Patents

Literature

185results about How to "Meet structural requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

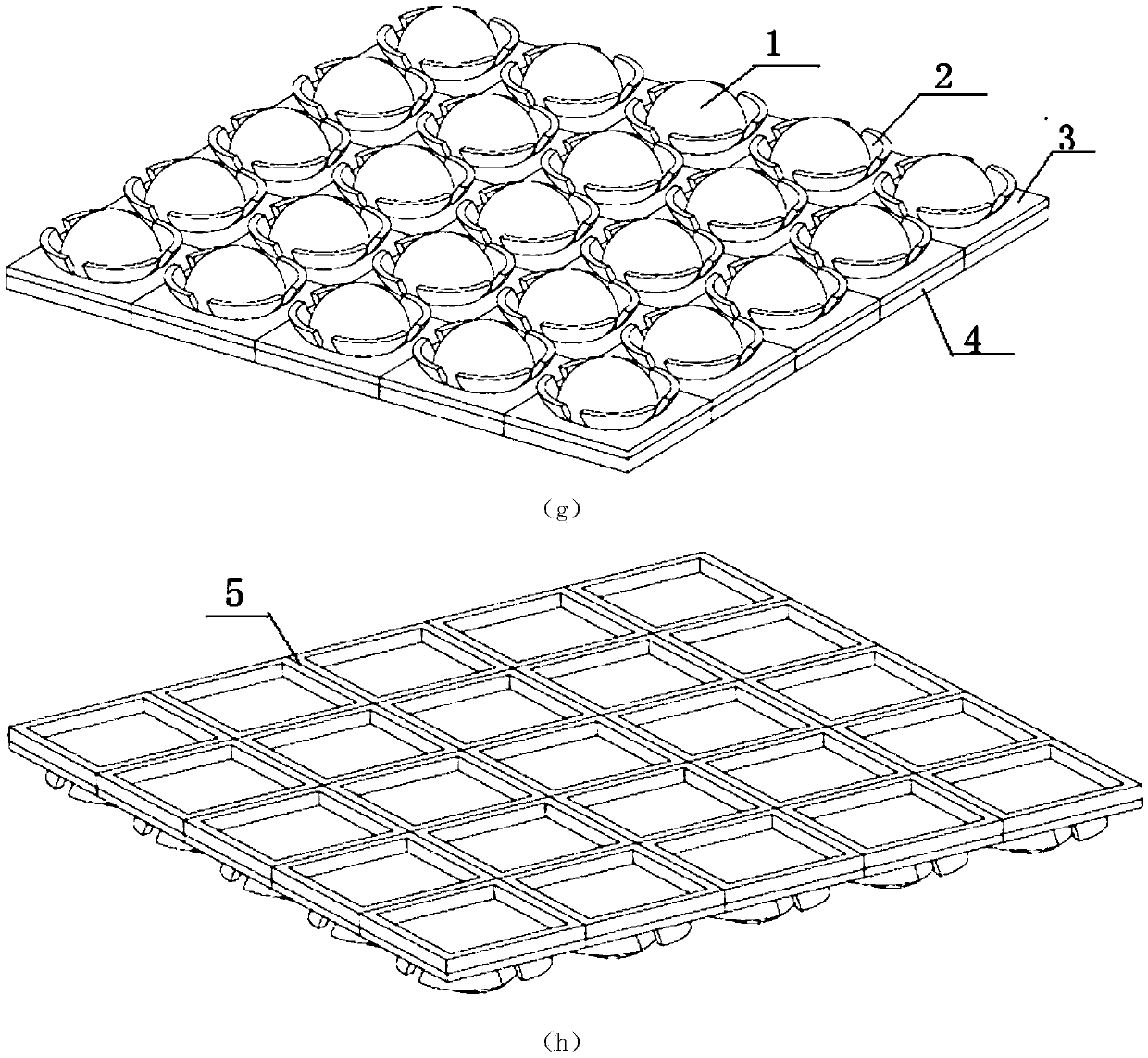

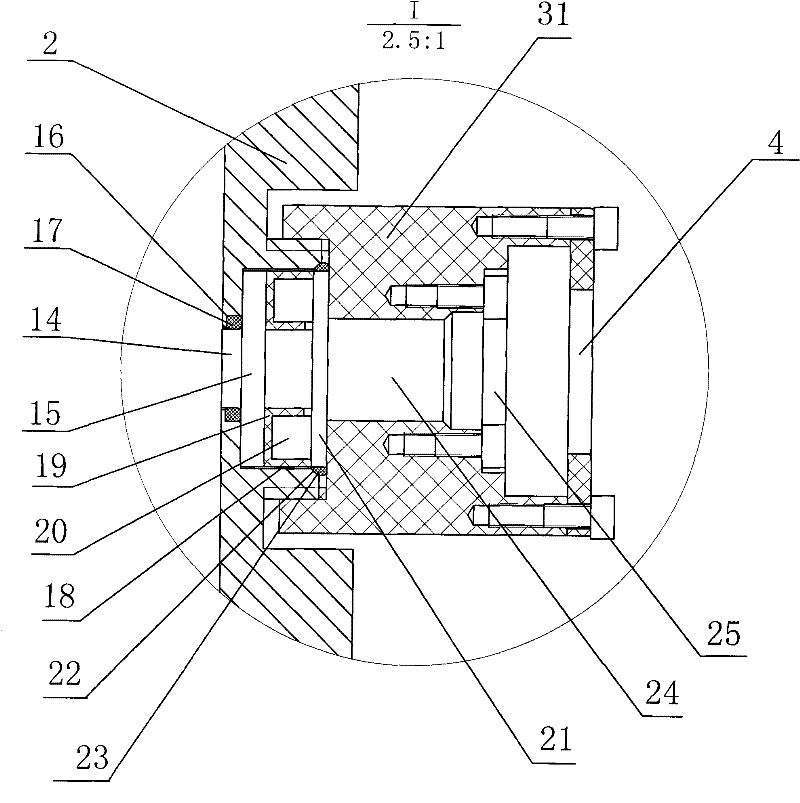

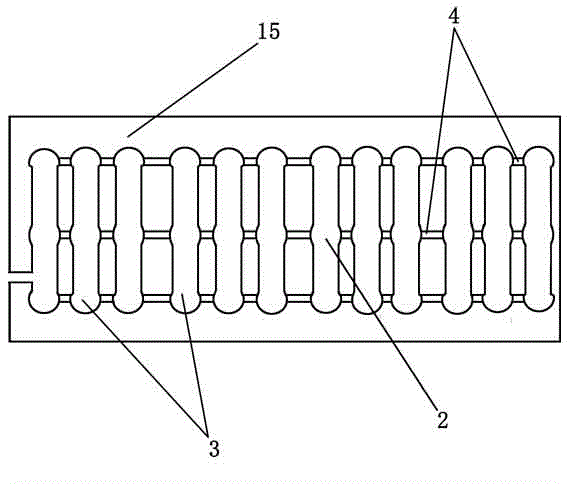

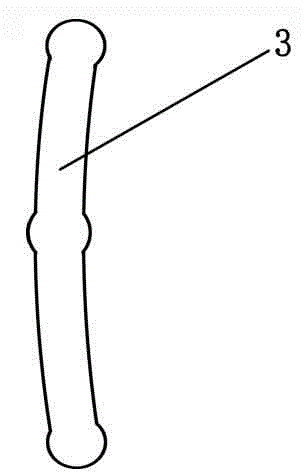

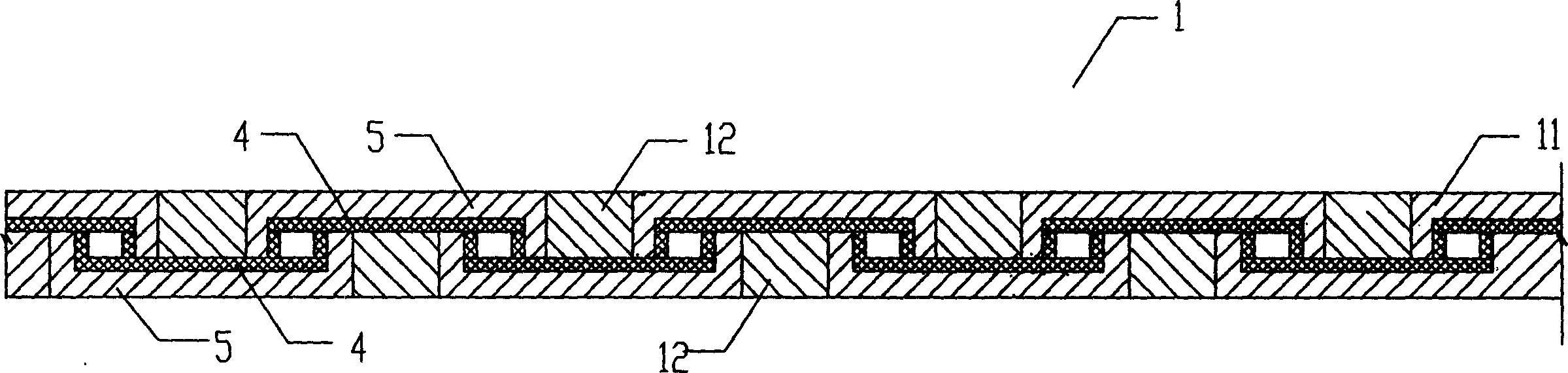

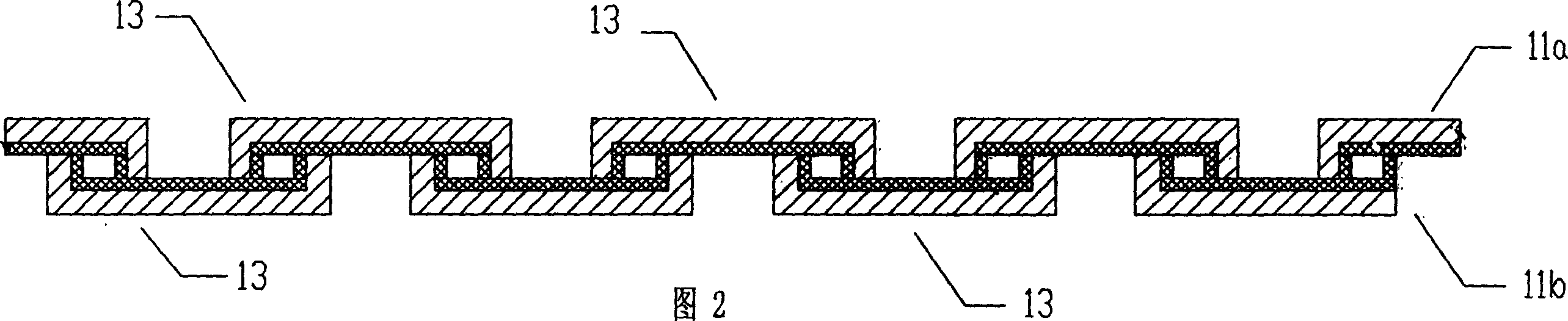

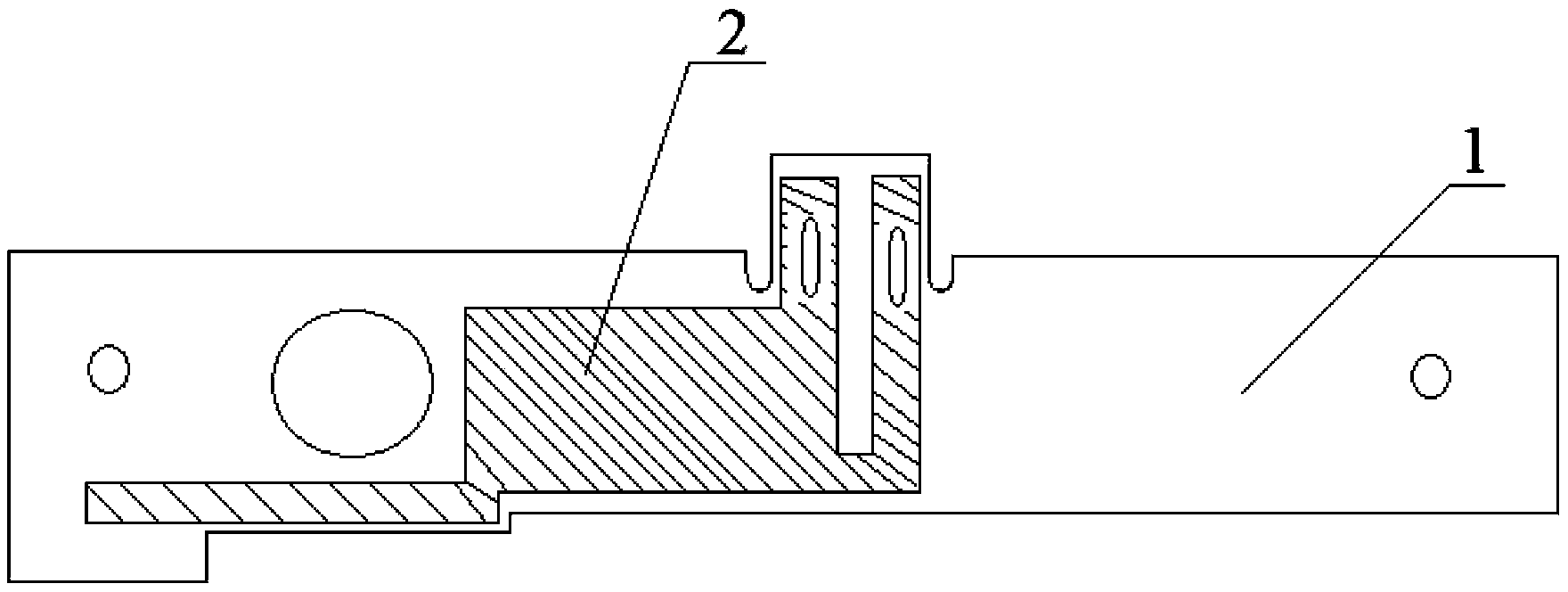

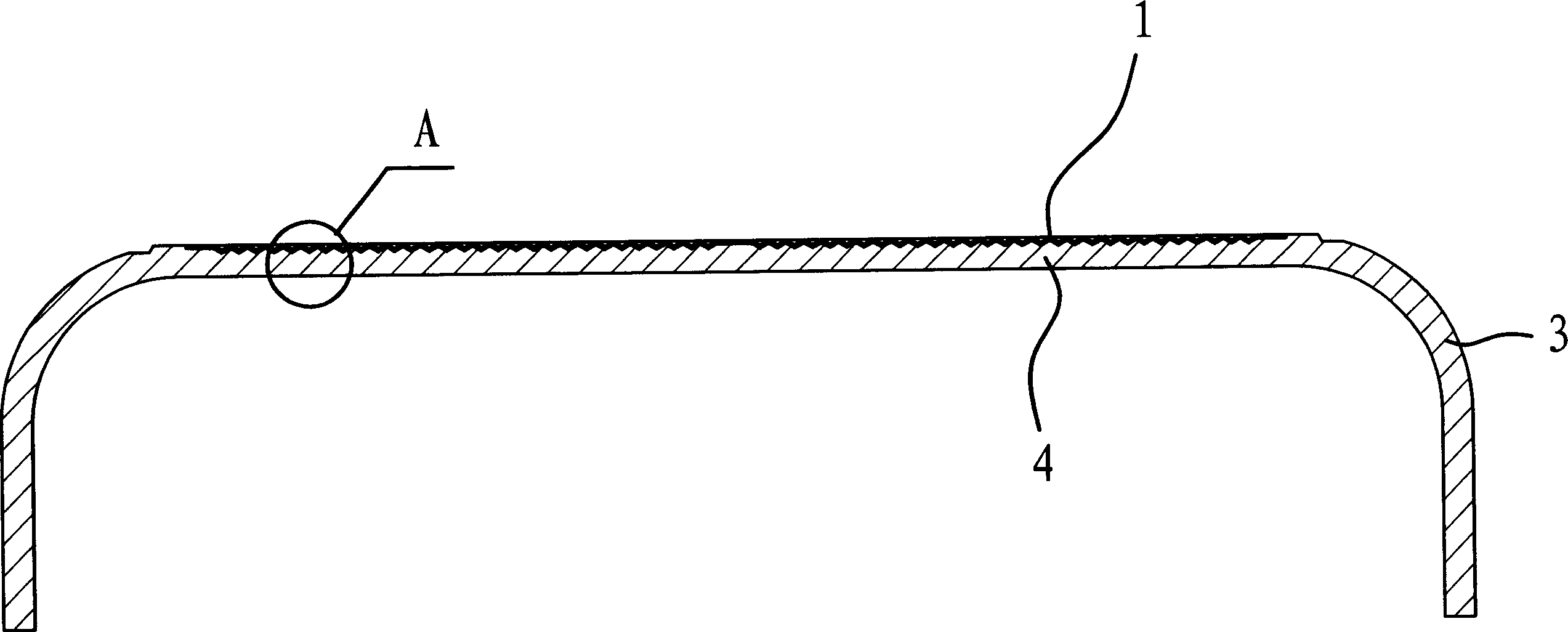

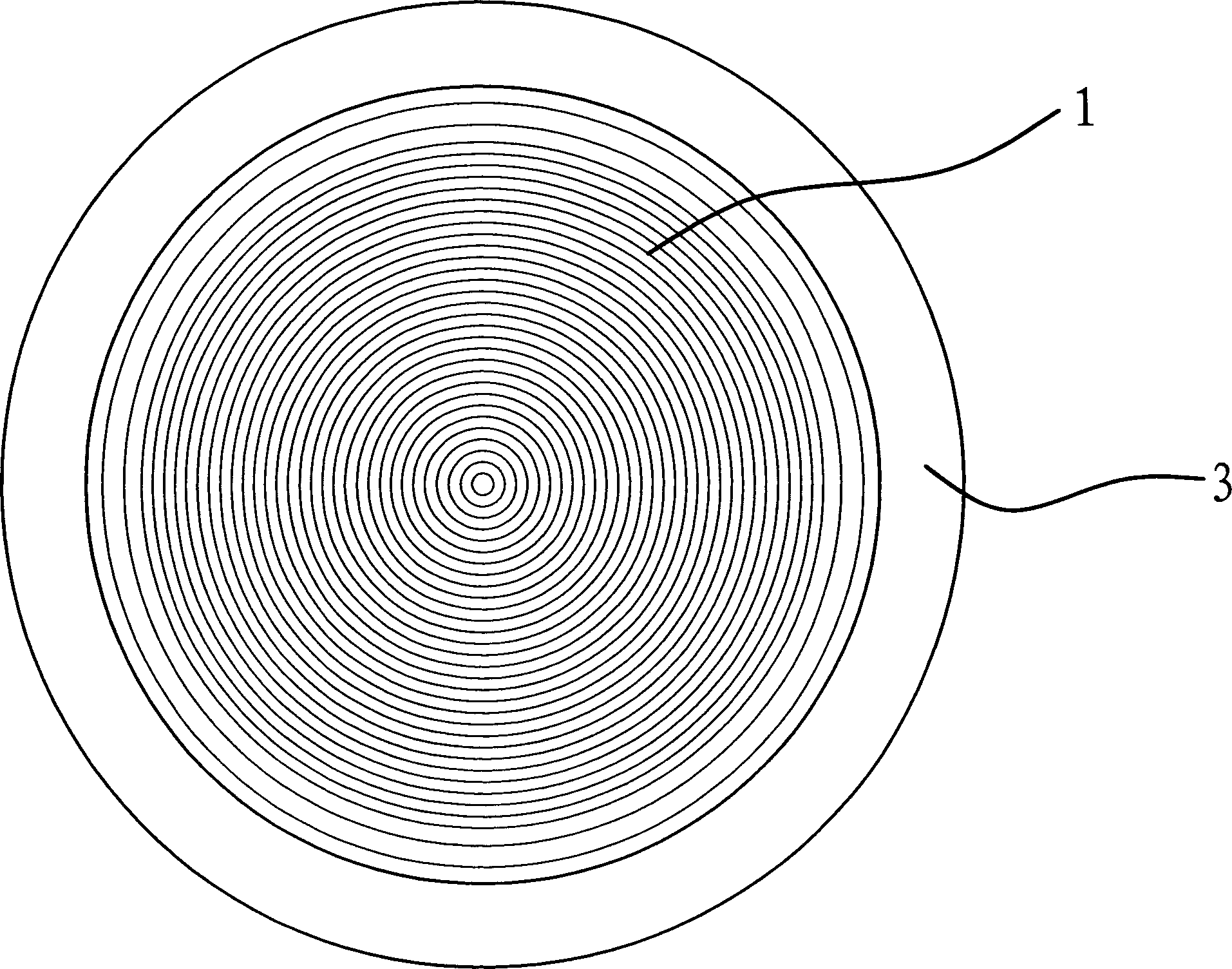

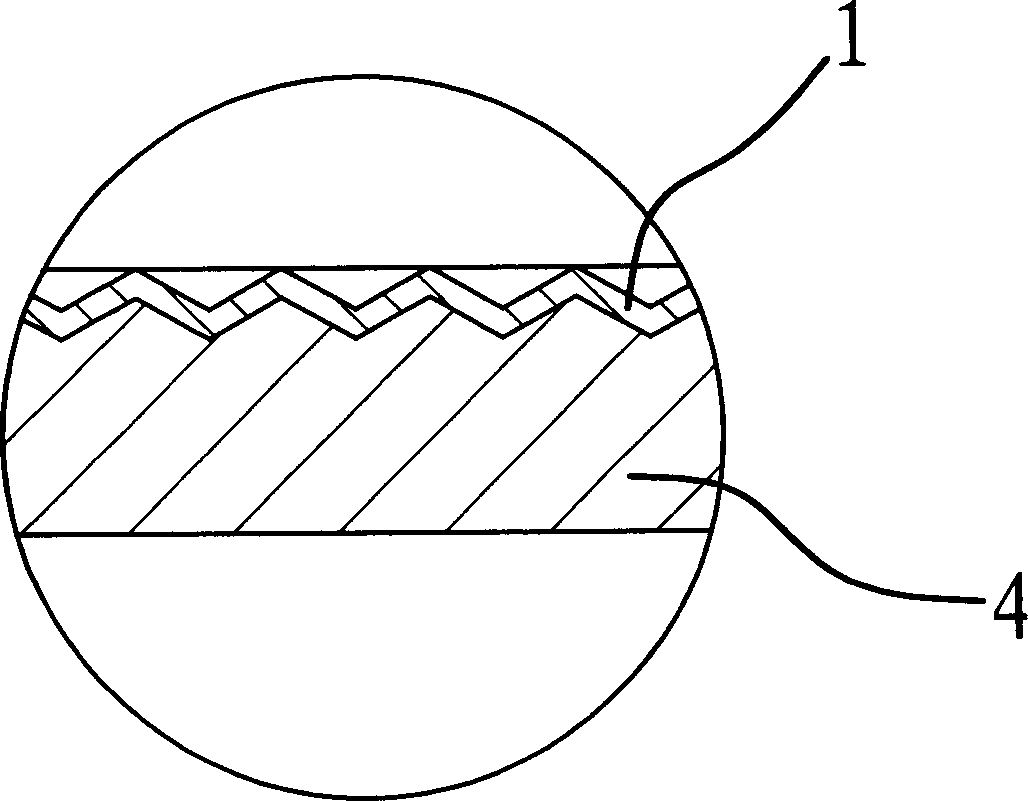

Elastic membrane-type low-frequency sound insulation metamaterial structure

InactiveCN103996395AMeet the requirements of low frequency sound insulationImprove sound insulationSound producing devicesLow noiseBroadband

The invention discloses an elastic membrane-type low-frequency sound insulation metamaterial structure which comprises two frames and a silicone rubber elastic membrane arranged between the two frames. A plurality of mass blocks are pasted on one side of the silicone rubber elastic membrane, and the mass blocks are separated with one another through the frames. The elastic membrane-type low-frequency sound insulation metamaterial structure solves the problems that a traditional sound insulation material is poor in low-frequency sound insulation performance, large in thickness, heavy in mass and the like and meets the five requirements of low-frequency sound insulation, wherein the five requirements include the low-frequency sound insulation requirement for noise below 500 Hz, the broadband requirement, the requirement for low structural thickness and low weight, and the requirement of easy design processing and low processing difficulty. The elastic membrane-type low-frequency sound insulation metamaterial structure has excellent low-frequency sound insulation performance, can effectively isolate low-frequency noise ranging from 200 Hz to 500 Hz, and can be applied to various carrying tools such as planes, automobiles, trains and ships and various types of building decoration. A brand new sound insulation solution is provided for creating low-noise working and living environments.

