Patents

Literature

54results about How to "Improve composition segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing aluminum foil for lithium battery

ActiveCN105063429AImprove performanceUniform compositionMetal rolling arrangementsFiltrationAluminum foil

The invention relates to a method for preparing an aluminum foil for a lithium battery and belongs to the technical field of machining of aluminum alloy materials. The method for preparing the aluminum foil for the lithium battery includes the steps of performing smelting and cast rolling processes: heating and smelting raw materials of the aluminum foil for the lithium battery to form an aluminum alloy melt, sequentially carrying out refining slagging-off, grain refining, degassing deslagging and filtration treatment and subjecting the filtered aluminum alloy melt to continuous cast rolling to form a blank; performing a cold rolling process: subjecting the blank to cold rolling firstly and then to primary annealing treatment, rough rolling and secondary annealing treatment; performing foil pressing treatment: carrying out finish rolling on the annealed aluminum foil, and finally slitting the foil to obtain the aluminum foil finished product for a lithium battery finished product. According to the method for preparing the aluminum foil for the lithium battery, composition segregation in the process of alloy cast rolling is improved through added uniform annealing treatment; an original cast rolling structure is improved so that the product with uniform constituents and structure and stable performances can be obtained; moreover, the performances of the aluminum foil for the lithium battery can be improved.

Owner:浙江中金铝业有限公司

Method for producing 65Mn hot rolled steel plate

InactiveCN101773930AImprove product qualityUniform tissue performanceMetal rolling arrangementsContinuous rollingSmelting

The invention discloses a method for producing a 65Mn hot rolled steel plate, which comprises the steps of smelting, refining, thin slab casting, soaking, high pressure water descaling, hot continuous rolling, cooling and reeling based on the process of thin slab casting and rolling. The molten steel superheat temperature is T superheat (30 DEG C <T superheat < / = 45 DEG C), the charging temperature of casting blanks is T charging (900 DEG C < / = T charging < / = 1050 DEG C), the final rolling temperature is T final (850 DEG C < / = T final < / = 950 DEG C), the reeling temperature is T reeling ( 550 DEG C < / = T reeling < / = 650 DEG C), the liquid core pressure of casting blanks is L pressure (2 < / = L pressure < / = 20mm), and the depth of a single-surface decarburized layer is 0.3 to 0.9 percent of the depth of the steel plate. The chemical constitutes of molten steel after being alloyed in a refining process comprise 0.62-0.70 wt.% of C, 0.17-0.37 wt.% of Si, 0.90-1.20 wt.% of Mn, less than or equal to 0.035 wt.% of P, less than or equal to 0.035 wt.% of S, less than or equal to 0.25 wt.% of Cr, less than or equal to 0.25 wt.% of Ni and the balance of Fe and inevitable impurities. The 65Mn hot rolled steel plate produced in the method has the characteristics of uniform structure property, high thermal stability and high strength, and the quality of the 65Mn hot-rolled steel plate is obviously improved.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

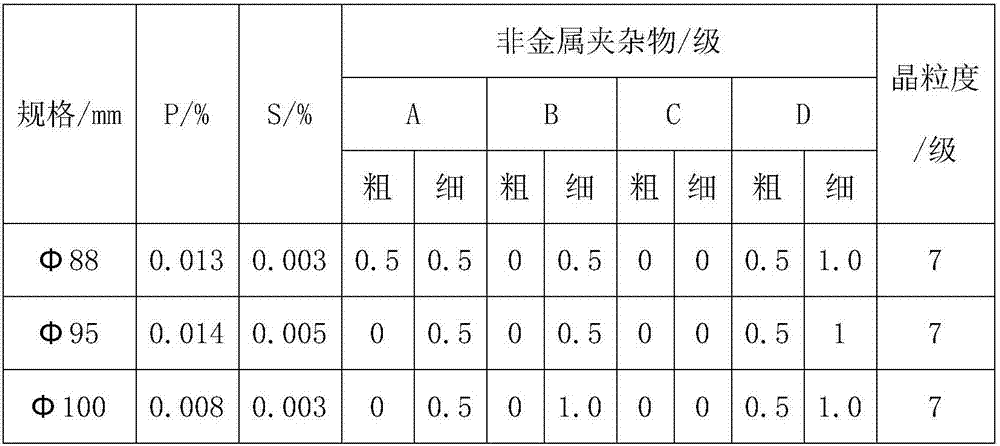

Steel for carbon hub bearing of microalloying car and production method thereof

InactiveCN105568134AGuaranteed normal growthImprove composition segregationRolling contact bearingsHubsChemical compositionMetallurgy

The invention relates to steel for a carbon hub bearing of a microalloying car. The steel comprises the following chemical components: 0.45-0.70% of C, 0.10-0.50% of Si, 0.30-0.70% of Mn, 0.20-0.60% of Cr, P not more than 0.025%, 0.003-0.030% of S, Mo not more than 0.1%, Ni not more than 0.2%, Al not more than 0.04%, Cu not more than 0.3%, Ca not more than 0.001%, Ti not more than 0.003%, O not more than 0.001%, As not more than 0.04%, Sn not more than 0.03%, Sb not more than 0.005%, Pb not more than 0.002%, and the balance of Fe and inevitable impurities. A production method comprises an electric furnace or a converter-refining out of the furnace-VD or RH vacuum degassing-continuous casting-continuous rolling-sawing-cooling in heap-finishing-surface and internal flaw detection-packing. The steel for the hub bearing improves the mechanical performance, the element segregation and the structure uniformity, and belongs to a brand new hub bearing steel type.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-toughness and high-thermal-stability hot work die steel and preparation method thereof

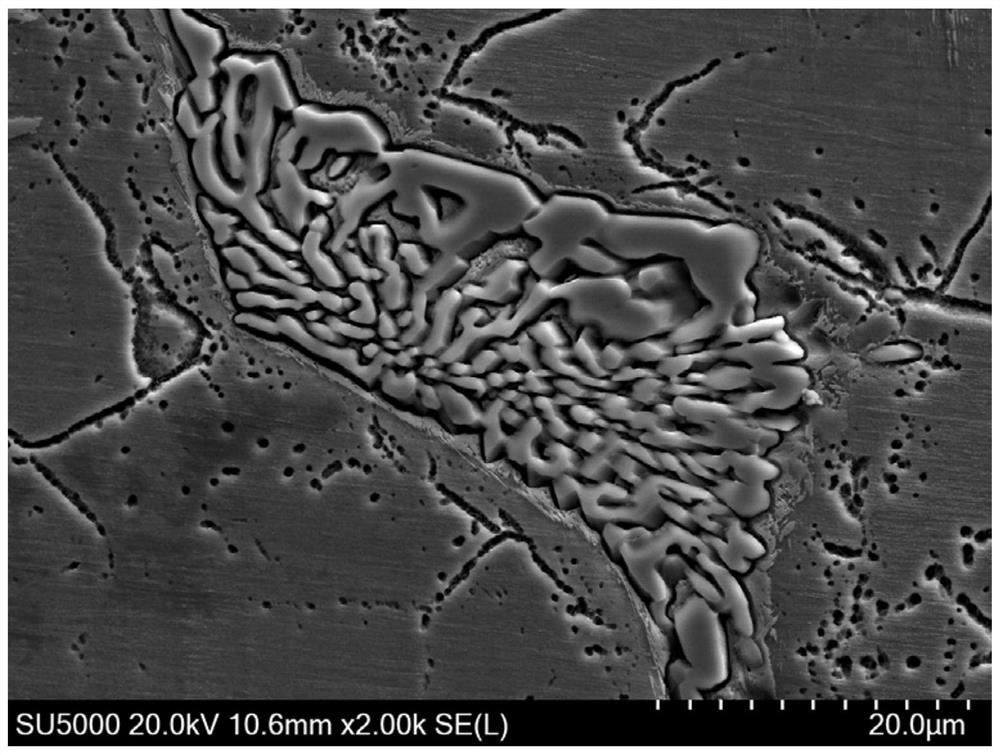

ActiveCN111593257AImprove toughnessImprove thermal stabilityProcess efficiency improvementMaterials scienceMicrostructure

The invention relates to a preparation method of high-toughness and high-thermal-stability hot work die steel. The preparation method comprises the following steps of optimizing alloy components, andstrictly controlling the production process; and the specific process route is as follows, electric furnace smelting, ladle refining furnace refining, vacuum refining furnace refining, electrode blankcasting, protective atmosphere electroslag furnace remelting, forging, ultrafine treatment and spheroidizing annealing production processes are adopted at the same time. The invention further relatesto the high-toughness and high-thermal-stability hot work die steel prepared through the preparation method. The product has the advantages of uniform annealed microstructure, favorable spheroidizedstructure, fine and uniform grain distribution and uniform quenched and tempered structure, and the fine precipitated phases of the Mo and Cr carbides have the dispersion strengthening action in the use process, thereby enhancing the properties of the material and endowing the material with high toughness and high isotropy. The product can be widely used for manufacturing hot extrusion dies, mandrels, hammer dies of die forging hammers, dies of forging presses and dies for precision forging machines, and particularly can be used as a high-end die-casting die made of aluminum, copper and alloysthereof.

