Patents

Literature

81results about How to "Quality will not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting method for low-carbon low-silicon wire-welding steel

ActiveCN104862443AGood welding performanceSolve the problem of nodulation in submerged nozzlesManufacturing convertersOxygen contentRegular Production

The invention discloses a smelting method for low-carbon low-silicon wire-welding steel. The process flow of the smelting method comprises the following procedures: pretreatment and desulphurization of molten iron; treatment in a converter; LF refining; and continuous casting of small square billet with a size of 150 mm * 150 mm. With the smelting method, carbon content is stably controlled to be less than or equal to 0.08%; silicon content is stably controlled to be less than or equal to 0.027%; total oxygen content is no more than 0.0040%; the problem of nozzle clogging is overcome; and surface and internal quality of a casting blank is greatly improved. The process flow of the smelting method is simple and has low cost; and equipment used in the smelting method is conventional production equipment for iron and steel manufacture, is simple to operate, has good versatility and saves energy.

Owner:QINGDAO SPECIAL STEEL CO LTD

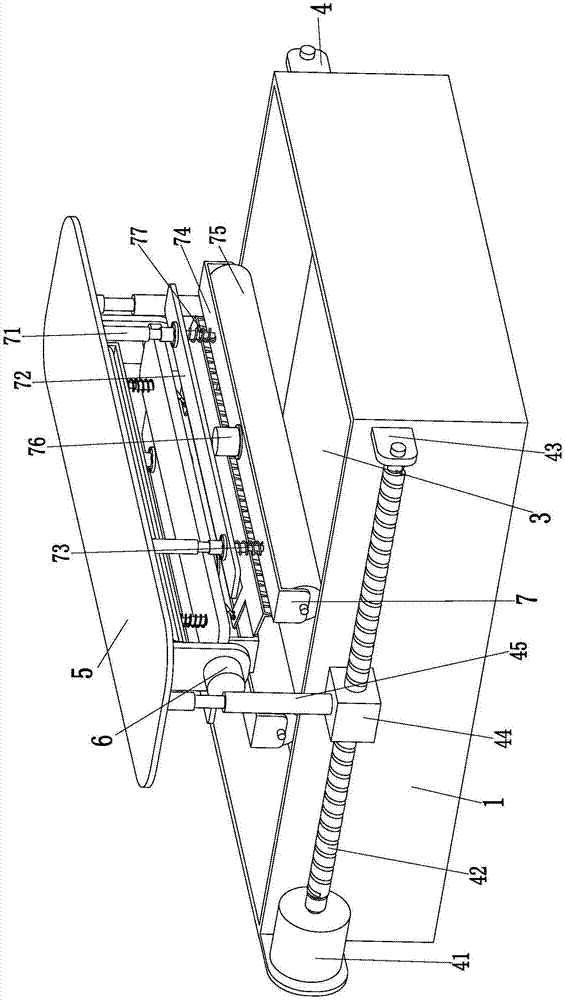

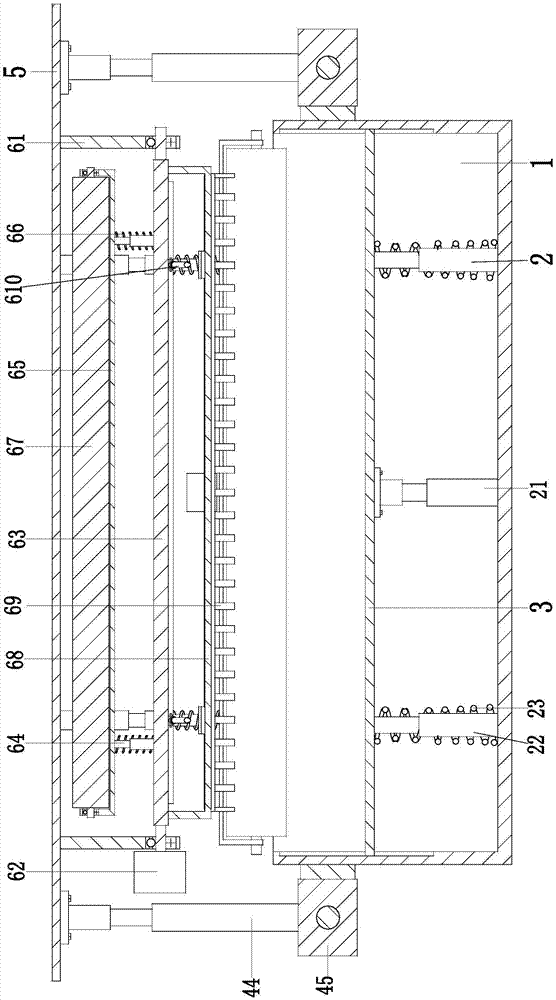

