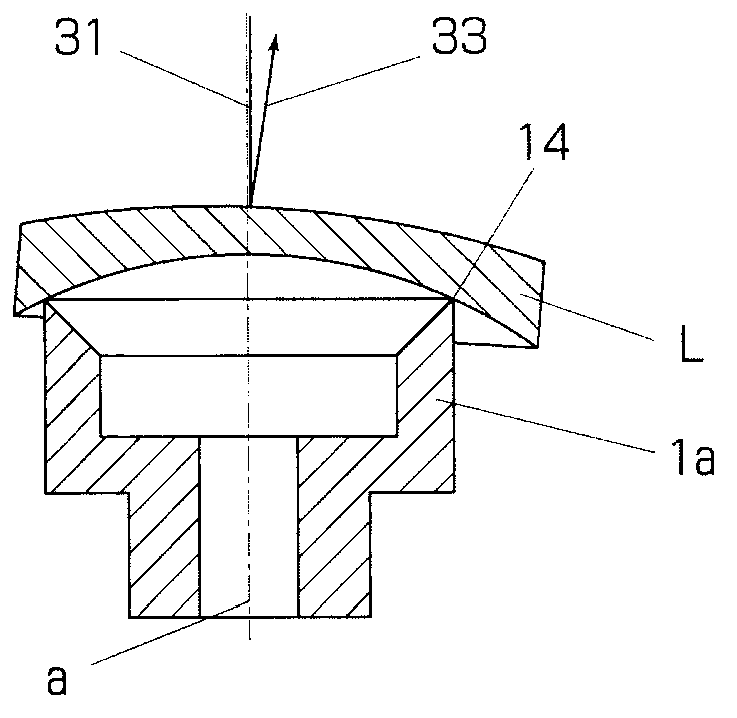

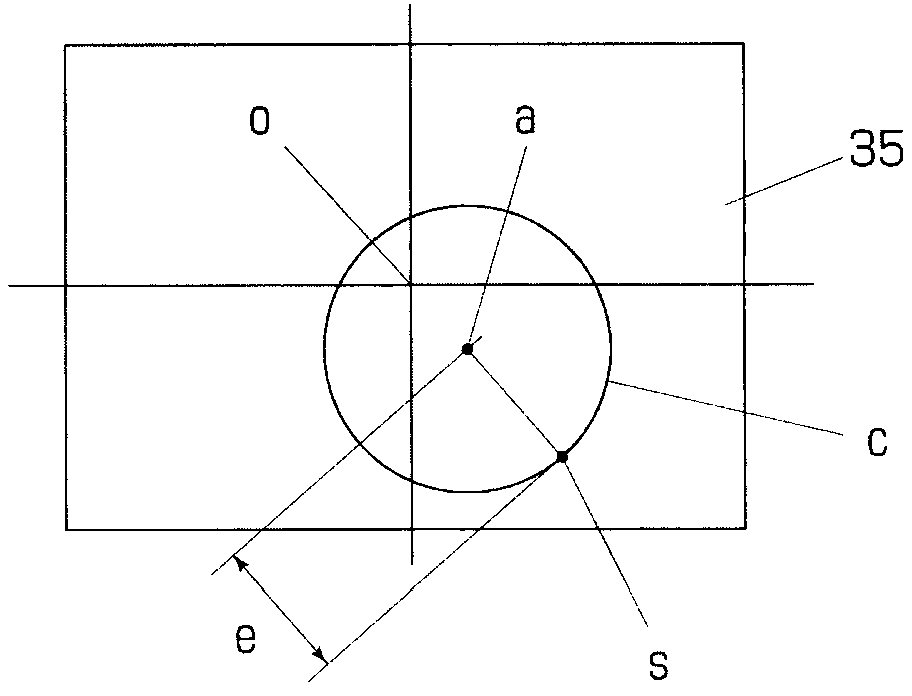

Method and apparatus for centering lens aligner

ActiveCN103084954ABe at easeControl the amount of pushingEdge grinding machinesOptical surface grinding machinesPhysicsOptical measurements

A method and an apparatus for centering lens aligner are disclosed. Small lens of the Z value can be accurately centered without causing damages to the lens. The apparatus is provided with a optical measurement device for receiving reflected light or transmission light of light beams projected from the surface of the lens facing a holding frame and outputting photic positions; a push rod arranged independently from a spinning grinding apparatus for processing the periphery of the lens; and a conveying apparatus enabling the push rod to move towards the axis of the holding frame. According to the measurement value of the optical measurement device, the eccentric direction of the lens is made to face the direction of the push rod so as to keep the holding frame rotating, and the push rod is made to move forwards towards the holding frame.

