Patents

Literature

226results about How to "Reduce composition segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

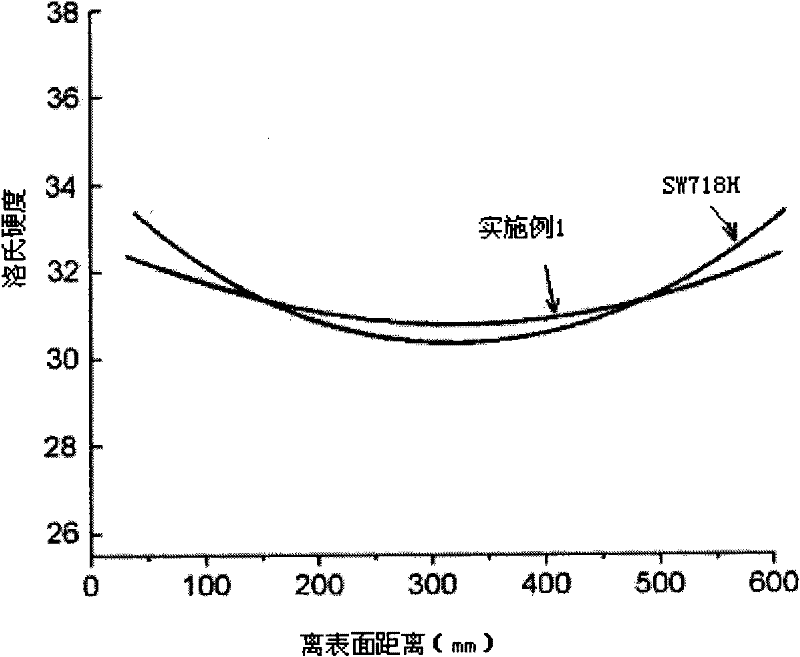

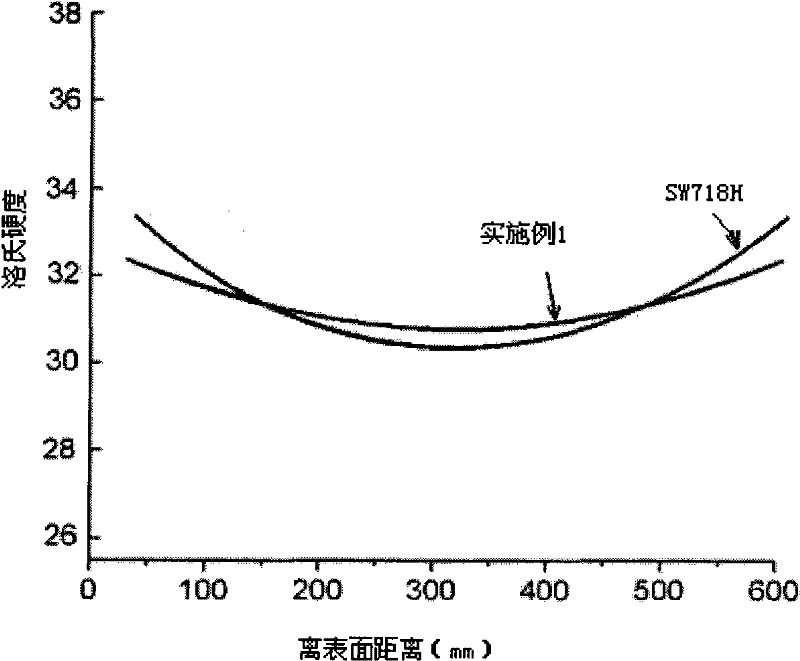

A kind of plastic mold steel and its manufacturing method

The invention discloses a plastic mold steel which comprises the following chemical components in percentage by weight: 0.25-0.29% of C, 1.30-1.50% of Mn, 0.40-0.60% of Si, 1.20-1.50% of Cr, 0.40-0.50% of Mo, 0.02-0.05% of Nb, less than or equal to 0.15% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.012% of N and the balance of iron and inevitable impurities. In the manufacture method of the plastic mold steel, a quenching and tempering heat treatment process is not used, and direct air cooling after forging is carried out, thus prehardened plastic mold steel with thickness above 600 mm and uniform hardness from core to surface is manufactured. According to the plastic mold steel disclosed by the invention, the limit that the existing non-quenched and tempered mold steel has thickness smaller than 400 mm is overcome, and the requirements of mold industries on low-cost high-quality large-sized prehardened plastic mold steel are reached.

Owner:宝武特种冶金有限公司

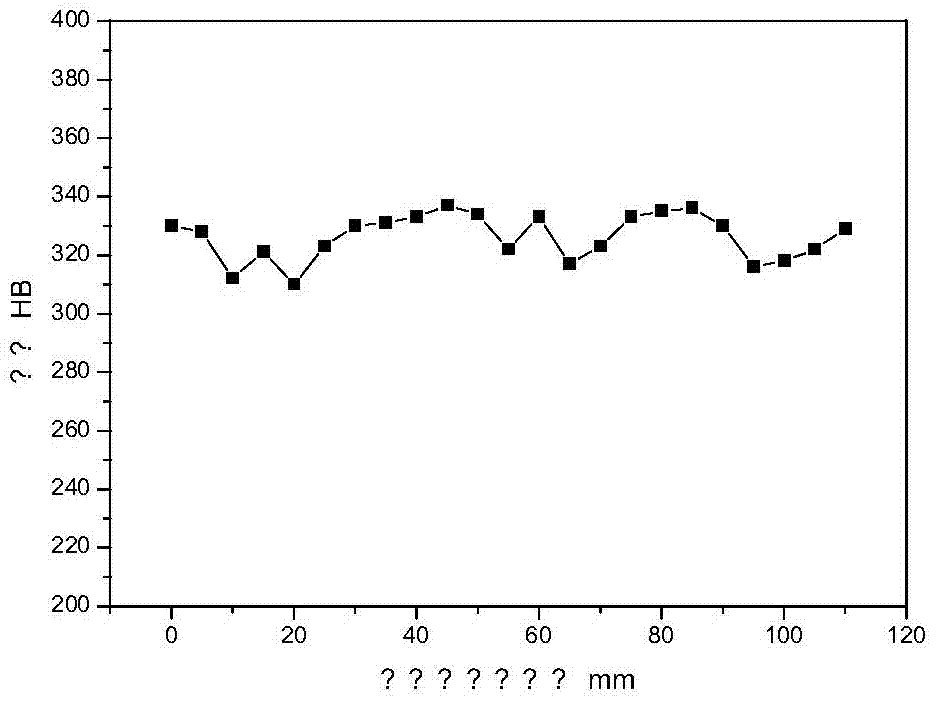

Economical non-quenched and non-tempered micro-alloyed plastic die steel plate and making method thereof

The invention discloses an economical non-quenched and non-tempered micro-alloyed plastic die steel plate and a making method thereof. The economical non-quenched and non-tempered micro-alloyed plastic die steel plate comprises 0.32-0.40wt% of C, 0.20-0.50wt% of Si, 1.00-1.50wt% of Mn, 1.20-1.70wt% of Cr, 0.20wt% or less of Mo, 0.0025wt% or less of B, 0.03wt% or less of Ti, 0.03wt% or less of Nb, and the balance Fe. The making method comprises the following steps: carrying out converter smelting, LF+RH refining and continuous slab casting; heating the obtained slab at 1200-1230DEG C, carrying out precision rolling at 900-950DEG C, and carrying out finishing rolling at 870-920DEG C; carrying out controlled cooling after the steel plate rolling; and tempering the steel plate obtained after the controlled rolling and controlled cooling at 550-600DEG C to obtain the finished pre-hardened plastic die steel plate having a bainite structure. The yield strength, the normal temperature impact toughness and the cross section hardness of the steel plate are above 800MPa, above 20J and 310-350HB respectively. The making method is suitable for the production of pre-hardened plastic die steel plates with the specification of below 120mm from 320mm continuous casting blanks.

Owner:NANJING IRON & STEEL CO LTD +1

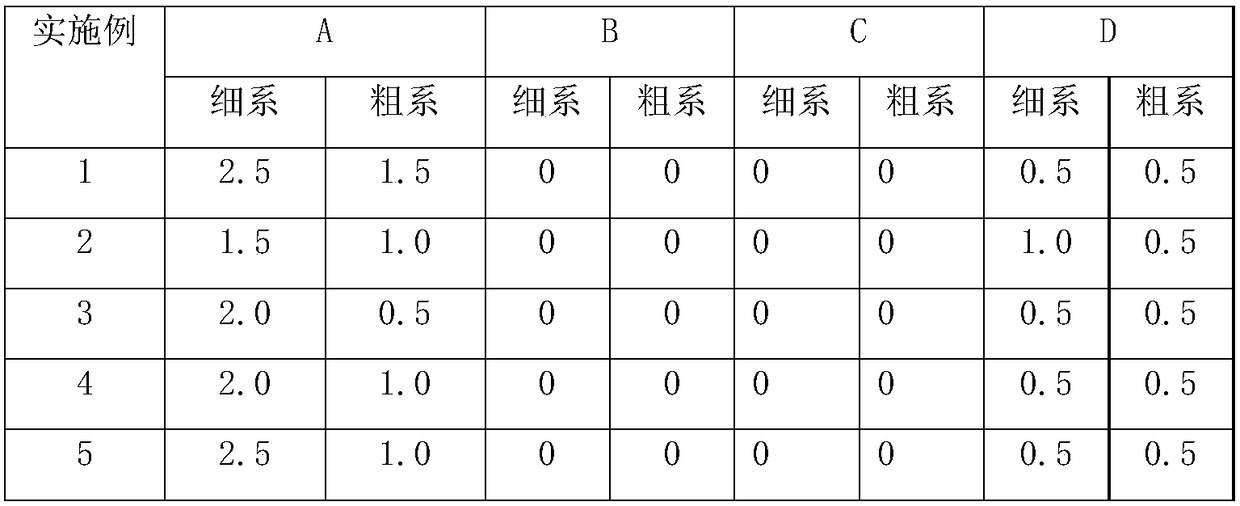

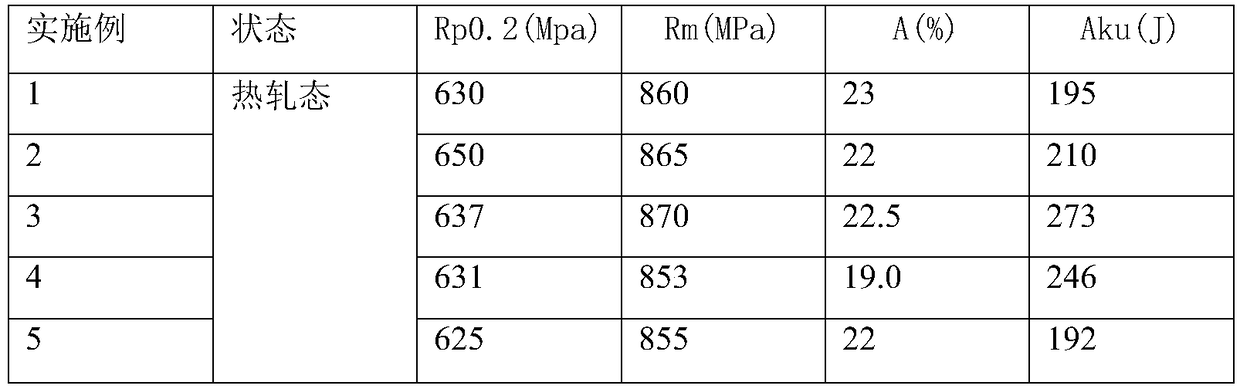

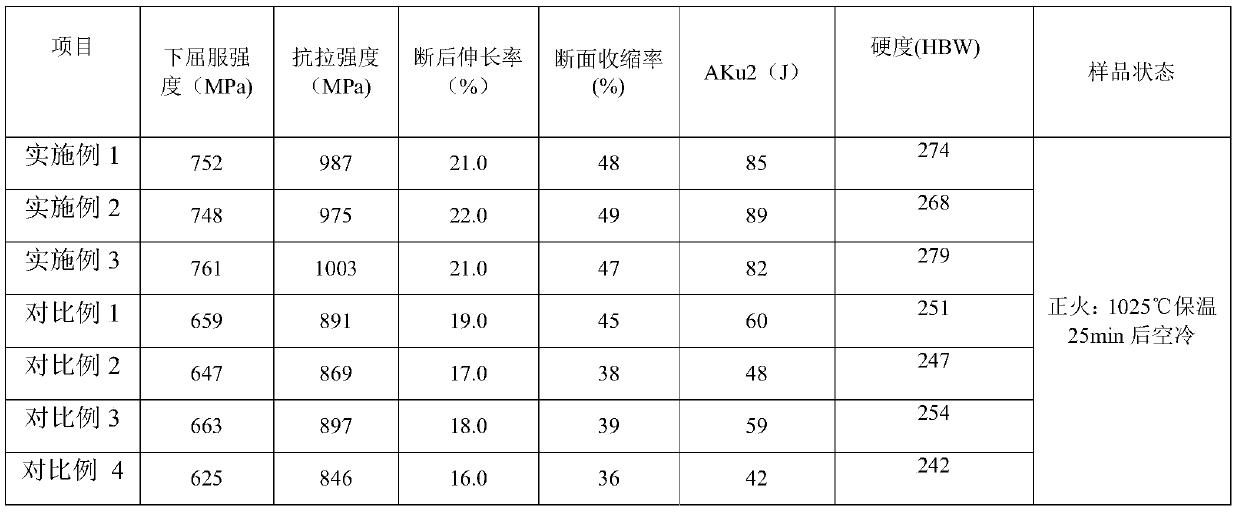

High-strength high-tenacity non-quenched-and-tempered round steel and preparation method

ActiveCN109234627AGuaranteed stabilityHigh yieldFurnace typesHeat treatment furnacesTemperature controlChemical composition

The invention discloses high-strength high-tenacity non-quenched-and-tempered round steel, and relates to the technical field of non-quenched-and-tempered steel. The high-strength high-tenacity non-quenched-and-tempered round steel is prepared from the following chemical components by mass percent: 0.27%-0.33% of C, 0.40%-0.70% of Si, 0.10%-0.30% of Cr, 1.30%-1.65% of Mn, 0.065%-0.100% of S, 0.005%-0.040% of Al, 0.06%-0.020% of V, 0.010%-0.040% of Ti, 0.0120%-0.0250% of N, the balance of Fe and unavoidable impurities, wherein manganese equivalent Mneq is 1.70%-2.10%. The high-strength high-tenacity non-quenched-and-tempered round steel is capable of increasing a free-cutting element S with low cost, forming dispersed distribution of a sulfide and a V (N, C) compound, through continuous uniform cooling rolling and temperature control cooling after rolling, a high-tenacity non-tempering steel bar with a good mechanical property is obtained, wherein rolled metal ballistic work reaches 190 J or more.