Owner:XI AN JIAOTONG UNIV

Inorganic heat insulation load-bearing concrete

InactiveCN101628797AImprove insulation effectHigh strengthSolid waste managementCeramicwarePulverized fuel ashMix proportion

Owner:李珠 +1

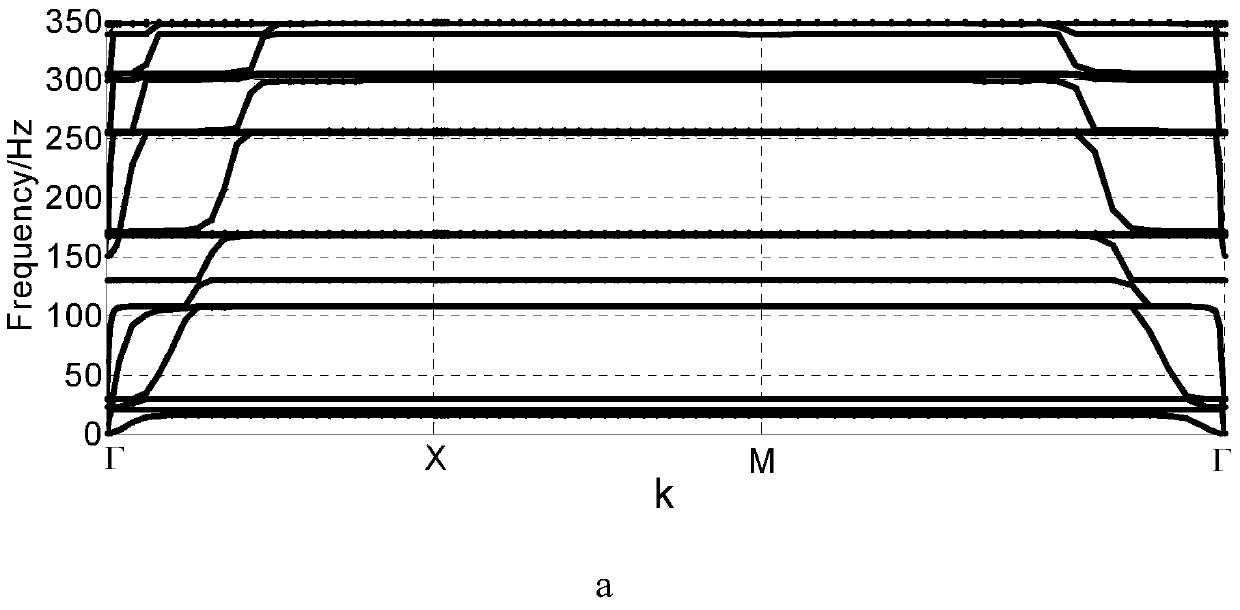

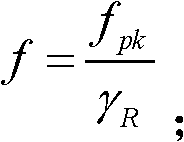

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

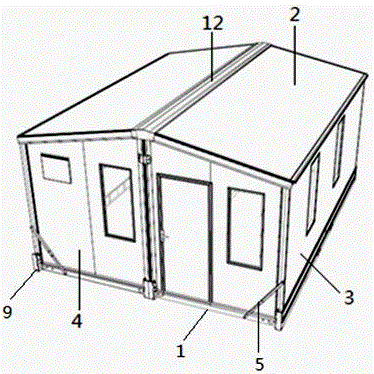

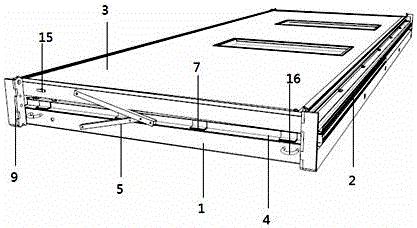

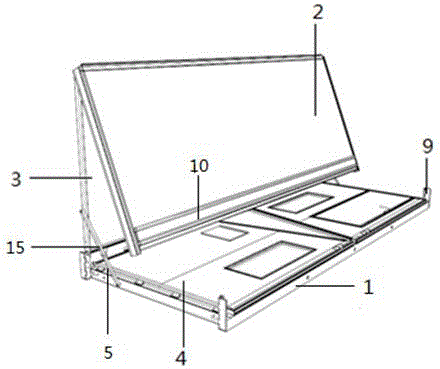

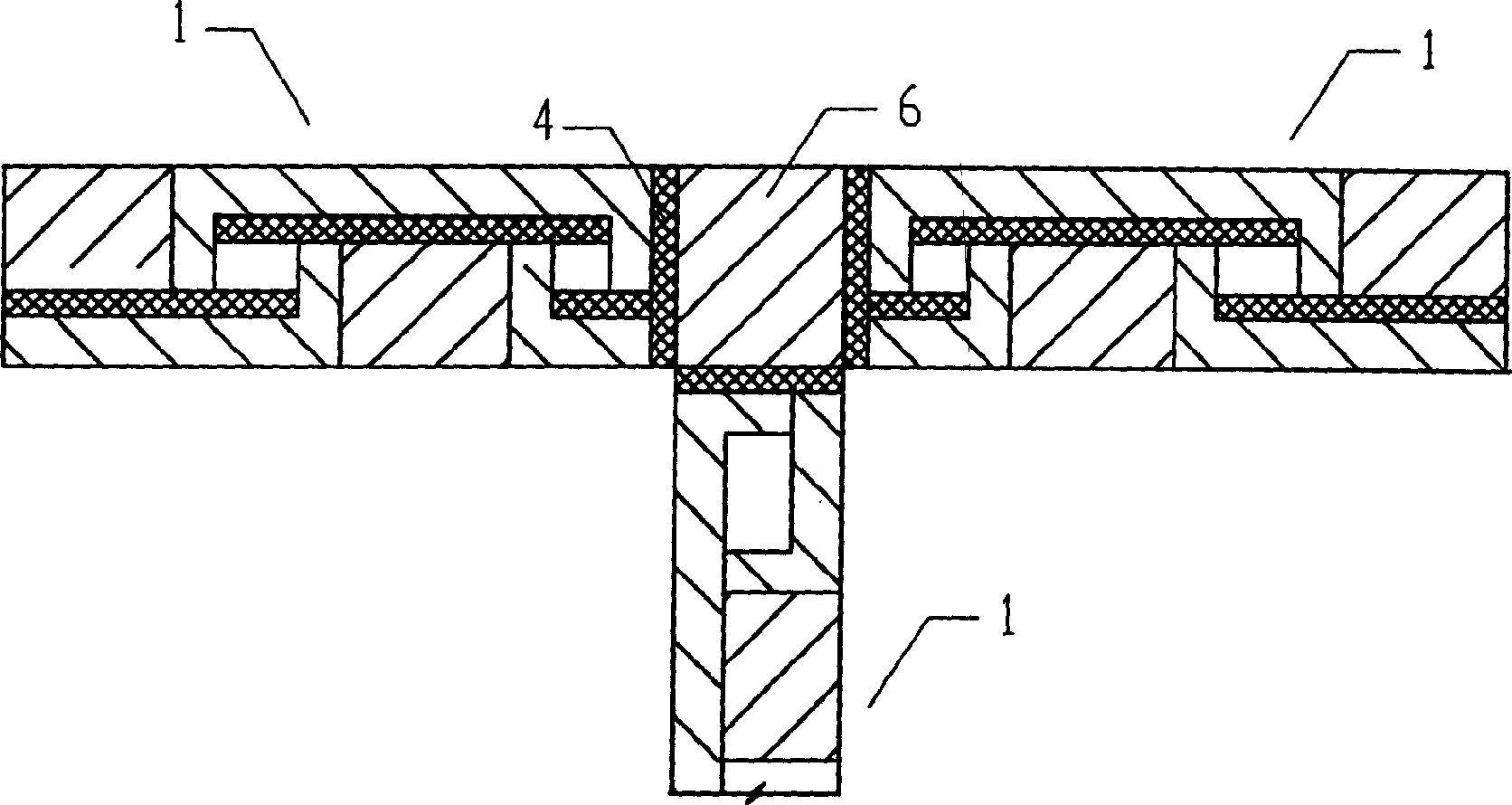

Foldable house and assembling and disassembling method thereof

ActiveCN105735480AReasonable structural designIncrease the usable areaBuilding constructionsEngineeringWall plate

The invention relates to a foldable house and an assembling and disassembling method thereof, and belongs to the technical field of moveable house structures. The foldable house comprises a first unit and a second unit, wherein the first unit and the second unit are structurally symmetric and can be integrally assembled with each other to form the foldable house; the first unit and the second unit both comprise bottom plates and mountain wall plates which are hinged to two opposite sides of the bottom plates; side wall plates are arranged between the two mountain wall plates; the bottoms of the side wall plates are hinged to the bottom plates; a top plate is hinged to the tops of the side wall plates; side surface connecting parts and top connecting parts of both the first unit and the second unit are respectively assembled integrally through detachable side connecting members and top connecting members. The foldable house is smart in structural design, small in space, light in weight, rapid in assembly and disassembly, and convenient and rapid in transport, and can be repeatedly assembled and disassembled for use.

Owner:WANHUA MODULAR PROJECTS

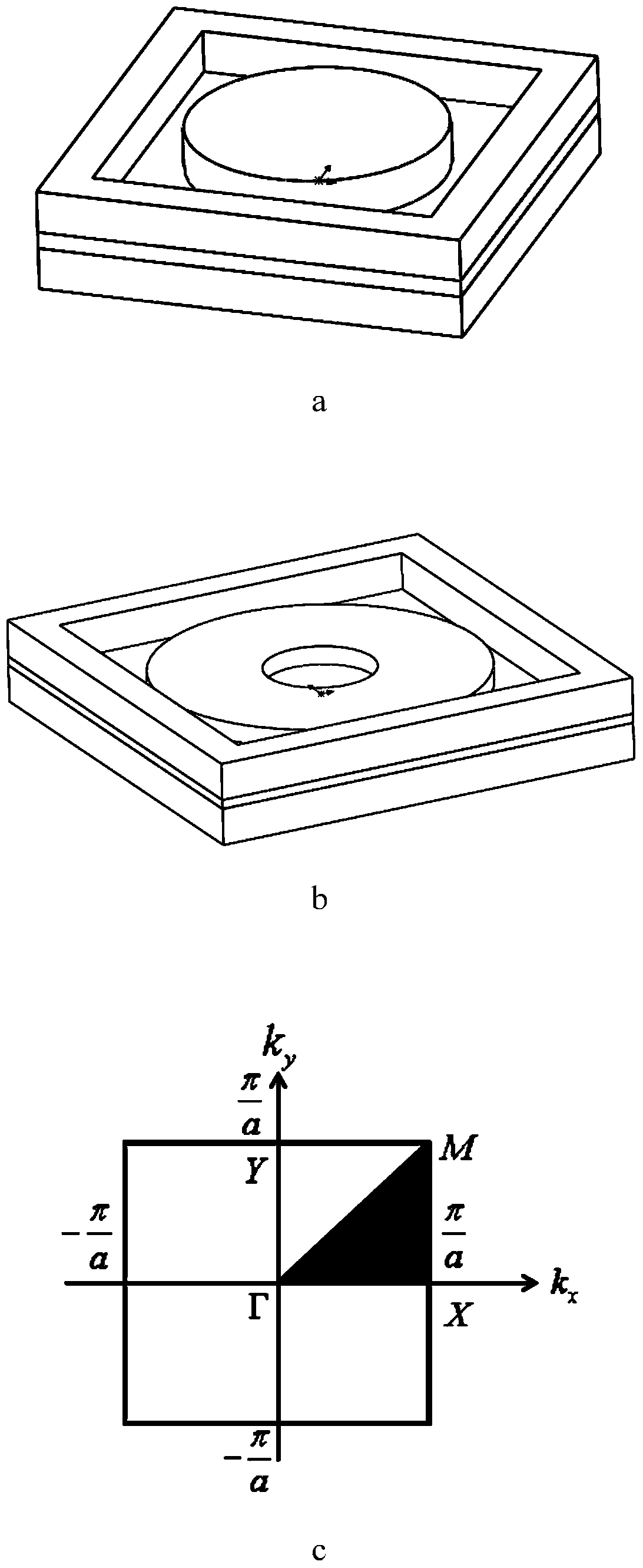

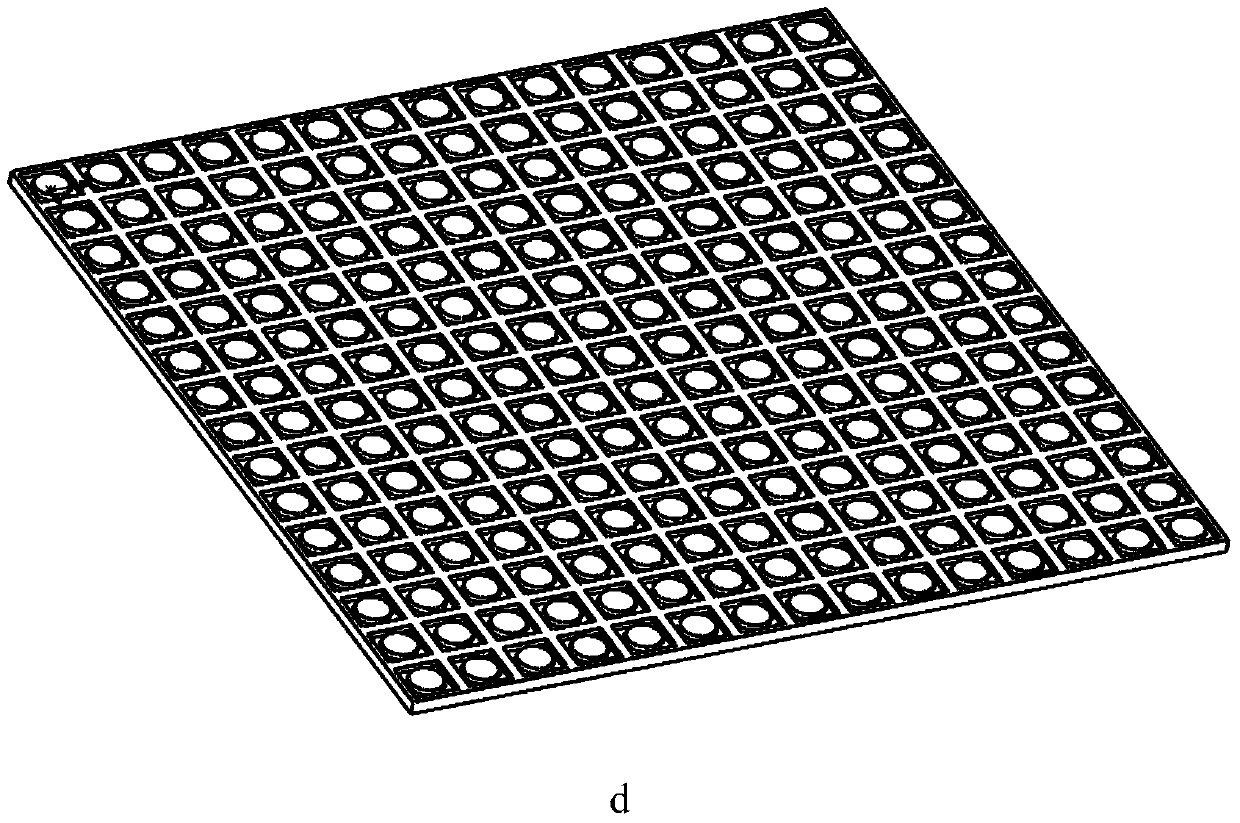

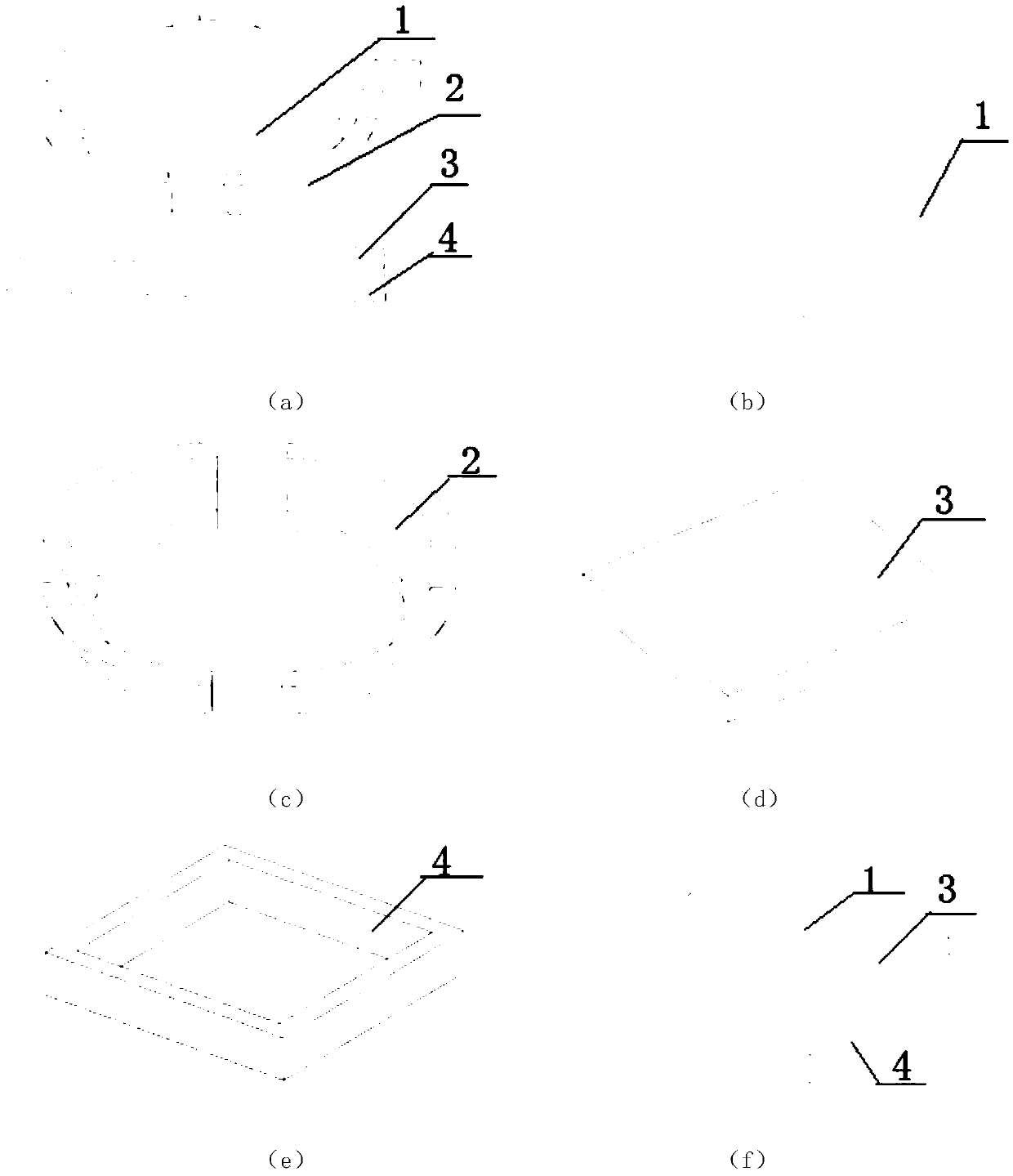

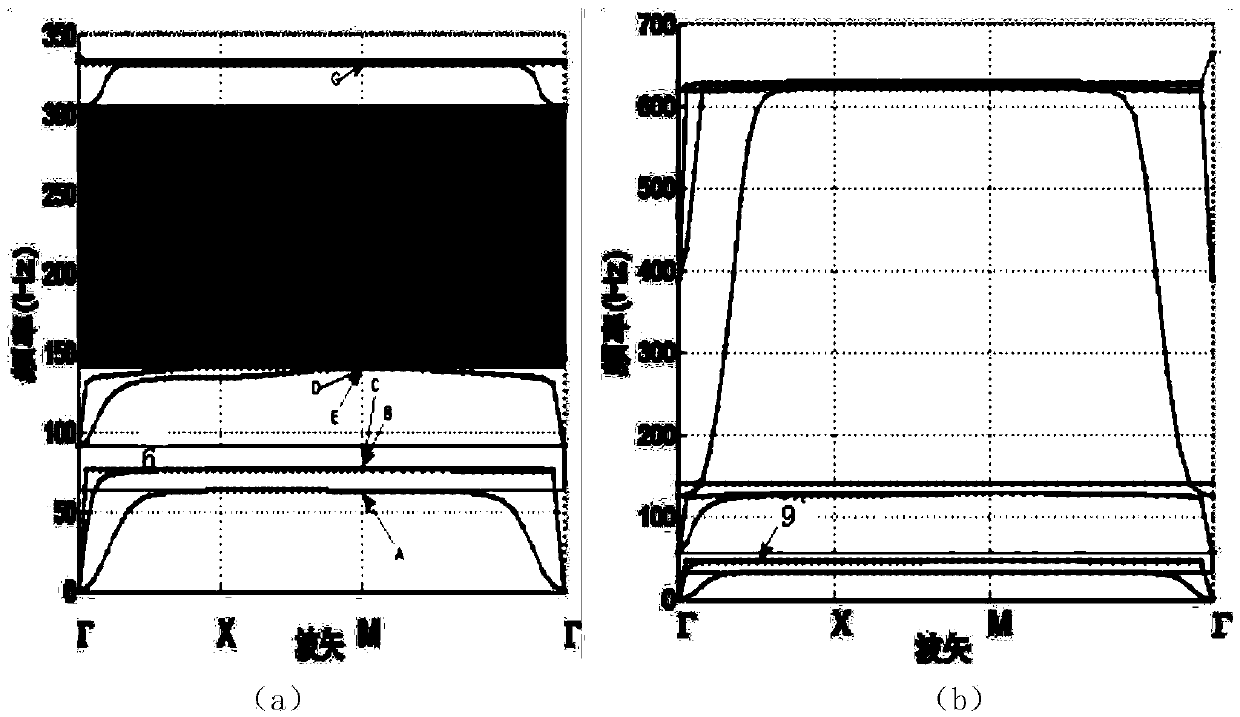

Low-frequency ultra-wide-band-gap petal-shaped local resonance acoustic meta-material

InactiveCN105374348ARaise the ratioImproves acoustic stabilitySound producing devicesChinese charactersResonance

The invention provides a low-frequency ultra-wide band gap petal-shaped local resonance acoustic meta-material. The low-frequency ultra-wide band gap petal-shaped local resonance acoustic meta-material comprises a support in the shape of a Chinese character 'tian', elastic films, hemispheres and a plurality of pairs of petal-shaped structures. Square frames periodically extend in x and y directions to form the support in the shape of a Chinese character 'tian'. The elastic films are pasted to the upper parts of the square frames. Corresponding to the square frames, the hemispheres are periodically pasted on the upper parts of the elastic films. The petal-shaped structures are identical in geometrical size, symmetrically surround the peripheries of the hemispheres and are fixed on the elastic films. One square frame, the corresponding elastic film arranged on the upper part of the square frame, the hemisphere and the petal-shaped structures form one cell. The single layer structure made of one kind of cell is adopted for realizing an ultra-wide band gap, the composition or stacking of a plurality of kinds of cells is not needed, the arrangement difficulty of the structure is lowered, and the acoustic stability of the structure is improved; in addition, in a low frequency range, a relative band gap ([delta]f / fc) is as high as 84%, and the proportion of the band gap range in an effect frequency total range is substantially improved.

