Energy-saving cooking utensils

A technology for cooking utensils and cooking utensils, applied in the field of kitchen utensils, can solve the problems of affecting the service life of the cooking utensils, high production cost, complex gap structure, etc., and achieves the effects of being conducive to heat conduction, low production cost, and increasing receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

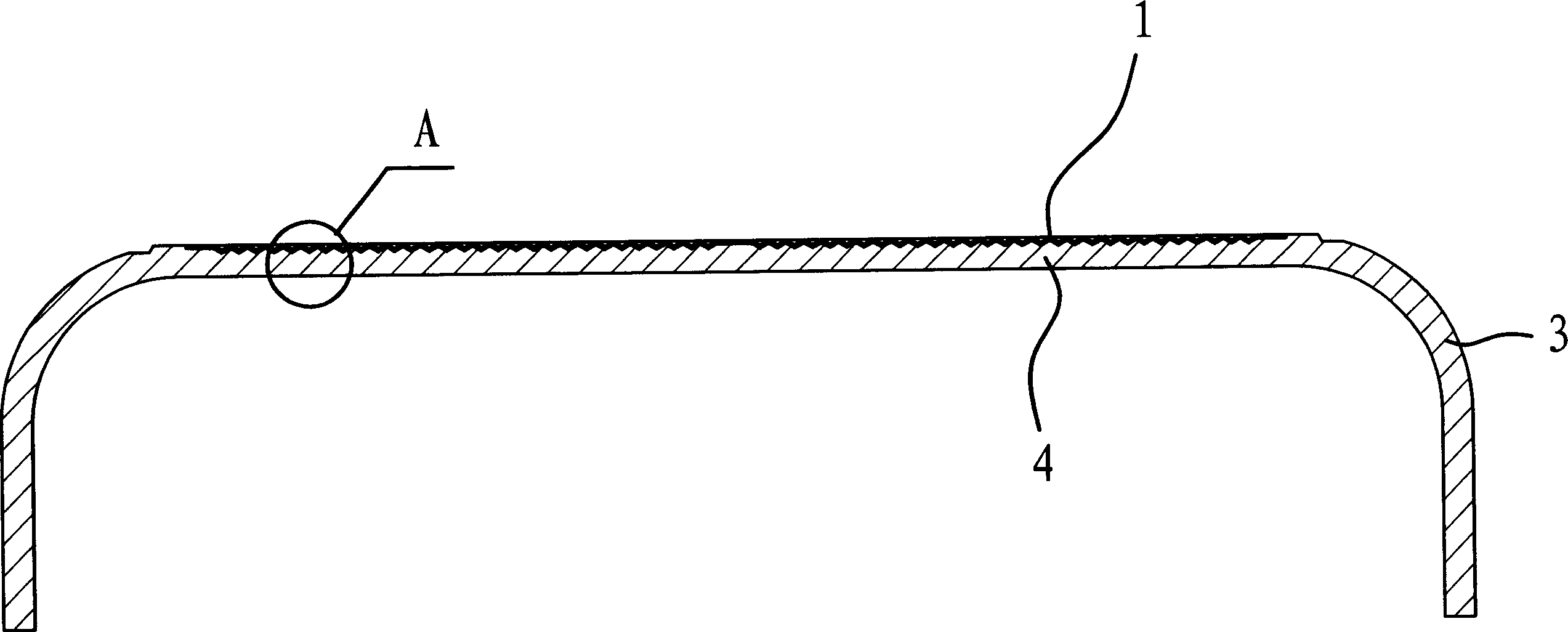

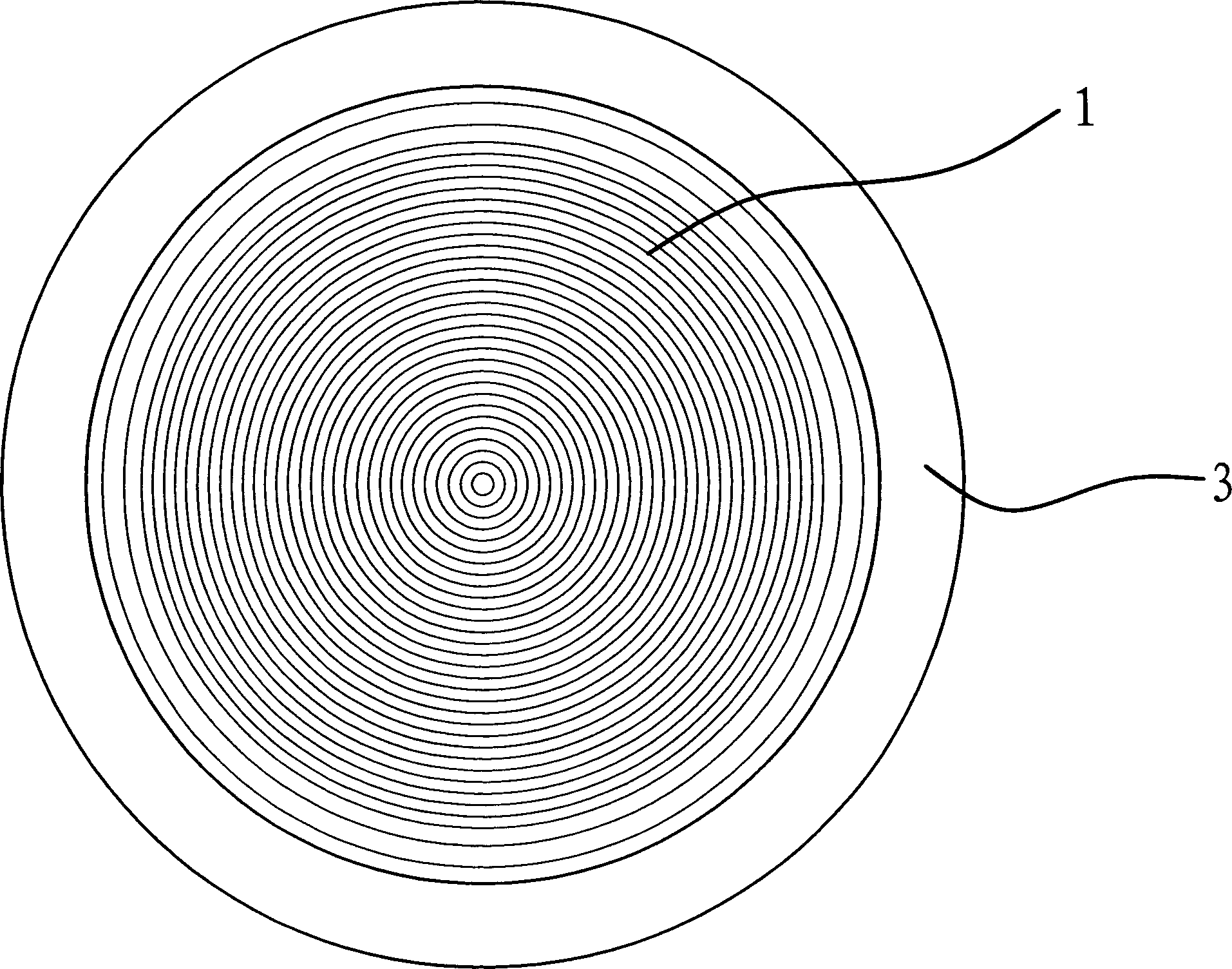

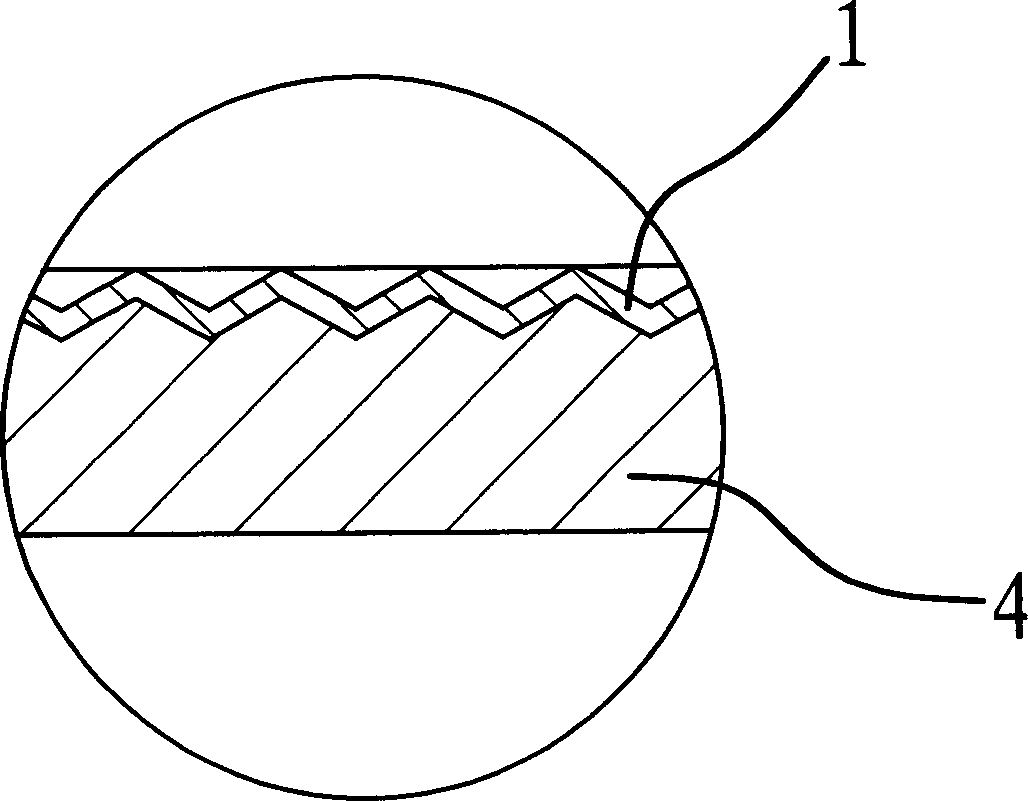

[0037] Such as figure 1 with figure 2 with image 3 As shown, the energy-saving cooking appliance includes a cooking appliance wall 3 and a cooking appliance bottom 4 integrated with the cooking appliance wall 3 for heating.

[0038] A metal sheet 1 with a corrugated outer surface is fixed on the outside of the cooker bottom 4, and the metal sheet 1 and the cooker bottom 4 are combined by hot forging or