Patents

Literature

312results about How to "Increase slump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic retaining type polyether assemblage carboxylic acid high-performance water reducing agent and preparation method thereof

The invention discloses a plastic retaining type polyether assemblage carboxylic acid high-performance water reducing agent and a preparation method thereof, mainly being applicable to the field of building materials. The water reducing agent is obtained in the following method: with the action of initiating agent, copolymerizing unsaturated polyalkyl ether monomer (A), unsaturated monocarboxylic acid and derivative monomer thereof (B), unsaturated dicarboxylic acid and derivative monomer thereof (C) and unsaturated sulfonic acid or salt monomer (D) in water solution for 2-8h at 50-80 DEG C and then reducing temperature to 35-45 DEG C, using alkaline solution to neutralize the mixture to a pH value of 5-7, thus obtaining the water reducing agent. The synthesized water reducing agent of the invention features changeable molecular structure, high water reducing ratio, high dispersion property under low dosage and fine slumps-retaining property, good adaptability to concrete raw material; in addition concrete with the water reducing agent added enjoys good peaceability; with the one-step method synthesis technology employed, the preparation method has the advantages of simple operation, low energy consumption in production and freedom from pollution.

Owner:CNBM ZHONGYAN TECH

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

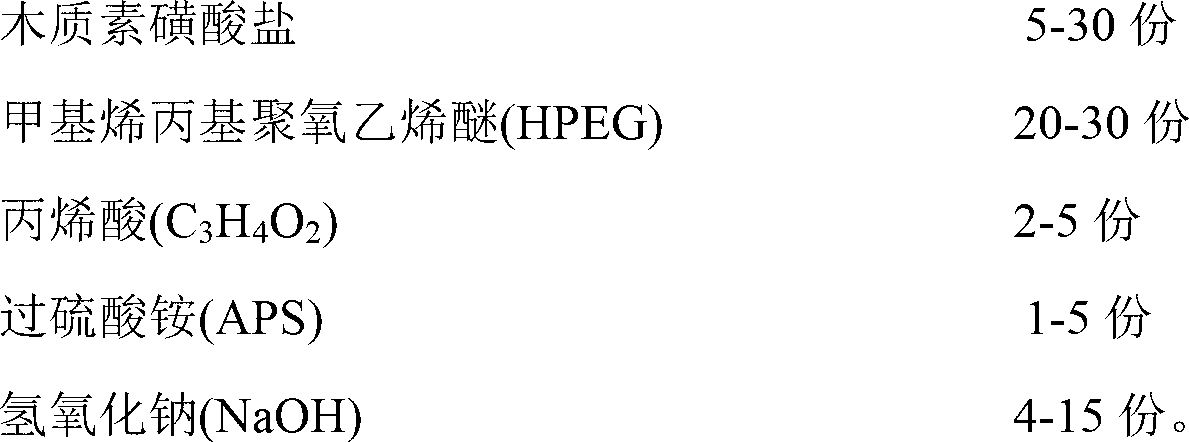

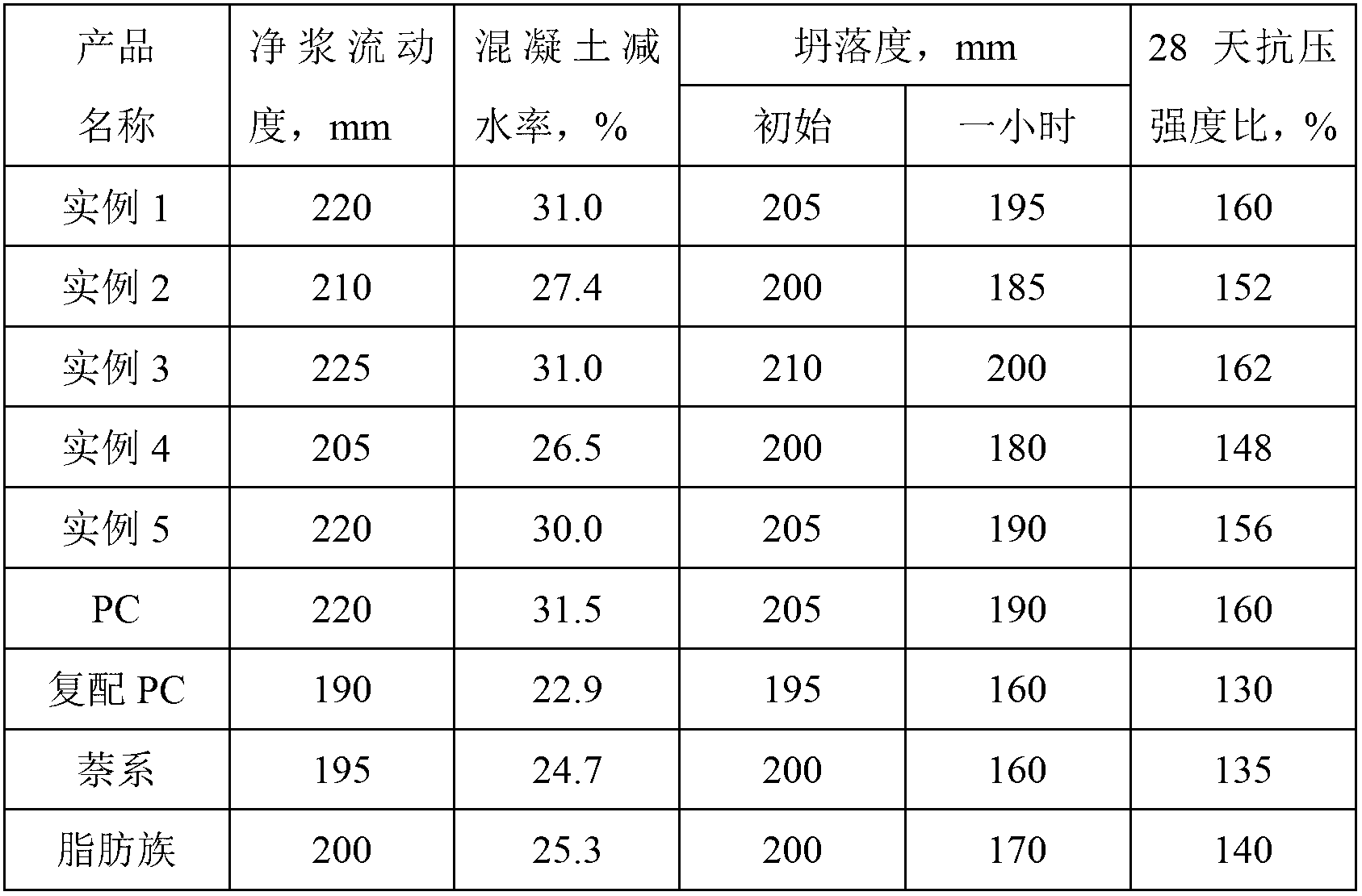

Lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and preparation method thereof

The invention discloses a lignosulfonate-polycarboxylic acid copolymerized composite high-performance water reducer and a preparation method thereof. The high-performance water reducer comprises the components in parts by weight: 5-30 parts of lignosulfonate, 20-30 parts of methyl allyl polyethenoxy ether, 2-5 parts of acrylic acid, 1-5 parts of ammonium persulfate, 4-15 parts of sodium hydroxide and water. The preparation method comprise the steps as follows: lignosulfonate, methyl allyl polyethenoxy ether and acrylic acid are directly synthesized under the action of ammonium persulfate, and the mixture is neutralized by sodium hydroxide to obtain the high-performance water reducer. As the high-performance water reducer is made from natural recycled materials, the high-performance water reducer is low in price, stable in performance, high in water-reducing rate, good in collapse prevention property, remarkable in improved effect, and is unlikely to bleed, separate and deposit after concrete is added, the quality problems of sand leakage, honeycomb-like phenomenon and leakage due to cracking in the middle and low-strength concretes are effectively avoided, and the safety performance is improved.

Owner:MAANSHAN CHINASEA NEW MATERIAL

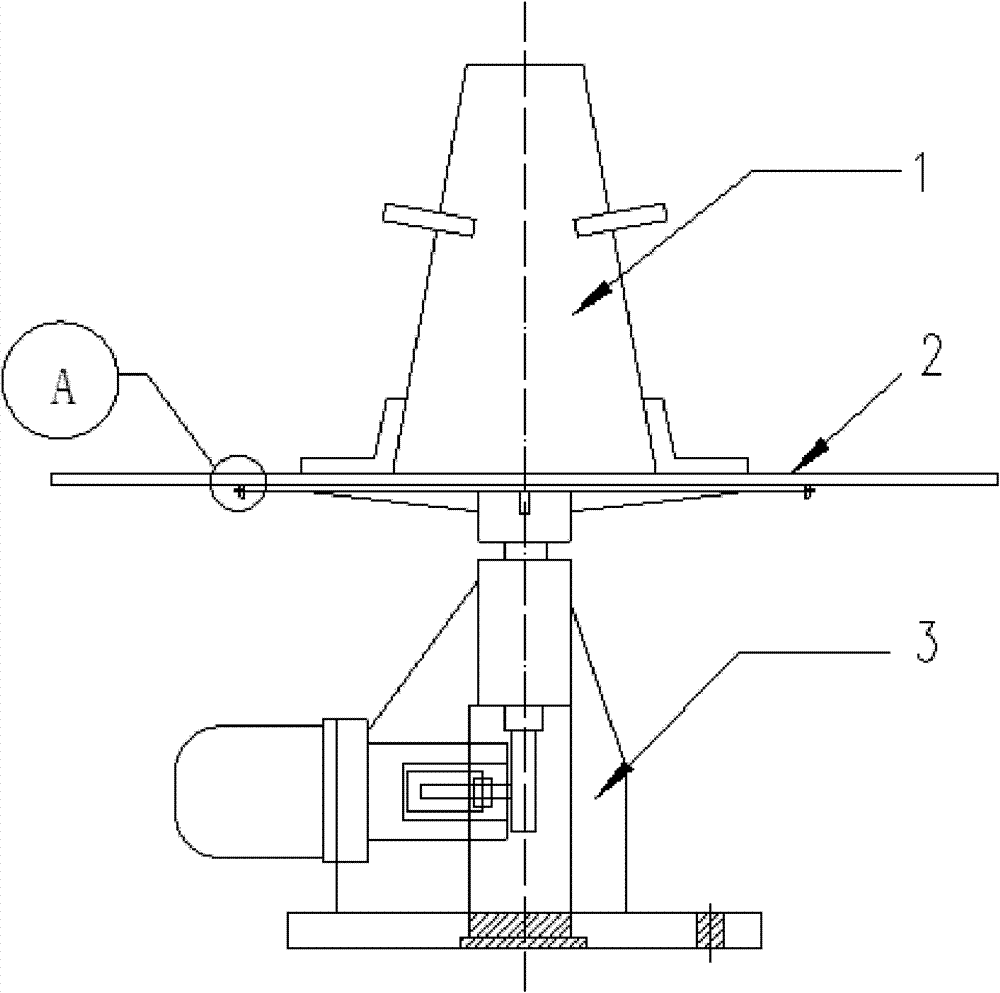

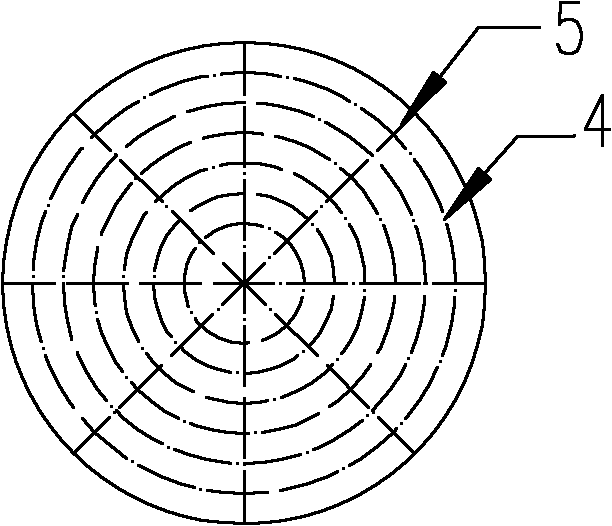

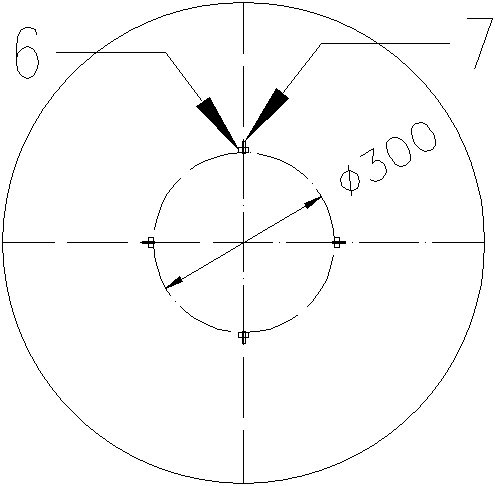

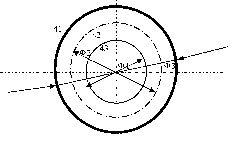

Testing method for working performance of concrete and apparatus implementing same

