Patents

Literature

129results about How to "Easy to control feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

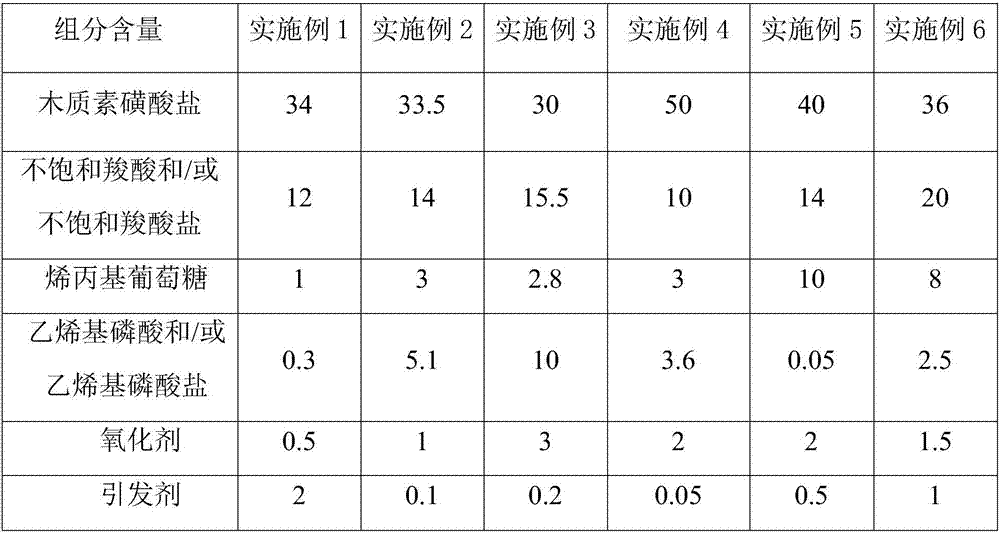

Coal water slurry additive and preparation method thereof

ActiveCN105154151AImprove stabilityImprove liquidityLiquid carbonaceous fuelsCoal waterPhosphoric acid

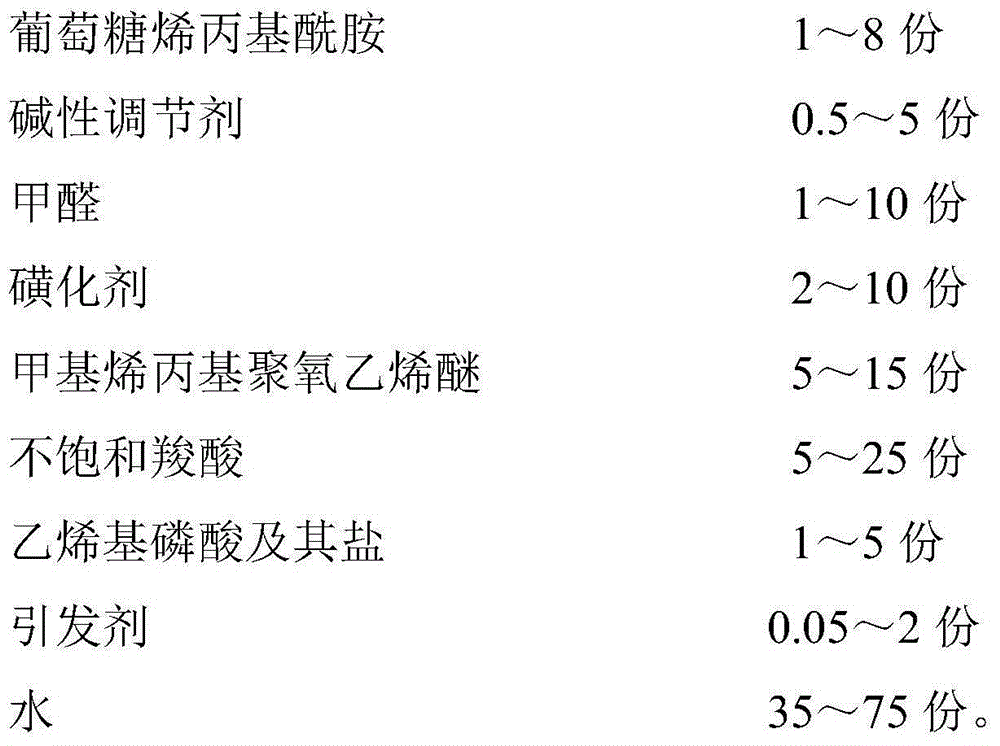

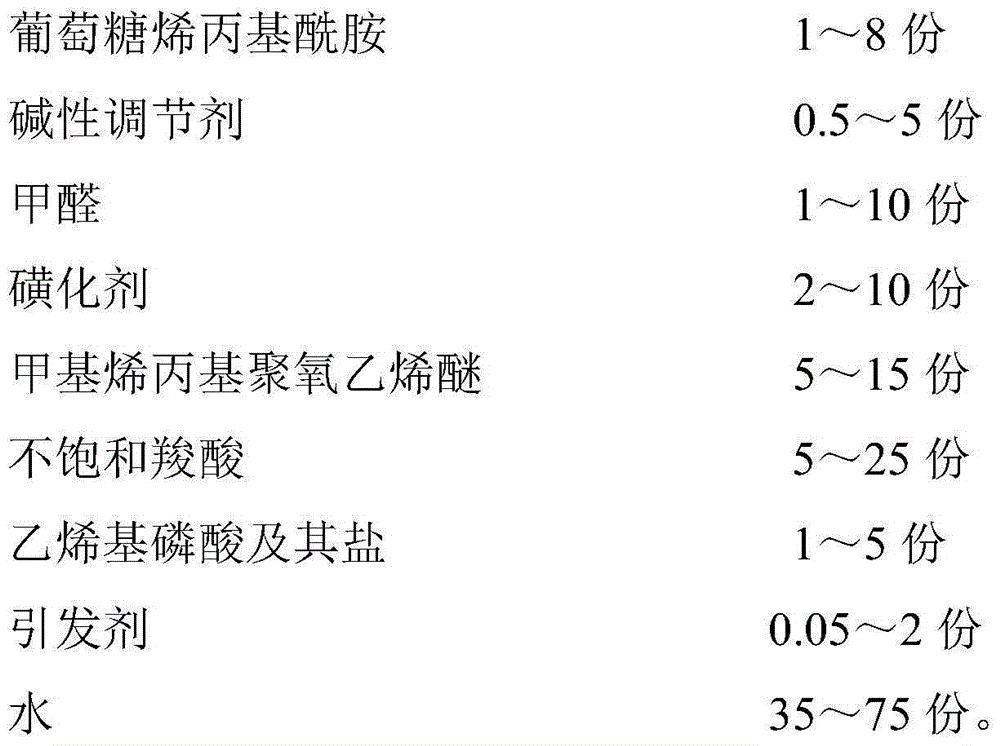

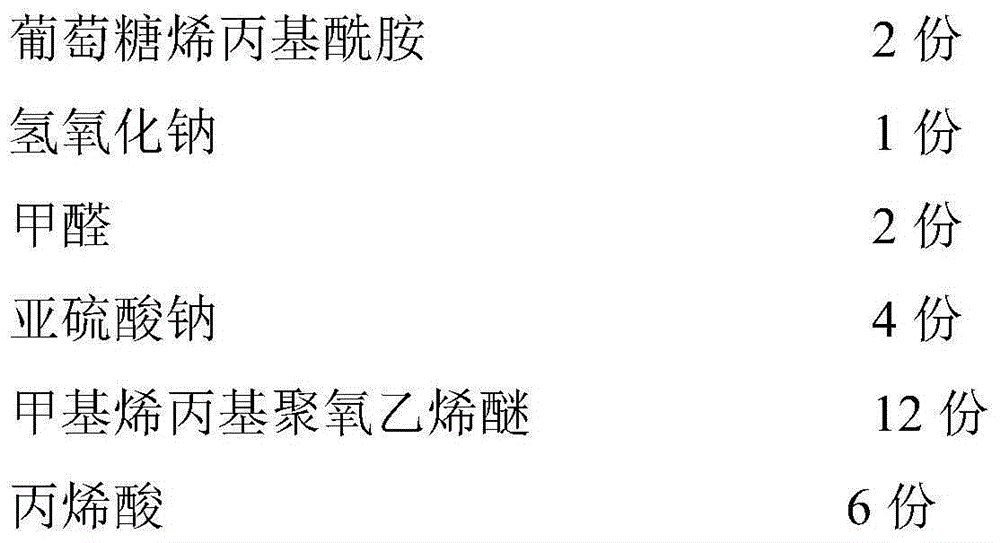

The invention provides a coal water slurry additive and a preparation method thereof. The method comprises the following steps: (1) adding glucose allyl amide, an alkaline regulator and water into a reaction kettle, starting stirring, and starting heating; (2) after the temperature rises to 55-70 DEG C, adding formaldehyde, continuing reacting for 0.1-1 hour, adding a sulfonating agent, and keeping the temperature for 0.1-1 hour; (3) continuing heating to 70-90 DEG C, adding methyl allyl polyethenoxy ether, unsaturated fatty acid, vinyl phosphoric acid and salt thereof, stirring uniformly, and dropwisely adding a 1-10 wt% initiator solution, wherein the initiator solution is prepared from the initiator and water, the dropwise addition time is controlled at 0.5-4 hours, and the dropwise addition temperature is controlled at 90-100 DEG C; and (4) after the dropwise addition, keeping the temperature to continue reaction for 1-4 hours, cooling and discharging to obtain the coal water slurry additive.

