Patents

Literature

73results about How to "Avoid remelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

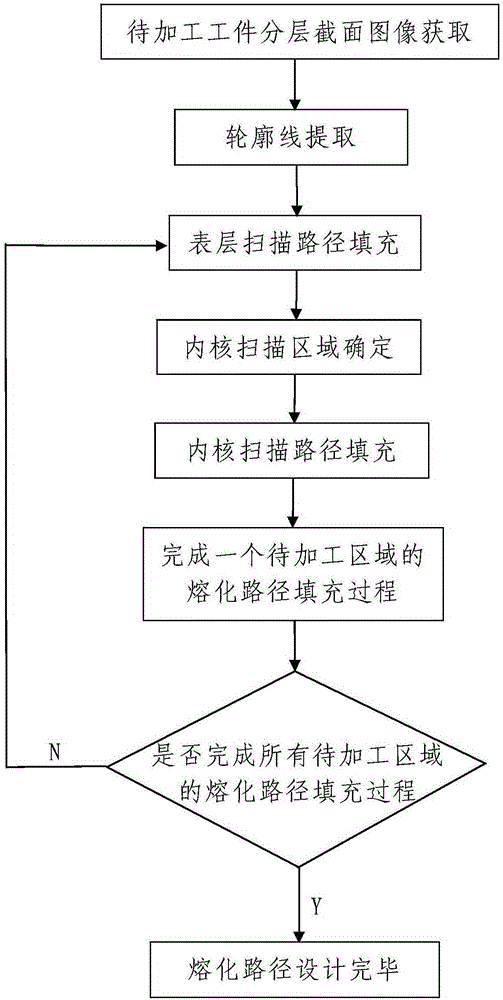

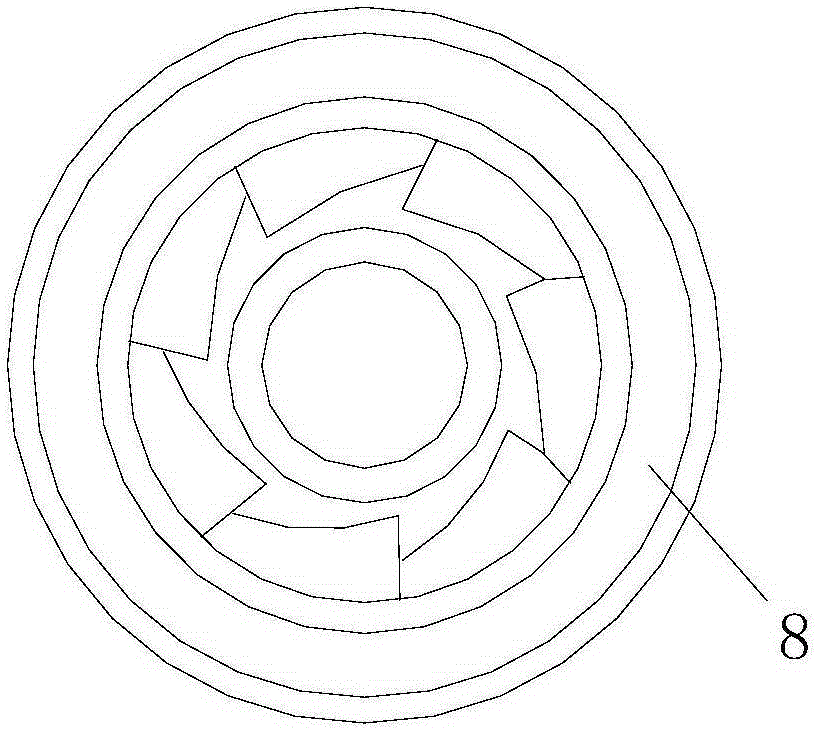

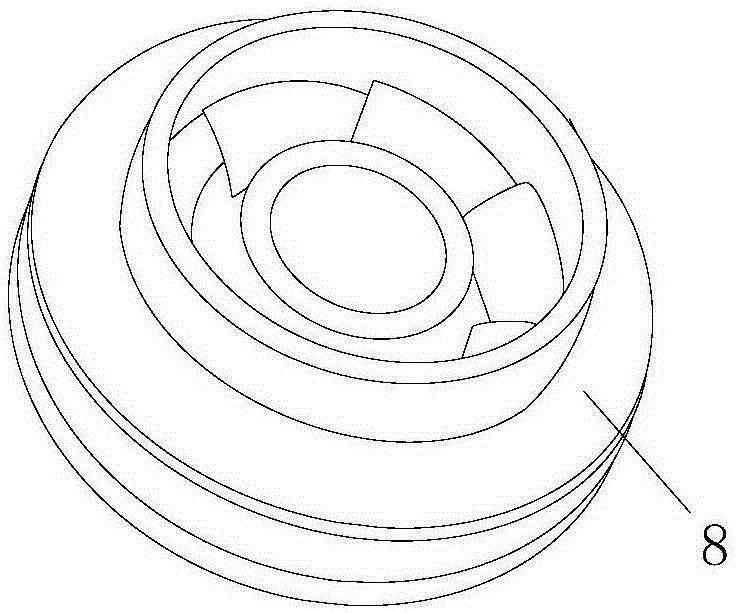

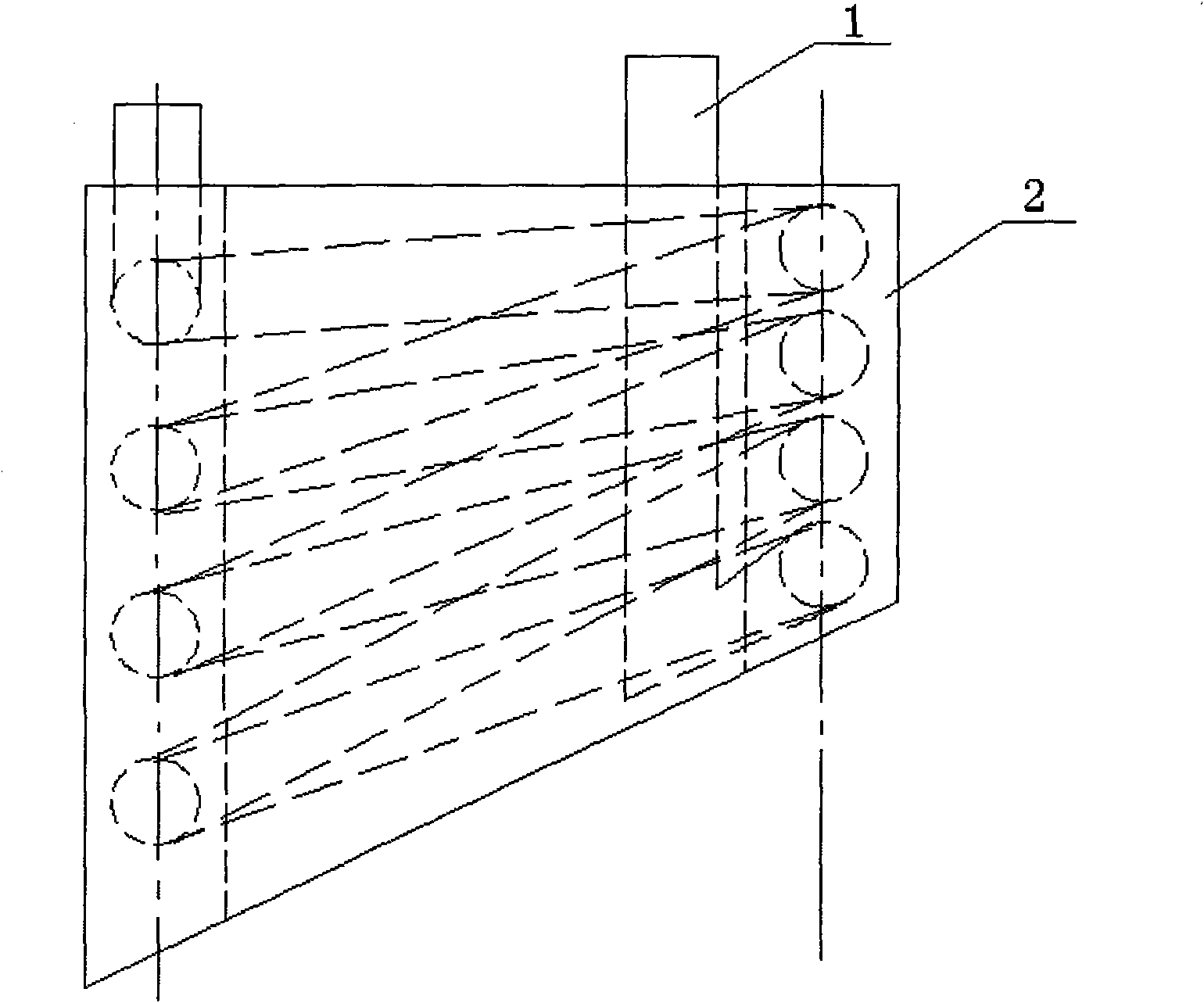

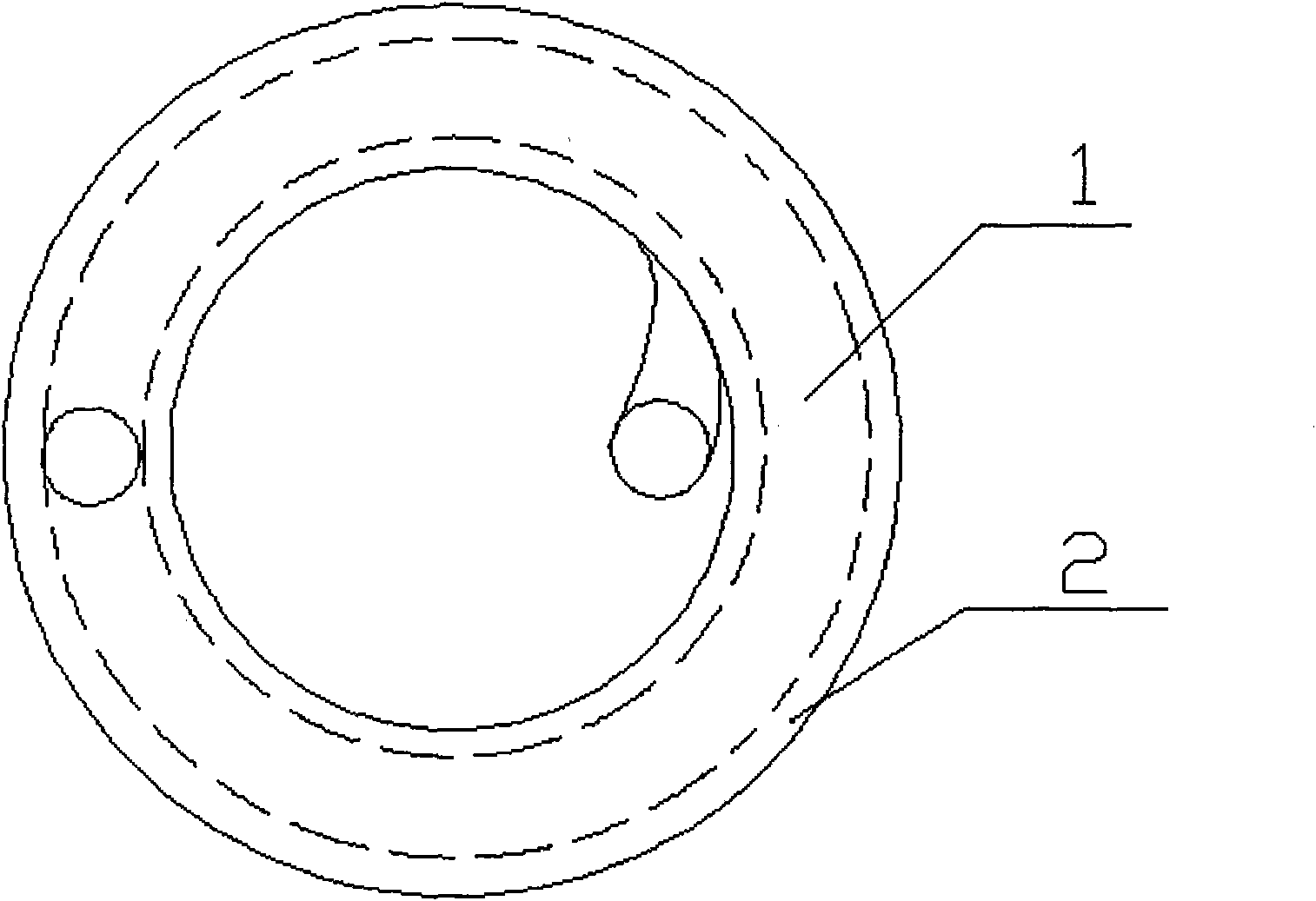

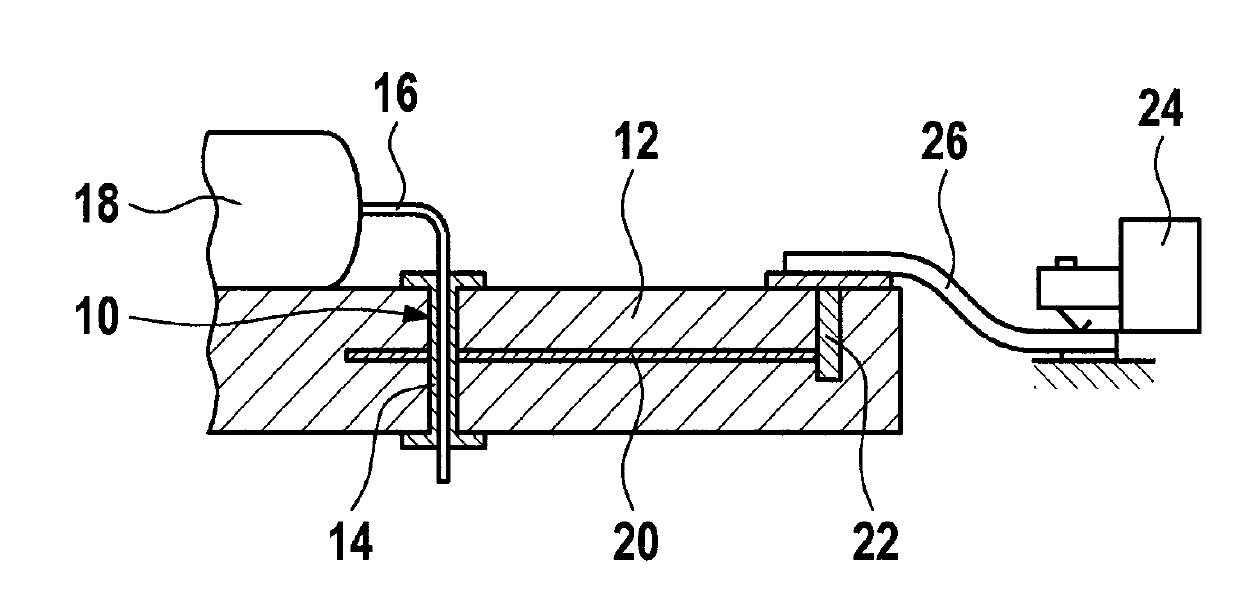

Melting path design method for high energy beam selective melting forming

ActiveCN105195742AThe method steps are simpleReasonable designAdditive manufacturing apparatusSurface layerComputer science

The invention discloses a melting path design method for high energy beam selective melting forming. The method comprises the following steps: 1, acquisition of layered section images of a to-be-machined workpiece: layered section images of multiple layers of the to-be-machined workpiece are acquired and stored, wherein the section of each layer is a to-be-machined area; 2, contour extraction: the contour of each layer of section image is extracted; 3, melting path filling: melting path filling is performed on the multiple to-be-machined areas respectively, melting path filling for any to-be-machined area comprises the following steps: surface layer scanning path filling, inner core scanning area determining and inner core scanning path filling. The method has simple steps and is reasonable in design, convenient to implement and good in use effect; a melting path for high energy beam selective melting forming can be designed simply, conveniently and rapidly, the designed melting path is reasonable, the workpiece machining precision is high, all parts of the workpiece are uniformly heated, and the workpiece has excellent mechanical properties.

Owner:西安赛隆增材技术股份有限公司

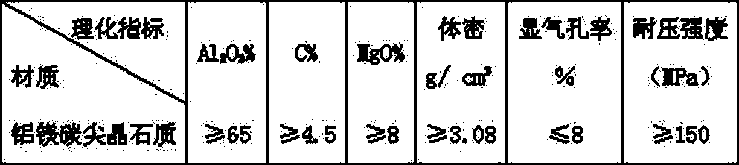

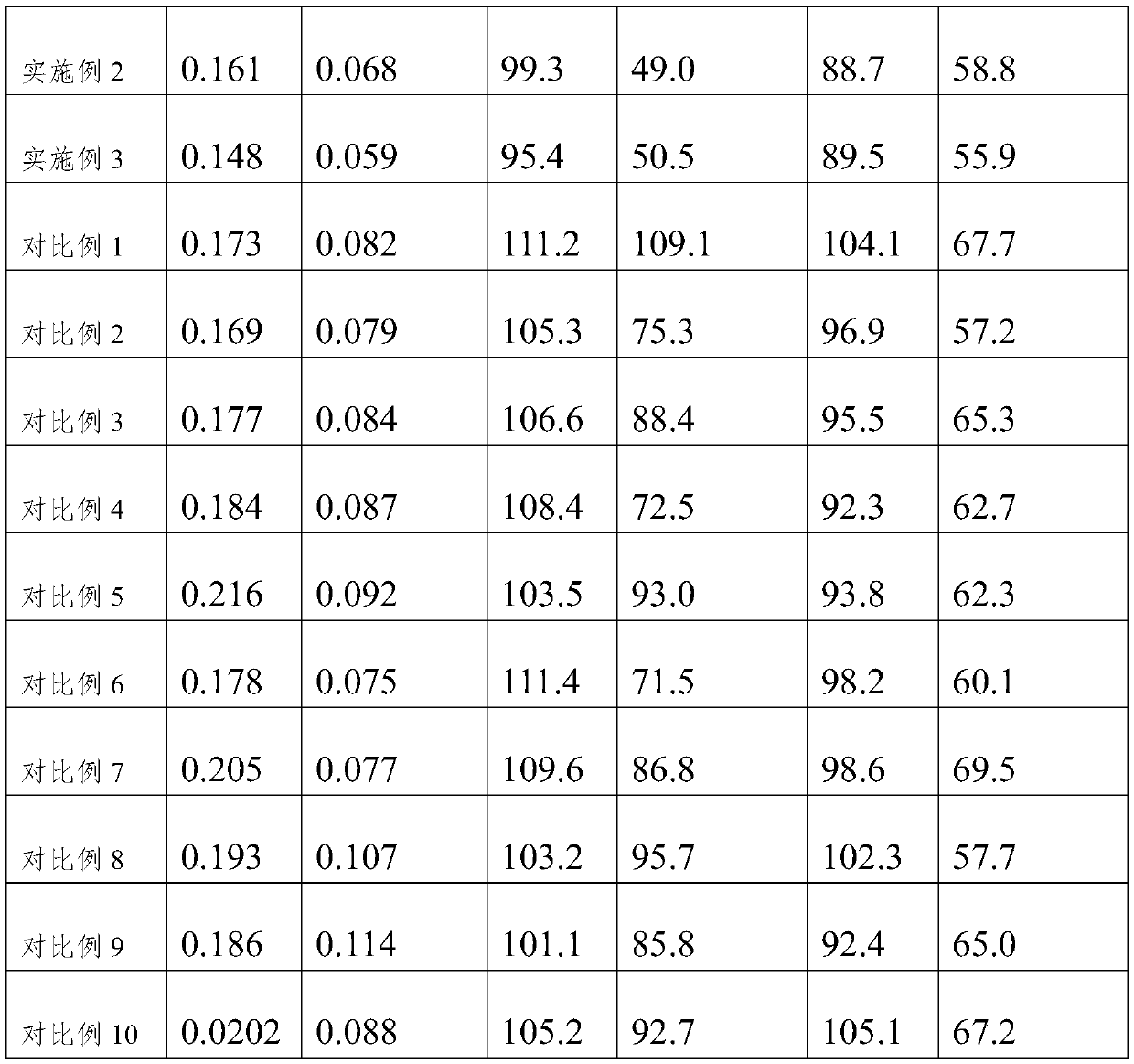

Novel slide plate brick for automatic slag-retaining slide gate of converter and preparation method of slide plate brick

The invention discloses a novel slide plate brick for an automatic slag-retaining slide gate of a converter and a preparation method of the slide plate brick. The slide plate brick is characterized by containing the following components in percentage by weight: 58%-68% of tabular corundum, 6%-8% of 98 magnesia, 8%-11% of electrically-fused spinel, 3%-5% of graphite, 4%-7% of a-aluminum oxide powder, 1%-2% of sintering agent, 2%-7% of aluminum-silicon alloy powder and 4%-5% of resin. The slide plate brick can be prepared from the components through the processes of mixing, shaping, drying, sintering, oil immersing, roasting, and machining. By virtue of adjustment on the formula of the slide gate brick and simplification on the production technology of the slide gate brick, the comprehensive performance of the slide gate brick is enhanced, the direct benefit of slag-free tapping with the slide plate brick is high, and beneficial conditions are provided for development of good-quality steel grades, so that the slide plate brick and the preparation method of the brick have a very wide application prospect and remarkable economic and social benefits.