The invention relates to a testing method for working performance of concrete and an apparatus implementing the same. The testing apparatus comprises a concrete slump tester, a cement mortar fluidity testing jumping table and a circular extending table. In similar testing of the slump of concrete disposed on a large table-board, the jumping table vibrates preset times according to certain frequency and certain vibration amplitude after a slump cylinder is hoisted, which enables the slump and flowing of the concrete to be improved and the concrete to form a circular truncated cone shape with a larger area; the slump H after vibration, the mobile extended diameter D of the concrete, center thickness h1 and edge thickness h2 after vibration are measured, the inclination angle theta of a frustum after slump of the concrete is calculated through conversion, bleeding and the segregation degree of the concrete are observed, and thus, working performance of the concrete can be comprehensively estimated. Compared with the prior art, the invention has the following advantages: working performance of fresh concrete can be conveniently and quickly tested and distinguished, and the method and the apparatus are applicable to a wide variety of concrete.

Owner:TONGJI UNIV

Cement dispersant and methods of making and using the same

The present invention relates to cement dispersant that is a copolymerization product of a first monomer (A) comprising a carboxylic acid, a second monomer (B) comprising an alkoxylated allyl alcohol sulfate, and, optionally, a third monomer (C) comprising an alkoxylated allyl alcohol. The cement dispersant according to the invention provides improved slump life properties and water reduction properties in cement admixtures.

Owner:GEO SPECIALTY CHEM

Lead-free solder solder paste for electronic industry and method for manufacturing soldering fluid

InactiveCN101244491AHigh expansion rateImprove wettabilityWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention relates to a welding material, in particular to a preparation method of electronic industry-used lead-free solder paste and flux; wherein, the welding material comprises 85 to 90% lead-free solder powder and 10 to 15% flux; the lead-free solder powder is a 25 to 45 micrometer lead-free solder made by tin, copper, silver and titanium; the flux comprises a high viscosity rosin, an organic acid activator, a thixotropic agent, a wetting agent and a solvent. The welding material has the advantages of green environmental protection of lead-free solder, resolving the drawbacks of lead-free solder of high melting point and low fluidity, high expansion rate, no- halogen, low post-weld residue and corrosive property, high insulation resistance, and good protection performance.

Owner:TIANJIN QINGHE TECH DEV

Water-retaining polycarboxylic acid type water reducer containing beta-cyclodextrin, preparation method thereof and usage method thereof

The invention discloses a water-retaining polycarboxylic acid type water reducer containing beta-cyclodextrin, a preparation method thereof and a usage method thereof. The water-retaining polycarboxylic acid type water reducer containing beta-cyclodextrin is prepared through a method of free-radical polymerization in an aqueous solution with treating allyl polyethylene glycol, acrylic acid, sodium methyl allyl sulfonate, beta-cyclodextrin, maleic anhydride, dimethyl formamide, sodium hydroxide, ammonium persulfate and azobis (isobutylamidine hydrochloride) as raw materials. The polycarboxylic acid type water reducer, which allows water reducing rate to be high, enhancement effect to be good and water retention and cohesiveness of concrete to be greatly improved, has large technical advantages in high fluidity concrete, self-compacting concrete, grouting materials and lean concrete, so the reducer provided by the invention has a broad market prospect.

Owner:河北红墙新材料有限公司

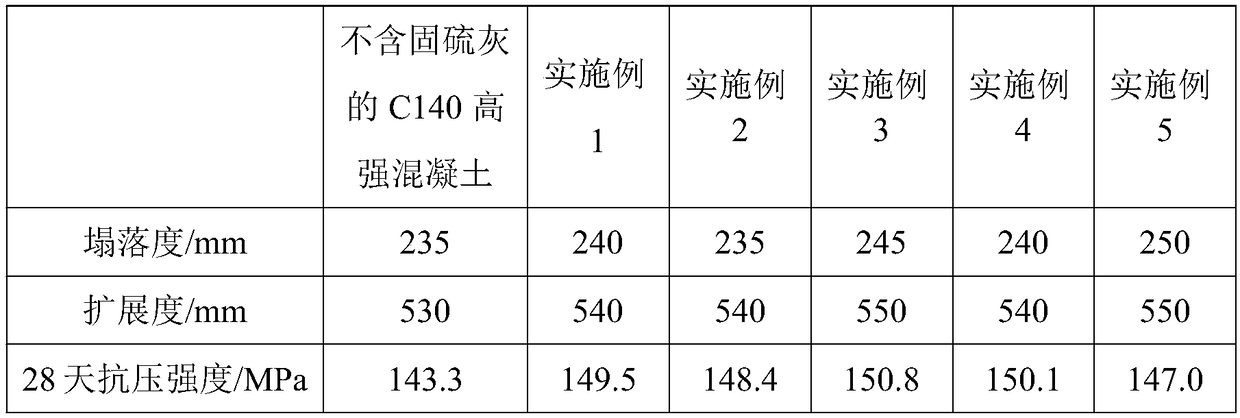

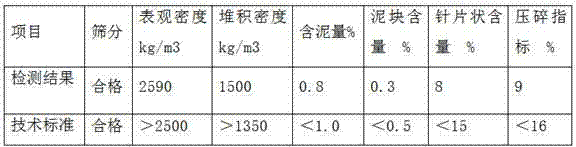

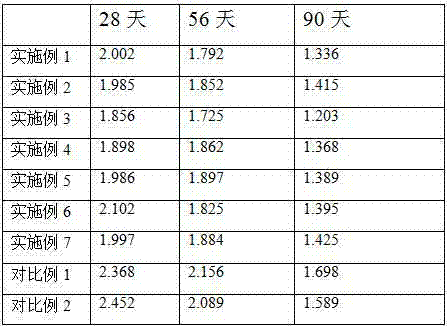

C140 high-strength concrete and preparation method thereof

The invention belongs to the field of concrete, and particularly discloses C140 high-strength concrete and a preparation method thereof. The concrete is prepared from the following materials in partsby weight: 490-570 parts of cement, 45-65 parts of coal ash, 100-120 parts of mineral powder, 65-85 parts of desulphurization ash, 20-40 parts of silica fume, 750-950 parts of coarse aggregate, 400-600 parts of fine aggregate, 5.5-7.5 parts of a water reducer, 10-20 parts of a corrosion inhibitor, 60-100 parts of fibers and 145-160 parts of water. The invention provides the C140 high-strength concrete; the concrete has a good slump, good extended degree, good compressive strength, and excellent comprehensive performance, and meanwhile, the problems of resource shortage of traditional cement admixtures of the mineral powder, the coal ash, the silica fume and the like, and limited resourced approaches and a low utilization rate of the desulphurization ash are solved.

Owner:成都宏基建材股份有限公司

Marine concrete

InactiveCN103936373AIncreased durabilityHigh compressive strengthMining engineeringMechanical engineering

The invention discloses marine concrete. The marine concrete is characterized by being prepared from the following raw materials in parts by weight: 380-500 parts of cementing material, namely 175-225 parts of cement, 135-163.8 parts of mineral powder and 79-100 parts of coal ash, 730-773 parts of fine aggregate, 1050-1112 parts of coarse aggregate, 150 parts of water and 14.22-19.5 parts of additive. The marine concrete disclosed by the invention overcomes the defects of the existing marine concrete of low corrosion resistance and poor durability and can be applied to marine construction with strong corrosion resistance and good durability.

Owner:CHONGQING CONSTR BRIDGE ENG +2

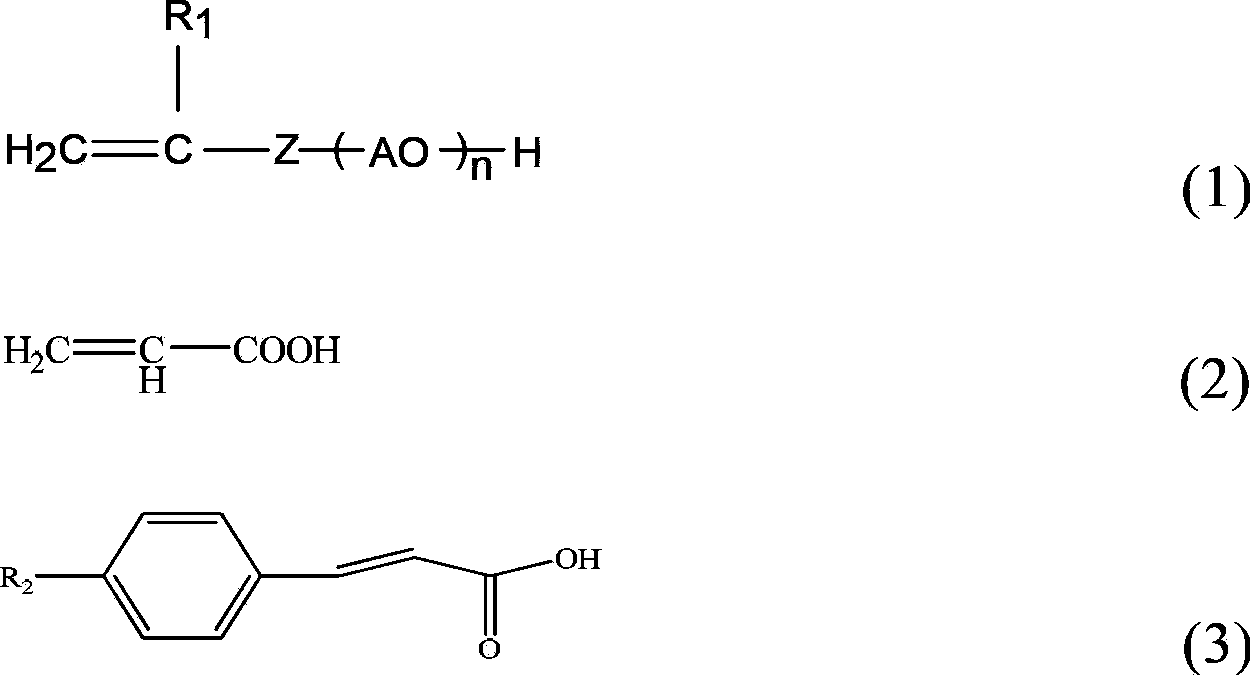

Allyl polyglycol ether type polycarboxylic acid series dehydragent and preparation method thereof

InactiveCN101386490AMolecular structure changeableImprove performanceHigh strength concretePolyethylene glycol

The invention discloses an allyloxypolyethyleneglycol type polycarboxylate water reducing agent and a method for preparing the same, wherein the water reducing agent is a polymer obtained through polymerization; the polymer comprises the following components in weight percentage: 30 to 50 percent of unsaturated polyoxyalkylene group ether monomer(a), 5 to 20 percent of unsaturated monocarboxylic acid and derivative monomer(b) of unsaturated monocarboxylic acid, 1 to 20 percent of unsaturated dicarboxylic acid(c) and 40 to 60 percent of water; the components undergo polymerization in a water solution at a temperature of between 45 and 70 DEG C in the presence of a redox initiator to form the water reducing agent. The polycarboxylate water reducing agent has the advantages of high conversion rate of reaction product, good cohesiveness and super high dispersibility and excellent performance when applied to high strength concrete.