Owner:NANJING IRON & STEEL CO LTD

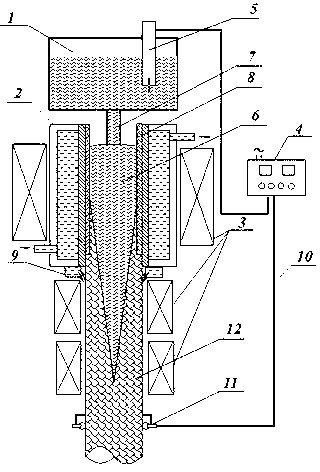

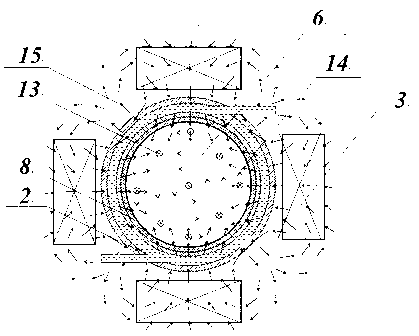

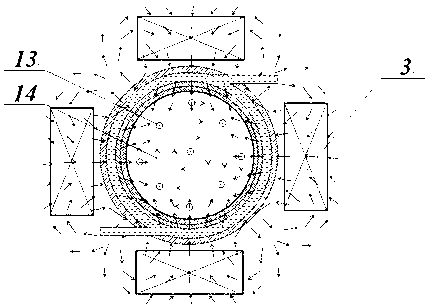

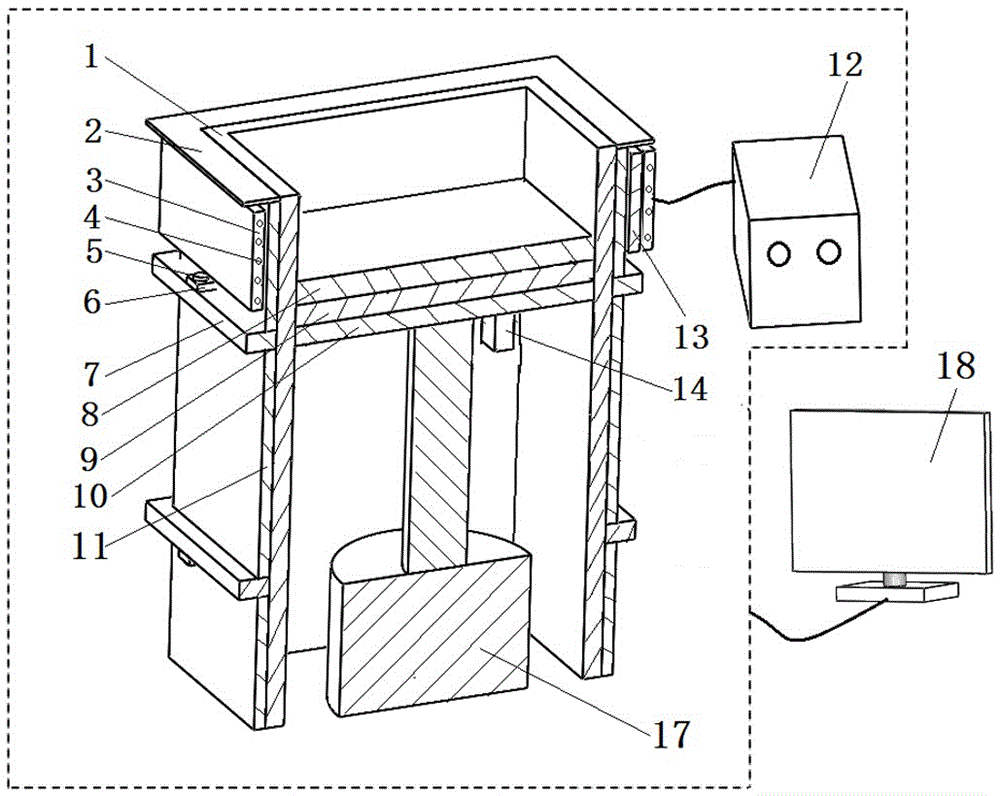

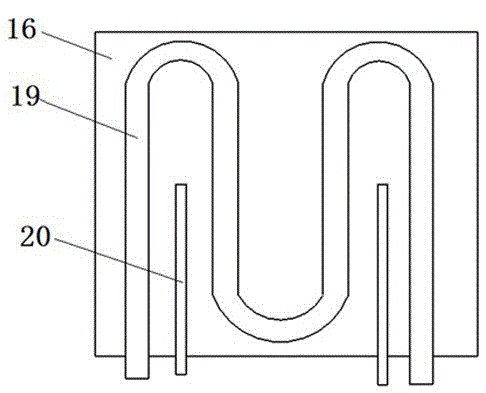

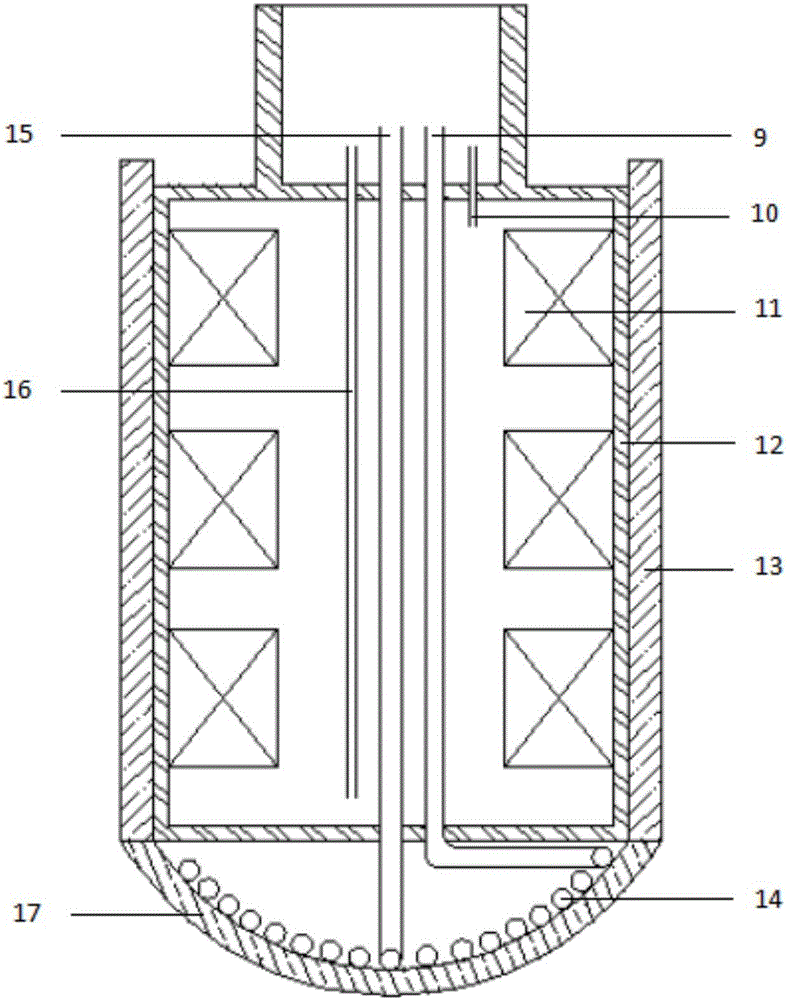

Low-energy-consumption electromagnetic stirring method for continuous casting and metal continuous casting device

The invention discloses a low-energy-consumption electromagnetic stirring method for continuous casting. The hot top composite novel low-energy-consumption electromagnetic stirring technique is used. A hot top is arranged in a crystallizer, a steady magnetic field with no energy consumption and low energy consumption is exerted on the periphery simultaneously, an electrode bar is inserted in a tundish, a roller electrode is arranged at the solidifying tail end of a continuous casting billet, and therefore alternating current can be exerted on all non-solidification metal melts between the crystallizer and the solidifying tail end. The alternating current and an additional steady magnetic field are acted with each other so as to enable all the non-solidification metal melts in the whole continuous casting billet in a continuous casting process to generate electromagnetic stirring force for driving the continuous casting melts to rotate clockwise and counterclockwise, thereby stirring non-solidification structures, smashing dendrites of solidification front edges of the melts, refining the solidification structures, reducing segregation and cracks. The invention further provides a metal continuous casting device which can be applied to a continuous casting process of various molten metals prone in segregation and draw an alloy continuous casting billet with refined solidification structure, small segregation and no crack.

Owner:SHANGHAI UNIV +1

Copper chromium zirconium alloy and preparing method thereof

A copper chromium zirconium alloy comprises, by weight, 0.7% to 2.0% of chromium, 0.05% to 0.3% of zirconium, 0.01% to 0.08% of magnesium, 0.01% to 0.1% of yttrium and the balance copper. The invention further provides a preparing method of the copper chromium zirconium alloy. The preparing method sequentially comprises the following steps that firstly, the copper, the chromium, the zirconium, the magnesium and the yttrium are prepared according to the proportion and are subject to vacuum purified smelting and flow dividing type casting, and a casting blank is prepared; secondly, the casting blank is subject to homogenization treatment and hot extrusion, and a sheared billet is prepared; thirdly, the sheared billet is subject to solid-solution treatment; fourthly, the sheared billet obtained after the solid-solution treatment is subject to cold deformation machining; and fifthly, a material obtained after cold deformation machining is subject to aging treatment, and the needed copper chromium zirconium alloy is obtained. The copper chromium zirconium alloy has the good comprehensive performance, the room temperature tensile strength of the copper chromium zirconium alloy is larger than 520 MPa, the room temperature elongation of the copper chromium zirconium alloy is larger than or equal to 22%, the room temperature electric conductivity of the copper chromium zirconium alloy is larger than or equal to 90%IACS, and the 350 DEG C high-temperature tensile strength of the copper chromium zirconium alloy is larger than 390 MPa.

Owner:SHANTOU HUAXING (RAOPING) COPPER IND CO LTD +1

High-carbon microalloy round steel for fracture splitting connecting rod of automotive engine and production method thereof

InactiveCN102108472AImprove cleanlinessReduce composition segregationTemperature control deviceHigh surfaceChemical composition

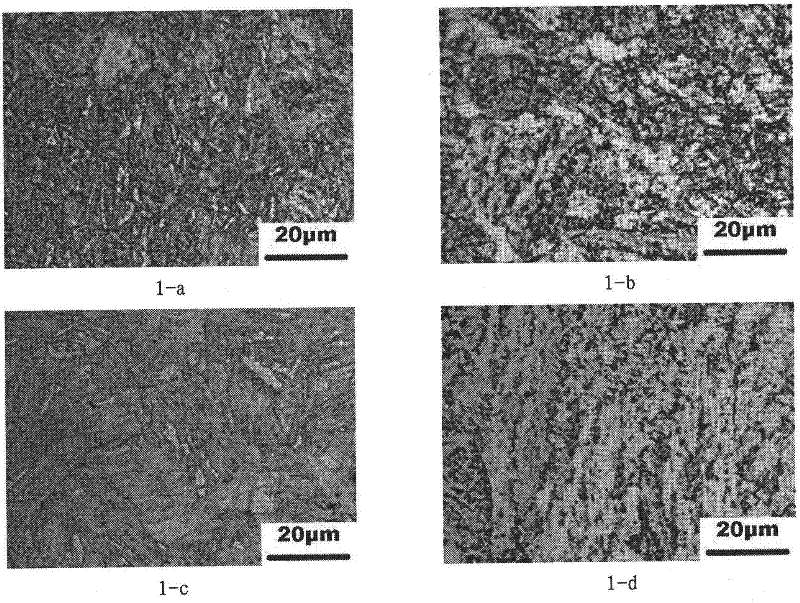

The invention discloses high-carbon microalloy round steel for a fracture splitting connecting rod of an automotive engine and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.60 to 0.80 percent of C, 0.17 to 0.37 percent of Si, 0.30 to 0.90 percent of Mn, 0.020 to 0.60 percent of P, 0.050 to 0.080 percent of S, 0.015 to 0.0300 percent of N, one or several of microally elements V, Nb, Ti and B, and the balance of Fe and inevitable impurities. The production method of the high-carbon microalloy round steel comprises: (1) steel tapping by high catching carbon; (2) vacuum degassing (VD) vacuum treatment; (3) treatment in ladle furnace (LF); (4) execution of a continuous casting process; and (5) heating and rolling of continuously cast blank, and execution of a segmental cooling process of high-temperature quick cooling and low-temperature slow cooling. The high-carbon microalloy round steel provided by the invention has the characteristics of high cleanness, small composition segregation, low crack sensitivity, uniform and fine texture and high surface quality, and the provided production method has the characteristics of low production cost, energy conservation, simple process route, high maneuverability and simplicity of control.

Owner:WUHAN IRON & STEEL (GROUP) CORP

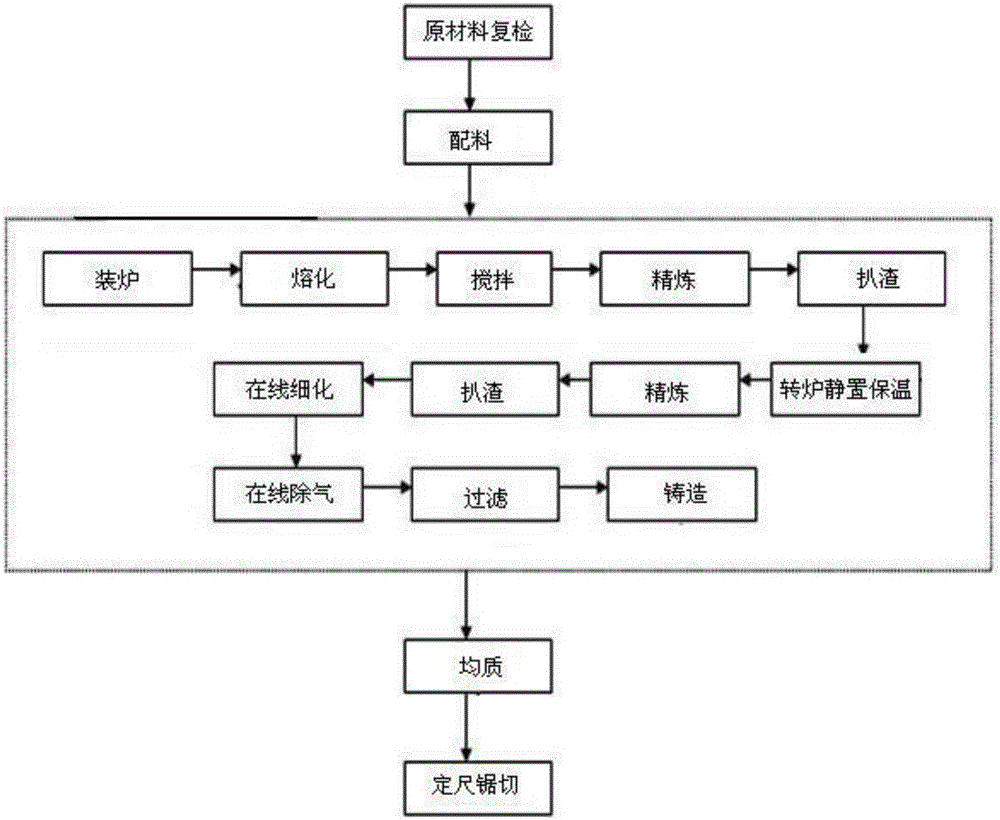

Hot top casting process for phi 784-mm 7xxx-series superhard aluminum alloy round bar

The invention discloses a hot top casting process for a phi 784-mm 7xxx-series superhard aluminum alloy round bar. The aluminum alloy round bar is composed of, by mass, 0.25% of Si, 0.4% of Fe, 1.55-1.65% of Cu, 0.25% of Mn, 2.55-2.65% of Mg, 0.19-0.25% of Cr, 5.6-5.7% of Zn, 0.15% of Ti, 0.03% of Zr and the balance Al. The manufacturing process comprises the steps of a, material preparation; b, smelting; c, stirring; d, refining; e, slagging-off; f, heat preservation and standing; g, online thinning; h, online degassing; i, filtration; j, casting; k, homogenizing. Through the process, the defects, such as cracks, component segregation, bright grains, thick grains and loose pores, which often appear when a direct condensation casting technology is adopted for large-diameter superhard aluminum alloy are overcome, and by the adoption of hot top casting, the defects of surface segregation tumors, thick coarse-grain layers and the like are overcome.

