Preparation method of carbon nanotube polyaniline coating knitted fabric strain sensor

A technology of strain sensor and carbon nanotubes, which is applied in the direction of plant fibers, textiles, papermaking, fiber types, etc., can solve the problems of easy aggregation of carbon nanotubes, poor dispersion, insoluble polyaniline, etc., to improve electrical conductivity and promote adhesion Attachment, the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

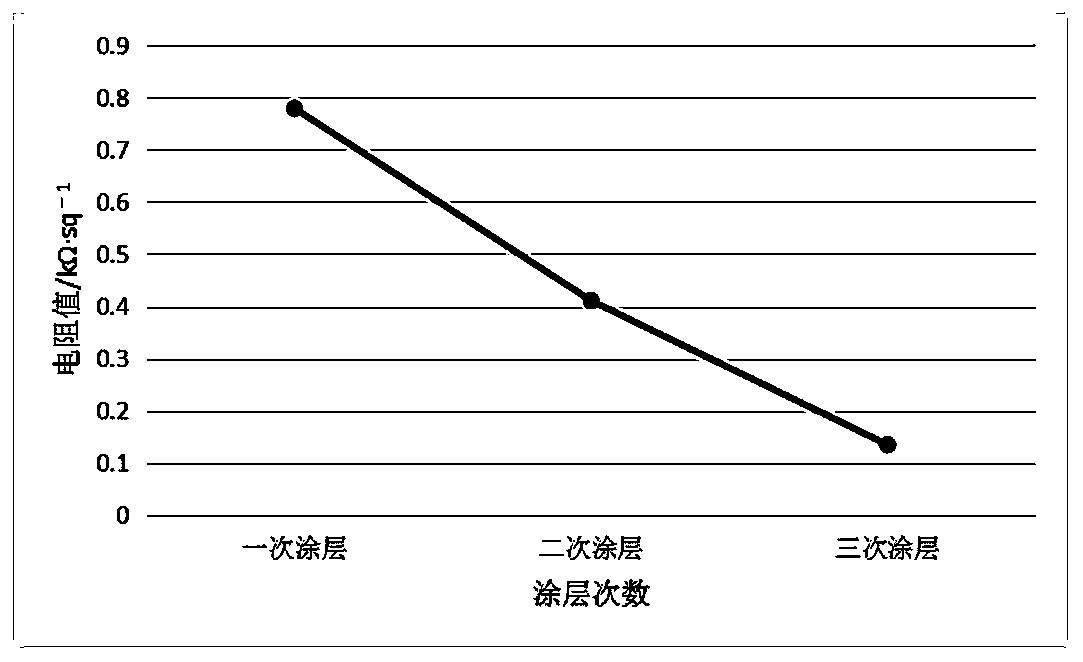

[0032] Embodiment 1: selected is the polyester-cotton rib knitted fabric, prepares carbon nanotube / polyaniline coated knitted fabric according to the following steps:

[0033] Step 1: Pretreat the woven knitted fabric, measure 500ml of deionized water in a beaker with a measuring cylinder, weigh 10g of NaOH with an electronic balance, put it into the beaker and stir until dissolved, put the knitted fabric into the beaker, After soaking at a constant temperature of 85°C for 1 hour, take it out, wash it until neutral, dry it and weigh it for later use;

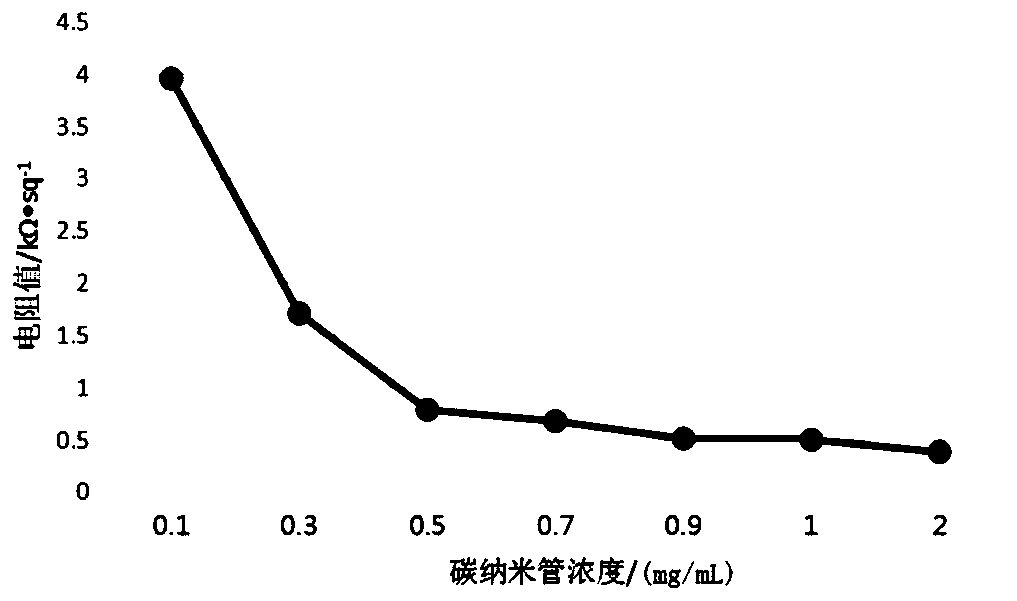

[0034] Step 2: Due to the poor solubility of carbon nanotubes, they are difficult to dissolve in organic solvents and water, and are extremely prone to agglomeration. In order to make up for this defect, it is necessary to modify the surface of carbon nanotubes. Preparation of the carbon nanotube dispersion: put the carbon nanotubes into the pickling solution for immersion pickling, pickling for 1 hour, suction filtration to rem...

Embodiment 2

[0040] Embodiment 2: the polyester-cotton knitted fabric sample selected in this embodiment and embodiment 1 is the same, the difference is that the parameters of the method steps are different, and the specific method steps of this embodiment are as follows:

[0041] Step 1: Pretreat the woven knitted fabric, measure 500ml of deionized water in a beaker with a measuring cylinder, weigh 10g of NaOH with an electronic balance, put it into the beaker and stir until dissolved, put the knitted fabric into the beaker, After soaking at a constant temperature of 85°C for 1 hour, take it out and wash it until neutral, dry it and weigh it for later use.

[0042] Step 2: Due to the poor solubility of carbon nanotubes, they are difficult to dissolve in organic solvents and water, and are extremely prone to agglomeration. In order to make up for this defect, it is necessary to modify the surface of carbon nanotubes. Preparation of carbon nanotube dispersion: put the carbon nanotubes into ...

Embodiment 3

[0047] Embodiment 3: The polyester-cotton knitted fabric sample selected in this embodiment is the same as that in Embodiment 1, the difference is that the parameters of the method steps are different, and the specific method steps of this embodiment are as follows:

[0048] Step 1: Pretreat the woven knitted fabric, measure 500ml of deionized water in a beaker with a measuring cylinder, weigh 10g of NaOH with an electronic balance, put it into the beaker and stir until dissolved, put the knitted fabric into the beaker, After soaking at a constant temperature of 85°C for 1 hour, take it out, wash it until neutral, dry it and weigh it for later use;

[0049] Step 2: Prepare the carbon nanotube dispersion: put the carbon nanotubes into the pickling solution for immersion and pickling, pickle for 2.5 hours, remove the pickling solution by suction filtration, and repeatedly wash and filter the carbon nanotubes with deionized water until the pH of the carbon nanotubes is 7 .5; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com