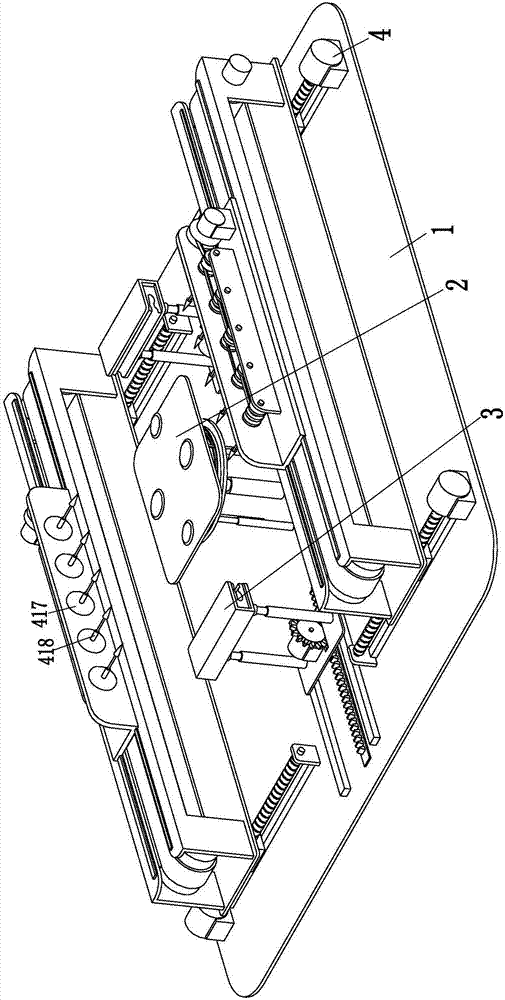

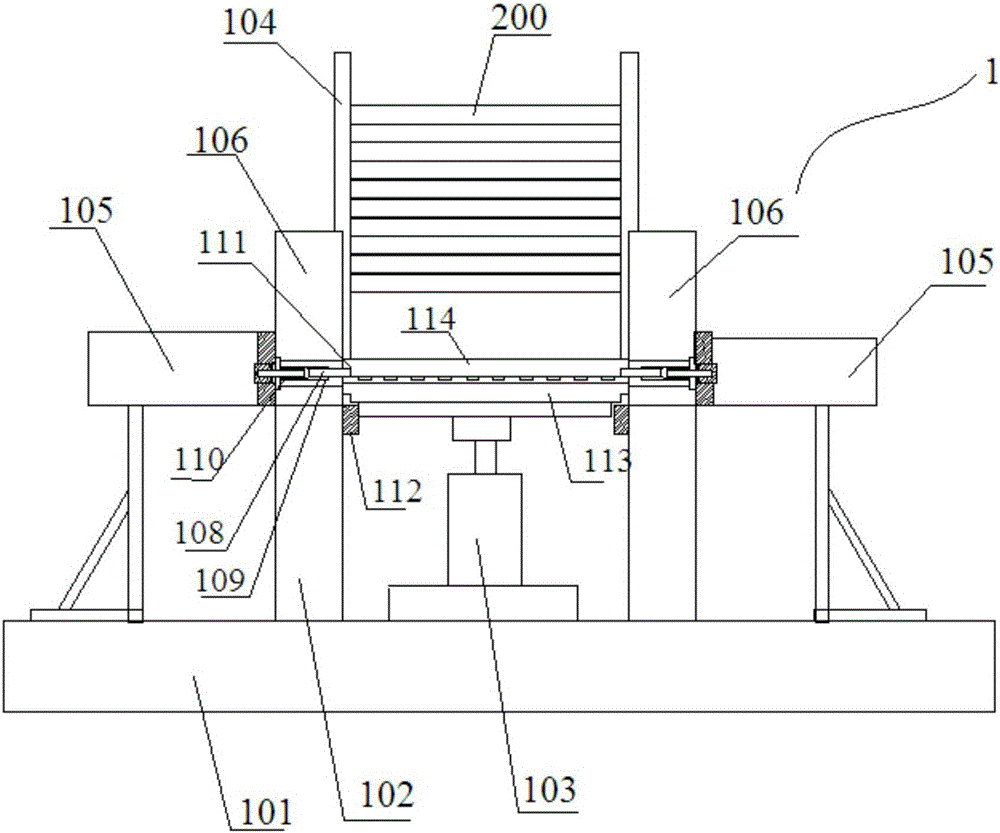

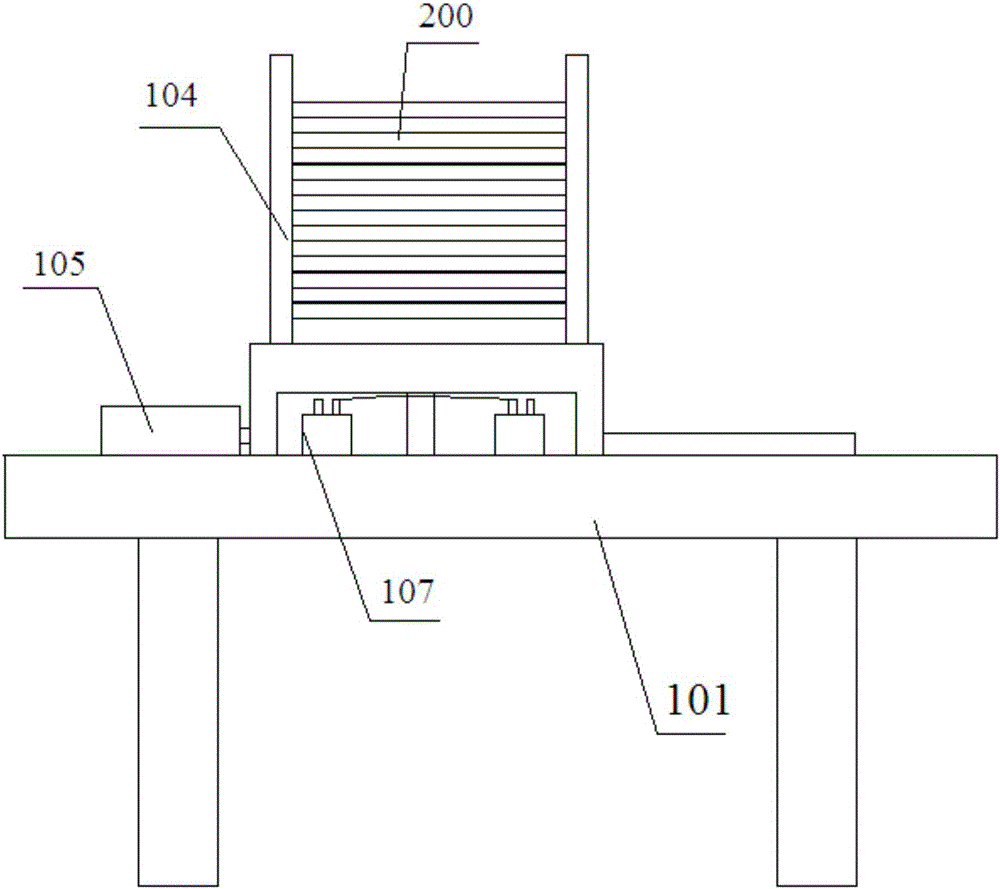

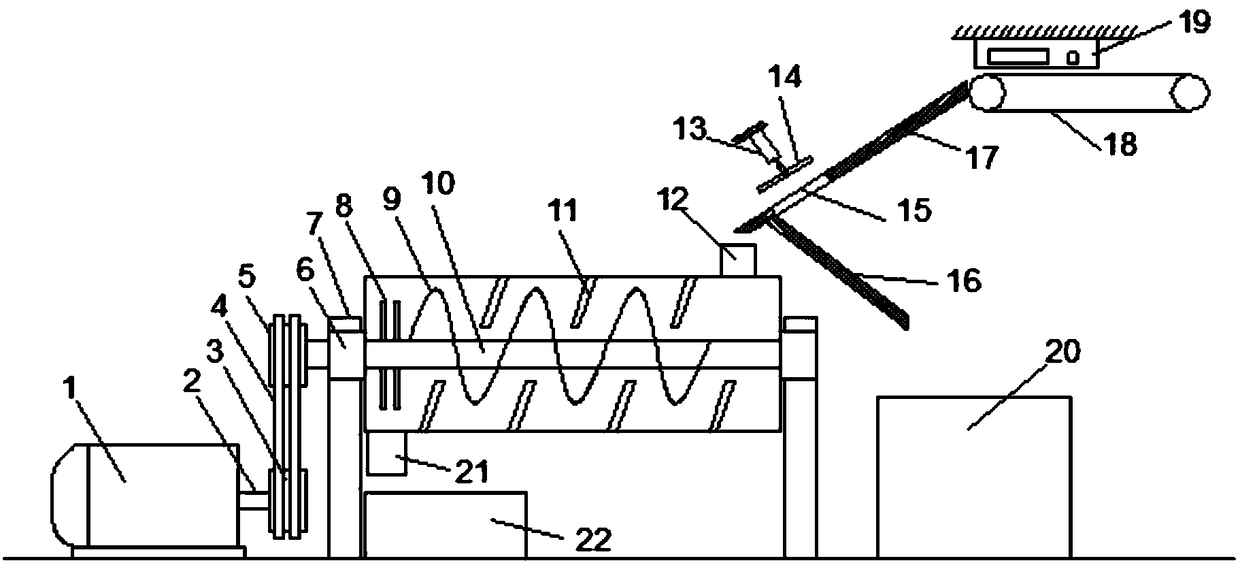

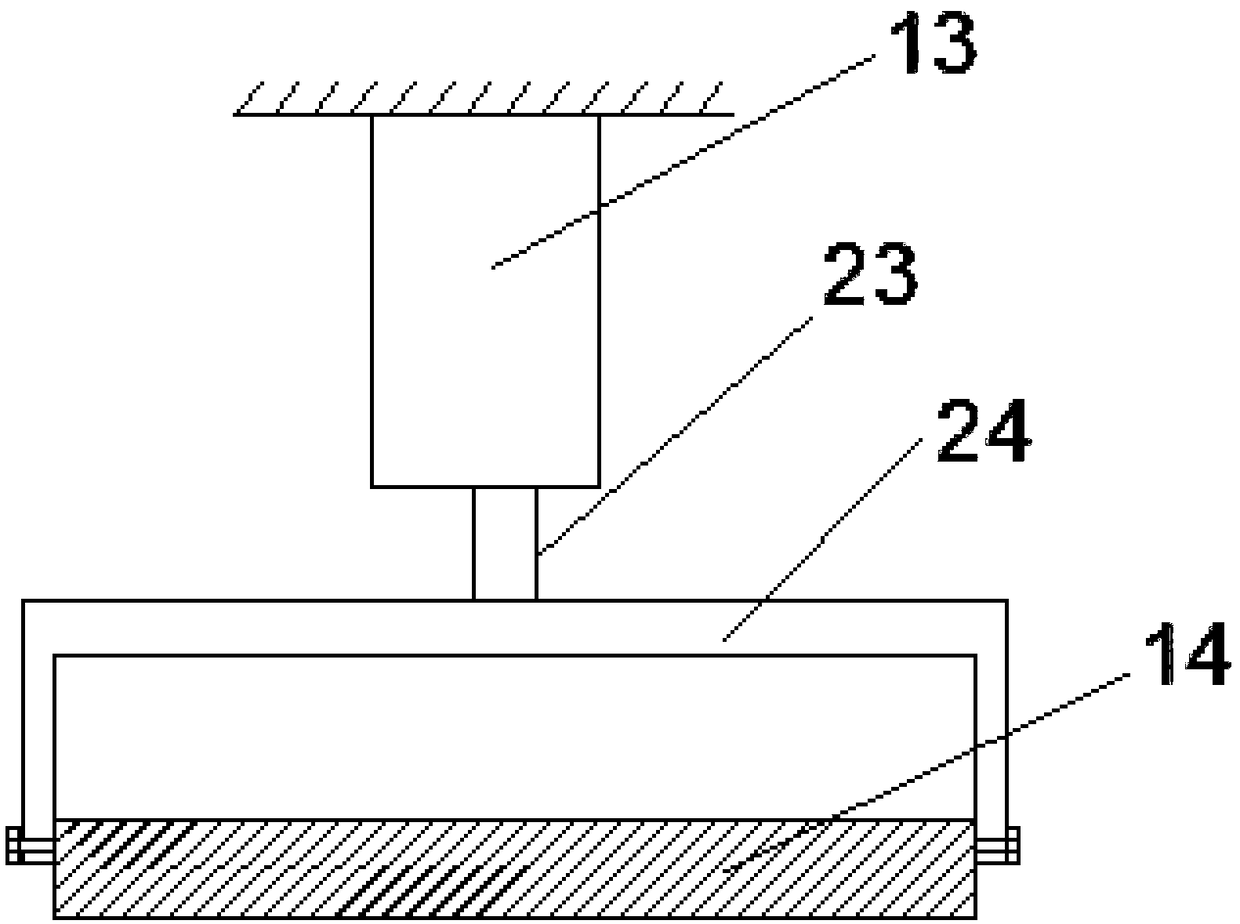

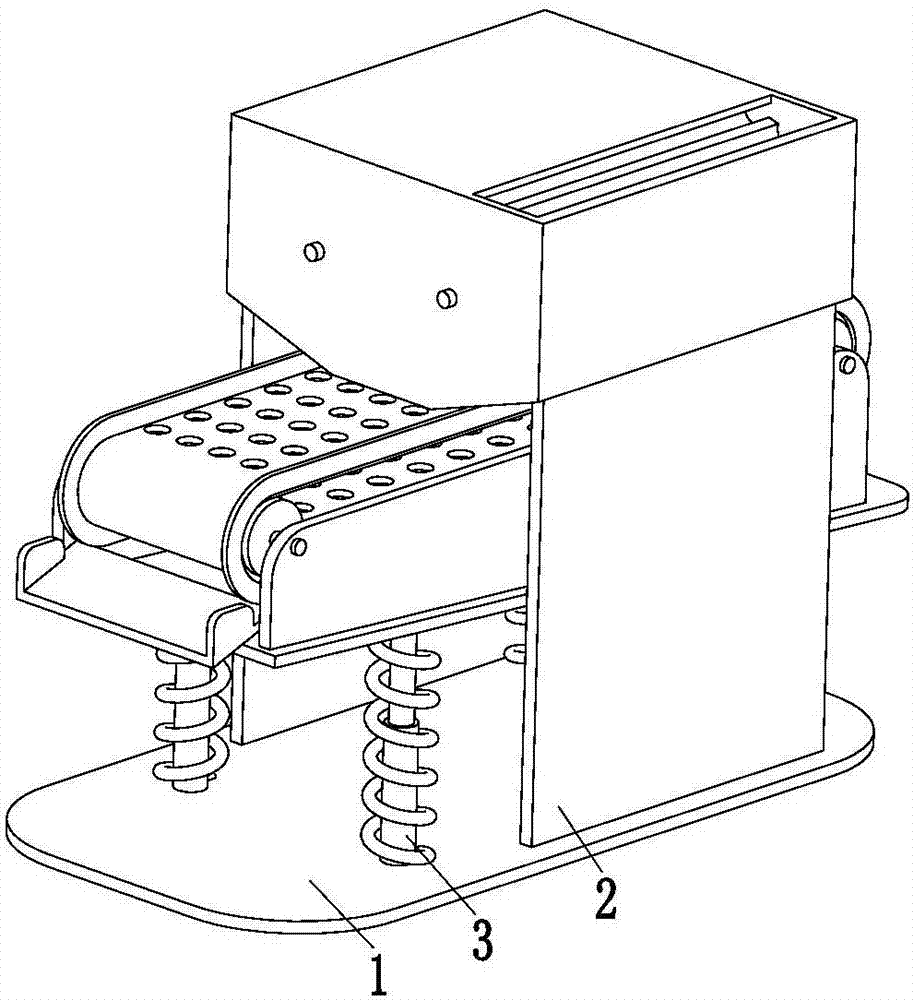

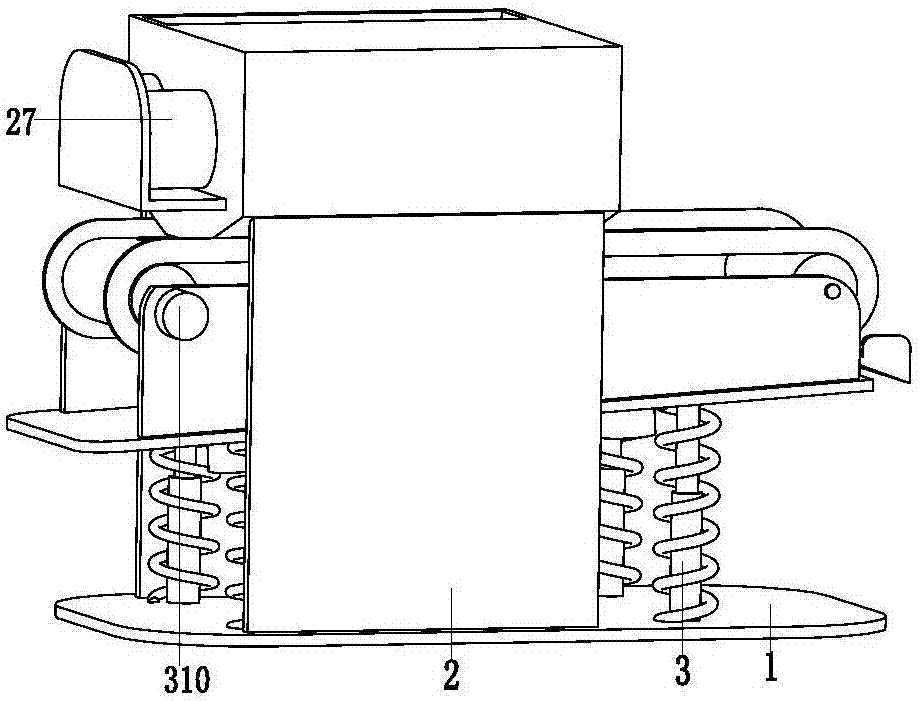

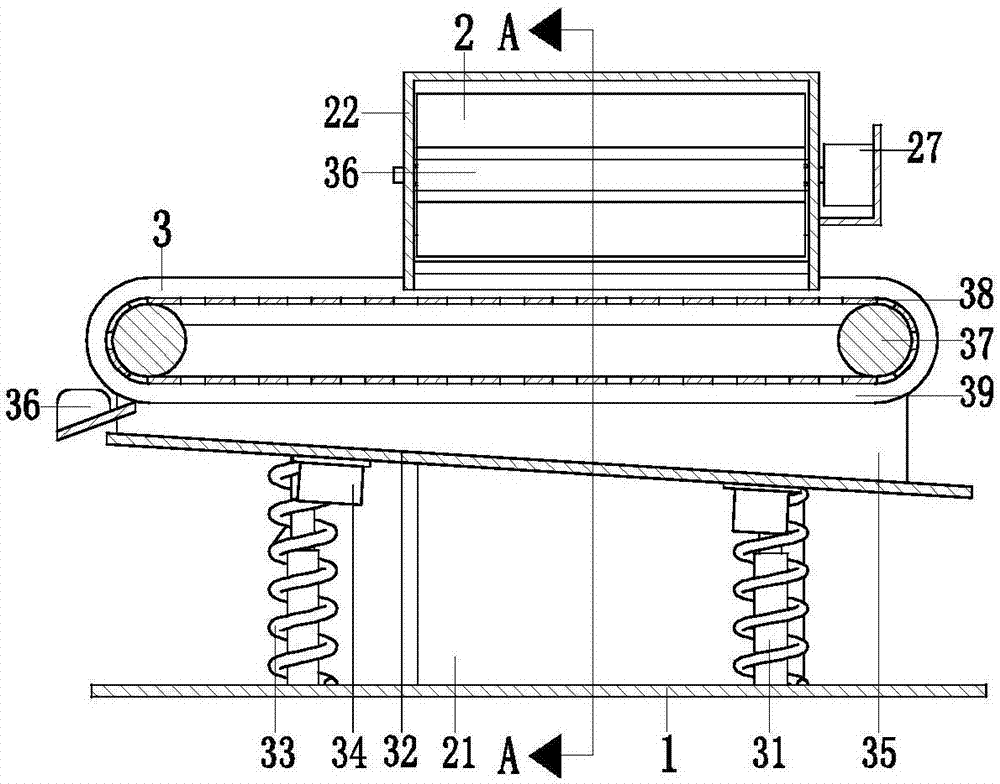

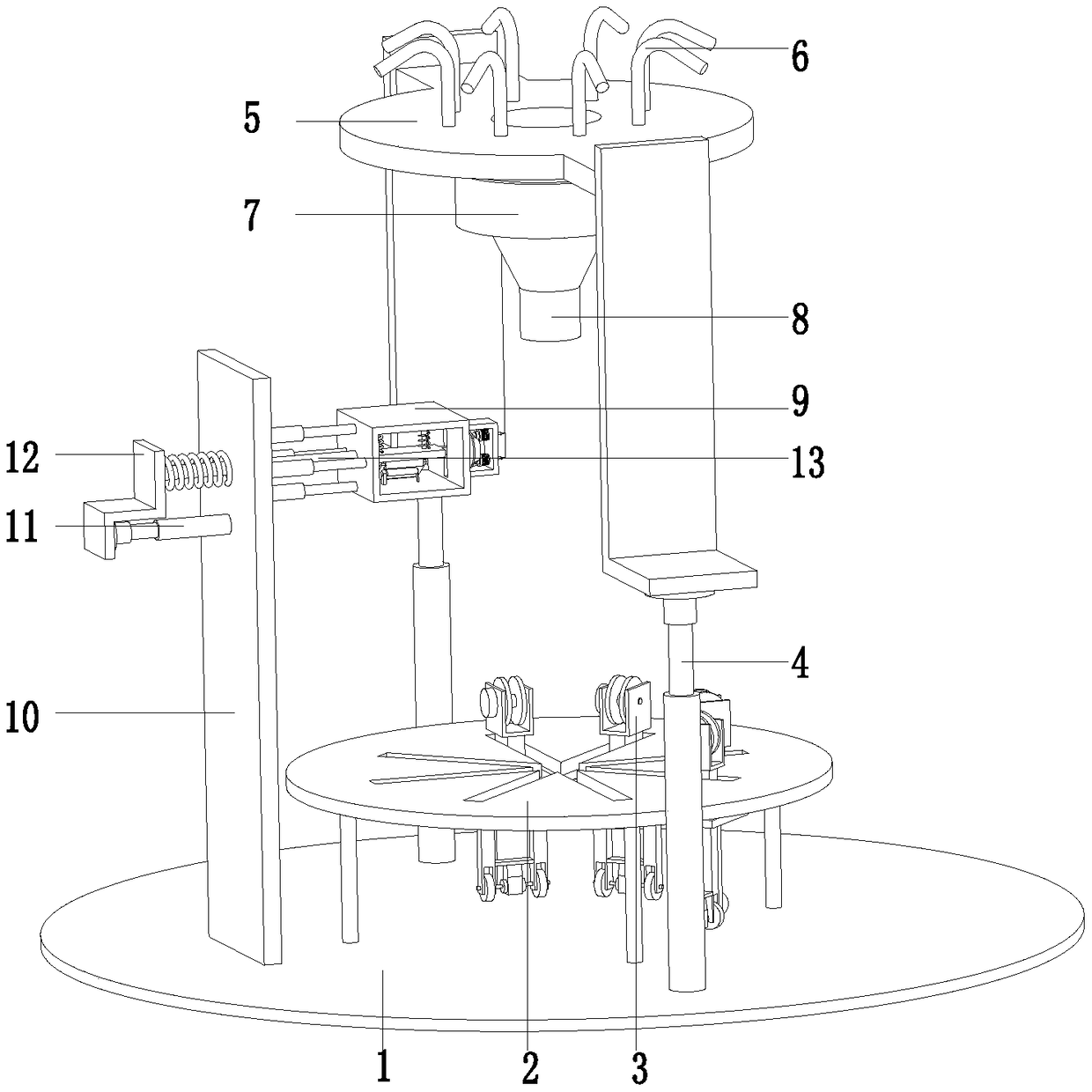

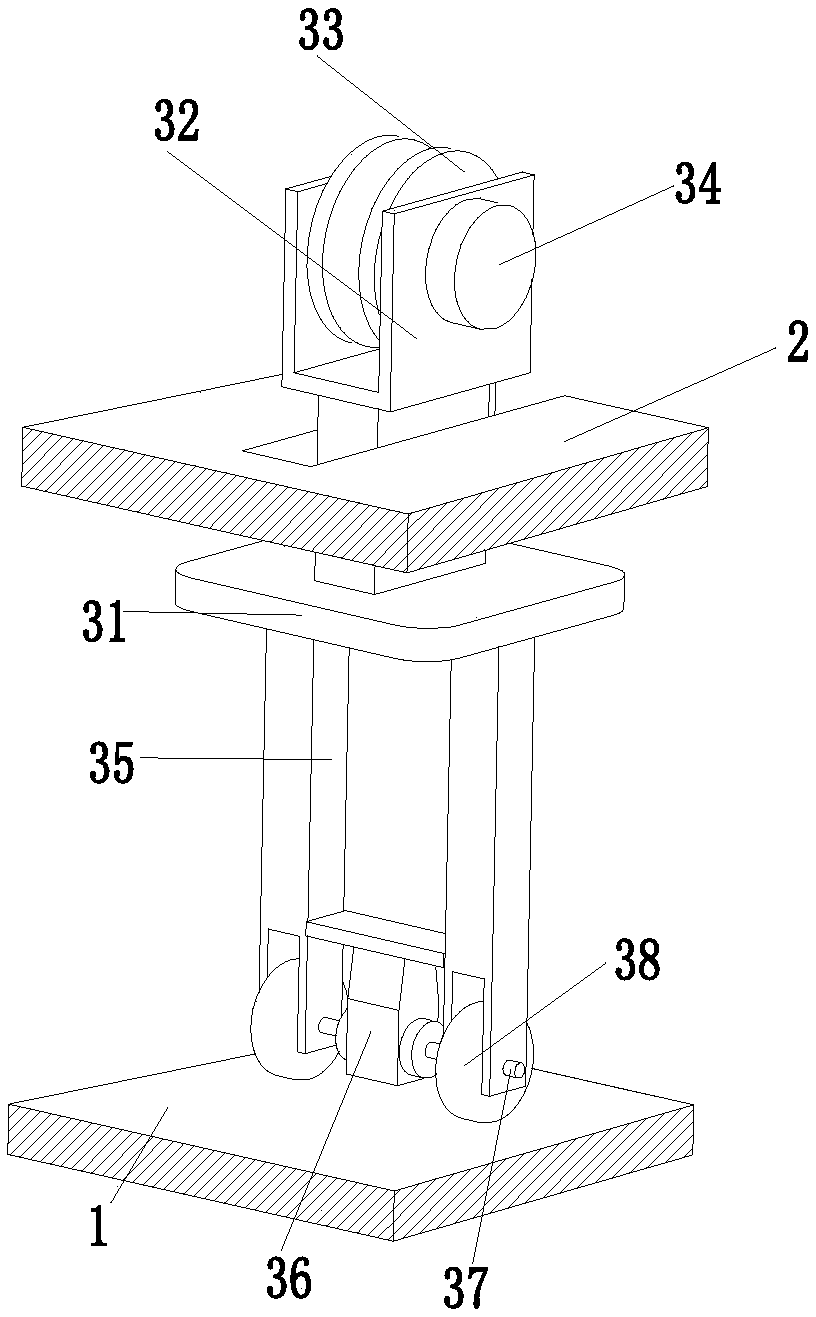

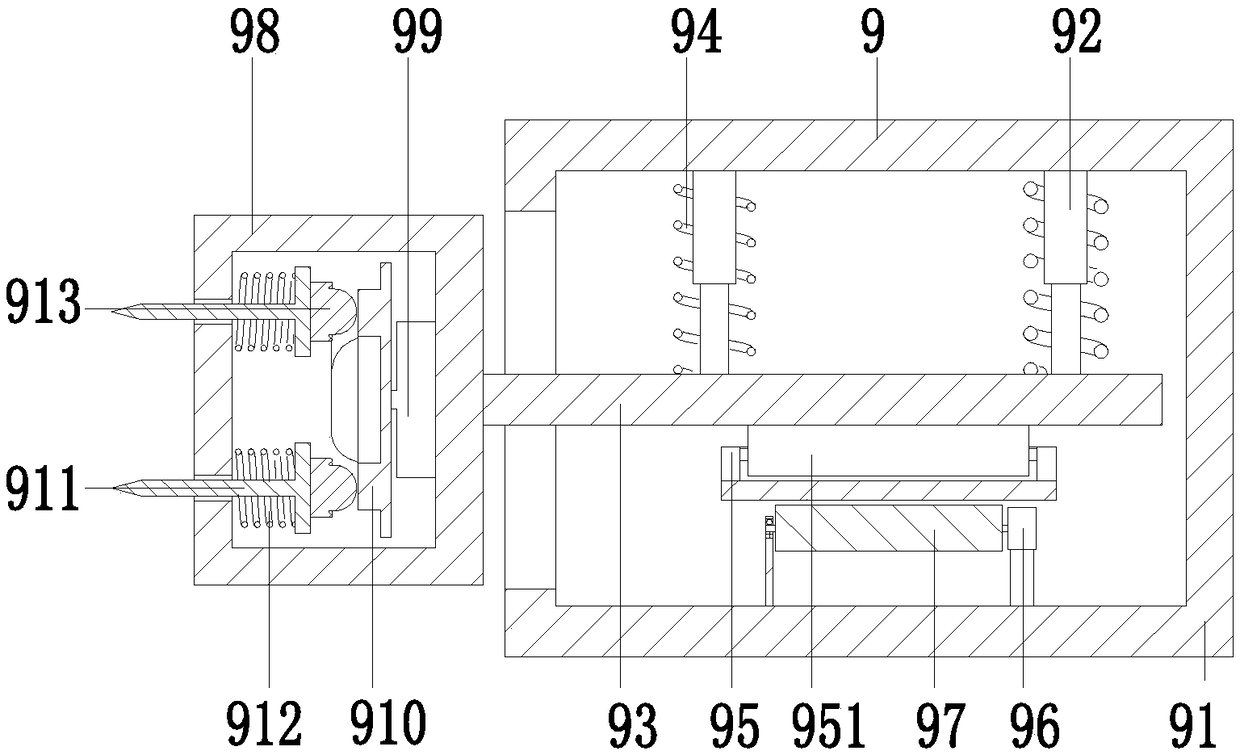

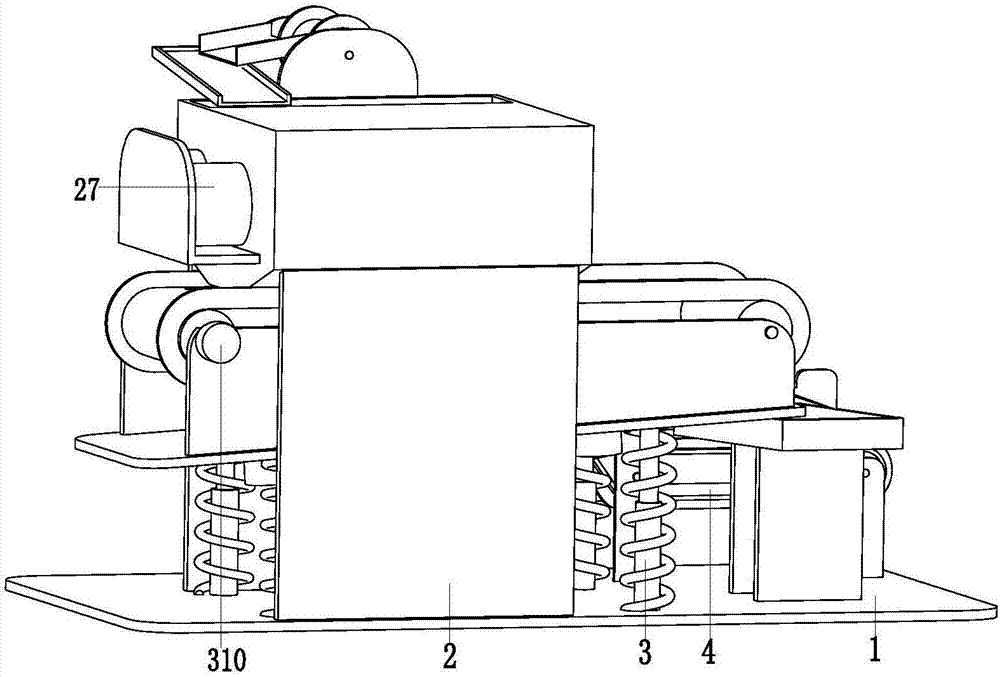

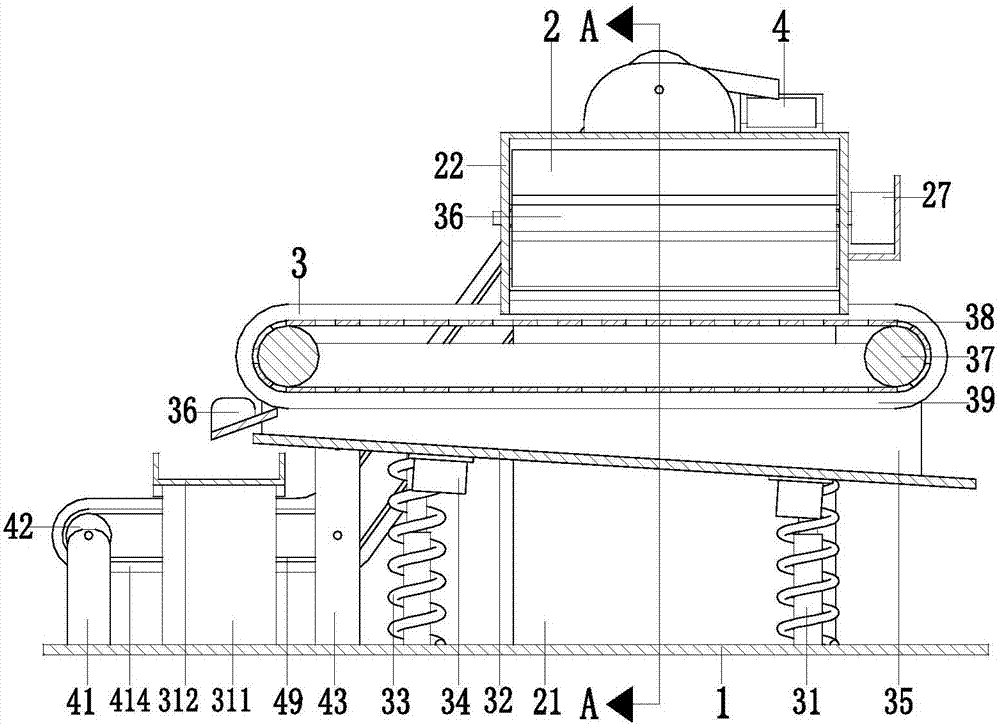

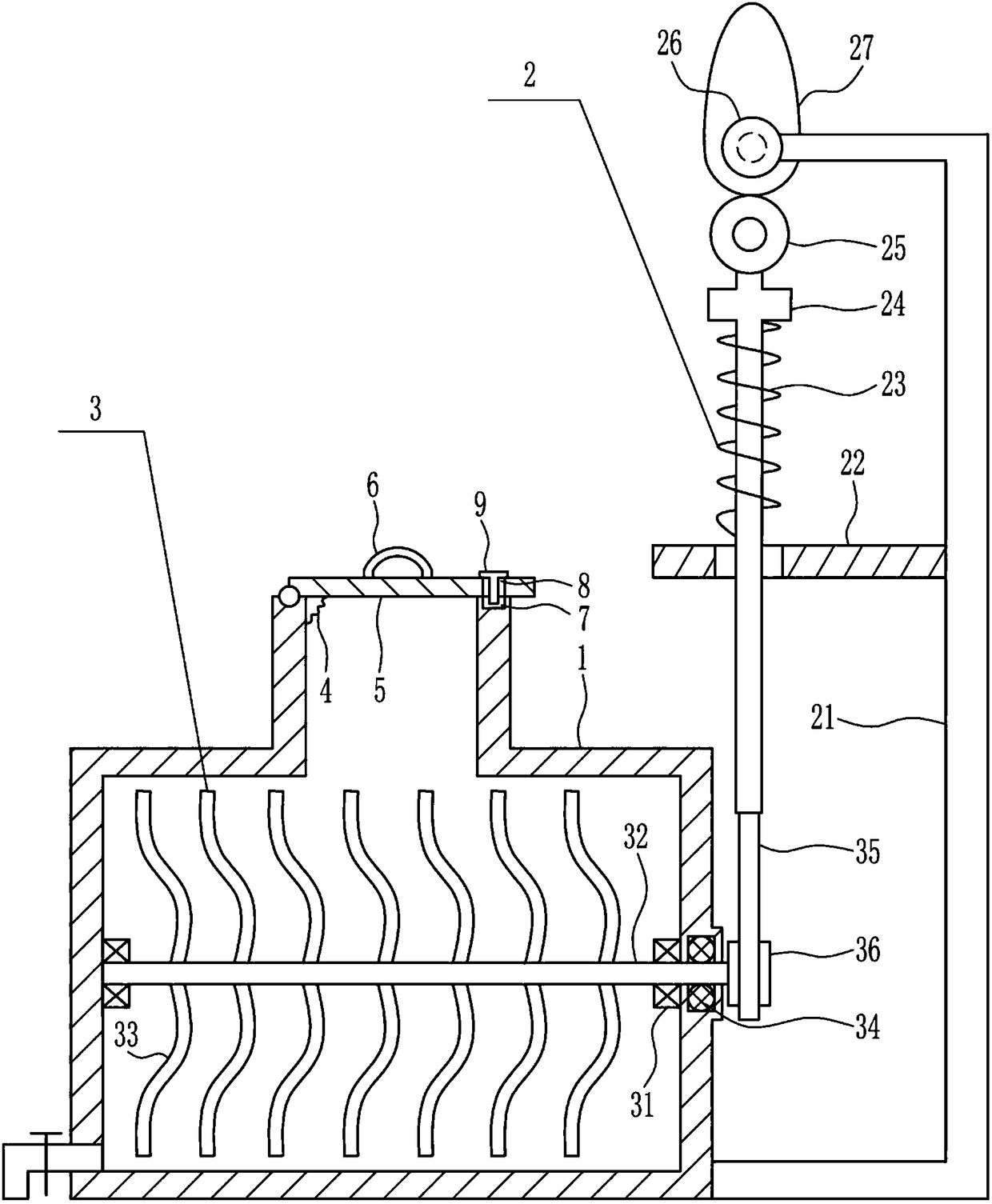

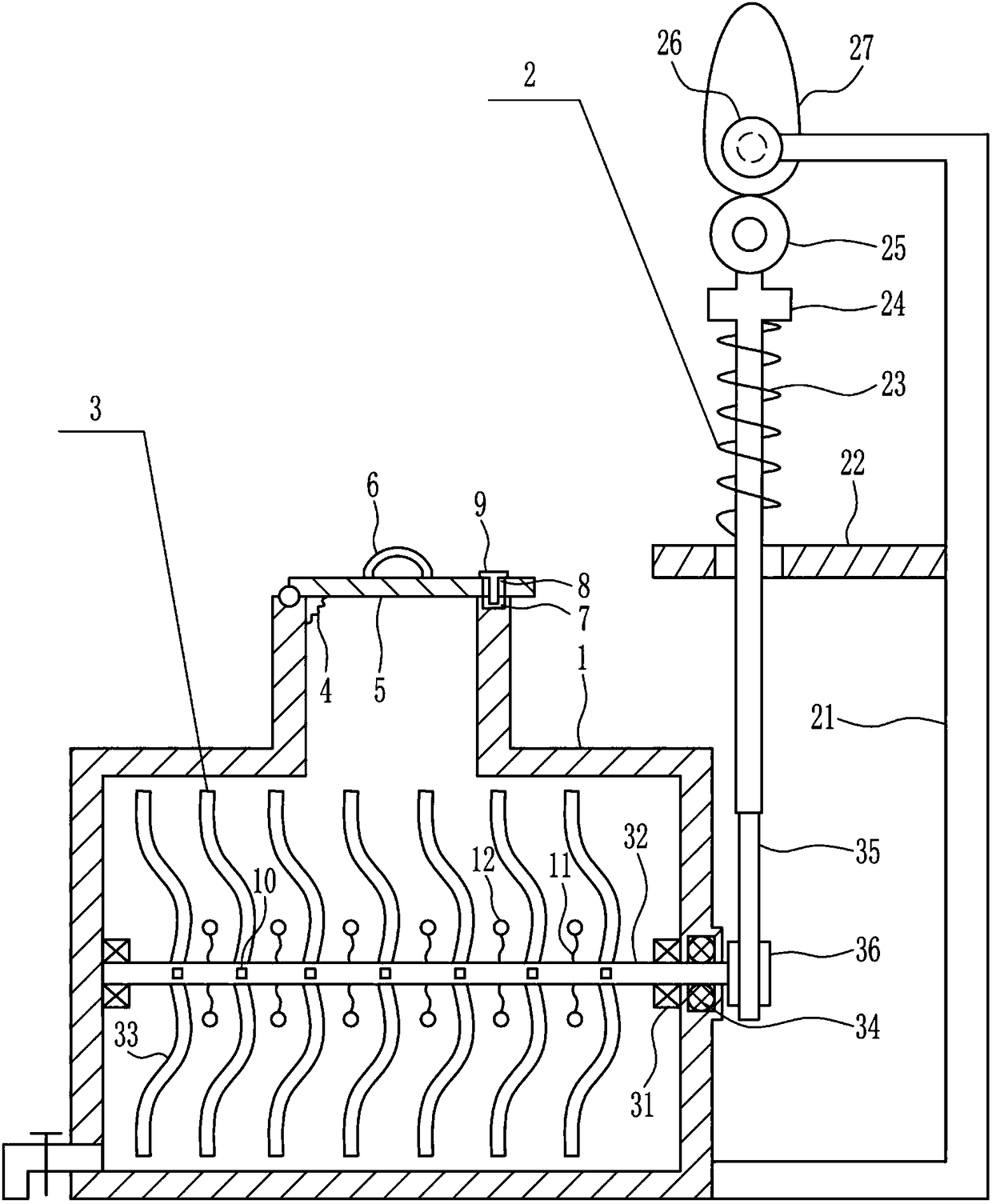

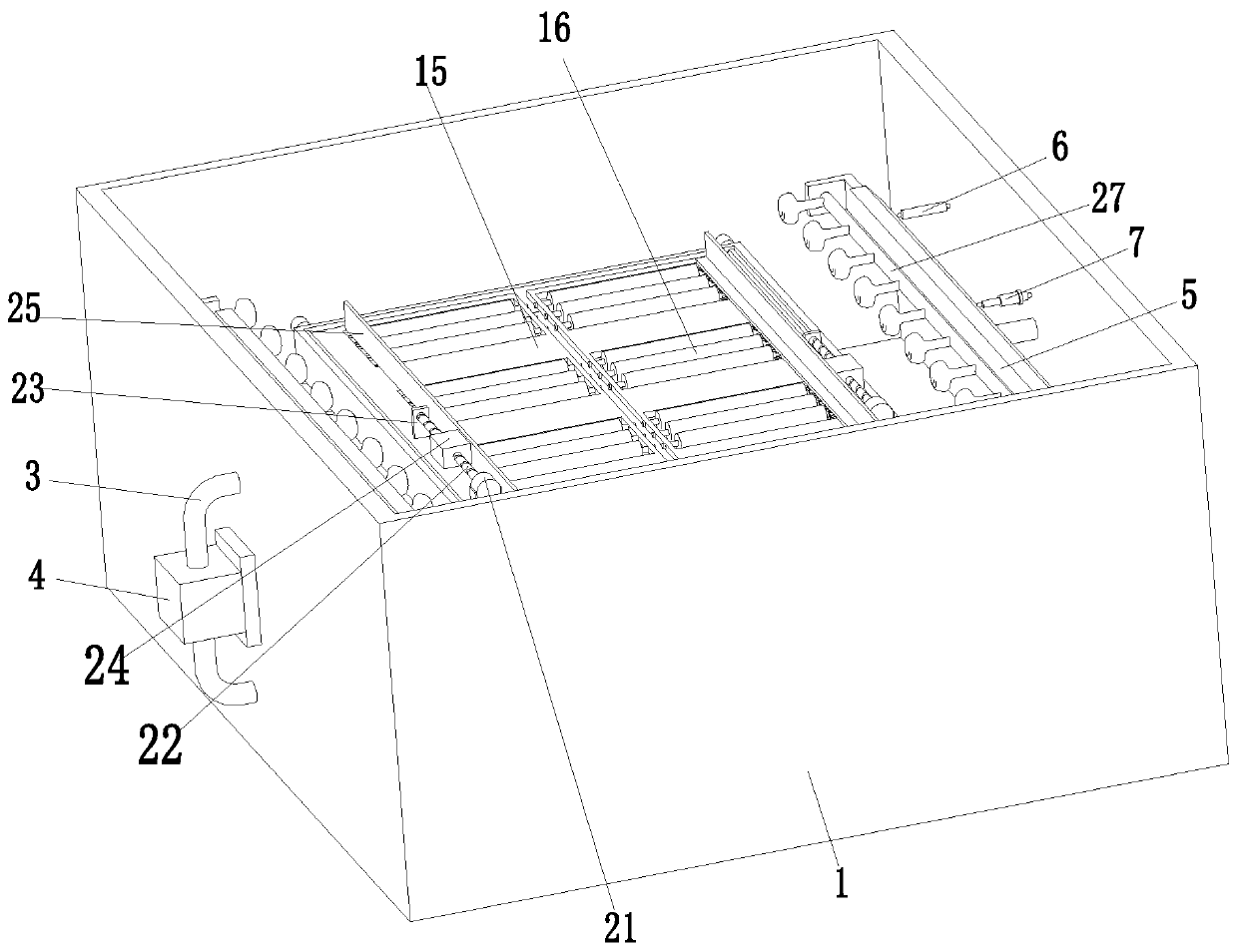

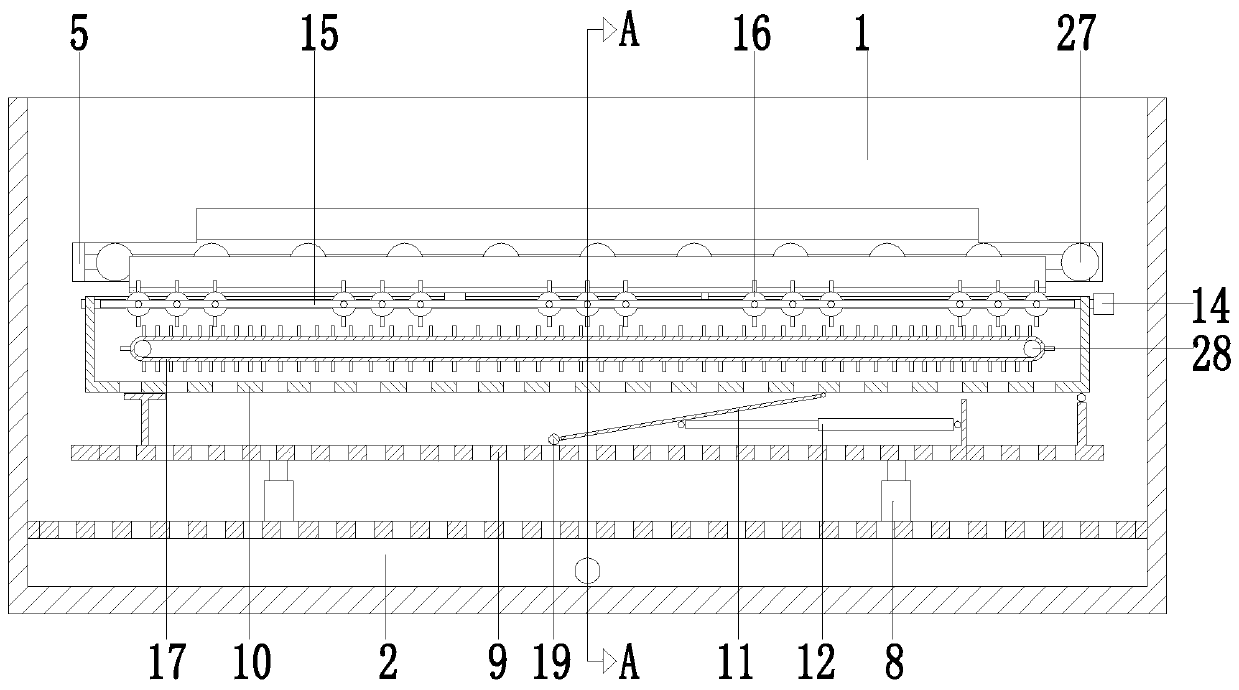

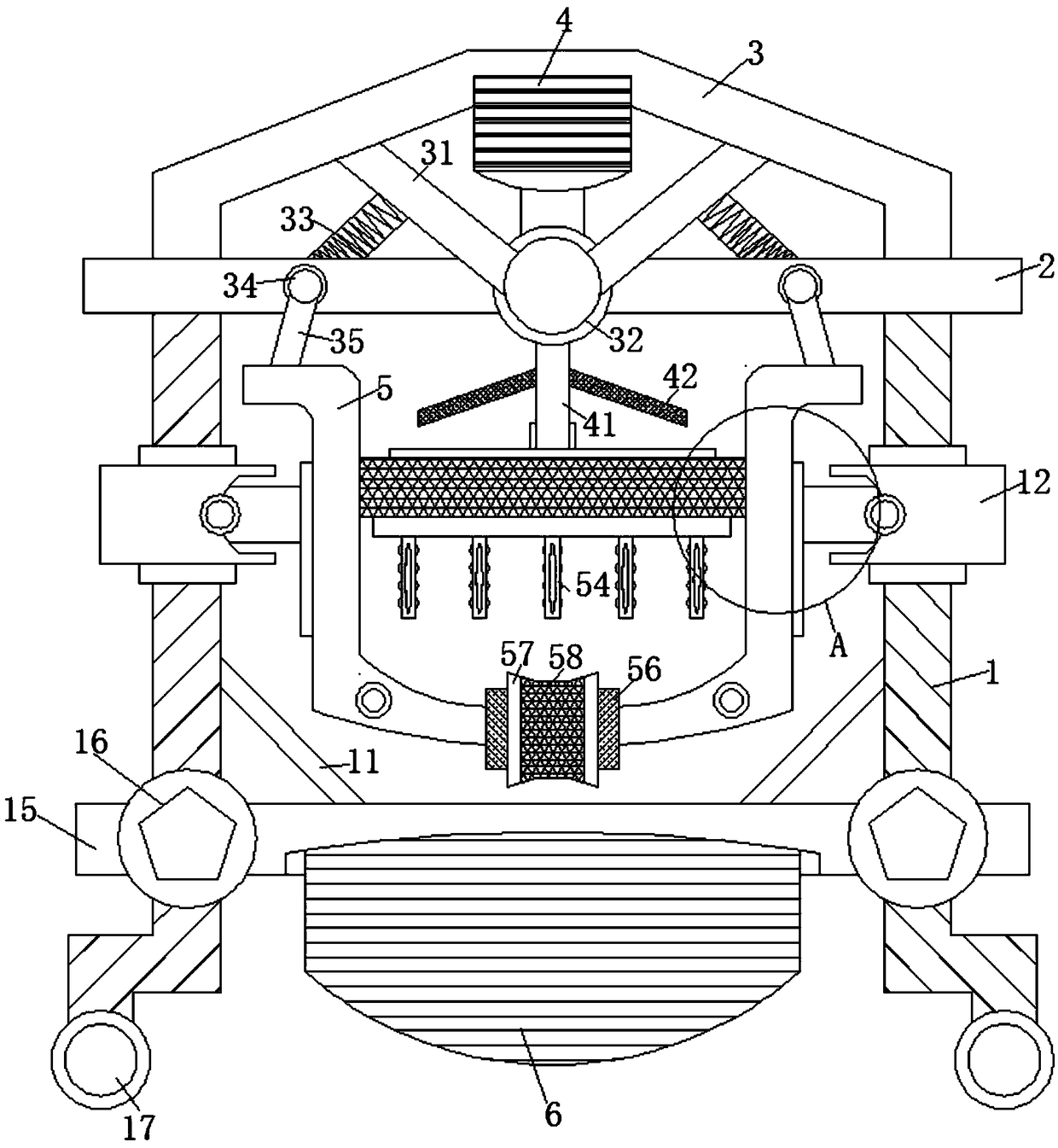

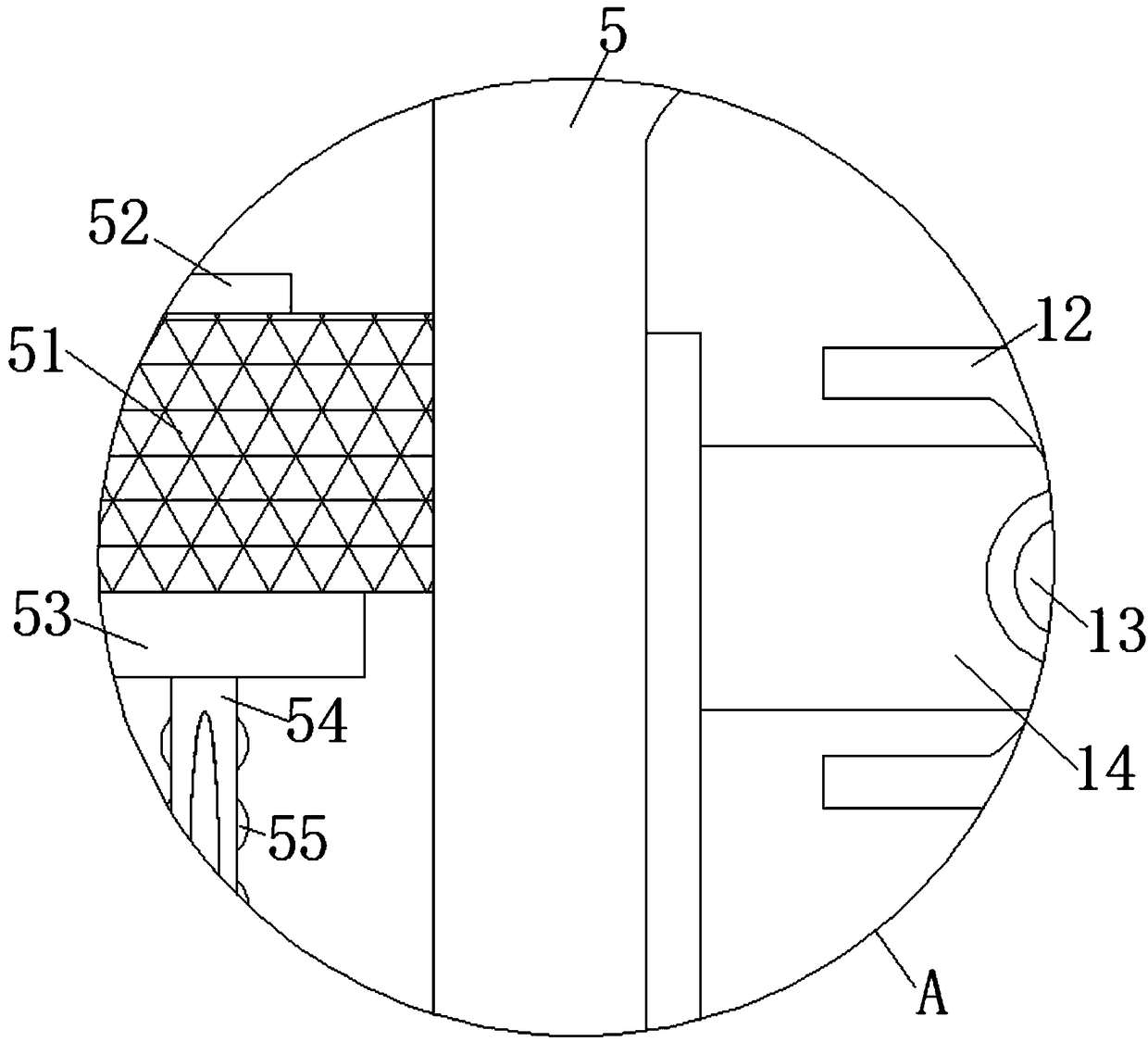

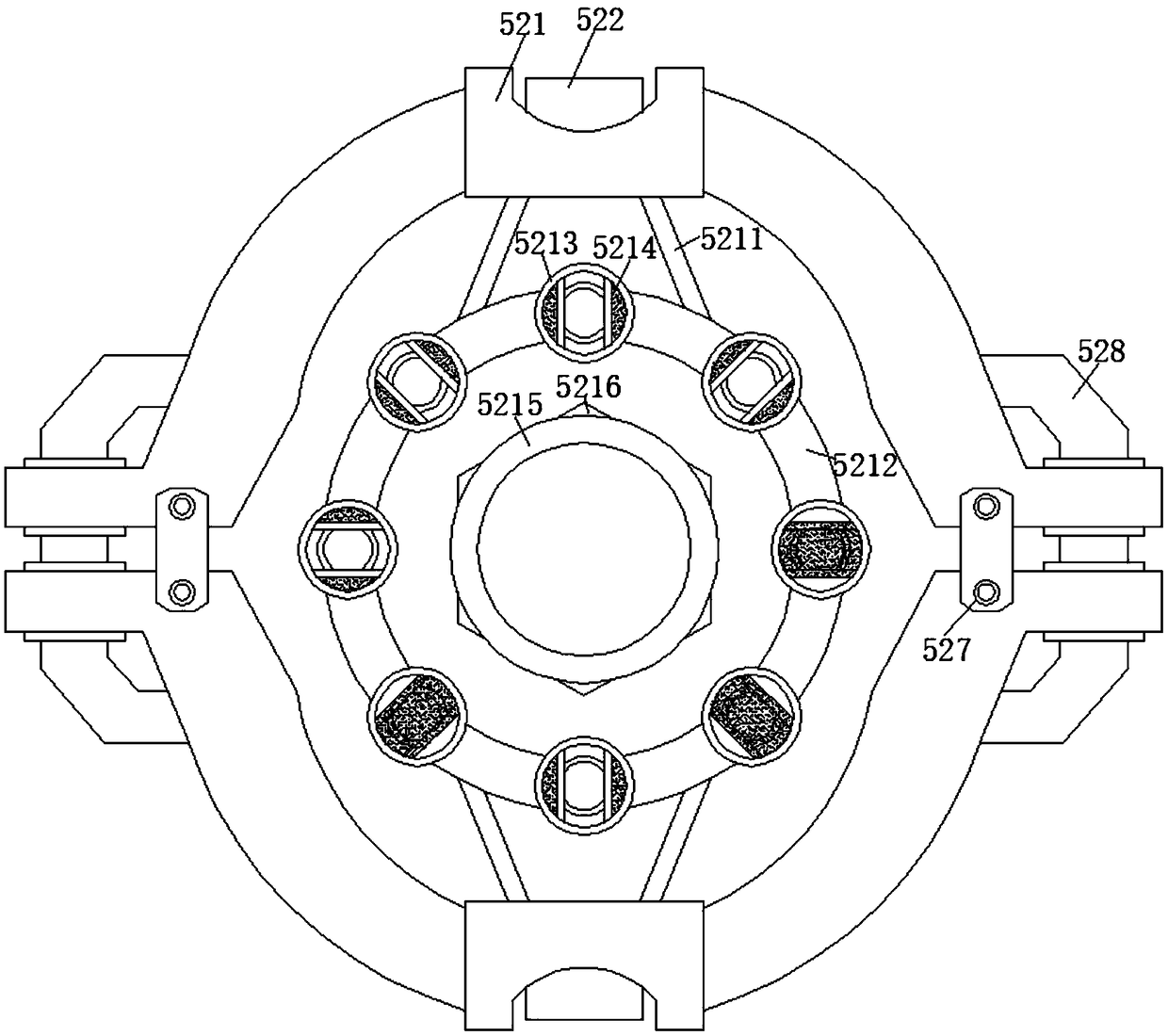

Automatic processing and manufacturing equipment for shaving boards

ActiveCN107283554AQuality will not affectSmall savings in qualityPlywood pressesVeneer pressesEngineeringMachining process

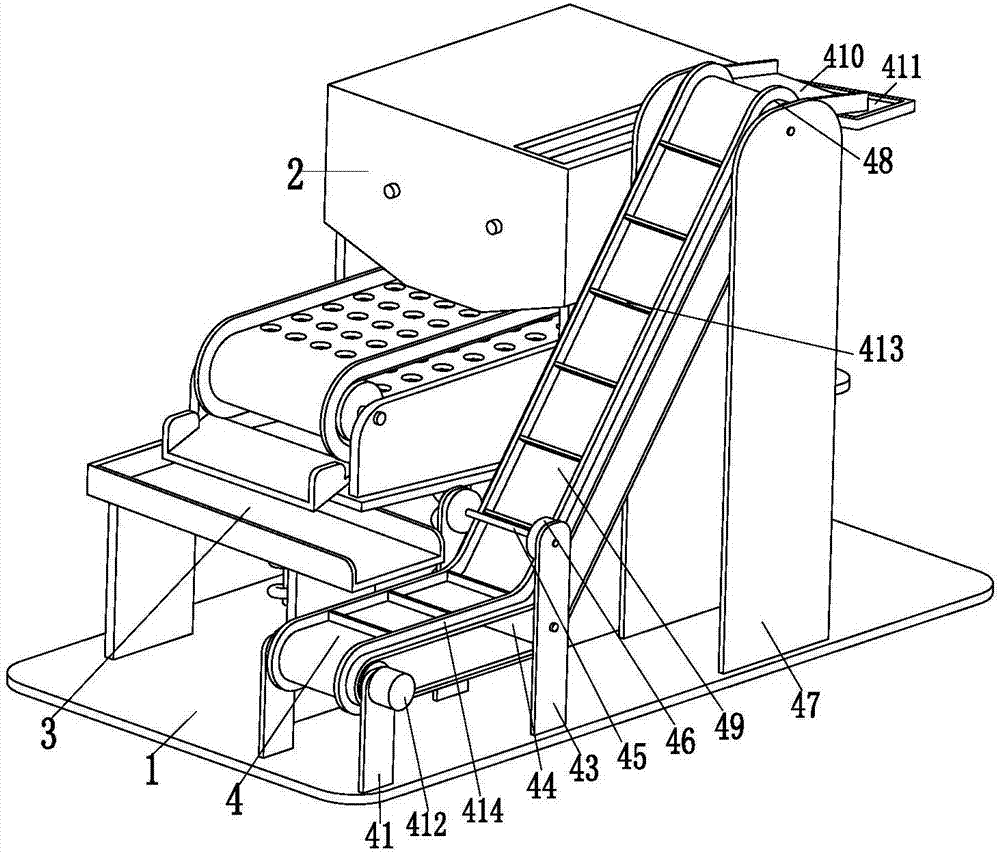

The invention relates to automatic processing and manufacturing equipment for shaving boards. The automatic processing and manufacturing equipment comprises a working box, wherein two supporting mechanisms are symmetrically mounted at the front end and the rear end of the bottom of the working box separately; a working plate is mounted at the upper ends of the two supporting mechanisms; two moving and lifting mechanisms are symmetrically mounted on the left side and the right side of the working box separately; a transverse plate is mounted at the upper ends of the two moving and lifting mechanisms; an auxiliary material rolling mechanism is mounted at the middle of the transverse plate; two vibration extrusion mechanisms are symmetrically mounted on the two sides of the transverse plate separately; and the supporting mechanisms, the moving and lifting mechanisms, the auxiliary material rolling mechanism and the vibration extrusion mechanisms well coordinate with each other to complete the automatic processing and manufacturing process of shaving boards. According to the automatic processing and manufacturing equipment for shaving boards, the problems that during the conventional processing process of shaving boards, the occupied space of the equipment is large, stirred materials are easy to cake after being fed into a die to affect the quality of shaving boards, the die needs to be manually adjusted when shaving boards with different thicknesses are processed, the labor intensity of working personnel is improved and the working efficiency is reduced are solved, and the function of automatically processing and manufacturing shaving boards is realized.