Owner:CHINA ZHONGWANG

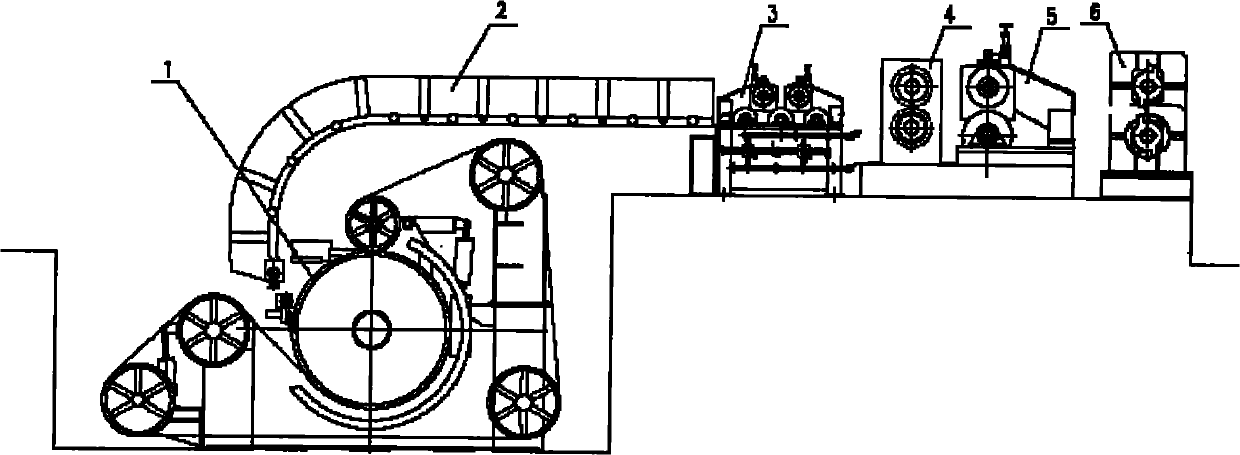

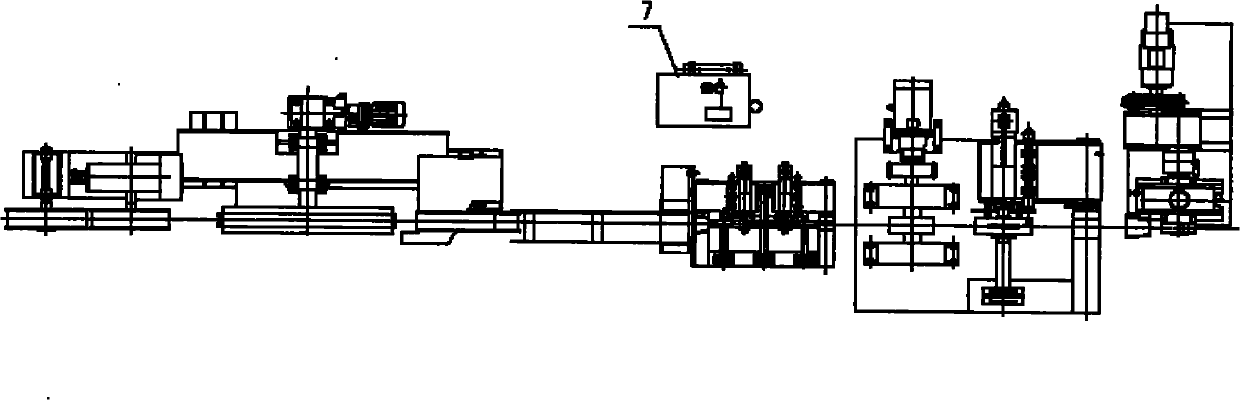

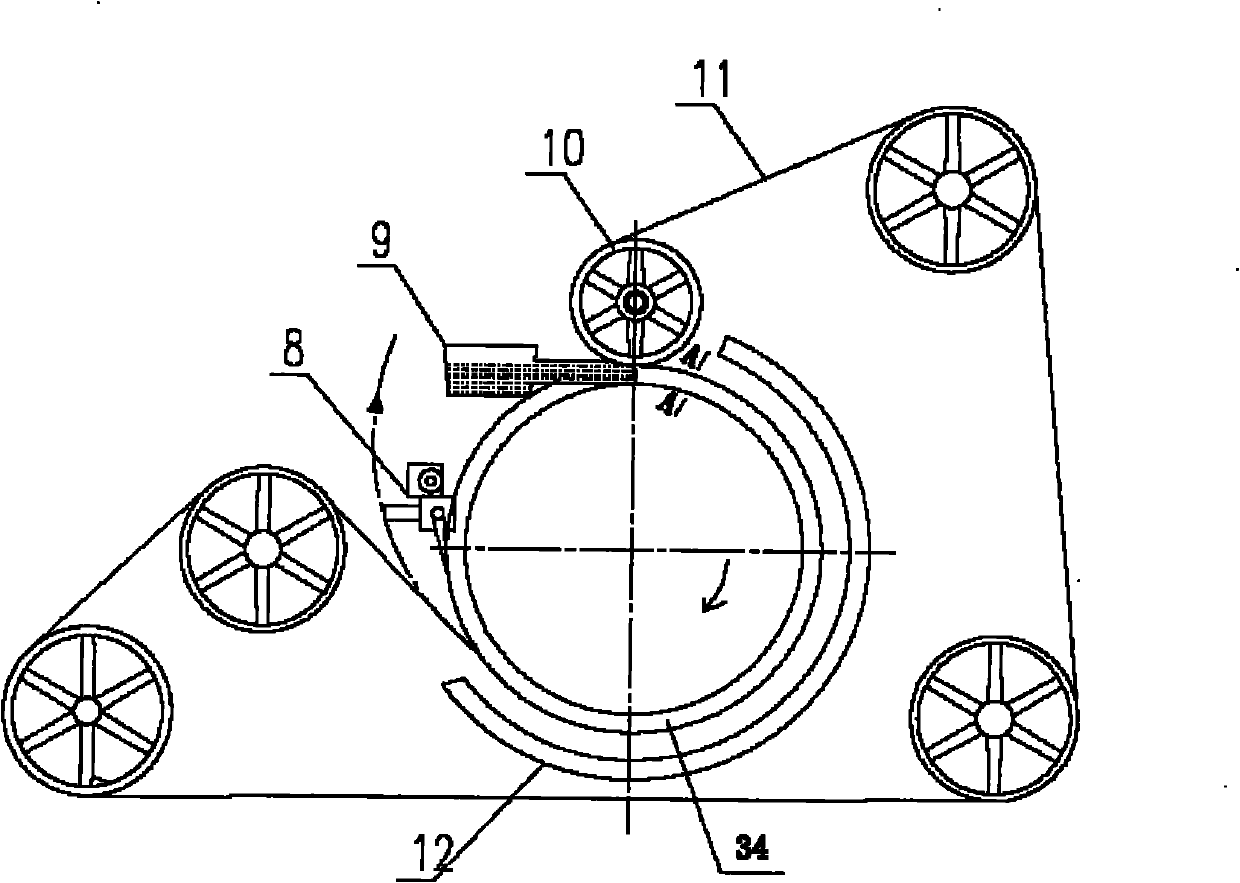

Method and device for producing A356 aluminum alloy by belt casting

The invention discloses a method and a device for producing A356 aluminum alloy by belt casting. The prepared A356 aluminum alloy liquid is subjected to furnace refining and on-line degassing filtration, and then is continuously poured into a crystallizer of a casting machine; and the periphery of the crystallizer is continuously filled with cooling water for crystallization. A crystalline region is divided into five sections from the higher temperature to the lower temperature, and a cooling region is divided into twelve regions according to different flow rates of the cooling water distributed at the periphery of the crystallizer. The belt casting machine comprises a casting machine, a straightening machine, a blank guiding machine, a rolling code machine, a roller shearing machine, and the like, which are arranged in turn; and an approach bridge is arranged between the casting machine and the straightening machine. Compared with the prior art, the method and the device have the advantages of simple production equipment, less investment, short production flow, low production cost, advanced technology, low gas-slag content in the products, low composition segregation, stable product quality, and excellent production flexibility, quickly adjustable product types, and safe working environment.

Owner:YUNNAN ALUMINUM

Steel for carbon hub bearing of microalloying car and production method thereof

InactiveCN105568134AGuaranteed normal growthImprove composition segregationRolling contact bearingsHubsChemical compositionMetallurgy

The invention relates to steel for a carbon hub bearing of a microalloying car. The steel comprises the following chemical components: 0.45-0.70% of C, 0.10-0.50% of Si, 0.30-0.70% of Mn, 0.20-0.60% of Cr, P not more than 0.025%, 0.003-0.030% of S, Mo not more than 0.1%, Ni not more than 0.2%, Al not more than 0.04%, Cu not more than 0.3%, Ca not more than 0.001%, Ti not more than 0.003%, O not more than 0.001%, As not more than 0.04%, Sn not more than 0.03%, Sb not more than 0.005%, Pb not more than 0.002%, and the balance of Fe and inevitable impurities. A production method comprises an electric furnace or a converter-refining out of the furnace-VD or RH vacuum degassing-continuous casting-continuous rolling-sawing-cooling in heap-finishing-surface and internal flaw detection-packing. The steel for the hub bearing improves the mechanical performance, the element segregation and the structure uniformity, and belongs to a brand new hub bearing steel type.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

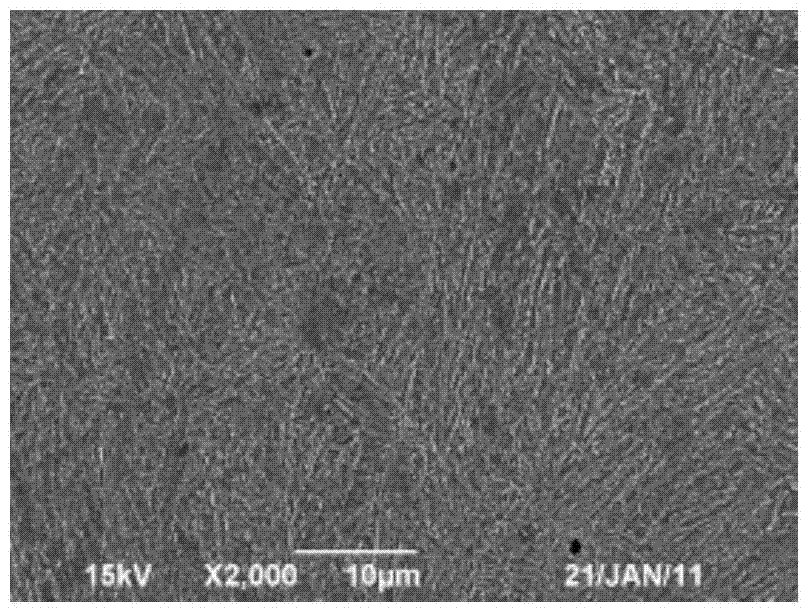

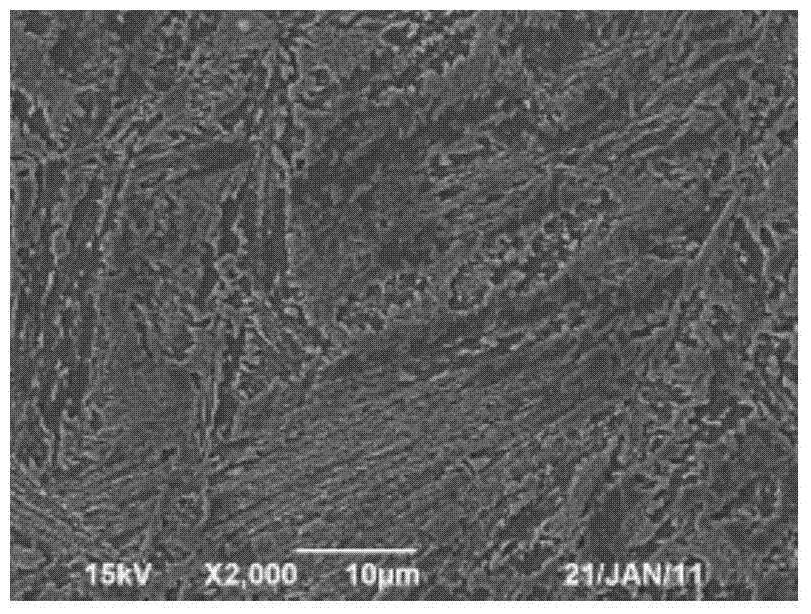

Middle-chromium rare earth-containing high-purity ferrite wrinkle-resistant stainless steel and manufacturing method thereof

InactiveCN101148739AImprove wrinkle resistanceImprove wrinkle defectsRoll mill control devicesHeat treatment process controlChemical compositionRare earth

The RE-containing medium Cr wrinkling resistant ferritic stainless steel has the chemical components including C not more than 0.02 wt%, N not more than 0.02 wt%, Si not more than 0.50 wt%, Mn not more than 0.50 wt%, P not more than 0.03 wt%, S not more than 0.02 wt%, Cr 16-20 wt%, Ni not more than 1.00 wt%, Mo not more than 2.00 wt%, Ti not more than 0.30 wt%, Nb not more than 0.40 wt%, O not more than 0.015 wt%, RE 0.01-0.20 wt%, and Fe and inevitable impurity for the rest. The ferritic stainless steel features low C and N contents, medium Cr content, containing RE, high wrinkling resistance, etc. It is suitable for punching formation to make product.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-quenched and tempered steel for automobile parts and production process thereof

ActiveCN110791708APromote precipitationPlay a role in precipitation strengtheningUltimate tensile strengthToughness

The invention discloses non-quenched and tempered steel for automobile parts and a production process thereof. The non-quenched and tempered steel comprises less than or equal to 0.20% of Ni, 0.010-0.025% of Ti, 0.012-0.025% of Nb and 0.013-0.019% of N. The process comprises converter smelting, LF refining, RH vacuum treatment, continuous casting and rolling. According to the non-quenched and tempered steel, through reasonable design of components, trace elements such as Ni, Nb, Ti and N are added to refine grains and improve the strength and toughness of the material; refining is carried outthrough a narrow component control technology, soft reduction is used in the continuous casting process, reasonable parameters are adopted to reduce the low-power defects of a casting blank, and the density of the material can be improved; and the structure is uniform through a high-temperature diffusion process in the rolling process, the grains are refined through a controlled cooling and controlled rolling technology, the strength is improved, and finally the comprehensive performance of the material is greatly improved.