Owner:上饶市天佳新型材料有限公司

Polyether amine modified polycarboxylic water reducer and preparation method thereof

The invention discloses a polyether amine modified polycarboxylic water reducer and a preparation method thereof. The water reducer is a polyether amine modified polycarboxylic acid copolymer which has the weight-average molecular weight of 5,000 to 120,000 and is obtained by performing amidation on polycarboxylic acid copolymer which has the weight-average molecular weight of 1,000 to 30,000 andcomprises 5.0 to 50.00 weight percent of carboxylic structural unit I and a carboxylic structural unit II, and a polyether amine monomer A at the temperature of between 80 and 200 DEG C; the preparation method comprises the following steps of: copolymerizing itaconic acid, and unsaturated carboxylic monomer B under the action of an initiator in a solution at the temperature of between 50 and 100 DEG C to obtain a polycarboxylic copolymer with the molecular weight of between 1,000 and 3,000; and performing amidation on the copolymer and the polyether amine monomer A at the temperature of between 80 and 200 DEG C. The polyether amine modified polycarboxylic water reducer is high in concrete water-reducing rate under the condition of low accretion, and keeps good concrete slump simultaneously.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Slow-release high-adaptability polyester polycarboxylic acid water-reducing agent and preparation method and application thereof

The invention discloses a method for preparing a slow-release high-adaptability polyester polycarboxylic acid water-reducing agent. According to the method, a slow-release positive-negative non-ionic mud-resistant polyester polycarboxylic acid water-reducing agent product is synthesized by utilizing a high-molecular structural design principle. The invention also discloses the slow-release high-adaptability polyester polycarboxylic acid water-reducing agent prepared through the method and an application of the slow-release high-adaptability polyester polycarboxylic acid water-reducing agent in concrete. Compared with the prior art, the slow-release high-adaptability polyester polycarboxylic acid water-reducing agent disclosed by the invention has the advantages that the molecular structure of the product contains an ester group and an amide group which are unstable in a cement strong-alkali environment, positive amine ions generated by hydrolyzing the amide group achieve a sealing effect on mud carried with negative charges so that the mud-resistant effect is achieved, the thickening effect is achieved on cement mortar, and the hydration of cement particles is postponed. The slow-release high-adaptability polyester polycarboxylic acid water-reducing agent disclosed by the invention has the advantages of high water-reducing rate, good slump ageing stability, high tolerance on the mud and good adaptability on coal ash, fine ore, stone powder, clays and the like.

Owner:广西红墙新材料有限公司

Slump retaining polyocarboxy acid superplasticiser

The invention discloses a slump maintaining type poly carboxylic acid superplasticizer, and the poly carboxylic acid superplasticizer is prepared by taking, according to the weight percentage, 10 to 60 percent of unsaturated polyalkylene glycol ether, 30 to 80 percent of alkoxy polyalkylene glycol ether (methyl) acrylic ester, 3 percent to 12 percent of unsaturated monocarboxylic acid or the salt and 2 percent to 8 percent of itaconic acid or the salt as the copolymerization monomers and carrying out the free radical copolymerization at the reaction temperature of 60 DEG C to 95 DEG C and in the presence of a free radical initiator and a chain transfer agent. The slump maintaining type poly carboxylic acid superplasticizer has the advantage of maintaining the high slump under the condition of low mixing amount.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

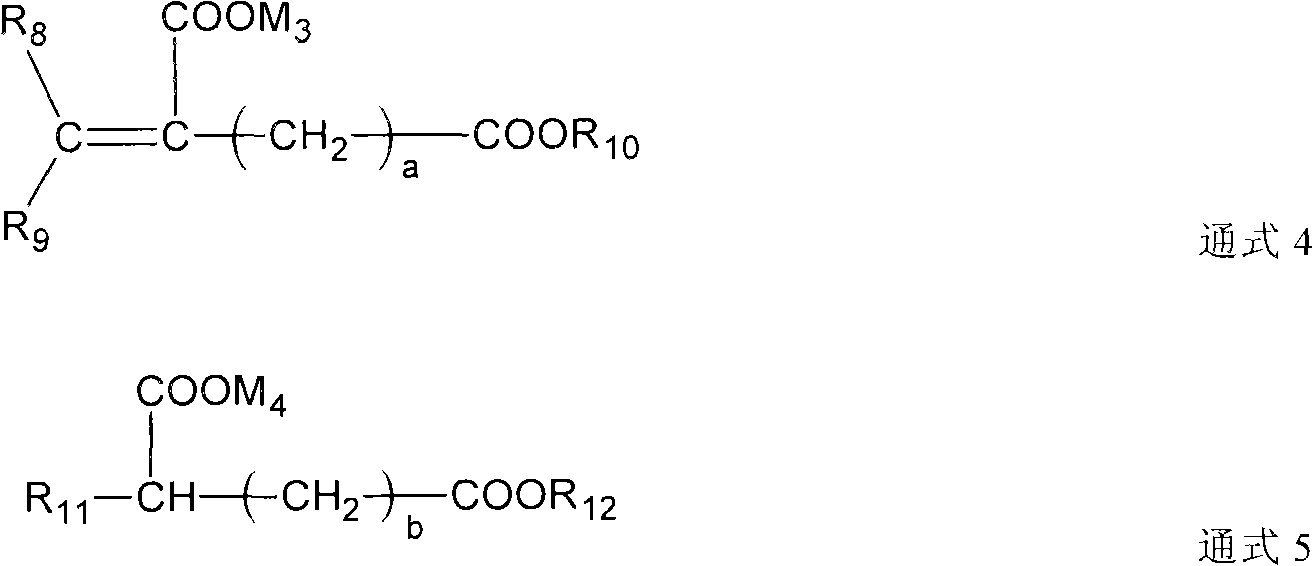

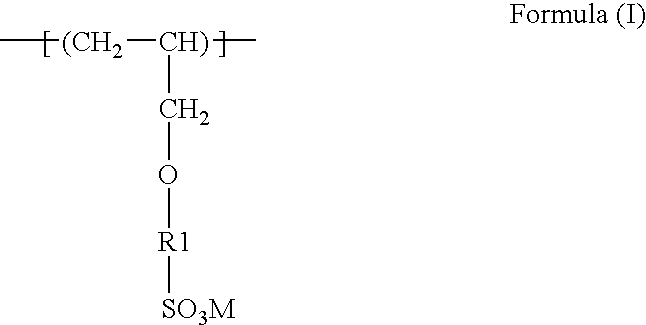

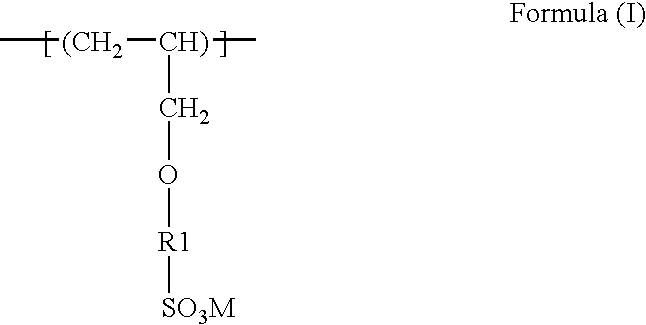

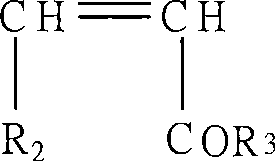

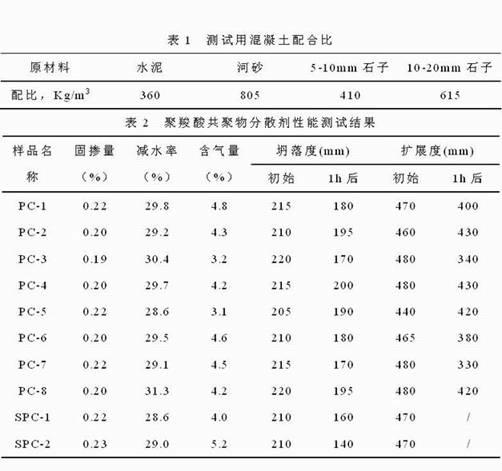

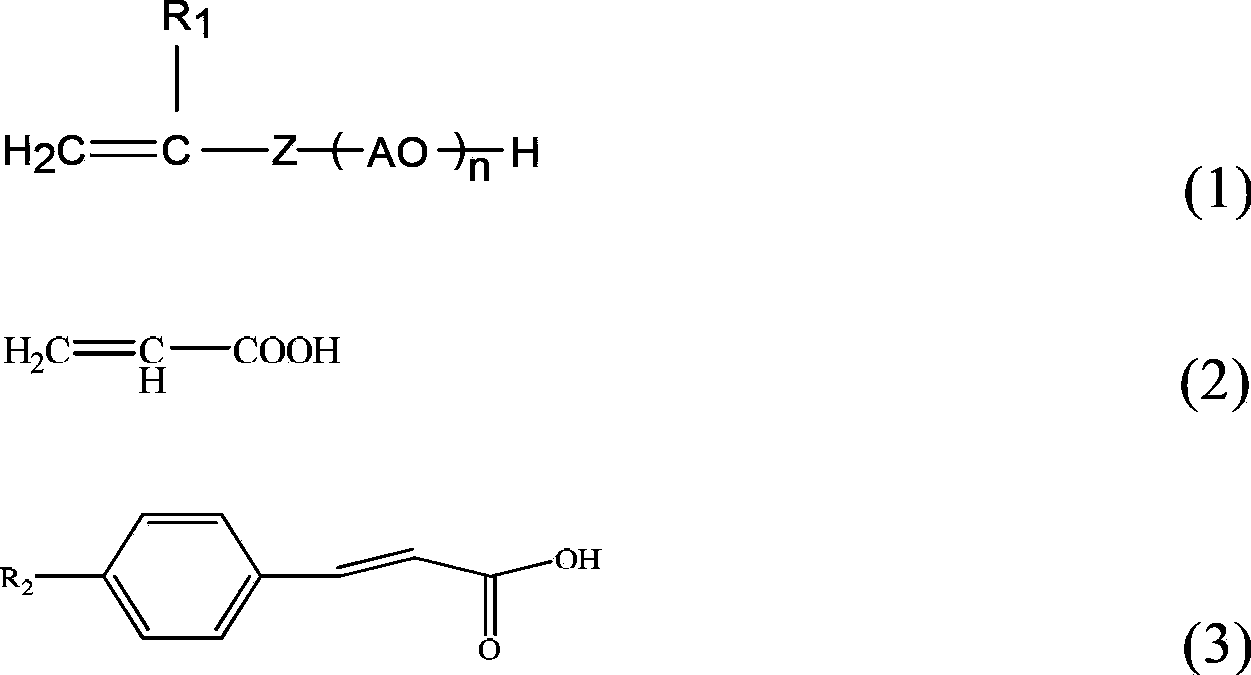

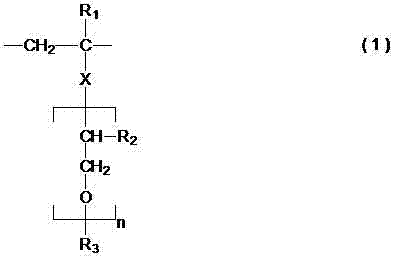

Polycarboxylic-acid copolymer dispersant and preparation method thereof

ActiveCN102030496AHigh water reduction rateIncrease slumpNature of treatment waterStructural unitChain transfer

