Patents

Literature

285 results about "Prestressed structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A prestressed structure is one whose overall integrity, stability and security depend, primarily, on prestressing: the intentional creation of permanent stresses in the structure for the purpose of improving its performance under various service conditions.

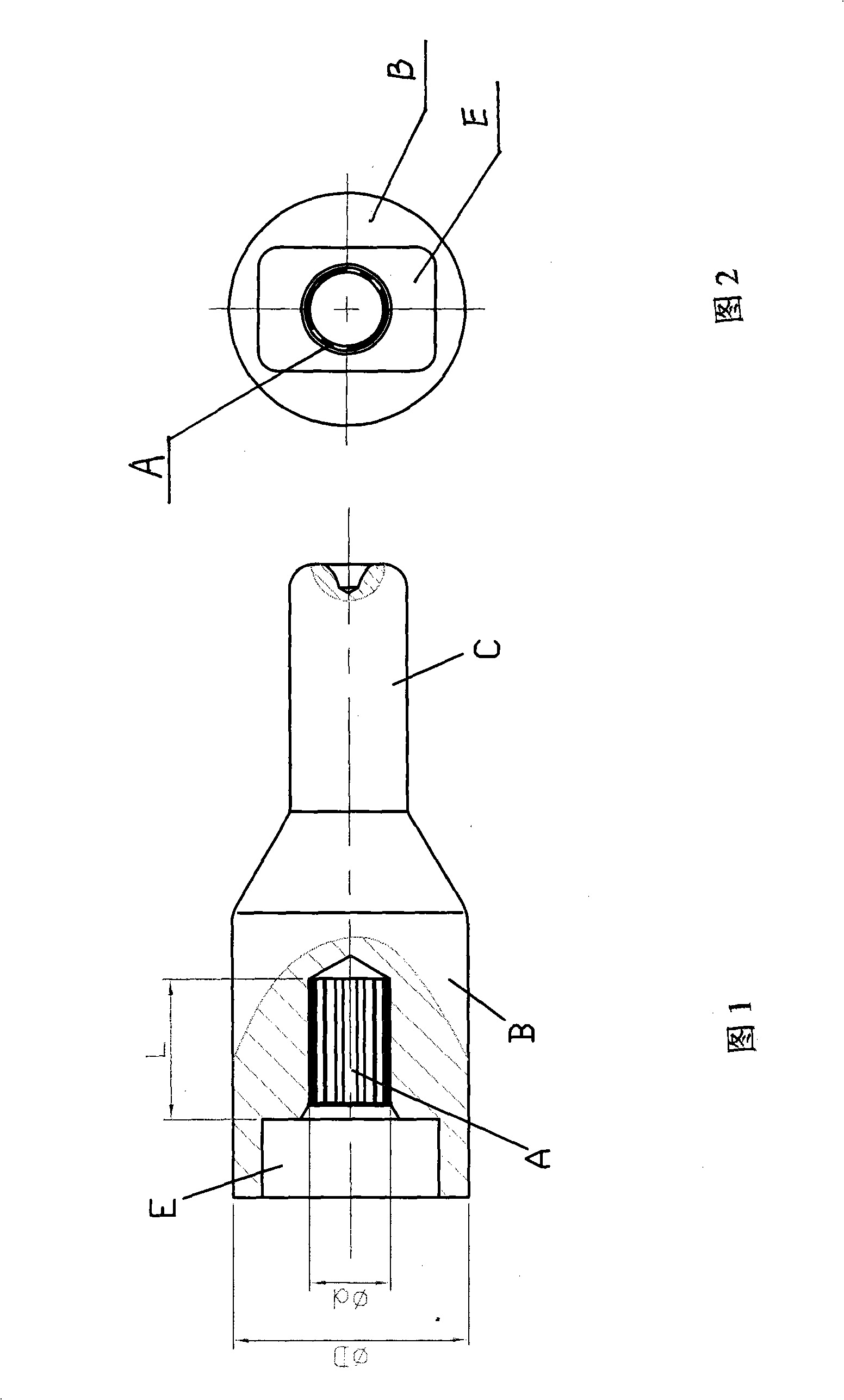

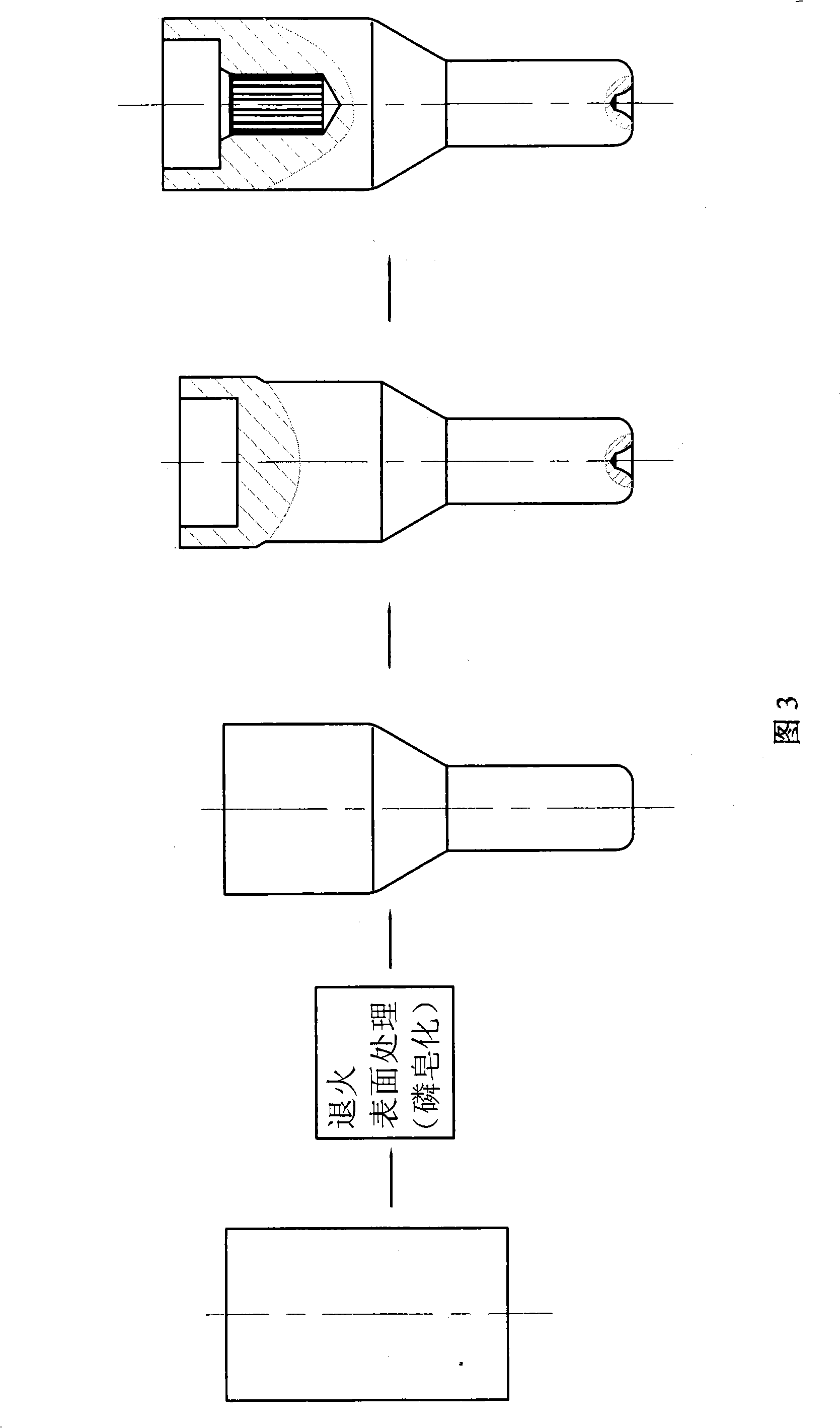

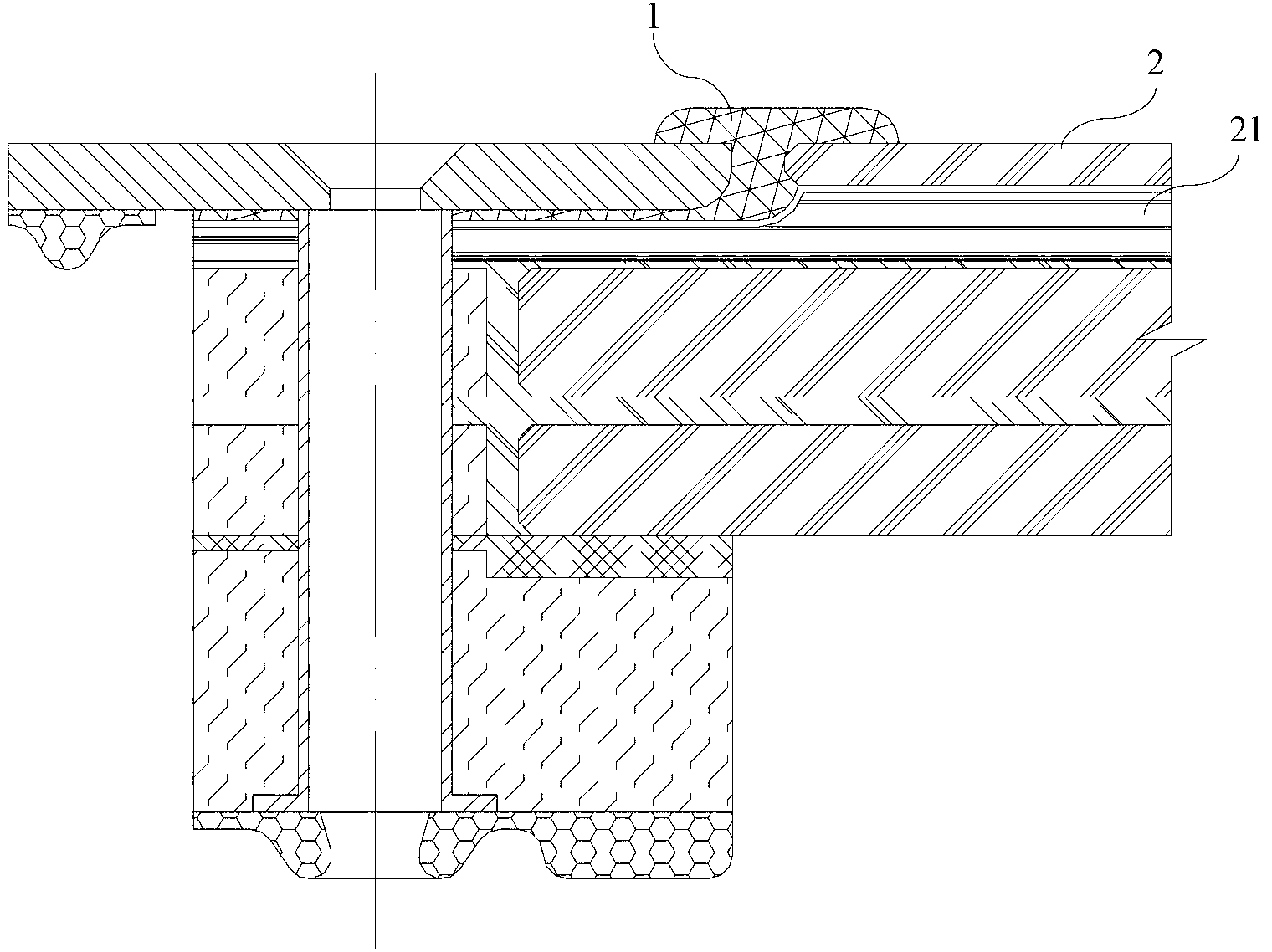

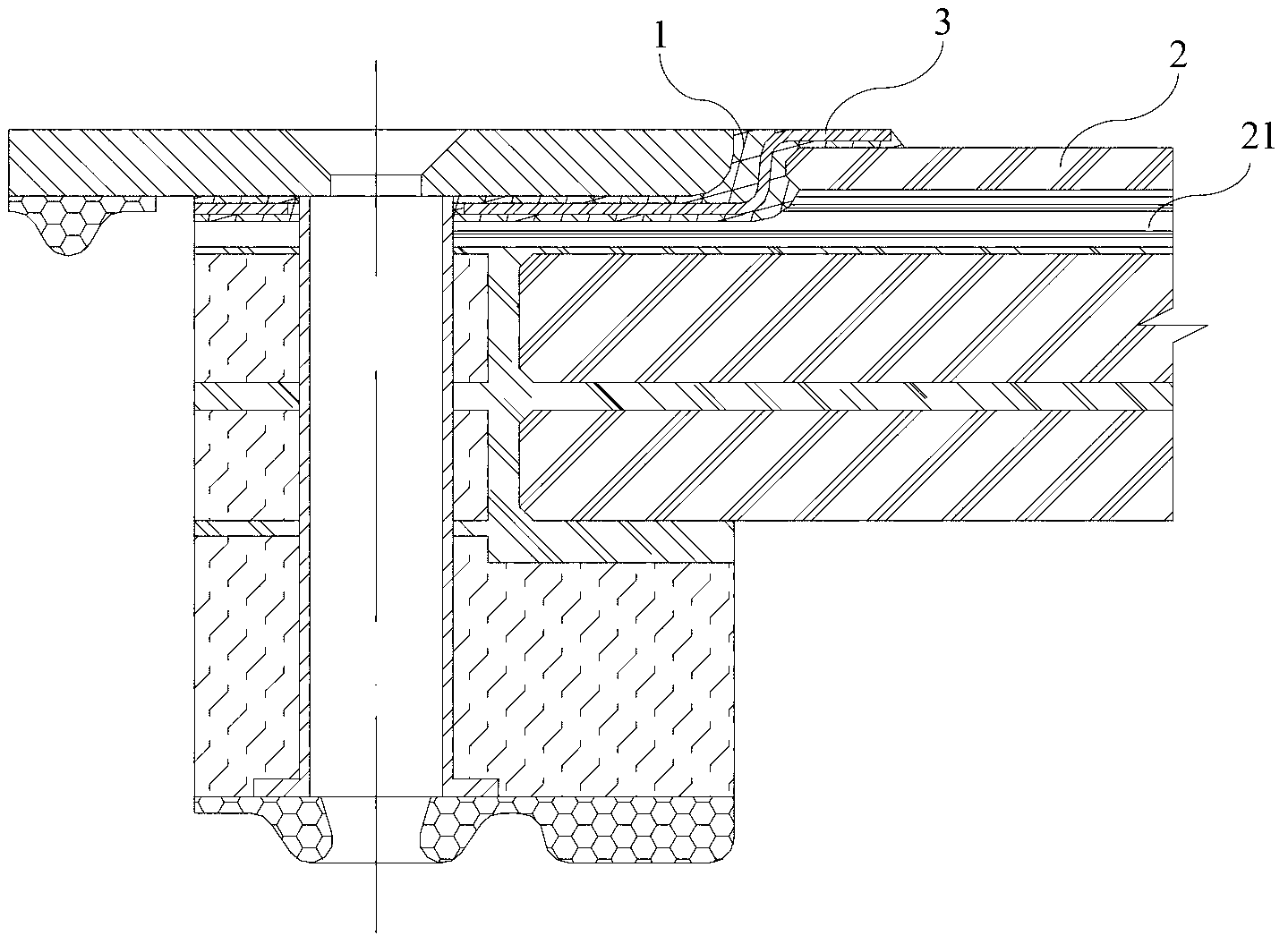

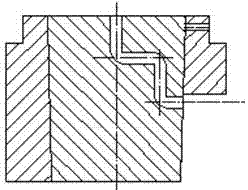

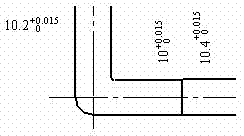

Cold-forging technique of gear shaft

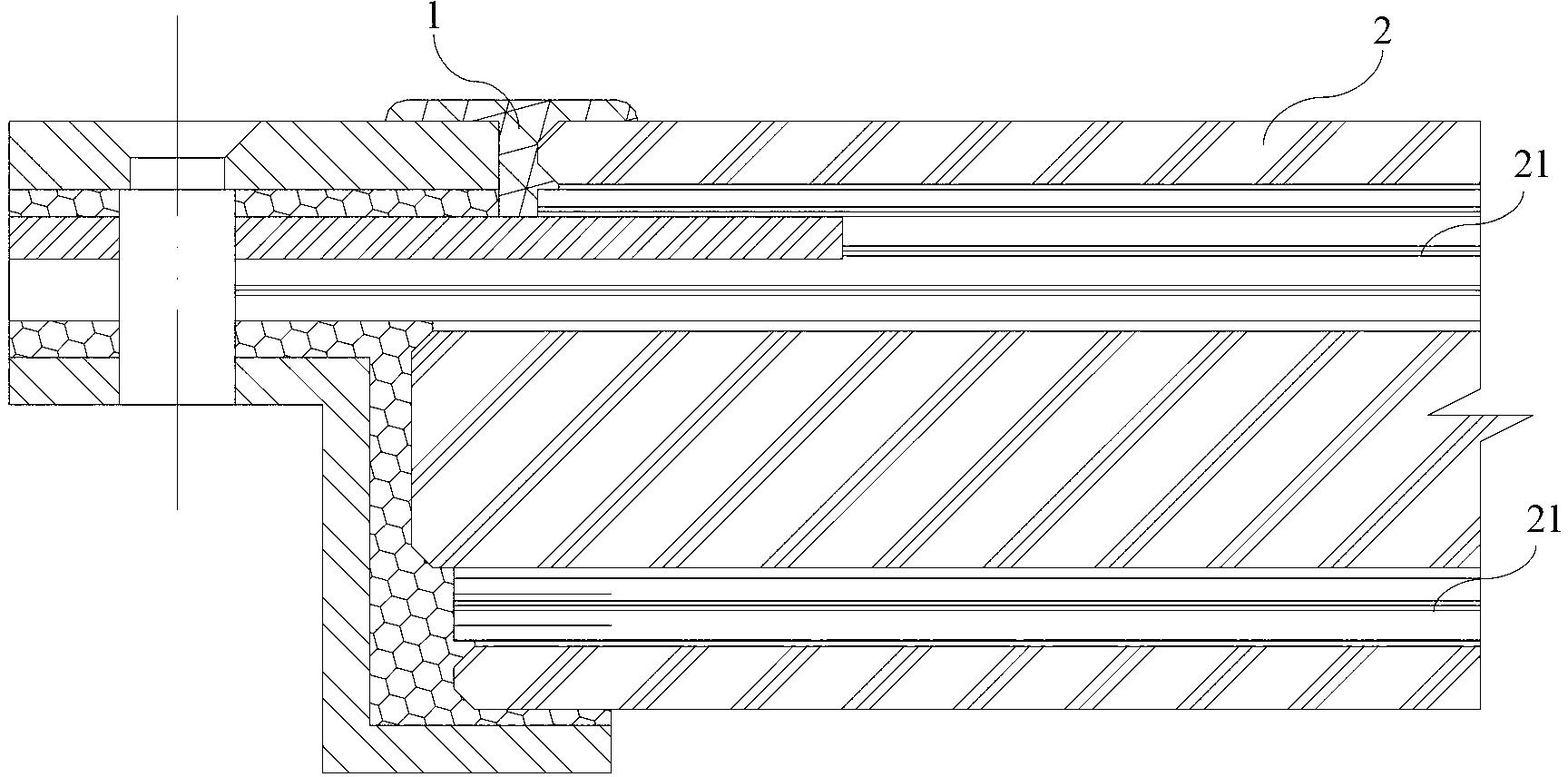

InactiveCN101332488ALow flow resistanceReduce the bearing unit extrusion forceForging/hammering/pressing machinesMetallic material coating processesGear wheelPre stress

The invention relates to a cold forging technology for a gear shaft; the cold forging technology is characterized in that a new technology of the cold forging forming of the inside and outside and split flow forging, a volume split flow space is arranged between the gear shaft diameter and a concave die, the metal flow resistance is reduced and the unit extruding force carried by the die is lowered by split flow; high-strength die steel and split structure are adopted to produce a gear hole forming die; the concave die is produced by adopting three-layer sleeve prestressed structure so as to improve the compression resistance of the die; a punch is made from an alloy steel material and used for the cold forging and precision forming of a complex gear form blind hole, which improves the forming quality and production efficiency of the gear hole, and lowers the consumption of the raw materials markedly. The cold forging technology of the invention has the advantages of achieving the smooth forming of the gear form blind hole, improving the production efficiency greatly, and improving the quality of the gear hole and the qualification rate of the product markedly.

Owner:SHANGHAI DONGFU COLD FORGING MFG

Test method and system for grouting compactness of pre-stressed duct of bridge

InactiveCN102818852AHigh precisionImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructivePre stress

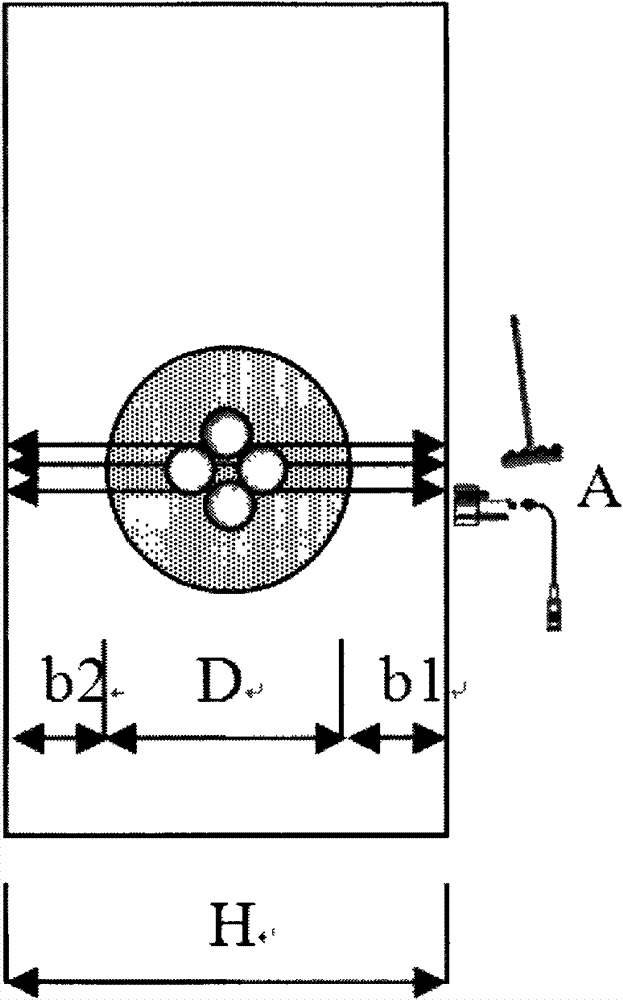

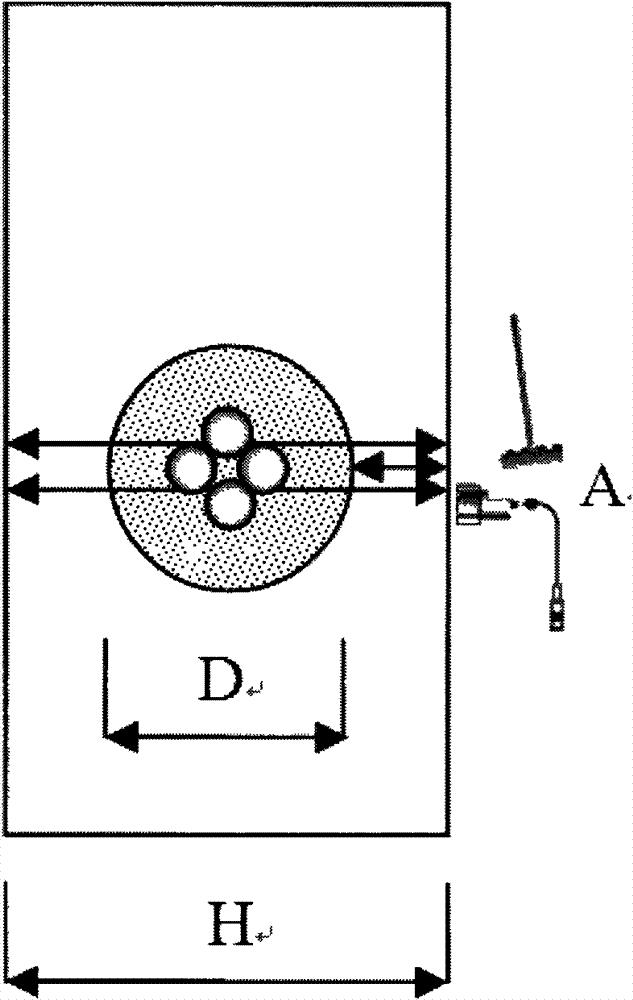

The invention discloses a test method and a system for grouting compactness of a pre-stressed duct of a bridge. The test method includes determining the center line position of the pre-stressed duct to be tested and fixing an acceleration transducer at the center line position; performing knocking and excitation around the acceleration transducer through an excitation hammer, and collecting elastic wave data produced by excitation through the acceleration transducer; and calculating the equivalent reflection wave velocity according to the elastic wave data and determining the grouting compactness of the pre-stressed duct of the bridge according to the equivalent reflection wave velocity. According to an embodiment of the test method and the system, the non-destructive testing technology is adopted to detect the whole grouting quality of the duct with a pre-stressed structure; and the test method and the system have the advantages of high accuracy and efficiency and low cost, have great significance for objective evaluation of quality conditions of the pre-stress structure, and are suitable for being widely applied to engineering.