Owner:ZENITH STEEL GROUP CORP

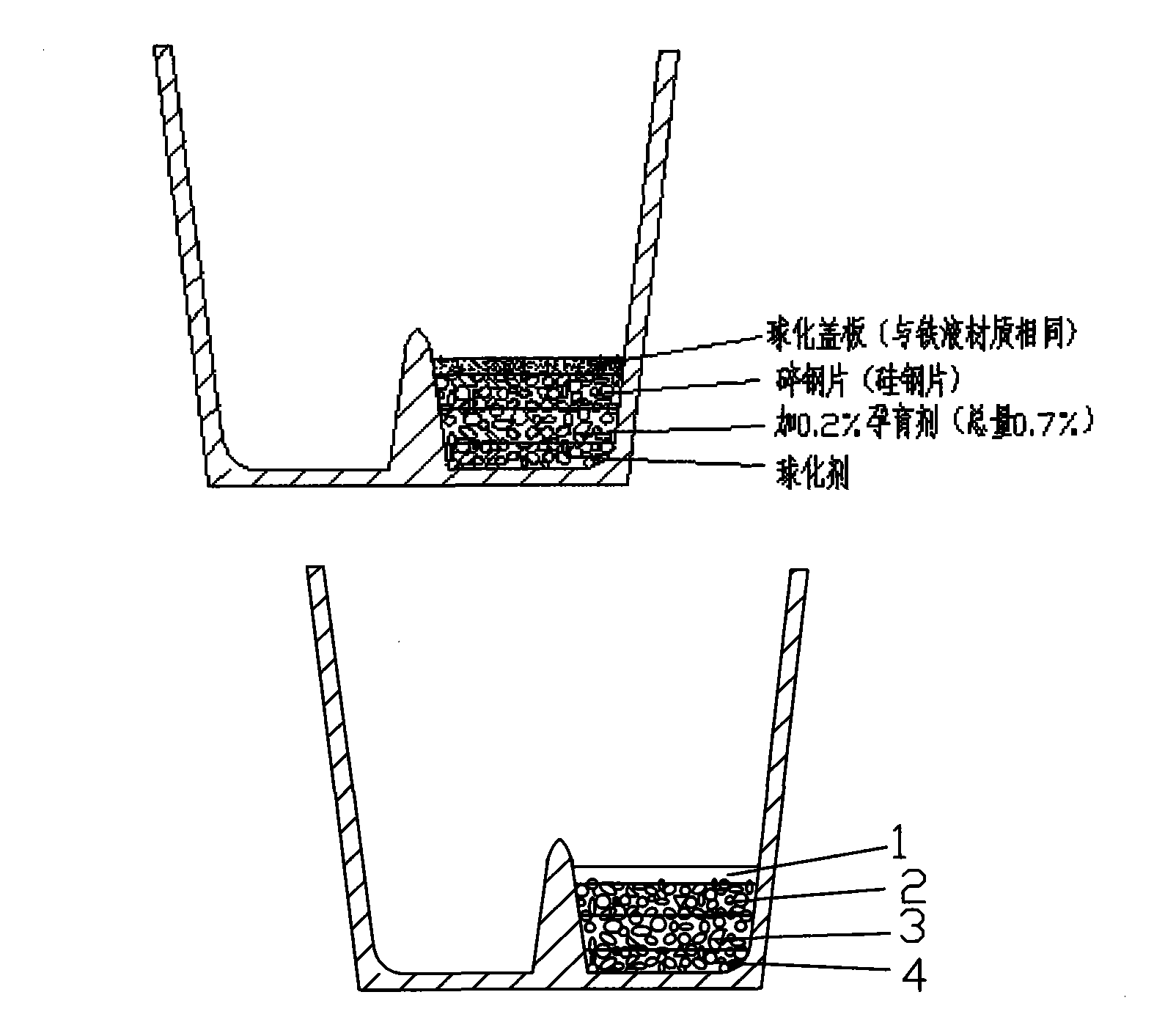

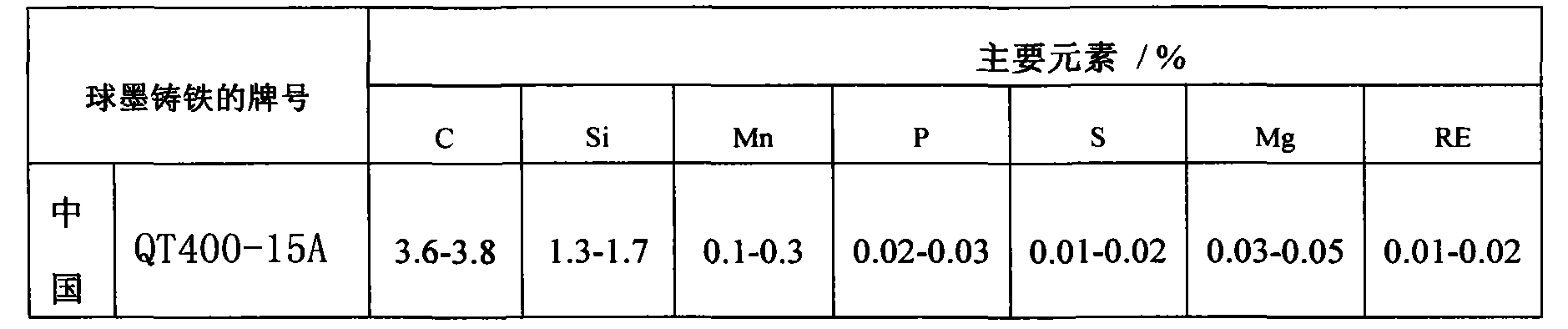

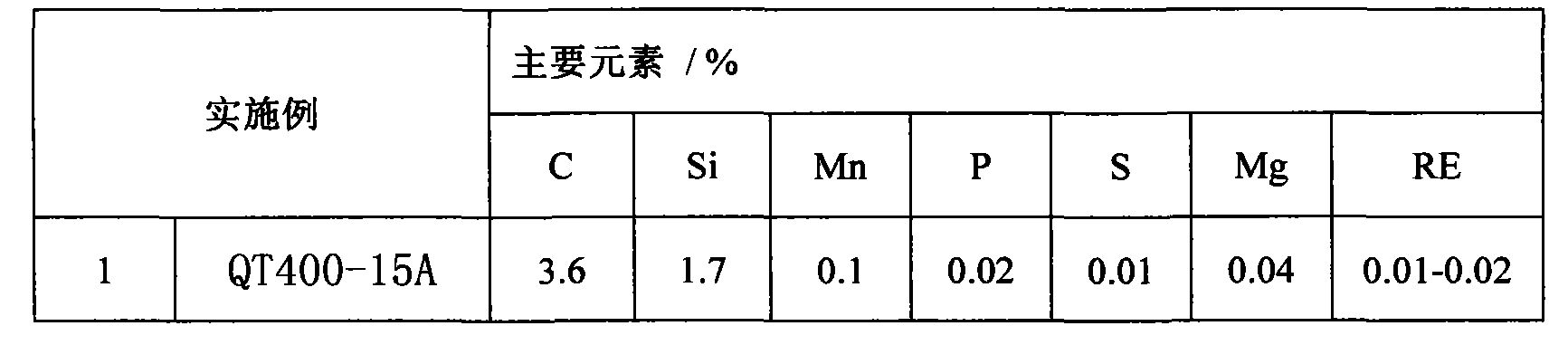

Method for integrally casting large-sized V-shaped diesel engine body by utilizing nodular cast iron

The invention discloses a method for integrally casting a more-than-25-ton large-sized diesel engine V-shaped body by utilizing nodular cast iron. The method comprises the following steps of A1, smelting the nodular cast iron in a smelting furnace, and adding bariumsili and metallurgical carborundum pretreatment agent after the smelting; A2, placing a spheroidizing agent into a bottommost layer of a dam-type spheroidizing ladle, utilizing a nucleating agent to cover a second layer, and utilizing a low-maganese low-alloy broken steel sheet to completely cover and compact a third layer; A3, adding a calcium-barium nucleating agent, charging the melted iron in one step to carry out the tapping metal-stream inoculation, realizing the nucleating effect while carrying out the spheroidizing treatment on charged melted iron, and carrying out the pouring pretreatment on the melted iron in the ladle; A4, placing the metal-stream inoculation agent into a funnel to carry out the pouring metal-stream inoculation; and A5, finally pouring the melted iron with the temperature being more than or equal to 1400 DEG C into a sand box, forming a cast by mold filling and solidifying the melted iron under the feeding of the feeder head liquid metal, and carrying out the heat treatment by utilizing the waste heat of the cast.

Owner:宜宾普什联动科技有限公司

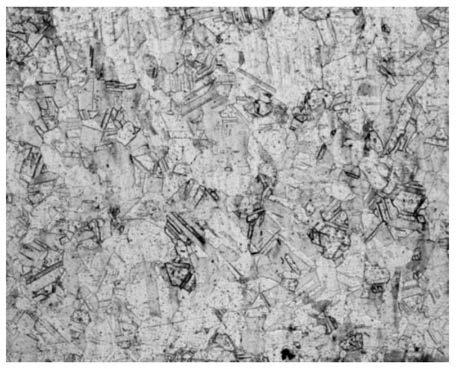

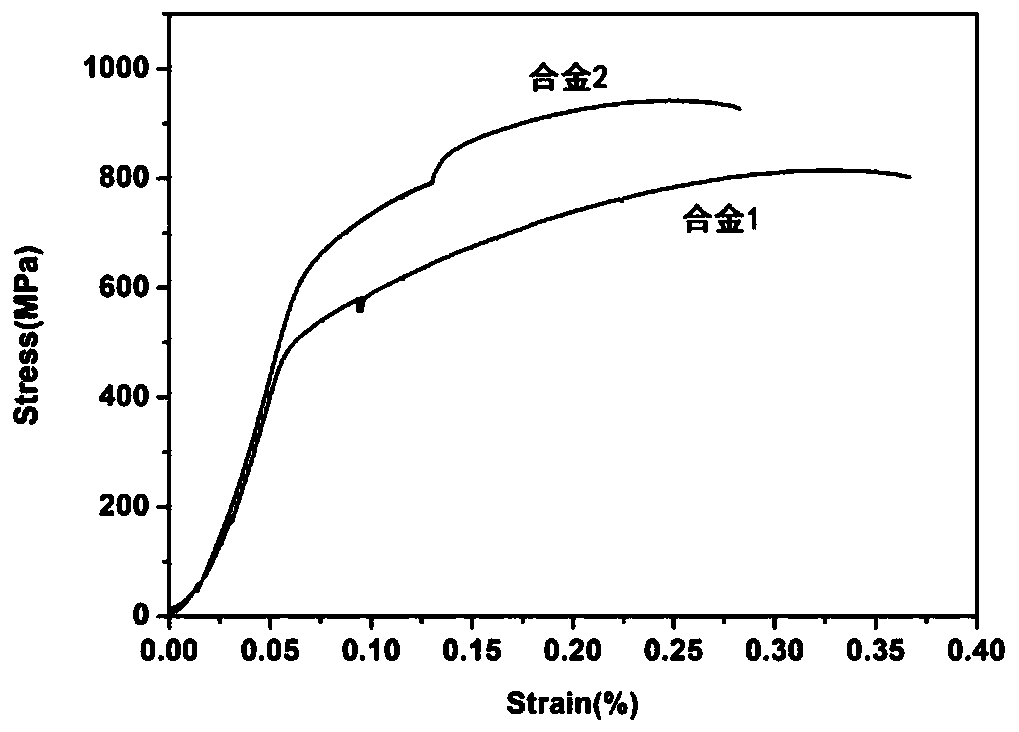

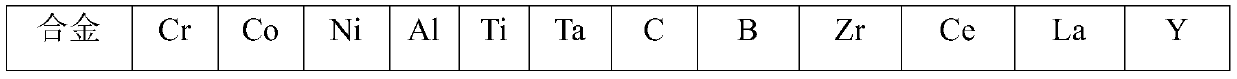

High-toughness medium entropy high temperature alloy and preparing method thereof

ActiveCN111500917AHigh strengthImprove high temperature mechanical propertiesIndustrial gasManufactured material

The invention discloses a high-toughness medium entropy high temperature alloy and a preparing method thereof. The alloy comprises chemical components including, by weight percent, 28.5 to 32.5% of Cr, 31.5 to 33.4% of Co, 32 to 35% of Ni, 0.5 to 6% of Al, 0 to 6% of Ti, 0 to 3% of Ta, 0.02 to 0.12% of C, 0.002 to 0.015% of B, 0.005 to 0.12% of Zr, 0.005 to 0.15% of RE, and larger than or equal to2% and smaller than or equal to 6% of Al+Ti+Ta, wherein Re is one of Ce, La and Y. The preparing method of the alloy comprises the steps that the raw materials are burdened and smelted according to the proportion, an electrode bar is forged and subjected to remelting, forging is carried out, an alloy bar is prepared, and the alloy bar is subjected to solid solution and aging heat treatment. The alloy is provided with a reasonable component ratio, a wide heat machining window and a heat processing system, the prepared alloy bar has the higher temperature strength, good heat machining and oxidation resistance properties, and the alloy is a candidate material of aero-engine and industrial gas turbine heat end parts.