Owner:佛山市天亿化工有限公司

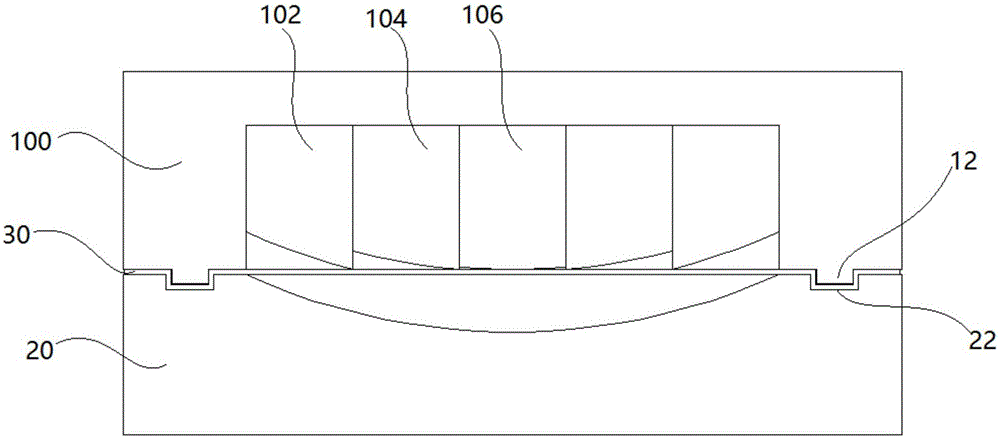

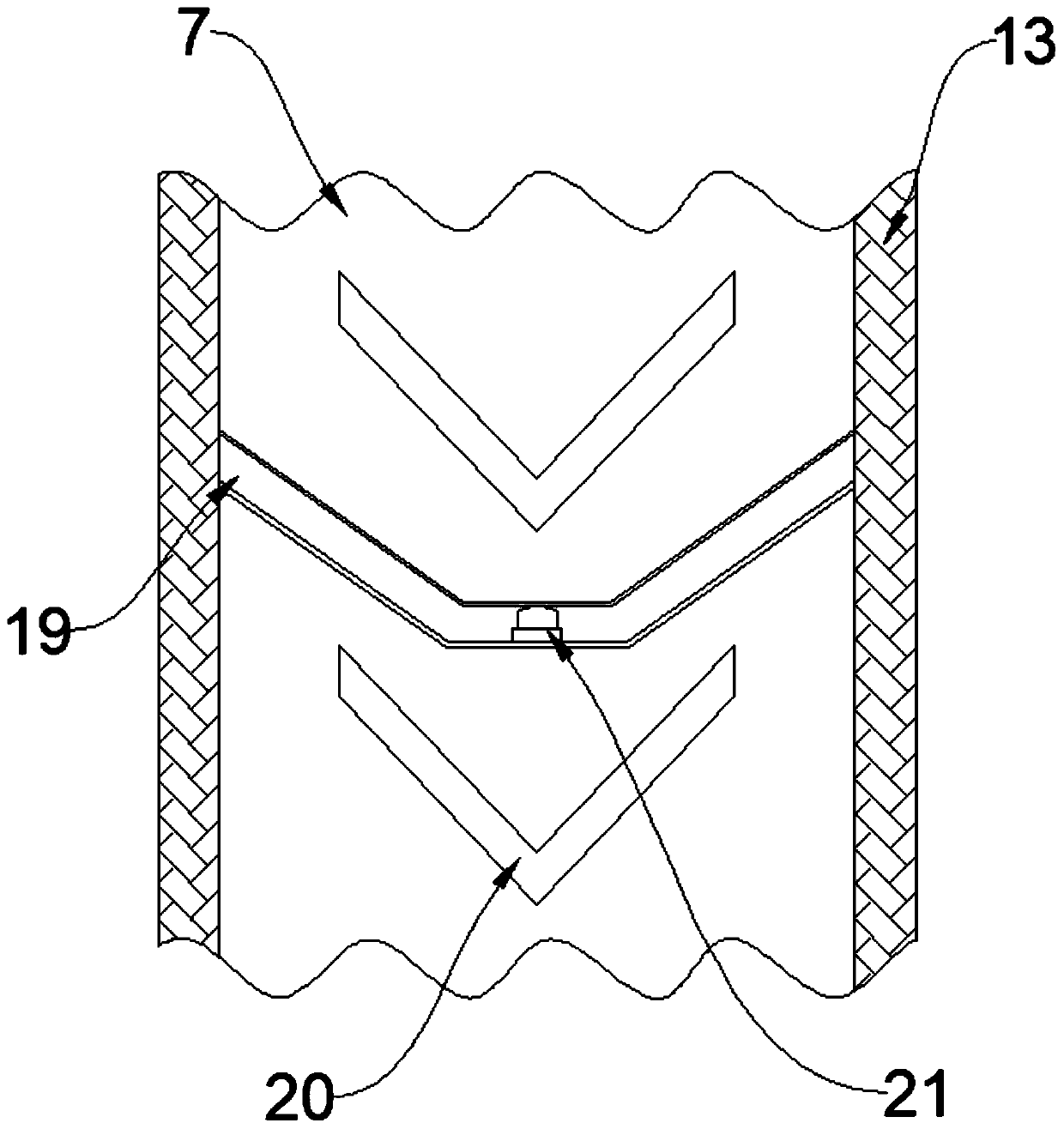

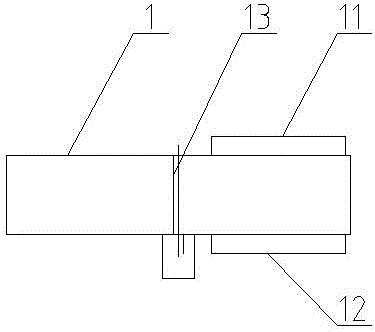

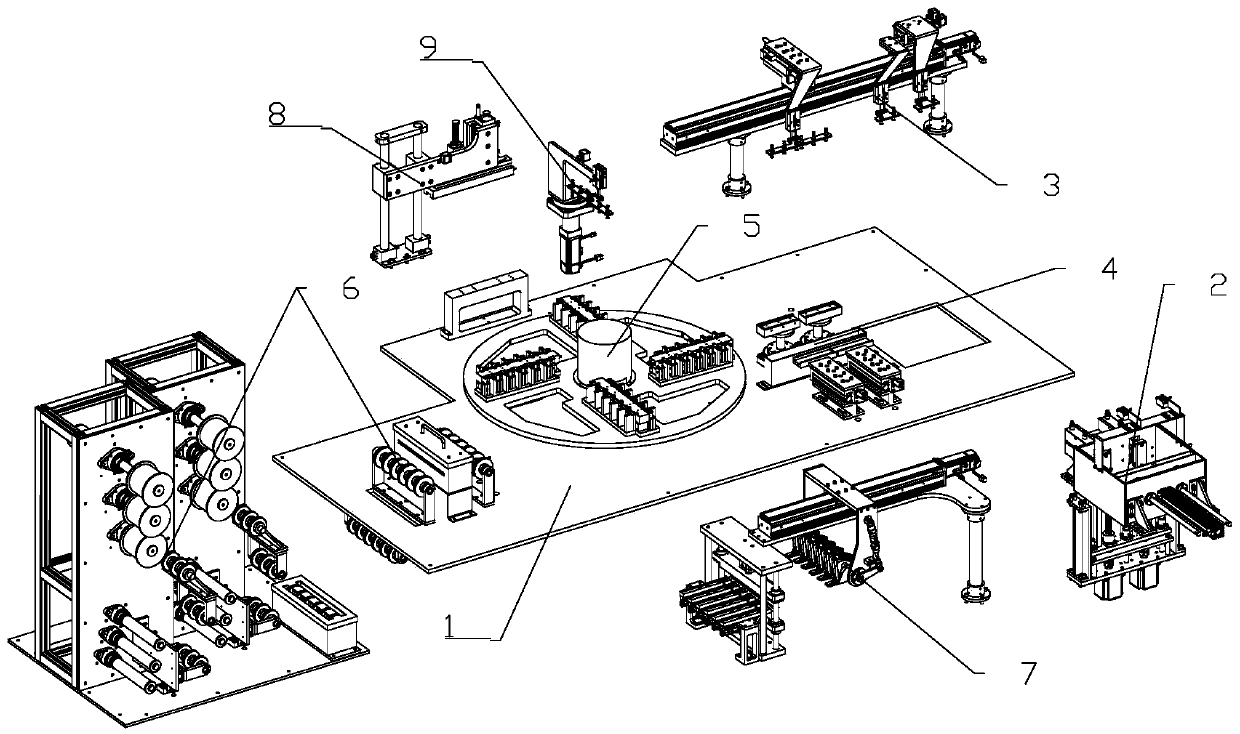

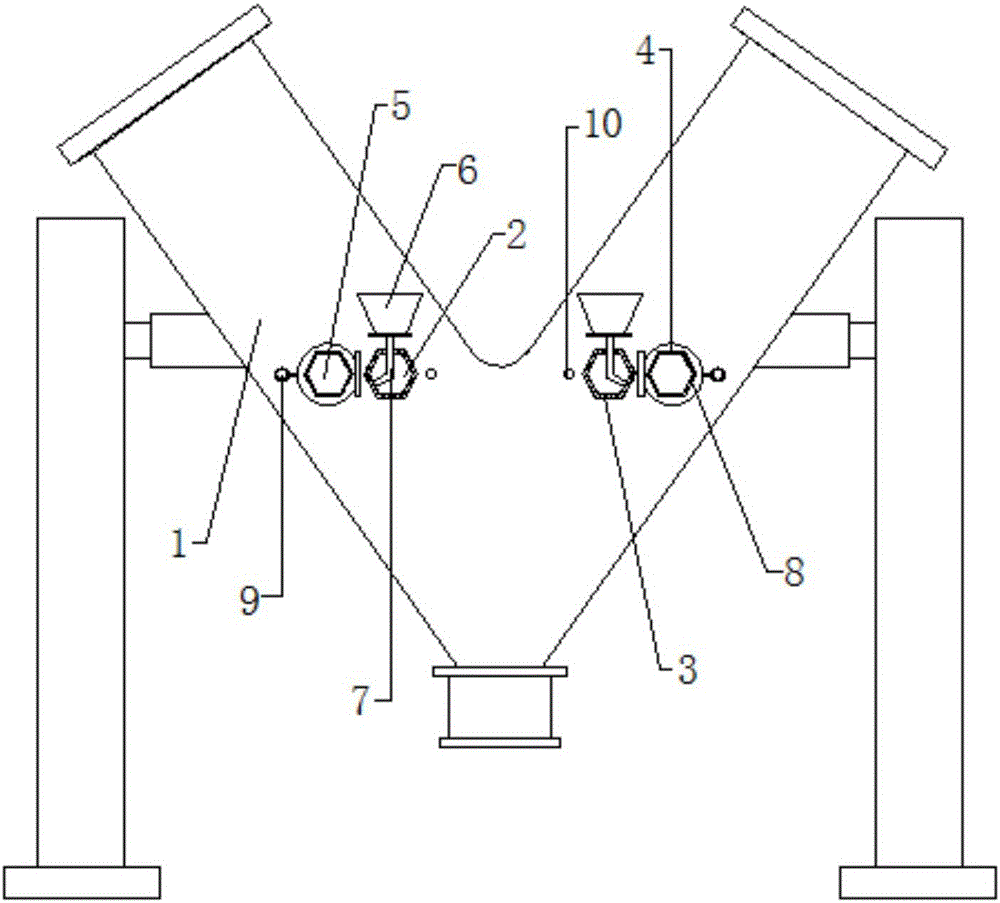

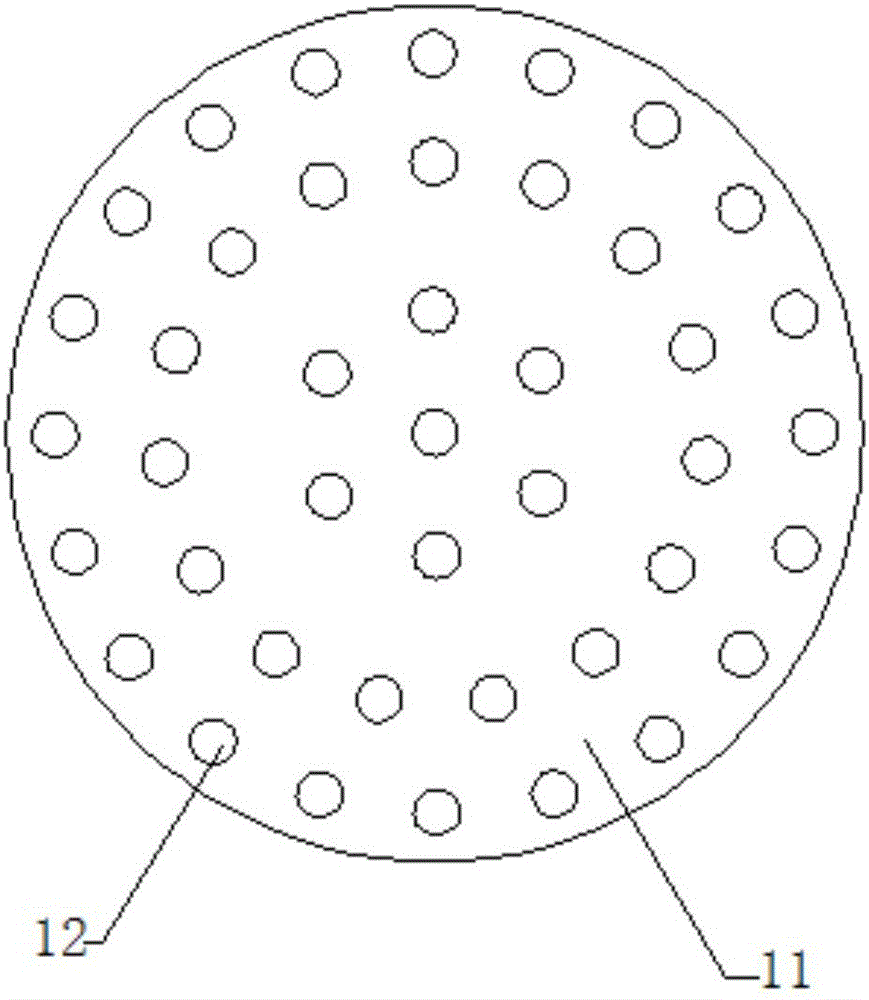

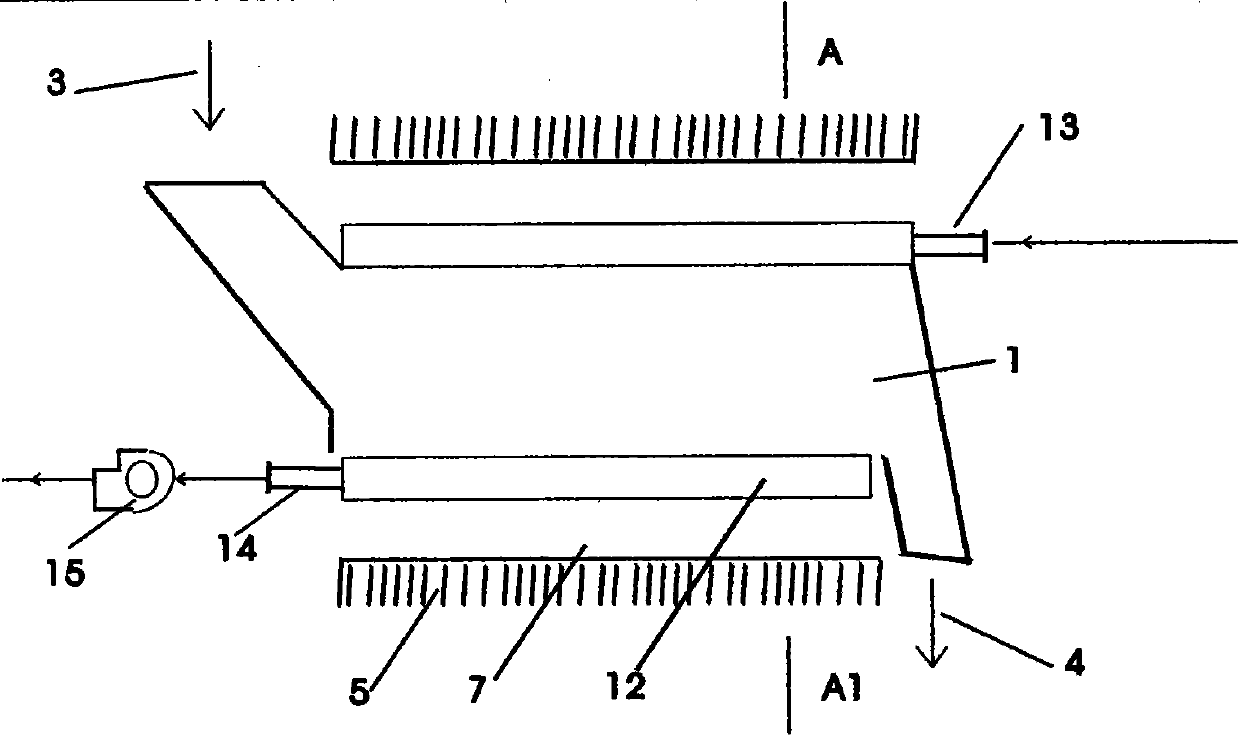

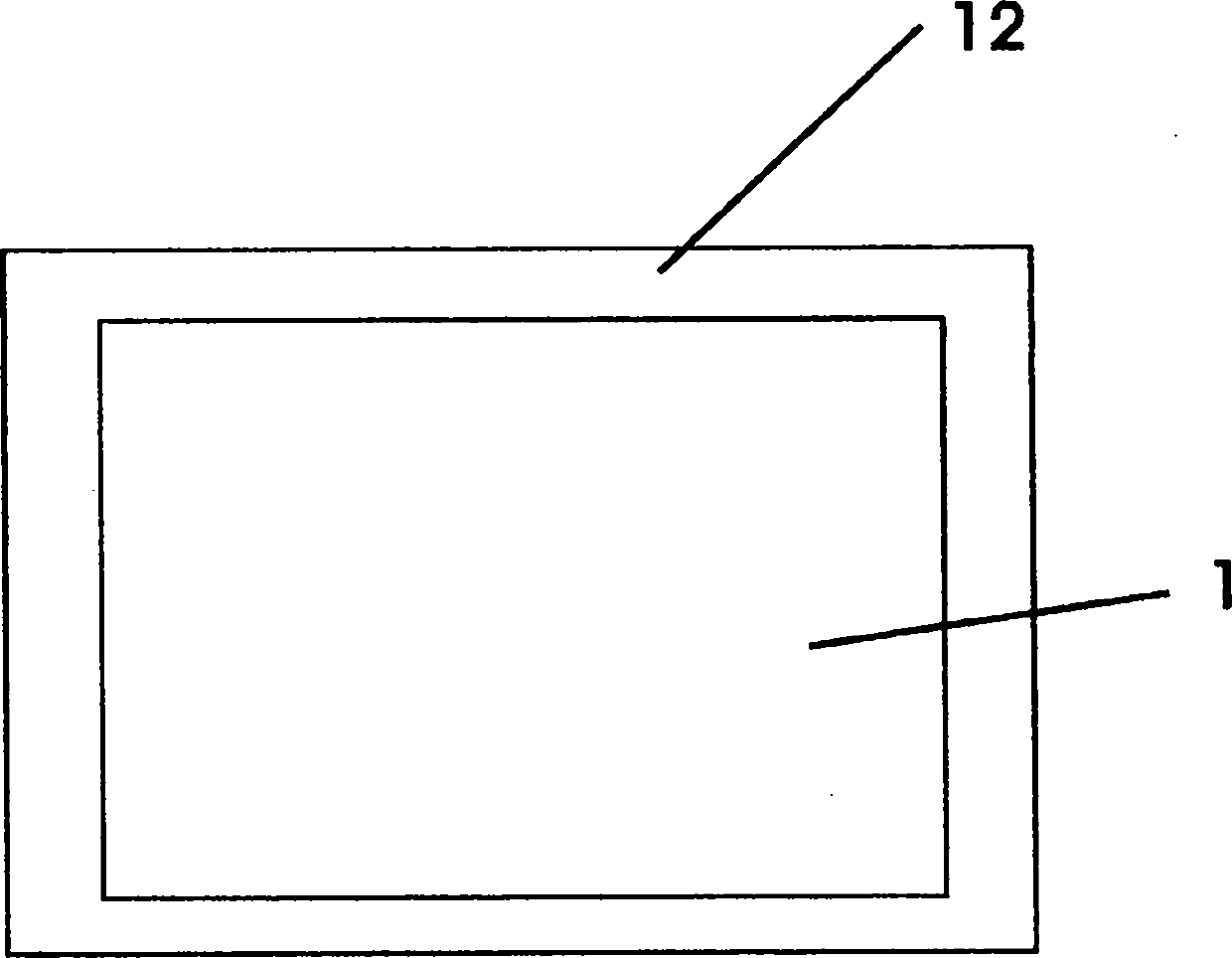

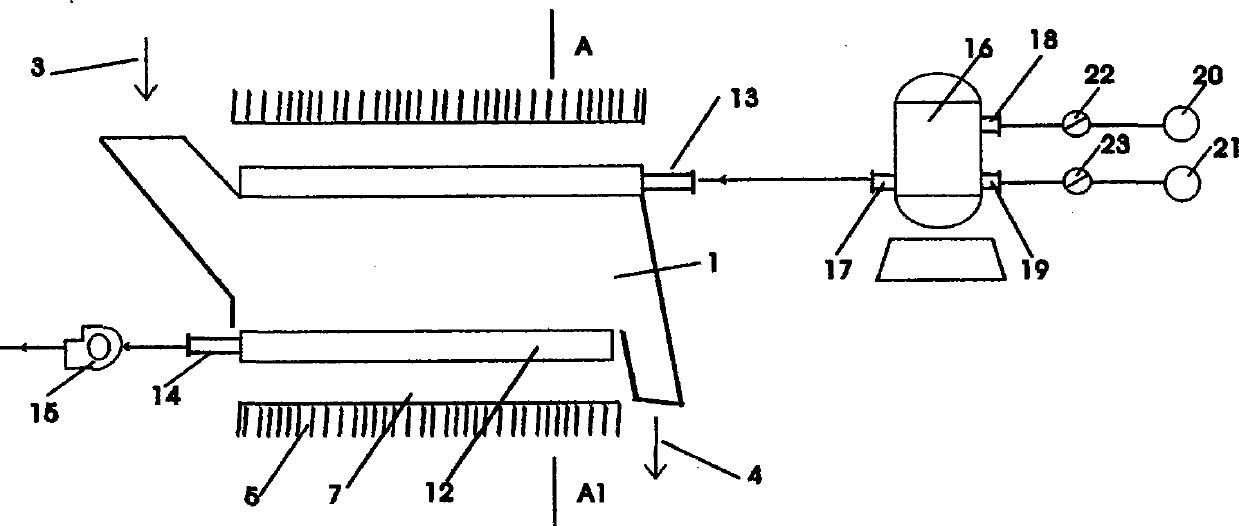

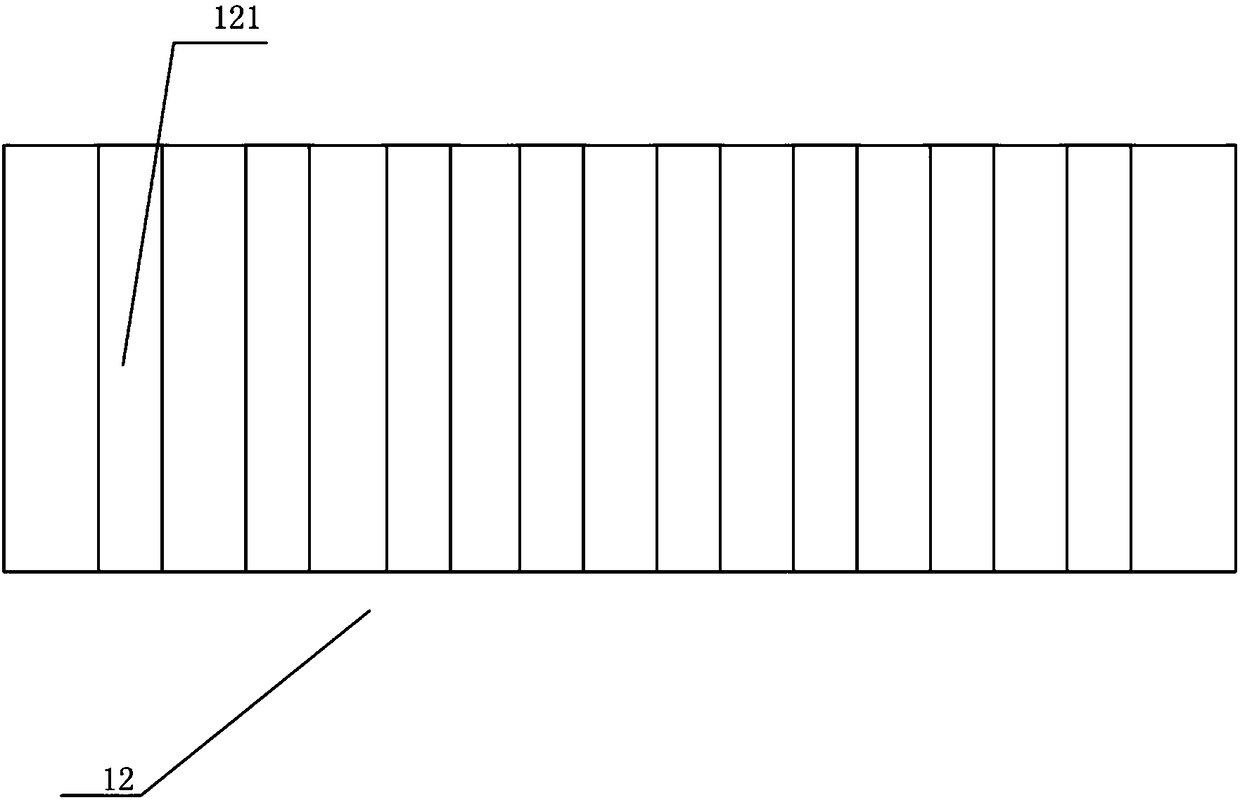

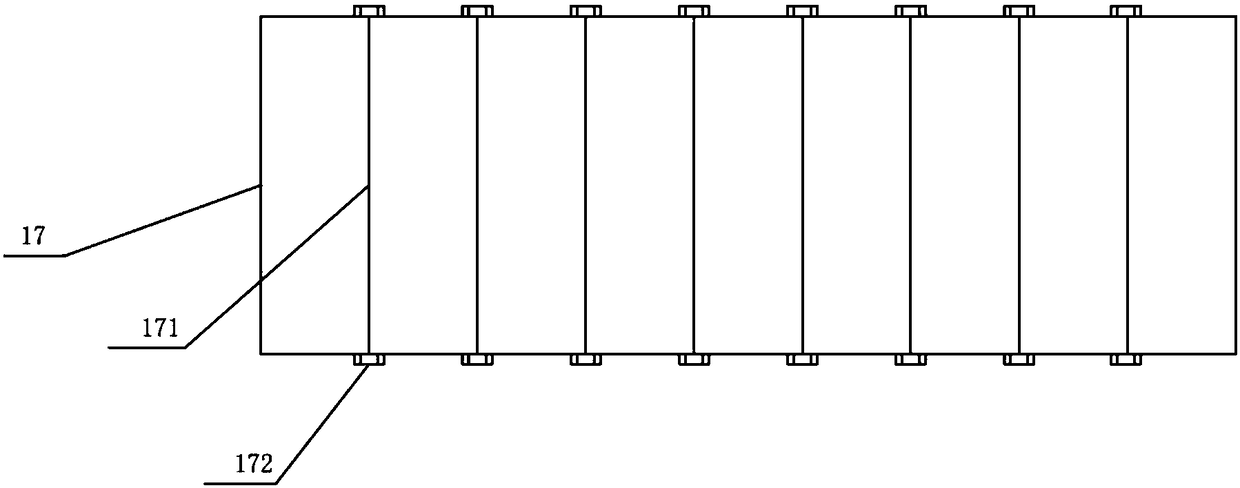

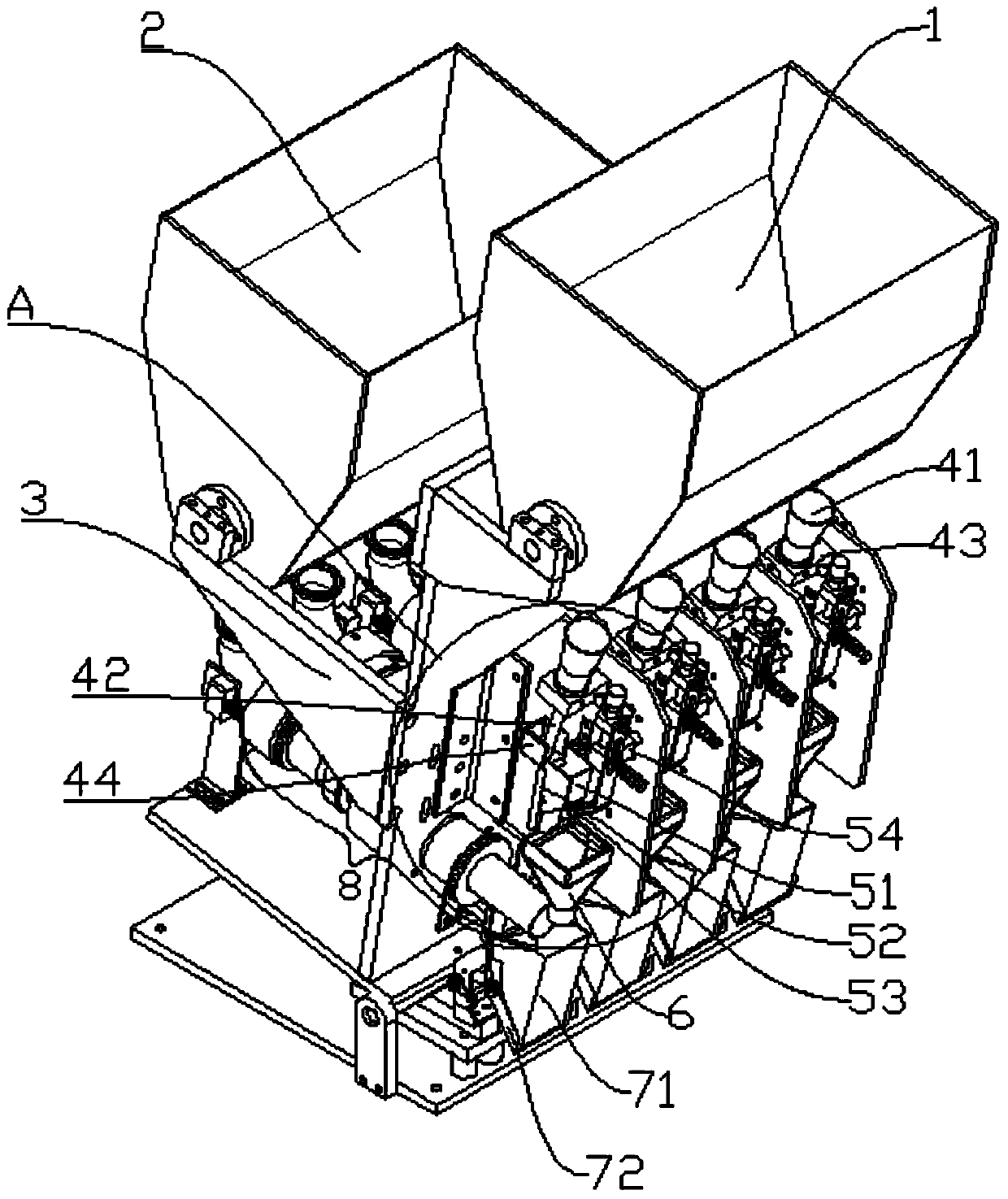

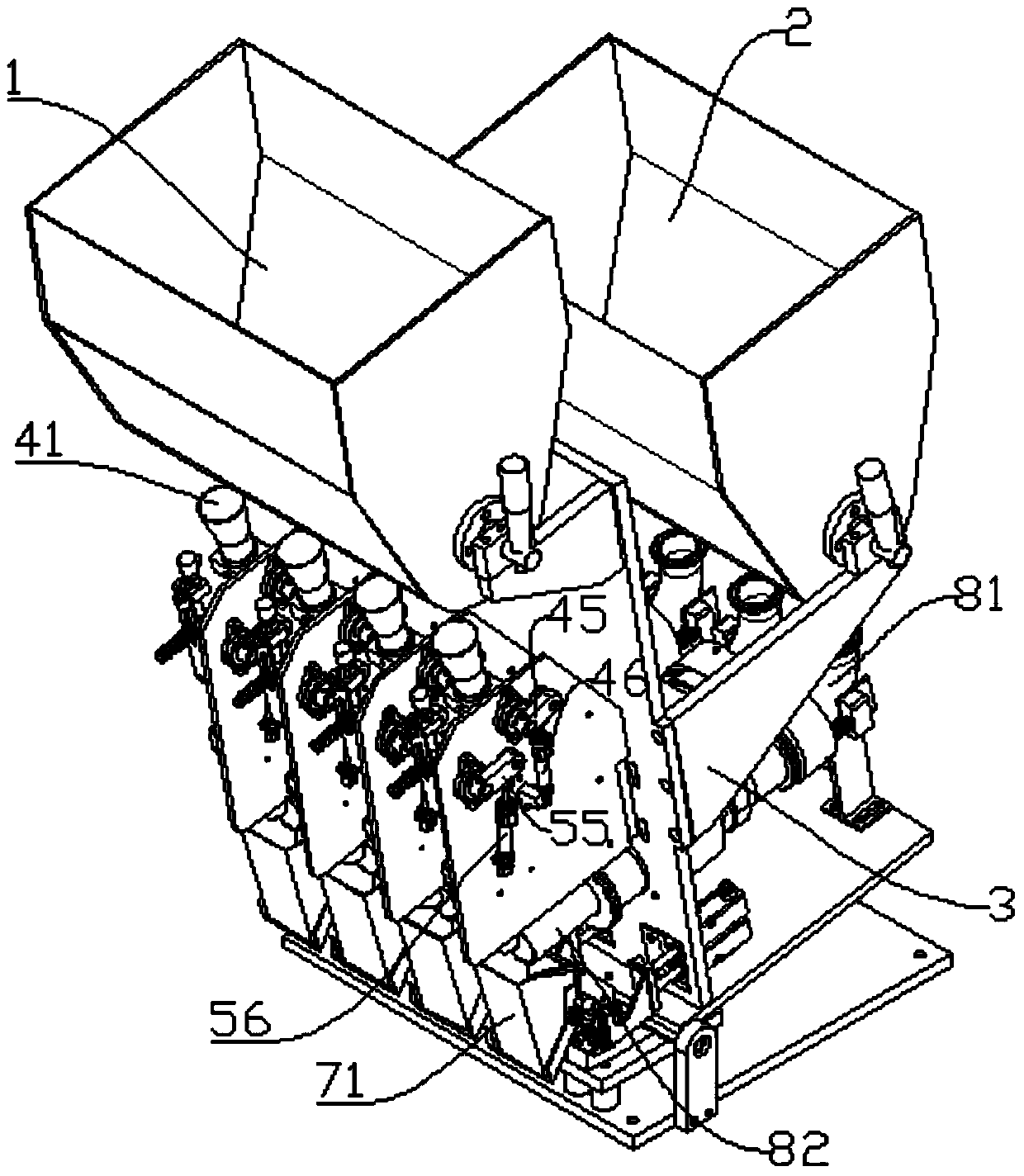

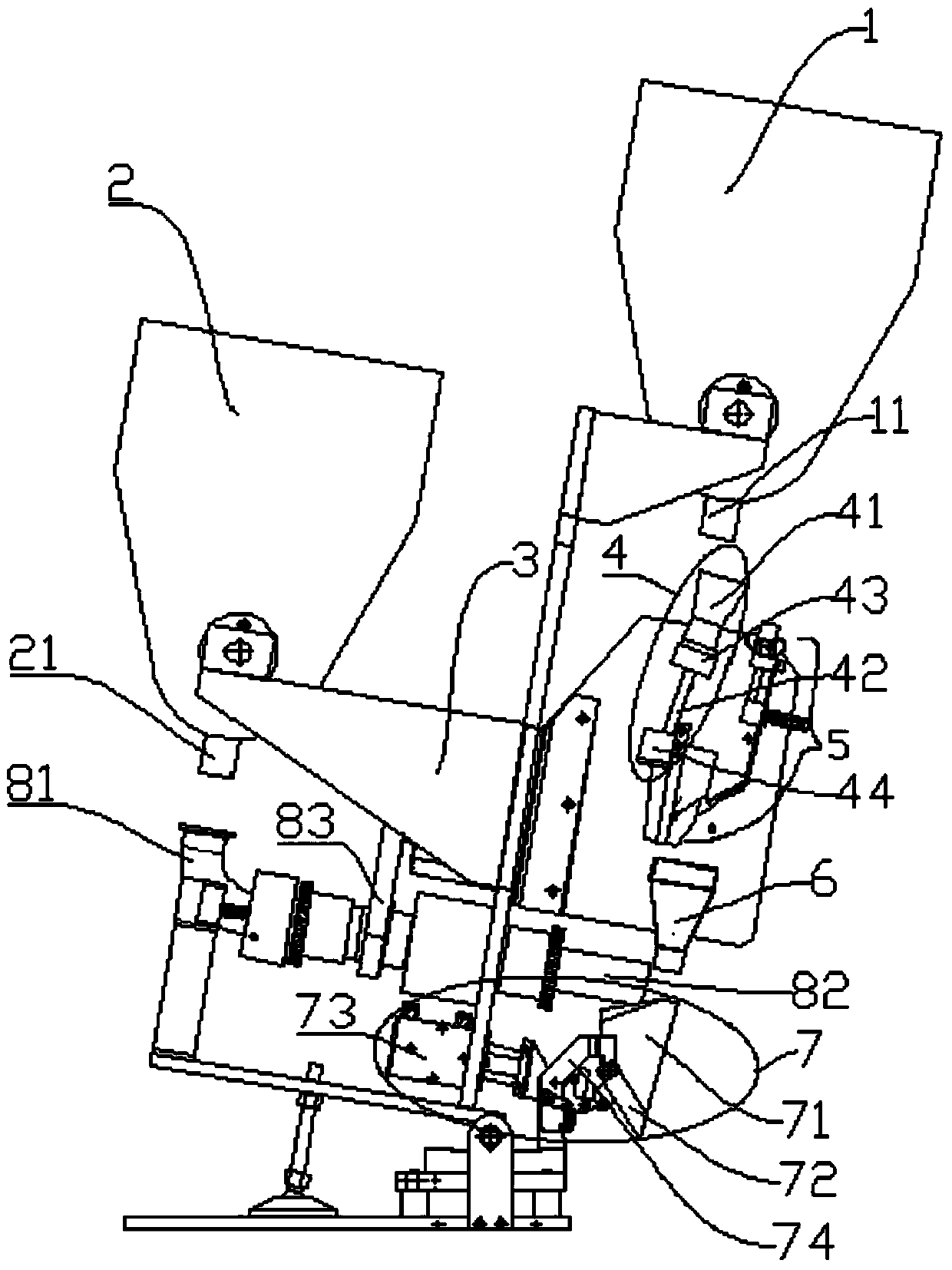

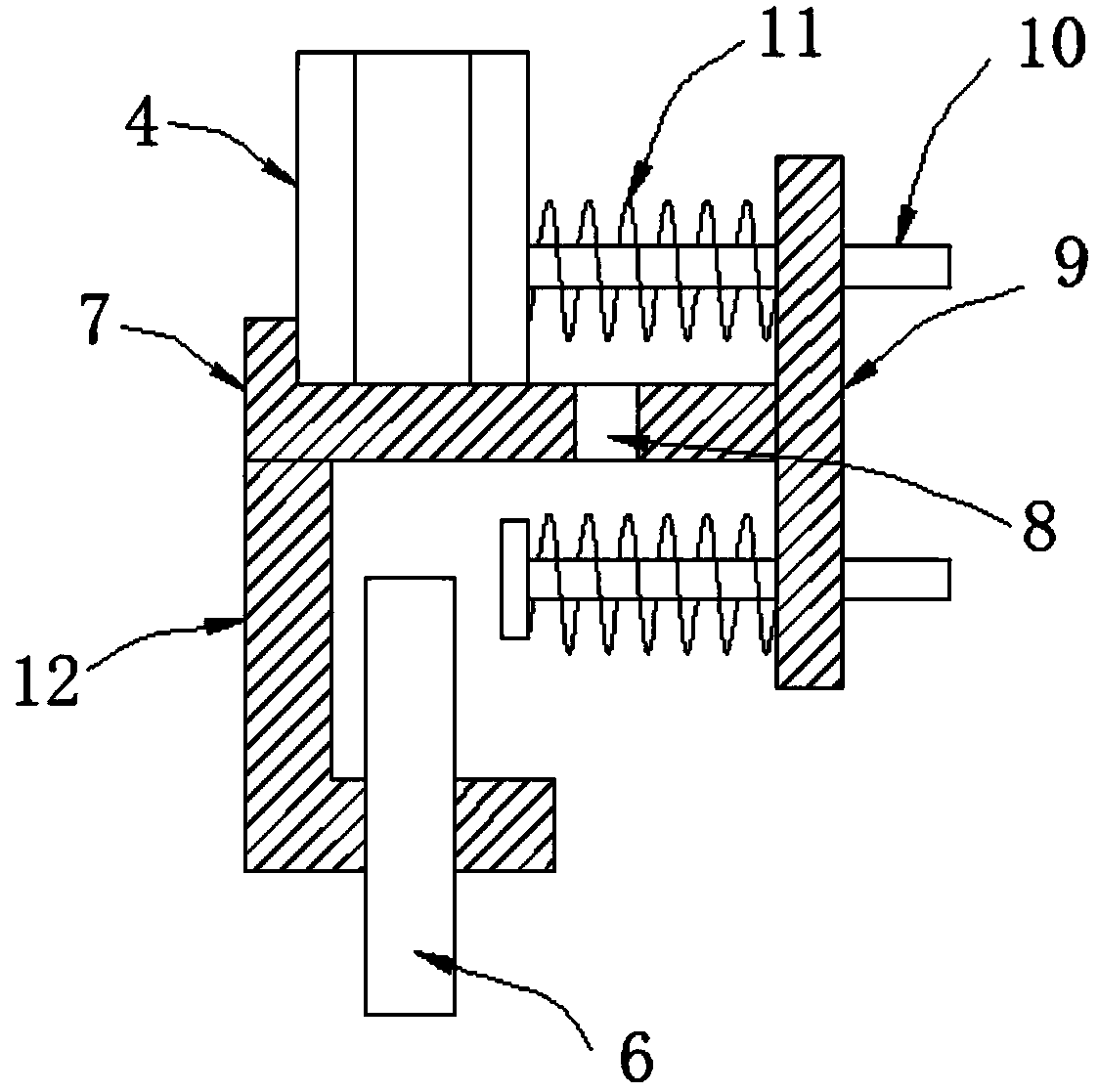

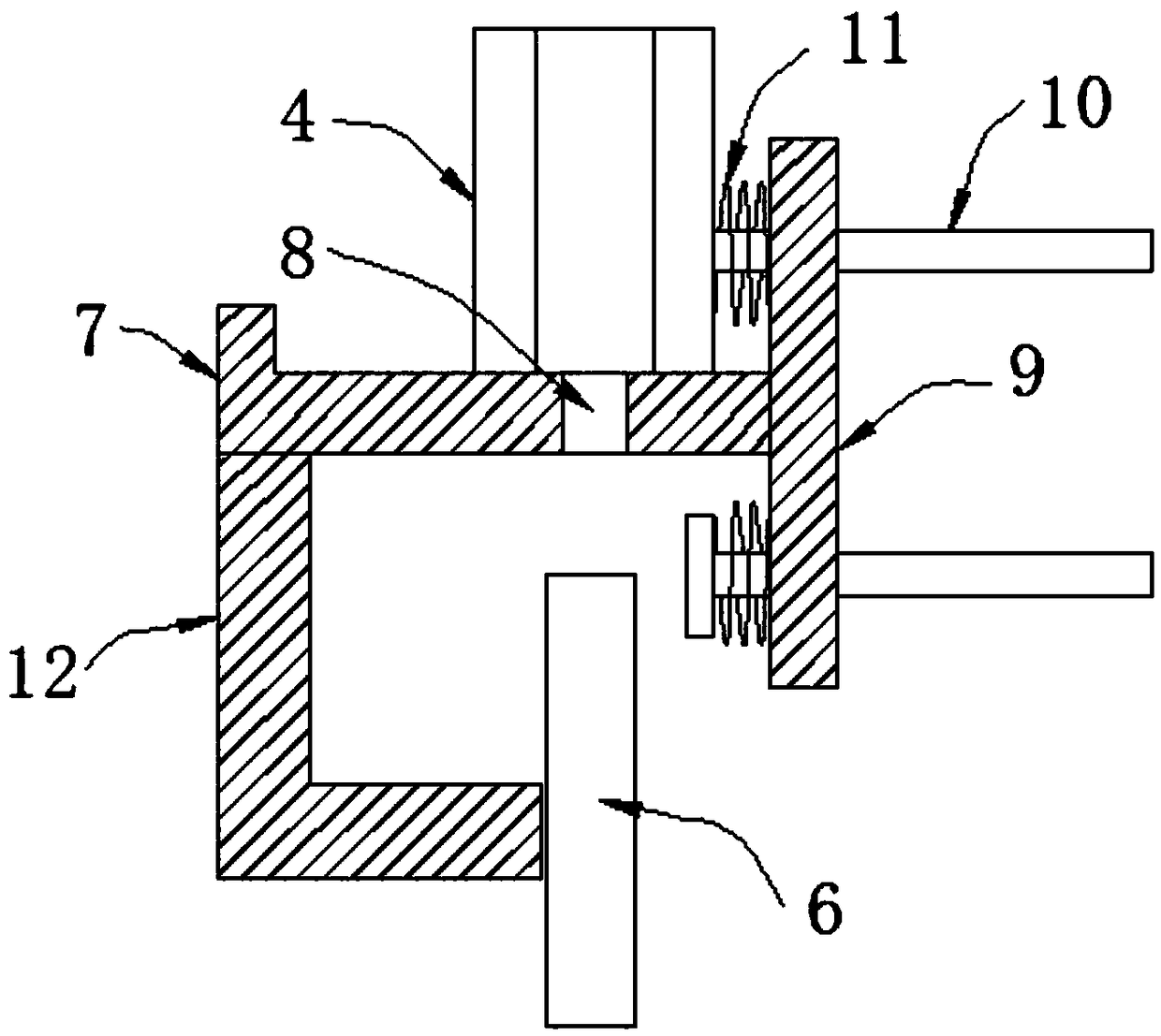

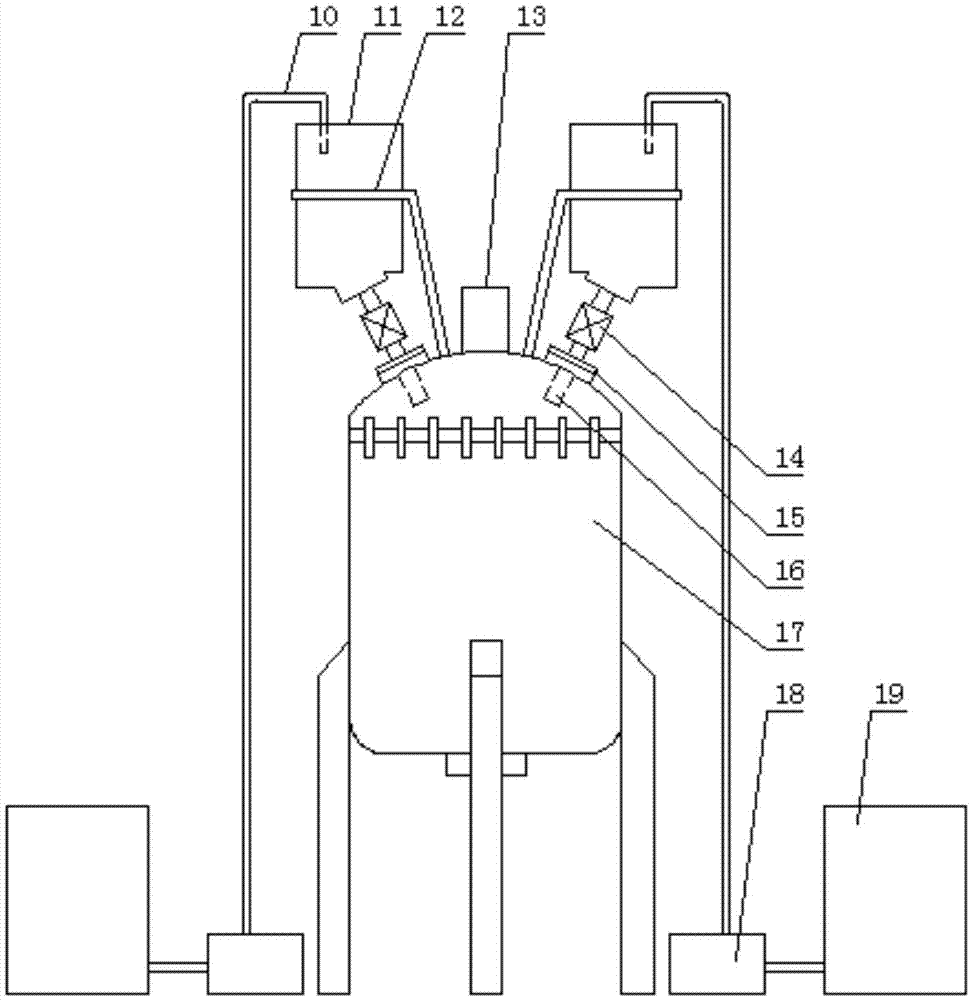

Hook-face displayer back plate forming equipment and method

ActiveCN105903796AEasy to control feedingStretch smoothlyShaping toolsDomestic articlesPunchingDisplay device

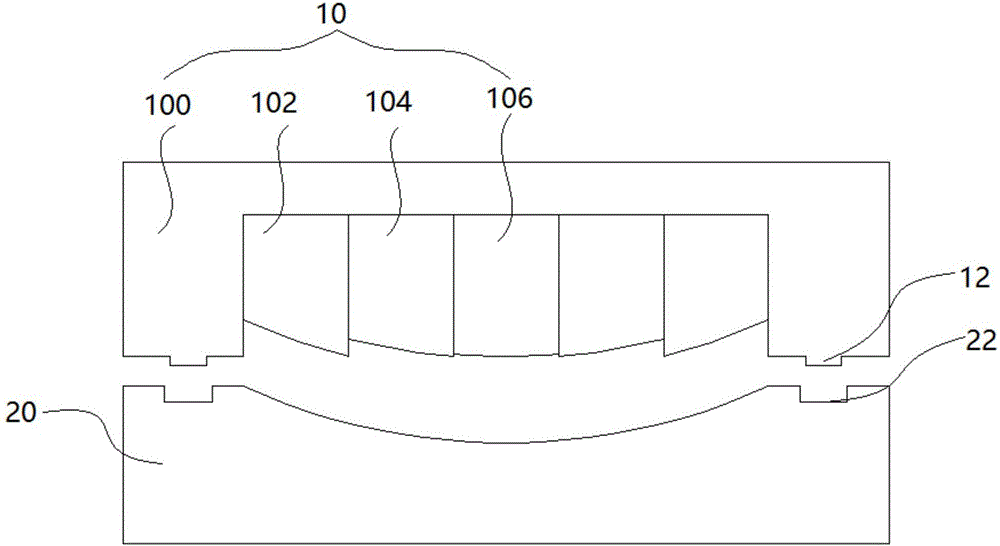

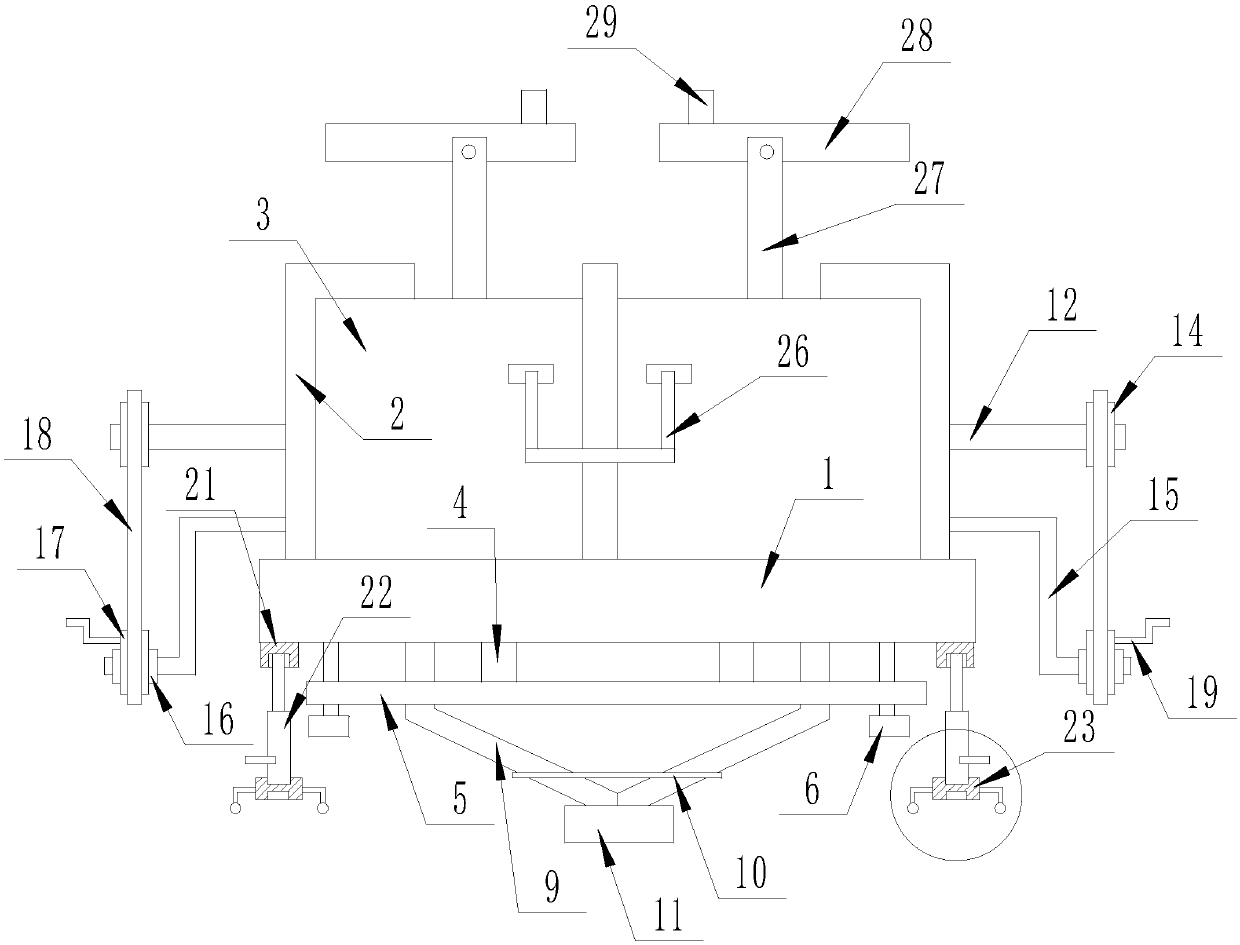

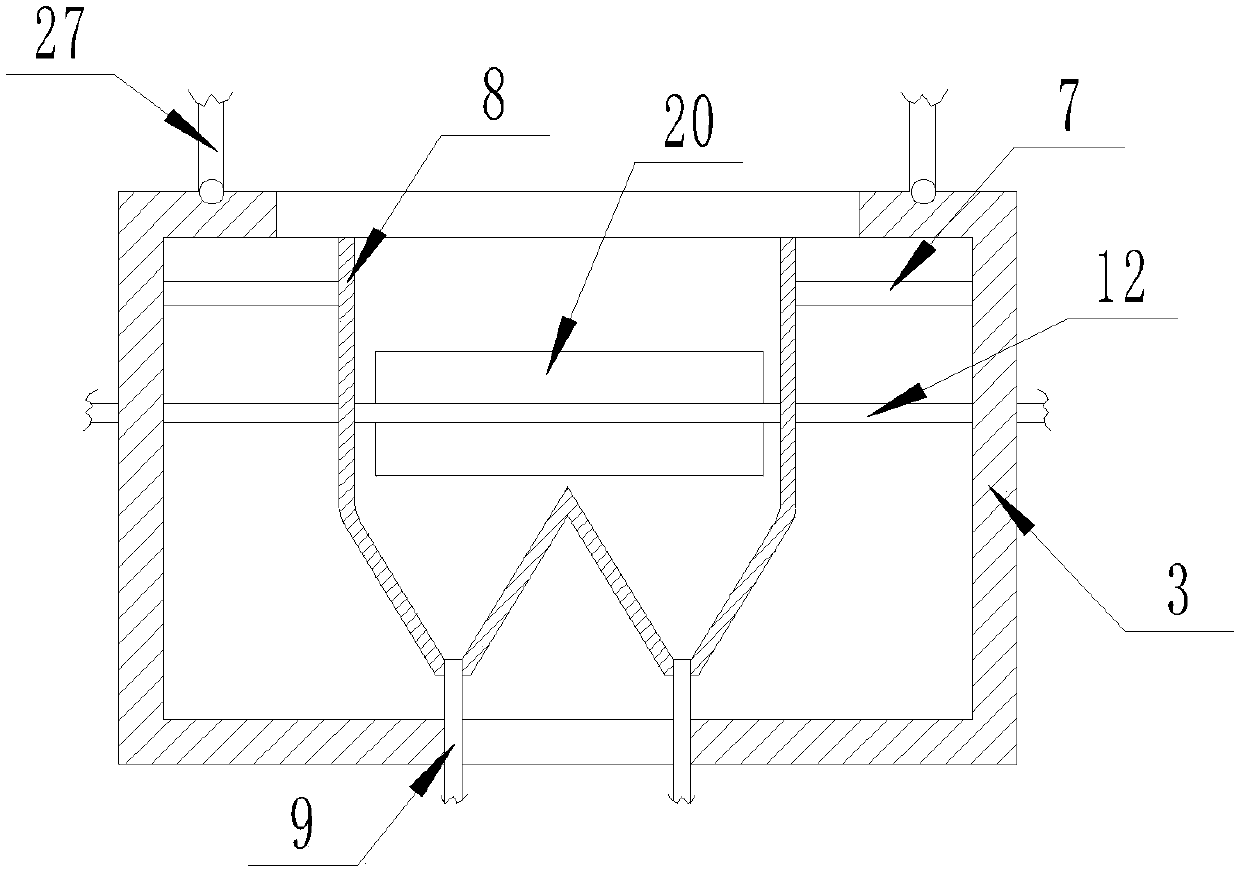

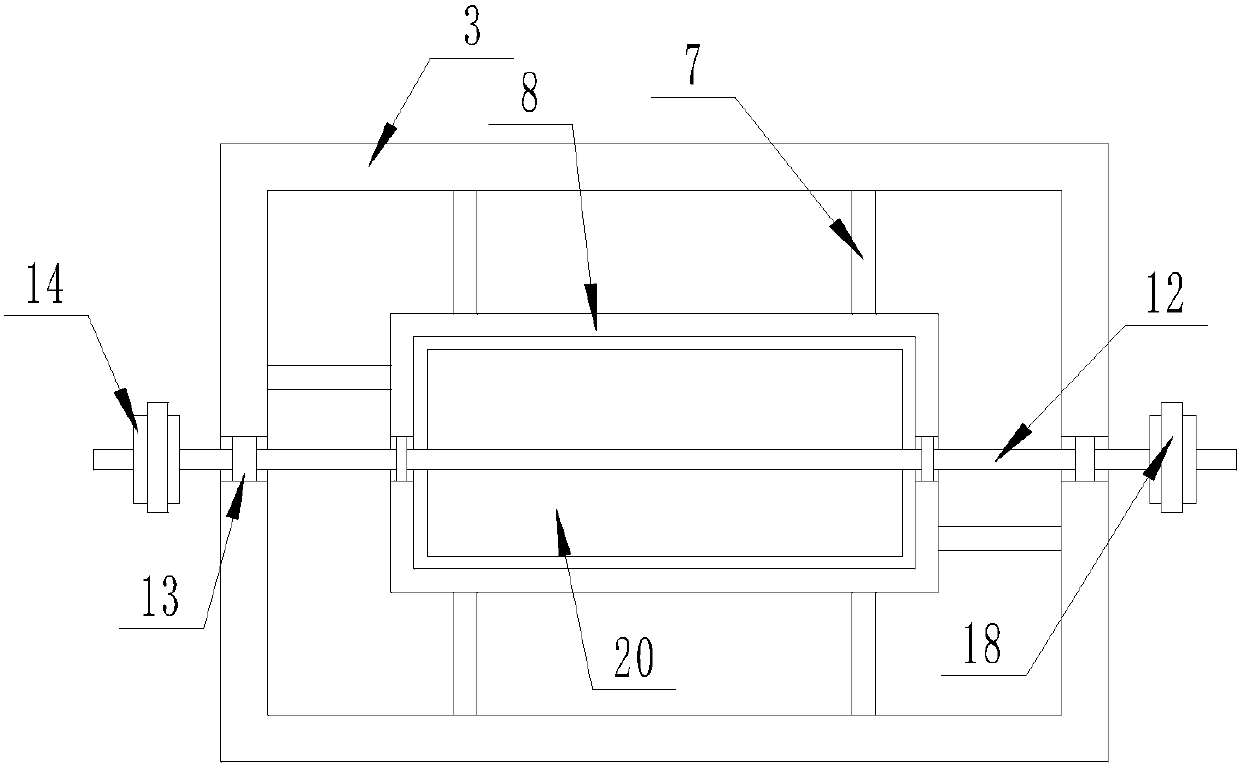

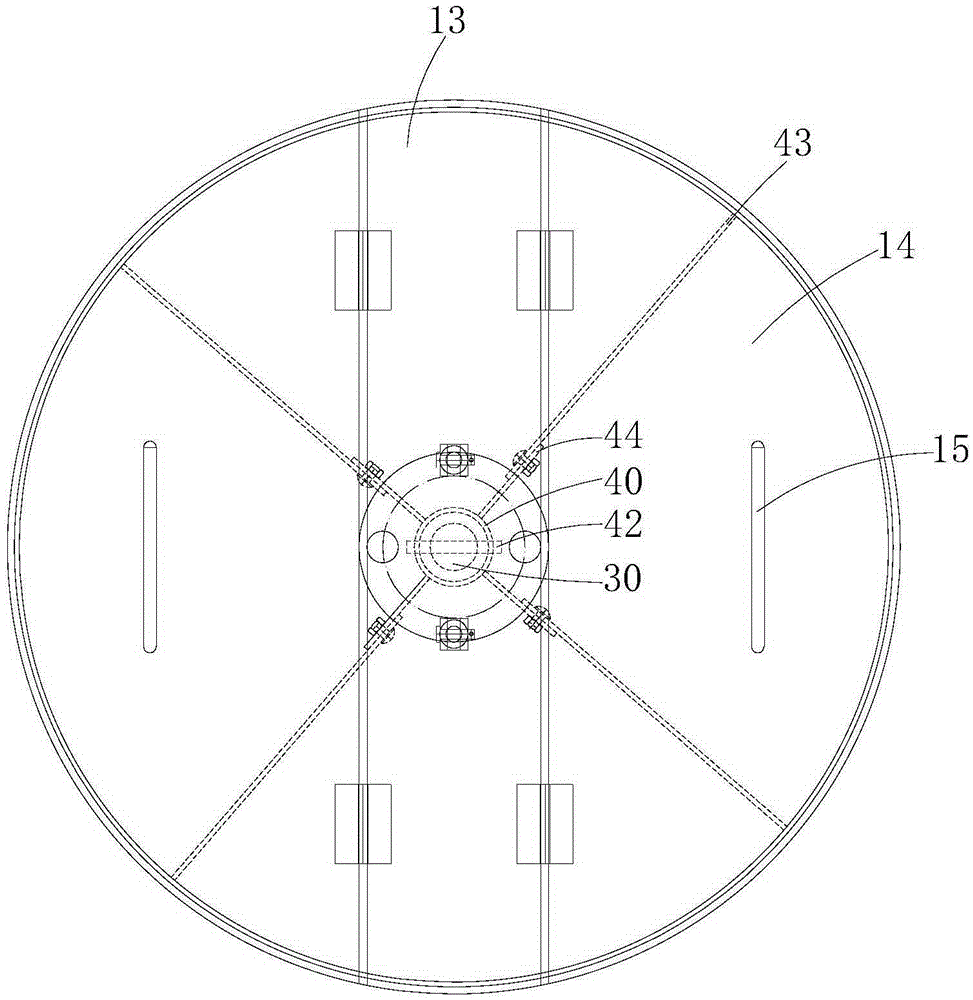

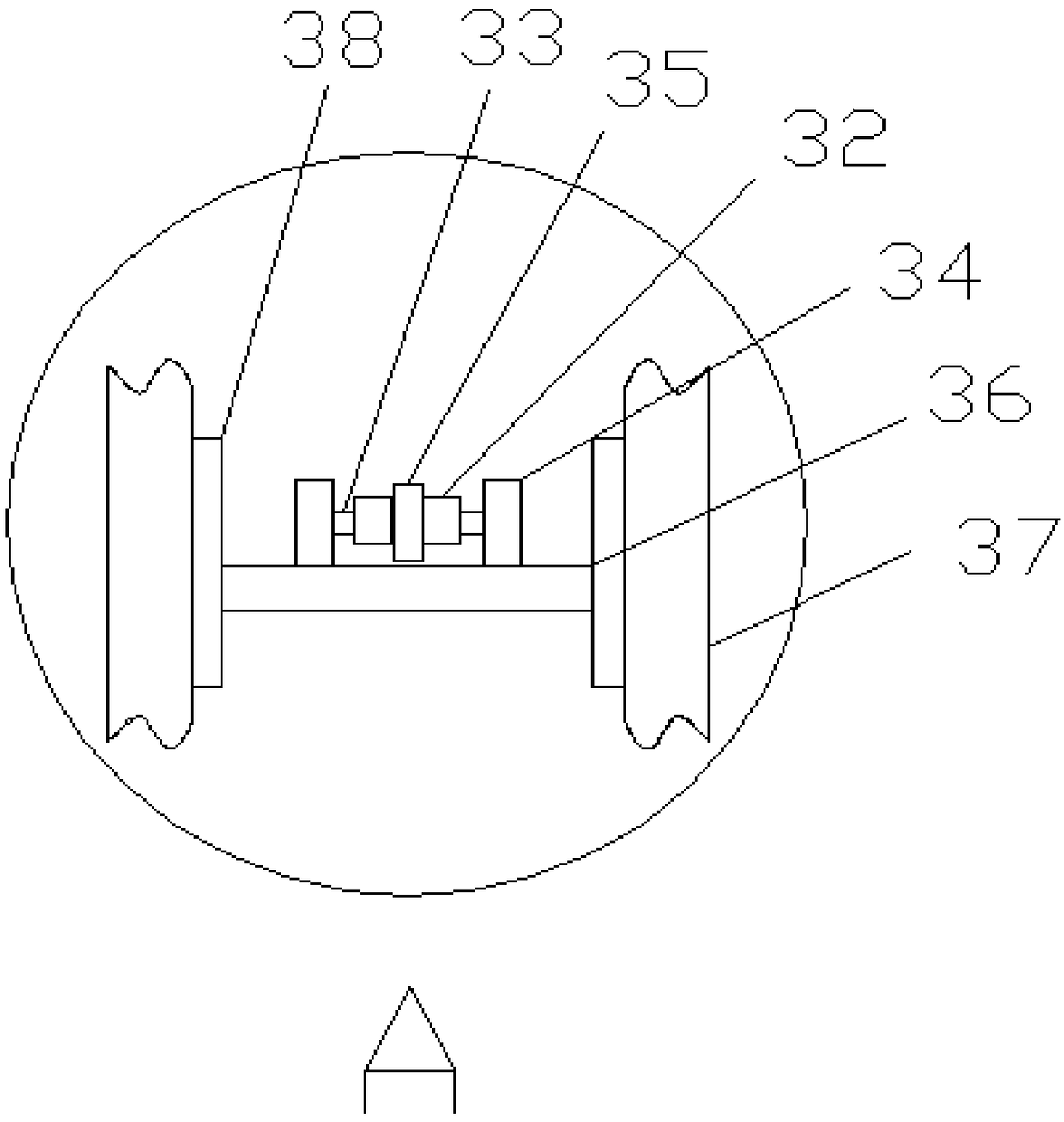

The invention provides hook-face displayer back plate forming equipment. The hook-face displayer back plate forming equipment comprises an upper die and a lower die. The upper die comprises a plurality of segmented punching heads and a material pressing plate, wherein the working surfaces of the segmented punching heads are hook faces, and the material pressing plate is arranged on the outer sides of the segmented punching heads. The working surface of the lower die is a hook face matched with the working surfaces of the segmented punching heads. The edge of the lower die and the material pressing plate are matched to fix a back plate raw material. The working surfaces of all the segmented punching heads are sequentially attached to the working surface of the lower die to punch the back plate raw material, so that the back plate raw material is subjected to plastic deformation. The invention further provides a hook-face displayer back plate forming method. A workpiece is punched through the segmented punching heads in sequence, workpiece feeding is easy to control, the workpiece is uniformly stretched, an obtained hook-face back plate is thin and has certain strength, and the precise hook face can be maintained.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