Owner:JIANGSU UNIV

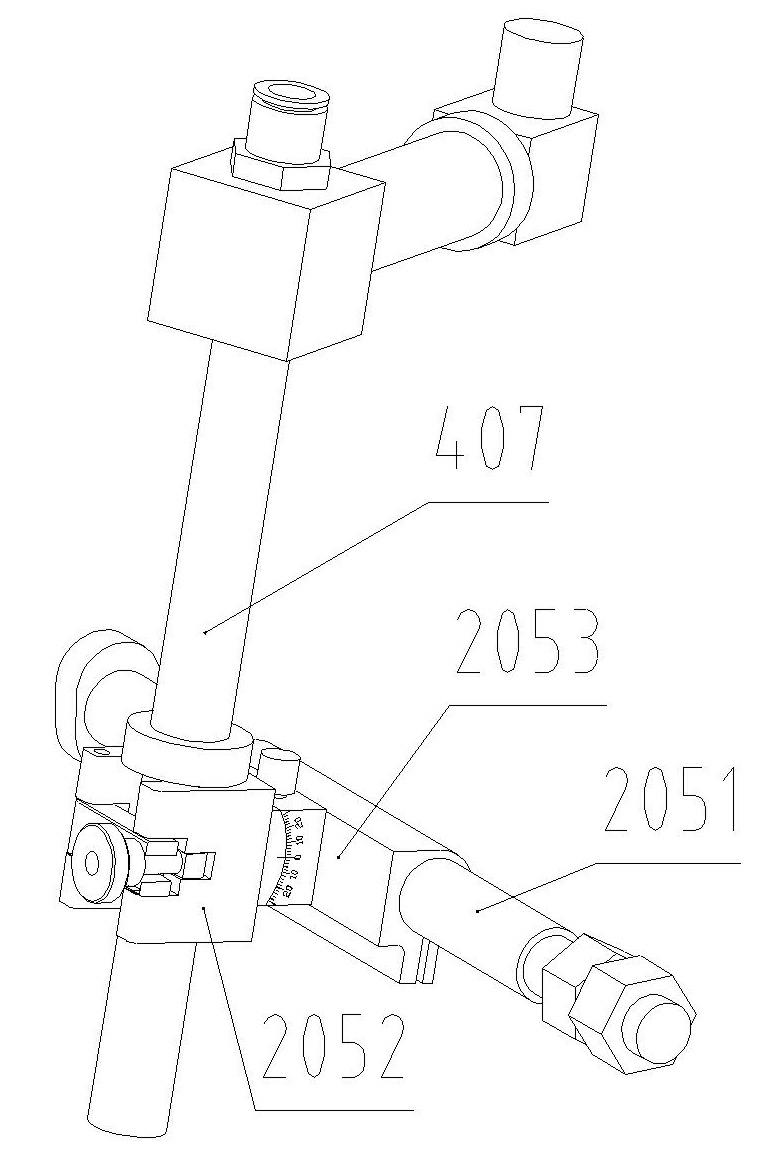

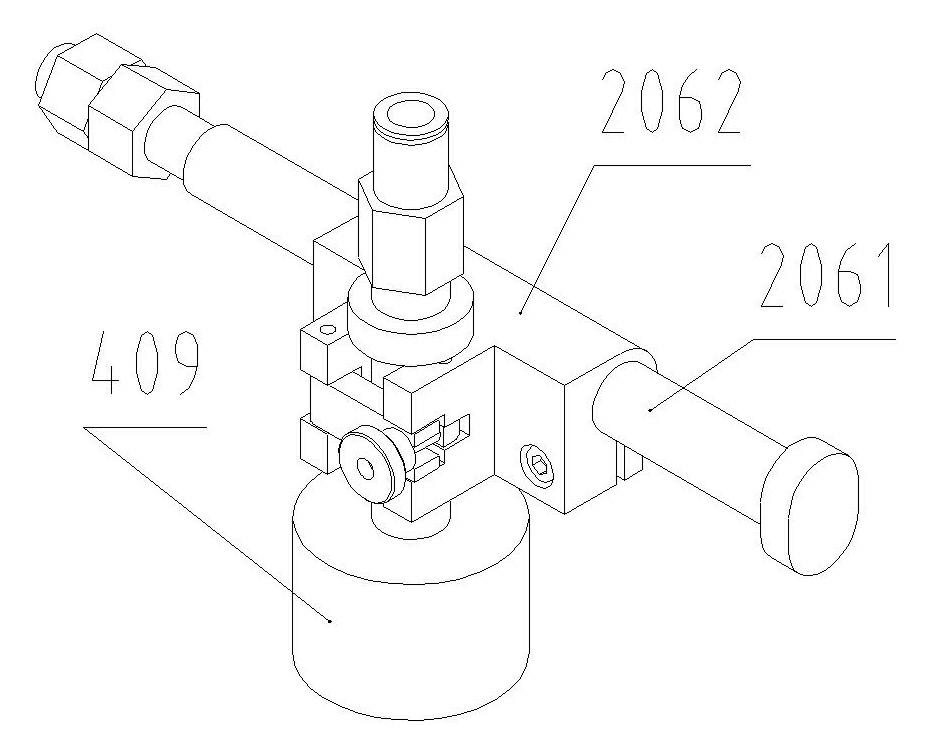

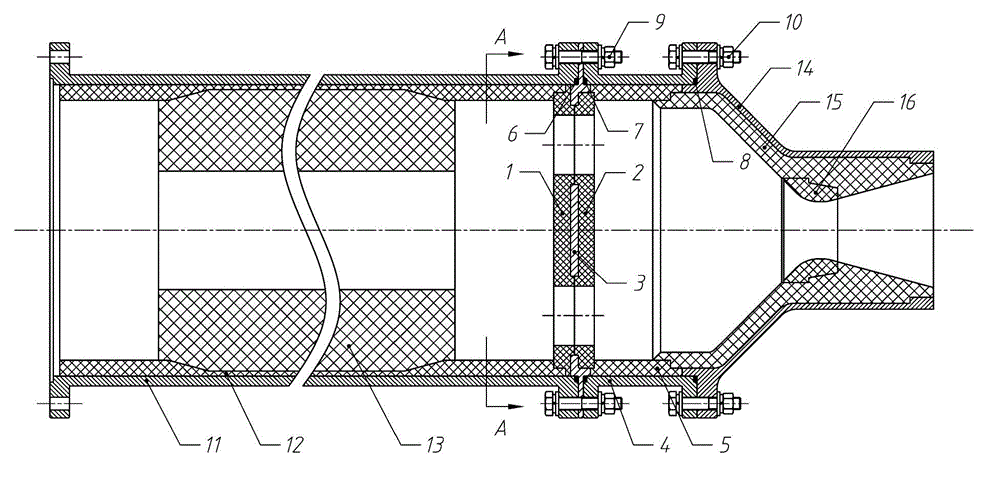

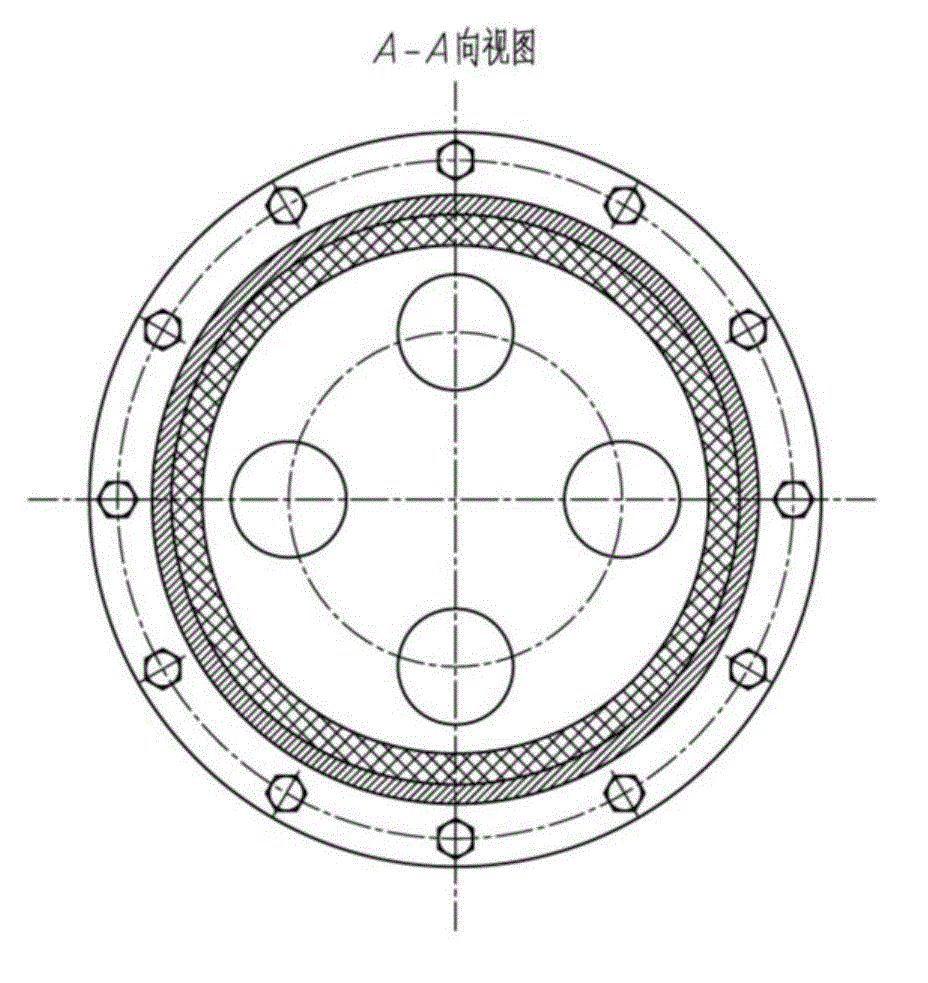

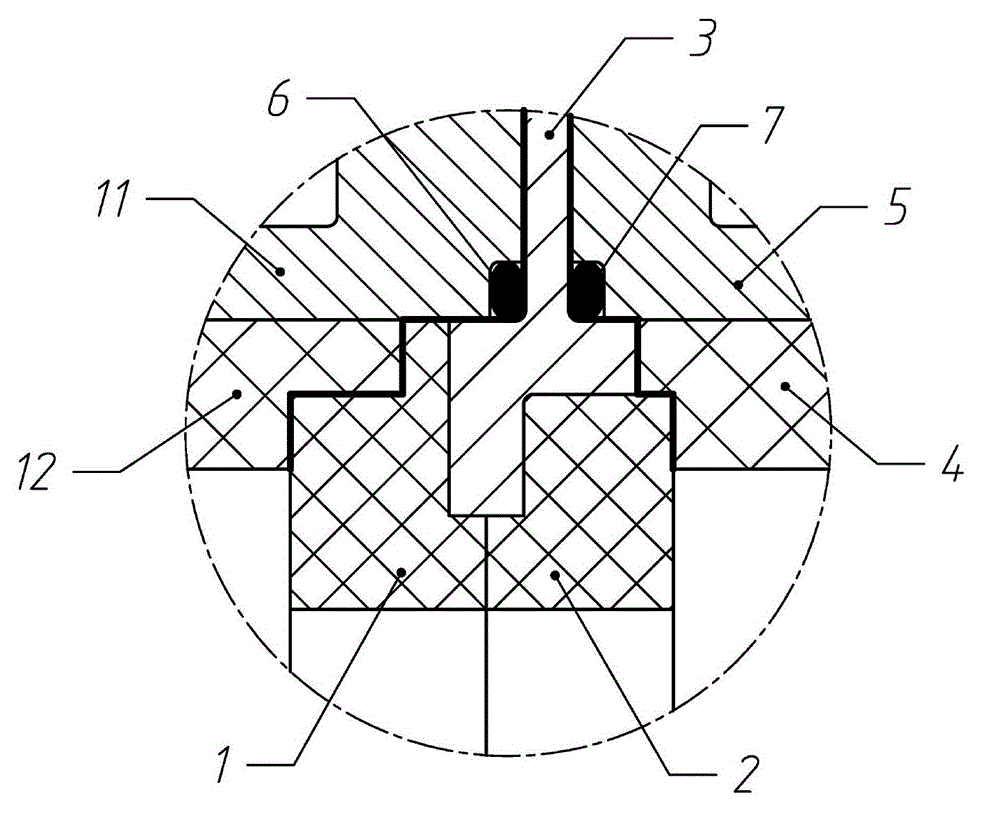

Turbulence device for postcombustion chamber of hybrid rocket engine

ActiveCN102943719ANo need to change charge designPlay structural strengthRocket engine plantsCombustion chamberAir tightness

The invention discloses a turbulence device for a postcombustion chamber of a hybrid rocket engine, which is suitable for ground heat run test of the hybrid rocket engine, is applied to a central single-channel hybrid rocket engine, but is not limited by specific propellant forms. The turbulence device comprises a combustion chamber component, a spoiler component, a spoiler postcombustion chamber component, a sealing and connecting component and a spray pipe component. The spoiler component and the spoiler postcombustion chamber component are combined into a whole so as to be connected with the spray pipe component through the sealing and connecting component and the spoiler postcombustion chamber component. The spoiler component consists of an internal metal spoiler and an external heat insulating structure, and spoiling holes are uniformly distributed in a circle taking the axis of the engine as the center. The spoiler component is used for realizing the turbulence function in gas in the central area, requirements on structural strength and thermal protection of the turbulence device can be satisfied during the working process of the engine, all the components are connected through a stepped fold line mode and O-shaped sealing ring connection, so that the requirements on airtightness and thermal protection are ensured during the working of the engine.

Owner:BEIHANG UNIV

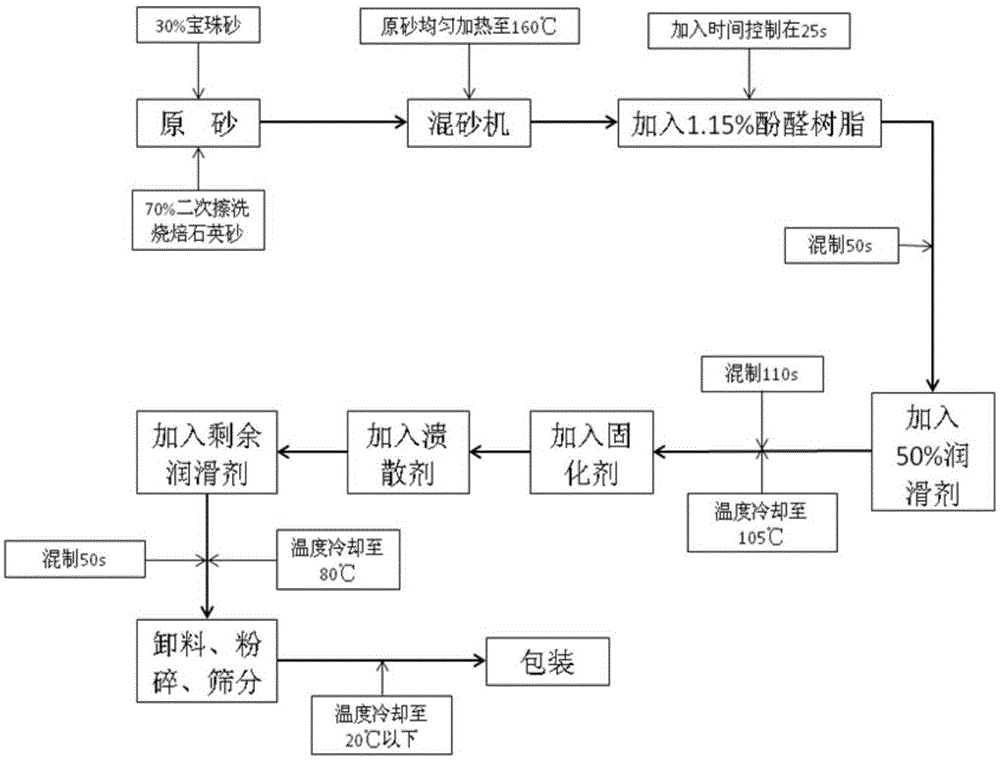

High-strength, deformation-resisting and collapsible precoated sand and preparation technology thereof

InactiveCN105033164AHigh heat normal temperature strengthImprove deformation resistanceFoundry mouldsFoundry coresHigh intensityUltimate tensile strength

The invention belongs to the field of casting, and particularly relates to high-strength, deformation-resisting and collapsible precoated sand and a preparation technology thereof. The precoated sand and the preparation technology aim to solve the technical problem that a sand core made of precoated sand according to a ratio is low in strength and prone to deformation. The high-strength, deformation-resisting and collapsible precoated sand is composed of crude sand, phenolic resin, curing agents, lubricants and disperser, wherein the crude sand is composed of 20%-30% of nice foundry sand and 70%-80% of quartz sand, the addition quantity of the phenolic resin is 0.9%-1.2% of the mass of the crude sand, the addition quantity of the curing agents is 9%-13% that of the phenolic resin, the addition quantity of the lubricants is 0.1%-0.15% of the mass of the crude sand, and the addition quantity of the disperser is 0.05%-0.4% of the mass of the crude sand. The invention further provides the preparation technology of the precoated sand. The precoated sand has the advantages of high temperature and normal temperature strength, high deformation resistance, good formability, easy collapsibility, good mobility and low gas-forming amount, and completely meets the production technology requirements of an engine with complex structure and high performance.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

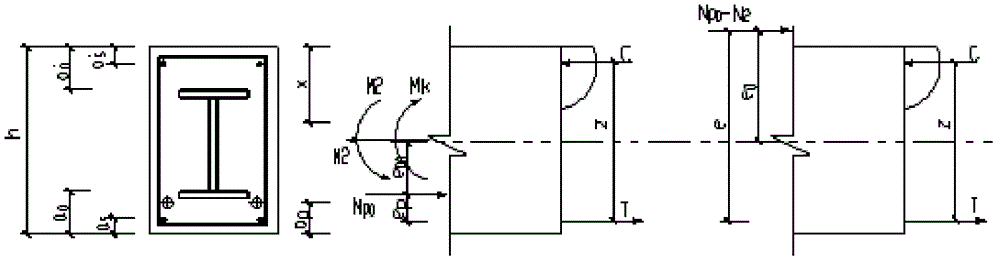

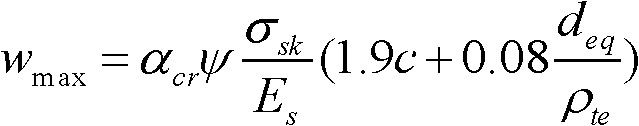

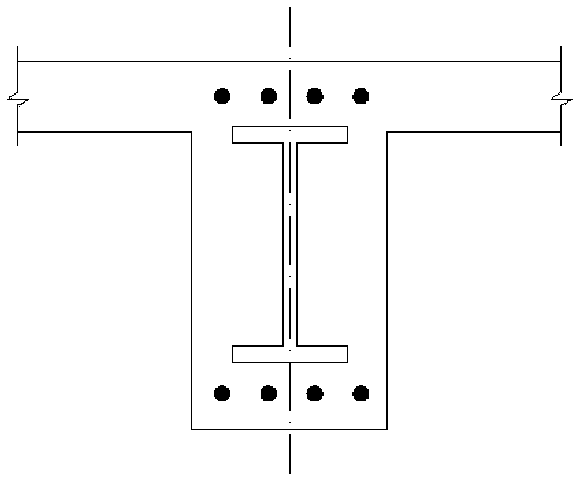

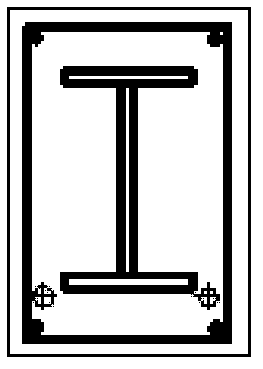

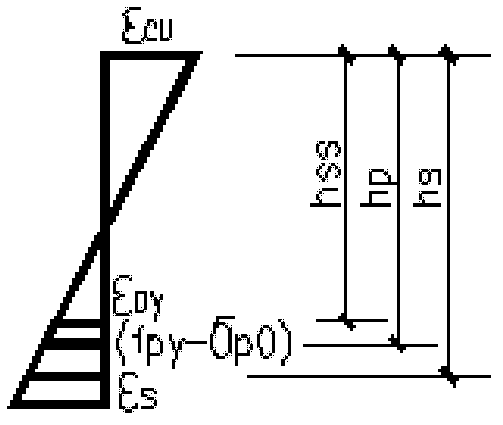

Prestress type steel-concrete structure using performance design method

InactiveCN102749246AMeet structural requirementsImprove securityLoad-supporting elementsStrength propertiesPre stressAxial force

The present invention relates to a prestress type steel-concrete structure design, and belongs to the field of civil engineering. The prestress type steel-concrete structure using performance design method is characterized by: considering constraint and distribution thereof, wherein the using performance design during structure construction designing comprises calculating deflection of a frame beam under a normal use limit state and carrying out checking computation on a maximum crack width of the frame beam. Considerations of the constraint and the distribution thereof are the entity generated by the internal forces, the constraint causes the influence of the secondary axial force, such that the prestressed frame beam becomes a tension bending member from a flexural member so as to impact deflection and crack width of the prestressed frame beam. With the calculation formula of the design method provided by the present invention, the influence of the secondary axial force is considered, and the prestress type steel-concrete structure design theory is quantitatively established by using a constraint viewpoint.

