Patents

Literature

56results about How to "Reduce raw material consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method for 3D (three-dimensional) printing shoe pad

InactiveCN104647757AReduce cumbersome proceduresReduce raw material consumptionAdditive manufacturing apparatusInsolesThree dimensional modelSpray nozzle

The invention discloses a manufacturing method for a 3D (three-dimensional) printing shoe pad. The manufacturing method comprises the following steps: acquiring foot data in sequence, scanning feet to obtain foot shape dimension data, and obtaining sole pressure data during various daily activities through a pressure test; generating a three-dimensional model by data processing software according to the acquired foot shape dimension value, combining the three-dimensional model with measured pressure value to analyze multi-layer shoe pad plane data, and inputting the multi-layer shoe pad plane data into a 3D printer; respectively sintering various powdered thermoplastic materials and then supplying the sintered various powdered thermoplastic materials to a spray head of the 3D printer; selecting the sintered thermoplastic materials by the 3D printer according to the shoe pad plane data, heating the thermoplastic materials through a spray nozzle of the 3D printer, and then printing corresponding shoe pad layers layer by layer on a shoe pad mould, fusing and depositing the thermoplastic materials on each plane layer to form a shoe pad finished product. According to the manufacturing method disclosed by the invention, the customization of high-quality shoe pads can be realized, complex processes can be eliminated, meanwhile, the raw material consumption is reduced, the production efficiency can be improved effectively, and the cost can be saved greatly.

Owner:刘轶

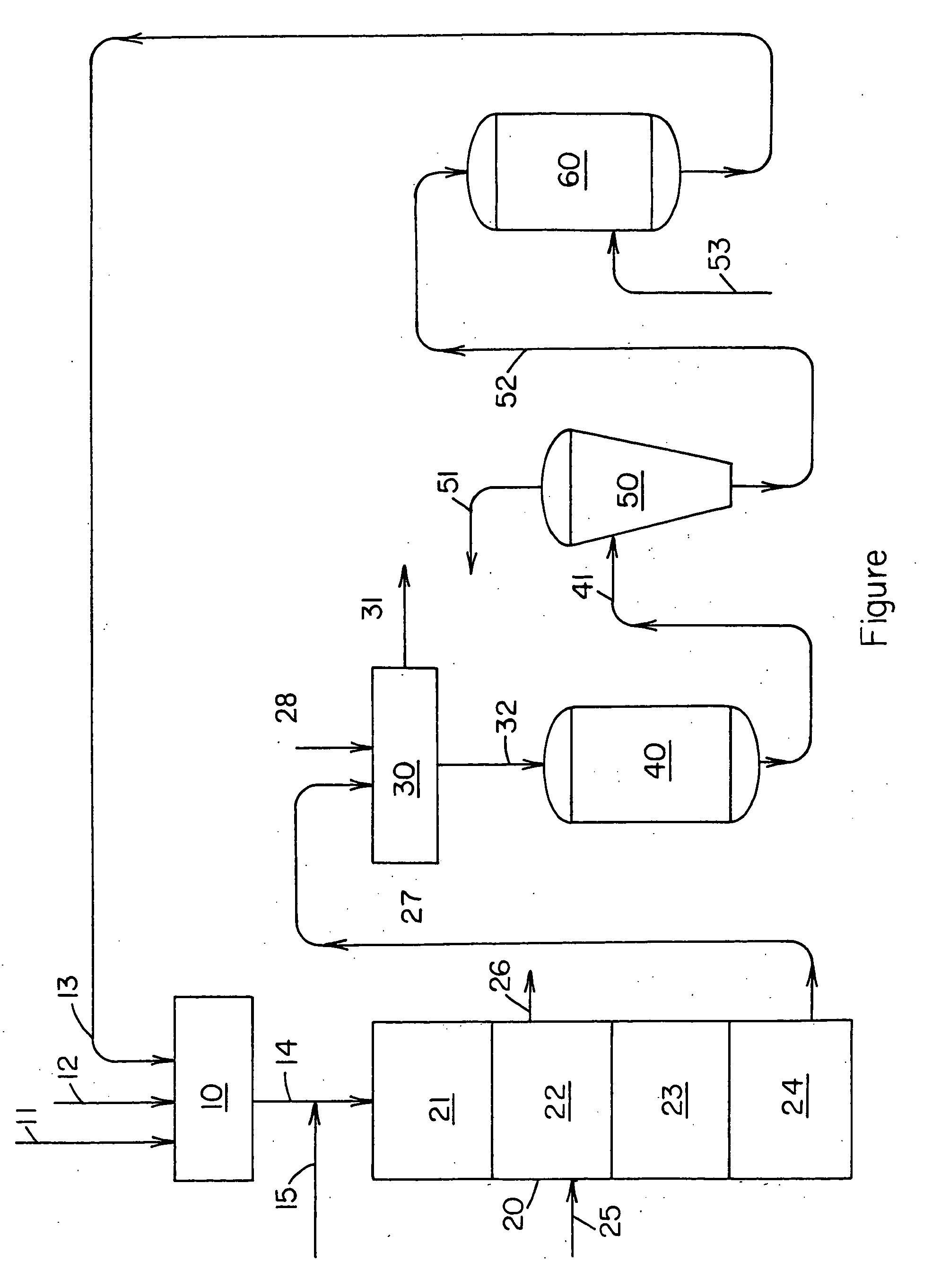

Production of synthesis gas

InactiveUS20060165582A1Improve efficiencyReduce raw material consumptionGasification processes detailsCombustible gas purificationSyngasPartial oxidation

Disclosed are gasification processes for the production of mixtures of carbon monoxide and hydrogen, by the partial oxidation of a carbonaceous feedstock material wherein carbon values contained in a solid slag effluent from the partial oxidation reactor are recovered and recycled to the gasification reactor.

Owner:EASTMAN CHEM CO

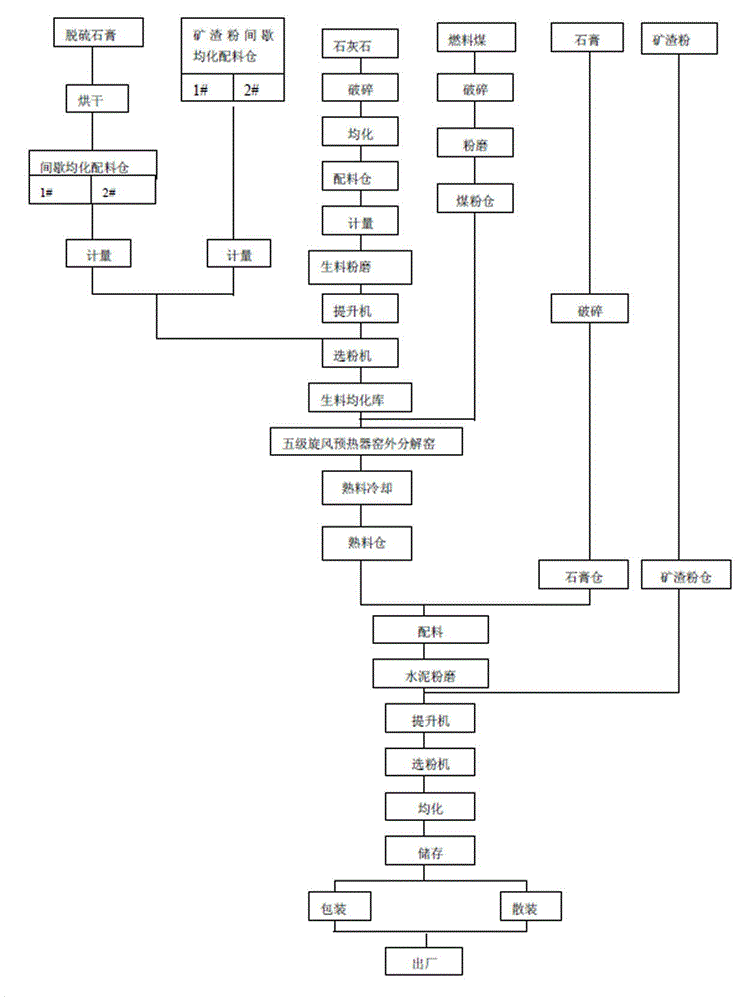

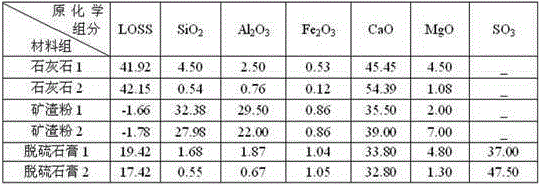

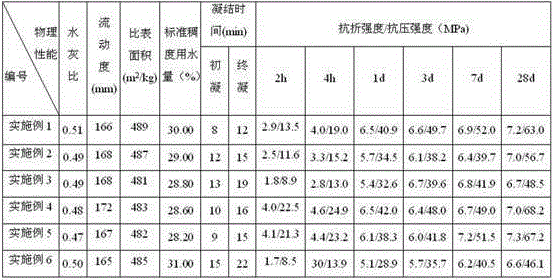

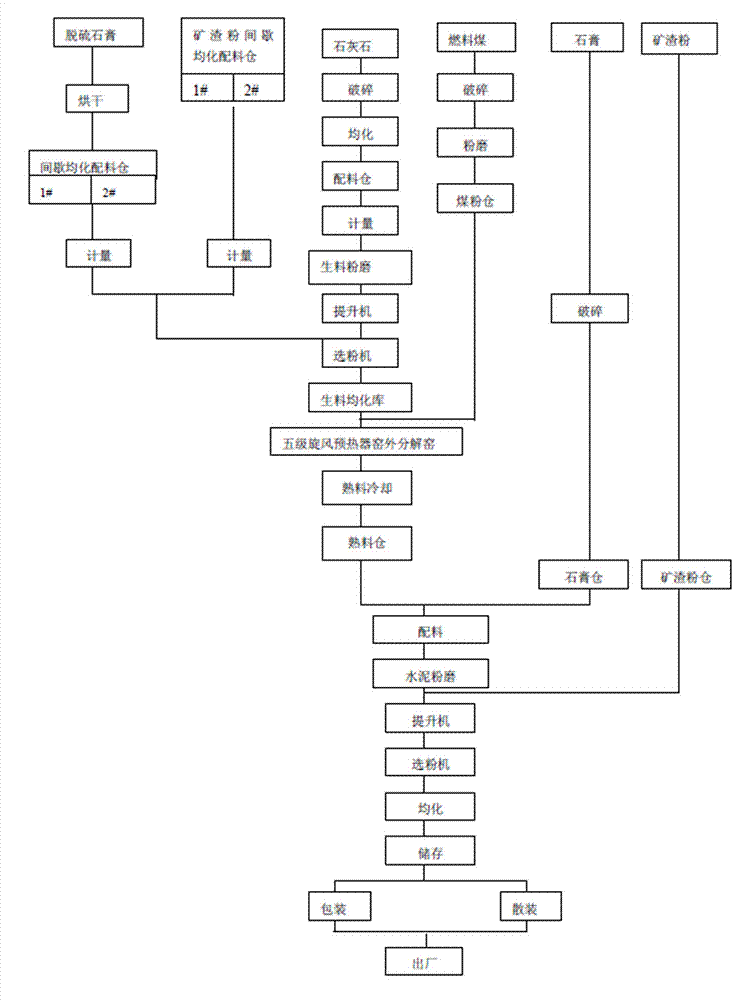

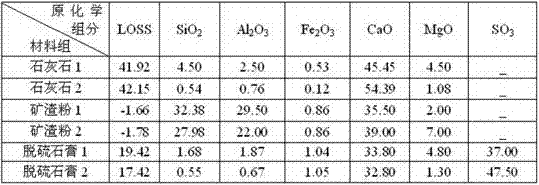

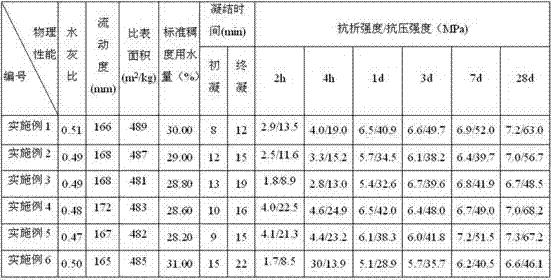

White fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and application and production technology thereof

The invention relates to a white fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and also relates to an application and a production technology thereof. The mineral component of the cement clinker comprises 0.5-4.6% of f-CaO; the chemical component of the cement clinker comprises 12.9-16.1wt% of SiO2, 12-19wt% of Al2O3, 0.15-1.0wt% of Fe2O3, 49-53wt% of CaO and 12-18.5wt% of SO3; and the clinker rate range Cm is 1.01-1.137, and P is 0.62-1.44. The clinker is produced through calcining 30-50wt% of limestone, 26-46wt% of slag powder and 21.1-40wt% of desulfurized gypsum in a rotary kiln at 1250-1350DEG C. 26-97% Of the clinker, 3-19% of anhydrite and 0-55% of the slag powder, or 5-25% of the clinker, 14.4-19.0% of the anhydrite and 55.8-79% of the slag powder are mixed and ground to form white fast-setting, fast-hardening and high-belite sulphoaluminate cement and high-late strength and high-belite sulphoaluminate cement.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL +1

Separation and extraction process of oligomer proanthocyanidin from pine bark

InactiveCN1436777AReduce production energy consumptionReduce raw material consumptionOrganic chemistrySolventChemistry

The separation and extraction process of oligomer proanthocyanidin from pine bark includes the steps of: pre-treatment, extraction, recovering solvent, concentration, solid-liquid separation, concentration, counter current extraction, concentration, drying, sterilizing and packing. During the extraction, water and ethyl acetate are used as solvent. The said process has high extraction rate, low cost, high product yield and quality, product OPC content as high as 95%. The product of the present inventino has high solubility in both water and alcohol, bright color and obvious curative effect.

Owner:GUILIN NATURAL INGREDIENTS CORP

Method for fermenting and preparing citric acid by adding saccharifying enzyme

InactiveCN101942487AReduce raw material consumptionRaw material conversion rate is highMicroorganism based processesFermentationIon exchangeChemistry

The invention discloses a method for fermenting and preparing citric acid by adding saccharifying enzyme and belongs to the technical field of fermentation engineering. In the traditional citric acid fermentation, a method of mixing water and starch raw materials for size mixing and adding amylase so as to liquefy, heat, sterilize and ferment the raw materials is adopted, and in the fermentation process, saccharifying enzyme secreted by a production strain aspergillus niger per se is saccharified and fermented simultaneously. The method has the disadvantages that: a time process is needed for the aspergillus niger to grow and secrete saccharifying enzyme; and the acidity is continuously increased along with the increase of the produced acid, and the saccharifying enzyme of the aspergillus niger per se is gradually inhibited and cannot play a role in saccharifying normally at the later stage of the fermentation, so that the residual sugar content in the fermented liquor of the citric acid is higher in the end. The citric acid is prepared by the following steps of: adding the amylase to liquefy the starch raw materials, and heating for sterilization; adding a proper amount of saccharifying enzyme, and fermenting, filtering, decoloring, exchanging ions, separating, crystallizing and performing other processes according to the conventional technology. The method for fermenting and preparing the citric acid has the advantages of reducing raw material consumption, improving the conversion rate of the raw materials, improving the acid-producing rate, shortening the fermentation time and reducing CODCr discharge of wastewater.