Owner:无锡市南方耐材有限公司

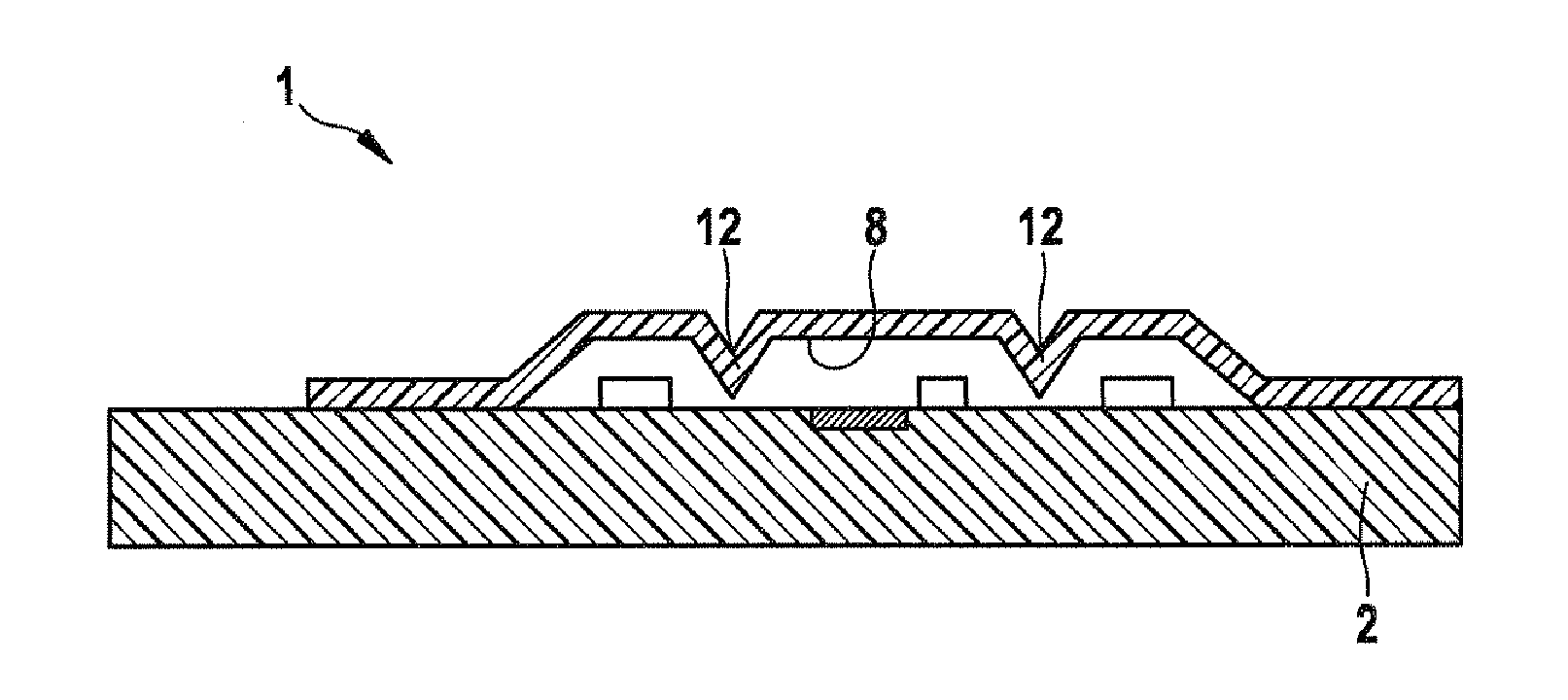

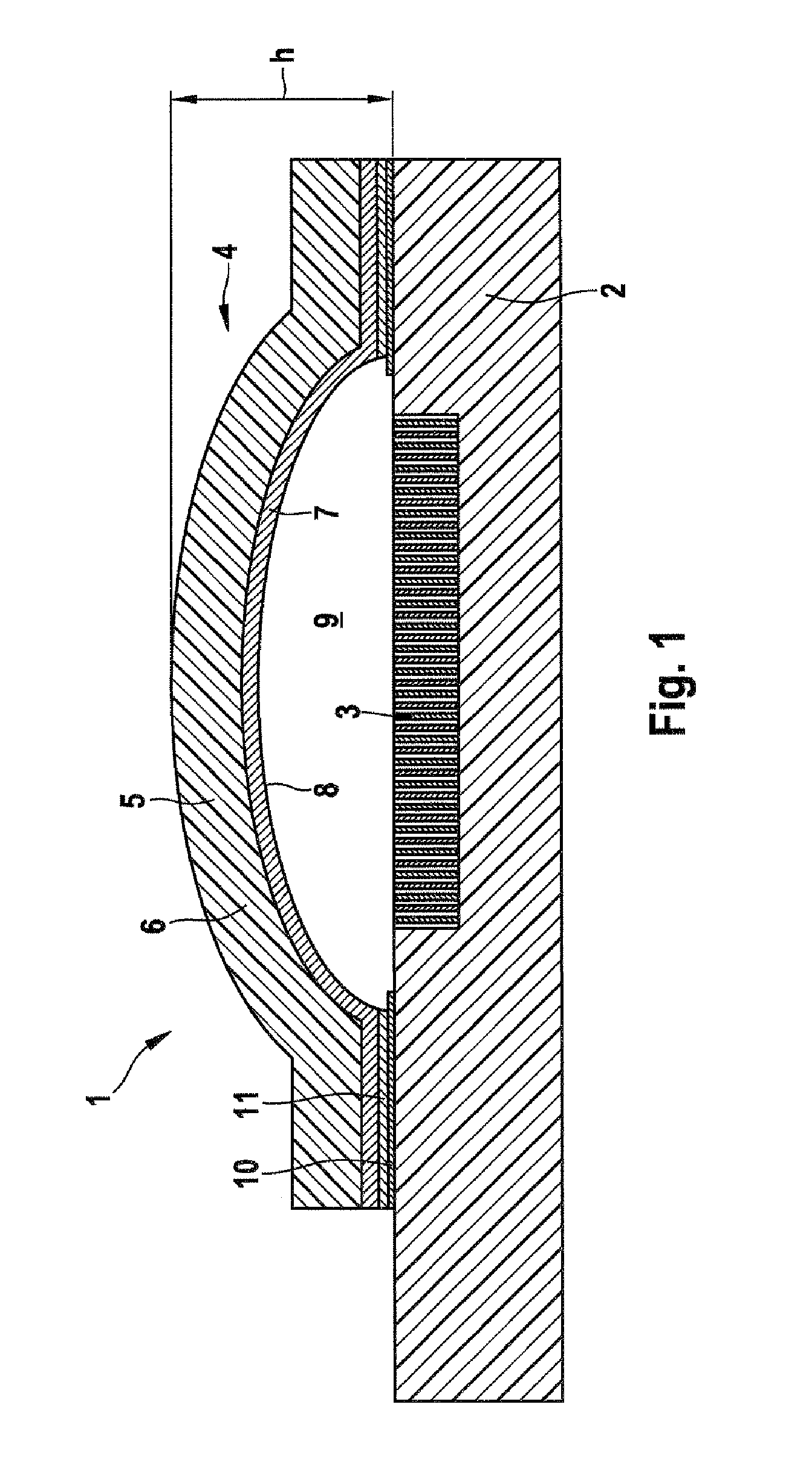

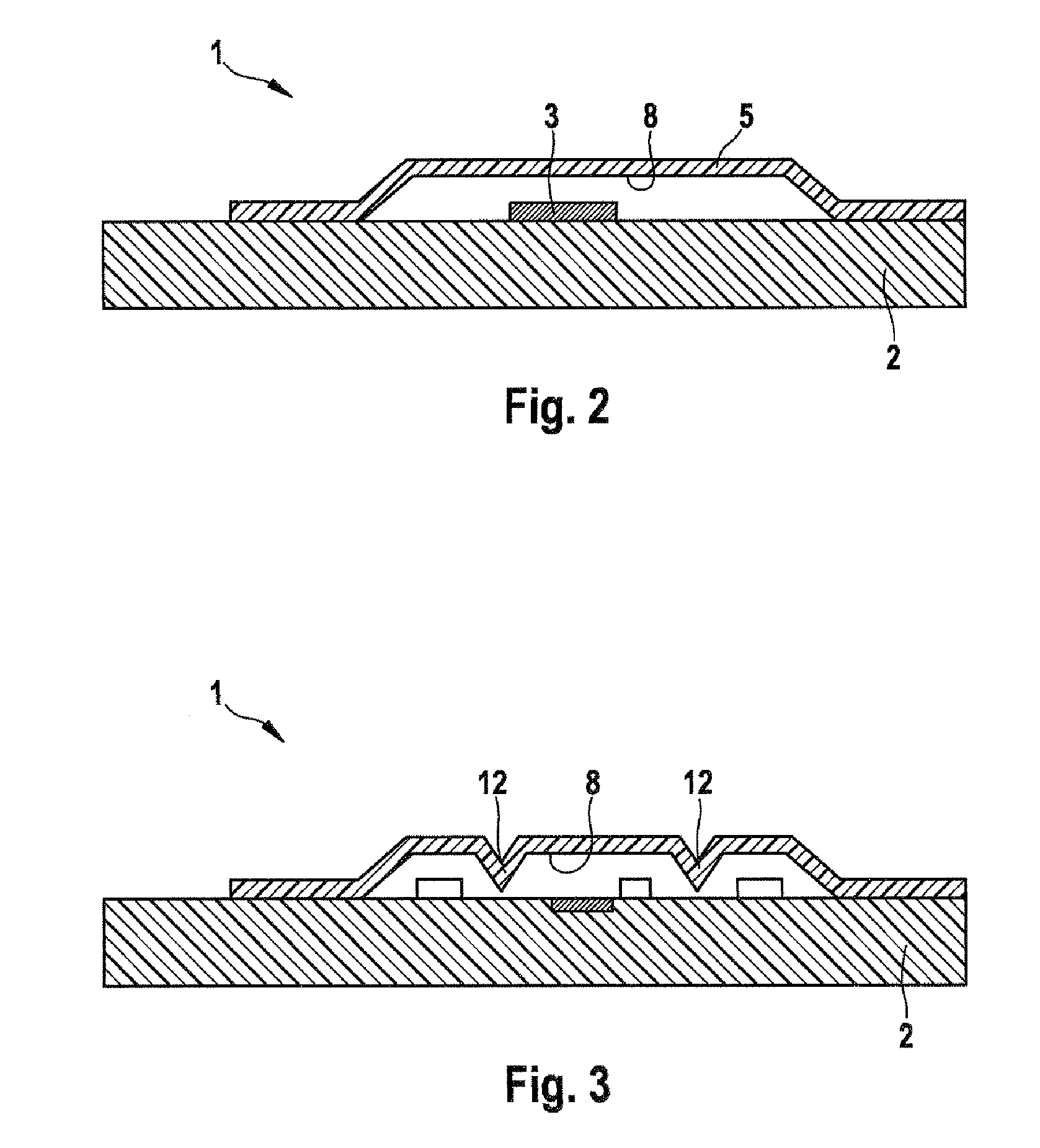

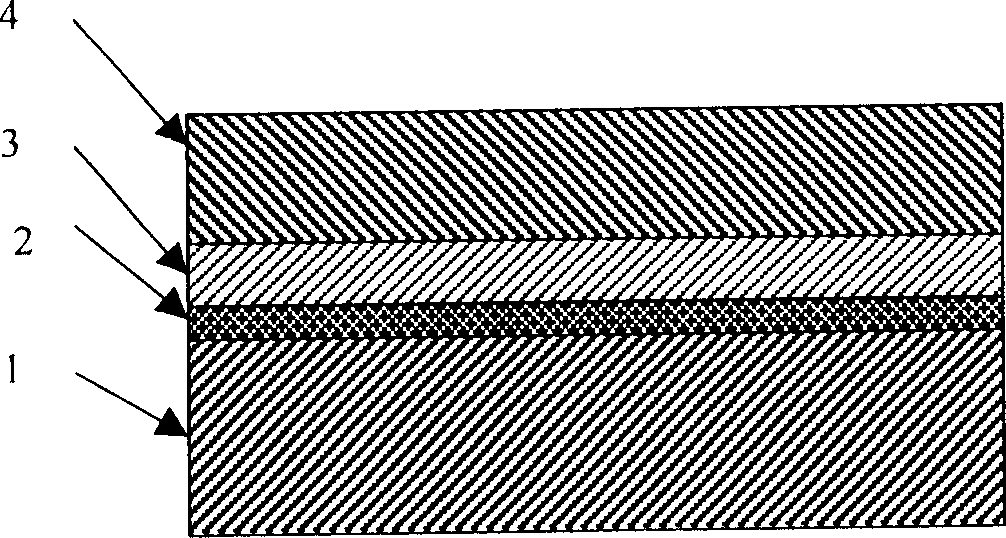

Encapsulation, MEMS and Method of Selective Encapsulation

InactiveUS20110121414A1Improve stabilityInhibition of attachmentImpedence networksSemiconductor/solid-state device detailsEngineeringSemiconductor

The invention relates to an encapsulation (4) of a sensitive component structure (3) on a semiconductor substrate (2) with a film (5) covering the component structure (3). According to the invention, it is provided that a cavity (8) for the component structure (3) is provided in the film (5). The invention also relates to a MEMS (1) and to a method for encapsulating a sensitive component structure (3).

Owner:ROBERT BOSCH GMBH

Method for reducing molten steel nitrogen in steelmaking link

The invention discloses a method for reducing molten steel nitrogen in a steelmaking link. The method comprises the following steps: controlling combined blowing parameters of a converter, and carrying out phased adjustment; controlling the bottom blowing manner and the flow rate of a steel ladle; adjusting a furnace rear alloying sequence, and adopting a deoxidation principle from weak to strong in sequence; judging whether the converter needs after-blow or not, wherein, for a steel ball of which temperature is increased by blowing oxygen through an RH technology, the converter endpoint temperature is within10 DEG C lower than the lower limit of a key point specified steel tapping temperature, and after-blow warming is not needed; for a steel ball capable of blowing oxygen in the RH technology, the converter endpoint carbon is smaller than or equal to 0.02% higher than aim carbon, and when the temperature reaches a required value, after-blow is not needed. According to the method for reducing molten steel nitrogen in the steelmaking link provided by the invention, by optimizing converter combined blow flow, steel ladle argon bottom blowing and deoxidation alloying sequence and establishing an after-blow principle, under the condition that other technological parameters are not changed, the content of nitrogen in a finished product is averagely reduced by 12 ppm, the performance of steel billets is stably improved, and a larger operation space is provided for a latter process; the method is easy to operate, the cost is not increased, and the practical application effect is good.