Owner:NAKAMURATOME SEIMITSU IND

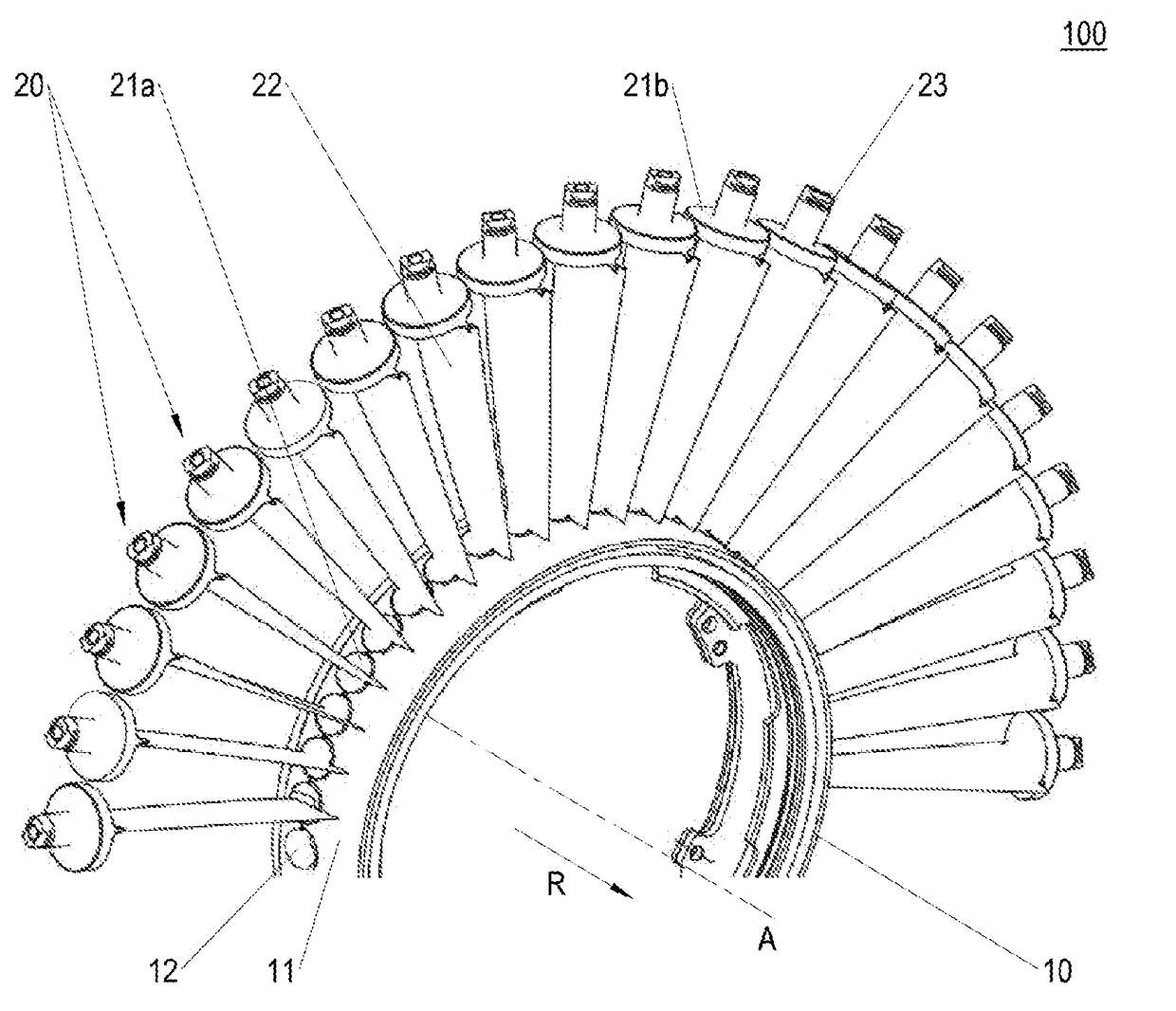

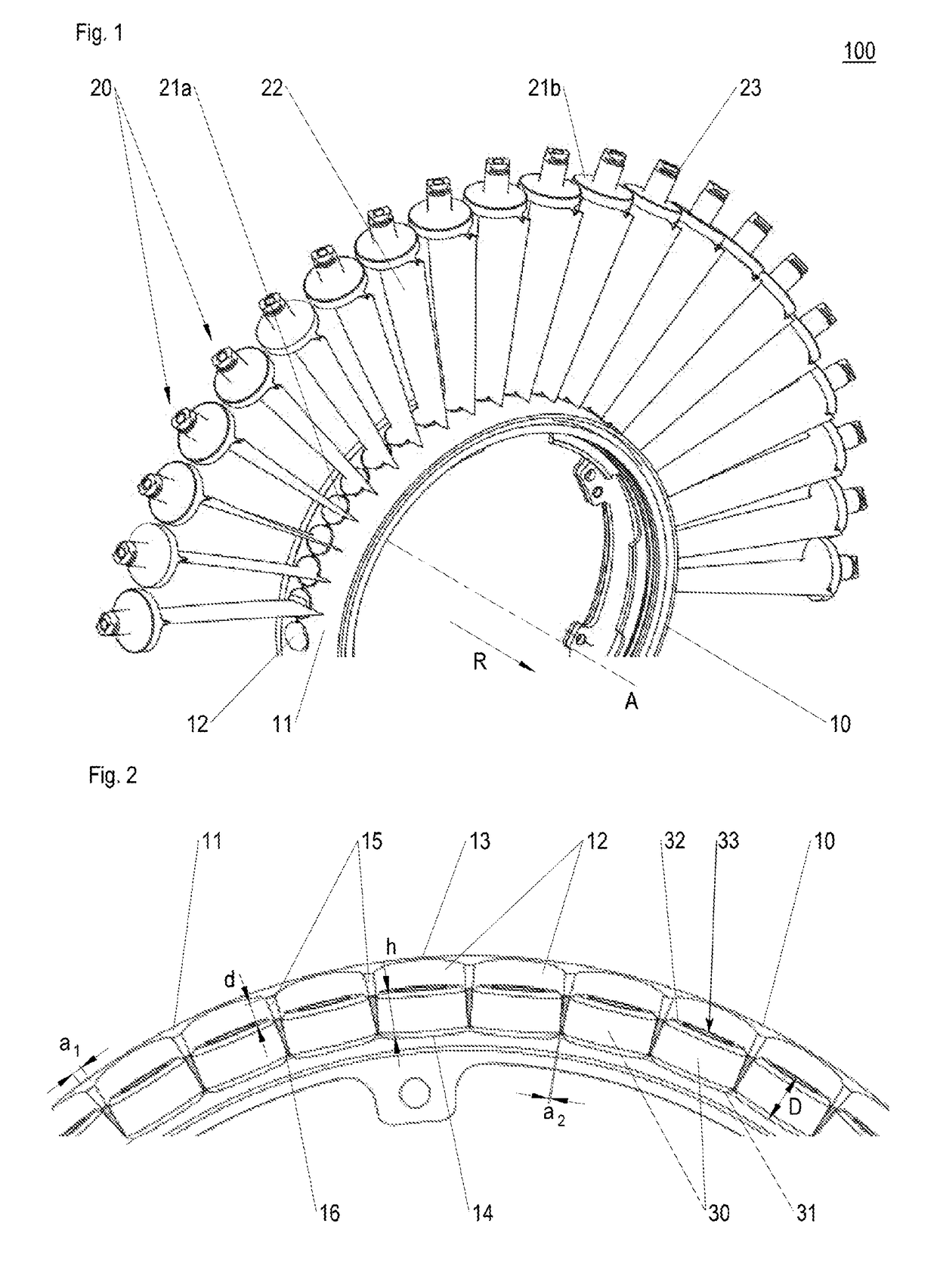

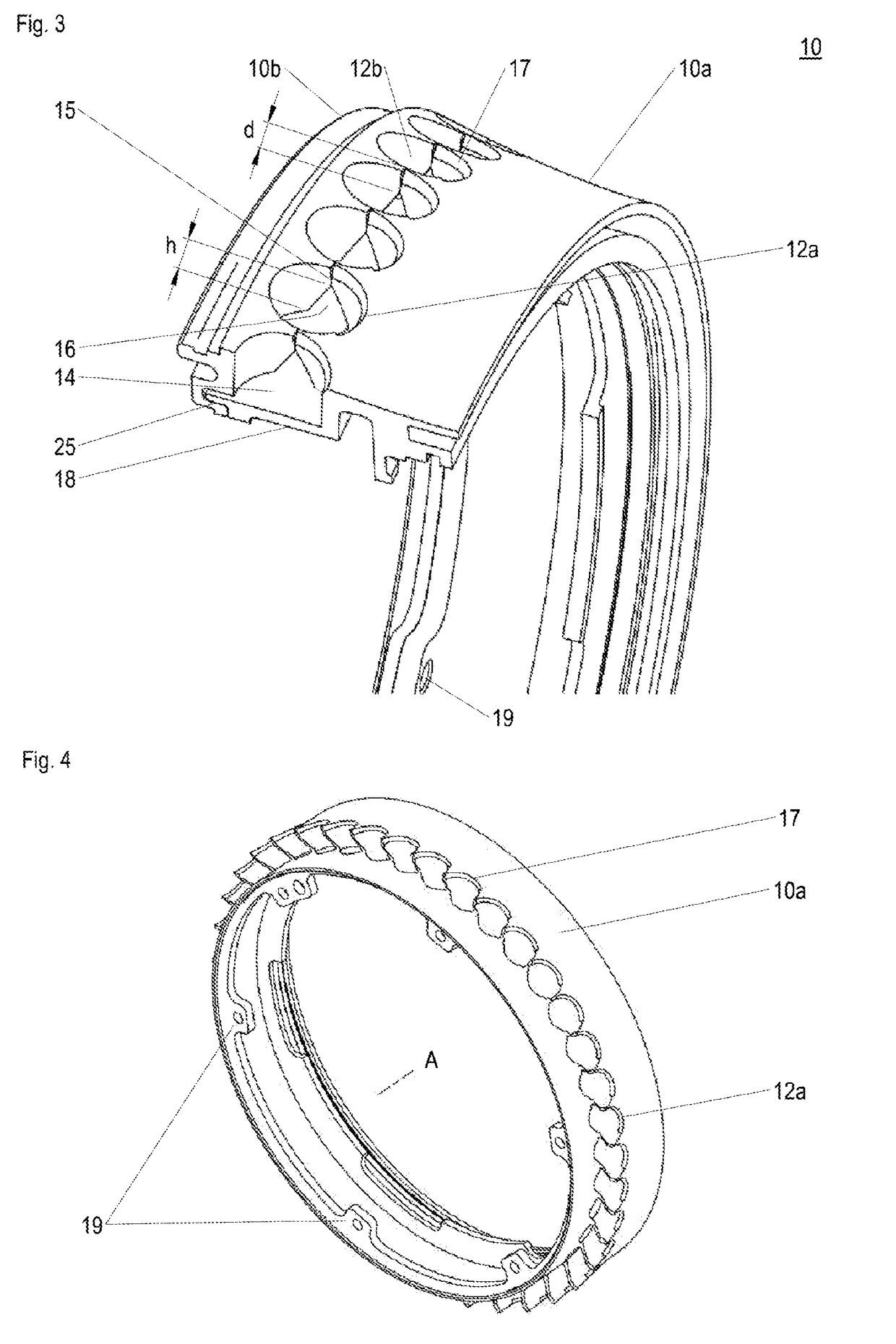

Inner ring and guide vane cascade for a turbomachine

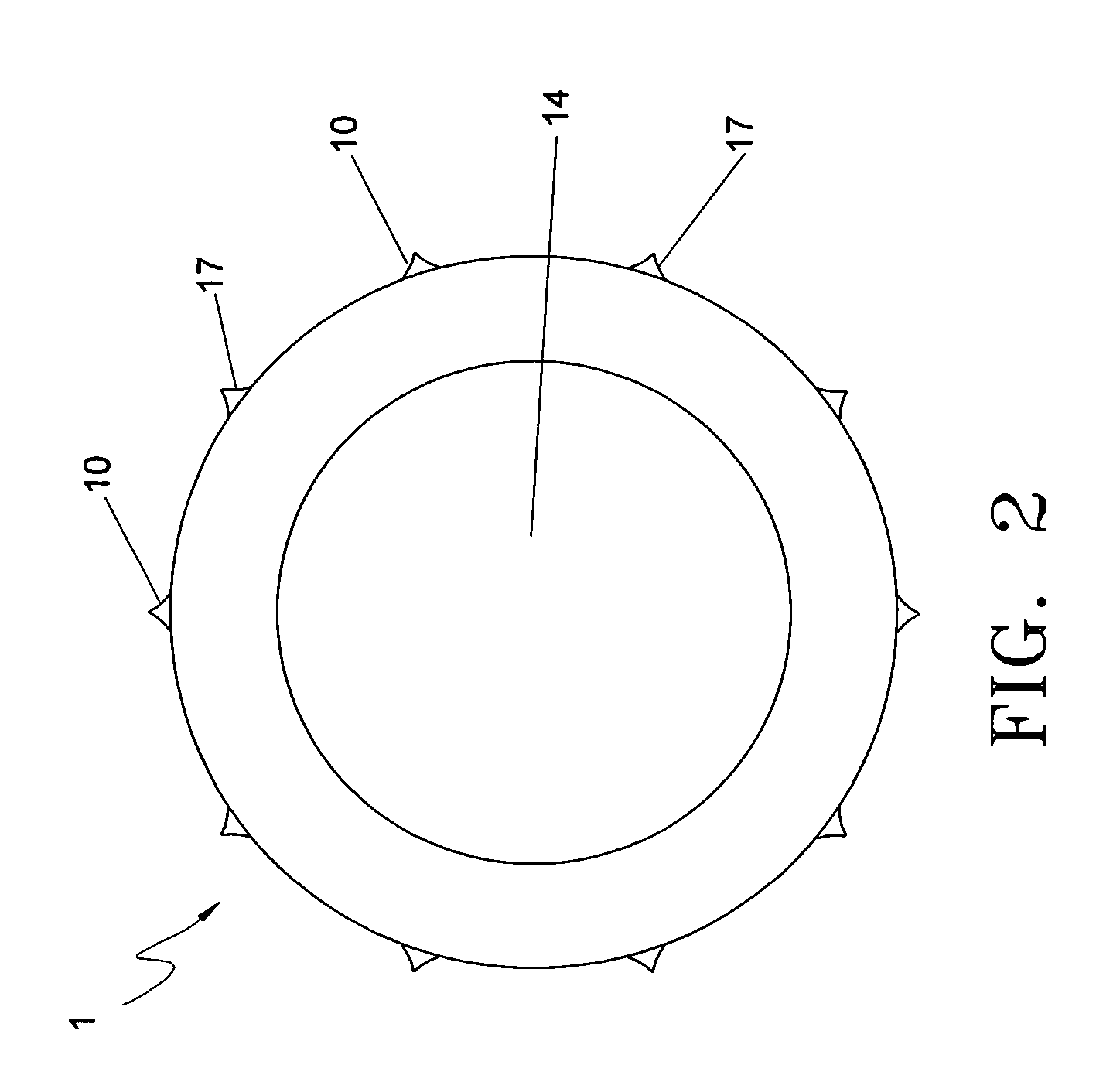

An inner ring 10 according to the invention for a guide vane cascade of a turbomachine has a radially outer inner ring surface 11 as well as a plurality of bearing mounts 12 for a respective guide vane plate 21a of a guide vane 20. The bearing mounts 12 each have an opening 13 in the outer inner ring surface 11 as well as a bottom face 14 lying radially opposite the opening. At least two of the bearing mounts 12 are separated from each other by a separating wall 15 and are connected to each other in a region of their bottom face 14 by a through-opening 16. A guide vane cascade 100 according to the invention for a turbomachine has an inner ring 10 according to the invention and a plurality of guide vanes 20 inserted into the bearing mounts 12.

Owner:MTU AERO ENGINES GMBH

Pipe billet cooling centering machine

ActiveCN103084415AReduce consumptionReduce generationGuiding/positioning/aligning arrangementsHydraulic cylinderProcess equipment

The invention relates to a pipe billet cooling centering machine and belongs to processing equipment of a pipe billet producing preparation period of seamless steel pipes and is particularly suitable for rolling pipe billets of large-diameter think-wall seamless pipes and pipe billet prepares of alloy steel pipes. The pipe billet cooling centering machine structurally includes that a hydraulic clamp is installed on the front potion of the base seat through a fastening bolt and a location pin, a min machine is fixed on the upper portion of the base seat through the fastening bolt and a location key, a magnetism chip cleaner is placed on the lower portion of the base seat and is used for collecting scrap irons machining down from the pipe billets when the pipe billets in centering, an emulsified liquid cooling system is connected on the back portion of a draw rod on the main machine through a rotating connecter and used for providing cooling liquid for drilling tools, one fixing end of a position detecting device is fixed on the base seat, and one moving end is fixed on a sliding seat of the main machine, the position of a detecting sliding seat is the position of a drill on the main machine, a hydraulic system is used for providing hydraulic oil for a hydraulic clamping cylinder of the hydraulic clamp and driving the hydraulic cylinder to operate, a sweep collecting frame is placed on the lower portion of a chip removal opening of the magnetism chip cleaner. The pipe billet cooling centering machine has the advantages of being novel in structure, easy and convenient to manufacture, convenient to use, capable of reducing energy consumption, accurate in centering, capable of reducing pollutions and the like.