Owner:TONGJI UNIV +1

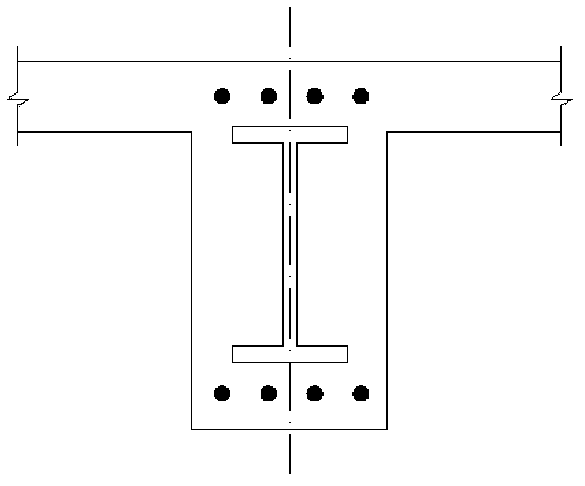

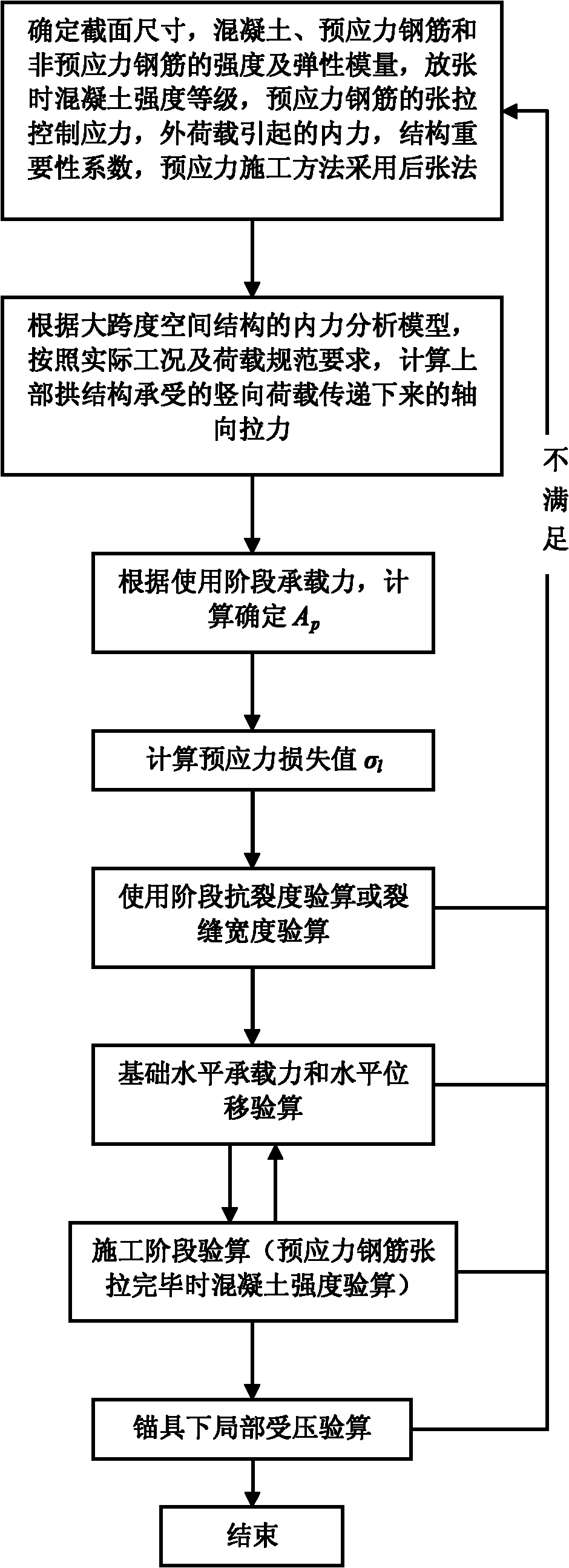

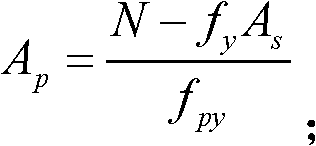

Flexural bearing capacity designing method for frame beam adopting pre-stressed steel reinforced concrete structure

InactiveCN102650579AMeet structural requirementsImprove securityLoad-supporting elementsMaterial strength using steady bending forcesReinforced concretePre stress

The invention relates to a flexural bearing capacity designing method for a frame beam adopting a pre-stressed steel reinforced concrete structure and belongs to the field of civil engineering. The flexural bearing capacity designing method for the frame beam adopting the pre-stressed steel reinforced concrete structure is characterized in that when the frame beam adopting the pre-stressed steel reinforced concrete structure is designed, the influence on a flexural bearing capacity and bending moment of a front section of the frame beam caused by lateral restraint is considered; and by adopting a method that the calculation is influenced by the restraint during the structure construction, a new formula for calculating the flexural bearing capacity and the bending moment is provided. According to the design method disclosed by the invention, complex restraint conditions of the pre-stressed steel reinforced concrete structure and the influence on the calculation of the flexural bearing capacity of the front section of the frame beam caused by the restraint and distribution of the pre-stressed steel reinforced concrete structure are fully considered, so that the design of the structure better meets the requirement of an actual structure and better safety performance is obtained.

Owner:TONGJI UNIV +1

Prestressed pull rod foundation design method for large-span space structure

ActiveCN102651042AMeet structural requirementsImprove securitySpecial data processing applicationsStructure analysisPre stress

The invention relates to a prestressed pull rod foundation design for a large-span space structure, belonging to the field of civil engineering. A prestressed pull rod foundation design method for the large-span space structure is disclosed by the invention, which changes the current situation that the foundation and upper part of the current large-span space structure are designed separately, establishes a simplified design method for the prestressed concrete foundation tie beam of the large-span space structure in consideration of the interaction between the upper structure and the foundation, fills in the blank in the foundation design of the large-span space structure, and develops an interaction analysis method for the foundation and the upper structure of the large-span space structure. Based on this, the designed structure fully considers the mutual mechanism between the upper structure and the foundation of the large-span space structure in each stage of construction, normal usage and bearing, and also distinguishes the structure analysis model and calculation method in different stages in detail so as to meet the requirement of the practical structure more and have better safety performance.

Owner:TONGJI UNIV +2

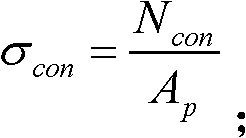

Prestressed cable foundation design method for large-span space structure

ActiveCN102651041AMeet structural requirementsExcellent securitySpecial data processing applicationsStructure analysisPre stress

The invention relates to a prestressed cable foundation design for a large-span space structure, belonging to the field of civil engineering. A prestressed cable foundation design method for the large-span space structure is disclosed by the invention, which changes the current situation that the foundation and upper part of the current large-span space structure are designed separately, establishes a simplified design method for the prestressed concrete foundation tie beam of the large-span space structure in consideration of the interaction between the upper structure and the foundation, fills in the blank in the foundation design of the large-span space structure, and develops an interaction analysis method for the foundation and the upper structure of the large-span space structure. Based on this, the designed structure fully considers the mutual mechanism between the upper structure and the foundation of the large-span space structure in each stage of construction, normal usage and bearing, and also distinguishes the structure analysis model and calculation method in different stages in detail so as to meet the requirement of the practical structure more and have better safety performance.

Owner:TONGJI UNIV +2

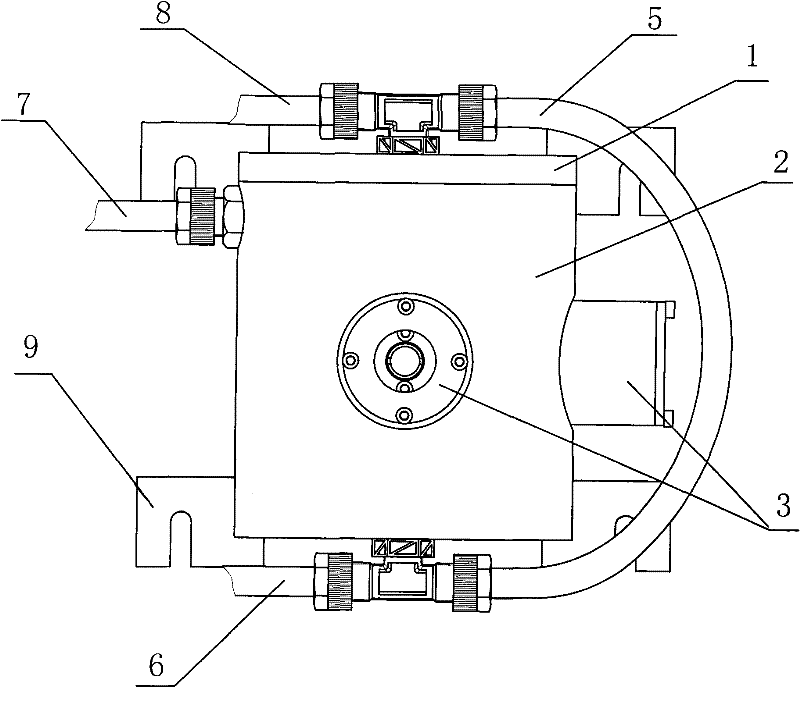

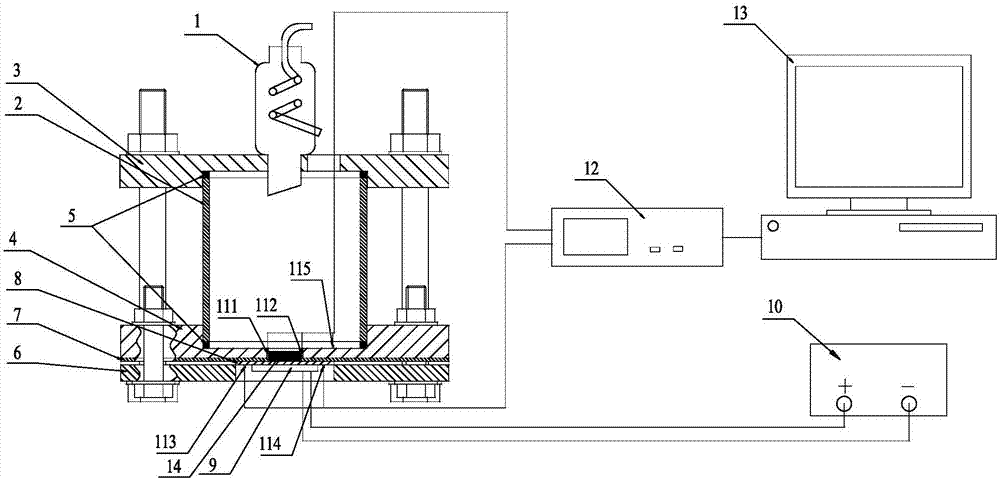

Turbidity Flow Cell

ActiveCN102288544AImprove sealingShorten the straight line distanceMaterial analysis by optical meansFlow cellTurbidity

The invention provides a turbidity flowing cell. Trough holes on the side wall of the main body of the flowing cell form two light source transmission holes through which light can penetrate, light emitted by a light-emitting device is directly transmitted into the inner cavity of the flowing cell by virtue of one light source transmission hole, and the light in the inner cavity of the flowing cell is received by a receiving device by virtue of the other light source transmission hole. The invention also provides another turbidity flowing cell which also comprises a transmitting / receiving device besides the main body the flowing cell, wherein one part of the transmitting / receiving device is embedded into the side wall of the main body of the flowing cell with certain thickness to form an integrated structure with the main body of the flowing cell. The flowing cell and a light source structure form a unified whole, thus linear distance between sample liquid in the flowing cell and a light source is greatly shortened and measuring accuracy is improved.

Owner:北京利达科信环境安全技术有限公司

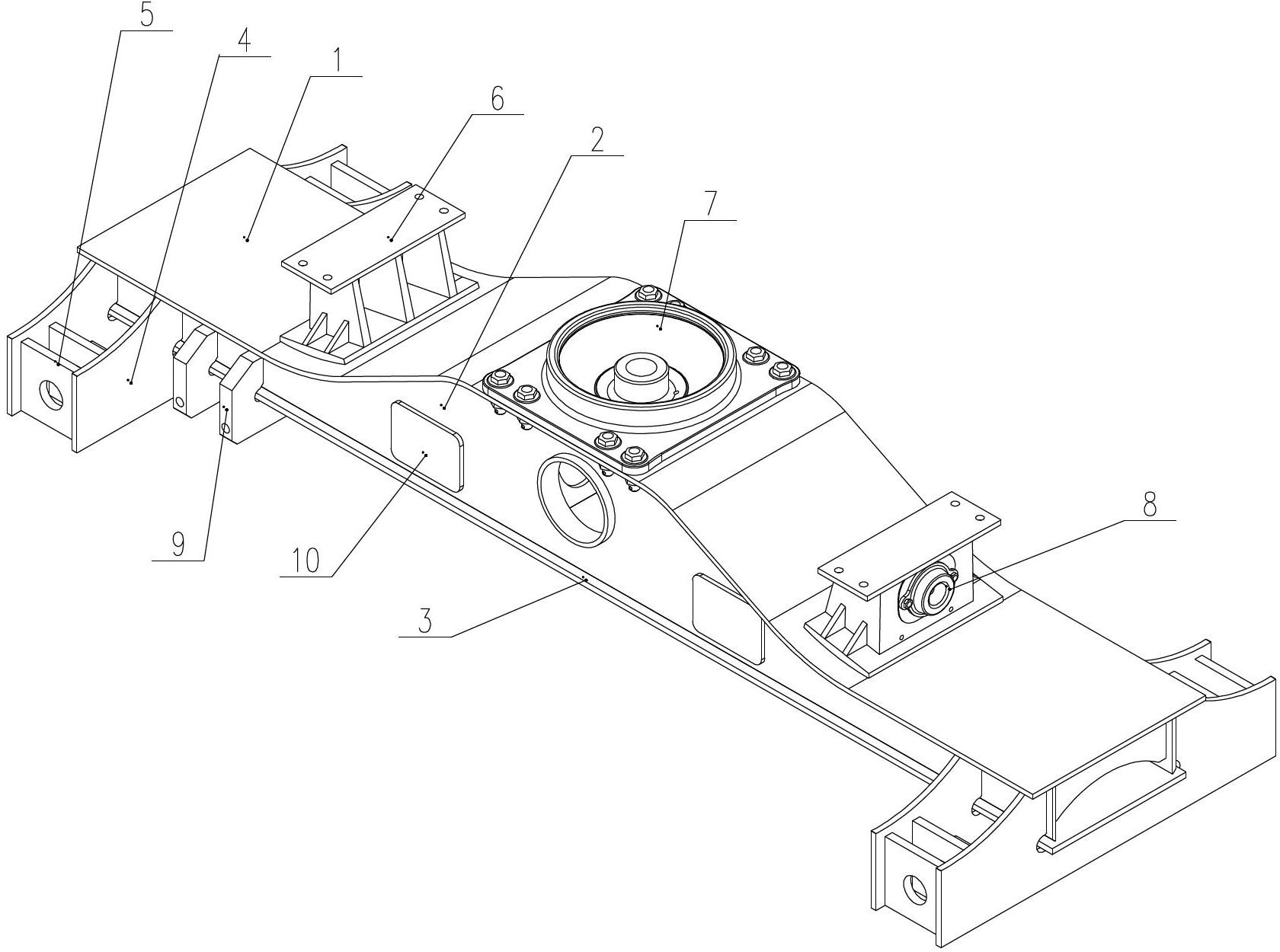

Bolster of express railway freight car bogie

ActiveCN102658824AMeet structural requirementsSimple structureBogie-underframe connectionsEngineeringTruck

The invention discloses a bolster of a high-speed railway freight car bogie. The bolster comprises a bolter upper cover plate, bolster web plates, a bolster lower cover plate and bolster end plates. The bottoms of the two bolster web plates are symmetrically arranged on the bolster lower cover plate. The bolster upper cover plate is arranged at the upper parts of the two bolster web plates. A spherical hole is arranged at the middle part of the bolster upper cover plate. The bolster upper cover plate is connected with a spherical center plate. The spherical hole is matched with the external spherical surface of the spherical center plate. Side bearing installation seats are arranged on the two sides of the upper end surface of the bolster upper cover plate. Transverse elastic bolster guides are arranged on the side bearing installation seats. The bolster upper cover plate is connected with the bolster end plates. Bolster lower hanger rod seats are arranged on the bolster end plates. Longitudinal bolster guide wearing plates are arranged on the bolster web plates. The bolster of the express railway freight car bogie has the advantages of simple structure and reliable performance, is suitable for a bogie structure which adopts a hanger rod method, can effectively transmit all-direction loads coming from a car body to the frame of the bogie and can satisfy the structural requirement on the swing bolster of the 160km / h high-speed railway freight car bogie.