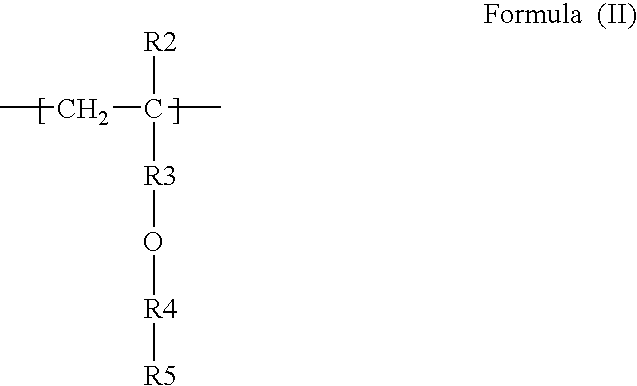

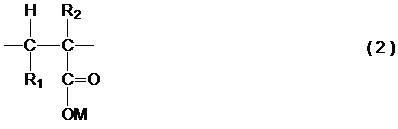

The invention discloses a polycarboxylic-acid copolymer dispersant and a preparation method thereof, wherein the dispersant is a polycarboxylic-acid copolymer which contains a structural unit (1), a structural unit (2) and a structural unit (3) and has the weight average molecular weight of 5000-120000, wherein the structural unit (1) is derived from an unsaturated polyether monomer, the structural unit (2) is derived from an unsaturated polyether monomer, and the structural unit (3) with the concentration of 5.0-30.0 percent by weight is derived from an unsaturated carboxylic-acid monomer; and the preparation method of the polycarboxylic-acid copolymer dispersant comprises the step of copolymerizing the unsaturated polyether monomer (A), the unsaturated polyether monomer (B) and the unsaturated carboxylic-acid monomer (C) at the temperature of 20-110 DEG C and in the presence of a chain transfer agent and an initiator to obtain the polycarboxylic-acid copolymer dispersant. Concrete still has high water-reducing rate under the condition of lower blending quantity of the copolymer dispersant of the invention, and meanwhile, the concrete still has better slump and fluidity after thecopolymer dispersant of the invention is blended.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

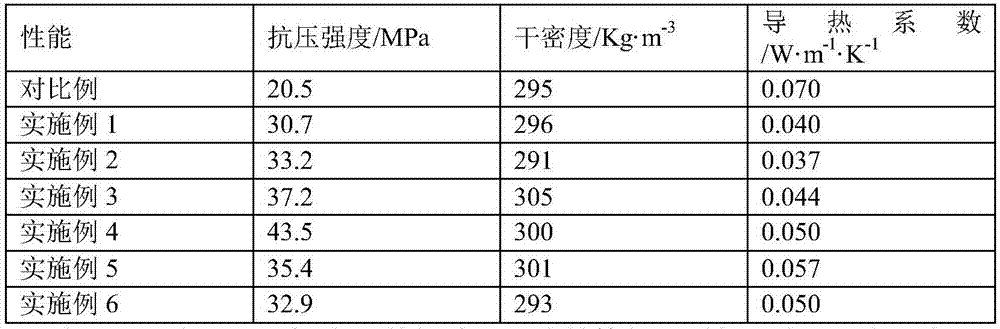

Foam concrete

The invention discloses foam concrete. The foam concrete comprises following raw materials in parts by mass according to a formula: 210-300 parts of cement, 1.0-1.5 parts of a water reducing agent, 5.1-5.5 parts of an early strength agent, 2.1-2.9 parts of a coagulant, 1.7-3.4 parts of fibers, 12-20 parts of a chemical foaming agent, 0-90 parts of superfine slag powder and 100-160 parts of water, wherein the superfine slag powder is formed by aluminosilicate glass particles smaller than 15 mu m, and the specific surface area is 450-500 m<2>*kg<-1>. The compressive strength of the foam concrete is improved on the premise that the foam concrete keeps low density.

Owner:BEIJING MINJIA NEW BUILDING MATERIALS CO LTD

Composite concrete agent

The invention discloses a concrete complexing agent as additive in the architectural material technical domain, which comprises the following parts: 48-55% silica, 27.5-45% fluorite, 2.5-8% sodium cetylsulfate, 4-9% hydroxy carboxyl acid and 0.5-1% aliphatic hydroxy sulfonate high-effective dehydragent. The complexing agent improves particle bond of concrete aggregate, which saves cement quantity by 10-20%.

Owner:王衡

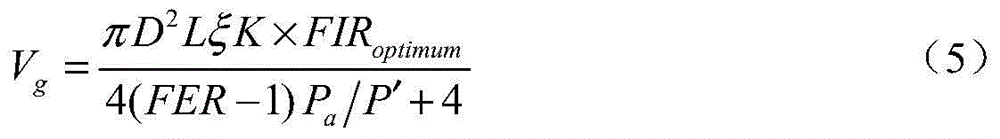

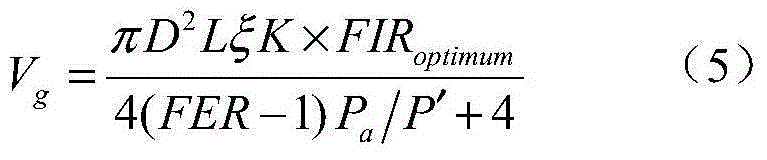

Selection method for earth pressure balance shield muck improvement parameters of viscous formation adopting foam as additive

The invention relates to a selection method for earth pressure balance shield muck improvement parameters of viscous formation adopting foam as an additive and belongs to the technical field of earth pressure balance shield construction. According to the method, the function relation of liquid-plastic limit and the foam injection ratio, the function relation of the slumps and the foam injection ratio and the function relation of the slumps and the water content are obtained through fitting of curve mathematical relationships. In order to facilitate establishment of effective earth pressure balance in the shield tunneling process, based on the requirement that the viscosity index is 0.4-0.75, the relation of the water content and the foam injection ratio is established, and a relation curve is drawn. On coordinate axes of the relation curve, the optimum foam injection ratio range is determined through the optimum slump range, and then the optimum water content range of muck is determined according to the relation of the water content and the foam injection ratio. In the process of field application, the influences of soil warehouse pressure on the volume of the foam, the bulk factor of the muck and the moisture of undisturbed soil are taken into account, and finally the use amount of foaming agents and the water injection ratio needed for muck improvement of each ring duct piece footage of the earth pressure balance shield are obtained. Experiments needed by the method are simple in operation, low in experiment cost and can be effectively applied to field construction.

