Patents

Literature

66 results about "Stannane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stannane /ˈstæneɪn/ or tin hydride is an inorganic compound with the chemical formula SnH 4. It is a colourless gas and the tin analogue of methane. Stannane can be prepared by the reaction of SnCl₄ and LiAlH₄. Stannane decomposes slowly at room temperature to give metallic tin and hydrogen and ignites on contact with air.

Preparation method of antibacterial mildewproof silk wallpaper

ActiveCN103538306ANo pollution in the processSimple preparation processSynthetic resin layered productsFoaming agentPlasticizer

The invention relates to a preparation method of antibacterial mildewproof silk wallpaper and antibacterial mildewproof silk wallpaper obtained according to the preparation method. The preparation method comprises the following steps: drying, colloidizing and cooling a functional layer, and then compounding with silk fabric base layer through hot rolling process to produce silk wallpaper; the quality ratio and preparation method of the functional layer are as follows: adding 100 parts of polyvinyl chloride (PVC) and 10-50 parts of dioctyl phthalate plasticizer into a dispersing bucket and stirring uniformly; sequentially adding 20-100 parts of calcium carbonate filler, 5-10 parts of azodicarbonamide foaming agent, 10-25 parts of titanium dioxide, 2-8 parts of styrene acrylic binder and 2-8 parts of butylmercaptooxo-stannane stabilizer; after stirring and dispersing uniformly, further adding 2-10 parts of nano zinc oxide-nano bamboo charcoal composite particles and dispersing uniformly; grinding and filtering; and thus obtaining the functional layer. The silk wallpaper prepared according to the preparation method provided by the invention is obviously persistent in antibacterial and mildewproof effect, strong in odor removing effect and long in service life, and is an environment-friendly decorating material.

Owner:HANGZHOU WENSLI SILK TECH +1

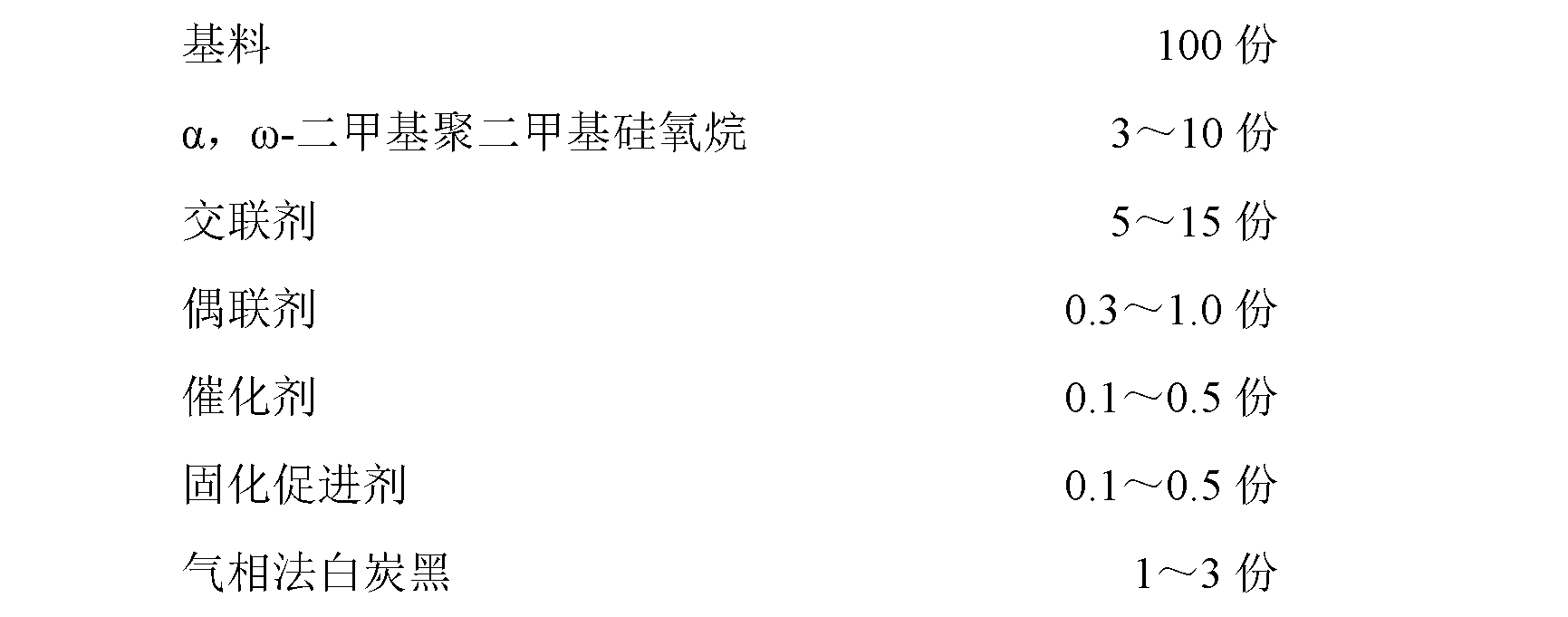

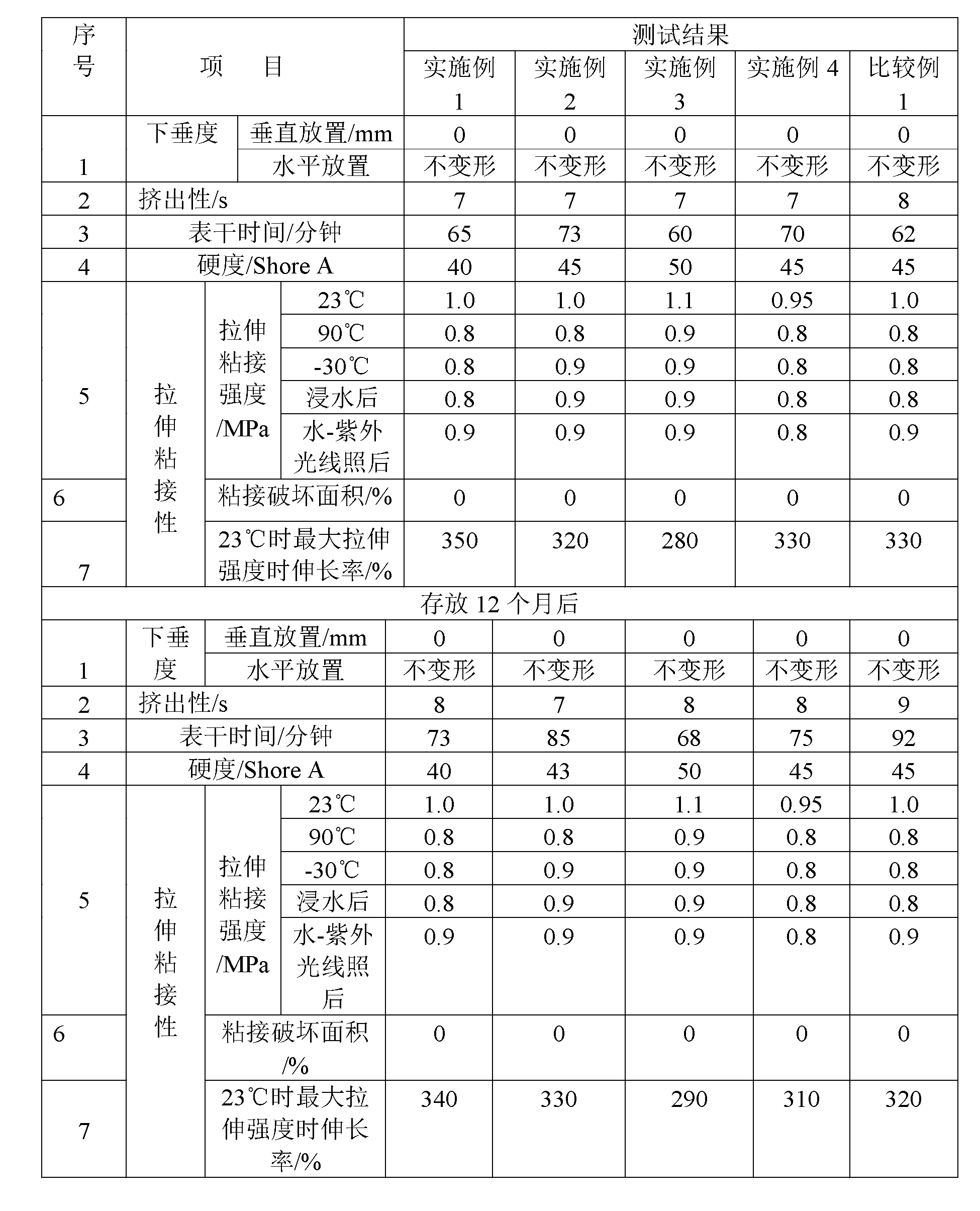

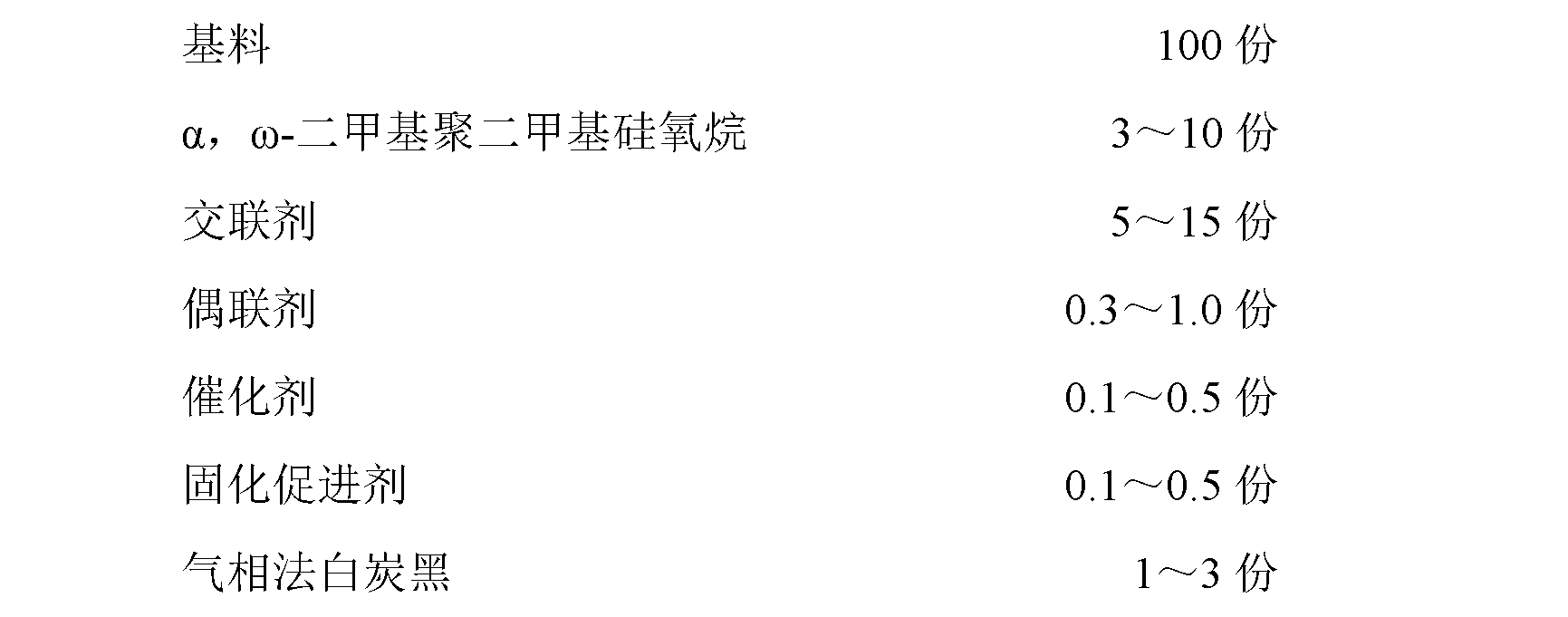

Environment-friendly organosilicone sealant and manufacturing method thereof

InactiveCN103013430AEnvironmentally friendly and healthyReduce dosageNon-macromolecular adhesive additivesOmegaSealant

