Composite concrete antiseptic agent

A concrete preservative and composite technology, applied in the field of concrete admixtures, can solve problems such as technical performance not really solving problems, achieve good self-corrosion performance, improve workability, improve slump and pumpability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

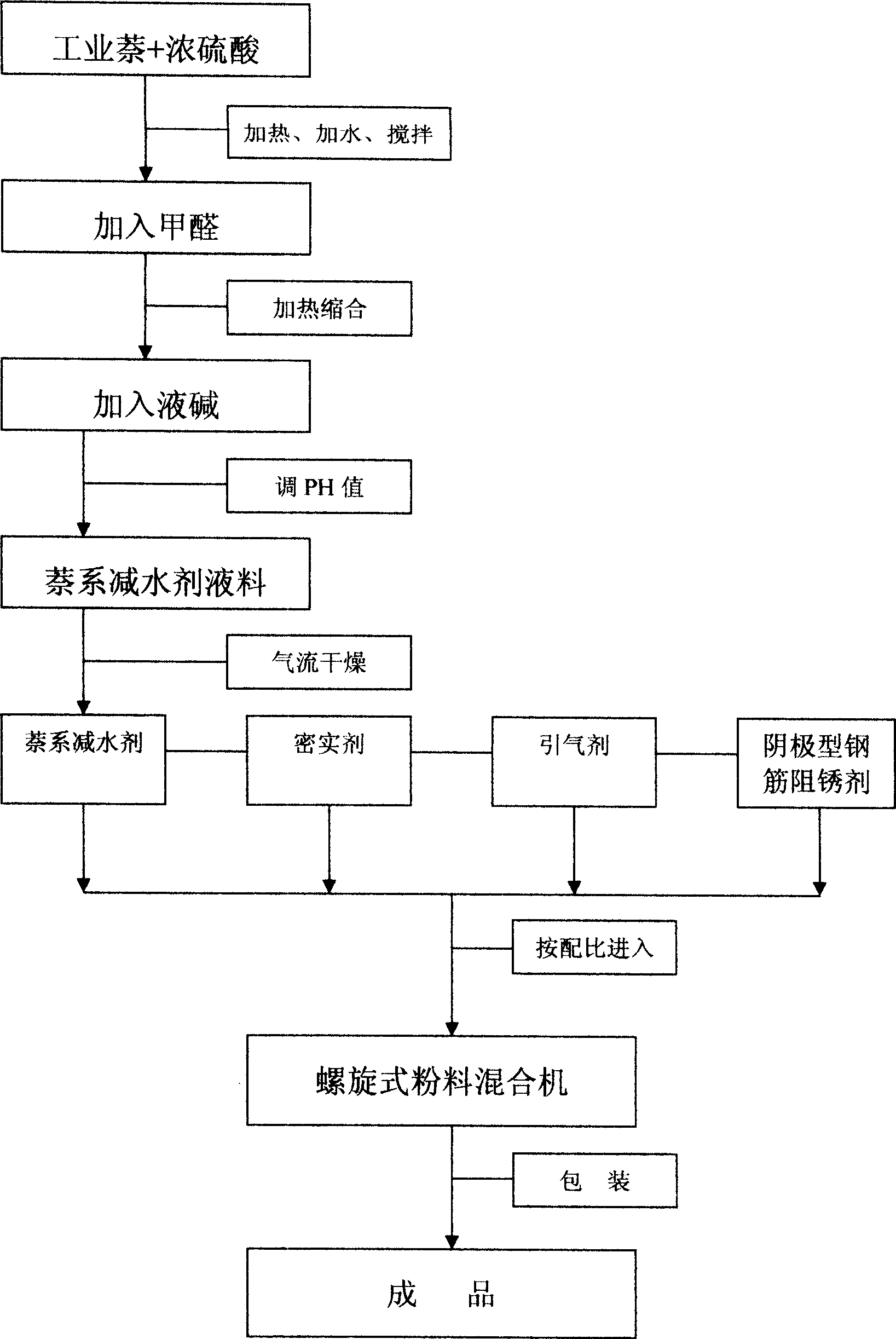

Image

Examples

Embodiment 1

[0018] A. Naphthalene-based superplasticizer 10%

[0019] B. Na 2 PO 4 2%

[0020] C. Fatty alcohol sulfonate 1%

[0021] D. Expansion agent 47%

[0022] E. Silica fume 40%

[0023] This formula is mainly used for high-fluidity concrete, such as underground cast-in-situ piles, drainage channels and other concrete with poor construction conditions and high requirements. The amount of antiseptic is 10% of the cement amount.

Embodiment 2

[0025] A. Naphthalene superplasticizer 5%

[0026] B. Na 2 PO 4 2%

[0027] C. Fatty alcohol sulfonate 0.5%

[0028] D. Expansion agent 80%

[0029] E. Silica fume 12.5%

[0030] This formula is mainly used for concrete that does not require high fluidity but requires high anti-seepage. Such as basement post-pouring tape, pool wall, etc., the amount of preservatives is 10% of the cement amount.

[0031] At present, our composite concrete preservative has been well applied in engineering. The "Golden Water Bay" project constructed by China Nonferrous Metallurgical No. 4 Company, the "Xishuangbanna Golden Land Hotel" project constructed by Yunnan Construction Engineering Group No. In projects such as the staff housing foundation project and the "Guodian Yangzonghai Power Generation Co., Ltd." developed by the No. Requirements, the performance of concrete meets the requirements of national standards, and has obtained obvious economic and social benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com