Owner:CENT SOUTH UNIV

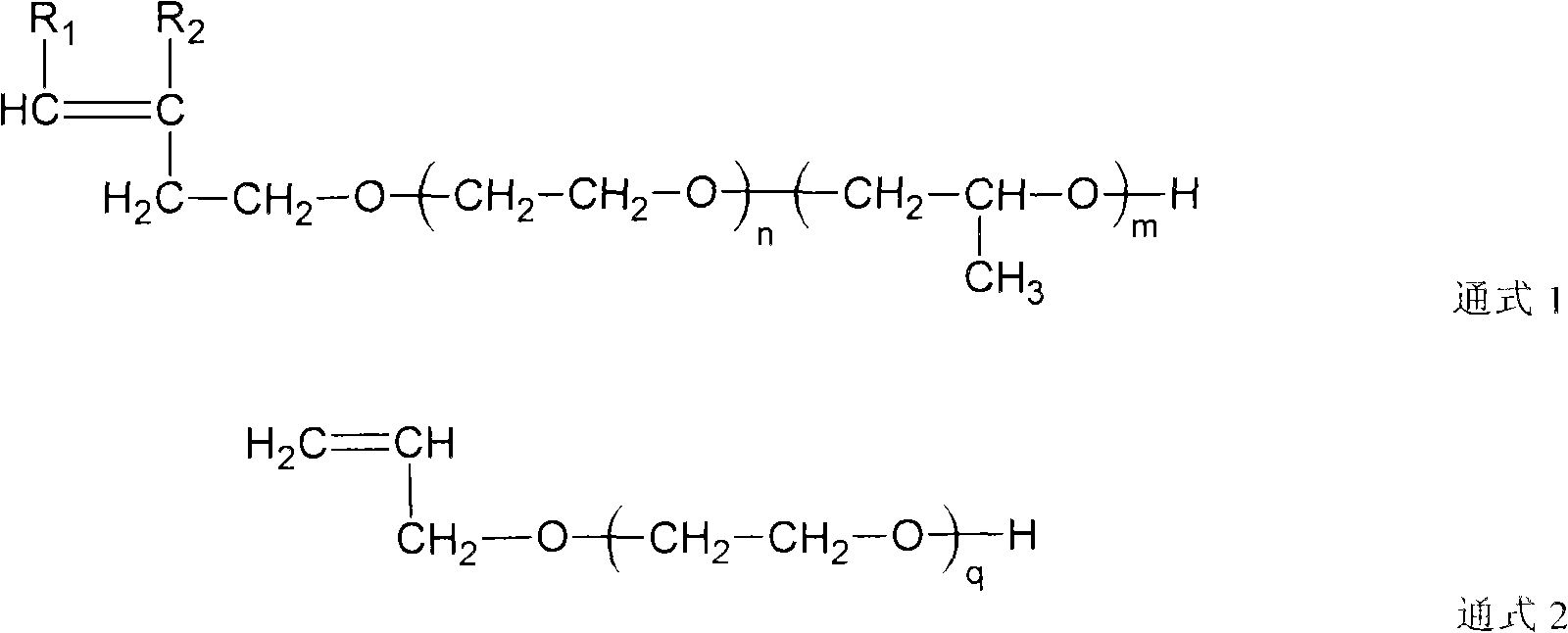

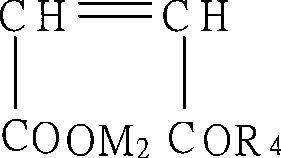

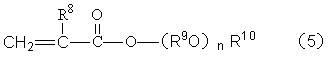

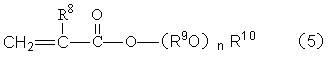

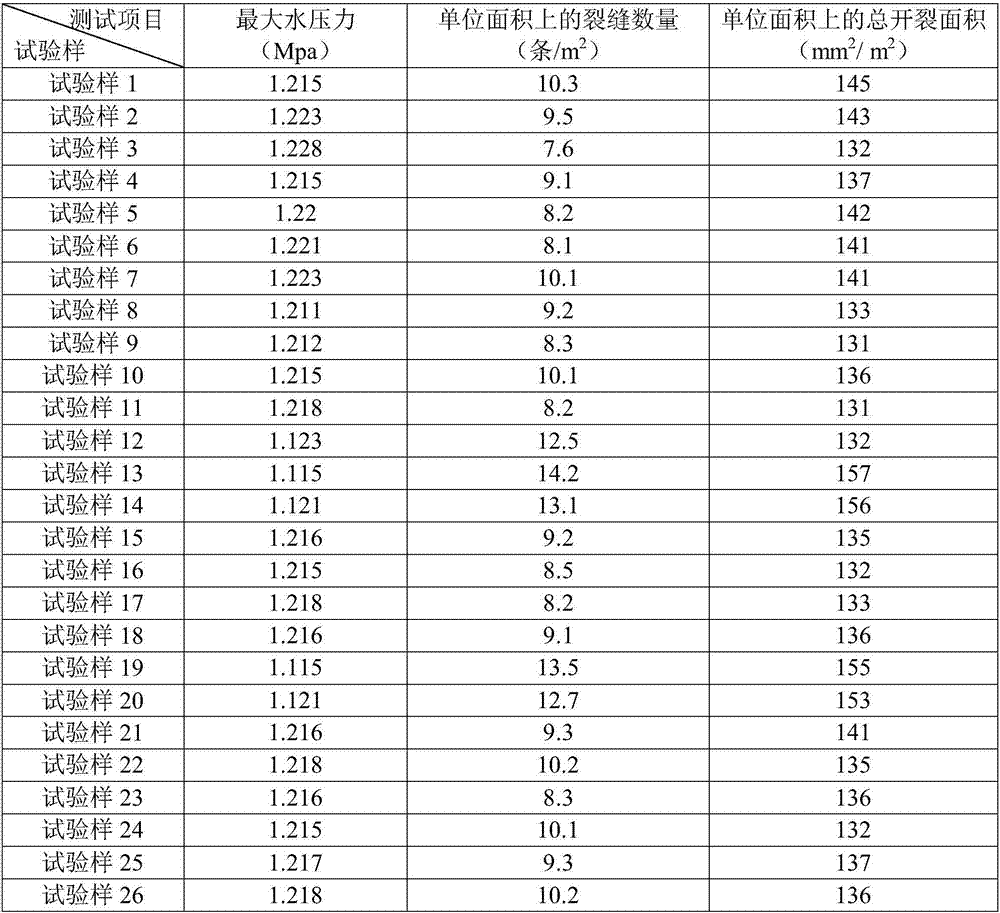

Polycarboxylate superplasticizer with high dispersion and high slump protection and preparation method of polycarboxylate superplasticizer

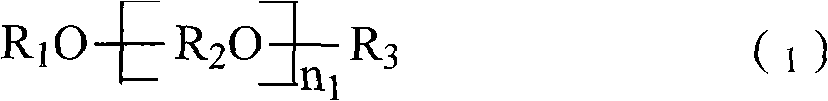

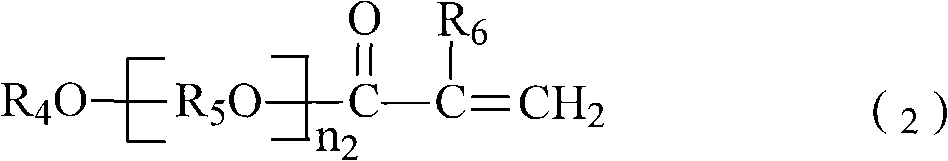

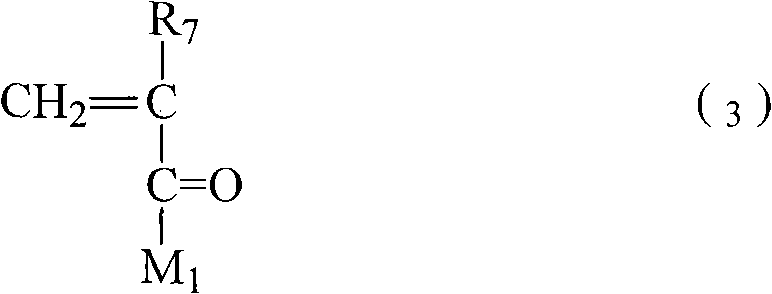

The invention discloses a polycarboxylate superplasticizer. The superplasticizer is prepared from monomers A, B and C as shown in the formulae (1), (2) and (3) by virtue of random copolymerization, and the molar ratio of A to B to C is 2.5:(7.5-10):1, wherein the symbols in the formulae are as definitions in the specification. The invention also discloses a method for preparing the polycarboxylate superplasticizer, which comprises the following steps: (1) dissolving the alkenyl-terminated polyoxyethylene ether serving as the monomer A in deionized water in a reaction container, heating to 60-65 DEG C under stirring; (2) adding a hydrogen peroxide aqueous solution, and stirring for about 3-5 minutes; (3) simultaneously dripping crylic acid serving as the monomer B and an aqueous solution serving as the monomer C to substitute crylic acid, and an aqueous solution for ascorbic acid and chain transfer agent; and (4) stirring and insulating for about 1-2 hours after the dripping is finished, cooling, and neutralizing with sodium hydroxide to obtain the polycarboxylate superplasticizer. According to the polycarboxylate superplasticizer, the contact among cement particles can be reduced due to the steric hindrance of a benzene ring in the structure of the polycarboxylate superplasticizer, so that the dispersion and slump protection of concrete can be improved.

Owner:LIAONING OXIRANCHEM INC

Concrete light silicon fibre crack-proof intensifier

InactiveCN101058499AReduce water-cement ratioIncrease slumpSolid waste managementSuperplasticizerHigh density

The invention discloses a light-silicon fiber crack-proof reinforcer of concrete in the making domain of organic and inorganic material, which comprises the following parts: anhydrous calcium sulphoaluminate, raw alunite, ripe alunite, anhydrite, naphthalene-system high-effective dehydragent, grammite, polypropylene fibre, sodium lignosulfonate and coal ash. The invention confers high-density and superior constructing property for concrete with modified boundary structure and high-concrete compactness, strength and durability, which improves stretching resistance greatly.

Owner:HUNAN CONSTR ENG GRP COR

Multi-strength regeneration brick aggregate fiber concrete and preparing method thereof

The invention relates to multi-strength regeneration brick aggregate fiber concrete and a preparing method thereof. The multi-strength regeneration brick aggregate fiber concrete is prepared from cement, fine aggregate, natural coarse aggregate, regeneration brick coarse aggregate, polyolefin fiber, steel fiber and water according to the weight ratio of 1: (0.780-1.309) : (0-1.830) : (0.390-1.568) : (0-0.019) : (0-0.161) : (0.33-0.48). The regeneration brick aggregate fiber concrete with the target strength grade of CF30-CF50 can be prepared by means of the raw materials, strength grade is high, and application range is wide. The obtained regeneration brick aggregate fiber concrete has high working performance including peaceability and water-retaining property, compressive strength and splitting-tension strength are high, the preparing process is simple and environmentally friendly, and construction is easy.

Owner:ZHENGZHOU UNIV

Preparation method of carboxylated lignin

The invention relates to a preparation method of carboxylated lignin, belonging to the fields of new low-carbon preparation technology of new materials and cyclic reutilization of renewable resources. The method of the invention comprises the following steps: pressing air into an air distributor in a reaction kettle by utilizing an air compressor; fully and uniformly mixing the air with lignin liquor under the condition of stirring; and under the aid of a composite catalyst, reacting at 50-140 DEG C under 0.02-1.0MPa for 30-480 minutes to obtain the carboxylated lignin, wherein the dosage of the composite catalyst is 0.01-5.0wt.% of the dry weight of the lignin; the composite catalyst at least contains more than one transition metal salt and at least contains one rare earth metal salt, and the mol ratio range of the transition metal salt to the rare earth element salt is 3:1-20:1; and the number of the air distributor is at least one, and the air distributor is a plurality of perforated pipes the pore diameter of which gradually increases from top to bottom and the pore number of which gradually decreases. The invention can carry out reasonable adjustment and control on molecular chains, chain structures and functional groups thereon of the lignin and reduce the cost.

Owner:BEIJING GHEMU TECH

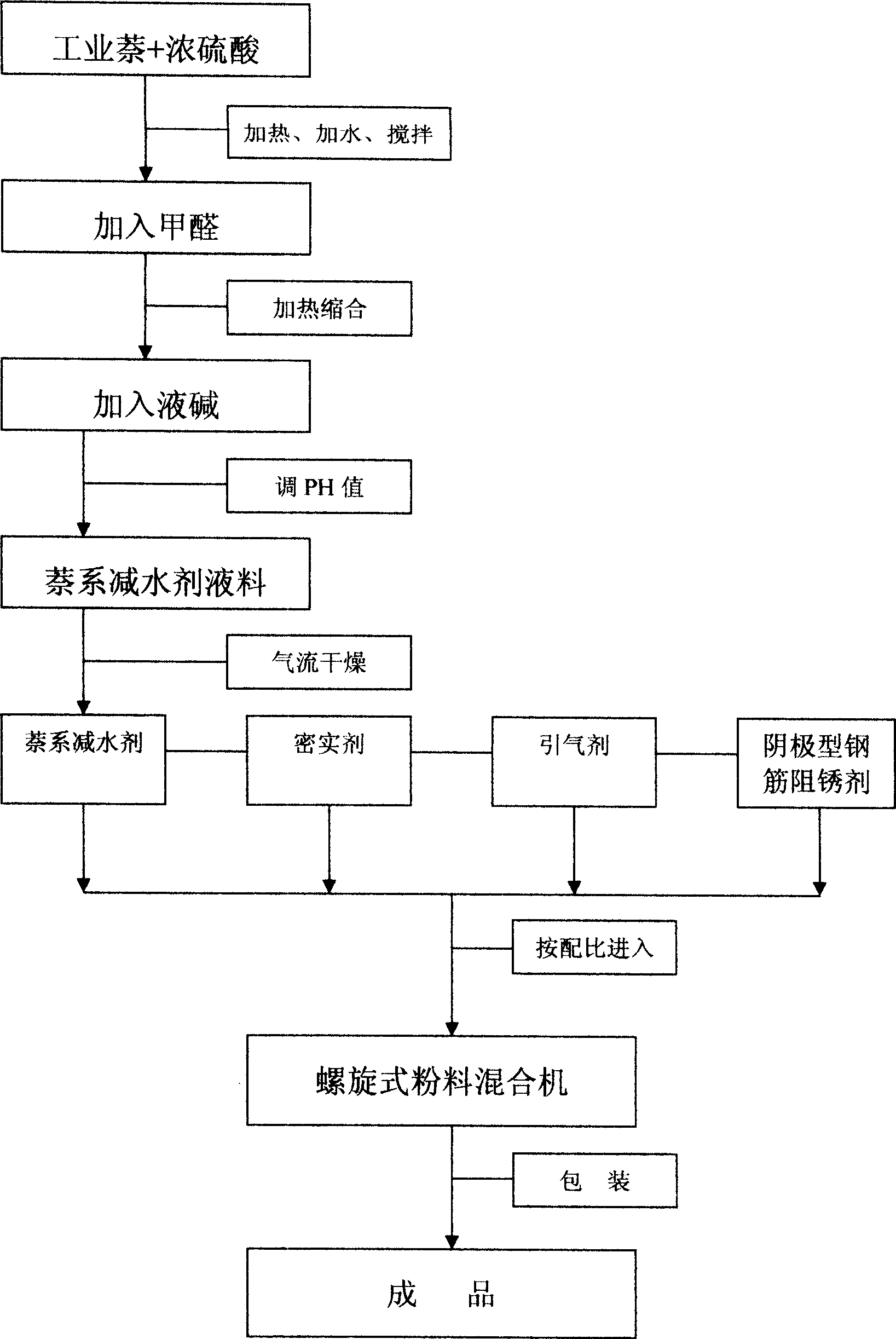

Composite concrete antiseptic agent

The invention relates to a compound concrete corrosion remover. Aiming at the serious hazard brought to concrete by corrosion, the foreign standards and the advanced technical ideas are used for reference so as to improve the anti-corrosive property of the concrete starting from improving four technical points of intensity, compactness, reduction of bleeding and rust resistance of the concrete. The compound concrete corrosion remover changes the prior concrete corrosion prevention thought and technical means. The developed compound concrete corrosion remover can ensure that the concrete has good comprehensive anti-corrosive property. Besides, the compound concrete corrosion remover can improve the construction operation working performance, improve the workability, the cohesive quality and the water preserving capability, and improve the slump and the pumpability. While satisfying the anti-corrosive property, the compound concrete corrosion remover still has the performances of a water reducing agent, a pumping agent and a waterproofing agent. The application of the compound concrete corrosion remover can substantially improve the lasting quality and the comprehensive corrosion resistance of the concrete, remarkably prolong the service life of a building and bring remarkable economic and social benefits.