Owner:JIANGNAN UNIV +1

Methods for enhancing the efficiency of rhenium-promoted epoxidation catalysts and epoxidation methods utilizing these

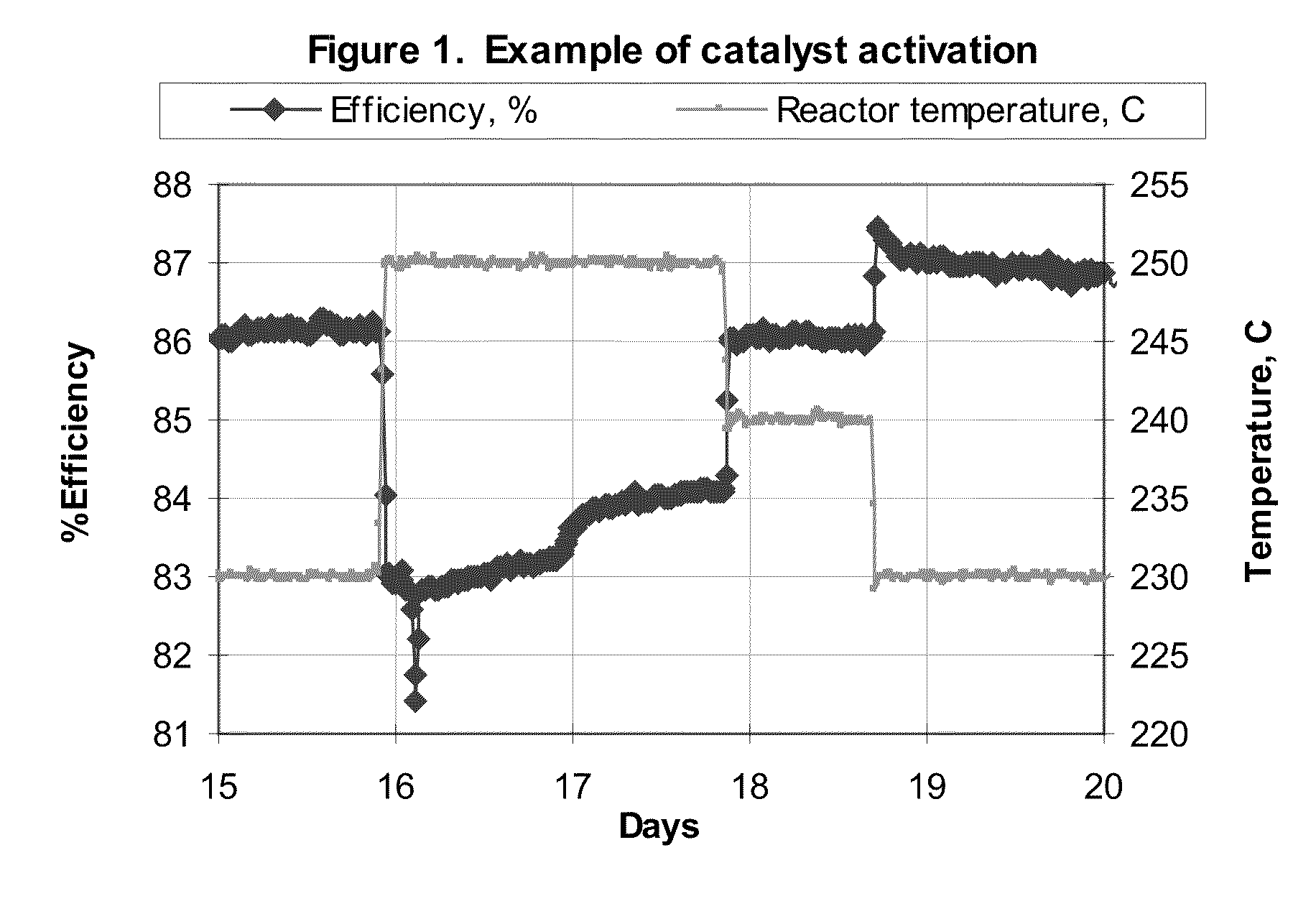

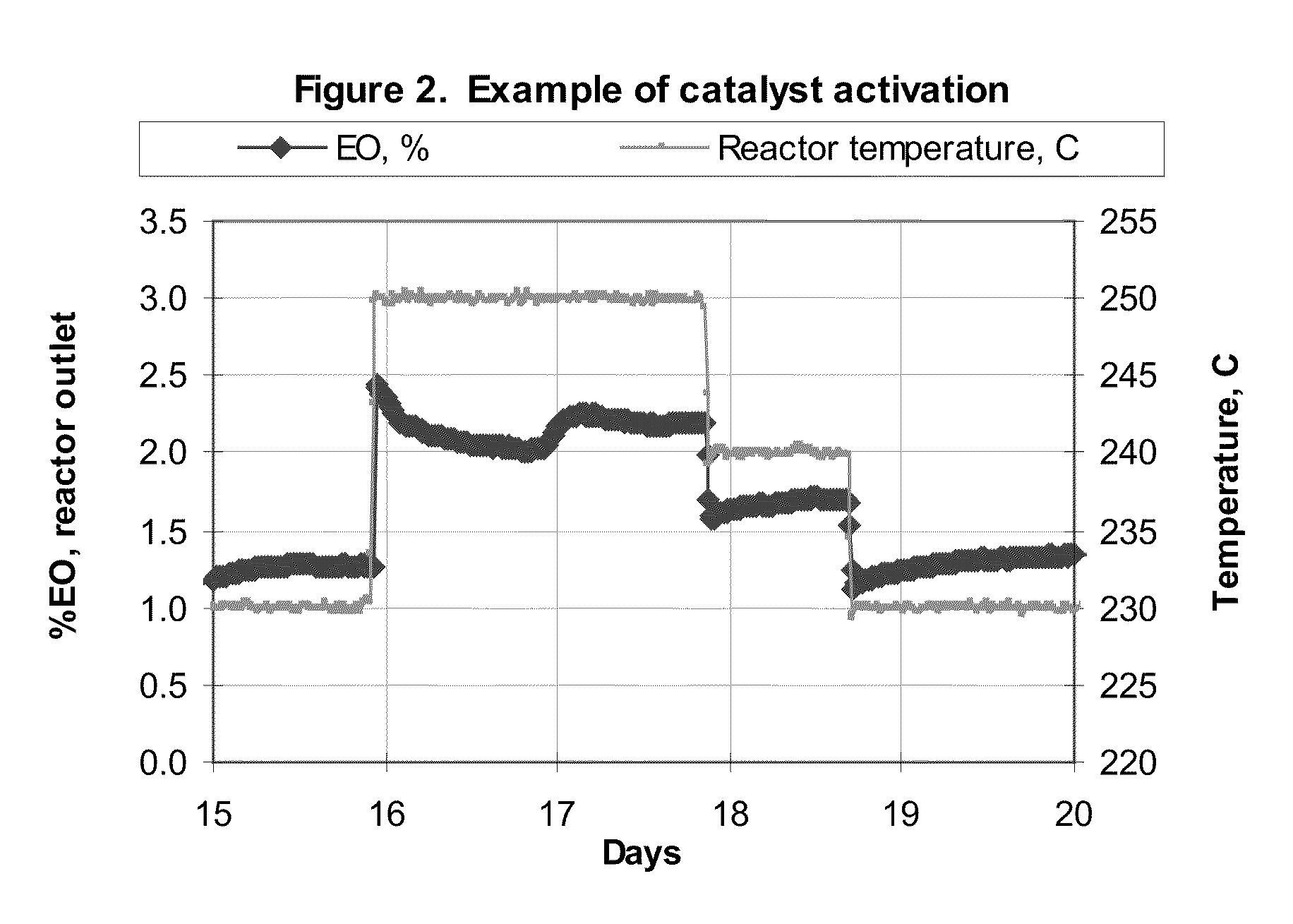

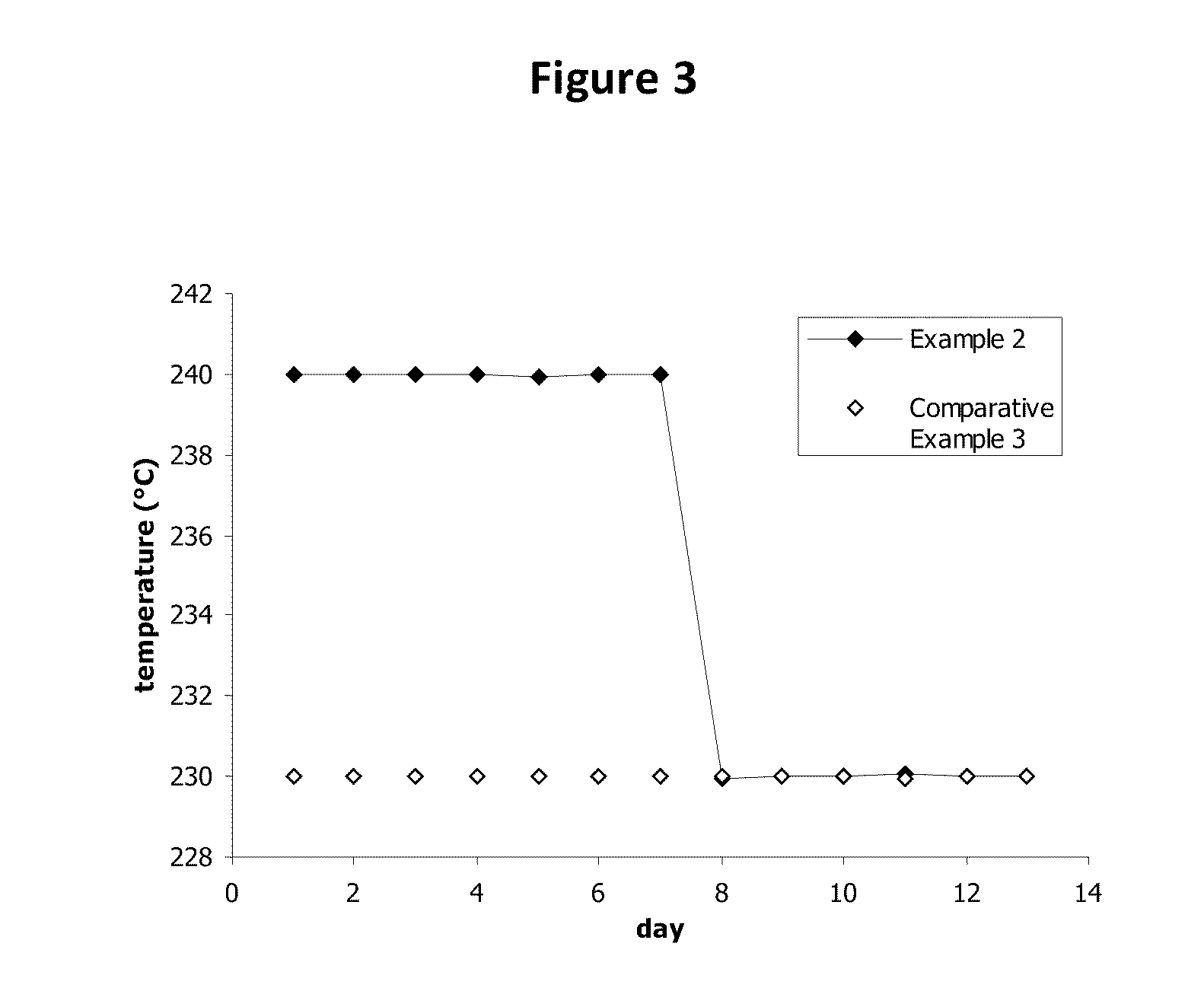

ActiveUS20100267973A1Improve efficiencyReduce raw material consumptionOxygen-containing compound preparationOrganic compound preparationRheniumEther

A method for enhancing the efficiency of a rhenium-promoted epoxidation catalyst is provided. Advantageously, the method may be carried out in situ, i.e., within the epoxidation process, and in fact, may be carried out during production of the desired epoxide. As such, a method for the epoxidation of alkylenes incorporating the efficiency-enhancing method is also provided, as is a method for using the alkylene oxides so produced for the production of 1,2-diols, 1,2-carbonates, 1,2-diol ethers, or alkanolamines.

Owner:THE DOW CHEM CO +1

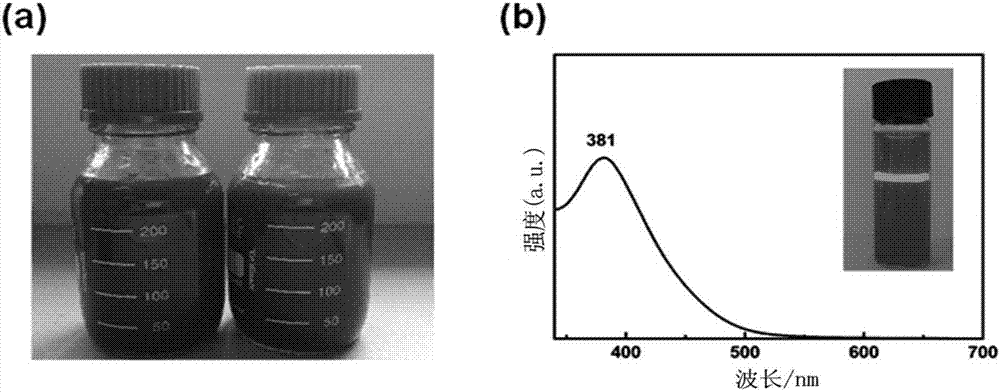

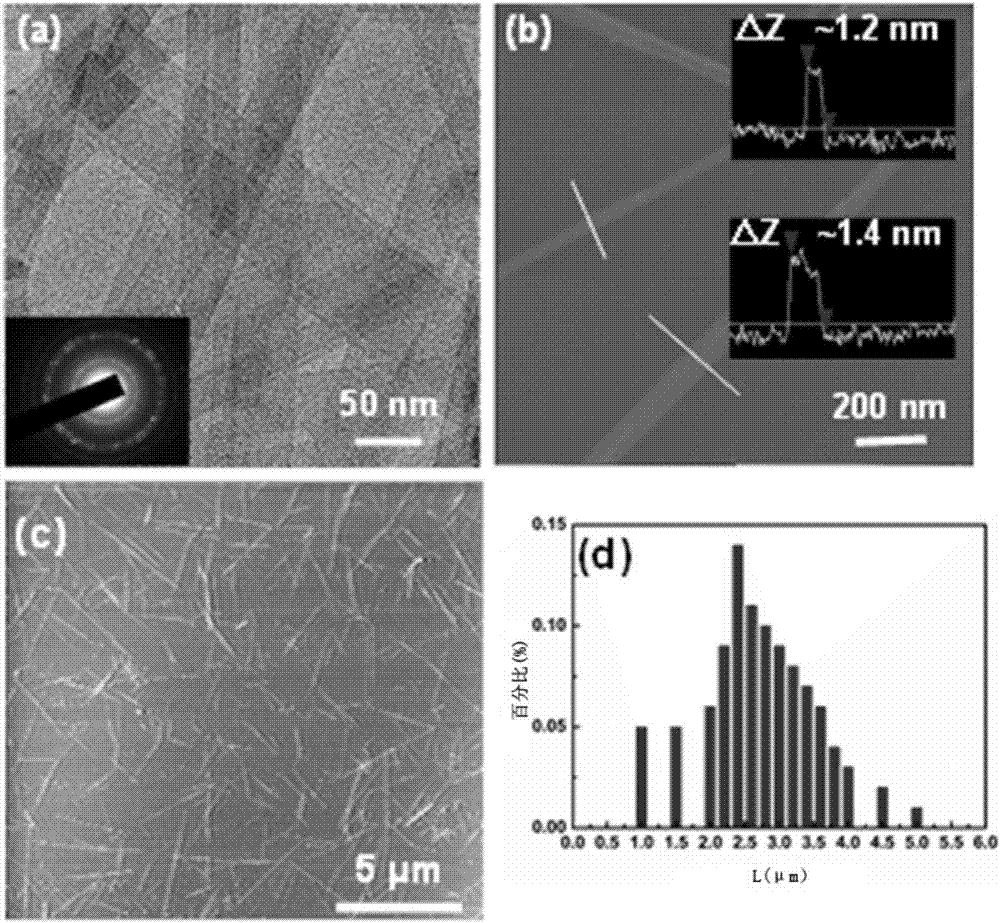

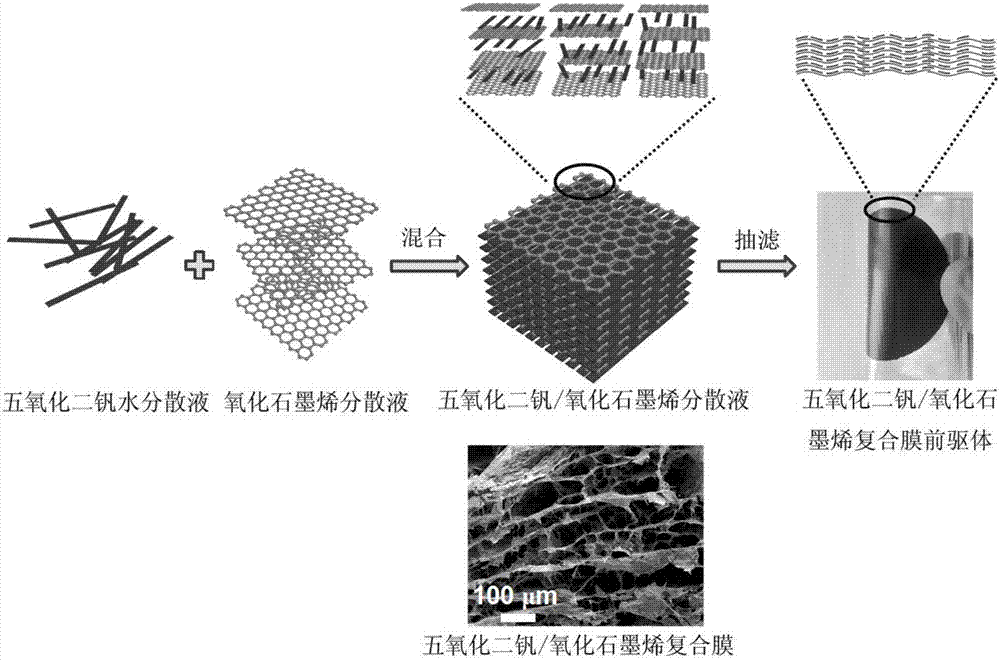

Preparation method and application thereof for vanadium pentoxide/oxidized graphene composite film

InactiveCN106941049AEasy to operate and controlReduce raw material consumptionHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneGraphite oxide

The invention provides a preparation method and an application thereof for a vanadium pentoxide / oxidized graphene composite film, and relates to the technical field of composite nano-materials. The preparation method comprises the following steps of (a) preparing a vanadium pentoxide aqueous dispersion; (b) preparing an oxidized graphene aqueous dispersion; (c) preparing a suction filtrate; (d) preparing a precursor of a vanadium pentoxide / oxidized graphene composite film; (e) preparing the vanadium pentoxide / oxidized graphene composite film. According to the technical scheme of the invention, the technical problems in the prior art that, existing preparation methods are complicated in process and prepared vanadium pentoxide / oxidized graphene composite films are poor in uniformity and are difficult to be applied to flexible energy-storage devices can be solved. The vanadium pentoxide aqueous dispersion and the oxidized graphene aqueous dispersion are mixed up, so that a flexible vanadium pentoxide / oxidized graphene composite film can be prepared through the pressure-reduced suction and filtration method, wherein the method is easy to control and operate. Meanwhile, the prepared vanadium pentoxide / oxidized graphene composite film can be applied to flexible capacitor devices. Therefore, the problem that the materials of traditional processes are hardly applied to flexible energy-storage devices can be solved.