Owner:BEIJING SHOUGANG CO LTD

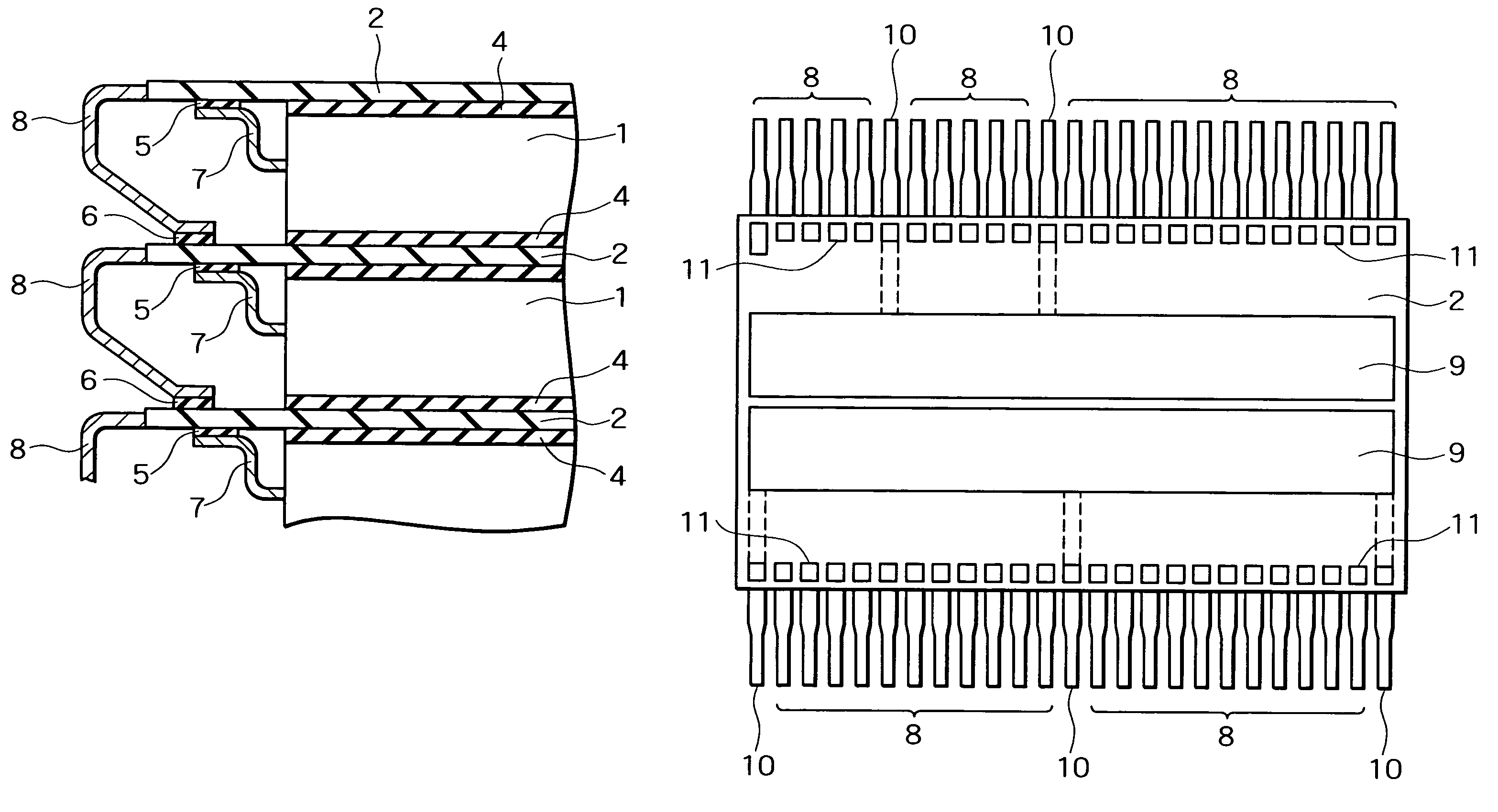

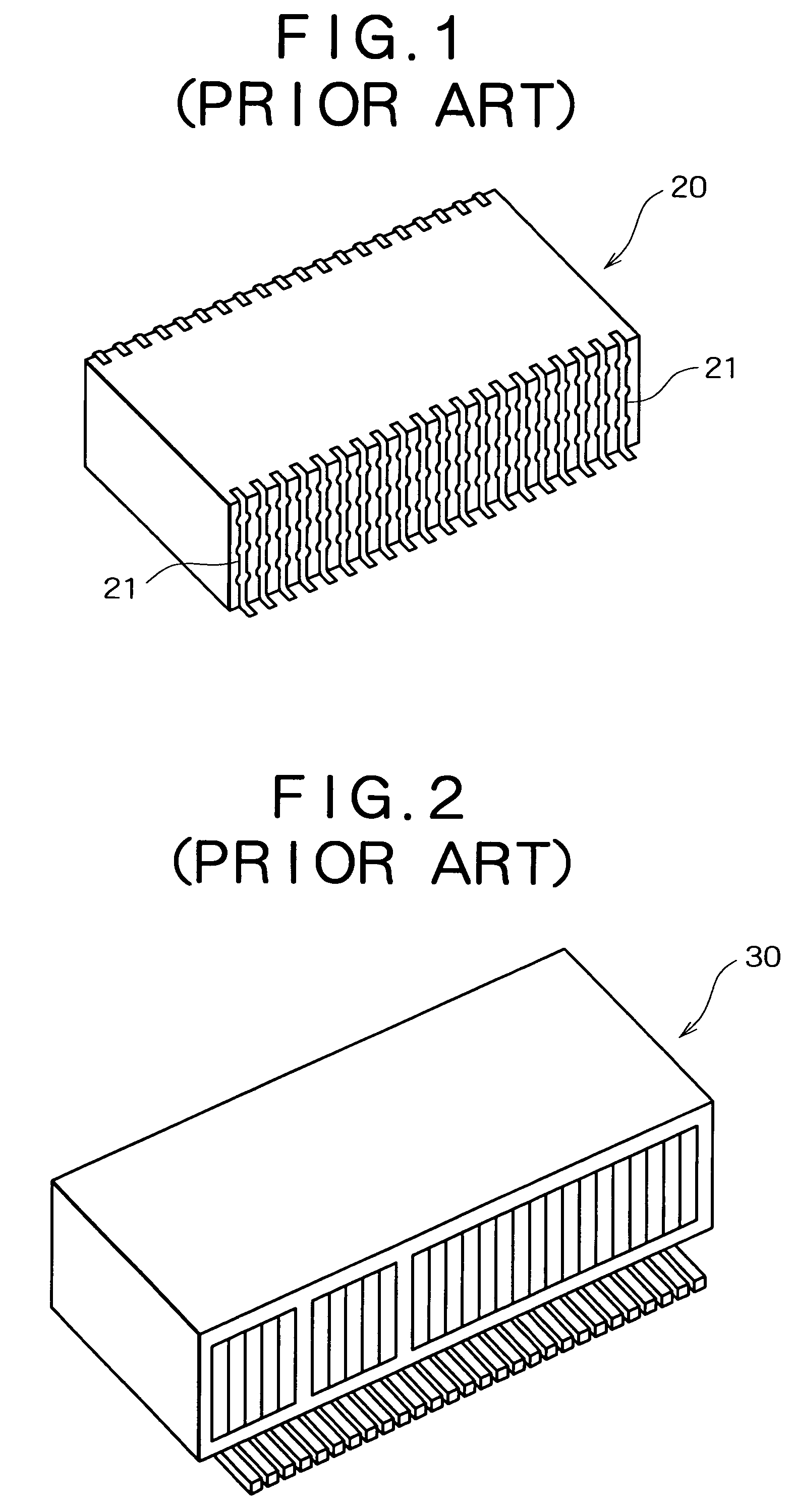

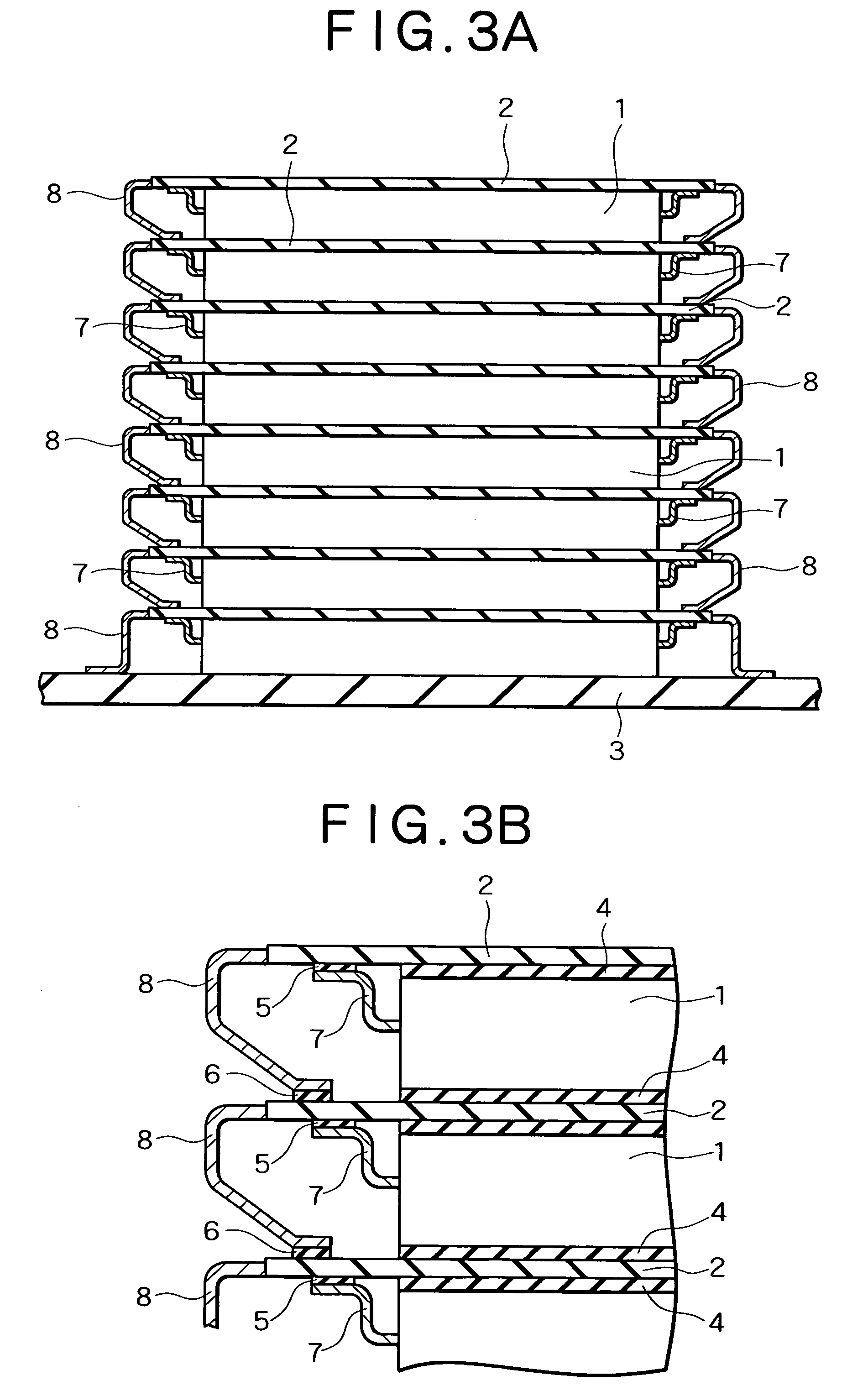

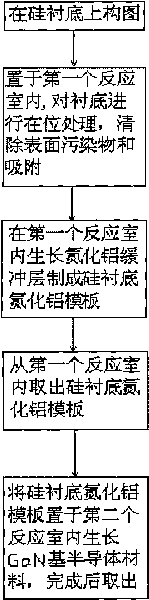

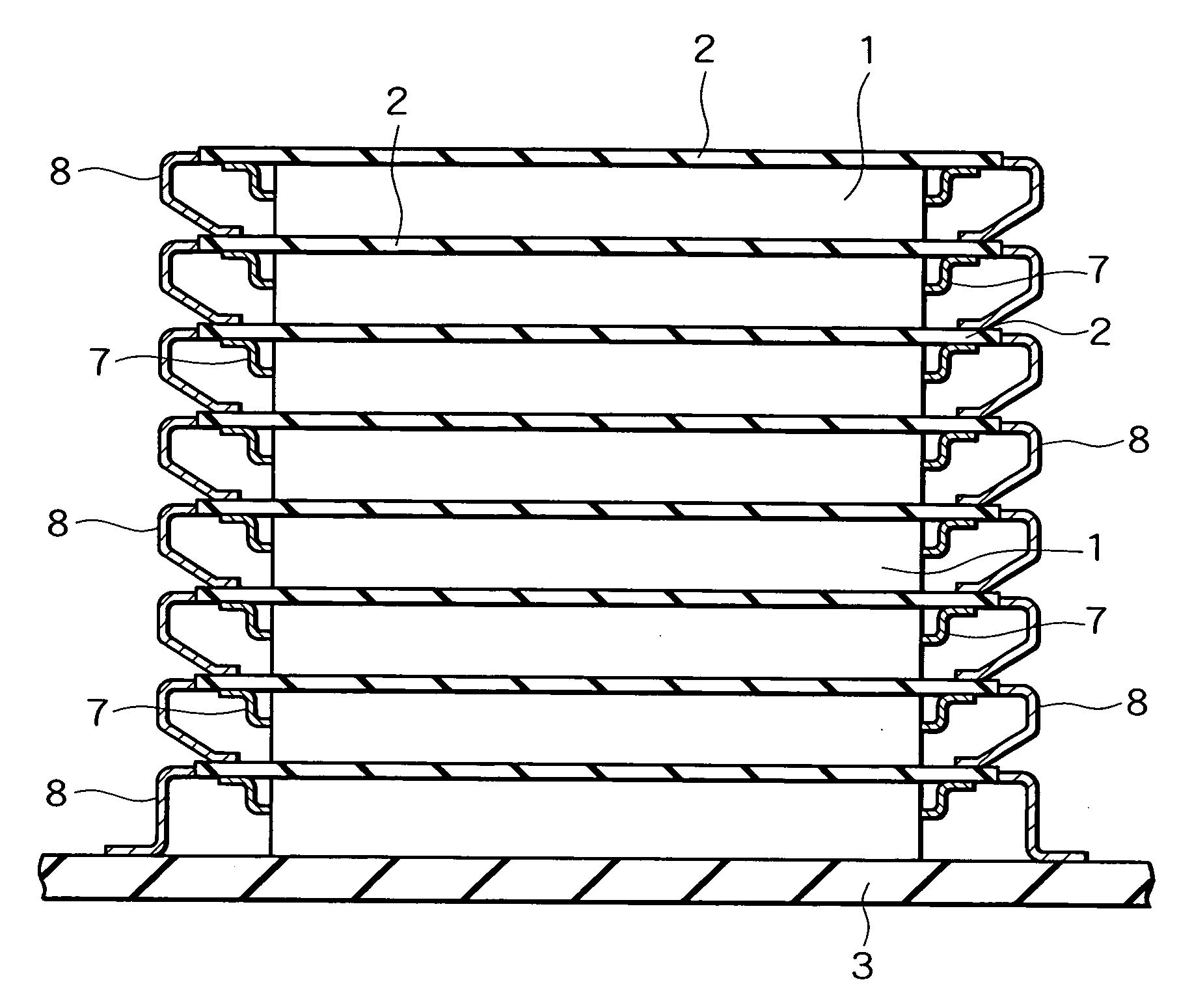

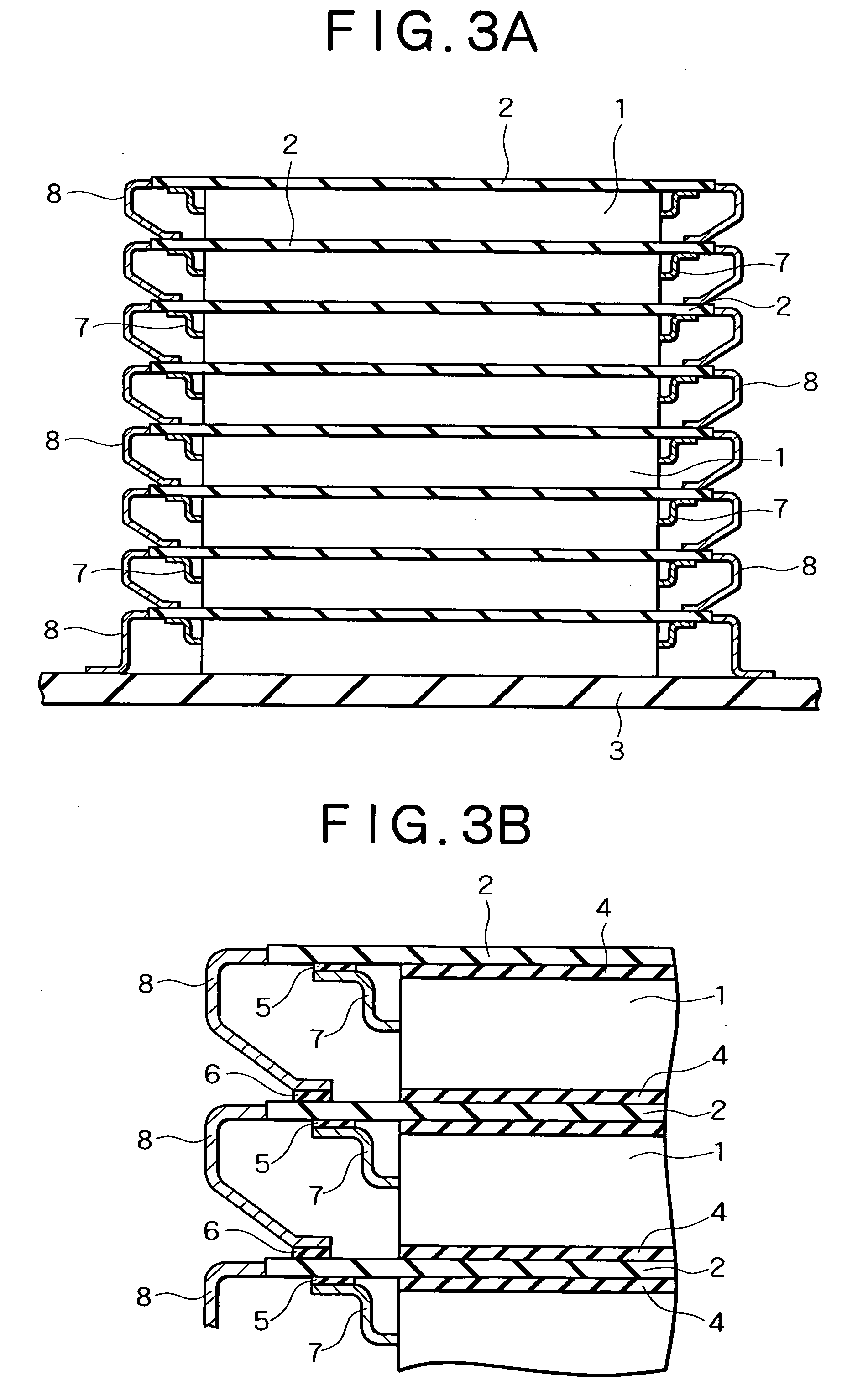

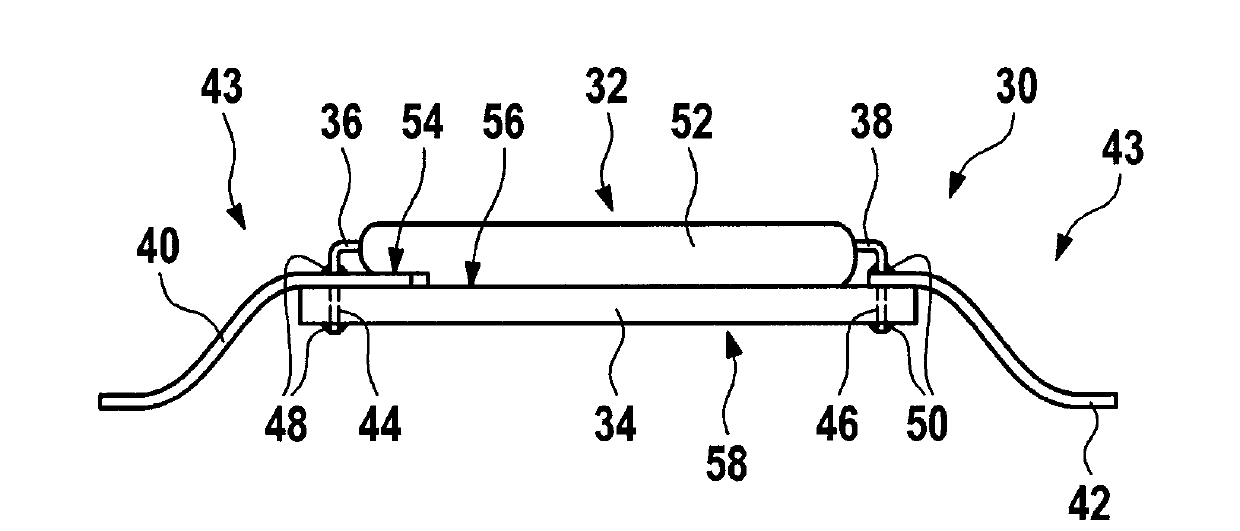

Stacked memory and manufacturing method thereof

InactiveUS7145227B2Increase heat radiationEasy to manufacturePrinted circuit assemblingSemiconductor/solid-state device detailsInterposerEngineering

To mount a TSOP on an interposer substrate, leads provided to the TSOP are joined to pads of the interposer substrate by a thermosetting conductive resin, and the TSOP exclusive of the leads is joined to ground layers formed in the interposer substrate by a thermosetting conductive resin. The interposer substrates with the TSOPs mounted thereon are stacked in eight layers in such a manner that the TSOPs face downward. Then, leads of the upper interposer substrate are joined to pads formed in the rear face of the lower interposer substrate by a thermosetting conductive resin, so that the interposer substrates adjacent in a vertical direction are connected.

Owner:NEC TOSHIBA SPACE SYST

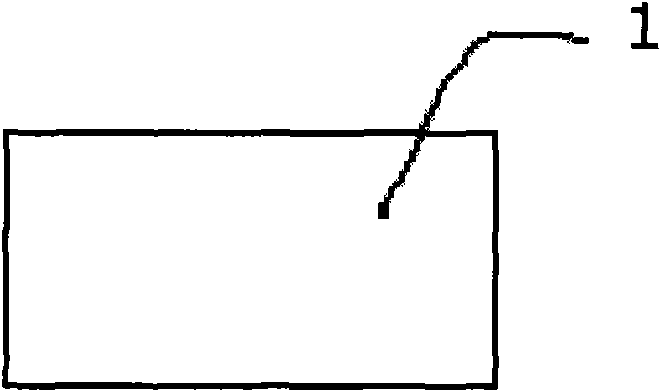

Method for manufacturing silicon substrate GaN-based semiconductor material

InactiveCN101719465AImprove stabilityAvoid remeltingSemiconductor/solid-state device manufacturingSemiconductor materialsLight-emitting diode

The invention provides a method for manufacturing a silicon substrate GaN-based semiconductor material, aiming at solving the problem of re-melting a silicon surface by Ga in the process of extending GaN-based semiconductor material to improve the quality of the product and the production efficiency. The method comprises the following steps of: generating an aluminum nitride buffer layer on the silicon substrate in a reaction chamber of a first MOCVD specially for growing the aluminum nitride buffer layer, and taking out the aluminum nitride buffer layer after the step is completed to form a silicon substrate aluminum nitride template for later use; and placing the silicon substrate aluminum nitride template for later use into a reactor of a second MOCVD for growing a GaN-based semiconductor material to extend the GaN-based semiconductor material; and taking out the silicon substrate aluminum nitride template after the step is completed to form a silicon substrate GaN-based semiconductor material. The method can be applied to production manufacture of light-emitting diodes, diode lasers, power devices and the like.