Owner:CRRC SHANDONG CO LTD

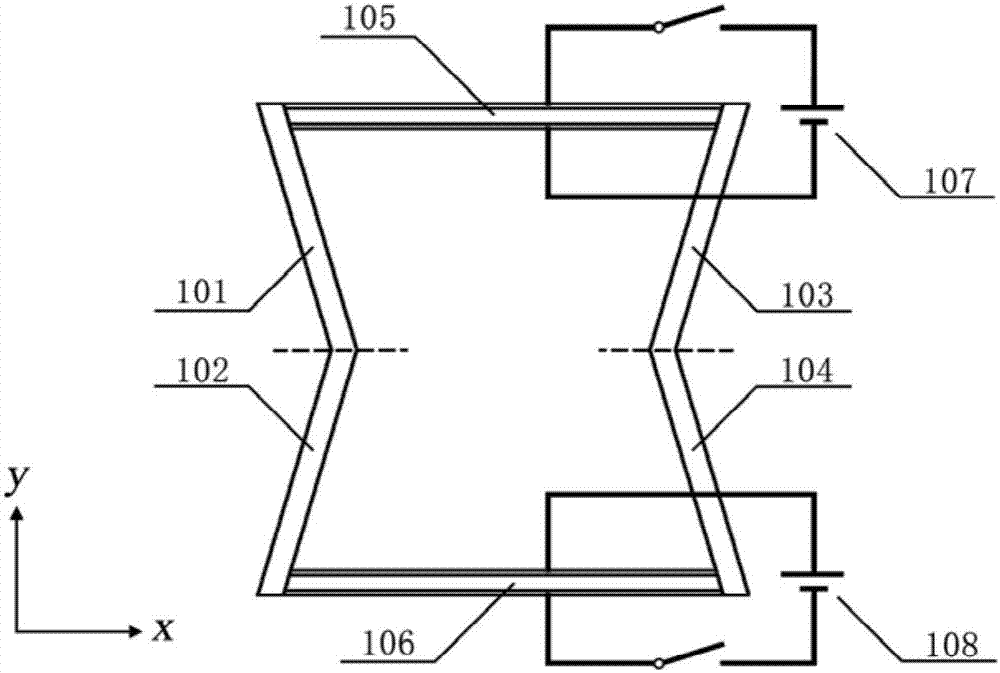

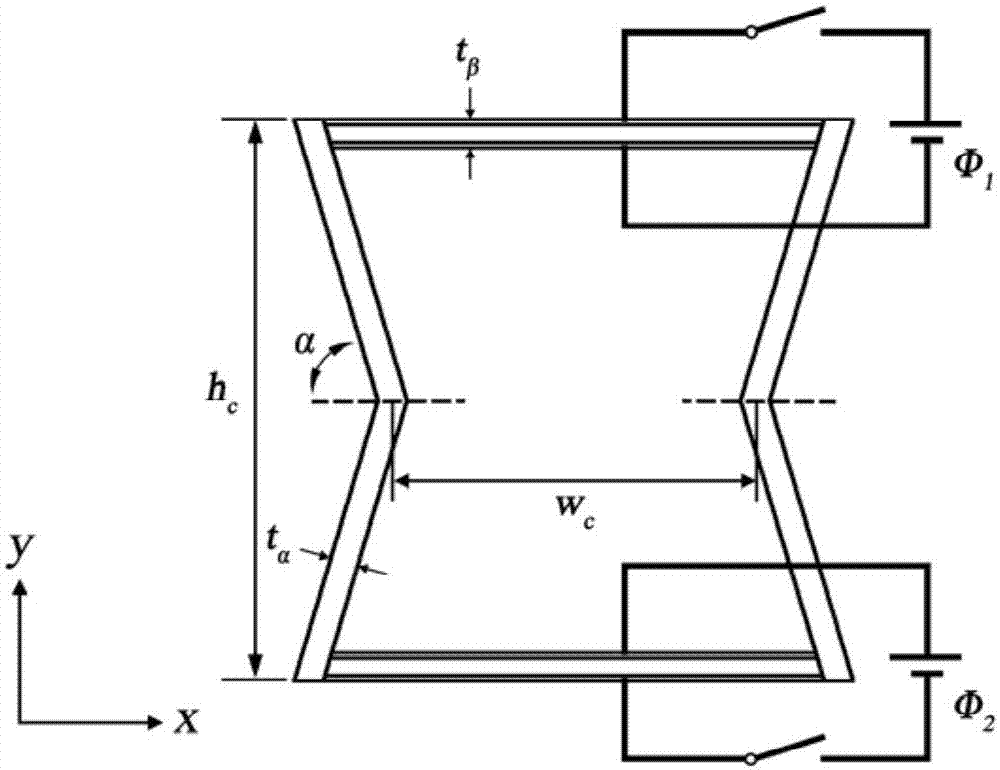

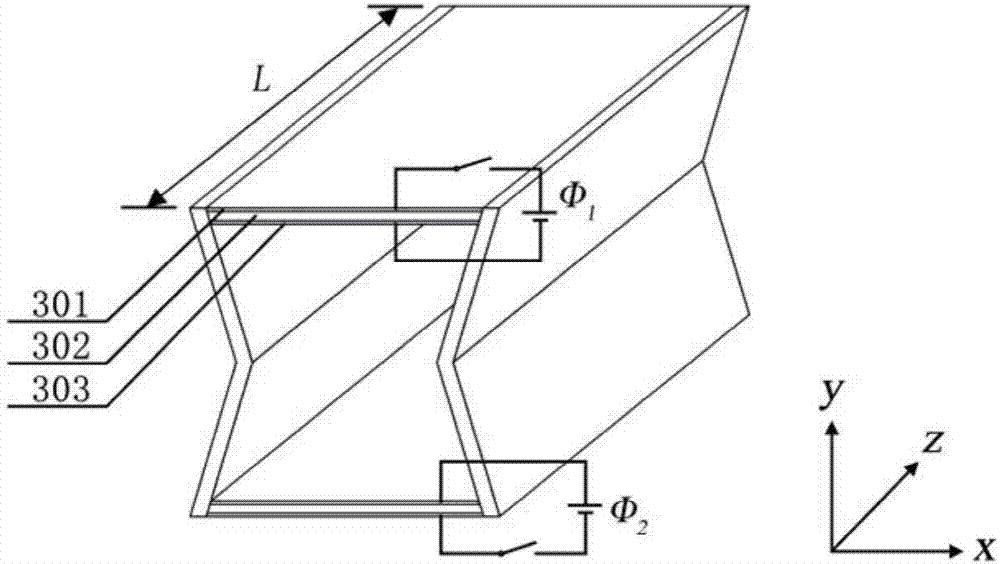

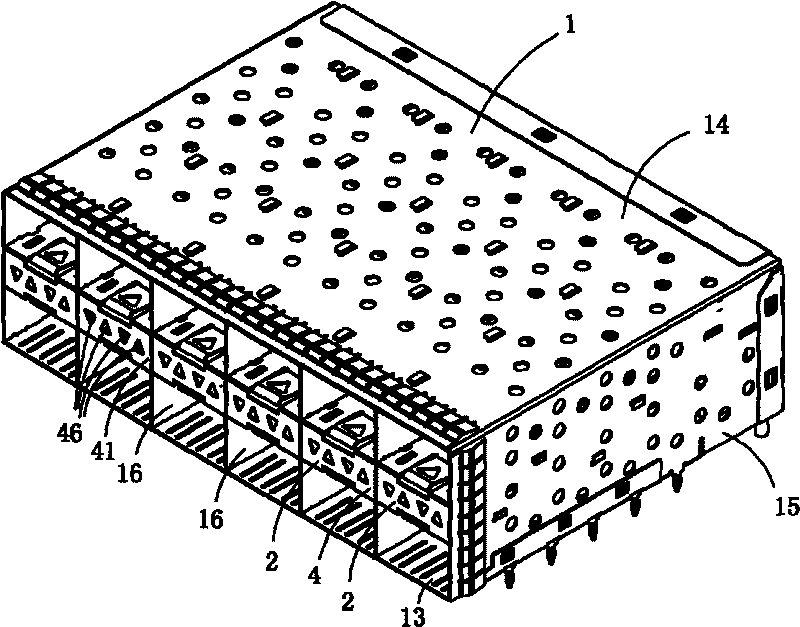

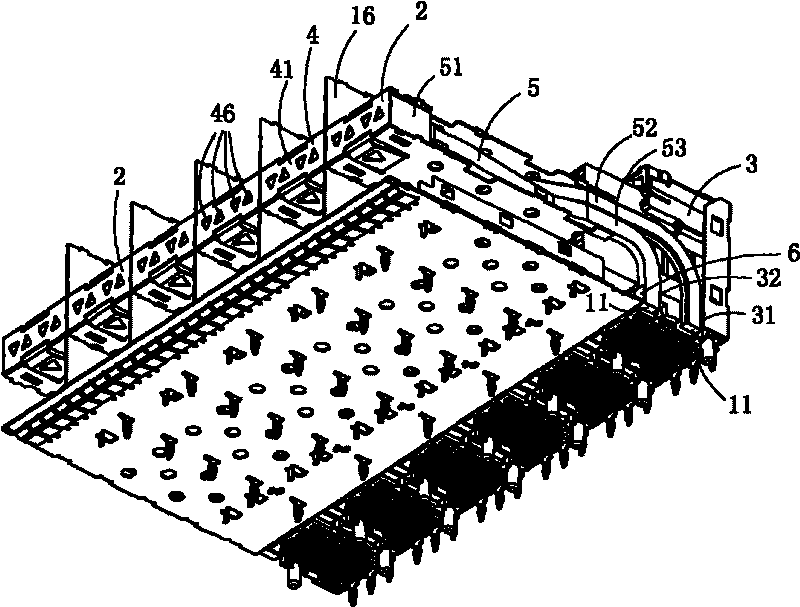

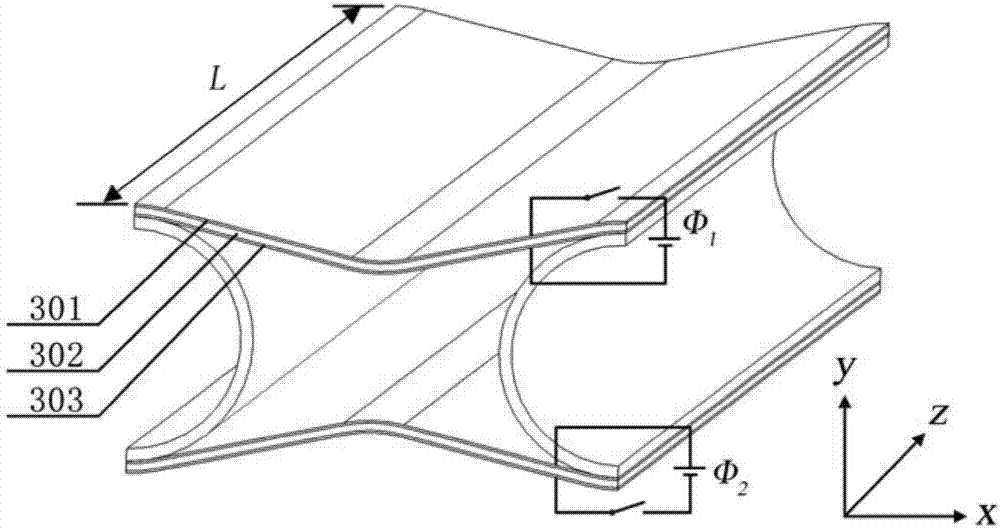

Concave hexagonal negative Poisson's ratio structure based on dielectric electroactive polymers

InactiveCN107276451AImprove energy absorptionImprove vibration damping effectPiezoelectric/electrostriction/magnetostriction machinesSandwich boardMechanical energy

The invention discloses a concave hexagonal negative Poisson's ratio structure based on dielectric electroactive polymers. The structure is formed by a concave hexagonal negative Poisson's ratio cell array, and the cells consist of bones (101~104) and tendons (105~106). The tendons are made of dielectric electroactive polymers, and are of a sandwich board structure, sandwich materials are dielectric elastomers, two sides are flexible electrodes, and the Young's modulus of bone materials is larger than that of the tendon materials. The flexible electrodes of upper and lower surfaces of the tendons 105 and 106 are connected with the positive electrode and the negative electrode of high-voltage direct current power supplies 107 and 108 respectively, and the voltage and path open-circuit state are adjustable. The concave hexagonal negative Poisson's ratio cells are arrayed, and thus the concave hexagonal negative Poisson's ratio structure can be formed. Since the mechanical states and electrostatic states of the dielectric electroactive polymers are mutually coupled, mutual conversion between mechanical energy and electric energy can be realized, and functions of structure real-time variability, actuation, energy recovery and sensing of the concave hexagonal negative Poisson's ratio structure are realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

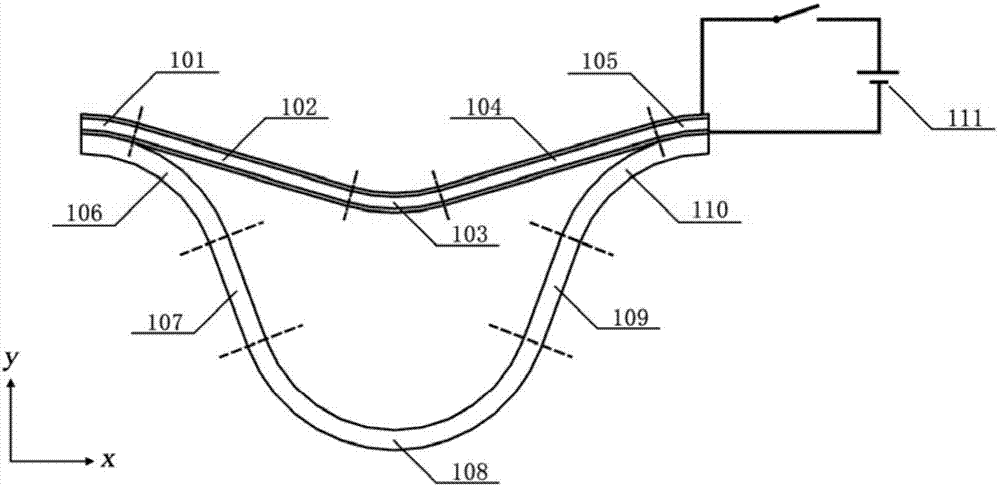

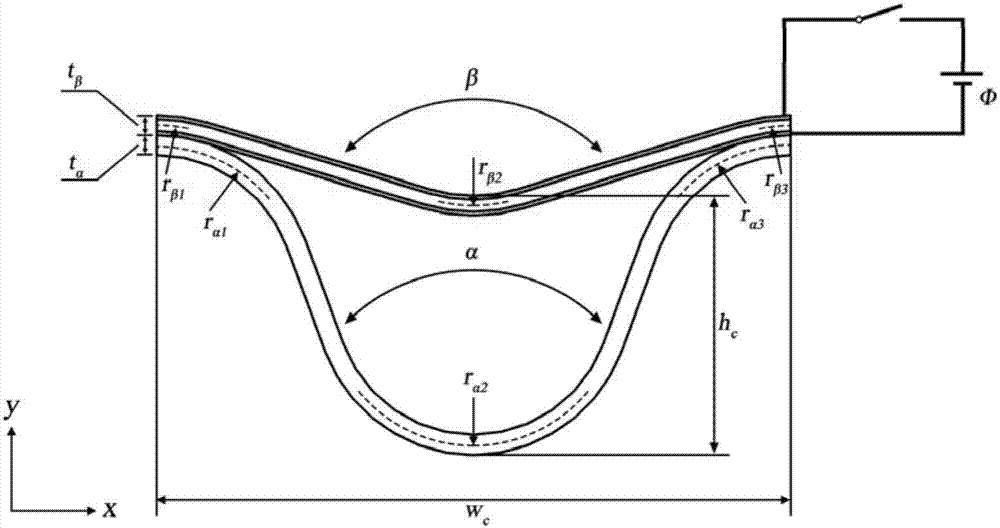

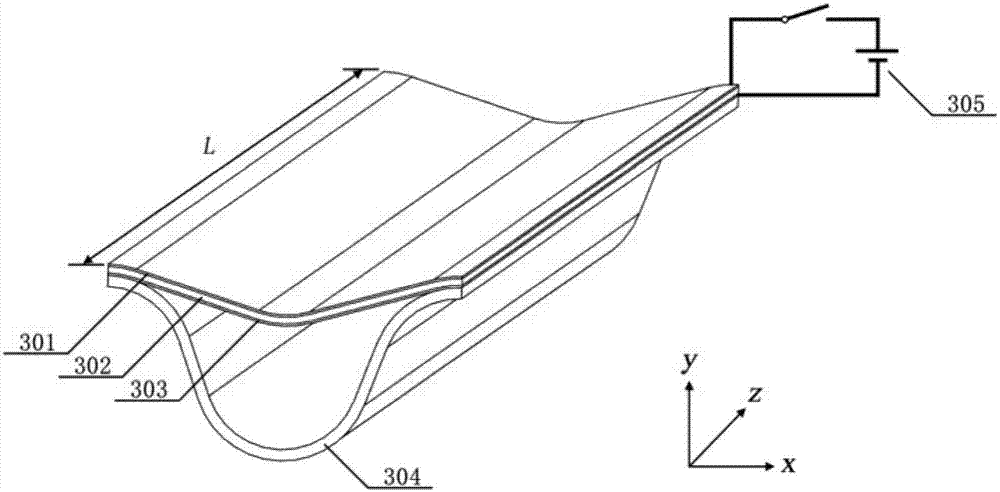

Double-waveform negative Poisson's ratio structure based on dielectric electroactive polymer

InactiveCN107294421AImprove energy absorptionImprove vibration damping effectPiezoelectric/electrostriction/magnetostriction machinesTime transformationMutual transformation

The invention discloses a double-waveform negative Poisson's ratio structure based on a dielectric electroactive polymer, and the structure consists of a double-waveform negative Poisson's ratio cell array. The cell array consists of waveform muscle tendons (101-105) and bones (106-110). Each muscle tendon is made of the dielectric electroactive polymer, and is of a sandwich board structure which is made of a dielectric elastomer, wherein two sides of the sandwich board structure are respectively provided with a flexible electrode. The Young modulus of the bones is greater than the Young modulus of the tendons. The flexible electrodes on the upper and lower surfaces of the tendons are respectively connected with the positive and negative electrodes of a high-voltage DC power supply 111, and the voltage and on and open-circuit states can be adjusted. The double-waveform negative Poisson's ratio cells are arranged in an array, thereby forming a double-waveform negative Poisson's ratio structure. Because the mechanical state and static state of the dielectric electroactive polymer are coupled mutually, the structure can achieve the mutual transformation between the mechanical energy and electric energy, and achieves the real-time transformation, actuation, energy recycling and sensing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

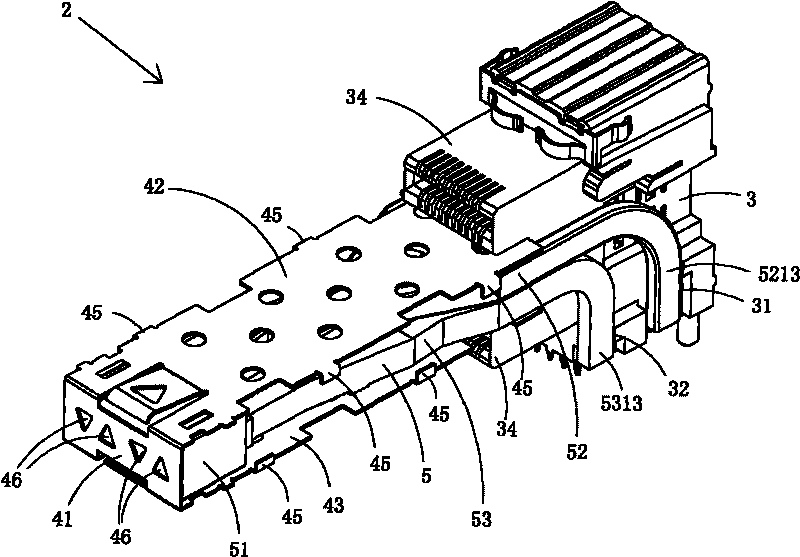

Hot swap type interface connector

ActiveCN101710198ACompact structureMeet structural requirementsCoupling light guidesMechanical engineering

Owner:WENZHOU YIHUA CONNECTOR

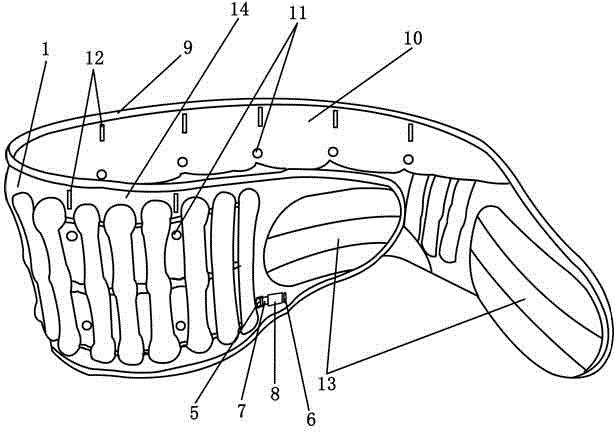

Traction fixing belt for lumbar vertebra

InactiveCN104800045AShrinkage stableMeet structural requirementsChiropractic devicesHuman bodyCotton cloth

The invention relates to the field of medical apparatuses and instruments, and particularly relates to a traction fixing belt for a lumbar vertebra. The traction fixing belt for the lumbar vertebra comprises a belt body, wherein a telescopic air bag layer is arranged in the belt body; the belt body consists of PU (polyurethane) leather, pure-cotton cloth and the telescopic air bag layer; the telescopic air bag layer is formed by using a one-step air bag molding technique; after being inflated, at joints of all transverse air passages and all longitudinal air passages of the telescopic air bag layer, all the longitudinal air passages are outwards convex; the whole air bag layer is in an inverted C shape. The structural requirements of the normal physiological curve of a human body are met much more; the belt is attached to a waist more easily; moreover, an air faucet is provided with an inflation connector; the inflation connector is of a copper structure; the conventional rotation deflation is changed through the connector; the push-pressing deflation is used; the deflation is uniform; the belt shrinks stably; the left end and the right end of the belt body are provided with a hook and loop fastener, so that the traction fixing belt for the lumbar vertebra is more convenient and quicker to use and disassemble.