Owner:SHANGHAI JIAO TONG UNIV

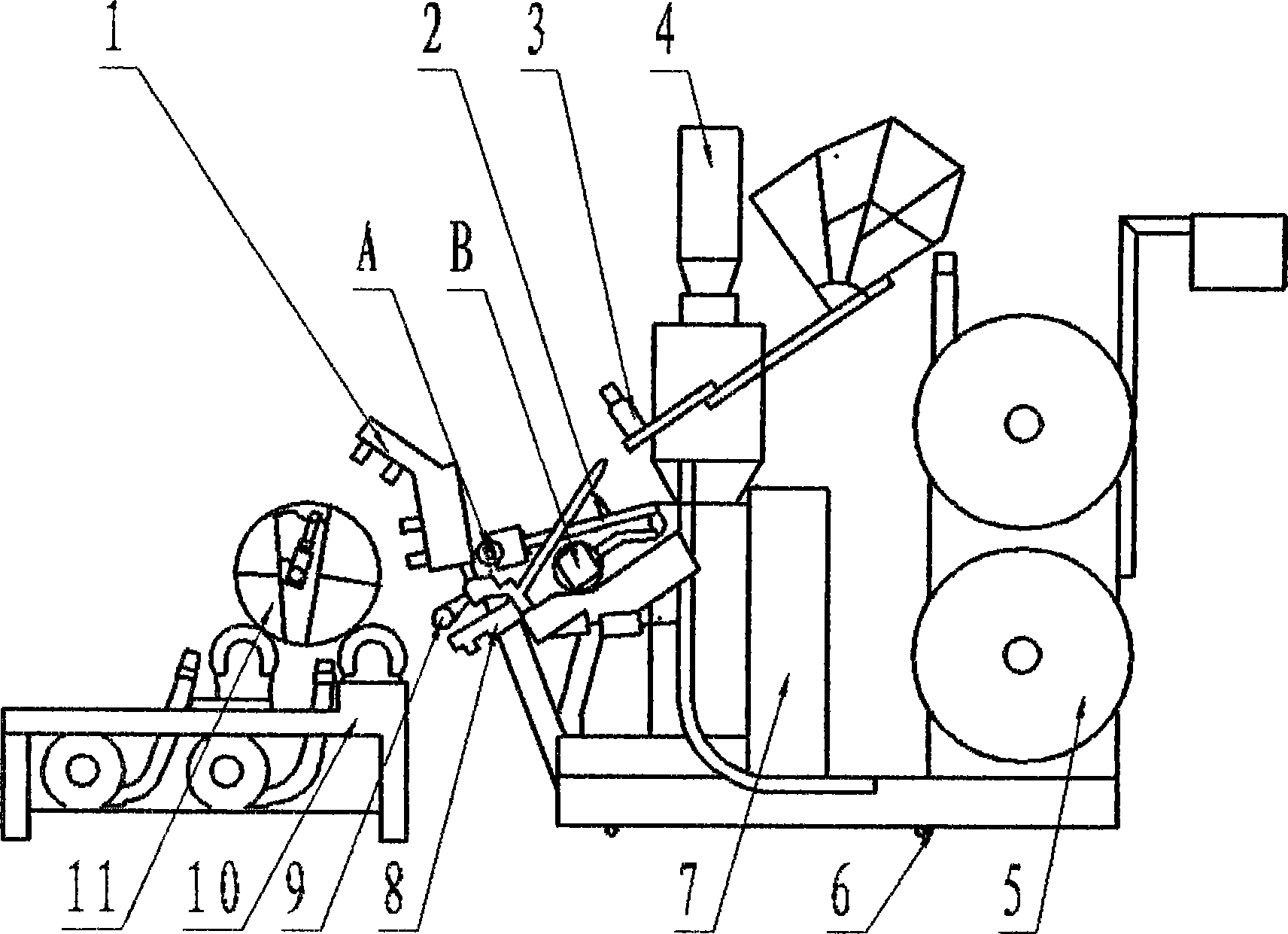

Production device of wall tube of large aperture framework-tube polyethylene winding structure

InactiveCN101380819AReduce weightReduce raw material consumptionTubular articlesElectrical controlEngineering

The invention discloses a production equipment of a polythene winding structural wall tubular product of a large-caliber framework pipe, belonging to the technical field of plastic pipe processing. The invention is used for solving the problem that the raw material consumption for manufacturing the polythene winding structural wall tubular product is huge, the product is heavy and the cost is high. The production equipment of the polythene winding structural wall tubular product of the large-caliber framework pipe comprises a combustion system, a framework pipe transportation system, a plastic extruding machine, a framework pipe bobbin disk, a mobile trolley, an electric control cabinet, a circulation cooling device, a pressure bracket and a rotary mill frame; especially, the length of a flat die opening in a channel system is 170 to 230 mm and the angle of a coating die is 181 to 200; one end of a support connecting rod in a roller is connected with a transmission shaft sleeve by a pin and the other end thereof is connected with a support connecting rod rest; the support connecting rod rest is formed by connecting a long pin and a main transmission shaft. The production equipment of the polythene winding structural wall tubular product of the large-caliber framework pipe can be widely used in the field of the plastic pipe processing.

Owner:石家庄宝石克拉大径塑管有限公司

Sintered hollow brick prepared from silt and dumped stone powder

InactiveCN105693208AReduce raw material consumptionIntrinsic quality is stableCeramic materials productionClaywaresCoal gangueSodium fluosilicate

Provided is a sintered hollow brick prepared from silt and dumped stone powder.The sintered hollow brick is prepared from, by weight, 40% of silt, 25% of dumped stone powder, 20% of coal gangue, 0.5% of plant straw powder, 3% of modified ceramic powder, 4% of sea mud, 1.5% of amorphous quartz particles, 1.5% of sodium fluosilicate, 1% of kyanite, 0.5% of polyvinyl alcohol resin, 1.5% of sepiolite and 1.5% of shells.According to the sintered hollow brick prepared from the silt and the dumped stone powder, raw material consumption can be reduced, and it is guaranteed that the inherent quality of a formed green body is stable; the molding pressure is large, and the green body strength is high; combustion is achieved by means of the calorific value of the coal gangue itself, energy is saved, and pollution is reduced; the produced coal gangue hollow brick reduces the structure weight of a building, improves the building function and has good heat preservation and sound insulation properties.

Owner:JINZHAI GAOFENG NEW BUILDING MATERIAL CO LTD

Fine-denier air-jet texturing polyester filament fabric

InactiveCN103290600AReduce raw material consumptionImprove economic efficiencyWoven fabricsEngineeringFilament yarn

The invention provides a fine-denier air-jet texturing polyester filament fabric, and particularly provides a composite fiber fabric made of 75D (denier) polyester. The composite fiber fabric is of a double-layer hollow structure and comprises superficial warps, superficial wefts, inner warps and inner wefts, and a surface formed by the superficial warps and the superficial wefts is selectively intersected with an inner face formed by the inner warps and the inner wefts, so that double-layer multi-point connection is formed. The superficial warps and the inner warps are made of 70D lustrous nylon, the superficial wefts are made of 75D rayon, the inner wefts are made of 75D polyester twisted silk yarn, and accordingly the fine-denier air-jet texturing polyester filament fabric is soft in hand feeling, breathable, hygroscopic, bright in color and lustrous.

Owner:SUZHOU CINC TEXTILE TECH RP

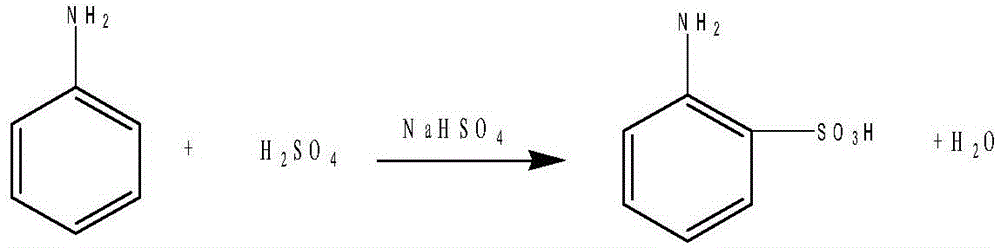

Method for preparing aniline-2-sulfonic acid

ActiveCN105481735AReduce raw material consumptionReduce process costSulfonic acid preparationChemistryHydrogen Sulfate

The invention relates to a method for preparing aniline-2-sulfonic acid, in particular to a method for preparing aniline-2-sulfonic acid through aniline catalysis and sulfonation. With metal hydrogen sulfate serving as a catalyst, aniline is directly catalyzed and sulfonated to prepare aniline-2-sulfonic acid in a transposition mode. According to the method, aniline is directly catalyzed and sulfonated to prepare aniline-2-sulfonic acid in the transposition mode, so that aniline-2-sulfonic acid is prepared from aniline through a one-step method, and the total yield of aniline-2-sulfonic acid reaches 95% or above; the process route is short, the quantity of the three wastes is small, and the cost is low.

Owner:SHENYANG RES INST OF CHEM IND +1

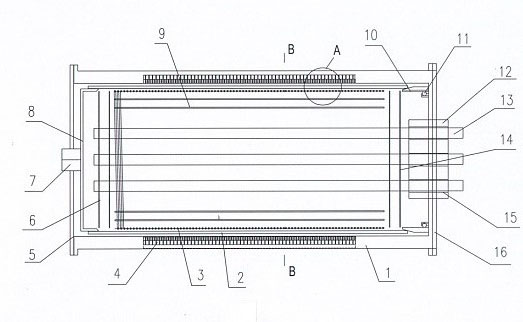

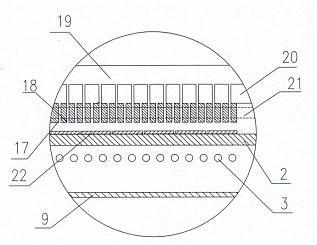

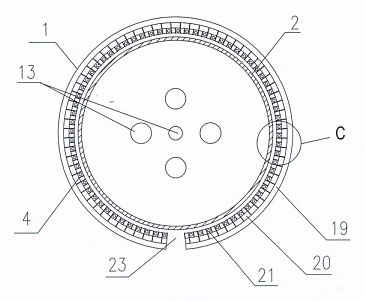

Barrel-shaped metal organic chemical vapor deposition reaction tube

ActiveCN102094185AReduce power consumptionReduce raw material consumptionChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention discloses a barrel-shaped metal organic chemical vapor deposition reaction tube which comprises a barrel body. The barrel type metal organic chemical vapor deposition reaction tube is characterized in that the barrel body is in a barrel shape with an open left end and an open right end, and a graphite barrel, an electric stove wire barrel and a molybdenum sheet heat insulation barrel are sequentially sleeved in the barrel body. The left end and the right end of the electric stove wire barrel are respectively provided with a left heat insulation molybdenum sheet and a right heat insulation molybdenum sheet which are sleeved on an electrode stem. A multiple-layer spray tube is arranged in the barrel body and is composed of a liquid cooling tube, an ammonia spray tube and a metal organic source spray tube. An ammonia nozzle connected with the ammonia spray tube and a metal organic source nozzle connected with the metal organic source spray tube are arranged on the inner wall of the barrel body, and an exhaust port is arranged on the inner wall of the barrel body. The barrel type metal organic chemical vapor deposition reaction tube has the advantages that the throughput can be raised on a large scale, the product cost can be reduced, the production efficiency can be increased, the surface temperature uniformity of graphite is good, the product percent of pass is high, and the energy consumption is low. The productivity is 20 times as high as that of three kinds of popular MOVCD great machines at present.

Owner:南昌硅基半导体科技有限公司

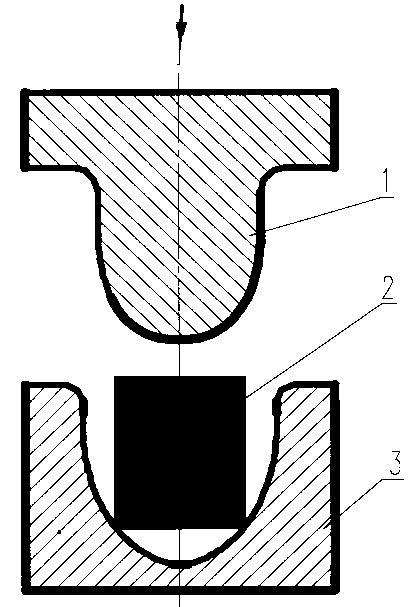

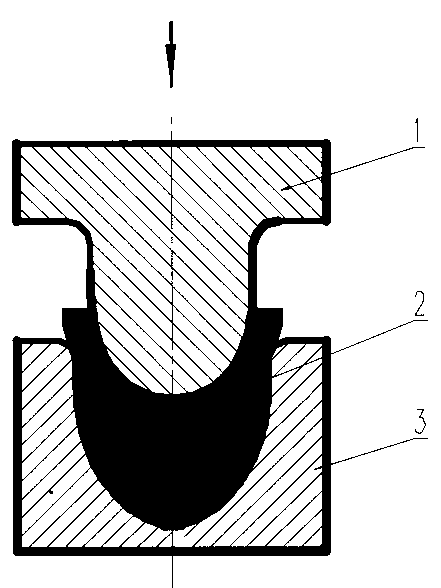

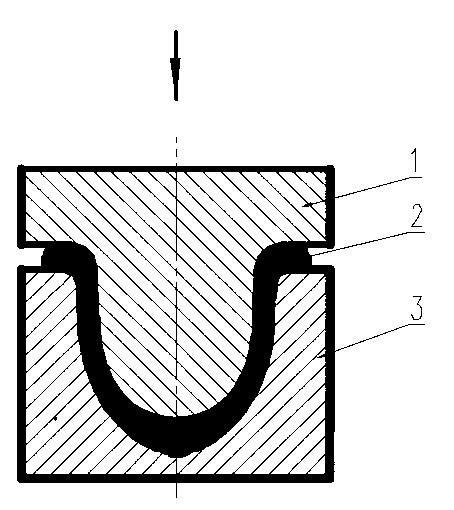

Cold extrusion moulding process of aluminium alloy complex cup-shaped thin-wall part

InactiveCN102989985AImproved dimensional accuracy and surface roughnessReduce raw material consumptionEngine componentsRound barDimensional precision

The invention discloses a cold extrusion moulding process of an aluminium alloy complex cup-shaped thin-wall part. The cold extrusion moulding process includes the steps that a male die and a female die are mounted on forging equipment which can be a 3150T electric screw press or a 2500T hydraulic press, the distance and offset of the dies are adjusted, and the dies are lubricated by lubricant industrial lard; a softened cold round bar stock with a diameter of 200mm is put into the female die under room temperature; under the pressure action of the equipment, the metal flows in the female die until the cavity is full of metal and the excess metal is extruded backward to the space between the male die and the female die, forming a flange at the opening of the forged piece; and after the stroke of the equipment is over, the metal no longer flows and forms the shape and the size of a final cold extruded piece. The cold extrusion moulding process has the advantages that the size and the property of the aluminium alloy forged piece produced through the process satisfy the requirement of the design drawing, the aluminium alloy forged piece has high surface roughness and dimensional precision; and most of all, the consumption of raw material is greatly reduced, the forging procedure is reduced, processing time is saved during the mechanical processing procedure and the processing period is shortened.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A white fast setting rapid hardening high belite sulfoaluminate cement clinker, its application and its production process