Owner:江苏宏晟模具钢材料科技有限公司

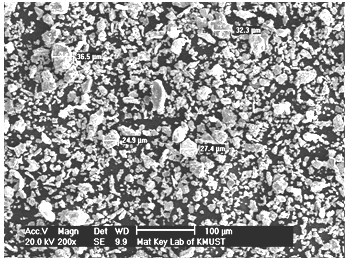

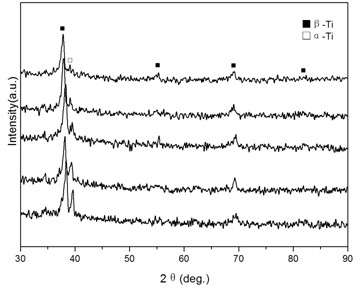

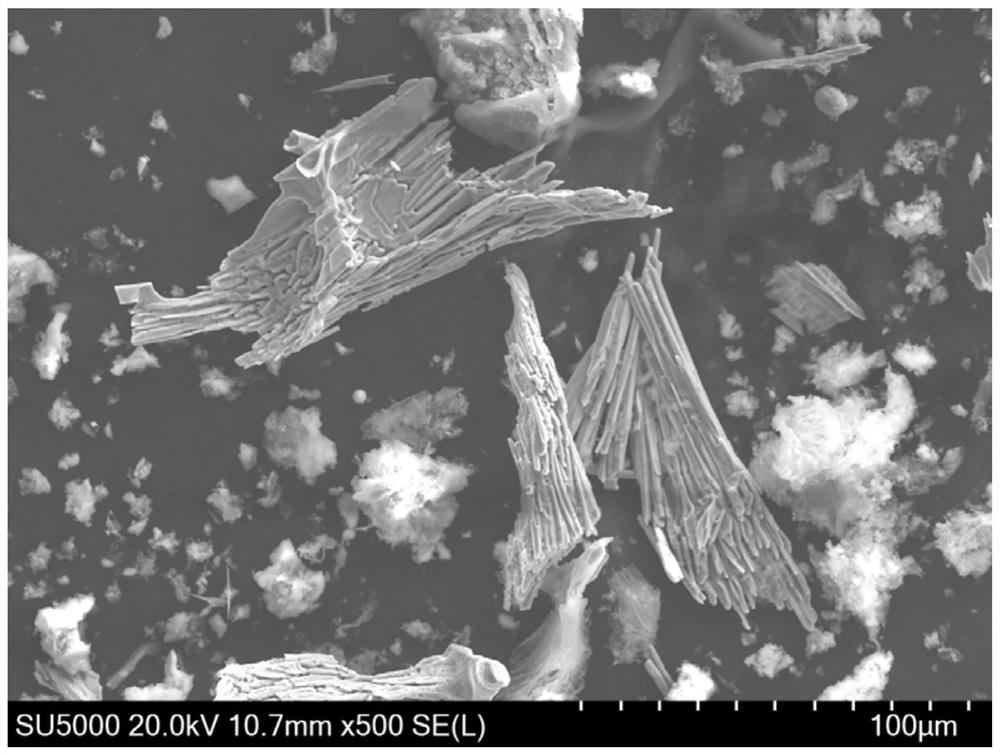

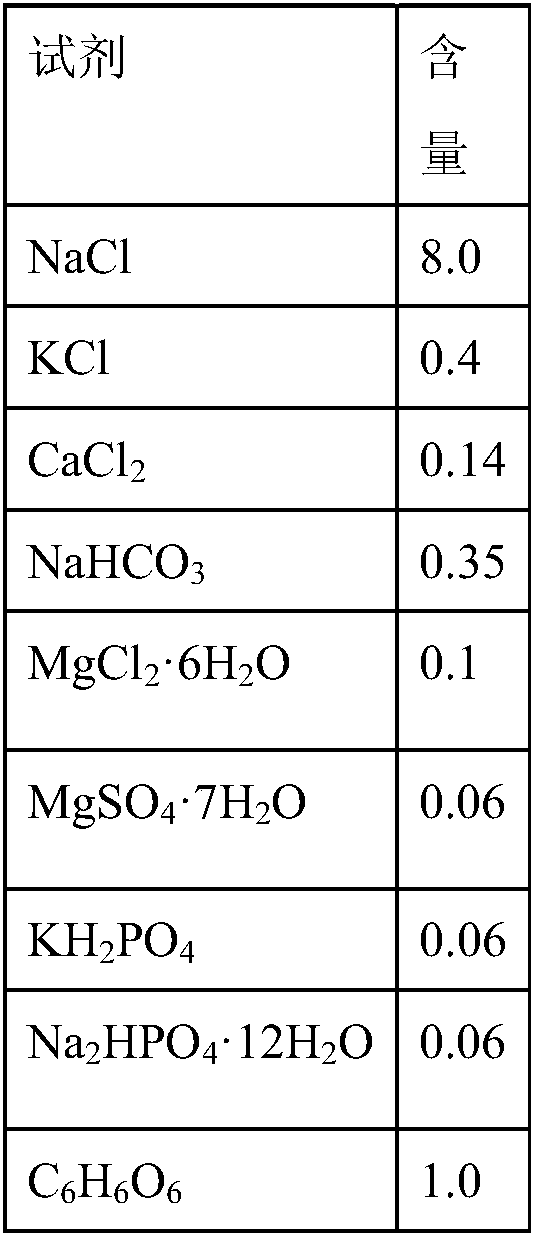

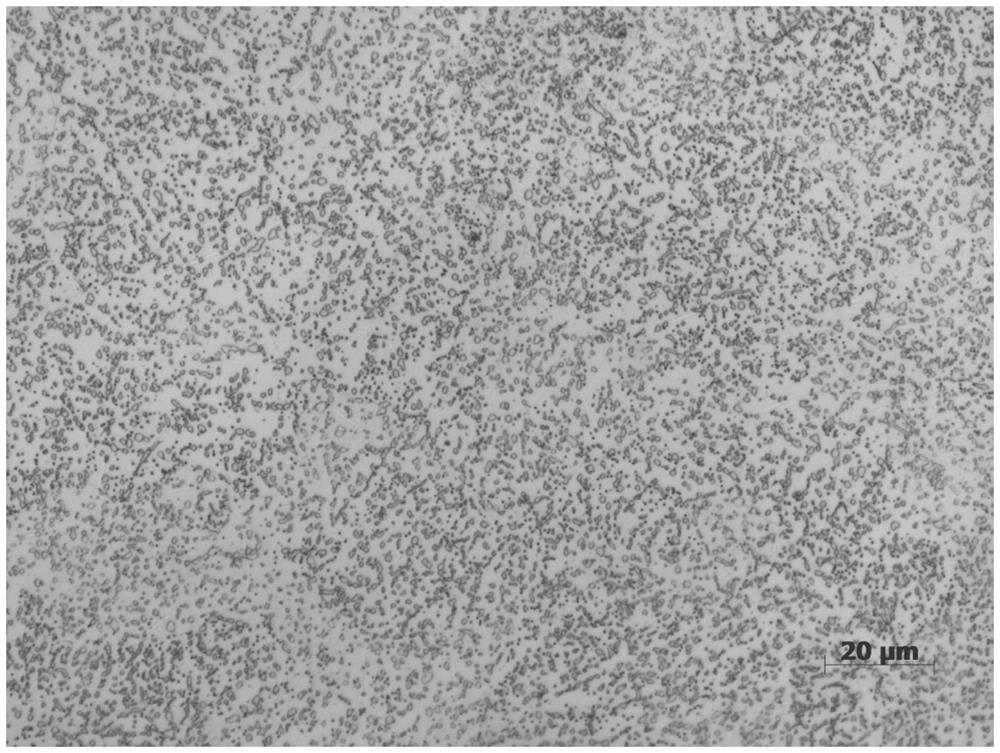

Method for preparing titanium niobium zirconium tin biomedical titanium alloys by discharge plasma sintering

The invention relates to a method for preparing titanium niobium zirconium tin biomedical titanium alloys by discharge plasma sintering, and belongs to the technical field of biomedical material preparation. The method provided by the invention comprises the following steps of: weighing Ti, Nb, Zr and Sn metal powders according to a chemical composition ratio, mixing the powders by a ball mill, putting into a graphite die, then placing into a discharge plasma sintering furnace, applying axial pressure of 10-40MPa, sintering in vacuum with the vacuum degree being 2-6 Pa while the heating rate is 50-100 DEG C / min and the sintering temperature is 950-1100 DEG C, keeping warm for 5-10 min after reaching the sintering temperature, and cooling in furnace to room temperature to obtain the titanium niobium zirconium tin biomedical titanium alloy material. The titanium niobium zirconium tin biomedical titanium alloys prepared by the method has uniform components and microstructure, high density (more than 98%), low elastic modulus (41-50GPa) and the like. In the mean while, the method provided by the invention has advantages of simple process, convenient operation and low cost, and is easy to realize industrial production.

Owner:KUNMING UNIV OF SCI & TECH

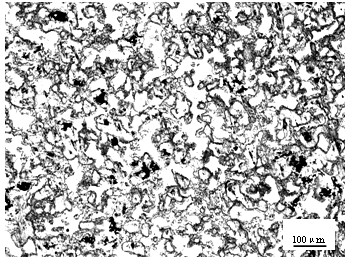

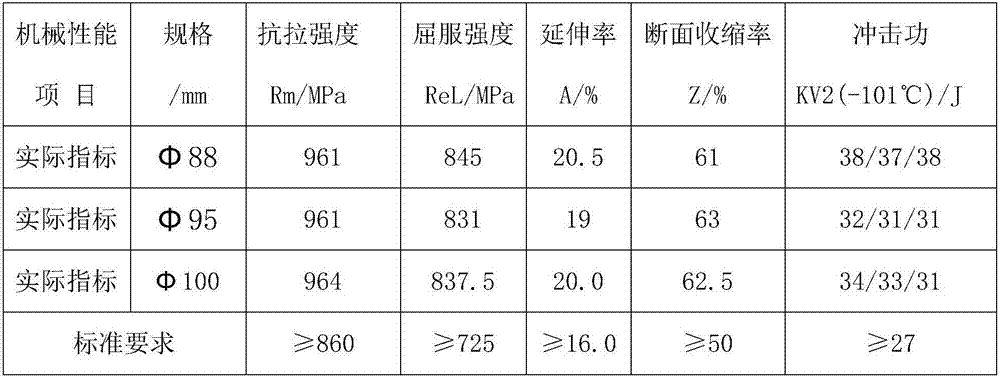

Manufacturing method of ultralow-temperature-impact resistant steel for high-intensity bolt of wind turbine generator set

ActiveCN107299278AImprove uniformityImprove performance indicatorsManufacturing convertersProcess efficiency improvementElectricityPerformance index

A manufacturing method of ultralow-temperature-impact resistant steel for a high-intensity bolt of a wind turbine generator set comprises the following steps: primarily melting by a top-bottom combined blowing basic converter; refining by an LF refining furnace; degassing by a VD vacuum furnace; continuously casting by a round billet arc-shaped continuous casting machine; heating rolled steel; dephosphorizing and oxidizing iron scales; rolling; and drawing into a pit and slowly cooling. According to the method, the development and design are on the basis of three aspects, namely, high toughness, delayed fracture resistance and cold deformability; after the whole round steel is thermally processed, the performance indexes reach that Rm is not less than 950Mpa, Re is not less than 830Mpa, A is not less than 20%, Z is not less than 60%, and KV2 (-101 DEG C) is not less than 30J.