The invention discloses an environment-friendly organosilicone sealant which is characterized in that 100 parts by mass of alpha,omega-dyhydroxyl polydimethylsiloxane and 50-150 parts by mass of packing are added into a vacuum kneader for dehydration and blending for 120-240min at 120-170 DEG C and at the vacuum degree of 0.06-0.099MPa, and a base stock is obtained. 100 parts by mass of base stock, 3-10 parts by mass of alpha,omega-dimethyl polydimethylsiloxane, 5-15 parts by mass of cross-linking agent, 0.3-1.0 parts by mass of coupling agent, 0.1-0.5 parts by mass of dimethylbis [(1-oxoneodecyl) oxy] stannane, neodecanoic acid zinc and organic bismuth, 0.1-0.5 parts by mass of curing accelerator and 1-3 parts by mass of fumed silica are added into a dispersion machine for vacuum mixing for 20-4040 at a room temperature and at the vacuum degree of 0.06-0.099MPa, and the environment-friendly organosilicone sealant is obtained. Various performances of the environment-friendly organosilicone sealant meet requirements of building sealants, and can be widely applied to the field of buildings.

Owner:CHENGDU GUIBAO SCI & TECH

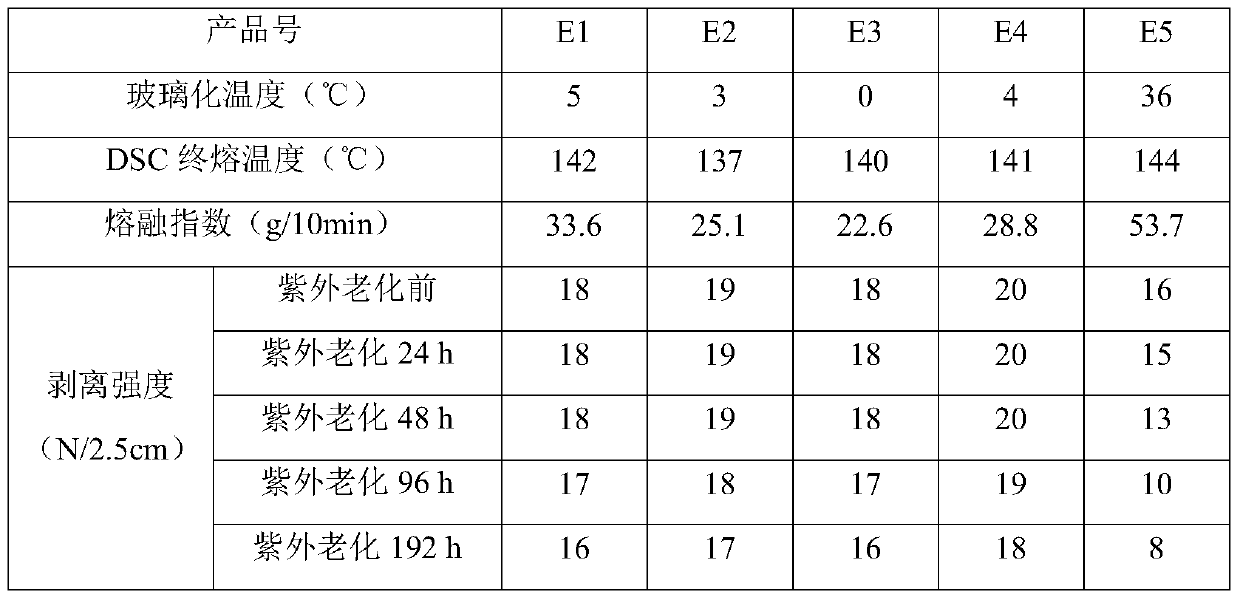

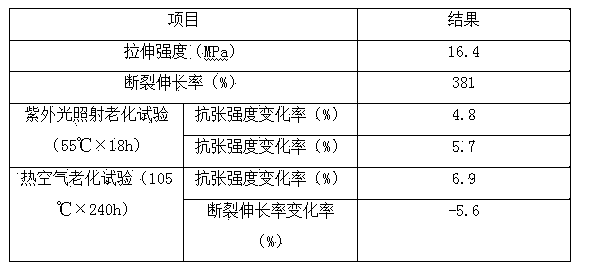

Preparation method of polyester hot melt adhesive with good weather resistance

The invention discloses a preparation method of a polyester hot melt adhesive with good weather resistance. The preparation method mainly comprises the following steps of: (1) carrying out esterification reaction on terephthalic acid, isophthalic acid, sebacic acid, and C2-C4 dihydric alcohol under the composite catalysis action of tetrabutyl titanate and butylhydroxyoxo-stannane; and (2) adding an antioxidant of tetrapentaerythritol ester, a light stabilizer, 4-benzoyloxy-2,2,6,6-tetramethyl piperidine and a nucleating agent of talcum powder at normal pressure, and carrying out copolycondensation under reduced pressure for 40-100min at 240-250 DEG C and 50-160Pa to obtain a copolyester product. The product has excellent performances such as low temperature resistance, high temperature resistance, ultraviolet resistance and the like; and the thermal decomposition resistance temperature is above 320 DEG C, the performance of the hot melt adhesive is not greatly changed under the ultraviolet radiation, and therefore the hot melt adhesive can be used as the sticking adhesive for the clothes of outdoor staff.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Polyurethane mirror surface coating and preparation method thereof

The invention discloses polyurethane mirror surface coating. The polyurethane mirror surface coating is composed of a component a and a curing agent component in a weight ratio of (3-4):1. Butylmercaptooxo stannane, stannous sulfide, ricinoleic acid and the like added in the polyurethane mirror surface coating can effectively improve stability and strength of the finished product film, and modification of a monomer through esterification improves the viscosity of the polymer finished product, improves anti-peel strength between the film and a base material, and enhances adhesion.

Owner:SUZHOU LAVENNANO TECH INC

Impact and cracking resistant material for combustion gas pipelines

The invention discloses an impact and cracking resistant material for combustion gas pipelines. The material comprises, by weight, 40-60 parts of high density polyethylene, 30-40 parts of ethylene propylene diene monomer, 20-30 parts of acrylonitrile-butadiene-styrene copolymer, 30-40 parts of carbon black, 1.8-2.6 parts of modified montmorillonite, 0.9-0.13 parts of modified carbon nanotubes, 20-30 parts of nonyl cyclohexanedicarboxylate, 20-30 parts of methyl acetylricinoleate, 15-20 parts of ammonium polyphosphate, 10-15 parts of zinc borate, 5-8 parts of red phosphorus, 1-3 parts of di-tert-butyl peroxide, 0.4-0.6 parts of dimethylaminopropylamine, 0.1-0.3 parts of a promoter CZ, 2-4 parts of a Ca / Zn composite stabilizer, 1-2 parts of zinc stearate, 1-2 parts of butylmercaptooxo stannane, 0.5-1 part of an antioxidant D, 0.3-0.5 parts of an antioxidant RD and 1-3 parts of polyethylene wax. The material has the advantages of good impact resistance and high toughness.

Owner:安徽宁国市高新管业有限公司

Ultraviolet resistant heat dissipation coating and preparation method thereof

The invention discloses an ultraviolet resistant heat dissipation coating and a preparation method thereof. The coating comprises 65-70 parts of a ketone-aldehyde resin, 2.0-2.5 parts of triethanolamine, 80-90 parts of methyl ethyl ketone, 5.0-5.5 parts of nanocarbon, 3.5-4.0 parts of tributyl citrate, 4.5-5.0 parts of ultramicro wax powder, 7.0-8.5 parts of methyl silicate, 0.5-0.7 parts of an ultraviolet ray absorber, 2.0-2.5 parts of calcium stearate, 0.9-1.1 parts of diatomite powder, 1.5-2.0 parts of bis-myristyl alcohol ester, 28-32 parts of aluminum nitride and 1-2 parts of butylmercaptooxo stannane. The preparation method adopts a reaction of the ultraviolet ray absorber with diatomite, bis-myristyl alcohol ester and butylmercaptooxo stannane, so the ultraviolet ray absorber is well attached to diatomite and can well absorb ultraviolet rays, thereby the ultraviolet resistance of the heat dissipation coating is improved; and the film of the coating has the advantages of good durability, good water resistance, good moisture resistance, good corrosion resistance and extremely good adhesiveness.

Owner:广东涂派涂料化工有限公司

Adsorptive magnetic nano material and preparation method thereof

InactiveCN105642257AGood dispersionResolve separabilityOther chemical processesAlkali metal oxides/hydroxidesDispersitySorbent

The invention discloses an adsorptive magnetic nano material. The adsorptive magnetic nano material is prepared from, by weight, 0.5-1 part of ammonium molybdate, 1-2 parts of polyvinylpyrrolidone, 80-90 parts of ferrous sulfate heptahydrate, 100-110 parts of ferric chloride hexahydrate, 4-5 parts of graphite powder, 10-18 parts of nano carbon powder, 3-4 parts of sodium nitrate, 27-30 parts of potassium permanganate, 170-200 parts of 96-98% sulfuric acid, 27-30 parts of 28-30% hydrogen peroxide, 0.3-1 part of lauroyl diethanolamide, 1-2 parts of calcium stearate, 0.1-0.2 part of silane coupling agent kh550, 0.1-0.13 part of 8-hydroxyquinoline, 1.7-3 parts of sodium potassium silicate and 0.2-0.4 part of butylmercaptooxo stannane. Since magnetic nano ferroferric oxide particles are introduced into the composite material and loaded on the surface of the composite material, dispersity of ferroferric oxide can be improved, and the problem of difficulty in separation and recovery of traditional adsorbent materials from reaction systems is effectively solved. The adsorptive magnetic nano material has an excellent adsorption performance and can be widely applied to magnetically targeted drug loading, bioseparation and the like.