Owner:LATTICE POWER CHANGZHOU

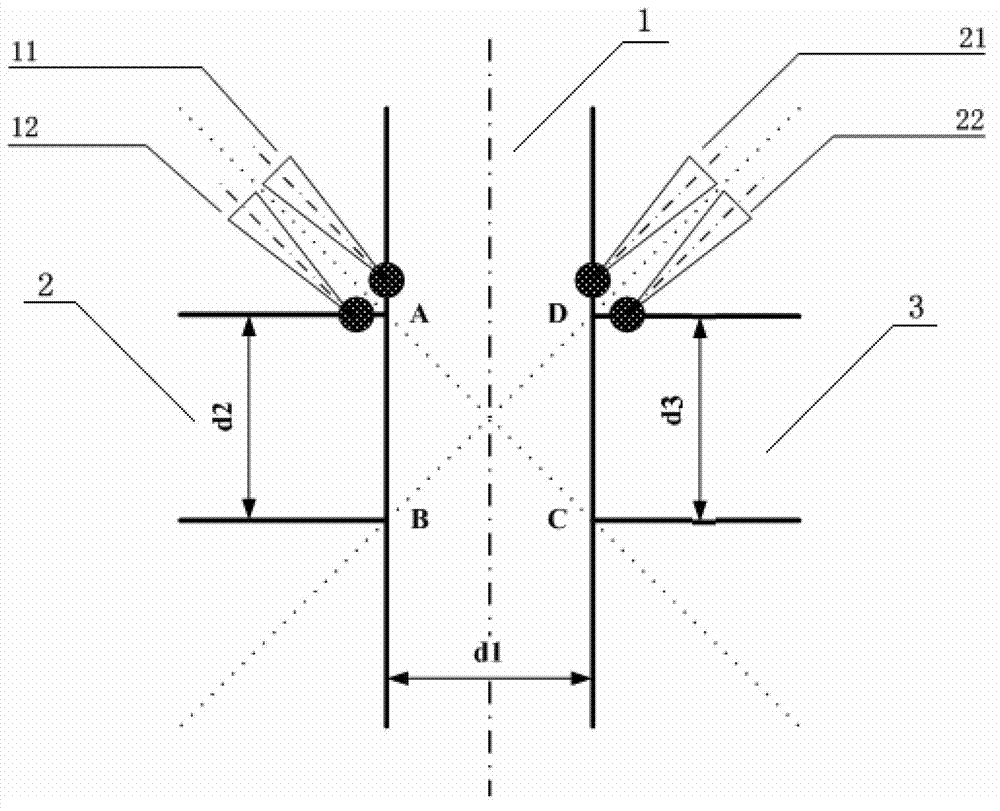

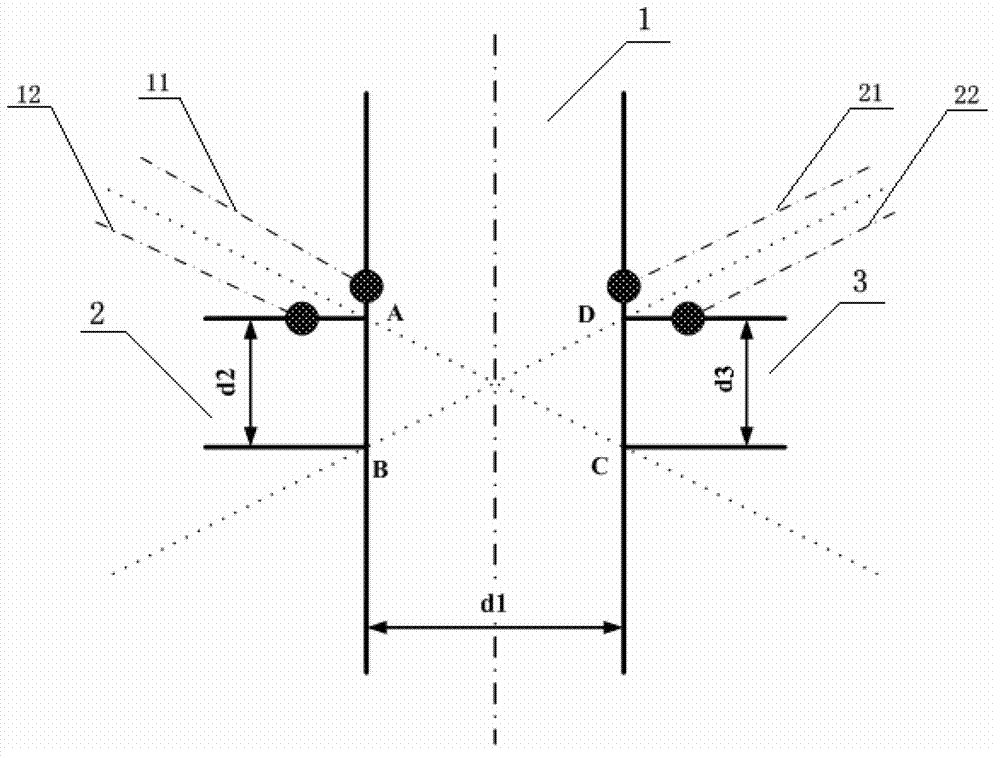

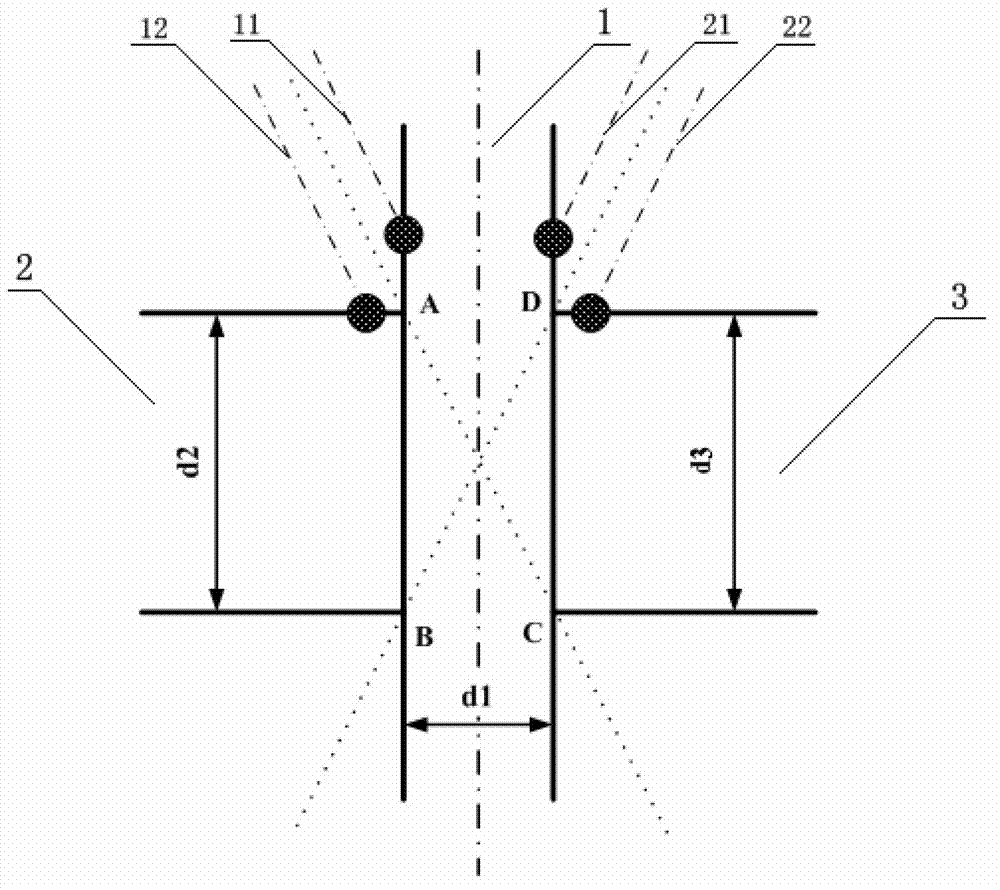

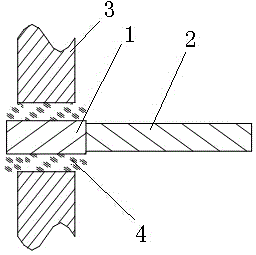

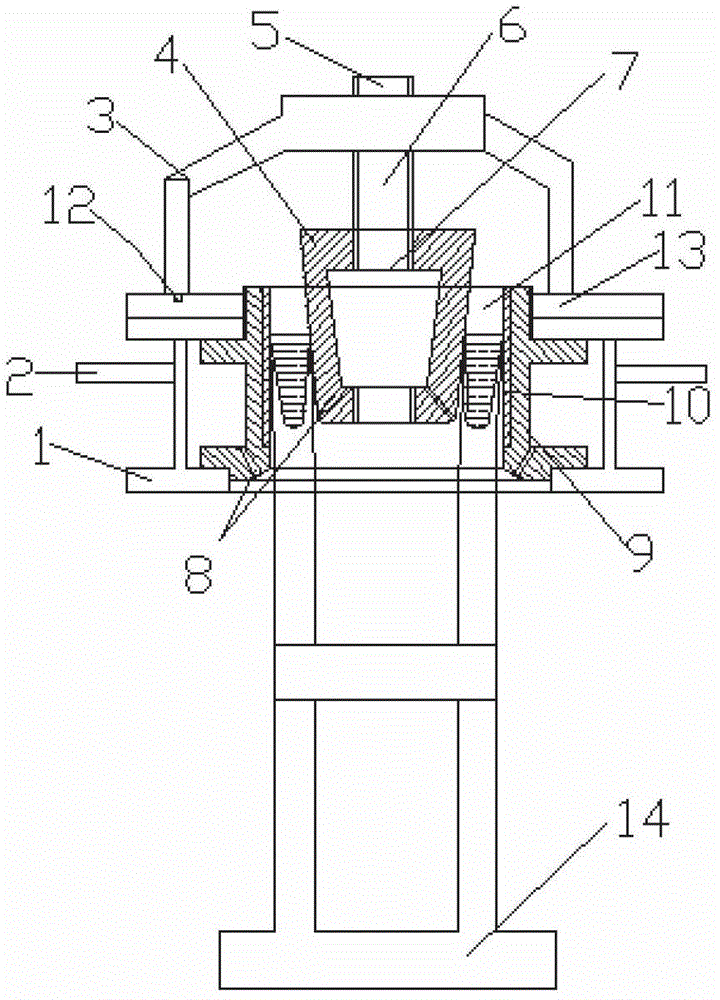

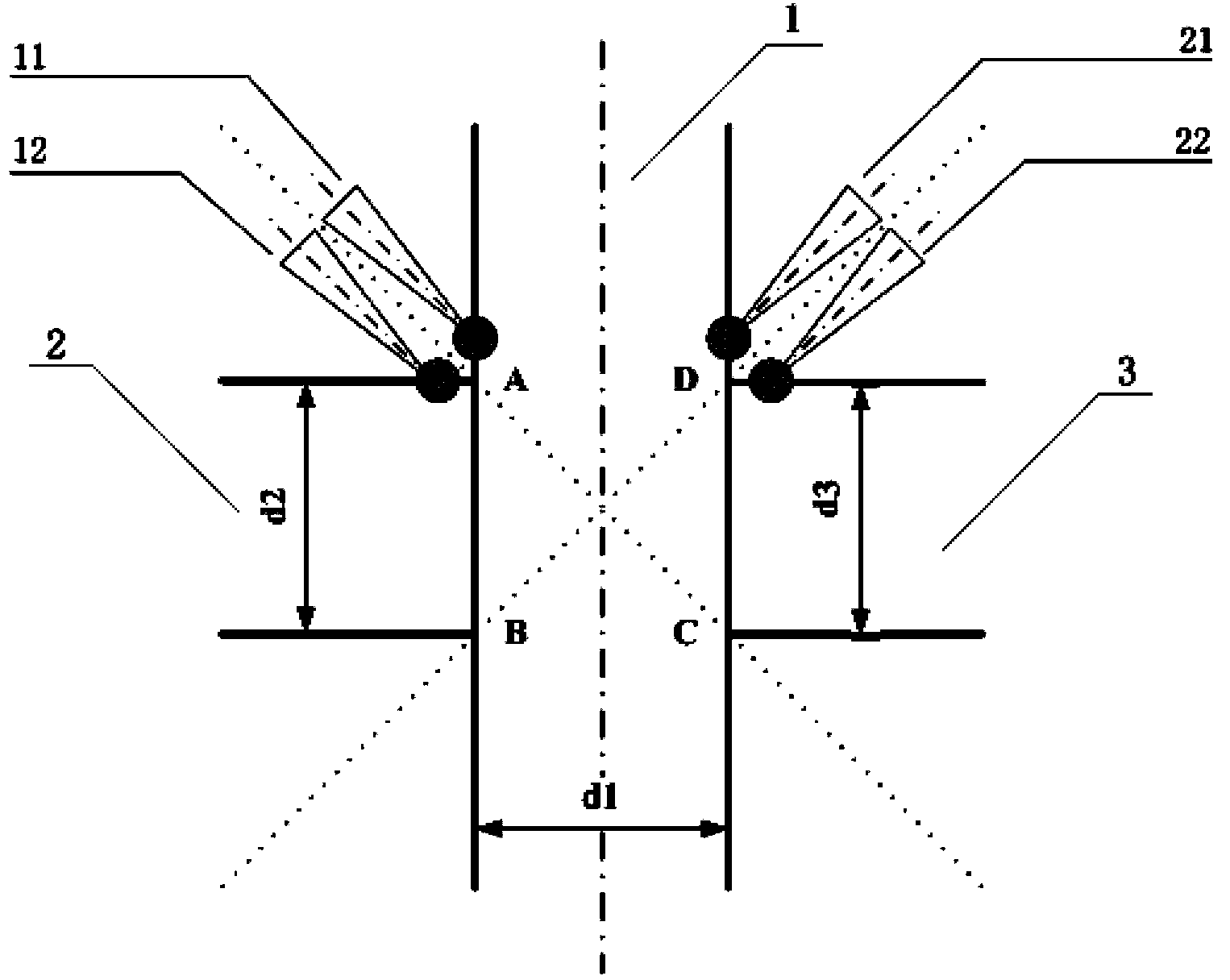

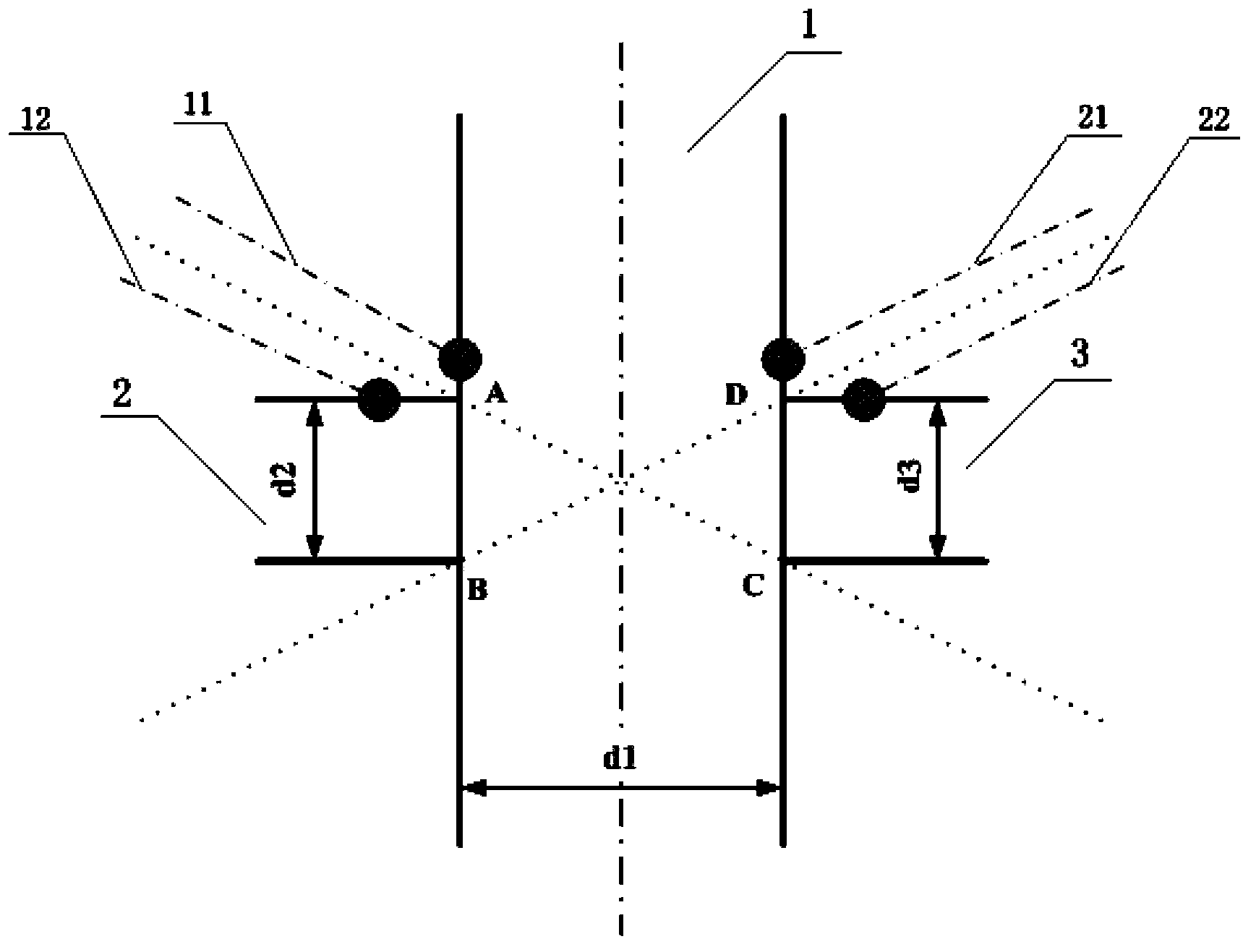

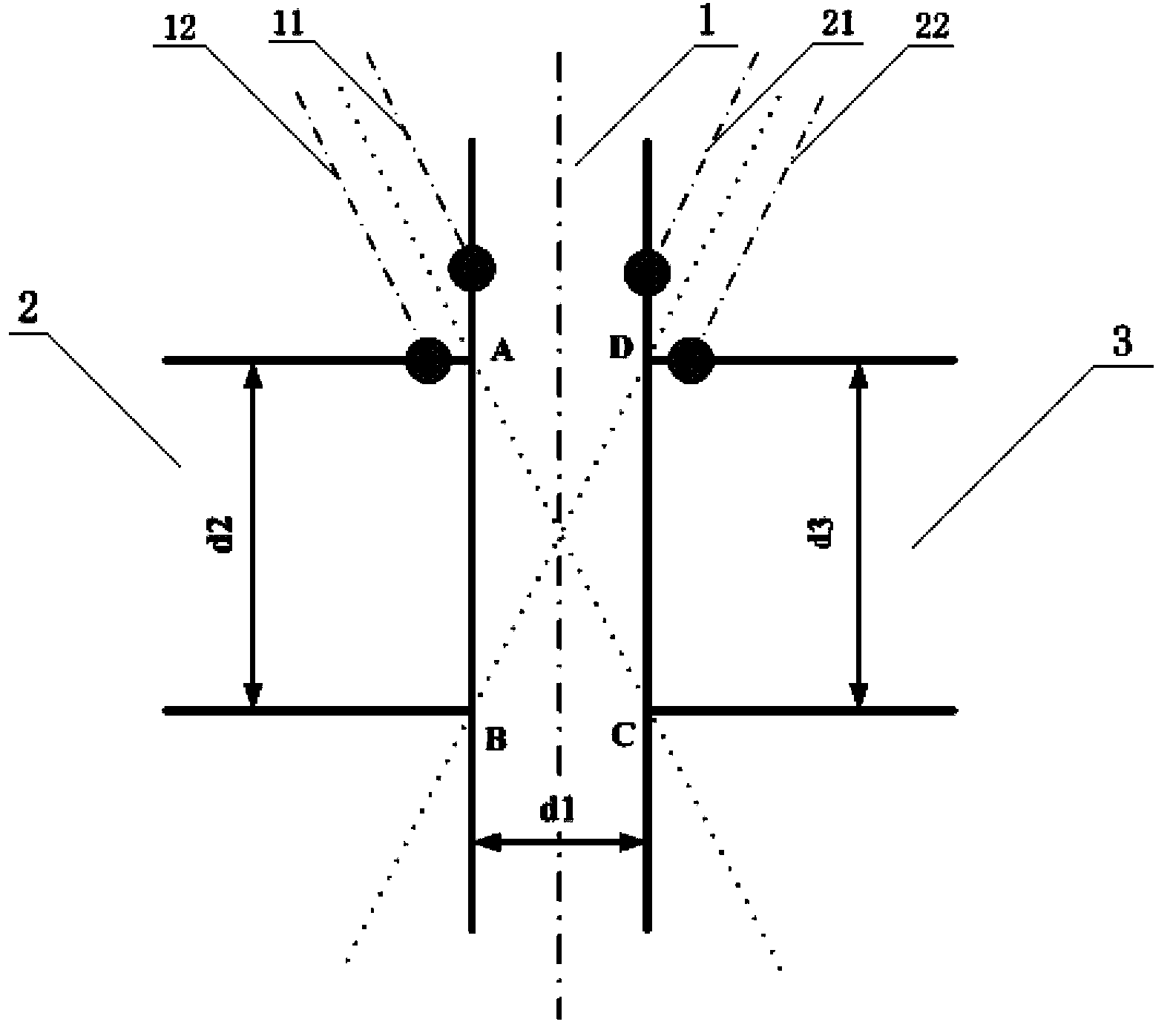

Synchronous dual-light beam laser welding method of crossed joint

ActiveCN102922135AImprove performanceEasy to overflowLaser beam welding apparatusLight beamOptoelectronics

The invention provides a synchronous dual-light beam laser welding method of a crossed joint and relates to a welding method. The invention solves the technical problem of low welding efficiency and poor weld quality existing in the existing single-light beam laser welding method. The welding method comprises the following steps: respectively emitting a main light beam a and a main light beam b by applying two lasers, arranging the two lasers on the two sides of a crossed joint supporting plate in an imaging manner, dividing the main light beam a into a welding light beam 11 and a welding light beam 12, dividing the main light beam b into a welding light beam 21 and a welding light beam 22 and synchronously welding the welding light beam 11, the welding light beam 21 and the welding light beam 12. The synchronous dual-light beam laser welding method has the beneficial effect that aiming at the weld characteristics and the quality requirements of the crossed joint, the problems of uneasiness in stress deformation control, poor weld quality and low welding efficiency existing in the current crossed joint welding process are solved.