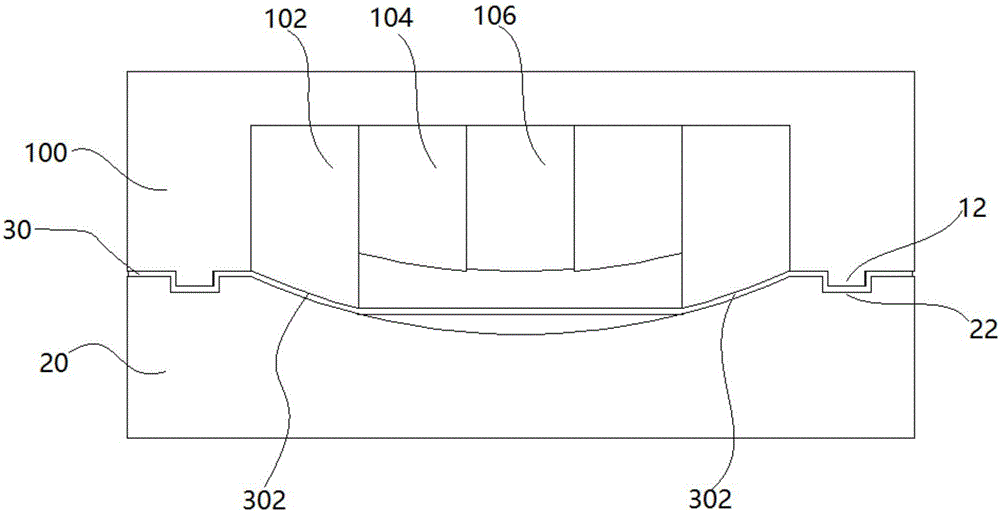

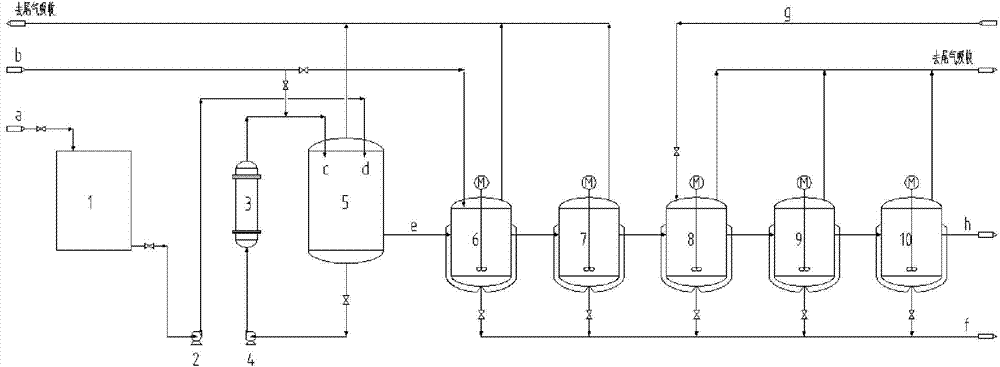

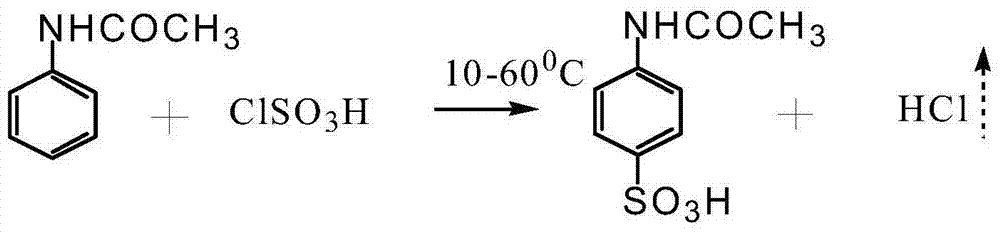

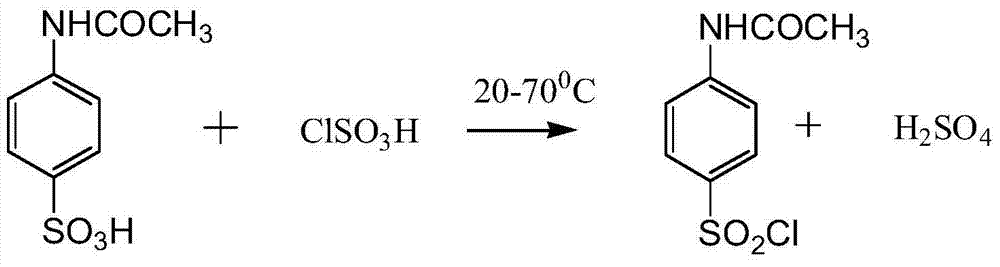

Continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate

ActiveCN104496866AImprove conversion rateThe reaction temperature is easy to controlSulfonic acid preparationMolten stateChlorosulfuric acid

The invention discloses a continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate. The process comprises the steps: performing reaction on chlorosulfonic acid and acetanilide which serve as raw materials; respectively atomizing chlorosulfonic acid and molten-state acetanilide and contacting with each other during feeding to perform reaction. According to the continuous sulfonating process for synthesizing p-aminophenyl-beta-hydroxyethyl sulfone sulphate, the molten-state acetanilide is used as a raw material, and the reaction on the acetanilide in an atomizing state and chlorosulfonic acid which is also in an atomizing state are carried out and the reaction temperature is easily controlled, so that the production of byproducts such as parachloroaniline is avoided, and the conversion rate of acetanilide serving as a raw material is high. The process is convenient to operate, short in production period, controllable in reaction process, less in labor demands, low in cost and easy for industrial production.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

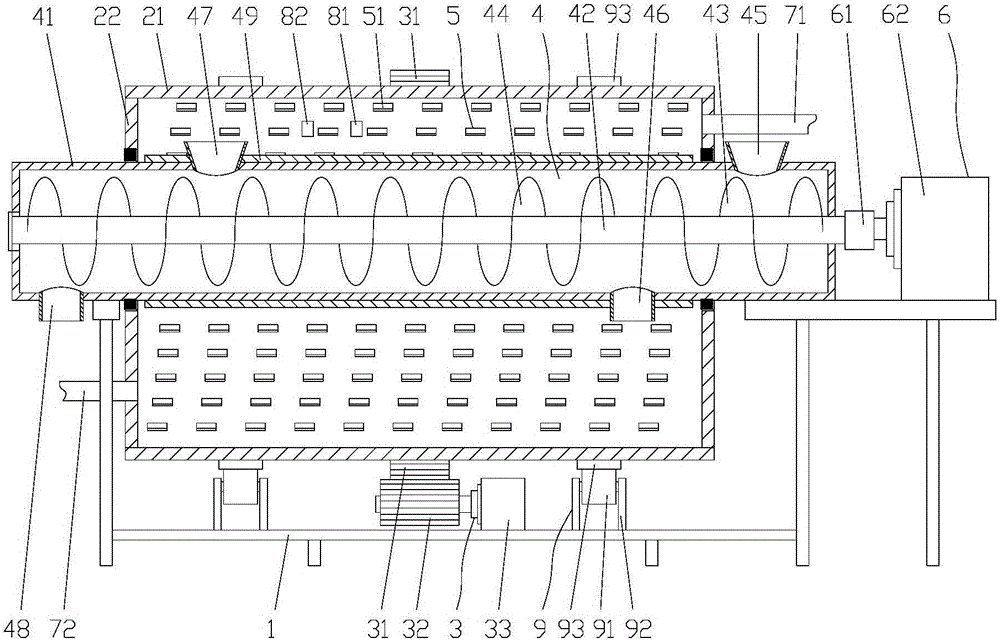

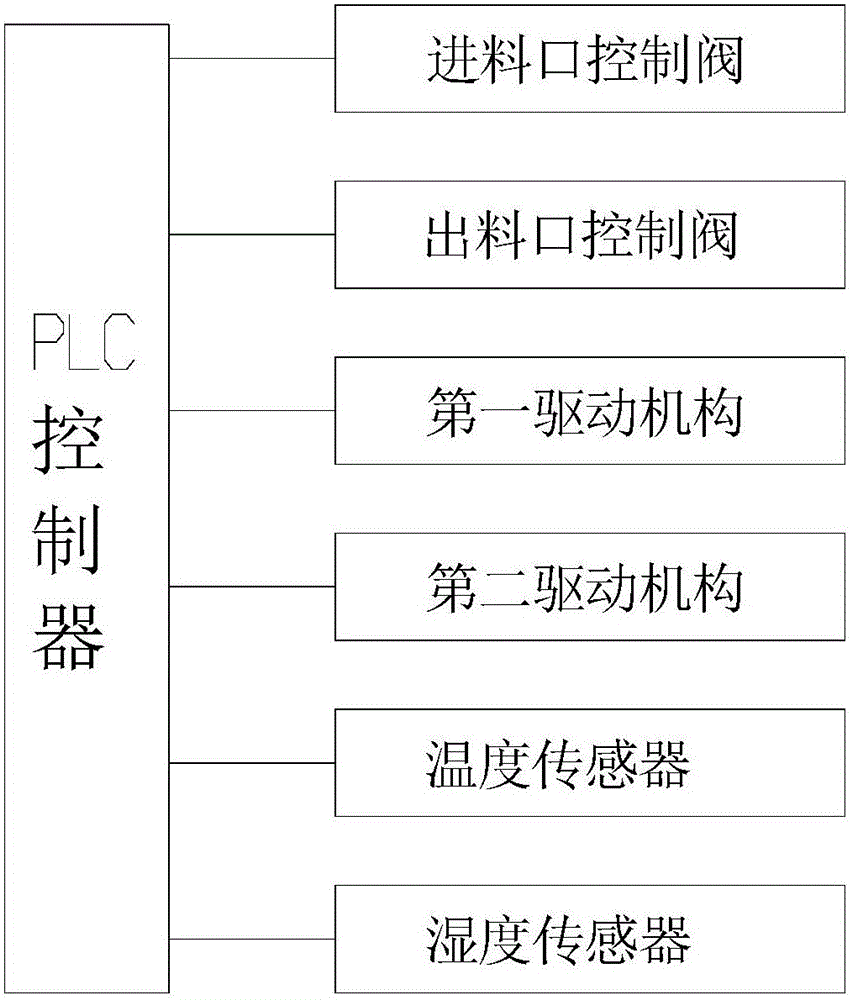

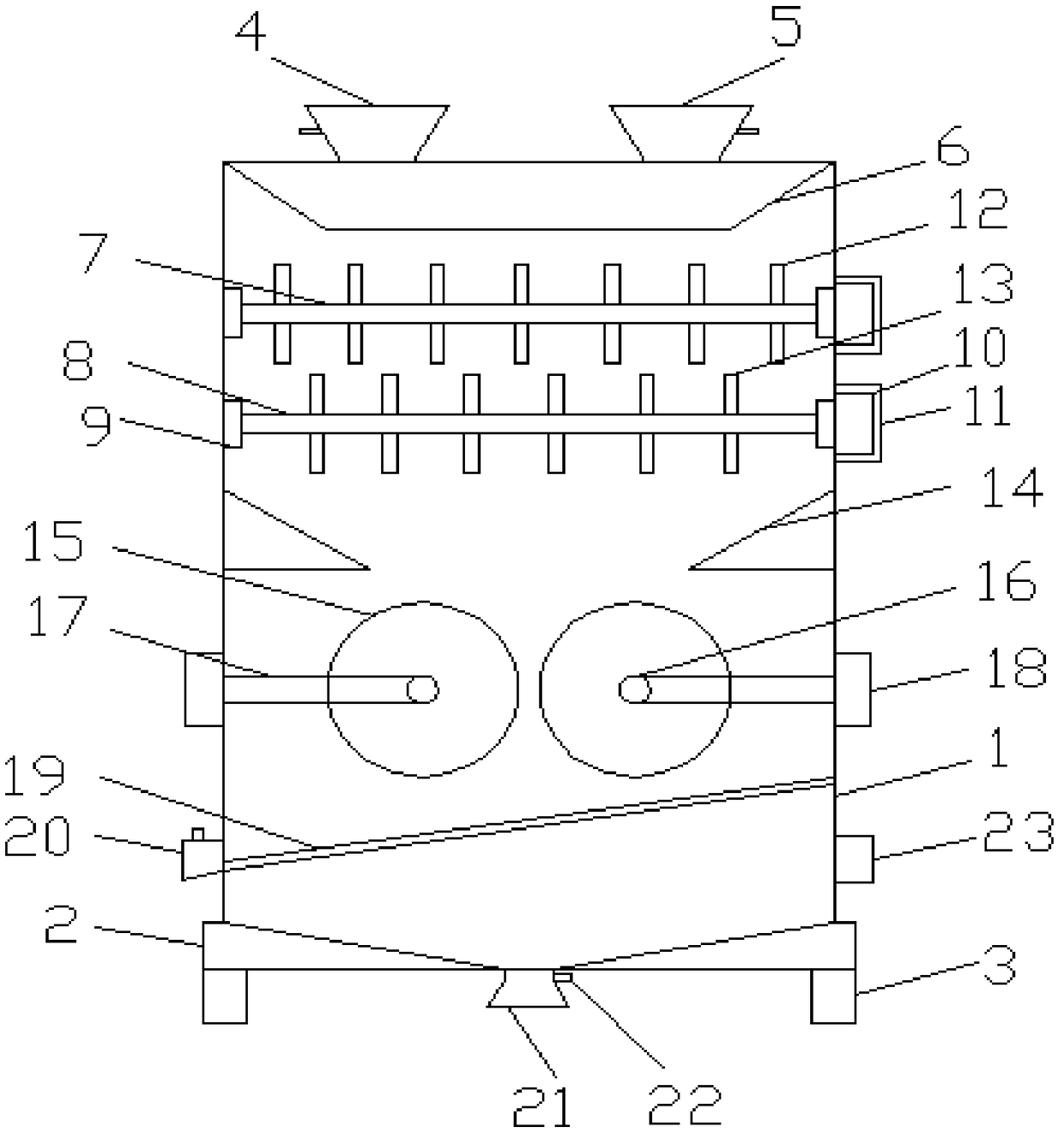

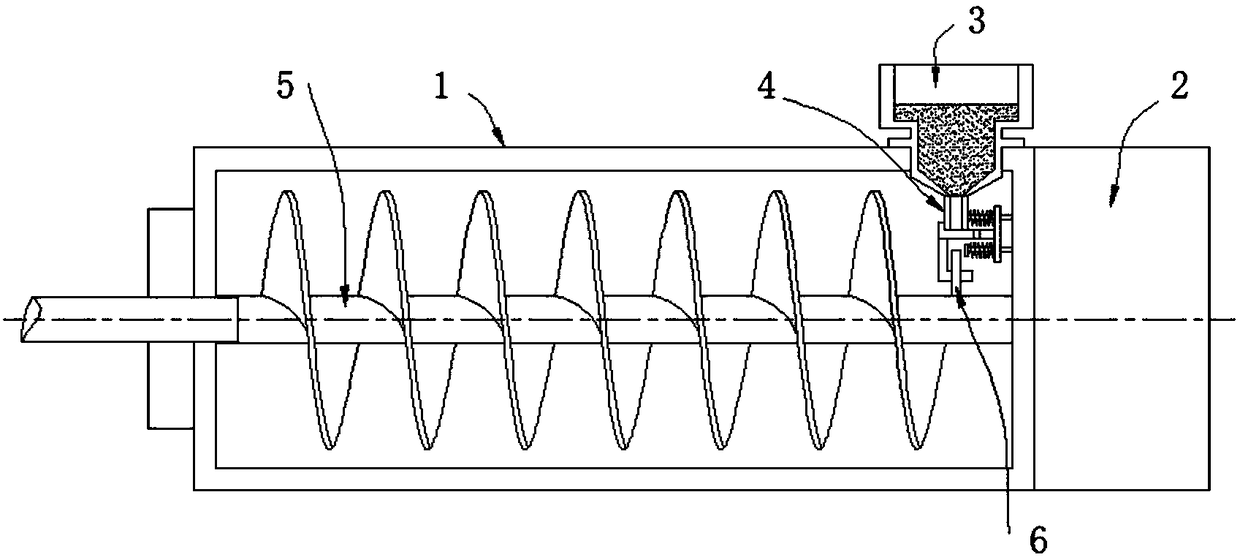

Quick drying and fermenting device for livestock and poultry faeces

ActiveCN105753519AEasy to control feedingSimple designClimate change adaptationExcrement fertilisersSpiral bladeAnimal feces

The invention relates to a quick drying and fermenting device for livestock and poultry faeces. The quick drying and fermenting device comprises a machine frame, a first spiral transmission mechanism, a horizontal tank body, a supporting mechanism which is used for supporting the tank body, a first driving mechanism which is used for driving the tank body to rotate circumferentially, and an air inlet pipe which is used for feeding hot air into the tank body to dry materials; the first spiral transmission mechanism comprises a transmission cylinder which is arranged in the tank body in a penetrating manner in the axial direction; a spiral shaft is arranged in the transmission cylinder; one end of the spiral shaft is driven to rotate through a second driving mechanism; a first spiral blade and a second spiral blade which have opposite spiral directions are connected in series and are arranged on the spiral shaft; a feeding opening which is positioned outside the tank body is formed in one end of the transmission cylinder; a material falling opening which is positioned in the tank body is formed in the lower wall, corresponding to the connecting position of the first spiral blade and the second spiral blade, at one end of the tank body, of the transmission cylinder; a material returning opening which is positioned in the tank body is formed in the position, at the other end of the tank body, of the transmission cylinder; a material discharging opening which is positioned outside the tank body is formed in the other end of the transmission cylinder; a second spiral transmission mechanism which is used for conveying the materials in the tank body to the material returning opening is arranged on the inner wall of the tank body.

Owner:FUJIAN EF GREEN TECH CO LTD +1

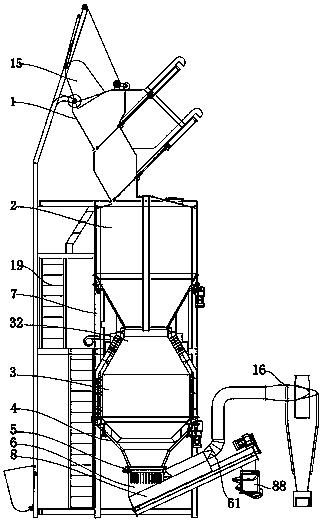

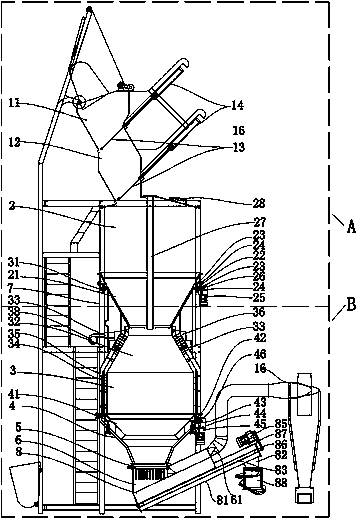

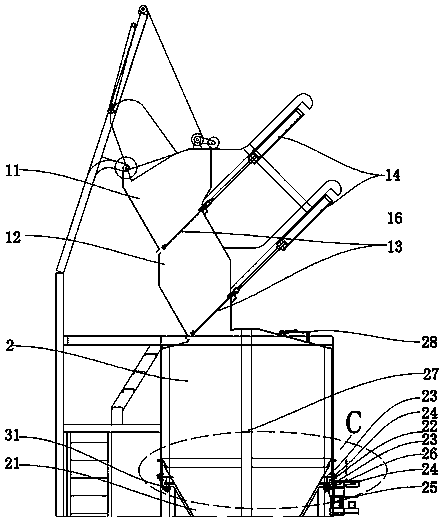

Downdraft carbon-gas co-production gasifier

The invention discloses a downdraft carbon-gas co-production gasifier. The main structure of the gasifier comprises a feed hopper, a stock bin, a gasification reaction chamber, a double-section bucket-shaped water cooling sleeve, a turnover grate and a settling chamber from top to bottom; a carbon discharging auger is arranged at the bottom of the settling chamber; a bucket-shaped conical materialdrawing disc is arranged inside the lower part of the stock bin; and a bucket-shaped conical disc is stacked inside the upper part of the double-section bucket-shaped water cooling sleeve. Biomass fuel is firstly subjected to a high-temperature cracking gasification reaction in the gasification reaction chamber to generate fuel gas, and the fuel gas is discharged downwards from a fuel gas outletin the side wall of a settling chamber; and biomass fuel which is not completely reacted in the gasification reaction chamber is carbonized, then falls into the settling chamber and is cooled to formbiomass carbon, so that simultaneous co-production of carbon and gas of the biomass fuel is realized. The gasifier has the following characteristics: the structure is scientific and ingenious and thefeeding hopper with a double-layer structure can prevent gas from escaping during feeding; the bucket-shaped conical material drawing disc prevents the material bin from material bridging and arching;a gas supply pipe is used as a middle air inlet channel, so that gas feeding is more uniform without dead angles; and the turnover grate has a function of spraying water mist at the same time.

Owner:周勇

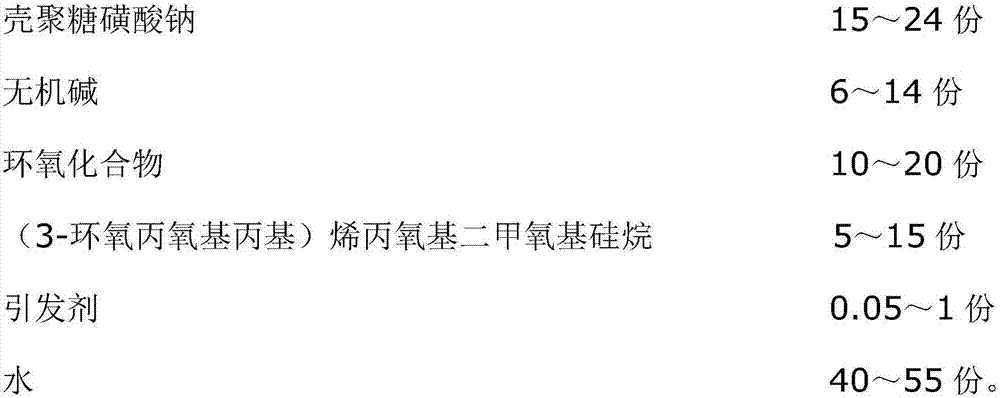

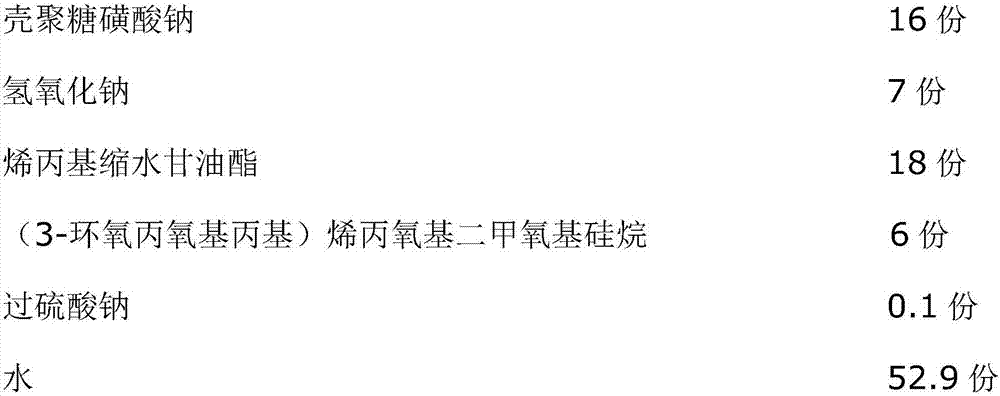

Chitosan sodium sulfonate containing concrete synergist and preparation method thereof

The invention discloses a chitosan sodium sulfonate containing concrete synergist and a preparation method thereof, and belongs to the field of a concrete additive. The synergist comprises chitosan sodium sulfonate, inorganic base, an epoxy compound, (3-epoxy propoxy propyl) allyloxy dimethoxy silicane, an initiator and water, wherein the initiator is a mixture made from one or more than two of sodium persulfate, potassium persulphate or ammonium persulfate. The preparation method comprises: adding weighed chitosan sodium sulfonate, inorganic base and water to a reaction vessel, then adding the epoxy compound and (3-epoxy propoxy propyl) allyloxy dimethoxy silicane to the reaction vessel; and adding the initiator to obtain the concrete synergist. The synergist improves the dispersity of cement particles, stimulates the action of cement, allows the hydration reaction to be fully carried out, improves the comprehensive properties of concrete, raises the strength level of concrete, saves the concrete consumption by about 10%, and reduces the production cost of concrete.

Owner:华海菲菲(河北)混凝土外加剂有限公司

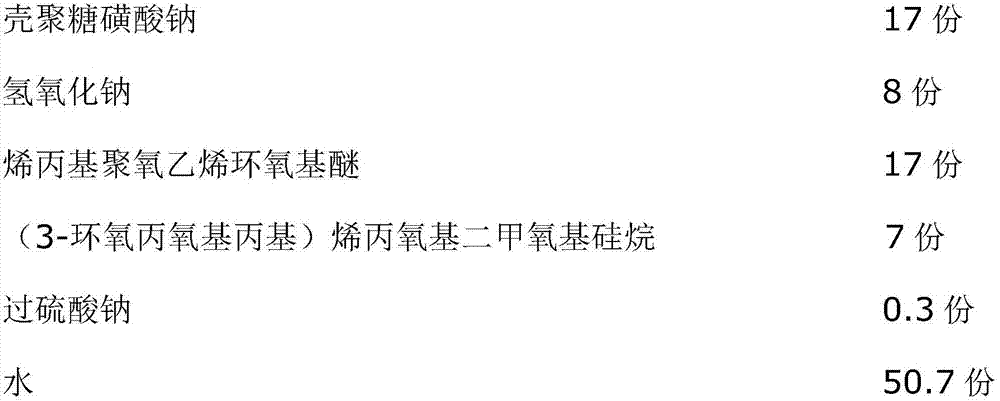

Automatic control device of belt conveying device

InactiveCN110803485AReduce deliveryRealize fixed-point feeding and conveyingConveyorsControl devices for conveyorsDrive wheelAutomatic control

The invention discloses an automatic control device of a belt conveying device and relates to the technical field of automatic control conveying. The automatic control device aims at solving the problems that an existing belt conveying device cannot ensure that a conveying groove is located below a discharging pipe during discharging, materials are not placed in a standard manner or disengage fromthe conveying belt during feeding, and conveying is affected. A lifting seat is arranged below one supporting frame, conveying rollers are arranged between the supporting frames, a conveying belt isarranged between the two conveying rollers, a supporting plate is arranged on one side of one supporting frame, a servo motor is arranged above the supporting plate, a driven wheel is arranged on oneside of the conveying roller, and a rotating shaft is arranged on one side of the output end of the servo motor. A drive wheel is arranged on one side of the rotating shaft, a discharging bin is arranged above the supporting frame, a discharging pipe is arranged on one side of the discharging bin, and a second electric telescopic rod is arranged on one side of the discharging bin. Limiting platesare arranged at the outer portion of the conveying belt, and a dividing plate is arranged between the two limiting plates.