Owner:临沂兴滕人造板机械有限公司

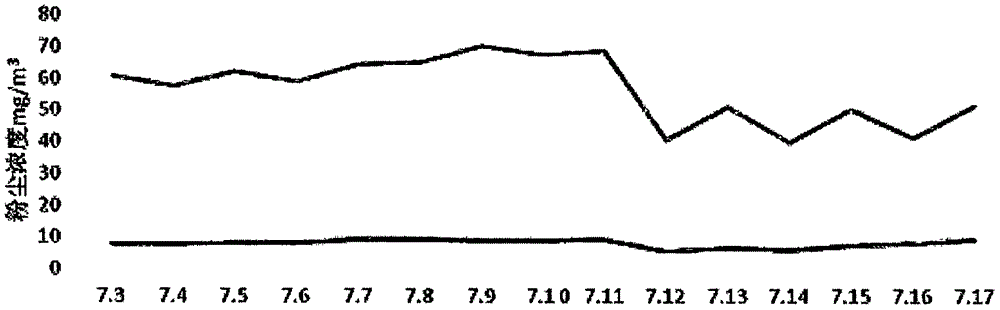

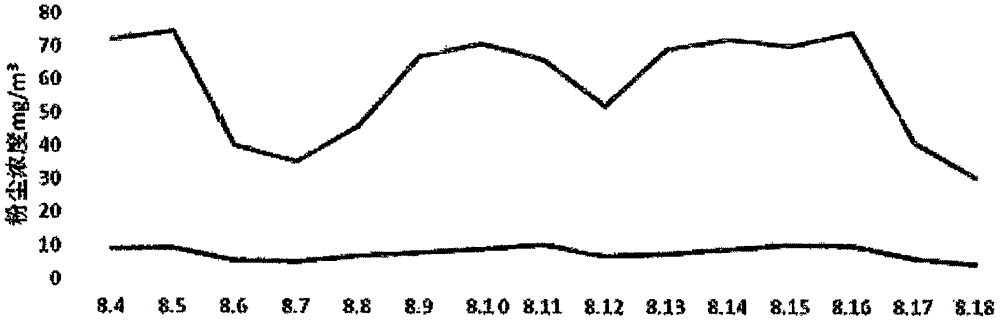

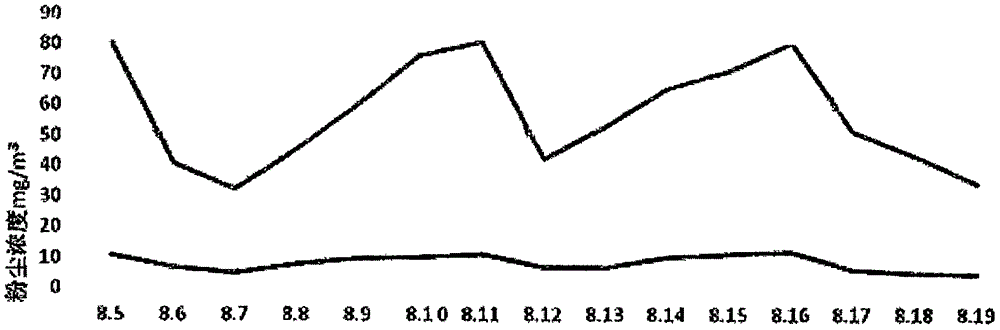

Stockyard dust emission inhibitor as well as preparation method and application thereof

InactiveCN106479277AHigh strengthQuality improvementLiquid surface applicatorsStarch dervative coatingsEmulsionPolyvinyl alcohol

The invention provides a stockyard dust emission inhibitor as well as a preparation method and an application thereof. The stockyard dust emission inhibitor is prepared from components forming the formula in parts by weight as follows: 5-20 parts of oxidized starch, 0.8-2.0 parts of modified cellulose, 2-10 parts of EVA emulsion, 0.6-0.8 parts of polyvinyl alcohol, 0.1-1 part of an emulsifier, 0.2-2 parts of a penetrant, 0.05-0.2 parts of a coalescing agent and the balance of water. The preparation method of the stockyard dust emission inhibitor comprises steps of preparing the oxidized starch, pretreating the raw materials, premixing the raw materials and mixing and stirring the raw materials. The dilution ratio and the spray times are determined according to the actual dust capacity, the dust emission inhibitor is diluted with water in a ratio of the dust emission inhibitor to water being 1:(10-20), then the solution is injected into high-pressure spray equipment and uniformly sprayed to the surfaces of stock piles in the dosage of 1.5 L / m<2> or higher, after the solution is dried, a polymer solidified layer with certain strength is formed on the stock surface, and stockyard dust emission inhibition is completed. The stockyard dust emission inhibitor is stable in quality, good in film-forming performance, high in solidified layer strength and wide in suitable material range, improves the environment after spray, can resist heavy weather and is long in spray cycle.

Owner:TANGSHAN JINSHA WATER TREATMENT COMPANY

High-efficiency humidifying treatment device special for chipboard

ActiveCN107042557AQuality will not affectImprove stabilityWood dampingEngineeringUltimate tensile strength

Owner:丰林亚创(惠州)人造板有限公司

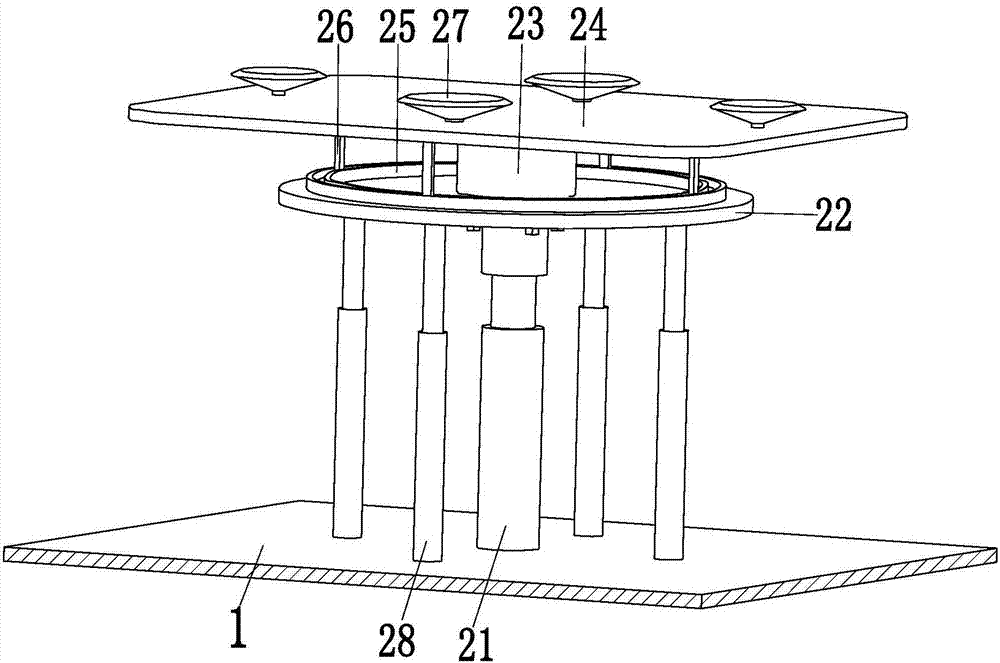

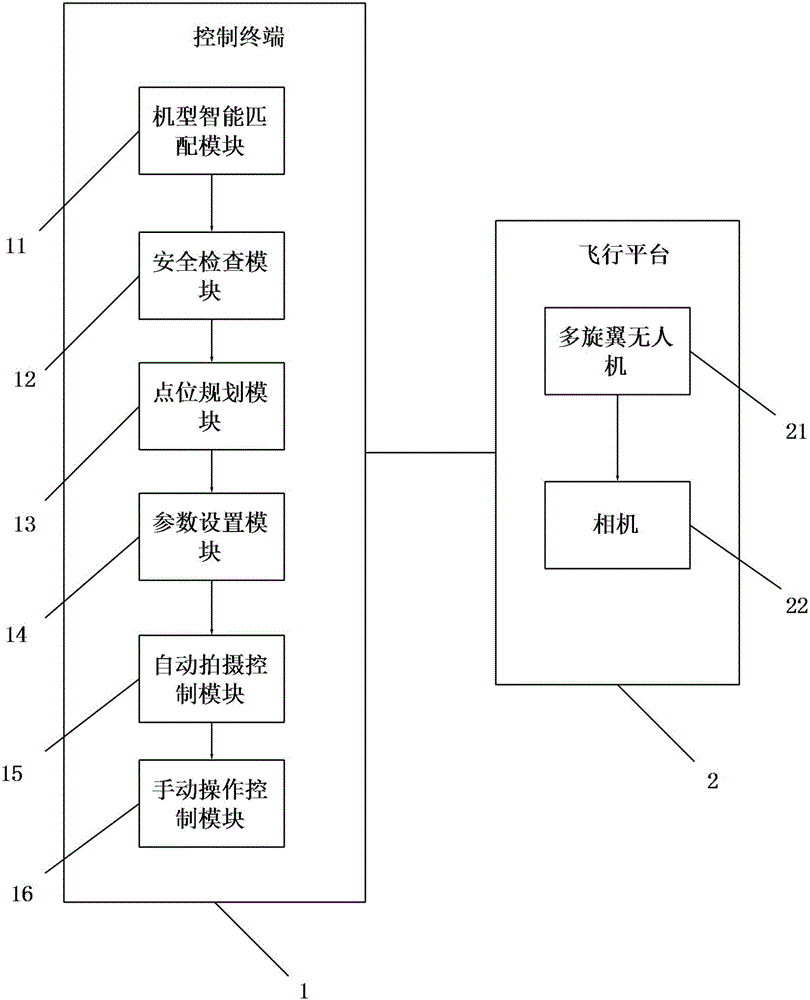

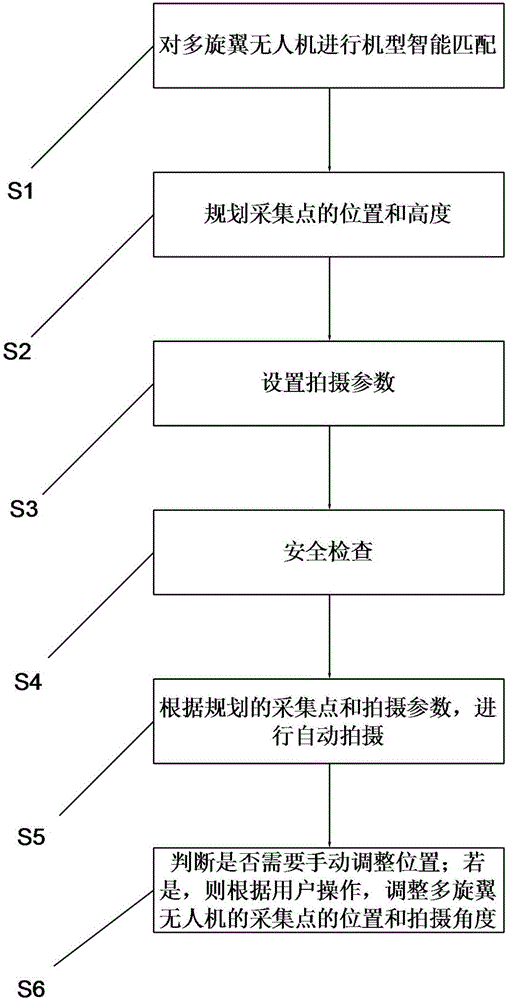

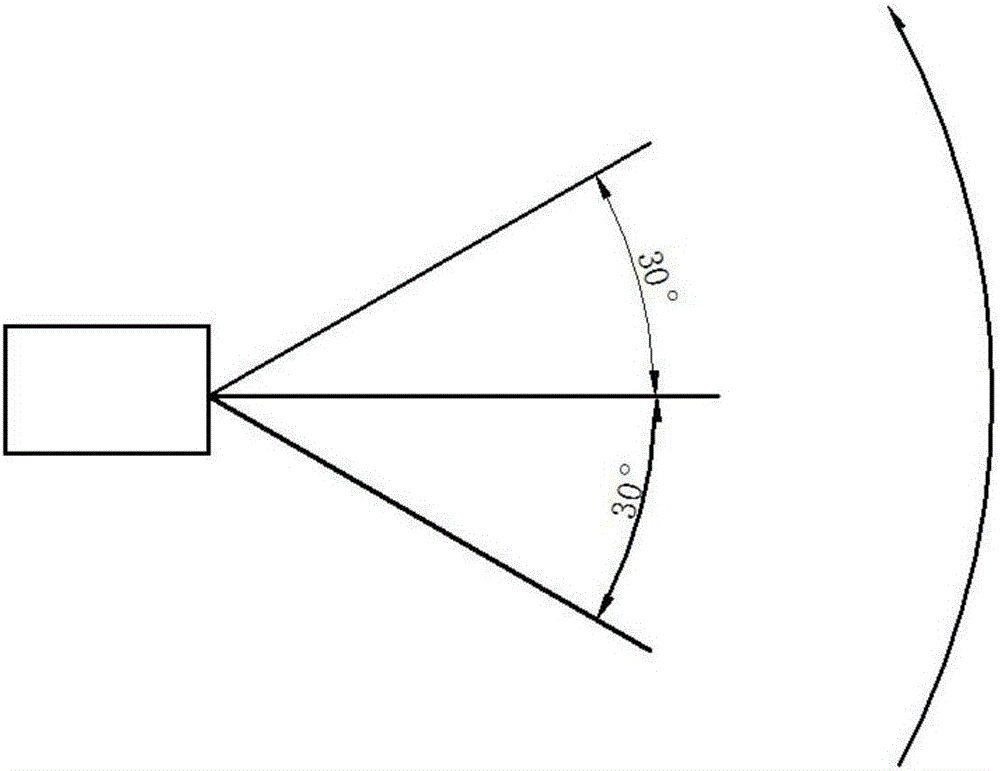

Full-automatic air panoramic data collection system and method, and control terminal

InactiveCN106231191AReduce energy consumptionImprove shooting efficiencyTelevision system detailsColor television detailsComputer terminalEngineering

The invention relates to a full-automatic air panoramic data collection system. The system comprises a control terminal and a flying platform, wherein the flying platform comprises a multi-rotor unmanned aerial vehicle (UAV) and a camera mounted on the multi-rotor UAV; the control terminal comprises a point location planning module used for planning the location and the height of a collection point, and a parameter setting module used for setting a horizontal spacing angle and a vertical inclination angle; the multi-rotor UAV carries out positioning and shooting angle adjustments according to the planned collection point and set parameters; and the camera is used for shooting when the multi-rotor UAV is located at the set collection point and the set shooting angles. Compared with the prior art, the system and the control terminal provided by the invention have the advantages that automatic shooting is achieved, and manual operations are not required, so that the accuracy is high.

Owner:广州优飞信息科技有限公司

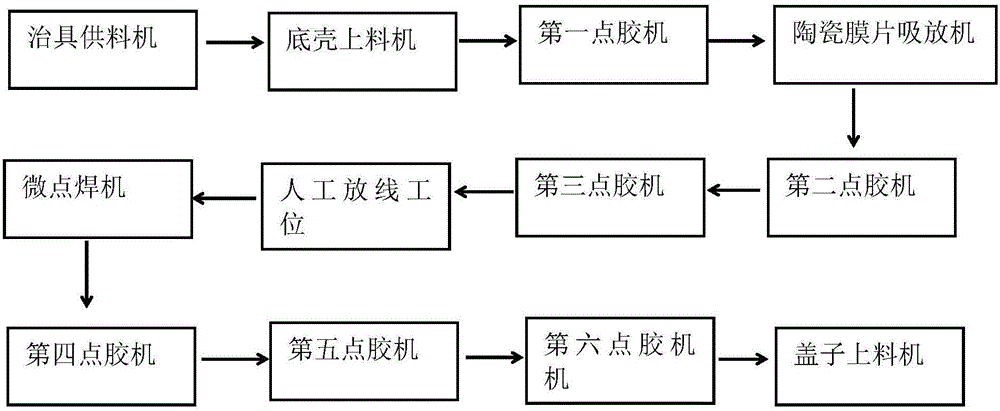

Buzzer automatic assembling equipment and assembling technology

ActiveCN106763041AImprove assembly efficiencySmall footprintLiquid surface applicatorsMaterial gluingEngineeringAssembly line

The invention discloses buzzer automatic assembling equipment. The buzzer automatic assembling equipment comprises a machine frame, wherein an assembly line is arranged on the table board of the machine frame, and runs through all stations on the assembling equipment; and according to an assembling technology, the assembling equipment sequentially comprises a jig feeder, a bottom shell feeder, a first glue dispenser, a ceramic film sheet sucking and releasing machine, a second glue dispenser, a third glue dispenser, a manual setting-out station, a miniature spot welding machine, a fourth glue dispenser, a fifth glue dispenser, a sixth glue dispenser and a cap feeder. The buzzer automatic assembling equipment disclosed by the invention has the advantages that the whole buzzer automatic assembling technology can be completed, the assembling efficiency is improved, and the area occupied by the equipment is reduced; and automatic jig feeding is realized by the jig feeder, so that manual feeding is not needed, not only efficiency is improved, but also human input and labor cost are reduced.