Owner:UNIV OF SCI & TECH BEIJING +1

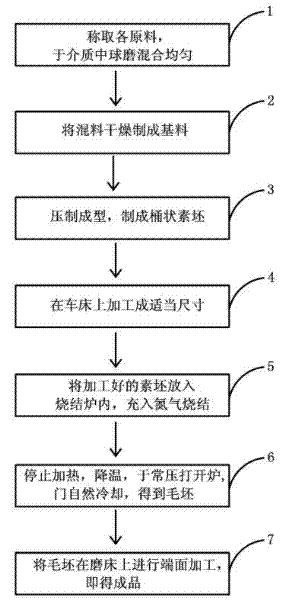

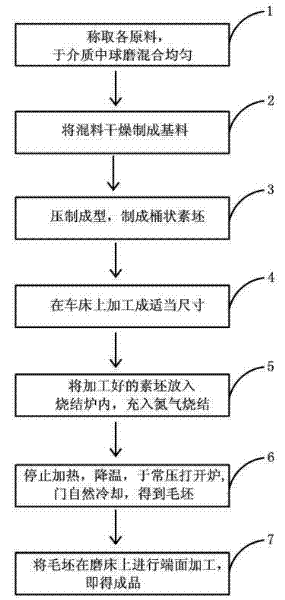

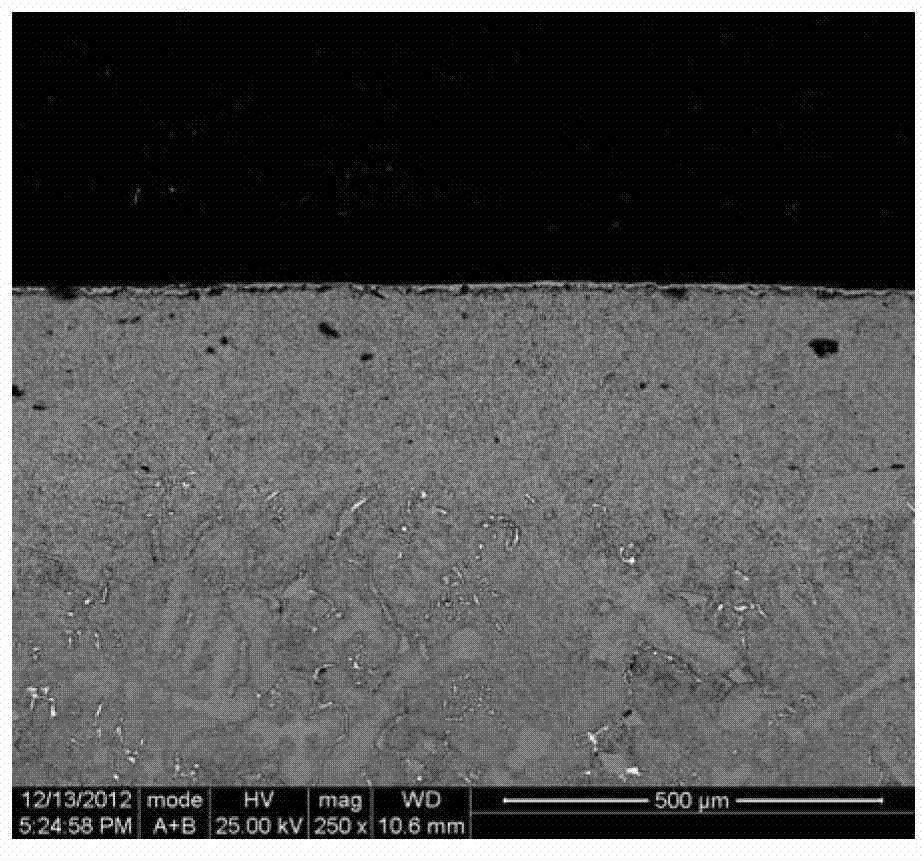

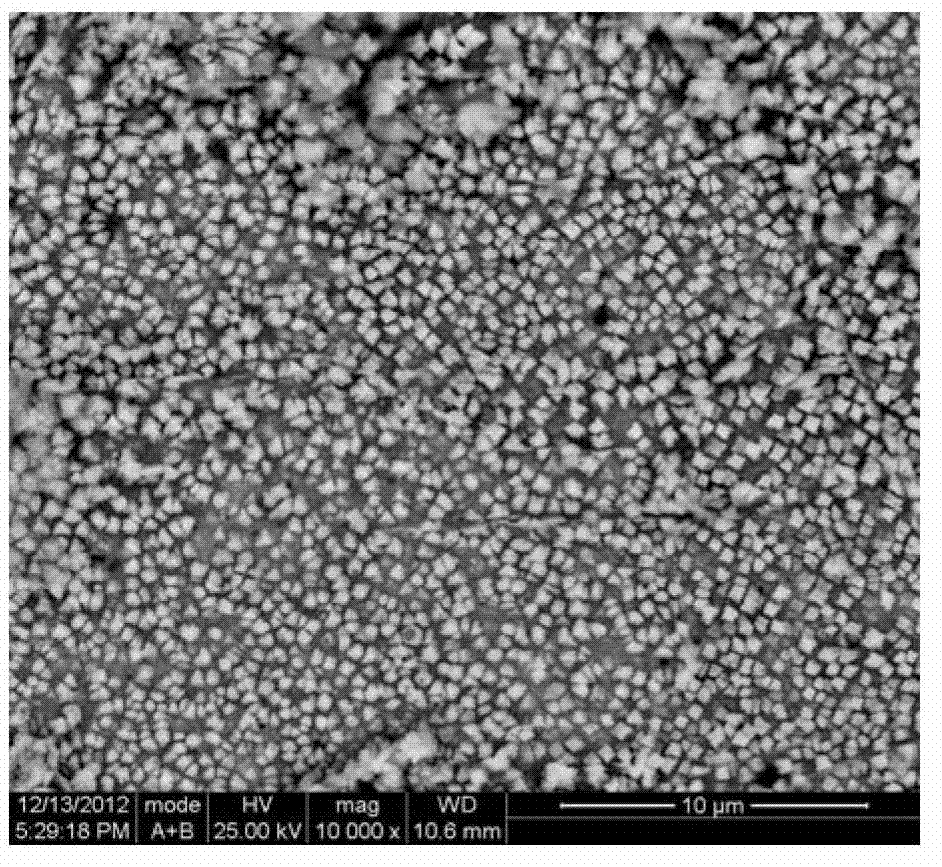

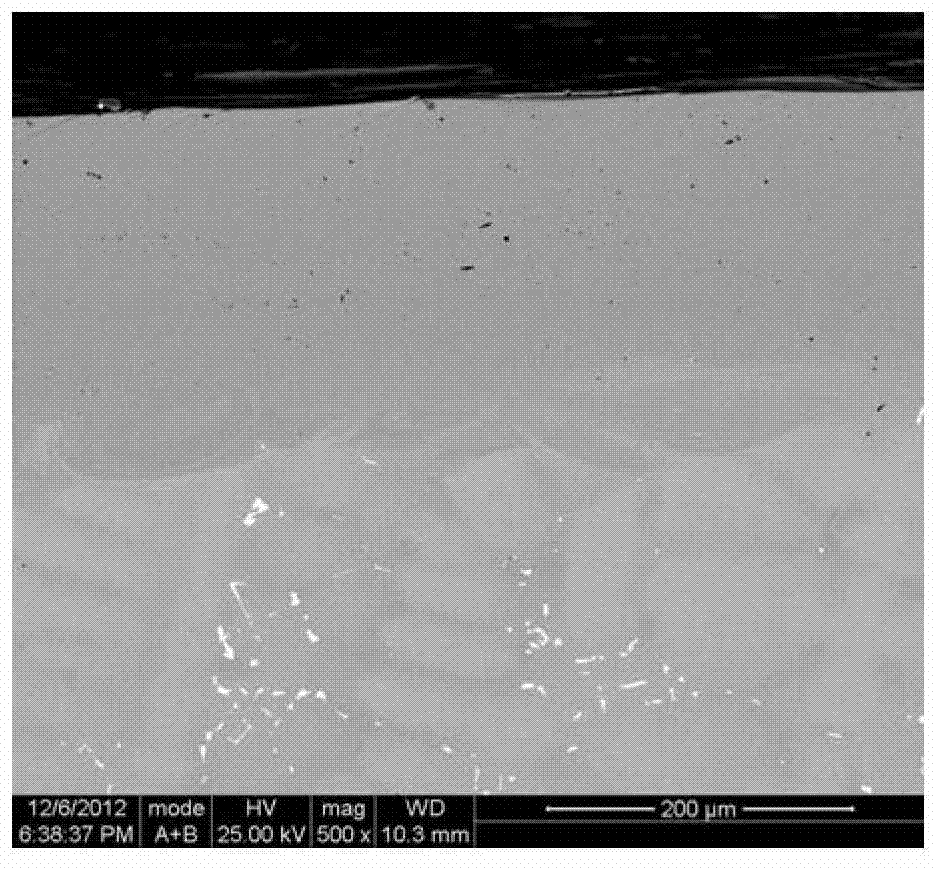

Silicon nitride material and preparation method of heat insulating disc cover prepared from same

The invention relates to a silicon nitride material and a preparation method of a heat insulating disc cover prepared from the same. The silicon nitride material consists of the following raw materials in percentage by weight: 65-87.5 percent of silicon nitride, 5-15 percent of nano-silicon nitride, 8-15 percent of a sintering aid and 0.5-5 percent of tungsten carbide; and the preparation method of the heat insulating disc cover prepared from the silicon nitride material comprises the following steps of: weighing the silicon nitride, nano-silicon nitride, sintering aid and tungsten carbide according to the percentage by weight, performing ball milling and mixing uniformly; drying a mixed material to obtain a substrate; performing press molding to obtain a cylindrical biscuit; processing to a proper size on a lathe; putting the processed biscuit into a sintering furnace, and charging nitrogen gas for sintering; stopping heating, cooling, opening a furnace door under the normal pressure, and cooling naturally to obtain a blank; and performing end face processing on the blank on a grinding machine to obtain a finished product.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD

High-temperature alloy turbine blade repair material and repair process using same

ActiveCN103243242AEnables direct depositionAchieve Fusion Weld DepositionArc welding apparatusDefect repairSuperalloy

The invention belongs to high-temperature alloy turbine blade repair and remanufacturing technology, and in particular discloses a high-temperature alloy turbine blade repair material and a repair process using the repair material. The micro-arc spark deposition repair material comprises the following ingredients based on weight percent: 45-60% of Ni, 0-25% of Co, 10-25% of Cr, 5-7% of Al, 2-8% of Ta, 0-6% of Re, 0-2% of Hf, 0-1% of Y and 0-0.1% of C, and the total weight is 100%. The repair process comprises the following steps of: fabricating a round bar with 2-6mm of diameter and 20mm of length using the above repair material, carrying out surfacing on the to-be-repaired area using the micro-arc spark deposition process, wherein the surfacing process parameters are as follows: power is 100W-1500W and the frequency is 100-500HZ, and the processing process is carried out under argon protection or in a vacuum glove box; placing the repair part into a vacuum furnace for thermal treatment after the processing is finished, wherein the thermal treatment process is as follows: solution treatment is carried out at 1150-1230 DEG C for 1-6 hours, and the aging is 4-20 hours at 800-900 DEG C. The novel repair material and the repair process using the repair material are provided for defect repair on the surface of the turbine blade so that the repair of high gamma' high-temperature alloy blade using the high gamma' high-temperature alloy repair material is possible and a novel solution plan is provided for the near / equal strength repair of the high-temperature alloy blade.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

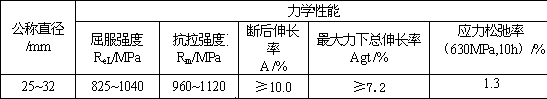

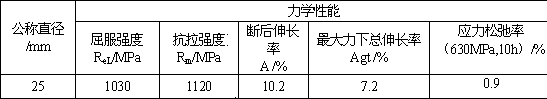

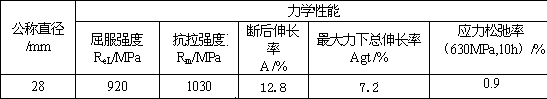

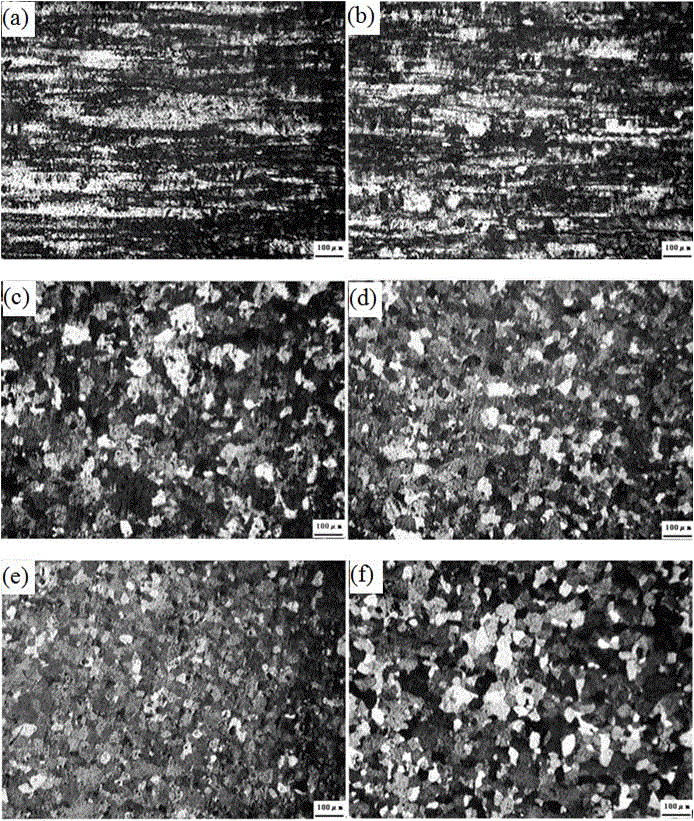

Twisted steel for 785 MPa-level high-strength prestressed structure and preparation method of twisted steel

The invention discloses a twisted steel for a 785 MPa-level high-strength prestressed structure and a preparation method of the twisted steel. The twisted steel comprises following constituents in percentage by weight: 0.50-0.55% of C, 0.80-1.10% of Si, 1.00-1.30% of Mn, 0.060-0.12% of V, 0.60-0.95% of Cr, 0.0015-0.0040% of B, 0.010-0.025% of S, 0.010-0.025% of P, and the balance of Fe and unavoidable impurities. The preparation method comprises steps of billet preparation, rolling and after treatment. In the preparation process, when vanadium is utilized to conduct microalloying and reinforcement, the alloying element B is appropriately added to improve the steel hardenability, and the addition of the microalloying reinforcing elements is lowered. As the controlled rolling technology is combined and the cooling technology is applied, the grain refinement of steel structure is obvious, the net-like ferritic structure at the core of the steel is lowered, the steel strength is increased, the hardness gradient change is slow, and the stability of the precision rolled twisted steel is improved. The processed steel is stable in technologic and mechanical performances, and good in prestress relaxation performance.