Owner:YUNNAN INST OF BUILDING RES +1

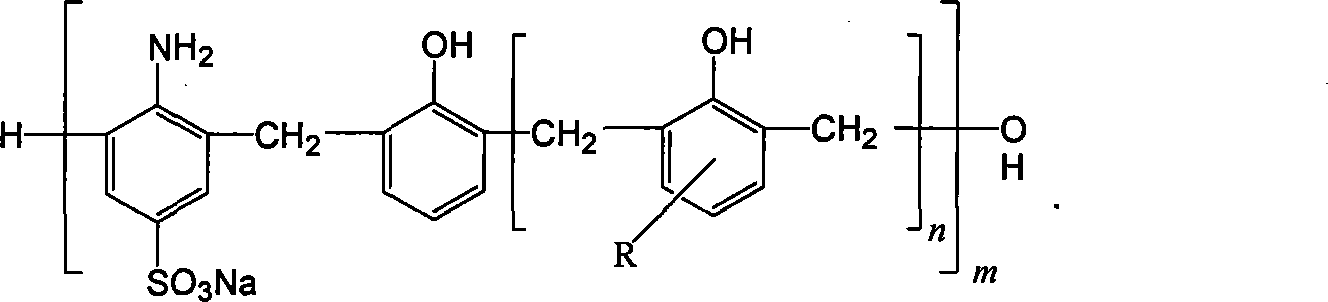

Alkali lignin modified sulfamate high-effective water reducer and preparation method thereof

The invention discloses a preparation method of alkali lignin modified sulfamate highly effective water reducing agent, which includes the steps that: firstly, alkali lignin, phenol and water are evenly mixed, and an alkaline regulator is used to adjust the pH value of a reaction system to 8.0-10.0 and heat the temperature to 80-100 DEG C for half an hour to two hours; secondly, the pH value is adjusted to 9.0-11.0, and aminobenzene sulfonic acid sodium is added to react under the temperature of 60 to 80 degrees for half an hour to one hour; thirdly, the temperature is heated to 75-95 DEG C, and condensing agent is dropped. After that, the reaction continues for three to six hours and then the temperature is lowered. The obtained water reducing preparation, having low cost and small content of free formaldehyde and phenol, can improve the fluidity of concrete and compressive strength significantly. The preparation method is a simple technique without the discharge of three wastes in production.

Owner:SOUTH CHINA UNIV OF TECH

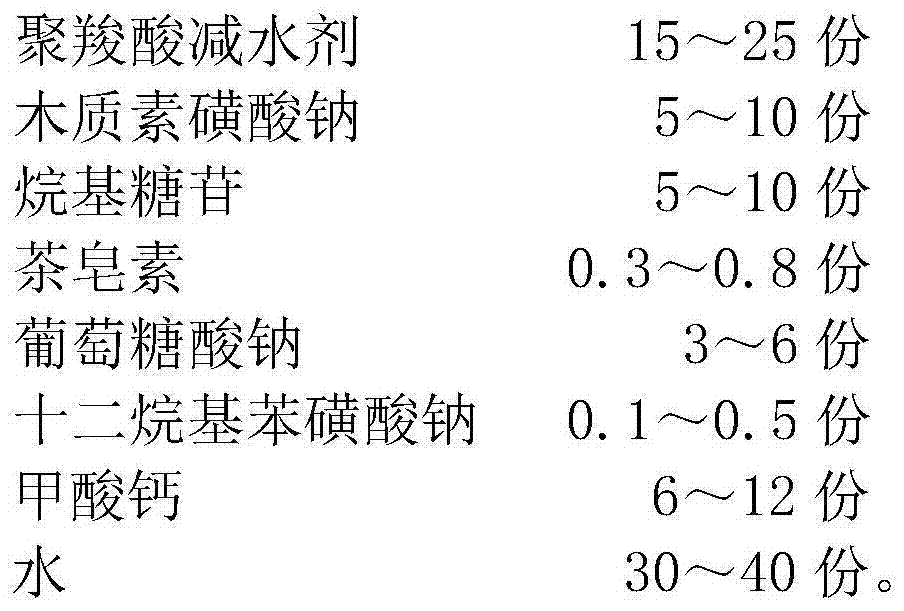

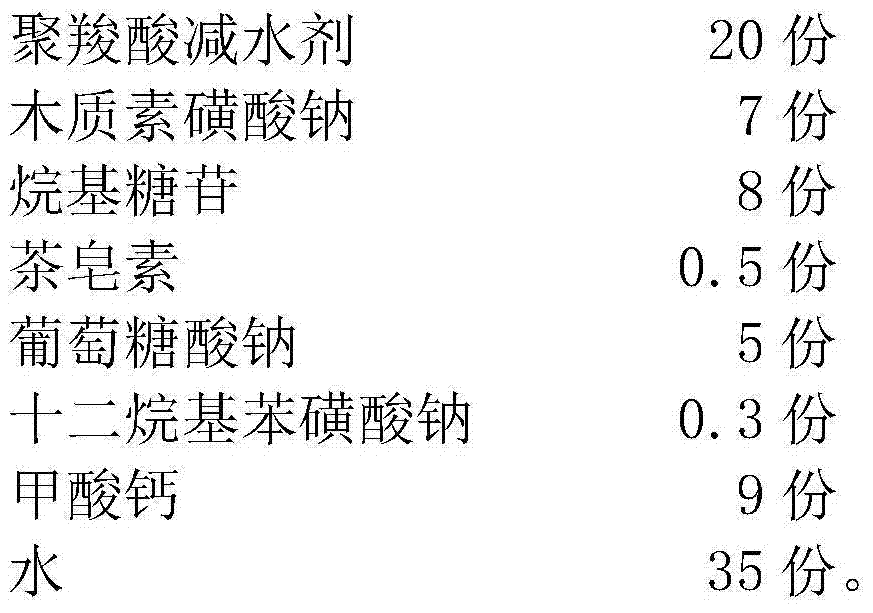

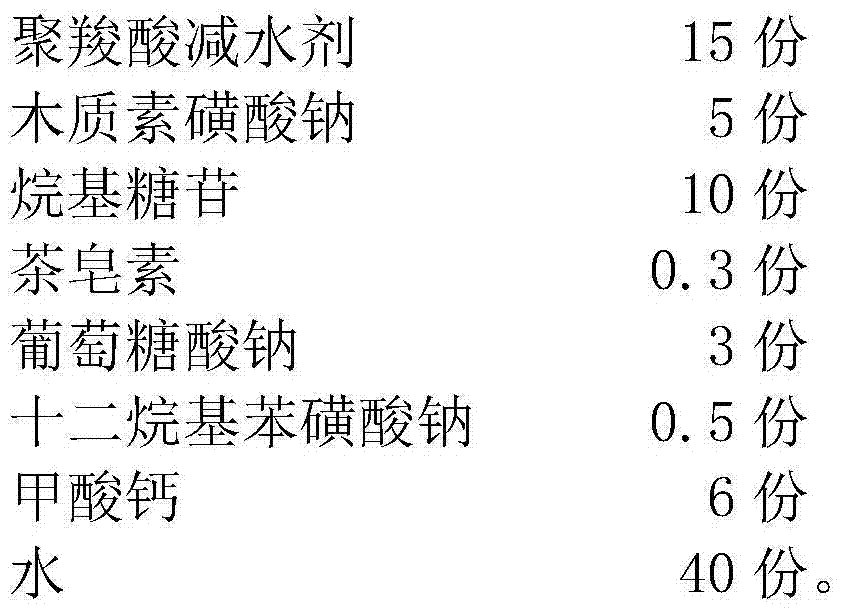

Concrete anti-freezing agent

The invention relates to the technical field of anti-freezing agents, particularly to a concrete anti-freezing agent. The concrete anti-freezing agent is formed by the following raw materials of, by weight, 15 to 25 parts of poly carboxylic acid water reducing agents, 5 to 10 parts of sodium lignin sulfonate, 5 to 10 parts of alkyl glycoside, 0.3 to 0.8 part of tea saponin, 3 to 6 parts of sodium gluconate, 0.1 to 0.5 parts of sodium dodecyl benzene sulfonate, 6 to 12 parts of calcium formate and 30 to 40 parts of water through preparation. According to the concrete anti-freezing agent, the adaptability to concrete is good, the quality is stable, the product is environmentally-friendly, various engineering requirements can be met, and the concrete can be maintained not to freeze at minus 30 DEG C to minus 20 DEG C.