Owner:KINGSTATE ELECTRONICS SUZHOU

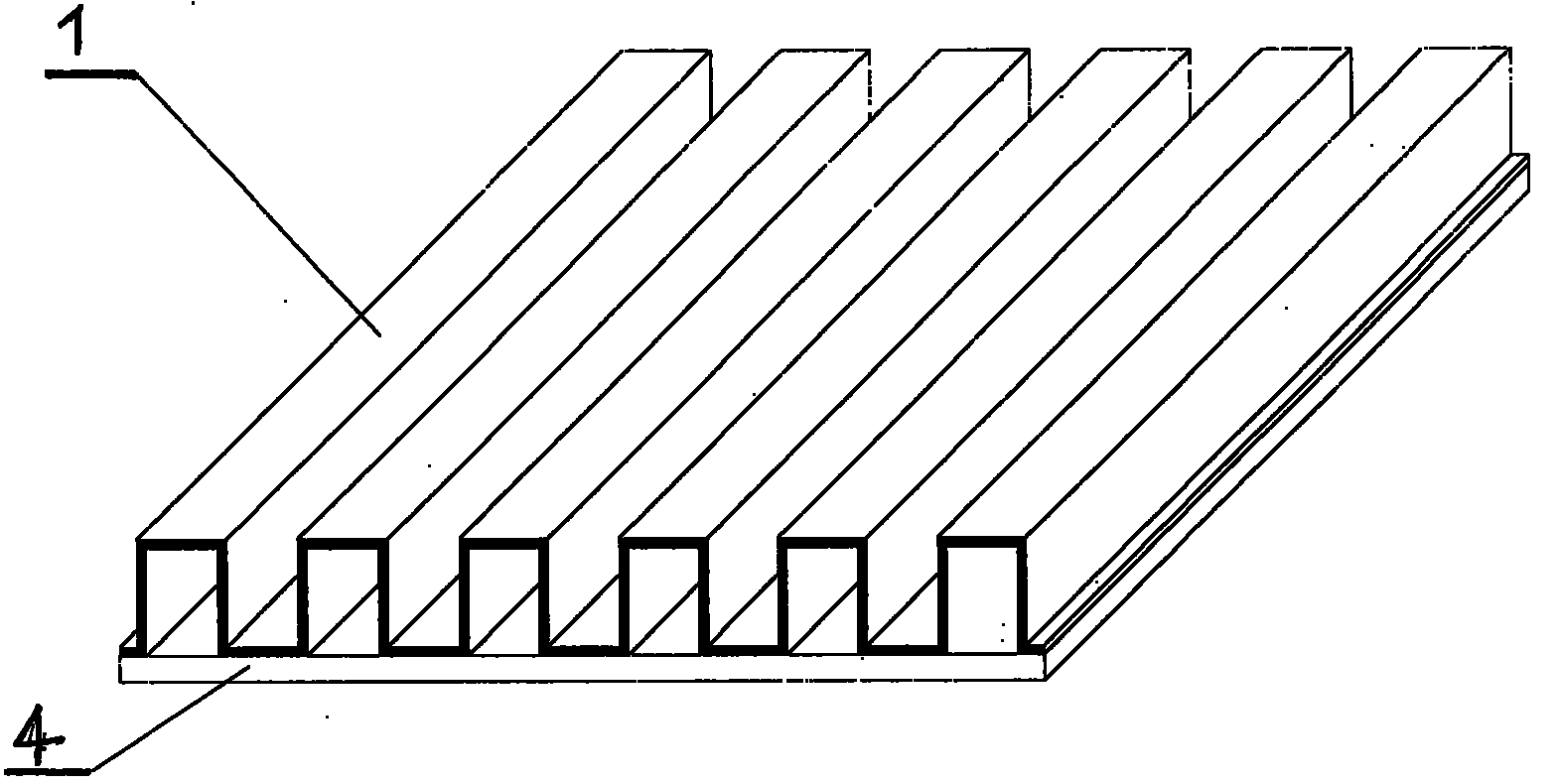

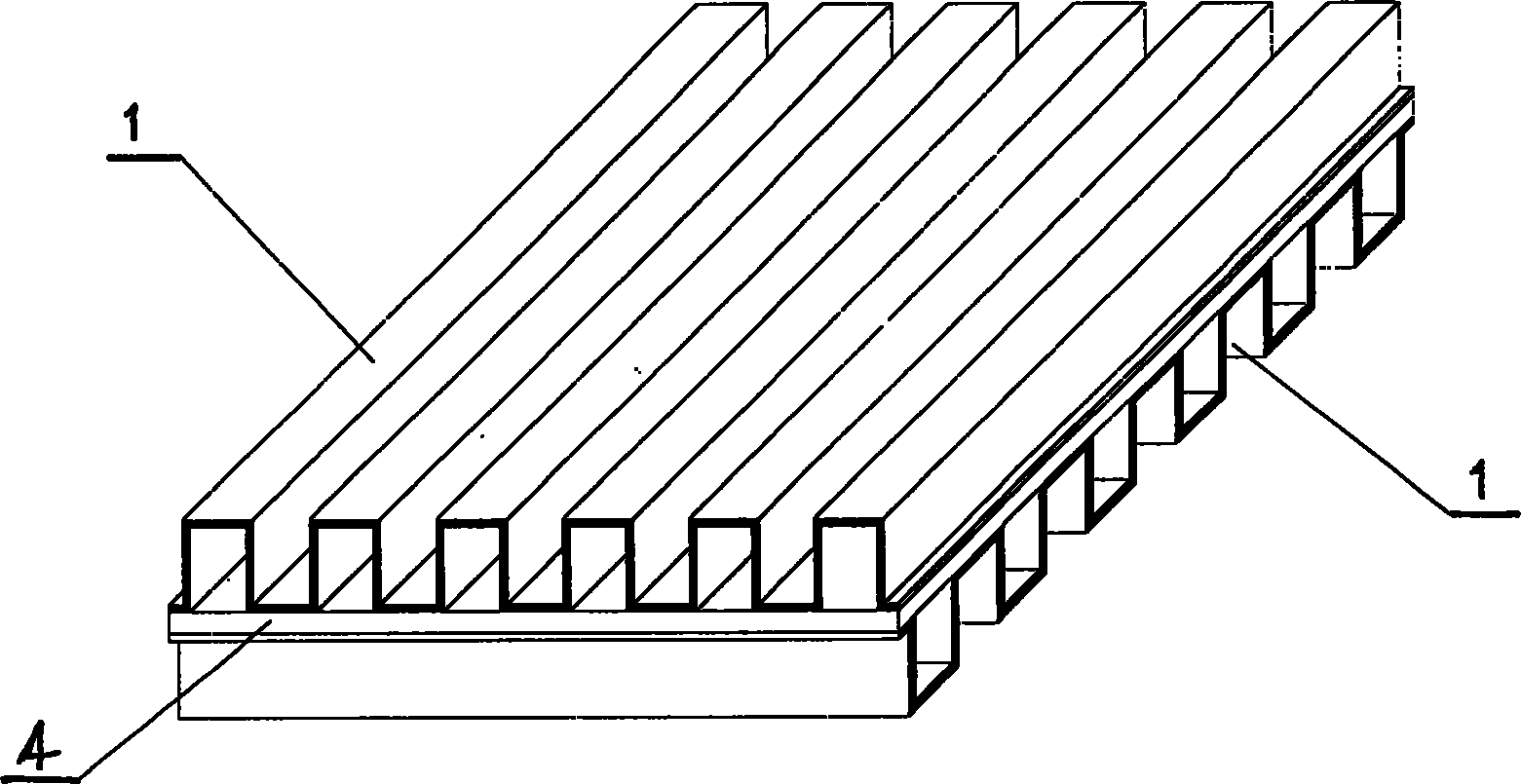

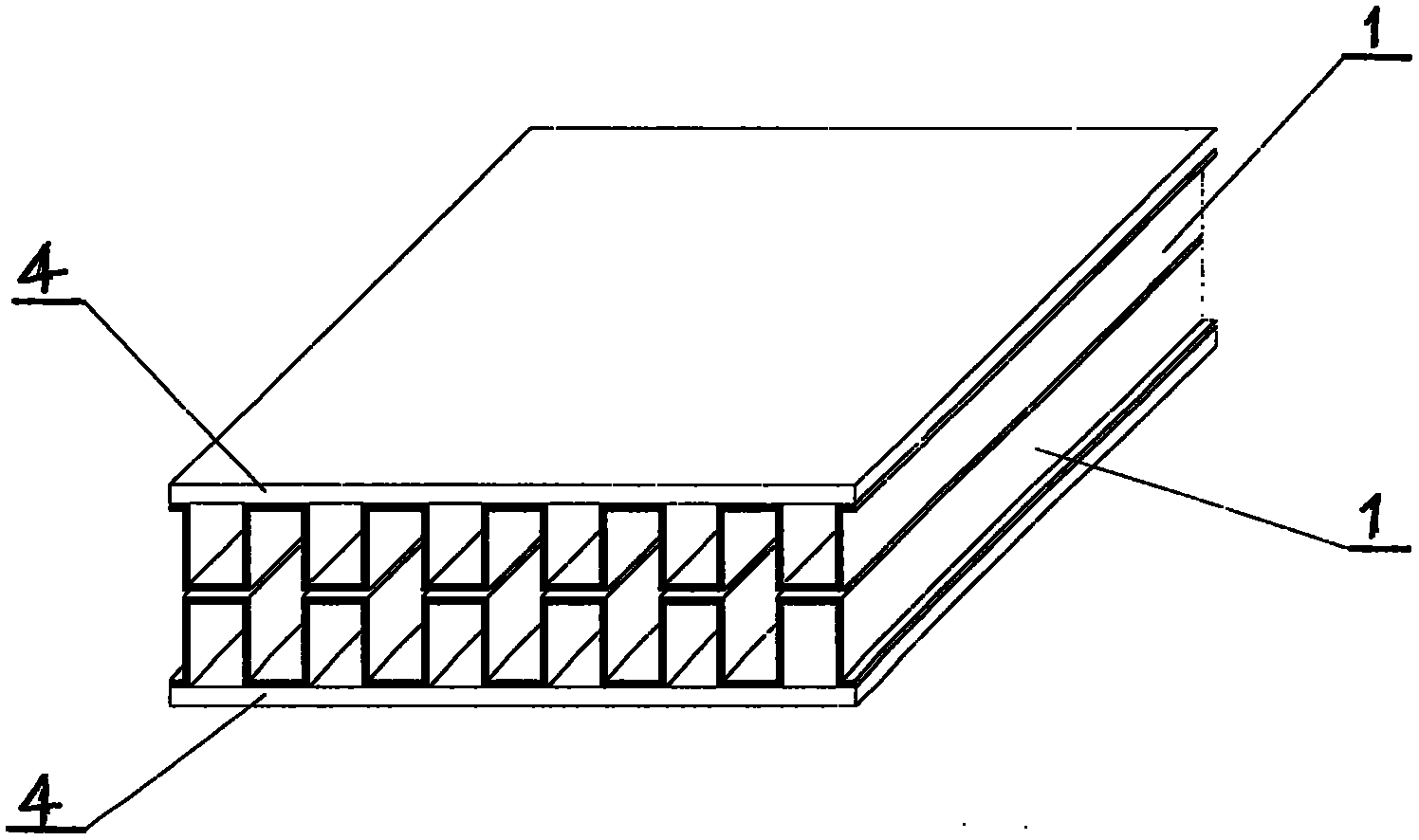

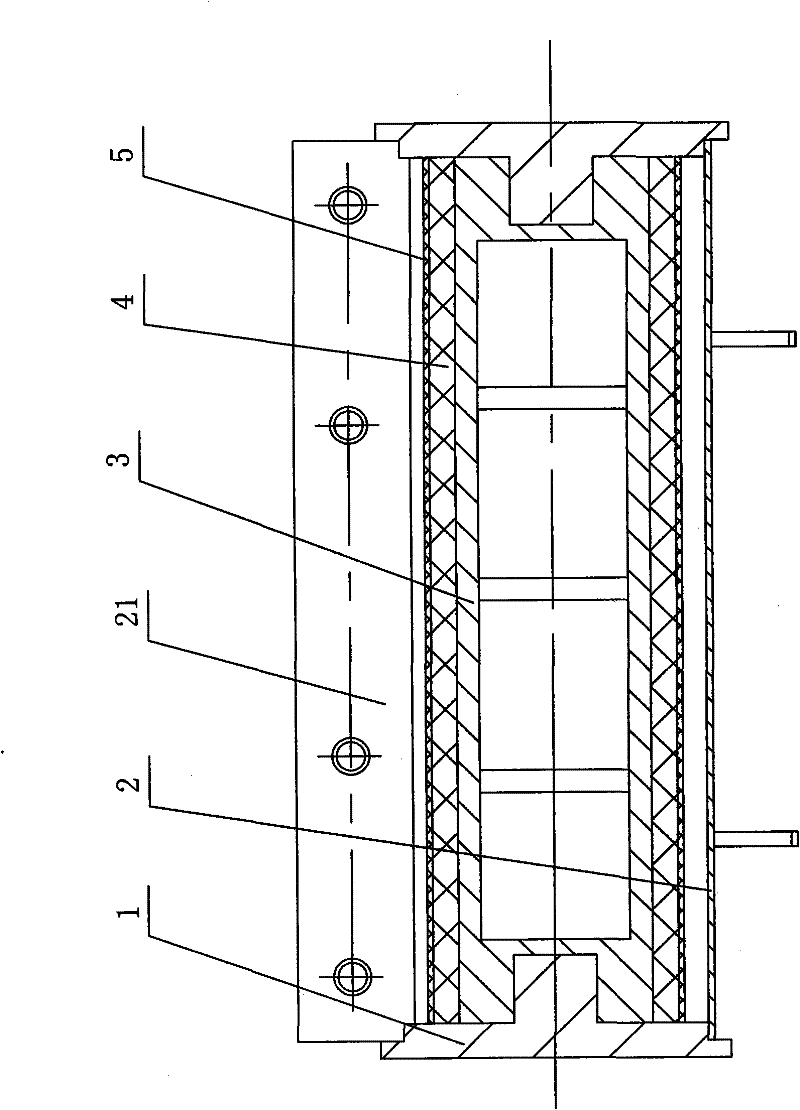

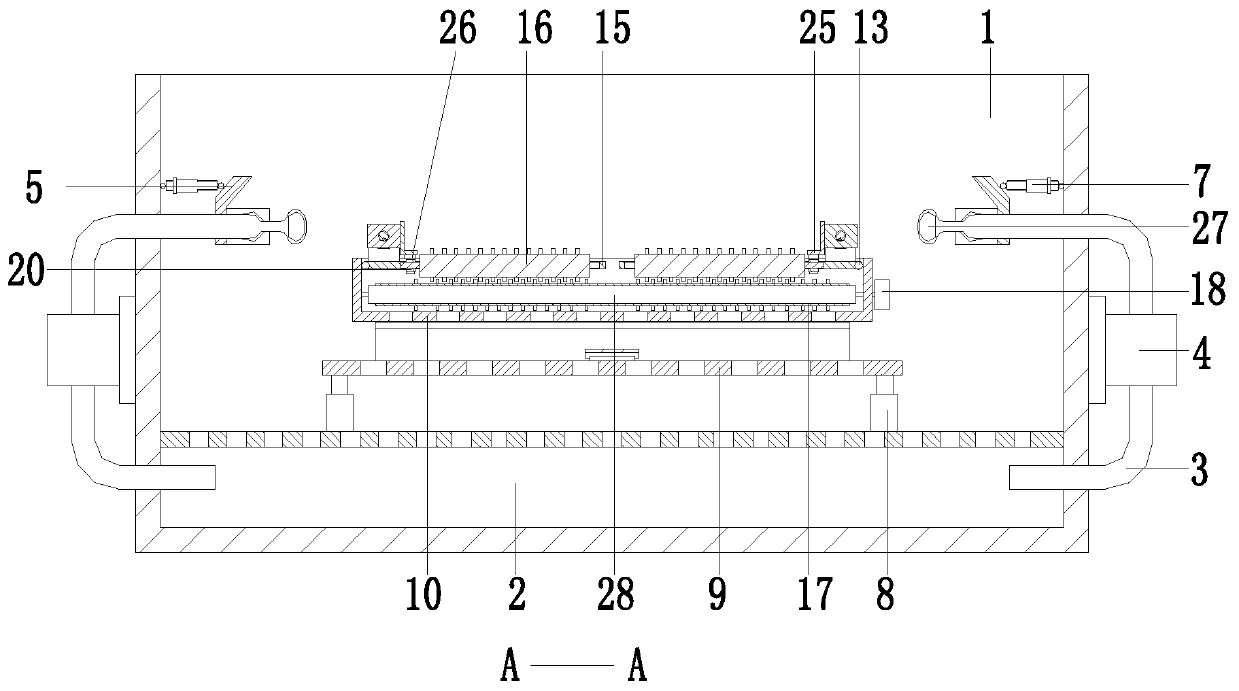

Plate-fin heat exchanger

InactiveCN104296566AQuality assuranceQuality will not affectStationary plate conduit assembliesEngineeringHeat exchanger

The invention discloses a plate-fin heat exchanger. According to the abstract drawing of the plate-fin drawing, all passageway units of a middle partition plate-fin structure (8) are overlapped and arrayed at intervals in a 90-degree crossing mode, and outer partition plate-fin structures (7) are arranged on the two outer sides of the middle partition plate-fin structure (8); at the moment, a complete plate-fin can be assembled only by installing sealing strips (3) in place, then a diversion plate (2), a connecting pipe (5) and an end socket (6) are installed according to requirements, and the whole plate-fin heat exchanger can be used. The outer partition plate-fin structures (7) and the middle partition plate-fin structure (8) can be independently manufactured, and therefore manufacturing can be independently achieved; in this way, the combining quality can be ensured, no large device is needed when a large-size heat exchanger is produced, the manufacturing difficulty is lowered, and cost is reduced. The heat exchange capacity of the plate-fin heat exchanger is determined by the area and shape of fins (1) and the combining quality of the fins (1) and partition plates (4), and therefore the heat exchange capacity of the plate-fin heat exchanger designed and produced through the method is not lower than that of a current well-known plate-fin heat exchanger.

Owner:无锡协丰节能技术有限公司

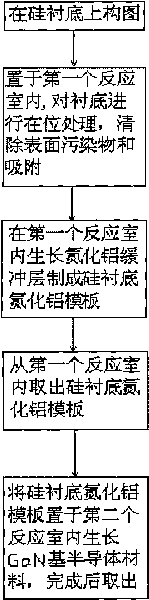

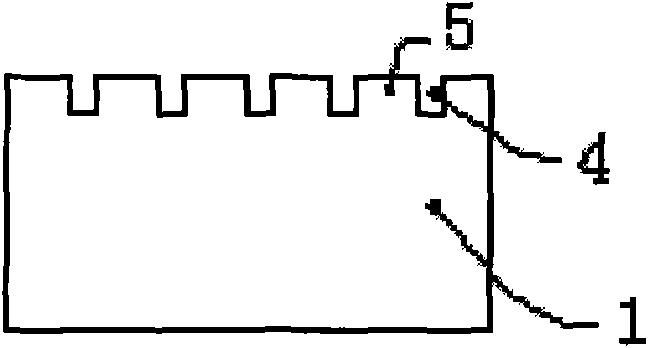

Method for manufacturing silicon substrate GaN-based semiconductor material

InactiveCN101719465AImprove stabilityAvoid remeltingSemiconductor/solid-state device manufacturingSemiconductor materialsLight-emitting diode

The invention provides a method for manufacturing a silicon substrate GaN-based semiconductor material, aiming at solving the problem of re-melting a silicon surface by Ga in the process of extending GaN-based semiconductor material to improve the quality of the product and the production efficiency. The method comprises the following steps of: generating an aluminum nitride buffer layer on the silicon substrate in a reaction chamber of a first MOCVD specially for growing the aluminum nitride buffer layer, and taking out the aluminum nitride buffer layer after the step is completed to form a silicon substrate aluminum nitride template for later use; and placing the silicon substrate aluminum nitride template for later use into a reactor of a second MOCVD for growing a GaN-based semiconductor material to extend the GaN-based semiconductor material; and taking out the silicon substrate aluminum nitride template after the step is completed to form a silicon substrate GaN-based semiconductor material. The method can be applied to production manufacture of light-emitting diodes, diode lasers, power devices and the like.

Owner:LATTICE POWER CHANGZHOU

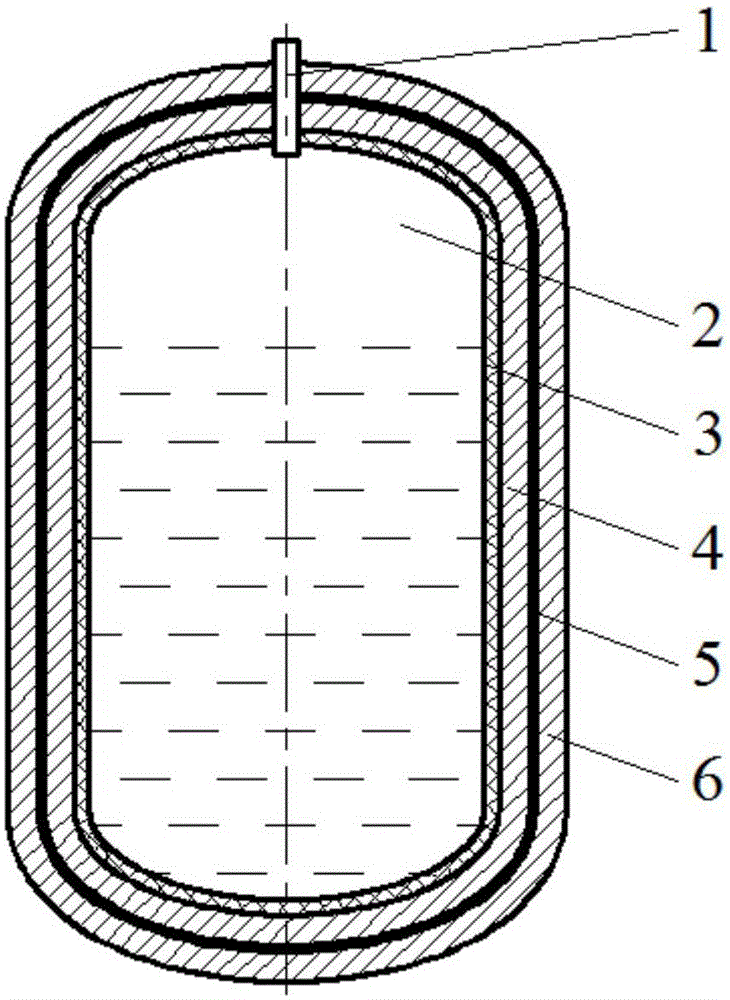

Air-ground dual-purpose composite heat insulation structure based on air cooling screen

ActiveCN105065855ALight in massQuality will not affectThermal insulationPipe protection by thermal insulationEvaporationVolumetric Mass Density

The invention discloses an air-ground dual-purpose composite heat insulation structure based on an air cooling screen. The structure is installed outside a low-temperature storage tank and is characterized by comprising a polyurethane foam heat insulating layer and a variable-density heat insulating layer, the polyurethane foam heat insulating layer adheres to the outer wall of the low-temperature storage tank, and the outer wall of the polyurethane foam heat insulating layer is coated with the variable-density heat insulating layer; the variable-density heat insulating layer is composed of three layers, namely the low-density layer, the intermediate-density layer and the high-density layer in sequence starting from the outer wall of the polyurethane foam heat insulating layer, and the three layers are of the same thickness and are machined from eight heat insulating layers, fourteen heat insulating layers and twenty heat insulating layers in sequence. By the adoption of the structure, heat leakage of the low-temperature storage tank of a spacecraft is reduced passively to the minimum, so that evaporation of low-temperature propellant is reduced and the in-orbit life of the spacecraft is prolonged; furthermore, the structure has the advantage of being light.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Process for producing bauxite homogenized materials in rotary kiln

The invention relates to a process for producing bauxite homogenized materials in a rotary kiln, which comprises the following steps: (1) crushing raw bauxite ores, then carrying out deironing processing on the obtained raw bauxite ores so as to obtain a material a; (2) mixing the material a with water, sodium carboxymethyl starch, aluminium dihydrogen phosphate and polymeric AlCl3, then carrying out ball-milling on the obtained mixture so as to obtain a clay material b, wherein the amount of the sodium carboxymethyl starch is 0.3 to 0.6 percent of that of the material a, the amount of the aluminium dihydrogen phosphate is 0.1 to 0.3 percent of that of the material a, the amount of the polymeric AlCl3 is 0.2 to 0.5 percent of that of the material a, and the amount of the water is 30 to 50 percent of that of the material a; and (3) carrying out dehydration, molding and drying on the clay material b sequentially, and then sending the dehydrated, molded and dried clay material b to the rotary kiln to calcine so as to obtain the bauxite homogenized material. The method of the invention rewrites the history that the bauxite homogenized materials can not be produced in the rotary kiln, and the cost of bauxite homogenized material per ton can be reduced by **-**, therefore, the method of the invention has remarkable economic benefits.

Owner:SANMENXIA XINYANGSHAO SYNTHETIC MATERIALS

Method of preparing large-dimension cadmium sulfide film by chemical water-bath method

ActiveCN103643225ASimple equipmentReduce thicknessLiquid/solution decomposition chemical coatingIonCompound (substance)

The invention relates to a method of preparing a large-dimension cadmium sulfide film by a chemical water-bath method. The method comprises the following steps: fixing one surface, which does not need to be coated with a film, of at least one substrate in a reaction container in a closed manner; injecting reaction liquor containing a cadmium salt, a sulfur source, ammonia water and deionized water into the reaction container, and then sealing the reaction container, wherein volume of the reaction liquor is smaller than that of the reaction container; horizontally immersing the sealed reaction container into a constant-temperature water bath oscillator, heating and carrying out water-bath, so that the reaction container upwards circles round and reciprocates in the horizontal direction or uniformly mixes the reaction liquor without stop in a moving mode of swinging up and down by taking a middle axle as a shaft center to deposit a uniform cadmium sulfide film on one un-sealed surface of at least one substrate; and after depositing the cadmium sulfide film to needed thickness, taking out, cleaning and drying to prepare the large-dimension cadmium sulfide film.

