Patents

Literature

1897results about How to "Quick clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

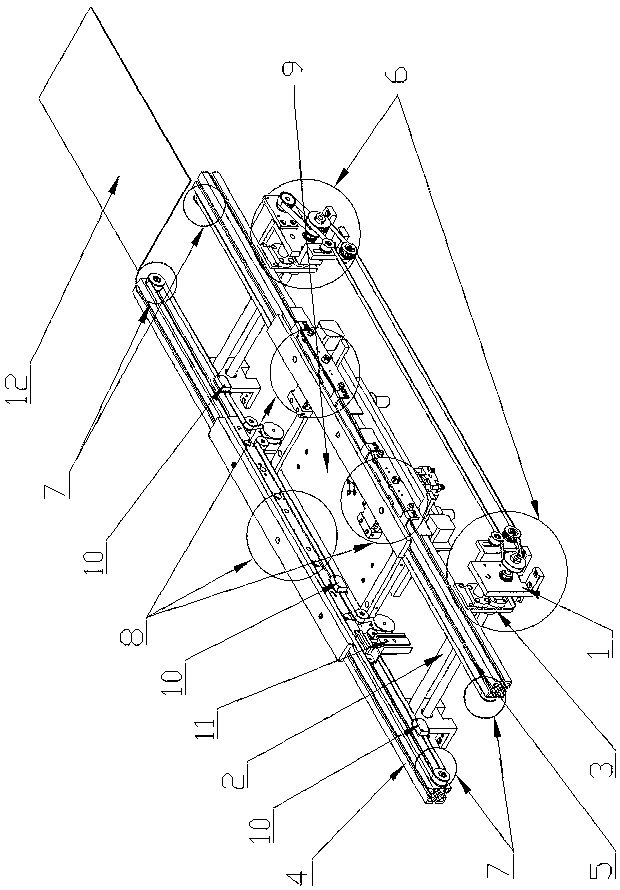

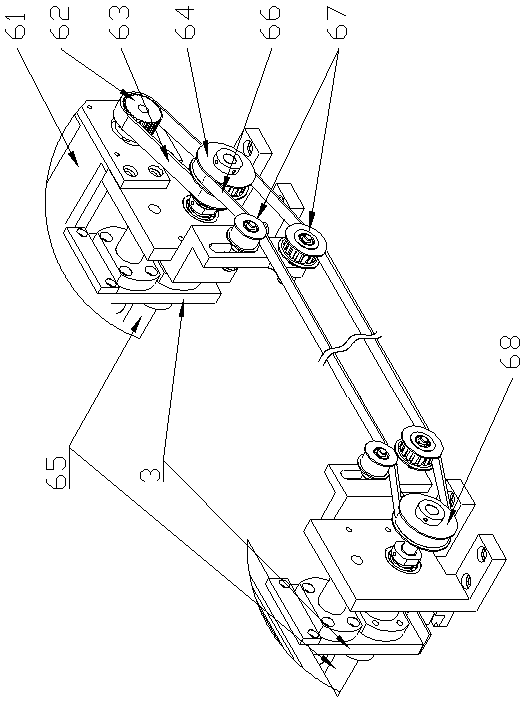

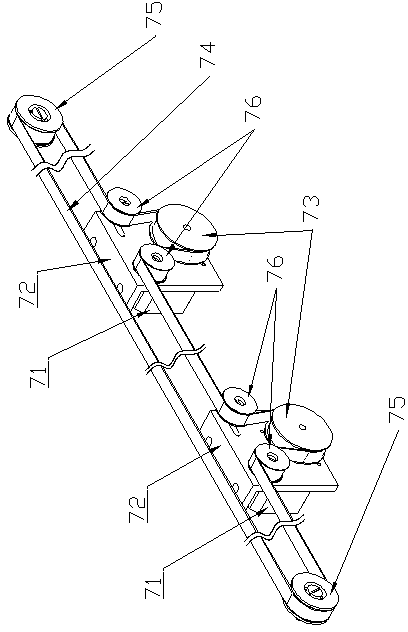

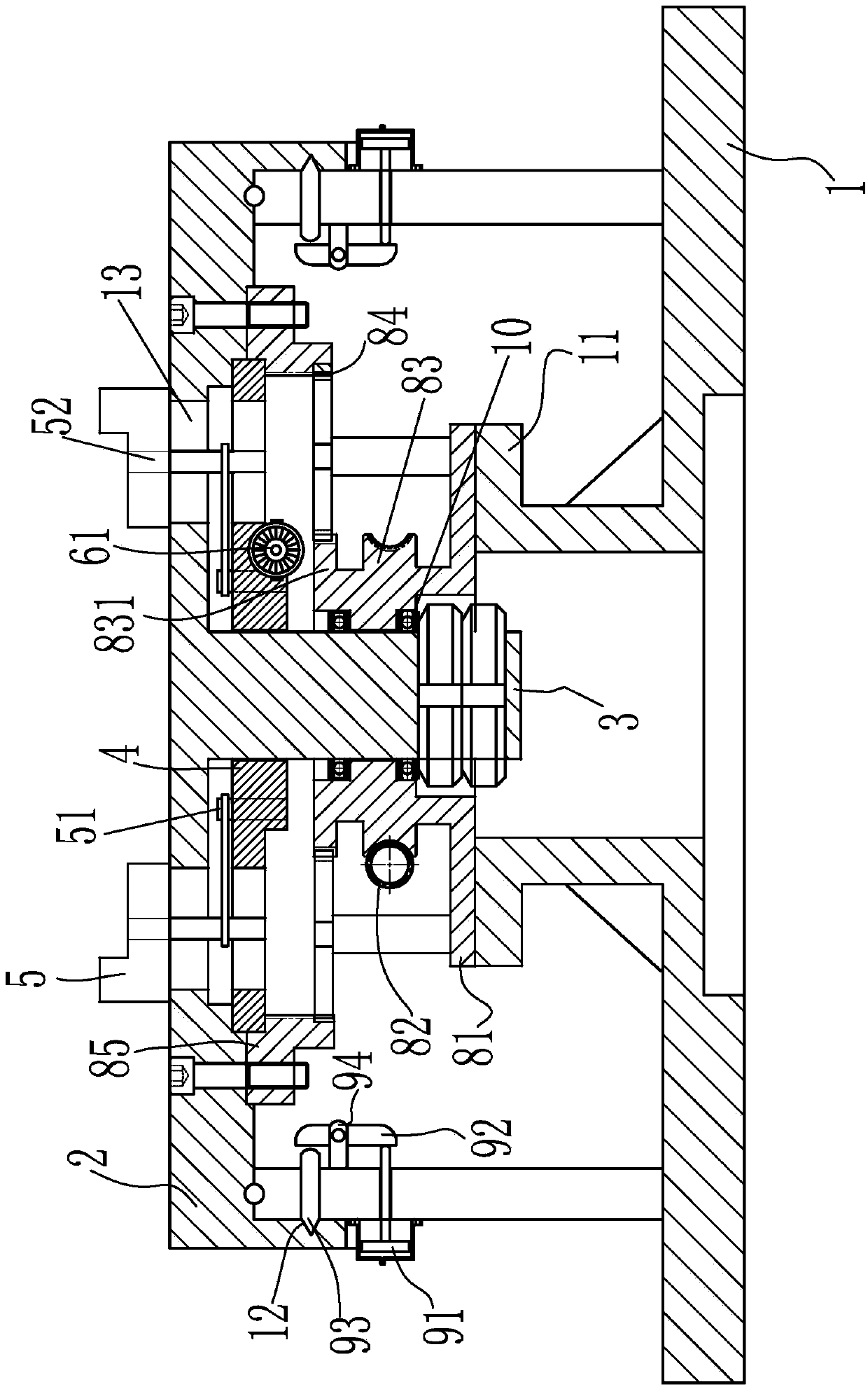

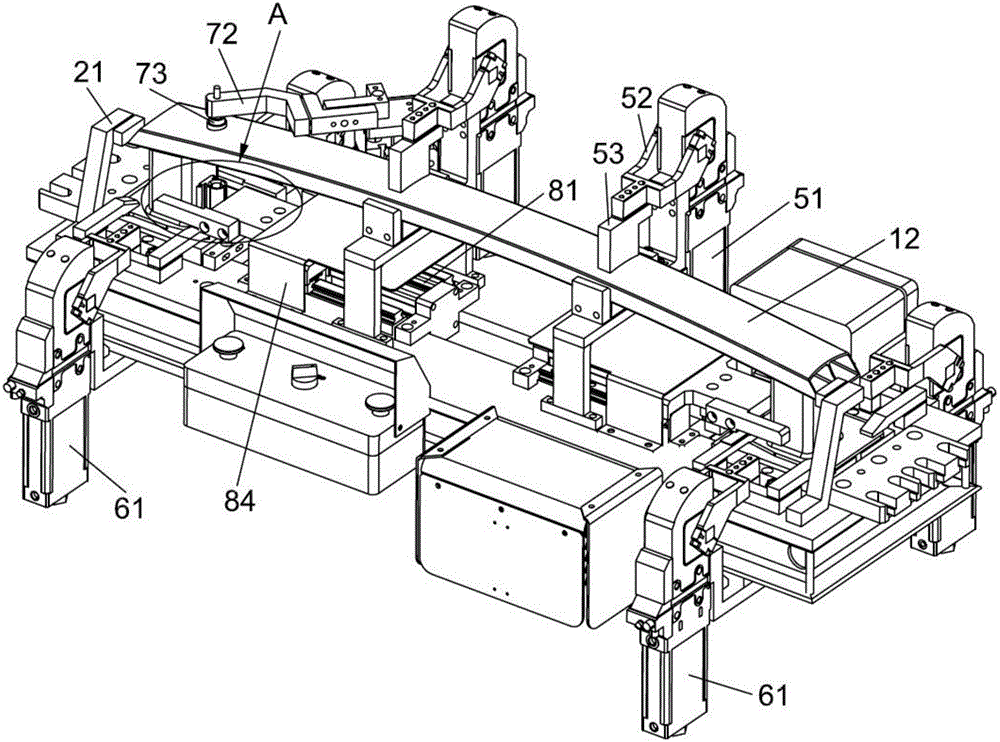

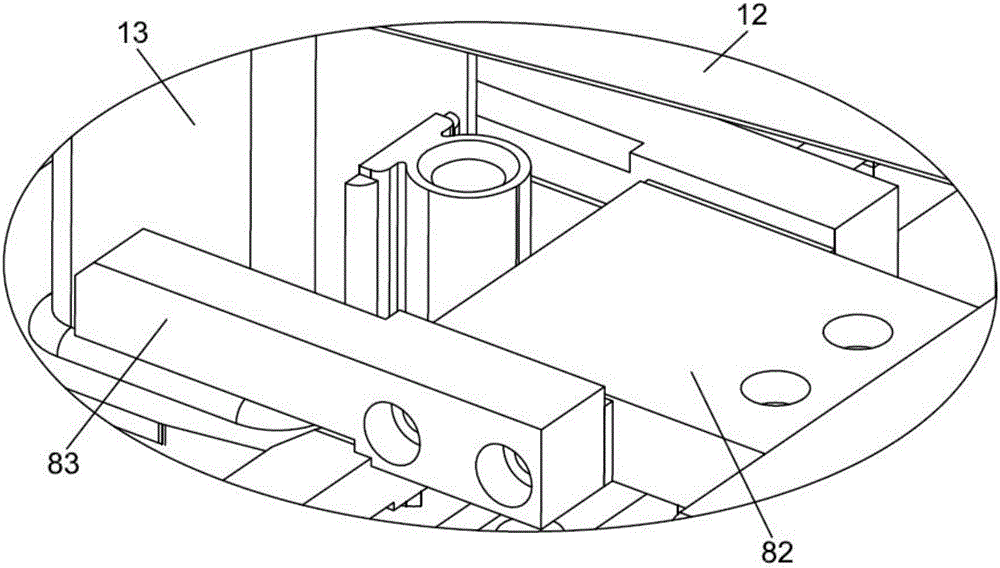

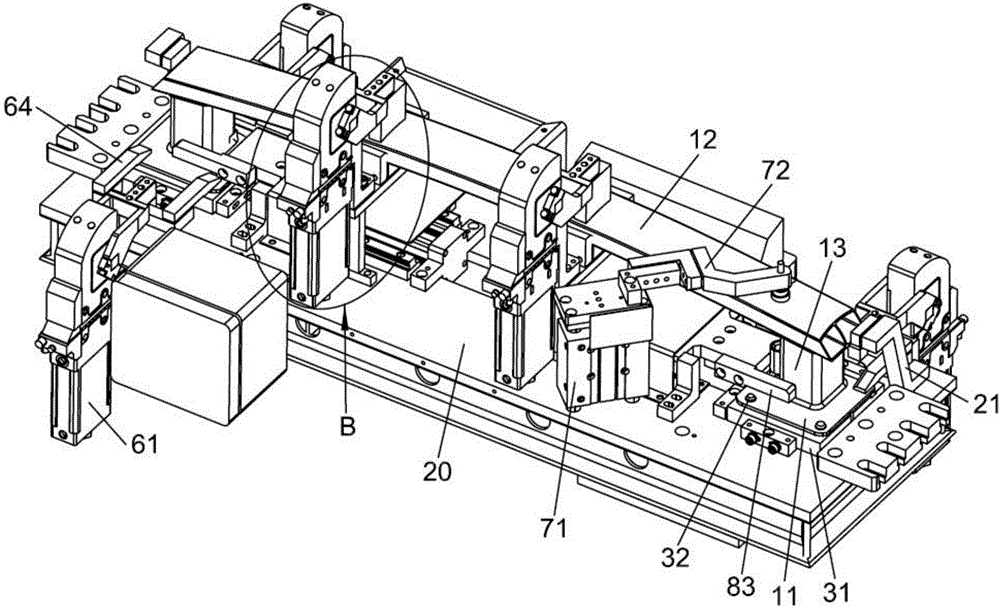

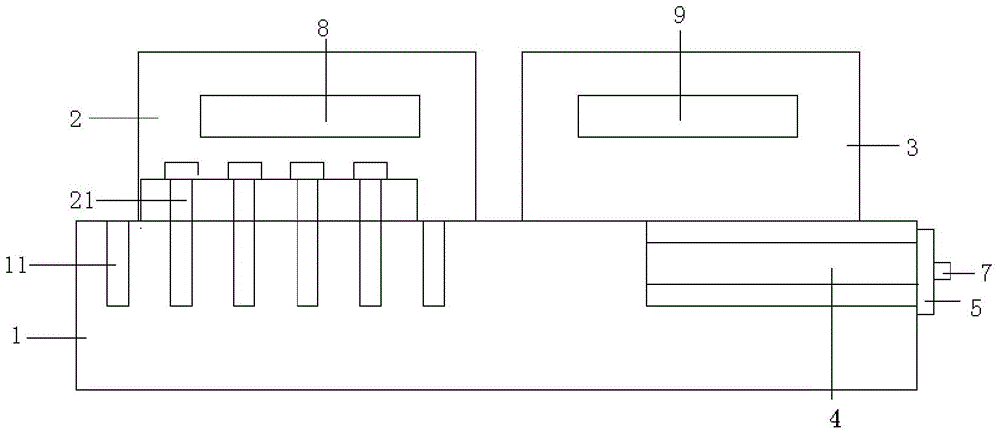

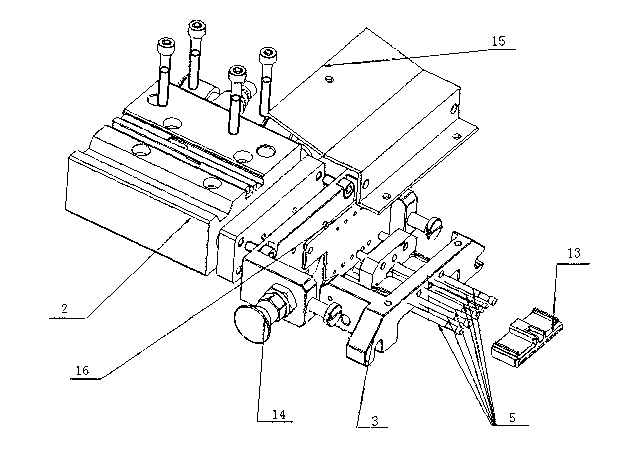

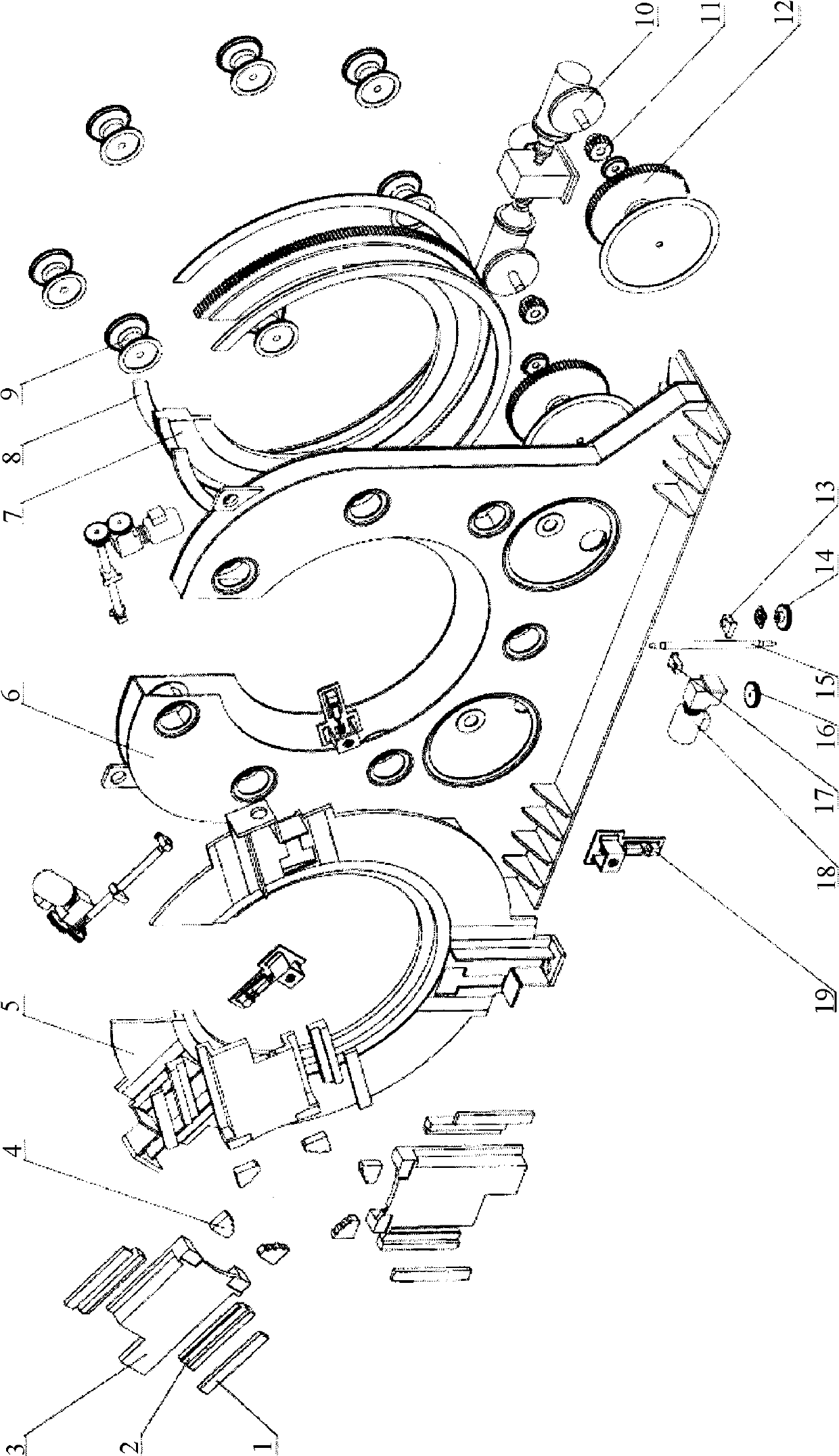

Full-automatic PCB (printed circuit board) positioning clamp

ActiveCN103025077AAccurate positioning and clampingReliable and easy positioning and clampingPrinted circuit assemblingPrinted circuit boardAssembly line

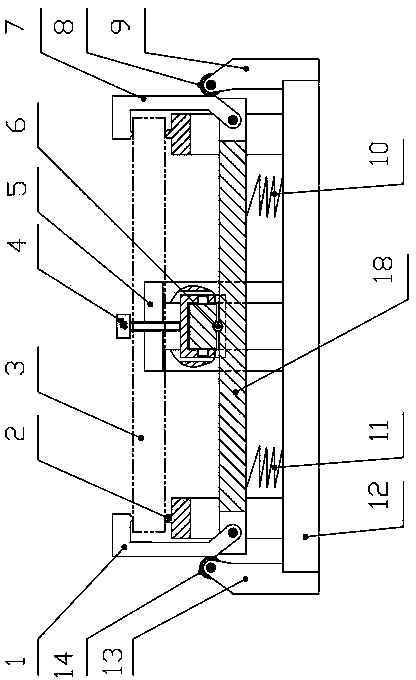

The invention provides a full-automatic PCB (printed circuit board) positioning clamp. The full-automatic PCB positioning clamp comprises a support seat, a support rod, a sliding support plate, a fixed-side railing, a movable-side railing, width adjusting mechanisms, conveying mechanisms, clamping mechanisms, a top plate mechanism, a detecting mechanism and a positioning mechanism, wherein the support rod and the width adjusting mechanisms are assembled on holes reserved on the lateral side of the support seat, the fixed-side railing is fixed on the support seat, the sliding support plate is slidably connected with the support rod, the movable-side railing is fixed on the sliding support plate which is connected with the width adjusting mechanisms, the conveying mechanisms are mounted on the inner sides of the fixed-side railing and the movable-side railing to form a PCB delivery rail, the clamping mechanisms are fixed on the fixed-side railing and the movable-side railing, the detecting mechanism is mounted on the fixed-side railing, and the positioning mechanism used for positioning the PCB when entering is fixed at a positioning position on the fixed-side railing. The full-automatic PCB positioning clamp can quickly automatically deliver the PCB, and can position and clamp the PCB accurately, reliably and conveniently, and production efficiency of an assembly line is improved.