Owner:杭州海儿科技有限公司 +1

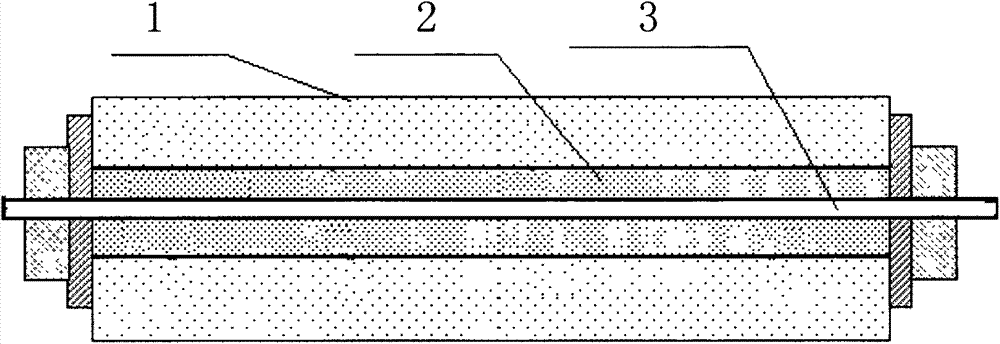

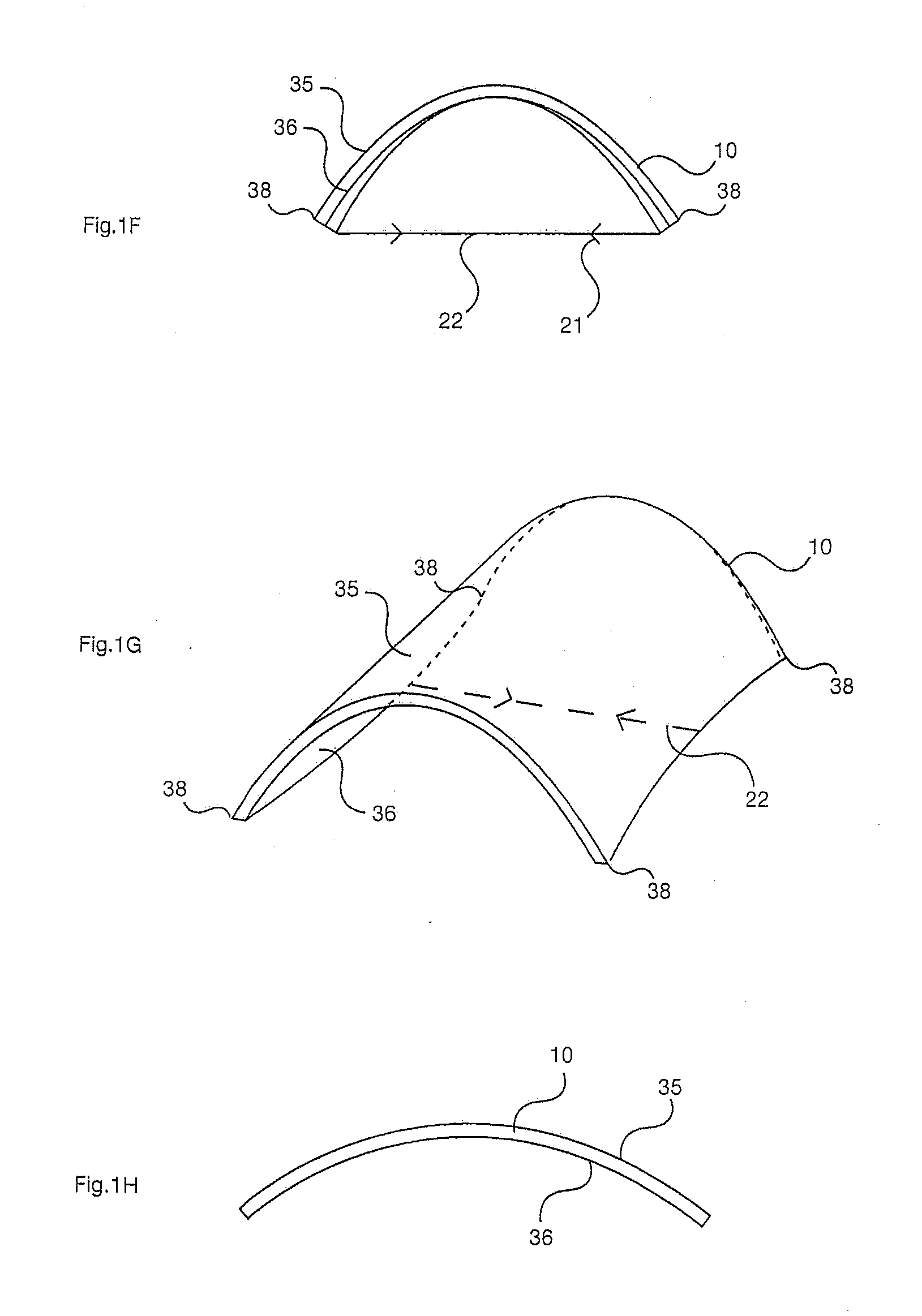

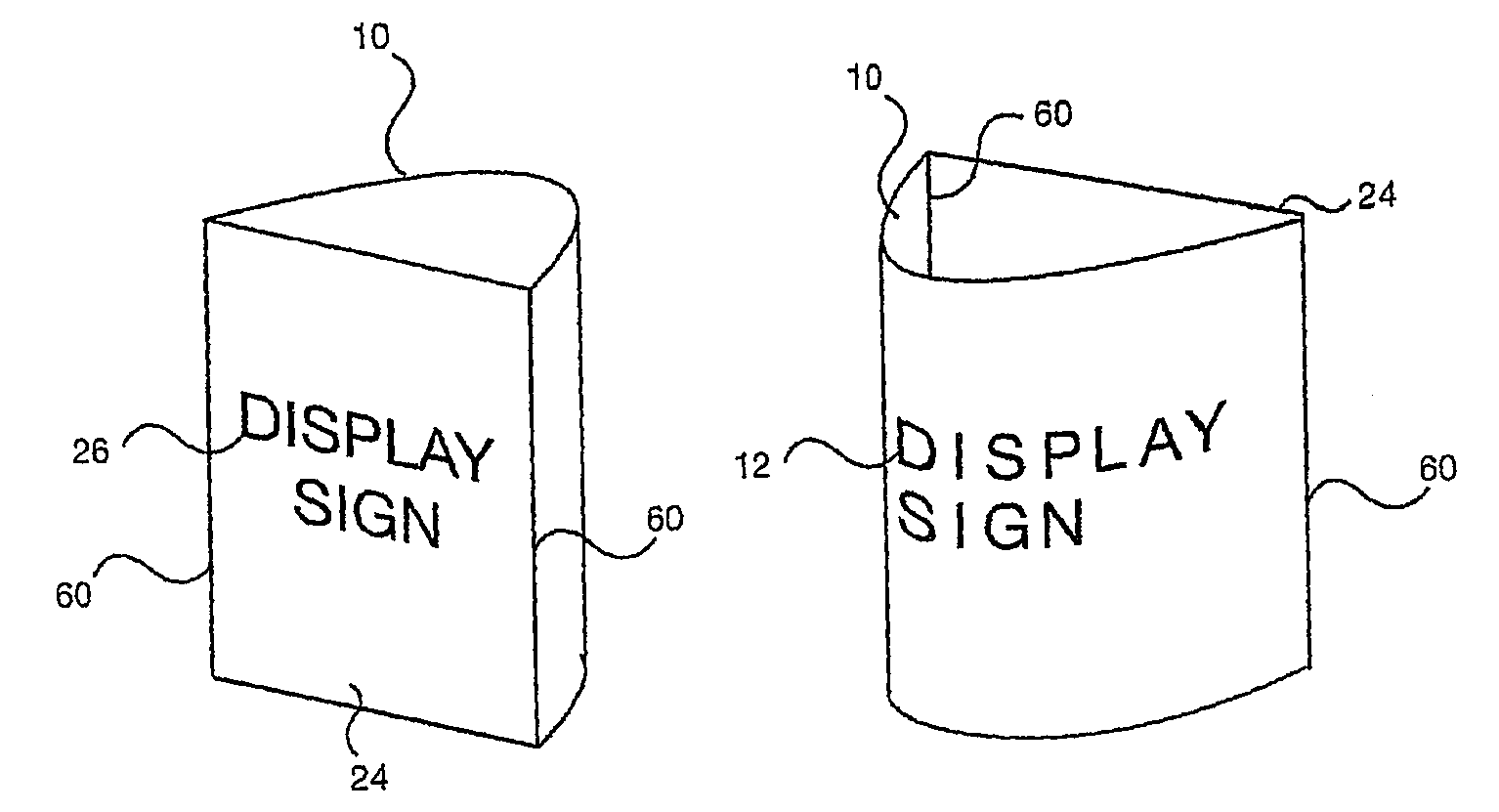

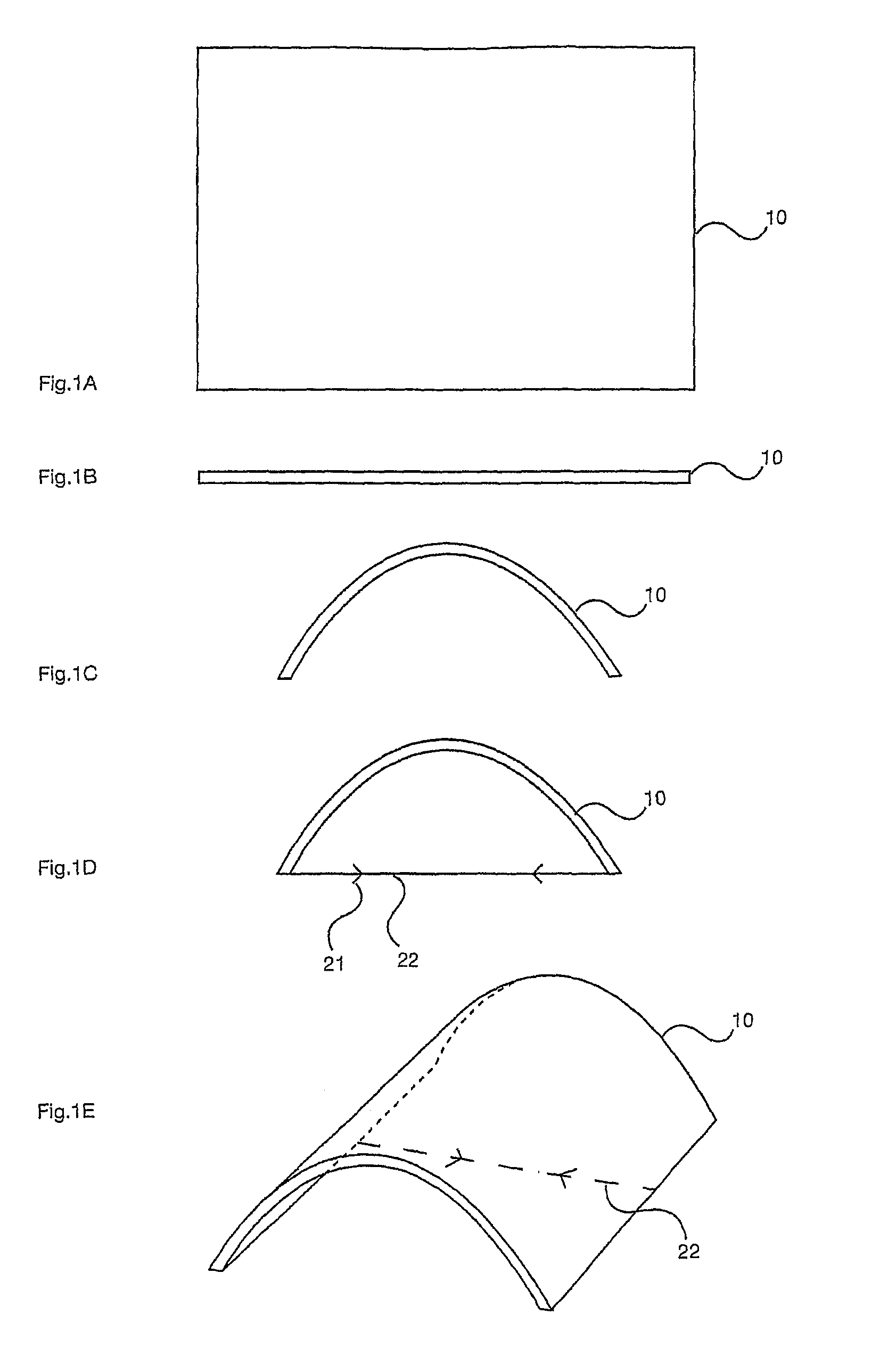

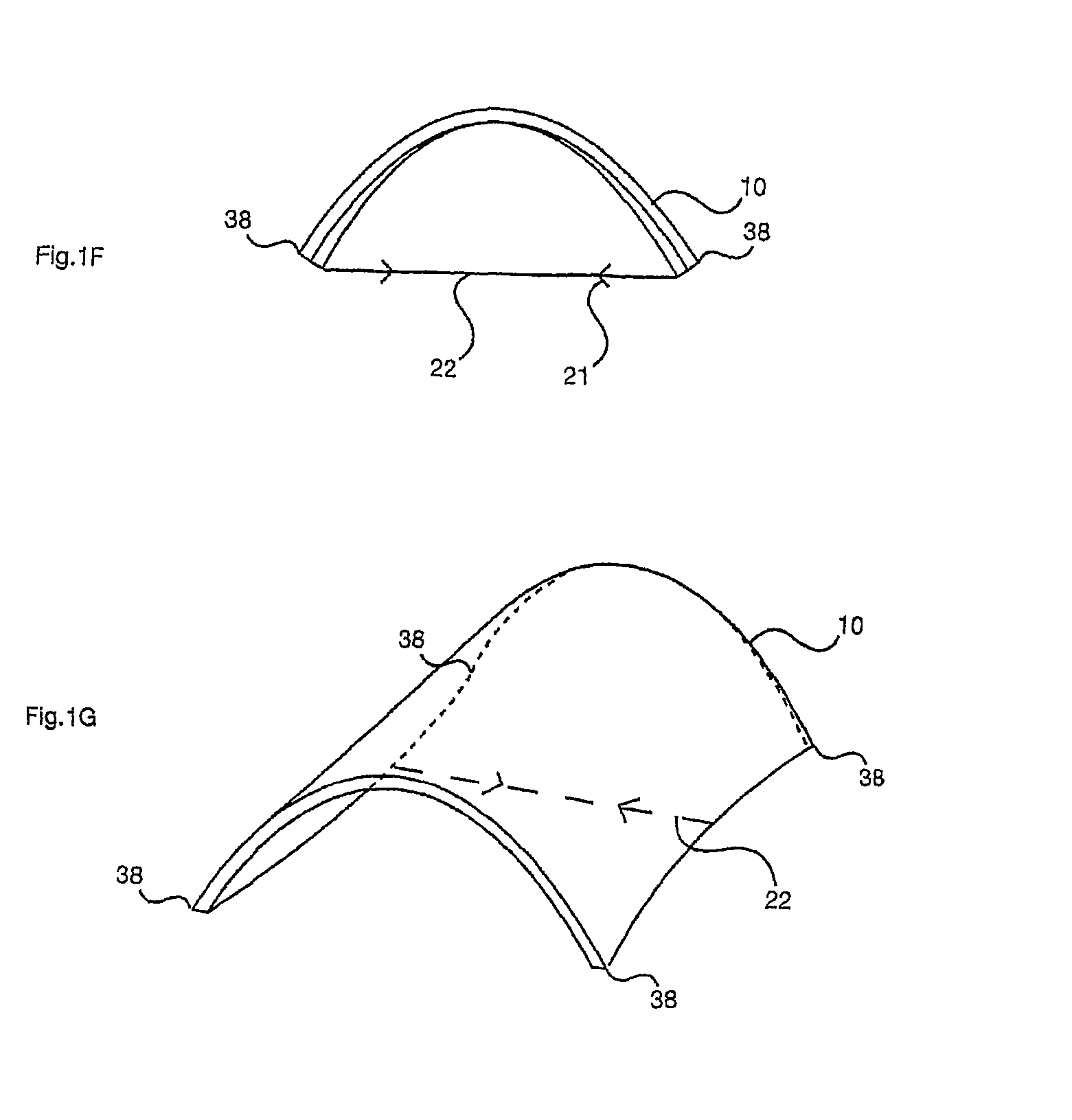

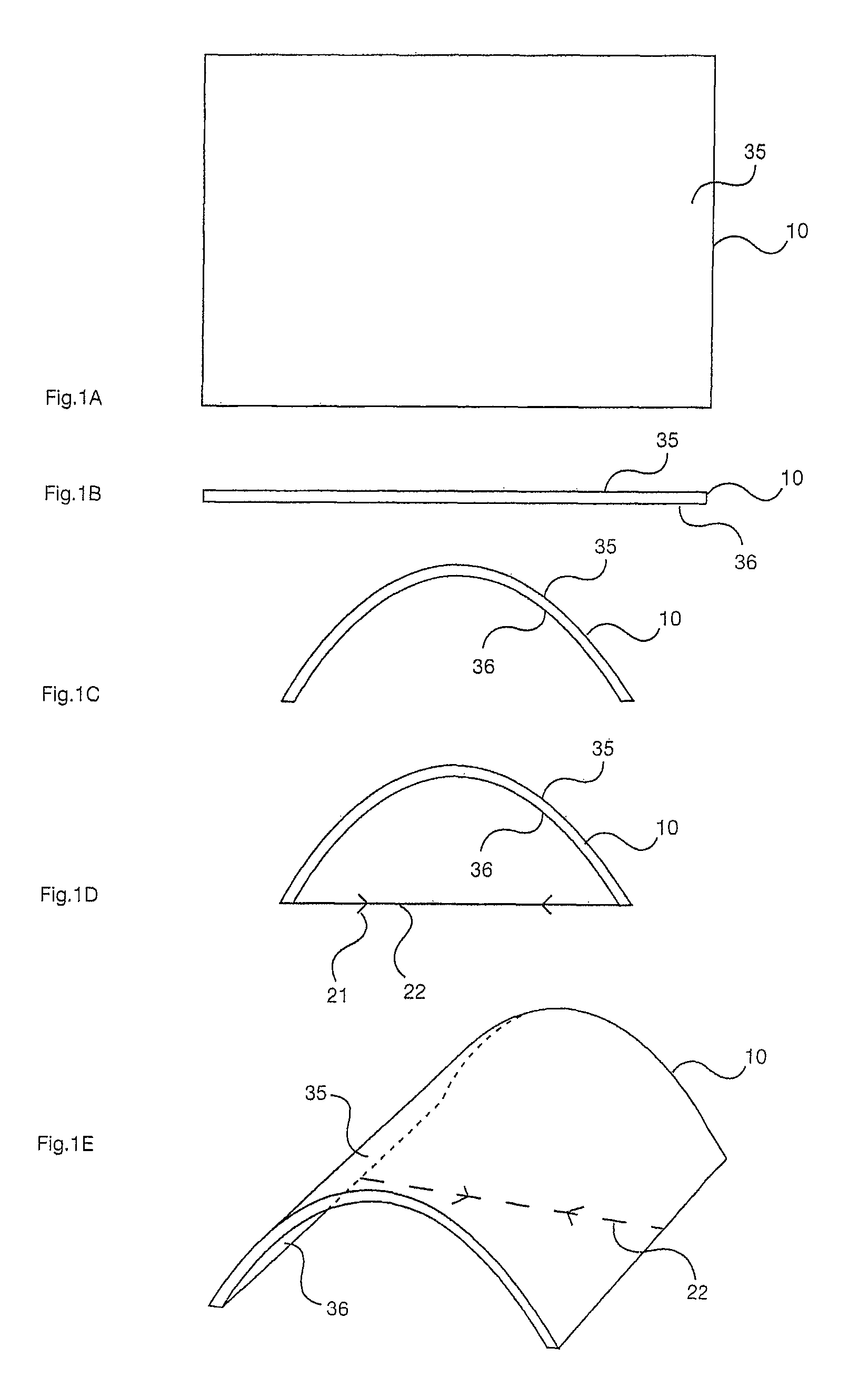

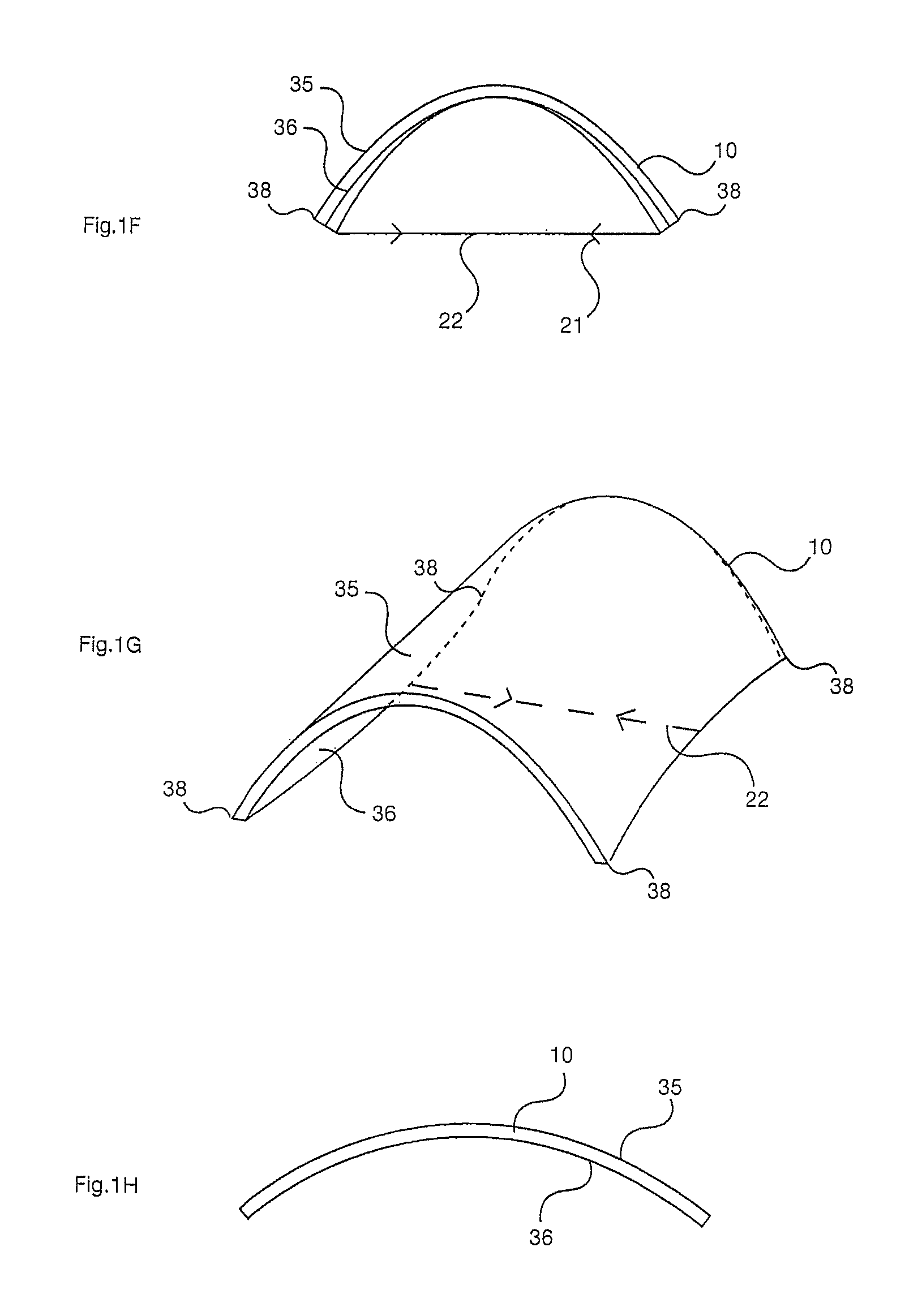

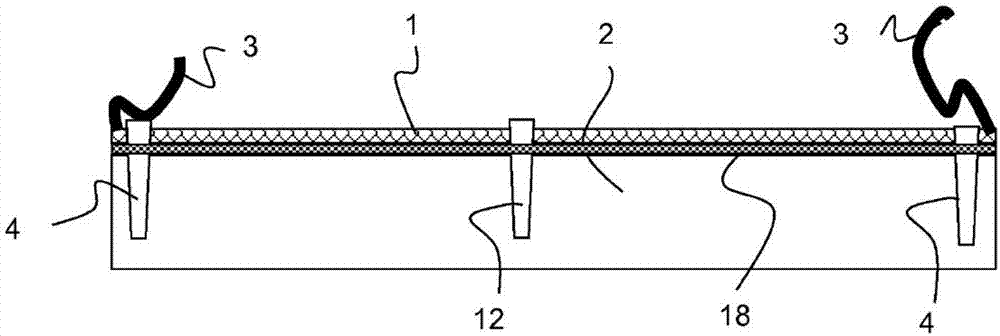

Structural assembly with a flexed, tied panel

InactiveUS20100011641A1Improvement factorBurglar alarm by openingCurtain accessoriesCarbon fibersPre stress

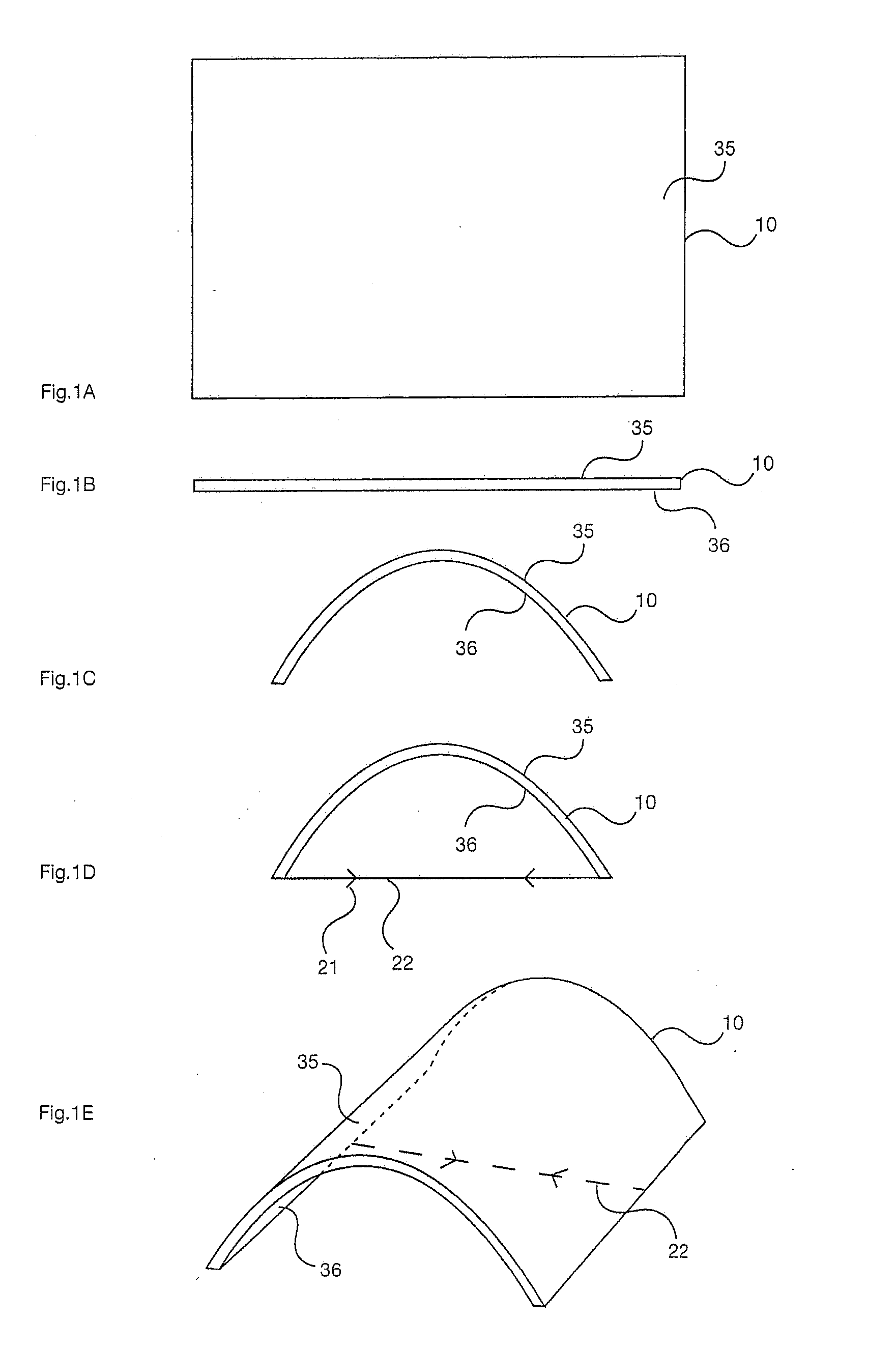

An assembly includes a flexurally deformed panel, which is connected to a membrane tie by a linear connector and is tied by the membrane tie to form a geometrically stable pre-stressed structure. More than one panel may be flexurally deformed and tied together in an assembly and more than one membrane tie may be present within an assembly. Panels are typically semi-rigid sheet materials, for example metal sheets, plastic sheets, or sheets of composite materials, such as glass or carbon fibre reinforced plastics or resins. Membrane tie members are typically flexible, for example plastic films, fabrics or nets or arrays of rods or cables. The assemblies have many different geometric forms and many different practical applications. Assemblies may be relatively large, for example demountable and reusable shelters or flat-pack point-of-purchase display assemblies, or may be relatively small, for example a photograph or postcard display system.