Owner:宿州学院

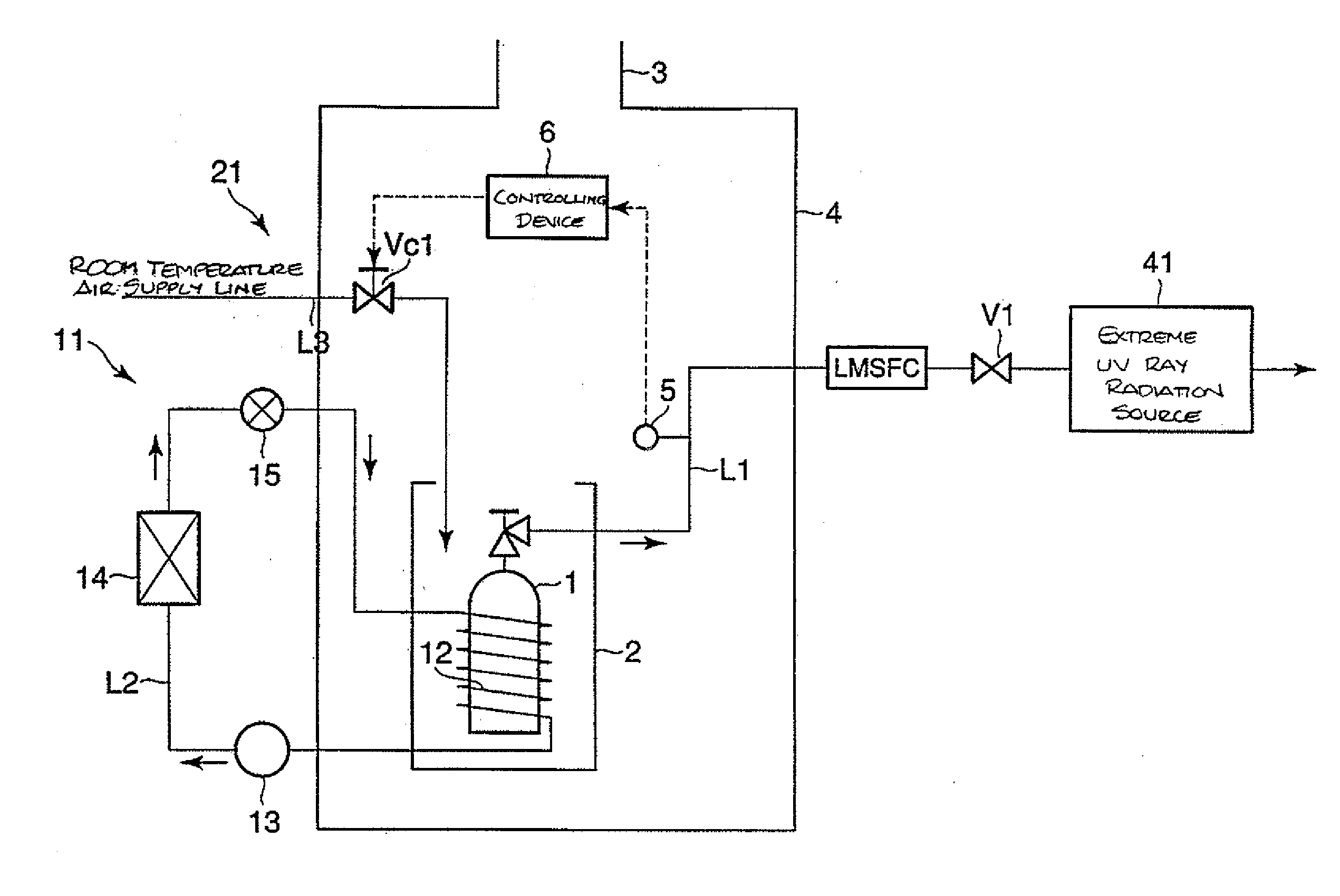

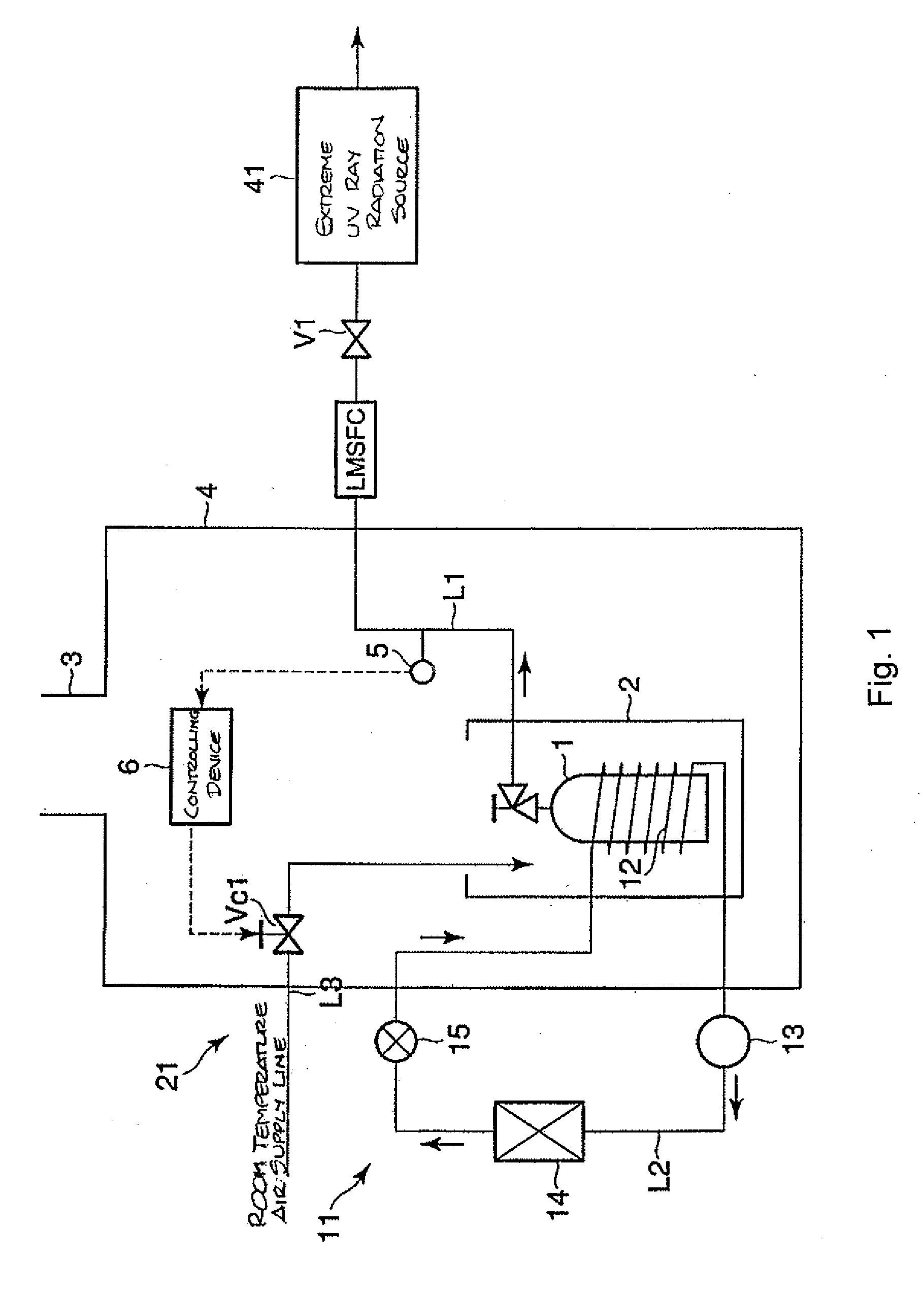

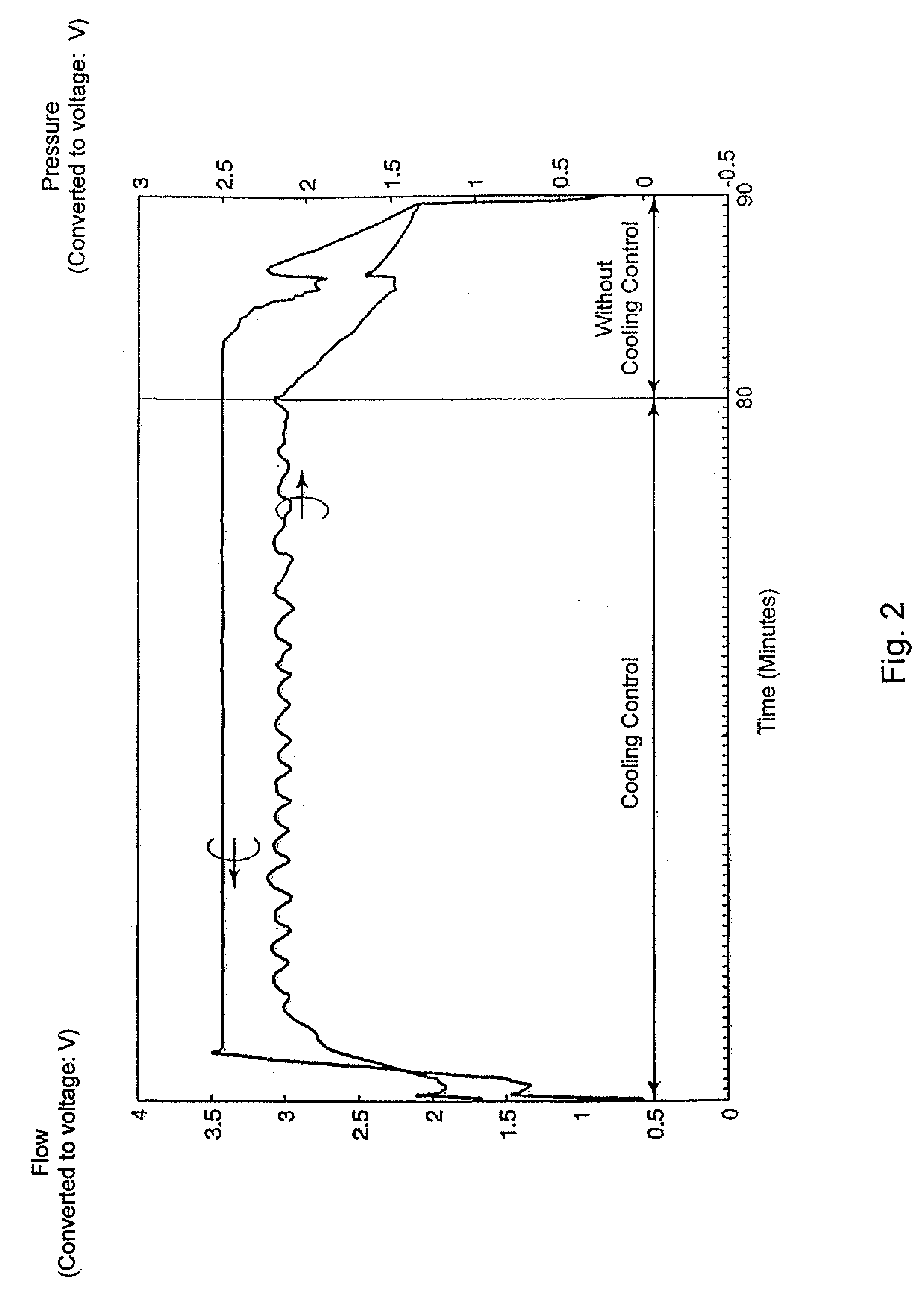

Stannane Gas Supply System

InactiveUS20080041074A1Stable flow rateRefrigeration safety arrangementX-ray apparatusUltravioletProduct gas