Owner:SUZHOU DESIMIER SMART TECH CO LTD

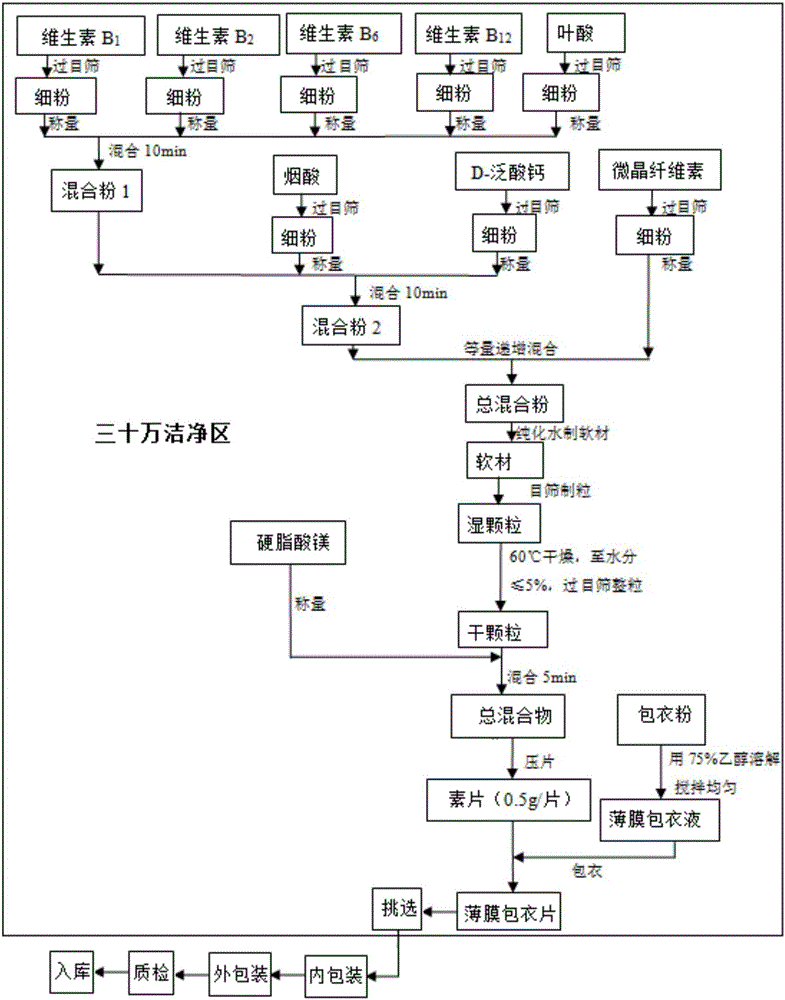

Vitamin B tablets and preparation method thereof

ActiveCN105962379AEfficient SupplementConvenient supplementSugar food ingredientsFood coatingNutrientFolic acid

The invention discloses vitamin B tablets and a preparation method thereof. Vitamin B1, vitamin B2, vitamin B6, vitamin B12, niacin, D-calcium pantothenate, folic acid, microcrystalline cellulose, magnesium stearate and coating powder are used as main raw materials and auxiliary materials. The preparation method comprises the following technological steps of screening the raw materials, performing weighing, performing mixing, making soft materials, performing granulation, performing drying, separating granules, performing whole mixing, performing tabletting, performing coating, performing selecting, performing packaging and the like. The preparation method is a novel tablet preparing technology. According to the vitamin B tablets, the compatibility of a new formula is adopted, all elements are reasonable in compounding ratio and mutually have extremely important synergistic effects, and the absorption and the utilization of nutrients are facilitated; besides, the invention discloses a new preparation method in accordance with the new formula, and the vitamin B tablets prepared by the new preparation method are high in quality, high in efficiency, and environmentally-friendly and pollution-free in preparation process.

Owner:BRAVEIY BIOTECHNOLOGY (ANHUI) CO LTD

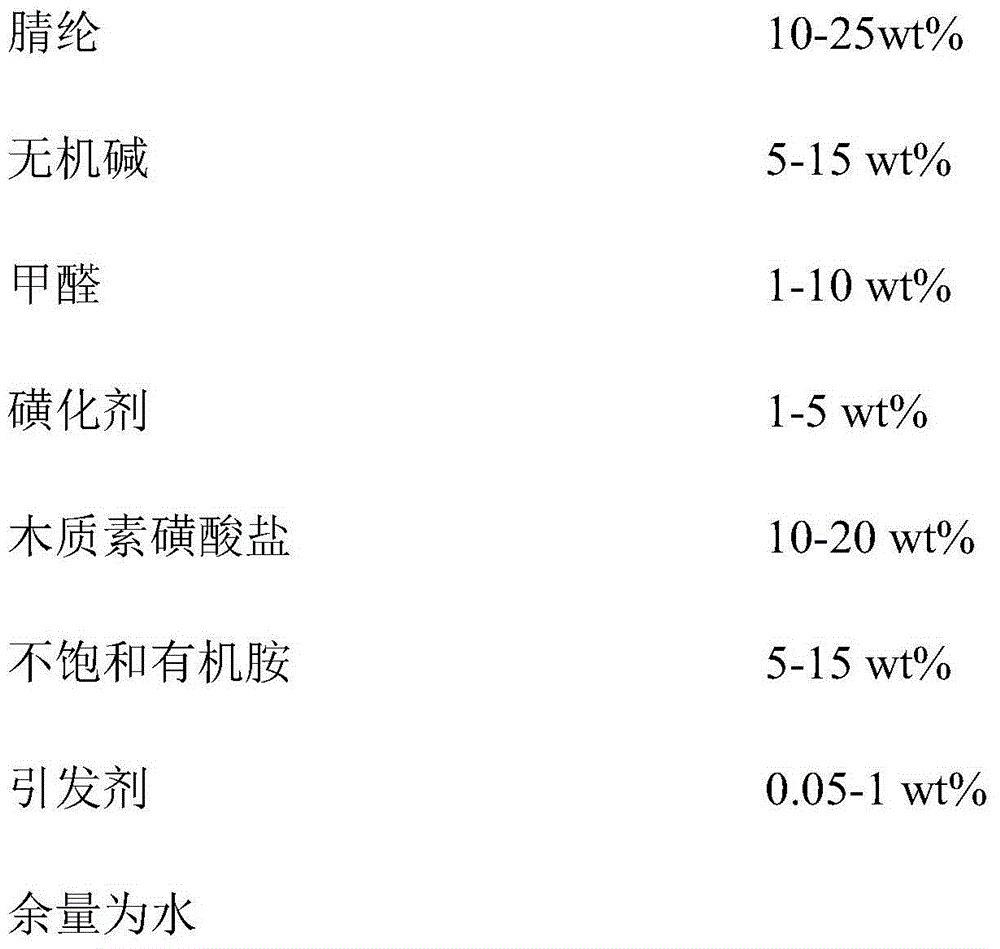

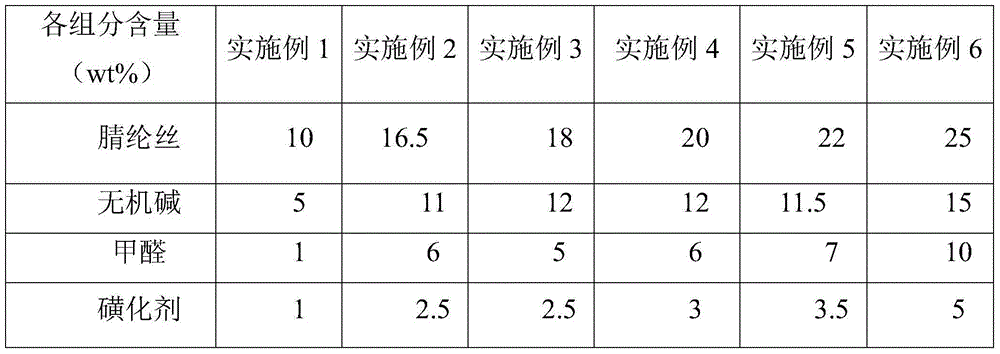

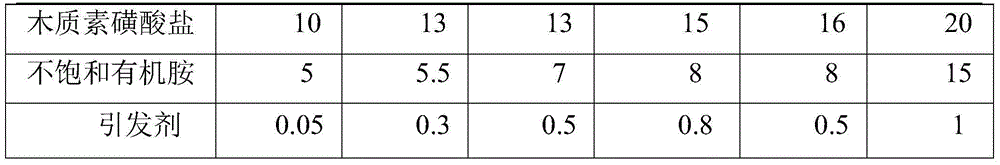

Concrete synergist and preparation method thereof

The invention discloses a concrete synergist and a preparation method thereof. The acrylic fibers in the textile industry are used as the main raw material for preparing the concrete synergist; the concrete synergist prepared by the method is able to improve the strength grade of concrete, about 10% cement of the concrete can be saved, and meanwhile, the working performance and strength of the concrete can be ensured, and the production cost is decreased; the acrylic fibers serving as the main material for preparing the concrete synergist can be waste acrylic fibers obtained from acrylic fibers production and processing or other plants using acrylic fibers as the main raw materials. The method for preparing the concrete synergist has the advantages that the waste acrylic fibers are effectively utilized, so that the environmental burden caused by the waste acrylic fibers can be decreased, and a good application prospect is brought; the concrete synergist aims at improving concrete performances.

Owner:郝旭晖

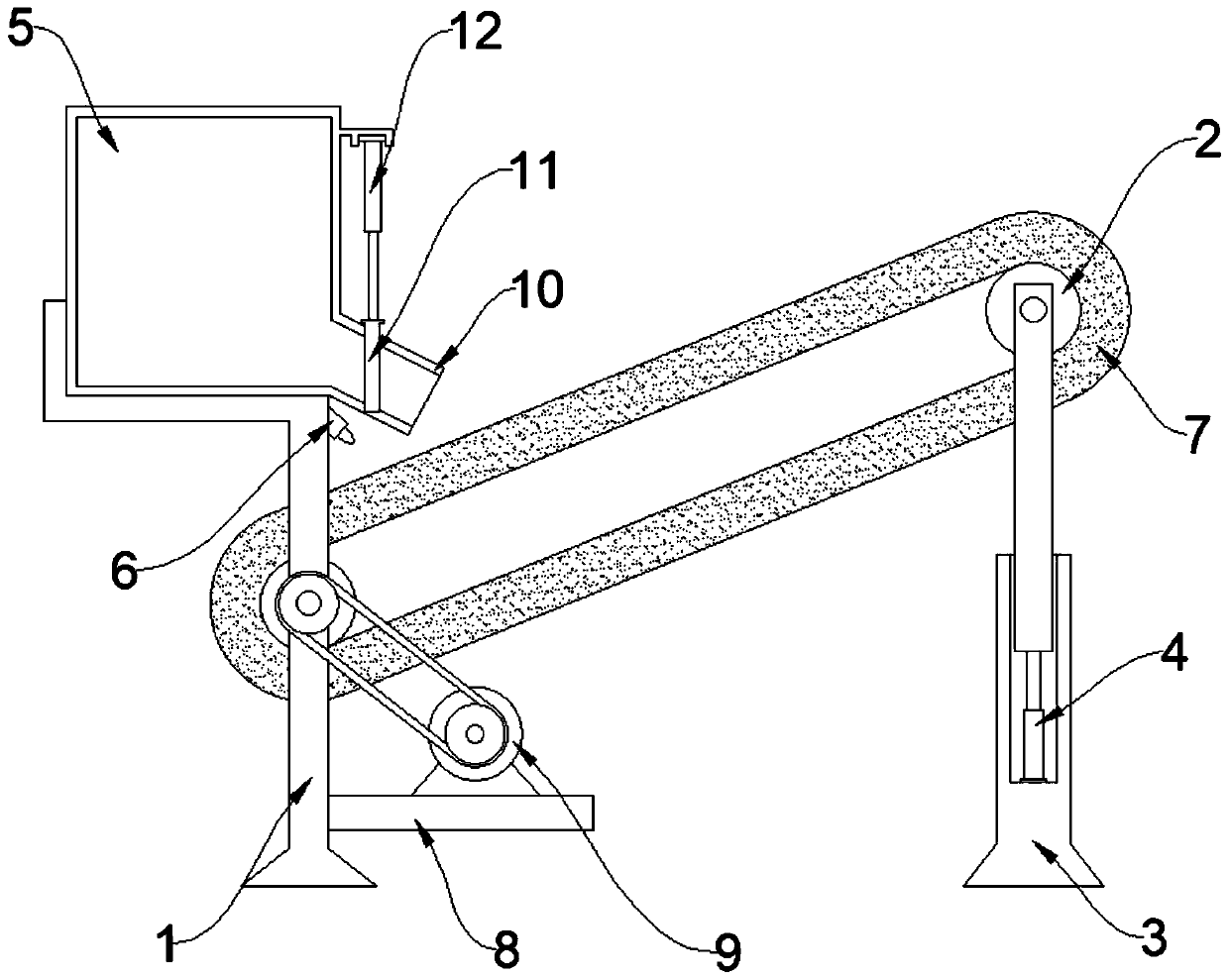

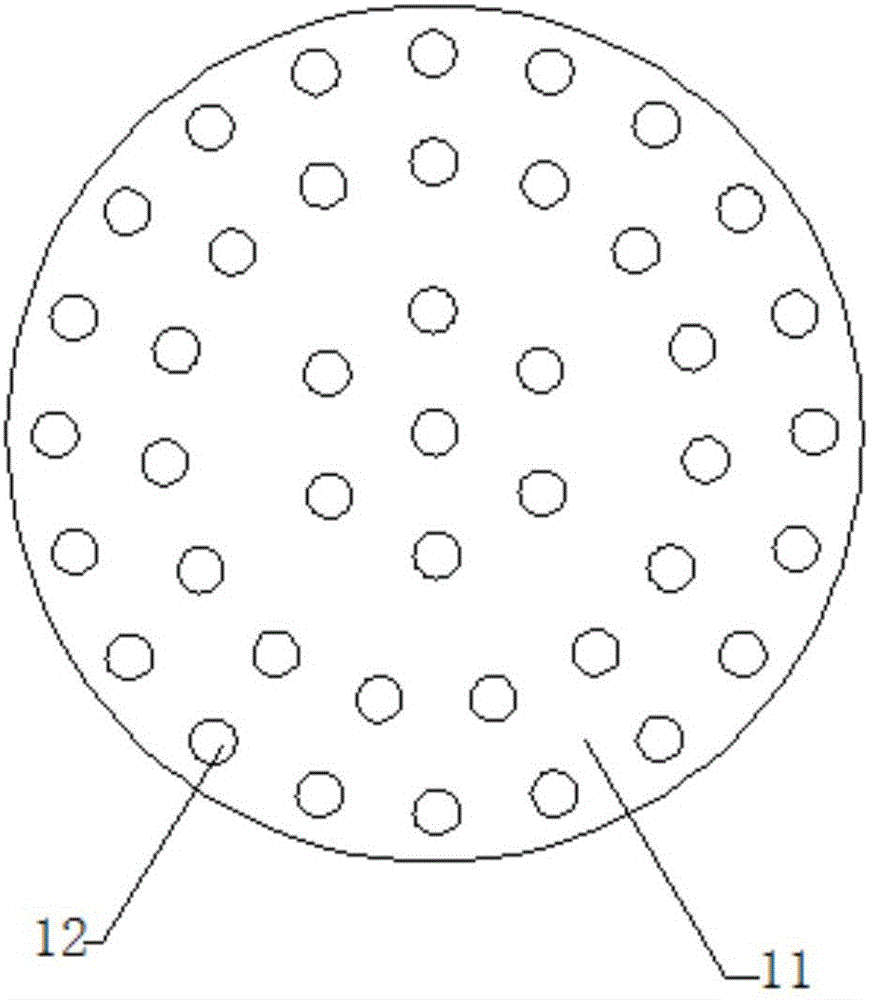

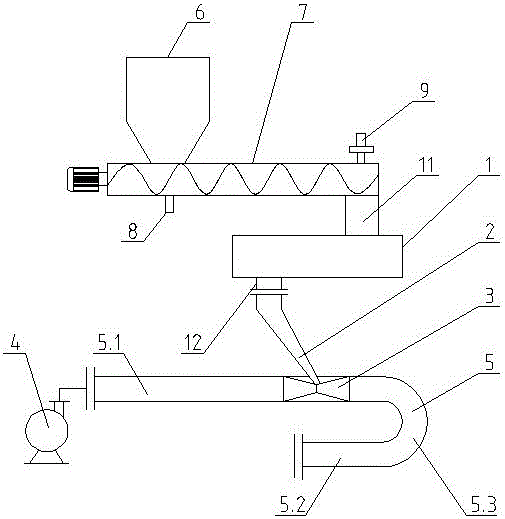

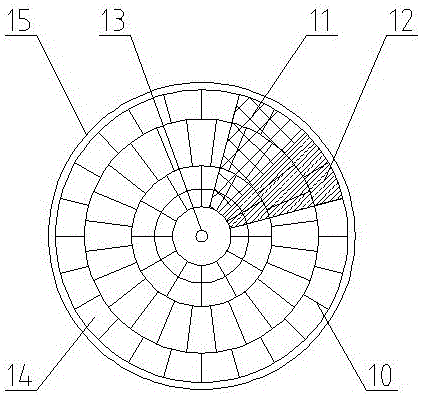

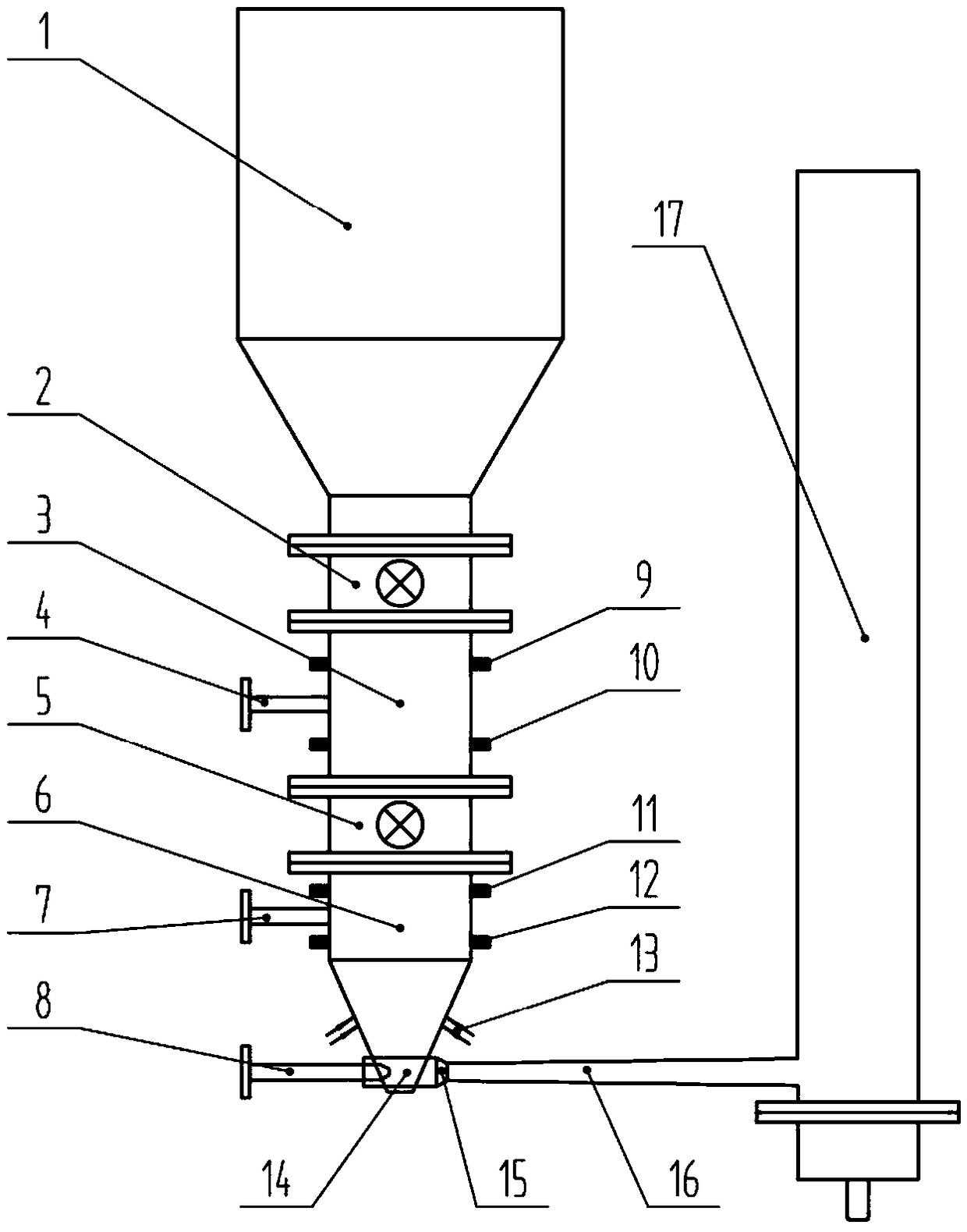

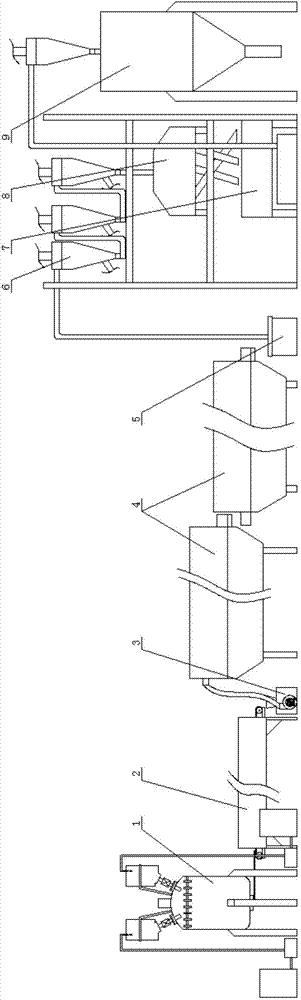

Coal powder feeding device

ActiveCN106185368ASmooth feedingEasy to control feedingBulk conveyorsLoading/unloadingMechanical engineeringCoal

The invention relates to a coal powder feeding device. The coal powder feeding device comprises a bin (6), a rotor type speed regulation feeder (1) and a rotary air pipe (5) which are arranged sequentially from top to bottom. The top of the rotor type speed regulation feeder (1) and the bottom of the bin (6) are connected through an inlet connection pipe (11). The bottom of the rotor type speed regulation feeder (1) and the rotary air pipe (5) are connected through an outlet connection pipe (12). The rotary air pipe (5) comprises a first horizontal pipe segment (5.1), a second horizontal pipe segment (5.2) and a connection bent pipe segment (5.3). A Roots blower (4) is connected to one end of the first horizontal pipe segment (5.1). Venturi equipment (3) is arranged in the other end of the first horizontal pipe segment (5.1). The lower end of the outlet connection pipe (12) is connected with the venturi equipment (3) through a blanking device (2). Through the coal powder feeding device, the effect that blocking does not occur to coal powder can be ensured, continuous and stable feeding can also be achieved, and the powder feeding quantity is adjusted according to the boiler load tendency.

Owner:JIANGSU SHUANGLIANG BOILER

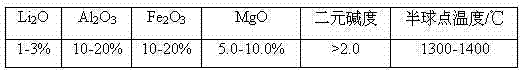

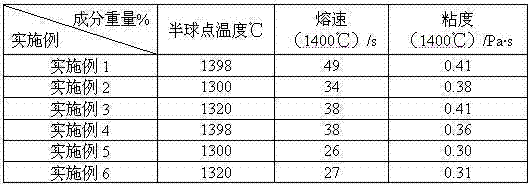

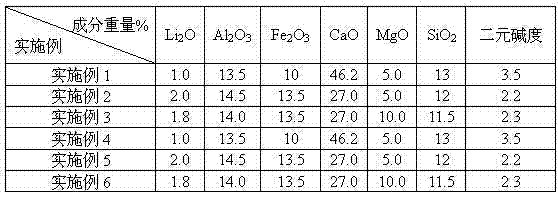

Fluoride-free slagging flux for electric-arc furnace steelmaking

The invention belongs to the technical field of iron and steel smelting and particularly relates to a fluoride-free slagging flux for the electric-arc furnace steelmaking and a preparation method thereof. The invention aims to provide the fluoride-free slagging flux for the electric-arc furnace steelmaking and the preparation method thereof and solve various problems of low slagging speed, poor slag melting effect, fluorine pollution, high cost, serious corrosion of a furnace lining, large dust capacity and the like which are generated due to the case that currently, lime, fluorite, calcium aluminate and iron oxide are used as slags. The fluoride-free slagging flux is characterized by being prepared from the following raw materials in percentage by weight: 20 to 40 percent of spodumene, 15 to 20 percent of red bauxite, 30 to 50 percent of active lime, 5 to 10 percent of iron oxide and 5 to 10 percent of magnesia.

