Quick drying and fermenting device for livestock and poultry faeces

A rapid drying technology for livestock and poultry manure, which is applied to fertilization devices, organic fertilizers, climate change adaptation, etc., can solve problems such as uneven drying, low motor power, and low production efficiency, and achieve good heating and drying effects, Good thermal stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

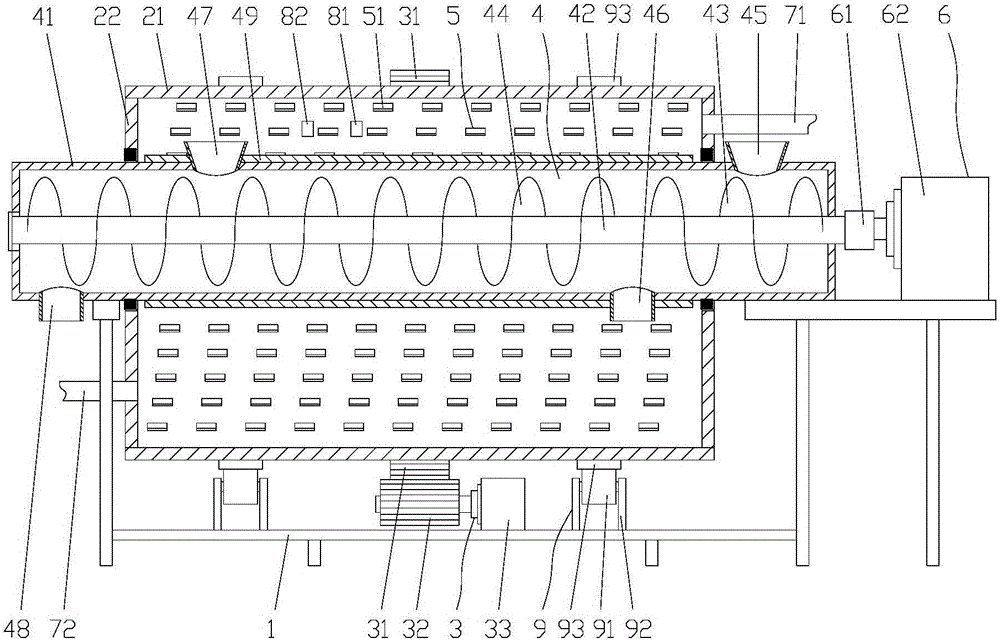

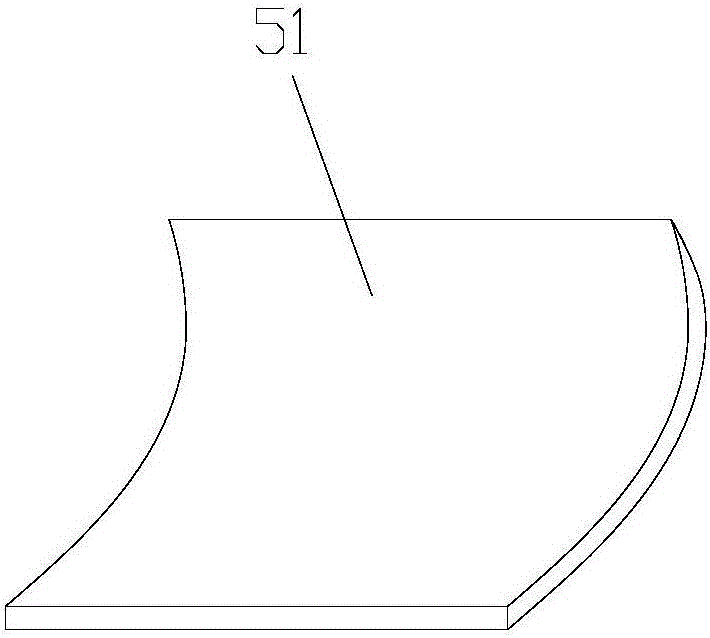

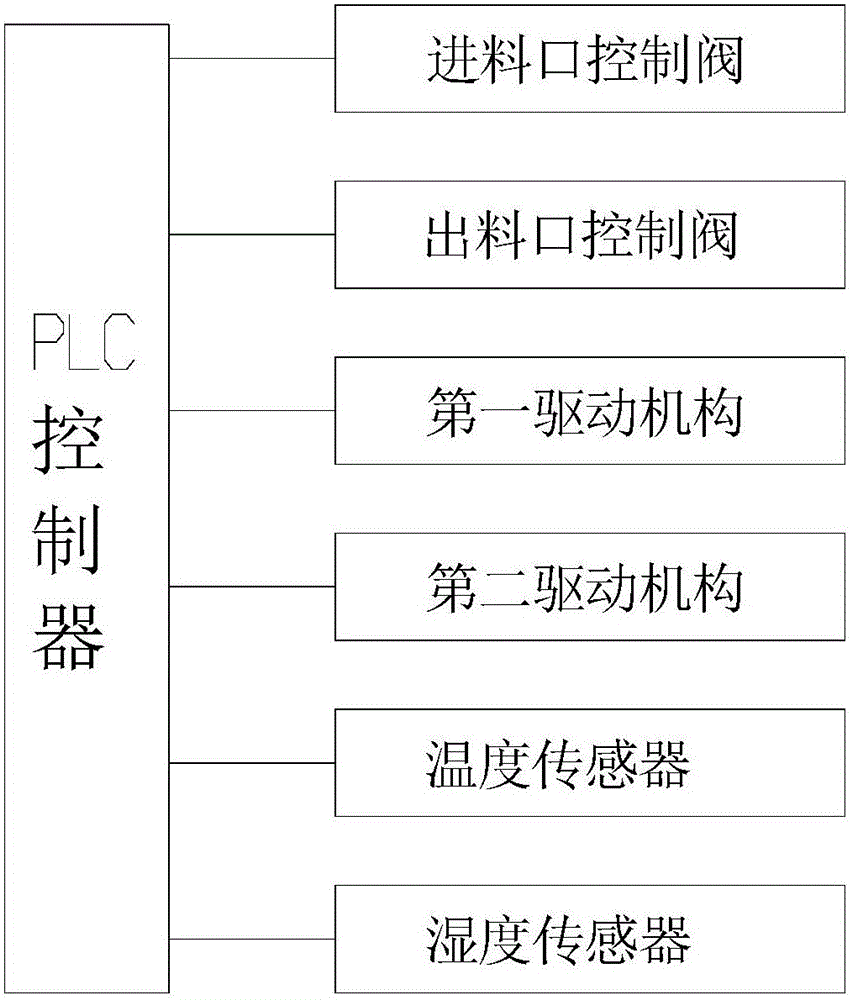

[0023] Such as Figure 1-3 As shown in one of them, the present invention comprises frame 1, and described frame 1 is provided with the tank body 21 of first screw transmission mechanism 4, horizontal arrangement, is used for supporting tank body 21 support mechanism 9 and is used for driving tank body. Body 21 circumferentially rotates the first driving mechanism 3, and the two ends of the tank body 21 are respectively provided with a sealing cover 22 that does not rotate with the tank body 21. The air inlet pipe 71 for drying materials, the first screw transmission mechanism 4 includes a transmission cylinder 41 axially penetrated in the tank body, and two sealing covers 22 extend from both ends of the transmission cylinder 41, and are respectively supported on the tank body On the frame 1 outside 21, a screw shaft 42 is provided in the transmission cylinder 41, and one end of the screw shaft 42 is driven to rotate by the second drive mechanism 6 provided on the frame 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com