To provide a stannane gas supply system capable of supplying a stannane gas to an extreme ultraviolet ray radiation source with a stable flow rate. A stannane gas supply system for supplying a stannane gas to an extreme ultraviolet ray radiation source characterized by comprising a sealed container for storing a mixture of a stannane liquid and a stannane gas, connected with the extreme ultraviolet ray radiation source via a pipe, cooling means for cooling the sealed container to a temperature lower than −60° C., a low pressure mass flow controller provided in the pipe, a pressure detecting device mounted in the pipe part disposed between the sealed container and the low pressure mass flow controller, for detecting the pressure of the stannane gas in the pipe part, and controlling means for controlling the cooling degree of the sealed container by the cooling means based on the pressure detection value by the pressure detecting device.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Preparation method of light-color glycerol ester of rosin

ActiveCN104694015AHigh hardnessIncrease brightnessNatural resin chemical modificationLithium hydroxidePhosphoric acid

The invention provides a preparation method of light-color glycerol ester of rosin. The method comprises the steps of 1) performing pressure-reduced rectifying for rosin to obtain refined rosin; 2) adding glycerinum and a composite catalyst to the refined rosin using as the raw material to obtain a reactant, wherein the composite catalyst is prepared from butylhydroxyoxo-stannane, trisnonvlphenyl phosphosphite, neodymium oxide, lithium hydroxide and bi[-ethyl(3,5-di-tert-4-acrinyl) phosphoric acid] calcium salt in weight ratio (1-5): (1-3): (1-4): (1-3): (1-2); 3) reducing the pressure of the reactant until the vacuum degree reaches 0.2 to 2KPa, maintaining for 5 to 60min, and removing to obtain low-boiling substances to obtain the light-color glycerol ester of rosin. The preparation method is free of inert gas protection during preparing the light-color glycerol ester of rosin, so that the esterification needs a short time, and the prepared glycerol ester of rosin is light in color.

Owner:桂林兴松林化有限责任公司

Scouring resistant alloy steel anticorrosive paint and preparation method thereof

InactiveCN106189815AUniform particlesFine grainAnti-corrosive paintsMetallic material coating processesEpoxyALUMINUM STEARATES

The invention discloses scouring resistant alloy steel anticorrosive paint. The scouring resistant alloy steel anticorrosive paint is prepared from the following raw materials in parts by weight: 0.5-1 part of sodium borate, 2-3 parts of polyisobutylene, 1-2 parts of butylmercaptooxo-stannane, 0.1-0.4 part of 2-mercaptobenziMidazole, 50-60 parts of aniline, 30-40 parts of pyrrole, 7-9 parts of sulphosalicylic acid, 3-4 parts of epoxy resin E51, 1.3-2 parts of ammonium persulfate, 4-6 parts of molybdic acid, 3-5 parts of polyamide resin, 160-170 parts of n-butanol, 20-30 parts of ethylene glycol monobutyl ether, 2-3 parts of ammonium metaboragte, 0.7-1 part of alkenyl succinic anhydride, 1-2 parts of hydroxyethyl acrylate, 0.8-2 parts of benzyltrimethylammonium chloride and 0.6-1 part of aluminum stearate. The paint disclosed by the invention can form a hard paint film on a base material, and has good scouring resistance.

Owner:TIANCHANG YINHU PAINT

Galling paint and preparation method thereof

The invention discloses a galling paint, which is characterized by being prepared from the following raw materials by weight: 72-77 parts of epoxy resin E-12, 12-14 parts of fumed silica, 1-2 parts of 2-aminoethyl-C17 alkenyl imidazoline, 4-6 parts of diatomite, 2-3 parts of ethyl acrylate, 3-4 parts of cobalt naphthenate, 4-5 parts of zinc stearate, 20-30 parts of 2-hydroxyethyl methacrylate phosphate, 2-3 parts of dimethicone, 1-2 parts of zinc oxide, 1-2 parts of butylmercaptooxo stannane, 12-15 parts of ethyl acetate and 3-4 parts of a dispersing auxiliary. The galling paint provided by the invention has high strength, good abrasion resistance and good cleaning effect, and change of surface state of the paint film can increase the friction coefficient, so as to integrate skid resistance, environmental protection, protection, decoration, cleaning and stain resistance in one, and endow the galling paint with stereoscopic effect and artistic effect.