Owner:JIANGSU UNIV

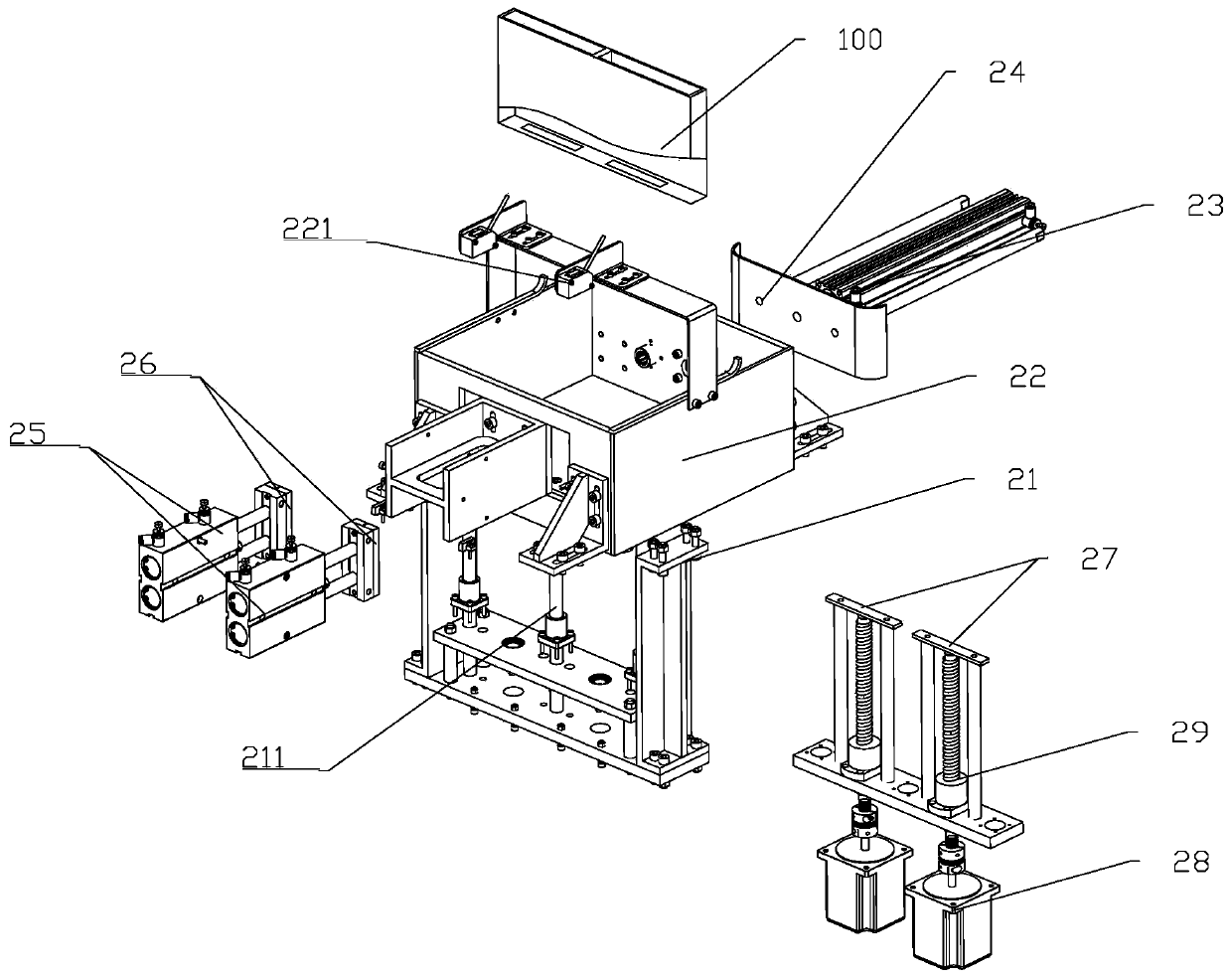

Cell feeding device of solar cell welding machine

ActiveCN111168188AIncrease capacityEasy to unloadFinal product manufactureWelding/cutting auxillary devicesDC - Direct currentElectrical battery

The invention relates to solar cell production equipment. A cell feeding device of a solar cell welding machine comprises a bottom frame, a material frame, a material pushing cylinder, a material pushing plate, a positioning cylinder, a positioning plate, a lifting frame, a direct current motor and a lead screw assembly; the material frame is fixedly arranged on the bottom frame; the bottom frameis fixedly arranged on a frame; the lifting frame is movably matched with the bottom frame; the direct current motor and the lead screw assembly are arranged on the bottom frame; the direct current motor is connected with an input end of the lead screw assembly; an output end of the lead screw assembly is connected with the lifting frame; the material pushing plate is movably connected in the material frame; the positioning cylinder is arranged on the side of the material frame; and a telescopic end of the positioning cylinder is connected with the material pushing plate. According to the solar cell production equipment, cell pieces are stacked in solar boxes, and multiple solar boxes are stacked, so that the capacity of the solar cells is greatly improved, and the empty solar boxes can return materials automatically.

Owner:润达光伏盐城有限公司

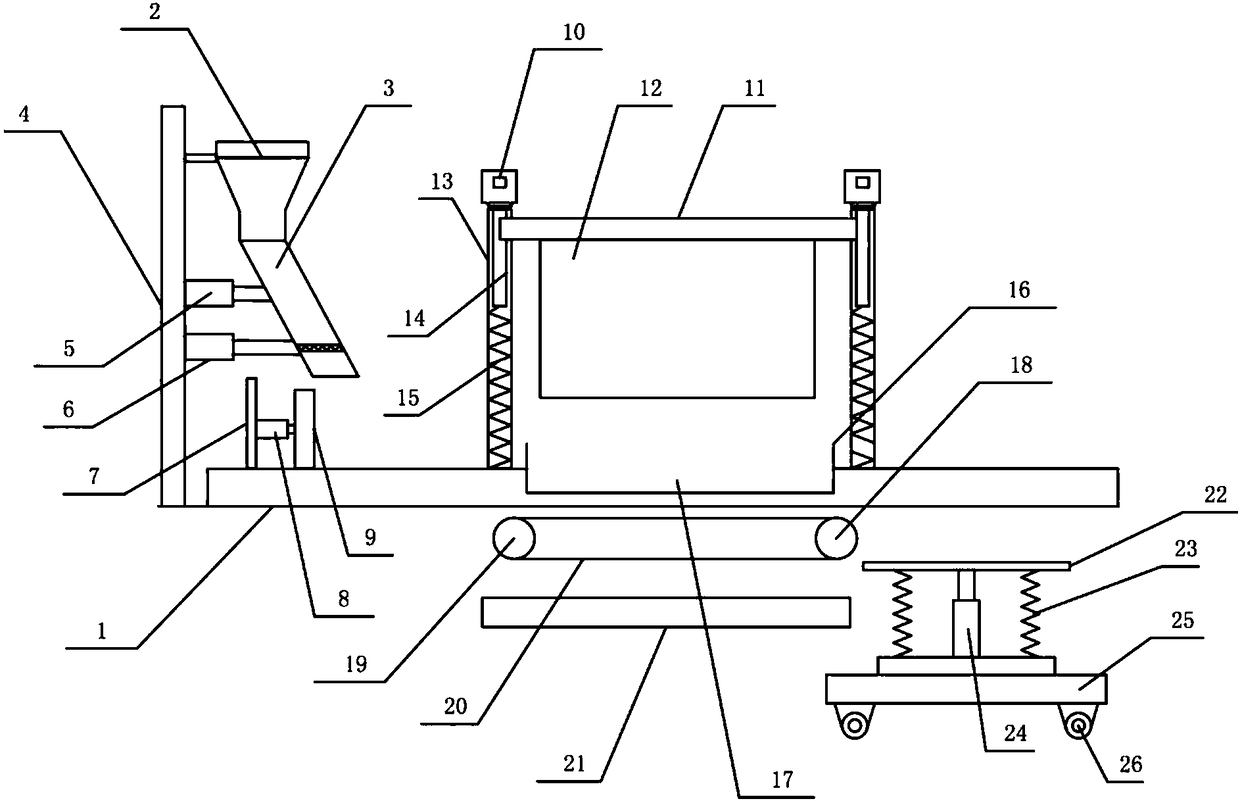

Device for performing lifting concrete pouring on building wall faces

InactiveCN107558736AEasy to useEasy to control feedingBuilding material handlingBraced frameEngineering

The invention discloses a device for performing lifting concrete pouring on building wall faces. The device comprises a bar-shaped support frame and is characterized in that a plurality of L-shaped fixing plates are embedded into the lateral surface of the bar-shaped support frame, a bar-shaped bearing tank which is in lap joint with the inner surface of the bar-shaped frame is arranged on the lower surfaces of the L-shaped fixing plates, two groups of support standing columns are fixedly connected to the lower surface of the bar-shaped bearing tank, and a fixing rack which is in lap joint with the lower surface of the bar-shaped support rack is fixedly connected to the lower surface of the support standing columns. The device is convenient to use, convenient in discharge control, capableof relieving labor intensity, even in discharge, capable of increasing work efficiency and capable of conveniently adapting to the wall faces of different heights.

Owner:邰学兰

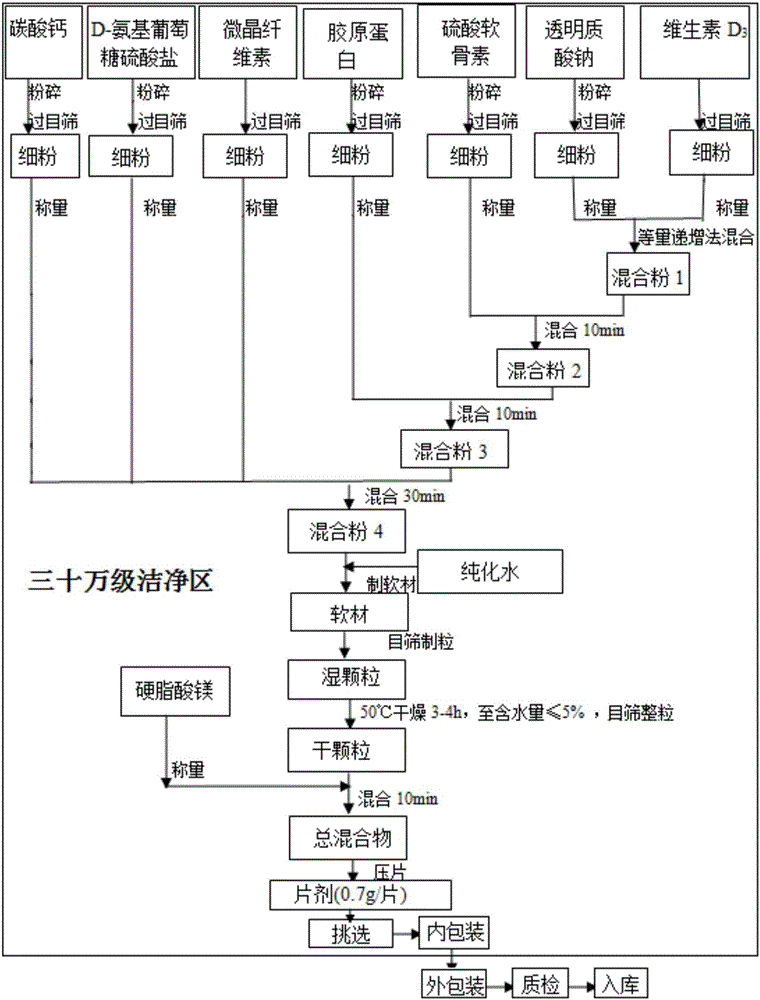

Tablets capable of increasing bone density and preparation method of tablets

The invention discloses tablets capable of increasing bone density and a preparation method of the tablets. Every 1000 tablets contain raw materials including 210-220g of calcium carbonate, 190-200g of D-glucosamine sulfate, 20-30g of chondroitin sulfate, 80-85g of collagen, 0.10-0.20g of vitamin D3 and 3-8g of sodium hyaluronate, and auxiliary materials including 160-165g of microcrystalline cellulose and 5-10g of magnesium stearate. The preparation method comprises the following technological steps of crushing the raw materials and the auxiliary materials, performing screening, performing weighing, performing mixing, making soft materials, performing granulation, performing drying, performing size stabilization, performing integral mixing, performing tabletting, performing selection, performing packaging and the like. According to the tablets and the preparation method thereof disclosed by the invention, the D-glucosamine sulfate, the chondroitin sulfate, the collagen, the vitamin D3 and the sodium hyaluronate are used as main raw materials, the technology is simple, and the industrial production is facilitated; in addition, the dosage is accurate, the quality is stable, the tablets conform to the hygienic standard, the appearances of the tablets are clean and beautiful, the tablets are easy to accept by consumers, and the tablets are convenient to carry and transport.

Owner:XUANCHENG BRAVEIY BIOENG

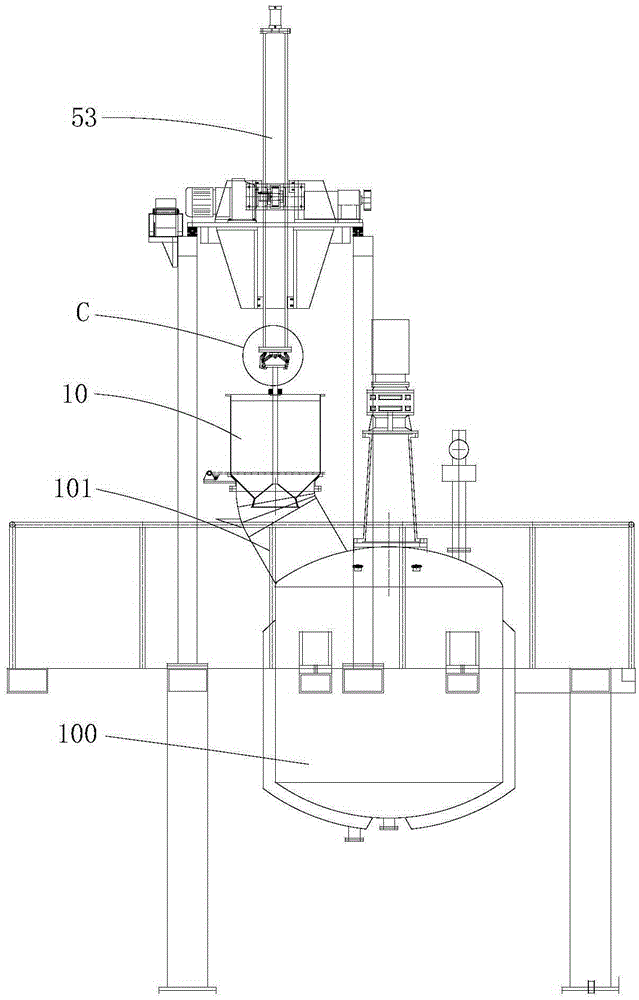

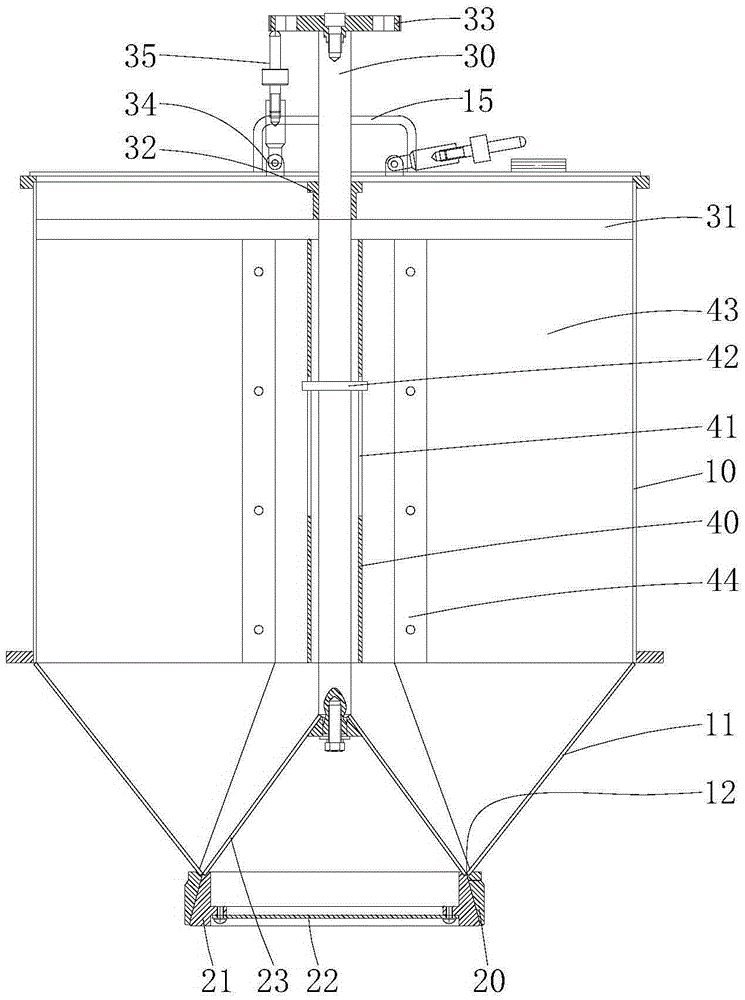

Feeding device for reaction vessel

The invention discloses a feeding device for a reaction vessel. The feeding device comprises a material storage vessel, a valve mechanism, a connecting rod and a driving mechanism; the material storage vessel is provided with an opening end and a material output port; the valve mechanism performs opening and closing control on the material output port and is arranged at the material output port; the connecting rod drives the valve mechanism to be opened and closed, at least one part of the connecting rod is located in the material storage vessel, and one end of the connecting rod is connected with the valve mechanism; the driving mechanism enables the connecting rod to do rising and falling and / or rotating actions and is connected with the other end of the connecting rod or connected with the other end of the connecting rod in a work state and separated from the connecting rod in a non-work state. The feeding device has the advantages of being high in automation degree, capable of conveniently feeding materials, low in labor intensity, high in efficiency, capable of conveniently controlling the feeding amount, safe and reliable.

Owner:常州君合表面涂覆工程有限公司

Modified wash oil coal water slurry additive and preparing method thereof

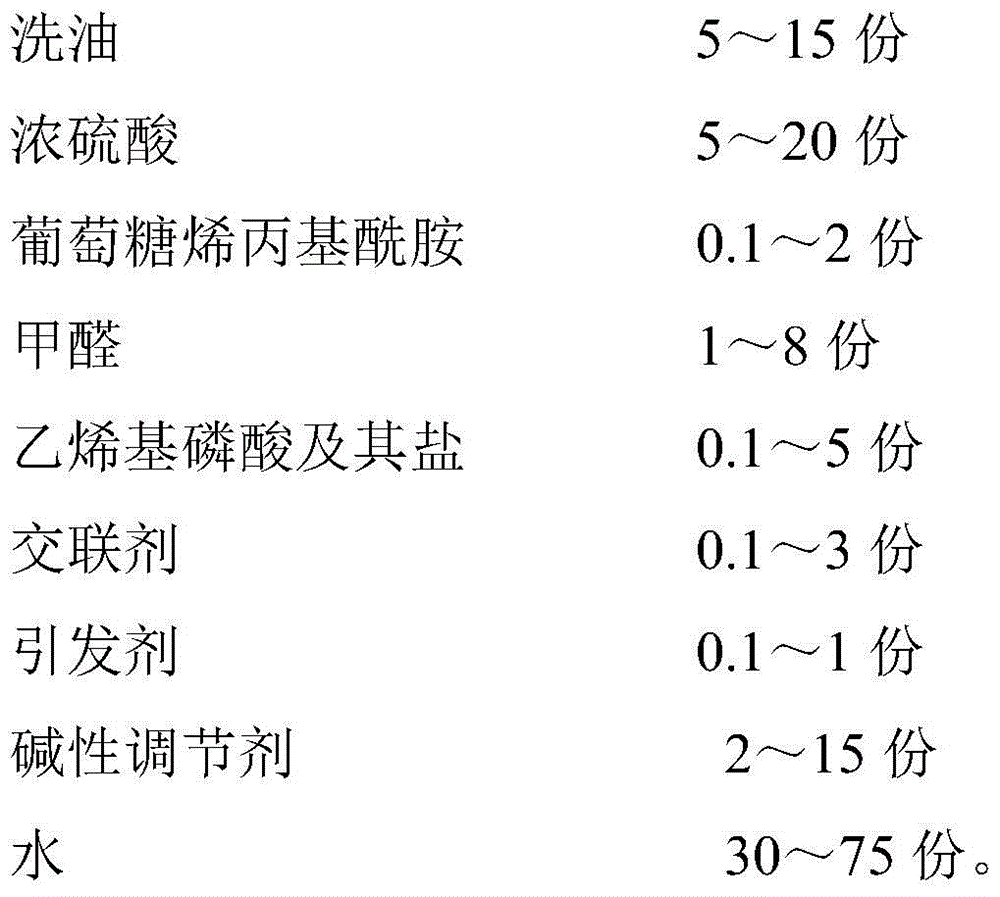

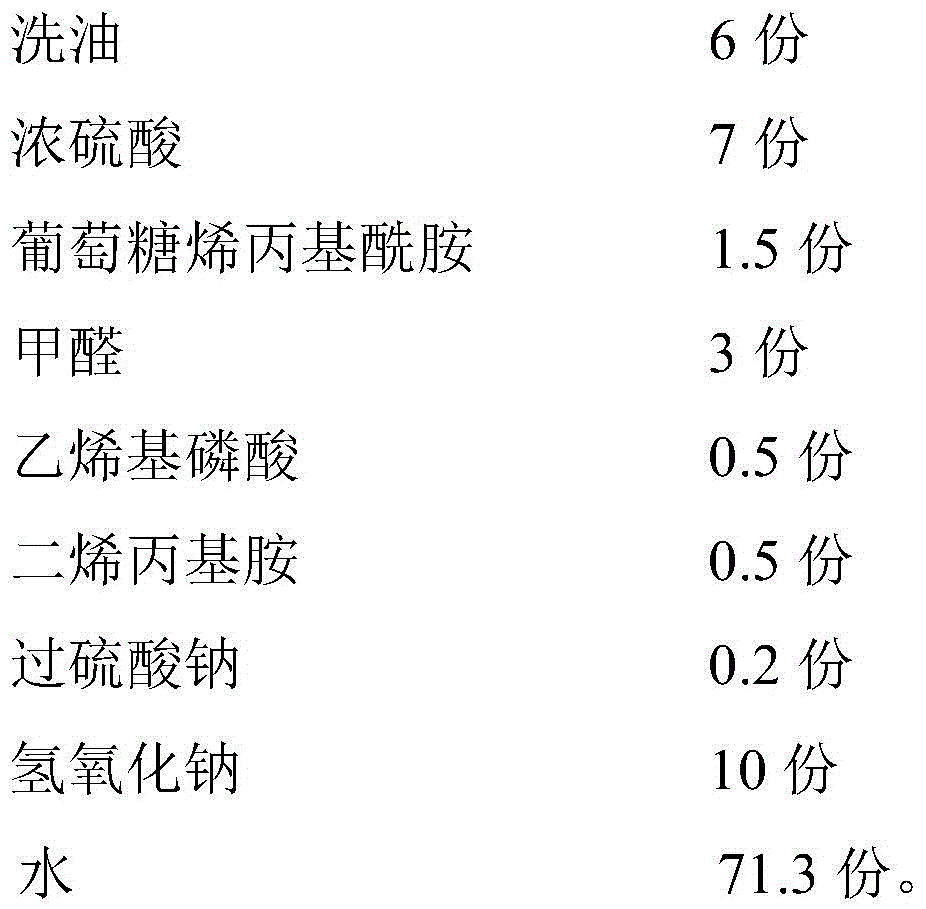

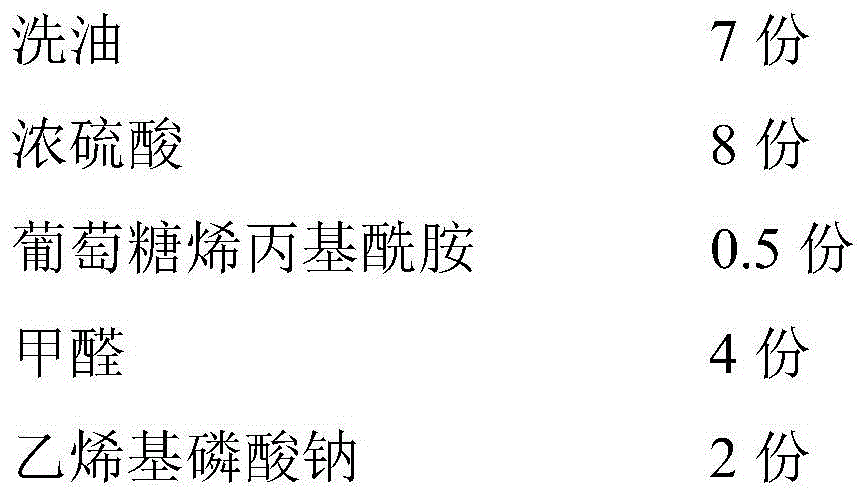

The invention provides a modified wash oil coal water slurry additive and a preparing method thereof. According to the method, wash oil serves as a starting raw material, and is subjected to a sulfonation reaction with concentrated sulfuric acid, and then subjected to concentration polymerization with glucose allyl amide and formaldehyde under a certain technology condition, after the reaction is finished, under existence of an initiator, the product is subjected to a polymerization reaction with vinyl phosphoric acid, salt of vinyl phosphoric acid and a cross-linking agent, finally an alkaline conditioning agent is added for carrying out neutralization, and the product is cooled and discharged to obtain the modified wash oil coal water slurry additive. The coal water slurry additive product contains multiple functional groups such as a glucosyl group, a phosphate group, an amide group and a sulfo group and has the advantages of being small in mixing amount, excellent in dispersity, high in stability and the like.

Owner:桐乡市腾飞家纺股份有限公司

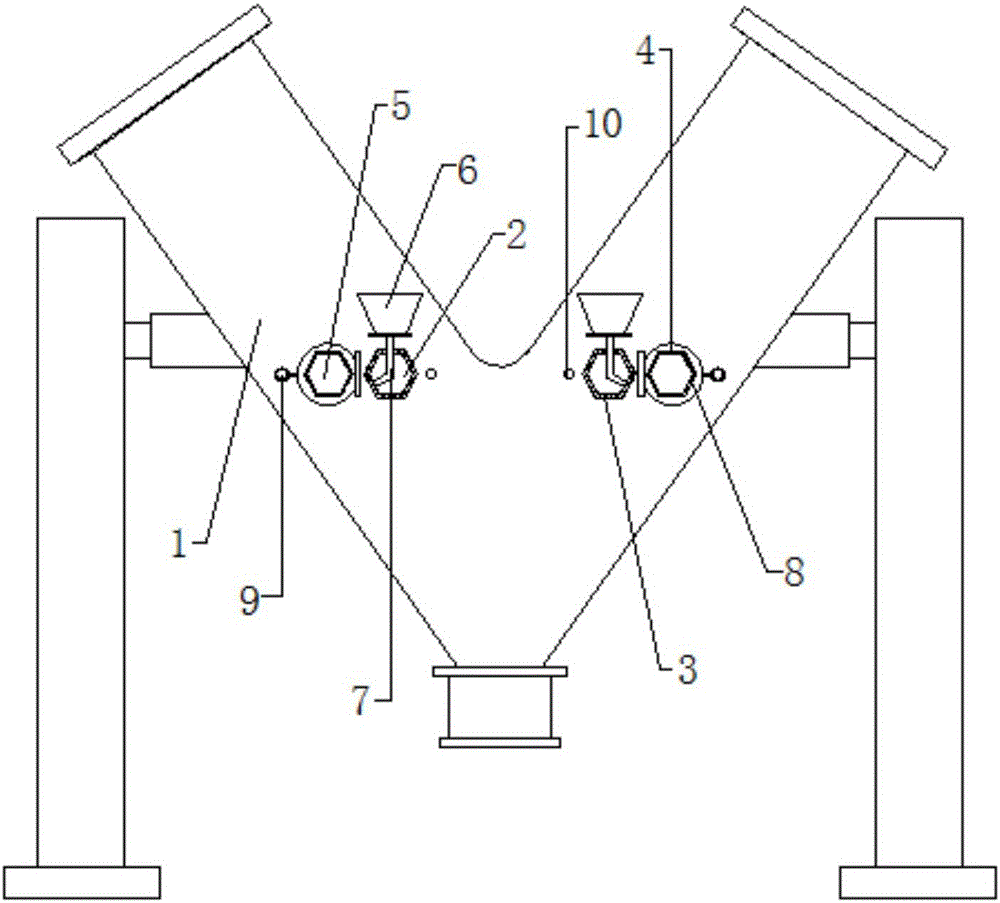

Low temperature sterilization equipment and method thereof

InactiveCN103990157AGood sterilization effectReduce the negative effects of thermal effectsFood preservationRadiationEngineeringRadiation

The invention discloses low temperature sterilization equipment and a method thereof. The equipment contains a microwave machine which is provided with a microwave cavity for generating a sterilization microwave radiation source. The sterilization equipment also comprises a container arranged inside the microwave cavity. The container is equipped with a feed inlet and a discharge port. An interlayer is disposed outside the container. The interlayer is provided with a fluid inlet and a fluid outlet. A fluid is arranged in the interlayer. The fluid is a mixed liquid containing microwave absorbing material. The method contains the following steps: a material enters the container arranged in the microwave cavity from the feed inlet; the mixed liquid containing the microwave absorbing material is guided into the interlayer through the fluid inlet to form an external wave-absorbing layer of a sterilized material, and temperature control can be carried out through the fluid; The microwave radiation acts on the wave absorbing layer and a material layer; the mixed liquid of the wave absorbing layer also absorbs part of heat energy of the sterilized material so as to adjust thickness of the material layer as well as material temperature; and the material is discharged out of the discharge port of the container after sterilization.

