Prestress type steel-concrete structure using performance design method

A technology of concrete structure and design method, which is applied in the direction of structural elements, long-strip structural members for load-bearing, building components, etc., and can solve the problems of ignoring constraints, engineering safety hazards, and the failure of normal performance of prestressed concrete beams to meet structural requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

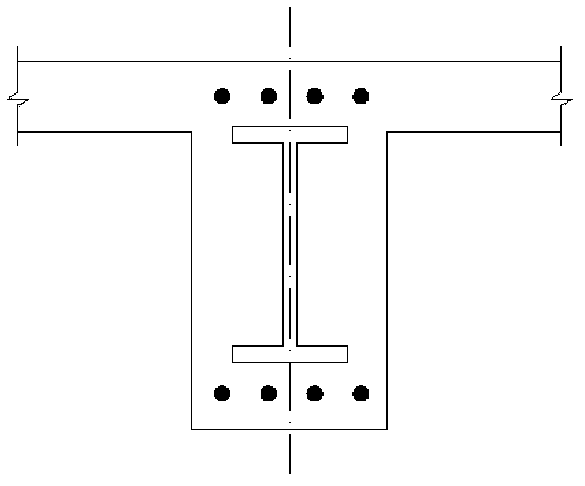

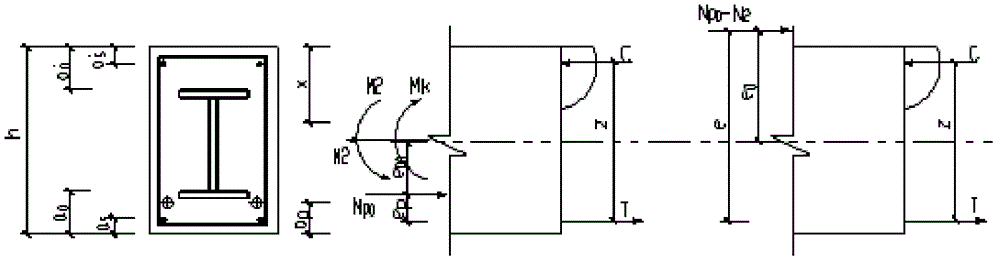

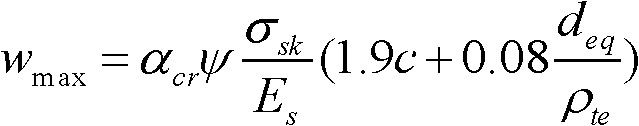

[0052] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0053] The long-term research of our research group shows that in prestressed steel concrete structures with complex constraints, the effective prestress in prestressed concrete beams is greatly reduced due to the influence of column anti-sway stiffness, so the actual prestressed concrete beams Normal use and ultimate bearing capacity cannot meet the structural requirements, which will cause safety hazards to the project. Therefore, a prestressed steel concrete structure design method based on complex constraints is considered to solve the above two requirements, thereby eliminating potential safety hazards. Moreover, the research group also found that constraints and their distribution are the essence of secondary internal forces, and the distribution of effective stress also has a certain impact on constraints. Therefore, it is scientific and saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com