Owner:大连三高科技发展有限公司

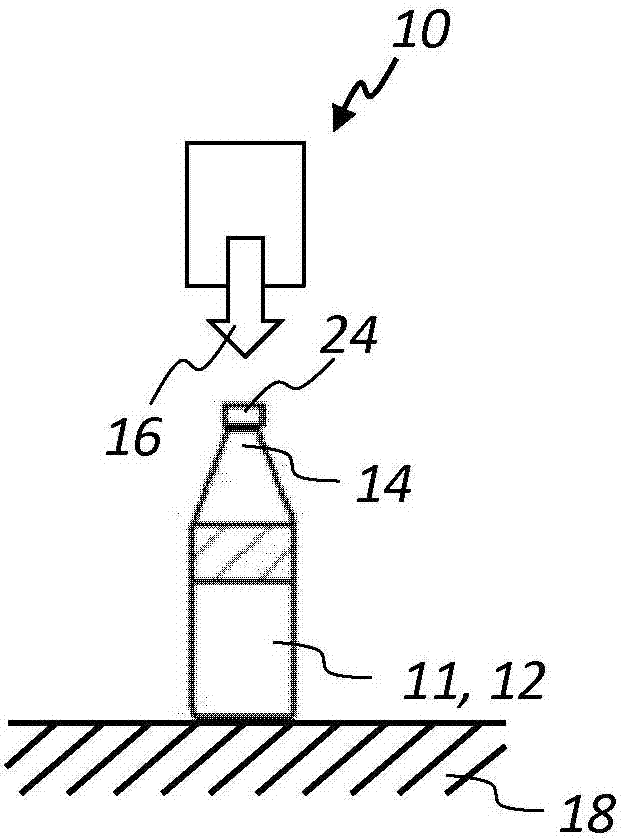

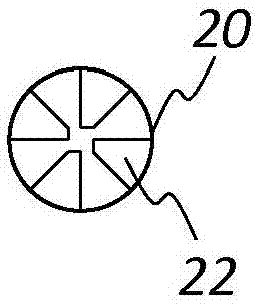

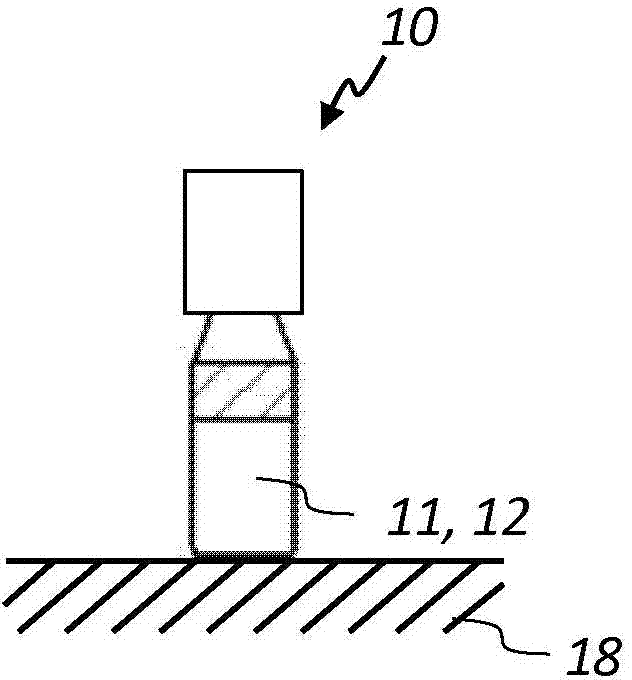

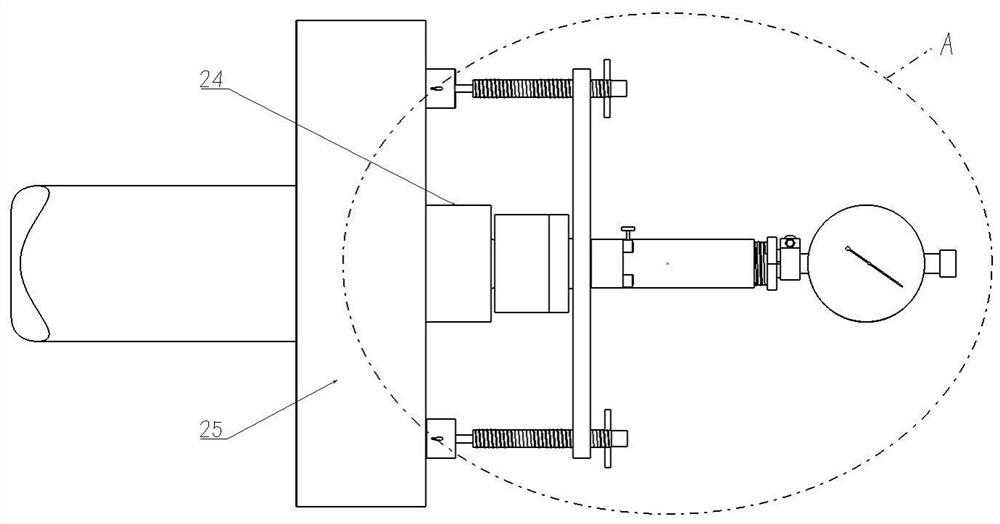

Gripping device

The invention relates to a gripping device (10) which is used for gripping and / or keeping a preferably vertical article (11) such as a bottle (12), a can, a container and the like at a contact section (15) of a peripheral side face of the article. The device is provided with at least three gripping tongue-shaped members (22) which roundly surround the contact section (15) at roughly the same height, the gripping tongue-shaped members are suspended on a retaining frame (20) of the device (10) in a pivoted and / or elastic manner, and the gripping tongue-shaped members are also supported on the retaining frame while inwardly pointing to one another. By passing the device (10) through the neck part section of the article (11) and thrusting the device along the longitudinal extending direction parallel to the article (11) , the gripping tongue-shaped members are upward pressed apart in an inclined manner against the elastic reset force and are respectively arranged at angle positions relative to the retaining frame (20), and end faces (21) of the gripping tongue-shaped members and / or side edges are supported relative to the contact section (15) of the article in a shape cooperation and / or force cooperation manner,

Owner:KRONES AG

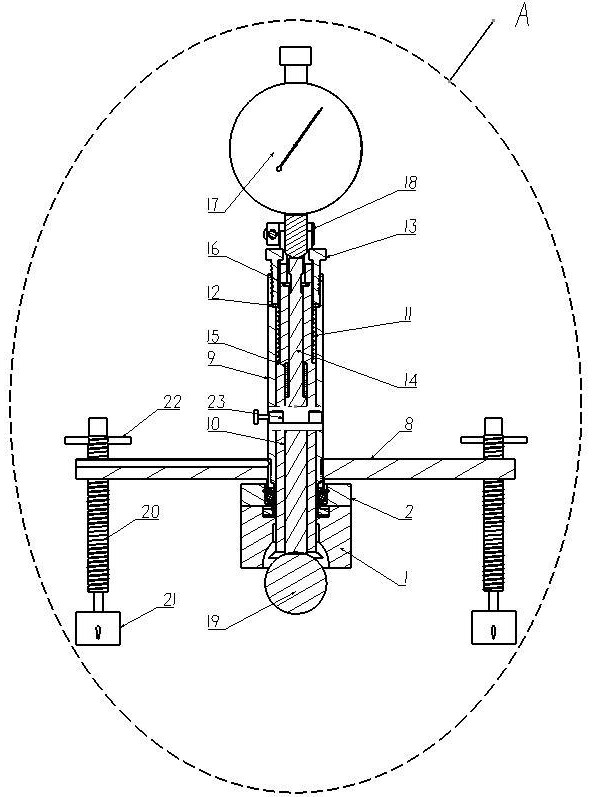

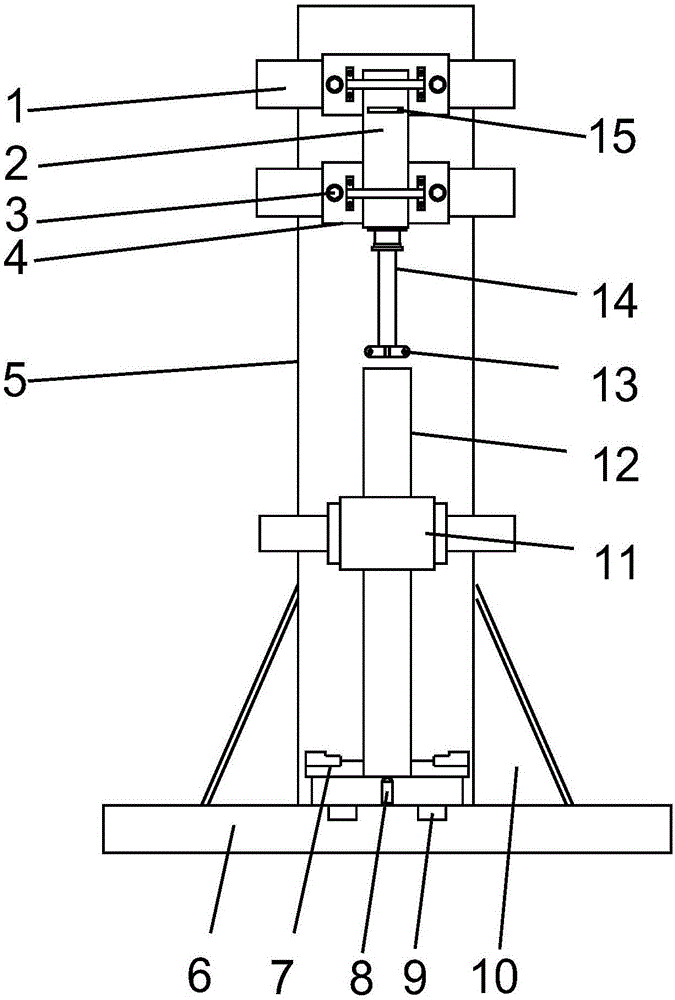

Ball screw axial runout rapid detection device

ActiveCN112179234AGood practicalityEasy to operateMechanical measuring arrangementsRapid detectionBall screw

The invention discloses a ball screw axial runout rapid detection device, which comprises a high-precision ball body, a rotary separation mechanism which is installed on the end face of a screw and performs separation circular motion, a pre-tightening adjustment mechanism which is used for pre-tightening the high-precision ball body to be attached to the wall of a center hole of the screw, a precision measurement mechanism and a supporting assembly. The pre-tightening adjusting mechanism is installed on the end face of the screw through the supporting assembly and connected with the rotary separation mechanism. The precision measurement mechanism passes through the rotary separation mechanism and is in point contact with the high-precision ball body. According to the invention, the circumferential rotation precision of the screw can be converted into the axial run-out precision of the high-precision ball body, the axial run-out precision is transmitted to a dial indicator through a mandrel, and the detection of the axial run-out precision is realized by reading the change of the pointer of the dial indicator; the device is simple to operate, rapid in detection and high in practicability.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Aligning station device

PendingCN108161261APrecise positioningBe at easeWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelSlide plate

The invention relates to an aligning station device. A driving wheel and a driven wheel are rotatably and freely supported on a base plate; a synchronous belt sleeves on the driving wheel and the driven wheel; a first clamping block is arranged on one side of the synchronous belt; a second clamping block is arranged on the other side of the synchronous belt; a right sliding plate and a left sliding plate are correspondingly arranged on the first clamping block and the second clamping block; an aligning left barrier strip and an aligning right barrier strip are correspondingly arranged on the left sliding plate and the right sliding plate, and are arranged in parallel; the synchronous belt drives the first clamping block and the second clamping block to linearly move in an opposite movementdirection, so that the left sliding plate and the right sliding plate linearly move in the opposite movement direction, the aligning left barrier strip and the aligning right barrier strip are drivento move face to face or oppositely at the same time, and a closing action or an opening action is produced for positioning and centering a carrier. The aligning station device is used for aligning the carrier transported from a taking mechanism, and automatically positioning and centering, so that a preparation is made for a following process, and the point-to-point transporting accuracy during transporting is improved.