Owner:上海绿昂生物科技有限公司

Automatic melon and fruit slicer

InactiveCN108214584AEliminate inefficienciesImprove work quality and efficiencyMetal working apparatusPneumatic cylinderEngineering

The invention discloses an automatic melon and fruit slicer. The automatic melon and fruit slicer comprises a rack, a melon and fruit feeding device, a melon and fruit pushing device, a slicing deviceand a cut slice discharging device. The melon and fruit feeding device comprises a hopper, a charging barrel, a first pneumatic cylinder and a second pneumatic cylinder. The melon and fruit pushing device comprises a first hydraulic cylinder fixing plate, a first hydraulic cylinder and a push plate. The slicing device comprises a stamping plate and a combined cutter holder. The stamping plate isconnected with a stamping plate bracket. The stamping plate bracket is slidably connected to stand columns. Each stand column is provided with a sliding groove and a return spring. The stamping plateis provided with stamping plate grooves. The cut slice discharging device is provided with a conveyor belt device and an automatic discharge device. The automatic melon and fruit slicer controls feeding through the two cylinders, can fix the combined cutter holder to conduct cutting and conduct slicing on melons and fruits in an automatic discharging mode, achieves the effects that feeding is controllable, the slicing thickness is uniform and adjustable, cut slices are complete and beautiful are discharged automatically and improves the working efficiency.

Owner:青岛恒孚食品有限公司

Modification method for improving saline tolerance of acrylic acid macromolecule water uptake resin

InactiveCN101402702AImprove salt toleranceIncrease salt water absorption rateWater bathsAmmonium peroxydisulfate

The invention relates to a modification method for improving the salt tolerance of a crylic acid macromolecule absorbent resin. The modification method for improving the salt tolerance of the crylic acid macromolecule absorbent resin is characterized by comprising the following steps: 1) according to the parts of all component raw materials by weight as follows: 90 portions to 140 portions of n-hexane, 30 portions to 50 portions of coconut oil diethanolamide, 20 portions to 40 portions of crylic acid, 5 portions to 12 portions of sodium hydroxide, 3 portions to 15 portions of calcium chloride, 0.03 portion to 1 portion of N, N'- methylene bisacrylamide, 0.05 portion to 1 portion of ammonium peroxydisulfate and 32 portions to 100 portions of water, raw materials are selected; 2) water is respectively mixed with the sodium hydroxide and the calcium chloride so as to obtain sodium hydroxide solution and calcium chloride solution; and 3) all raw materials are added into a reaction kettle with a water bath, the water bath temperature is risen to 70 DEG C to 80 DEG C, the raw materials are stirred for 4 hours to 6 hours at the temperature for reaction, finally a reaction product is taken out; and after being dried, the reaction product is the modified crylic acid macromolecule absorbent resin. The method can evidently improve the salt tolerance of the crylic acid macromolecule absorbent resin and has low production cost.

Owner:WUHAN UNIV OF TECH

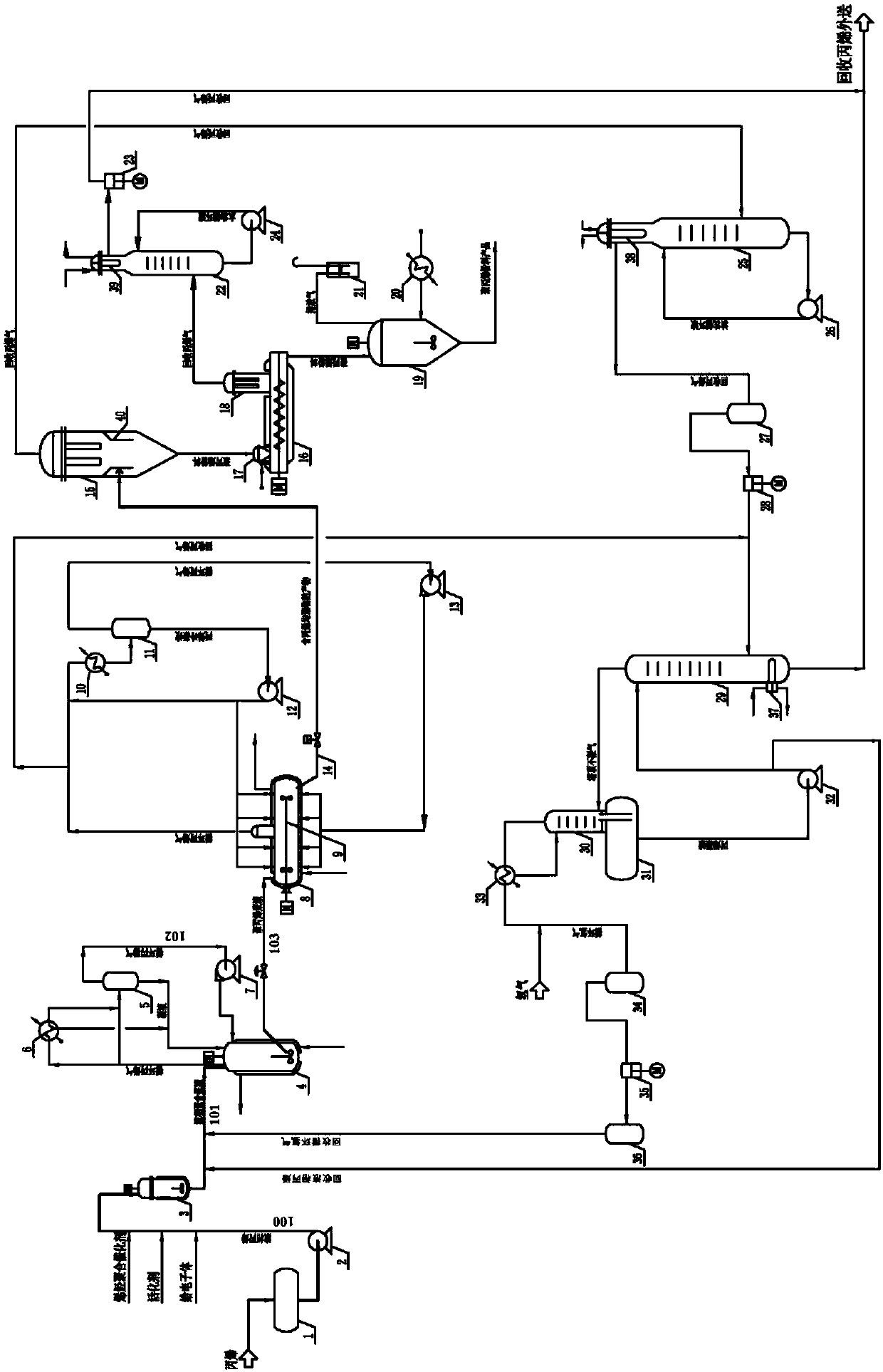

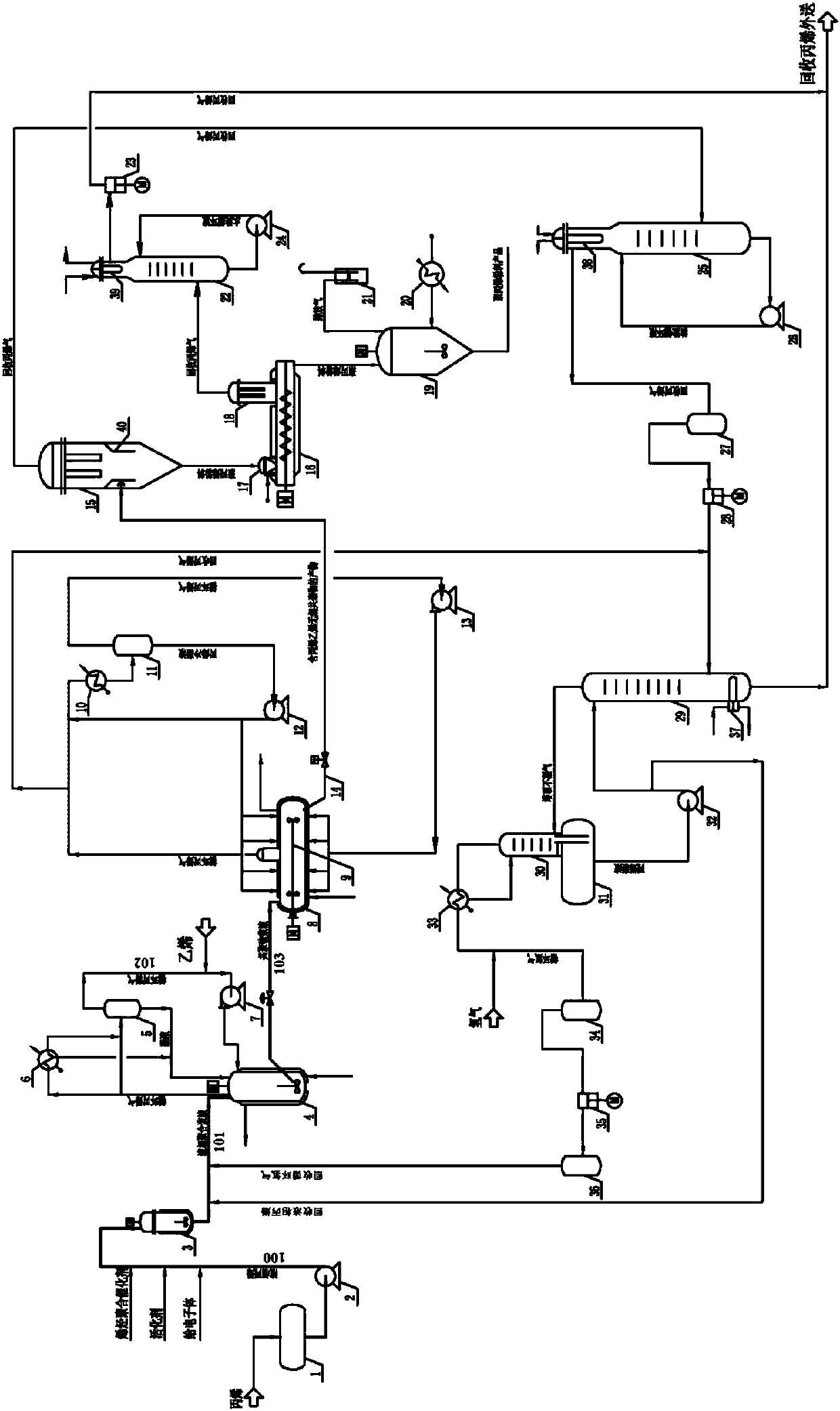

Polypropylene or propylene-ethylene copolymer preparation method

The invention relates to the field of propylene homopolymerisation or random copolymerization and discloses a polypropylene or propylene-ethylene copolymer preparation method. The preparation method comprises the steps: (1) performing propylene prepolymerization on liquid-phase propylene carrying a polymerization catalyst to obtain raw material slurry containing propylene prepolymer, wherein a prepolymerization temperature is 40 to 45 DEG C, prepolymerization pressure is 3.2 to 3.9 MPaG, and the olefin polymerization catalyst is 0.04 to 0.06 weight% of the liquid-phase propylene; (2) mixing the raw material slurry, recycled liquid-phase propylene and recycled circulation hydrogen into a liquid-phase polymerization raw material; (3a) performing propylene liquid-phase homopolymerization andpropylene gas-phase homopolymerization on the liquid-phase polymerization raw material to obtain a product containing propylene homopolymer; or (3b) performing liquid-phase random copolymerization andgas-phase random copolymerization on the liquid-phase polymerization raw material and ethylene to obtain a product containing propylene ethylene random copolymer and performing gas-solid separation on the product to separate polymer out and recycle propylene and hydrogen, wherein the ethylene feeding quantity is 5 weight% or less of the liquid-phase propylene. The method can reduce unit product energy consumption and propylene loss in propylene polymerization.

Owner:BEIJING HUAFU ENG

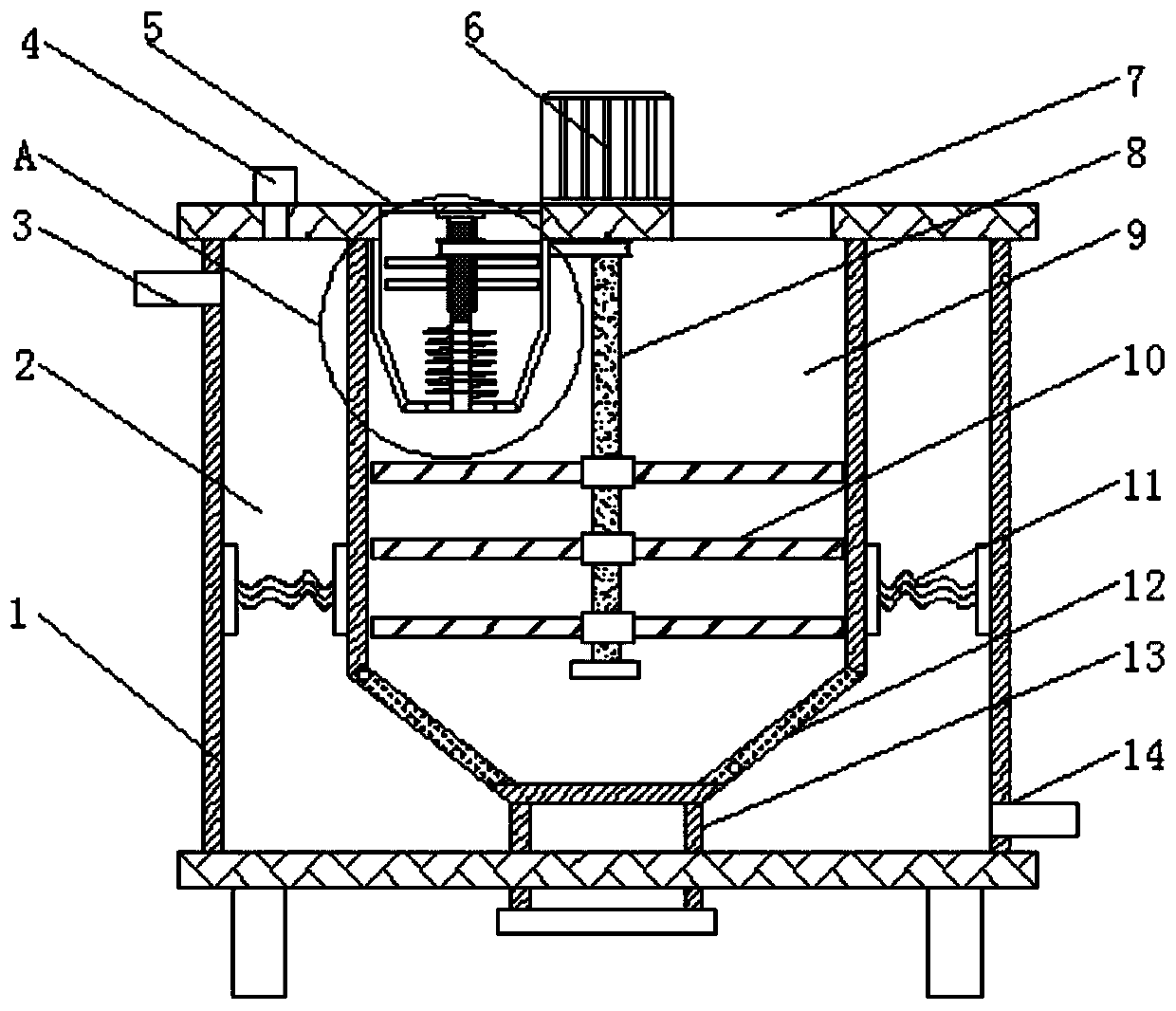

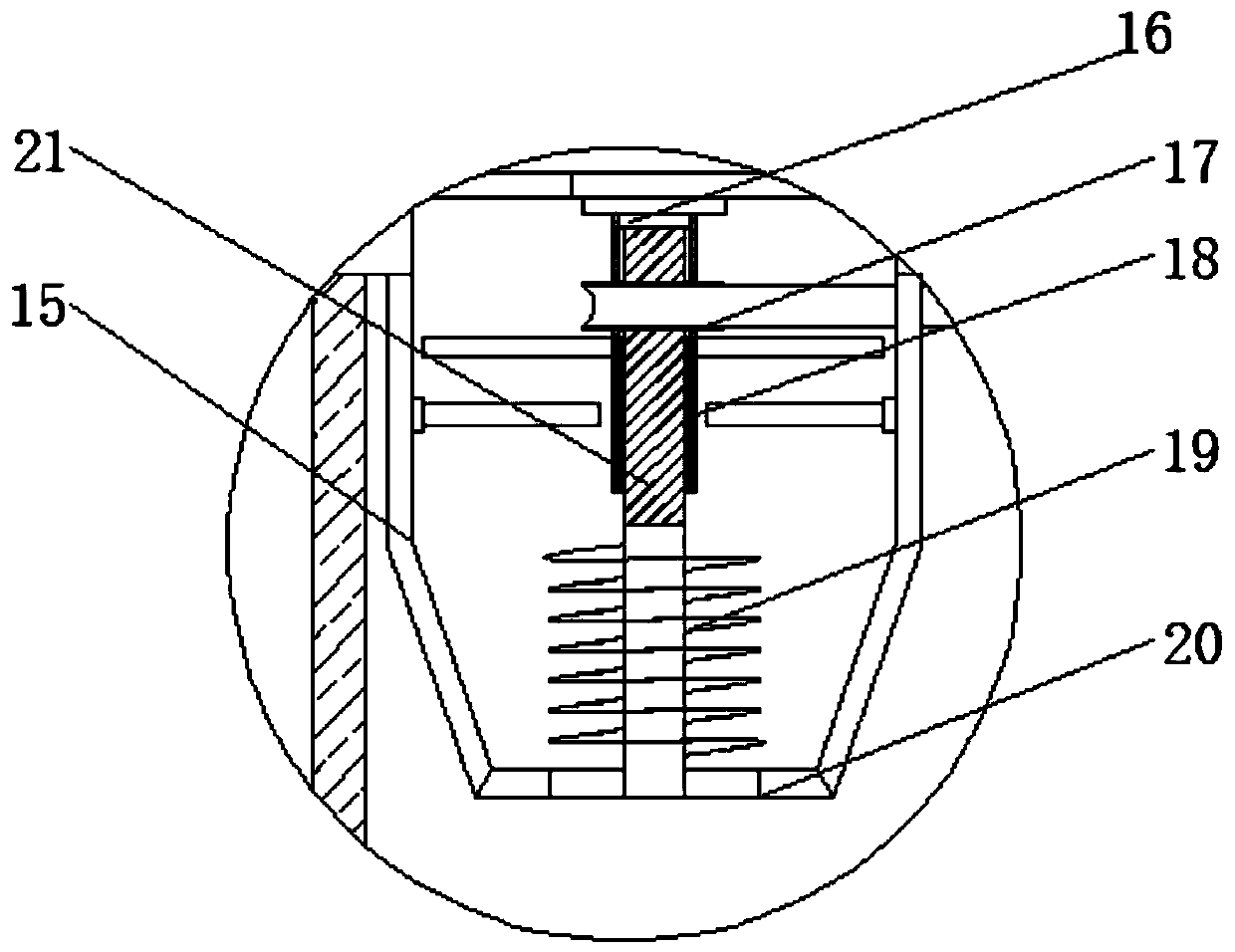

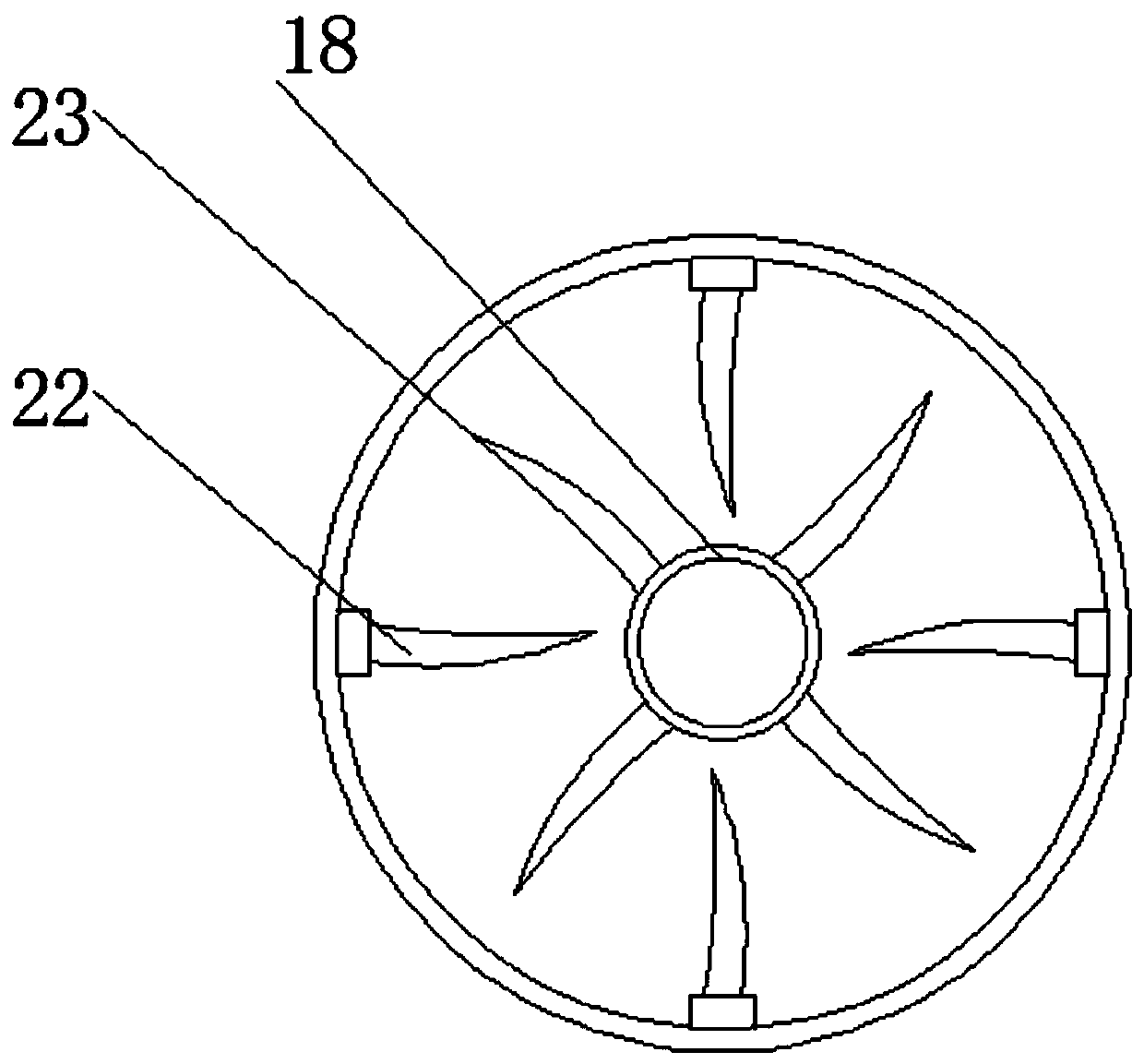

Rapid organic fertilizer reaction kettle

PendingCN110218131AEasy to control feedingEasy to control the fallChemical/physical/physico-chemical stationary reactorsOrganic fertilisersEngineeringReaction speed

The invention discloses a rapid organic fertilizer reaction kettle which comprises a device main body, wherein support blocks are mounted on both sides of the lower end of the device main body; heating cabins are formed inside the device main body; a reaction stirring cabin is formed in the middle inside the heating cabin; a rotating shaft is moveably mounted in the middle inside the reaction stirring cabin; the upper end of the rotating shaft is positioned outside the device main body; at least three pairs of stirring racks are fixedly mounted on the surface of the rotating shaft; the stirring racks are in horizontal symmetric distribution on the surface of the rotating shaft; a discharge tube is arranged at the lower end of the reaction stirring cabin; one end of the discharge tube is positioned in the middle of the lower end of the device main body; guide plates are mounted on both sides of the upper end of the discharge tube; and a crushing cabin is formed in one side of the upperend inside the reaction stirring cabin. Due to adoption of a series of structures, the device has the characteristic of being rapid in reaction speed.