Owner:CONTRA VISION

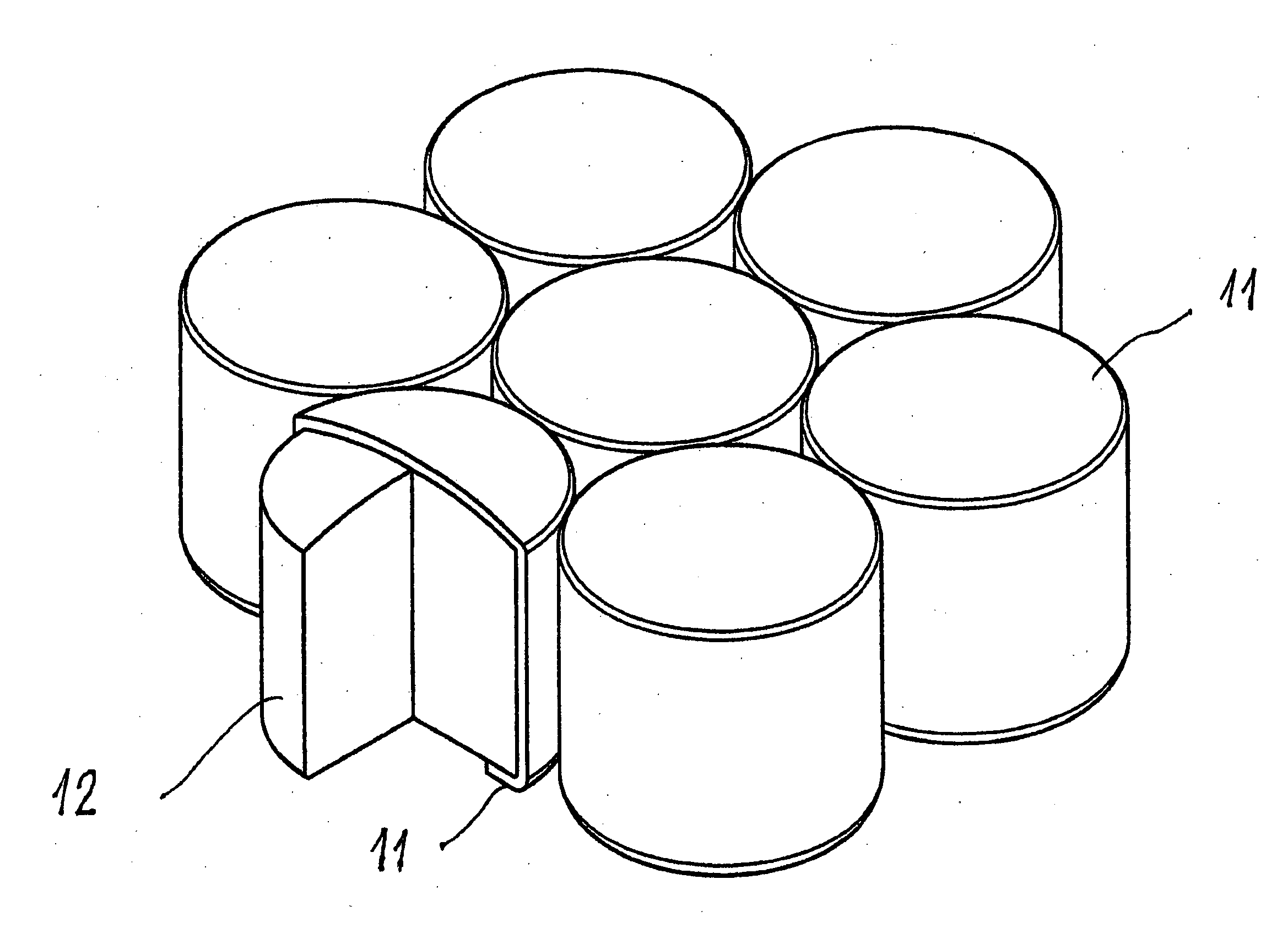

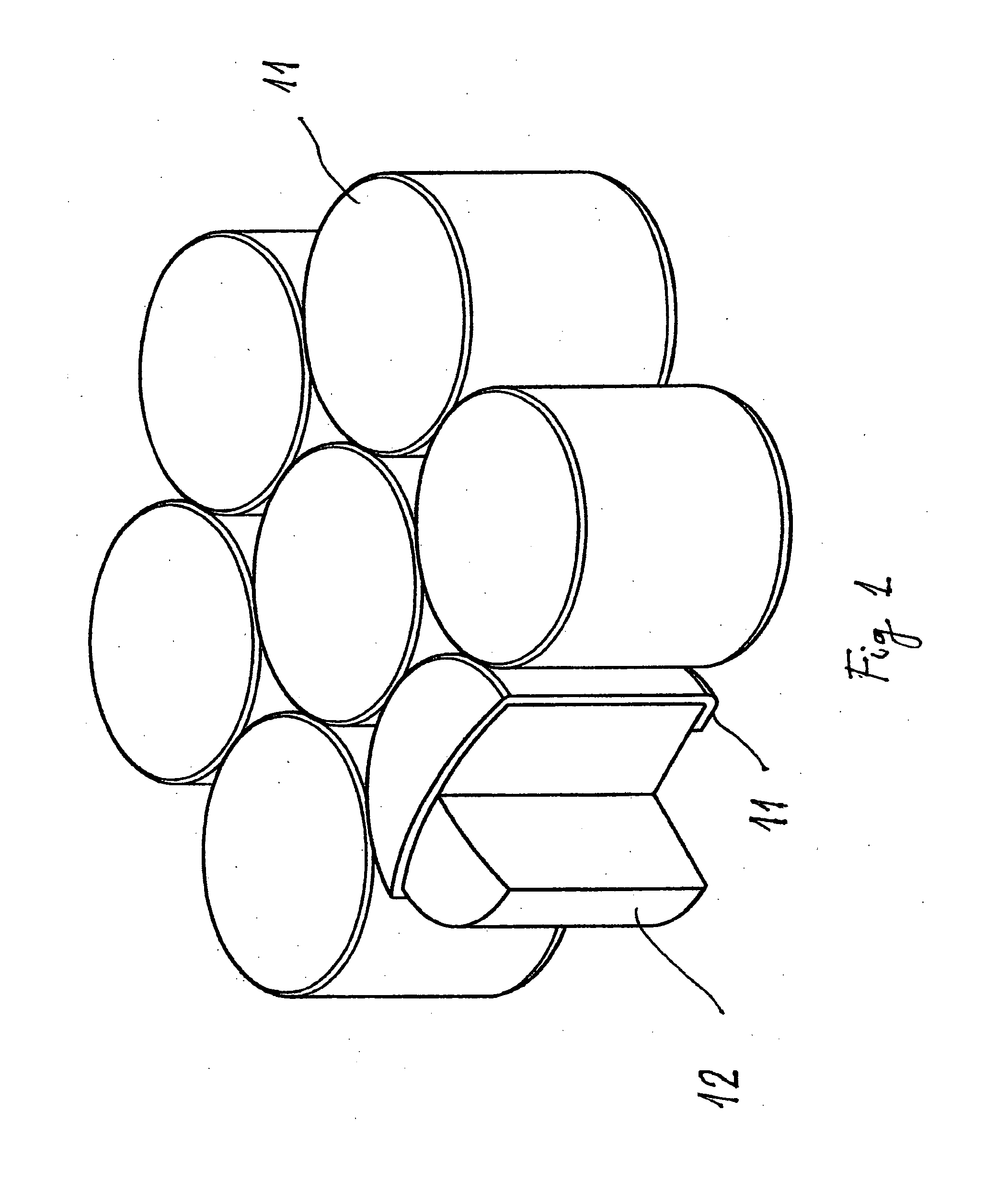

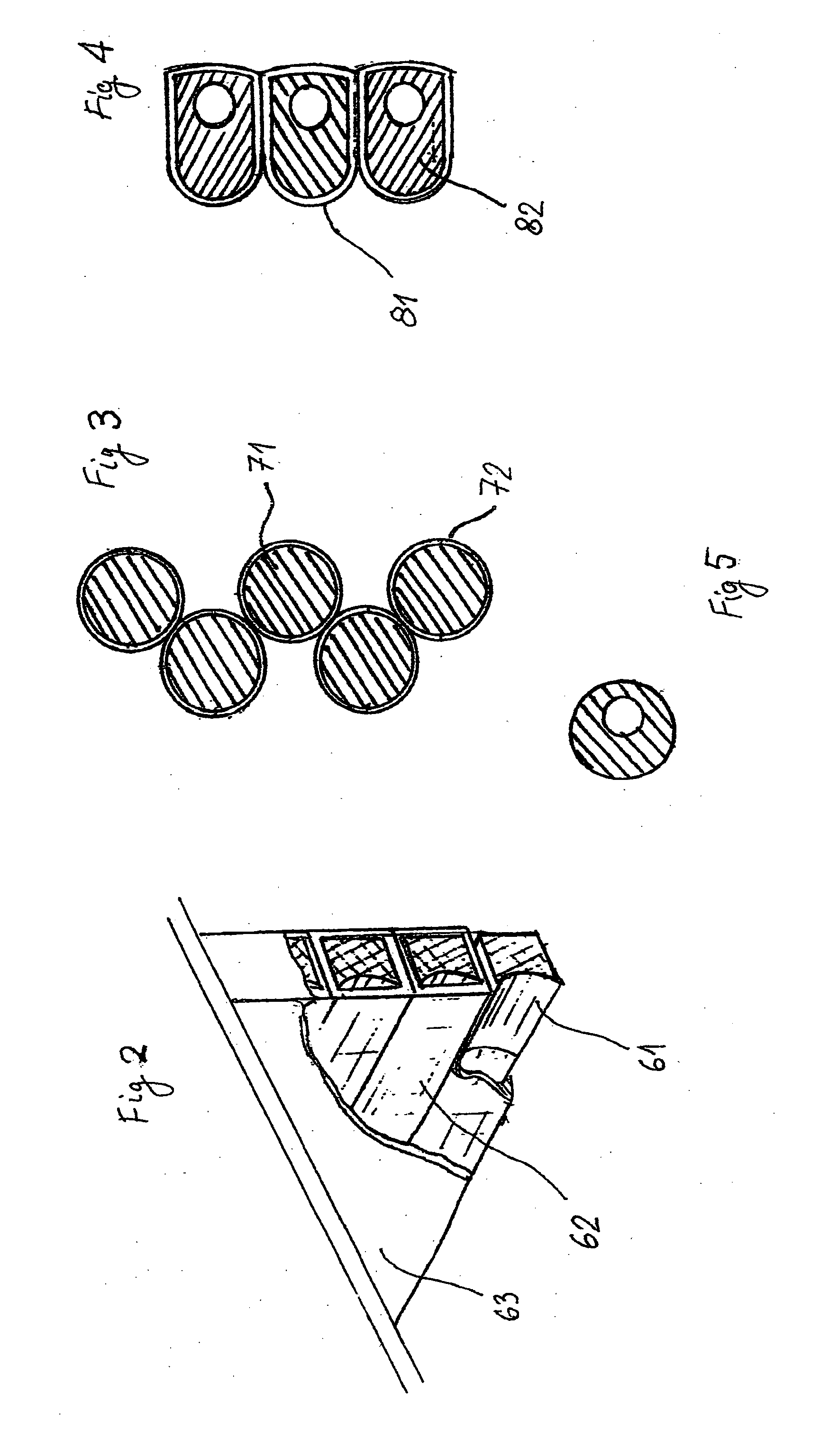

Prestressing system for wood structures and elements

The present invention is a prestressing system for wood elements and structures and a method from prestressing wood beams. In its most basic form, the system for prestressing structures comprises a plurality of members arranged in a predetermined configuration, at least one non-metallic prestressing tendon, having a material stiffness less than that of steel, disposed in such a manner as to fasten together the members, and stressing means attached to at least one end of the prestressing tendon to exert a tensile force on the tendon and an equal and opposite compressive force drawing the members together. In the preferred embodiment, the tendons are manufactured from fiber reinforced plastic and the members are arranged in side by side relation to form a deck. The deck includes a series of aligned holes through the members, through which the prestressing tendons pass and are secured and prestressed. In alternate embodiment of the invention, prestressing tendons are used to secure and prestress stress laminated T sections and box sections and to secure timber trusses. The present invention is also directed to a system and method for prestressing beams. In its most basic form, the system comprises at least one nonmetallic tendon, at least one opening disposed longitudinally through a lower portion of the element, a pair of anchors disposed at the ends of each prestressing tendons, and a pair of bearing plates disposed between the anchors and the bearing surface of the beam. In operation, the tendons are disposed within the opening, the bearing plates are disposed against the bearing surfaces and the anchors are tightened such that a tensile force is exterted on the tendons and such that said bearing plates exert a substantially equal an opposite compressive force on the element beam. In an alternate embodiment, the opening is filled along the tendon with a resin and the anchors are removed after the resin has cured.

Owner:UNIVERSITY OF MAINE

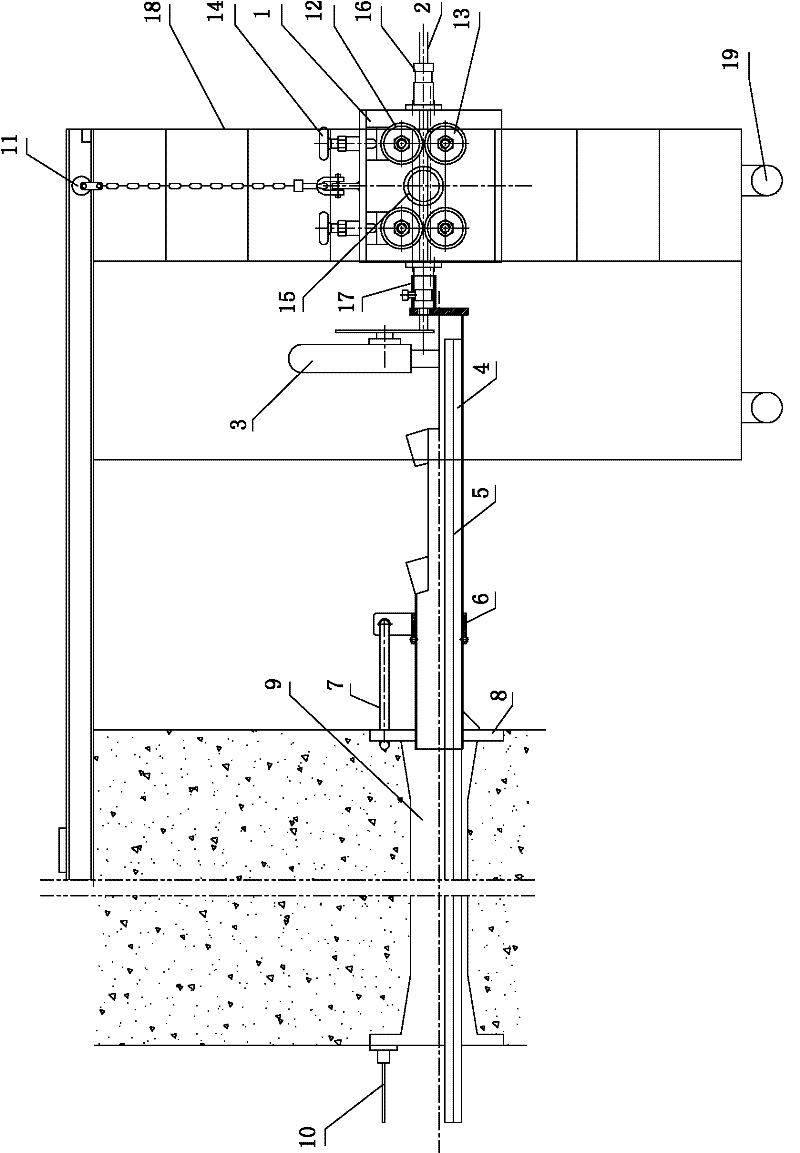

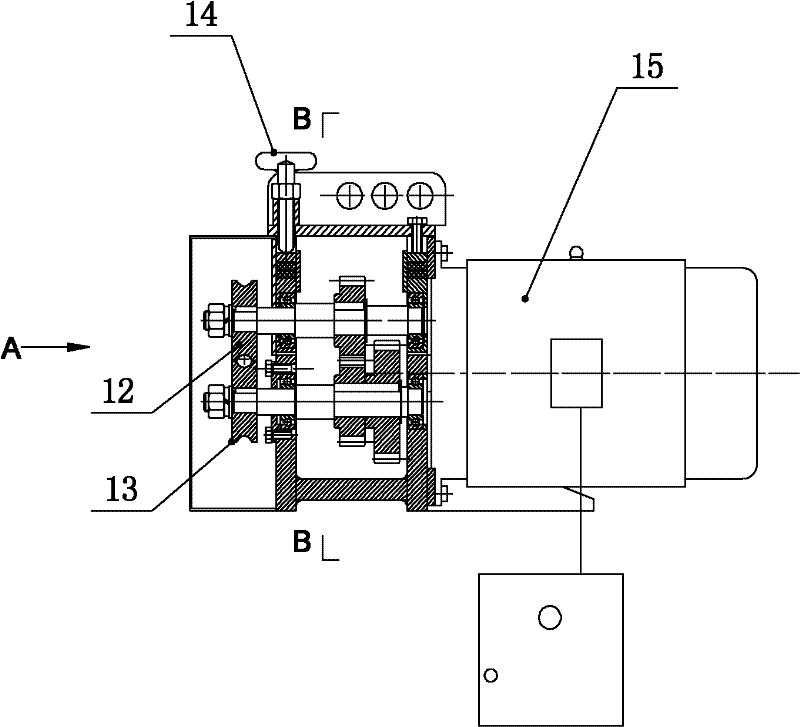

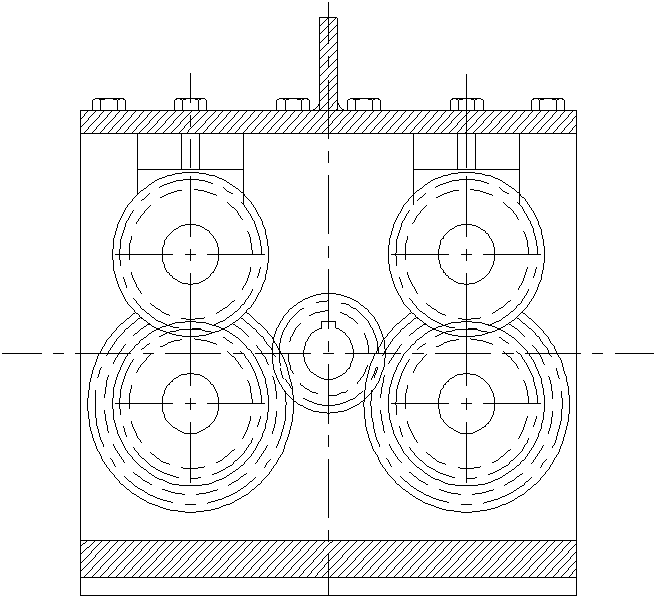

Construction method utilizing steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures

InactiveCN102383377AAvoid wastingReduce investmentBridge erection/assemblyBuilding material handlingPre stressArchitectural engineering

The invention discloses a construction method utilizing a steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures, which belongs to the technical field of building construction. The steel-strand strand pulling machine is provided with two pairs of pressing wheels capable of clamping steel strands to advance or retreat are arranged at intervals. The steps are that fixing the steel-strand strand pulling machine on a movable strand pulling platform through a pull piece in suspension mode, cleaning mortar on a mortar filling port of an anchorbacking plate on an opening of a prestress hole passage, then connecting the steel-strand strand pulling machine with the prestress hole passage to be strand-pulled, further utilizing the steel-strand strand pulling machine to enable the steel strands to be strand-pulled according to numbers till the steel strands reach predetermined positions, utilizing a cutting device to cut off the steel strands, and accordingly the strand pulling work of one steel strand is completed. Repeating the steps till the strand pulling work of all the steel strands of the prestress hole passage is completed, andthe steel strands are automatically bundled according to stacking mode after cut from bottom to top. The construction method utilizing the steel-strand strand pulling machine to perform fast strand pulling during construction of prestress structures integrates fast blanking, fast bundling and fast stand-pulling into a whole, thereby being convenient to operate and fast and efficient in strand-pulling construction.

Owner:RAILWAY NO 10 ENG GRP CO LTD

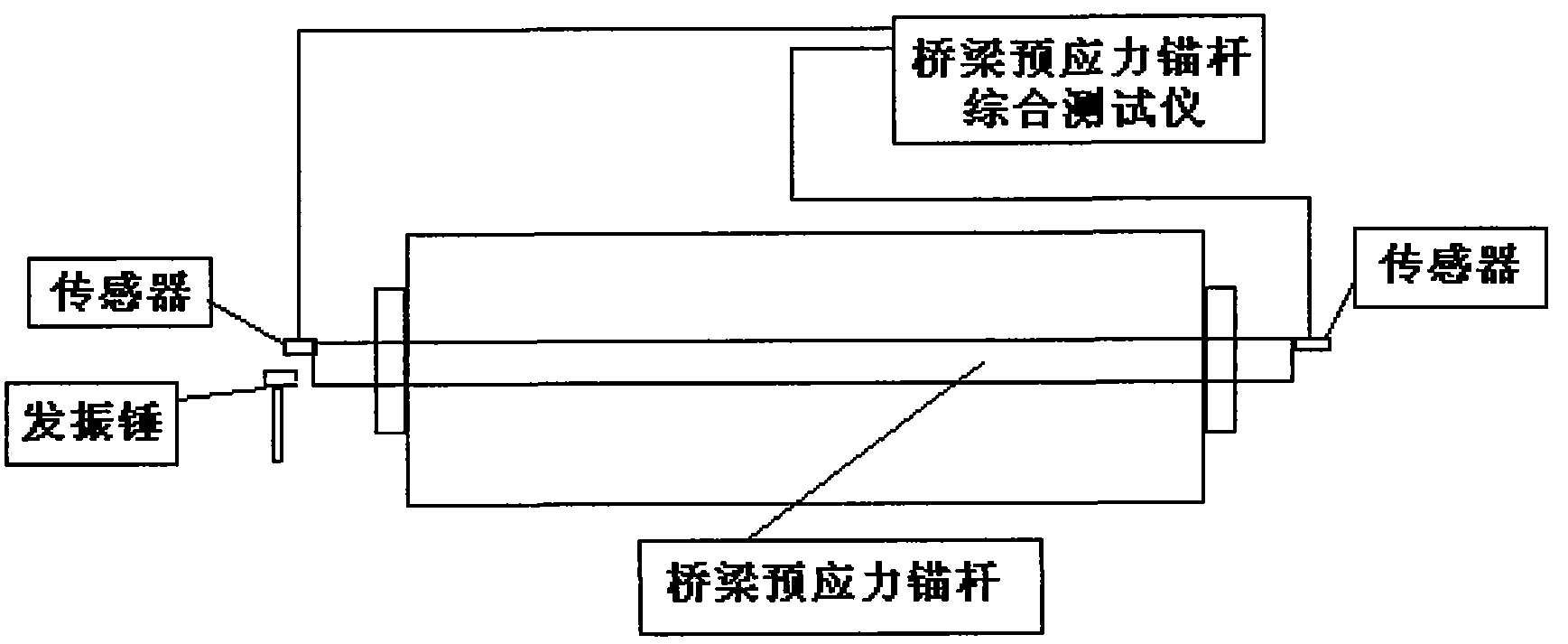

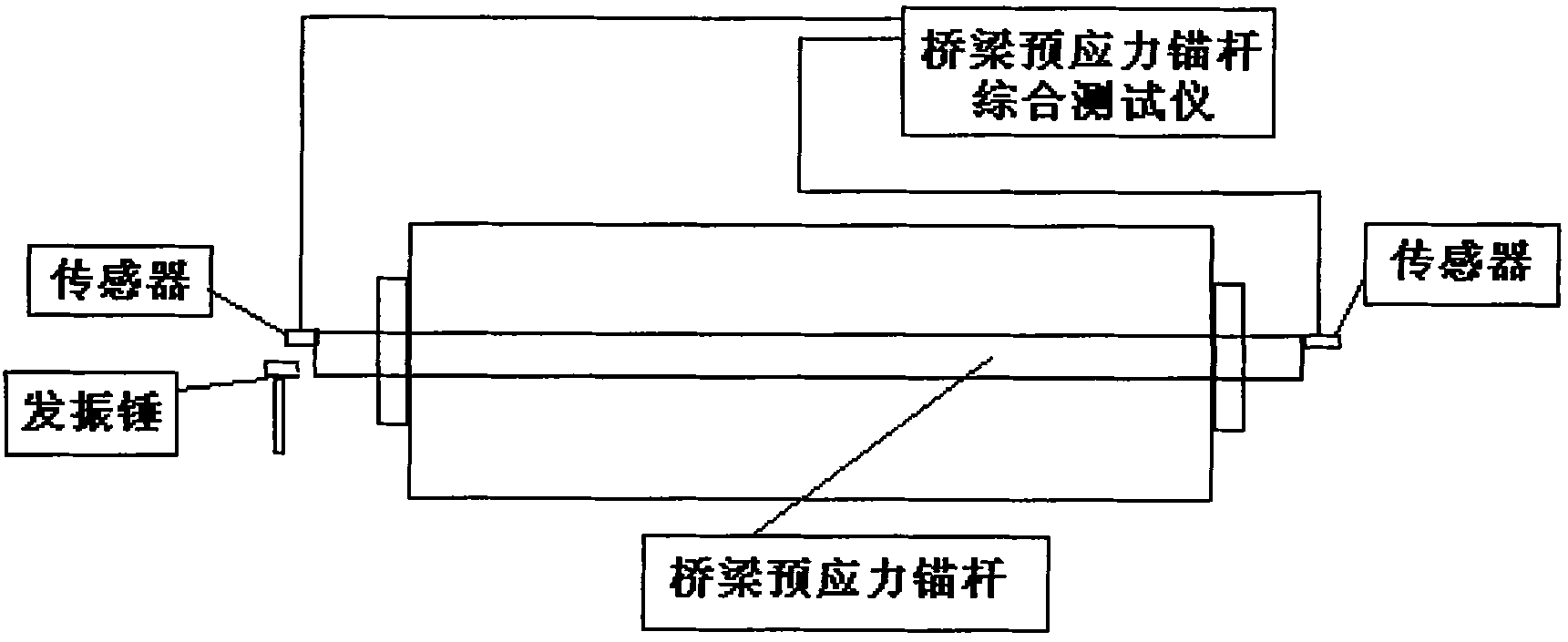

Method for testing grouting compactness degree of prestressed pore of bridge based on elastic-wave energy dissipation rate

InactiveCN102053117AAvoid systematic errorsEliminate systematic errorsAnalysing solids using sonic/ultrasonic/infrasonic wavesPre stressEngineering

The invention discloses a method for testing the grouting compactness degree of a prestressed pore of a bridge based on an elastic-wave energy dissipation rate, belonging to the technical field of quality detection on bridge / culvert engineering. In the grouting construction on a prestressed anchor (cable) of a bridge, the prestressed anchor (cable) can be corroded caused by undesirably-packaged cement mortars and anchor rods, thereby causing the failure of the prestressed anchor (cable) and then endangering the safety of structures. In the prior art, the anchoring quality of an anchor rod can not be evaluated completely. The method provided by the invention is implemented through analyzing the fluctuation characteristics (speed, frequency, elastic-wave energy dissipation, and the like) of pickup signals of sensors at the two ends of the prestressed anchor by adopting impact elastic waves generated by vibrations at the two ends of the prestressed anchor of the bridge so as to detect the grouting compactness degree of the prestressed anchor (cable) of the bridge. The method provided by the invention has the advantages of maximizing the elimination of system errors caused in the process of test, accurately testing the elastic-wave energy dissipation rate of the prestressed anchor (cable), and effectively completing the test on the grouting compactness quality of the prestressed anchor (cable) of the bridge. The method provided by the invention is also applicable for the test on the grouting compactness qualities of all prestressed structures the two ends of which are provided with exposed anchor heads.

Owner:上海建科建设发展有限公司 +2

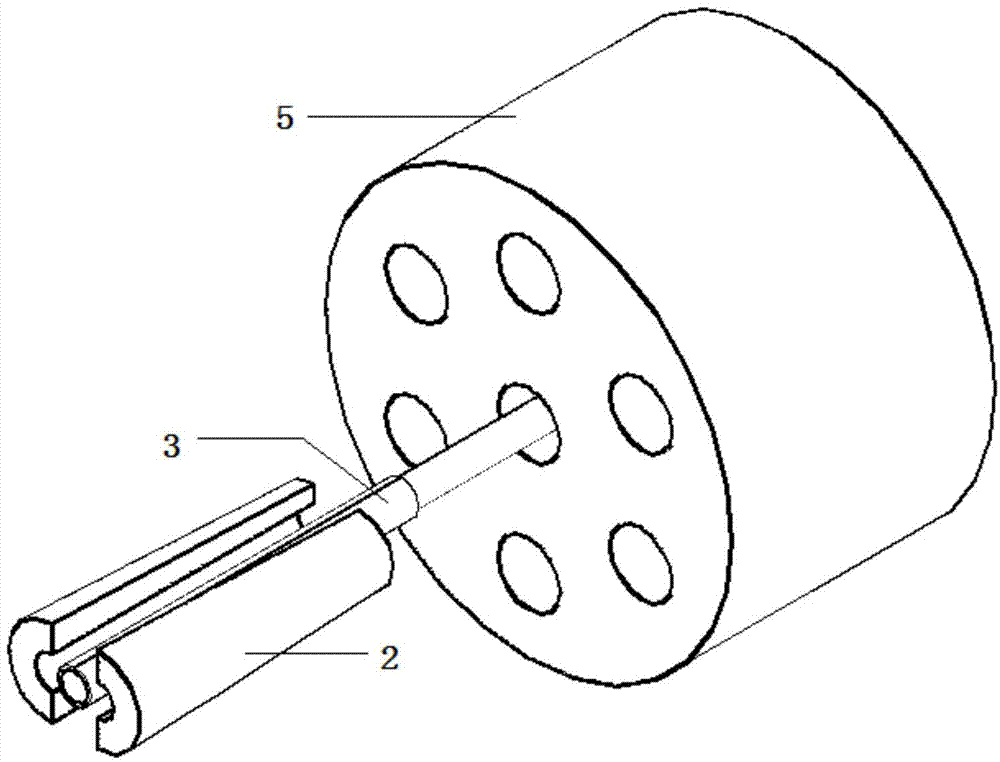

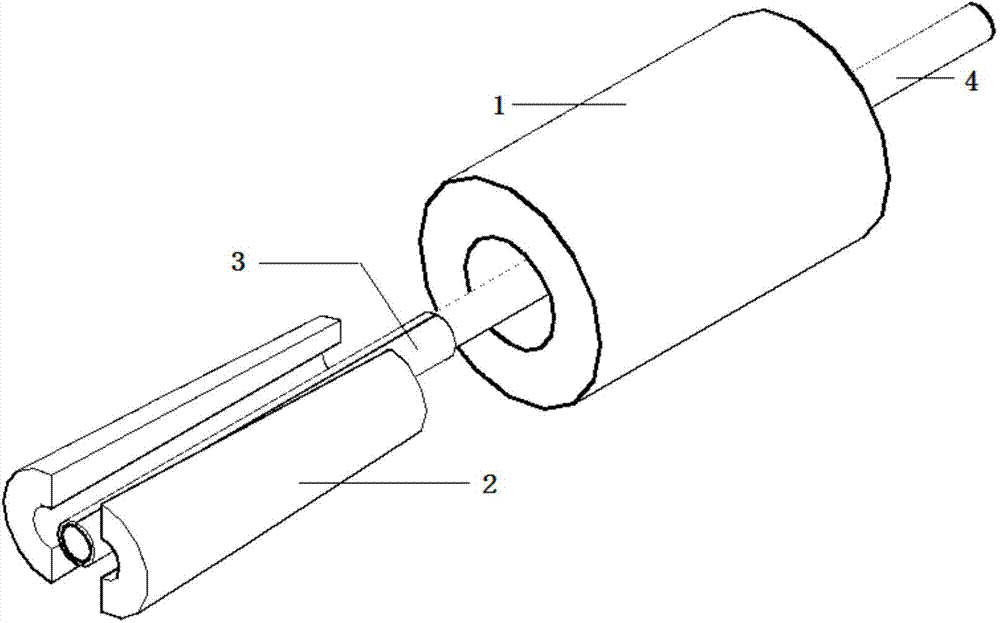

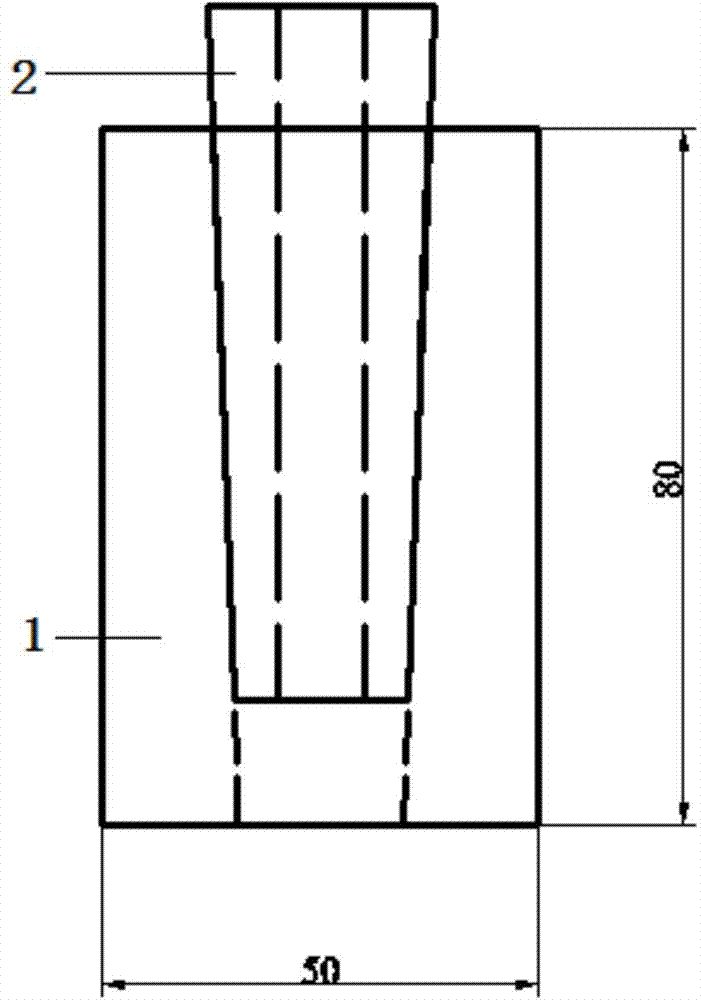

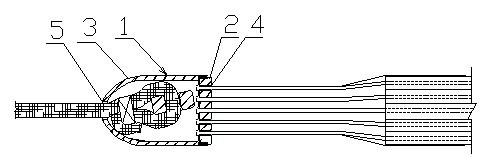

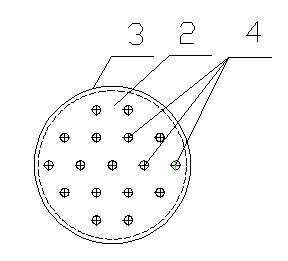

Composite CFRP (Carbon Fibre Reinforced Polymer) tendon anchoring system

InactiveCN104727487ASolve the problem of small anchoring forceSolve the disadvantages that it is not suitable for anchoring multiple CFRP tendonsBuilding reinforcementsTransverse forcePre stress

The invention discloses a composite CFRP (Carbon Fibre Reinforced Polymer) tendon anchoring system which comprises an anchor ring, a two-piece wedge-shaped clip, a soft metal sheath and an epoxy adhesive film, wherein the soft metal sheath is fixed at the anchoring end of a CFRP tendon by the epoxy adhesive film so as to form an integral apparatus; and the integral apparatus is inserted in the two-piece wedge-shaped clip, and the two-piece wedge-shaped clip extends in the anchor ring and then is fixed. The composite anchorage device has the characteristics of small size, large anchoring force, and easiness for installation and use, and is applicable to the on-site construction of prestressed structures. Under the condition of not increasing the size of the anchor ring, the anchoring force can be increased in a mode of increasing the bonding length of the soft metal sheath, and the transverse force of the CFRP tendon is protected. The composite CFRP tendon anchoring system can anchor a single tendon, and also can anchor multiple tendons, thus being extremely applicable to prestressed structures.