The invention relates to a white fast-setting, fast-hardening and high-belite sulphoaluminate cement clinker, and also relates to an application and a production technology thereof. The mineral component of the cement clinker comprises 0.5-4.6% of f-CaO; the chemical component of the cement clinker comprises 12.9-16.1wt% of SiO2, 12-19wt% of Al2O3, 0.15-1.0wt% of Fe2O3, 49-53wt% of CaO and 12-18.5wt% of SO3; and the clinker rate range Cm is 1.01-1.137, and P is 0.62-1.44. The clinker is produced through calcining 30-50wt% of limestone, 26-46wt% of slag powder and 21.1-40wt% of desulfurized gypsum in a rotary kiln at 1250-1350DEG C. 26-97% Of the clinker, 3-19% of anhydrite and 0-55% of the slag powder, or 5-25% of the clinker, 14.4-19.0% of the anhydrite and 55.8-79% of the slag powder are mixed and ground to form white fast-setting, fast-hardening and high-belite sulphoaluminate cement and high-late strength and high-belite sulphoaluminate cement.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL +1

Method for manufacturing polypropylene woven water tape and products thereof

InactiveCN1631660AReduce weightReduce raw material consumptionFlexible pipesTubular articlesMaterial consumptionPolypropylene

The invention is a polypropylene weaving water belts producing method and its product. The method includes following steps: adding anti-oxidating medium 1010 of 0.4 weight share, UV-327 of 0.5 weight share, aiding anti-oxidating medium DLTP of 0.6 weight share, into the polypropylene new material t30s or 5000s of 100 weight shares and mix them up; draw the obtained product with plastic drawing machine; tram locate the obtained product with plastic wire rolling machine and then weaving the product with plastic round weaving machine into cylinder water belts which is first coated with plastic films by cylinder weaving plastic-coating composite machine into a cylinder, and then inverted with belt inverting machine outside in to transform the inner surface into outer surface which also will be coated the plastic films. The invention objective is to provide with a polypropylene weaving water belts producing method of less material consumption, lower cost, lighter weigh and longer service life and the product itself.

Owner:罗衍宾 +1

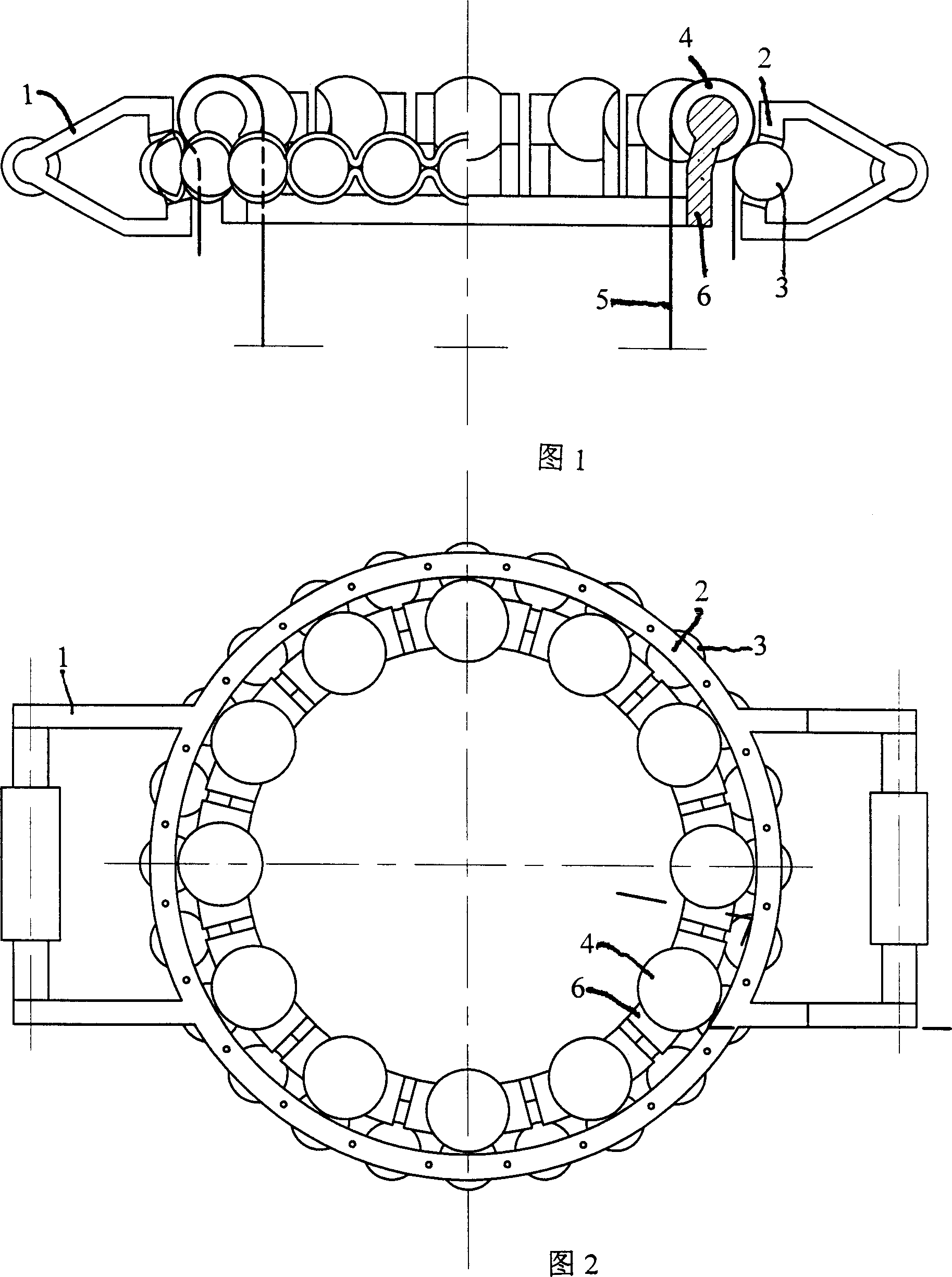

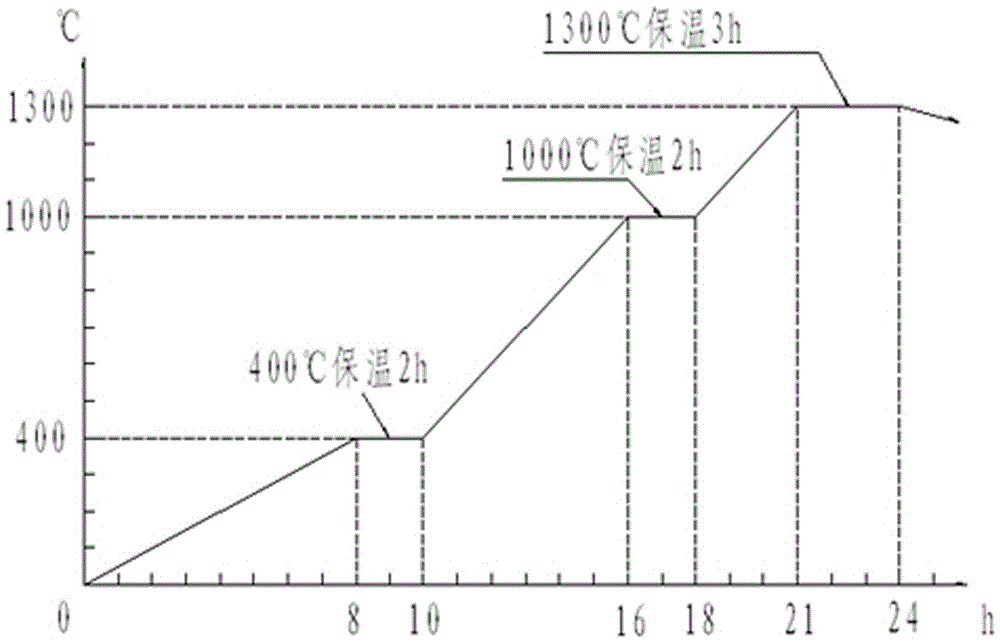

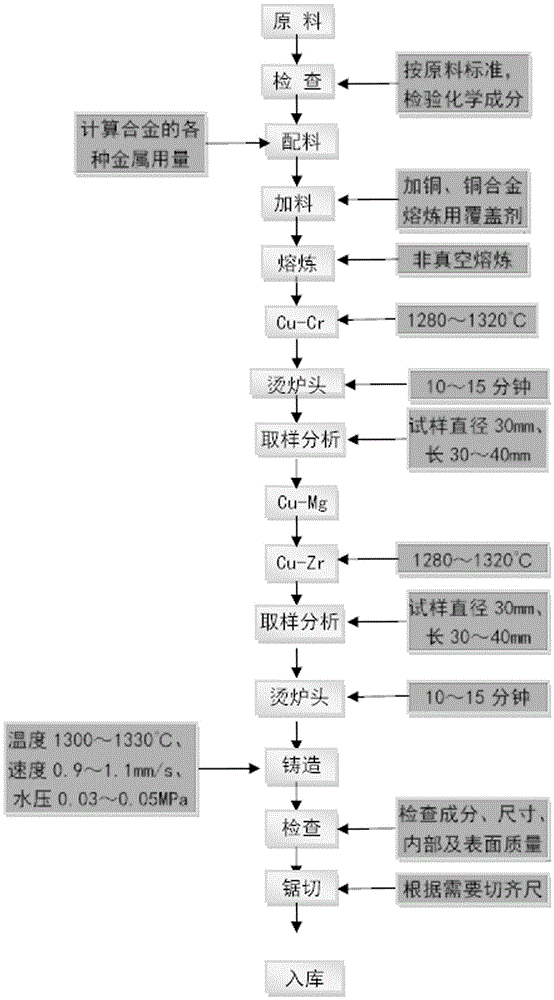

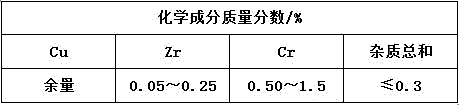

Technology for smelting and casting C18150 alloy under atmosphere condition

A technology for smelting and casting a C18150 alloy under the atmosphere condition comprises steps as follows: (1), furnace casting, baking and sintering: a basic refractory material is to be selected as a furnace liner material, acid refractory materials such as silica sand and the like cannot be utilized, and the operational process is as follows: furnace forging, furnace baking and sintering; (2), smelting and casting: a, baking of a covering agent, b, blending, c, smelting, d, casting, e, checking, f, sawing and g, warehousing. According to the technology for smelting and casting the C18150 alloy under the atmosphere condition, the problem of burning loss of Cr and Zr is solved fundamentally, meanwhile, melts are purified, consumption of raw materials is reduced, the production cost is greatly reduced, the ingot metallurgy quality is improved, the defects of pores, impurity inclusion, slag inclusion and the like caused by air absorption and oxygen absorption due to adoption of a traditional method for conveying molten metal by a launder are overcome, the ingot quality is improved, the technology further has the advantages of small occupied space, low labor intensity, low metal loss and the like, and low-cost production is realized truly.

Owner:SHENYANG NONFERROUS METALS PROCESSING CO LTD

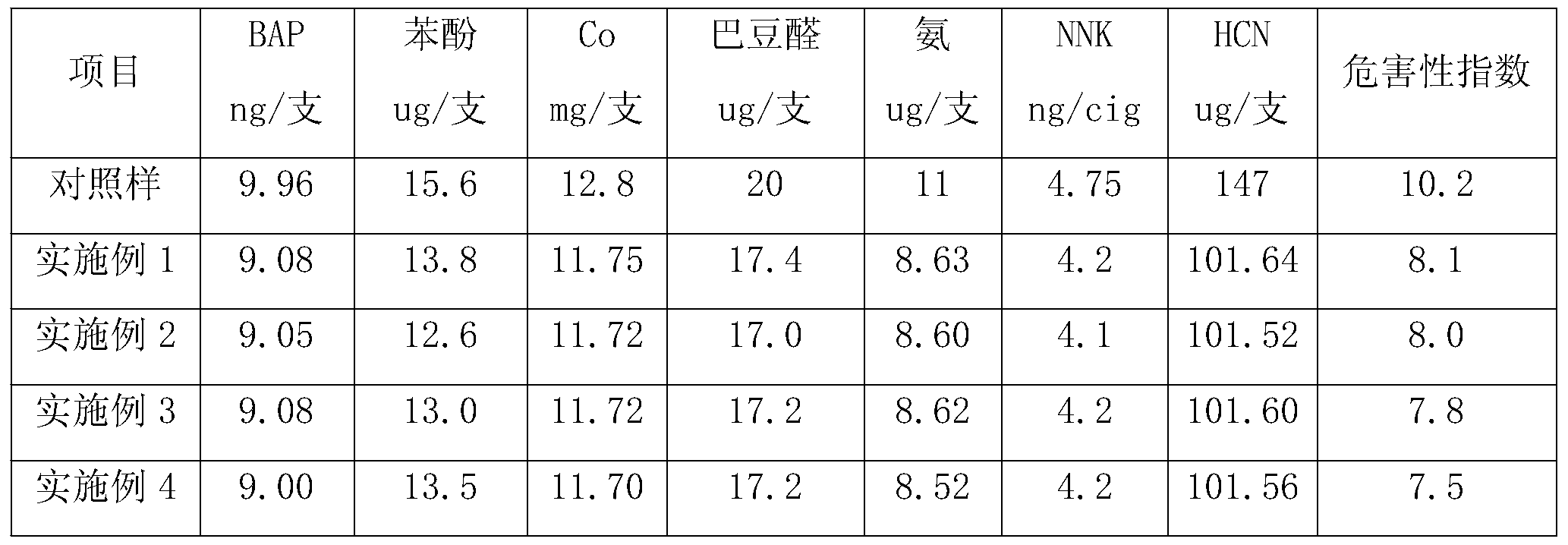

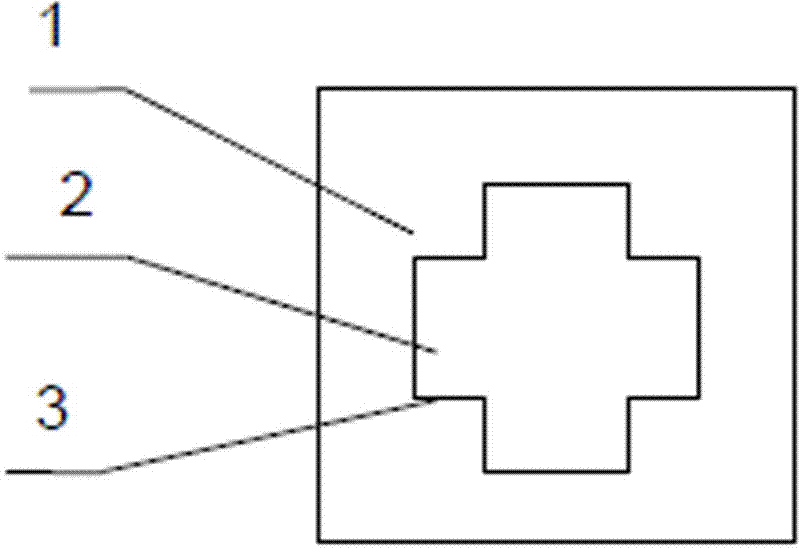

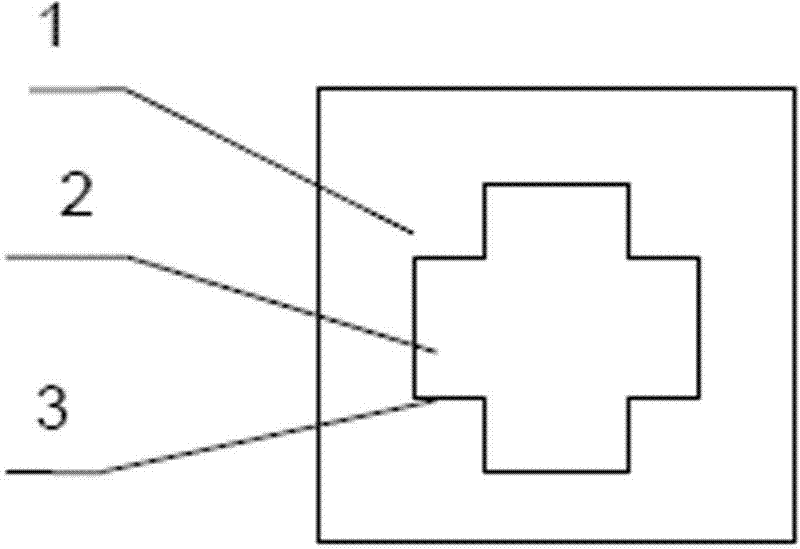

Preparation method of self-colored bamboo fiber filter tip

ActiveCN104138031AEliminate residual pollutionReduce raw material consumptionTobacco smoke filtersPaper sheetPotassium permanganate

The invention discloses a preparation method of a self-colored bamboo fiber filter tip. The method comprises the first step of disintegrating raw materials, that is, disintegrating the bamboo fiber raw materials into sheets through a dry method, the second step of digesting, that is, mixing the sheets and digesting liquor evenly and then digesting the mixture to obtain high-hardness bamboo pulp with a potassium permanganate value ranging from 26 to 38, the third step of washing, that is, washing and screening the high-hardness bamboo pulp through a pressure screen and a vacuum washing and starching machine to obtain clean bamboo pulp with the concentration ranging from 3% to 8%, the fourth step of manufacturing paper with the pulp, that is, manufacturing thin paper sheets with the quantification of 25-40 g / cm3 with the clean bamboo pulp on a paper machine, the fifth step of dividing the thin paper sheets into rolls, that is, slitting the thin paper sheets into the paper rolls with the width ranging from 20 cm to 28 cm, and the sixth step of preparing filter sticks, that is, feeding the paper rolls into a horn mouth of a filter stick forming machine and machining the paper rolls into the circular filter sticks with the diameter ranging from 7.5 mm to 8.0 mm. The preparation method has the advantages that the raw materials are convenient to get, the preparation process is simple, harm to operators is small, the cost is low, and the environment is protected.