Owner:HARBIN INST OF TECH

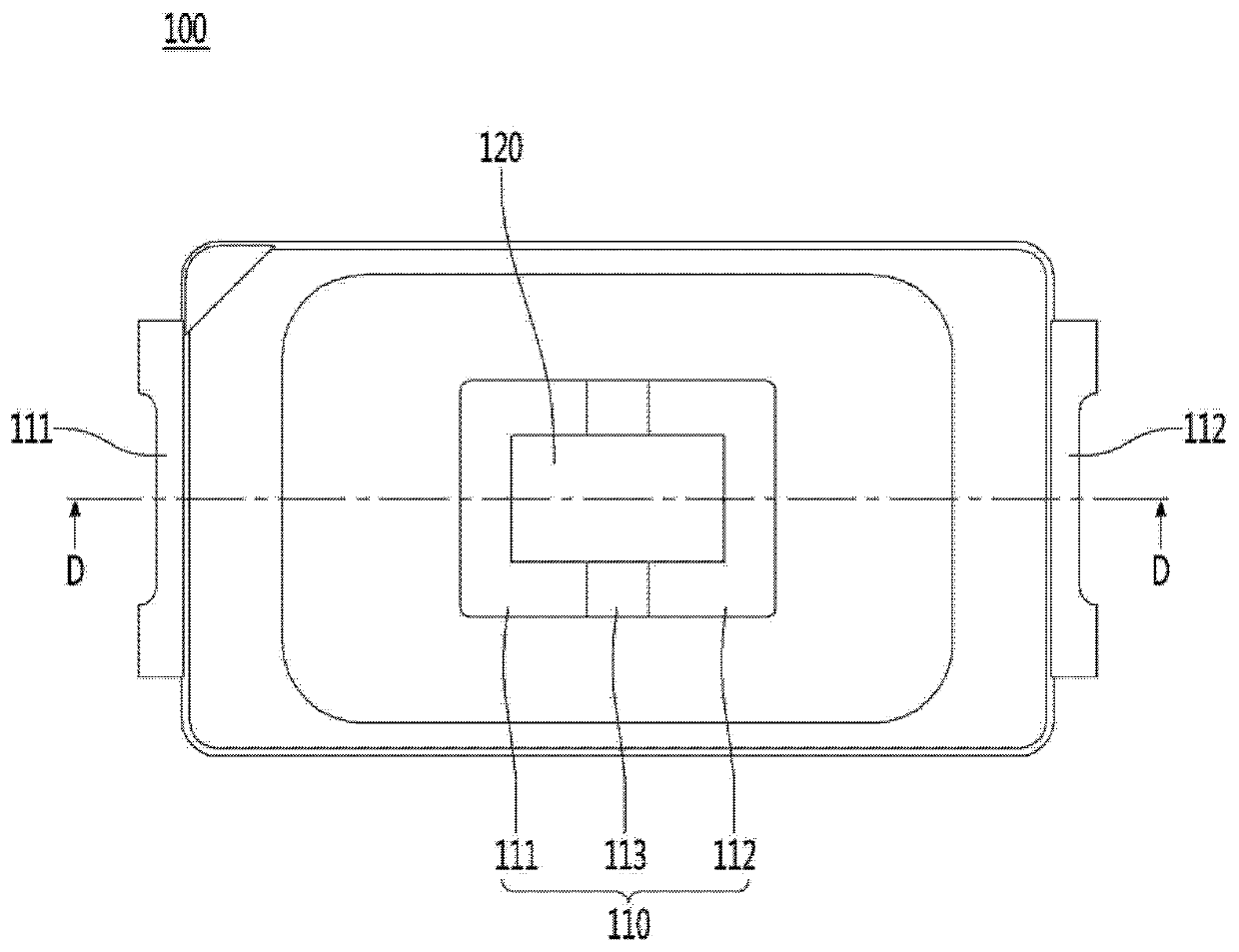

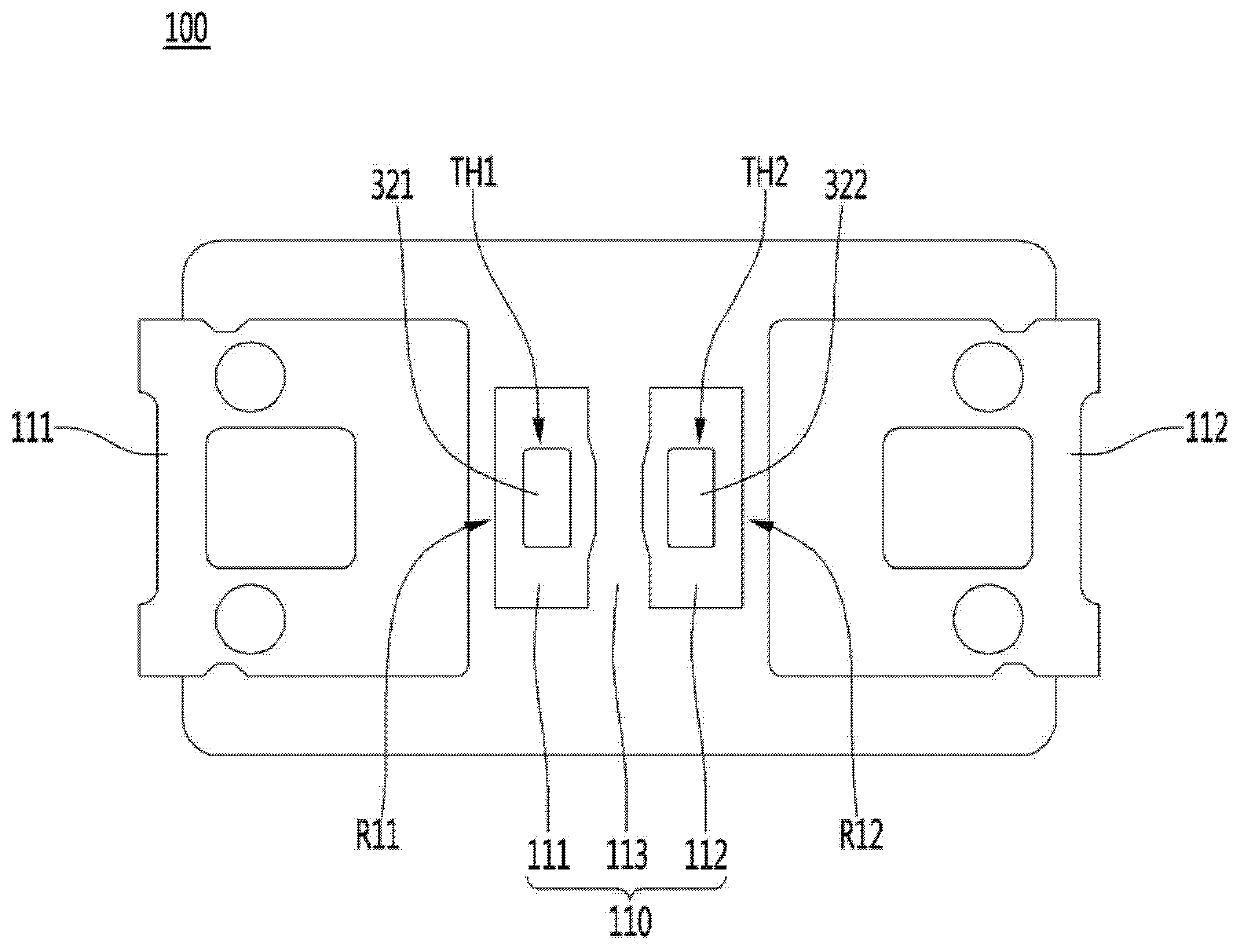

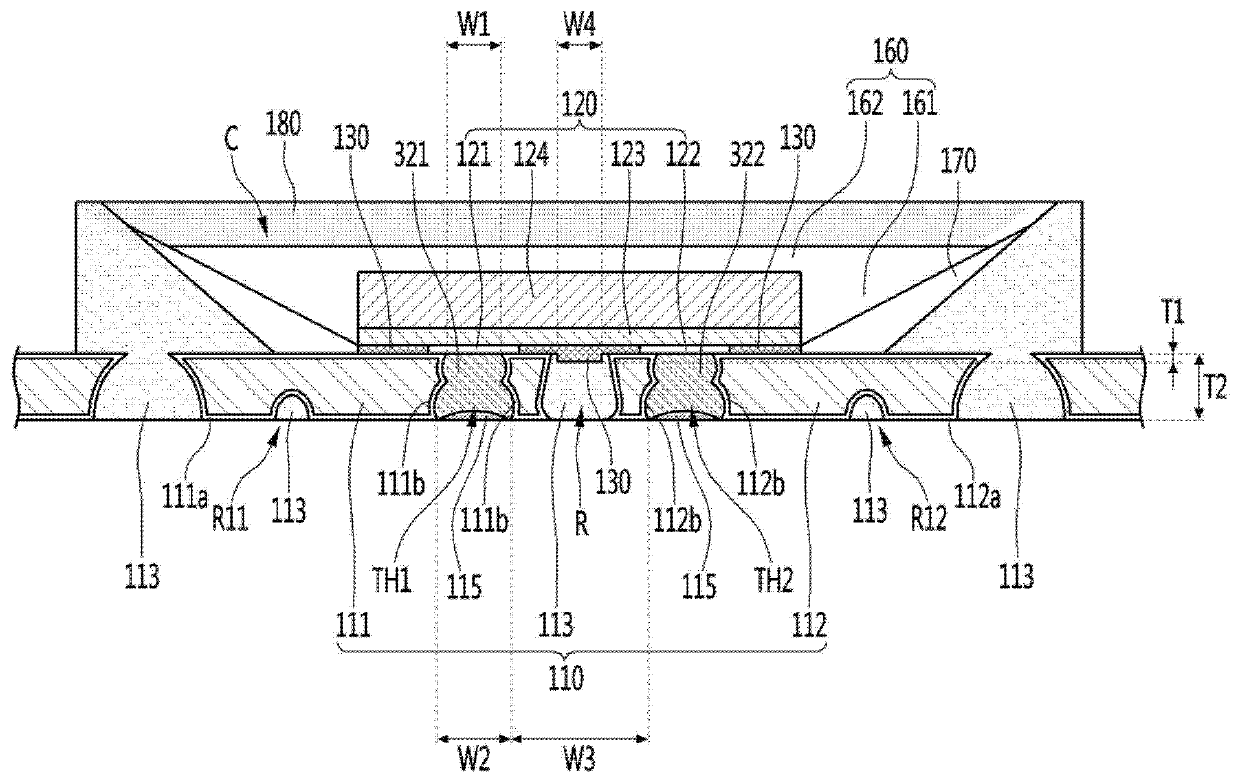

Light emitting device package and lighting apparatus comprising sam

ActiveCN109964323AIncrease brightnessImprove light extraction efficiencySemiconductor devices for light sourcesSemiconductor devicesSemiconductor packageLight emitting device

An embodiment relates to a light emitting device, a method for manufacturing the light emitting device, a light emitting device package, and a lighting apparatus. The light emitting device package, according to an embodiment, can comprise: a package body (110) comprising frames (111, 112) and a body; a light emitting device (120) comprising first and second bonding parts (121, 122) so as to be arranged on the body (13); a reflective resin layer arranged between the light emitting device and the lateral side of a cavity (C) provided in the body; a transparent resin layer on the light emitting device; and a phosphor layer arranged on the transparent resin layer while being spaced from the light emitting device.

Owner:SUZHOU LEKIN SEMICON CO LTD

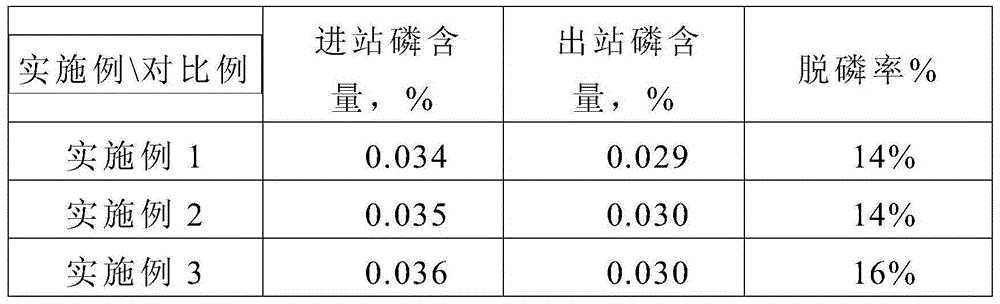

LF furnace shallow dephosphorization refining method

The invention discloses an LF furnace shallow dephosphorization refining method. The method comprises the following steps that firstly, after molten steel enters an LF furnace, a steel ladle bottom blowing pipe and an external oxygen source are connected, bottom oxygen blowing is carried out, and bottom argon blowing is carried out in the whole refining process; secondly, current delivery and slagging are carried out; thirdly, after slag is molten thoroughly, power is cut off, the bottom argon blowing flow is increased to 800-850 NL / min, stirring is carried out, and dephosphorization is carried out; and fourthly, after dephosphorization is finished, lime is added so as to prevent rephosphorization. Dephosphorization is finished in the LF furnace, molten steel furnace returning is avoided, and the steel making production cost is reduced. Converter terminal point slag returning is mainly adopted to finish dephosphorization, secondary utilization of resources is effectively achieved, and good social benefits and economic benefits are achieved. The molten steel dephosphorization task can be finished only by adopting fluorite, ore, fluorite powder and other conventional materials as the auxiliary dephosphorization materials, the medicament input is little, and cost is saved; and the technology process is simple and clear, operability is high, and control is easy.

Owner:武钢集团有限公司

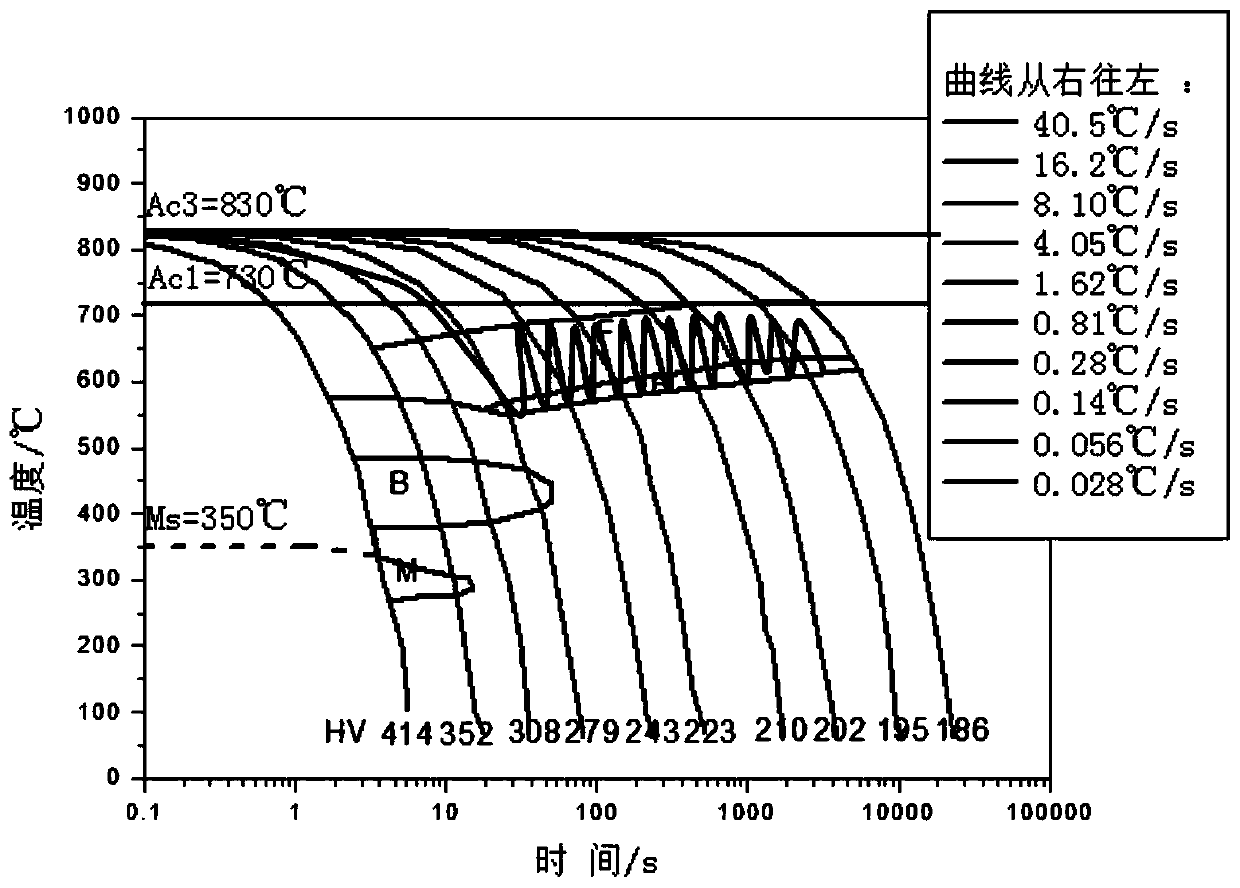

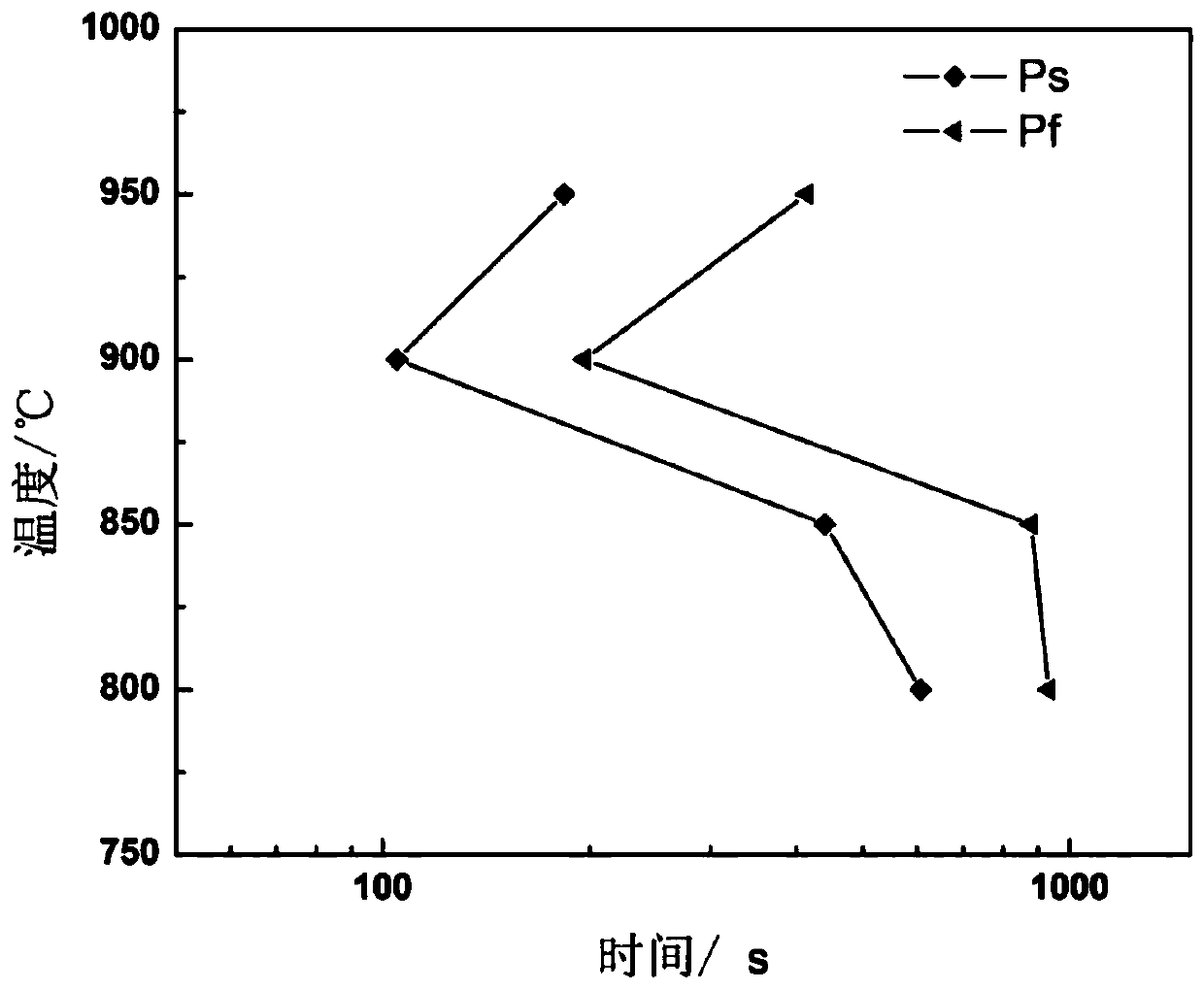

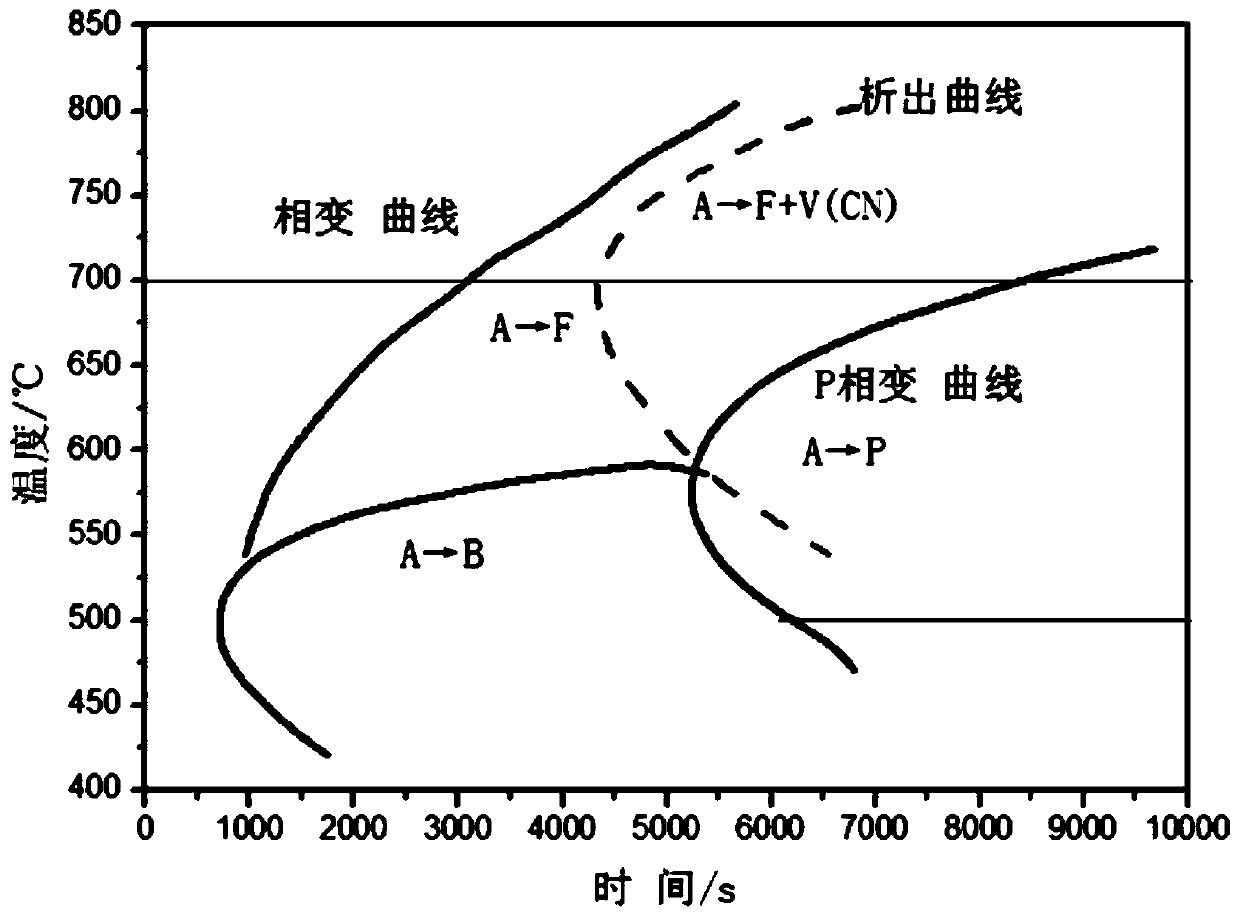

Grading control cooling process of 600Mpa-grade high-strength anti-seismic weather-proof hot-rolled steel bar

ActiveCN111074152AFlexible control of cooling speedIncrease contentTemperature control deviceEngineeringRebar

The invention relates to a grading control cooling process of a 600Mpa-grade high-strength anti-seismic weather-proof hot-rolled steel bar and belongs to the technical field of a new steel process. The control cooling process belongs to a whole-process grading control cooling process and is combined with cooling path control on the basis of the original air cooling, and composite enhancement of cooling among mills, cooling after precision rolling and the whole-process cooling process on a cooling bed is emphasized, so that fine pearlite mass size and small interlamellar spacing are achieved, the precipitation enhancing effect of microalloy elements is improved, and the best composite enhancement effect of the 600Mpa-grade high-strength anti-seismic weather-proof hot-rolled steel bar is achieved.

