Precise centering fixture for repairing back lining bearing

A technology for centering fixtures and bearings, which is used in manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, grinders, etc. Fixture accuracy and service life and other issues, to achieve the effect of good sealing, high clamping efficiency and high centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

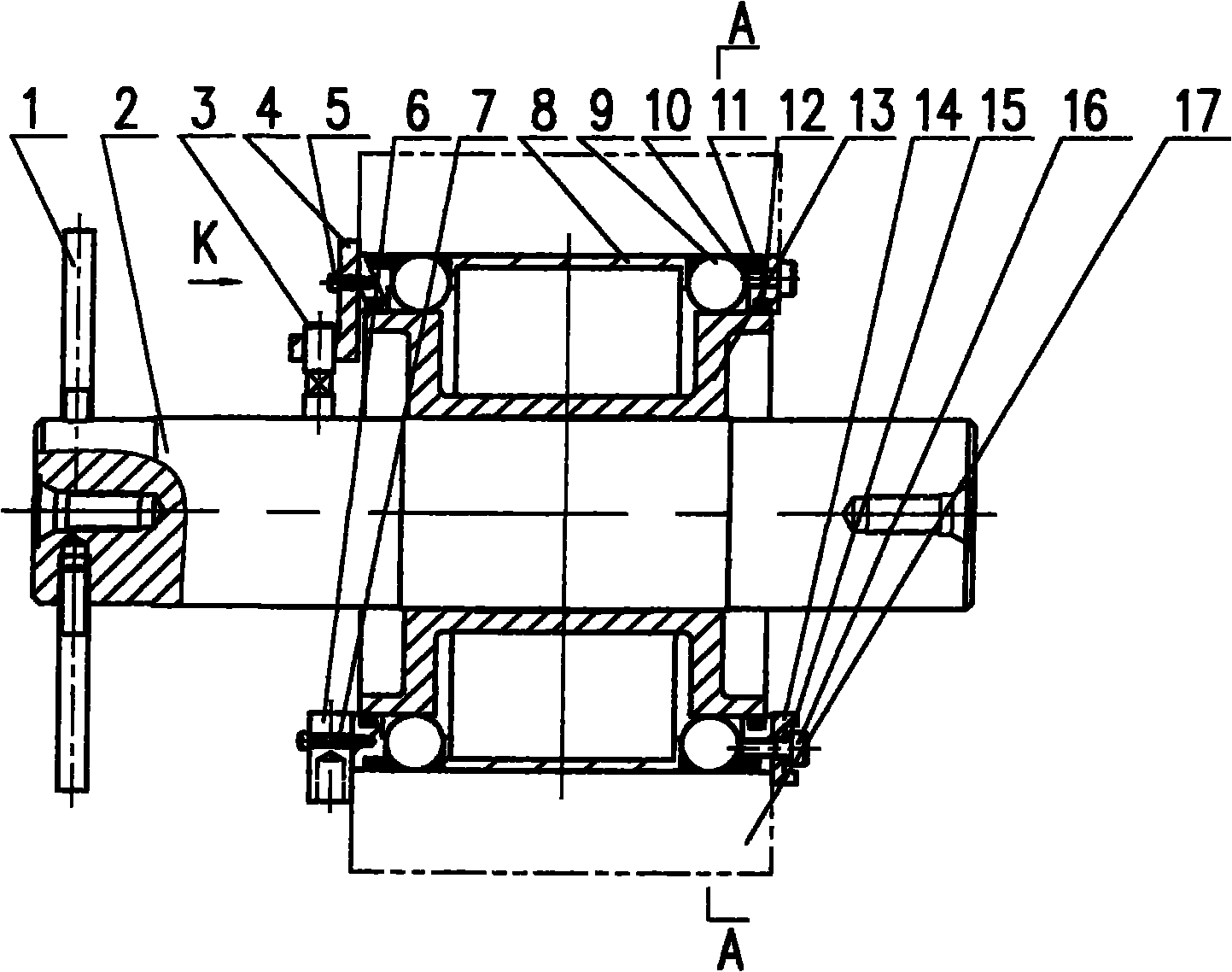

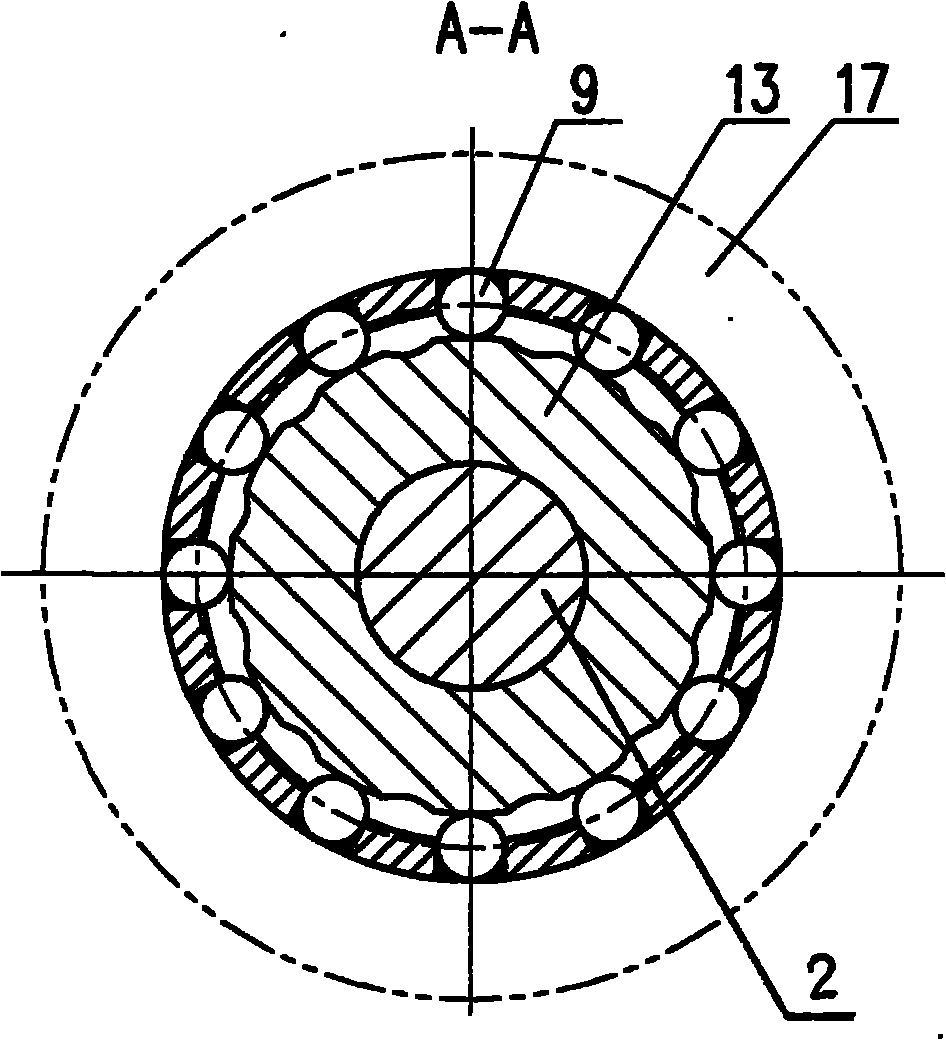

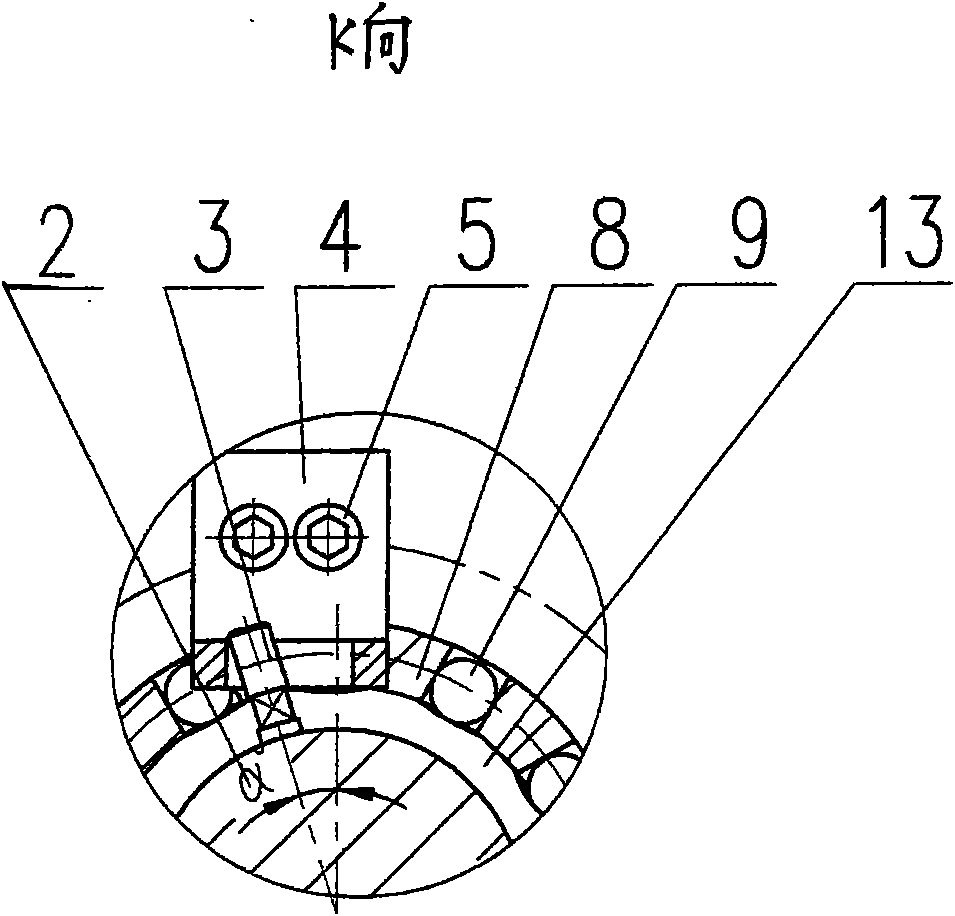

[0025] The pull rod 1 is cylindrical, with two threads on one end, and is threadedly connected with the mandrel 2; the mandrel 2 is a stepped shaft with precision center holes at both ends, and the two center holes of the mandrel 2 are connected with the precision top of the grinding machine Fixed, the grinding machine drives the mandrel 2 to rotate, the mandrel is made of alloy nitride steel technology, the hardness can reach more than HV900, which improves the wear resistance and life of the center hole, and the center hole of the mandrel is precisely ground to ensure the accuracy of the mandrel; positioning Rod 3 is used to adjust the angle of retainer 8, and its one end is cylindrical, has thread, is threadedly connected with mandrel 2, and the middle part is cuboid, and the other end is cylinder, inserts in the waist-shaped groove of limit plate 4, and limit The position plate 4 is a clearance fit; the limit plate 4 is a plane of L-shaped structure, has a waist-shaped groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com