Owner:广州弘高科技股份有限公司

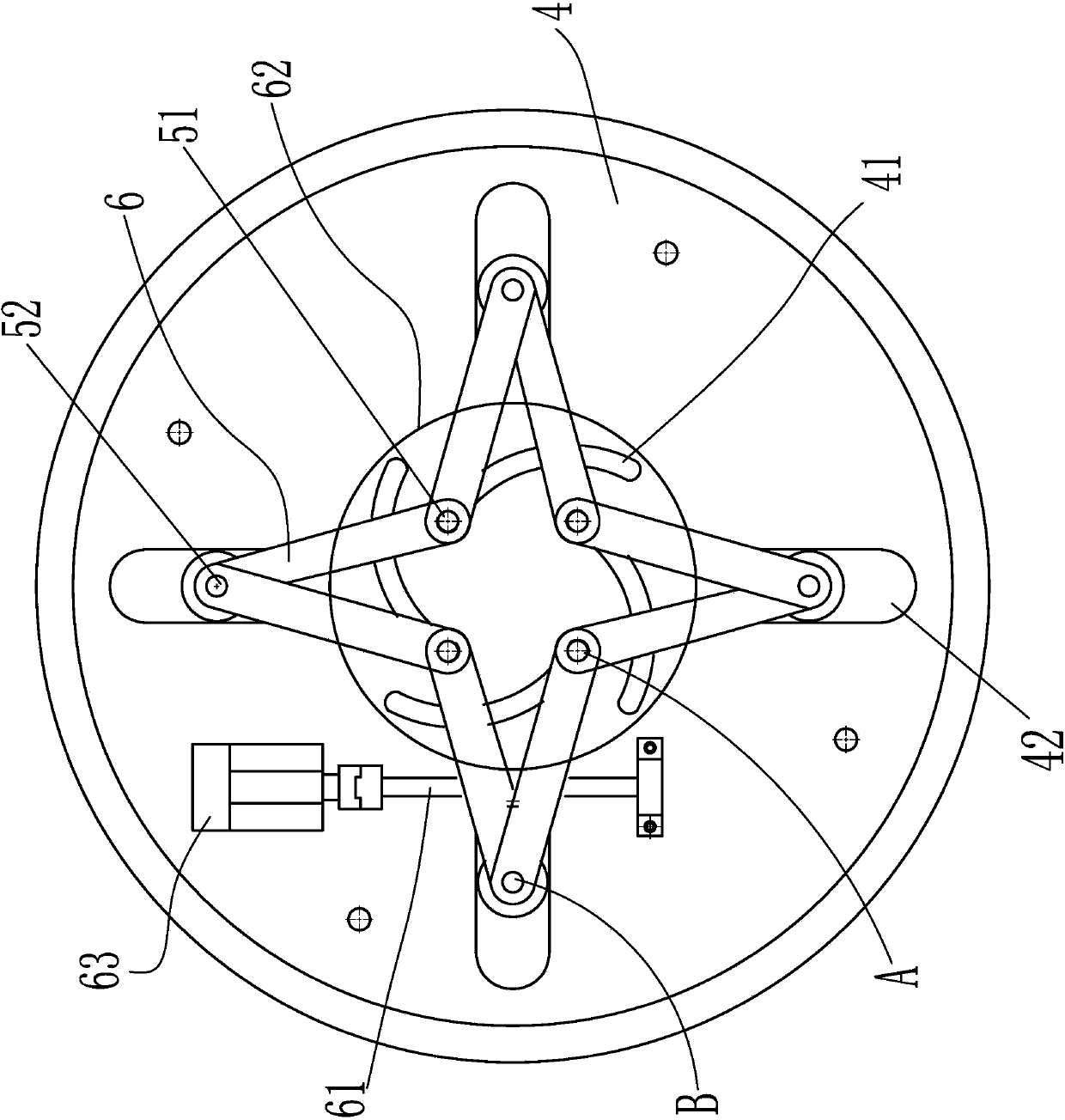

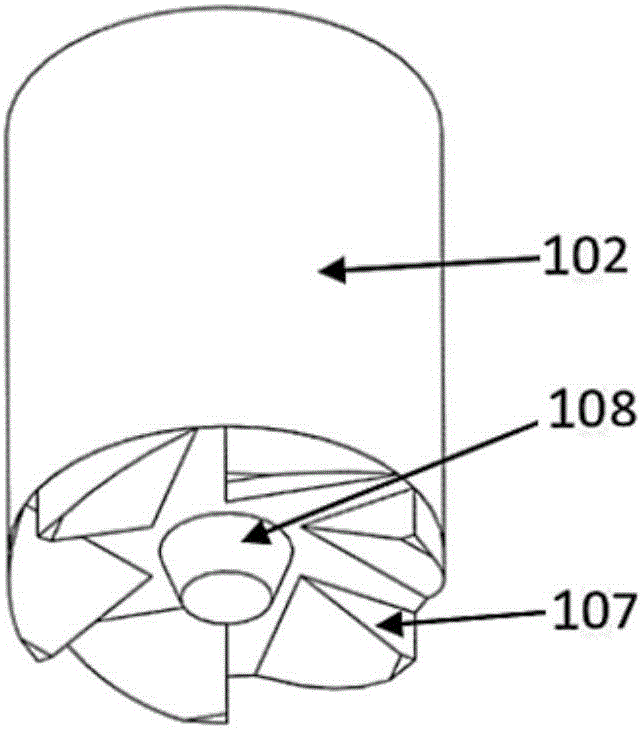

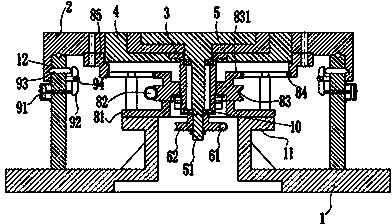

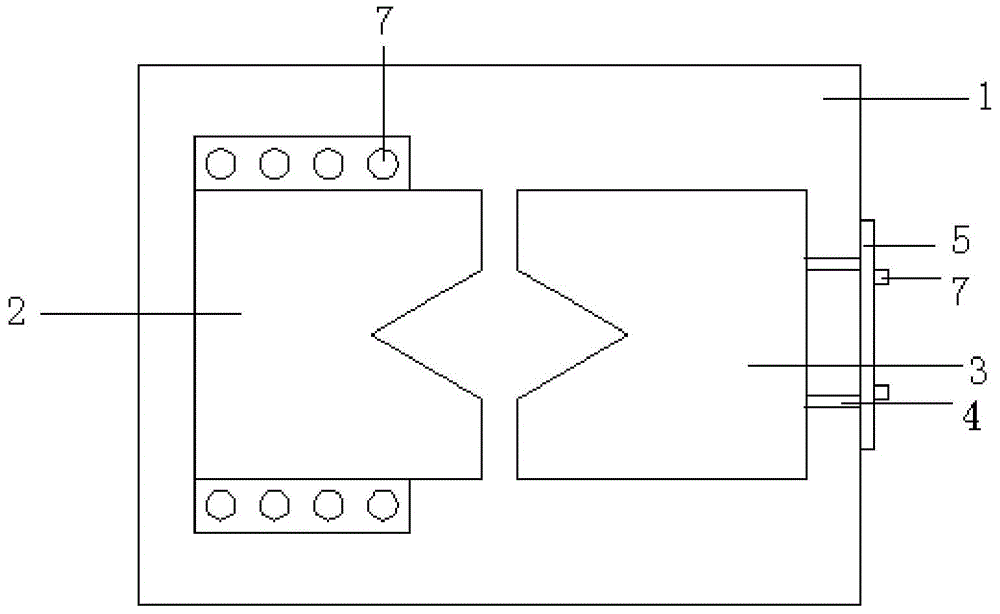

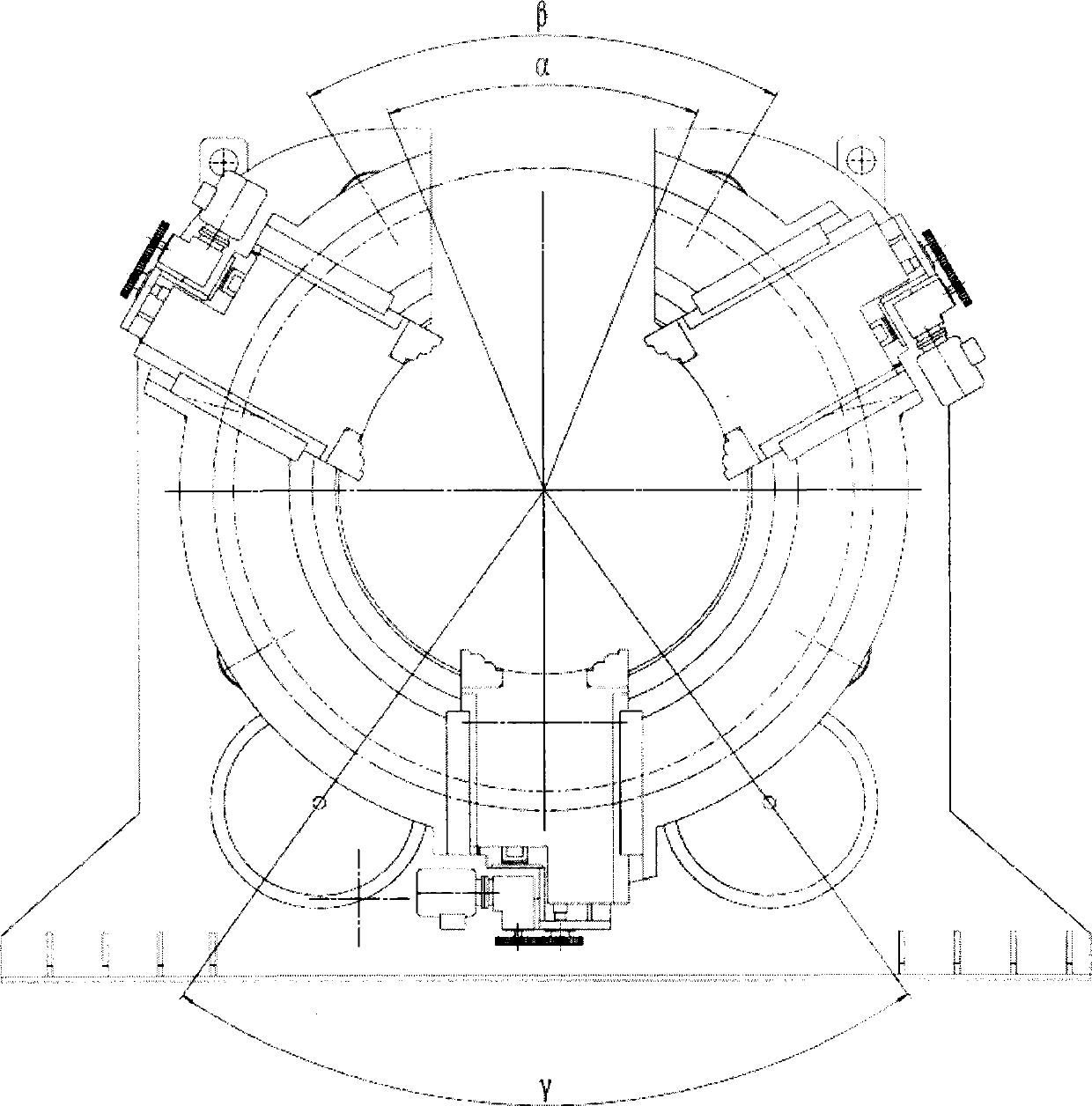

Self-centering clamping device of drill press workpiece

ActiveCN103801959AImprove processing efficiencyEasy to operateWork clamping meansFeeding apparatusLathe faceplateEngineering

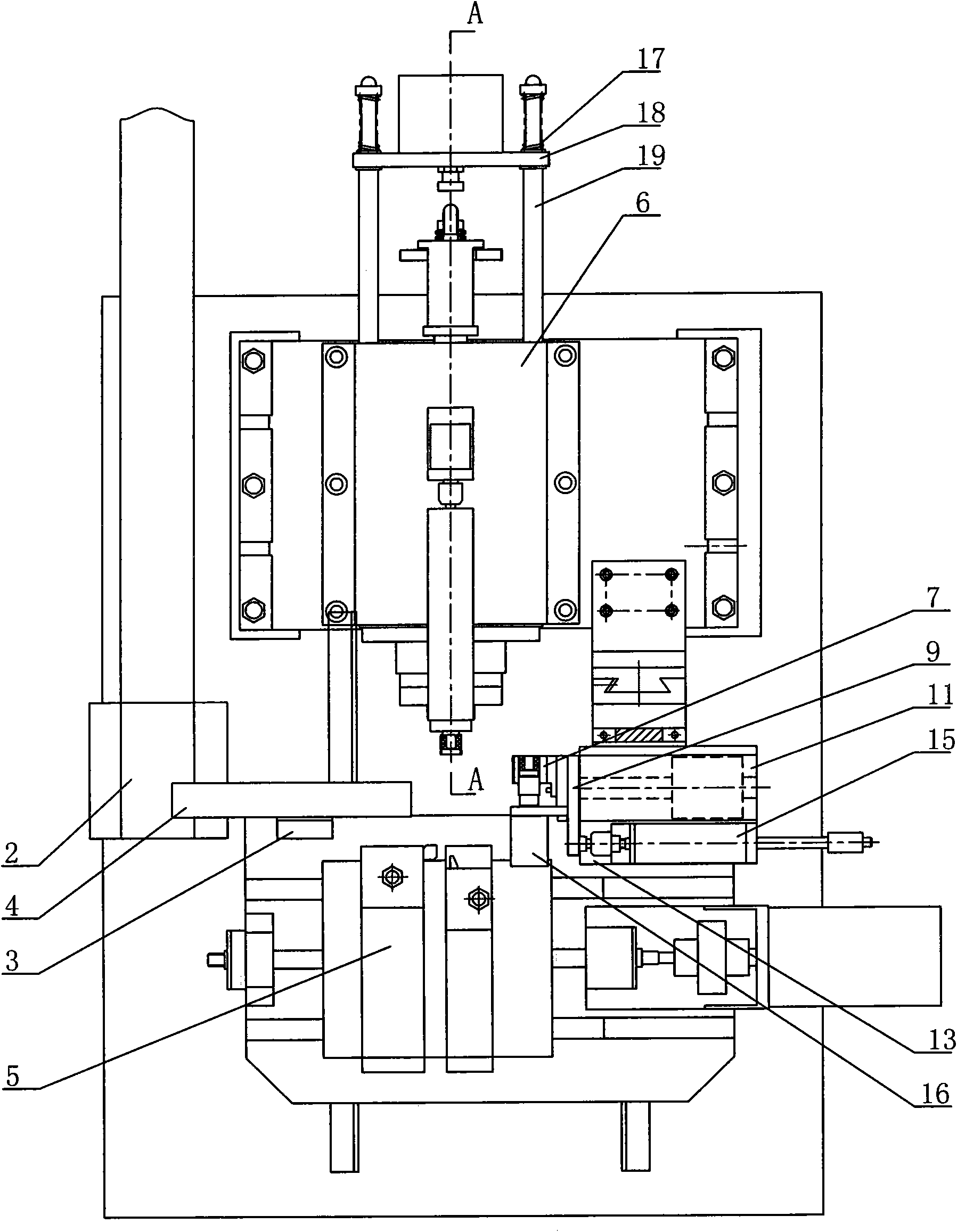

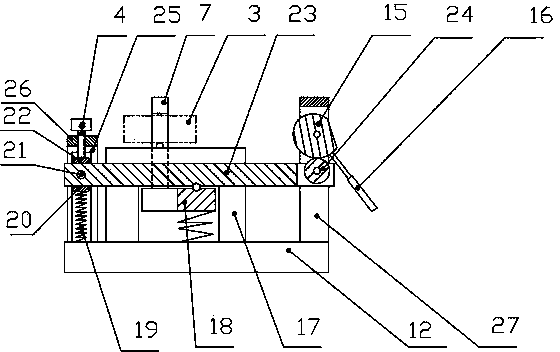

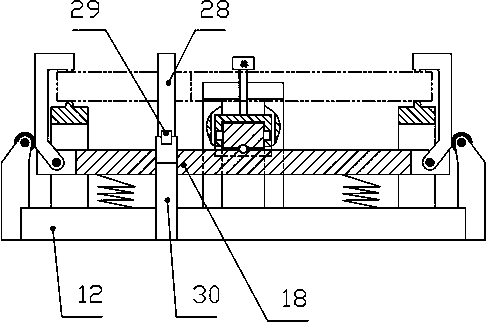

The invention provides a self-centering clamping device of a drill press workpiece. The device can realize the self-centering function for a workpiece. The device comprises a connecting base, a workbench rotary disc, a main shaft, a parabola self-centering flower disc, a plurality of connecting rods and a plurality of positioning pawls, wherein the workbench rotary disc can be arranged above the connecting base in a rotary way, the main shaft is fixedly arranged below the middle part of the workbench rotary disc, the parabola self-centering flower disc can be arranged below the workbench rotary disc on the main shaft by a transmission mechanism in a rotary way, arc-shaped gradually slotting grooves are uniformly formed in the parabola self-centering flower disc in the radial direction, the head of one connecting rod is hinged to the end of the other connecting rod, both ends of each of the connecting rods are respectively a first hinging end and a second hinging end, the first hinging ends are respectively hinged to the arc-shaped gradually slotting grooves on the parabola self-centering flower disc, long hinging grooves corresponding to the positions of the peripheral sides of the arc-shaped gradually slotting grooves are respectively formed in the parabola self-centering flower disc, the second hinging ends are respectively hinged to the long hinging grooves in a hinge way, and the positioning pawls are respectively arranged above the second hinging ends of the connecting rods.

Owner:HUHANG TECH GRP CO LTD

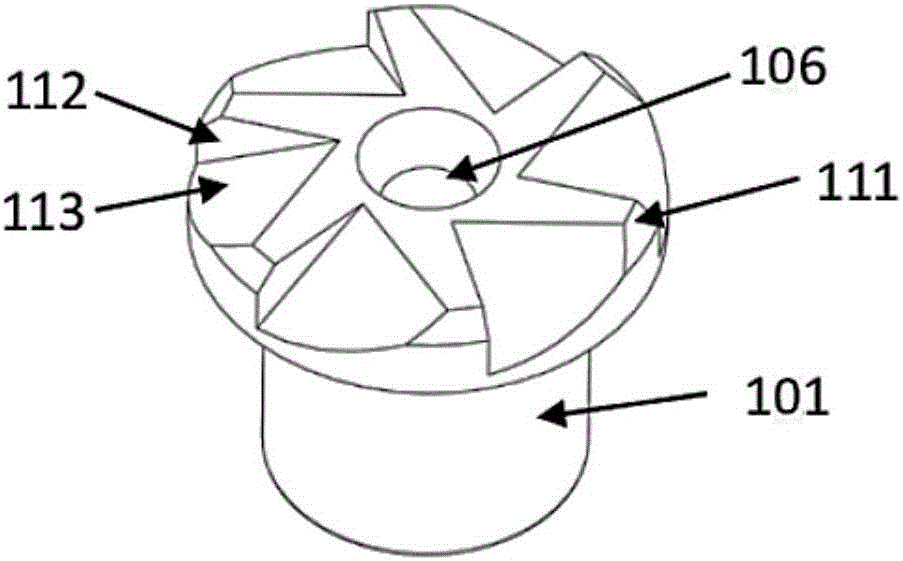

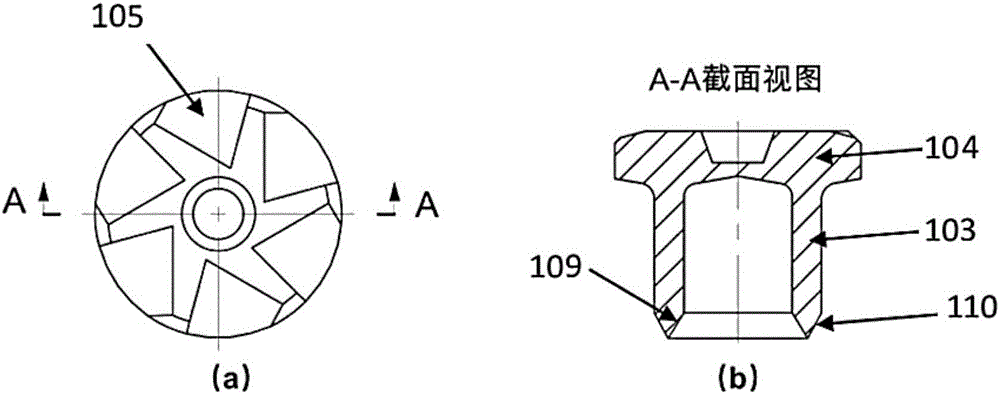

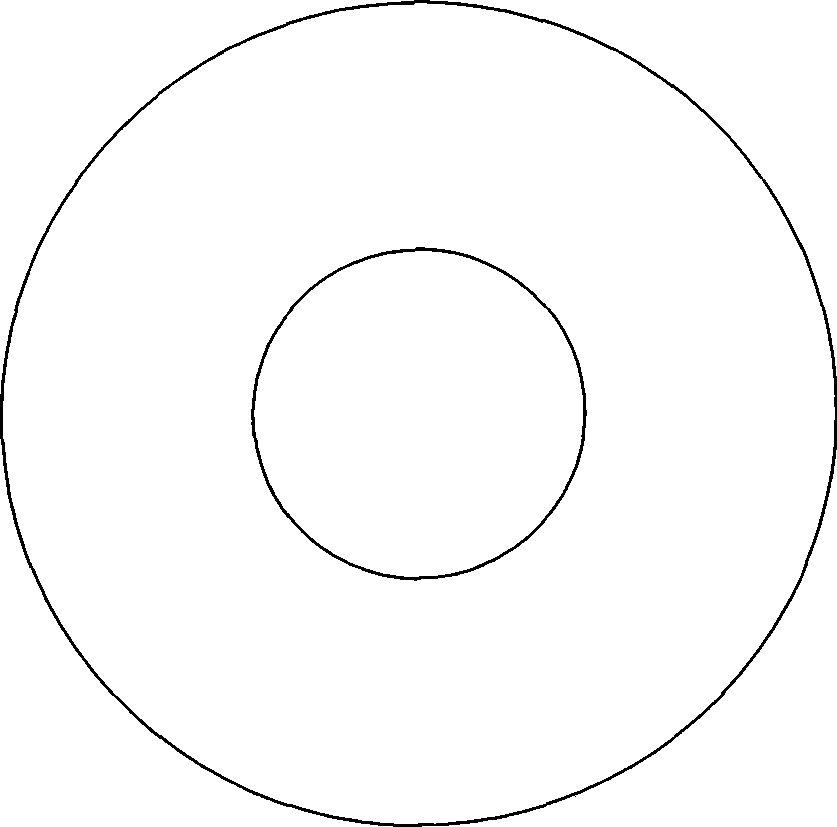

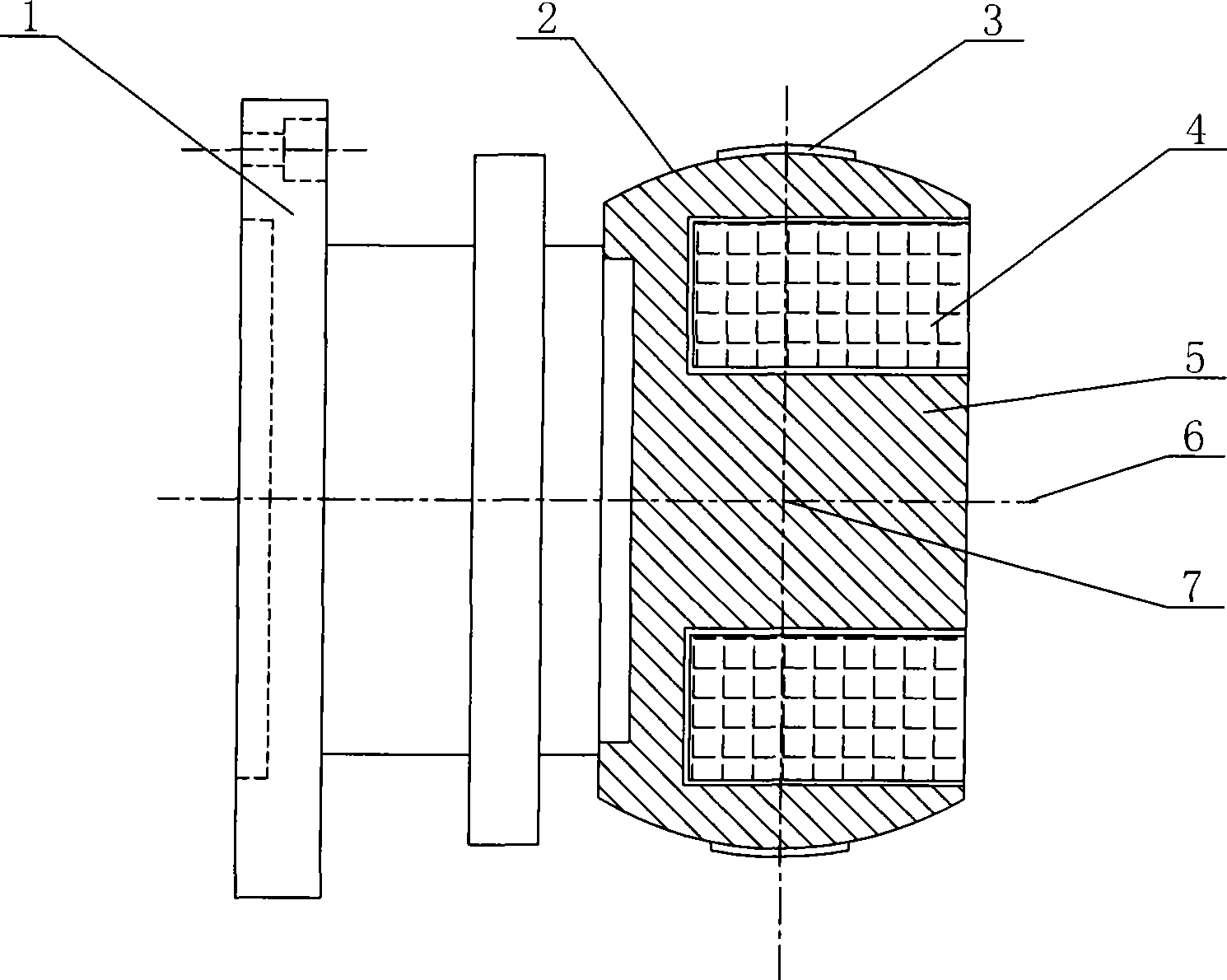

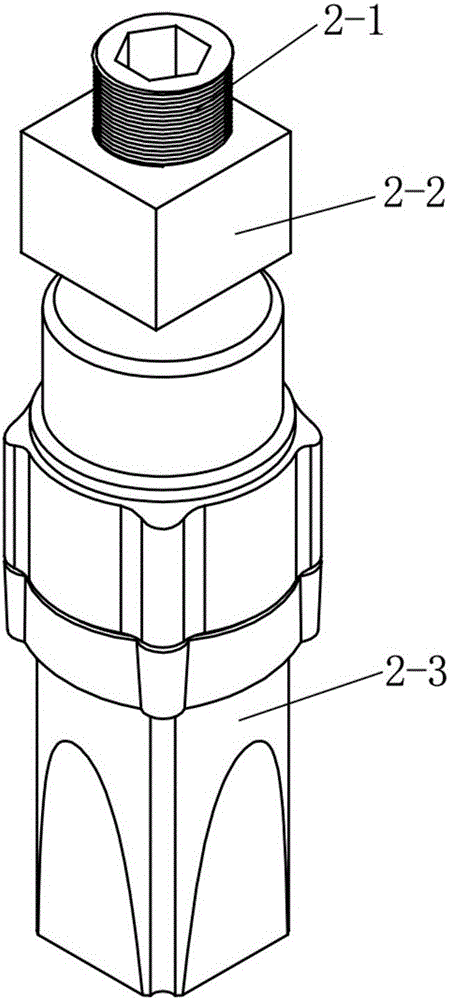

Rivet for friction-self piercing riveting (F-SPR) and F-SPR connecting system thereof

ActiveCN106112543AQuick clampingReduce weightScrewsOther manufacturing equipments/toolsEngineeringRivet

The invention discloses a rivet for friction-self piercing riveting (F-SPR) and an F-SPR connecting system thereof. The rivet comprises a semi-hollow rivet body and a rivet cap, wherein the lower surface of the rivet cap is connected with the semi-hollow rivet body; a wedge-shaped taper corner is arranged at the bottom end of the semi-hollow rivet body; chamfers for assembly and disassembly and a rotating driving structure are arranged on the edge of the upper end of the rivet cap; a locating structure is arranged in the center of the rivet cap; the rotating driving structure is a directed concave surface or a directed convex surface in central symmetry; and the locating structure is a convex surface or a concave surface in central symmetry and mirror symmetry. When the rivet is matched with a driving system for utilization, the driving rigidity and locating accuracy of the rivet during the F-SPR process can be improved, the problems that during the high-speed rotation process of the semi-hollow rivet, the stability is poor and the rivet axis and the rotation axis do not overlap are solved, the probability that a connector loses efficacy is reduced, the problem that a clearance is formed between the rivet and a panel is avoided, and the technological reliability of an F-SPR technology when connecting steel, aluminum, magnesium materials, composites and heterogeneous materials is guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

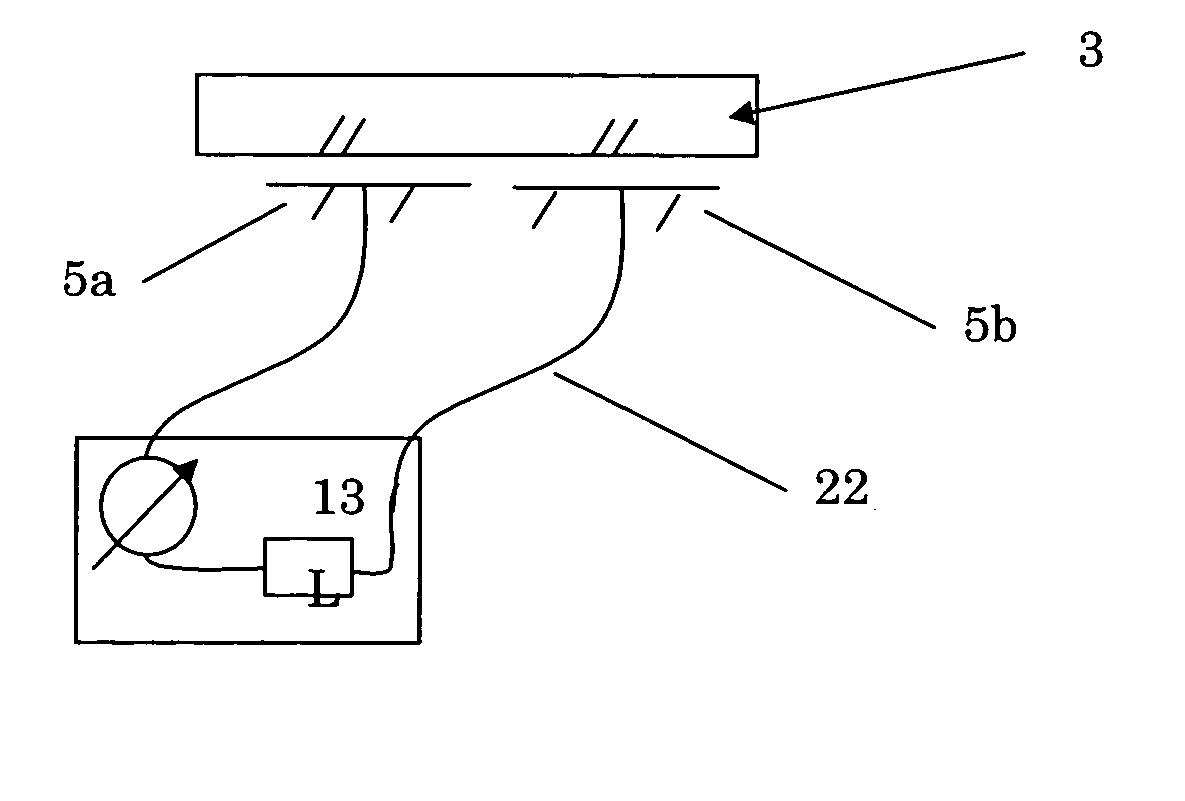

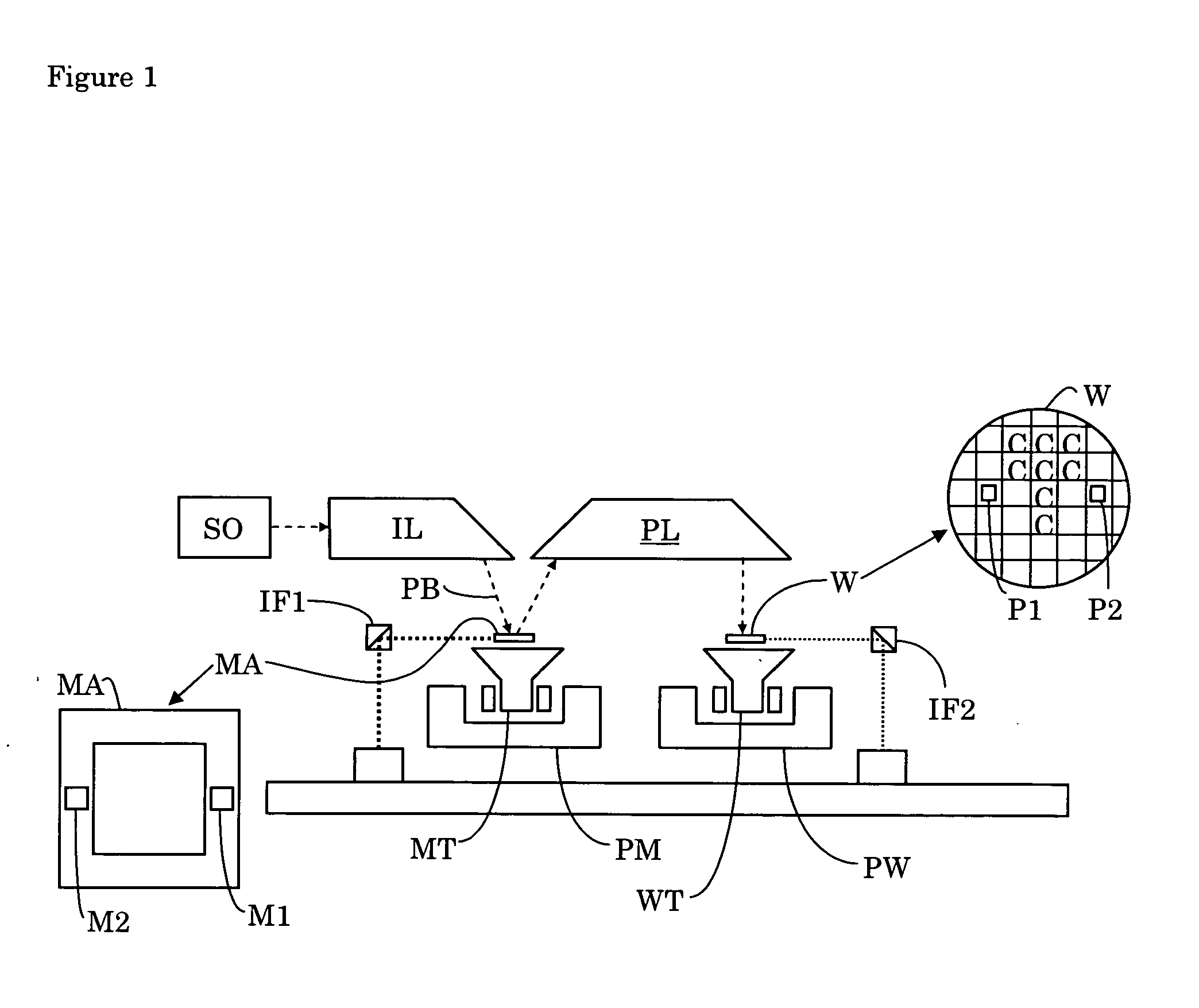

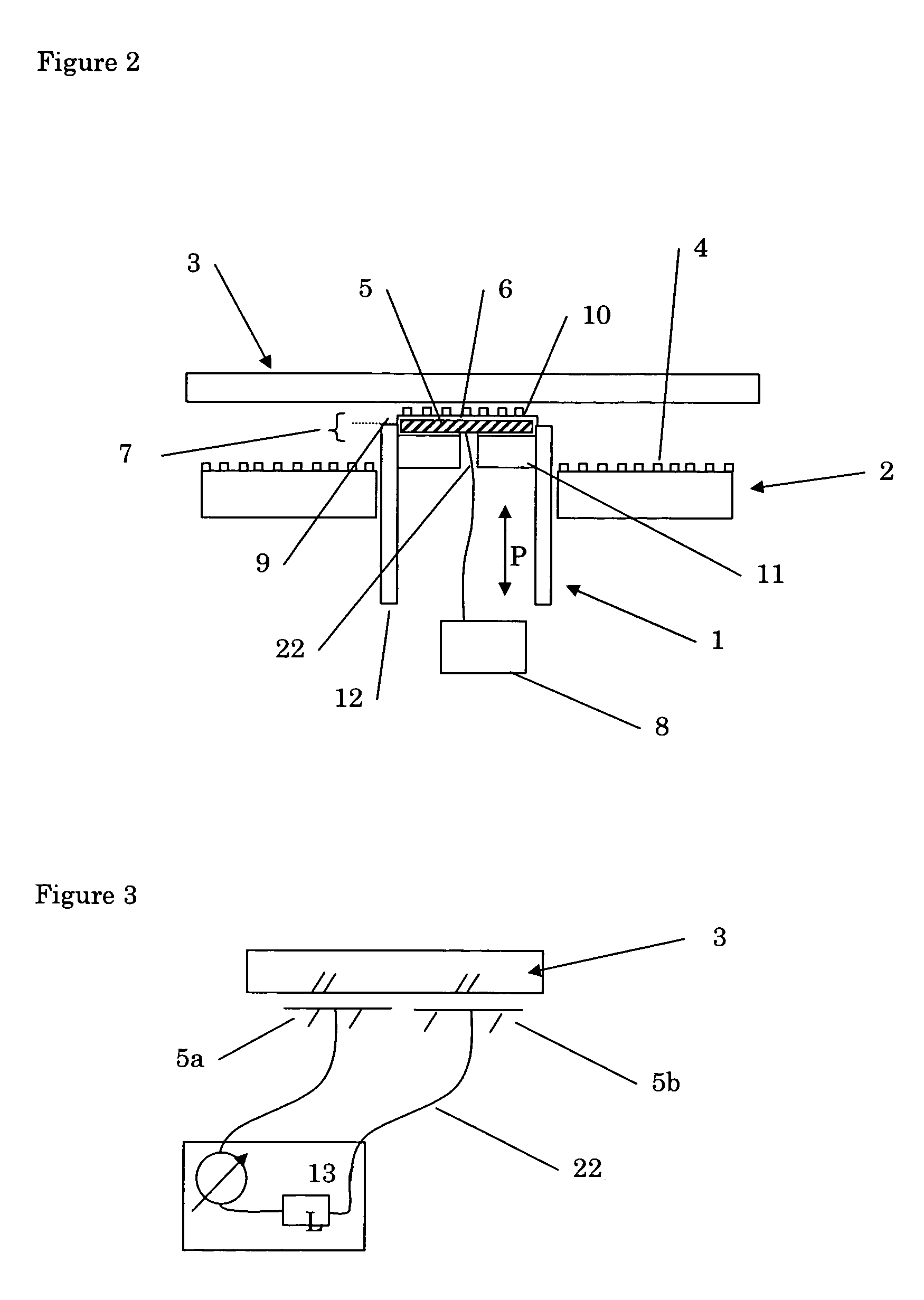

Lithographic apparatus and device manufacturing method

InactiveUS20050128459A1Quick clampingReliable handlingSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight beamEngineering