Owner:WUHU HONGKUN AUTO PARTS

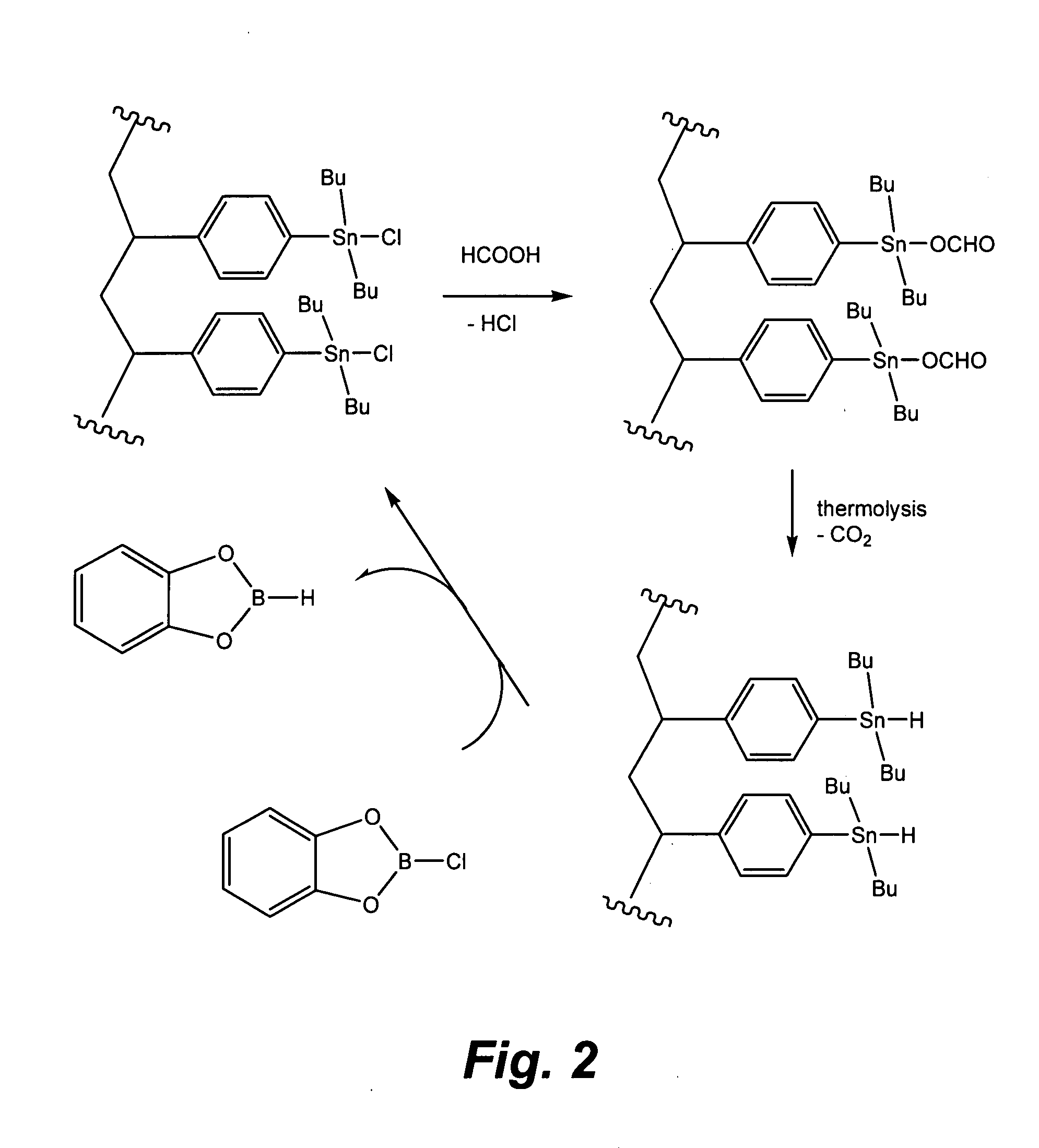

Energy efficient synthesis of boranes

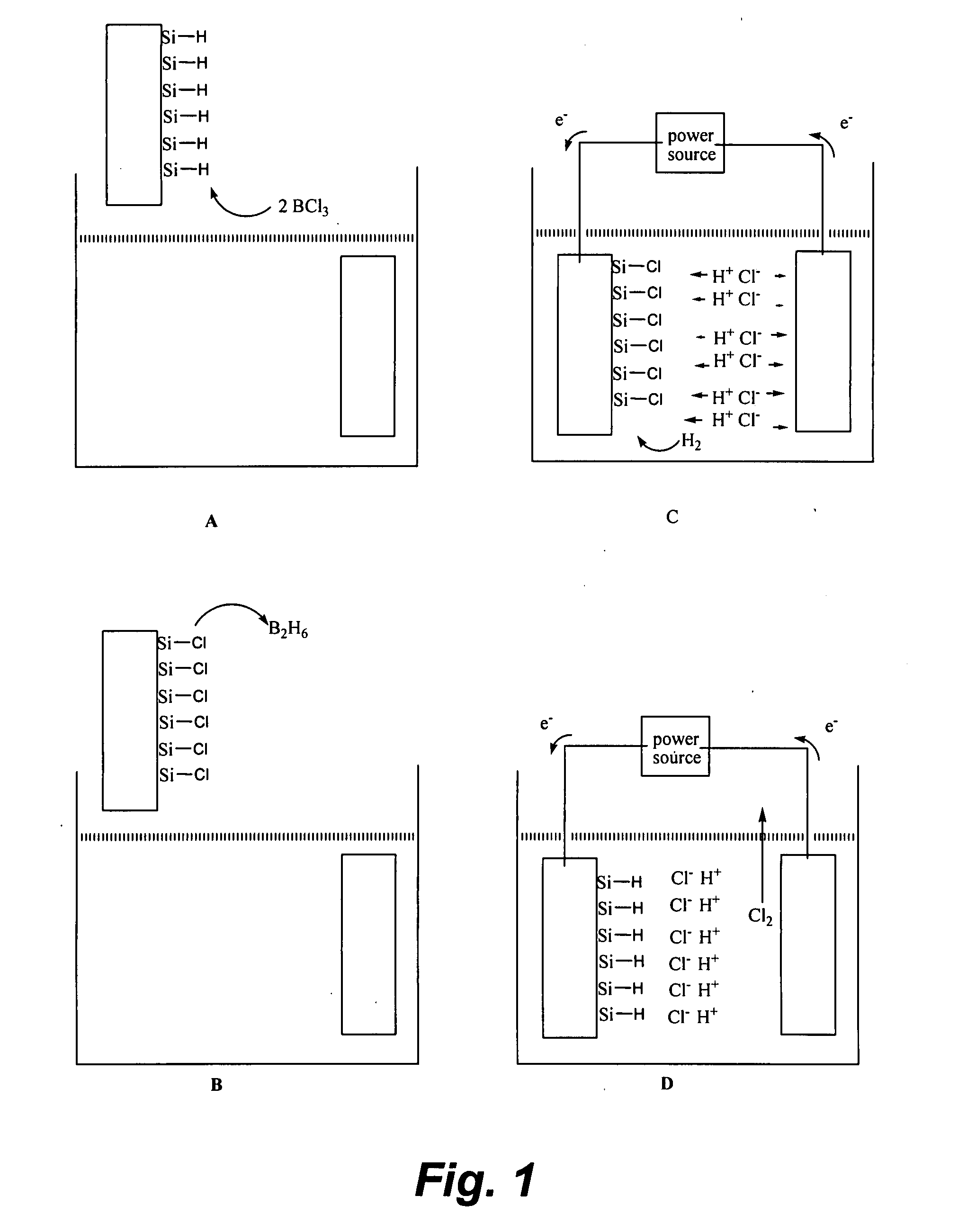

The reaction of halo-boron compounds (B—X compounds, compounds having one or more boron-halogen bonds) with silanes provides boranes (B—H compounds, compounds having one or more B—H bonds) and halosilanes. Inorganic hydrides, such as surface-bound silane hydrides (Si—H) react with B—X compounds to form B—H compounds and surface-bound halosilanes. The surface bound halosilanes are converted back to surface-bound silanes electrochemically. Halo-boron compounds react with stannanes (tin compounds having a Sn—H bond) to form boranes and halostannanes (tin compounds having a Sn—X bond). The halostannanes are converted back to stannanes electrochemically or by the thermolysis of Sn-formate compounds. When the halo-boron compound is BCl3, the B—H compound is B2H6, and where the reducing potential is provided electrochemically or by the thermolysis of formate.

Owner:RGT UNIV OF CALIFORNIA LOS ALAMOS NAT LAB +1

Mirror plane wear-resistant nanometer polyester coating for TMT industry

InactiveCN107057563AGood antifoulingImprove smoothnessAntifouling/underwater paintsPaints with biocidesDiacetone alcoholPolyester

The invention discloses a mirror plane wear-resistant nanometer polyester coating for a TMT industry. The mirror plane wear-resistant nanometer polyester coating is prepared from, by weight, 10-14 parts of 1,2-ethylidene-diisocyanate, 15-20 parts of poly-dimethyl-siloxane, 17-20 parts of fluorinated polyethylene, 0.4-1 part of divinyl benzene, 1-2 parts of azodicarbonamide, 3-5 parts of diacetone alcohol, 1-3 parts of trifluoroethyl methacrylate, 0.6-1 part of allylsulfocarbamide, 0.5-1 part of tert-Butylhydroquinone, 0.7-2 parts of zinc acetylacetone, 2-5 parts of butylmercaptooxo stannane, 3-6 parts of stannous sulfide and 3-4 parts of silica powder. Through organic treatment of inorganic filler, the dispersity of all raw materials of the coating is improved, the compatibility between filler and polymers is improved, and the stability and strength of coating film is improved.

Owner:SUZHOU LAVENNANO TECH INC

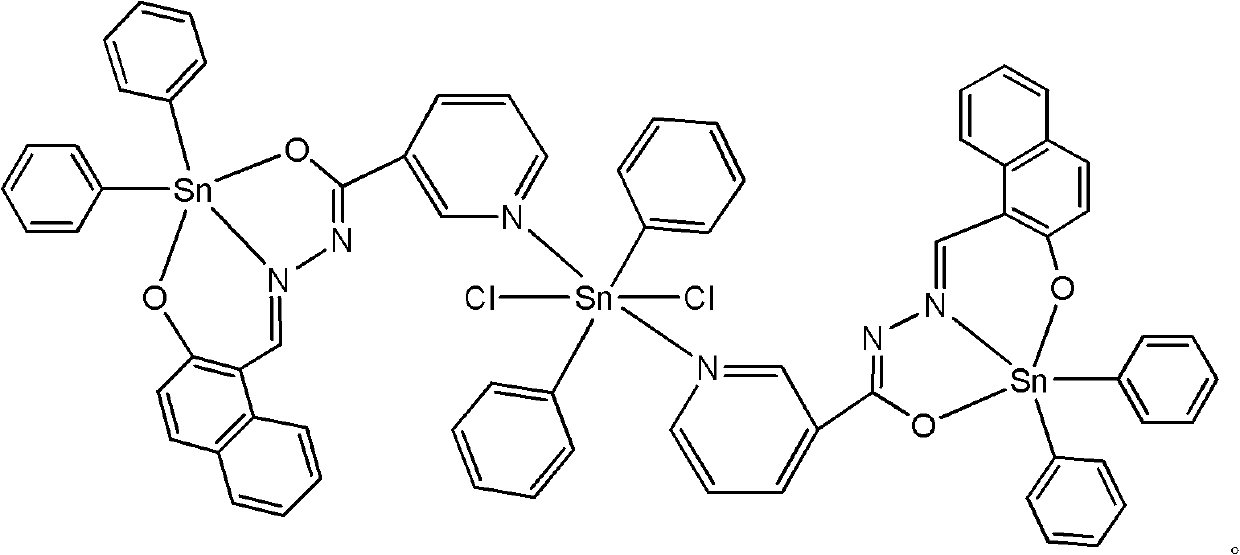

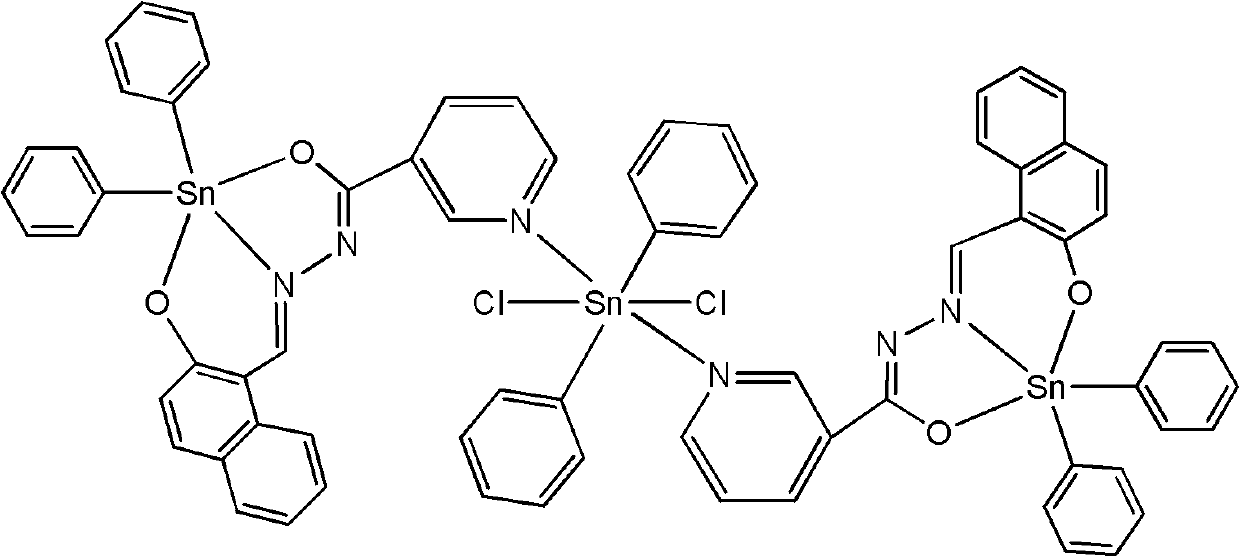

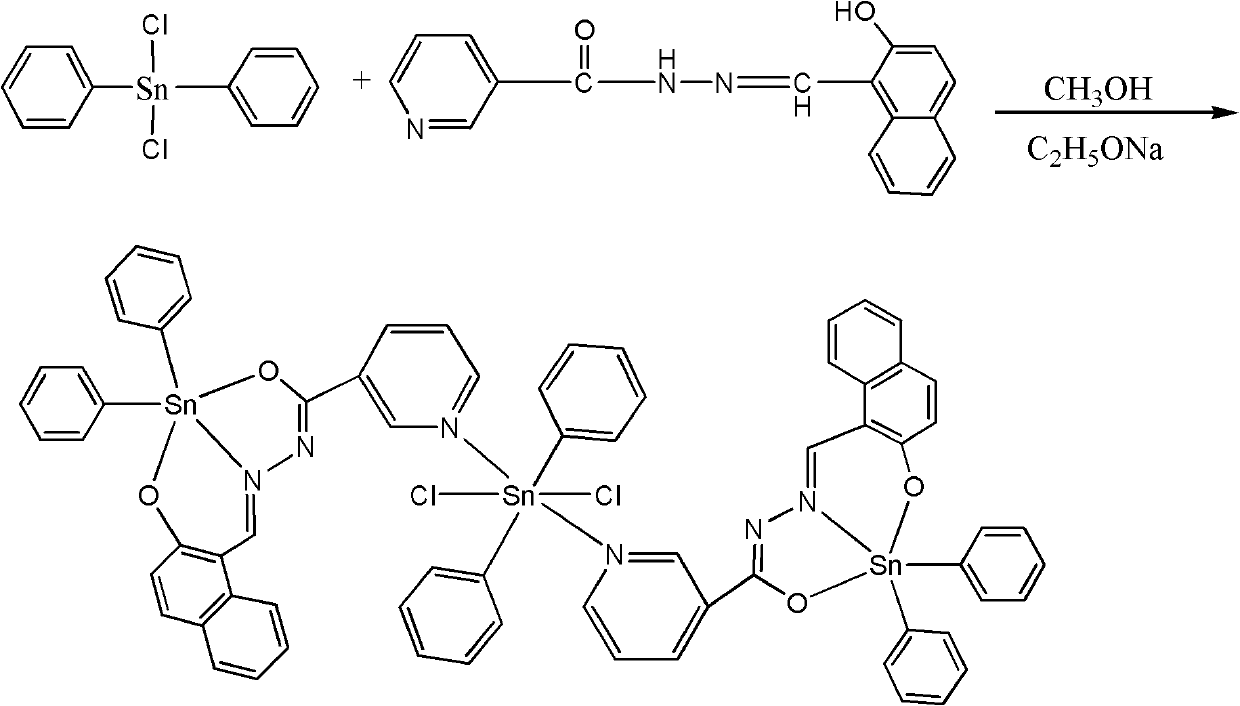

Dichlorodiphenyl-stannane complex and preparation method and application thereof

InactiveCN102127106AImprove herbicidal activityIncrease fat solubilityBiocideTin organic compoundsSolubilityEvaporation