Owner:王文军

Wind power blade girder cloth paving method

ActiveCN107813509ASave human effortReduce labor intensityDomestic articlesEngineeringUltimate tensile strength

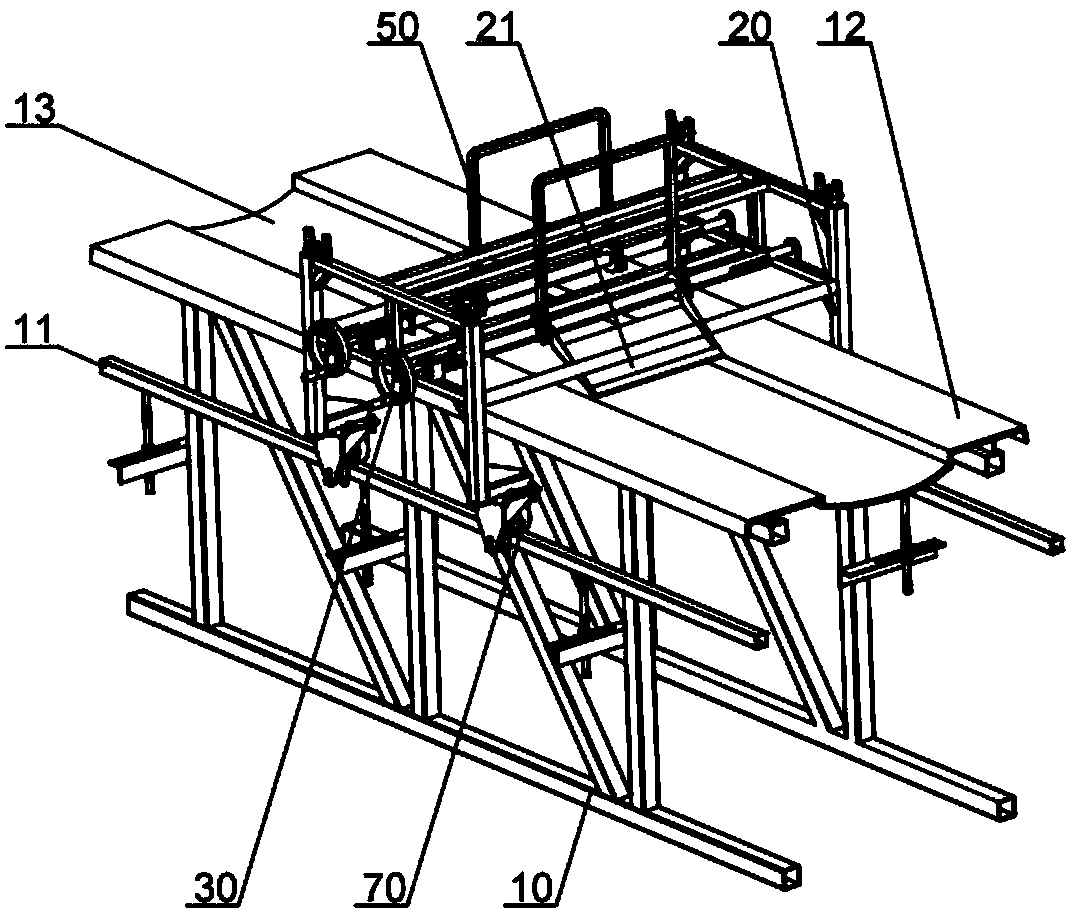

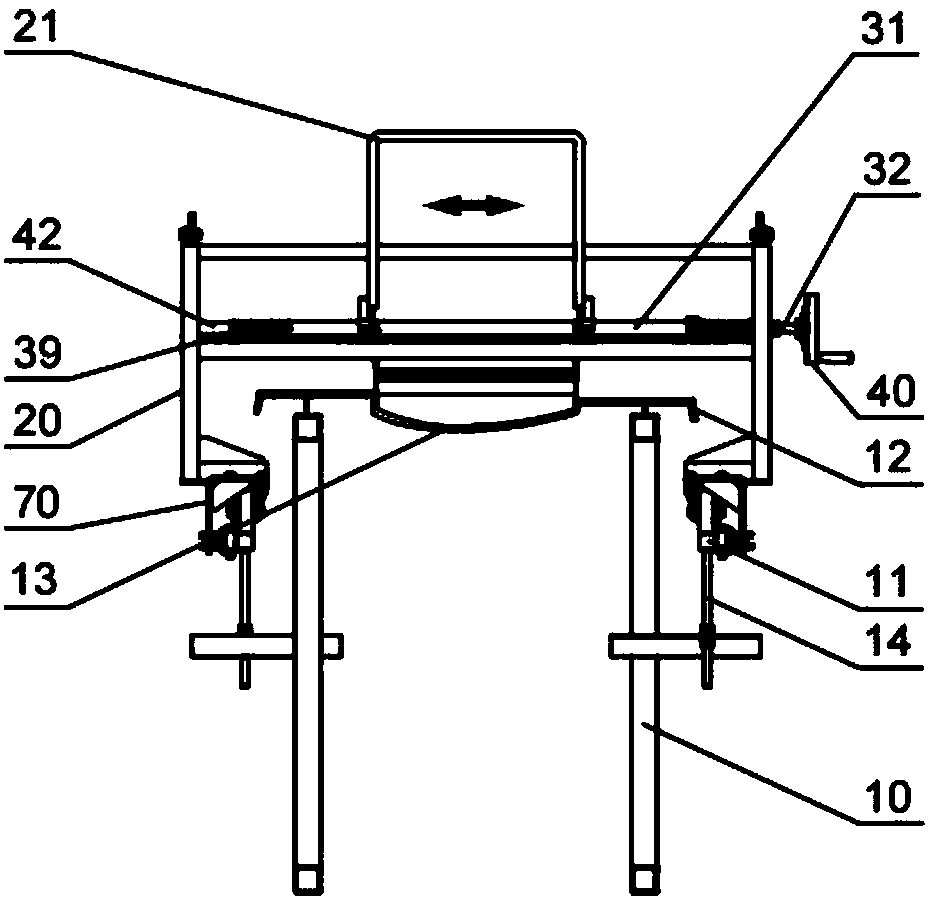

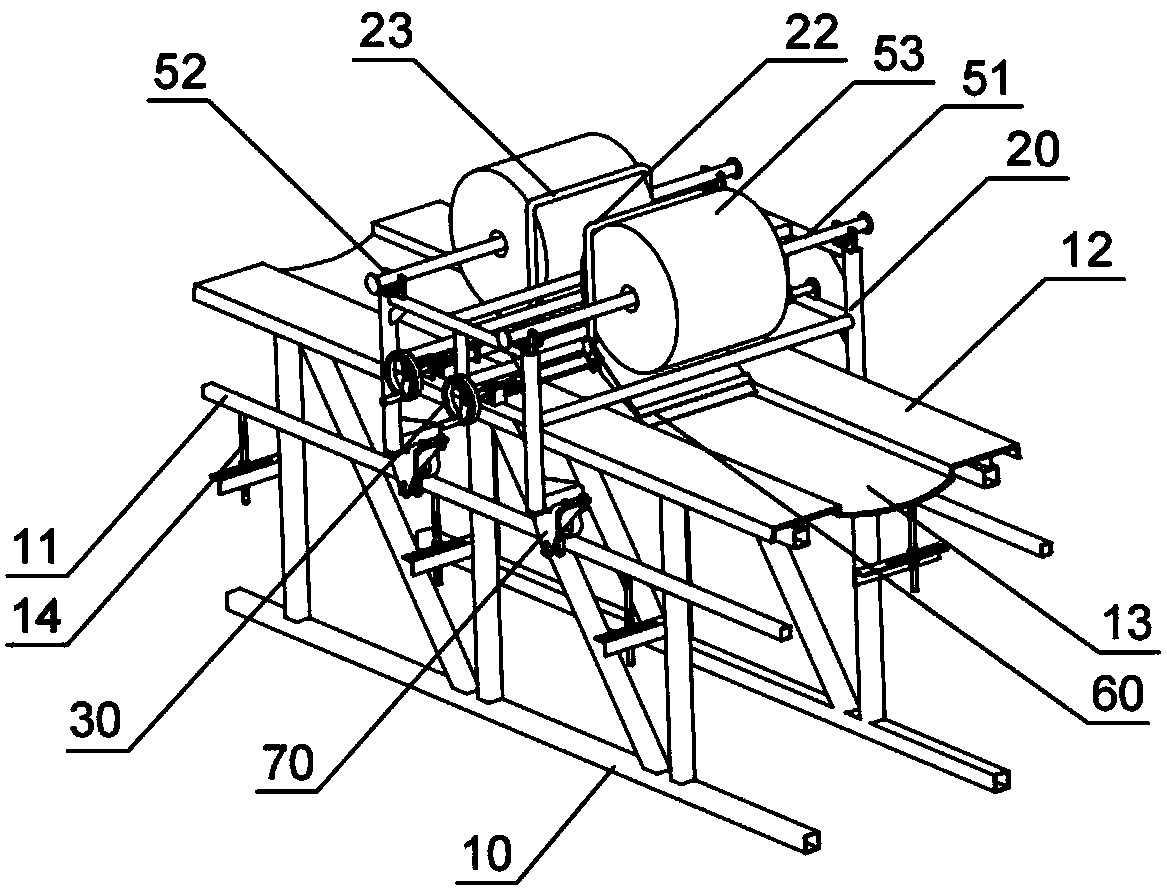

The invention relates to a wind power blade girder cloth paving method, and is used for paving a wind power blade girder. The method comprises the following steps of 1, a wind power blade girder paving device is provided, the device comprises a girder die and guide rail assemblies arranged on two sides of the girder die, and a girder die cavity is formed in the girder die, a moving frame, the moving frame is in sliding connection with the guide rail assemblies through a driving assembly, two paving mechanisms arranged on the movable frame, each paving mechanism comprises a cloth roll supporting mechanism and a cloth guide mechanism, which are used for storing cloth rolls, and the cloth guide mechanism is used for paving the cloth rolls on the cloth roll supporting mechanism in the grinderdie cavity; 2, a first layer is paved through a first laying mechanism; 3, a second layer is paved through a second laying mechanism; and 4, methods of the step 2 and the step 3 are circulated and repeated until the girder paving is completed. The paving method has the advantages that labor is saved, labor intensity is reduced, and working efficiency is improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

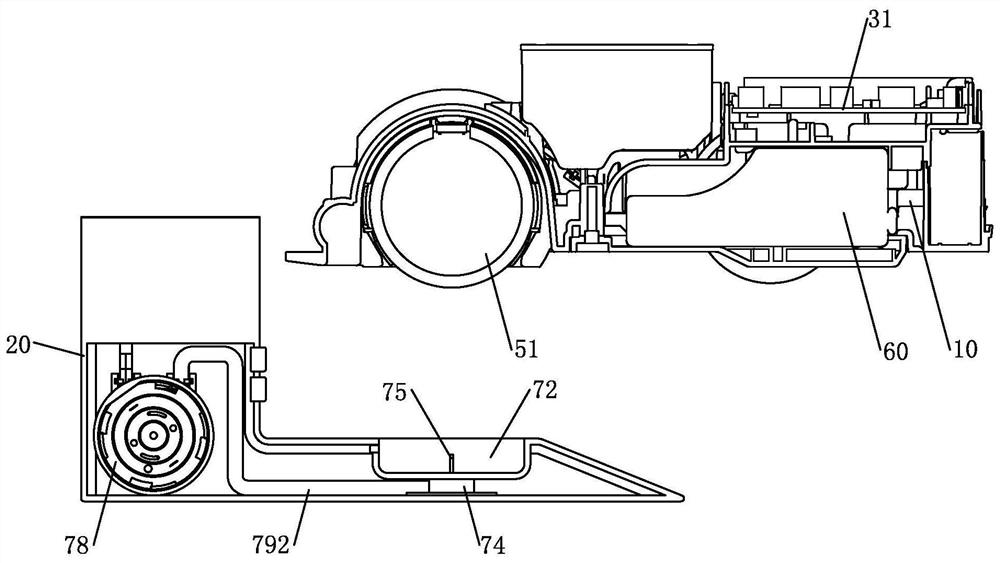

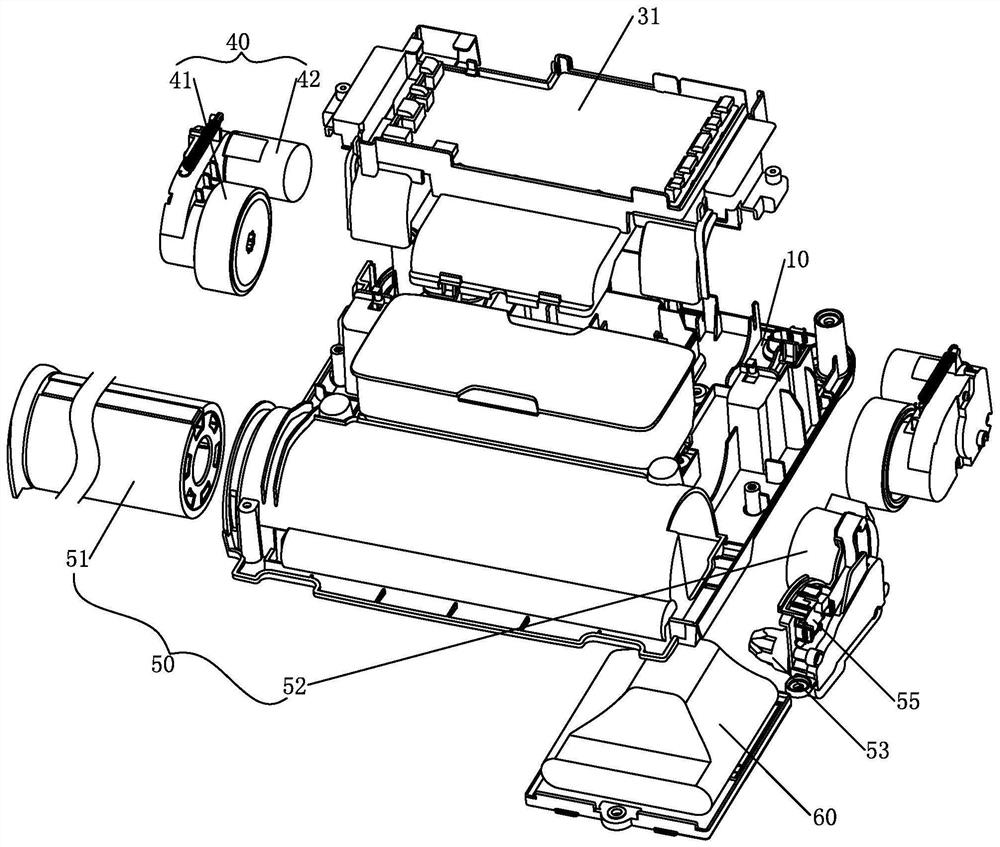

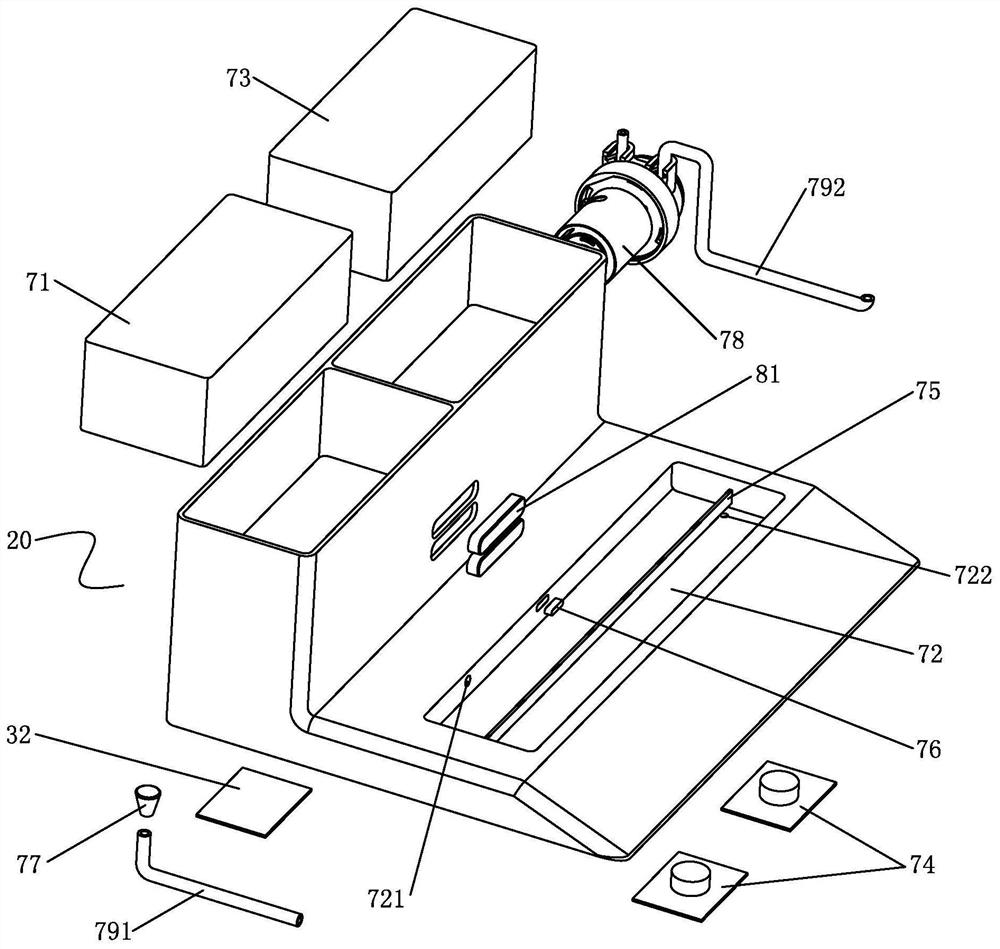

Working method of floor mopping robot

ActiveCN111820824AHigh degree of intelligenceTo achieve the purpose of dryingCarpet cleanersFloor cleanersProcess engineeringIndustrial engineering

The invention discloses a working method of a floor mopping robot, which belongs to the technical field of cleaning equipment working methods. The floor mopping robot enters a self-cleaning program under the condition that the starting condition of a self-cleaning program is met. In the self-cleaning procedure, the floor mopping robot returns to a base station firstly, then the floor mopping robotcompletes cleaning of a to-be-cleaned wiping surface on a wiping piece on the premise that the electric quantity meets the preset requirement, and the floor mopping robot enables the wiping piece torotate for a period of time to complete dehydration after the wiping piece is cleaned. The purpose of automatic cleaning of the wiping piece can be achieved through the self-cleaning program, a user does not need to manually detach or replace the wiping piece, the use cost of the whole floor mopping robot can be reasonably reduced on the premise that the intelligent degree of the floor mopping robot is improved, and the use experience of the user is improved.

Owner:PANASONIC APPLIANCES CHINA CO LTD

Composite thermal insulation concrete load-bearing wall

The present invention relates to a concrete load-bearing wall with compound heat-insulating layer. Said load-bearing wall includes wall body and connecting beam. In the wall body of external wall two layers of prefabricated heat-insulating concrete wall bodies are set, said prefabricated heat-insulating concrete wall body is a concrete plate whose external surface is covered with heat-insulating material, every layer of prefabricated heat-insulating concrete wall body is composed of several trough-type or L-shaped prefabricated heat-insulating concrete wall body units. Besides, said invention also provides the concrete assembly and construction method and steps of said compound heat-insulating concrete load-bearing wall.

Owner:陈信孚 +1

High-strength high-temperature-resistance anti-deforming precoated sand and processing technology thereof

InactiveCN108580794AHigh strengthHigh strength high temperature resistantFoundry mouldsFoundry coresAdditive ingredientHexamethylenetetramine

The invention discloses a high-strength high-temperature-resistance anti-deforming precoated sand and a processing technology thereof, and belongs to the technical field of new materials. The high-strength high-temperature-resistance anti-deforming precoated sand is prepared from the following components of, by weight, 100 parts of roughing sand, 2 to 4 parts of ferroferric oxide, 1.5 to 5.6 partsof antiadhesion sand, 1.8 to 3 parts of anti-veining additive, 1.5 to 5 parts of phenolic resin, 0.5 to 1.5 parts of No.1 enhancer, 0.3 to 1.0 part of No.2 plasticizer, 0.1 to 0.5 part of urotropinesolution, and 1.2 to 2.5 parts of lubricating agent. According to the precoated sand provided by the invention, by improving and optimizing the matching ratio of raw ingredients and a preparation process, the precoated sand has the advantages of high temperature resistance, high deformation resistance, good formability, high strength, good fluidity and low gas content at the same time, fully meetsthe production technology requirements of engines of complicated structures and with high performance, and particularly meets the production technology requirements of small sand cores with complicated shapes and thick walls, so that not only are the high-temperature strength and the collapsibility of the sand core after casting during a nonferrous metal casting process ensured, but also the mechanical property of a casting piece can be further improved.

Owner:南通美莱达科技有限公司

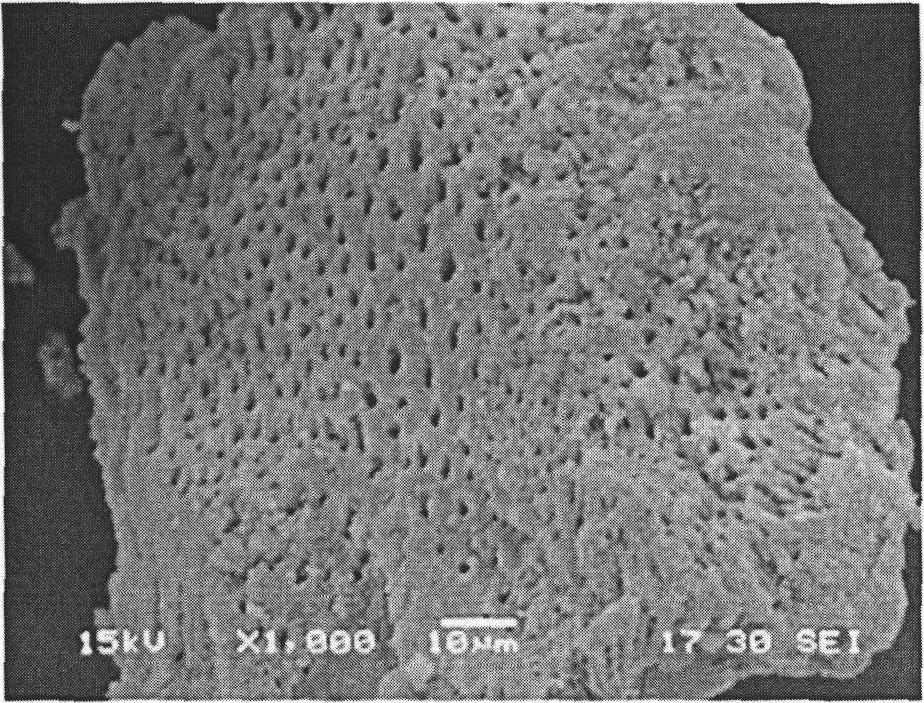

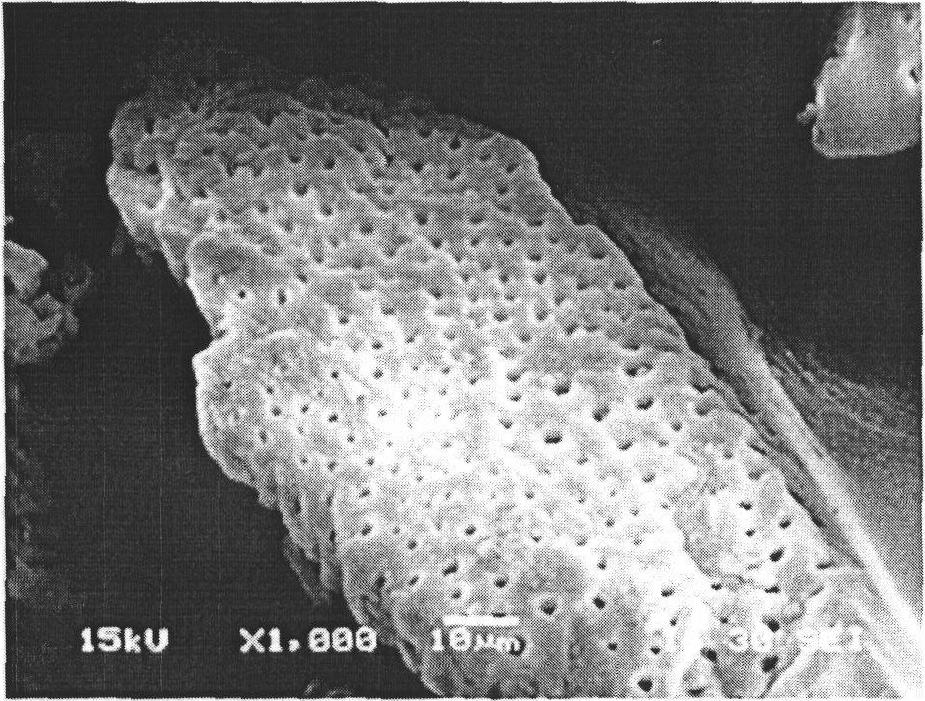

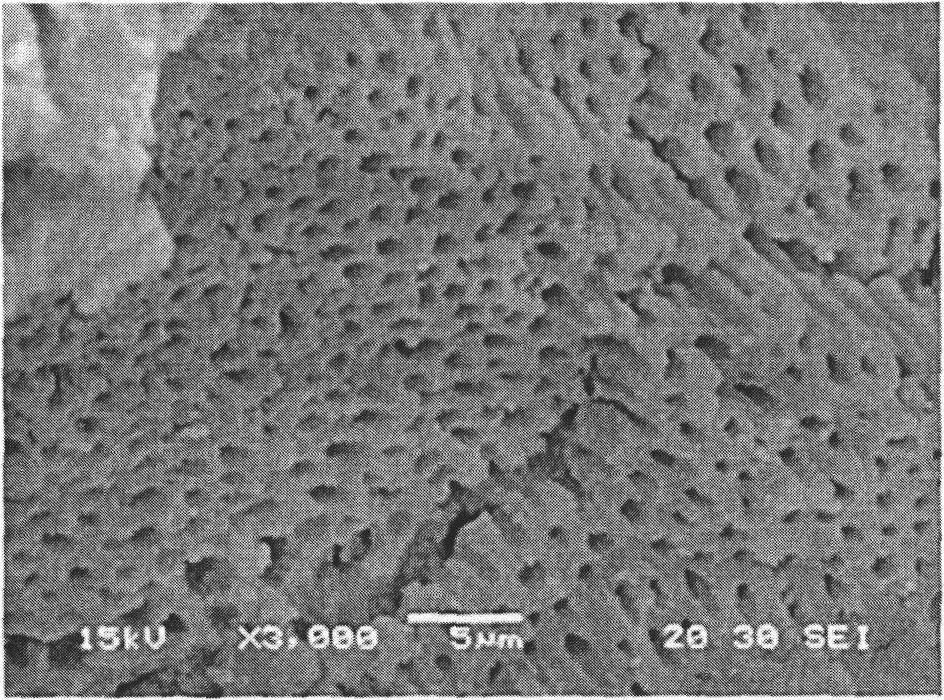

Ordered double porosity Al203-TiO2 and preparation method thereof and application thereof

InactiveCN101791578AReducing Diffusion EffectsGood thermal stabilityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsComposite oxideAmount of substance

The invention discloses an ordered double porosity Al203-TiO2 and a preparation method thereof and application thereof; the preparation method comprises the following steps: adding the mixture of an aluminum source and a titanium source into solution A, hydrolyzing, collecting the sedimentation, and roasting at the 200-1000 DEG C temperature for 3-5 hours after drying, thus obtaining the product. The aluminum source is selected from aluminum iso-propoxide or aluminum tri-sec-butoxide; the titanium source is selected from the titaniumethoxide, metatitanic acid isopropyl ester or metatitanic acid N-Butyl acetate; and the solution A is the aqueous solution containing acidic material, the solution of the mixture of the water containing the acidic material cosolvent, the aqueous solution containing the alkaline matterial or the solution of the mixture of the water containing the alkaline material and the cosolvent. The ordered double porosity Al203-TiO2 composite oxides prepared by the method can be used as a catalyst carrier. The ordered double porosity Al203-TiO2 is provided with an ordered macropore-middle pore structure, can meet the structural requirement put forward by different reaction pair catalysts, has simple preparation technology and is apt to the large-scale industrialization production.