Owner:山东寿光巨能特钢有限公司

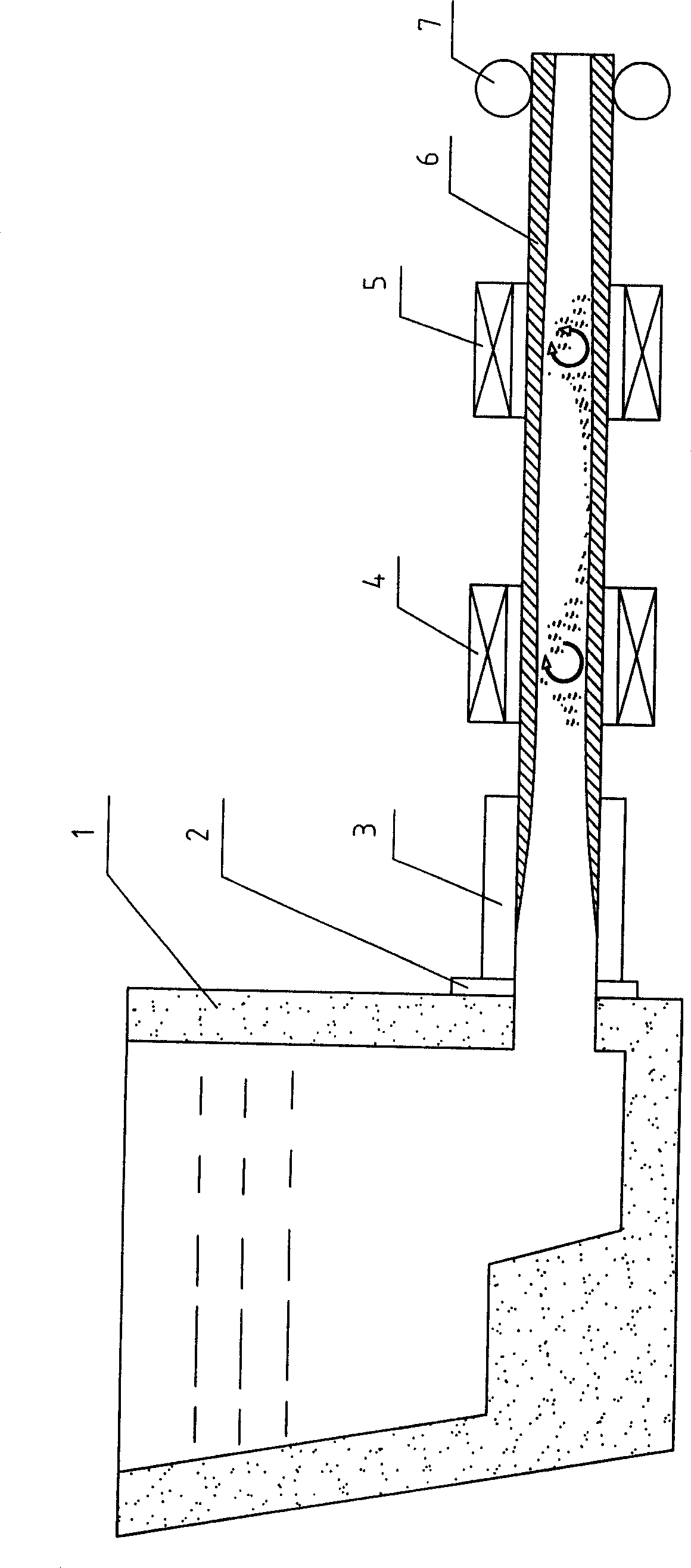

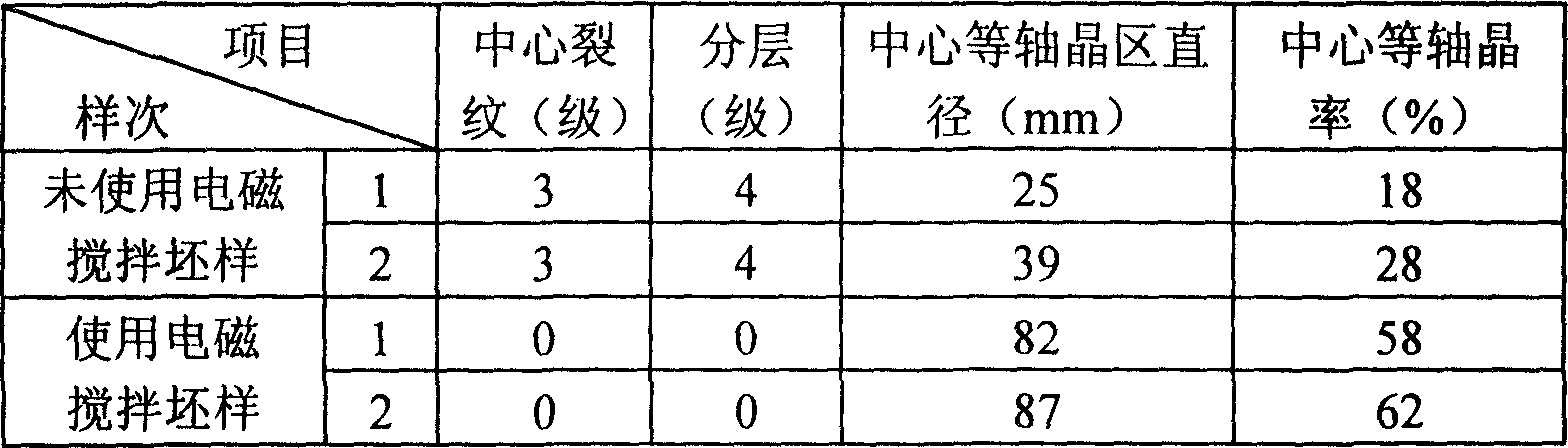

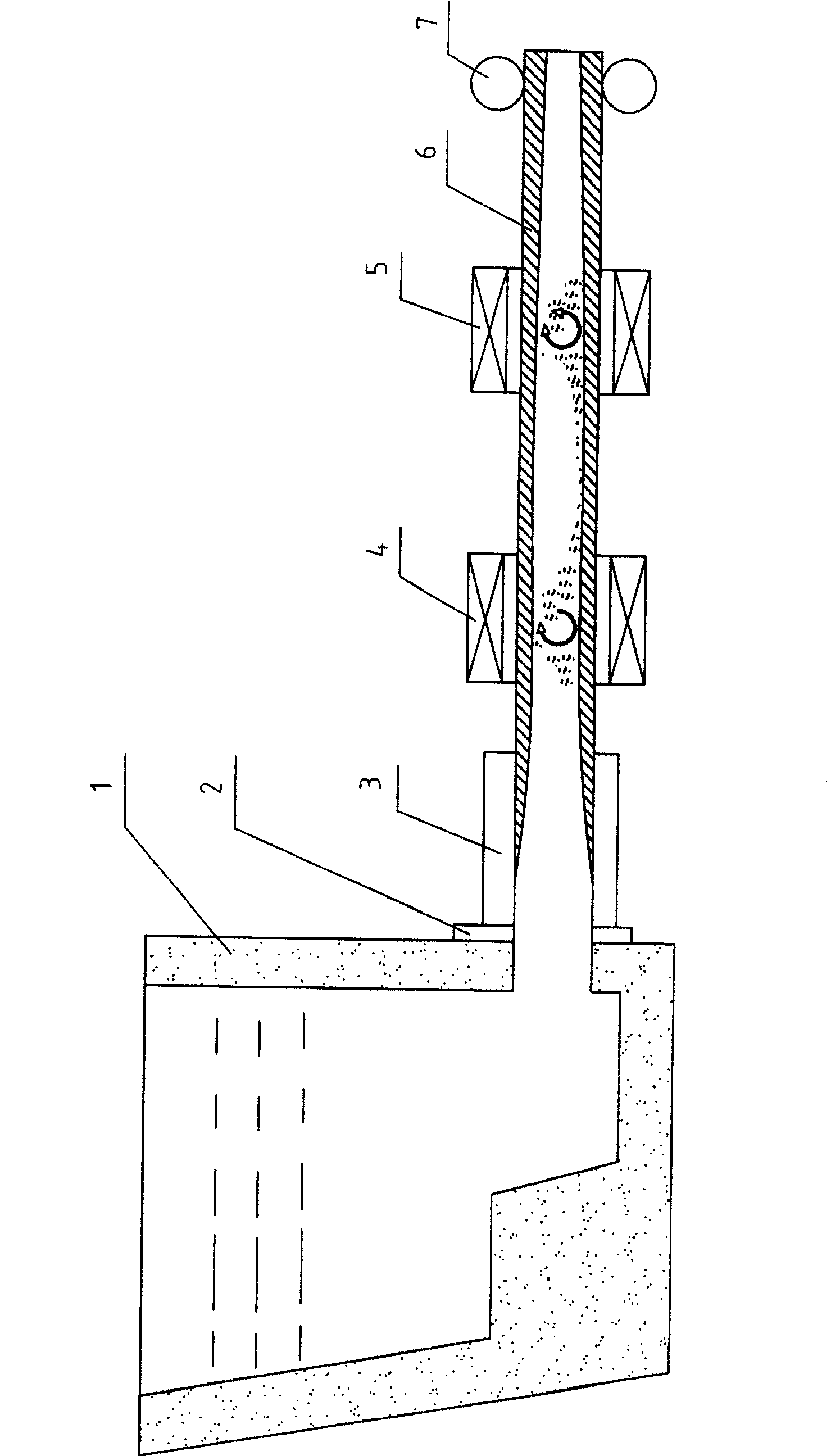

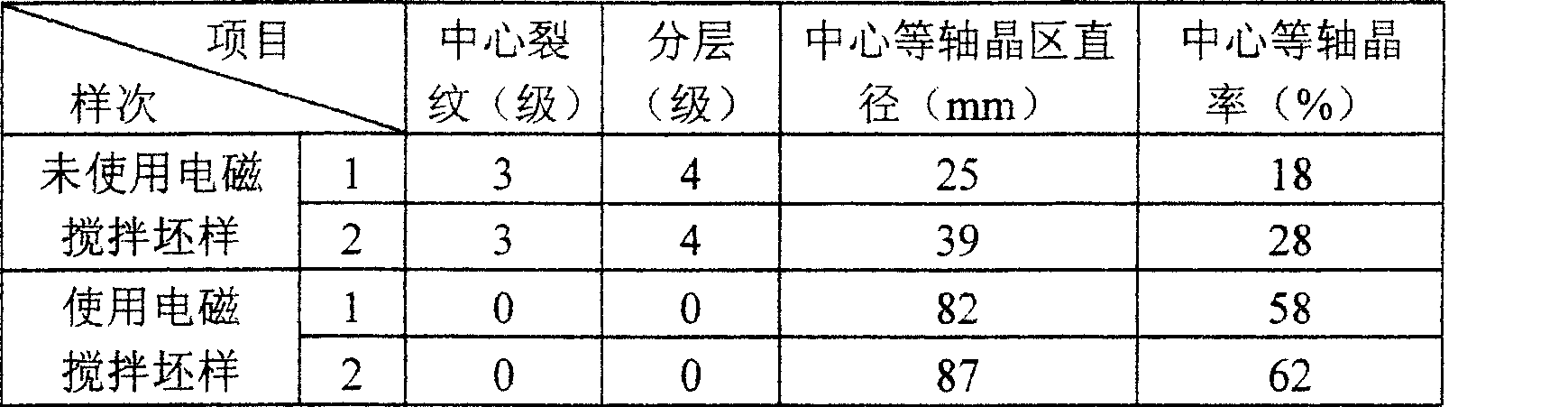

Horizontal continuous-casting electromagnetic agitating technology

ActiveCN1978092AImprove composition segregationImprove organizational defects such as stratificationWater treatment systemControl system

The present invention provides a horizontal continuous casting electromagnetic stirring technique. It includes water treatment system for cooling electromagnetic stirrer, electric control system for producing low-frequency power supply and working control system capable of setting and regulating stirring parameter. Said electromagnetic stirring technique can obviously raise central equiaxed crystal rate of casting blank (central equiaxed crystal zone diameter and casting blank diameter percentage).

Owner:衡阳华菱连轧管有限公司

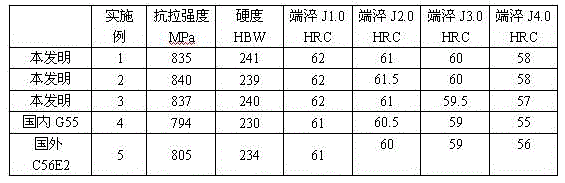

Method for producing low-cost high-hardenability medium carbon chromium steel

ActiveCN107012393AReduce in quantityImprove low temperature ductile-brittle transition temperatureManufacturing convertersCrankshaftContinuous casting

The invention discloses a method for producing low-cost high-hardenability medium carbon chromium steel. The method includes the following steps of top and bottom combined blowing basic converter primary smelting, LF finery refining, VD vacuum furnace degassing, continuous casting by a curved spray continuous casting machine, rolled steel heating, combined dephosphorization, rolling and stacking. By the adoption of the method, the design philosophy of fine adjustment Mo+V is adopted for improving the hardenability, a good tempered sorbite structure can be obtained, the high-end crankshaft steel quality requirement is met, a new approach is opened up, and the problems that the hardenability of 40Cr is insufficient and production cost of 42CrMoA is high are solved successfully.

Owner:山东寿光巨能特钢有限公司

Steel for ball screw bearing and manufacturing method thereof

ActiveCN110983178AImprove composition segregationConvenient spacingShaftsBearing componentsTemperingAustenite grain

The invention relates to steel for a ball screw bearing. Alloy components of the steel comprise, by mass, 0.45-0.60% of C, 0.15-0.40% of Si, 0.50-0.80% of Mn, 0.15-0.40% of Cr, 0.002-0.006% of B, 0.02-0.07% of V, less than or equal to 0.015% of S, less than or equal to 0.025% of P, less than or equal to 0.10% of Mo, less than or equal to 0.08% of Al, less than or equal to 0.0010% of Ca, less thanor equal to 0.0010% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb, and the balance Fe and inevitable impurities. A preparation process of a bar product comprises the steps of molten steel smelting, continuous casting, cogging-down, hot rolling, tempering, stress relief annealing and the like. The final properties meet the conditions that the surface hardness of the bar reaches 220-260 HBW, the metallographic structure of the bar is a uniform sorbite structure, the austenitic grain size of the bar is higher than or equal to the seven-level, the yield strength of the bar is 600-800 MPa, the tensile strength of the bar is 800-900 MPa, and the percentage elongation of the bar is greater than orequal to 15%.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Steel for ball screws and manufacturing method thereof

PendingCN110484837ALow content of harmful elementsGuaranteed amount of residual aluminumBall screwWater immersion

The invention relates to steel for ball screws. The steel for ball screws comprises, by mass: 0.45%-0.60% of C, 0.15-0.40% of Si, 0.90-1.10% of Mn, 0.70-1.20% of Cr, less than or equal to 0.015% of S,less than or equal to 0.025% of P, less than or equal to 0.25% of Ni, 0.15-0.40% of Mo, less than or equal to 0.30% of Cu, less than or equal to 0.05% of Al, less than or equal to 0.0010% of Ca, lessthan or equal to 0.003% of Ti, less than or equal to 0.0010% of O, 0.0050-0.0090% of N, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, lessthan or equal to 0.002% of Pb, and the balance Fe and inevitable impurities. The delivery state of the steel is as follows: high-temperature quenching and tempering are carried out, and the hardness meets 220-280 HBW, and the microscopic structure is of a sorbite and bainite structure, and is subjected to SEP 1927 water immersion high-frequency flaw detection, so that the defect length is requirednot to exceed 5 mm. The manufacturing process comprises the steps of electric furnace or converter, external refining, VD or RH vacuum degassing, continuous casting, continuous casting blank squaringto form an intermediate billet (a square billet), intermediate billet heating and rolling, finishing, quenched-tempered heat treatment (including high temperature quenching and tempering), surface lathing and warehousing.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