Owner:SICHUAN HUANLONG NEW MATERIAL

Feces occult blood test paper and preparation method thereof

InactiveCN102331423AReduce raw material consumptionLow costMaterial analysis by observing effect on chemical indicatorHb - HemoglobinBiomedical engineering

The invention relates to feces occult blood test paper and a preparation method thereof. The feces occult blood test paper comprises a test paper body and is characterized by further comprising a color developing layer and latex, wherein the color developing layer is formed on the test paper body and can have color change in the presence of hemoglobin, the latex is arranged on the test paper body and used for sealing the periphery of the color developing layer. The feces occult blood test paper is adopted for testing without professional testing people, and is very simple to operate, sanitary and environmentally-friendly; and the result can be fast obtained.

Owner:SUZHOU HAOOUBO BIOPHARML

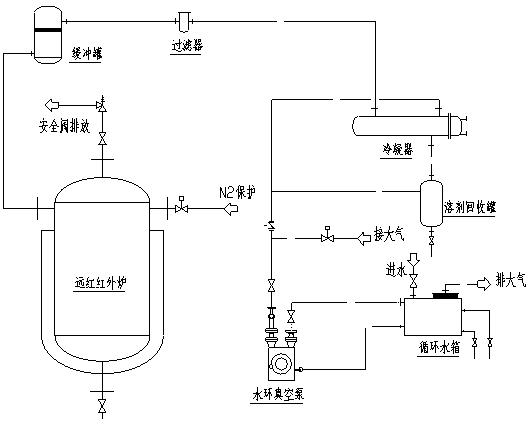

Device and method for recovering organic solvents in flammable explosive high-viscosity polymer waste

ActiveCN108452548AHeating evenlyReduce raw material consumptionCombination devicesSolid waste disposalSolventScrap

The invention discloses a device and a method for recovering organic solvents in flammable explosive high-viscosity polymer waste. A far-infrared furnace, a buffer tank, a filter and a condenser are connected in sequence; the condenser is connected with a solvent recovery tank while connected with a water tank via a vacuum pump; the side surface of the water tank has an overflow port; the heatingelement of the far-infrared furnace is a silicon carbide plate arranged out of the furnace and coated with a far-infrared paint; a far-infrared heating wire is arranged in the silicon carbide plate; and one surface, coated with the far-infrared paint, of the silicon carbide plate clings to the outer wall of the far-infrared furnace. According to the invention, waste slurry blocks and solvents in flammable and explosive materials adhered onto metal surfaces are recovered in a vacuum state by heating and condensing; the far-infrared furnace is employed for heating, so uniform heating in the furnace is realized, local high temperature and open flames do not occur, and the phenomenon of flash explosion is eliminated; the waste slurry blocks and the flammable and explosive melt materials adhered onto metal surfaces are separated under high vacuum and high temperature, and the separated and evaporated flammable and explosive organic solvents are condensed into liquid which is collected for recycling; so spinning solvents can be recycled, raw material consumption is reduced, and production cost is lowered.

Owner:SINOPEC YIZHENG CHEM FIBER +1

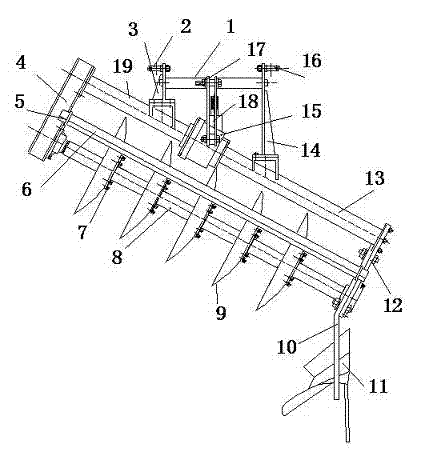

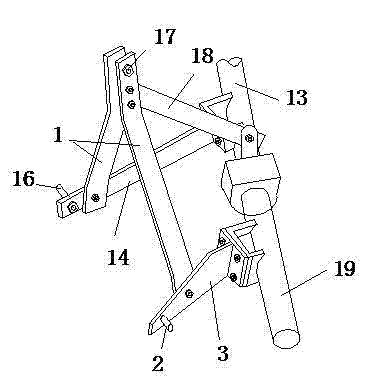

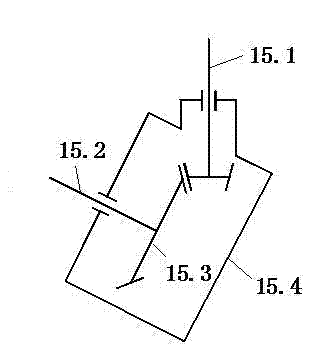

Tail-wheel-free combined left-turning driven disk plow

InactiveCN102726130AImprove balanceImprove adaptabilityAgricultural machinesPloughsProduction rateAgricultural engineering

A tail-wheel-free combined left-turning driven disk plow is a drive tillage implement, consisting of a drive tillage disk and a moldboard plow, and having the advantages of low oil consumption, low traction resistance, high production efficiency and high oil penetrating performance. The structure of the disk plow comprises a suspension bracket assembly, a central transmission assembly, a main beam, a side transmission box assembly, a disk tillage component assembly, a right side plate, a tail plow assembly, and on the like. With the adoption of the implement, the complex tail wheel device is eliminated and the machining cost and the raw material consumption are reduced; the lateral force is mainly balanced by a plow side plate of the moldboard plow arranged on the tail part, so the balancing property is high, the disk plow is suitable for paddy field dry tillage and dry land tillage, and capable of being developed and used in large dry farming areas, so that the novel tillage implement which saves energy, reduces emission, enhances gain and reduces cost is provided to the agricultural industry.

Owner:FUJIAN AGRI & FORESTRY UNIV

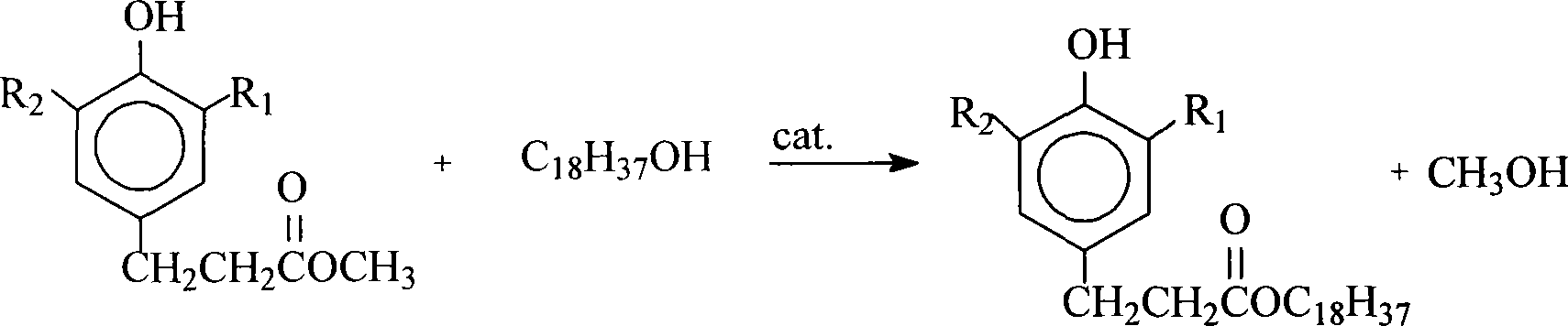

Preparation method of anti-oxidizing agent

InactiveCN101225307AReduce raw material consumptionLow costPreparation by caroxylic acid/anhydride-hydrocarbon reactionCarboxylic acid esters separation/purificationSolventOctadecyl Alcohol

The invention relates to a preparation method for an antioxidant of 3-(3,5-Di-tertbutyl-4-hydroxyphenyl) propionic octadecyl alcohol ester, which comprises following steps: adding 3-(3,5-Di-tert-butyl-4-hydroxyphenyl) propionic acid, octadecyl alcohol and butylhydroxyoxo-stannane; dewatering through azeotropic esterification reaction; decolorizing using active carbon and active bentonite; filtrating to removing solvent, then melt solution with antioxidant is obtained; adding crystallizing solvent in the melt; crystallizing and filtering to obtain antioxidant; recovering crystallizing solvent in filtrate to obtain distillation residue; adding sodium hydroxide in the distillation residue for reaction; adding extractant to extract octadecyl alcohol; adding sulfate in aqueous phase for acidification reaction; recovering raw material of 3-(3,5-Di-tert-butyl-4-hydroxyphenyl) propionic acid through crystallization and filtration. The antioxidant of 3-(3,5-Di-tertbutyl-4-hydroxyphenyl) propionic octadecyl alcohol ester has the advantages of fully recovering and utilizing raw material of 3-(3,5-Di-tert-butyl-4-hydroxyphenyl) propionic acid and improving yield of product.

Owner:RIANLON

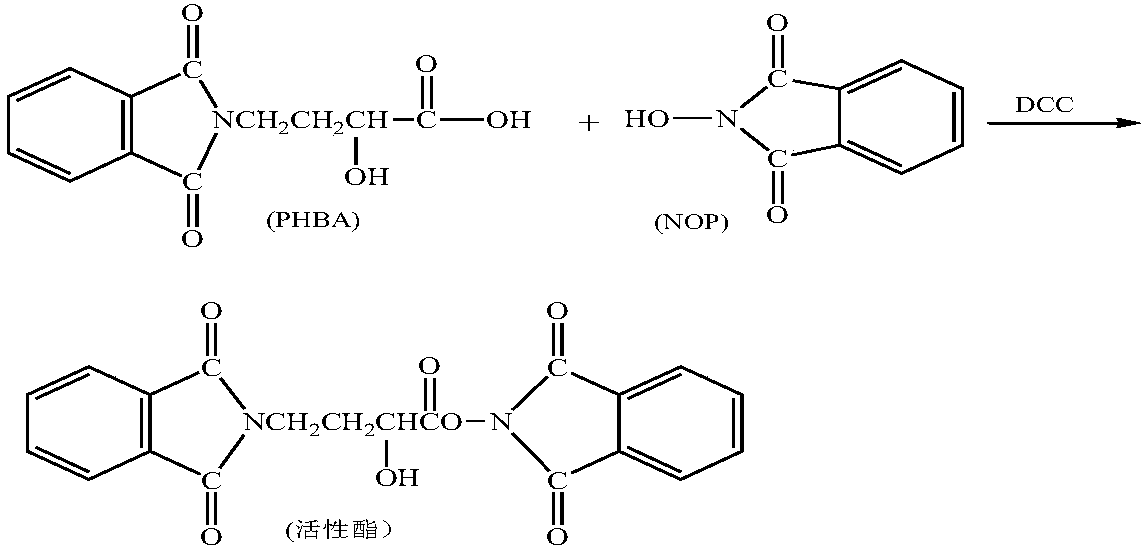

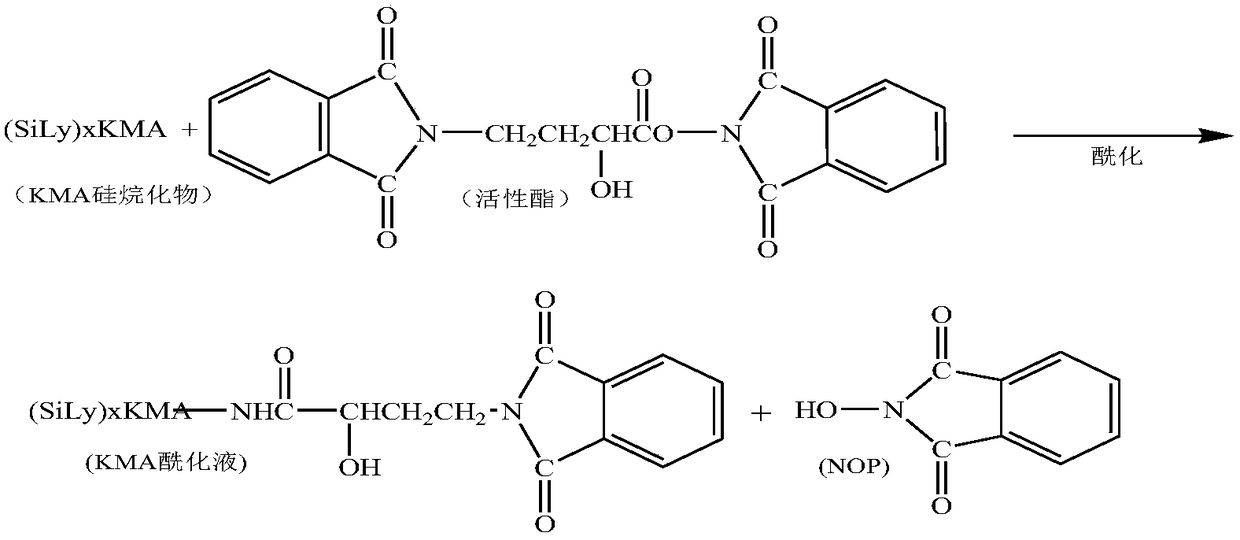

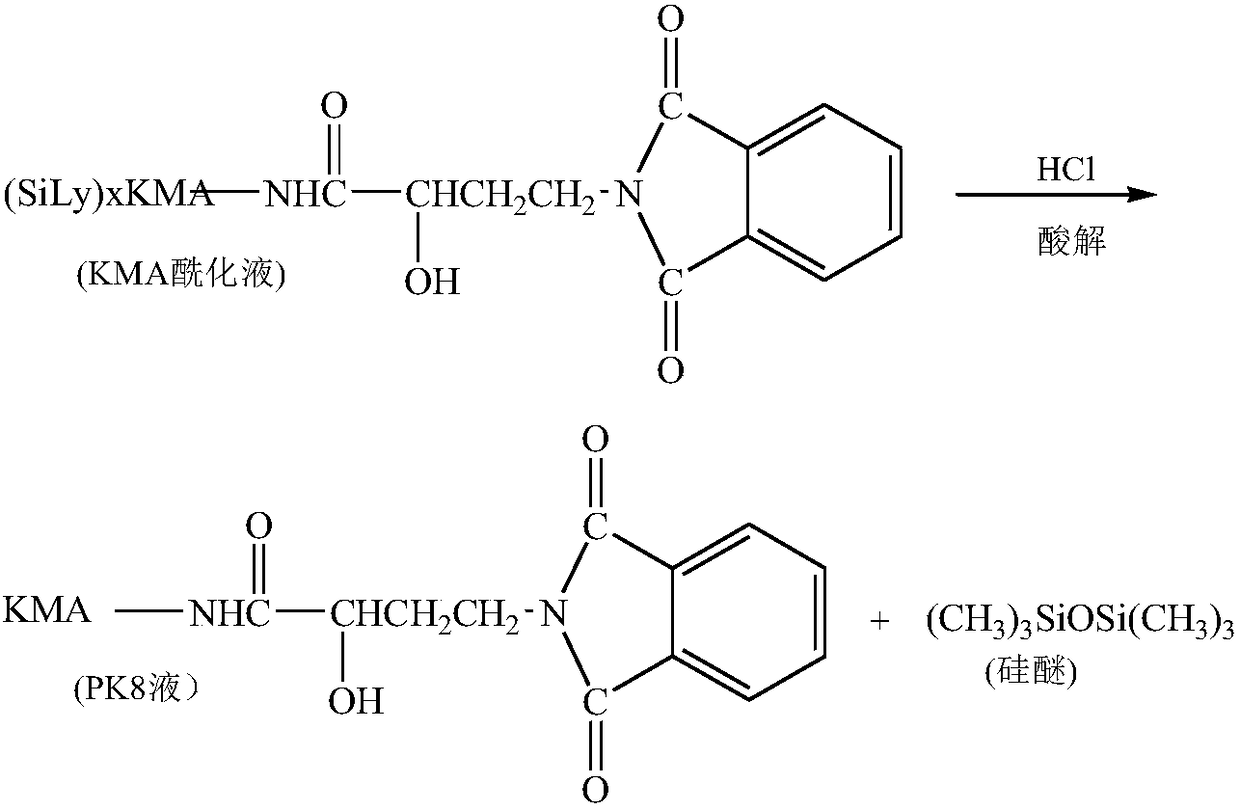

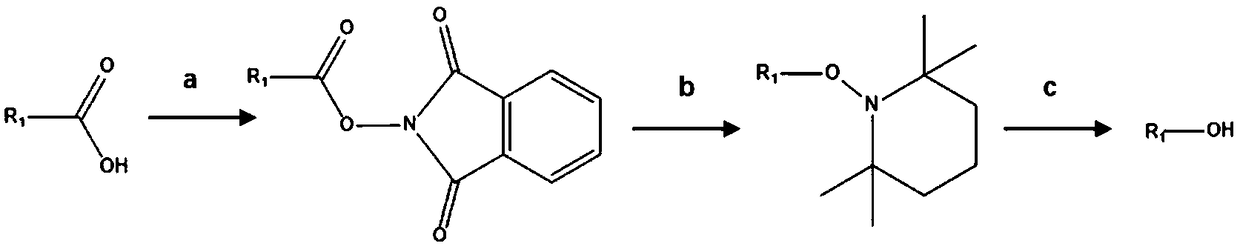

Synthesis method of amikacin

ActiveCN108976267AReduce preparation operationsReduce raw material consumptionSugar derivativesSugar derivatives preparationAmikacinButyric acid