Owner:EAST CHINA UNIV OF SCI & TECH

Transparent medium antenna

ActiveCN104078742AImprove conductivityPerformance will not affectAntenna supports/mountingsRadiating elements structural formsState of artFrequency spectrum

The invention relates to a transparent medium antenna which comprises a radiation carrier and a substrate, wherein the radiation carrier is made of graphene; the substrate is a transparent, plastic and viscous substrate; and the radiation carrier is bonded on the substrate. Compared with the prior art, the antenna keeps transparent and ultrathin within a visible spectrum range; the antenna can achieve all functions of a traditional technology antenna; the conductivity of the antenna is much higher than that of a traditional copper antenna; the antenna is convenient to use, and can be mounted in any position inside and outside equipment in a bent shape by the substrate; the wear resistance, the tensile property and the flexibility of the antenna are much higher than those of the traditional copper antenna; and the antenna is convenient to mount, and can meet a stricter structural requirement.

Owner:SHANGHAI DEMAN ELECTRONICS TECH +1

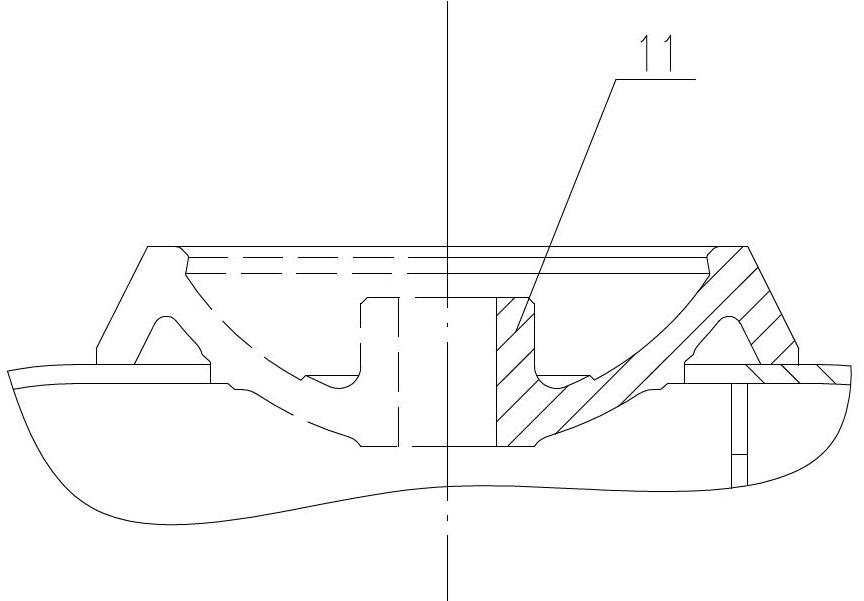

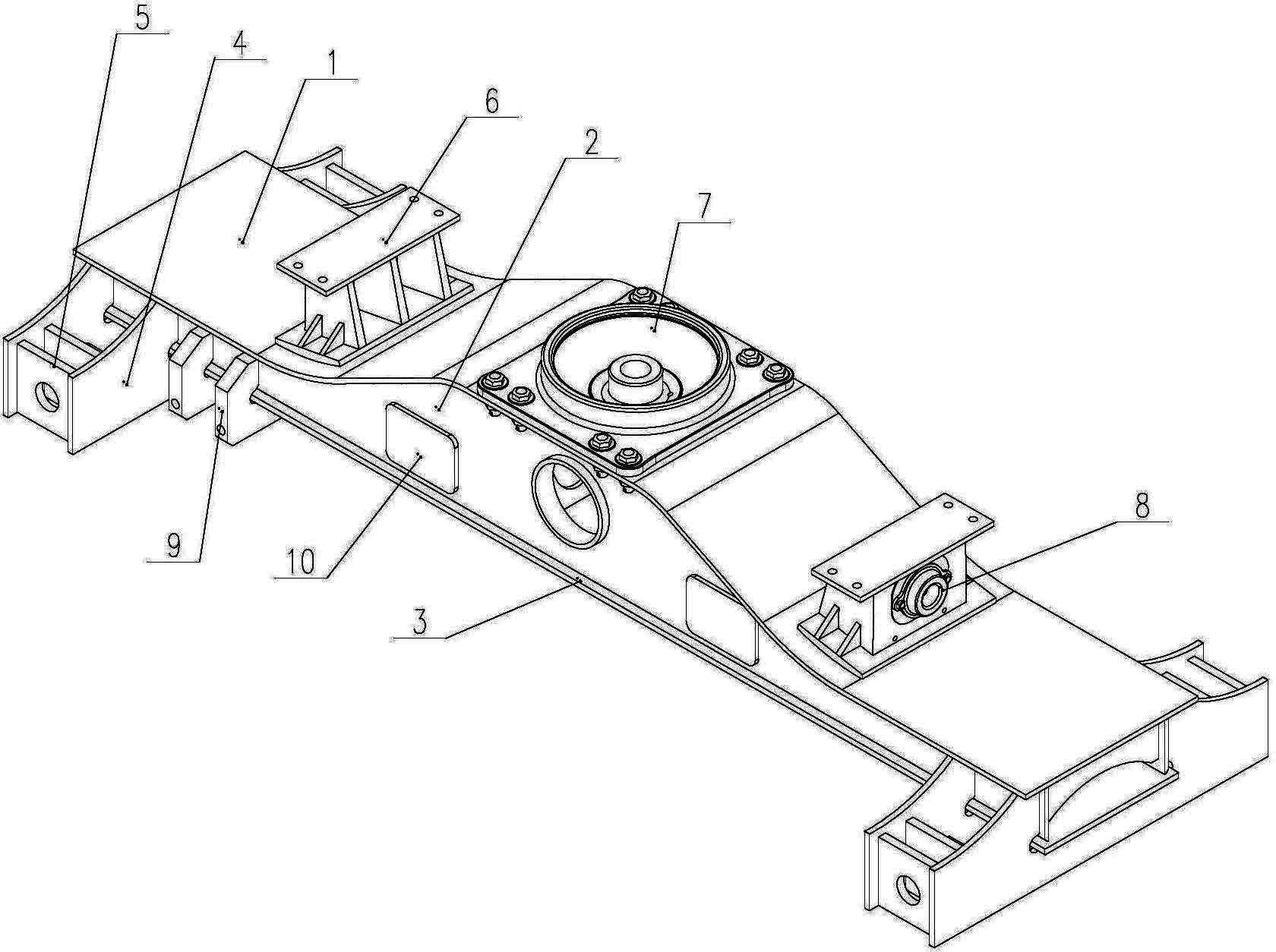

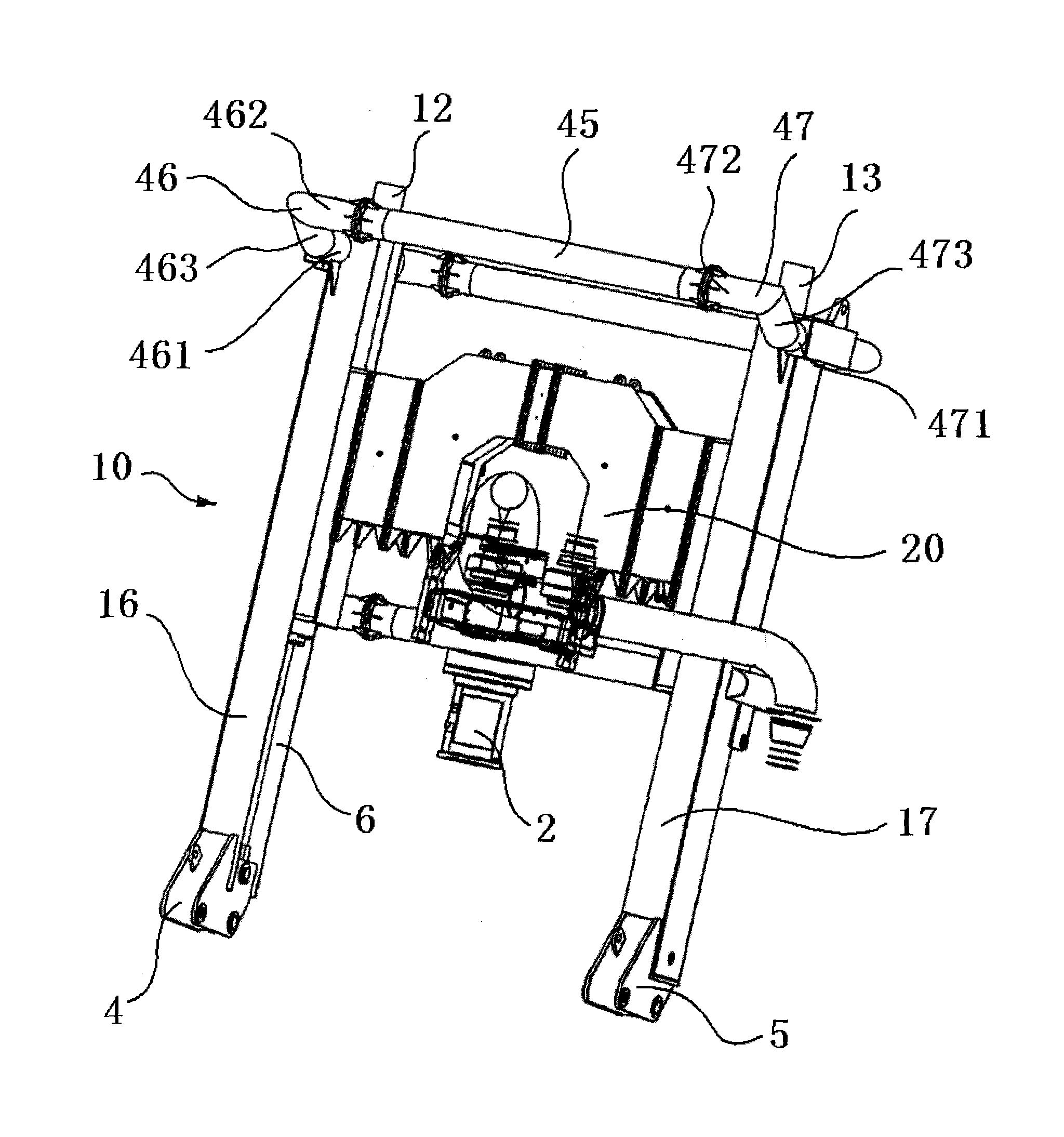

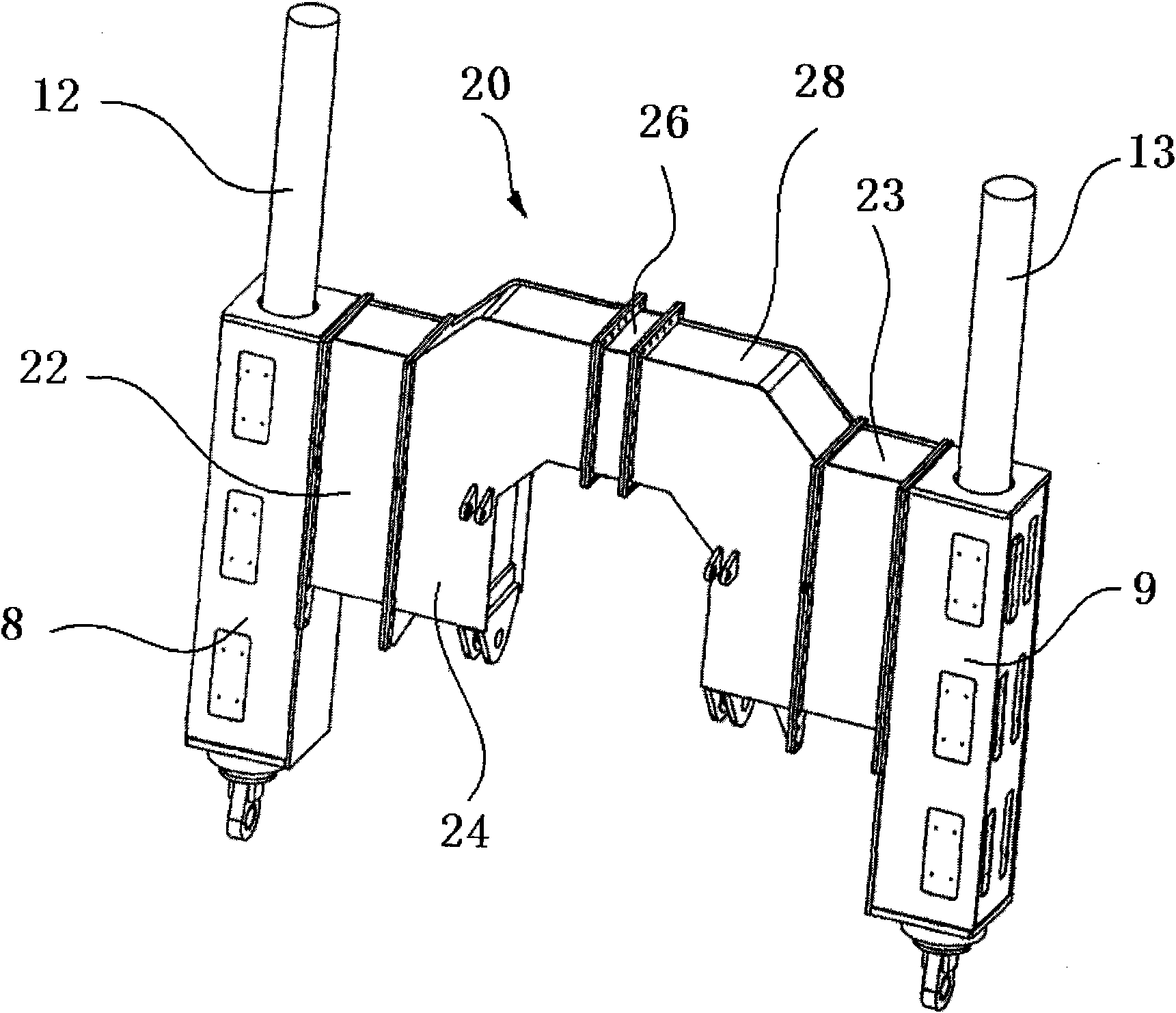

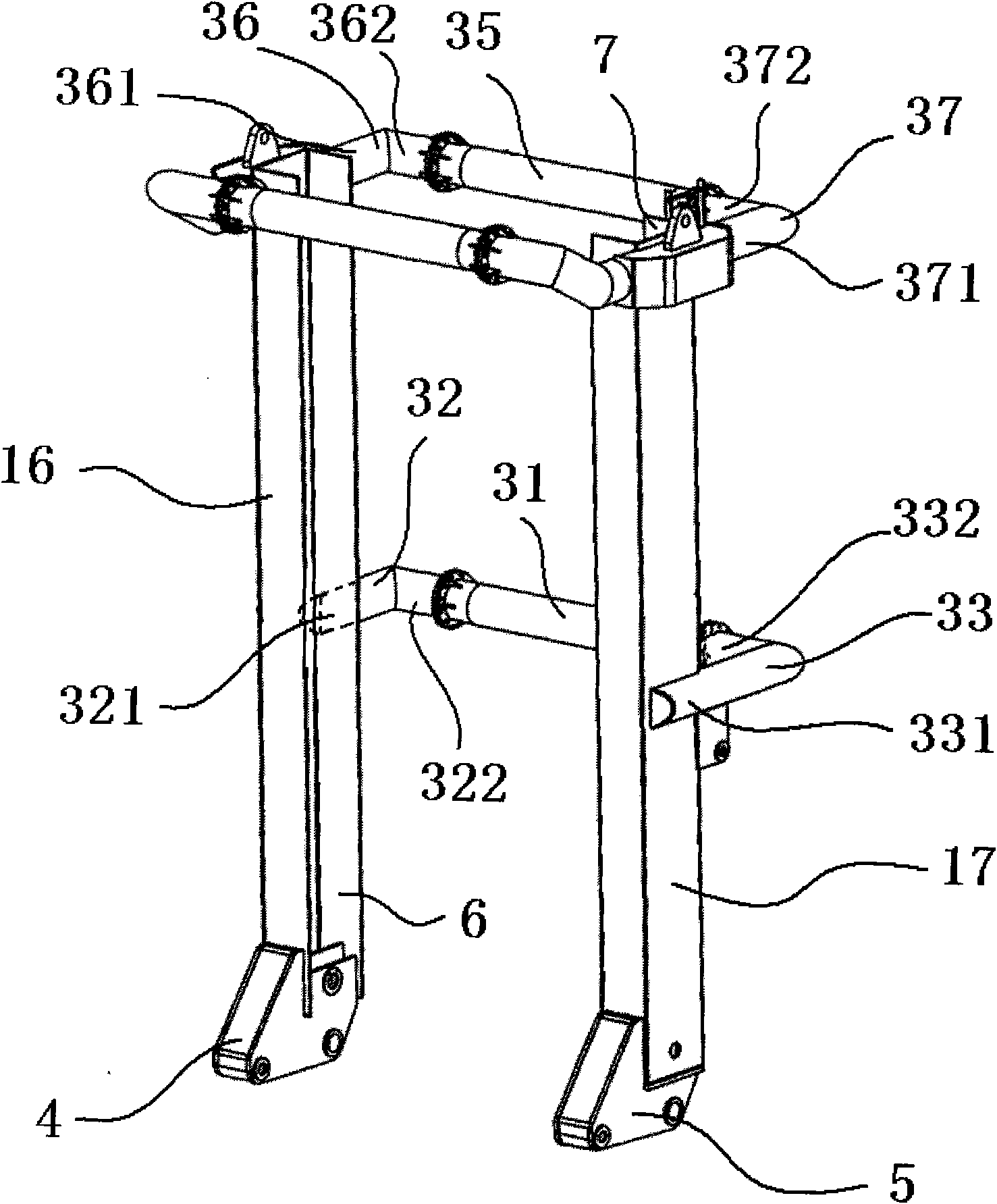

Driller support device

The invention discloses a driller support device (10). A slide frame (20) can move along a left mast (16) and a right mast (17), and a power head (2) is detachably installed on the slide frame (20). The slide frame (20) comprises a saddle-shaped frame first support pin (24) and a saddle-shaped frame second support pin (28) which are detachably connected. The saddle-shaped frame first support pin (24) with an L-shaped outline is symmetric with the saddle-shaped frame second support pin (28) with an L-shaped outline, and a detachable middle connecting piece (26) is installed between the saddle-shaped frame first support pin (24) and the saddle-shaped frame second support pin (28). A detachable left connecting box (22) is arranged between the saddle-shaped frame first support pin (24) and a left slide box (8), and a detachable right connecting box (23) is arranged between the saddle-shaped frame second support pin (28) and a right slide box (9). The invention can be suitable for the change of drilling hole diameter by changing the connecting box and the transverse connecting piece of the masts in the slide frame.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Heat exchange surface coating heat transfer performance testing system

The invention discloses a heat exchange surface coating heat transfer performance testing system which comprises a boiling pool. The boiling pool is connected with a condenser. The boiling pool comprises a shell. The upper end of the shell is connected with an upper cover plate. The lower end of the shell is connected with a lower cover plate. A hole is formed in the lower cover plate. The hole is used for containing a testing workpiece. A bottom pressing plate is arranged below the lower cover plate. A heat insulation silica gel pad and a heat conduction paster are arranged between the lower cover plate and the bottom pressing plate. The testing system further comprises a heater. The heater comprises a direct-current voltage stabilizing power source and a ceramic heating piece. The testing system further comprises a data collection system. The data collecting system comprises a plurality of thermocouples, a temperature patrol instrument and an upper computer. The testing system has the advantages that the application range is wide, the cost performance is high, operation is easy, replacement is easy and convenient, the requirement for machining test workpieces is simple, and the testing accuracy and stability are good.