Owner:CENT IRON & STEEL RES INST

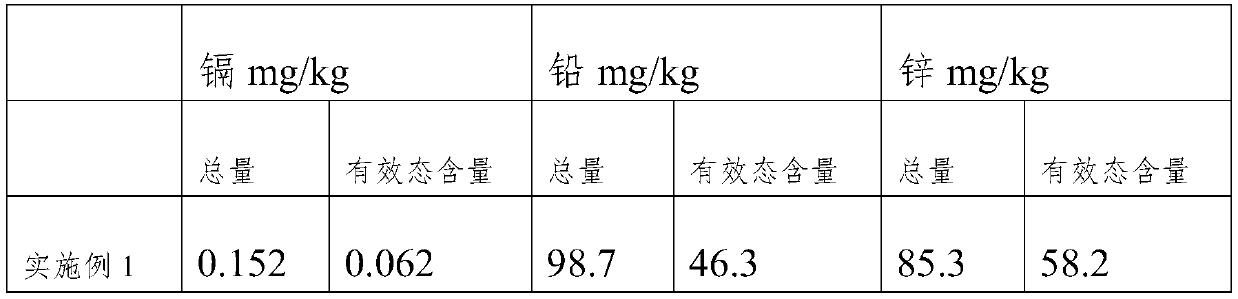

Method for remediation of lead-cadmium polluted soil

ActiveCN110586642AReduce heavy metal contentPrevention and treatment of heavy metalsContaminated soil reclamationHeavy metalsEnvironmental geology

The invention belongs to the technical field of soil remediation, and particularly relates to a method for remediation of lead-cadmium polluted soil. A combined remediation method of adsorption solidification and microbial remediation is adopted to remediate lead-cadmium polluted soil. The method particularly comprises the following steps: spreading an adsorbent and a passivator into the soil before crop seeds are sown, spraying water at the same time, then carrying out deep tillage by 5-8 cm, and standing the soil for 10-15 days; and spreading a compound bacterial preparation into the soil, carrying out shallow tillage by 3-5cm, then spraying a film forming solution into the soil, and standing the soil for 10-15 days. Through adoption of the combined remediation method of adsorption solidification and microbial remediation, heavy metals are firstly adsorbed and solidified under action of the adsorbent and the passivator, and then the adsorbed and solidified heavy metals are digested and converted by microorganisms, so that the content of the heavy metals in the soil is reduced, and the heavy metals are prevented from being dissolved again.

Owner:铜仁市万山区植保植检站

Preparation method for precision-investment casting mold shell of easily-oxidized metals

ActiveCN107159869ASimple configurationHigh strengthFoundry mouldsFoundry coresPrecision castingCoating

The invention provides a precision-investment casting method for easily-oxidized metals. The precision-investment casting method comprises the following steps of (1) preparation of a surface layer of a mold shell, specifically, a refractory powder is added into a binder and evenly mixed, a wetting agent and an antiforming agent are further added, and even mixing is conducted to prepare surface layer coating; and the coating is smeared on a wax patter, and after drying, the above operations are repeated for many times to form a surface layer mold shell; (2) preparation of a reinforcement layer of the mold shell, specifically, a bauxite powder is added into a silica sol binder and evenly mixed, bauxite sand is adopted to conduct stuccoing, and after drying, the above operations are repeated for many times to form a reinforcement layer mold shell; (3) mold shell dewaxing and roasting, specifically, an infrared dewaxing technology is adopted; and (4) melting and pouring, a vacuum consumable kish melting method is adopted to conduct melting, and a centrifugal pouring technology is adopted to conduct pouring. According to the precision-investment casting method for easily-oxidized metals, a casting produced by adopting the method is precise in size, the minimum wall thickness is small than or equal to 1.0 mm, the surface roughness is smaller than or equal to 6.3 mu m, the surface reaction layer is smaller than or equal to 0.03 mm, and the surface is free of the defects of cold shut, flow marks, microcracks and the like; and moreover the production cost is reduced, the production cycle is shortened, and the method is suitable for volume production.

Owner:SHENYANG RES INST OF FOUNDRY

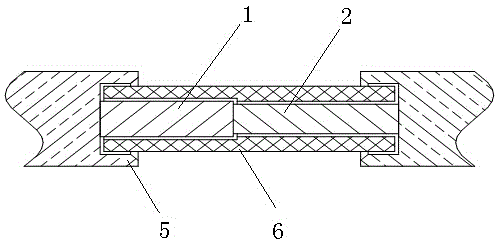

Stacked memory and manufacturing method thereof

InactiveUS20050023668A1Avoid remeltingSimple manufacturing processPrinted circuit assemblingSemiconductor/solid-state device detailsElectrically conductiveEngineering

To mount a TSOP on an interposer substrate, leads provided to the TSOP are joined to pads of the interposer substrate by a thermosetting conductive resin, and the TSOP exclusive of the leads is joined to ground layers formed in the interposer substrate by a thermosetting conductive resin. The interposer substrates with the TSOPs mounted thereon are stacked in eight layers in such a manner that the TSOPs face downward. Then, leads of the upper interposer substrate are joined to pads formed in the rear face of the lower interposer substrate by a thermosetting conductive resin, so that the interposer substrates adjacent in a vertical direction are connected.

Owner:NEC TOSHIBA SPACE SYST

Method for preparing high quality GaInAlN material on silicon substrate

InactiveCN1734799AInhibition formationAvoid remeltingSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumNitrogen

This invention discloses a preparation method for high quality material of indium gallium aluminum nitrogen on silicon substrate. For the method, first, forming a titan transition layer on silicon substrate surface, then forming indium gallium aluminum nitrogen stack with at least one low-temperature buffer layer of aluminum nitride that grows directly on titan transition layer. This invention can prevent the harm to metal back of silicon nitride and gallium metal and grow material of high quality.

Owner:LATTICE POWER (JIANGXI) CORP

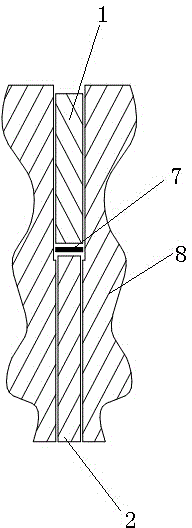

Butt-joint low-resistance lead for electronic packaging and manufacturing method thereof

InactiveCN104439784ANot easy to deform by annealingNo crackingWelding/cutting auxillary devicesSolid-state devicesMetallic materialsElectric resistance welding

The invention provides a butt-joint low-resistance lead for electronic packaging and a manufacturing method of the butt-joint low-resistance lead for electronic packaging. The butt-joint low-resistance lead comprises a feed-through lead segment, wherein one end of the feed-through lead segment is in butt joint with a low-resistance lead segment, and the length of the feed-through lead segment is matched with the length of packaged glass; the low-resistance lead segment is made of metal materials with the electric resistivity smaller than that of the materials of the feed-through lead segment, and the electric resistivity of the metal materials is smaller than or equal to 2 microhm*cm. According to the butt-joint low-resistance lead for electronic packaging, the feed-through lead segment and the low-resistant lead segment are welded into a whole through electric resistance welding and a brazing method. The manufactured butt-joint low-resistance lead for electronic packaging is high in butt-joint strength, small in resistance and suitable for making high current pass; the butt-joint low-resistance lead for electronic packaging is resistant to high temperature and not prone to annealing deformation at the high temperature of 950 DEG C. Thus, the requirements of a power electronic device shell for high lead current carrying of the lead and high lead arrangement density are both met.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Remediation agent for cadmium and arsenic polluted soil

ActiveCN110669524AImprove adsorption capacityPrevent remeltingAgriculture tools and machinesContaminated soil reclamationMolten stateArsenic pollution

The invention belongs to the technical field of soil remediation agents, and particularly relates to a cadmium-arsenic polluted soil remediation agent which is prepared by taking manganese ore slag and goethite slag for mixing and then crushing to pass through a 200-mesh sieve to obtain mixed powder; calcining the mixed powder to a molten state, adding a surfactant with the mount of 15-20% of themixed powder for heat preservation treatment for 20-30 min, cooling to normal temperature, and performing flash explosion treatment and passivation treatment to obtain the product. The cadmium-arsenicpolluted soil remediation agent can effectively repair cadmium-arsenic polluted soil, has the function of inhibiting harmful microorganisms, and also has the function of preventing heavy metal from dissolving back. The goethite and manganese ore slag are used as curing agents for cadmium and arsenic, so that ion mobility and back dissolution are reduced, and the curing effect is improved; by adding the surfactant in the molten state, the specific surface area is increased, and the adsorption capacity for the cadmium and arsenic in the soil is improved, so that the cadmium and arsenic in the soil can enter crystal lattices.

Owner:铜仁市万山区植保植检站

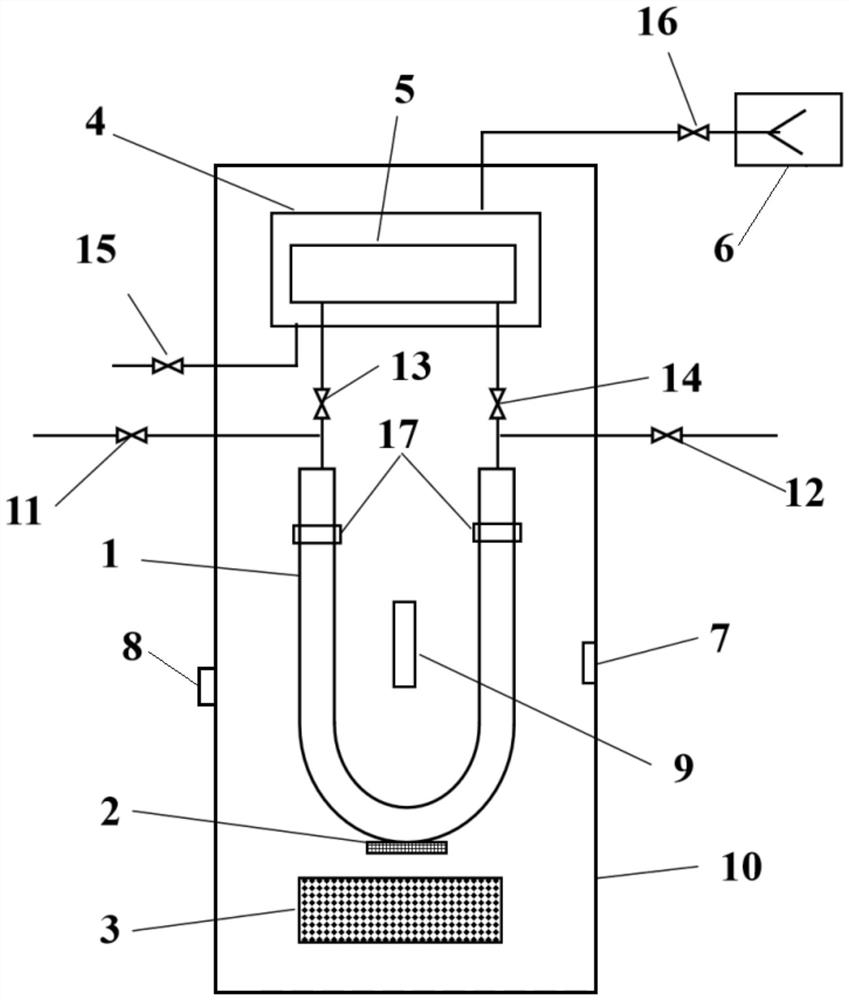

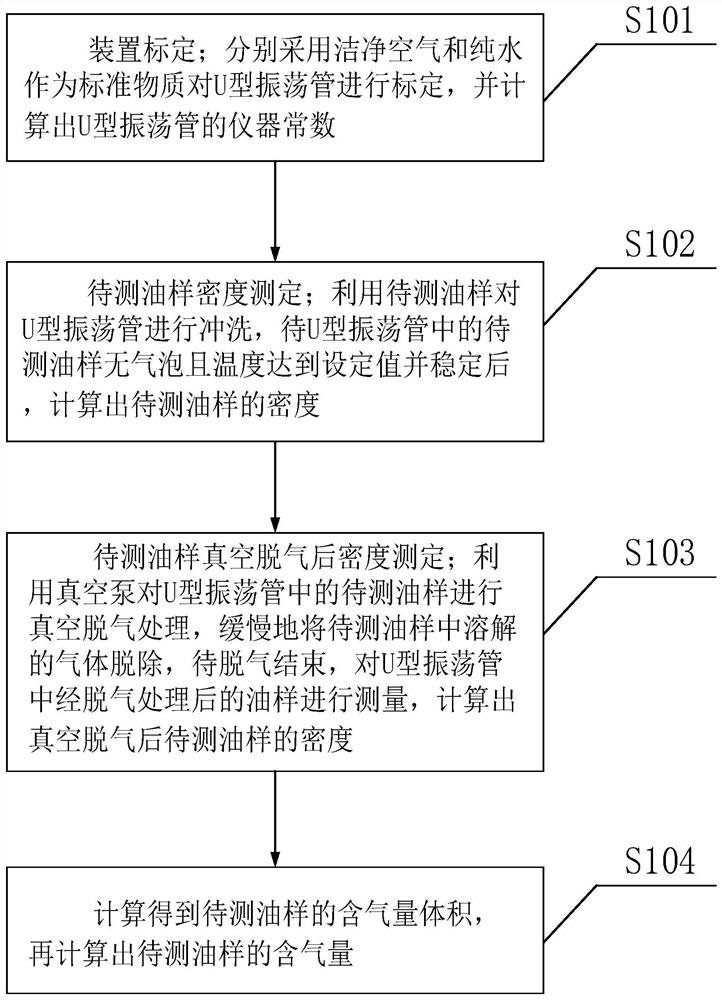

Transformer oil gas content testing device and a transformer oil gas content testing method and device for measuring density through U-shaped oscillation tube

PendingCN113092310AAccurate measurementHigh measurement accuracySpecific gravity measurementThermodynamicsElectric power system

The invention discloses a transformer oil gas content testing device and a transformer oil gas content testing method for measuring density through a U-shaped oscillation tube, belongs to the technical field of electric power system detection, and solves the problem of how to calculate the gas content in oil according to the change of the density of a tested oil sample before and after vacuum degassing so as to improve the testing precision. According to the device, the U-shaped oscillation tube is used for measuring the density of the oil sample, the measuring precision is very high, the requirement for accurate measurement of the density change of the oil sample before and after degassing can be met, and the gas content in the oil is calculated according to the density change of the oil sample before and after vacuum degassing of the measured oil sample for the first time. The method is a test method with a brand new test principle, is simple to operate, facilitates field test and can adapt to measurement of oil samples with different gas contents.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

Preparation method of electrode bar for PREP

A preparation method of an electrode bar for PREP comprises steps as follows: collected waste powder is loaded into a cylindrical sheath, vibrating compacting is performed in the powder loading process, the frequency ranges from 15 Hz to 60 Hz, and the vibration amplitude ranges from 0.1 mu m to 1.0 mu m. The size of the cylindrical sheath is required to meet the requirement of the electrode bar, and then degassing and sheath sealing welding are performed on special vacuum equipment; and the cylindrical sheath is subjected to hot isostatic pressing. Then the prepared electrode bar is subjected to machining and subsequent plasma atomization, collected powder is screened, and the waste powder is collected in a separate container and is loaded into the sheath for preparation of the powder after a certain amount of the waste powder is collected. With the method, the powder with the unqualified particle size can be completely recycled, and the yield is increased.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

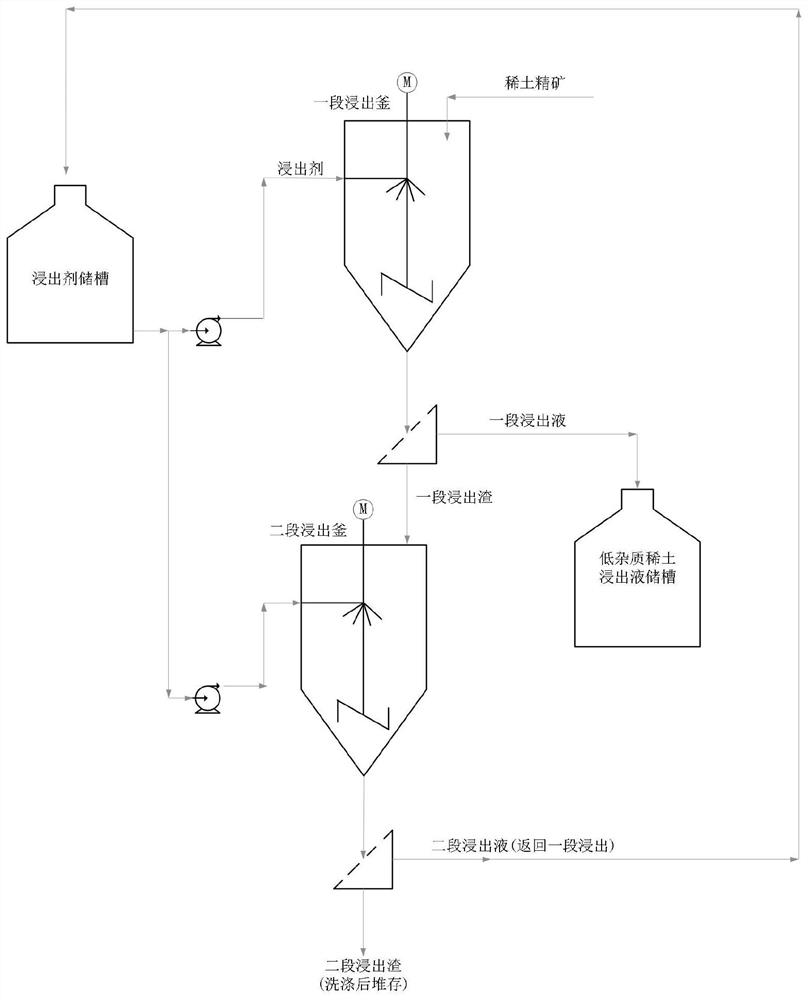

Leaching-purifying method for rare earth concentrate

ActiveCN113699389AIncreased solubility selectivityImprove separation characteristicsProcess efficiency improvementPregnant leach solutionNonferrous metal

The invention relates to a leaching-purifying method for rare earth concentrate, and belongs to the field of non-ferrous metallurgy. According to the method, a leaching process is adjusted, and a two-stage reverse feeding countercurrent process is adopted, namely, in first-stage leaching, rare earth concentrate slurry is used as a base solution, and a leaching agent is added into the base solution, so that low-impurity rare earth leaching liquid is obtained; in second-stage leaching, first-stage leaching residues serve as raw materials, after a certain number of seed crystals are added, a leaching agent hydrochloric acid is added into the first-stage leaching residues, so that the leaching residues low in rare earth content and an acid leaching solution high in impurity content are obtained, and the acid leaching solution is returned to the first-stage leaching for use; and by means of the leaching process, separation of impurities can be achieved, and rare earth resources can be fully utilized. The method has the advantages of being simple in process, low in cost, high in impurity removal rate, high in rare earth recovery rate and the like, and has good industrial application prospects.