Owner:SUZHOU DELPHI LASER +1

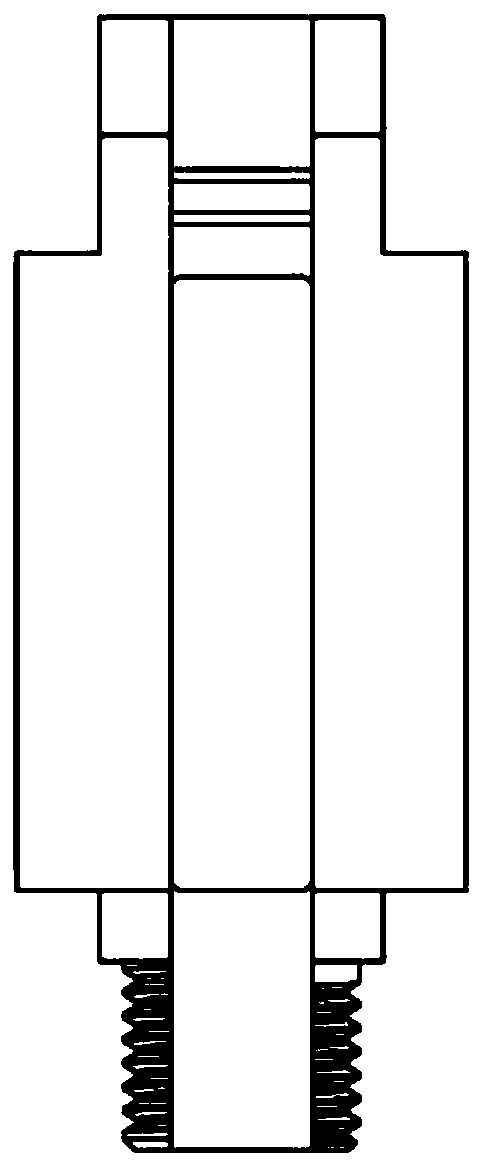

Novel efficient screw tap

The invention discloses a novel efficient screw tap and relates to the technical field of cutters. The screw tap comprises a handle part, a working part, cutting chip accommodating grooves, a cutting cone, a guiding part, a guiding chip accommodating groove and a positioning column; one end of the handle part is connected with the working part; the cutting cone is arranged at one end of the working part; a plurality of longitudinal cutting chip accommodating grooves are formed in one end of the working part; one end of the working part is connected with the guiding part; the guiding chip accommodating groove is formed in the guiding part; the guiding chip accommodating groove is consistent with the cutting chip accommodating grooves in direction; and the center of one end of the guiding par is connected with the positioning column. With the novel efficient screw tap, the machining accuracy can be guaranteed, the service life is prolonged, the problem that a traditional handle part and a traditional working part are subjected to friction welding and are broken easily is solved, and the screw tap has the advantages of being simple in structure, reasonable in arrangement, low in manufacturing cost and the like.

Owner:JIANGSU TIANGONG TOOLS CO LTD

Vertical steel pipe self-centering straightening equipment

InactiveCN106670268AReduce frictionBe at easeMetal-working feeding devicesPositioning devicesSteel tubePiston rod

The invention discloses vertical steel pipe self-centering straightening equipment. The vertical steel pipe self-centering straightening equipment comprises a machine frame, a machine seat, an oil cylinder and straightening rollers; the machine frame is fixed to the machine seat; a three-claw clamping disc is welded and fixed to a welding block which is positioned on the machine seat; the oil cylinder is vertically downward and is fixedly mounted on a sliding seat; the sliding seat is arranged on a transverse guide rail which is positioned on the machine frame in a sliding manner; the straightening rollers are mounted on a connecting shaft; the connecting shaft is welded and fixed to a piston rod of the oil cylinder; at least four straightening rollers are uniformly arranged in the circumferential direction of the connecting shaft; the maximum distance between opposite two straightening rollers is equal to the inside diameter of a steel pipe. According to the vertical steel pipe self-centering straightening equipment, the friction between each straightening roller and the inner wall of the steel pipe is small, and the outer wall of the steel pipe cannot be worn, so that the surface quality of the outer wall of the steel pipe cannot be influenced; during a straightening process, the steel pipe is fixed; the problem of twisting or rotating is avoided; therefore, other negative effects cannot be produced.

Owner:合肥九州龙腾科技成果转化有限公司

Saucepan provided with detachable stirring rod

ActiveCN105852656AEasy to disassembleEasy to installBoiling over preventionCooking utensils shields/jacketsPulp and paper industry

Owner:ZHEJIANG XIANGYING CENT KITCHEN EQUIP CO LTD

Shaft sleeve groove automatic polishing equipment

ActiveCN110076678ABe at easeEasy loadingPolishing machinesGrinding drivesEngineeringMechanical engineering

The invention provides shaft sleeve groove automatic polishing equipment. The equipment is characterized in that a clamping positioning device, a polishing device and an automatic feeding and discharging device are included; the clamping positioning device is fixedly installed on the upper portion of the polishing device and comprises a clamping motor and a clamping plate, and the clamping motor is rotated to drive the clamping plate to automatically clamp and position a to-be-processed shaft sleeve; an annular groove formed in the surface of the shaft sleeve is automatically polished by the polishing device, the polishing device can move up and down to make feeding and discharging convenient, the automatic feeding and discharging device are fixedly installed at the front end of the polishing device to automatically feed and discharge materials for the shaft sleeve.

Owner:自贡中兴耐磨新材料有限公司

Partition alignment tool and method

ActiveCN105215668ABe at easeImprove coaxialityMetal working apparatusWire tensionPartition alignment

The invention provides a partition alignment tool and method, and belongs to the technical field of condenser partition mounting processes. The problems that alignment of partitions is difficult and low in accuracy in the prior art are solved through the partition alignment tool and method. The partition alignment tool comprises a steel wire, a centering bolt, a steel wire fixator, a steel wire tension measurer, a partition aligner and the like. The alignment method comprises the steps of tube plate mounting, steel wire centering, partition alignment measurement and the like. The partition alignment tool is simple in structure, low in cost, convenient to operate and high in alignment accuracy.

