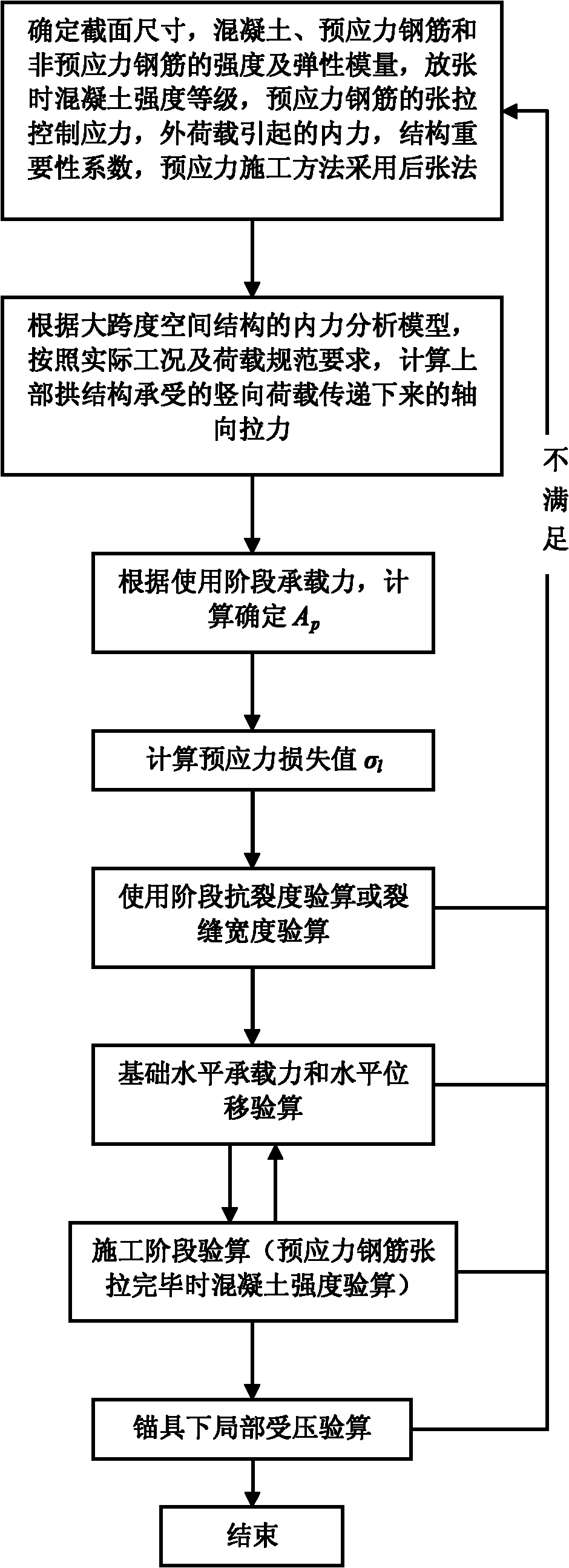

Prestressed pull rod foundation design method for large-span space structure

A technology of prestressed tie rods and space structures, applied in calculation, special data processing applications, instruments, etc., can solve engineering safety hazards, the normal use and ultimate bearing capacity of prestressed tie rod foundations cannot meet structural requirements, and there is no detailed distinction between different stages Structural analysis models and calculation methods and other issues, to achieve the effect of outstanding safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

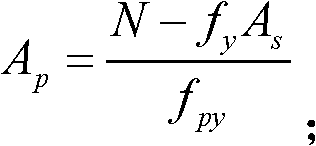

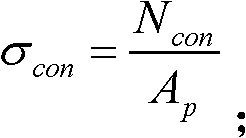

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0042] The overall structure of the long-span space structure is composed of three sub-structures: superstructure, foundation and tension beam. The upper structure is composed of bar elements and beam elements, and the elastic stiffness matrices of bar elements and beam elements are used in the calculation respectively. During the entire construction stage and use stage, the work of the superstructure is in the elastic stage, and the tension beam is in close contact with the superstructure and foundation at the bottom.

[0043] The basic equation of the whole structure of the whole stage is:

[0044] [K i ]{U i}={P i};

[0045] where [K i ]——total stiffness matrix of the i-th stage;

[0046] {U i}——displacement vector of the i-th stage;

[0047] {P i}——load vector of stage i.

[0048] The stress of the long-span space structure is multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com