Owner:南通惠农生物有机肥有限公司

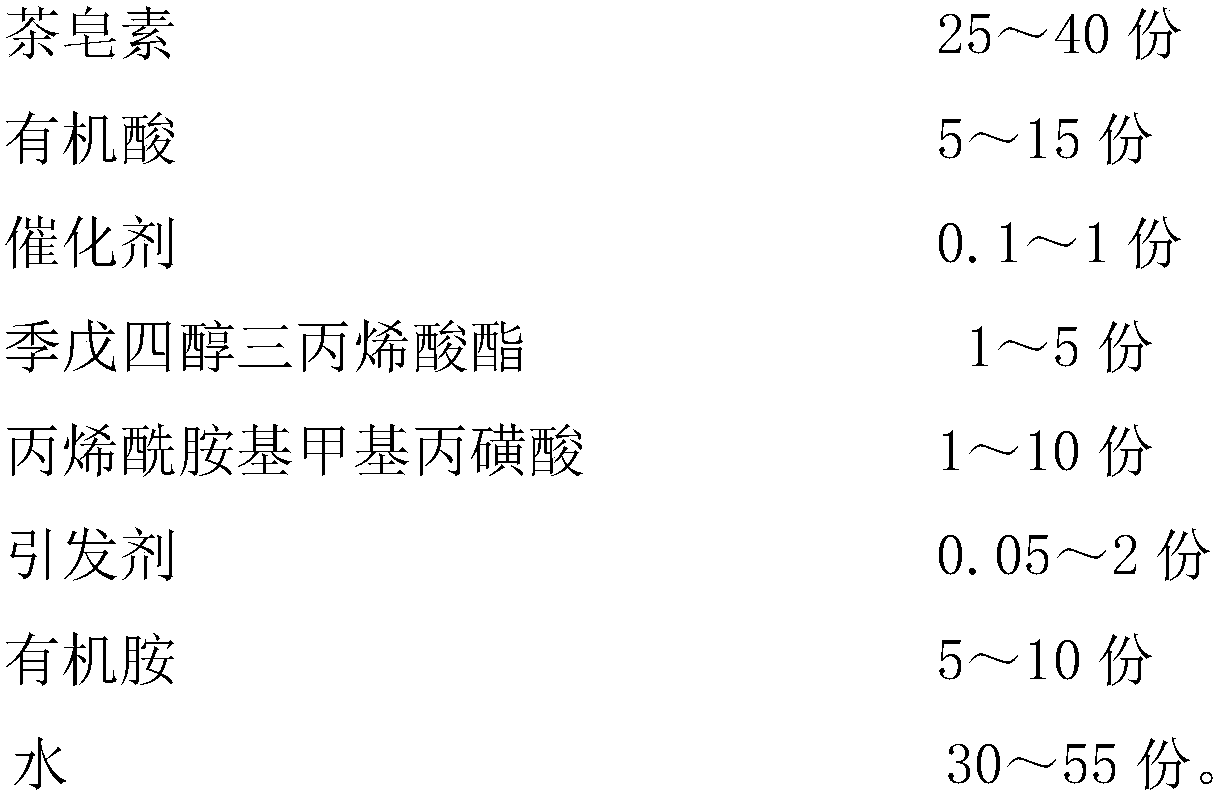

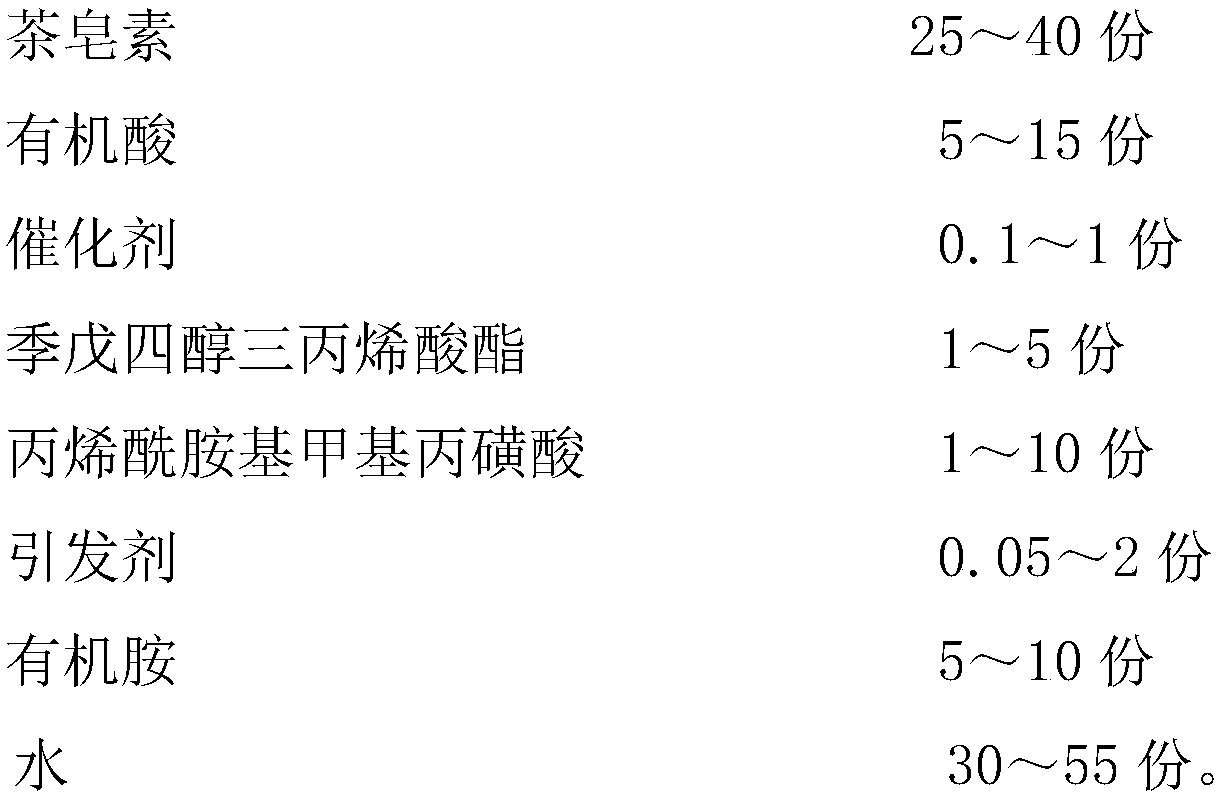

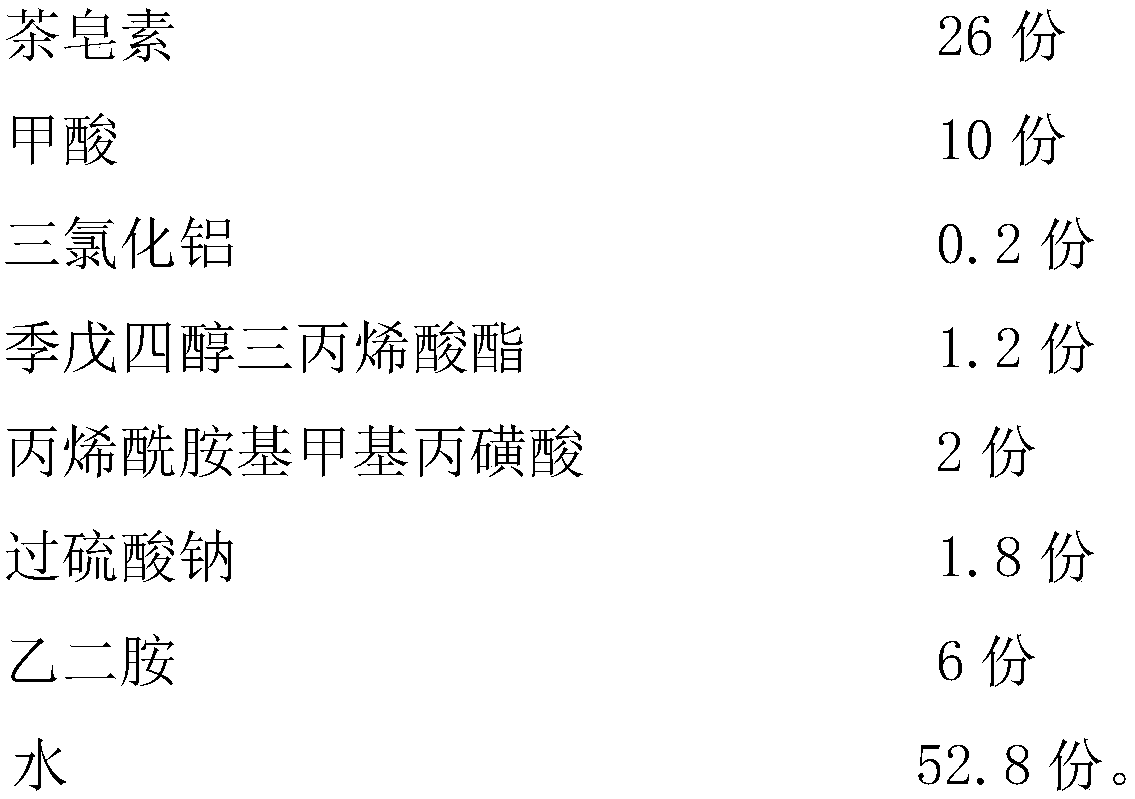

Concrete synergist containing sulfonic acid group and preparation method thereof

The invention provides a concrete synergist containing a sulfonic acid group and a preparation method thereof. The preparation method comprises the following steps: (1) adding tea saponin, organic acid and a catalyst into a reaction tank; starting to stir and raising the temperature; after raising the temperature to 100 DEG C to 120 DEG C, reacting for 1 to 5h; (2) then adding water, pentaerythritol triacrylate and acrylamide methyl propane sulfonic acid into the reaction tank and stirring for 0.5 to 1h; (3) then dripping an initiator solution with the mass percent concentration of 1 to 10 percent, wherein the initiator solution is prepared from an initiator and part of the water; controlling the dripping time to 3 to 5h and controlling the dripping temperature to 90 to 100 DEG C; (4) after dripping, adding organic amine and continuously reacting for 0.5 to 2h; then cooling and discharging to obtain the concrete synergist.

Owner:李达峰

Cup swinging scale

InactiveCN104176287AHigh precisionIncrease work rateSolid materialProduction lineProcess engineering

The invention provides a cup swinging scale which comprises a coarse feed mechanism and a fine feed mechanism, wherein the coarse feed mechanism comprises coarse feed hoppers; coarse blanking components, weighing components and discharging components are correspondingly arranged below the outlets of the coarse feed hoppers; each coarse blanking component comprises a swinging cup; the swinging cup is connected to the outlet of the corresponding coarse feed hopper in a swinging manner and is communicated with a weighing hopper of the corresponding weighing component; a weighing sensor is arranged at the bottom of the weighing hopper; one side wall of the weighing hopper is open; the open side wall of the weighing hopper is in butted with a striker plate; the weighing hopper is connected to one side of the striker plate in a swinging manner; each discharging component comprises a material collection hopper which is arranged below the corresponding weighing hopper. The cup swinging scale is suitable for weighing light products such as powdered products and small granular products, is higher in weighing precision, and has the advantages that the work rate of a production line adopting the cup swinging scale for packaging is improved, and the blanking speed of a product is accelerated to accelerate the weighing speed.

Owner:天津奥特玛科技有限公司

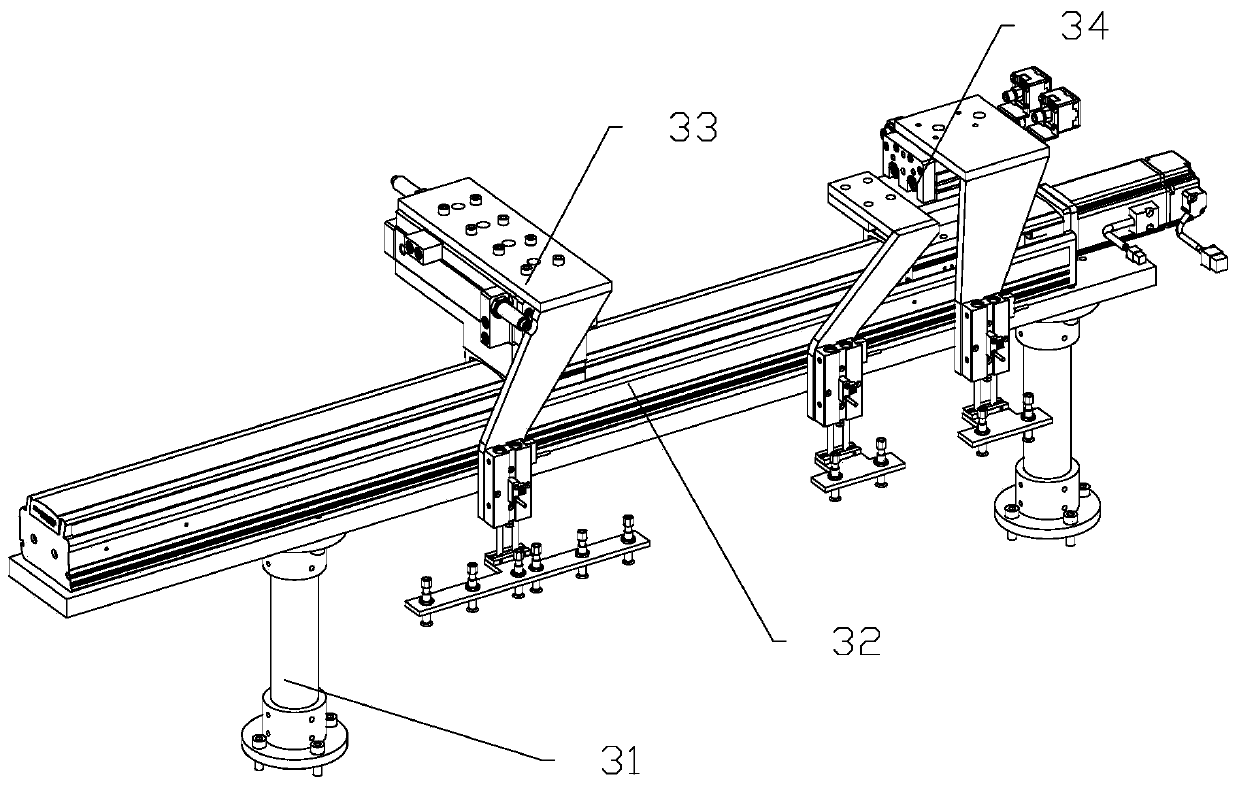

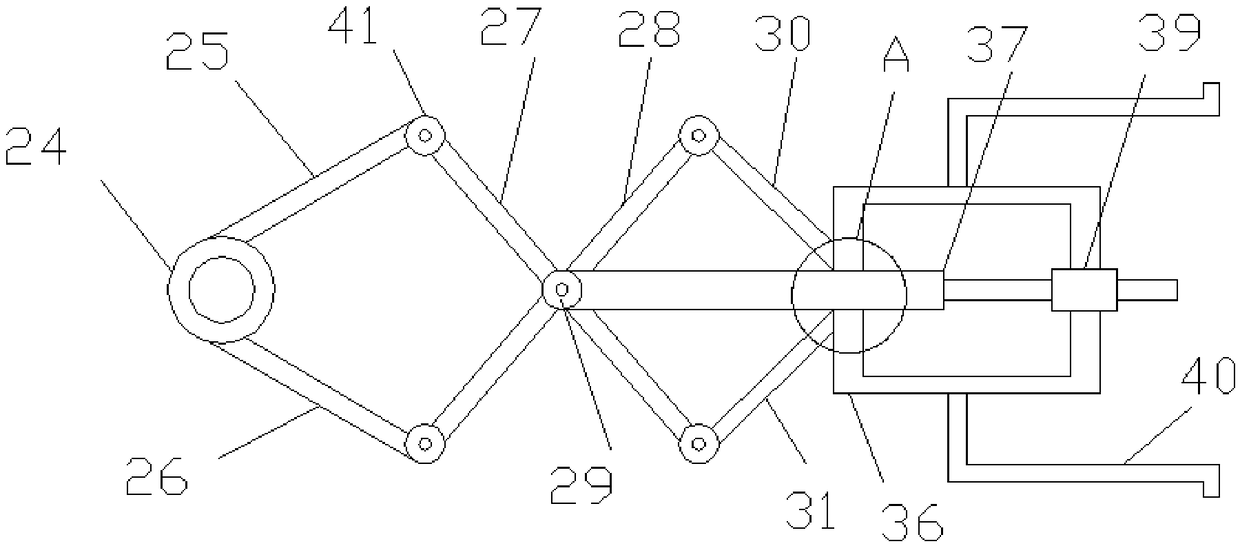

Voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking

ActiveCN109305564AThe feeding process is controllablePrevent blowbackBulk conveyorsAutomatic controlBiomass

The invention relates to a voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking, and belongs to the technical field of biomass thermal cracking. The voltagestabilization-continuous pneumatic conveying feeding system comprises a material transition bin, a conical pressure bin, a material receiving chamber and the like. A dual-material bin and a double butterfly valve design are adopted by the feeding system, so that the effects of pressure isolation, air locking and environment sealing are achieved, the feeding process is controllable, the phenomenonthat materials are reversely sprayed is avoided, and the reliability and the stability of the thermal cracking process are improved. A laser-photosensitive sensor and a PLC are used as an automatic control system, a two-stage electric butterfly valve is adopted as an execution component, and the materials automatically fall into the conical pressure bin from the material transition bin. Aerationair is added into the conical section of the conical pressure bin, and the materials in the conical pressure bin are fluidized, so that the phenomena of bridging, wall hanging and material bursting are avoided. Thermal cracking by-product non-condensable gas generated by biomass rapid thermal cracking which serves as spraying, pressurization and pressure maintaining gas is adopted by the feeding system, so that resources can be saved, self-powered energy is achieved, and pollution is avoided.

Owner:BEIJING FORESTRY UNIVERSITY

Grinding machine

InactiveCN109365087AIncrease profitImprove feeding efficiencyGrain treatmentsEngineeringMechanical engineering

The invention discloses a grinding machine including a grinding machine body. The bottom of the grinding machine body is provided with a support frame, two sides of the top of the grinding machine body are symmetrically provided with a first feeding mouth and a second feeding mouth, the inner top of the grinding body is provided with a first discharging plate, a first rotary shaft is arranged under the first discharging plate, the first rotary shaft is provided with a plurality of sets of the first crushing knives, a second rotary shaft is arranged under the first rotary shaft, the second rotary shaft is provided with a plurality of sets of the second crushing knives, the second rotary shaft and two sides of the first rotary shaft are connected with the grinding machine body through a first bearing seat. The grinding machine has the beneficial effects of reasonable design and convenient usage. Compared with the traditional grinding machine, the grinding machine adds a crushing device,so that the grinding effects and grinding efficiency can be effectively improved and the grinding can better meet the needs of the modern production.

Owner:刘理想

Continuous acidification process for synthesizing 2-naphthol

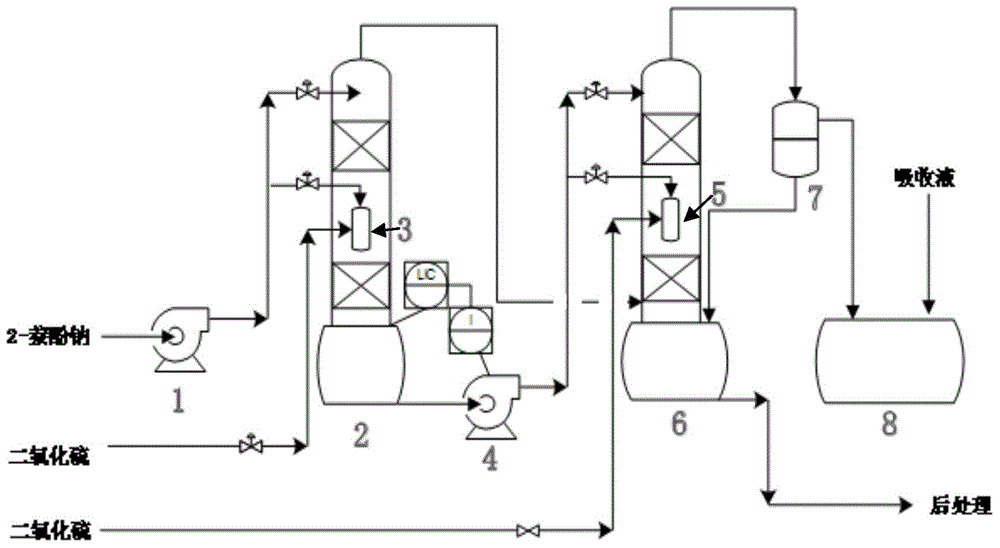

ActiveCN104447215AReduce utilizationFeeding is not easy to controlOrganic chemistryOrganic compound preparationWastewaterTower

The invention discloses a continuous acidification process for synthesizing 2-naphthol. Sodium 2-naphthol and sulfur dioxide are adopted as starting raw materials and are subjected to continuous acidification by virtue of a multi-stage acidification tower so as to obtain 2-naphthol. By specially designing the acidification tower and optimizing the process, the defects of complicated operation, low utilization rate of sulfur dioxide, large amount of wastewater, difficulty in control of the sulfur dioxide feed, large labor demand and high cost in the traditional process are overcome. Compared with the traditional process, according to the continuous acidification process disclosed by the invention, the utilization rate of sulfur dioxide is increased by about 7%, the amount of wastewater is decreased by about 9.8%, the production period is shortened by 5% and meanwhile, the sulfur dioxide feed is easily controlled, the labor demand is small and the cost is low.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

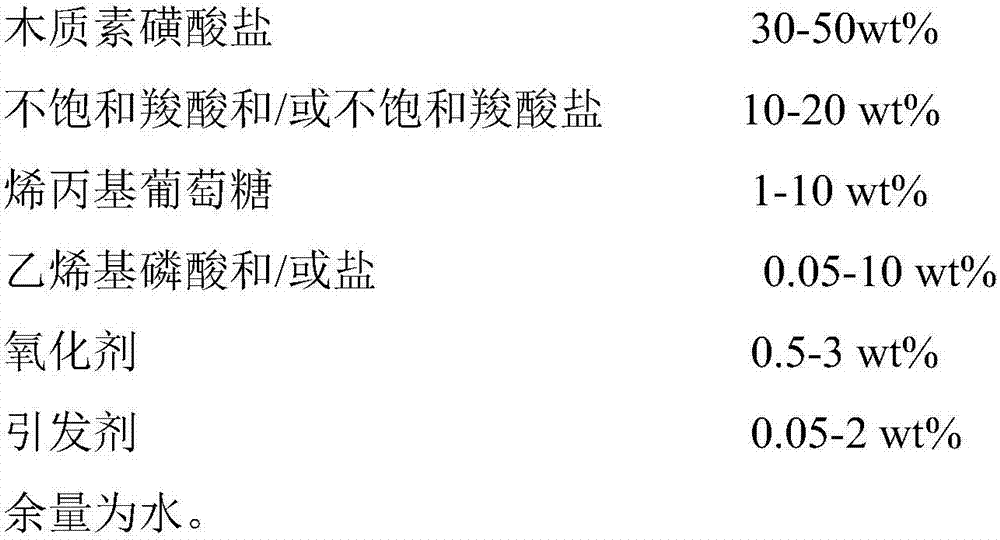

A modified lignosulfonate water reducer and its preparation method

The invention discloses a modified lignosulfonate water-reducing agent and a preparation method thereof. Firstly, lignosulfonate is oxidized by an oxidizing agent so as to improve the chemical activity of the lignosulfonate, and then the modified lignosulfonate is polymerized with unsaturated carboxylic acid and salts thereof, allyl glucose, and vinyl phosphonic acid and salts thereof to achieve a purpose of chemical modification, so that the modified sodium lignosulfonate is connected to a carboxyl group, a glycosyl group, a phosphonic group and other anionic groups for further improving the performance of a product. The modified lignosulfonate water-reducing agent is mainly used for improving the performance of concrete.

Owner:FUJIAN QINGYUAN TECH

Special granulation extruder for FEP powder materials

The invention discloses a special granulation extruder for FEP powder materials. An extruder body is included; a storage hopper is fixedly installed on the top of one side of the extruder body; the bottom of the storage hopper is connected with a guide-out pipe; the guide-out pipe is located in the extruder body; a spiral conveying shaft is rotationally installed in the extruder body; a verticallyarranged linkage pushing rod is welded to the outer wall of one side of the spiral conveying shaft; a movable sealing plate corresponding to the linkage pushing rod is further arranged at the bottomof the guide-out pipe; one side of the movable sealing plate is provided with a discharging port; one end of the movable sealing plate is connected with a sliding plate perpendicular to the movable sealing plate; the two sides of the sliding plate are each connected with a supporting sliding rod in a sliding manner; each supporting sliding rod is provided with a spring; and a movable sliding rod matched with the linkage pushing rod is welded to the bottom of the other side of the movable sealing plate. According to the special granulation extruder for the FEP powder materials, design and arrangement are reasonable, the purpose that material conveying and quantitative feeding are performed at the same time is achieved, cost is low, and the machining quality of the extruder is improved.

Owner:湖州和轩翥新材料科技有限公司

Feeding-controllable water absorbing resin particle production system

InactiveCN104497177AIncrease productivityFeeding quantity and frequency are accurateChemical/physical/physico-chemical stationary reactorsMaterial granulationGastric tube feedingColloid mill

The invention relates to a feeding-controllable water absorbing resin particle production system comprising a reaction kettle, a polymerization plant, a colloid mill, a dryer, a material pool, a separator, a screening machine, a grinder and a stock bin, the reaction kettle comprises a kettle body and a feeding-controllable feeding mechanism, the feeding-controllable feeding mechanism comprises sealing covers, feeding tubes, hydraulic control valves, feed tanks, mounting racks, material conveying pipes, material pumping pumps and raw material barrels, two feeding mouths of the kettle body of the reaction kettle are provided with the sealing covers, one ends of the feeding tubes pass through the sealing covers to extend into the kettle body, the other ends of the feeding tubes are installed on the bottom of the feed tanks, the hydraulic control valves are installed on the feeding tubes, the feed tanks are arranged on the mounting racks, the mounting racks are symmetrically arranged on both sides of a mixing mechanism in the kettle body, and the feed tanks are connected, by the material conveying pipes, with the raw material barrels connected with the material pumping pumps. The feeding-controllable water absorbing resin particle production system has the advantages of scientific and reasonable structure design, low labor intensity, saving manpower, controllable material feeding, satisfaction of the technology demand, safety and reliability, and high production efficiency.

Owner:凯姆勒科技发展(天津)有限公司

Method for synthesizing butylhydroxyoxo-stannane

InactiveCN105198929AEasy to synthesizeEasy to control feedingGroup 6/16 element organic compoundsTemperature and pressureStannane

The invention belongs to the field of chemical engineering, and particularly relates to a method for synthesizing butylhydroxyoxo-stannane. The method comprises the following five steps of material adding control, constant-temperature reaction, water washing, centrifugalization and drying. The method disclosed by the invention is simple in synthesis, and butyltin trichloride and alkali liquor are directly reacted at ambient temperature and pressure; material adding is easy to control, and the reaction is stable and easy-going; and through the implementation of a method for controlling the pH value of an end point, the conversion rate of products production is high, the recovery rate is more than 98%, and the main content is 98% or more.

Owner:云南锡业锡化学品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com