The invention relates to a synthesis method of amikacin, the synthesis method of amikacin comprises the following steps: 1) performing silanization on kanamycin A to form silanized kanamycin A; 2) taking the silanized kanamycin A and 4-phthalimido-2-hydroxy butyric acid as raw materials, N,N-bicyclohexyl carbodiimide as a condensing agent, performing acylation reaction, obtaining an acylated product; 3) sequentially performing acidolysis reaction and hydrazolysis reaction on the acylated product so as to obtain the amikacin. The synthesis method provided by the invention is simple in preparation, low in requirements for production equipment, mild in condition, simple and easy to operate, high in synthesis yield, and suitable for large-scale production, and is obvious in economic benefits.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

Preparation method of anode for producing metallic titanium by electrolysis

InactiveCN104451781ASimple processReduce raw material consumptionElectrodesParaffin oilsCarbon composites

The invention provides a preparation method of an anode for producing metallic titanium by electrolysis, and relates to a preparation method of a titanium-oxygen-carbon porous anode for producing the metallic titanium by the electrolysis in alkaline-earth metal halide fused salt. The preparation method is characterized in that the preparation process comprises the following steps: by taking titanium dioxide and graphite powder as raw materials, and taking asphalt, PVA or paraffin as a binding agent and a pore-forming agent, carrying out pulping, uniformly mixing and drying to obtain dry powder; carrying out mold pressing and molding on the dried powder; and finally, drying and sintering the powder to obtain the titanium-oxygen-carbon porous anode. The preparation method of the anode for producing the metallic titanium by the electrolysis has the advantages that the flow is simple, fewer raw materials are consumed, the porosity of an obtained titanium-oxygen-carbon composite material is relatively great, the dissolving speed of the anode in electrolyte is high, the residual anode rate after the electrolysis is relatively small, and guarantees are provided for industrial production of electrolyzed titanium. The method provided by the invention can be used for finishing a primary formation process of electrolyzing the titanium composite anode by adopting a simple technological process, and an industrialized progress of directly electrolyzing the titanium is accelerated.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

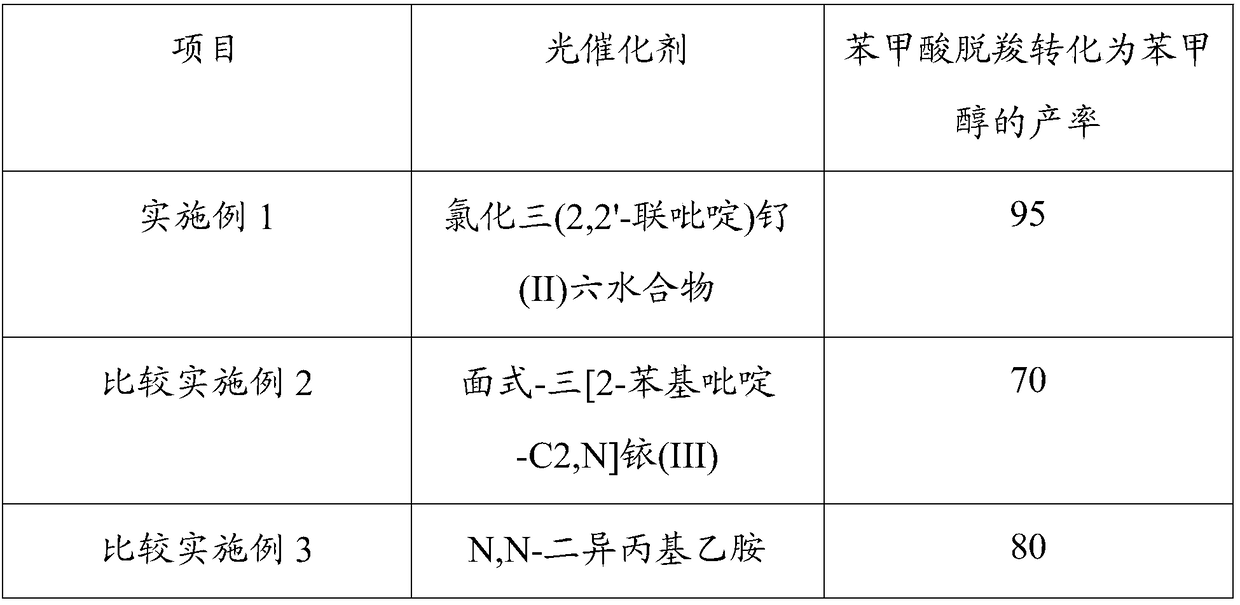

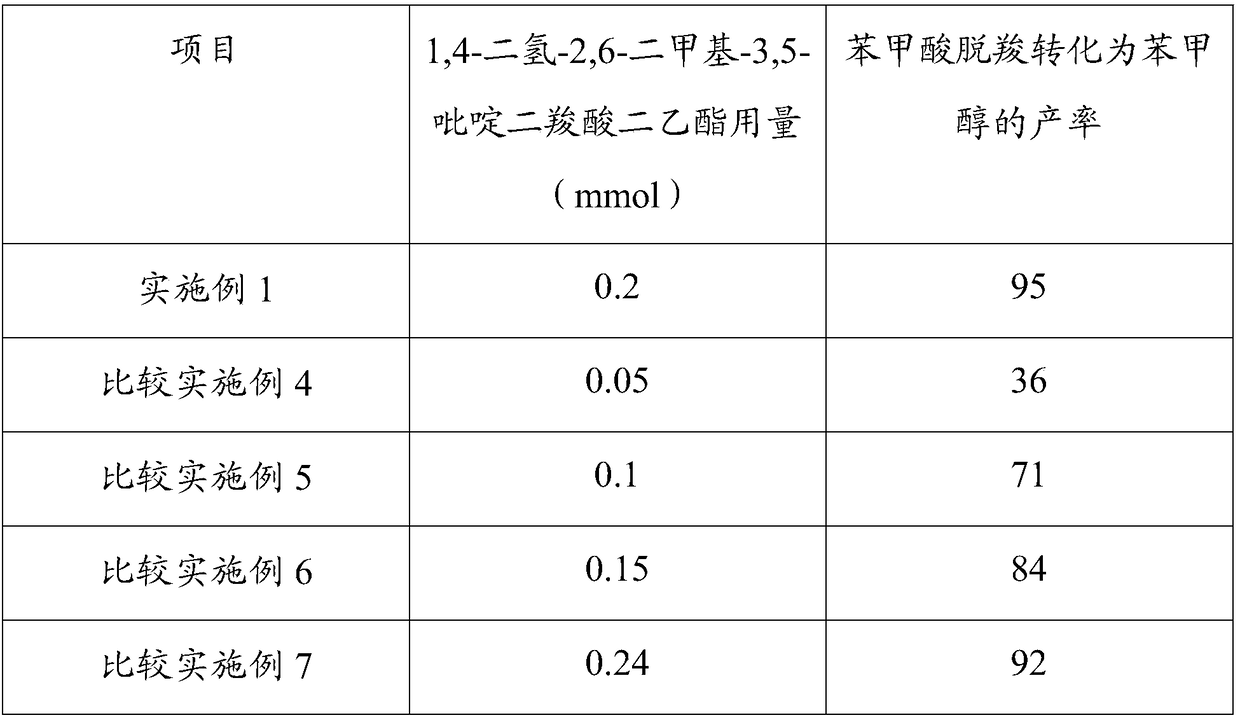

Application of tris(2,2'-bipyridyl)ruthenium(II) chloride hexahydrate as catalyst

InactiveCN108704665AGood chemoselectivityReduce energy consumptionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsCHLORIDE HEXAHYDRATEChemoselectivity

The invention relates to application of tris(2,2'-bipyridyl)ruthenium(II) chloride hexahydrate as a catalyst for preparing fatty alcohol through decarboxylation of aliphatic carboxylic acid. The application has the advantages that chemical selectivity is high, and materials are extensive and easy to acquire; defects in aliphatic carboxylic acid conversion based on conventional thermochemical methods, including high energy consumption such as high temperature and high pressure, and harsh reaction conditions, are avoided; the reaction process is simple, convenient, and easy to operate, and repeated extraction is avoided; additional injection of high-purity hydrogen is not needed, and reaction energy consumption and raw material consumption are greatly reduced; environment protection is realized, and environment pollution is small; a wide application prospect is achieved.