A lithographic apparatus is disclosed. The lithographic apparatus includes an illumination system for providing a beam of radiation on a flat article to be placed in a beam path of the beam of radiation, and an article handler for handling the article during placement or removal of the article. The article handler includes an electrode and a dielectric layer in order to form an electrostatic clamp for electrostatically clamping the article.

Owner:ASML NETHERLANDS BV

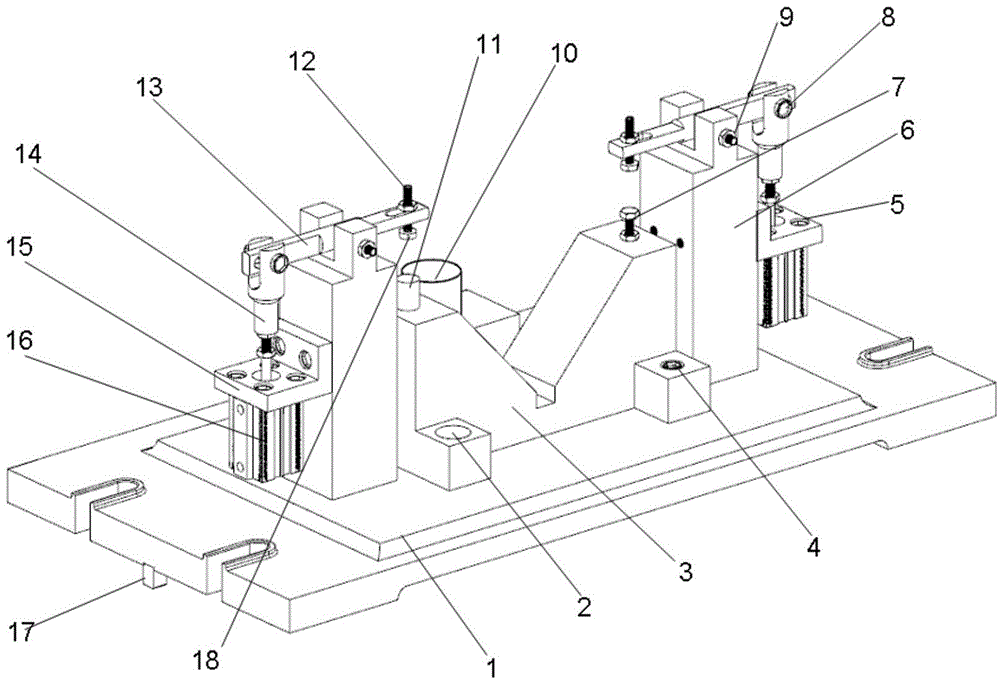

V-block-positioning pneumatic clamping machining center fixture

InactiveCN104128829ANovel structureEasy to operateWork clamping meansPositioning apparatusClassical mechanicsEngineering

The invention discloses a V-block-positioning pneumatic clamping machining center fixture comprising a fixture body, a positioning mechanism and a clamping mechanism. The positioning mechanism comprises a V-block fixed on the fixture body, a fixed support and an auxiliary support are fixed on the upper end faces of two ends of the V-block respectively, and a cylindrical stop pin is arranged on one side corresponding to the center of a V-opening of the V-block. The clamping mechanism comprises two cylinders respectively located on two sides of the V-block, a column is arranged between each cylinder and the V-block, the bottoms of the two columns are fixed on the fixture body, push rods of the cylinders are arranged vertically, a lever is mounted on the top of each push rod transversely and rotationally, the middle of each lever is rotationally mounted at the top of the corresponding column, the other end of each lever is fixed with a pressing block, and each pressing block is located on the lower end face of the corresponding lever and located over the fixing support or the auxiliary support. The V-block-positioning pneumatic clamping machining center fixture is quick and accurate in positioning, quick, controllable and reliable in clamping, and capable of guaranteeing machining stability.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Hydraulic support plunger outer surface laser cladding repairing method

ActiveCN108559996AGuaranteed performanceImprove performanceMetallic material coating processesHardnessOptoelectronics

The invention discloses a hydraulic support plunger outer surface laser cladding repairing method. The hydraulic support plunger outer surface laser cladding repairing method comprises the following steps that firstly, turning is carried out on the outer surface of a hydraulic support plunger to be repaired to remove a fatigue layer and an electroplated layer on the outer surface of the hydraulicsupport plunger, and the outer surface of the hydraulic support plunger is washed; secondly, iron-base alloy powder for laser cladding is put into laser cladding equipment, the laser cladding equipment is used for carrying out laser cladding on the outer surface of the hydraulic support plunger, and a laser cladding layer is formed; thirdly, rough turning is carried out on the hydraulic support plunger which is subjected to laser cladding; fourthly, abrasive machining and polishing treatment are carried out on the hydraulic support plunger which is subjected to rough turning, and the roughnessRa of the outer surface of the polished hydraulic support plunger is smaller than or equal to 0.4; and fifthly, checking and flaw detection are carried out on the outer surface of the polished hydraulic support plunger, and laser cladding repairing of the outer surface of the hydraulic support plunger is completed after it is ensured that no defect exists. The laser cladding layer formed throughthe repairing method is high in hardness, large in thickness and high in corrosion resistance and longer in service life.

Owner:河南省煤科院耐磨技术有限公司

Clamp for grinding spherical pad

InactiveCN101391391AImprove efficiencyReduce processing costsSpherical surface grinding machinesBiomedical engineeringSurface smoothness

The invention discloses a fixture which is used for grinding a spherical gasket and is characterized in that the fixture comprises a flange and a clamp head which are fixedly connected; the clamp head has a same spherical arc surface as the spherical gasket, and the inside of the clamp head is provided with an electromagnetic coil. The fixture can fast clamp and fix a plurality of spherical gaskets, and is convenient for the processing device to finely process the spherical gasket with high efficiency. The accuracy and the surface smoothness of the spherical gasket are greatly increased without greatly increasing the processing cost..

Owner:RUIAN VEHICLE FITTING FACTORY

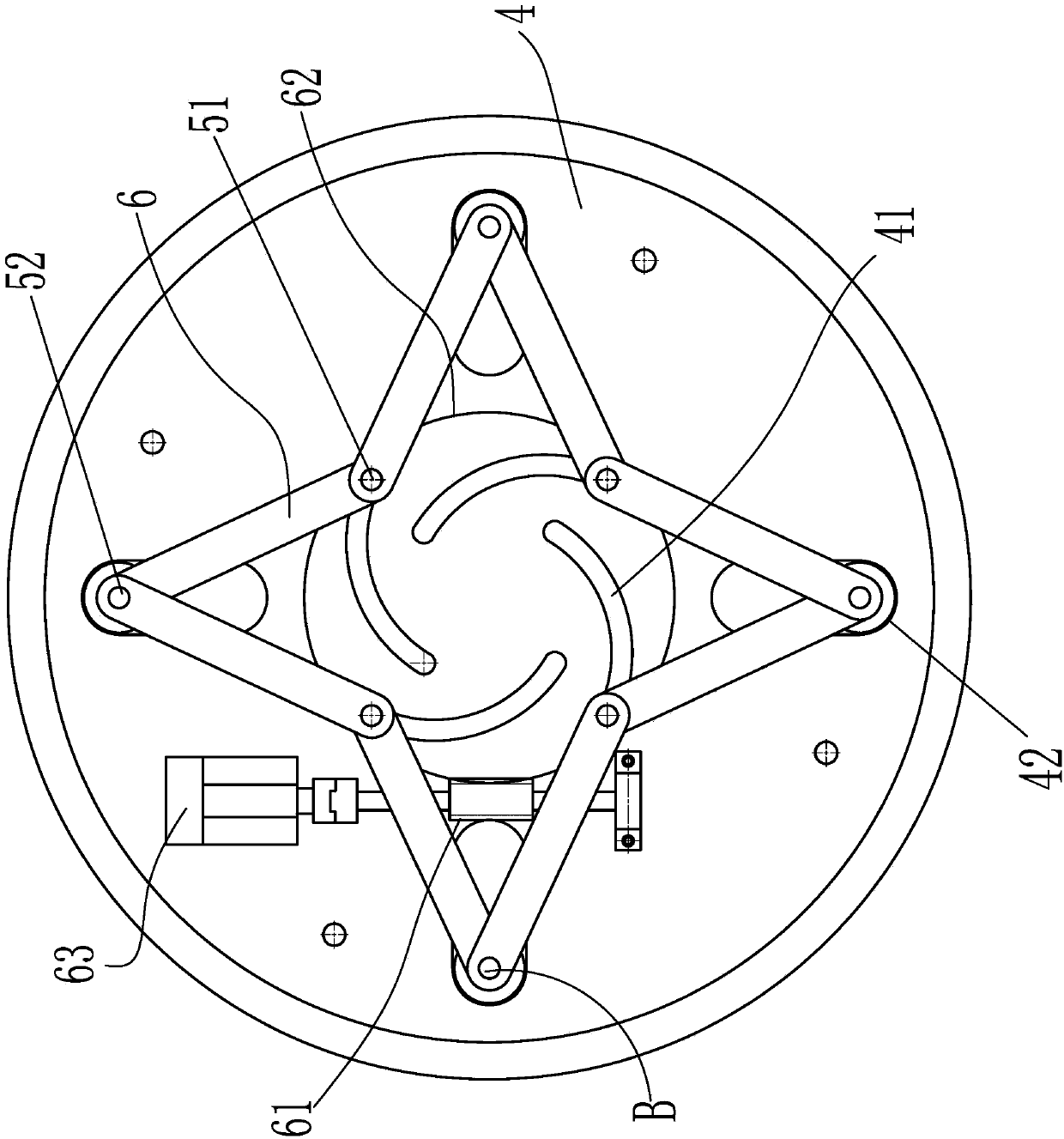

Workpiece automatic clamping device

ActiveCN103817553AAchieve self-centering functionImprove processing efficiencyWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention provides a workpiece automatic clamping device, which is convenient to operate, and the workpiece automatic centering function is realized. The workpiece automatic clamping device comprises a connecting base, a worktable turntable, a main shaft sleeve, an automatic centering disc chuck, a parabolic disc chuck, a plurality of connecting rods and a plurality of positioning claws, wherein the worktable turntable is rotationally arranged above the connecting base; the main shaft sleeve is fixedly arranged below the worktable turntable; the parabolic disc chuck is rotationally arranged on the worktable turntable; the automatic centering disc chuck is fixedly arranged on the worktable turntable; the parabolic disc chuck is provided with arc-shaped involute grooves from the inside to the outside in the radial direction; the connecting rods are hinged to each other end to end; two ends of each connecting rod are respectively a first hinge end and a second hinge end; the first hinge ends are respectively hinged to the involute grooves on the parabolic disc chuck; the automatic centering disc chuck is uniformly provided with long hinge grooves corresponding to the arc-shaped involute grooves in quantity; the second hinge ends are respectively hinged to the long hinge grooves; the positioning claws are respectively arranged above the connected first hinge ends.

Owner:南通棉锦纺织品有限公司

Tool for rapidly installing insulation piercing connector

InactiveCN106299765AWith self-hanging functionQuick installationApparatus for overhead lines/cablesFastening/insulating connecting partsEngineeringMechanical engineering

Owner:CAS HEFEI INST OF TECH INNOVATION +3

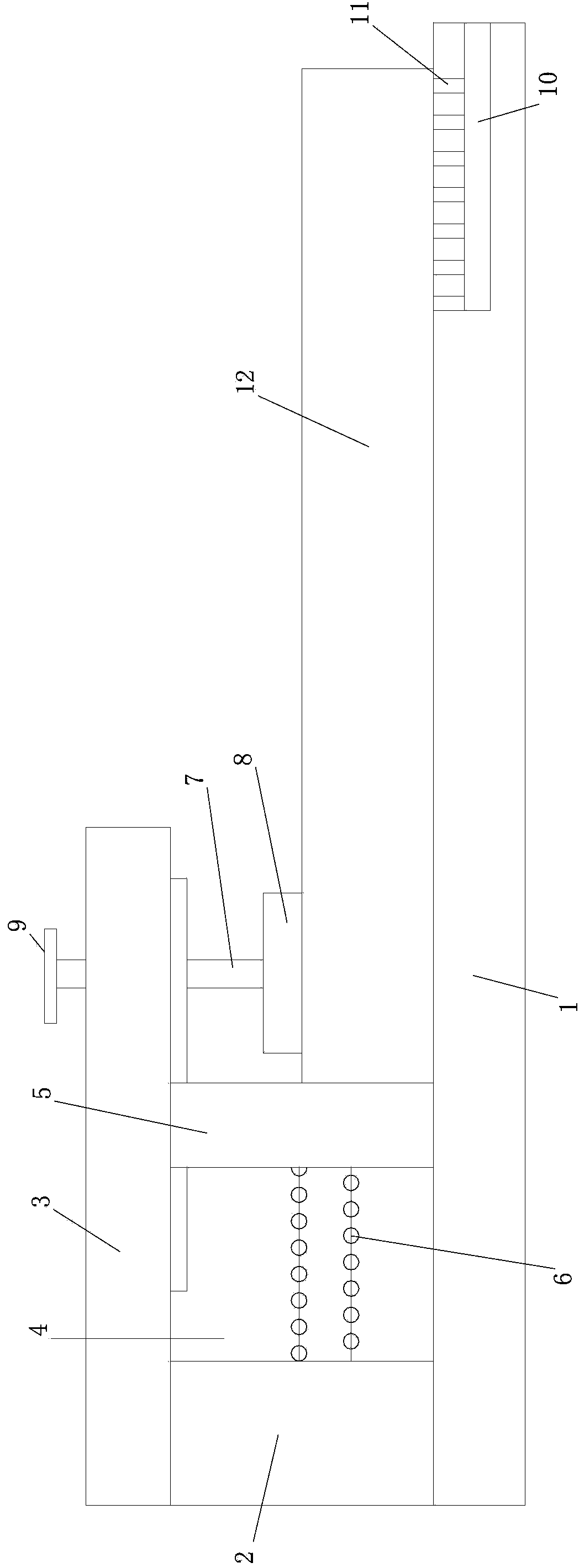

Machining tool for cylindrical workpieces

ActiveCN104985465AQuick clampingSmooth rotationWork clamping meansWelding/cutting auxillary devicesEngineeringMachine tool

The invention provides a machining tool for cylindrical workpieces. The machining tool comprises a bottom plate, a fixed support, a movable support, a first sliding groove, a fixed roller carrier, a sliding roller carrier, rollers, a first air cylinder, a second air cylinder and a locking bolt. By the adoption of the rollers, rapid workpiece clamping and accurate centering can be achieved, and workpieces can rotate conveniently in grinding or turning or welding or the like. By the adoption of the action of the air cylinders, automatic workpiece clamping can be achieved. By the arrangement of the first sliding groove and a second sliding groove, the distance between the fixed support and the movable support and the distance between the sliding roller carrier and the fixed roller carrier can be adjusted according to needs so that workpieces of different diameters can be clamped or different portions of workpieces can be clamped, and accordingly the universality and reliability of the tool are improved. The machining tool for the cylindrical workpieces is high in automation degree and clamping efficiency, greatly shortens the workpiece machining period, improves productivity and lowers the production cost.

Owner:ANHUI SCI & TECH UNIV

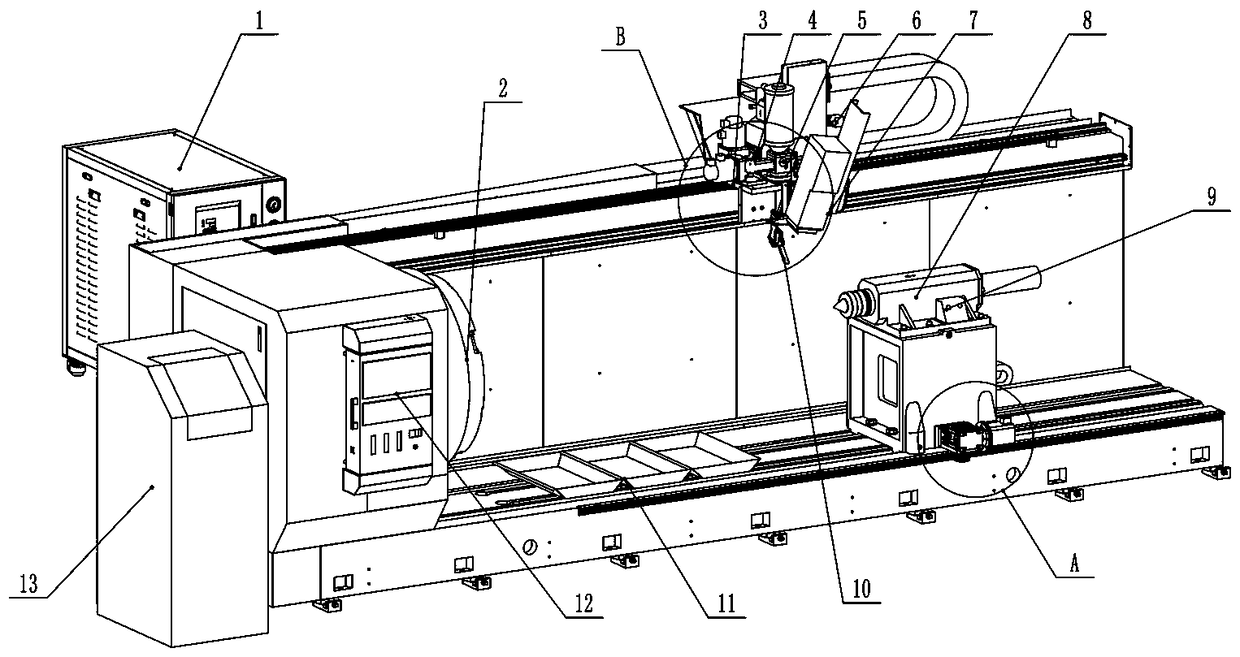

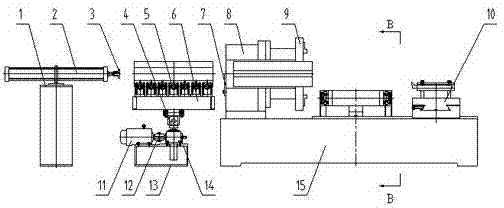

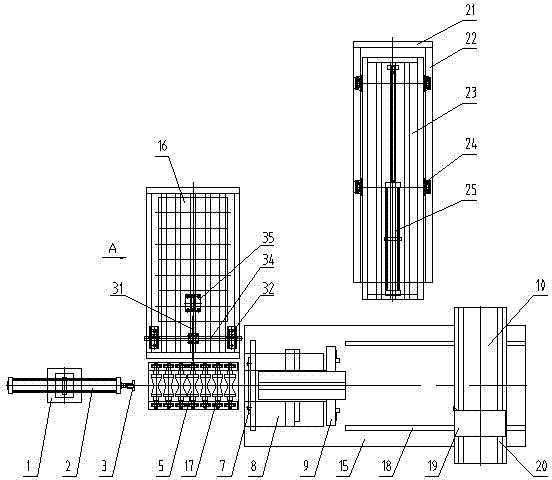

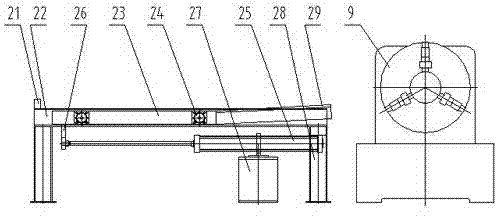

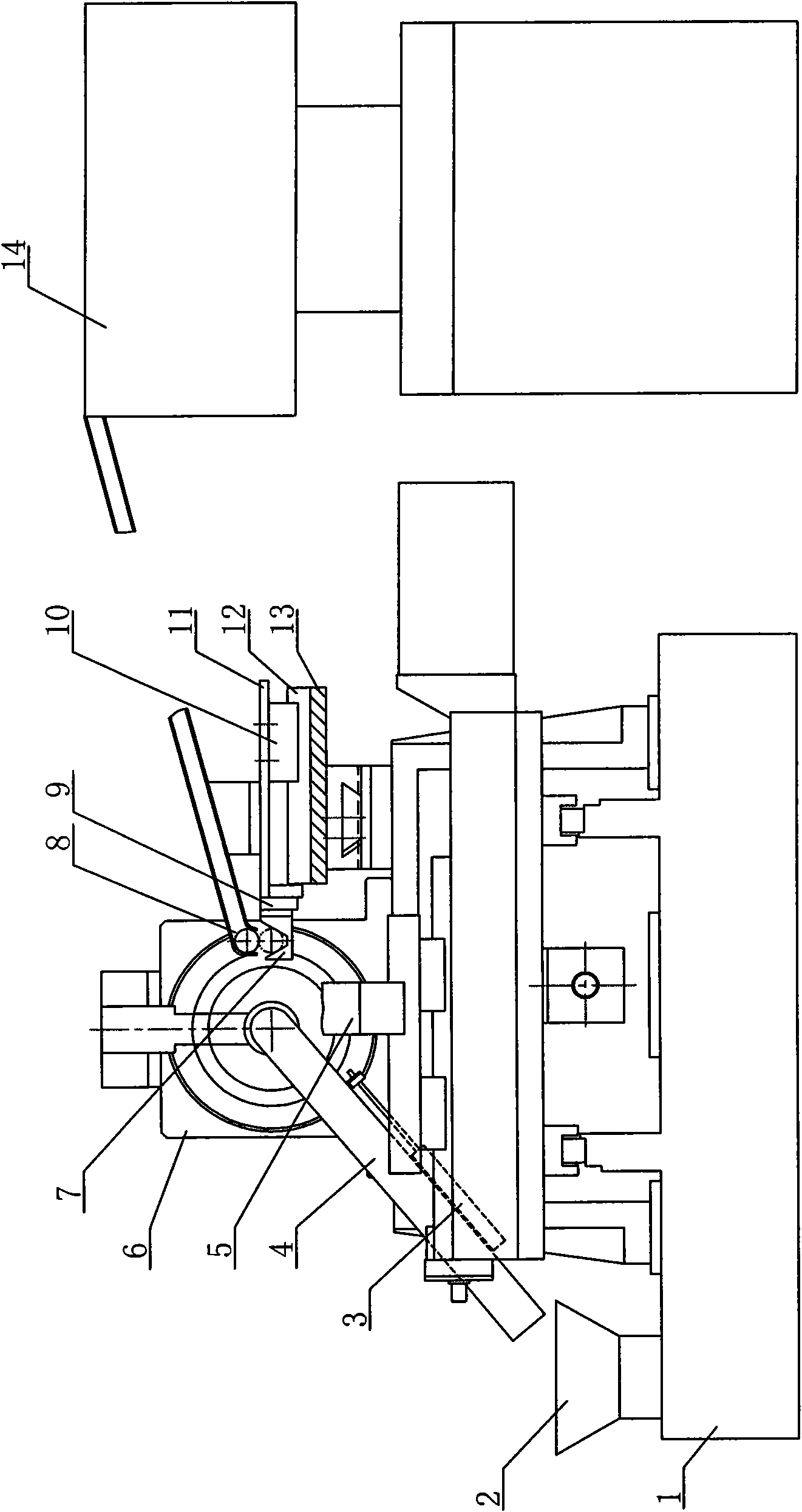

Large bar chamfering machine tool

The invention discloses a large bar chamfering machine tool, comprising a bed body, a machine tool bedside box, a three-claw chuck and transverse guide rails, as well as a loading device, a lifting device, a bar propulsion device and an unloading device, wherein the machine tool bedside box is installed on the front end of the bed body; the three-claw chuck is installed on the machine tool bedside box; the transverse guide rails are installed on the bed body and located behind the machine tool bedside box; a tool tail seat is installed on the transverse guide rails; longitudinal guide rails are arranged on the tool tail seat; the loading device is used for conveying large bars; the lifting device is located ahead of the bed body; the bar propulsion device is arranged ahead of the lifting device as well; and the unloading device is located on the side of the bed body. With the adoption of the chamfering machine tool provided by the invention, the automatic loading and unloading of the large bars are realized, the production efficiency is improved, the labor intensity is decreased, and the safety performance is good; and in addition, the large bar chamfering machine tool is compact in structure, simple to operate, reliable to work and convenient to control, and can effectively adapt to the rapid clamping and processing of the bars with various diameters and lengths.