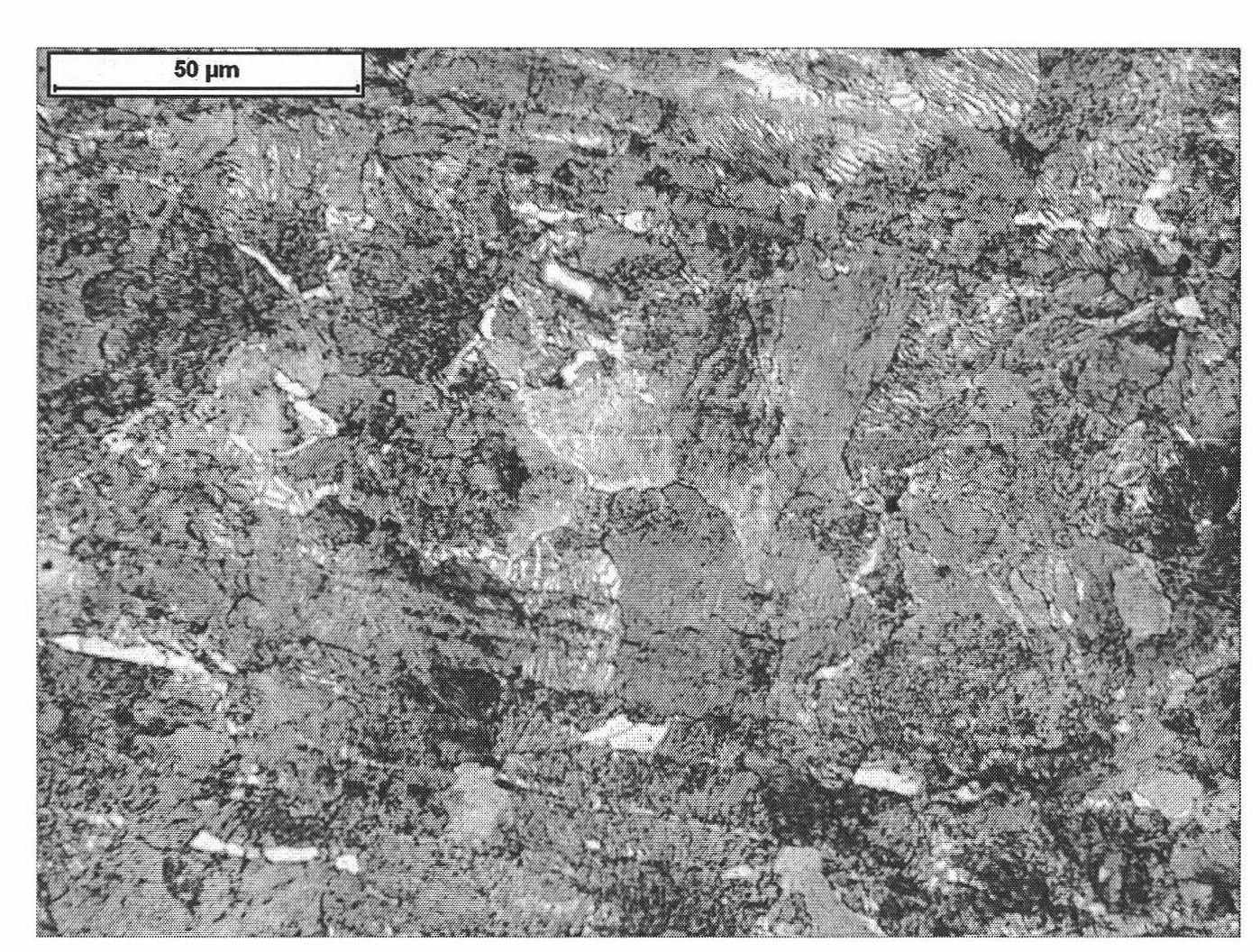

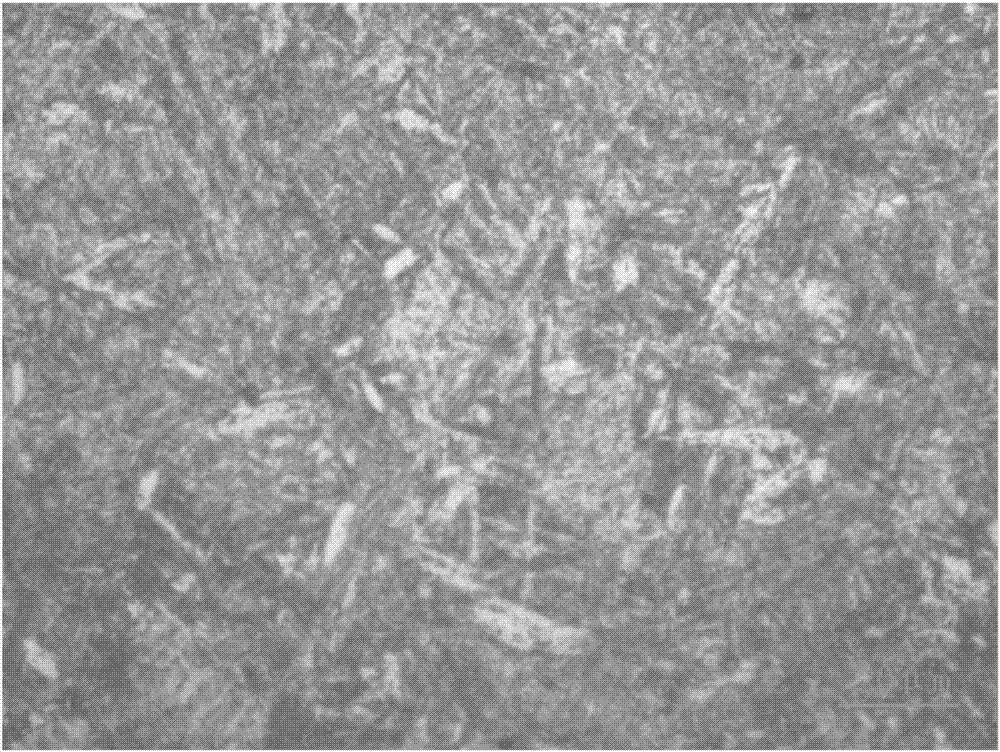

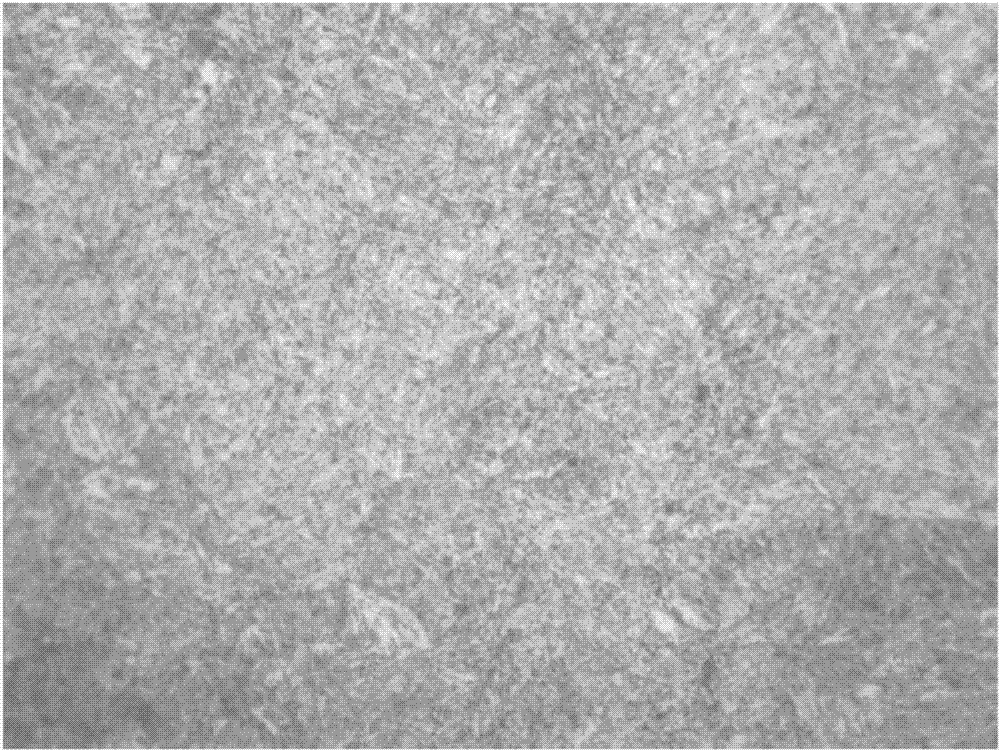

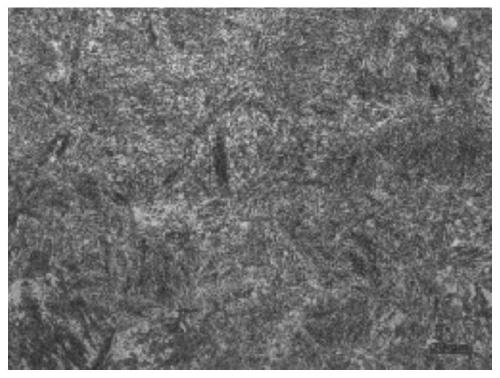

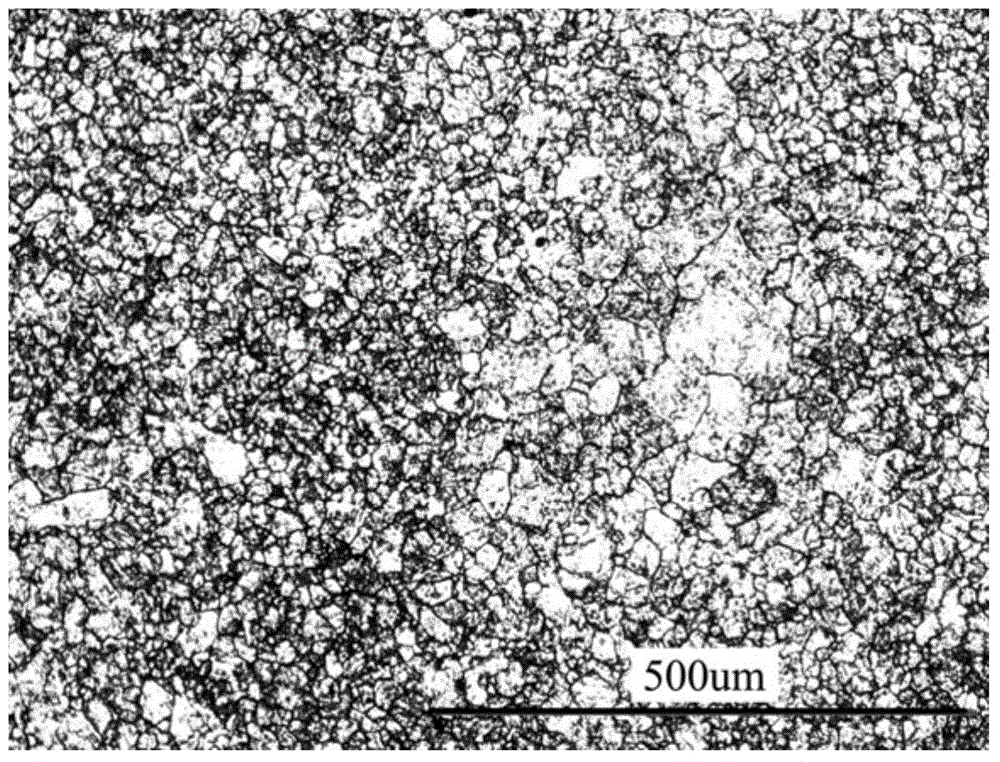

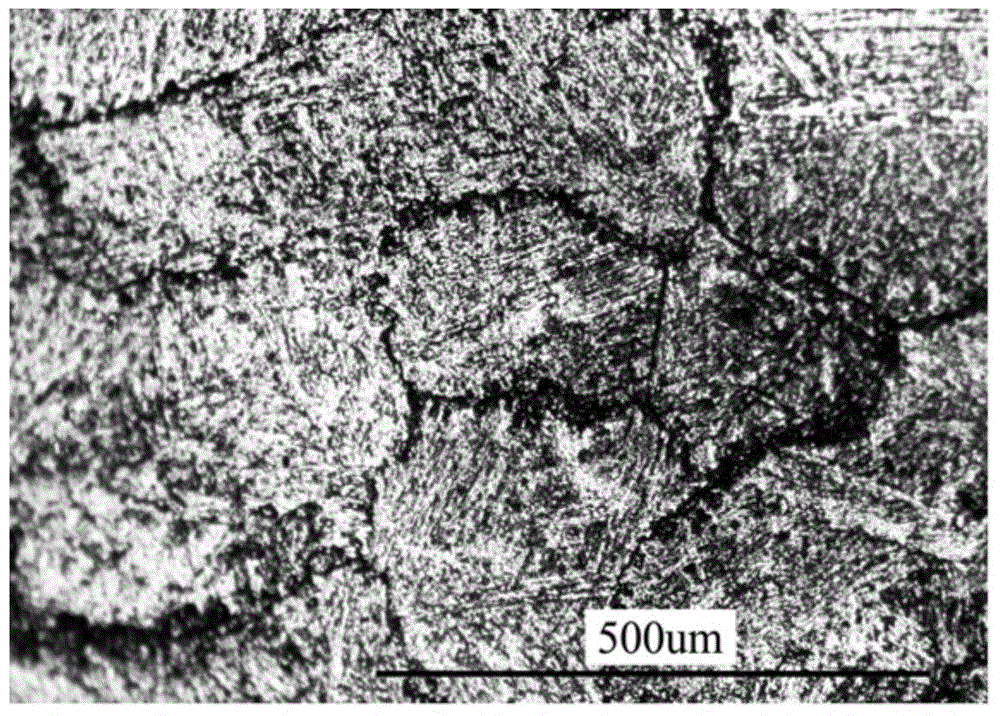

Heat treatment technology for improving tissue uniformity of H13 hot working die forged steel

The invention discloses a heat treatment technology for improving the tissue uniformity of H13 hot working die forged steel. The technology comprises following steps: loading forged H13 steel into a heating furnace, wherein the heating temperature is 860 to 880 DEG C, cooling the H13 steel in the air to the room temperature; then loading the forged steel into the heating furnace, heating to a temperature of 1030 to 1050 DEG C, cooling the forged steel to a temperature of 300 to 400 DEG C in the air; filling the forged steel into the heating furnace for a third time, heating to a temperature of1080 to 1100 DEG C, cooling the forged steel to a room temperature in the air; filling the forged steel into the heating furnace for a fourth time, heating to a temperature of 870 to 890 DEG C, maintaining the temperature for 4 to 6 hours, cooling to a temperature of 720 to 740 DEG C, maintaining the temperature for 6 to 8 hours, secondarily cooling to a temperature not higher than 500 DEG C, taking out the forged steel out of the heating furnace, and cooling the forged steel in the air. Compared with a conventional forging stock annealing treatment, the horizontal impact energy is not less than 12J; the ratio of horizontal impact energy to vertical impact energy is not less than 0.8; the size of grains in tissues is uniform; the mixed crystal tissue is avoided, banded segregation is reduced or eliminated; and horizontal impact toughness and isotropy are enhanced.

Owner:HEBEI IRON AND STEEL

Micro carbon micro phosphorus aluminum manganese iron alloy as well as production method thereof

The invention discloses a micro carbon micro phosphorus aluminum manganese iron alloy used as steel-making deoxidizer. The composition of the alloy in weight percent contains 49-58% of aluminum, 1-4% of manganese, 38-50% of iron, less than 0.6% of silicon, less than 0.06% of carbon, less than 0.02% of phosphorus and less than 0.02% of sulphur. The alloy has good deoxidizing effect, and is especially suitable for deoxidization of low carbon, low manganese and low phosphorus steel types. Meanwhile, the impurity content of the alloy is very low, structure organization is more compact, air holes are less, and non-chalking period is longer, etc.

Owner:LIAONING JIUTONG FRICTION MATERIALS

Method for producing 65Mn hot rolled steel plate

InactiveCN101773930BAdd depthImprove billet qualityMetal rolling arrangementsLiquid coreStructure property

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Cold-work mould steel material and alloy modifying agent

The invention relates to a cold-work mould steel material and an alloy modifying agent. In addition to Fe, the cold-work mould steel material further comprises the following elements in percentage by weight: 1.55%-1.75% of C, 11.50%-12.50% of Cr, 0.20%-0.30% of V, 0.45%-0.55% of Mo, not more than 0.25% of Si, not more than 0.20% of Mn, not more than 0.030% of S, not more than 0.030% of P, not more than 0.15% of Ni and not more than 0.2% of C. In addition to Fe, the alloy modifying agent further comprises the following elements in percentage by weight: 14.0%-20.5% of RE, 3.0%-4.5% of Mg, 25-30% of Si, 3.0%-4.0% of Mn, 3.0%-5.0% of Ca and 1.5%-2.5% of Ti. Compared with the prior art, the cold-work mould steel material can be applied to casting, and the performances of the cold-work mould steel material can be improved after the alloy modifying agent is added. A cold-work mould module can be manufactured by a casting process, so that the energy resources are saved, the material waste is reduced and the production period is greatly shortened.

Owner:WUHAN UNIV OF TECH

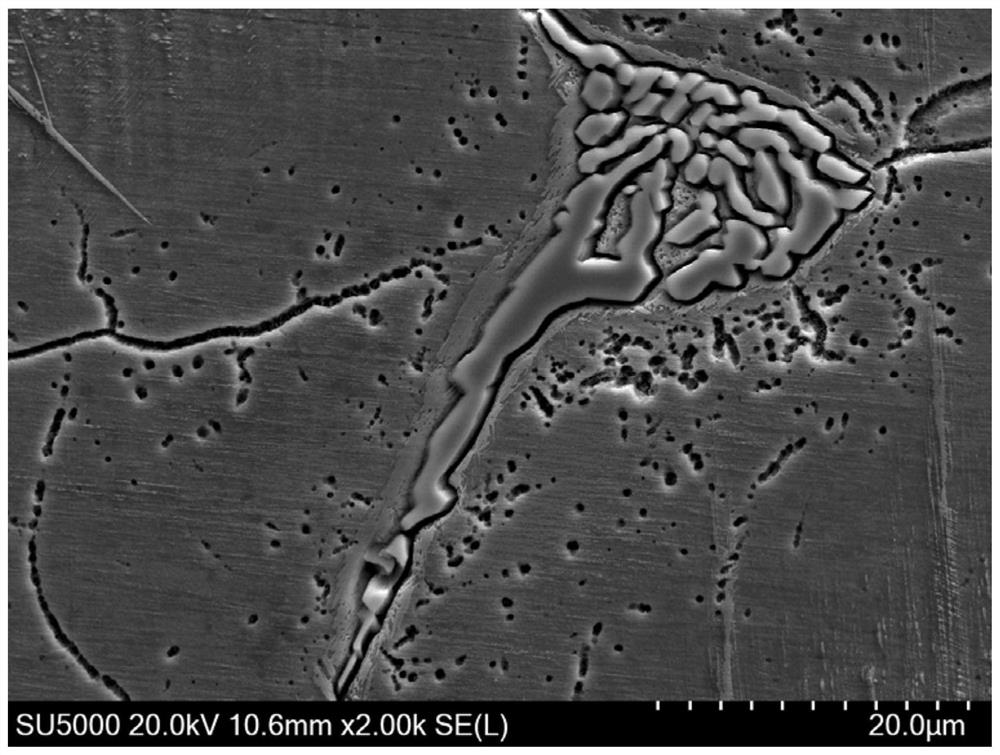

Treating agent and method for controlling primary carbide of high-carbon martensitic stainless steel through melt treatment

ActiveCN112795725AEffective controlImprove composition segregationProcess efficiency improvementTemperingMartensitic stainless steel

The invention discloses a method for improving an as-cast structure of a high-carbon martensitic stainless steel casting blank through melt treatment so as to control primary carbides. The control method comprises the following steps of induction furnace or converter and electric furnace, LF refining, RH refining, wire feeding and adding of a proper amount of melt treating agent, and blank casting; LF refining is selectively carried out according to the refining process requirement of the steel grade, and if not, the next step is directly carried out; RH refining is selectively carried out according to the refining process requirements of steel types, and if not, the next step is directly carried out; after selective LF refining or RH refining, a proper amount of melt treating agent is added through wire feeding; and the casting blank is produced by adopting a corresponding casting method and normal process parameters according to the steel grade and the production process requirement. The method for improving the as-cast structure of the high-carbon martensitic stainless steel casting blank through the melt treatment can effectively refine the primary carbide of high-carbon martensitic stainless steel and improve the composition segregation of the casting blank at the same time, and a structure and composition basis are provided for further refining the carbide through plastic deformation and effectively strengthening the secondary carbide through tempering.

Owner:ZHONGBEI UNIV

Casting method of cold working die module

The invention relates to a casting method of a cold working die module. The casting method comprises the following steps of: S1, smelting molten steel of a cold working die steel; S2, adding a rare earth alloy alterant in original molten steel, wherein the mass ratio of the added alterant is 0.15-0.45% of the mass of the original molten steel; S3, manufacturing an evaporative pattern foaming block according to the size of the cold working die module, and burying the foaming block in a sand box; S4, pouring the molten steel added with the alterant; and S5, taking out the cold working die module cast, and performing the heat treatment. Compared with the prior art, the cold working die module is manufactured through the casting process of the evaporative pattern, the machining amount of the die is greatly reduced, the energy is saved and the waste of the material is reduced while guaranteeing the performance of the cold working die, and the production period is greatly shortened. The cold working die module manufactured by the method provided by the invention is low in cost and high in production efficiency.

