Method for producing prestressed structures and structural parts by means of SMA tension elements, and structure and structural part equipped therewith

A technology of prestressed structures and structural components, applied in the direction of structural elements, building components, building structures, etc., can solve the problem that anti-corrosion is no longer guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

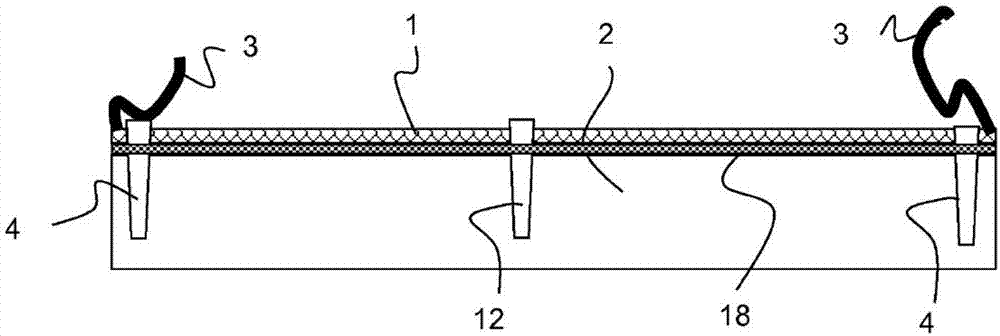

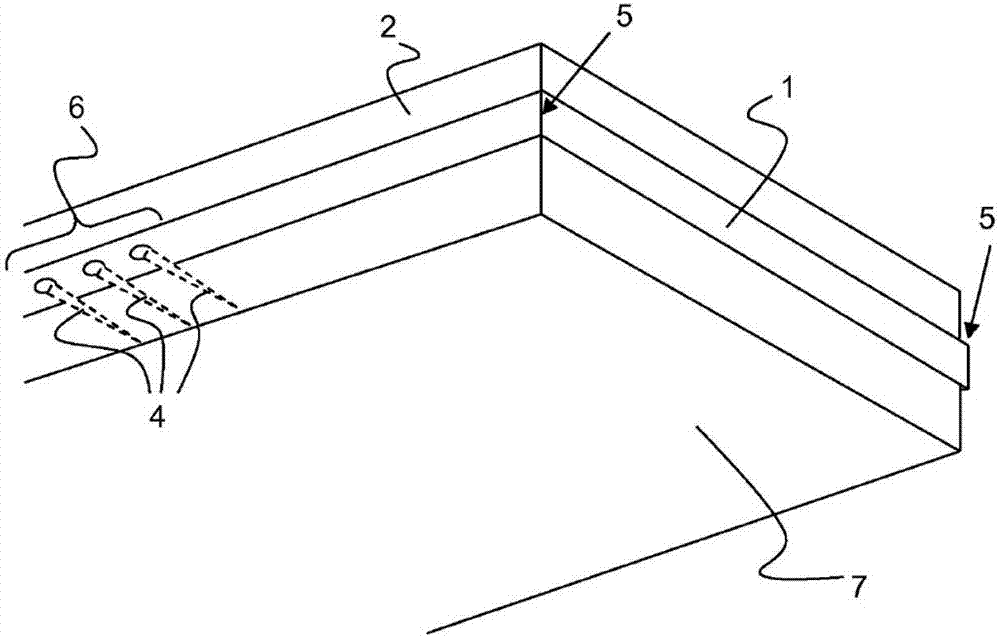

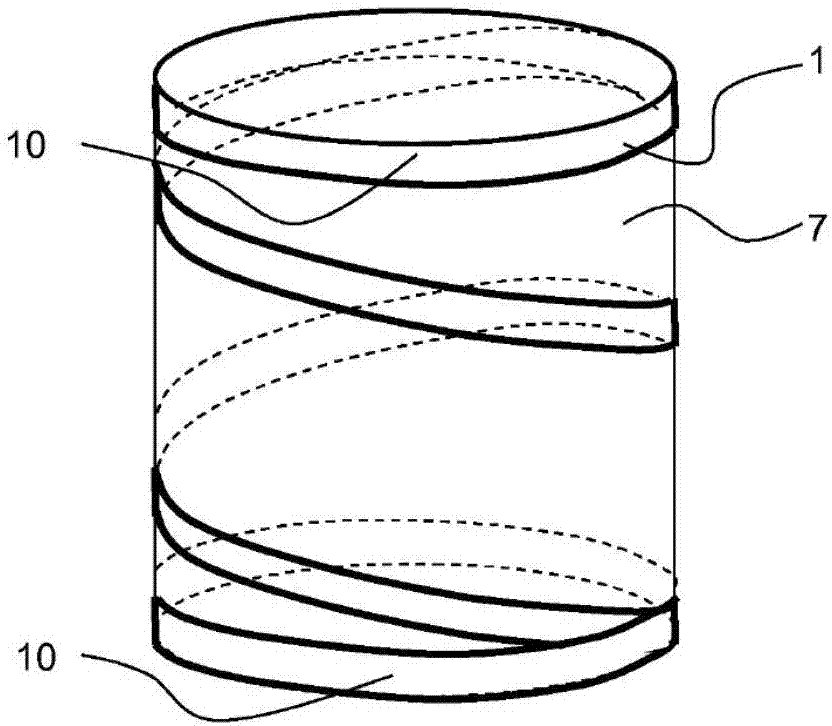

[0019] Initially, the properties of shape memory alloys (SMAs) should be understood. These structurally specific alloys can be modified by heat and return to their original condition after heat removal. Like other metals and alloys, shape memory alloys (SMAs) contain more than one crystal structure, ie, they are polymorphic and are thus polycrystalline metals. The dominant crystal structures of shape memory alloys (SMAs) depend on their temperature on the one hand and, on the other hand, on stresses - tension or pressure - acting from the outside. At high temperatures, the structure is austenite, however, at low temperatures, the structure is martensite. A peculiarity of these shape memory alloys (SMAs) is that, even though they have previously been deformed in the low temperature stage, after increasing their temperature, they recover their original structure and shape in the high temperature stage. This effect can be used to apply prestress within the structure.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com