Owner:JIANGXI UNIV OF SCI & TECH

Casting method of electric furnace water cooling cast steel furnace cover

InactiveCN101634524AGuaranteed micro-fusionImprove mechanical propertiesFurnace componentsProcess efficiency improvementAlloyMolten steel

The invention relates to a casting method of electric furnace water cooling cast steel furnace cover, which adopts a cast steel material to cast a base body and a cooling water pipe. The casting method comprises the following steps: adding a slagging agent and a silicon iron alloy block in molten steel for casting steel; putting the cooling water pipe into a casting model and leading a liquid cold medium and a composite solid cooling medium to pass through the cooling water pipe; using molten steel for casting steel to cast the base body, casting the middle part of the cooling water pipe into the base body and leading the two ends thereof to extend from the base body; leading the casting model to be horizontal when in modeling, leading a feeder head to be modeled lopsidedly toward one side and heightening one side of the feeder head of the model after the model is boxed; adopting an upper layer of inner sprue and a lower layer of lower sprue to carry out stepped casting so as to form sequential solidification; and cooling and disassembling the model. The casting method can effectively avoid the cooling water pipe from being penetrated in a fusing manner during the casting process, avoids air gaps from being generated between the base body and the cooling water pipe, avoids refusion and recrystallization, accurately realizes the microfusion of the outer surface of the cooling water pipe, prolongs the service life of the electric furnace water cooling cast steel furnace cover, further prolongs the service life of a metallurgical high-temperature kiln, saves production cost and improves the mechanical performance of the electric furnace water cooling cast steel furnace cover.

Owner:江苏联兴成套设备制造有限公司

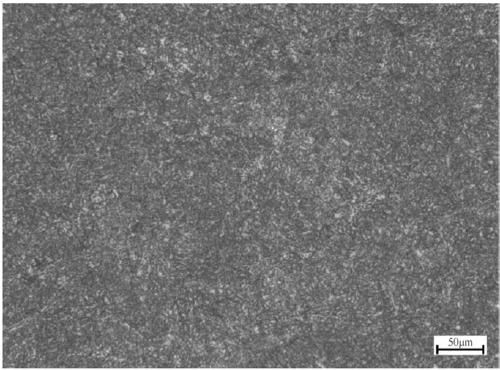

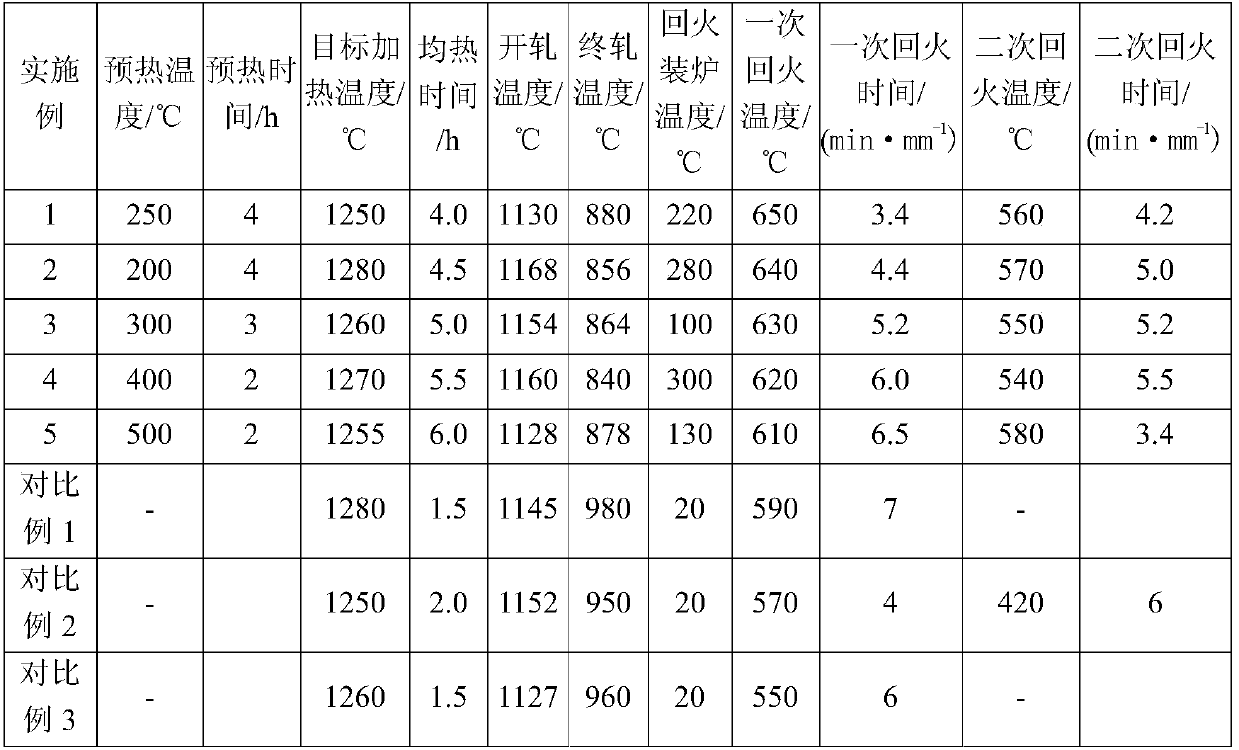

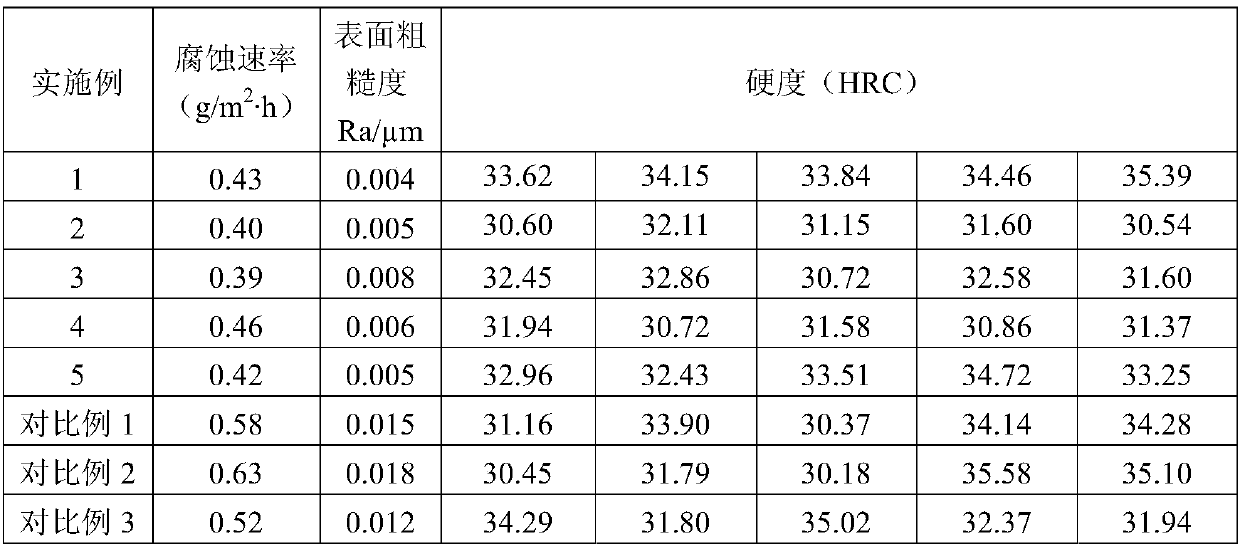

High mirror corrosion resistant plastic die steel and manufacturing method thereof

The invention discloses high mirror corrosion resistant plastic mold steel and a manufacturing method. The steel contains 0.32-0.46% of C, 0.4-1.2% of Si, 0.4-0.8% of Mn, P which is less than or equalto 0.020%, S which is less than or equal to 0.040%, 10.8-12.8% of Cr, 0.3-1.2% of Cu, 0.5-1.0% of Ni, 0.15-0.25% of Nb, and 0.01-0.03% of N, with the balance being Fe and inevitable impurities. A steel billet can be heated after being charged and preheated at 200-500 DEG C, the preheating time is greater than or equal to 2h, a heating temperature is 1,250-1,280 DEG C, the soaking time is 4-6 h, an initial rolling temperature is greater than or equal to 1,100 DEG C, and a finish rolling temperature is 840-880 DEG C; air cooling can be performed to 100-300 DEG C after rolling; the temperature of primary tempering is 610-650 DEG C, and the heat preservation time is 3.4-6.5 min / mm; the temperature of secondary tempering is 540-580 DEG C, and the heat preservation time is 3.4-5.5 min / mm. The produced die steel has excellent corrosion resistance and surface properties.

Owner:ANGANG STEEL CO LTD

Method for enriching and opening ways for impurities in zinc hydrometallurgy lixivium by means of zinc powder purification slag

ActiveCN109371244AReduce contentEasy to recycleProcess efficiency improvementPregnant leach solutionSlag

The invention relates to a method for enriching and opening ways for impurities in zinc hydrometallurgy lixivium by means of zinc powder purification slag. According to the method, after the zinc powder purification slag and water are stirred and pulpified, slurry is heated to 40-65 DEG C; and then zinc hydrometallurgy lixivium with the temperature being 40-65 DEG C is slowly added into the slurry, heat preservation reaction is performed, liquid-solid separation is performed after the reaction is completed, filtrate is purified lixivium, and filter residue is impurity metal enriched slag. By means of the method, copper, germanium, cobalt, nickel and cadmium are replaced into solid elementary substances which are enriched into slag phases, meanwhile, zinc in the zinc powder purification slag is dissolved into a solution as much as possible, thus, the main impurity elements including the copper, germanium, cobalt, nickel and cadmium in the lixivium are removed and enriched, and the zincin the zinc powder purification slag is efficiently utilized. The method has the advantages that the technology is simple, the cost is low, and the valuable metal utilization rate is high and has thegood industrialization application prospects.

Owner:JIANGXI UNIV OF SCI & TECH

Casting method of cast steel rotary furnace flue

ActiveCN101634521AGuaranteed micro-fusionImprove cooling effectFurnace cooling arrangementsProcess efficiency improvementAlloyMolten steel

The invention relates to a casting method of a cast steel rotary furnace flue, which adopts a cast steel to cast a base body and a cooling water pipe. The casting method comprises the following steps: adding a slagging agent and a silicon iron alloy block in molten steel for casting steel; putting the cooling water pipe into a casting model and leading a liquid cold medium and a composite solid cooling medium to pass through the cooling water pipe; using molten steel for casting steel to cast the base body; leading the casting model to be horizontal in the modeling process, leading a feeder head to be modeled lopsidedly toward one side and heightening one side of the feeder head of the model after the model is boxed; adopting an upper layer of inner sprue and a lower layer of lower sprue to carry out stepped casting so as to form sequential solidification; and cooling and disassembling the model. The casting method can effectively avoid the cooling water pipe from being penetrated in a fusing manner during the casting process, avoids air gaps from being generated between the base body and the cooling water pipe, avoids refusion and recrystallization, accurately realizes the microfusion of the outer surface of the cooling water pipe, prolongs the service life of the rotary furnace flue, further prolongs the service life of a metallurgical high-temperature kiln, saves production cost and improves the mechanical performance of the cast steel rotary furnace flue.

Owner:江苏联兴成套设备制造有限公司

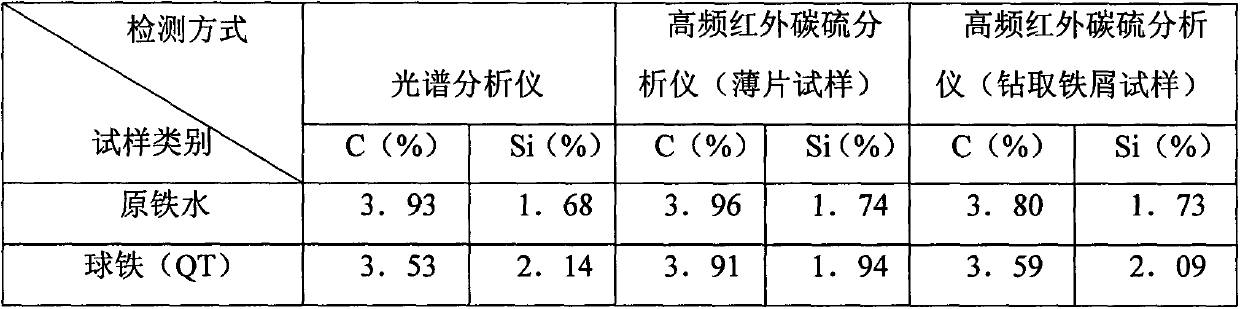

Method for controlling carbon equivalent of base iron and application of method

The invention relates to a method for controlling the carbon equivalent of base iron and an application of the method. According to the method for controlling the carbon equivalent of base iron and the application of the method, the influence of C and Si elements is mainly taken into consideration for calculation of the carbon equivalent and the influence of microelements on the carbon equivalent is ignored; a molten iron treating agent is quantitatively added to enable the Si content change delta Si before and after molten iron treatment to be a constant value, so the theoretical carbon equivalent CE2, namely (CE-delta Si / 3), of the base iron can be calculated according to the theoretical carbon equivalent value CE of the cast iron; the detection value CE1 of the carbon equivalent of the base iron is controlled to be near the theoretical carbon equivalent CE2, so the carbon equivalent of the base iron can be adjusted to an eutectic point quickly and effectively, the qualified rate of the nodulized molten iron is increased, return of nodular iron is avoided, and the production cost is effectively reduced.

Owner:TIANRUN IND TECH CO LTD

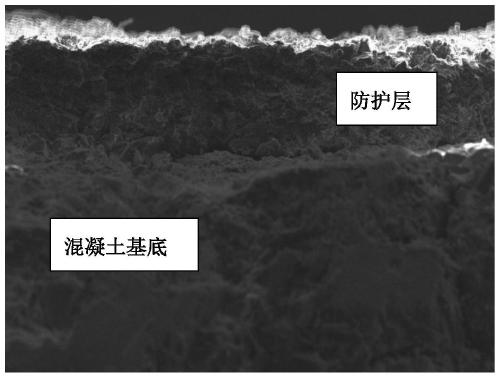

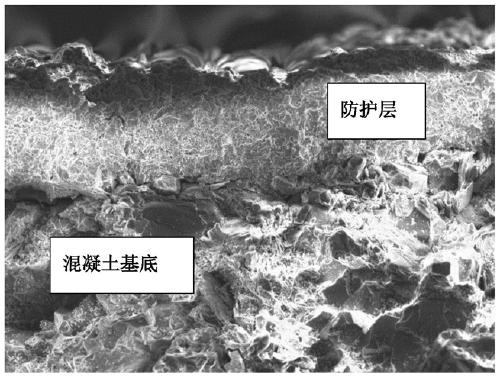

Concrete surface protection treatment method based on plasma hot-spraying technology

ActiveCN111575630AImprove frost resistanceImprove impermeability and durabilityMolten spray coatingWeather resistanceInorganic materials

The invention provides a concrete surface protection treatment method based on a plasma hot-spraying technology. According to the treatment method, firstly, high-pressure air at the temperature of 80DEG C to 100 DEG C is utilized to dry the surface of concrete; next, the high-pressure air is utilized to wrap and carry particles to roughen the surface of the concrete; then, high-pressure air at the temperature of 100 DEG C to 150 DEG C is utilized to flush and preheat the surface of the concrete; and finally, by the aid of plasma hot-spray equipment, a powdery inorganic non-metallic raw material with the particle size of 20 microns to 120 microns is used for hot-spraying an inorganic material protection layer on the surface of the concrete by adjusting the powder feeding rate, plasma power, the airflow rate, the moving velocity, the spraying distance and other parameters. Through the treatment method, the anti-freezing and anti-permeating abilities of the concrete are improved, the defects of poor weather fastness and short service life in traditional organic material protection coating brushing are overcome, and the method can be widely applied to surface protection on concrete prefabricated parts and cast-in-place concrete structures.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

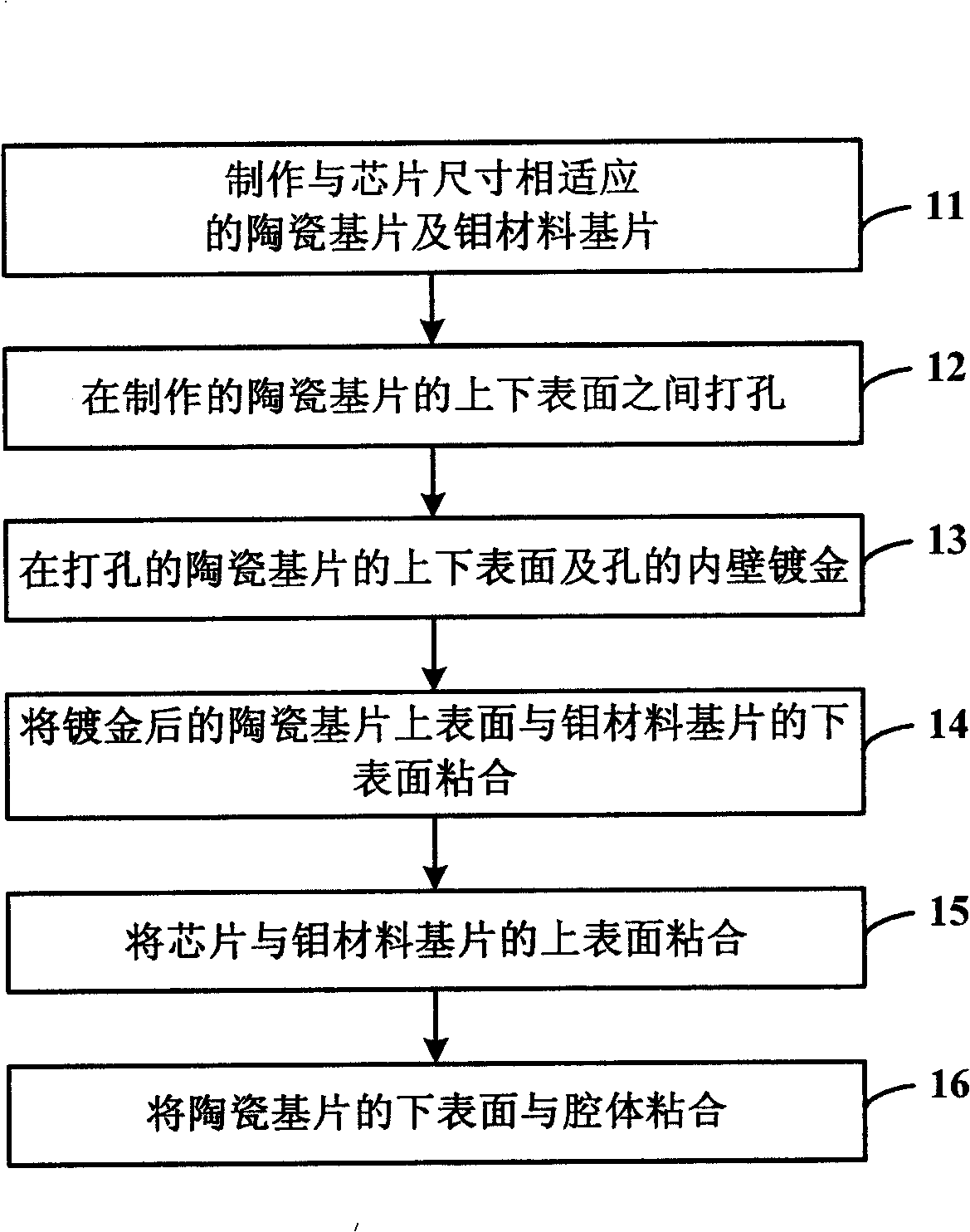

A making method for thermal sediment of GaAs single-chip microwave integration circuit power amplifier

InactiveCN100449717CAvoid breakingImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesMicrowaveChip size

The utility model discloses a manufacture method of heat sink of the GaAs MMIC power amplifier, comprising: A, a ceramic substrate surface and a substrate surface made of molybdenum matched with the size of a chip are made; B, holes are punched between an upper surface and a lower surface of the ceramic substrate surface; C, gold is plated on the upper surface and the lower surface of the punched ceramic substrate surface and the inner wall of the holes; D, the upper surface of the plated ceramic substrate surface is bonded with the lower surface of the substrate surface made of molybdenum; E, the chip is bonded with the upper surface of the substrate surface made of molybdenum; F, the lower surface of the substrate surface made of molybdenum is bonded a cavity, then the manufacture of the heat sink is completed. With the ceramic substrate surface and the substrate surface made of molybdenum, the utility model can avoid the fracture easily caused by bonding the chip to the ceramic substrate surface directly due to the different thermal expansion property of the two materials, solving the problems of the chip single-valve overburning caused by the bad heat conductivity of the GaAs chip and the heat dissipating not timely, so as to solve the adherence fracture of the GaAs chip and enhance the reliability of the chip.