Owner:HAINAN NORMAL UNIVERSITY

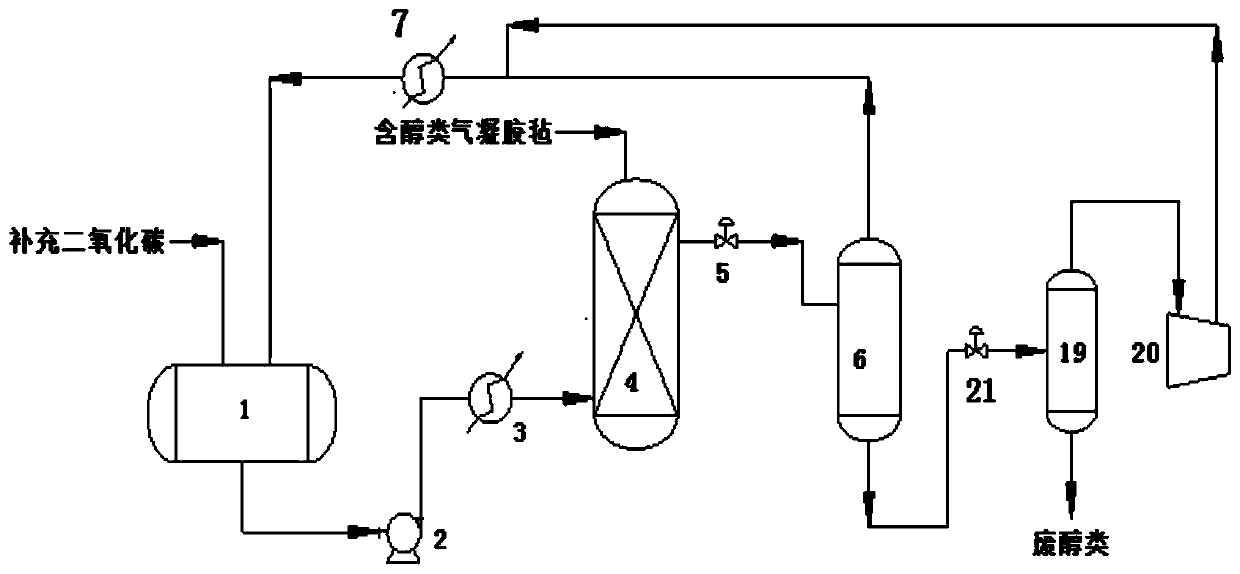

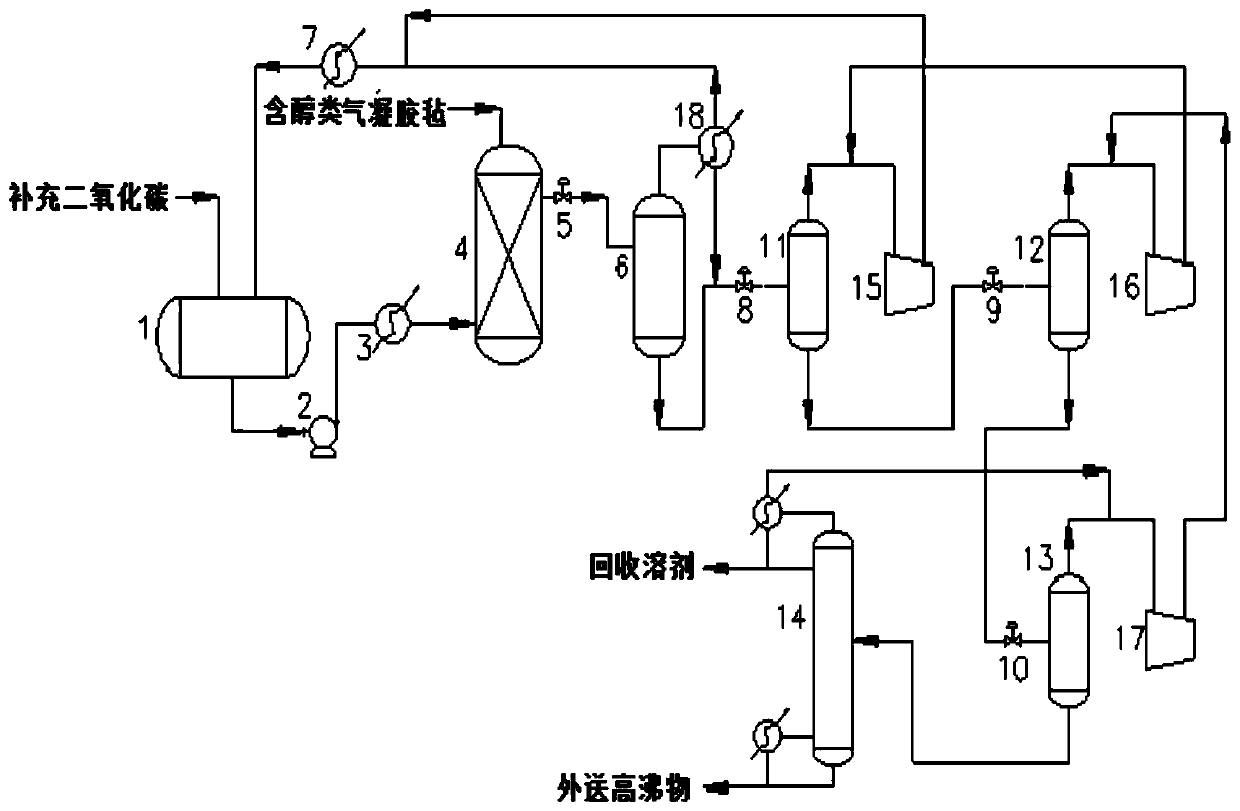

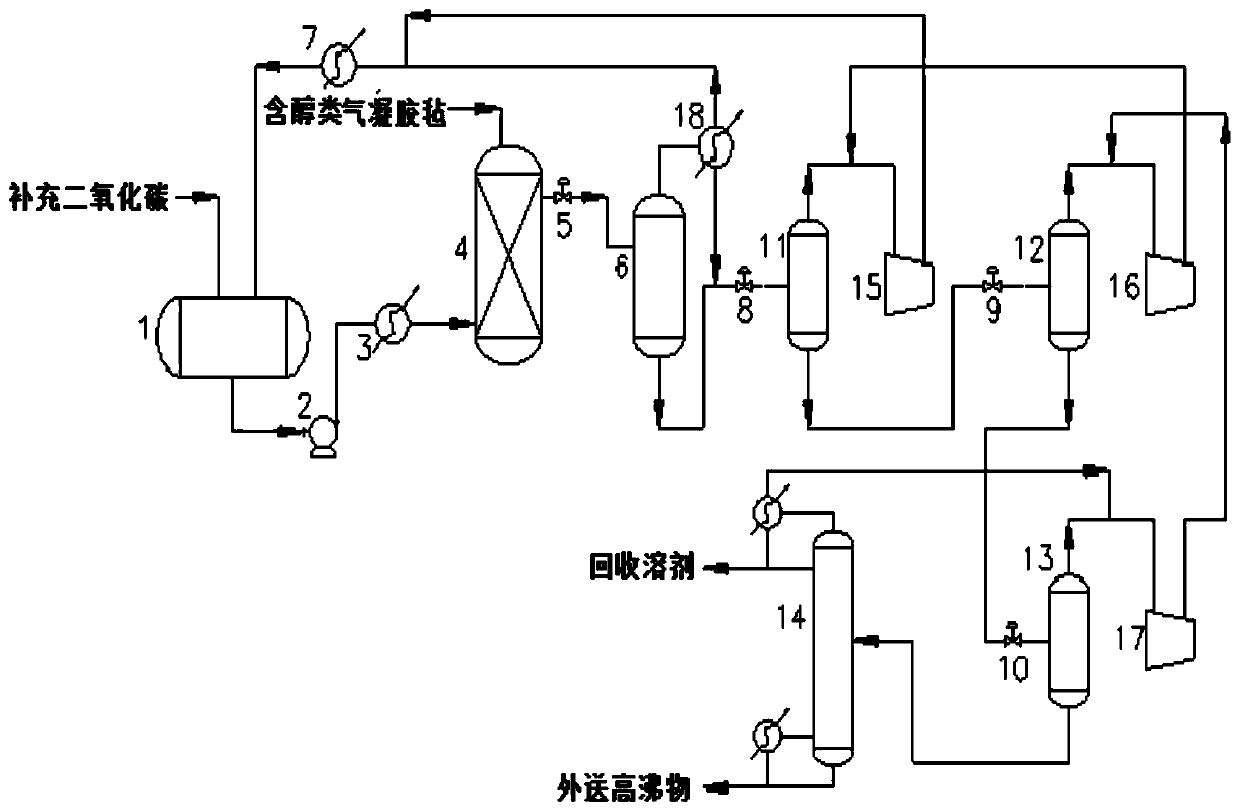

Solvent recovery method for supercritical CO2 drying in silicon-based aerogel production

PendingCN111111572AReduce energy consumption and difficulty in equipment manufacturing and processingReduce raw material consumptionLiquid degasificationCarbon compoundsSolventSupercritical drying

The invention discloses a solvent recovery method for supercritical CO2 drying in silicon-based aerogel production. A device involved in the recovery method mainly comprises a supercritical extractionkettle, a separation kettle, a multi-stage flash tank, a multi-stage compressor and a rectifying tower, and process equipment and a control system are simple and easy to realize. According to the solvent recovery method, the gas phase of the separation kettle is condensed to separate a solvent, a liquid phase solvent of the separation kettle is subjected to multi-stage flash evaporation compression, and finally rectification is performed, so that high-purity, high-quality and high-yield recovery of the solvent is realized, the treatment capacity of the compressor is more reasonable and accurate, and the purposes of saving energy consumption and reducing production investment cost are achieved. And moreover, wastewater discharge is reduced, and environmental friendliness is realized.

Owner:中化学华陆新材料有限公司

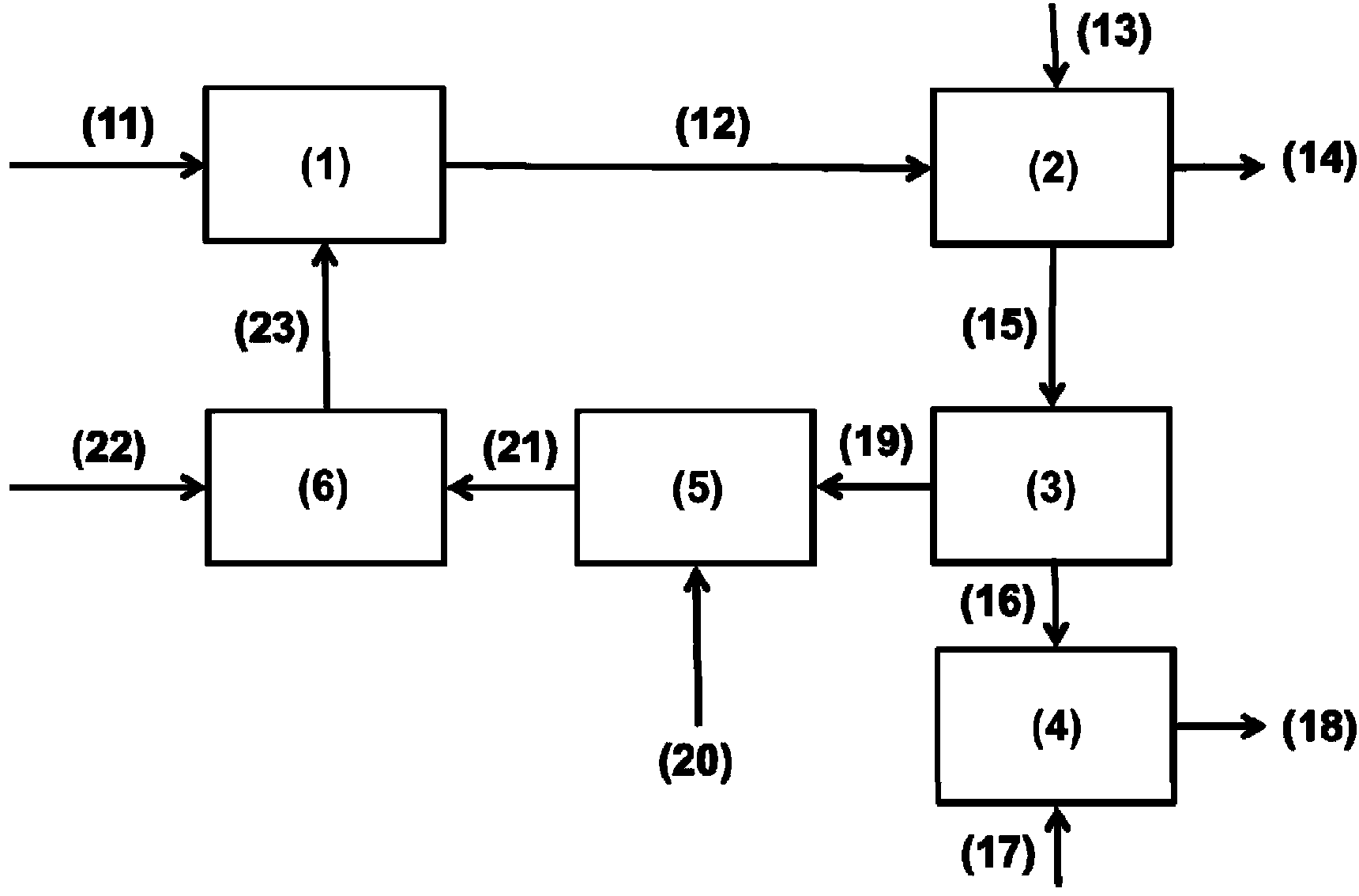

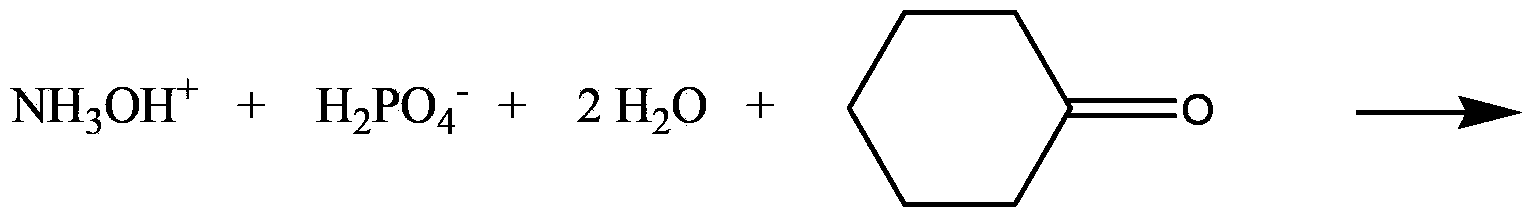

Process for the production of hydroxylamine by reduction of nitrate or nitrogen monoxide

ActiveCN103523759AHigh selectivityReduce raw material consumptionLactams preparationAlkali orthophosphate fertiliserFertilizerPhosphate

The present invention provides a process for the continuous production of hydroxylamine, comprising i) feeding to a hydroxylamine formation zone: a) hydrogen-containing gas; b) phosphate-containing acidic aqueous solution; and c) nitrate or nitrogen monoxide dissolved in said phosphate-containing acidic aqueous solution; ii) reducing, in said hydroxylamine formation zone, nitrate or nitrogen monoxide with hydrogen to form hydroxylamine; iii) removing hydroxylamine from said phosphate-containing acidic aqueous solution, in a hydroxylamine removal zone; iv) adding to said phosphate-containing acidic aqueous solution nitrous gases and / or nitrate; and v) returning to said hydroxylamine formation zone said phosphate-containing acidic aqueous solution; characterized in that a portion of said phosphate-containing acidic aqueous solution is removed; and phosphoric acid is added to the remaining phosphate-containing acidic aqueous solution; a process for preparing oximes therefrom; a process for preparing lactams therefrom; and a fertilizer product produced therefrom.

Owner:CAP III

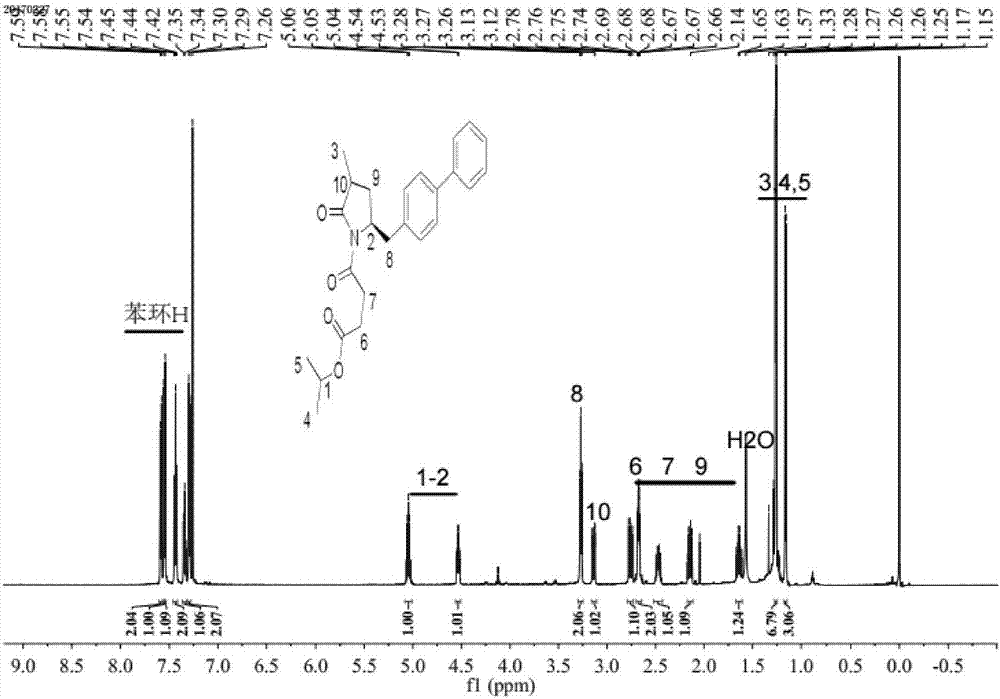

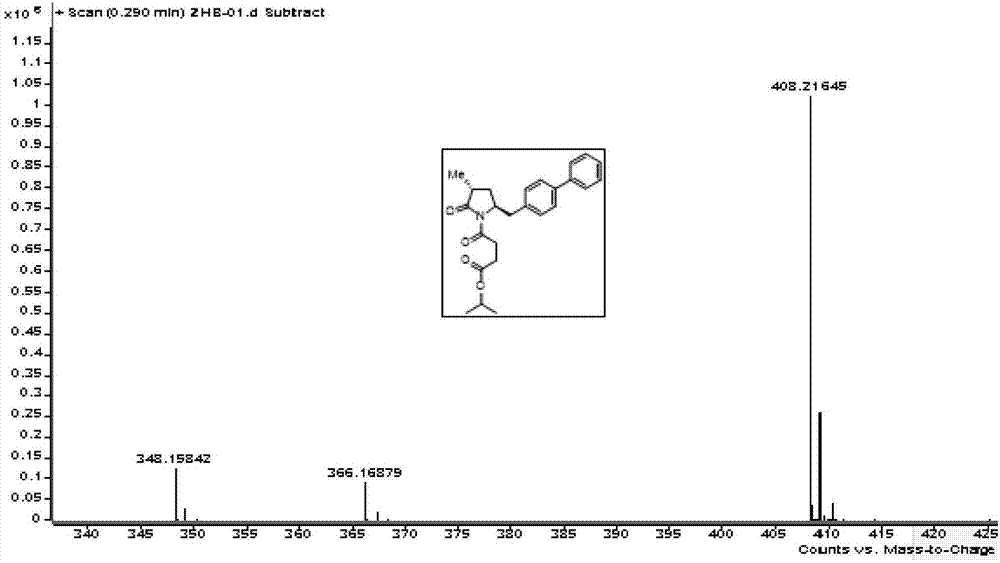

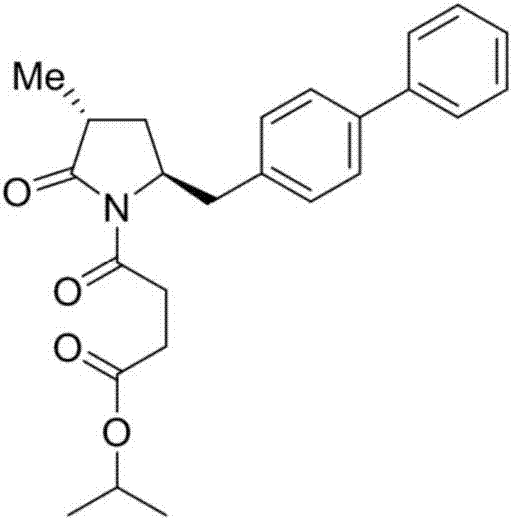

Method for preparing LCZ696 impurity reference substance

InactiveCN107311909AReduce raw material consumptionEase of occurrence and controlOrganic chemistryChemistryHeavy metals

The invention provides a method for preparing an LCZ696 impurity reference substance. The method comprises the following steps: performing a reaction on (2R, 4S)-5-(biphenyl-4-yl)-4-[(t-butyloxycarboryl) amino]-2-methylpentanoic acid and thionyl chloride in ethanol so as to obtain a compound of formula I; performing a reaction on the compound of the formula I under a weak alkali condition so as to obtain a compound of formula II; performing heating reflux on succinic anhydride in isopropanol so as to obtain a compound of formula III; performing a reaction on the compound of the formula III with thionyl chloride so as to obtain a compound of formula IV; preparing the LCZ696 impurity reference substance of formula V from the compound of the formula II and the compound of the formula IV under catalysis of a strong alkali catalyst. By adopting the method provided by the invention, consumption of raw materials is reduced as a whole, the method is economic and environmental-friendly, different steps of reactions can be relatively easily implemented and controlled, meanwhile the amount of heavy metal catalysts is reduced and avoided, and the quality indexes of final products are improved.