Owner:山东中科泰阳光电科技有限公司

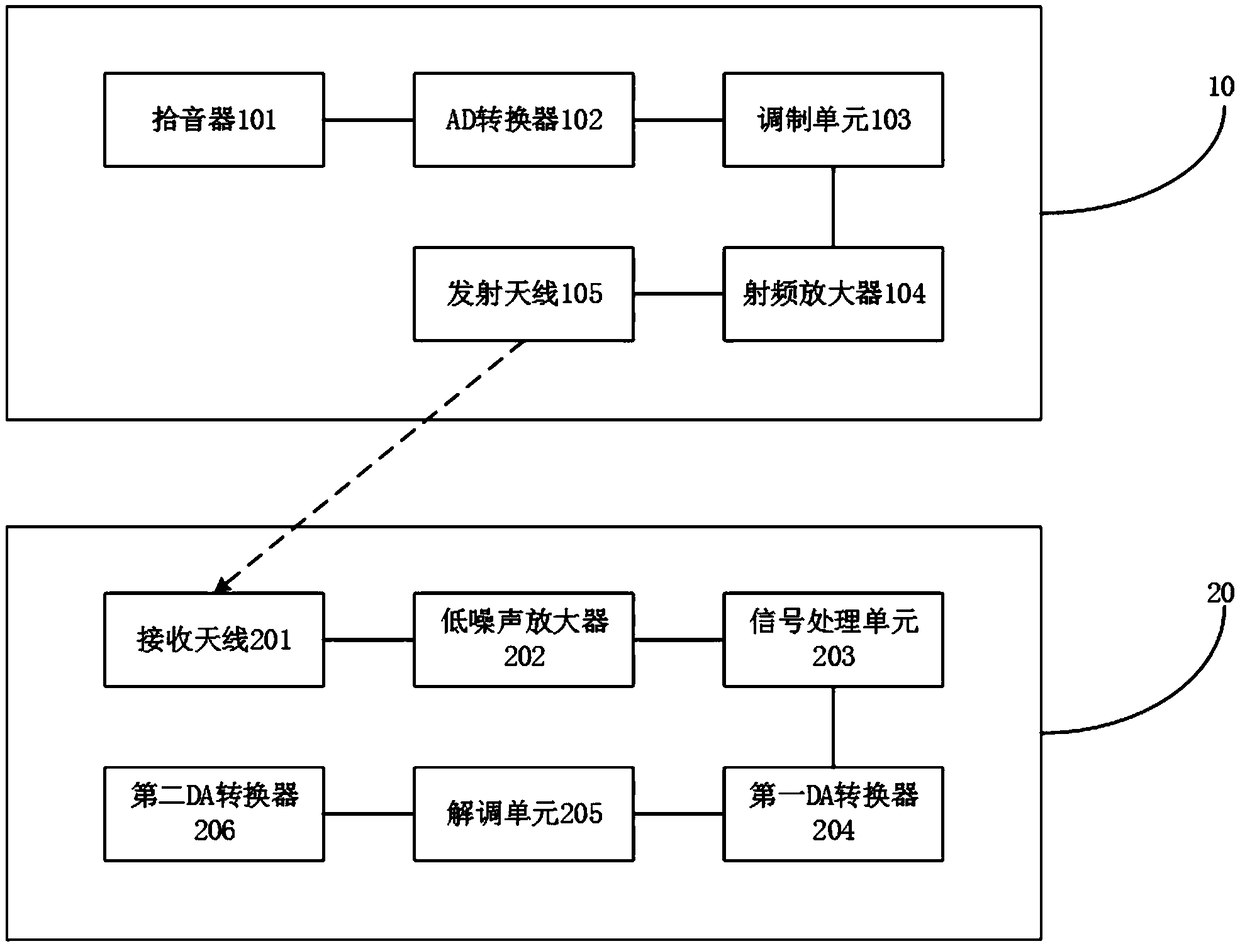

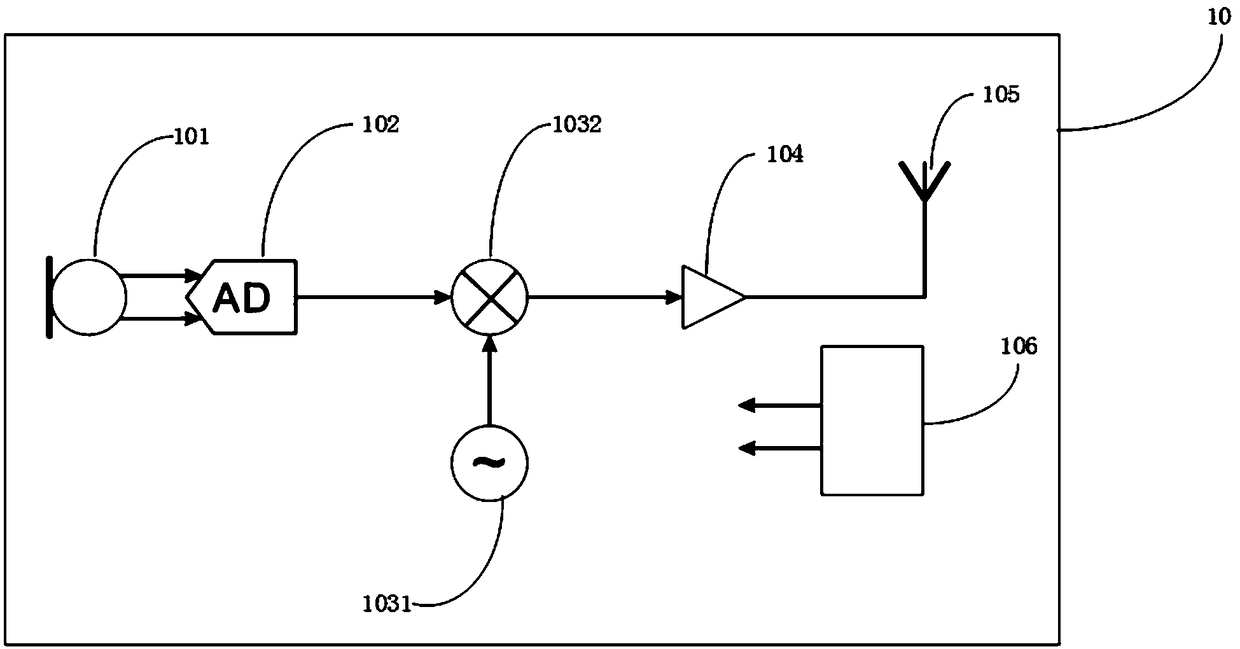

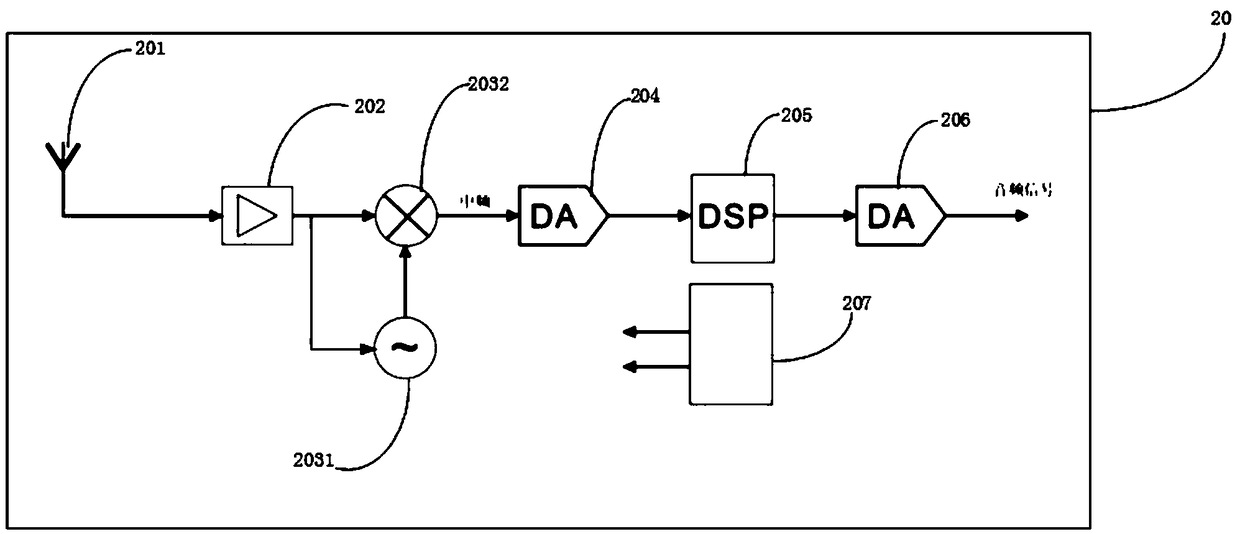

K-song system, wireless microphone and signal transmission device thereof

PendingCN109243414AImprove anti-interference abilityImprove qualityElectrophonic musical instrumentsSpeech analysisWireless microphoneCarrier signal

A K-song system A wireless microphone and a signal transmission device thereof, the signal transmission device comprises a transmitting end and a receiving end, the transmitting end includes a pickup,AD converter, modulation unit, RF Amplifiers and Transmitter Antennas, The receiving end comprises a receiving antenna, low noise amplifier, signal processing unit, first DA converter, the demodulation unit and the second DA converter, At that transmit end, the audio signal is converted into a digital audio signal by an AD convert, A modulation unit modulates the digital audio signal into a high-frequency digital signal, A high-frequency digital signal is transmitted after being power-amplified, the high frequency carrier signal is canceled at the receiving end by the inverted high frequencycarrier signal generated by the signal processing unit, The first DA converter performs digital-to-analog conversion, the demodulation unit restores the digital audio signal, and the second DA converter converts the digital audio signal into an audio signal for output without compressing and expanding the audio signal, so as to improve the quality of the output audio signal.

Owner:厦门轻唱科技有限公司

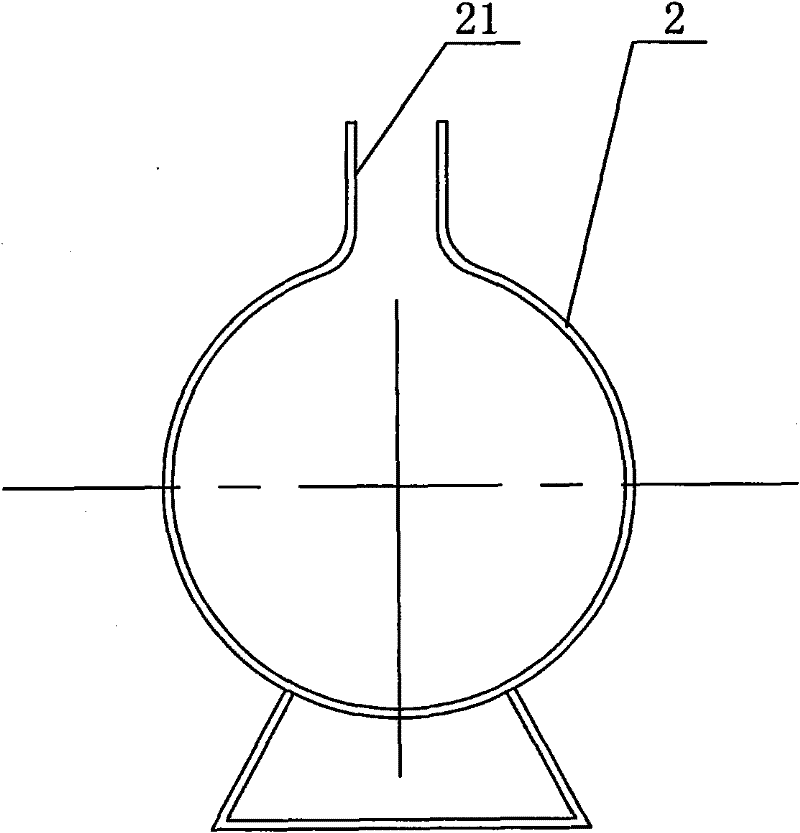

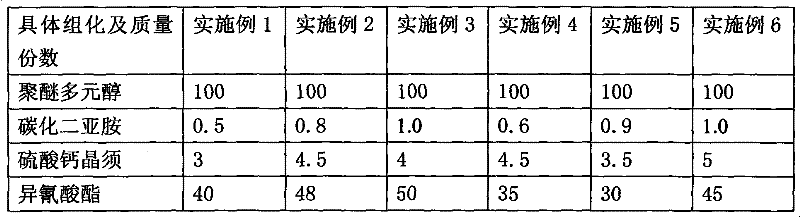

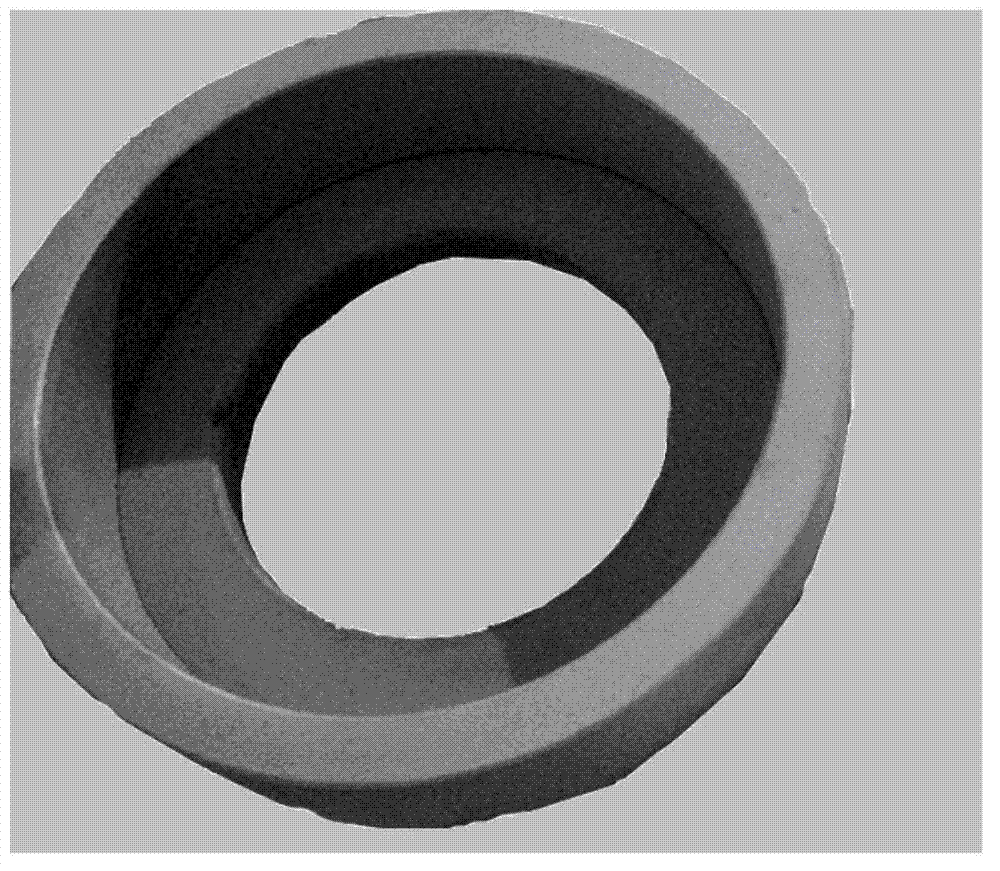

Method for preparing polyurethane fiber guide wheel used for cutting silicon slice

The invention relates to a method for preparing a polyurethane fiber guide wheel used for cutting a silicon slice. The method comprises the following steps of: mixing 0.5-1.0 part of carbodiimide and 3-5 parts of calcium sulphate crystal whisker with 100 parts of polyether polyol, then stirring, heating and dehydrating the materials in a reaction kettle, and adding 30-50 parts of isocyanate to the reaction kettle for a polymerization reaction to prepare a prepolymer and defoaming the prepolymer; mixing the defoamed prepolymer with a liquid polyurethane solidifying agent in the ratio of 100: (15-30) in a casting machine to prepare a polyurethane liquid material, placing an assembled die and a metal spindle into a heating box for heating, and pouring the polyurethane liquid material to a hollow cavity between an adhesive layer and the die and to a hooped pouring opening; and placing the die poured with the polyurethane liquid material into the heating box, then carrying out vulcanization forming treatment, demolding, carrying out additional vulcanization, and machining a guide groove on the surface of a polyurethane coating. The method for preparing the polyurethane fiber guide wheel used for cutting the silicon slice has the characteristics of light weight and improved production efficiency and quality of the guide wheel.

Owner:CHANGZHOU JUNHE TECH

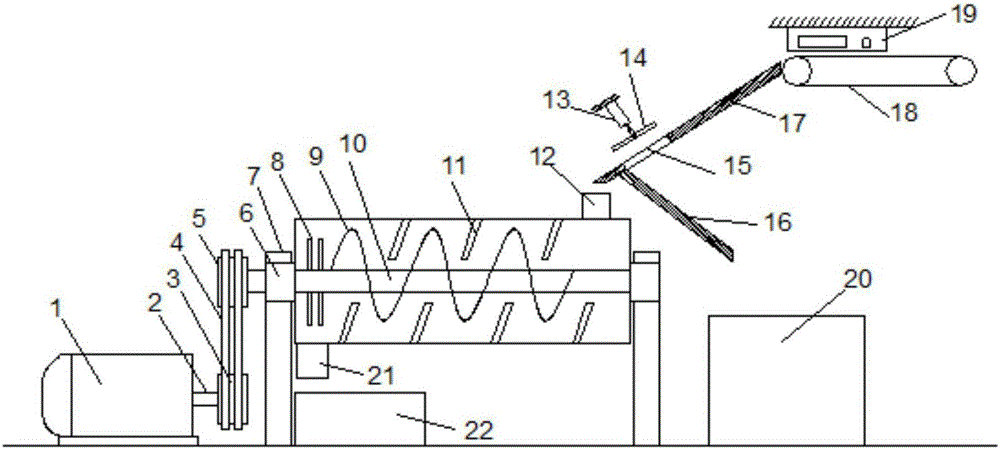

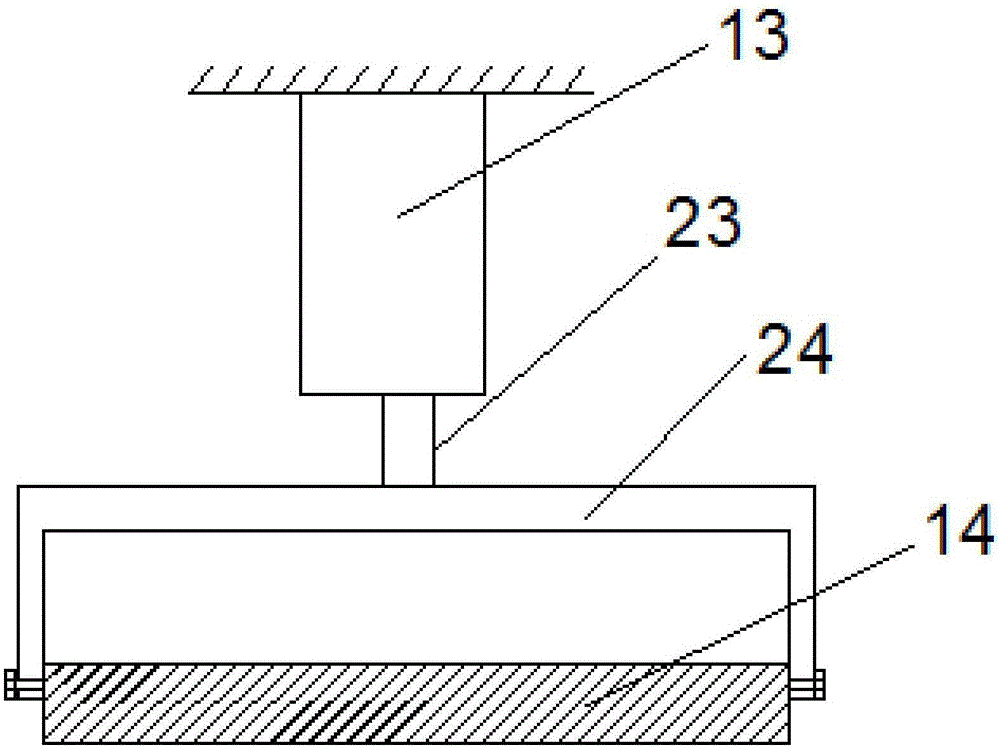

Automatic detecting and metal separating fertilizer crusher

The invention discloses an automatic detecting and metal separating fertilizer crusher. The automatic detecting and metal separating fertilizer crusher comprises a fertilizer crusher body and a metalimpurity removing device. The fertilizer crusher comprises two supporting frames. A smashing cylinder is arranged between the supporting frames. The smashing cylinder is internally provided with a horizontally arranged rotating shaft. The supporting frames are provided with bearings matched with the rotating shaft. The rotating shaft is sleeved with spiral smashing teeth, and the inner wall of thesmashing cylinder is fixedly provided with a plurality of helical teeth matched with the spiral smashing teeth. The rotating shaft extends out of the left side of the smashing cylinder to be connected with a belt wheel, the belt wheel is in transmission connection with a drive wheel through a belt, and the drive wheel is connected with a motor through a drive shaft. The automatic detecting and metal separating fertilizer crusher is reasonable in structural design and convenient to use, fertilizers containing metal impurities can be automatically detected and classified, the quality of the finished fertilizers can be guaranteed, the machine abrasion of the fertilizer crusher is reduced, and the service life is prolonged; and meanwhile, the smashing effect is good, blockage is not prone tobeing caused, and the automatic detecting and metal separating fertilizer crusher is suitable for automatic fertilizer production.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