Owner:WUKUN STEEL

Pure aluminum cathode foil for capacitors and manufacturing method thereof

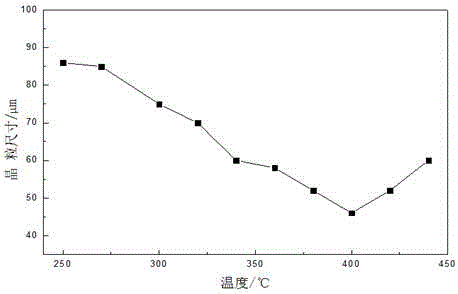

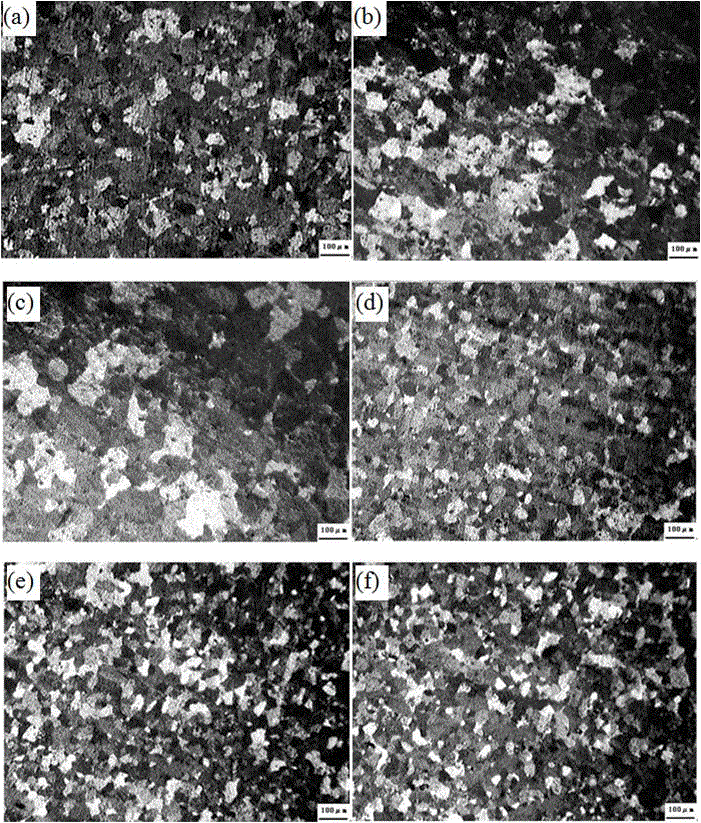

ActiveCN105908021AEffective control of grain sizeEvenly distributedElectrolytic capacitorsCapacitanceCapacitor

The invention belongs to the field of electrode foil for capacitors and particularly relates to pure aluminum cathode foil for the capacitors and a manufacturing method thereof. The pure aluminum cathode foil is composed of, in mass percentage, smaller than 0.1% of Si, 0.2-0.25% of Fe, 0.19-0.25% of Cu, 0.03-0.04% of Ti and the balance Al. The manufacturing method comprises the steps of 1, preparing casting-rolling blanks according to the components and the mass percent; and 2, carrying out the cold rolling and hot processing technology. The step 2 comprises the sub-steps of (1), cold-rolling the casting-rolling blanks in the step 1 to 3.8-4.2 mm in thickness, carrying out homogenizing annealing on the blanks at 500-550 DEG C for 8-12 hours and then air-cooling the blanks; (2), cold-rolling the blanks subjected to homogenizing annealing to 0.3-0.5 mm in thickness, carrying out recrystallization annealing on the blanks at 380-420 DEG C for 1.5-2.5 hours and then air-cooling the blanks; and (3), cold-rolling the blanks subjected to recrystallization annealing to the thickness required by the cathode foil. According to the pure aluminum cathode foil for the capacitors and the manufacturing method thereof, the problem that corrosion of common cathode foil is not uniform can be solved, and the cathode foil high in specific capacitance can be obtained.

Owner:河南恒纳百美装饰材料有限公司

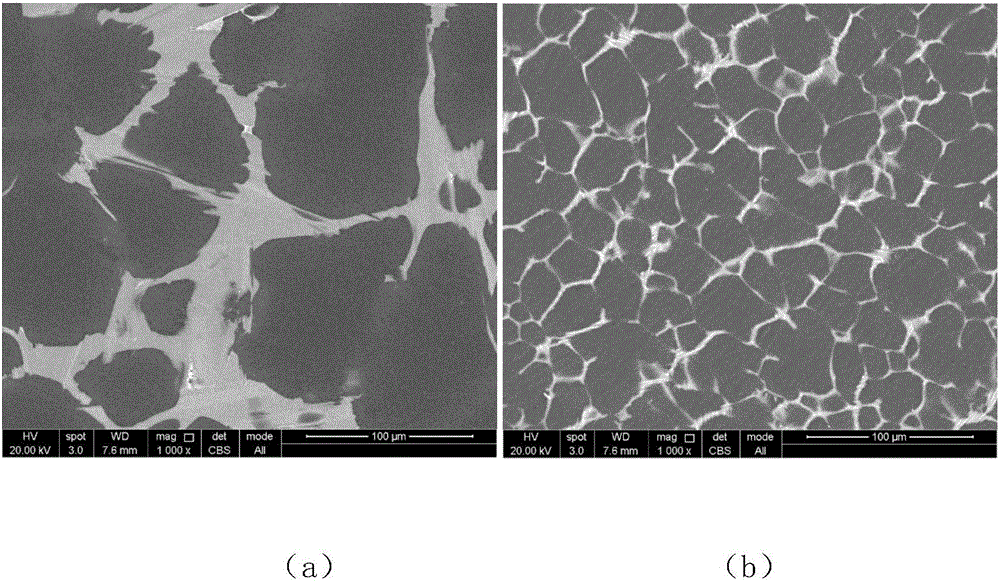

Method for adjusting and regulating long-periodic structure phase of magnesium alloy

ActiveCN106392044AImprove performanceFully exert the strengthening effectUltrasonic vibrationMagnesium alloy

The invention discloses a method for adjusting and regulating a long-periodic structure phase of magnesium alloy. The method comprises the steps of: firstly preparing Mg-Ni (or Zn)-Y alloy containing LPSO, and then adjusting and regulating form and distribution of a long-periodic structure by applying ultrasonic vibration and pressure in sequence in an alloy solidification process. The alloy preparing and processing comprises the following steps: melting the alloy under protection of mixed gas of N2 and SF6, after temperature reaches 720-730 DEG C, placing a melt in a container in a holding furnace, cooling to a temperature more than a liquidus temperature of the alloy by more than 10-50 DEG C, then performing ultrasonic vibration processing on the melt, lasting for 1-5min, after the vibration is finished, pouring into a preheated die of 200-300 DEG C for extruding to solidify under pressure, wherein an extruding pressure is 50-500 MPa, and pressure holding time is 1-3min. The LPSO phase in the alloy prepared by such method is obviously refined and uniformly distributed, and performances of the alloy are greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Civil aluminum alloy conductor, wiring and preparation method thereof

ActiveCN101937733AImprove corrosion resistanceStrong corrosion resistanceFlexible cablesMetal/alloy conductorsElectrical conductorManufacturing technology

The invention provides a method for manufacturing civil aluminum alloy wiring, belonging to the technical field of wire and cable design and manufacture. The manufacture method comprises the following steps: adding aluminum ingots, aluminum-iron master alloy, aluminum-boron master alloy and aluminum-rare earth master alloy into a shaft furnace; casting into a cast strip after smelting; rolling into an aluminum alloy rod through a rolling mill; preparing an aluminum alloy filament by the aluminum alloy through cold drawing; annealing, and performing extruded insulation on the aluminum alloy wire, wherein the insulation material is silane-crosslinked polyethylene; adding low halogen or halogen-free flame retardant during insulation; and performing warm water crosslinking or steam crosslinking treatment on the aluminum alloy wiring after the extruded insulation is completed. The aluminum alloy wiring has excellent conductivity, tensile property and bending performance; and the wire has better flame retardant performance and longer service life.

Owner:于贵良 +1

2007 aluminum alloy rod processing process

The invention discloses a 2007 aluminum alloy rod processing process. The 2007 aluminum alloy rod processing process includes the steps of dosing, smelting, stirring, detailing, drossing, heat preservation, detailing, filtering, casting, homogenizing treatment, extrusion, temperature compensation, on-line quenching, aging treatment, packaging and the like. The technological parameters needed during steps before on-line quenching are mainly controlled, so that cracks are effectively avoided, composition segregation and the depth of a coarse grain ring are reduced, and bright crystals and feather crystals are avoided; besides, a temperature compensation device is used for conducting temperature compensation on rods before quenching, and thus the overall performance of quenched rods can be improved. By means of the process, qualified 2007 round aluminum alloy rods can be extruded out successfully, produced aluminium alloy has a better mechanical property, and batch production is available.

Owner:CHINA ZHONGWANG

Zinc-aluminum binary intermediate alloy and uses in hot galvanizing alloy production

The invention relates to a production process of a hot galvanizing alloy and a master alloy thereof, which has the technical proposal that, the components and the weight ratio of a zinc-aluminum binary master alloy are that 16-24 percent is aluminum and the rest is zinc. A method for producing the hot galvanizing alloy by the zinc-aluminum binary master alloy comprises the steps: mixing the zinc and the aluminum by the weight ratio, adding the mixture to a master alloy smelting furnace with the melting temperature of 560-680 DEG C to be molten, uniformly stirring, ingoting to a zinc-aluminum binary master alloy pig, adding the solid zinc required by hot galvanizing alloy production to a hot galvanizing alloy smelting furnace to be molten into zinc liquid, adding the zinc-aluminum binary master alloy required by the produced hot galvanizing alloy to the zinc liquid, and stirring for 20-40min at the melting temperature of 480-520 DEG C to prepare the hot galvanizing alloy. The invention which is applicable to the hot galvanizing alloy production by a cored induction furnace has the advantages of reducing the temperature of the melting alloy, shortening the melting and stirring time, prolonging the service life of the cored induction furnace and ensuring uniform hot galvanizing alloying components.

