Partition alignment tool and method

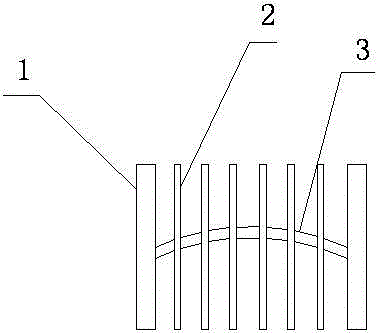

A clapboard and tool technology, which is applied in the field of aligning the clapboard of the tubular heat exchanger, can solve the problems of large tolerance of the tube hole, inaccurate axis, unusable, etc., achieves low cost, convenient alignment and positioning Accurate and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

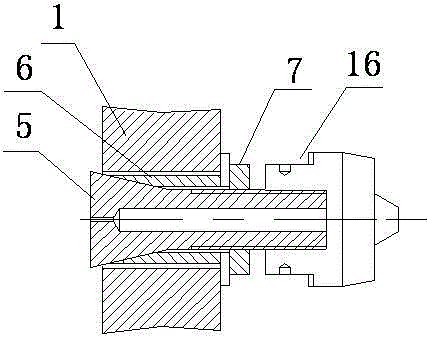

[0034] The straightening tool includes a steel wire 4, a centering bolt 5, a steel wire fixer, a steel wire tension measuring device, and a clapboard straightening device.

[0035] Such as figure 2 As shown, one end of the centering bolt is a thread and a nut that matches the bolt, and the other end is an outer cone with an enlarged diameter. The bolt is covered with an expansion sleeve 6, and one end of the expansion sleeve has an inner hole corresponding to the taper of the bolt’s tapered end and is opened. The gap, that is, the centering bolt is similar to the expansion bolt provided with the central axis hole. Tighten the nut 7, fix the centering bolt on the hole of the tube plate 1, the outer tapered end of the centering bolt fits closely with the hole, so that the steel wire can accurately pass through the axis of the tube hole during work. A drill chuck 16 is provided at the end of the centering bolt.

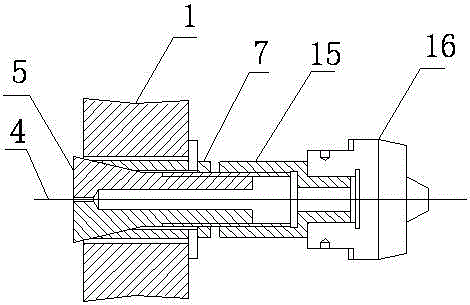

[0036] Such as image 3As shown, in order to tension the steel ...

Embodiment 2

[0044] The situation that this embodiment adapts to is that when the distance that the partition plate 2 moves relative to the tube sheet 1 exceeds the radius of the partition hole, such as Figure 8 As shown, the alignment device of the condenser diaphragm also includes a steel wire to raise the eccentric plate 18. At this time, the centering bolt has an oblique hole 22 and a boss 19, and the eccentric plate is provided with The hole of the interference fit of the boss, the eccentric plate is provided with an eccentric hole 20 that deviates from the central axis of the centering bolt, and the eccentric plate is also provided with a level bubble 21, which is used to accurately adjust the eccentric plate to make the position of the eccentric hole precise.

[0045] Such as Figure 9 As shown, when the moving distance of the diaphragm relative to the tube sheet exceeds the radius of the diaphragm hole, replace the centering bolt with a centering bolt with a boss and an inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com