Owner:WUHAN UNIV OF TECH

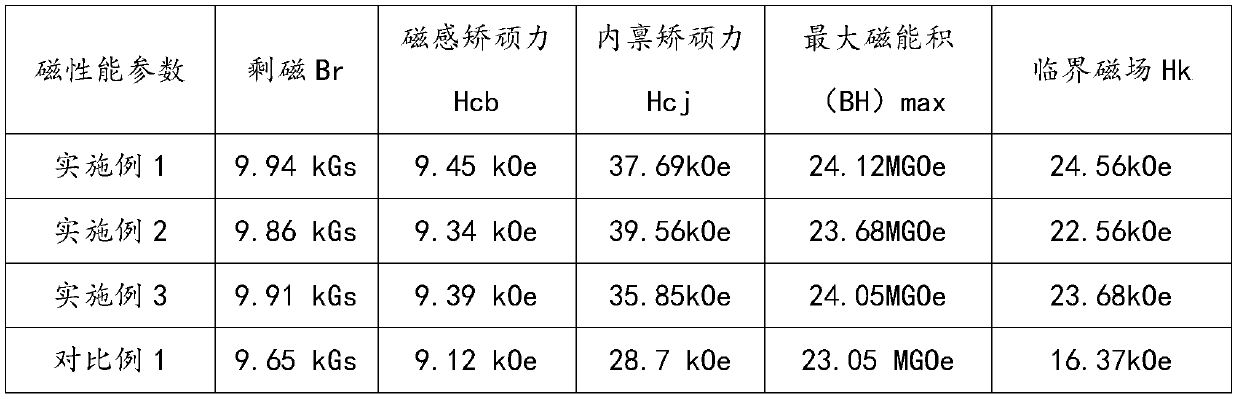

Samarium cobalt 1:5 type permanent magnet material and preparation method thereof

ActiveCN110957090AGood orientationSuppress generationInductances/transformers/magnets manufactureMagnetic materialsMetallurgySamarium

The invention relates to the technical field of permanent magnet materials, in particular to a samarium-cobalt 1:5 type permanent magnet material and a preparation method thereof. The samarium-cobalt1:5 type permanent magnet material is prepared from by weight fraction: 34%-36% of metal samarium and 64%-66% of metal cobalt. The preparation method of the samarium-cobalt 1:5 type permanent magnet material comprises the following steps: burdening, smelting of a cast sheet, homogenizing of the cast sheet, jet milling to obtain powder, molding, sintering and aging. According to the samarium-cobalt1:5 type permanent magnet material, the residual magnetism and coercive force performance of a 1:5 samarium-cobalt permanent magnet are improved by homogenizing the 1:5 samarium-cobalt quick-settingmelt-spinning sheet and matching with an appropriate jet milling process, the residual magnetism can reach 9.8 kGs or above, the coercive force can reach 35 kOe or above, the process can achieve stable mass production, and the percent of pass reaches 95% or above.

Owner:福建省长汀卓尔科技股份有限公司

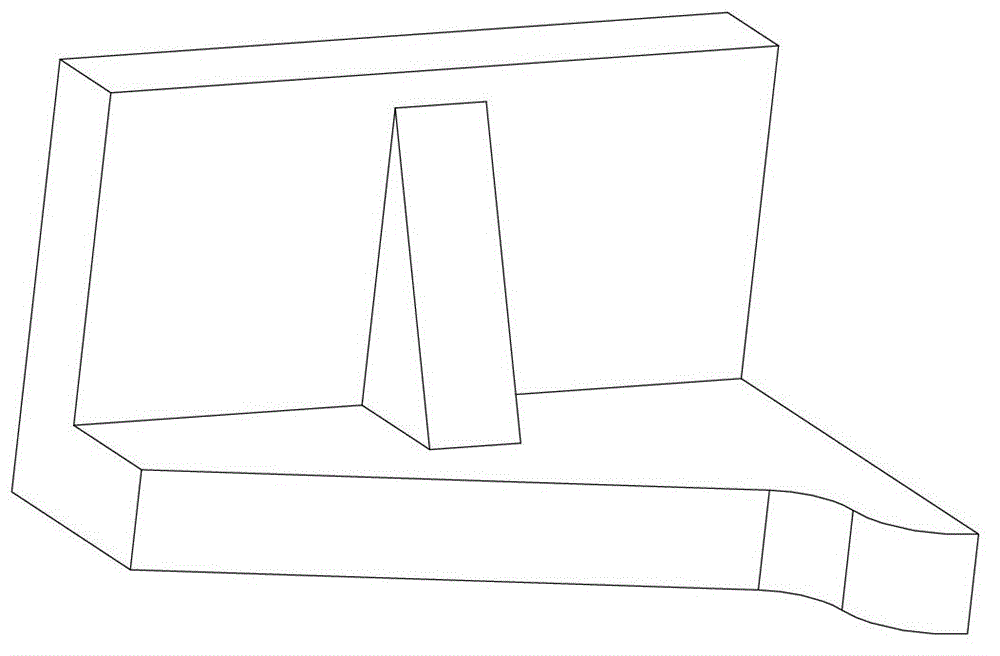

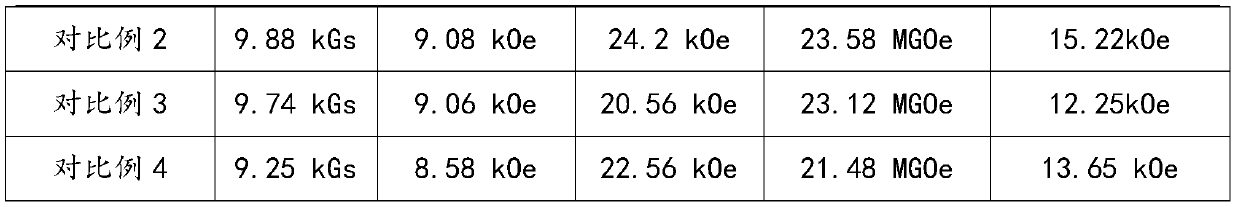

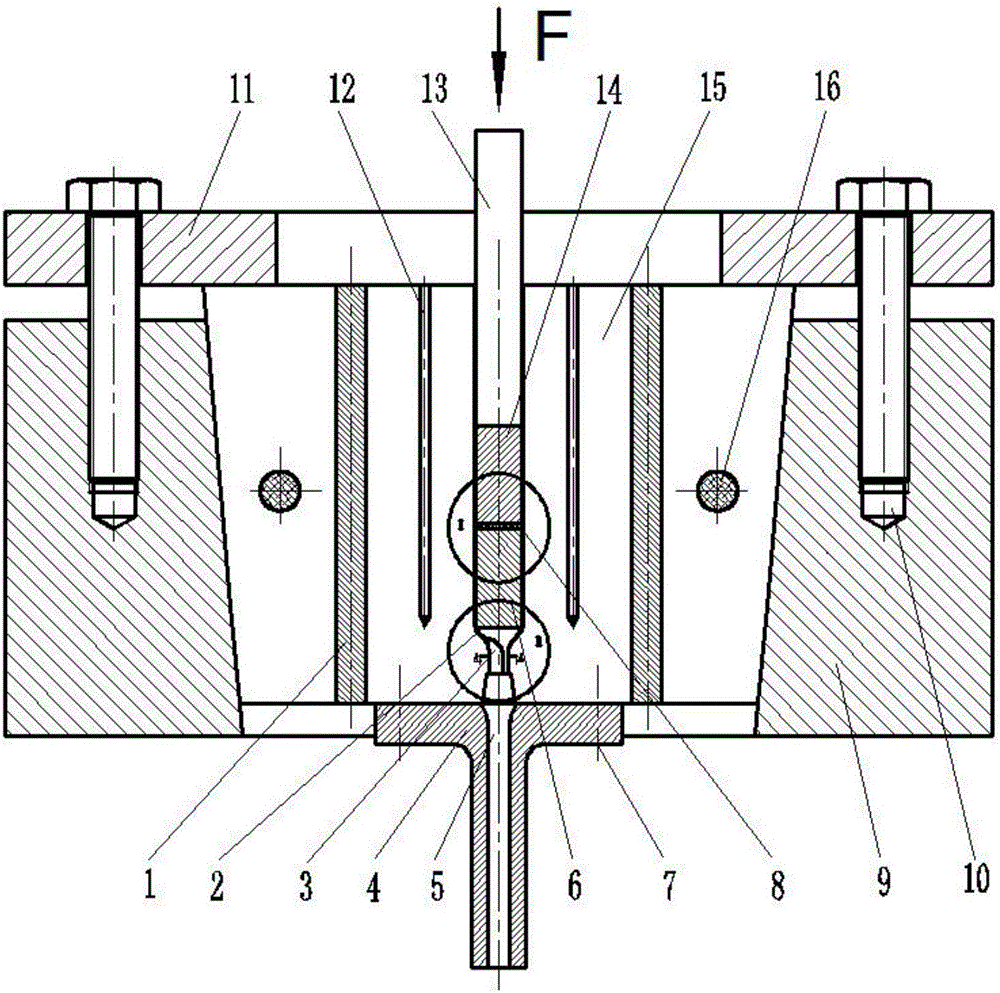

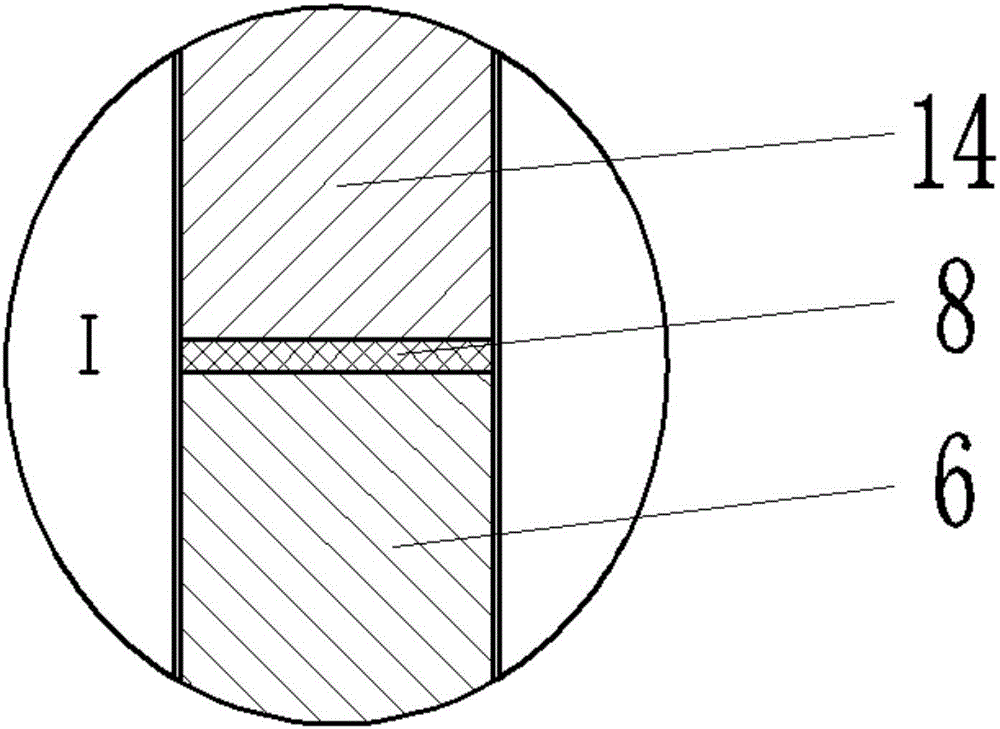

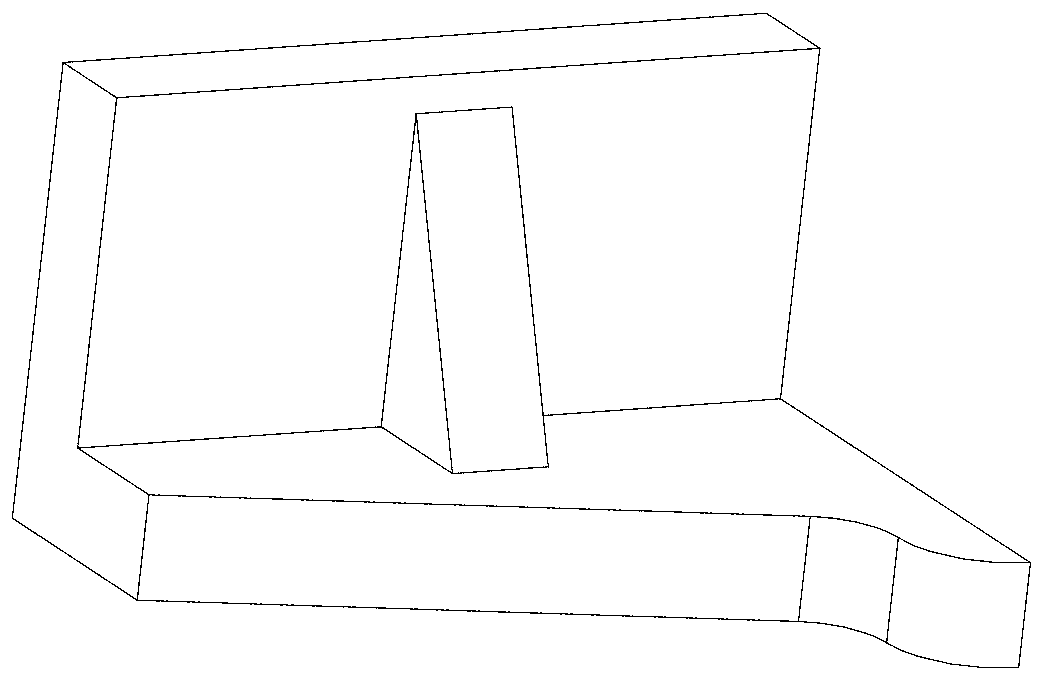

Extrusion device and method for connecting magnesium alloy with aluminum alloy

ActiveCN106391743AHigh strengthHigh strength connectionExtrusion diesExtrusion control devicesThermal deformationIntermetallic

The invention discloses an extrusion device and method for connecting a magnesium alloy with an aluminum alloy. The device comprises a male die and a female die with an extrusion cavity. The magnesium alloy, an amorphous alloy and the aluminum alloy are arranged in the extrusion cavity. The male die extrudes the magnesium alloy, the amorphous alloy and the aluminum alloy in the extrusion cavity under the effect of external force, the magnesium alloy, the amorphous alloy and the aluminum alloy are arranged in the female die and enter a forming cavity under the extrusion effect of the male die after being heated so as to be formed, common thermal deformation is conducted in the state of a high temperature and three-way pressure stress, and stable connection is achieved. According to the extrusion device and method, the amorphous alloy is used as an intermediate transition layer, direct contact between the aluminum alloy and the magnesium alloy is avoided, direct element diffusion between the aluminum alloy and the magnesium alloy is avoided, it is avoided that Al-Mg intermetallic brittle compounds and welding gaps are formed, the connection quality is improved, the magnesium alloy, the amorphous alloy and the aluminum alloy are all in the low-stress super-plasticity state by means of the combination of the optimal extrusion temperature and the optimal extrusion speed, and formation of a connector is promoted.

