High mirror corrosion resistant plastic die steel and manufacturing method thereof

A plastic mold steel, corrosion-resistant technology, applied in the high mirror surface corrosion-resistant plastic mold steel and its manufacturing field, can solve the problems of low production efficiency, high cost, steel plate edge cracks, etc., and achieve good comprehensive mechanical properties and high hardness uniformity. , the effect of saving manufacturing costs

Active Publication Date: 2019-04-30

ANGANG STEEL CO LTD

View PDF18 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The addition of Sn can improve the corrosion resistance of steel, but due to the small amount of addition, it cannot solve the serious problem of alloy carbides, and the addition of Sn will make the hot workability of steel worse and easily cause edge cracking of steel plates

[0006] CN102796959A discloses a corrosion-resistant martensitic die steel, the chemical composition of which is: C: 0.16%-0.24%, Si≤0.15%, Mn≤0.15%, P﹤0.015%, S﹤0.005%, Cr: 12.0% ~12.6%, N: 0.13%~0.20%, Ta: 0.03%~0.08%, C+N=0.30%~0.37%, the balance is Fe, and the method of electroslag remelting + forging is adopted to improve the eutectic carbonization of steel However, there are disadvantages such as complex process, low production efficiency and high cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

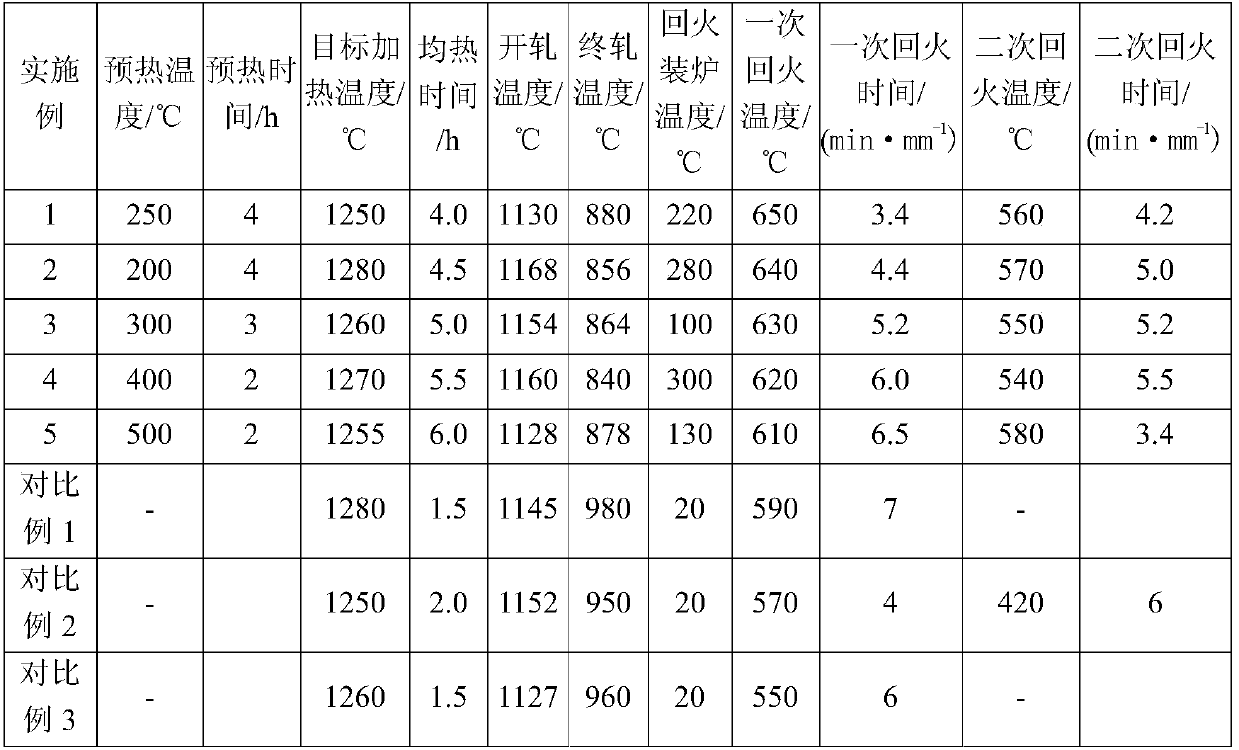

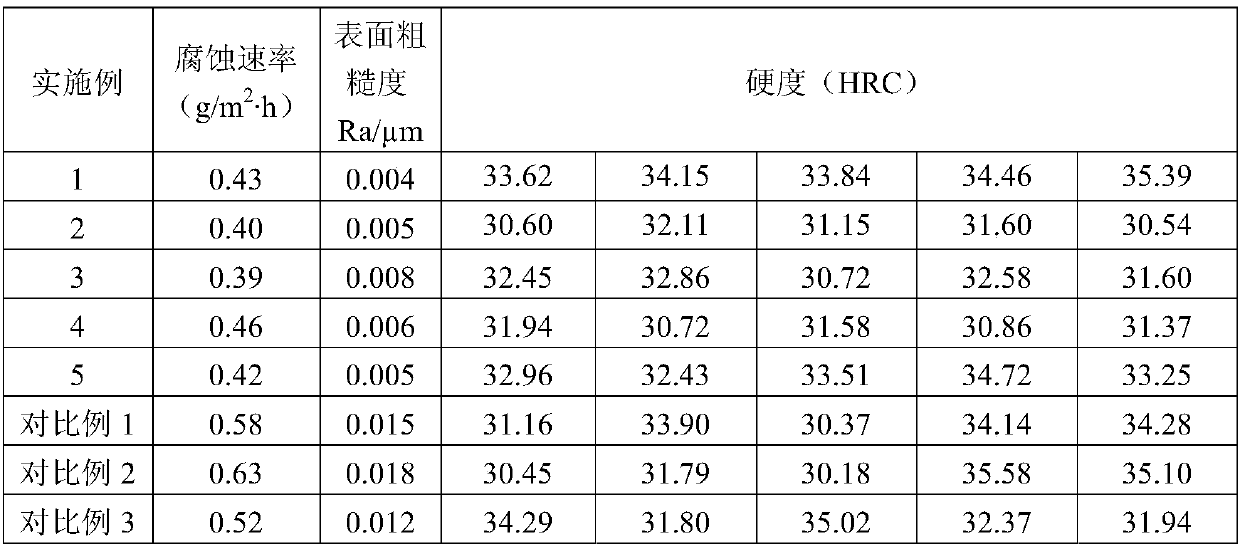

[0031] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

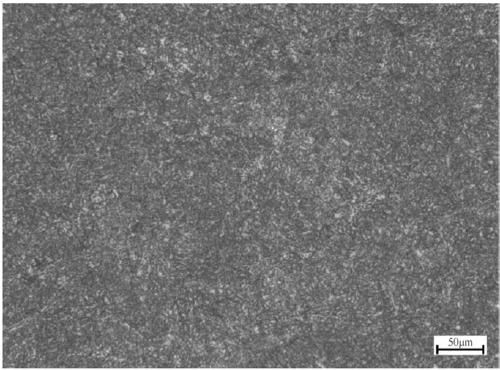

The invention discloses high mirror corrosion resistant plastic mold steel and a manufacturing method. The steel contains 0.32-0.46% of C, 0.4-1.2% of Si, 0.4-0.8% of Mn, P which is less than or equalto 0.020%, S which is less than or equal to 0.040%, 10.8-12.8% of Cr, 0.3-1.2% of Cu, 0.5-1.0% of Ni, 0.15-0.25% of Nb, and 0.01-0.03% of N, with the balance being Fe and inevitable