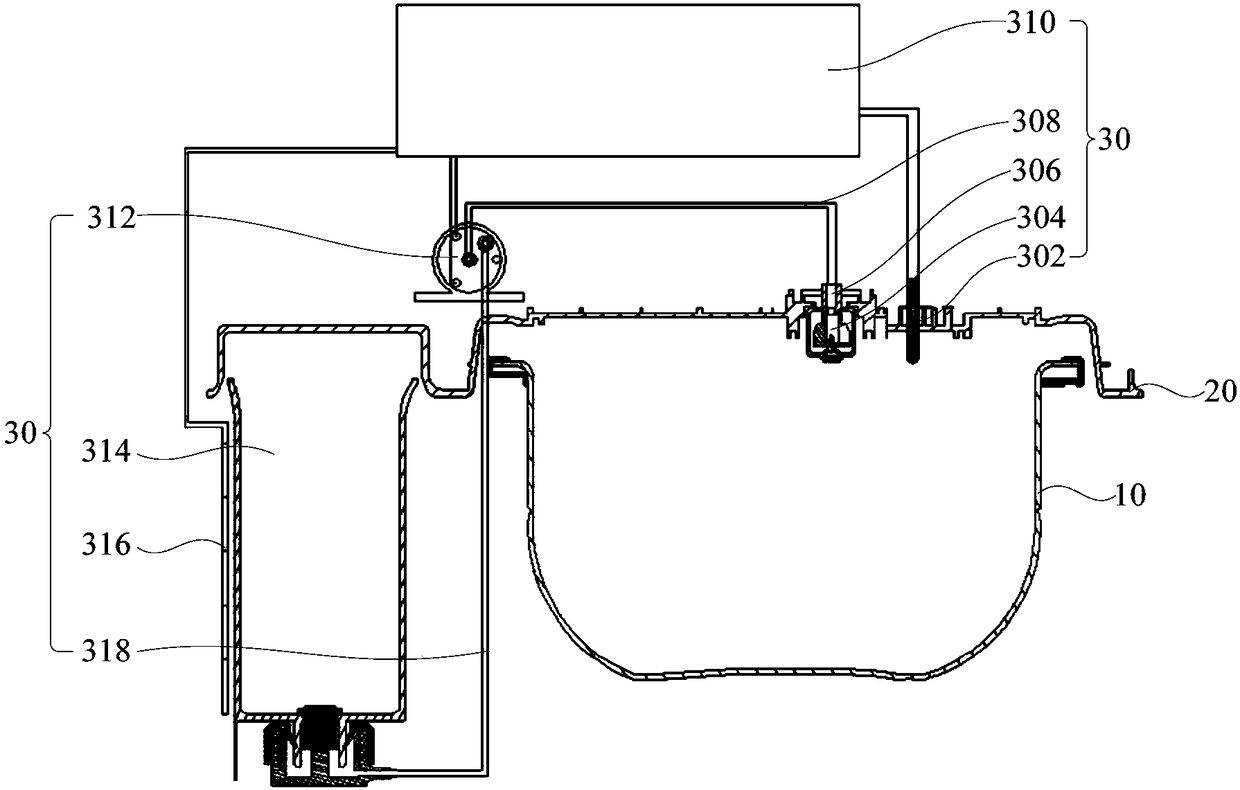

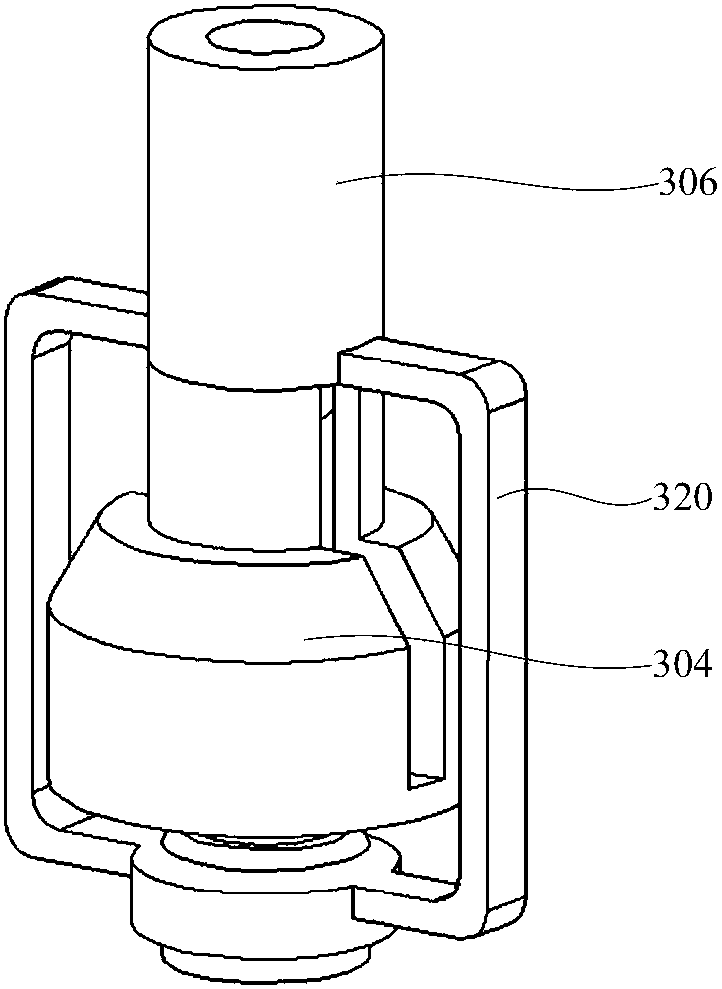

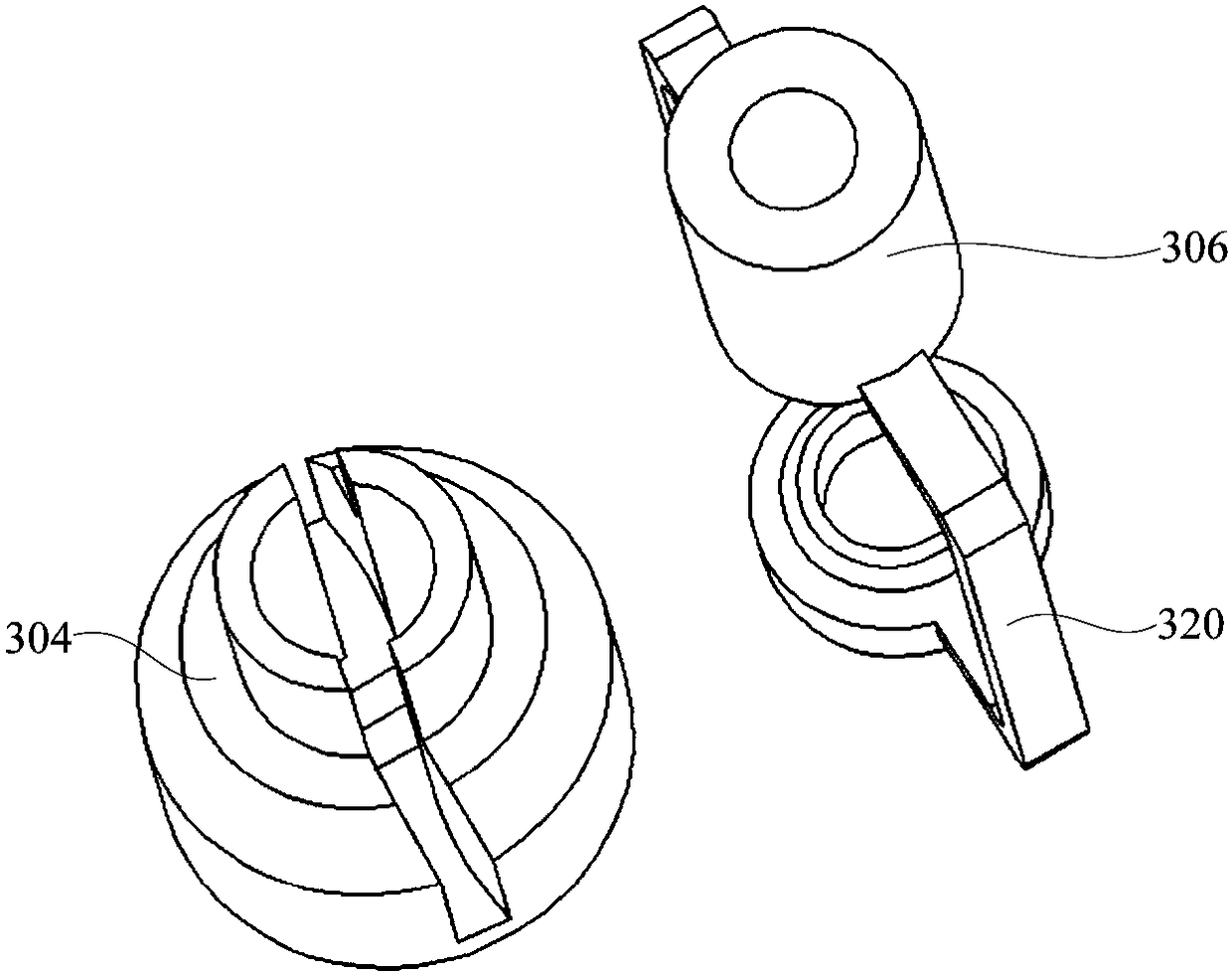

Anti-spilling assembly, method and system and cooking utensil

ActiveCN108201343AIncrease rotational torqueSimple structureBoiling over preventionHome appliance efficiency improvementAdditive ingredientSpray nozzle

The invention provides an anti-spilling assembly, method and system and a cooking utensil. The anti-spilling assembly comprises a water inlet pipe, a spraying nozzle and an anti-spilling detection device, the water inlet pipe is located above an inner pot, and a water outlet end of the water inlet pipe faces the inner pot; the spraying nozzle is provided with a cavity, a water inlet end of the spraying nozzle is connected with the water outlet end of the water inlet pipe, and the side wall of the spraying nozzle is provided with at least one water spraying port extending in the height direction of the spraying nozzle; the anti-spilling detection device is arranged on a cover body, connected with the cover body and used for controlling the spraying nozzle to start spraying water or stop spraying water. Through the arrangement of the anti-spilling detection device and the spraying nozzle, when the anti-spilling detection device detects that ingredients cooked in the inner pot are about to spill, the spraying nozzle is controlled to be opened to spray water into the inner pot, bubbles generated by boiling can be effectively reduced, and it is ensured that the ingredients in the innerpot can continuously be heated by the cooking utensil without spilling.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

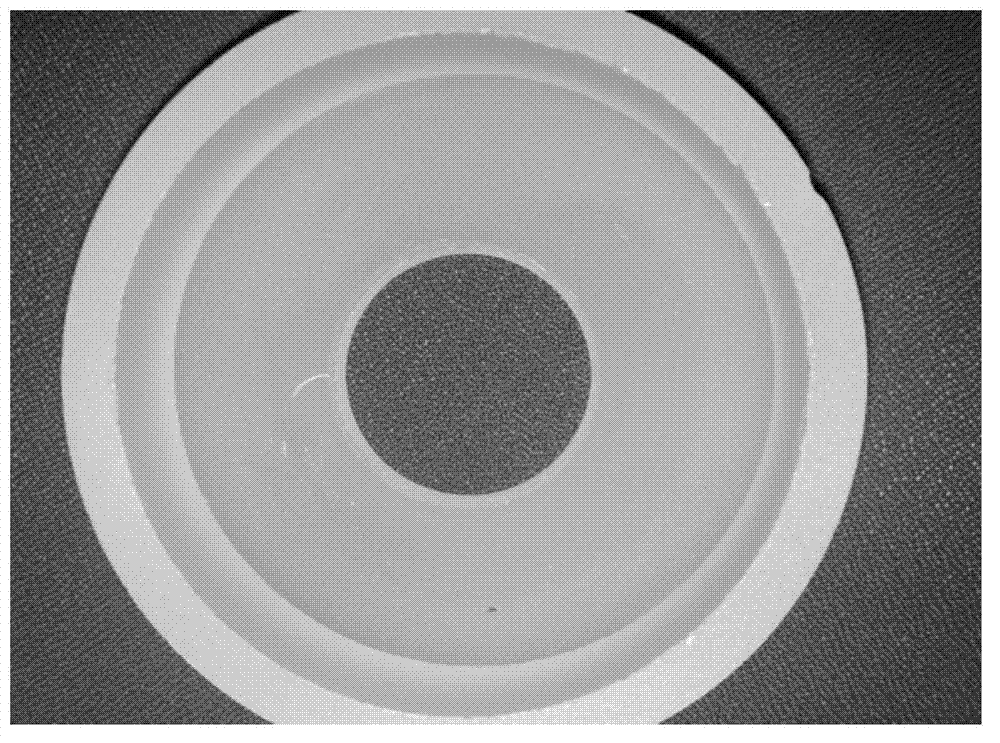

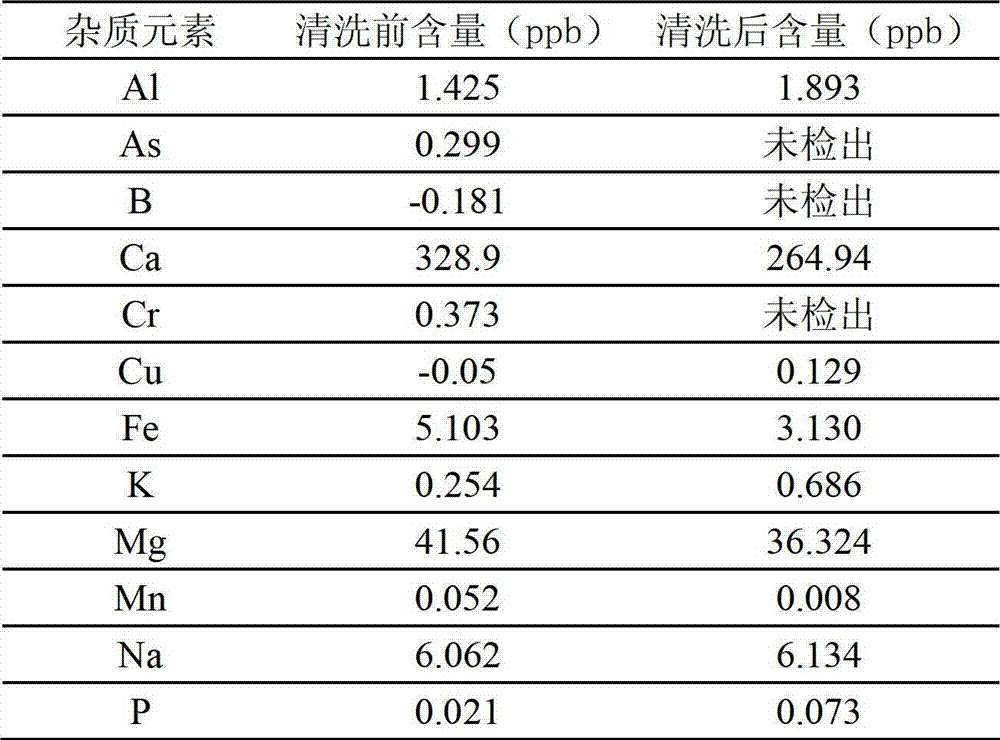

Method for cleaning an electrode shield for polysilicon production reduction furnaces

InactiveCN103042009AGuaranteed qualityQuality will not affectCleaning using liquidsPhysical chemistryNitrogen

The invention provides a method for cleaning an electrode shield for polysilicon production reduction furnaces. The method includes the steps: dipping the electrode shield to be cleaned in alkali liquor 6-12% in mass fraction, ultrasonically cleaning for 10-20 minutes at 30-60 DEG C, after ultrasonic cleaning, cleaning by bubbling and sprinkling of deionized water at 20-60 DEG C until washings are neutral, and performing nitrogen drying to obtain the cleaned regenerated electrode shield. The process combining physical and chemical methods is simple and is available in effectively removing polysilicon depositing on the surface of the electrode shield of a reduction furnace, the electrode shield is reused, production cost of polysilicon can be lowered, and cost competitive advantage of polysilicon products is increased.

Owner:江西赛维LDK光伏硅科技有限公司

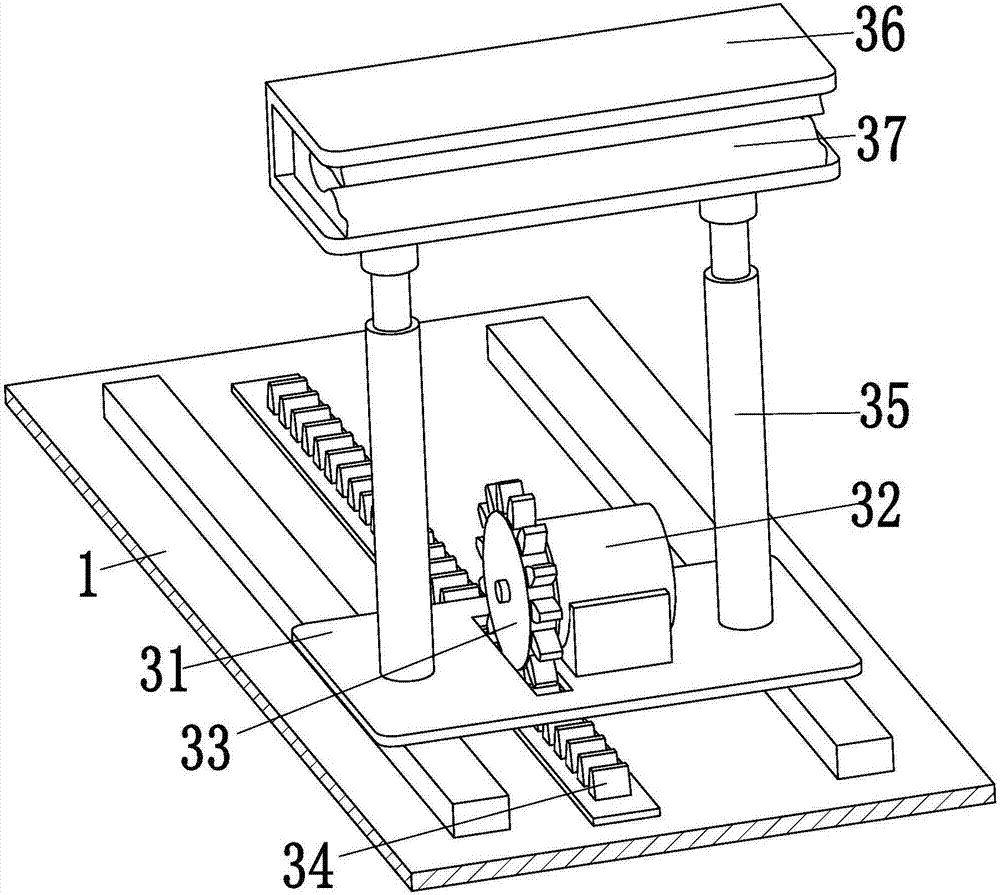

Raw material grinding and screening device special for building and ornament material granite tiles

InactiveCN107282176AEasy to operateReduce labor intensityGrain treatmentsMachining processRaw material

The invention relates to a raw material grinding and screening device special for building and ornament material granite tiles. The raw material grinding and screening device comprises a base plate, a grinding mechanism is installed on the base plate, a conveying and screening mechanism is installed on the base plate, the conveying and screening mechanism is located under the grinding mechanism, and the grinding mechanism and the conveying and screening mechanism are mutually matched for use to complete an automatic repeating grinding process of tile raw materials. According to the raw material grinding and screening device special for the building and ornament material granite tiles, the problems that in the existing tile raw material grinding and screening processing process of a small factory, grinding is insufficient, the tile quality is affected, ground tile raw material particles need to be manually screened, the screened tile raw materials which cannot meet the requirement need to be manually collected, operation is complex, the labor intensity is high, and the working efficiency is low can be solved, and the function of automatically grinding and screening the tile raw materials can be achieved.

Owner:合肥集知网信息技术有限公司

Long-acting environment-friendly nontoxic air purifying agent and preparation method thereof

InactiveCN107469120AEfficient removalQuality improvementGas treatmentDispersed particle separationIndoor air qualitySodium salt

The invention discloses a long-acting environment-friendly nontoxic air purifying agent and a preparation method thereof. The air purifying agent comprises the following components in parts by weight: 30-40 parts of active carbon granule, 15-25 parts of attapulgite, 10-15 parts of glycerol monolaurate, 5-10 parts of sodium dodecyl benzene sulfonate, 10-20 parts of polyacrylamide, 1-5 parts of chitosan, 5-10 parts of plant essential oil, 10-20 parts of alkali chelating agent, 5-10 parts of sodium salt and 40-50 parts of deionized water. The air purifying agent is capable of effectively removing pollutant components from indoor air, has an excellent removing effect, is capable of obviously improving the indoor air quality, has no influence on air quality, is reasonable in component design and has an excellent purifying effect.

Owner:SUZHOU SHUIMUKANGQIAO ENVIRONMENTAL ENG TECH CO LTD

Fertilizer crusher capable of automatically defecting and separating metal

ActiveCN106540789AImprove crushing effectExtended service lifeGrain treatmentsFertilizerElectric machinery

The invention discloses a fertilizer crusher capable of automatically defecting and separating metal, comprising a fertilizer crusher part and a metal impurity removal device, wherein the fertilizer crusher part comprises two support frames, a crushing cylinder is arranged between the support frames, a horizontally arranged rotating shaft is arranged in the crushing cylinder, and the support frames are respectively provided with bearings adaptive to the rotating shaft; spiral crushing teeth sleeve the rotating shaft, and the inner wall of the crushing cylinder is fixedly provided with multiple helical teeth adaptive to the spiral crushing teeth; the rotating shaft extends to the exterior of the left side of the crushing cylinder to be connected with a belt wheel, the belt wheel is in transmission connection with a driving wheel by a belt, and the driving wheel is connected with a motor by a driving shaft. The fertilizer crusher is reasonable in structure design and convenient to use, can be used to automatically defect fertilizer containing metal impurities and automatically classify, ensure the quality of finished fertilizer, reduce the machine wear of the fertilizer crusher, and prolong the service life, and also has the advantages of good crushing effect, low blocking possibility and suitability for automated fertilizer production.

Owner:NINGXIA RUISHENG MINGJIE INTPROP CONSULTING CO LTD

Rice rich in vitamin B and preparation method thereof

The invention discloses rice rich in vitamin B. The rice is characterized by being prepared from the following raw materials: common rice, vitamin B, sodium alga acid and calcium chloride. The nutritious rice has the same grains as common long-shaped rice or polished round-grained rice, has similar texture characteristic and organoleptic quality to the common rice, and cannot influence the quality of rice after the nutritious rice and the common rice are mixed and steamed so as to meet the requirement of users on the nutritious rice.

Owner:ANHUI YANZHIFANG FOOD

Intelligentized cotton yarn twisting-doubling production line and cotton yarn twisting-doubling process in textile industry

The invention relates to an intelligentized cotton yarn twisting-doubling production line and a cotton yarn twisting-doubling process in the textile industry. The intelligentized cotton yarn twisting-doubling production line comprises a base plate, wherein a supporting operation table is installed in the middle of the base plate, operation limiting grooves are uniformly formed in the supporting operation table, operation delivery pay-off mechanisms are arranged in operation limiting grooves, an adjusting liftable air cylinder is installed on the base plate, the top of the adjusting liftable air cylinder is provided with a lifting control frame through a flange, and the middle of the lifting control frame is provided with an operation groove. The problems can be solved by adopting the production line and the process that a plurality of cotton yarns need to be artificially twisted together according to a certain law in the existing textile making process, the time consumed for artificialyarn twisting and doubling is long, the twisting degree of the cotton yarns cannot be ensured, artificial twisting and doubling possibly cause disorder of the cotton yarn twisting and doubling mixture raw and affect the quality of the cotton yarns, the labor intensity is high, and the working efficiency is low, and the function of automatic cotton yarn twisting and doubling in the spinning operation can be achieved.

Owner:宛兴友

Durable antibacterial textile fiber and preparation method thereof

InactiveCN111041606AEvenly dispersedInhibit sheddingMelt spinning methodsConjugated synthetic polymer artificial filamentsTextile fiberPolymer science

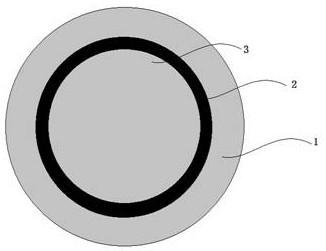

The invention belongs to the technical field of chemical fiber preparation, and particularly relates to a durable antibacterial textile fiber and a preparation method thereof. The preparation method of the durable antibacterial textile fiber comprises the following steps of a) mixing a nanoscale antibacterial agent with polyethylene wax, silicon dioxide aerogel, nylon 6 and high-melt-index EVA ina high-speed mixer, then performing melt co-extrusion by using a co-rotating twin-screw extruder, and performing water cooling, dicing and drying to obtain antibacterial master batch; b) adding the nylon 6, the antibacterial master batch and the nylon 6 into three screw extruders respectively for melting, performing compounding by using a multilayer die head to form a filament, wherein an inner layer is the nylon 6, a middle layer is the antibacterial master batch, and an outer layer is the nylon 6; then stretching the filament into a fiber, applying spinning oil, performing cold rolling and winding to obtain the durable antibacterial textile fiber. According to the preparation method, the nanoscale antibacterial agent is dispersed in a high-flow system for processing, so that the dispersity of the antibacterial agent is greatly improved; the master batch is independently formed in the middle layer of the spinning, so that on one hand, the antibacterial agent is prevented from fallingoff during washing, and on the other hand, the quality of the nylon 6 such as strength and color cannot be influenced.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Automatic raw material grinding equipment special for building decoration material marble tiles

InactiveCN107365157AQuality will not affectRealize the grinding functionRaw materialGrinding process

The invention relates to automatic raw material grinding equipment special for building decoration material marble tiles. The automatic raw material grinding equipment comprises a bottom plate and is characterized in that a grinding device and a conveying and sieving device are mounted on the bottom plate, a feeding device is mounted at the right end of the bottom plate, the feeding device is located on the lower side of the right end of the conveying and sieving device, and the grinding device, the conveying and sieving device and the feeding device are coordinated to complete the automatic and repeated grinding process of marble tile raw materials. The automatic raw material grinding equipment has the advantages that the problems that an existing marble tile raw material grinding process is insufficient in grinding, the quality of the marble tiles is affected, marble tile raw materials which do not meet the requirements after sieving needs to be collected manually, the marble tile raw materials which do not meet the requirements needs to be manually re-conveyed into the grinding equipment for repeated processing, operation is complex, labor intensity is high, work efficiency is low, and the like can be solved, and functions of marble tile raw material automatic and repeated grinding and sieving can be achieved.