Owner:SHANDONG UNIV OF SCI & TECH

Cold-work die steel material and alloy alterant

The invention relates to a cold-work die steel material and an alloy alterant. The cold-work die steel material is characterized in that: besides Fe, the material further comprises the following elements by weight: 1.55-1.75% of C, 11.50-12.50% of Cr, 0.20-0.30% of V, 0.45-0.55% of Mo, not more than 0.25% of Si, not more than 0.20% of Mn, not more than 0.030% of S, not more than 0.030% of P, not more than 0.15% of Ni, not more than 0.2% of Cu, and the balance Fe, wherein sum of weight percentage of each element is 100%. Compared with the prior art, the cold-work die steel material is used for casting, and the alloy alterant is added for raising performances of the cold-work die steel material. A cold-work die module is made by a casting technology, which saves energy, reduces waste of materials, and greatly shortens a production cycle.

Owner:WUHAN UNIV OF TECH

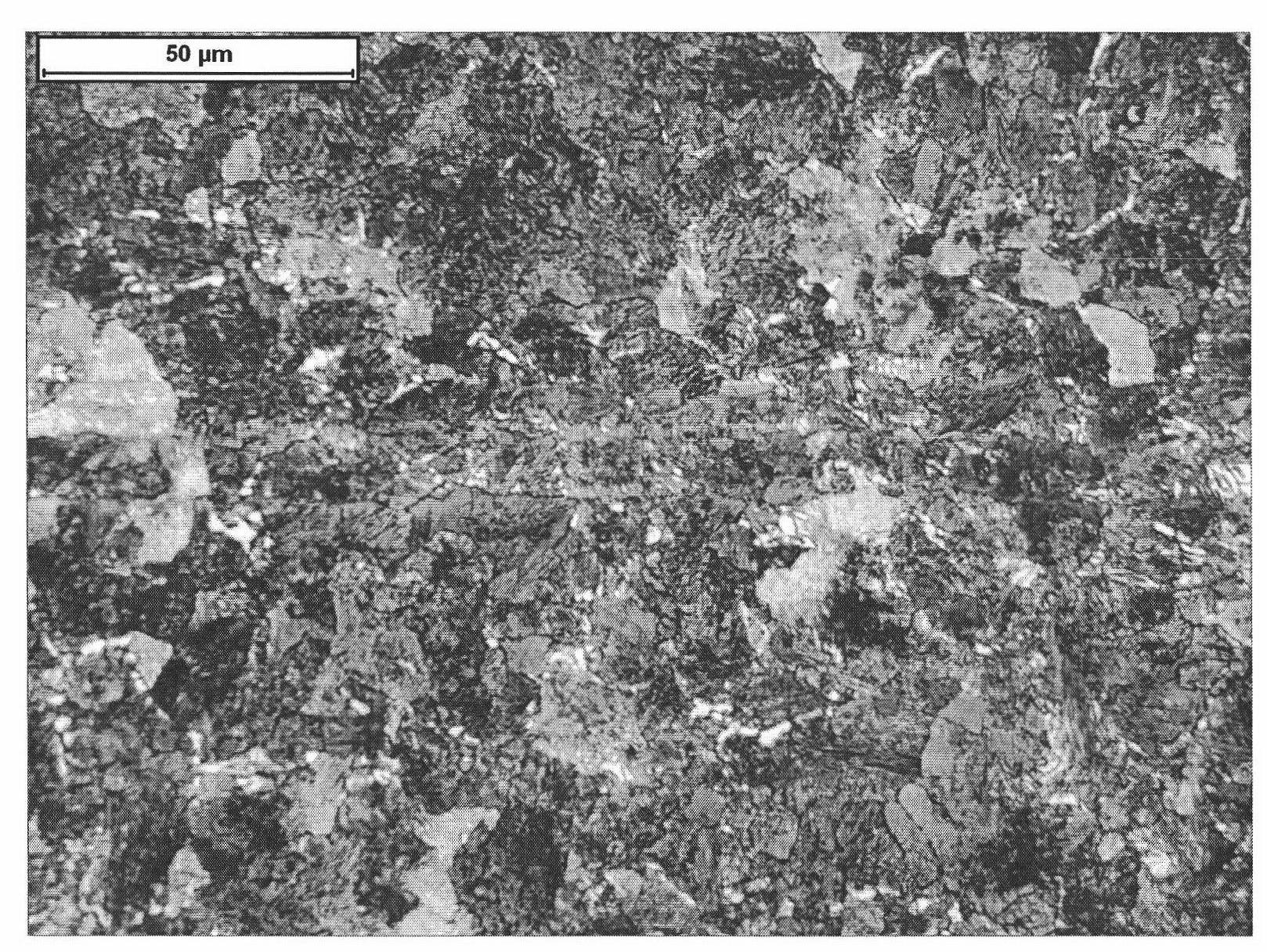

Hot work die steel and preparation method thereof

ActiveCN113528971AAddress tissue homogeneitySolve the problem of organizational refinementDie castingHot work

The invention provides a preparation method of hot work die steel. The preparation method comprises the following steps: carrying out EBT electric furnace smelting, LF refining and VD refining on alloy raw materials to obtain alloy liquid; carrying out die casting on the alloy liquid to obtain a casting; and carrying out electroslag remelting, primary annealing, forging and secondary annealing on the casting to obtain the hot work die steel. A PGH13 electrode bar is smelted by adopting an electric furnace, LF, VD and electroslag remelting, and the problems of structure uniformity and structure refinement of die-casting die steel are solved from the key technical angles of steel structure control and heat treatment; and meanwhile, a key process for stable production of the high-end die-casting die steel is provided by combining service performance evaluation and failure behavior research of the die-casting die steel, and finally, the high-end hot work die steel is mature in process, stable in quality, high in percent of pass, few in waste products and stable in yield at a high level. The invention further provides the hot work die steel.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

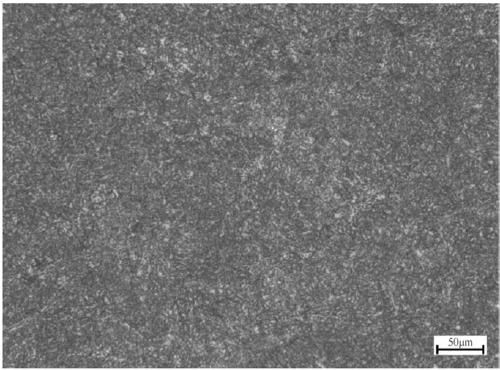

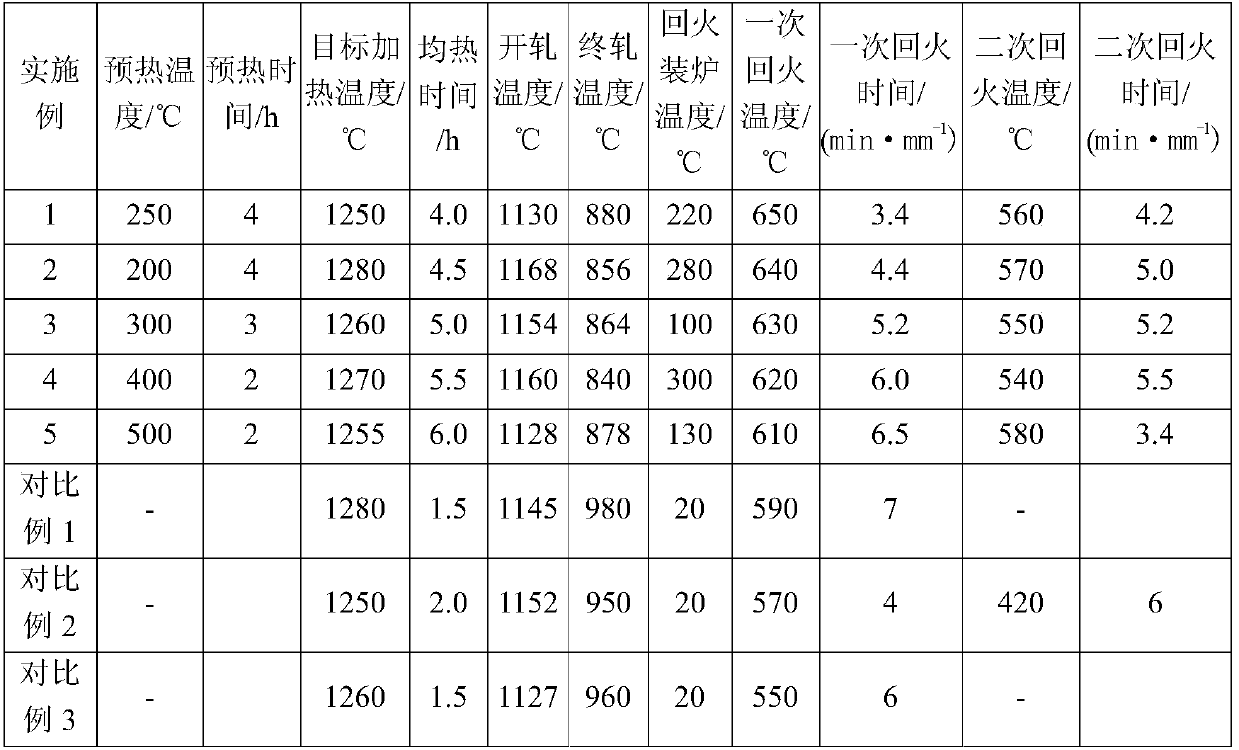

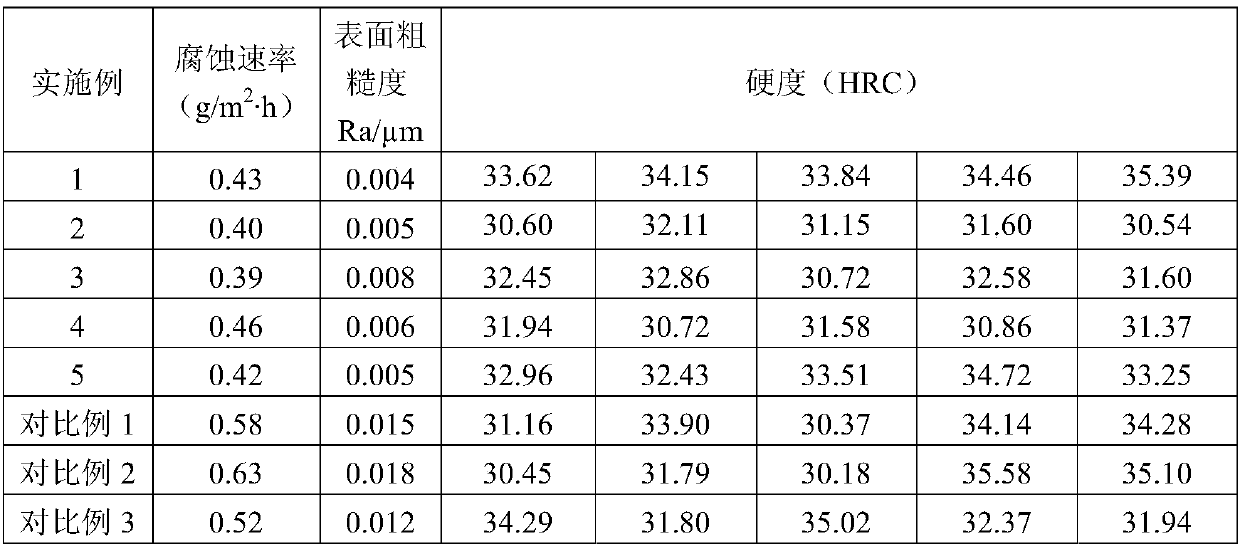

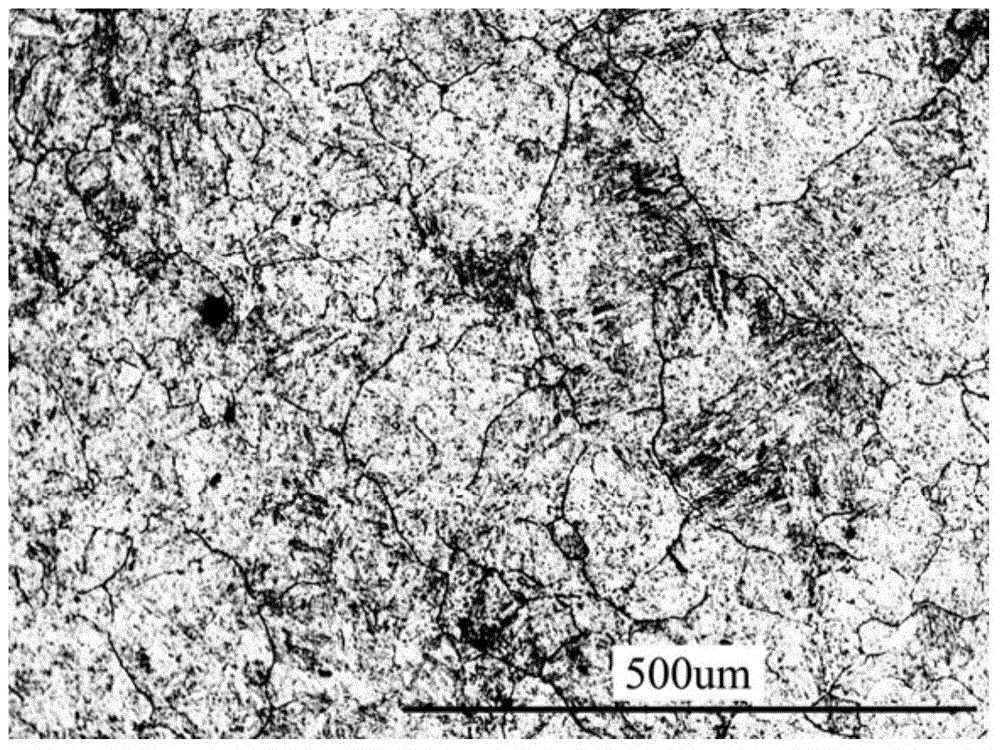

High mirror corrosion resistant plastic die steel and manufacturing method thereof

The invention discloses high mirror corrosion resistant plastic mold steel and a manufacturing method. The steel contains 0.32-0.46% of C, 0.4-1.2% of Si, 0.4-0.8% of Mn, P which is less than or equalto 0.020%, S which is less than or equal to 0.040%, 10.8-12.8% of Cr, 0.3-1.2% of Cu, 0.5-1.0% of Ni, 0.15-0.25% of Nb, and 0.01-0.03% of N, with the balance being Fe and inevitable impurities. A steel billet can be heated after being charged and preheated at 200-500 DEG C, the preheating time is greater than or equal to 2h, a heating temperature is 1,250-1,280 DEG C, the soaking time is 4-6 h, an initial rolling temperature is greater than or equal to 1,100 DEG C, and a finish rolling temperature is 840-880 DEG C; air cooling can be performed to 100-300 DEG C after rolling; the temperature of primary tempering is 610-650 DEG C, and the heat preservation time is 3.4-6.5 min / mm; the temperature of secondary tempering is 540-580 DEG C, and the heat preservation time is 3.4-5.5 min / mm. The produced die steel has excellent corrosion resistance and surface properties.