Owner:TIANJIN UNIV

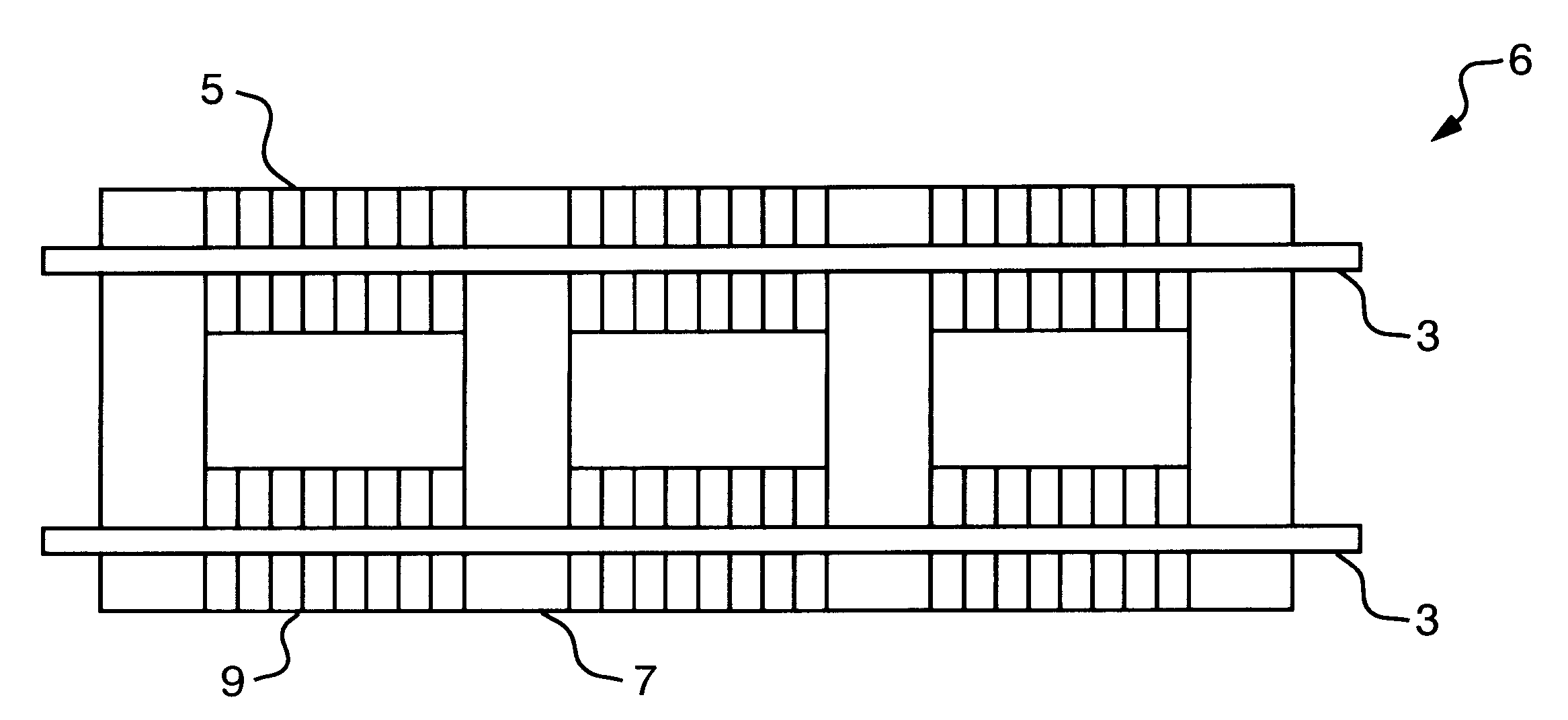

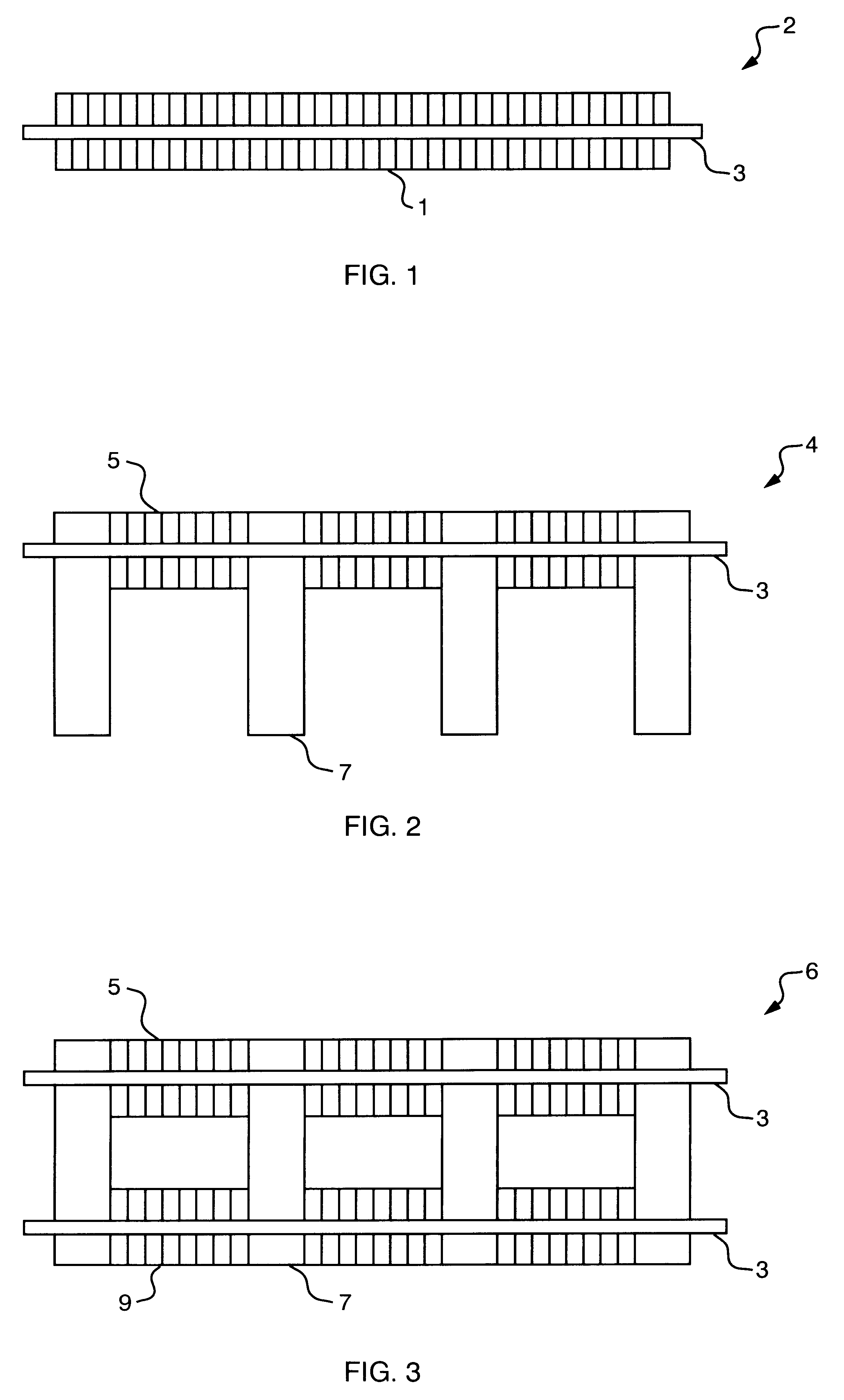

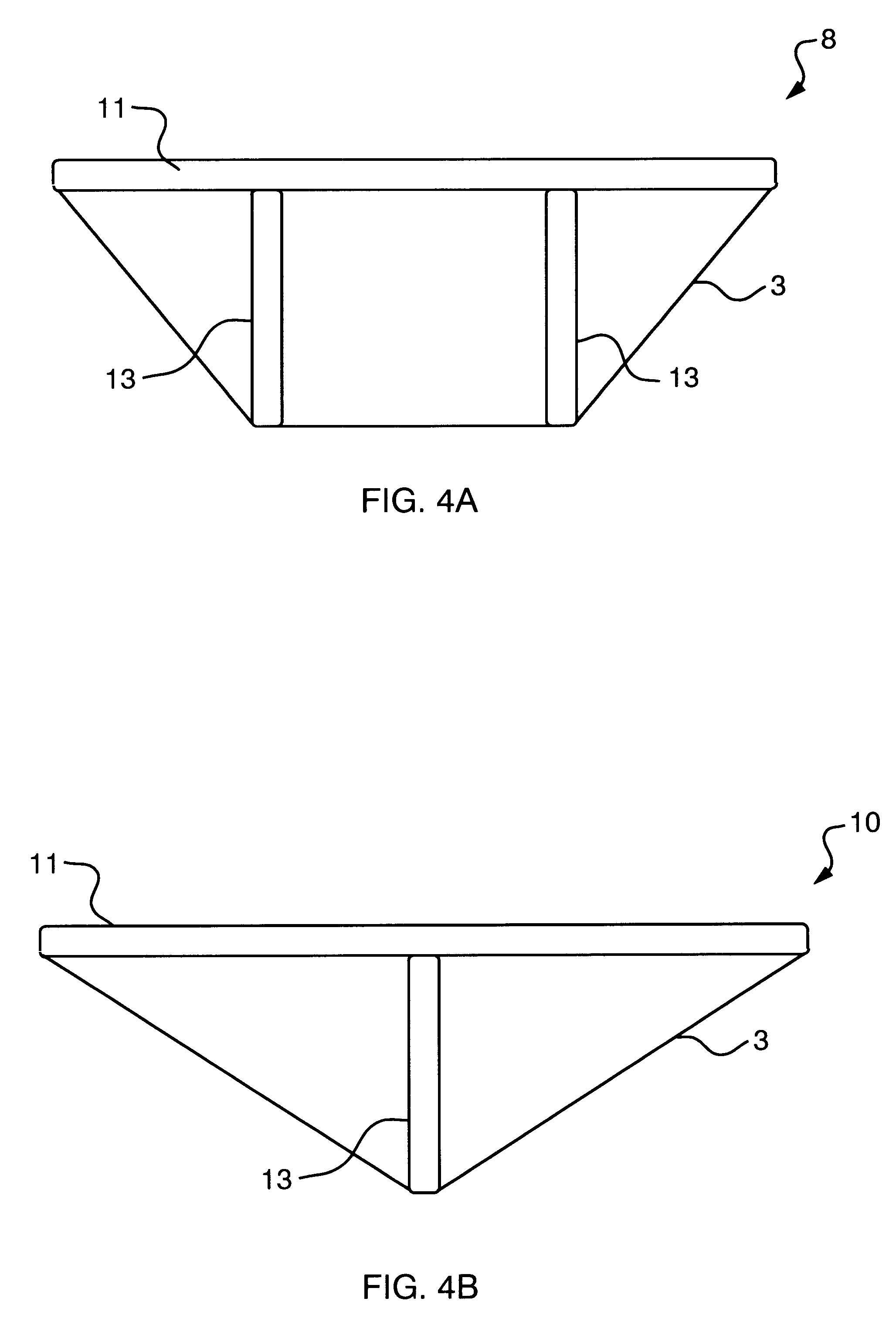

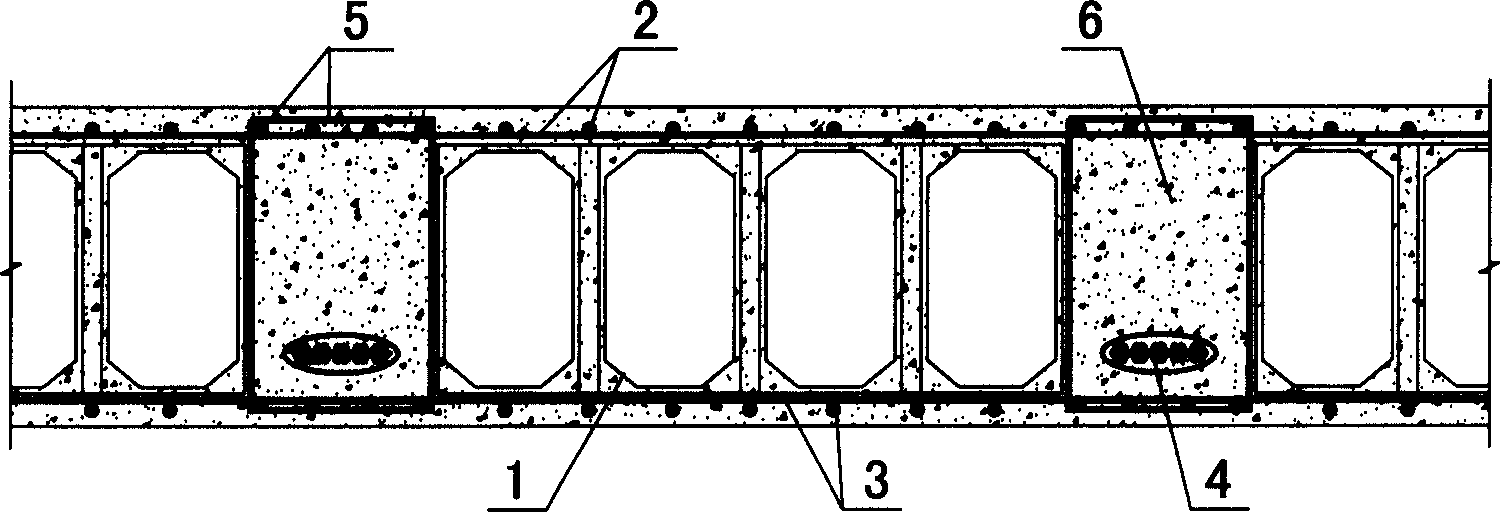

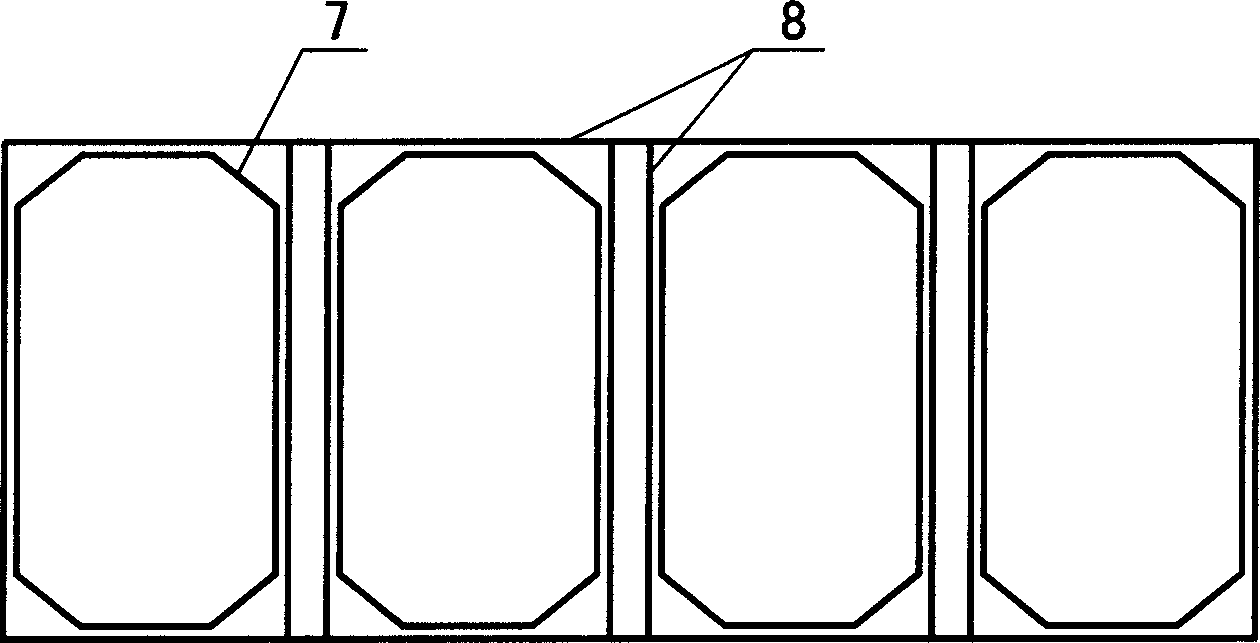

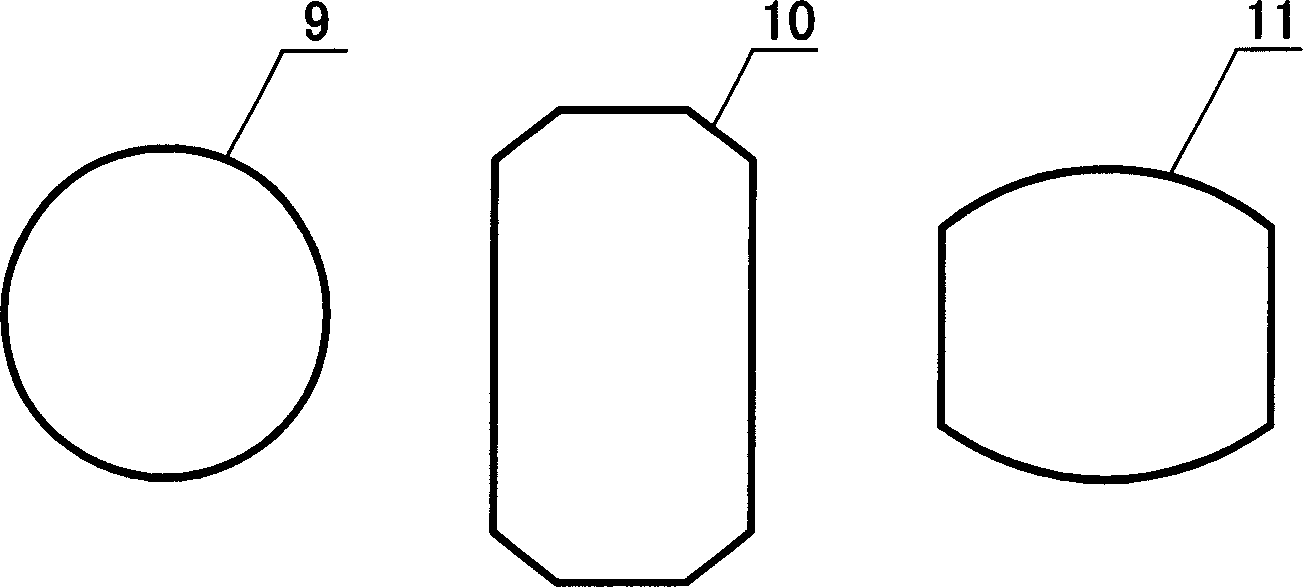

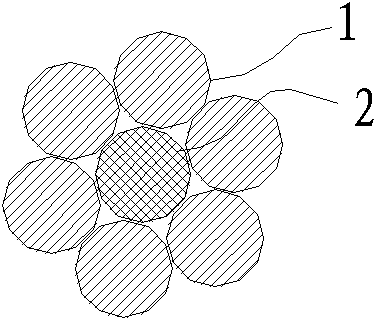

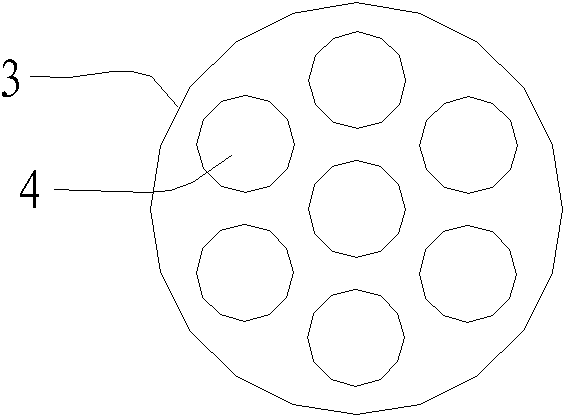

Lightweight material combination unit filled prestressed concrete cast-in-situ hollow slab

Disclosed is a prestressed concrete on-site pouring hollow slab filled with light material combined unit, which comprises light material combined unit, upper layer reinforcing steel bar, lower layer reinforcing steel bar, tendon, blind beam reinforcing steel bar and concrete. The light material combined unit consists of light tubes and connection bar, which is arranged between the upper layer reinforcing steel bar and the lower layer reinforcing steel bar, the combined unit tubes is in the same direction with the bigger bending moment within the slab, The blind beam is arranged at intervals of a certain distances, in which the tendon is centralized laid. Said on-site pouring slab has the advantages of both the prestressed structure and the hollow slab structure, has high hollow percentage, implements one time concrete pouring moulding, is suitable not only for one-way slab, but also for two-way slab. The slab has big span, light weight, good heat and sound insulation effects, good reliability, shock resistance and crack resistance.

Owner:徐焱

Prestressing structure for rotationally balancing a motor

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Structural assembly with a tied, flexurally deformed panel

InactiveUS8215041B2Easily manufactured and subsequently processedEasy to dismantlePicture framesSpecial ornamental structuresCarbon fibersPre stress

An assembly includes a flexurally deformed panel, which is connected to a membrane tie by a linear connector and is tied by the membrane tie to form a geometrically stable pre-stressed structure. More than one panel may be flexurally deformed and tied together in an assembly and more than one membrane tie may be present within an assembly. Panels are typically semi-rigid sheet materials, for example metal sheets, plastic sheets, or sheets of composite materials, such as glass or carbon fibre reinforced plastics or resins. Membrane tie members are typically flexible, for example plastic films, fabrics or nets or arrays of rods or cables. The assemblies have many different geometric forms and many different practical applications. Assemblies may be relatively large, for example demountable and reusable shelters or flat-pack point-of-purchase display assemblies, or may be relatively small, for example a photograph or postcard display system.

Owner:CONTRA VISION

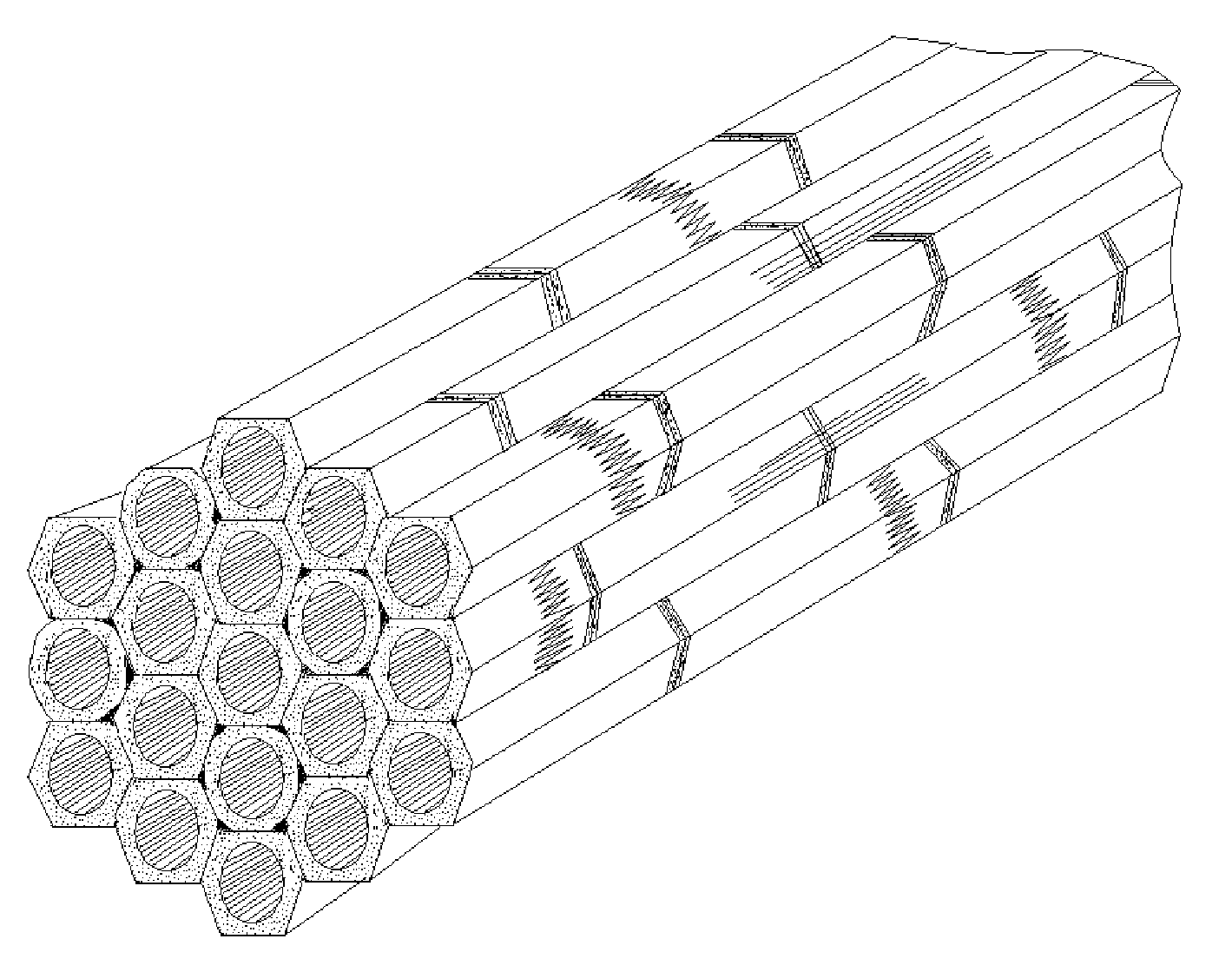

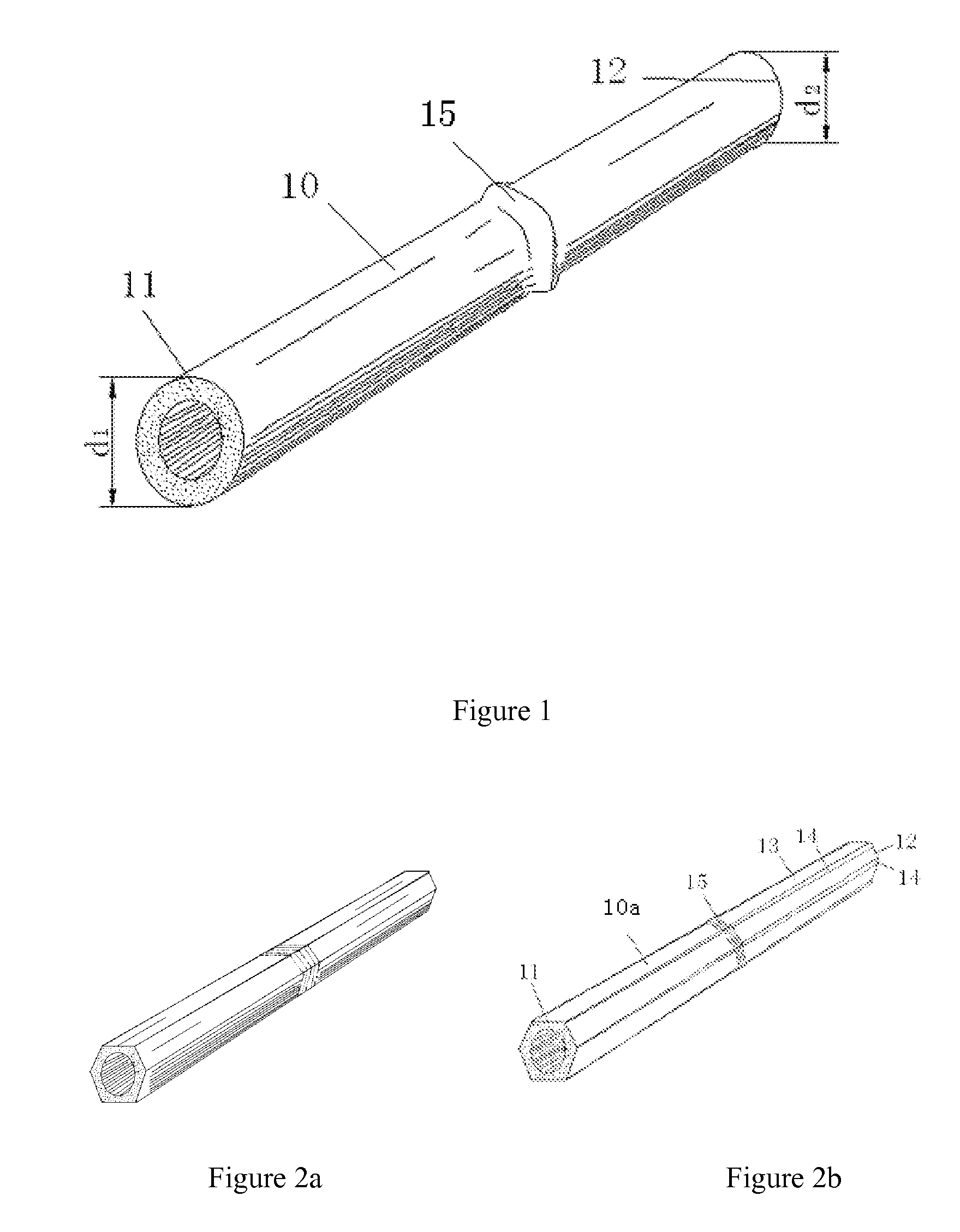

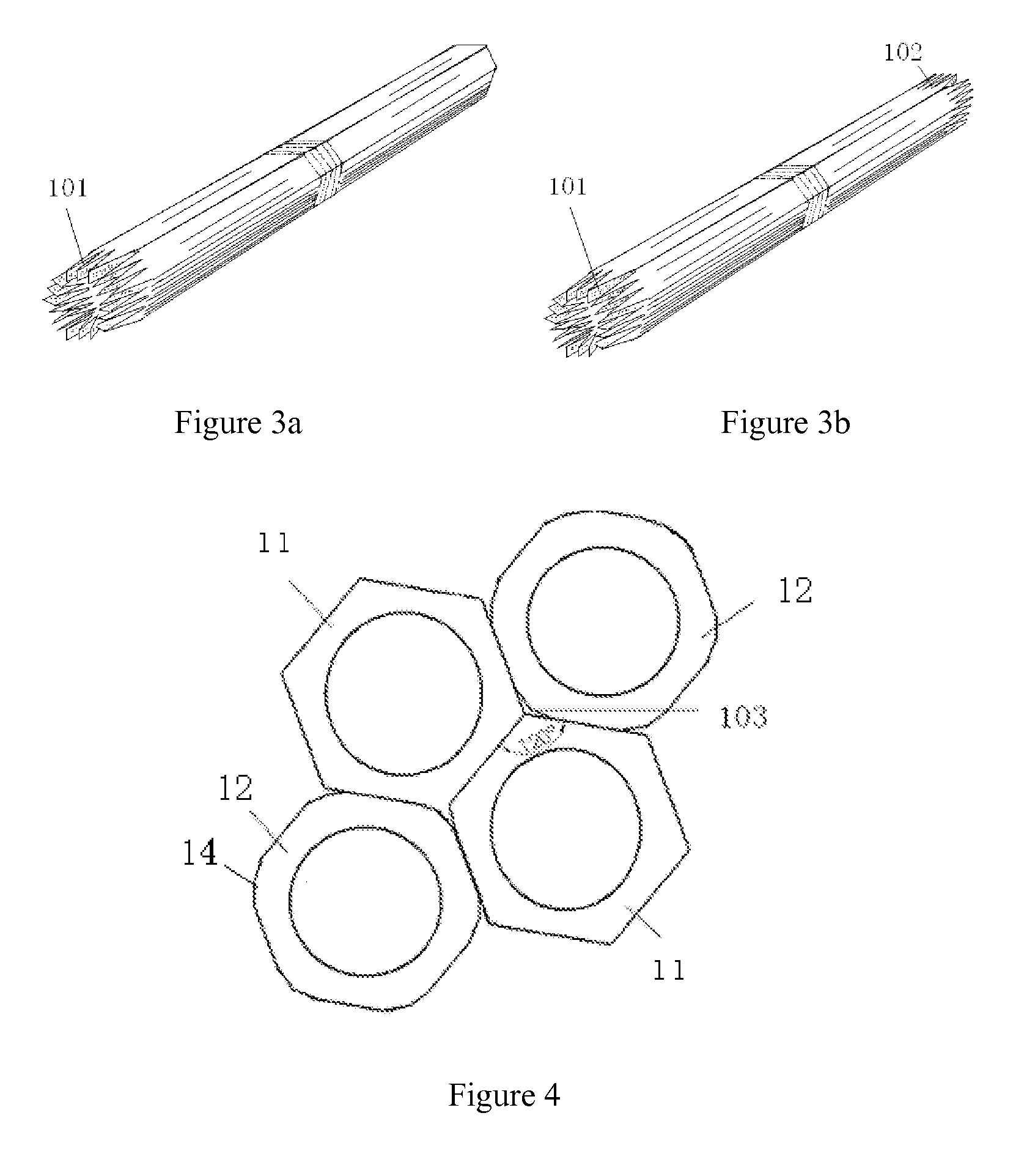

Prestress structural material formed by reorganization with polygonal original bamboo and the manufacturing method

InactiveUS20110151172A1Insufficient improvementHigh strengthLayered productsLoad-supporting elementsChemical solutionPre stress

The invention provides a prestress structural material formed by reorganization with polygonal bamboo units and the manufacturing method for it, the manufacturing method includes manufacturing substrate of prestress structural material formed by reorganization with polygonal bamboo units, and the adding of reinforcement material. Bamboo unit undergoes boiling with chemical solution, drying, and then milling the unit on its outer surface, in order to make it become polygonal bamboo segment, arranging abreast side by side in cross-section direction and longitudinally elongating by finger joints, after all, the substrate of prestress structural material formed by polygonal original bamboo units is formed; after those, extending the lacing wire through all or part of bamboo unit of substrate, and the high-strength baffles are disposed on both ends of substrate, fastening both ends of tautened substrate on baffles by anchors or nuts, allowing the lacing wire act as reinforcement material, then the prestress structural material is formed. The invention makes full use of the structure and physical characteristic of original bamboo, and the prestressed effect generated by lacing wire, the environmental friendly structural material with high-intensity, large span, low power, which effectively alleviates the contradiction between China's timber supply and demand, and partially substitutes for concrete and steel materials, it has broad development prospect.

