A modified lignosulfonate water reducer and its preparation method

A technology of lignosulfonate and potassium lignosulfonate, applied in the field of concrete admixtures, can solve problems such as difficulties in large-scale industrial production and popularization and application, disconnection between modification research and application research, and large performance fluctuation of modified products. , to achieve the effect of pollution-free and clean production process, slump maintenance and good slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

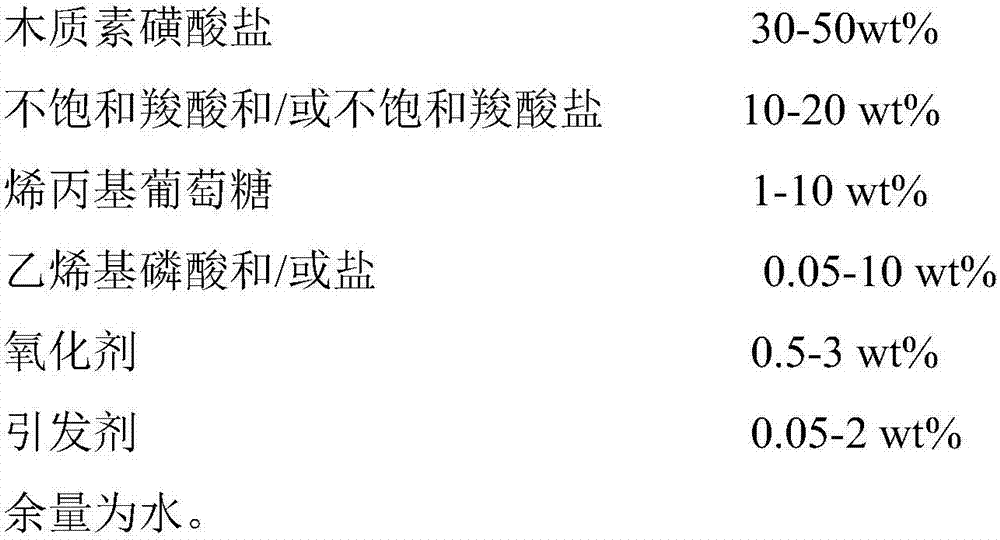

Method used

Image

Examples

Embodiment 1

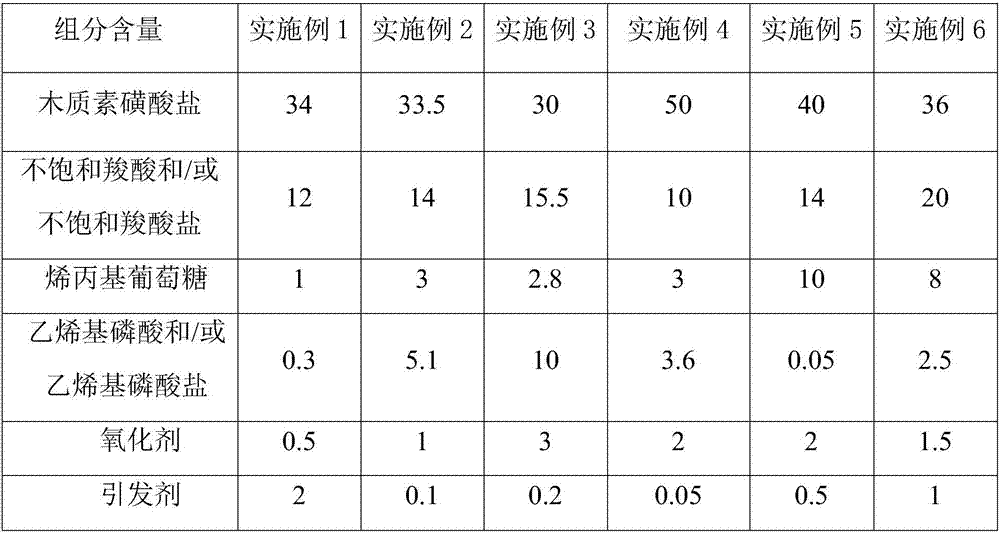

[0026] The content of each component required for the reaction is as shown in Table 1, wherein the lignosulfonate is sodium lignosulfonate, and the unsaturated carboxylic acid and / or unsaturated carboxylic acid salt are acrylic acid, vinyl phosphoric acid and / or The vinyl phosphate is vinyl phosphoric acid, the oxidizing agent is hydrogen peroxide, and the initiator is sodium persulfate.

[0027] A preparation method of a modified lignosulfonate water reducer is realized through the following steps:

[0028] It is achieved through the following steps:

[0029] (1) After adding sodium lignosulfonate and water into the reactor, start stirring, and start to heat up;

[0030] (2) When the temperature rises to 55°C, add hydrogen peroxide, continue the reaction for 2 hours, add acrylic acid, allyl glucose, and vinyl phosphoric acid, and heat up after the addition is complete;

[0031] (3) When the temperature rises to 70°C, start to add dropwise a sodium persulfate solution with a...

Embodiment 2

[0034] The content of each component required for the reaction is as shown in Table 1, wherein the lignosulfonate is magnesium lignosulfonate, and the unsaturated carboxylic acid and / or unsaturated carboxylic acid salt are acrylic acid, vinyl phosphoric acid and / or The vinyl phosphate is sodium vinyl phosphate, the oxidizing agent is sodium ferrate, and the initiator is potassium persulfate.

[0035] A preparation method of a modified lignosulfonate water reducer is realized through the following steps:

[0036] (1) After adding magnesium lignosulfonate and water into the reactor, start stirring, and start to heat up;

[0037] (2) When the temperature rises to 60°C, add sodium ferrate, continue the reaction for 1.5 hours, add acrylic acid, allyl glucose, and sodium vinyl phosphate, and heat up after the addition is complete;

[0038] (3) When the temperature rises to 85° C., start dripping the potassium persulfate solution whose mass percentage concentration is 1%; the droppi...

Embodiment 3

[0041] The content of each component required for the reaction is as shown in Table 1, wherein the lignosulfonate is a mixture of sodium lignosulfonate and potassium lignosulfonate, and the content of sodium lignosulfonate and potassium lignosulfonate The mass ratio is 1:1, the unsaturated carboxylic acid and / or unsaturated carboxylic acid salt is methacrylic acid, vinyl phosphoric acid and / or vinyl phosphate is potassium vinyl phosphate, the oxidizing agent is potassium permanganate, and the initiator is sodium persulfate.

[0042] A preparation method of a modified lignosulfonate water reducer is realized through the following steps:

[0043] (1) After adding sodium lignosulfonate, potassium lignosulfonate and water into the reaction kettle, start stirring, and start to heat up;

[0044] (2) When the temperature rises to 68°C, add potassium permanganate, continue the reaction for 1.8 hours, then add methacrylic acid, allyl glucose, and potassium vinyl phosphate, and heat up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com