The invention discloses a dichlorodiphenyl-stannane complex of which structural formula is shown as below. The preparation method comprises the following steps: adding 1mmol of 2-hydroxyl-1-naphthalene-3-pyridinecarboxamide, 1-1.5mmol of sodium ethoxide, 1-1.5mmol of dichlorodiphenyl-stannane and 20-30ml of methanol in a flask, stirring and refluxing at 60-70 DEG C for 6-7h, cooling to the room temperature, performing rotary evaporation to obtain yellow solid; and using dichloromethane-ethanol to recrystallize and obtain yellow transparent crystals, namely the dichlorodiphenyl-stannane complex. The organotin complex of the invention has higher herbicidal activity, can be used to prepare a herbicide for killing Echinochloa crusgalli, Digitaria sanguinalis, radish and rape. Compared with the common herbicide, the organotin complex of the invention is characterized by high herbicidal activity, good liposolubility, high water solubility, low cost, simple preparation method and the like, thus a new way is provided for the development of the herbicide.

Owner:LIAOCHENG UNIV

Environment-friendly package air bubble film and preparation method thereof

InactiveCN107903474AGood compatibilityImprove mechanical stability and strengthAluminateSodium Pyrithione

The invention discloses an Environment-friendly package air bubble film which comprises the following raw materials in parts by weight: 13-20 parts of titanium dioxide, 110-140 parts of high density polyethylene, 0.6-1 part of butylmercaptooxo stannane, 4-6 parts of ethylene glycol dimethacrylate, 1-2 parts of polybenzimidazole, 0.7-1 part of aminopropyltriethoxysilane, 3-5 parts of polyethylene glycol 1,000, 2-4 parts of aluminum stearate, 1-2 parts of hydroxyalkyl amide, 0.8-1 part of dodecenylsuccinic acid, 1-2 parts of zinc pyrithione and 3-5 parts of calcium aluminate. The air bubble filmdisclosed by the invention does not contain harmful and toxic volatile substances and is good in environmental protection property and superior in comprehensive performance; therefore, the air bubblefilm is especially suitable as a packaging material of a hospital and cannot cause pollution to packaging products.

Owner:安徽鸿宾医药包装有限公司

Graphene heat-dissipation coating and preparation method thereof

InactiveCN108299966AHigh bonding strengthImprove dispersion compatibilityCoatingsZinc ricinoleateHigh density

The invention discloses a graphene heat-dissipation coating which is composed of the following raw materials in parts by weight: 15-20 parts of graphene oxide, 120-131 parts of high-density polypropylene, 10-13 parts of an organic porous filler, 1-2 parts of triethanolamine, 3-4 parts of aluminum nitride, 0.5-1 part of beta-hydroxyalkyl amide, 0.1-0.2 part of butylmercaptooxo-stannane, 0.4-1 partof sp-80, 0.1-0.2 part of polybenzimidazole and 0.7-1 part of zinc ricinoleate. The graphene heat-dissipation coating improves the bonding strength of diatomite, aluminum nitride and graphene, also improves the dispersion compatibility of diatomite, aluminum nitride and graphene in the coating, and improves the uniform stability strength of a finished product coating film.

Owner:温州市赢创新材料技术有限公司

Preparation method of improved EPDM (Ethylene-Propylene-Diene Monomer) cable sheath material

The invention discloses a preparation method of an improved EPDM (Ethylene-Propylene-Diene Monomer) cable sheath material. The method comprises the following steps: mixing EPDM, chloroprene rubber, polypropylene and maleic anhydride grafted polypropylene to obtain a first rubber compound; adding montmorillonoid, nano aluminium nitride, barium sulfate and pre-dispersed phenolic aldehyde hollow microspheres to the first rubber compound, and mixing for 1 to 5 minutes; then adding 5, 5'-dimethyl-5, 10-dihydracridine, N'-(1, 3-dimethylbutyl)-N'-phenylenediamine, an age resister 2246, N-phenyl-naphthylamine, polybutylated bisphenol A, tri(nonylphenyl) phosphite, isproportionated potassium rosinate, vitamin C and pentaerythritol, and mixing for 2 to 5 minutes; adding stearic acid, a plasticizer TP-759, butylmercaptooxo stannane, phenolic resin, tin( II) chloride dehydrate, octadecylamine and an accelerant, and mixing for 3 to 8 minutes; performing thin-passing to obtain a second rubber compound; vulcanizing the second rubber compound to obtain the EPDM cable sheath material.

Owner:ANHUI HUAYU CABLE GRP

Masterbatch of bending-resistant highly pressure-bearing corrugated tube and preparing method thereof

ActiveCN105837961AImprove performanceImprove performance deficienciesRigid pipesPolymer sciencePolybutylene

A masterbatch of a bending-resistant highly pressure-bearing corrugated tube and a preparing method thereof are disclosed. The masterbatch comprises polybutylene resin, PA66 resin, biogas mud, butylmercaptooxo stannane, chitosan, tributyl phosphate, polyacrylonitrile, molybdenum sulfide, polyaluminium chloride, triethyl acetyl citrate, tantalum powder, white charcoal powder, oxidized polyethylene wax, a titanate coupling agent KR-38S, zinc stearate and maleic anhydride according to weight parts. The ring rigidity of the corrugated tube prepared from the masterbatch is 13.5-14.6 KN / m2, the bending strength of the corrugated tube is 27-34 MPa, the corrugated tube after a flattening deformation test is free of cracks, and the corrugated tube has excellent comprehensive performance, and improves performance disadvantages of traditional corrugated tube materials.

Owner:江门市蓬江区高威塑胶颜料有限公司

Anti-skid abrasion-resistance deck paint and preparation method thereof

The invention discloses anti-skid abrasion-resistance deck paint. The deck paint is characterized by being prepared from the following raw materials in parts by weight: 6-8 parts of novolac epoxy resin, 4-6 parts of dibenzyl amino ether, 10-13 parts of 40% chlorinated rubber liquid, 2-3 parts of polyphosphate, 2-3 parts of asbestos powder, 1-3 parts of silica-gel powder, 1-2 parts of quartz powder, 38-44 parts of modified asphalt, 2-3 parts of chlorinated paraffin, 1-2 parts of epoxy butyl oleate, 2-3 parts of light calcium carbonate, 1-2 parts of a silane coupling agent KH-5601, 5-6 parts of modified waste resin sand, 3-5 parts of yellow ground, 1-2 parts of butylmercaptooxo stannane, 2-3 parts of decabromobiphenyl, 2-4 parts of blanc fixe, 7-9 parts of n-butyl acetate and 8-10 parts of #200 solvent gasoline. According to the anti-skid abrasion-resistance deck paint, the added quartz powder has the effects of improving hardness and abrasion resistance and stabilizing chemical performance of paint, the added asbestos powder has the effects of increasing the contraction rate and improving heat resistance, and the added yellow ground has the anti-skid effect; the waste resin sand is modified, so that soil and water pollution can be solved, human body health can be guaranteed, the cost of the paint can be reduced, and the flame-proofing and anti-aging effects of the paint can be improved.

Owner:TIANCHANG YINHU PAINT

Method for synthesizing butylhydroxyoxo-stannane

InactiveCN105198929AEasy to synthesizeEasy to control feedingGroup 6/16 element organic compoundsTemperature and pressureStannane

The invention belongs to the field of chemical engineering, and particularly relates to a method for synthesizing butylhydroxyoxo-stannane. The method comprises the following five steps of material adding control, constant-temperature reaction, water washing, centrifugalization and drying. The method disclosed by the invention is simple in synthesis, and butyltin trichloride and alkali liquor are directly reacted at ambient temperature and pressure; material adding is easy to control, and the reaction is stable and easy-going; and through the implementation of a method for controlling the pH value of an end point, the conversion rate of products production is high, the recovery rate is more than 98%, and the main content is 98% or more.

