Short crystallizer for casting hollow aluminum ingots

A crystallizer and hollow ingot technology, which is applied in the field of aluminum processing, can solve the problems of difficult to meet the high requirements of structure and performance, internal and external surface cracking, run-off, coarse crystal grains, etc., and achieve excellent subsequent processing performance and surface quality , the effect of high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

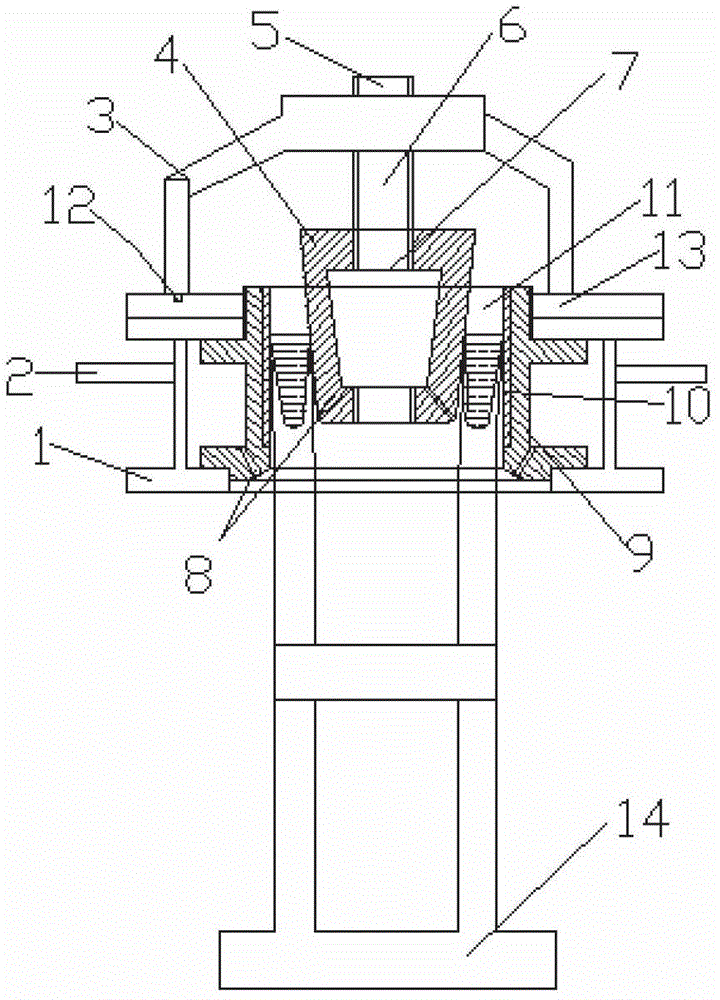

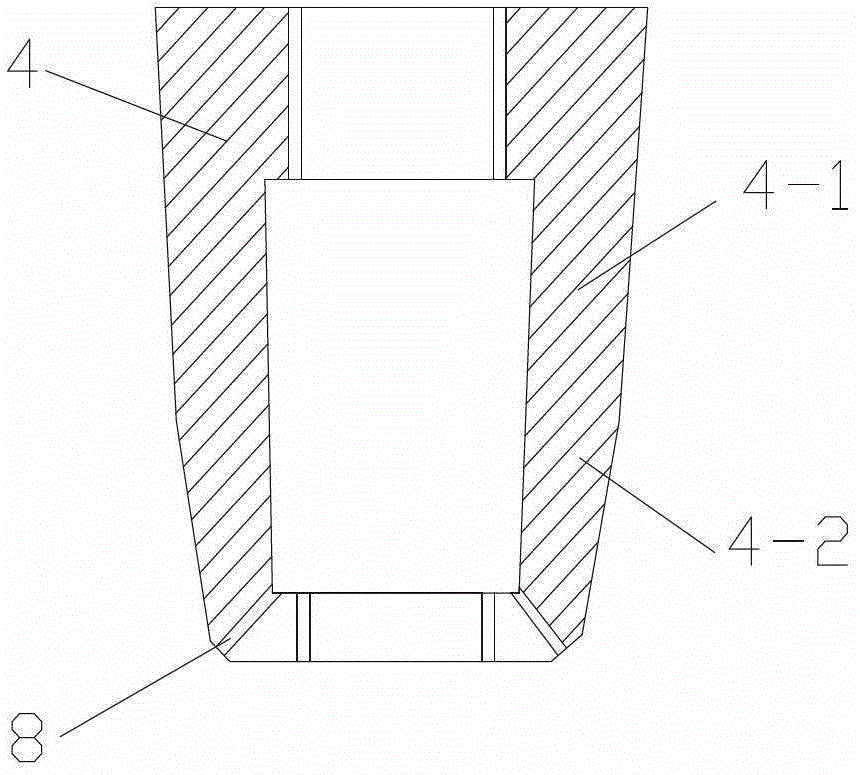

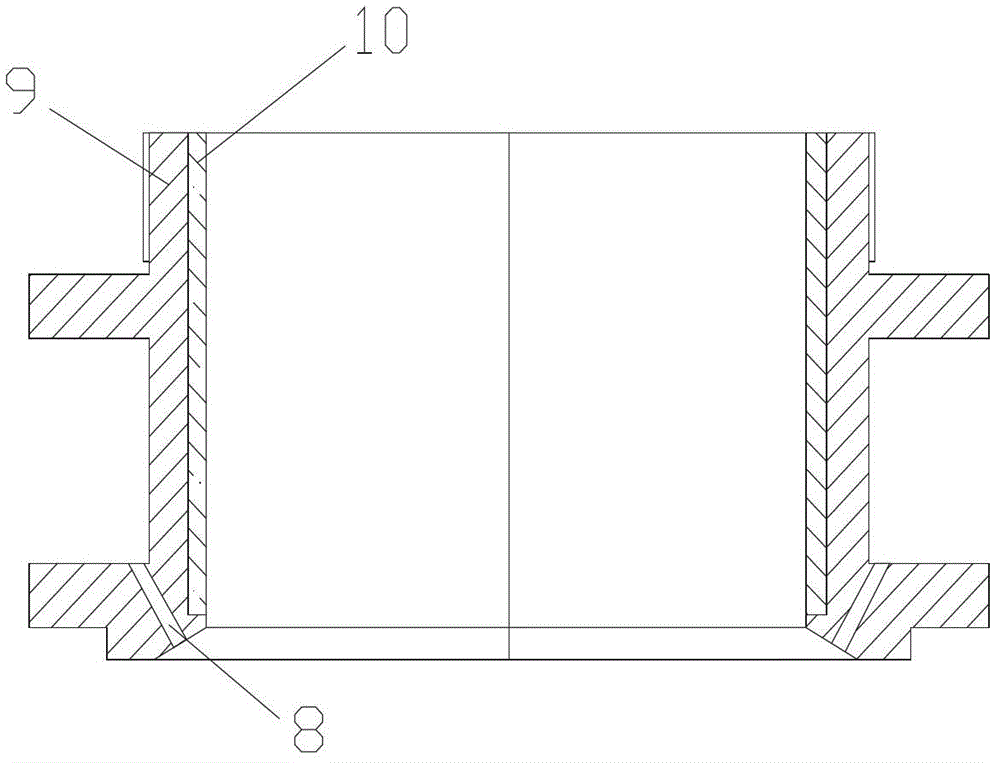

[0027] Such as figure 1 , 2 , 3, a short crystallizer for casting aluminum hollow ingots, the casting tooling of hollow ingots is composed of mold shell (1), inner sleeve (7), inner lining (8), core, tripod, etc. . The crystallizer shell (1) is provided with a shell water inlet pipe (2), and the tripod (3) snaps into the annular groove (13) of the shell (1), and can be snapped into the ring by the wedge (12) of the tripod (3) In the groove (13), the tripod (3) can rotate on the shell (1), and ensure that the shell (1) and the core (4) are concentric, and the shell (1) is fixed with the inner sleeve (9) and inner liner (10), fasten the inner sleeve (9) and the outer shell (1) with bolts, the inner lining (10) is sleeved in the inner sleeve (9), and the inner lining (10) and the inner sleeve (9) are connected by interference fit .

[0028] The core (4) is placed in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com