Owner:HANGZHOU GUONENG STEAM TURBINE ENGINEER

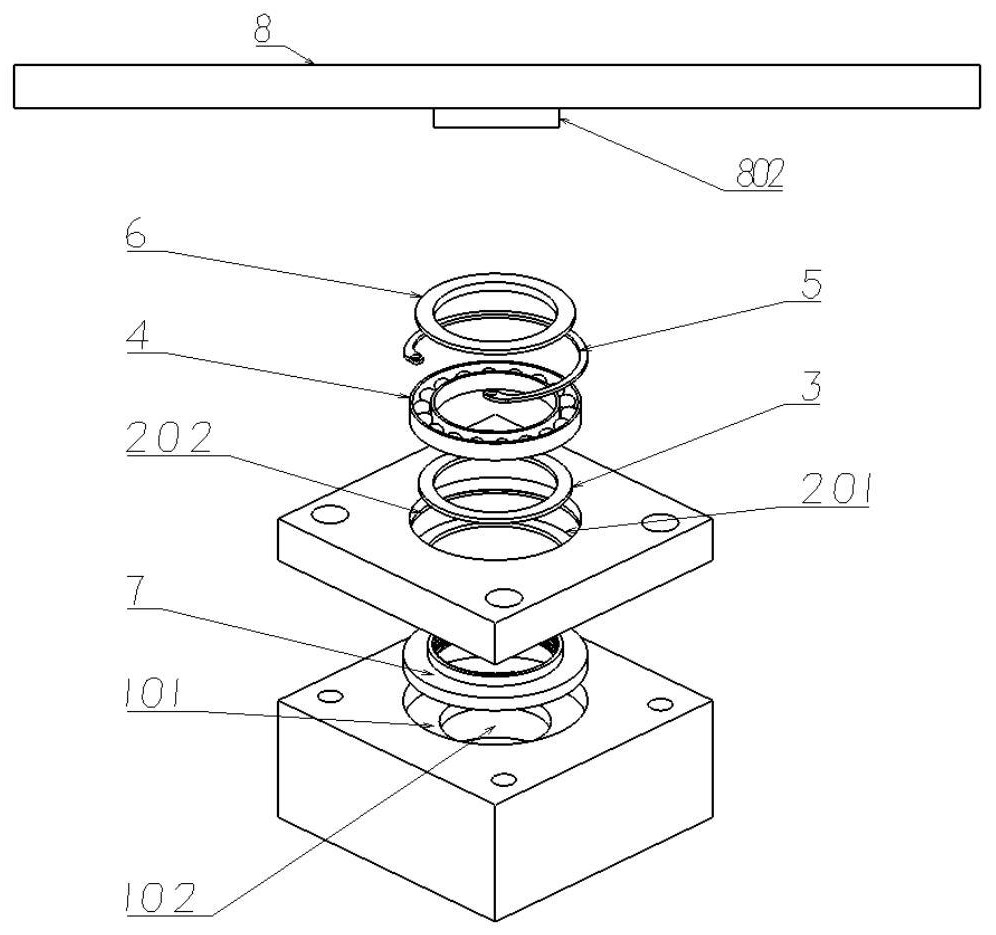

Precise centering fixture for repairing back lining bearing

ActiveCN101774138AEasy clampingEasy to operateRevolution surface grinding machinesInterference fitSteel ball

A precise centering fixture for repairing back lining bearing is used for repairing back lining bearing. An outer ring is arranged at the outer part of a keeping apparatus; a steel ball is embedded in the window of the keeping apparatus; a deflector rod is connected on a mandrel, and the mandrel is connected with a centering ring through interference fit integrally; one end of a positioning rod is connected with the mandrel and the other end thereof is inserted in the hole of a limiting plate; the limiting plate is connected on one side of the keeping apparatus; a limit stop is connected with one side of the keeping apparatus; a rigid ring is sheathed outside the steel ball in the window of the keeping apparatus; the longitudinal section of the centering ring is dumbbell-shaped, and uniformly distributed circular arcs with alternating wave crests and troughs are arranged at the contact positions of the radial circumferences on the edges of the two sides of the centering ring and the steel ball; and a baffle is connected on the other end of the keeping apparatus. The bearing is sheathed on the mandrel, the outer ring of the back lining bearing is accurately positioned on the mandrel through the elastic approach amount of the precise steel ball; enough load is used for bearing the grinding force in the tangential direction for grinding the outside diameter of the bearing sleeve with high precision to realize the centering maintenance of the back lining bearing. The mounting operation is convenient, the centering precision is high, the sealing property is good, the grinding precision is high, and the application range is extensive.