Owner:BEIJING FORESTRY MACHINERY RES INST OF THE FORESTRY ADMINISTRATION

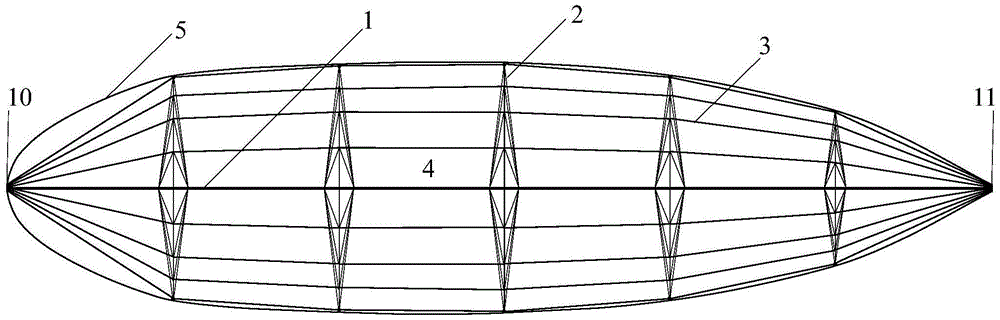

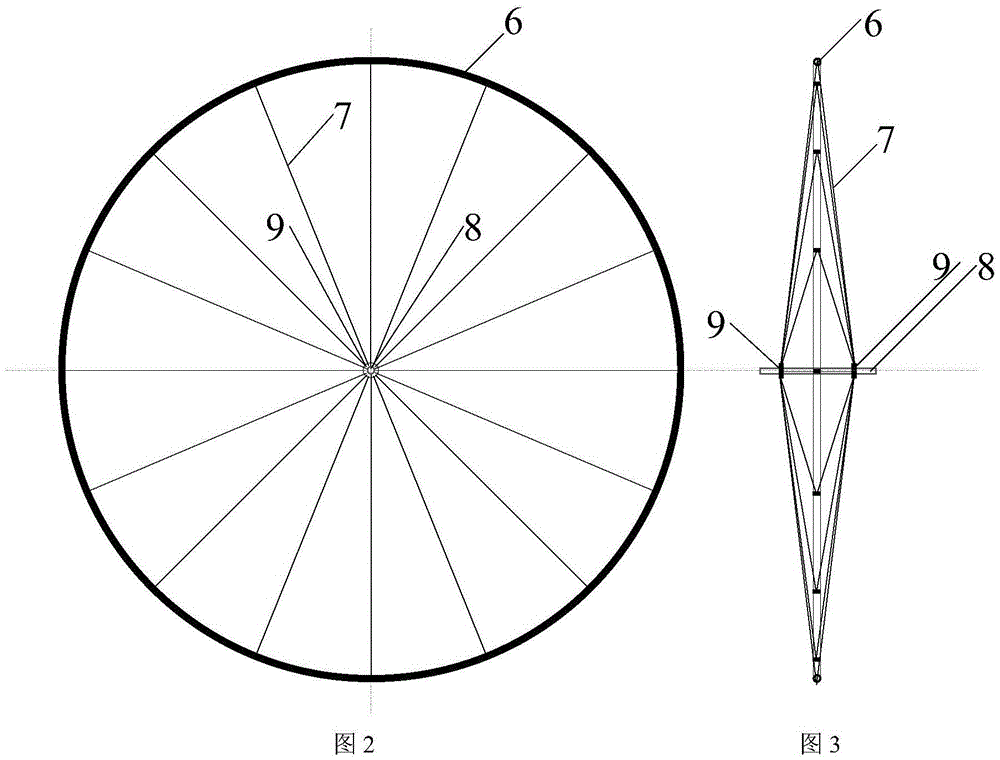

Rigid structure system of large airship

PendingCN105644761AImprove mechanical stabilityImprove mechanical propertiesRigid airshipsPre stressRigid structure

The invention relates to a rigid structure system of a large airship. The rigid structure system of the large airship comprises a prestressed structure system and a flexible outer envelop structure. The prestressed structure system is composed of a central spindle, a plurality of prestressed stiffening rings and longitudinal connecting rods. The central spindle is located in the longitudinal center of an airship envelop and penetrates through the head and tail of the airship envelop, the concentric prestressed stiffening rings are arranged on the central spindle, the outer ends of the prestressed stiffening rings are connected through the longitudinal connecting rods, and the closed structure system is formed. According to the flexible outer envelop structure, a thin film material is used for being wrapped outside the structure. The rigid structure system improves the overall mechanical property and flight capacity of the large airship, the large airship can ascend / descend in a shape-preserving mode, and the airship has good flight capacity in a specified atmospheric environment and return capacity in an emergency state.

Owner:付功义 +3

Airliner window transparent part fastening structure and fastening method thereby

ActiveCN103291184AGuaranteed StrengthNo stress weak pointsVehicle componentsGlass/slag layered productsEngineeringInternal stress

The invention discloses an airliner window transparent part fastening structure comprising an airliner body and a transparent part mounted on the airliner body. A prestressed structure frame is connected to the periphery of the transparent part. A mounting structure matching with the airliner body is formed on the prestressed structure frame. The transparent part of the fastening structure is provided with no screw holes, internal stress balance of the transparent part is not damaged, and no stress weakness exists. The circular prestressed frame is formed on the periphery of the transparent part, the overall stress structure with the transparent part and the airliner body and having the function of prestress buffering is formed, difference of pressure borne by the transparent part and loads such as bird impact can be transmitted to the airliner body effectively, and structure stability is guaranteed. Coverage with seal glue and the like through a prestress component makes the fastening structure to be more firmly and more durably adhered to the edge of the transparent part, and accordingly the service lives of the seal glue and a polyurethane interlayer are prolonged greatly, conductive strips in the laminated transparent part are protected, and arcs and even breakage are avoided for the transparent; replacing frequency of the transparent part is reduced and using cost is reduced.

Owner:高峰

Functional admixture used for early tensioning prestressed structural concrete and purposes of functional admixture

InactiveCN102584063AImprove early strengthHigh early modulusSolid waste managementPre stressUltimate tensile strength

The invention relates to a functional admixture used for early tensioning prestressed structural concrete. The functional admixture comprises the following materials in percent by weight: 5%-95% of carbonate stone powder and mineral admixture; the carbonate stone powder is obtained by processing carbonate ores through processes such as breaking and fine grinding. A preparation process comprises the following steps of: grinding the carbonate ores into fine powder, and uniformly mixing with other mineral powders according to the proportion to obtain the functional admixture. The prepared functional admixture is applied in preparation of cast-in-situ beam concrete; the concrete capable of meeting fast tensioning requirement can be prepared under the premise without increasing the design strength of the concrete; and the problems that the conventional in-cast-situ beam concrete is long in prestressed age and long in construction period are solved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

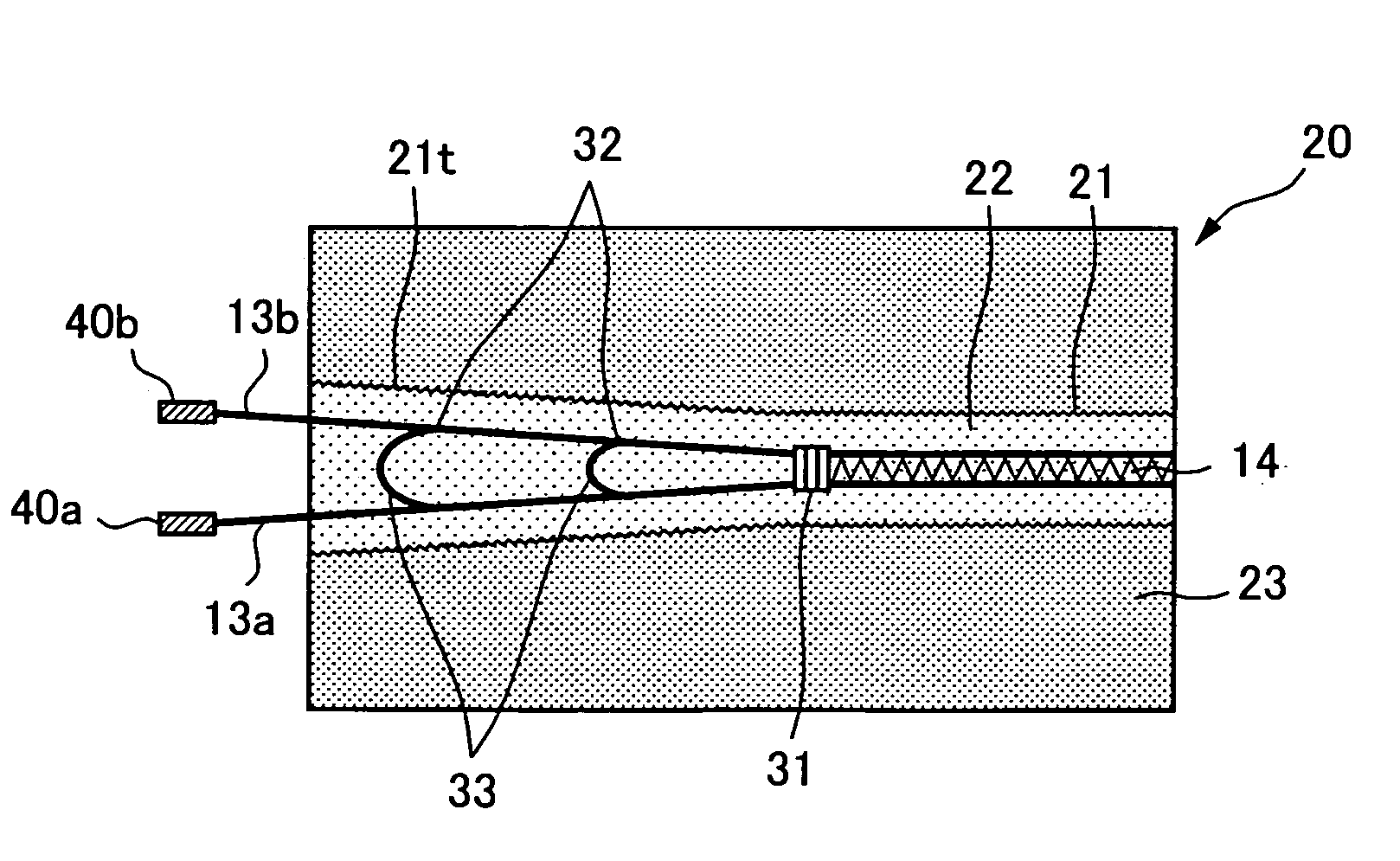

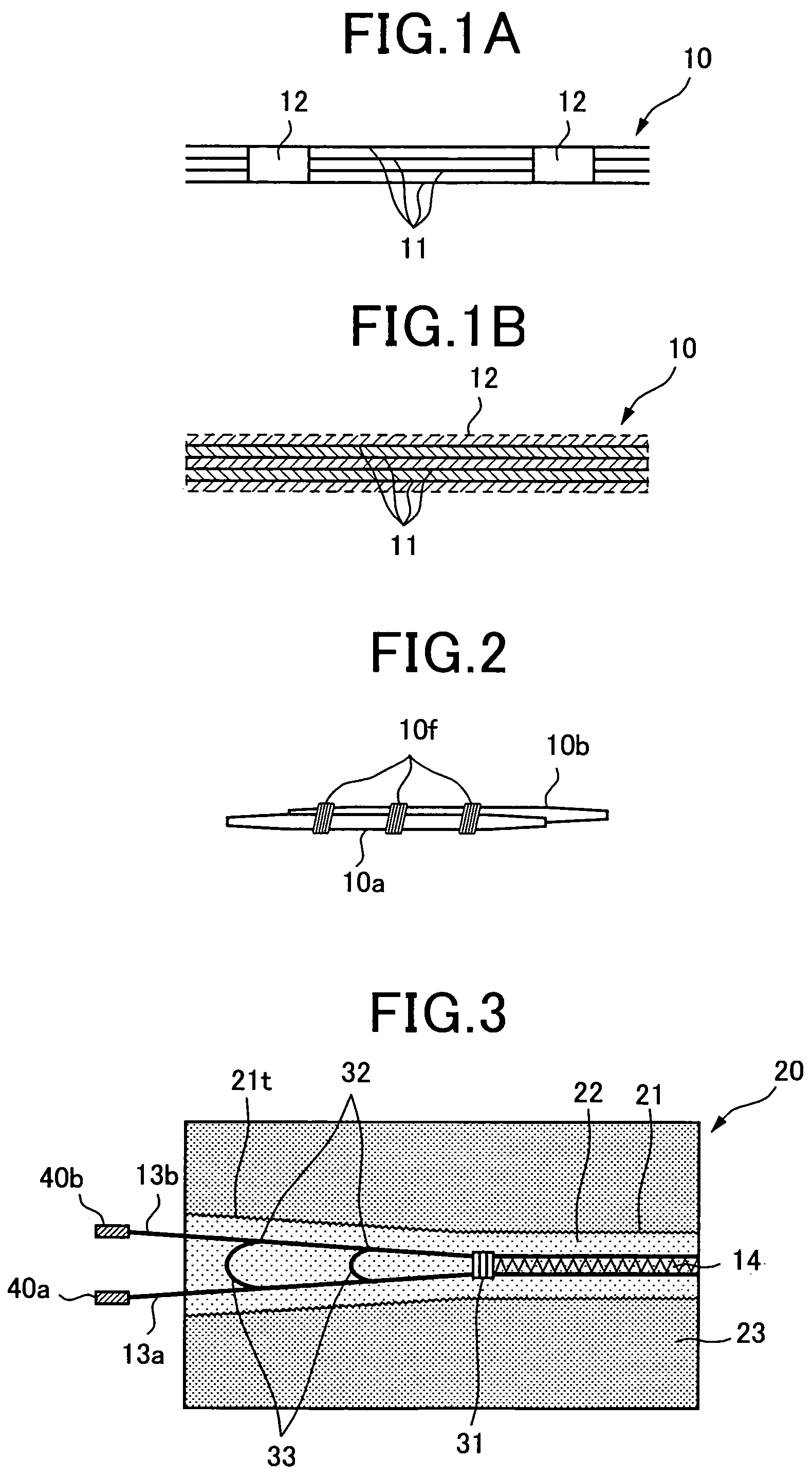

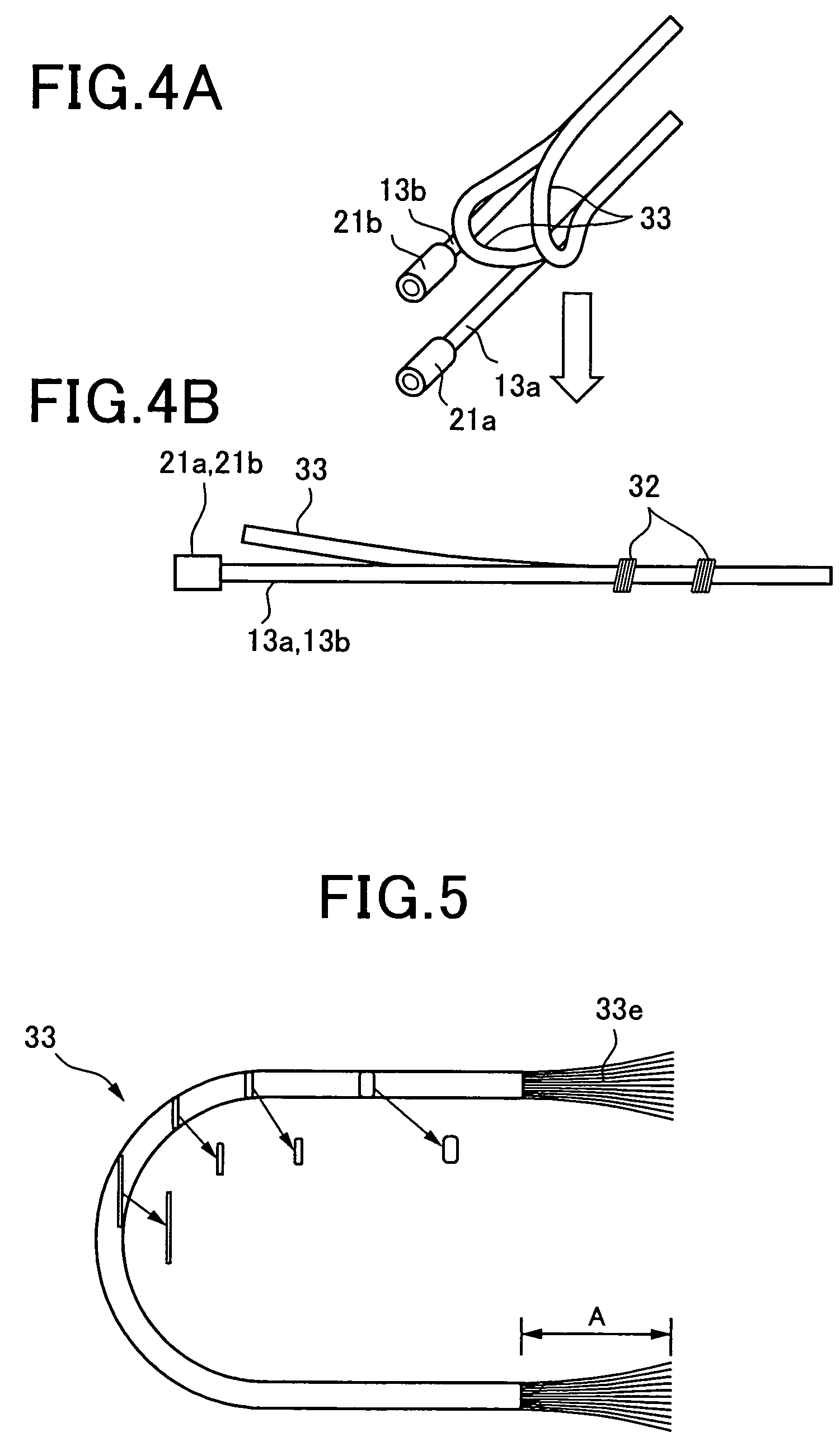

Method of manufacturing prestressed concrete

InactiveUS7056463B2Improve fatigue strengthExcellent in corrosion-resistanceCeramic shaping apparatusBuilding reinforcementsFiberCarbon fibers

Pre-tension and post-tension processes for the manufacture of pre-stressed structures in which bonded carbon fiber cables are provided with burial anchors and temporary anchors outward of the burial anchors. The burial anchors are embedded in the structure. The temporary anchors enable stressing of the carbon fiber cables.

Owner:JAPAN SCI & TECH CORP

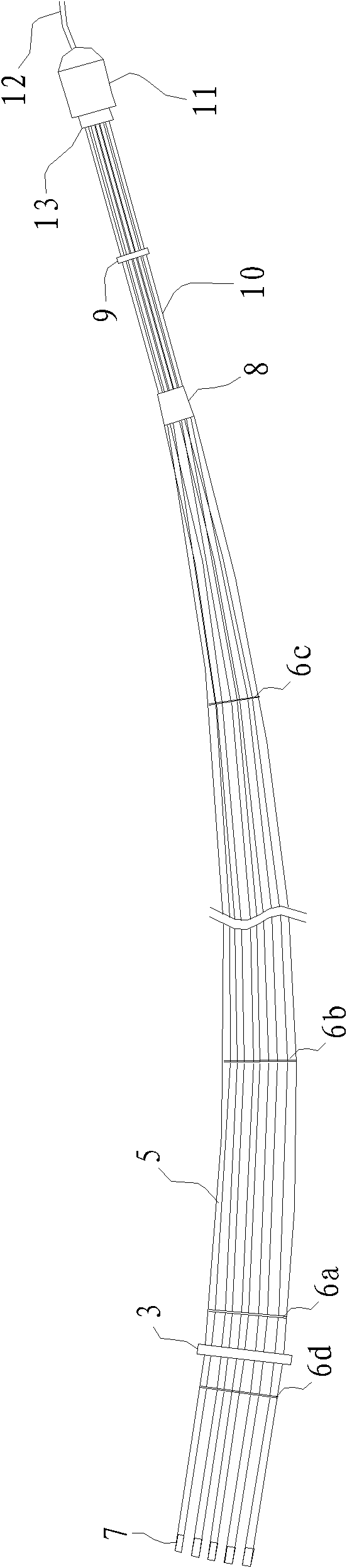

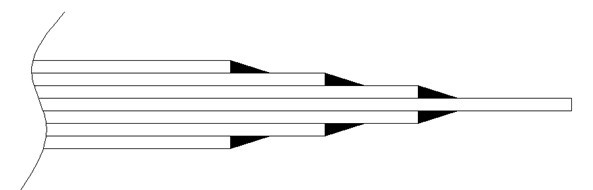

Steel strand bundle-weaving and crossing construction method

InactiveCN102003072AAvoid entanglementAvoid uneven forceBuilding reinforcementsBuilding material handlingMetallurgyPre stress

The invention discloses a steel strand bundle-weaving and crossing construction method, comprising the following steps of: intercepting a steel strand; peeling and cutting an outer-layer steel wire at one end of the steel strand; drawing the steel strand to pass through a through hole corresponding to a duplicating wire combing board; enabling the central steel wire to pass through the duplicating wire combing board according to the position of the steel strand in the duplicating wire combing board; installing the end of the central steel wire, passing through the duplicating wire combing board, in a cross guiding base; coating the end of the steel strand and the part of the steel strand with the out-layer steel wire peeled; introducing a cross guiding head to pass through a corrugated pipe or a sheath in a pre-stress member to be fixed with the cross guiding base; drawing the steel strand to enter the corrugated pipe or sheath in the pre-stress member in a guiding mode; and cutting off the central steel wire exposing from one end of the steel strand, together with the cross guiding base. The invention can effectively avoid uneven stress of the steel strand during tensioning when the steel strands are wound to each other caused by improper bundle crossing, improve the construction quality of a pre-stress structure and save the working time.

Owner:TIANJIN BINHAI YINGXIN INVESTMENT

Constructing method for threading pre-stress structure steel strands

InactiveCN102003073ANo thermal stressWon't scratchBridge erection/assemblyBuilding reinforcementsPre stressThreading (manufacturing)

The invention discloses a constructing method for threading pre-stress structure steel strands in a corrugated pipe. In the procedure of manufacturing each bundle of the steel strands, a dragging end of each steel strand is processed; a steel wire is exposed into a certain length relative to the other steel wires; all steel strands are bound to form a bundle; the steel wire exposed out of each steel strand is fixed with a threading anchor fastener; the front end of the threading anchor fastener is connected with a dragging steel wire rope of a dragging device; the back end of the threading anchor fastener is connected with the steel wire exposed out of the steel strand; the dragging steel wire rope drives the steel strand bundle to move in the corrugated pipe so as to pass through the pipe through the threading anchor fastener. The constructing method does not use an end head welding method; the steel strand bundle does not have the thermal stress action; and the end head is not cut again. In addition, the steel strand is good in flexibility and suitable for the linear changing of the pipeline; and the constructing speed is improved by threading the whole steel bundle, and the threading anchor fastener can be reused, therefore, the construction cost is reduced, and the quality and the building construction period are ensured.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

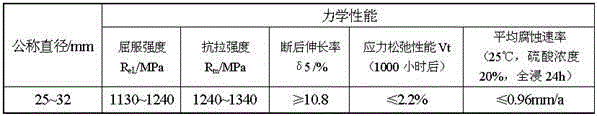

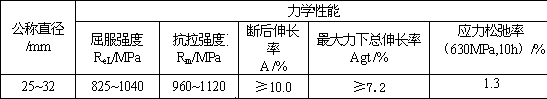

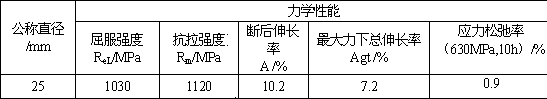

1080MPa high-strength corrosion-resistance twisted steel for prestressed structure and preparation method of 1080MPa high-strength corrosion-resistance twisted steel

The invention discloses 1080MPa high-strength corrosion-resistance twisted steel for a prestressed structure and a preparation method of the 1080MPa high-strength corrosion-resistance twisted steel. The 1080MPa high-strength corrosion-resistance twisted steel for the prestressed structure is characterized by being composed of 0.50-0.60wt% of C, 1.25-1.50wt% of Si, 1.20-1.40wt% of Mn, 0.40-0.60wt% of Cr, 0.040-0.070wt% of Mo, 0.040-0.070wt% of Ti, 0.15-0.30wt% of Ni, at most 0.010wt% of S, at most 0.015wt% of P and the rest of Fe and unavoidable impurities. The preparation method includes billet preparation, rolling, aftertreatment and the like, control of amount, size and distribution of the impurities is realized, and cracking of billets is avoided due to hot delivery of casting blanks. Due to addition of Cr, Ni and Mo alloy elements to the steel, hardenability and corrosion resistance are improved, and crack initiation is prevented. Owing to controlled rolling and cooling, grain refinement of rebar structures is realized, and ferrite network structures of core portions are reduced. The twisted steel has the advantages of high toughness, high corrosion resistance and excellent prestressing looseness and is capable of keeping stable performances in various atmospheric environments for a long term to guarantee stability in long-term use of anchored objects.

