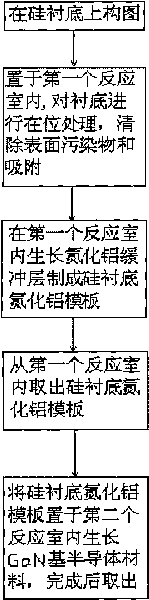

Method for manufacturing silicon substrate GaN-based semiconductor material

A manufacturing method and technology of silicon substrates, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unstable growth and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

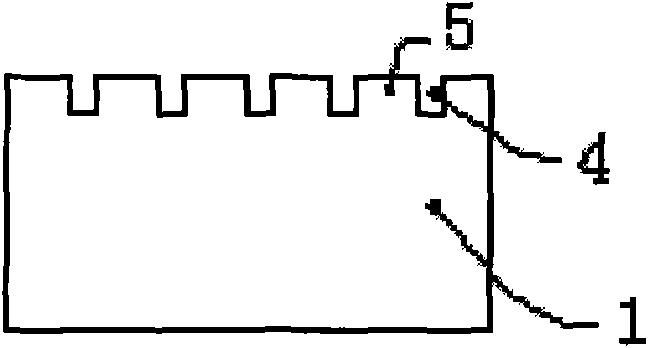

[0044] Based on the above conditions, for a silicon substrate sheet that has been patterned and grooved, the first embodiment of the method for producing a GaN-based semiconductor material on a silicon substrate according to the present invention is as follows:

[0045] 1. Silicon substrate in-situ high-temperature hydrogen treatment: put the silicon substrate into the first reaction chamber, and perform in-situ treatment on the silicon substrate under a relatively high temperature and hydrogen-containing atmosphere to remove the impurities on the substrate. organic pollutants and adsorbed oxygen atoms.

[0046] 2. After the in-situ processing of the silicon substrate is completed, the temperature is lowered to prepare for the growth of aluminum nitride. The growth temperature of aluminum nitride is 500-1000 degrees Celsius.

[0047] 3. In order to realize the transition from Si lattice to AlN lattice smoothly, a trimethylaluminum source can be introduced into the first reacti...

Embodiment 2

[0052] Compared with Example 1, the difference is that the above steps 3 and 4 are changed to: first inject ammonia gas to form a thin layer of SiN, and then grow AlN with a thickness of 1200 angstroms.

Embodiment 3

[0054] The difference compared with the first embodiment is that the above steps three and four are changed: in the process of forming the aluminum nitride buffer layer on the silicon substrate, the high-pressure growth is performed first, and then the low-pressure growth is performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com