Owner:唐山嘉业建材有限公司

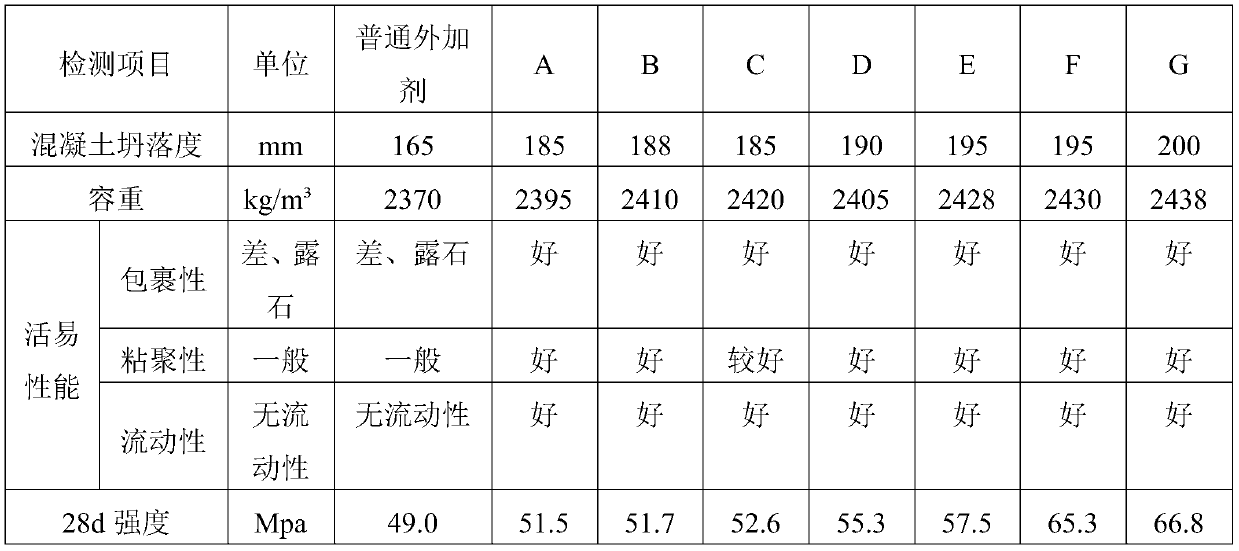

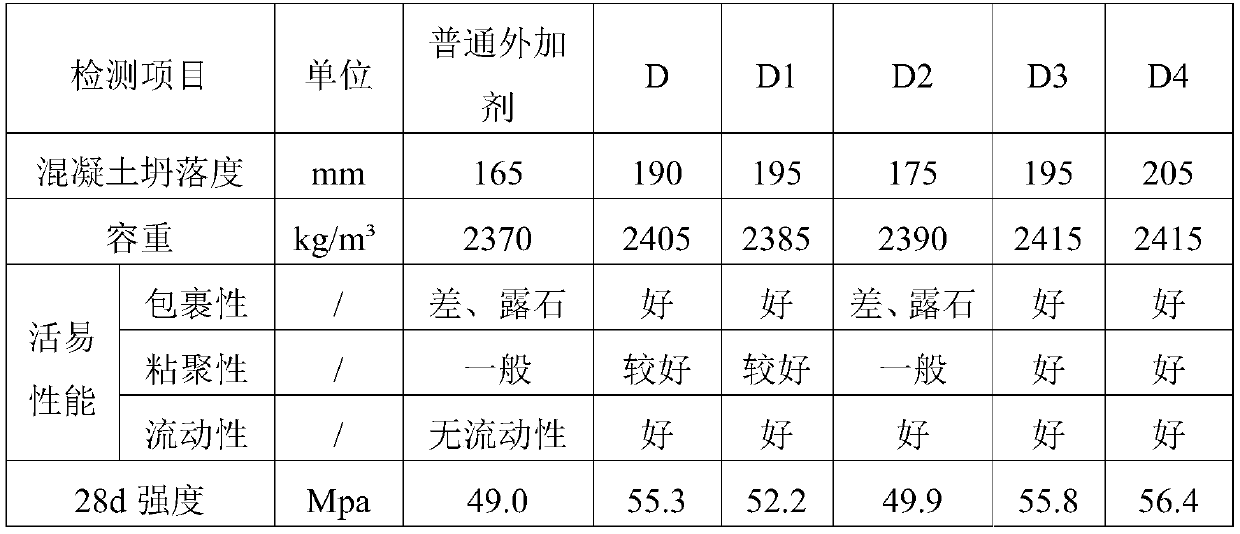

Machine-made sand regulator and preparation method thereof

InactiveCN110655346AImprove work performanceGuaranteed durability requirementsProcess engineeringCarboxylic acid

The embodiment of the invention provides a machine-made sand regulator and a preparation method thereof. The machine-made sand regulator comprises a polycarboxylate water reducing agent, a glue reducing agent, an early strength agent, an air entraining agent, a polyether type defoaming agent, a compact repairing agent, a viscosity thixotropic agent and water; the machine-made sand regulator is suitable for machine-made sand with different gradations; the durability requirement of the concrete can be ensured while good working performance of the concrete can be controlled. According to the machine-made sand regulator, various detection indexes of the newly mixed concrete can be obviously superior to those of a common admixture in the market at present, the slump of the concrete is as high as 200 mm, the volume weight reaches 2438 kg / m<3>, meanwhile, the workability is good, the 28-day strength reaches 66.8 MPa, and the strength increment is increased by more than 30% compared with thatof the common admixture.

Owner:HUNAN ZHONGYAN BUILDING MATERIAL TECH CO LTD

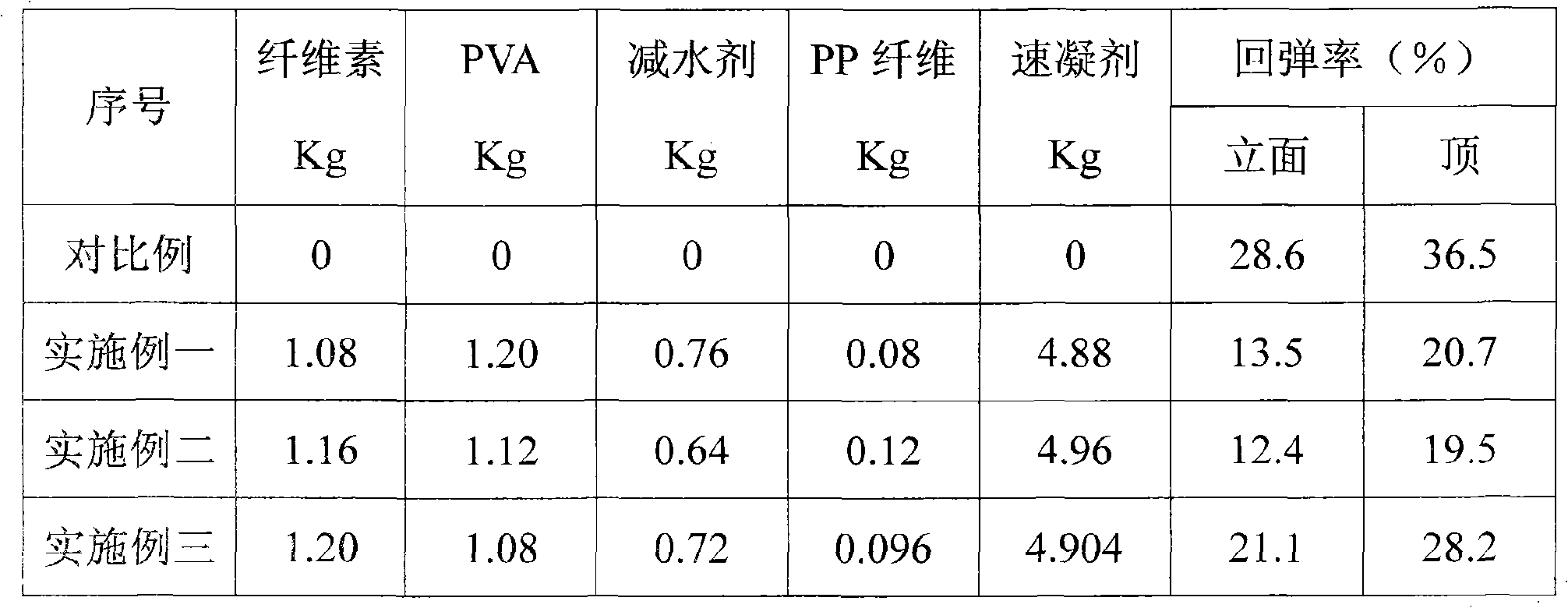

Concrete spraying additive

The invention discloses a shotcrete admixture, comprising: 13 to 15 parts by weight of cold water quick dissolving powdery methylcellulose ether or cold water quick dissolving powdery hydroxyethyl cellulose ether, 13 to 15 parts by weight of cold water quick dissolving powdery polyvinyl alcohol, 8 to 11 parts by weight of naphthalene-series powdery water-reducing agent, 1 to 2 parts by weight of mesh polypropylene fiber and 58 to 62 parts by weight of cement accelerator. The shotcrete admixture is prepared by adding the constituents into the concrete together for increasing the cohesion of concrete and viscosity of early-stage slurry, the slurry initial setting time is short, and the resilience amount of concrete can be reduced by 30 to 50 percent.

Owner:山东科技大学教育服务有限公司

Polyether amine modified poly carboxylic acid superplasticizer and preparation method thereof

The invention discloses a polyether amine modified poly carboxylic acid superplasticizer and a preparation method of the superplasticizer. The dispersant is a poly carboxylic acid copolymer with weight-average molecular weight of 10,000-120,000, which contains structural unit I originated from polyether, structural unit II originated from carboxyl and structural unit III originated from acylaminopolyether. The preparation method comprises the following steps: adding unsaturated polyether monomer A and unsaturated carboxylic acid monomers into a 50-100 DEG C water solution and carrying out a copolymerization reaction at the presence of a initiator and a chain transfer agent to obtain carboxyl polymer with molecular weight of 5,000-30,000; and allowing the carboxyl polymer and polyether amine monomers to carry out an amidation reaction at temperature of 80-200 DEG C to obtain the final product. The polyether amine modified poly carboxylic acid superplasticizer provided by the inventionstill has high concrete water-reducing rate, and keeps good concrete slump even under a low accretion condition.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

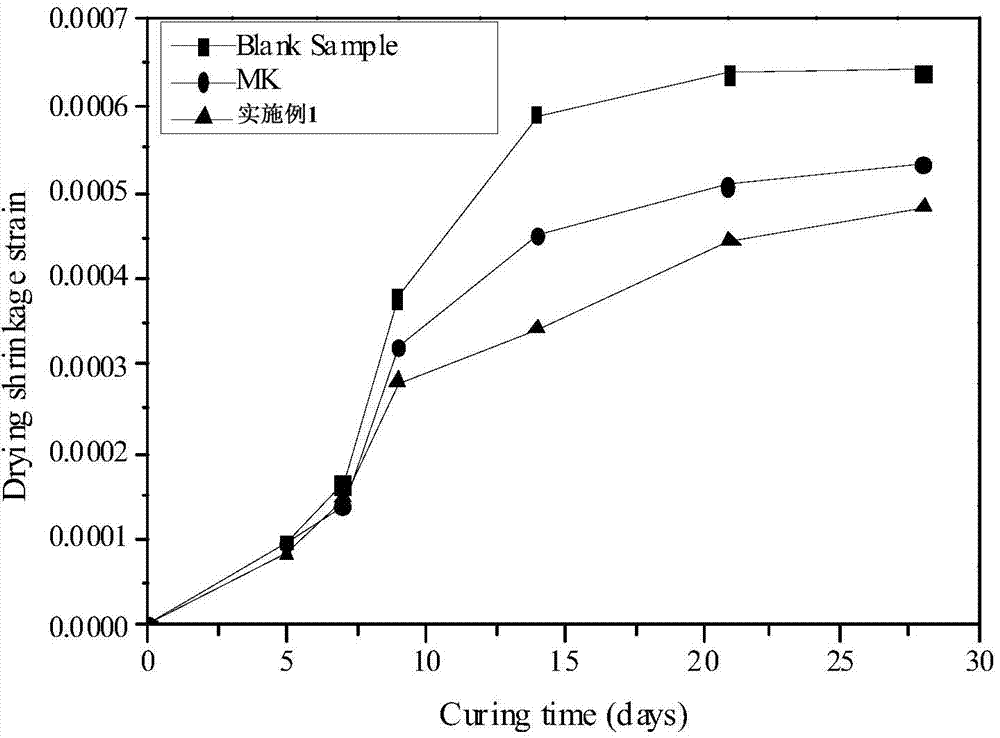

Retarding type high-fluidity high-strength underwater concrete additive and preparation method thereof