Owner:SOUTHEAST UNIV

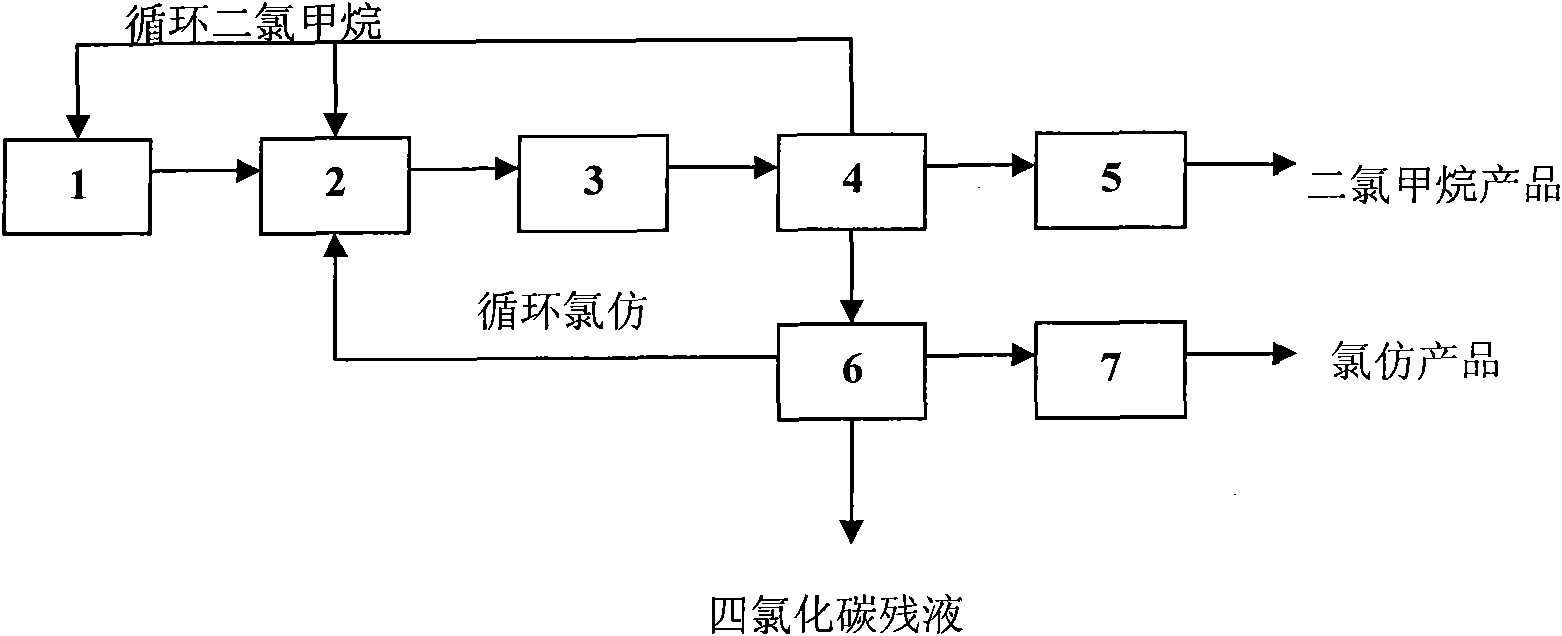

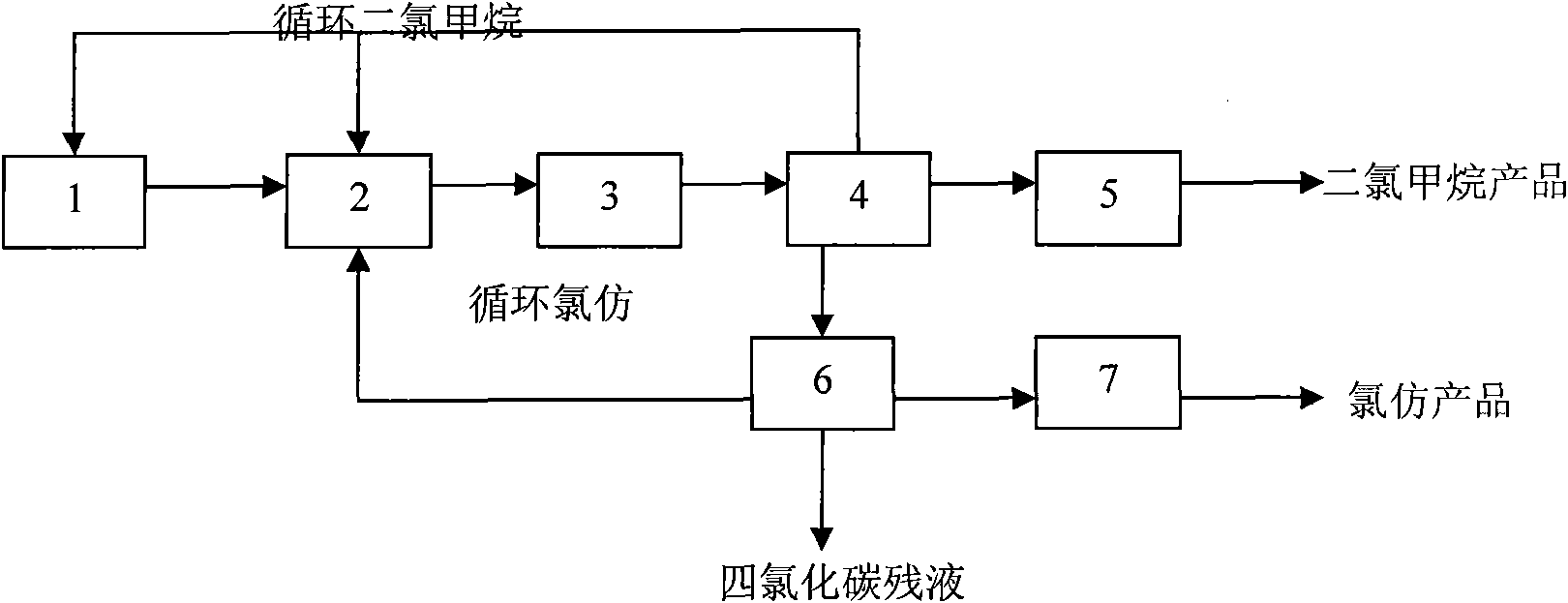

Method for refining methane chloride crude product

InactiveCN101967080AEmission reductionReduce consumptionHalogenated hydrocarbon preparationChlorideChloroform

The invention discloses a novel process for refining a methane chloride crude product. The process comprises the step of directly rectifying the methane chloride crude product without alkali cleaning or dehydrating, wherein, in a rectifying process, acid accumulated by a system is returned to a chlorination system by circulating a small quantity of dichloromethane and chloroform, the rectified product passes through a solid caustic soda treater to ensure the product quality and realize excellent energy-saving consumption-reducing effect. The process is particularly suitable for a device for producing the methane chloride requiring high chloroform proportion, and realizes economic, energy-saving and eco-friendly operation.

Owner:NINGBO JUHUA CHEM TECH CO LTD

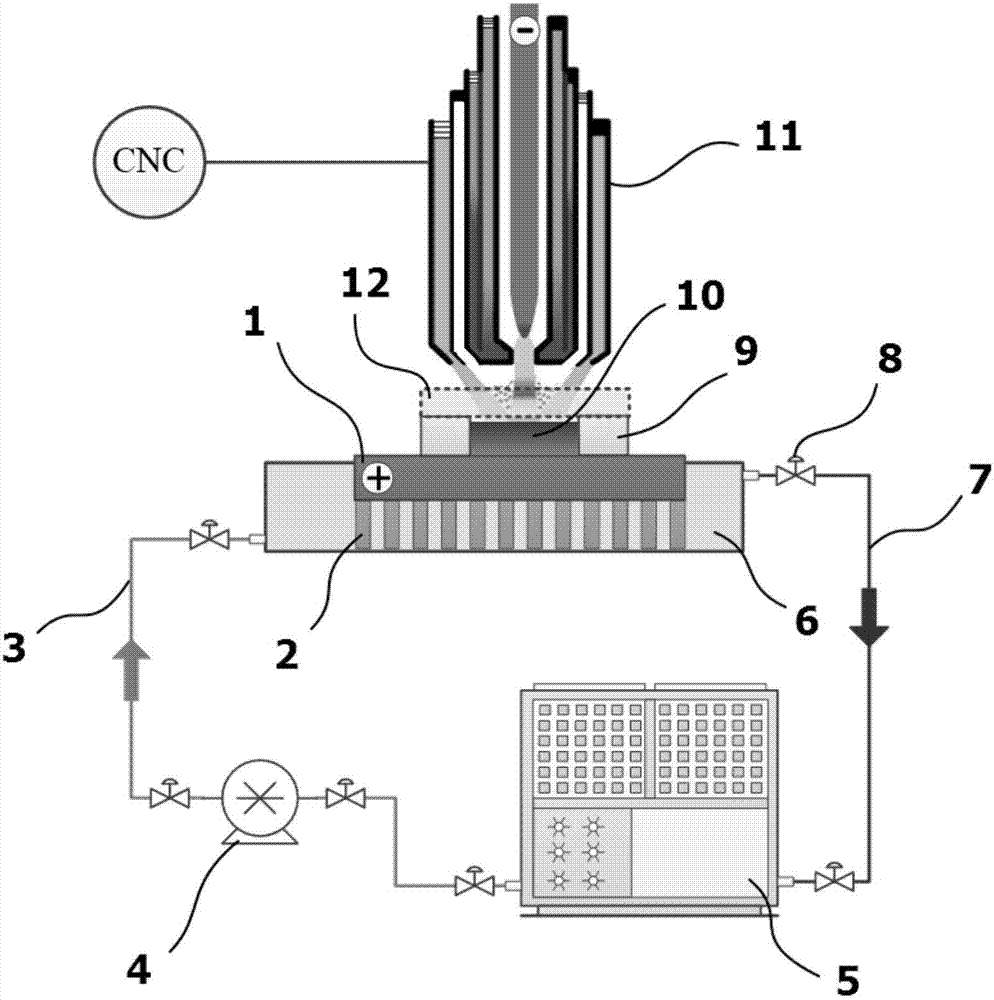

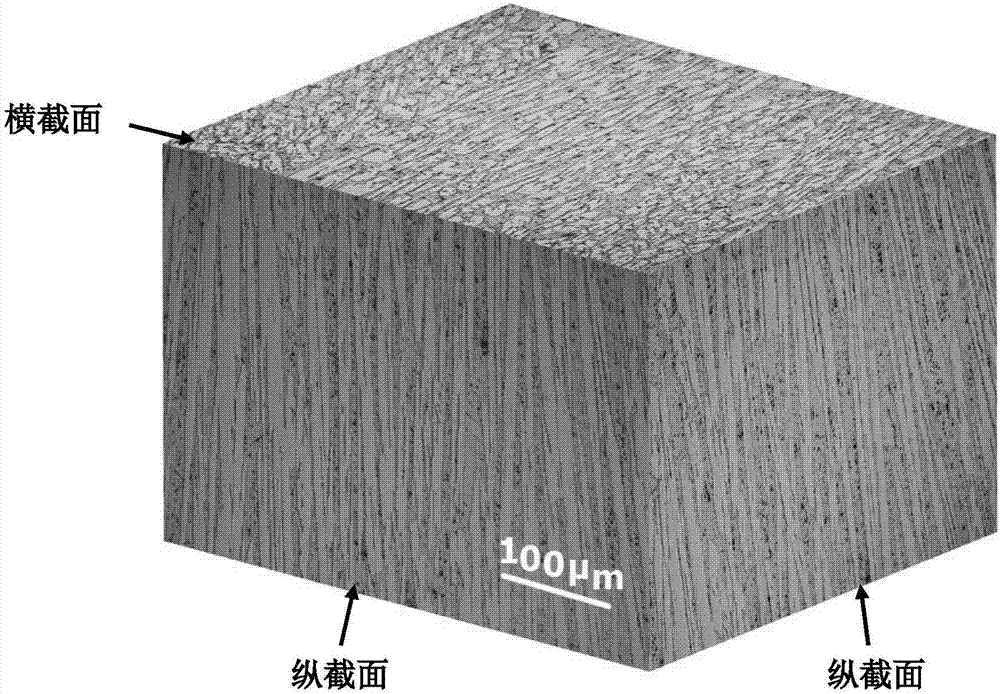

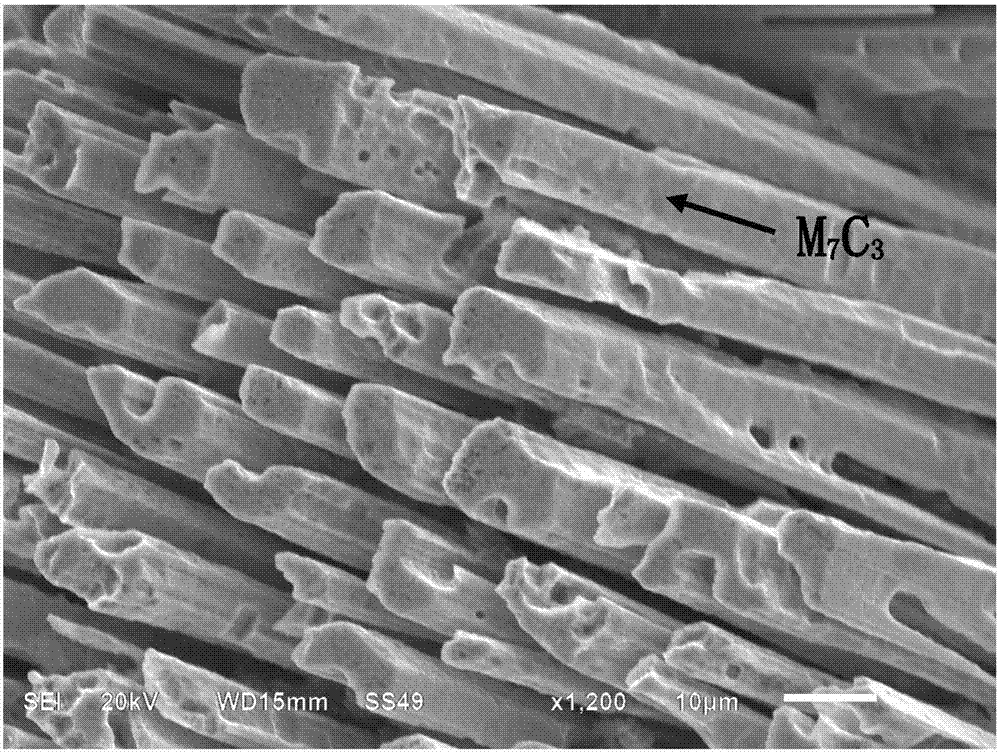

Preparing method for in-situ synthesis oriented growth M7C3 coating

PendingCN107022760ASimple equipmentReduce raw material consumptionMetallic material coating processesFiberAluminum silicate

The invention relates to the field of wear-resisting coatings, in particular to a preparing method for an in-situ synthesis oriented growth M7C3 coating. By means of the method, Cr, C and Fe-Ni powder serve as raw materials, are mixed according to a proportion and are pre-laid on a coating base plate to be rammed and flattened, and high-temperature-resisting ceramic is adopted on the two sides of a pre-laid coating for heat preservation; meanwhile, aluminum silicate ceramic fiber is used for conducting heat preservation on the part above a molten pool while the coating is prepared, and heat is prevented from being dissipated from the upper portion of the coating; and forced cooling is adopted on the bottom of the coating base plate so that heat of the molten pool can be controlled to be guided out from the bottom of the base plate from top to bottom, the temperature gradient needed by oriented growth of M7C3 is obtained, and preparing of the oriented growth M7C3 coating is achieved. Due to the fact that one-dimensional guiding-out of coating heat is achieved through the preparing method, growth of M7C3 crystals in other directions is inhibited, and the oriented growth M7C3 is obtained; and generation of columnar M7C3 crossed cracks is reduced, material toughness is improved, in addition, a column cross section with higher wear resistance is located on a work face, and wear resistance of the materials can be improved.

Owner:CHINA THREE GORGES UNIV

Automobile hub outer ring closed forging technology

InactiveCN107617715AReduce raw material consumptionPrecision Forging TechnologyWheelsMetal-working apparatusEngineeringForging

The invention discloses an automobile hub outer ring closed forging technology. The automobile hub outer ring closed forging technology comprises the technological steps of blanking, heating, upsetting, pre-forging, precision forging, cooling and the like; according to blanking, a material sawing technology is adopted, and therefore the accuracy of a blanked blank can be better controlled, and burrs generated after forging can be reduced; and according to the cooling step, the lingering warmth normalizing technology can be adopted, it is guaranteed that forging waste heat is sufficiently used,the energy using high efficiency is improved, it is guaranteed that a metallographic structure of a treated forging piece is fine and evenly distributed, and the good mechanical property is achieved.By means of the automobile hub outer ring closed forging technology, trimming-free forging is achieved, and raw material consumption of the forging piece can be reduced; and the more accurate forgingtechnology is adopted, the product rejection rate is reduced, the product yield is improved, and the production cost of the forging piece is reduced.

Owner:WANXIANGQIANCHAO CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com