brazing. The metal The sheet 1 is made of ferrite or martensitic stainless steel with strong flux capability. And the corrugated shape of the metal sheet 1 is a plurality of concentric circumferential structures with the center of the metal sheet 1 as the center.

[0039] It can be seen that the corrugated metal sheet 1 on the outer surface enlarges the electromagnetic wave receiving area of the bottom 4 of the cooker, and can effectively absorb the electromagnetic energy converted by electric energy and convert it into heat energy, which improves the utilization rate of electr...

Embodiment 2

[0042] Figure 6 and Figure 7 with Figure 8 As shown, the structure and principle of this embodiment are basically the same as those of the first embodiment. The difference is that a metal plate 2 is provided between the bottom 4 of the cooker and the metal sheet 1, and the outer surface of the metal plate 2 is similar to the metal sheet. 1 The corrugated shape of the same shape and size, the metal sheet 1 and the metal plate 2, and the metal plate 2 and the bottom 4 of the cooker are combined together by hot forging or brazing. The metal plate 2 is made of aluminum, and the metal plate 2 plays a role of heat conduction and corrosion resistance.

Embodiment 3

[0044] Such as Picture 9 with Picture 10 with Picture 11 As shown, the structure and principle of this embodiment are basically the same as those of the second embodiment. The difference is that the corrugated shape of the metal sheet 1 is a point-shaped or strip-shaped concave-convex shape on the bottom surface, and is formed with the center of the metal sheet 1 as a starting point. Structure that emits outwards. Of course, the outer surface of the metal plate 2 also has a corrugated shape with the same shape and size as the metal sheet 1 or the bottom 4 of the cooker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com