Owner:XIANGYANG BOYA PRECISION IND EQUIP

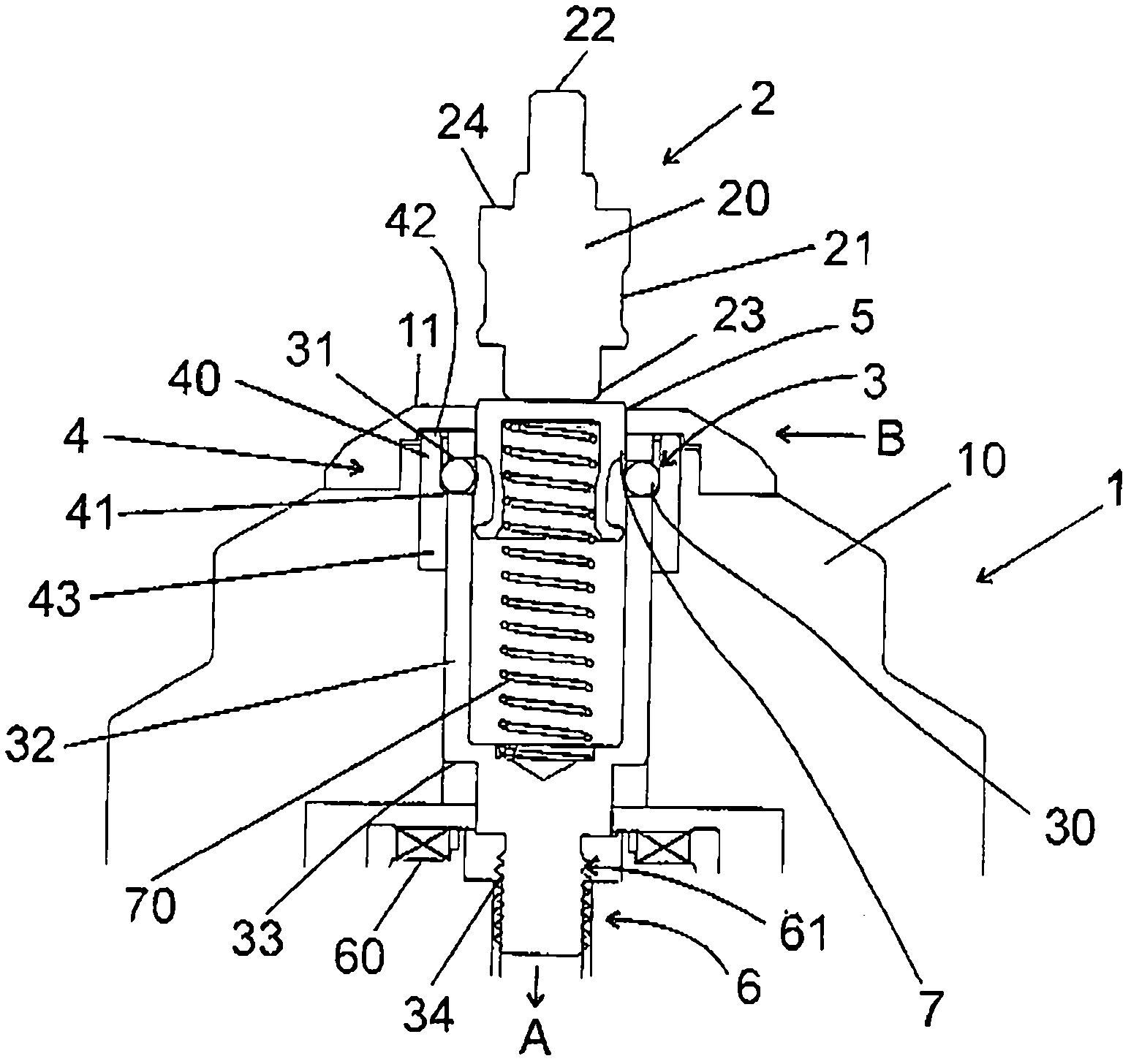

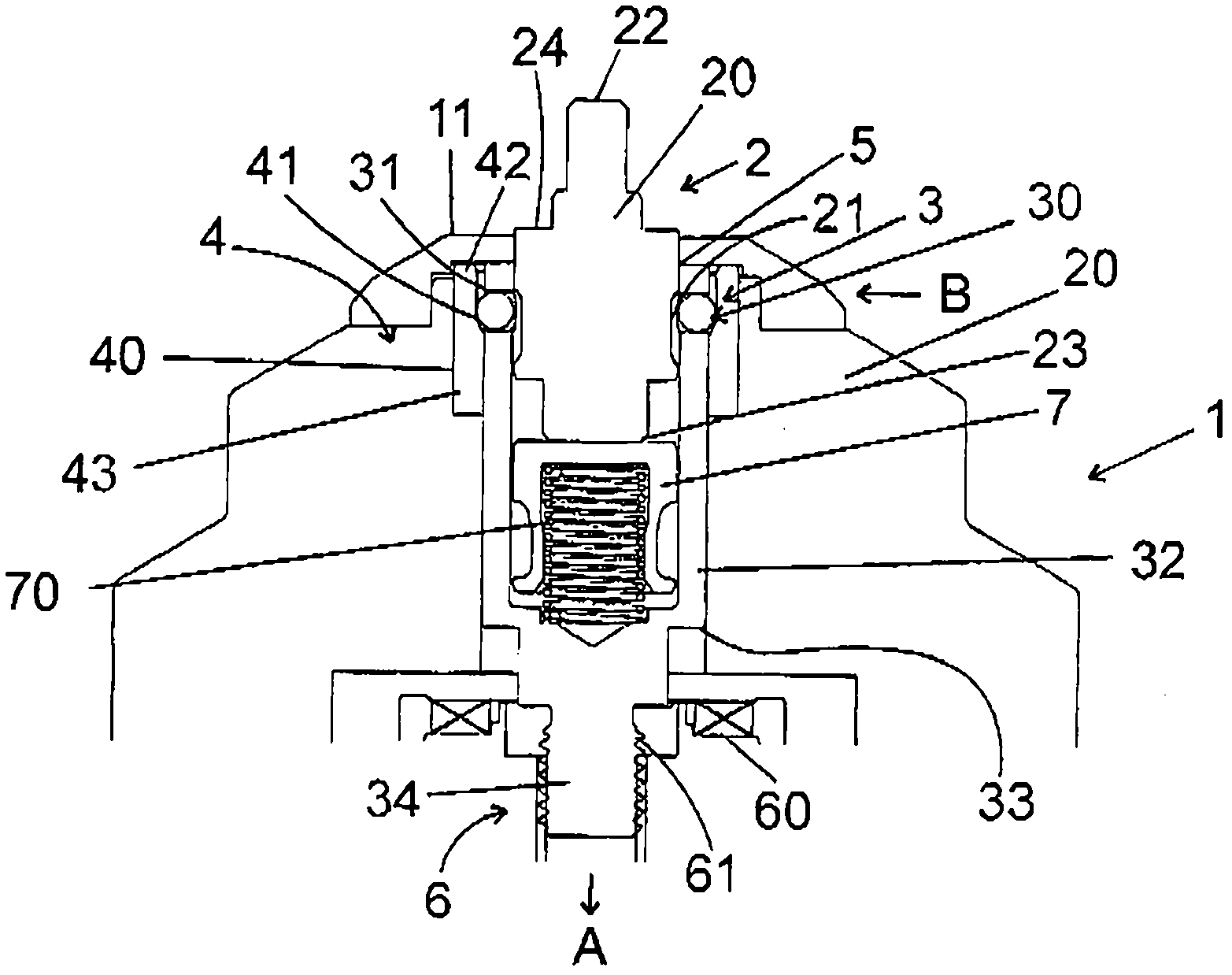

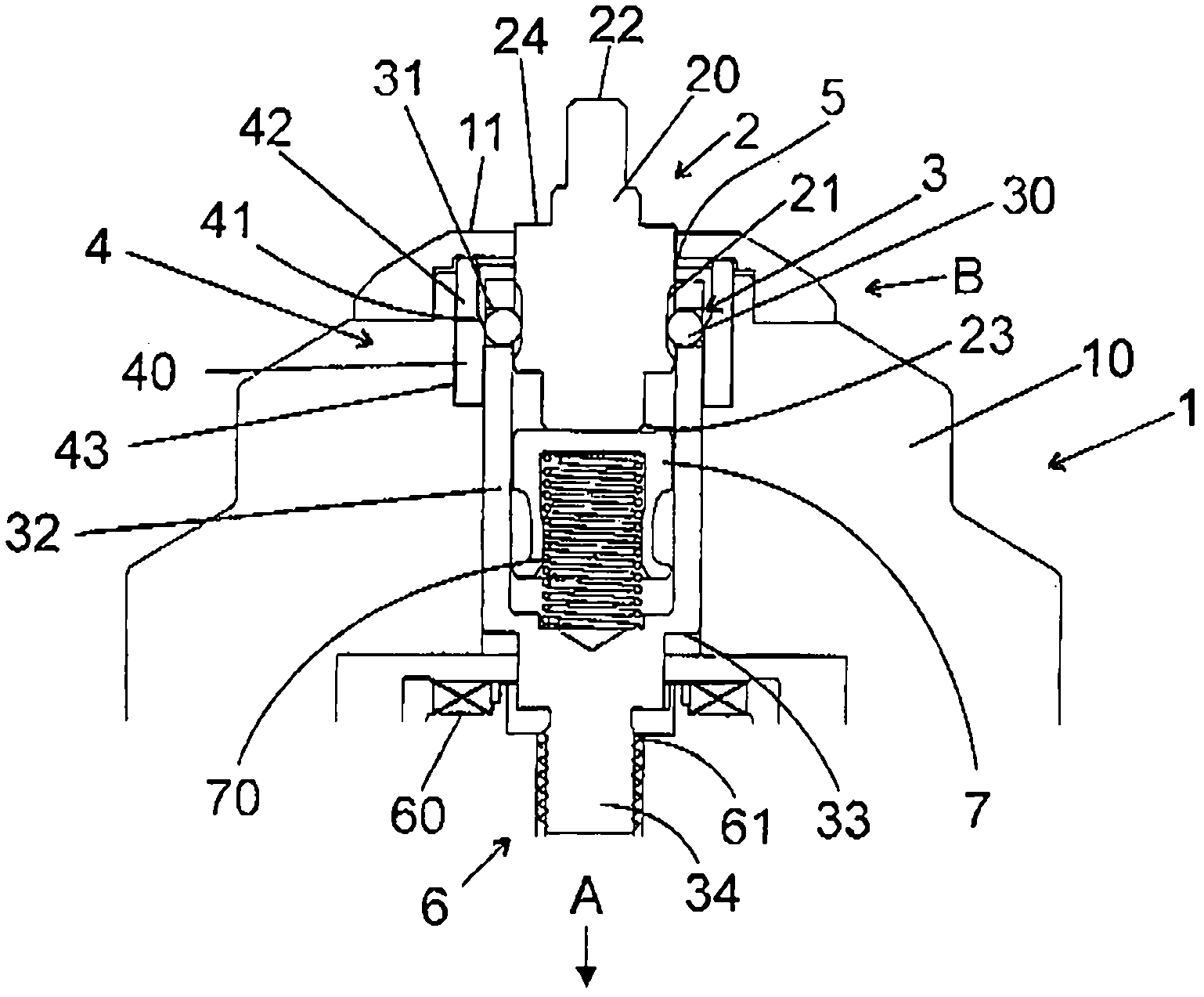

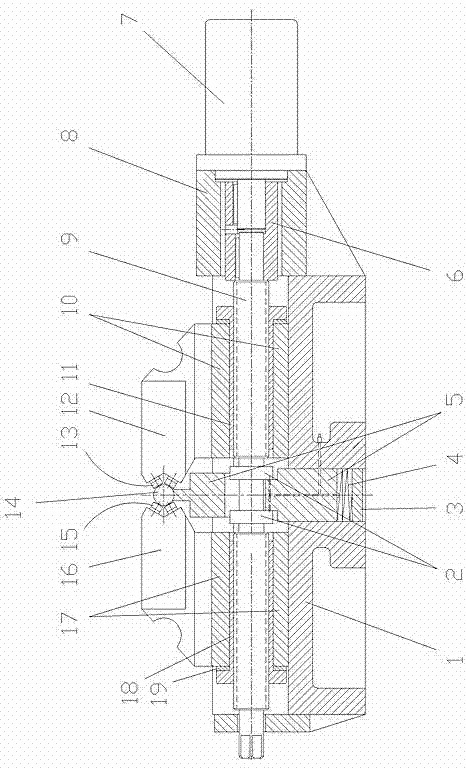

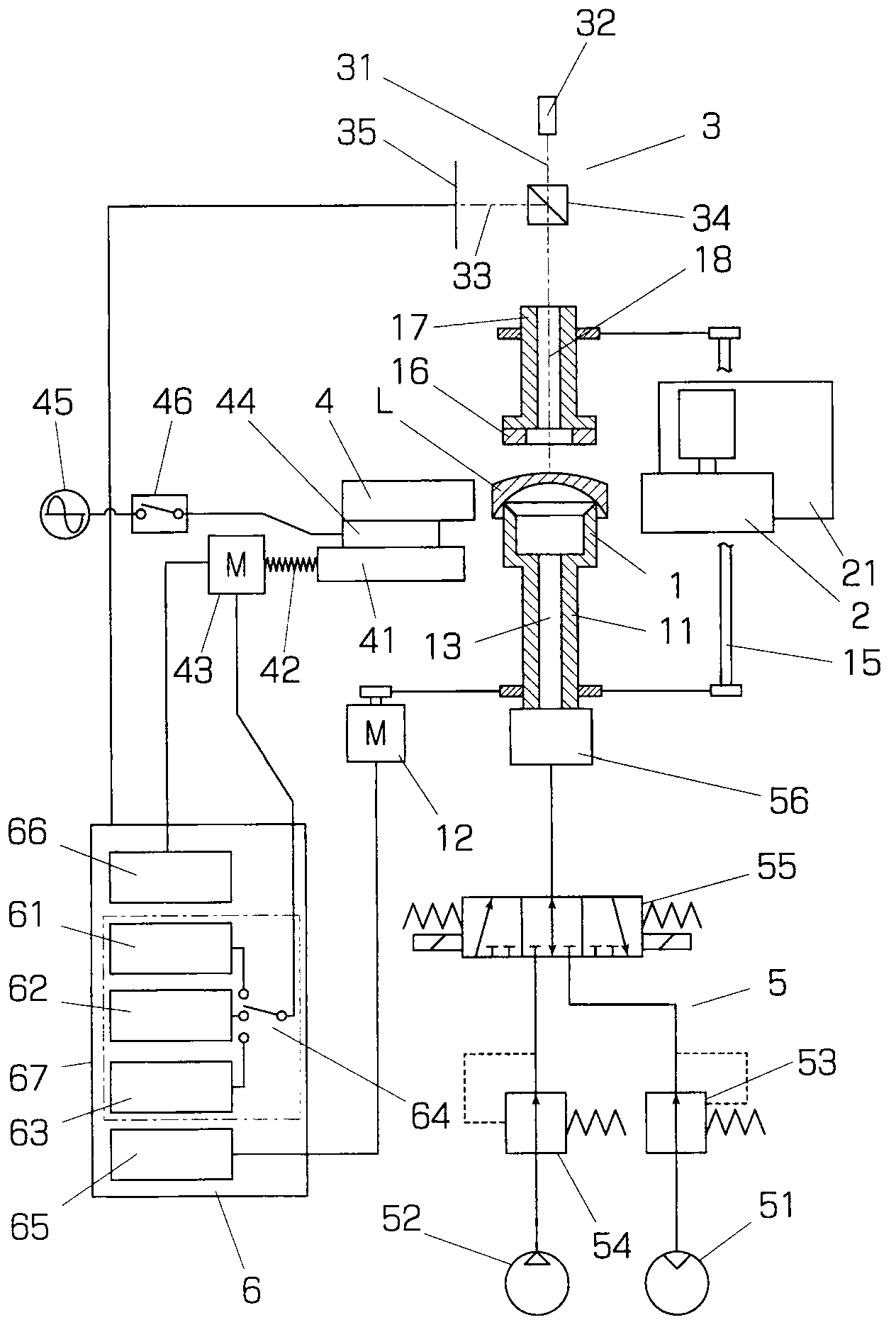

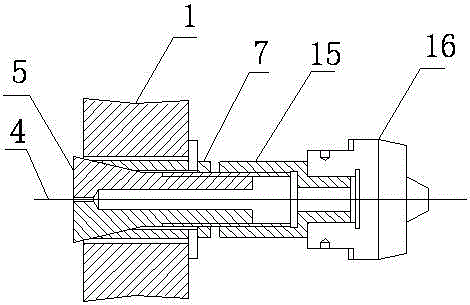

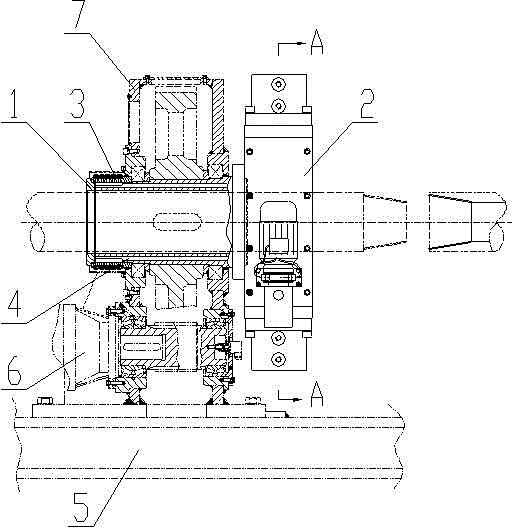

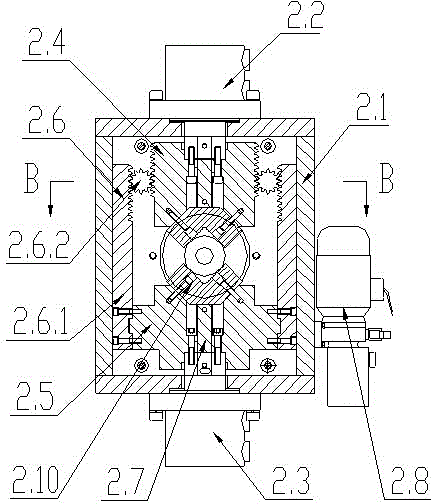

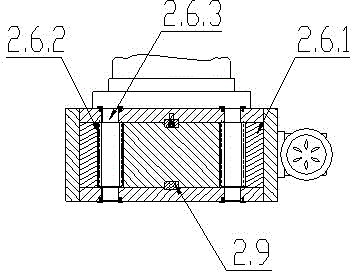

Continuous rotating automatic centering hydraulic clamping mechanism and hydraulic control system thereof

InactiveCN104440065AReduce in quantityLarge boreMetal working apparatusControl systemHydraulic control

The invention relates to a continuous rotating automatic centering hydraulic clamping mechanism and a hydraulic control system thereof. The mechanism comprises a hollow main shaft (1) and a clamping mechanism (2), wherein the clamping mechanism (2) comprises a clamping mechanism frame body (2.1); an upper clamping cylinder (2.2) and a lower clamping cylinder (2.3) are arranged on the clamping mechanism frame body (2.1); an upper sliding block (2.4) and a lower sliding block (2.5) are respectively arranged on the upper clamping cylinder (2.2) and the lower clamping cylinder (2.3); V-shaped blocks (2.10) are arranged on the upper sliding block (2.4) and the lower sliding block (2.5); a gear and rack synchronizing mechanism (2.6) is arranged between the upper sliding block (2.4) and the lower sliding block (2.5). The continuous rotating automatic centering hydraulic clamping mechanism and the hydraulic control system thereof are simple in motion and accurate in centering, and can continuously rotate in forward and reverse directions, greatly shorten the connection and disassembly time for a stator casing, and greatly improve the operating efficiency.

Owner:JIANGYIN DONGCHEN PETROLEUM DRILLING EQUIP