Owner:ANGANG STEEL CO LTD

Rail junction and method for manufacturing steel used for rail junction

The invention relates to a rail junction and a method for manufacturing steel used for rail junction, which belong to the steel metallurgy field. The method comprises the following steps: forging a 35CrMoSiMnVTiB rail junction by steel, and directly performing hot delivery and charging, cooling a furnace to 400-500 DEG C, insulating for 3-4 hours; heating the insulated forge piece, wherein the heating temperature is 950-990 DEG C, insulating for 6-8 hours and cooling the furnace; cooling the furnace to 620-660 DEG C, insulating for 10-12 hours, cooling in air to the surface temperature of the forge piece to 200-240 DEG C; heating the cooled forge piece to 860-900 DEG C, insulating for 6-8 hours, and cooling in air to room temperature. According to the invention, after the steel forge piece used for the rail junction is forged and then is performed with heat treatment, segregation degree in steel can be obviously improved, crystal grain is fine and uniform, and the usage performance of the rail junction after final heat treatment can be fully ensured.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

High-strength biomedical Mg-Zn-Zr-Fe alloy material with rapid biodegradability, and preparation method thereof

The invention discloses a high-strength biomedical Mg-Zn-Zr-Fe alloy material with rapid biodegradability, and a preparation method thereof. The magnesium alloy is prepared from the components in percentage by mass: 5.0 to 6.0 percent of Zn, 0.5 to 1.0 percent of Zr, 0.01 to 0.09 percent of Fe, and the balance Mg and inevitable impurities. The preparation method comprises the concrete steps of smelting, carrying out casting homogenization treatment, hot-extruding and carrying out artificial aging treatment, so that biomedical magnesium alloy sheets, rods and wires meeting the service requirement of the biological fluid environment are obtained. According to the high-strength biomedical Mg-Zn-Zr-Fe alloy material with rapid biodegradability provided by the invention, the alloy elements harmless to a human body are added into the magnesium alloy, so that the alloy has no any toxicity on the human body after being degraded in vivo, and has excellent mechanical property, favorable mechanical property and processability, and appropriate corrosion rate. The high-strength degradable biomedical Mg-Zn-Zr-Fe alloy material provided by the invention has the tensile strength being larger thanor equal to 360MPa and the yield strength being larger than or equal to 320MPa, and is suitable for preparing medical materials such as bone nails.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

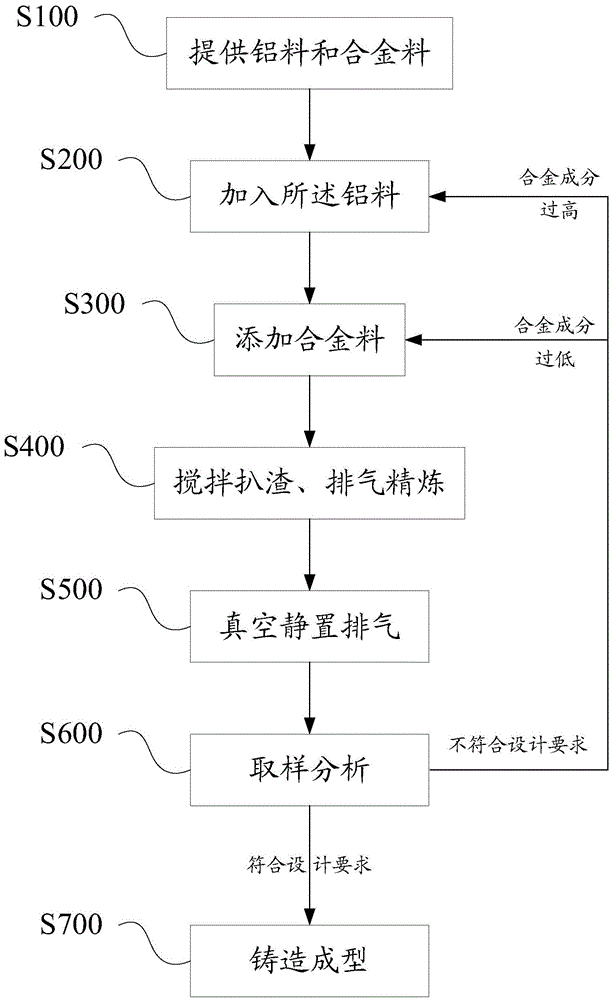

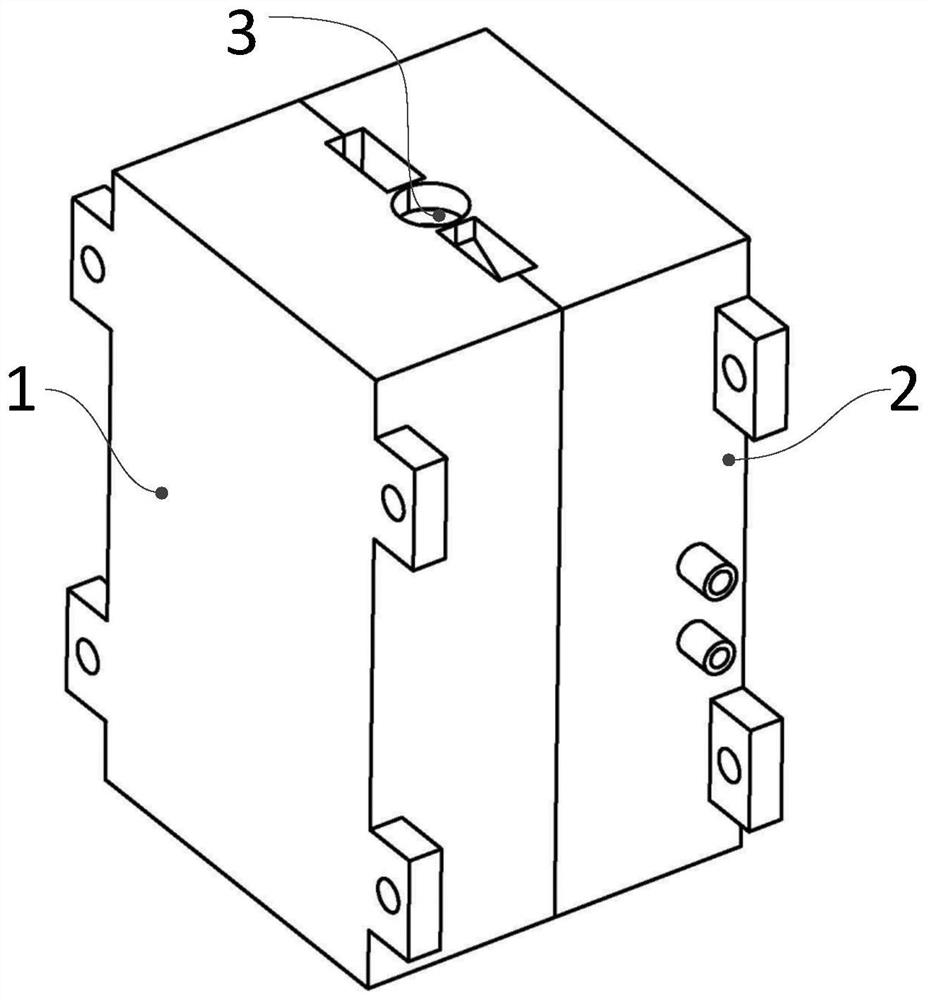

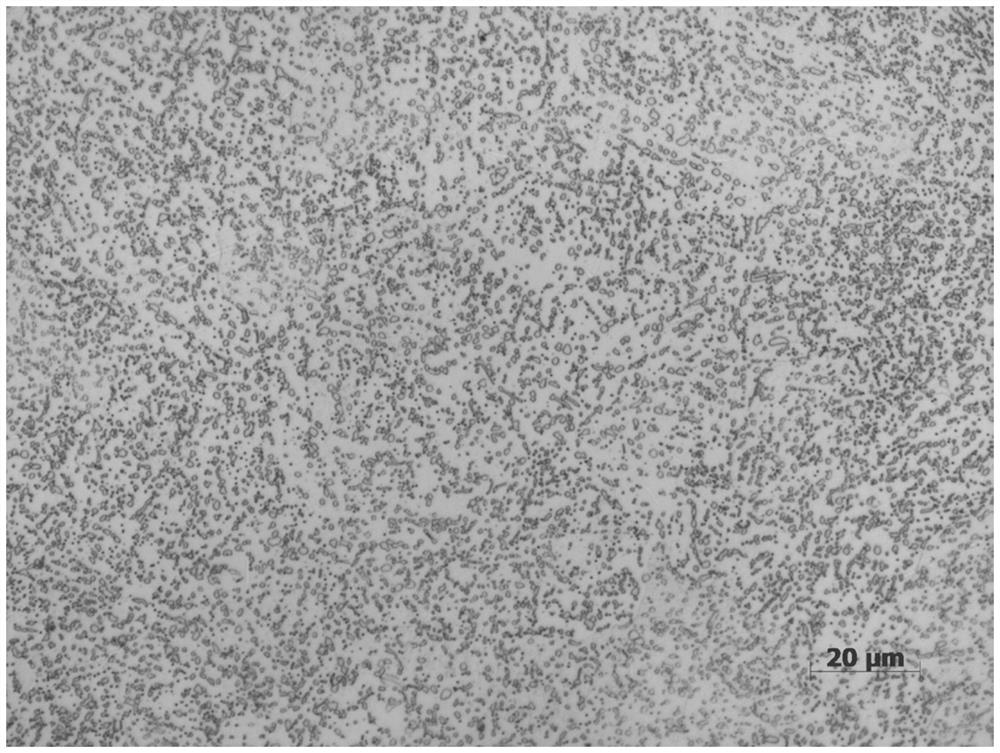

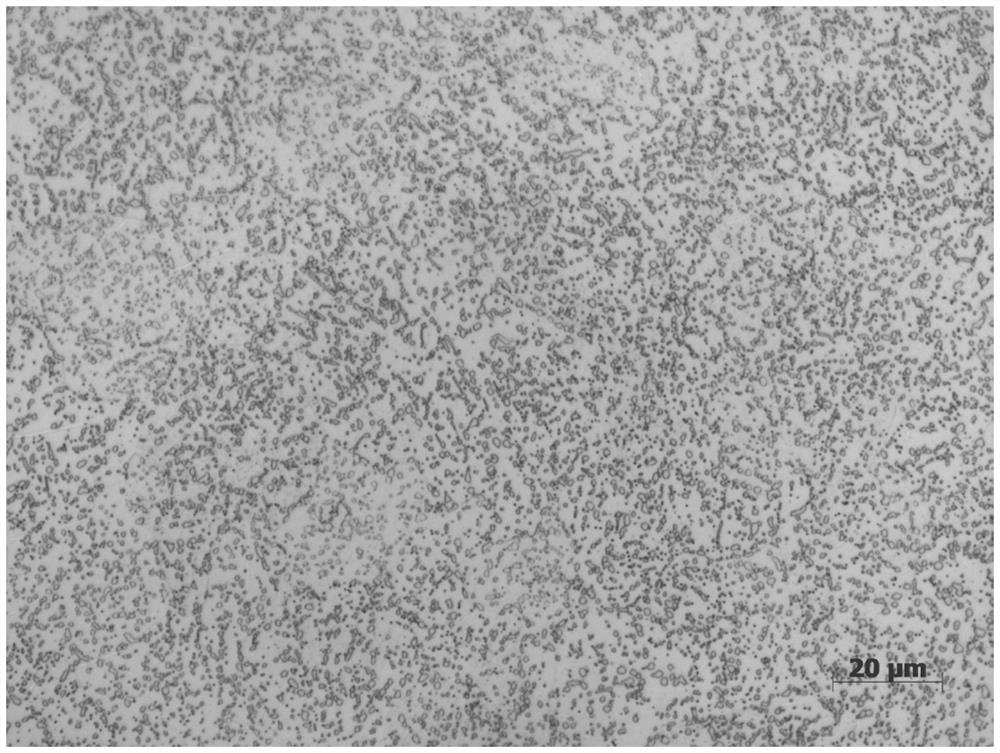

Preparation method of aluminum alloy for semiconductor

A preparation method of aluminum alloy for a semiconductor comprises the following steps: preparing aluminum and alloy; smelting the aluminum; adding the alloy to the molten aluminum to form aluminum alloy; sequentially performing stirring, slagging off, exhausting and refining; performing vacuum standing and exhausting treatment on the aluminum alloy; sampling the aluminum alloy, and analyzing to determine whether the component ratio of the aluminum alloy meets the design requirement; if the component ratio does not meet the design requirement, adding the alloy or the aluminum again based on the analyzing result until the component ratio of the aluminum alloy meets the design requirement, and performing the steps of stirring, slagging off, exhausting, refining, vacuum standing and exhausting treatment, and sampling and analyzing; and if the component ratio meets the design requirement, casting and forming to obtain the aluminum alloy. The aluminum alloy prepared by the method is uniform in mixing of main elements, and low in impurity content, and meets the requirement on the material components of the semiconductor.