Owner:WUKUN STEEL

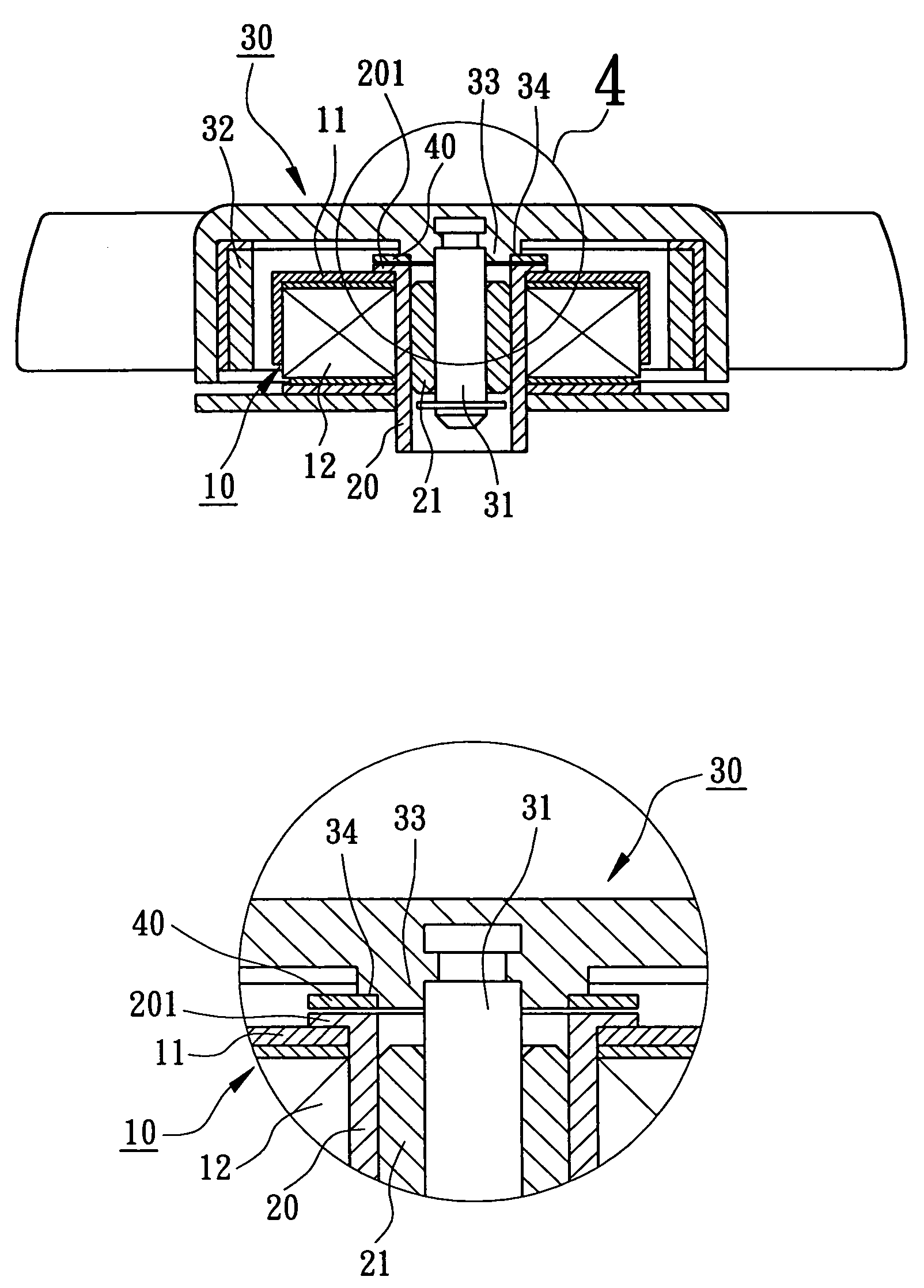

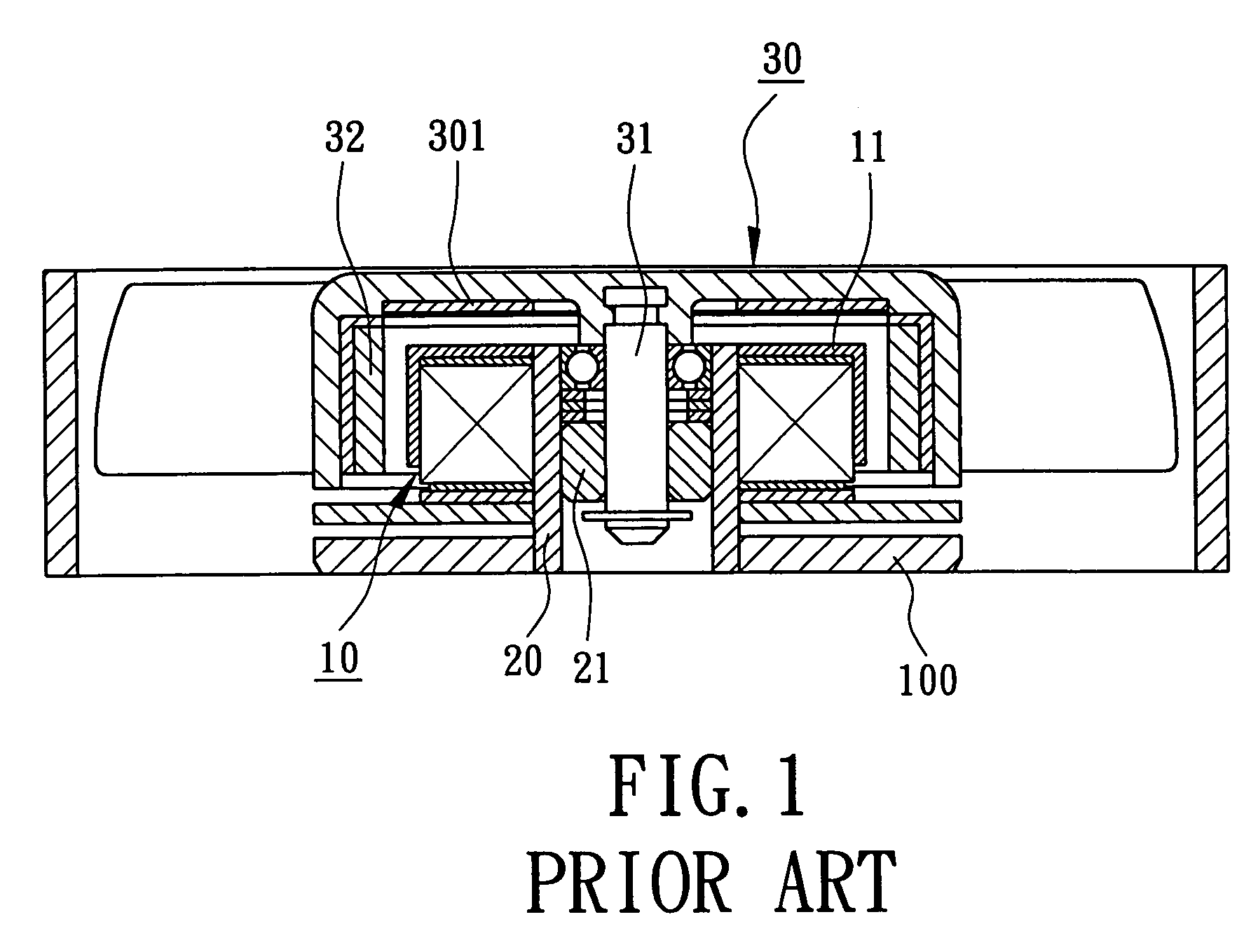

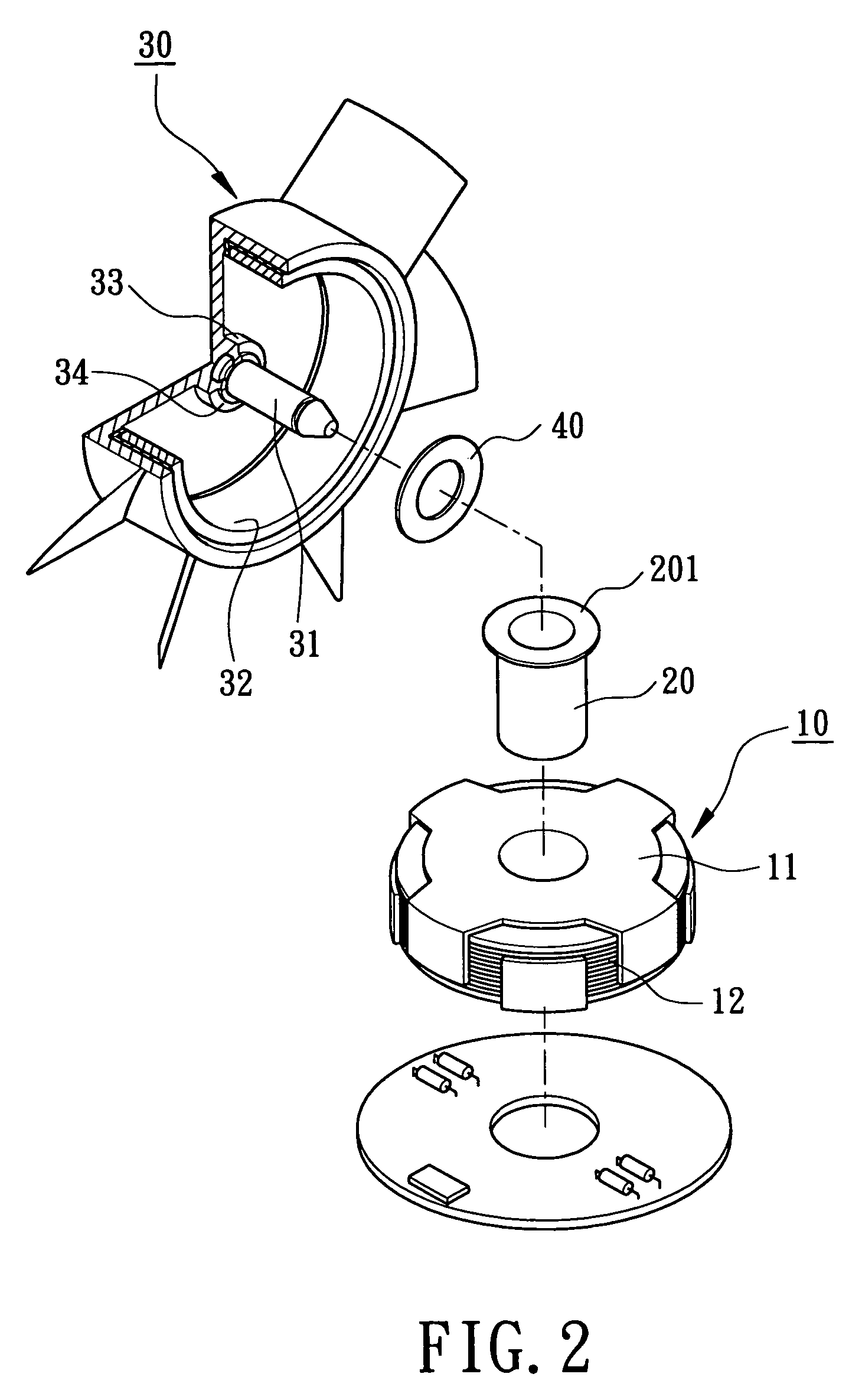

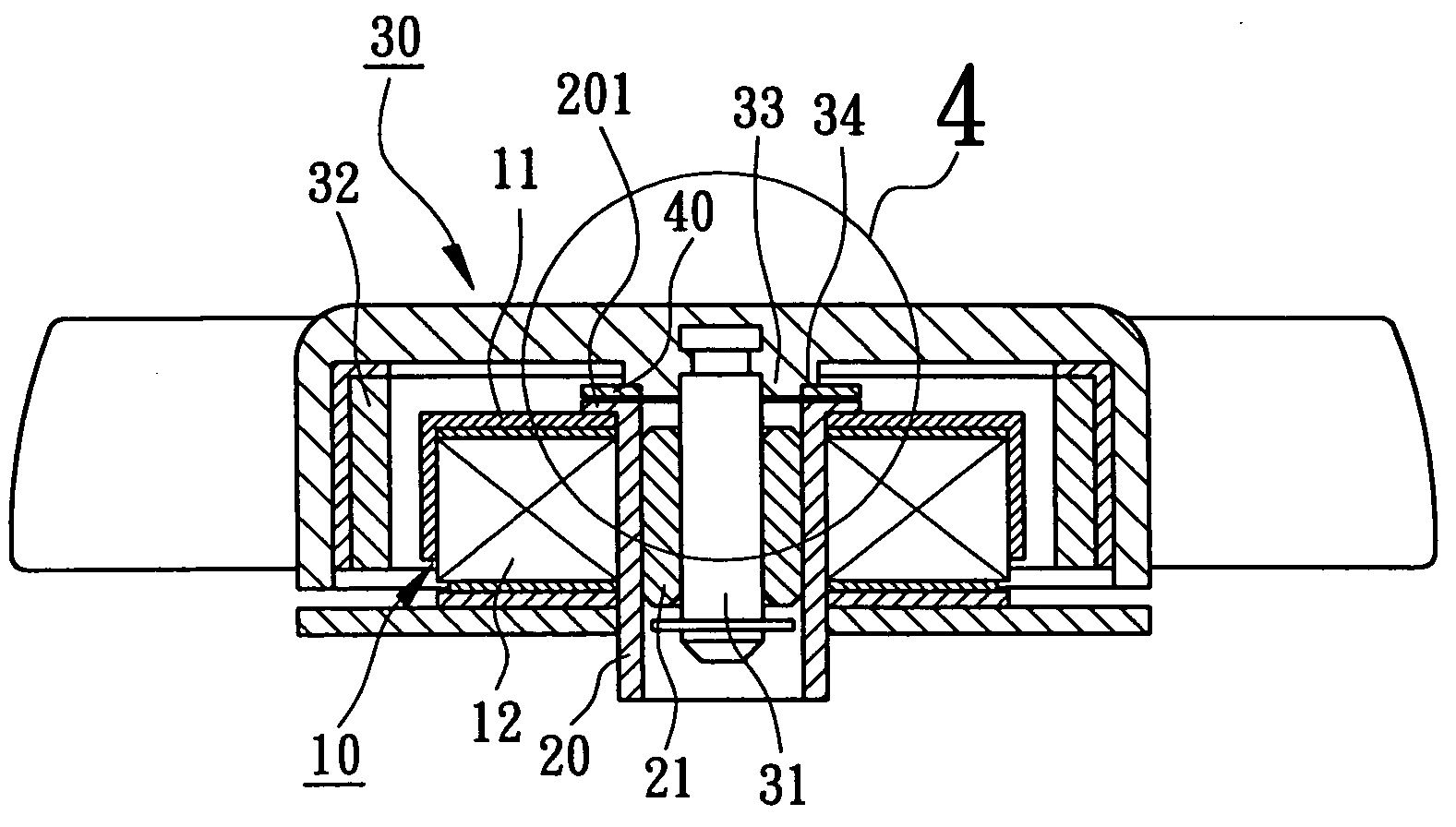

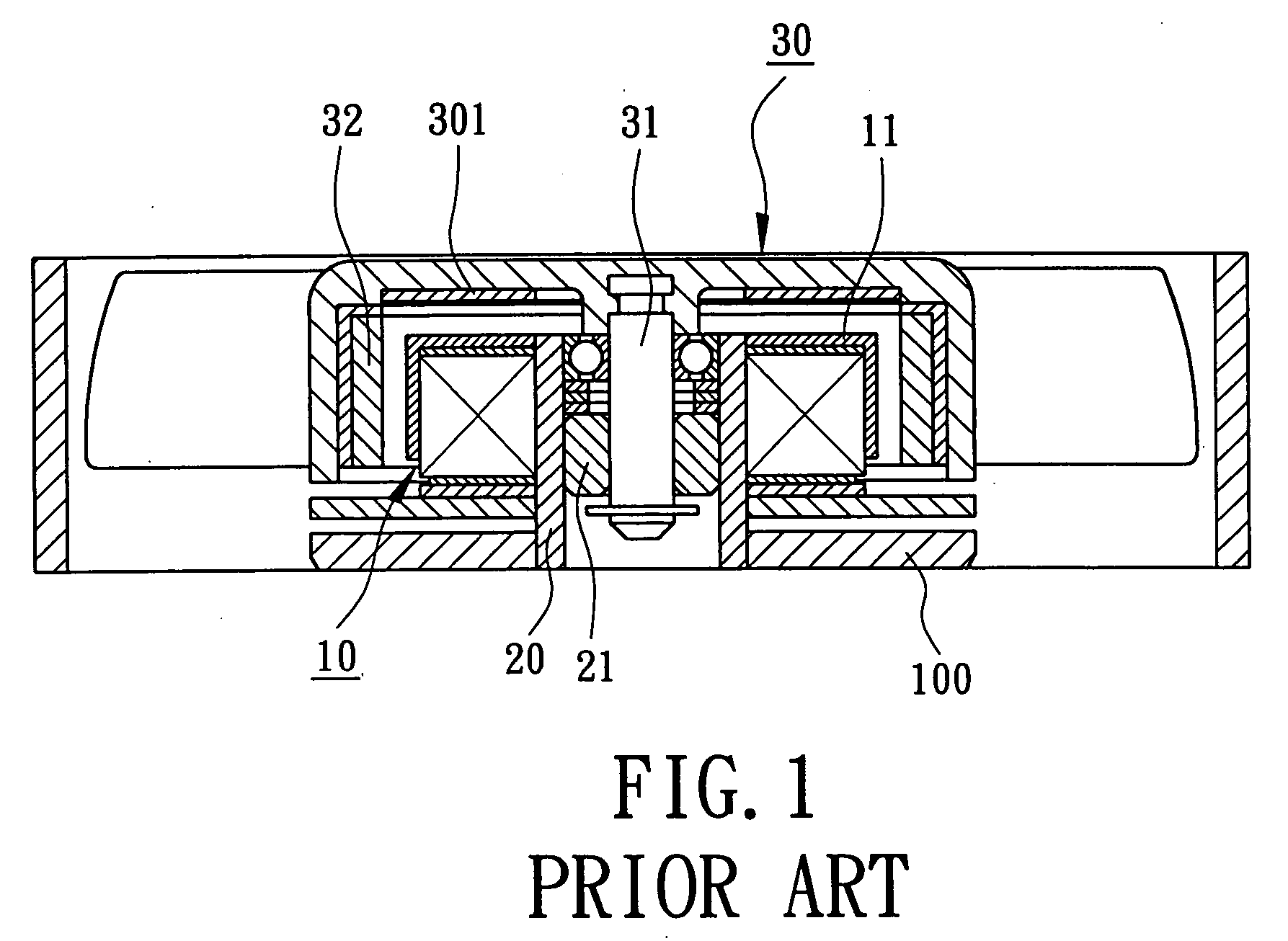

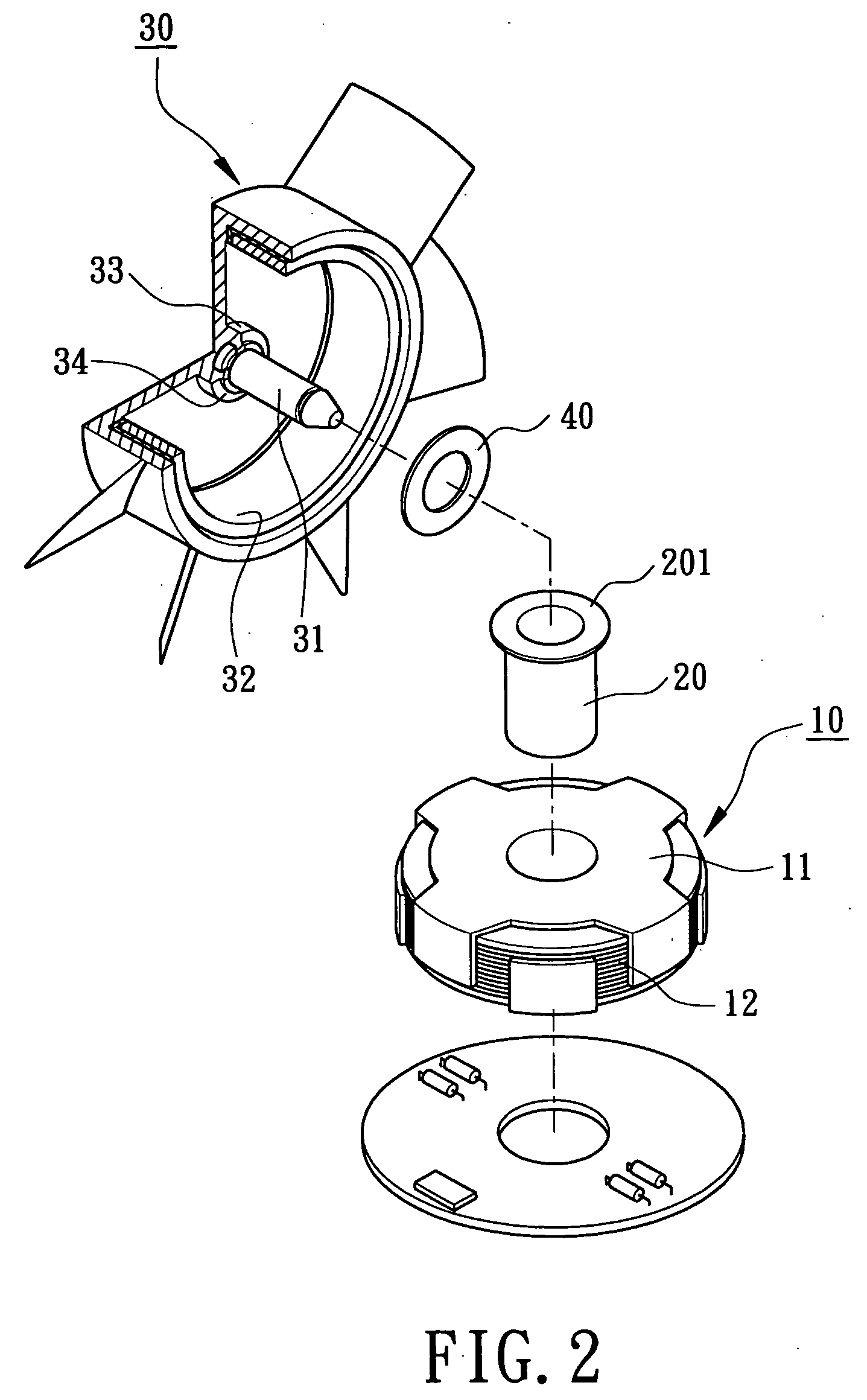

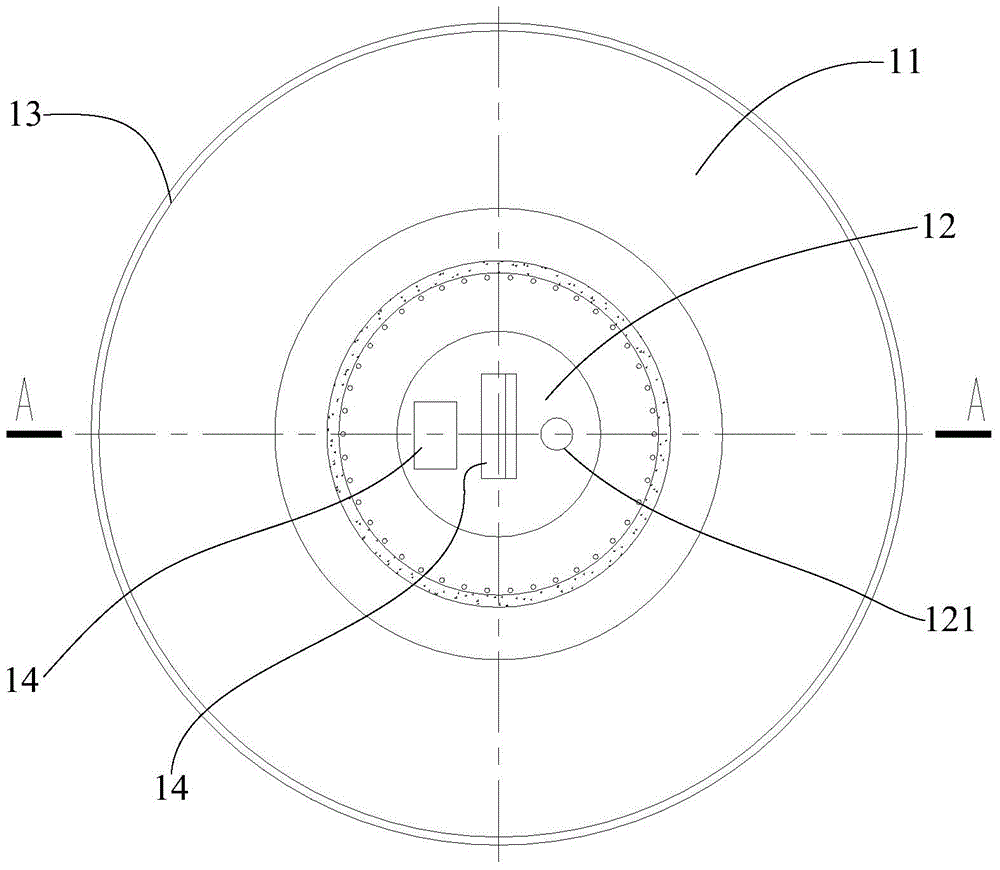

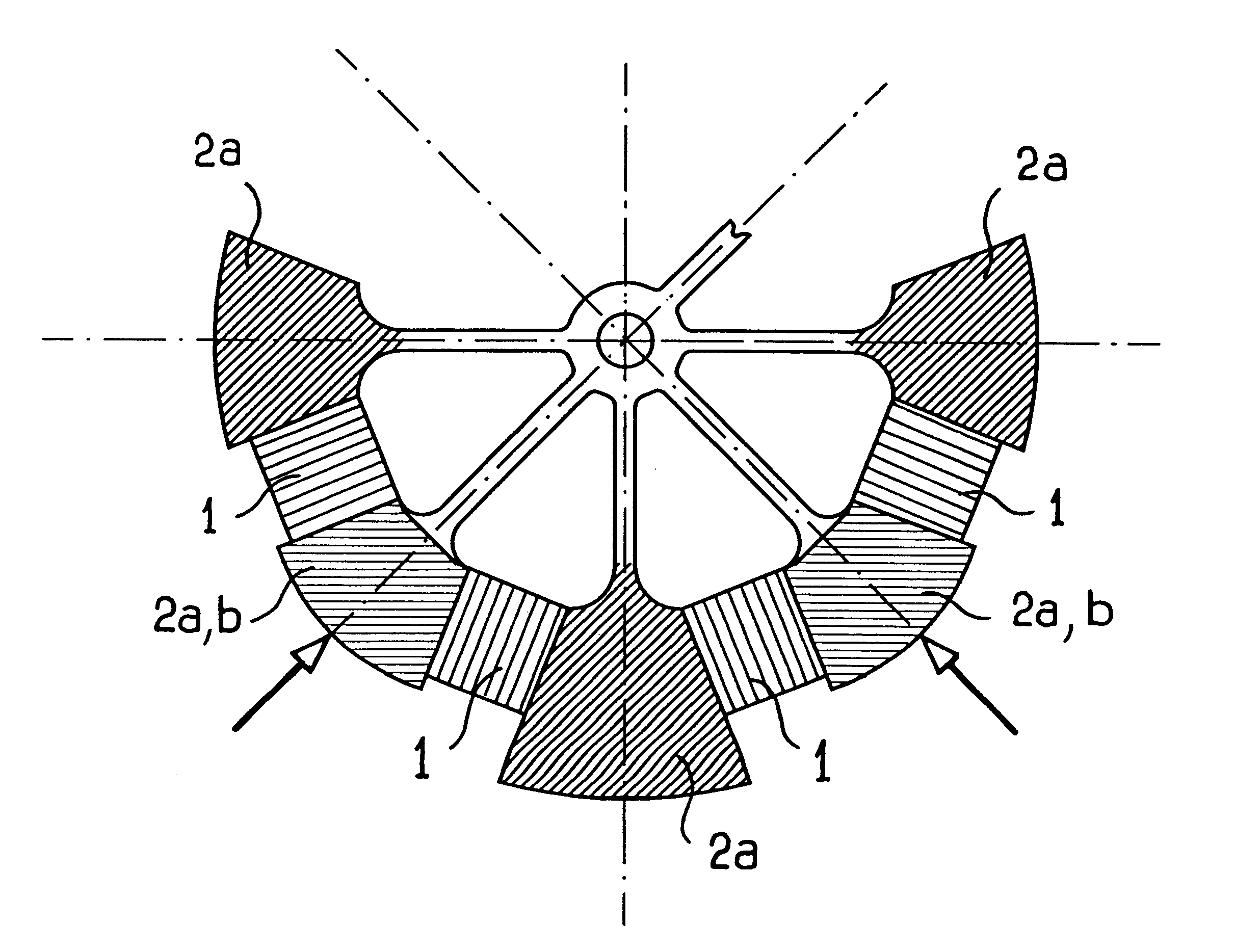

Prestressing structure for rotationally balancing a motor

A prestressing structure for rotationally balancing a motor includes a motor stator, a motor rotor, a magnetically conductive member and a balancing magnet. The motor stator has an axial hole and an axial tube extending therethrough. An end of the axial tube provides with the magnetically conductive member. The motor rotor has an inner surface and a shaft seat mounted thereon. A top portion of the shaft seat provides with the balancing magnet which has at least one surface successively attracting at least one surface of the magnetically conductive member for stabilizing rotary movement of the motor.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

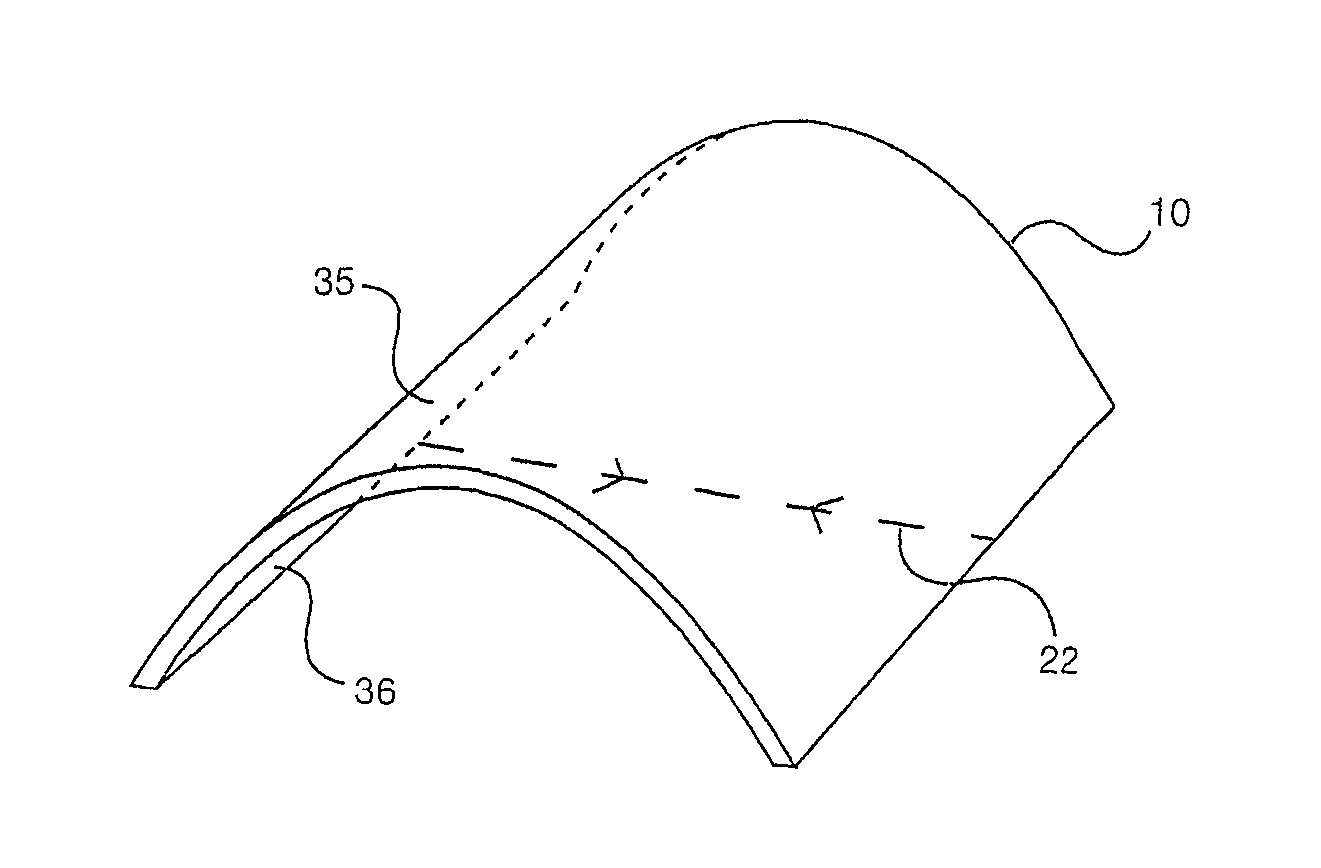

Structural assembly with a flexed, tied panel

An assembly includes a flexurally deformed panel, which is connected to a membrane tie by a linear connector and is tied by the membrane tie to form a geometrically stable pre-stressed structure. More than one panel may be flexurally deformed and tied together in an assembly and more than one membrane tie may be present within an assembly. Panels are typically semi-rigid sheet materials, for example metal sheets, plastic sheets, or sheets of composite materials, such as glass or carbon fiber reinforced plastics or resins. Membrane tie members are typically flexible, for example plastic films, fabrics or nets or arrays of rods or cables. The assemblies have many different geometric forms and many different practical applications. Assemblies may be relatively large, for example demountable and reusable shelters or flat-pack point-of-purchase display assemblies, or may be relatively small, for example a photograph or postcard display system.

