Method of preparing large-dimension cadmium sulfide film by chemical water-bath method

A chemical water bath and cadmium sulfide technology, applied in the field of solar cells, can solve the problems of affecting the experimental environment, low utilization rate of raw materials, slow heating rate, etc., and achieve the effects of less raw material consumption, simple equipment, and reduced solution consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Preparation of reaction solution: Weigh 0.58g of cadmium sulfate and 7.4g of thiourea and dissolve them in 1.3L of deionized water, then add 0.2L of 25% ammonia water to obtain a reaction solution;

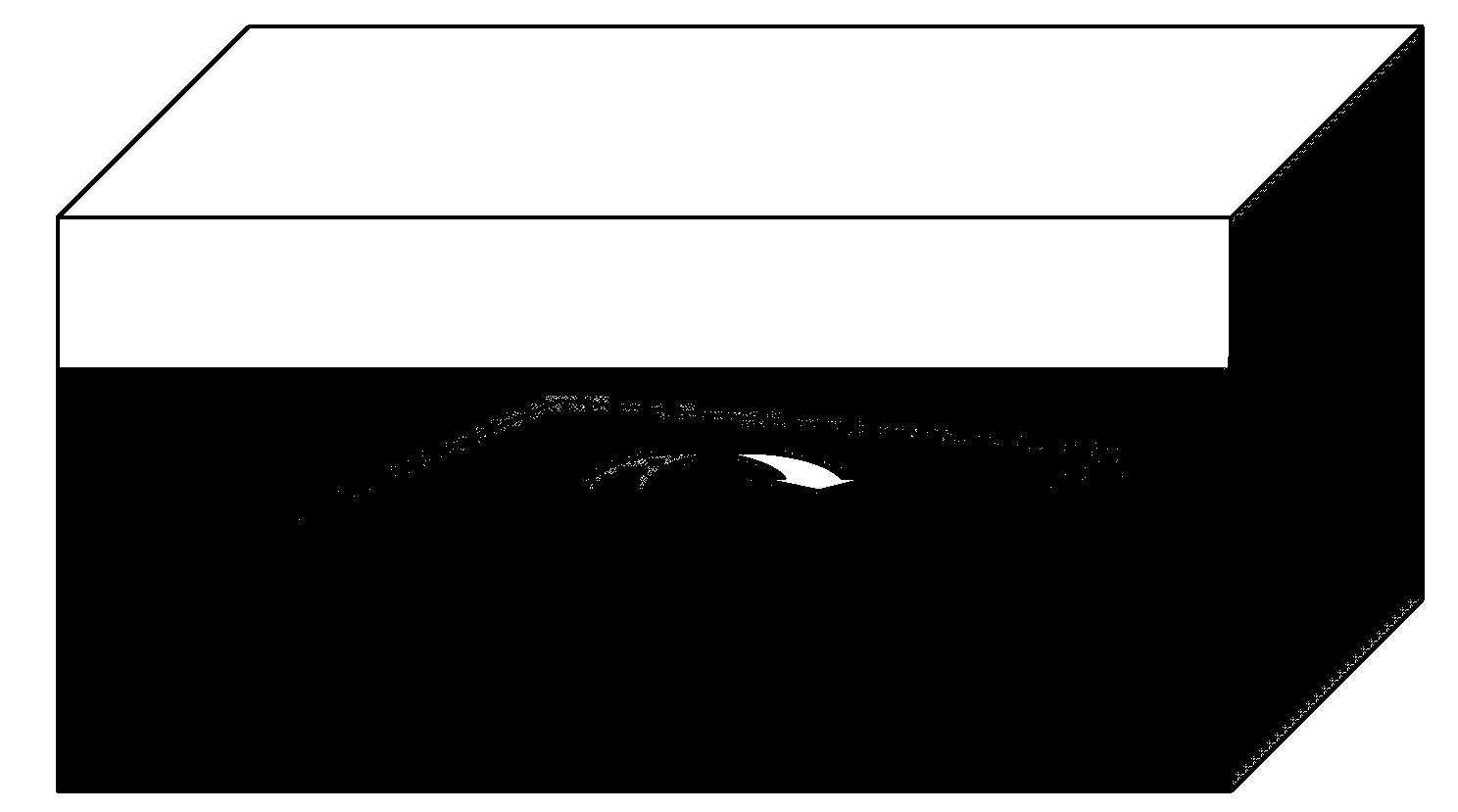

[0047] 2. Substrate installation: clean two 30×30cm substrates ultrasonically, dry them with nitrogen, and insert them into the groove of the reaction vessel, keep the two substrates closely attached to the upper and lower surfaces of the reaction vessel, and then Pour the reaction solution, keep the volume of the reaction solution smaller than the volume of the reaction vessel, and seal the reaction vessel;

[0048] 3. Deposition of thin film: Put the sealed reaction vessel horizontally into the constant temperature water bath oscillator, and the reaction vessel will mix the solution evenly in a reciprocating motion. The temperature of the water bath is 60°C, and the reaction time is 20 minutes;

[0049] 4. Cleaning of the substrate: The substrate deposited with the CdS...

Embodiment 2

[0051] 1, the preparation of reaction solution: with embodiment 1;

[0052] 2, the installation of substrate: with embodiment 1;

[0053] 3. Deposition of thin film: Put the sealed reaction container horizontally into the constant temperature water bath oscillator, and the reaction container swings up and down to mix the solution evenly. The temperature of the water bath is 60°C, and the reaction time is 20 minutes;

[0054] 4. Cleaning of the substrate: same as in Example 1.

Embodiment 3

[0056] 1, the preparation of reaction solution: with embodiment 1;

[0057] 2, the installation of substrate: with embodiment 1;

[0058] 3. Deposition of thin film: Put the sealed reaction vessel horizontally into the constant temperature water bath oscillator, and the reaction vessel will mix the solution evenly in a reciprocating motion. The temperature of the water bath is 80°C, and the reaction time is 15 minutes;

[0059] 4. Cleaning of the substrate: same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com