Owner:宁波创润新材料有限公司

Forging die for heat insulation part, and forming process thereof

PendingCN113999955AUniform structureWell organizedForging/hammering/pressing machinesHeat conservationElectro-slag remelting

The invention relates to a forging die for a heat insulation part, and further relates to a forming process of the forging die for the heat insulation part. The forming process comprises the following steps: performing electric furnace smelting; casting an electrode blank; annealing the electrode blank: annealing at an annealing temperature of 710-760 DEG C under a heat preservation time of 1-1.5 min / mm, and discharging out of the furnace after being cooled to 300-350 DEG C; carrying out electroslag remelting; forging: heating an electroslag ingot to 1240-1280 DEG C, performing heat preservation for 15-30 h, performing diffusion homogenization, then heading, drawing, forging and cogging, carrying out multi-direction drawing in the X direction, the Y direction and the Z direction to the size of a finished product, and then performing primary water cooling till the temperature of the core of a blank is smaller than or equal to 500 DEG C; and carrying out ultrafine treatment. According to the forging die for the heat insulation part, and the forming process thereof, component design is conducted by adopting the low-Si, high-Mo and low-V alloy element design concept, so that a prepared product has good structure performance and mechanical performance, and the requirement of modern production for a high-end die is better met.

Owner:扬州市龙江工矿机械有限公司

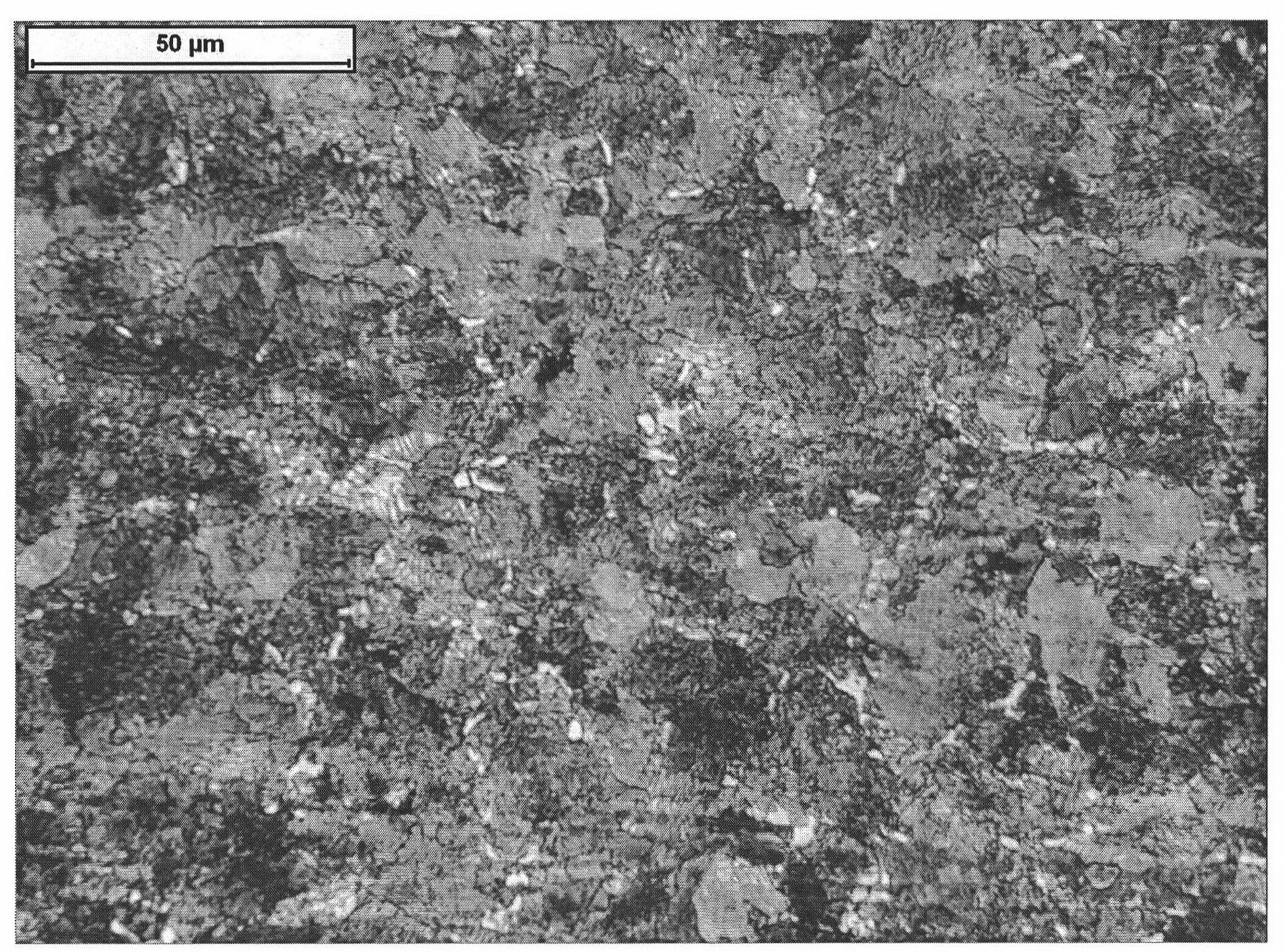

High-performance hot work die steel and preparation method thereof

ActiveCN114540699AImprove purityImprove band segregationMetal-working apparatusProcess efficiency improvementHigh heatMicrostructure

The invention relates to a preparation method of high-performance hot work die steel, which is characterized in that on the basis of H13 steel components, alloy components are optimized by adopting a component design thought of microalloying of low C, low Si, high Mo and composite Ni, and meanwhile, the production process is strictly controlled; the specific process route is as follows: electric furnace smelting, ladle refining furnace refining, vacuum refining furnace refining, inert gas shielding electrode blank casting, protective atmosphere constant melting speed electroslag furnace remelting, high-temperature homogenization treatment, multi-directional forging, pre-treatment after forging and ultra-refining treatment production process are adopted at the same time. The invention further relates to the high-performance hot work die steel, the product is uniform in annealed microstructure structure, good in spheroidized structure, fine and uniform in grain distribution and uniform in quenched and tempered structure, fine precipitated phases of Mo, Cr and V carbides play a role in dispersion strengthening in the using process, meanwhile, a proper amount of Ni element can increase hardenability and refine grains, and the hardness of the die steel is improved. And the toughness and fatigue resistance of the steel are improved.

Owner:江苏宏晟模具钢材料科技有限公司

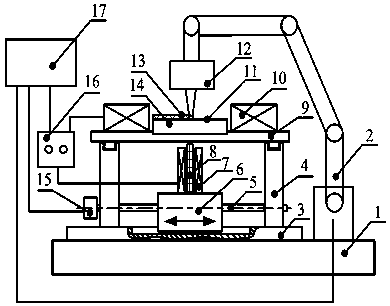

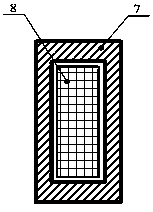

Method and device for preparing high-entropy alloy coating through alternating-current and direct-current composite magnetic field with assistance of laser cladding

InactiveCN111519182AImprove composition segregationMake up for the problem that the refinement effect is not obviousMetallic material coating processesHigh entropy alloysAlloy coating

The invention provides a method and device for preparing a high-entropy alloy coating through an alternating-current and direct-current composite magnetic field with assistance of laser cladding. Thedevice comprises a transverse direct-current magnetic field generating device, a longitudinal alternating-current magnetic field generating device and a position moving mechanism, and the method comprises the steps that a base material is placed on an upper supporting plate with a clamp, an alternating-current / direct-current power module of an alternating-current / direct-current power supply is started through a controller to supply power to a rectangular magnet exciting coil I and a magnet exciting coil II, a longitudinal alternating-current magnetic field and a transverse steady direct-current magnetic field are synchronously generated; and meanwhile, the controller controls the position moving mechanism and a robot, a moving nut drives the alternating current magnetic field generating device to follow a laser cladding head, it is ensured that the upper end of square silicon steel always corresponds to a laser molten pool, and the molten pool is subjected to the equal-strength alternating / direct current magnetic field synergistic effect at each moment. According to the method and device for preparing the high-entropy alloy coating through the alternating-current and direct-currentcomposite magnetic field with assistance of laser cladding, effectively regulating and controlling the microstructure form and solute distribution in the high-entropy alloy coating through laser cladding are carried out through the synergistic effect of the alternating current magnetic field and the direct current magnetic field, and the high-performance high-entropy alloy coating which is uniform in structure distribution and remarkably improved in component segregation can be obtained.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Preparation method capable of remarkably overcoming surface defect of copper alloy material for lead frame

ActiveCN107447121AImprove surface propertiesImprove performanceSemiconductor/solid-state device detailsSolid-state devicesRare earthZinc alloys

The invention discloses a preparation method capable of remarkably overcoming the surface defect of a copper alloy material for a lead frame. The preparation method comprises the following steps that S1, a copper-iron alloy with the iron content being 7% is refined; S2, high-purity copper and wood coal are added into a high-frequency induction smelting furnace, heating is conducted until the high-purity copper is completely melted to obtain copper liquid, heating continues to be conducted, the copper-iron alloy with the iron content being 7%, a copper-zinc alloy, a copper-phosphorus alloy, a copper-tin alloy, a copper-titanium alloy and mixture rare earths are added, and stirring and smelting are conducted to obtain a copper-alloy solution; S3, the components of the copper-alloy solution are detected, and casting is conducted to obtain strips; S4, the strips are subjected to uniform annealing, the annealing temperature is 650-730 DEG C, repeated hot rolling is conducted, then the strips are transferred to be subjected to intermediate annealing finish rolling, the intermediate annealing temperature is 690-710 DEG C, and then a finish rolling product is obtained; and S5, the finish rolling product is subjected to ageing treatment and cooled with a furnace to obtain the copper alloy material, with the surface defect remarkably overcome, for the lead frame. According to the preparation method capable of remarkably overcoming the surface defect of the copper alloy material for the lead frame, uniformization of the copper alloy material for the lead frame is promoted, the surface performance of the alloy material is improved, and the comprehensive performance of the copper alloy material is improved.

Owner:安徽晋源铜业有限公司

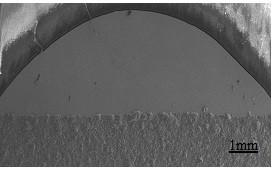

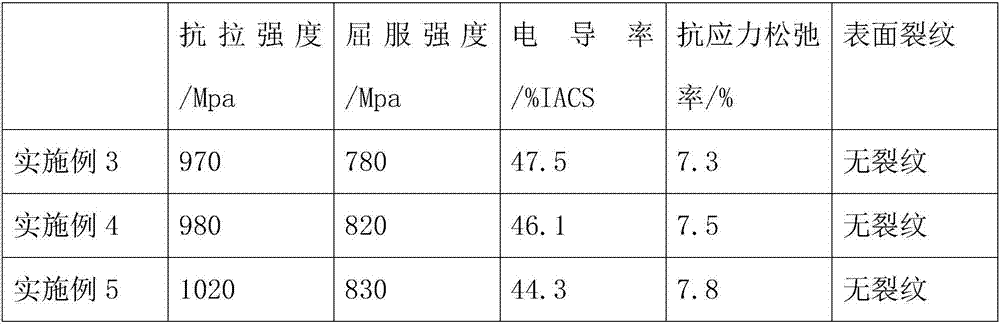

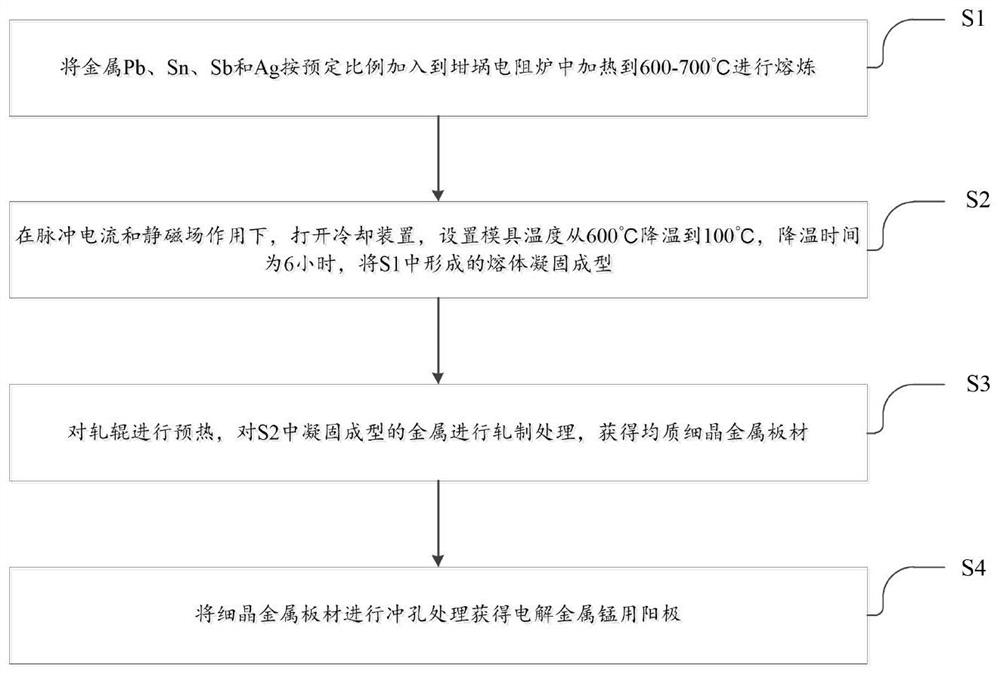

Anode for electrolytic manganese metal and preparation method thereof

PendingCN114789240ALow Ag contentReduce use costPhotography auxillary processesElectrodesElectrolysisThin slab

The invention provides a preparation method of an anode for electrolytic manganese metal. The preparation method comprises the following steps: adding metals Pb, Sn, Sb and Ag into a crucible resistance furnace according to a preset proportion, heating to 600-700 DEG C, and smelting; under the action of pulse current and a static magnetic field, a cooling device is started, the temperature of the mold is reduced to 100 DEG C from 600 DEG C, the cooling time is 6 hours, and the melt is solidified and formed; a roller is preheated, the solidified and formed metal is rolled, and a homogeneous fine-grain metal plate is obtained; and the fine-grain metal plate is subjected to punching treatment, and the anode for electrolytic manganese metal is obtained. Through the continuous casting and rolling process, the current treatment and the external magnetic field treatment, the corrosion resistance, the mechanical strength and the electrocatalytic activity of the anode material for electrolytic manganese are improved, the service life of the anode material is prolonged, the material cost, the cell voltage and the energy consumption in the hydrometallurgy process are greatly reduced, and a thin plate which is uniform in structure and fine in grain is obtained; and the technical requirements of electrolytic manganese metal in the field of hydrometallurgy are met.

Owner:GUIZHOU R & D CENT ON MODERN MATERIALS

Horizontal continuous-casting electromagnetic agitating technology

ActiveCN100479947CImprove composition segregationImprove organizational defects such as stratificationWater treatment systemControl system

Owner:衡阳华菱连轧管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com