Owner:ZHEJIANG JIULI HI TECH METALS

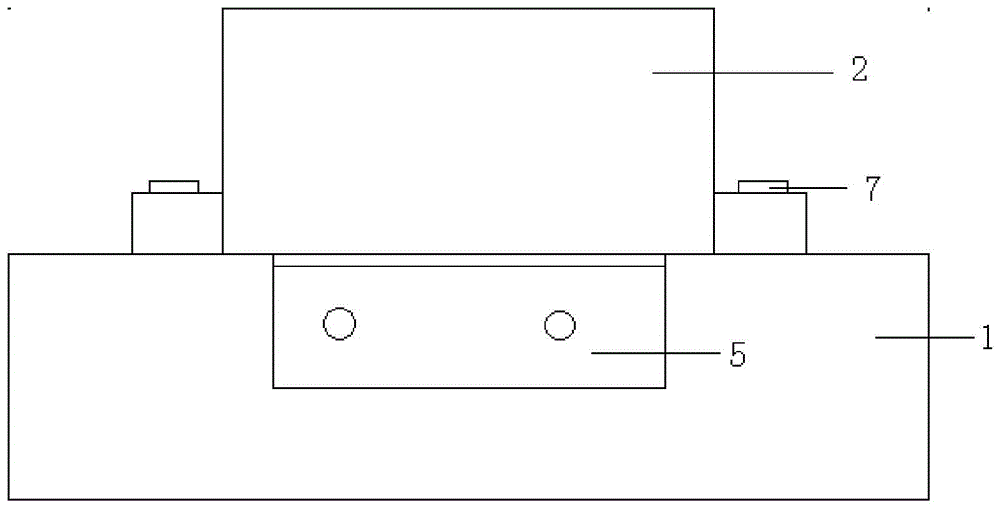

Plate workpiece machining fixture

InactiveCN104339286AEasy to removeQuick clampingWork holdersPositioning apparatusEngineeringMachining

The invention relates to the technical field of machining, in particular to a plate workpiece machining fixture comprising a base. A supporting block is fixed at one end of the base. An extension support is disposed at the upper end of the supporting base. A clamping space is provided between the lower end face of the extension support and the upper end face of the base. An ejector block which slides back and forth along the upper end face of the base is disposed within the clamping space. An elastic member is provided between the ejector block and the supporting block. A compression screw is disposed on the extension support; the lower end of the compression screw is located in the clamping space and is provided with a presser; the upper end of the presser is located at the upper end of the extension support and fixedly connected with a hand wheel. The plate workpiece machining fixture has the advantages that a plate workpiece can be quickly clamped, the plate workpiece is convenient to extract after machining, and work efficiency is improved.

Owner:常州鑫鹏工具制造有限公司

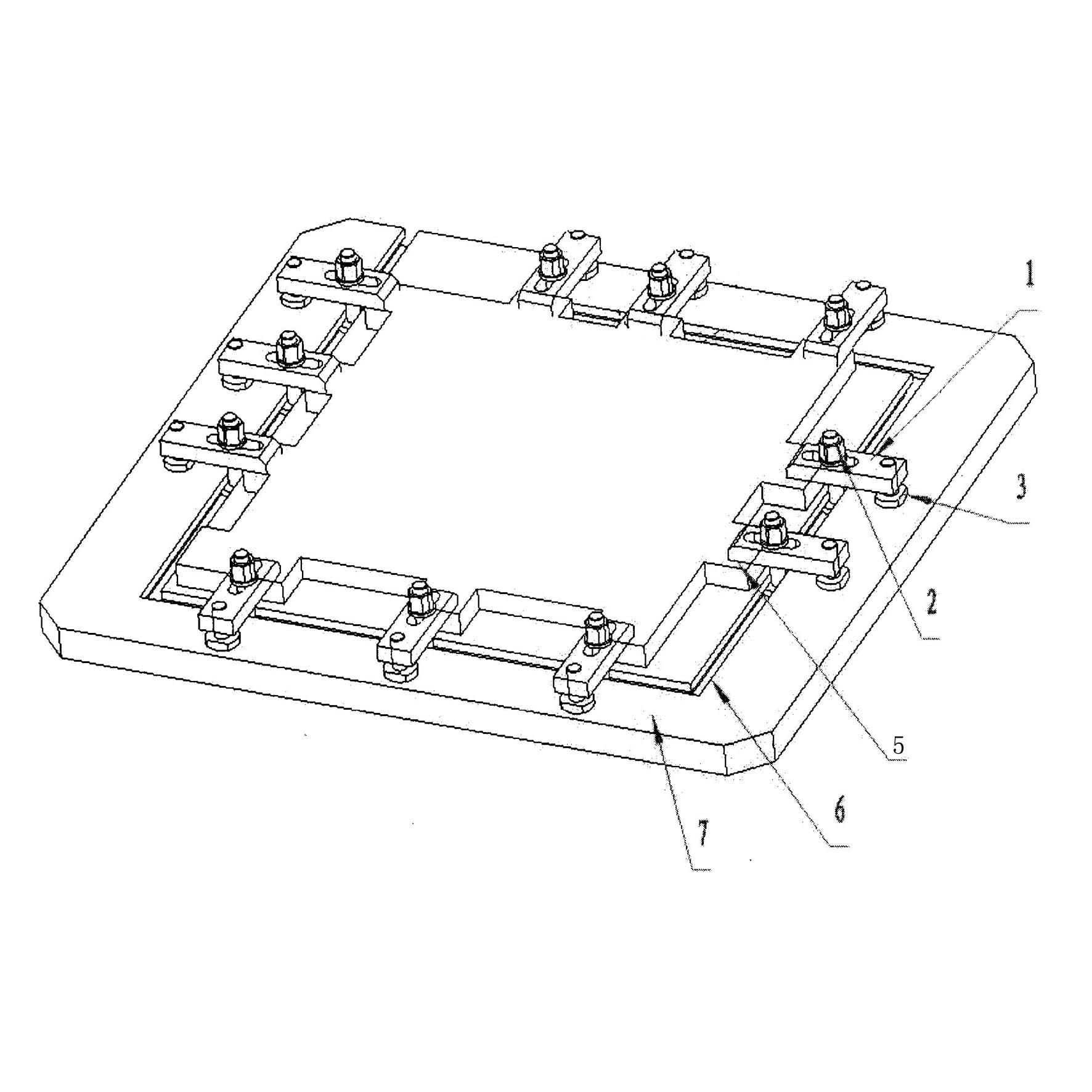

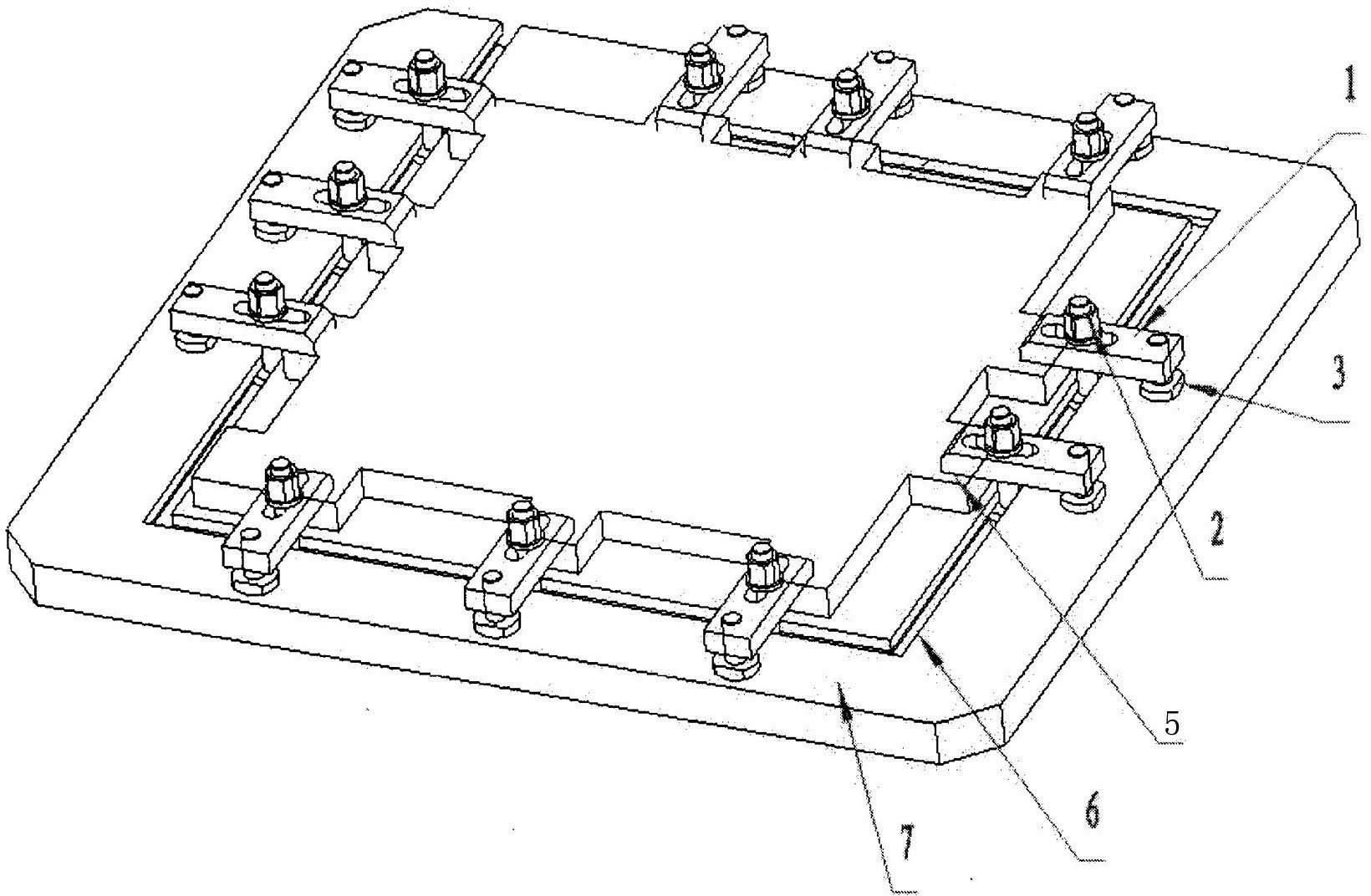

Dimension correction device in large double-curved surface plate part processing and method thereof

InactiveCN102528501AHigh precision of curvatureQuick clampingMilling equipment detailsPositioning apparatusEngineeringCorrection method

The invention relates to a dimension correction device in large double-curved surface plate part processing; a T-shaped groove in a rectangular direction is arranged on the upper surface of the workbench surface of a milling machine, and a plurality of connecting bolts are arranged in the T-shaped groove; and one end of a pressure plate is provided with a long strip hole and the other end of the pressure plate is provided with a reverse support bolt, wherein the long strip hole is connected with the connecting bolt, and the bottom surface of the support bolt is contacted with the surface of the workbench surface of the milling machine. According to the correction device, the structure is simple, the correction method is easy and convenient, simultaneously the working efficiency is improved, the problems of a large vacuum absorption platform that the fixation is not firm and the hole positioning stress cannot be released are solved, and the number of various other positioning clamps in processing is greatly reduced.

Owner:SHENYANG AIRCRAFT CORP

Clamping type integral shrinking and overturning climbing robot

InactiveCN102632505AFast straight climbImprove terrain adaptabilityGripping headsEngineeringClimbing robots

The invention aims at providing a clamping type integral shrinking and overturning climbing robot comprising two clamping parts, an internal extension tube, an external extension tube, a shrinking motor, an extension tube connecting frame, an overturning frame and an overturning motor, wherein each clamping part comprises a clamping paw, a clamping motor, a clamping motor rack, a guide shaft and a paw lead screw, and the two clamping parts are respectively located on the two ends of a main body of the clamping type integral shrinking and overturning climbing robot and are connected with the corresponding overturning motors through the respective clamping motor racks. According to the invention, a shrinking mechanism is designed according to the helical lead screw transmission principle to enable the robot to quickly and linearly climb in a shrinking manner; the integral shrinking and overturning design mode entitles better terrain adaptability to the robot; and the shrinking part utilizes an internal and external extension tube structure so as not to bear radial force.

Owner:HARBIN ENG UNIV

Full-automatic commutator excircle lathe

ActiveCN101972857ARealize fully automatic processingSimple structureTurning machinesEngineeringAutomatic testing

The invention discloses a full-automatic commutator excircle lathe which comprises a lathe bed, a main spindle box and a tool rest, wherein the main spindle box is fixedly arranged on the lathe body and is internally provided with an electrical main spindle; and the tool rest is slidably arranged on the lathe body and is driven by a motor. The invention is characterized in that the full-automatic commutator excircle lathe also comprises an automatic loading device, a rapid clamping device and an automatic unloading device. The lathe can realize full-automatic processing of the excircle of a commutator, has simple structure, greatly improves the processing efficiency and lightens the labor intensity.

Owner:ANGU GRP CO LTD

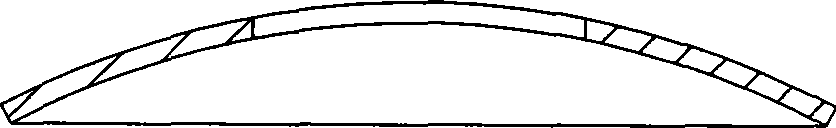

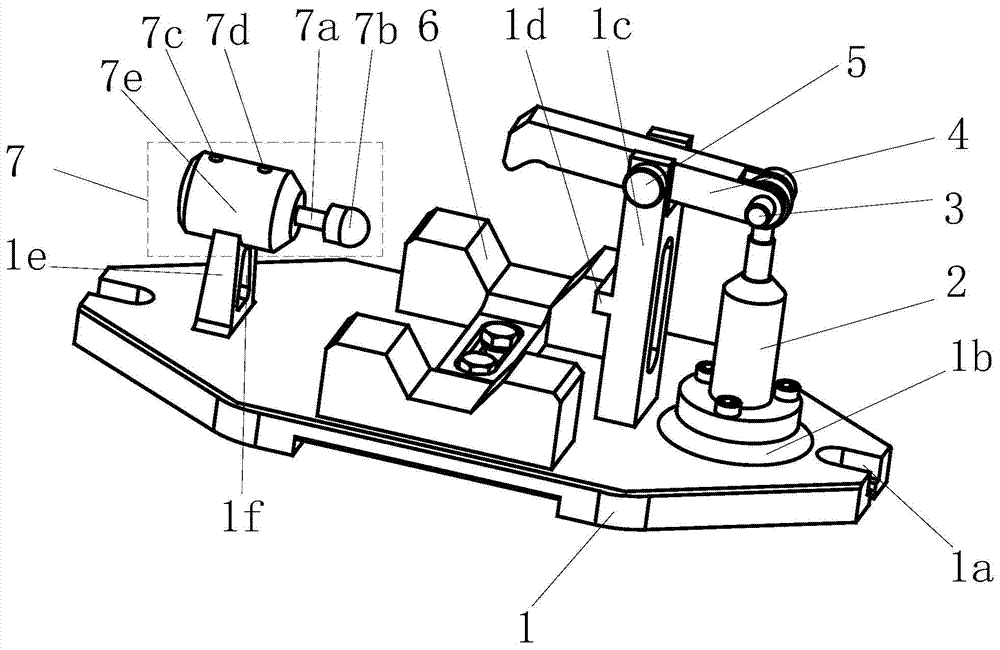

Welding tool of anti-collision beam and mounting plate

InactiveCN106670709AClamp firmlyQuick clampingWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringEnergy absorbing

The invention discloses a welding tool of an anti-collision beam and a mounting plate. The welding tool comprises a mounting plate body, the anti-collision beam and an energy absorbing box, wherein the anti-collision beam is welded to the energy absorbing box. Positioning holes are formed in the mounting plate body. The mounting plate body comprises a mounting platform. The mounting platform is provided with a supporting platform, a supporting assembly, a first pressing assembly, a second pressing assembly, a transverse pushing positioning assembly and end part positioning blocks. A positioning column is arranged on the supporting platform. The supporting platform and the positioning column position the mounting plate body. The second pressing assembly compresses the mounting plate body and the supporting platform. A positioning circular hole is formed in the anti-collision beam. A circular hole positioning assembly are arranged on the mounting platform. The supporting assembly, the end part positioning blocks and the circular hole positioning assembly position the anti-collision beam. The first pressing assembly compresses the anti-collision beam. The transverse pushing positioning assembly positions the energy absorbing box, so that the welding positions of the energy absorbing box and the mounting plate body are determined. Clamping is reliable, rapid and accurate, and efficiency is improved greatly.

Owner:成都凌云汽车零部件有限公司

Clutch master cylinder body piston hole drilling clamp

InactiveCN104289945AImprove securityReasonable structural designPositioning apparatusMetal-working holdersHydraulic cylinderMaster cylinder

A clutch master cylinder body piston hole drilling clamp comprises a base, a first hydraulic cylinder, a first pin, a pressing plate, a second pin, a V-shaped locating block and a second hydraulic cylinder. Lug seats are arranged at the left end and the right end of the base, a round boss is arranged at the right end of the upper surface of the base, a supporting frame is arranged on the left side of the round boss, a trapezoid supporting table is arranged at the left end of the upper surface of the base, the first hydraulic cylinder is fixed to the round boss of the base through screws, the tail end of the pressing plate is hinged to one end of a first piston of the first hydraulic cylinder through the first pin, the middle of the pressing plate is hinged to the supporting frame through the second pin, the V-shaped locating block is located between the supporting frame and the trapezoid supporting table, and is fixed to the base through bolts, and the second hydraulic cylinder is welded to the trapezoid supporting table. Fast clamping can be achieved, work efficiency is greatly improved, machining precision is guaranteed, meanwhile, labor force is saved, and the investment of production cost is lowered.

Owner:WUHU HENGHAO MACHINERY MFG

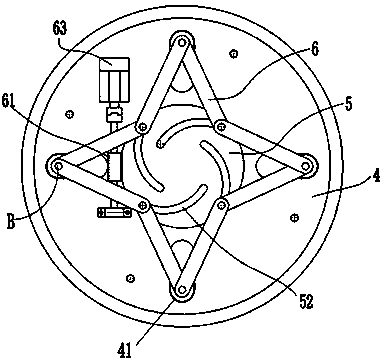

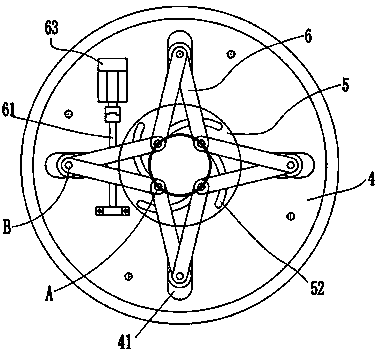

Pneumatic clamping mechanism

InactiveCN105108678ASimple mechanical movementSimple structureWork holdersEngineeringMechanical engineering

The invention relates to a pneumatic clamping mechanism which comprises a chuck body, an air cylinder, a plurality of clamping mechanisms and a guiding mechanism, wherein a cavity for placing the guiding mechanism is formed at one side inside the chuck body; sliding chutes for placing the plurality of clamping mechanisms are formed in the end part of the chuck body; a push rod is connected onto a piston rod of the air cylinder; one sliding block group A is arranged at each of two ends of the push rod; each clamping mechanism comprises a clamping block arranged in the corresponding sliding chute; a sliding block group B is connected to the bottom end of each clamping block; the guiding mechanism comprises guide rails A, guide rails B and a crank; the guide rails A are arranged in the cavity; the sliding block groups A are in inserted fit with the insides of the guide rails A; two ends of the crank are respectively hinged to the sliding block group A and the sliding block group B which are positioned at the lower end of the same sliding chute. The pneumatic clamping mechanism disclosed by the invention has the advantages of consisting of the air cylinder and a crank sliding block mechanism, being simple in mechanical motion and integral structure, and being easy to process; a clamping block is clamped by the motion of pushing the crank sliding block mechanism through the air cylinder; higher precision can be obtained; meanwhile, the pneumatic clamping mechanism is quick in clamping process, so that the working efficiency is improved.

Owner:NANTONG HUAXING OIL EQUIP

Electromagnetic clamp

ActiveCN103909437AAchieve clampingSuitable for fixingPositioning apparatusMetal-working holdersElectricityEngineering

The invention discloses an electromagnetic clamp. The electromagnetic clamp comprises a base seat, wherein a left clamping portion and a right clamping portion which are connected together in separable mode are oppositely arranged on the base seat, a containing space which contains a work piece is formed after the left clamping portion and the right clamping portion are connected together, the left clamping portion is connected with the base seat in detachable mode, the right clamping portion is connected with the base seat in sliding mode, the left clamping portion and the right clamping portion are both provided with cavities, controllers are arranged in the cavities, a first electromagnet is arranged in the cavity of the left clamping portion, a second electromagnet is arranged in the cavity of the right clamping portion, winding directions of coils of the first electromagnet and the second electromagnet are opposite, the first electromagnet and the second electromagnet are both connected with the controllers, and the controllers are electrically connected with a power source. The electromagnetic clamp can be used in individual product production and large batch production, avoids repeated actions of drawing lines and aligning, improves production efficiency, and guarantees quality of the work piece.

Owner:浙江西塘实业有限公司

Connector product test device

ActiveCN103018608ANot easy to damageReduce manufacturing costElectrical testingMeasurement instrument housingTest efficiencyElectricity

The invention discloses a test device, in particular to a connector product test device which is high in test accuracy, reduces test cost and improves test efficiency. According to the connector product test device, a test pin is adopted to replace the test connector in the prior art for product testing, is arranged on a movable carrier and is electrically connected with a test terminal. During testing, the carrier moves by aid of manual operation or through a power device and drives the test pin to move in the direction of a connector to be tested, and finally the tail end of the test pin is contacted with a metal sheet of the connector to be tested to achieve testing. The connector product test device is widely applied to the connector test field.

Owner:珠海市运泰利自动化设备有限公司

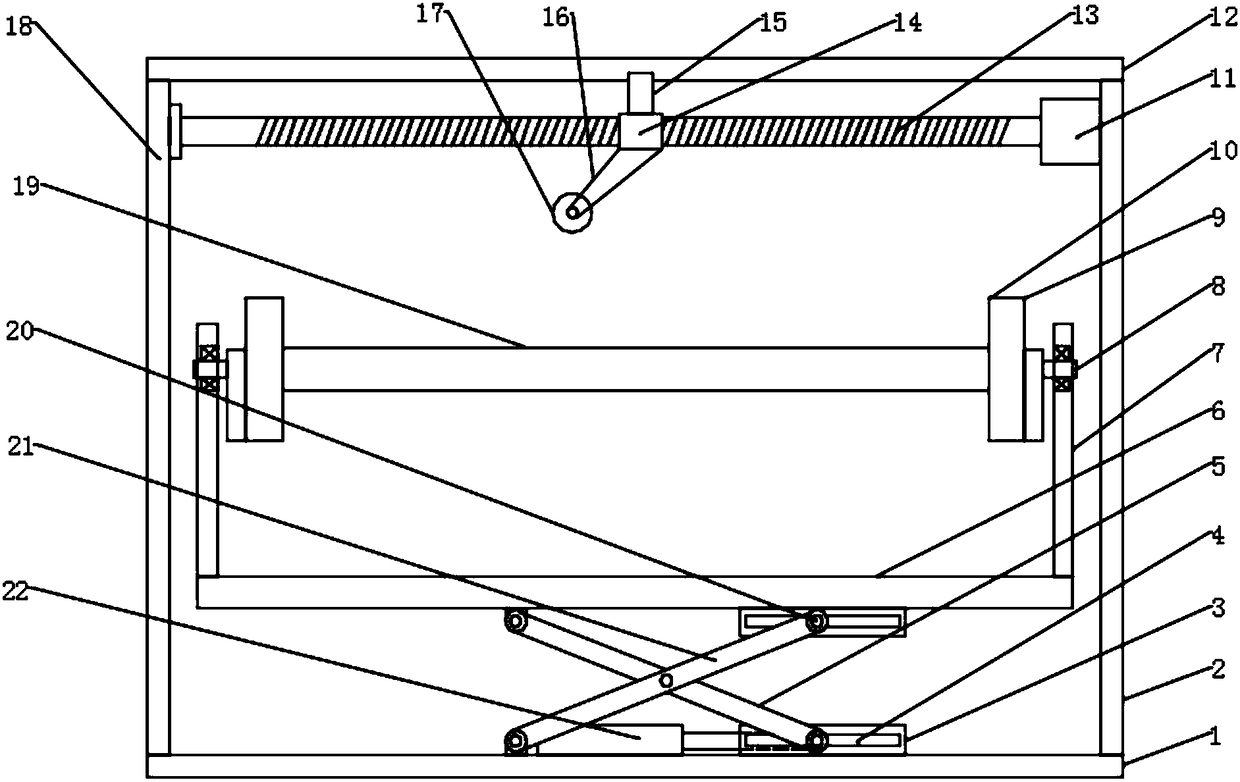

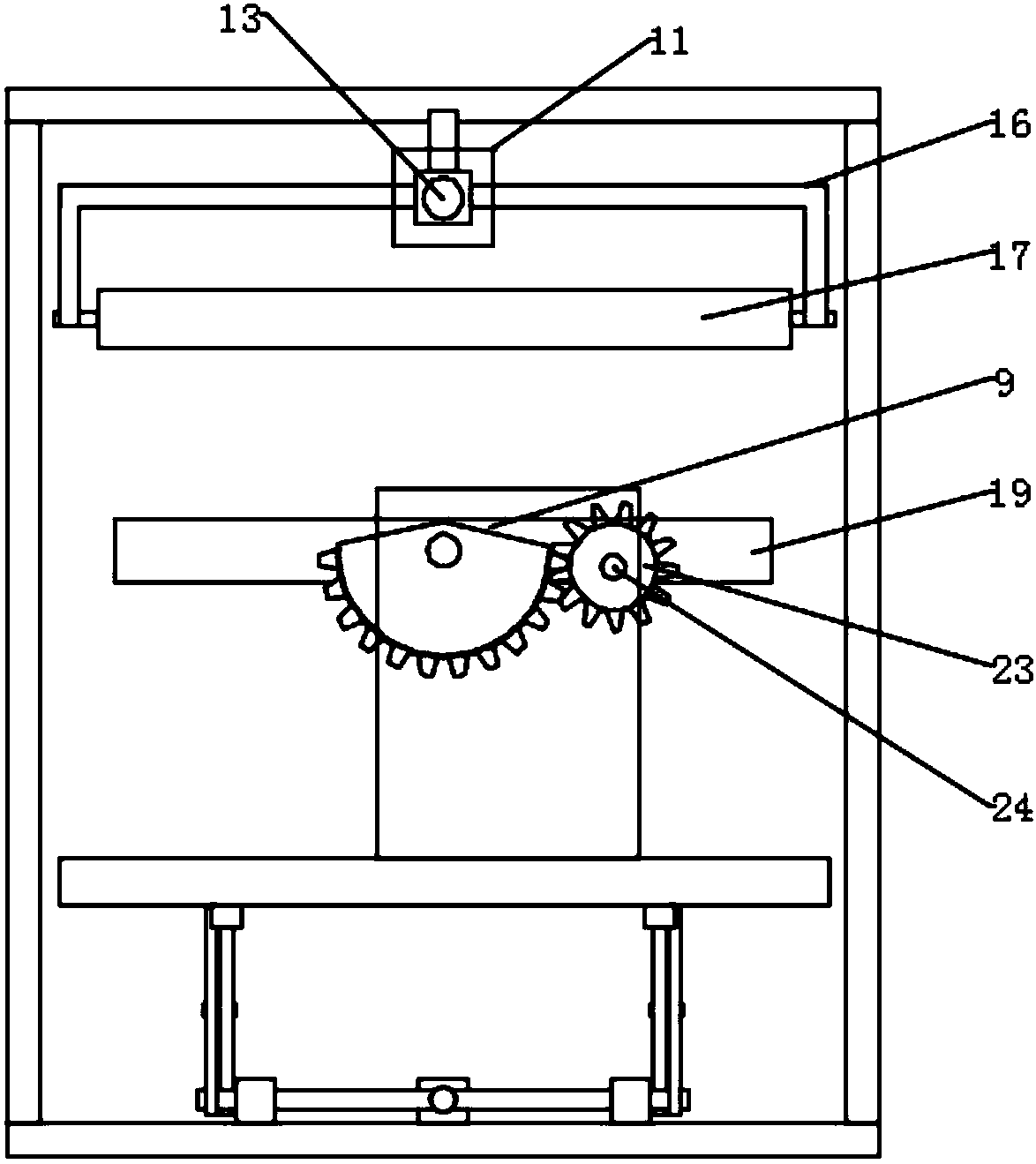

Efficient furniture board polishing device

InactiveCN108115516ASimple structureEasy to operateGrinding carriagesGrinding drivesEngineeringWood panel

The invention discloses an efficient furniture board polishing device. The efficient furniture board polishing device comprises a bottom plate, a left side plate, a right side plate, a top plate, a supporting plate, a first connecting rod, a second connecting rod, slide rails, a first electric push rod, mounting plates, rotating shafts, semicircular gears, clamping devices, a gear, a first motor,a second motor, a threaded rod, an internal threaded sleeve, a connection rod and a polishing roller. By joint action of the first connecting rod, the second connecting rod and the first electric pushrod, the supporting plate is driven to perform lifting motion, then the supporting plate drives boards to realize lifting motion, and convenience in polishing of the boards in different thicknesses is achieved; by combination with translation of the polishing roller, arc polishing of the boards on a polishing table can be realized through joint motion; by arrangement of the clamping devices, theboards are clamped or released by clamping plates through part cooperation, and convenience in operation and reliability in clamping are realized; by arrangement of the semicircular gears and the gear, quick turning of the boards is realized, double-side polishing of the boards is facilitated, and simplicity in operation, convenience and practicality are realized.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