Automatic centering and pressing device for balancing machine rotor with conical inner hole

PendingCN110926695AQuick positioning and clampingGuaranteed peace of mindStatic/dynamic balance measurementBalancing machineEngineering

The invention discloses an automatic centering and pressing device for a balancing machine rotor with a conical inner hole. The power element is fixed to the bottom face of the bottom plate, the bottom of the cone base is fixed to the top face of the bottom plate, and a workpiece is set outside the top of the cone seat. A power rod of the power element penetrates through the bottom plate and thenis coaxially and fixedly connected with the lower end of the pull rod in the cone base, the guide base is fixedly installed at the top of the cone base and mainly comprises semi-cylinders on the two sides and a guide block, and a hollowed-out cavity is formed below the guide block of the guide base. The size of the two sides of the guide block decreases downward, the pull rod penetrates out of theconical seat and then is coaxially and fixedly connected with the pressing rod in the hollow cavity of the guide seat, the middles of two rotating rods of the pressing rod are hinged, the upper portions of the two rotating rods are connected to the two side faces of the guide block, and the lower portions of the two rotating rods are connected through an elastic element. In the dynamic balance detection process of the rotor with the conical inner hole, rapid positioning and clamping of the rotor are achieved through cooperation of the center positioning component and the pressing positioningcomponent, so that accurate centering is guaranteed, and the system measurement precision is improved.

Owner:杭州集智机电股份有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com