Owner:SHENYANG ZHONGKE MICROELECTRONICS

Electric connection and method for building electric connection

InactiveCN102630130ASimplified brazed connectionsAvoid spreadingPrinted circuit assemblingElectrical connection printed elementsComputer moduleSoldering

The invention refers to electric connection and a method for building the electric connection. The electric connection is established between an in-line package member which has at least one connection pin inserting into a circuit board penetrating sleeve on a circuit board and a soft cloth line path. Conductive connecting points are provided among the at least one connection pin of the in-line package member, the soft cloth line path and the penetrating sleeve. The electric connection enables a transmission control unit (TCU) with a plurality of connecting pins or connecting pins of any electric module to continuously touch with the soft cloth line path and to realize the electric connection between the connecting pins of the TCU and the penetrating sleeve in the electric board. The soft cloth line path is formed by printed wiring membranes which have a plurality of printed lines basically parallel with each other, uniformly extending at intervals and arranged among covering membranes. Accordingly each connecting pin only needs another one soldering joint which can meanwhile be established on a soldering side of the circuit board by any number and using a same soldering method, i.e., a selected soldering method.

Owner:ROBERT BOSCH GMBH

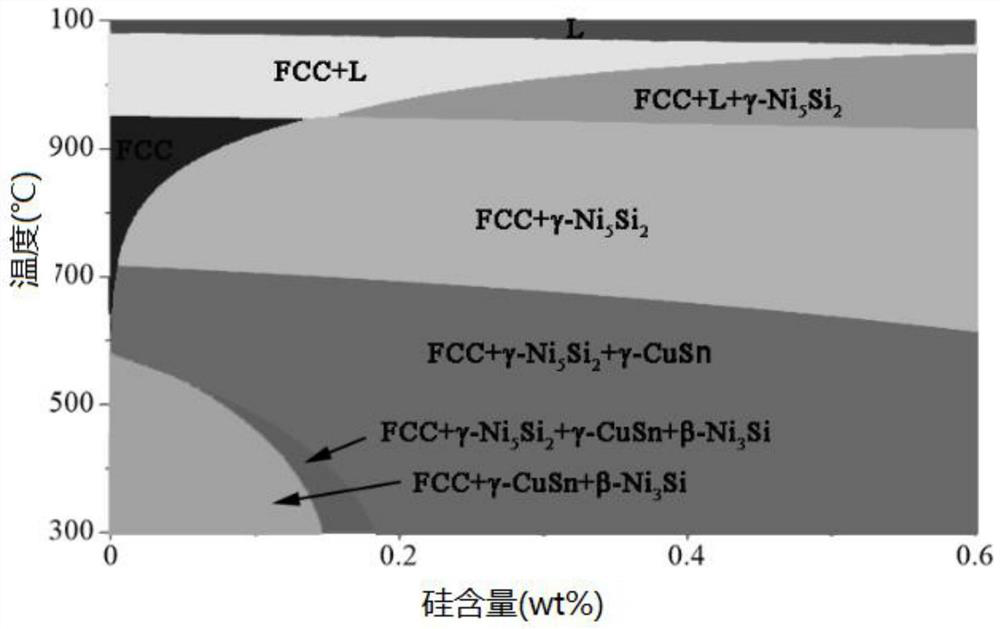

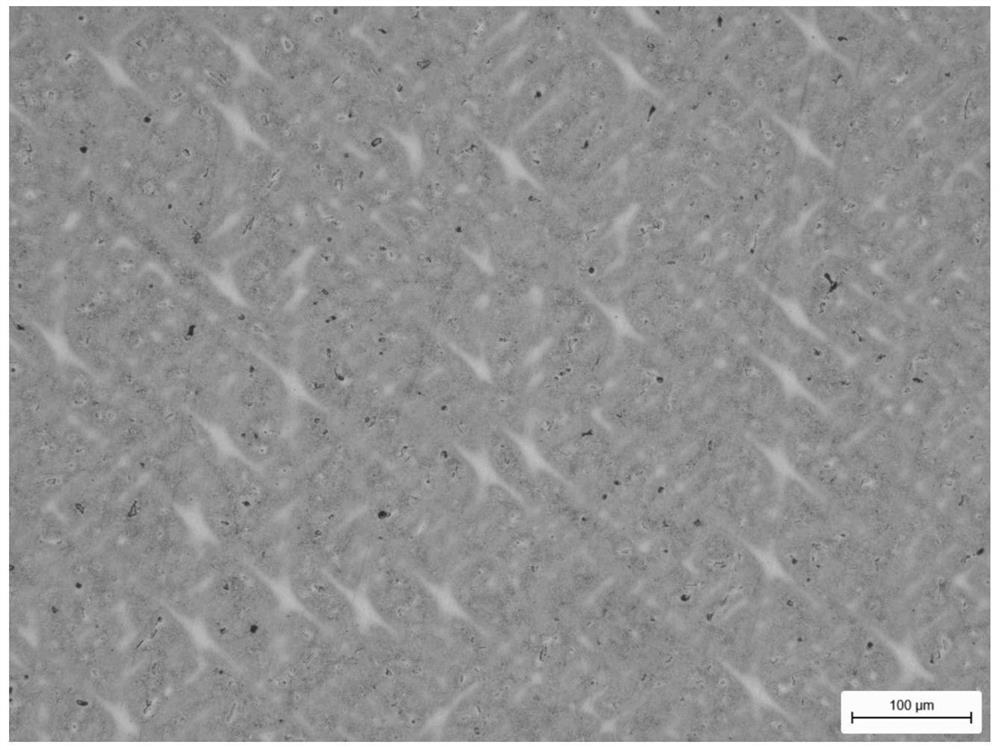

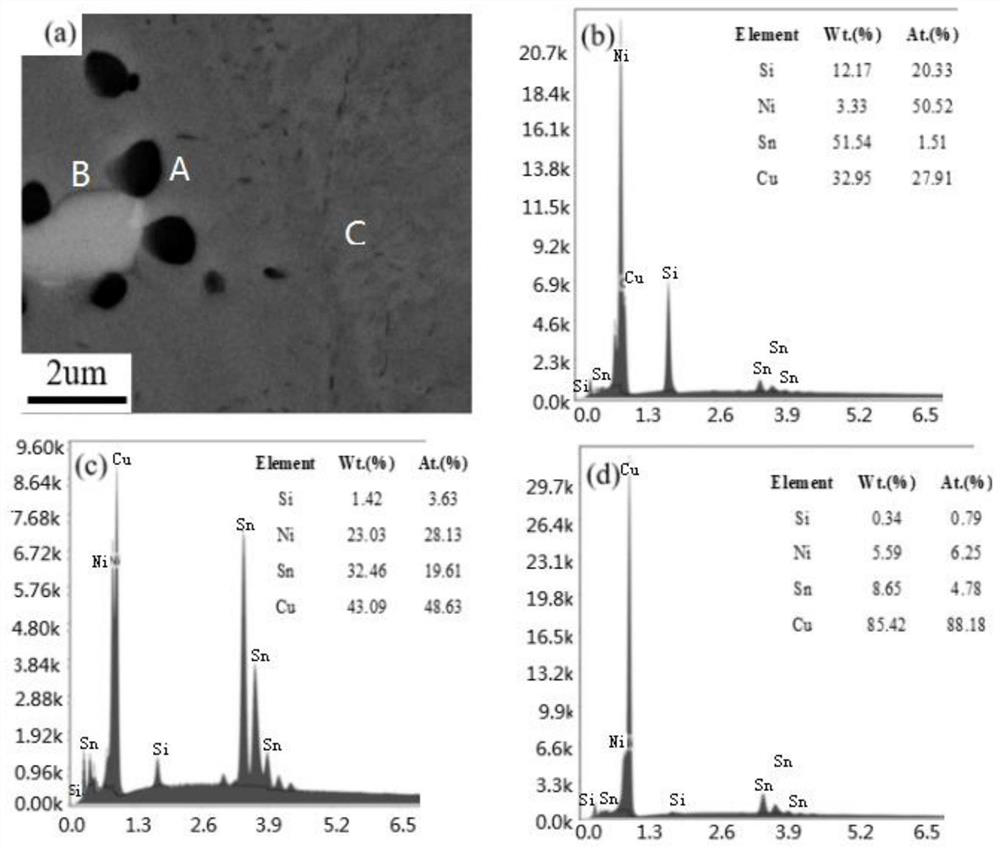

Copper-nickel-tin-silicon alloy and preparation method and application thereof

ActiveCN113564415AAvoid remeltingImprove mechanical propertiesSolution treatmentChemical composition

The invention provides a copper-nickel-tin-silicon alloy and a preparation method thereof, and belongs to the technical field of alloys. The copper-nickel-tin-silicon alloy comprises the chemical composition of 6wt% of Ni, 6wt% of Sn, 0.15-1wt% of Si and the balance of copper, and the phase composition of the copper-nickel-tin-silicon alloy comprises a copper matrix, a gamma-Ni5Si2 primary phase, a DO22 type precipitated phase and an L12 type precipitated phase. According to the copper-nickel-tin-silicon alloy, 0.15-1wt% of Si is added into the Cu-6Ni-6Sn alloy, and gamma-Ni5Si2 primary phase can be introduced into the structure as a nucleation particle in the alloy solidification process so as to achieve the purpose of refining crystal grains or dendritic crystals, so that the serious segregation phenomenon of the alloy in the solidification structure is improved; and meanwhile, a primary phase still exists in the alloy after solution treatment, generation of a discontinuous precipitation gamma phase in the aging treatment process of the alloy can be effectively inhibited, abnormal growth of crystal grains in the aging treatment process can be avoided, and therefore the mechanical property and the wear resistance of the copper-nickel-tin-silicon alloy are improved.

Owner:ZHONGBEI UNIV

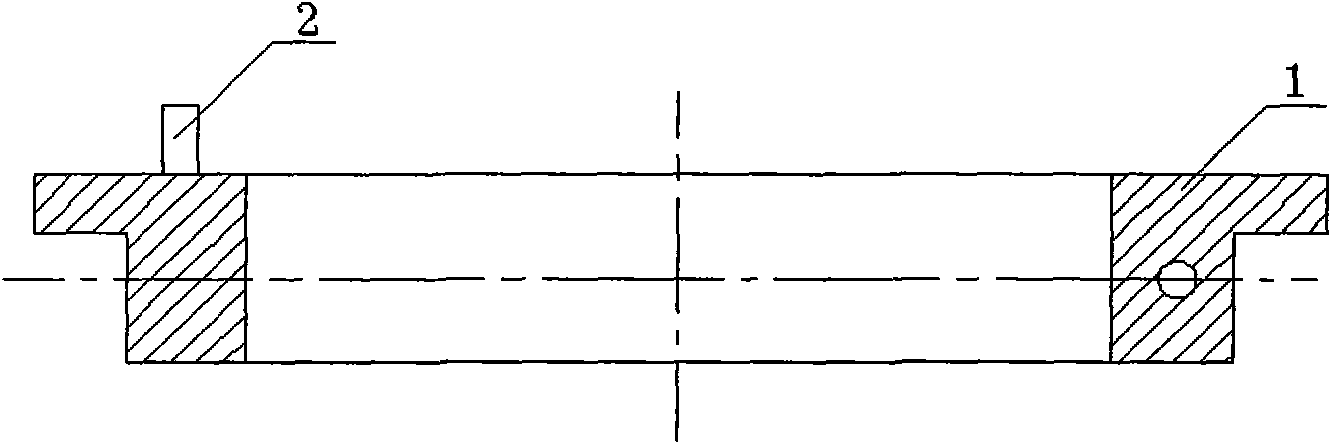

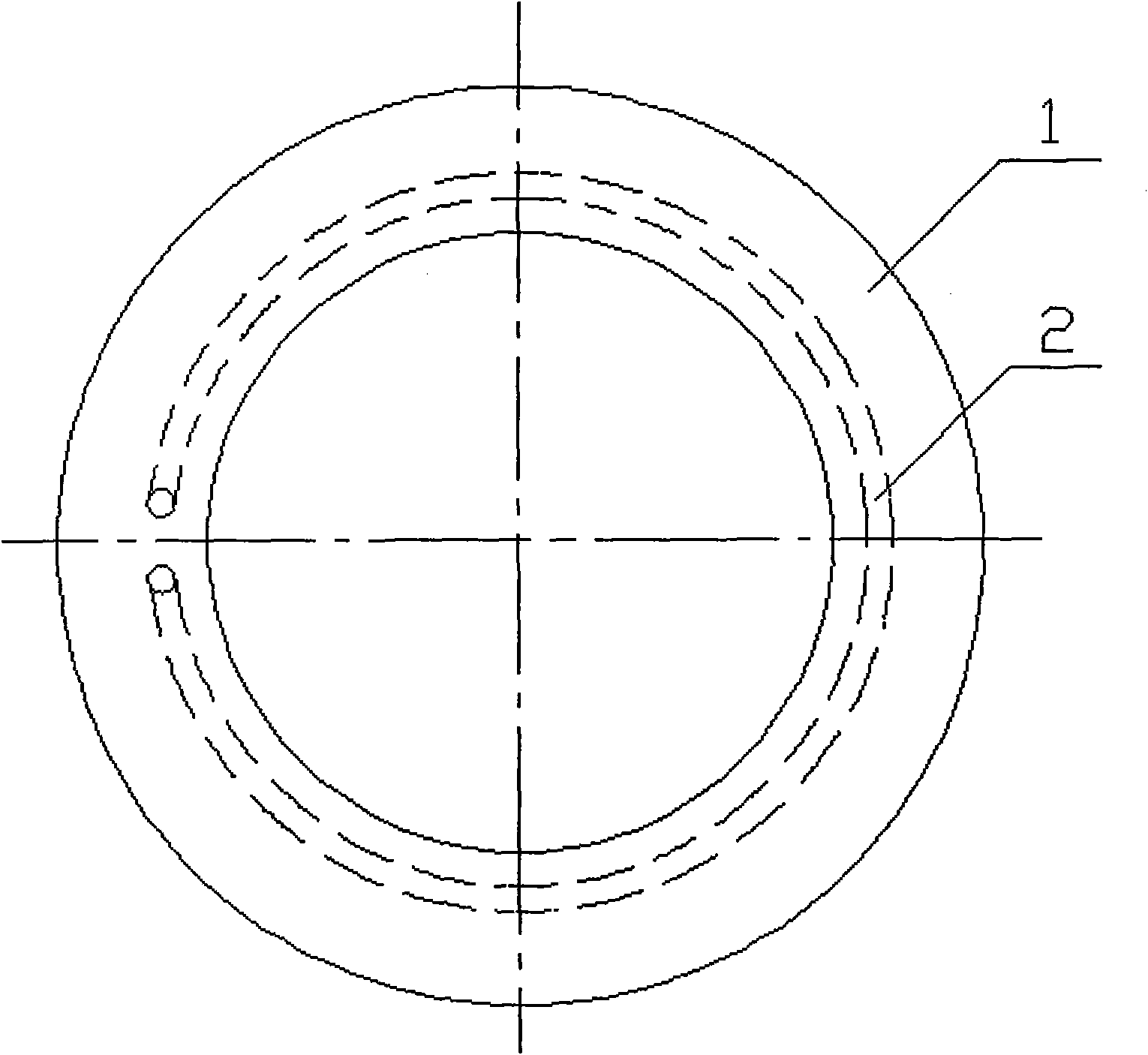

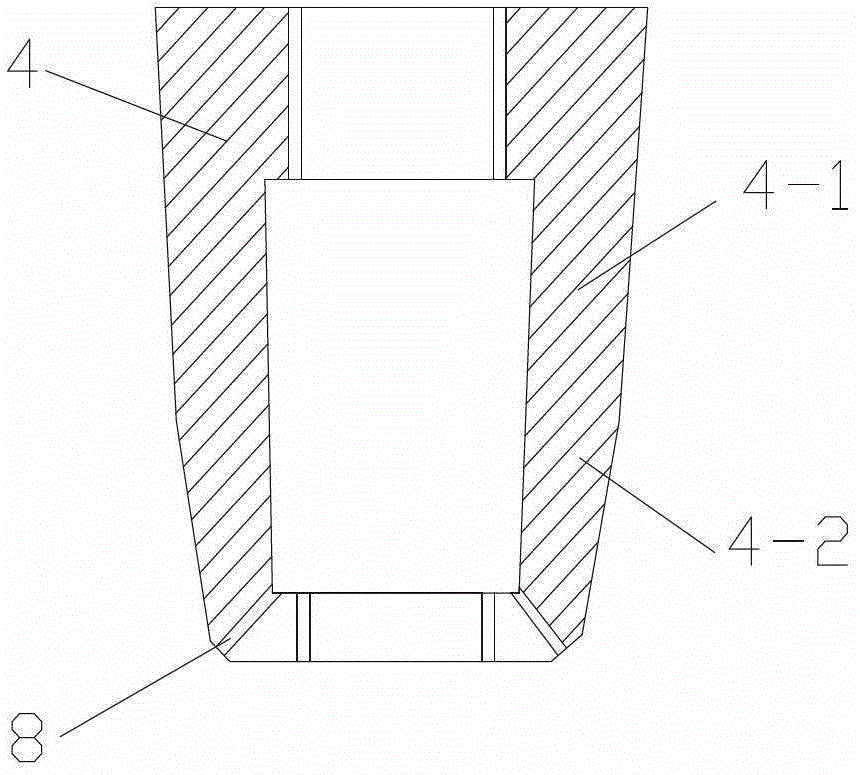

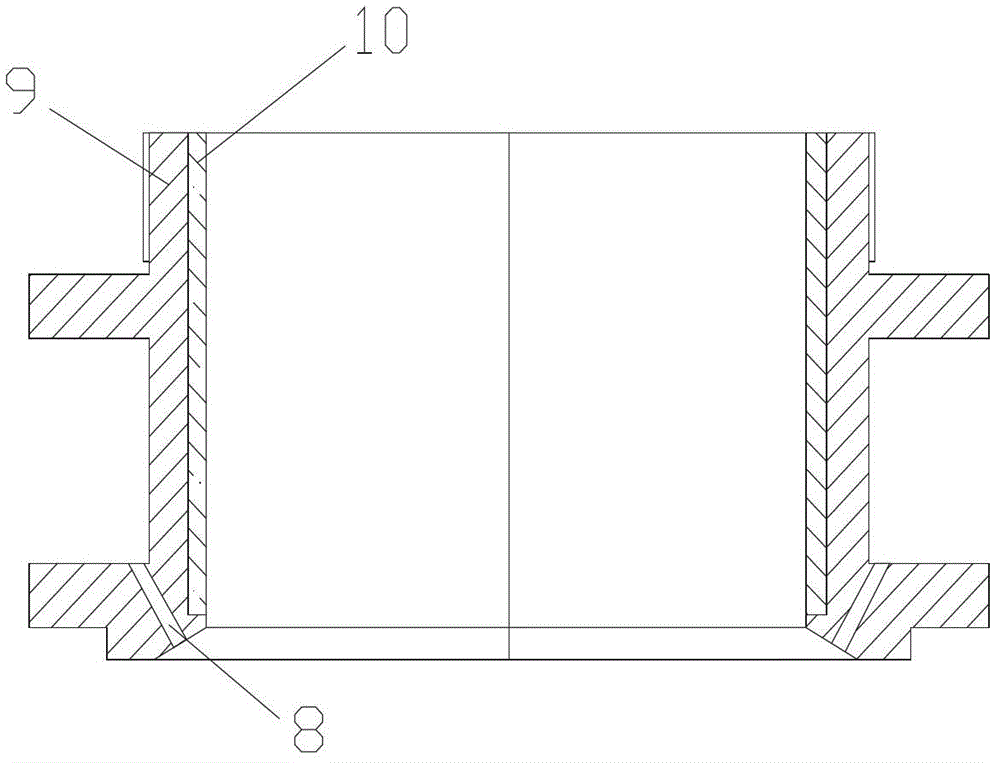

Short crystallizer for casting hollow aluminum ingots

The invention discloses a short crystallizer for casting hollow aluminum ingots. The short crystallizer comprises a crystallizer housing, wherein a triangular support is clamped inside an annular groove of the housing and can rotate on the housing; an internal sleeve and an liner are fixedly arranged inside the housing; a core is placed inside the liner; a water inlet is formed above the core, is connected with a core water inlet pipe and is arranged on the triangular support; a water outlet and a water outlet hole are formed below the core; and an aluminum liquid inlet is formed between the core and the liner. The short crystallizer is characterized in that the core (4) is internally hollow and conical, and the height of the core is 80mm-120mm; the height of the upper part of the core (4) is 65%-70% of that of the core, and the conical degree of the upper part of the core (4) is 1: (30-50); the height of the lower part of the core (4) is 30%-35% of that of the core, and the conical degree of the lower part of the core (4) is 1: (15-17); the internal sleeve is made of aluminum alloy; and the liner is made of copper and can be pulled out from the internal sleeve to be and replaced. By shortening the length of the crystallizer, the crystal grains of the hollow ingots are relatively thin, and the surface quality of finished tubes is good; and through the improvement that the upper and lower parts of the core of the crystallizer have two different conical degrees, the remelting and cracking of crystal membranes are avoided.

Owner:ANLU PHOENIX ALUMINUM LIMITED LIABILITY

Synchronous dual-light beam laser welding method of crossed joint

ActiveCN102922135BImprove performanceEasy to overflowLaser beam welding apparatusLight beamOptoelectronics

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com