Owner:合肥集知网信息技术有限公司

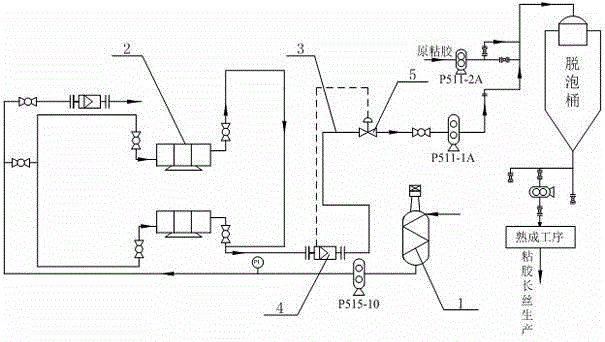

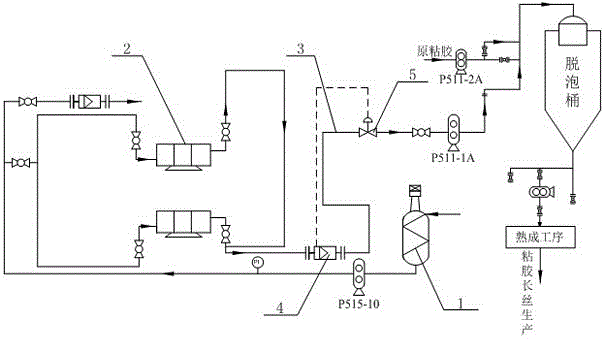

Recycling process of waste viscose

ActiveCN104862829AGood economic benefitsReduce pressure on environmental protectionArtificial filament recoveryTextile/flexible product manufactureViscoseFiltration

The invention discloses a recycling process of waste viscose. The waste viscose obtained through collection is fed into the viscose filament production process after filtration, defoaming and ripening, wherein the waste viscose is dismantling waste viscose of a filter in a viscose production system. According to the recycling process of the waste viscose, the technical problem that the waste viscose cannot be recycled to continue to be applied to the viscose filament production in the existing waste viscose recycling scheme is solved, the waste viscose cannot be directly added into normal viscose after the filtration treatment and can enter the large viscose production system to be applied to the viscose filament production, the economic benefit is obvious in comparison with the way that the waste viscose is applied to viscose staple production, meanwhile the environment-friendly pressure can be reduced, and the viscose production efficiency can be improved.

Owner:YIBIN GRACE GROUP CO LTD +2

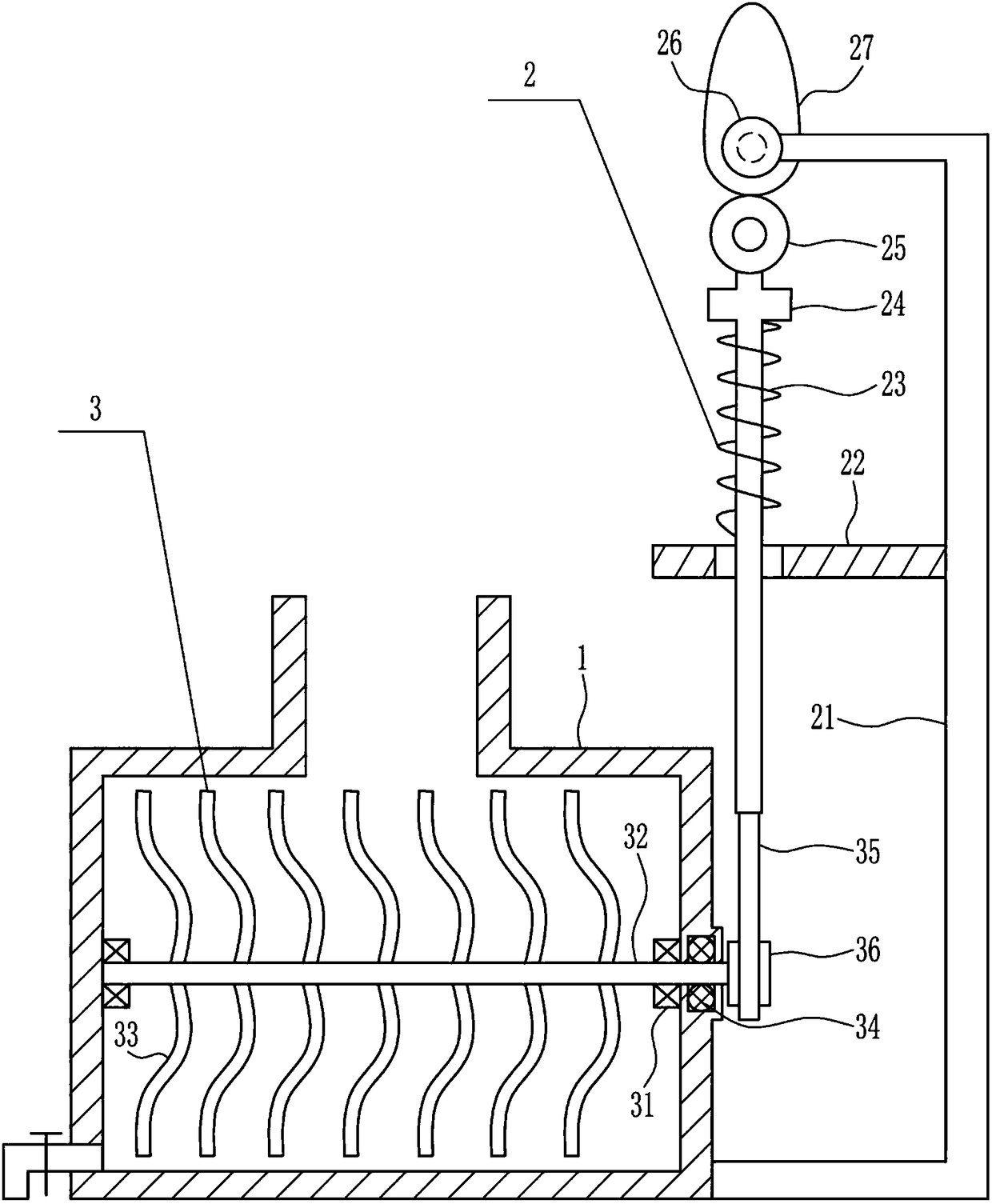

Traumatic-injury-treating-drug preparing equipment for acupuncture and massage department

InactiveCN108096024AAffect qualityQuality will not affectRotary stirring mixersTransportation and packagingInjury causeMedicine

The invention relates to preparing equipment, in particular to traumatic-injury-treating-drug preparing equipment for the acupuncture and massage department. The traumatic-injury-treating-drug preparing equipment comprises a preparing box and the like and is characterized in that a lifting mechanism is connected to the right wall of the preparing box, and a preparing mechanism is connected into the preparing box and coordinated with the lifting mechanism. The traumatic-injury-treating-drug preparing equipment has the advantages that sufficient preparing is achieved, dust entering, which affects quality, during preparing can be prevented, and preparing capacity can be increased; preparing speed can be increased by the lifting mechanism, and uniform drug preparing can be achieved by the preparing mechanism.

Owner:李刚

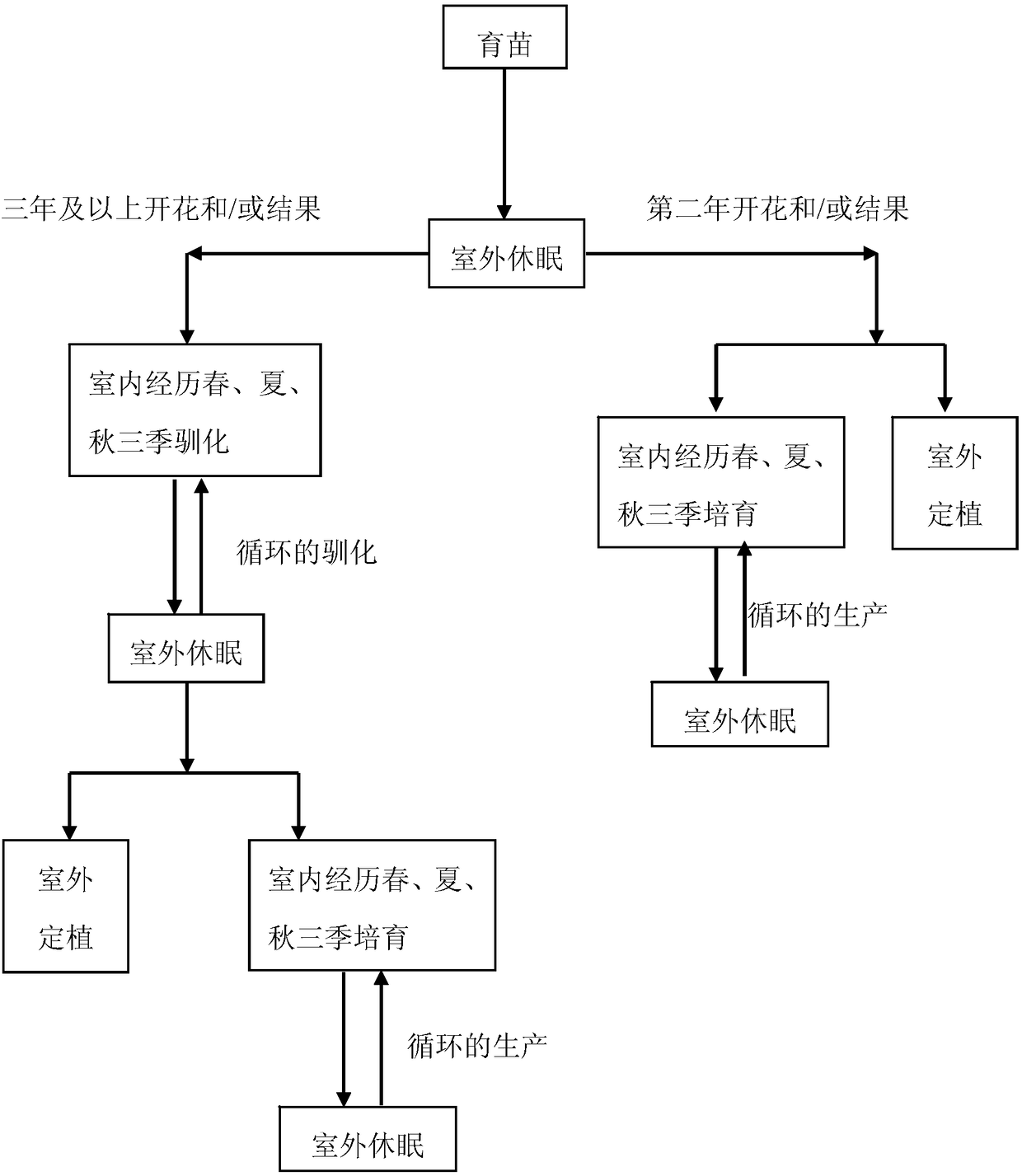

Seedling raising acclimation method for dormancy plant

ActiveCN108157041AShorten the timeDoes not affect growth and developmentFlowers cultivationCultivating equipmentsAutumn seasonOutdoor area

The invention discloses a seedling raising acclimation method for a dormancy plant. The method comprises the following steps: cultivating the plant in a pot prepared from a degradable material to forma seedling, placing the seedling together with the pot prepared from the degradable material into a pot prepared from a non-degradable material, and performing cultivation to obtain a plant to be dormant; placing the plant in an outdoor area of China north in a frosty season, performing dormancy acclimation, moving the plant to an indoor area, enabling the plant to undergo spring, summer and autumn cultivation indoors according to cultivation conditions of spring, summer and autumn seasons, moving the plant in an outdoor area of China north in a frosty season for dormancy acclimation...... and completing acclimation through above cycles; and performing field planting on the plant which completes dormancy, or continuing acclimation after indoor spring, summer and autumn cultivation...... and completing cycle production. The method provided by the invention can rapidly complete growth and development of the plant, not only can shorten flowering and fruiting time of the plant, but also does not affect the growth and development of the plant; and the method can also greatly increase the yield of the plant without affecting the quality of products.

Owner:锡林浩特市森华生态建设有限公司

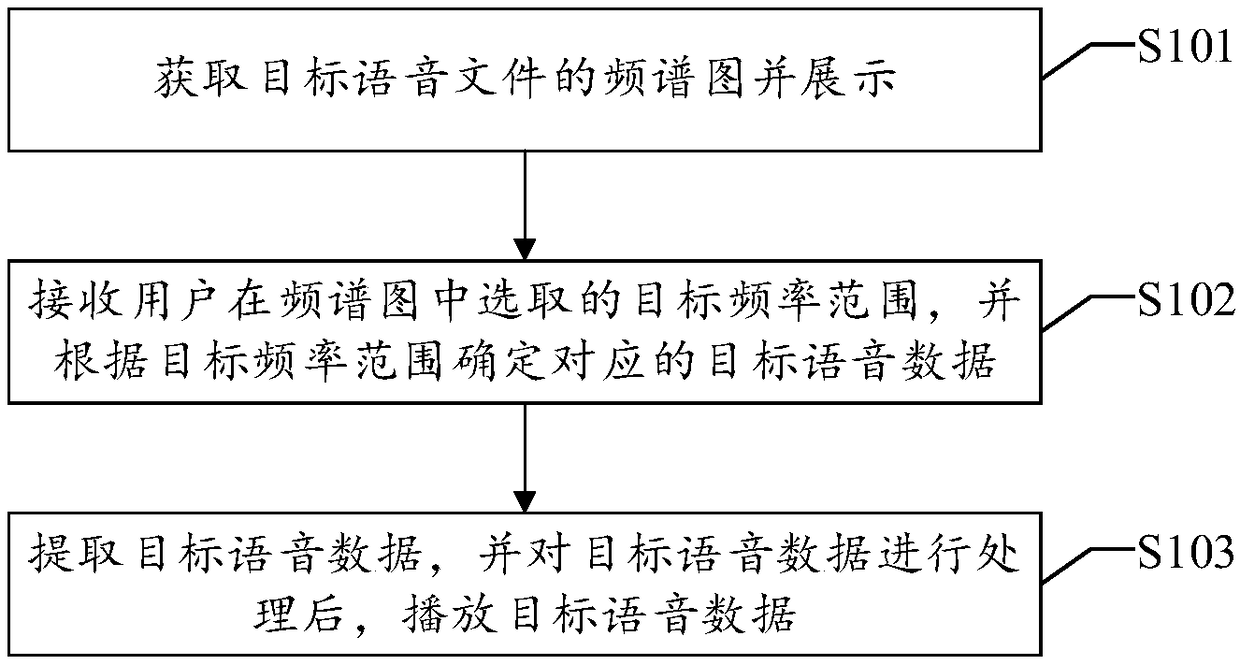

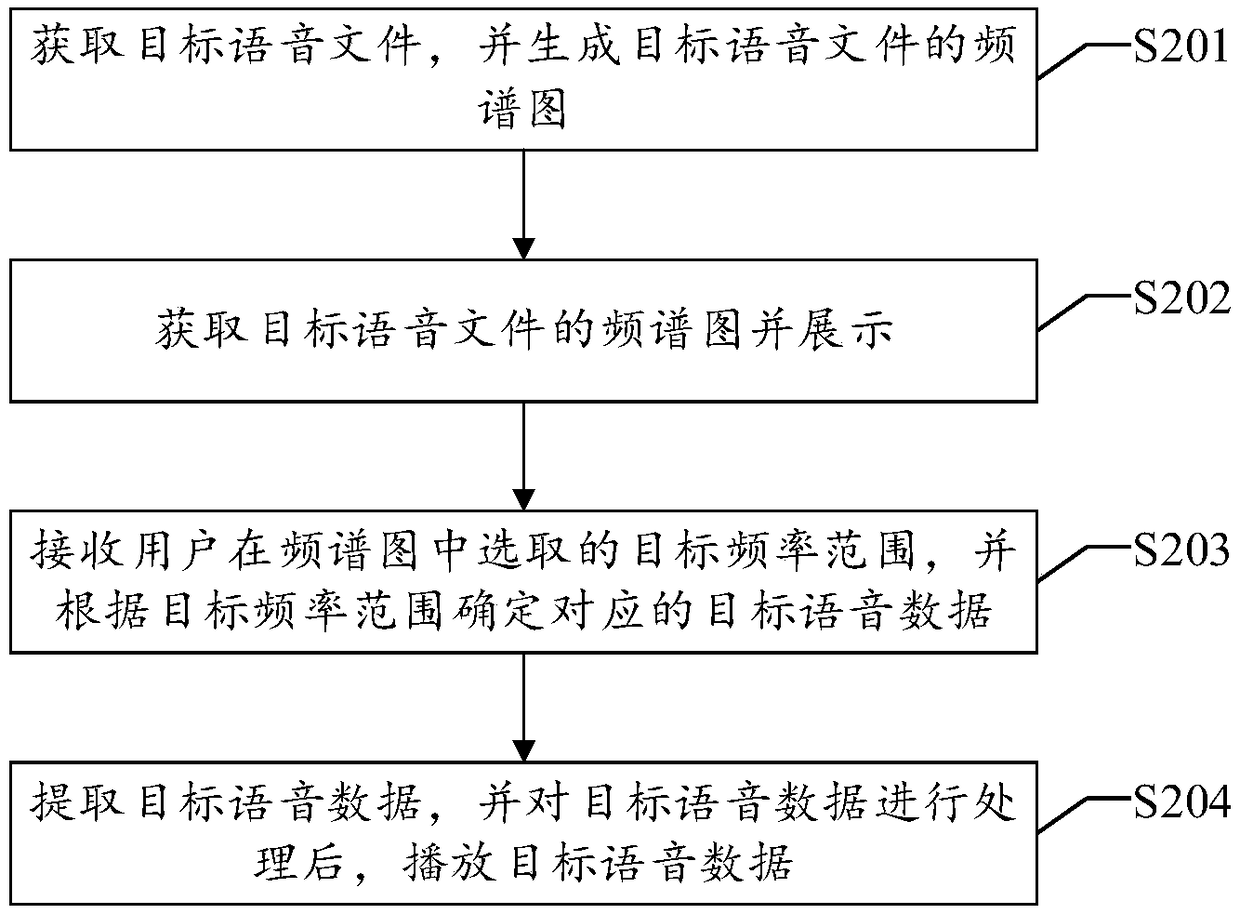

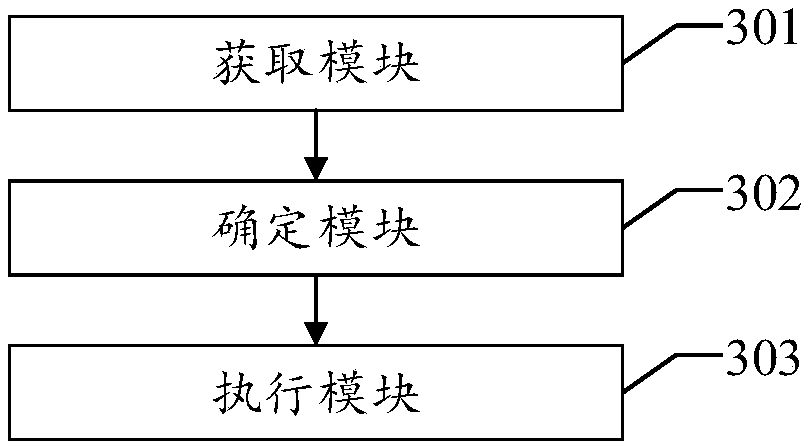

Method, apparatus, and equipment for processing voice data, and readable storage medium

ActiveCN108831492AQuality improvementQuality will not affectSpeech analysisFrequency spectrumSpeech sound

The invention discloses a method for processing voice data. The method comprises: a frequency spectrogram of a target voice file is obtained and the obtained frequency spectrogram is displayed; a target frequency range selected by a user in the frequency spectrogram is received and corresponding target voice data are determined based on the target frequency range; and the target voice data are extracted, the extracted frequency spectrogram processed, and the frequency spectrogram are played. According to the method, the user is able to select a specific determined frequency range automaticallyaccording to the frequency spectrogram of the target voice file; and because the voice data are selected by the user based on the frequency spectrogram, the selected voice data have the optimized quality; no denoiding process is needed for the voice data, so that the original voice audio quality is not affected and thus the voice audio file is played clearly; and the voice data processing efficiency is improved because of the low selected voice volume. Correspondingly, the invention also discloses an apparatus and equipment for processing voice data, and a readable storage medium that have the same technical effects.

Owner:广州国音科技有限公司

An automatic processing system for plastic granules regeneration

ActiveCN109433698BPrecision cleaningQuality will not affectPlastic recyclingCleaning using toolsWater resourcesEngineering

The invention relates to an automatic processing system for plastic particle regeneration, which includes a cleaning box. A water supply tank is provided at the lower end of the cleaning box. Screen holes are evenly provided at the upper end of the water supply tank. Water pipes are connected to the left and right sides of the water supply tank. The water pipes It is installed on the high-pressure water pump. The upper end of the water pipe passes through the cleaning box and is connected to the water spray pipe. The water spray pipe is fixed on the water spray frame. The side wall of the water spray frame is connected to one end of the connecting rod through a pin. The invention can solve the existing problem in the production process of recycled plastic particles that the crushed plastics need to be cleaned manually. Manual cleaning cannot be comprehensive and accurate, which affects the quality of the plastic particles, and water resources cannot be fully used during manual cleaning. It can realize the function of automatically cleaning plastic fragments in the production of recycled plastic granules without causing resource waste and other problems.

Owner:上海龙程塑料制品有限公司

A recycling process of waste viscose

ActiveCN104862829BReduce manufacturing costReduce pressure on environmental protectionArtificial filament recoveryTextile/flexible product manufactureFiltrationEconomic benefits

The invention discloses a recycling process of waste viscose. The waste viscose obtained through collection is fed into the viscose filament production process after filtration, defoaming and ripening, wherein the waste viscose is dismantling waste viscose of a filter in a viscose production system. According to the recycling process of the waste viscose, the technical problem that the waste viscose cannot be recycled to continue to be applied to the viscose filament production in the existing waste viscose recycling scheme is solved, the waste viscose cannot be directly added into normal viscose after the filtration treatment and can enter the large viscose production system to be applied to the viscose filament production, the economic benefit is obvious in comparison with the way that the waste viscose is applied to viscose staple production, meanwhile the environment-friendly pressure can be reduced, and the viscose production efficiency can be improved.

Owner:YIBIN GRACE GROUP CO LTD +2

Collecting and processing device for pea dehulling and selection

InactiveCN109077338AImprove shelling effectImprove the effect of precision screeningSievingScreeningEngineeringMechanical engineering

The invention relates to the technical field of food processing and discloses a collecting and processing device for pea dehulling and selection. The collecting and processing device comprises a supporting-bearing device, wherein one end of the top of the supporting-bearing device is welded with two sides of the bottom of a top blocking mechanism, two sides, located at the top, of the top blockingmechanism are respectively welded with two sides of the bottom of a top limiting mechanism, the middle, located on the inner side of the top, of the top limiting mechanism is welded with a driving device, one end of an output shaft of the driving device is insert-connected into the inner cavity of a driving rotary shaft, two sides of the outer surface of the driving rotary shaft are welded with breaking driving blades, and a discharging processing structure is insert-connected to the middle of the inner cavity of a screen net disc. Peas needing dehulling are put in a force-borrowing swing processing device, the driving device drives the breaking driving blades, breakage processing can be conducted on the peas, the force-borrowing swing processing device is driven to perform swing processing by utilizing the rotation power of the driving rotary shaft, and the effect of finely screening peas can also be improved.

Owner:崔永平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com