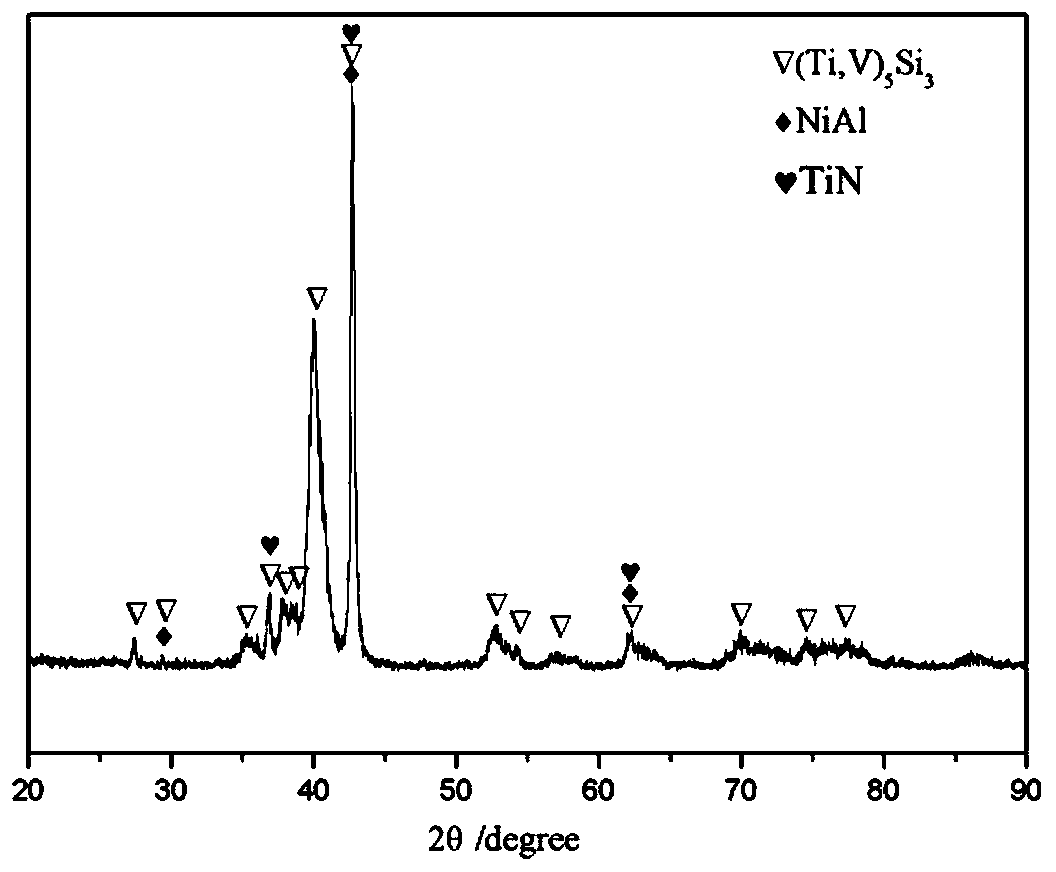

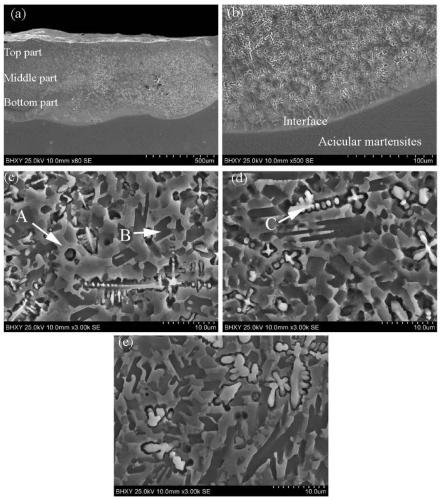

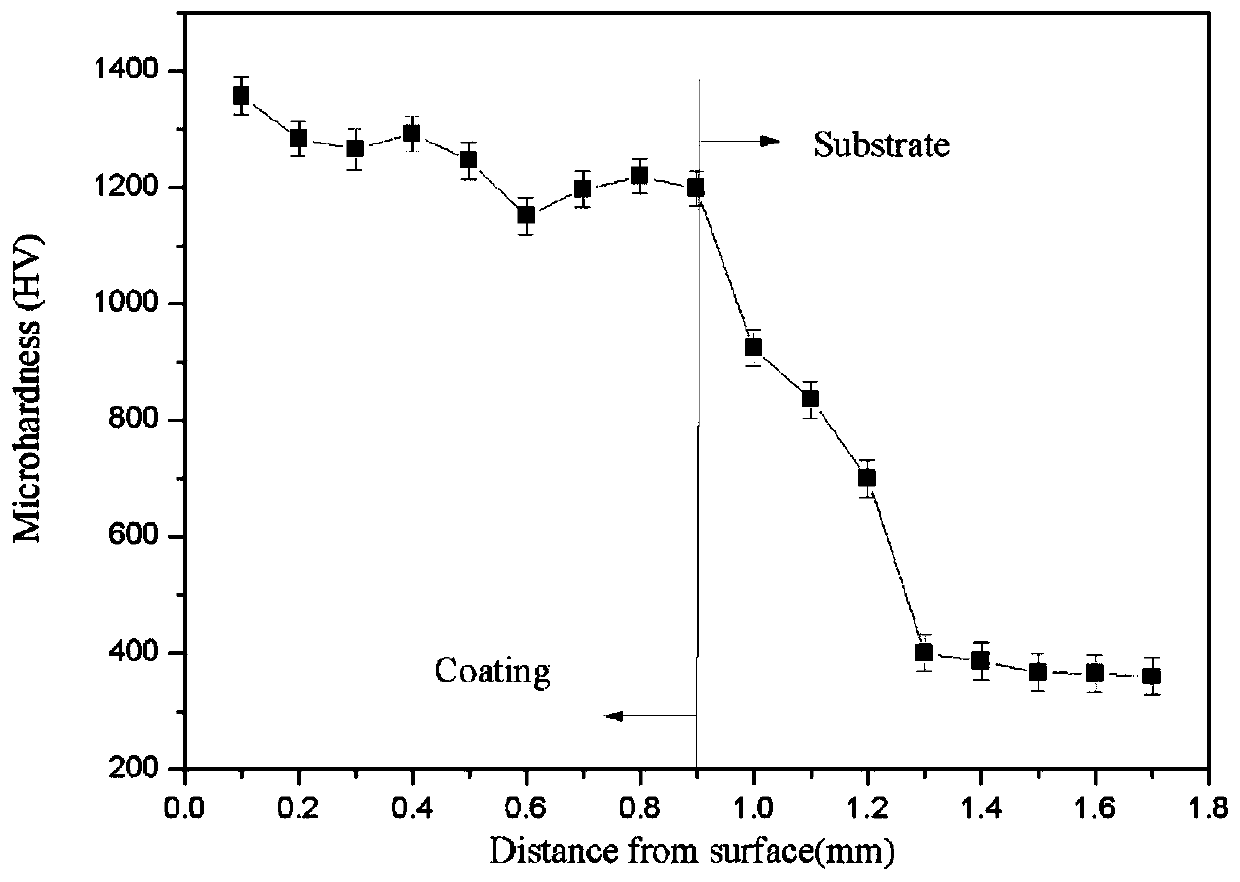

High-entropy alloy coating resistant to high-temperature abrasion and preparation process and application thereof

ActiveCN109763125AHigh hardnessImprove wear resistanceMetallic material coating processesHigh entropy alloysRare earth

The invention relates to a high-entropy alloy coating resistant to high-temperature abrasion and a preparation process and application thereof. The preparation process comprises the following steps: (1) the surface of a titanium alloy sample is polished and washed; (2) metal powder, a ceramic hard phase and rare earth oxide are evenly mixed, and cladding material powder is formed to be flatly laidon the washed surface of a titanium alloy; and (3) the titanium alloy coating is prepared through laser cladding, wherein the metal powder includes Ti, Ni, Al, Si and V, a ceramic phase material is B4C or TiC or TiN, and the rare earth oxide is Y2O3. According to the high-entropy alloy coating, the hardness of a titanium alloy part can be remarkably improved, abrasion resistance of the titanium alloy part is improved, and the using range of the titanium alloy part is enlarged.

Owner:QINGDAO BINHAI UNIV

Steel for hot-rolling ultra-thin laser welding saw blade base and production method

The invention discloses steel for hot-rolling an ultra-thin laser welding saw blade base. The steel comprises the following components in percentage by weight: 0.26-0.34% of C, 0.25-0.37% of Si, 0.40-0.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.006% of N, 0.80-1.10% of Cr, 0.15-0.25% of Mo and 0.005-0.045% of Ti. Production comprises the following steps: smelting and continuously casting to prepare a blank, heating a cast blank, rolling, performing laminar cooling, coiling, slowly cooling a steel roll in a warehouse or insulating hood to be the room temperature, and finely settling. The tension strength of a steel plate is 600-900MPa, the ductility A is 15-28%, the hardness is 160-260HB, the tensile strength fluctuation between the head part and the middle part of the steel roll is smaller than 150MPa, the thickness of a single side decarburized layer is less than or equal to 1.1% of the thickness of the steel plate, the hardness fluctuation after quenching is less than 2HRC, the thickness reduction of an edge part is less than or equal to 100mu m, the unflatness is less than or equal to 12mm / m, the thickness of a product is 1.0-3.0mm, the effect of replacing cold rolling by hot rolling can be partially achieved, and the cost is lowered.

Owner:武汉钢铁有限公司

Steel for ball screw bearing and manufacturing method thereof

ActiveCN110983178AImprove composition segregationConvenient spacingShaftsBearing componentsTemperingAustenite grain

The invention relates to steel for a ball screw bearing. Alloy components of the steel comprise, by mass, 0.45-0.60% of C, 0.15-0.40% of Si, 0.50-0.80% of Mn, 0.15-0.40% of Cr, 0.002-0.006% of B, 0.02-0.07% of V, less than or equal to 0.015% of S, less than or equal to 0.025% of P, less than or equal to 0.10% of Mo, less than or equal to 0.08% of Al, less than or equal to 0.0010% of Ca, less thanor equal to 0.0010% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb, and the balance Fe and inevitable impurities. A preparation process of a bar product comprises the steps of molten steel smelting, continuous casting, cogging-down, hot rolling, tempering, stress relief annealing and the like. The final properties meet the conditions that the surface hardness of the bar reaches 220-260 HBW, the metallographic structure of the bar is a uniform sorbite structure, the austenitic grain size of the bar is higher than or equal to the seven-level, the yield strength of the bar is 600-800 MPa, the tensile strength of the bar is 800-900 MPa, and the percentage elongation of the bar is greater than orequal to 15%.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

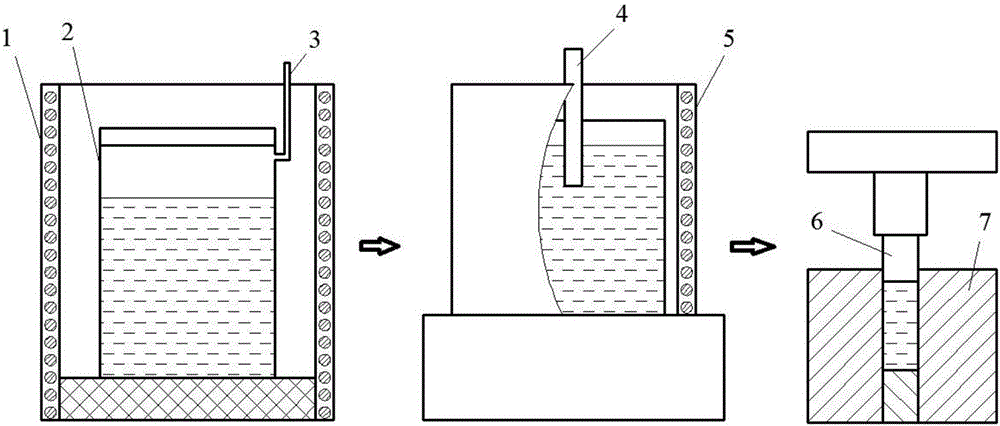

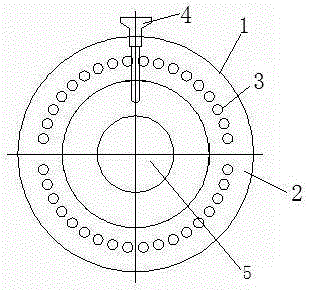

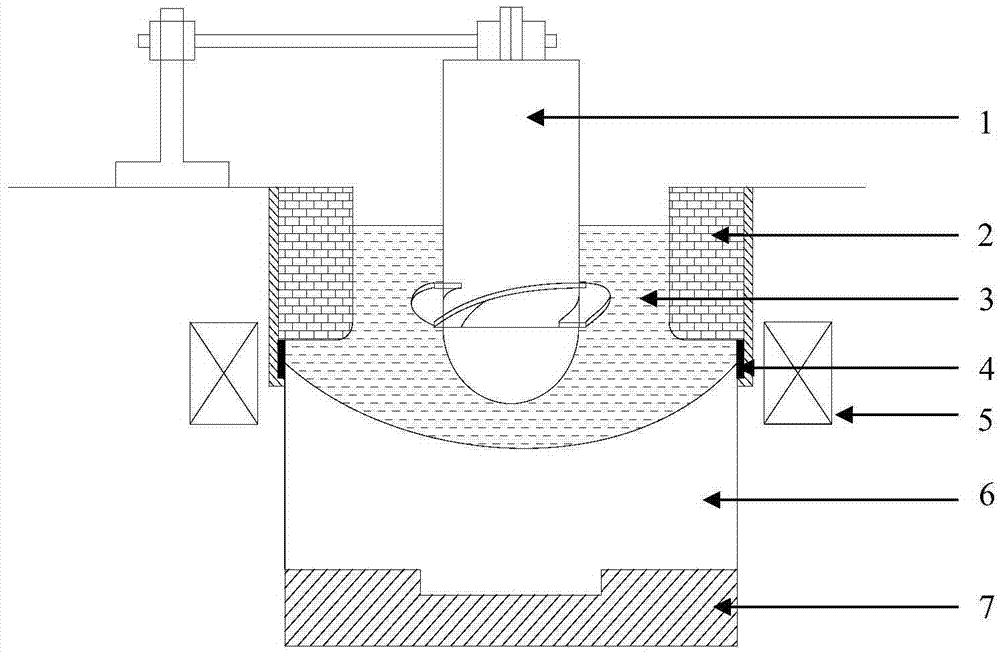

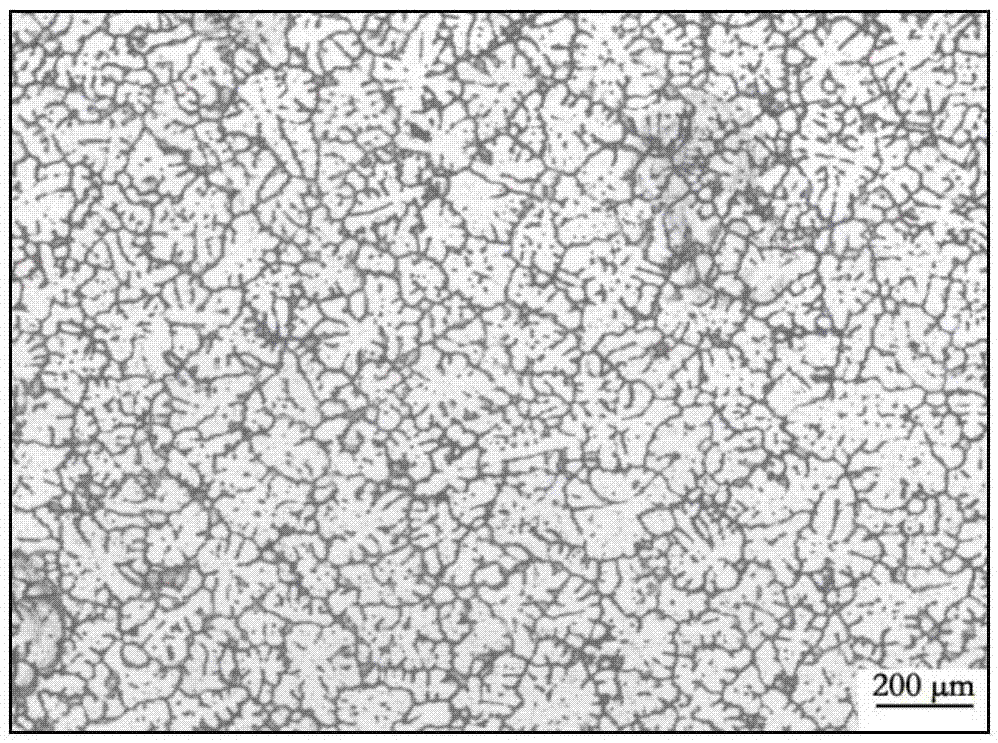

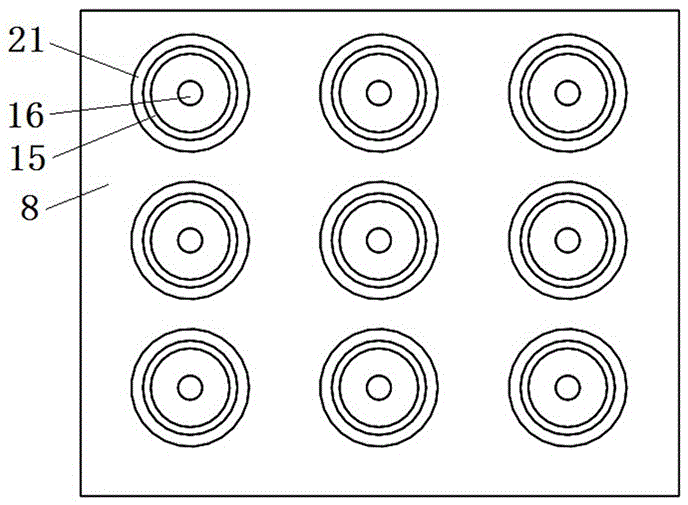

Manufacture device and method for large-size fine-grain homogeneous aluminum alloy cast ingot

The invention relates to a manufacture device and method for a large-size fine-grain homogeneous aluminum alloy cast ingot, belonging to the field of metal material machinery. The device mainly comprises a uniform cooler, a thermal ejector, an electromagnetic stirrer, a crystallizer and a dummy ingot, wherein the thermal ejector is arranged above the crystallizer; the electromagnetic stirrer is arranged on the periphery of the thermal ejector and the crystallizer; the dummy ingot is arranged below the crystallizer; the uniform cooler is arranged in the crystallizer; and the uniform cooler consists of an inner pipe and an outer pipe. According to the manufacture device and method, through special coupling treatment of uniform cooling in the crystallizer and electromagnetic stirring outside the crystallizer is applied to an alloy melt, so that effective control on uniformity of a temperature field and a component field of the large-size alloy melt is realized, and the large-size aluminum alloy cast ingot with uniform and fine structure and uniform components is manufactured. The manufacture device is simple in structure, feasible in method, obvious in effect, high in production efficiency and easy for combination with large-scale industrial production, and has a wide industrial application prospect in the fields of aerospace, rail transportation and manufacture of ships and the like.