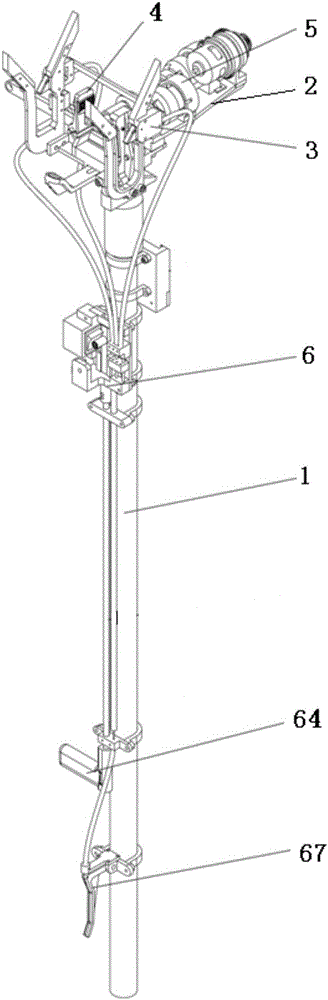

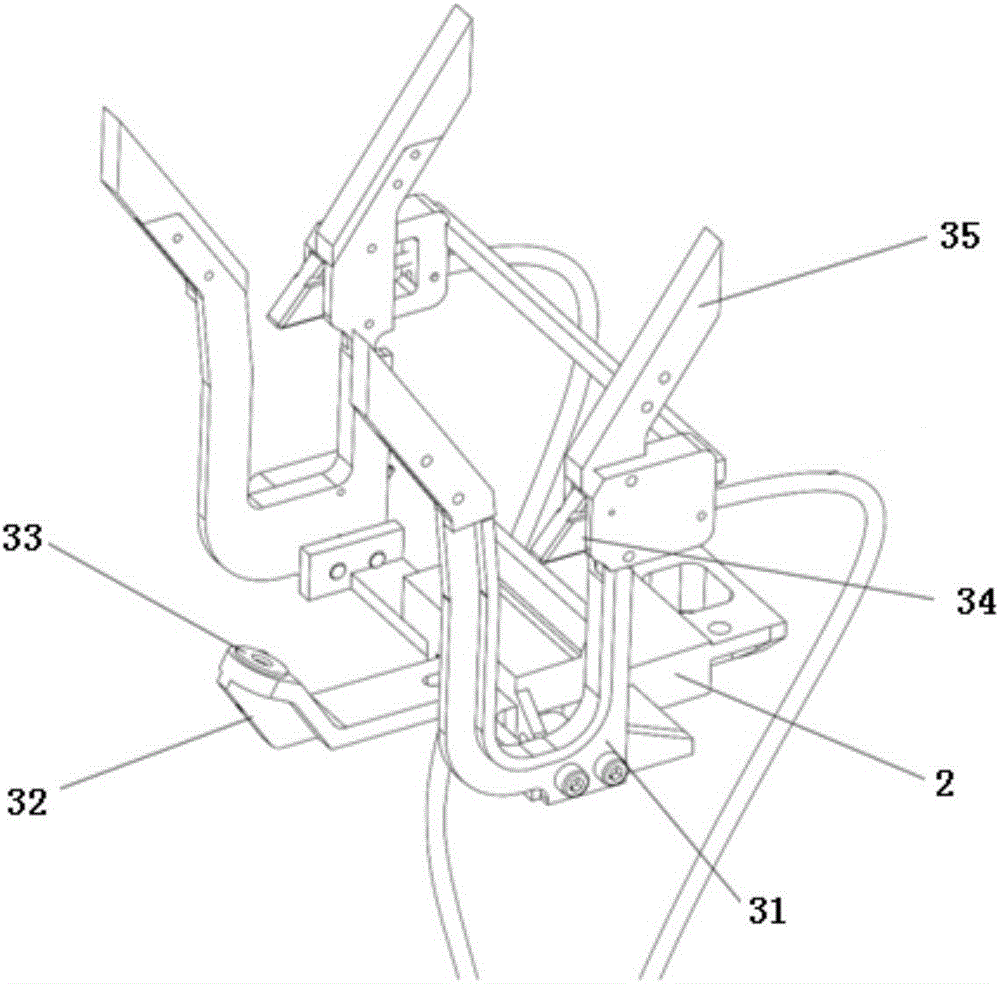

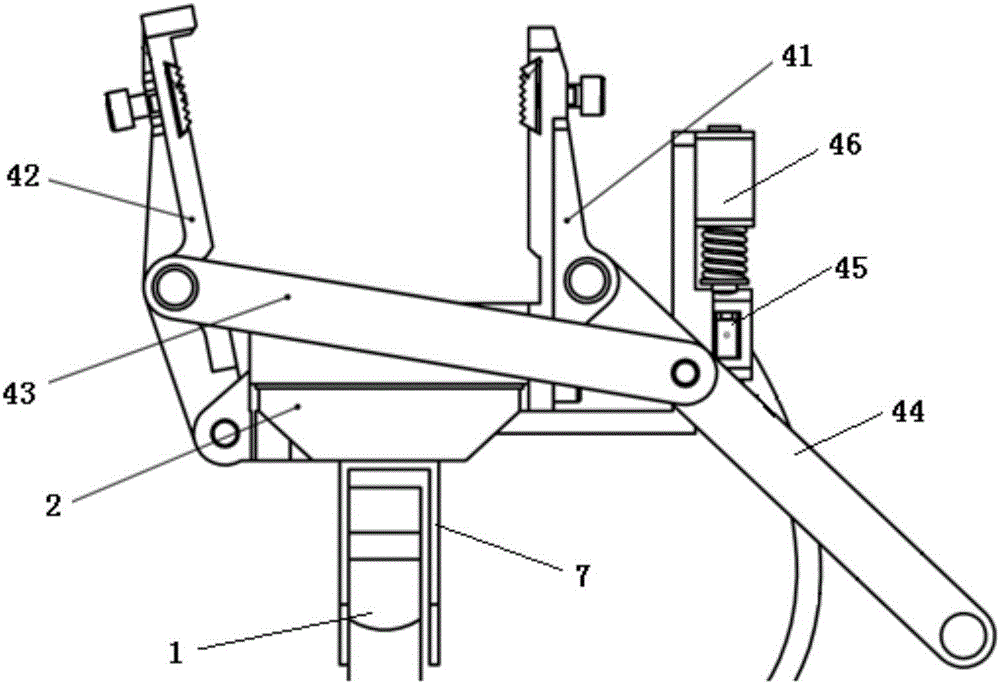

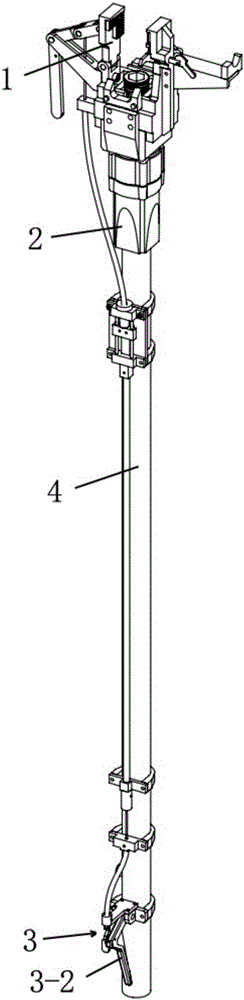

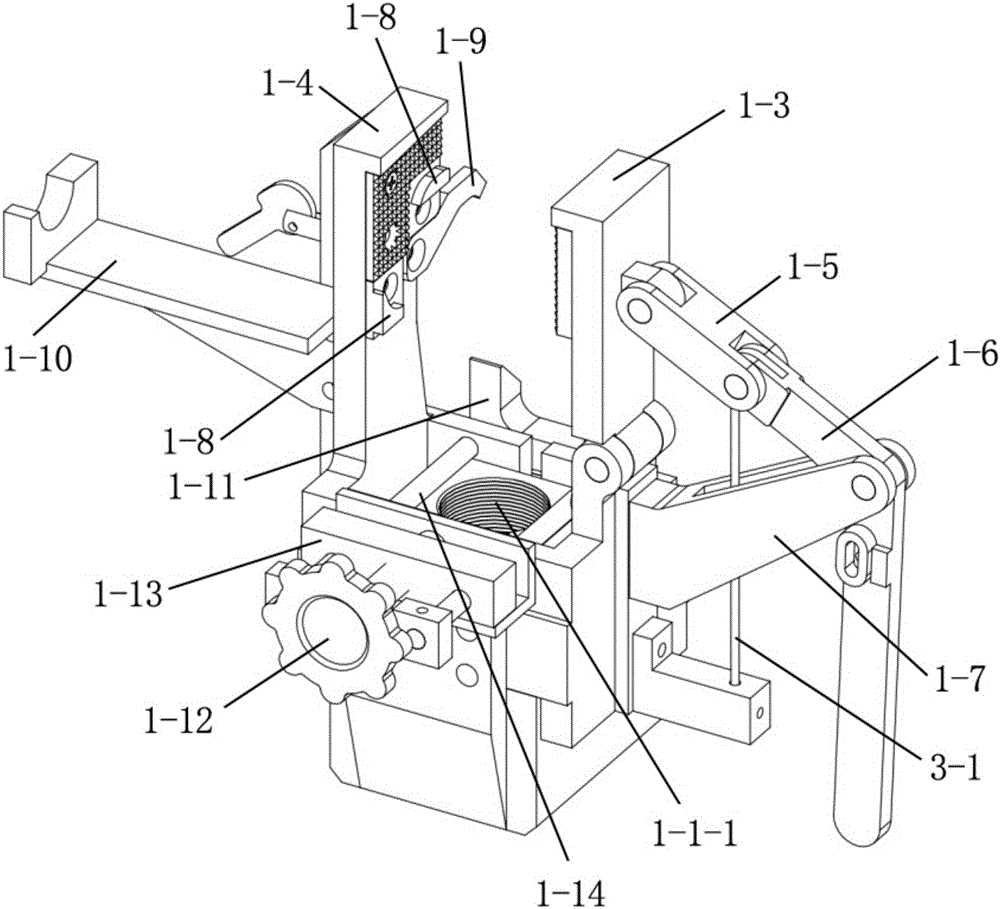

Quick automatic installation tool for charged fire welding operation

ActiveCN106786182ARapid positioningSave work on position adjustmentApparatus for overhead lines/cablesEngineeringScrew thread

The invention relates to a quick automatic installation tool for charged fire welding operation. The tool comprises a clamping device, a screwing device, an unlocking device and an insulating rod, wherein the screwing device comprises a spiral self-elevating sleeve, a rotary sleeve fixing seat and a fixed torque spanner; the spiral self-elevating sleeve has external threads, and the rotary sleeve fixing seat has internal threads; the spiral self-elevating sleeve is connected with the rotary sleeve fixing seat by the threads; one end of the spiral self-elevating sleeve is connected with the fixed torque spanner in a transmission way, and the other end of the spiral self-elevating sleeve is in profile connection with a nut of a J-shaped parallel groove clamp; the rotary sleeve fixing seat is fixed relative to the clamping device; the clamping device and the screwing device are positioned at one end of the insulating rod, and the unlocking device is positioned at the other end of the insulating rod or is close to the other end of the insulating rod. The quick automatic installation tool is used for installing the J-shaped parallel groove clamp applied to the fire welding operation, can realize long-distance operation, is convenient in clamping and rapid in fire welding process, and is capable of realizing automatic long-distance quick unlocking.

Owner:HEFEI CAS LANRUI TECH CO LTD

Quick clamping type clamp

ActiveCN104384985AQuick clampingAchieve clampingPositioning apparatusMetal-working holdersMechanical engineeringEngineering