Owner:云南锡业锡化学品有限公司

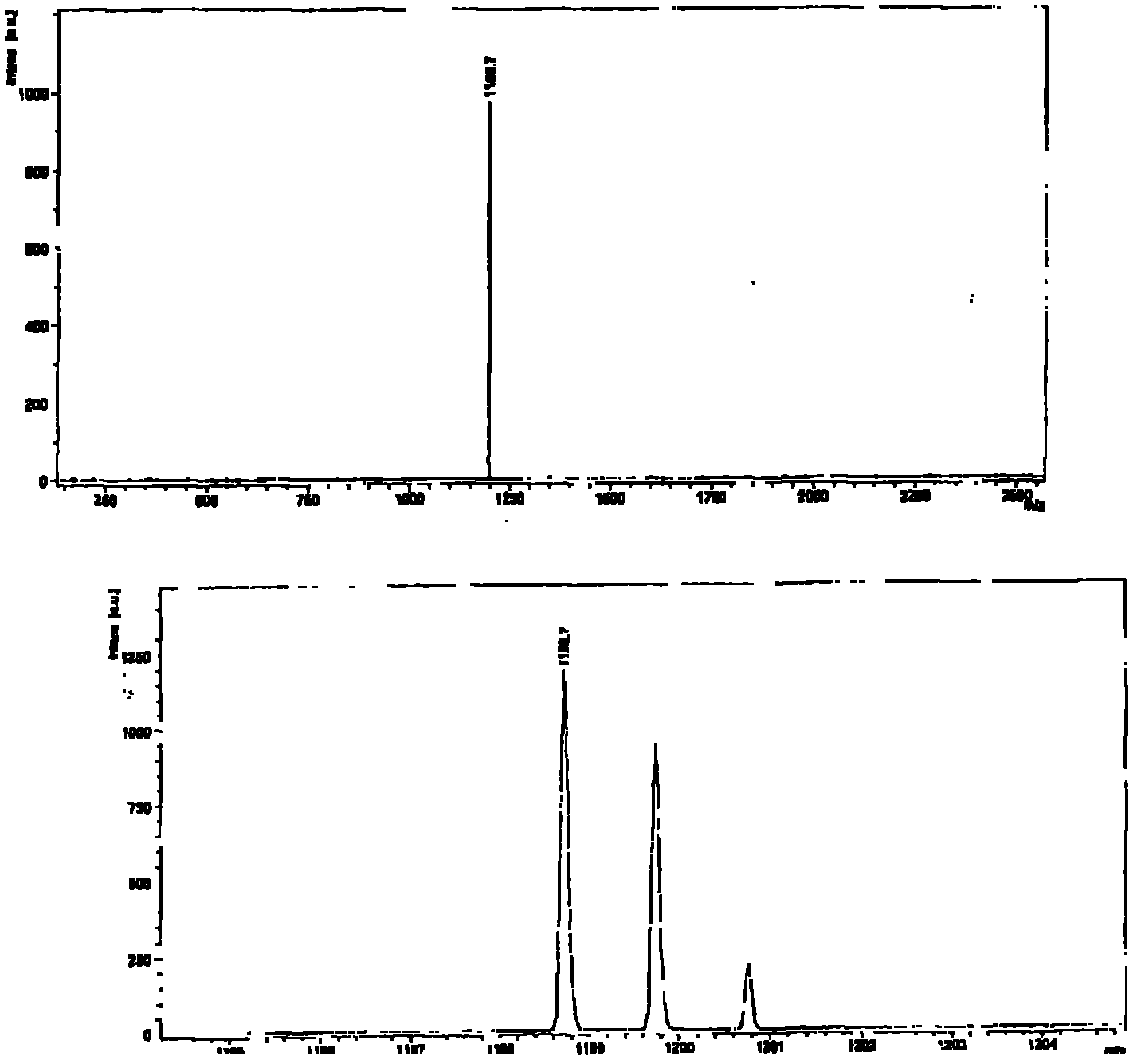

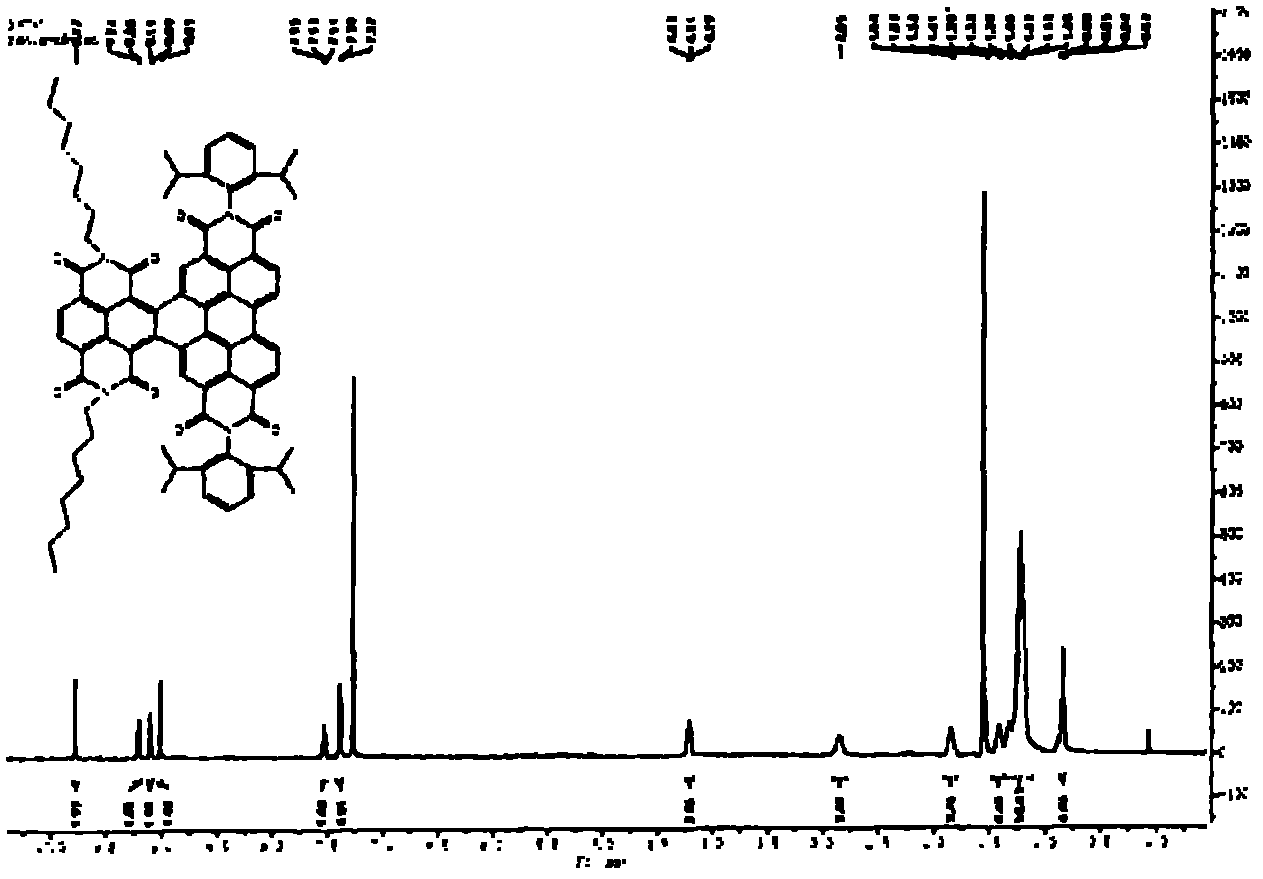

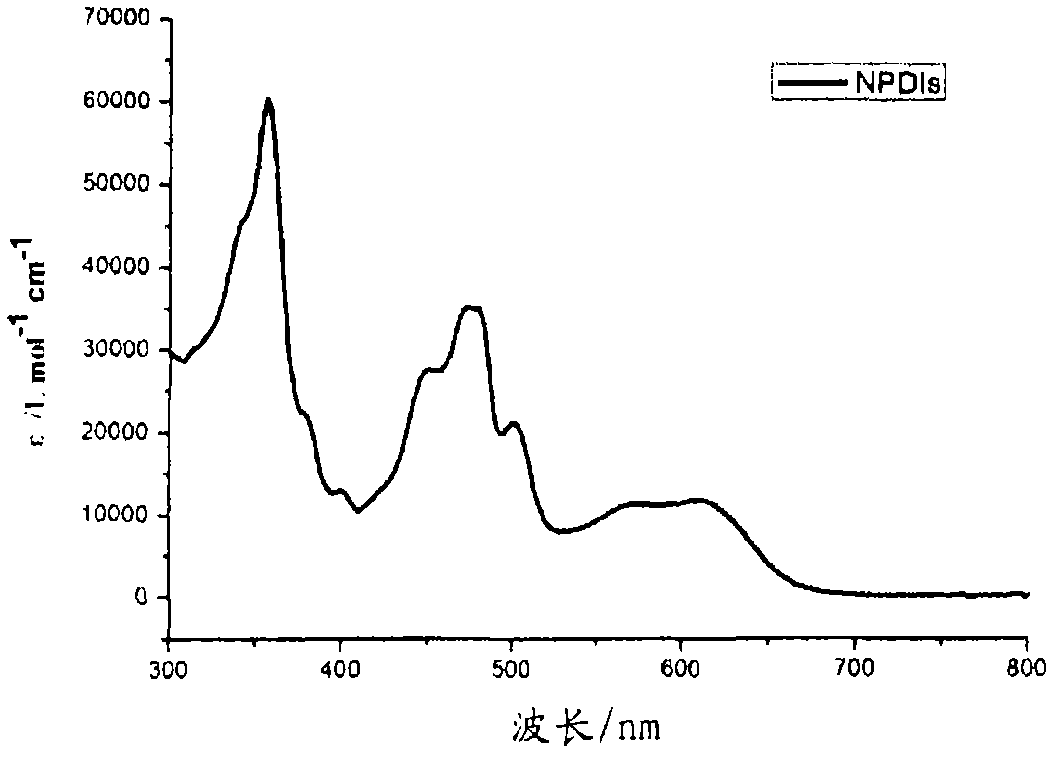

Reaction product of stannyl derivative of naphthalimide and rylene

InactiveCN103172632AEasy to manufactureGood Electron Mobility ValuesOrganic chemistrySolid-state devicesField-effect transistorNaphthalene diimide

The invention provides an NDI (naphthalene diisocyanate)-rylene compound formed by the reaction between a NDI tin compound and a rylene compound. The rylene compound can be a perylene compound, and the NDI-rylene compound can be used in an organic electronic device (including a field effect transistor).

Owner:INST OF CHEM CHINESE ACAD OF SCI

Ultraviolet radiation aging resistant PVC material for automobile exterior and preparation method thereof

InactiveCN104140611AOutstanding anti-ultraviolet aging performanceGood chemical stabilitySlagTert butyl

The invention discloses an ultraviolet radiation aging resistant PVC material for an automobile exterior and a preparation method thereof. The ultraviolet radiation aging resistant PVC material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type PVC resin, 35-45 parts of bisphenol A type polysulfone, 20-30 parts of epoxy rubber seed oil, 16-22 parts of botryolite powder, 15-20 parts of iron-ore slag, 4-8 parts of glyceride monobehenate, 3-6 parts of cctadecyl stearate, 2-5 parts of low molecular weight polypropylene, 1-2 parts of magnesium myristate, 2-3 parts of zinc myristate, 1.5-2.5 parts of methyl 3,5-di-tert-butyl-4-hydroxybenzoate, 4-6 parts of dipropylene glycol monosalicylate, 15-25 parts of BOVC resin, 2-3 parts of butyl mercaptooxo stannane, 10-15 parts of titanium dioxide, 2-3 parts of inositol hexaphosphate, 10-15 parts of dipropylene glycol dibenzoate, 1-2 parts of 2-hydroxyl-4-methoxy diphenyl ketone and 19-27 parts of compound nano powder. The ultraviolet radiation aging resistant PVC material for the automobile exterior has excellent ultraviolet radiation aging resistant property, good chemical stability, lasting sunlight resistance, no cracking, long service life and good safety, also has good heat resistance, corrosion resistance and weather resistance and can completely meet performance requirements of a PVC material for the automobile exterior.

Owner:六安市协诚车辆配件有限公司

Low-cost fire-retardant polyurethane foaming heat-preservation material

The invention discloses a low-cost fire-retardant polyurethane foaming heat-preservation material. The low-cost fire-retardant polyurethane foaming heat-preservation material is characterized by being prepared from a material A and a material B in parts by weight as follows through the steps of mixing, casting, reacting and ageing: the material A comprises 100 parts of polyether glycol, 3-4 parts of a silane coupler KH-550, 2-3 parts of nanometer ore residue, 1.0-1.2 parts of magnesium stearate, 1-2 parts of butylmercaptooxo-stannane, 3-4 parts of water, 10-20 parts of aluminum hydroxide powder, 12-16 parts of expanded perlite powder, 10-12 parts of talcum powder, 2-3 parts of methylisothiazolinone and 6-8 parts of modified attapulgite; and the material B comprises 30-34 parts of diphenyl methane diisocyanate. According to the low-cost fire-retardant polyurethane foaming heat-preservation material disclosed by the invention, the modified attapulgite and the aluminum hydroxide powder are added, so that the low-cost fire-retardant polyurethane foaming heat-preservation material is a good physical fire retardant, and has an excellent fire-retardant effect; and the nanometer ore residue, the expanded perlite powder and the talcum powder are used for filling, so that the strength of the material is enhanced; besides, the low-cost fire-retardant polyurethane foaming heat-preservation material has definite tenacity, and is relatively low in density, resistant to ageing, resistant to yellowing, non-toxic, harmless and environmentally friendly.