Owner:CONTRA VISION

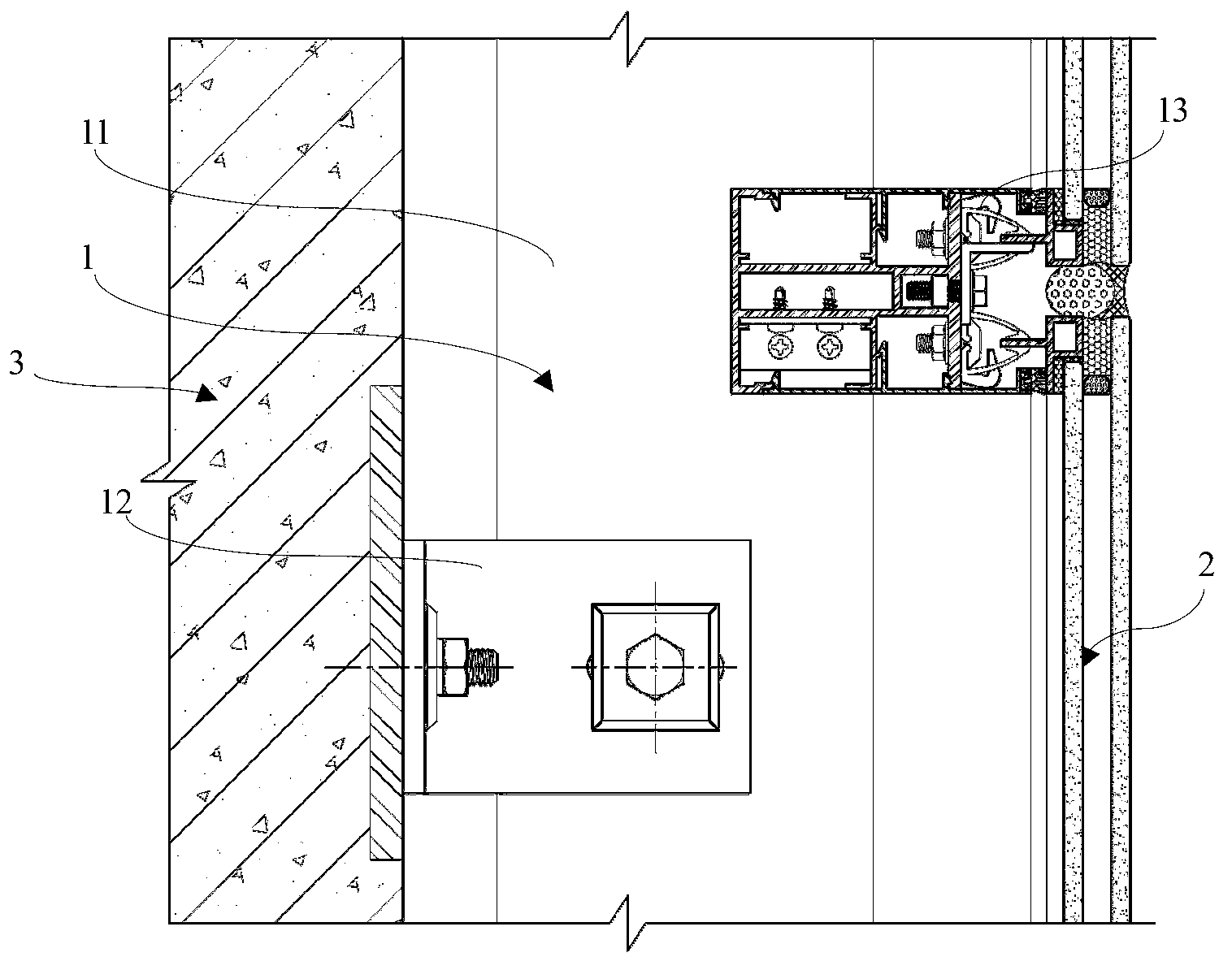

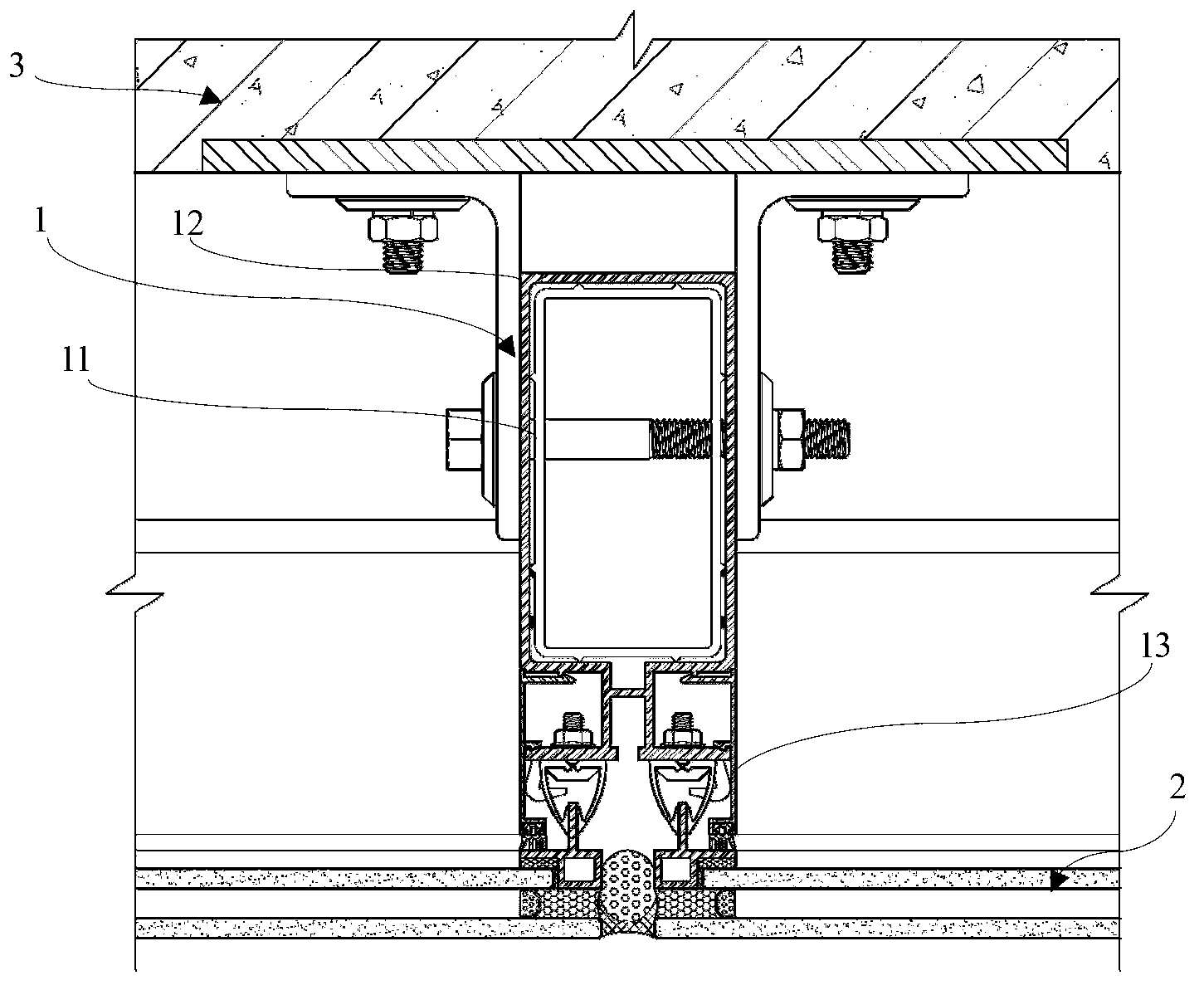

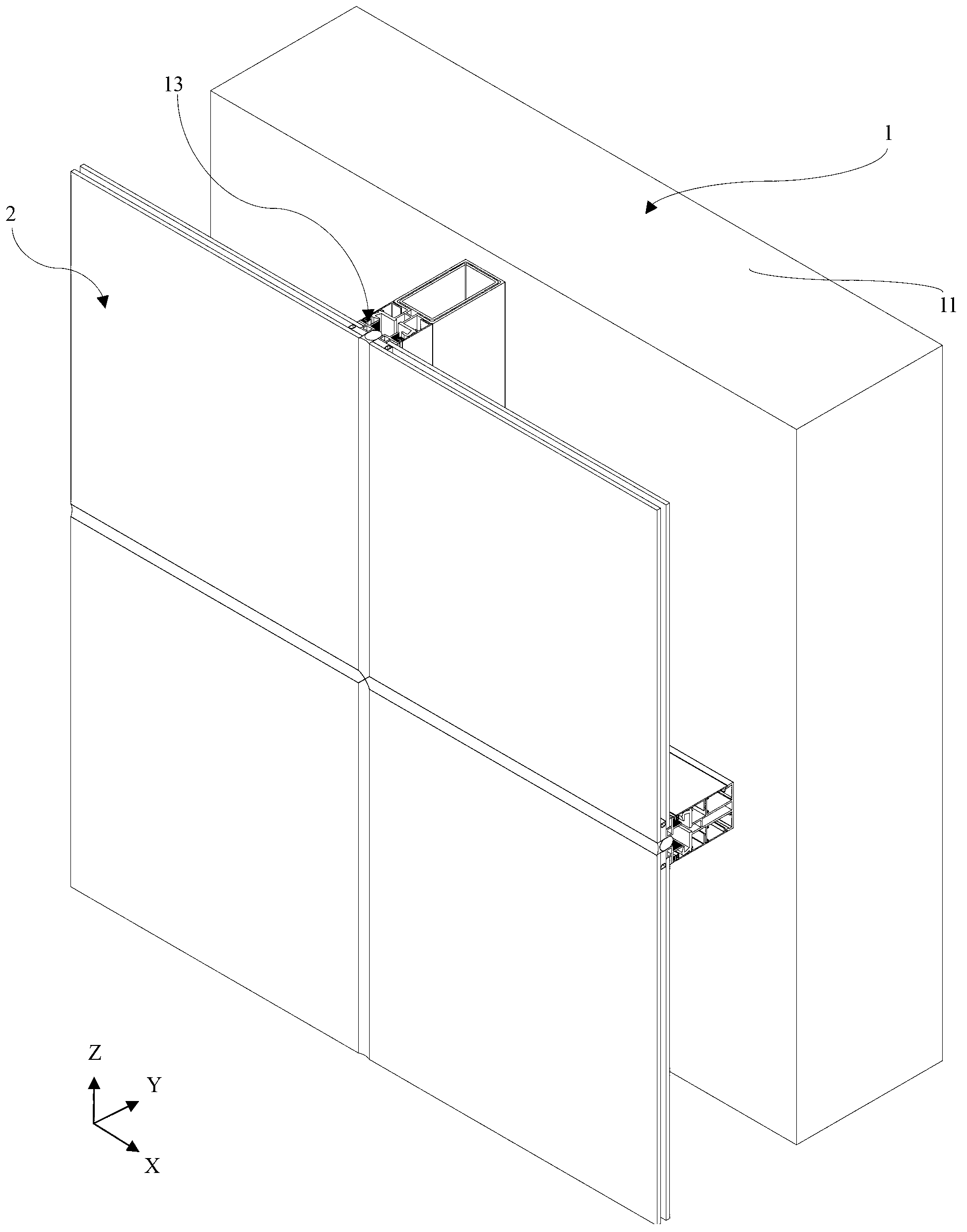

Hidden frame glass curtain wall installation structure and hidden frame glass curtain wall installation method

ActiveCN103306409AEffective prestressed fasteningMeet the requirements of installation accuracyCovering/liningsWallsChassisPrestressed structure

The invention discloses a hidden frame glass curtain wall installation structure which comprises a building main body and a glass curtain wall installed on the building main body, wherein the installation structure further comprises an installation chassis, the glass curtain wall is regulated through the installation chassis to a set position and is fastened, and the position of the glass curtain wall is unchanged in the fastening process. Due to the adoption of the hidden frame glass curtain wall installation structure, the hidden frame glass curtain wall installation structure exciting and controlling the dynamic production process of prestress of an elastic material to form a stable prestress structure and conducting three-dimensional regulation in the installation process to substantially improve the installation accuracy is provided, and the hidden frame glass curtain wall installation structure has the characteristics of excellent firmness, accuracy, safety, convenience and replacement.

Owner:明威科技集团股份有限公司

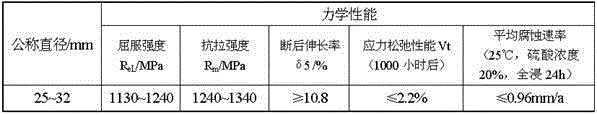

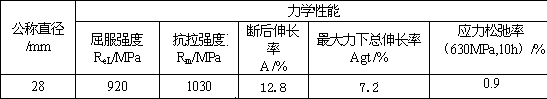

Twisted steel for 785 MPa-level high-strength prestressed structure and preparation method of twisted steel

The invention discloses a twisted steel for a 785 MPa-level high-strength prestressed structure and a preparation method of the twisted steel. The twisted steel comprises following constituents in percentage by weight: 0.50-0.55% of C, 0.80-1.10% of Si, 1.00-1.30% of Mn, 0.060-0.12% of V, 0.60-0.95% of Cr, 0.0015-0.0040% of B, 0.010-0.025% of S, 0.010-0.025% of P, and the balance of Fe and unavoidable impurities. The preparation method comprises steps of billet preparation, rolling and after treatment. In the preparation process, when vanadium is utilized to conduct microalloying and reinforcement, the alloying element B is appropriately added to improve the steel hardenability, and the addition of the microalloying reinforcing elements is lowered. As the controlled rolling technology is combined and the cooling technology is applied, the grain refinement of steel structure is obvious, the net-like ferritic structure at the core of the steel is lowered, the steel strength is increased, the hardness gradient change is slow, and the stability of the precision rolled twisted steel is improved. The processed steel is stable in technologic and mechanical performances, and good in prestress relaxation performance.

Owner:WUKUN STEEL

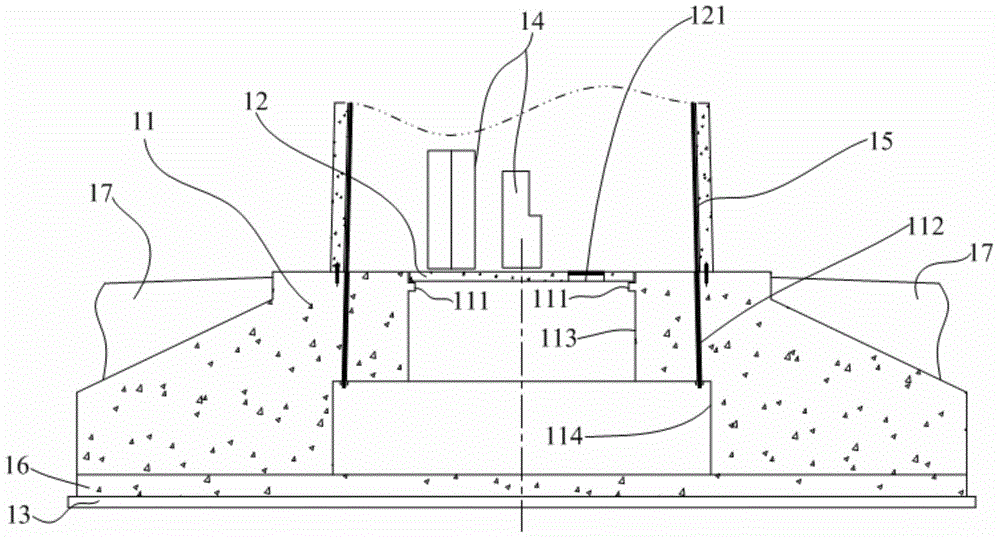

Prestress concrete filled steel tube self-balancing type static load test table for bridge static load test

PendingCN107340185AIncrease stiffnessLess consumablesMaterial strength using tensile/compressive forcesTest beamPre stress

The invention relates to a bridge static load test device, in particular to a large-span simple supported beam prestress self-balancing type static load test table. The test table comprises a test beam, jacks, counter-force beams, upper cross beams, vertical pull rods, support piers, lever beams and ground counter-force piers. The counter-force beams are located on the test beam, the jacks are located between the counter-force beams and the test beam, the upper cross beams are located at the two ends of the counter-force beams, and the vertical pull rods are arranged at the two ends of the upper cross beams; the lower ends of the vertical pull rods are connected with the rear ends of the lever beams, the lever beams penetrate through the support piers through pin shaft connection, and the front ends of the lever beams are in contact with the ground counter-force piers to provide test counter-force. The counter-force beams are of a section spliced prestress structure so that a large quantity of materials can be saved. The situation that a bridge deck slab is drilled to allow the vertical pull rods to penetrate for testing is avoided. The test table is scientific in structure, economical and applicable, on-site fabricated beams can be transferred conveniently, the problem is solved that a foundation pit concrete heavy counter-force test table base is used in an existing 40 m beam and accordingly blow-up and second ploughing are caused, and the test table is suitable for static load tests of various spans and beam types.

Owner:BEIJING HUAHENG NEW TECH DEV +2

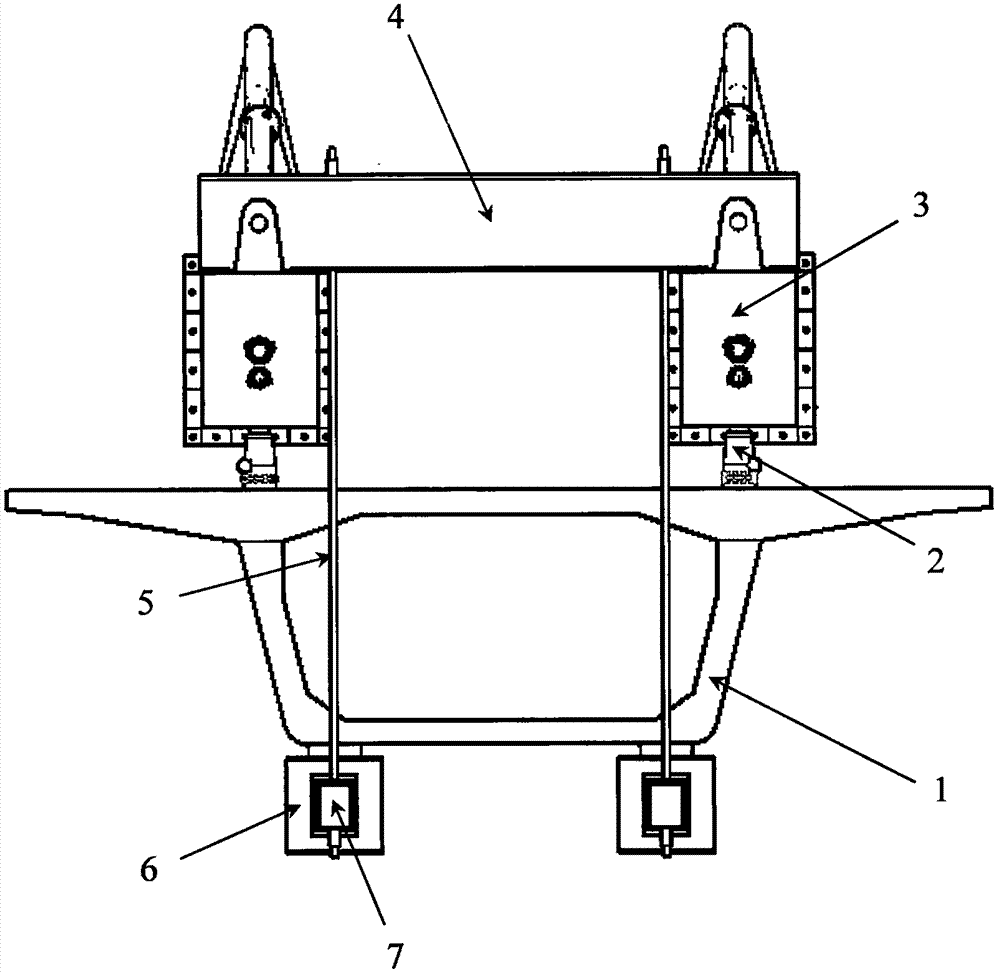

Tower foundation of wind generating set

The invention discloses a tower foundation of a wind generating set and relates to the technical field of wind power generation, aiming to solve the problems that an existing tower foundation cannot meet requirements on anchoring at two ends of the bottom of a prestressed cable in a prestressed structure and maintenance and replacement of other components in the prestressed structure are not facilitated. The tower foundation comprises a hollow tower foundation body, a cover plate is arranged at the top of the tower foundation body, and a manhole is formed in the cover plate; ring beams used for supporting the cover plate are arranged on the inner wall of the tower foundation body; prestressed cable channels are arranged in the tower foundation body and penetrate the side wall of the tower foundation body, one ends of the prestressed cable channels are communicated with the top of the tower foundation body, and the other ends of the prestressed cable channels are communicated with the hollow part of the tower foundation body. The bottom of the tower foundation body is connected with a concrete cushion which is located on the surface of the foundation.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

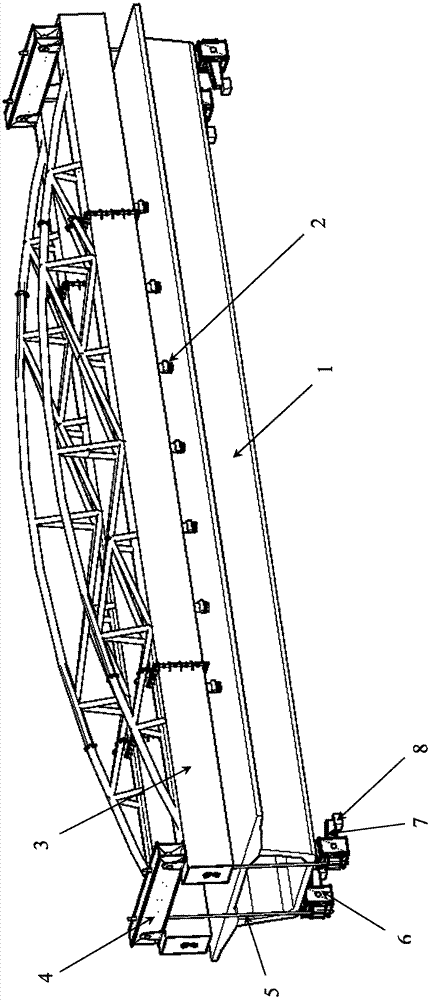

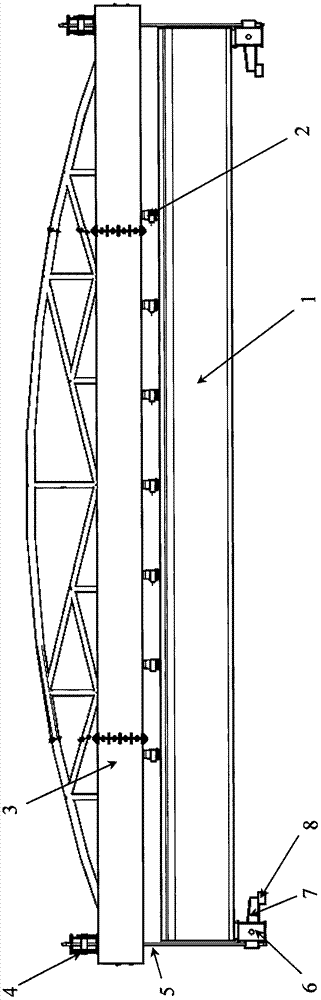

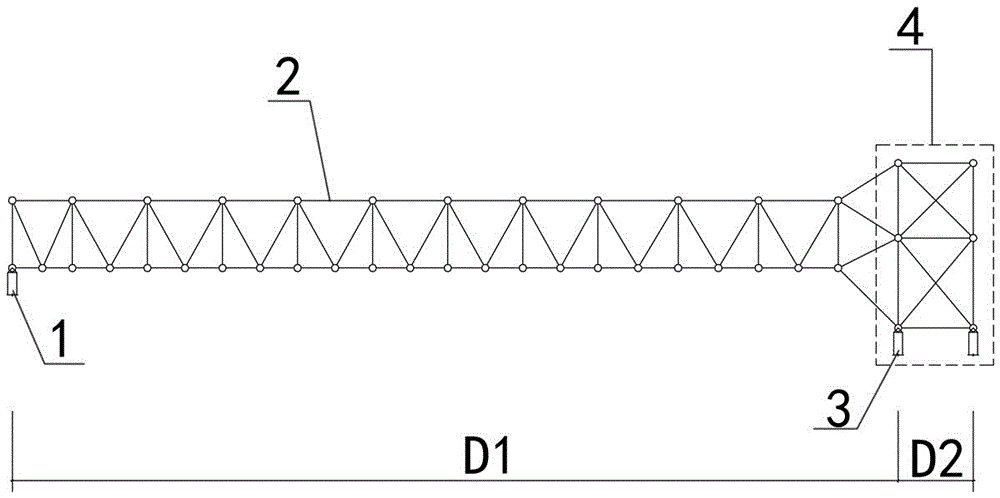

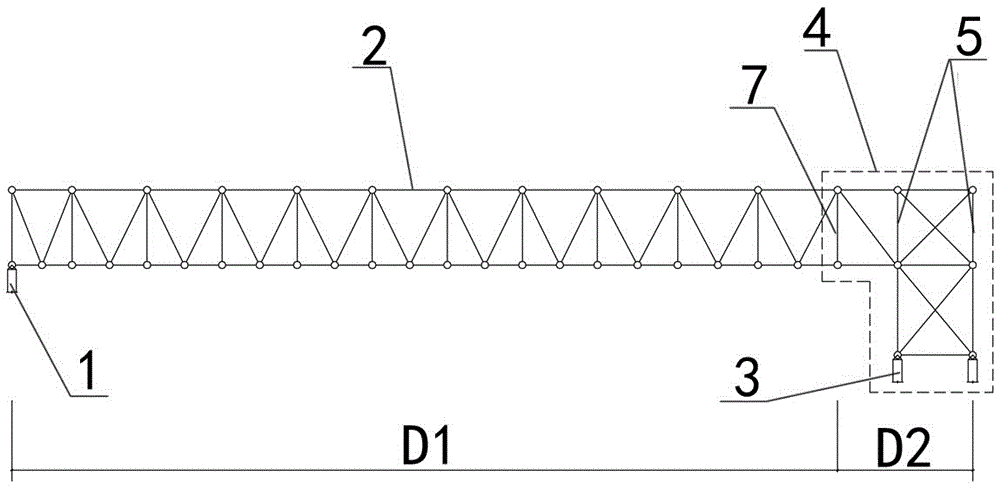

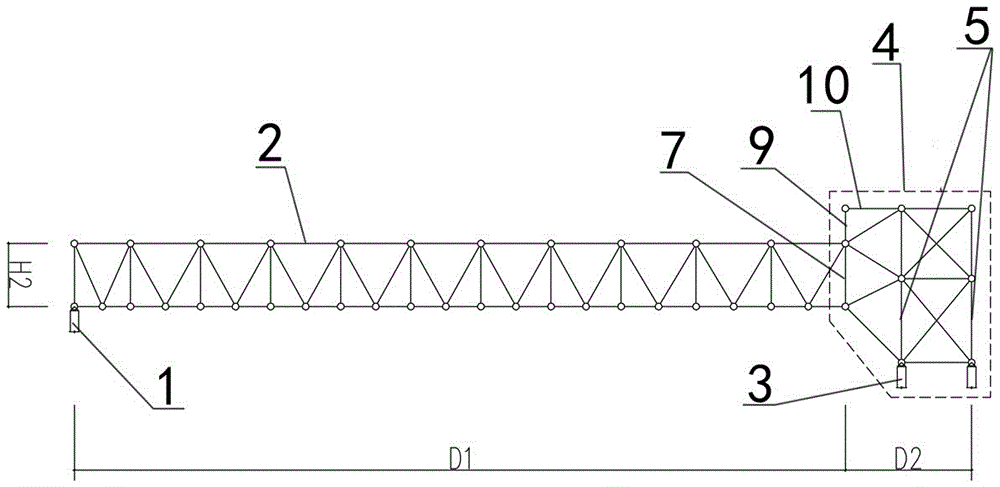

Large-span hangar fringe truss prestressed structure system and construction method thereof

ActiveCN106193306AImprove mechanical performanceImprove vertical support stiffnessBuilding roofsPre stressEngineering

The invention discloses a large-span hangar fringe truss prestressed structure system and a construction method of the large-span hangar fringe truss prestressed structure system. The structure system comprises roof supporting columns, a roof steel structure, gate truss supporting columns and a gate truss, wherein the roof supporting columns are arranged along the three edges of a hangar at intervals, the roof steel structure is fixed to the tops of the roof supporting columns and is in a flat plate shape, the gate truss supporting columns are located on the sides of the opening edges of the root supporting columns and arranged in the depth direction of the hangar at intervals, and the gate truss is fixed to the tops of the gate truss supporting columns. The root steel structure is directly connected with the gate truss. A body interior prestressed steel strand cable is arranged in a lower chord of the gate truss and completes pretension through an anchoring end joint and a tension end joint at the two ends of the lower chord correspondingly. The two ends of the lower chord and adhesive sections on the outer sides of the two ends of the prestressed steel strand cable are filled with concrete. By the adoption of the body interior prestressed technology, a ball or pipe truss can be adopted to successfully span a single-span hangar with the span larger than 140 m, and the technical and economical index of the structure is greatly improved.