Owner:湖南凯斯机械股份有限公司

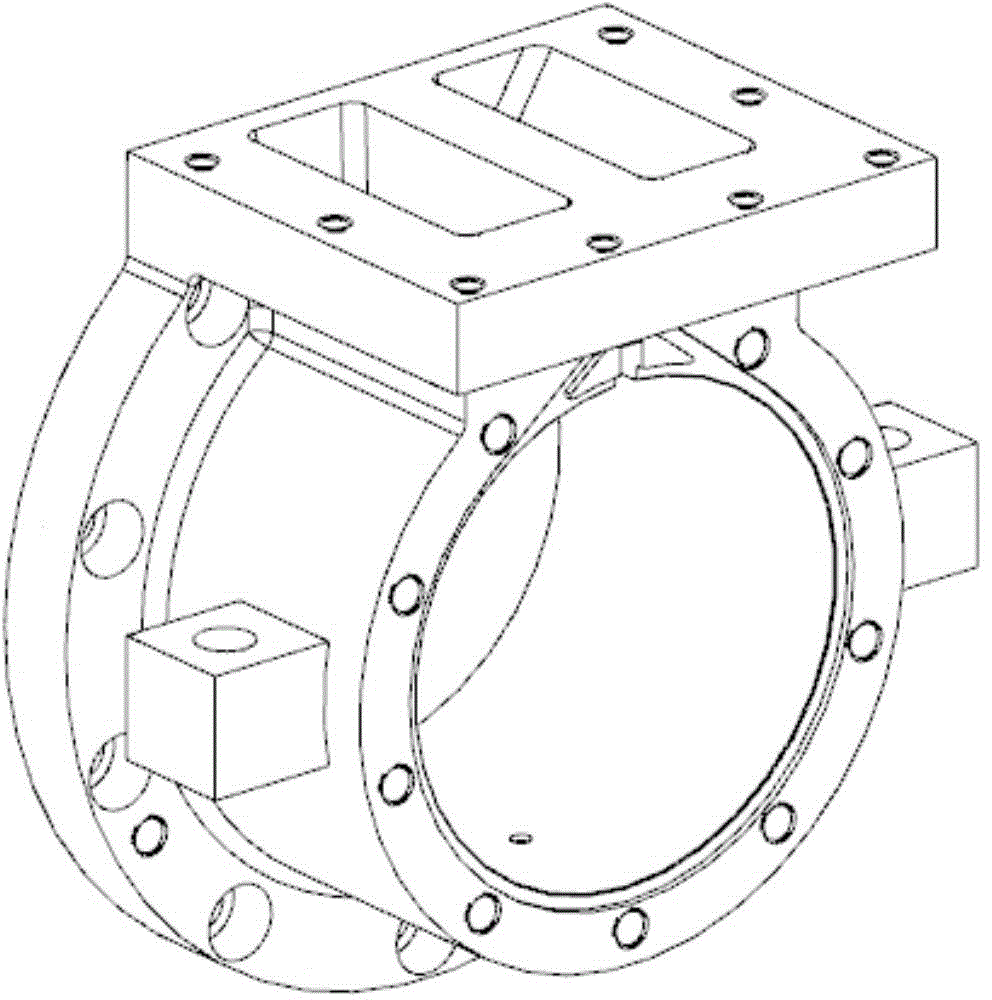

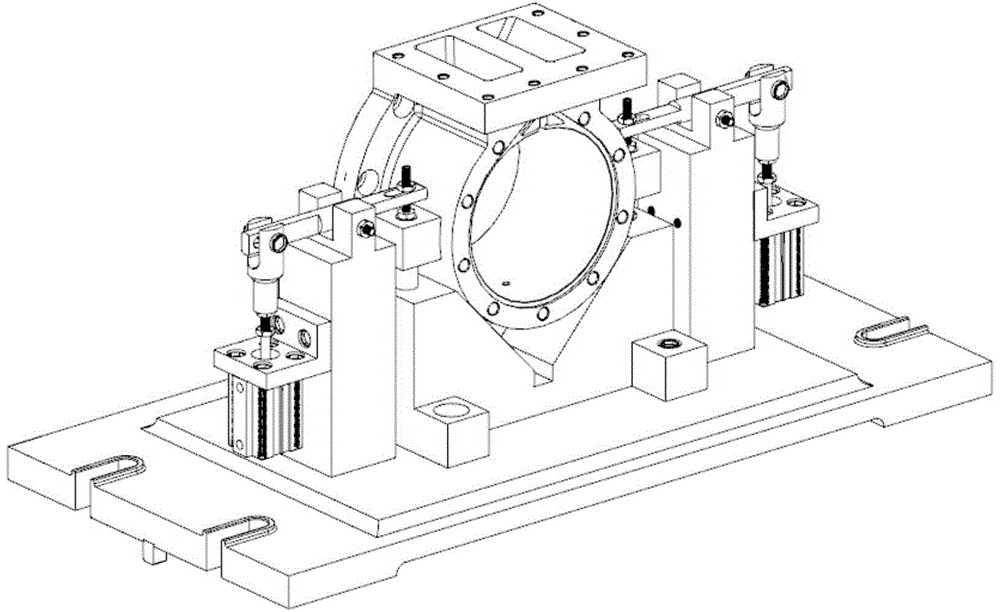

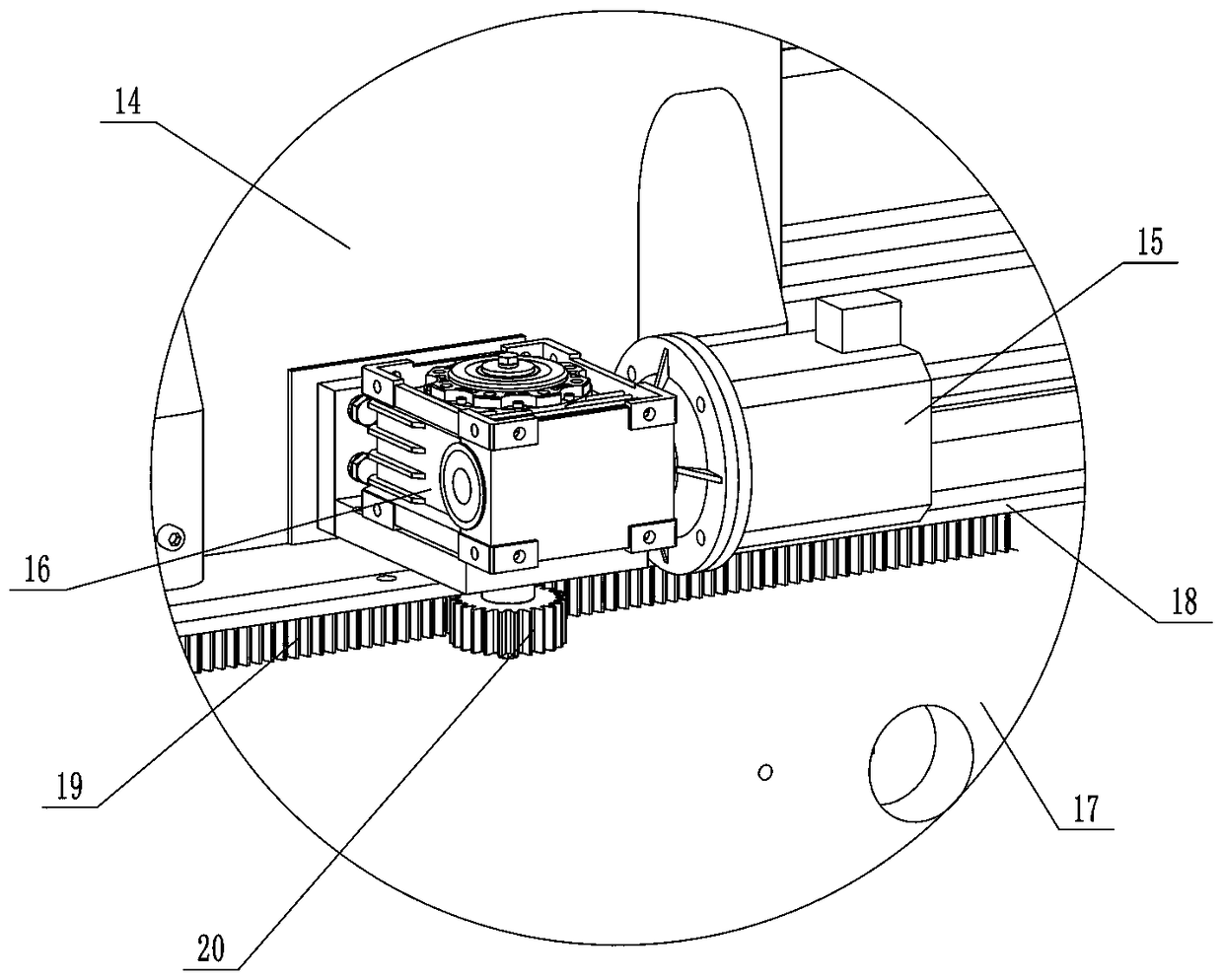

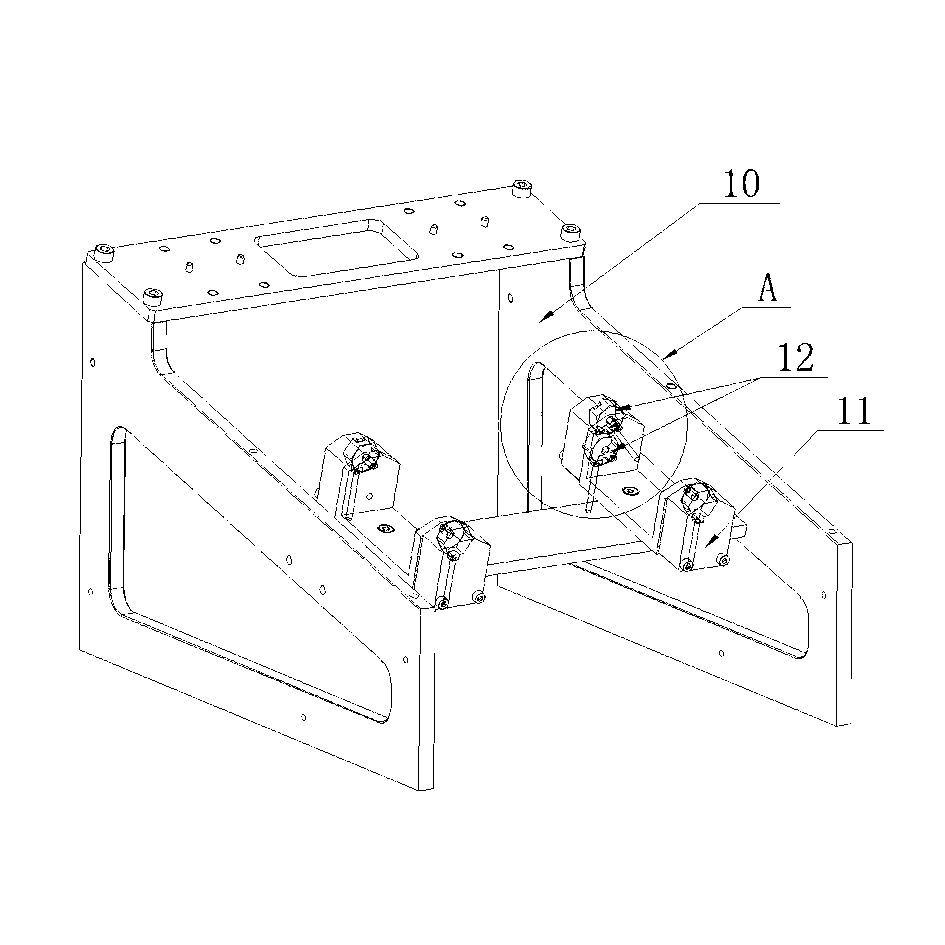

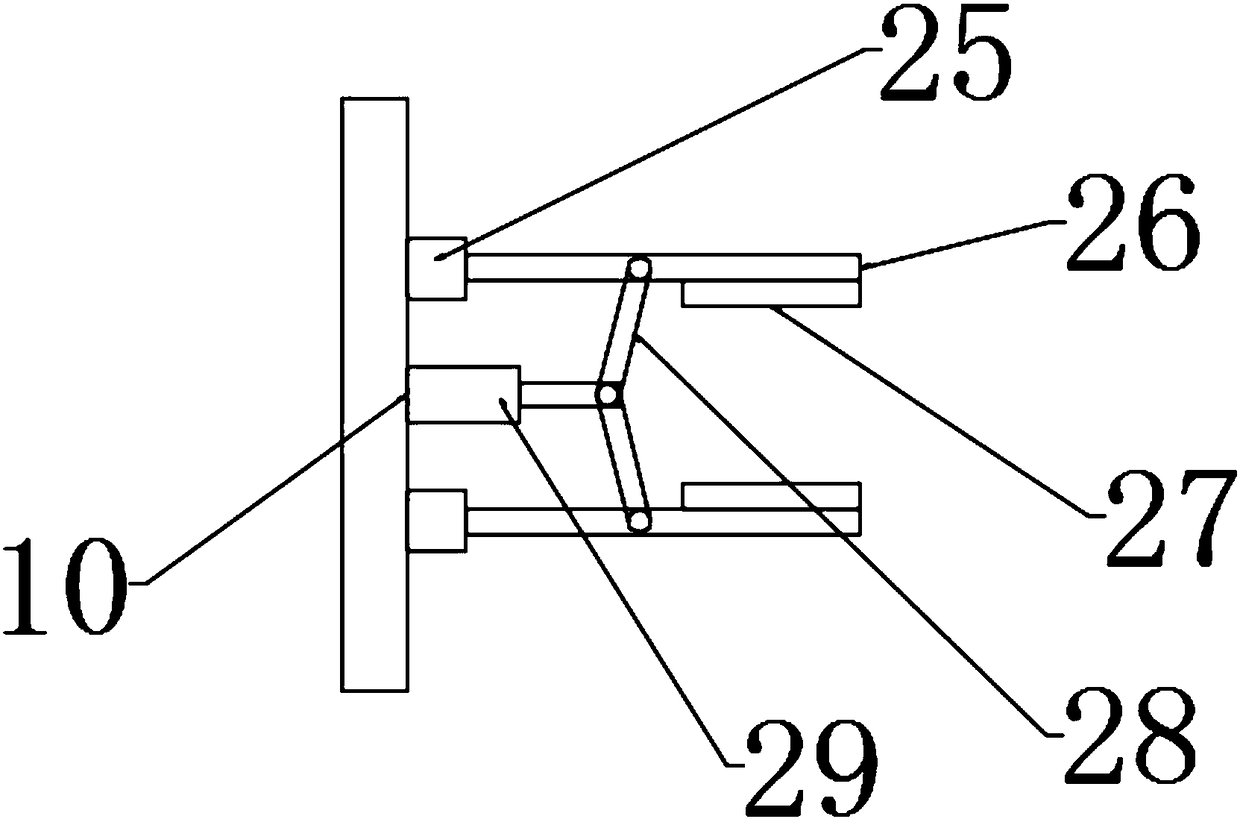

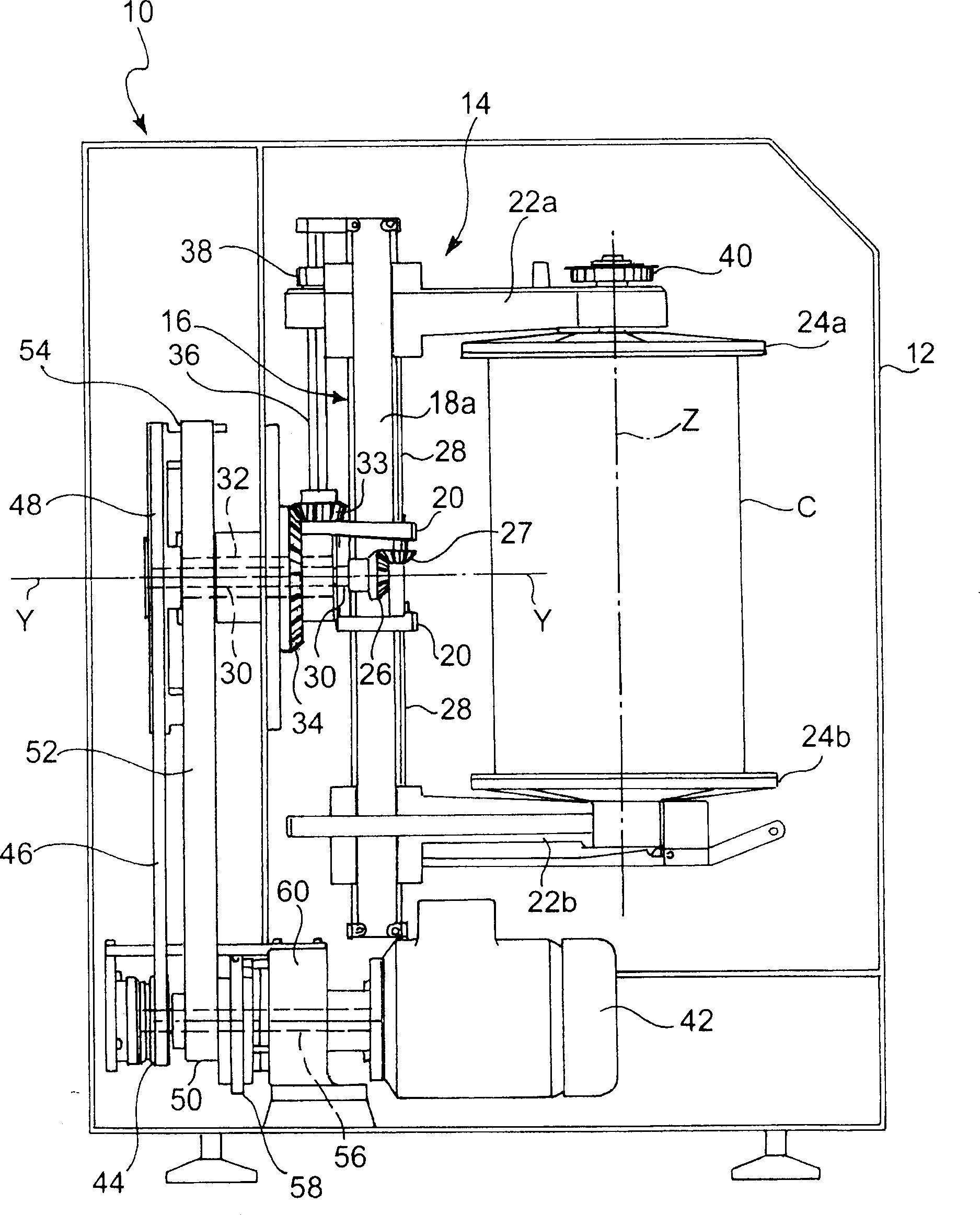

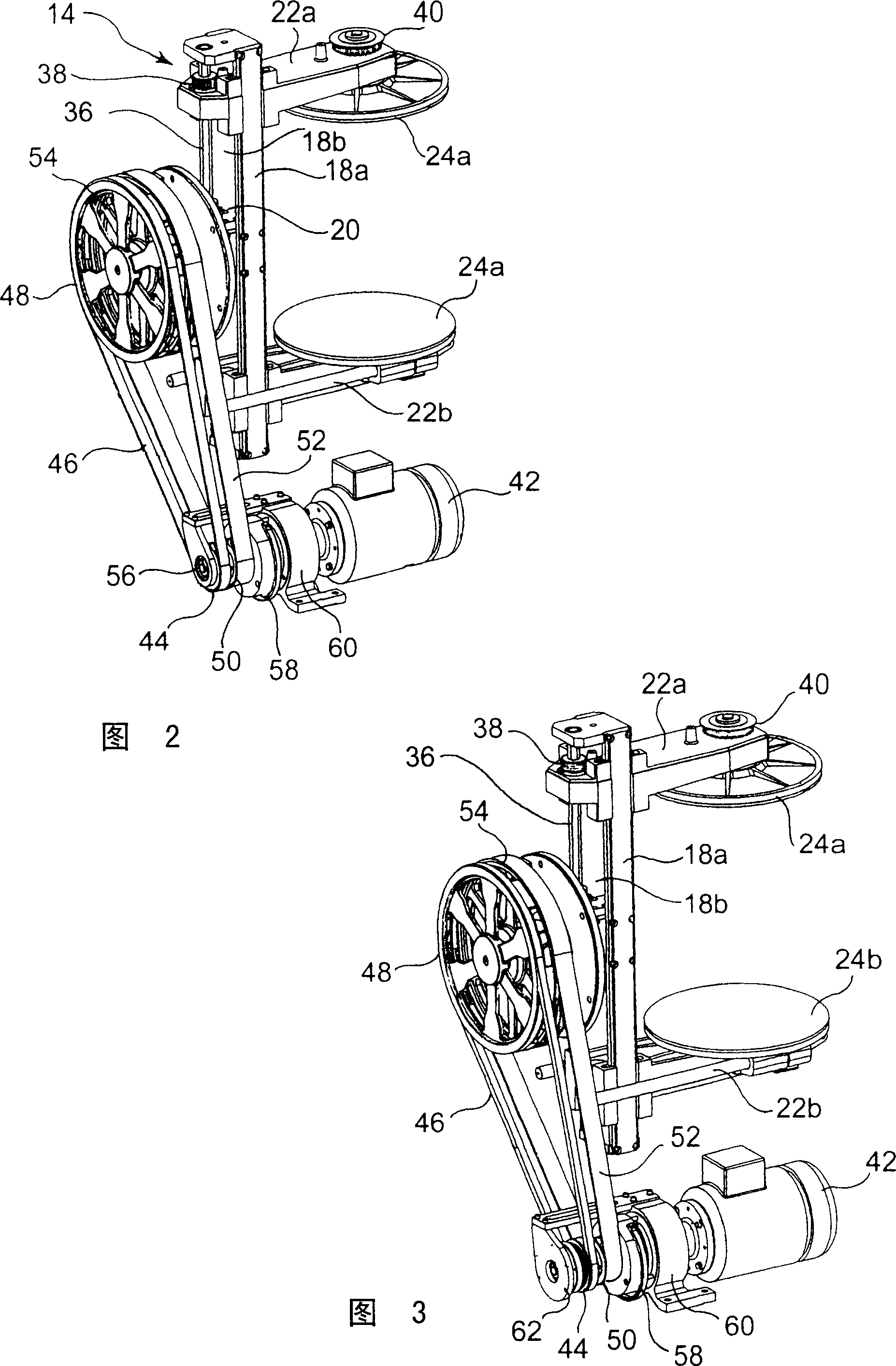

Alignment clamp with top opening and 360-degree rotation function

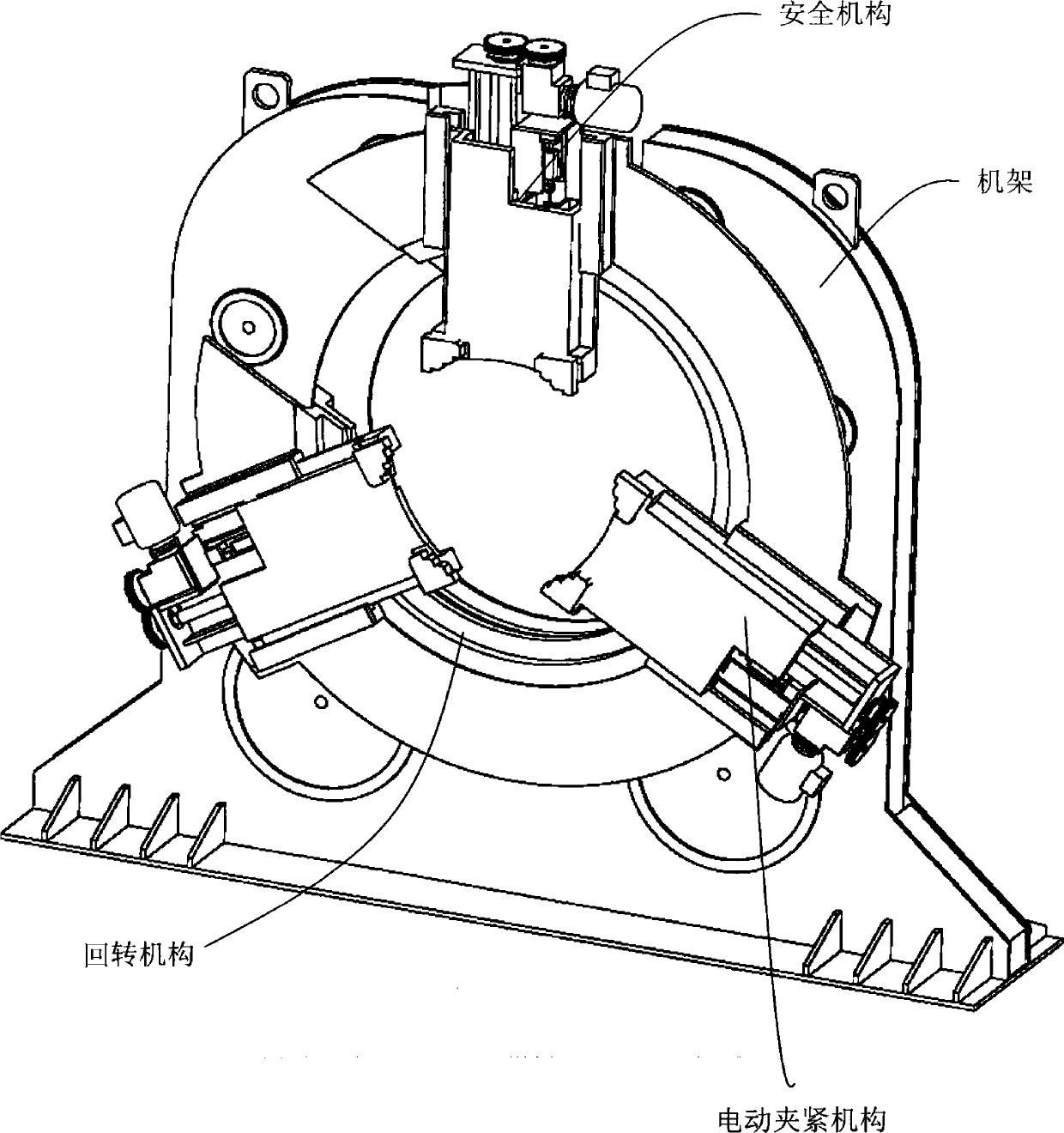

InactiveCN103801889AMeet structural requirementsSmooth transmissionWelding/cutting auxillary devicesAuxillary welding devicesRotation functionGravity center

The invention discloses an alignment clamp with a top opening and the 360-degree rotation function. The alignment clamp with the top opening and the 360-degree rotation function is a clamping and turnover device for welding a weld assembly which is of a long-box-shaped steel structure, can achieve rapid clamping and high-accuracy and 360-degree continuous rotation of the weld assembly of the long-box-shaped steel structure, and can stop at any position. When the center of gravity of the weld assembly of the long-box-shaped steel structure and the alignment clamp with the top opening and the 360-degree rotation function do not share the same axis, the center of gravity of the weld assembly of the long-box-shaped steel structure can coincide with the center of rotation by adjusting the positions of three sliding plates. The alignment clamp with the top opening and the 360-degree rotation function comprises a rack, a rotation mechanism, an electric clamping mechanism and a safety mechanism.

Owner:TANGSHAN KAIYUAN ROBOT SYST

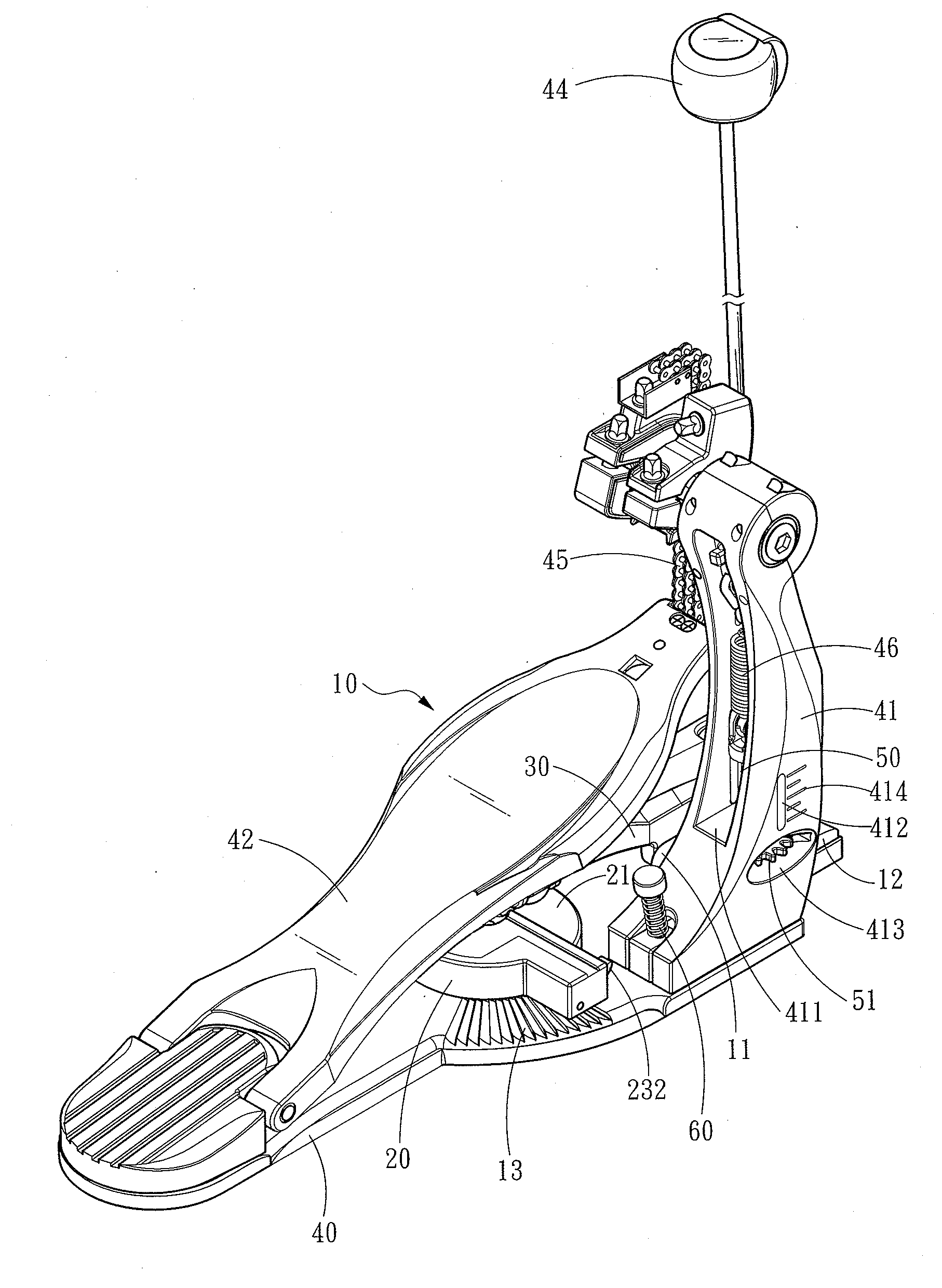

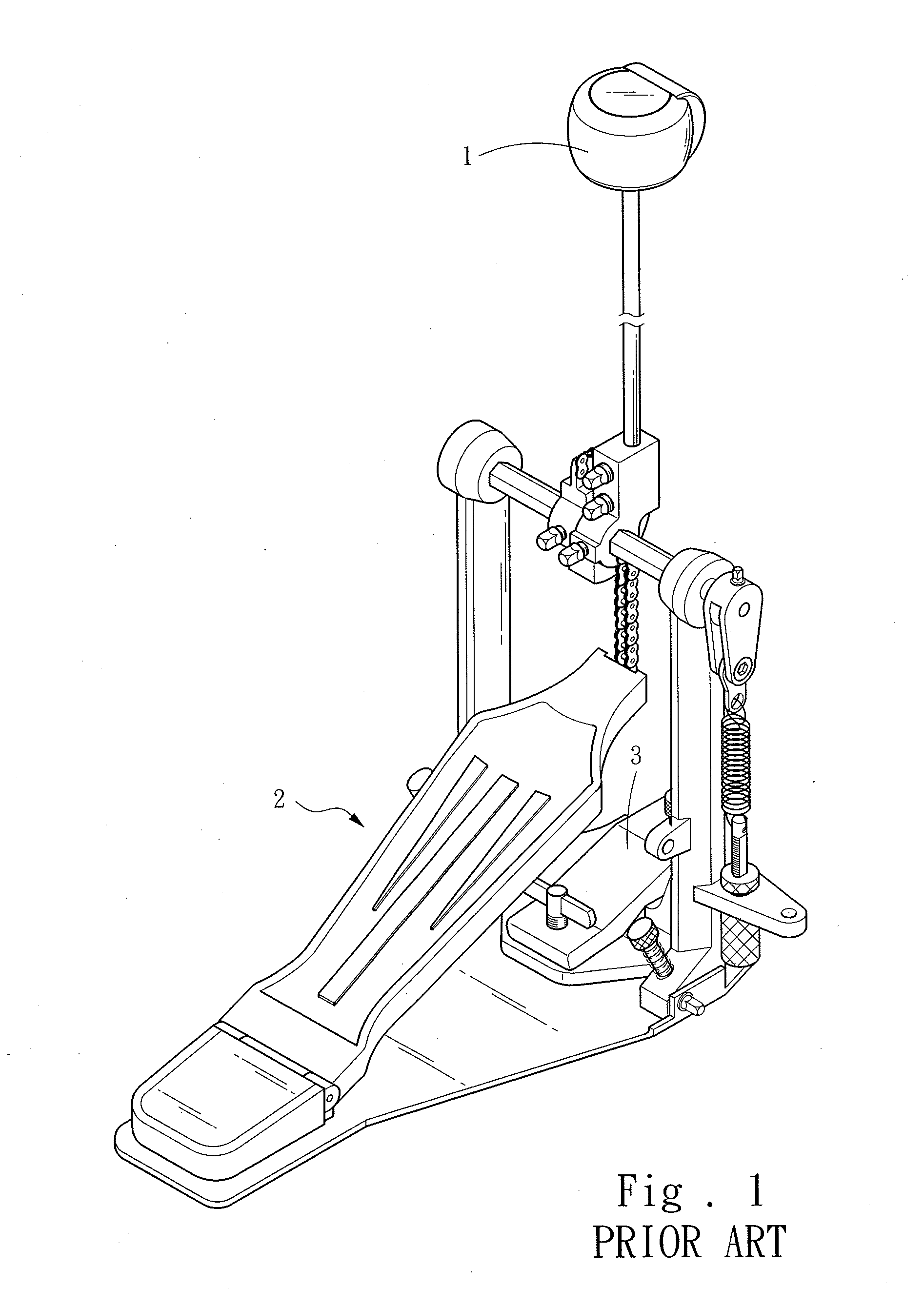

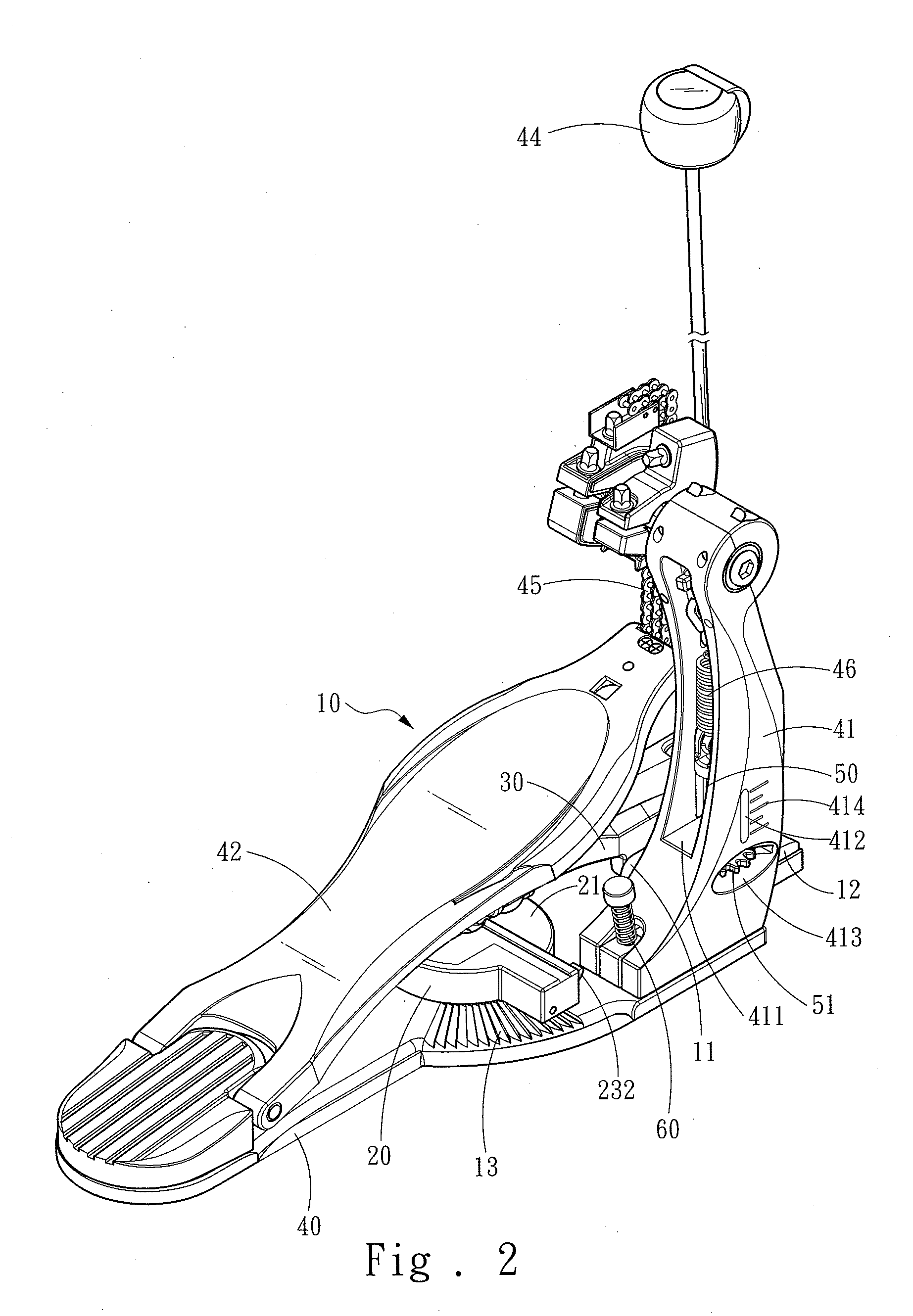

Pedal beating apparatus for musical instruments

ActiveUS20140182445A1Quick clampingEasy clampingPercussion musical instrumentsEngineeringVarying thickness