Owner:GUANGDONG UNIV OF TECH

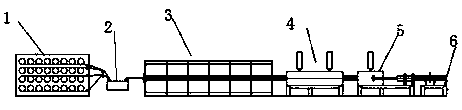

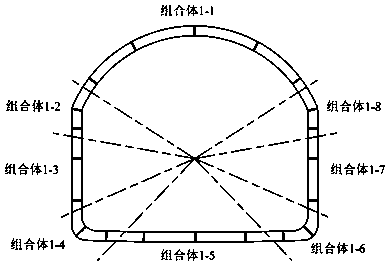

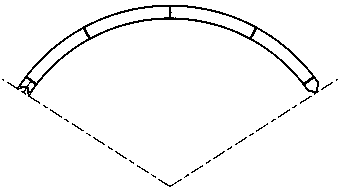

Automatic forming method of high-speed rail composite material vehicle body

ActiveCN110328871ASolve the shortcomings of weak horizontal binding abilityReduce in quantityDomestic articlesMaterials scienceCarbon fiber composite

The invention provides an automatic forming method of a high-speed rail composite material vehicle body. The method comprises the following steps of (1) firstly carrying out partition treatment on a cylindrical section of the vehicle body, and dividing the vehicle body into a multi-cavity carbon fiber composite material structure with different section shapes; (2) carrying out pultrusion molding on the multi-cavity carbon fiber composite material for a high-speed rail through pultrusion equipment; (3) positioning and gluing adjacent high-speed rail vehicle body composite material assemblies through a positioning and clamping tool; (4) carrying out winding through a forming device for winding a reinforcing layer, and completing forming of the reinforcing layer in the blank direction and + / -45-degree direction in the length direction of the high-speed railway vehicle body assemblies ; (5) adopting a shot blasting surface treatment mode; and (6) coating and spraying the surface of the carbon fiber composite material high-speed railway vehicle body. Automatic vehicle body integration and automatic forming are achieved, the number of connecting pieces is greatly reduced, and the reliability, safety and comfort of the vehicle body structure are guaranteed, and automatic forming of the high-speed railway vehicle body is completed.

Owner:NANJING KANGTE FRP

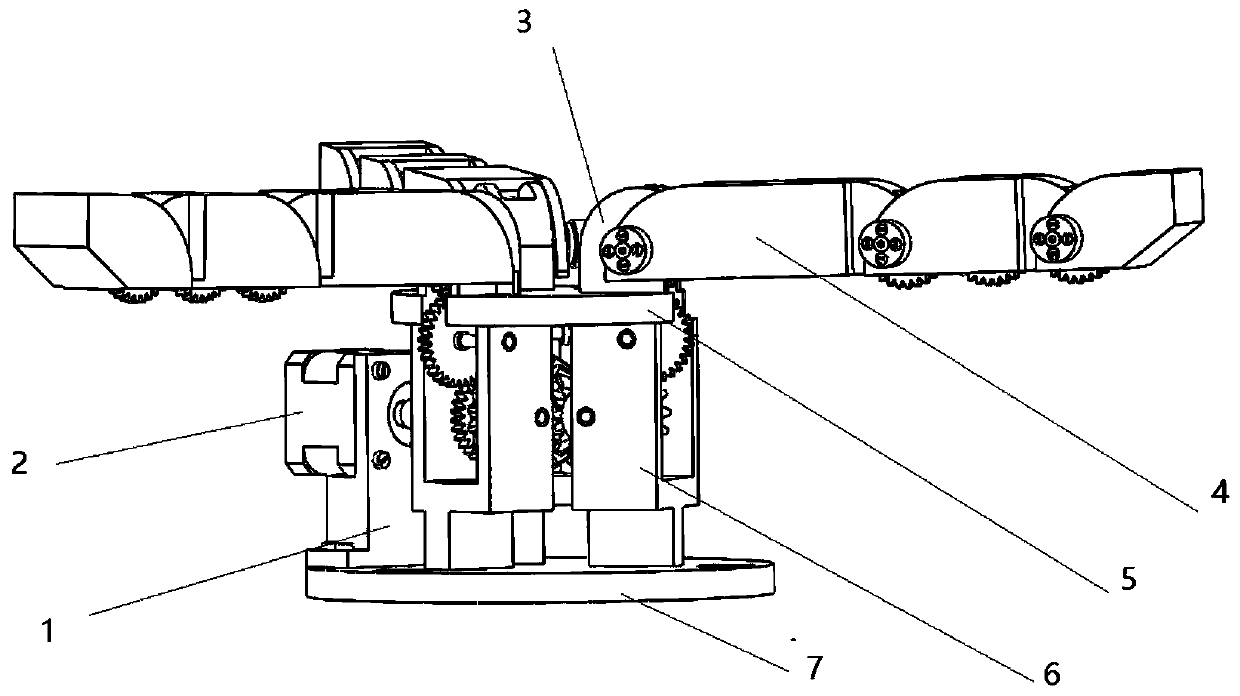

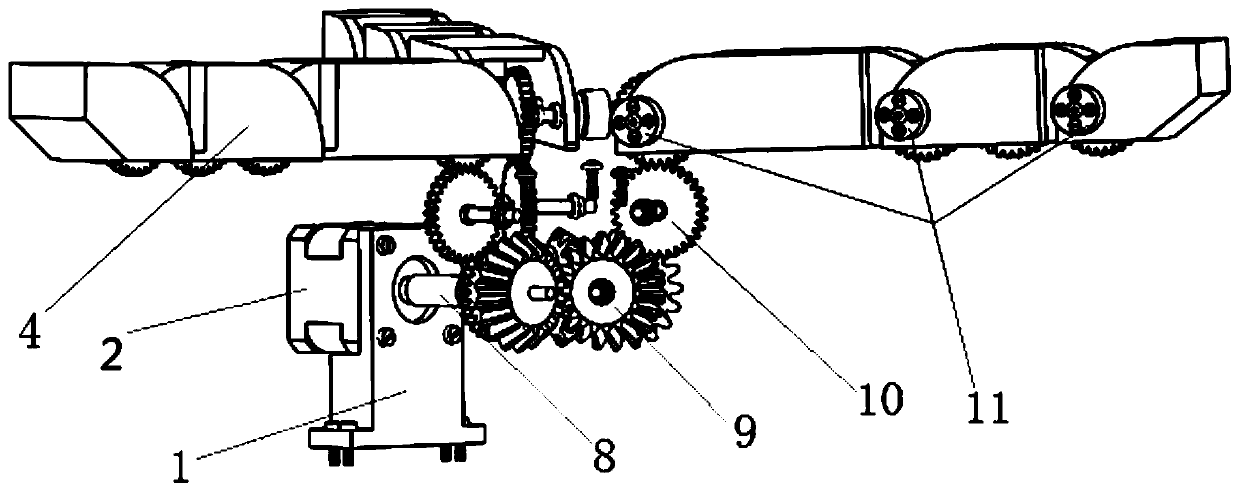

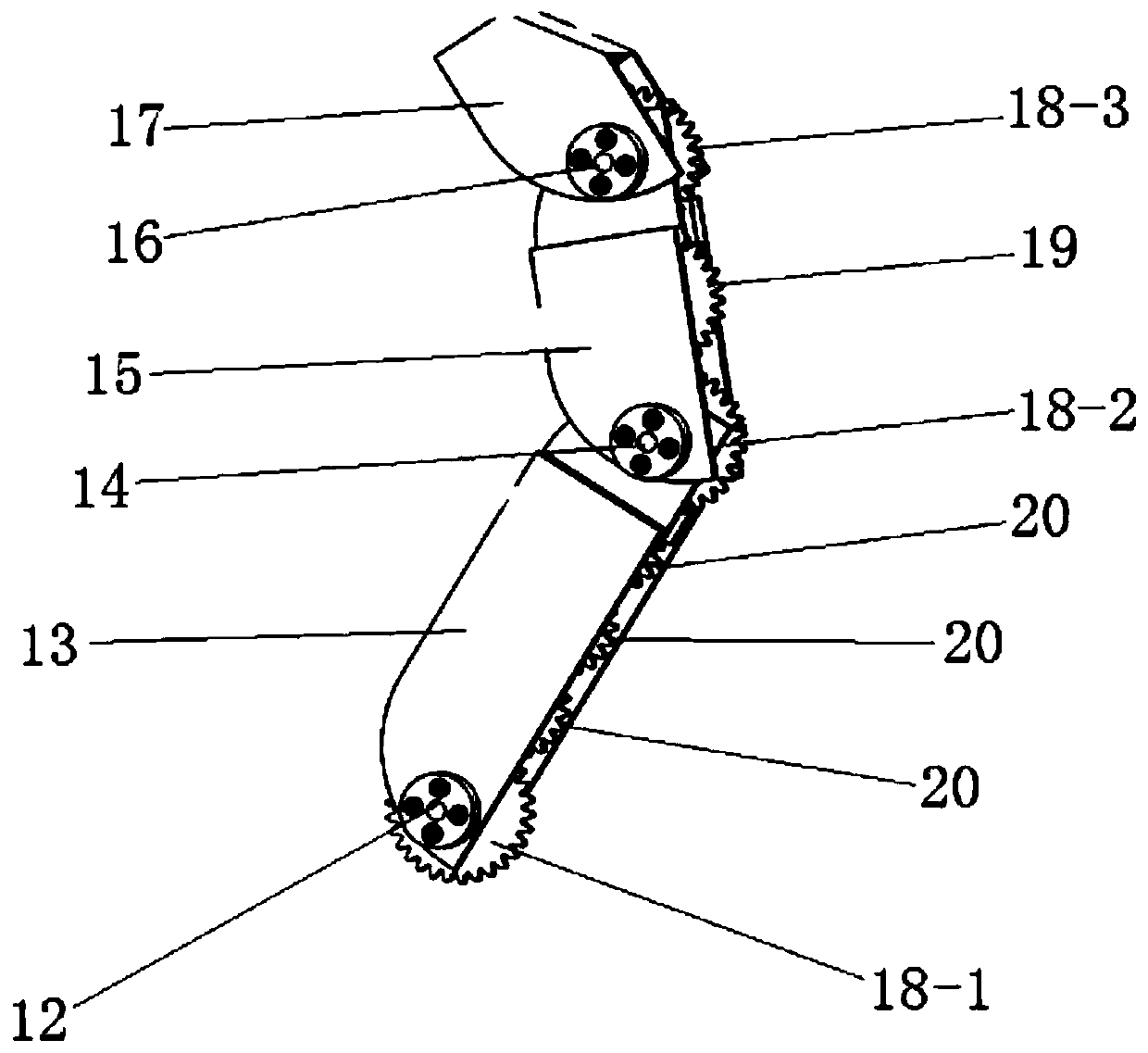

Gear differential type under-actuated three-joint mechanical finger structure and operation method thereof

The invention discloses a gear differential type under-actuated three-joint mechanical finger structure and an operation method thereof. The structure comprises three three-joint fingers, wherein thethree three-joint fingers are arranged at an angle of 120 degrees, each three-joint finger comprises a lower knuckle, a middle knuckle and an upper knuckle, the lower knuckles, the middle knuckles andthe upper knuckles are connected in a meshing mode through gears, joint shafts at the joints of the lower knuckles, the middle knuckles and the upper knuckles are provided with decoupling devices forachieving under-actuation correspondingly, the lower knuckles of the three three-joint fingers are connected with a bevel gear transmission system through gears correspondingly, the bevel gear transmission system is formed by meshing four bevel gears with the sub-taper angle being 30 degrees, the bevel gear transmission system is connected with a stepping motor, and the stepping motor drives thebevel gear transmission system to achieve motion control over the three three-joint fingers. The structure is simple in structure, few in driving elements and capable of being self-adaptive to the surface shape of a grabbed object, and then nondestructive and reliable grabbing is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

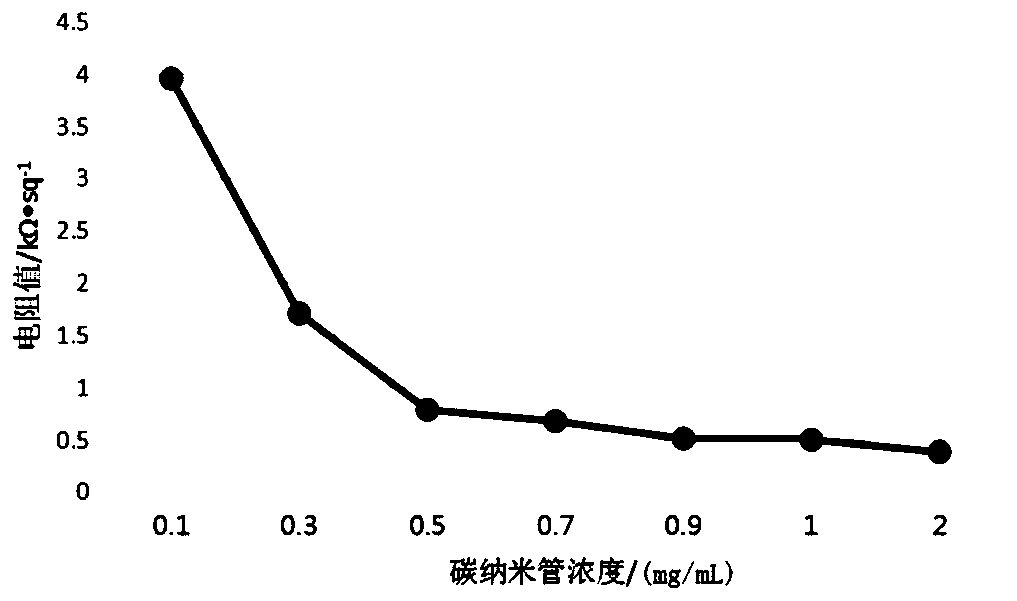

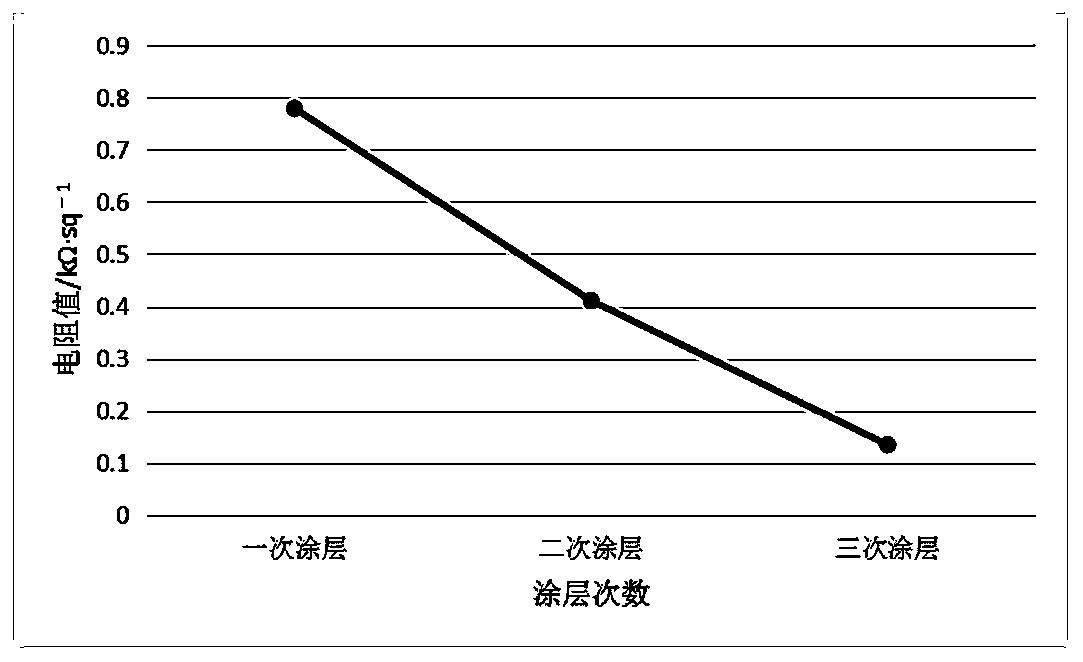

Preparation method of carbon nanotube polyaniline coating knitted fabric strain sensor

The invention discloses a preparation method of a carbon nanotube polyaniline coating knitted fabric strain sensor and belongs to the field of knitted fabric strain sensors. The preparation method includes: subjecting woven rib fabric to carbon nanotube coating, and using an in-situ polymerization method to generate polyaniline on the surface of the fabric so as to finally generate the compound ofcarbon nanotubes and polyaniline, wherein compound is used as the raw material of the strain sensor. The rib fabric has good elasticity and ductility due to self-structural features and can satisfy the structural requirements of the sensor. The polyaniline is poor in electric conductivity in neutral and alkaline environments, the defect is overcome by adding the carbon nanotubes, and the polyaniline attached to the surface of the carbon nanotubes improve the problems that the carbon nanotubes are poor in dispersity and prone to agglomeration; by adding sodium dodecyl benzene sulfonate and / ordodecylbenzene sulfonic acid to serve as the doping agent, the electric conductivity of the knitted fabric strain sensor is further increased.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

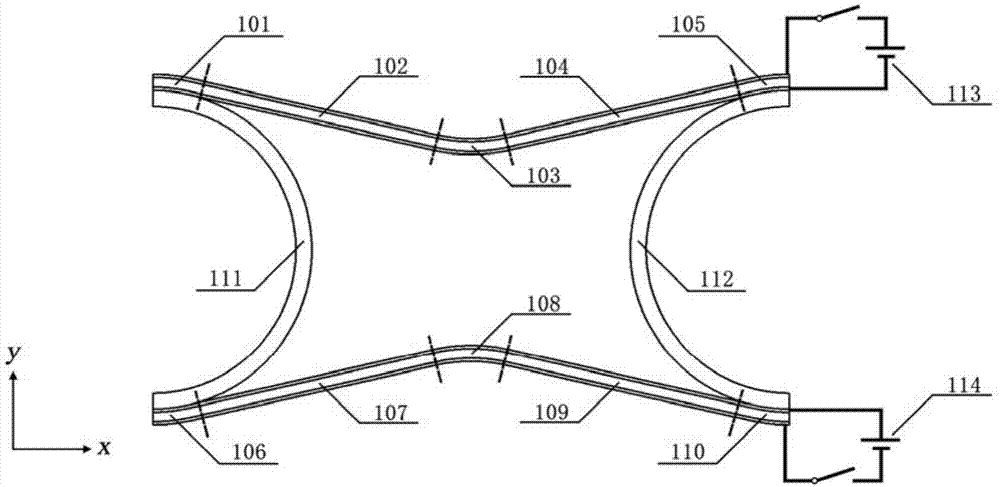

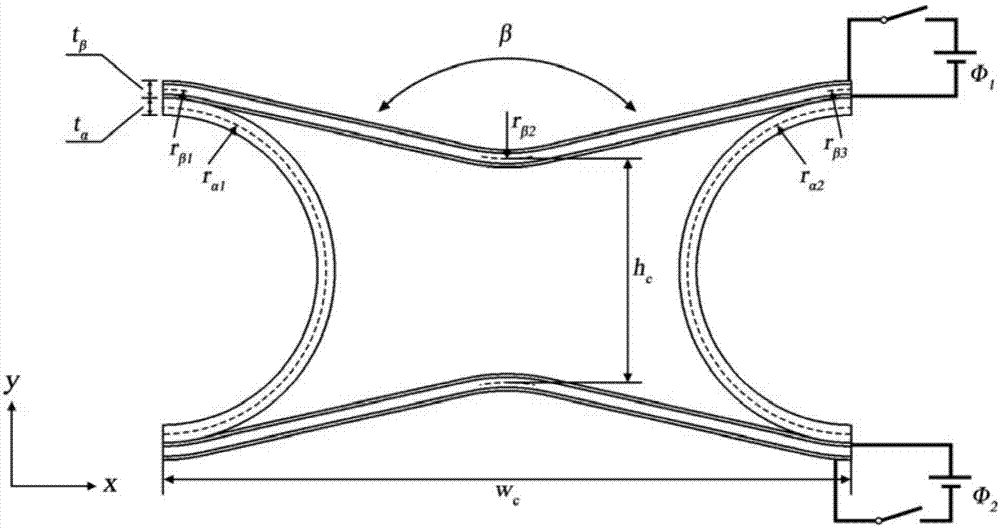

Concave wave-shaped negative Poisson's ratio structure based on dielectric electroactive polymers

InactiveCN107276450AImprove energy absorptionImprove vibration damping effectNon-rotating vibration suppressionForce measurementSandwich boardMechanical energy

The invention discloses a concave wave-shaped negative Poisson's ratio structure based on dielectric electroactive polymers. The structure is formed by a concave wave-shaped negative Poisson's ratio cell array, and the cells consist of wave-shaped tendons (101~105 and 106~110) and bones (111 and 112). The tendons are made of dielectric electroactive polymers, and are of a sandwich board structure, sandwich materials are dielectric elastomers, two sides are flexible electrodes, and the Young's modulus of the bones is larger than that of the tendon materials. The flexible electrodes of upper and lower surfaces of the tendons at upper and lower sides are connected with the positive electrode and the negative electrode of high-voltage direct current power supplies 113 and 114 respectively, and the voltage and path open-circuit state are adjustable. The concave wave-shaped negative Poisson's ratio cells are arrayed, and thus the concave wave-shaped negative Poisson's ratio structure can be formed. Since the mechanical states and electrostatic states of the dielectric electroactive polymers are mutually coupled, mutual conversion between mechanical energy and electric energy can be realized, and functions of structure real-time variability, actuation, energy recovery and sensing of the concave wave-shaped negative Poisson's ratio structure are realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Energy-saving cooking utensils

ActiveCN1817276AIncrease profitIncrease the receiving areaCooking vesselsEngineeringUltimate tensile strength

An energy-saving cooker is composed of a main body consisting of wall and bottom, and a corrugated metallic plate fixed to the external surface of said bottom for increasing the electromagnetic wave receiving area, so saving electric energy.

Owner:ZHEJIANG SUPOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com