Shaft sleeve groove automatic polishing equipment

An automatic polishing and shaft sleeve technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of automatic loading and unloading, shaft sleeve groove deviation, and inaccurate centering, etc. problems, to achieve the effect of convenient loading and unloading, accurate centering of the workpiece, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

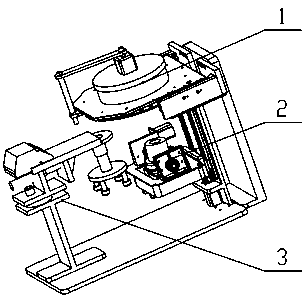

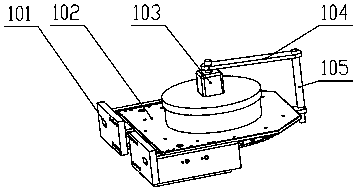

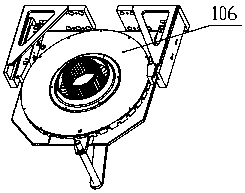

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, an automatic polishing equipment for shaft sleeve grooves, including: clamping and positioning device 1, polishing device 2 and automatic loading and unloading device 3;

[0033] The clamping and positioning device 1 is fixedly installed on the upper part of the polishing device 2, and it includes a clamping motor 103 and a splint 108. The clamping motor 103 rotates to drive the splint 108 to automatically clamp and position the bushing to be processed; The annular groove is polished, and it can move up and down to facilitate loading and unloading; the automatic loading and unloading device 3 is fixedly installed on the front end of the polishing device 2 to automatically load and unload the shaft sleeve; automatic loading when in use The power source 302 of the unloading device 3 drives the slewing bearing 303 to rotate, and then drives the upper frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com