Owner:LIAO TSUN CHI

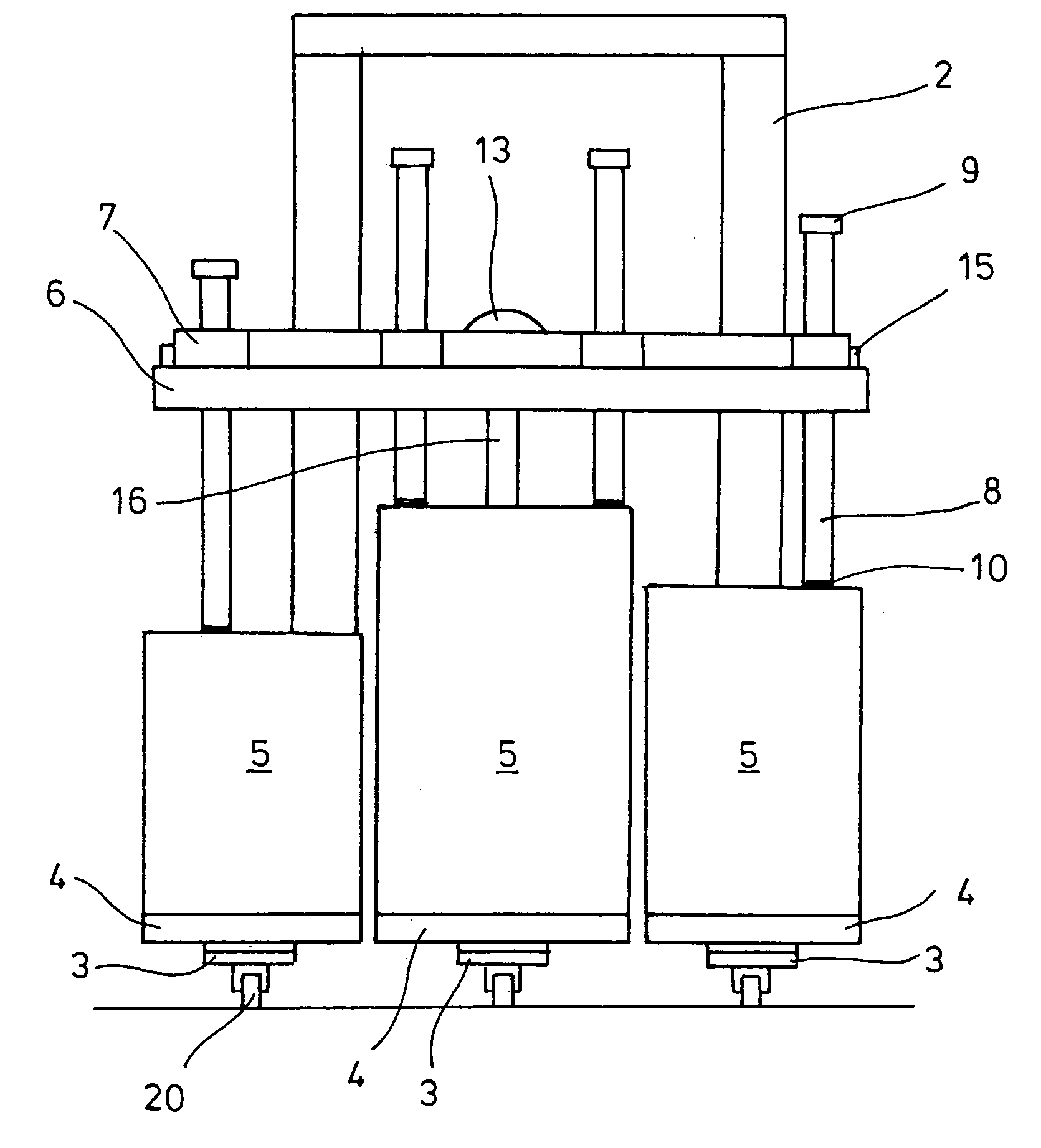

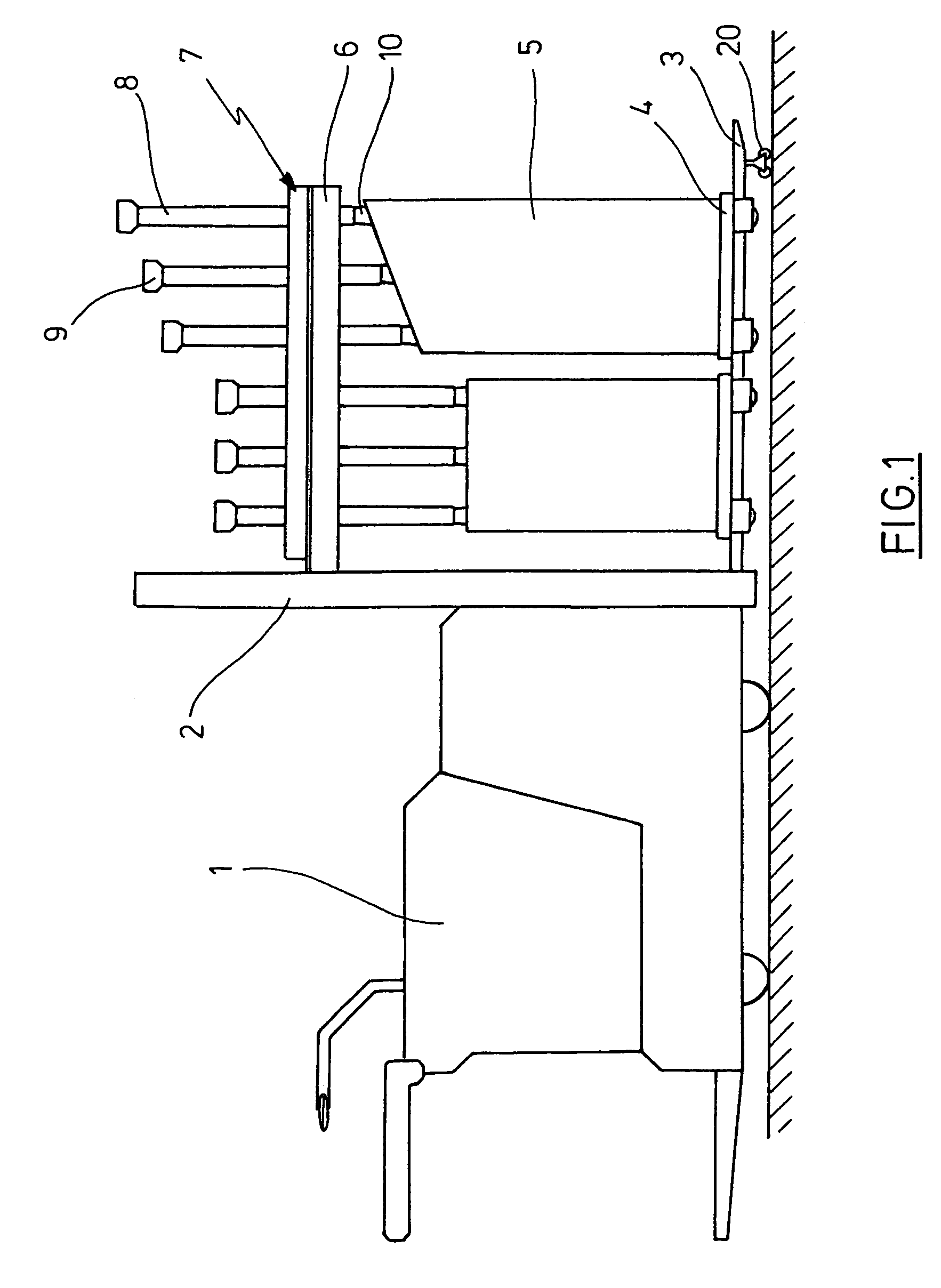

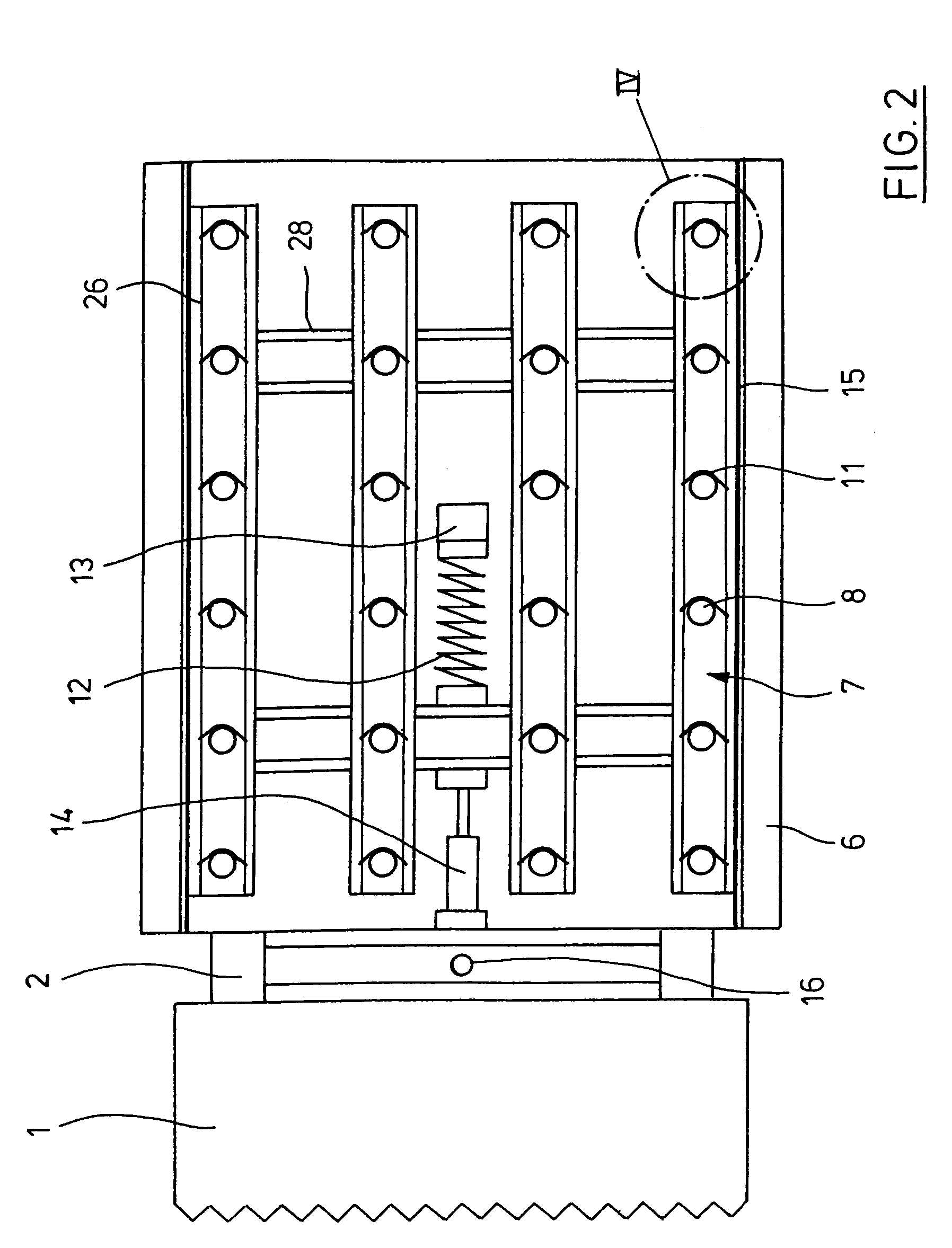

Device for holding a load on a load support of an industrial truck

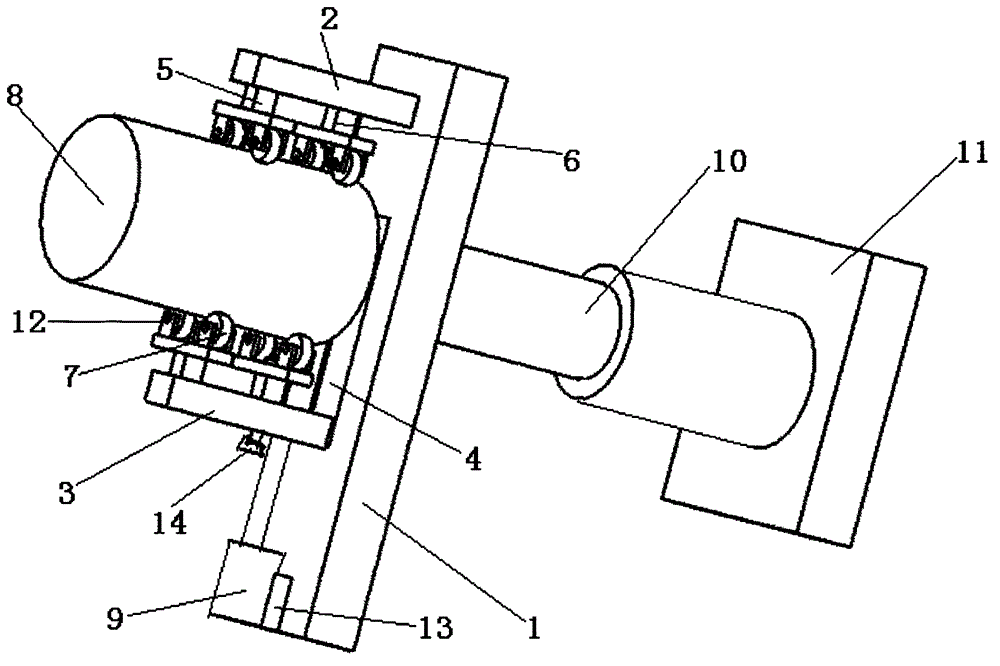

ActiveUS7213684B2Fixed securityQuick clampingLifting devicesOther load carrying vehiclesTruckIndustrial engineering

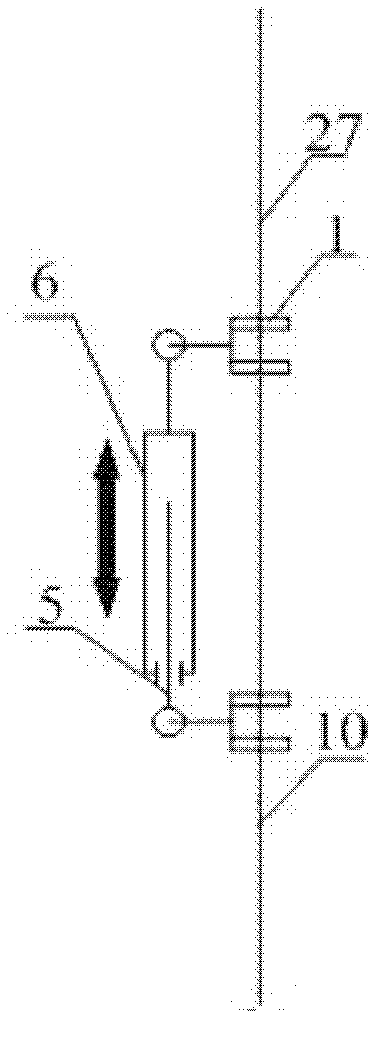

Device for holding a load on a load support of an industrial truck with the following characteristics:a support construction, adjustable in its height by a lifting drive, is mounted above the load supportthe support construction has several vertical guidances, distributed across a plane, in each of which one plunger (8) is vertically guideda clamping device is attached on the support construction, by means of which the plungers are fixable in the guidances in an arbitrary height position, andan actuation device for the clamping device for optional clamping or releasing the plungers in their guidances.

Owner:JUNGHEINRICH AG

Mixing machine

ActiveCN1768917AReduce in quantityLow costRotating receptacle mixersTransportation and packagingEngineeringRelative motion