Owner:四川方壹特建筑工程有限公司

Light graphene absorbing material and preparation method thereof

InactiveCN108620028AImprove adsorption capacityImprove stabilityOther chemical processesDispersed particle separationStearic acidDipropylene glycol monomethyl ether acetate

The invention discloses a light graphene absorbing material. The light graphene absorbing material comprises the following materials by weight: 5-8 parts of light calcium carbonate, 110-130 parts of activated graphene, 1-2 parts of lauryl trimethyl ammonium chloride, 0.1-0.3 part of butylmercaptooxo stannane, 2-3 parts of propylene glycol methyl ether acetate, and 1-2 parts of sodium alginate. Thegraphene is firstly activated by using the stearic acid, the light calcium carbonate is dispersed in an amide solution and blended together with the activated graphene, a calcium carbonate compoundedgraphene material is obtained, the adsorptivity of the product is good, the stability is high, and the repeating utilization factor is high.

Owner:ANHUI ZHONGHONG TECH DEV CO LTD

Packaging plastic thin film containing modified kaolinite powder

The invention discloses packaging plastic thin film containing modified kaolinite powder. The packaging plastic thin film containing the modified kaolinite powder is prepared from, by weight, 50-62 parts of ethylene-vinyl acetate copolymer, 10-20 parts of triethylene glycol di-2-ethylhexoate, 2-6 parts of polyethylene wax powder, 2-6 parts of vinyltriethoxysilane, 1-2 parts of butylmercaptooxo stannane, 6-12 parts of fimethyl fumarate, 5-13 parts of disulfide carbamate, 1-4 parts of nano titanium dioxide, 1-3 parts of antioxidant, 5-7 parts of plasticizer, 1-5 parts of nano clay, 8-12 parts ofstearic acid, 4-9 parts of cellulose acetate butyrate, 5-10 parts of carbon black, 3-7 parts of attapulgite and 3-6 parts of modified kaolinite powder. Compared with the prior art, the packaging plastic thin film containing the modified kaolinite powder has good pressure resistance and impact resistance, and the service life is prolonged conveniently.

Owner:桐城市桃花制刷有限公司

Nanometer environmentally friendly pbt material

ActiveCN104140652APromote environmental protectionImprove wear resistancePolytetramethylene terephthalateBrick

The invention discloses a nanometer environmentally friendly pbt material. The nanometer environmentally friendly pbt material comprises, by weight, 92-100 parts of polybutylene terephthalate, 0.7-1 part of methyl ethyl ketone oxime, 1-2 parts of tricalcium silicate, 1-2 parts of butylmercaptooxo stannane, 1-2 parts of sebacic dihydrazide, 1-2 parts of polyhexamethylene guanidine, 1-2 parts of sodium fluoride, 2-4 parts of nanometer brick slag powder, 1-2 parts of aluminum dihydrogen phosphate, 1-2 parts of molybdenum boride, 2-3 parts of phosphate ester, 2-4 parts of dioctyl phthalate, 0.1-0.2 part of cross-linking agents TAC and 1-2 parts of processing agents. The nanometer environmentally friendly pbt material is good in environmental protection performance, compatibility among the materials is well promoted due to the added nanometer materials, and the comprehensive performance of products is increased. The finished product is good in anti-abrasion performance and tensile resistance, high in heat resistance and acid and alkali resistance, wide in application range and good in safety and environmental protection performance.

Owner:广东森绅实业有限公司

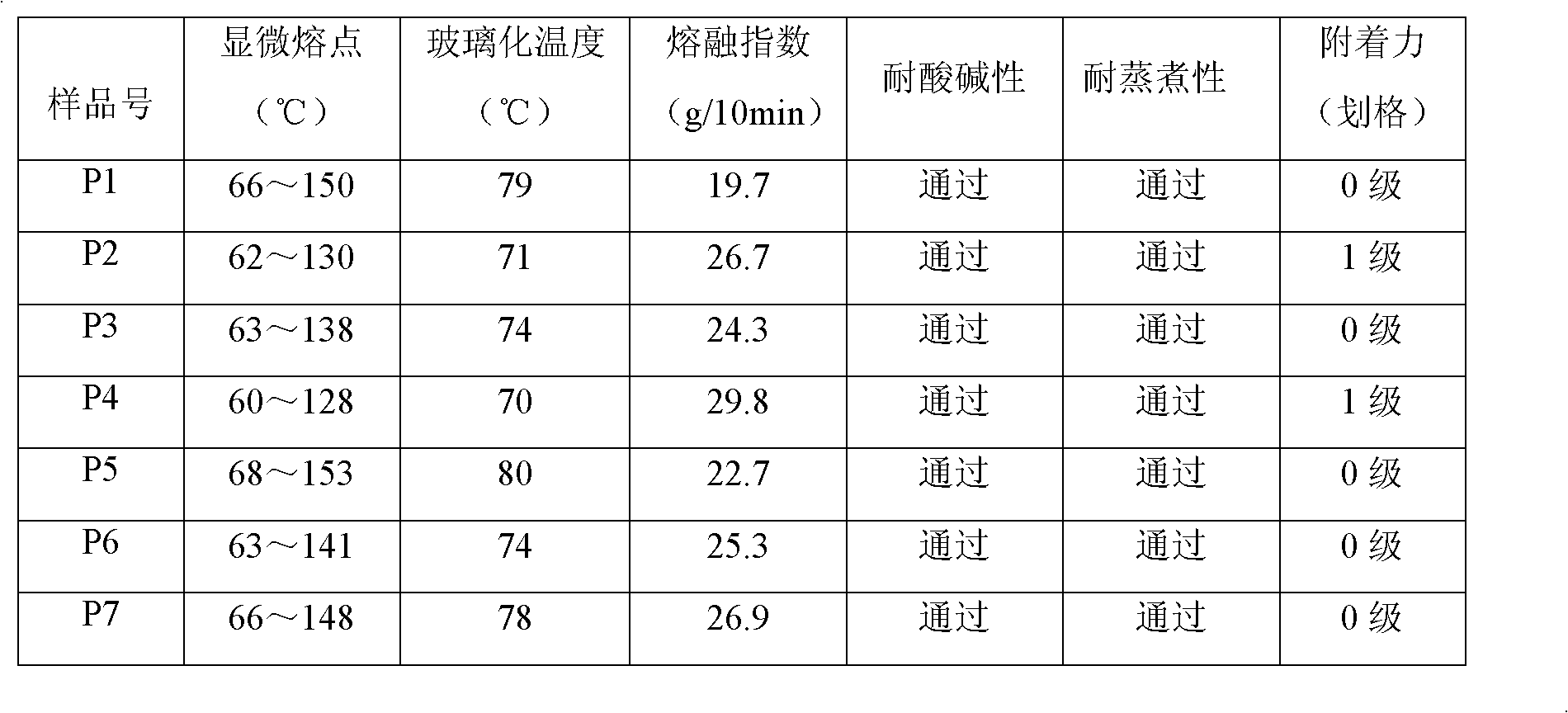

Preparation method of copolyester for metal powder coating

ActiveCN102492125BHigh viscosity strengthRetortPowdery paintsPolyester coatingsBisphenol AStabilizing Agents

The invention relates to a preparation method of a copolyester for a metal powder coating, mainly comprising the following steps of: (1) carrying out transesterification reaction between terephthalic acid, isophthalic acid, hydroxyethyl bisphenol A and C2-C6 dihydric alcohol under the action of a tetrabutyl titanate / butylhydroxyoxo-stannane catalyst; and (2) adding a stabilizer triphenyl phosphite into the product obtained from Step (1) at atmospheric pressure and carrying out decompressing copolycondensation at 230-250 DEG C and at 80-130 Pa to obtain the copolyester. The obtained copolyester has advantages of steaming and boiling resistance, acid and alkali resistance and strong adhesive force. The coating provided by the invention can be applied in the field of metal can coating.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

Degradable material for tableware

The invention relates to a degradable material for tableware. The degradable material comprises the following raw materials by weight percentage: 40-50% of polylactic acid, 0.1-1% of dialkyl p-biphenol, 0.1-3% of boron nitride, 0.1-3% of butylhydroxyoxo-stannane, 0.1-3% of calcium stearate and 40-60% of polypropylene. The material has the characteristics of high degradable efficiency, excellent mechanical properties, and low raw material cost.

Owner:罗嘉辉

Light stable-type plastic container

InactiveCN104845294AImprove anti-agingExcellent caking resistancePolyethylene glycolPolyethylene terephtalate

The invention discloses a light stable-type plastic container, which consists of the following raw materials in parts by weight: 0.1 to 0.2 parts of benzophenone, 6 to 10 parts of graphene, 3 to 4 parts of sulfonated-pheno-formoldehyde resin, 0.5 to 1 part of hydroxypropyl methyl cellulose, 0.3 to 0.4 parts of mercaptoacetic acid, 0.7 to 1 part of butynediol, 1 to 2 parts of magnesium oxide, 0.8 to 2 parts of sodium dihydrogen phosphate, 1 to 2 parts of dimethyl succinate, 1.5 to 2 parts of ammonium molybdate, 0.4 to 1 part of butylmercaptooxo stannane, 90 to 96 parts of polyethylene glycol terephthalate, and 10 to 17 parts of modified sizing materials. The plastic container provided by the invention has the advantages of light weight, good stability, high weather ability, good adaptation to environment, and high corrosion resistance, and can be used for containing medicine raw materials and the like.

Owner:安徽省佳艺休闲用品有限公司

Special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for ship cable

InactiveCN105860373AImprove low temperature resistanceEasy to processRubber insulatorsCalcium silicateCarbon nanotube

The invention discloses a special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for a ship cable. The material is prepared from fluoride rubber, fluorine-containing acrylate rubber, epoxy acrylate rubber, HNBR, maleic anhydride grafted polyethylene, stearic acid, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, trimethylolpropane trimethacrylate, phenolic resin, carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofiber, magnesium hydroxide, calcium hydroxide, inositol hexaphosphate, epoxidation triglyceride fatty acid, epoxy linseed oil, 2,6-ditert-butyl-p-aminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane and accelerant. The special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for the ship cable is high in strength, good in anti-ageing performance, excellent in oil resistance and low temperature resistance and capable of meeting use requirements of ship cable sheaths.

Owner:ANHUI HUAYU CABLE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com