impurities. A steel billet can be heated after being charged and preheated at 200-500 DEG C, the preheating time is greater than or equal to 2h, a heating temperature is 1,250-1,280 DEG C, the soaking time is 4-6 h, an initial rolling temperature is greater than or equal to 1,100 DEG C, and a finish rolling temperature is 840-880 DEG C; air cooling can be performed to 100-300 DEG C after rolling; the temperature of primary tempering is 610-650 DEG C, and the heat preservation time is 3.4-6.5 min / mm; the temperature of secondary tempering is 540-580 DEG C, and the heat preservation time is 3.4-5.5 min / mm. The produced die steel has excellent corrosion resistance and surface properties.

Description

technical field [0001] The invention belongs to ferrous metal materials, in particular to high-mirror corrosion-resistant plastic mold steel and a manufacturing method thereof. Background technique [0002] Plastic products have the advantages of low cost and strong plasticity, and are widely used in national economic life. Plastic products are usually thermoformed in plastic molds using processes such as compression molding, extrusion molding, injection molding, and blow molding. Among them, polyvinyl chloride, polypropylene, ABS, EVA, polyurethane and other materials will decompose and generate a large amount of acid gas in the hot-melt state, causing serious corrosion to the surface of the mold steel, greatly reducing the service life of the mold and the product qualification rate. Therefore, for such products, the mold steel is required to have strong corrosion resistance. At the same time, the rapid development of the plastic mold industry has also put forward higher ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/42C22C38/48C22C33/04C21D8/02

CPCC21D8/0205C21D8/0221C21D8/0247C22C33/04C22C38/02C22C38/04C22C38/42C22C38/48

Inventor 范刘群赵坦李云石锋涛渠秀娟冯丹竹李广龙

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com