Owner:有研金属复材技术有限公司

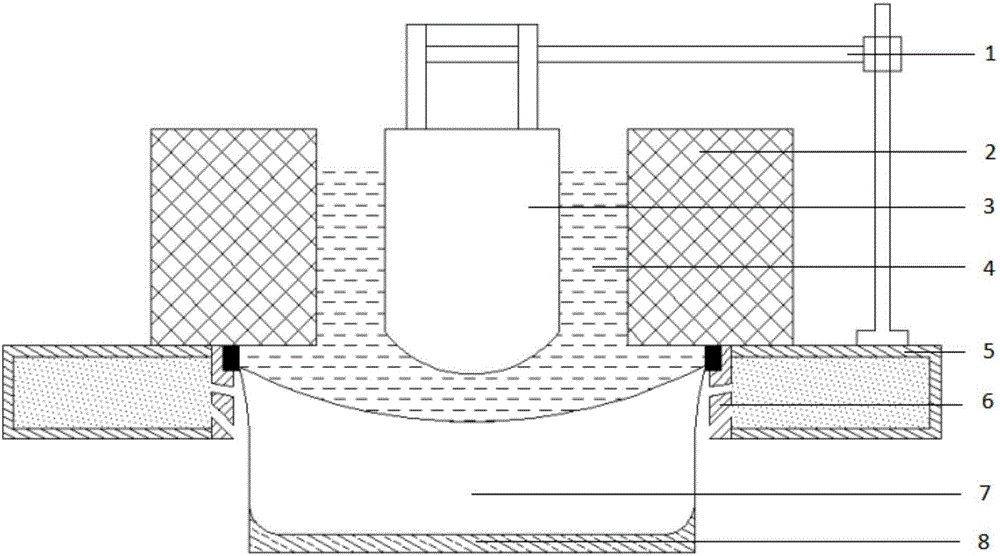

Selective laser melting SLM formation cylinder in high-intensity magnetic field

InactiveCN106141185ARapid coolingUniform temperature distributionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing technology

The invention relates to a selective laser melting SLM formation cylinder in a high-intensity magnetic field and belongs to the technical field of 3D printing material additive manufacturing. The invention provides the selective laser melting SLM formation cylinder in the high-intensity magnetic field, wherein parts and powder in the formation cylinder can be heated to prevent the thin-walled parts of the parts from being cooled too quickly, so that the internal temperature distribution of the parts is tend to be uniform. The technical scheme adopted is as follows: a hydraulic cylinder is arranged in the cylinder body, a bottom plate is arranged on a piston rod of the hydraulic cylinder, a heating tube and a first temperature-sensing galvanic couple are arranged in the wall body of the cylinder body, an insulating layer is arranged outside the cylinder body, an electromagnetic inductor and a magnetic field measuring instrument are arranged in the upper part of the cylinder body, a magnet exciting coil is arranged in the electromagnetic inductor, a medium-frequency power supply is connected to the electromagnetic inductor, a shielding hood is arranged on the top of the cylinder body, and the heating tube, the electromagnetic inductor, the medium-frequency power supply and the magnetic field measuring instrument are connected to a master control system. The selective laser melting SLM formation cylinder in the high-intensity magnetic field is widely applied to selective laser melting SLM processes.

Owner:ZHONGBEI UNIV

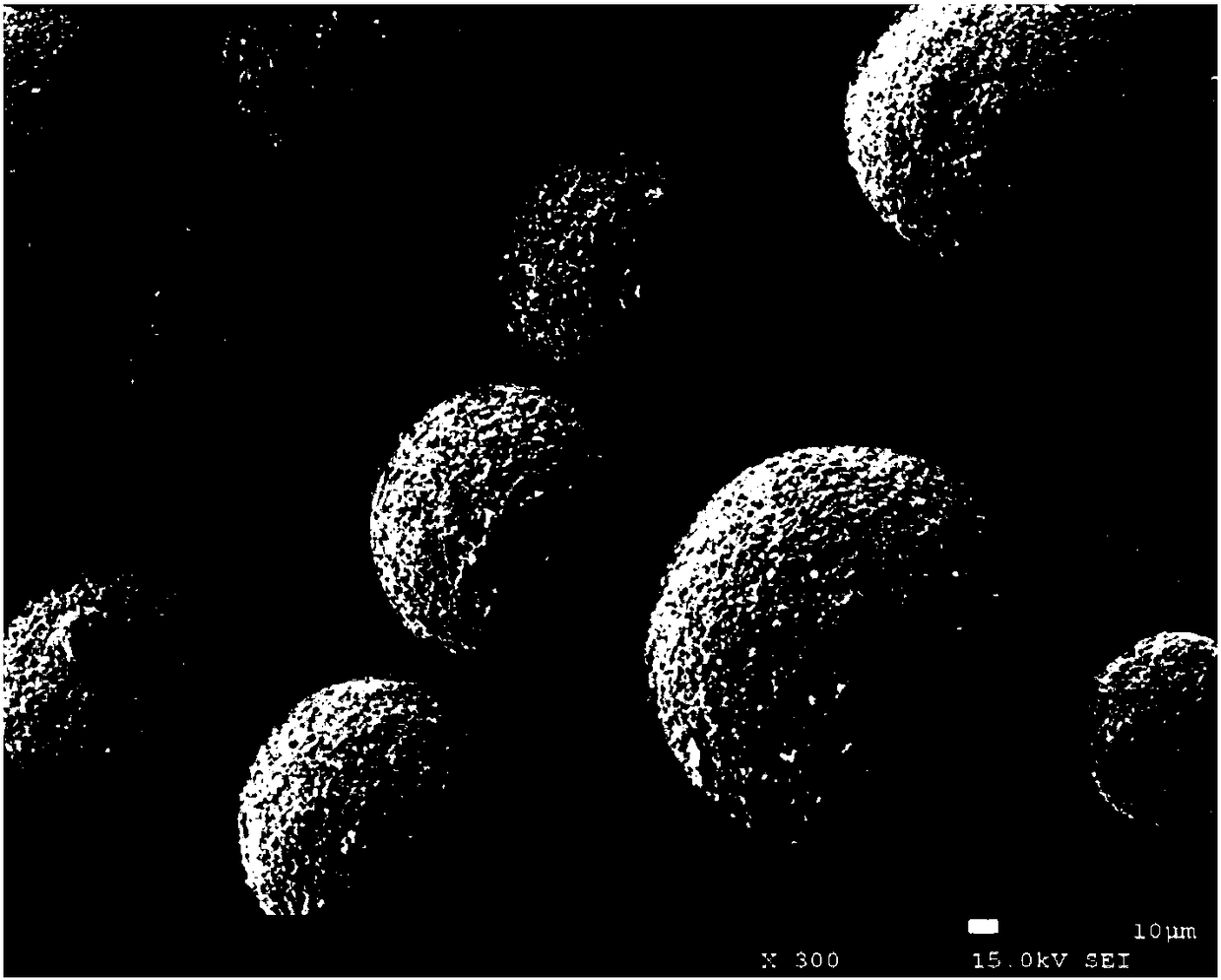

Coating spraying and 3D printing cermet material based on TiCN-MxC-Co and preparation method of coating spraying and 3D printing cermet material based on TiCN-MxC-Co

ActiveCN108213411AReduce composition segregationUniform microstructureAdditive manufacturing apparatusMolten spray coatingSpray GranulationCarbide

The invention disclose a coating spraying and 3D printing cermet material based on TiCN-MxC-Co and a preparation method of the coating spraying and 3D printing cermet material based on TiCN-MxC-Co. The cermet material is spherical powder and comprises TiCN-MxC-Co and at least one selected from Ni, Mo and Fe, wherein, by mass percentage, 20-94% of TiCN, 1-40% of MxC and 5-40% of Co and at least oneselected from Ni, Mo and Fe are included, and carbide MxC is at least one of WC, MoC, Mo2C, TaC, Cr3C2, NbC, VC and ZrC. The material is prepared through the steps of mixing, drying, powder spheroidization and sintering, wherein powder spheroidization can be carried out by the adoption of a roller spheroidization method or a radio frequency plasma spheroidization method or a spray granulation spheroidization method and the like. The cermet material can be used as a coating material to improve the bonding force between the coating and a substrate and can be used as a 3D printing material to improve the quality of 3D printing products.

Owner:成都锦钛精工科技有限公司

Zinc alloy for die

The invention provides a zinc alloy for a die. The zinc alloy for the die comprises the following components in percentage by mass: 5 percent to 22 percent of aluminium, 0.01 percent to 0.03 percent of magnesium, 1 percent to 10 percent of copper, 0.05 percent to 0.5 percent of rare earth, 0.01 percent to 0.05 percent of boron, 0.05 percent to 0.1 percent of zirconium, 0.03 percent to 0.1 percent of bismuth and the balance of zinc. According to the zinc alloy for the die, which is provided by the invention, not only can the hardness and the wear resistance be further improved, but also the phenomena of composition segregation and bottom shrinkage are obviously reduced; and on the premise of ensuring the tensile strength basically constant, the size stability and the die making accuracy of the zinc alloy are obviously improved.

Owner:ZHUZHOU SMELTER GRP

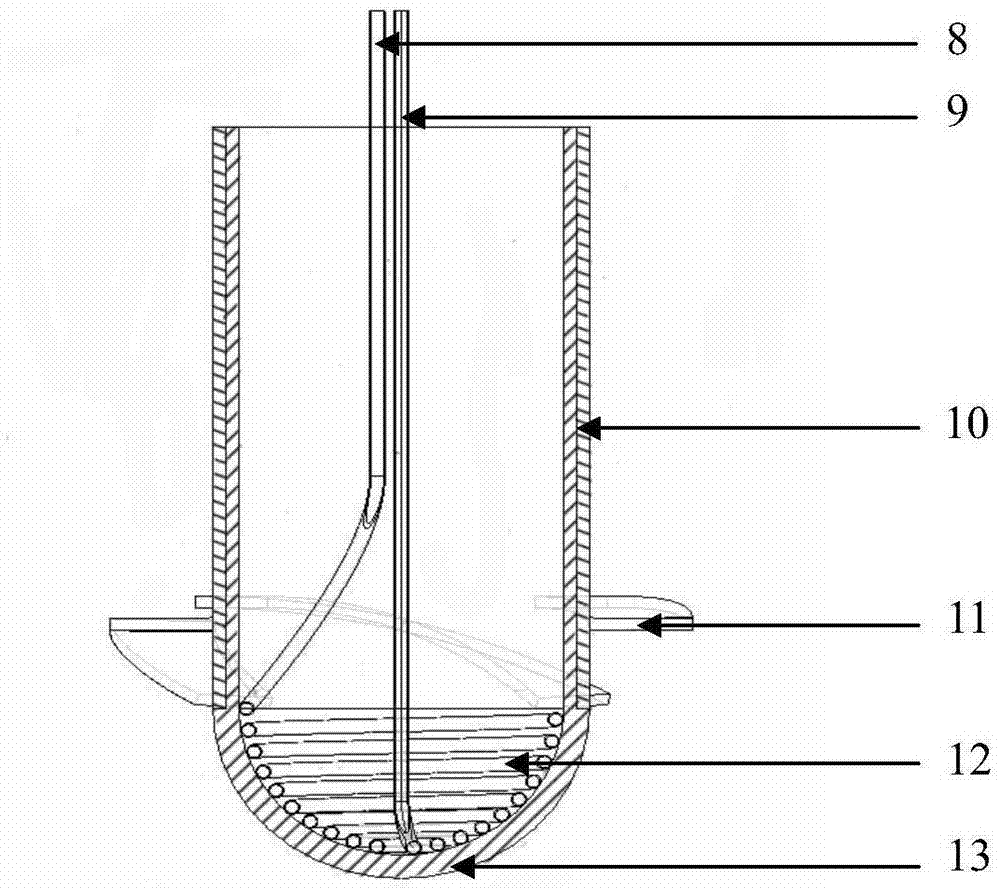

Preparation device and method of aluminum alloy ingot with ultra-large dimension

ActiveCN106623832AUniform temperatureUniform composition fieldMetallic materialsMaterials processing

The invention relates to a preparation device and method of an aluminum alloy ingot with the ultra-large dimension, and belongs to the field metal material processing. The device mainly comprises a melt processor, a lifting mechanism, a hot top, a crystallizer, a water tank and a dummy ingot; the hot top is installed above the crystallizer, the dummy ingot is arranged below the crystallizer, the crystallizer is fixedly installed on the water tank, the metal processor is connected with the lifting mechanism, the lifting mechanism is fixed to the water tank, and in the casting process, the melt processor is placed on the hot top and / or inside the crystallizer through the lifting mechanism. Accordingly, electromagnetic field applying and forced cooling are conducted on alloy melt on the hot top and inside the crystallizer in the continuous casting process from the interior, heat exchange and mass transfer of the core of the alloy melt are accelerated, the uniformity of a temperature field and a component field of the melt is improved, and fine grain homogeneous casting of the aluminum alloy ingot with the ultra-large dimension is achieved. According to the preparation device and method of the aluminum alloy ingot with the ultra-large dimension, the implementation effect is significant, the production efficiency is high, and the preparation device and method are likely to be combined with large-scale industrial production and have a wide industrial application prospect in the manufacturing fields of aerospace, rail transit, ships and the like.

Owner:有研金属复材技术有限公司

Preparation method of magnesium-lithium alloy with reinforced LPSO (long-period stacking ordered) structure

The invention provides magnesium-lithium alloy with a reinforced LPSO (long-period stacking ordered) structure and a preparation method thereof, which belong to the technical field of high-strength alloy and preparation thereof. The magnesium-lithium alloy with the reinforced LPSO structure is prepared from the following components: Li, Gd, Y, Zn, Zr, Mg and inevitable impurity elements. Accordingto the preparation method of the magnesium-lithium alloy with the reinforced LPSO structure, Gd, Y and Zn elements are added at the same time, so that the Gd, Y and Zn elements are solidly dissolvedin a magnesium-lithium alloy substrate, and homogenization, plastic deformation and aging heat treatment are performed, so that authigene occurs in an alpha-Mg phase and a beta-Li phase so as to obtain the laminar LPSO structure, and the effect of reinforcing the beta-Li phase is achieved, thereby reinforcing the alloy. By adopting the preparation method, the two-phase magnesium-lithium alloy which has the advantages of low density and high strength and can satisfy the requirement of plastic deformation at room temperature is obtained, the elongation of the two-phase magnesium-lithium alloy isgreater than or equal to 20%, and especially, the requirements of light materials with high strength and high plasticity are satisfied.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com