Owner:STARDALE

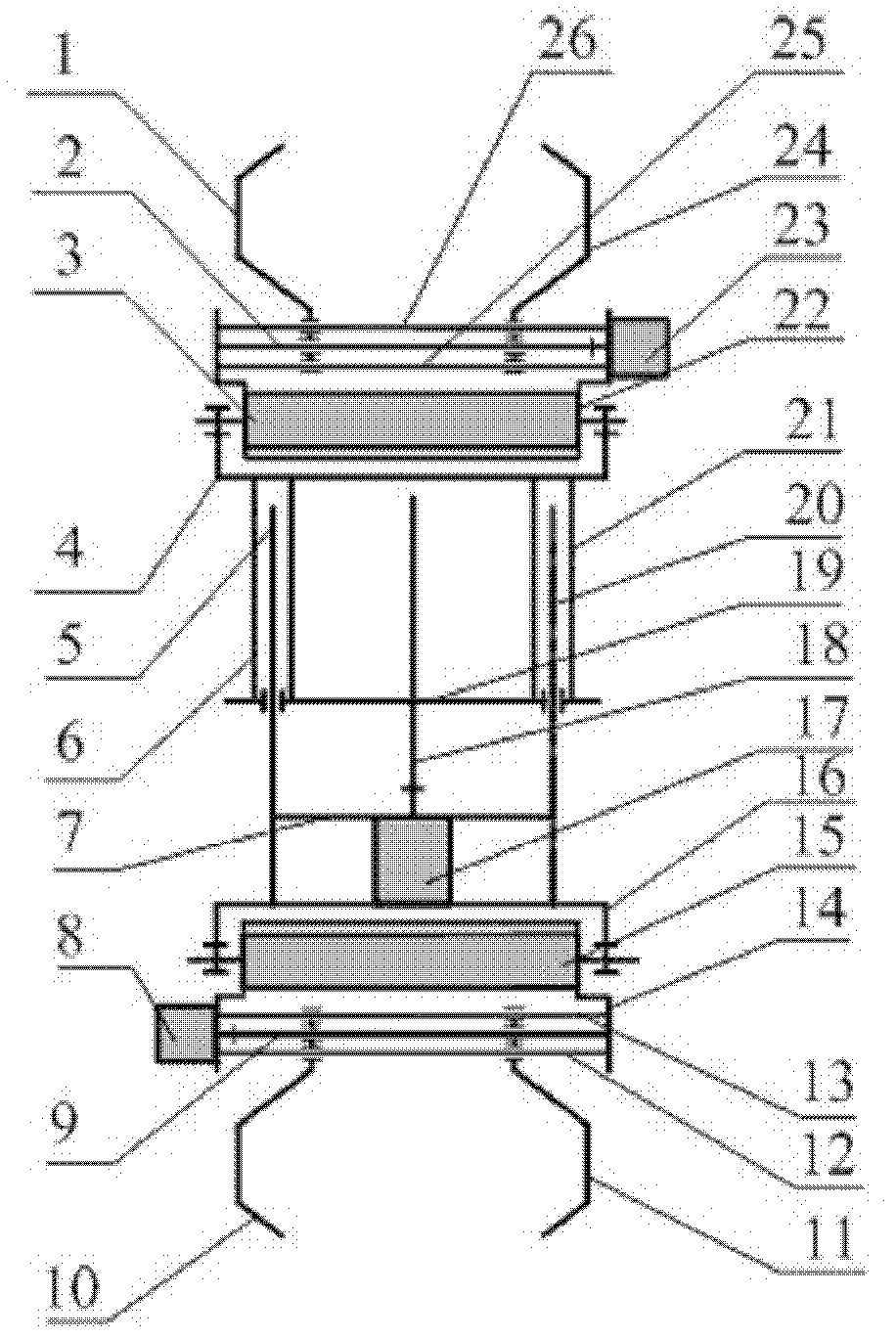

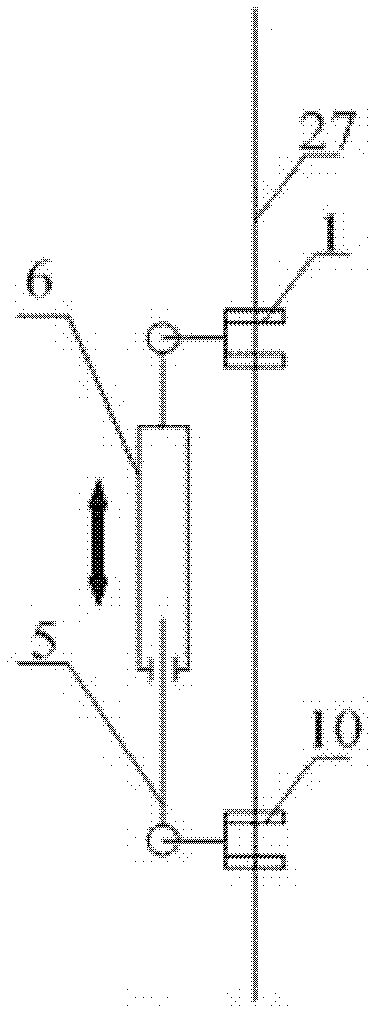

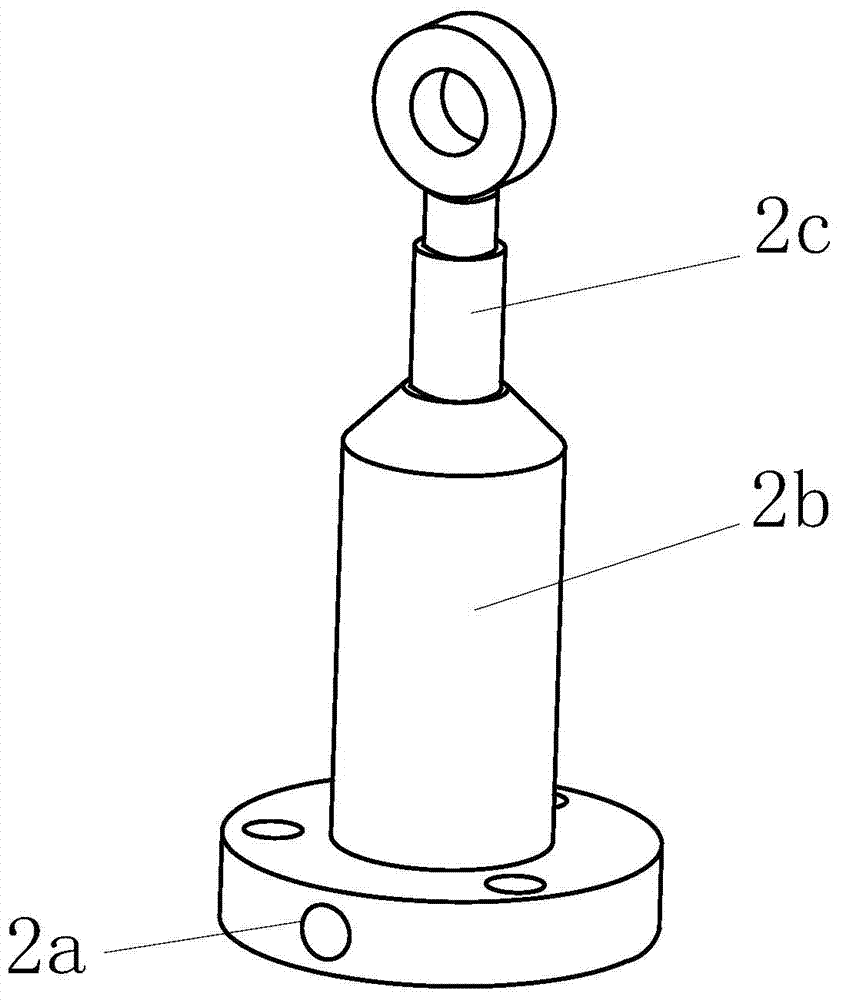

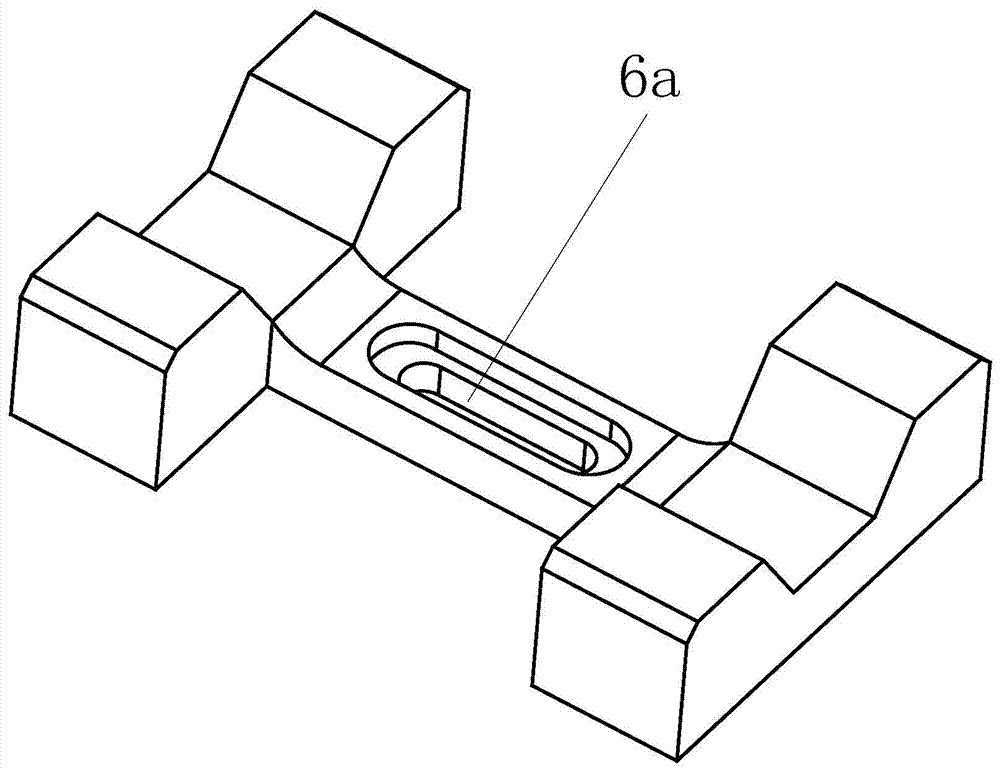

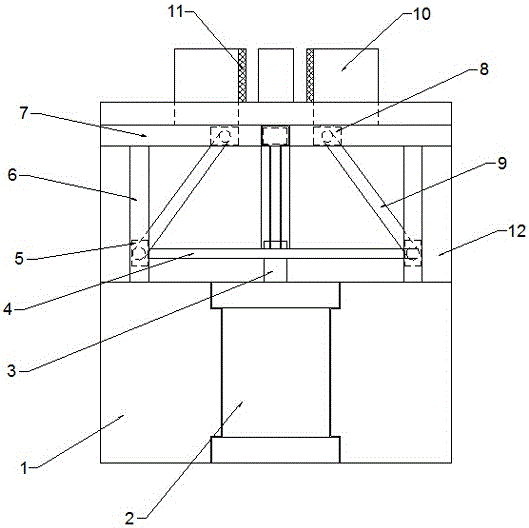

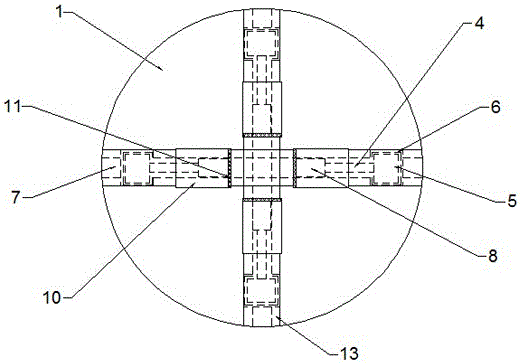

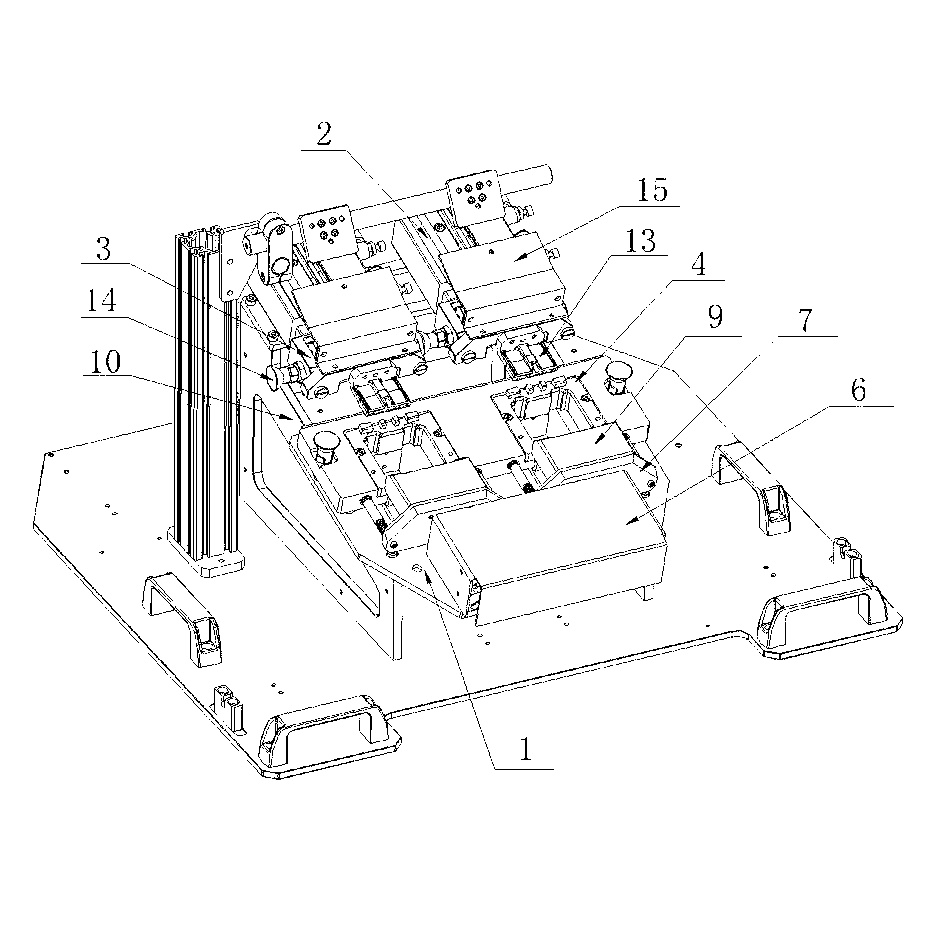

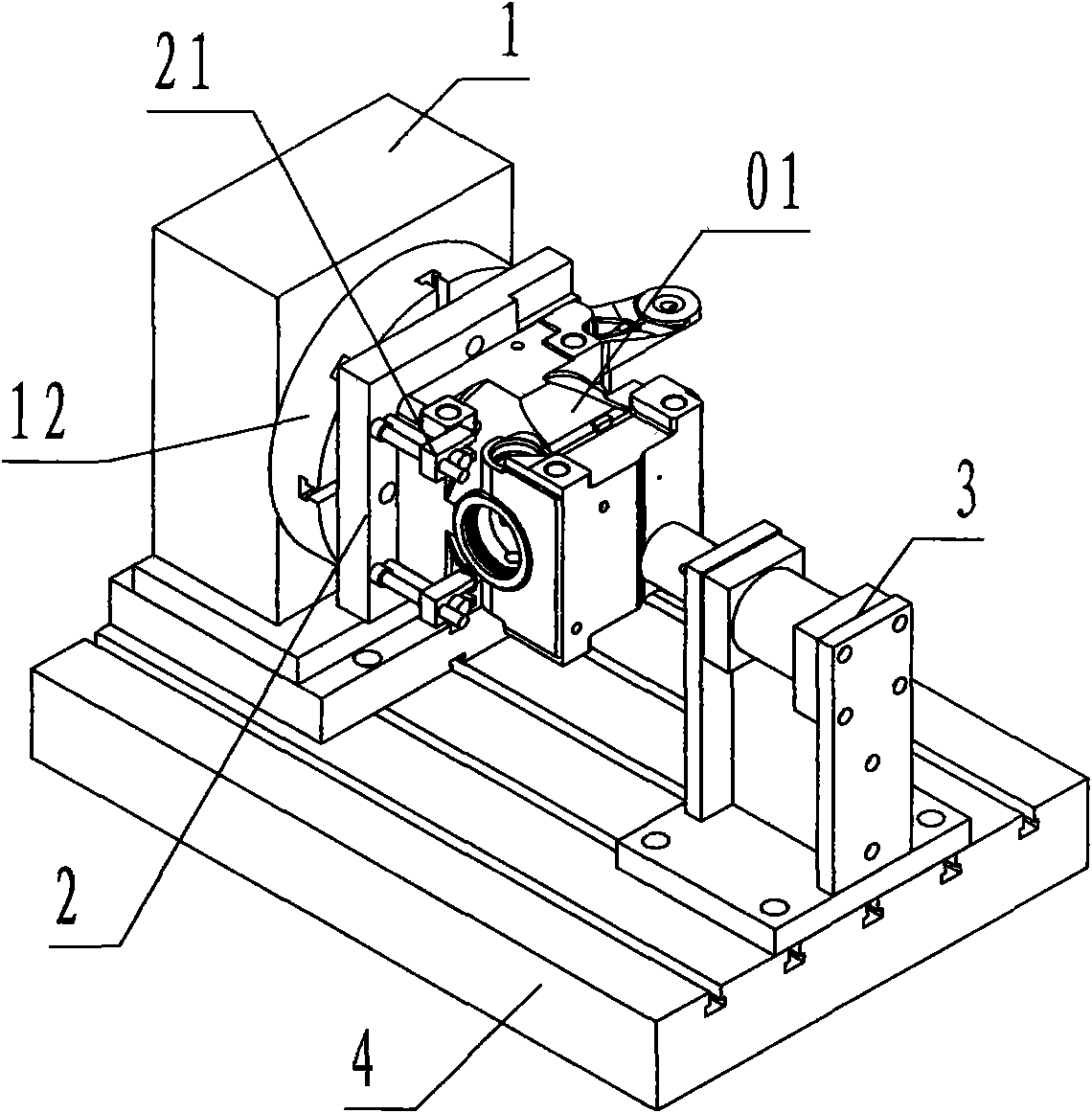

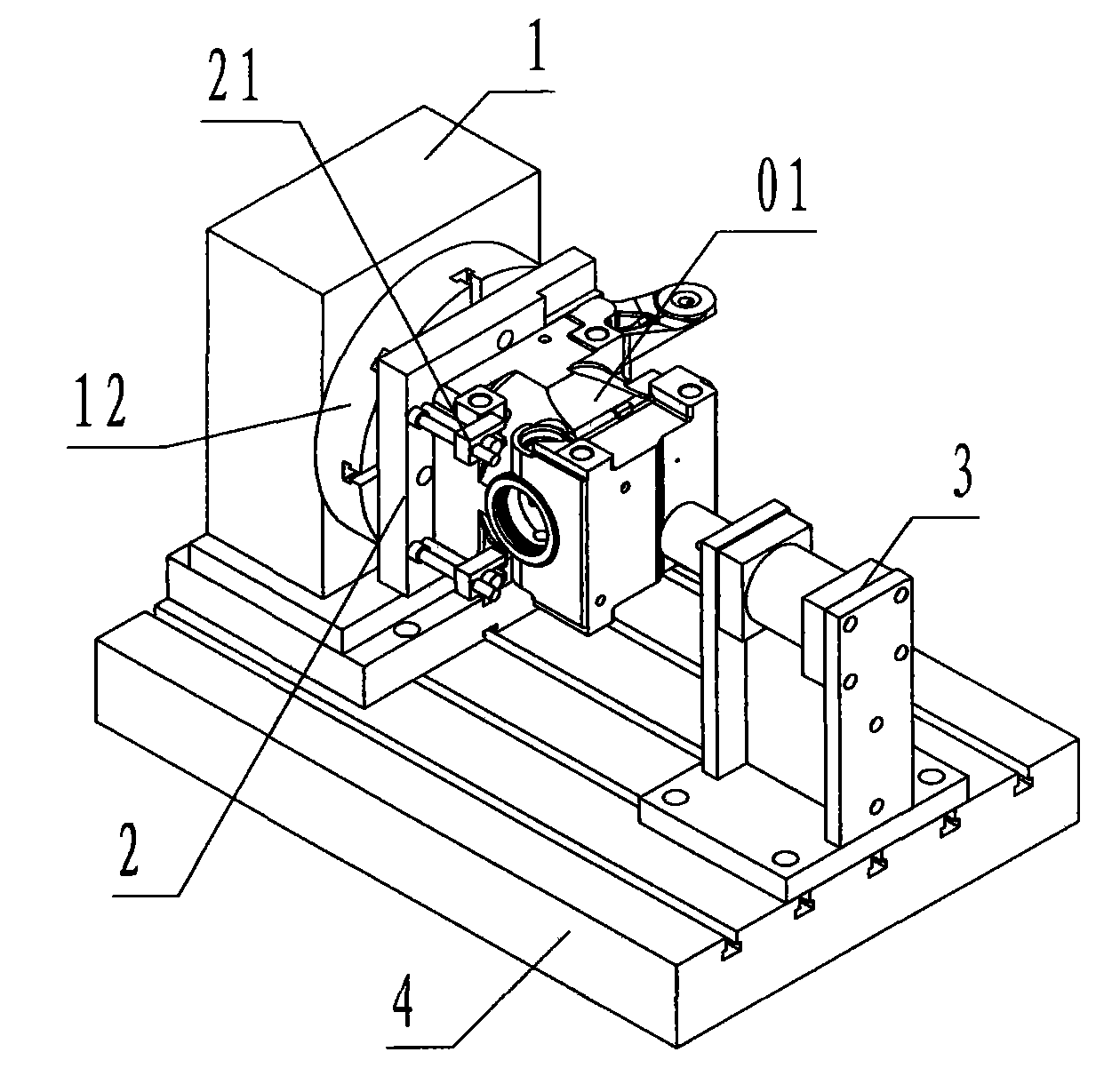

Clamp device for processing brake cylinder of high-speed rail train

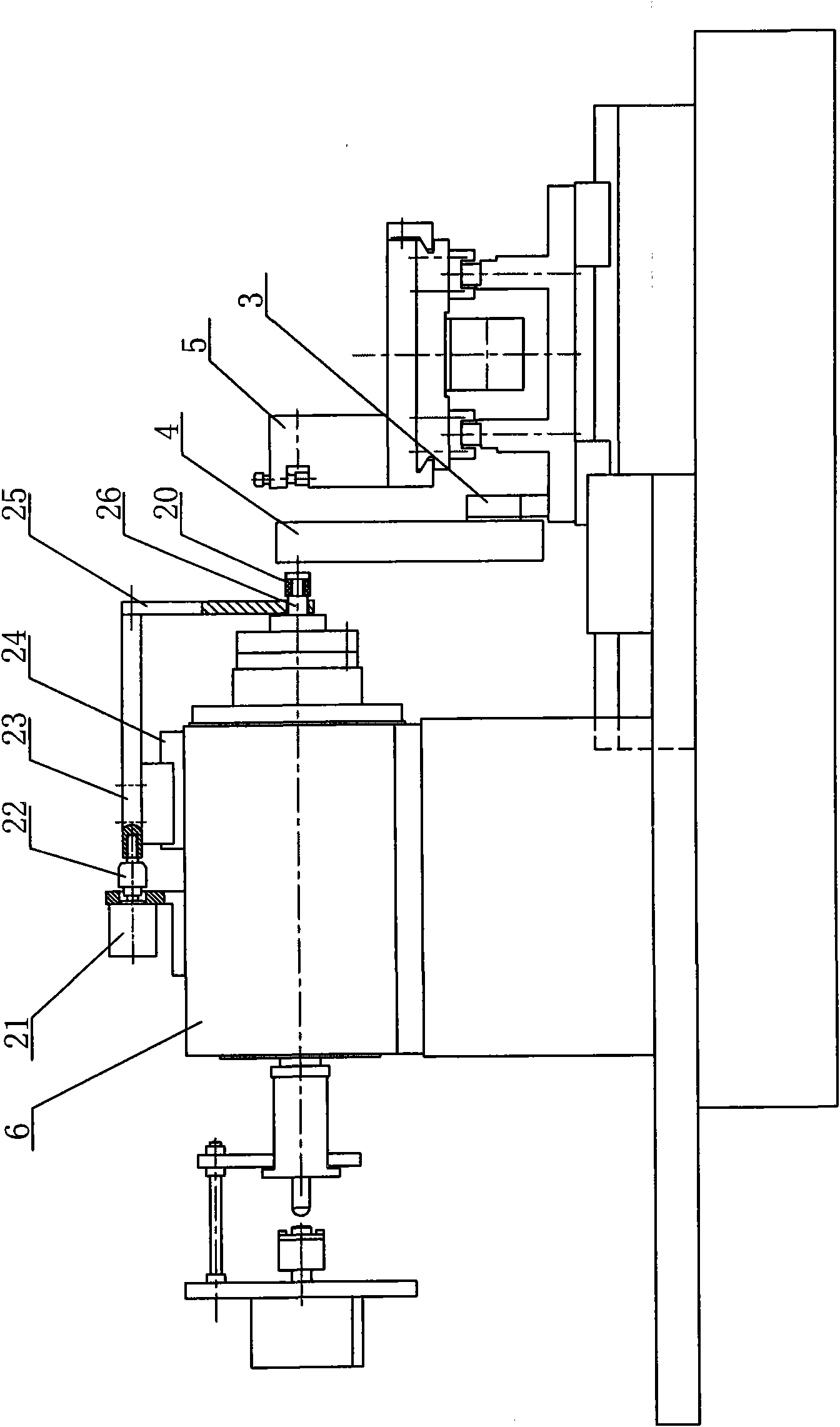

InactiveCN102152145AQuick clampingOvercome costsPrecision positioning equipmentPositioning apparatusNumerical controlEngineering

The invention discloses a clamp device for processing a brake cylinder of a high-speed rail train, comprising a dividing head (1), a positioning clamp (2), a cylinder tail stock (3) and a pedestal. In the technical scheme, the clamp device is formed by the quarter dividing head driven and locked by a high-accuracy hydraulic valve, the positioning clamp, the cylinder tail stock and the pedestal; when in application, the positioning clamp is clamped by a dividing head clamping disc; a workpiece is clamped by the positioning clamp and is tightly pressed on the positioning clamp by means of the cylinder tail stock; and the hydraulic valve of the dividing head is driven by a numerical control milling machine to control the dividing head to drive the workpiece to be matched with the cutting of a cutting tool in a controlled mode so as to automatically rotate and change the surface. Thus, the invention overcomes the problems and defects of high cost, low efficiency and possible out-of-tolerance in the prior art, and ensures that the multi-surface processing of the brake cylinder of the high-speed rail train can be finished in one-time clamping procedure on a general numerical control milling machine through fast clamping and controlled rotation and surface changing, thereby achieving the purposes of reducing the cost, improving the efficiency and improving the product qualification rate.

Owner:NINGBO YONGXIN AUTO COMPONENTS MFG

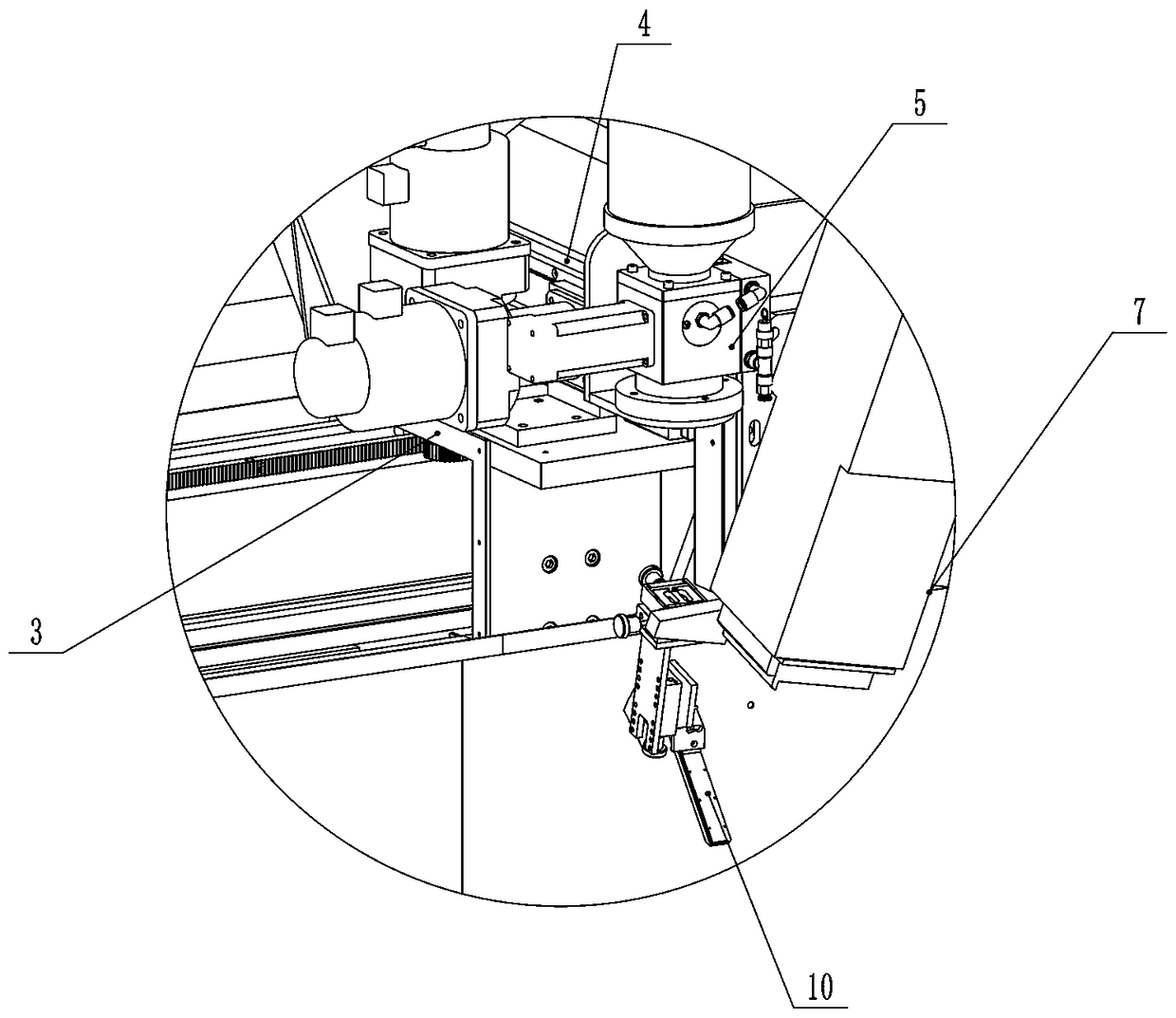

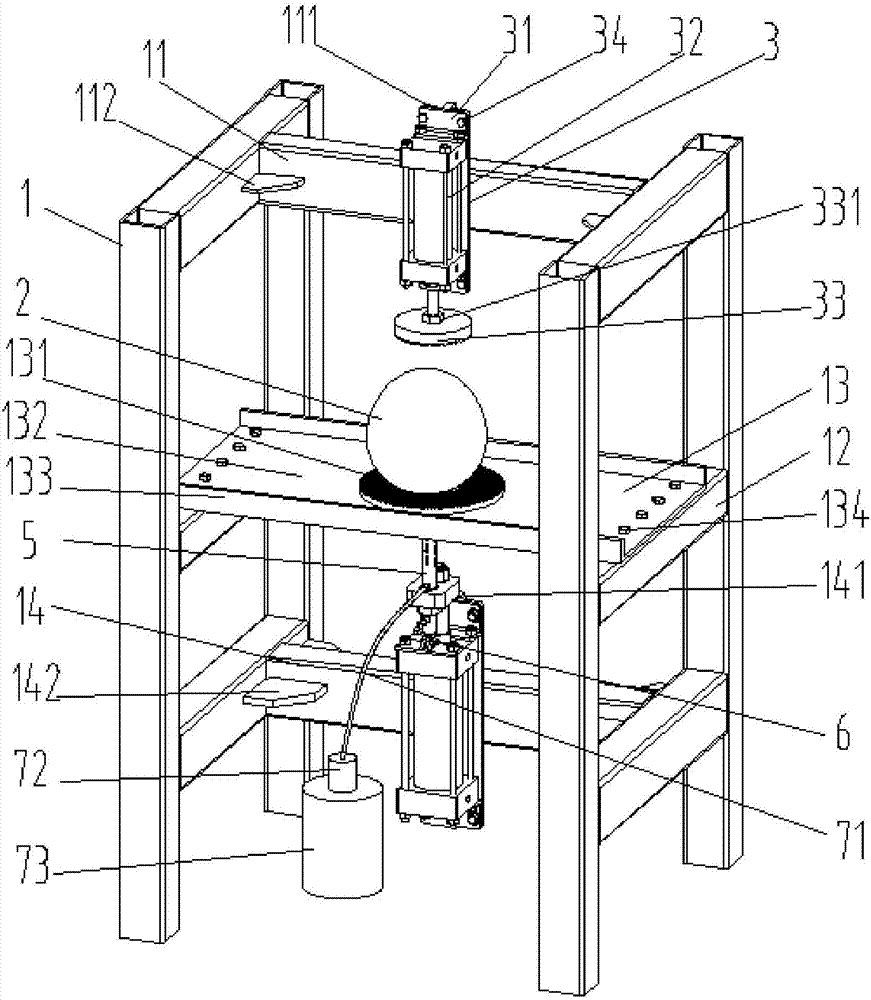

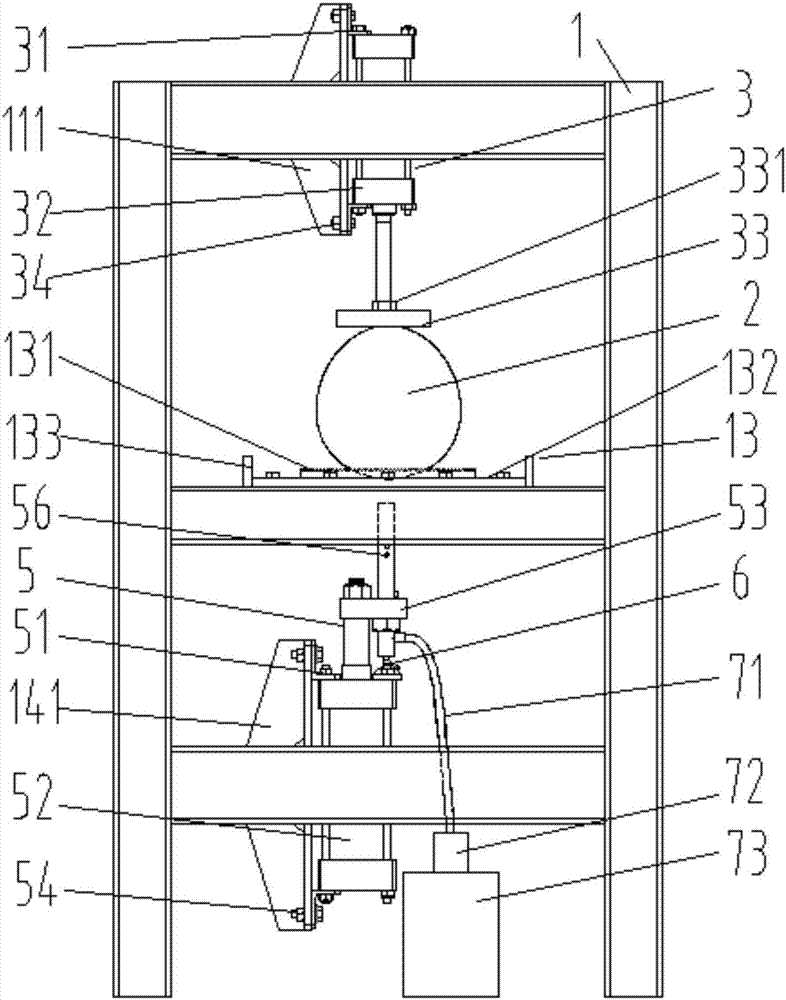

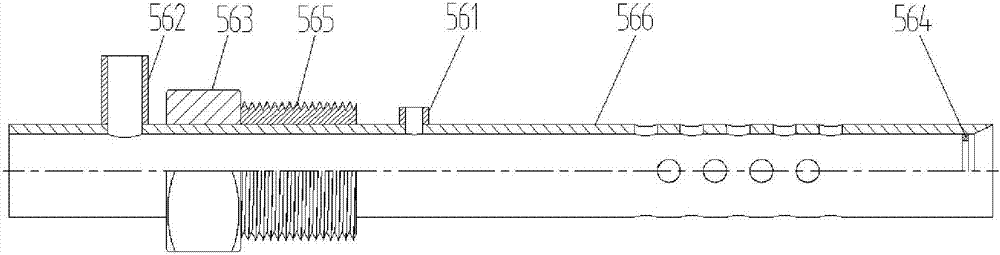

Machine for automatic hole opening and juice extraction of coconut, and method for hole opening and juice extraction

ActiveCN107242584AReliable clamping forceAvoid blockingJuice extractionHuskingMechanical engineeringCocos nucifera

The invention relates to the technical field of fruit processing equipment and especially relates to a machine for automatic hole opening and juice extraction of a coconut, and a method for the hole opening and juice extraction. The machine for the automatic hole opening and juice extraction of the coconut provided by the invention comprises a supporting tray mechanism and at least one set of clamping mechanism and hole opening cutter, wherein each set of clamping mechanism and hole opening cutter are coaxially disposed on two sides of the supporting tray mechanism and can be moved relatively along the axis; and each clamping mechanism is used to clamp and fix the coconut on the supporting tray mechanism, and the hole opening cutter is inserted into the coconut for synchronous hole opening and juice extraction of the coconut. The machine and method for the automatic hole opening and juice extraction of the coconut have the advantages that the juice extraction operation can be executed automatically during the hole opening; operation processes are simplified; the structure is simple; and production efficiency is increased.

Owner:HAINAN UNIVERSITY

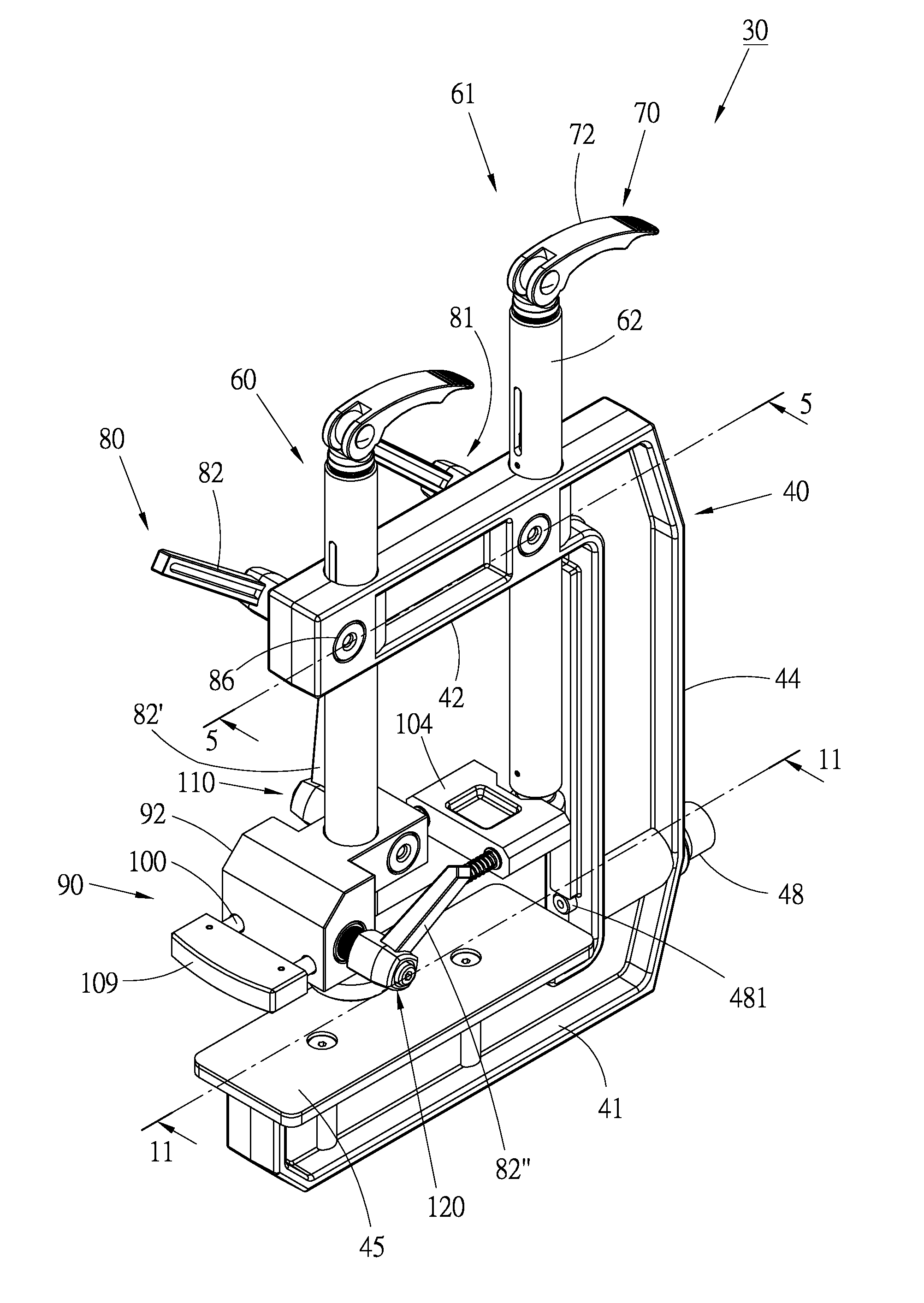

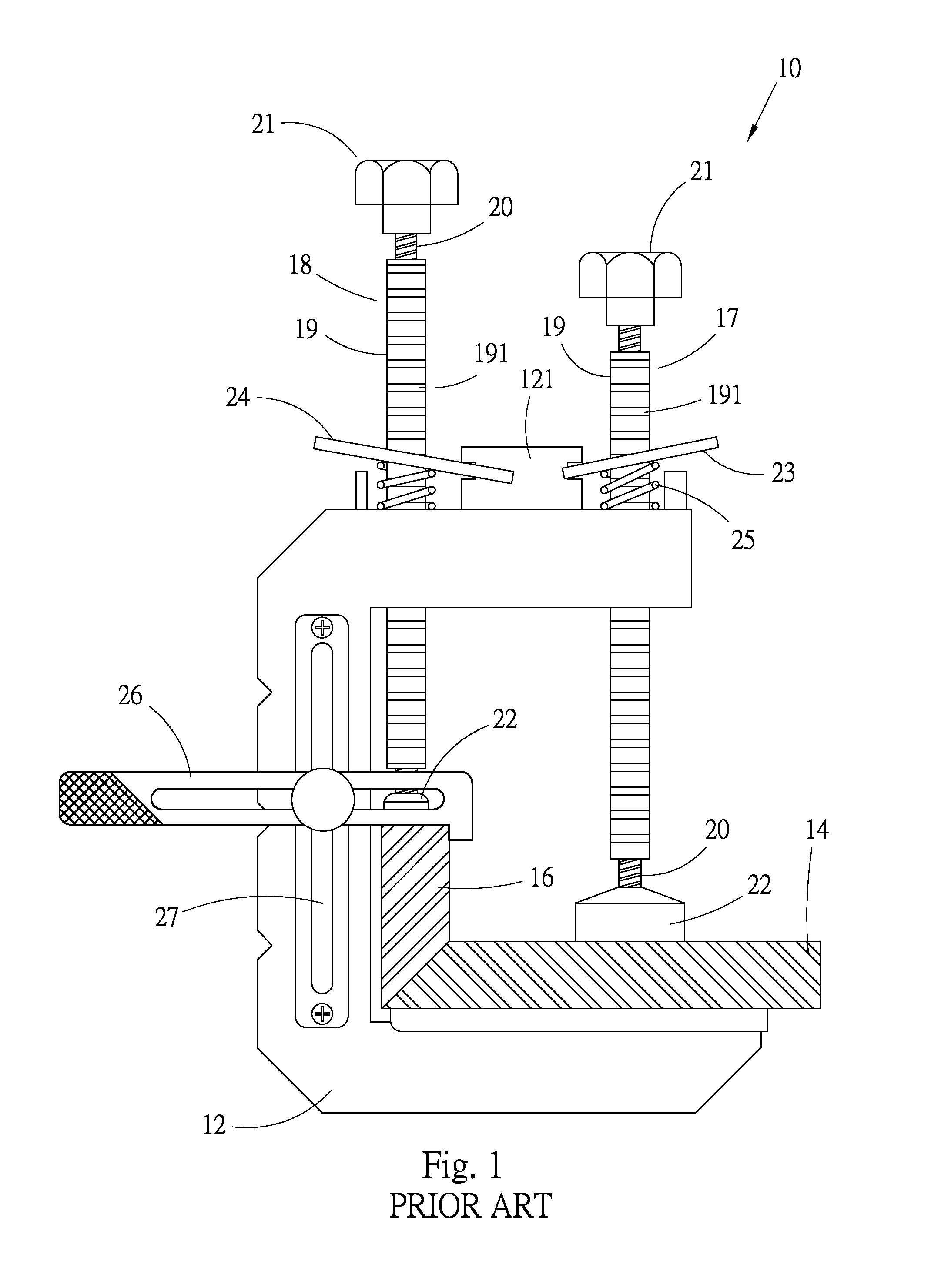

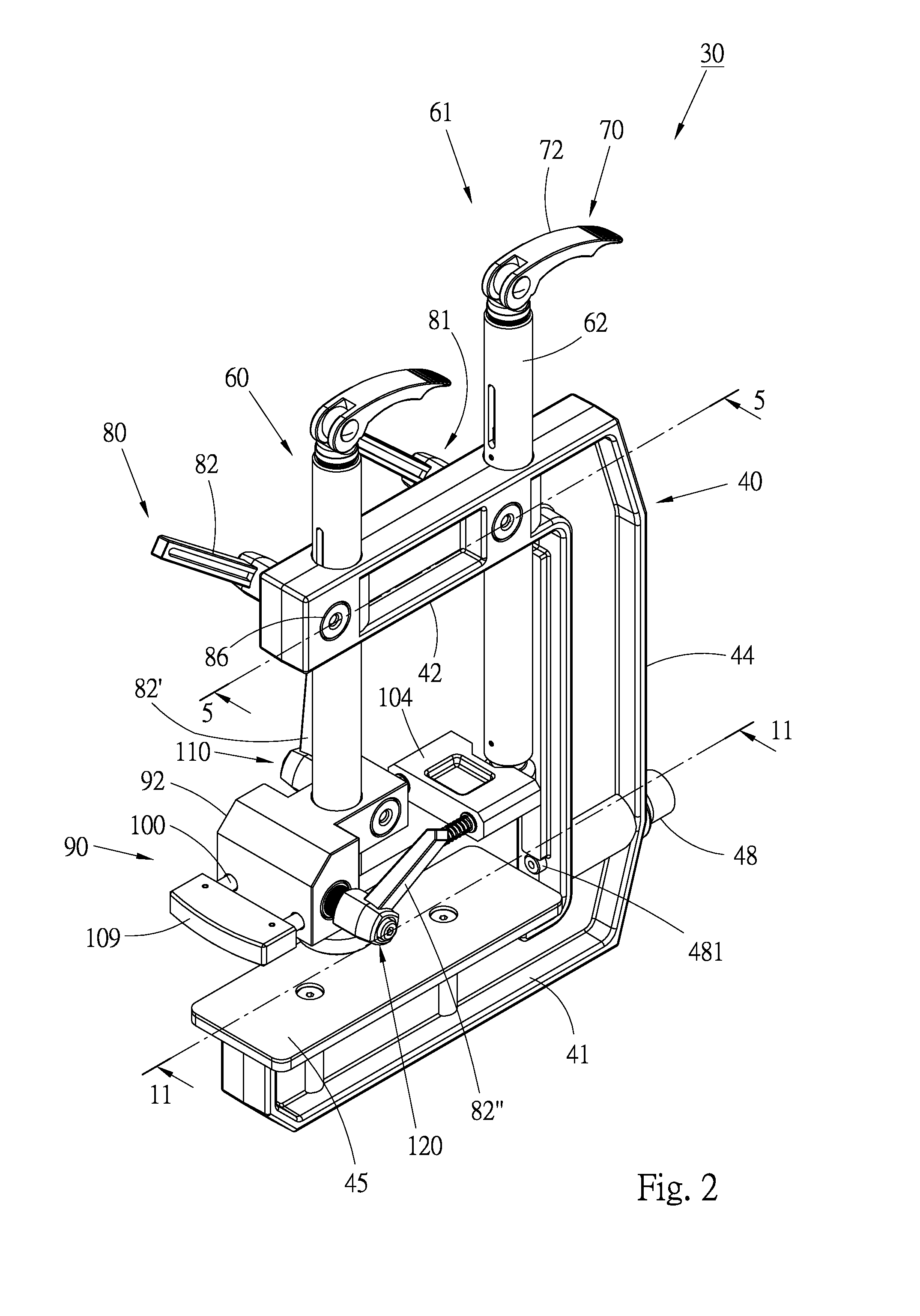

Clamping device for adjoining board materials

A clamping device for adjoining board materials includes: a C-shaped base having a base section, a top arm and an upright arm; a first press rod and a second press rod vertically movably fitted through the top arm; two first fastener assemblies for fastening and locating the press rods; a horizontal holder mechanism fitted on the first press rod and vertically movable along the first press rod; and a second fastener assembly for adjustably fastening the holder mechanism to the first press rod at a height. The holder mechanism includes at least one horizontally movable guide pin and an abutment member disposed at a front end of the guide pin. In use, a horizontal board material and an upright board material are placed in the base and fixedly held with the first and second press rods respectively. The abutment member serves to abut against and hold the upright board material.

Owner:GISON MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com