Owner:CHINA AVIATION INT CONSTR & INVESTMENT CO LTD

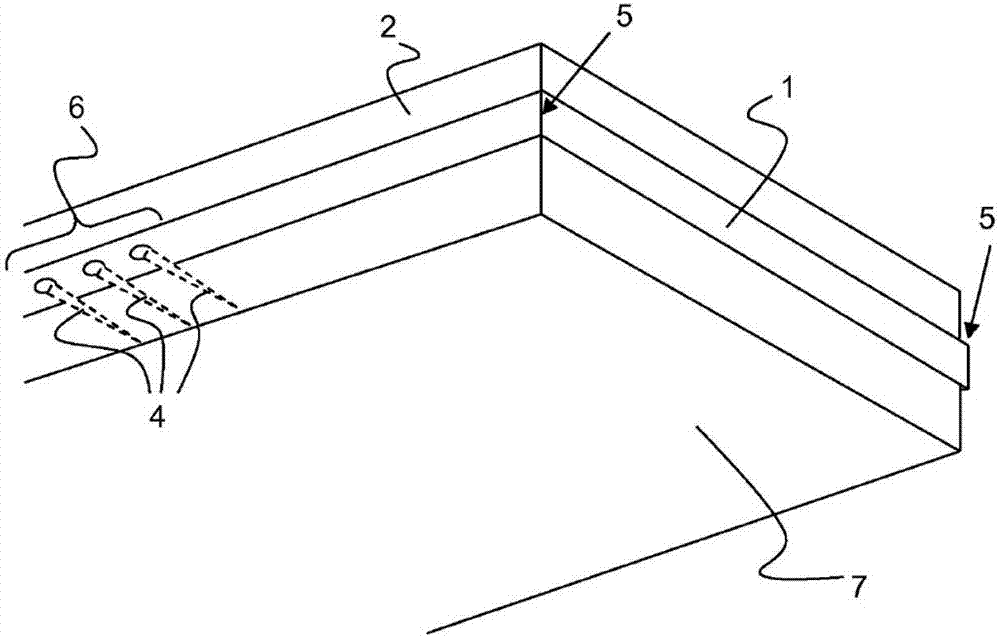

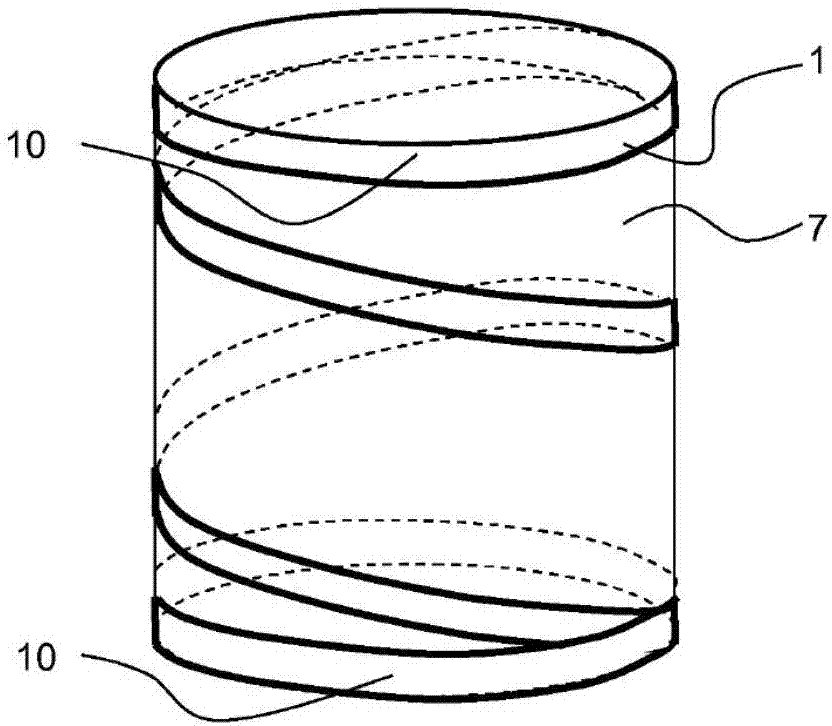

Method for producing prestressed structures and structural parts by means of SMA tension elements, and structure and structural part equipped therewith

ActiveCN107407100AReduce thicknessBuilding repairsBuilding reinforcementsPre stressShape-memory alloy

The method is distinguished in that at least one tension element (1), for example in the form of a flat steel composed of a shape memory alloy of polymorphic and polycrystalline structure which can be brought from its state as martensite to its permanent state as austenite by increasing its temperature, is placed on the structure or structural part (2). The tension element (1) can also be guided around one or more corners (5). One or more end anchors (4) penetrate into the structure or structural part (2). Such a flat steel can also wrap one or more times as a band around a structure or structural part (2), in which case the two ends of the flat steel are either connected to one another so as to be fixed in terms of tensile force or are each separately connected to the structure or structural part (2) by one or more end anchors (4) which penetrate into the structure or structural part (2), or else intersect one or more times to produce a clamping connection. The flat steel (1) contracts as a result of a subsequent active and controlled input of heat using heating means and generates a permanent tensile stress and correspondingly a permanent prestress on the structure or the structural part (2). A structure or structural part thus equipped is characterized in that it has at least one tension element (1) composed of a shape memory alloy which extends along the outer side of the structure or structural part and is connected thereto by means of end anchors (4). Alternatively, the structure or structural part (2) can also be completely enclosed by a tension element (1) in the form of a flat steel as a band, wherein the two end regions are connected so as to be fixed in terms of tensile force, and the flat steel is permanently prestressed by the input of heat.

Owner:RE FER +1

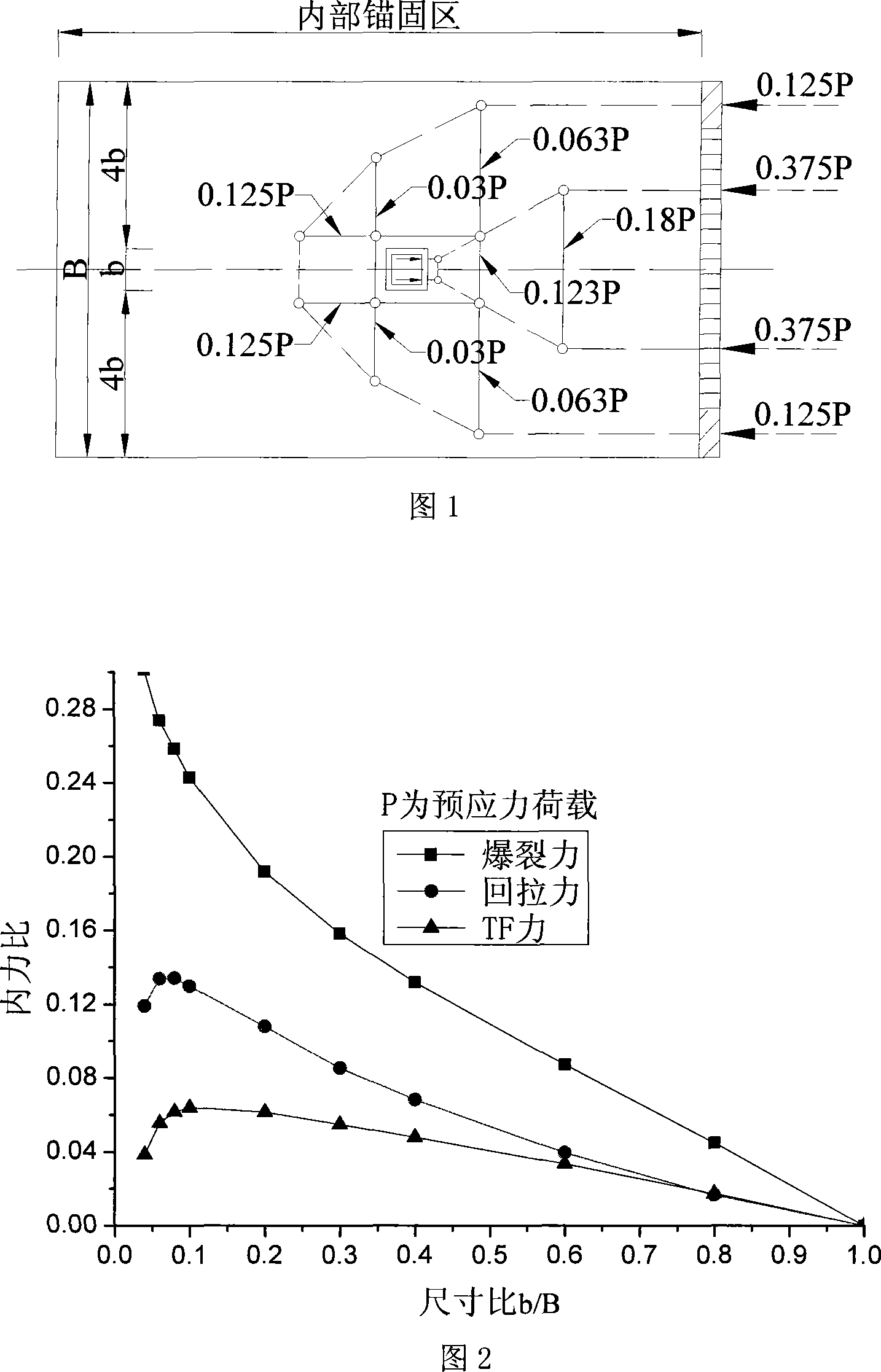

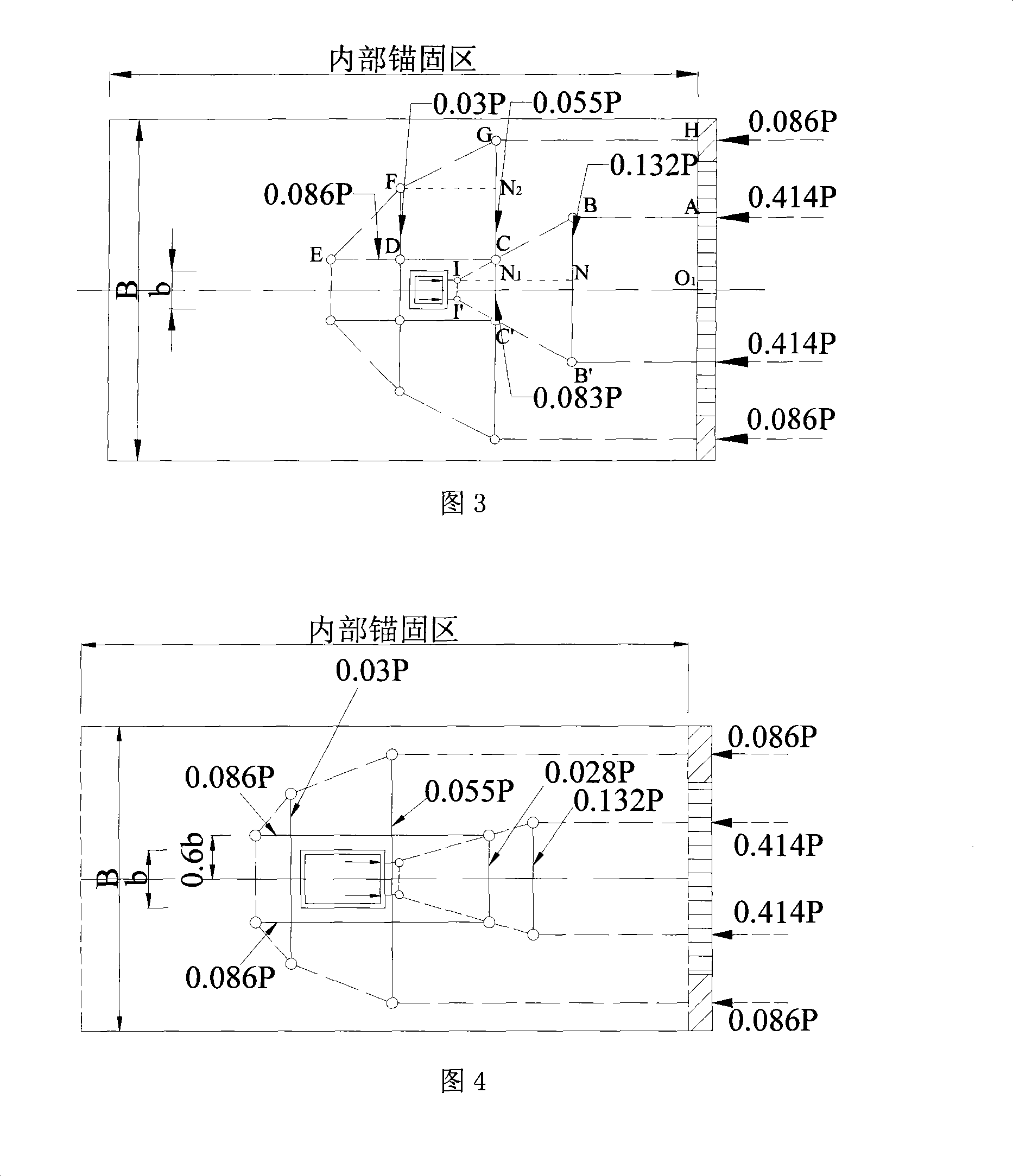

Inside anchorage zone reinforcing bars construction method of post-stressed concrete structure

The invention relates to a reinforcement bar construction method inside anchorage zone of pre-stressed concrete structure by way of post-tension, the procedure comprises the following steps: first, dividing the inner anchorage zone range; second, determining the anchorage zone internal force ratio-size ratio b / / B curve; third, establishing the compression model of the inner anchorage zone according to the anchorage zone inner force ratio-size ratio b / B curve, if the size ratio b / B is less than or equal to 1 / 9, the international pre-stressing institution model is used directly, or the international pre-stressing institution mode is adjusted or modified;fourth, reinforcing bar model of the inner anchorage zone. The invention has the advantages that 30 percent of the anchorage zone common reinforced bars are saved, according to the modified model in the invention; the invention is suitable for inner anchorage zone reinforced bar design of construction adopting the post-tensioned method.

Owner:SHANGHAI JIAO TONG UNIV

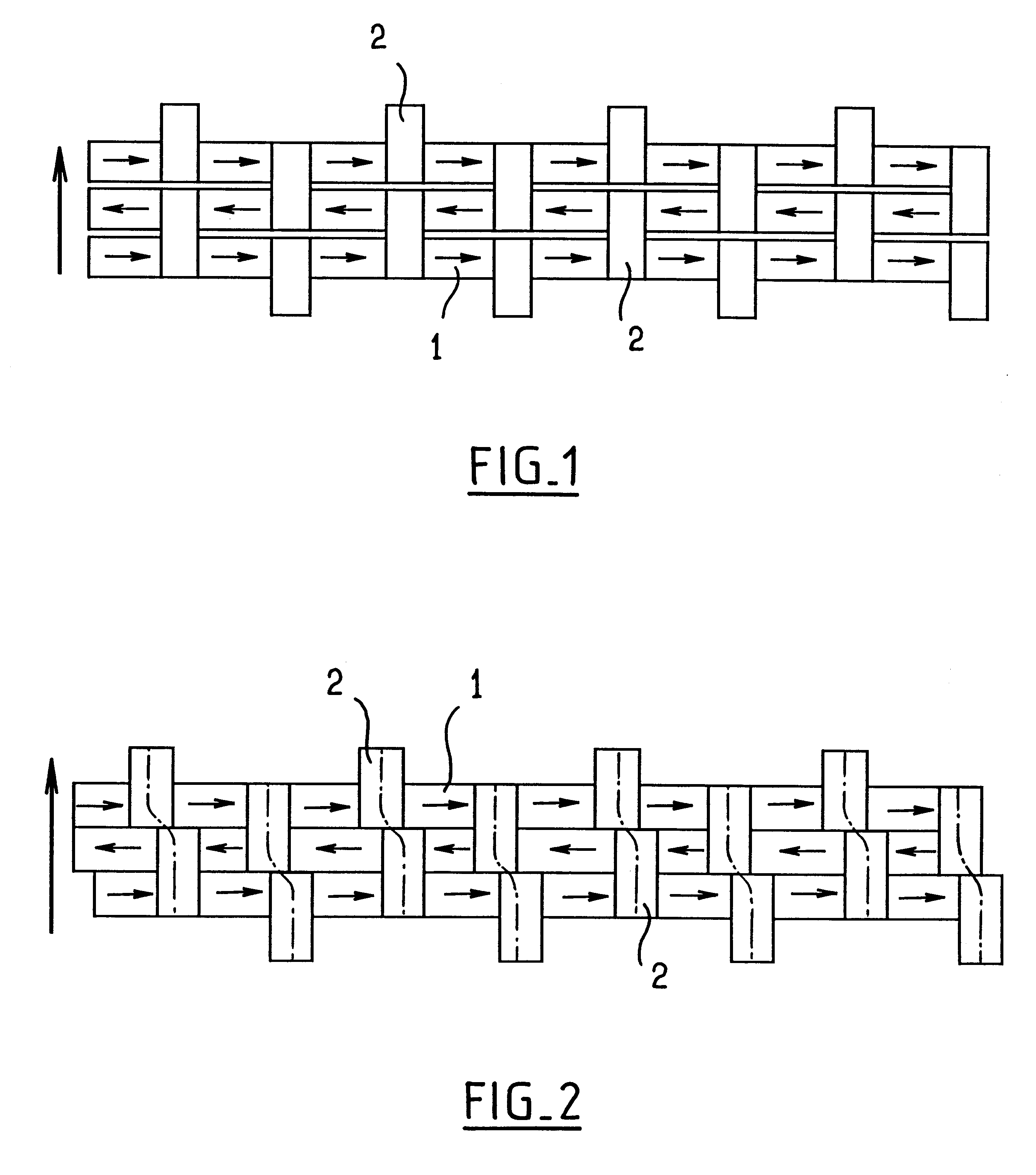

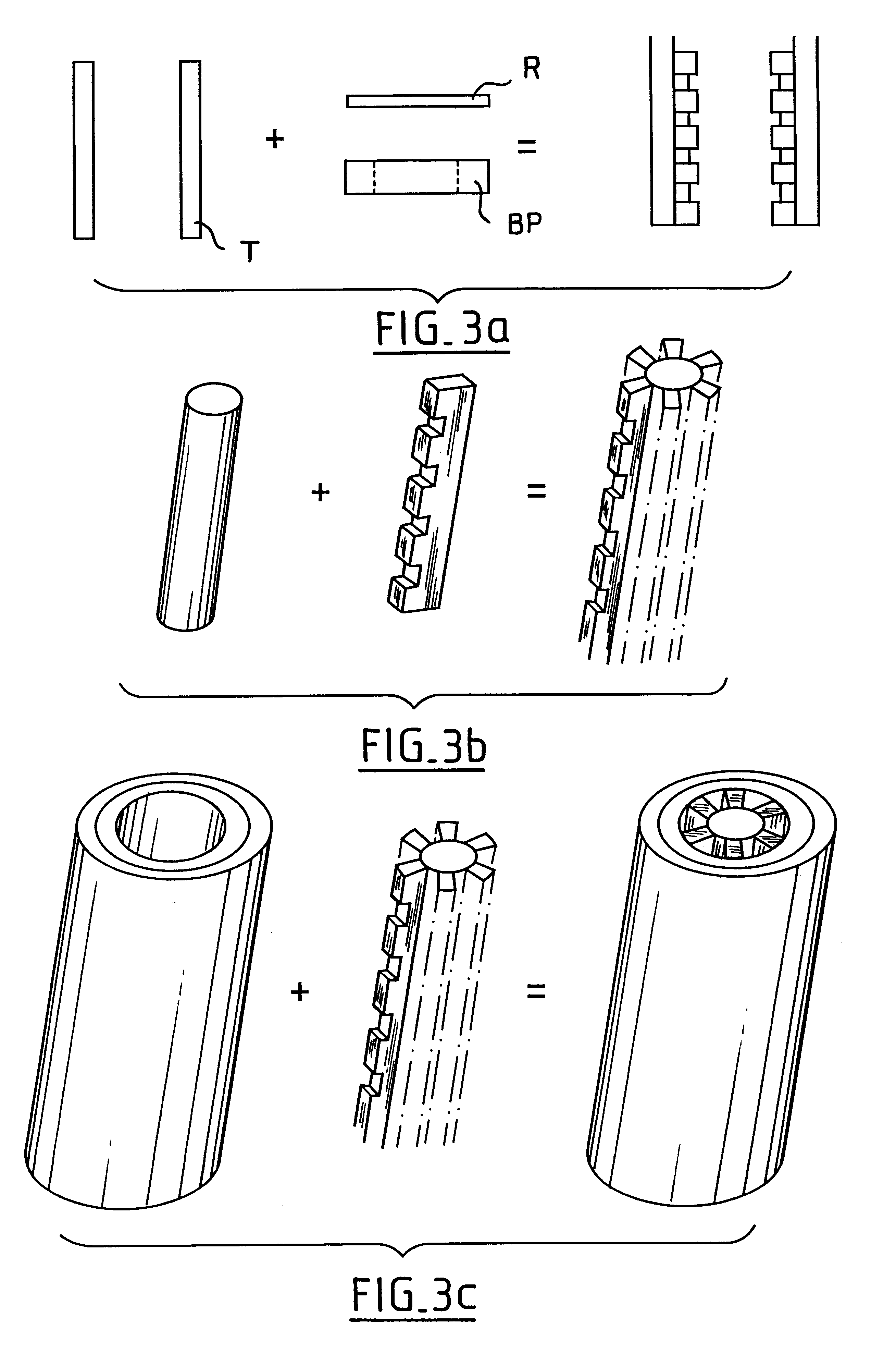

Actuators of active piezoelectric or electrostrictive material

InactiveUS6222306B1Mitigate such drawbackPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringActuator

A piezoelectric or electrostrictive actuator, comprising a plurality of stages of piezoelectric or electrostrictive active blocks distributed so as to form a tubular structure, the polarization of the active blocks alternating from one stage to the next, separation elements separating the unit active blocks of any one stage in pairs, said elements being superposed on one another in the height direction of the structure, being suitable for sliding over one another, and being of stiffness greater than that of the unit active blocks, a separation element extending over the height of two stages of active blocks, the separation elements on either side of a given unit active block extending respectively through both stages on either side of said unit active block, electrode-forming means enabling voltages of alternating sign to be applied to the various stacks of active blocks, and wherein a separation element is constituted by two bonded-together slabs each belonging to a different stage, the slabs of any one stage alternating between slabs that are integral with a prestress structure which extends inside said stage, and slabs that are bonded to slabs of the preceding stage which are integral with the prestress structure of said other stage.

Owner:SAGEM SA

Method and a device for pre-stressed armor

Composite materials in various shapes and sizes and in various configurations for use in ballistic armor confined in cylindrical and dome shaped enclosures; held under pressure to increase the impact absorption factor. An armor comprising an auxiliary layer disposed in front thereof at a determined distance wherein said layer comprises pre-stressed members arranged in a spacious pattern. A method is proposed for manufacturing of pre-stressed structure and armor by expanding the cavity into which ceramic materials are inserted so that pressure is applied to the ceramic materials.

Owner:SIMOVICH GIGI

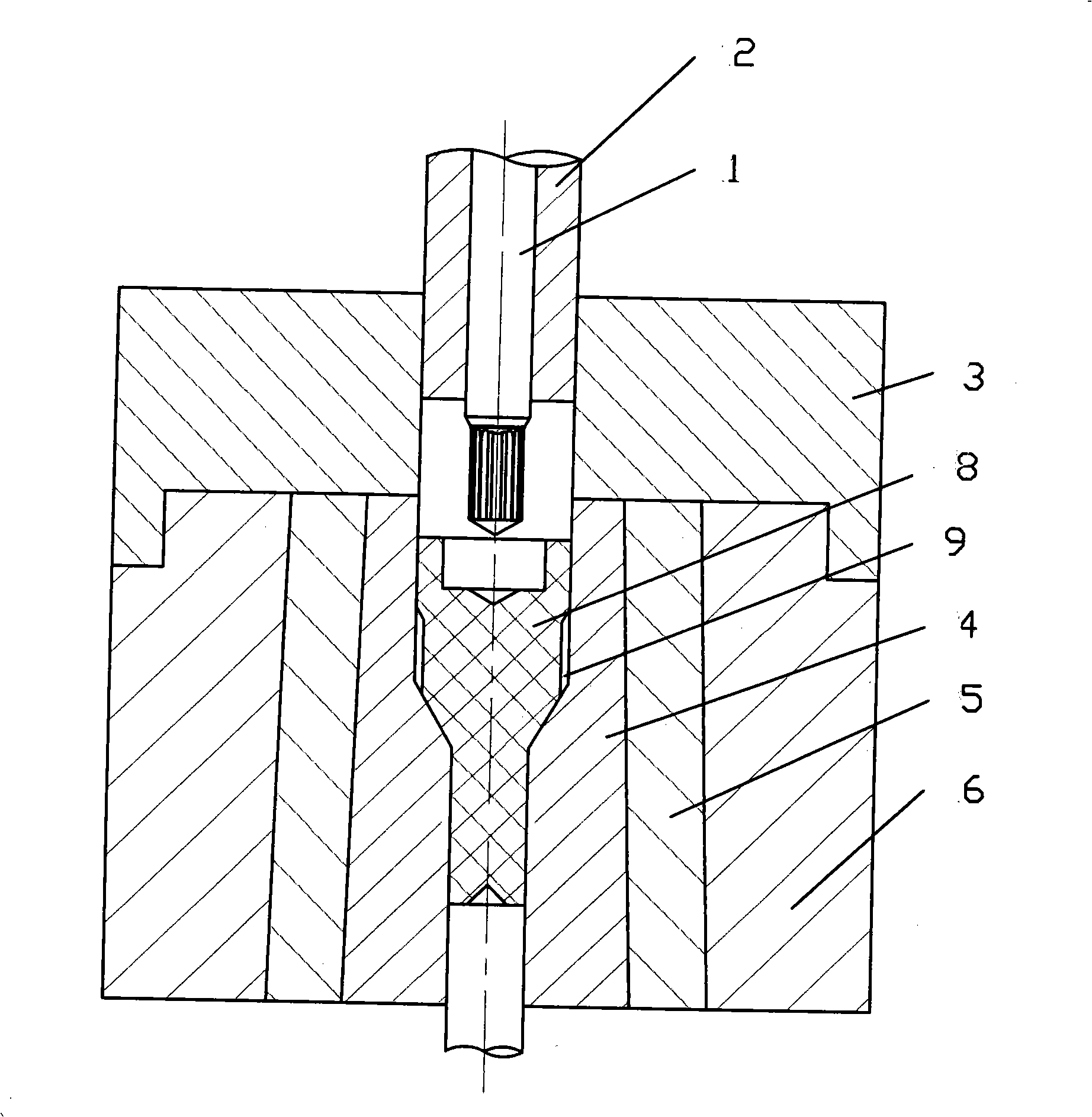

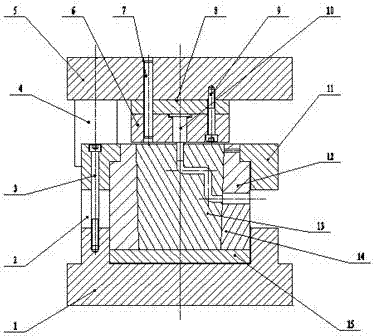

Warm extrusion method and mould for continuous equal-square channel with pre-stress structure

The invention discloses a warm extrusion method and a mould for a continuous equal-square channel with a pre-stress structure. The structural characteristics are that a reversed-bell-shaped double-layered combined concave mould pre-stress structure is adopted so that not only can mould materials be utilized effectively, but the bearing capability can also be guaranteed. The warm extrusion method comprises the following steps: analyzing a warm extrusion process of the continuous equal-square channel through finite elements by a continuous equal-square channel to obtain an optimized mould geometrical shape and a technological parameter; designing a warm extrusion experiment mould of the continuous equal-square channel according to basic requirements of low-carbon steel extrusion and molding; and improving a regular structure of a concave mould. The strength and the service life of a convex mould are not only considered in the aspect of the used materials, but also are guaranteed in the aspect of the structural design of the convex mould. With the adoption of the warm extrusion method and mould, the concave mould can be effectively prevented from being fractured; the service life of the mould is prolonged and the efficiency of experiment researches is improved; the time and the money are saved.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com