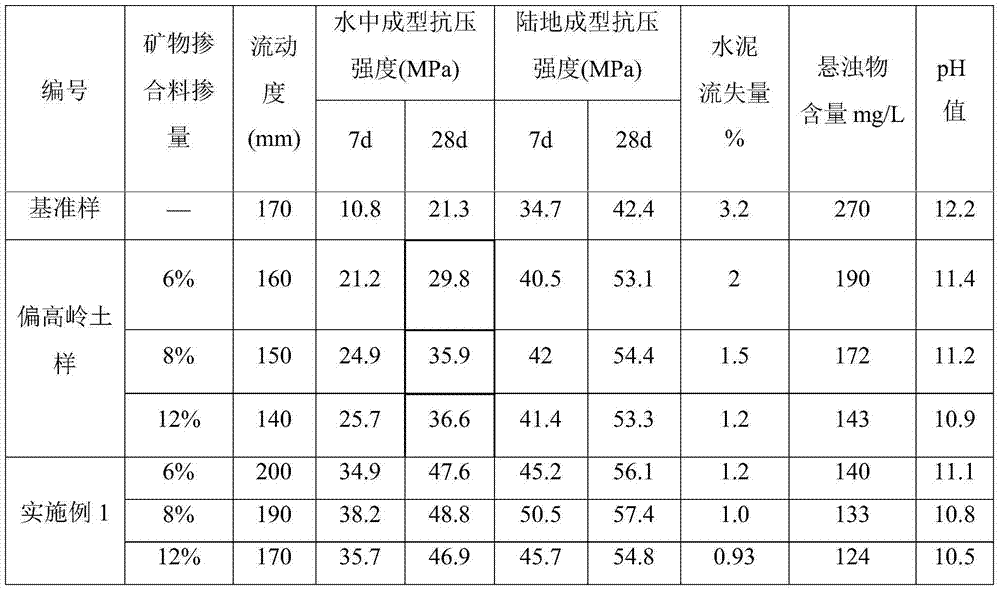

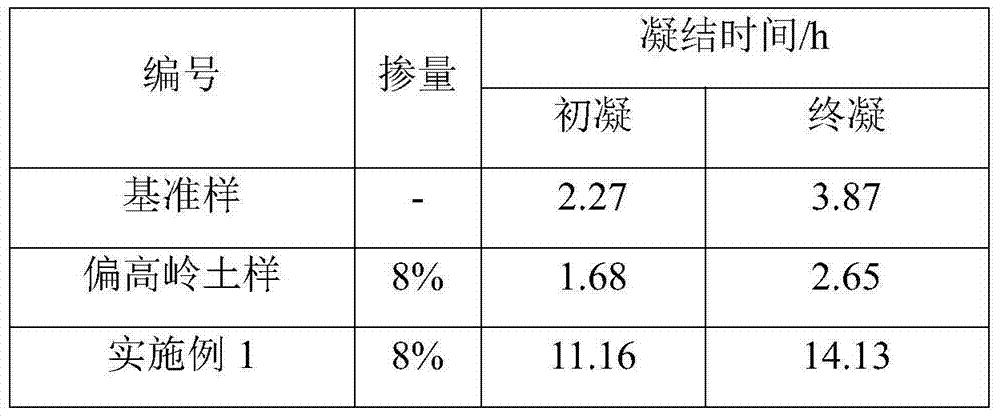

The invention belongs to the technical field of building materials, and particularly relates to a retarding type high-fluidity high-strength underwater concrete additive. The additive can effectively improve the strength and dispersion resistance of concrete and has the advantages of simple preparation process, low production cost and the like. The additive is characterized by comprising metakaolin and a composite modifier. The mass ratio of the metakaolin to the composite modifier is (50:1)-(15:1); the composite modifier is prepared by mixing 70-85% of polyacrylamide, 10-20% of superplasticizer and 5-15% of organic water-soluble polysaccharide substances all by mass based on a total of 100%. As an additive for underwater concrete, the additive can improve the working performance and dispersion resistance of underwater concrete and delay the setting time; and the strength at each age, particularly the early age strength of underwater concrete is remarkably improved. Meanwhile, the volume stability of underwater concrete can be effectively improved.

Owner:WUHAN UNIV OF TECH +1

Concrete and preparation technology thereof

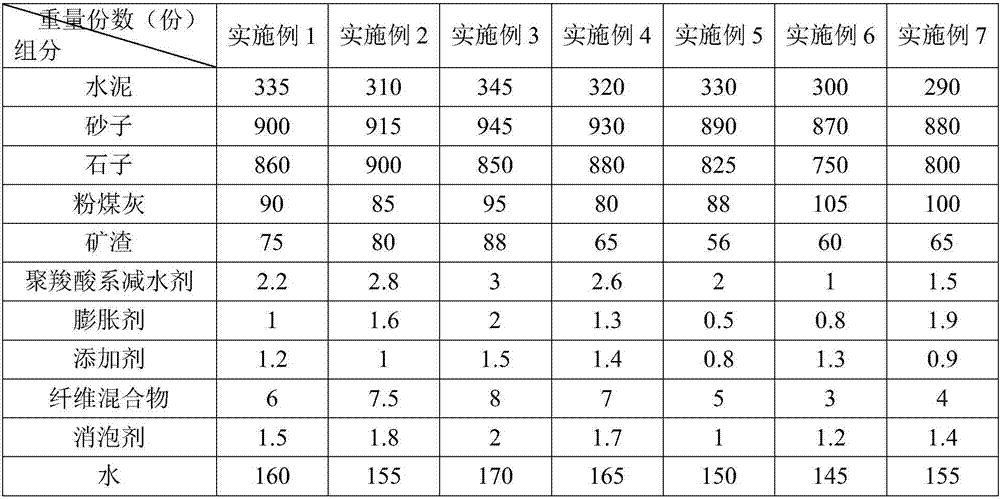

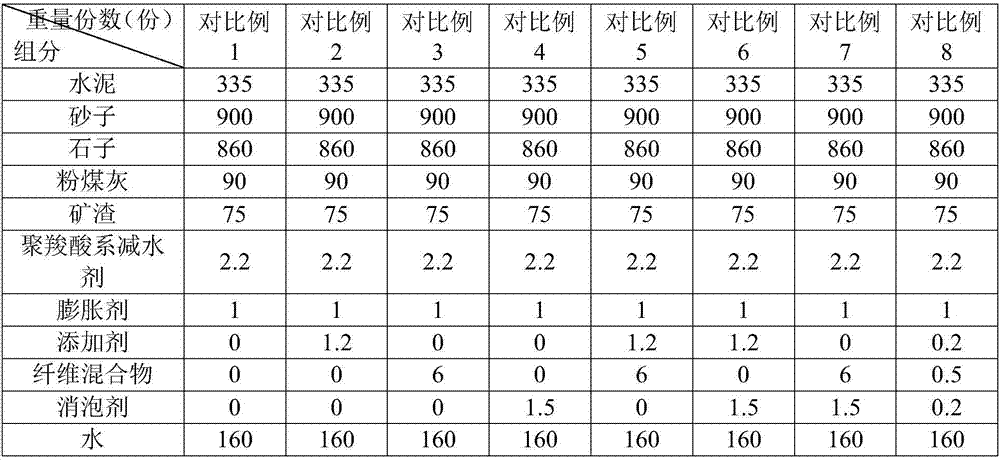

The invention discloses concrete and a preparation technology thereof. The concrete comprises, by weight, 290-345 parts of cement, 870-945 parts of sand, 750-900 parts of stones, 80-105 parts of fly ash, 56-88 parts of slag, 1-3 parts of polycarboxylate-type water reducing agent, 0.5-2 parts of expanding agent, 0.8-1.5 parts of addictive, 3-8 parts of fiber mixtures, 1-2 parts of defoaming agent and 145-170 parts of water. The cement is P.O 42.5 cement, the additive comprises MCC, xanthan gum and polyvinylpyrrolidone, the fiber mixtures comprise at least two kinds of glass fiber, steel fiber and carbon fiber, and the defoaming agent comprises at least one kind of polysiloxane and polyether modified polysiloxane. The concrete and the preparation technology have the advantages that the air content is lowered, and the impervious performance and the crack resistance of the solidified concrete are improved.

Owner:深圳市圣威宝混凝土有限公司

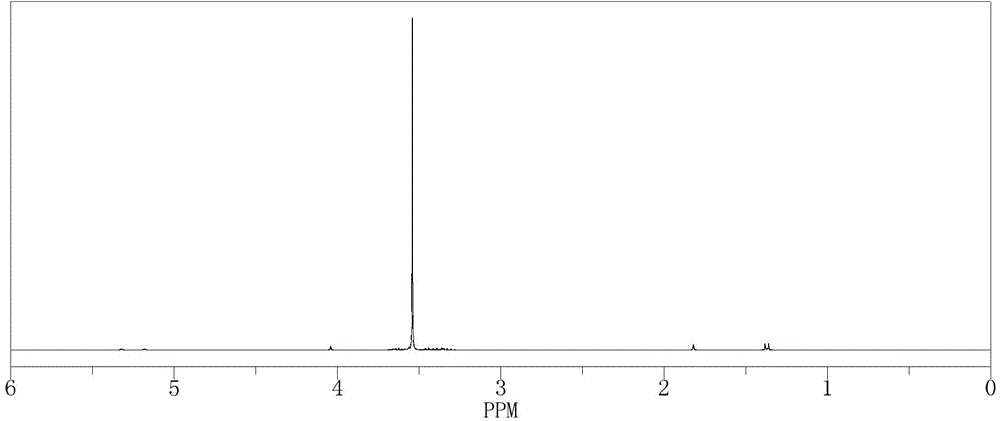

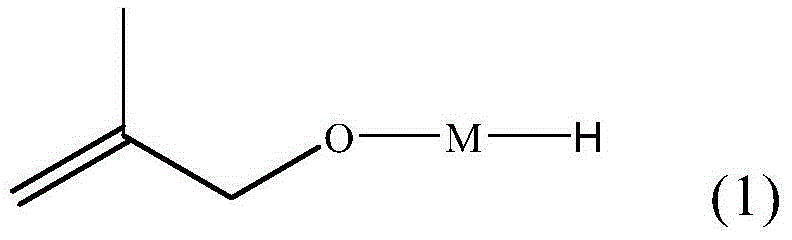

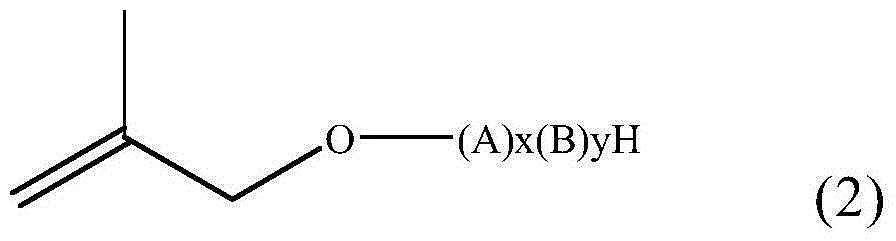

Terminal alkenyl nonsaturated polyether and purpose thereof

ActiveCN105330830AGood performance for decentralized applicationsFlexible adjustment of densityAcid waterReducer

The invention provides terminal alkenyl nonsaturated polyether shown in a formula (1), and the invention also provides a purpose of the terminal alkenyl nonsaturated polyether. According to the provided terminal alkenyl nonsaturated polyether, a polyether chain segment can be adjusted through different structural units, so that dispersion effect of a prepared water reducer on concrete is increased, and water-reducing rate of a polycarboxylic acid water reducer and slump constant are obviously increased. The preparation method has the advantages of simple operation, mild condition and easy industrial application.

Owner:SICHUAN SEDAR CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com